Patents

Literature

145 results about "Cement mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

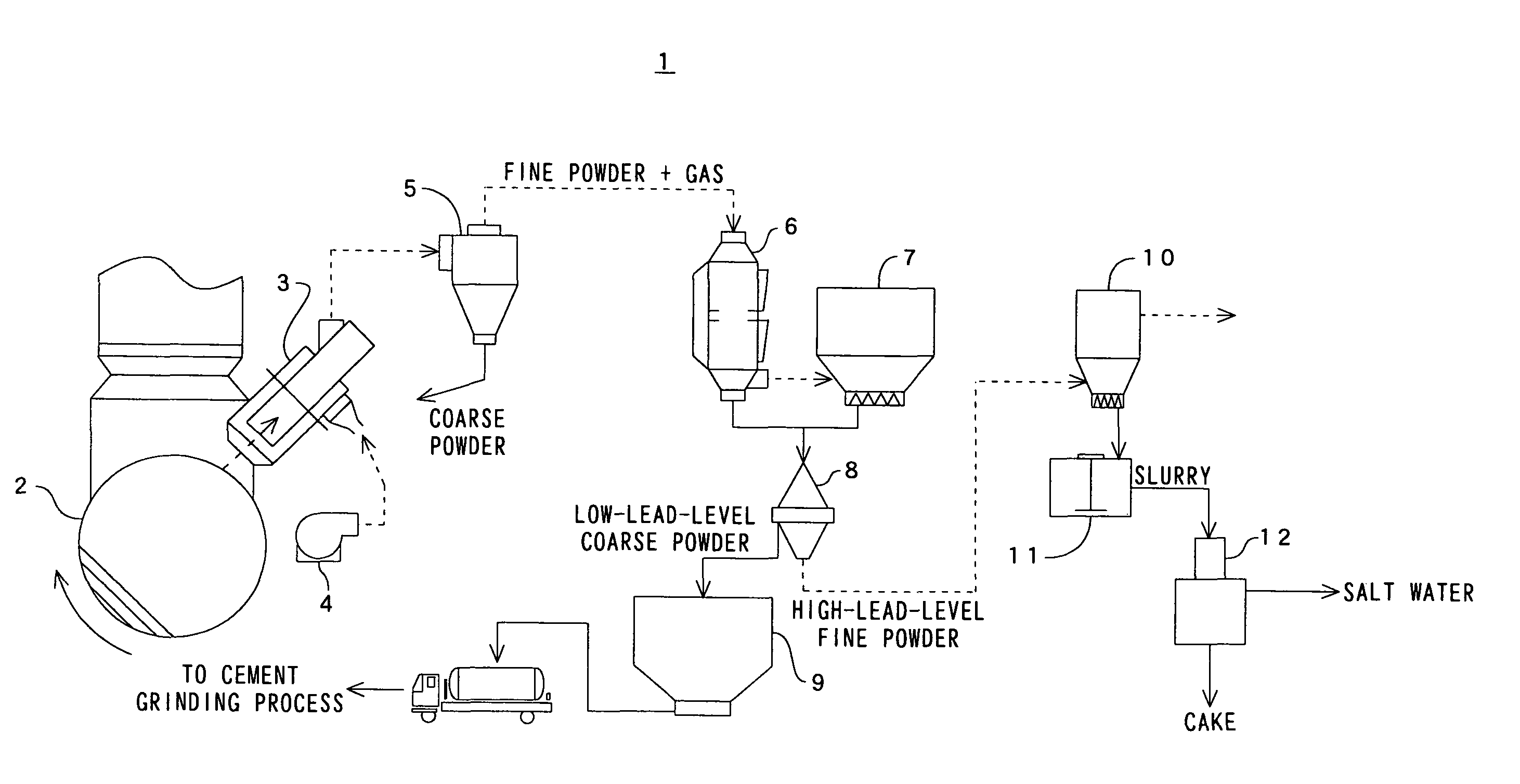

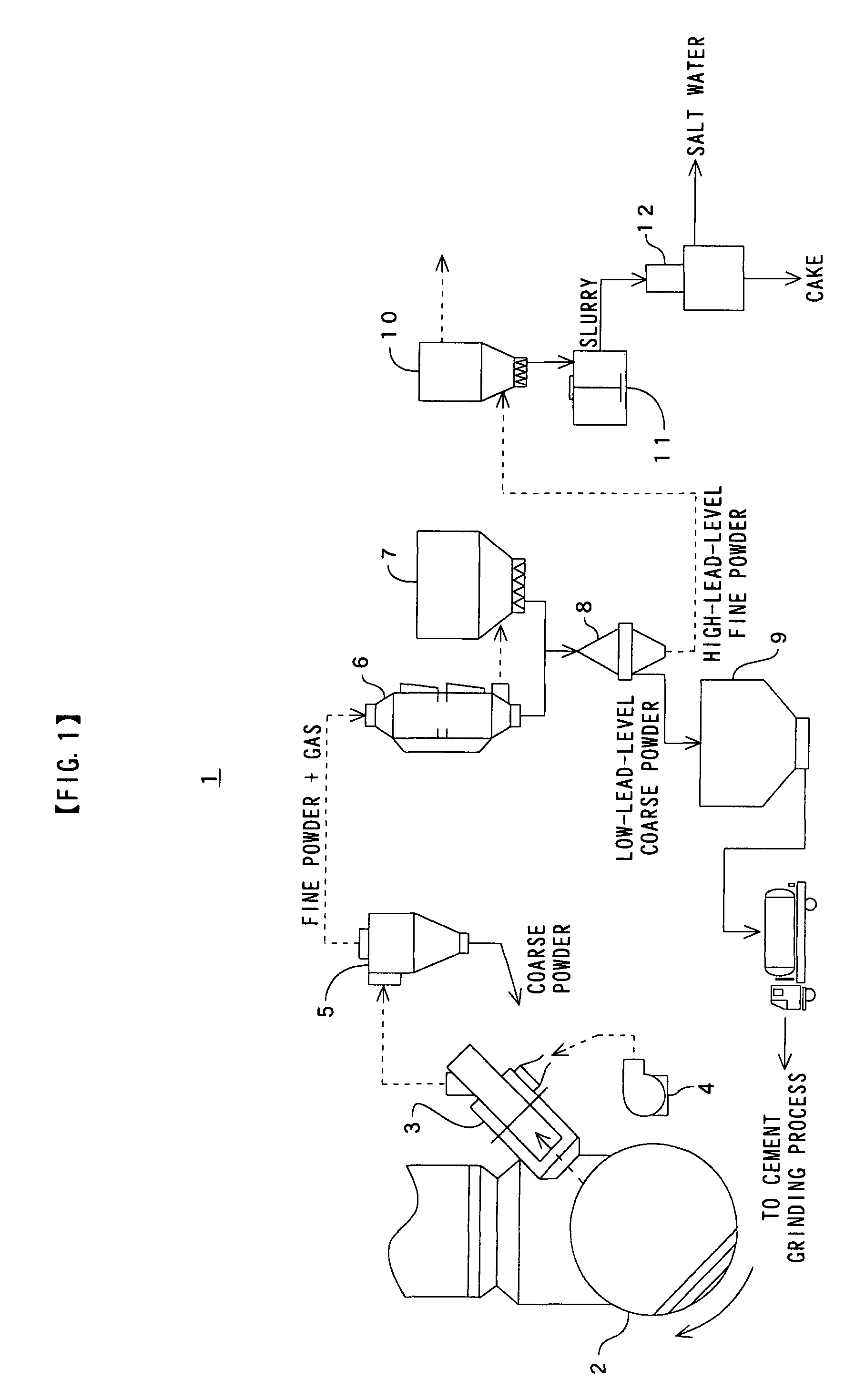

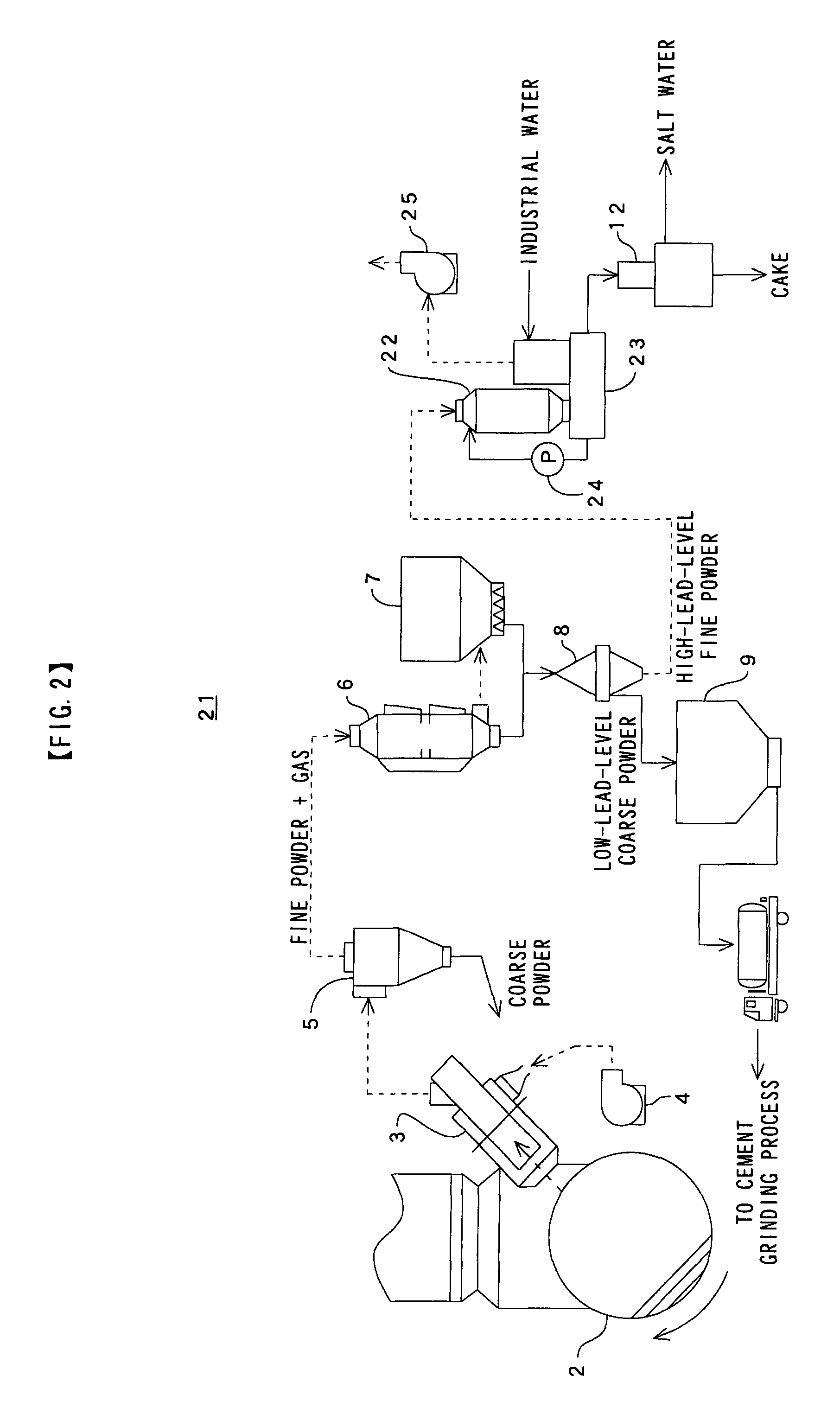

System and method for treating dust contained in extracted cement kiln combustion gas

