Patents

Literature

355results about How to "Obvious price advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

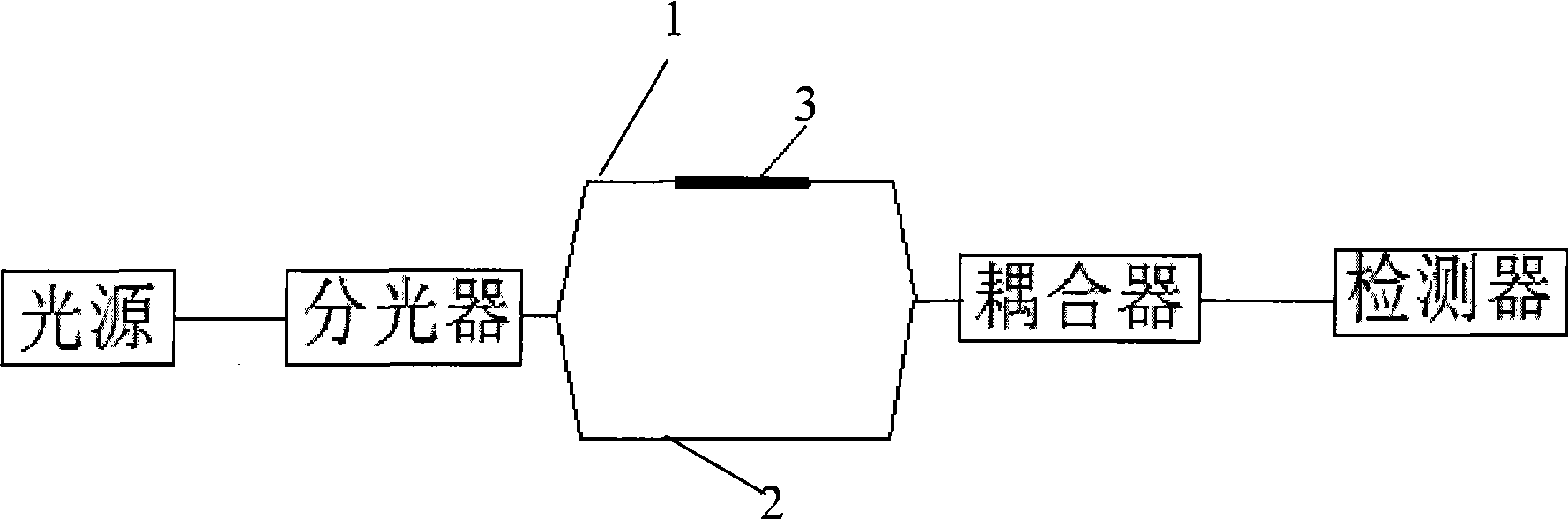

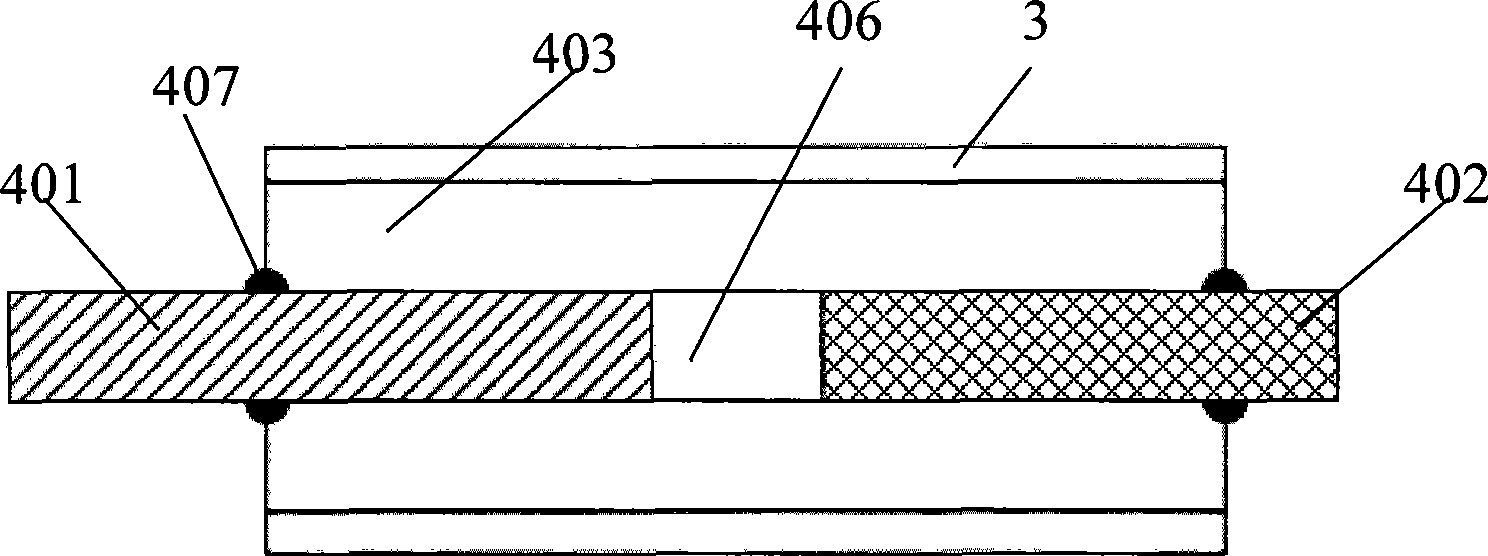

Hydrogen sensor and pd film hydrogen sensing system

InactiveCN101451959AWill not affect measurement resultsOvercome susceptibility to ambient temperature disturbancesMaterial analysis by optical meansFiberAlloy

The invention relates to a hydrogen sensor and a Pd film hydrogen sensitive system, wherein the hydrogen sensor comprises introduction fiber, reflection fiber and a hollow tube, a surface of which has a Pd or Pb alloy film, the introduction fiber and the reflection fiber are respectively connected with two ends of a cavity of the hollow tube, two opposite fiber end faces are parallel and constitute an intervene cavity with the tube cavity. According to the Pd film hydrogen sensitive system, light with wide spectrum is transmitted to the introduction fiber of a hydrogen sensor, and intervene light generated on two opposite end of the introduction fiber and the reflection fiber is received, change of the length of the intervene cavity is determined through collecting intervene spectrum signals, further computing concentration of hydrogen. The invention overcomes problems that it is difficult to realize high resolution stable measurement due to light source fluctuation and optical fiber disturbance and the like, and is easy to be affected by temperature in prior art. Measurement result is correct and temperature is strong, cost is low.

Owner:TSINGHUA UNIV

Method for constructing surgical virtual operation teaching and training system

InactiveCN101996507AImprove teaching qualityReduce teaching costsCosmonautic condition simulationsSimulatorsSimulationVRML

The invention provides a method for constructing a surgical virtual operation teaching and training system. The method comprises the following concrete steps: (1) acquiring various inspection data classified according to normal people and patients, intensively storing the acquired data, and constructing an integrated male virtual human model and an integrated female virtual human model; (2) carrying out geometric modeling, computational modeling and deformation computation on medical data, and carrying out modeling on bones and soft tissues by adopting a multi-outline three-dimensional reconstruction algorithm; (3) reconstructing by adopting a three-dimensional model of 3DMAX10, mapping and giving physiological characteristics to organic tissues; (4) compiling related objects and simulated scenes of a virtual operation by virtual reality modeling language (VRML); (5) carrying out preoperative preparation in the virtual operation scenes, and checking and confirming patient information; (6) carrying out complete operational details of the actual method of the virtual operation again; (7) establishing a simulated operation teaching evaluation system; and (8) carrying out comprehensive evaluation and examination on a teacher and each trainee. In the method, the simulated operation teaching system is constructed by utilizing the virtual reality technology, thereby providing a wide and transparent simulated teaching and research platform for hospitals and medical schools.

Owner:罗伟

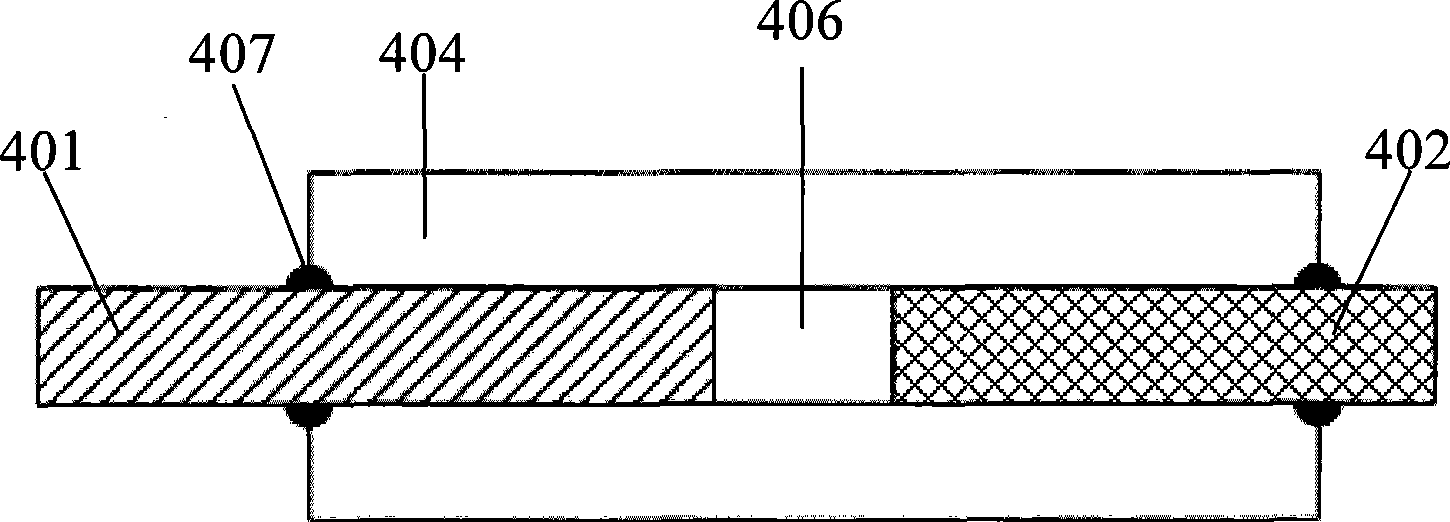

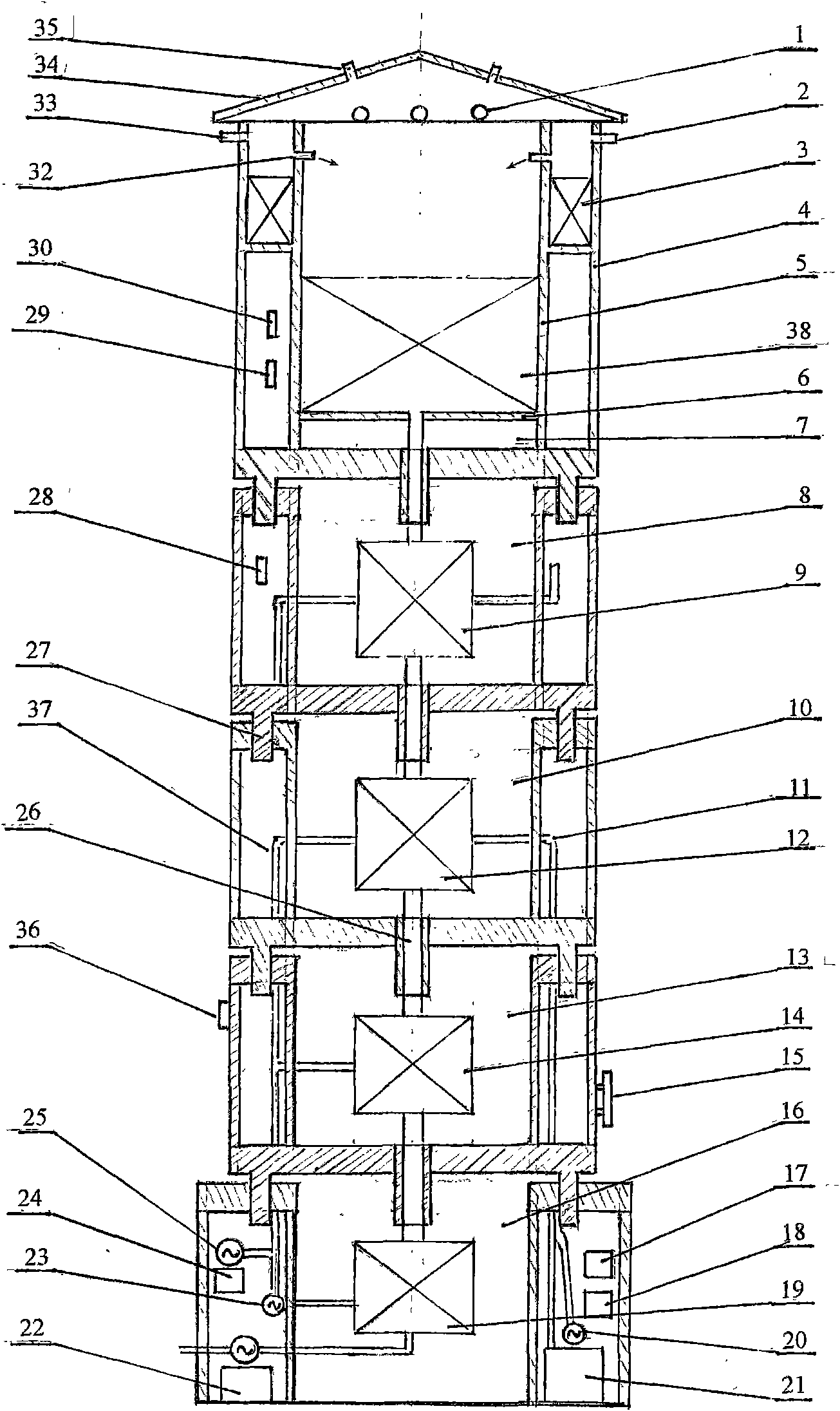

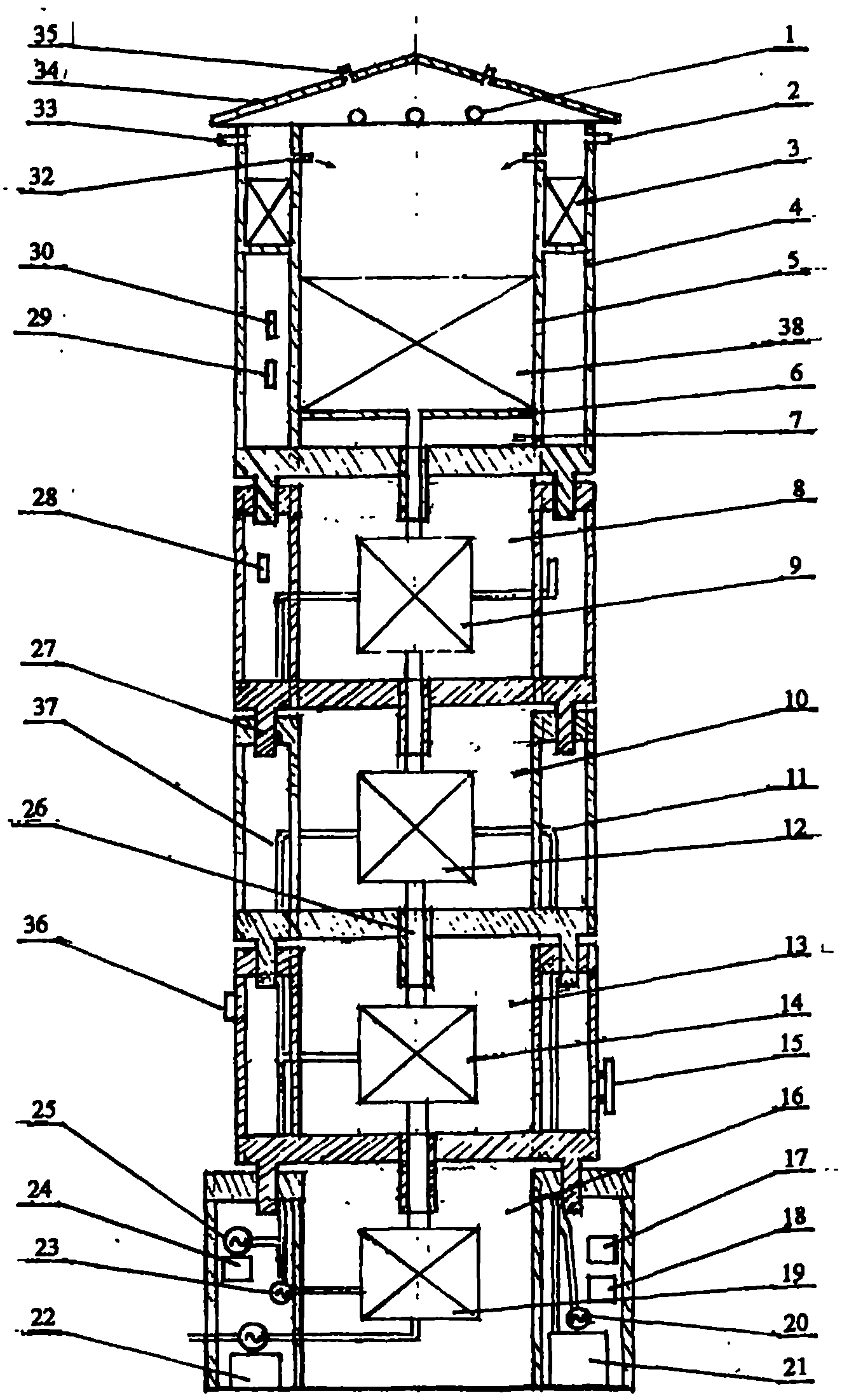

Device for filtering various water sources into direct drinking water

InactiveCN102107994AFlexible configurationRough surfaceEnergy based wastewater treatmentMultistage water/sewage treatmentLarge applicationsSmall footprint

