Patents

Literature

1057results about "Artificial filament washing/drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

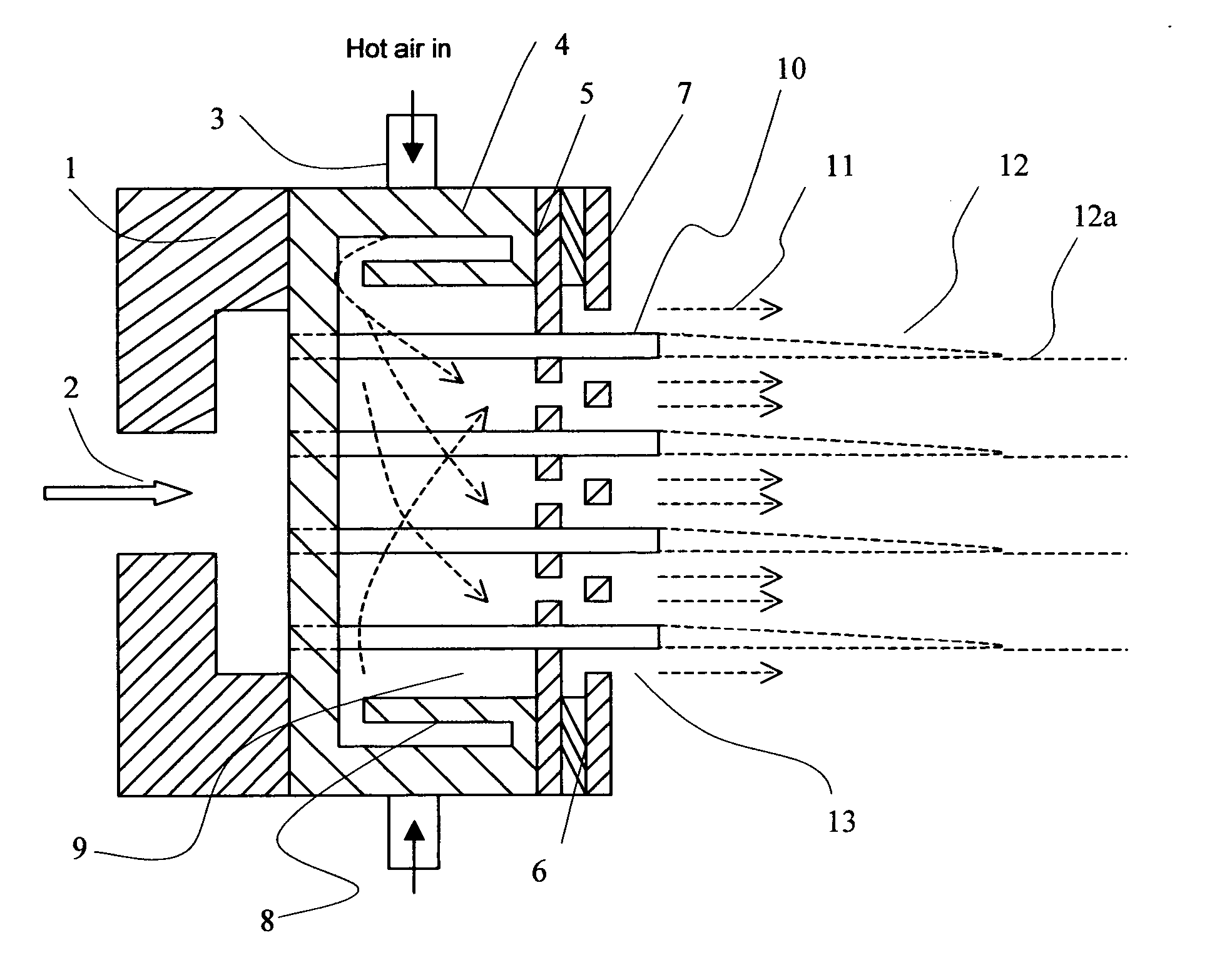

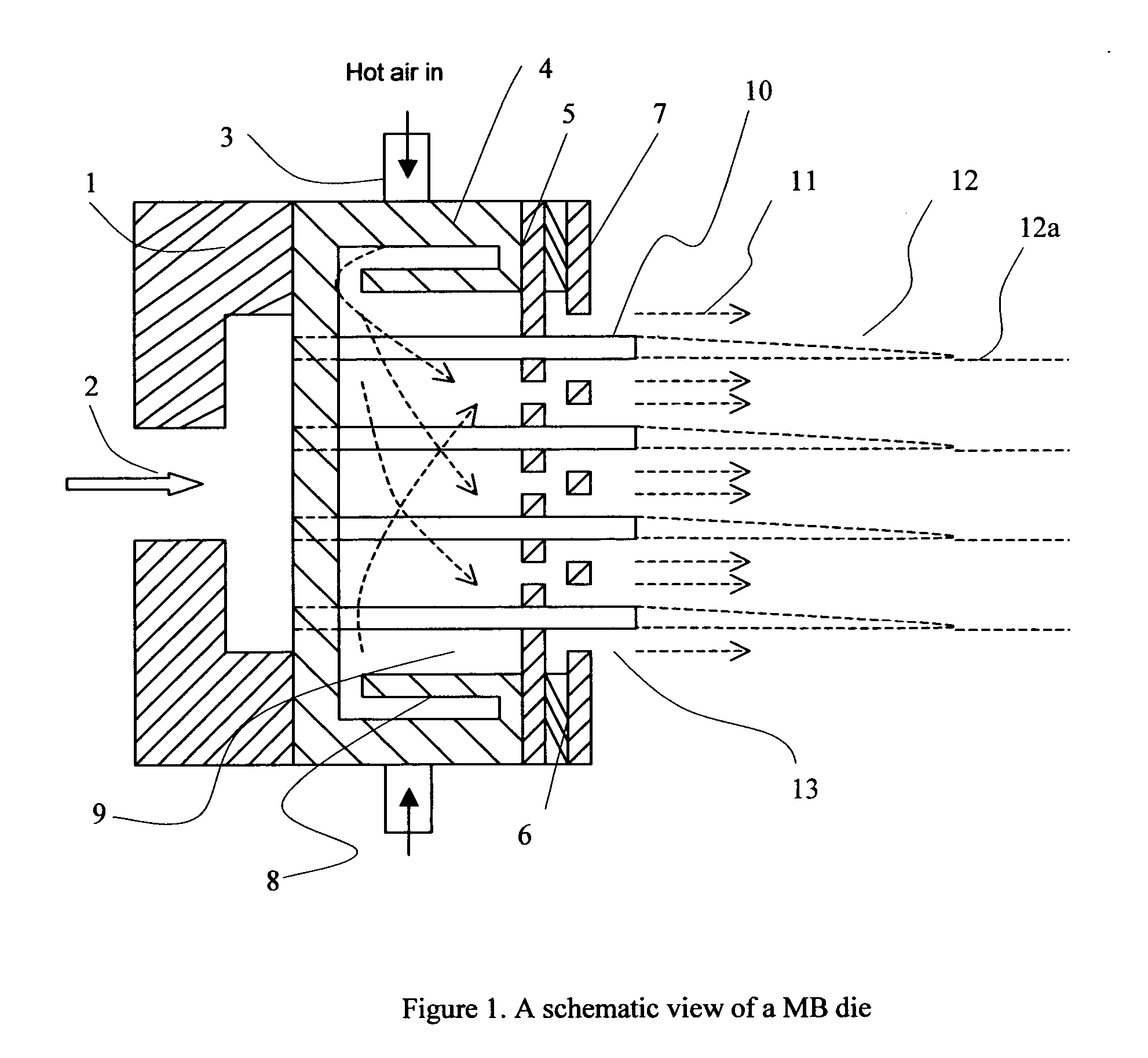

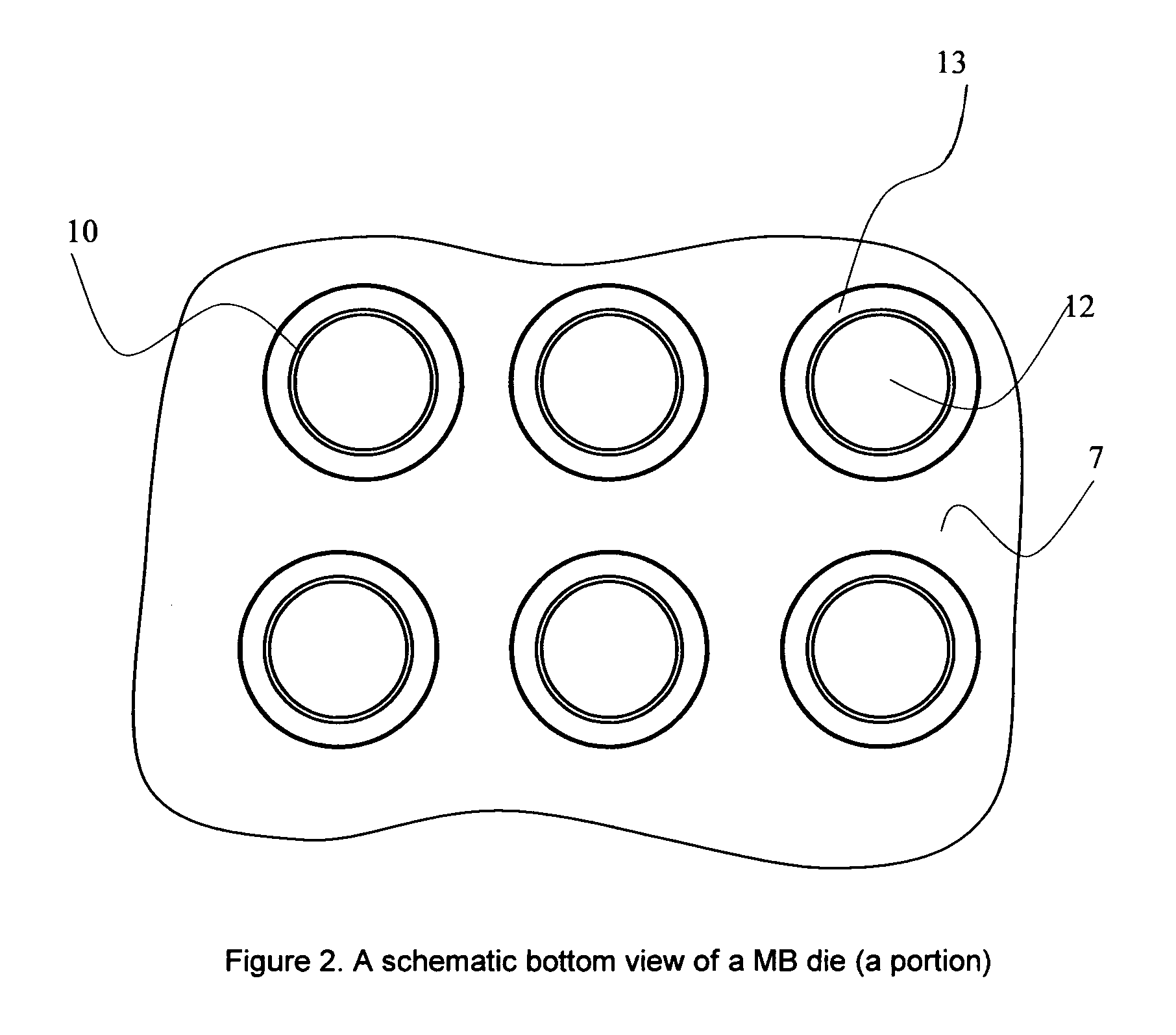

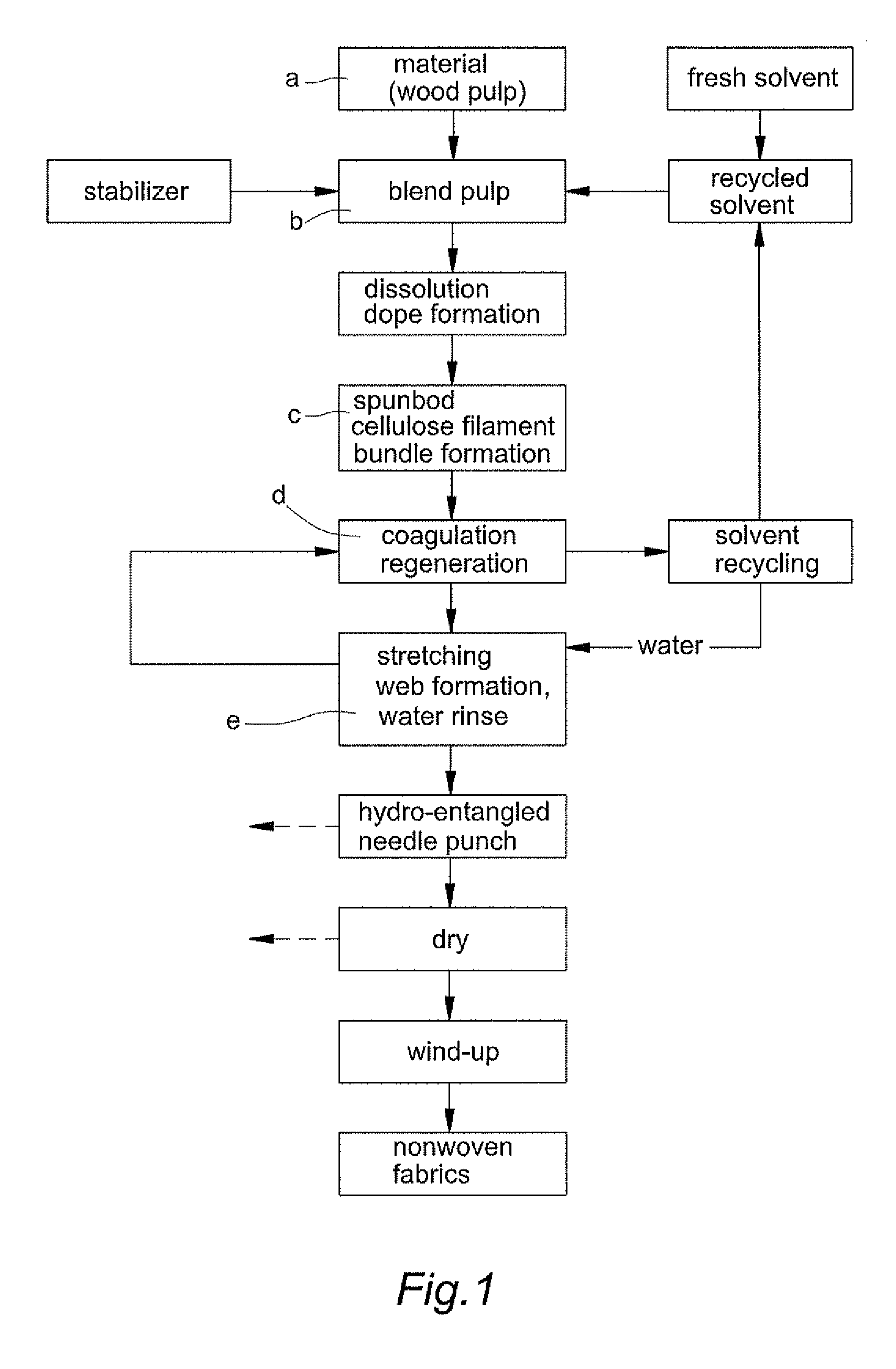

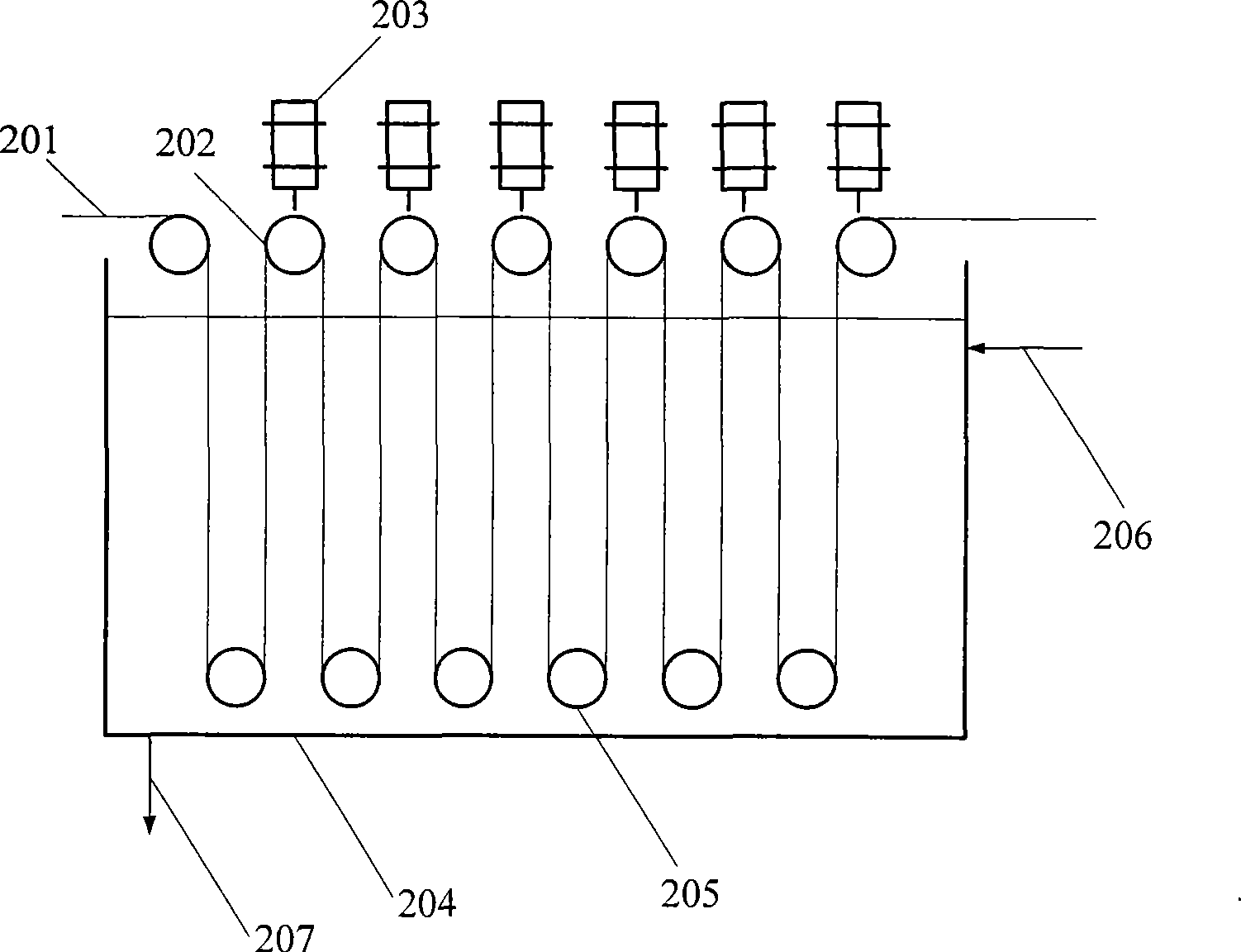

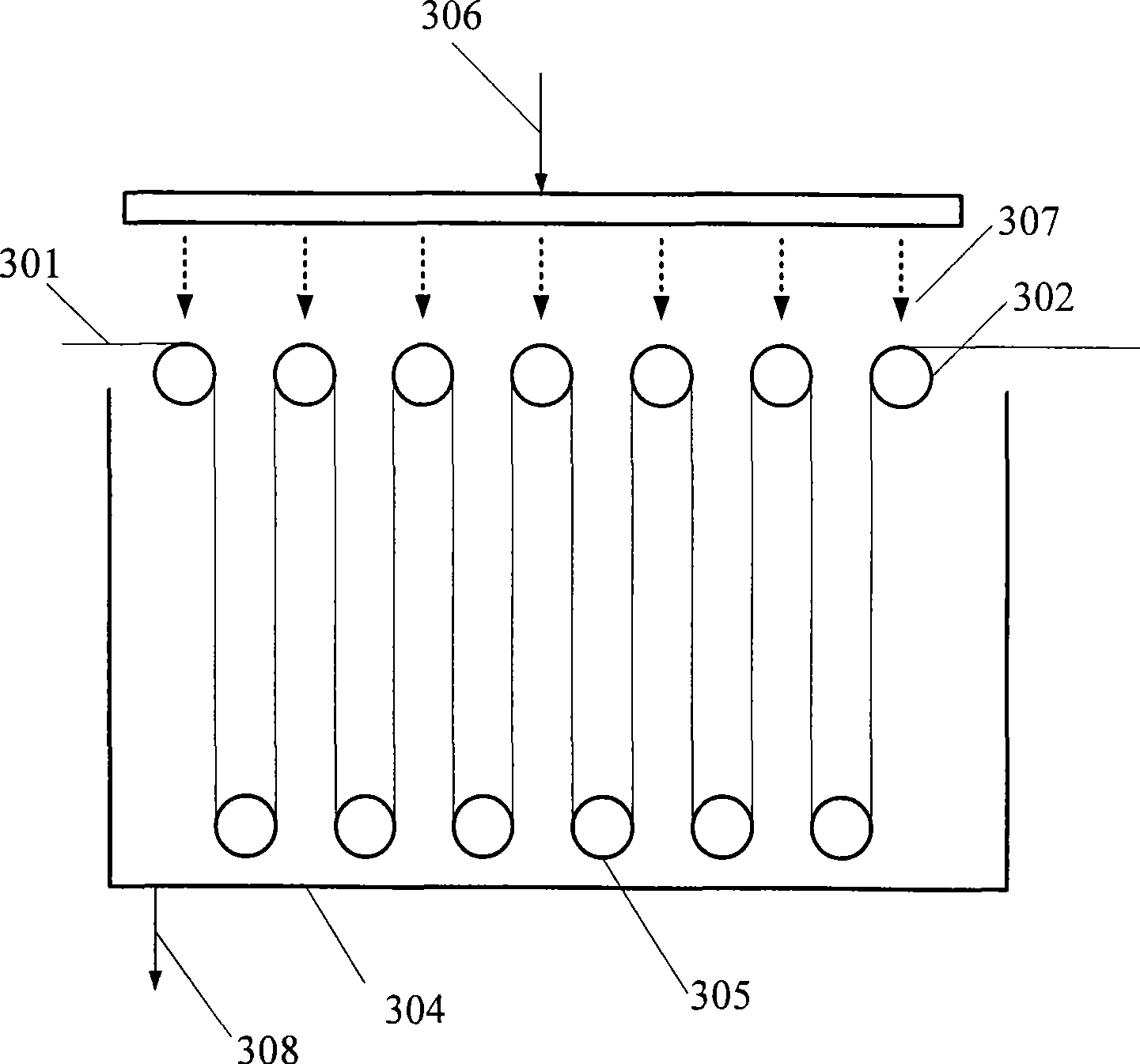

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

Method for preparing polytetrafluoroethylene superfine fiber

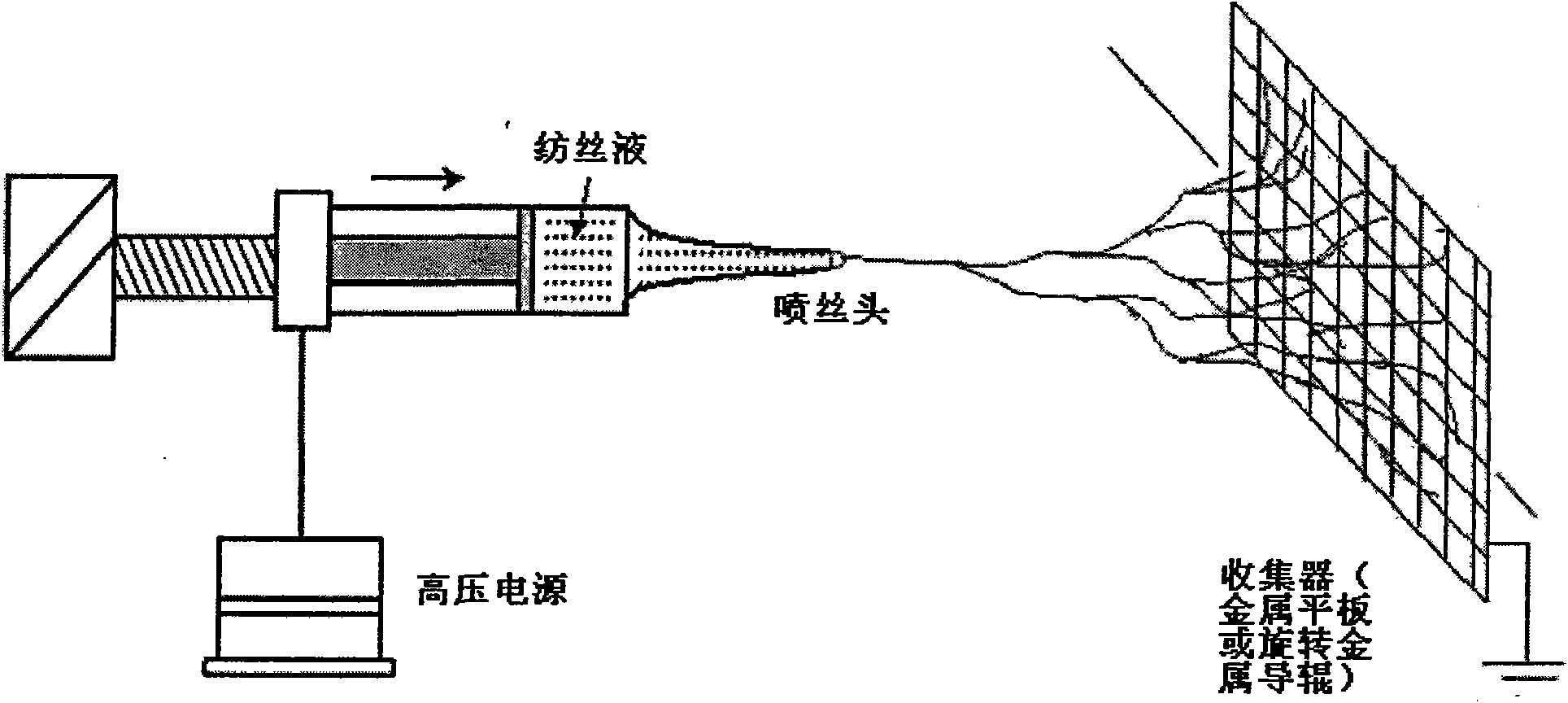

InactiveCN101994161AEasy to prepareArtificial filament washing/dryingFilament/thread formingFiberElectrospinning

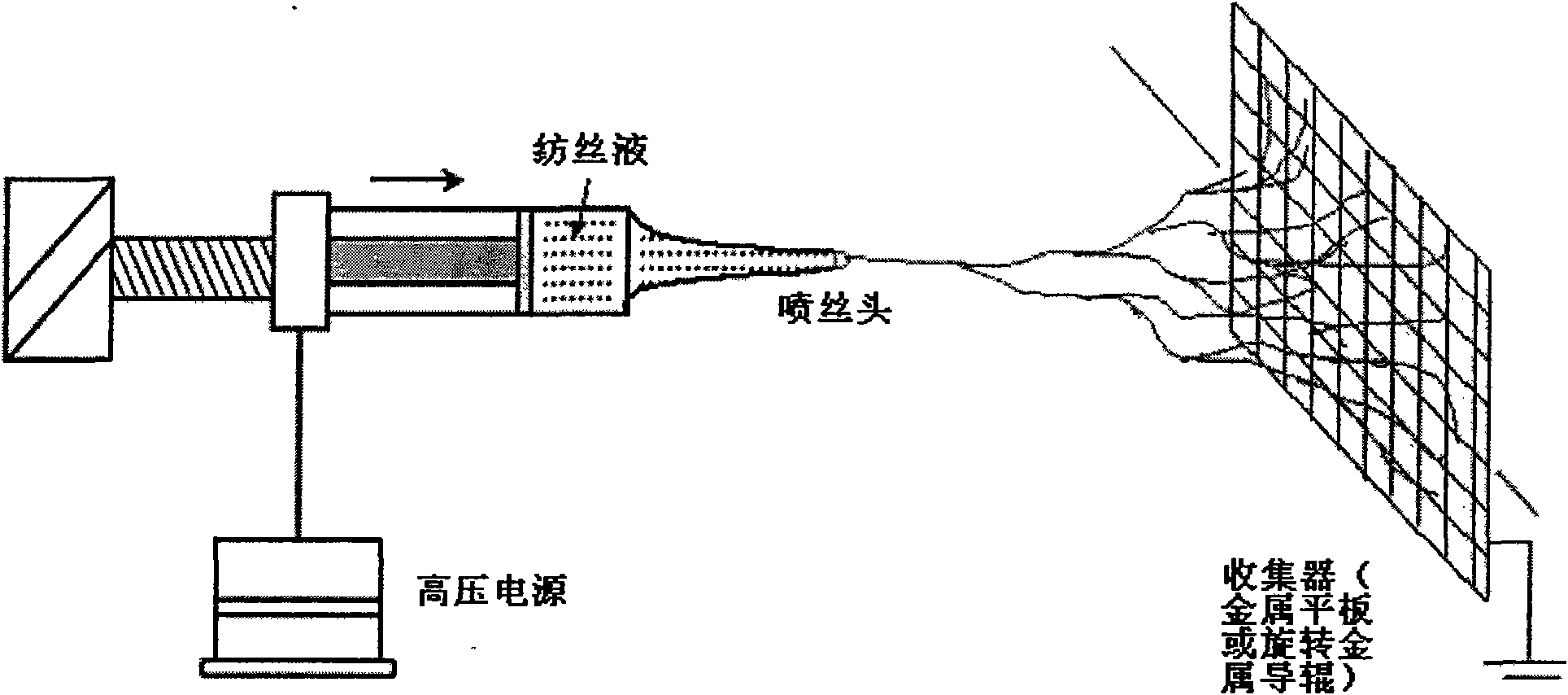

The invention discloses a method for preparing a polytetrafluoroethylene superfine fiber, comprising the following steps of: firstly dissolving polyvinyl alcohol into water to prepare a polyvinyl alcohol solution, then evenly mixing the polyvinyl alcohol solution with polytetrafluoroethylene concentrated dispersion to prepare a spinning solution; then making the spinning solution into a polytetrafluoroethylene / polyvinyl alcohol superfine fiber by adopting an electrostatic spinning method; and finally, carrying out polyvinyl alcohol removal aftertreatment on the prepared polytetrafluoroethylene / polyvinyl alcohol superfine fiber to obtain the polytetrafluoroethylene superfine fiber. The prepared polytetrafluoroethylene superfine fiber is white or dark brown, and the diameter of the fiber is 30-2000nm.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Medical chitosan fibre and preparation method thereof

ActiveCN101250759AHigh molecular weightEnough aminoFilament manufactureArtificial filament washing/dryingAcetic acidBrute force

The invention relates to medical chitosan fiber in the textile processing field and a preparing method thereof, the method for preparing spinning fluid comprises the following steps: arranging the chitosan powder in glacial acetic acid water solution and slowly dissolving by stirring under the condition of controlling temperature and time, wherein the dissolution temperature is 10-30DEG C, the dissolution time is 10-48h, and the stirring speed is 60-180r / min, wherein the chitosan powder occupies 3%-10%, dissolvent glacial acetic acid occupies 1%-5% and the other is water in the spinning raw materials, the chitosan content is more than 99.9% in chitosan fiber, and the chitosan fiber has higher molecular weight, sufficient amido, steady fiber structure, and good antibacterial property, brute force and hygiene security property.

Owner:HISMER BIO TECH

Method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods

InactiveCN102146595AGive full play to the advantages of dry and wet methodsGive full play to the advantagesArtificial filament washing/dryingFilament/thread formingPolymer scienceCarbon fibers

The invention discloses a method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods. The method comprises the steps of polymerization, demonomerization and defoaming, filtration, coagulation, washing and drafting, oiling densification, steam drafting, heat setting and drying. Three-level coagulating baths at the temperature of between 10 DEG C below zero and 70 DEG C and with dimethyl sulfoxide with concentration of 10 to 60 mass percent are adopted in the coagulation step, and the first coagulating bath contains aqueous ammonia accounting for 0.05 to 1 percent of the mass of the first coagulating bath; and a spinning head is subjected to 1.5 