Patents

Literature

36results about How to "No rust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based organic silicon waterproof agent

InactiveCN101580355AGive full play to the effect of waterproofImprove impermeabilityOther chemical processesWater basedBrick

The invention relates to a water-based organic silicon waterproof agent by taking sodium methylsilanolate as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

Water-emulsion organic silicon waterproof agent

InactiveCN101580356AGood chemical propertiesImprove bindingOther chemical processesEmulsionCement slurry

The invention relates to a water-emulsion organic silicon waterproof agent by taking alkylalkoxy silane as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

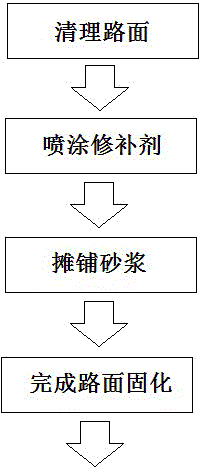

Modified cement mortar pavement patching material and pavement patching construction method

The invention discloses a modified cement mortar pavement patching material and a pavement patching construction method. The modified cement mortar pavement patching material is prepared by uniformly mixing the following components: silicate cement, sand, macadam, a component A, a component B and water, wherein the macadam is an optional component material or a default component material; the component A is epoxy resin; the component B is an epoxy resin curing agent. The modified cement mortar pavement patching material is applied to the patching construction of microcracks, pitted surfaces and pits in a cement concrete pavement; the early compression strength, the breaking strength and the bonding strength of the modified cement mortar pavement patching material are higher than the early compression strength, the breaking strength and the bonding strength of normal cement mortar; the modified cement mortar pavement patching material is beneficial for the rapid patching of damaged concrete pavements, good in patching quality and low in cost.

Owner:SHANGHAI UNIV

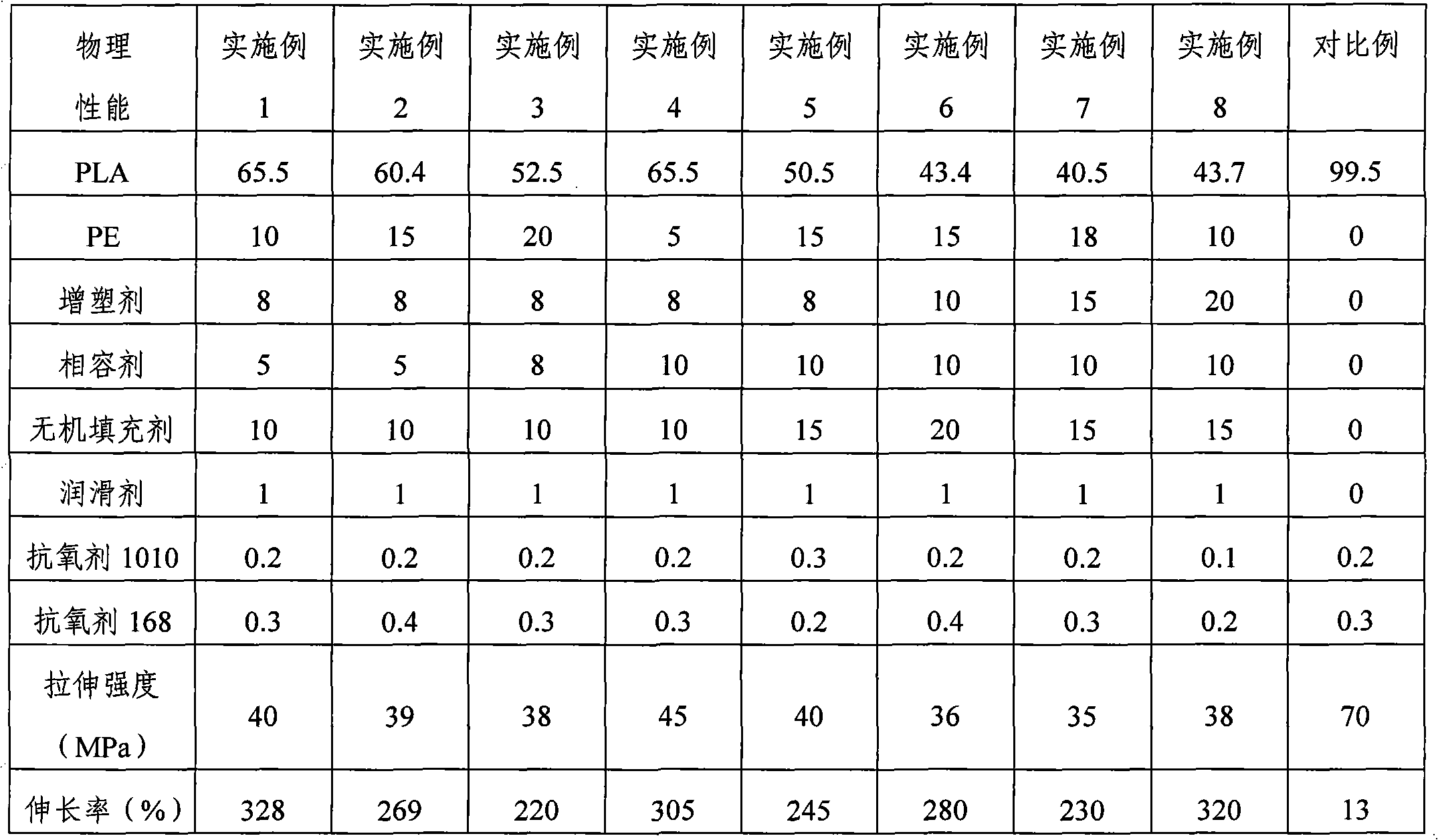

Formable polylactic resin composition and preparation method for plastic strip thereof

The invention relates to a formable polylactic resin composition. The composition consists of the following components in percentage by weight: 20 to 70 percent of polylactic resin, 5 to 50 percent of polyethylene resin, 5 to 20 percent of plasticizer, 3 to 20 percent of inorganic filler, 0.5 to 10 percent of compatilizer, 0.1 to 2 percent of lubricating agent and 0.1 to 2 percent of antioxidant. The invention also relates to a method for preparing a plastic strip from the polylactic resin composition. The method comprises the following steps of: A, mixing; B, injection forming; and C, hot-press forming. The polylactic resin composition is biologically degradable, has superior mechanical property, ductility and high roughness and can be used for preparing the formable plastic strip; and the preparation method has the advantages of simple process flow, high processing performance, low cost and capability of realizing large-scale industrial production.

Owner:CHINA NAT BLUESTAR GRP CO LTD

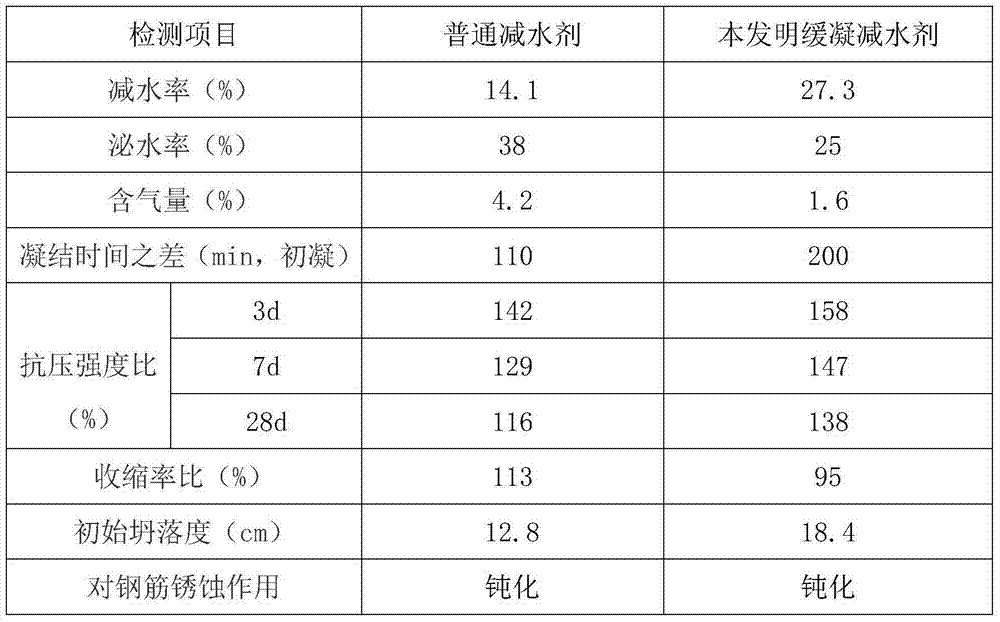

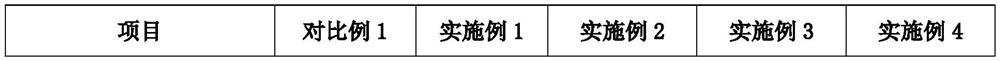

Retarding and water reducing agent

The invention discloses a retarding and water reducing agent prepared by mixing the following raw materials in parts by weight: 35-45 parts of beta-naphthalene sulfonated formaldehyde condensates, 20-30 parts of sulfonated acetone-formaldehyde condensates, 10-15 parts of hydroxypropyl methyl cellulose, 6-12 parts of casein, 3-6 parts of mirabilite, 4-8 parts of sulfonated coal tar, 2-4 parts of borax, 5-10 parts of slaked lime, 8-14 parts of activated sludge, 5-10 parts of sodium fluosilicate, 2.5-4.5 parts of oil foot, 2-3 parts of tartaric acid, 3-5 parts of zinc molybdate, 4-6 parts of triethyl phosphate, 2-4 parts of maltodextrin, 4-8 parts of sodium methallyl sulfonate and 3-6 parts of auxiliary. The water reducing agent disclosed by the invention is good in retarding effect, good in adaptability to various kinds of cement, free of corrosion to reinforcing steel bars and capable of prolonging the setting time by 2-4h, achieving the water reducing rate of 15-20%, greatly improving the workability of concrete and improving various mechanical properties of the concrete, and can be used for various reinforced concrete works.