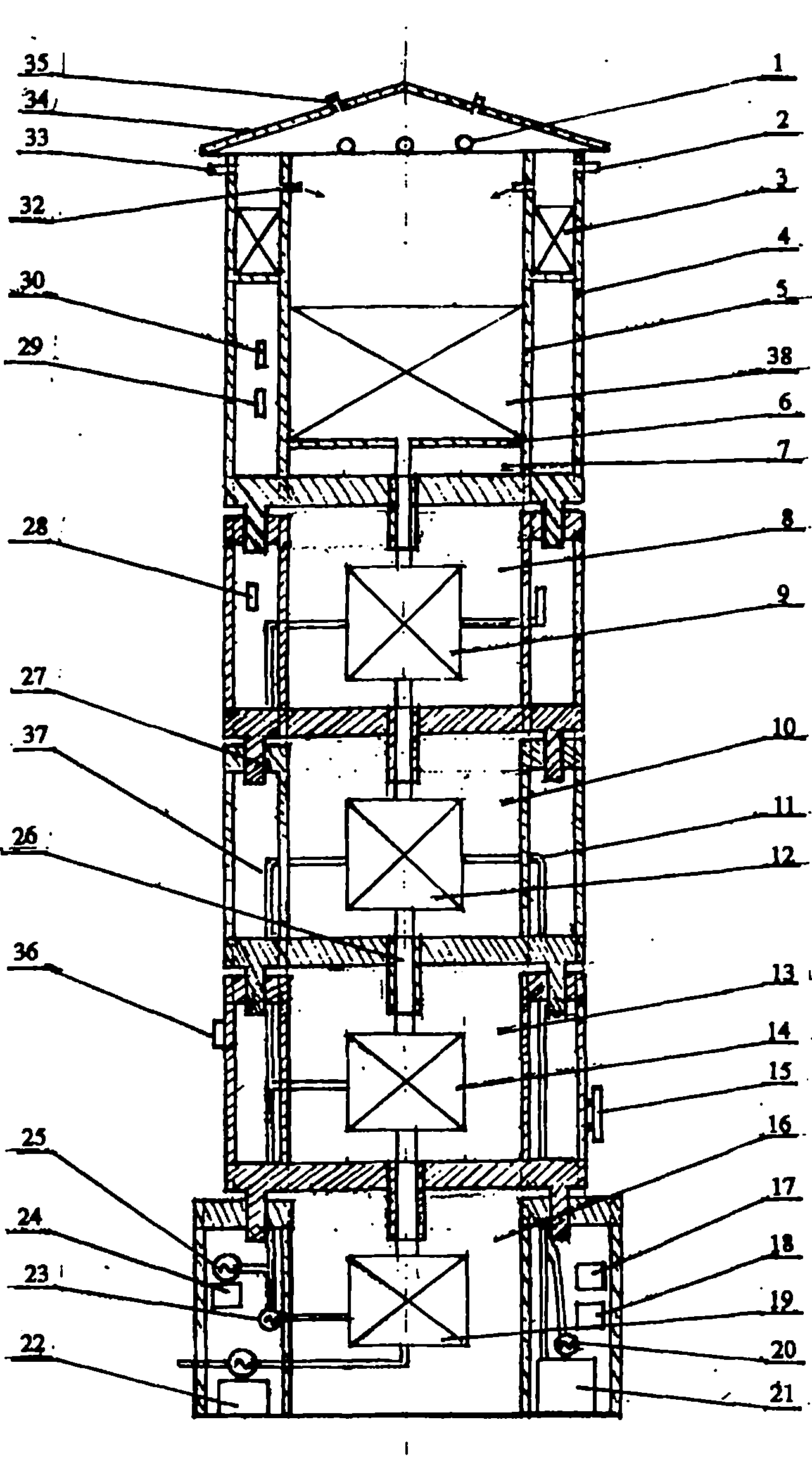

The invention discloses a device for filtering various water sources into direct drinking water. A primary biological-purification combined filter core water purifying module is added in front of conventional water purifying treatment equipment according to a water body purifying principle; and the steps of ozone pre-oxidation and chlorine sterilization are not needed, and pollutants in water, which are harmful to human bodies, are removed by relying on the metabolism effect of clustered microorganisms in the water. The device has the advantages of compact structure, small occupied area, low water making cost and large application range; the made purified water can be afforded by vast numbers of rural population and urban population. The invention is implemented through the following technical scheme: the disclosed biological-purification combined filter core water purifying module and the conventional water purifying treatment unit thereof are designed and manufactured into standard combined filter core modules; the combined filter core modules are buckled with each other from up to down to form a tower-shaped water purifying device according to the sequence of a water purifying treatment process; as for different water resources and different customer requirements, all that is needed is to replace the combined filter core modules in different processes according to the local water quality situation; and various water sources can be filtered into the direct drinking water.

Owner:郑高宽

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

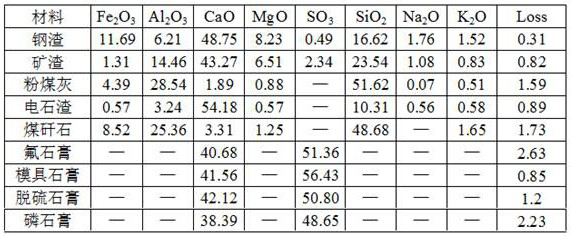

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

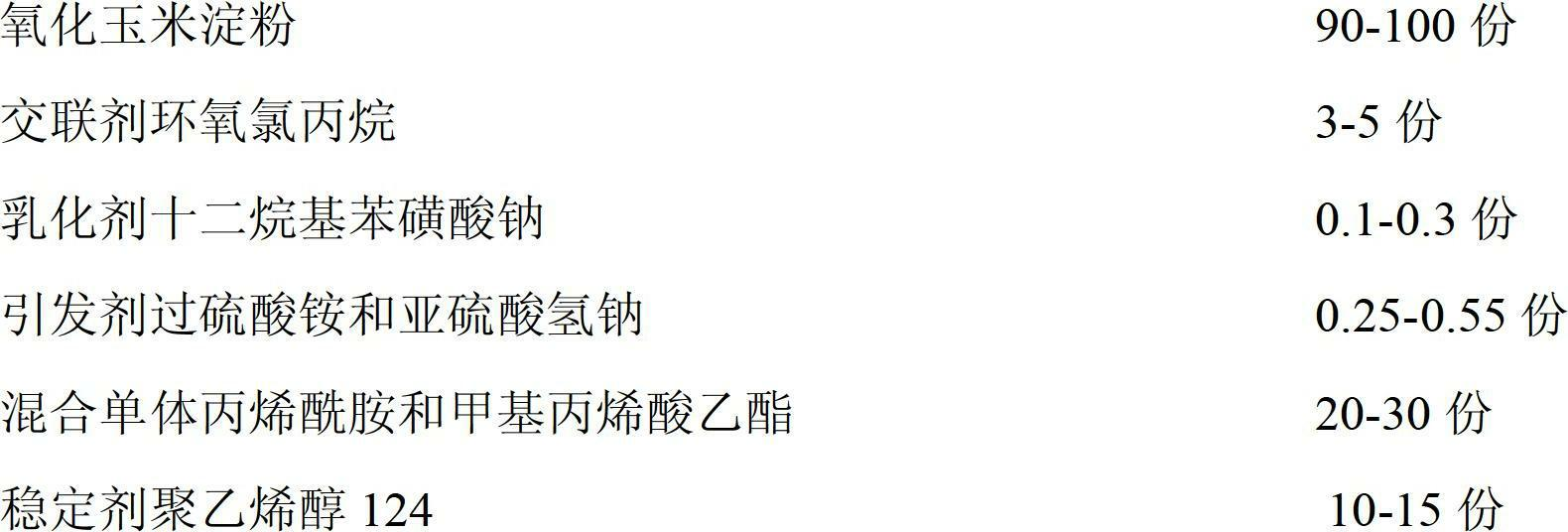

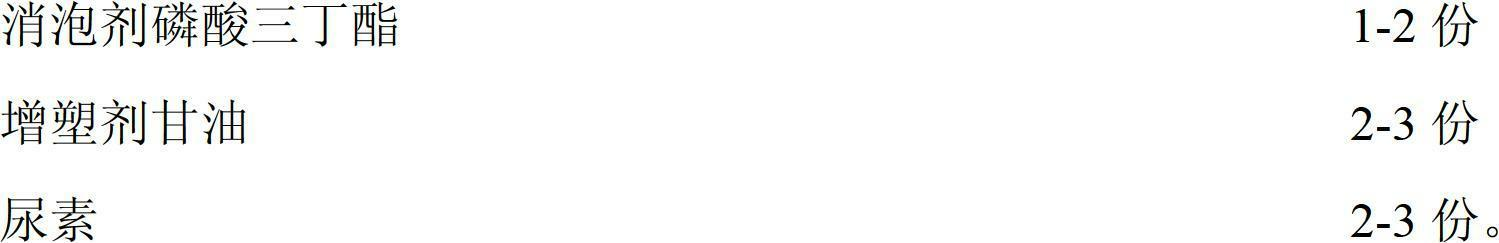

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

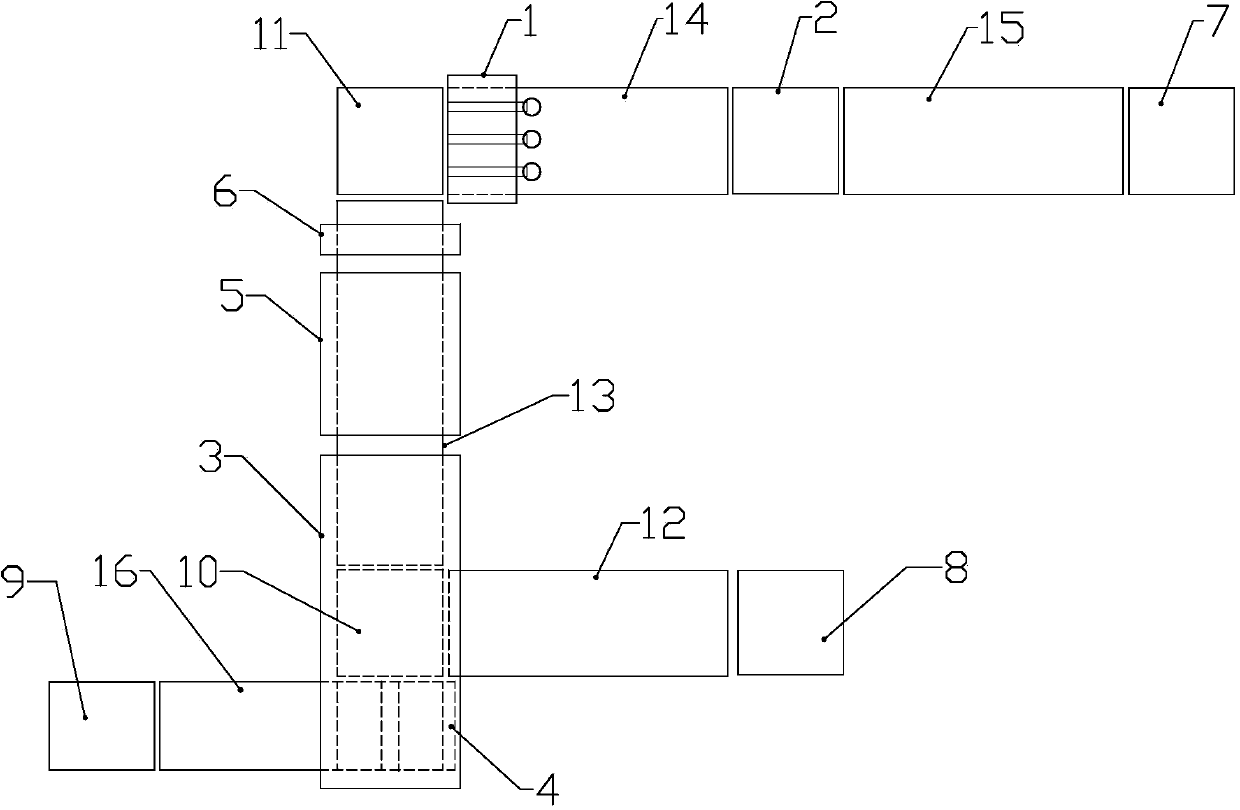

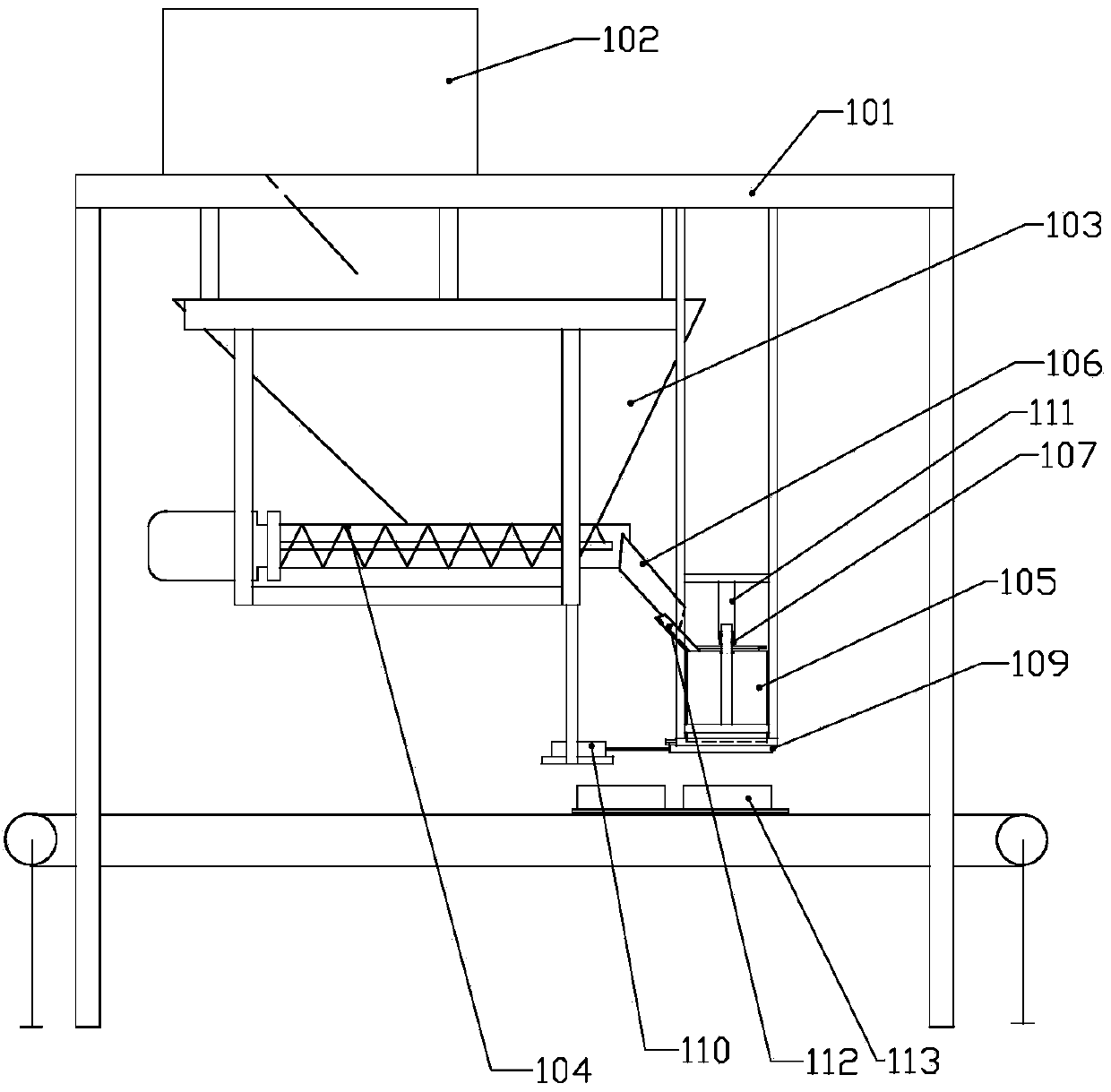

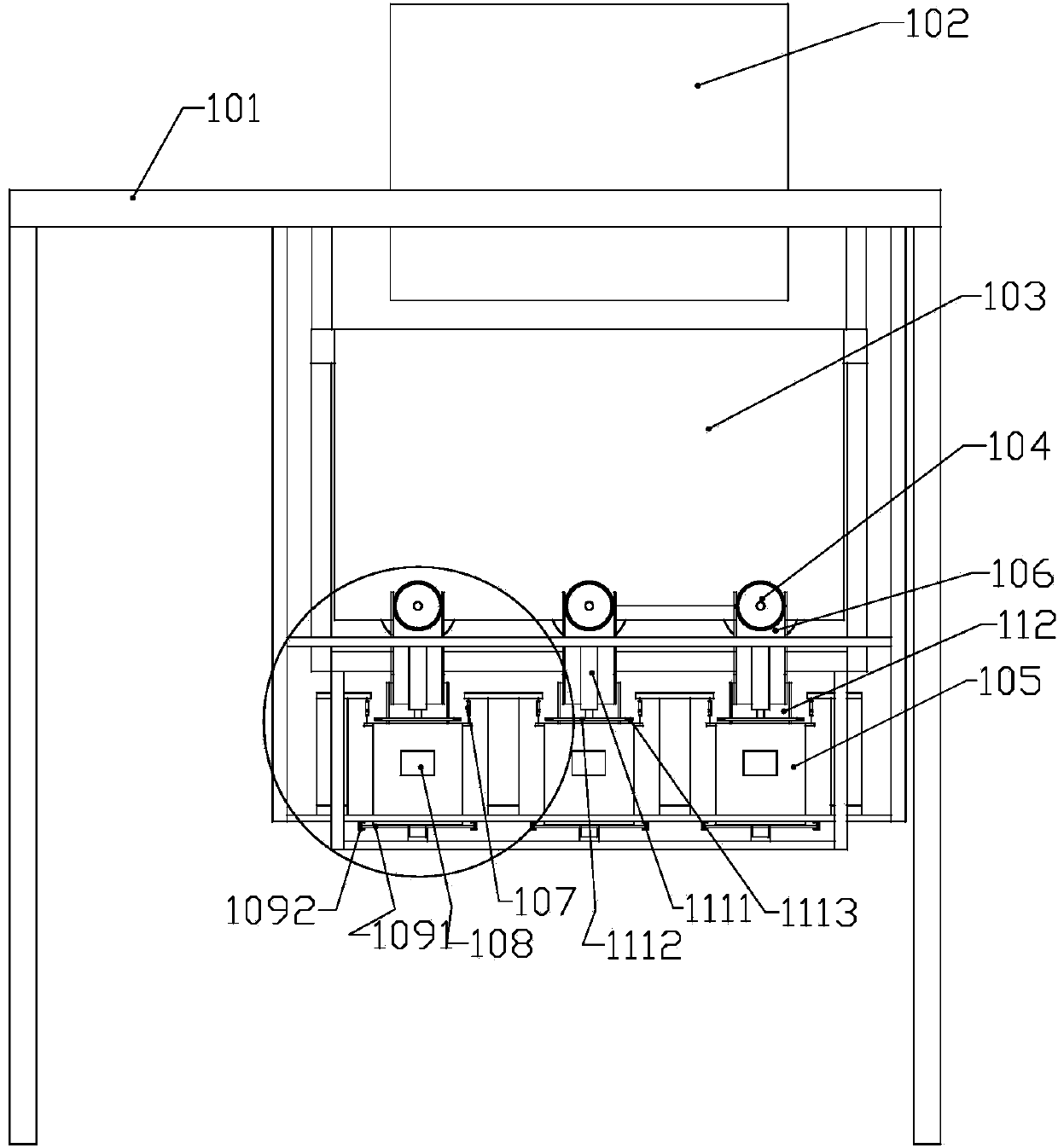

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

Method for preparing positive electrode material of lithium ion accumulator

InactiveCN1595680AReduce manufacturing costImprove securityElectrode manufacturing processesSecondary cellsLithium hydroxideLithium carbonate

The invention relates to a manufacture method for positive material of lithium ion accumulator , whose component concentration is: at least one element between LiNi0.5-xM0.5-XM2xO2 (M=Co,Ti,Al) (0<=X<0.5). The manufacture method includes the following steps: dry or wet mix of sentiment hydroxide or carbonate compounds of at least one element between Ni,Mn,Co,Ti and Al or its oxide and lithium hydroxide or carbonate lithium (dry for the material of wet mixture); accumulate the mixture whose width is 2mm~60mm; make particle under the pressure of 4MPa~40MPa; high temperature solid state reaction happens under the temperature of 700~1050deg.C; shatter it after cooling, the diameter of particle is 0.5~25mu m. The manufacture method can make the density of products reach 2.0g / cm3~2.8g / cm3, increase positive filler level of lithium ion and lithium polymer accumulator and its capacity.