to 5 times positive drafting in the first coagulating bath, and the drafting is 0 in the second and third coagulatingbathes. According to the method for preparing the polyacrylonitrile carbon fiber protofilament, the spinning process is stable, the broken filament is little, the spinning speed is high, the spinningis stable, the prepared protofilament has few defects, the density is not less than 1.180g / cm<3>, and the tensile strength is not less than 7cN / dtex. The protofilament can be prepared into a high-performance carbon fiber with tensile strength of more than 4.9GPa and elastic modulus of between 260 and 280GPa by high-temperature carbonization.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation method of p-aramid nanofiber

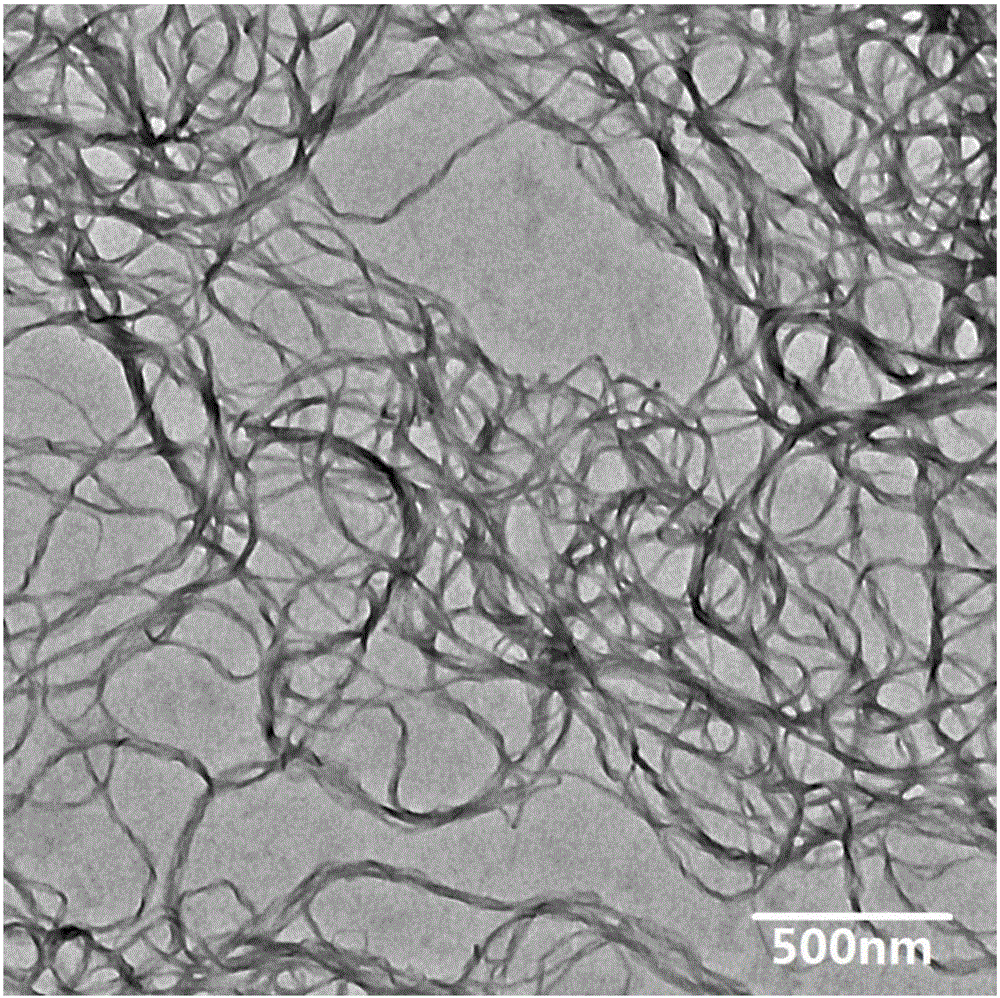

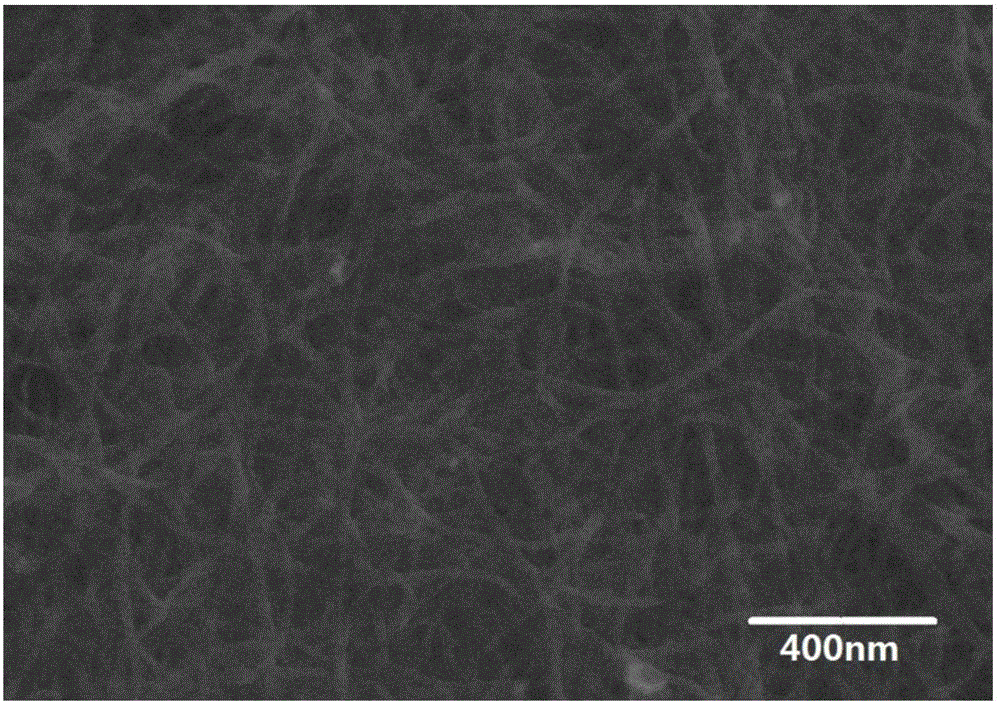

ActiveCN105153413AReduce usageSimple processArtificial filament recoveryArtificial filament washing/dryingMicrometerNanofiber

The invention relates to a preparation method of p-aramid nanofiber, and belongs to the technical field of polymer new materials. The diameter of the prepared p-aramid nanofiber ranges from tens of nanometers to hundreds of nanometers, and the length of the prepared p-aramid nanofiber ranges from hundreds of nanometers to tens of micrometers. According to the preparation method, a certain amount of surface active agents are added in the PPTA low-temperature polymerization process, aggregation of PPTA molecules is controlled while PPTA molecule chains are lengthened, and the p-aramid nanofiber which is uniform in size and has the diameter capable of being regulated within the range between nanometer and submicron can be prepared under the auxiliary effect of other means (for example, precipitator and high-speed shearing and dispersing). The preparation method is short in production flow, devices are simple, batched and stable production can be achieved, and therefore the requirement for industrially producing the p-aramid nanofiber on a large scale is met; the preparation method has wide application prospects and can be used for preparing lithium-ion battery separators and high-performance composites.

Owner:SHANDONG JUFANG NEW MATERIAL CO LTD

Preparation method of ultra-high molecular weight polyethylene fiber

InactiveCN101575742AImprove mechanical propertiesReduce internal stressArtificial filament washing/dryingWet spinning methodsFiberPolymer science

The invention relates to a preparation method of ultra-high molecular weight polyethylene fiber, which comprises the following steps: firstly, mixing ultra-high molecular weight polyethylene powder with solvent for swelling to obtain suspending liquid, and then extruding and dissolving the suspending liquid through a double screw extruder to obtain 4-25 percent of spinning solution, wherein the solvent is liquid hydrocarbon under room temperature; secondly, spraying and cooling the spinning solution to obtain gel filament; thirdly, applying 1-10 times of pretensioning to the gel filament, settling the pretensioned gel filament for 12-48h, extracting and drying the gel filament; fourthly, applying 4-130 times of heat drawing to the dried gel filament 70-160 DEG C to obtain the ultra-high molecular weight polyethylene fiber. After the gel filament is formed and pretentioned to a certain degree, the primary filament can be more uniform and has higher tension property , and the ultra-high molecular weight polyethylene fiber with excellent property can be prepared.

