Patents

Literature

135results about How to "Adjust intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

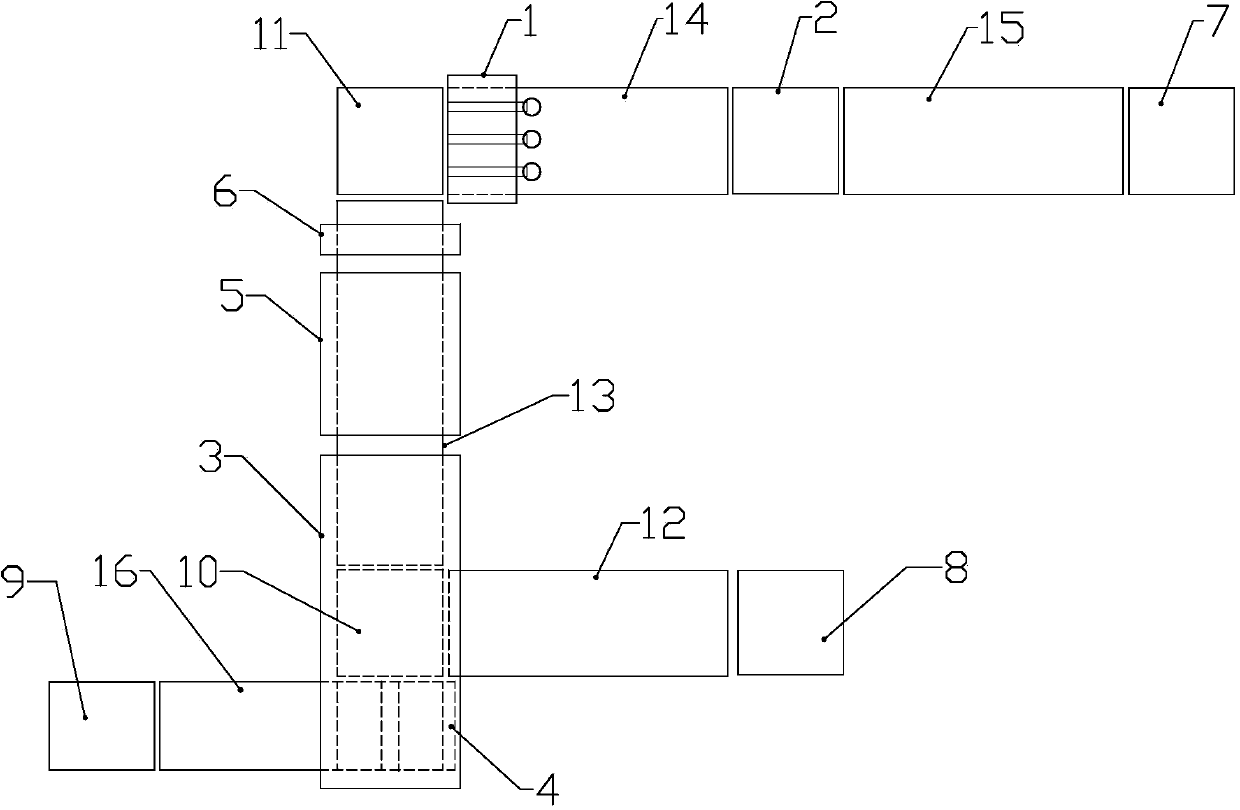

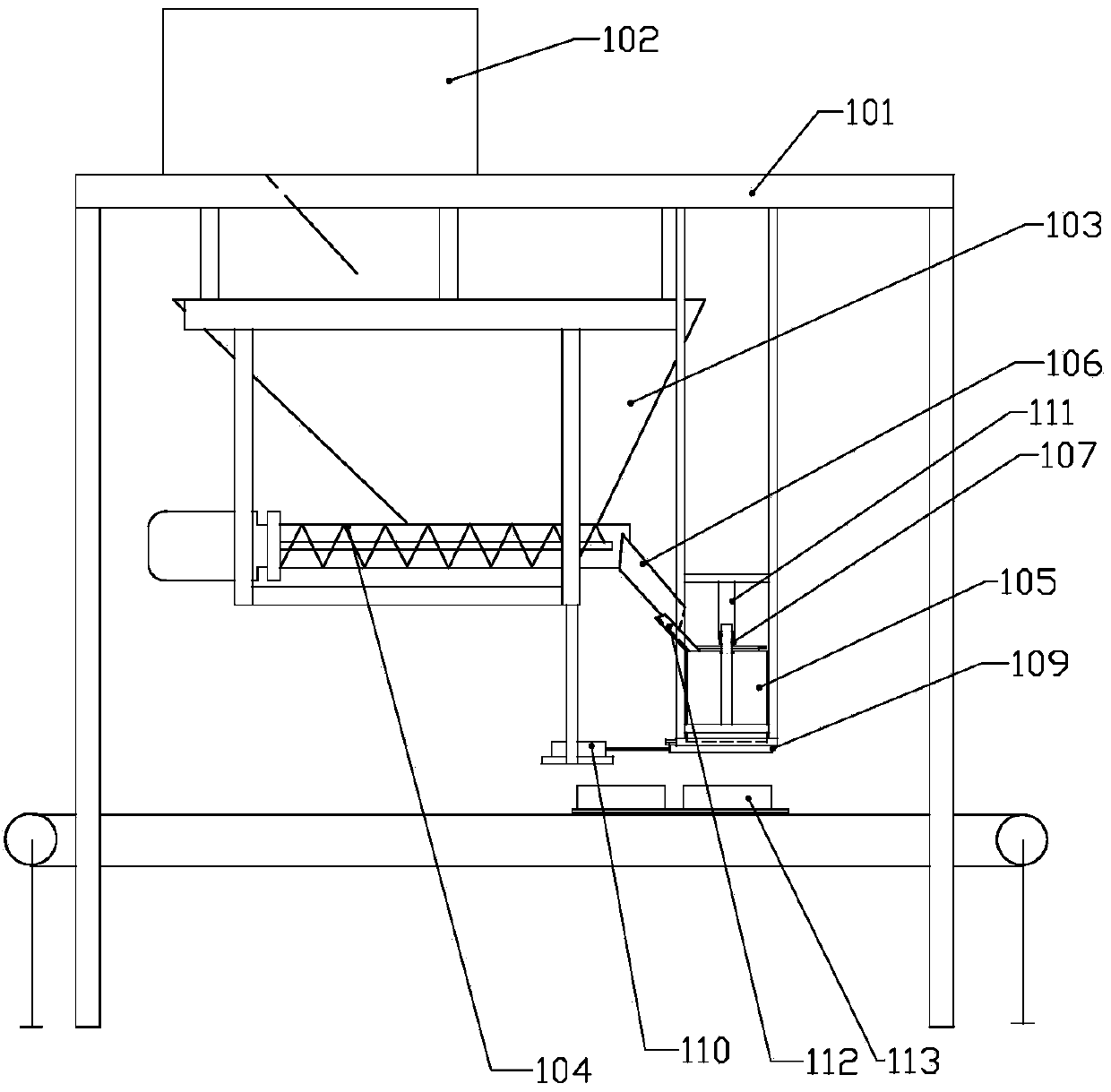

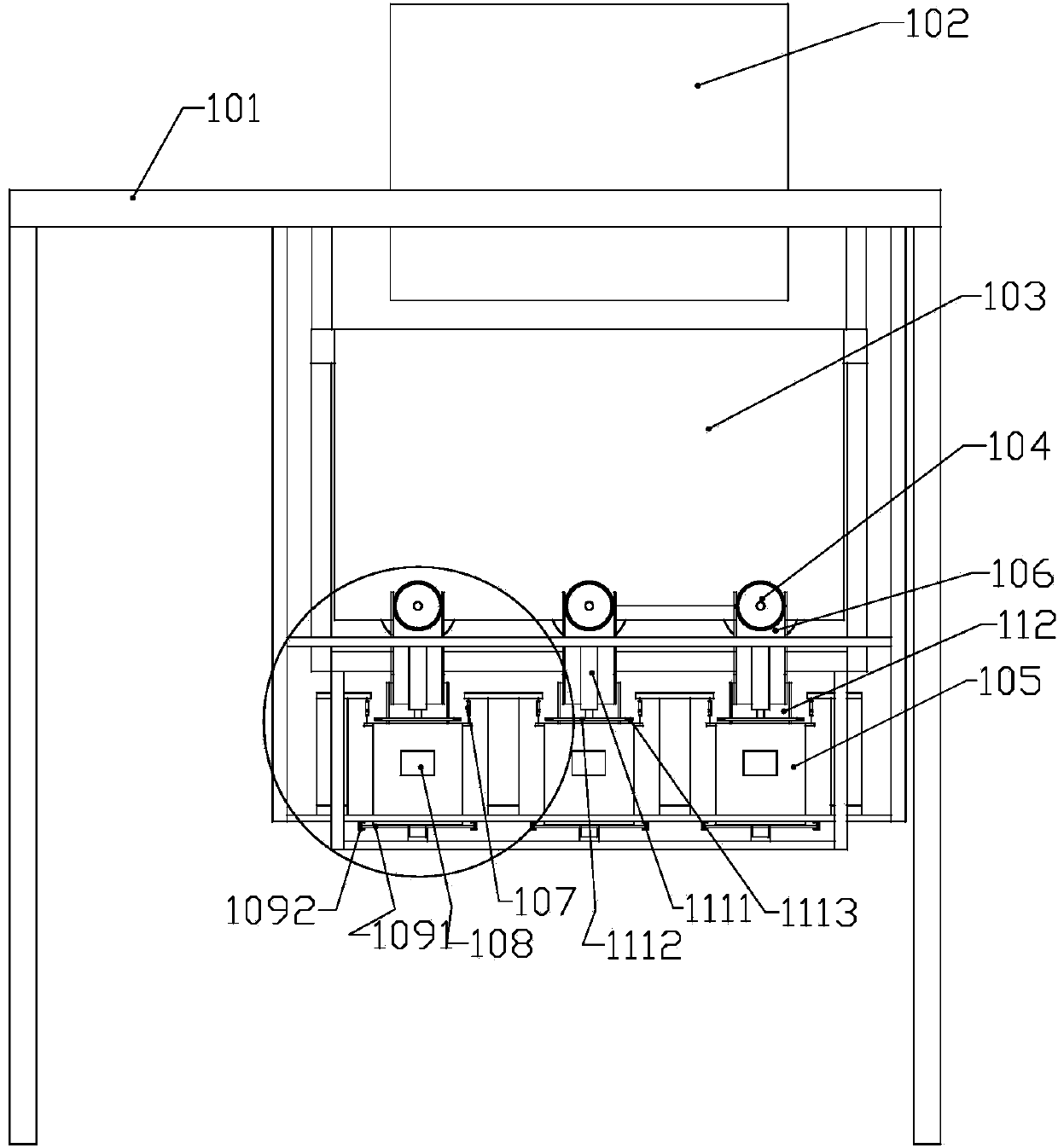

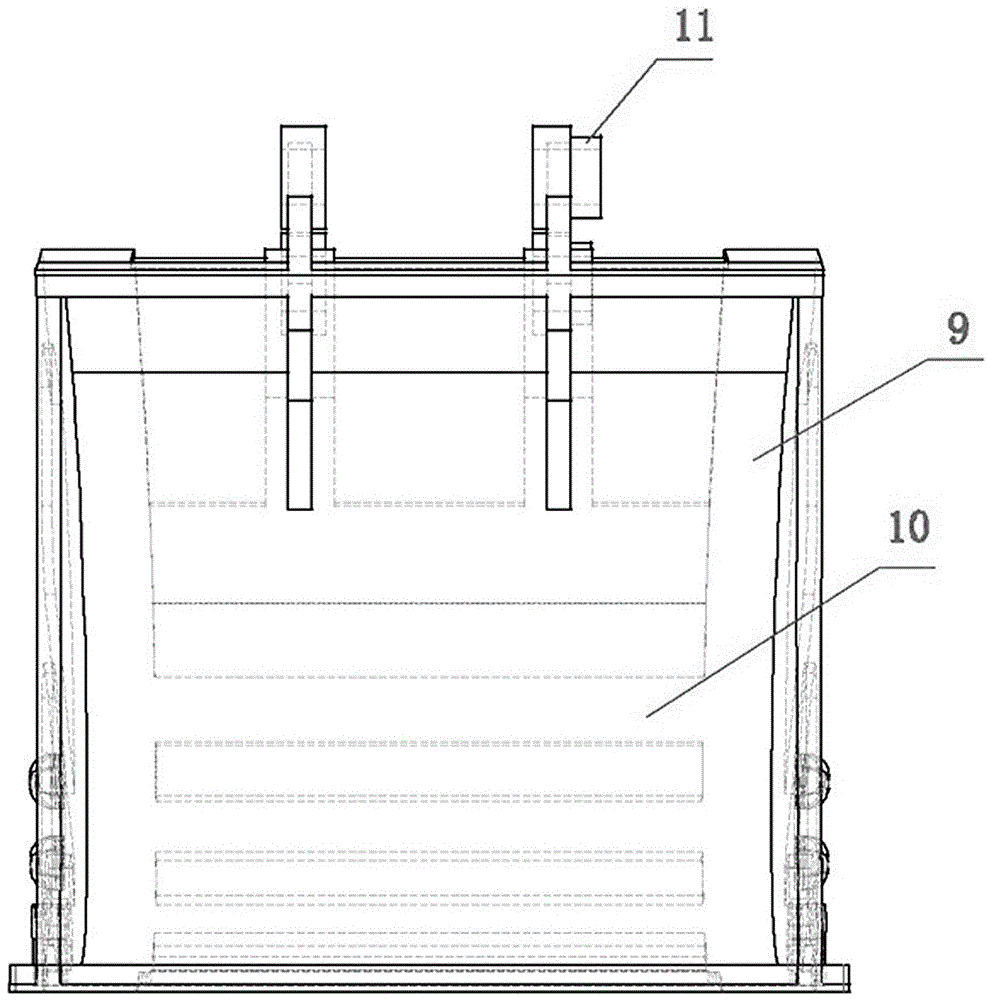

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

Dry powder of active powder concrete and use method of dry powder

The invention relates to dry powder of active powder concrete and a use method of the dry powder. The dry powder comprises the following components by weight percent: 25%-55% of concrete, 5%-20% of blending stock, 30%-60% of fine aggregate, 5%-20% of micro powder, 2-5% of super plasticizing agent powder, 1-3% of air entraining agent powder, 0.2-1% of defoamer powder, and 0%-25% of fibers. According to the invention, through industrial production, water, of which the weight is 5%-10% of the weight of the dry powder, is added into the products on site, a conventional stirring technology and equipment are used for uniformly stirring, and a mixture meets a certain fluidity of construction performance and is used for easily preparing an active powder concrete prefabricated part or meets the requirement of cast in situ. The dry powder of active powder concrete and the use method of the dry powder have the advantages of stable and reliable quality, small air-entraining volume, excellent homogeneity and convenience in construction, can be widely applied to the engineering fields, such as petroleum, railway, nuclear power, municipal administration, ocean, military facilities and the like, and have excellent economic benefits.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

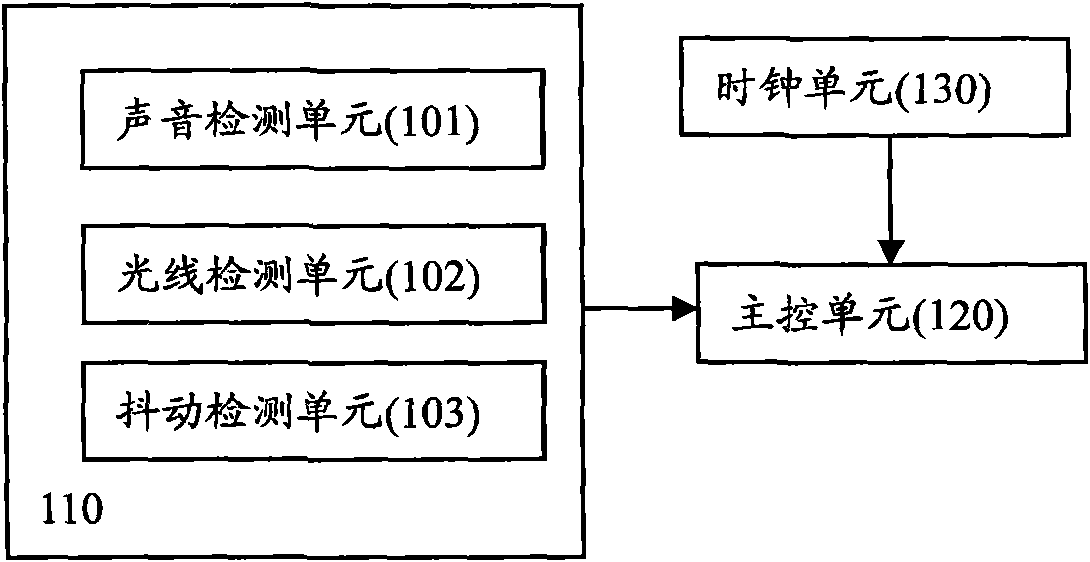

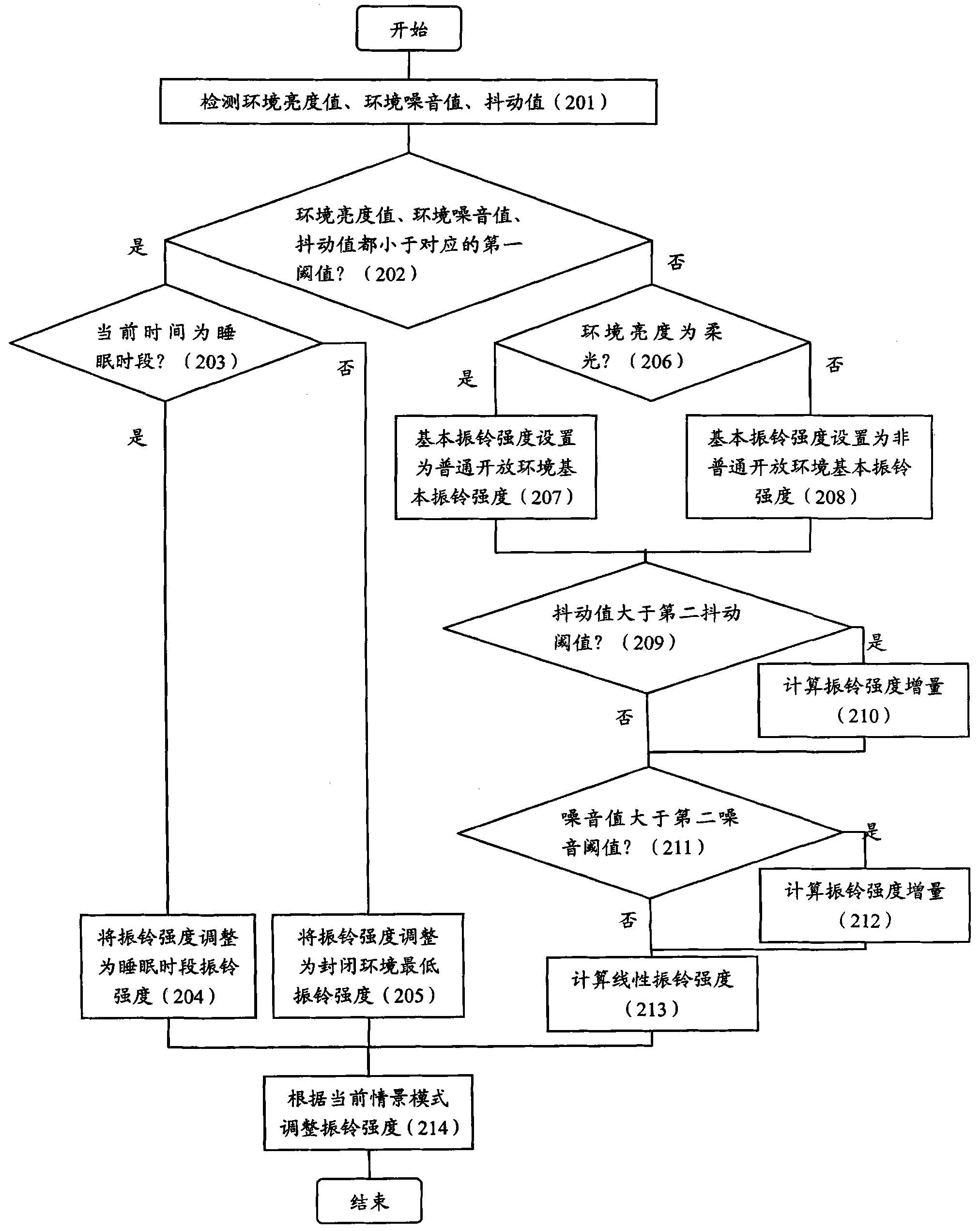

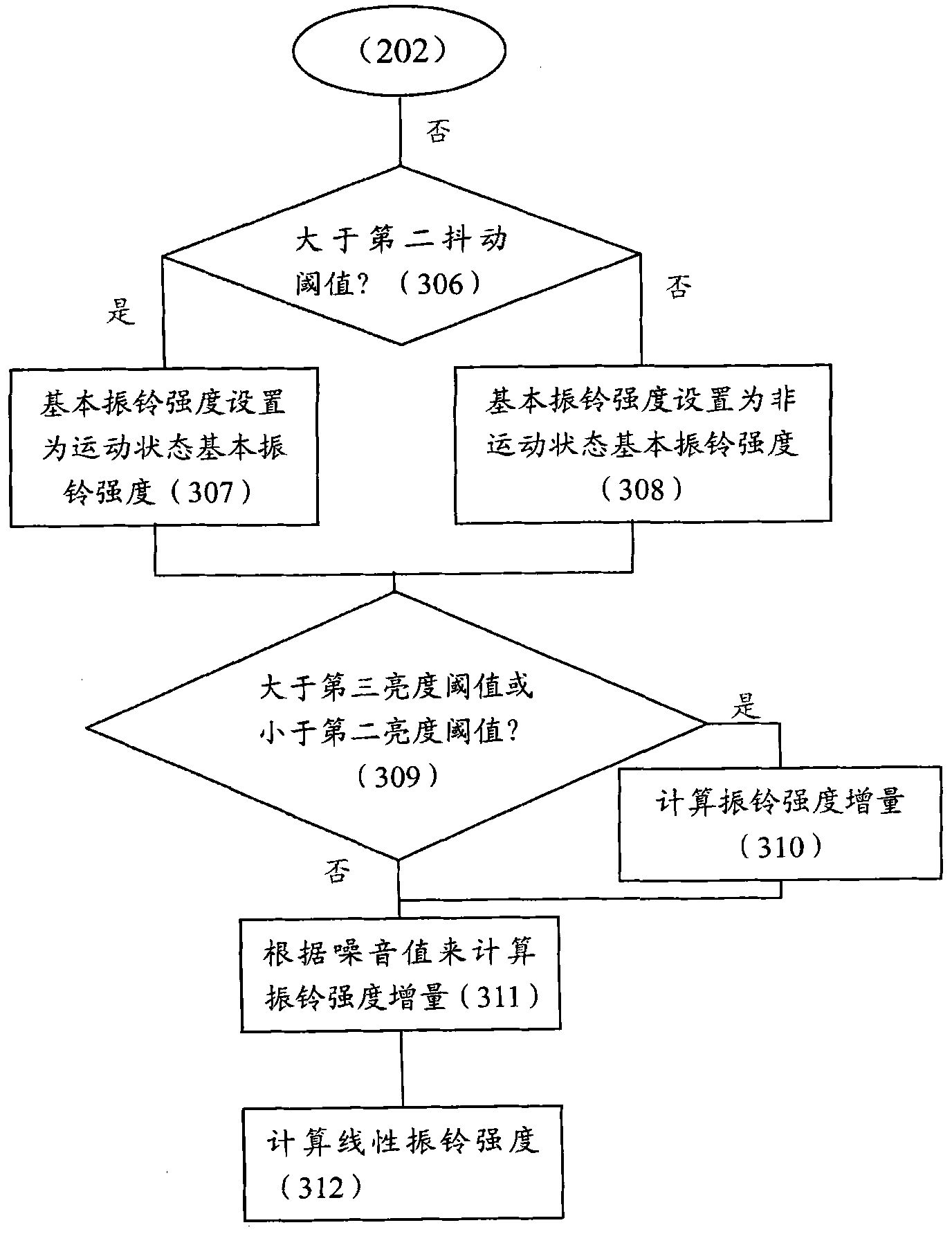

Device and method for adjusting ringing strength of portable terminal

ActiveCN102572088AAdjust the intensity of the ringingAvoid interferenceSubstation equipmentEngineeringUltimate tensile strength

The invention provides a device and a method for adjusting the ringing strength of a portable terminal. The method comprises the following steps of: detecting an environment brightness value and an environment noise value as well as a vibration degree value of the portable terminal; and adjusting the ringing strength according to the comprehensive influence of the environment brightness value, the environment noise value and the vibration degree value, wherein the ringing strength represents the vibration strength and / or the ringing volume. According to the method and the device, an environment, in which the portable terminal is positioned, can be judged precisely, and the efficiency for reminding or alarming can be improved; and interference of unnecessary reminding or alarming to a user can be avoided.

