Patents

Literature

604results about How to "Good slump performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

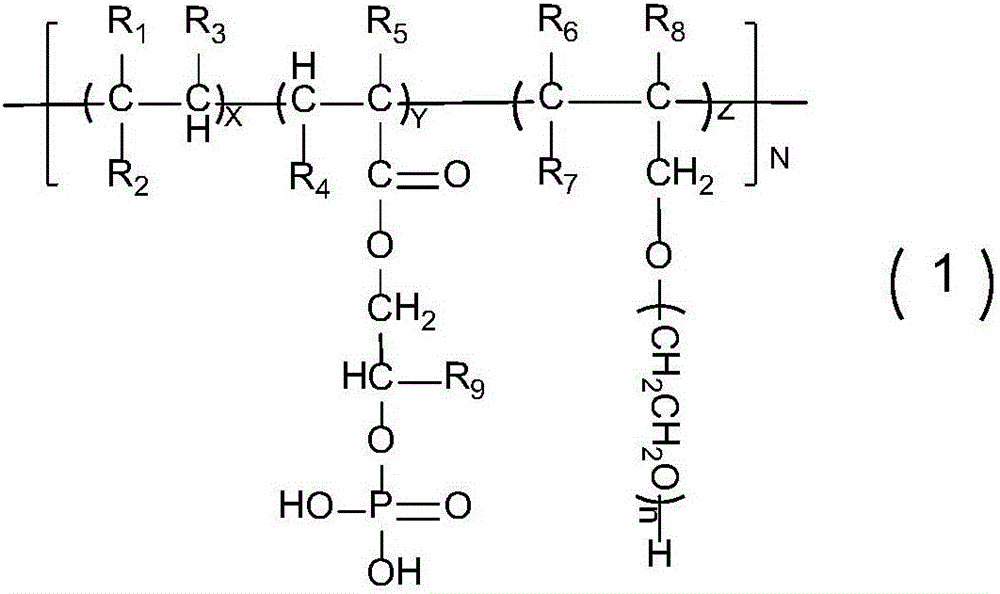

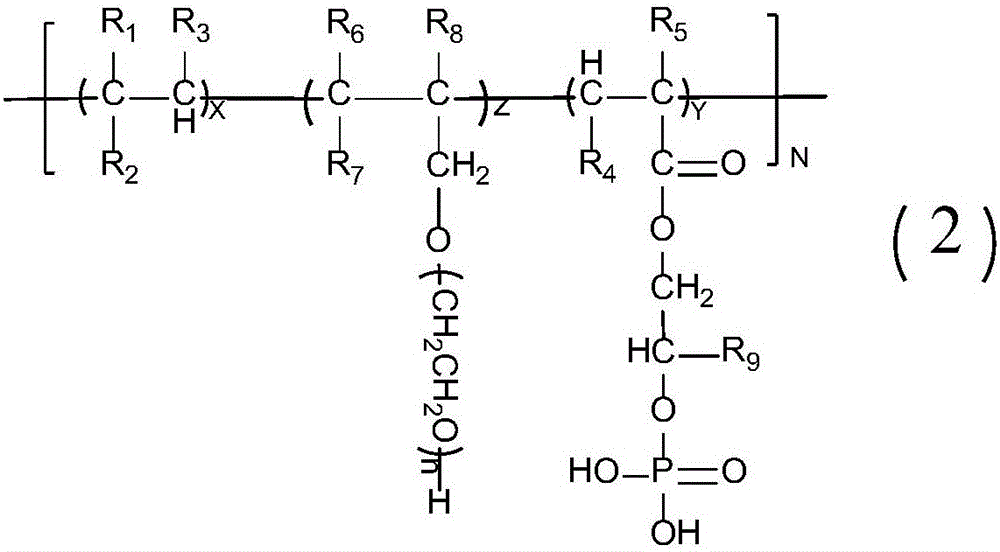

High-performance polycarboxylate water reducing agent and preparation method thereof

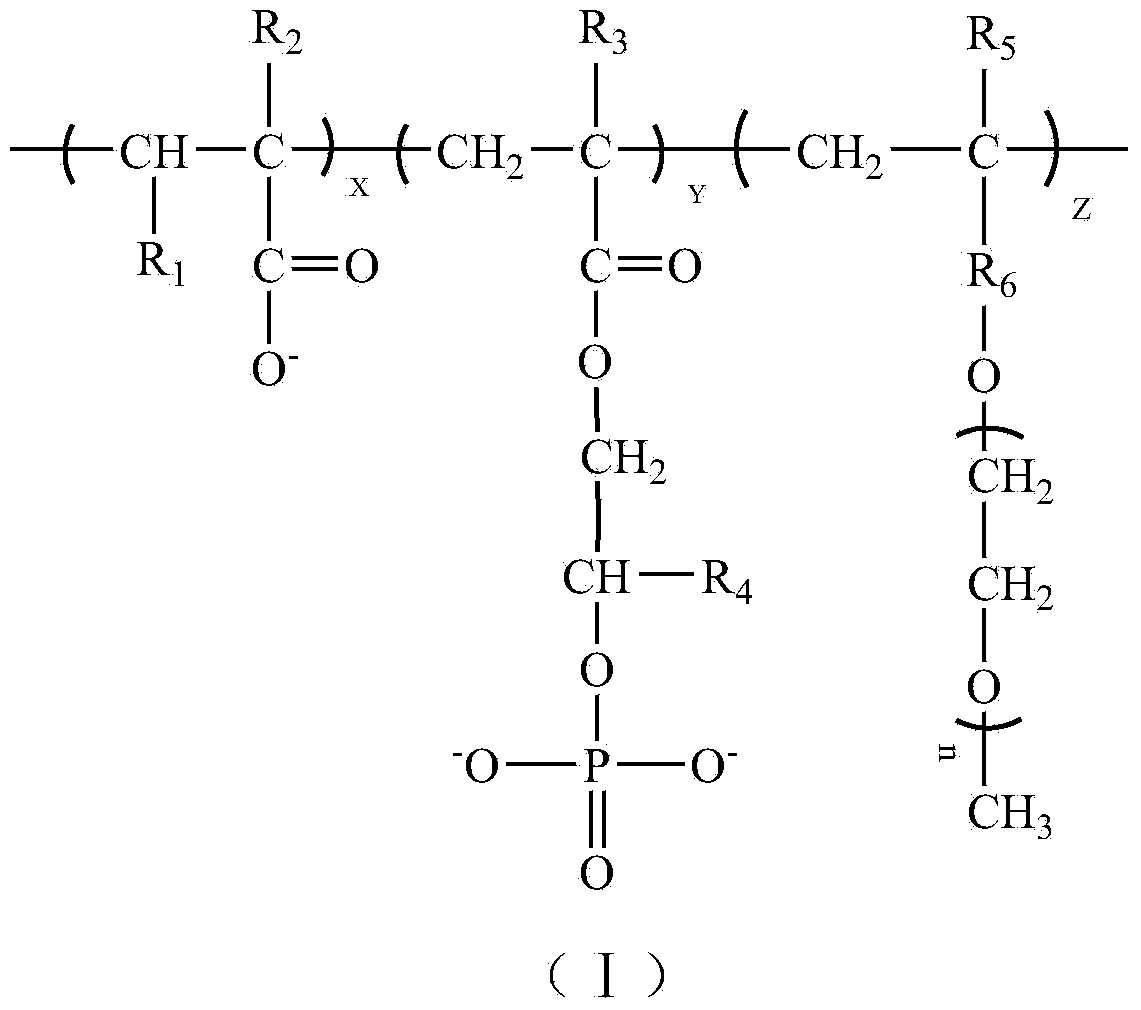

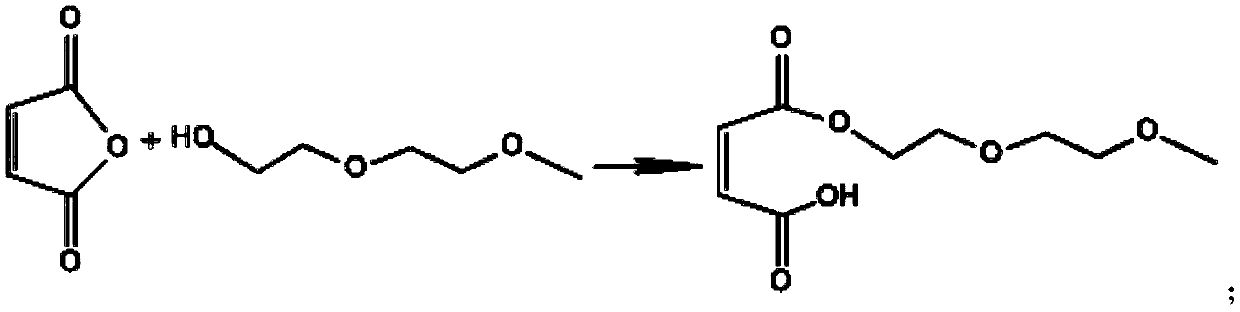

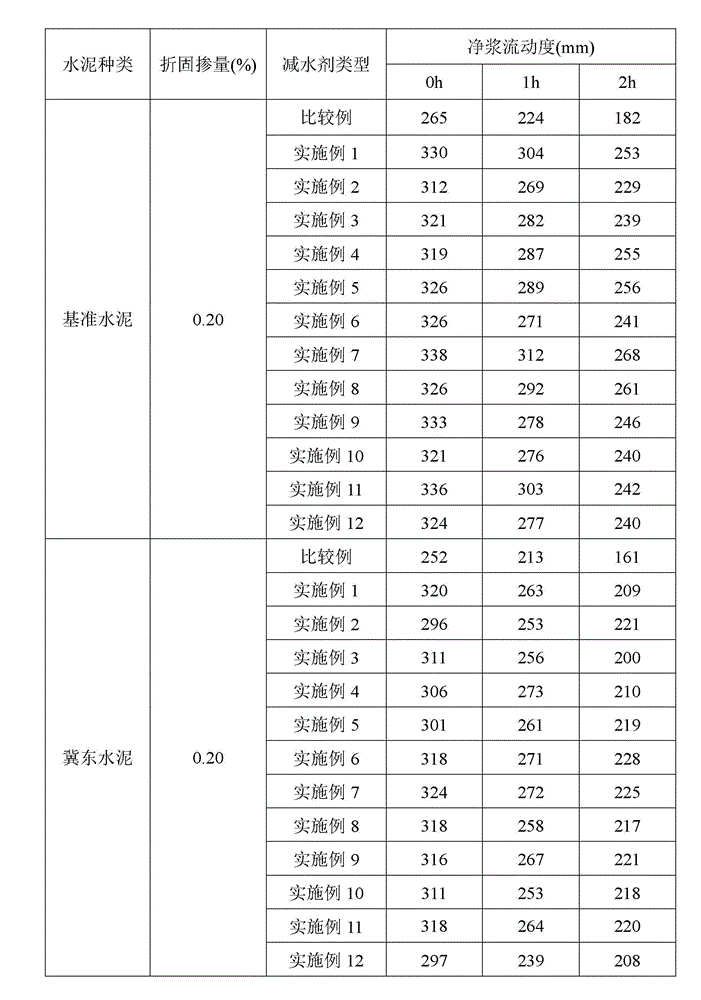

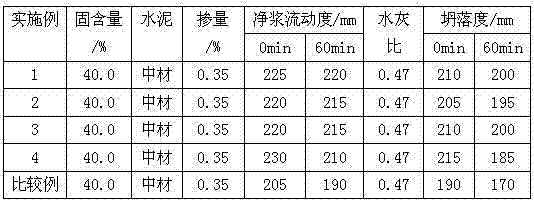

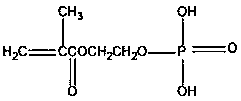

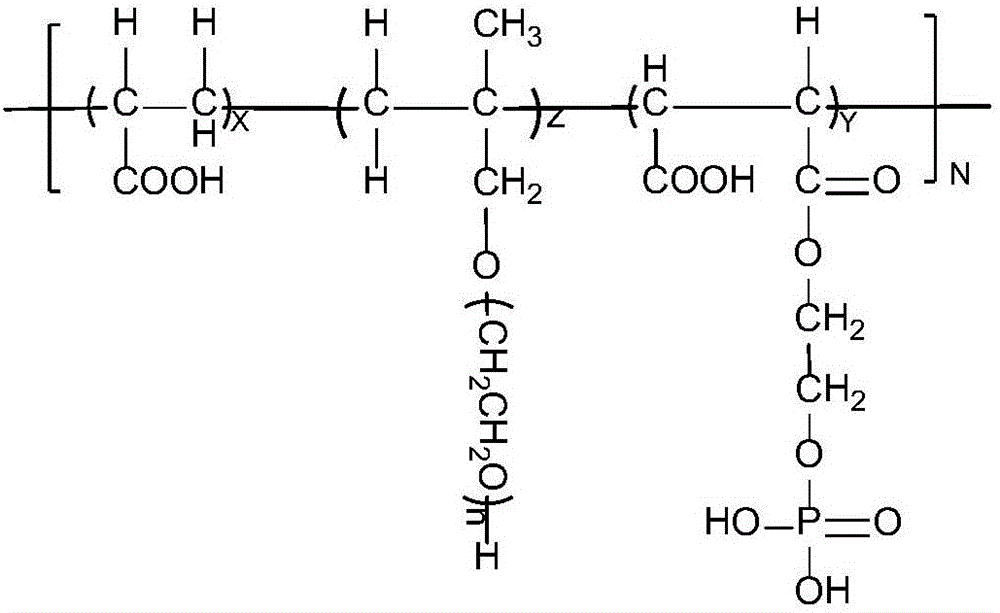

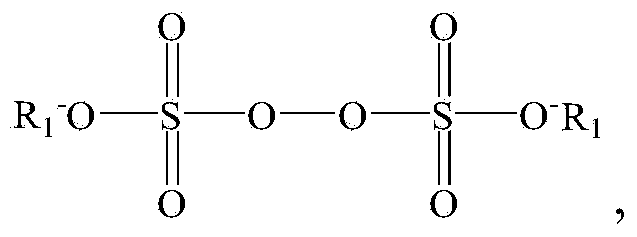

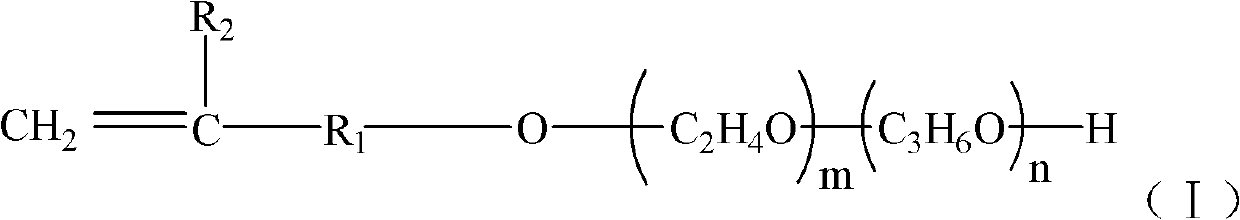

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

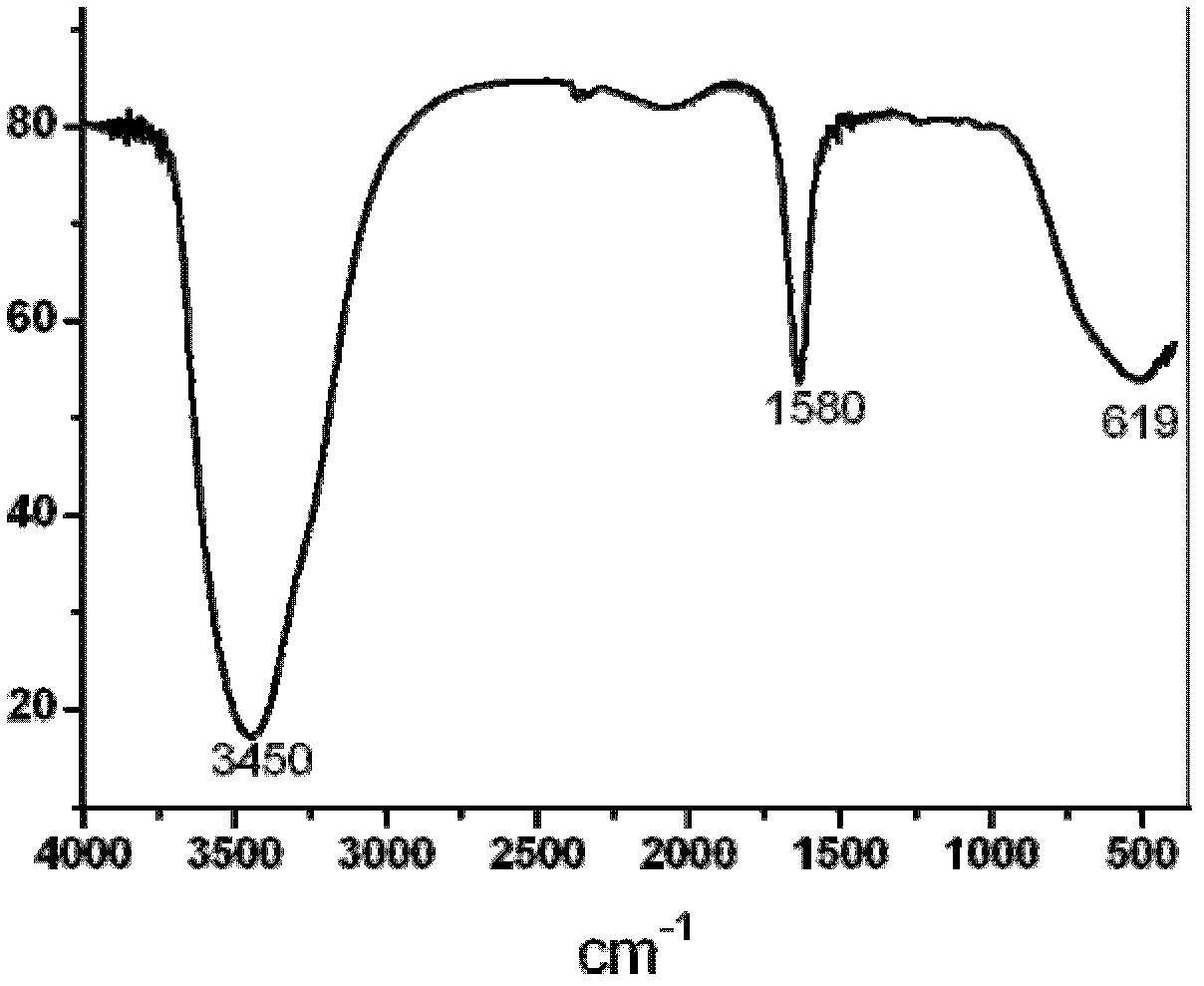

Silane coupling agent modified polycarboxylate superplasticizer and preparation method thereof