Owner:吴孟涛

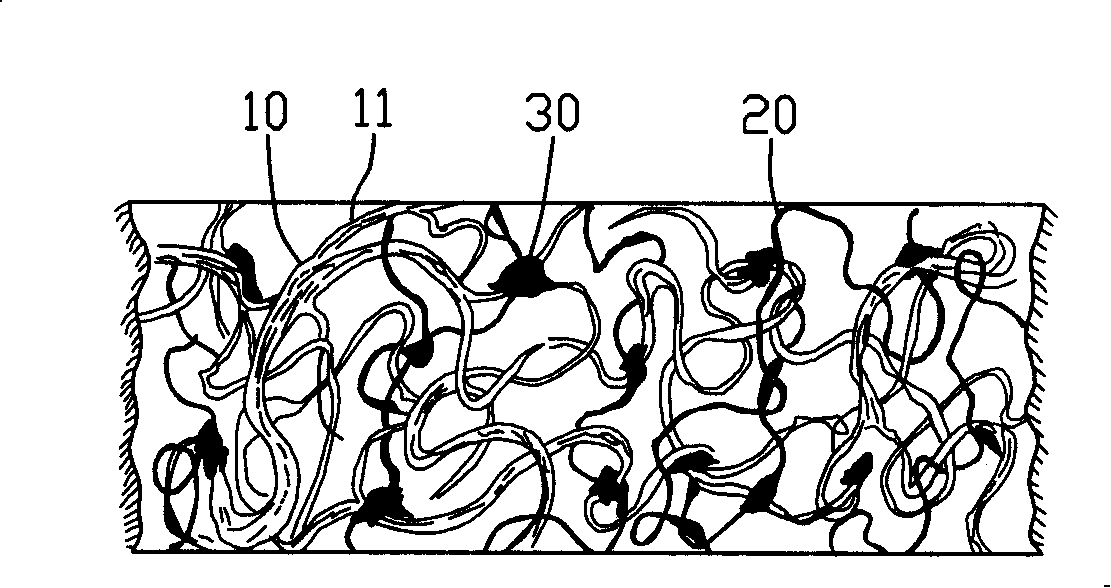

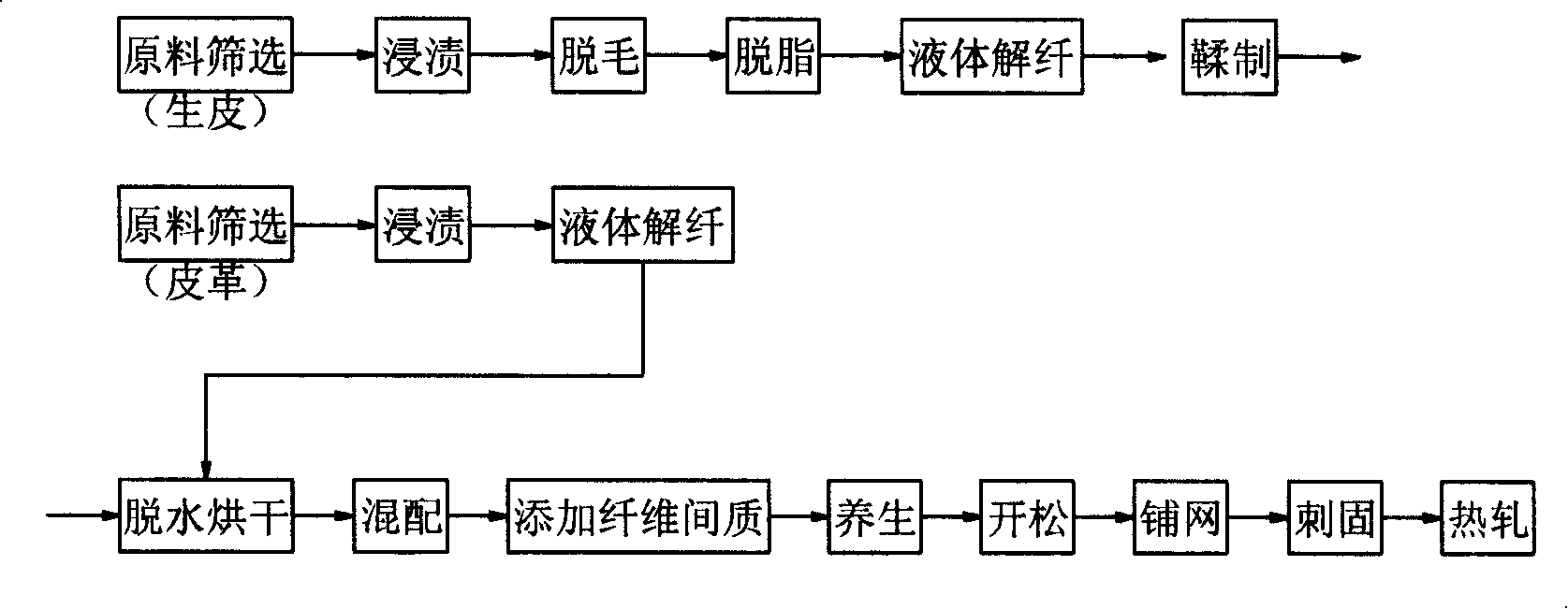

Spun laced fabric and processing method thereof

InactiveCN101235579ANot easy to slip offRich varietyAnimal materialNon-woven fabricsFiberCollagen fiber bundle

The invention discloses spun-laced cloth and a method for manufacturing the spun-laced cloth. The spun-laced cloth is composed of collagen fiber bundles, other textile-used staple fibers and interstitial fibers, wherein the collagen fiber bundles are mutually interpenetrated and interweaved with branches of the collagen fiber bundles to form stereo reticular braided structures, other textile-used staple fibers are located on skeleton of the stereo reticular braided structures, reticular entwining is formed between the textile-used staple fibers mutually or between the textile-used staple fibers and the collagen fiber bundles and the branches of the collagen fiber bundles, and fiber is adhered or bound by the interstitial fibers. The method of the invention can take animal raw hide as raw materials and can be realized through following technical steps: screening the raw materials, dipping, unhairing, degreasing, defibering liquid, tanning, dewatering and drying, mixed liganding, adding the interstitial fibers, health preserving, opening, combing,laying net, spunlacing, and hot rolling, furthermore, the method of the invention can also take the animal leather after tanning as the raw material and can be realized through following steps: screening the raw materials, dipping, defibering the liquid, dewatering and drying, mixed liganding, adding the interstitial fibers, health preserving, opening, combing, laying net, spunlacing, and hot rolling.

Owner:ZHEJIANG HONGZHAN NEW MATERIALS

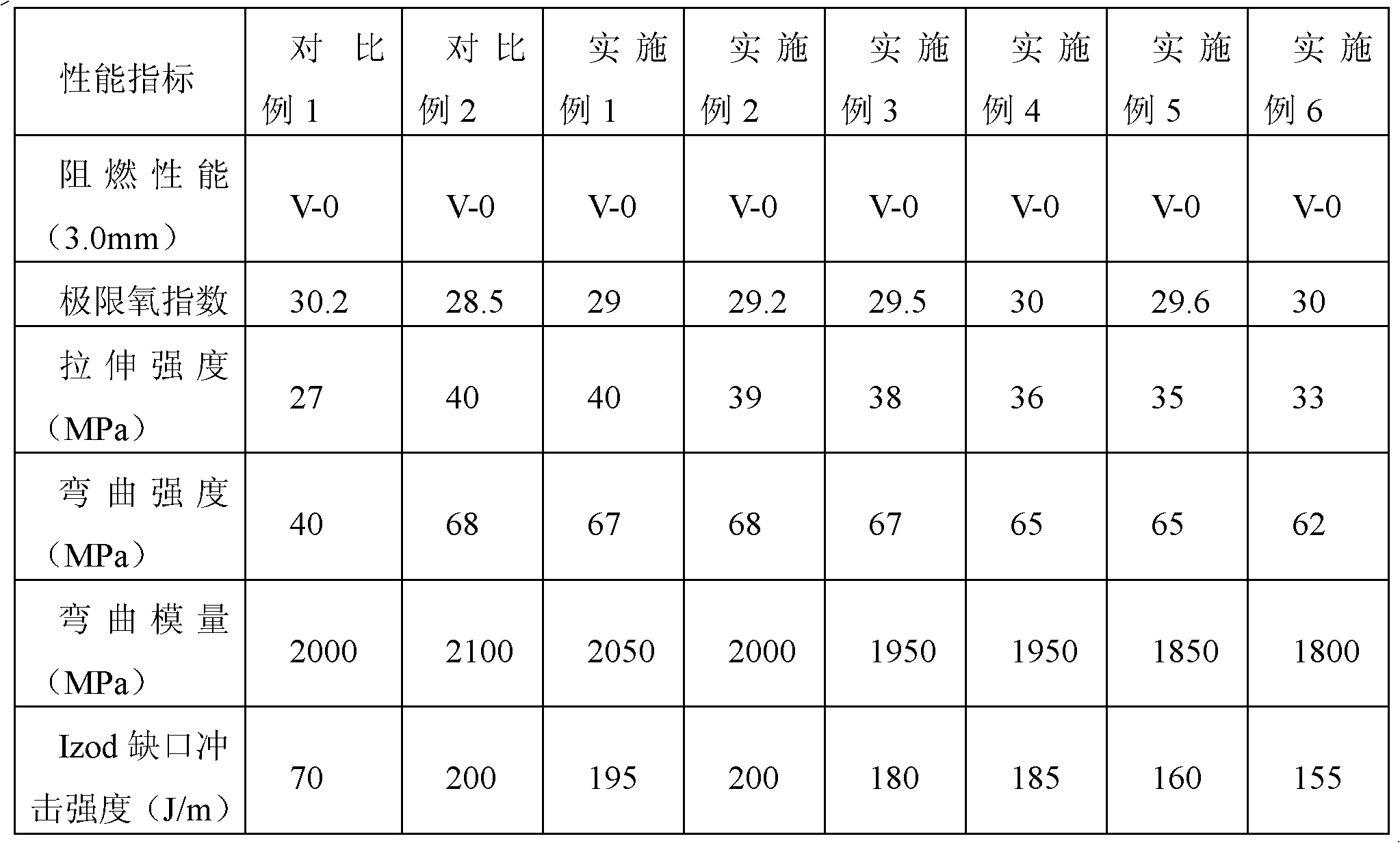

Polyolefin/styrene resin composition and preparation method thereof

The invention relates to the technical field of polymer / styrene resin composition and a preparation method thereof. The composition comprises the following compositions, by weight, 100-800 parts of polyolefin, 100-800 parts of styrene resin, 30-100 parts of compatilizer, 30-200 parts of flexibilizer, 50-200 parts of flame retardants, 40-80 parts of effect assisting flame retardants, 10-100 parts of compound flame retardants, 0-30 parts of enhancer, 0-10 parts of anti-oxidation additives and 0-5 parts of processing aids. The preparation method of the composition comprises the steps of placing the compositions of the proportion in a high-speed mixer and mixing the compositions for 1-3 minutes; conveying evenly-mixed materials into a double-screw extruder through a precise metering material-conveying device; sufficiently mixing the materials through the shearing function of screw rods, and feeding the compound flame retardants and the enhancer into the extruder in a melting section of the extruder through a side direction forced feeding device; and packing the melted mixing materials into finished products after extrusion, strip pulling, cooling and dicing. The composition has remarkable flame retarding effect and is stable in mechanical performance.

Owner:HEFEI GENIUS NEW MATERIALS

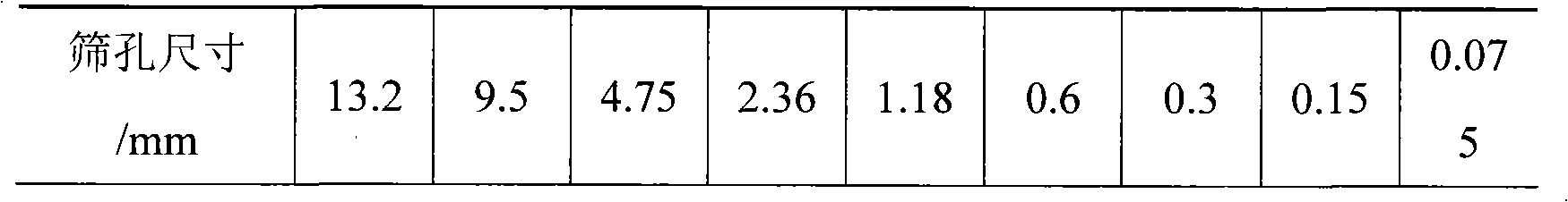

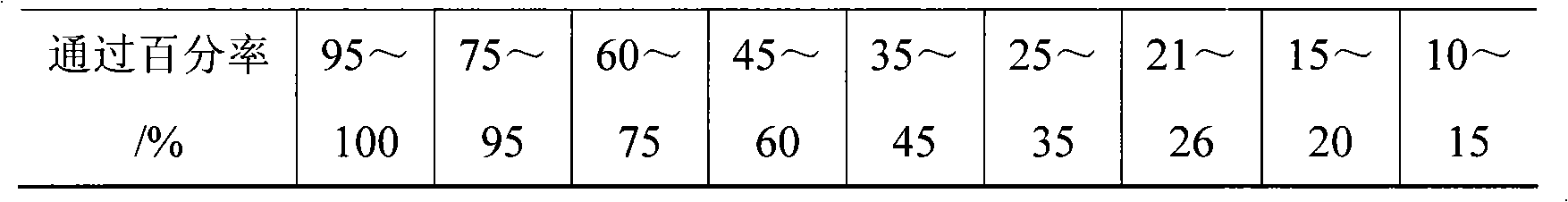

Asphalt mixture for rapid repair of hot-mix-cold-laid pavement

InactiveCN101353481AHigh porosityImprove the compaction effectIn situ pavingsBuilding insulationsDiluentMaterials science

The invention relates to a road restoration asphalt mixture, and discloses a hot-mixing cold-paving road restoration asphalt mixture which comprises modified asphalt, additives and aggregates, wherein, the additives include a diluent, petroleum resin and an anti-stripping agent, the aggregates include coarse aggregate, fine aggregate and mineral powder. While preparing liquid asphalt, using the weight of the modified asphalt as reference, the weight proportion of the diluent is 14 percent to 22 percent, the weight proportion of the petroleum resin is 1.8 to 2.2 percent and the weight proportion of the anti-stripping agent is 0.4 to 0.6 percent. The asphalt mixture of the invention has strong comprehensiveness, performs excellently in poriness, compactibility, initial strength, workability, the strength of formed mixture, anti-water damage property and storage property, can be mixed easily and operated conveniently and is suitable for practical application and generalization.