Owner:SAMSUNG GUANGZHOU MOBILE R&D CENT +1

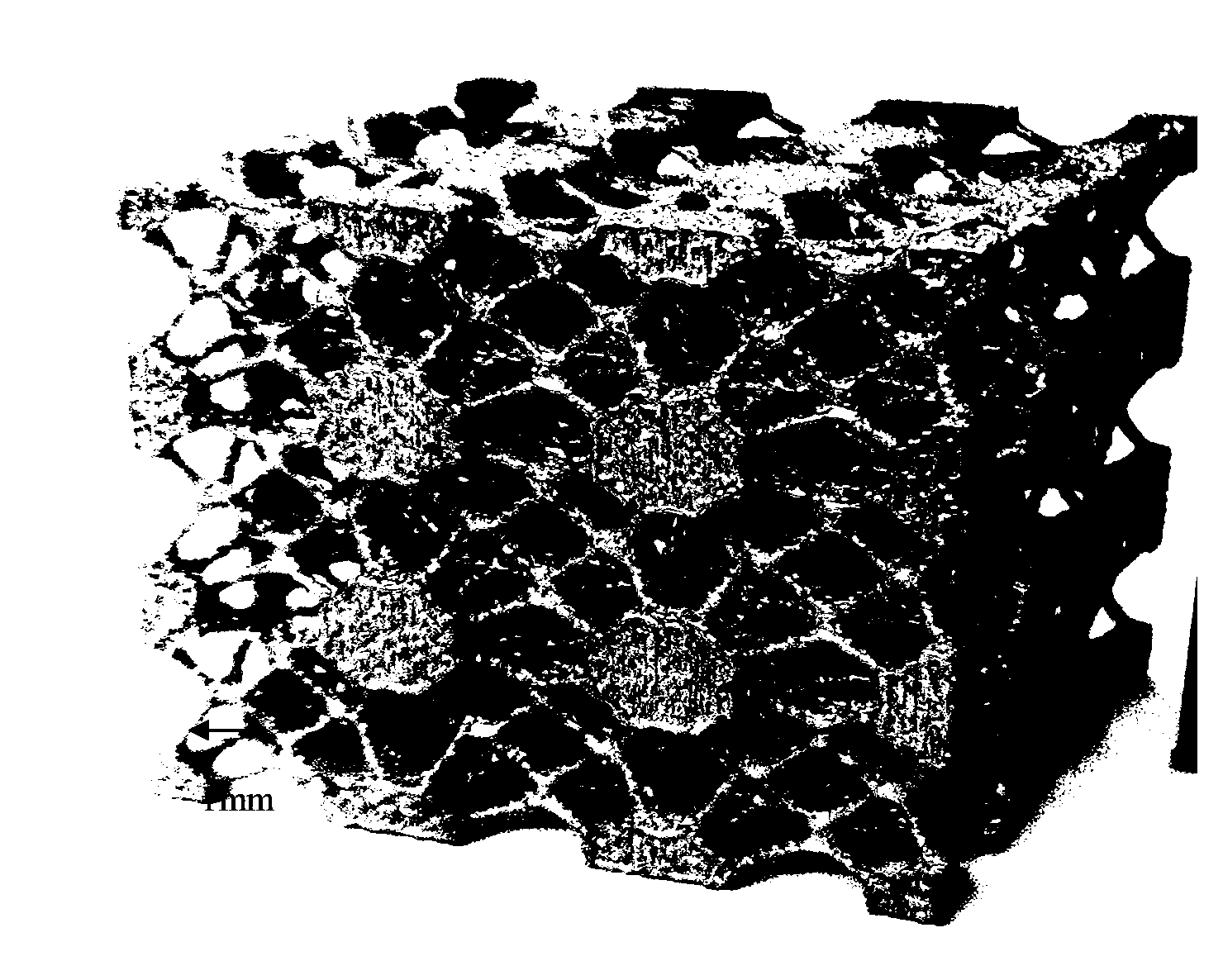

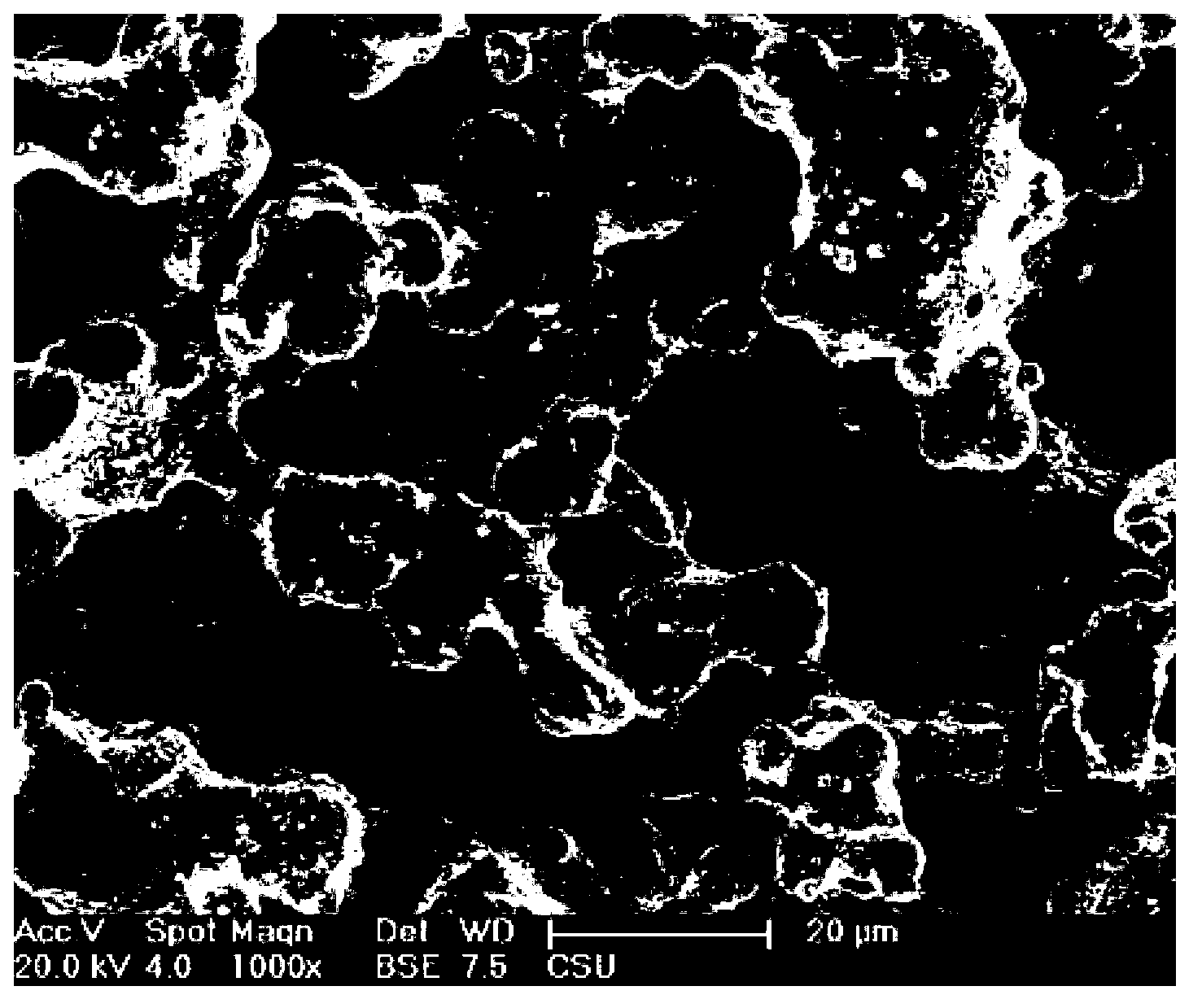

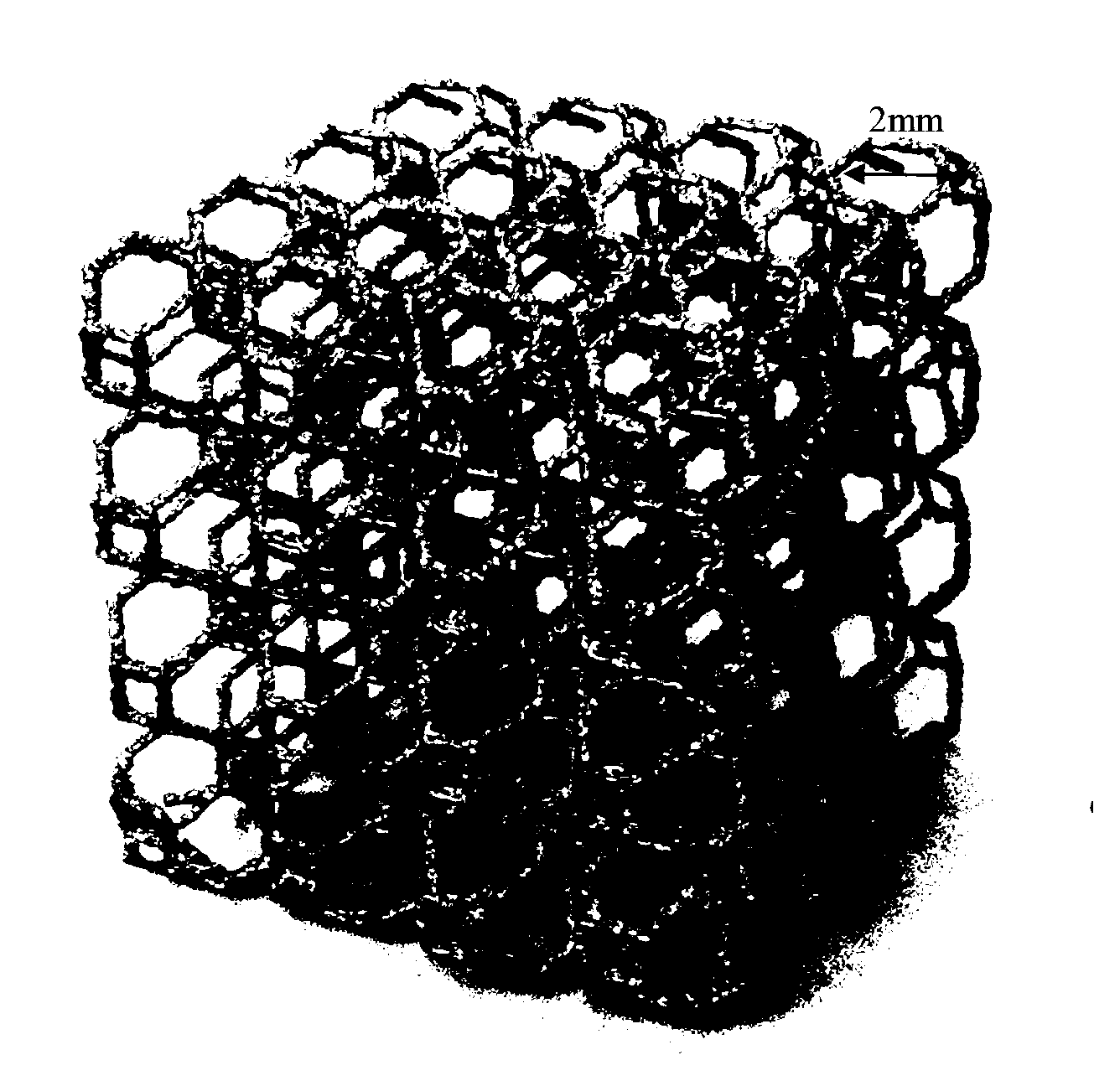

Medical multi-hole implanted alloy material and preparation method thereof

ActiveCN103074511ALow modulusGood biocompatibilityManufacturing cost reductionBiocompatibility Testing

The invention discloses a medical multi-hole implanted alloy material which is a multi-hole body made of an alloy including four elements of Ti, Ta, Nb and Zr, wherein the multi-hole body comprises a plurality of large holes with pore diameters ranging from 200 to 500 Mum; a plurality of small holes with pore diameters ranging from 5 to 30 Mum are formed in the hole wall of each large hole; and the porosity of the multi-hole body is larger than or equal to 30 percent. The medical multi-hole implanted alloy material contains no toxic element, and has lower modulus and better biocompatibility. The invention further provides a method for preparing the medical multi-hole implanted alloy material. The medical multi-hole implanted alloy material and the preparation method provided by the invention have the advantages that 1), personalized design directed towards different patients can be realized; 2), the characteristics of high speed, accuracy and goodness at manufacture of substances with complex shapes are achieved; 3), no die is required, so as to reduce manufacturing cost; 4), the porosity of the large holes and the connectivity among the large holes can be adjusted freely, so as to accelerate the ingrowth of osseous tissues and adjust the strength, the modulus and other mechanical properties of an implanted body; and 5), the formation is carried out in a vacuum environment, which facilitates utilization of active metal.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

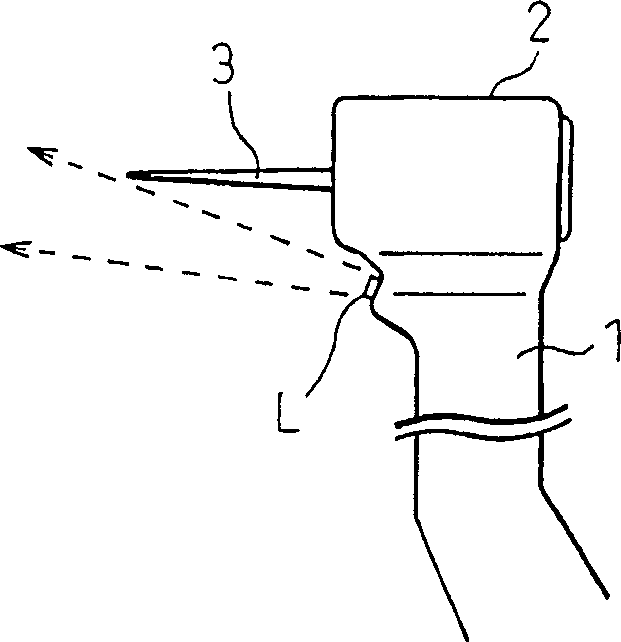

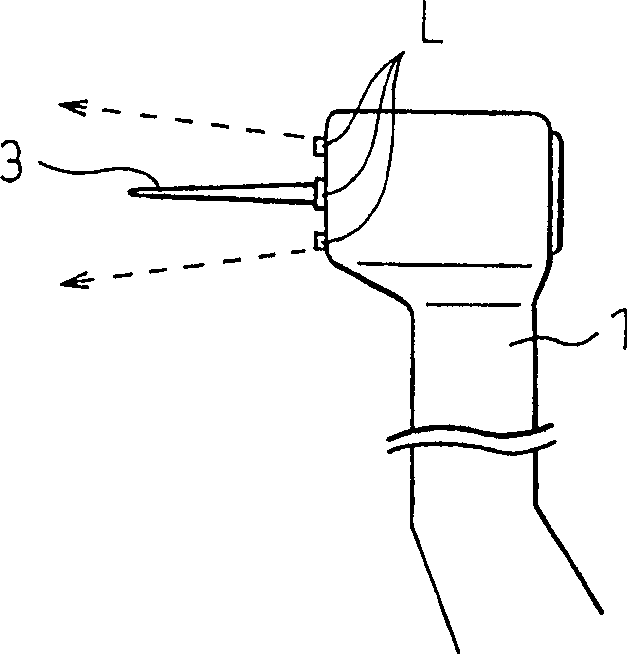

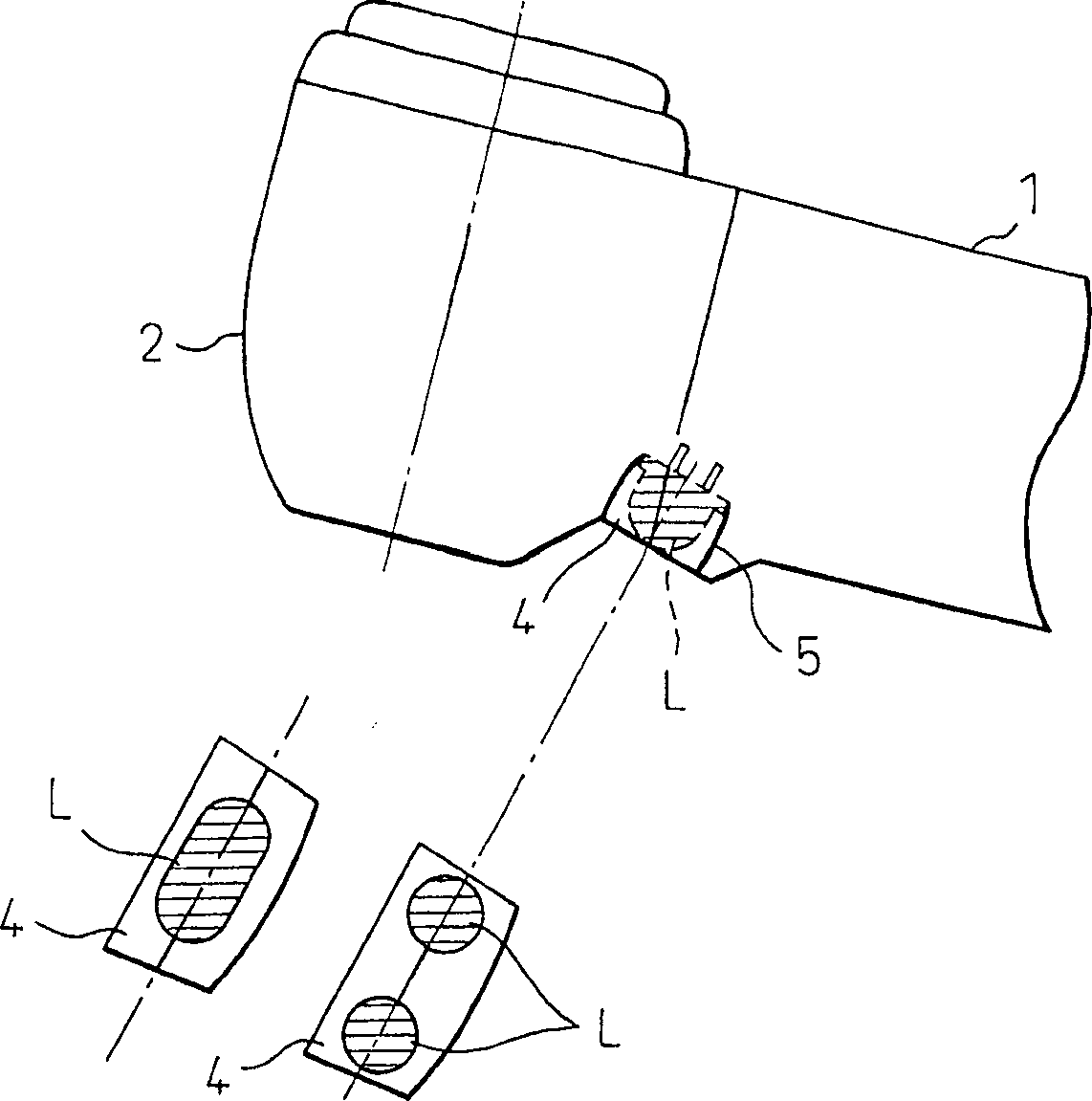

Dental diagnostic device

InactiveCN1889894AImprove operational efficiencyConvenient treatmentDiagnostic recording/measuringSensorsMedicineFluorescent light

A light irradiating means capable of specifically extracting the affected part of a tooth is provided to a treating instrument such as a hand-piece provided with a dental treating tool or the like to facilitate the treatment of the affected part. A light emitting light source able to specifically extract an affected part is provided in the vicinity of a hand-piece-head for permitting the mounting of a treating tool thereto. Light emitted from the light source irradiates a portion in front of the treating tool. Or, a light source includes a plurality of light emitting elements and is disposed at the peripheral edge of the tip end of the hand-piece-head so as to surround the treating tool to thereby irradiate a portion in front of the treating tool. When the interior of an oral cavity is irradiated with the light, the treating operator can observe it by using a filter function for its fluorescent reflection light to thereby able to confirm the affected part while treating it.

