Patents

Literature

43 results about "Collagen fiber bundle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

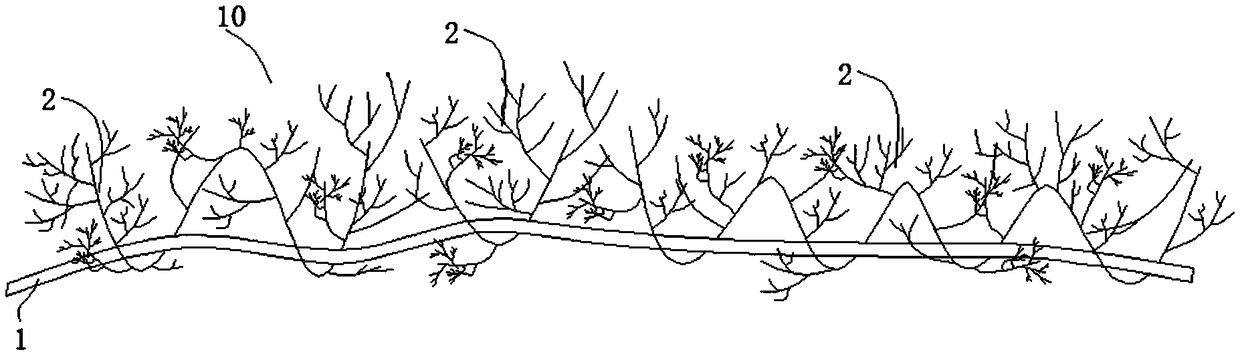

Spun laced fabric and processing method thereof

InactiveCN101235579ANot easy to slip offRich varietyAnimal materialNon-woven fabricsFiberCollagen fiber bundle

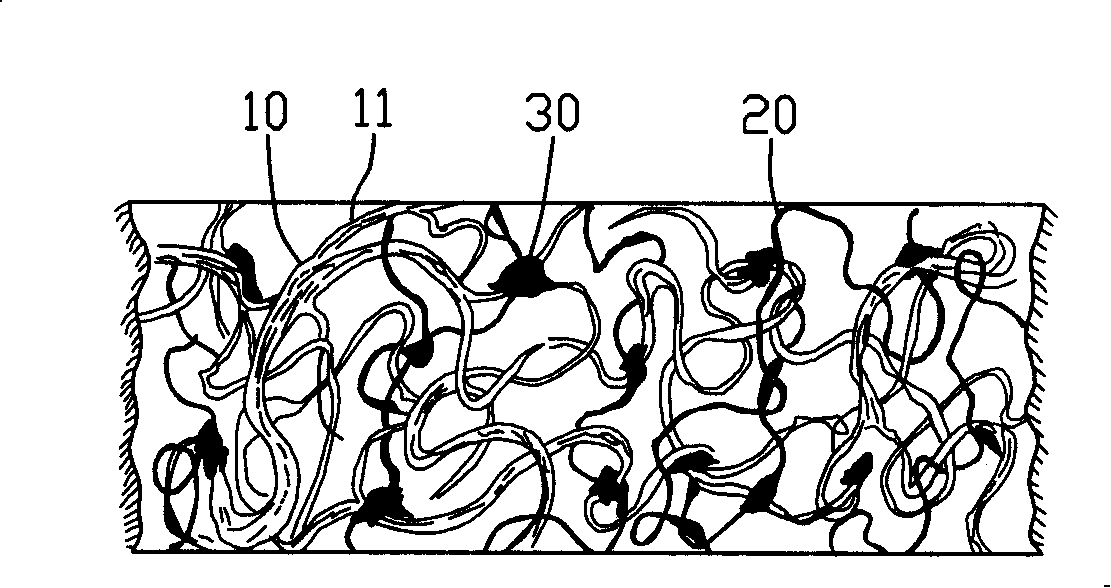

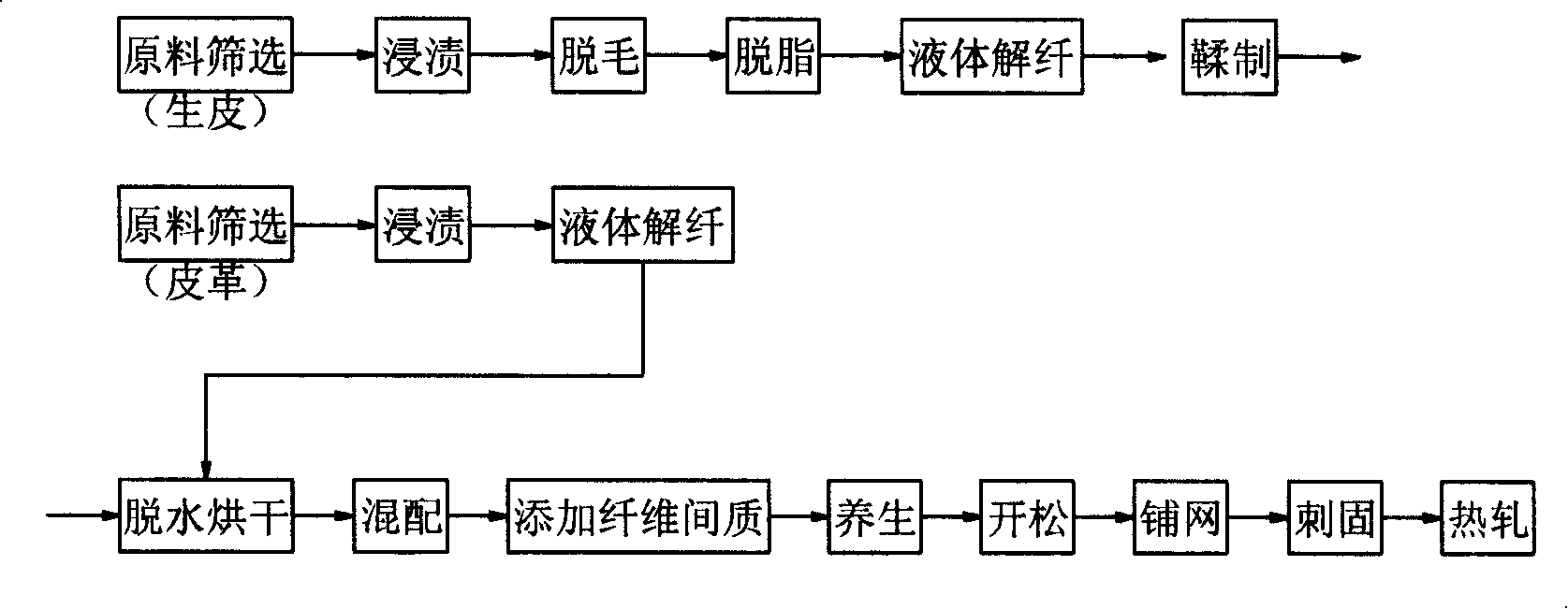

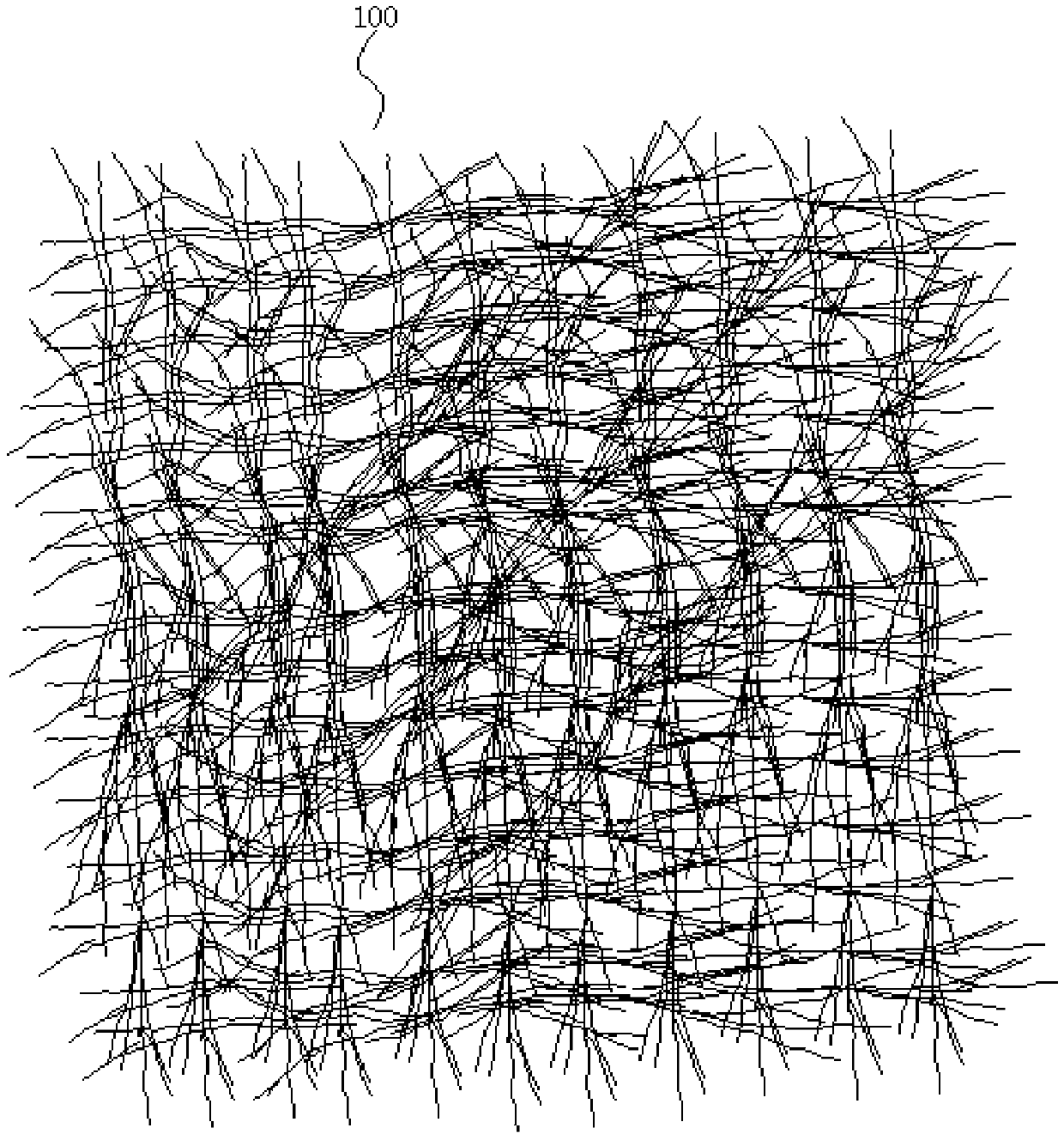

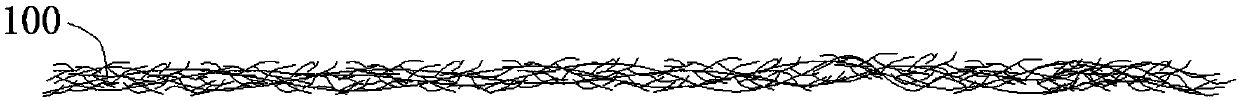

The invention discloses spun-laced cloth and a method for manufacturing the spun-laced cloth. The spun-laced cloth is composed of collagen fiber bundles, other textile-used staple fibers and interstitial fibers, wherein the collagen fiber bundles are mutually interpenetrated and interweaved with branches of the collagen fiber bundles to form stereo reticular braided structures, other textile-used staple fibers are located on skeleton of the stereo reticular braided structures, reticular entwining is formed between the textile-used staple fibers mutually or between the textile-used staple fibers and the collagen fiber bundles and the branches of the collagen fiber bundles, and fiber is adhered or bound by the interstitial fibers. The method of the invention can take animal raw hide as raw materials and can be realized through following technical steps: screening the raw materials, dipping, unhairing, degreasing, defibering liquid, tanning, dewatering and drying, mixed liganding, adding the interstitial fibers, health preserving, opening, combing,laying net, spunlacing, and hot rolling, furthermore, the method of the invention can also take the animal leather after tanning as the raw material and can be realized through following steps: screening the raw materials, dipping, defibering the liquid, dewatering and drying, mixed liganding, adding the interstitial fibers, health preserving, opening, combing, laying net, spunlacing, and hot rolling.

Owner:ZHEJIANG HONGZHAN NEW MATERIALS

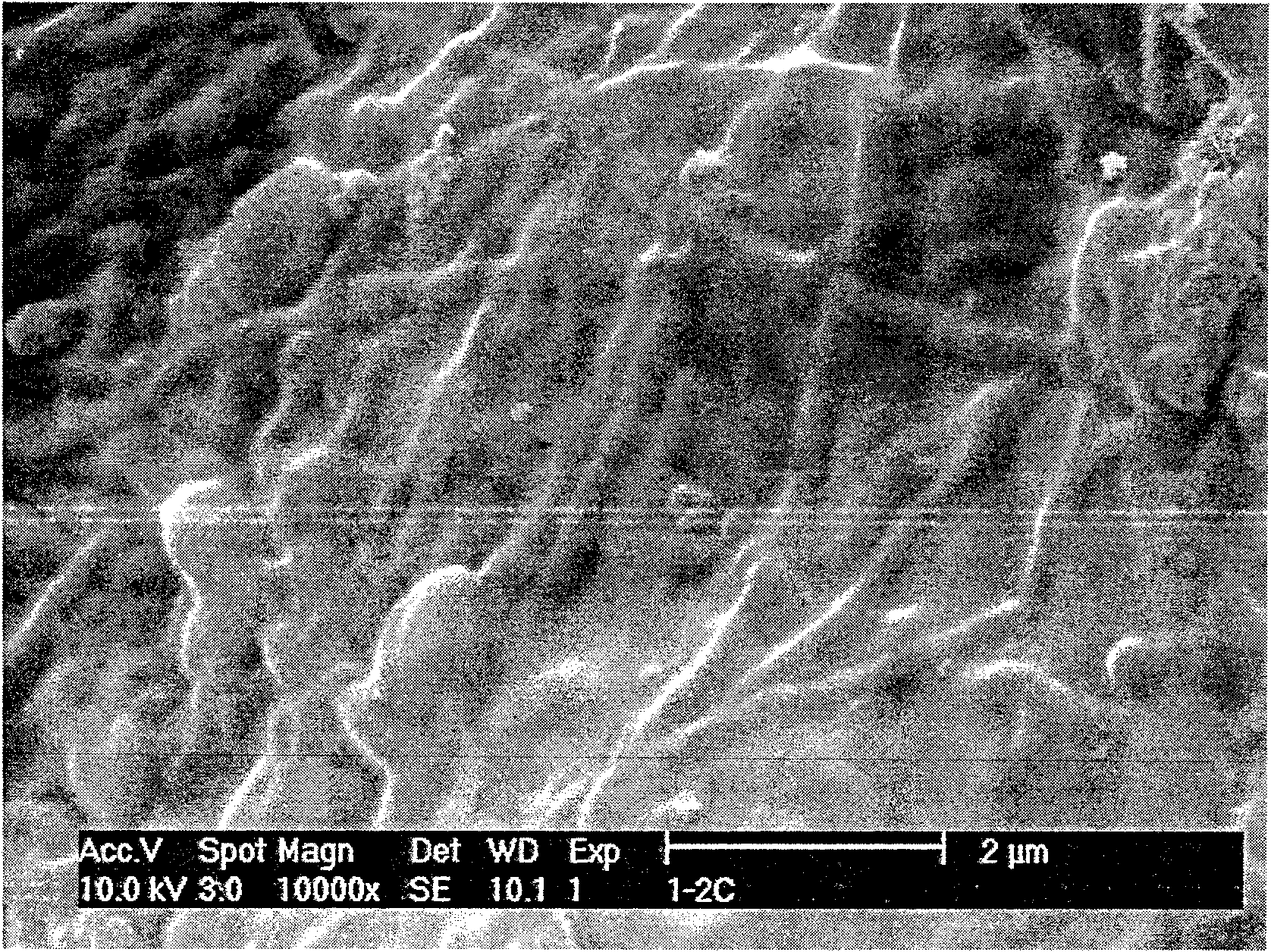

Antigen-free collagen aggregate and preparation method thereof

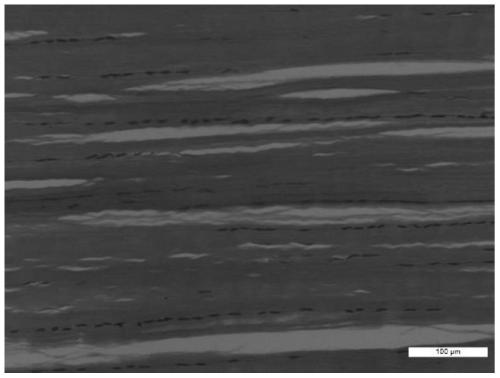

The invention discloses an antigen-free collagen aggregate and a preparation method thereof. The preparation method is characterized by comprising the following steps: with traceable animal skin or tendo calcaneus as a raw material, performing operations by the process such as fleshing, stripping fascia, degreasing, removing foreign protein and decellularizing; performing fine purification on the animal skin or tendo calcaneus, and then carrying out separation and purification on the collagen aggregate by the methods of acid fluffing, homogenizing, salting out for a plurality of times, centrifuging for a plurality of times and the like, thereby finally obtaining the antigen-free collagen aggregate. The collagen aggregate is a mixture of a collagen fiber and a collagen bundle, and has a periodic light and shade horizontal grain structure; and the space between the horizontal grains is about 67nm. The material has good biocompatibility, biodegradability, mechanical property and hemostatic performance, also has the characteristics of low antigenicity, biological activity and the like, and can be widely applied to preparation of biomedical materials such as a hemostatic material, a tissue engineering material, a biological dressing, a biodegradable medical suture and a plastic material.

