Horizontal spiral cement cooler

A horizontal screw and cooler technology, applied in the field of cooling devices, can solve the problems of limited cooling effect, large investment and high operating cost, achieve good heat conduction effect, strengthen heat dissipation and cooling, and prevent corrosion damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

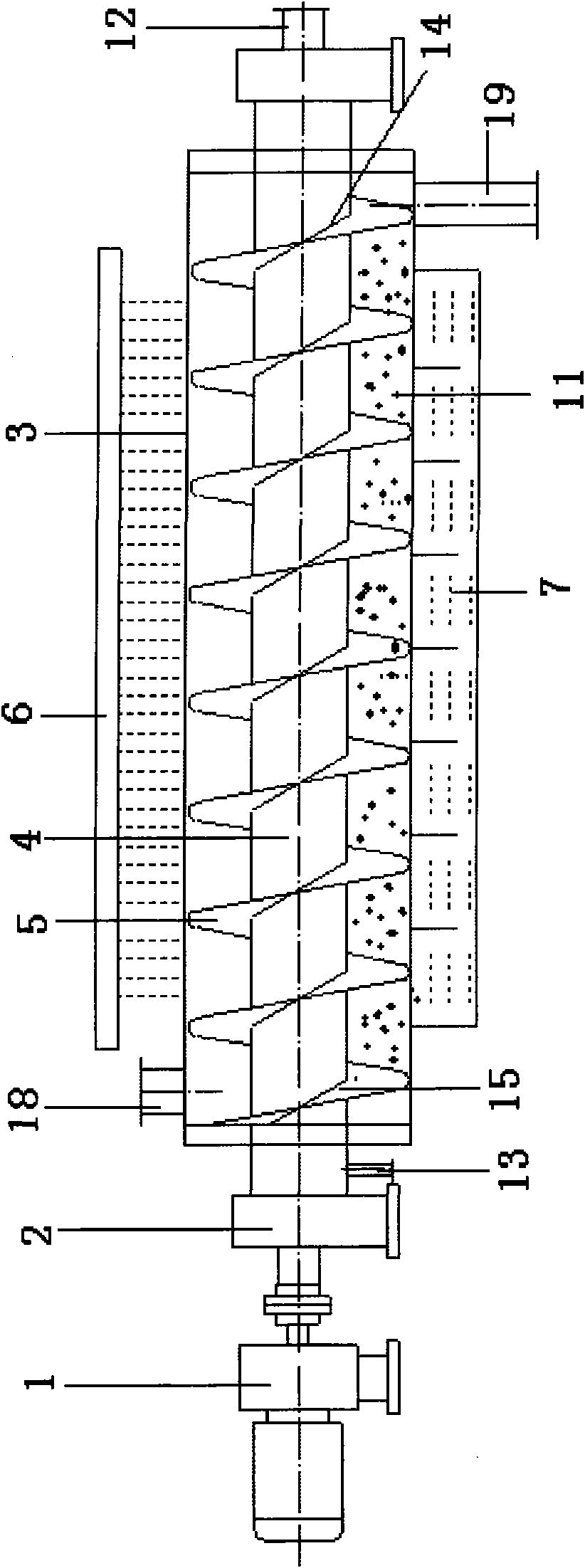

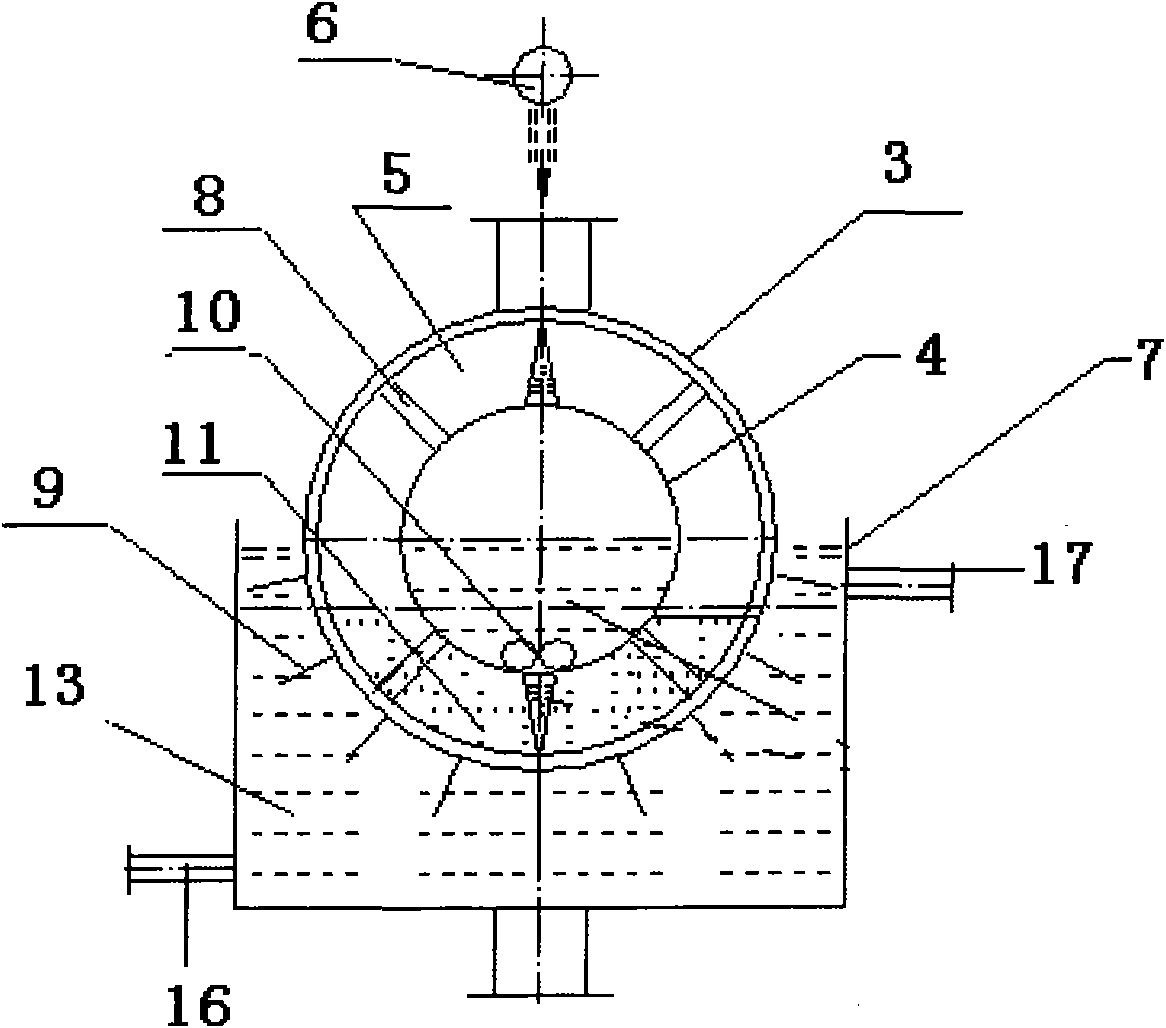

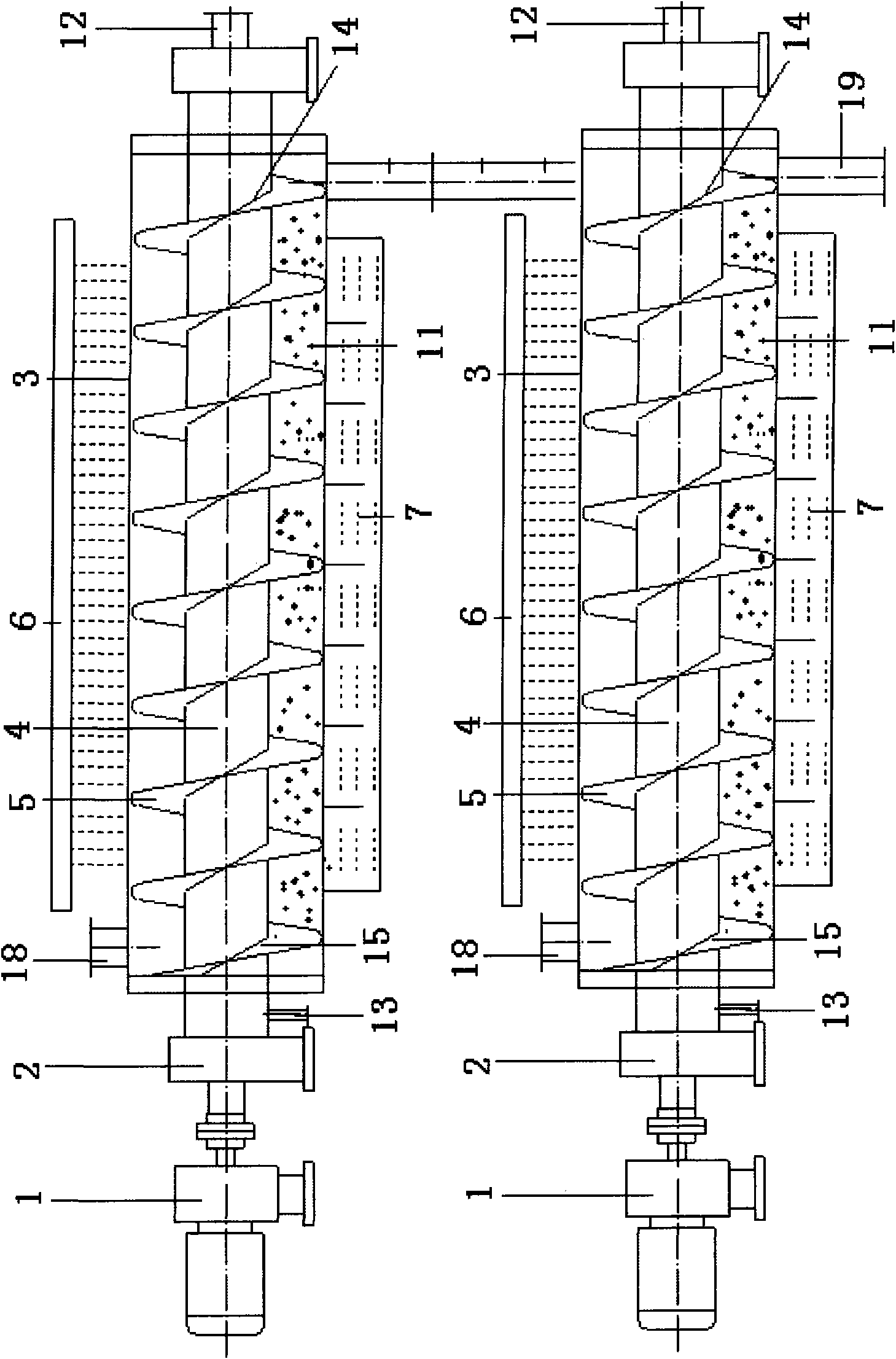

[0035] A horizontal spiral cement cooler, including a support 2, a horizontal cylinder 3 is installed on the support 2, a material inlet is provided above one end of the cylinder 3, and a discharge is provided below the other end There are multiple rows of cooling fins 9 installed on the outer circumferential surface of the cylinder body 3 . A hollow shaft 4 is rotatably installed in the cylinder body 3 , and an anti-scaling ball 10 is stored in the hollow shaft 4 . One end of the hollow shaft 4 is provided with a water inlet 12, and the other end is provided with a water outlet 13, through which cooling water is passed through, and is sealed and connected with a speed-adjustable transmission device. The outer circumference of the hollow shaft 4 is provided with a hollow helical blade 5 communicating with it, and the hollow shaft 4 is provided with a helical blade water inlet 14 and a helical blade water outlet 15 respectively connected with the helical blade 5; A plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com