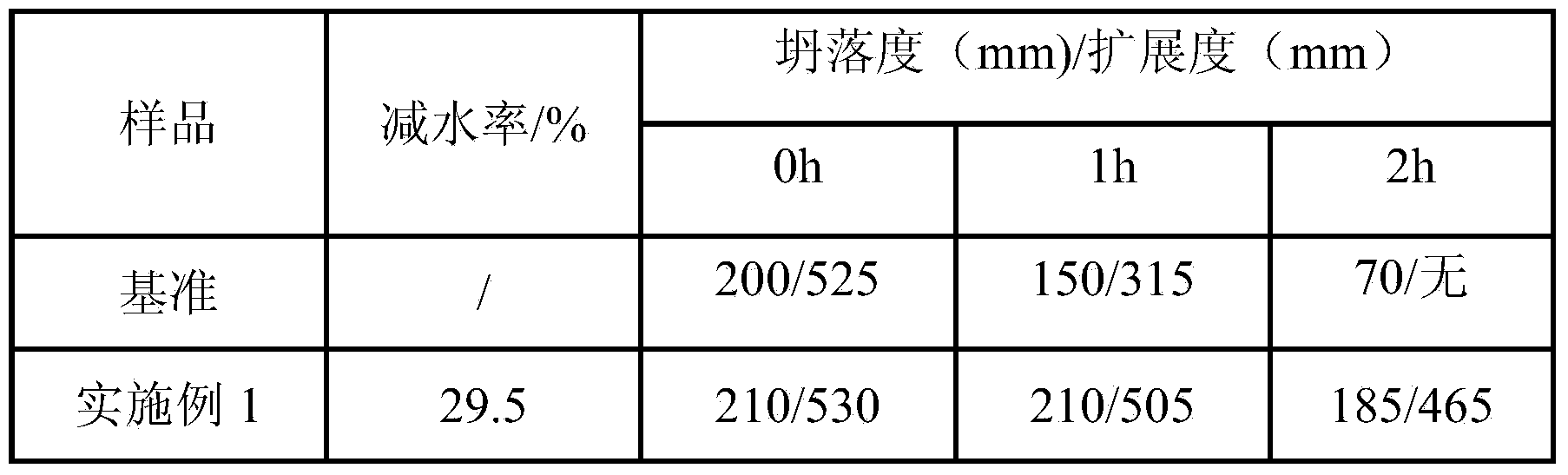

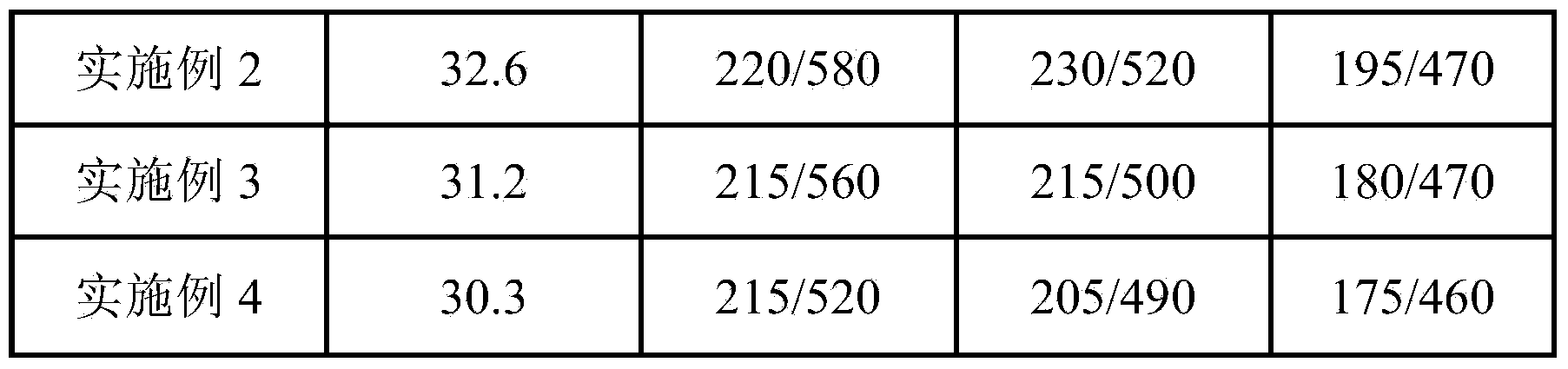

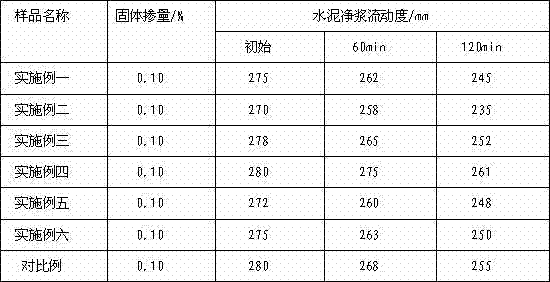

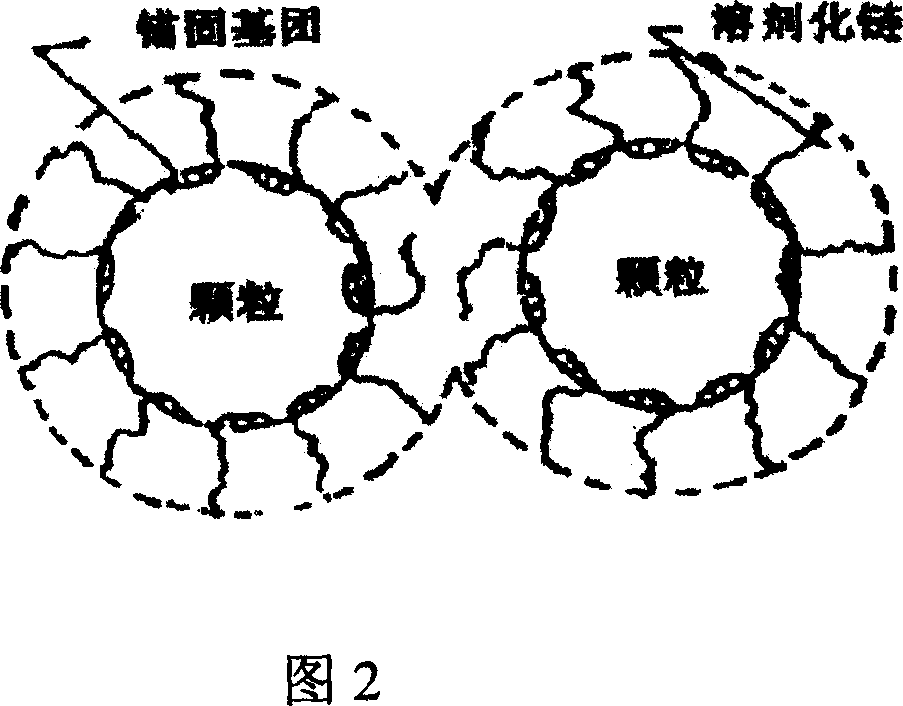

The invention discloses a silane coupling agent modified polycarboxylate superplasticizer and a preparation method thereof, belonging to the field of cement additives. The preparation method comprises the following steps: adding a certain amount of acrylic acid into a polyether macromonomer solution, and stirring uniformly; adding a double bond-containing silane coupling agent; stirring the solution to a clear state and continuously stirring; adding an oxidizing agent, an initiator solution and a small monomer solution while keeping the stirring state; after the stirring, curing for 1-2h; adding liquid caustic soda for neutralization and stabilizing the pH value at 6; and adding a silane coupling agent without double bond to obtain a finished product of silane coupling agent modified polycarboxylate superplasticizer. In the invention, a functional group with a siloxane structure is introduced into the main chain of polycarboxylate molecule, and an anchoring ability in chemical bonding strong interaction with cementing material particles is provided for the branch chain of the comb-shaped polycarboxylate superplasticizer; and with the increase of the anchoring ability, the adaptability and slump loss resistance of the superplasticizer can be remarkably enhanced, and the application of the superplasticizer in the field of mineral micropowder dispersion is expanded to a certain degree.

Owner:HAINAN TAIHOO TECH CO LTD

High-performance polycarboxylic acid water reducing agent and preparation method thereof

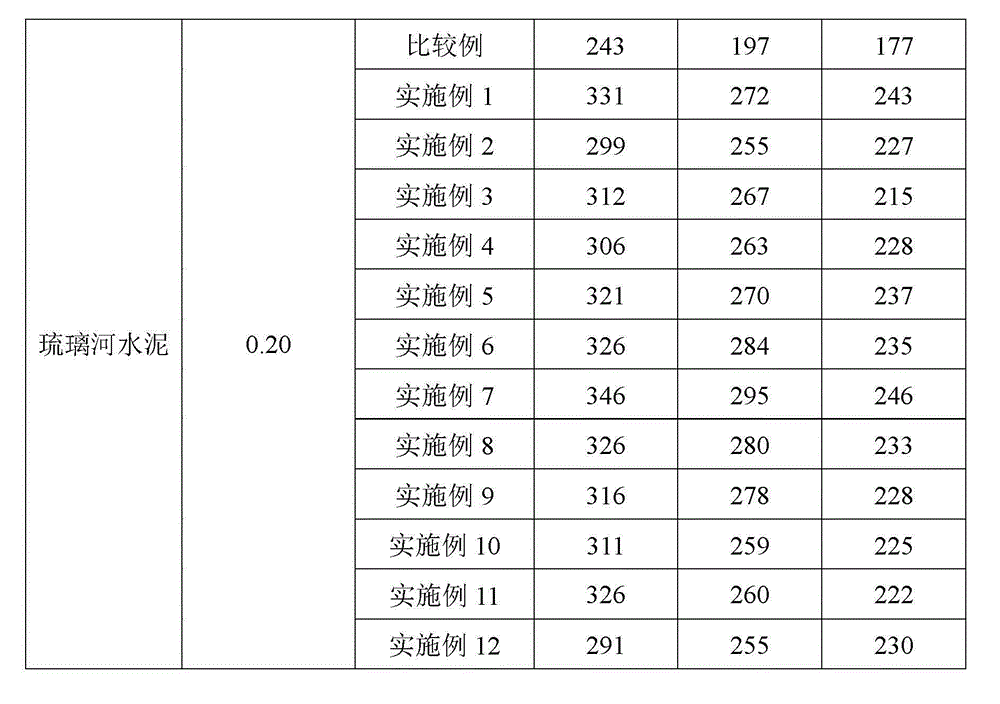

The invention discloses a preparation method of a high-performance polycarboxylic acid water reducing agent. The preparation method of the high-performance polycarboxylic acid water reducing agent comprises the following steps of: adding an unsaturated polyether macromonomer A and water into a reactor, uniformly stirring and dissolving, and then adding an initiator F hydrogen peroxide; then respectively dropwise adding unsaturated carboxylic acid or an unsaturated carboxylic acid anhydride small monomer B, an unsaturated carboxylate ester small monomer C, an aqueous solution of an initiator D, an aqueous solution of an initiator E and an aqueous solution of a molecular weight regulator, and carrying out reaction for 3-5 hours at the room temperature of 10-40 DEG C, so as to obtain a copolymerization product; carrying out a neutralization reaction, namely regulating the pH value of the copolymerization production to be 6-7 by adopting sodium hydroxide, so as to obtain the high-performance polycarboxylic acid water reducing agent. The invention also discloses a high-performance polycarboxylic acid water reducing agent prepared by adopting the preparation method. By controlling a material adding manner, two initiators are compounded, initiated and synthesized to form the high-performance polycarboxylic acid water reducing agent, the synthesized high-performance polycarboxylic acid water reducing agent is environmentally-friendly, pollution-free and high in reaction conversion ratio, and concrete doped with the high-performance polycarboxylic acid water reducing agent has better water reducing property, slump loss resistant property, dispersibility and workability.