Owner:MORITA MFG CO LTD

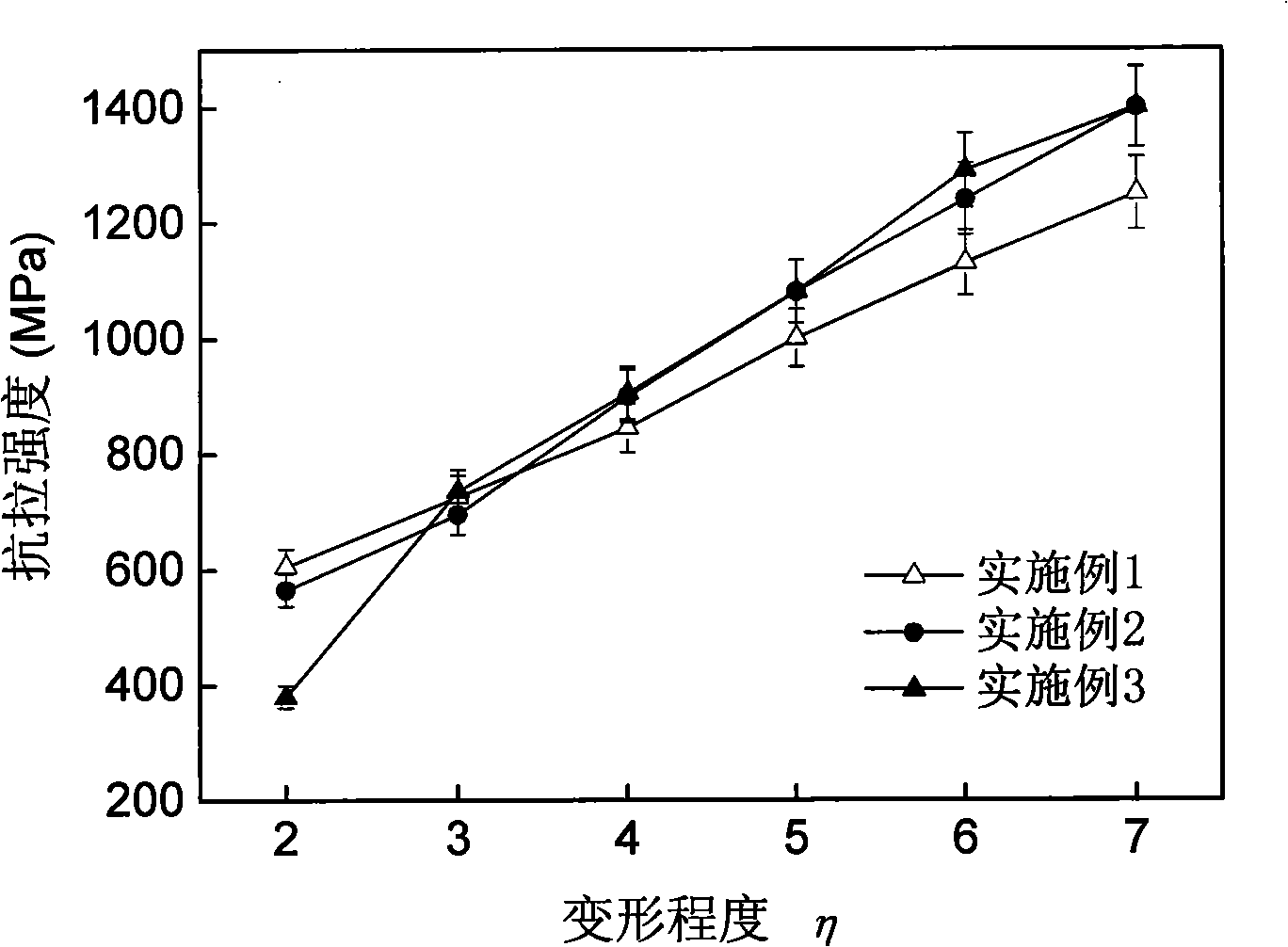

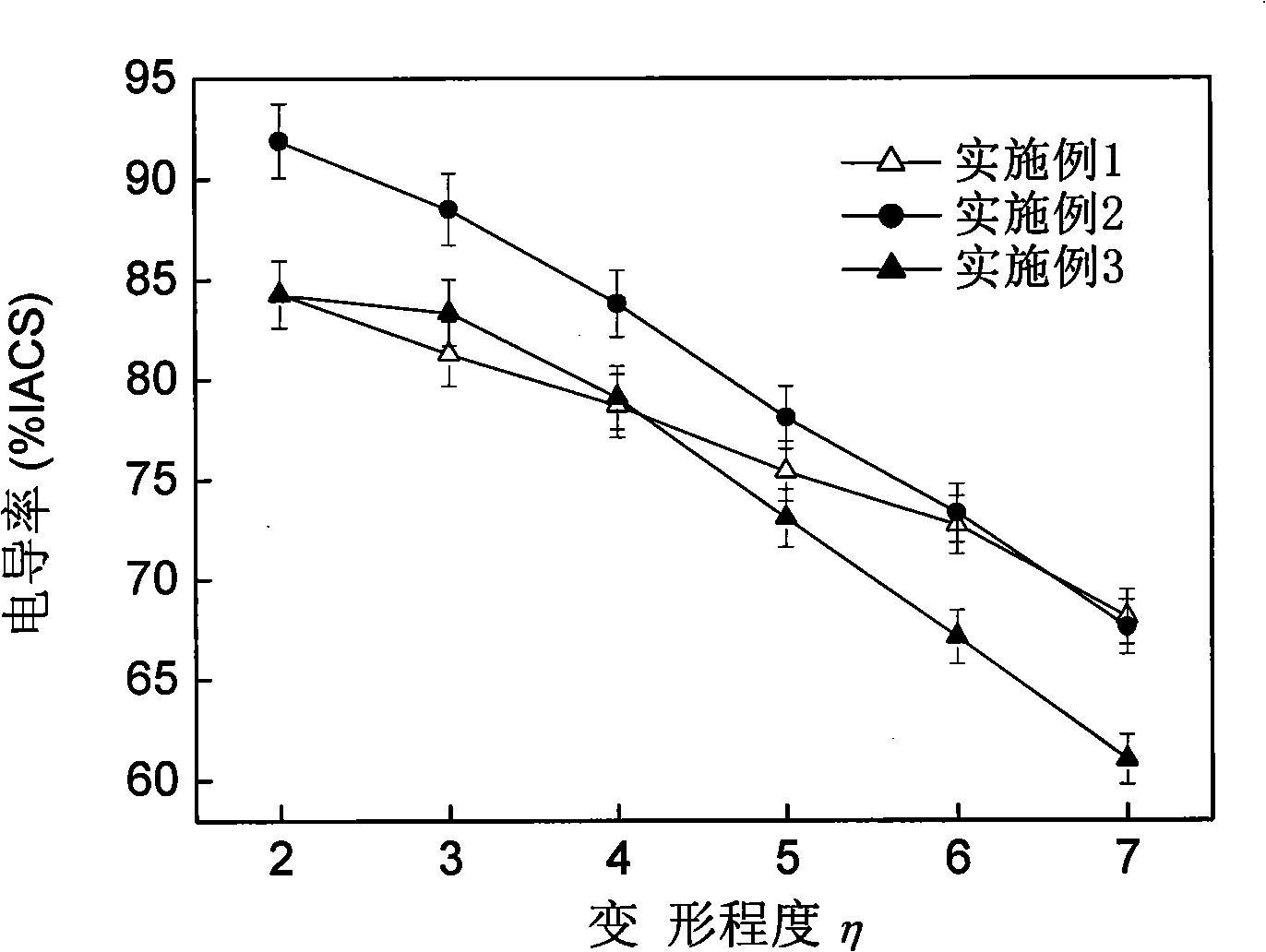

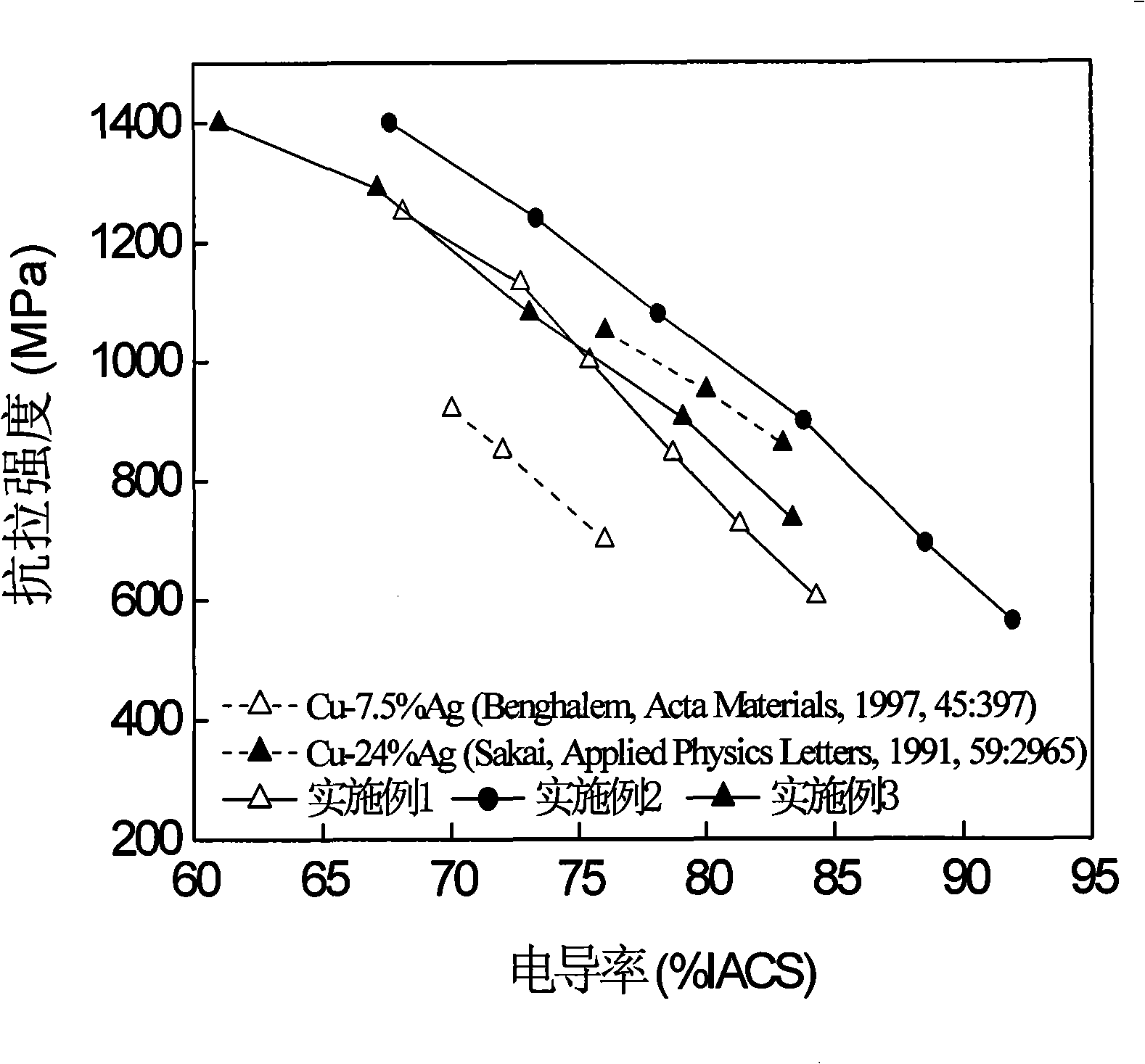

Solid solution and aging treatment method for cooperating Cu-Ag alloy cold drawing processing

The invention discloses a method for solution treatment and aging treatment which are matched with the processing of Cu-Ag alloy cold-finish drawing. A mixture with 7%-12% of Ag by weight and the rest of electrolytic Cu is melted in a vacuum induction furnace and carries out ingoting under the protection of Ar gas, the solution treatment and the aging treatment are carried out to the ingot, and the drawing deformation is carried out several times at the normal temperature. The fiber-phase composite strengthened Cu-(7-12)% Ag alloy obtained by matching the solution treatment and the aging treatment with the deformation processing has the strength of 380-1400MPa and the relative conductivity of (60-92)% IACS. The method simplified the technological process and the combination property of the alloy is close to or even exceeds the alloy with high Ag-content.

Owner:ZHEJIANG UNIV

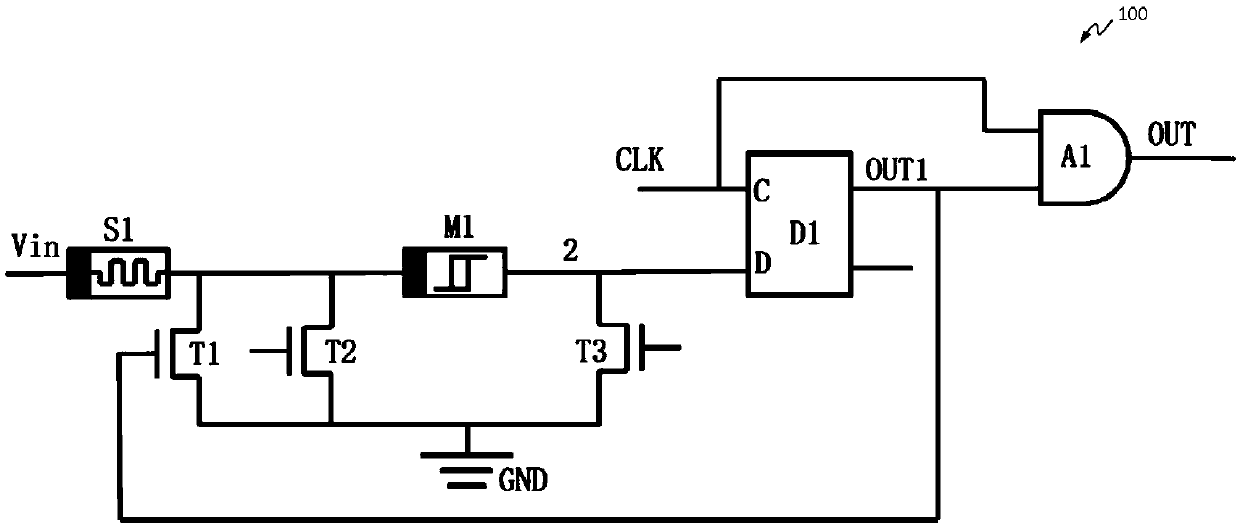

A neuron circuit and a neural network circuit

ActiveCN109102071AAchieve preparationImprove driving abilityPhysical realisationNeuron circuitExcitation signal

The invention discloses a neuron circuit including memristor elements, a trigger element, feedback elements and AND gates, wherein the memristor element is configured to receive an excitation signal,the trigger element is connected to the memristor element, and receives a clock control signal of the circuit and a signal outputted from the memristor element, the feedback element is used for connecting the output terminal of the trigger element and the input terminal of the memristor element, and controlling the voltage of the input terminal of the memristor element. The AND gate circuit is used for performing AND operation on the output signal of the trigger element and the clock control signal, and the output signal of the AND gate circuit is used as the output signal of the neuron circuit. The invention also relates to a neural network circuit.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

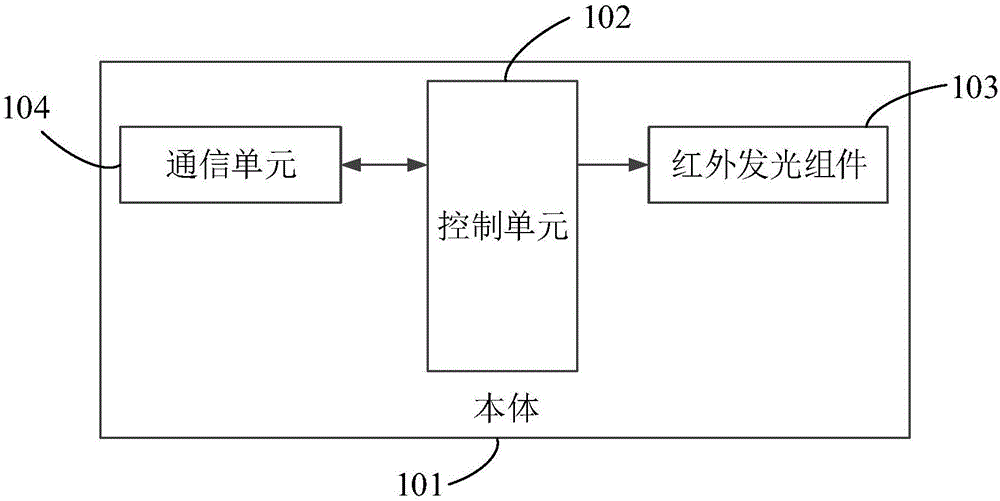

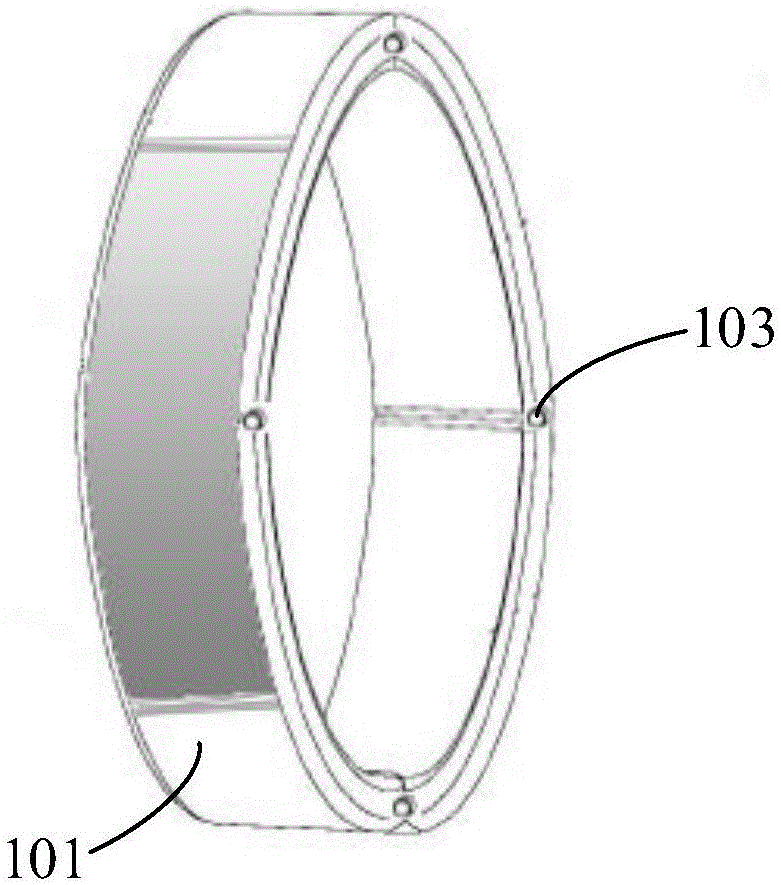

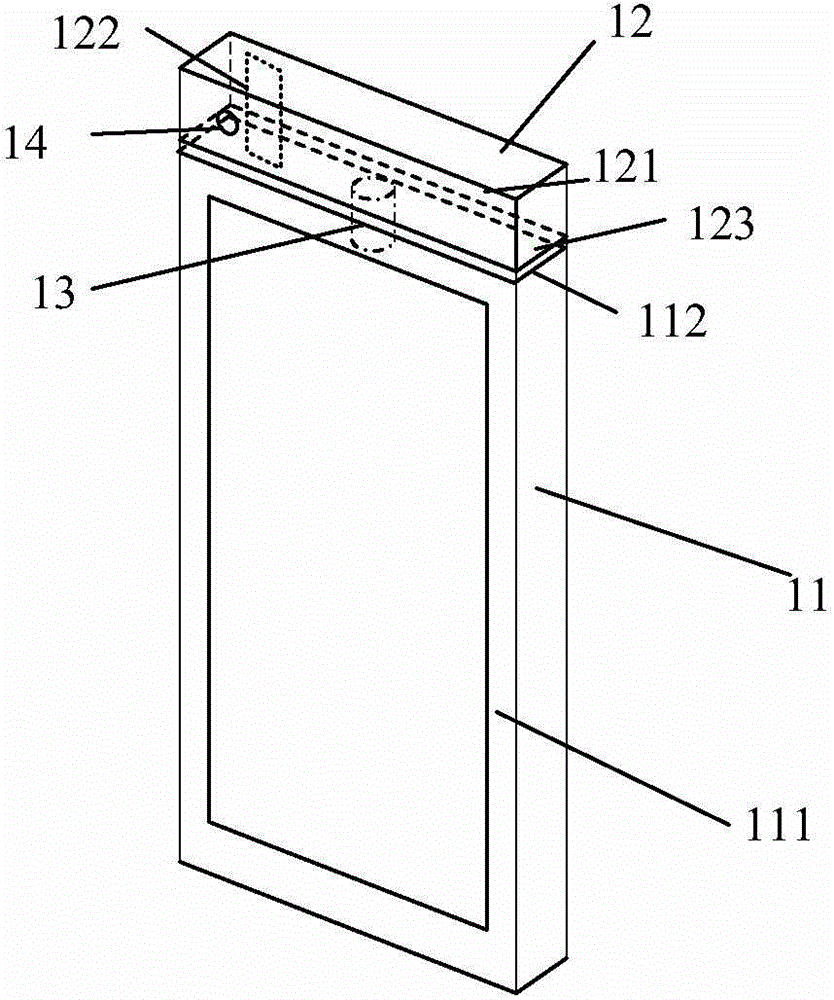

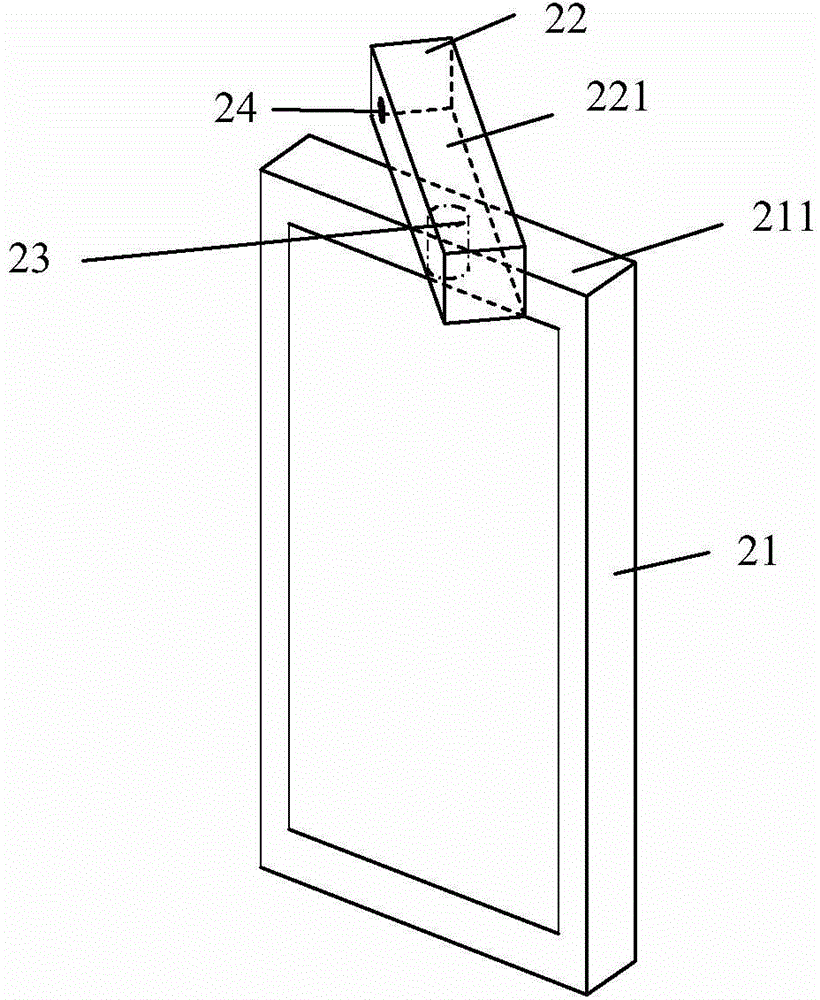

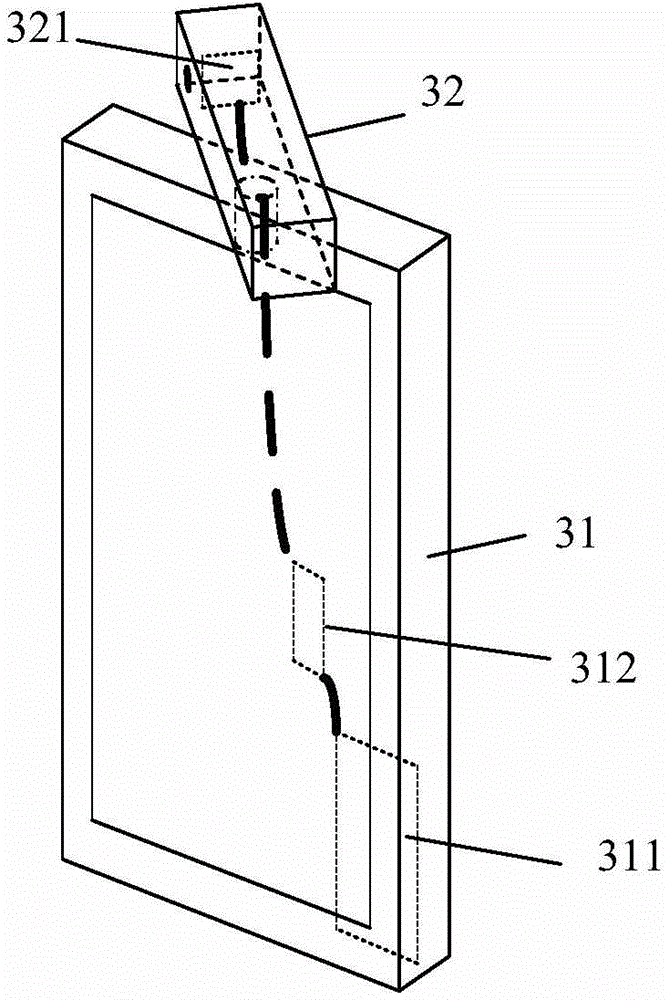

Wearable device

InactiveCN106293081AImprove discriminationReduce occupancyInput/output for user-computer interactionDetails for portable computersCommunication unitComputer science

The invention discloses a wearable device which comprises an infrared light-emitting component, a communication unit, a control unit and a body. The infrared light-emitting component comprises infrared light-emitting diodes and used for emitting infrared light, the communication unit is used for trustfully connecting with an infrared gesture recognition device and receiving driving instructions and closed instructions transmitted by the infrared gesture recognition device, the control unit responds the driving instructions and the closed instructions and correspondingly controls the infrared light-emitting component to emit or close the infrared light, the communication unit and the control unit are arranged in the body, the body is provided with a flexible part, and the infrared light-emitting diodes of the infrared light-emitting component are linearly arranged along the sides of the flexible part. According to the wearable device, distinction degree of a gesture area and a background area can be effectively improved, response time of a gesture recognition system is shortened, recognition rate and instantaneity of gesture recognition of an operator under the conditions of complicated background and dark light are improved, and human-computer interaction experience is improved.

Owner:BEIJING QIHOO TECH CO LTD +1

Cast-in-situs polystyrene cement composite foaming material and constructing method thereof

InactiveCN1490272ASignificant advantagesRemarkable effectSolid waste managementCeramic shaping apparatusPolymer scienceFoaming agent

A composite foaming material is prepared from foamed polystyrene particles, silicate cement, powdered coal ash, affinity agent and foaming agent through proportional mixing. Its in-situ application method includes such steps as foaming the polystyrene particles by portable electrothermal steam foaming machine, stirring cement mortar by stirrer, sequentially mixing with others, stirring, and in-situ pouring.