Owner:TONGJI UNIV

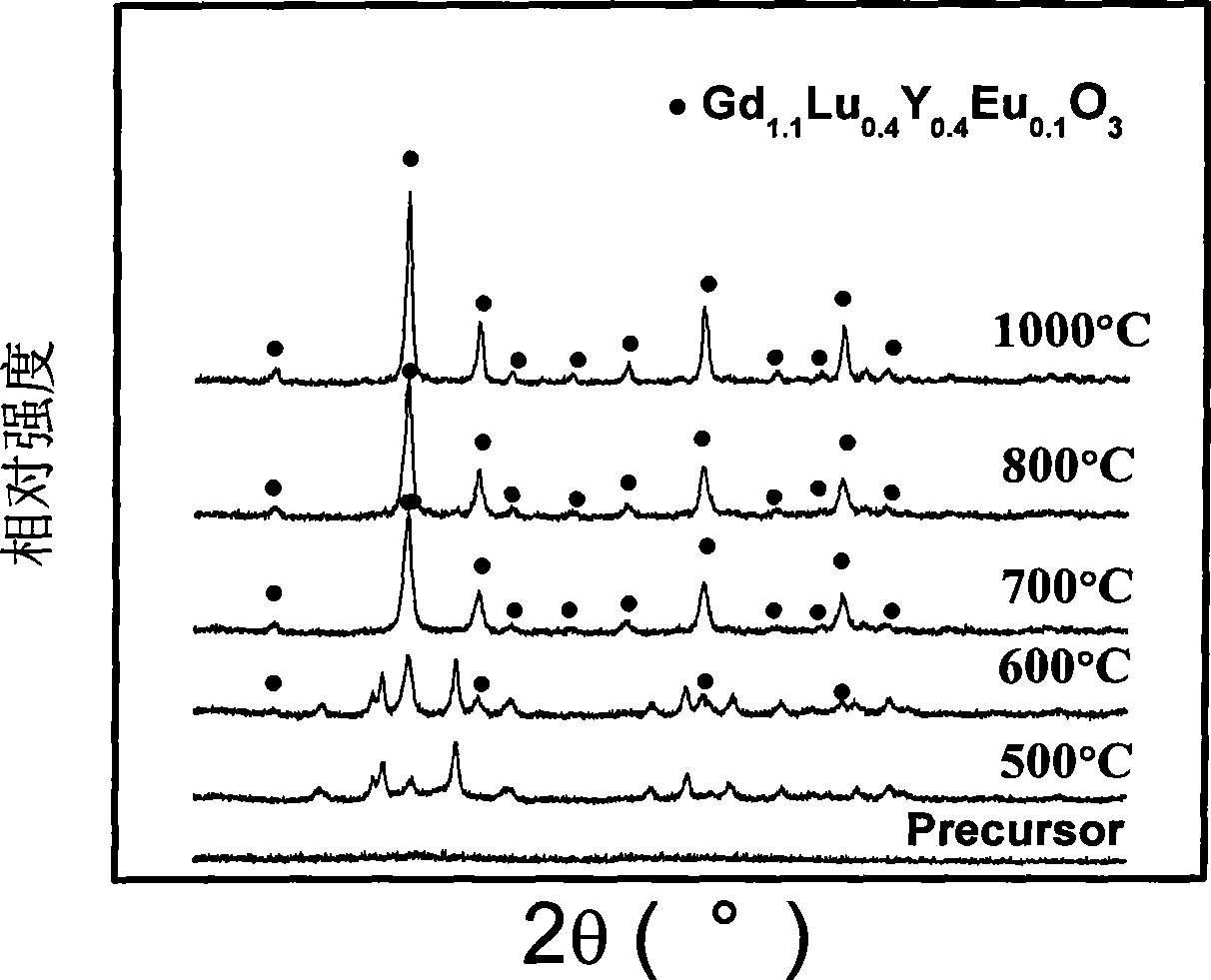

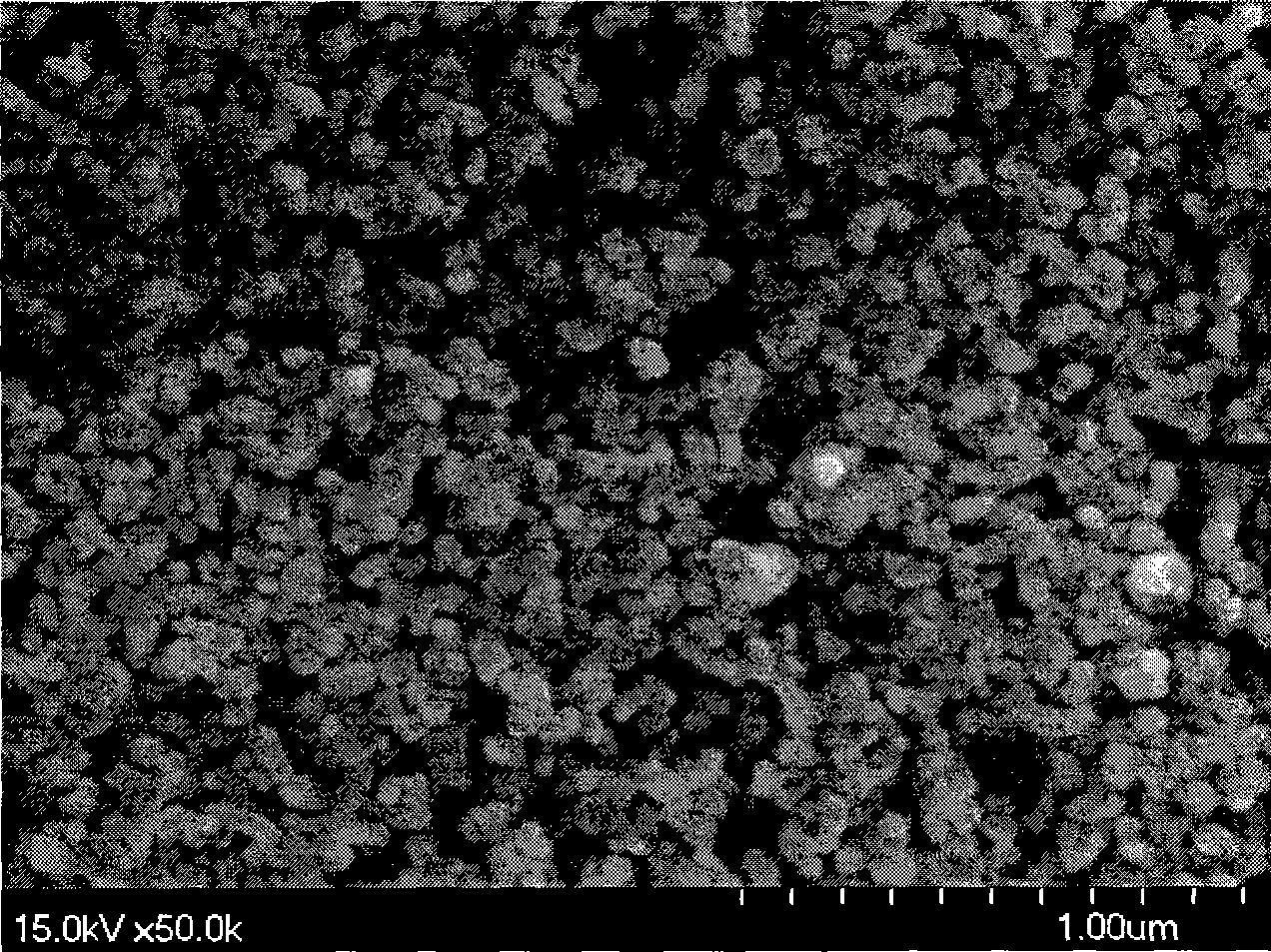

Rare earth oxide solid solution ceramic scintillator and preparation method thereof

The invention discloses a rare earth oxide solid solution ceramic scintillator and a preparation method thereof. The main component of the ceramic scintillator is Gd2xLu2yY2(1-x-y-z)Eu2zO3 (the x is more than or equal to 0.1 and less than or equal to 0.6, the y is more than or equal to 0.1 and is less than or equal to 0.4, and the z is more than or equal to 0.01 and less than or equal to 0.1), and the ceramic scintillator has a crystal structure with a cubic Ia3 point group. Ceramic powder can be synthesized by a chemical coprecipitation method. The coprecipitation method adopts ammonia, ammonium hydrogen carbonate or a mixed solution of the ammonium water and the ammonium hydrogen carbonate as a precipitating agent, titrates the precipitating agent into a solution of gadolinium nitrate, lutecium nitrate, yttrium nitrate and europium nitrate to obtain a precipitate, and then the precipitate is dried and calcined to obtain nano-powder. The obtained powder is pressed into a ceramic blank through an isostatic compaction method, then the pressureless sintering is performed in vacuum or hydrogen atmosphere, the sintering temperature is between 1,600 and 1,900 DEG C, transparent Gd2xLu2yY2(1-x-y-z)Eu2zO3 ceramic can be obtained, a ceramic product with the needed dimension is prepared after the cutting, grinding and polishing, and the transmission rate of the ceramic in a visible region (400-800 nanometers) is more than or equal to 65 percent. The ceramic scintillator emits red light with a main wavelength of 610 nanometers under the excitation of ultraviolet light or X rays, and can be used for scintillating materials of imaging and detection of medical and industrial X rays.

Owner:CHINA JILIANG UNIV

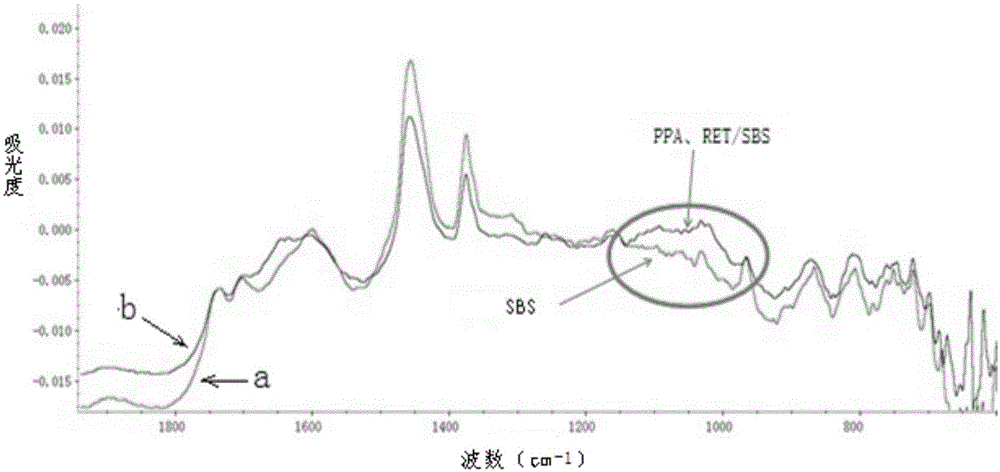

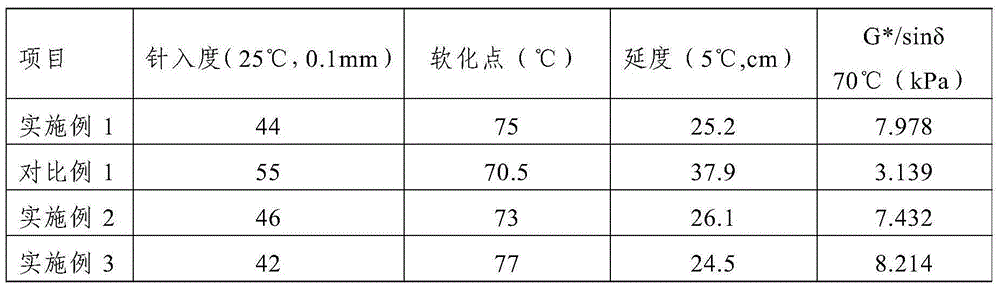

SBS modified asphalt and preparation method thereof

ActiveCN105038280AGood storage stabilityImprove stabilityBuilding insulationsPhosphoric acidHeat stability

The invention discloses SBS modified asphalt. The SBS modified asphalt is prepared with, by weight, 100 parts of matrix asphalt, 2.0-3.5 parts of SBS asphalt modifier, 1-2 parts of RET asphalt modifier, 0.2-0.5 part of polyphosphoric acid, 3-4 parts of compatilizer and 0.1-0.15 part of stabilizer. In addition, the invention further discloses a method for preparing the SBS modified asphalt. The method comprises the steps of 1, heating the matrix asphalt, adding the matrix asphalt into the compatilizer, stirring the mixture uniformly, and obtaining mixed materials; 2, adding the SBS asphalt modifier and the RET asphalt modifier into the mixed materials, stirring the mixture uniformly, conducting cutting, adding the stabilizer, continuing cutting, adding polyphosphoric acid, stirring the mixture uniformly, and obtaining the SBS modified asphalt. The SBS modified asphalt is chemical stabilization type SBS modified asphalt, great high temperature performance and anti-track performance are achieved, and the heat stability of the SBS modified asphalt is superior to that of traditional SBS modified asphalt.

Owner:CHANGAN UNIV

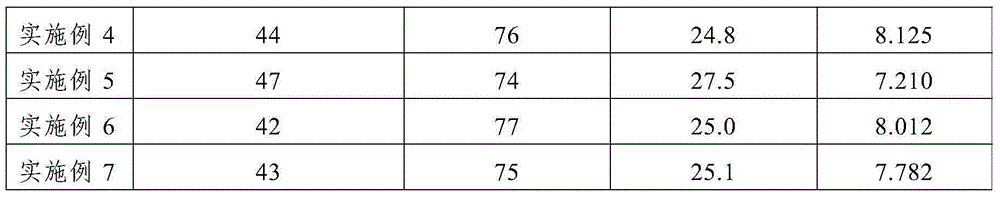

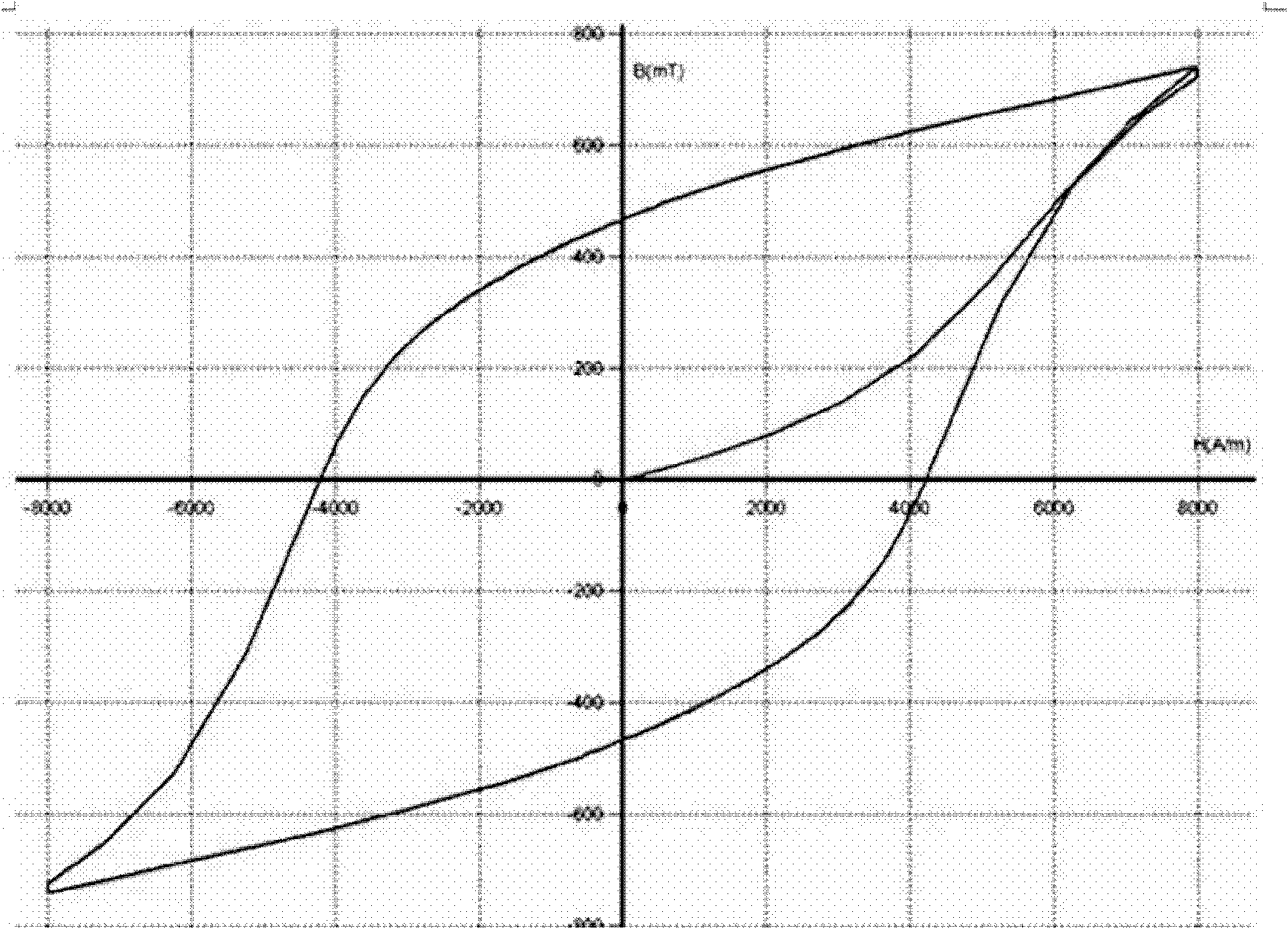

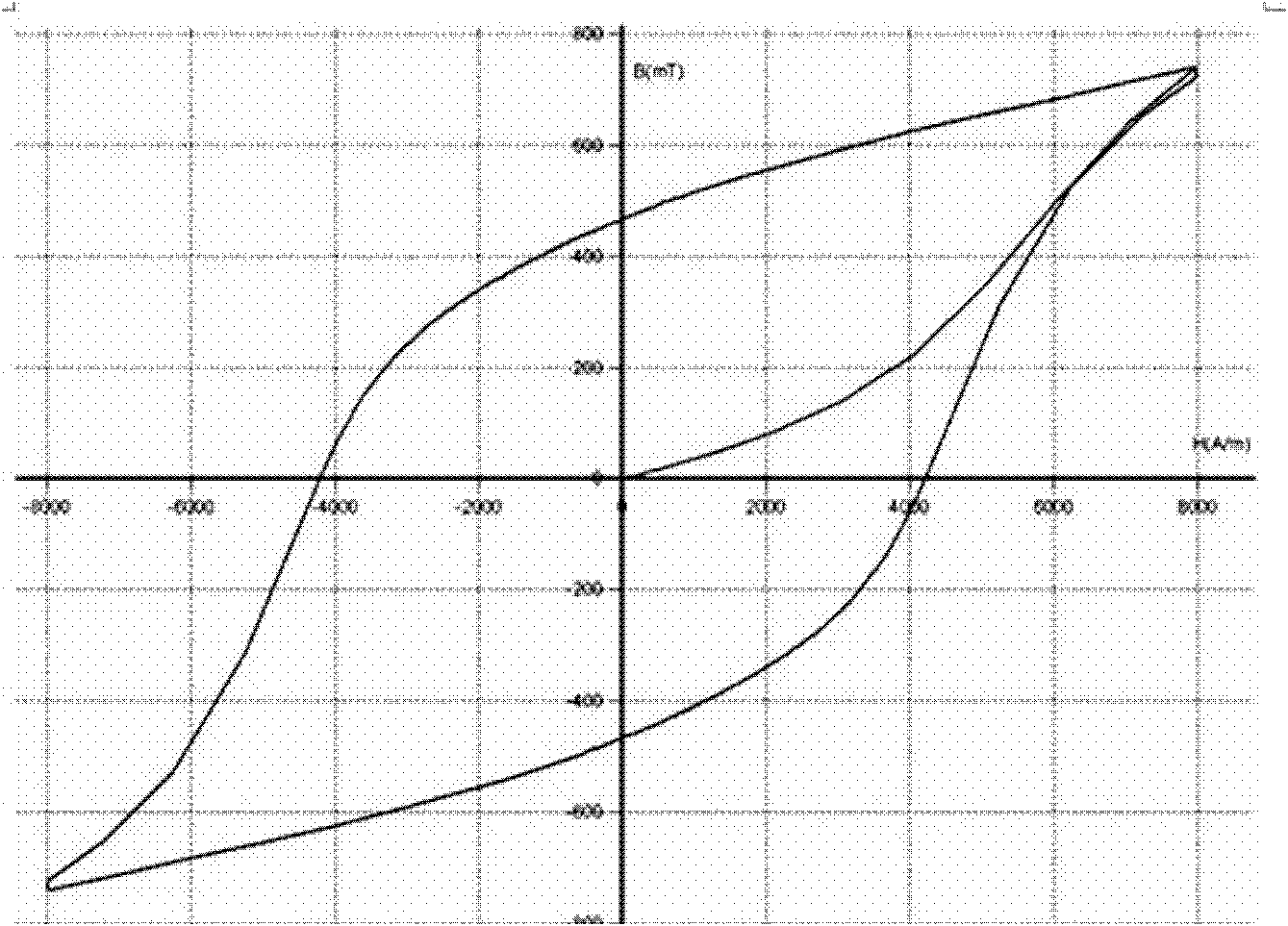

Alizarin flow battery negative electrode electrolyte, and alizarin flow battery adopting electrolyte

InactiveCN107171012ASolve the problem of electrolyte penetrationImprove cycle lifeRegenerative fuel cellsAlkaline electrolytesRare-earth elementPotassium hydroxide

