Patents

Literature

205 results about "Chlorine.free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

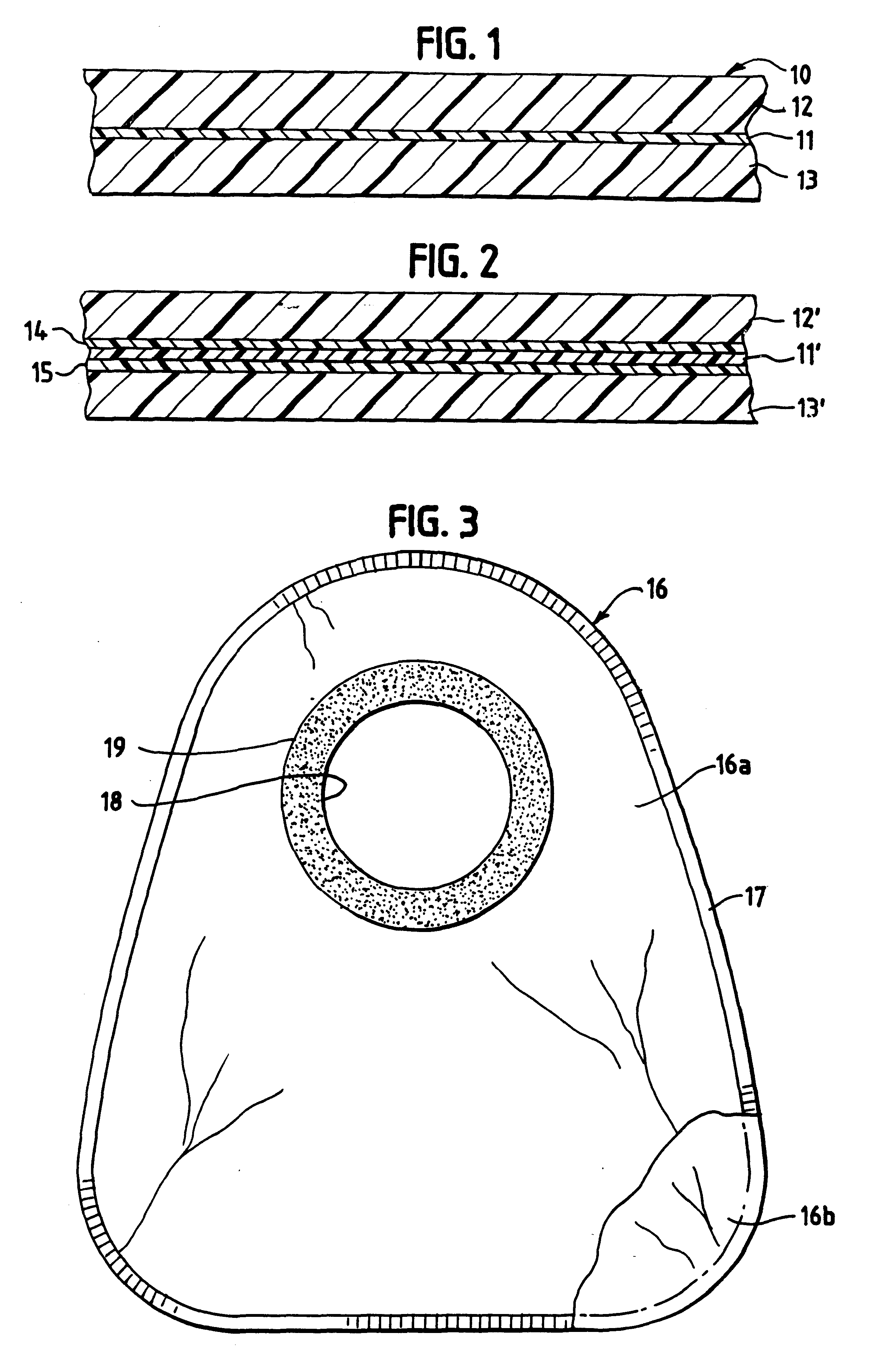

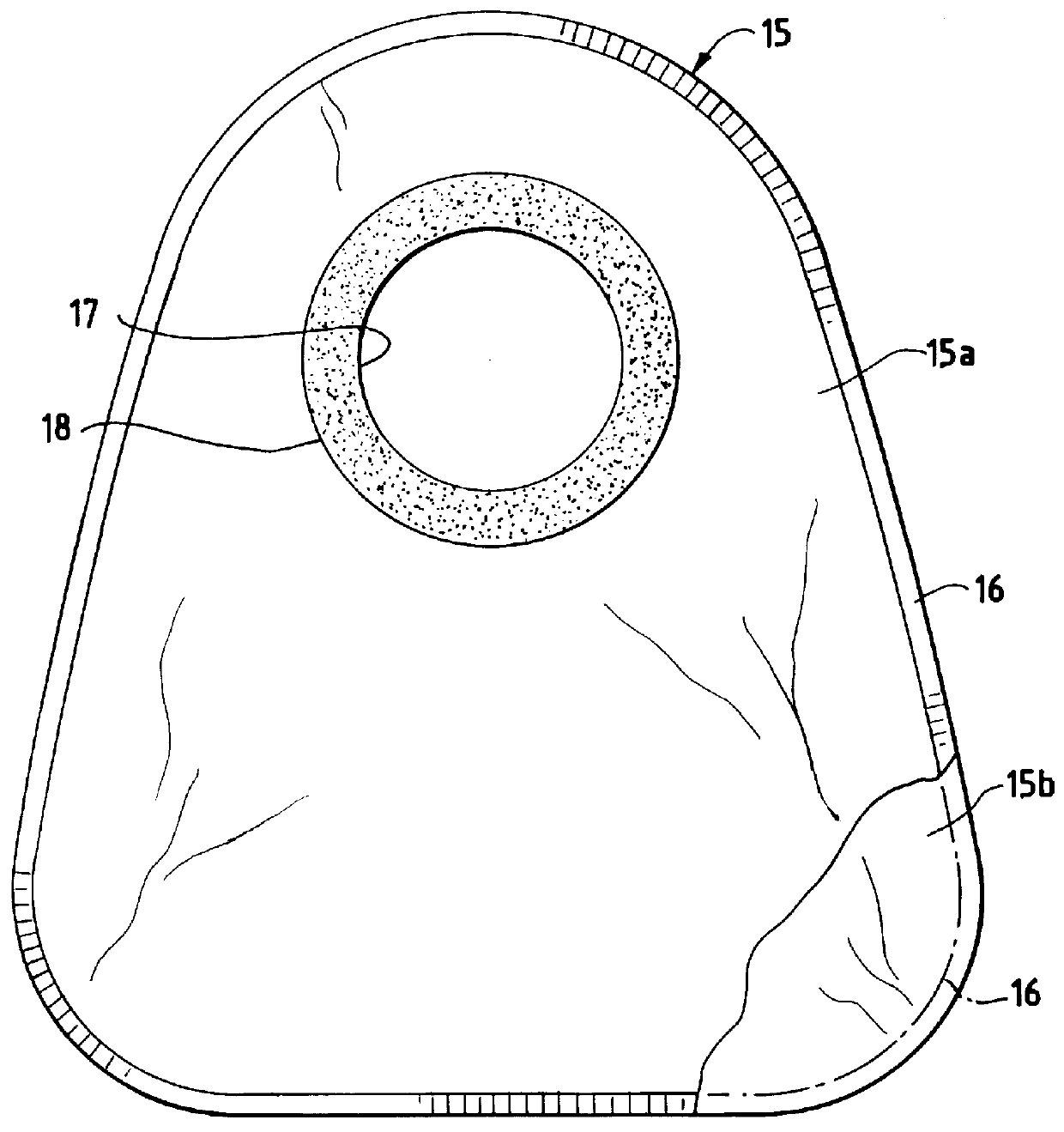

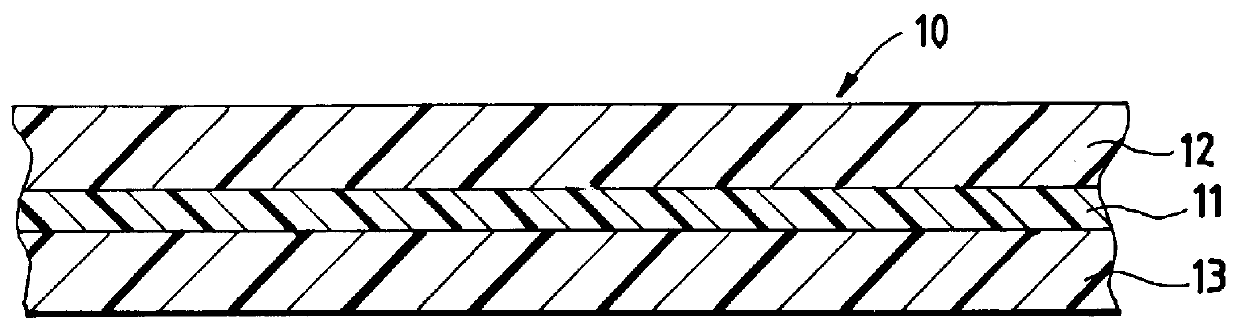

Multilayer chlorine-free film with polyester barrier layer and ostomy pouches formed therefrom

InactiveUS6258423B1Good odor barrier propertyMinimal noiseSynthetic resin layered productsColostomyLow noisePolyethylene terephthalate glycol

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film comprises an odor barrier layer of polyester resin and at least one heat-sealable skin layer, preferably two such skin layers on opposite sides of said odor barrier layer, composed of a homopolymer of ethylene or a copolymer of ethylene and an alpha-olefin or an ester-containing monomer. In a preferred embodiment, the odor barrier layer is formed of polyethylene terephthalate and adhesive tie layers are interposed between the odor barrier layer and the skin layers, resulting in a multilayer film of five layers. Pouches formed of such multilayer films are also disclosed.

Owner:HOLLISTER INCORPORAED

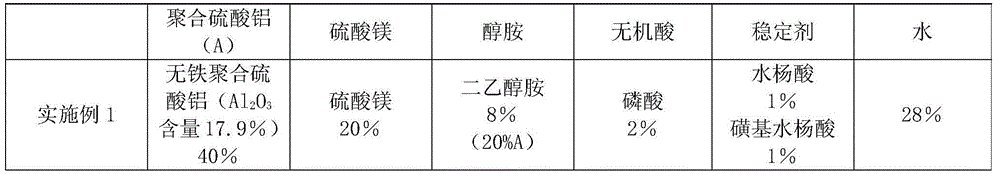

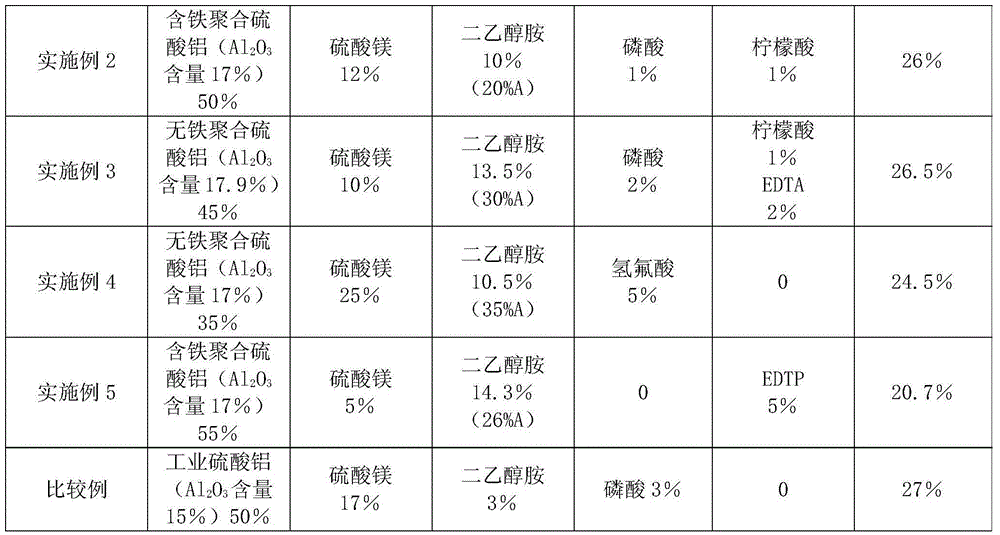

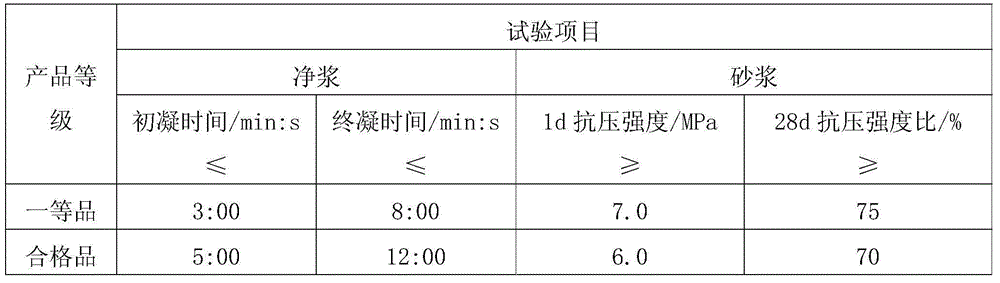

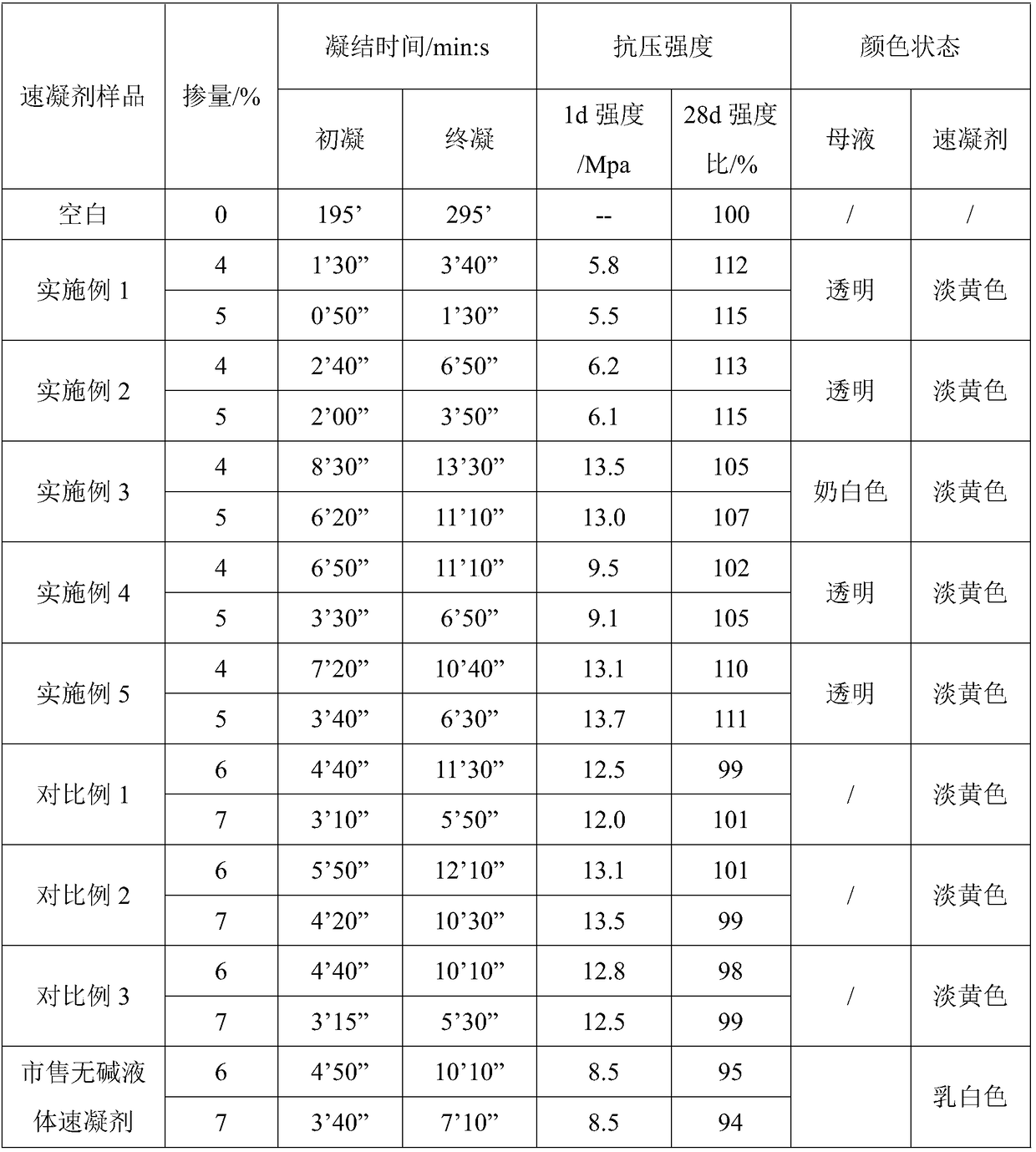

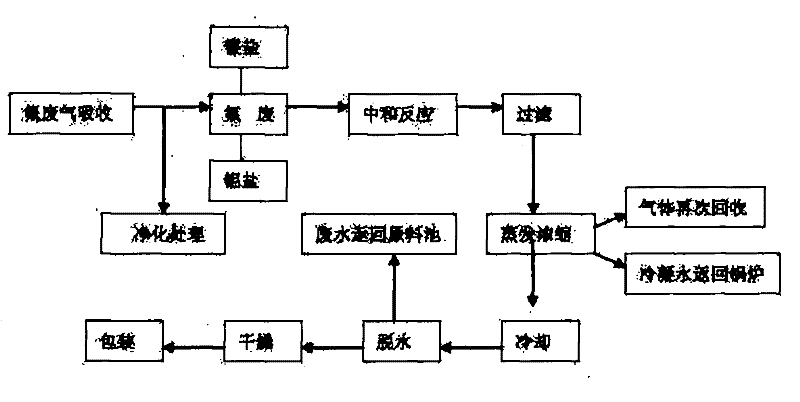

Alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate and its preparation method

The invention discloses an alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate. The liquid setting accelerator comprises the following raw materials by weight: 35-55% of polyaluminium sulfate, 5-25% of magnesium sulfate, alcohol amine accounting for 15-30% of the polyaluminum sulfate, 0-5% of an inorganic acid, 0-5% of a stabilizer, and the balance water. The liquid setting accelerator provided by the invention can be used in the wet jetting industry of sprayed concrete, belongs to alkali and chlorine-free liquid setting accelerators, has a stable period of more than 6 months, a 28d compressive strength ratio of greater than 100%, and good adaptability to different cement. When the dosage is 4.5%, the technical requirements of the JC477-2005 ''setting accelerators for sprayed concrete'' can be satisfied. The liquid alkali-free setting accelerator has superior performance, and can be widely used in tunnels, bridges, first-aid repair and other projects.