Owner:重庆砼磊高新混凝土有限公司

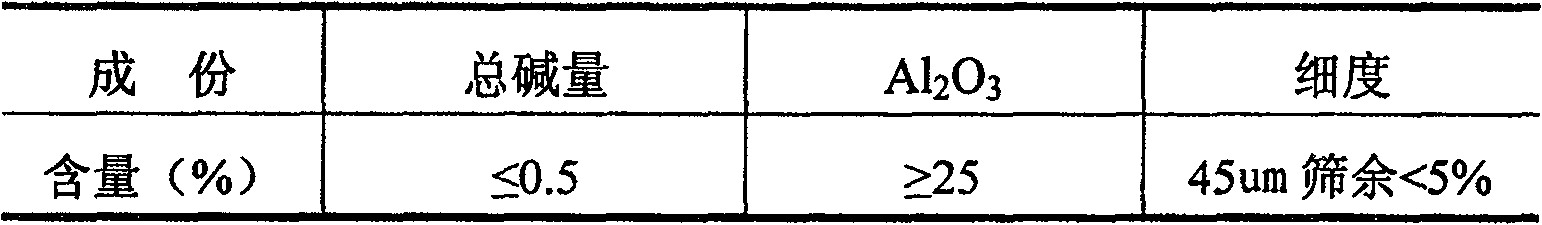

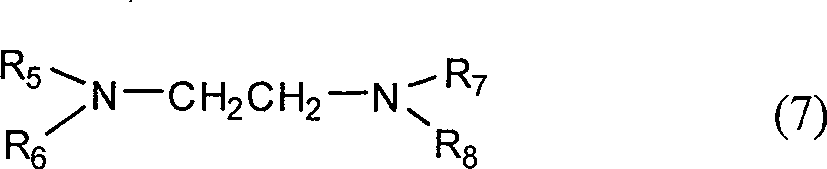

Chlorine-free highly effective composite enhanced solid cement grinding aids and production method

The invention provides a chlorine-free high-efficiency composite reinforcing type solid cement grinding aid and production method, the grinding aid is composed of inorganic substrate material, organic material and water, strong antifreeze and antirust; the inorganic substrate material is composed of powder coal ash, sodium carbonate and sodium silicate, the mixing solution of any three or four among triethanolamine, glycol, propanediol, glycerolor paper pulp waste liquid is selected as the organic material, the inorganic strong antifreeze is composed of aluminum sulfate, calces or sodium hydrogen, sodium acetate or carbamide, and the antirust is sodium dihydrogen phosphate. The production method is the following: first the inorganic strong antifreeze is utilized to perform the complexation and modification of the organic material solution, and then the obtained mixing solution and the inorganic substrate material are furthermore compounded, reacted, blended and crushed. The invention has simple process, low cost, wide application range, good anti-freezing anti-rusting functions, and can improve later strength of cement obviously without disadvantage influence, and also obviously reduce the using amount of cement clinker by 20 percent, thereby having outstanding economical benefit.

Owner:DALIAN UNIV OF TECH

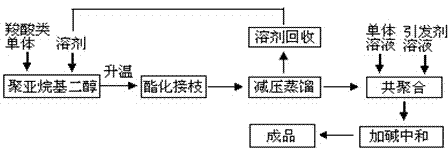

Preparation method of grafted copolymer and air-entraining and slump-retaining polycarboxylate concrete water reducer

The invention belongs to the technical field of concrete admixtures in chemical building materials, and particularly relates to a preparation method of a grafted copolymer and an air-entraining and slump-retaining polycarboxylate concrete water reducer. The air-entraining and slump-retaining polycarboxylate air-entrained concrete efficient water reducer is synthesized by the following steps: introducing a double bond in the process of preparing a macromonomer with reaction activity through utilization of polyoxyalkylene ether monomers; copolymerizing a product obtained from the former step and carboxylic acid monomers and allylsulfonate monomers in a solution so as to introduce a long side chain. The preparation technology is very simple; the reaction condition is easy to control; industrial three wastes are not generated in the production process; the solvent can be recycled after being recovered; and the solvent recovery rate reaches 98%-100%, so that the economic benefits are ensured; and the environmental pollution is avoided.

Owner:山东天汇科技有限公司

Novel melamine water reducer and preparation method

The invention relates to a novel melamine water reducer which comprises the following raw materials by mass: 18.7-23.2% of melamine, 38-42.6% of formaldehyde, 20-27% of sodium bisulfite, 2-3% of sulfuric acid, 3-5% of liquid alkali, and 20-30% of water. The method of the invention comprises the following steps: adding water, melamine, the formaldehyde solution into a reaction vessel, stirring and heating to 50-60 DEG C for reaction for 1-3 hours, performing heat preservation and reaction at 60-75 DEG C for 1-5 hours, adjusting the pH of the solution to 8.5-9.5 by the liquid alkali solution; adding sodium bisulfite, heating, reacting at 84-90 DEG C for 1-3 hours, maintaining the pH at 10-11; finally cooling the solution to 50 DEG C, adjusting the pH value to 5-6.5 by 30% sulfuric acid, continuing the reaction for 1-2 hours, neutralizing the solution to obtain a pH of 7, discharging to obtain the finished product. The water reducer prepared by the invention has strong water retention capacity for concrete, a high water-reducing rate, high early strength of concrete, low air entraining, and less slump loss.

Owner:江苏汇迪建材有限公司

Concrete accelerator

The invention discloses a concrete accelerator comprising the following components in parts by weight: 12-14 parts of naphthalene sulfonated formaldehyde condensates, 3-5 parts of efficient water reducing agent, 6-8 parts of calcium formate, 3-8 parts of sodium fluoride, 25-30 parts of cellulose, 16-20 parts of sodium metaaluminate, 8-12 parts of aluminum sulfate, 3-6 parts of aluminite, 4-8 parts of gas mud and 2-6 parts of silicon powder. The concrete accelerator has the beneficial effects that 1, the setting time is short: the initial setting lasts for 1-5min, the final setting lasts for 5-10min, and the optimal proportion is 3-5% of the dosage of a cementing material; 2, the concrete accelerator contains 1% of alkaline metal and lt and is nontoxic, tasteless and nonirritant; 3, the fineness is up to 80mum, and the content of screen tailings is less than 10%; 4, the early strength of the sprayed concrete is high, and the compressive strength preserving rate of the sprayed concrete with the age of 28 days is up to 80-100%; and 5, the concrete accelerator is good in cohesiveness for a sprayed material, antirust for reinforcing steel bars, capable of increasing the anti-permeability grade, rapid in setting, thick in one-step spray layer and capable of achieving a 130-mm sprayed arch and an over 200-mm sprayed wall.

Owner:LIUZHOU ZHENGLING GROUP

Concrete surface retarder and application method thereof

InactiveCN112299741AReduce labor intensitySimple and fast operationCeramic shaping apparatusPolymer sciencePolymer chemistry

The invention discloses a concrete surface retarder and an application method thereof, and belongs to the technical field of cement concrete retarders, the concrete surface retarder comprises at leastone cement retarding active component, the active component is dispersed in water, and the concrete surface retarder is environmentally friendly and belongs to an aqueous environmental protection product. The concrete surface retarder comprises one or more cement retarding active components, deionized water, a rheological additive, a humectant, an antifreezing agent, a preservative, an antirust agent, a pigment or dye coloring agent and a filler.