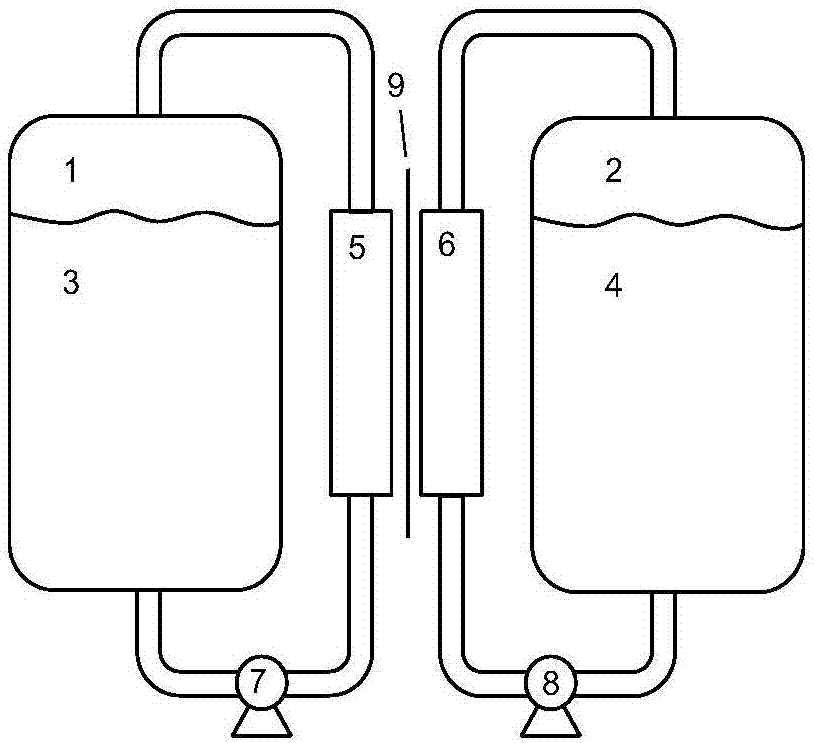

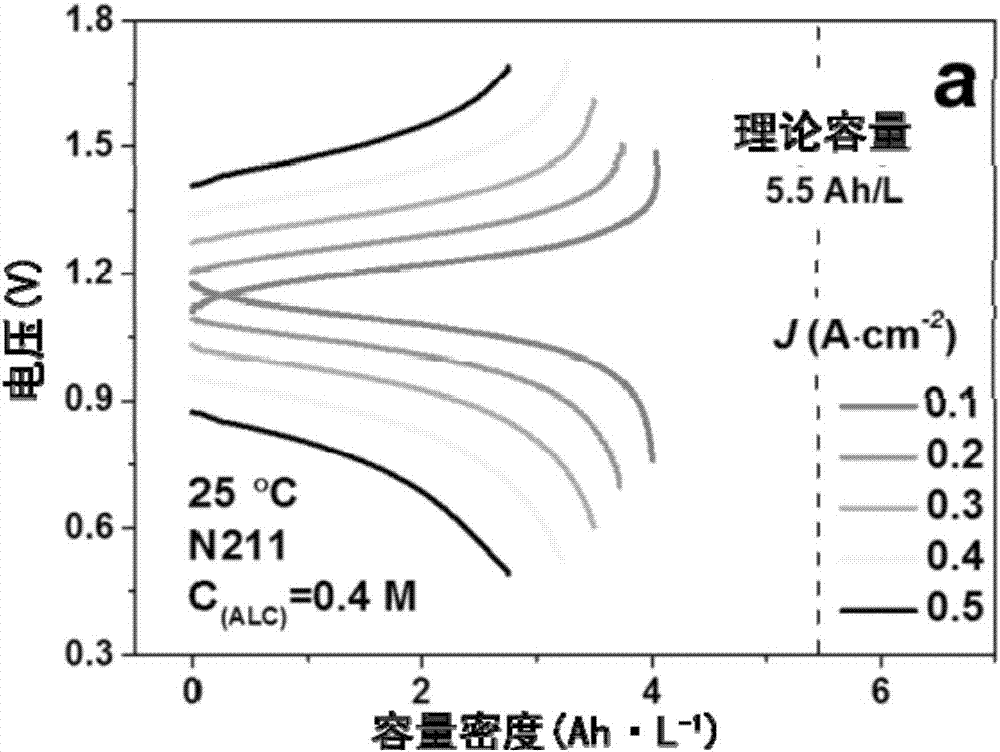

The invention provides an flow battery negative electrode electrolyte based on alizarin or derivatives thereof, and a flow battery adopting the electrolyte as a negative electrode. The electrolyte is an alkaline aqueous solution containing the alizarin or the derivatives thereof. The alizarin and the derivatives contain at least one of alizarin (1,2-dihydroxyanthraquinone), alizarin red (1,2-dihydroxyanthraquinone-3-sulfonic acid) or alizarin fluorin blue (3-alizarin methylamine-N,N-diacetic acid and mixtures thereof. An alkali used in the invention comprises at least one of sodium hydroxide, potassium hydroxide and a sodium hydroxide and potassium hydroxide mixture. The working temperature of the electrolyte is 10-50 DEG C; and the flow battery based on the electrolyte is a traditional structure, and comprises a positive electrode liquid storage tank 1, a positive electrode electrolyte 3, a negative electrode liquid storage tank, the negative electrode electrolyte 4, pumps 7 and 8, and a cation exchange membrane 9 for conducting cations. The active substance of the alizarin flow battery negative electrode electrolyte is bulk anions, and difficultly penetrates through a proton exchange membrane; and the electrolyte disclosed in the invention has the characteristics of no toxicity, no pollution, no rare earth elements, and obvious price advantage.

Owner:BEIHANG UNIV

Industrial waste residue soil stabilizer and preparation method and construction method thereof

The invention discloses an industrial waste residue soil stabilizer. The industrial waste residue soil stabilizer is prepared from 5-50% of raw material steel slag powder, 20-40% of slag powder, 5-30%of fly ash, 8-25% of waste gypsum, 0-17% of coal gangue and 10-30% of carbide slag through the following method: firstly, raw materials including fly ash, coal gangue powder, waste gypsum, steel slagpowder and slag powder are sequentially added into a coulter type stirrer and are uniformly mixed at a high speed of 1500-2000 r / min for 20-30 min, finally, the carbide slag is added, stirring continues to be conducted for 10-20 min, and an obtained curing agent finished product is bagged, sealed and stored. The industrial waste residue soil stabilizer prepared by the invention can replace cementand lime to be applied to roadbed improvement and treatment, has the outstanding advantages of no calcination, energy conservation, environmental protection and the like, has obvious price advantagecompared with cement and lime, plays a positive role in promoting the resource utilization of industrial wastes such as fly ash, carbide slag, steel slag and the like, and has wide and far-reaching significance.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Fish meal-free crucian breeding expanded compound feed and preparation method thereof

ActiveCN103461707AReduce feed costsImprove farming efficiencyAnimal feeding stuffFish mealAnimal science

The invention relates to fish meal-free crucian breeding expanded compound feed and a preparation method of the fish meal-free crucian breeding expanded compound feed. The feed disclosed by the invention comprises the following components in part by weight: 4 to 8 parts of blood cell protein powder, 6 to 10 parts of corn protein powder, 3 to 5 parts of fermented soybean meal, 20 to 32 parts of soybean meal, 20 to 35 parts of rapeseed meal, 3 to 6 parts of wheat, 12 to 20 parts of flour, 4 to 8 parts of rice bran, 4 to 5.5 parts of vegetable oil, 2.0 to 3.5 parts of calcium dihydrogen phosphate, 0.2 to 0.5 part of 98.5 percent lysine hydrochloride, 0.1 to 0.3 part of 99 percent DL-methionine, 0.3 to 0.8 part of vitamin premix, and 0.5 to 1.5 parts of mineral substance premix. Through the preparation method, the blood cell protein powder and the corn protein powder are used, meanwhile, partial grease, lysine and methionine are supplemented, the vitamins and mineral trace elements are balanced, fish meal in crucian feed is completely removed, and the fish meal-free crucian breeding expanded compound feed is developed, so that feed cost is greatly reduced, and breeding benefit is increased.

Owner:TONGWEI

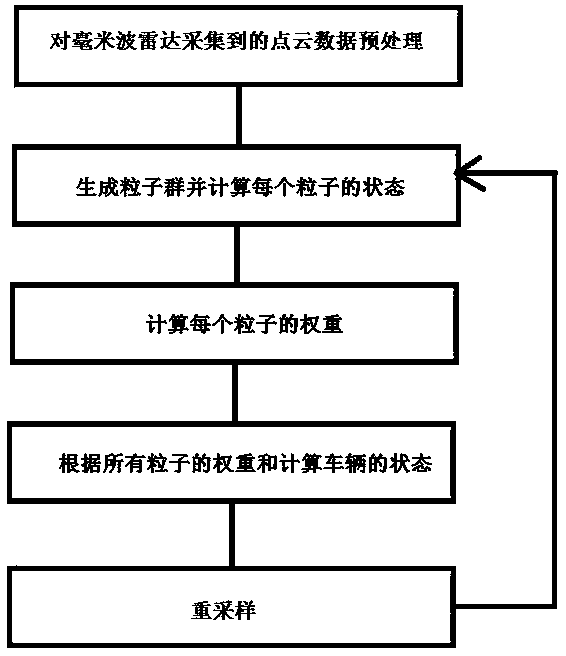

Automatic driving vehicle positioning method based on millimeter wave radar

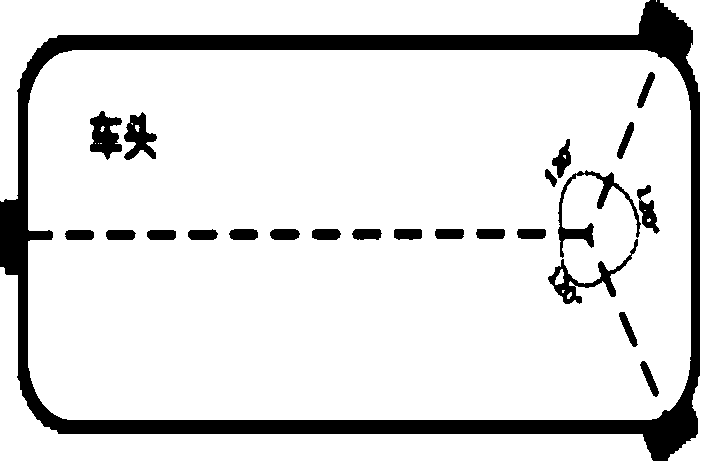

ActiveCN110888125AObvious price advantageSave computing powerSatellite radio beaconingRadio wave reradiation/reflectionData matchingPoint cloud

The invention discloses an automatic driving vehicle positioning method based on millimeter wave radar, which is mainly used for realizing vehicle lane level positioning based on vehicle information fed back by sensors such as millimeter wave radar, GPS and the like in combination with an improved particle filtering algorithm. According to the method, the linear velocity and the angular velocity of a vehicle in a vehicle ODOM are inputted into a prediction model of a filtering algorithm, point cloud data preprocessed by a millimeter-wave radar and a constructed occupied grid map are subjectedto data matching and a new particle weight is calculated. In addition, in order to improve the robustness of the positioning algorithm, the traditional algorithm is improved, and positioning results and corresponding confidence coefficients are calculated according to different weight sums of particles; and in the resampling stage, part of new particles calculated according to GPS position information are added into the particle swarm. The cost of the whole positioning system is effectively reduced while the vehicle positioning precision is ensured and the popularization of the automatic driving technology is facilitated.

Owner:AUTOCORE INTELLIGENT TECH NANJING CO LTD

Method for filtering various water sources into drinking water

InactiveCN102107993AAchieve protectionMeet the needs of drinking multifunctional healthy waterMultistage water/sewage treatmentEnergy based wastewater treatmentWater sourceWater quality

The invention discloses a method for filtering various water sources into drinking water. In the method, a first-level biological purification water preparation unit is added before the conventional water treatment process according to a water purification principle; pollutants harmful to a human body are removed from water without performing sterilization by using ozone and chlorine; a water purification device manufactured by the method has a simple structure and low water preparation cost and is reliable to operate; and people in vast rural areas and rural towns can drink and use the purified water produced by the device. The method is implemented by the following technical scheme: the public biological purification water preparation unit and the conventional water purification treatment unit are designed and manufactured into standard combined filter element modules; according to the sequence of a water purification treatment process, the combined filter element modules are buckled from top to bottom into a tower-shaped water purification device; according to requirements of different water sources and different clients, the modules of the combined filter elements by different processes are replaced only according to the local water quality condition, so that various water sources are filtered into the driving water.

Owner:郑高宽

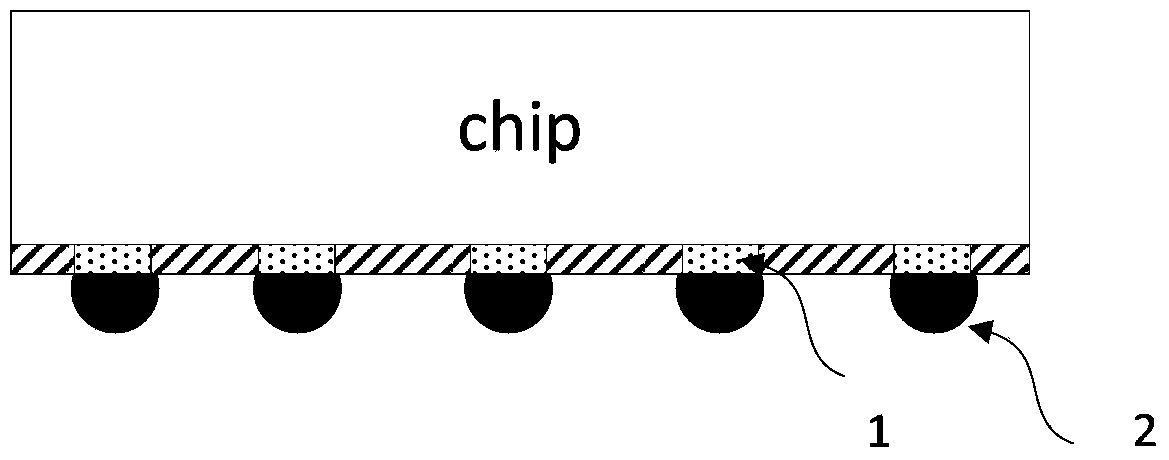

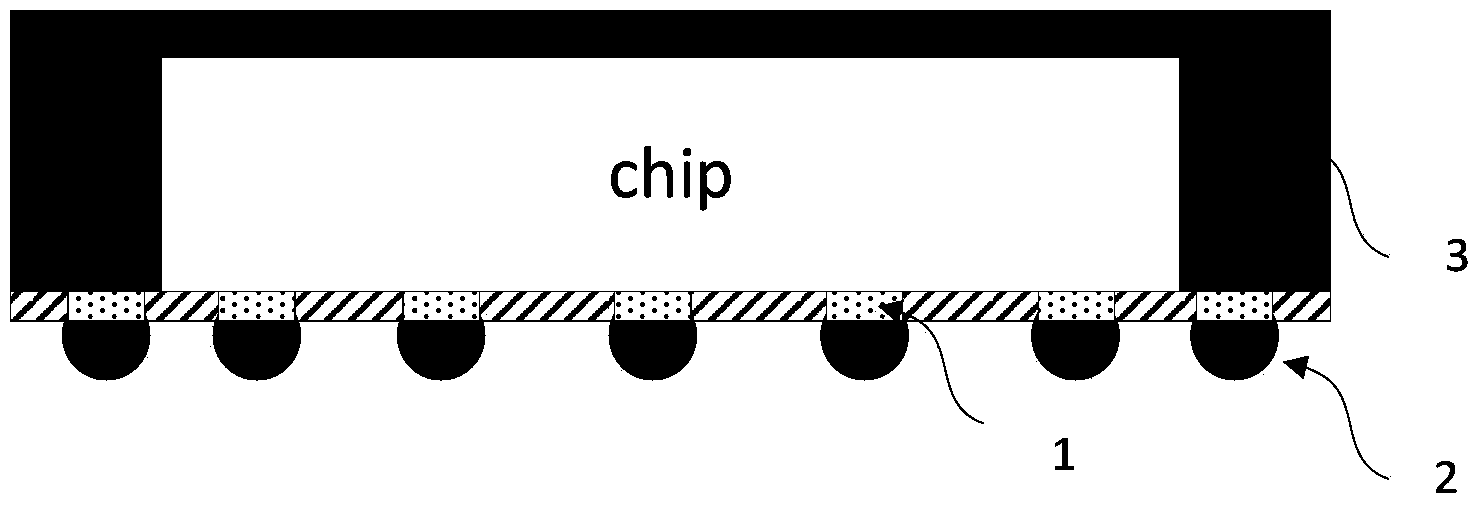

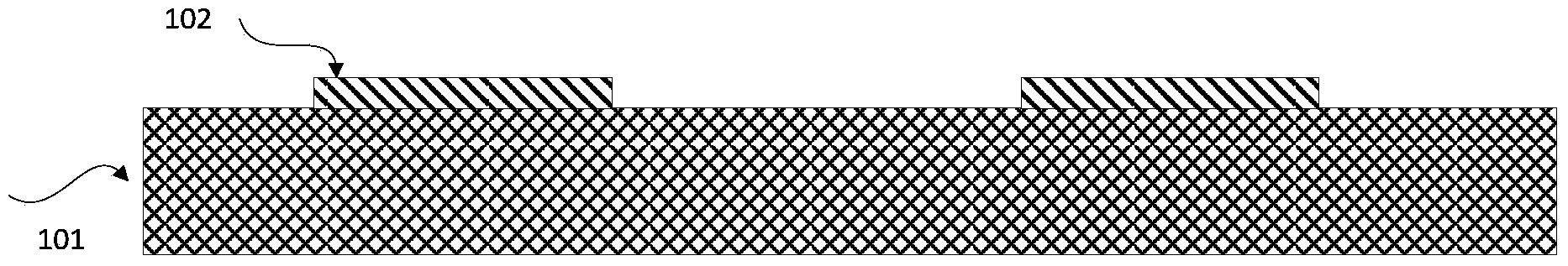

Multi-layer multi-chip fan-out structure and manufacturing method

ActiveCN103594451AOptimize Package SizeObvious price advantageSemiconductor/solid-state device detailsSolid-state devicesSolder maskEngineering

The invention provides a multi-layer multi-chip fan-out structure. The multi-layer multi-chip fan-out structure comprises a bearing plate, and a plurality of packaging sub bodies which are stacked are arranged on the bearing plate; at least one die is packaged into each packaging sub body; in each packaging sub body, the die is coated by a dielectric material of a dielectric layer, and the die is attached to a metal cushion block with the front face faces upwards; an RDL layer is arranged on the dielectric layer of each packaging sub body; a bonding pad of the front face of each die is electrically connected with the RDL layer of the corresponding packaging sub body where the die exists; insulating layers are arranged between adjacent packaging sub bodies, and the RDL layers of the adjacent packaging sub bodies are electrically connected through second interconnection holes between the layers. The metal cushion blocks in the bottom packaging sub bodies are pressed on the surface of the bearing plate, and the metal cushion blocks in the middle or top packaging sub bodies are pressed on the insulating layers of the packaging sub bodies; the surface of each top packaging sub body is provided with a solder mask layer in a distributed mode. According to the multi-layer multi-chip fan-out structure, three-dimensional multi-chip stacking can be easily achieved.