Owner:杨珍芬

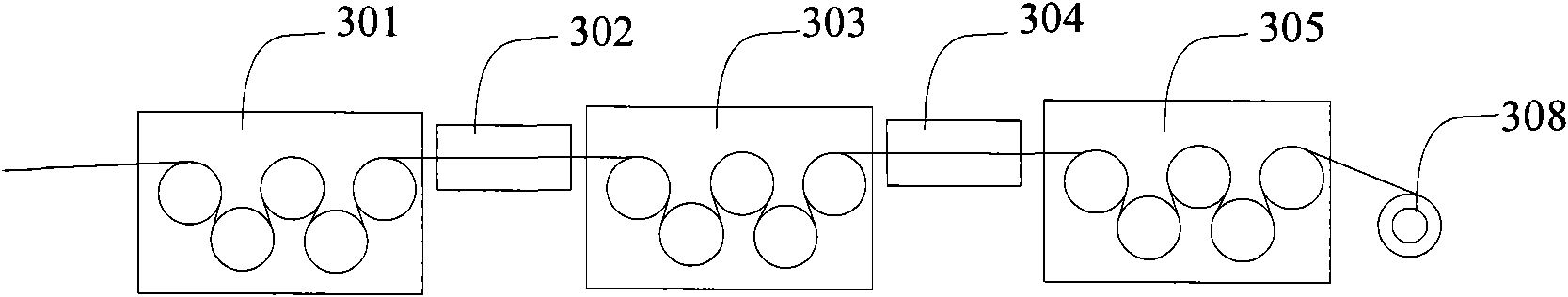

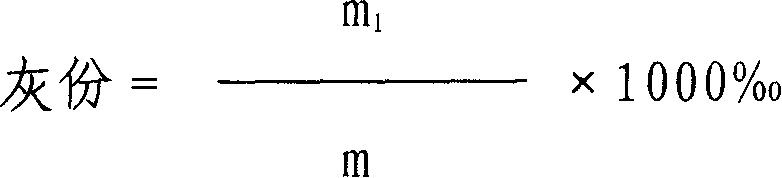

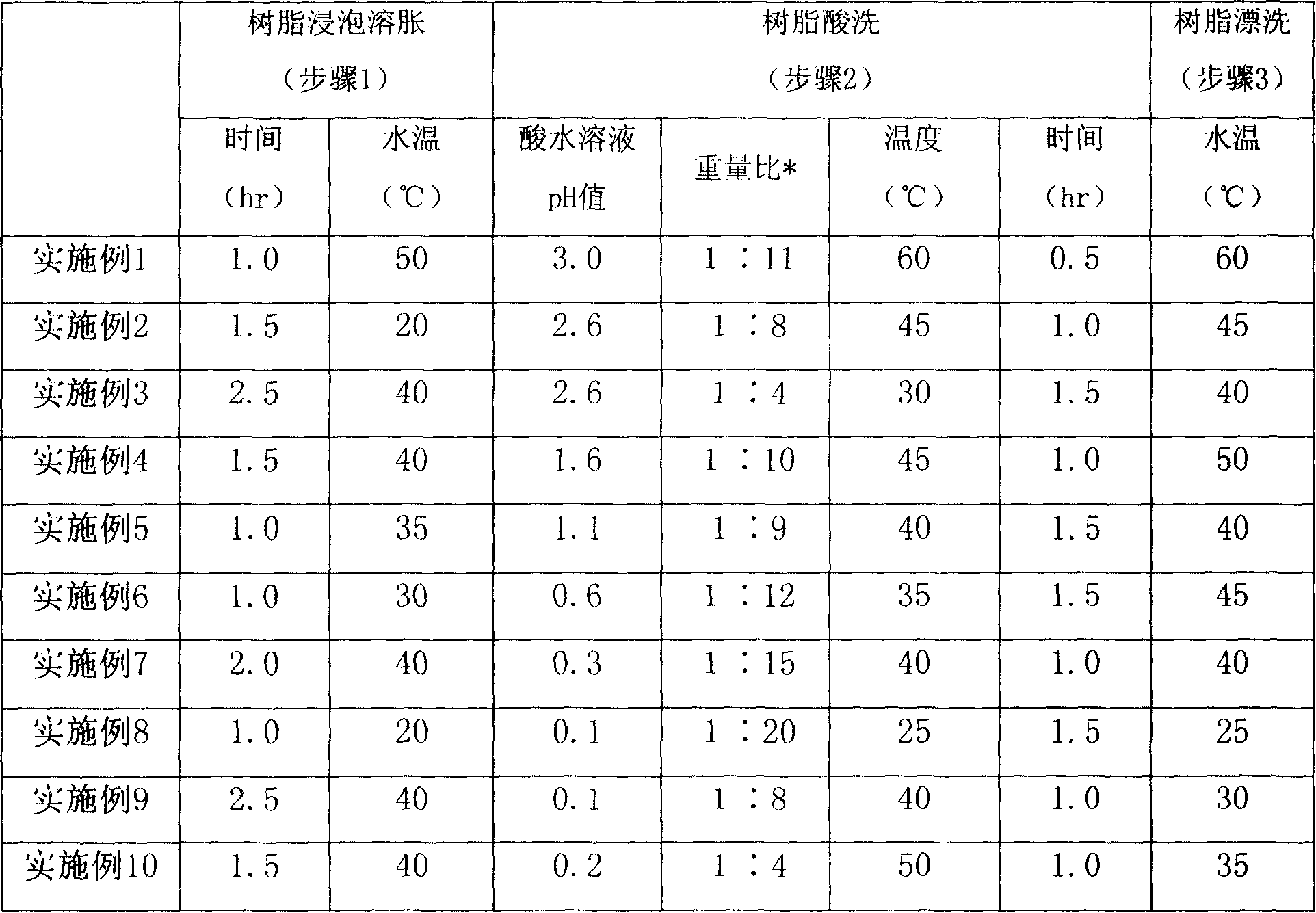

Method for preparing polyacrylonitrile-based carbon fiber protofilament

ActiveCN101165237AEfficient removalGood removal effectArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

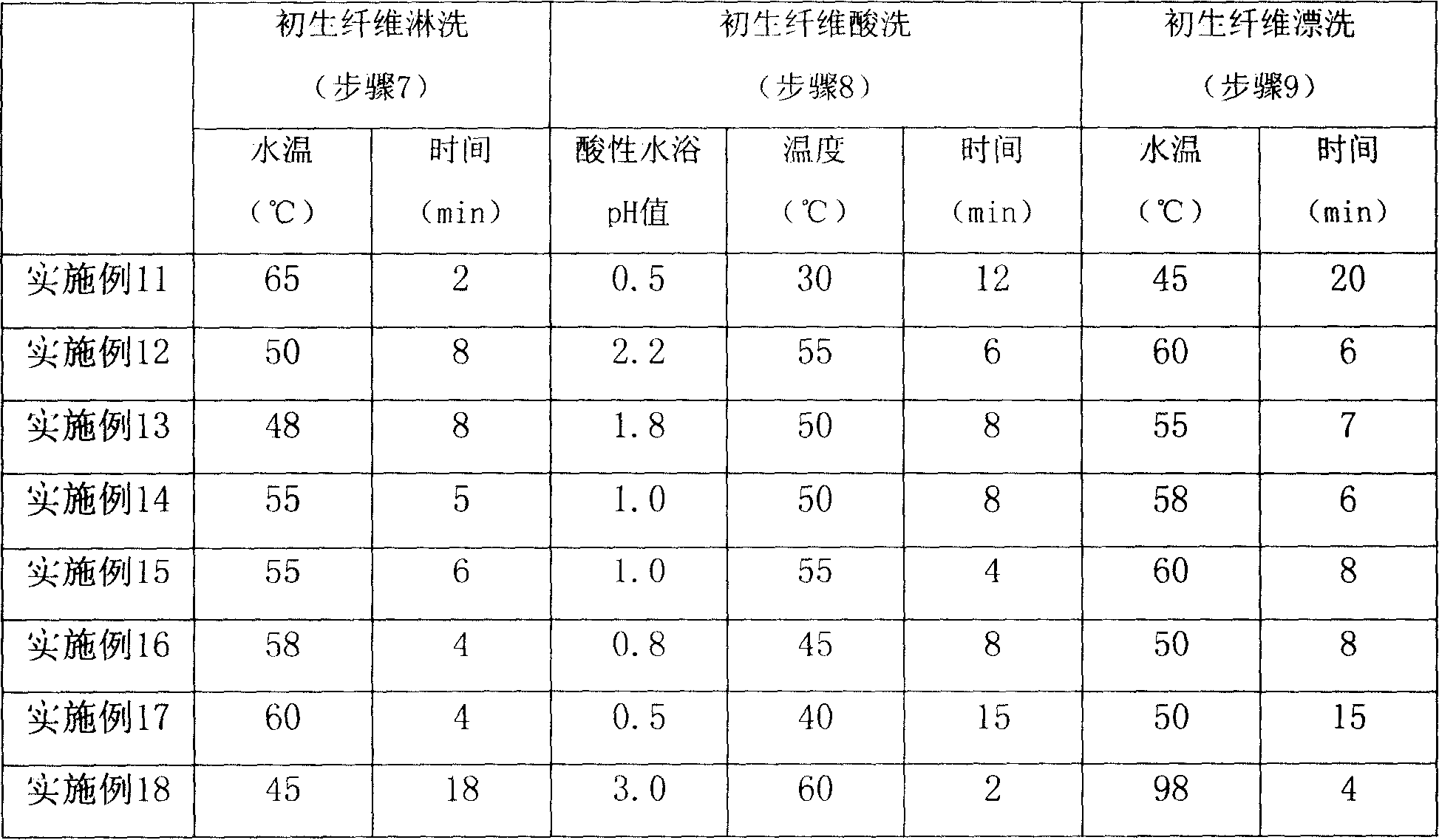

The process of preparing polyacrylonitrile fiber for carbon fiber includes the following steps: soaking resin in deionized water at 20-50 deg.c to swell for 1-2.5 hr; pickling in water solution of nitric acid or hydrochloric acid in pH 0.1-3.0 at 25-60 deg.c for 0.5-1.5 hr; rinsing with deionized water to neutral; dewatering and drying to water content lower than 3 %; dissolving in 35-58 wt% concentration NaSCN aqua to form spinning fluid in resin content of 8-16 wt%; debubbling and spinning to form initial fiber; washing with deionized water, acid aqua and hot water successively; drafting, oiling, drying, densifying, etc to produce polyacrylonitrile fiber for carbon fiber. The polyacrylonitrile fiber product has ash content not higher than 0.01% and alkali metal ion content not higher than 0.005%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Fabric of continuous graphitic fiber yarns from living graphene molecules

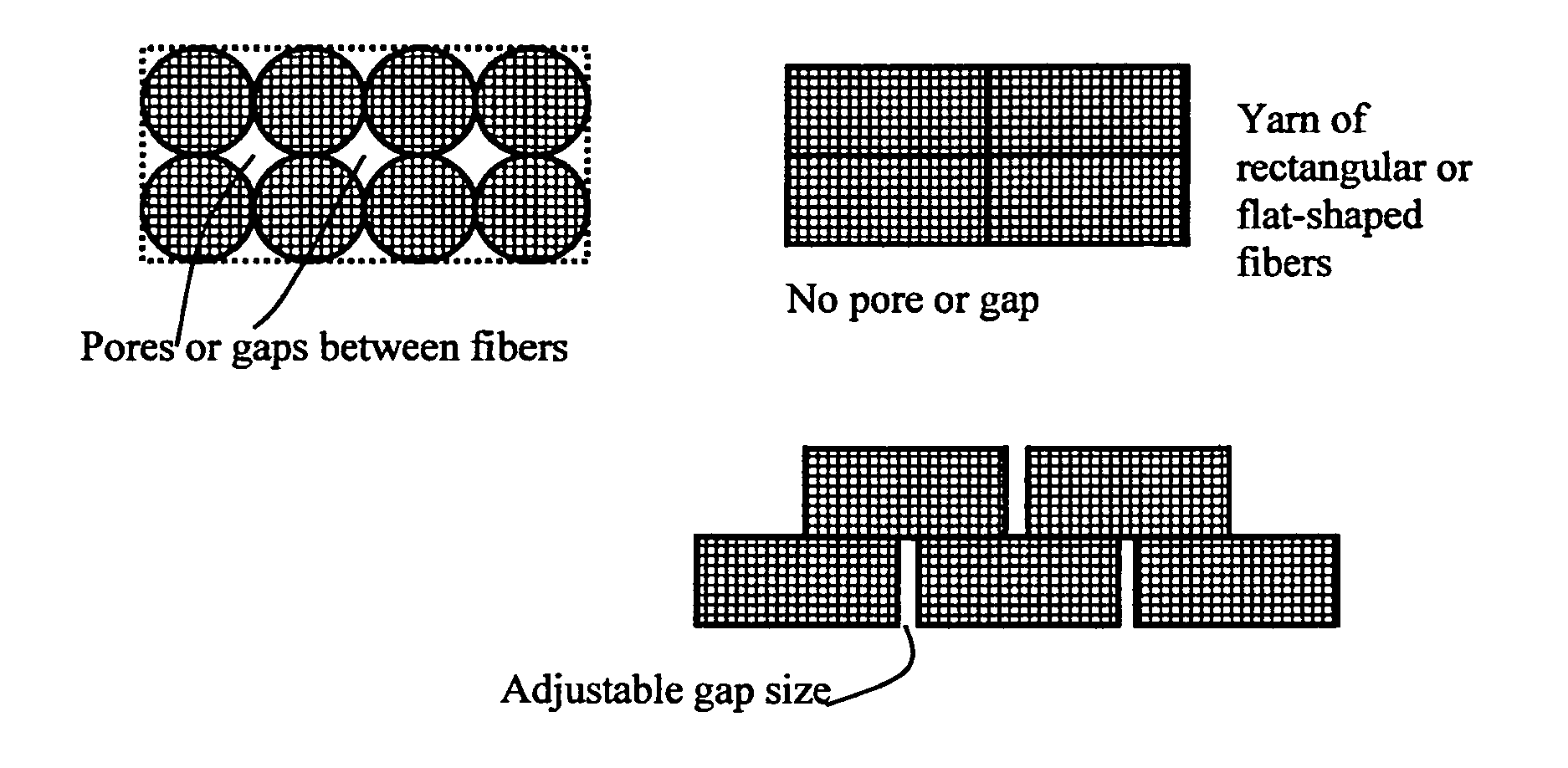

ActiveUS20150038041A1Low viscosityEffective shear stressLayered productsArtificial filament washing/dryingPorosityYarn

Owner:GLOBAL GRAPHENE GRP INC

Preparation method of ultra-high molecular weight polyethylene fiber

ActiveCN102002769ANo force lossHigh strengthSpinning head liquid feederArtificial filament washing/dryingEnvironmental resistanceYarn

The invention relates to a novel production method for preparing a high-strength and high-elongation polyethylene fiber at low energy consumption and low cost. The method comprises the following two steps: 1, preparing a polyethylene modified master batch; and 2, uniformly mixing ultra-high molecular weight polyethylene resin with the prepared polyethylene modified master batch to prepare an ultra-high molecular weight polyethylene melt spinning yarn, wherein the fiber strength of the prepared ultra-high molecular weight polyethylene fiber is 15-25 CN / dtex, and the breaking elongation is 5-8%. The invention has the advantages of short production flow, low energy consumption, environment friendliness, low manufacturing cost and high single-machine productive capacity. Besides, the product can be widely used in various fields such as the cable twisting and weaving field, the fishnet knitting field, the industrial cloth and belt weaving field and the like and the effective use of the fiber strength can be maintained.

Owner:宁波大盛新材料有限公司

Preparation method for polyacrylonitrile-based carbon fiber protofilament

InactiveCN101643943AGood orientationHigh strengthArtificial filament washing/dryingFilament/thread formingOrganic solventUltimate tensile strength

The invention relates to a preparation method for a polyacrylonitrile-based carbon fiber protofilament, comprising the following steps: firstly, polyacrylonitrile / organic solvent spinning solution isprepared; secondly, after defoaming, filter and metering, the spinning solution forms a spinning solution trickle by being extruded through a spinneret, and enters a coagulation bath to be shaped by coagulation through an air layer; and thirdly, air stretching, washing, prestretching, main stretching, dry collapse and steam stretching are carried out. The invention efficiently enhances the draft ratio of a strand silk during spinning, and can carry out scale production on the prior spinning plant, therefore, the prepared protofilament has uniform structure, little fibrousness and high strength.