Owner:天津富乐佳科技有限公司

Pipe lubricant used for pipeline transportation of concrete and using method thereof

InactiveCN106047450AGood self-lubricating performanceHigh viscosityBuilding material handlingLubricant compositionPipeline transportHuman health

The invention relates to a pipe lubricant used for pipeline transportation of concrete and a using method thereof. The effective constituents of the pipe lubricant include, by weight, 40-60 parts of polyacrylamide, 35-55 parts of hydroxyethyl cellulose, 3-7 parts of nekal BX and 2-6 parts of retarder. The pipe lubricant can be dissolved in water easily and quickly within 3-5 min through proper stirring, so that thick liquid is formed. The product is convenient to use, and inconvenience caused by on-site blending of multiple components is avoided. Harm to concrete quality, corrosion to rebars and conveying equipment and harm to human health and the environment are all avoided.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

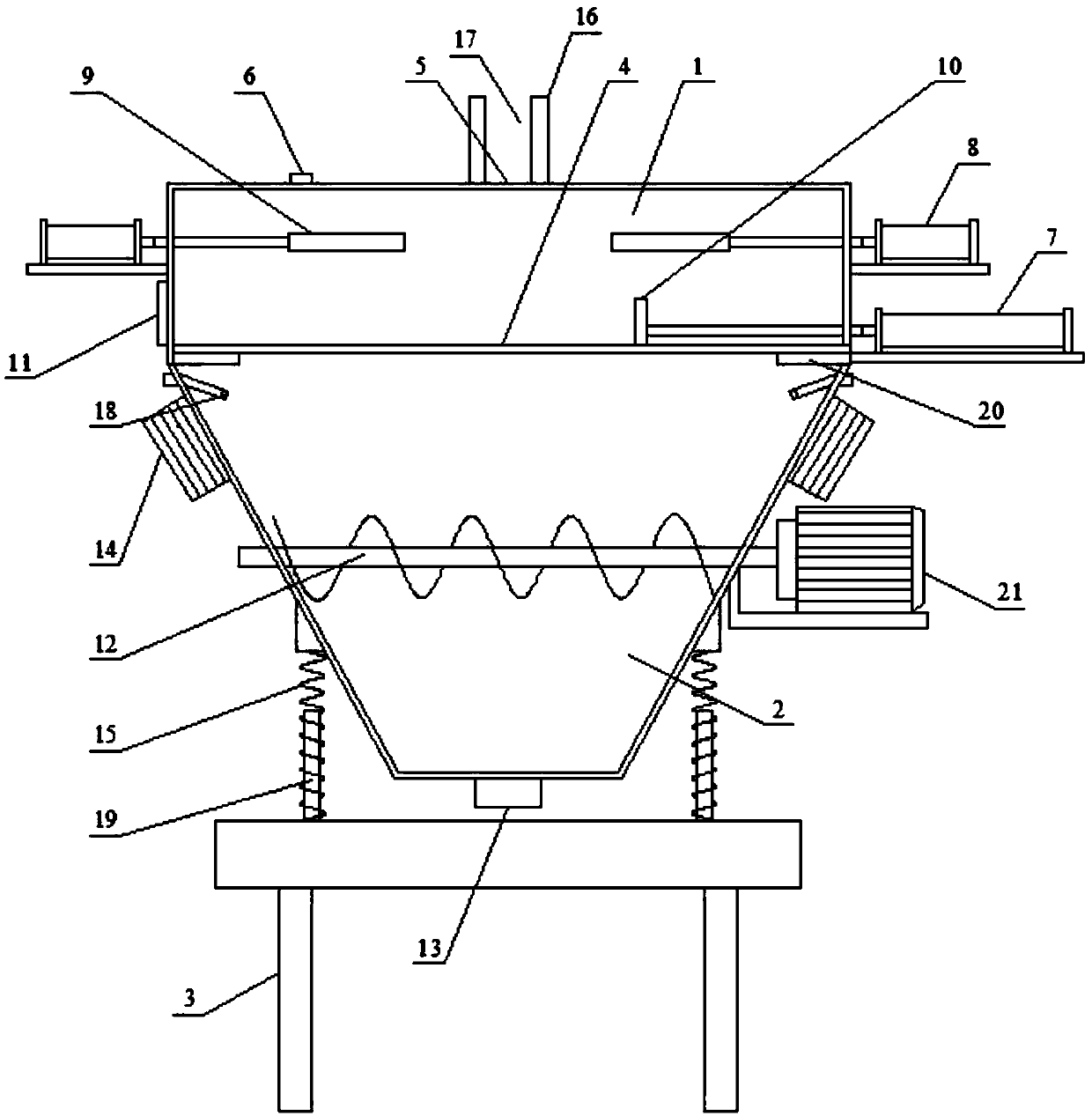

Premixing device for cement blended with concrete early-strength water reducing agent

InactiveCN107756629AEvenly dispersedReduce pollutionCement mixing apparatusSold ingredients supply apparatusWorking environmentWater reducer

The invention discloses a premixing device for cement blended with a concrete early-strength water reducing agent and relates to the technical field of concrete equipment. The premixing device comprises a mixing tank composed of a feeding chamber and a material mixing chamber and a tank body supporting platform, wherein a material passing screen mesh is arranged between the feeding chamber and thematerial mixing chamber. By adopting the structure of the device disclosed by the invention, automatic mixing of the cement and the water reducing agent is realized, so that manpower is saved, the material mixing uniformity is improved and the water reducing agent is uniformly dispersed into the cement; pollution, caused by dust in a cement bag cutting process, on a working environment is alleviated; meanwhile, the sieving of the cement is realized, and a phenomenon that an agglomeration phenomenon occurs in a material mixing process of the cement so that the uniform dispersion of the water reducing agent is influenced is prevented; a vibration motor and a vibration spring are further arranged so that the sieving speed of materials and the material mixing uniformity are improved; a mixedmaterial is humidified through a spraying humidification nozzle so that dust pressure in the material mixing chamber is reduced; meanwhile, further uniform dispersion of the water reducing agent in the cement is promoted.

Owner:马多浩

Energy-saving antifriction additive and preparation method thereof

The invention relates to the technical field of a lubricating oil additive, in particular to an energy-saving antifriction additive. The energy-saving antifriction additive is characterized by being prepared from the following raw materials in percentage by weight: 20-30% of oxymolybdenum dialkydithiophosphate, 15-25% of N-lauroyl alanine, 10-20% of borate, 10-20% of phosphate ester, 10-20% of polybasic alcohol ester, 10-20% of vulcanized isobutylene, 5-10% of alkenyl succinimide and 5-10% of polyester. The energy-saving antifriction additive can be added to other lubrication oil according to a ratio of 3-15%. Thus, the friction can be reduced by more than 50%, and friction energy loss can be also reduced.