Owner:KZJ NEW MATERIALS GROUP CO LTD

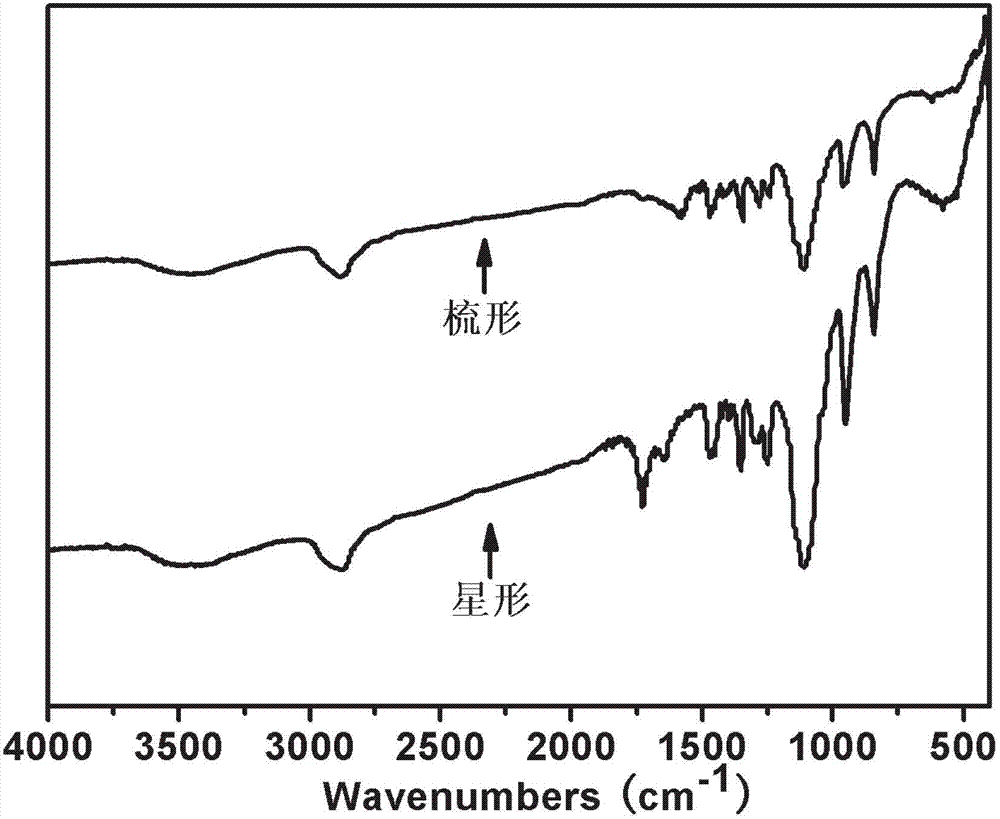

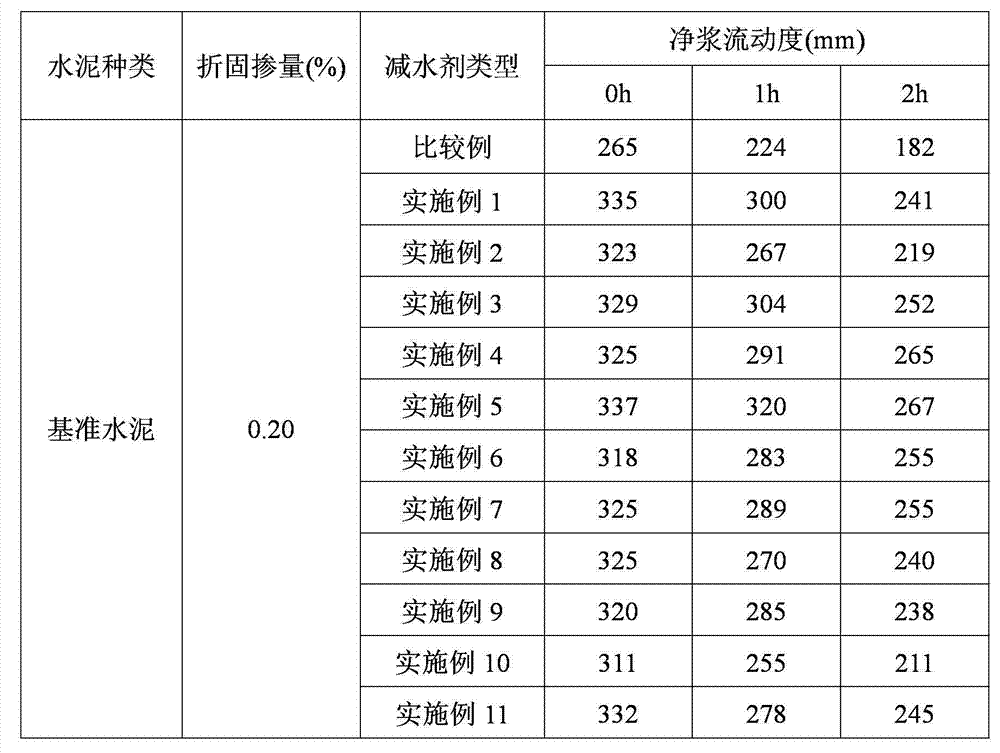

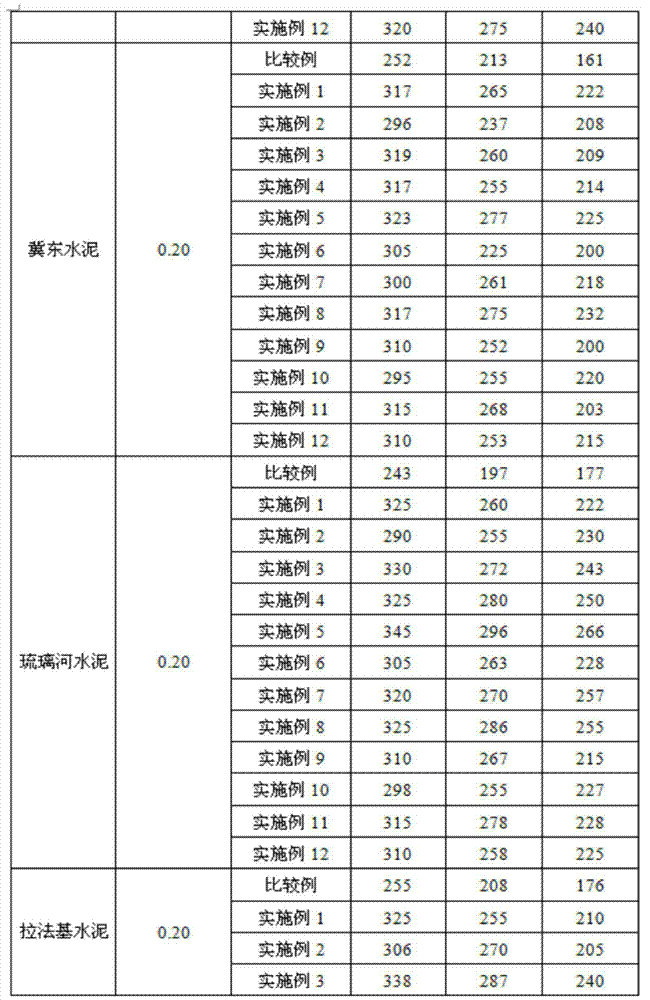

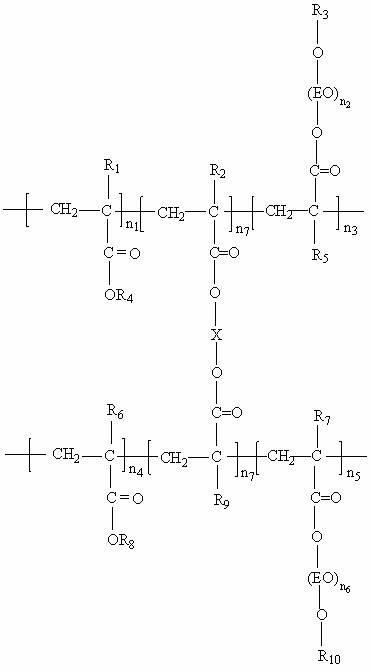

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

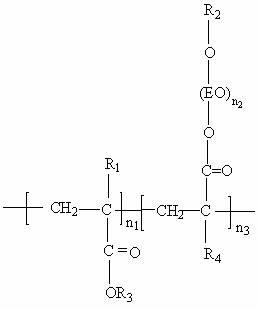

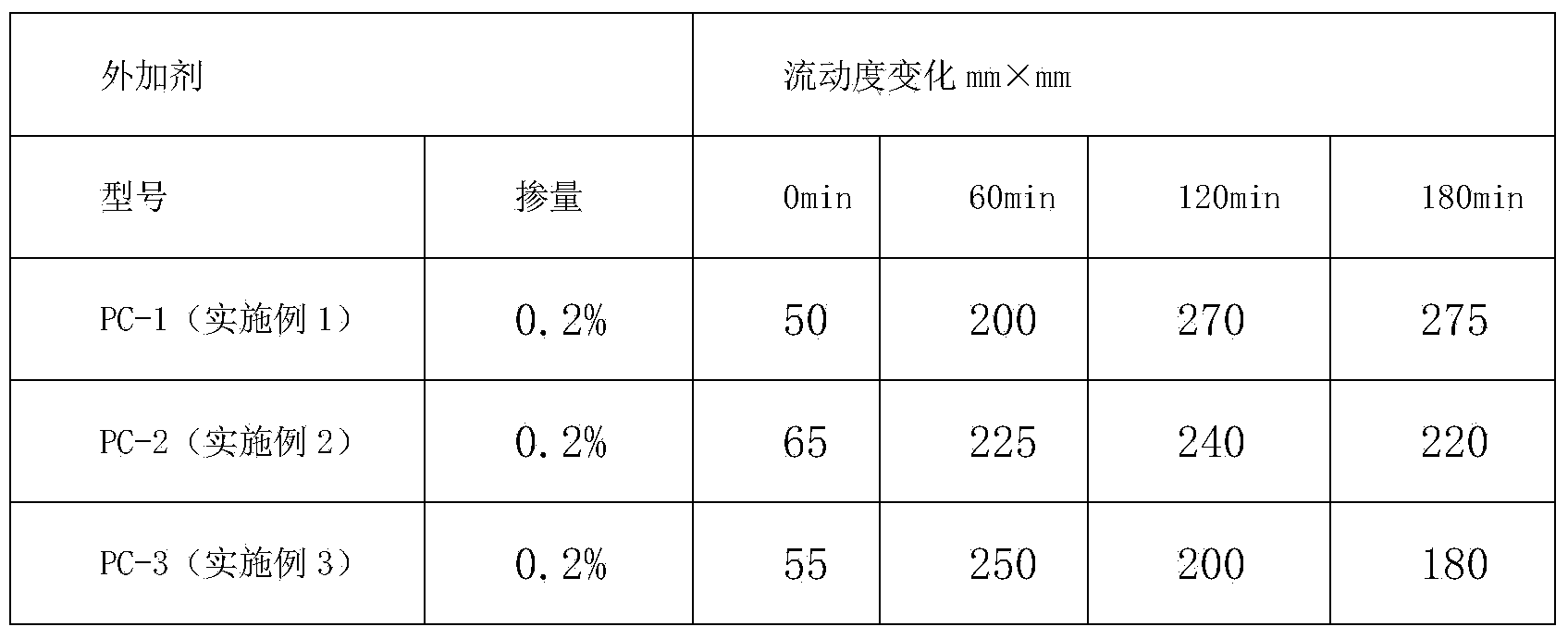

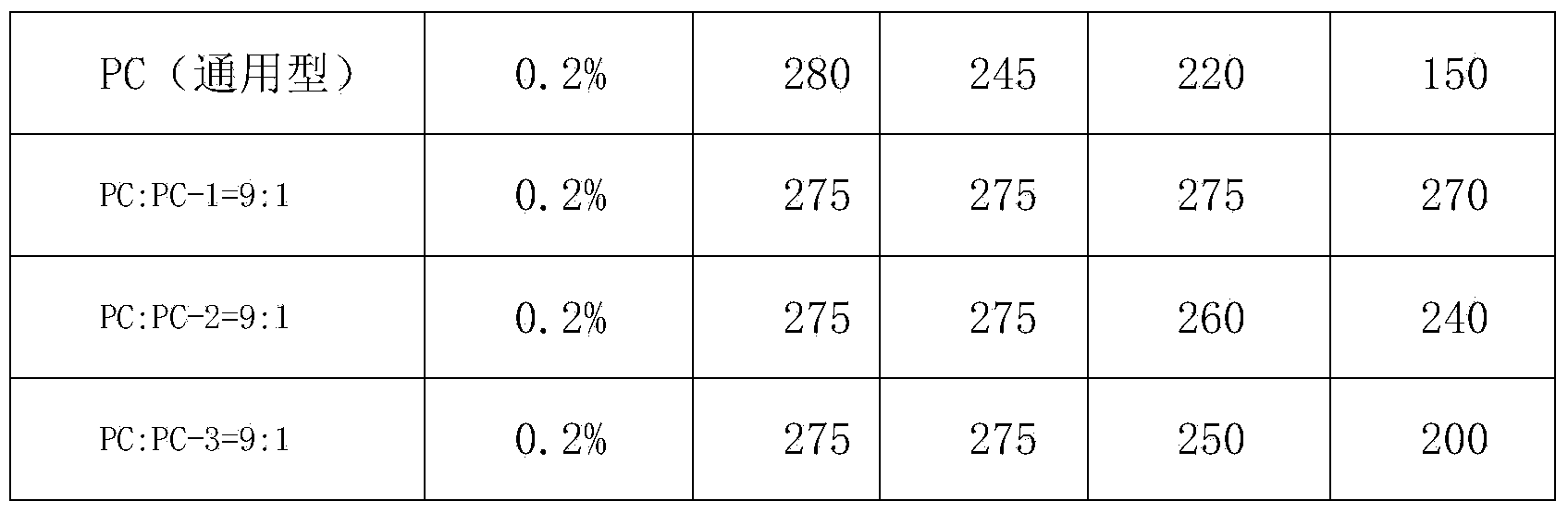

Slow release slump retaining polycarboxylate water reducer and preparation thereof

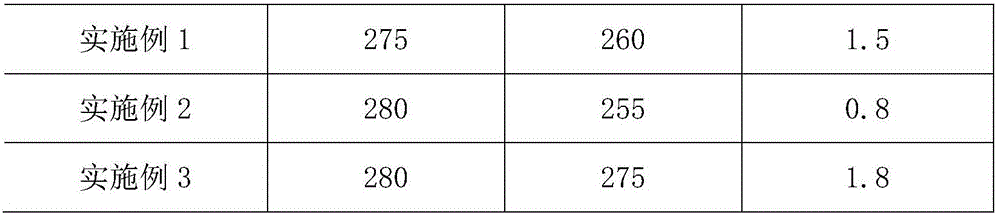

InactiveCN102515618AImprove the performance of water reducerDurable slump performanceComposite materialChain transfer

The invention relates to a slow release slump retaining polycarboxylate water reducer and a preparation method thereof. The method comprises the specific steps of: carrying out ration on unsaturated polyoxyethylene ether, acrylic acid, acrylic acid ester monomers, crosslinking monomer, initiator, chain transferring agent and water for 4-7 h at a reaction temperature of 80-90 DEG C; cooling to 35-40 DEG C; adjusting a pH value of the solution to neutral to obtain a colorless and transparent solution, namely the slow release slump retaining polycarboxylate water reducer. The water reducer prepared by the invention employs two modes of hydrolysis and maintains functions in a cement system for a long time through hydrolysis of ester group on polyacrylic acid monomers and ester group on crosslinking monomer, so as to realize control of slump loss. The slow release slump retaining polycarboxylate water reducer can obviously increase net paste fluidity after one hour, has good retentivity on net paste fluidity after two hours and can maintain nearly zero loss on slump after one hour.

Owner:SHANGHAI JUTONG IND

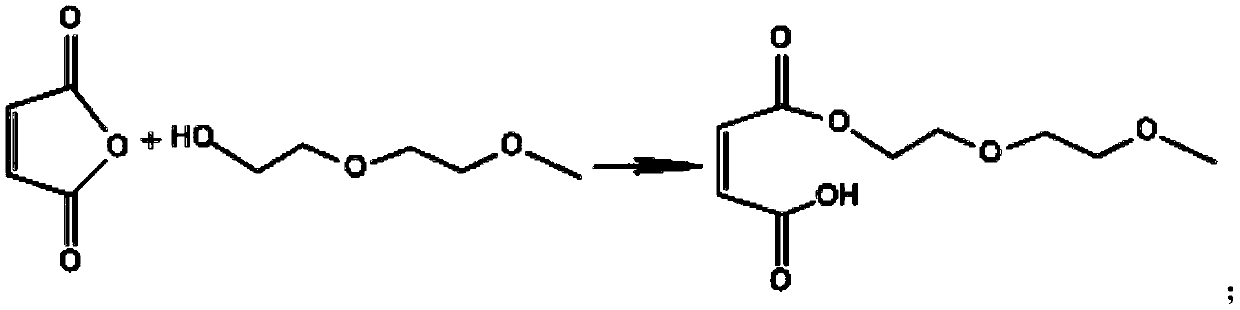

Mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and low-temperature preparation method thereof

InactiveCN110003402AImprove adaptabilityImprove mud slump performanceSuperplasticizerCarboxylic acid

The invention discloses a mud-proof slump-retaining type polycarboxylate superplasticizer with low shrinkage and high adaptability and a low-temperature preparation method thereof. The polycarboxylatesuperplasticizer is mainly prepared by the following steps: carrying out free radical polymerization on 4-hydroxybutylvinyl polyoxyethylene ether, unsaturated carboxylic acid, an unsaturated amide-type monomer, dipolyethylene glycol maleate, an unsaturated quaternary ammonium cationic monomer, an oxidizing agent, a catalyst, a reducing agent, a chain transfer agent and deionized water at 5-15 DEGC through an aqueous solution, regulating pH value by adding a sodium hydroxide solution, and supplementing water. The preparation method of the invention has advantages of low-temperature production, no heat source, simple equipment, no pollution, short reaction time and high production efficiency. The prepared mud-proof slump-retaining type polycarboxylate superplasticizer endows concrete withgood workability, good adaptability, low shrinkage and high strength, has excellent mud-proof slump-retaining property, and greatly reduces construction difficulty.

Owner:SICHUAN TONGZHOU CHEM TECH

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

Ester slump retaining type polycarboxylate water reducer and preparation method thereof

