Automatic light adhesive material feeding vibration hopper

A technology of automatic feeding and vibrating hopper, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve problems such as affecting work efficiency and product quality, increasing labor costs, small inertia, etc., to achieve reasonable structural design and improve work efficiency. Efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

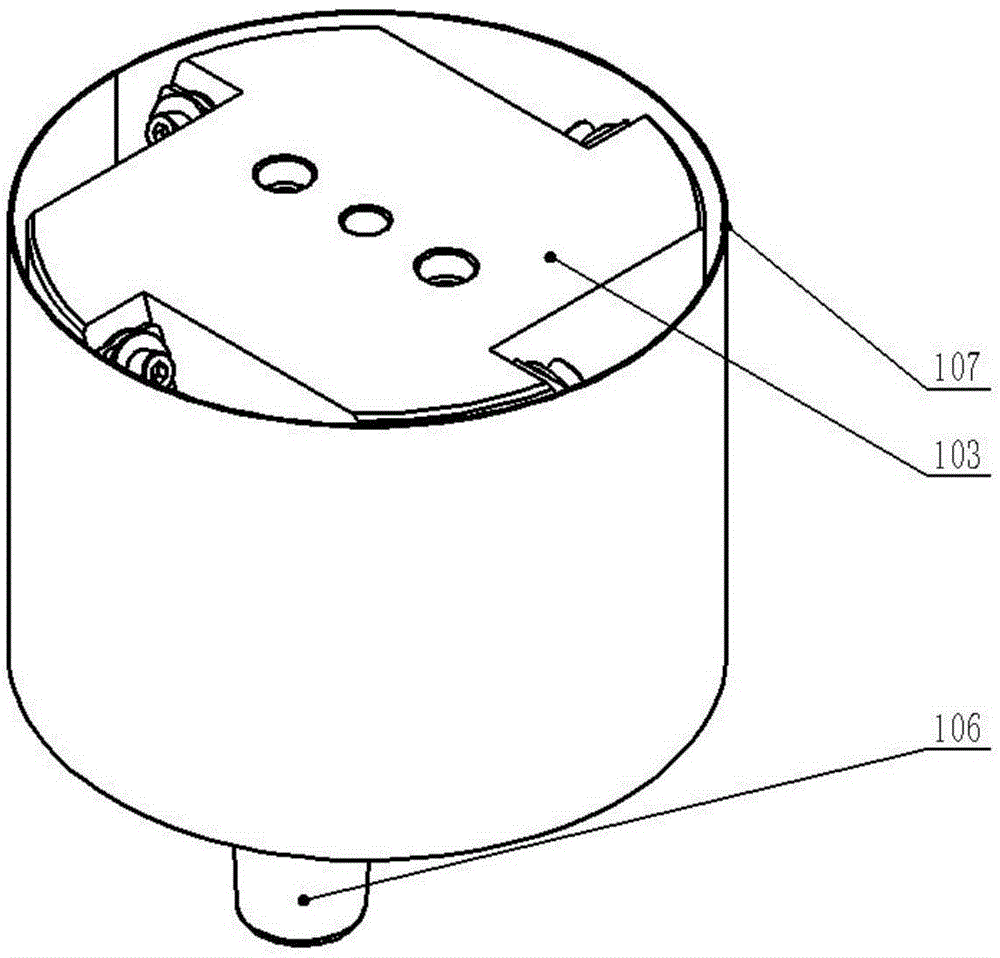

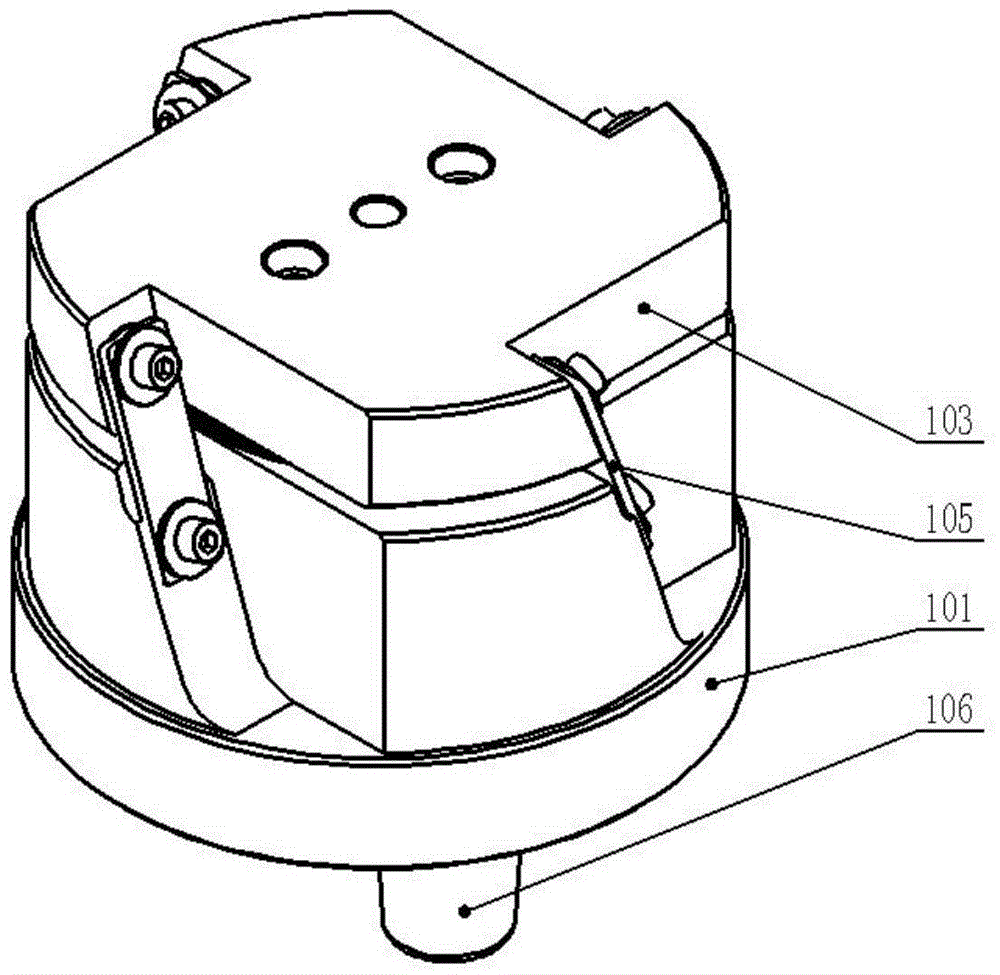

[0028] The present invention is a vibrating hopper for automatic feeding of light viscous materials, and the automatic feeding of cotton balls is taken as an example below. Its detailed working principle is described as follows:

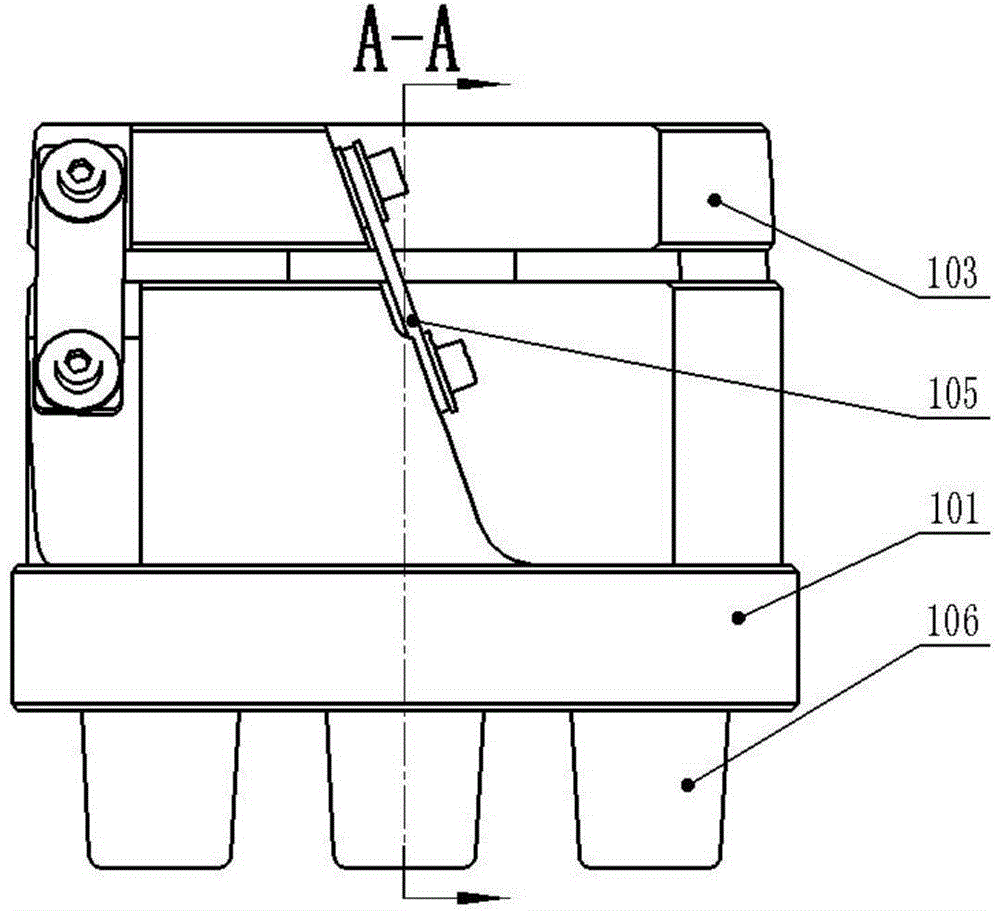

[0029] After the magnetic vibration host 100 is energized, the electromagnet 102 generates an electromagnetic field when the half-wave rectified alternating current is input to the electromagnet wire package. In one cycle, when the magnetic force of the magnetic field is strong enough, the armature 104 fixed below the top seat 103 is attracted to the bottom of the tray, and the top seat 103 drives the tray 200 to descend. While the tray 200 is descending, the four sets of vibrating leaf springs 105 are also driven by the top seat 103 to compress and deform. When the magnetic force of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com