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

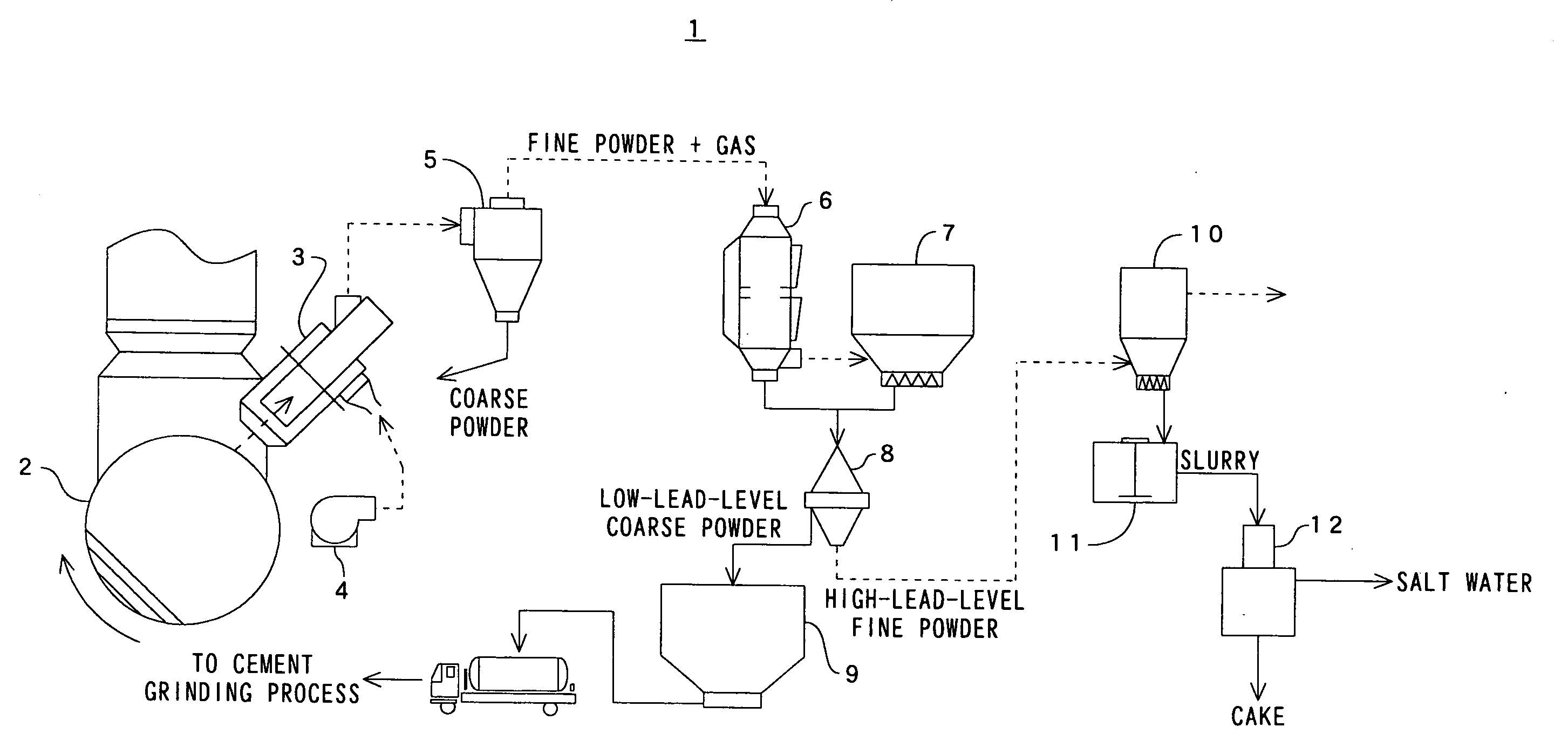

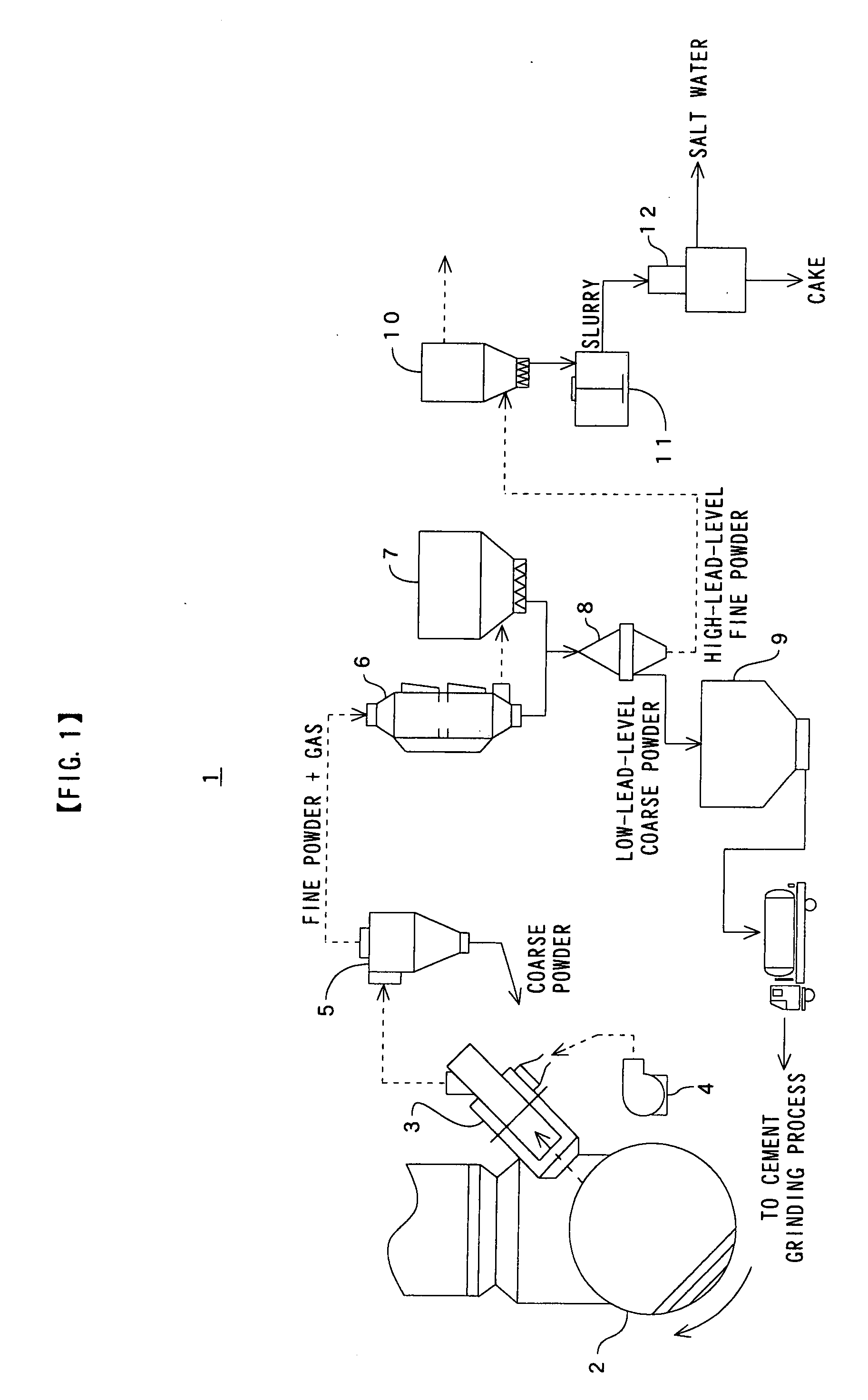

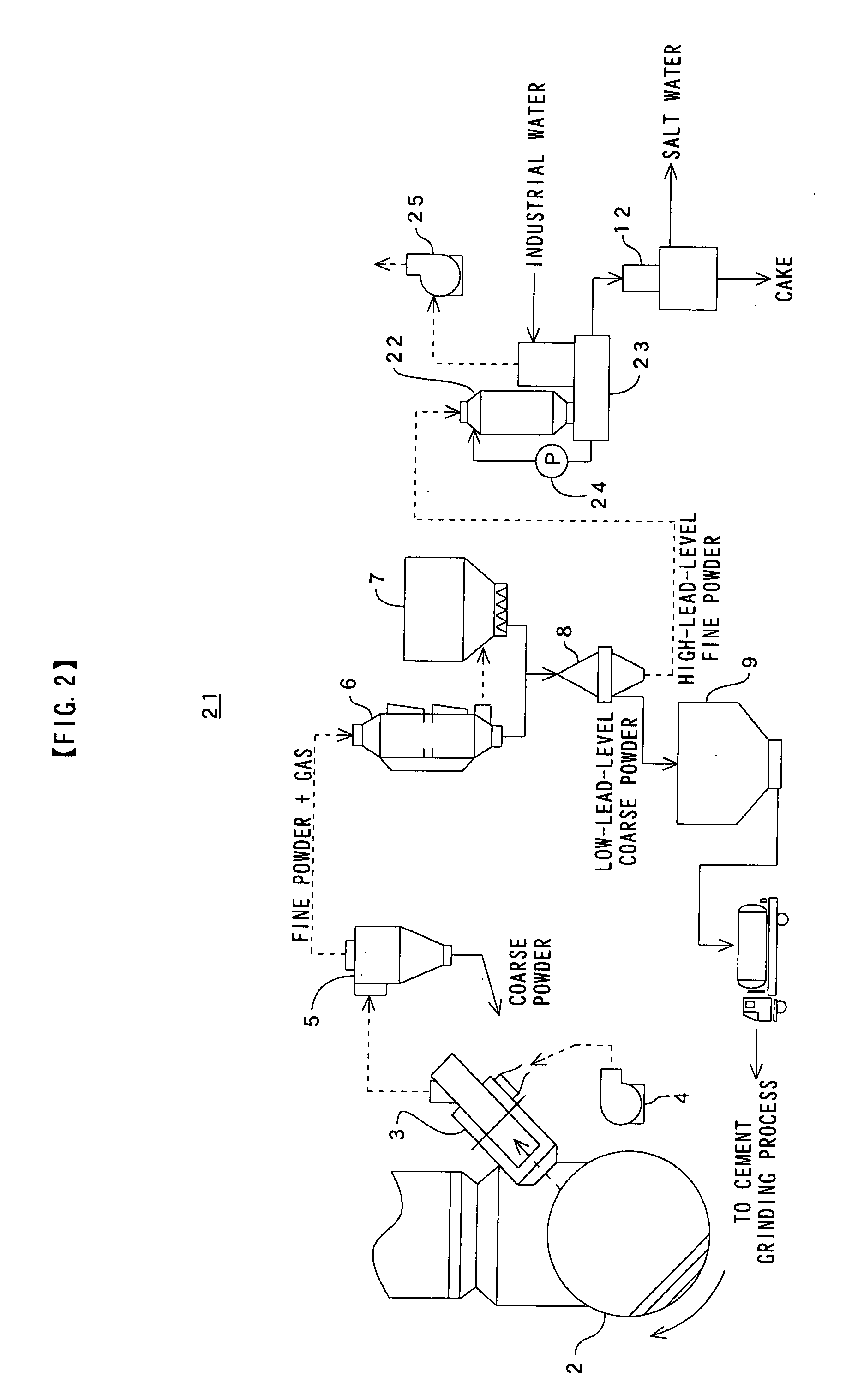

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

Method for preparation of polytetrafluorethylene microporous film for the processing of high-temperature fume and flour dust

InactiveCN101081356ASimple processReduce manufacturing costSemi-permeable membranesDispersed particle separationPolymer scienceBurn treatment

The present invention discloses one kind of microporous teflon film for treating high temperature fume and dust and its preparation process. The preparation process includes mixing powdered teflon resin and powdered catalyst, adding liquid lubricant to the mixture, extruding, rolling, longitudinally stretching, transversely stretching, heat setting and other steps. The microporous teflon film for treating high temperature fume and dust has simple preparation process and low cost. It has pore size of 0.5-5 micron and dioxins eliminating rate at 200 deg.c as high as 95-98 %. It may be applied widely for high temperature tail gas treatment in refuse burning treatment plant, refuse burning power plant, coal burning power plant, cement mill, etc.

Owner:ZHEJIANG SCI-TECH UNIV

Oil-extraction plant acidic gas processing method

InactiveCN1836767AEasy to handleSolve processing problemsDispersed particle separationChemical reactionDual purpose

The treating process of acid gas from oil refinery features that acid gas is used as the fuel in vertical kiln of cement mill. During the burning of acid gas in the kiln, the H2S component and cement material react chemically to produce CaSO4 while the other harmful components are sintered and converted. The treating process eliminates acid gas pollution radically while providing partial fuel for cement mill, reaching dual purpose of protecting environment and saving fuel.

Owner:淄博天工石化工程咨询有限公司

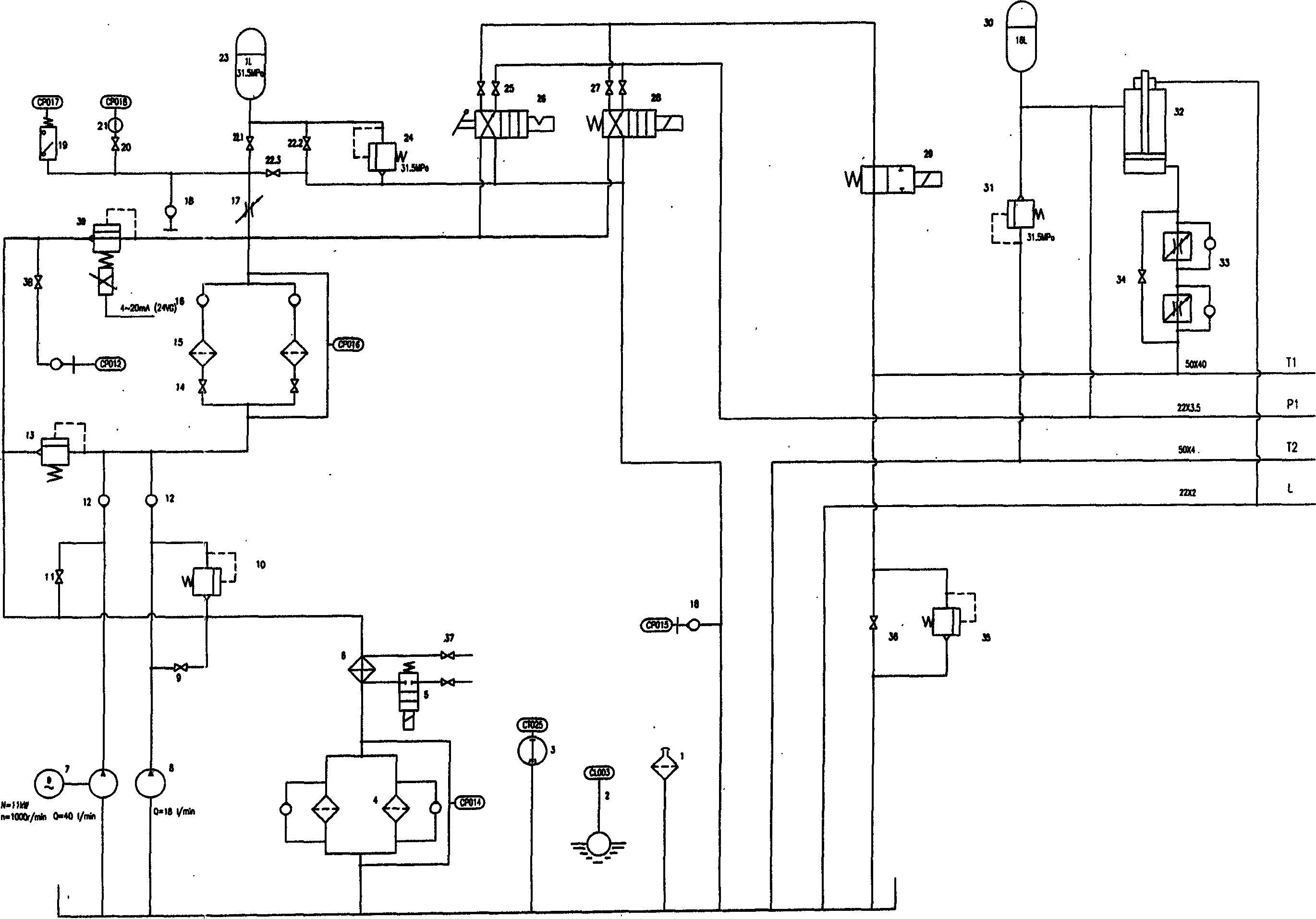

Hydraulic variable loading system for roller-plate coal mill

InactiveCN1672800AGrinding force to matchReduce operating load power consumptionCement productionGrain treatmentsSolenoid valveLow load

The hydraulic variable loading system for roller-plate coal mill in power station, cement mill, etc. consists of filter, motor, two-gang pump, high pressure bi-directional filter, pressure speed variator, energy accumulator, two-position four-way solenoid valve, hydraulic cylinder, proportional overflow valve, etc. The motor drives the two-gang pump to provide the hydraulic kinetic energy, and under the control in the central control room via the pressure speed variator, proportional overflow valve and the hydraulic variable loading system, the work pressure is applied to the hydraulic cylinder cavity. The system of the present invention is novel, safe and reliable, and makes the coal mill operate stably at low load.

Owner:SHENYANG HEAVY MACHINERY GROUP

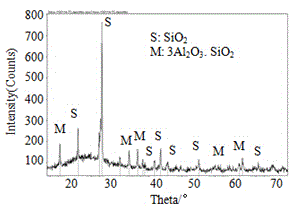

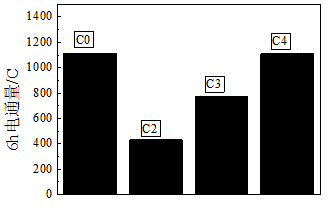

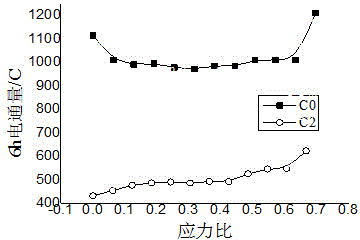

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

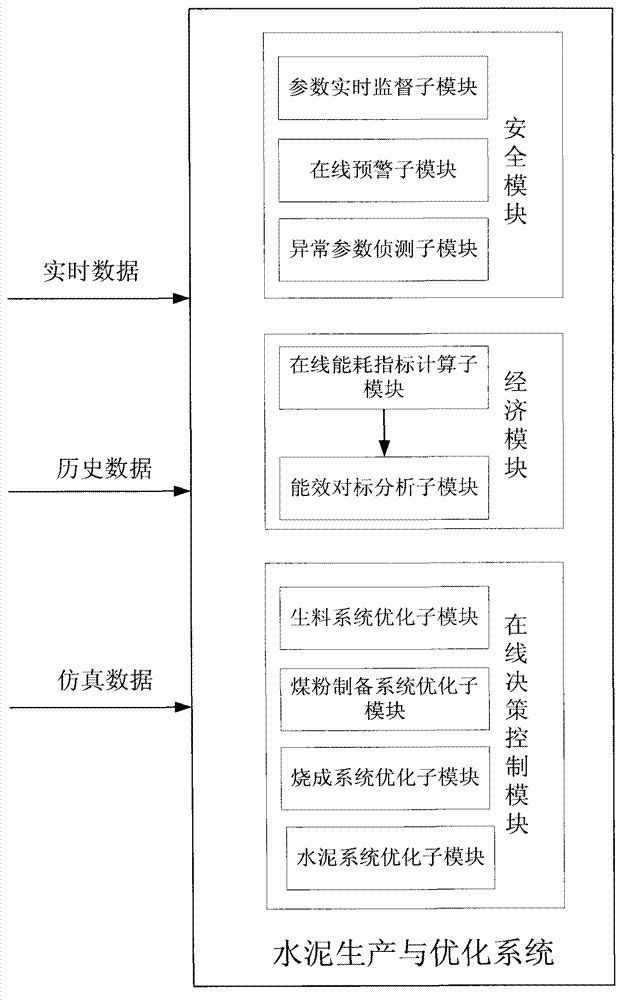

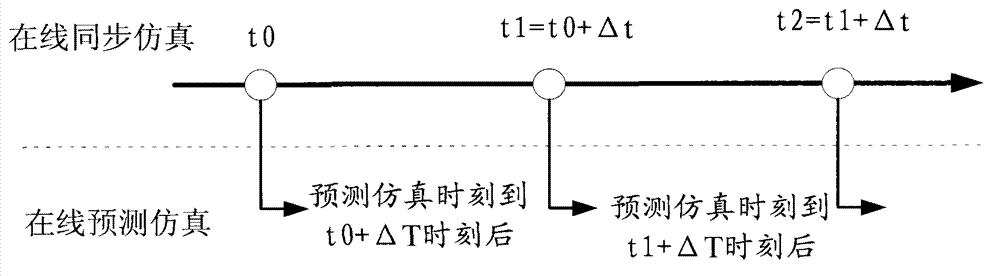

Cement production and optimization system

The invention discloses a cement production and optimization system which comprises a safety module, an economics module and an on-line decision control module. The safety module is used for analyzing and judging whether the current operating parameters and cement production equipment work normally or not according to real-time data, historical data and simulated data of operation of the cement production equipment and predicting whether the operating parameters are normal after the current time; the economics module is used for calculating the overall energy consumption and distributed energy consumption of cement production and comparing energy consumption data with international and domestic standard energy consumption index data; the on-line decision control module is used for optimizing raw material proportion and cement proportion of cement production and performing optimal control on a raw material mill system, a coal mill machine, a decomposition furnace, a pre-heater and a cement mill system. The cement production and optimization system disclosed by the invention integrates the functions of real-time production detection, optimal control and real-time production management, provides on-line analysis and guide, and can improve the operating safety and economy of the equipment.

Owner:武安市新峰水泥有限责任公司

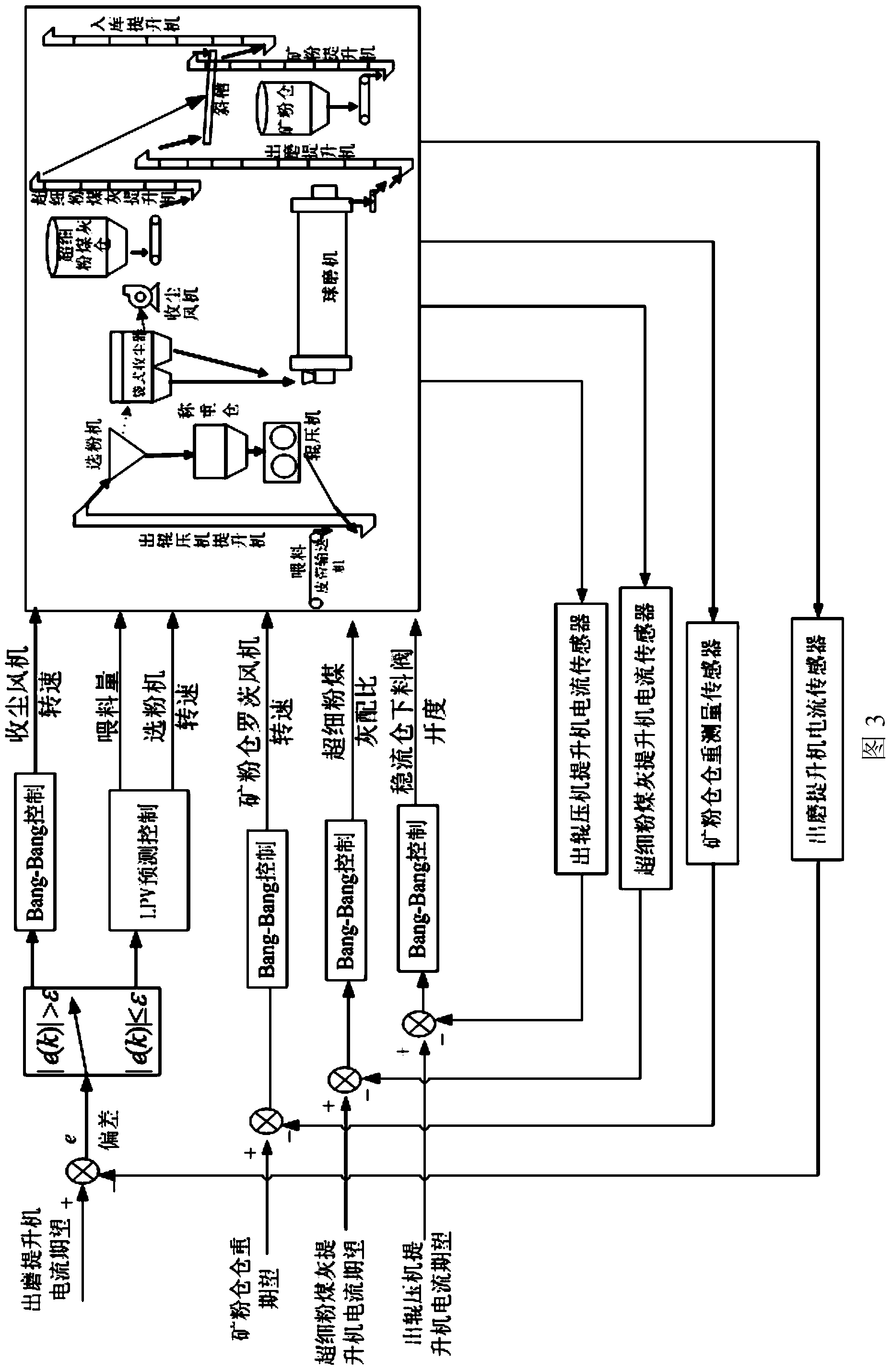

Cement combined-grinding prediction control method based on Bang-Bang control

ActiveCN104384009ASmall fluctuationAvoid the impact of subsequent controlGrain treatmentsControl theoryTime-variant system

The invention provides a cement combined-grinding prediction control method based on Bang-Bang control. The Bang-Bang control process is employed for mixing operation experiences such as observation, waiting, determination and adjusting of an operator into a control algorithm, the tracking error convergence rate is accelerated, and the system overshoot is reduced, and thus the combined-grinding system production process has good stability and the precise rapid control purpose is reached. Aiming at cement mill load control, LPV (Linear Parameter-Varying) prediction control is applied to solve control problems of variation and nondeterminacy of parameters of a linear time-varying system, and enable the system to have good robustness.