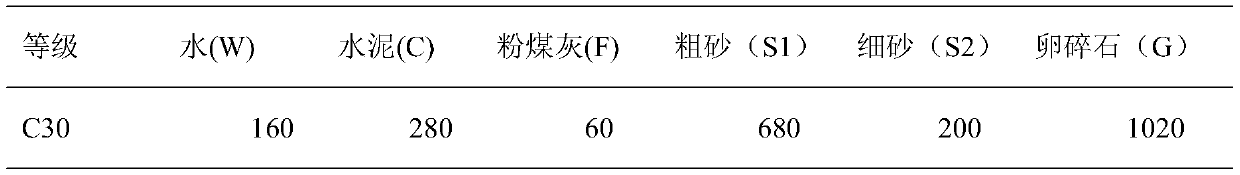

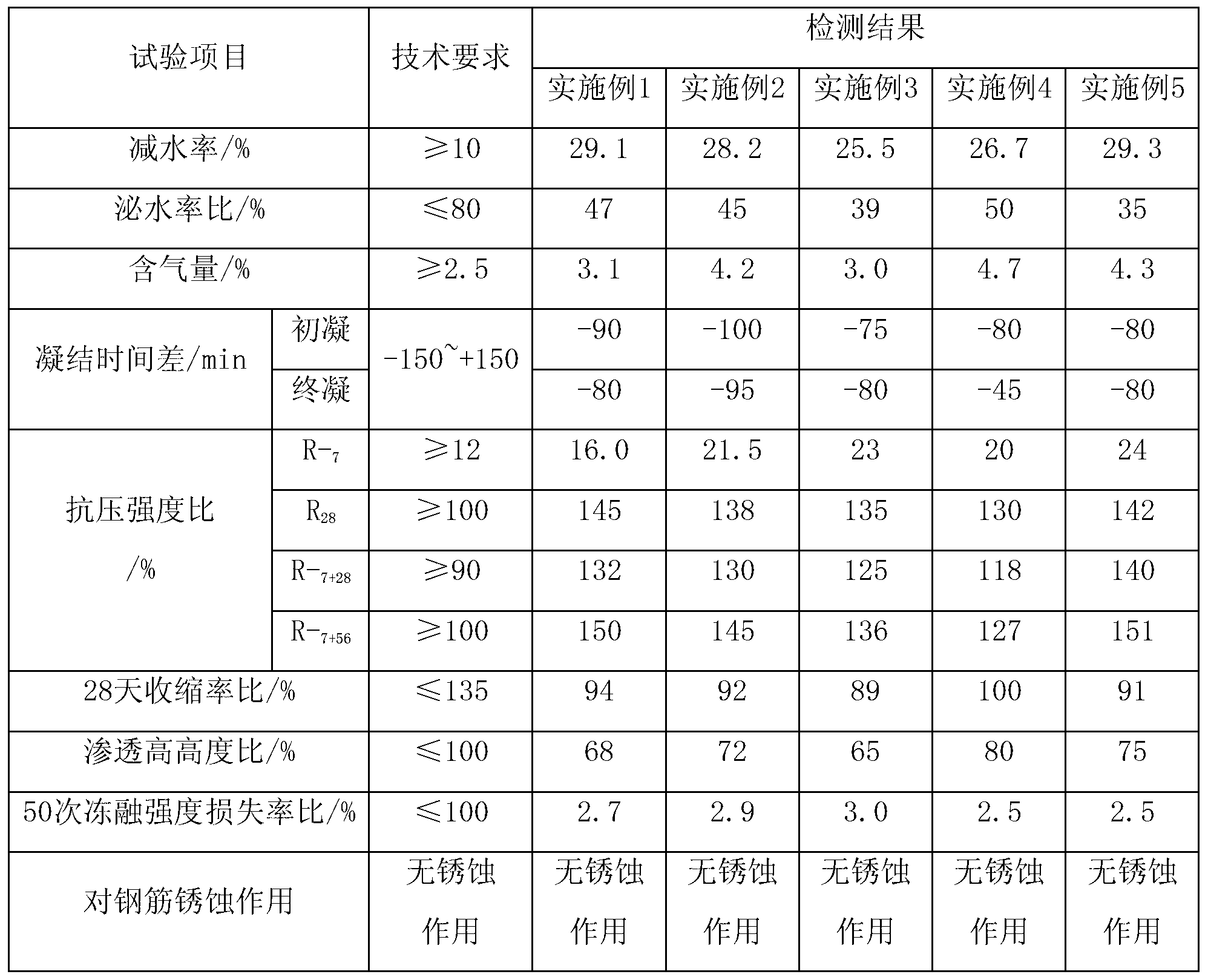

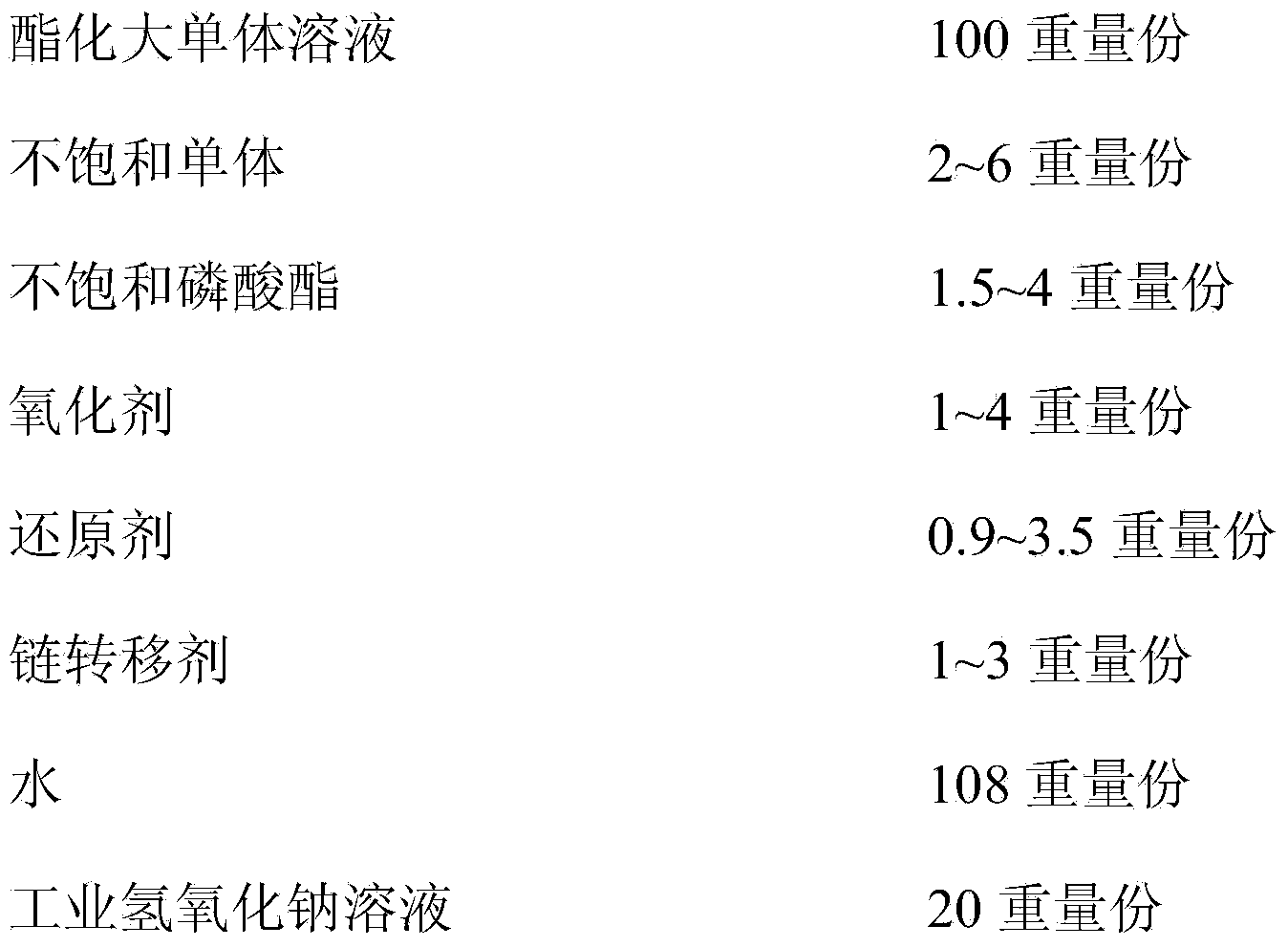

The invention discloses an ester slump retaining type polycarboxylate water reducer and a preparation method thereof. The ester slump retaining type polycarboxylate water reducer is made from raw materials comprising the following components in parts by weight: 100 parts of esterified macromer solution by weight, 2-6 parts of unsaturated monomer by weight, 1.5-4 parts of unsaturated phosphate by weight, 1-4 parts of an oxidizing agent by weight, 0.9-3.5 parts of a reducing agent by weight, 1-3 parts of a chain transfer agent by weight, 108 parts of water by weight, and 20 parts of industrial sodium hydroxide solution by weight, wherein the concentration of the esterified macromer solution is 75-85%, and a solute thereof is the mixture of methoxy polyethylene glycol methacrylate, crosslinking monomers triethylene glycol dmethylacrglate and methyl methacrylate; the unsaturated monomer is methacrylic acid, acrylic acid, hydroxyethyl methylacrylate, hydroxyethyl acrylate, hydroxypropyl methacrylate or hydroxypropyl acrylate. The ester slump retaining type polycarboxylate water reducer provided by the invention has good slump retaining performance, good dispersibility, good adaptability and low cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Polycarboxylate water reducer and preparation method thereof

InactiveCN102826784AOvercome the defect of high homopolymerization tendency of monomers with high activityGood dispersionCarboxylic acidWater reducer

The invention relates to a water reducer used for concrete and a preparation method thereof, in particular to a polycarboxylate water reducer and a preparation method thereof, belonging to the field of concrete admixture technology. The polycarboxylate water reducer comprises the following components, based on parts by mass: 100 parts of polyoxyethylene methyl alkenyl ether macromer, 4-18 parts of unsaturated carboxylic acid and acid amide or acid anhydride, 1-6 parts of unsaturated sulfonate monomer, 0.5-3 parts of oxidizer, 0.01-0.5 parts of a reducing agent, 3- 15 parts of sodium hydroxide and 100-200 parts of water. According to the method, the characteristics such as excellent ability of water-reducing, low slump loss and good adaptability to different types of cement and concrete admixture are shown in the product at low accretion by means of one time addition; and the cost performance is high. The method has advantages that requirements for production equipment and production conditions in industrial production can be further lowered, energy consumption is reduced, and the method is economical, environment-friendly and beneficial to be generalized.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Formula of sustained release type polycarboxylic acid series high-performance dehydragent and method for manufacturing same

The invention proposes a compounding formula and manufacture method of a sustained release-type polyocarboxy acid high performance water reducing agent. The compounding formula comprises esterification reaction formula and copolymerization reaction formula. The invention combines the esterification reaction and copolymerization reaction into one to carry on after the improvement of the craftwork. The invention utilizing non-solvent esterification method achieves the esterification reaction in the lower temperature (75 DEG C) through using the compound catalyst. Compared with the two steps, the invention has better application performance. The invention synthesizes sustained release-type polyocarboxy acid high performance water reducing agent through the adjustment of the reaction condition and the kind and type of components in each reaction. The product is suitable for the concrete with high request to the control of the slump.

Owner:重庆建研科之杰新材料有限公司

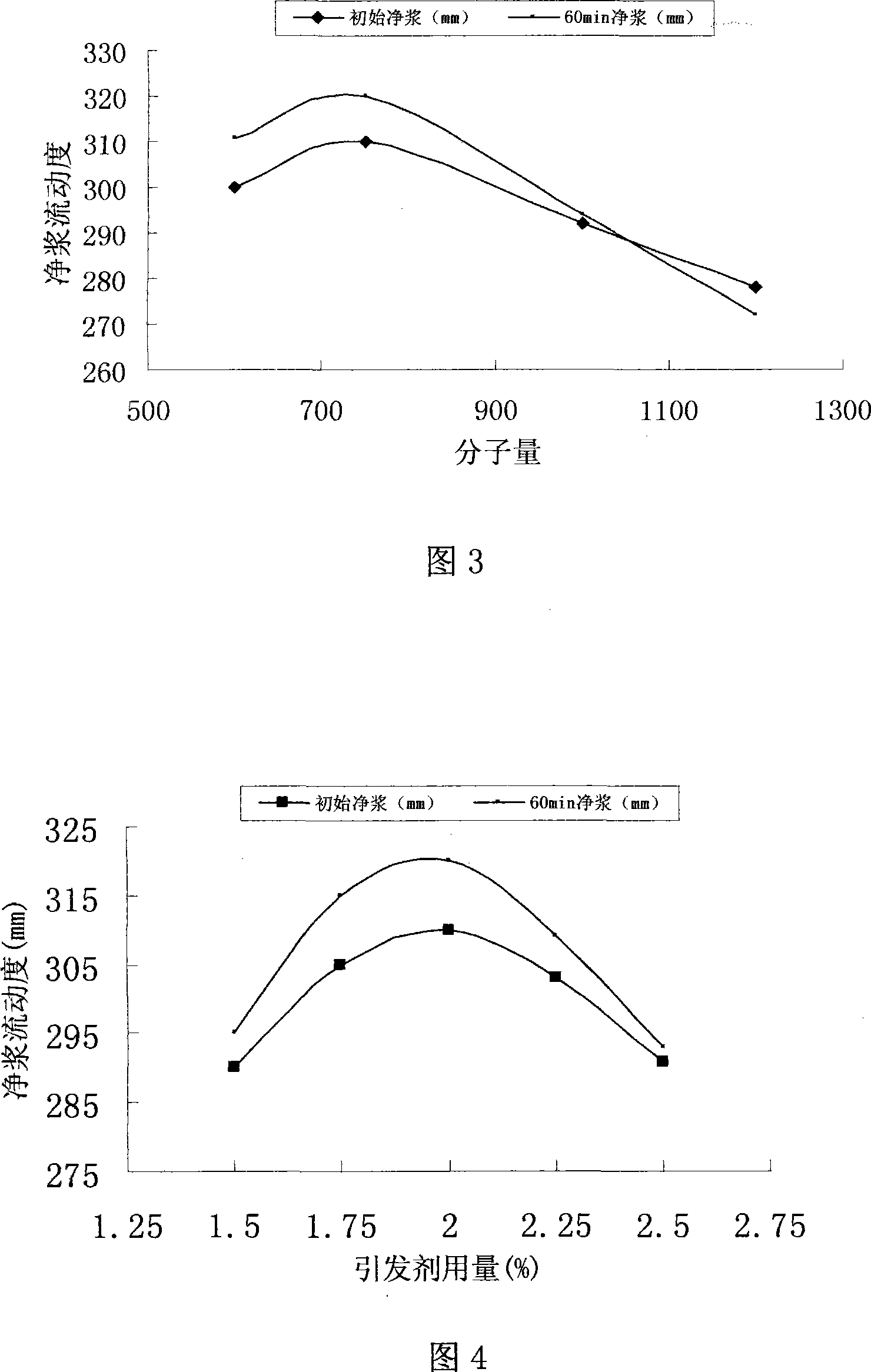

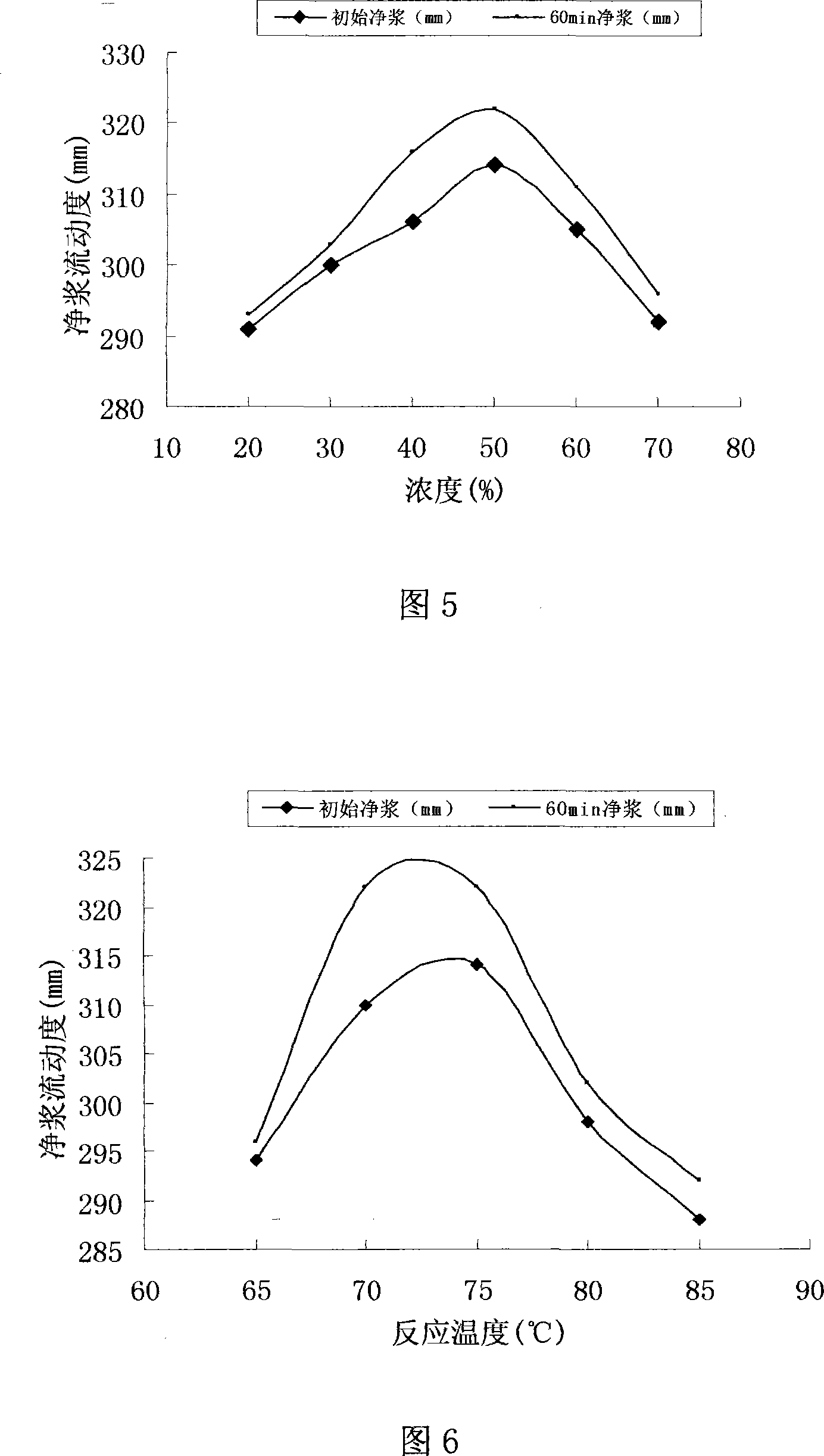

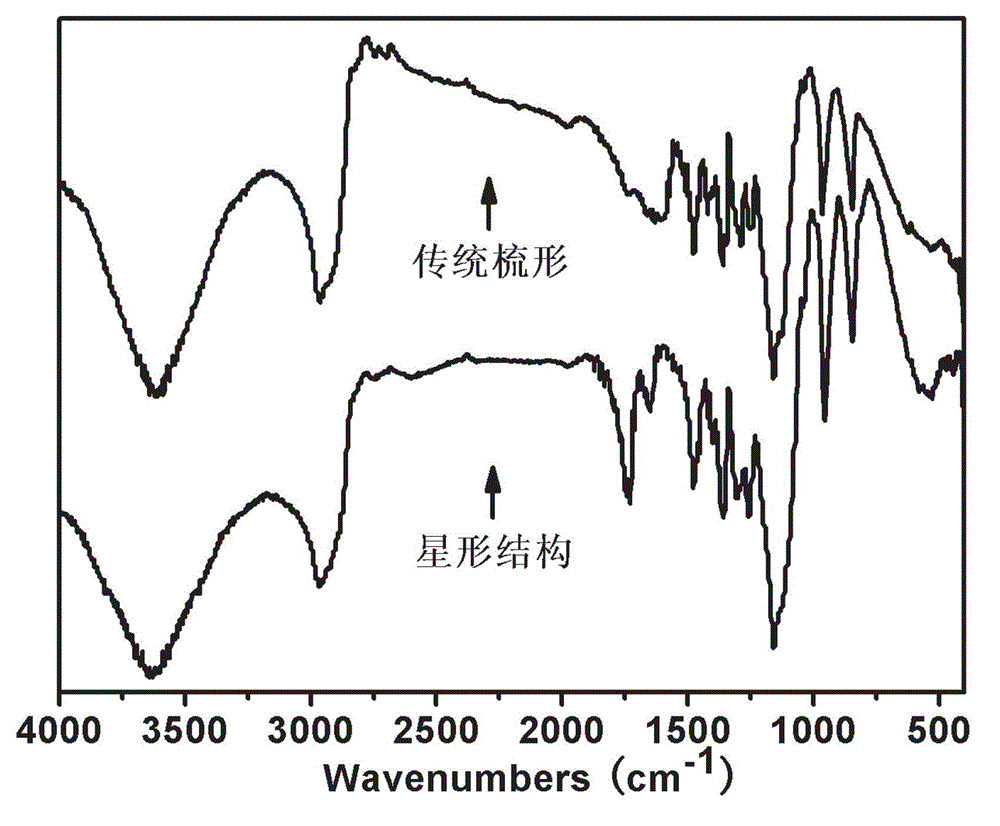

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

Cross-linked polycarboxylic acid water reducing agent and preparation method thereof

The invention relates to a preparation method of a cross-linked polycarboxylic acid water reducing agent. The molecular weight of the cross-linked polycarboxylic acid water reducing agent is 10000-100000. The preparation method comprises the following steps: sequentially adding methylallylalcohol polyethenoxy ether, polyethyleneglycol dimethyl acrylate, sodium methylacrylsulfonate and deionized water into a reaction kettle with good leak tightness while continuously stirring, heating to 45-50 DEG C, stirring for 10 minutes, continuing heating to 60-62 DEG C, adding oxydol, slowly and dropwisely adding an acrylic acid solution and a chain-transfer agent within 3-3.5 hours, keeping the temperature for 1-1.5 hours, cooling to 50 DEG C after the reaction finishes, supplementing water, and adding liquid alkali to neutralize until the pH value reaches 6.5-7, thereby obtaining the cross-linked polycarboxylic acid water reducing agent of which the solid content is 40%. The invention has the advantages of simple reaction equipment, easily controlled reaction, low cost and the like; and the prepared cross-linked polycarboxylic acid water reducing agent has the advantages of high water reducing rate, favorable workability and high slumping retention.

Owner:ZHUZHOU KAMILE SU BUILDING MATERIALS

Method for preparing high-efficiency water-reducing agent of poly-carboxylic acid

The invention discloses a preparation method for a polycarboxylate high-performance water reducer, comprising the following steps: based on weight proportion, mixing 5-50% of unsaturated carboxylic acid, a derivative a of the unsaturated carboxylic acid, 45-95% of polyoxyethylene vinyl propionate ester, a derivative b of the polyoxyethylene vinyl propionate ester, as well as 0-30% of propyl sulfonate c to prepare a mixed monomer solution; then adding the initiator which takes up 0.5-15% of the total weight of the mixed monomer solution, and the chain transfer agent which takes up 0-15% of thetotal weight of the mixed monomer solution into the mixed monomer solution so as to prepare the polycarboxylate high-performance water reducer through binary or ternary copolymerization. The polycarboxylate high-performance water reducer disclosed in the invention can be widely applied to grout, mortar, concrete, gypsum and coal-water slurry, so that the mixed material can have higher mobility tosignificantly reduce the actual water consumption in the mixing process and effectively improve the concrete strength and durability, thereby showing the advantages of low mixing amount, high dispersion and high slump retaining performance.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Method for preparing high-performance polycarboxylate superplasticizer via heat resource-free process

The invention discloses a method for preparing high-performance polycarboxylate superplasticizer via a heat resource-free process, and the method comprises the following steps of 1) adding unsaturated polyoxyethylene ether and water in certain proportion into a reaction still and stirring for dissolution, 2) adding oxidizing agent water solution at 5-30 DEG C at one time and stirring, and 3) respectively dropping mixed solution of accelerant and chain transfer agent in proper proportion and comonomer in 2-4h, after the dropping, curing for 1.5h, and finally adding alkaline modifier for neutralization so as to obtain the polycarboxylate superplasticizer. The method is simple in process and the prepared polycarboxylate superplasticizer has high dispersing performance in low amount of admixture. By using the heat resource-free process, the step of heating is decreased, so that the production is more simple and convenient, the cost is lower, the environmental-friendly property is provided and the energy consumption is decreased.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and preparation method thereof

InactiveCN109626859AStrong adsorption capacity and dispersion performanceImprove dispersionCarboxylic esterDibasic acid

The invention relates to the technical field of concrete admixtures, in particular to a clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and a preparation method thereof. With polyether macromonomers, unsaturated carboxylic acid, unsaturated carboxylic ester, dibasic acid anhydride, a crosslinking agent, amide monomers, unsaturated phosphate ester, phosphate, an oxidizing agent , a reducing agent, a chain transfer agent, a neutralizing agent and water as raw materials, the clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer is synthesized at normal temperature. Ester groups, amide groups and phosphate ester are introduced into the molecular structure of the polycarboxylate superplasticizer, and light crosslinking of the polycarboxylate superplasticizer is realized through the long-chain ester crosslinking agent, so that the superplasticizer has a good clay-resisting and slump-retaining effect and has the advantages of low mixing amount, high water reducing rate, high adaptability to clay-containing sand, good slump retaining performance and the like; besides, only normal-temperature polymerization is needed, the processis simple, the production cost is low, and the superplasticizer is suitable for industrial production.

