Molding equipment for collagen fiber bundle used for hemostatic material

A technology of collagen fiber and hemostatic material, which is applied in the bundle of newly sprayed silk, textile and paper making, and rayon cleaning/drying, etc. It can solve the problems of product quality and degradation without fiber protection, and avoid foreign substances. Touch, easy to use, fine fiber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is attached Figure 1-11 The specific implementation manner of the present invention will be described in further detail.

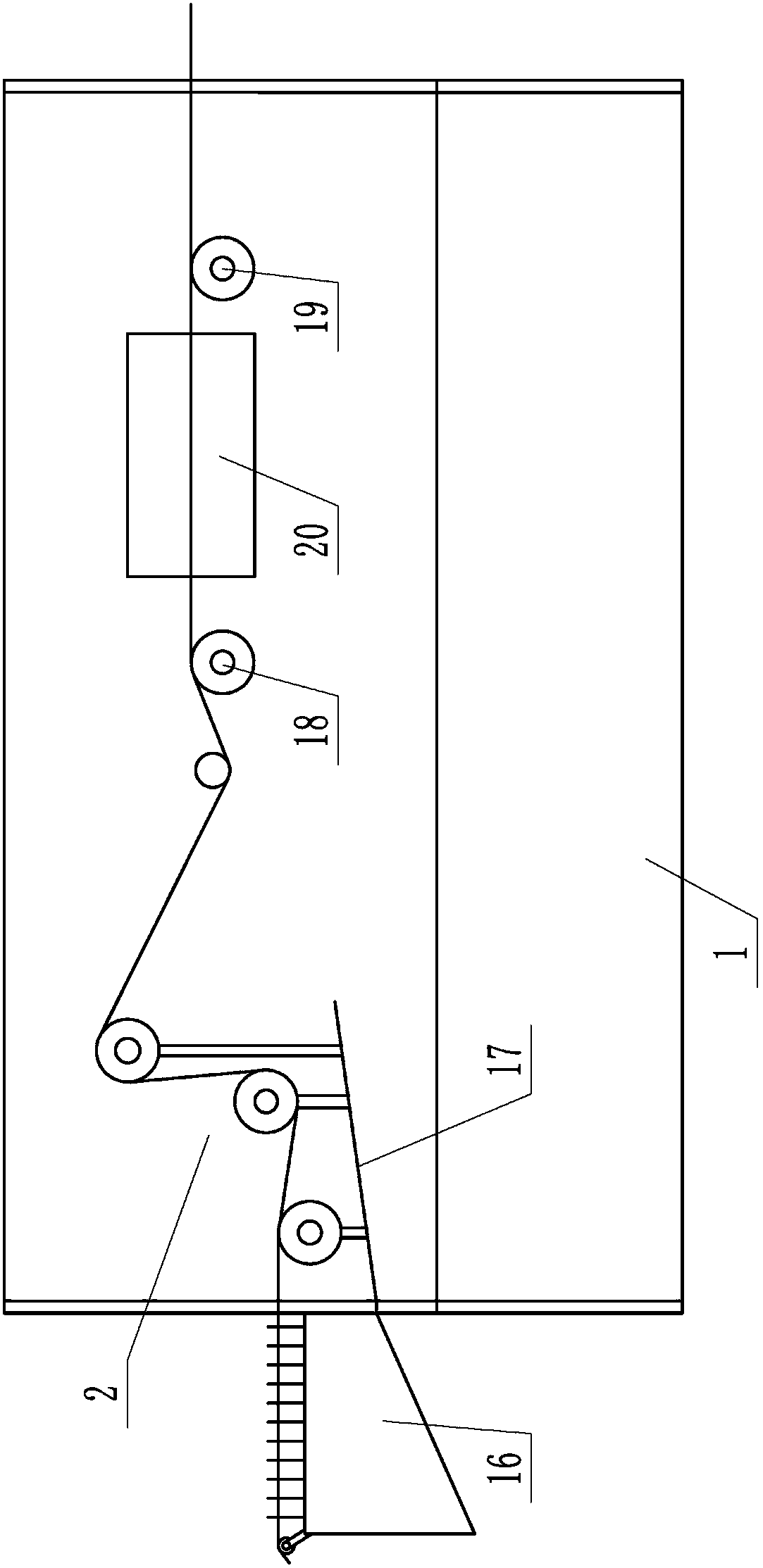

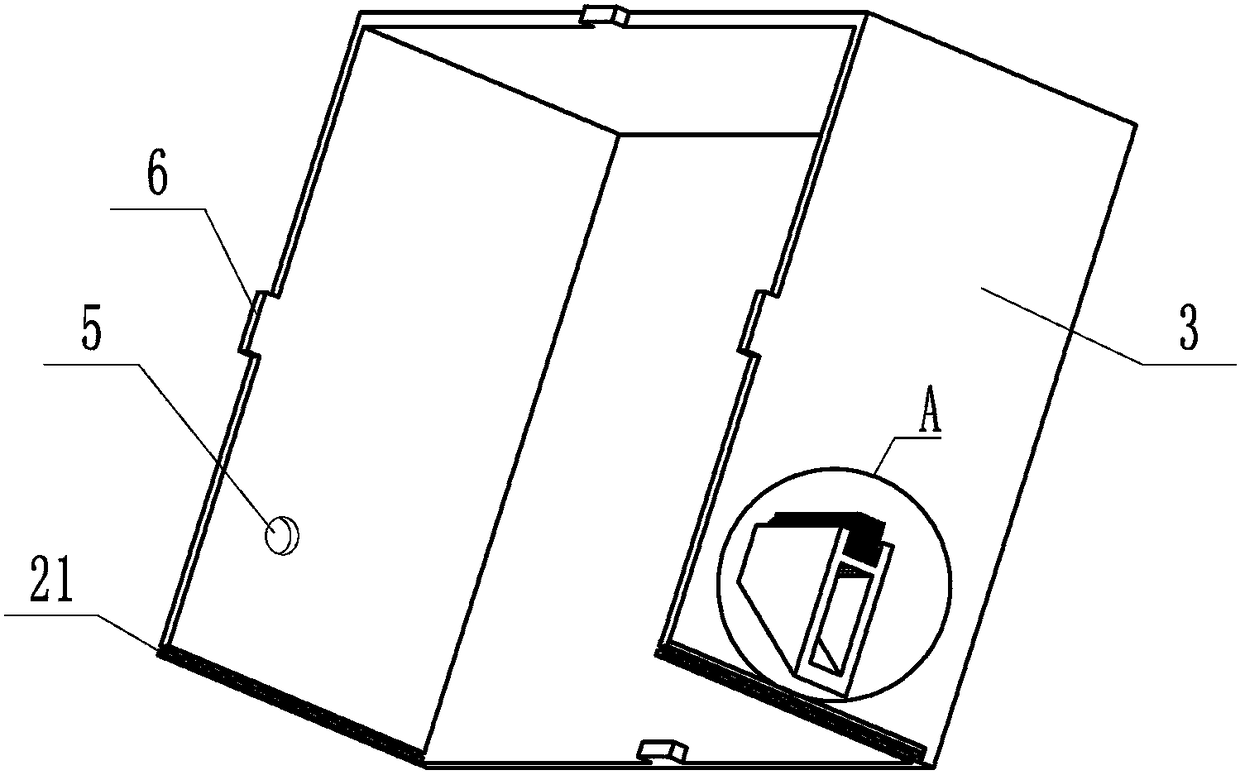

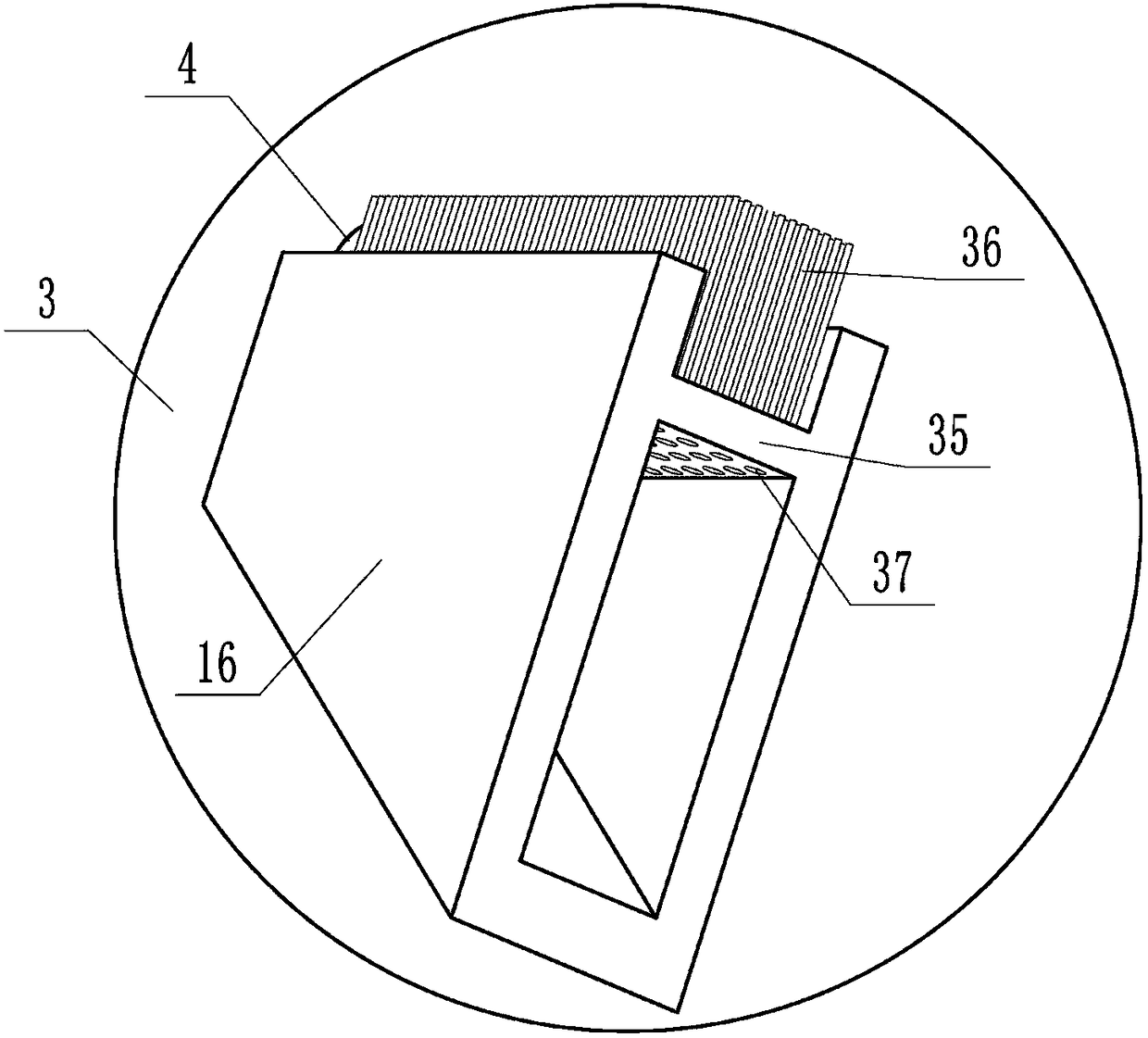

[0021] Depend on Figure 1 to Figure 11 It can be seen that the collagen fiber bundle forming equipment for hemostatic materials includes a main body 1, the lower part of the main body 1 is a frame, the upper part of the main body 1 is a control mechanism and an actuator, the width of the upper part of the main body 1 is smaller than the width of the lower part, and the upper part of the main body 1 is fixed with a godet wheel group 2 and the godet roller group, the main body 1 is slidingly provided with a cover plate 3, the cover plate 3 covers the upper part of the main body 1, the cover plate 3 is made of transparent material, the left side of the cover plate 3 is provided with a fiber inlet 4, and the right side of the cover plate 3 is provided with There is a fiber outlet 5, and the rear side of the cover plate 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com