Owner:SICHUAN UNIV

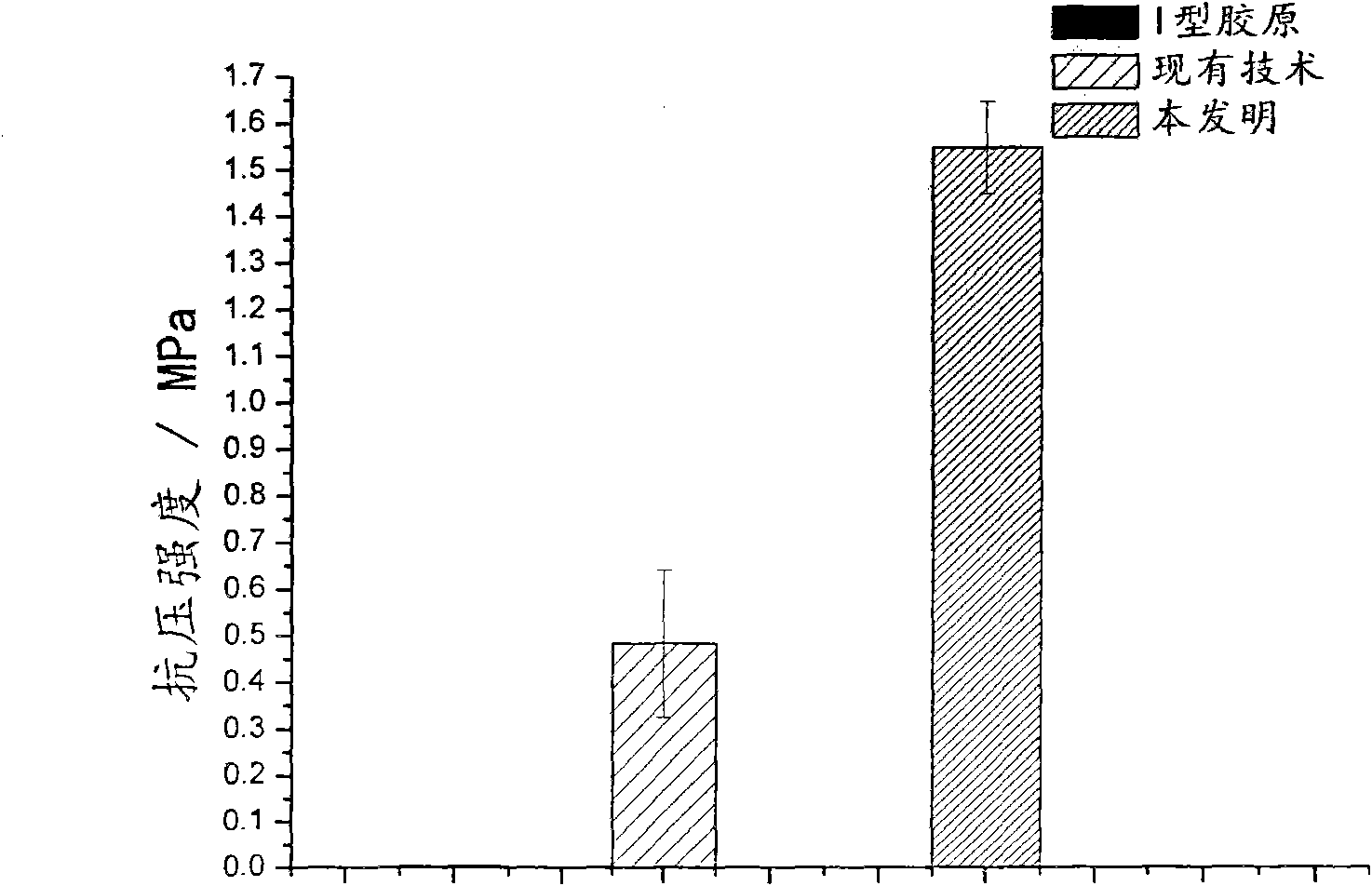

Method for preparing collagen/bioglass/hyaluronic acid tissue repairing materials

The invention discloses a method for preparing collagen / bioglass / hyaluronic acid tissue repairing materials, comprising the following steps: combining I-type collagen and bioglass, static layering, filtering, adjusting pH value, adding hyaluronic acid, cross linking, molding, freezing and drying and the like. In the process of preparing the collagen / bioglass / hyaluronic acid tissue repairing materials, the diameter of the collagenous fiber bundle composing the network structure of the tissue repairing materials is increased by adjusting the ratio of the I-type collagen and bioglass and the pH value of the combined solution, and the microstructure of the materials is adjusted, thus achieving the aim of improving mechanical strength thereof. The collagen / bioglass / hyaluronic acid tissue repairing materials prepared by the invention has improvement in mechanical property and degradation performance, can be widely used in medical field, also can be used in tissue engineering scaffolds and bone defects and soft tissue injuries repairing.

Owner:SOUTH CHINA UNIV OF TECH

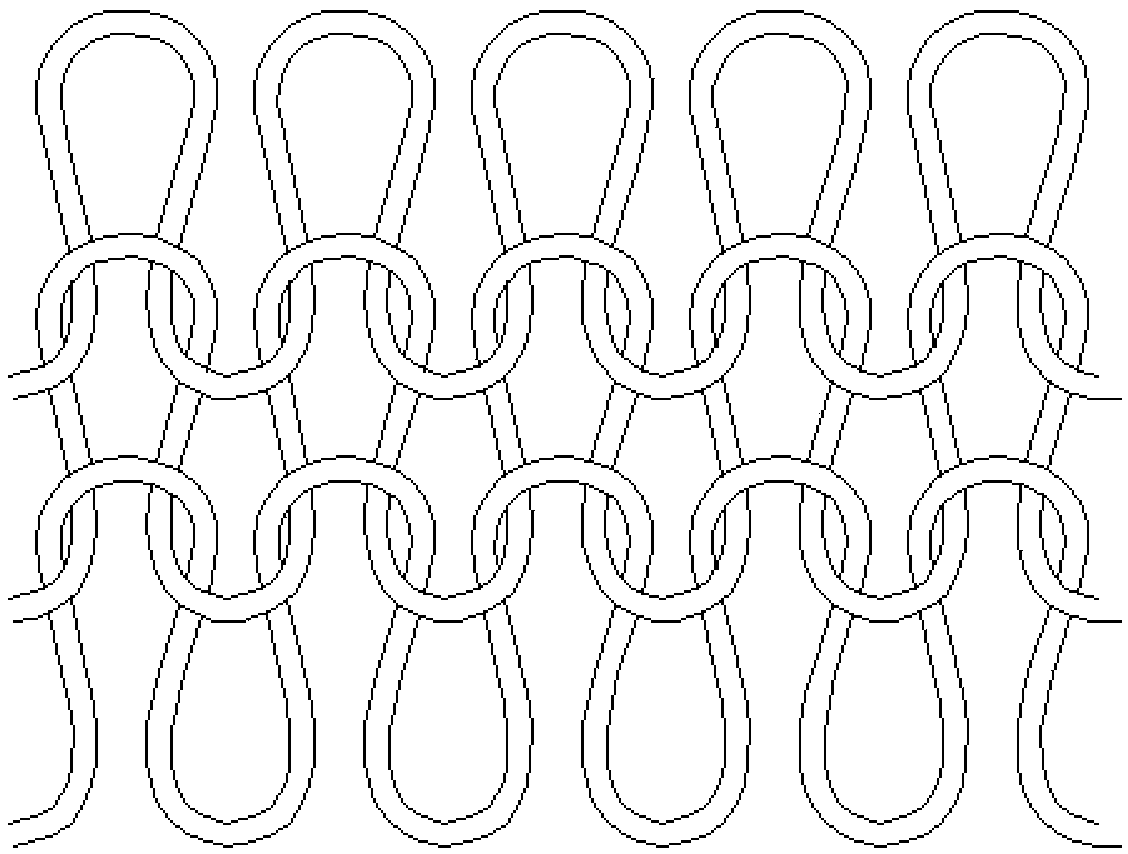

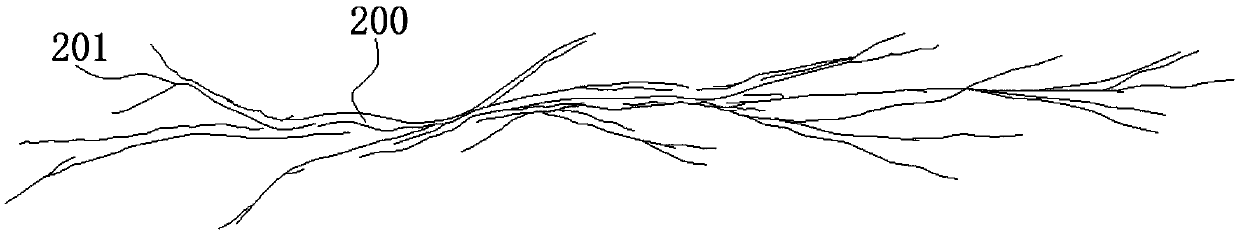

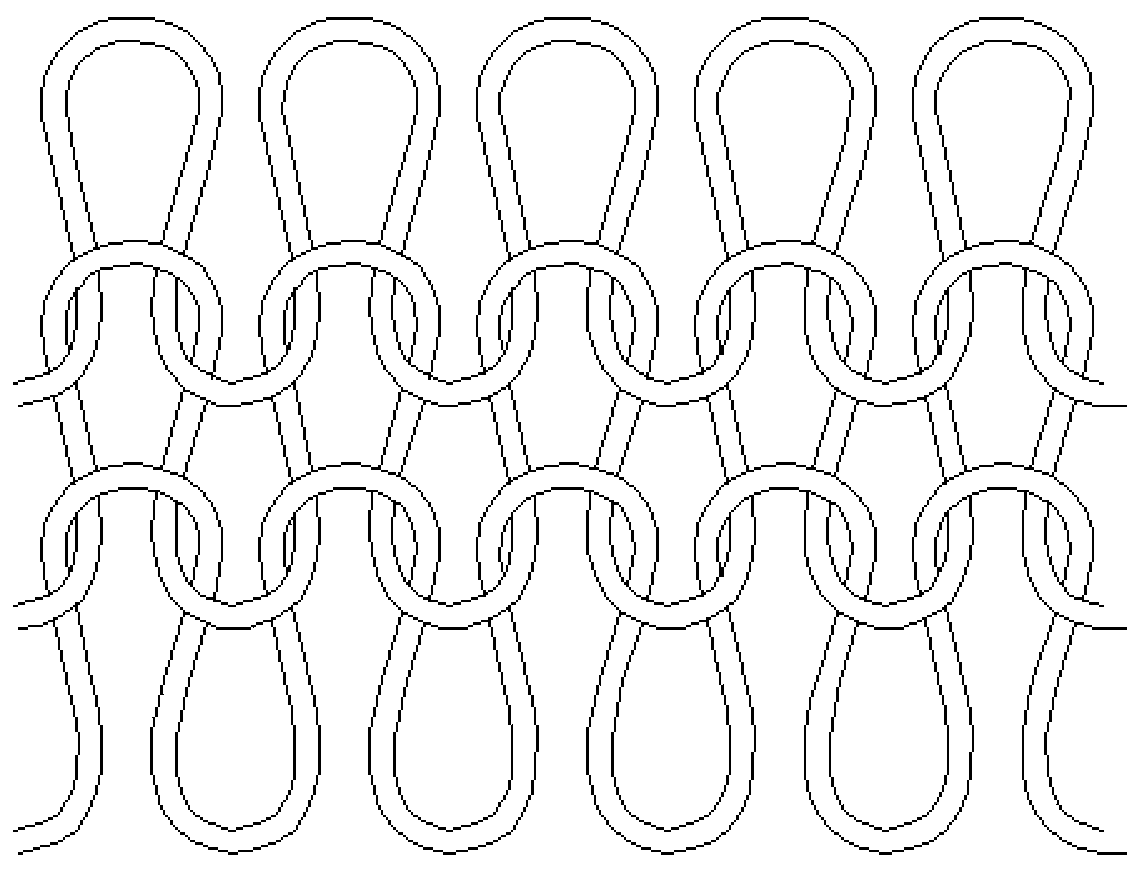

Core spun yarn taking collagenous fibers as main material and as leather layer and processing method of core spun yarn

InactiveCN105671723AHigh tensile strengthTensile strength does not affectCarding machinesLap forming devicesYarnTextile fiber

The invention discloses a core spun yarn taking collagenous fibers as a main material and as a leather layer and a processing method of the core spun yarn. The core spun yarn comprises a core yarn, wherein a leather layer formed by collagenous fiber bundles or a collagenous fiber bundle and other textiles covers or cover the core yarn; a collagenous fiber bundle and a branch thereof and an adjacent collagenous fiber bundle and a branch thereof form three-dimensional meshed structures which are mutually staggered, twisted and combined and axially arrayed. The processing method of the core spun yarn taking the collagenous fibers as the main material and as the surface layer comprises the following steps: (1) extracting collagenous fibers; (2) carding and striping the fibers; (3) drawing the fibers; and (4) performing spinning. According to the core spun yarn and the processing method thereof, the problem that the basic tensile strength cannot be achieved by extracting the collagenous fibers from leather and directly spinning the fibers in the prior art is solved, and the shortcoming that fine yarns are very hard to process or cannot be processed and the shortcoming that a product cannot fully exert the characteristic of the collagenous fibers as a large number of other textile fibers must be blended for spinning are overcome.

Owner:张立文

Composites comprising collagen extracted from sarcophyton sp. coral

Isolated composites are disclosed comprising collagen fibers isolated from a Sarcophyton sp. coral. An exemplary composite comprises as a first component a bundle of collagen fibers, the collagen fibers being isolated from a Sarcophyton sp. coral, and a second component selected from the group consisting of a polysaccharide, a polypeptide, polylipid, a synthetic polymer, a metal and a mineral, wherein the bundle of collagen fibers comprise woven fibers, twisted fibers, braided fibers, knitted fibers, tied fibers, or sutured fibers. Uses thereof and method of generating are also disclosed.

Owner:RAMOT AT TEL AVIV UNIV LTD

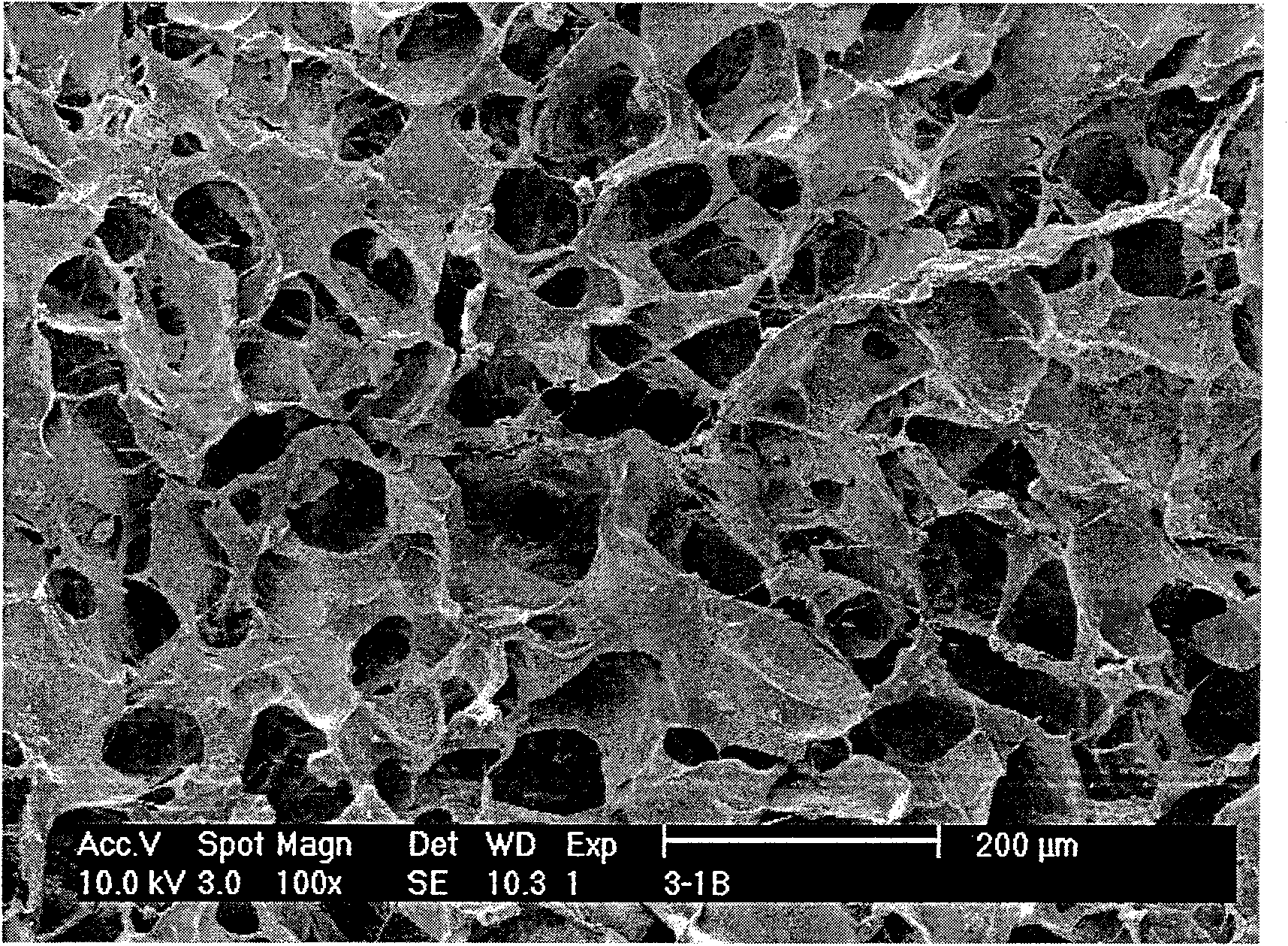

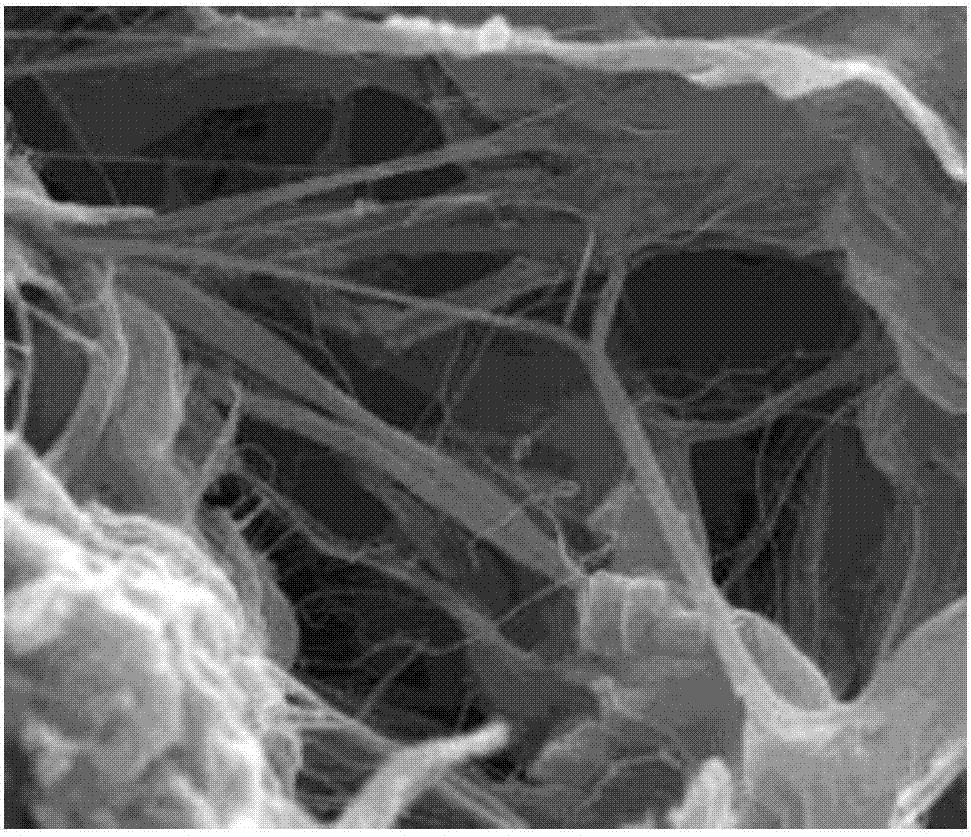

Preparation method of anti-infectious lower biomaterial of small intestinal mucosa

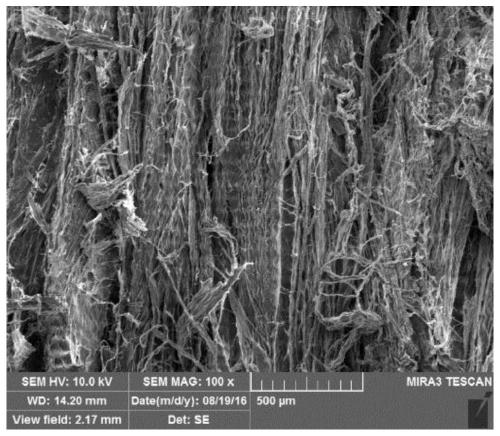

InactiveCN109331228AImprove solubilityPromote digestionProsthesisFreeze-dryingScanning electron microscope

The invention relates to a preparation method of an anti-infectious lower biomaterial of small intestinal mucosa. The method comprises the following steps: primarily treating; degreasing; inactivatingvirus; decellularizing; loading antibacterial components; forming; freezing drying or soaking in a storing solution; packing; sterilizing. The lower biomaterial prepared according to the method is good in decellularizing effect; the damage to the structure of a raw material is reduced; an SIS material subjected to decellularizing is complete and uniform in a collagenous fiber structure by observing through a light microscope; the collagenous fiber beam is complete; extremely few cells are residual; complete cells cannot be observed; the collagenous fibers of the material are of three-dimensional net shaped structures by being observed under a scanning electron microscope, and cells are not observed, and few broken cell pieces are residual; after the antibacterial components are loaded tothe SIS, the antibacterial effect is obvious; the clinical demand can be met.

