Patents

Literature

2153results about How to "Orderly rows" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

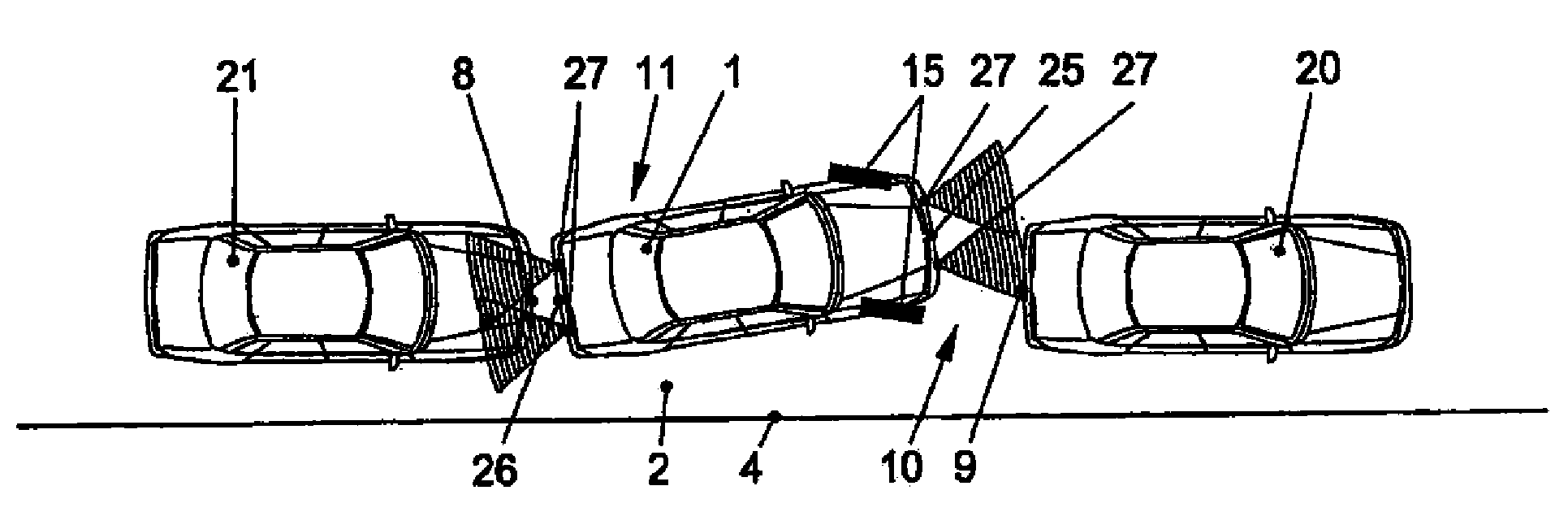

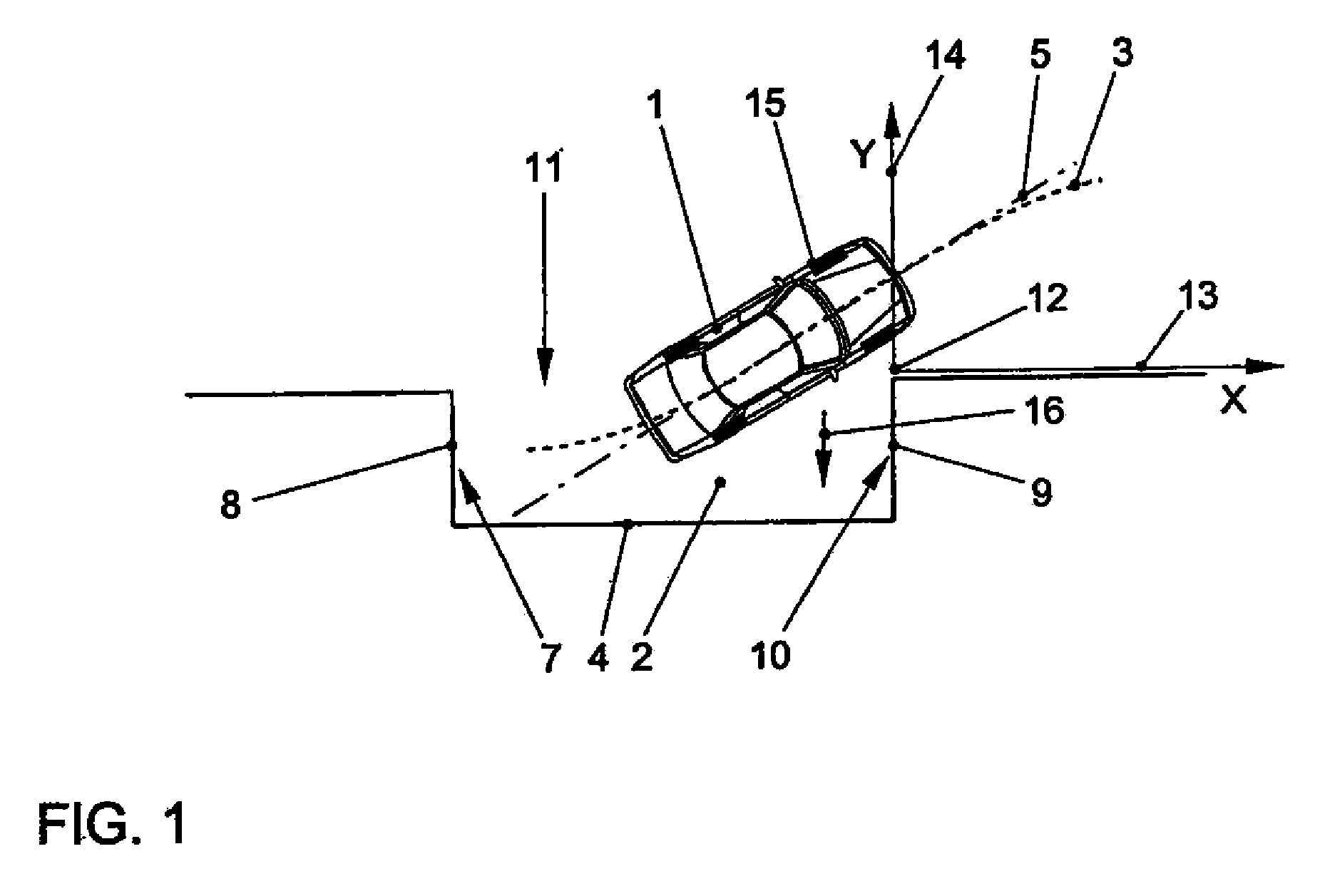

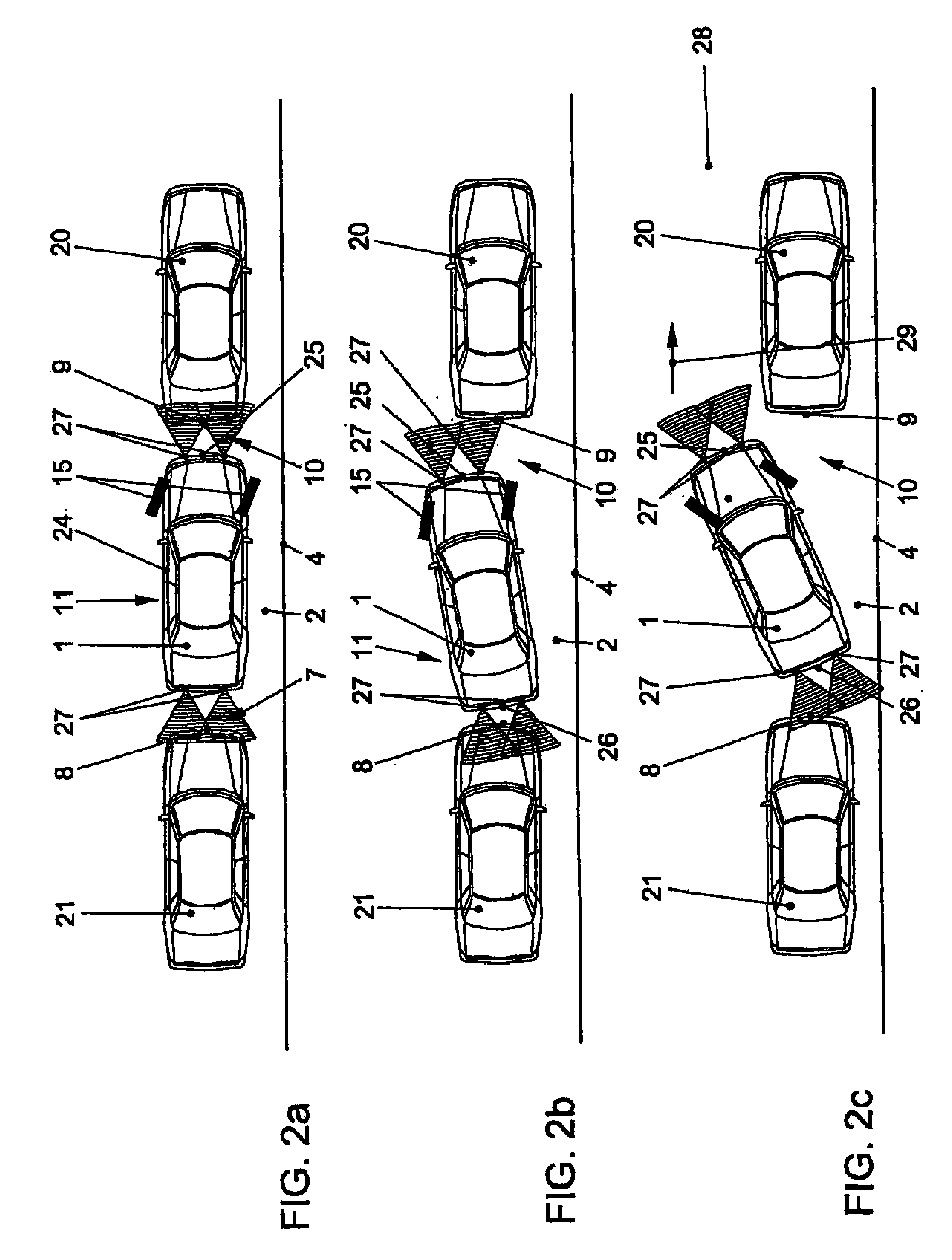

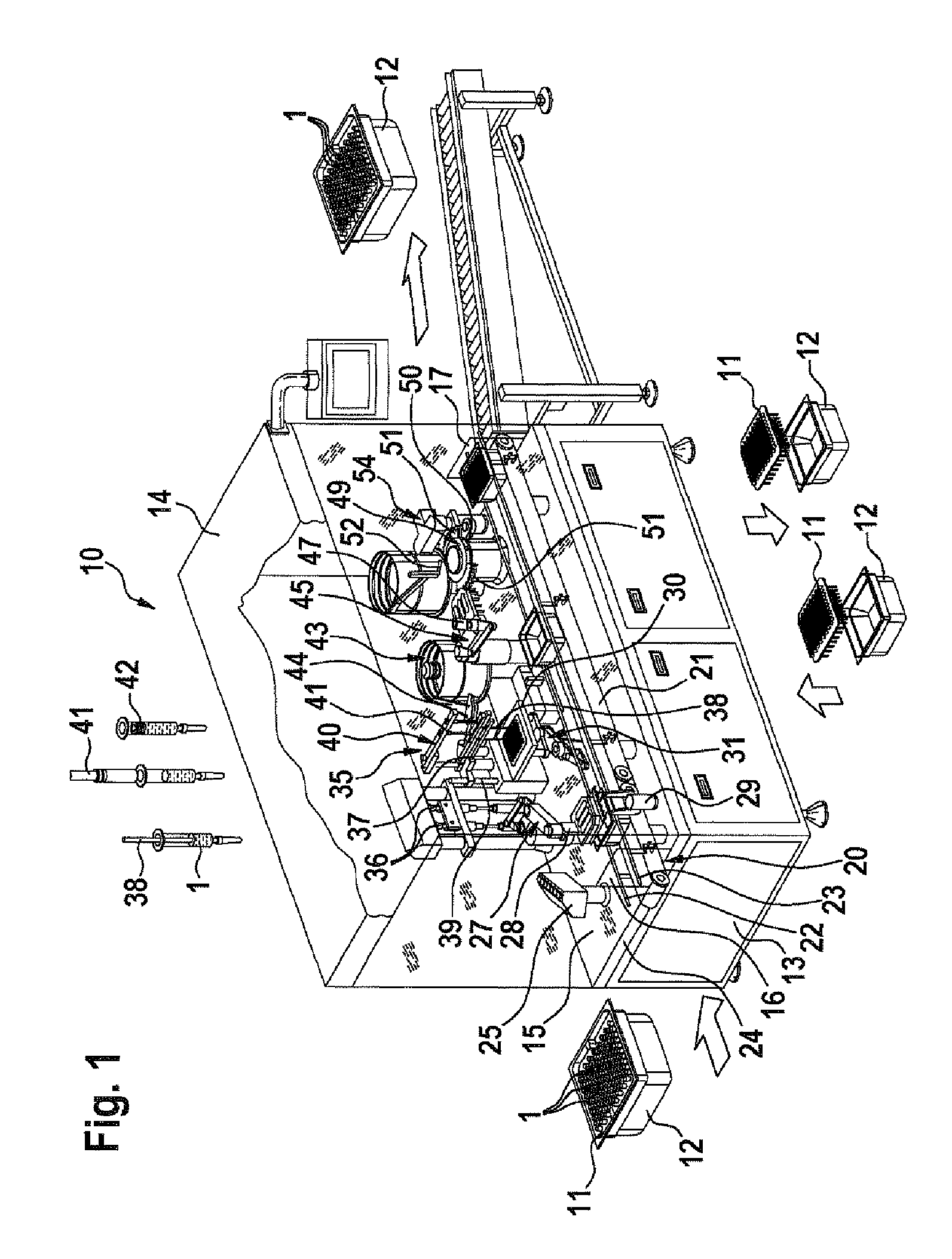

Park-steer assist system and method for operating a park-steer assist system

ActiveUS20090259365A1Orderly rowsEasy to driveSteering initiationsDigital data processing detailsMobile vehicleSemi automatic

The method relates to an operating method for a semi-automatic park-steer assist system (30) and to a semi-automatic park-steer assist system (30) of a motor vehicle (1) for aiding in an alignment of the motor vehicle (1) in a parking space (2), including means (42) for detecting an activation signal; means (47) for determining a change direction in which an alignment of the motor vehicle (1) is to be changed; means (50) for detecting a set drive direction; and a control unit (40) which controls at least one actuator (38) in an active state of the park-steer assist system (30) in such a way that steerable wheels (15) of the motor vehicle (1) are turned in the change direction when the set drive direction is forward, and the steerable wheels (15) are maximally turned counter to the change direction when the set drive direction is reverse.

Owner:VOLKSWAGEN AG

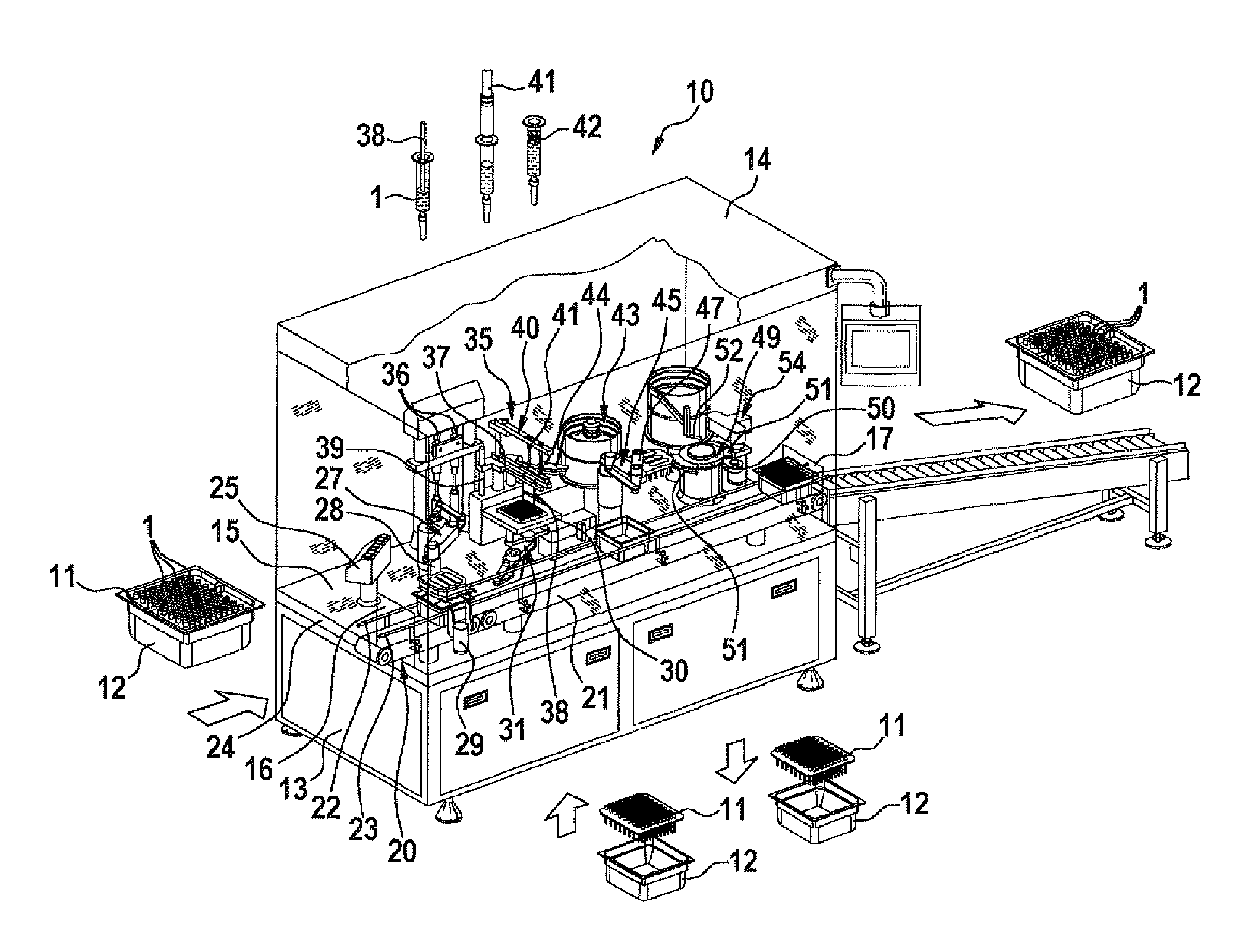

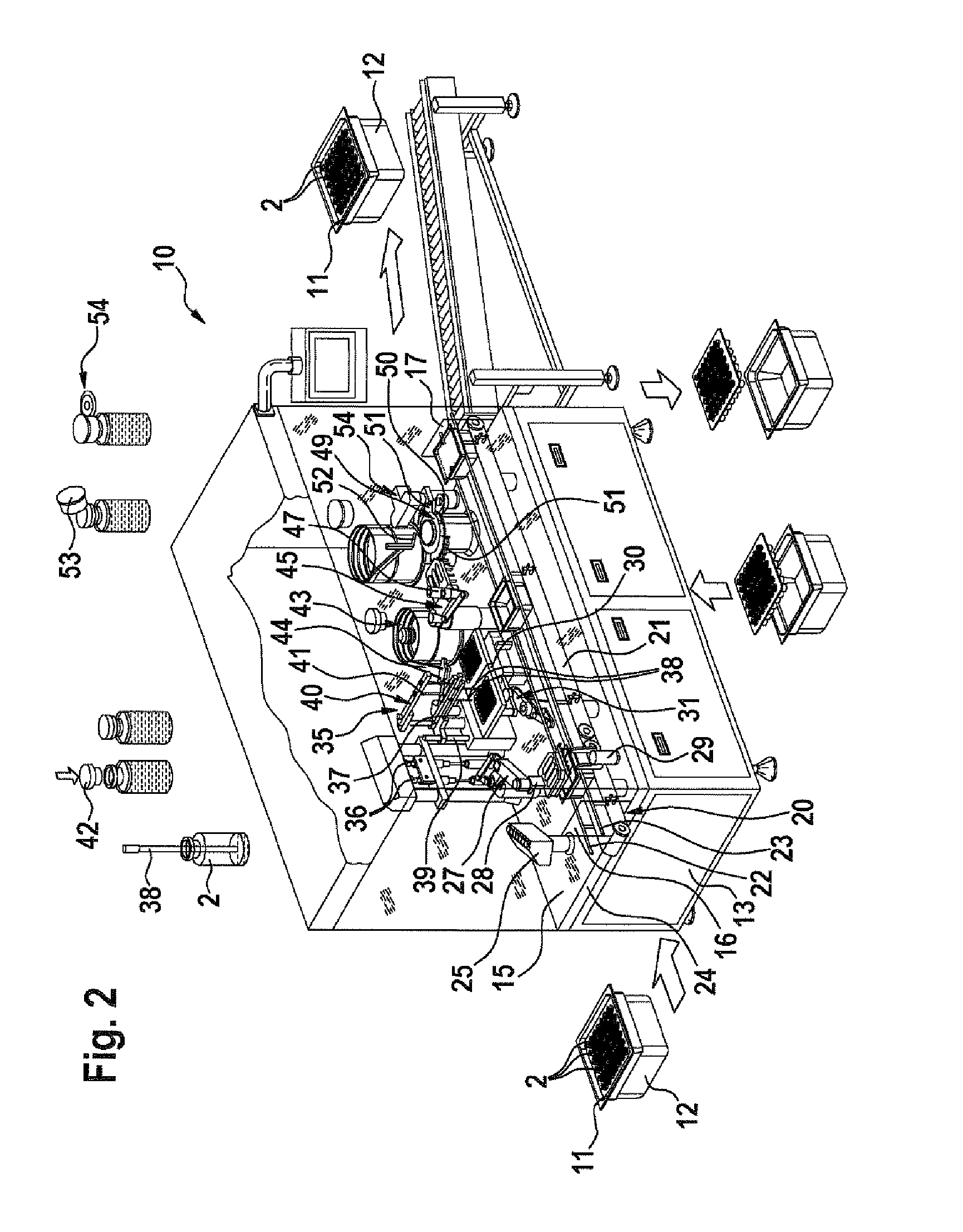

Device for filling and sealing pharmaceutical containers

ActiveUS20120090268A1Chance is lostNo longer be conveyedIntravenous devicesSolid materialAmpouleTreatment unit

The invention relates to a device (10) for filling and sealing pharmaceutical containers, wherein the containers are received in a receptacle (12), which is in particular tub-shaped and in which a carrier element (11) is inserted, said carrier element being removable from the receptacle (12). The containers are arranged in receivers of the carrier element (11) in multiple rows next to one another and behind one another. Said device further comprises a first handling unit (27) for removing the carrier element (11) from the receptacle (12), a filling and sealing device (35) for the containers, and a second handling unit (45) for reinserting the carrier element (11) into the receptacle (12) which is conveyed with the carrier element (11) on a conveying device (20). According to the invention, the containers are embodied as syringe barrels (1) or as containers which are to be provided with crimp caps (53), such as vials (2) or cylindrical ampoules (3), and the second handling device (45) is associated with a crimping device (54). When handling containers which are to be provided with crimp caps, the crimping device is controlled by the second handling device (45) so that the second handling device (45) first feeds the containers into the crimping device (54) then reinserts the containers which were sealed by means of the crimping device (54) into the carrier element (11).

