Chlorine-free early strength cement grinding aid and preparation method thereof

A technology of cement grinding aid and early-strength cement, applied in the field of cement admixtures, can solve the problems of insignificant cement strengthening effect, high chloride ion content in cement, affecting concrete durability, etc., so as to promote crystal growth and adaptability. Good, improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

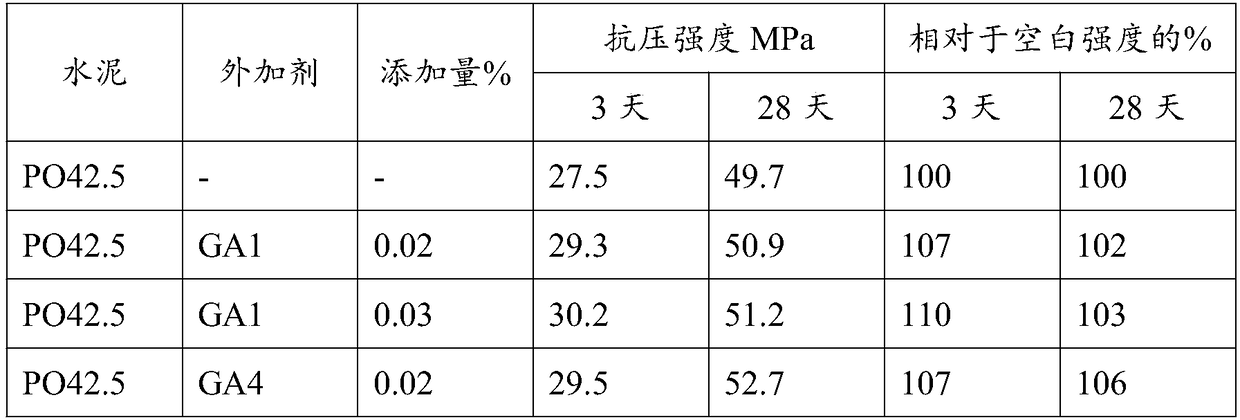

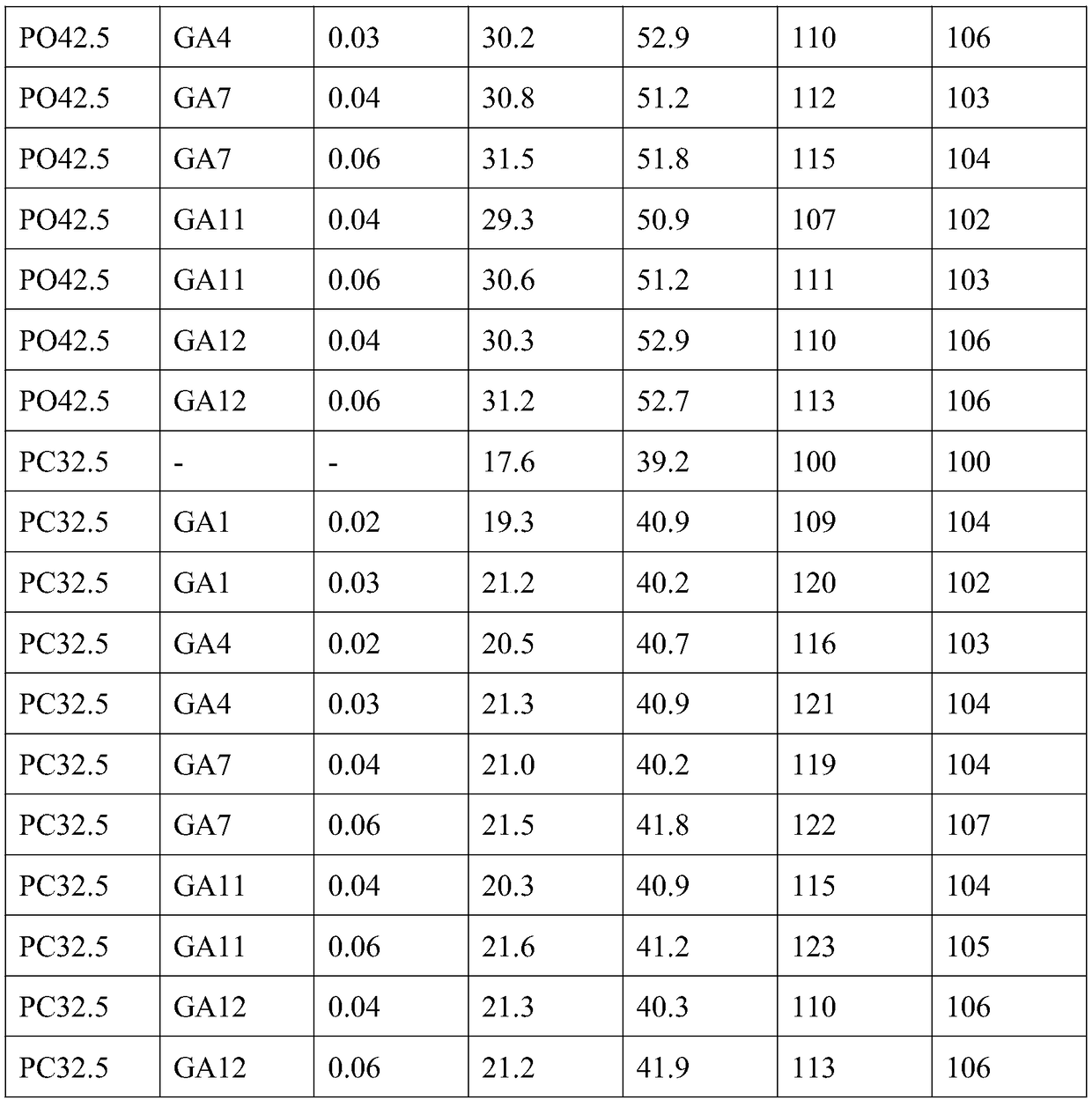

Examples

Embodiment 1

[0045] According to parts by weight, weigh 7KG of ammonium acetate, 23KG of triethanolamine and 25KG of water, add them into the reaction kettle, stir and mix for 1 hour to prepare 55KG of cement grinding aid. Expressed in GA1.

Embodiment 2

[0047] According to parts by weight, weigh 25KG of amine acetate, 65KG of triethanolamine and 75KG of water, add them into the reaction kettle, stir and mix for 2 hours to prepare 165KG of cement grinding aid.

[0048] Example: 3:

[0049] According to parts by weight, weigh 20KG of ammonium acetate, 40KG of triethanolamine and 60KG of water, add them into the reaction kettle, stir and mix for 2 hours to prepare 120KG of cement grinding aid.

Embodiment 4

[0051] According to parts by weight, weigh 10KG of ammonium acetate, 35KG of triethanolamine and 45KG of water, add them into the reaction kettle, stir and mix for 2 hours to prepare 90KG of cement grinding aid. Expressed in GA4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com