Owner:陈德夫

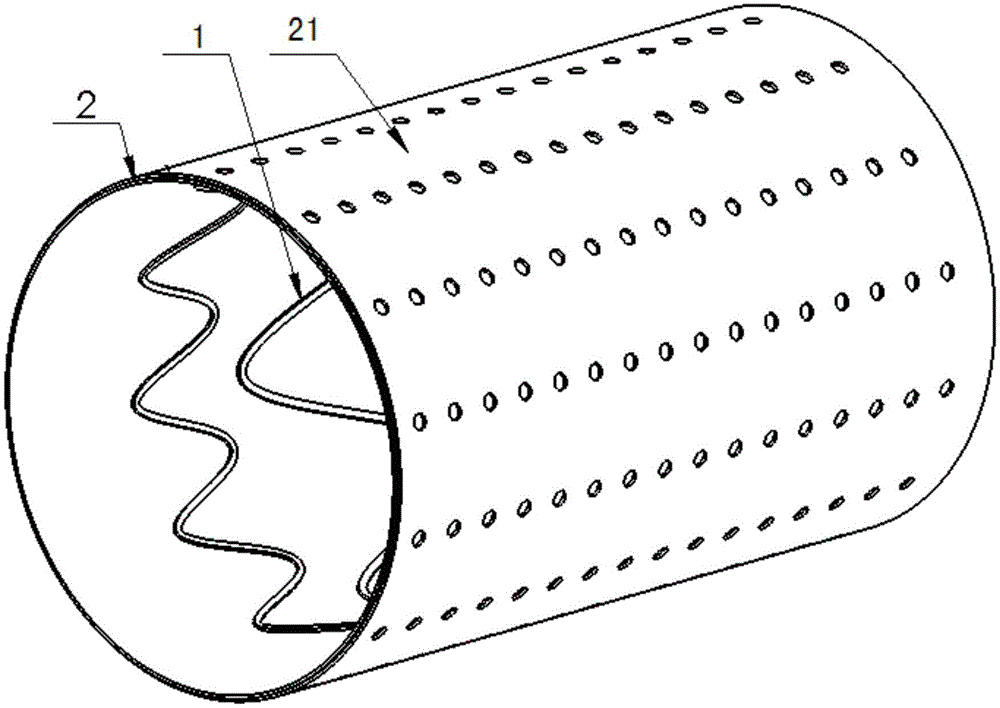

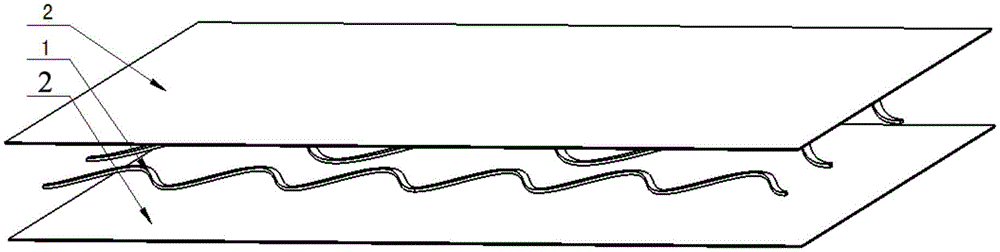

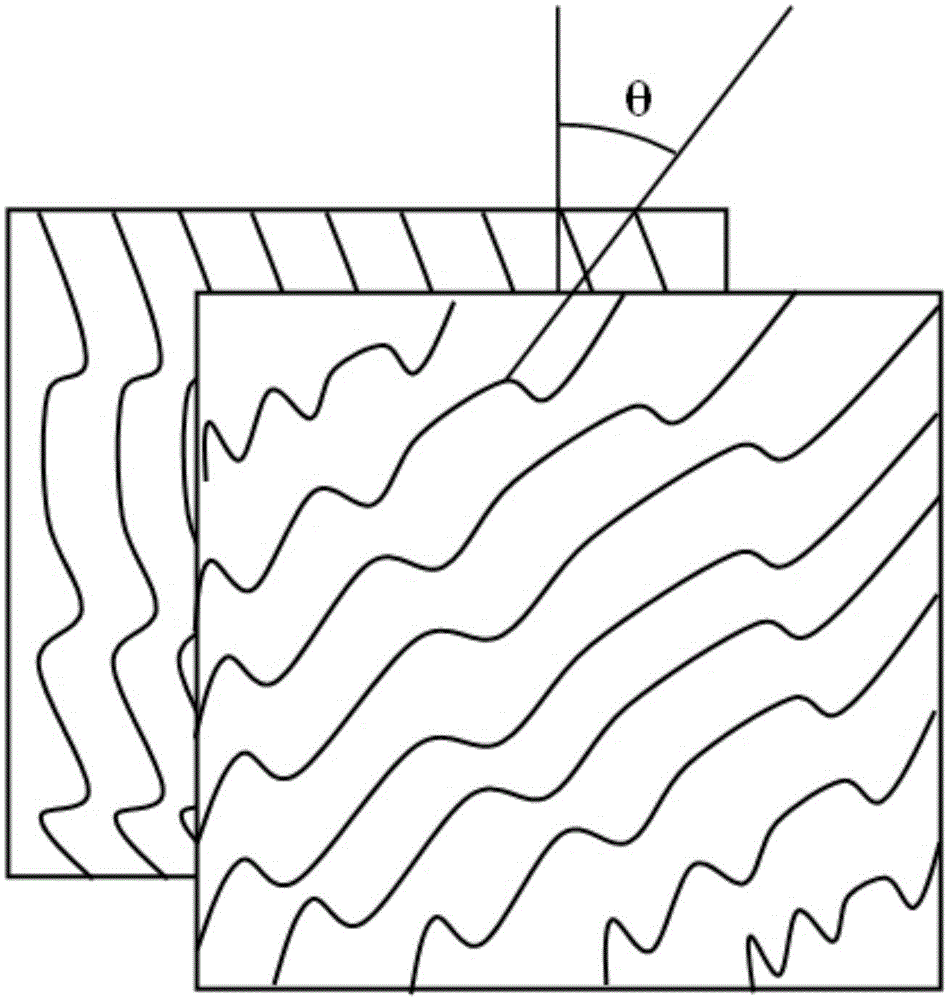

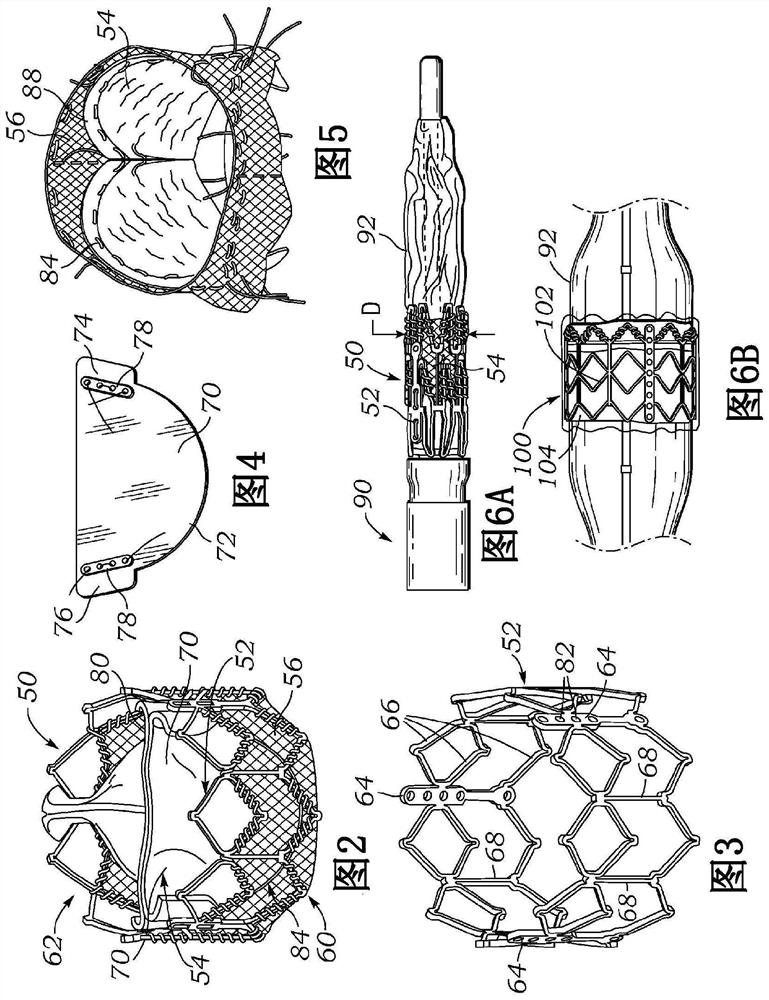

Filming support

A filming support comprises a supporting structure and a film covering the supporting structure, wherein the film is composed of at least two stacked layers of allogeneic acellular tissue base film, the smooth side of each layer of the base film faces the supporting structure while the rough side faces out; the adjacent two layers of base film are arranged by crossing at a certain angle along a growth direction of a collagen bundle. In the at least two layers of the allogeneic acellular tissue base film, all base film is provided with a plurality of through holes expect for the innermost layer, and the hole diameter increases gradually from the inner layer to the outer layer. The use of the filming support is effective in reducing the formation of thrombus and endotheliosis, in enhancing film strength and reducing the axial tension of the film during the release of the filming support, and in adhering endothelial cells to promote cell differentiation to promote the ingrowth of tissues and vessels, and quickening the endothelialization of lesion areas of arterial aneurysm to give better effect in treating arterial aneurysm.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

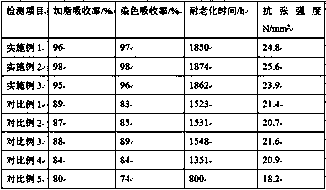

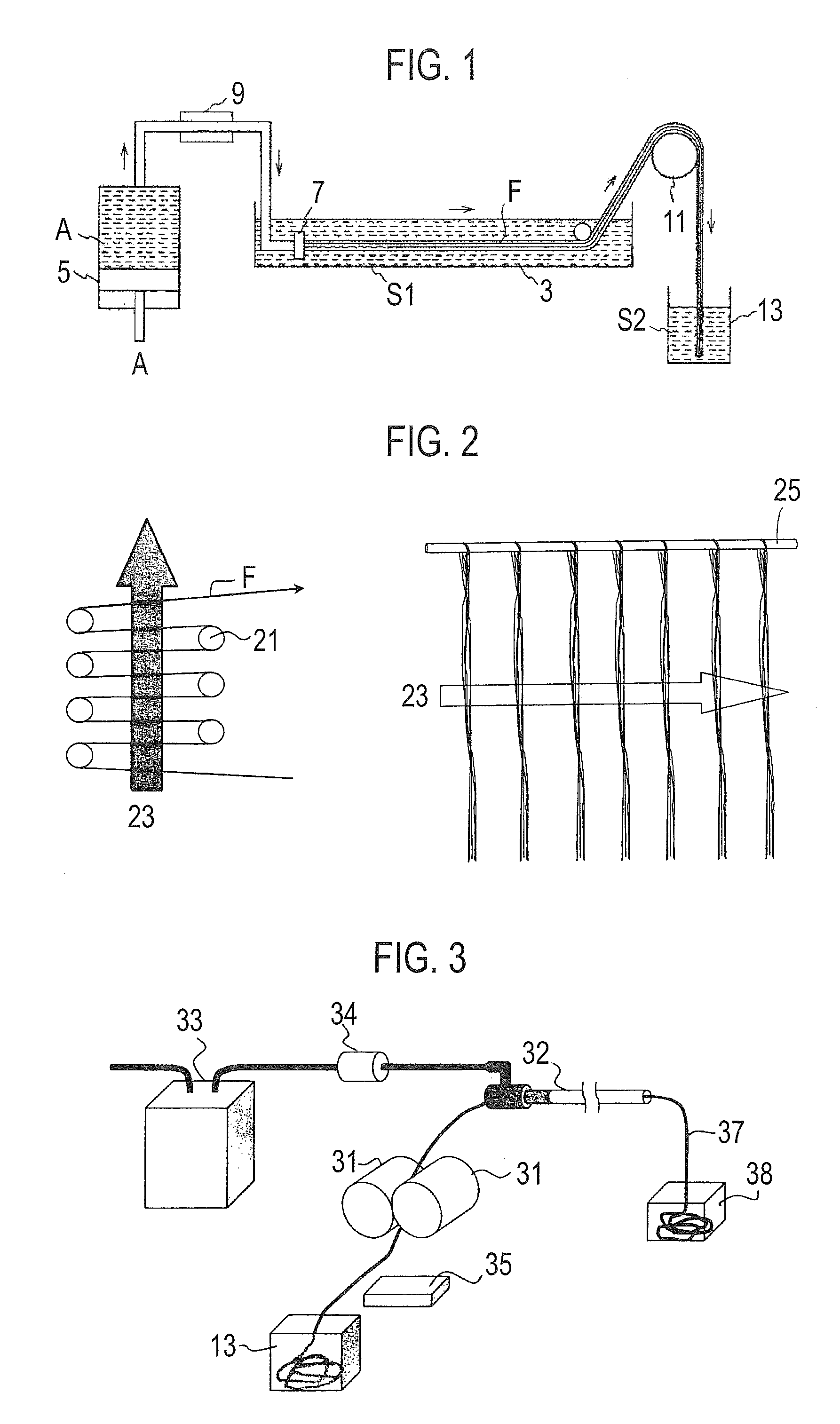

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653AEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processFiberHigh concentration

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

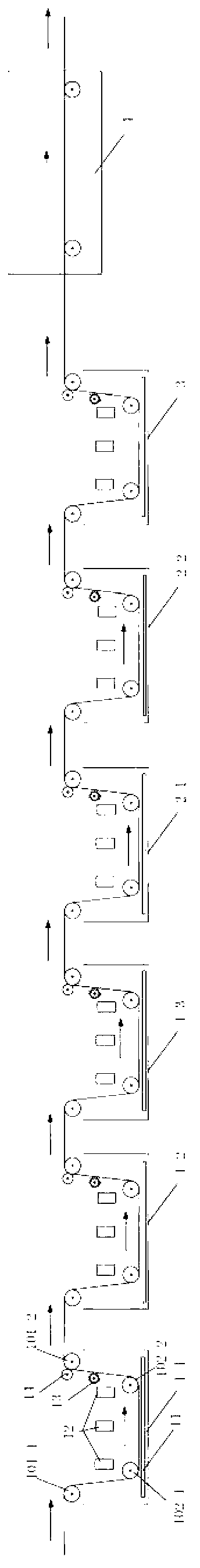

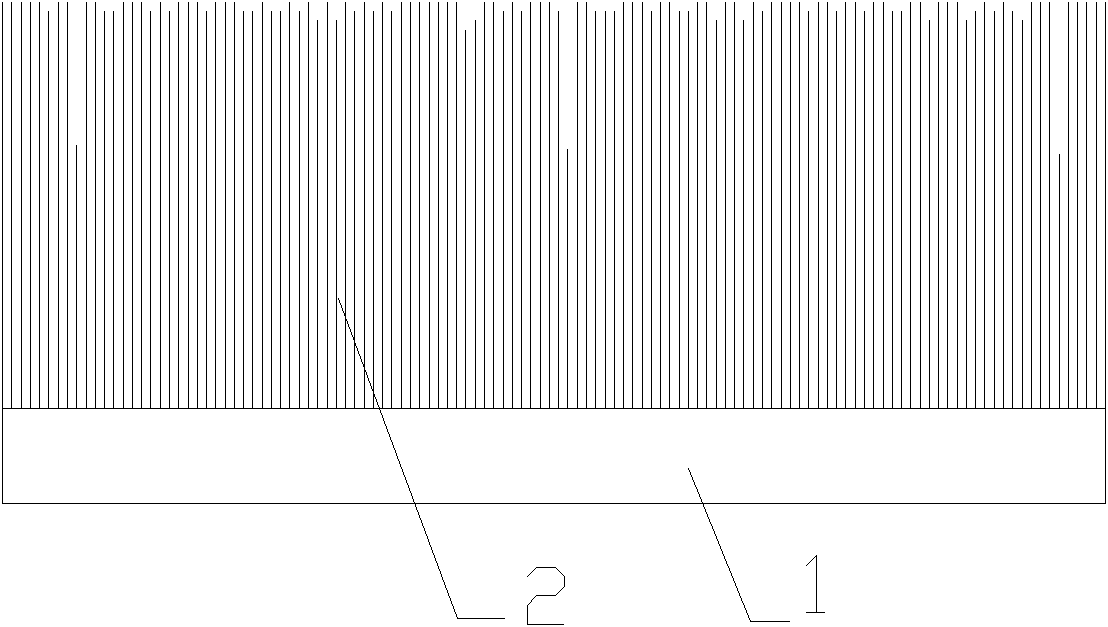

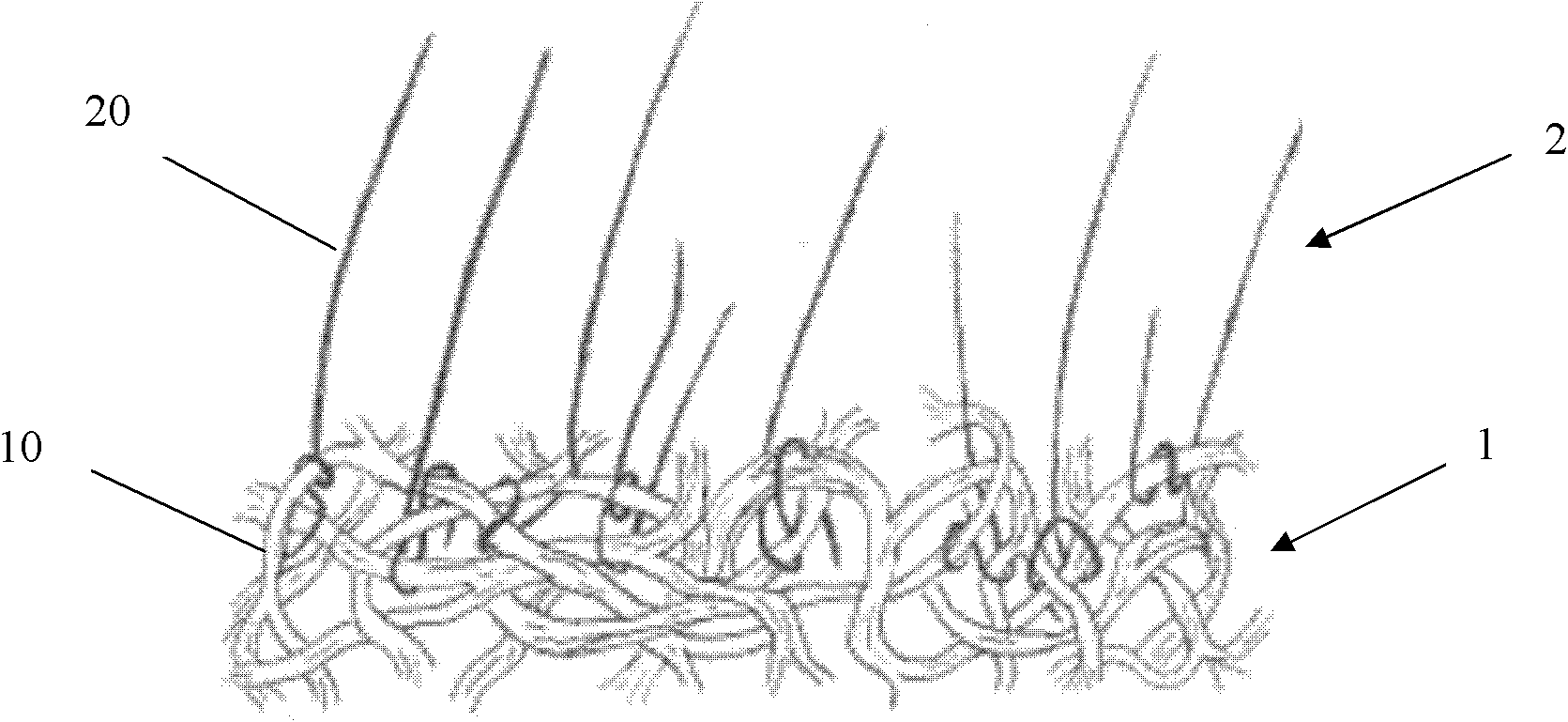

Novel fabric and novel leather product in which collagen fiber bundle forms network structure

