Special additive for self-dense concrete

A self-compacting concrete and admixture technology, which is applied in the field of self-compacting concrete admixtures, can solve the problems of weakening the interface bond between concrete and steel pipes, long concrete pouring time, and inability to vibrate concrete, so as to improve volume stability , avoid segregation and stratification, and improve the effect of volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

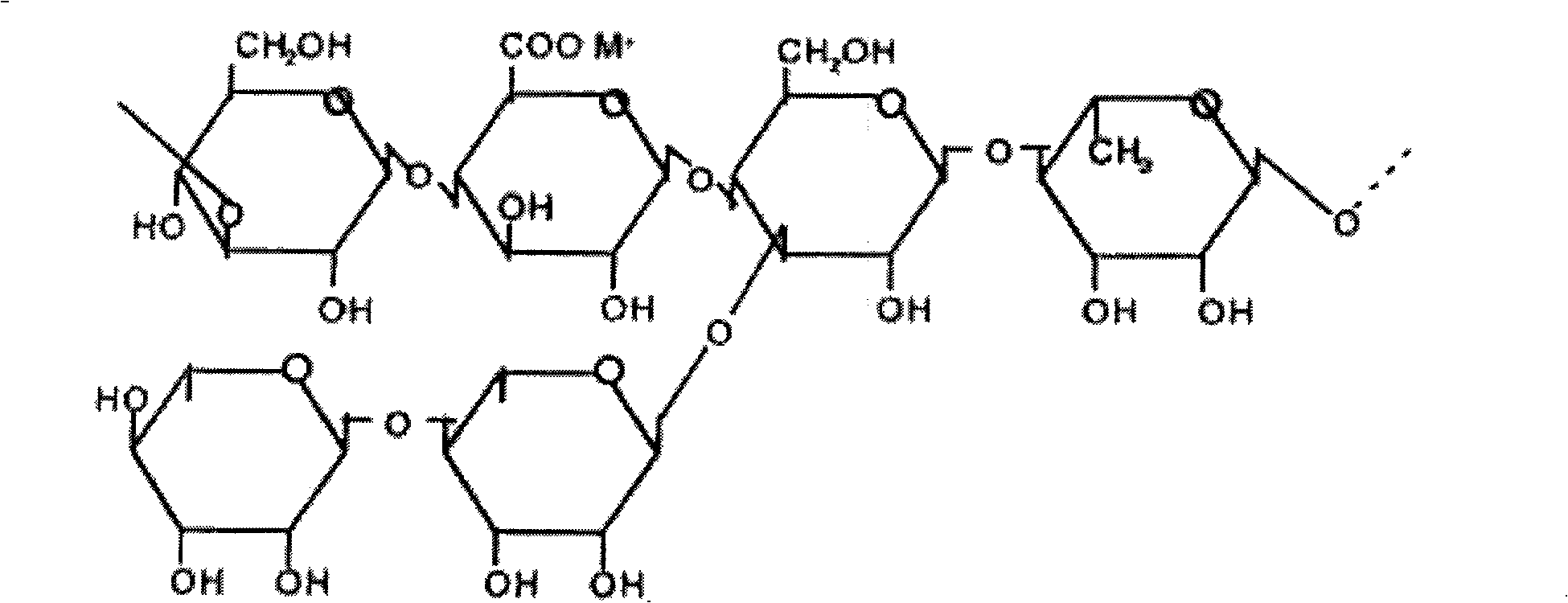

Method used

Image

Examples

Embodiment 1

[0025] Component 1: 9.0% Component 2: 0.1%

[0026] Component 3: 55% Component 4: 17.57%

[0027] Component 5: 17.57% Component 6: 0.05%

[0028] Component 7: 0.06% Component 8: 0.65%.

[0029] The present invention is obtained by mixing the components together in the above weight ratio.

[0030] Adopt the performance of the concrete prepared by the present invention prepared by above-mentioned formula to be:

[0031] Concrete ratio (kg / m 3 ) Table 2

[0032]

[0033] Concrete Properties Table 3

[0034]

Embodiment 2

[0036] Component 1: 12.6%; Component 2: 0.02%

[0037] Component 3: 52.6%; Component 4: 16.8%

[0038] Component 5: 16.8%; Component 6: 0.03%;

[0039] Component 7: 0.05%; Component 8: 1.05%.

[0040] The present invention is obtained by mixing the components together in the above weight ratio.

[0041] Adopt the performance of the concrete prepared by the present invention prepared by above-mentioned formula to be:

[0042] Concrete ratio (kg / m 3 ) Table 4

[0043]

[0044] Concrete Properties Table 5

[0045]

Embodiment 3

[0047] Component 1: 11.0%; Component 2: 0.01%

[0048] Component 3: 53.7%; Component 4: 17.2%

[0049] Component 5: 17.2%; Component 6: 0.05%;

[0050] Component 7: 0.07%; Component 8: 0.70%.

[0051] The present invention is obtained by mixing the components together in the above weight ratio.

[0052] Adopt the performance of the concrete prepared by the present invention prepared by above-mentioned formula to be:

[0053] Concrete ratio (kg / m 3 ) Table 6

[0054]

[0055] Concrete Properties Table 7

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com