Repairing and changing method of full rotation steering oar device

A full-turn, rudder-propeller technology, applied in transportation and packaging, ship propulsion, ship parts, etc., can solve the problems of poor corrosion resistance, huge economic losses, and low scope of application, so as to reduce maintenance costs, avoid economic losses, The effect of enhancing usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

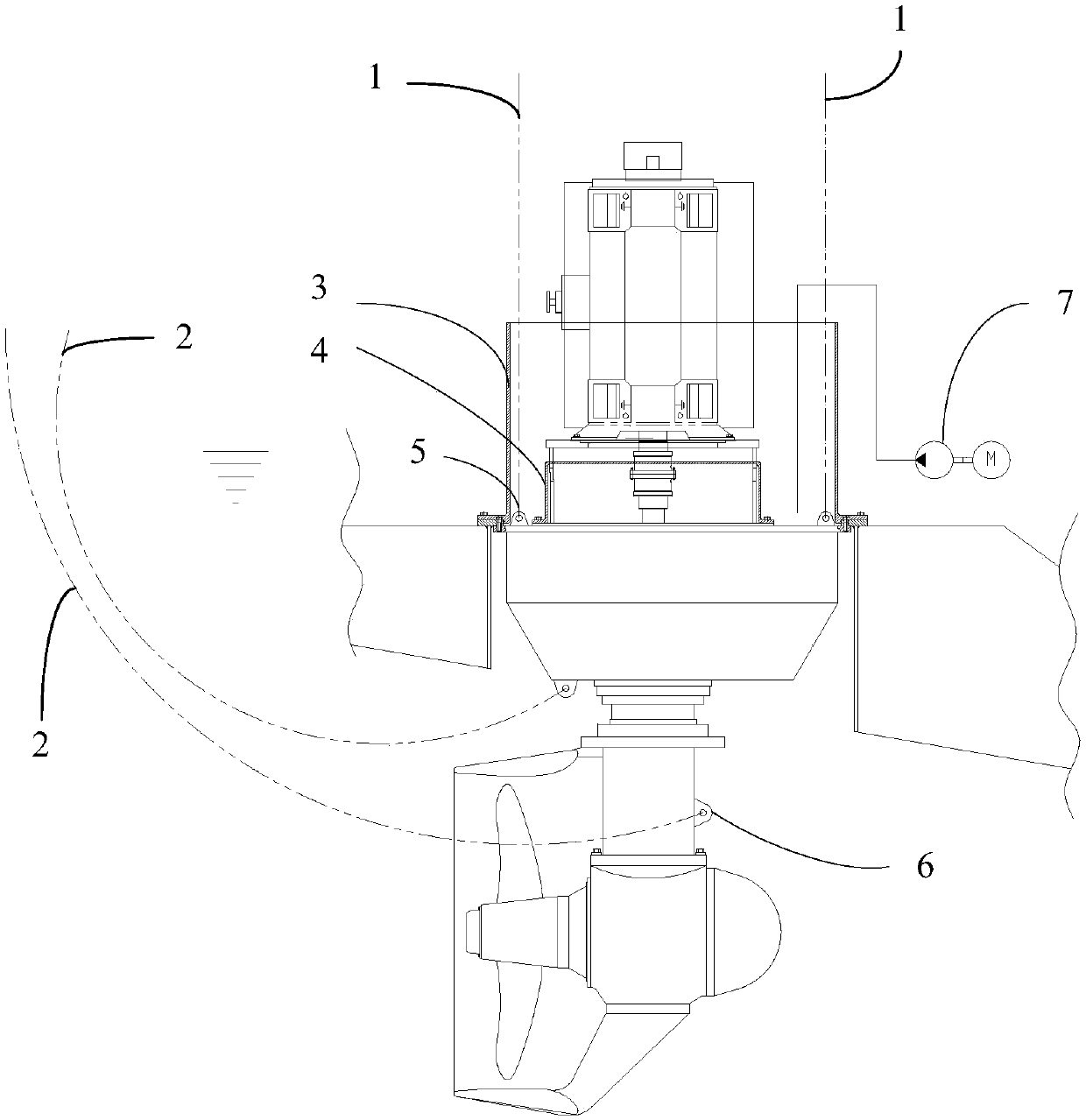

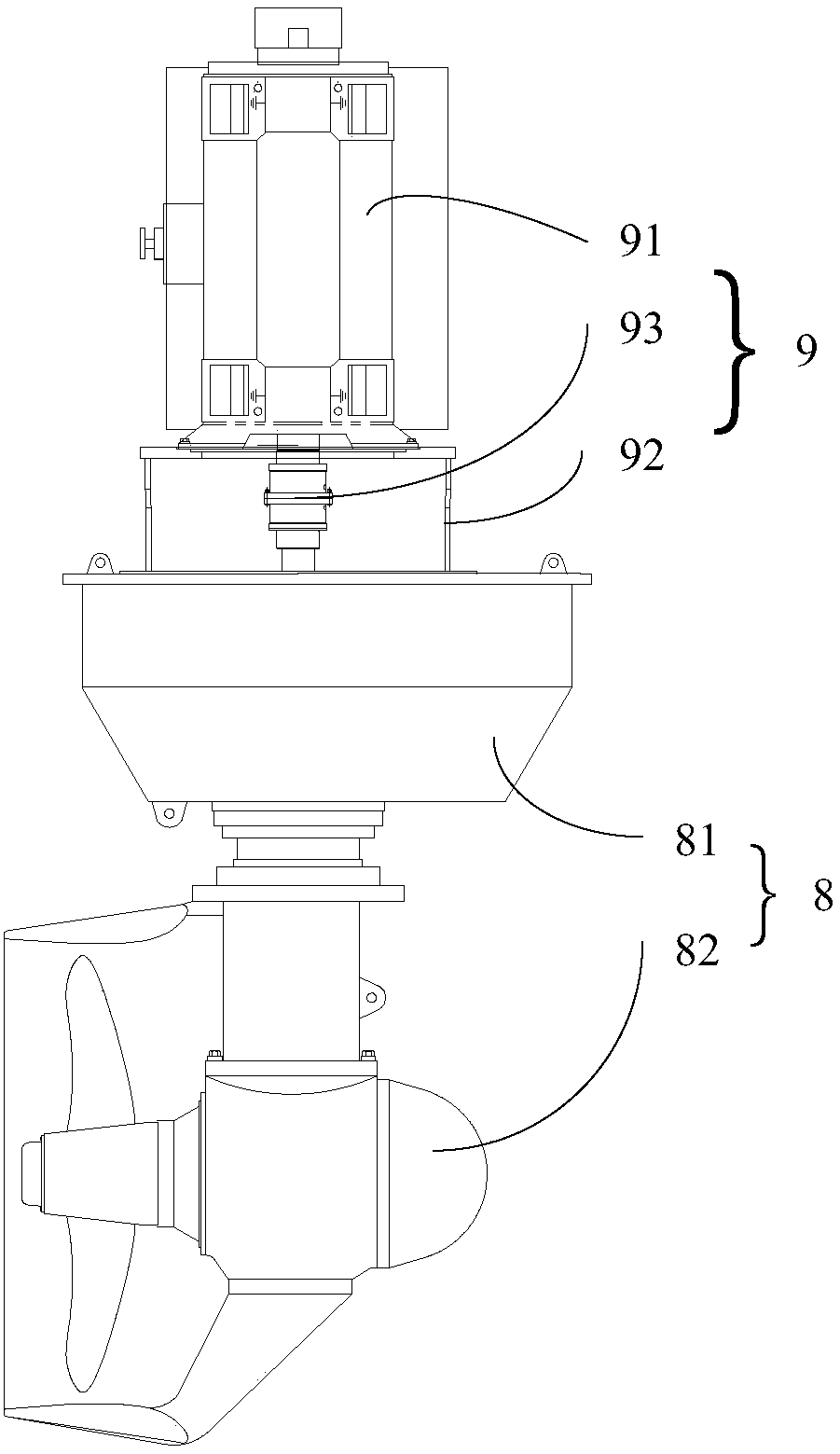

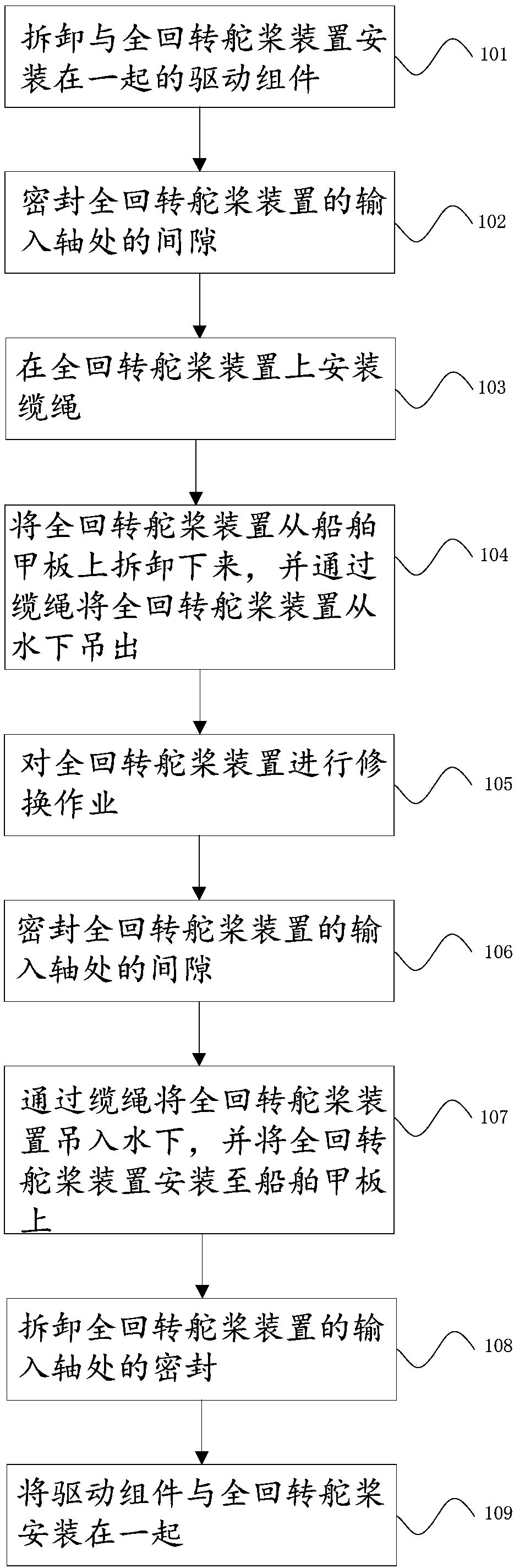

[0038] The embodiment of the present invention provides a method for repairing a full-turn rudder propeller device, figure 1 It is a general drawing of the technical scheme of the repair method of the full-turn rudder propeller device, figure 2 It is a schematic diagram of the connection between a full-turn rudder propeller device and the drive assembly provided by the embodiment of the present invention, as shown in figure 1 , 2 As shown, the full-turn rudder paddle device 8 is transmission-connected with the drive assembly 9 through the input shaft, and the drive assembly 9 includes: a drive motor 91, a motor support 92 and a coupling 93, and the full-turn rudder paddle device 8 includes: a housing 81 And propeller 82, when the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com