Owner:CHINA BUILDING MATERIALS ACAD

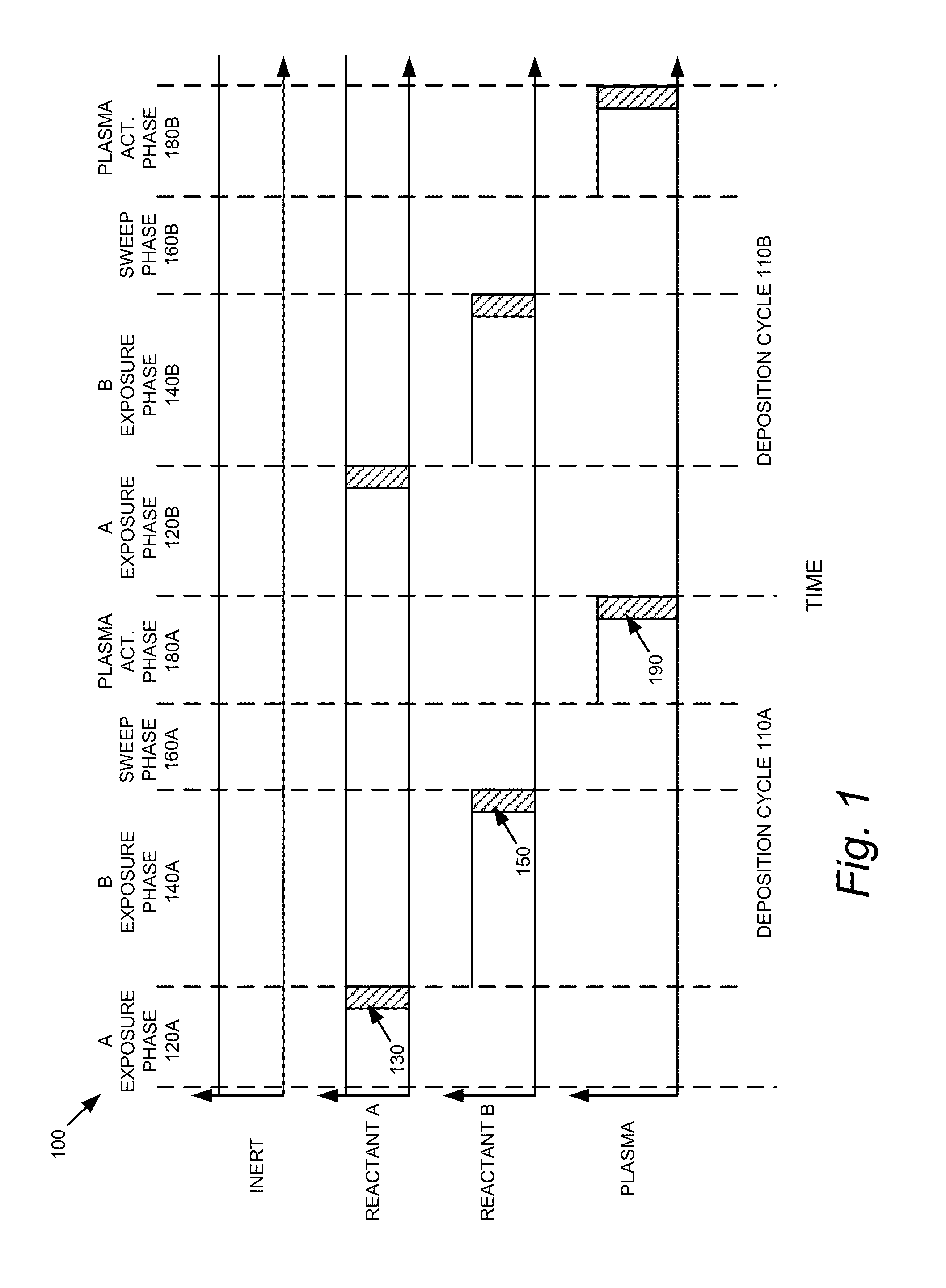

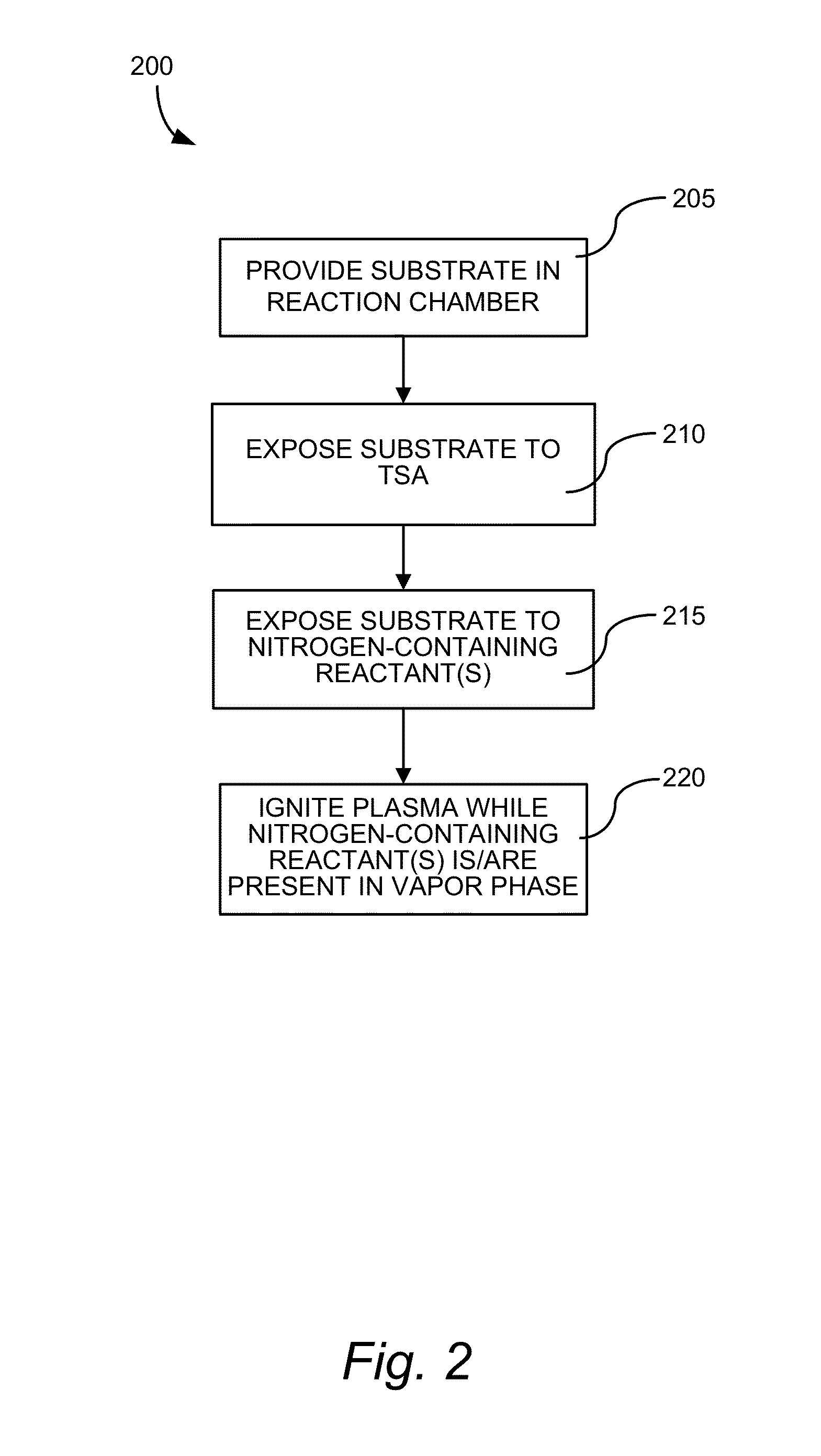

Method for depositing a chlorine-free conformal sin film

ActiveUS20140141626A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorine.freeChemistry

Described are methods of making silicon nitride (SiN) materials on substrates. Improved SiN films made by the methods are also included. One aspect relates to depositing chlorine (Cl)-free conformal SiN films. In some embodiments, the SiN films are Cl-free and carbon (C)-free. Another aspect relates to methods of tuning the stress and / or wet etch rate of conformal SiN films. Another aspect relates to low-temperature methods of depositing high quality conformal SiN films. In some embodiments, the methods involve using trisilylamine (TSA) as a silicon-containing precursor.

Owner:NOVELLUS SYSTEMS

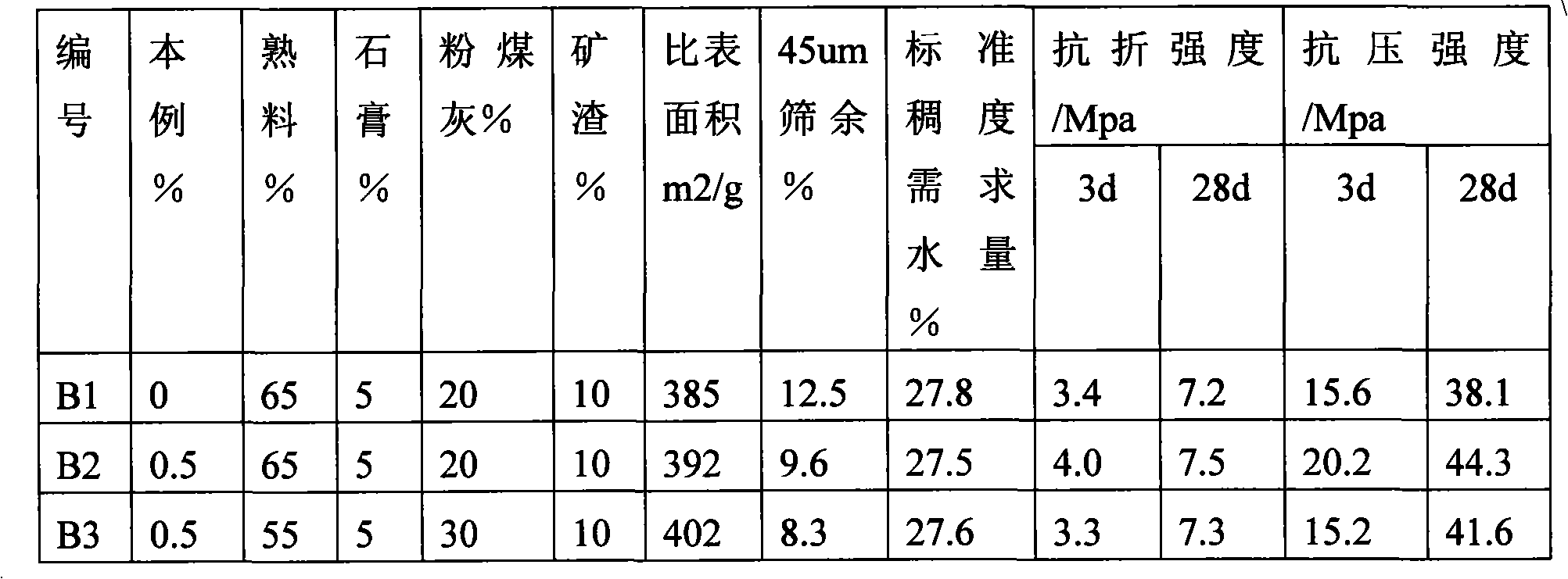

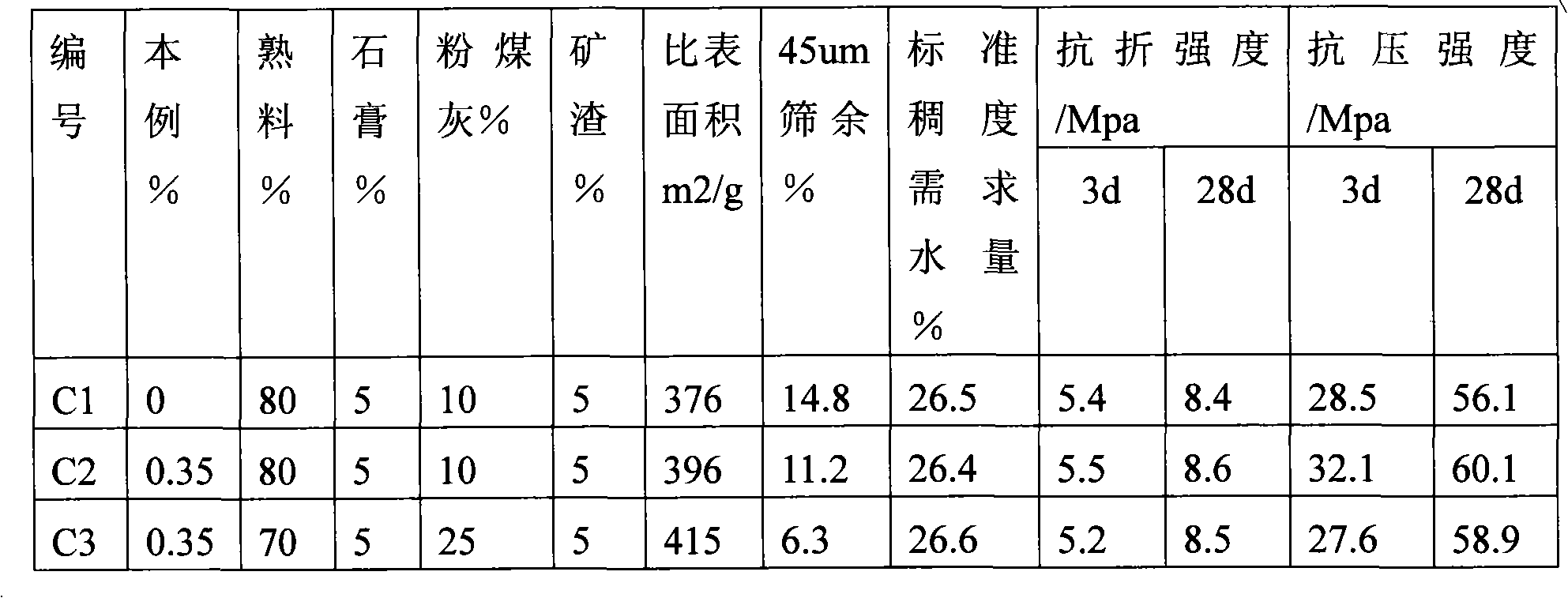

Chlorine-free powdery cement grinding aid and preparation method thereof

InactiveCN101665338AHigh strengthStrong compound synergistic effectCement productionSulfateLignosulfonates

The invention discloses a chlorine-free powdery cement grinding aid suitable for fly ash, which comprises the following components in parts by weight: 0-5 parts of alkanolamine, 2-5 parts of polylol,15-75 parts of sulfate, 5-20 parts of acetate, 0-5 parts of lignosulphonate, 2-6 parts of carbohydrate organic matter, 5-25 parts of miltonite, 0-25 parts of carbamide and 5-50 parts of inorganic carrier material. The invention also discloses a preparation method of the chlorine-free powdery cement grinding aid suitable for the fly ash. A compound grinding aid can lower the cement cost and uses the fly ash for replacing partial clinker to save the clinker dosage by 10-15 percent on the premise of keeping the cement strength unchanged, and uses extra 10-15 parts of fly ash without increasing the required water amount of cement standard consistency; the cost of the cement per ton is lowered by more than 10 Yuan.