Owner:DONGHUA UNIV

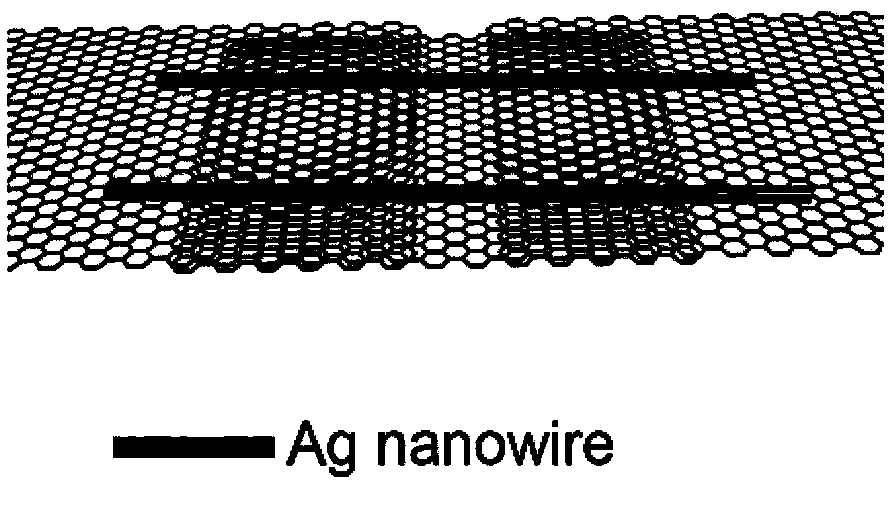

Graphene fiber and preparation method thereof

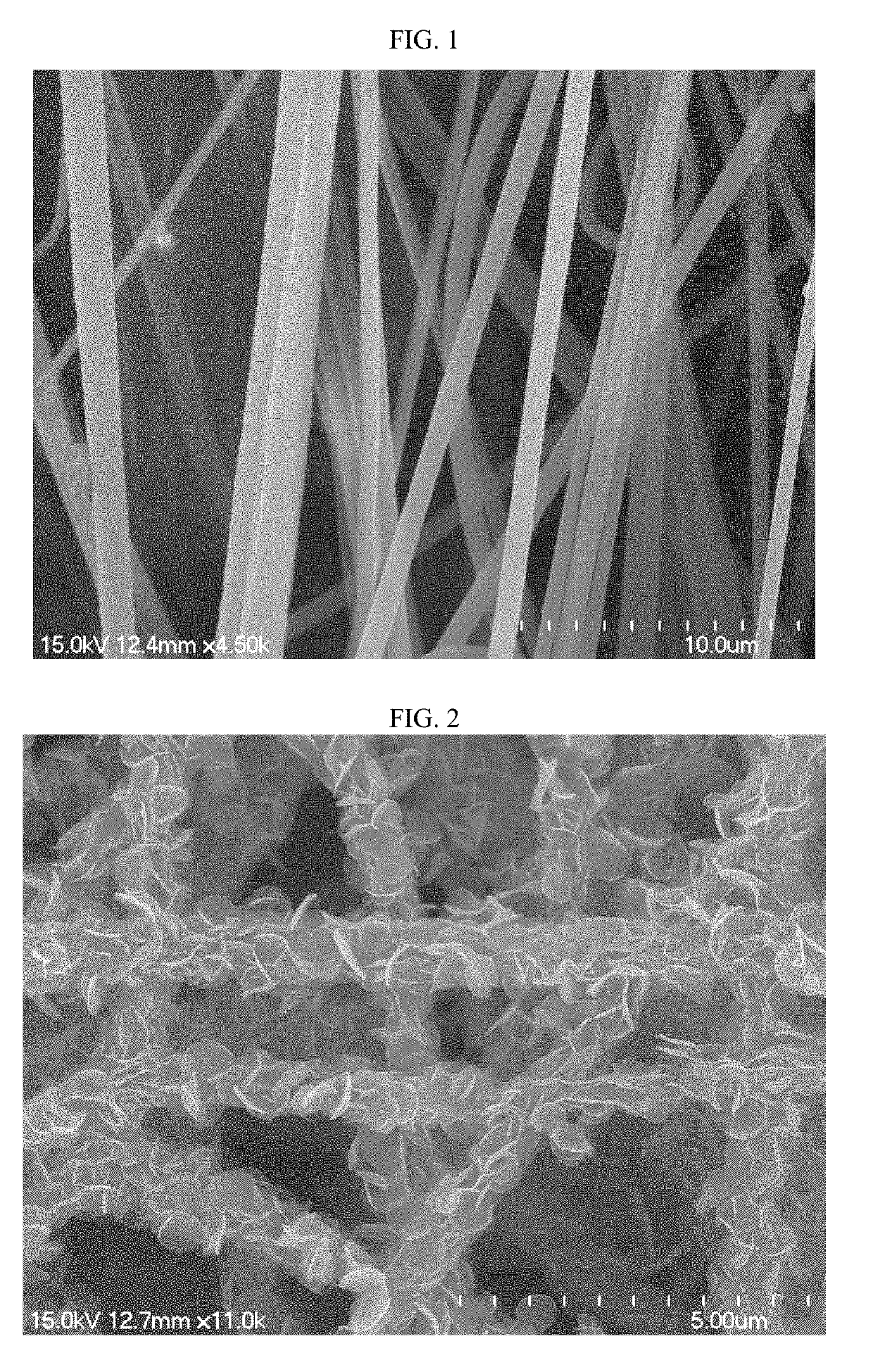

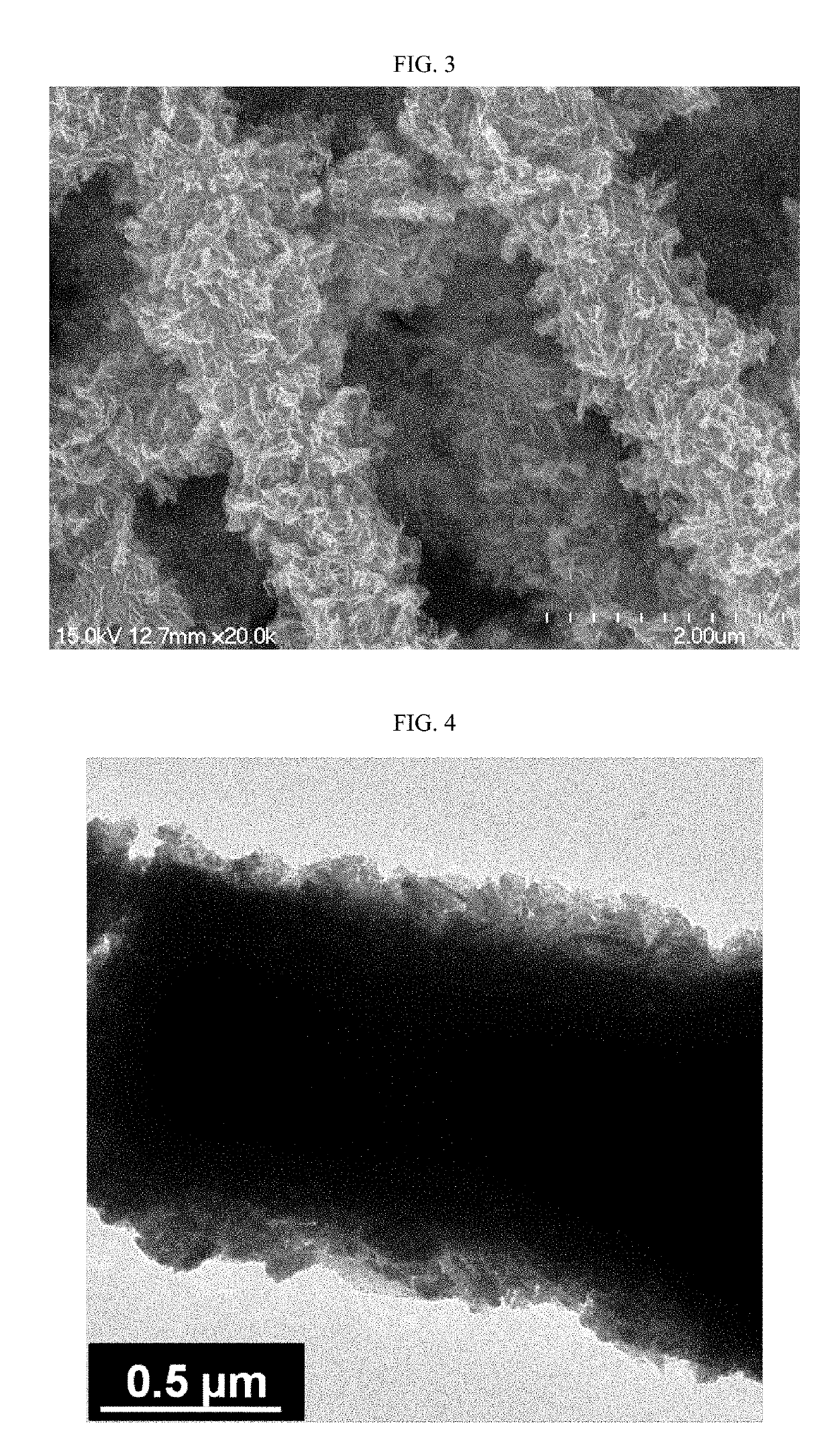

ActiveCN104099687AArranged in orderConvenient ArrangementElectroconductive/antistatic filament manufactureInorganic material artificial filamentsFiberDoped graphene

The invention discloses a graphene fiber and a preparation method thereof, wherein the graphene fiber is a composite fiber obtained by doping graphene fiber with metal nanowires, the composite fiber comprises the main components of graphene and the metal nanowires, wherein the mass ratio of the metal nanowires is 0.1% ~ 50%, the graphene is in lamellar morphology, and the metal nanowires and the graphene layers are parallelly and simultaneously arranged along the axial direction of the graphene fiber. The metal nanowire doped graphene fiber is a new high performance and multifunctional fiber material, by doping of the metal nanowires, fiber conductive rate is greatly improved, meanwhile the graphene fiber exhibits good tensile strength and excellent toughness, has the very strong potential application value in many fields such as use as lightweight flexible wires and the like.

Owner:HUAWEI TECH CO LTD +1

Lyocell multi-filament for tire cord and method of producing the same

InactiveUS20050079348A1Good tenacityModulus improvementArtificial filaments from cellulose solutionsArtificial filament washing/dryingCellulosePolyvinyl alcohol

Owner:HYOSUNG CORP

High whiteness and strength adhesive short fiber and process for making same

ActiveCN1632189AImprove qualityHigh whitenessArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceAdhesive

The invention relates to a viscose staple fiber with high white strength and fine denier and a production process thereof, which belong to the viscose staple fiber and the production method of the textile spinning industry and the non-woven fabric industry. Its raw materials and weight percent content are: 86.7-92 percent of cellulose fiber, 7.7-13 percent of water, and 0.15-0.30 percent of oil agent. The raw materials are impregnated, squeezed, yellowed, spun, drawn, bundled, scoured, bleached twice with hydrogen peroxide, and dried to make finished products. The product of the present invention has finer denier, higher strength, higher yarn count and higher strength, and the garment fabric has higher strength, strong abrasion resistance, delicate hand feeling, wrinkle resistance and resistance to multiple deformations than ordinary viscose of the same process. Short fiber processing clothing fabrics and other advantages. High-count yarn products have thinner fabrics and lower grammage. The area of fabrics processed from raw materials of the same weight is increased and the cost is reduced.

Owner:唐山三友集团兴达化纤有限公司

Method for preparing high-performance polyacrylonitrile-based carbon fiber protofilament through dry spraying and wet spinning

InactiveCN101760791AIncrease spinning speedIncrease productivityArtificial filament washing/dryingFilament manufactureCarbon fibersSolvent

The invention relates to a method for preparing high-performance polyacrylonitrile-based carbon fiber protofilament through dry spraying and wet spinning, which comprises the following steps: preparing a polyacrylonitrile spinning stock solution; filtering and metering the polyacrylonitrile spinning stock solution after the demonomerization and deaeration; squeezing obtained materials through a spinning jet for forming fine spinning streams for entering a coagulating bath for coagulating forming through an air section; and carrying out drafting, water washing, drying densification, steam drafting and drying hot forming to obtain the high-performance polyacrylonitrile-based carbon fiber. The fiber firstly passes through a section of air layer, and then enters the coagulating bath for spinning forming by a wet method. The fine streams of the spinning solution is in a cylindrical shape after leaving spinneret orifices under the action of the gas-liquid interface tension, a primary cuticular layer is formed, and the cuticular structure is smooth. The method has the advantages of simple process, easy control and relatively low cost. In addition, the method also has the advantages that the spinning speed is high, the production efficiency can be improved, in addition, the surface of the obtained protofilament is smooth, the residual quantity of the solvents is greatly reduced, the quality homogenization degree of the protofilament is improved, and the mechanical property is excellent.

Owner:ZHONGFU SHENYING CARBON FIBER

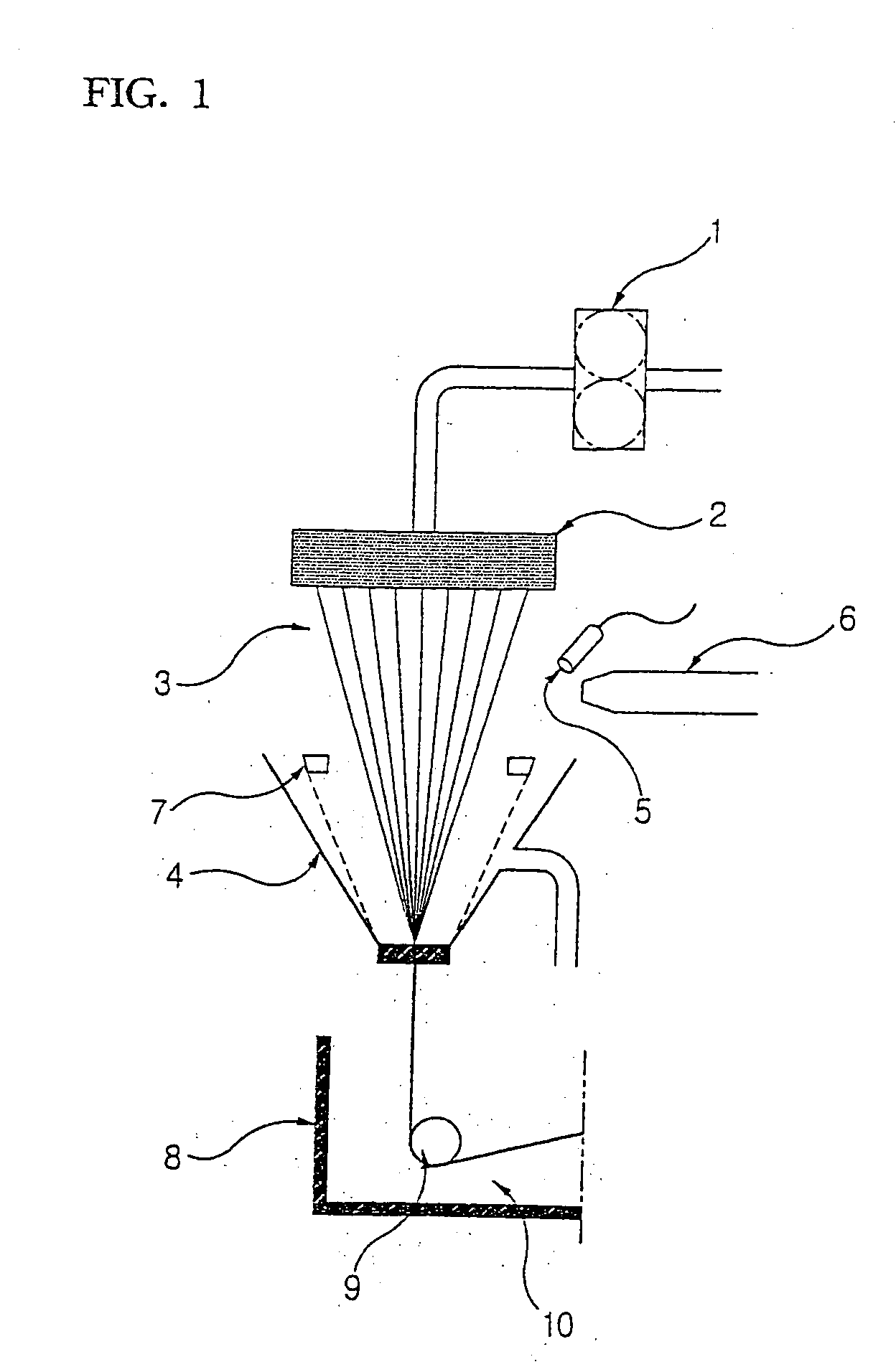

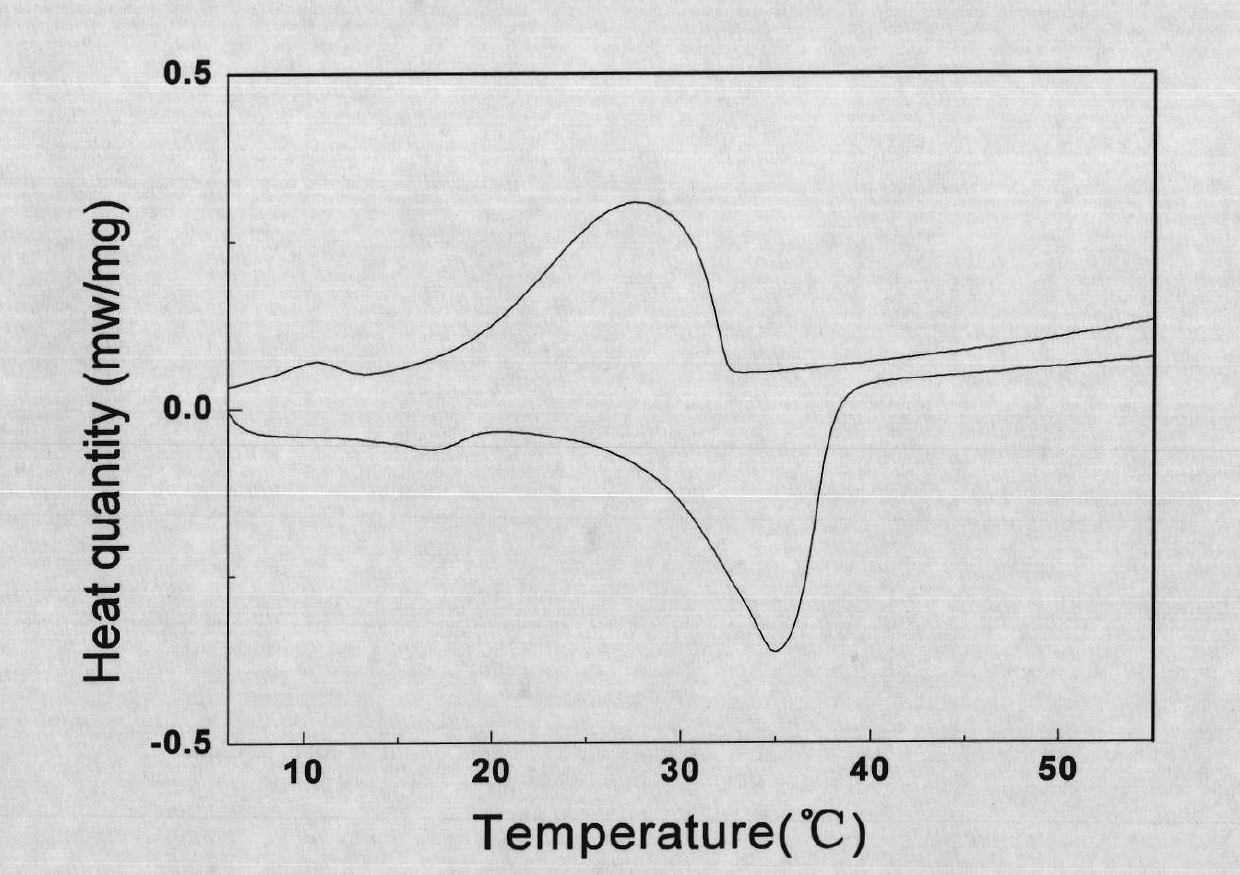

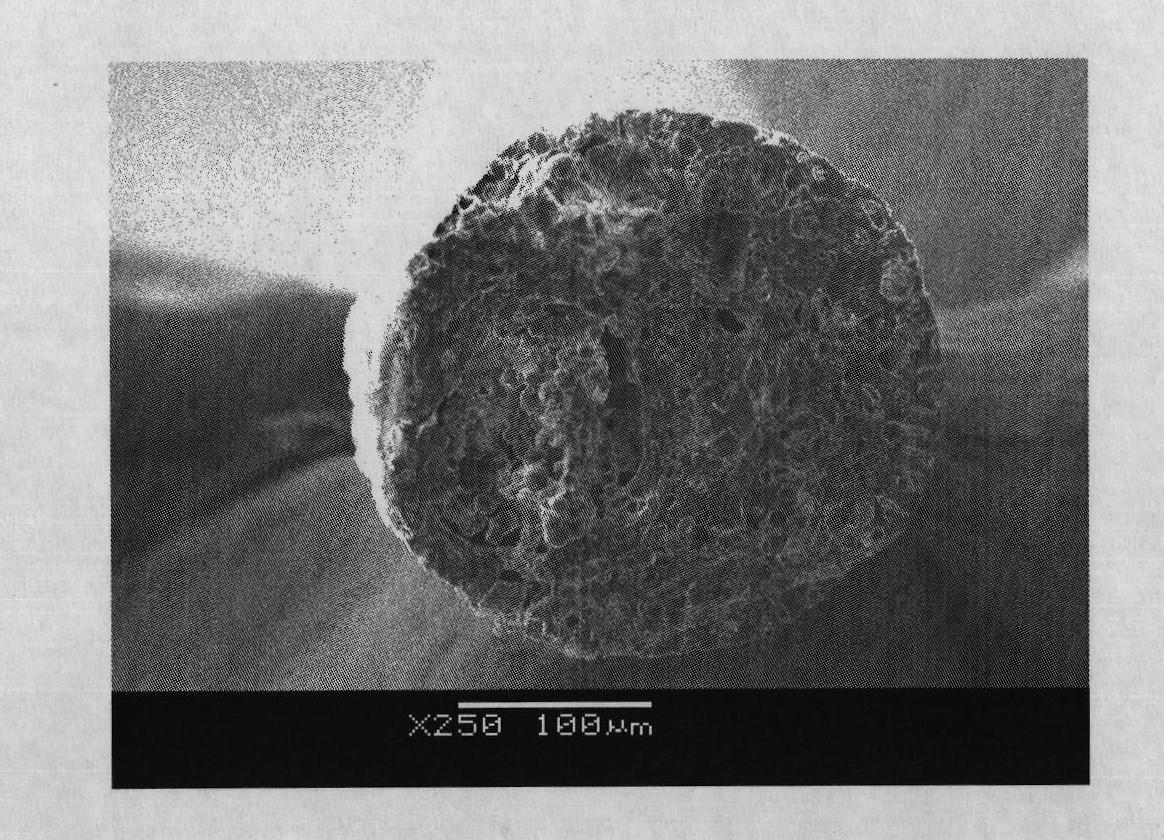

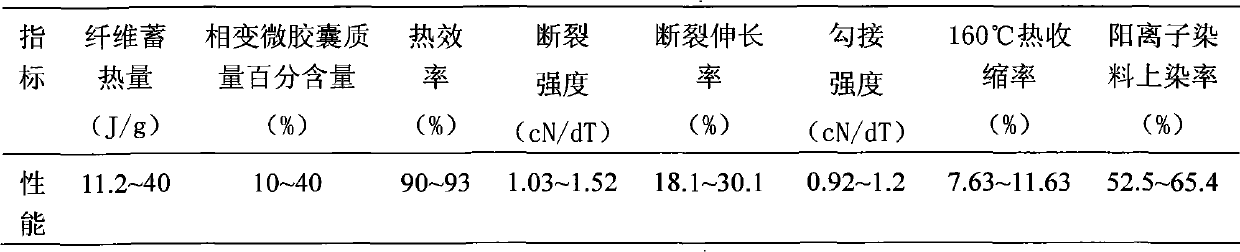

Phase-change microcapsule heat storage and temperature adjustment polyacrylonitrile fiber and wet spinning preparation method thereof

InactiveCN102002771AAvoid damageReduce lossesArtificial filament washing/dryingWet spinning methodsParaffin waxPolymer science

The invention discloses heat storage and temperature adjustment polyacrylonitrile fiber and a wet spinning preparation method thereof. Paraffin wax which has a phase change point of about 30 DEG C and has been industrially produced is used as a phase change material and aqueous solution of sodium rhodanate is used as a solvent, and the phase-change microcapsule heat storage and temperature adjustment polyacrylonitrile fiber is prepared by adding phase-change microcapsules into solution of polyacrylonitrile polymer and taking the aqueous solution of sodium rhodanate as a gelling agent by a wet spinning method. The fiber prepared by the technology has higher thermal efficiency, high physical and mechanical properties, wearability, workability and dyeing property; and the used phase change material is the paraffin wax which has been industrially produced and has the advantage of low cost.