Owner:UNIV OF JINAN +1

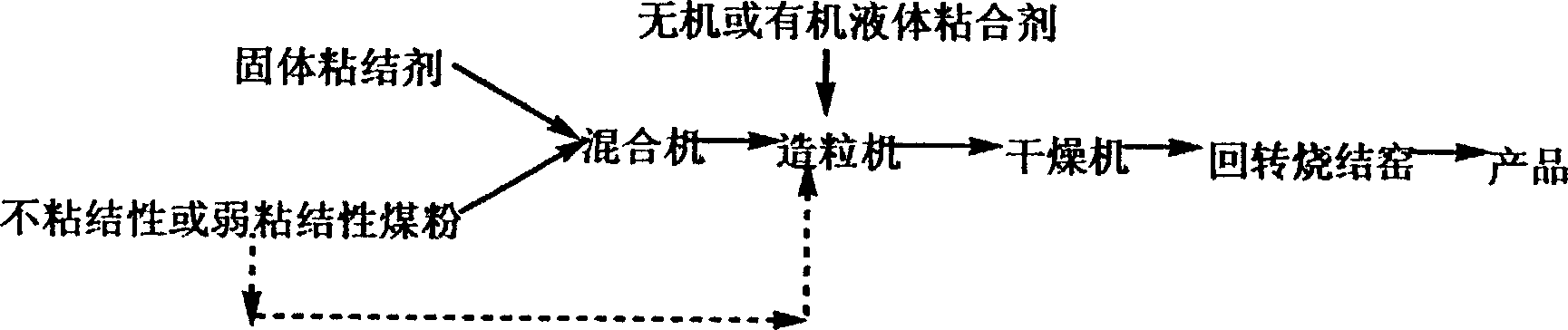

Making process of spherical porous coaly biological filtering material for processing waste water

InactiveCN1548385ALarge specific surface areaRealize added valueSustainable biological treatmentFiltration separationPorosityAdhesive

The present invention relates to the making process of spherical porous coaly biological filtering material for processing waste water. The making process with coal with poor adhesivity as main material includes adding small amount of inorganic-organic composite adhesive, crushing, pelletizing, drying and sintering. The spherical porous coaly biological filtering material is used specially for water treatment and has performance according with relevant environment protecting requirement. It has the main quality indexes of: specific surface area 20-100 sq m / g, average pore size 5-250 microns, apparent density 0.8-1.2 g / cu cm, bulk density 0.5-0.8 g / cu cm, porosity 30-60 % and ash content lower than 25 %. The product of the present invention may be produced with available production apparatus in cement mill, and the used product may be used as fuel, producing no secondary pollution.

