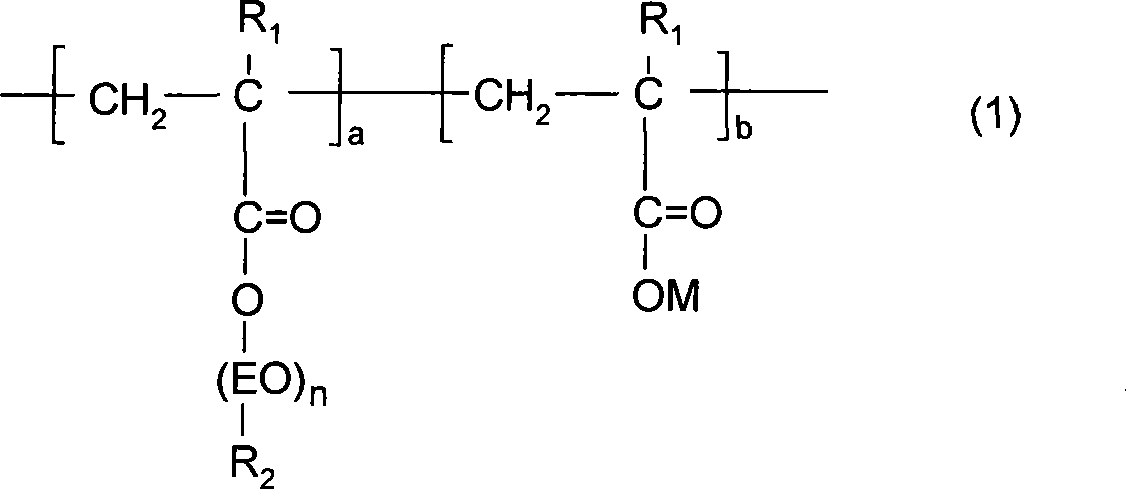

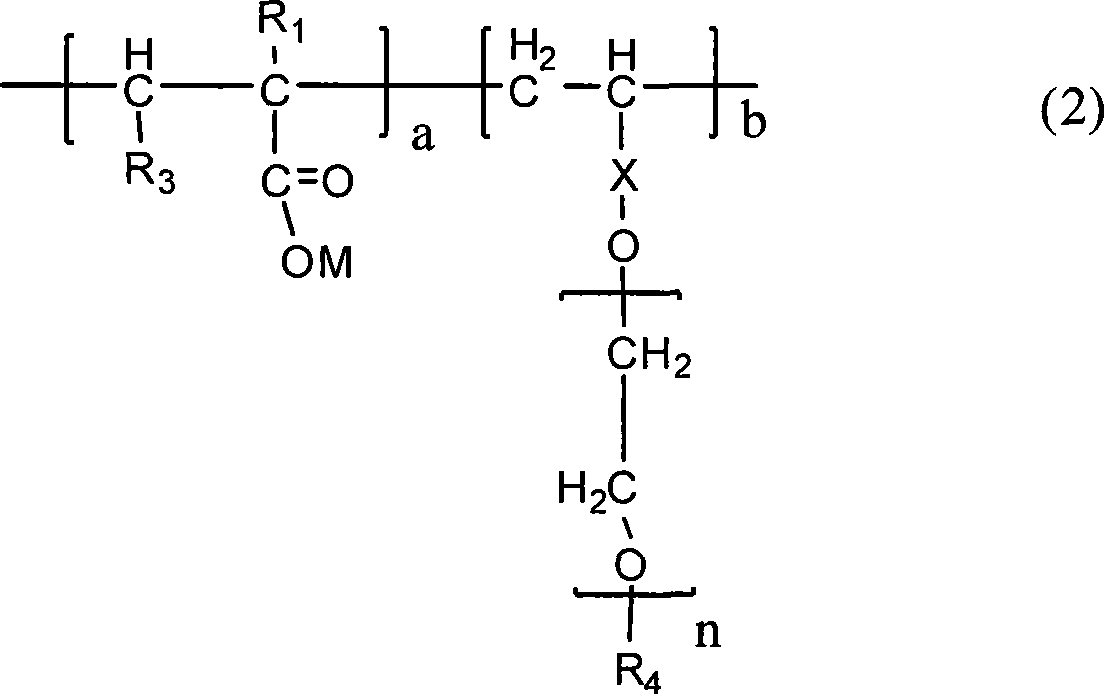

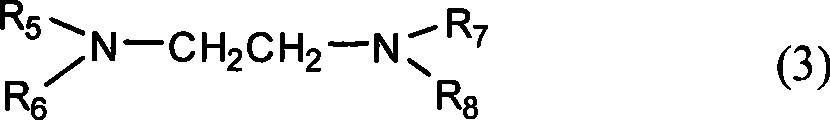

Liquid, chlorine-free, early-strength anti-freezing polycarboxylate composite water reducing agent and preparation method thereof

A technology of composite water reducer and polycarboxylate, which is applied in the field of early-strength antifreeze polycarboxylate composite water reducer and its preparation, and antifreeze concrete admixture, which can solve the problem of high alkali content of antifreeze and harm to human health , high alkali content and other problems, to achieve uniform and stable long-term storage, good anti-freeze performance, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add water 367kg in 1000L reactor, drop into polycarboxylate superplasticizer (PC (a)) 200kg (40% effective weight concentration) successively behind, ethylene glycol 60kg, tetrahydroxypropyl ethylenediamine 20kg, thiocyanate Magnesium acid 100kg, calcium formate 50kg and rosin resin air-entraining agent 3kg, stir until it dissolves into a uniform solution (about 20min), and the weight concentration is 39.2%.

Embodiment 2-4

[0056] The preparation process is the same as in Example 1, except that the types and proportions of raw materials used are different, as listed in Table 2.

[0057] Table 2

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com