Owner:沈阳金铠建筑科技股份有限公司

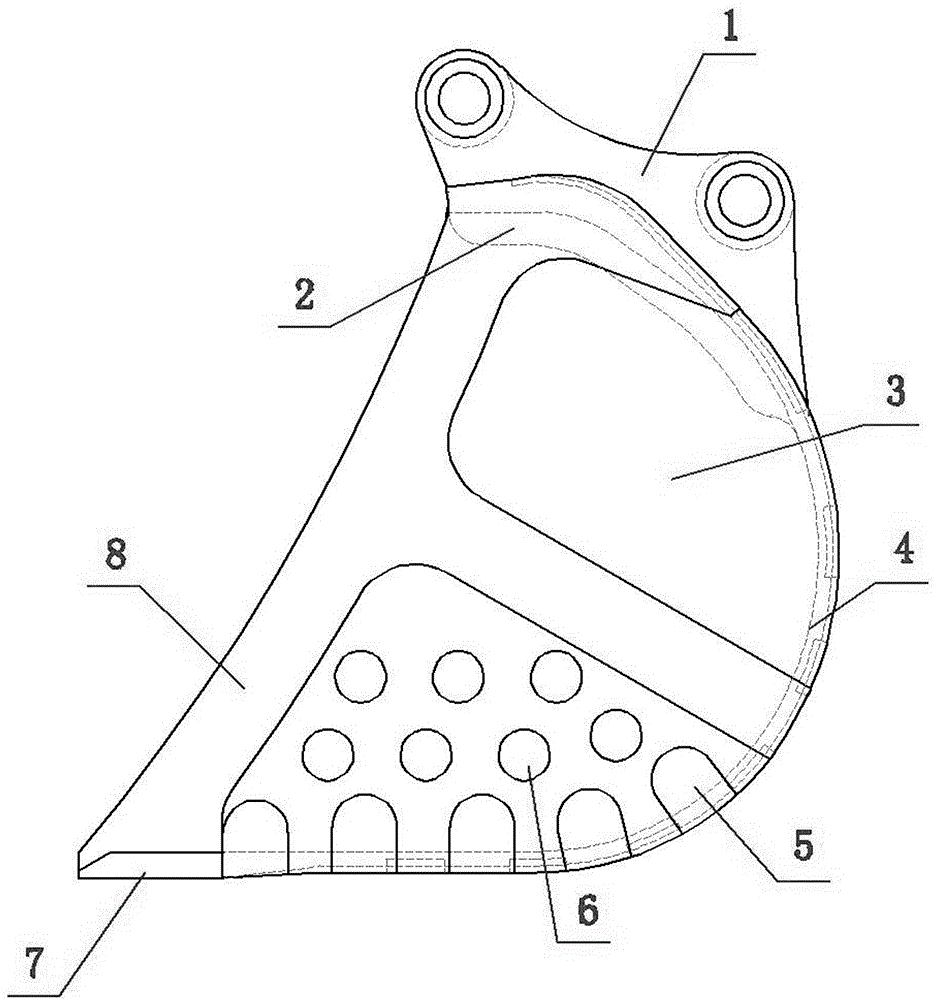

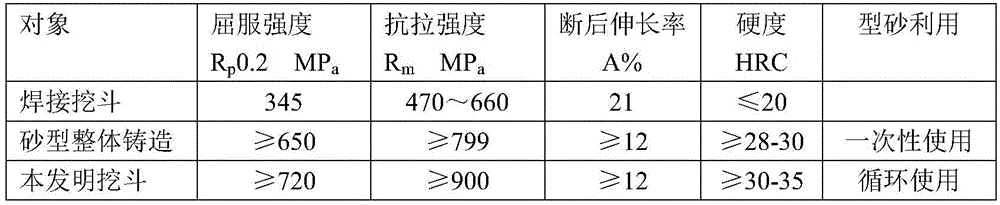

Integral casting digging bucket and manufacturing method thereof

ActiveCN106001439AIncrease frictionImprove wear resistanceMechanical machines/dredgersFoundry mouldsQuenchingCorrosion

The invention belongs to the field of engineering machinery, and particularly relates to an integral casting digging bucket and a manufacturing method thereof. The integral casting digging bucket comprises a lifting lug, a top plate, two side plates and a bottom plate connected with the two side plates, and the lifting lug, the top plate, the two side plates and the bottom plate are integrated. Cast steel for casting the digging bucket comprises the following components: 0.1%-0.6% of C, 0.2%-0.6% of Si, 0.5%-1.8% of Mn, 0.5%-1.6% of Cr, 0.2%-0.75% of Ni, 0.1%-0.6% of Mo, less than or equal to 0.035% of P, less than or equal to 0.035% of S, and the balance of iron. The method for manufacturing the integral digging bucket of an excavator by using the cast steel comprises the following steps: smelting the components of the cast steel in a smelting furnace; and after smelting is finished, carrying out modification treatment in front of a furnace, manufacturing models and mould plates, coating, heating, vacuumizing, placing a sandbox, adding sand, modeling, carrying out mould assembling, pouring, quenching, and tempering and cooling to the normal temperature to finish casting of the digging bucket. A vacuum sealing technology and a low alloy steel material are adopted, the integral casting digging bucket is formed by one-time pouring, and the product is high in strength, high in wear resistance, corrosion resistance and impact force resistance and long in service life.

Owner:HUBEI WANXIN PRECISION CASTING & FORGING INC

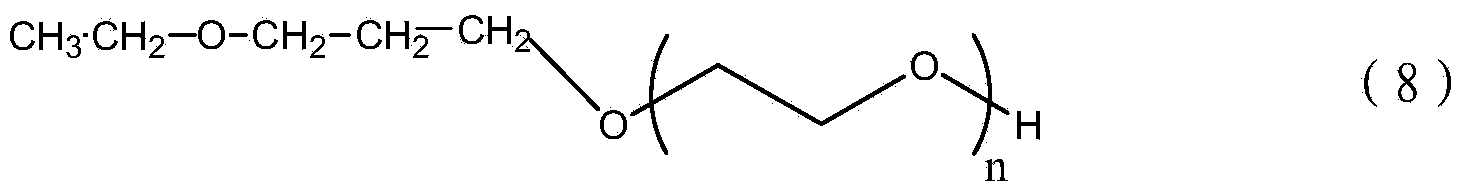

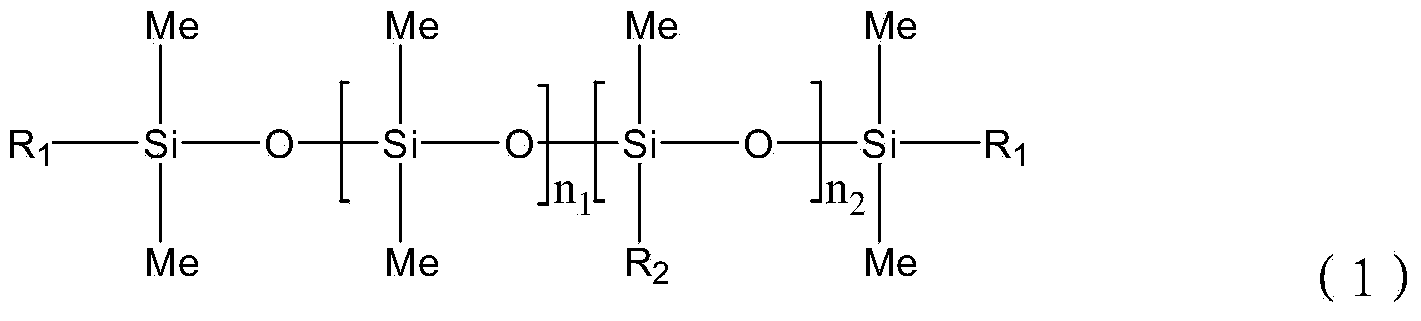

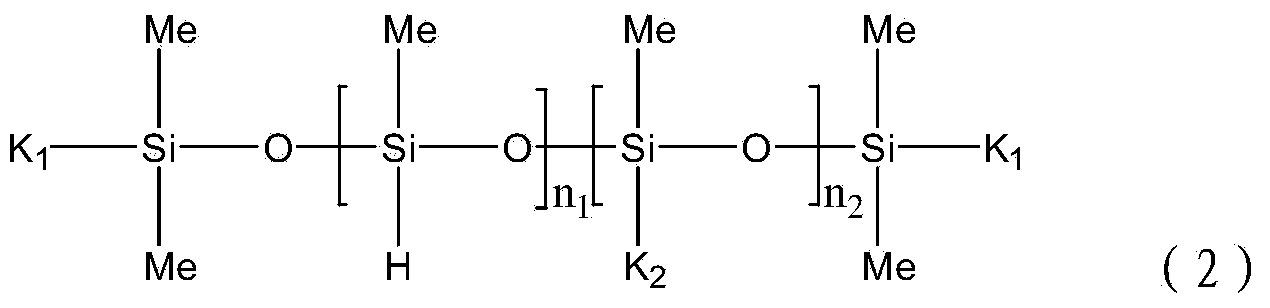

Antistatic organosilicon gel used for heat-conducting gasket and preparation method of the organosilicon gel

The invention relates to antistatic organosilicon gel used for a heat-conducting gasket and a preparation method of the organosilicon gel. The organosilicon gel comprises an A component and a B component in a weight ratio of 1:1. The A component comprises following raw materials by weight: 95-99.84 parts of a basic material, 0.1-1 part of a catalyst, 0.05-2 parts of an adhesive and 0.01-2 parts of an antistatic agent. The B component comprises following raw materials by weight: 84-94.9 parts of the basic material, 5-15 parts of a cross-linking agent and 0.1-1 part of an inhibitor. The organosilicon gel prepared by the invention has good fluidity. After sulfuration, the organosilicon gel has excellent adhesive property, holding power and antistatic property.

Owner:YANTAI DARBOND TECH

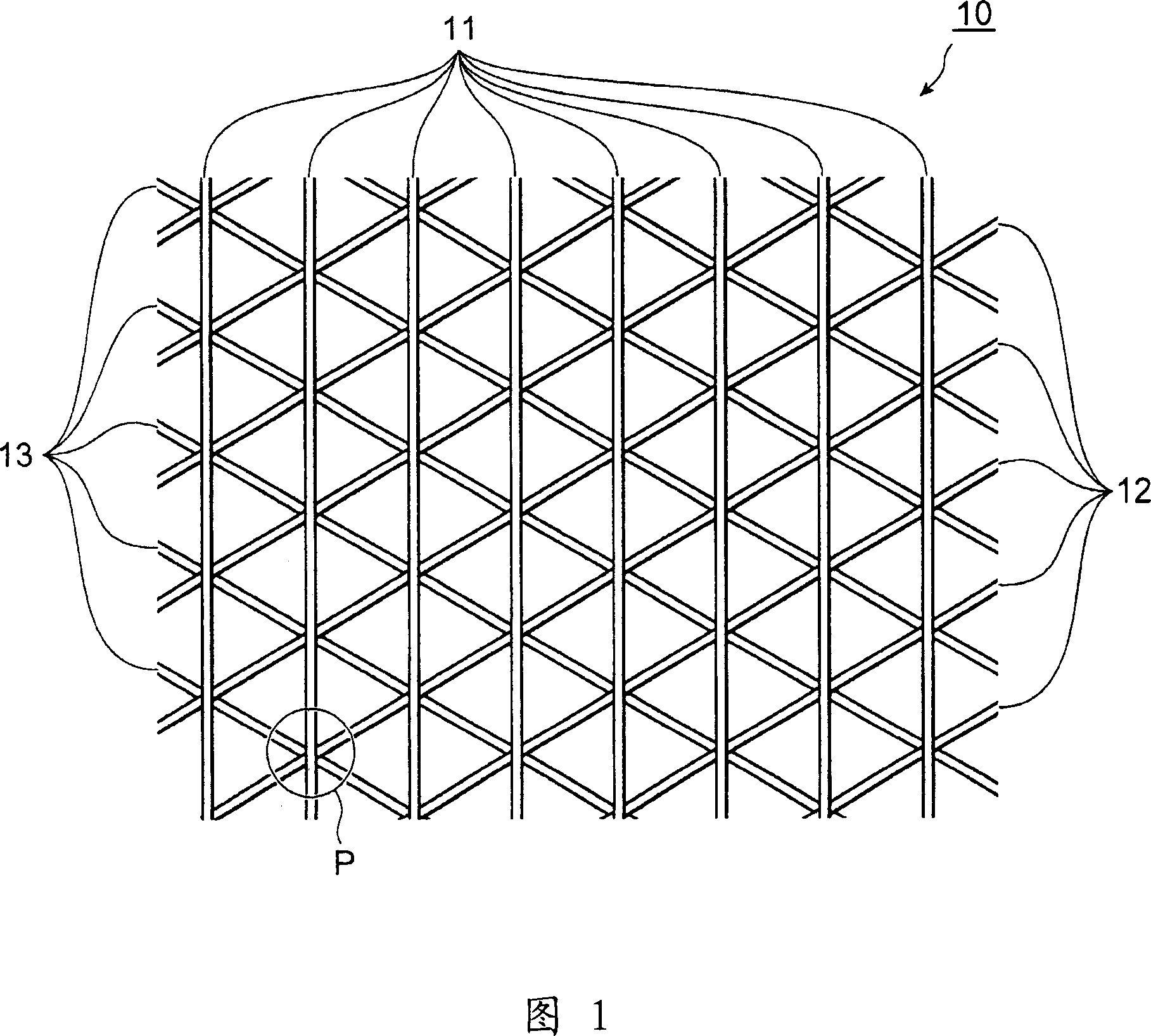

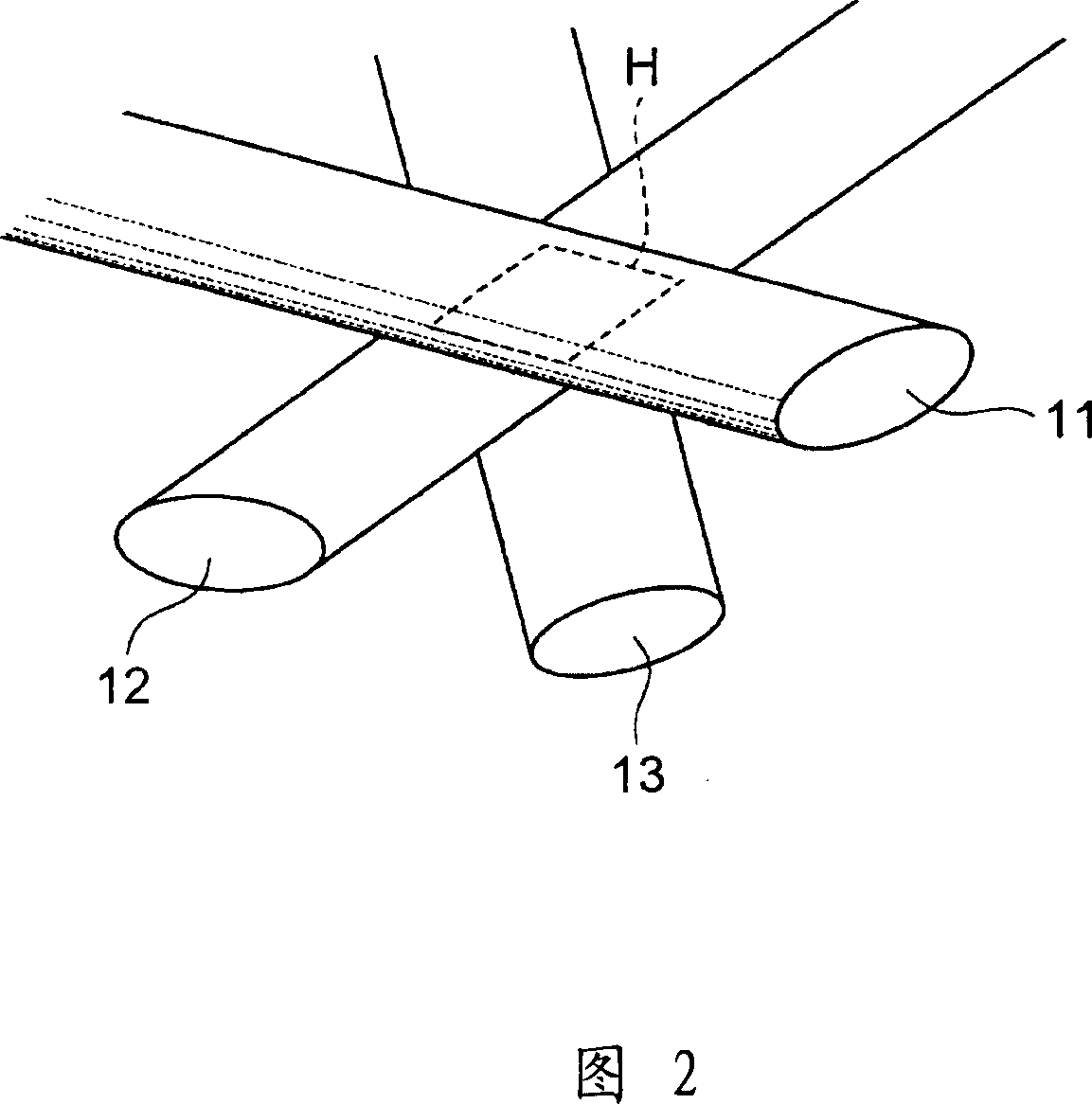

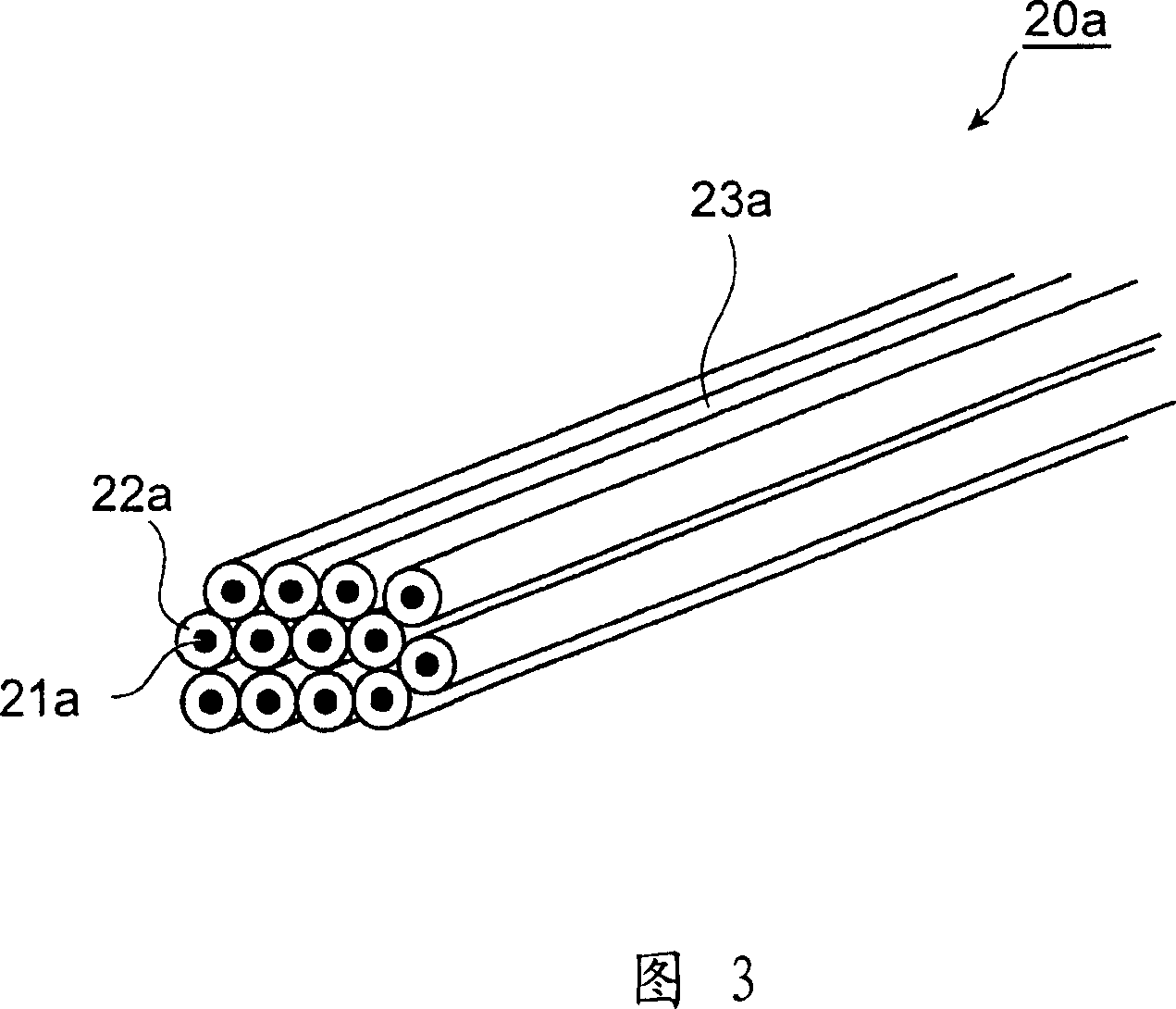

Process for producing nonwoven fabric and nonwoven fabric

ActiveCN1926272AGood flexibilityHigh strengthWoven fabricsNon-woven fabricsEngineeringNonwoven fabric

The nonwoven fabric production process of the invention comprises a laminating step in which composite yarn, obtained by bundling a plurality of resin single filaments each having a core-sheath structure with a filamentous core resin surrounded by a sheath resin with a melting point of at least 20°C lower than the core resin and fusing the sheath resin together, is laminated in at least the three directions of warp direction, slant direction and reverse slant direction, and a bonding step of heating the laminated filament bundles at a temperature lower than the melting point of the core resin and higher than the melting point of the sheath resin for bonding. According to the invention, it is possible to provide a nonwoven fabric production process and nonwoven fabrics with excellent plasticity and shape following property, as well as adjustable strength for adaptation to different purposes and required properties.

Owner:UBE NITTO KASEI CO LTD

3D printing method for ceramic-based nickel alloy composite material

ActiveCN105256160AHigh strengthImprove toughnessAdditive manufacturing apparatusMicrometerBiocompatibility Testing

A 3D printing method for a ceramic-based nickel alloy composite material is characterized in that ZrO2 ceramic powder and Ni-based alloy powder which are evenly mixed according to a proportion are put into a metal 3D printing work chamber, printing is conducted on the conditions that power is 100-400 W, the scanning speed is 200-600 mm / s, the diameter of light spots is 30-60 micrometers, the scanning interval is 40-70 micrometers and the oxygen concentration of the work chamber is smaller than 50 ppm, and a product obtained through 3D printing is annealed under the protection of N2 gas at the temperature of 800-890 DEG C for 8-12 hours. The biocompatibility of the material of the product obtained through the printing and a human body is good; the structure is compact and controllable; the mechanical property is good, the product has good corrosion and abrasion resistance, and is short in production period and low in manufacturing cost; the whole strength of the formed product can be adjusted by changing the proportion of Ni60 alloy in a base material.

Owner:GUANGDONG INST OF NEW MATERIALS

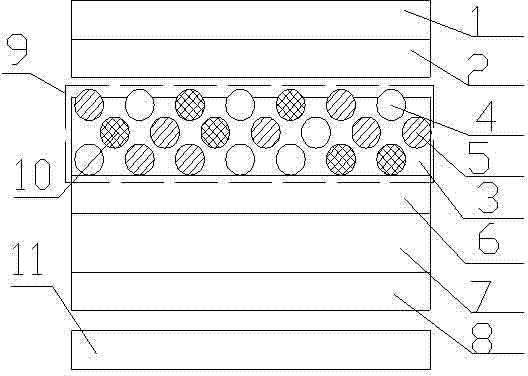

Shockproof, anti-skidding and antistatic protective film

ActiveCN103753913AAdjust densityAdjust intensitySynthetic resin layered productsPolyethylene terephthalateCompanion animal

The invention discloses a shockproof, anti-skidding and antistatic protective film. The shockproof, anti-skidding and antistatic protective film comprises a protective layer, a using layer and a releasing layer, wherein the protective layer consists of an optical PET (Polyethylene Terephthalate)film and a low-mucilage-glue layer; the using layer mainly consists of a polyurethane foam layer, an antistatic priming coat, an optical PET film and a middle- and high-mucilage-glue layer; the releasing layer mainly comprises an optical PET releasing membrane; the polyurethane foam layer comprises some or all of waterborne polyurethane, sealed hollow expansion spheres, open air bubbles and fluorescent particles. The shockproof, anti-skidding and antistatic comprehensive protective film prepared by the invention is used for protecting the back of a cell phone; the shockproof function of the PU foam layer provides a certain drop-resistant effect for the cell phone; the flexibility and self-adsorption of the PU foam layer can prevent the cell phone from moving after being stressed when the cell phone is put on an object evenly; fluorescent particles in the PU foam layer can glow at night.