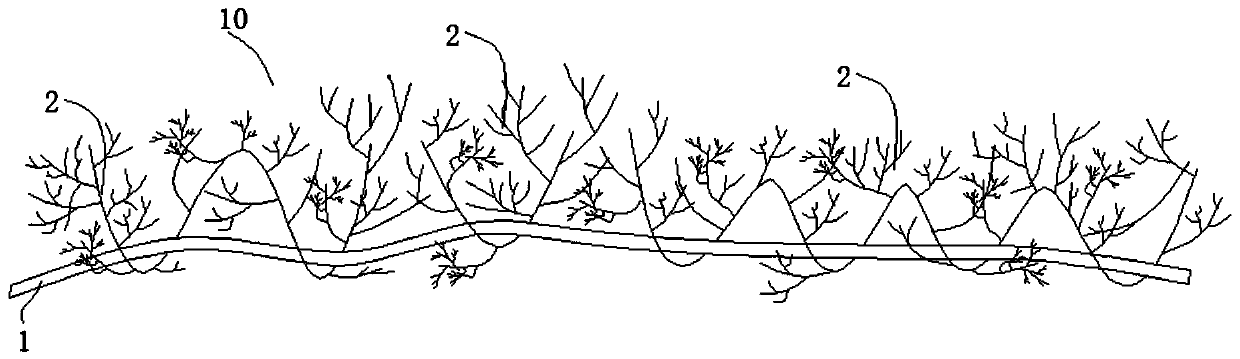

ActiveCN109082763ANot easy to hardenAct as a lubricantWeft knittingOrnamental textile articlesYarnCollagen fiber bundle

The invention discloses a novel fabric and novel leather product in which a collagen fiber bundle forms a network structure. The fabric comprises a bottom yarn woven layer, and further comprises the collagen fiber bundle, the collagen fiber bundle is sleeved with the bottom yarn of the bottom yarn woven layer and protrudes from the surface of the bottom yarn woven layer, the protruding collagen fiber bundle and its branches are interwoven to form the network structure, and portions of the branches of the collagen fiber bundle are sleeved with the bottom yarn so that at least the ends of the portions of the branches protrude from the bottom yarn woven layer. The leather product includes the novel fabric and a leather surface course. The novel fabric and the leather product have good mechanical properties due to the formation of the network structure.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

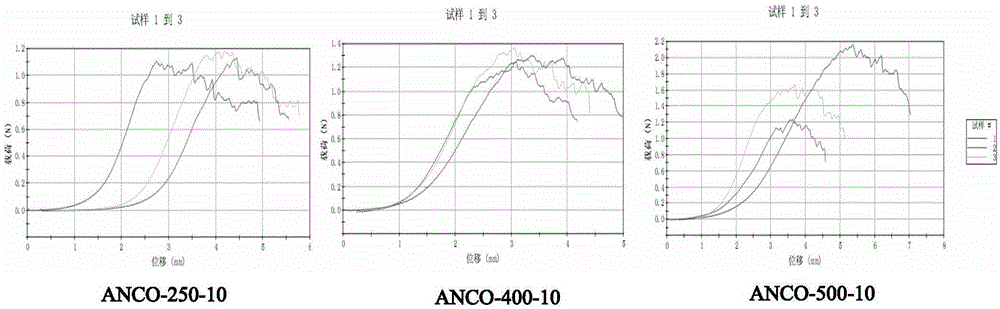

Core-spun yarn with collagenous fiber bundles as sheath layer and processing method thereof

ActiveCN106592042AHigh tensile strengthImprove wear resistanceCarding machinesLap forming devicesYarnTextile fiber

The invention disclosesa core-spun yarn with collagenous fiber bundles as a sheath layer and a processing method thereof, wherein the core-spun yarn comprises a core yarn. The collagenous fiber bundles and residual other textile fibers wrap the core yarn. The collagenous fiber bundles, branches thereof, adjacent collagenous fiber bundles and the branches thereof are intertwined. The processing method of the core-spun yarn with the collagenous fiber bundles as the sheath layer comprises the following steps of (1), extracting the collagenous fiber bundles; (2), performing carding and strip forming; (3), combining the strips; and (4), performing spinning. The core-spun yarn and the processing method settle defects of incapability of reaching basic tensile resistance in direct spinning of the collagenous fiber which is extracted from leather, high difficulty in processing high-count yarn or incapability of processing the high-count yarn. Furthermore a defect of incapability of sufficiently exerting characteristics of the collagenous fiber in the core-spun yarn caused blending a large amount of textile fiber in spinning.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Composites comprising collagen extracted from sarcophyton sp. coral

Owner:RAMOT AT TEL AVIV UNIV LTD

Dyeing process and dyeing apparatus for collagen fiber regenerated leather

ActiveCN103255653BEffective penetrationUniform dyeing effectTextile treatment machine partsDyeing processPolymer scienceCollagen fiber bundle

The invention relates to a dyeing process for collagen fiber regenerated leather. The process successively comprises at least two dyeing treatment, at least one fixation treatment, at least one handfeel modification and drying treatment, wherein dyeing, fixation and handfeel modification are all carried out in an supersonic sound field, so a coloring agent, a fixing agent and a handfeel modifier can effectively penetrate into collagen fiber bundles so as to obtain a more uniform dyeing effect. The concentration of the coloring agent in sequentially used bath liquids increasingly decreases, temperatures of the bath liquids gradually increase, the power of the supersonic sound field increasingly decreases, so bath liquids with high concentration can infiltrate into a leather blank at first, and flooding which is serious in the process of filtration can be eliminated in subsequent dipping in liquids with low concentration; thus, flooding generated in subsequent procedures increasingly decreases, and uniform dyeing of the leather blank is realized. Moreover, surface flooding is eliminated in virtue of a brush of a brush roller in the invention. The invention also relates to a dyeing apparatus capable of realizing continuous uniform dyeing of cloth and leather.

Owner:JIANGYIN JUNHUA TEXTILE TECH

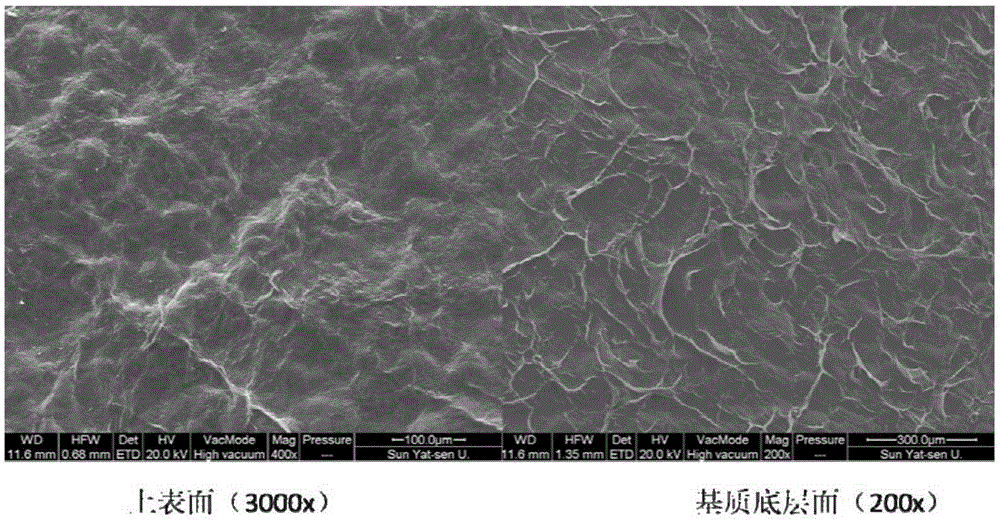

Leather material based on artificial grain surface layer, artificial grain surface layer and processing method

The invention discloses a leather material based on an artificial grain surface layer, the artificial grain surface layer and a processing method of the leather material based on the artificial grainsurface layer. The leather material comprises the artificial grain surface layer and a bottom layer, wherein the artificial grain surface layer comprises a fine collagen fiber bundle, the fine collagen fiber bundle in the artificial grain surface layer and branches of the fine collagen fiber bundle are intertwined mutually, and the fineness of a main body of the fine collagen fiber bundle in the artificial grain surface layer is smaller than that of the main body of fibers in the bottom layer. The processing method comprises the following steps: (1) manufacturing the fine collagen fiber bundle; (2) forming a web by using the manufactured fine collagen fiber bundle; (3) processing the leather material formed by the artificial grain surface layer formed by intertwining the fine collagen fiber bundle and the branches of the fine collagen fiber bundle mutually and the bottom layer combined with the artificial grain surface layer through a spunlace process. In the invention, the leather material is formed by remanufacturing the artificial grain surface layer by using the collagen fiber bundle in leather, so that the performance, structure and appearance of the artificial grain surface layer in the leather material are extremely similar to the grain surface layer of the leather, to improve comfort, affinity, breathability and hygroscopicity of the leather material.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

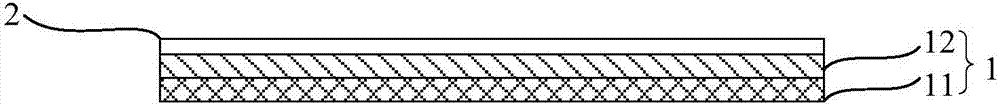

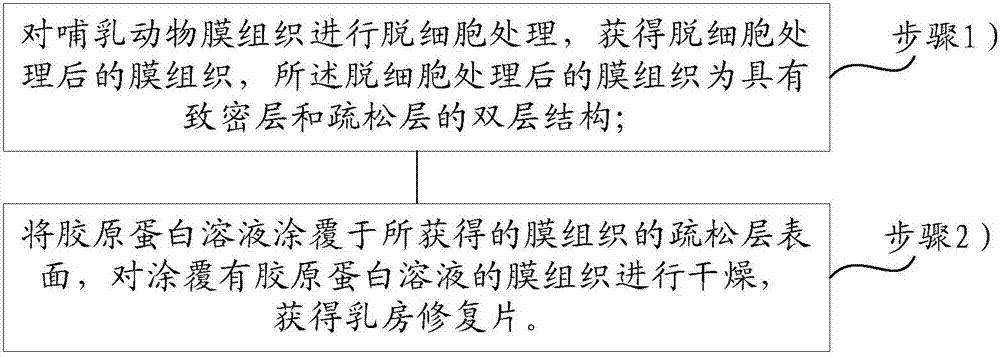

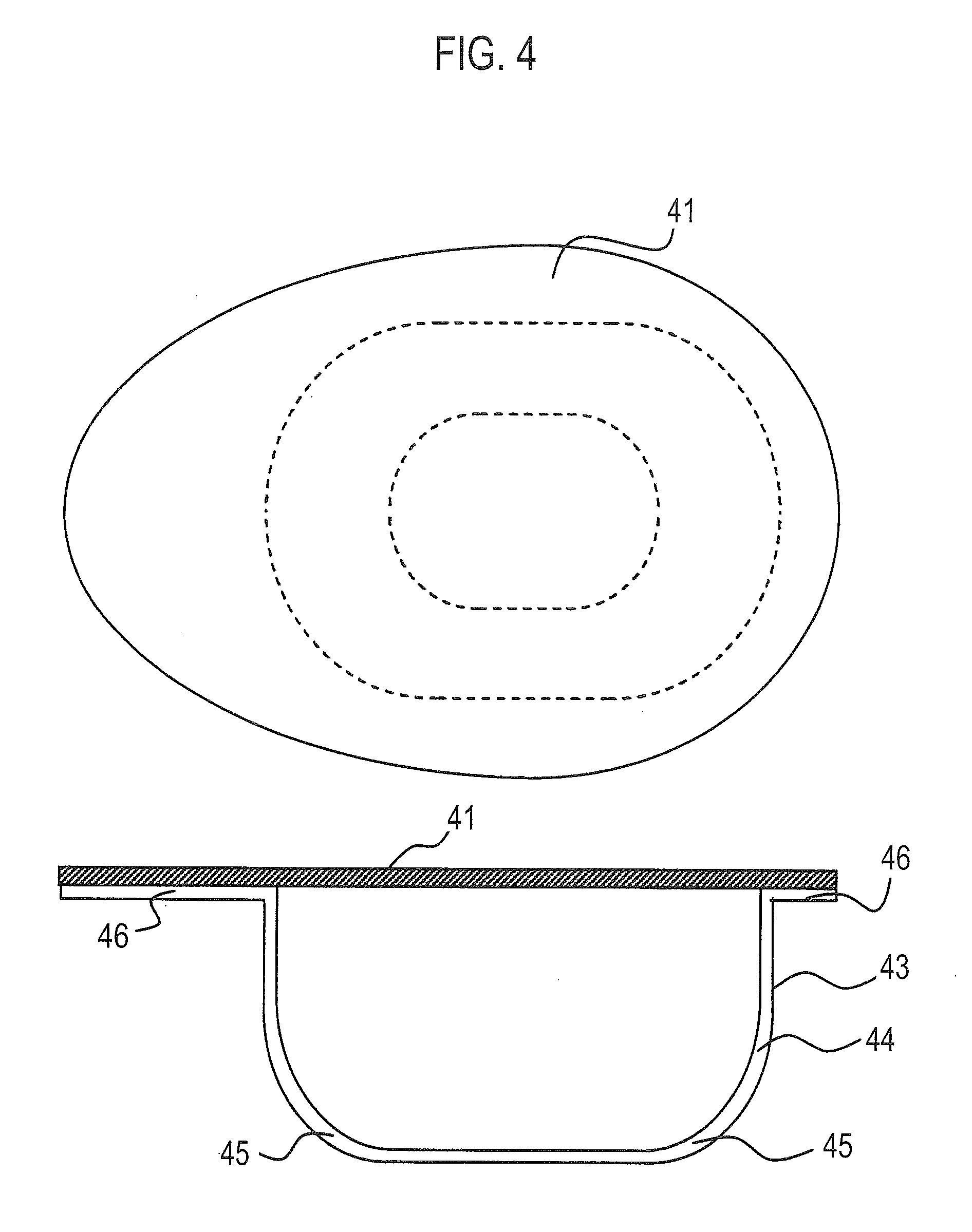

Breast repair patch and preparation method thereof

InactiveCN107412866AImprove appearance qualityImprove the quality of lifeTissue regenerationCoatingsFiberCollagen fiber bundle

The invention relates to the field of tissue engineering technology, and in particular to a breast repair patch and a preparation method thereof. Problems in the prior that collagen bundles on the surface of a loose layer become free, floating and even falling off are solved; appearance quality of the finished product (the breast repair patch) is improved and service cycle of tissue preservation liquid and preservation cycle of the finished product are prolonged; and meanwhile, the breast repair patch, when used, can facilitate adhesion and fixation of the membrane tissue loose layer, accelerate in-growth and migration of breast cells and tissues, induce generation of new tissues and greatly relieve such symptoms as hard breasts, pain and the like after an operation. According to the embodiment, the breast repair patch provided by the invention comprises a mammal membrane tissue which comprises a dense layer and the loose layer and a collagen coating which is formed on the surface of the loose layer.