Owner:DALIAN POLYTECHNIC UNIVERSITY

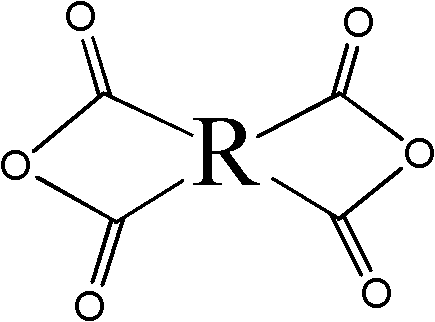

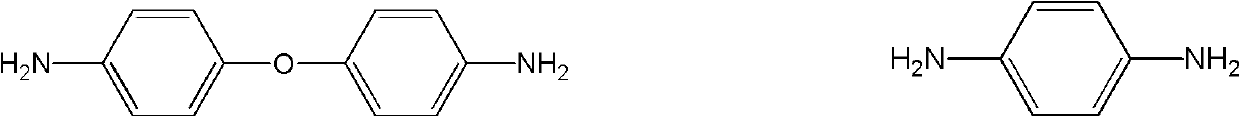

Method for preparing polyimide fibers

ActiveCN102168317AGood effectImprove performanceArtificial filament washing/dryingArtificial filament heat treatmentFiberPolyamide

The invention discloses a method for preparing polyimide fibers, and belongs to the technical field of the polyimide fibers. The method is characterized in that: polyamide acidic solution is subjected to spinning by adopting a wet spinning or dry wet spinning process, and fibers are subjected to processes of coagulating and drying or processes of washing, drying, heat treatment cyclizing and stretching continuously and are rolled finally to form the polyimide fibers. The method comprises the following specific steps of: reacting diamine with dianhydride in solvent under the protection of nitrogen to obtain polyamide acidic spinning solution; filtering the spinning solution, pouring the filtered spinning solution into a storage tank for defoaming, spinning according to the wet spinning or dry wet spinning process, pumping the spinning solution by a metering pump, and spraying from a spinneret plate; dragging by a silk guide roller, coagulating in coagulating bath, drying directly by a hot roller or a hot plate or drying by the hot roller or the hot plate after washing, and performing heat cyclizing and stretching by three sections or more than three sections of furnace sections; and finally, rolling silk. In the method, the integral process is continuous, smooth, compact and short in time, high imidization degree and degree of orientation are realized, and the high-performance fibers are obtained.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

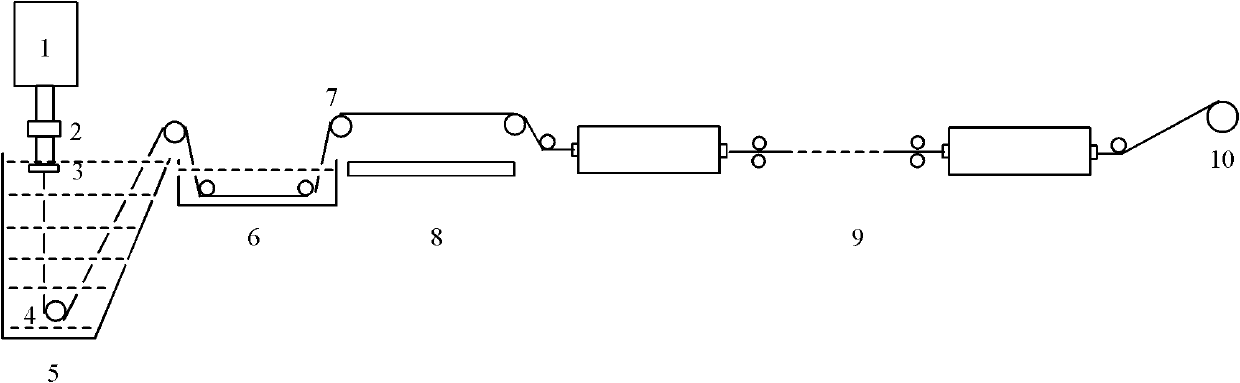

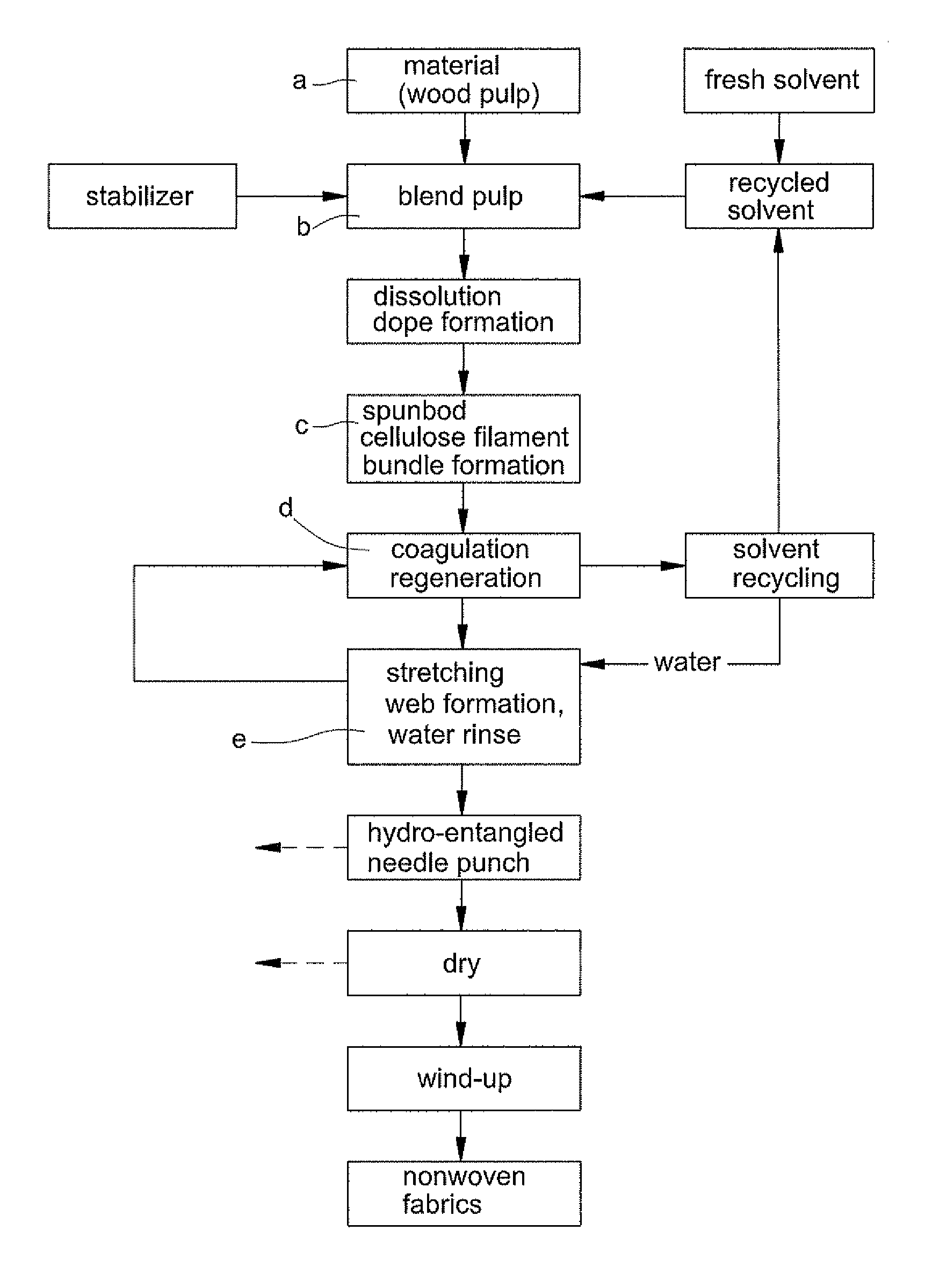

Spunbond wetlaid method for producing non-woven fabrics from natural cellulose

ActiveUS8366988B2Reduce manufacturing costDegree of air permeabilityArtificial filaments from cellulose solutionsPattern makingPunchingWater rinsing

Owner:LIN CHIH HSIN

Method for producing regenerated cellulose fiber by dual-bath coagulation

InactiveCN101429682ASlow down the curing speedFully curedArtificial filaments from cellulose solutionsFilament manufactureThioureaCellulose fiber

The invention belongs to the material field, and provides a method for preparing a regenerated cellulose fiber by double solidification bath. The method comprises the following steps: precooling cellulose to a temperature of between 8 DEG C below zero and 12 DEG C below zero in a mixed solution which contains the following compositions in weight percentage: 7 to 10 percent of sodium hydroxide, 4.5 to 7 percent of thiourea, 1 to 10 percent of urea, and 73 to 87.5 percent of water to prepare a cellulose solution with concentration of between 2 and 12 percent through filtering and defoaming; spinning the cellulose solution through a spinning machine, and presolidifying and predrafting the cellulose solution in a first solidifying bath; sufficiently solidifying, regenerating, drafting and orientating the cellulose in a second solidifying bath; washing and drying cellulose; and finally, oiling the fiber through a prepared composite oil solution, and winding the fiber to obtain the regenerated cellulose fiber with excellent mechanical performance.

Owner:DONGHUA UNIV

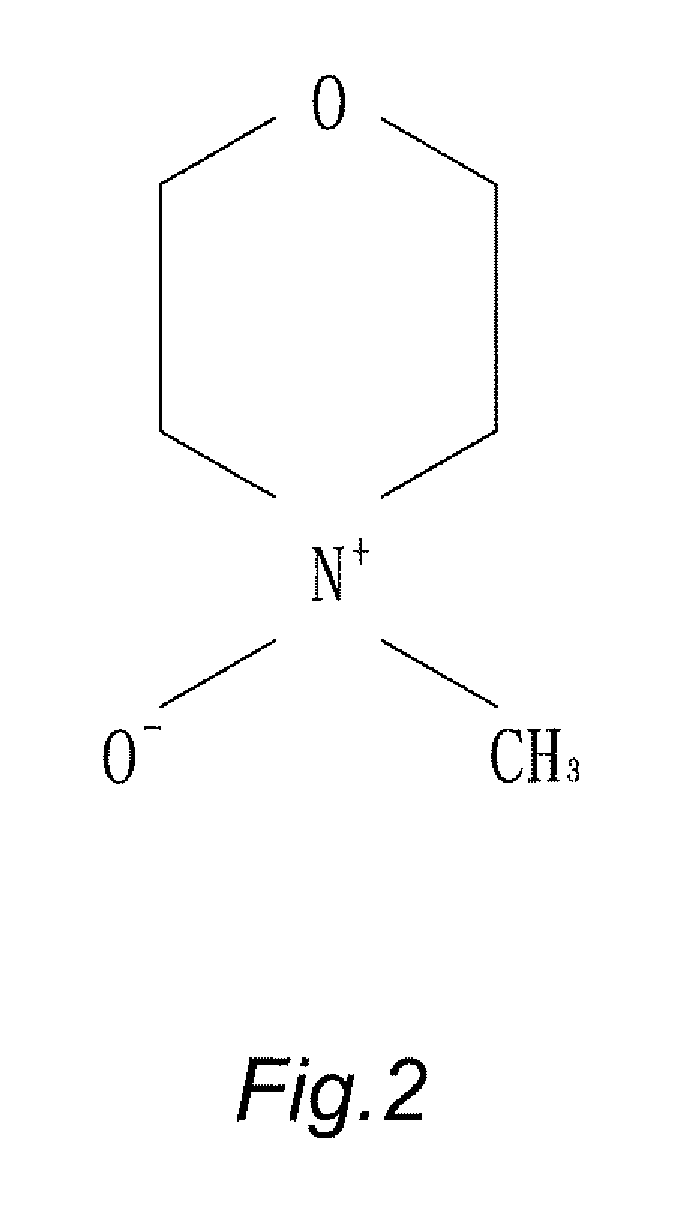

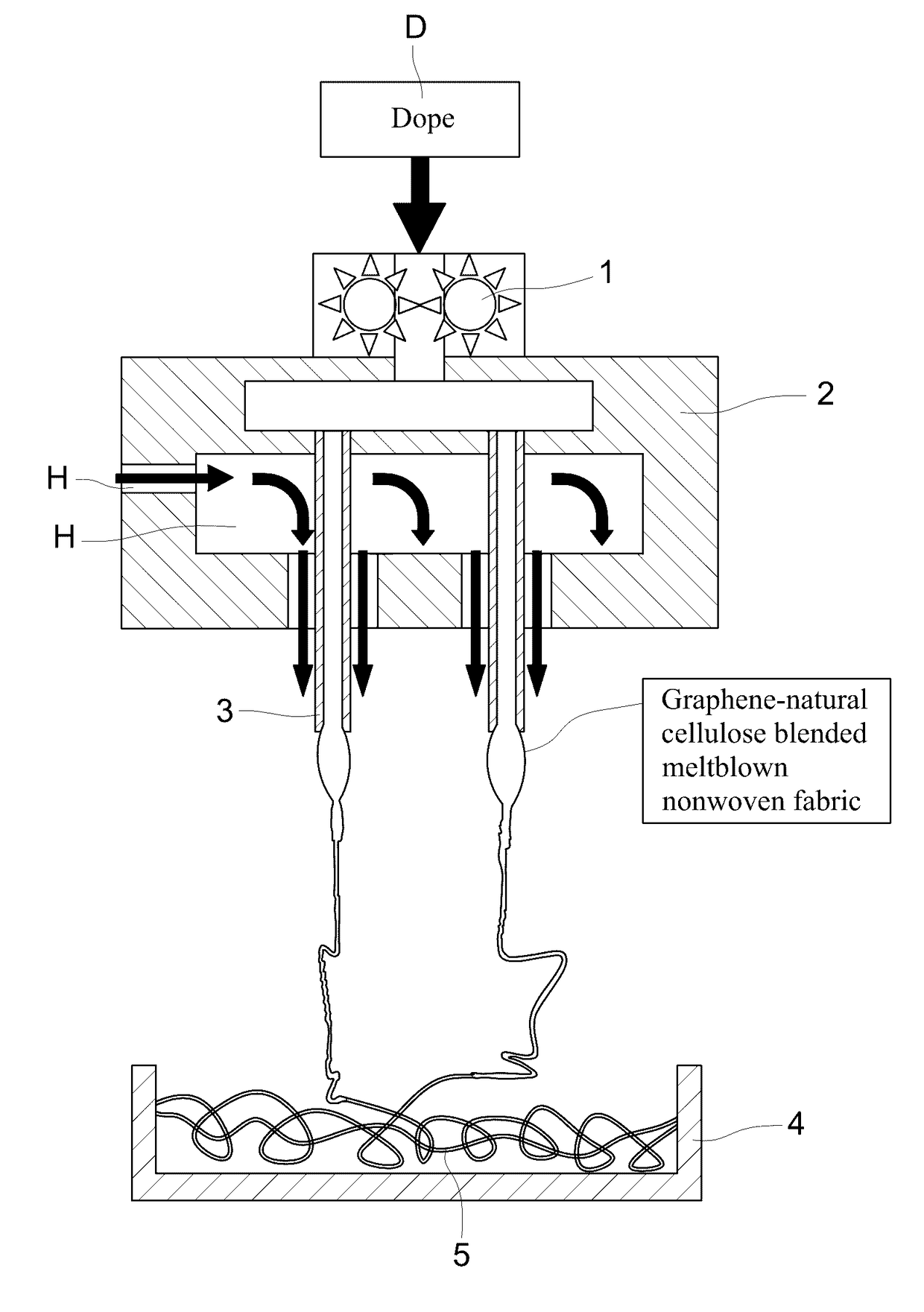

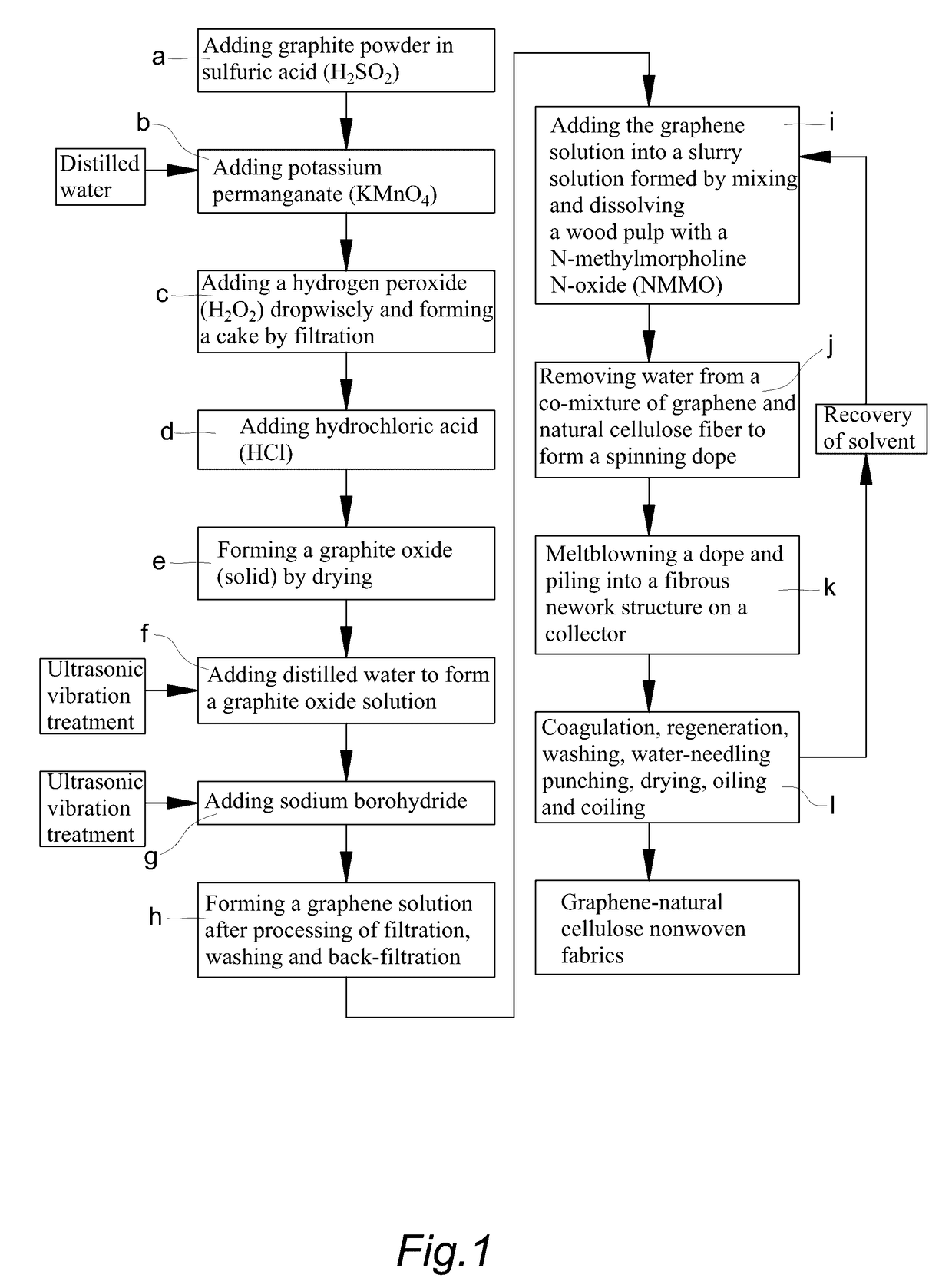

Method of Preparing of Natural Graphene Cellulose Blended Meltblown Nonwoven Fabric