Owner:YIDONG ELECTRONICS CHANGSHU

3D printing method of ceramic titanium alloy composite biological implanting product

InactiveCN105728722AHigh strengthImprove toughnessAdditive manufacturing apparatusIncreasing energy efficiencyBiocompatibility TestingAlloy composite

A 3D printing method of a ceramic titanium alloy composite biological implanting product is characterized in that ceramic powder ZrO2, Al2O3 or ZrO2 / Al2O3 and titanium alloy powder which are evenly mixed according to the proportion are placed in a metal 3D printing work chamber, and printing is carried out under the conditions that power ranges from 200 W to 500 W, the scanning speed ranges from 200 mm / s to 600 mm / s, the spot diameter ranges from 30 micrometers to 60 micrometers, the scanning gap ranges from 40 micrometers to 70 micrometers and the working chamber oxygen concentration is smaller than 50 ppm; and the product obtained through 3D printing is subject to isostatic pressing or solid solution treatment under the Ar gas protection and at the temperature ranging from 950 DEG C to 1050 DEG C, and time ranges from 1.5 h to 4 h. The printed product material is good in biocompatibility with the human body, compact and controllable in texture, adaptive in mechanical property, short in production period and low in manufacturing cost and has the excellent corrosion-resisting wear-resisting performance, and the whole strength of the forming product can be adjusted by changing the proportion of a titanium alloy in a base body material.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

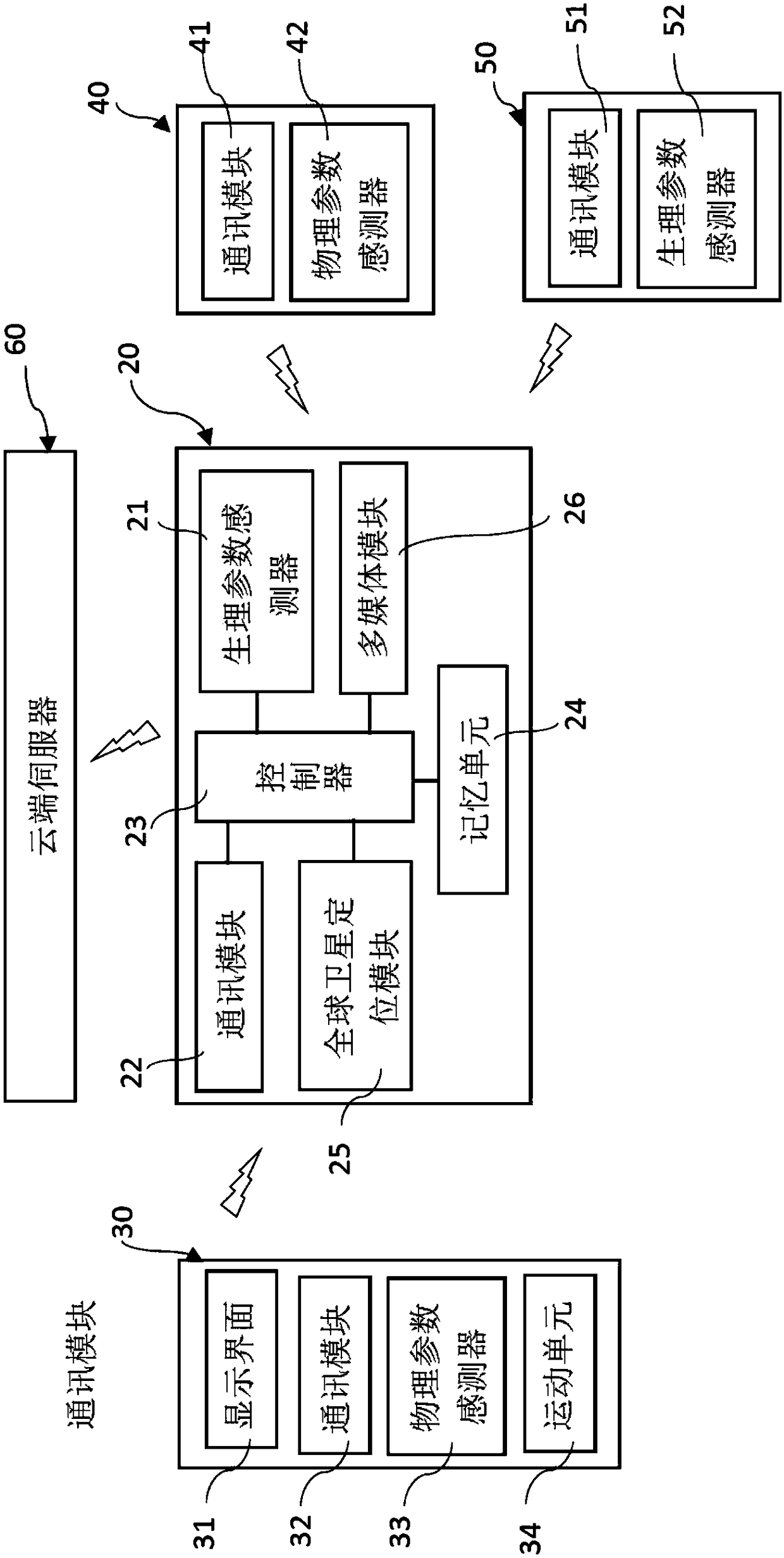

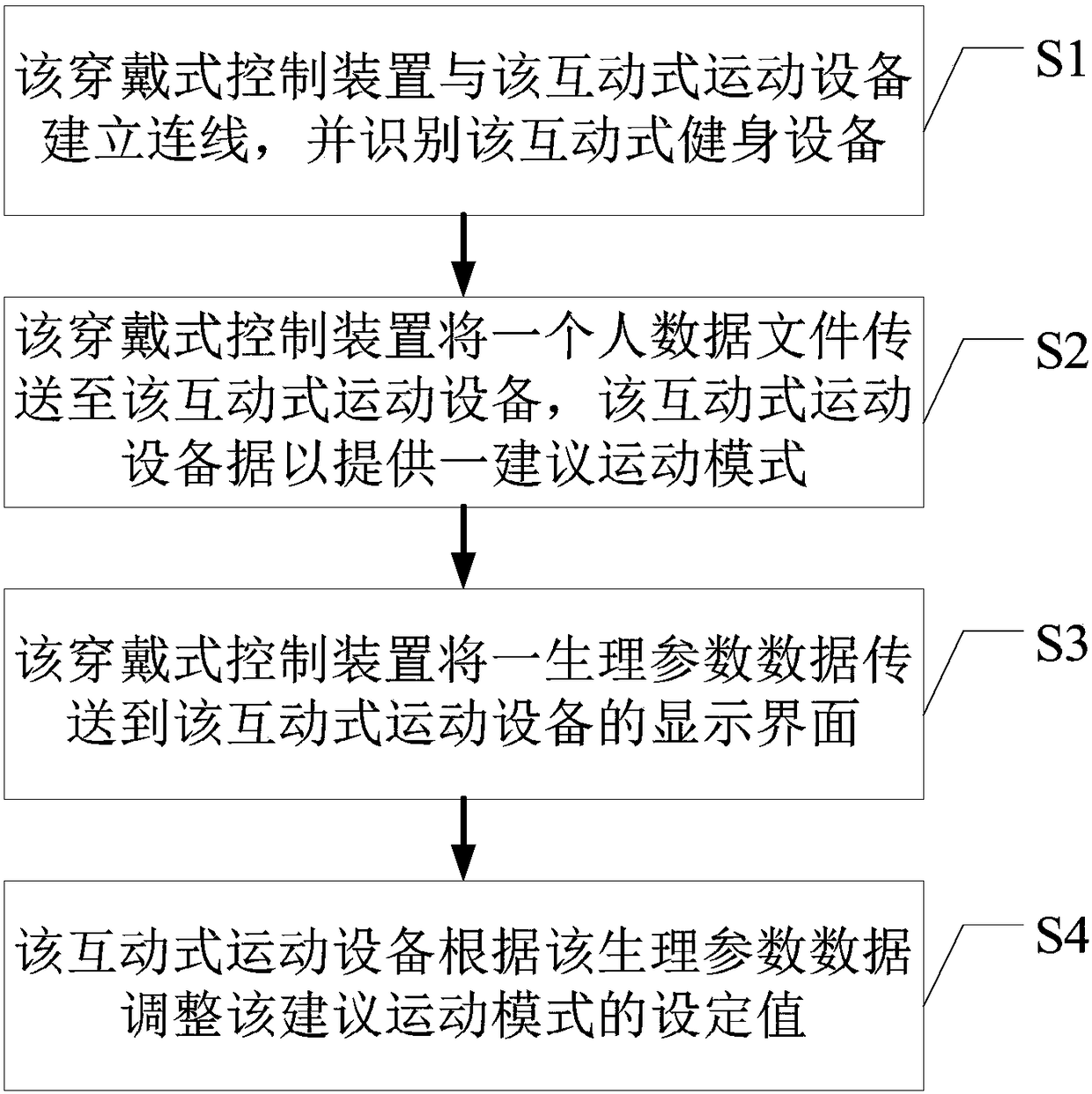

Health management system and method

InactiveCN108261732APromote sportsReal-time monitoring of physiological parametersInput/output for user-computer interactionGymnastic exercisingSports equipmentComputer module

The disclosure provides a health management system and method, mainly applied in--interactive sports equipment and at least--wearable control device, wherein the interactive sports equipment has a display interface, a physical parameter sensor, a communication module and a motion unit. The physical parameter sensor can be used to detect and obtain physical parameter data. The wearable control device has physiological parameter sensor and / or physical parameter sensor. The communication module, the controller as well as the memory unit can identify with the interactive sports device and can transmit the physiological parameter data to the display interface of the interactive sports device. In this way, the interactive sports equipment can provide the function of real-time interaction with users and improve user satisfaction.

Owner:吴明哲

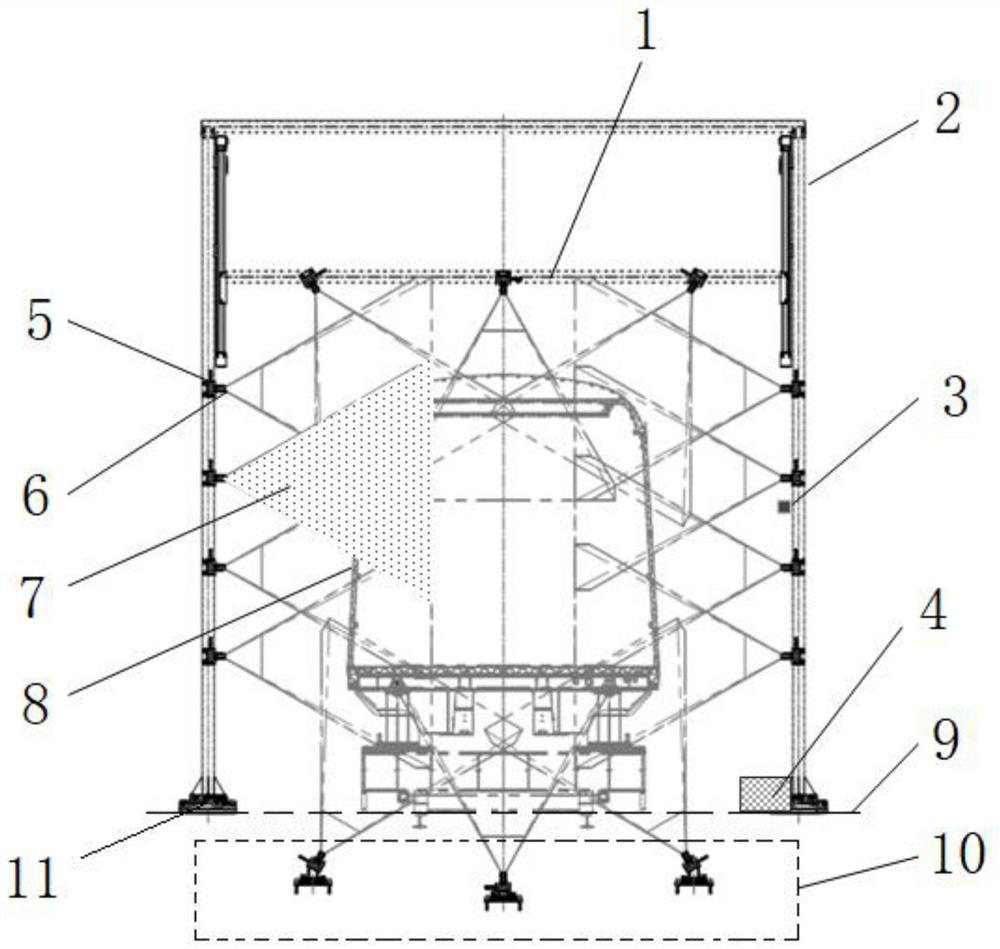

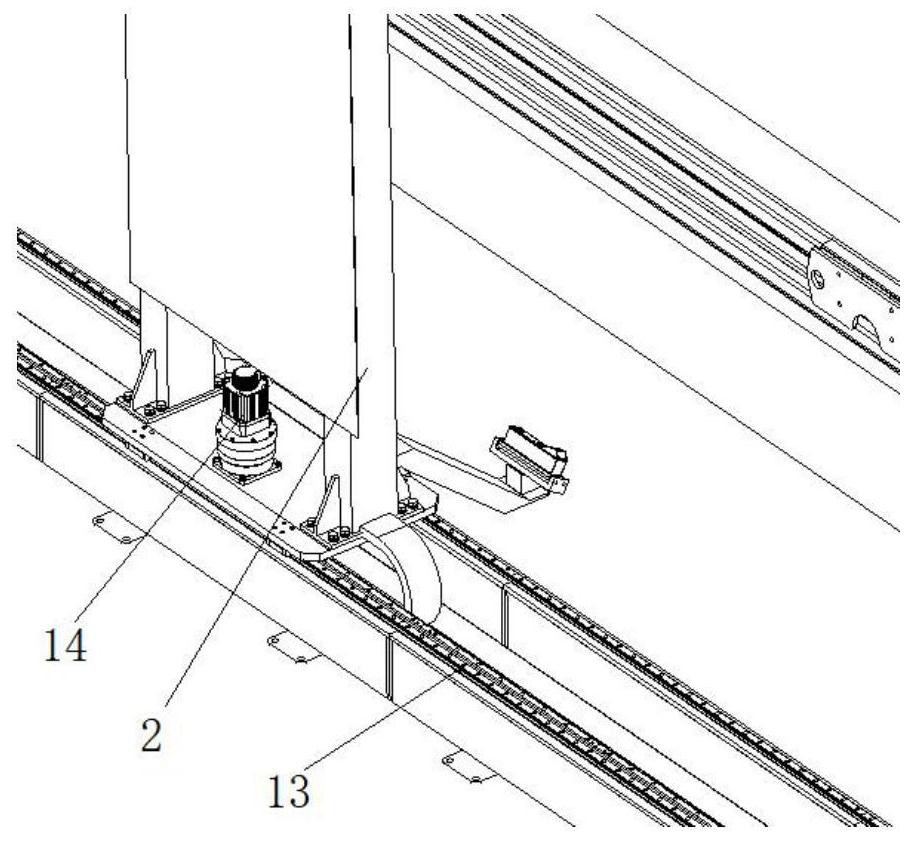

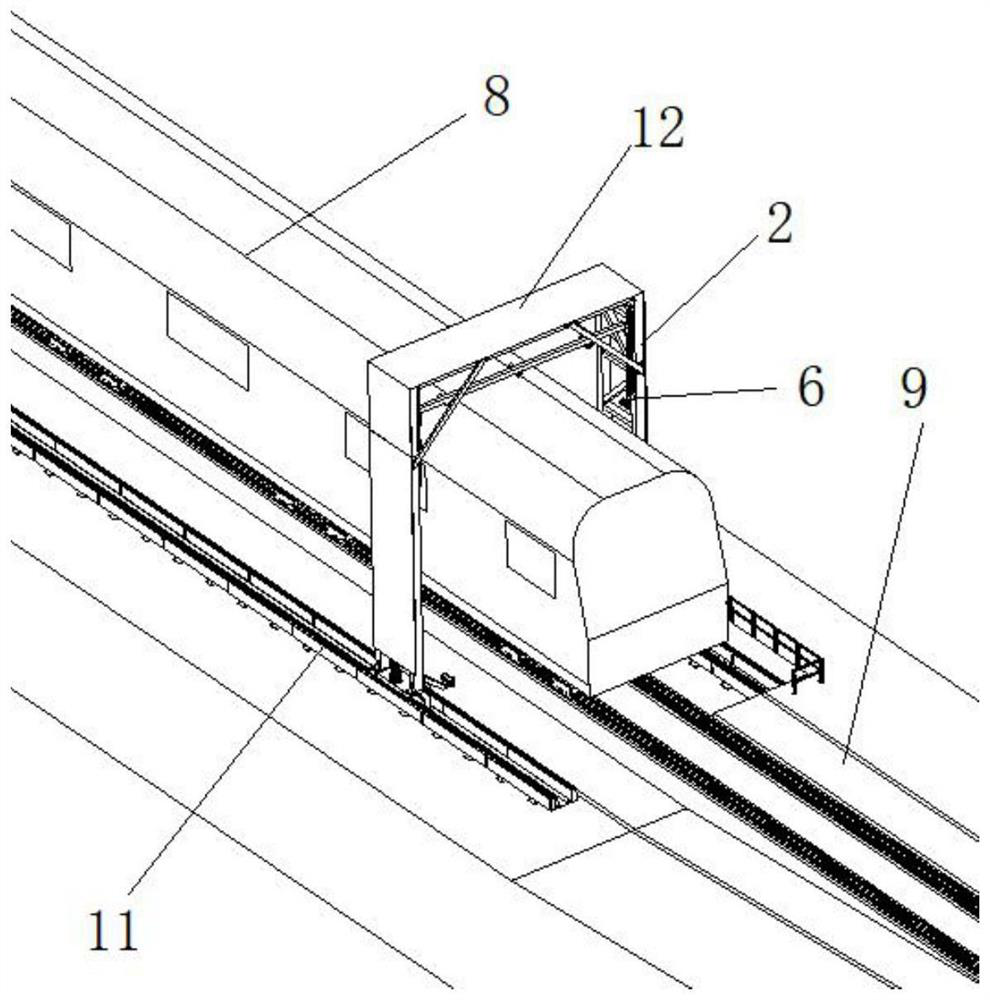

Train clearance detection device and method

PendingCN112432610AAdjust intensityRestore the real cross-sectional sizeUsing optical meansData acquisitionEngineering

The invention provides a train clearance detection device. The train clearance detection device comprises a portal frame, a range finder, camera brackets and laser cameras; the portal frame is mountedon a foundation; the portal frame comprises two stand columns and a cross beam connected with the two stand columns; the range finder is installed on the stand columns and used for monitoring the position of a train body; a plurality of camera brackets are arranged on the cross beam, the stand columns and in a trench, and the camera brackets in the trench are connected with the portal frame through connecting rods; and each camera bracket is provided with a laser camera. The invention further provides a train clearance detection method. The train clearance detection method comprises the stepsof camera group calibration, detection system verification, coordinate system establishment, data acquisition, contour correction, real-time monitoring and the like. A contour splicing technology isadopted, all contour points are spliced into a complete vehicle body section contour in a sensor cascading mode, the real size condition of the train body is accurately restored, line laser local detection and overall detection are achieved through calibration of the camera group, and the detection precision is greatly improved.

Owner:ZHUZHOU CSR SPECIAL EQUIP TECH

Noise control device, electrical equipment and noise control method of electrical equipment

PendingCN111681633AAdjust intensityImprove Active Noise CancellationSound producing devicesNoise controlNoise