Owner:SHENGRANSHANGHAI ENERGY INVESTMENT

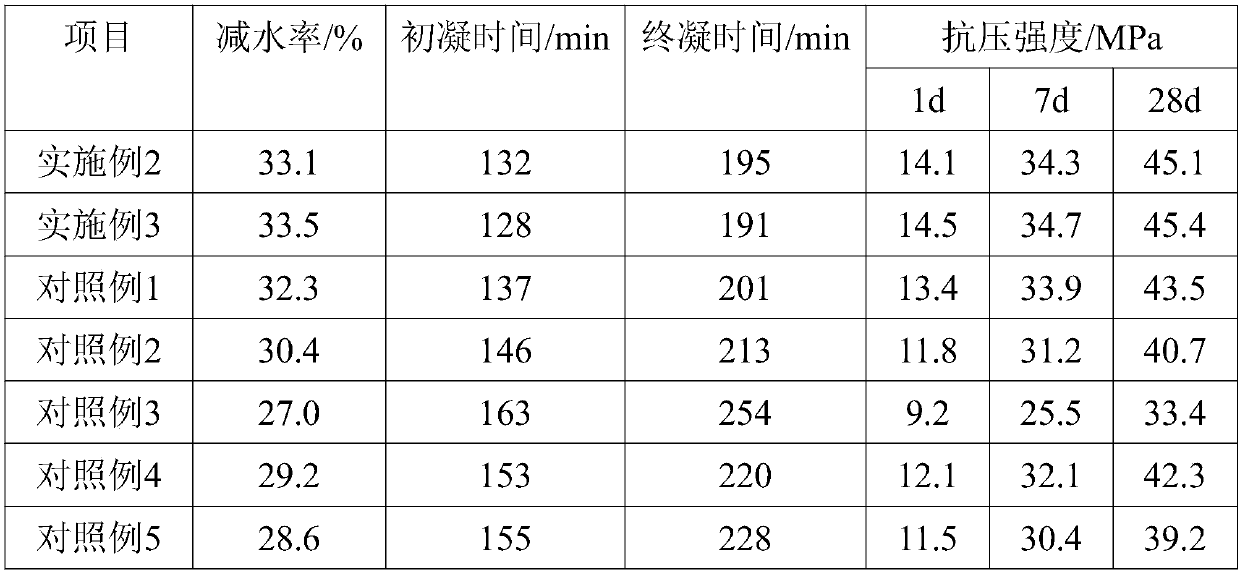

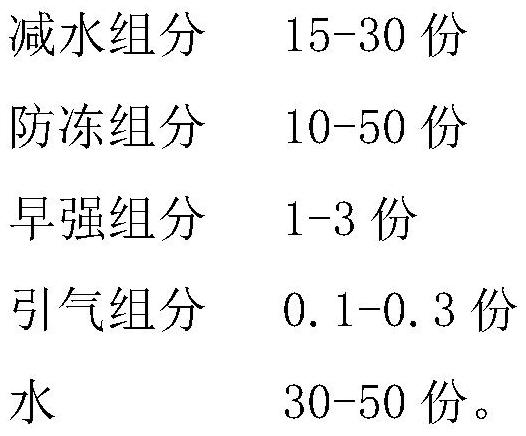

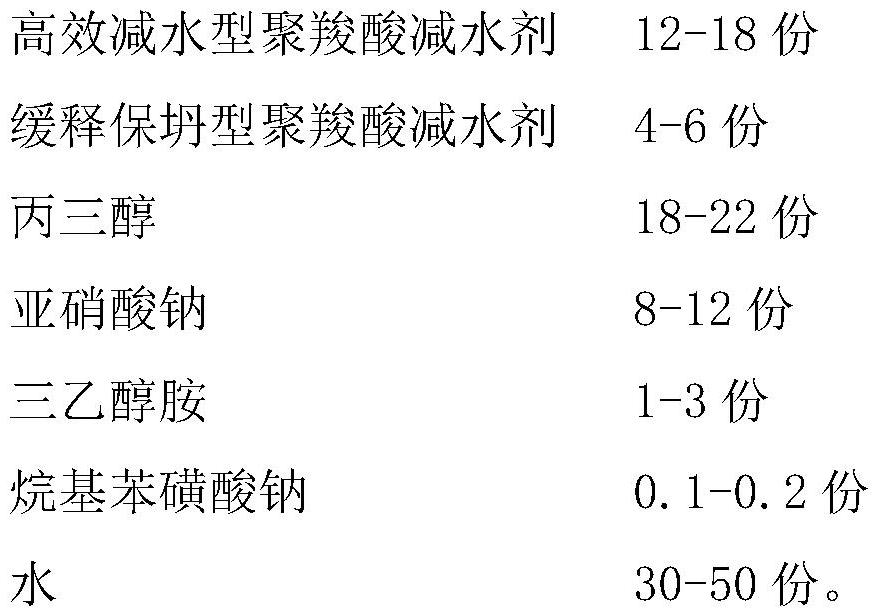

Concrete composite anti-freezing agent and preparation method thereof

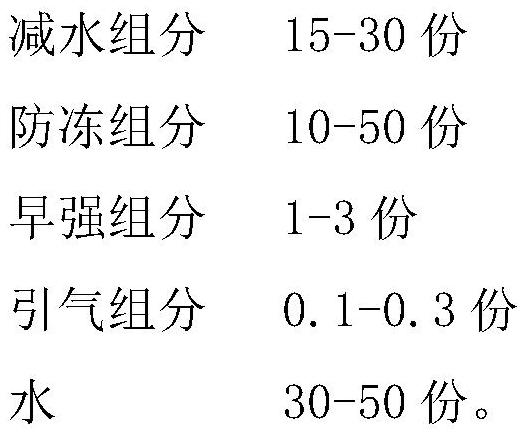

The invention discloses a concrete composite anti-freezing agent and a preparation method thereof. The concrete composite anti-freezing agent comprises the following raw materials by mass: 15-30 parts of a water reducing component, 10-50 parts of an anti-freezing component, 1-3 parts of an early strength component, 0.1-0.3 part of an air entraining component, and 30-50 parts of water. The obtained composite anti-freezing agent is free of pungent smell; the doping amount in a cementing material is small; the composite anti-freezing agent is free ofchlorine and low in alkali, and has no corrosion effect on reinforced concrete; no flocculent substance overflows after the anti-freezing agent solution is stored at the temperature of -20 DEG C for 7 days; and the compressive strength ratio of the concrete composite anti-freezing agent at the temperature of -20 DEG C is obviously higher than the set requirement of -15 DEG C specified in JC457-2004.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

Chloride-free ammonia-free environment-friendly type concrete antifreezing agent

The invention discloses a chloride-free ammonia-free environment-friendly type concrete antifreezing agent and relates to the technical field of concrete admixtures. The antifreezing agent is prepared from, by weight, 70-80 parts of polyacrylamide, 25-30 parts of modified starch, 20-25 parts of sorbitol, 15-20 parts of polyamide resin, 15-20 parts of methyl silicone oil, 12-18 parts of tea saponin, 10-15 parts of alkyl glycoside, 10-15 parts of sodium alpha-olefin sulfonate, 8-12 parts of diethyleneglycolmonomethylether, 8-12 parts of gleditsia sinensis powder, 6-10 parts of cyclodextrin, 6-10 parts of naphthalene water reducer, 4-7 parts of calcium aluminate, 50-60 parts of glycerinum and 200-250 parts of water. The prepared antifreezing agent is high in water-reducing rate and good in plasticity retention performance, the water freezing point can be greatly lowered, it is guaranteed that concrete is not damaged due to freezing at a low temperature (above minus 15 DEG C), and normal running of winner construction is guaranteed.

Owner:滁州京安工贸有限责任公司

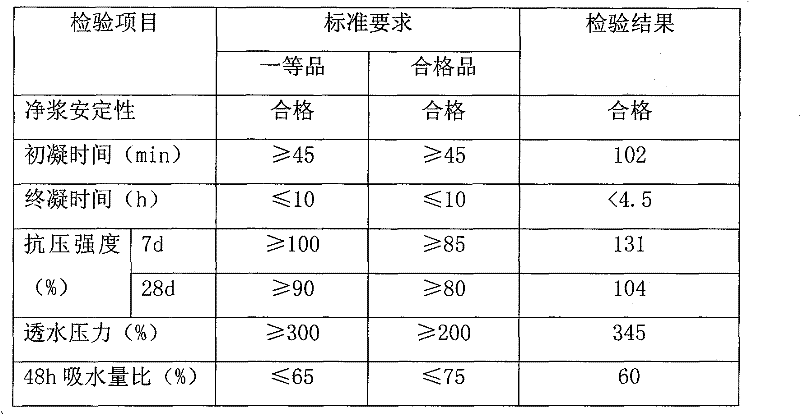

Special additive for self-dense concrete

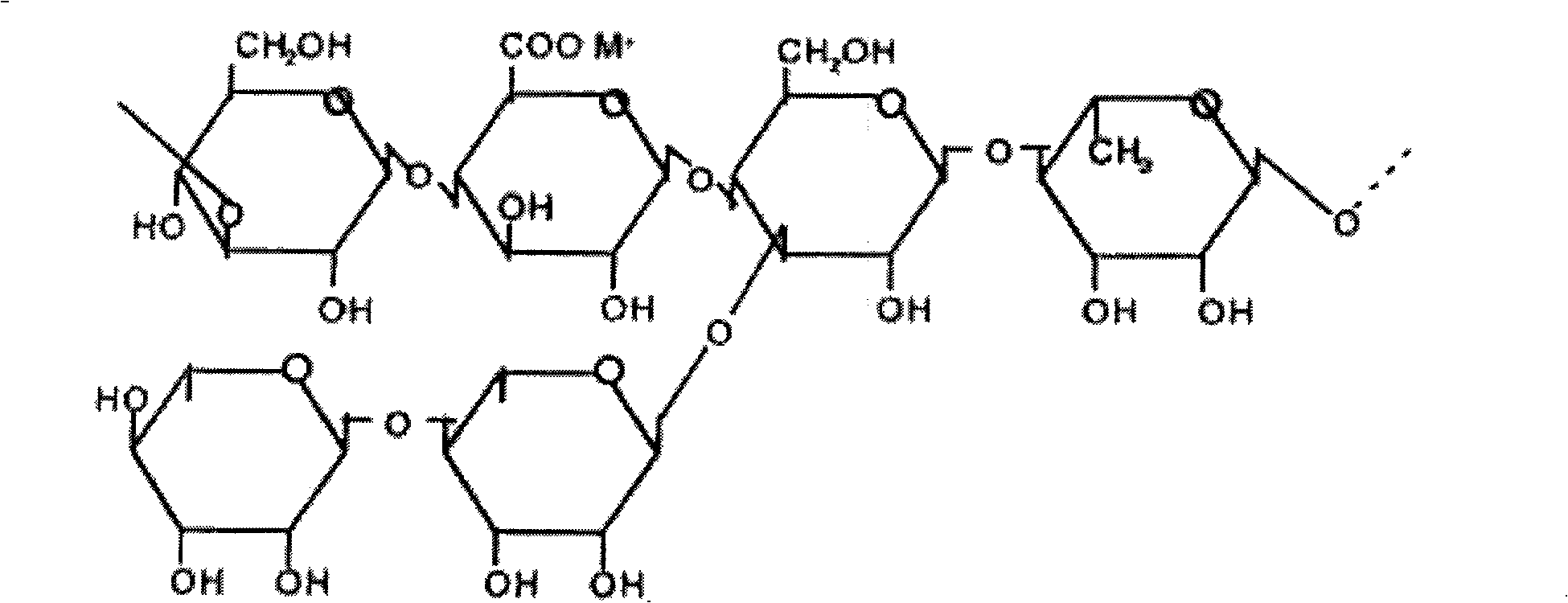

ActiveCN100545120CHas micro-expansion propertiesImprove volume stabilityTriterpenoid saponinLinear polymer