Owner:NANJING ZHUJI ENERGY SAVING TECH

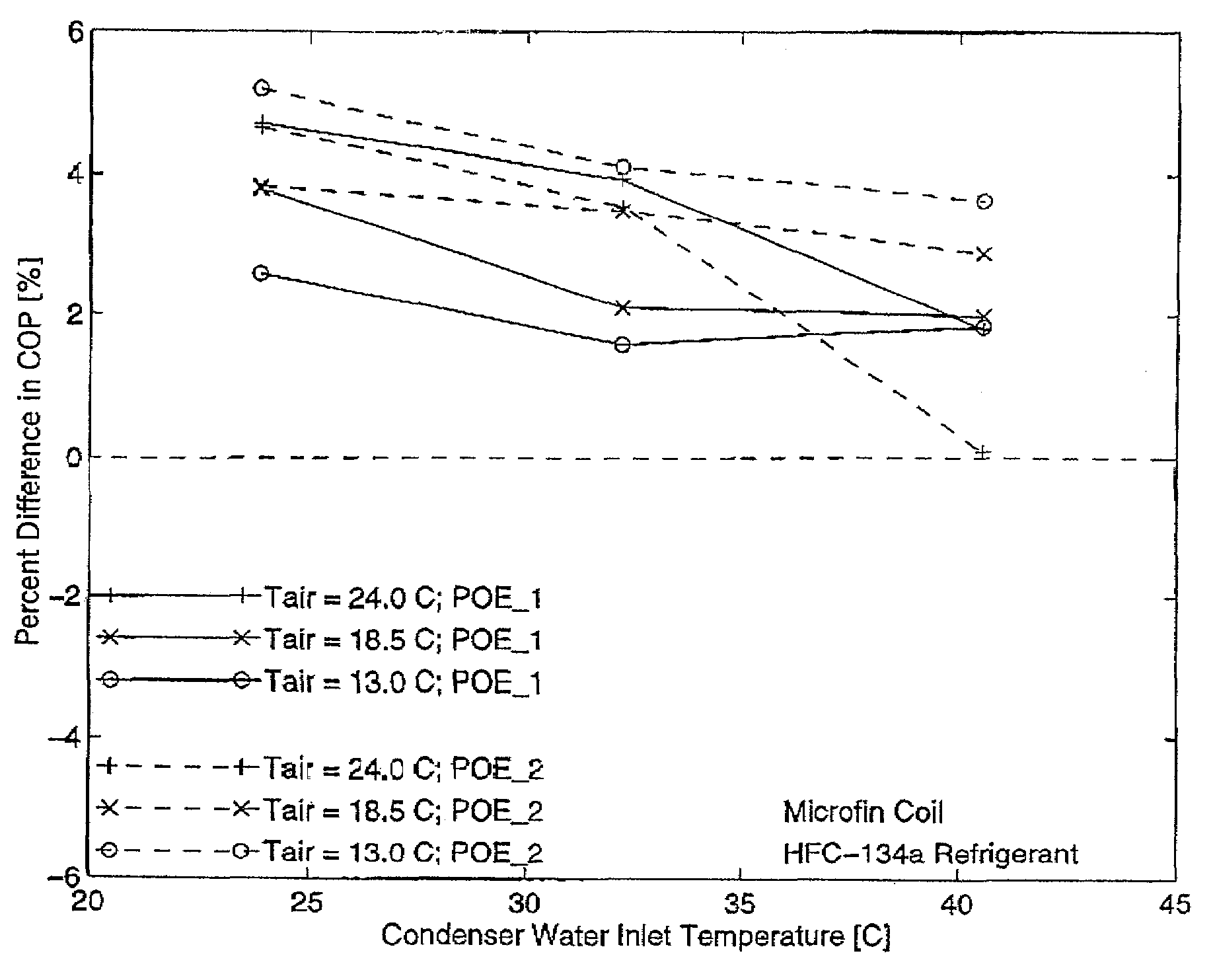

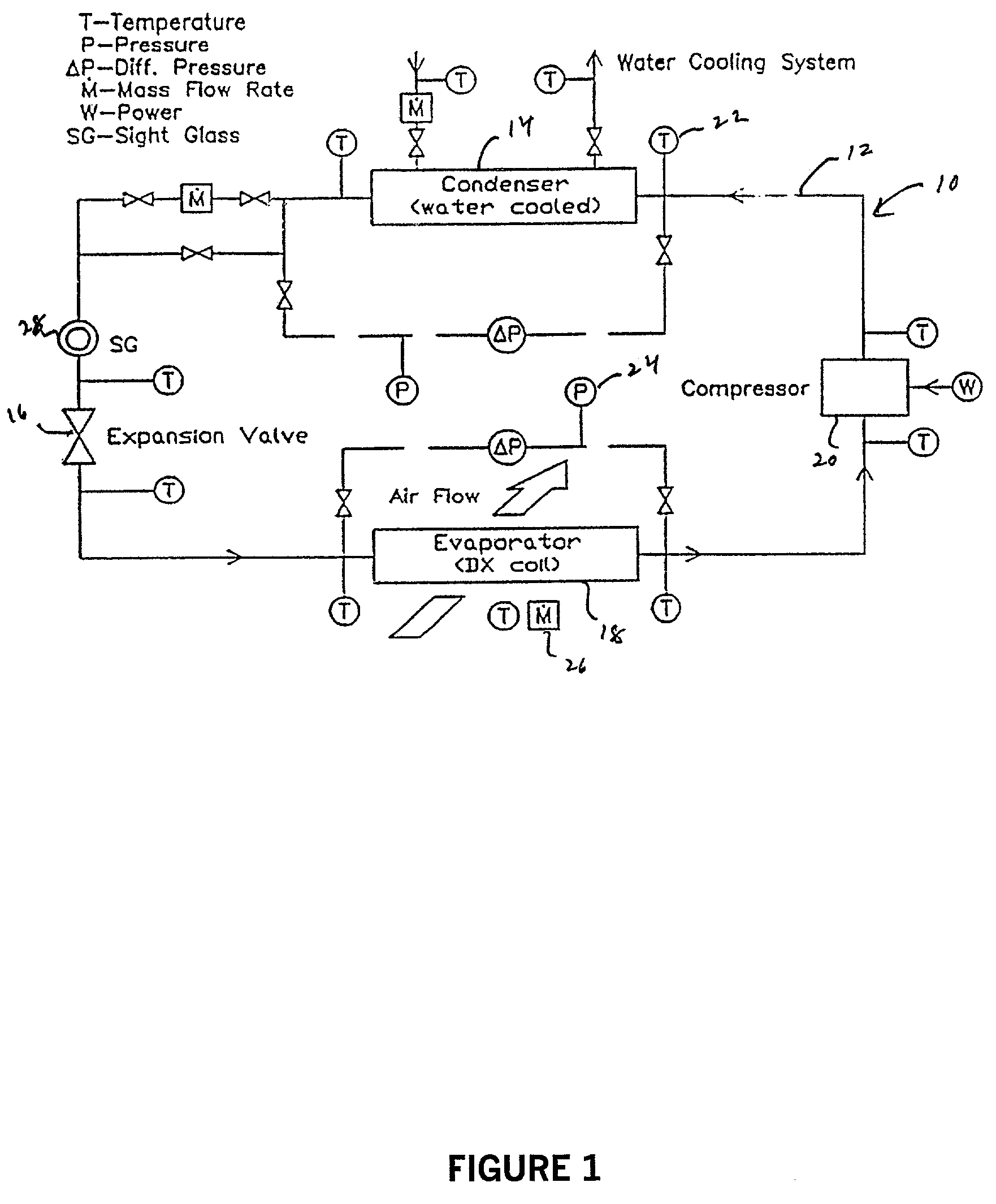

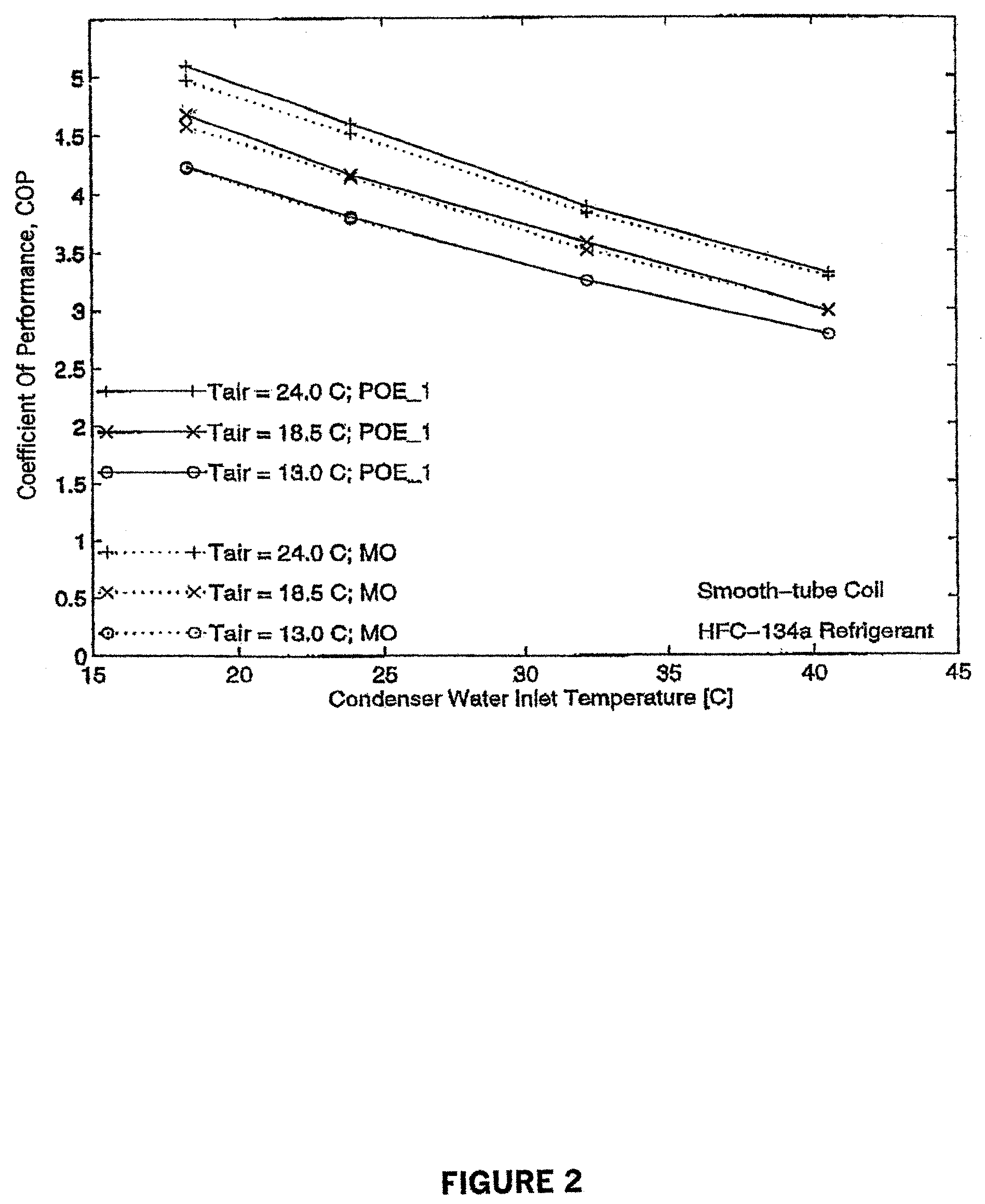

Method of improving performance of refrigerant systems

InactiveUS7018558B2Improve performancePerformance of a refrigerant system such as in air conditionerCompression machines with non-reversible cycleHeat-exchange elementsPolyolesterWorking fluid

A method of improving performance of refrigerant systems such as refrigerators and air conditioners that utilize a refrigerant working fluid. The working fluid consists essentially of a heat transfer fluid and a lubricant that is miscible and is otherwise compatible with the heat transfer fluid at all operating temperatures of the refrigerant system. The method is directed particularly to chlorine-free fluoro-group organic fluids and more particularly to hydrofluorocarbon heat transfer fluids. The preferred lubricants comprise polyol ester basestocks and compounded polyol esters that are highly miscible with such hydrofluorocarbon heat transfer fluids.

Owner:COGNIS IP MANAGEMENT GMBH

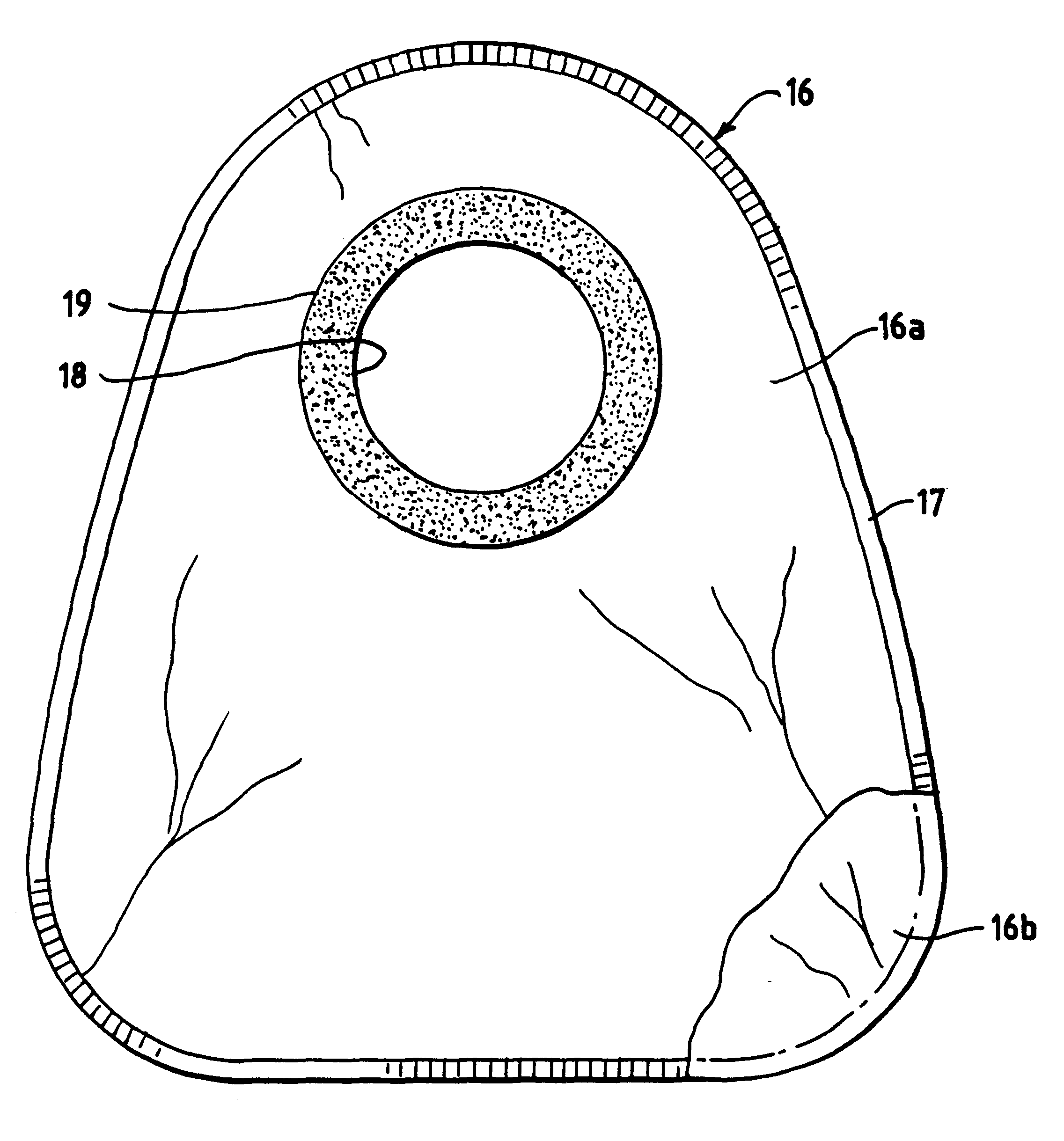

Multilayer chlorine-free film with barrier layer of a polyamide blend and ostomy pouches formed therefrom

InactiveUS6143383AGood odor barrier propertyMinimal noiseSynthetic resin layered productsBagsHigh resistanceLow noise

A multilayer heat-sealable chlorine-free film of relatively low modulus, high interlaminar strength, and low noise upon flexing is provided. The film includes an odor barrier layer and at least one directly adjoining heat-sealable skin layer. The barrier layer is composed of either an aliphatic or partially aromatic polyamide resin, or a blend thereof, blended with an ionomer resin consisting essentially of a partially neutralized ethylene-methacrylic acid copolymer, and the heat-sealable skin layer or layers bonded directly to the barrier layer are composed of copolymers of ethylene and an ester-containing comonomer. High resistance to delamination of the barrier layer and skin layer(s) is achieved without tie layers therebetween. Pouches formed of such multilayer chlorine-free films are also disclosed.

Owner:HOLLISTER INCORPORAED

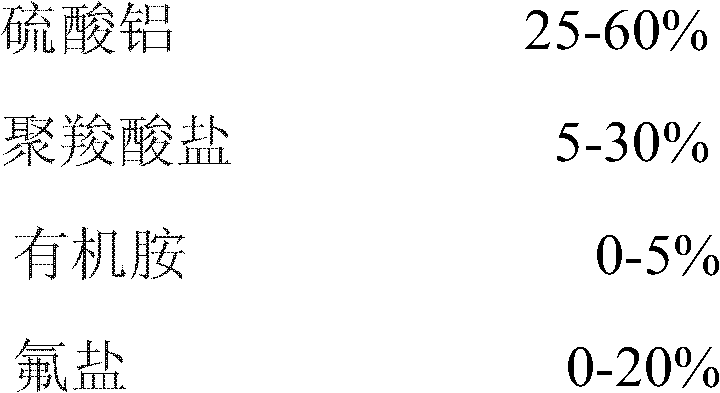

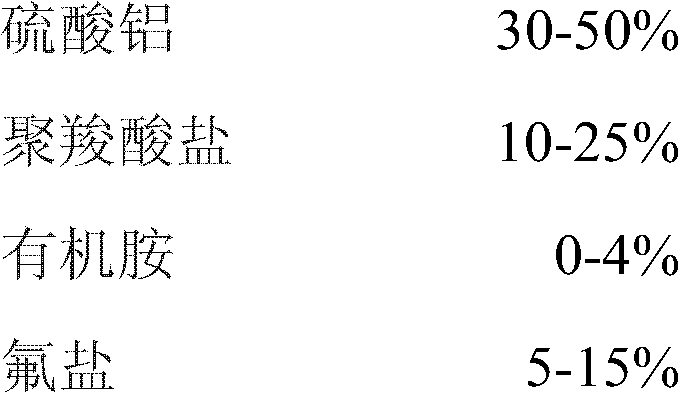

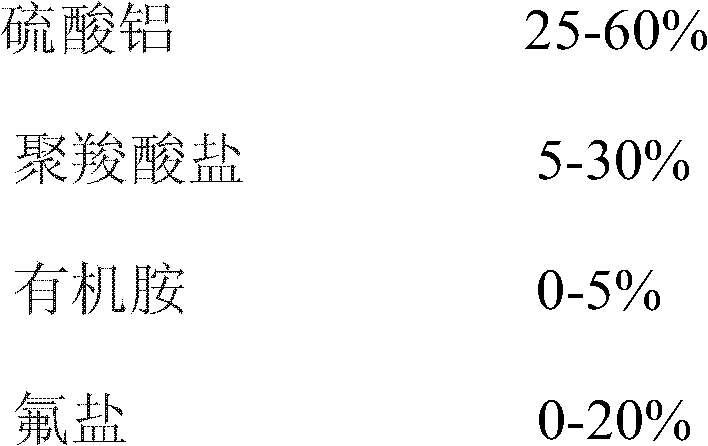

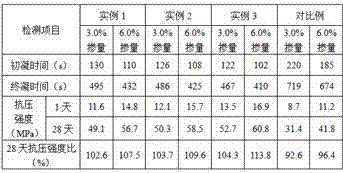

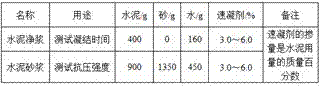

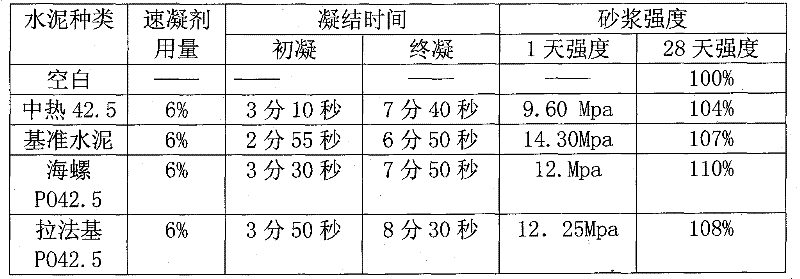

Alkali and chlorine free liquid setting accelerator

The invention relates to an environment-friendly alkali and chlorine free liquid setting accelerator used for sprayed concrete. The setting accelerator is composed of the following components by weight: 25-60% of aluminum sulfate, 5-30% of a polycarboxylic acid salt, 0-5% of organic amine, 0-20% of a fluoride salt, and the balance water. The dosage of the setting accelerator doped into sprayed concrete accounts for 3-7 wt% of cement. The initial setting time is less than 4 minutes, and the final setting time is not more than 9 minutes. The invention also relates to a preparation method of the environment-friendly alkali and chlorine free liquid setting accelerator.

Owner:高永会

Efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush

InactiveCN101748631AEfficient continuous production technologyLabor intensiveWashing/displacing pulp-treating liquorsPulp de-wateringBlack liquorMagnesium salt

The invention discloses an efficient and clean puling and bleaching method dissolving alpha-pulp by Chinese alpine rush. The method comprises the steps of stock preparation, prehydrolysis, alkaline cooking, black liquor extraction, closed screening, total chlorine free bleaching, bleached pulp treatment and the like, namely, adding stock blank after prehydrolysis into a continuous digester to carry out alkaline cooking; adopting a vacuum pulp washer to extract black liquor from sizing agent, sealing and screening, then washing and concentrating the sizing agent through a vacuum filter, wherein the mass concentration of pulp after concentration is larger than or equal to 10%; adding NaOH solution and magnesium salt protective agent in concentrated pulp, then sequentially passing through a medium concentration pump and a medium concentration mixer to enter an upflow type bleaching tower to carry out total chlorine free bleaching. In the invention, the productive process is continuous, and non chlorine bleaching agent is utilized in the production, waste water can flow reversely for reuse and does not contain toxic and harmful adsorbable organic chloride AOX, thereby realizing energy saving and emission reduction, cleaning and bleaching of alpha-pulp production, improving the additional value of Chinese alpine rush, thus the method can be promoted and utilized industrially.