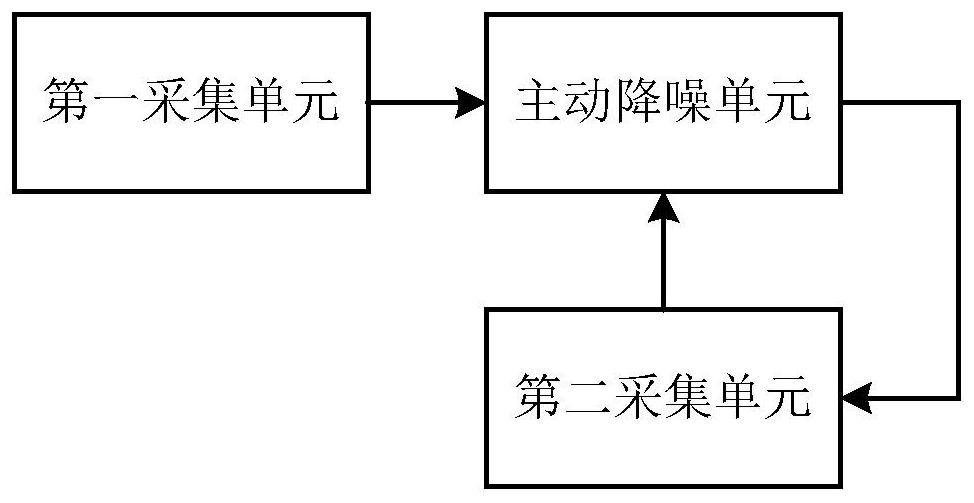

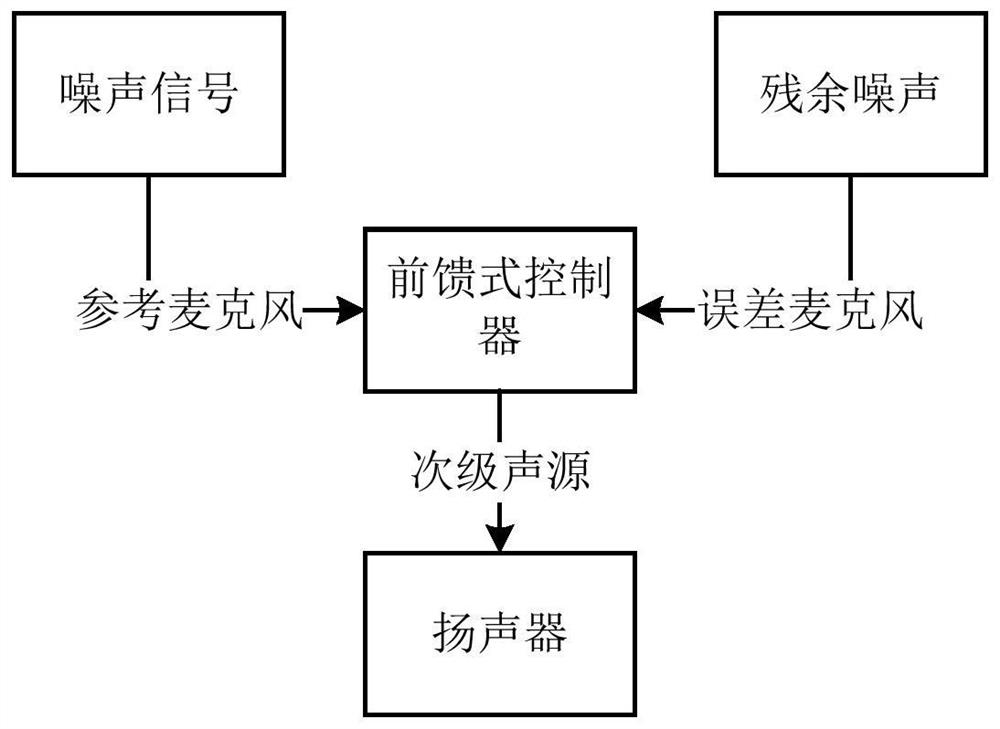

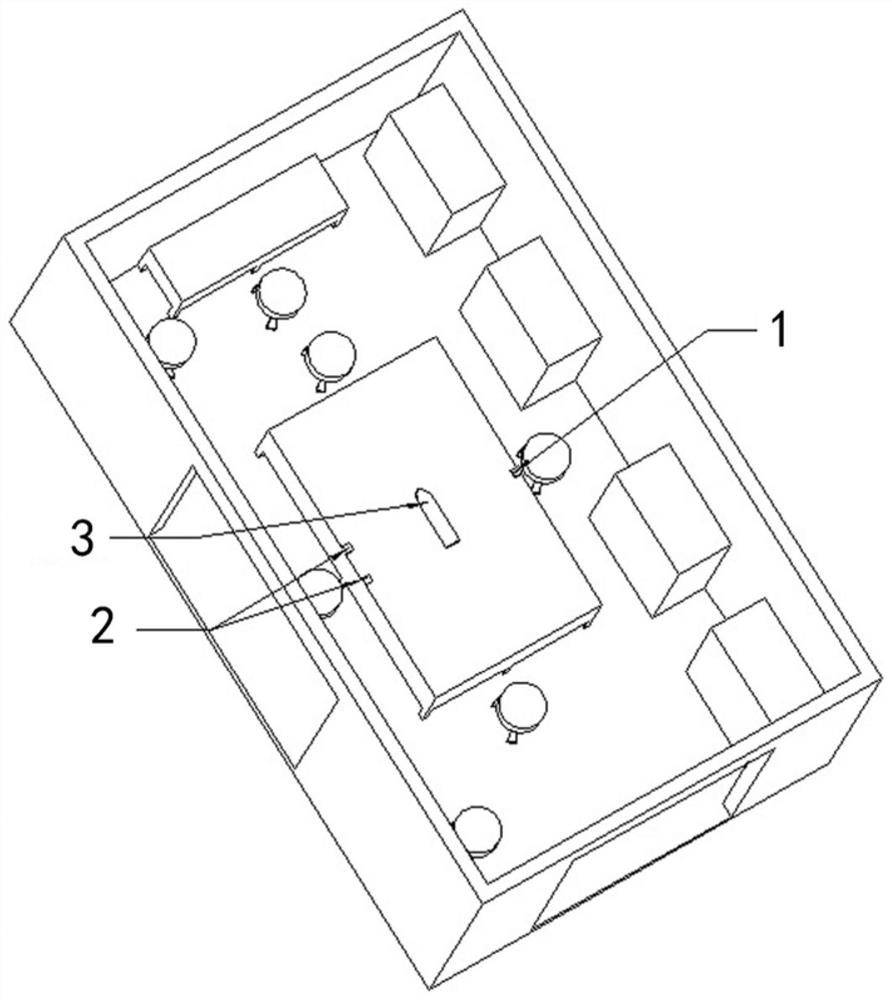

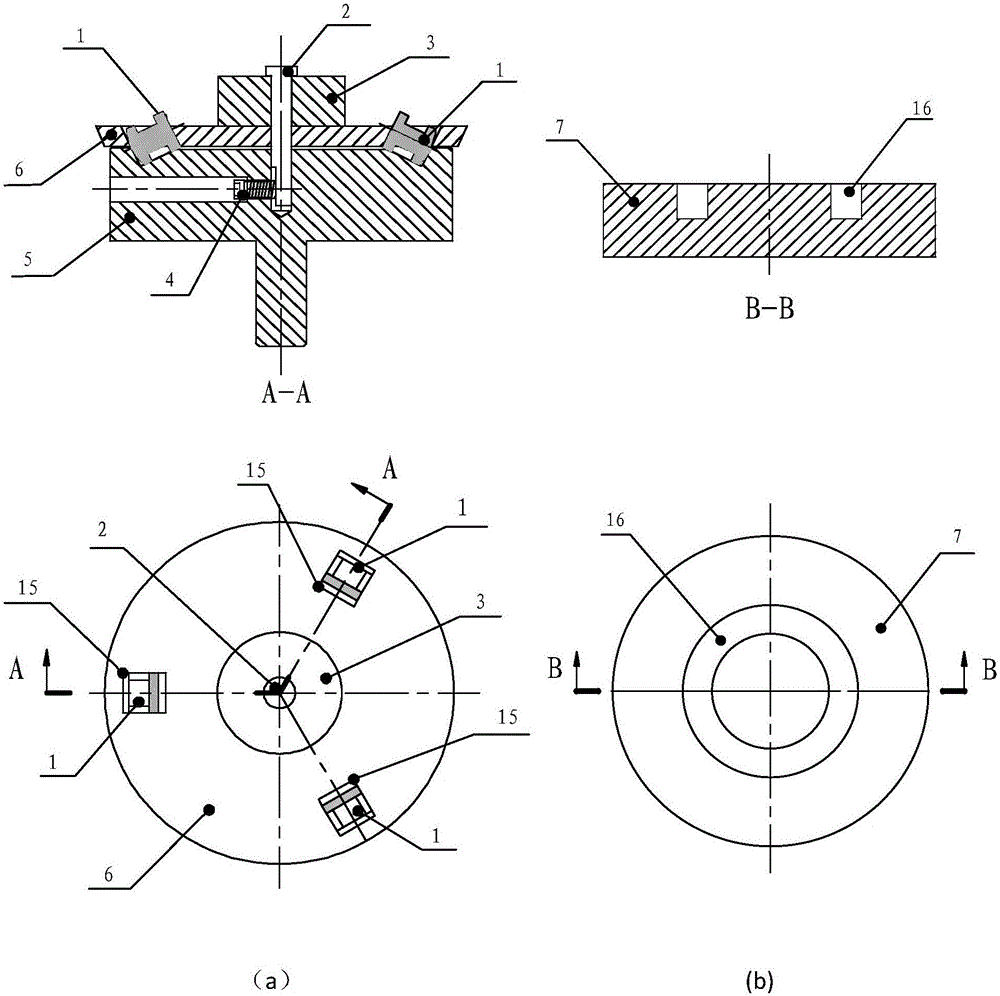

The invention discloses a noise control device, electrical equipment and a noise control method of the electrical equipment, wherein the device comprises a first collection unit, an active noise reduction unit and a second collection unit; the first collection unit acquires a first noise signal transmitted by the electrical equipment, and takes a sound field where the first noise signal is locatedas a primary sound field; the active noise reduction unit generates a second noise signal according to the first noise signal sent by the electrical equipment, and takes a sound field where the second noise signal is located as a secondary sound field; the primary sound field and the secondary sound field are controlled to be superposed; the second acquisition unit acquires an error noise signalgenerated by superposing the primary sound field and the secondary sound field; the active noise reduction unit is also used for adjusting the secondary sound field according to an error noise signalgenerated by superposing the primary sound field and the secondary sound field; and the primary sound field and the adjusted secondary sound field are controlled to be superposed. According to the scheme, the problem that the noise reduction effect is poor due to the fact that the noise reduction frequency band cannot be expanded in the active noise reduction mode of the electrical equipment can be solved, and the effect of improving the noise reduction effect of the electrical equipment is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

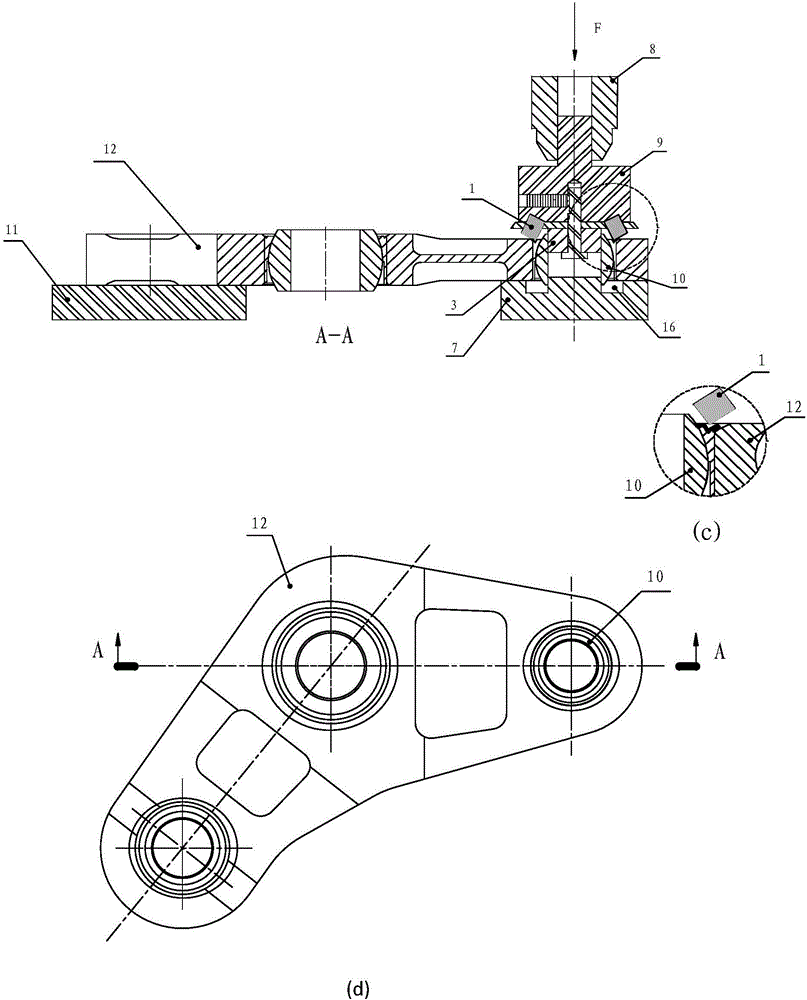

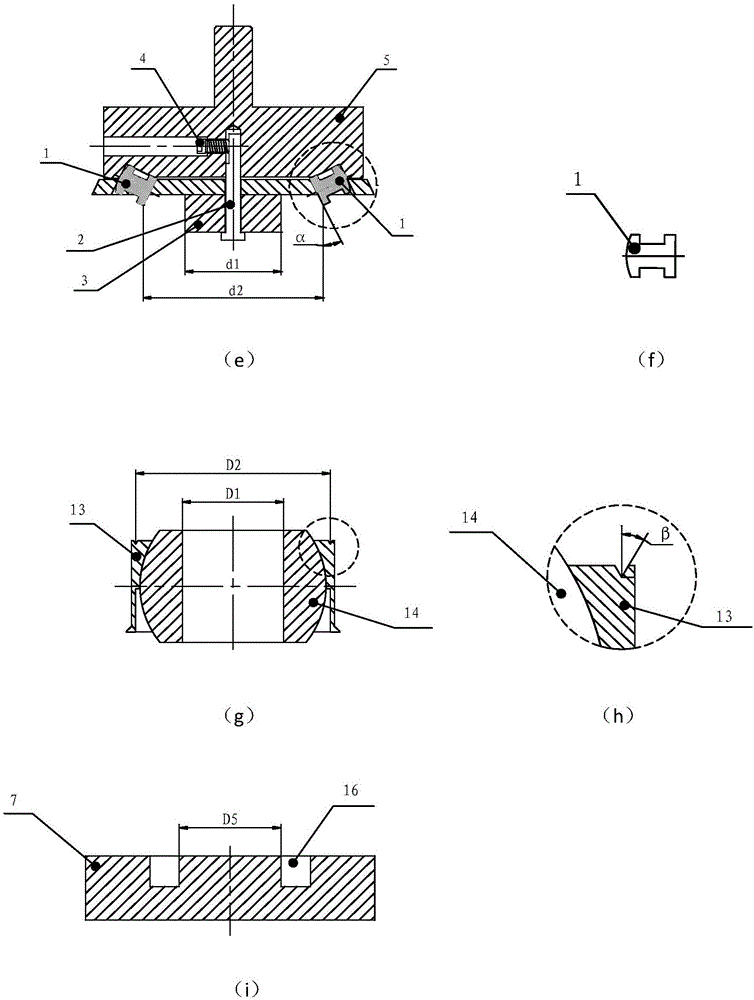

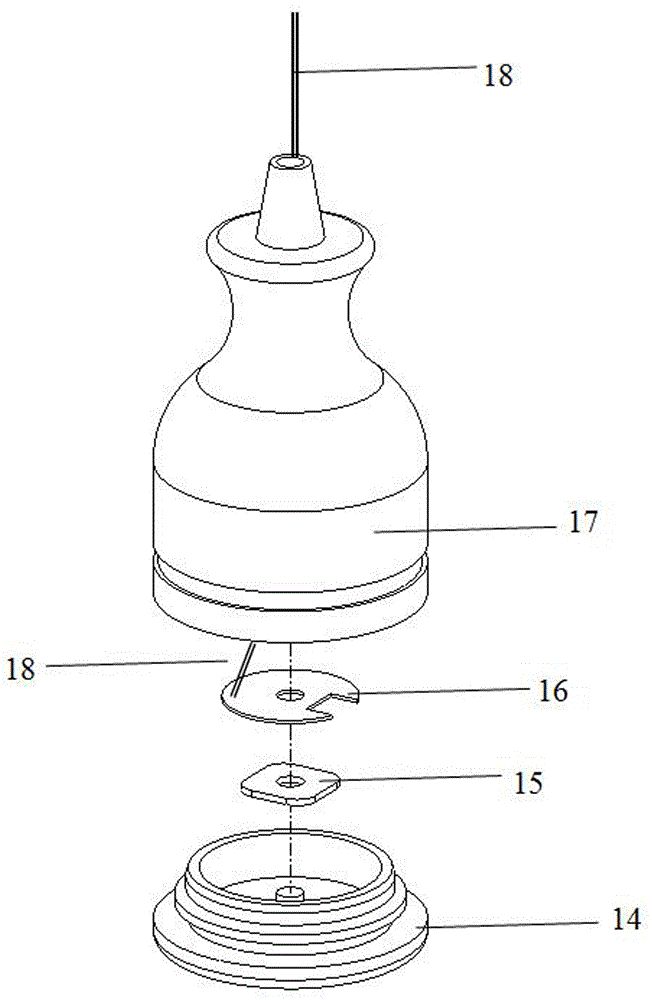

Joint bearing flanging tool and process of using same for joint bearing flanging

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

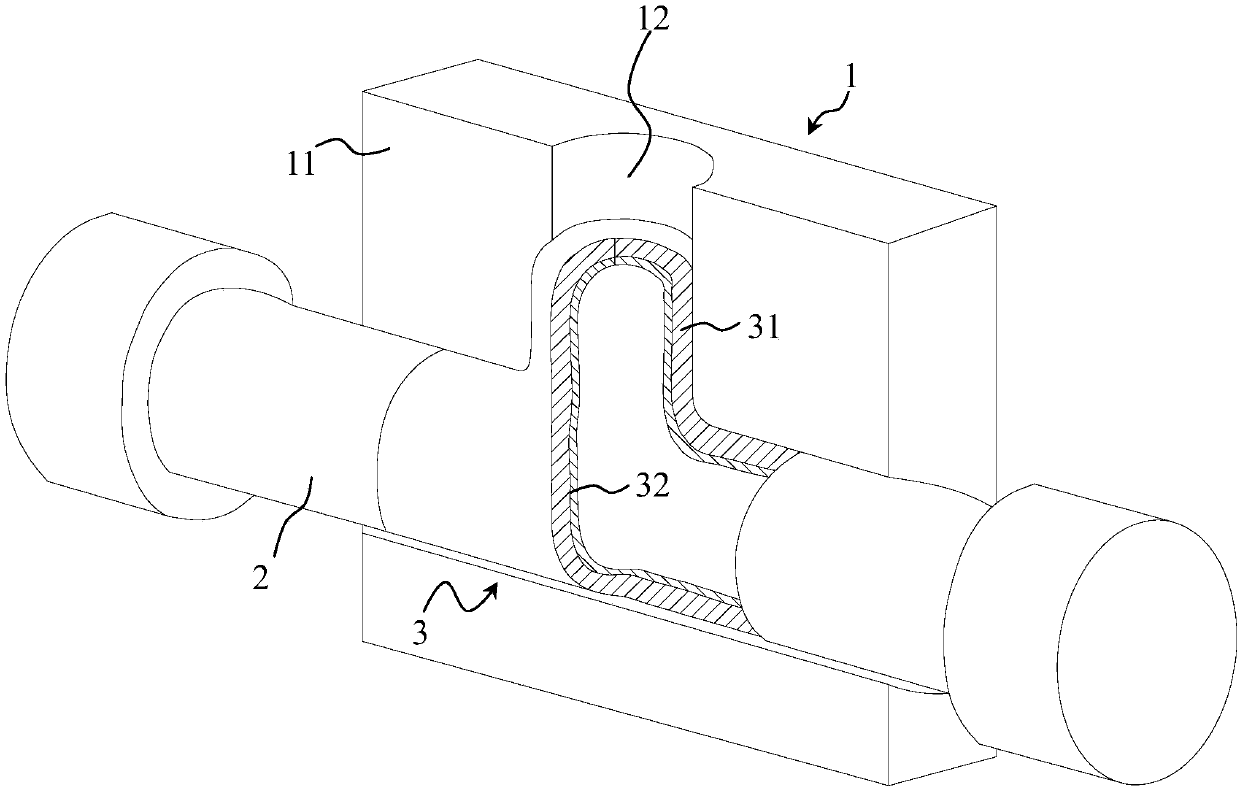

Forming process of nickel-based bimetal composite tube

InactiveCN107774737AImprove the bonding strength of the interfaceHigh yieldFurnace typesHeat treatment furnacesSolution treatmentIron oxide

The invention discloses a forming process of a nickel-based bimetal composite tube, comprising the steps of pretreating, forming by cold pushing, performing solution treatment, and tempering; the stepof forming by cold pushing includes placing a nickel-based bimetal composite tube in a die of a cold-extrusion former, and allowing a punch of the cold-extrusion former to act on the nickel-based bimetal composite tube through a forming hole arranged in the die so as to finish forming by cold pushing; the forming by cold pushing, solution treatment and tempering are performed sequentially repeatedly until the nickel-based bimetal composite tube reaches finish specifications; ends of the nickel-based bimetal composite tube are cut off by flame cutting, sawing, toothless saw cutting or plasma cutting, and the finished composite tube is obtained; iron oxide skin on the inner and outer surfaces of the finished composite tube is removed by chemical or mechanical means. The forming process of the nickel-based bimetal composite tube can provide reduced production cost and improved production efficiency.

Owner:YANGZHOU PIPE FITTING FACTORY

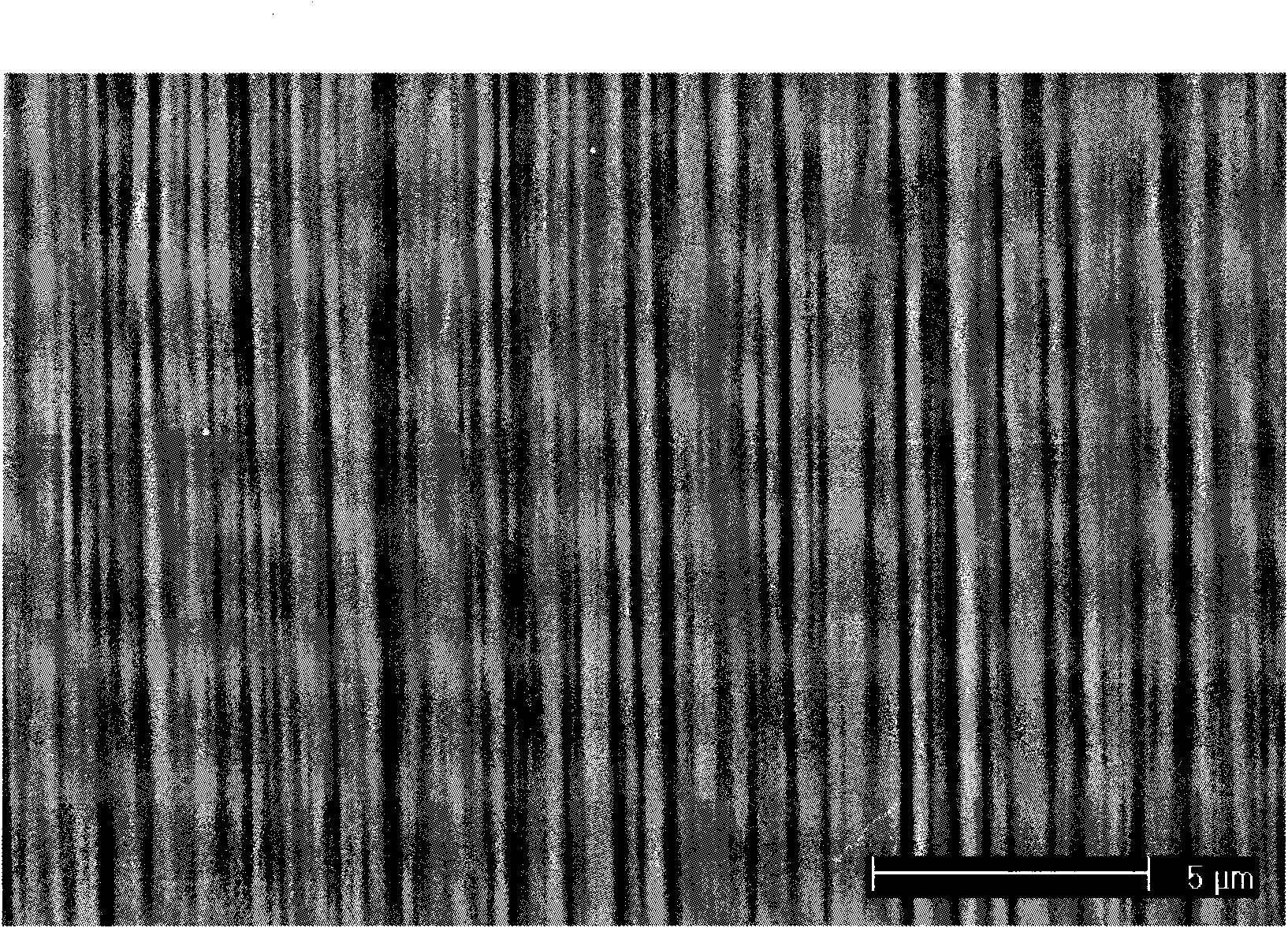

Ag-Cu in-situ fiber composite material and preparation method thereof

The invention discloses an Ag-Cu alloy in-situ fibre composite material with high strength, high electrical conductivity and low Cu content and a preparation technology thereof. The Cu content of thecomposite material is equal to or less than 20% by weight percent; the in-situ fiber composite material is formed by utilizing Ag-Cu alloy eutectic structure and adopting great deformation and reasonable heat treatment technology. The preparation technology comprises the following steps: pouring Ag-Cu alloy in the protective atmosphere after vacuum smelting; carrying out hot extrusion, ageing preheat treatment, cold large strain processing, intermediate heat treatment and stabilizing heat treatment to manufacture Ag-Cu composite material with strengthened Cu fiber in the dimensions of micron,submicron or nanometer. Composite material with optimal combination of tensile strength and electrical conductivity performance can be obtained by optimizing various technological parameters in the manufacturing process. The highest performance can reach that the ultimate tensile strength UTS is equal to or greater than 1GPa, and the relative electrical conductivity is equal to or greater than 60%IACS. The Ag-Cu in-situ composite material can be used as conducting material with high strength and high electrical conductivity.

Owner:KUNMING INST OF PRECIOUS METALS

Electronic equipment

ActiveCN104617974AAdjust intensityImprove user experienceTransmissionIndependent non-interacting antenna combinationsEngineeringElectric equipment

The invention provides electronic equipment. The electronic equipment is provided with a body part, a movable part and a connecting fitting, wherein the relative positions of the body part and the movable part can be changed through the connecting fitting; the body part comprises a first surface; a display unit is arranged on the first surface; the movable part comprises a second surface; the long edge of the second surface is equal to the short edge of the first surface; a first communication antenna unit is arranged in the movable part.