ActiveUS20170107650A1Avoiding health hazard associated with solutionAltered propertyArtificial filament recoveryGraphitePresent methodSlurry

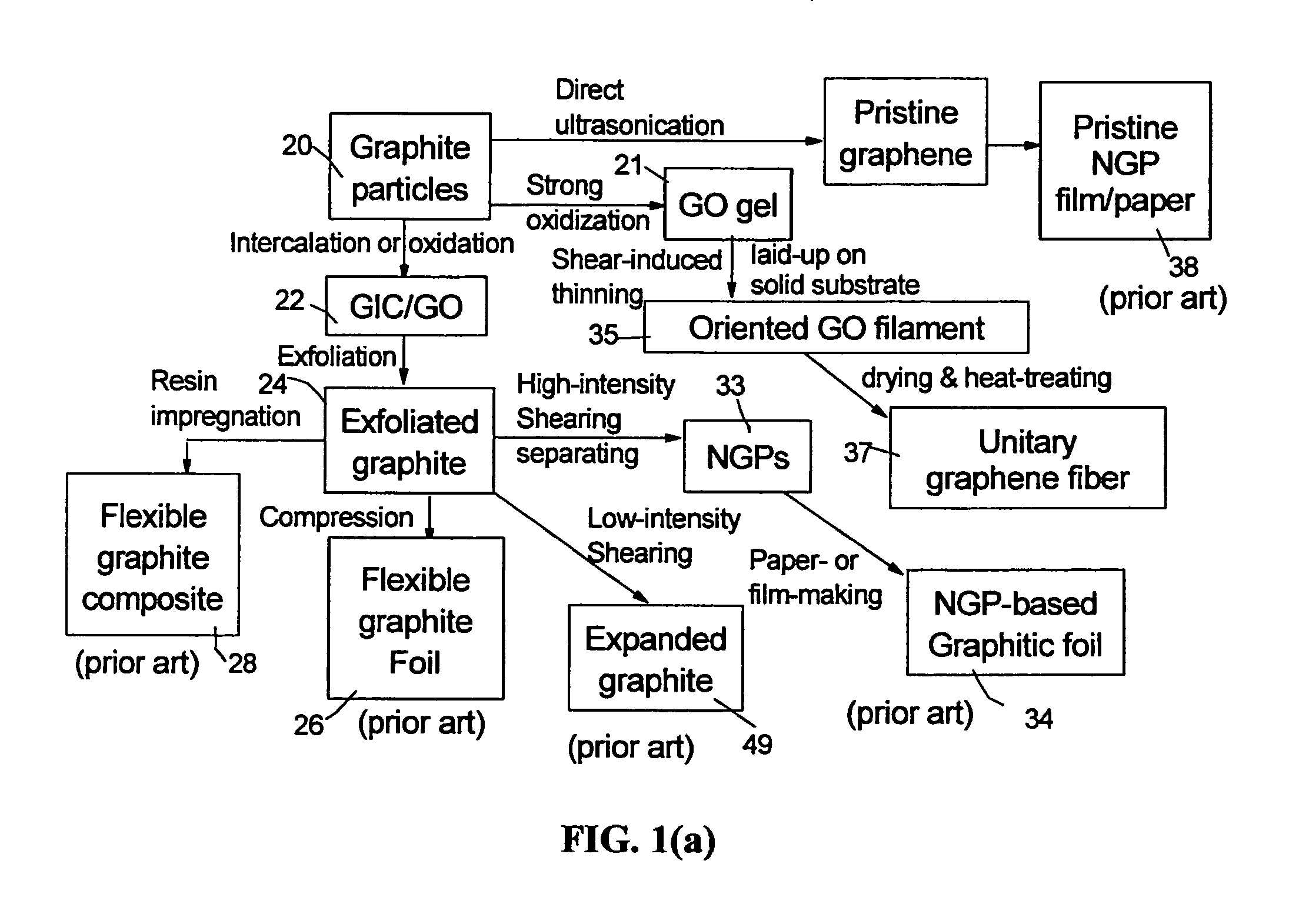

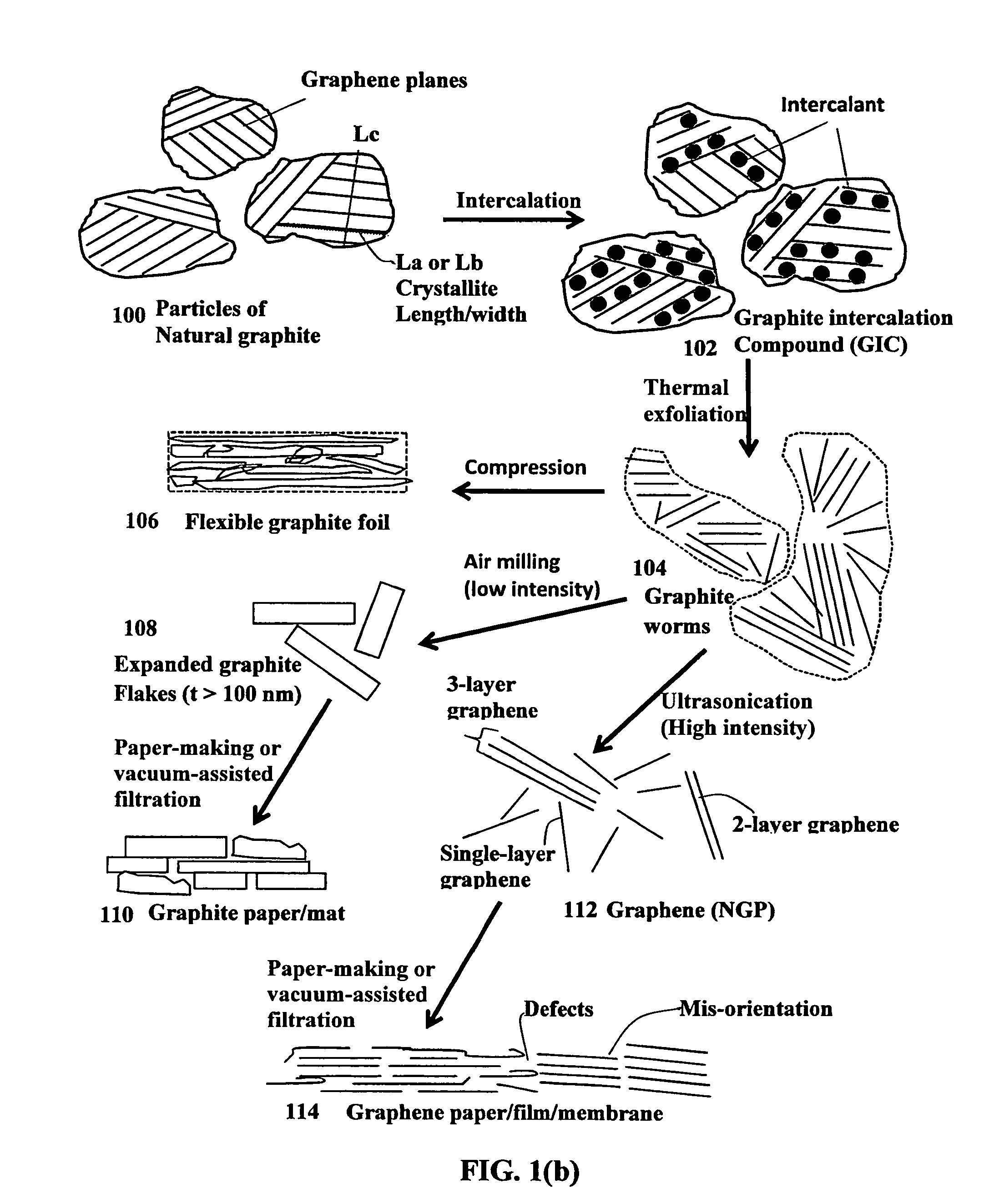

This application describes a method of preparation of a natural graphene cellulose blended meltblown nonwoven fabric, which comprises using a graphite powder as a raw material for preparing a graphene solution, adding the graphene solution to a slurry formed by mixing and dissolving a wood pulp with N-methylmorpholine N-oxide (NMMO), removing the water content thereof to form a spinning dope, and then directly preparing the natural graphene cellulose blended meltblown nonwoven fabric by a meltblown process. The present method does not require a highly toxic hydrazine hydrate solution. Further, by increasing the adding ratio of the graphene solution in the manufacturing process, control of the antistatic properties and thermal transferring function can be achieved, and thereby various requirements of different consumers can be satisfied. Besides, the fabric can decompose naturally after being used, and thus the product is harmless, natural, and environmentally friendly.