Owner:山西黄河新型化工有限公司

Green preparation method of slow-release polycarboxylic-acid high-performance water reducing agent

The invention relates to a green preparation method of a slow-release polycarboxylic-acid high-performance water reducing agent, which comprises the following steps: firstly, dissolving unsaturated polyethenoxy ether in water, adding an oxidant solution, and evenly stirring; then, respectively and dropwisely adding a reducer / chain-transfer agent mixed solution and a comonomer solution, and polymerizing; and finally, adding an alkaline regulator to neutralize and age the solution, thereby obtaining the slow-release polycarboxylic-acid high-performance water reducing agent. In the invention, hydrogen on the terminal hydroxyl group of the original unsaturated polyethenoxy ether is substituted by an allyl group containing unsaturated bond, so that the terminal group of methoxypolyethylene glycol is converted from the original active hydroxyl group into the inert methoxy group at present; and thus, the byproducts of the copolymerization product are greatly reduced, and the molecular weight distribution is narrow, so that the synthesized water reducing agent has the advantages of high water reduction rate and slump resistance. The redox system with low activation energy is used for initiating the monomer copolymerization, so that the polymerization can be implemented at normal temperature, thereby implementing the production of the product by a no heat source method, simplifying the production equipment and lowering the energy consumption and cost.

Owner:NANJING RUIDI HIGH TECH

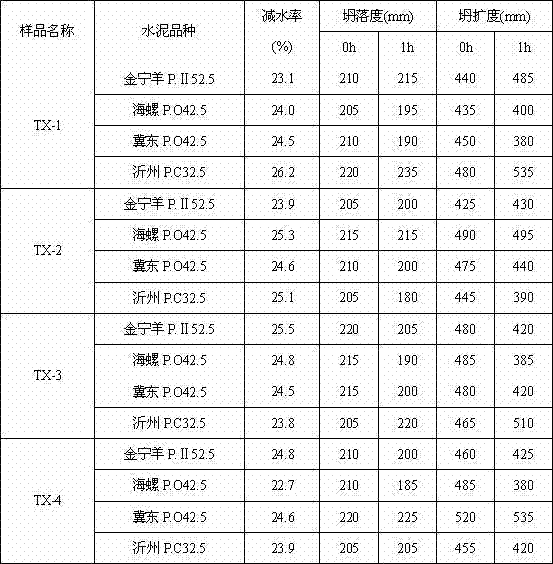

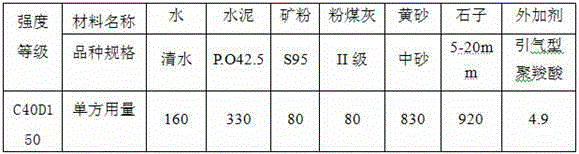

Highly-antifreezing highly-slump retaining self-compacting C40 concrete

The invention relates to highly-antifreezing highly-slump retaining self-compacting C40 concrete which comprises the following components by kg / m3: 330 parts of cement, 80 parts of granulated blast-furnace slag, 80 parts of fly ash, 830 parts of natural medium sand with a fineness modulus of 2.3-3.0, 920 parts of stone, 4.9 parts of additives, and 160 parts of mixing water; the additive is a modified air-entraining polycarboxylic water reducer, wherein the mixing amount of an air-entraining agent in the polycarboxylic water reducer RP325 is 0.1%, and the mixing amount of the additive for large-scale production is 1.0% of the total amount of gel materials; the air content in the concrete is 5.0%+ / -1.0%; the air-entraining amount in the poured structure from the beginning to the third hour is stabilized within a range of 5.0%+ / -1.0%, and the concrete expansion degree in 3 hours is maintained at 600+ / -50 mm; the number of antifreezing cycle is not less than 150, and the lowest temperature and the highest temperature in the antifreezing cycle are respectively -18 DEG C and 35 DEG C. The concrete of the invention can meet the concrete performance requirements for a skating rink in Shanghai oriental sports center with respect to high slump retaining performance, self-compacting performance, strength performance, high antifreezing performance, and the like.

Owner:TONGJI UNIV +1

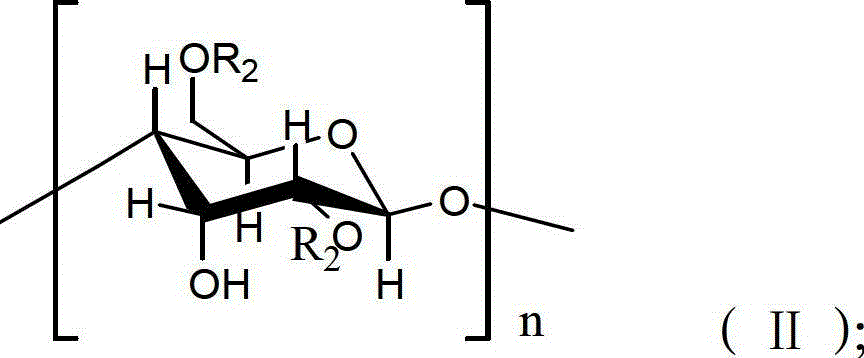

Hyperbranched polymer, hyperbranched polycarboxylic acid-series super plasticizer and preparation method thereof

ActiveCN102504247AEasy to getSimple processSulfonic acids salts preparationEthylene diaminePolymer science

The invention provides a hyperbranched polymer, a hyperbranched polycarboxylic acid-series super plasticizer and a preparation method thereof. The preparation method comprises the following steps of: undergoing an addition reaction and an ammonolysis reaction on alkenyl amine, polymethylmethacrylate, ethylene diamine and 2-acrylamide-2-sodium methylacrylsulfonate serving as raw materials to obtain a hyperbranched polymer with a structure shown as a formula (I), (II), (III) or (IV); undergoing a polymerization reaction on the hyperbranched polymer, an esterification monomer and a crosslinking agent; and preparing a hyperbranched polycarboxylic acid-series super plasticizer with a two-step process. The preparation method provided by the invention has the advantages of simple process, easiness for controlling a preparing process and operating, readily-available raw materials, low production cost and suitability for industrial production. Due to the adoption of the hyperbranched polycarboxylic acid-series super plasticizer, the comprehensive performance of concrete is improved. As proved by an experiment result, the hyperbranched polycarboxylic acid super plasticizer provided by the invention has high slump loss resistance, high water-reducing rate and high compressive strength.

Owner:安徽海螺材料科技股份有限公司

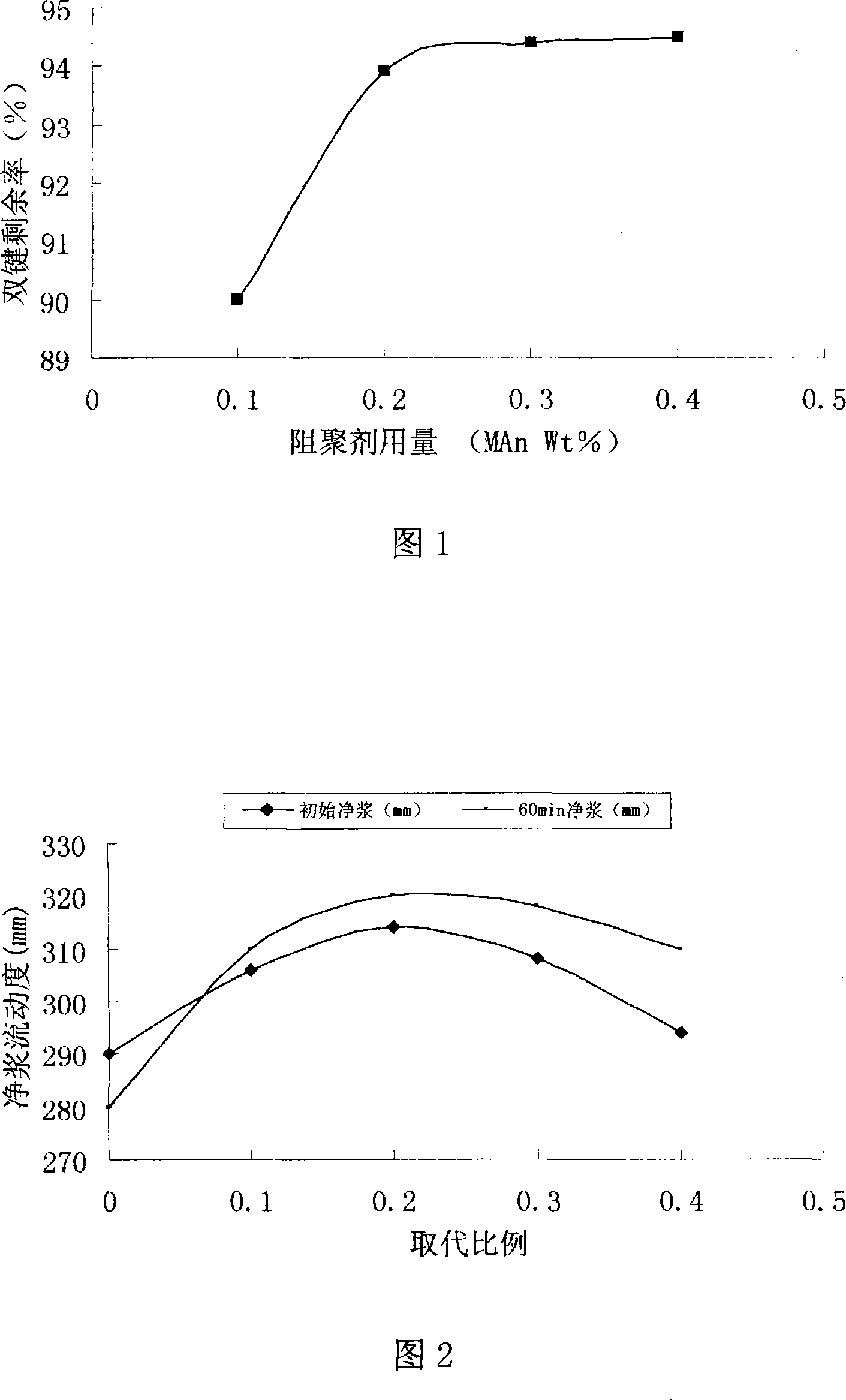

Preparation method for polycarboxylic acid high-performance water reducer

The invention discloses a preparation method of a poly-carboxylic acid water reducing agent with high performance, the water reducing agent is made in simple process with low mixing amount and high dispersive property. The technical proposal is as the follow: A) methacrylic acid and methoxy polyethylene glycol with a mole ratio of 1 to 1.2: 1 are put into a reactor with catalyst, polymerization inhibitor and water carrying agent being added to be mixed and heated to 100 to 150 DEG C and kept reacting within 8 to 12 hours to obtain polyoxyethylene methacrylate; B) water and initiator are added into the reactor, then a mixing solution containing sodium allylsulfonate, the polyoxyethylene methacrylate and the methacrylic acid is added drop by drop slowly into the reactor, wherein the weight proportion of the water and the mixing solution is 2: 1 to 1.2, the solution is mixed and heated to the temperature of 80 to 120 DEG C. Chain transfer agent is added after reaction of 4 to 6 hours and the adding drop by drop being finished, and the solution is discharged after being kept mixing with heat preserved for 1 to 2 hours, the poly-carboxylic acid water reducing agent with high performance is obtained.

Owner:JIANGSU CHEM RES INST

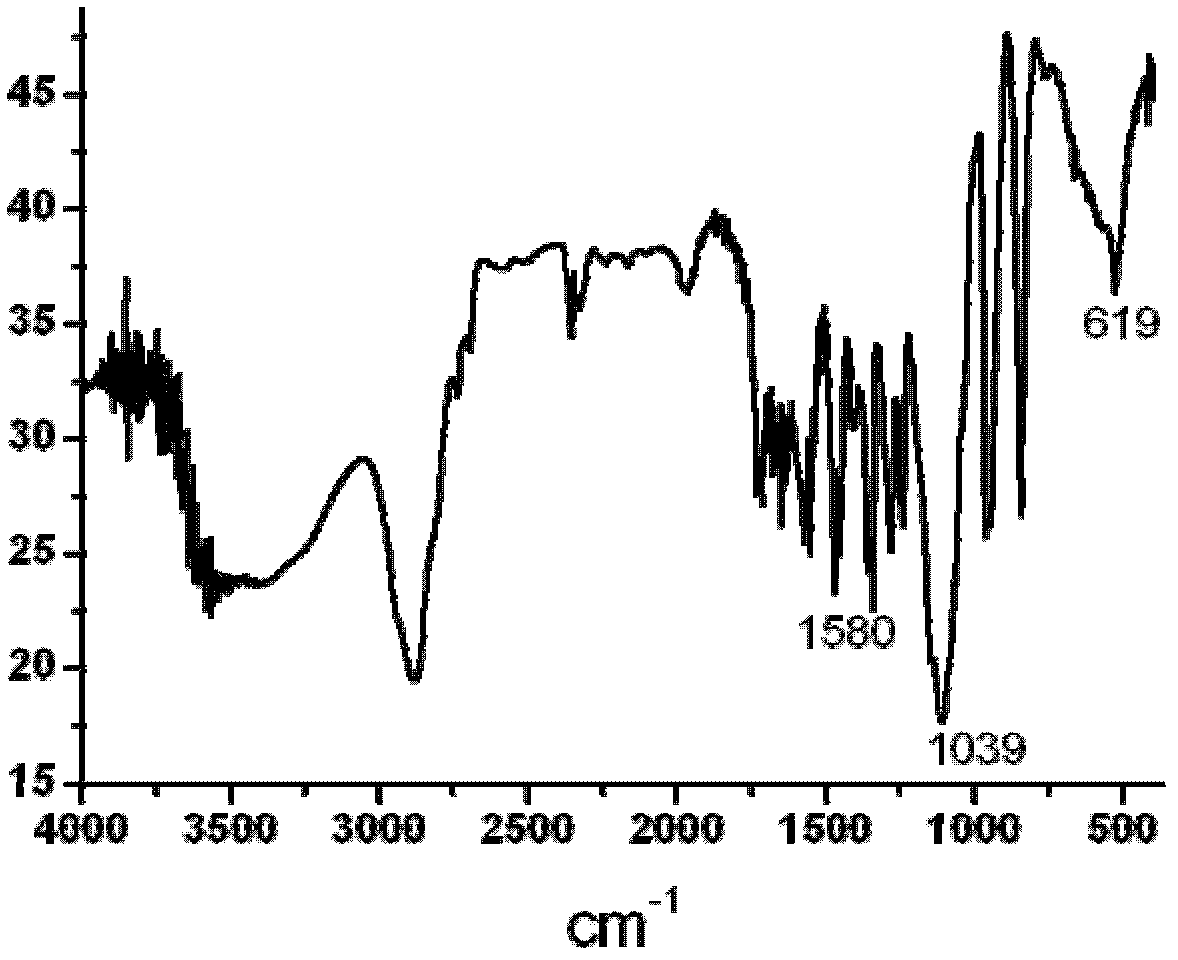

Phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent and preparation method thereof

InactiveCN105837761AHigh carboxyl contentSlow down the hydration processOrganic compound preparationCarboxylic acid esters preparationAcid derivativeChain transfer

The invention relates to a structural formula and a preparation method of a phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The method includes: performing esterification reaction of alcohol and a mixture of one or more of unsaturated acids and unsaturated acid anhydrides, performing phosphorylation of a phosphatizing agent and prepared unsaturated acid ester, subjecting prepared phosphate and isobutene or TPEG, a chain transfer agent and a mixture of one or more of unsaturated acids and unsaturated acid derivatives to free radical polymerization reaction at the normal temperature, and after reaction is finished, adding an alkali solution to regulate a pH to be 7-9 to obtain the phosphate-based high slump loss resistant type polycarboxylate high-performance water reducing agent. The water reducing agent has the advantages of excellent performances, low admixing quantity, high water reducing rate, excellent slump loss resistance, high cement adaptability, insensitivity to mud content of concrete materials and the like.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

Super slump type polycarboxylate water reducing agent for bored pile concrete and preparation method thereof