Owner:SYNTEGON TECHNOLOGY GMBH

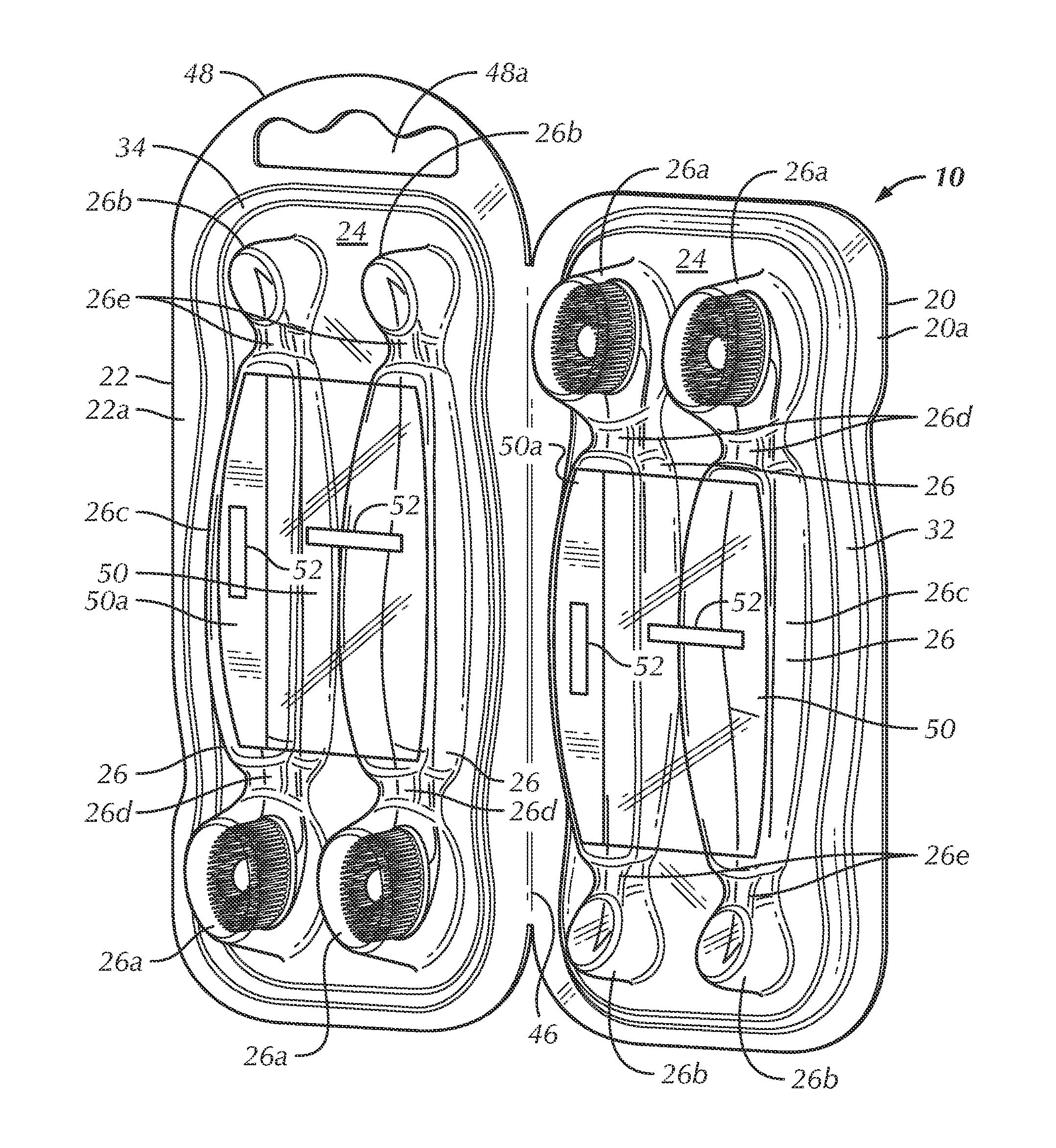

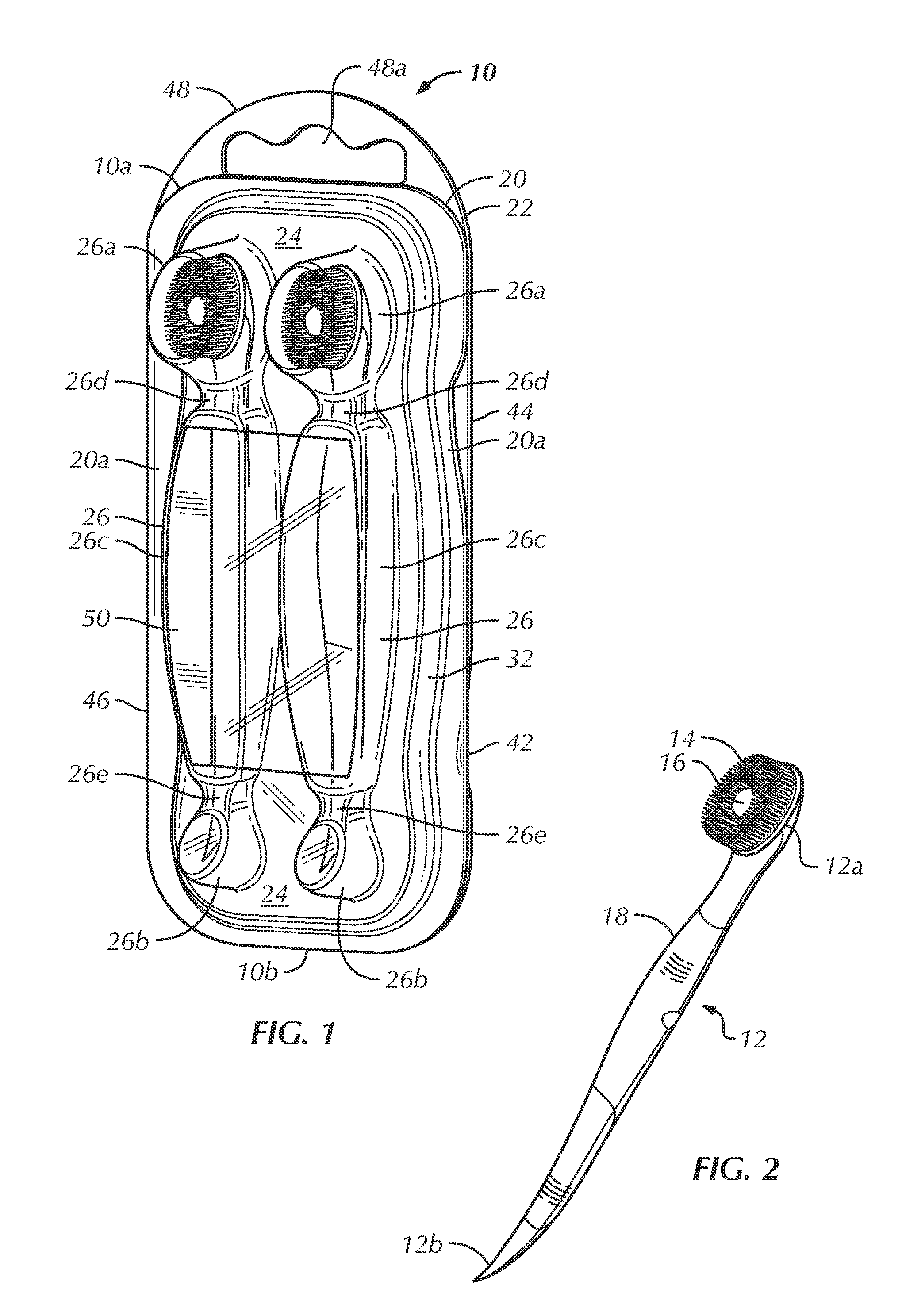

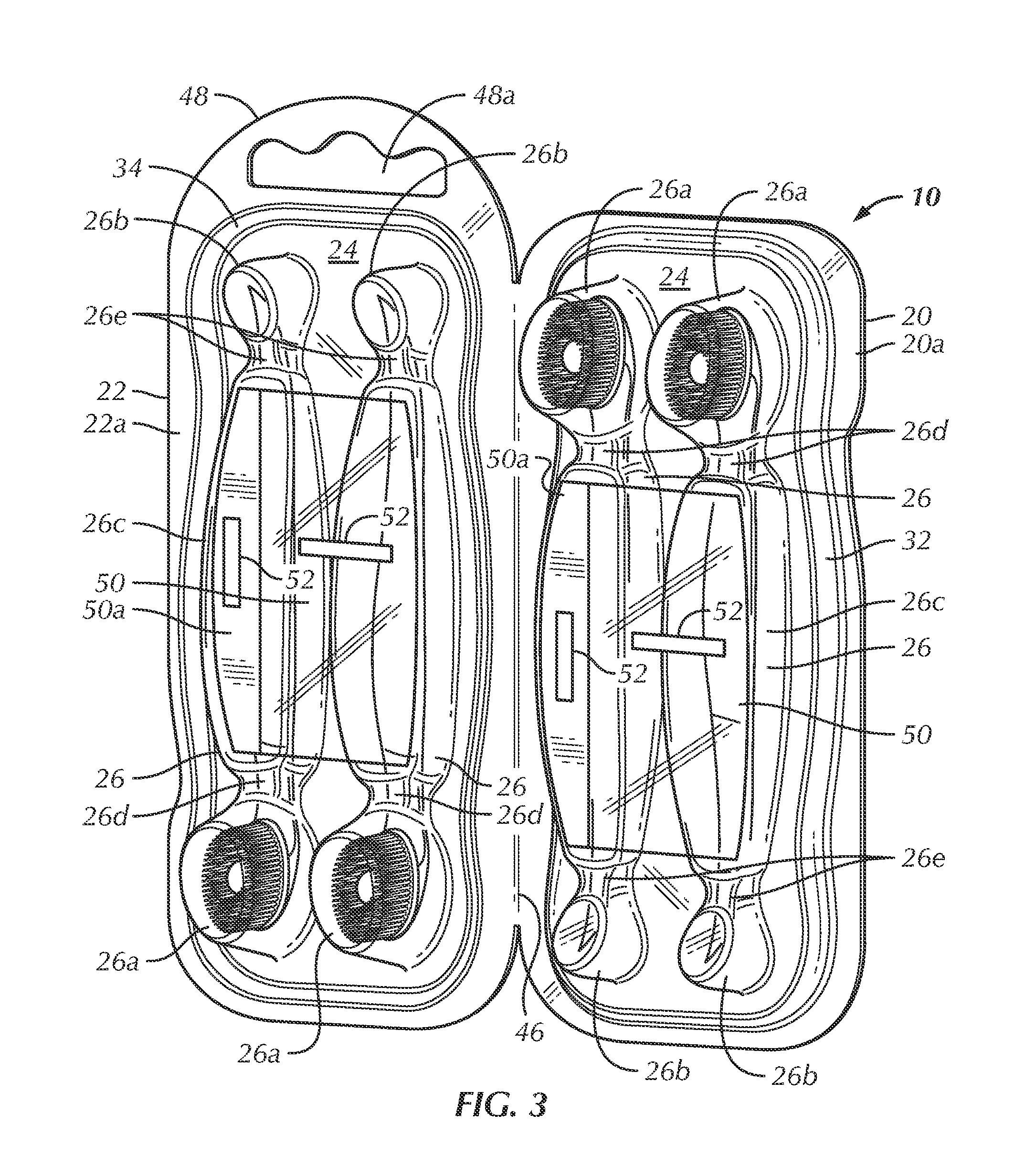

Display package

InactiveUS20100230312A1High degreeImprove sustainabilityContainer decorationsLevel indicationsEngineeringMechanical engineering

A package for displaying a plurality of items where the package has first and second containers connectable between an open position and a closed position, each container having an outer surface having at least one elongated protrusion, the at least one protrusion having a head end and a tail end, the head end extending further outwardly from the package than the tail end, and an inner surface having at least one inner cavity aligned with the at least one protrusion, the cavity having a depth varying along the protrusion and configured to receive one of the plurality of items, wherein the head end of the at least one protrusion of the first container is proximate the tail end of the at least one protrusion of the second container in the closed position.

Owner:COLGATE PALMOLIVE CO

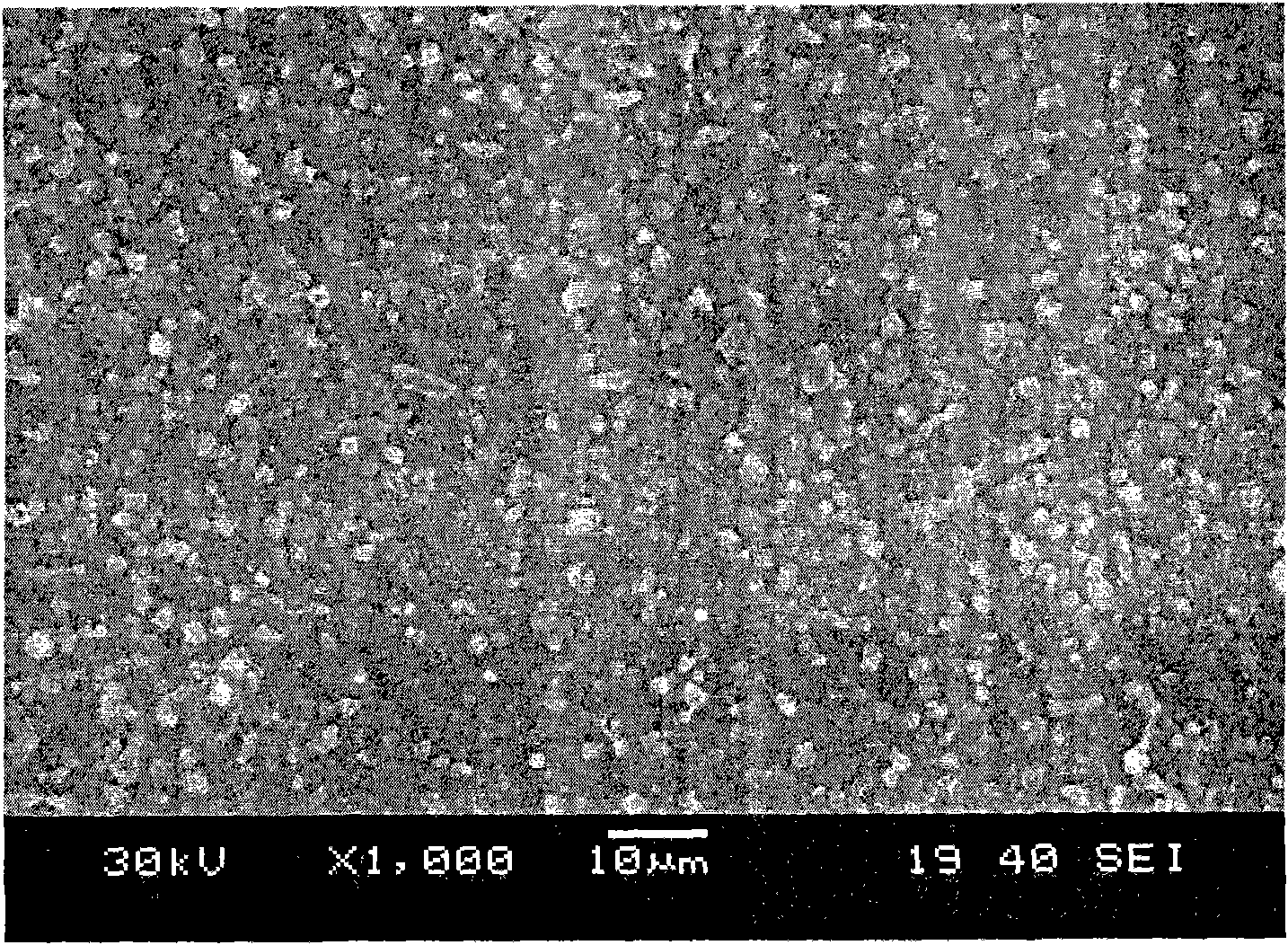

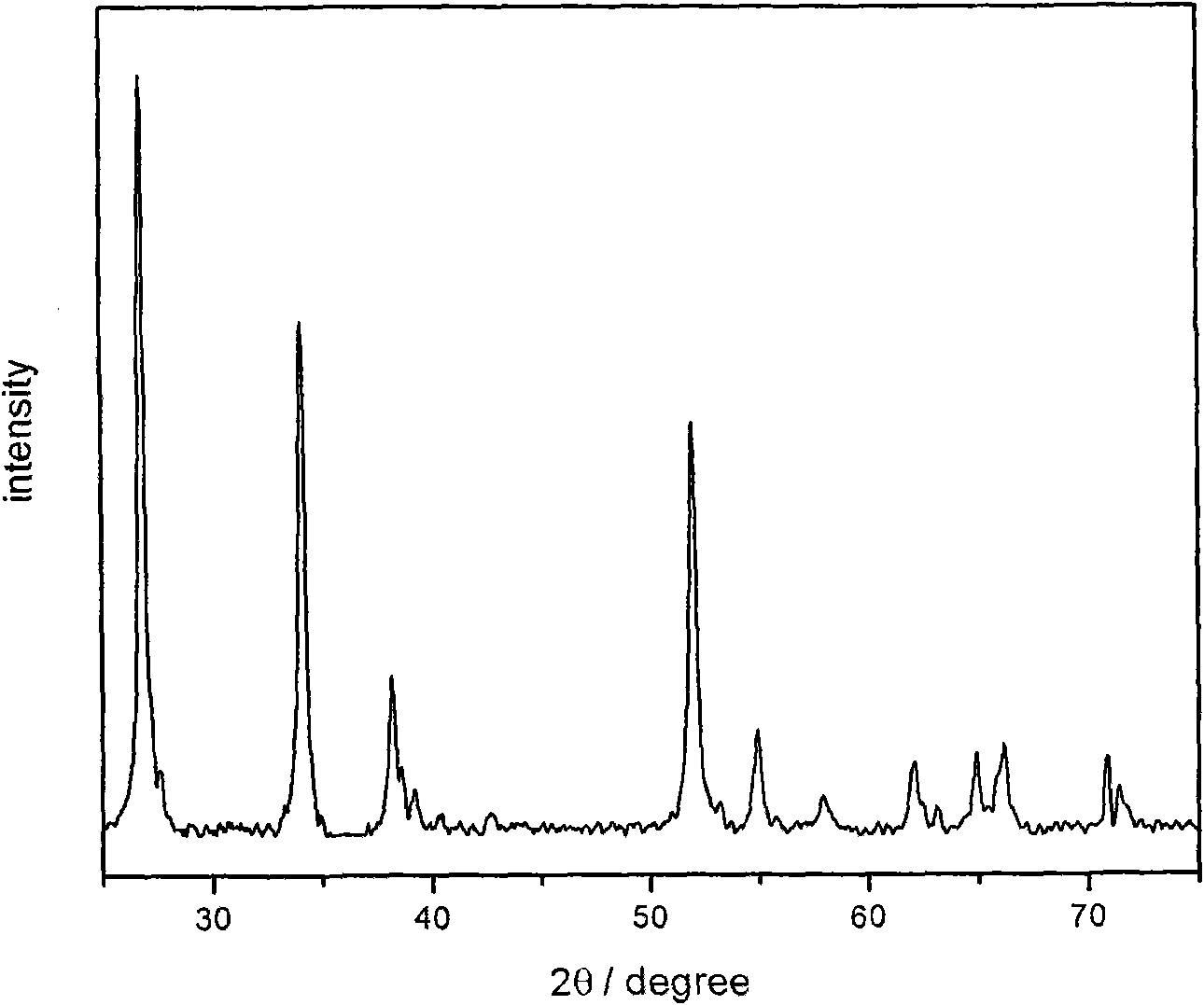

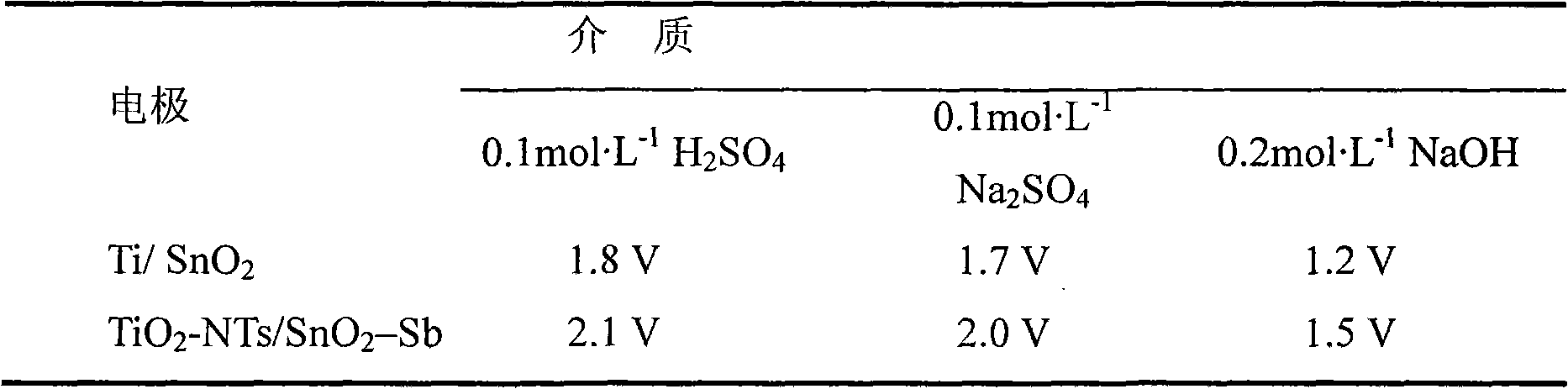

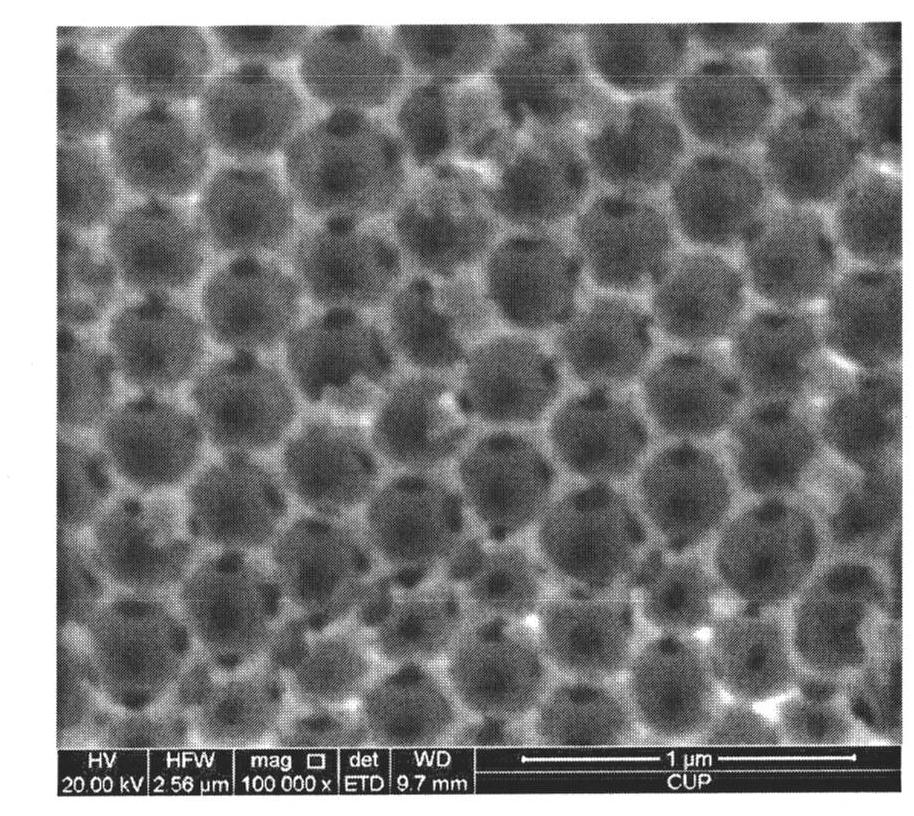

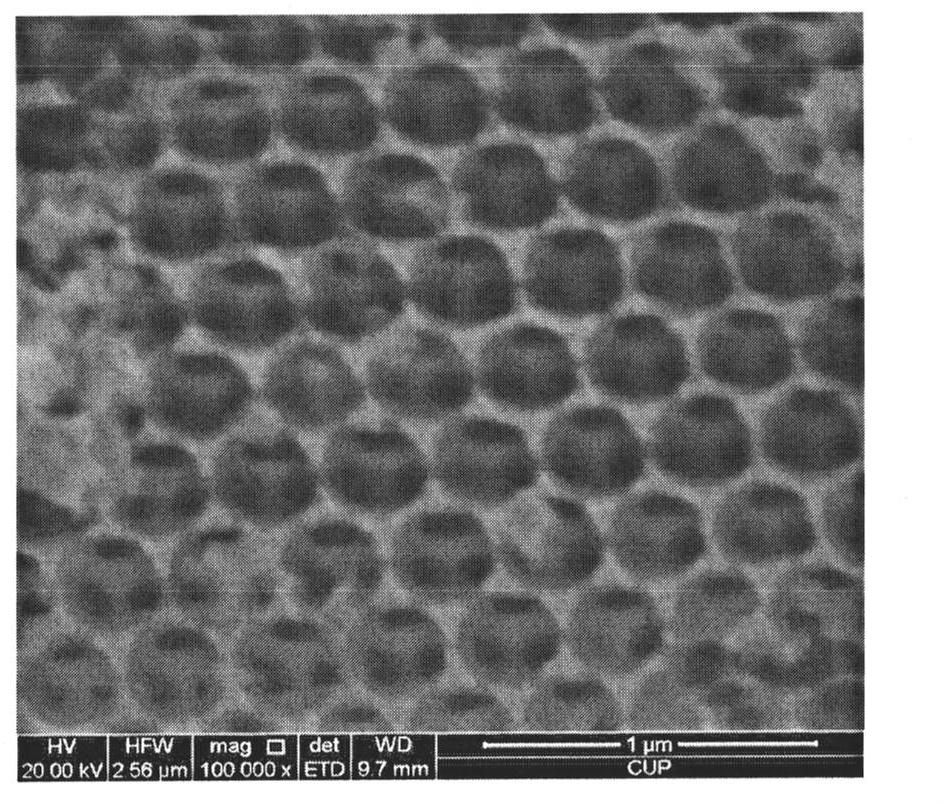

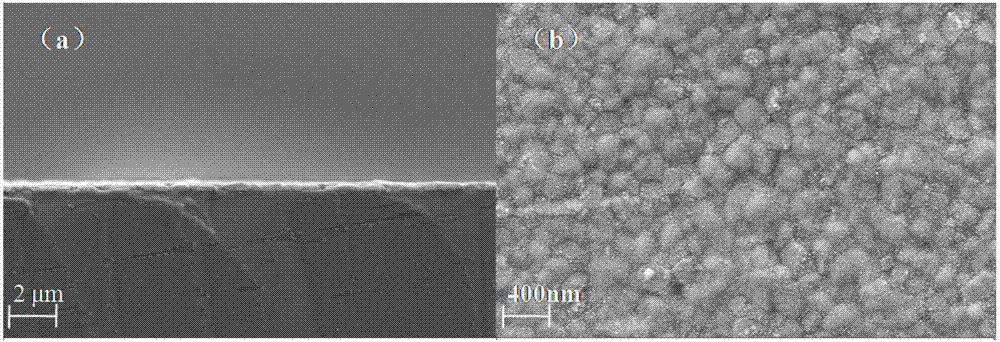

Preparation method of titanium-based titanium dioxide nanotube stannic oxide electrode

ActiveCN101857288AOrderly rowsHigh specific surface areaWater/sewage treatmentAnodic oxidationTin dioxide

The invention relates to a preparation method of a titanium-based titanium dioxide nanotube stannic oxide electrode, belonging to the technical field of electro-catalysis electrode preparation. The method comprises the following steps: firstly adopting an anodic oxidation method to prepare a titanium dioxide nanotube on a titanium matrix, thus improving the specific surface area of the titanium matrix; and depositing stibium and tin in the titanium dioxide nanotube by an electro-deposition method successively, and performing thermal oxidation to lead the stibium doped stannic oxide to be bonded firmly with the titanium dioxide nanotubes directly connected with the titanium matrix. The stannic oxide crystal particles prepared by the electro-deposition method are dispersed evenly, and the electrode surface is compact and has no crack. The method overcomes the defect that crack is generated on the surface of the electrode prepared by the traditional brush coating thermal decomposition method. The electrode prepared by the invention has high potential for oxygen evolution, high electric catalytic activity and long service life and the like; the preparation process is easily controlled, has low cost and lower equipment requirements; and the prepared electrode can effectively treat pollutants that are poorly biodegradable.