Owner:SHANGHAI INST OF TECH +1

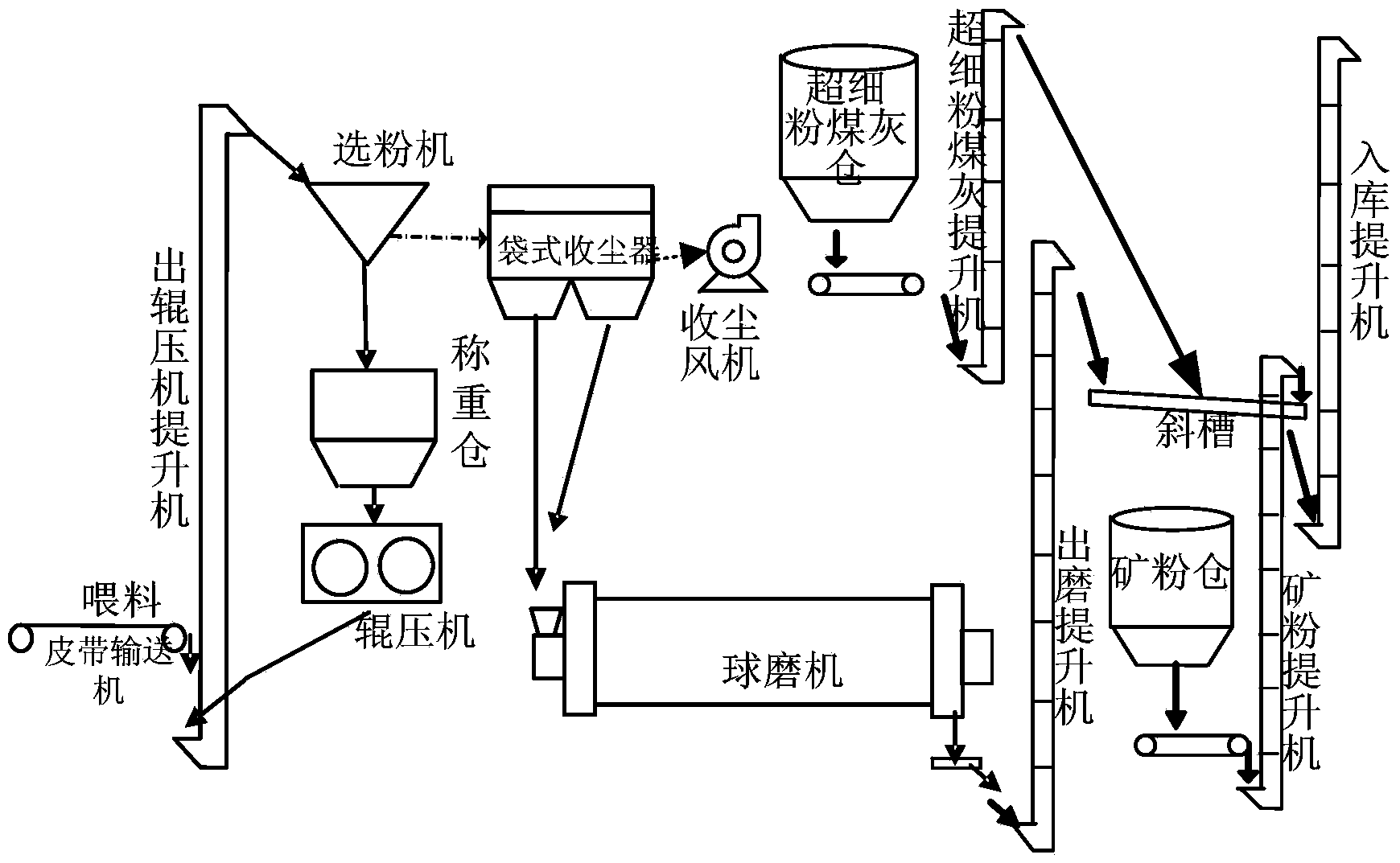

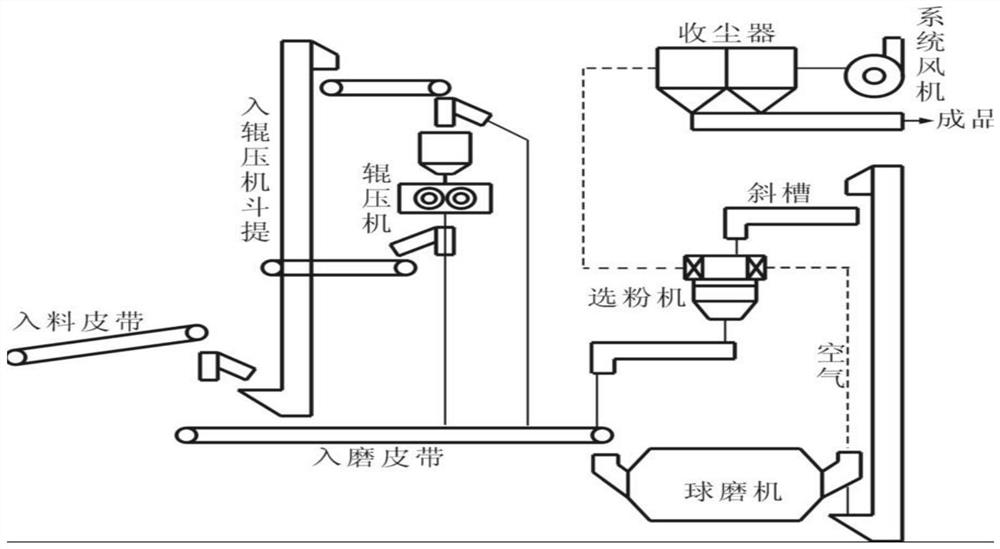

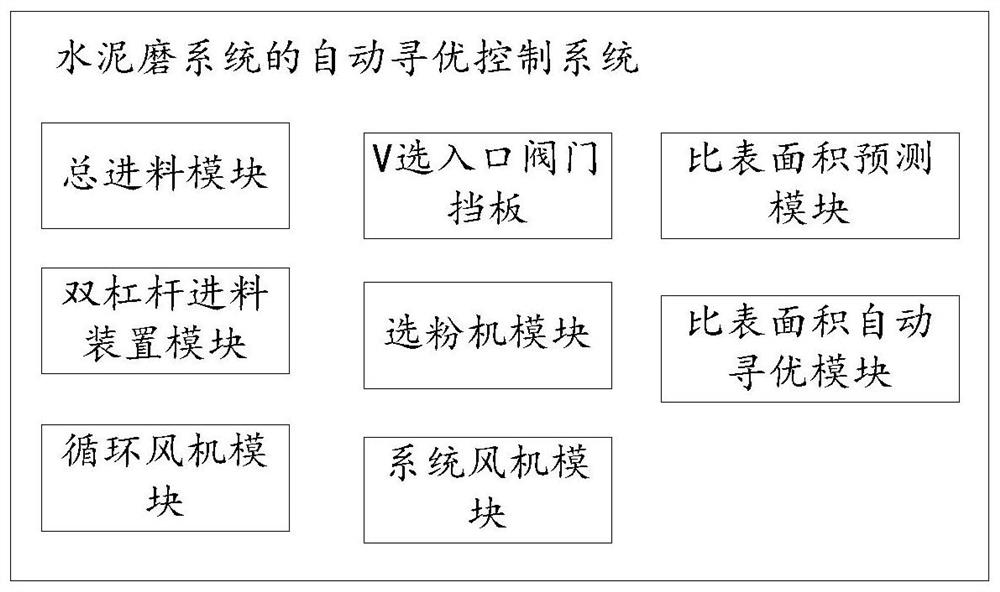

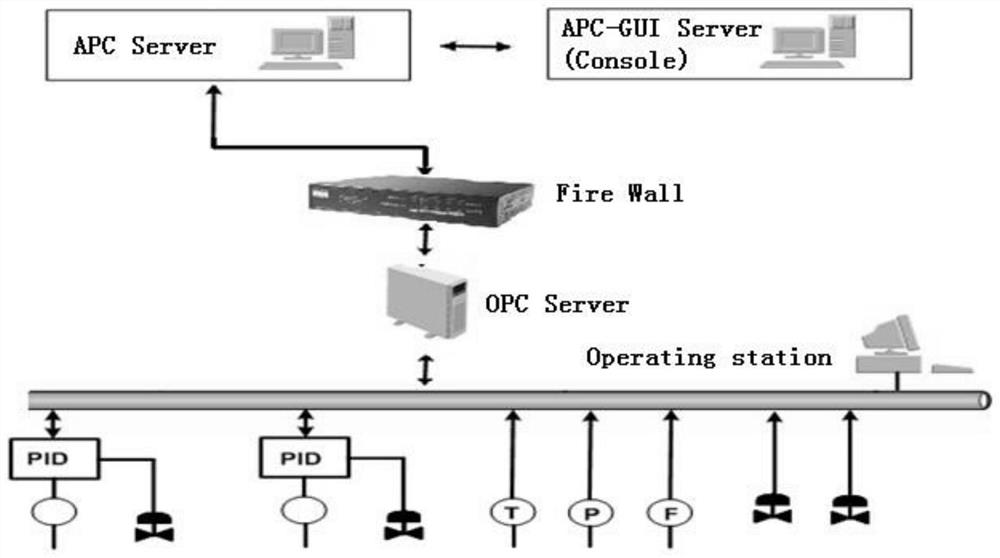

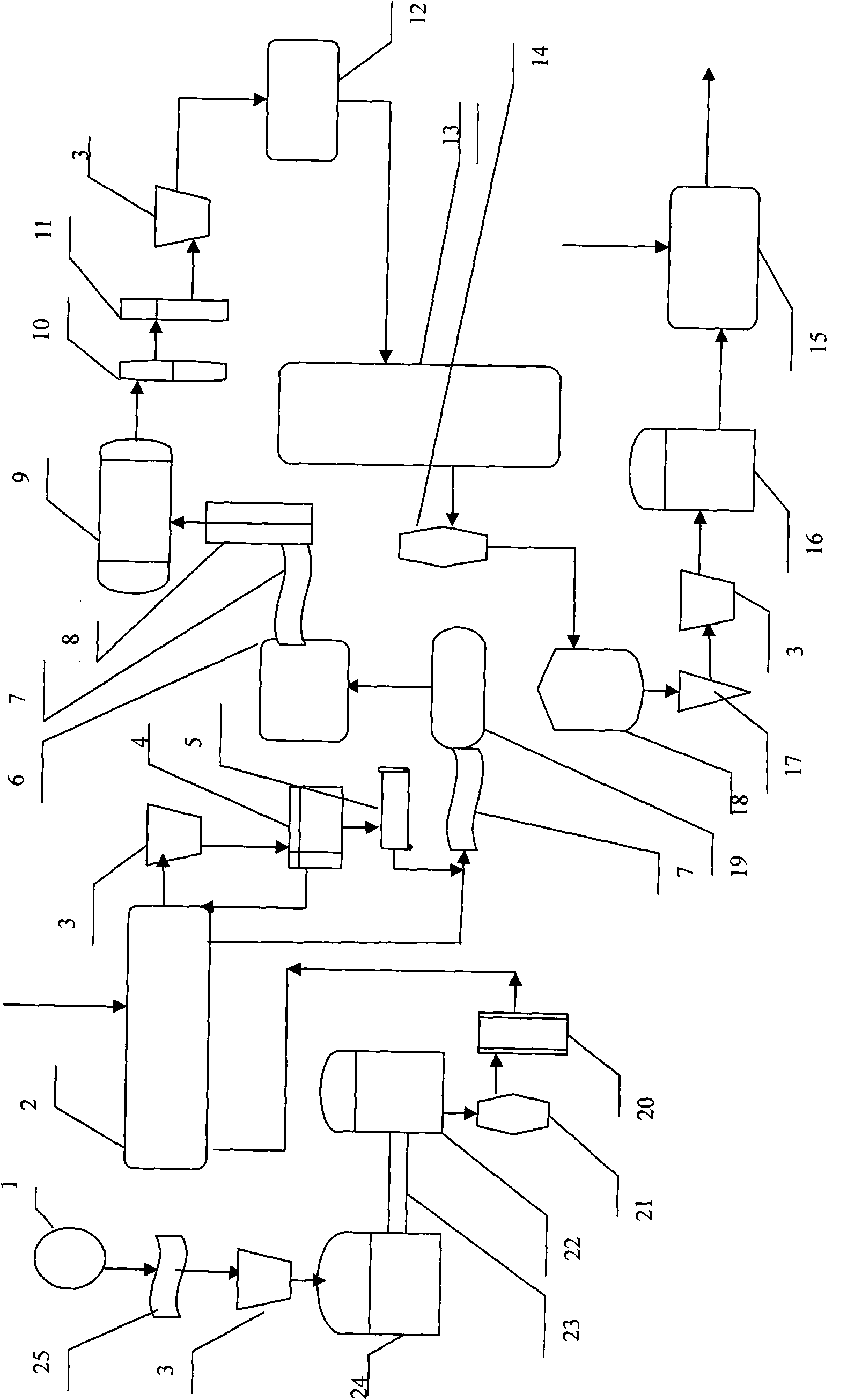

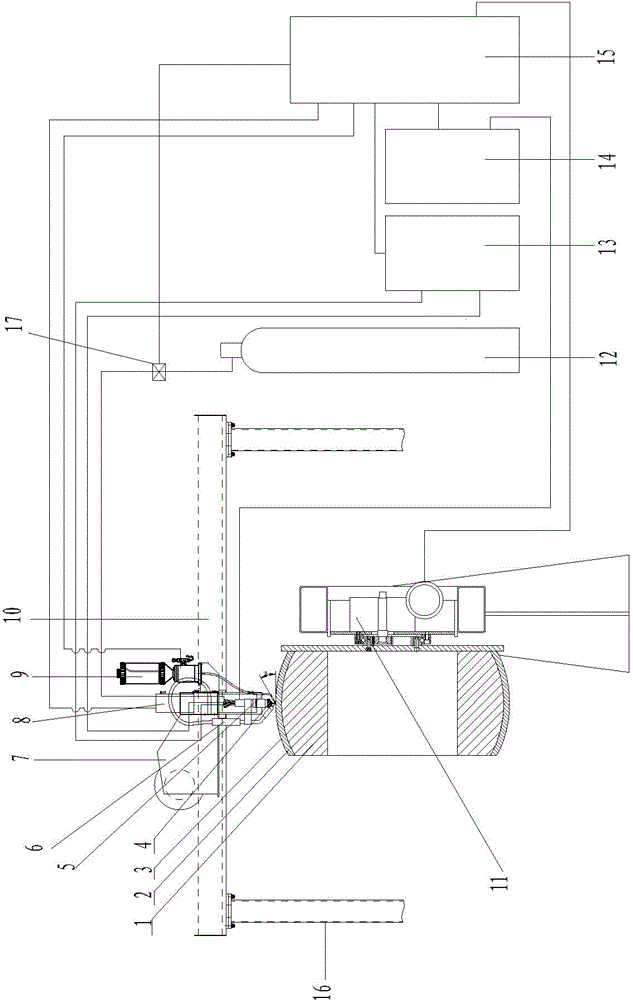

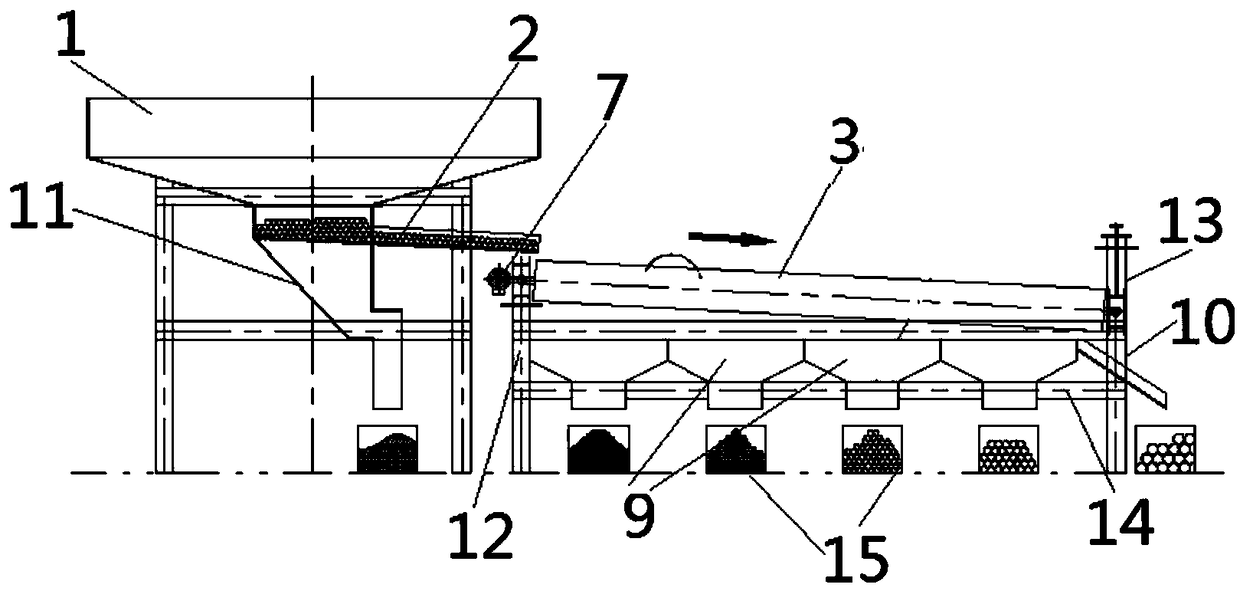

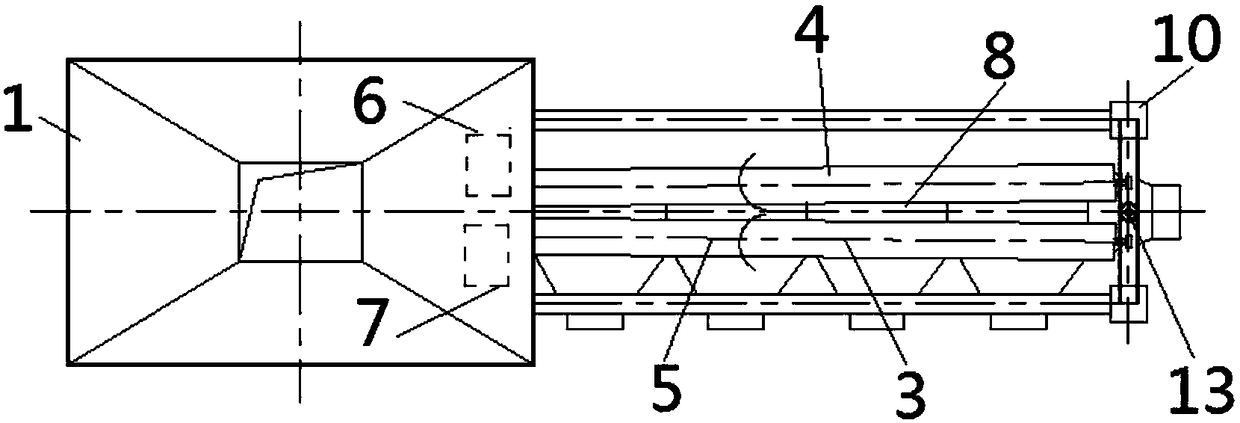

Cement mill system and automatic optimizing control system and method thereof

ActiveCN111701698AReduce consumptionIncrease productionGas current separationGrain treatmentsControl systemControl engineering

The invention relates to an automatic optimizing control system of a cement mill system. The automatic optimizing control system is used for controlling the operation of the cement mill system and comprises a total feeding module, a double-lever feeding device module, a circulating fan module, a V-type inlet valve baffle, a powder concentrator module, a system fan module, a specific surface area prediction module and a specific surface area automatic optimizing module, wherein the total feeding module is used for controlling the total feeding amount according to the bin weight of a steady flowbin and a grinding hopper lifting current; the double-lever feeding device module is used for controlling the opening degree of a feeding device according to a roller press current and a roller presslifting current; the circulating fan module is used for controlling the rotating speed of a circulator according to the grinding hopper lifting current and a main motor current; the V-type inlet valve baffle is controlled according to the total feeding amount; the system fan module is used for controlling the rotating speed of a powder concentrator according to the fineness quality; the system fan module is used for controlling the rotating speed of a system fan according to the fineness quality; the specific surface area prediction module takes corresponding measures according to the changetrend of the specific surface area; and the specific surface area automatic optimizing module is used for predicting and controlling a plurality of process parameters in real time and calculating thespecific surface area. The automatic optimizing control system of the cement mill system can increase the yield, reduce the specific energy consumption, stabilize the quality and improve the economicbenefits of cement production enterprises.

Owner:上海万澄环保科技有限公司

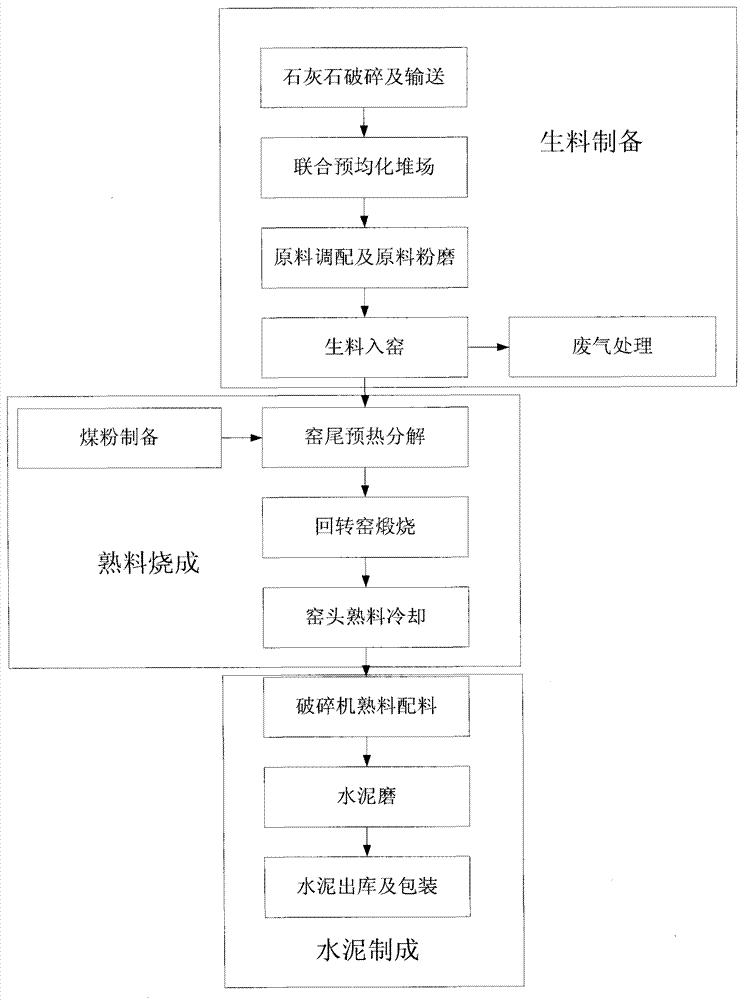

Technology for preparing cement by dry carbide slag method

ActiveCN101560067ASolve the land occupation of stackingSolve processingClinker productionSlagMoisture

The invention relates to a technology for preparing cement by a dry carbide slag method, which comprises the following steps: raw material storage, transportation, mixture, calcinations, grinding, and the like. Dry carbide slag powder with the moisture from 5 percent to 8 percent, which is discharged by a dry acetylene technical generator, is sealed, transported and stored by a pipe chain machine and a bucket lifting machine; stored raw materials and black raw materials ground in a drying process comprise aeolian sand, sulfate slag and lime slag; carbide ash is transported to a dry pipe by an FU chain transporting machine for initially mixing and drying after being automatically matched and ground by a reservoir bottom microcomputer; raw materials with the moisture which is less than 1 percent are collected by a high-efficiency cyclonic collector and are transported to a raw material homogenizing storehouse to mix by gravity; the raw materials are calcined from a three-grade preheater and a decomposing furnace to a rotary kiln; and after the raw materials are cooled, the raw materials, fly ash, carbide ash and citric acid slag are transported to a cement mill to grind after being metered by a speed-regulating constant feed weigher. The technology increases the participation quantity and the economic benefit of the carbide slag, reduces the environmental pollution and the resource waste, can be used by combining the dry acetylene producing technology and the traditional technology and can be singly used.

Owner:天能水泥有限公司

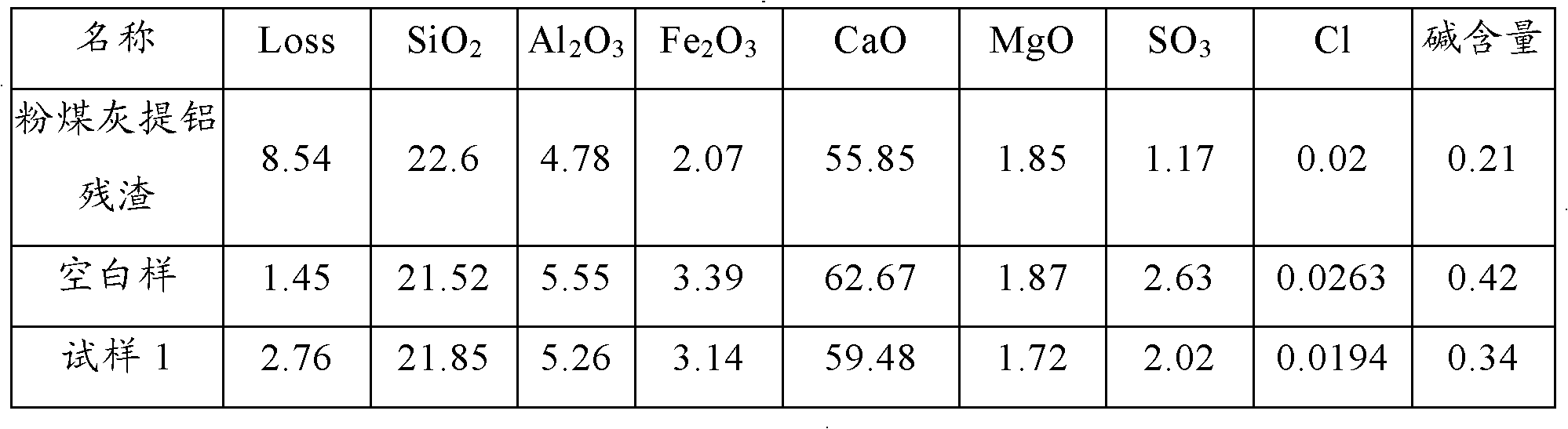

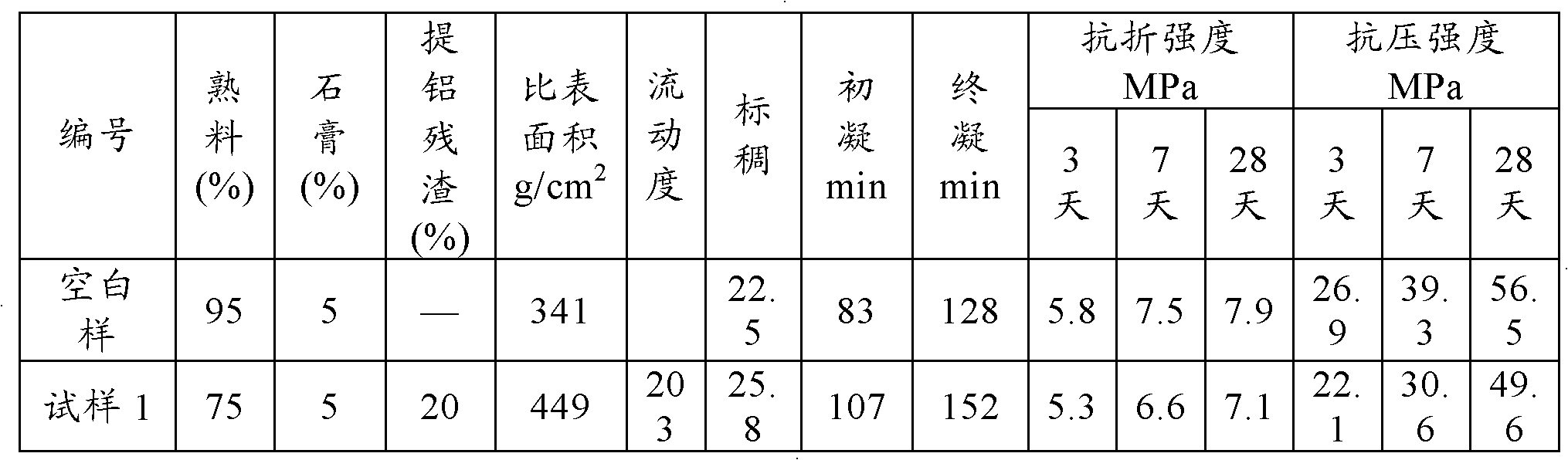

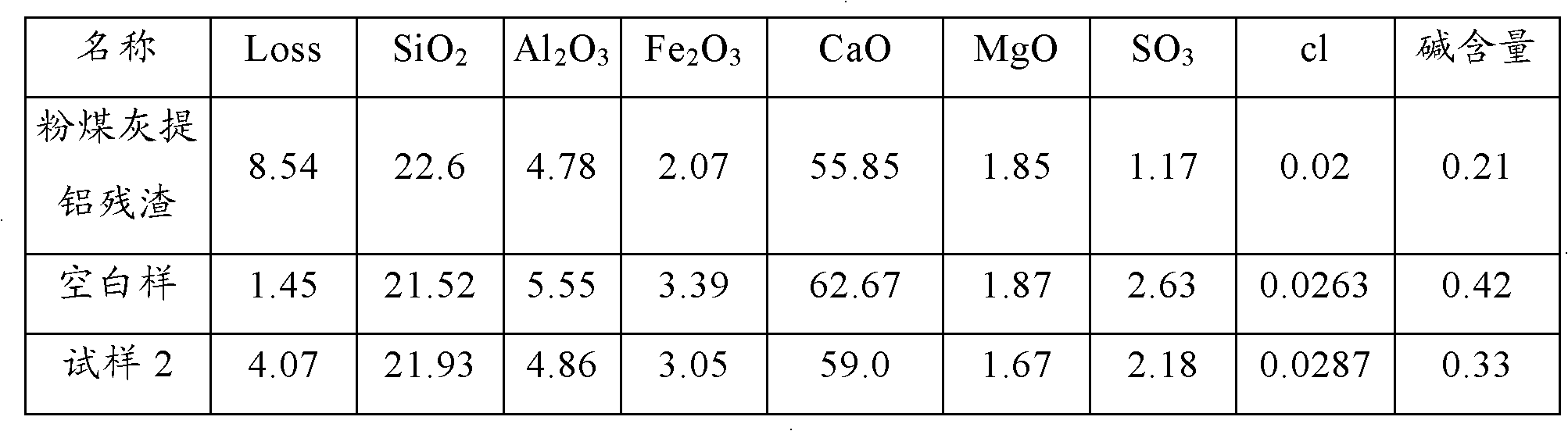

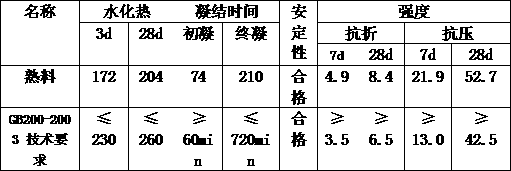

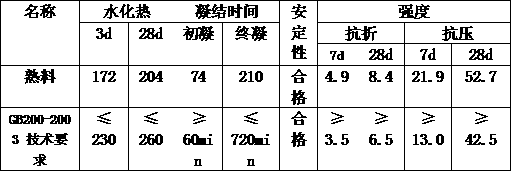

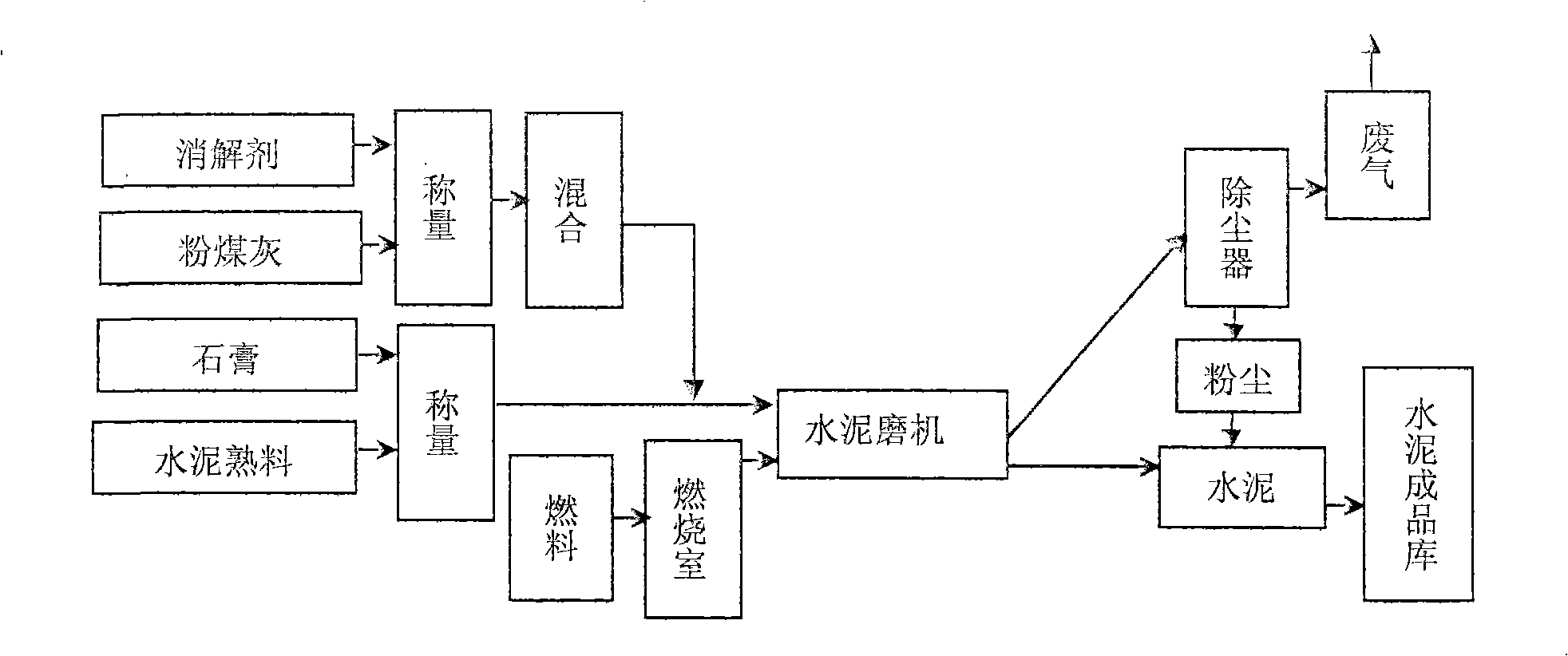

Fly ash aluminum extraction residue cement

InactiveCN102276175AWear value is smallReduce wearCinker content reductionUltimate tensile strengthFly ash

