Green preparation method of slow-release polycarboxylic-acid high-performance water reducing agent

A slow-release polycarboxylate, high-performance technology, applied in the green preparation field of slow-release polycarboxylate high-performance water reducer, polycarboxylate high-performance water reducer, can solve the problem of concrete slump maintenance Insufficient performance, can not meet the requirements of simple production, can not meet the high water reducing rate and requirements, etc., to achieve the effect of good slump retention performance, simplified production equipment, and reduced energy consumption costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

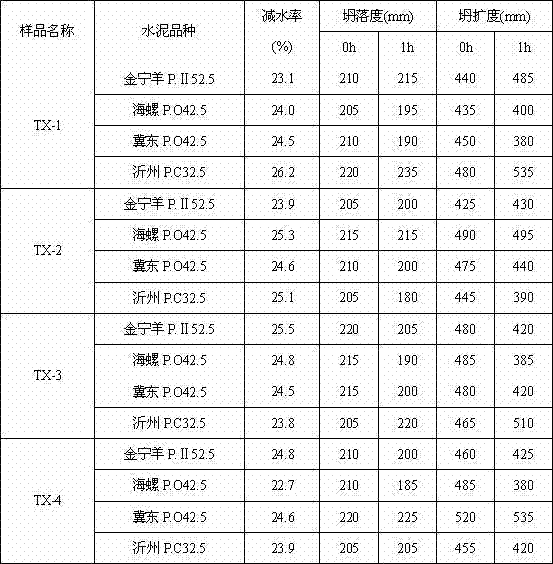

Embodiment 1

[0037] Add 300 parts of methoxypolyethylene glycol allyl-terminated polyether and 240 parts of water into the reaction kettle, and keep stirring to make them all dissolve in water; then add 1.6 parts of hydrogen peroxide and stir for half an hour. Take 0.6 parts of mercaptopropionic acid and 0.9 parts of sodium sulfite, dissolve them in 190 parts of water, and add them dropwise (1); take 45 parts of methacrylic acid and dissolve them in 170 parts of water, and add them dropwise (2); within 3~4 hours, At the same time, add it dropwise into the reactor evenly, and ensure that the dropwise addition (1) is completed half an hour later than the dropwise addition (2). The temperature will rise slightly during this period, so it can be controlled not to exceed 40°C. Continue to stir for 1 hour after the addition, add 50 parts of 30% liquid caustic soda, and continue to stir for 30 minutes to obtain the product (TX-1).

Embodiment 2

[0039] Add 315 parts of methoxypolyethylene glycol allyl-terminated polyether and 240 parts of water into the reaction kettle, and keep stirring to dissolve them in water; then add 2.1 parts of iron sulfate and stir for half an hour. Take 0.6 parts of thioglycolic acid and 0.9 parts of sodium ascorbate, dissolve them in 188 parts of water, and add them dropwise (1); take 42 parts of acrylic acid and dissolve them in 175 parts of water, and add them dropwise (2); Add dropwise to the reactor, and make sure that the dropwise addition (1) is completed half an hour later than the dropwise addition (2). The temperature will rise slightly during this period, so it can be controlled not to exceed 40°C. After the addition, continue to stir for 1 hour, add 36 parts of ethanolamine, and continue to stir for 30 minutes to obtain the product (TX-2).

Embodiment 3

[0041]Add 380 parts of methoxypolyethylene glycol allyl-terminated polyether and 215 parts of water into the reaction kettle, and keep stirring to make them all dissolve in water; then add 1.6 parts of hydrogen peroxide and stir for half an hour. Take 0.6 parts of mercaptoethanol and 1.2 parts of sodium hypophosphite, dissolve them in 180 parts of water, and add them dropwise (1); take 38 parts of acrylic acid, dissolve them in 130 parts of water, and add them dropwise (2); within 3~4 hours, simultaneously Add it dropwise to the reactor evenly, and make sure that the dropwise addition (1) is completed half an hour later than the dropwise addition (2). The temperature will rise slightly during this period, so it can be controlled not to exceed 40°C. Continue to stir for 1 hour after the addition, add 50 parts of 30% liquid caustic soda, and continue to stir for 30 minutes to obtain the product (TX-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com