The special admixture for self-compacting concrete is prepared by weight ratio of the following components: naphthalenesulfonate formaldehyde advanced condensate 7-16%, aluminum powder 0.01-0.22, anhydrite 40-65%, calcined kaolin 10-10% 25%, kaolin 10-25%, linear polymer anionic polysaccharide 0.02-0.09%, triterpene saponin 0.03-0.11%, sodium tripolyphosphate 0.5-1.5%. The invention has multiple functions of improving the rheology and volume stability of concrete, can significantly improve the slump retention capacity of self-compacting concrete, has micro-expansion characteristics, does not need to compound other materials after mixing, and can effectively improve the flow of concrete Denaturation, greatly reducing bleeding, avoiding segregation and delamination, basically no loss of fluidity for 5 hours, and can effectively compensate shrinkage in plastic and hardened states, and improve the volume stability of concrete. The invention has no corrosion effect on the steel, and is especially suitable for the construction of the steel pipe self-compacting concrete jacking method of the screw rod arch bridge.

Owner:JIANGSU SOBUTE NEW MATERIALS

High-strength no-shrink grouting material and preparation method thereof

The invention relates to a high-strength no-shrink grouting material and a preparation method thereof. The high-strength no-shrink grouting material comprises the following raw materials in parts by mass: 80-150 parts of cementing material, 50-120 parts of fine aggregate, 1-5 parts of an expanding agent, 0.1-1 part of a water reducing agent and 0.5-5 parts of synergistic additive. The preparationmethod comprises the following steps of: (S1) accurately weighing raw-material components except the cementing material according to the proportion, and then uniformly mixing in a mixer; (S2) adding the cementing material into a product obtained in the step (S1), continuously stirring for a preset time and obtaining the high-strength no-shrink grouting material. The high-strength no-shrink grouting material provided by the invention is prepared by adopting the high-strength cementing material, a composite additive and special fine aggregate as well as auxiliary substances with high flow state,slight expansion and segregation prevention and the like, an equipment base and a concrete foundation are fully combined, and the stressing condition of the equipment base is fundamentally changed; the use method is simple; the high-strength no-shrink grouting material can be used after addition of a certain amount of water and uniform stirring on a construction site.

Owner:YUN COUNTY CHENGLIN IND & TRADE CO LTD

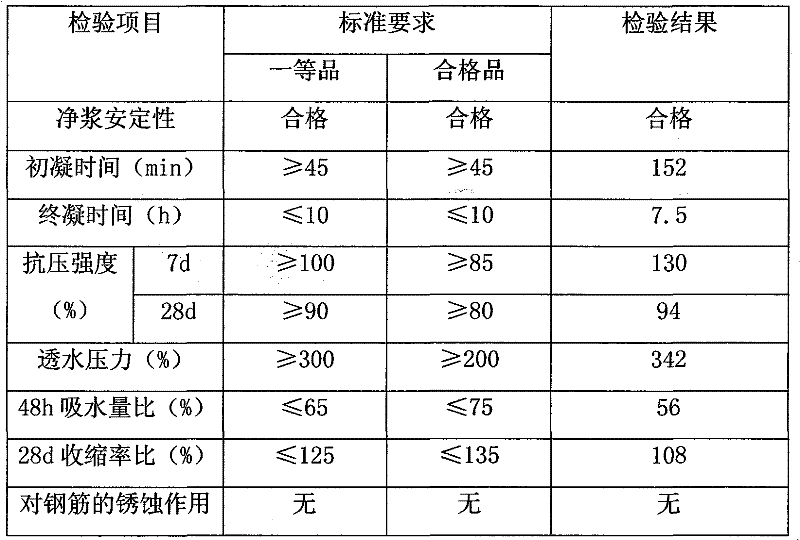

Method for producing anti-freezer

InactiveCN1616583AReduce manufacturing costNo rust effectOther chemical processesSteel barCarbon.organic

The present invention discloses the production process of antifreezer. The production process includes the reaction between low-carbon organic acid with metal oxide, hydroxide or carbonate at 50-80 deg.c to produce low carbon organic salt as the antifreezing component; adding early strength agent, early strength catalyst, additive, stuffing, water reducing agent, air entraining agent, rust inhibitor and other components, mixing and drying to form the antifreezer. The present invention has low production cost, no rustiness to steel bar, no toxicity, no smell and no harm to the operator.

Owner:王建国

Concrete anti-seepage and anti-freezing admixture for plateau complex environment and preparation method thereof

ActiveCN114014581AImprove mechanical propertiesIncreased durabilityCalcium formateStructural engineering

The invention discloses a concrete anti-seepage and anti-freezing admixture suitable for a plateau complex environment and a preparation method thereof. The concrete anti-seepage and anti-freezing admixture comprises the following raw materials in percentage by mass: 10-15% of sodium dodecyl benzene sulfonate, 7-10% of calcium nitrite, 3-6% of calcium formate, 5-8% of methanol, 4-7% of ethylene glycol, 2-5% of sodium gluconate, 1-3% of sodium polyacrylate, 11-14% of polyoxyethylene ether and the balance of deionized water. According to the anti-seepage and anti-freezing admixture disclosed by the invention, the construction of concrete under low-temperature and negative-temperature conditions can be realized, the construction period of the concrete can be prolonged, the early strength of the concrete can be improved, and the durability of the concrete and the service capacity of the concrete under complex plateau environment conditions can be effectively improved.

Owner:中交二公局第四工程有限公司

Zero-chlorine and low-alkali concrete antifreeze and corrosion resistance pumping agent

InactiveCN105271910AGood dispersionImprove liquiditySolid waste managementAluminum magnesium silicateCarboxymethyl-chitosan

The invention discloses a zero-chlorine and low-alkali concrete antifreeze and corrosion resistance pumping agent, and relates to the technical field of building materials. The pumping agent is prepared from, by weight, 50-60 parts of modified starch, 30-40 parts of modified kaolin, 20-25 parts of straw powder, 15-20 parts of aluminum magnesium silicate, 10-15 parts of glazed hollow beads, 12-18 parts of polyacrylamide, 12-18 parts of carboxymethyl chitosan, 10-15 parts of calcium stearate, 8-12 parts of sodium gluconate, 6-10 parts of epoxidized soybean oil, 5-8 parts of polyethylene wax, 20-25 parts of glycerin and 120-150 parts of water. The pumping agent prepared in the invention has the advantages of zero chlorine, low alkali, strong cement dispersion, high water reducing rate, obvious improvement of the workability of concrete, reduction of the slump, and effective adjustment of the setting time of concrete.

Owner:滁州京安工贸有限责任公司

Chloride-free early-strength water-reducing agent capable of improving concrete workability