Owner:SOUTH CHINA UNIV OF TECH

Chlorine-free and alkali-free liquid setting accelerator and preparation method thereof

The invention belongs to the technical field of preparation of additives, and in particular relates to a chlorine-free and alkali-free liquid setting accelerator and a preparation method thereof. The preparation method comprises the steps of adding aluminum sulfate and aluminum hydroxide into deionized water, and heating to obtain mother liquor of aluminate; then, adding magnesium fluosilicate and disodium ethylenediamine tetraacetate into the deionized water, and heating to obtain a magnesium fluosilicate solution; mixing the magnesium fluosilicate solution with the mother liquor of aluminate, then adding organic amine, organic acid and a stabilizer, and stirring to obtain the chlorine-free and alkali-free liquid setting accelerator. The setting accelerator prepared by the method has the characteristics of being small in mixing amount and good in setting acceleration effect; furthermore, after the setting accelerator is used, the mechanical properties of the concrete are improved, and the compressive strength of the concrete is increased; therefore, the chlorine-free and alkali-free liquid setting accelerator is an ideal concrete additive.

Owner:常州文诺纺织品有限公司

Production method of bamboo chemical dissolving pulp

ActiveCN101457494ASimple switching processHighly corrosiveWashing/displacing pulp-treating liquorsDigestersMaterial consumptionDissolving pulp

Aiming at the current situation of the cotton dissolving pulp and the wood dissolving pulp and the characteristics of the bamboo and the defects in the existing preparation of the dissolving pulp, the invention provides a method for preparing a chemical bamboo dissolving pulp. The chemical dissolving pulp produced can be widely applied in the cellulose derivative industries such as spinning viscose fiber, nitrocellulose and acetate fiber. The method comprises the following steps of: material preparation, cooking, screening, scrubbing, bleaching and paper making. The cooking procedure comprises two grades of cooking steps, wherein the primary cooking procedure is continuous cooking and the secondary cooking procedure is continuous cooking or intermittent cooking; and the bleaching procedure is elemental chlorine free bleaching or totally chlorine free bleaching. The invention solves the problems existed in the cooking and bleaching procedures. The chemical bamboo dissolving pulp can be prepared with high efficiency, low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

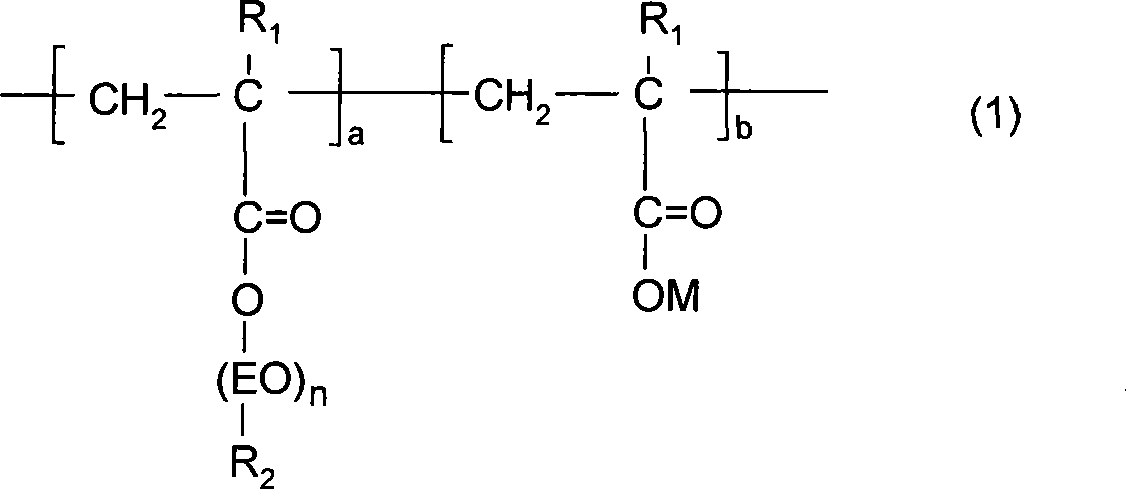

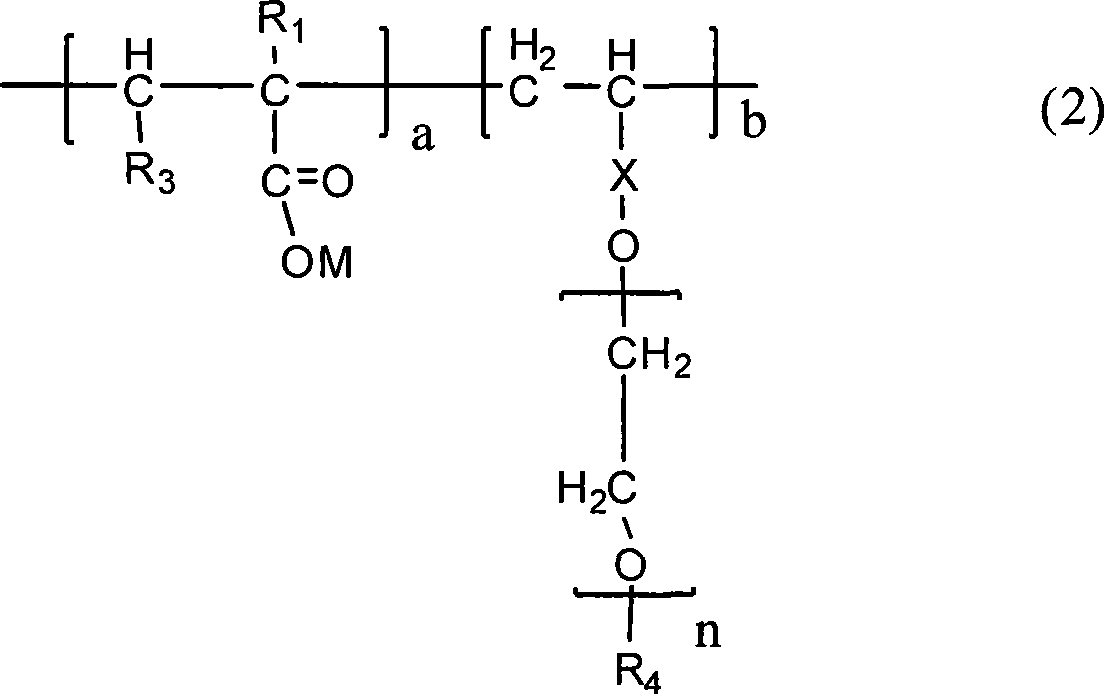

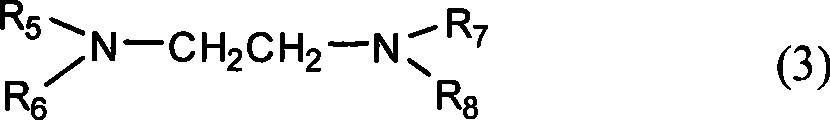

Liquid, chlorine-free, early-strength anti-freezing polycarboxylate composite water reducing agent and preparation method thereof

ActiveCN101186462AHigh long-term strengthLowering the freezing pointAnti freezingUltimate tensile strength

The invention relate to a liquid early-strength and antifreezing type polycarboxylate compound water reducer without chlorine and a preparation method thereof. The water reducer is prepared with the following components in weight proportion: 6-12percent of early-strength type polycarboxylate water reducer, 4-10 percent of organic antifreezing component, 1.5-3 percent of organic early-strength component, 10-25 percent of inorganic early-strength catalyst, 0.3-0.5 percent of air-entrained component, and the rest is water. The preparation method is that every component is weighed according to the weight percentage of every component and then put into a reaction vessel and stirred slowly for 10-30 minutes. The addition of the invention is 0.5-1.5 percent of cementing material content, compared with the normal concrete; the water-reducing rate can amount to more than 20 percent, and the long-term strength of concrete is obviously increased. The liquid early-strength and antifreezing type polycarboxylate compound water reducer can be used for preparation of concrete with various strength grades from C20 to C80, has good antifreezing performance and can be used for the concrete constructed under circumstance with daily minimum temperature above 20 DEG C below zero.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

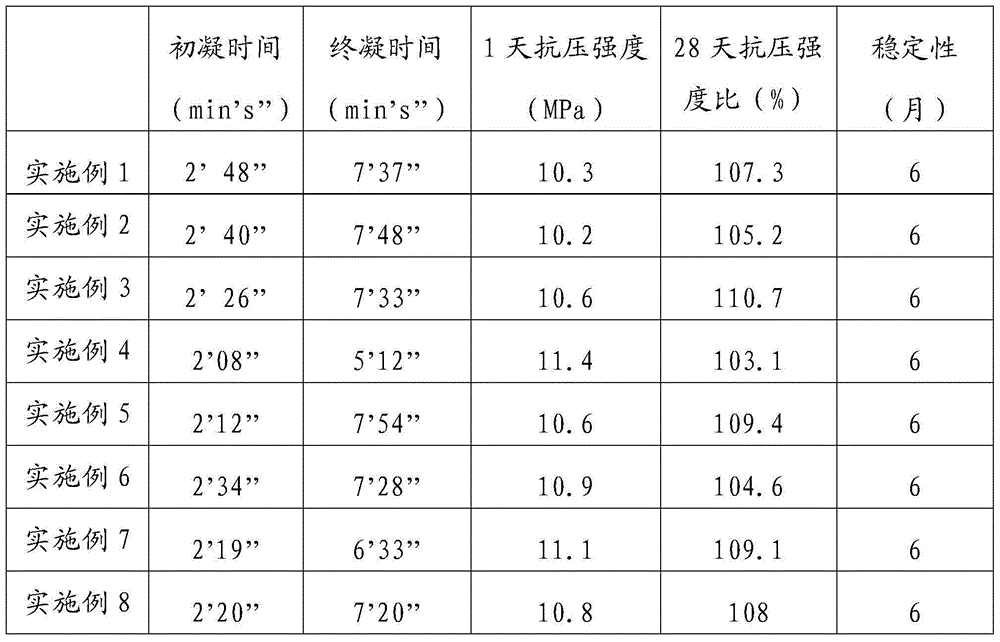

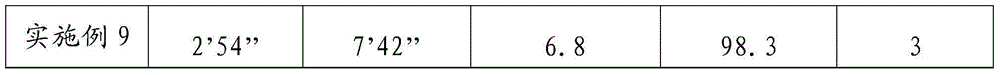

Liquid alkali and chlorine free setting accelerator and preparation method thereof

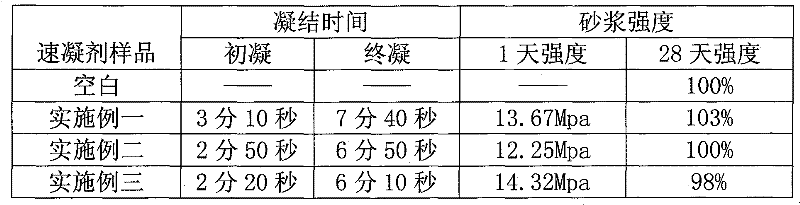

ActiveCN105000820AShort initial setting timeShort final setting timeCompressive strengthUltimate tensile strength

The invention discloses a liquid alkali and chlorine free setting accelerator and a preparation method thereof. The raw materials comprises, by weight, 60-130 parts of aluminum sulfate, 0.5-2 parts of a coagulation accelerator, 0.5-2 parts of a coagulating early strength agent, 0.5-5 parts of an early strength agent, 5-15 parts of a complexing accelerator, 8-20 parts of a stabilizer, 1-5 parts of inorganic acid, 0.25-2 parts of a defoaming agent, and 50-75 parts of water. The prepared liquid alkali and chlorine free setting accelerator solves the problems that alkali and chlorine free setting accelerators in the prior art cannot combine the properties of short initial setting time, short final setting time, high 1 day compressive strength, high 28-day compressive strength rate, and good stability, etc.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

Low-doping-amount and high-performance alkali-free and chlorine-free liquid setting accelerator and preparation method thereof

The invention provides a low-doping-amount and high-performance alkali-free and chlorine-free liquid setting accelerator and a preparation method thereof and belongs to the field of building materials. The setting accelerator is prepared from the following raw materials in percentage by weight: 30 to 60 parts of potassium sulfate, 0 to 20 parts of magnesium sulfate, 0.5 to 2.0 parts of precipitated magnesium silicate hydrate, 0.5 to 2.0 parts of magnesium oxide, 1 to 3 parts of magnesium fluosilicate, 1 to 3 parts of alkylol amine, 0.5 to 1.5 parts of a high polymer, 0.2 to 1.0 part of a stabilizing agent, 5 to 40 parts of a mother solution and 30 to 50 parts of water. The obtained liquid setting accelerator has the density of 1.3 to 1.5g / cm<3>, the pH (Potential of Hydrogen) value of 2.5to 3.5, the solid content of 37 to 45 percent and the alkali content of less than or equal to 1.0 percent. The alkali-free liquid setting accelerator provided by the invention has the advantage of nocorrosive and irritating odor, low doping amount, good adaptability to cement, rapid condensation speed and high strength and good stability; and the stabilization period reaches 180 days or more, thetechnology feasibility is strong and the liquid setting accelerator is suitable for large-scale industrial production.

Owner:PANZHIHUA CITY JIYUAN TECH

Whiten method for preparing bamboo chemical dissolving pulp and application thereof

InactiveCN101446053AIncrease contentImprove physical strengthWashing/displacing pulp-treating liquorsPulp bleachingMaterial consumptionDissolving pulp

Aiming at current situations of cotton and wood dissolving pulp, characters of bamboo material and many disadvantages existing in the existing whiten method for preparing dissolving pulp, the invention provides a whiten method for preparing bamboo material chemical dissolving pulp. The chemical dissolving pulp produced by the invention can be widely applied to derivant industry of celluloses, such as spinning viscose fiber, cellulose nitrate, acetate fiber, etc. The whiten method in the invention uses element-free chlorine bleaching or total chlorine free bleaching, thereby solving the problems existing in the whiten method of bamboo material chemical dissolving pulp and preparing bamboo material chemical dissolving pulp high-efficiently with low energy consumption, low material consumption and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

Liquid alkali-free and chlorine-free accelerating agent for spraying concrete and preparation method of liquid alkali-free and chlorine-free accelerating agent

The invention discloses a liquid alkali-free and chlorine-free accelerating agent for spraying concrete and a preparation method of the liquid alkali-free and chlorine-free accelerating agent. The liquid alkali-free and chlorine-free accelerating agent for spraying the concrete, provided by the invention, is prepared from an accelerating component, a stabilizing component, a concrete enhancing component and a pH adjusting component. The liquid alkali-free and chlorine-free accelerating agent provided by the invention has the advantages of no corrosivity and pungent smell, stable state and excellent adaptability. According to experimental conditions of JC-477-2005, the liquid alkali-free and chlorine-free accelerating agent provided by the invention is a qualified product when the parameter is 5 to 7 percent.