Owner:NANJING UNIV OF SCI & TECH

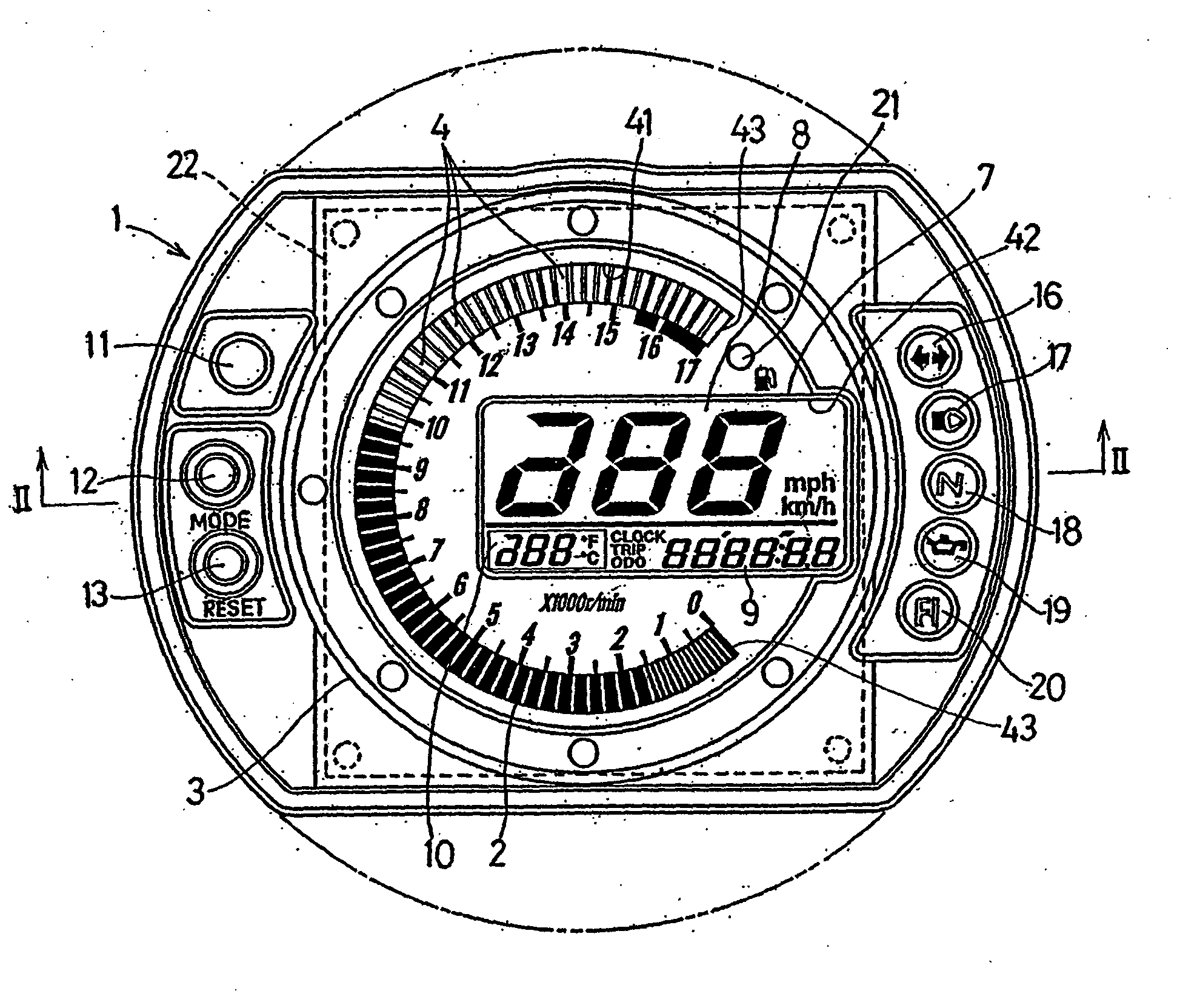

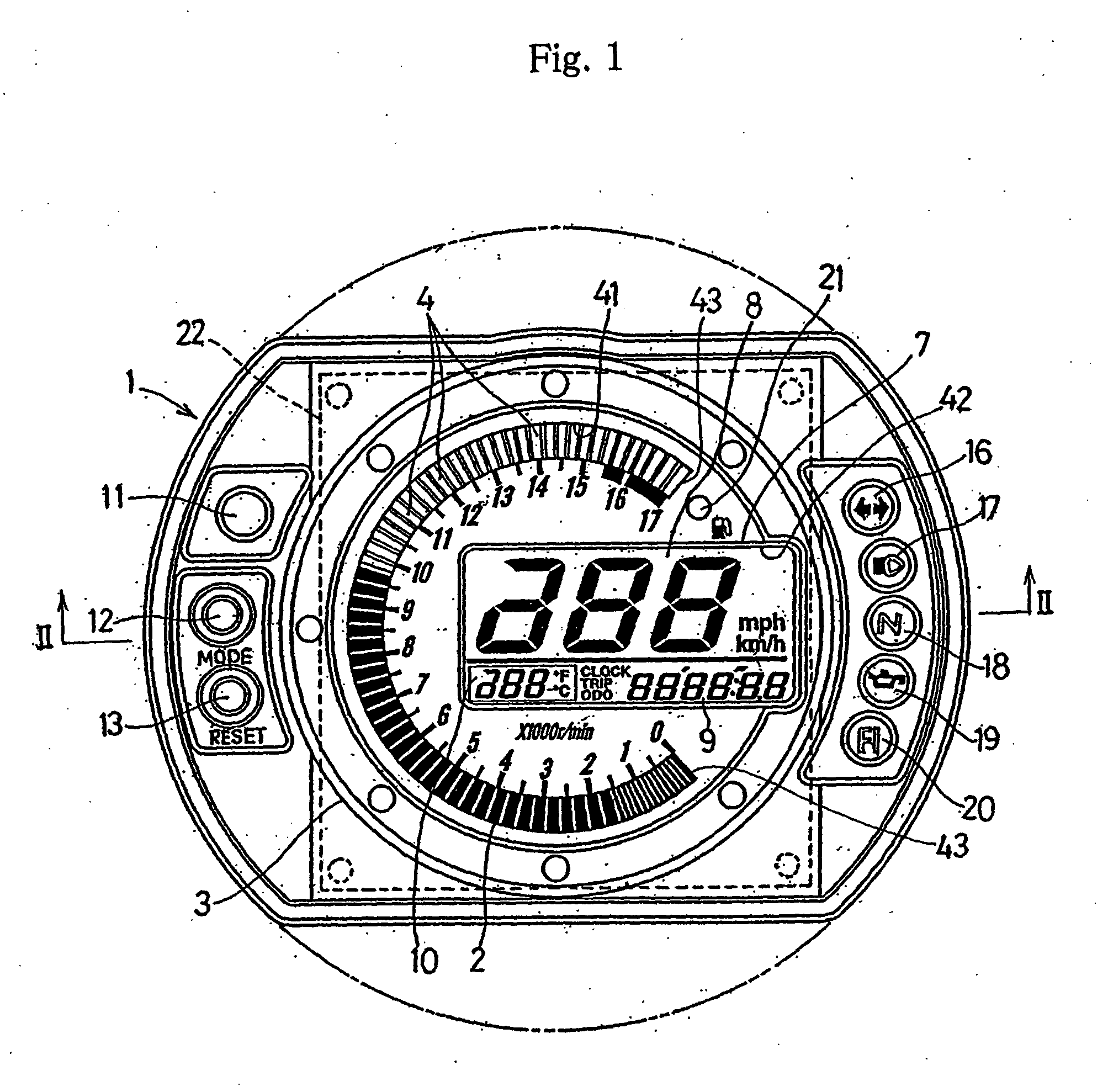

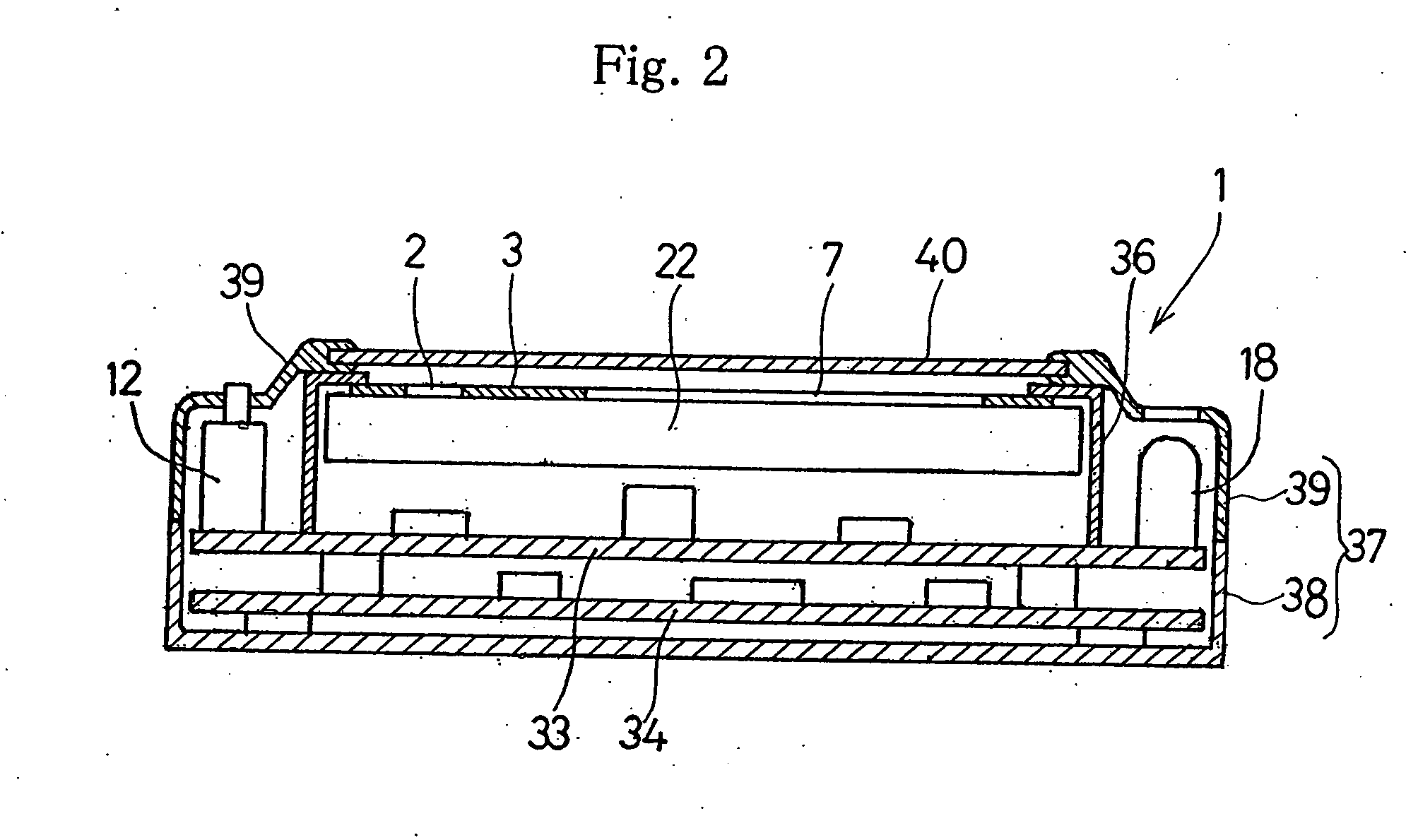

Combination indicator assembly in vehicle instrument panel

InactiveUS20040046713A1Improve visibilityEasy to viewStatic indicating devicesInstrument arrangements/adaptationsIn vehicleEngineering

To provide a combination indicator assembly (1) of a minimized size to provide a sporty feeling and easy to view various displayed parameters while having an increased display functionality, the combination indicator assembly (1) includes a generally arcuate analog display unit (2) for displaying the number of revolutions of a vehicle engine, and a generally rectangular digital display unit (7) disposed inside the analog display unit (2). The digital display unit (7) includes a speedometer region (8), a distance meter region (9) for displaying the distance of travel of the vehicle or a coolant temperature display region (10) for displaying the temperature of a coolant used to cool an engine of the vehicle.

Owner:HOIST FITNESS SYST +1

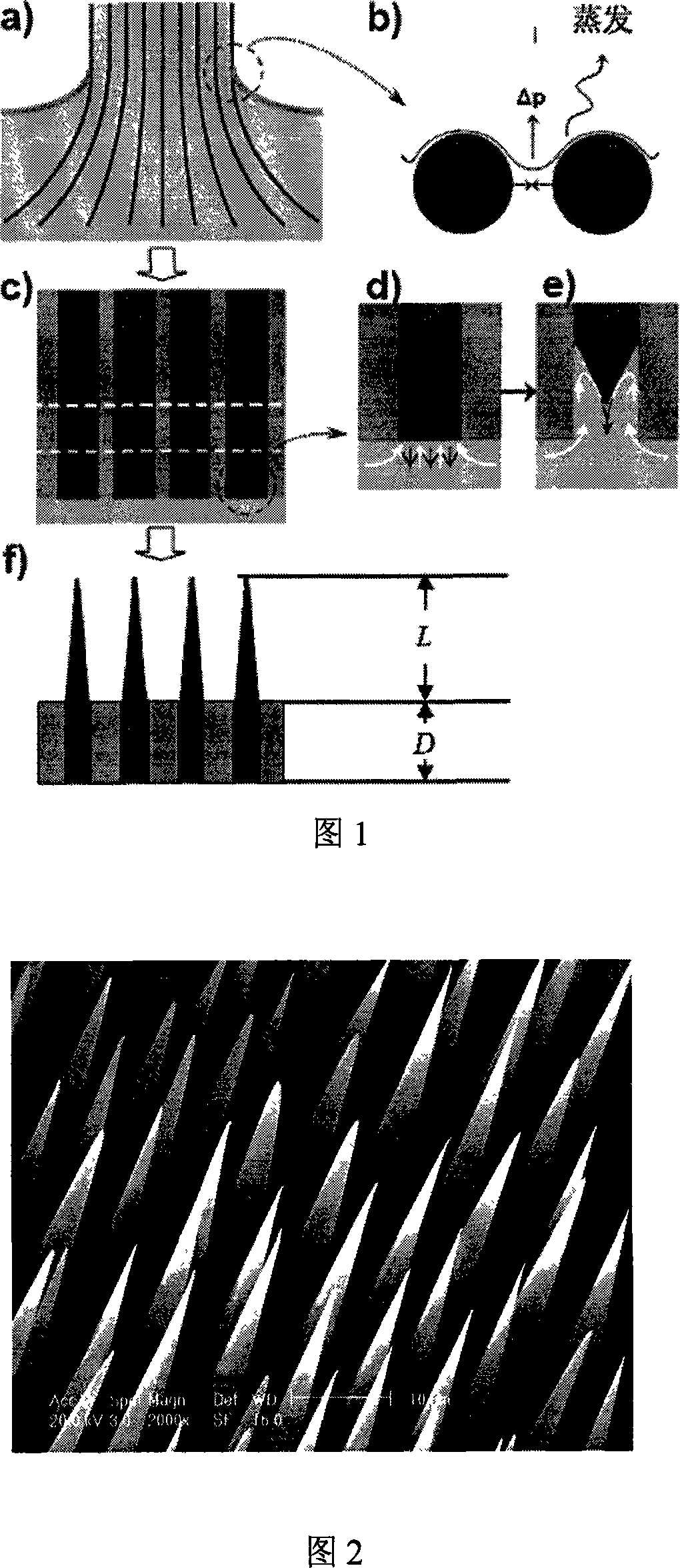

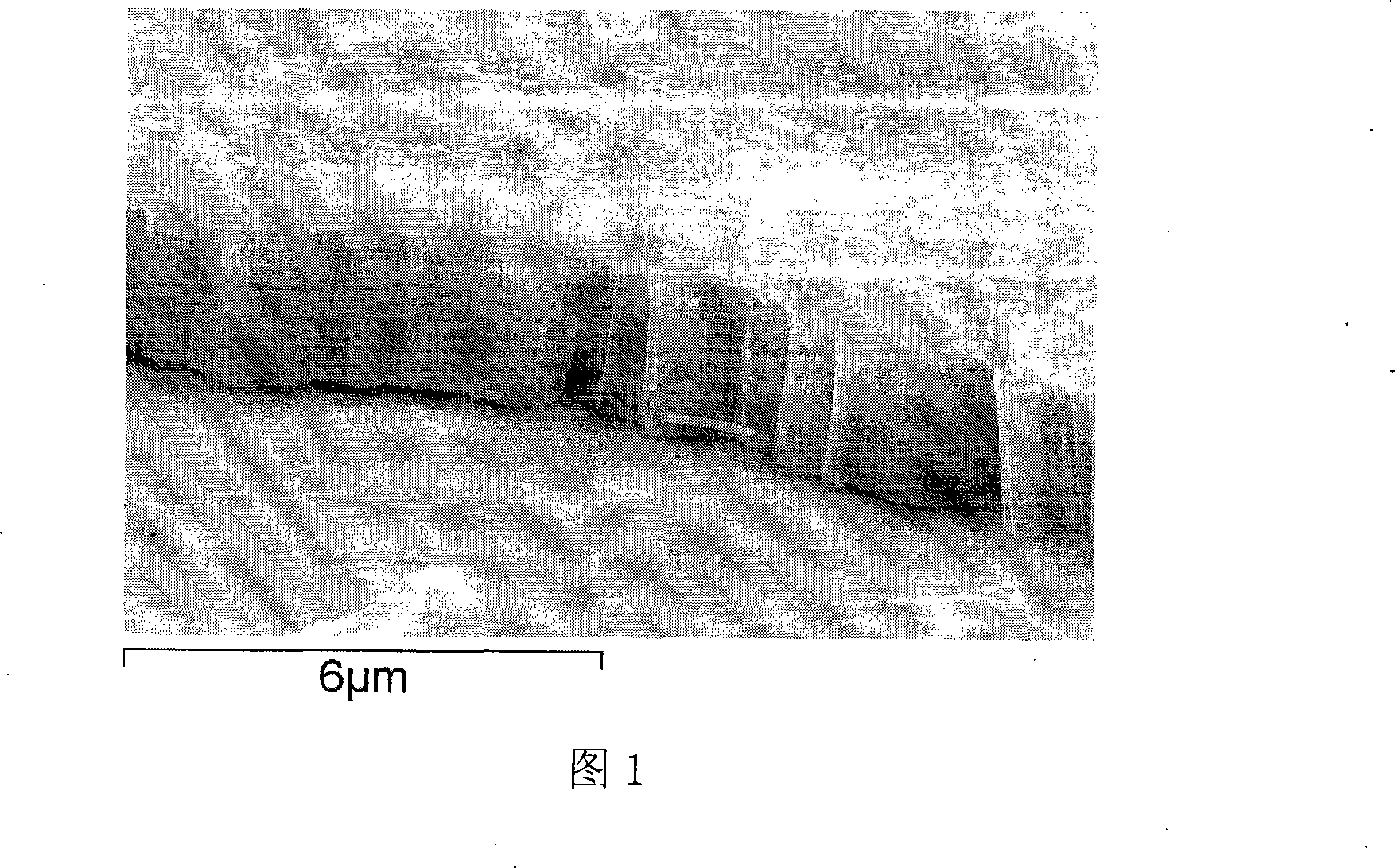

Method for preparing micrometer and submicron probe arrays

InactiveCN101143705AOrderly rowsReduce manufacturing costSemi-permeable membranesPiezoelectric/electrostrictive/magnetostrictive devicesFiberMicrometer

The invention discloses a method of preparing a micrometer and sub-micrometer needle array. The method adopts the self-assembly technology and integrates the filling, cutting and controllable corrosion technologies. First, the self-assembly technology is adopted to technically assemble the micrometer / sub-micrometer fiber; and then the polymeric compound is filled, finally the micrometer and sub-micrometer needle array is prepared by the cutting and the controllable corrosion technologies. The invention has the advantages of low cost, no need of complicate equipments and technologies, capability of quick batch production, large area of needle array, smooth needle surface, adjustable diameter, length and taper, etc., and is widely applicable in the detecting, sensing, optical, biology and medicine fields, etc.

Owner:NANJING UNIV

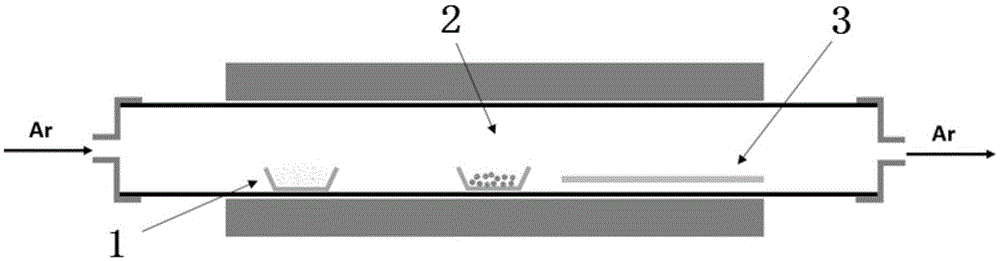

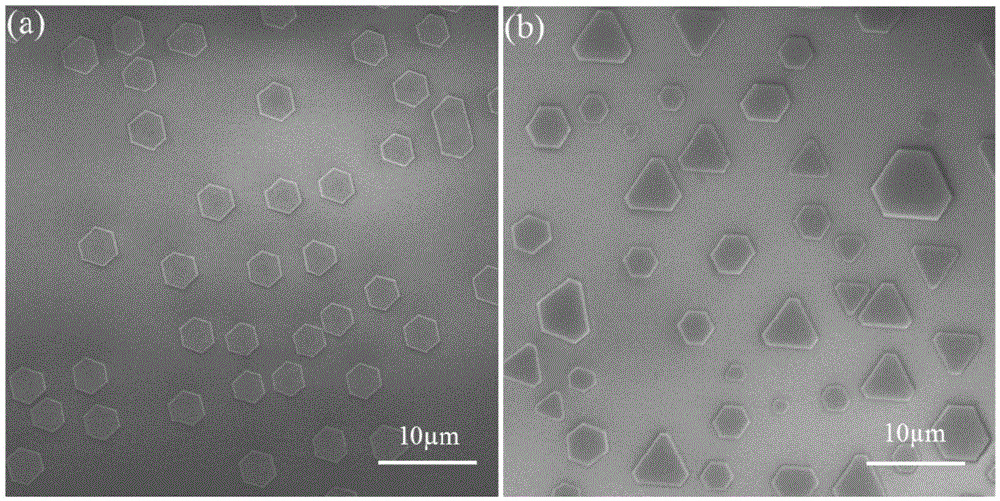

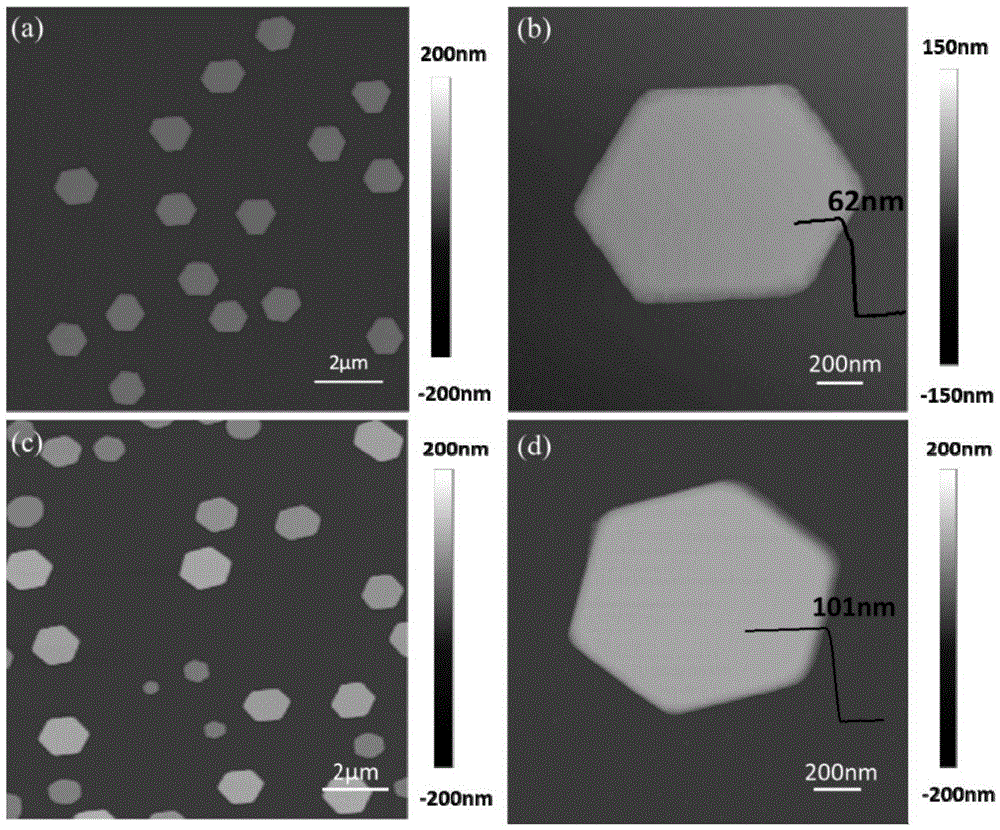

Preparation method of cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet

ActiveCN105463580AIncrease the areaHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesSource materialSingle crystal

The invention discloses a preparation method of a cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet. The method comprises the steps that the CdSe or CdS two-dimensional monocrystal nanosheet is prepared through a van der Waals epitaxial growth technology, the method is characterized in that a mica sheet which is smooth in surface and free of chemical dangling bond is adopted to serve as a substrate, CdCl2 powder or Se powder or S powder serves as a source material, argon serves as carrier gas, CdCl2 stream is reacted with Se or S steam to form CdSe or CdS steam at high temperature, and the steam is deposited on the mica sheet for nucleation and epitaxially grows into the CdSe or CdS two-dimensional monocrystal nanosheet. The preparation method of the cadmium selenide or cadmium sulfide two-dimensional monocrystal nanosheet is easy to operate, low in cost and strong in controllability, the obtained CdSe or CdS has the advantages of being good in size uniformity, high in degree of crystallinity and the like, and important research value and wide application prospect in the fields of solar cells, field effect transistors, photoelectric detectors, photocatalyses and the like are achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

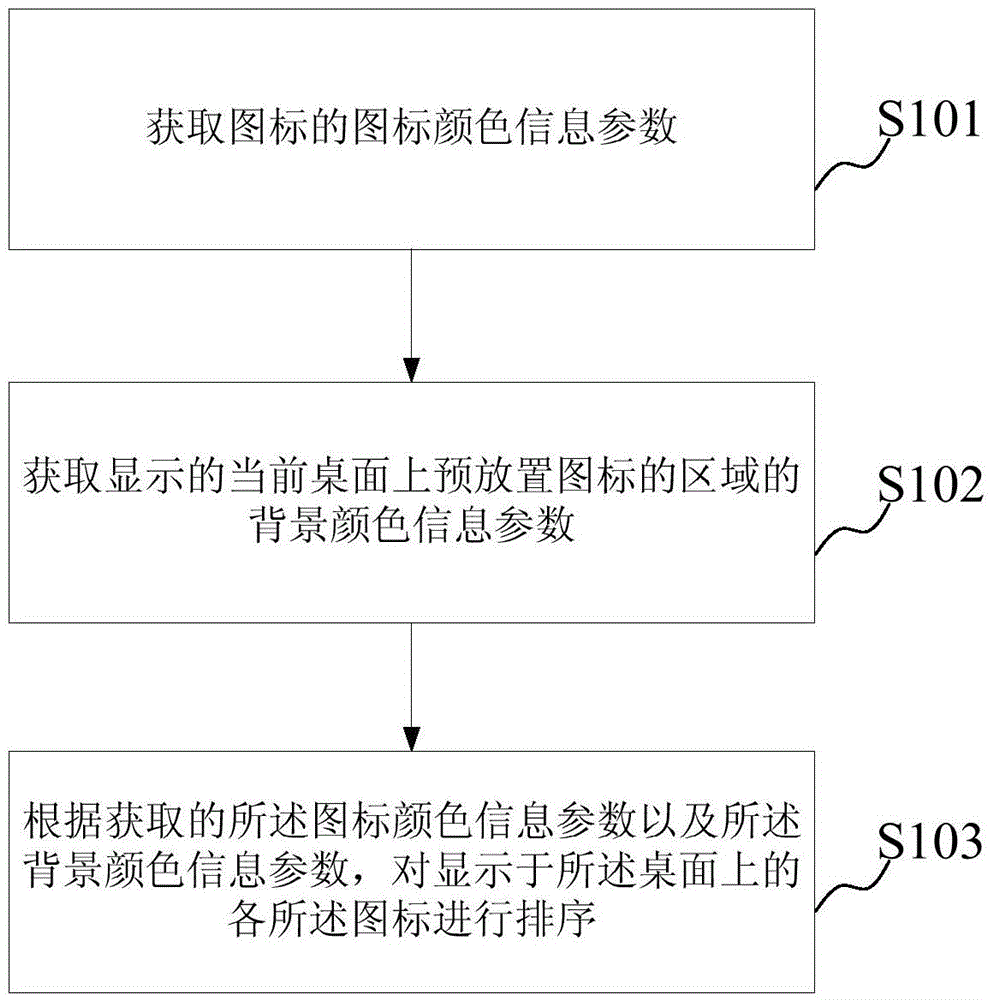

Icon displaying method and device

InactiveCN104063123AGuaranteed to stand outImprove operational efficiencyInput/output processes for data processingComputer graphics (images)Terminal equipment

The embodiment of the invention discloses an icon displaying method and device. The method comprises the following steps: acquiring the icon color information parameters of icons and displayed information parameters of background color of areas used for pre-placing the icons on the current desktop; sorting the icons displayed on the desktop according to the acquired icon color information parameters and the background color information parameters. In the embodiment of the invention, the icons are not displayed on the desktop randomly, instead, the icon color information parameters of the icons and the background color information parameters of various areas of the desktop are acquired firstly, and then the icons are sorted (or arrayed) based on the two color information parameters, for example, the icons are enabled to be not placed on areas with the color similar to the icons through the sorting, so that the fact that the icons can be highlighted in a desktop background can be guaranteed, therefore, the speed for searching for icons can be increased, and further the operating efficiency of a terminal device is improved.