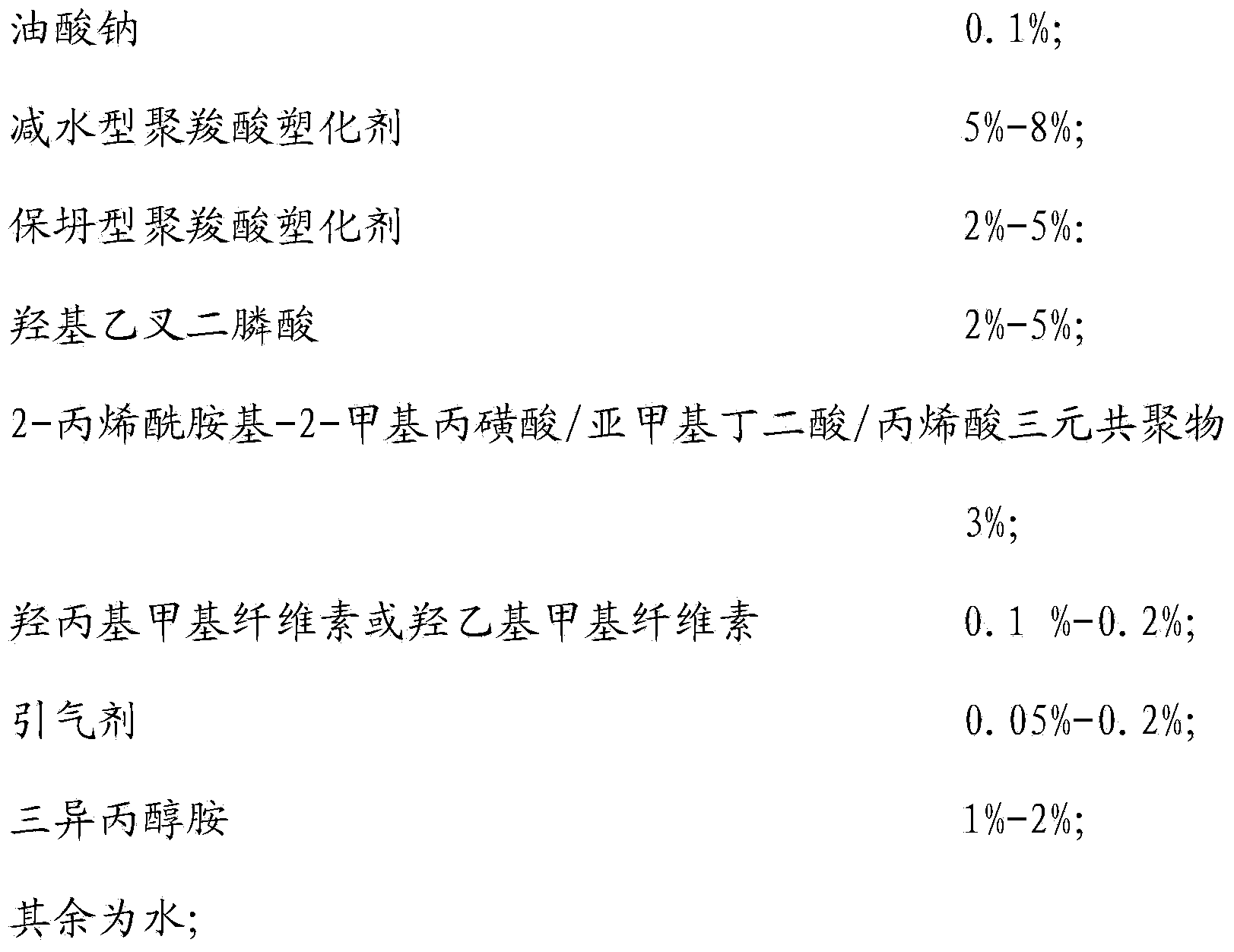

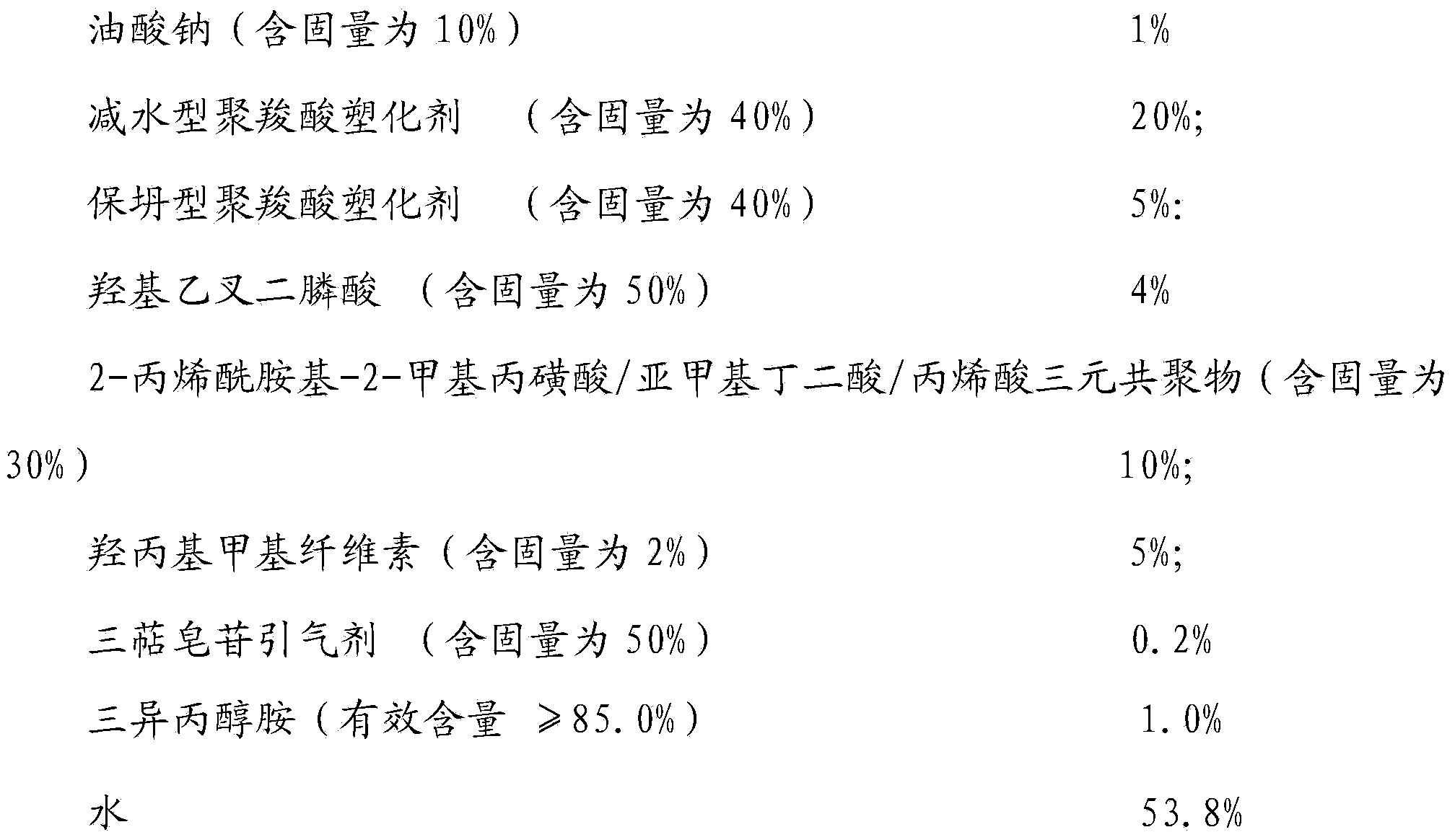

ActiveCN103408242AGood slump performanceReduce bleedingWater reducerHydroxyethylidene Diphosphonic Acid

The invention provides a super slump type polycarboxylate water reducing agent for bored pile concrete. The water reducing agent is in a liquid state and comprises the following ingredients: sodium oleate, water reducing type polycarboxylate plasticizer, slump type polycarboxylate plasticizer, hydroxyethylidene diphosphonic acid, 2-acrylamide-2-methylpropanesulfonic acid / itaconic acid / acrylic acid terpolymer, hydroxypropyl methyl cellulose or hydroxyethyl methyl cellulose, air entraining agent and triisopropanolamine. The super slump type polycarboxylate water reducing agent for bored pile concrete provided by the invention has the following beneficial effects that by using the super slump type polycarboxylate water reducing agent, the bored pile concrete is good in homogeneity, the static bleeding rate of the bored pile concrete can be generally less than 1%, stable working performance can be maintained within a long time span, meeting the working property of concrete after 0.5-5.0h can be met by adjusting the formulation and dosage and improving the compressive strength ratio of the concrete, and the 28 d strength can be more than 130% of that of benchmark concrete. The invention further provides a preparation method of the super slump type polycarboxylate water reducing agent for bored pile concrete.

Owner:北京金隅节能科技有限公司

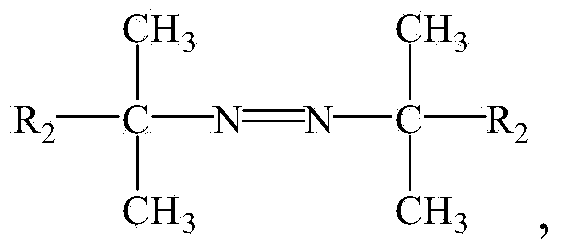

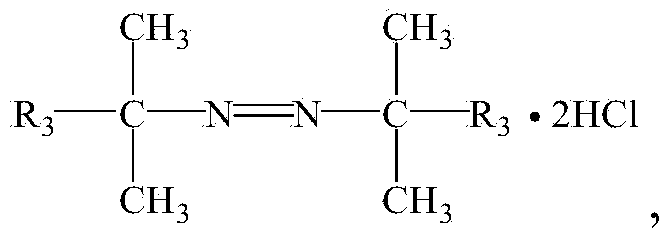

Method for preparing polycarboxylic acid grafted copolymer superplasticizer

The invention discloses a method for preparing a polycarboxylic acid grafted copolymer superplasticizer. In the method, the preparation is implemented at the low temperature of 5-30 DEG C; a used initiating system is a complex initiating system which adopts the combination of one initiator I and various reducers R, or one reducer R and various initiators I or various initiators I and various reducers R, wherein the initiator (s) I is (are) selected from hydrogen peroxide, persulfate salt LS2O8 and a water-soluble azo initiator W, and the reducer (s) R is (are) selected from ascorbic acid and certain kinds of inorganic salt. The preparation method is simple, excellent in repetition stability and low in cost, does not require heating, and avoids toxicity and pollution; the prepared superplasticizer is high in water-reducing rate, and excellent in adaptability and slump-retaining capability, thereby being suitable for popularization and application.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Super controlled release type polycarboxylate slump retention agent and preparation method thereof

The invention discloses a super controlled release type polycarboxylate slump retention agent and a preparation method thereof. The preparation method of the polycarboxylate slump retention agent comprises the following steps: carrying out free radical polymerization on a monomer A, namely polyoxyethylene ether (TPEG), a monomer B, namely maleic anhydride or polyethylene glycol maleic acid esters, a monomer C, namely acrylic acid, a monomer D, namely hydroxyalkyl acrylate or vinyl acetate, an initiator, a chain transfer agent and water, adding an alkaline liquor to neutralize the mixture, wherein a molar ratio of the monomer A to the monomer B to the monomer C to the monomer D is 1 to (1.0-2.5) to (1.0-2.5) to (2.0-4); the dosage of the initiator accounts for 1%-8% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D; the dosage of the chain transfer agent is 1%-3% of the total mole number of the monomer A, the monomer B, the monomer C and the monomer D. The super controlled release type polycarboxylate slump retention agent disclosed by the invention is in a liquid state, has solid content of 50%, and has performances of low alkaline content, a low water-reducing rate and excellent slump retention performance. Besides, the production process is simple, the reaction conditions are easy to control, and the environmental pollution is avoided.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

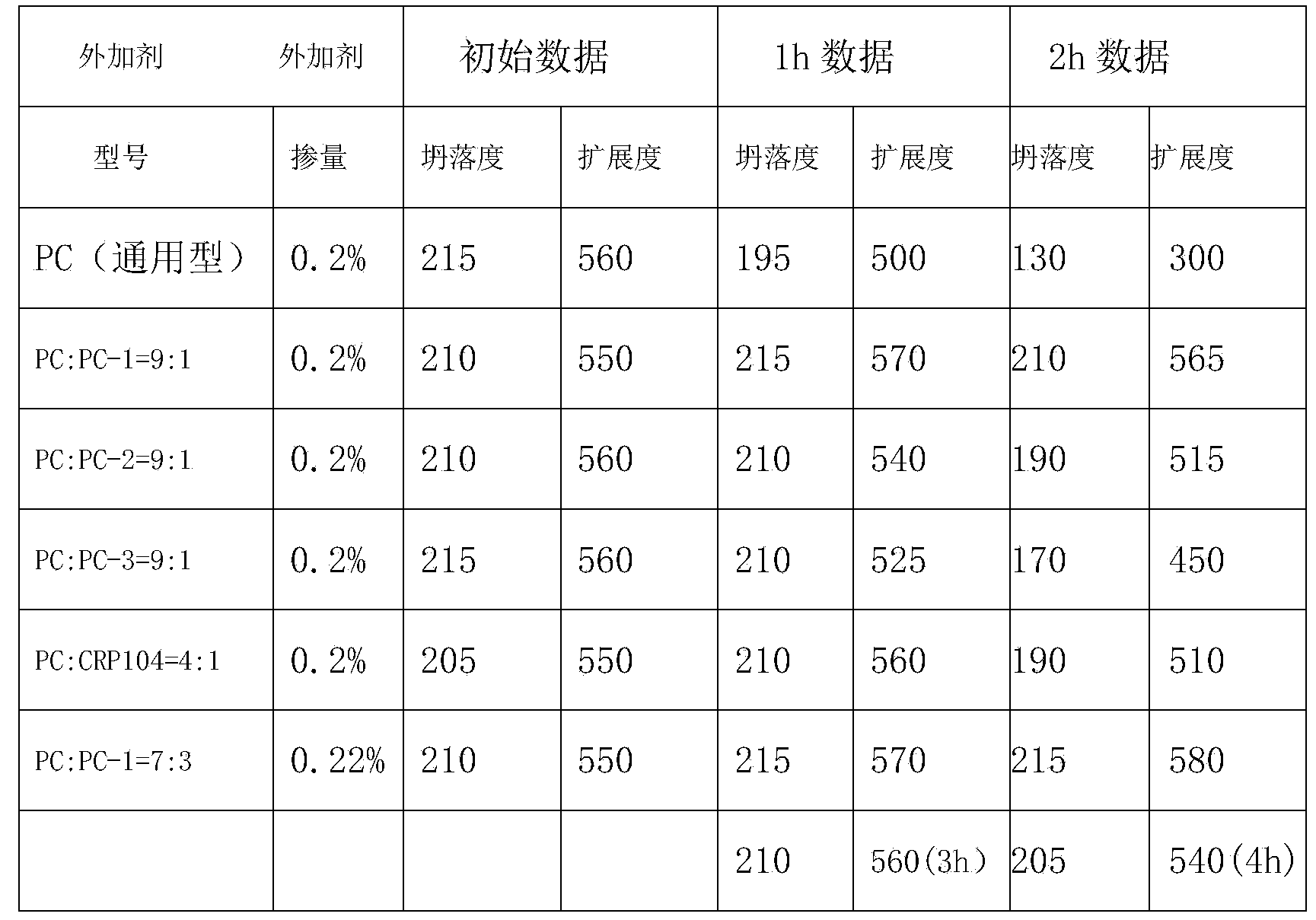

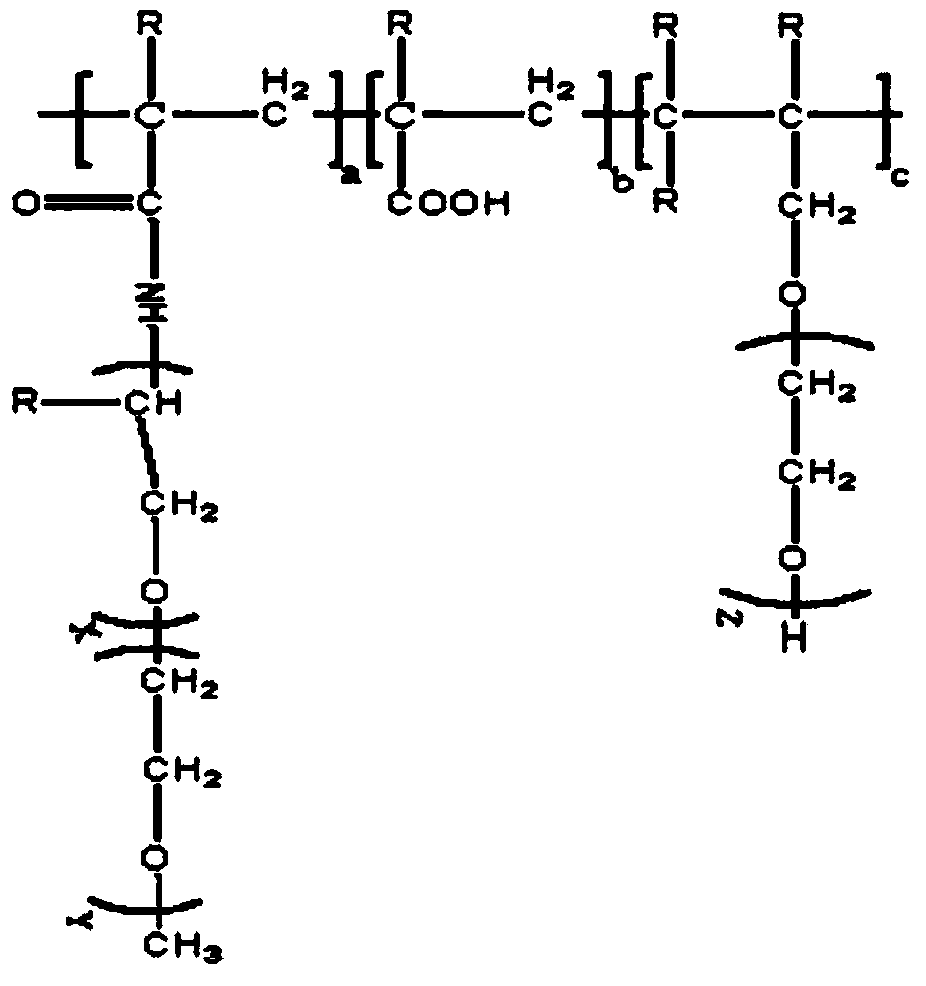

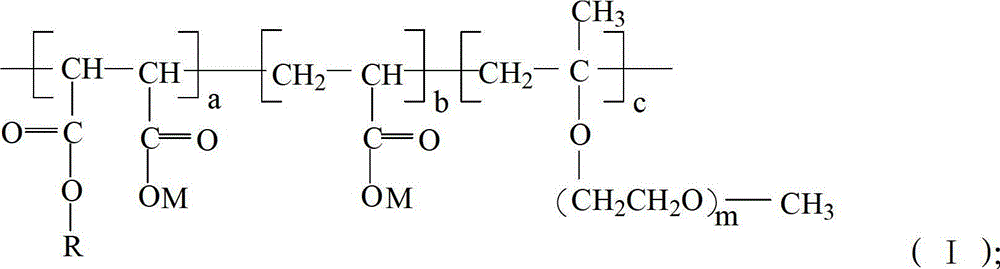

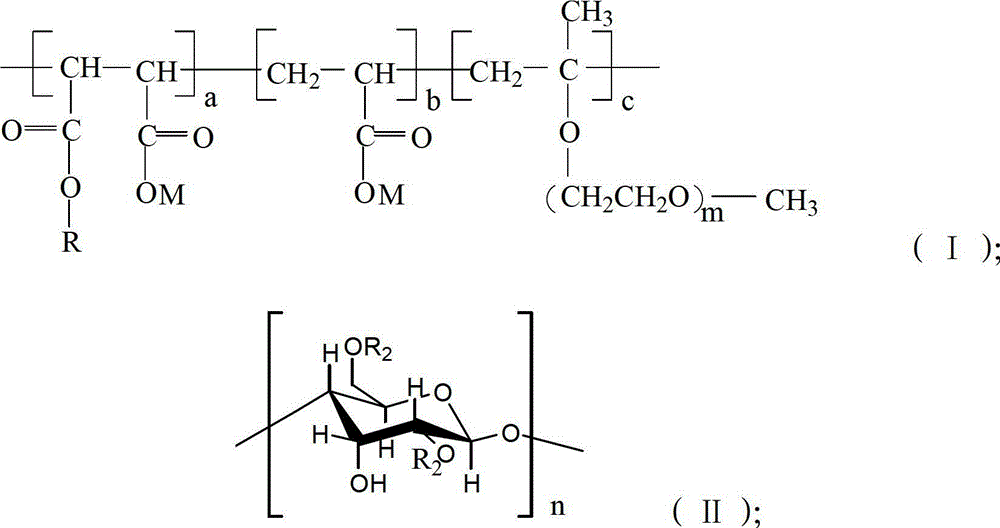

Polyether-amide type polycarboxylic high-efficiency water reducer and preparation method thereof

The invention belongs to the technical field of concrete additives, and discloses a polyether-amide type polycarboxylic high-efficiency water reducer and a preparation method thereof. The polyether-amide type polycarboxylic high-efficiency water reducer adopts the following structure, wherein R is H or CH3, x=5-15, y=20-50, z=8-16, a=20-150, b=30-1200, and c=10-150. The preparation method of the polyether-amide type polycarboxylic high-efficiency water reducer comprises the following steps of: firstly reacting polyetheramine and acyl chloride monomer to obtain a polyether amine monomer; then adding a polyoxyethylene ether monomer and a carboxyl monomer to carry out radical copolymerization in a water solution under the condition of an initiating agent and a chain transfer agent so as to obtain the polyether-amide type polycarboxylic high-efficiency water reducer with good dispersibility and slump retaining property. The preparation method disclosed by the invention is simple, low in raw material cost and outstanding in economic benefit and environmental benefit without using an organic solvent.