The invention discloses a fly ash aluminum extraction residue cement, which is prepared from raw materials in the following weight proportions: 10-50 parts of fly ash aluminum extraction residue; 90-50 parts of clinker; and 1-5 parts of gypsum. After the above raw materials are mixed according to the ratio, they are sent to the cement mill, and the coarse powder is selected by the powder separator and returned to the cement mill, and the fine powder is directly sent to the cement storehouse to be the fly ash aluminum extraction residue cement. The performance of the fly ash aluminum extraction residue cement of the present invention meets the requirements of the 32.5 or 42.5 label. It overcomes many shortcomings of the prior art and realizes the advantages of simple and easy-to-obtain raw materials, scientific and reasonable process, small investment in equipment, good physical and chemical properties of cement, high early strength, and relatively stable strength increase.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

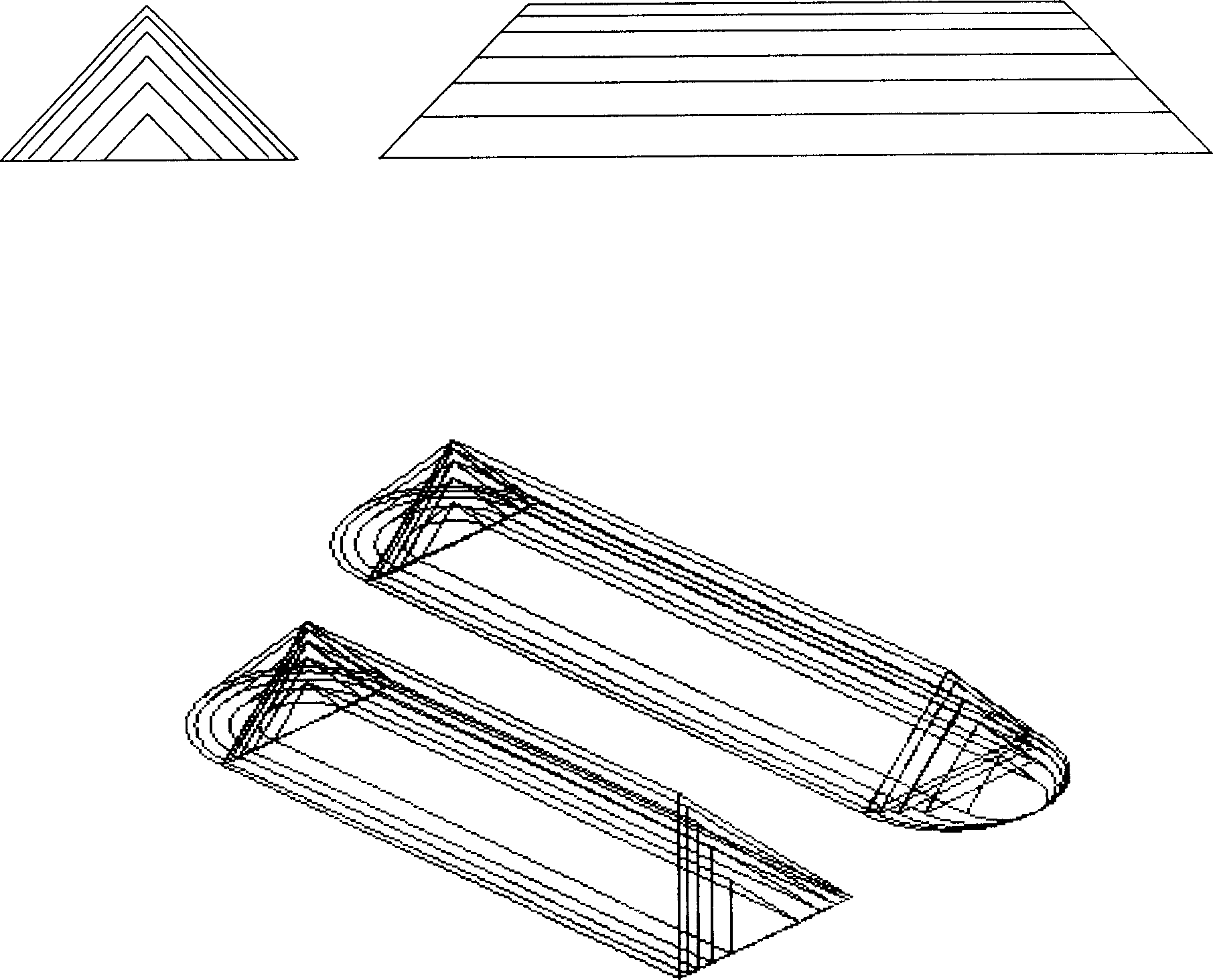

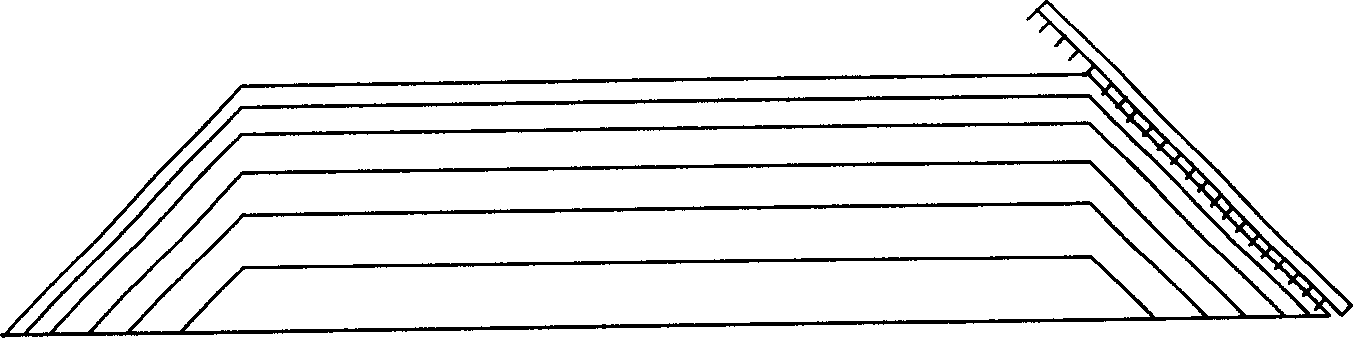

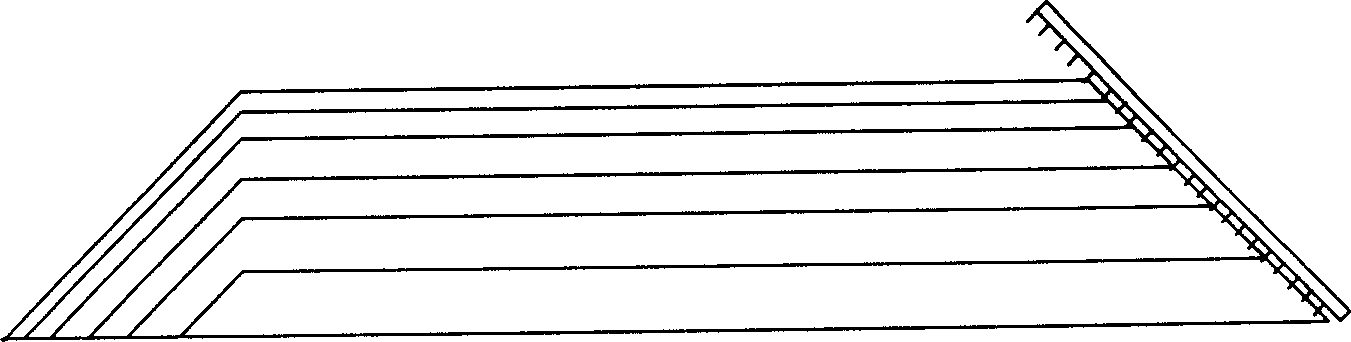

Materials piling method at end of rectangular pre-equalizing materials field

InactiveCN1817769AGuaranteed mixing effectEliminate the "end pile effect"Loading/unloadingProgramme control in sequence/logic controllersStack machineEngineering

A material stacking method for the stack end in rectangular pre-homogenized raw materials field of cement mill features that when the stacking machine moves the right end of a stack, its return point is shifted left by a certain distance as compared with previous return point, and it stays for a certain time for stacking. The higher the stack, the less the shift and the longer the stacking time.

Owner:沈阳矿山机械有限公司

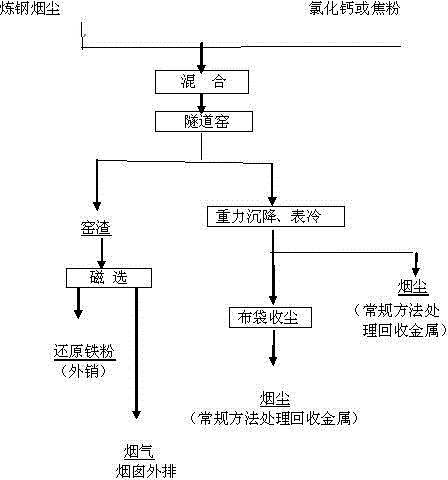

Method for recovering nonferrous metals, rare and noble metals and iron powder from steelmaking flue dust

InactiveCN106282582AEfficient separationImprove thermal efficiencyProcess efficiency improvementSteelmakingResource utilization

The invention provides a method for recovering nonferrous metals, rare and noble metals and iron powder from steelmaking flue dust. The method comprises the following steps: mixing the steelmaking flue dust with a chlorination agent and a reducing agent, adding the obtained mixture to a tunnel furnace, and carrying out a two-stage reaction, wherein a primary stage reaction is a medium temperature chlorination reaction and allows nonferrous metals and precious metals to volatilize and enter flue gas, the flue gas is used as a nonferrous metal and precious metal extraction raw material after dusts are collected, and a secondary stage reaction is a high temperature reduction reaction and reduces iron into elemental iron which is discharged with kiln slag; and carrying out cooling, crushing and ball milling on the kiln slag to form a slag slurry with the granularity being smaller than 60 meshes, and carrying out magnetic separation to obtain the elemental iron powder and waste slag, wherein the iron content of the iron powder is greater than 86%, the iron powder can be used as commercial reduced iron powder, and the waste slag is sold to cement mills. The method allowing the chlorination and reduction metallurgy processes to be carried out in the tunnel furnace in a segmental manner has the advantages of process simplification, simplicity in operation, high thermal efficiency, low production cost and high comprehensive utilization rate, and is a new way for reasonable recovery of valuable metals in the steelmaking flue dust and high-efficiency resource utilization.

Owner:KUNMING METALLURGY COLLEGE

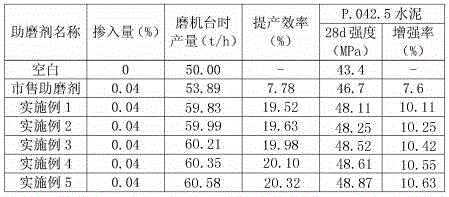

Liquid cement grinding aid

InactiveCN102115315AIncrease late strengthImprove mill grinding efficiencyCement millSodium lignosulfonate

The invention relates to a liquid cement grinding aid capable of increasing the grinding efficiency of a cement mill and enhancing cement strength. The liquid cement grinding aid is prepared from the following components in percentage by weight: 10-20 percent of triethanolamine, 5-10 percent of tri-isopropanolamine, 2-5 percent of diethylene glycol, 2-5 percent of sodium formate, 2-5 percent of sodium acetate, 1-3 percent of sodium lignosulphonate and the balance of water.