Owner:XIAOMI INC

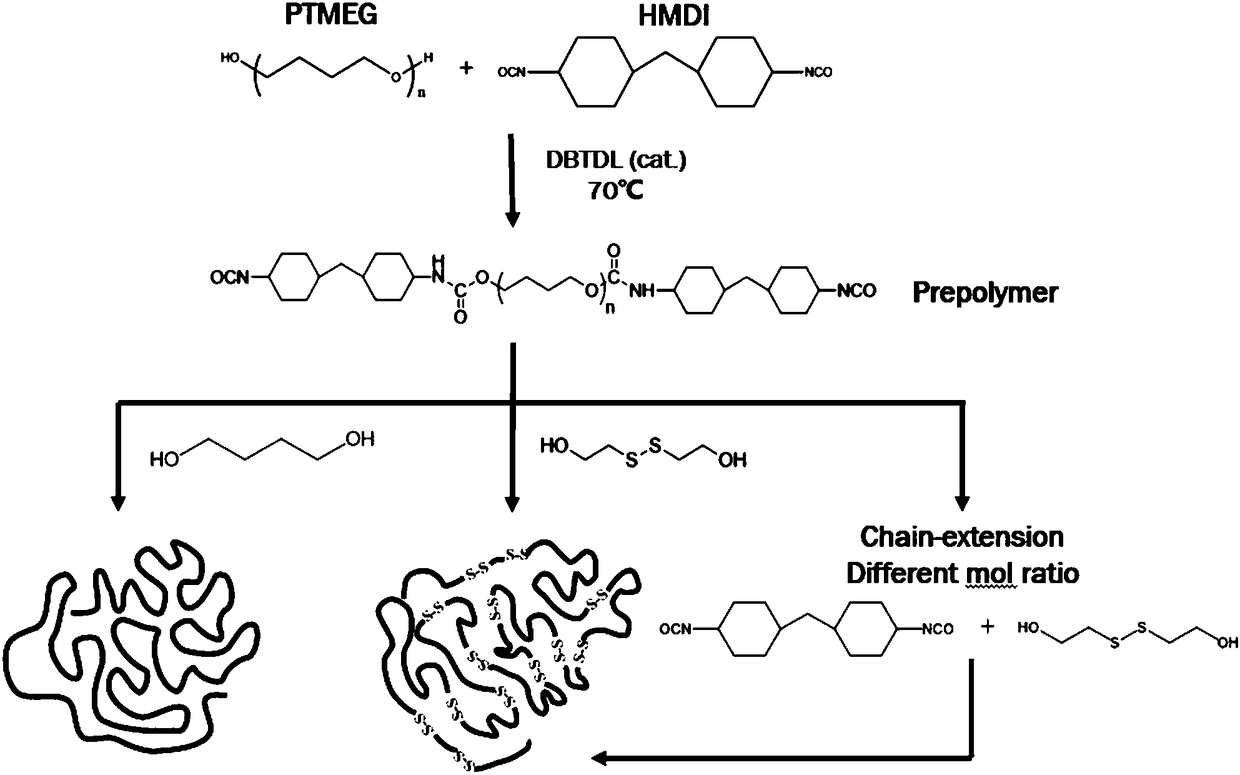

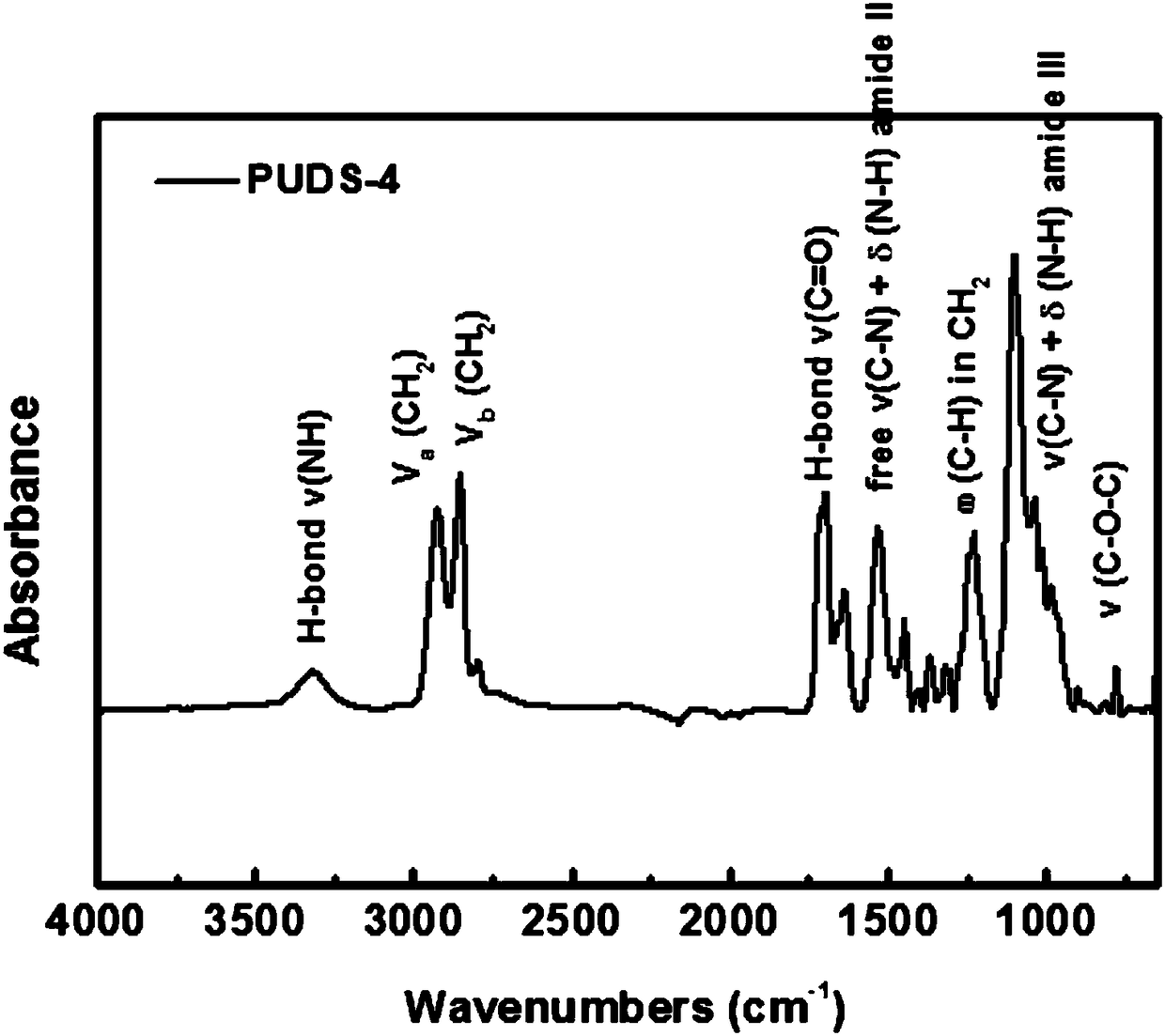

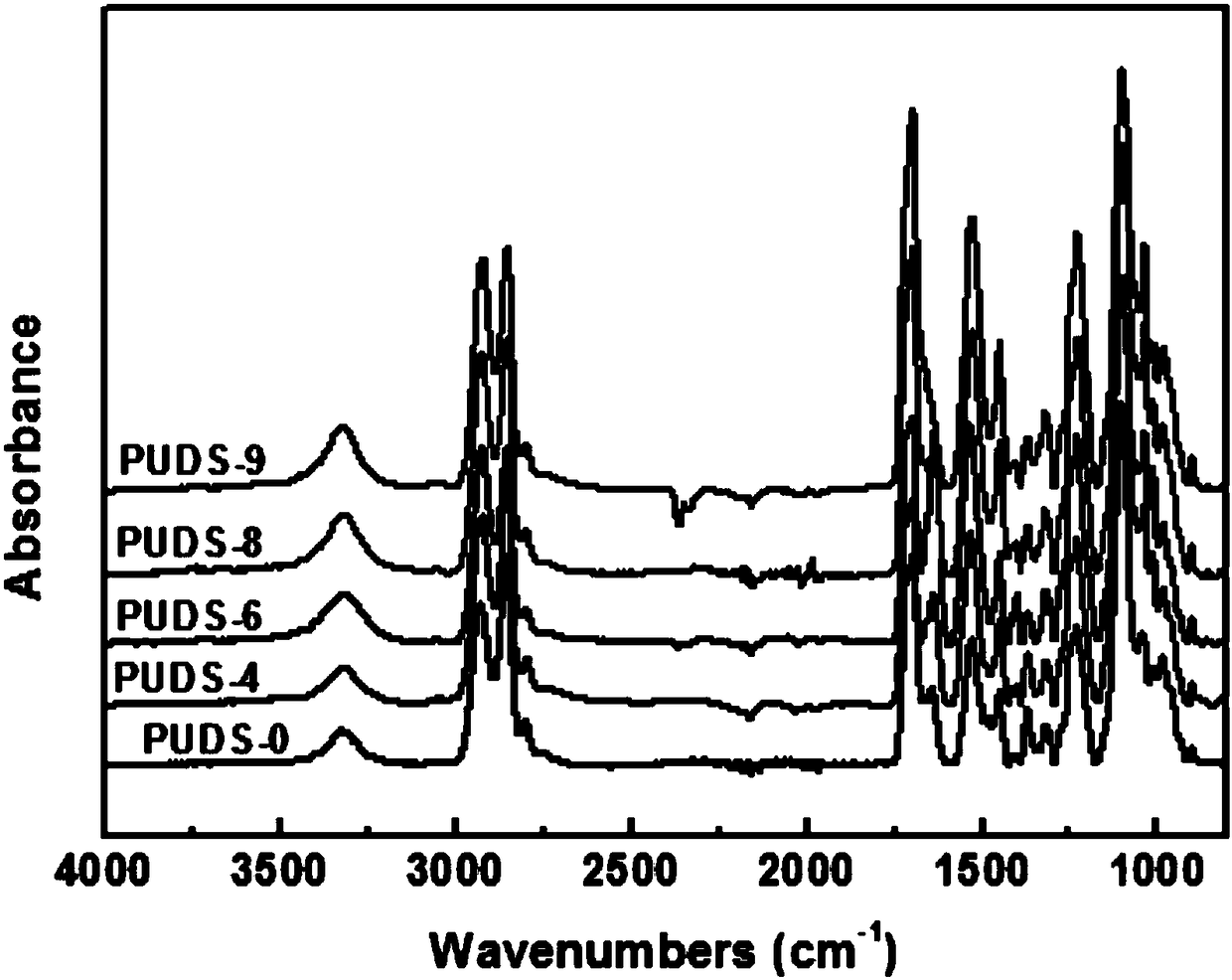

Full-transparence high-strength self-repairing polyurethane elastomer as well as preparation method and application thereof

The invention belongs to the technical field of materials, and particularly relates to full-transparence high-strength self-repairing polyurethane elastomer as well as a preparation method and application thereof. The full-transparence high-strength self-repairing polyurethane elastomer comprises carbamate and a disulfide bond structure unit, wherein the structural formula is shown in formula (I):(shown in the description), wherein the disulfide bond is designed and distributed in a hard section area in a split-phase control manner, so that a self-repairing and differential structure adjusting effect can be realized, and the physical and mechanical performance such as the strength and toughness can be improved. Compared with the polyurethane copolymer elastomer comprising the disulfide bond in the prior art, the full-transparence high-strength self-repairing polyurethane elastomer disclosed by the invention is far better in the mechanical strength, toughness, transparence and the likecompared with the traditional polyurethane elastomer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Pen bag of marker pens

Owner:PANZHIHUA UNIV

Lamellar corneal stroma bracket as well as preparation method and application thereof

The invention discloses a lamellar corneal stroma bracket as well as a preparation method and application thereof. The method comprises the following steps: carrying out low-permeability swelling, repetitive freeze-thawing, enzyme digesting, drying and sterilizing treatment on a corneal stroma sheet of a fresh animal eyeball cut down under a sterile condition, wherein the enzyme digesting adopts buffer liquor containing DNA (deoxyribonucleic acid) enzyme and RNA (ribonucleic acid) enzyme to treat, ultrasonic treatment is carried out after the enzyme digestion treatment, and then drying and sterilizing treatment is carried out. The invention further provides application of the lamellar corneal stroma bracket as a corneal stroma substrate. The method disclosed by the invention can be used for reducing damages on a corneal stroma collagen structure to the greatest extent; collagenous fiber arrangement is orderly, holes are uniform and regular, cell residues are avoided, the lamellar structure is kept complete, and the biocompatibility of the bracket material is improved.

Owner:QINGDAO CHUNGHAO TISSUE ENG

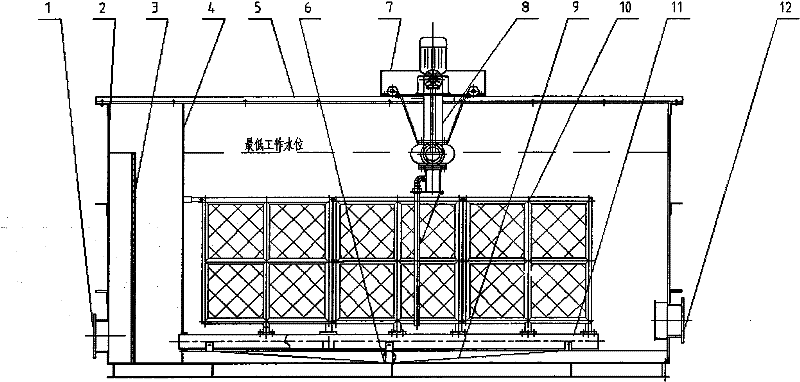

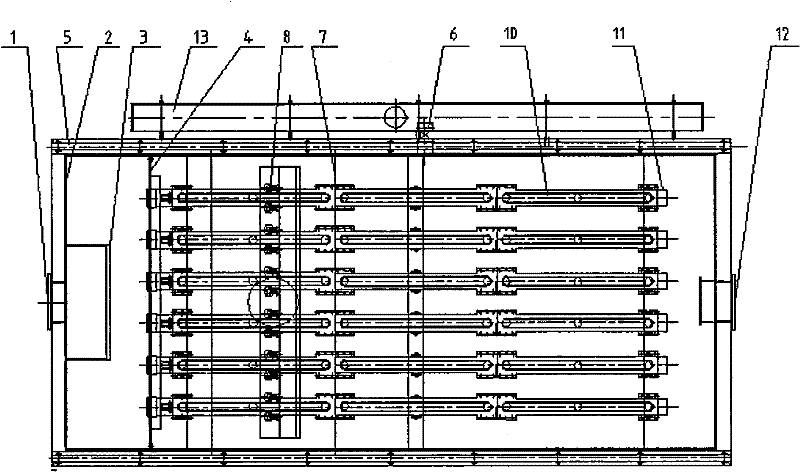

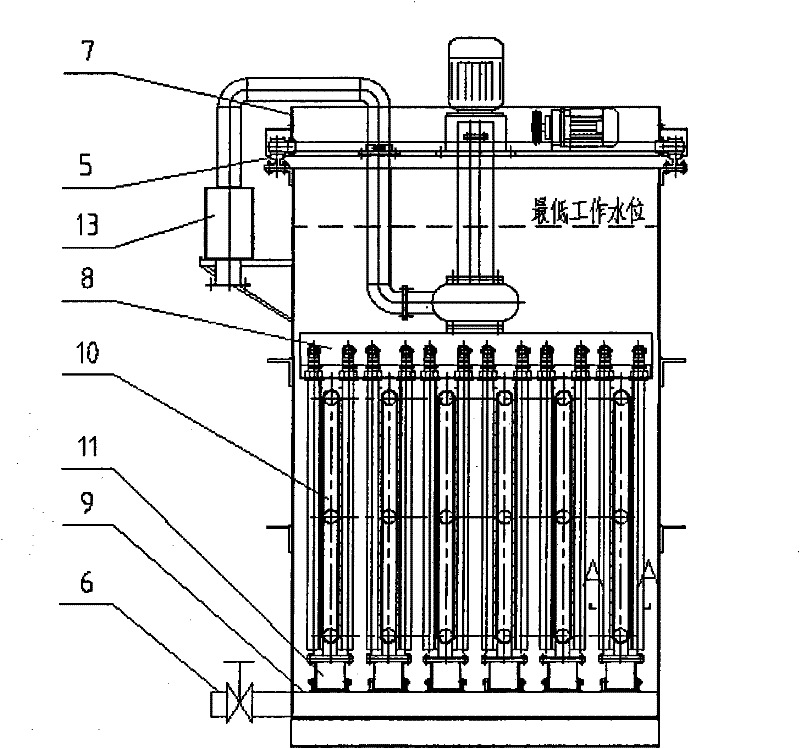

Vertical sheet filter

InactiveCN102343171AEliminate settingsLarge filter areaStationary filtering element filtersSludgeEngineering

The invention belongs to the technical field of water treatment, and specifically relates to a vertical sheet filter. The vertical sheet filter comprises a water outlet, a housing, an effluent weir, a side splitter, a guide rail, an emptying port, a dolly, a backwashing component, a filtering component, a water header, a water inlet and a sludge chamber. The water inlet, the water outlet and the emptying port are respectively arranged under the housing; the sheet filtering component is vertically arranged in the housing; the dolly is arranged on a dolly guide rail on top of the housing and can move on the guide rail; a dredge pump is fixed under the dolly; one end of a dredge tube is on two sides of the sheet filtering component, and the other end is connected to the dredge pump through a dredge header tube; and a spoil disposal plate with a certain gradient is arranged at the housing bottom. Because of usage of a light filter material and valve-free operation, the invention has characteristics of large filtering area, low filtering load, small backwashing water consumption, flexible system configuration, low energy consumption, small land occupation, simple operation and maintenance and high degree of automation, and can be combined with routine water treatment technology to realize a higher purifying efficiency.

Owner:上海安鼎济水处理科技有限公司

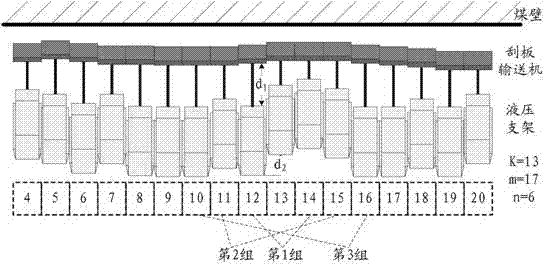

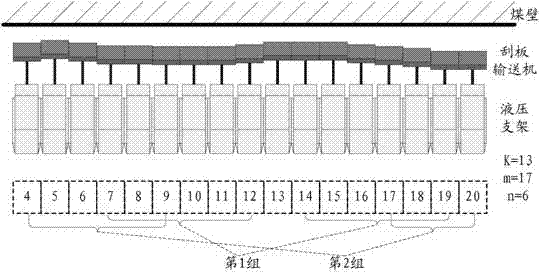

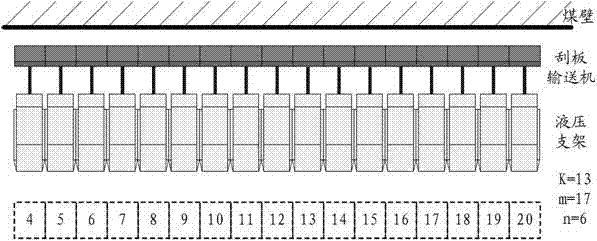

Automatic straightening method and system for hydraulic supports and scraper conveyors of fully-mechanized coal mining working faces

ActiveCN103114867AGuarantee "Three Directions and One Equalization"Orderly rowsMine roof supportsEngineeringCoal mining

The invention provides automatic straightening method and system for hydraulic supports and scraper conveyors of fully-mechanized coal mining working faces. The automatic straightening method includes steps of during continuous propelling of the fully-mechanized coal mining working faces, acquiring relative positions between every two hydraulic supports by first travel sensors mounted on the hydraulic supports; acquiring a relative position between each hydraulic support and one scraper conveyor; utilizing the appointed hydraulic support as reference, and straightening the hydraulic supports within an appointed range according to the relative positions between every two hydraulic supports until readings of the first travel sensors are zero; and utilizing the relative position of the appointed hydraulic support and the scraper conveyor as reference, and straightening the scraper conveyors within an appointed range according to the relative position between each hydraulic support and each scraper conveyor. By the automatic straightening method and system, the scraper conveyors and the hydraulic supports can be guaranteed to arrange orderly, and 'keeping the hydraulic supports, the scraper conveyors and cut coal walls straight and flat' of the fully-mechanized coal mining working faces is guaranteed.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD +1

Three-dimensionally ordered macroporous gold-loaded catalyst with composite oxide as carrier and for catalytic combustion

ActiveCN101982234AIncreased oxidation catalytic activityHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParticulatesRare earth

The invention relates to a macroporous noble metal-loaded catalyst with metal oxide as a carrier and for purifying soot exhausted by diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for combustion of soot particles exhausted by diesel vehicles. The catalyst is obtained by taking the simple metal oxide or composite metal oxide which contains more than one of rare earth metals, transition metals and alkaline metals and has three-dimensionally ordered macroporous structure as a carrier and loading the noble metal active ingredient, wherein the simple metal oxide is any one of metallic elements; the composite metal oxide is perovskite or perovskite-like composite metal oxide; the noble metal active ingredient is gold; and the mean size of the macropores in the carrier is 50nm-1mu m. The catalyst conduces to diffusion of the soot particles in the pore canal, improves the use ratio of the active surface area and greatly reduces the combustion temperature of the soot particles. The invention also provides the preparation method of the catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Automatic light adhesive material feeding vibration hopper

InactiveCN104444132AContinuous deliveryConvey evenlyJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic light adhesive material feeding vibration hopper which comprises a main magnetic vibration machine and a material tray. The vibration hopper generates electromagnetic force through an electromagnetic coil of the main magnetic vibration machine, the material tray with vibration plate springs is stimulated to vibrate, boosting nuts in the material tray vibrate and ascend along a spiral feeding rail, light adhesive materials in the material tray are cyclically boosted to transmit along the feeding rail, and in the discharging stage, air blowing pipes are used for blowing air in an oriented mode, so that the materials are finally conveyed. The air blowing pipes located accurately are used in cooperation with the boosting nuts, so that the light adhesive materials are automatically and rapidly fed in order. According to the automatic light adhesive material feeding vibration hopper, structural design is reasonable, certain universality is achieved, the materials which are adhesive, low in mass, small in inertia and the like can be continuously and evenly conveyed to the position to be machined, the conveying speed is high, work efficiency is improved, and production cost is reduced.

