Graphene fiber and preparation method thereof

A graphene fiber and graphene technology, applied in the field of fiber materials, can solve structural conductive defects, limit the conductive properties of graphene fibers, etc., and achieve the effect of reducing resistance and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

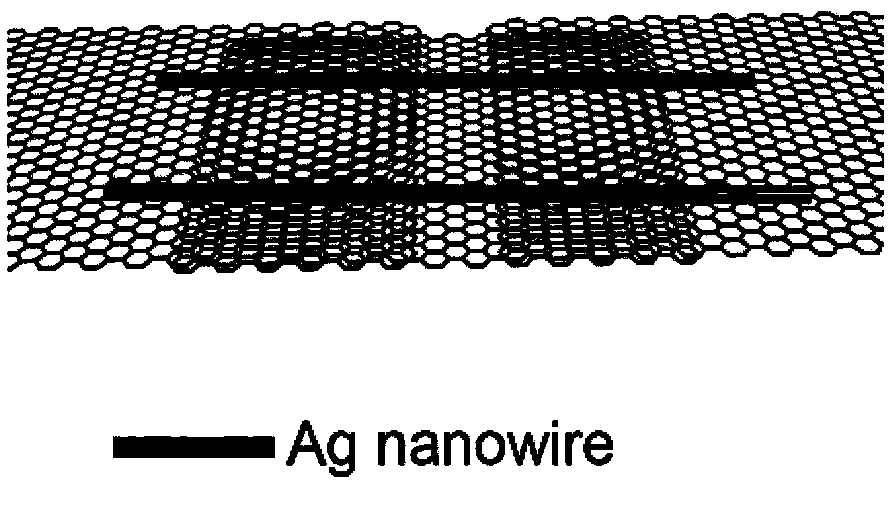

[0013] Such as figure 1 As shown, the graphene fiber provided in Embodiment 1 of the present invention is a composite fiber in which metal nanowires are doped with graphene fibers. The main components of the composite fiber are graphene and metal nanowires, wherein the mass of metal nanowires is When the ratio is 0.1% to 50%, the graphene is in a sheet state, and the metal nanowires and the graphene sheet are arranged parallel to the axis of the graphene fiber at the same time.

[0014] Scanning electron microscope image of the surface of graphene fiber doped by metal nanowires figure 1 As shown, the metal nanowires in the graphene fiber lead to the arrangement; the scanning electron micrograph of the surface of the graphene fiber doped by metal nanowires figure 2 As shown, the graphene is distributed in sheets and parallel to each other. The spots pointed by the arrows are the end faces of the metal nanowires. It can be seen that the metal nanowires are arranged vertically ...

Embodiment 2

[0024] Embodiment 2 of the present invention provides a method for preparing graphene fibers. The method mainly prepares graphene oxide through an oxidation method, disperses graphene oxide in a solvent to prepare graphene oxide liquid crystals, and adds metal nanowires to graphene oxide. After the graphene oxide-metal nanowire spinning liquid sol is prepared in the liquid crystal, wet spinning is carried out, and the obtained metal nanowire-doped graphene oxide fiber is reduced to obtain the metal nanowire-doped graphene fiber, wherein the specific steps include :

[0025] Step 201, adding metal nanowires with a mass fraction of 0.1 to 50% in the graphene oxide liquid crystal with a mass concentration of 0.3% to 3%, stirring evenly at a stirring speed of 100 to 1000rpm to form graphene oxide-metal nanowire spinning lyosol;

[0026] Step 202: Take the graphene oxide-metal nanowire spinning solution sol obtained in step 201, pass it through a spinning tube with a diameter of 5...

Embodiment 3

[0038] The preparation method of a graphene fiber provided by Embodiment 3 of the present invention is similar to the method of Embodiment 2, the difference is only in the graphene oxide liquid crystal concentration, graphene oxide liquid crystal solvent, metal nano The types of wires, the mass percentage of metal nanowires, and the reduction process are different, and specifically include the following steps:

[0039] Step 301, adding silver nanowires with a mass fraction of 0.5% to the graphene oxide liquid crystal aqueous dispersion with a mass concentration of 0.3%, and stirring at a stirring speed of 100 rpm to form a graphene oxide-silver nanowire spinning liquid sol;

[0040] Step 302, take the graphene oxide-silver nanowire spinning solution sol obtained in step 301, pass it through a spinning tube with a diameter of 30 μm at an extrusion speed of 1 mL / h, and stay in a 5 wt% calcium chloride aqueous solution at 5°C 100s solidified into silk, washed and dried to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com