Owner:CHONGQING SANSHENG IND CO LTD

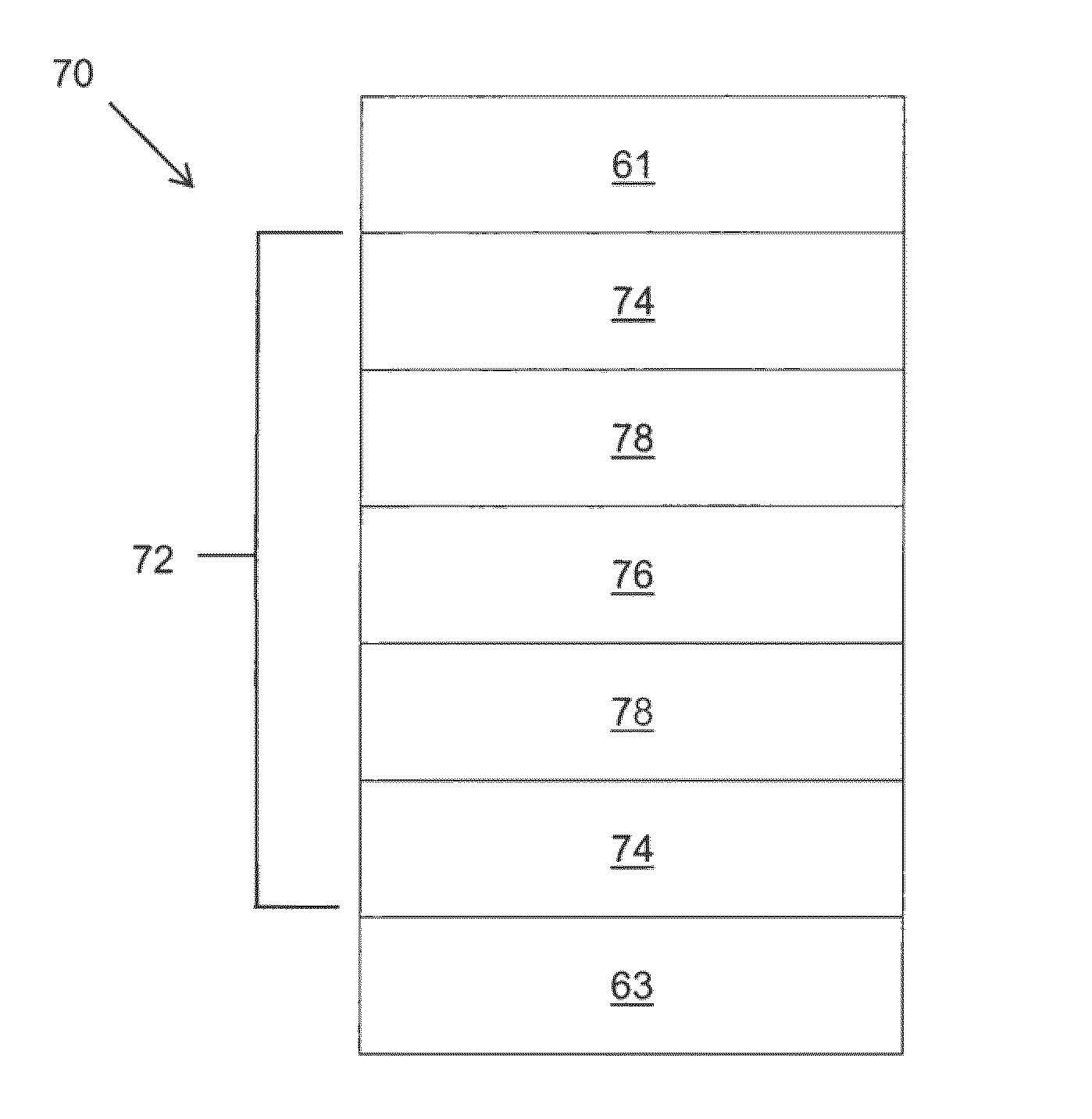

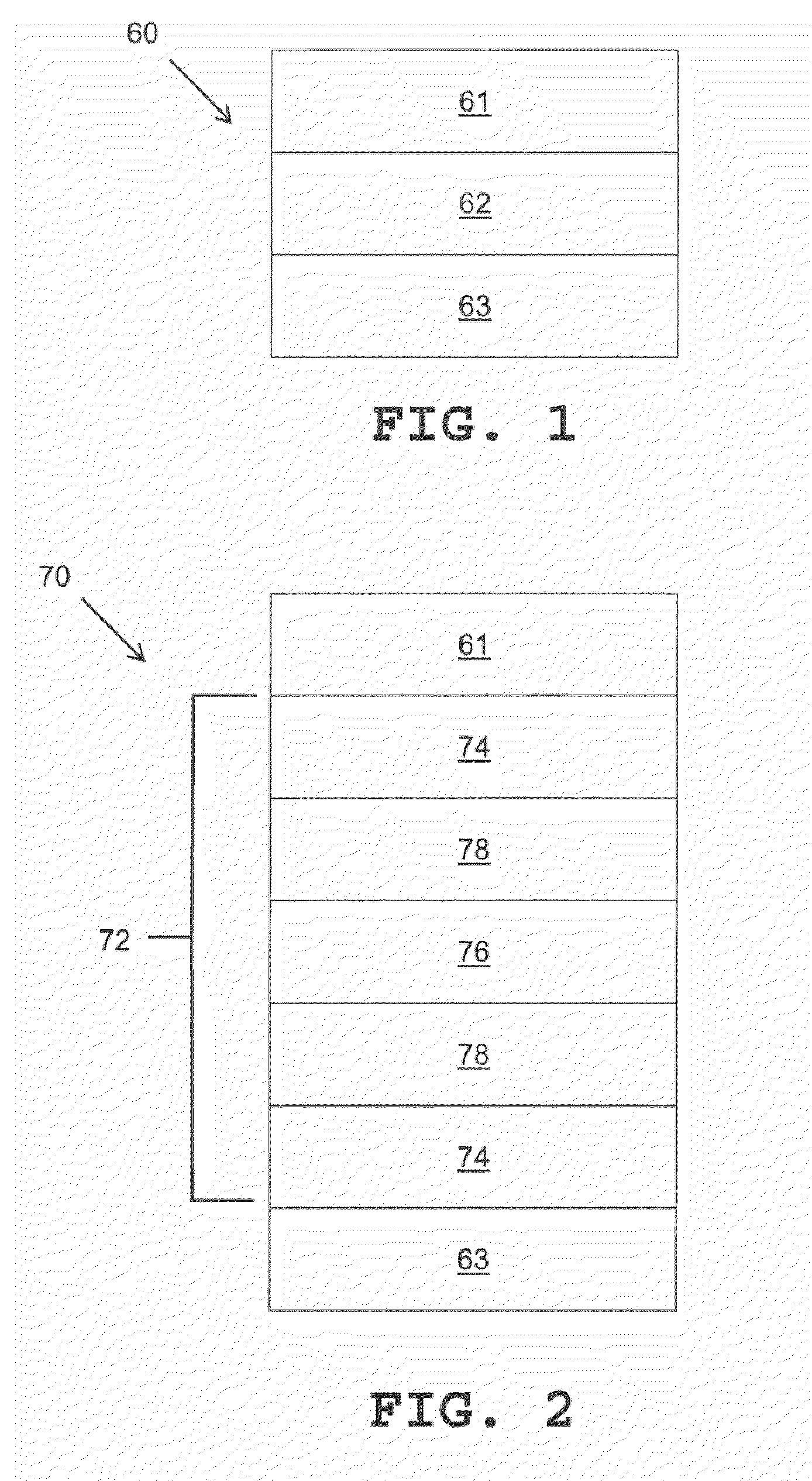

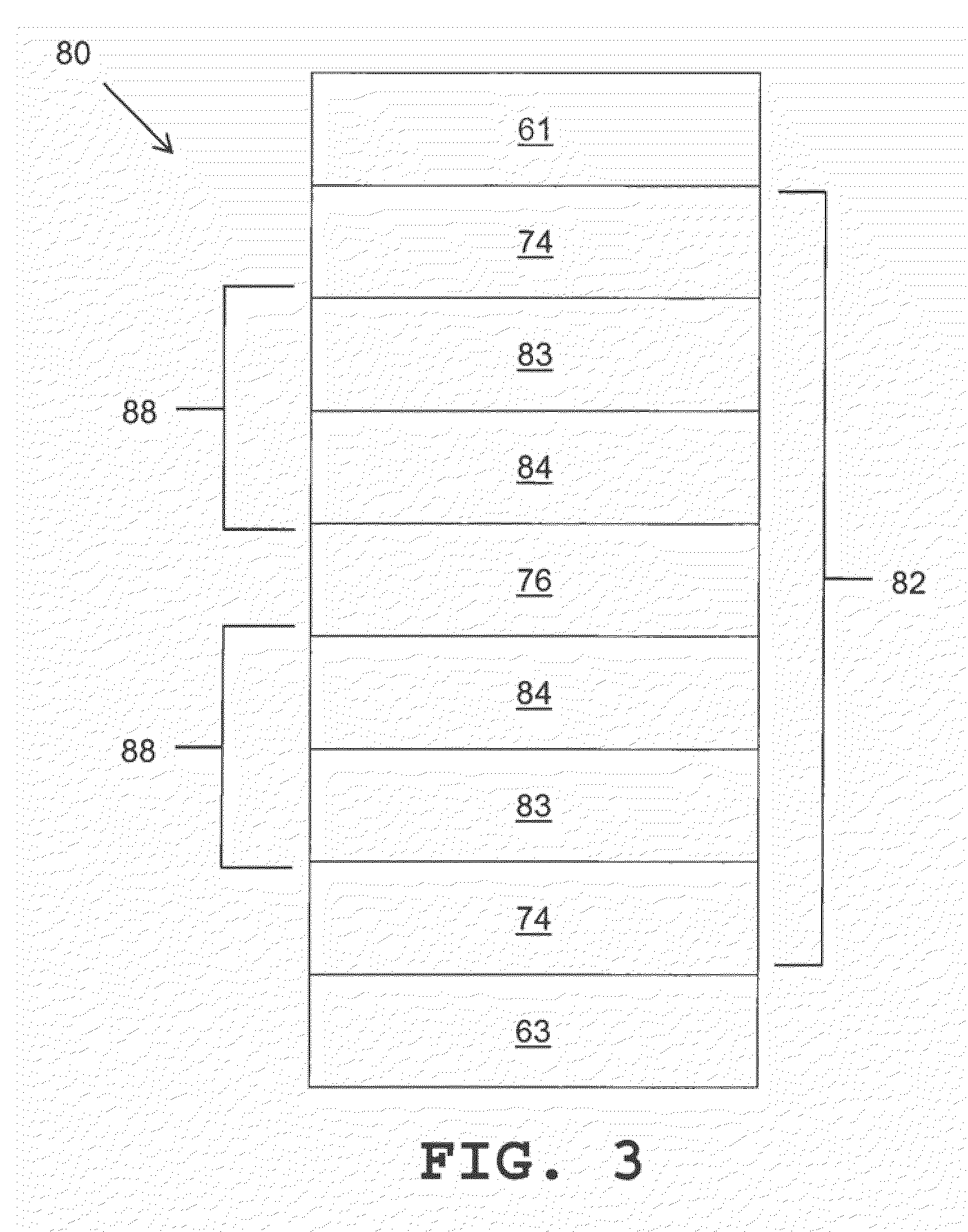

Chlorine-Free Packaging Sheet with Tear-Resistance Properties

InactiveUS20110104342A1Lower the resistance valueEnvelopes/bags making machineryDomestic containersMultilayer membraneTear resistance

A chlorine-free packaging sheet having a first rigid component, a second rigid component and a multilayer film positioned between the first rigid component and the second rigid component, a package comprising such packaging sheet and a method of manufacturing such sheet. The packaging sheet has a normalized combined tear initiation and propagation resistance in both the machine direction and the transverse direction of less than about 0.115 in*lbf / mil energy to break and less than about 0.800% / mil elongation, and a normalized tear propagation resistance in both the machine direction and the transverse direction of less than about 0.300 in*lbf / mil energy to break and less than about 0.145 lbf / mil peak load.

Owner:BEMIS COMPANY INC

Dispersive chlorine-free low-temperature early-strength agent used for oil well cement and cement mortar including same

ActiveCN105347716AImprove early strengthImprove compactnessDrilling compositionSodium aluminateSilicon dioxide

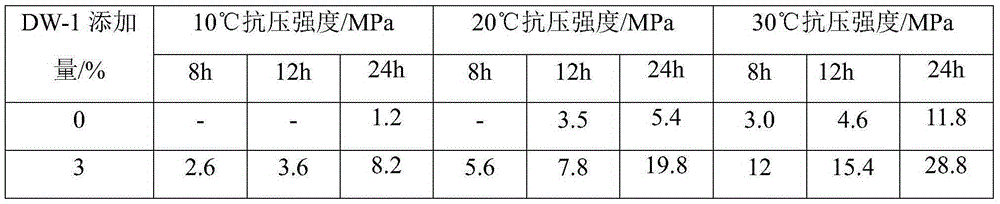

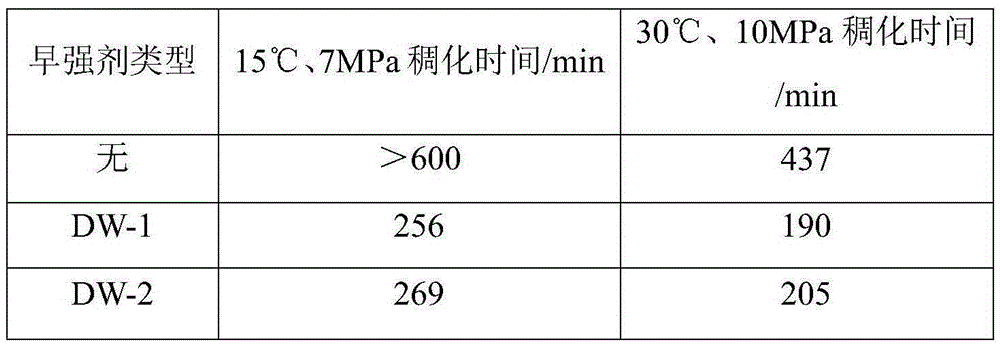

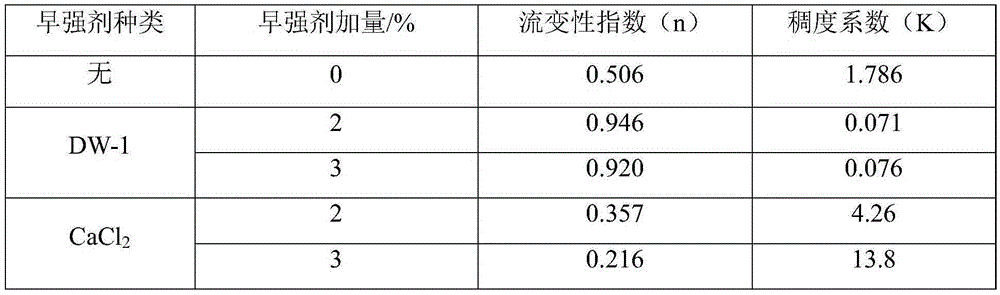

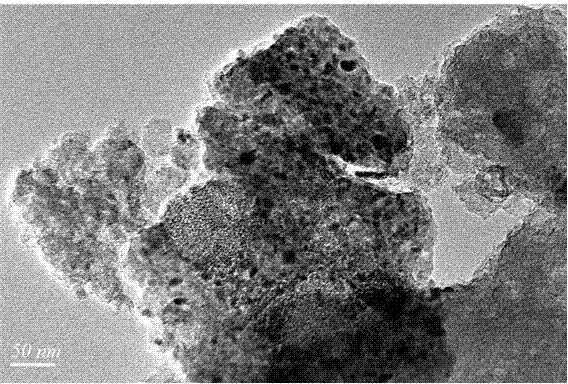

The invention provides a dispersive chlorine-free low-temperature early-strength agent used for oil well cement and a cement mortar including the same, belonging to the technical field of oil and gas well cementing. The low-temperature early-strength agent comprises, by weight, 1.5 to 2.5 parts of sodium sulfate, 0.6 to 1 part of nanometer silica, 0.15 to 0.3 part of sodium aluminate, 0.04 to 0.06 part of triethanolamine and 0.3 to 0.5 part of a water reducer. The low-temperature early-strength agent can effectively shorten time for waiting on cement setting during oil and gas well cementing at low temperature, substantially improves early strength of the oil well cement, enhances the rheological properties of the cement mortar and enables the oil well cement to have strength of 3.6 MPa in 12 h at 10 DEG C, strength of 8.2 MPa in 24 h at 10 DEG C, strength of 15.4 MPa in 12 h at 30 DEG C and strength of 28.8 MPa in 24 h at 30 DEG C; and the early-strength agent does not contain chloride ions and can be used together with lightening admixtures like hollow glass beads and floating beads so as to prepare cement mortar meeting different density requirements.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polyol ester lubricants, especially those compatible with mineral oils, for refrigerating compressors operating at high temperatures

InactiveUS20010038088A1Good hygroscopicityPromote undesirable corrosionHeat-exchange elementsRefrigeration componentsSolubilityRefrigeration compressor

A high quality lubricant for compressors operated during at least part of their compression cycle at temperatures above normal human comfort temperatures, such as most automotive air conditioners, especially those using chlorine free hydro-fluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some iso-pentanoic acid along with one or more of iso-nonanoic acid, isooctanoic acid, and dibasic acids such as adipic. When the mixture includes about 7% adipic and amounts of branched C8-9 and C5 monobasic acids in a ratio of at least 0.75:1.00, the esters formed have excellent solubility for paraffinic and naphthenic mineral oils and are therefore especially well suited for lubricating vehicle air conditioners formerly containing chlorine containing heat transfer fluids and mineral oil lubricants.

Owner:COGNIS CORP

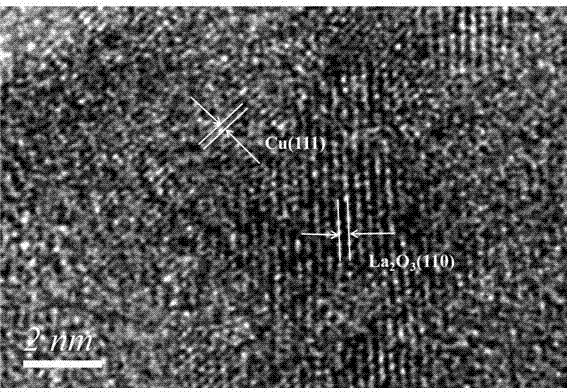

Chlorine-free bimetallic catalyst for gas phase synthesis of dimethyl carbonate and preparation and application

InactiveCN102872879AEvenly dispersedNot easy to agglomerate and sinterOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonMethyl carbonate

A chlorine-free bimetallic catalyst for gas phase synthesis of dimethyl carbonate is characterized in that the catalyst comprises an active component of copper, an additive, and active carbon; on a metal basis, the catalyst comprises 10.0-25.0 wt% of Cu, 1.0-10.0 wt% of the additive, and 65-85 wt% of active carbon. The catalyst of the invention has the advantages of high conversion rate and good selectivity.

Owner:TAIYUAN UNIV OF TECH

High-performance chlorine-free alkali-free liquid accelerating agent

The invention discloses a high-performance chlorine-free alkali-free liquid accelerating agent which is prepared from the following materials by weight percent: 6 to 15 percent of magnesium aluminum fluoride, 20 to 50 percent of aluminum sulfate, 2 to 6 percent of organic amines, 0 to 2 percent of stabilizer, and the balance of water. The production process comprises the following steps of: adding water at the given weight percent to a stirring drum, adding magnesium aluminum fluoride and stirring to dissolve, adding organic amines and stirring to dissolve, adding aluminum sulfate and stirring to dissolve, and making the final product. The high-performance chlorine-free alkali-free liquid accelerating agent is free of chlorine and alkali and non-corrosive to human beings and steel-bar-made machines, and has the advantages of long holding period, low addition amount, quick setting action, low rebound rate, high one-day strength, substantially no loss of long-term strength and good material compatibility. The production process is simple, pollution-free and noise-free, does not produce gas discharge or waste water, and is safe and environment-friendly. The materials are abundant, the production cost is low, and the social and economic benefits are extremely good.