Owner:LIN CHIH HSIN

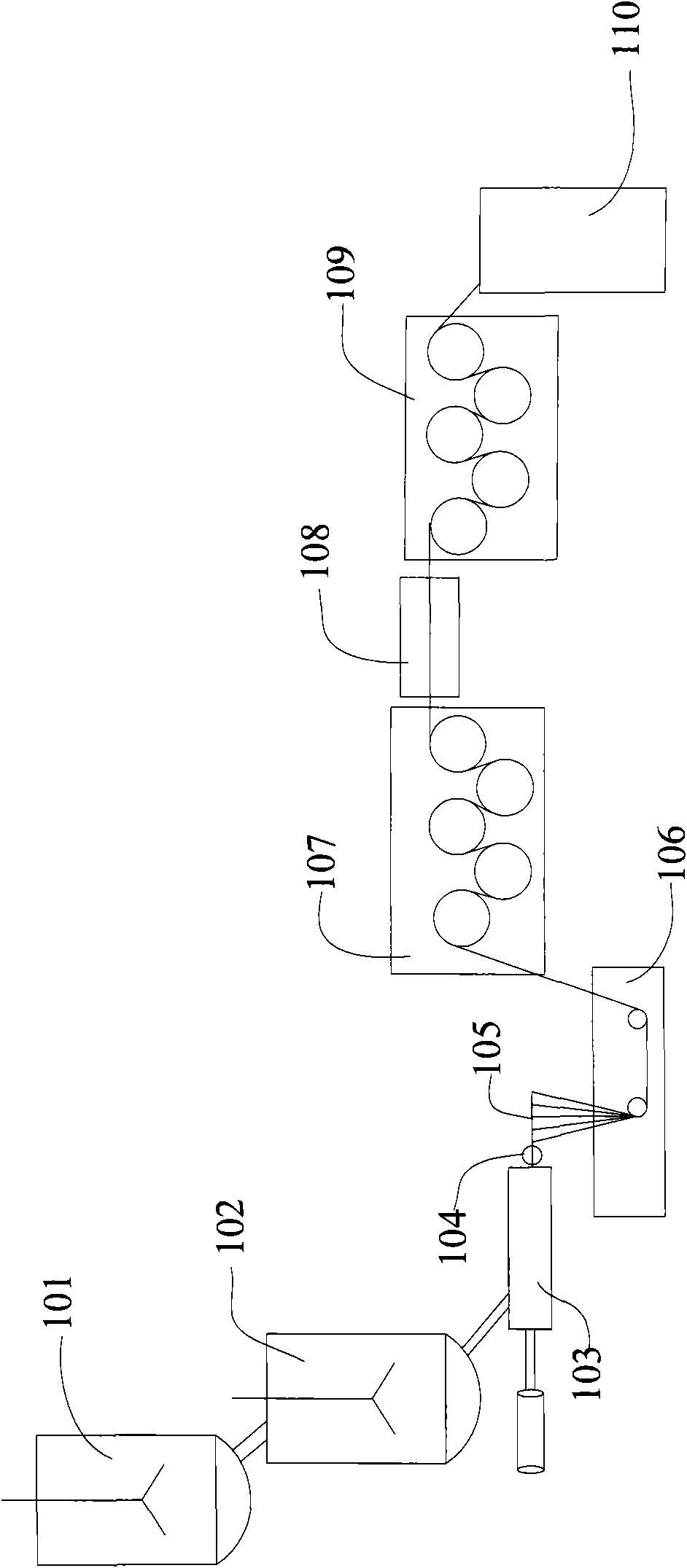

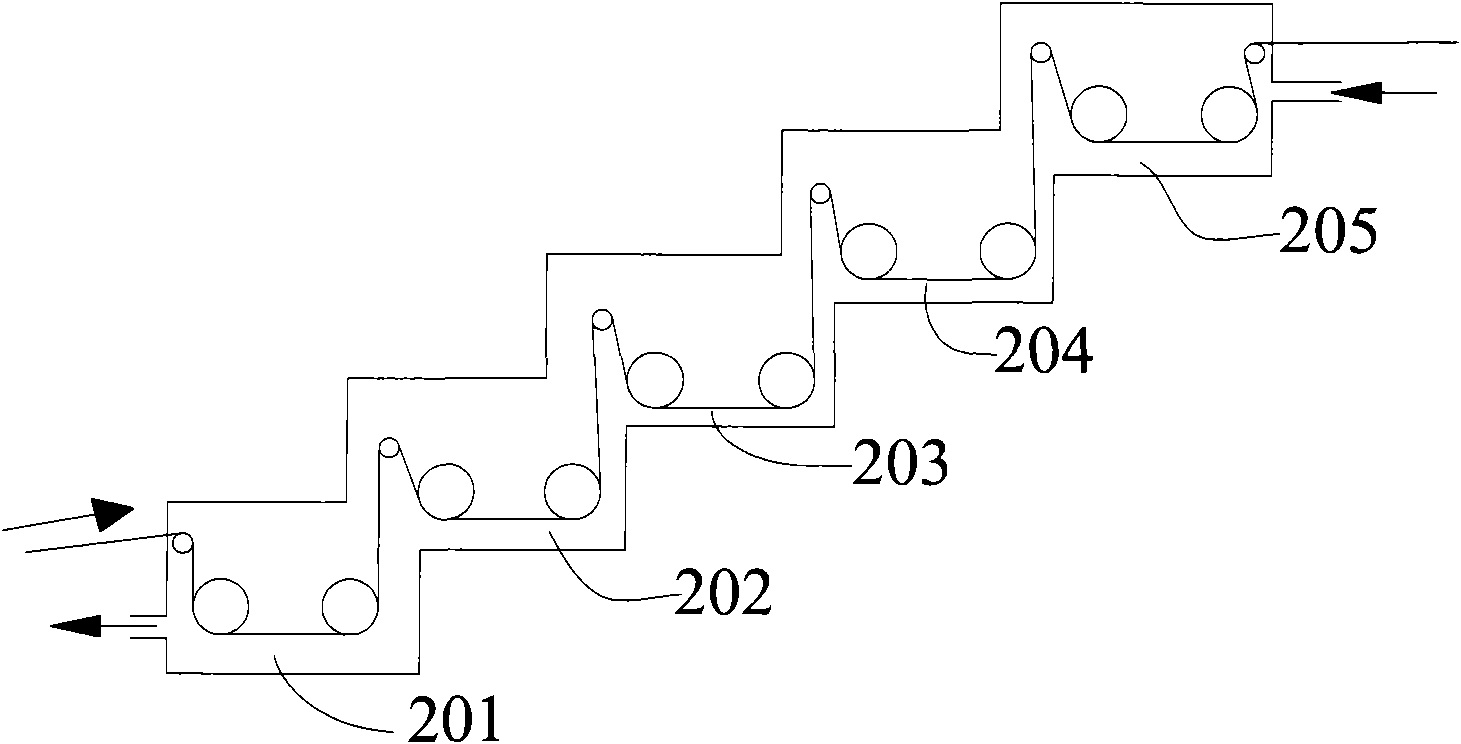

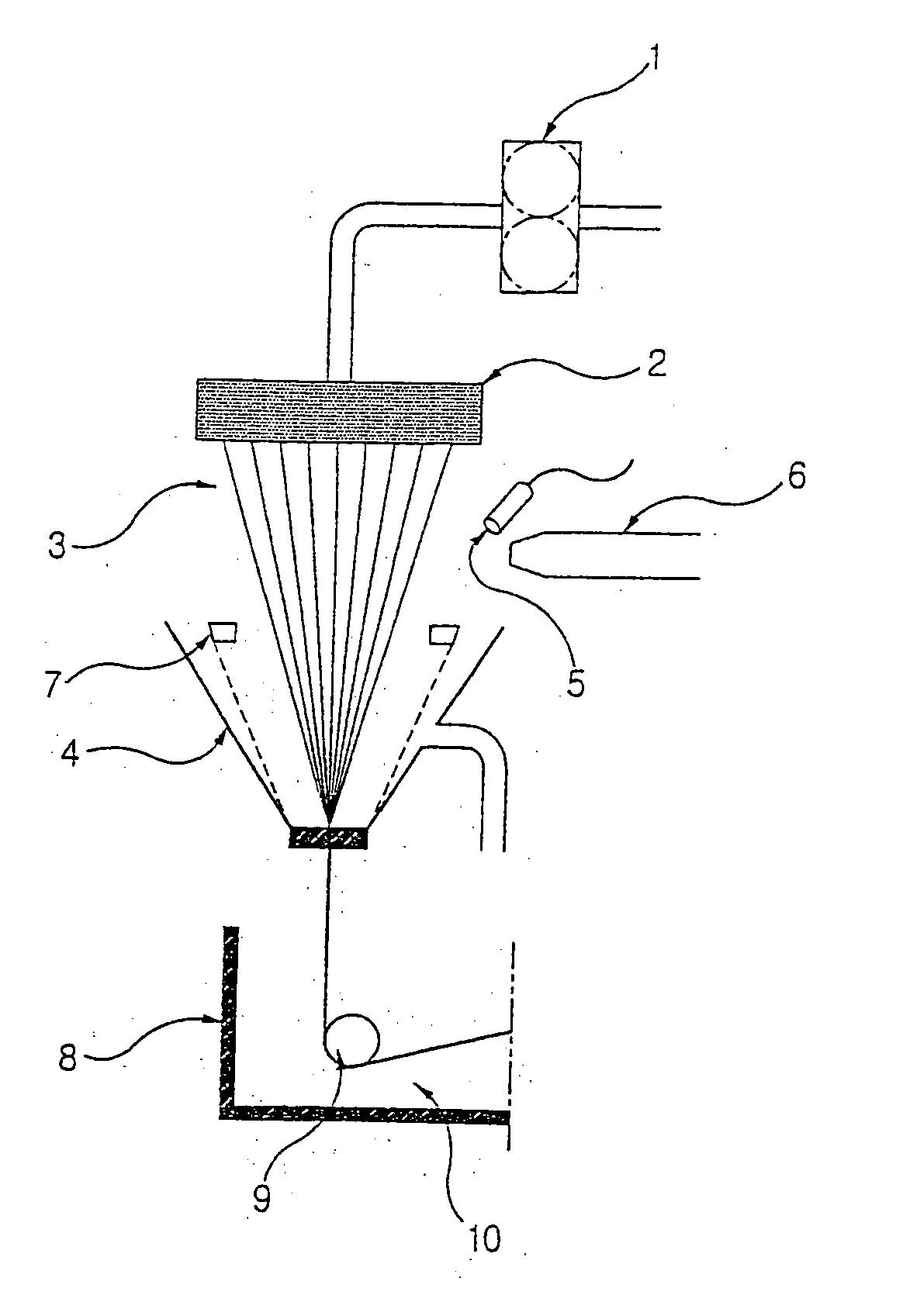

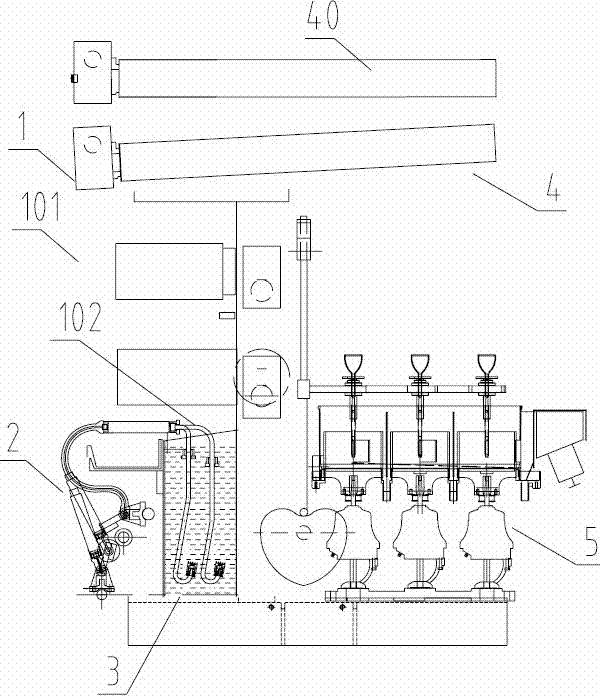

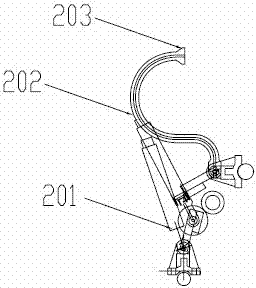

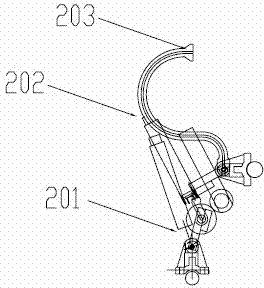

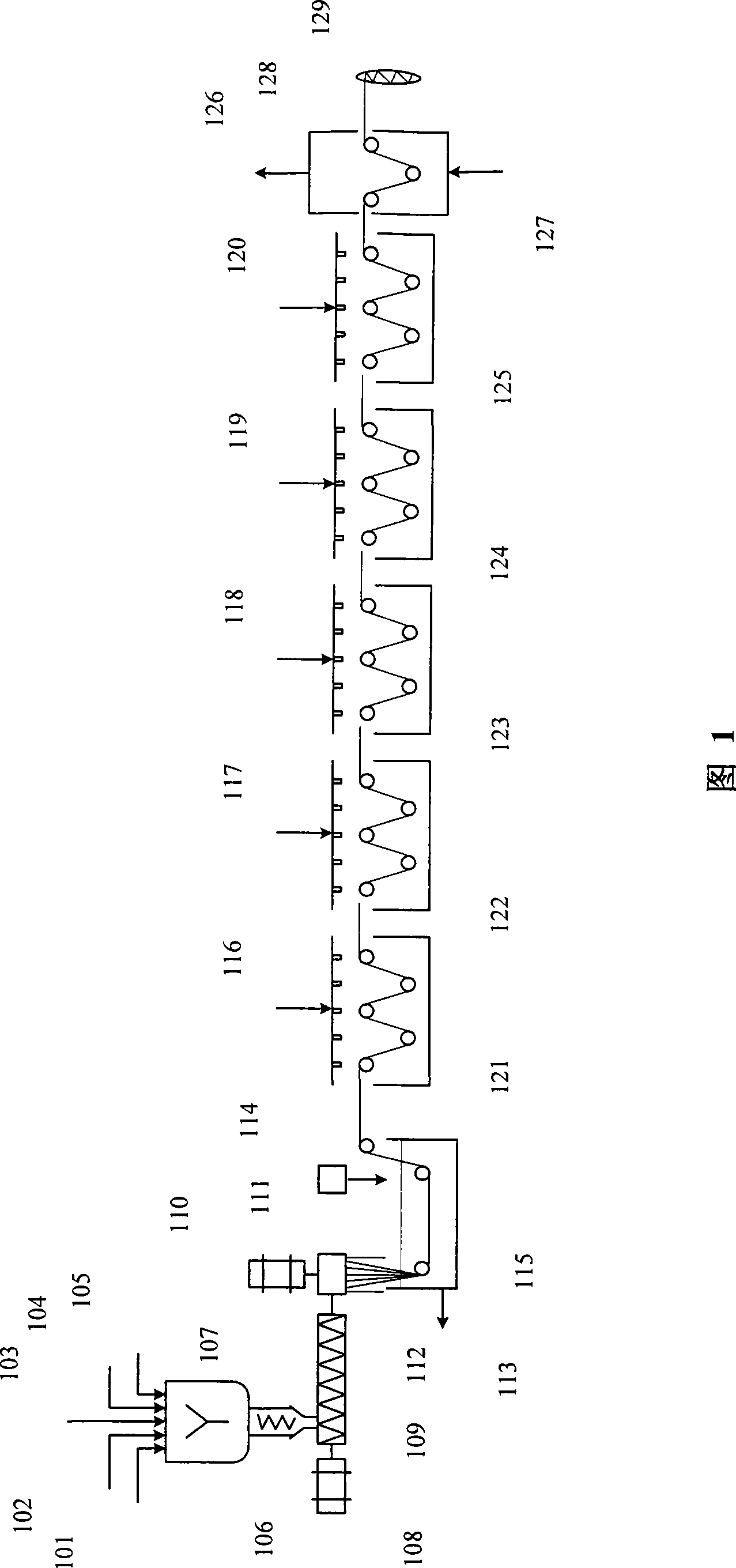

Semi-continuous high-speed spinning machine

ActiveCN103290501AEasy to operateControllableNew-spun product collectionArtificial thread manufacturing machinesEngineeringMechanical engineering

The invention relates to spinning equipment, in particular to a semi-continuous high-speed spinning machine. The semi-continuous high-speed spinning machine comprises a rack, a glue supply device, a strip forming device, a spinning device and a winding device, wherein a spinning roller of the spinning device is horizontally arranged relative to an operating surface of a spinning surface. The operating surface of the spinning surface is a horizontal working surface in a spinning surface area, and the fact that the spinning roller is horizontally arranged relative to the operating surface of the spinning surface refers to that the spinning roller is horizontally installed relative to spinning workers when the spinning workers face towards the winding device. According to the semi-continuous high-speed spinning machine, the spinning roller is horizontally arranged relative to the operating surface of the spinning surface, and two ends of the horizontally arranged spinning roller are fixed, so that the spinning speed can be increased on the basis of the semi-continuous high-speed spinning machine, the spinning roller is ensured to rotate stably without shaking, and the problems of intertwining and breakage of strips caused by shaking of the spinning roller during spinning are solved.

Owner:YIBIN HIEST FIBER +2

Method for preparing water soluble polyvinyl alcohol fiber through melt spinning

InactiveCN103409837AMelt spinningReduce pollutionArtificial filament washing/dryingArtificial filament heat treatmentSolubilityDecomposition

The invention relates to a method for preparing water soluble polyvinyl alcohol fiber through melt spinning. The method comprises the following steps: adding polyvinyl alcohol into a composite plasticizer, and mixing for 0.5-24 h at the temperature of 0-120 DEG C; performing melt spinning to obtain polyvinyl alcohol nascent fiber; stretching, shaping and drying to obtain the water soluble polyvinyl alcohol fiber. According to the invention, the fusing point of modified polyvinyl alcohol is reduced to the decomposition temperature below to realize the melt spinning of the water soluble polyvinyl alcohol fiber, and the plasticizer is not needed to be removed; besides, the environmental pollution is eliminated, the production efficiency is improved, and the water-solubility of the water soluble polyvinyl alcohol fiber is superior to that of the traditional polyvinyl alcohol fiber.

Owner:DONGHUA UNIV

Preparation method of chitosan fiber

InactiveCN101550610AMild reaction conditionsSimple and fast operationSpinnerette packsArtificial filament washing/dryingIonSolvent

The invention relates to a preparation method of chitosan fiber, which conquers the defects of highly volatile of solvent, difficult recovery, serious pollution and large treatment amount of three-wastes in preparing the chitosan fiber. 0.5-20% mass% of ion liquid aqueous solution is used as solvent and the quantitative chitosan powder is slowly added into the solvent at normal temperature and pressure, the mixture is stirred up for 2-48h to make the chitosan completely dissolve and then subjected to twice extrusion and filter through a filter cloth of 400-800 mesh and deaeration using a high-speed centrifuge or decompression, finally the 3-7.5% of homogeneous transparent chitosan spinning fluid with moderate viscosity. The spinning machine is used for simulating the spinning and the extruded thread processed by the coagulating bath, the draw bath, water washing and drying, finally the chitosan fiber is obtained.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing polybenzazole fiber

InactiveCN101423986AEliminate oxidationHelp to closeArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a method for preparing poly (p-phenylene) bis (benzoxazolyl) fibers, which belongs to the technical field of preparation of polymer materials. The method comprises the following steps: firstly, composite salt is prepared by diamino hydroxyphenol hydrochloride and a terephthalic acid, and phosphorus pentoxide, a polyphosphoric acid and an auxiliary agent are added into the composite salt, and subjected to prepolymerization under the condition of stirring and heating; secondly, a polymer reaction mixture after prepolymerization is over enters a screw extruder for further polymerization under the pressure of high-pressure inert gas or under the actuation of mechanical propulsion; thirdly, the polymer reaction mixture is extruded by the screw extruder, filtered, accurately measured, ejected, and solidified and formed in a solidification liquid after passing through a section of spinning shaft of inert gas; and fourthly, the polymer reaction mixture is subjected to five procedures of a diluted phosphoric acid aqueous solution, water, hot water, an alkaline solution and purified water for cleaning and removal of a phosphoric acid, and dried, rolled and formed. The method completely removes the phosphoric acid; the process is tempered; drying under the condition of exertion of a tensile force helps to close fiber holes; and the products produced have high strength and modulus.

Owner:BEIJING TEX STRONG NEW MATERIAL DEV +1

Preparing method of high-strength regenerated cellulose fiber

InactiveCN106435799AGood physical and mechanical propertiesSimple processArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthPolymer science

The invention relates to a preparing method of a high-strength regenerated cellulose fiber. The preparing method of the high-strength regenerated cellulose fiber is characterized by comprising the steps of preparing cellulose sulphonate, preparing a spinning solution, spinning, conducting drafting and postprocessing. The preparing method is simple in technology and convenient to carry out. Compared with a traditional regenerated cellulose fiber, the high-strength regenerated cellulose fiber obtained through the preparing method is high in dry and wet strength and has a good spinning property; in addition, physical and mechanical properties of the fiber are excellent, the dry breaking strength is 3.40 CN / dtex or above, the dry elongation at break is 13-16%, the wet breaking strength is 2.0 CN / dtex or above, and the wet breakage modulus is 0.45 CN / dtex or above. The high-strength regenerated cellulose fiber can be applied to textile industries of textile and garment materials, underwear and the like.

Owner:山东银鹰化纤有限公司

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and application thereof

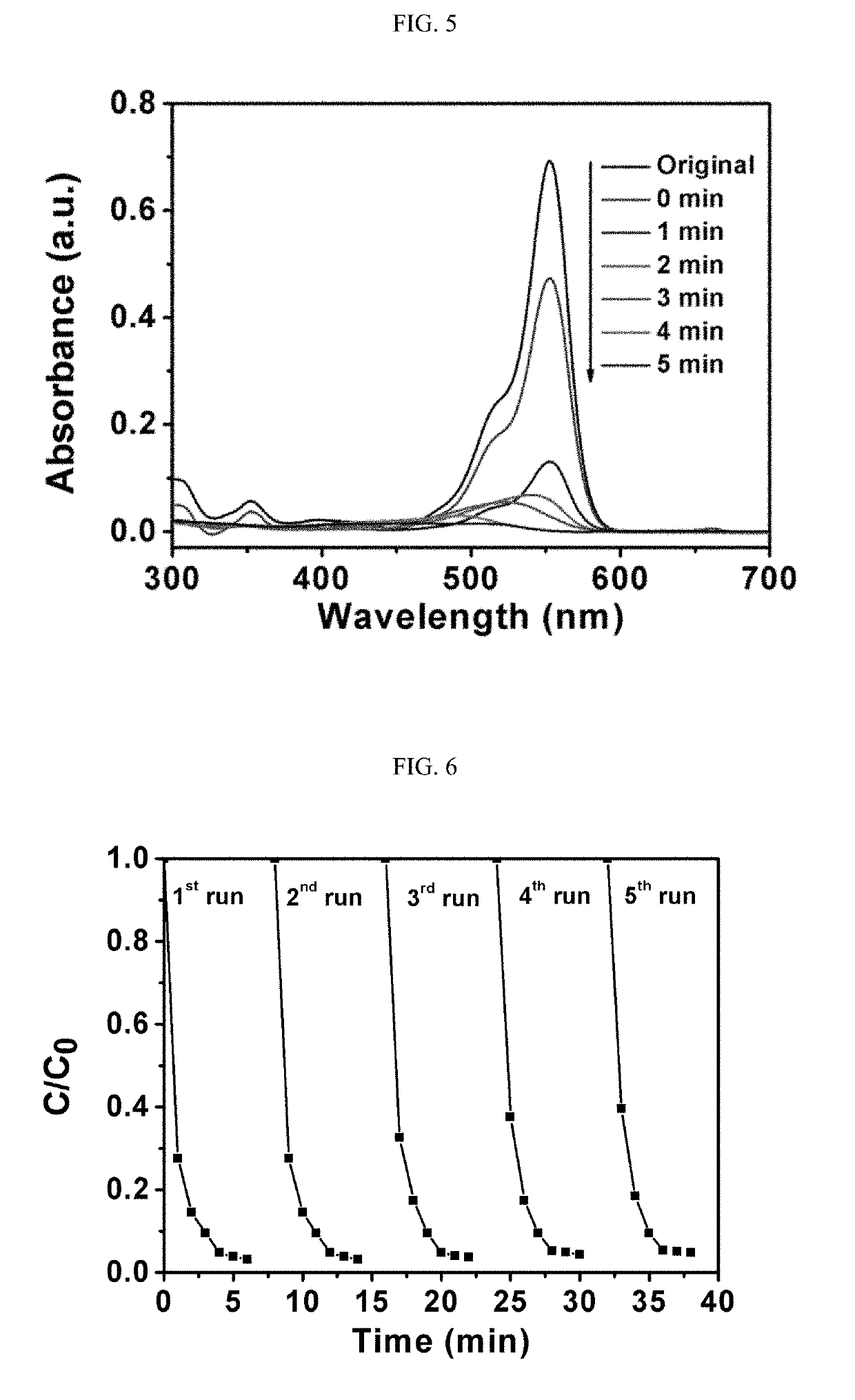

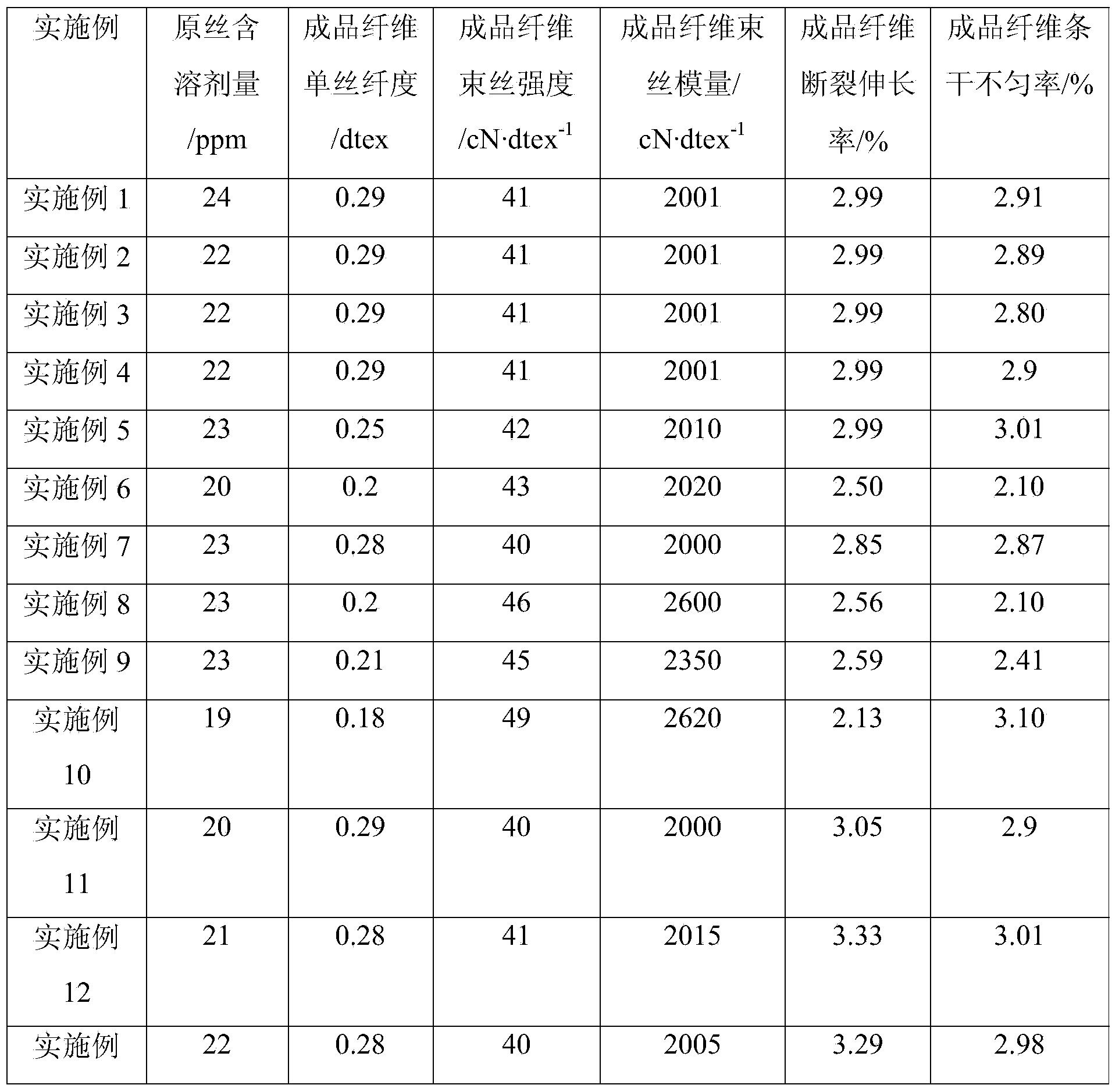

ActiveUS20190127883A1Low costEasy to operateFullerenesArtificial filament washing/dryingFiberSodium iodide

Iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites, preparation method and its application in wastewater treatment are disclosed. Bismuth citrate and sodium carbonate as precursors, sodium carbonate as a precipitating agent, dispersed in a mixed solution of water and ethylene glycol, sodium iodide as a iodine source, nano carbon fiber membrane act as the carrier, to synthesis carbon fiber membrane that modified by iodine-doped Bi2O2CO3 nanosheets; then sodium molybdate and thioacetamide as precursors, dispersed in water to react to obtain iodine doped bismuthyl carbonate nanosheet and molybdenum disulfide modified carbon nanofiber composites. The composite material synthesized through a series of steps exhibit excellent photocatalytic activity for the degradation of Rhodamine B and can be recycled for many times. And this invention has the advantages of simple preparation process, easy recovery and multiple use, etc., and has industrial application prospect in water pollution treatment.