Owner:LENOVO (BEIJING) CO LTD

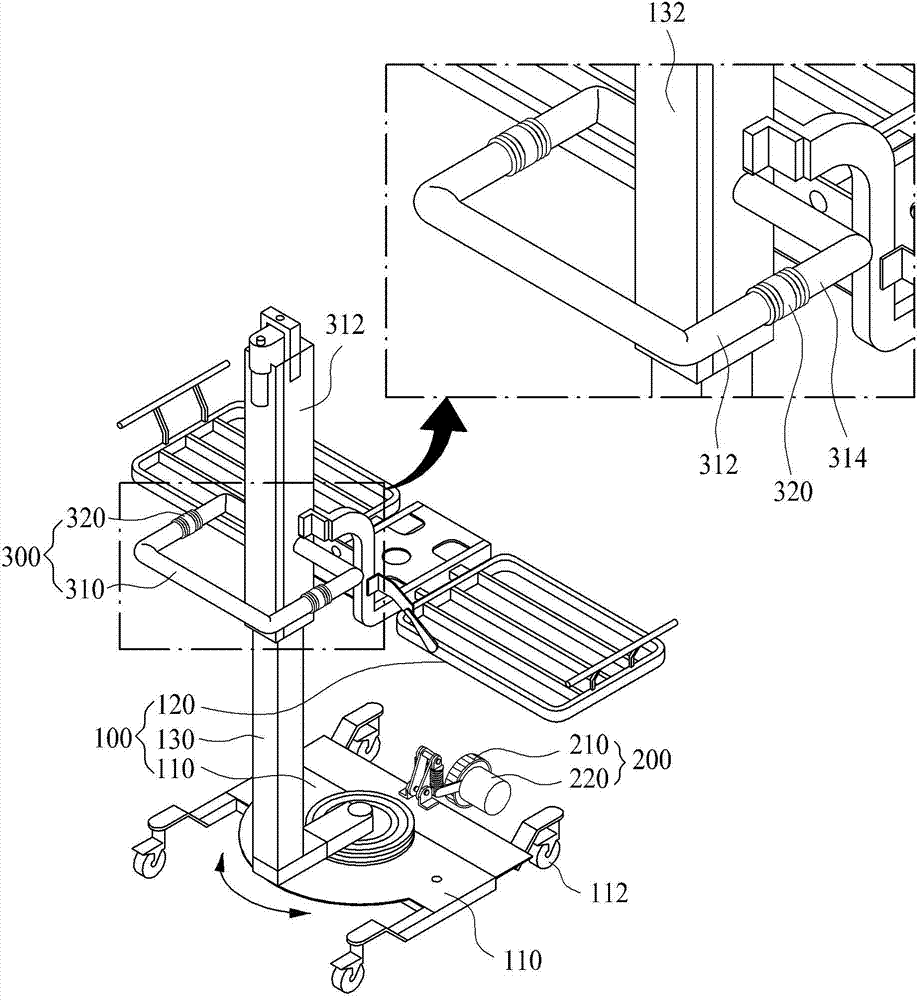

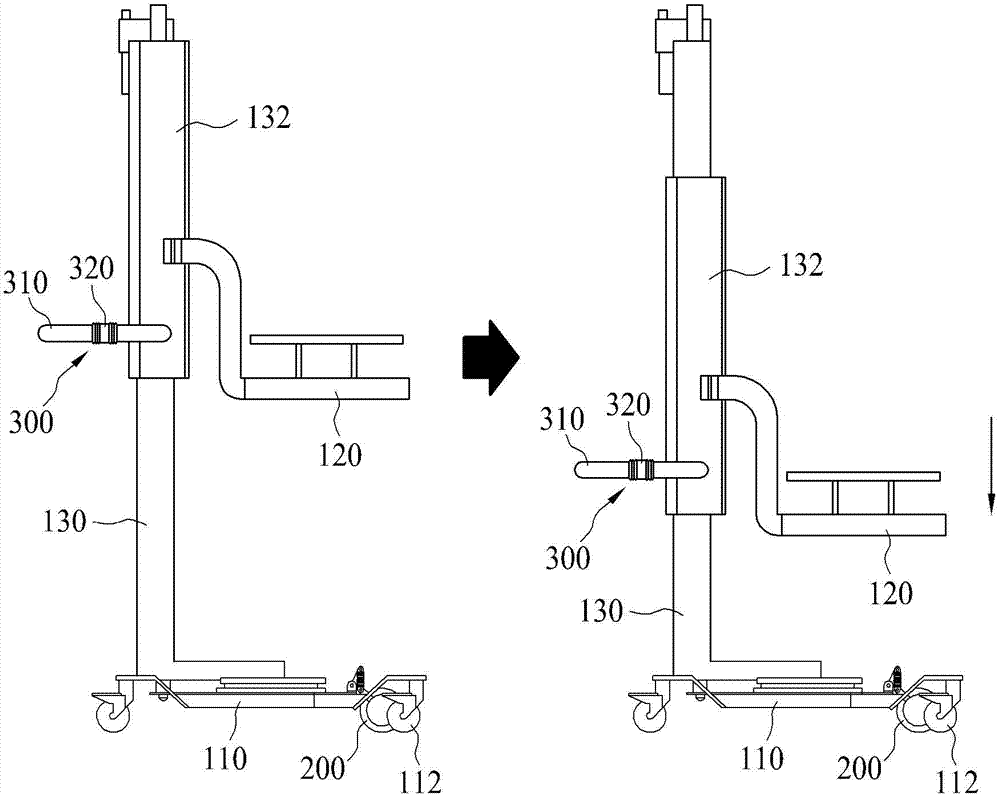

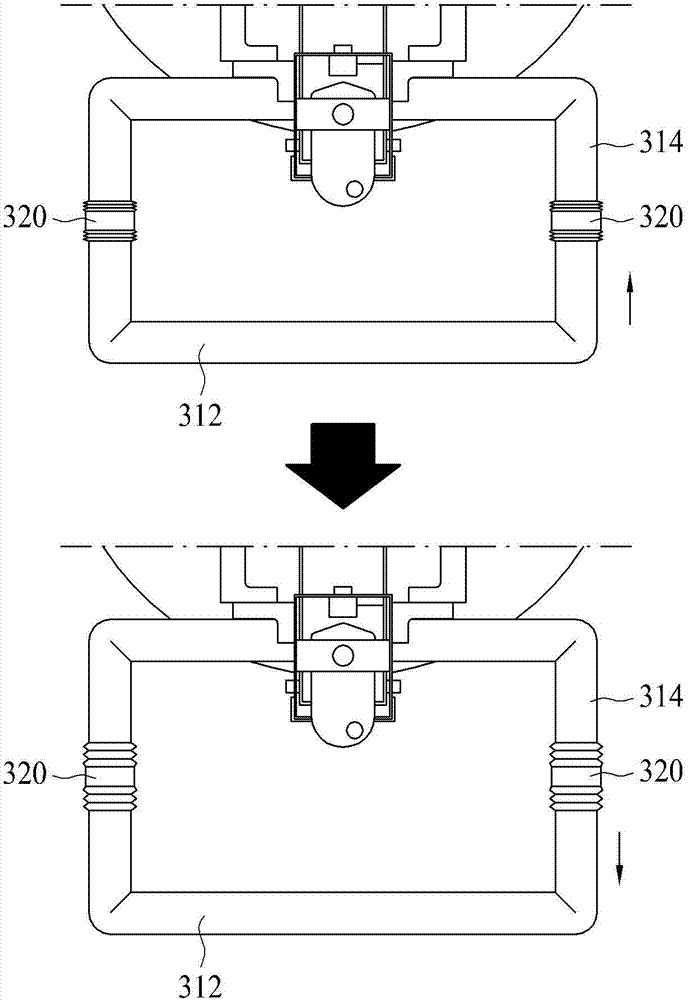

Movable lifting device comprising auxiliary travel system capable of adjusting rotating force

ActiveCN104717949AAdjust the rotation forceReduce physical burdenNursing bedsAmbulance serviceDrive wheelDrive motor

The present invention relates to a movable lifting device comprising an auxiliary travel system capable of separately adjusting rotating force. Disclosed is a movable lifting device comprising an auxiliary travel system capable of adjusting rotating force, wherein the movable lifting device comprises: a base having a plurality of moving wheels; a lifting unit including a bed part on which a user lies, and an elevating frame which is coupled to the base and extends in an upward direction, wherein the elevating frame supports the bed part such that the bed part is located at a predetermined height or higher from the ground, and the elevating frame is arranged to selectively adjust the height of the bed part; an auxiliary travel unit including a driving wheel which is coupled to the base and which contacts the ground, and a driving motor for providing power to the driving wheel, the auxiliary travel unit selectively adjusting the rotating force of the driving wheel; and a control unit including a handle connected to the lifting unit so as to be gripped by a user, a sensor arranged on the handle to sense the working external force and transmit an electrical signal, and a control part for controlling whether to operate the driving wheel and rotating force of the driving wheel based on the electrical signal measured by the sensor.

Owner:KOREA INST OF IND TECH

Porous cross pin for operational internal fixation of anterior cruciate ligament for tissue engineering

The invention discloses a degradable and resorbable porous magnesium compound biological factor cross pin for tissue engineering. The cross pin comprises a body which is cylindrical or rhombic magnesium alloy (1), part of the body (1) is provided with a plurality of porous regions used for containing biological factors with bone growth promoting or tendon differentiation effect, one end of the body is sharp and beneficial to cross transplantation of tendons in operation, and a host material of the body is magnesium or magnesium alloy and is subjected to surface modification. The cross pin can improve integration capability between the transplanted tendon and a bone tunnel to stimulate bone growth or induce bone mesenchymal stem cells (BMSC) in the bone tunnel to form tendon differentiation, and the process of tendon-bone healing is accelerated.

Owner:张强 +1

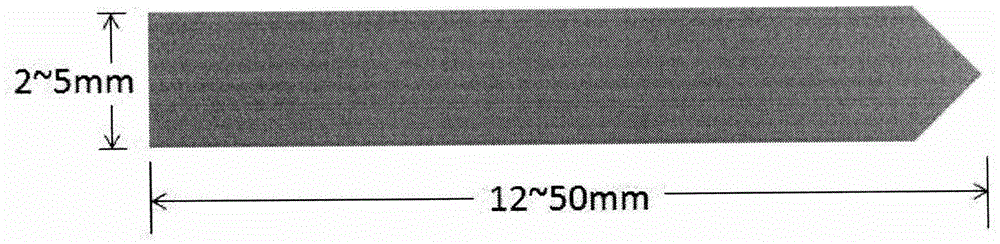

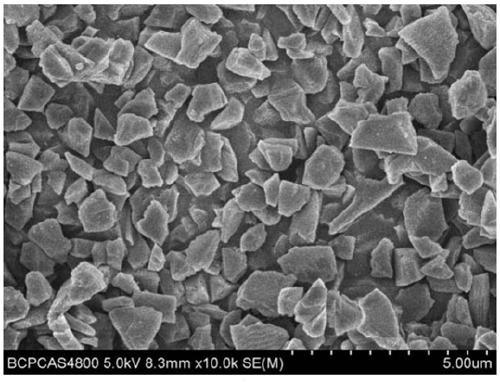

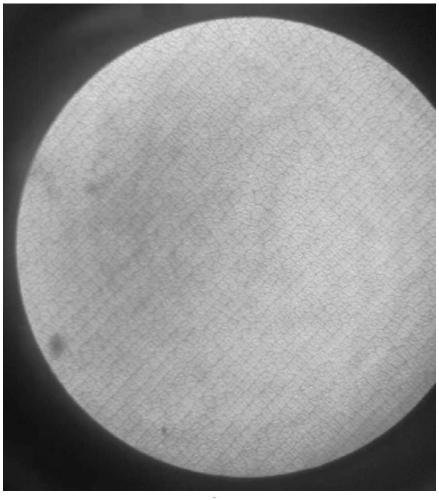

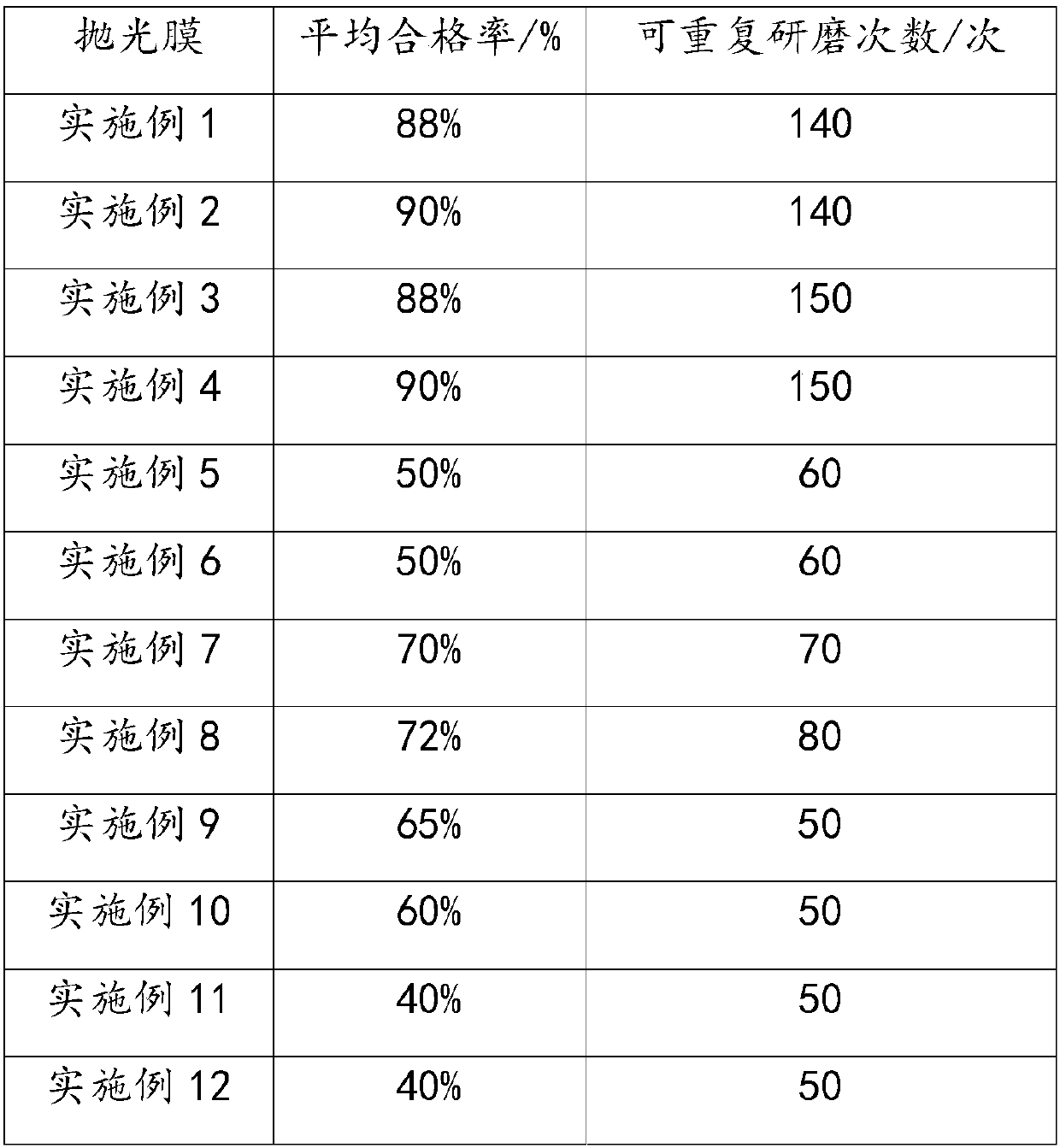

Diamond polishing film as well as preparation method and application thereof

ActiveCN109571237AExtended service lifeHigh bonding strengthAbrasion apparatusGrinding devicesAdhesiveSolvent

The invention relates to the technical field of high-precision grinding and polishing, in particular to a diamond polishing film as well as a preparation method and application thereof. The diamond polishing film comprises a base material and a polishing coating, wherein the polishing coating is mainly prepared with the following components of, by weight: 4-6 parts of coupling-process diamond micro-powder, 3-9 parts of adhesives, 1-5 parts of solvents and 0.04-1 of a hardening agent. The preparation method comprises the following steps that the coupling-process diamond micro-powder, the adhesives, the solvents and the hardening agent are mixed in proportion, a curing agent is added, then the mixture is used for coating the surface of the base material, and curing is conducted to obtain thepolishing film. The diamond polishing film prepared through the method has the advantages that in the processing process of an optical communication device, such as an optical fiber connector, the processing requirements of an optical fiber connector can be effectively met, the processing yield is improved, and the service life of the polishing film is prolonged.

Owner:BEIJING POLYSTAR HITECH CO LTD

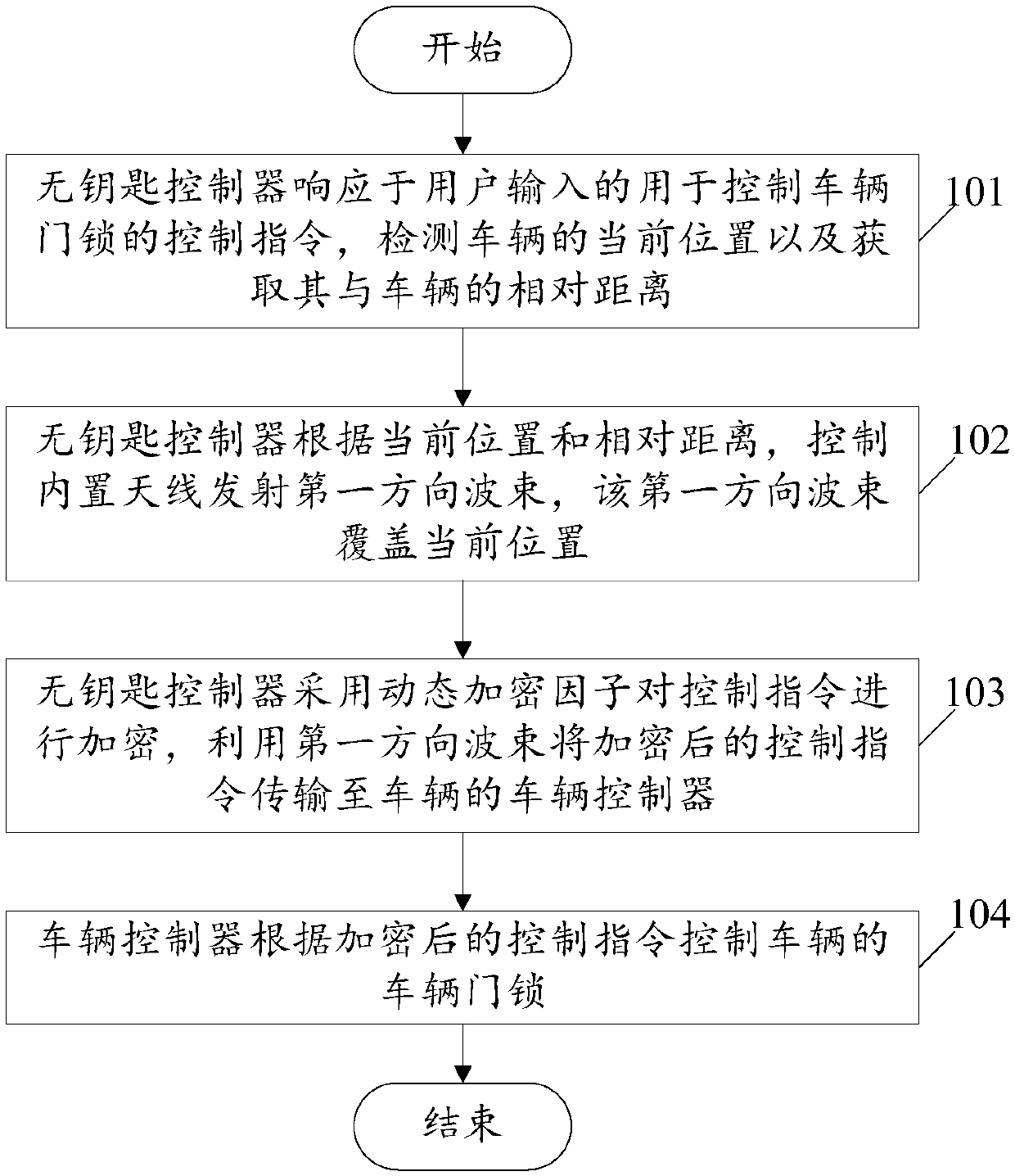

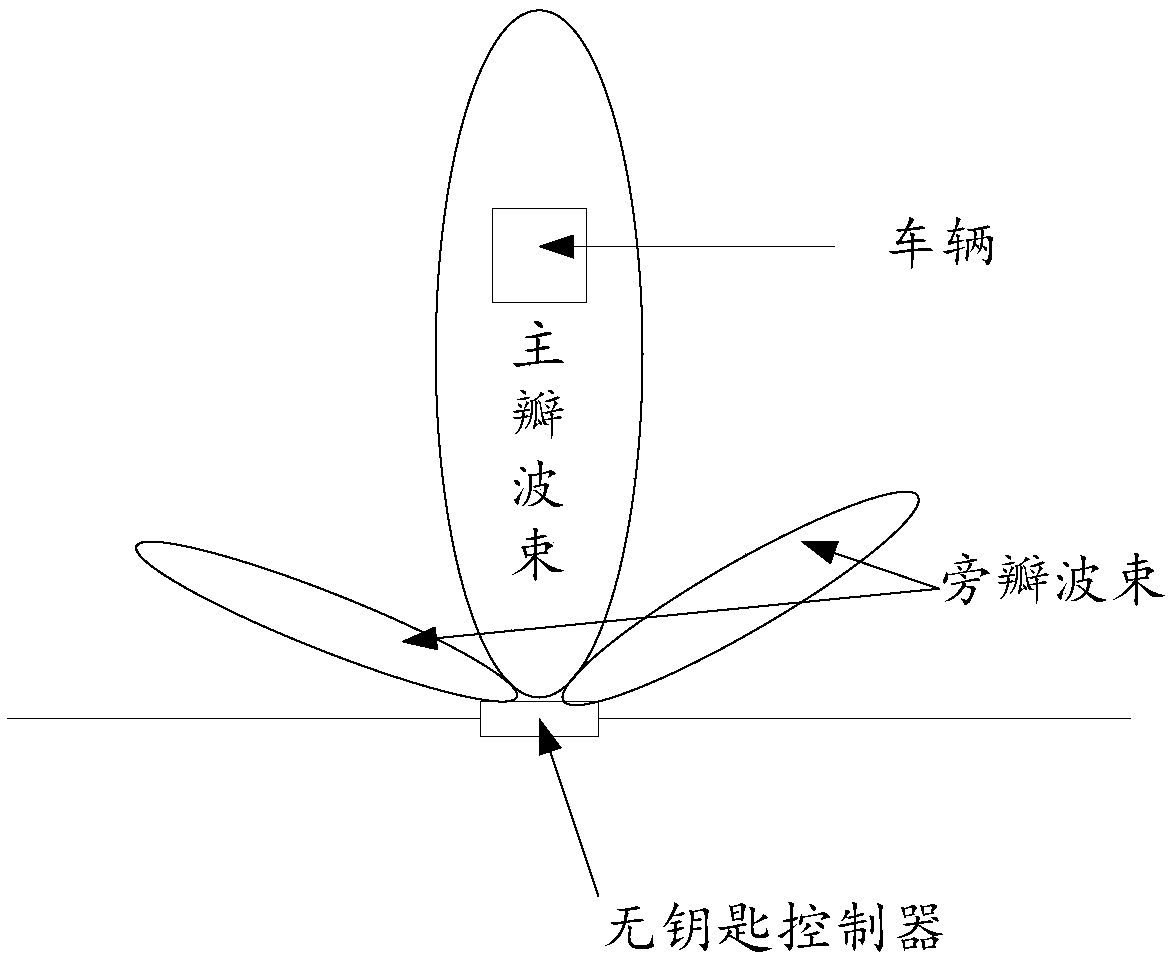

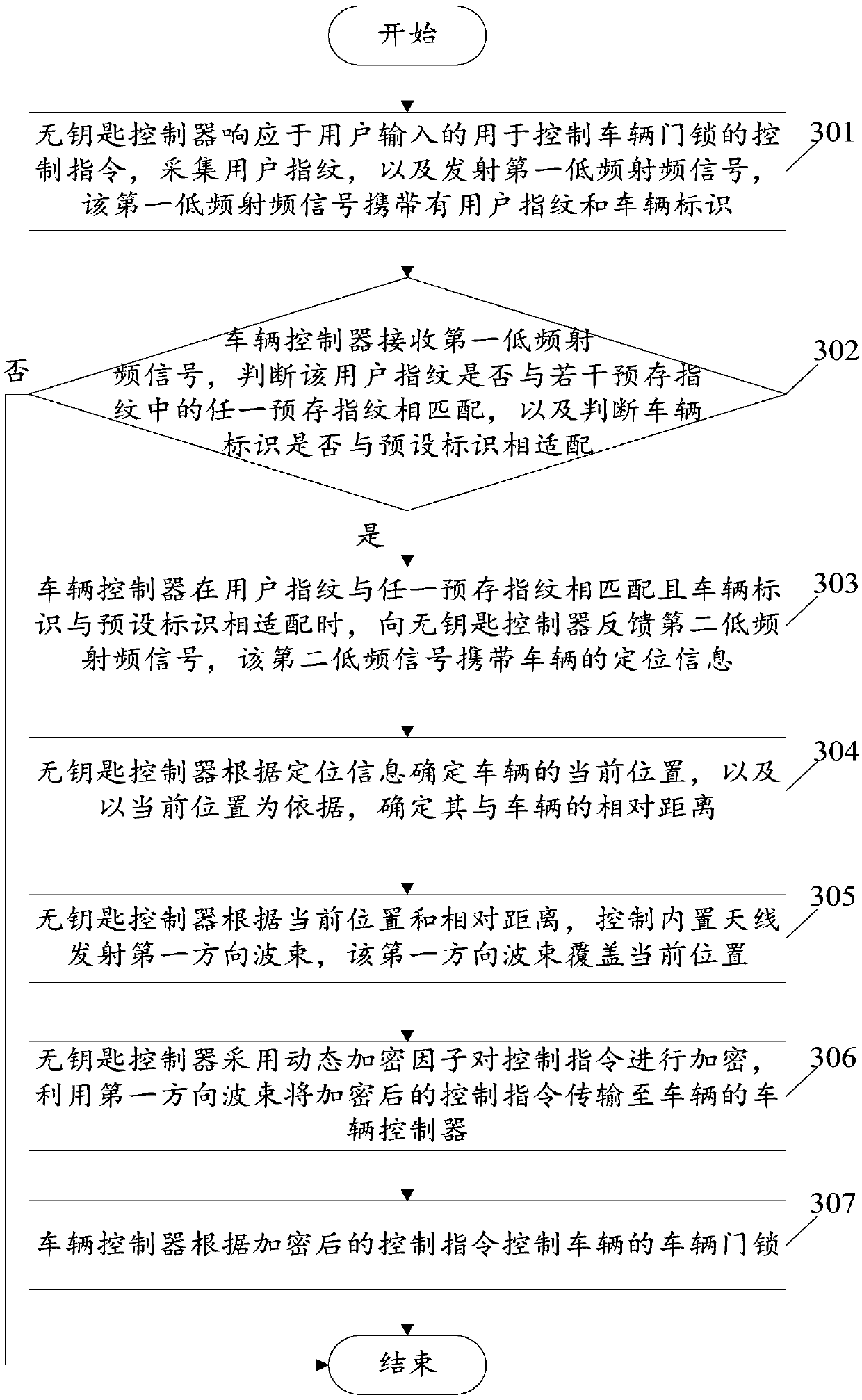

Method and system for achieving remote control over vehicle through antenna orientation