Owner:SOUTHEAST UNIV

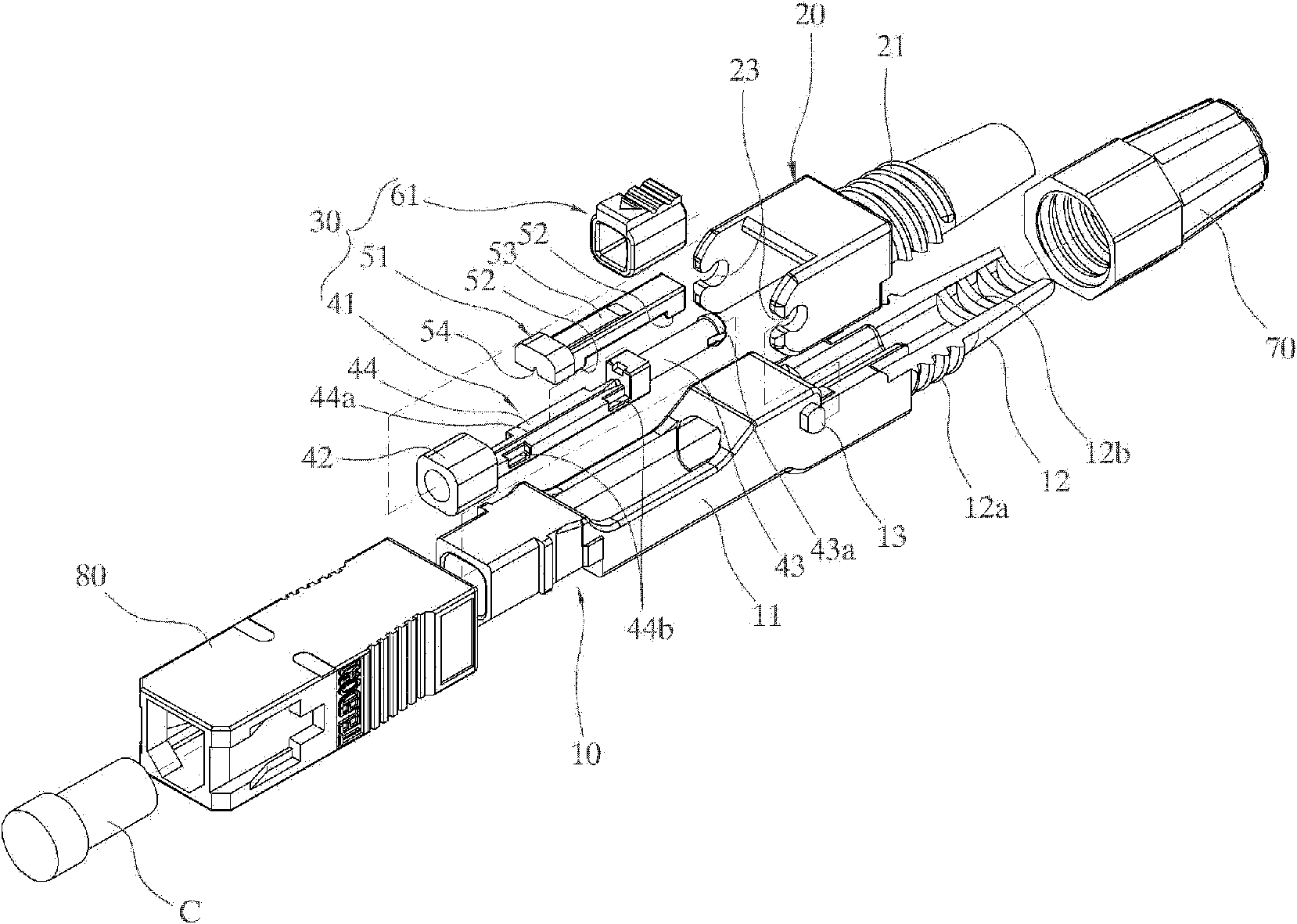

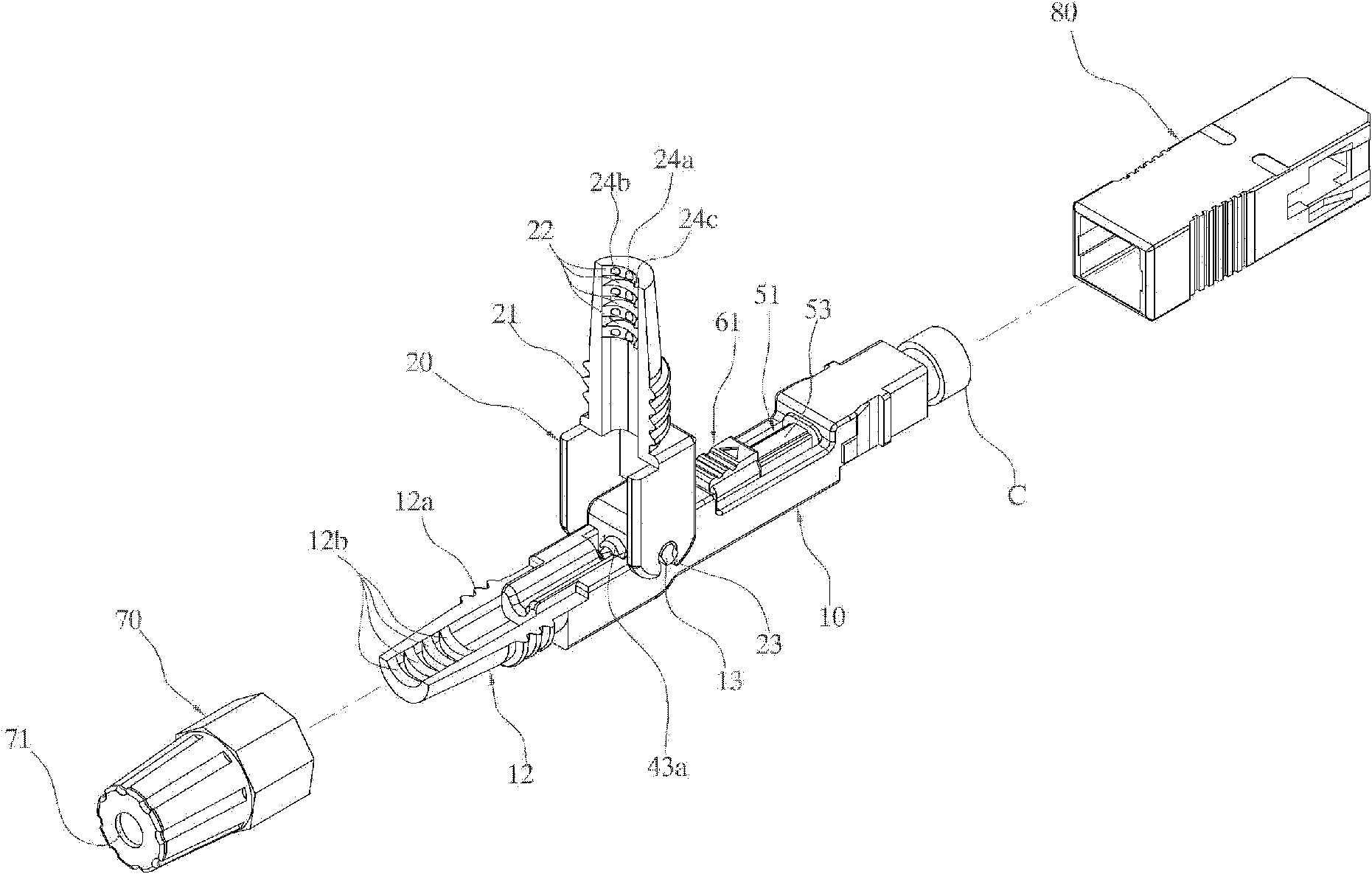

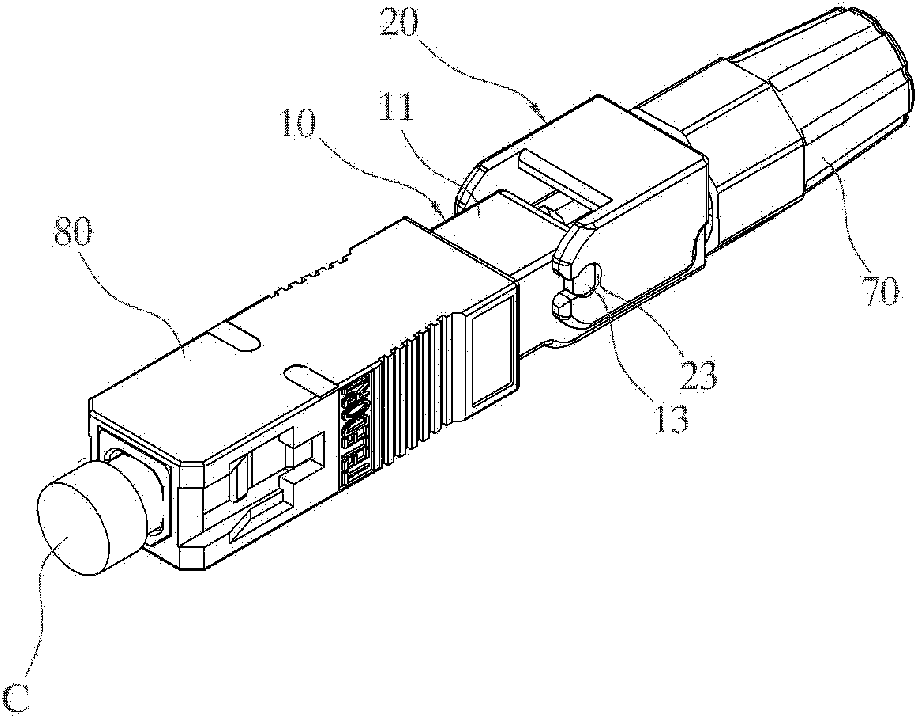

Field assembling optical connector

The invention relates to a field assembling optical connector, comprising: a ferrule provided with optical fibers; a connector housing; a plug with one side of a receiving part inserted and combined in the connector housing, and the other side connected with a tail sleeve part as an integration; an optical connecting element inserted in the internal of the plug; a sleeve cover connected with the tail sleeve and rotatable; and a nut on the tail sleeve part and the sleeve cover, and combining a screw. The inner side of the tail sleeve part and the sleeve cover are in an armour attachment with the external of the optical fibers inserted in the tail sleeve part, and is provided with loop projections pressing towards the optical fibers, disposed at certain distance, and arranged in plural rowsand arrays; the sleeve cover is provided with a plurality of pressing projections formed at the internal side and projecting on at least a projection toward the tail sleeve part. Via the above way, in an optical fiber connecting process, optical fibers of optical cables can be inserted in the optical connecting element in a safer and easier way, assembly of other tail sleeves used for protecting optical fibers is not needed, an armour part of the optical cable optical fibers can be firmly and fixedly connected, effect of orderly arrangement of core wires can be improved, and the optical cablewith different shapes such as a circular shape or a square, etc. can be firmly fixed, making the optical fibers be in an orderly connection, greatly improving assembly efficiency of connector, and making assembly easier.

Owner:A J WORLD CO LTD

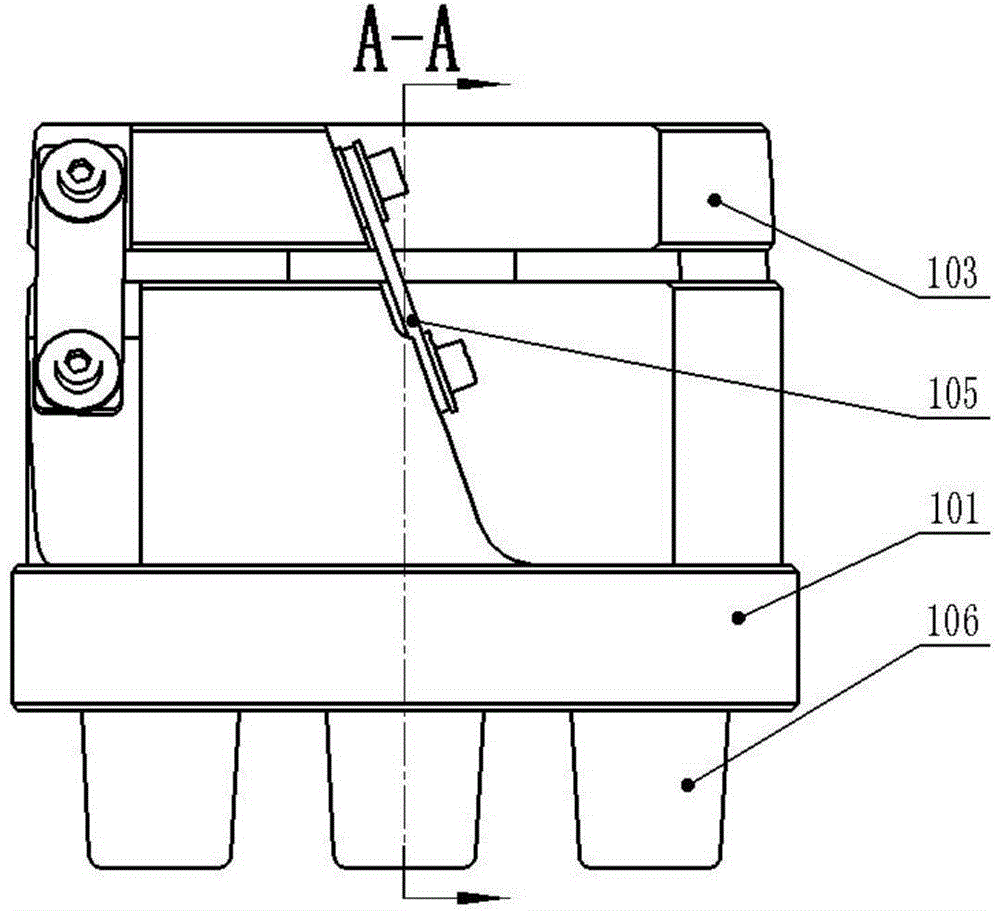

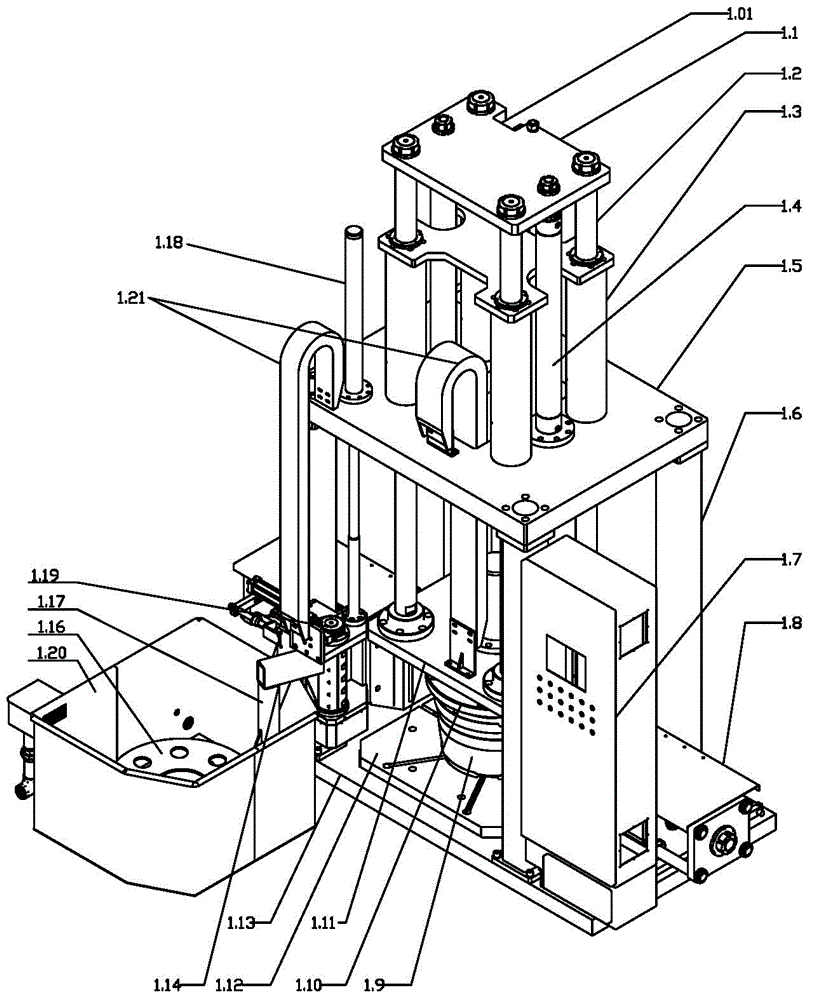

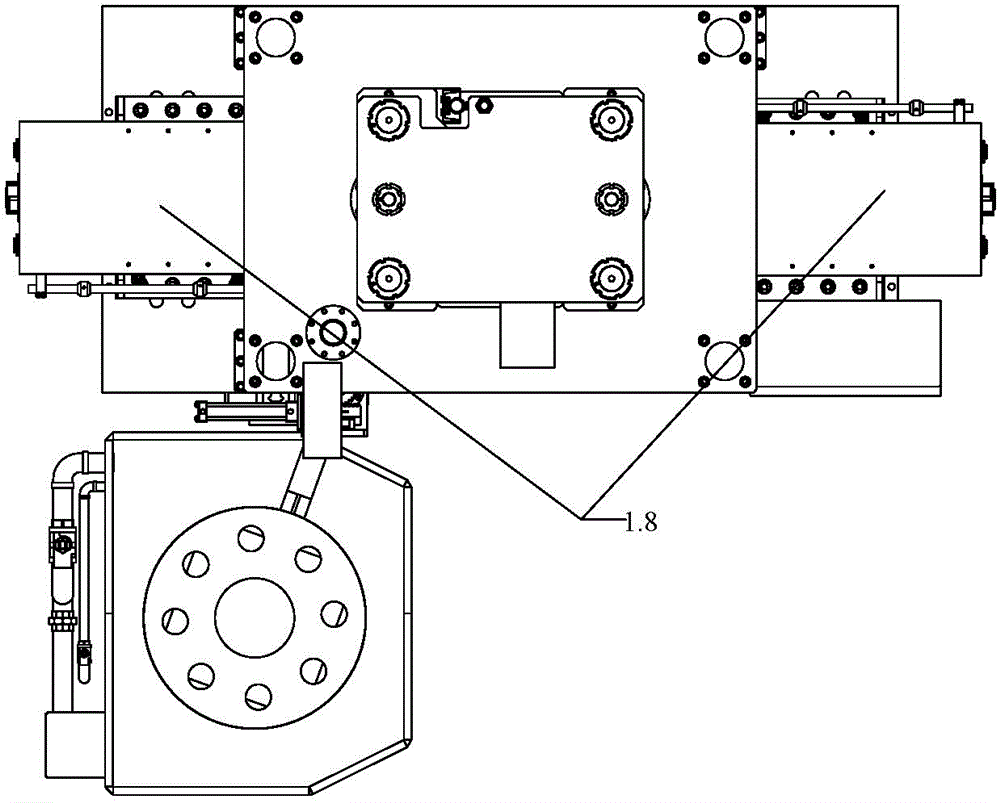

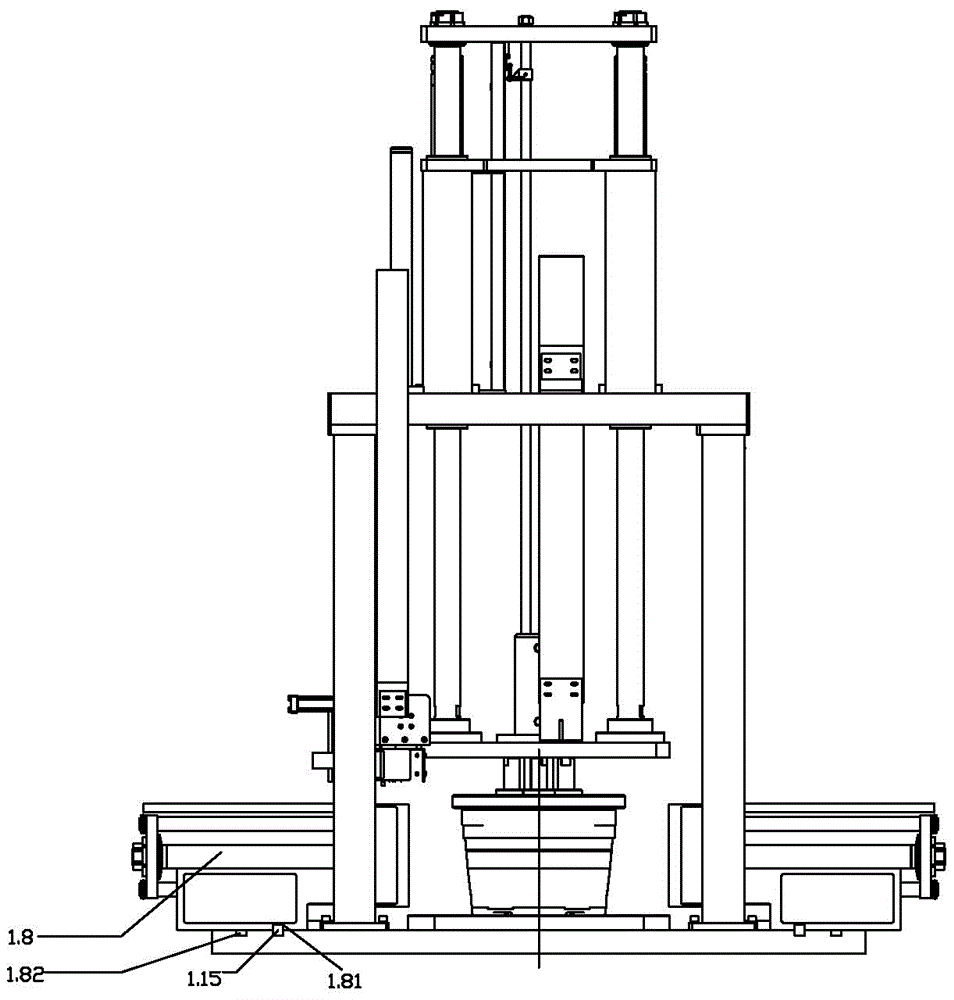

Pressurizing casting device and method for automobile hub

The invention discloses pressurizing casting device and method for an automobile hub. The device comprises a device body, a casting die, a movable sliding table, a die closing oil cylinder, a pressurizing mechanism, a side die closing mechanism, a quenching device and a control cabinet. The device has the advantages that 1, the pressurizing mechanism is additionally arranged on the basis of the existing gravity device and process; the pressurizing mechanism drives a pressurizing ring above the die to pressurize molten aluminum alloy in a die cavity; 2, a center riser is removed, and an exhaust plug is provided for exhausting; 3, a cooling system is improved, the multi-point multi-form cooling manner is carried out, and therefore, the cooling effect is improved, and the sequential solidifying process of a product can be effectively controlled; 4, a feeding opening forced cooling system is additionally arranged, so that the molten aluminum at a feeding opening can be solidified firstly, and as a result, the molten aluminum in the die cavity can be avoided reflowing. The invention also discloses a casting method of the gravity pressurizing casting device for the automobile hub. With the adoption of the device and method, the yield of castings is more than 99%; the percentage of pass of air tightness of finished product is up to 99.3%, and the elongation is up to 9.5%.

Owner:SUMEC WHEELS CO LTD

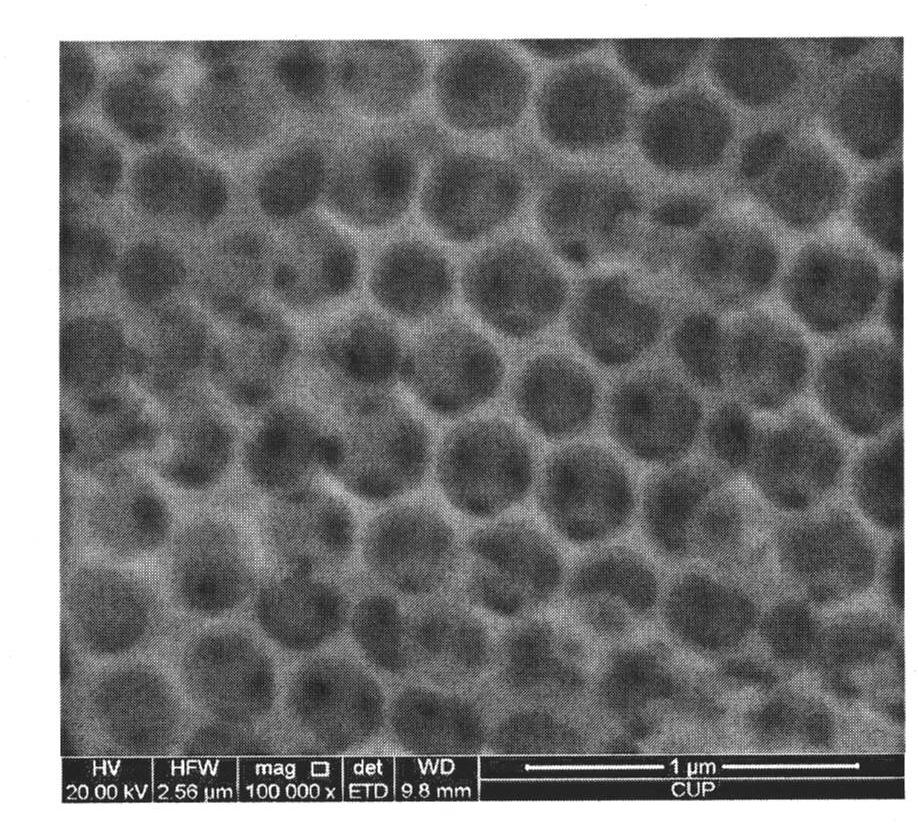

Method for preparing gradient TiO2 nano-tube arrry thin film by using multistep anodic oxidation process

InactiveCN101230479AReduce energy consumptionSimple processPolycrystalline material growthSurface reaction electrolytic coatingWater basedTio2 nanotube

The invention relates to a method of preparing a gradient TiO2 nanotube array film by utilizing the method of multi-step anodic oxidation. Firstly, phosphoric acid, hydrofluoric acid, ammonium fluoride, glycerin and deionized water are adopted as raw materials and prepared into a water-base electrolyte and an organic electrolyte respectively; secondly, the two electrode systems composed of a titanium foil sheet and a platinum sheet are placed into the water-base electrolyte and the organic electrolyte for a repeated anodic oxidation; and finally, the TiO2 nanotube array film material with a gradient structure is generated on the titanium foil sheet. The method is fit for manufacturing photoelectrochemical apparatuses of various types and has a far-ranging application prospect in the industrial fields of light energy utilization, green energy development, sewage disposal and so on.

Owner:TSINGHUA UNIV

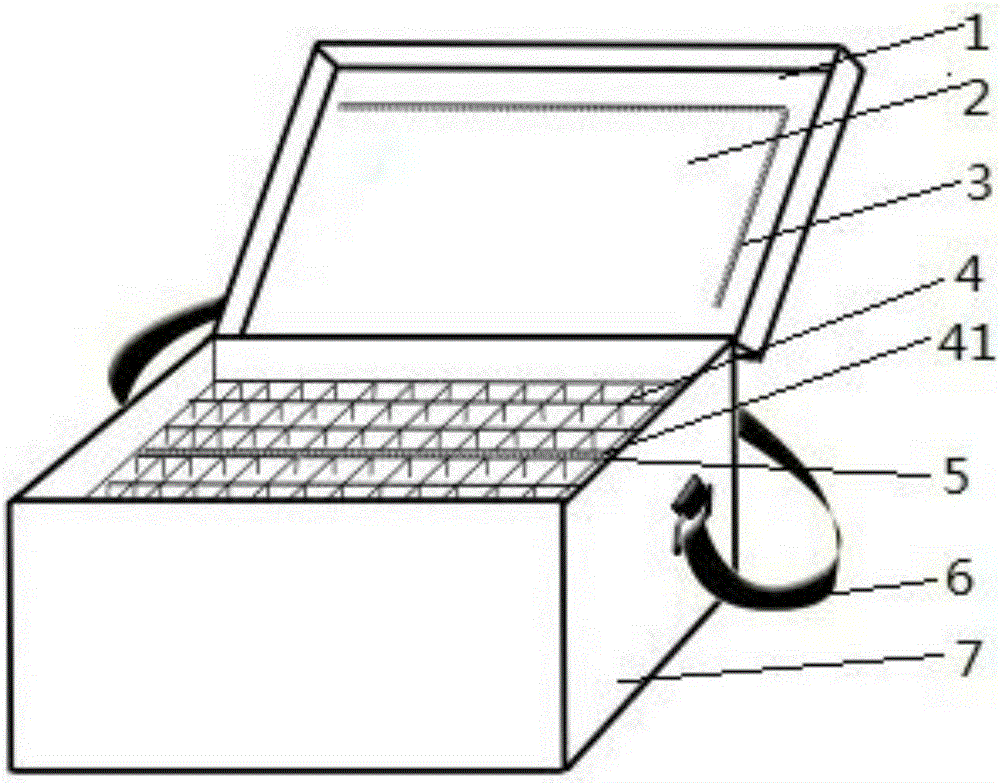

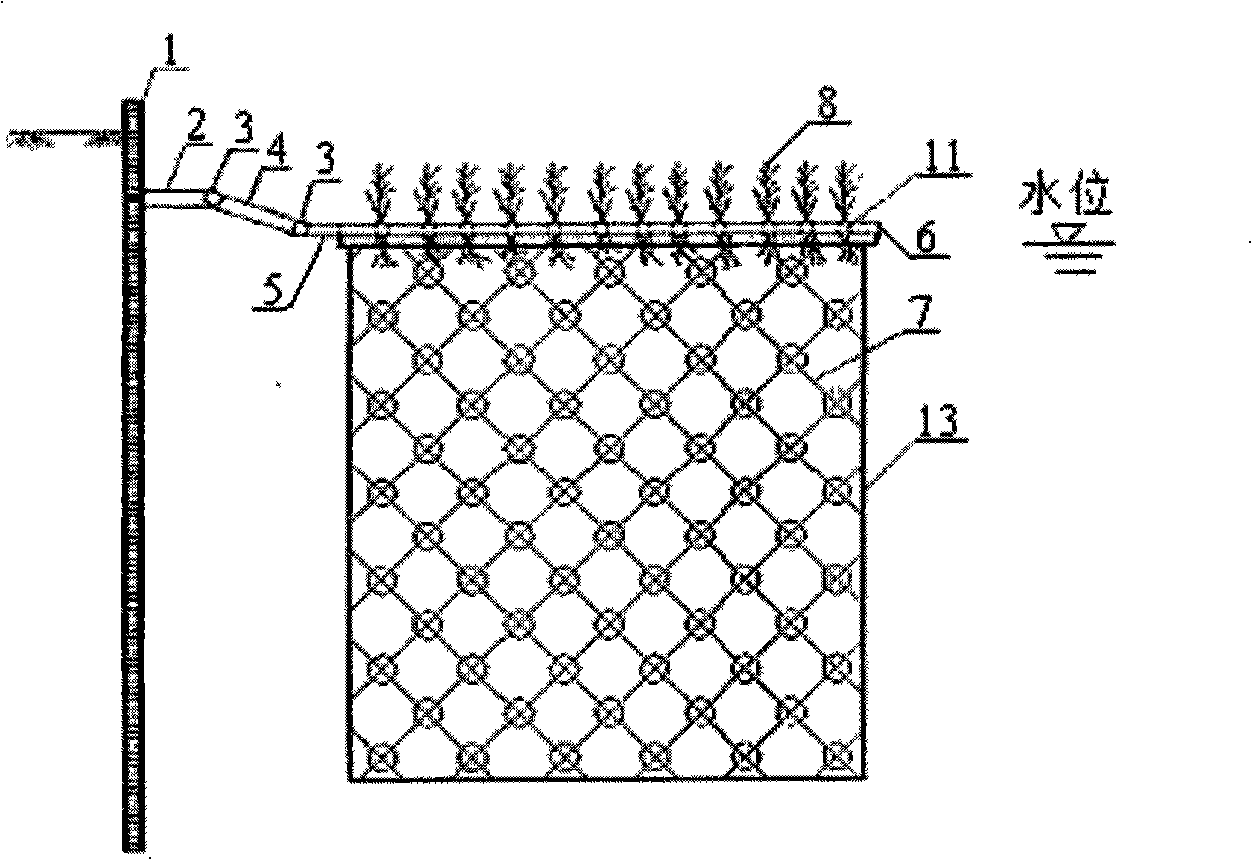

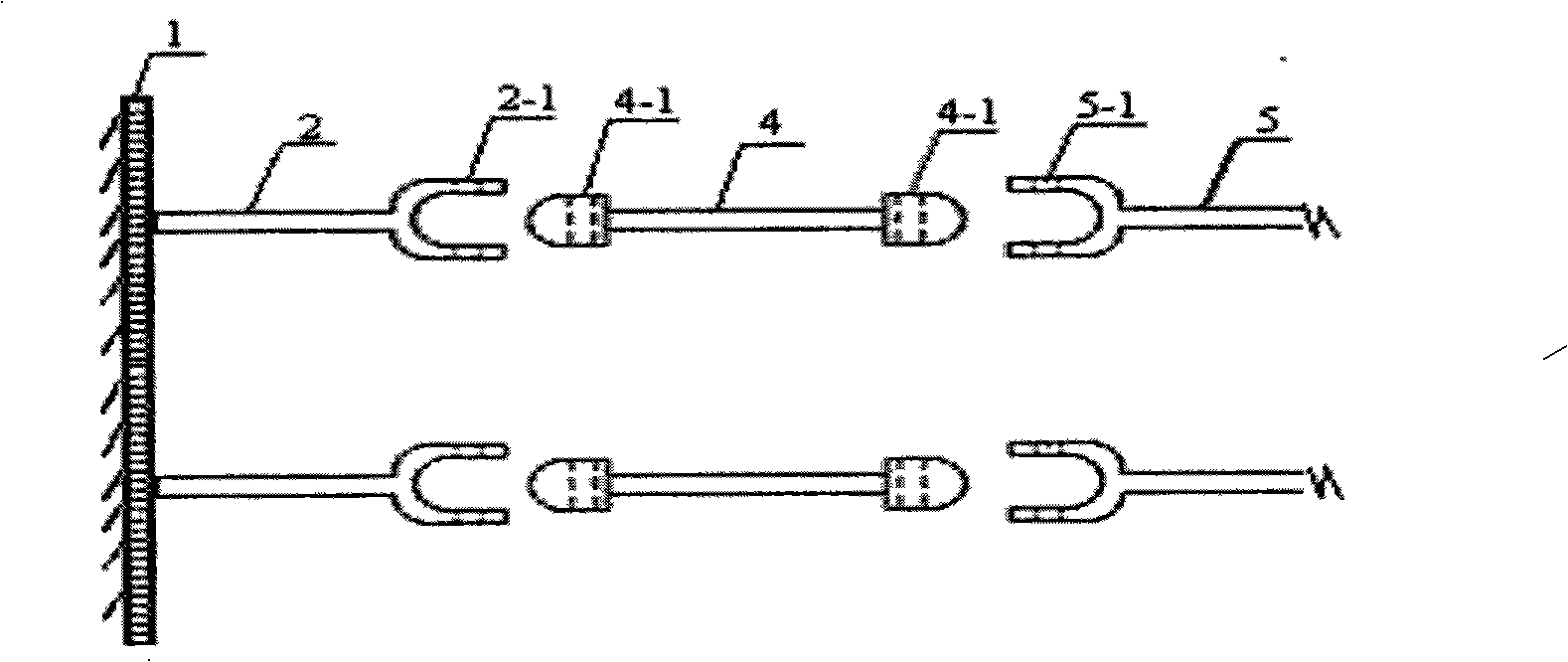

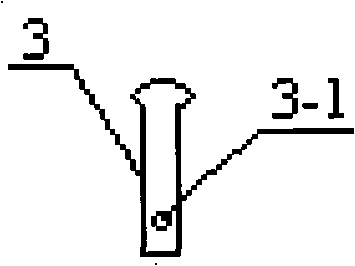

Combined ecological floating bed device

InactiveCN101514054AIncrease the number of microorganismsGood removal effectSustainable biological treatmentBiological water/sewage treatmentWater flowWater quality