Owner:江苏中科智芯集成科技有限公司

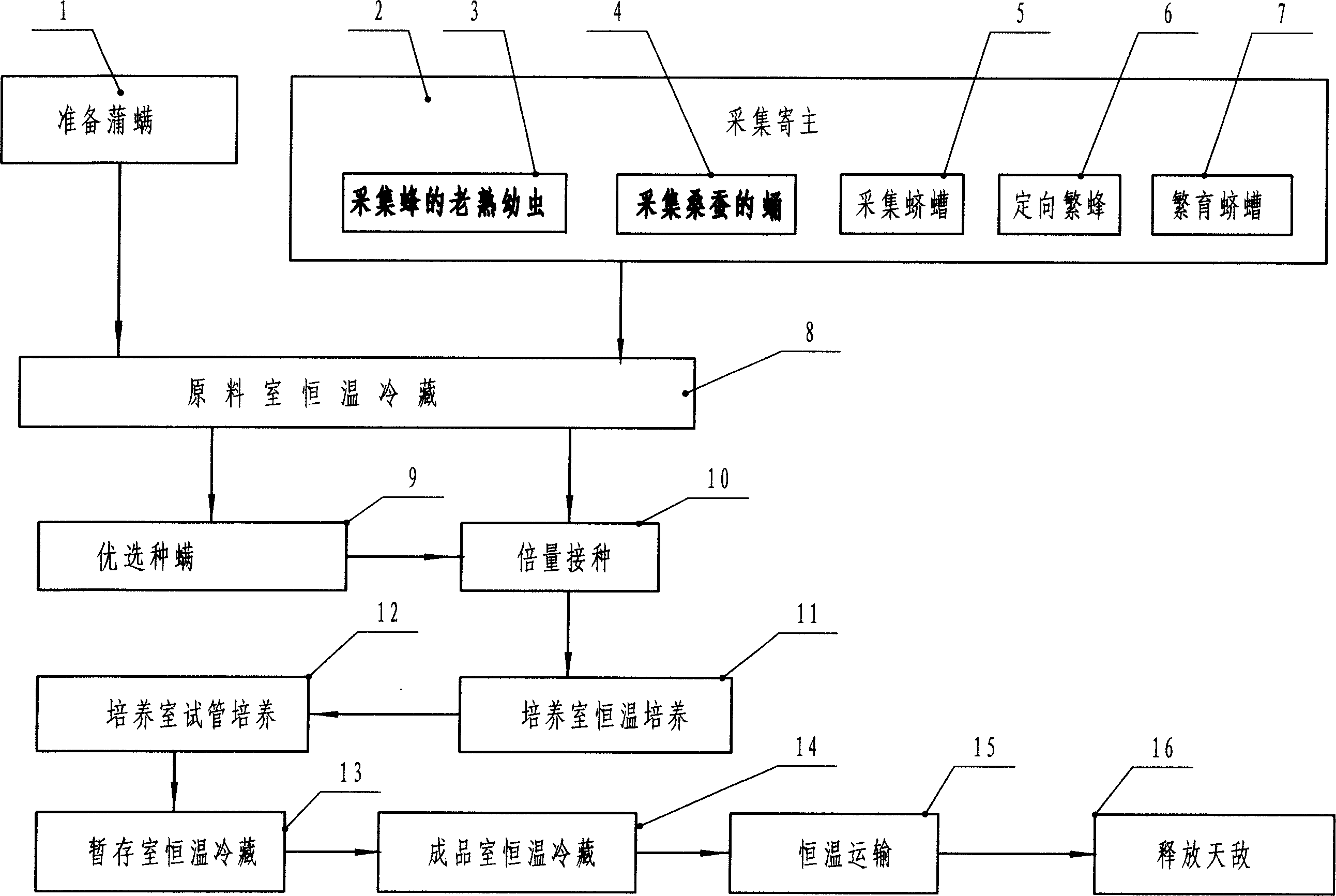

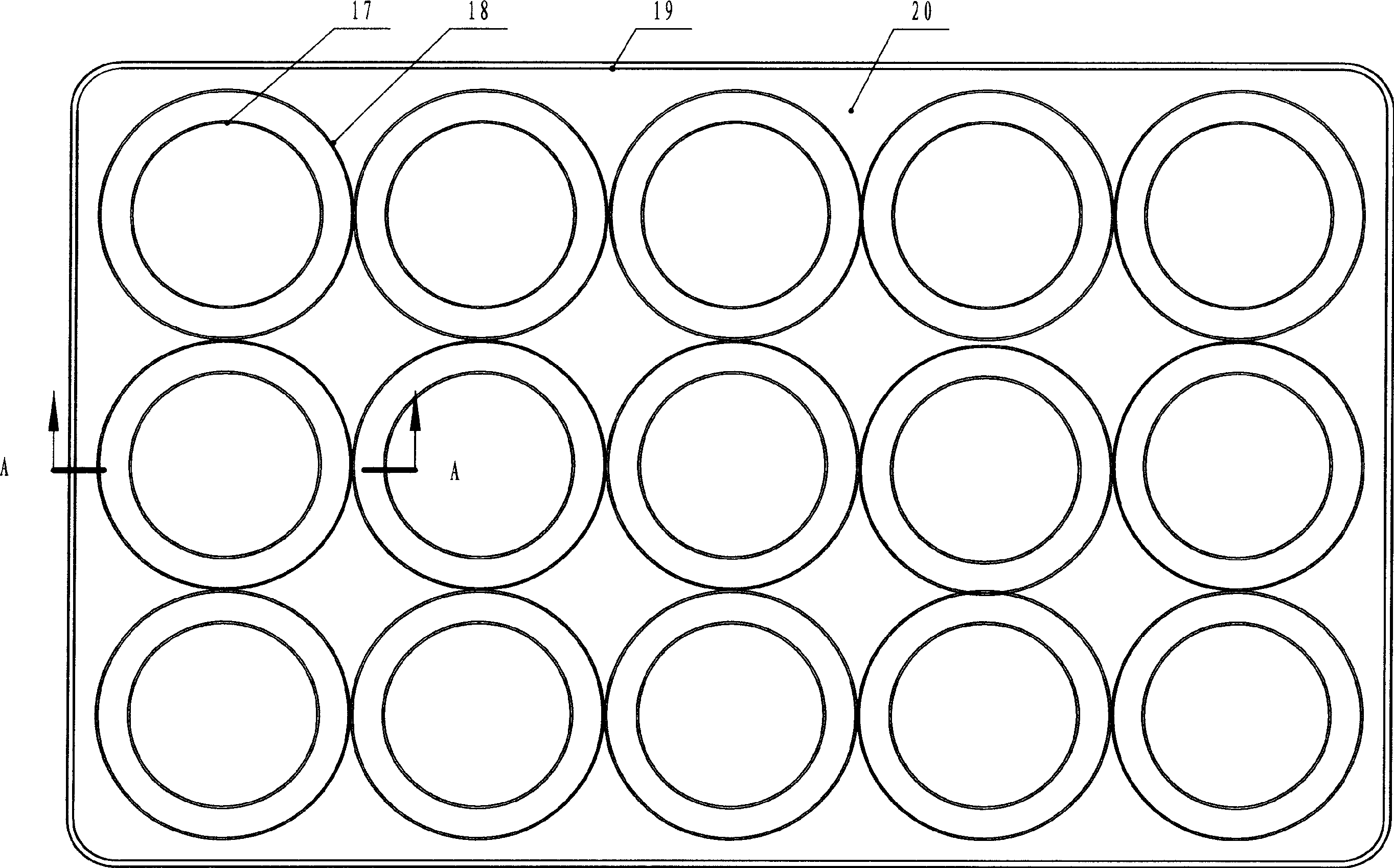

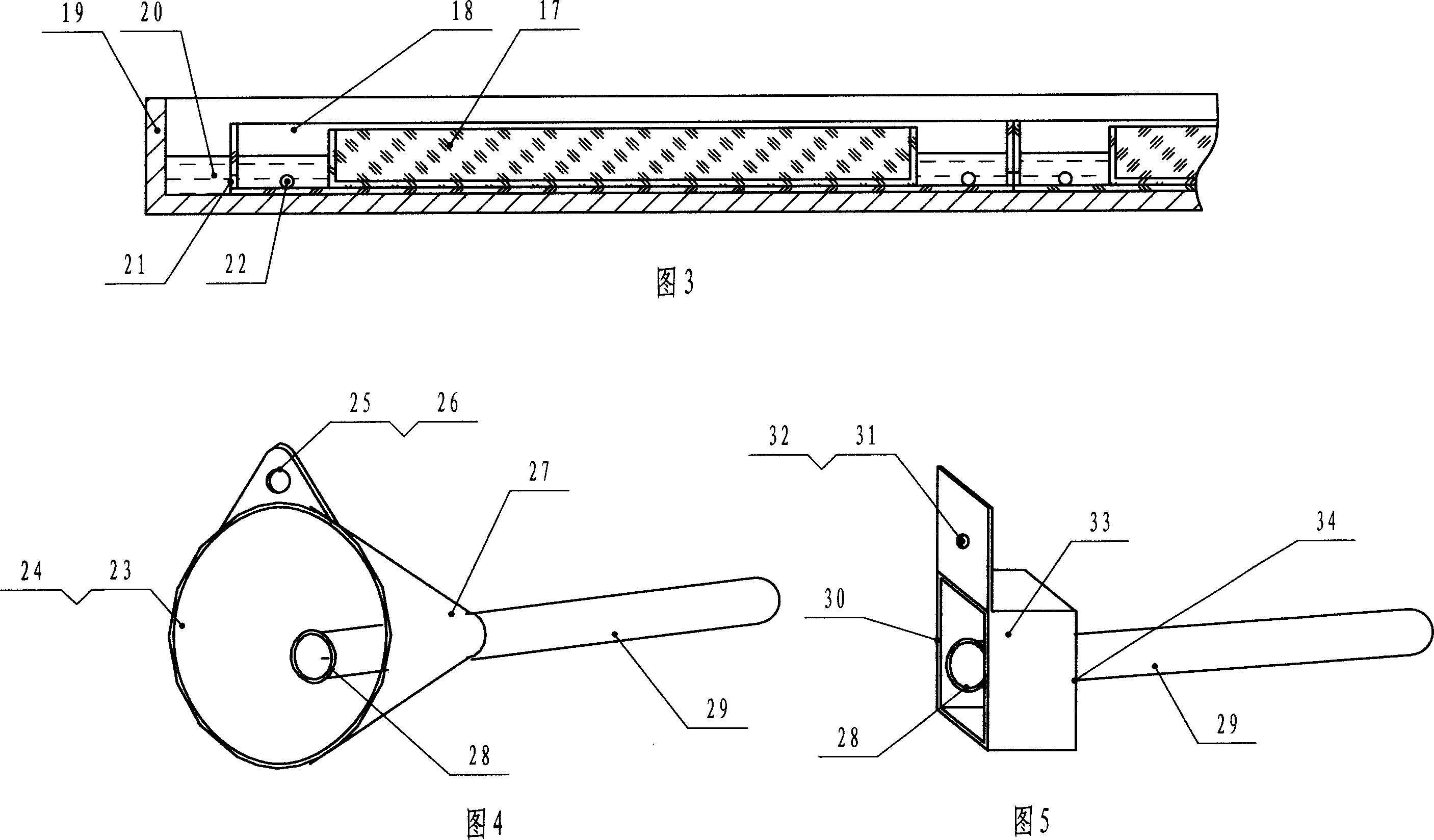

Method for breeding pyemote, and its culturing vessel, and method for releasing same

InactiveCN1757283AEasy to operateRealize factory breedingPlant protectionAnimal husbandryCulture vesselZoology

A method for reproducing pyrmotide includes such steps as buying the developed pyrmotides, storing in cold storage case at -5-15 deg.C, choosing the bee larva, silkworm pupa, or grub as host, putting it in the internal plastic culture utensil, preferably selecting seed pyrmotide, inoculating it to said host, and test tube culture to obtain the second generation pyrmotide. It culture device is composed of a culture tray made of stainless steel and several pairs of internal and external culture utensils. A method for releasing the pyrmotides features that the cultured pyrmotides are loaded from test tubes to an open release box.

Owner:段东红

Method for degrading chlorinated phenol by sodium persulfate

InactiveCN101774677ASimple technologyGood effectWater contaminantsContaminated soil reclamationChlorinated phenolsHandling system

The invention relates to a degradation processing process of chlorinated phenol, particularly to application of sodium persulfate in the degradation processing process of the chlorinated phenol, and belongs to the technical field of environmental management. In the method of the invention, the chlorinated phenol is degraded in the degradation process under the condition of ensuring the existence of Na2S2O8; and meanwhile, H2SO4 or NaOH is added, and the pH value of a processing system is regulated to be 1.0-9.0. The invention is simple and easy to operate and has remarkable effect; and the removal rate of the chlorinated phenol is high, and the removal rate of 2, 4-dichlorophen is as high as 99.76 percent.

Owner:KUNMING UNIV OF SCI & TECH

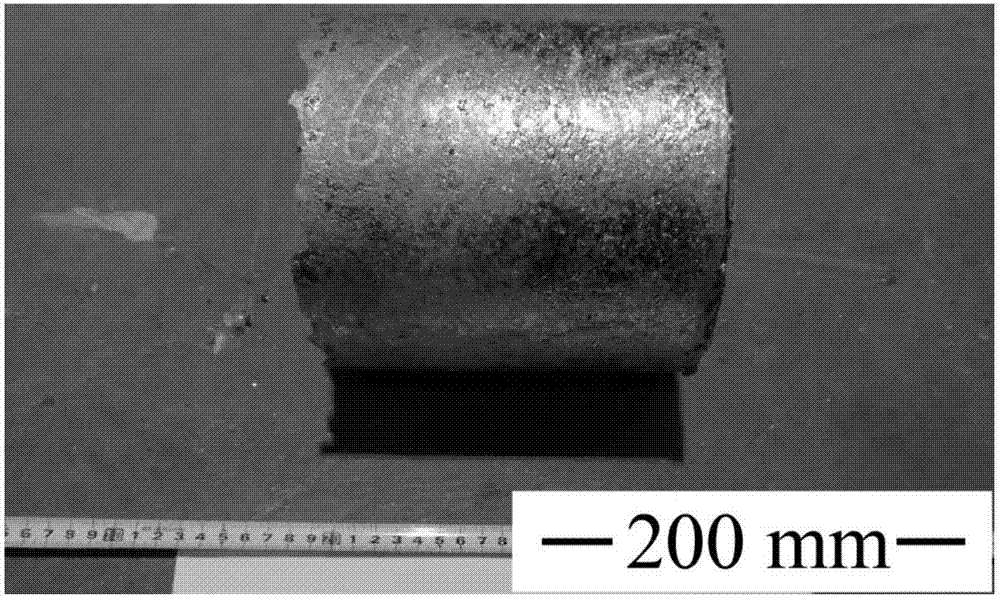

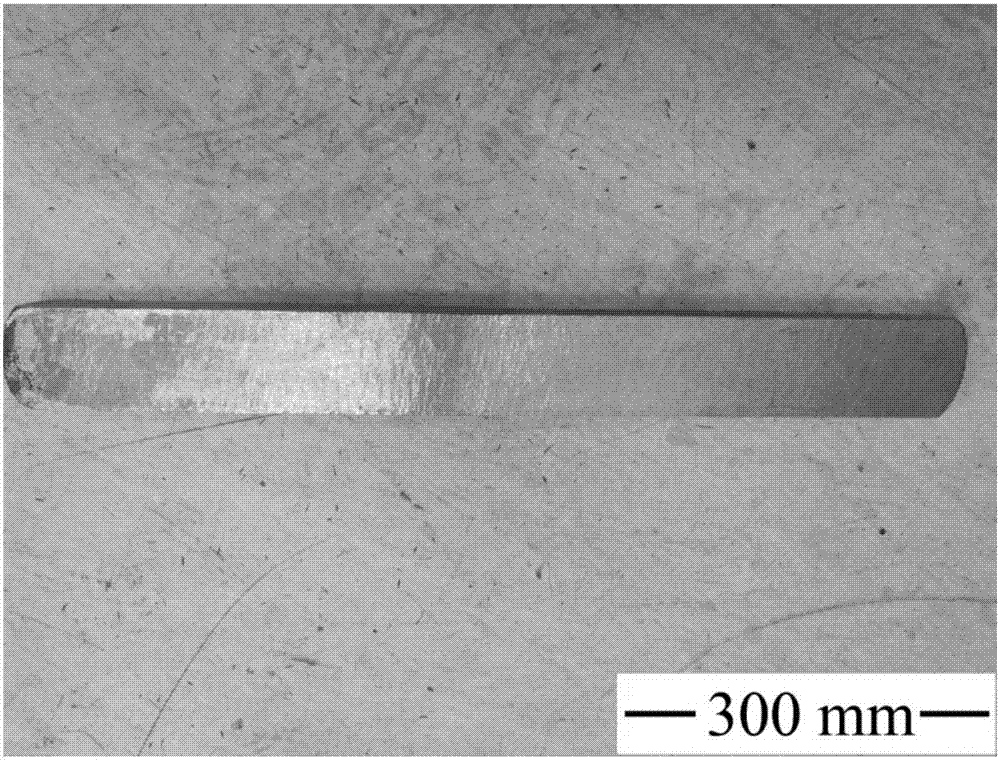

Low-cost, high-strength and high-plasticity metastable beta titanium alloy and preparation method thereof

The invention discloses a low-cost, high-strength and high-plasticity metastable beta titanium alloy and a preparation method thereof. The titanium alloy comprises the following components in percentage by weight: 3-7% of Fe, 4-7.75% of Al, 3-5% of V, O not more than 0.2%, C not more than 0.08%, N not more than 0.05%, and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: sponge titanium, an Al-V intermediate alloy, pure Al and pure Fe are weighed according to ratios; the raw materials are mixed to press as an electrode; a Ti-Al-Fe-V alloy cast blank is prepared by secondary smelting; the cogging and the primary forging are performed to obtain a large-scale forging; the secondary forging is performed to obtain a larger-size rod; the ternary forging is performed to obtain a small-size rod; the solid-solution treatment and the air cooling are performed; and then, the aging treatment and the air cooling are performed to obtain the low-cost, high-strength and high-plasticity metastable beta titanium alloy. The titanium alloy contains higher-content beta elements and stable elements Fe, and has such advantages as low cost, high strength and high plasticity.

