Sanitary towel production line high-speed buck stacker and stacking method

A technology of production line and sanitary napkins, which is applied in the field of equipment for stacking sanitary napkins at high speed, can solve the problems of slow response speed, synchronous movement of pinnae, inaccurate positioning, etc., to achieve neat product arrangement, fast running speed and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

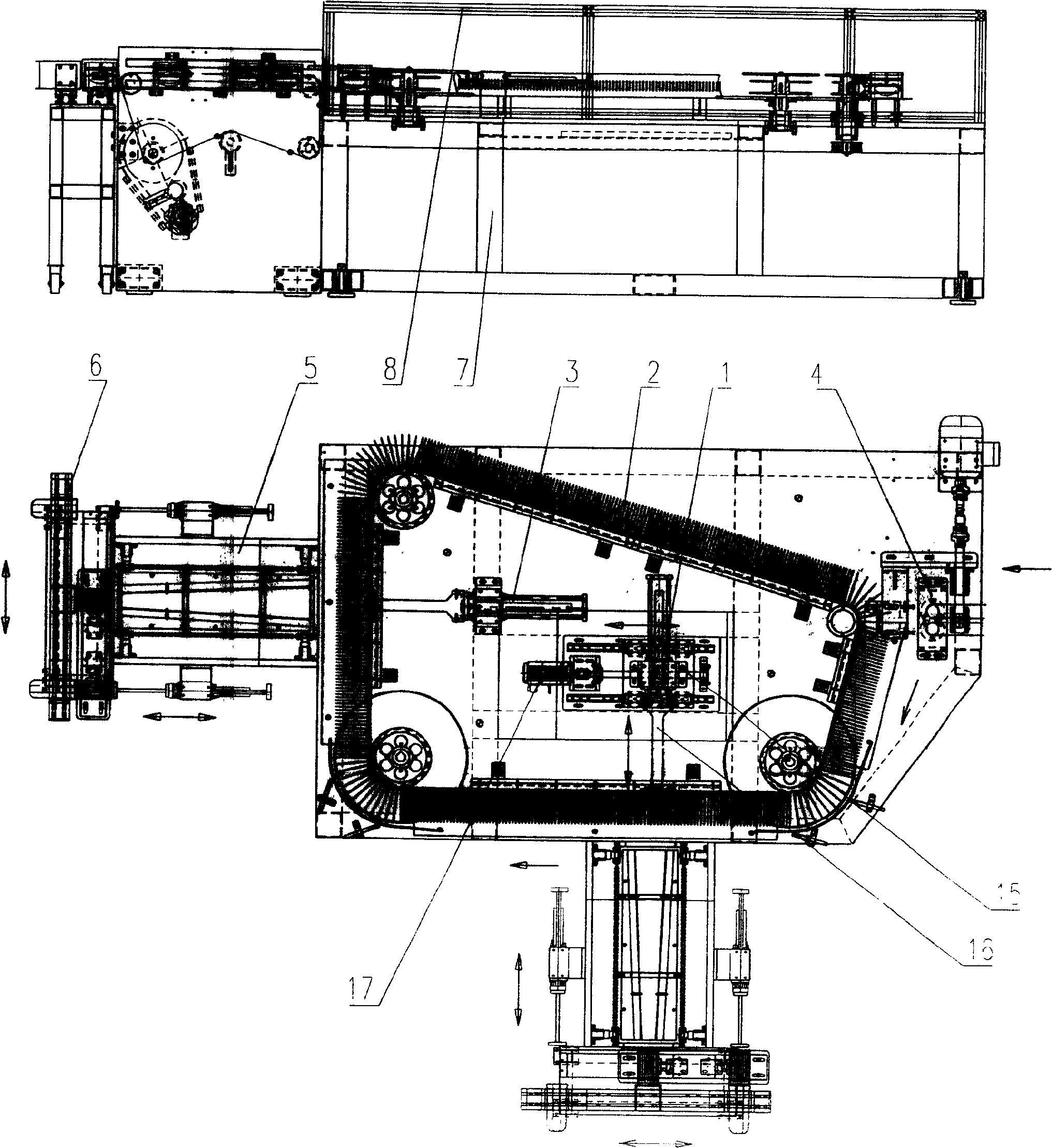

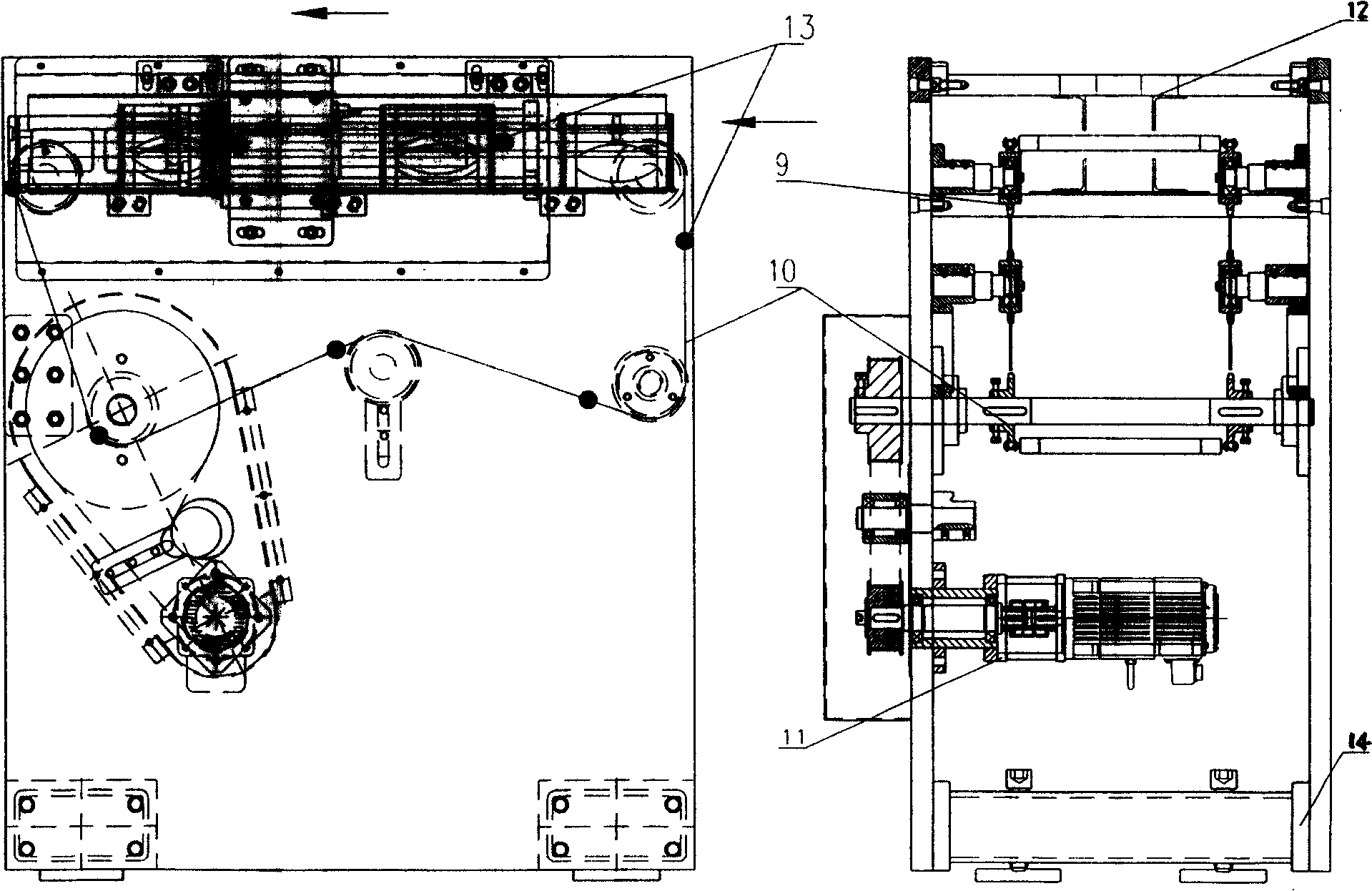

[0012] Embodiment 1: with reference to attached Figure 1~4 . Sanitary napkin production line high-speed stacker, including belt clip conveying mechanism 4, bagging mechanism 6, frame 7, the design, processing and production of belt clip conveying mechanism 4, bagging mechanism 6, frame 7 are prior art, in This will not be described. The group push-out mechanism I 1 and the group push-out mechanism II 3 are located (installed) in the arrangement arrangement 2, and the two clamping output devices 5 are located outside the arrangement arrangement 2 and are respectively matched with the group push-out mechanism I 1 and the group push-out mechanism II 3, The clamping channel in the clamping output device 5 has a wide inlet and a narrow outlet. Grouping push-out mechanism I 1 is made of guide rail 15, release cylinder assembly 16 and motor drive assembly 17, two guide rails 15 adopt prior art to be positioned at (installed on) frame 7 in parallel, release cylinder assembly 16 out...