Owner:SHAANXI RUISHENG BIOTECH

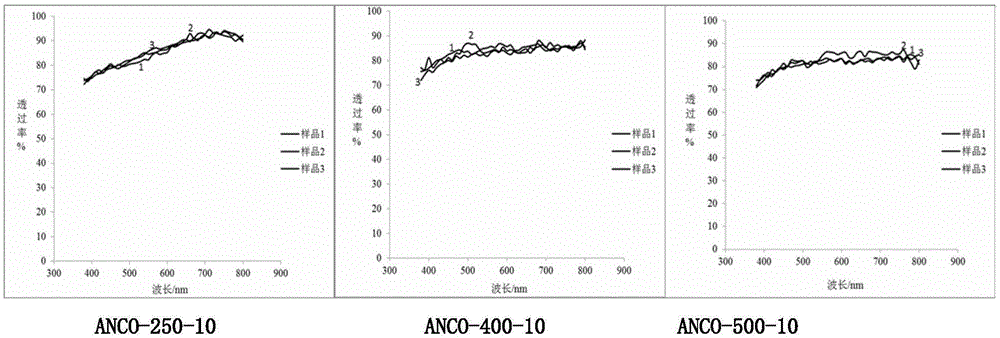

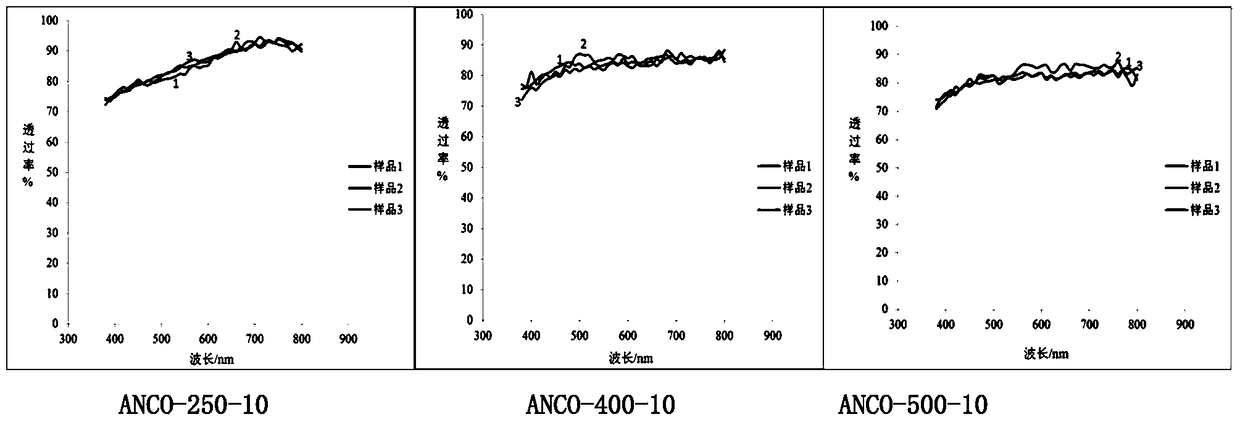

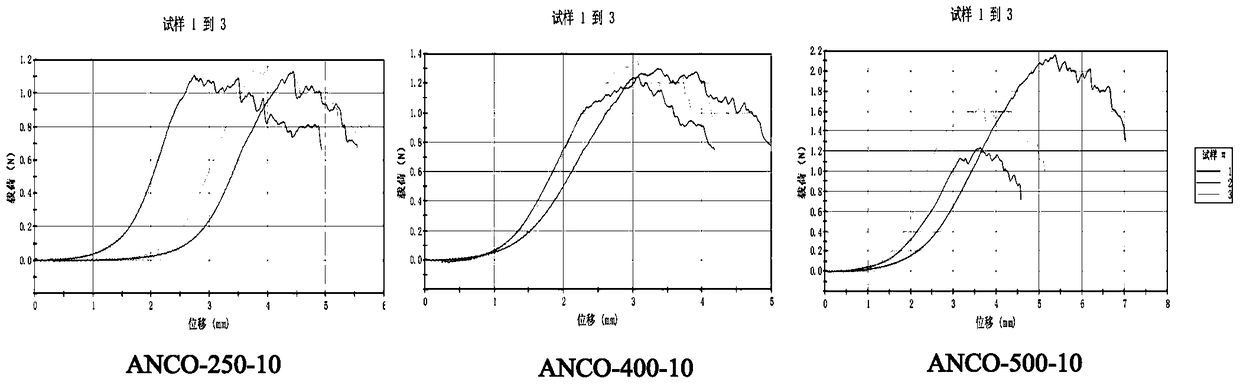

Artificial cornea and preparation method thereof

The invention discloses an artificial cornea, made by soaking animal decellularized corneal stroma in a photosensitizer first and performing uniform crosslinking in ultraviolet light. A photo-oxidation collagen crosslinking method comprises following steps: (1), soaking animal decellularized corneal stroma in a photosensitizer solution 1-5 mg / ml for 1-60 min; (2), taking the soaked animal decellularized corneal stroma, placing it in a culture vessel, and exposing it to ultraviolet light 100-400 nm in wavelength for 1-60 min; (3), soaking the stroma in a PBS solution for 0.5-4 h, and shaking for 0.5-2 h. The invention has the advantages that the biomechanic characteristics such as mechanical strength of the animal decellularized corneal stroma can be effectively improved; as the biomechanic characteristics are mainly determined by collage fiber, collagen fiber bundles and the composition of their spatial structures, the biomechanic properties and stability of the animal decellularized corneal stroma can be improved through photo-radiation / photosensitizer crosslinking.

Owner:GUANGZHOU YUEQING REGENERATION MEDICINE TECH CO LTD

Artificial fur and preparation method thereof

InactiveCN101949083AConsistent weave structureConsistent appearanceHeating/cooling textile fabricsNon-woven fabricsFiber bundleCollagen fiber bundle

The invention discloses artificial fur and a preparation method thereof. The fur comprises a leatherboard layer and a fleece layer, and is characterized in that: the leatherboard layer has a three-dimensional netlike weaving structure with a collagenous fiber bundle as a main body; and one end and / or the middle end of the fiber of the fleece layer is entangled on the collagenous fiber bundle of the leatherboard layer and is firmly locked by the collagenous fiber bundle. The preparation method comprises the following steps of: web formation, fiber web superposition, spunlaced consolidation, texturing and raising, and contraction shaping before and after the texturing and raising as required to prepare the artificial fur. The weaving structure, appearance and sanitation performance of the fur are consistent with those of natural fur leatherboard and the fur has higher stretching amplitude and wider application field than those of natural fur; the fiber of the fleece layer is embedded into the leatherboard layer by physical entanglement, and the fur does not contain any adhesive and has the operational performance far higher than that of artificial fur manufactured by flocking through an adhesive; and the artificial fur can be manufactured from various leather scraps and waste animal fur and is more environmental-friendly.

Owner:张立文

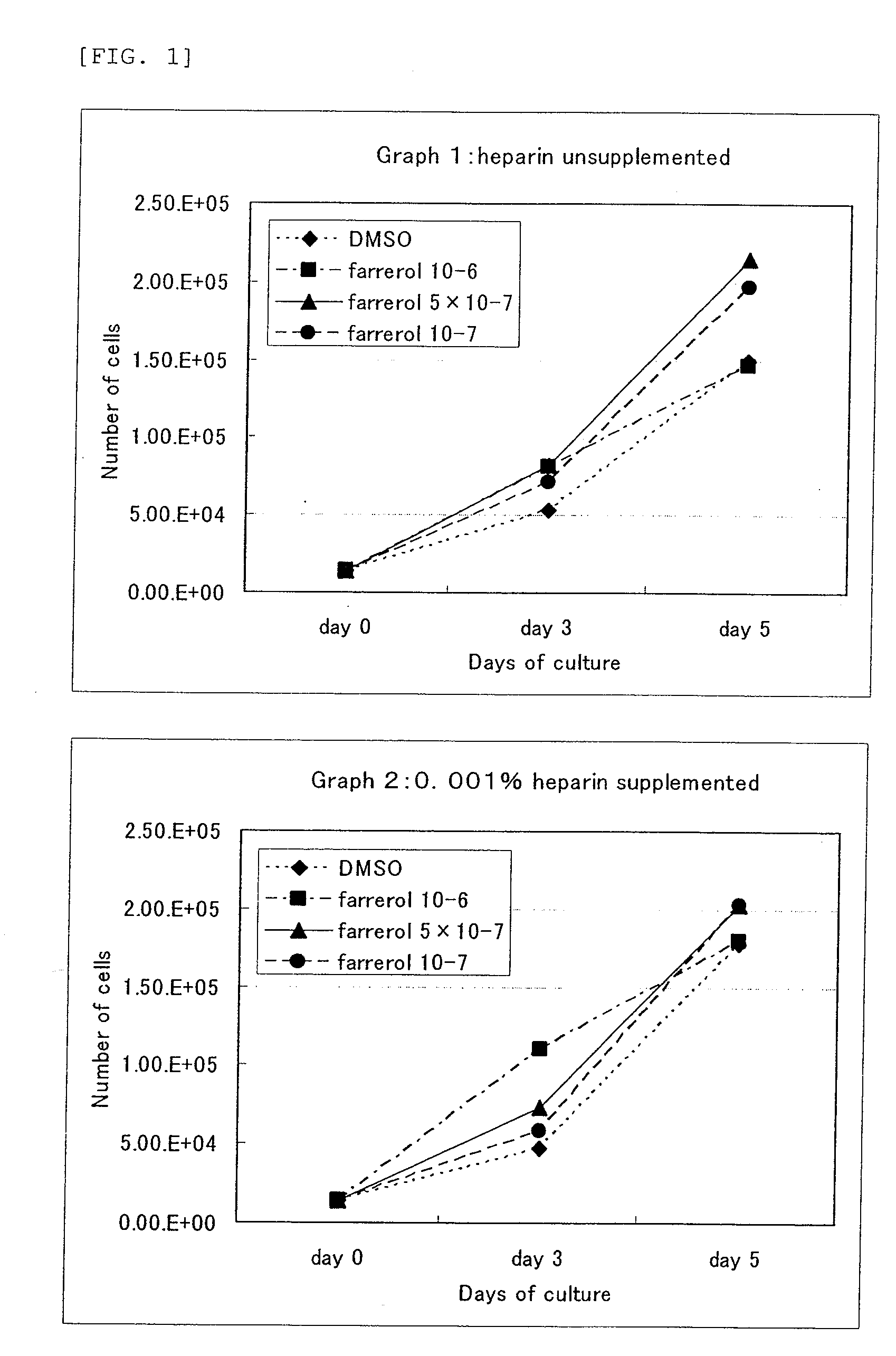

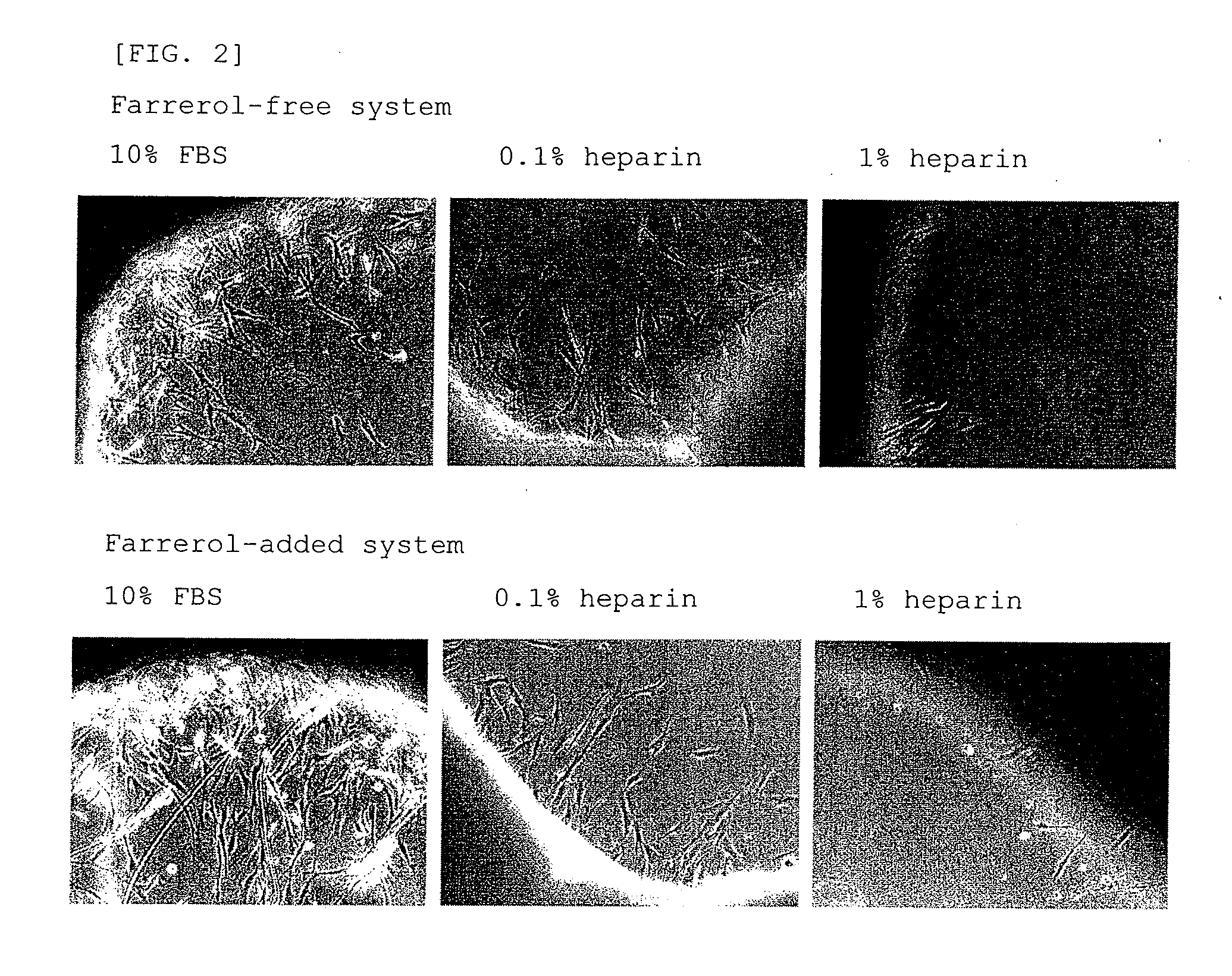

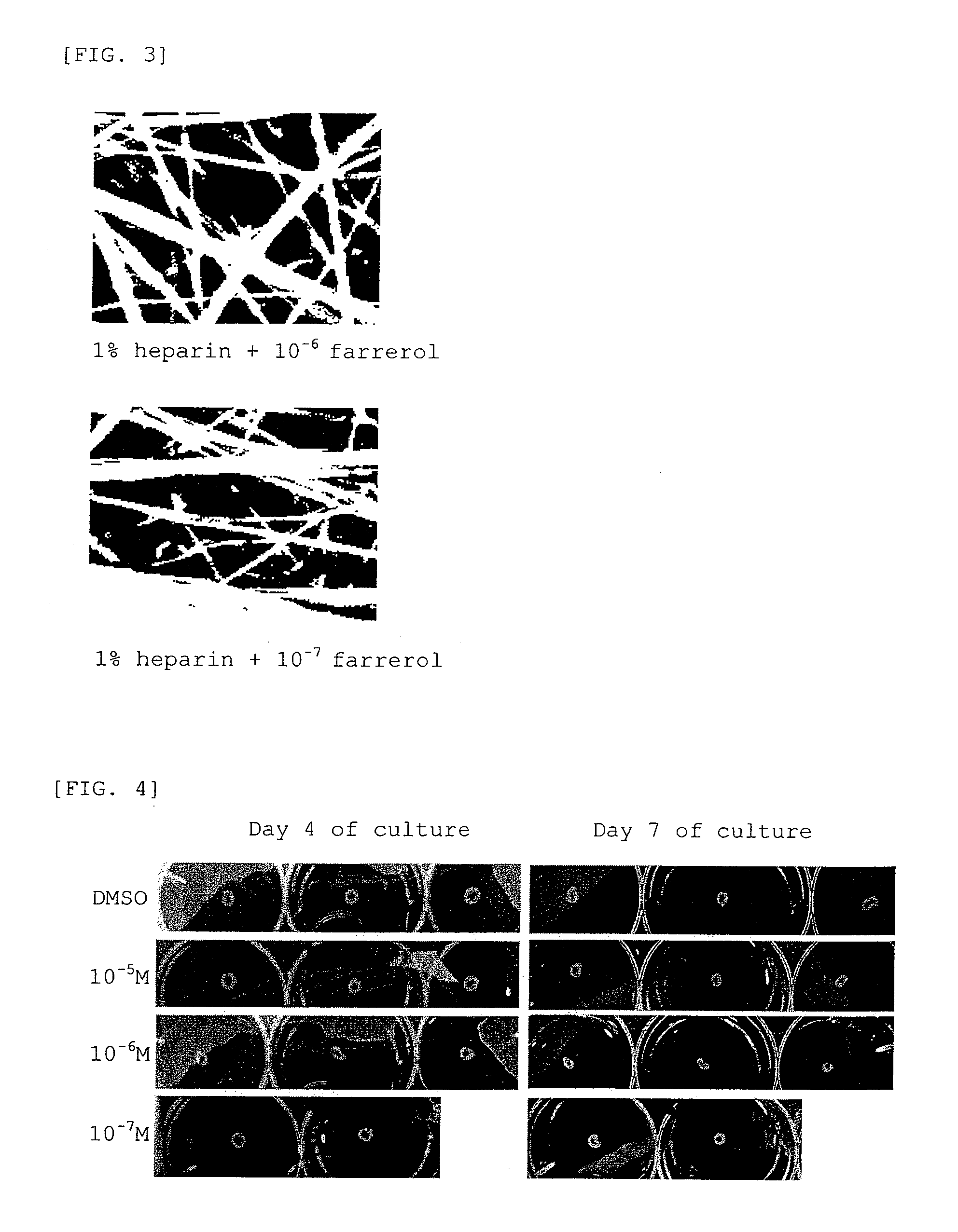

External preparation for skin containing flavanone derivative

InactiveUS20090030070A1Excellent remodeling actionPromote wound healingCosmetic preparationsBiocideWrinkle skinFiber

To increase a tissue regeneration ability of a living body such as a collagens production ability of fibroblast in the dermis in a skin defect area typified by a large wrinkle or wound, a flavanone derivative such as farrerol is used as an active ingredient of an external preparation for skin. Further, to efficiently screen a substance having an excellent effect on promoting wound healing, the remodeling action of collagen fiber bundle is tested by using skin wound model.