Owner:CENT SOUTH UNIV

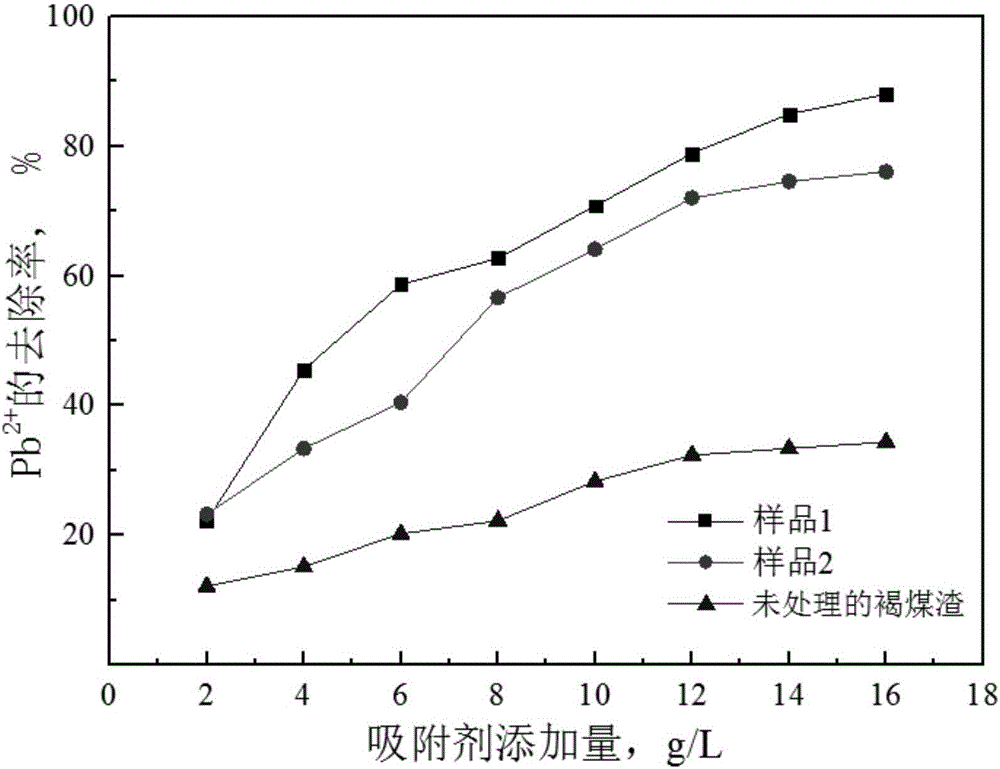

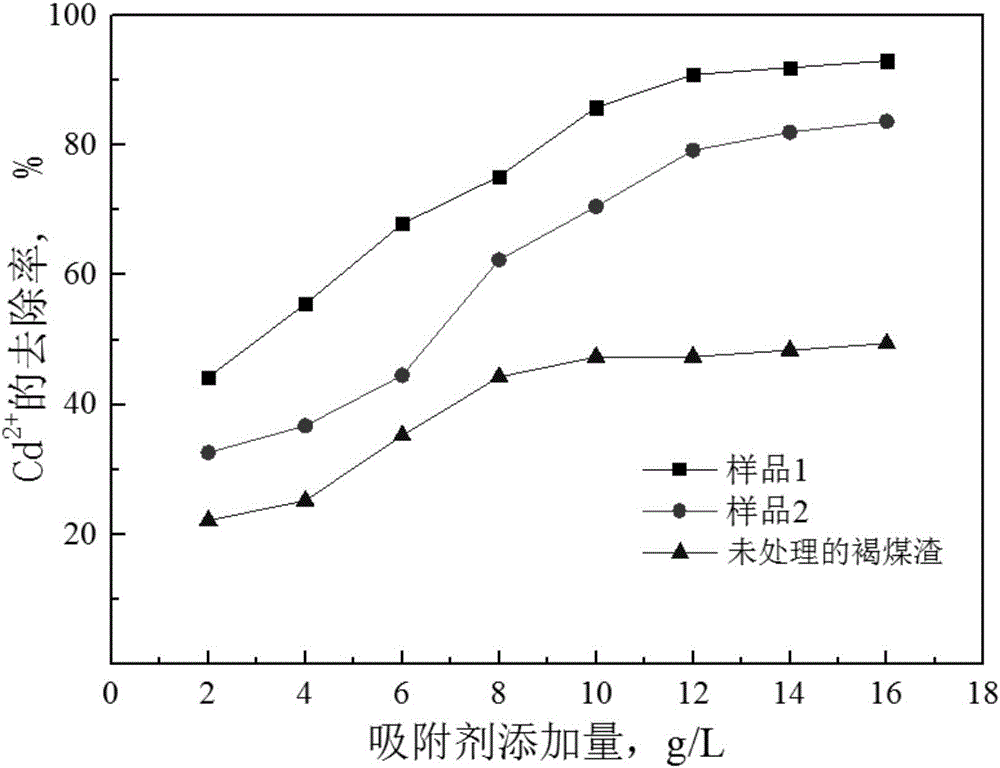

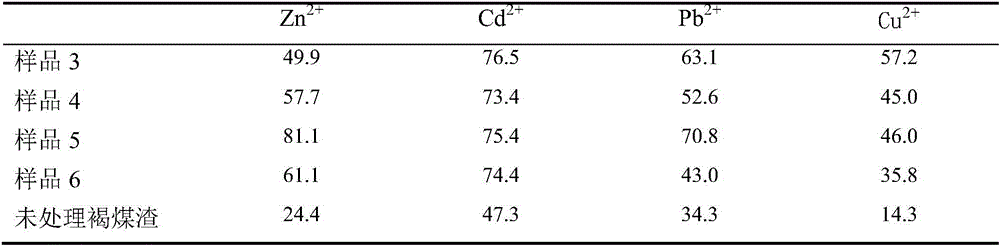

Modified cinder adsorbent and preparing method and application

InactiveCN106215857AUniform particle size distributionGood dispersionOther chemical processesAluminium silicatesDispersityLiquid waste

The invention discloses modified cinder adsorbent and a preparing method and application. The preparing method includes the steps that 1, ignite cinder is washed, dried and mixed with pyrite cinder, and the mixture is smashed; 2, the mixture obtained in the step 1 is soaked in inorganic acid water solution and is treated in a acidification modification mode; the solution is filtered, filter liquor is recovered, solid is washed with water, dried and calcinated to obtain the modified cinder adsorbent. The ignite cinder and pyrite cinder are used for preparing the modified cinder adsorbent which is uniform in particle size distribution and high in dispersity; the modified cinder adsorbent is high in adsorbability to heavy metal ions in waste liquid, high in adsorption efficiency and capable of being used for treating heavy metal in multiple kinds of industrial waste water and has the advantages of being easy to operate, low in cost and good in effect; the ignite cinder and pyrite cinder are residue waste. The two kinds of raw materials are wide in source, cheap and easy to obtain, are used for preparing the modified cinder adsorbent and have obvious price advantages. The adoption of the ignite cinder and pyrite cinder belongs to recycle of solid waste, and the environment burden is greatly reduced.

Owner:TIANJIN UNIV

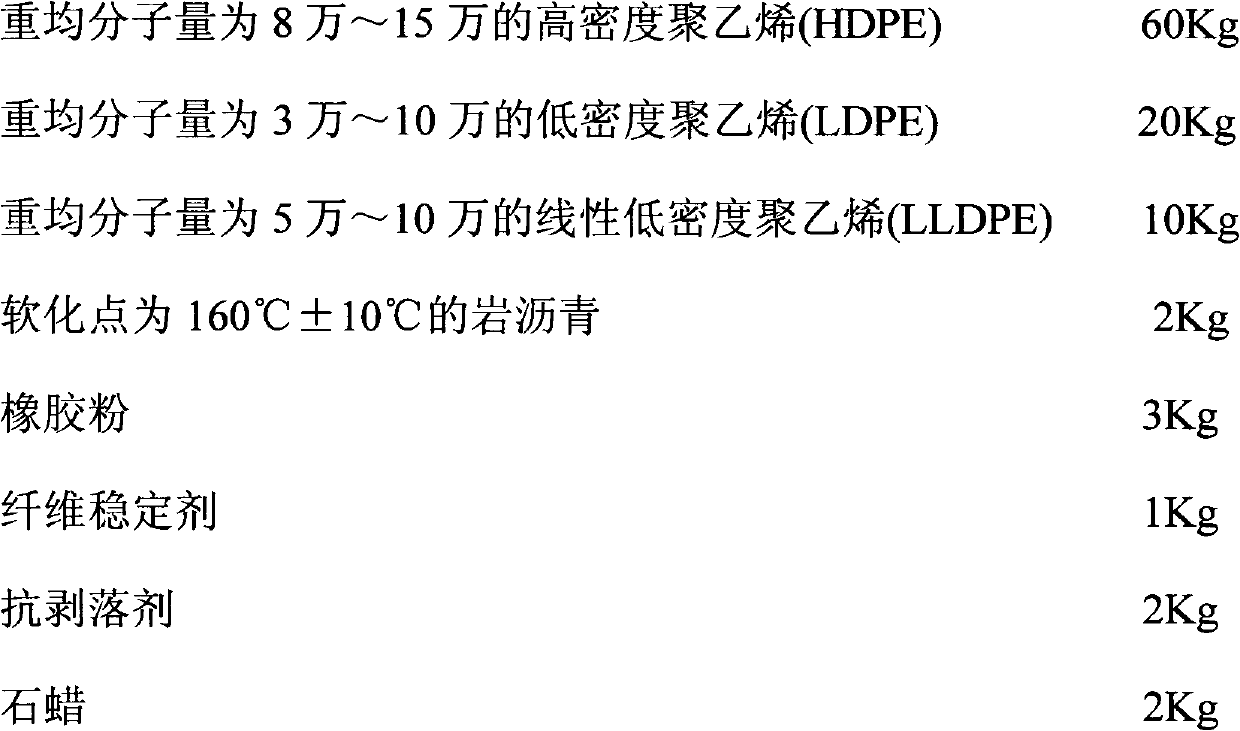

Admixing type modifier of asphalt mixture

InactiveCN103289420AImprove stabilityImprove water stabilityBuilding insulationsLow-density polyethyleneFiber

The invention discloses an admixing type modifier of an asphalt mixture. The modifier comprises the following components by weight: 60-80% of high density polyethylene (HDPE) with weight-average molecular weight of 80,000-150,000, 20-35% of low density polyethylene (LDPE) with weight-average molecular weight of 30,000-100,000, 10-20% of linear low density polyethylene (LLDPE) with weight-average molecular weight of 50,000-100,000, 1-5% of rock asphalt with softening point of 160+ / -10 DEG C, 3-10% of rubber powder, 1-5% of fiber stabilizing agent, 1-3% of antistripping agent and 1-2% of paraffin. The modifier adopts the above components by weight percent, can be directly added during production of the asphalt mixture by way of admixing type modification, can substantially improve the high-temperature property of the mixture and effectively improve the low-temperature property, water stability and fatigue property of the mixture after being added, so the improved mixture can meet the use requirements.

Owner:XIAN RONGTAI POLYMERIC MATERIALS

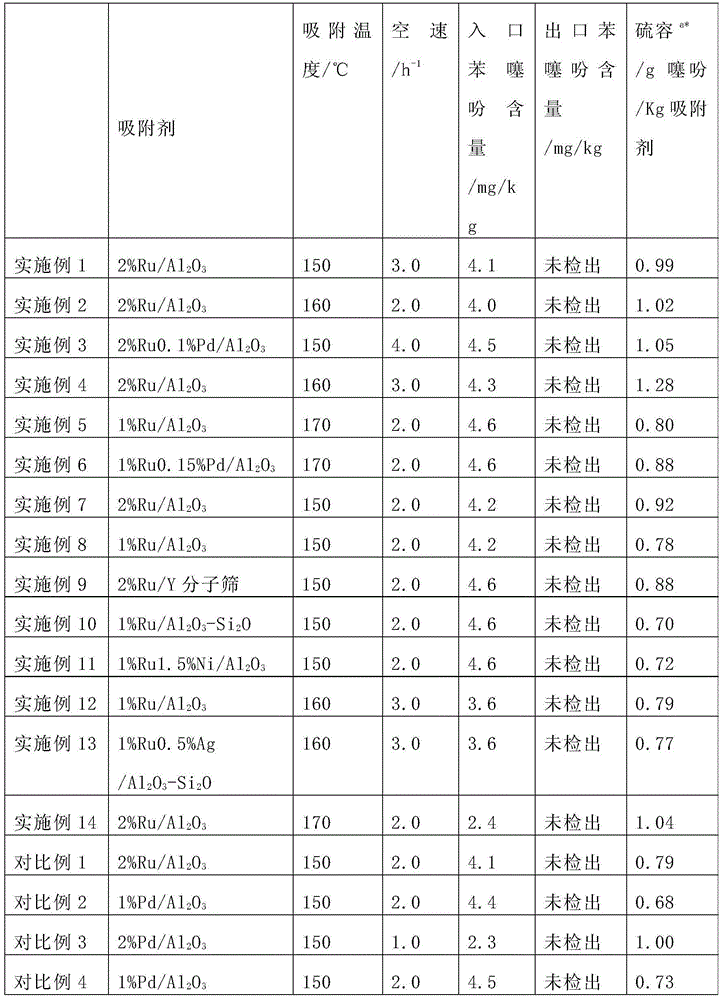

Ruthenium-based adsorbent for deeply removing thiophene of benzene as well as preparation method and application of ruthenium-based adsorbent

ActiveCN104307464AObvious price advantageSimple preparation processOther chemical processesAdsorption purification/separationBenzeneMolecular sieve

The invention provides a ruthenium-based adsorbent for deeply removing thiophene of benzene as well as a preparation method and application of the ruthenium-based adsorbent. The ruthenium-based adsorbent comprises metal ruthenium loaded on a carrier, wherein the carrier is selected from aluminum oxide, silicon oxide, titanium oxide and a molecular sieve, and a mixture of any two or more thereof. The preparation method comprises the following steps: adopting a molded porous grain-shaped carrier; carrying out modification treatment on the carrier in advance and loading pre-blended ruthenium-containing compound slurry by an immersion or spraying method; adding an inorganic alkali solution to carry out sedimentation and transformation; and carrying out liquid-phase reduction and / or gas-phase reduction to obtain the ruthenium-based adsorbent. The benzene, which is treated by the novel ruthenium-based adsorbent, can meet the requirements on content and quality of thiophene in the raw material benzene in a process of preparing cyclohexene through hydrogenating the benzene. Compared with the prior art, the ruthenium-based adsorbent has high thiophene removal precision, high sulfur capacity, low price and simple production process and equipment; and industrialized production is easy to realize and the ruthenium-based adsorbent has good application prospect and great economic benefits.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

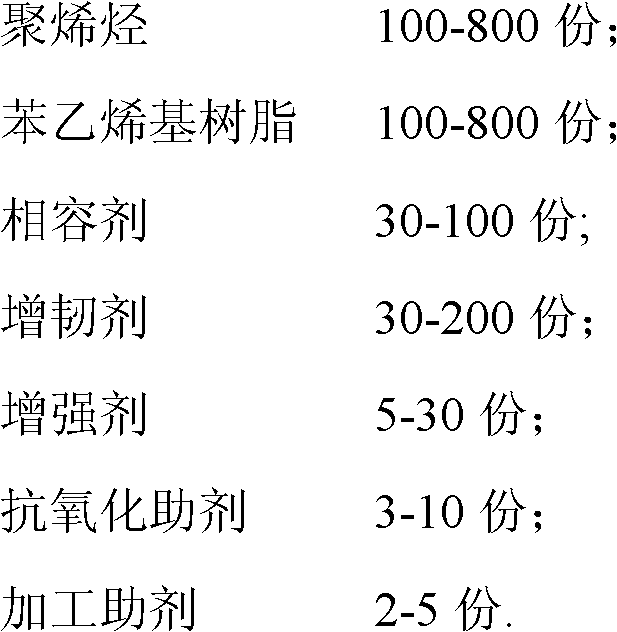

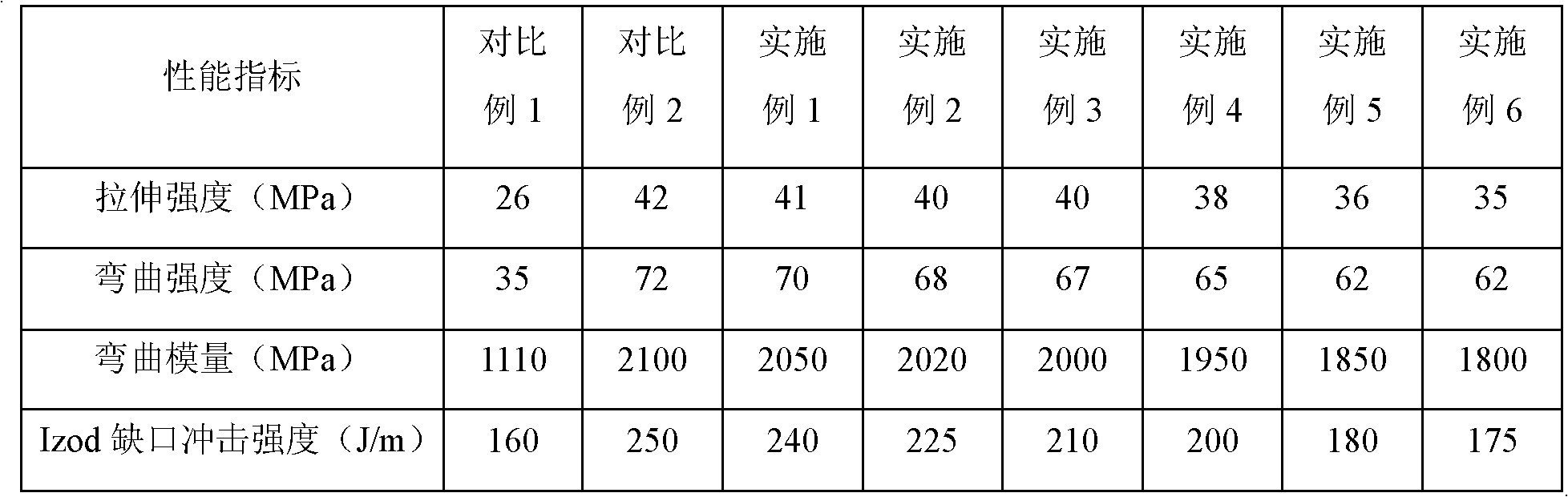

Polyolefin/styrene based resin composition and preparation method thereof

Belonging to the technical field of high polymer materials, the invention relates to a polyolefin / styrene based resin composition and a preparation method thereof. The composition is prepared from the following components by weight part: 100-800 parts of polyolefin; 100-800 parts of styrene based resin; 30-100 parts of a compatilizer; 30-200 parts of a toughening agent; 5-30 parts of a reinforcing agent; 3-10 parts of an antioxidant aid; and 2-5 parts of a processing aid. The polyolefin / styrene based resin composition prepared by the invention has stable mechanical properties. Compared with styrene based resin, the composition maintains comparable properties, and has an obvious price advantage, can partially or completely replace styrene based resin, and the economic benefits are significant. The polyolefin / styrene based resin composition provided in the invention is prepared by a twin-screw extrusion technology. Lateral forced feeding is preferably adopted in the production process, and the reinforcing agent can be dispersed better, so that the product can have excellent comprehensive properties.