Owner:海南中科翔新材料科技有限公司

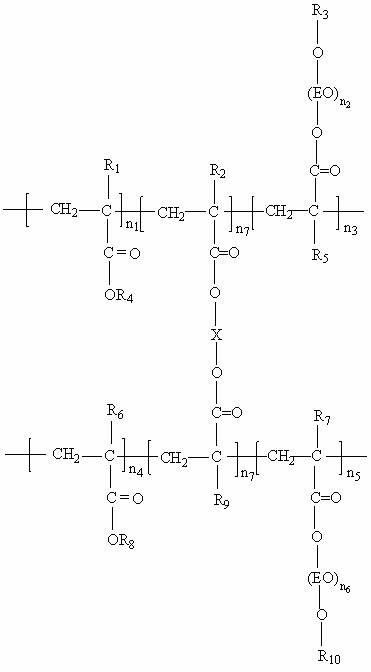

Concrete polycarboxylate water reducer and preparation method thereof

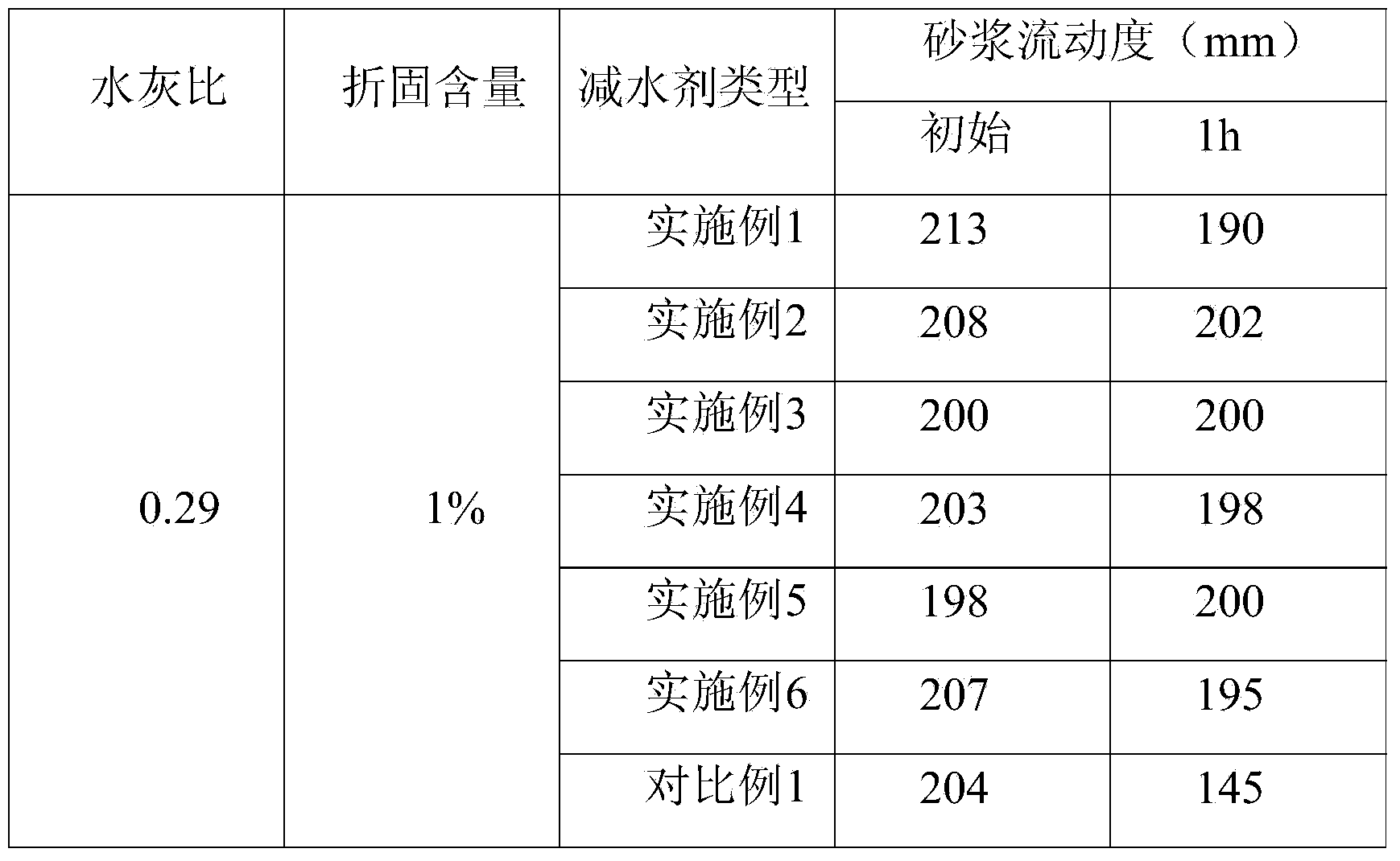

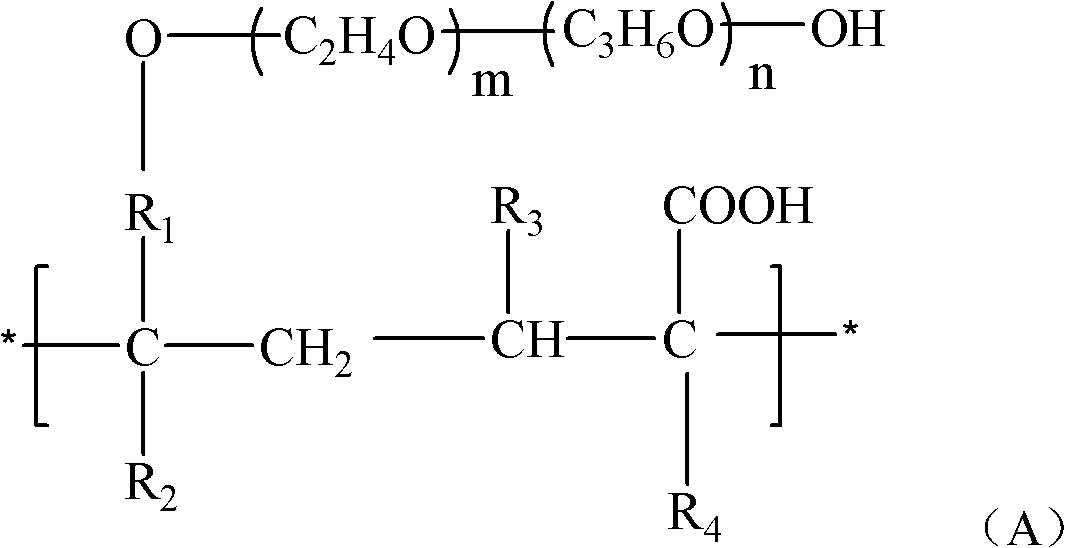

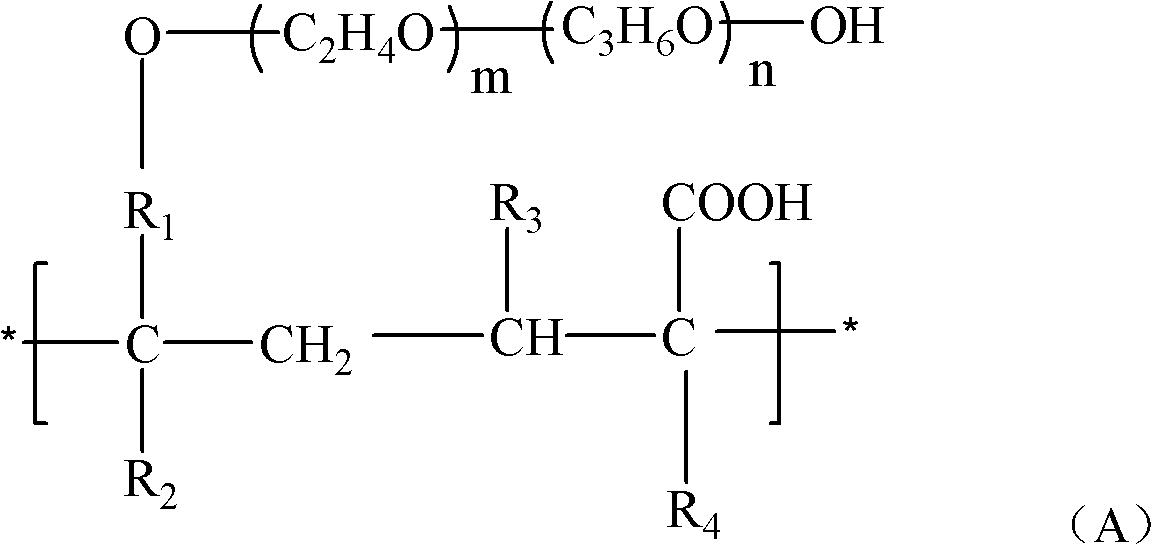

The invention provides a concrete polycarboxylate water reducer, which is shown in the formula (A), wherein R1 is alkyl having 1 to 10 carbon atoms, R2 is alkyl having 1 to 10 hydrogen or carbon atoms, R3 is H or COOH, and R4 is H or CH3. The water reducer has stable performance and high water-reducing rate and slump retention. The invention also provides a preparation method of the water reducer, which has the advantages of simple process, convenience for operation, environmental friendliness, low energy consumption and the like.

Owner:LIAONING OXIRANCHEM INC +3

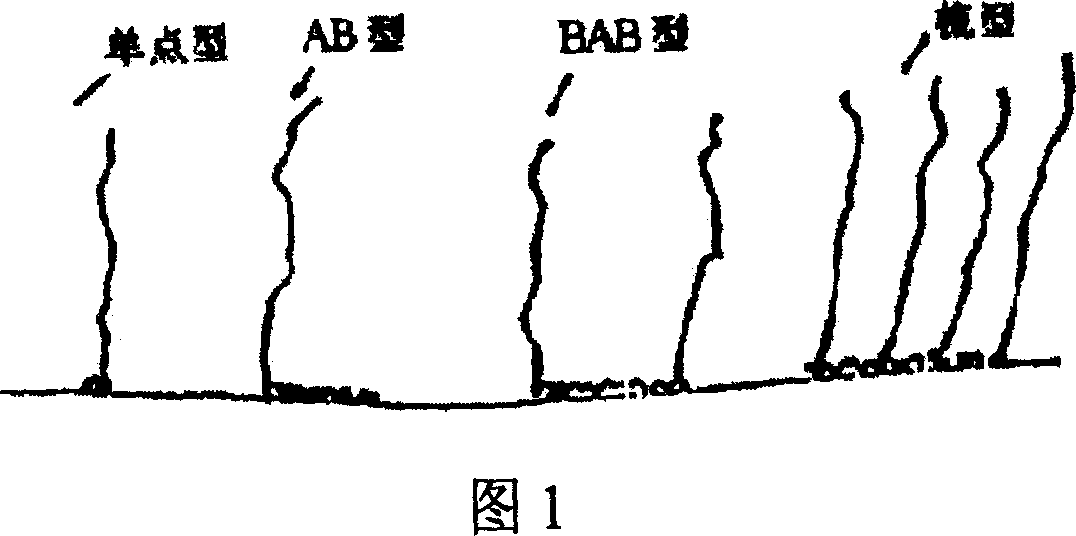

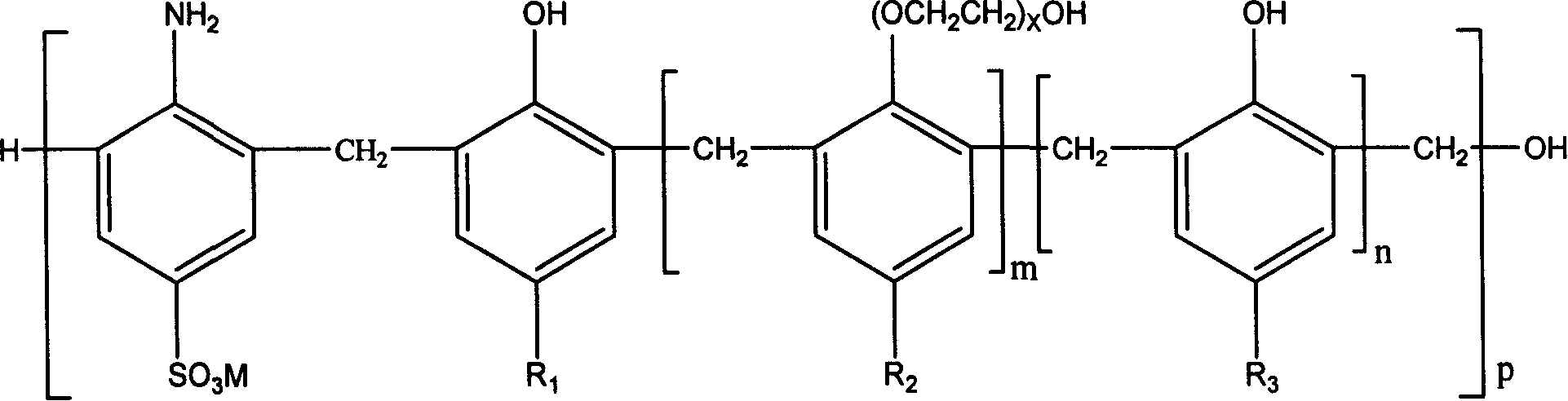

High performance water reducing agent in new type comb shaped molecular structure

This invention relates to a method for preparing high-performance aminosulfonic acid-series water reducer with polyether-grafted comb-like molecular structure for cement. The high-performance aminosulfonic acid-series water reducer is prepared from: p-aminobenzenesulfonic acid 100 parts, NaOH 115-140 parts, phenol 10-100 parts, modified polyether 0-90 parts, formaldehyde 300-600 parts, and water 3000-10000 parts. The method comprises: dissolving p-aminobenzenesulfonic acid, NaOH, phenol and modified polyether in water at 5-50 deg.C, heating to 50-120 deg.C, dropping formaldehyde, and keeping the temperature for 1-9 h. The high-performance aminosulfonic acid-series water reducer can effectively inhibit the collapse loss of concrete. The high-performance aminosulfonic acid-series water reducer has high workability, and water cannot infiltrate into concrete containing it.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

Slushing agent for concrete and preparation method thereof

The invention provides a preparation method of a slushing agent for concrete. The preparation method comprises the following steps in sequence: implementing the first reaction between maleic anhydride and hydroxypropyl methyl cellulose in glacial acetic acid under the catalysis of acetate, so as to obtain the hydroxypropyl methyl cellulose monomaleate; and carrying out free radical polymerization between methyl allyl polyoxyethylene ether, acrylic acid solution and hydroxypropyl methyl cellulose monomaleate under an oxidentive-reductive initiation system, so as to obtain the slushing agent for concrete. According to the slushing agent for concrete, prepared by the preparation method provided by the invention, the molecular structure contains the hydroxypropyl methyl cellulose molecular structure unit, so that the macromolecules of the slushing agent can be entangled with each other to form a net-shaped structure to wrap cement and water for effectively preventing the moisture in the mortar from evaporating, and as a result, the slump keeping property is good. The invention also provides the slushing agent for concrete, and the slushing agent for concrete has the structure as shown in formula (1).