Owner:SUZHOU UNIV

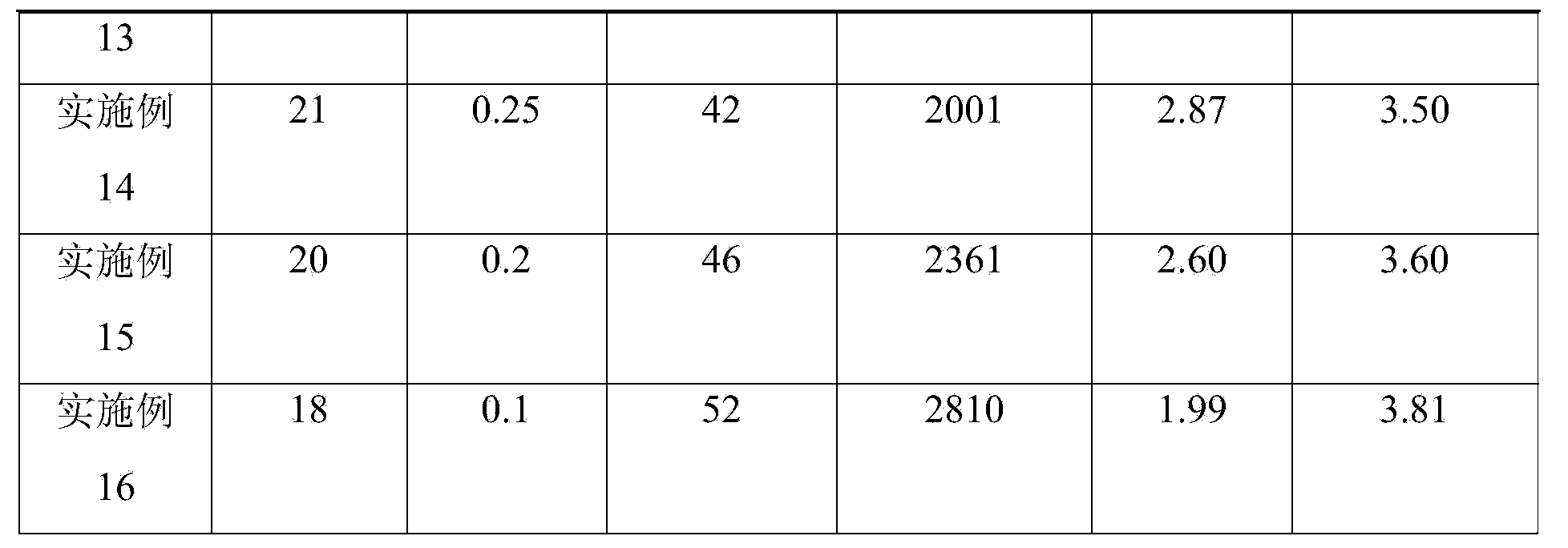

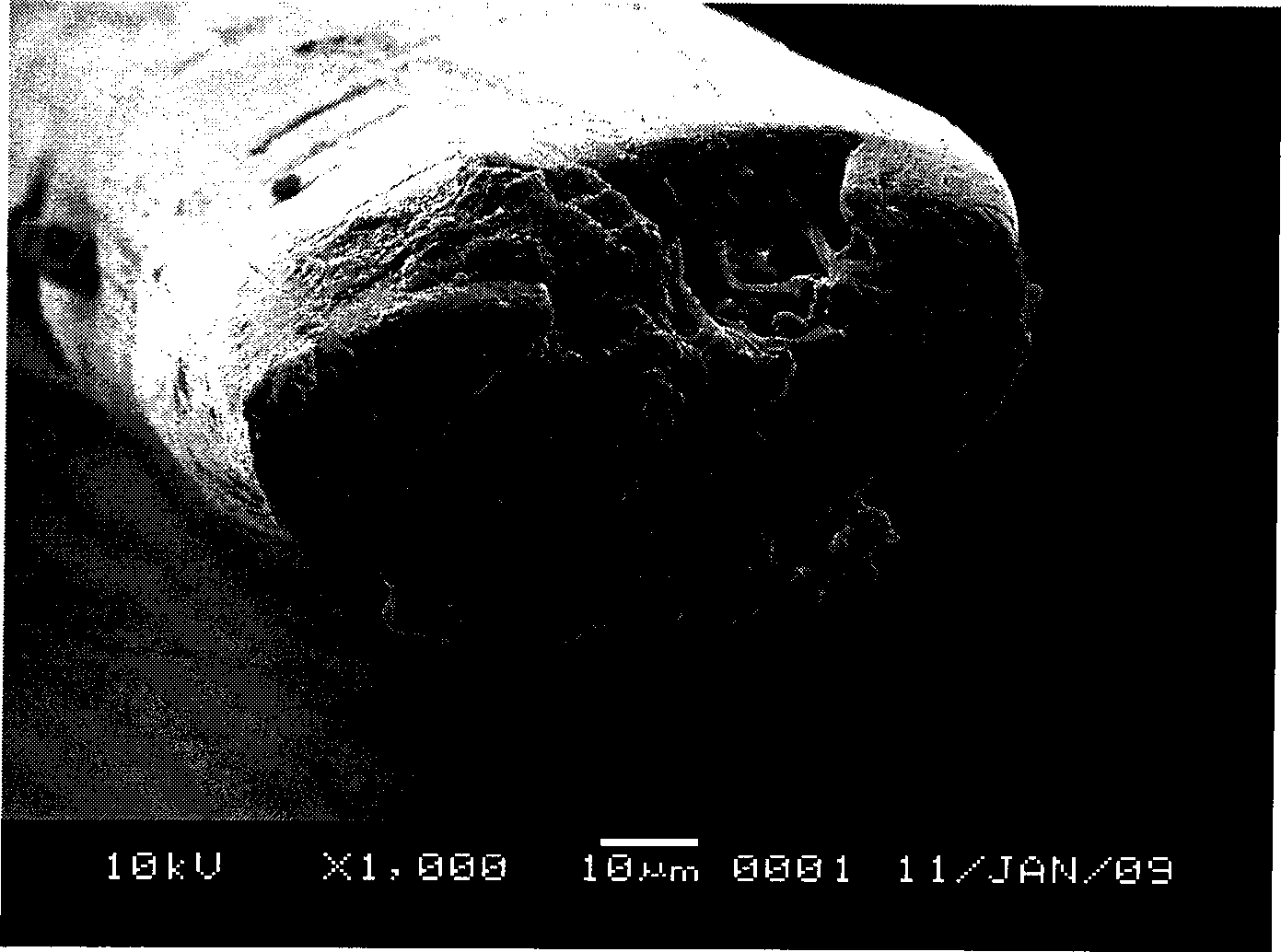

Method for preparing ultra-high molecular weight polyethylene fiber and fiber

ActiveCN104032402AIncrease stickinessImprove cohesionArtificial thread manufacturing machinesArtificial filament washing/dryingPolymer scienceGas phase

The invention discloses a method for preparing an ultra-high molecular weight polyethylene fiber. According to the method, an ultra-high molecular weight polyethylene decahydronaphthalene solution is extruded through a spinneret plate to form a spinning trickle flow; the spinning trickle flow sequentially passes through a gas-phase section, a liquid-phase section, a physical extrusion section, a drying heat tank section and the like to obtain raw filaments; meanwhile, thin spinning filaments exiting from the liquid-phase section have stretching stress, and the raw filaments are subjected to high-power thermal stretching to obtain the ultra-high molecular weight polyethylene fiber of which the single-filament fineness is lower than 0.3dtex. The breaking strength of fiber bundle filaments is not lower than 40cN.dtex<-1>, and the modulus is not lower than 2,000cN.dtex<-1>. The method has the characteristics that the production energy consumption is reduced; the energy is saved, the emission amount is reduced, and the production cost is low. The prepared ultra-high molecular weight polyethylene fiber has excellent quality and is used for preparing public safety protection articles, labor safety products and medical materials such as bulletproof and stab-resistant clothes, explosion-proof blankets, explosion-proof tanks, anti-puncturing shoes, anti-puncturing shoe soles and operation suture lines.

Owner:CHINESE TEXTILE ACAD

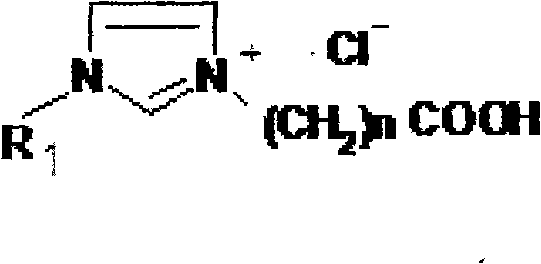

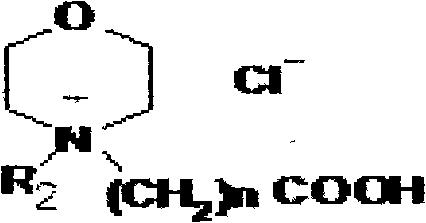

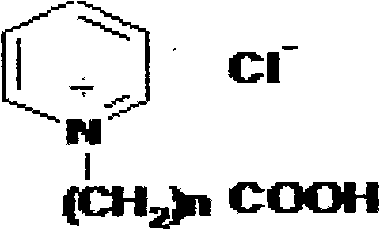

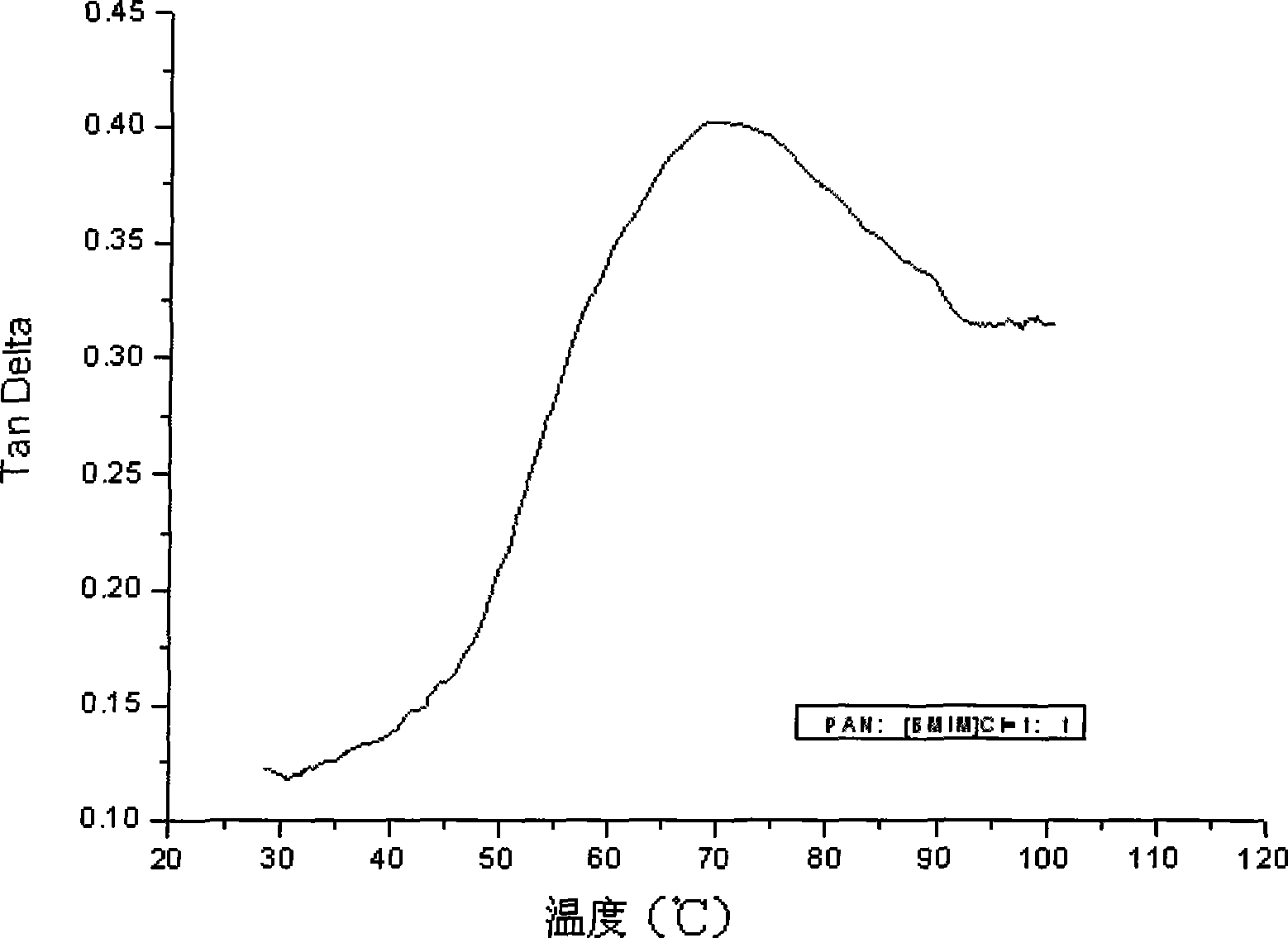

Method for melt spinning of polyacrylonitrile PAN by taking imidazole ionic fluid as plasticizing agent

InactiveCN101545148AReduce usageReduce consumptionArtificial filament washing/dryingArtificial filament heat treatmentWater bathsUltimate tensile strength

The invention relates to a method for melt spinning of polyacrylonitrile PAN by taking imidazole ionic fluid as a plasticizing agent. The method comprises the following steps: (1) evenly mixing polyacrylonitrile powder which is dried to an anhydrous state with ionic fluid; (2) adding the mixture into a hopper of a double-screw spinning machine, regulating the rotating speed of screws of between 40 and 120 revolutions / minute, setting the spinning temperature of between 170 and 220 DEG C, and carrying out melt spinning; directly carrying out dry heat stretching on filament which is spun by a spinneret plate without water bath with stretching temperature of between 80 and 180 DEG C and stretching times of between 1 and 8 times; and (3) washing the stretched fiber with water, and carrying out heat setting and winding on the fiber to obtain the polyacrylonitrile fiber. The method has low cost, reduces environmental pollution, and is applicable to industrial production; and the produced fiber can be subjected to super stretching, has a section without a cavity structure, and improves the strength.

Owner:DONGHUA UNIV

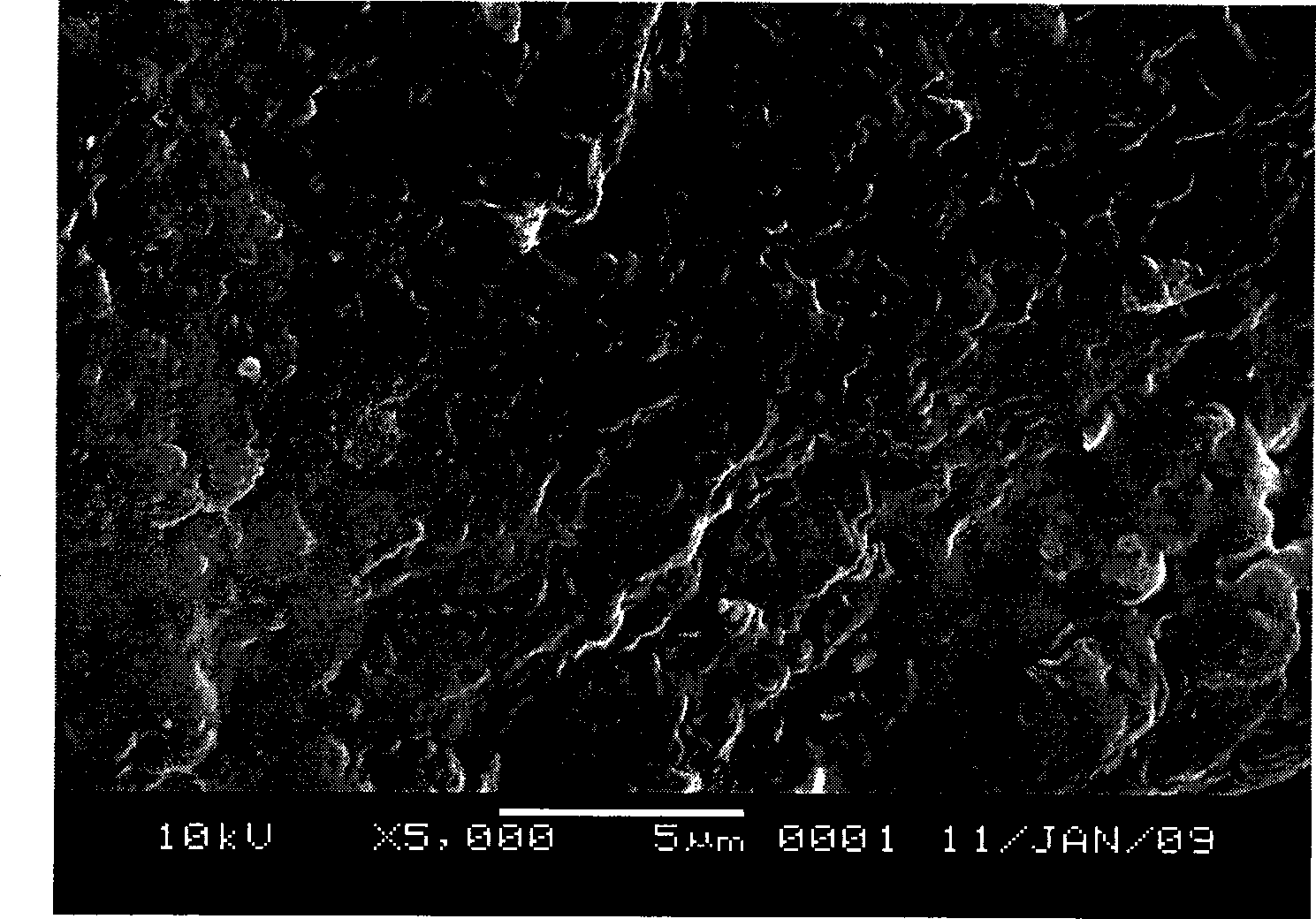

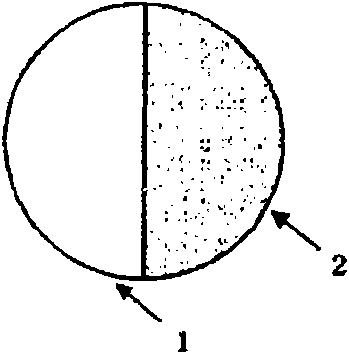

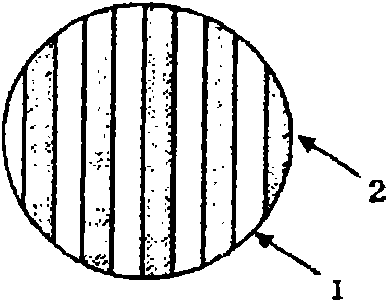

Splittable conjugate fiber, fiber structure using the same, and wiping cloth

A dividual conjugate fiber for obtaining a fiber structure excelling in denseness and bulkiness. The dividual conjugate fiber is one having a polyamide resin composition and a fiber forming polymer with no compatibility with the polyamide resin composition bonded together in the direction of fiber length, characterized in that the polyamide resin composition is composed of an aromatic polyamide and an aliphatic polyamide. Preferably, the aromatic polyamide is a nylon MXD6 polymer, and the aliphatic polyamide is a nylon 6 polymer.

Owner:SEIREN CO LTD

High-strength and high-modulus polyvinyl alcohol fiber and melt spinning method of high-strength and high-modulus polyvinyl alcohol fiber

InactiveCN102776597AHigh strengthMeet toughnessFilament forming substance formingArtificial filament washing/dryingAlcoholPolymer science

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

Preparation method of polyacrylonitrile-based carbon fiber precursor

ActiveCN104562265AArtificial thread manufacturing machinesArtificial filament washing/dryingCarbon fibersItaconic acid

The invention relates to a preparation method of a polyacrylonitrile-based carbon fiber precursor, and mainly aims at solving the problems that a carbon fiber spinning solution prepared from azobisisoheptonitrile as an initiator in the prior art is over-large in viscosity, and poor in spinnability, and the carbon fiber precursor obtained by spinning is low in strength and unstable in property. Through the technical scheme, the preparation method of the polyacrylonitrile-based carbon fiber precursor comprises the following steps: by taking azobisisoheptonitrile as an initiator, polymerizing a first monomer acrylonitrile and a second monomer itaconic acid through initation of a solvent dimethyl sulfoxide to obtain the spinning solution; carrying out vacuum removal on residual monomer and bubbles from the spinning solution; filtering to obtain a high-property polyacrylonitrile copolymer spinning solution; and carrying out solidifying, drafting, washing, oiling, compacting by drying, steam drafting and steam heat setting on the spinning solution, and then rolling to obtain the carbon fiber precursor with high compactness and high strength, the problems are relatively well solved, and the method can be applied to industrial production of the carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com