Owner:滁州京安工贸有限责任公司

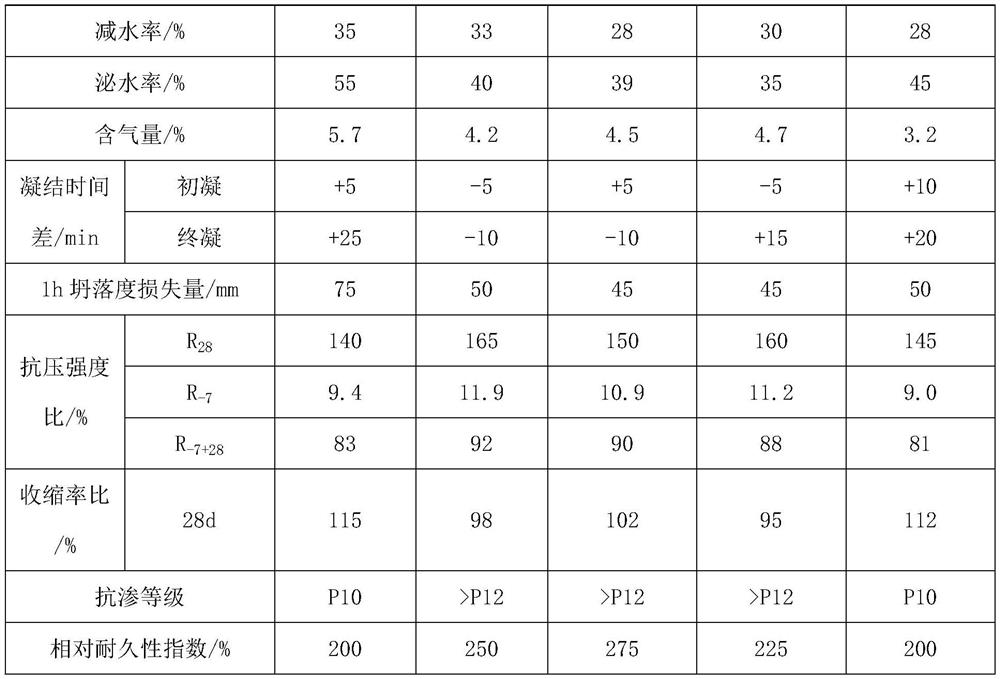

Retarder water reducer

Owner:重庆砼磊高新混凝土有限公司

Chlorine-free concrete and mortar waterproof agent

The invention discloses a chlorine-free concrete and mortar waterproof agent, and belongs to the technical field of additive. The chlorine-free concrete and mortar waterproof agent is prepared from, by weight, 80 to 90 parts of blast furnace slag, 20 to 25 parts of an expanding agent, 18 to 22 parts of furan resin, 15 to 20 parts of a naphthalene water reducer, 15 to 20 parts of sepiolite powder, 12 to 18 parts of cyclodextrin, 10 to 15 parts of nano silicon micro powder, 10 to 15 parts of organic bentonite, 8 to 12 parts of sugarcane wax, 6 to 10 parts of palmitic acid, 5 to 8 parts of hydrogenated castor oil, and 250 to 300 parts of water. The chlorine-free concrete and mortar waterproof agent possesses stable and reliable water resistance; insoluble silicates can be obtained via reaction of the active ingredients of the chlorine-free concrete and mortar waterproof agent with cement hydration products, so that water seepage channels can be blocked, and water tightness and impermeability of concrete and mortar are improved greatly.

Owner:滁州京安工贸有限责任公司

Concrete pumping retarder

The invention discloses a concrete pumping retarder, and relates to the technical field of concrete admixtures. The concrete pumping retarder is prepared from, by weight, 40 parts to 50 parts of soybean molasses, 30 parts to 40 parts of isomaltitol, 20 parts to 25 parts of sulfonated melamine, 15 parts to 20 parts of tephra, 15 parts to 20 parts of modified starch, 13 parts to 17 parts of polyacrylamide, 12 parts to 15 parts of fatty alcohol-polyoxyethylene ether, 12 parts to 15 parts of microcrystalline cellulose, 10 parts to 13 parts of fructus gleditsiae powder, 10 parts to 13 parts of tea seed powder, 8 parts to 11 parts of naphthalene water reducers, 6 parts to 10 parts of nanometer rubber powder, 6 parts to 10 parts of polycarbamate, 5 parts to 8 parts of palmitic acid, 15 parts to 20 parts of coconut oil and 300 parts to 400 parts of water. The prepared retarder is free of chloride and alkali, the setting time of concrete can be effectively prolonged, heat of hydration can be reduced, generation and development of temperature cracks of the concrete can be greatly reduced and even avoided, the workability of the concrete can be further obviously improved, the bleeding rate can be greatly reduced, and endurance performance such as freezing resistance and corrosion resistance can be improved.

Owner:滁州京安工贸有限责任公司

Water-based organic silicon waterproof agent

InactiveCN101580355BImprove waterproof performanceGood weather resistanceOther chemical processesWater basedBrick

Owner:郭元华

Nano-alumina enhanced concrete pumping agent

The invention discloses a nano-alumina enhanced concrete pumping agent, and relates to the technical field of concrete additives. The nano-alumina enhanced concrete pumping agent is prepared from, by weight, 10-15 parts of nano-alumina, 40-45 parts of volcanic ash, 25-30 parts of modified straw powder, 15-20 parts of beta-naphthalenesulfonic acid sodium-formaldehyde condensate, 13-18 parts of an air entraining agent, 12-16 parts of polyamide resin, 10-15 parts of calcium lignosulfonate, 10-15 parts of erythritol, 8-12 parts of polyurethane, 6-10 parts of calcium superphosphate, 10-15 parts of palm oil, 30-40 parts of waste diesel oil, 50-60 parts of ethanol and 250-300 parts of water. The pumping agent prepared in the invention has the characteristics of high water reduction rate and no chloride ions, can substantially improve the workability of concrete and reduce the water segregation rate, also can greatly reduce the slump loss, and completely meets long-distance transportation and construction requirements of pumped concrete.