Owner:SHANDONG HONGYI TECH

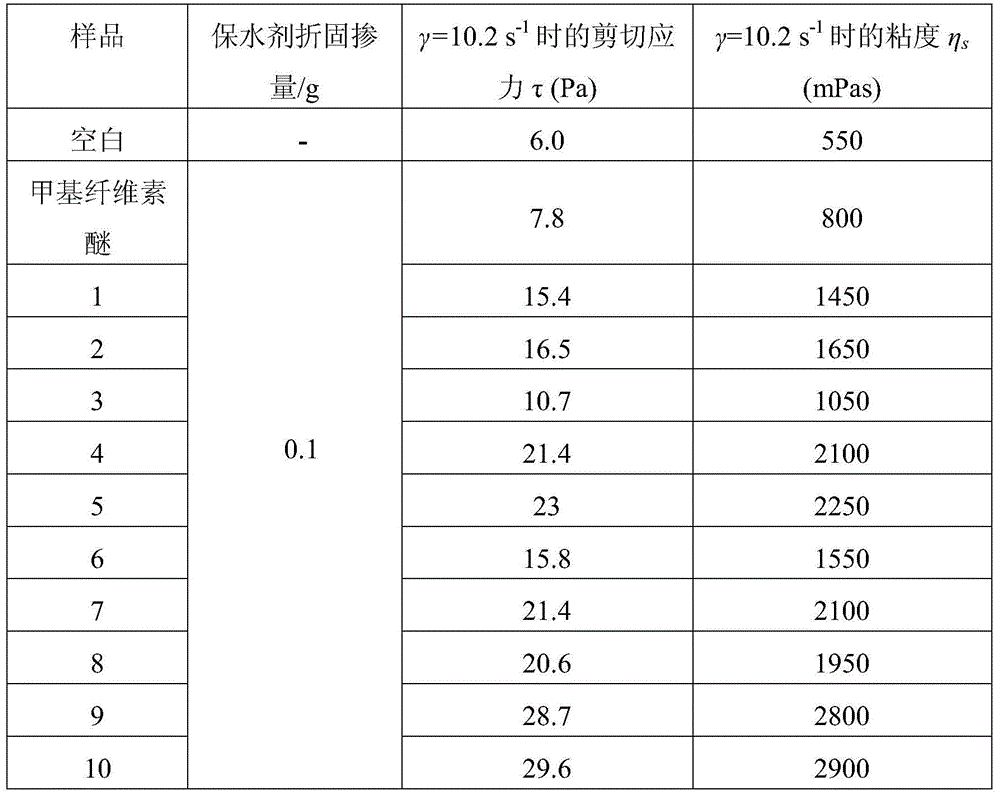

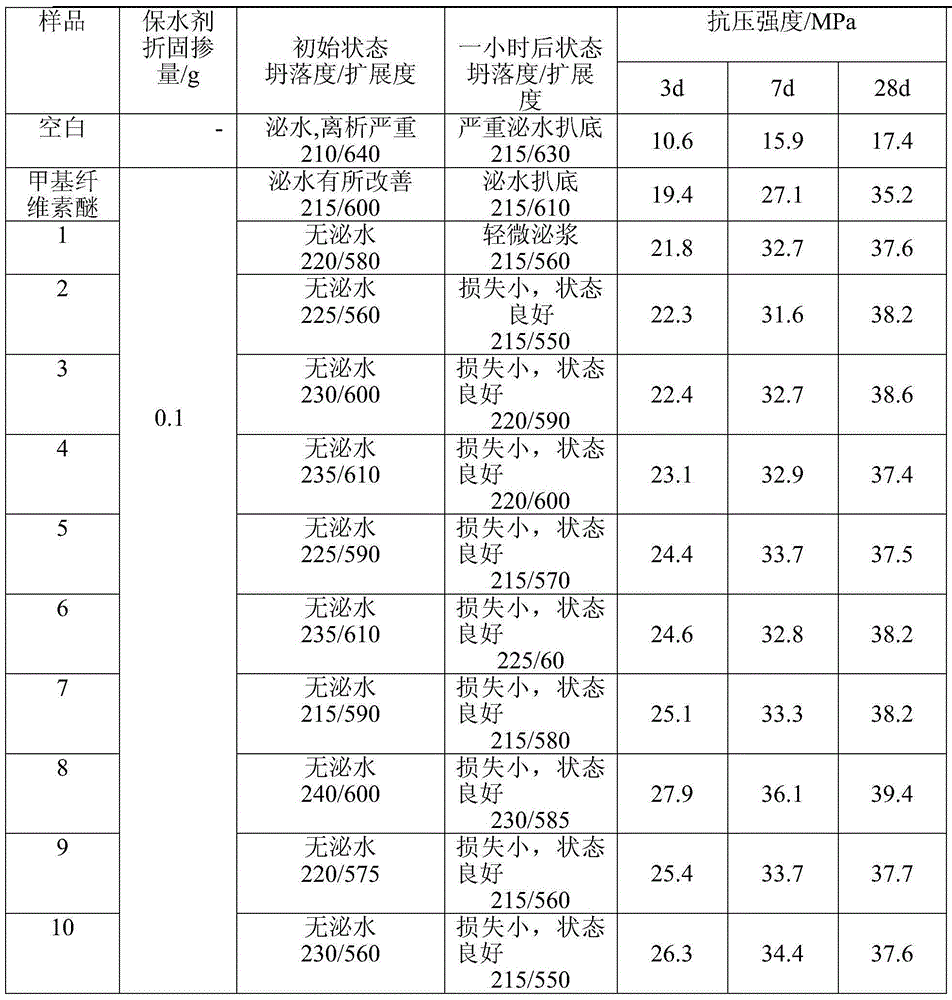

Preparation method of water retaining agent

InactiveCN104628968AAddressing Adaptive IssuesSolve the problem of adaptability, especially the large mud content of sand and gravelAcid waterOrganic solvent

The invention discloses a preparation method of a water retaining agent. The preparation method comprises the following steps: carrying out an aqueous phase radical polymerization reaction on unsaturated amide micro-monomers, unsaturated sulphonic acid micro-monomers and unsaturated polyether macromers or unsaturated ester macromonomers under the coaction of an oxidation-reduction system composed of an initiator and a reducing agent to obtain a copolymerization product, regulating the pH value to 6-7 after the reaction, and adding water to obtain the water retaining agent with mass concentration of 1-60%. The preparation method disclosed by the invention is used for adjusting the product properties by controlling the monomer proportion, the temperature and the dosage of the initiator and the reducing agent, the reaction speed is high, the efficiency is high, no organic solvent is used, no toxin or pollution is generated, and the operation is simple. The unsaturated macromonomers are introduced into the prepared concrete / mortar water retaining agent to ensure excellent water retaining property and obviously perfect such stirring states of the concrete / mortar as bleeding / separation and the like without generating such adverse effects as strength and the like, meanwhile, the water retaining agent can be compounded with a polycarboxylic acid water reducing agent at any proportion to ensure good intermiscibility. The product performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and preparation method and application thereof

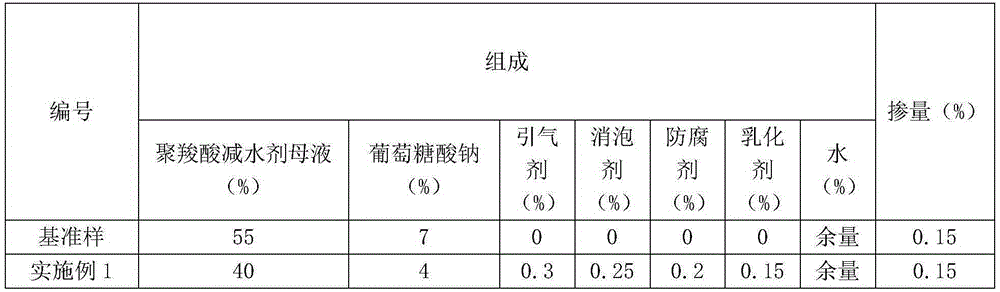

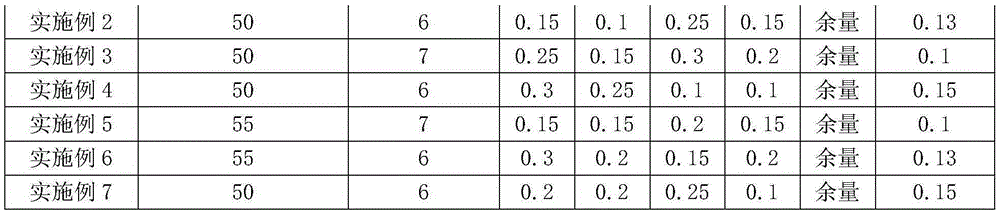

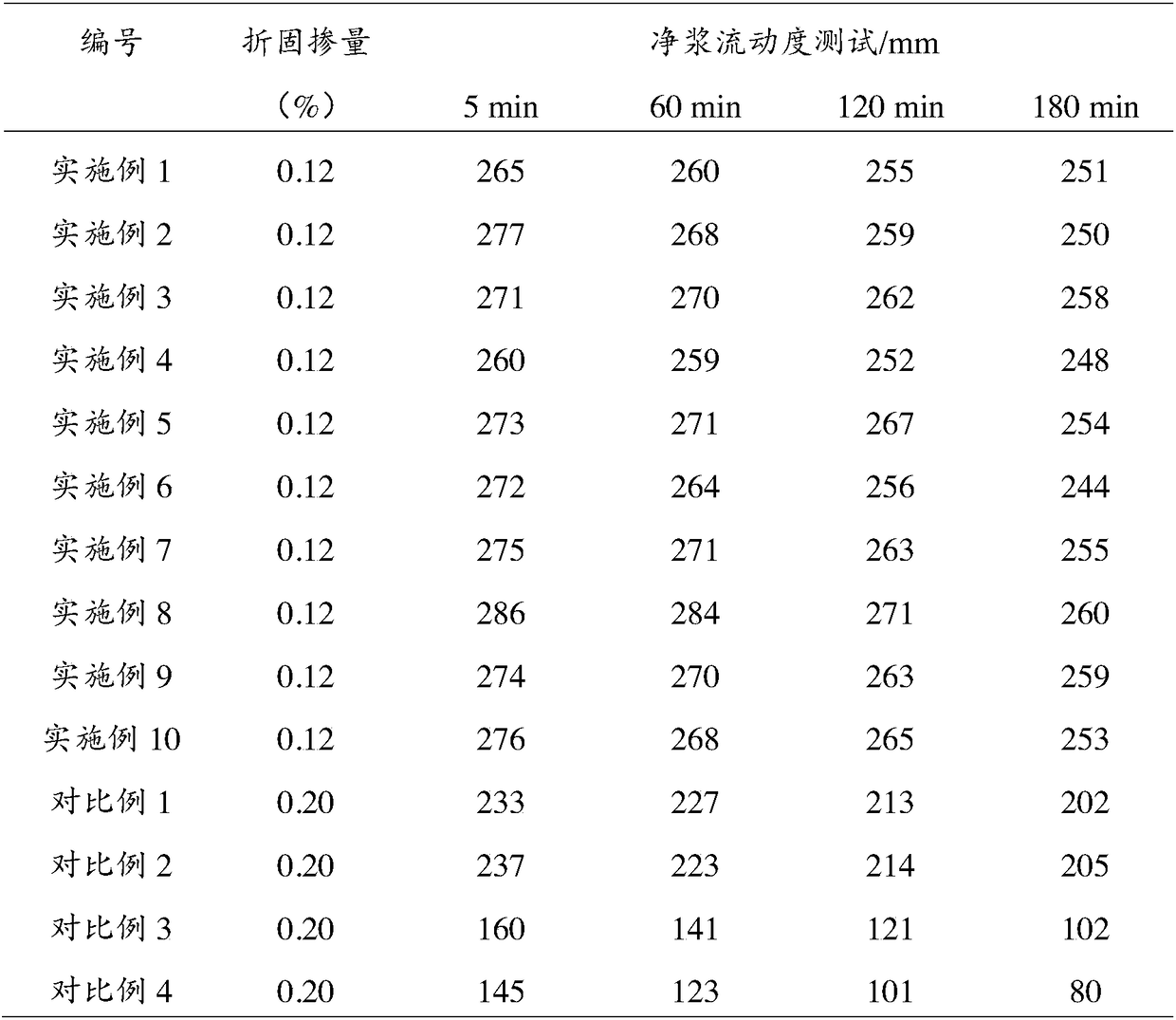

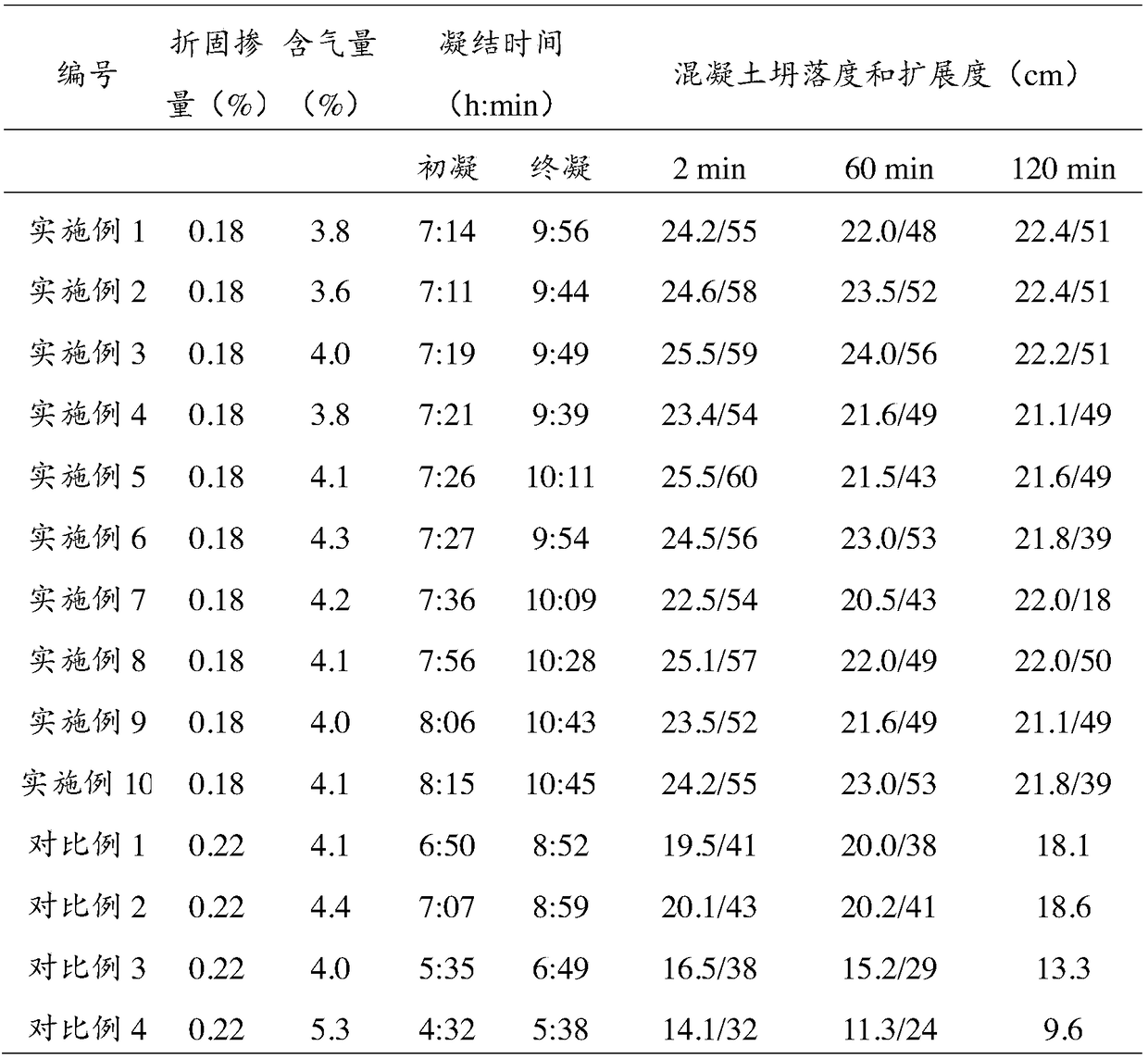

The invention relates to an anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and a preparation method and application thereof. The composite polycarboxylate superplasticizer comprises, by mass, 40 to 55% of mother liquor of a polycarboxylate superplasticizer, 4 to 7% of sodium gluconate, 0.15 to 0.3% of an air entraining agent, 0.1 to 0.25% of an antifoaming agent, 0.05 to 0.2% of an emulsifying agent and 0.1 to 0.3% of an anticorrosive bactericide, with the balance being water, wherein the mass percents of every component sum to 100%. The composite polycarboxylate superplasticizer is prepared by placing the mother liquor of the polycarboxylate superplasticizer, sodium gluconate, the air entraining agent, the antifoaming agent, the anticorrosive bactericide and the water in a container together according to the above-mentioned mass percents under the conditions of normal temperature and normal pressure and carrying out uniform mixing under stirring. In use, the composite polycarboxylate superplasticizer is added into a concrete cementing material according to a mass ratio of the composite polycarboxylate superplasticizer to the concrete cementing material of 0.1-0.15: 100. Compared with the prior art, the composite polycarboxylate superplasticizer provided by the invention has the advantages of convenience in usage, stable performance, no phenomena of mildew, smelliness and layering due to long-term storage, capacity of introducing small bubbles when used in fresh mixed concrete, and excellent water-reducing and slump-retaining performances.

Owner:TONGJI UNIV

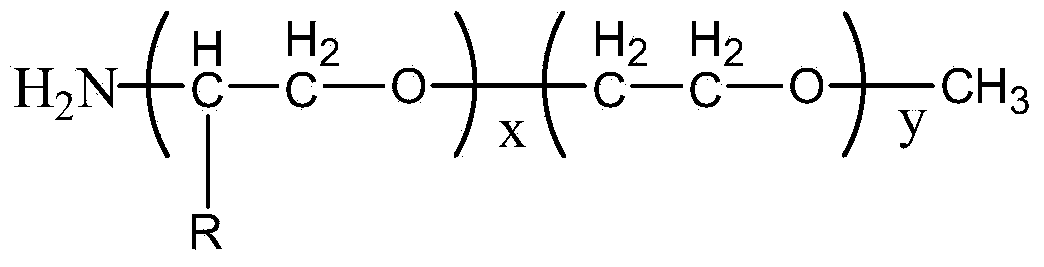

Preparation method and use of micromolecule water reducer with delayed coagulation and slump retaining properties

ActiveCN108239279AImprove adsorption capacityImprove environmental adaptabilityPhosphorous acidMannich reaction

The invention provides a preparation method and use of a micromolecule water reducer with delayed coagulation and slump retaining properties. The preparation method has the beneficial effects that a preparation method is strong in adjustability and high in cost performance, a preparation process is simple, the prepared micromolecule water reducer has excellent slump retaining property, delayed coagulation property and clay tolerance. The preparation method comprises the following steps: (1) carrying out amination reaction: carrying out C=C double bond Michael addition reaction by virtue of organic amine with a specific structure and unsaturated carboxylate with a specific structure, and purifying, so as to obtain an organic amine intermediate with an amino hydrogen and carboxylic ester group structure; (2) carrying out Mannich reaction by virtue of the organic amine intermediate, formaldehyde and phosphorous acid, and purifying, so as to obtain phosphorylated organic amine intermediate; and (3) carrying out condensation reaction by virtue of carboxyl of the phosphorylated organic amine intermediate and polyether with a specific structure and a terminal OH or a terminal NH2 so as toconvert carboxyl into an ester group or acylamino, and alkalizing for neutralization so as to obtain the micromolecule water reducer with the delayed coagulation and slump retaining properties.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com