A combined ecological floating bed device relates to a combined ecological floating bed device for in-situ purification of polluted water of rivers and lakes, comprising an anchoring rod (2), a fixing rotary shafts (3), a connecting rod (4), a fixing rod (5), a floating body (6), bio-net filler (7) and aquatic plants (8). The floating body (6) is fixedly connected with the fixing rod (5) which is movably connected with the connecting rod (4) and anchoring rod (2) through two fixing rotary shafts (3), the anchoring rod (2) is fixedly connected with a revetment (1), and the floating body (6) is provided with the bio-net filler (7) thereunder and aquatic plants (8), such as iris pseudacorus, scirpus tabernaemontani, canna, torilisjaponica and vetiver, thereon. The invention has the characteristics of simple structure, convenient installation and management, good effect of purifying water, strong stream shock resistance, automatic elevation along with the water level change, no influence to the safety of river channel navigation and the like, thus being very suitable for the in-situ purification of natural river channels, lakes and scenic waters.

Owner:TONGJI UNIV

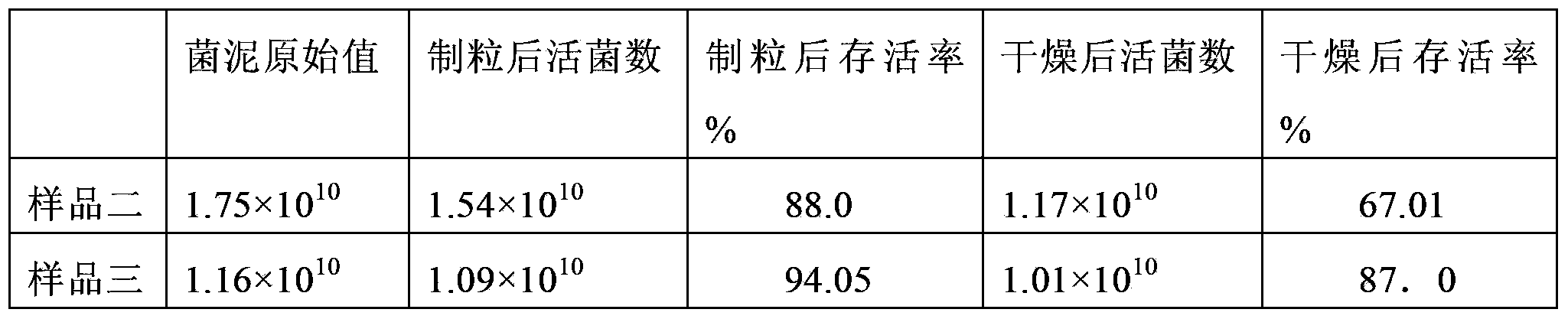

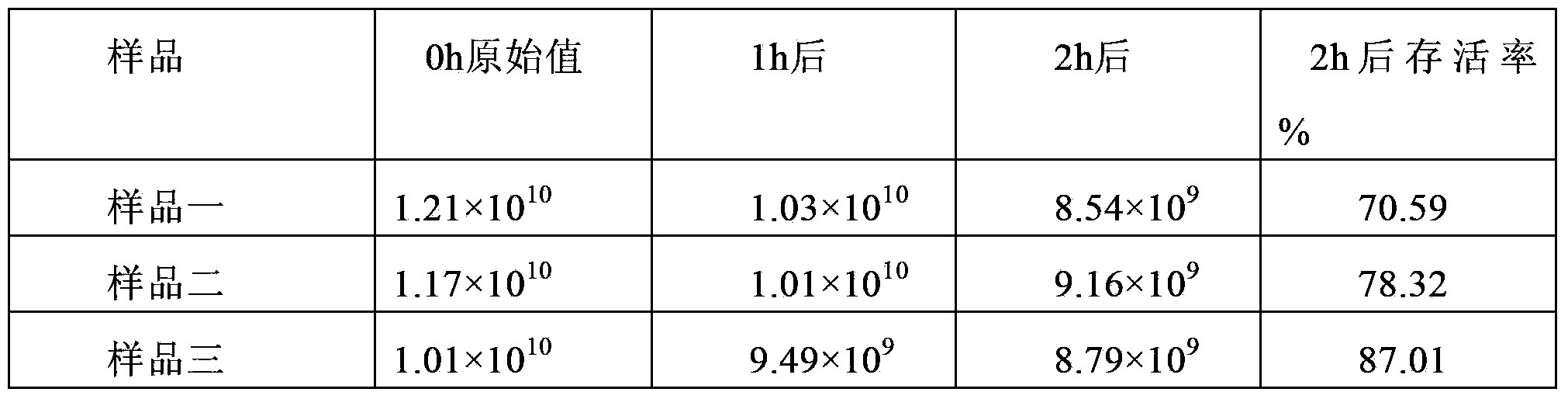

Feed-use high-activity lactobacillus solid preparation and preparation method thereof

ActiveCN103392911AMorphological stabilityEffective protectionAnimal feeding stuffIntestinal fluidHigh humidity

The invention discloses a feed-use high-activity lactobacillus solid preparation and a preparation method thereof. The feed-use high-activity lactobacillus solid preparation comprises growing beneficial lactobacillus bacterium mud, a protection formula and a basic formula. The invention also provides the preparation method of the feed-use high-activity lactobacillus solid preparation, lactobacillus can be protected through synergistic effects of components in the protection formula and the basic formula, and the living bacterium survival rate in the whole process can be improved. The lactobacillus in the prepared feed-use high-activity lactobacillus solid preparation has improved high temperature and high humidity resistances, has a high survival rate in a simulated intestinal fluid, and a substantial improved animal application effect.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

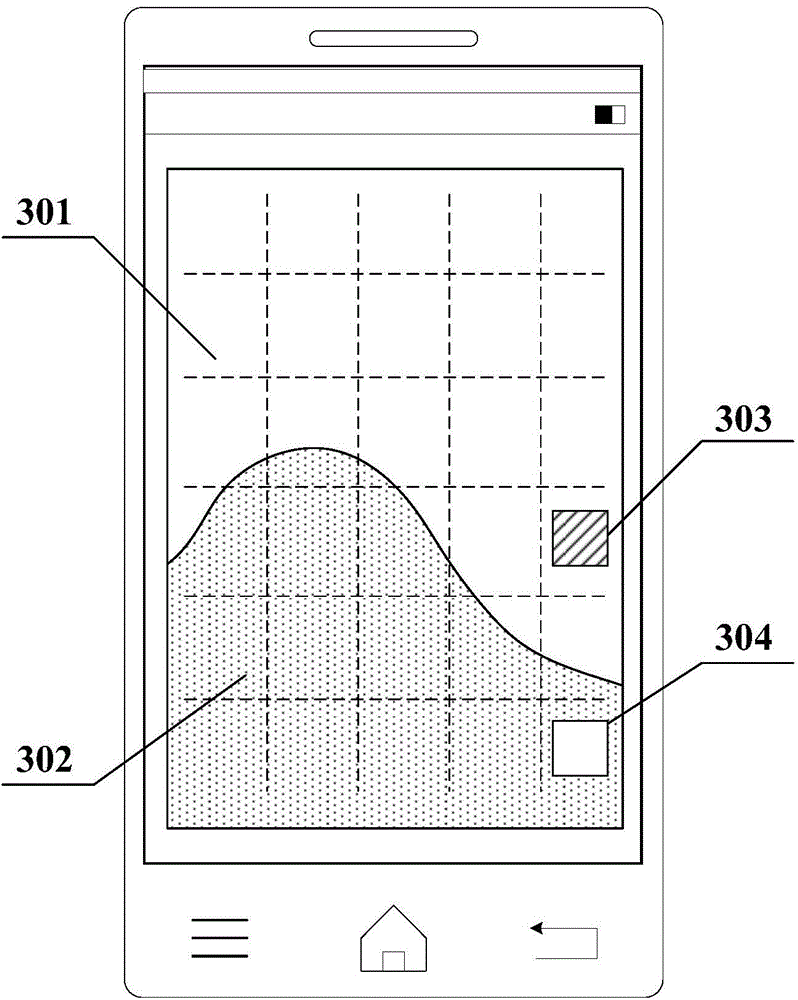

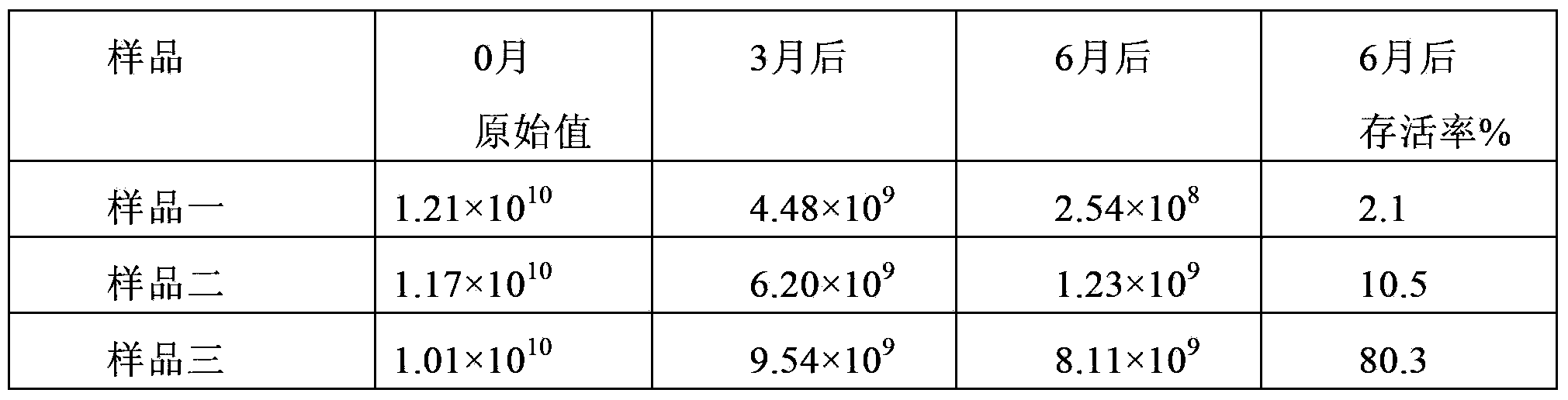

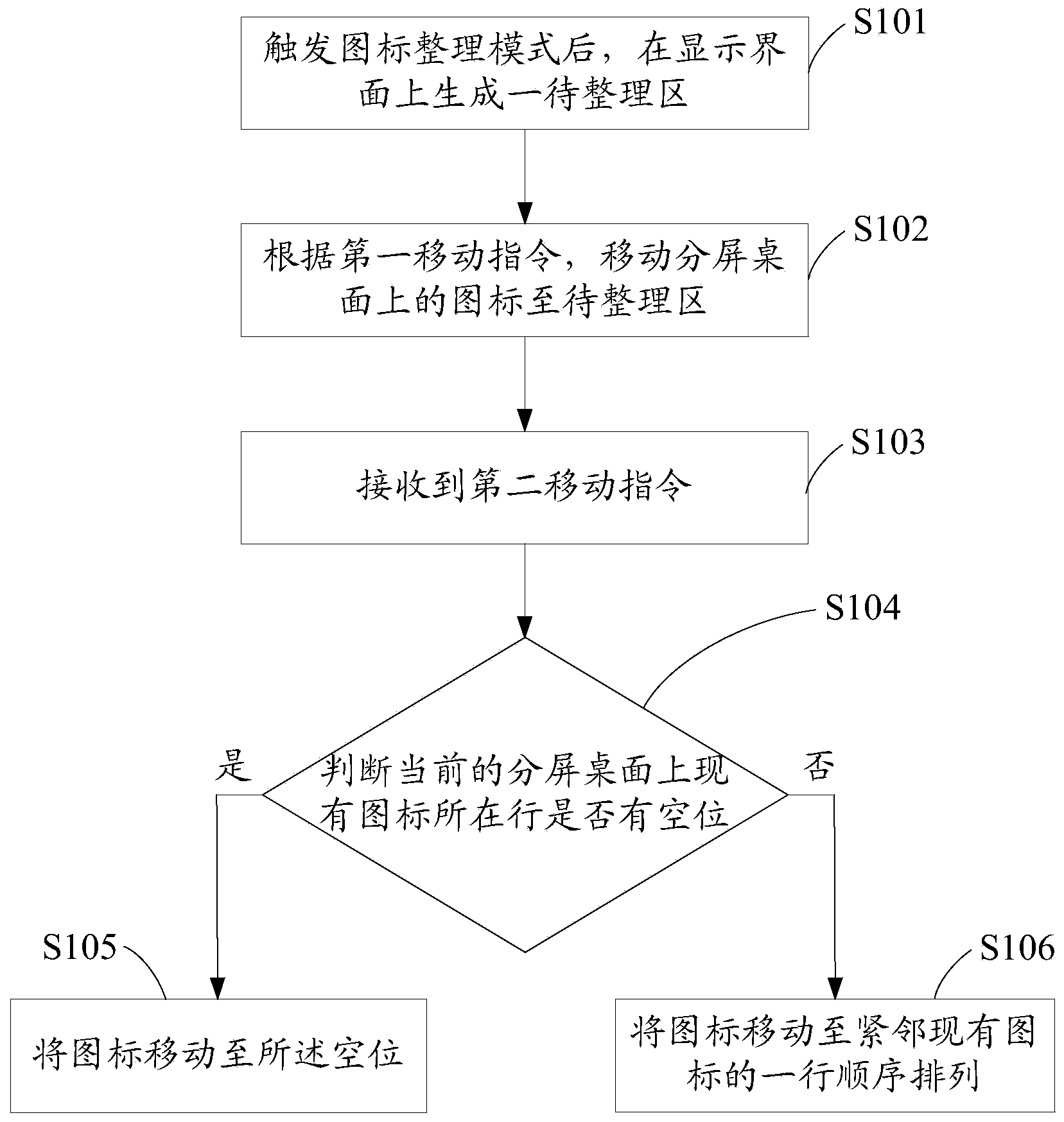

Desktop icon arrangement method and intelligent terminal

ActiveCN103902163AOrderly rowsReduce or save post-processing workInput/output processes for data processingHuman–computer interaction

The invention discloses a desktop icon arrangement method and an intelligent terminal. The method includes the following steps: after an icon arrangement mode is triggered, generating a to-be-arranged area on a display interface; according to a first moving instruction, moving icons on a split screen desktop to the to-be-arranged area; according to a second arrangement instruction, judging whether vacancies exist in a row that existing icons are positioned on the current split screen desktop or not; if yes, moving the icons to the vacancies. By the method, the icons on the split screen desktop are enabled to be arranged more orderly, so that subsequent processing work of a user is reduced or omitted, operating efficiency is improved, and user experience is improved. In addition, when the to-be-arranged area is filled with the icons, the to-be-arranged area can be expanded on the current display interface to contain more icons, more icons can be displayed on the current display interface in each time, and frequency of split screen sliding is reduced, so that operating efficiency is further improved.

Owner:NUBIA TECHNOLOGY CO LTD

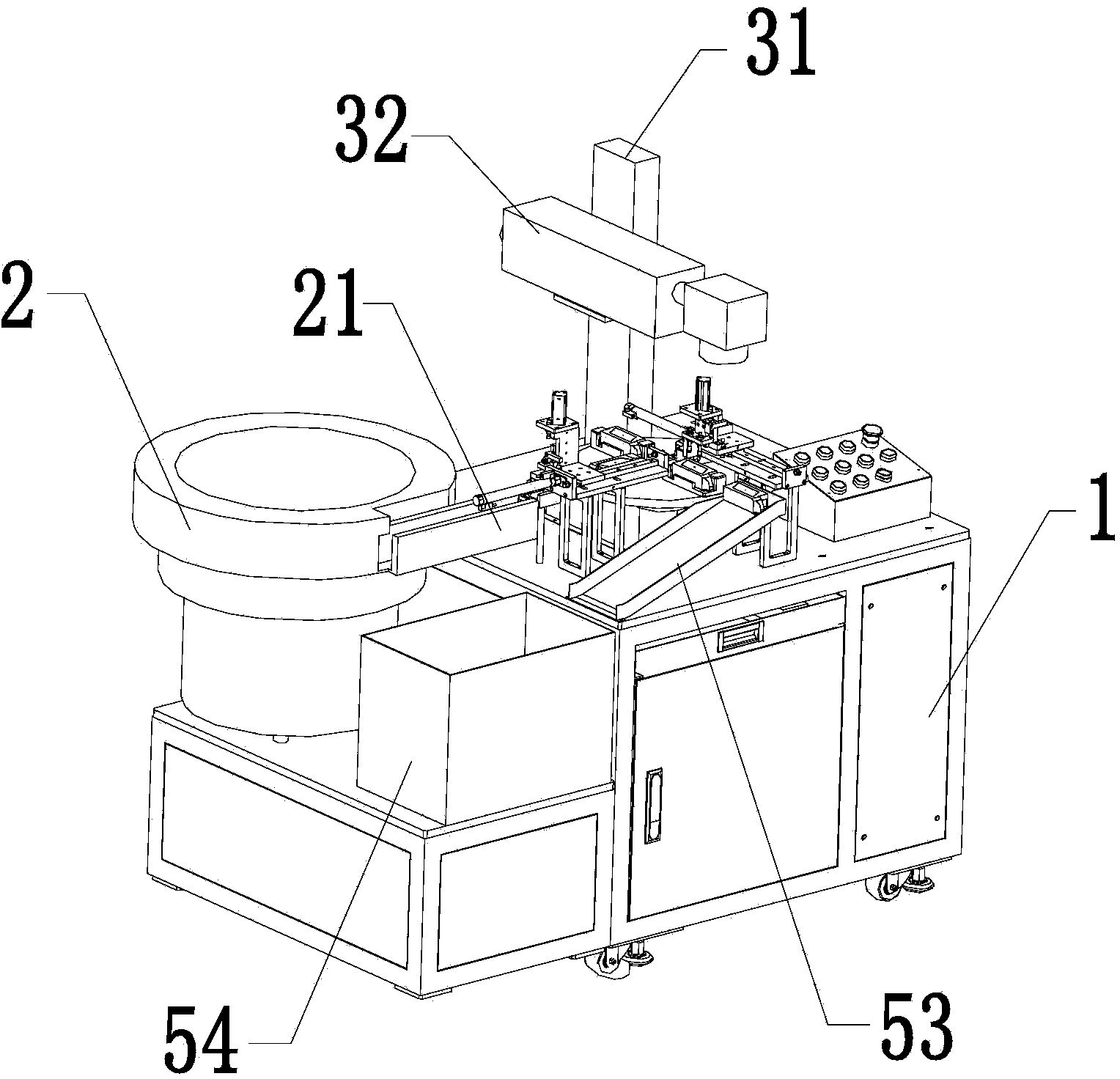

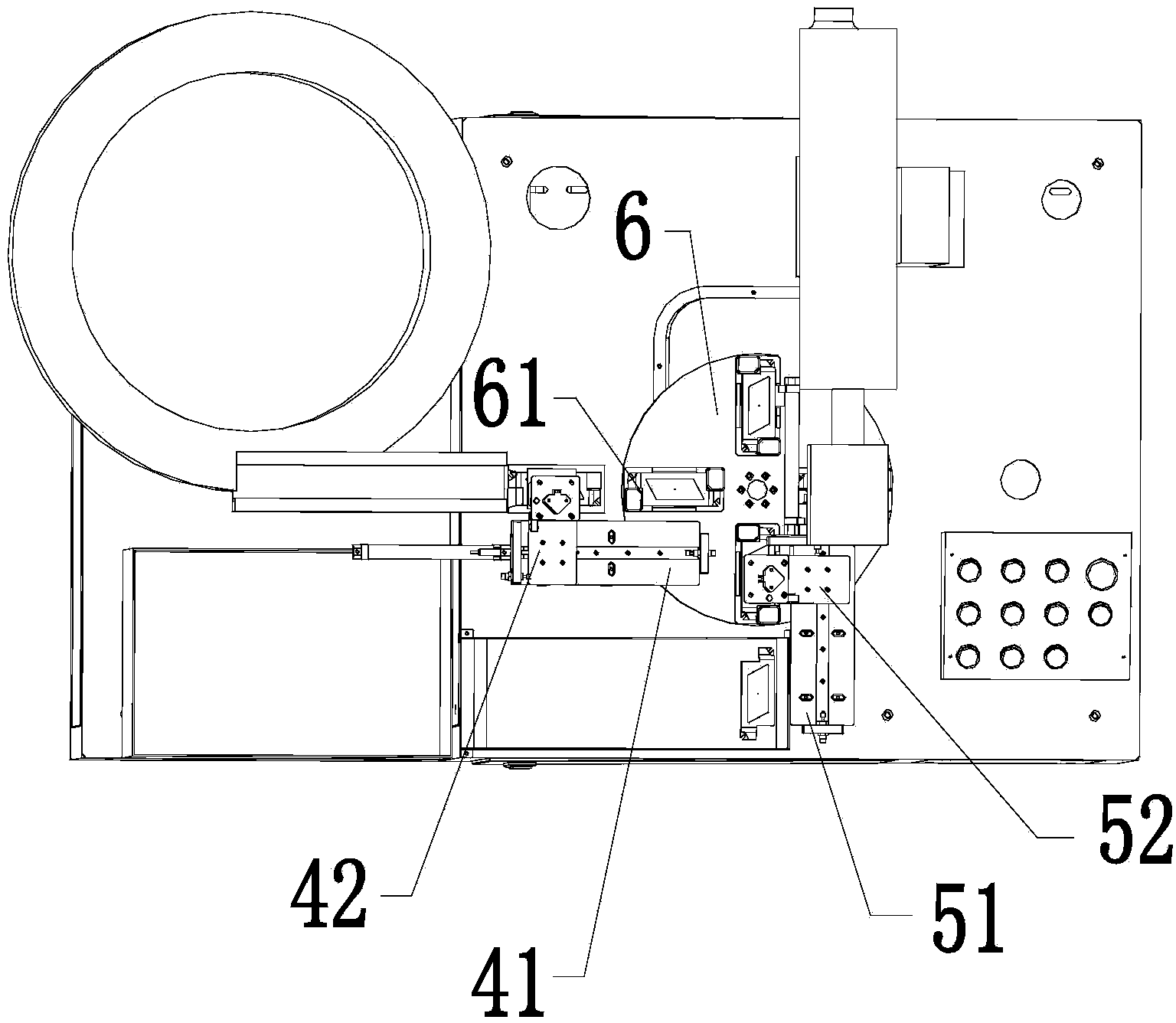

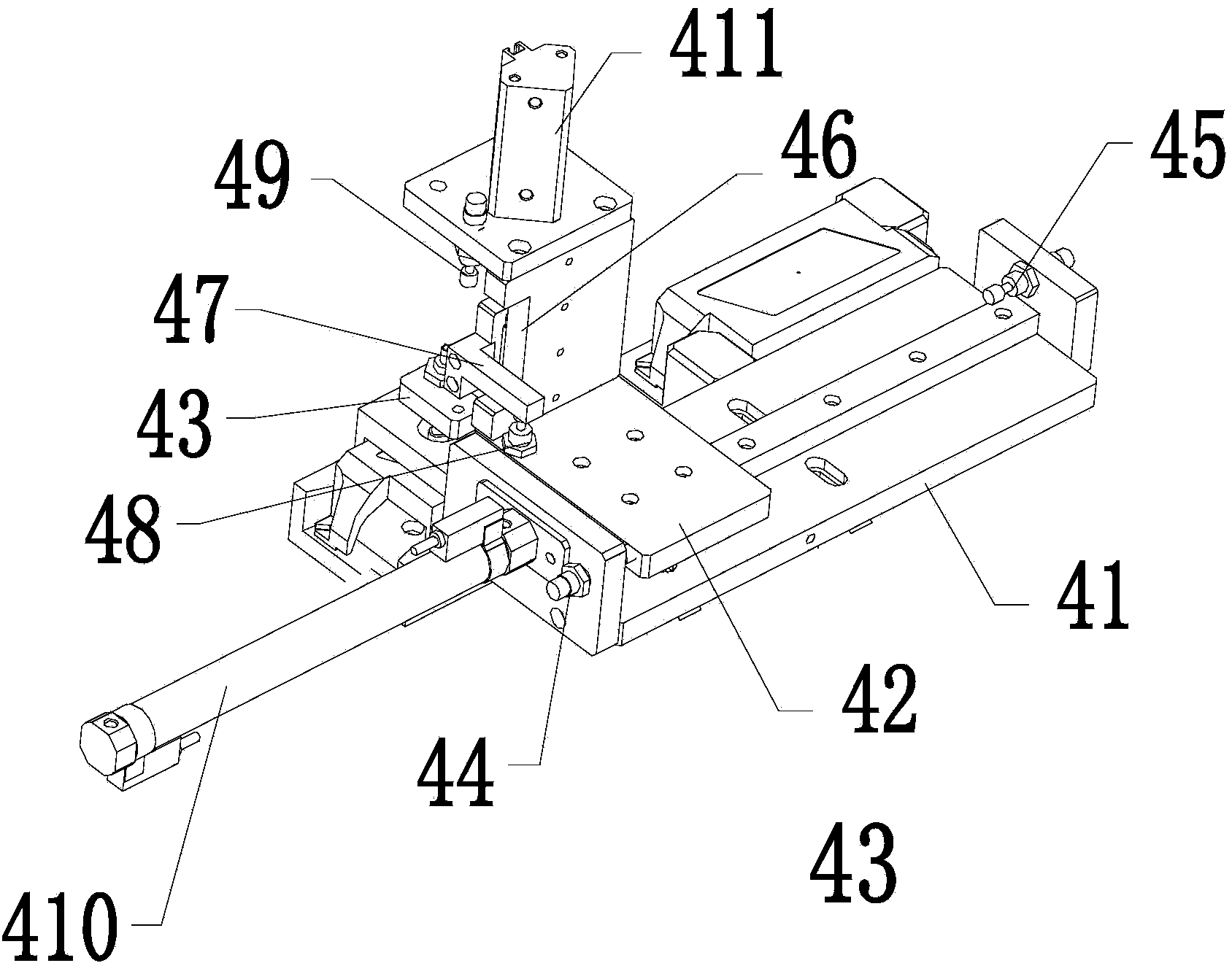

Laser marking device capable of feeding and discharging materials automatically

ActiveCN103832085ARealize fully automatic markingSolve the problem that marking products cannot be transportedPrintingLaser etchingEngineering

The invention discloses a laser marking device capable of feeding and discharging materials automatically and belongs to the field of laser marking. The laser marking device capable of feeding and discharging the materials automatically comprises a vibrating disk, a machine base, a laser etching mechanism and a central processing unit which controls the laser marking device capable of feeding and discharging the materials automatically to operate. The vibrating disk is provided with a conveying track. The machine base is provided with a material taking mechanism, a discharging mechanism and a rotating disk which can rotate around the center. The material taking mechanism is arranged at the discharging position of the conveying track. The rotating disk is arranged at the discharging position of the material taking mechanism. The rotating disk is provided with multiple carrying frames. The laser etching mechanism is arranged above the marking position of the rotating disk. The discharging mechanism is arranged at the discharging position of the rotating disk. According to the laser marking device capable of feeding and discharging the materials automatically, the vibrating disk is used for solving the problem that an existing laser marking device cannot adjust marked products to be conveyed in a correct state; as a result, full-automatic marking through the laser marking device is realized, marking efficiency is greatly improved, and labor cost is reduced.