Owner:JIESHOU SANBAO BODA BUILDING MATERIAL

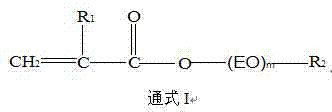

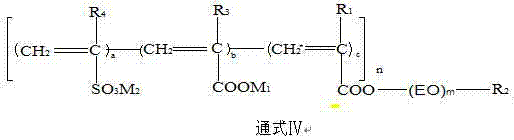

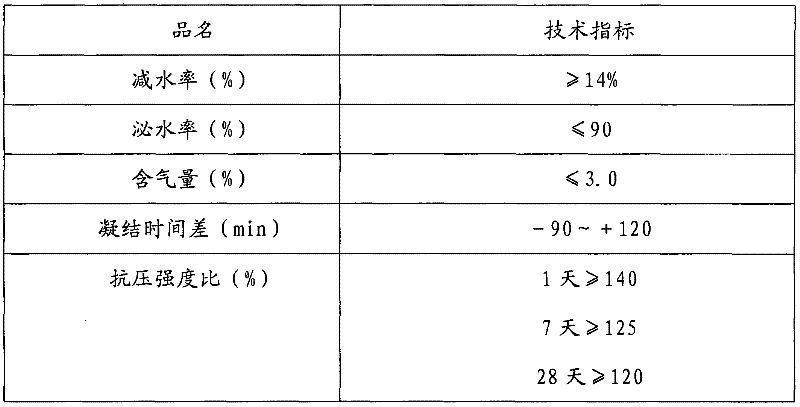

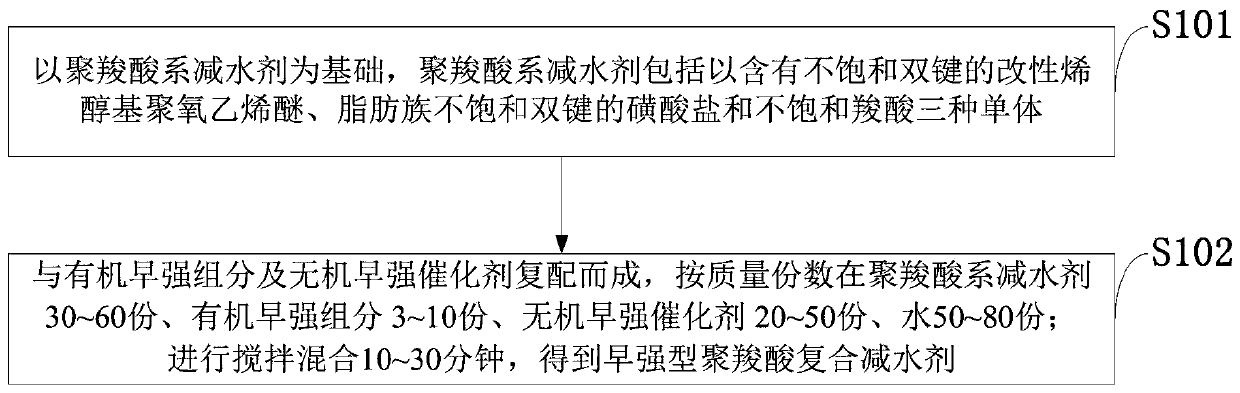

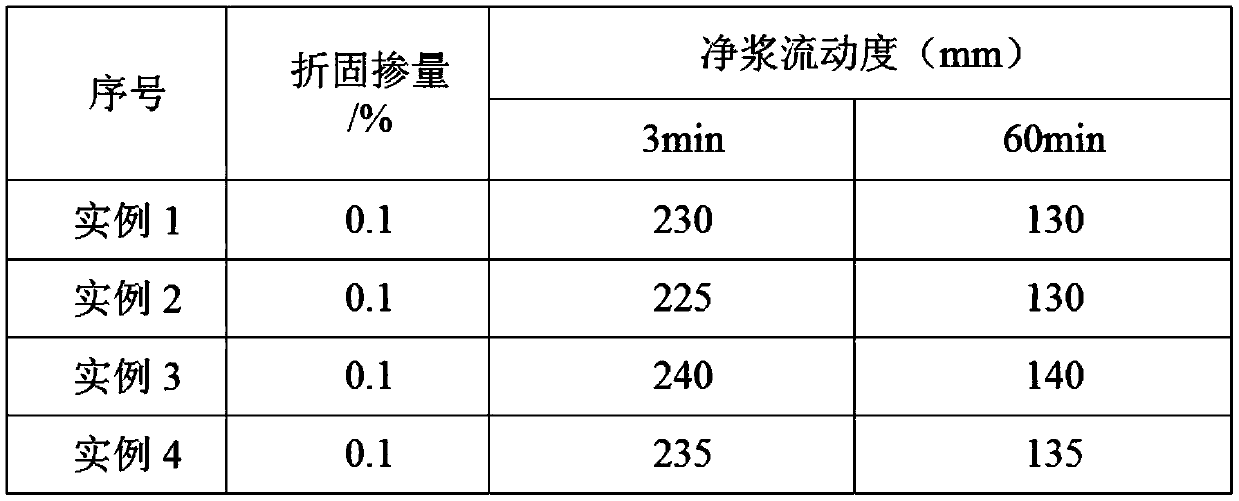

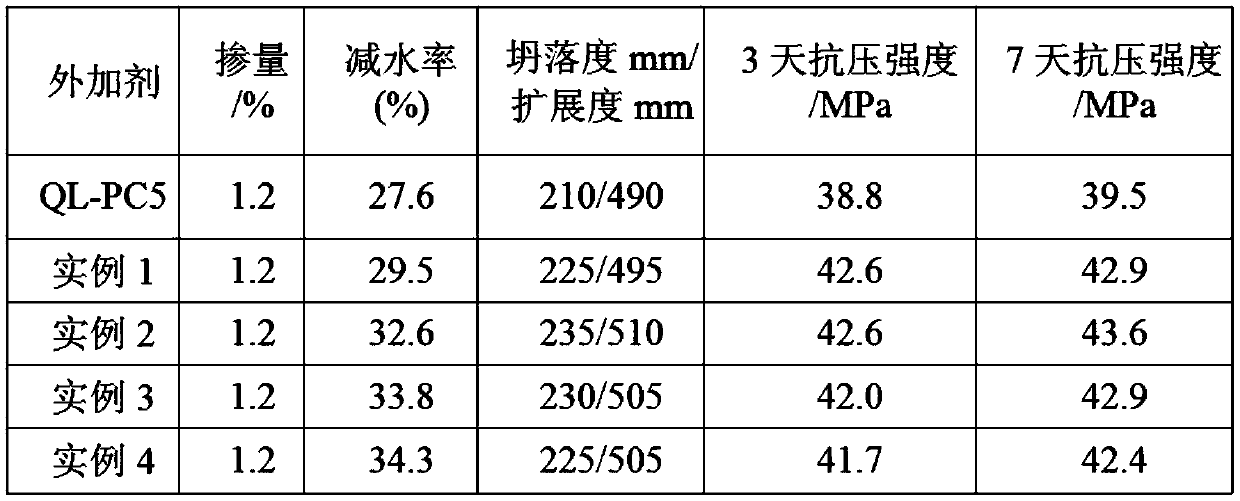

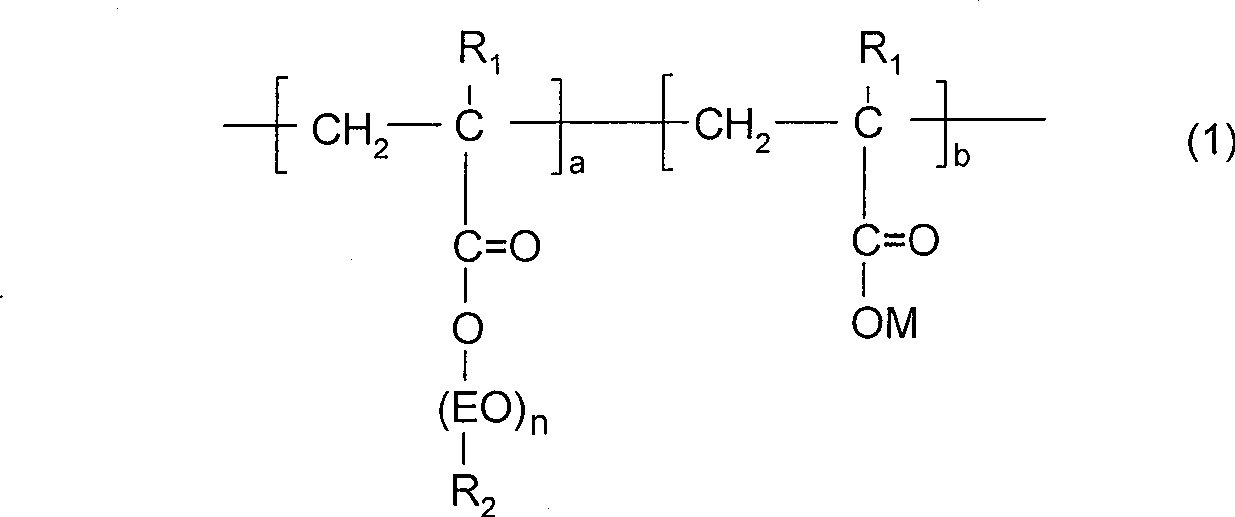

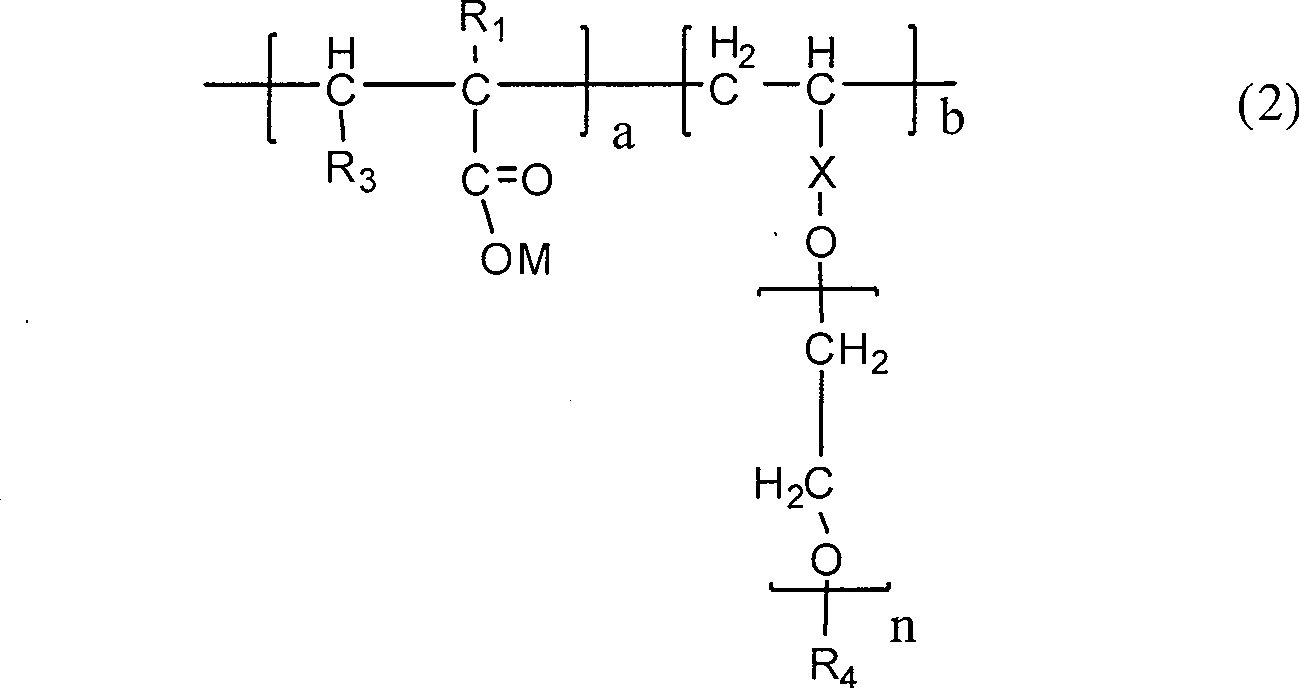

Early-strength polycarboxylic acid composite water reducer and preparation method thereof

PendingCN109851273ARelatively small molecular massModerate side chain densityCarboxylic acidDouble bond

The invention belongs to the technical field of concrete admixture and discloses an early-strength polycarboxylic acid composite water reducer and a preparation method thereof. As the early-strength composite water reducer is prepared by compounding a polycarboxylic acid-based polymer as the base and the optimized early-strength components, wherein the polycarboxylic acid-based polymer uses threemonomers of modified enol-based polyoxyethylene ether containing unsaturated double bond, aliphatic unsaturated double-bond sulfonate and unsaturated carboxylic acid as main raw materials under the action of initiator and chain transfer agent; the polycarboxylic acid water reducer is prepared by aqueous solution copolymerization initiated by free radicals. The early-strength polycarboxylic acid composite water reducer prepared by the invention has the advantages of small dosage, low alkali content, high water reduction rate, remarkable improvement of early strength, good product stability, simple preparation process and no environmental pollution. It can be widely used in various concrete engineering construction with early strength requirements under lower temperature conditions, especially in the low energy consumption production process of precast concrete members, and has a good application prospect.