ActiveCN107719304ARaise Receive InstructionsEffective remote controlAnti-theft devicesUser inputRemote control

The embodiment of the invention relates to the technical field of electronic vehicle control, and discloses a method and system for achieving remote control over a vehicle through antenna orientation.The method comprises the steps that a key-free controller responds to a control instruction which is input by a user and used for controlling a vehicle door lock, the current position of the vehicleis detected, and the relative distance between the key-free controller and the vehicle is obtained; the key-free controller controls a built-in antenna to transmit a first-direction wave beam according to the current position and the relative distance, wherein the current position is covered with the first-direction wave beam; the key-free controller encrypts the control instruction by using dynamic encryption factors, and the encrypted control instruction is transmitted to a vehicle controller by using the first-direction wave beam; the vehicle controller controls the vehicle door lock according to the encrypted control instruction. When the embodiment is implemented to adjust the signal transmission distance and enhance the signal intensity, the instruction receiving capacity of the vehicle controller is easily improved, and the effective remote control over the vehicle is achieved.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

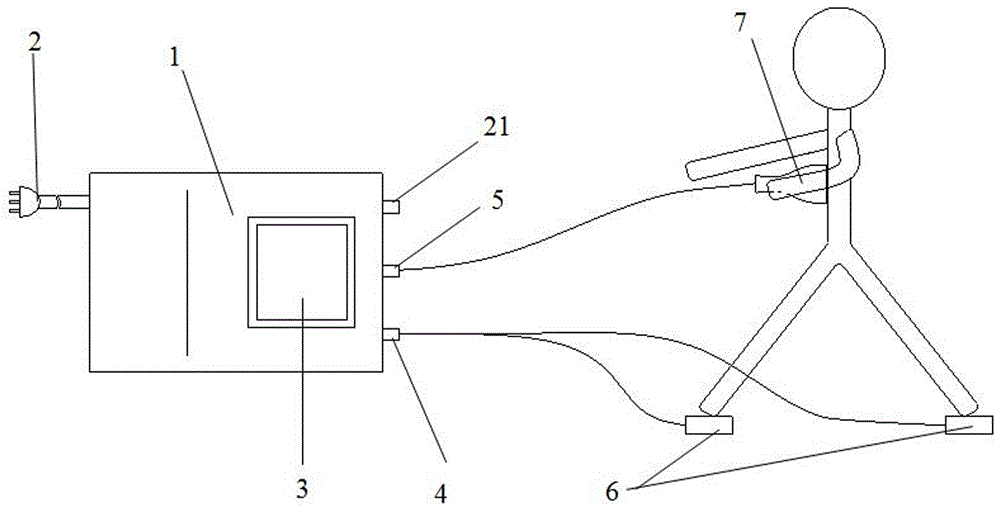

Bodybuilding physical therapy device

ActiveCN105662842APromote circulationEliminate fatigueDevices for heating/cooling reflex pointsElectrotherapyClosed loopEngineering

The invention discloses a bodybuilding physical therapy device which comprises a control host and a physical therapy contact assembly.The control host is provided with a power connection device connected with an external alternating current power source.The control host is provided with an interface I and an interface II.The interface I and the interface II are communicated with two poles of alternating current respectively.A conductive physical therapy contact in the physical therapy contact assembly is connected with the interface I and the interface II respectively, and therefore the two poles of the alternating current and the human body form a closed loop during use.The control host is provided with a pulse generation circuit, a frequency modulation circuit, a voltage regulation circuit and a current control circuit and used for generating alternating current pulses, regulating the polarity change frequency of the two poles, regulating the voltage between the two poles and controlling the current flowing through the human body to be lower than 10 mA.The two poles of the bodybuilding physical therapy device and the human body form the closed loop, pulse alternating current produced between the two poles alternately stimulates main and collateral channels and blood vessels in the human body, circulation and the stimulation or restraining effect are achieved, the physical therapy bodybuilding effect is remarkable, and the bodybuilding physical therapy device is safe and reliable.

Owner:黎富尧

High-strength conductive aggregate applied to conductive concrete and preparation method of conductive aggregate

The invention discloses a high-strength conductive aggregate applied to conductive concrete and a preparation method of the conductive aggregate. The conductive aggregate is characterized by being prepared from following four components in percentage by mass: 70-93 percent of clay, 1-6 percent of iron powder, 1-10 percent of Fe3O4 and 5-14 percent of polyacrylate-styrene copolymer. The preparation method is implemented according to the following steps: (1) pretreating the clay and synthesizing the polyacrylate-styrene copolymer; (2) weighing all the components; (3) pressing a mixed material of all the components into a columnar blank body by adopting a dry-pressing method; and (4) sending the blank body into a reducing atmosphere furnace for roasting to obtain the high-strength conductive aggregate. The conductive aggregate prepared by the method disclosed by the invention has the advantages of low cost, good conductivity, excellent mechanical properties and the like and is applied to the conductive concrete, so that the concrete can present good conductivity and mechanical properties.

Owner:WUHAN UNIV OF TECH

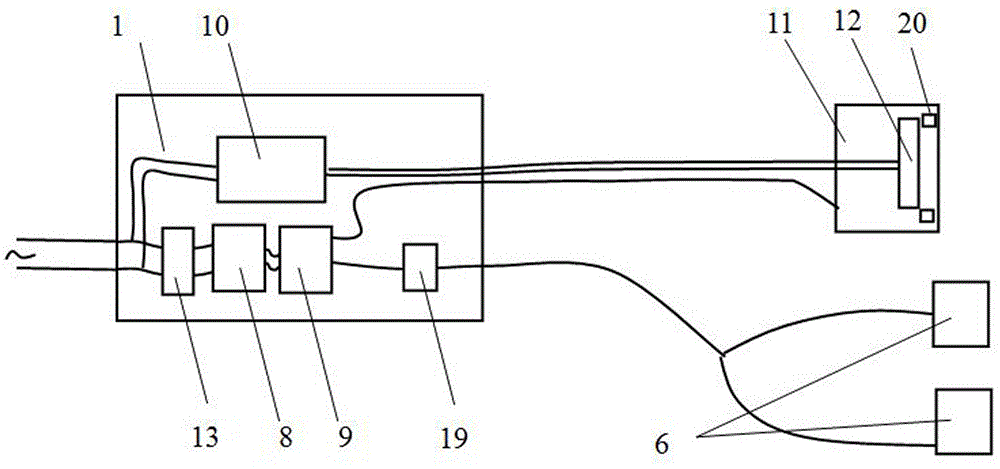

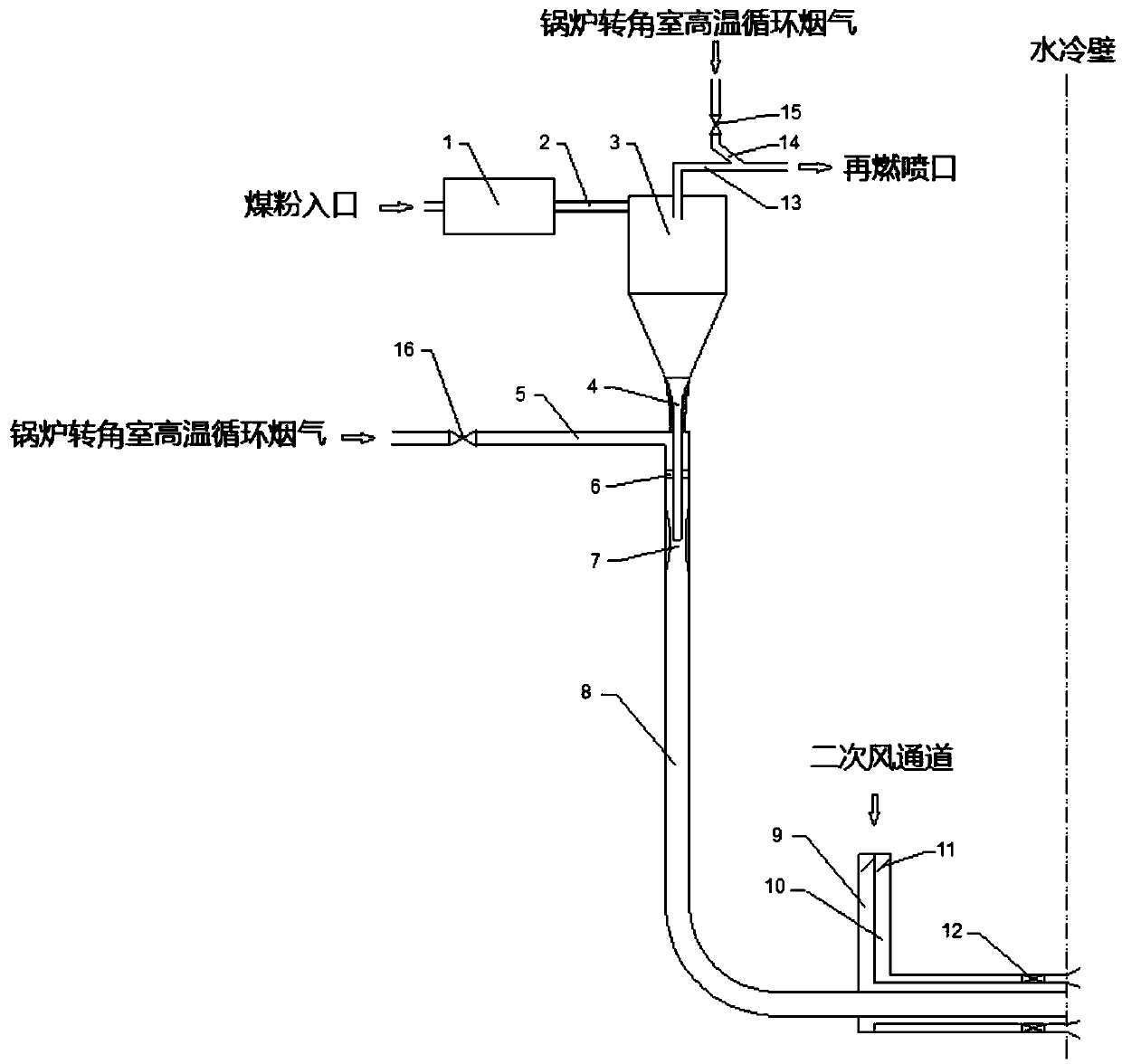

Pulverized coal pre-pyrolyzation decoupling combustion device

ActiveCN109539245AHigh reactivityEfficient combustionNon-combustible gases/liquids supplyDraught inductionProcess engineeringCoal

The invention discloses a pulverized coal pre-pyrolyzation decoupling combustion device comprising a pyrolysis chamber, a cyclone separator, an ejector device and a particle burning device; the pyrolysis chamber is provided with a raw material inlet and a product outlet; the cyclone separator is provided with a product inlet, a volatile component outlet and a particle outlet; the product inlet ofthe cyclone separator communicates with the product outlet of the pyrolysis chamber through a pyrolysis product transport passage; a reburning fuel pipe is arranged at the volatile component outlet ofthe cyclone separator; a discharging pipe is arranged at the particle outlet of the cyclone separator; the reburning fuel pipe is used for being led into a hearth; the discharging pipe communicates with a particle combustion device through the ejector device; ejector gas flow is led into the ejector device; a particle combustion device comprises an air duct; and the air duct is led into the hearth. The pulverized coal pre-pyrolyzation decoupling combustion device is based on the decoupling idea, is suitable for pulverized coal decoupling combustion, can achieve the higher pulverized coal combustion rate, is relatively good in combustion stability, and can effectively suppress NOx generation.

Owner:XI AN JIAOTONG UNIV

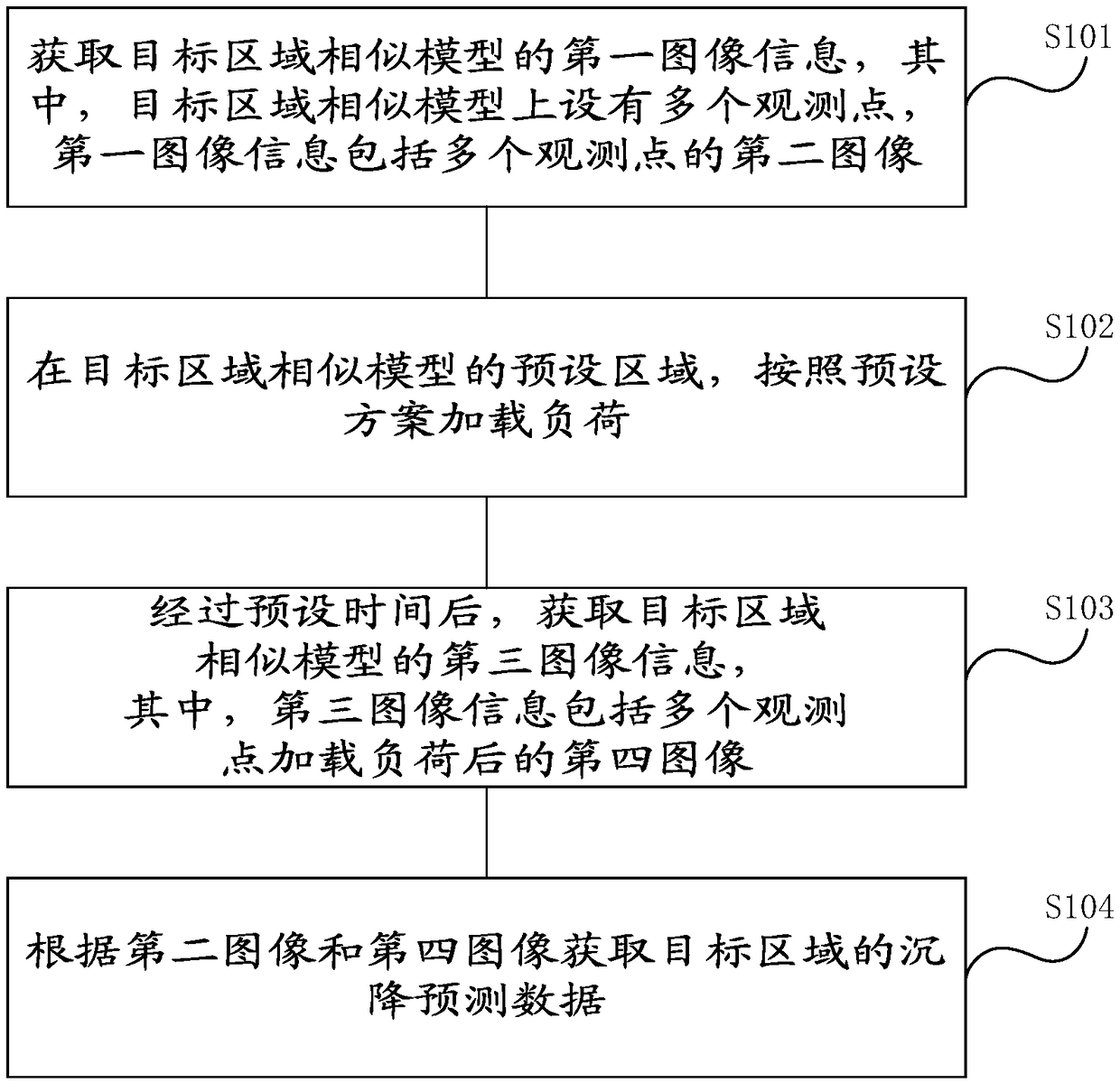

Settlement prediction method and system

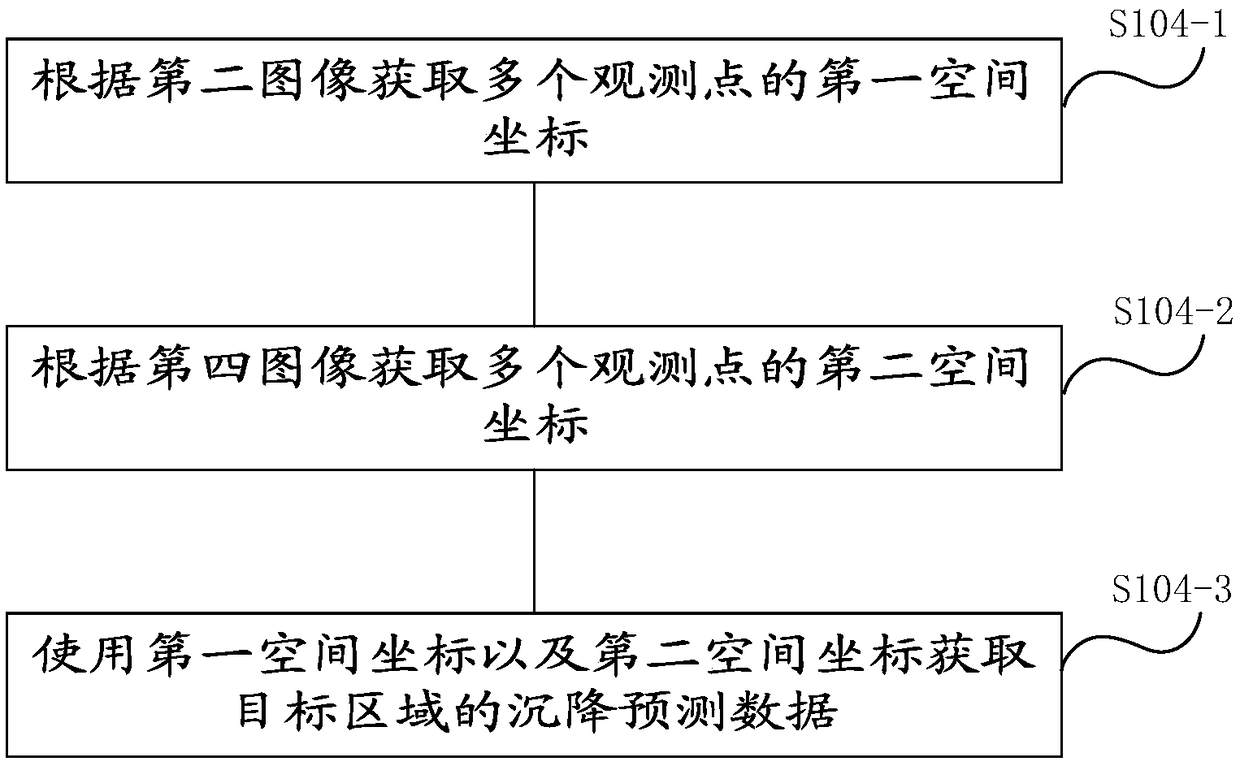

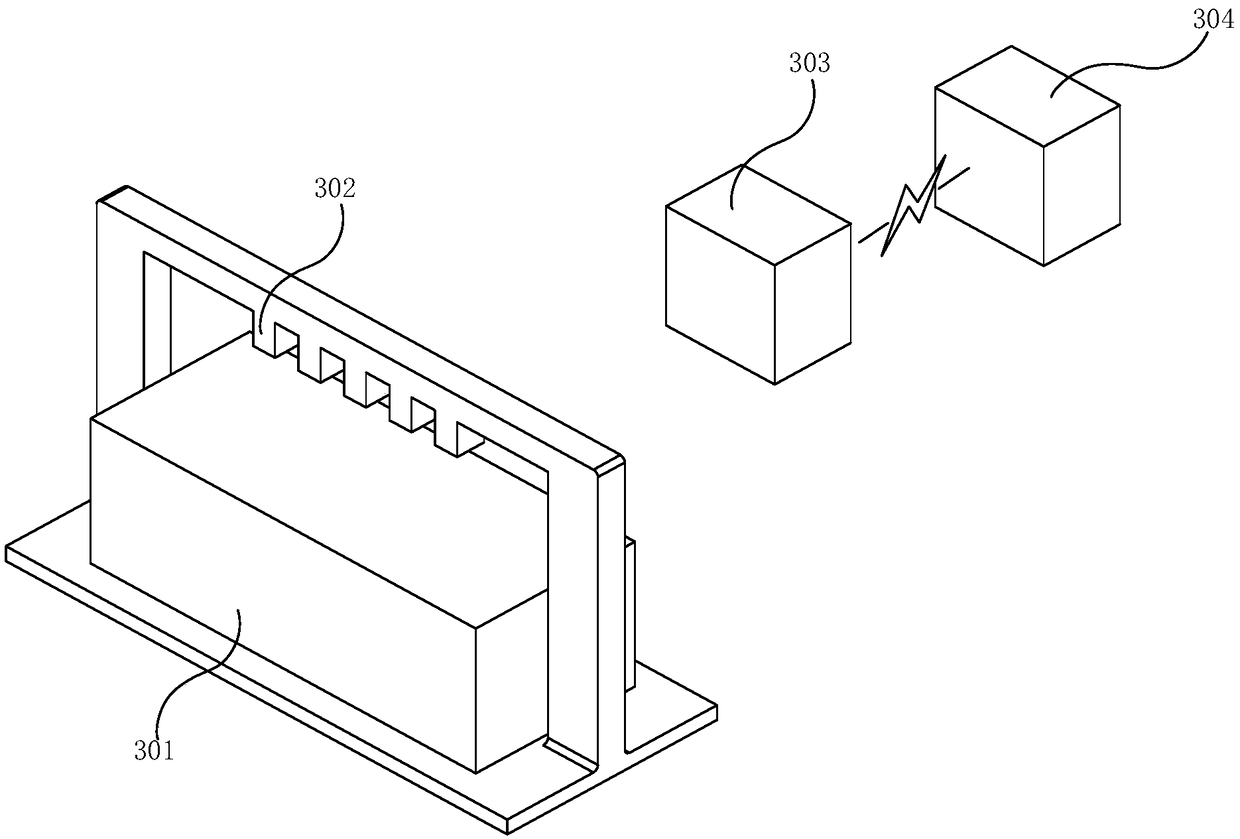

The invention provides a settlement prediction method and a system, which relate to the field of geographic information technology. The settlement prediction method comprises: acquiring first image information of a target region similarity model, wherein a plurality of observation points are arranged on the target region similarity model, and the first image information comprises a second image ofa plurality of the observation points; Loading a load according to a preset scheme in a preset area of the target area similar model; Acquiring third image information of the target region similaritymodel after a predetermined time elapses, wherein the third image information comprises a fourth image after a plurality of the observation points are loaded with the load; Acquiring settlement prediction data of the target region according to the second image and the fourth image. The invention realizes the effect of adjusting the intensity of the load, lowering the cost and forecasting more accurately.

Owner:AERIAL PHOTOGRAMMETRY & REMOTE SENSING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com