Owner:山东国元新材料有限公司

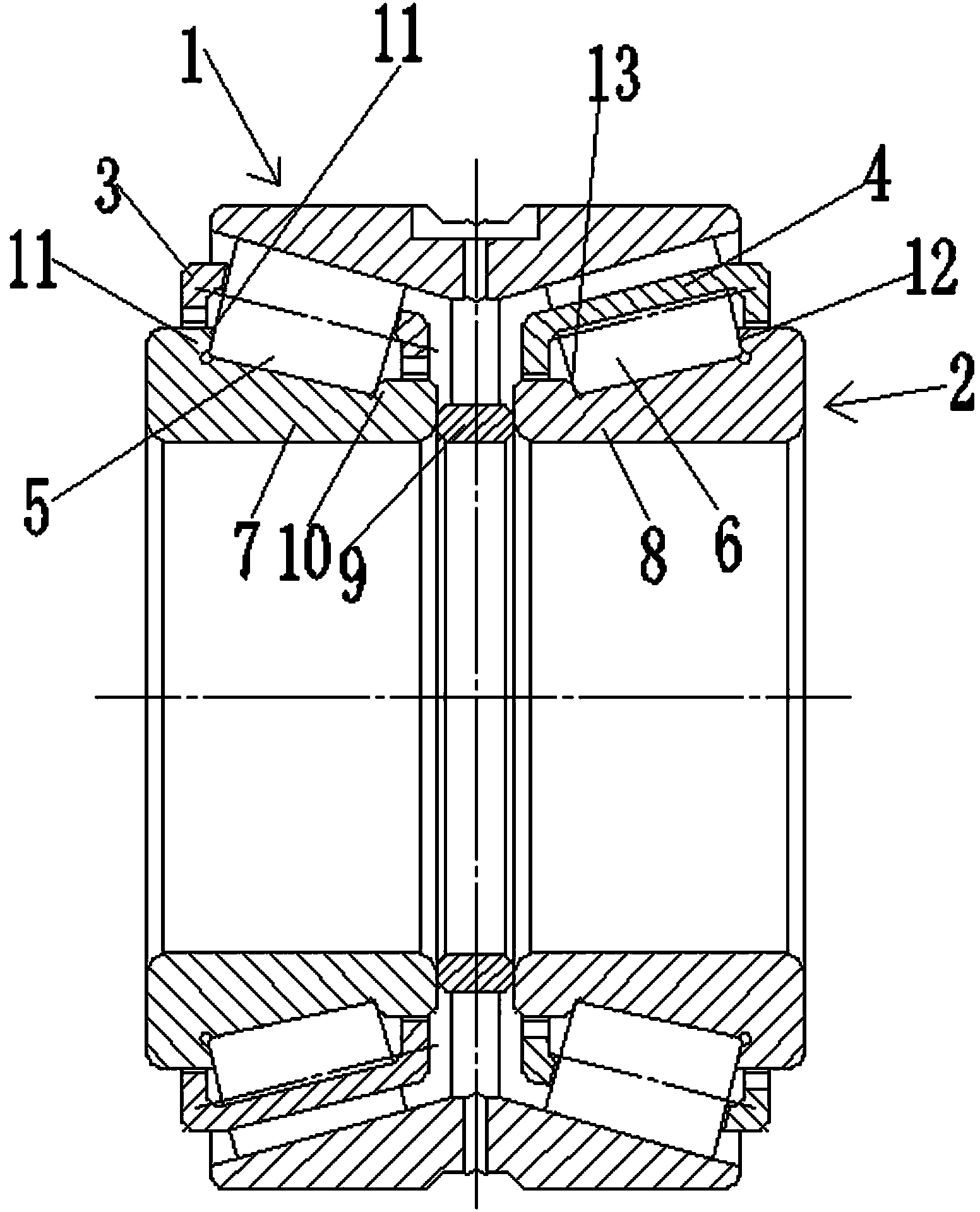

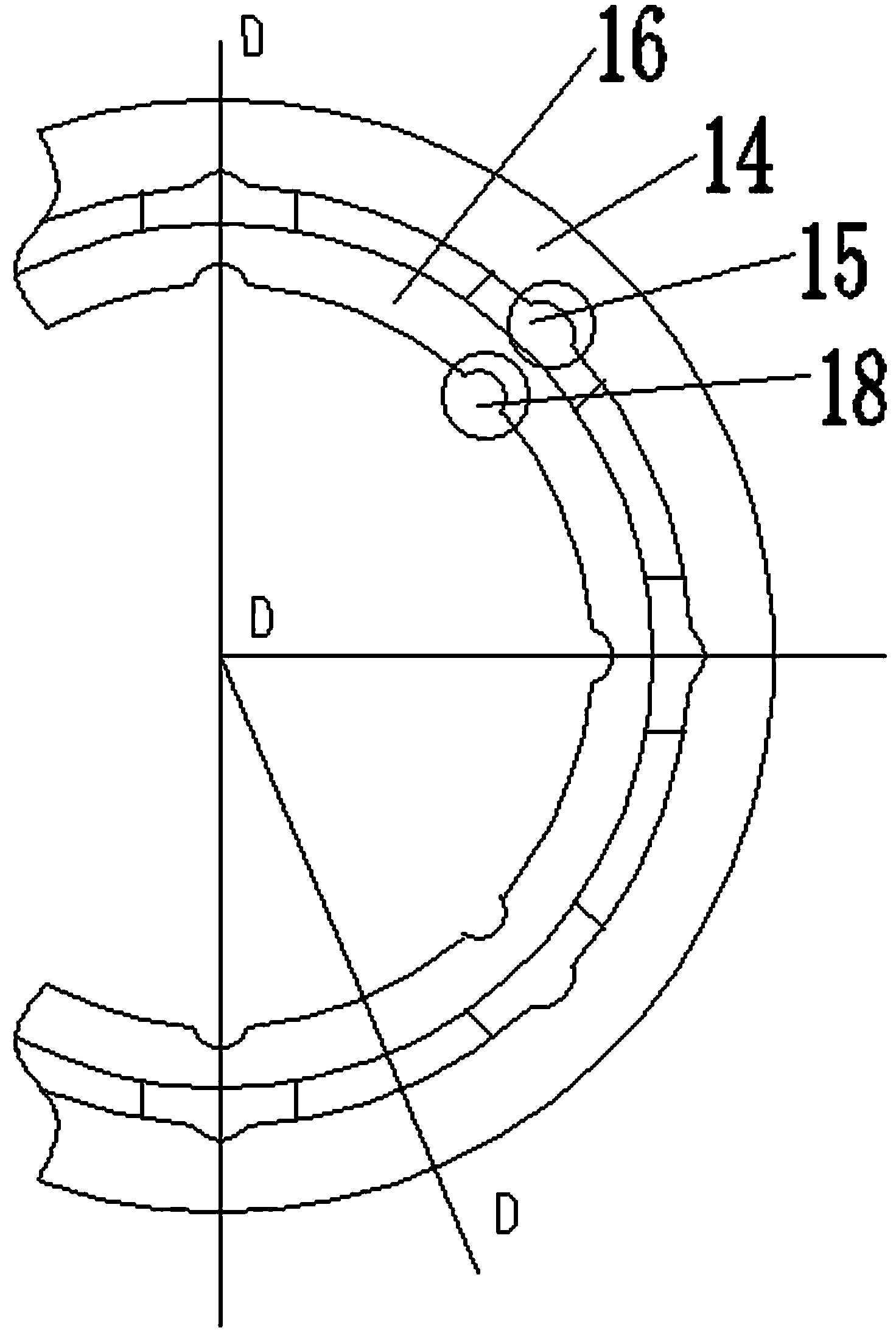

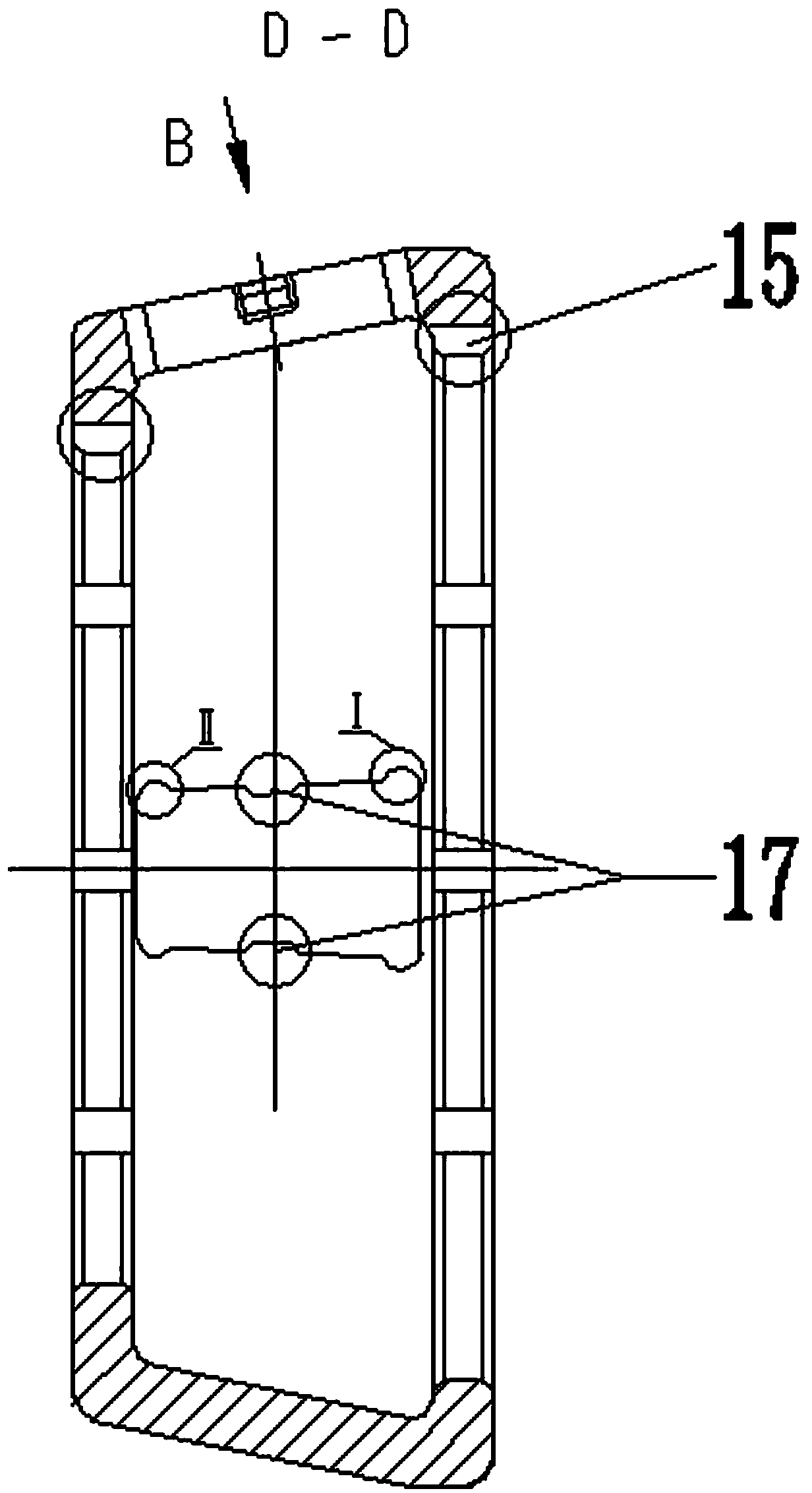

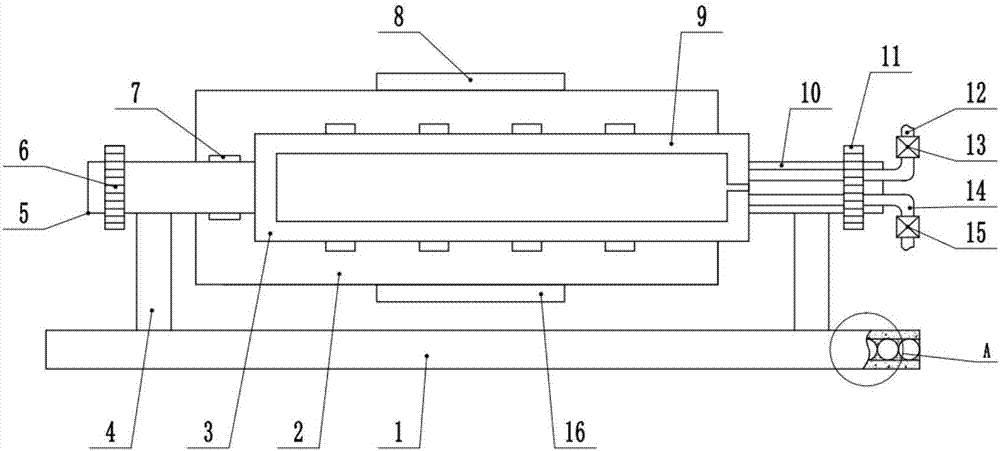

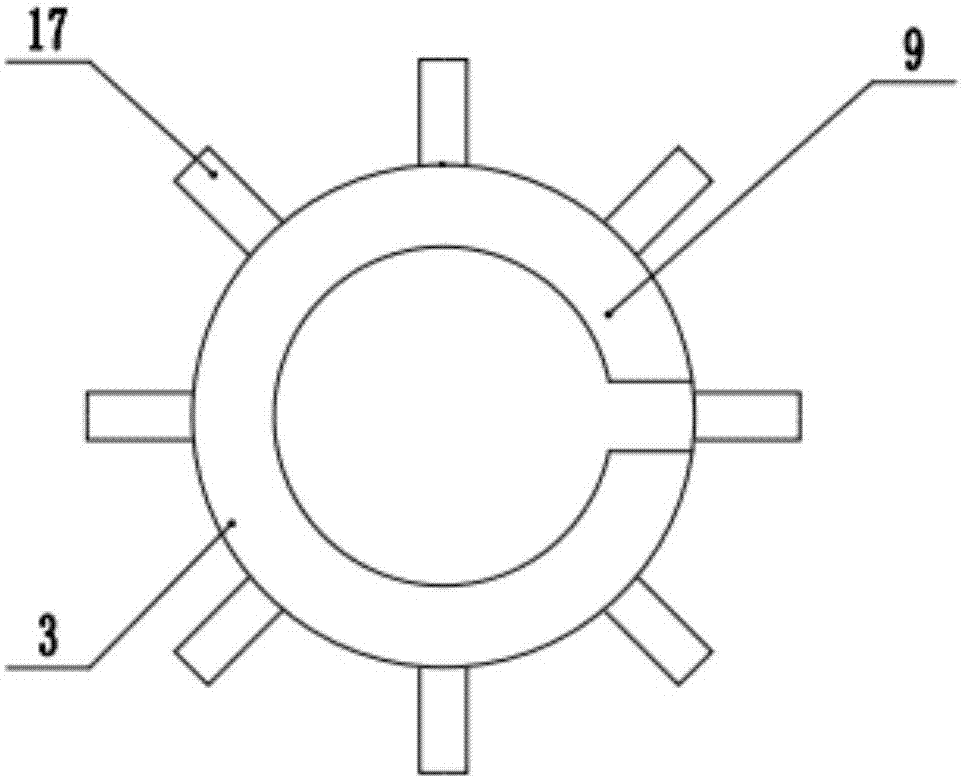

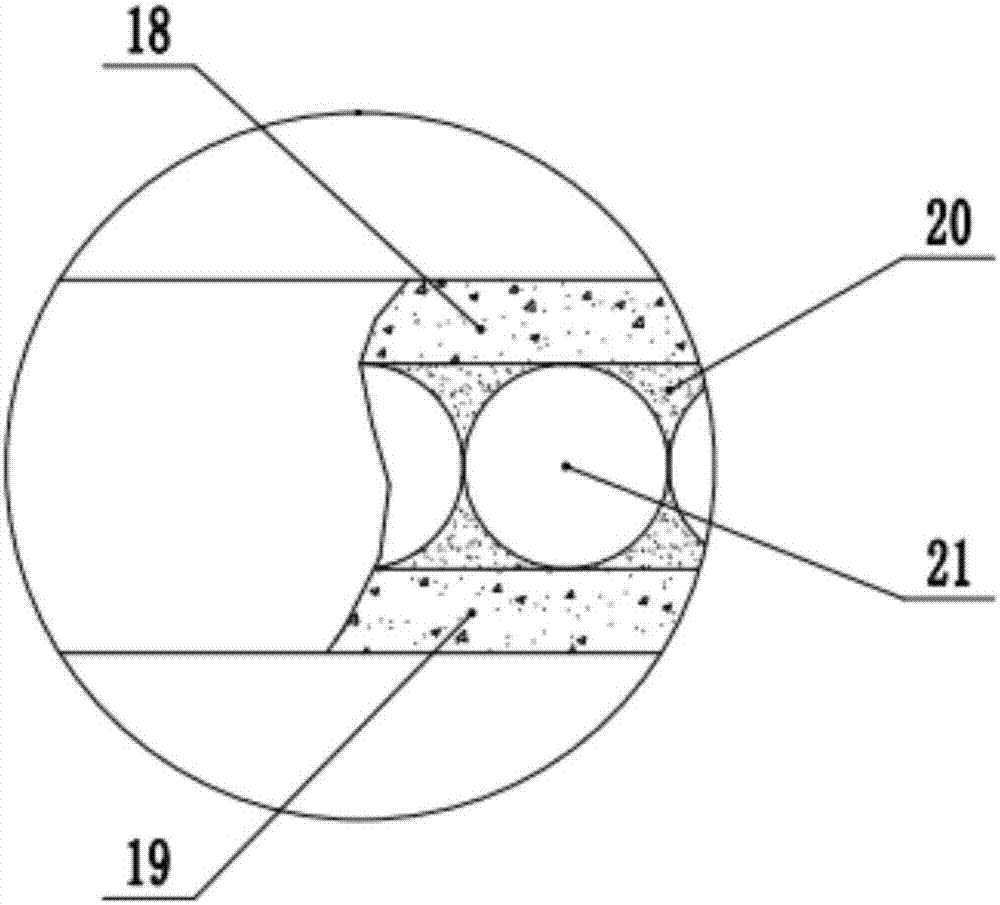

Special bearing for speed reducer of vertical cement mill

InactiveCN103410853AReduce frictionImproved high-rpm performanceRoller bearingsBearing componentsReducerLubrication

A special bearing for a speed reducer of a vertical cement mill is formed by assembling an outer ring, an inner ring, a first retainer, a second retainer, a first row of rolling bodies and a second row of rolling bodies and is a back-to-back double-row tapered roller bearing. The bearing is characterized in that (1) the inner ring is composed of a first half inner ring and a second half inner ring; an inner spacer ring is arranged between the first half inner ring and the second half inner ring; each rolling body is a tapered roller; (2) the guide clearance between the large flange and the small flange of the first half inner ring is consistent with the inner diameter guide clearance of the first retainer; the large flange and the small flange of the first half inner ring are used for guiding the first retainer; the guide clearance between the large flange and the small flange of the second half inner ring is consistent with the inside diameter guide clearance of the second retainer; the large flange and the small flange of the second half inner ring are used for guiding the second retainer; a plurality of first lubrication grooves are equidistantly formed in the large end of the first retainer; a plurality of second lubrication grooves are equidistantly formed in the small end of the first retainer. The bearing has the advantages that the stationarity at high rotating speed is high, the lubricity is high, and the service life is long.

Owner:DALIAN METALLURGICAL BEARING

Double-barrel ball mill for massive cement

InactiveCN107159400AQuick flipImprove grinding efficiencyNon-rotating vibration suppressionGrain treatmentsCushioningBall mill

The invention discloses a double-barrel ball mill for massive cement. The double-barrel ball mill for the massive cement comprises a base, an outer barrel and an inner barrel; the outer barrel is arranged on the inner side of the inner barrel in a sleeving manner, a first rotating shaft is fixedly connected to the left side of the outer barrel, and the left end of the first rotating shaft is rotationally installed on a supporting frame; a second rotating shaft is fixedly connected to the right end of the inner barrel, and is rotationally installed on the portion, on the right side of the base, of the supporting frame; a plurality of material overturning plates are evenly arranged outside the inner barrel; an annular cavity is further formed in the inner wall of the inner barrel; and a first shock absorbing layer and a second shock absorbing layer are arranged in the base. The design of the double barrels opposite in rotating direction is adopted for the double-barrel ball mill for the massive cement, the powder grinding efficiency is high, the material overturning plates are arranged on the surface of the inner barrel and promote overturning of cement blocks and steel balls, and the powder grinding efficiency is further improved; the annular cavity is further formed in the inner barrel so that cold water can be conveniently introduced to lower the temperature of the inner space of the outer barrel, and it is prevented that abrasion is serious when the steel balls are heated; and the shocking absorbing base is further arranged, and the stability of the device is improved.

Owner:殷志成

Method for preparing composite ceramic alloy layer on grinding roller/lining tile through plasma wire filling and powder feeding

ActiveCN103556147AImprove wear resistanceEasy to installMetallic material coating processesWear resistantComposite ceramic

The invention relates to a method for preparing a composite ceramic alloy layer on a grinding roller / lining tile through plasma wire filling and powder feeding in order to effectively solve the problems of poor surface wear resistance and short service life of the grinding roller / lining tile of a medium-speed coal mill / vertical cement mill. The method comprises the steps of firstly, mounting equipment, carrying out clearing and interior flaw detection on the worn surface of the grinding roller / lining tile to be subjected to fusion covering, mounting the grinding roller / lining tile on a positioner of the equipment, and placing a plasma torch on a place 20-30mm away from the upside of the worn surface of the grinding roller / lining tile to be subjected to fusion covering; then, starting power sources of the positioner and the plasma torch, an argon storage tank, a water chiller, a wire feeder and a powder feeder to work under the control of a controller, delivering welding wires and ceramic powder to the worn surface of the grinding roller / lining tile to be subjected to fusion covering by using the wire feeder and the powder feeder, and enabling the welding wires and the ceramic powder to be fused and covered on the worn surface of the grinding roller / lining tile under the fusion of the plasma torch to form a wear-resistant ceramic alloy layer. The method provided by the invention is easy to operate, high in work efficiency, good in effect and capable of effectively improving the wear resistance of the grinding roller / lining tile, greatly prolonging the service life of the grinding roller / lining tile and saving the cost.

Owner:洛阳骄一新材料科技有限公司

Preparation method for calcining Portland cement clinker from oil-based drill cuttings

The invention discloses a preparation method for calcining a low-hydration heat Portland cement clinker from oil-based drill cuttings, and relates to the technical field of oil-based drill cutting treatment. The preparation method comprises the following steps: pretreating diesel oil-based drill cuttings, uniformly mixing limestone, a high-iron aluminum waste stone, the pretreated diesel oil-baseddrill cuttings and non-ferrous metal slag according to a certain ratio, then grinding into raw meal, then feeding the raw meal into a novel dry-process rotary kiln, performing high-temperature calcination, and cooling to obtain the clinker. By the preparation method, major difficulties troubling oilfield drilling exploitation can be overcome, enrichment of heavy metal ions such as copper, zinc, lead, chromium, mercury and barium in the diesel oil-based drill cuttings in nature can be reduced, and damage to groundwater and soil can be reduced; diesel oil and organic substances in the drill cuttings can provide heat in the clinker calcinating process, so that the energy consumption of the clinker can be significantly reduced, the CO2 emission can be reduced, the clinker calcinating temperature can be lowered, the outputs of a cement mill and the rotary kiln are obviously increased, the burnability of the raw meal is enhanced, the liquid phase content of the clinker is increased, latticedefects of dicalcium silicate in the clinker are increased, the activity of the dicalcium silicate is improved, and the hydration heat value of cement is reduced.