Owner:POLA CHEM INDS

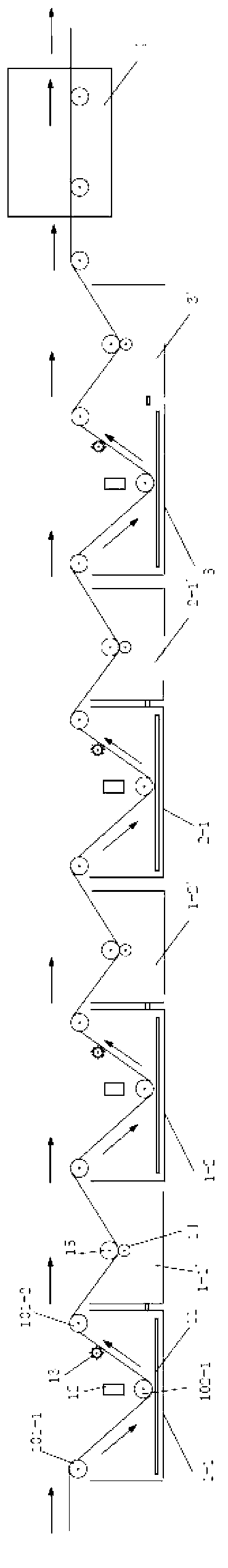

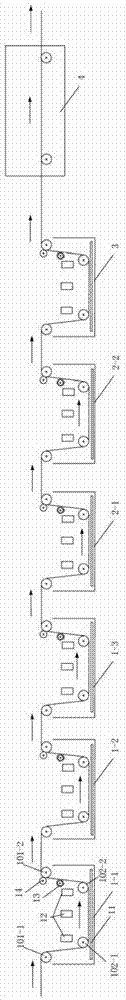

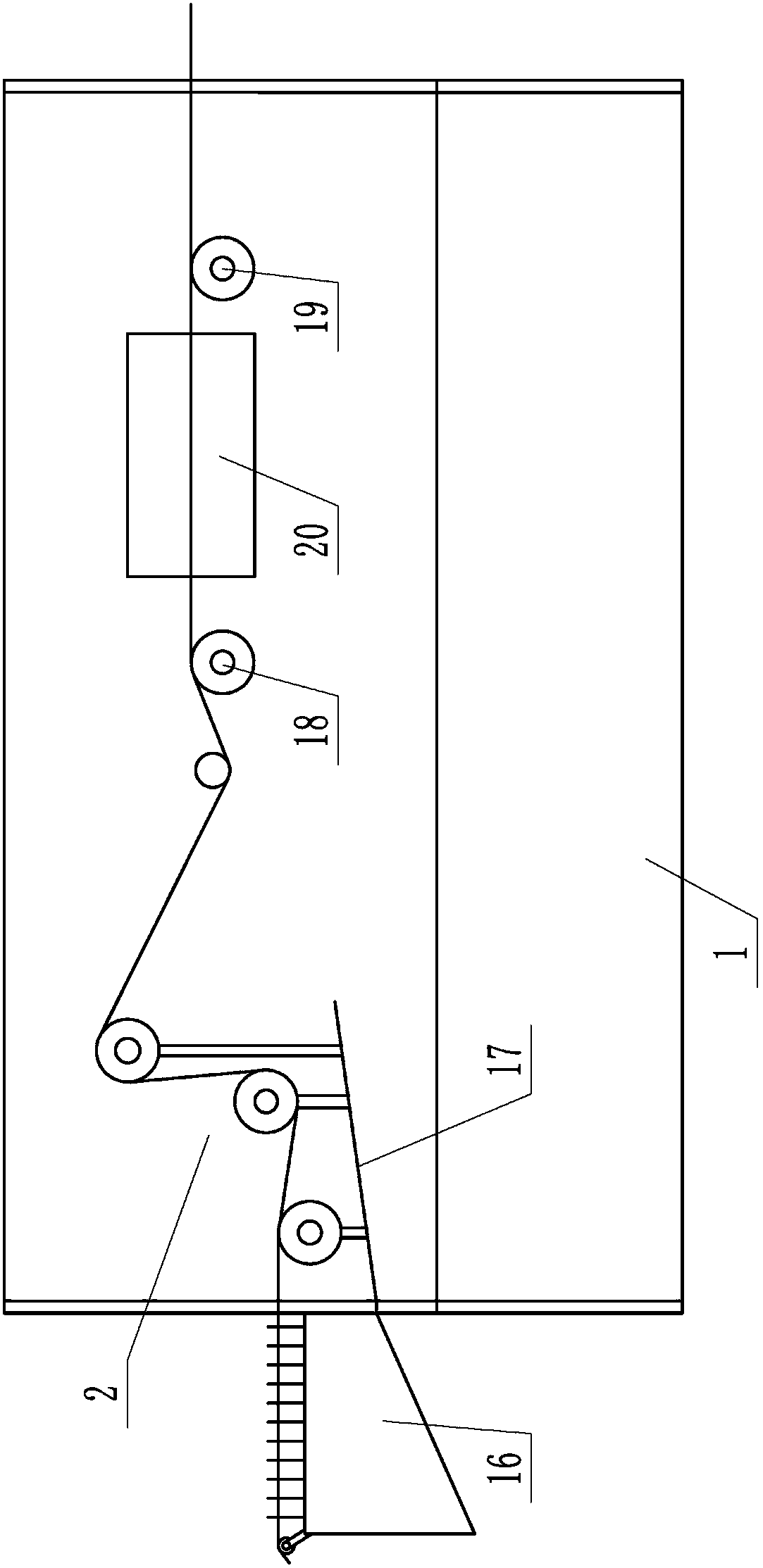

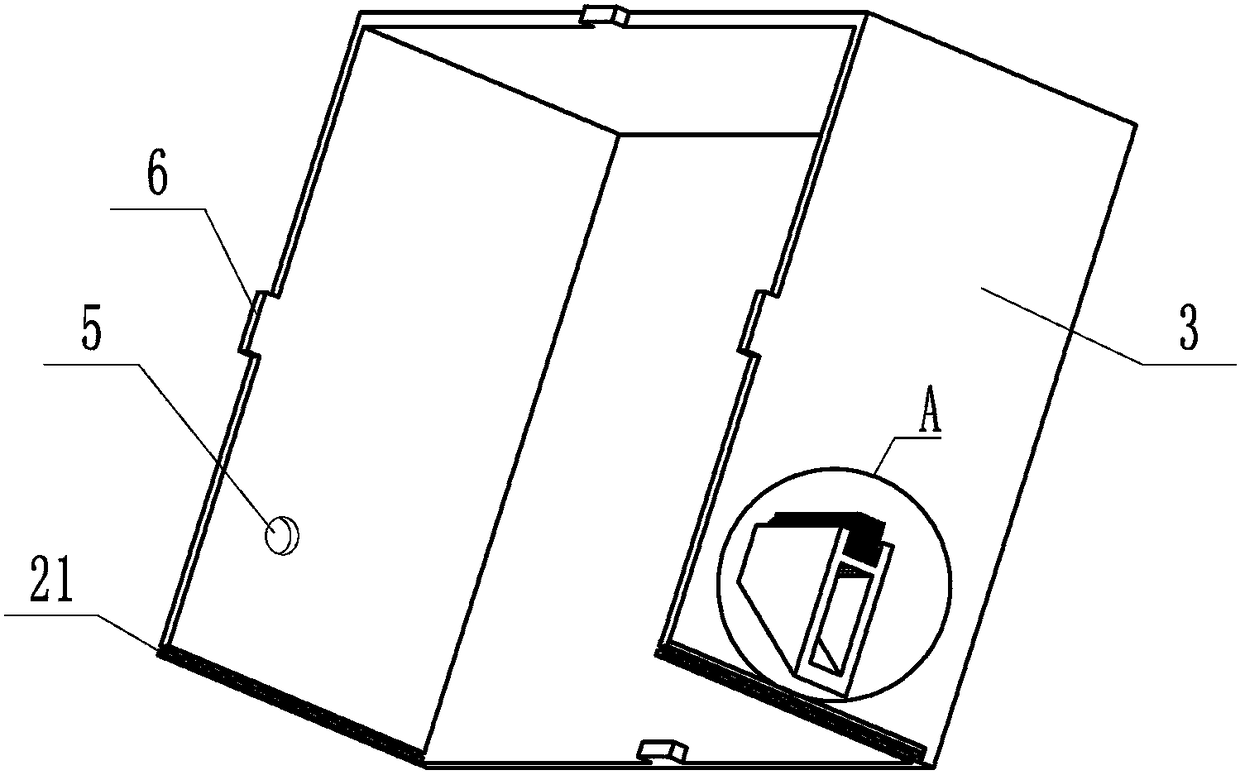

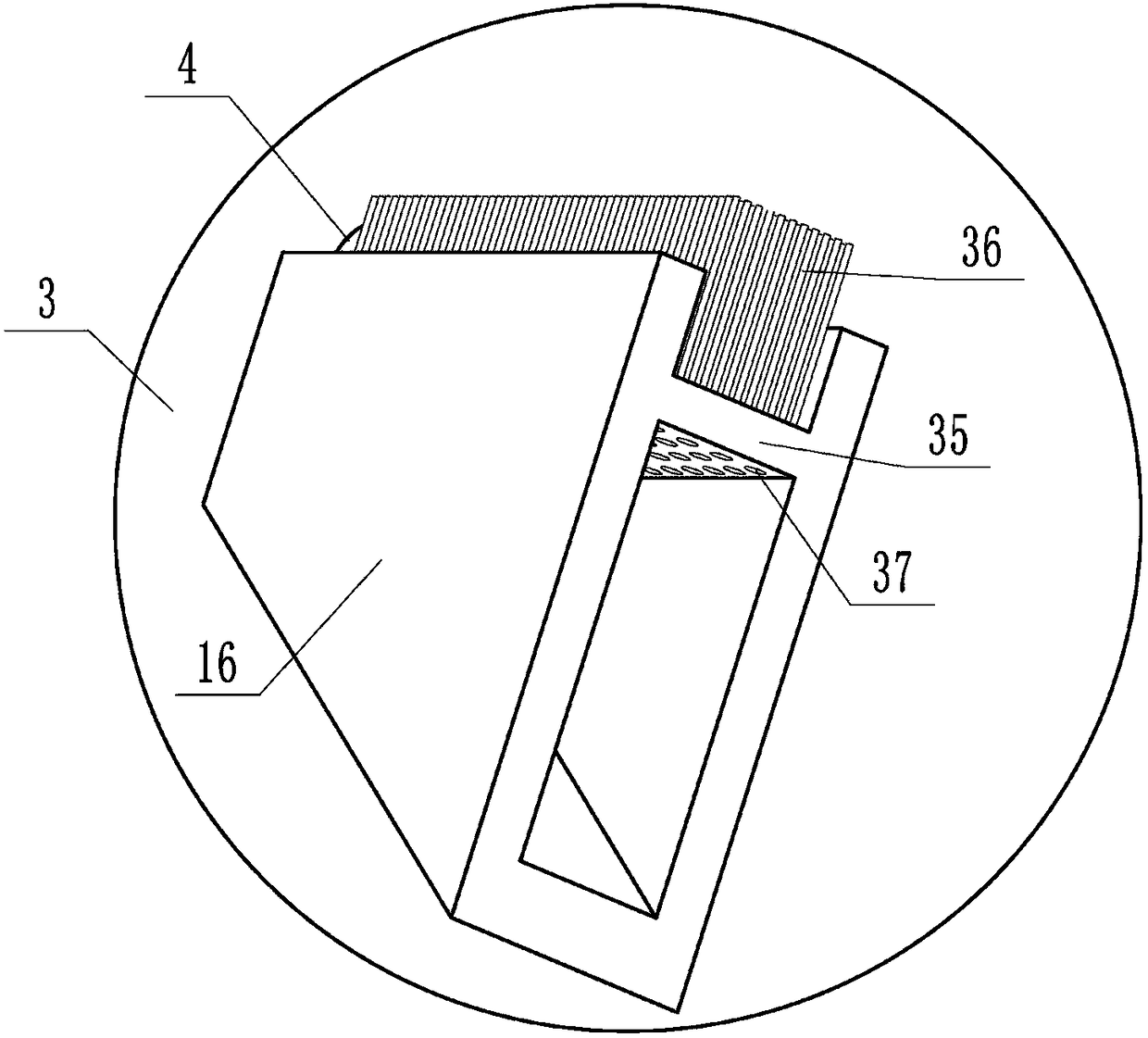

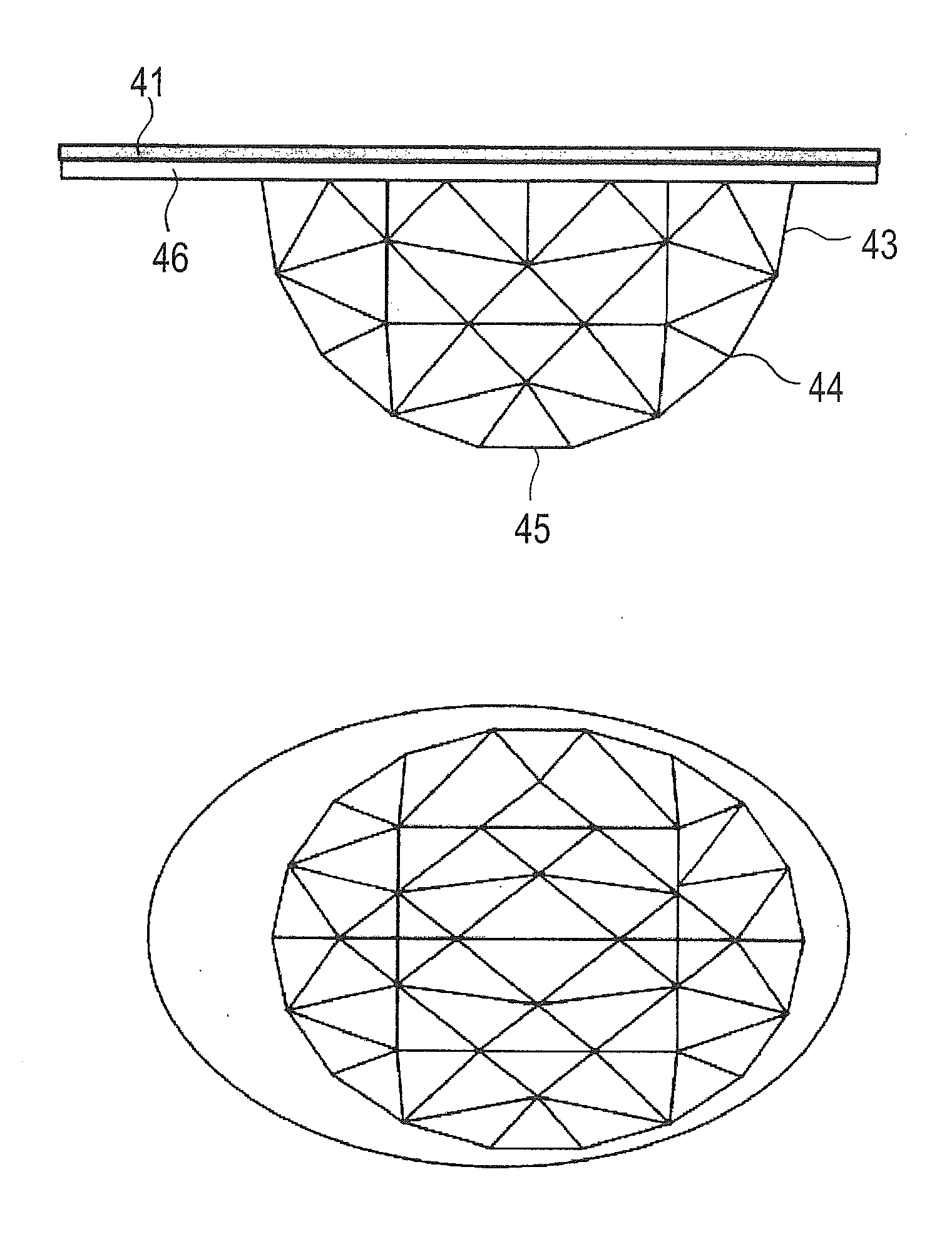

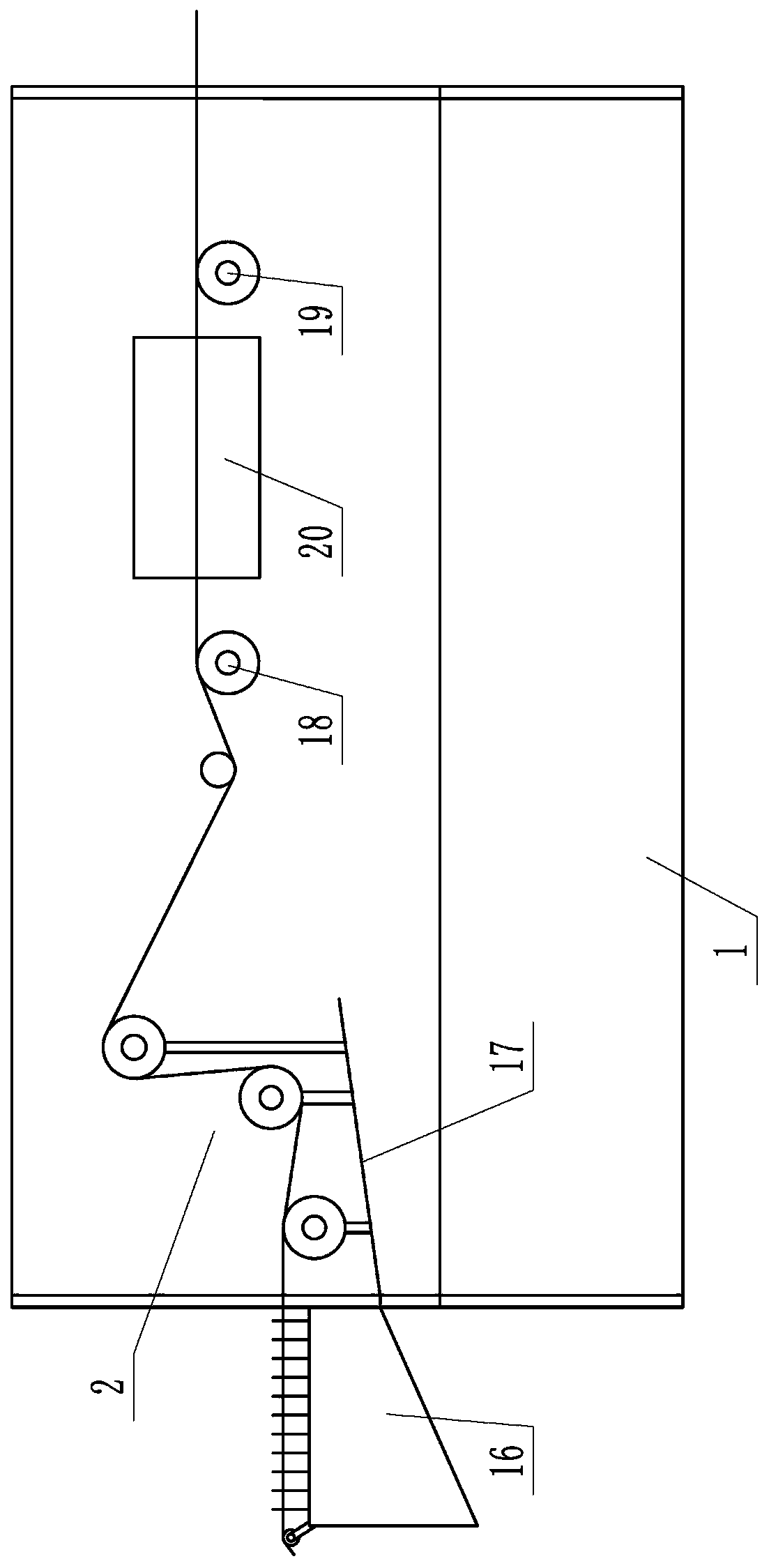

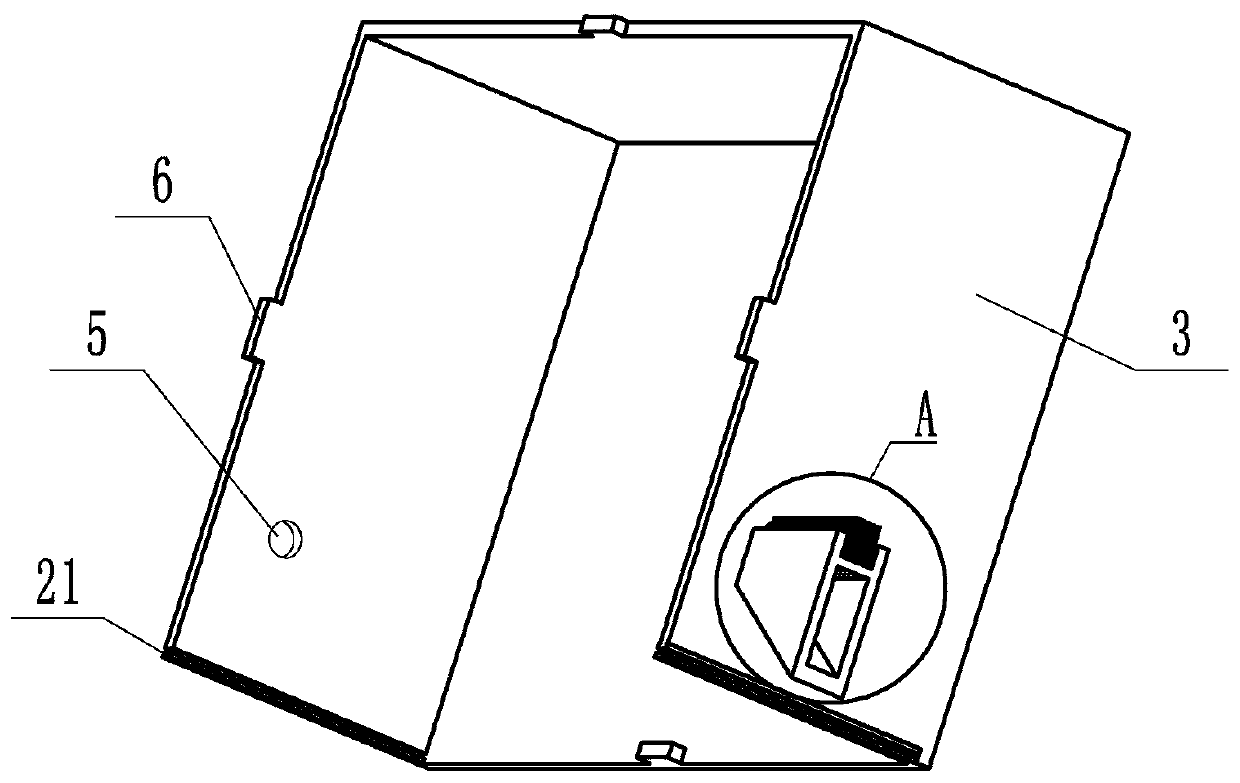

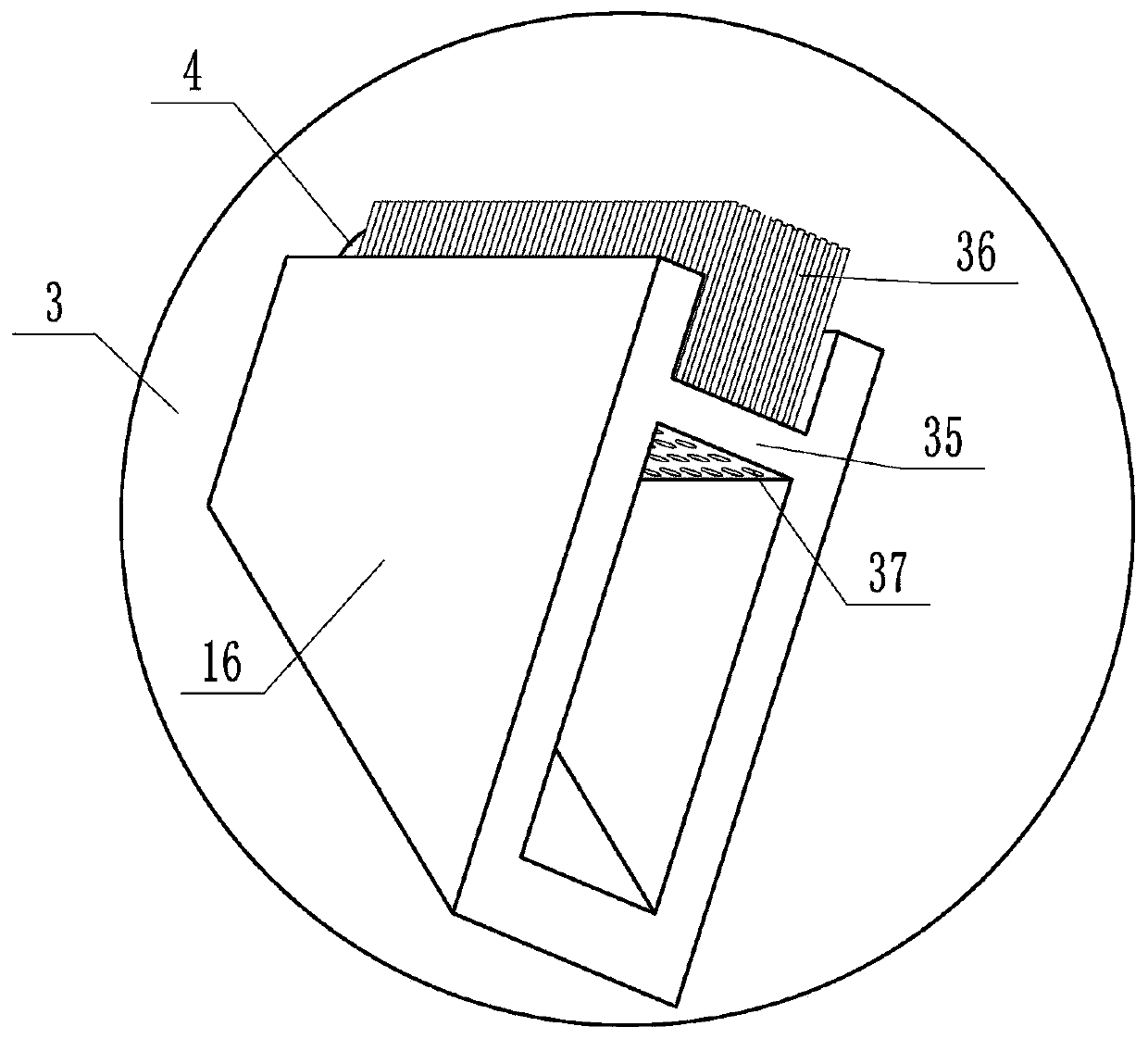

Molding equipment for collagen fiber bundle used for hemostatic material

InactiveCN108251900AImprove cleanlinessReasonable structureNew-spun product collectionArtificial filament washing/dryingFiberCollagen fiber bundle

The invention relates to molding equipment for a collagen fiber bundle used for a hemostatic material, which effectively solves the problem in the prior art that product quality is reduced because fiber is not protected in the processing process. The molding equipment comprises a main body, wherein the lower part of the main body is a rack, a guide wire wheel set and a guide wire roller set are fixed at the upper part of the main body, a cover plate is arranged on the main body in a sliding way, the cover plate covers the upper part of the main body and is made from a transparent material, a fiber inlet is formed in the left side of the cover plate, a fiber outlet is formed in the right side of the cover plate, and a plurality of locking devices connected with the main body are arranged atthe rear side of the cover plate; the molding equipment is reasonable in structure, convenient to use, and is in a sealed environment all the time in the molding process of the collagen fiber bundle,so as to prevent contact with the external substances, and ensure the cleanness of the production environment; furthermore, liquid contained in the collagen fiber is cleared to a certain extent, so that the fiber is finer, and the produced product does not contain impurities and is better in quality.

Owner:桂林福康森医疗器械有限公司 +1

Leather-protective fat liquoring agent and preparation method thereof

InactiveCN109735669AImprove plumpnessGood light fastnessLeather impregnationFiberCollagen fiber bundle

The invention discloses a leather-protective fat liquoring agent and a preparation method thereof and belongs to the field of leather chemical engineering. A fat liquoring active agent prepared by themethod increases intervals among collagen fiber bundles to realize effect of loosening and lubricating leather collagen fiber and enhances toughness of leather, and the fat liquoring agent has high auxiliary functionality like softness, plumpness and light resistance; a prepared loading additive provides a framework structure for leather fiber, plumpness after fat liquoring is improved, low surface energy of the loading additive is utilized to accelerate compatibility among components, and fat liquoring efficiency is improved; through a prepared silane additive, a hydrophobic leather surfaceis resistant to dry scrubbing and air and moisture permeable, so that leather after fat liquoring has scrubbing-resistant efficacy, and maintaining time after fat liquoring is prolonged; an ultraviolet protection film is built on the surface of the leather after fat liquoring through polyvinyl alcohol,pullula and rutin, so that fat liquoring protection effect is improved. The problem that existingleather fat liquoring agents are poor in protection performance and low in fat liquoring efficiency is solved.

Owner:朱海鹏

Solubilized collagen fiber ball

InactiveUS20130134168A1Cosmetic preparationsMonocomponent protein artificial filamentPolymer scienceCollagen fiber bundle

Disclosed is solubilized collagen fiber ball: that is crimped and does not have fiber separation defects within which the amount of water content and the amount of hydrophilic organic solvent are evenly distributed; and that dissolve instantly and uniformly when used. The fiber ball has a composition that may comprise 66 to 87 wt % solubilized collagen, 2 to 6 wt % buffer salt, 10 to 22 wt % water content, and a trace amount to 6 wt % residual hydrophilic organic solvent, and is 3 to 25 mm in diameter, weighs 3 to 20 mg, has an average fiber size of 3 to 10 dtx, and a length of 1 to 20 cm. The fiber ball, which has a wavy shape and comprises uniform bundles of solubilized collagen fibers formed in a spherical shape, may have a bulk density of 4.0 to 8.0 mg / cm3, and a swab diameter of 3 to 25 mm.

Owner:MIDORI HOKUYO CO LTD