Embodiment 2

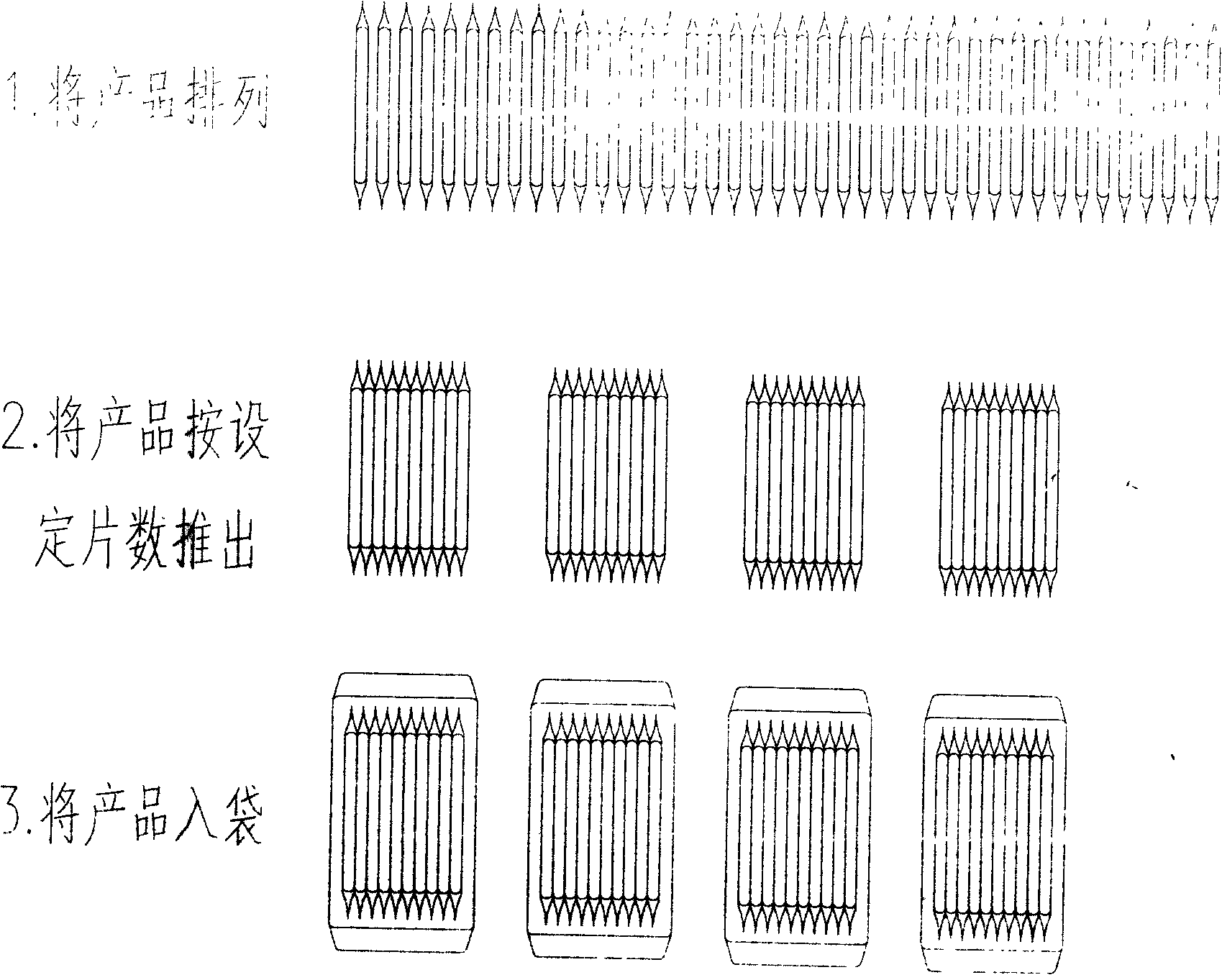

[0014]Embodiment 2: on the basis of embodiment 1, the stacking method of the high-speed stacker of the sanitary napkin production line, the finished product produced by the host machine is introduced by the belt clamping mechanism, inserted between the vanes of the device arrangement mechanism in order, and then The pinnaes move together, and when they pass through the arc guide wheel, the pinnaes open, and the external mechanism arranges the products to ensure that all sides of the products are neat. When the finished product passes through the group ejection mechanism I, the group ejection mechanism I moves with the finished product. When the clamping device I is reached, the push-out cylinder assembly in the group push-out mechanism I moves, and the product is pushed into the clamp device I according to the preset number of pieces, and the product reaches the entrance of the clamp device I from the group push-out mechanism for a short period of time. Stop, when the push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com