Owner:JIAHUA SPECIAL CEMENT

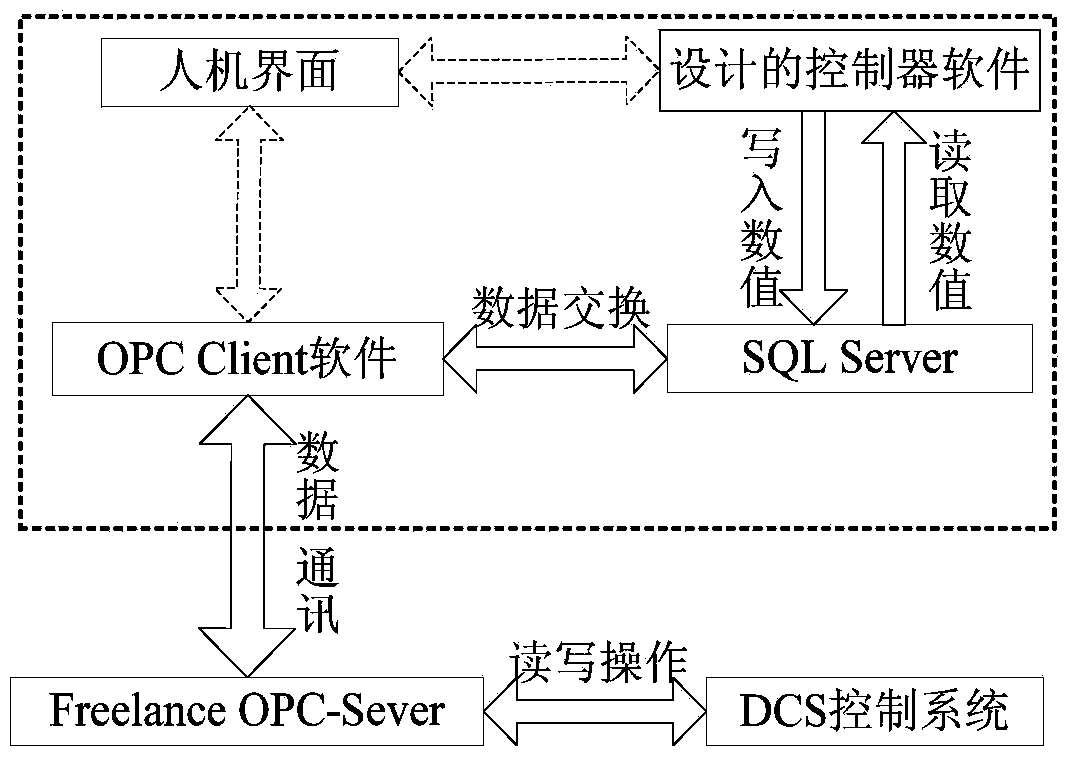

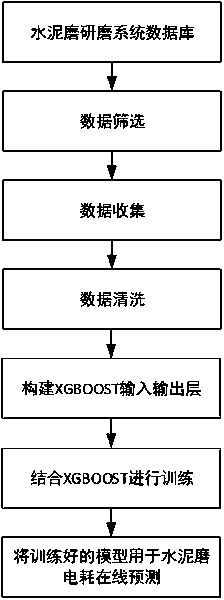

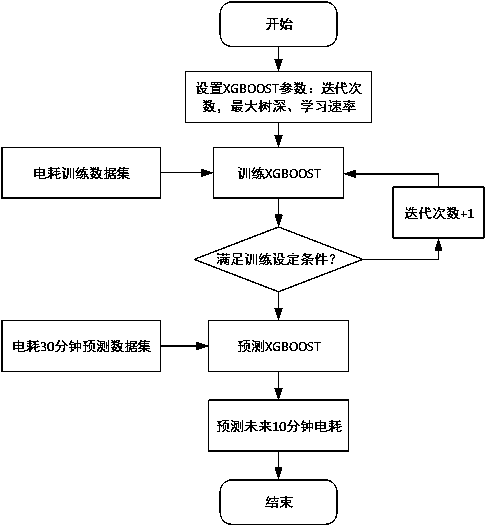

Cement grinding mill system power consumption index prediction method based on XGBoost

PendingCN110910277AEliminate the effects ofRealize online predictionForecastingData setProcess engineering

The invention discloses a cement grinding mill system power consumption index prediction method based on XGBoost. The cement grinding mill system power consumption index prediction method comprises the following steps: selecting eight variables related to the power consumption of the cement mill; collecting required variable data by adopting an OPC technology; removing abnormal data by adopting anartificial experience removal method and criterion; constructing an XGBoost model input and output layer; initializing a weight parameter according to the sample data; training a first tree accordingto the weight; updating the weight parameter according to the target function after the training is finished; performing a new round of decision tree training; when the weight sum of the samples is smaller than a set threshold value or the number of iterations reaches a set value, stopping tree building; completing the training of the XGBoost model; and substituting the industrial field sample data set into the trained model to complete the online prediction of the power consumption index of the cement grinding mill system, training the sample data through XGBoost, and inputting the variabledata of the actual cement production field into the trained model to realize the online prediction of the power consumption index of the cement grinding mill.

Owner:YANSHAN UNIV

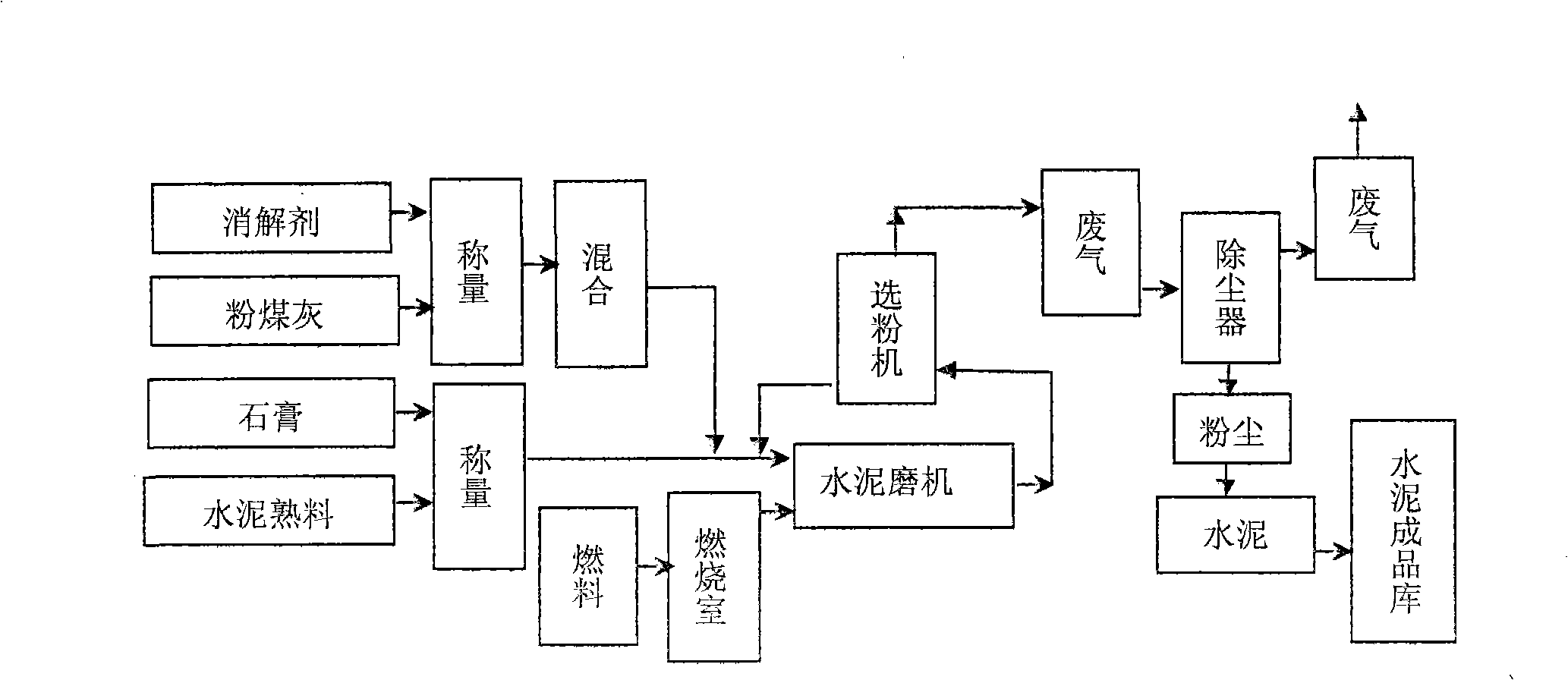

Method for preparing high-calcium fly-ash cement with high-calcium fly-ash

The invention discloses a process for preparing high calcium fly ash cement by high calcium fly ashes. A combustion chamber is arranged at the head part of the existing ball mill for pre-mixing measured high calcium fly ashes and a digesting agent and then feeding measured cement clinker, gypsum, blast furnace slag, etc. into a ball mill for ball grinding; and the material temperature in the mill is rising under the mechanical action of the mill, additionally, the grinding head combustion chamber provides heat, so the water in the digestion solution is evaporated and the digestion solution and free calcium oxide in the high calcium fly ashes have the mechanical and chemical action, the free calcium oxide digestion is realized during the cement grinding process, and finally the high calcium fly ash cement is prepared. The process is simple and needs not to add the special high calcium ash treating process before producing the cement, the free calcium oxide digestion effect is obvious, the mixing amount of the high calcium ashes in the cement can be greatly increased and the cement manufacturing cost is reduced. The process overcomes the defect that the humidity-control and digestion of fly ash free calcium oxide need two to seven days, and can implement the continuous production, and the ball-milling efficiency of the cement mill is improved by over 10 percent in the meantime.

Owner:榆林恒源利尔新型建材科技有限公司

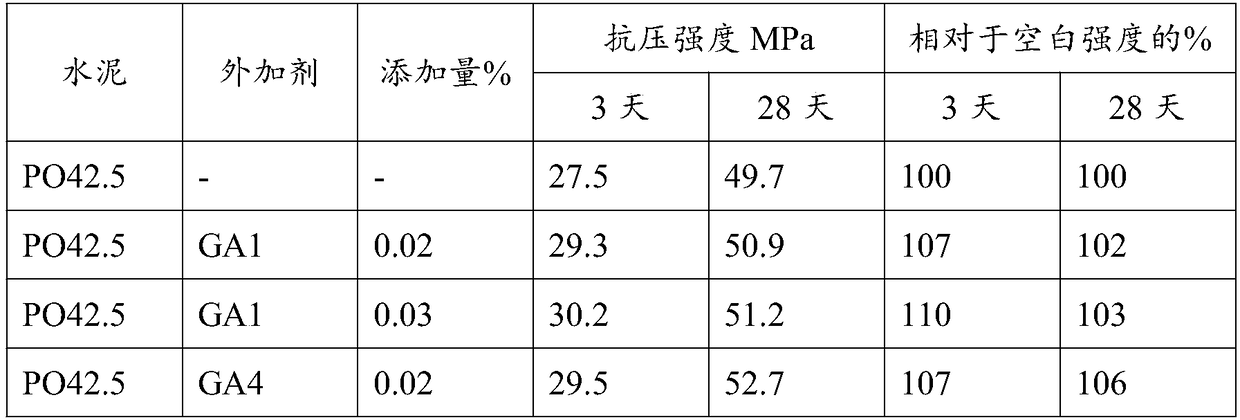

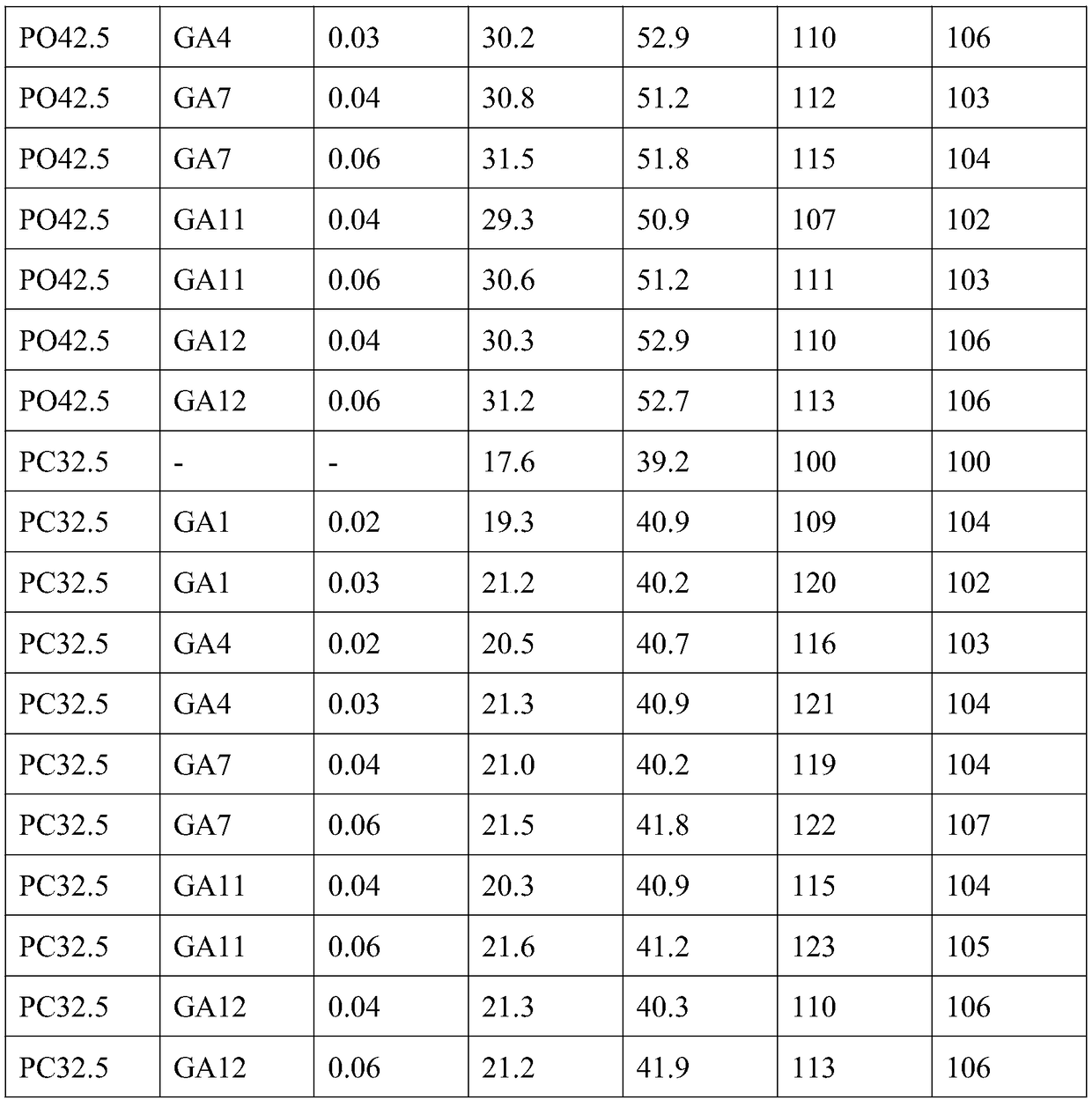

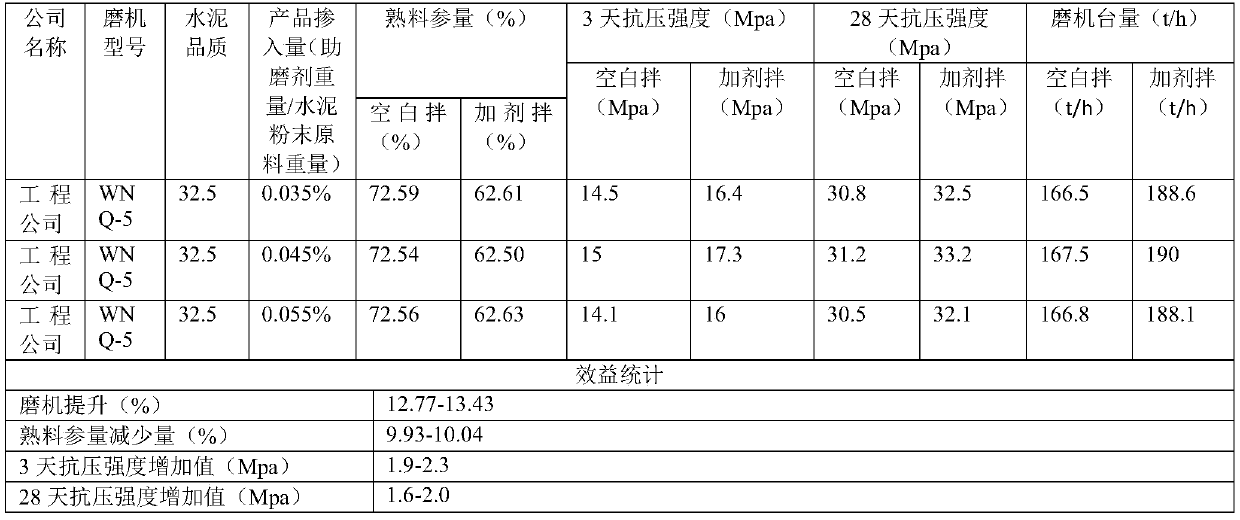

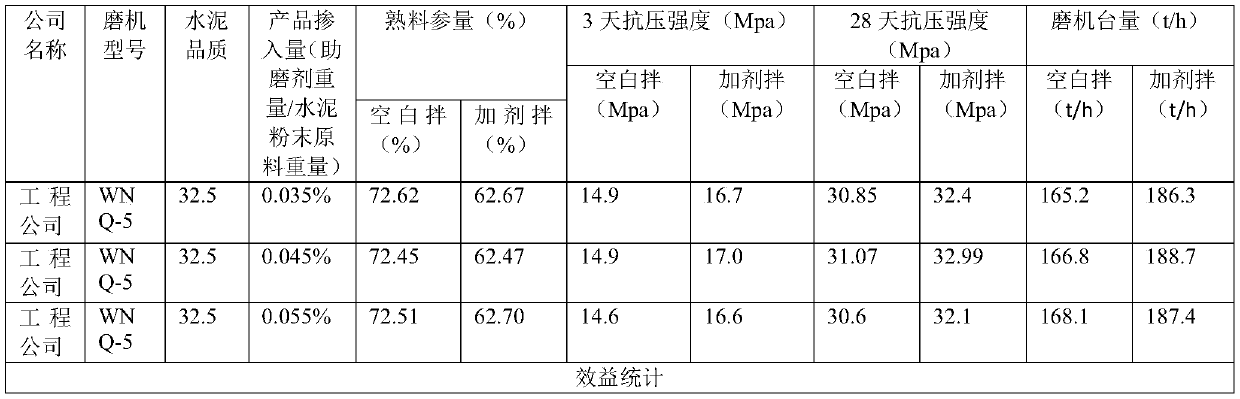

Improved cement grinding aid

InactiveCN104860565AIncrease late strengthImprove mill grinding efficiencySodium acetateEnvironmental resistance

The invention relates to an improved cement grinding aid. The improved cement grinding aid is characterized by comprising components in parts by weight as follows: 15-25 parts of triethanolamine, 2-8 parts of polytetrafluoroethene, 3-6 parts of propylene glycol, 2-5 parts of xanthan gum, 5-10 parts of sodium nitrite, 3-8 parts of calcium lignosulfonate, 5-10 parts of sodium acetate, 5-10 parts of a water-retention material, 5-10 parts of a papermaking black liquid, 6-12 parts of industrial salt and 5-10 parts of molasses. With the adoption of the improved cement grinding aid, the grinding efficiency of a cement mill can be remarkably improved by 8%-15%, the early strength of cement can be properly increased by 2-3 MPa, and the late strength of the cement can be increased by 2-4 MPa, and the formula of the improved cement grinding aid contains no harmful ingredient and meet the requirement of environment protection; the components cooperate with one another, and the adaptability of the grinding aid is improved, so that the grinding aid is applicable to cement at different grades, the use range is widened, the grinding aiding effect is greatly improved, the machine-hour yield is also increased, the energy consumption is reduced, and the mixing amount is little and accounts for 0.02-0.05% in per ton of cement.