Owner:JIANGMEN POLYTECHNIC

Liquid, chlorine-free, early-strength anti-freezing polycarboxylate composite water reducing agent and preparation method thereof

ActiveCN100526249CIncreased durabilityUniform and stable for long-term storagePtru catalystEnvironmental engineering

The invention relate to a liquid early-strength and antifreezing type polycarboxylate compound water reducer without chlorine and a preparation method thereof. The water reducer is prepared with the following components in weight proportion: 6-12percent of early-strength type polycarboxylate water reducer, 4-10 percent of organic antifreezing component, 1.5-3 percent of organic early-strength component, 10-25 percent of inorganic early-strength catalyst, 0.3-0.5 percent of air-entrained component, and the rest is water. The preparation method is that every component is weighed according to the weight percentage of every component and then put into a reaction vessel and stirred slowly for 10-30 minutes. The addition of the invention is 0.5-1.5 percent of cementing material content, compared with the normal concrete; the water-reducing rate can amount to more than 20 percent, and the long-term strength of concrete is obviously increased. The liquid early-strength and antifreezing type polycarboxylate compound water reducer can be used for preparation of concrete with various strength grades from C20 to C80, has good antifreezing performance and can be used for the concrete constructed under circumstance with daily minimum temperature above 20 DEG C below zero.

Owner:BOTE NEW MATERIALS TAIZHOU JIANGYAN CO LTD +1

Water-emulsion organic silicon waterproof agent

InactiveCN101580356BImprove waterproof performanceGood weather resistanceOther chemical processesEmulsionBrick

The invention relates to a water-emulsion organic silicon waterproof agent by taking alkylalkoxy silane as a main raw material, and is particularly suitable for moving penetration waterproof processing of a porous structure, such as bricks, stone materials, concrete, mortar, cement slurry and the like.

Owner:郭元华

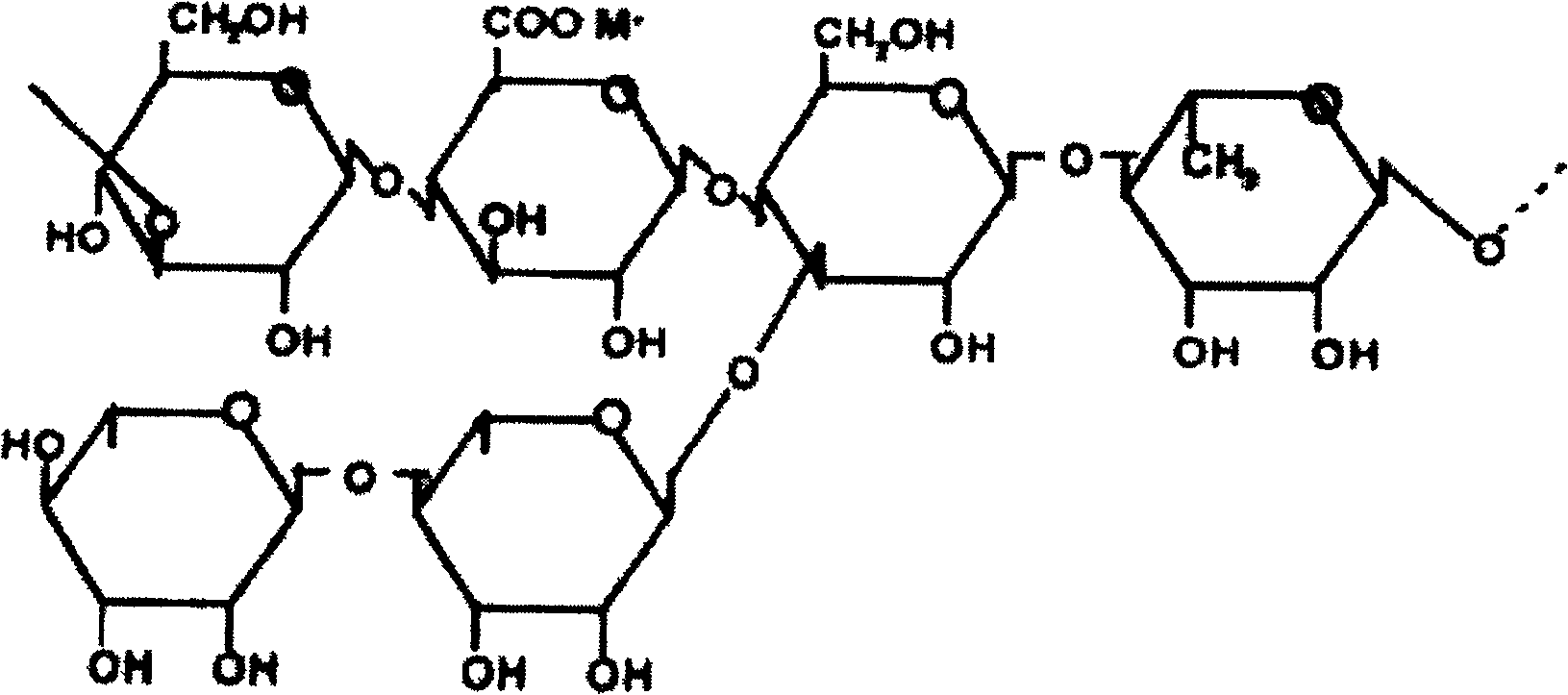

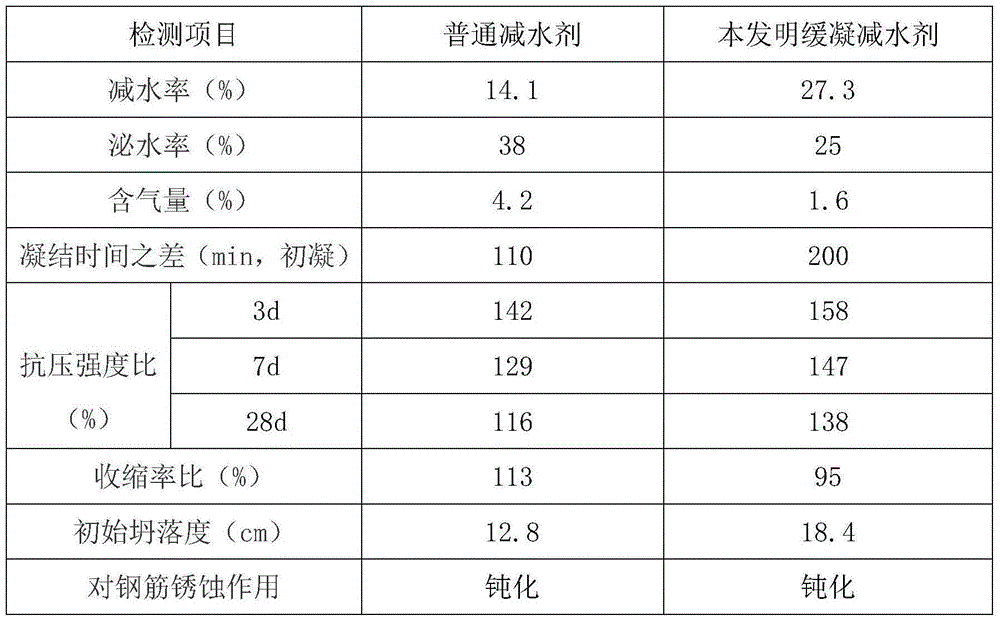

Prestressing anchoring and grouting material additive, as well as preparation method and application thereof

InactiveCN101830664BImprove rheologyGuaranteed StrengthSolid waste managementCeramicwareCement slurryUltimate tensile strength

The invention discloses a prestressing anchoring and grouting material additive, as well as a preparation method and an application thereof. The prestressing anchoring and grouting material additive comprises expansion components, active blending materials, crack resisting components, water reducing components and regulating components in definite proportions. The preparation method comprises the following steps of: (A) adding the expansion components, the active blending materials, the crack resisting components, the water reducing components and the regulating components in weight percentage to a ball grinding mill; (B) grinding for 10-30 min to be uniform at normal temperature and pressure to make Brinell specific surface area not less than 350 m<2> / kg to obtain the product. The invention has simple acquirement of raw materials, feasible method, easy and convenient operation, reasonable formulation and convenient use, overcomes the performance defects of a common cement based grouting material and the problems existing during use in the traditional prestressing anchoring engineering. The invention can effectively improve the workability of the anchoring and grouting material, can effectively increase slurry fluidity, greatly reduce sopreina and avoid segregation and delamination on the basis of ensuring the strength of cement slurry, and can effectively compensate shrinkage under the plastic hardening state so as to increase the volume stability of the cement slurry.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com