Owner:昆明合起工贸有限公司

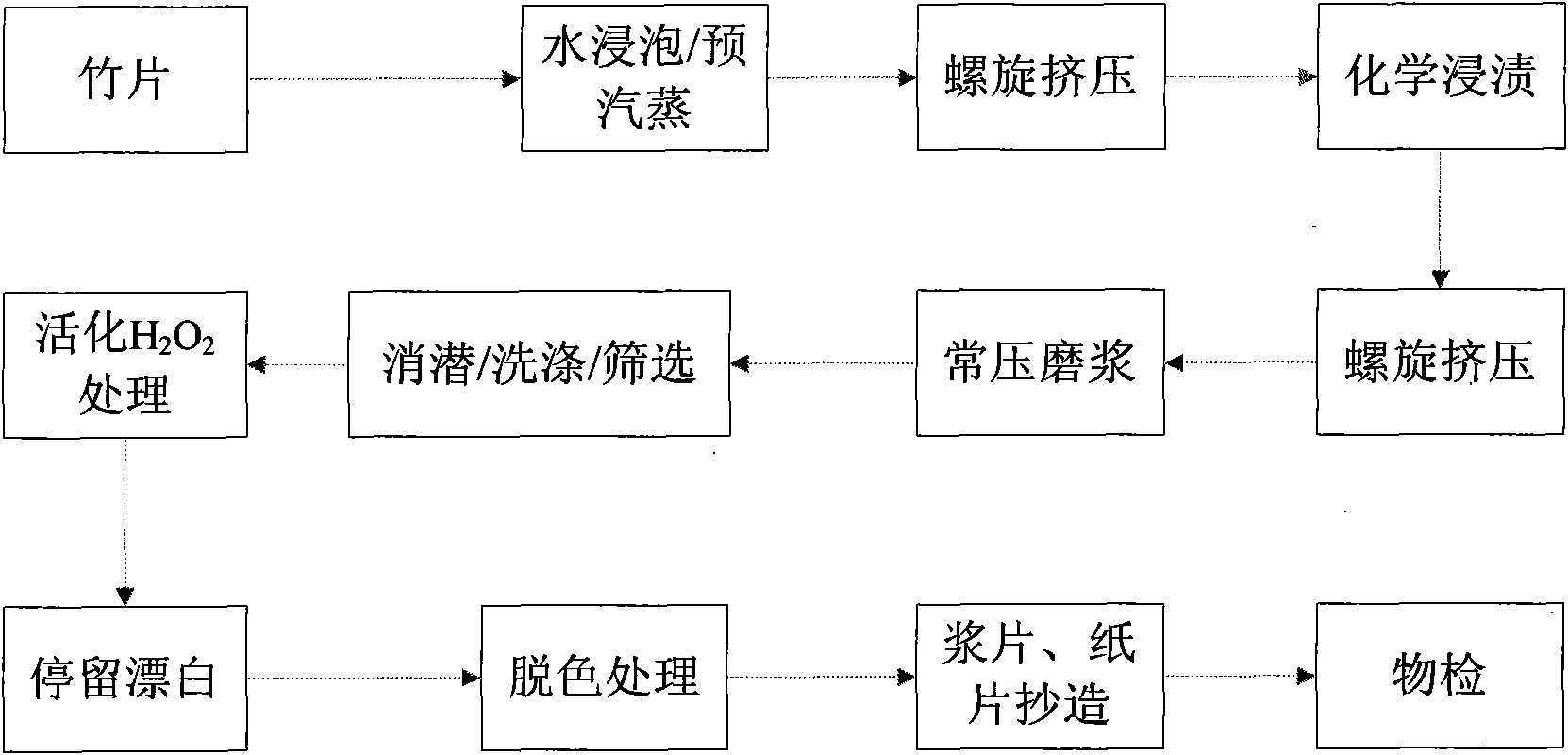

High-whiteness bleaching method for high-yield bamboo wood pulp

ActiveCN101638859AReduce dosageImprove bleaching efficiencyNon-macromolecular organic additionPulp bleachingHigh concentrationPre treatment

The invention discloses a high-whiteness bleaching method for high-yield bamboo wood pulp. The high-whiteness bleaching method comprises the following steps: firstly, using an extruder to carry out enhanced mechanical treatment on pretreated bamboo sheets; using a transition metal ion remover and the like to carrying out chemical impregnating treatment on extruded cizu materials; then, carrying out secondary spiral extrusion before pulping, straightening and screening; secondarily, using a peroxide activating agent and peroxide to carry out the activating treatment of 20 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 30-60 minutes; thirdly, using a chlorine-free bleaching medicine H2O2 to carry out high-concentration rested bleaching of 10-30 percent by weight of bamboo pulp at a treatment temperature of 60-90 DEG C for 60-180 minutes; and using a decoloring agent of thiourea dioxide to decolour the bamboo pulp, remove a ground color, adjust a color phase and improve the bleaching white content. The invention forcefully and mechanically treats the bamboo sheets, synchronously realizes pulping, the removal of transition metal ions and deep extractionsand the break of complex cells, reduces the consumption of the bleaching medicine and improves the bleaching efficiency.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Non-chlorine type high perpormance conrete accelerating agent

The invention relates to a chlorine-free high-performance concrete setting accelerator, composed of high-efficacy benzene solfonic acid formaldehyde condensation compound water reducer, sodium formate, sodium fluoride, fibrin and water. It can shorten the setting time of grout and concrete, and the initial setting time is in 5 min and the final setting time is in 10 min, and after setting, the strength of the grout rapidly develops. It can effectively avoid the corrosion damage of Cl- ions to the reinforcement in the concrete. It is applied to the shotcrete in tunnel, culvert and shoring engineering, and also the engineering of concrete emergency salvaging, anchoring, and water stopping and leakage stopping.

Owner:TONGJI UNIV

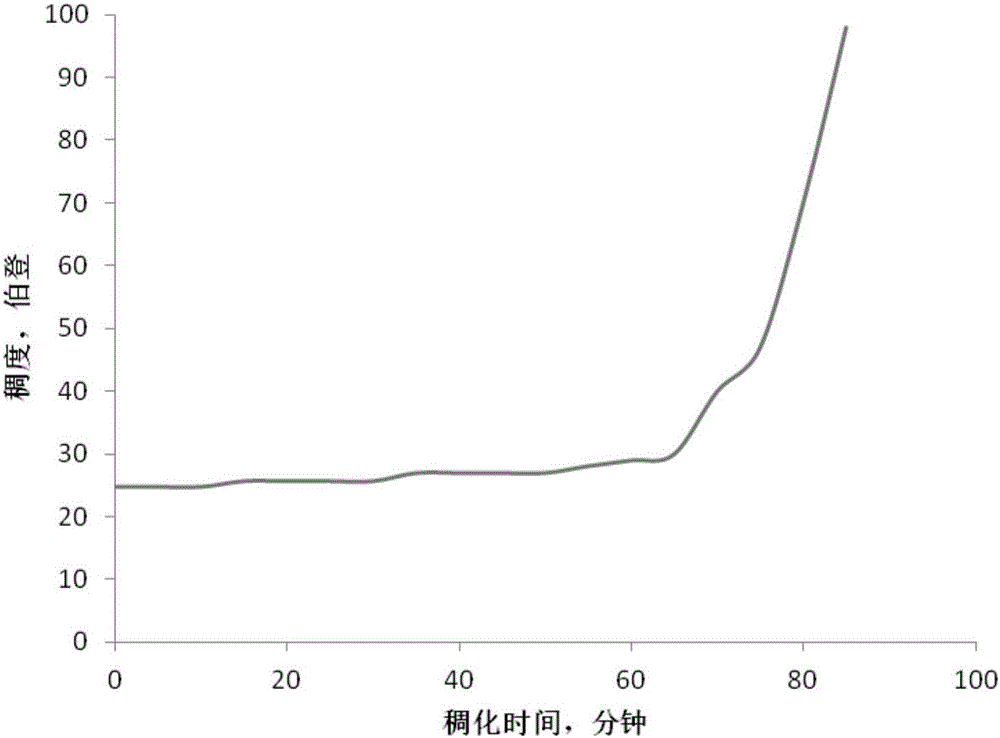

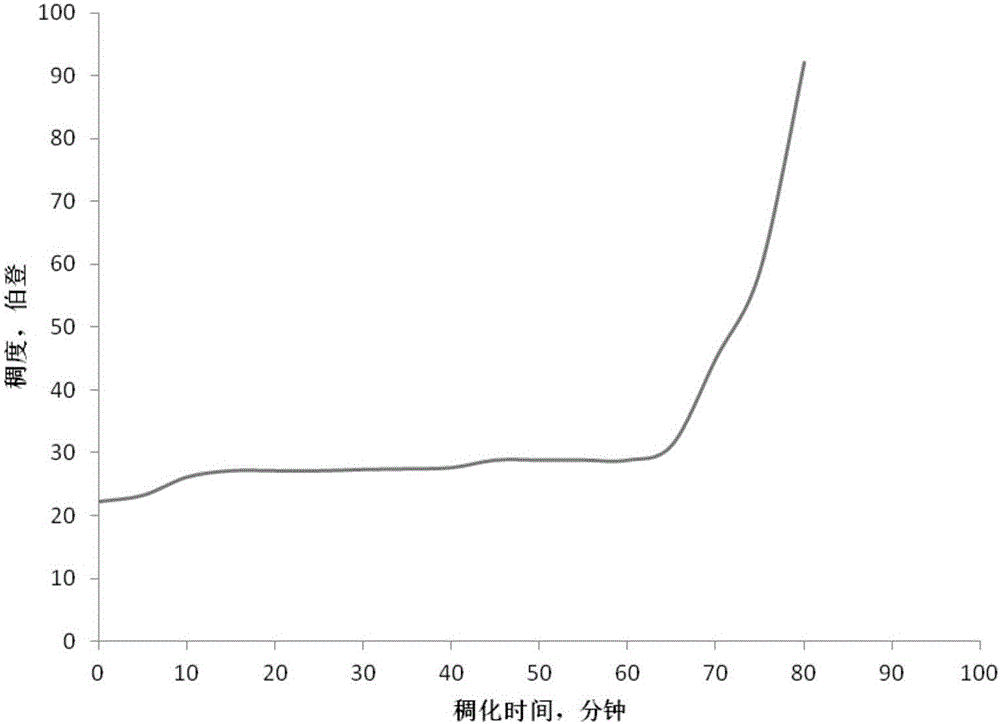

Wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement

ActiveCN106186777AImprove anti-channeling abilityImprove top strengthDrilling compositionOXALIC ACID DIHYDRATEApatite

The invention relates to a wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement. The early strength agent comprises the following raw materials in parts by weight: 1 to 1.5 parts of sodium salts, 1 to 1.5 parts of calcium salts, 1 to 1.5 parts of aluminum salts, and 1 to 1.5 parts of other materials, wherein other materials are one or more of hydroxyl apatite, meta-kaolin, magnesium trisilicate, magnesium oxide, strontium sulfate, strontium carbonate, strontium nitrate, lithium carbonate, and oxalic acid. The provided early strength agent is stable, and has an excellent coagulation accelerating performance and early strength property; the early strength is high, the strength development is fast, the thickening transition time and primary-final setting transition time are short; and the early strength agent is suitable for various cement slurry systems such as cement slurry system with a wide temperature range and large temperature difference, AMPS cement slurry system, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Multifunctional chlorine-free alkali-free compound concrete slag admixture and its preparation process

InactiveCN1699244AChange the expansion propertiesImprove compactnessSolid waste managementFiberAlkali free

Disclosed is a multifunctional chlorine-free alkali-free compound concrete slag admixture which comprises (by weight ratio) inorganic industrial waste material 90-95%, organic raw material 5-10%, the inorganic industrial waste material is selected from lithium slag powder, calcium slag powder, phosphogypsum slag, fluorite tailings, composite of silicon ash and rare earth waste material, the organic raw material is selected from organosilane, carbon fiber, methylvinyl silicone rubber, polyepoxysulfonate, polycarboxylate, low polyglycerol, compound of diethylene triamine condensate and tartaric acid. The preparation method comprises the following steps, mixing inorganic industrial waste materials by proportion and grinding to 0.08mm, grinding organic raw material to grain diameter of below 1um, charging 5-10% of organic raw materials into 90-95% of inorganic raw materials.