Owner:深圳市艾雷激光科技有限公司

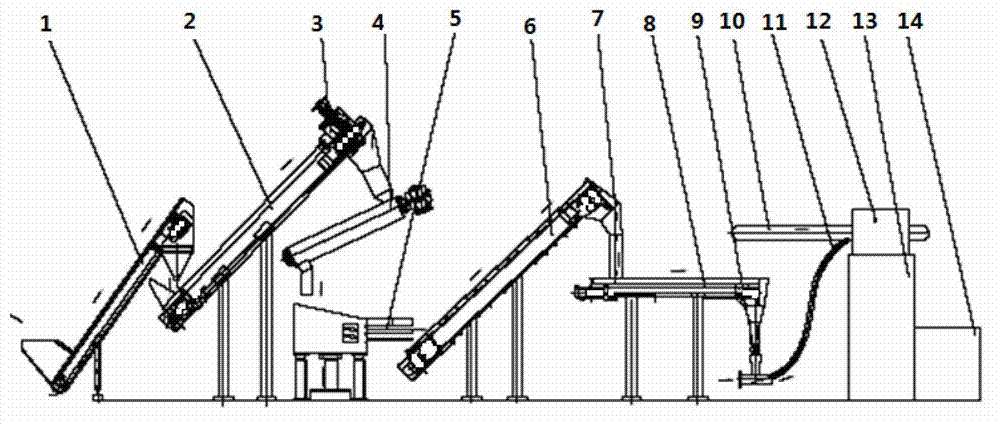

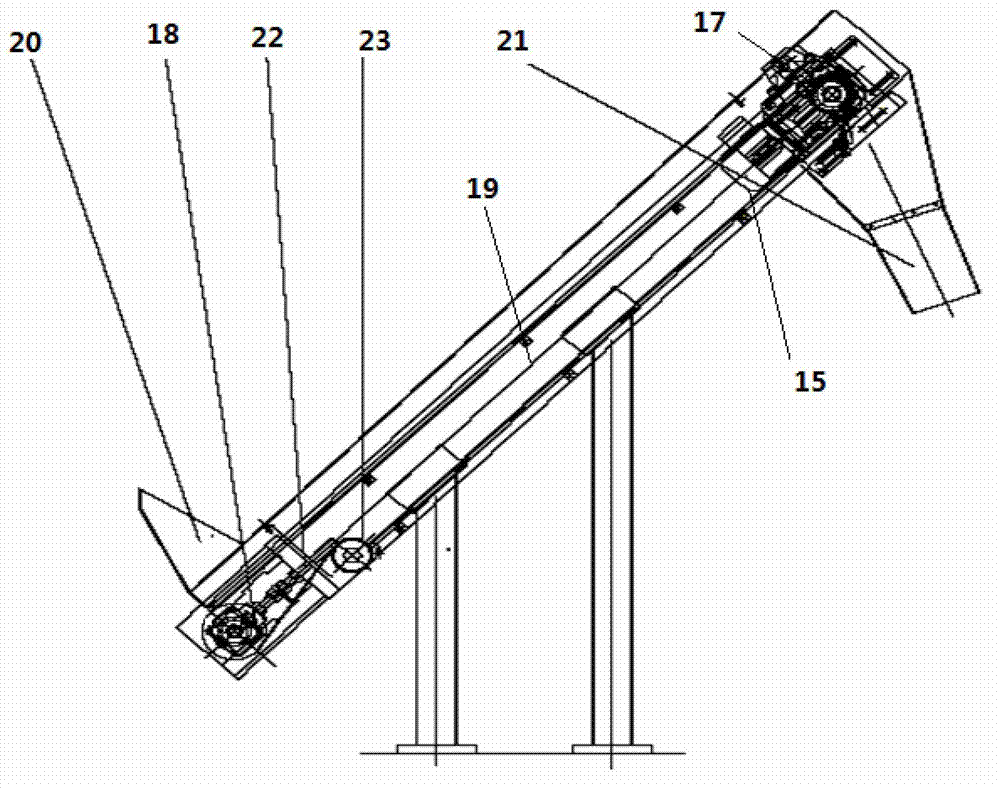

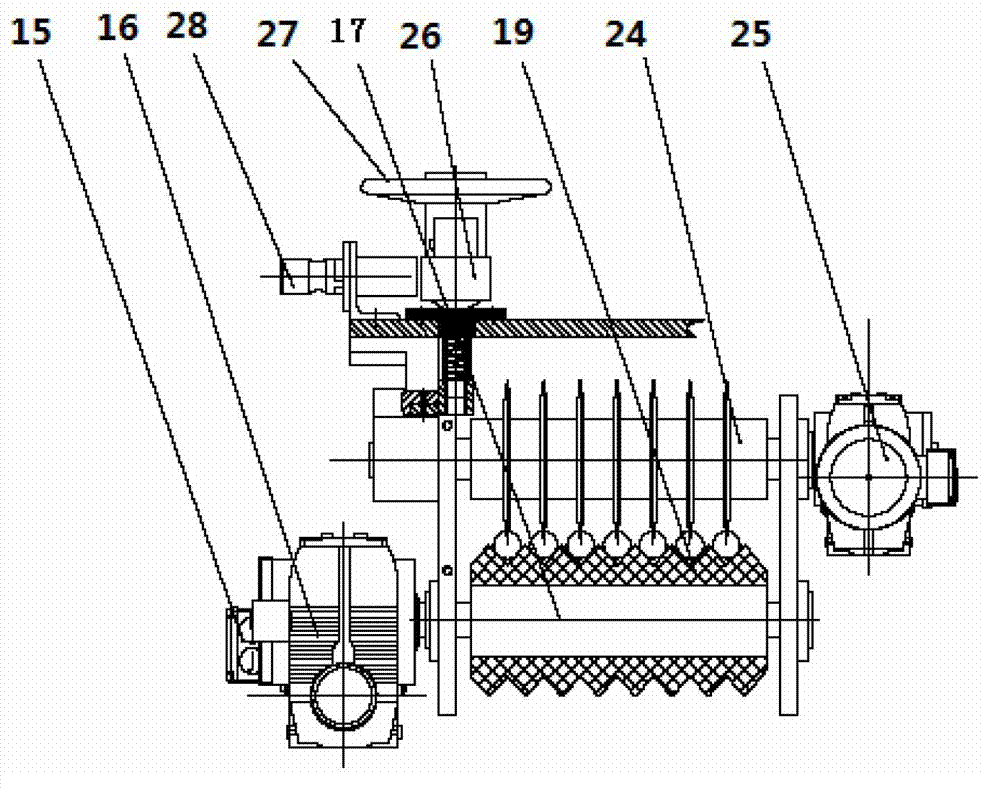

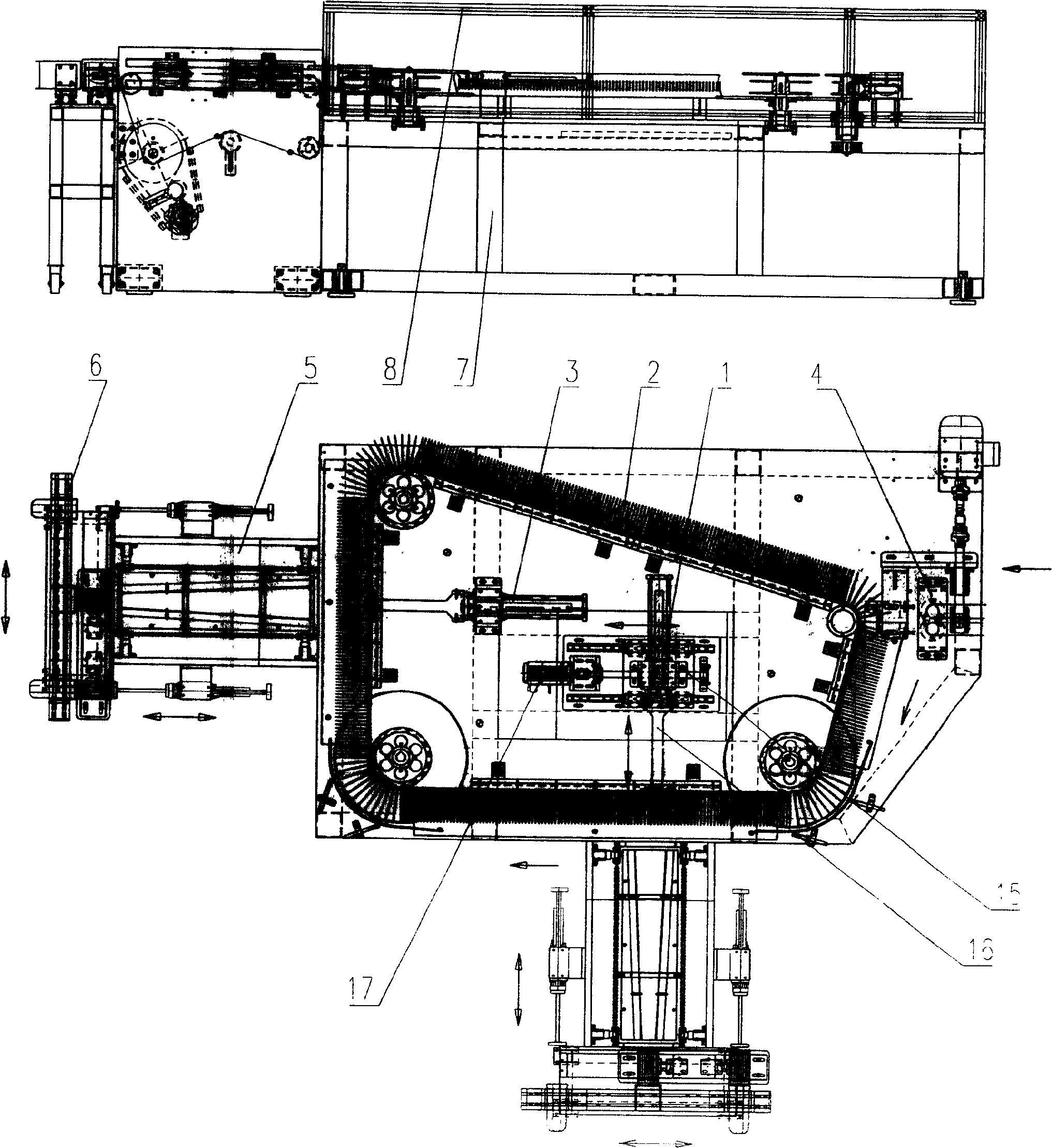

On-line recovery production line for cut tobacco of defective cigarettes

ActiveCN103082406AOrderly rowsGrade unchangedCigarette manufactureConveyor partsBiotechnologyAgricultural science

The invention discloses an on-line recovery production line for cut tobacco of defective cigarettes. The ingredients and the quality of the recovered cut tobacco are not affected and the grade is kept unchanged, the recovered cut tobacco is clean and can be directly transported into a cigarette making unit, the cut tobacco has high recovery rate, and the recovered cut tobacco has quite high social and economic values. The on-line recovery production line for cut tobacco of defective cigarettes comprises a defective-cigarette adding device (1) and a cigarette making machine (13) and further comprises a defective-cigarette sorting mechanism (2), a defective-cigarette breaking mechanism (3), a defective-cigarette loosening mechanism (4), a defective-cigarette vibrating and screening mechanism (5), a defective-cigarette isolation-plate conveying mechanism (6), a metering device (7), a variable-frequency speed-regulating conveying belt (8), an airlock (9), an electric-control butterfly valve (10), a wind-power cut-tobacco feeding aluminium pipe (11) and a cut-tobacco falling hopper (12).

Owner:昆明烟机集团三机有限公司

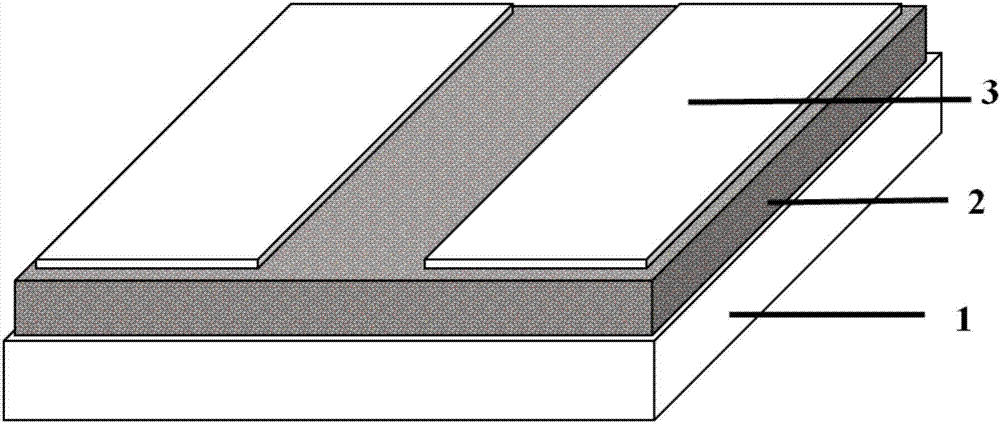

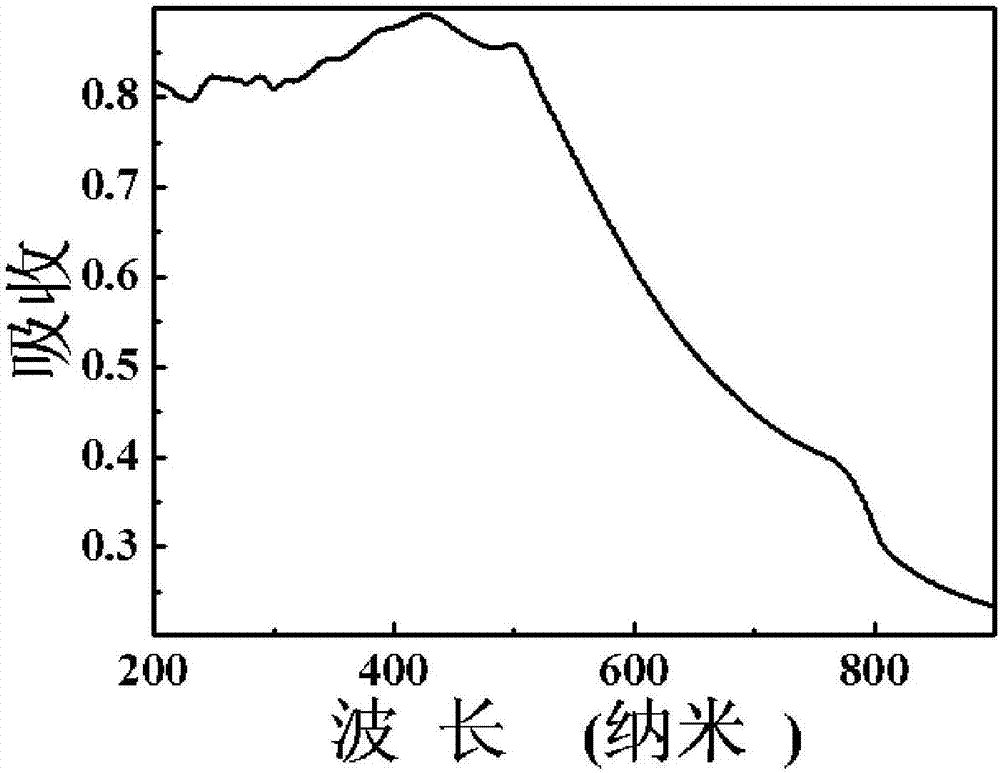

FA<0.85>Cs<0.15>PbI<3> membrane-based broadband superspeed photodetector and preparation method thereof

ActiveCN107316943AImprove photoelectric propertiesImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

The invention discloses a FA<0.85>Cs<0.15>PbI<3> membrane-based broadband superspeed photodetector and a preparation method thereof. A FA<0.85>Cs<0.15>PbI<3> membrane is arranged on the upper surface of insulating glass, and a pair of gold membrane electrode in ohmic contact with the membrane is arranged on the FA<0.85>Cs<0.15>PbI<3> membrane. Due to use of the characteristic of a large specific surface area of the FA<0.85>Cs<0.15>PbI<3> membrane and full use of the super high electronic mobility of the membrane, the photodetector has superfast response speed, high light absorption performance, and high electromagnetic immunity, and can sense light ranging from ultraviolet to visible light flexibly. The invention raises new prospect for application of Perovskite materials in the photodetector.

Owner:HEFEI UNIV OF TECH

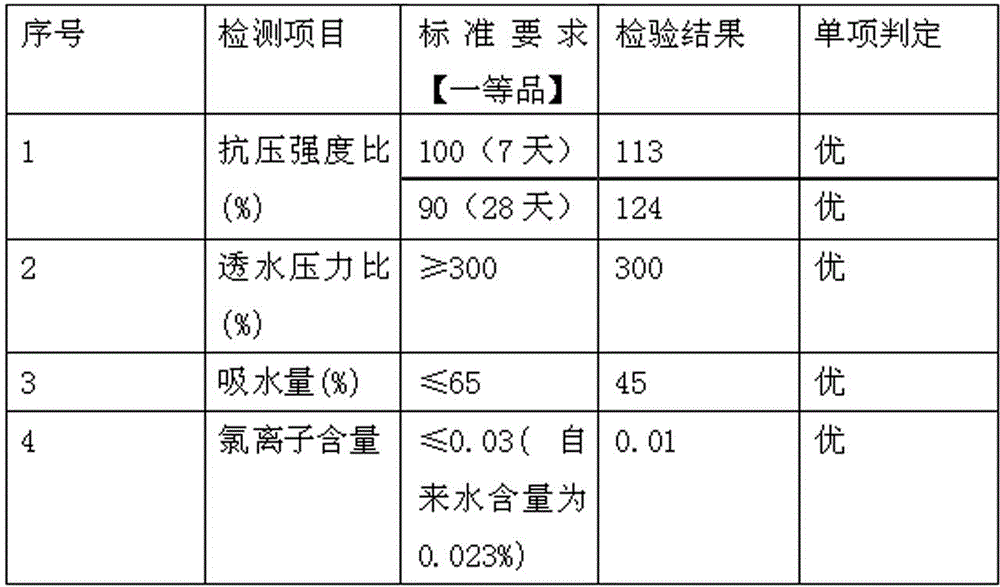

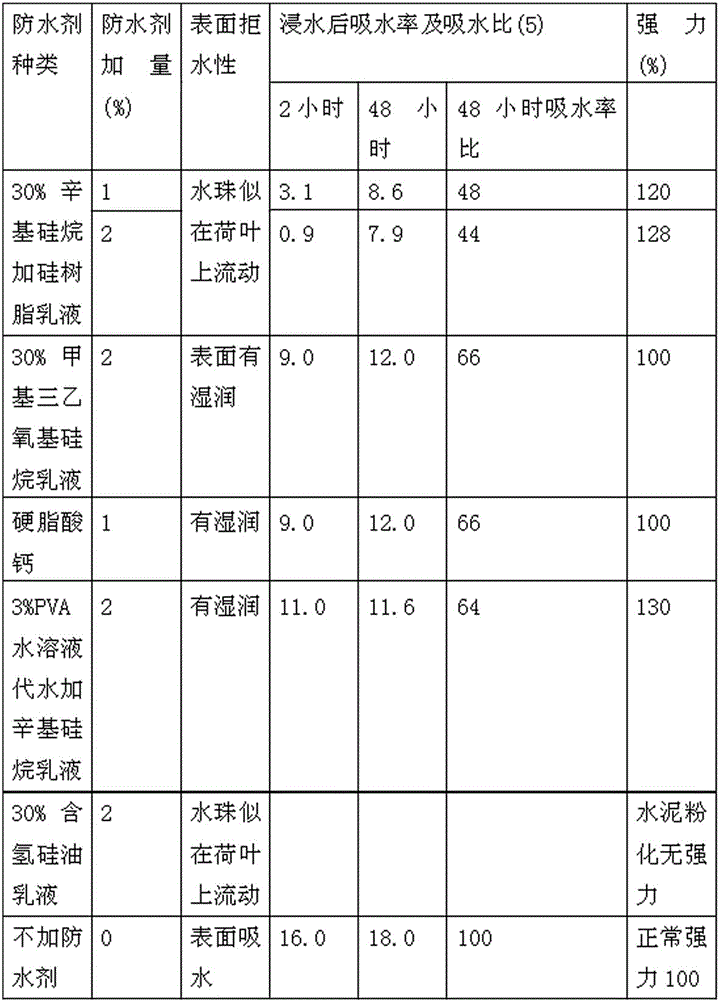

Preparation method of efficient organic silicon emulsion water-proofing agent for reinforcing cement mortar concrete

The invention relates to a preparation method of an efficient organic silicon emulsion water-proofing agent for reinforcing cement mortar concrete. The preparation method comprises the following steps: firstly adding octene and isopropanol in a three-necked flask, filling the flask with nitrogen, heating in water bath, reacting under a reflux condition, and depressurizing to steam out octyl triethoxysilane; adding methyl triethoxysilane and a dimethyl siloxane ring body in the three-necked flask, using a catalyst to balance the solution, performing hydrolysis on the solution, reacting to obtain a partial hydrolysis prepolymer of methyl silicone resin; at last, weighing octyl triethoxysilane and a methyl silicone resin prepolymer, adding a non-ionic surfactant alkyl alcohol polyoxyethylene ether, fully stirring the solution uniformly, adding water to emulsify the solution, and adding a buffer solution to obtain a waterproof emulsion; or, adding water in a emulsification kettle, adding the non-ionic surfactant and the buffer solution in the kettle, starting a high-speed shearing machine, slowly adding octyl triethoxysilane and the silicon resin prepolymer in the kettle, and emulsifying the substances to obtain the same waterproof emulsion. The efficient organic silicon emulsion water-proofing agent has the characteristics of high water seepage pressure resistance and the like.