Modification method of collagen fiber bundles

InactiveCN103088503ASolve technical problems that cannot be wovenReduce hair lossAdhesivesFiberCollagen fiber bundle

The invention provides a modification method of collagen fiber bundles. The collagen fiber bundles are dipped into aqueous binders and then are dried, carding and opening are carried out, and the collagen fiber bundles can become a novel fiber material capable of being used for non-woven and woven technology.

Owner:韩仕银

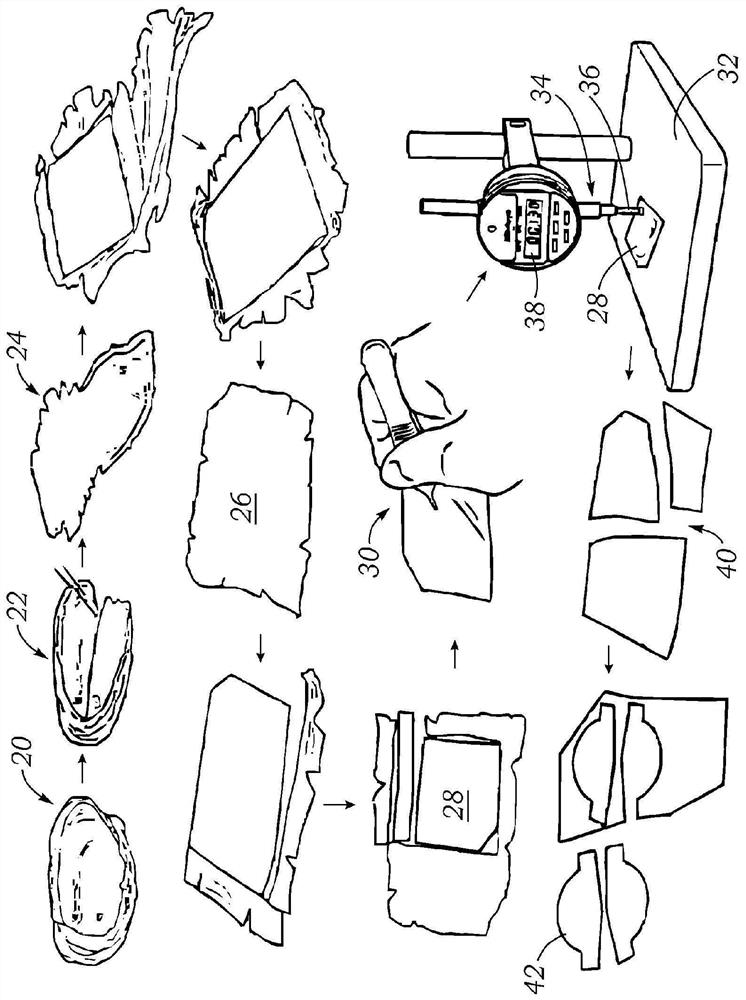

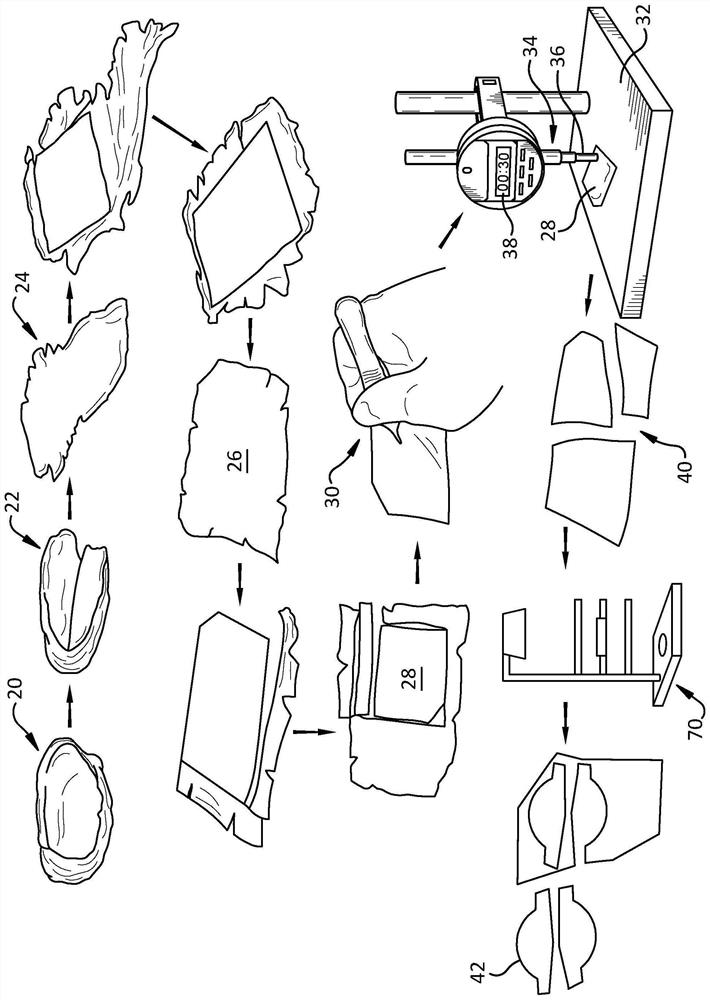

Optical tissue measurement

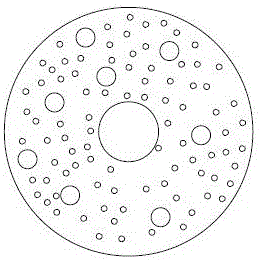

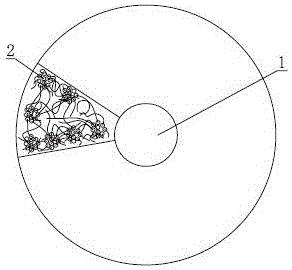

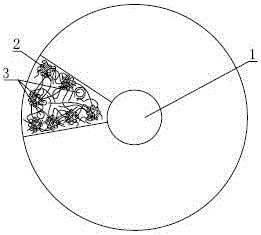

PendingCN112040994AProgramme controlPolarisation-affecting propertiesProsthetic valveCollagen fiber bundle

An optical method for determining collagen bundle orientation in bovine pericardium includes the use of a system having a light source which transmits light through a first polarizer, a tissue for making a prosthetic valve leaflet, and a second polarizer, where the light then illuminates a detector plate. The light that illuminates the detector plate is used to determine the orientation of collagen fiber bundles. The orientation of the collagen fiber bundles is used to determine where to cut the leaflet edges.

Owner:EDWARDS LIFESCIENCES CORP

A kind of artificial cornea and preparation method thereof

ActiveCN105343934BHigh mechanical strengthImprove mechanical propertiesProsthesisOptical radiationFiber

The invention discloses an artificial cornea. Animal decellularized corneal stroma is first soaked in a photosensitizer, and then uniformly cross-linked under ultraviolet light irradiation. The steps of a method for photooxidative collagen cross-linking are as follows: (1) Soak animal decellularized corneal stroma in 0.01-5mg / ml photosensitizer solution for 1-60min; (2) Take out the soaked animal decellularized corneal stroma Put it in a petri dish, irradiate with 100-400nm wavelength ultraviolet light for 1-60min; (3) Soak in PBS solution for 0.5-4h, then shake for 0.5-2h. The beneficial effects of the present invention are: the biomechanical properties such as the mechanical strength of the decellularized corneal stroma can be effectively improved; because the biomechanical properties mainly depend on the composition of collagen fibers, collagen fiber bundles and their spatial structures, therefore, through light radiation Irradiation / photosensitizer cross-linking can improve the biomechanical properties and stability of animal decellularized corneal stroma.

Owner:GUANGZHOU YUEQING REGENERATION MEDICINE TECH CO LTD

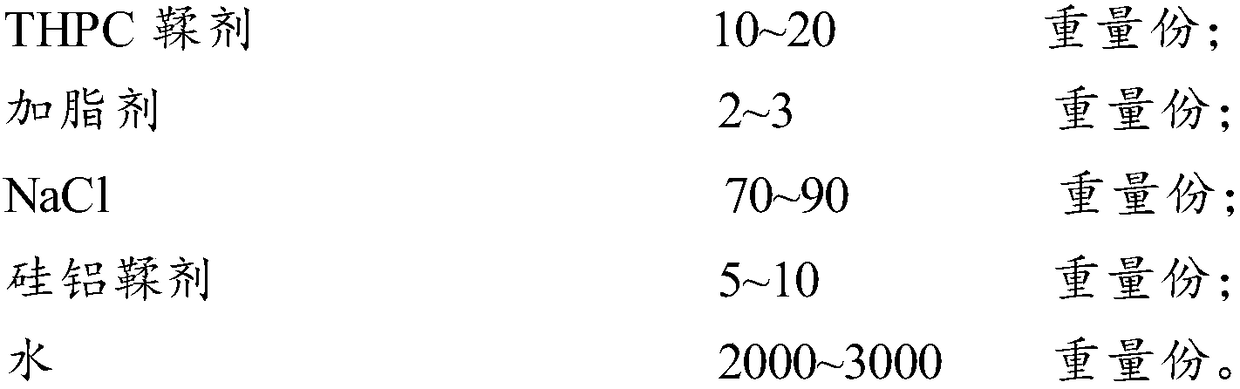

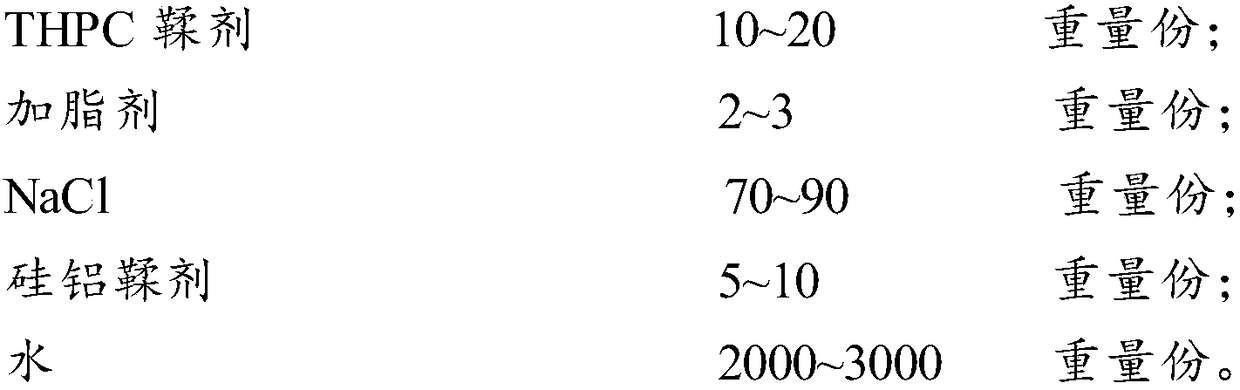

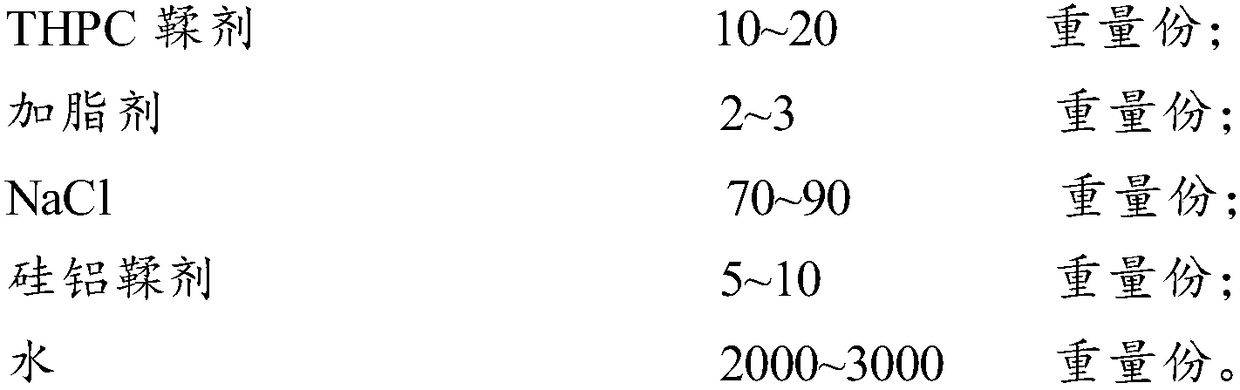

Comprehensive tanning agent for furs and no-dry-washing and no-chromium tanning process thereof

ActiveCN108165680ALow fat contentReduced chromium contentTanning treatmentFiberTetrakis(hydroxymethyl)phosphonium chloride

The invention provides a comprehensive tanning agent. The comprehensive tanning agent is prepared from the following components in parts by mass: 10-20 parts of THPC (Tetrakis Hydroxymethyl Phosphonium Chloride) tanning agent, 2-3 parts of fatting agent, 70-90 parts of NaCl, 5-10 parts of silicon-aluminium tanning agent and 2000-3000 parts of water. The invention also provides a no-chromium tanning process of the furs. The comprehensive tanning agent provided by the invention has the beneficial effects that the novel comprehensive tanning agent combined with the silicon-aluminium THPC is adopted, the THPC is firstly used for pre-tanning, and new intermolecular bonds are formed in a collagen structure, so that the strength of collagen fiber bundles can be improved, the fiber can be primarily sized and the shrinking temperature can be increased; then the silicon-aluminium tanning agent is used for re-tanning, so that the shrinking temperature of a leather board can be further increased,the insufficient pre-tanning can be supplemented, the plumpness and the fullness of the leather board can be improved and the quality requirements of a finished product for the leather board can be met; due to no adoption of the chromium tanning agent, the condition of existence of chromium liquid on the furs is also avoided; the method is simple and is suitable for application and promotion in industrial large-scale production.