Owner:HEFEI GENIUS NEW MATERIALS

Pollution-free recycling method of iron-based grinding waste material

InactiveCN101898247AWide variety of sourcesExtensive sources of raw materialsMolten spray coatingOther chemical processesThermal sprayingCircular economy

The invention provides a pollution-free recycling method of iron-based grinding waste material, belonging to the technical field of circular economy, and more particularly relating to the green circulating and recycling technology of the iron-based grinding waste material in the metallurgy industry. The recycling method of the iron-based grinding waste material comprises the steps of removing oil, heat treating, sieving and proportioning to obtain the iron-based alloy powder which can be used for an SHS lining steel tube, a powder metallurgy structural component, magnetic grinding and thermal spraying. The invention has the recovery rate of the iron-based alloy powder more than 95%, and the characteristics of wide raw material source, low cost, no secondary pollution, high circulating and recycling rate and wide powder use.

Owner:UNIV OF SCI & TECH BEIJING

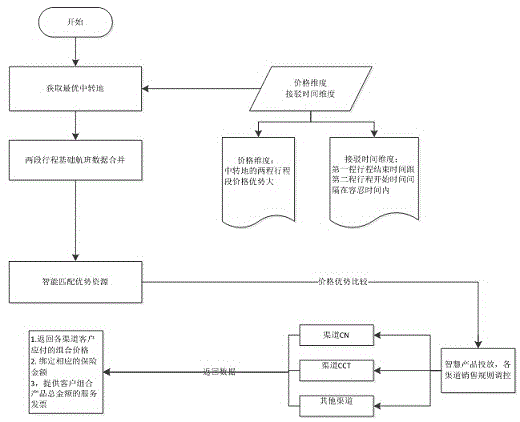

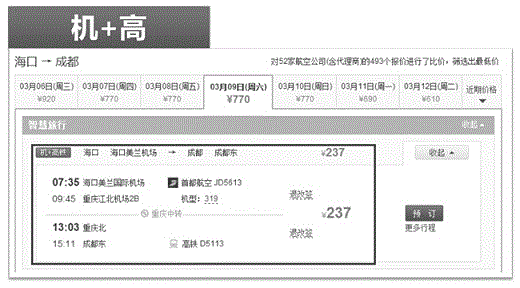

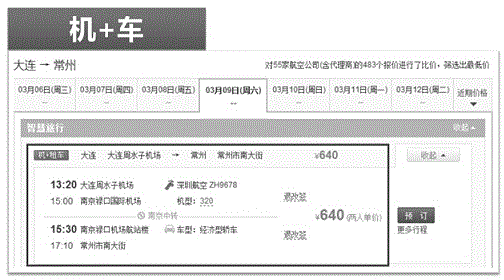

Travel transfer planning method based on airline ticketing

The invention relates to a travel transfer planning method based on airline ticketing. The travel transfer planning method is characterized by comprising the following steps: firstly, selecting an optimal transfer site; then, collecting the travel data of a first travel and a second travel, and selecting superior resources in the travel data; then, enabling the superior resources to correspond to different marketing channels, putting on the market, and returning the price combination of corresponding channels. Thus, after the travel transfer planning method is adopted, a series of problems such as inconvenience in subsequent travels caused by no direct flight, no airplane or relatively early or late takeoff and landing time can be solved, and a diversified traffic combination solution can be provided for customers.

Owner:TONGCHENG NETWORK TECH

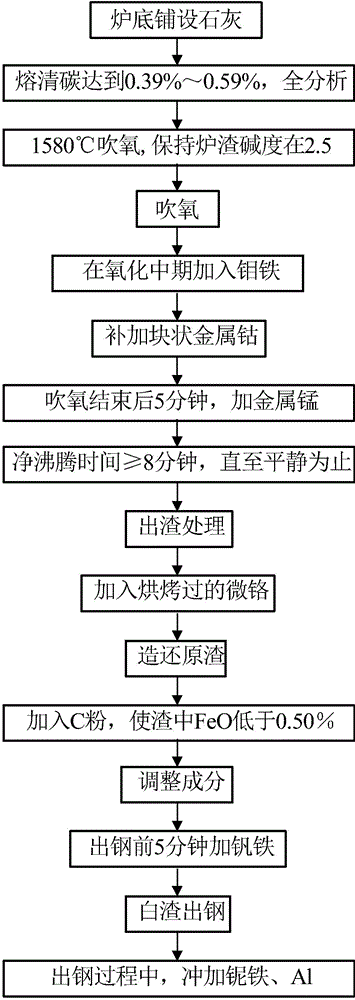

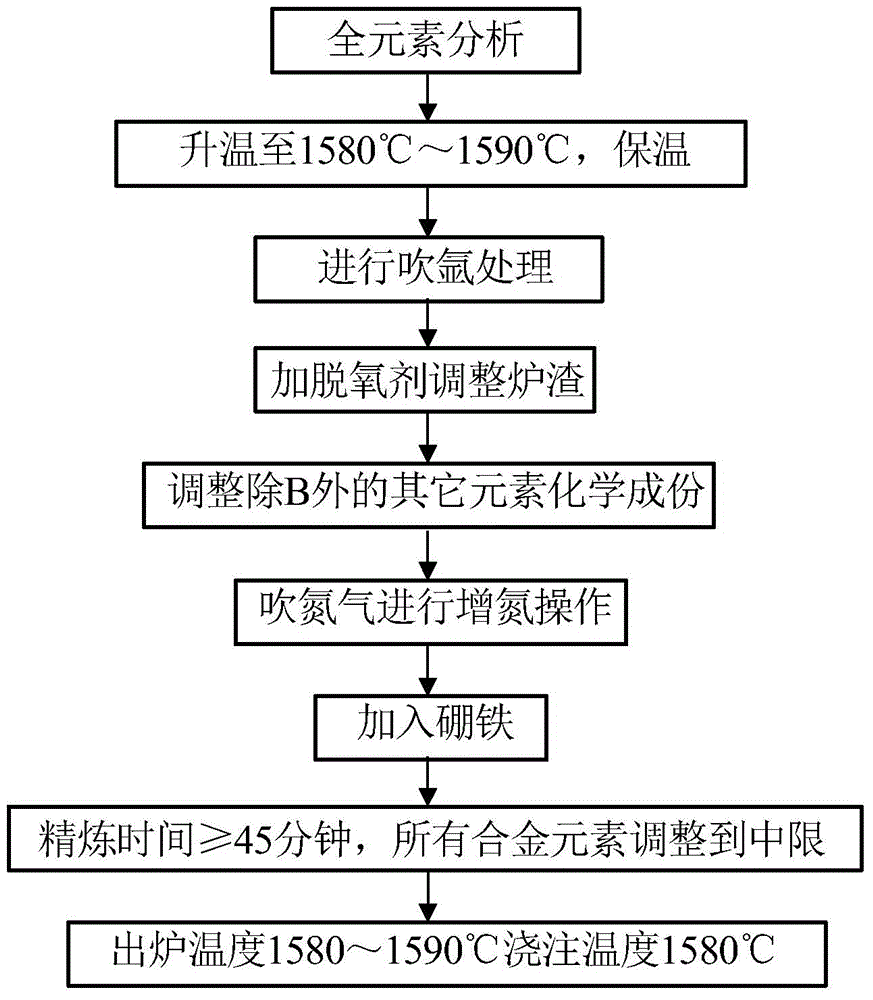

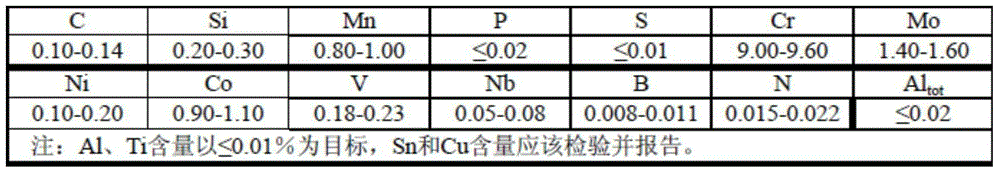

Preparation process of cast steel material capable of resisting high temperature of 620 DEG C

InactiveCN104911453AStrengthen the smelting processUnique preparation processProcess efficiency improvementElectric furnaceElectric arc furnaceSmelting process

The invention discloses a preparation process of a cast steel material capable of resisting a high temperature of 620 DEG C. The cast steel material is ZG13Cr9Mo2Co1NiVNbNB; the preparation process comprises a unique electric arc furnace smelting process and a ladle refining furnace smelting process; according to the preparation process, nitrogen is blown in the LF furnace smelting process to take the place of the process of adding a chromium nitride alloy to the electric arc furnace in the prior art, and therefore, the process performance is stabilized and the cost is greatly reduced. The electric arc furnace and the ladle refining furnace are taken as the basic smelting devices for the preparation process; the electric arc furnace smelting process is strengthened, and on the basis of obtaining good-quality primary smelting liquid steel, the control of the ladle refining furnace is refined; a unique, complete and exquisite preparation process is obtained by virtue of lots of experimental summary; the existing production equipment can be utilized without increasing investment to produce steel castings having the performance indices completely satisfying the use of high-efficiency ultra-supercritical units, and the steel castings have been successfully applied to the operation of high-efficiency ultra-supercritical turbine units.

Owner:上海宏钢电站设备铸锻有限公司

Method for preparing construction waste micro-powder composite admixture

InactiveCN103086619AHas hydration activityPromote participation in hydration reactionsSolid waste managementCement productionAlkalinityPowder mixture

The invention discloses a method for preparing a construction waste micro-powder composite admixture. The method comprises the steps of: evenly mixing construction waste with lime and desulfurized gypsum, and grinding at room temperature to obtain a micro-powder mixture with specific surface area larger than 400m<2> / kg, wherein the mixing weight of the construction waste accounts for 90%-98% total weight of the micro-powder mixture, the mixing weight of the lime accounts for 1%-5% and the mixing weight of the desulfurized gypsum accounts for 1%-5%; mixing the ground micro-powder mixture with an additive of which the weight accounts for 1%-5% total weight of the micro-powder mixture to obtain a mixed material; and mixing the mixed material with slag in a weight ratio of 1:1 and then carrying out ball milling until the specific surface area of the material is larger than 450m<2> / kg, thereby obtaining the construction waste micro-powder composite admixture. The method has the advantages that the alkalinity of concrete can be supplemented, the mixing quantity of a construction waste micro-powder auxiliary gelation material in the concrete is increased and the carbonization resisting capacity of the concrete can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

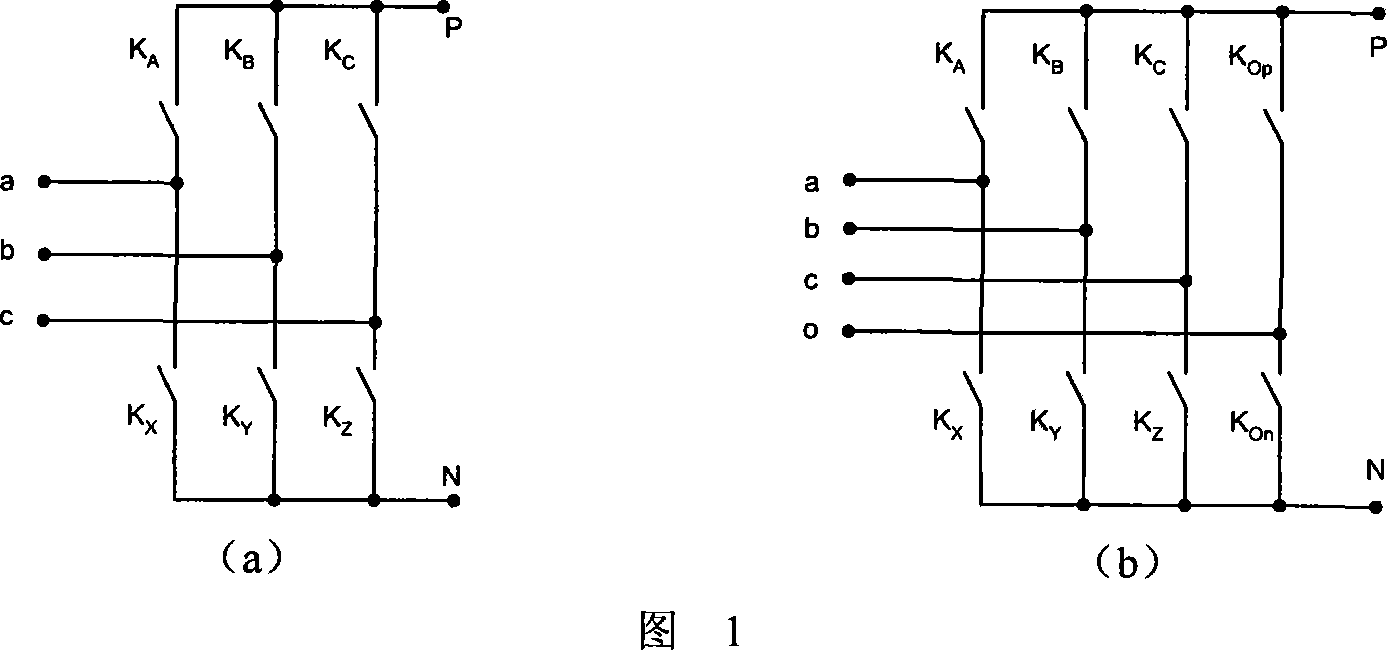

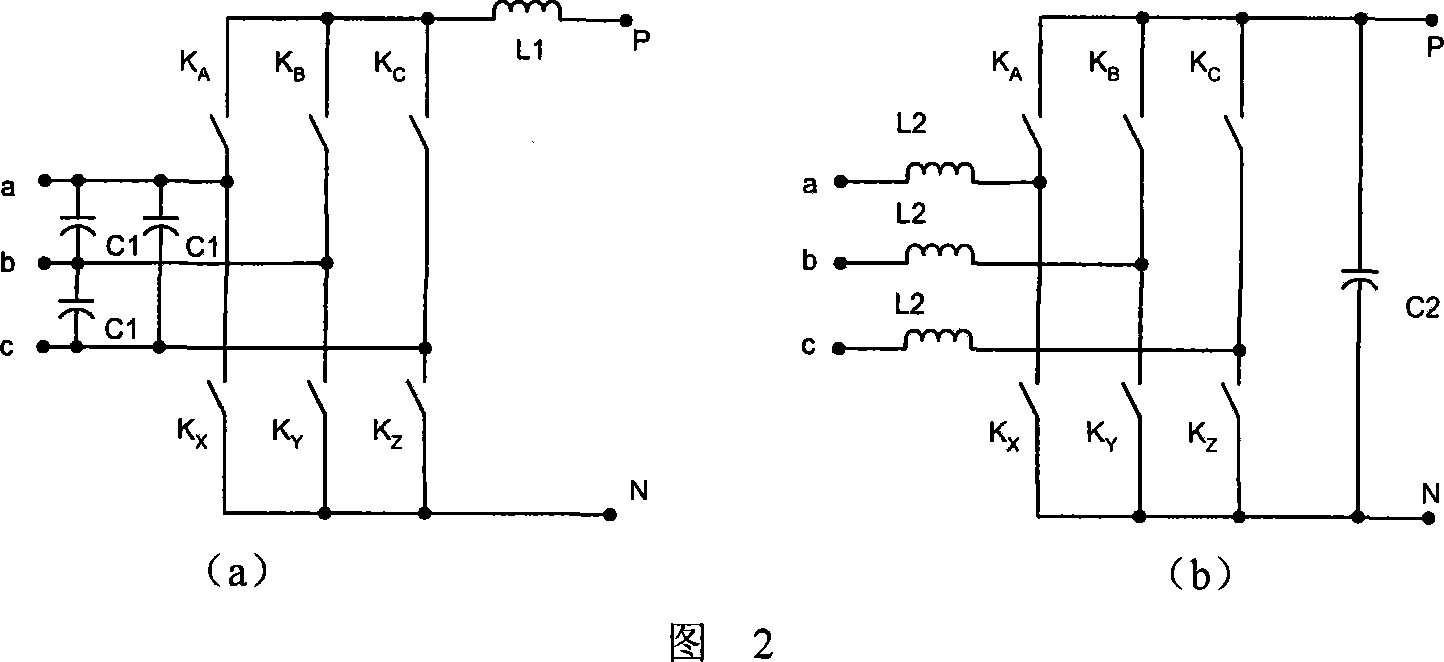

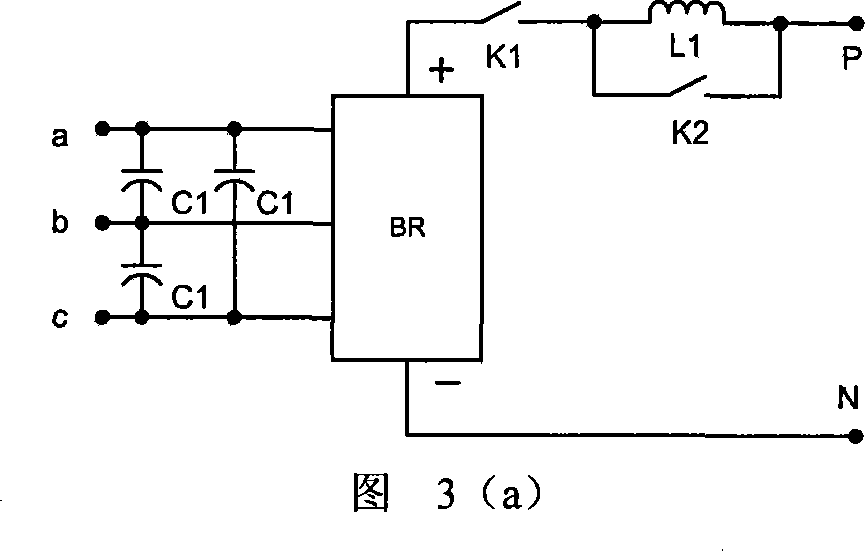

General convertor based on the mixed switch

InactiveCN101056070AObvious price advantageLow costEfficient power electronics conversionAc-dc conversionPower factorNew energy

The present invention provides a universal convertor based on a mixed type switch. The convertor circuit which is adapted to form a series of new switch power supply convertors almost having no energy saving ability only adopts a spot of all-controlled switches, and common thyristors. Devices derived from the present invention are: a reactive power compensator of electrical power grid, an active electric power filter, a sine inverter, a quasi-square wave inverter, an AC-DC transducer working in four quadrants, a bidirectional AC-DC-AC sine wave transducer, controllable rectifier having a power factor approximating to 1 and the content of harmonic wave approximating to 0, etc. The universal convertor can be applied widely in the fields of power supply of electric automobile, frequency and speed control, electric traction, uninterruption power sources, new energy convertor, electrochemistry power supply, medium frequency power supply, electrical energy quality improvement of electric power system. The device in the present invention has advantages of excellent electric property, reduced material cost, volume and weight, harmonic waves that are almost eliminated comparing to the common technology, and has a high value of application and generalizing.

Owner:杭州迪源电气科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com