Owner:NANJING NORMAL UNIVERSITY

Special lubricating oil for dobby

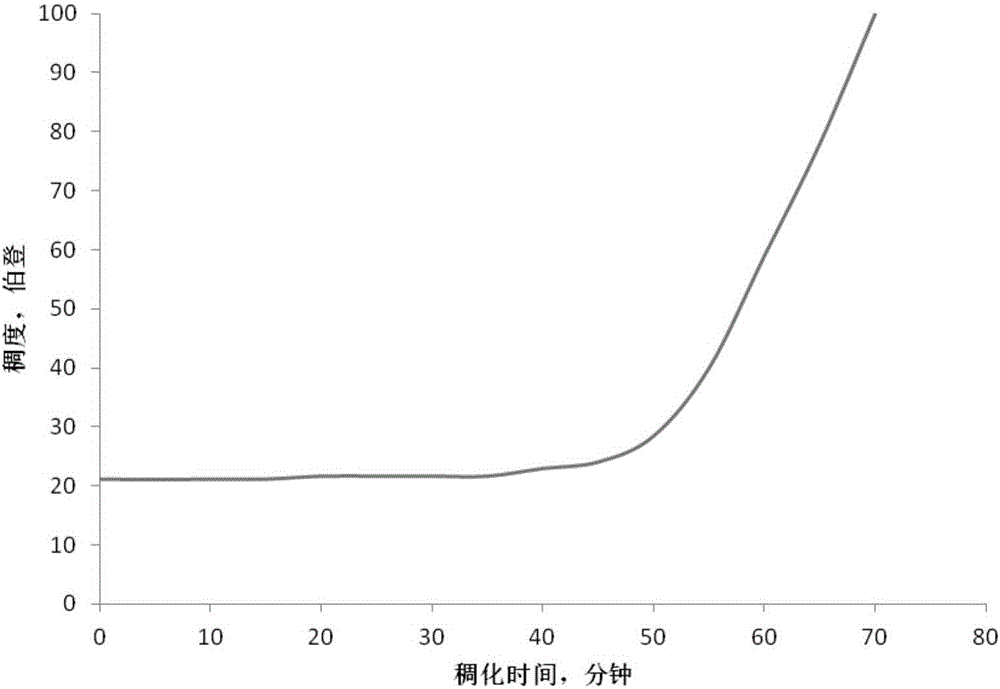

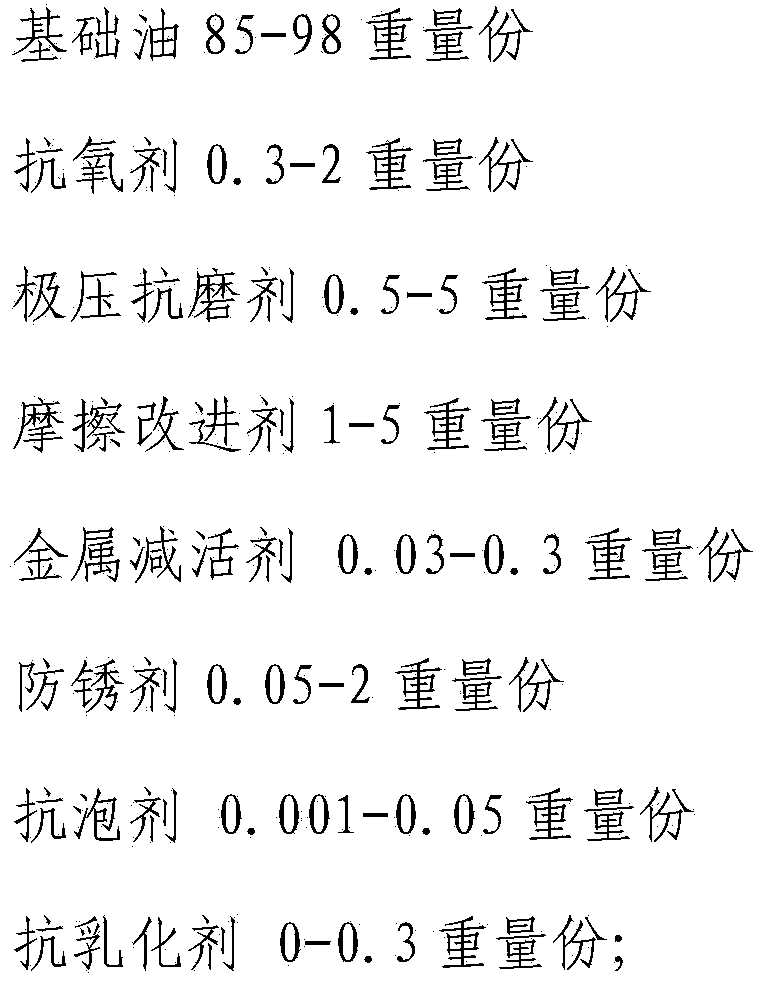

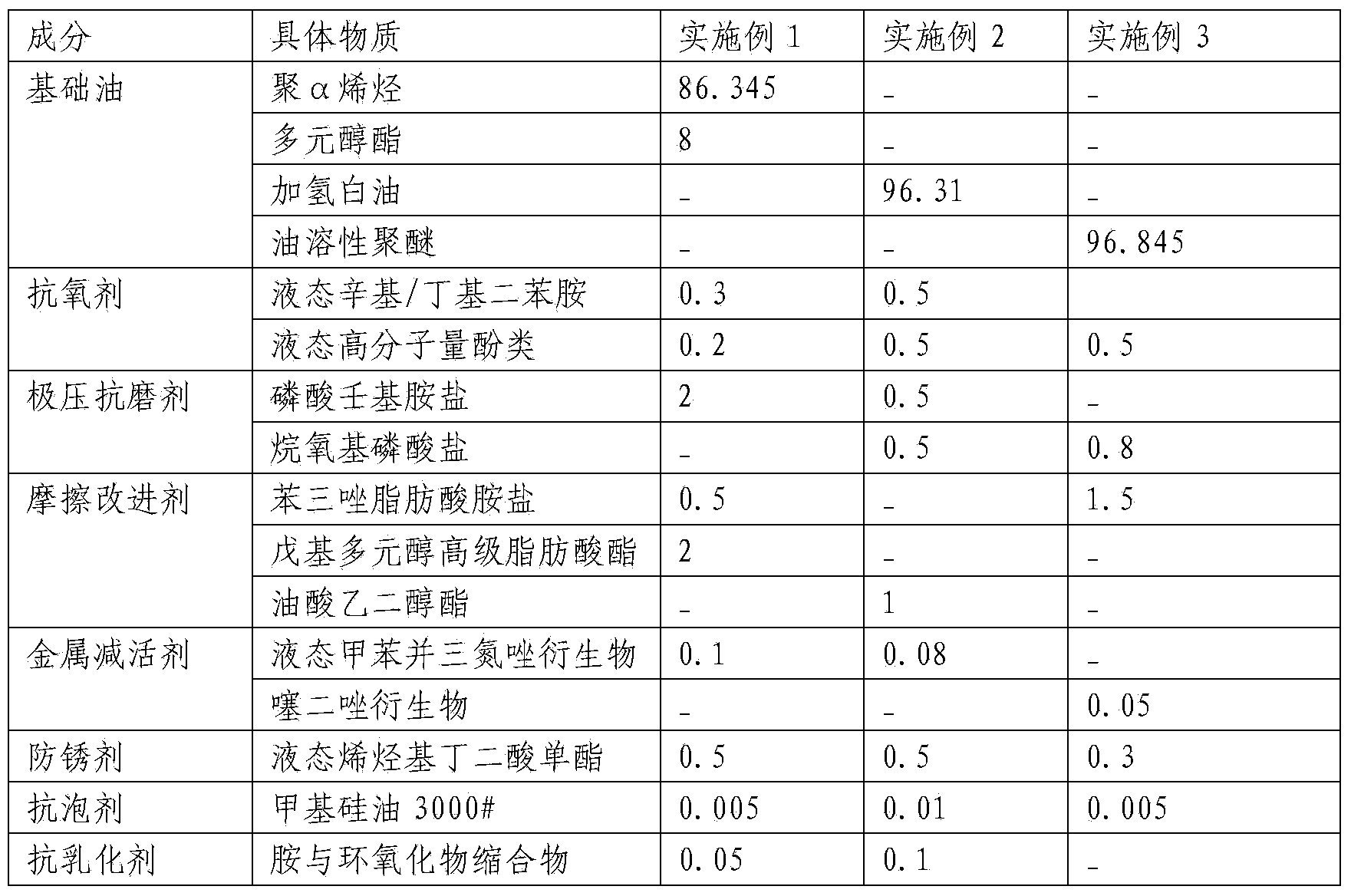

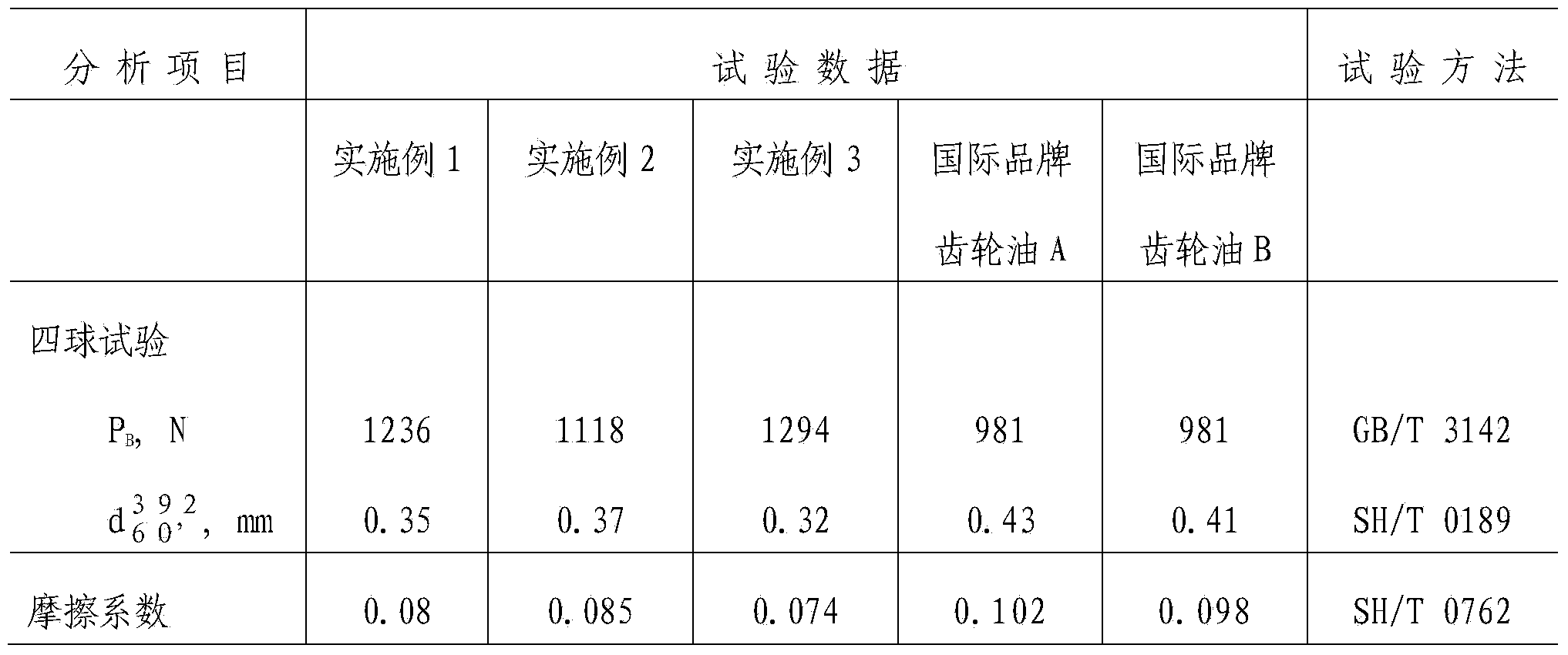

ActiveCN103865620AStrong extreme pressureImprove wear resistanceLubricant compositionFoaming agentAntioxidant

The invention discloses special lubricating oil for a dobby. The special lubricating oil comprises the following components in parts by weight: 85-98 parts of base oil, 0.3-2 parts of antioxidant, 0.5-5 parts of anti-wear reagent at extreme pressure, 1-5 parts of friction improver, 0.03-0.3 part of metal deactivator, 0.05-2 parts of antirust agent, 0.001-0.05 part of anti-foaming agent and 0-0.3 part of demulsifying agent. The special lubricating oil has the beneficial effect that the lubricating oil is prepared by using selected mineral oil and synthetic oil as the base oil and using the anti-wear reagent at extreme pressure, the friction improver, the antioxidant, the anti-foaming agent and the demulsifying agent as raw materials in matching; the lubricating oil is excellent in extreme pressure, abrasion resistance, oxidation resistance, foaming resistance, emulsifying resistance and extreme low in friction coefficient, is a new-generation lead-free and chlorine-free environment-friendly dobby lubricating oil, and is used for lubricating the dobby; the lubricating oil is capable of effectively reducing the temperature rise, reducing abrasion, and prolonging the oil change period.

Owner:深圳市超润达科技有限公司

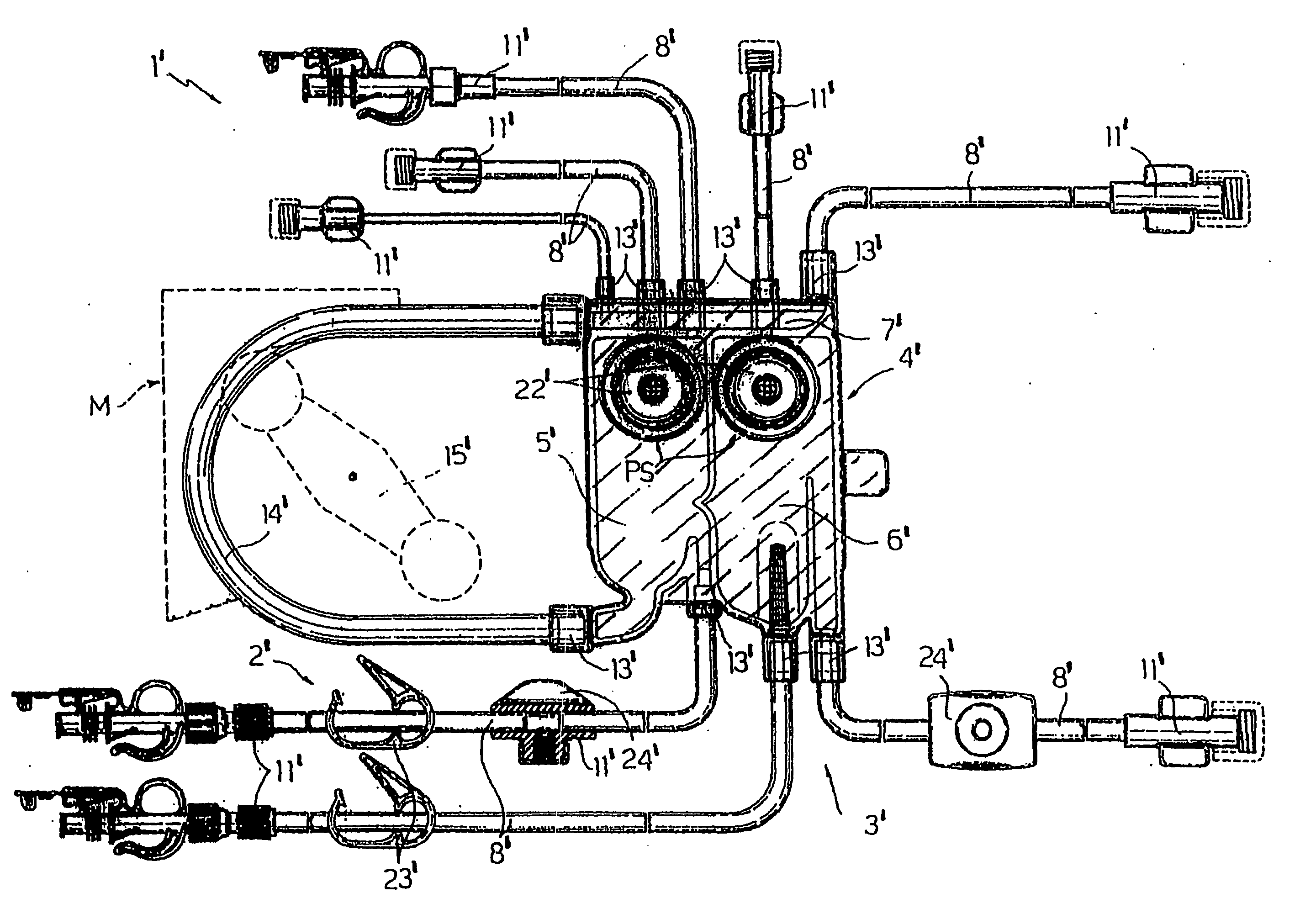

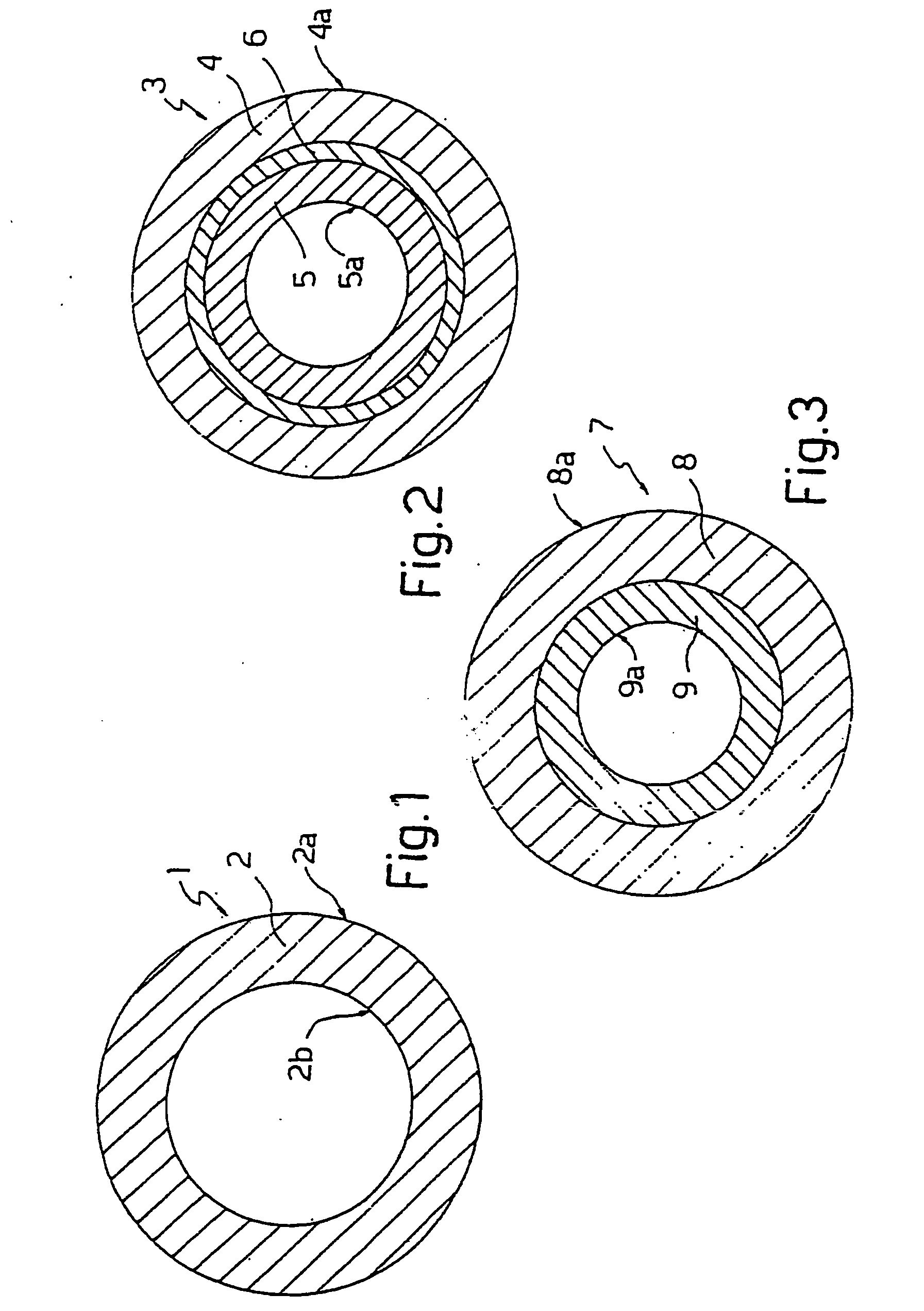

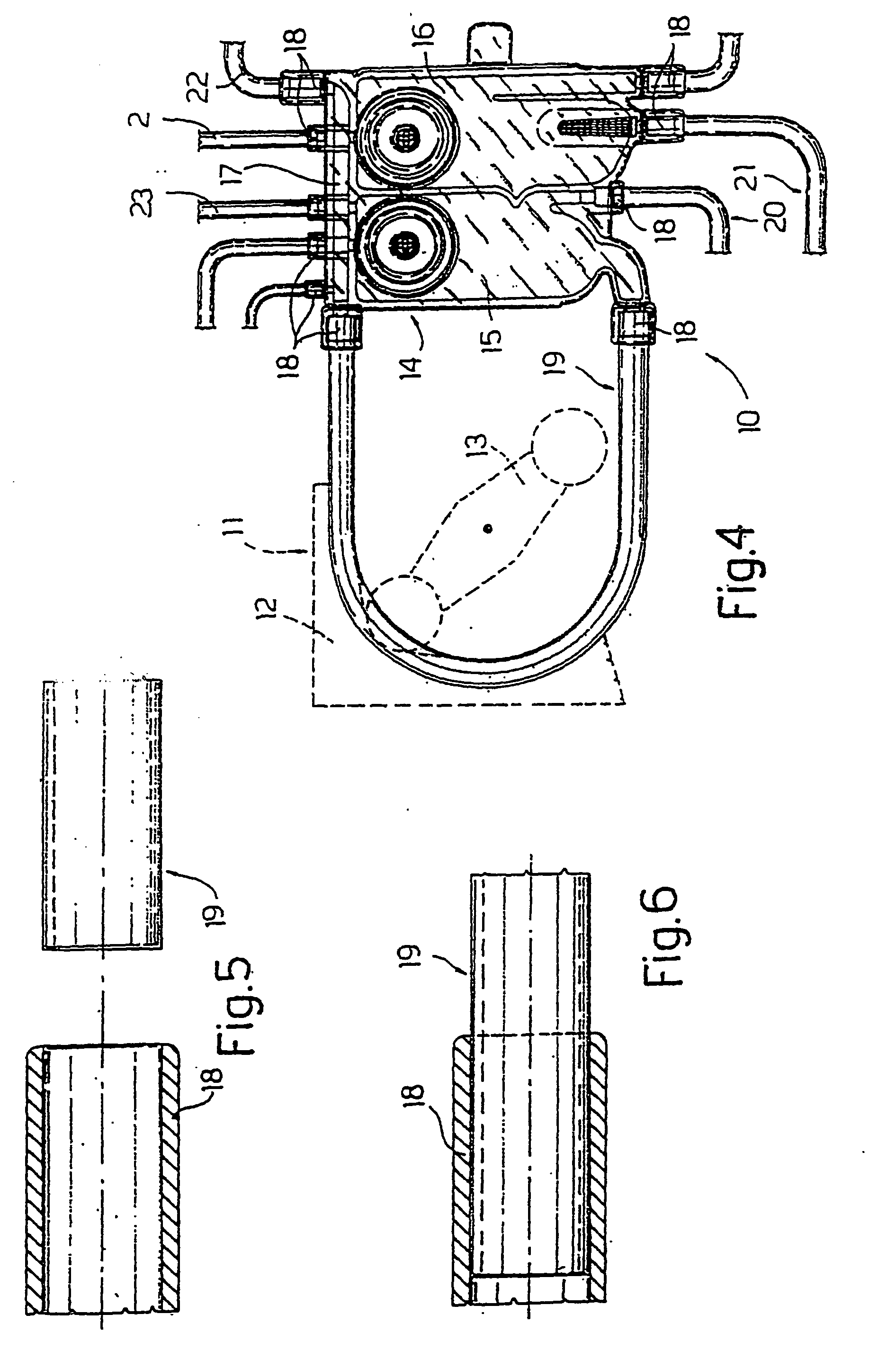

Tube for medical applications and circuit incorporating such tube

InactiveUS20050148924A1Simple and economical to manufactureSimple and economical wayOther blood circulation devicesLayered productsSolubilityChlorine.free

A tube for medical applications comprises a chlorine-free material and has a layer defining an outer surface of the tube. The tube is manufactured from a polymer material having a solubility parameter within the range 9.9±1.5 (cal / cm3)1 / 2.

Owner:GAMBRO LUNDIA AB

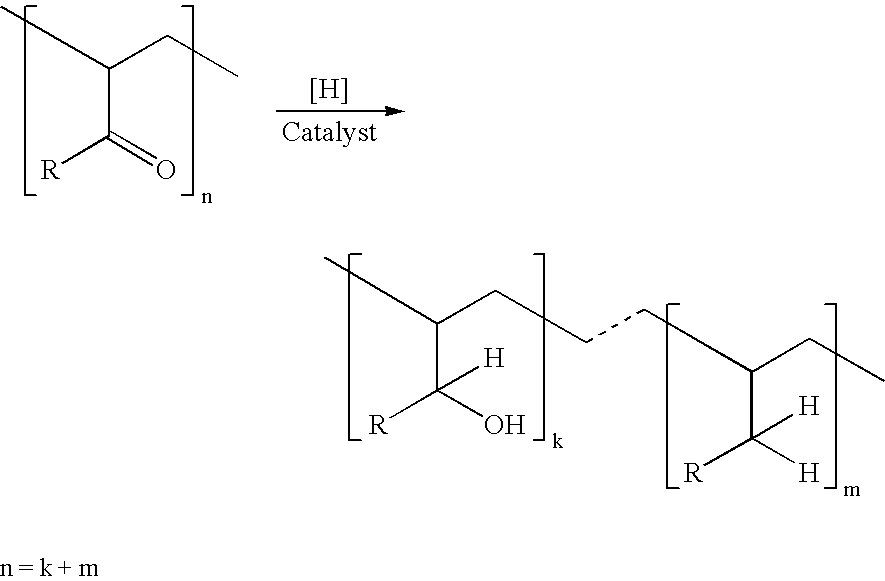

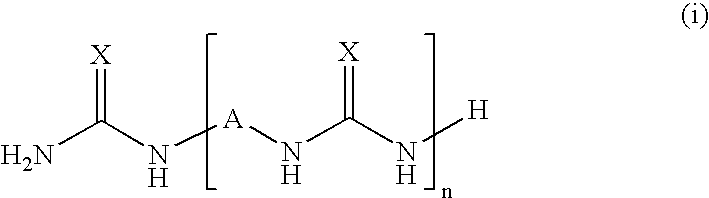

Silane-functional, chlorine-free composition

InactiveUS20080069949A1Improve adhesionRapid initial dryingPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePolyolefin

A compositions containing A) a silane-grafted, largely amorphous poly-α olefin which contains no organically bound chlorine, B) a ketone resin, ketone / aldehyde resin and / or urea / aldehyde resin and / or their hydrogenated derivatives, C) a solvent and D) optionally an auxiliary and / or additive, can be used as primers for promoting the adhesion of coating materials such as paints, varnishes, adhesives, sealants and inks, including printing inks, for example, to plastics, wood, paper, metals, glass, ceramics and concrete.