Owner:HENAN PROSPER SKINS & LEATHER ENTERPRISE

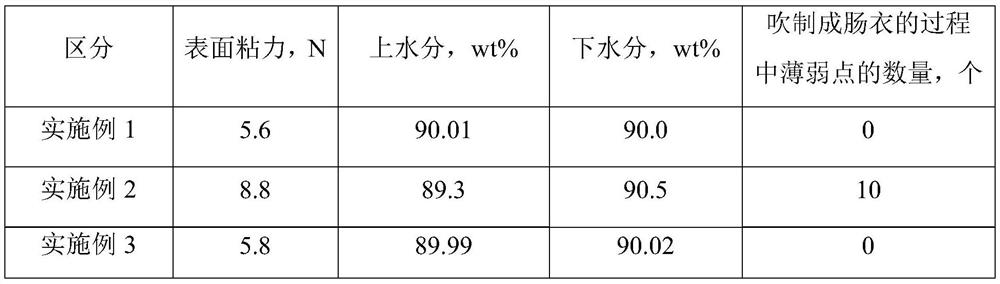

Collagen fiber quality judgment method

ActiveCN112526069AScientific and reasonable designEasy to operatePreparing sample for investigationUsing mechanical meansIce waterThermodynamics

The invention relates to a collagen fiber quality judgment method, and belongs to the technical field of collagen detection. The method comprises the following steps of: (1) taking treated and extracted collagen fibers, performing mixing and kneading, carrying out moisture detection, then conducting calculating according to a moisture detection result, supplementing ice water into a collagen fibercluster, and uniformly mixing and kneading the substances; (2) carrying out centrifugal treatment on the collagen fiber cluster; taking out the product and measuring moisture at the upper end and thelower end, and if moisture has no difference, indicating that the fiber water absorption capacity is strong; if the lower moisture is higher than the upper moisture, indicating that the water absorption capacity is weak; and (3) detecting the surface viscosity of the collagen fiber cluster: detecting the surface viscosity of the fiber cluster, and under the condition of the same moisture, the smaller the viscosity is, the better the moisture is bound by the fibers, and the better the opening degree of the collagen fiber bundle is; if collagen fibers are damaged, the water absorption capacitybecomes poor, and the surface viscosity is high. The method is scientific, reasonable, easy and convenient to operate and low in cost, and can better guide production by rapidly judging the quality ofthe collagen fibers.

Owner:山东海奥斯生物科技股份有限公司

A kind of photooxidative collagen cross-linking method and its application

ActiveCN105343933BHigh mechanical strengthImprove biomechanical propertiesProsthesisFiberAcellular scaffold

Owner:GUANGZHOU YUEQING REGENERATION MEDICINE TECH CO LTD

Collagen fiber bundle forming equipment for hemostatic materials

InactiveCN108251900BImprove cleanlinessReasonable structureNew-spun product collectionArtificial filament washing/dryingFiberState of art

The invention relates to molding equipment for a collagen fiber bundle used for a hemostatic material, which effectively solves the problem in the prior art that product quality is reduced because fiber is not protected in the processing process. The molding equipment comprises a main body, wherein the lower part of the main body is a rack, a guide wire wheel set and a guide wire roller set are fixed at the upper part of the main body, a cover plate is arranged on the main body in a sliding way, the cover plate covers the upper part of the main body and is made from a transparent material, a fiber inlet is formed in the left side of the cover plate, a fiber outlet is formed in the right side of the cover plate, and a plurality of locking devices connected with the main body are arranged atthe rear side of the cover plate; the molding equipment is reasonable in structure, convenient to use, and is in a sealed environment all the time in the molding process of the collagen fiber bundle,so as to prevent contact with the external substances, and ensure the cleanness of the production environment; furthermore, liquid contained in the collagen fiber is cleared to a certain extent, so that the fiber is finer, and the produced product does not contain impurities and is better in quality.

Owner:桂林福康森医疗器械有限公司 +1

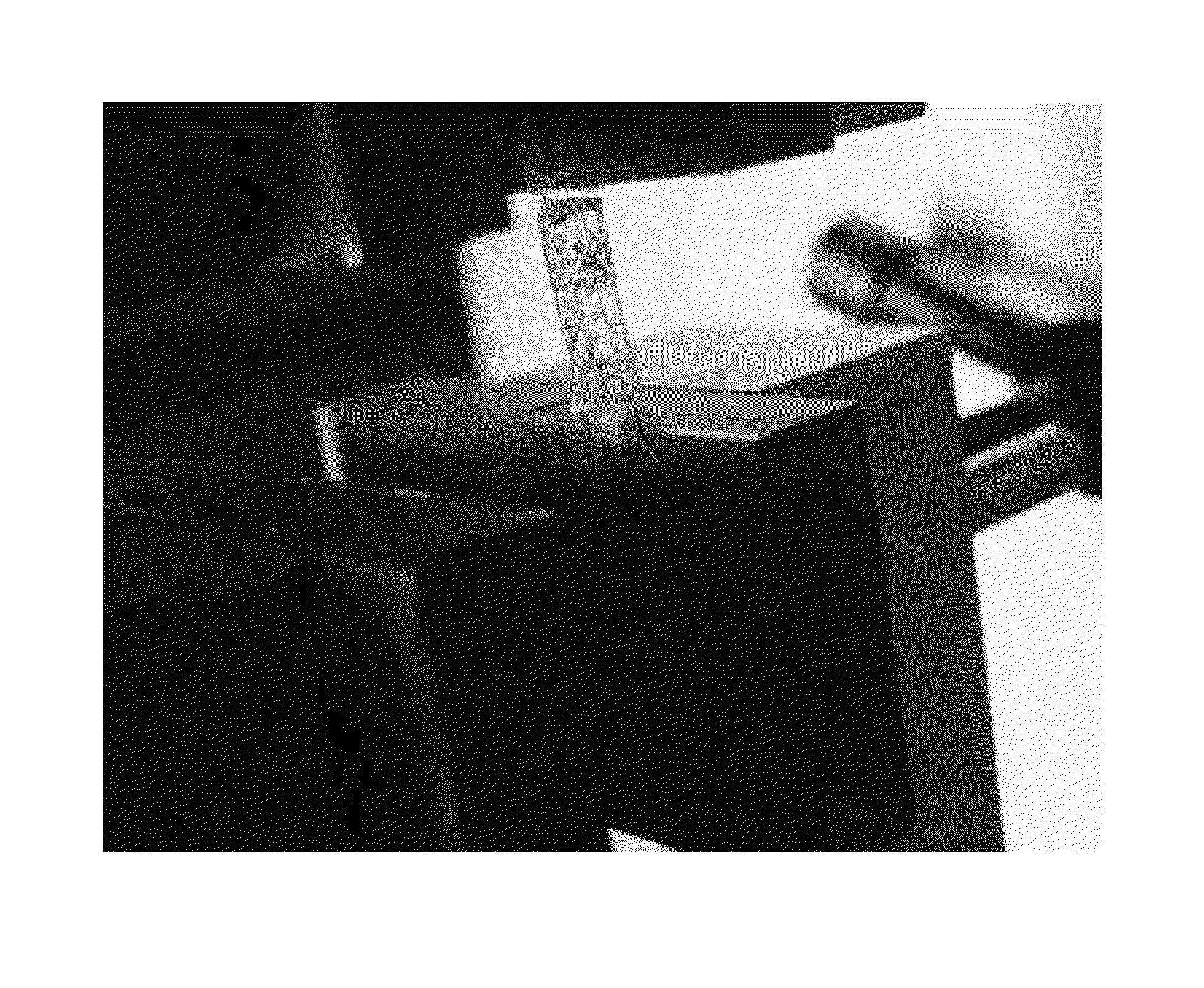

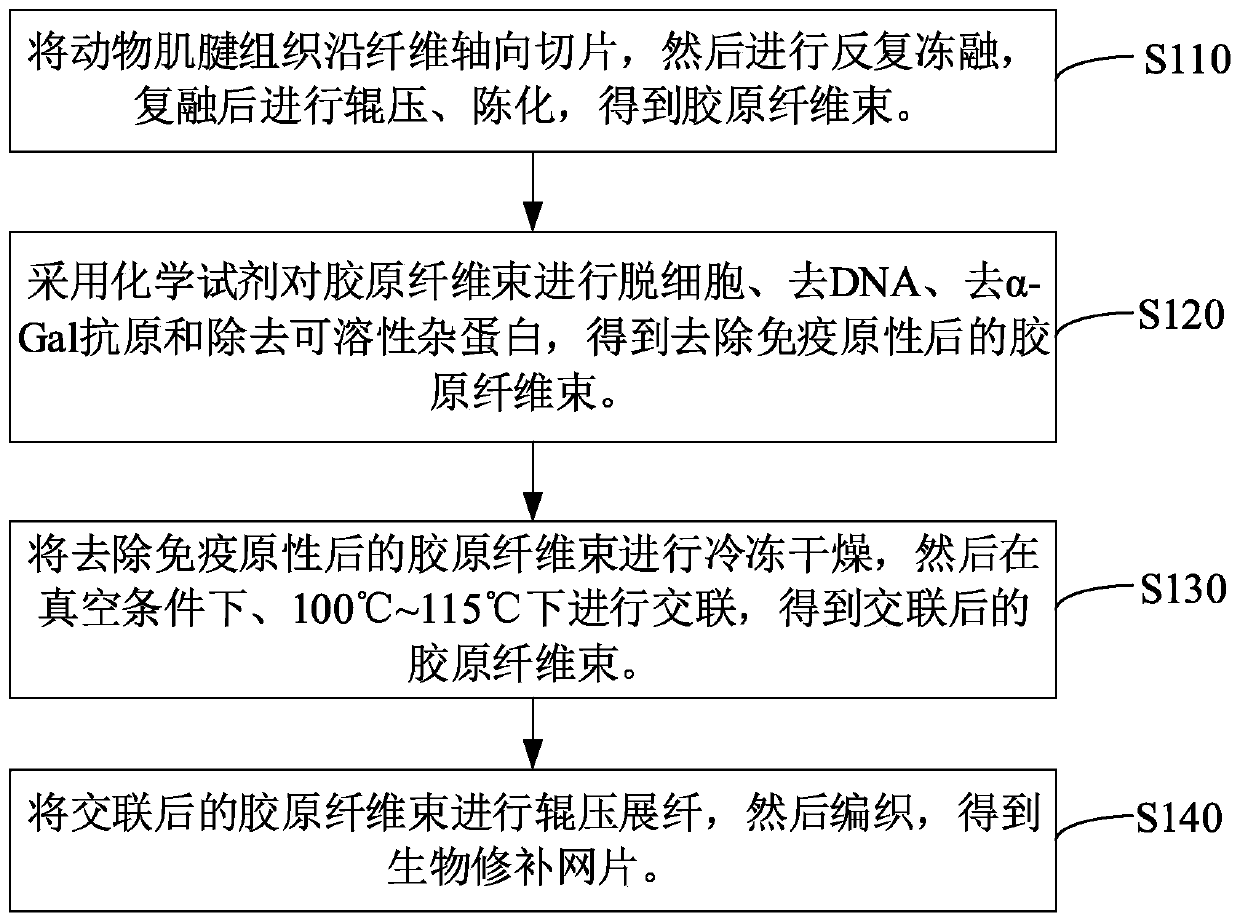

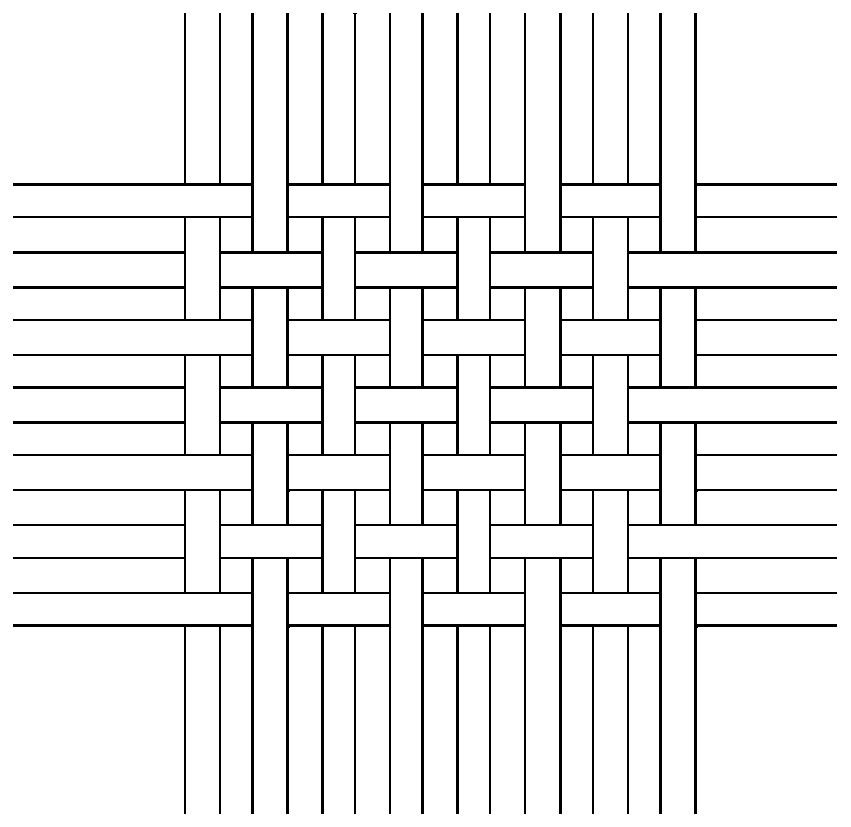

Biological repair mesh and preparation method and application thereof

ActiveCN111407926AImprove mechanical propertiesImproving immune securityTissue regenerationProsthesisFreeze-dryingHybrid protein

The invention relates to a biological repair mesh and a preparation method and application thereof. The preparation method of the biological repair mesh comprises the following steps of: slicing animal tendon tissues along the axial direction of fibers, then carrying out repeated freezing and thawing, and after repeated freezing and thawing, carrying out rolling and ageing to obtain a collagenousfiber bundle; carrying out decellularization, removal of DNA, removal of an alpha-Gal antigen an removal of a soluble hybrid protein on the collagenous fiber bundle by adopting chemical reagents to obtain the collagenous fiber bundle subjected to removal of immunogenicity; carrying out freeze-drying on the collagenous fiber bundle subjected to removal of immunogenicity, and then carrying out crosslinking under the vacuum condition and at a temperature of 100 DEG C to 115 DEG C to obtain the cross-linked collagenous fiber bundle; and carrying out rolling and fiber expansion on the cross-linkedcollagenous fiber bundle, and then carrying out weaving to obtain the biological repair mesh. By the preparation method of the biological repair mesh, the biological repair mesh with high immunizationsafety and a good mechanical property can be prepared.

Owner:SHENZHEN LANDO BIOMATERIALS

Bone tissue regeneration guiding membrane and preparation method thereof

ActiveCN102225219BThe isolation barrier works slowlyGood biocompatibilitySurgeryCoatingsFiberHazardous substance

A bone tissue regeneration guiding membrane. The invention employs an antigen-extracted mammal tissue membrane, which has a double layer structure of a compact layer and a loosening layer. The compact layer is formed by tightly arranged collagen fibers, and an external side of the compact layer is composited with a collagen coating containing active polypeptides; the loosening layer is formed by interlaced collagen fibers and is composited with ossification active factors. The prepared guiding membrane can prevent soft tissue from evolving and promote new bone formation, has good biological compatibility, hydrophilism and bone induction capability, and can be completely degraded in body without generation of harmful substances. Besides, the guiding membrane has an effect of isolating cell evolving, a characteristic of slow degradation and a longer retaining time in body than a current guiding membrane prepared from natural high-molecular polymer, and can provide enough time and space for new bone growth. The method of the invention is simple, and raw materials have wide sources and low prices, so that the method is suitable for large-scale industrial production and beneficial to lowering medical costs and mitigating patient burdens.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

A new type of fabric and a new leather product in which collagen fiber bundles form a network structure

ActiveCN109082763BNot easy to hardenAct as a lubricantWeft knittingOrnamental textile articlesYarnPolymer science

The invention discloses a new type of fabric and a brand new leather product in which collagen fiber bundles form a network structure. The fabric includes a bottom yarn weaving layer, and also includes collagen fiber bundles, and the bottom yarns inserted into the bottom yarn weaving layer protrude on the surface of the bottom yarn weaving layer, and the protruding collagen fiber bundles and their branches interweave to form a network structure, wherein a part of the branch in the collagen fiber bundle is sheathed on the ground yarn so that at least one end of the part of the branch protrudes from the ground yarn braided layer. Leather products include the aforementioned novel fabrics and leather coverings. The novel fabric and leather products have good mechanical properties due to the formation of a network structure.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com