Owner:湖州华仑助剂科技有限公司

System and Method for Treating Dust Contained in Extracted Cement Kiln Combustion Gas

ActiveUS20080092735A1Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

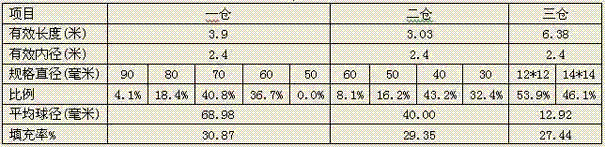

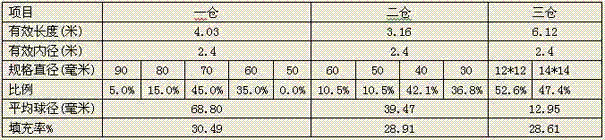

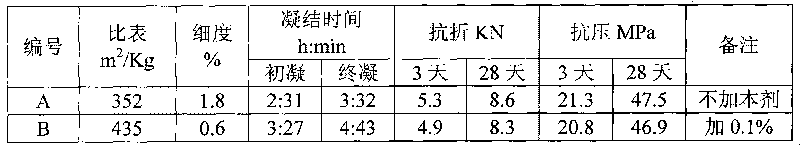

Control method of specific surface area of moderate heat cement

The invention discloses a control method of specific surface area of moderate heat cement, wherein the moderate heat cement clinker with average granularity smaller than or equal to 25mm and gyp are fed into a cement mill for open fine grinding, the air exhaust of an exhaust blower at the tail of the mill is 35000m<3> / h, the aperture of the air door of the exhaust blower is adjusted to 40-60%, the output of the mill is controlled to be 28-35t / h. The barrel of the mentioned cement mill has three grinding bins formed by separation of two screening bin-separation boards, the effective lengths of the three grinding bins I, II and III are respectively 28.40%-30.28%, 21.86%-23.74%, 49.74%-45.98% of the length of the overall grinding bin, and the filling rates of the three grinding bins I, II and III are respectively 30.49%-31.85%, 28.91%-31.39% and 26.45%-28.61%. The method disclosed by the invention is in favor of the balance of strength and aquation heat of the moderate heat cement, the specific surface area of the moderate heat cement is 280-320m<2> / Kg, and the percent of pass of the moderate heat cement can achieve 90% or above, the method mentioned is easy to control and the quality of the cement is stable.

Owner:GUANGXI YUFENG CEMENT

Chlorine-free early strength cement grinding aid and preparation method thereof

The invention provides a chlorine-free early strength cement grinding aid and a preparation method thereof, and relates to the technical field of cement additives. The grinding aid comprises a reinforcing agent, a dispersant and water, wherein the reinforcing agent is ammonium acetate, and the dispersant is modified alcohol amine. The grinding aid does not contain any chlorine ion, is harmless tohuman body and buildings, can effectively improve the strength and compressive strength of cement, effectively increases the cement output, effectively eliminates the mutual electrostatic attraction between cement particles and forged balls, improves the grinding efficiency of a cement mill and the powder selecting efficiency of a powder selecting machine, thus increases the yield of a cement grinding machine, and reduces the electricity consumption.

Owner:北京人众创新工贸有限公司

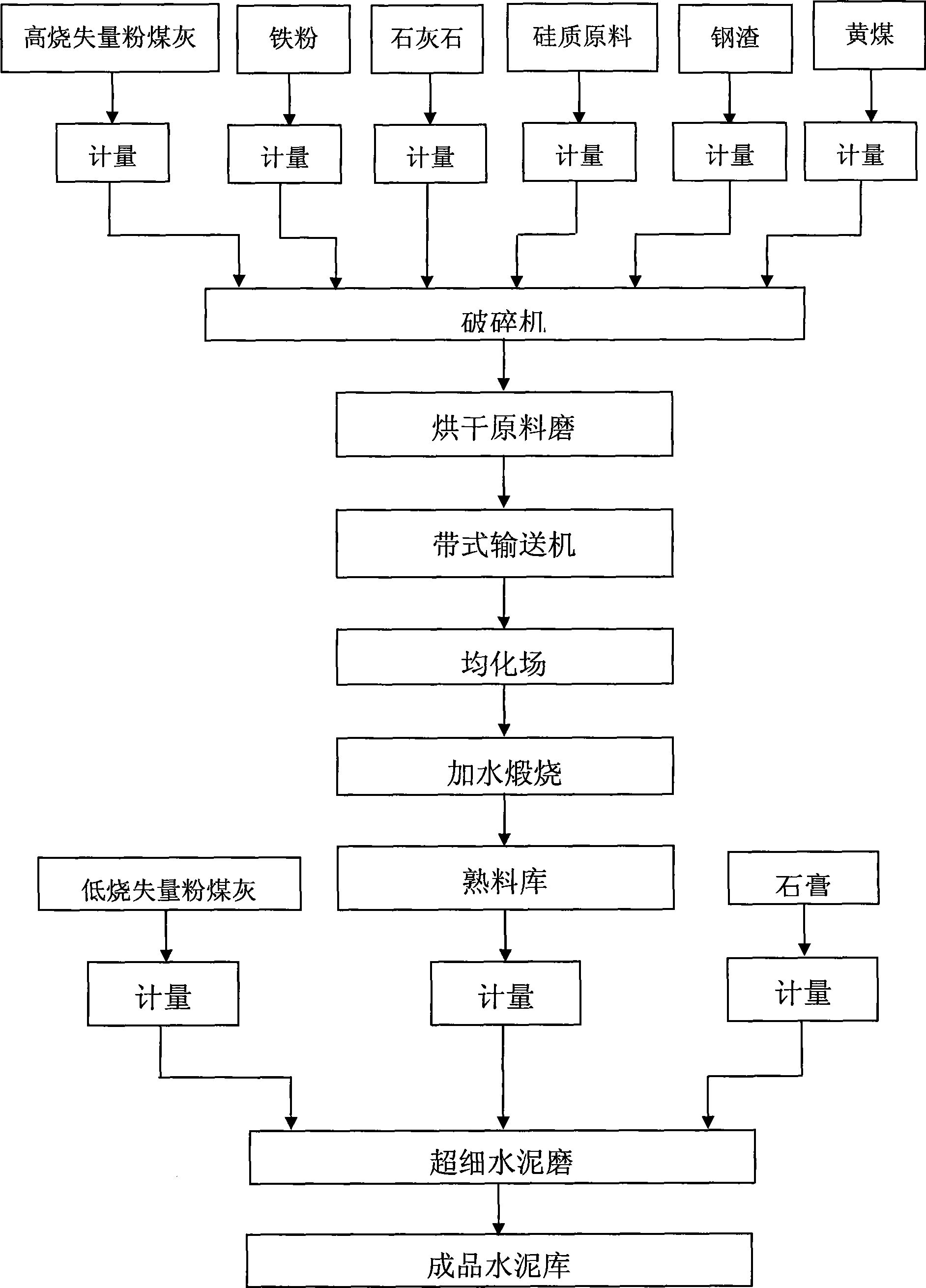

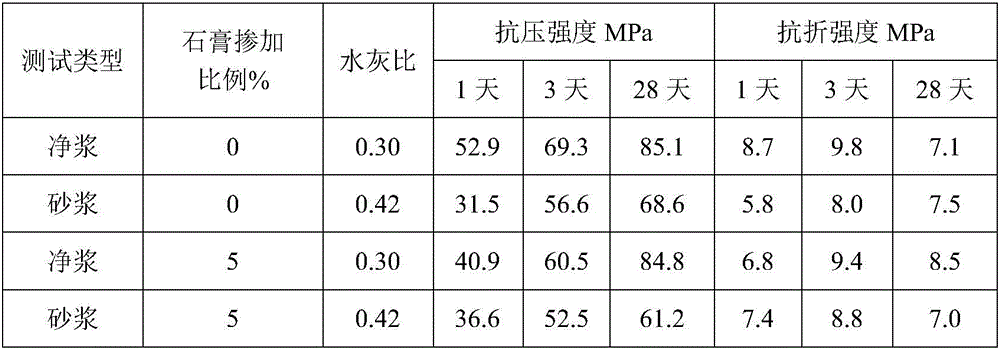

Method for preparing flyash cement

InactiveCN101372403AQuality improvementSignificant comprehensive benefitsClinker productionMicrofine cementIron powder

A method for preparing pulverized ash cement is characterized in that the preparation method comprises the following steps: A. clinker preparation: (1) firstly, according to weight percentages, 6 to 10% of high ignition loss pulverized ash, 2 to 3% of ferrous powder, 65.5 to 80% of limestone, 3 to 8% of sandstone silicious raw materials, 1 to 1.5% of steel slag and 8 to 12% of yellow coal are weighted; (2) the raw materials are mixed, pulverized and baked; (3) the baked raw materials are fed in a grinder to be finely ground; (4) the powdery materials which are finely ground are conveyed to a continuous homogenization field and are homogenized; (5) after water is added in the homogenized raw materials, the homogenized raw materials are fed in a kiln and are calcined to obtain the clinker; B. finished product preparation: (1) according to weight percentages, 56 to 75% of the clinker prepared by the step A, 25 to 38% of low ignition loss pulverized ash and 1 to 6% of gypsum are weighted; (2) the raw materials are mixed and are milled by a superfine cement mill; and then, a finished product is obtained.

Owner:DENGDIAN GROUP CEMENT

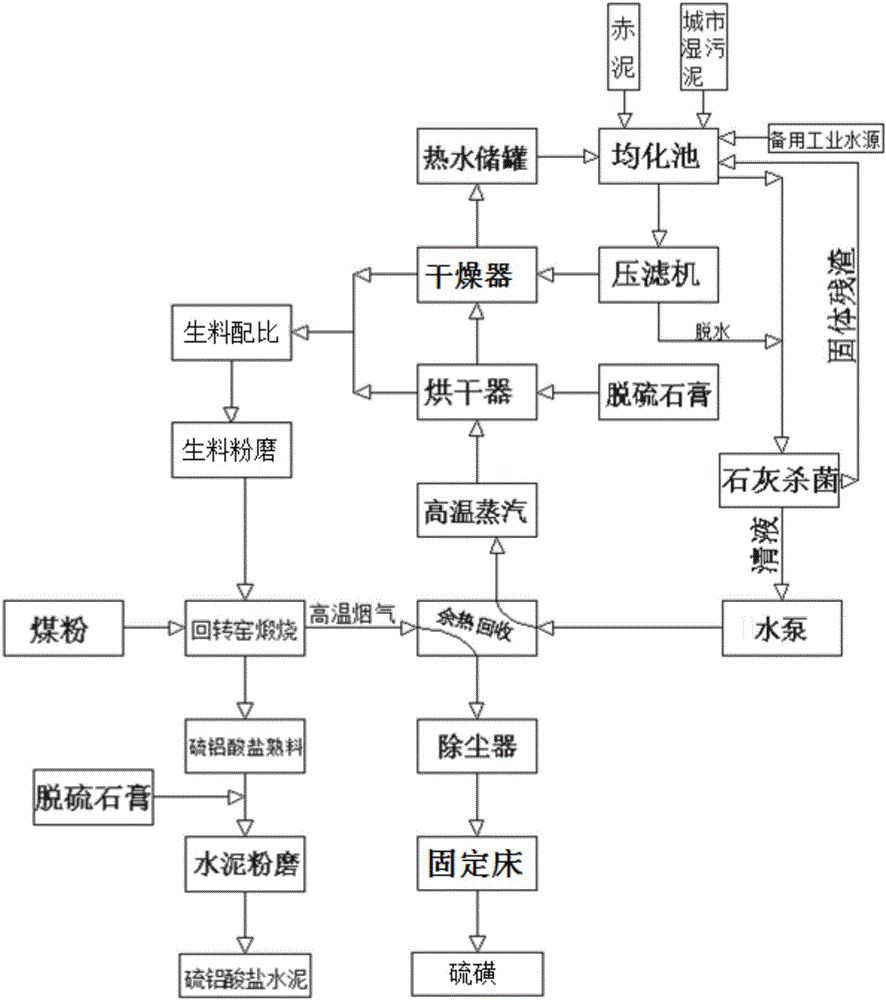

System and method for preparing cement co-production sulfur by utilizing urban wastes and industrial solid wastes

ActiveCN106810094ADifficult to useIncrease moisture contentEnergy inputSulfur preparation/purificationSludgeRed mud

The invention discloses a system and a method for preparing cement co-production sulfur by utilizing urban wastes and industrial solid wastes. The system comprises a homogenizing tank, a filter press, a drier, a raw material mill unit, a rotary kiln, a cement mill, a hot water storage tank, a dust remover and a reduction fixed bed; red mud, wet sludge and industrial water enter the homogenizing tank to be homogenized and dealkalized, and then enter the filter press to be filter-pressed; a filter-pressed solid material enters the drier to be dried, the dried solid material together with desulfurization gypsum enters the raw material mill unit for raw powder ratio milling; a milled material enters the rotary kiln for high-temperature calcination to obtain a sulphoaluminate clinker; the sulphoaluminate clinker together with desulfurization gypsum enters the cement mill for mixed milling to obtain sulphoaluminate cement; hot water in the hot water storage tank provides heat for the homogenizing tank; sulfur dioxide-containing flue gas generated in the rotary kiln is subjected to dust removal through the dust remover and is conveyed to the reduction fixed bed for reduction to obtain the sulfur.

Owner:SHANDONG UNIV

Liquid composite cement grinding aid and preparation method thereof

The invention relates to a cement additive, in particular to liquid composite cement grinding aid and a preparation method thereof, which solve the problems of bottleneck effect occurring in reactions among various components in cement caused by conventional cement grinding aid, poor effect in improving performance of each aspect of the cement and the like. The grinding aid is prepared from coconut oil diethan olamide, water, acetic acid, melamine, sodium nitrite, sodium acetate, sodium thiosulfate, molasses, sodium hexametaphosphate, calcium lignosulfonate and soap, can provide an intermediate platform for reactions among the components in the cement to ensure that the components in the cement can generate compound synergy and additive effects with one another, and more effectively excites potential activity of raw material components, thereby receiving sufficient reactions to play respective grinding aid effect in a powder grinding process, effectively eliminating ball stick and over grinding phenomena, improving the specific surface area of the cement, and simultaneously improving the machine-hour output of a cement mill; and the product which is added with 0.1 weight percent of cement can improve the 3-day strength of the cement by 4 to 7MPa, and improve the 28-day strength of the cement by 3 to 6MPa.

Owner:YANGCHENG JIXIN BUILDING MATERIAL

Steel ball grinding body classifying device applied to cement ball mill and classification method of steel ball grinding body classifying device

PendingCN108787058AReduce labor intensityImprove efficiencySievingScreeningClassification methodsSteel ball

The invention provides a steel ball grinding body classifying device applied to a cement ball mill which belongs to the technical field of cement ball mills. The invention further relates to a classification method of the steel ball grinding body classifying device applied to the cement ball mill. A discharging chute (2) is arranged below a receiving hopper of the steel ball grinding body classifying device applied to the cement ball mill; a sorting component (3) is arranged at the side surface of the receiving hopper (1); a long roller I (4) of the sorting component (3) is connected with a driving motor I (6); a long roller II (5) is connected with a driving motor II (7); a gap part (8) is arranged between the long roller I (4) and the long roller II (5); and the width size of the gap part (8) is set as a structure which is gradually increased from one end close to the receiving hopper (1) to one end far away from the receiving hopper (1). The steel ball grinding body classifying device and the steel ball grinding body classification method applied to the cement ball mill provided by the invention can realize automatic classification of steel balls according to the diameter of different steel balls, can realize precise control on classification of the steel balls, and improves the classification efficiency.

Owner:ANHUI CONCH GRP +2

Red mud cement and preparation method thereof

The present invention relates to a red mud cement, which is prepared from the following raw materials, by weight: 20-40% of red mud, 15-30% of sandstone, 30-50% of limestone, 2-5% of iron powder, 20-30% of blast furnace granulating slag, and 10-20% of gypsum. The preparation method comprises: co-grinding red mud, sandstone, limestone and iron powder into a raw slurry, adjusting to meet technical indexes, adopting an inflow method to remove most of water in an evaporator, placing into (or directly spraying into) a rotary kiln to fire a cement clinker at a temperature of 1400-1450 DEG C, and carrying out mixing grinding on the cement clinker, blast furnace granulating slag and gypsum in a cement mill to achieving a certain fineness so as to obtain the cement product. According to the invention, the industrial waste residue utilization rate is high, the cost is low, and the corrosion on iron and steel is low.

Owner:苏州负碳谷材料科技有限公司

Efficient cement grinding aid

The invention relates to the field of production of cement and particularly relates to an efficient cement grinding aid. The cement grinding aid is prepared from the ingredients in percentage by weight: 25% to 35% of modified triethanolamine, 20% to 25% of tri-isopropanolamine, 30% to 35% of modified propanetriol, 4% to 8% of modified molasses, 2% to 5% of sodium thiocyanate, 0.3% to 0.5% of expanded perlite, 1% to 5% of surfactant and 1% to 5% of water reducer. The efficient cement grinding aid provided by the invention is free of chloride ions, the effect of pulverizing can be improved, theyield of a cement mill is increased, and the strength of cement prepared by adding the cement grinding aid provided by the invention is improved obviously.

Owner:JIANGXI WANNIANQING ENGINEERING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com