Owner:EVONIK DEGUSSA GMBH

Method for producing and bleaching slasher sizing with oil windmill palm empty fruit fibre

InactiveCN101492891AHigh mechanical strengthReduce manufacturing costNon-fibrous pulp additionPulp bleachingFiberHigh concentration

The invention discloses a method for using oil palm hollow fruit fibers for the production of bleaching machine pulp, comprising: step 1, subjecting the oil palm hollow fruit fiber raw material to water scrubbing to remove oil stains, sands and dusts; step 2, adding a penetrant for pre-penetration treatment; step 3, extruding and dehydrating by a polishing splitting machine and pressing to filaments to then feed into a first thermofiner for rough grinding so that the fibers are split into coarse pulp; step 4, watering to dilute the coarse pulp roughly-grinded by the thermofiner in order to sieve out the coarse pulp and screened pulp which are extruded and filtered, respectively; step 5, Introducing the sieved coarse pulp into a second thermofiner for continuous thermal grinding, and mixing the grinded size with the screen pulp by a pulp screen in the fourth step; step 6, watering to dilute the grinded size followed by screening via a screen net, delivering the coarse pulp to the second thermofiner for regrinding, concentrating the screened pulp to prepare for bleaching; step 7, employing a high-concentration high-temperature chlorine-free hydrogen peroxide bleaching method to reach 75%-80%ISO of the whiteness of the bleached pulp, and obtaining the bleaching machine pulp via washing, filter-pressing and drying for the papermaking.

Owner:SHAANXI UNIV OF SCI & TECH

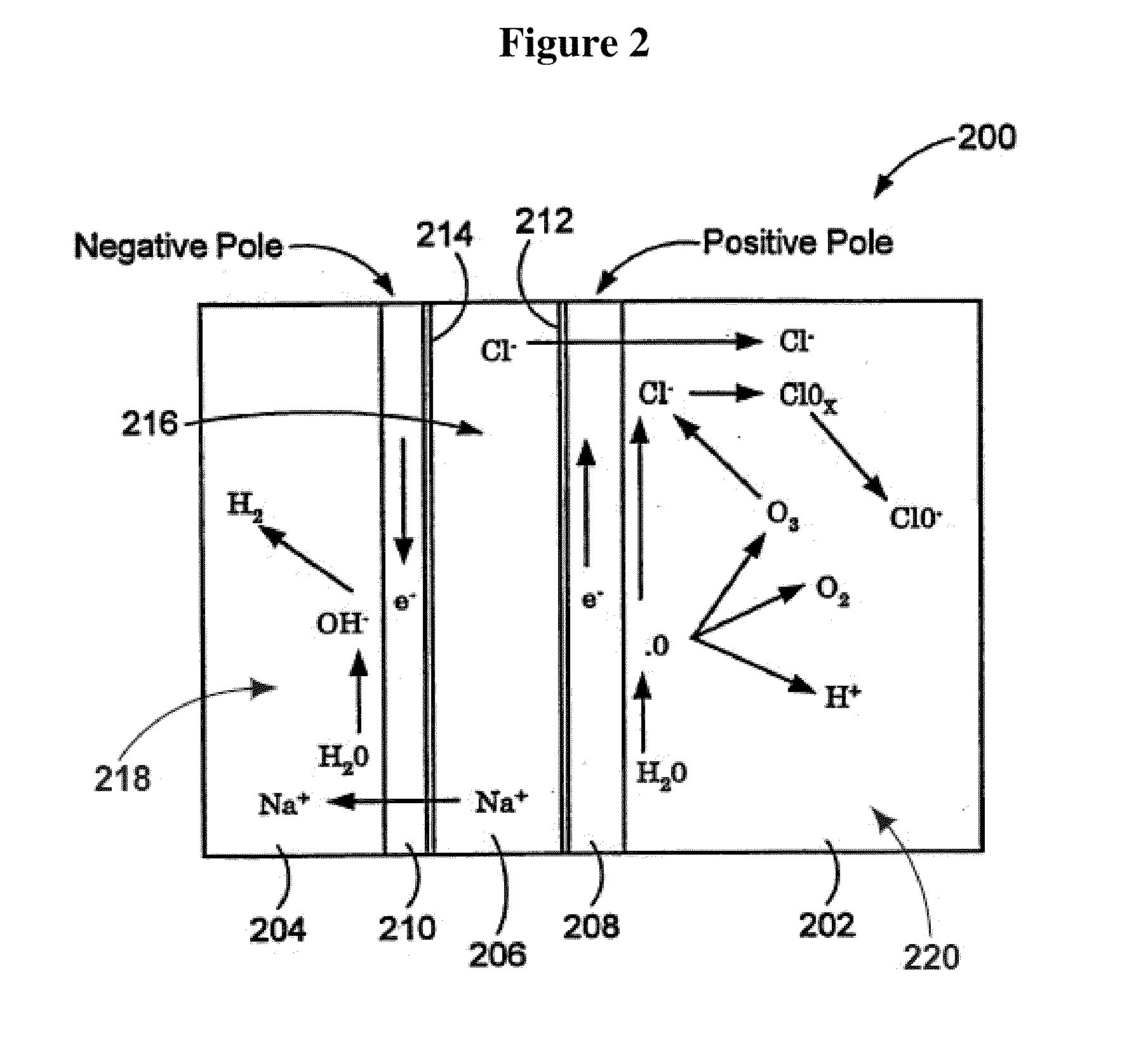

Methods of treating or preventing biofilm associated infections with free available chlorine free available chlorine water

ActiveUS20100166809A1Reduce morbidityReduce concentrationAntibacterial agentsRespiratorsBiofilmMicroorganism

The invention provides methods of treating or reducing the incidence of an infection in a mammal due to a biofilm associated infectious microorganism comprising administering a therapeutically effective amount of free available chlorine (FAC) water to a site populated with biofilm associated infectious microorganism.

Owner:SONOMA PHARMA INC

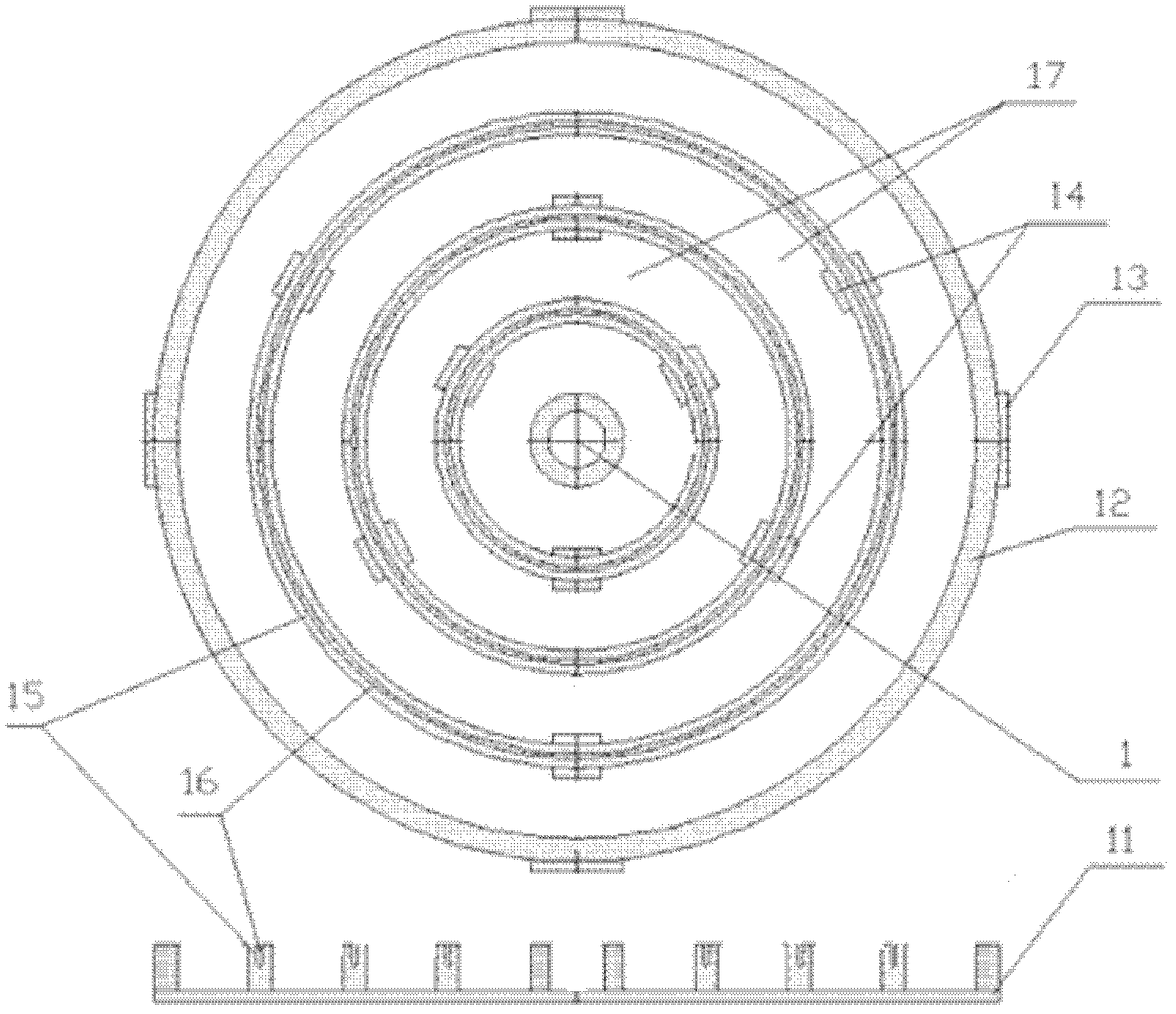

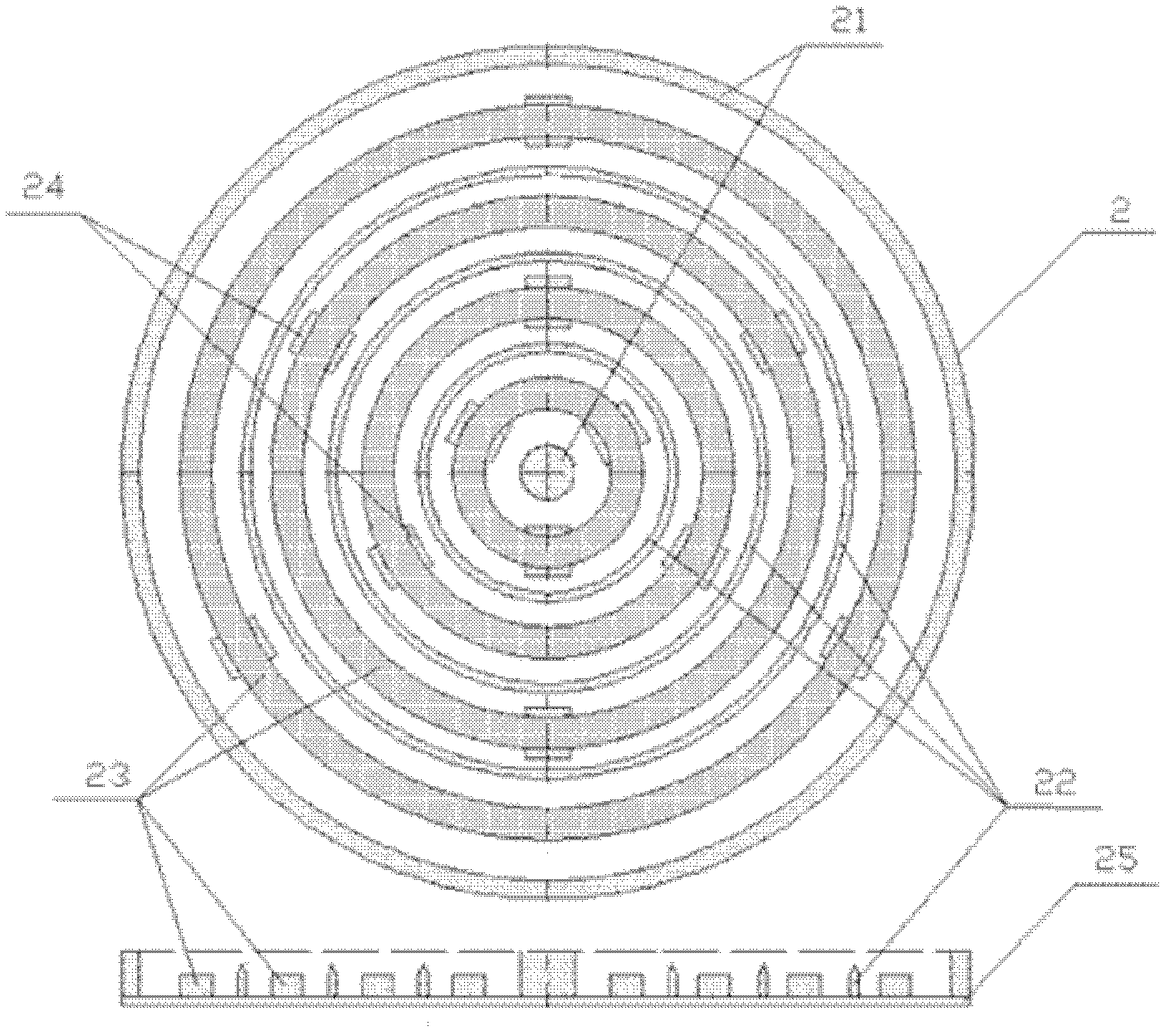

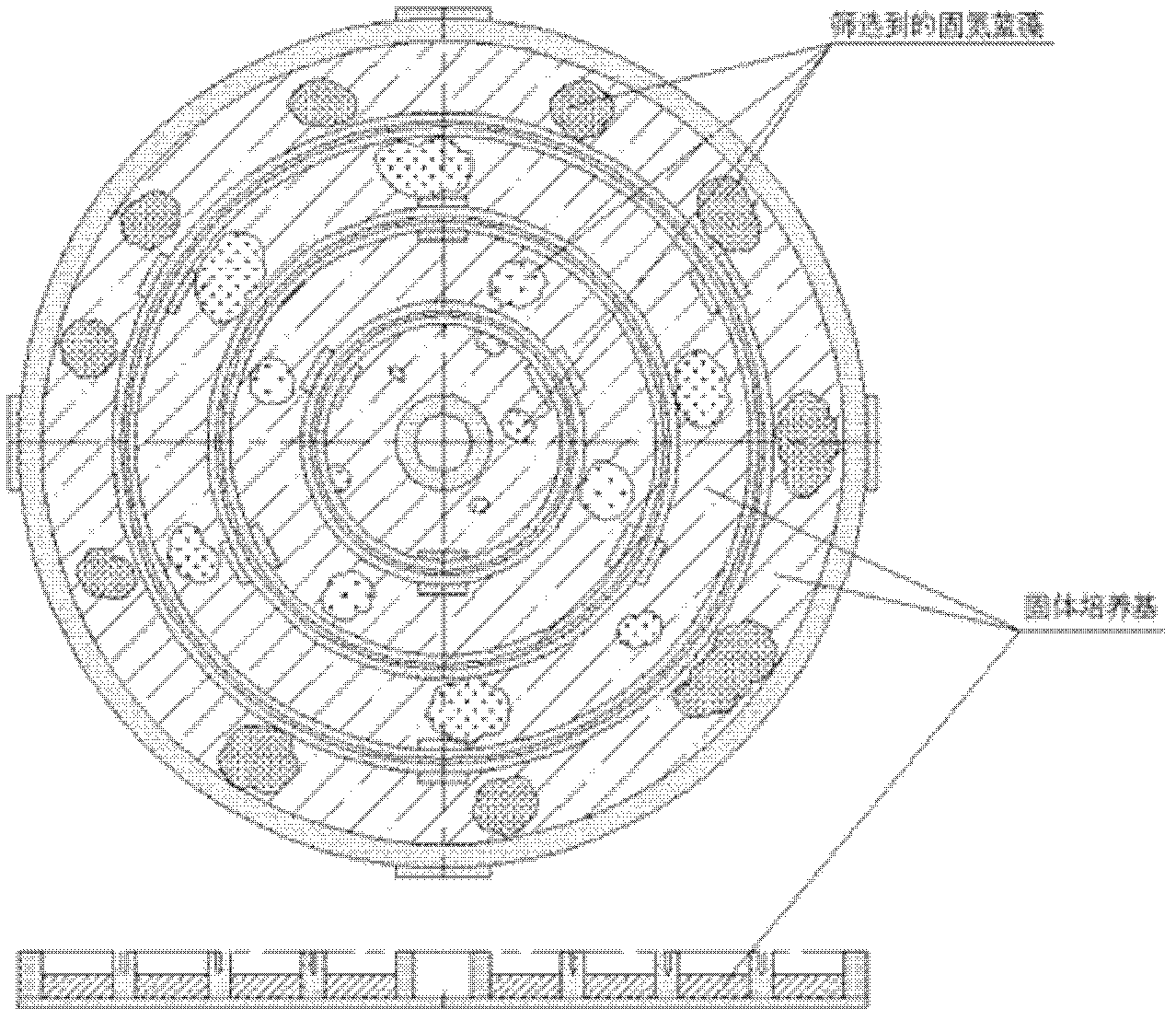

Method for separating and screening nitrogen fixation blue-green algae with polychlorinated biphenyl degradation function

ActiveCN102586118APromote growthAchieve the purpose of degradationUnicellular algaeMicroorganism based processesPolychlorinated biphenylBlue green algae

The invention discloses a method for separating and screening nitrogen fixation blue-green algae with polychlorinated biphenyl degradation function. The method comprises the following steps of: 1) preparing a chlorine-free culture medium, adding agarose and then sterilizing, cooling to temperature of 60 DEG C and adding polychlorinated biphenyl, mixing uniformly and then pouring the mixture into a corresponding screening zone of a separating and screening device, cooling and fixing to obtain a solid culture medium used for screening algaes, and placing the solid culture medium on a flat plate; 2) acquiring mixed algae solution subjected to pre-culture in soil in the field, carrying out centrifugal separation on the mixed algae solution, abandoning supernatant, suspending cells with the chlorine-free culture medium again, and mixing uniformly to obtain concentrated solution of the mixed algae solution; 3) pouring the concentrated solution of the mixed algae solution obtained in the step 2) into the solid culture medium in the step 1); and 4) placing the separating and screening device into a culture room and carrying out constant temperature culture. The method disclosed by the invention has high screening efficiency, a large quantity of target algaes can be screened in short time, and screening cost is low, thus being beneficial to practical application and popularization.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com