Owner:NANXIONG DING CHENG NEW MATERIAL TECH CO LTD

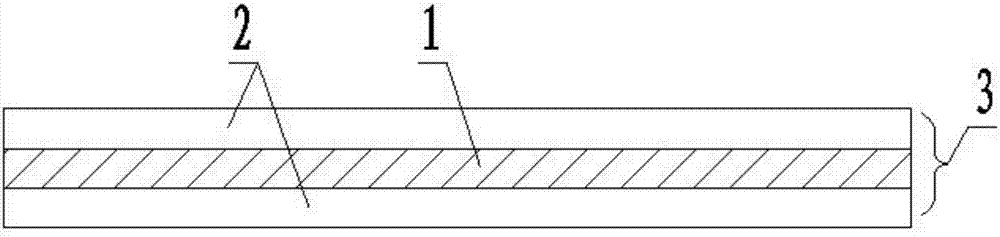

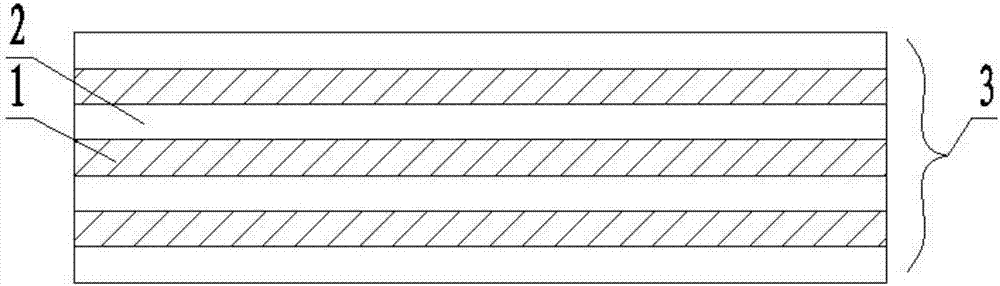

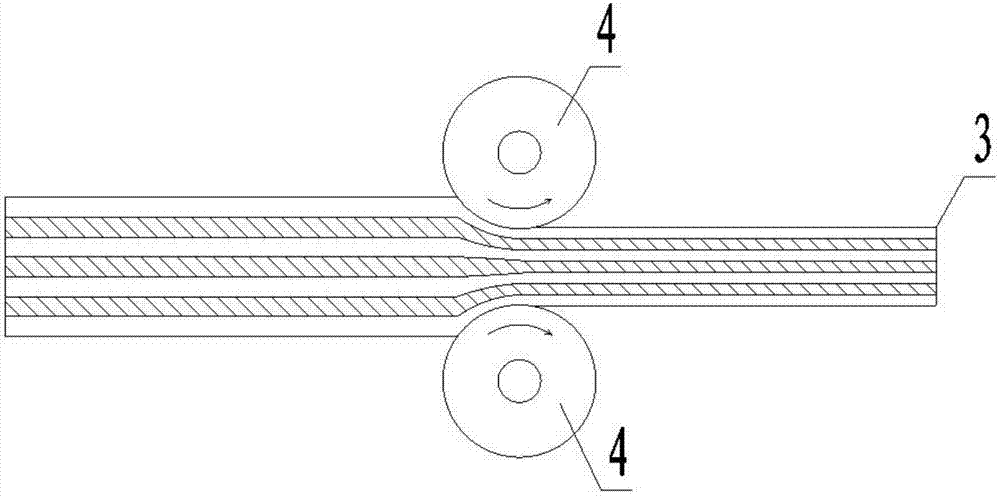

Graphene-based electrical conductor and preparation method thereof

InactiveCN106898408AHigh power transmission efficiencyIncrease contactStrip/foil conductorsConductive layers on insulating-supportsElectric power transmissionElectrical conductor

The invention discloses a graphene-based electric conductor and a preparation method thereof. The graphene-based electric conductor comprises a layered structure; the layered structure comprises graphene layers (1) and substrate layers (2) which are alternately arranged; and each graphene layer (1) is compressed between two adjacent substrate layers (2). The preparation method of the graphene-based electric conductor includes the following steps that: one or more graphene layers are laminated with two or more substrate layers, so that a graphene layer and substrate layer alternately connected sheet can be formed; and the sheet is compressed, so that the graphene layer can be compressed between two adjacent substrate layers, so that a layered structure can be formed, and the graphene-based electrical conductor is obtained. The graphene-based electric conductor of the invention has the advantages of low resistance and small electric power loss. With the graphene-based electric conductor and the preparation method thereof adopted, power transmission efficiency can be improved, the distribution range of a power grid can be expanded, and compression processing can be facilitated.

Owner:HANGZHOU CABLE +1

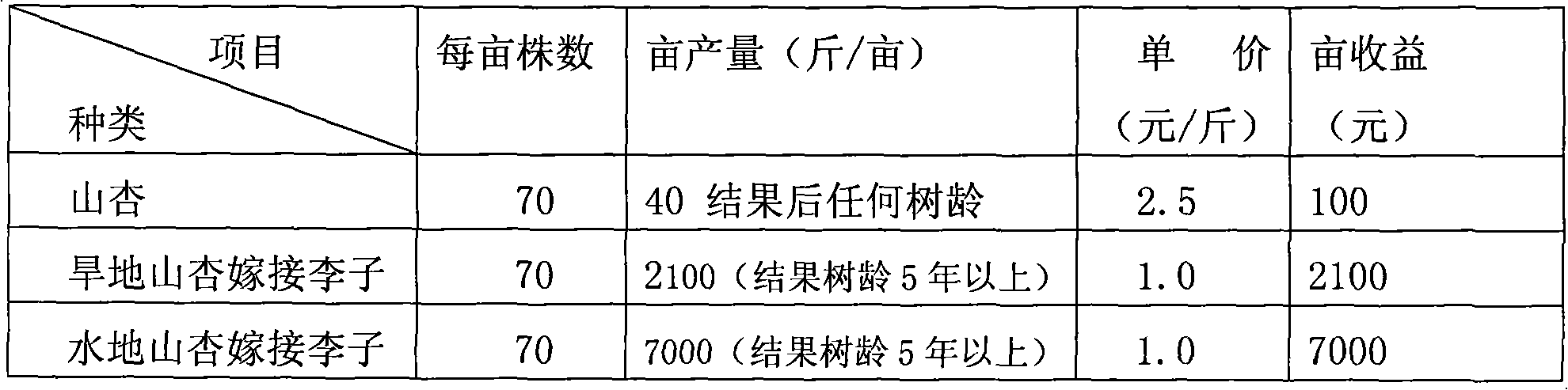

Method for grafting wild apricot and plum at mountainous regions and cultivation management technology

InactiveCN101669438AAbundant resourcesWidely distributedCultivating equipmentsHorticultureAridRootstock

The invention discloses a method for grafting wild apricot and plum at mountainous regions and a cultivation management technology. The method comprises the step of cleft grafting or bark grafting; cleft grafting, before the 5days of the wild apricot blossoms, sawing off the wild apricot, flatly cutting a sawing opening, ear grafting, tightly fastening with a plastic piece, covering a plastic bags, and tightly fastening under a grafting opening; bark grafting, when bark is separated from the tree, sawing off the parental stock, flatly cutting a cross section, ear grafting, covering a plastic bag and tightly fastening under a grafting opening; and managing after grafting, examining survival rate, putting into bags at proper time, erasing croth, piling and binding to be prevent from folding,pruning and shaping, removing weeds, digging a cistern to store water, and executing by means of insect prevention and hail prevention. The method and the technology is reasonable, is easily grasped,has high survival rate, play the advantage of the two trees by grafting, has good harvest at arid hilly regions, and can benefit for many years with one year investment, thereby being a good way forcreating income for famers in the arid northern China.

Owner:李化林

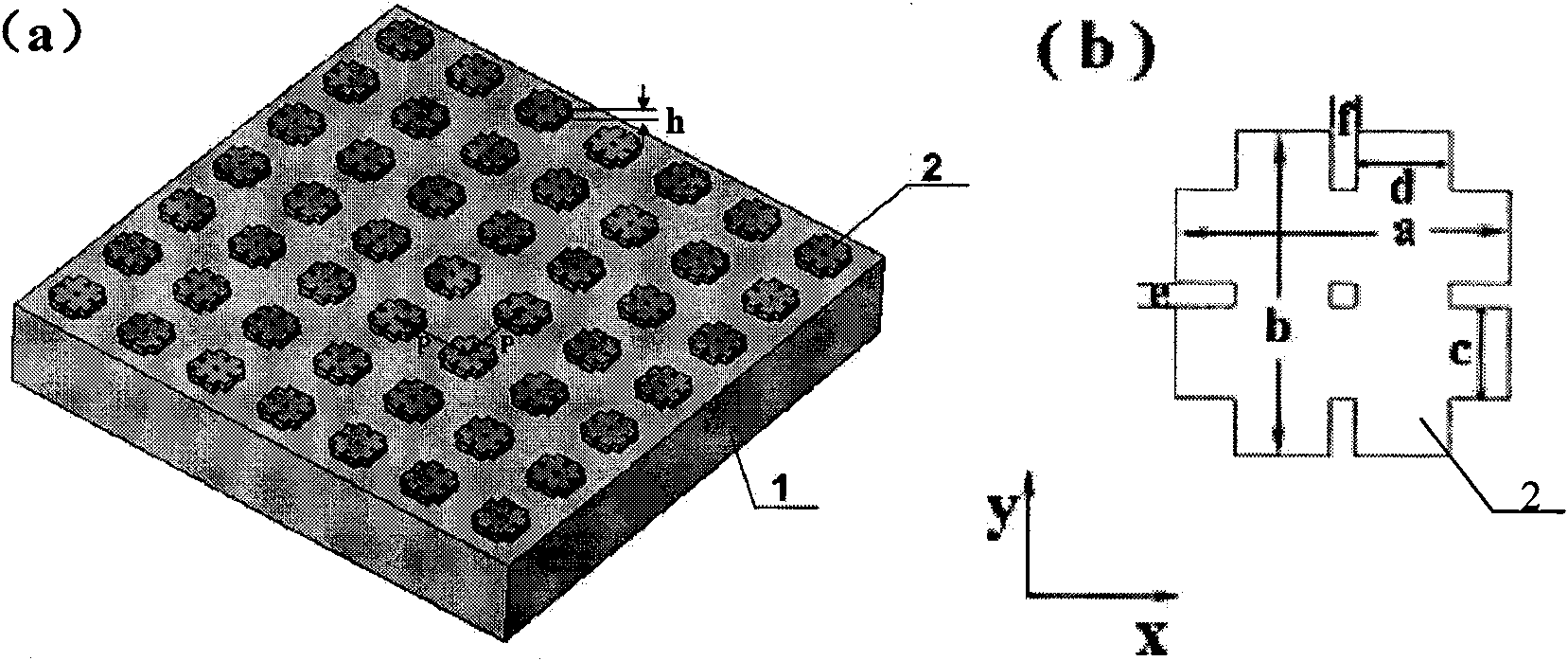

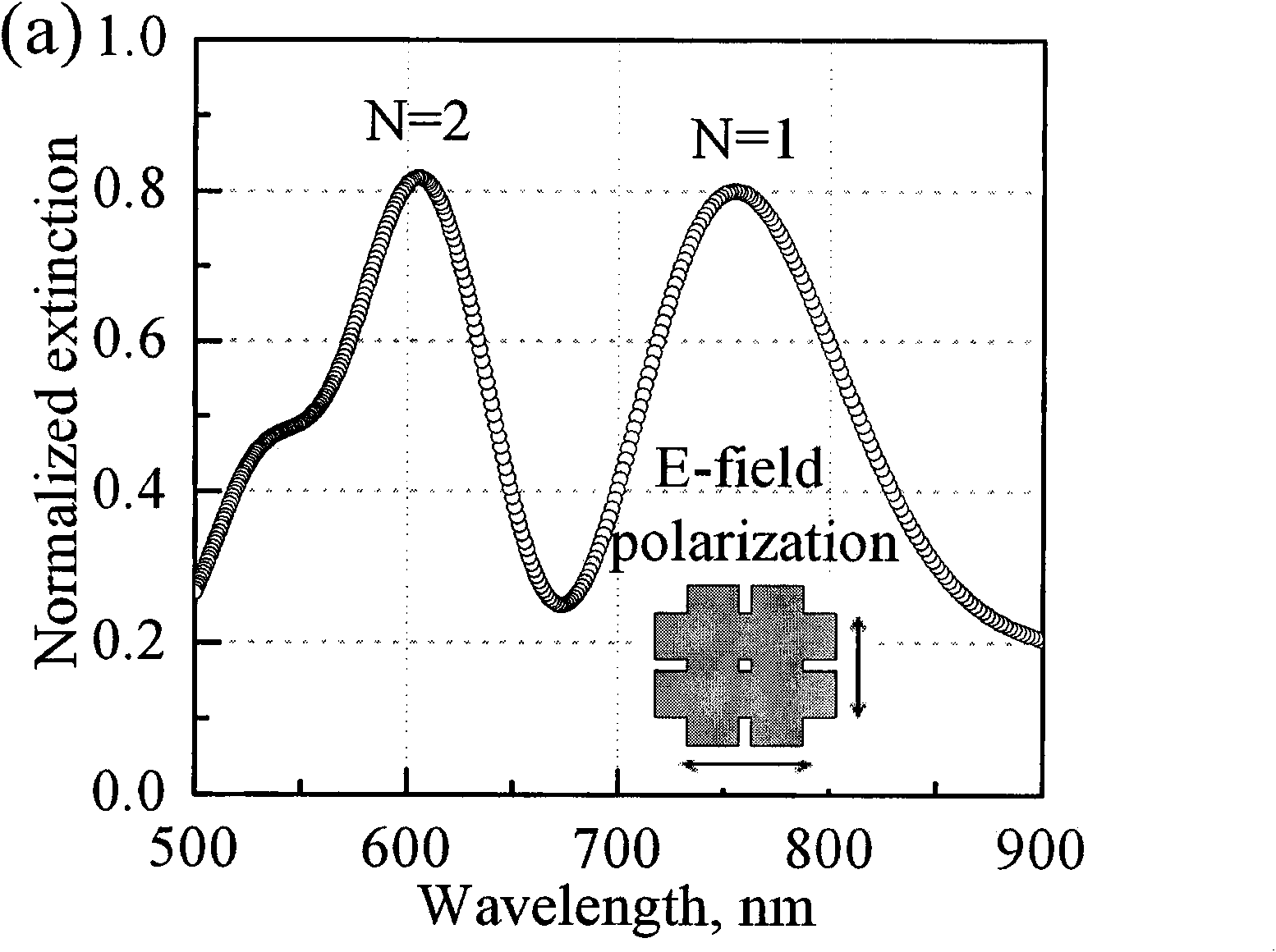

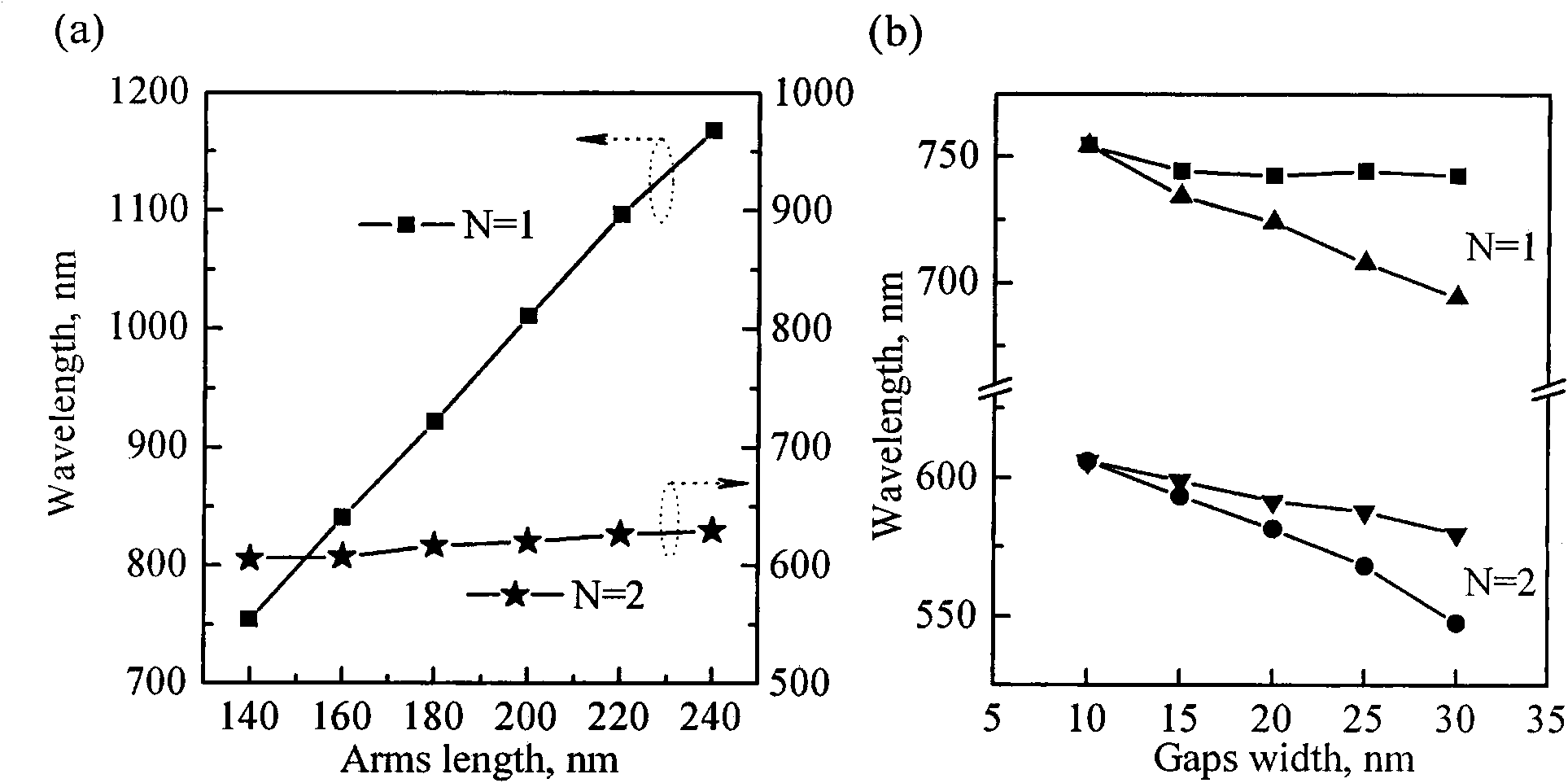

Surface-enhanced Raman scattering underlay of #-shaped nano electromagnetic super medium

InactiveCN101672784AImprove stabilityGood reproducibilityIndividual molecule manipulationRaman scatteringResonance wavelengthElectromagnetic field

The invention concretely discloses a surface-enhanced Raman scattering underlay of a #-shaped nano electromagnetic super medium, belonging to the technical field of surface optical spectrum. The underlay consists of a substrate and #-shaped nano metal structural units which are periodically arranged on the substrate to form a two-dimensional array on the substrate. The underlay of the invention has two-waveband electromagnetic field resonance response, high electromagnetic filed and Raman scattering enhanced effect, high stability and reproducibility; resonance wavelength can be adjusted within the range from visible light to near infrared light (from blue light to near infrared light) and cover most of laser wavelength of modern Raman spectrum technology; the simple structure is a single-layer plane structure capable of being realized by panel nanoimprint technology and suitably being manufactured in large scale; and the obtained underlay unit is arranged tidily, thereby greatly improving the reproducibility of the surface-enhanced Raman scattering test.

Owner:ZHENGZHOU UNIV

Knitting method of double-jacquard net cloth

ActiveCN107099926AClear and beautiful textureImprove product qualityOrnamental textile articlesFootwearYarnEngineering

The invention discloses a knitting method of a double-jacquard net cloth. The knitting method comprises the steps of firstly defining the basic structure of a guide bar, and then performing double-jacquard net cloth knitting, wherein double-jacquard net cloth knitting comprises the steps of conducting working of guide bar yarn laying by a ground guide bar GB1 in coordination with a jacquard pattern guide bar JB1 at a leading bar, and forming the jacquard pattern effect of the obverse side of a grey cloth through knitting; forming a base fabric of the grey cloth through joint knitting of a ground guide bar GB6 and a jacquard pattern guide bar JB2, and forming the V-point jacquard effect of the obverse side of the grey cloth through knitting of jacquard pattern guide bar JB2; forming an obverse and reverse face connecting line through knitting of a ground guide bar GB5, under the knitting effect of the ground guide bar GB5, integrally knitting and connecting the obverse and reverse faces of the grey cloth into one, and knitting and forming the double-jacquard net cloth. According to the knitting method of the double-jacquard net cloth, during knitting, the obverse and reverse faces of the grey cloth are knitted and connected into one closely without gap, the problems of blistering and wrinkling, irregular through holes, exposed stitching in the holes, low physical property, low support power and the like are solved, and the knitting production quality is greatly improved.

Owner:SINCETECH FUJIAN TECH CO LTD

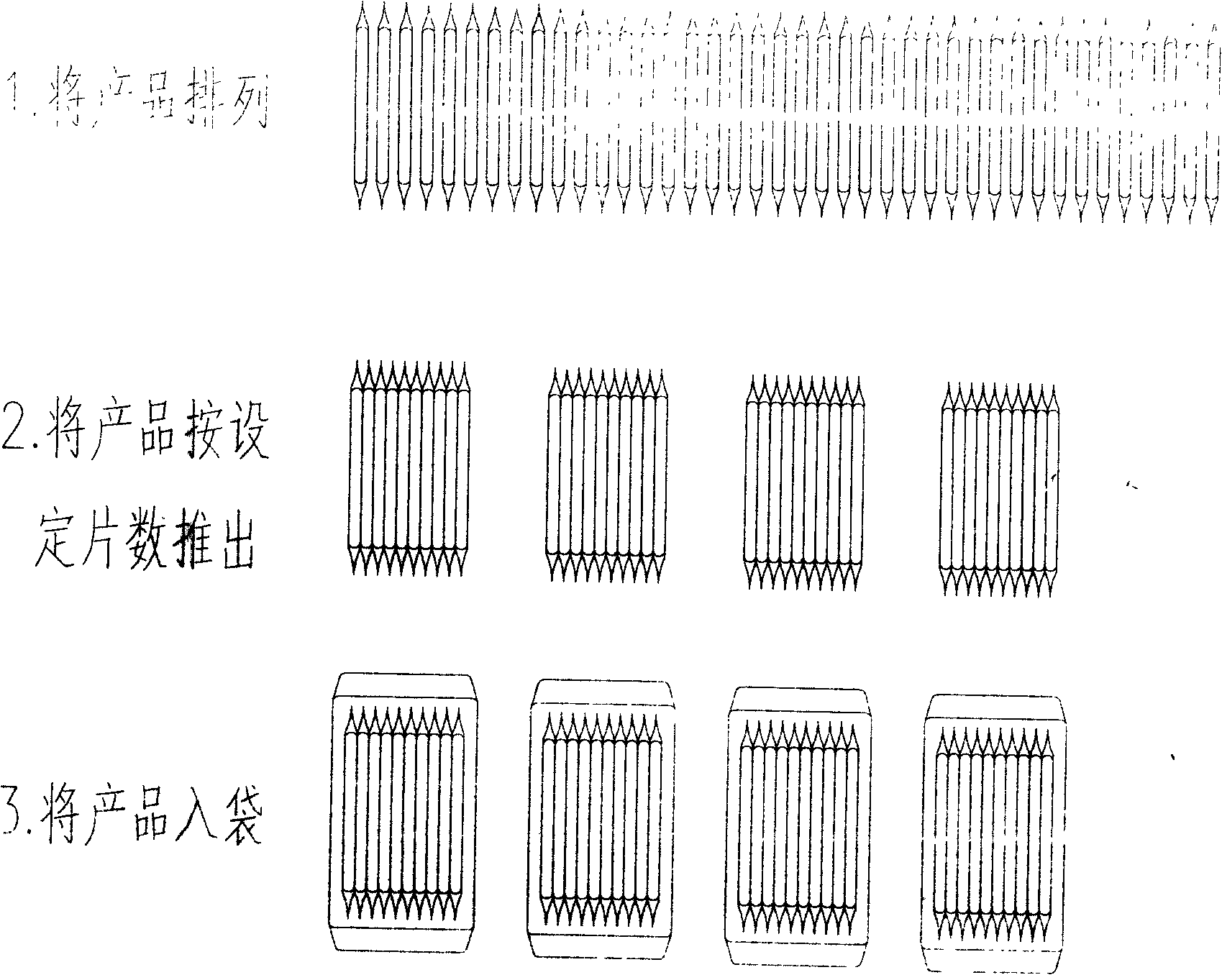

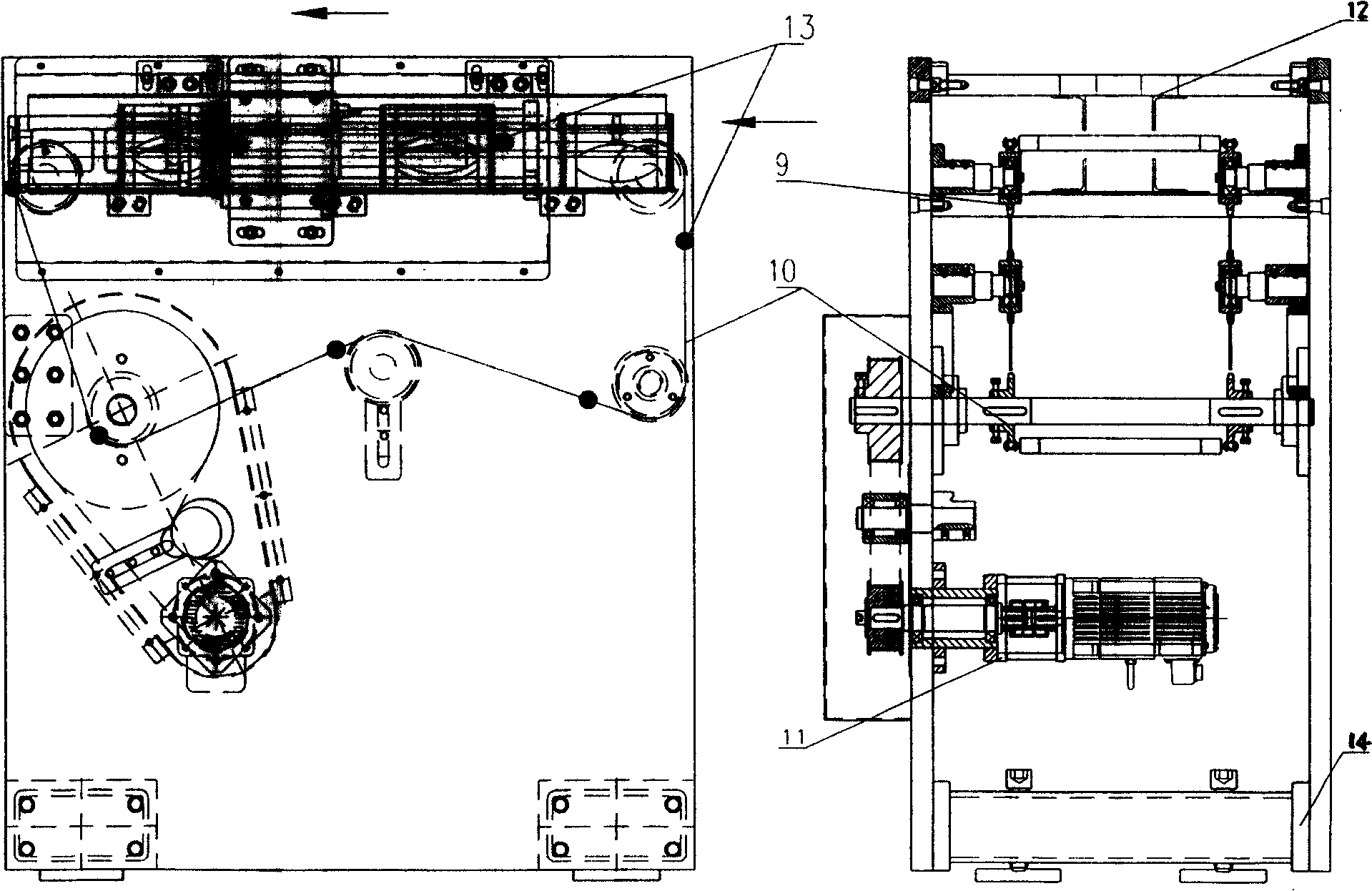

Sanitary towel production line high-speed buck stacker and stacking method

The invention relates to a device capable of stacking sanitary napkins at high speed and a method. A group ejecting mechanism I is composed of guide rails, an ejecting cylinder assembly and a motor drive assembly. The two guide rails are located on a frame, the ejecting cylinder assembly is located on the two guide rails, the motor drive assembly is located between the two guide rails, and a driving shaft in the motor drive assembly is connected with the cylinder assembly and drives the cylinder assembly to move back and forth along the guide rails. A group ejecting mechanism II formed by a cylinder assembly is located on the frame. Two clamping output devices are composed of a chain supporting mechanism, a push rod circulation mechanism, a power unit, a clamping device, a push rod device and a frame, wherein the chain supporting mechanism inside the frame is driven by the power unit, the clamping device on the frame is located between two chains of the chain supporting mechanism, the push rod circulation mechanism on the chain supporting mechanism is driven by and synchronously moves with the chain supporting mechanism, and two ends of the push rod device are respectively connected with the push rod circulation mechanism and driven by the push rod circulation mechanism.

Owner:HANGZHOU CREATOR MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com