Patents

Literature

281results about How to "Continuous delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

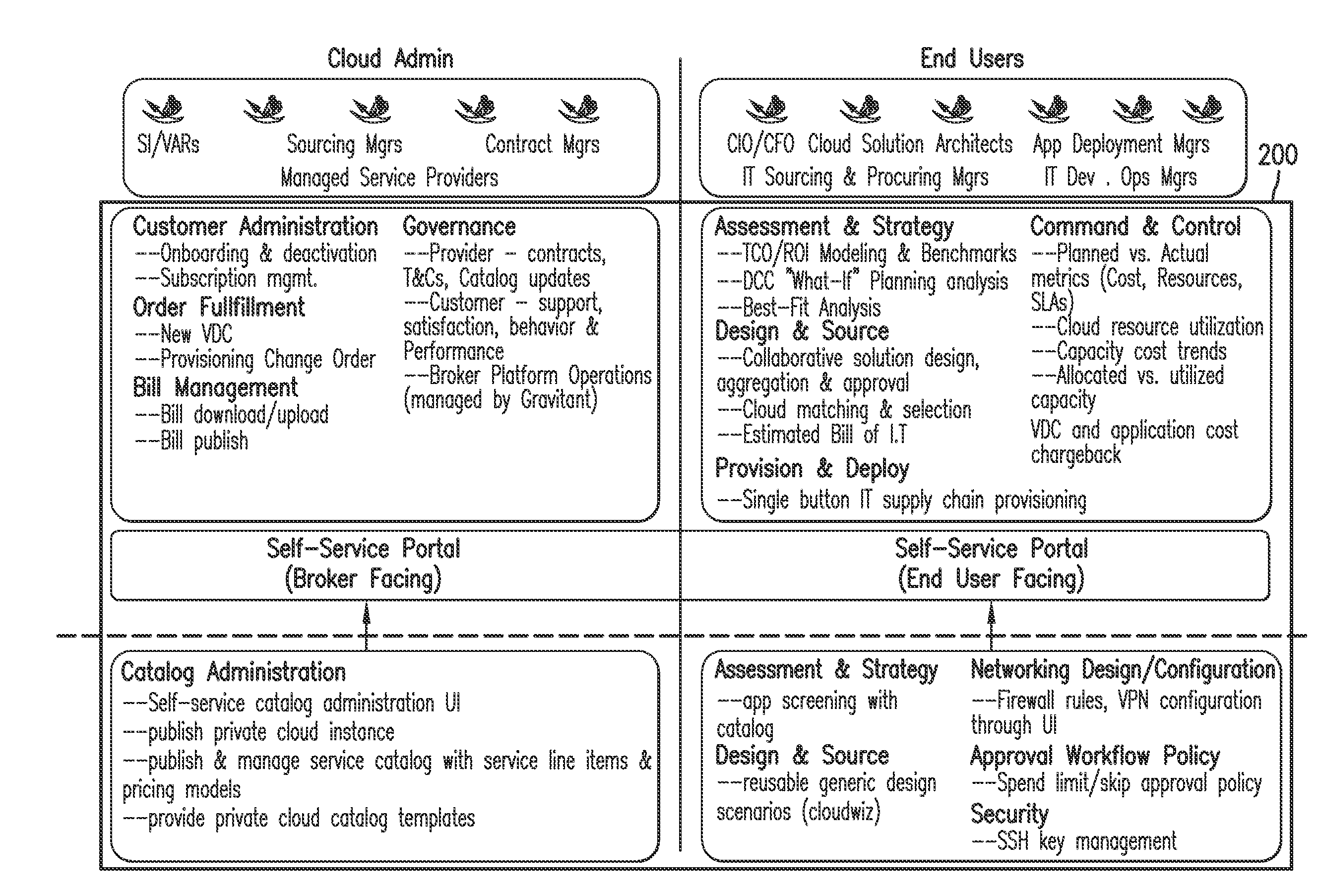

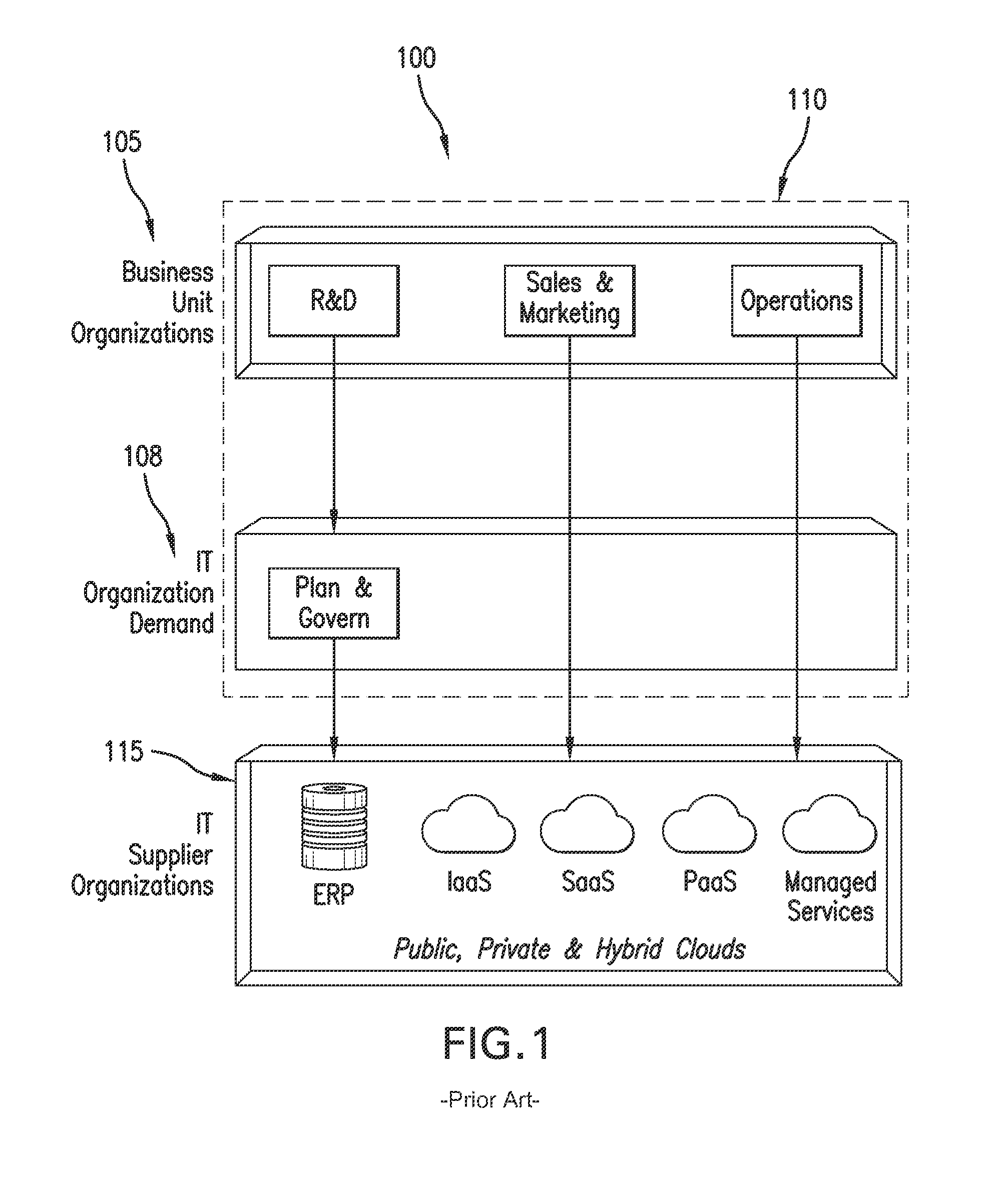

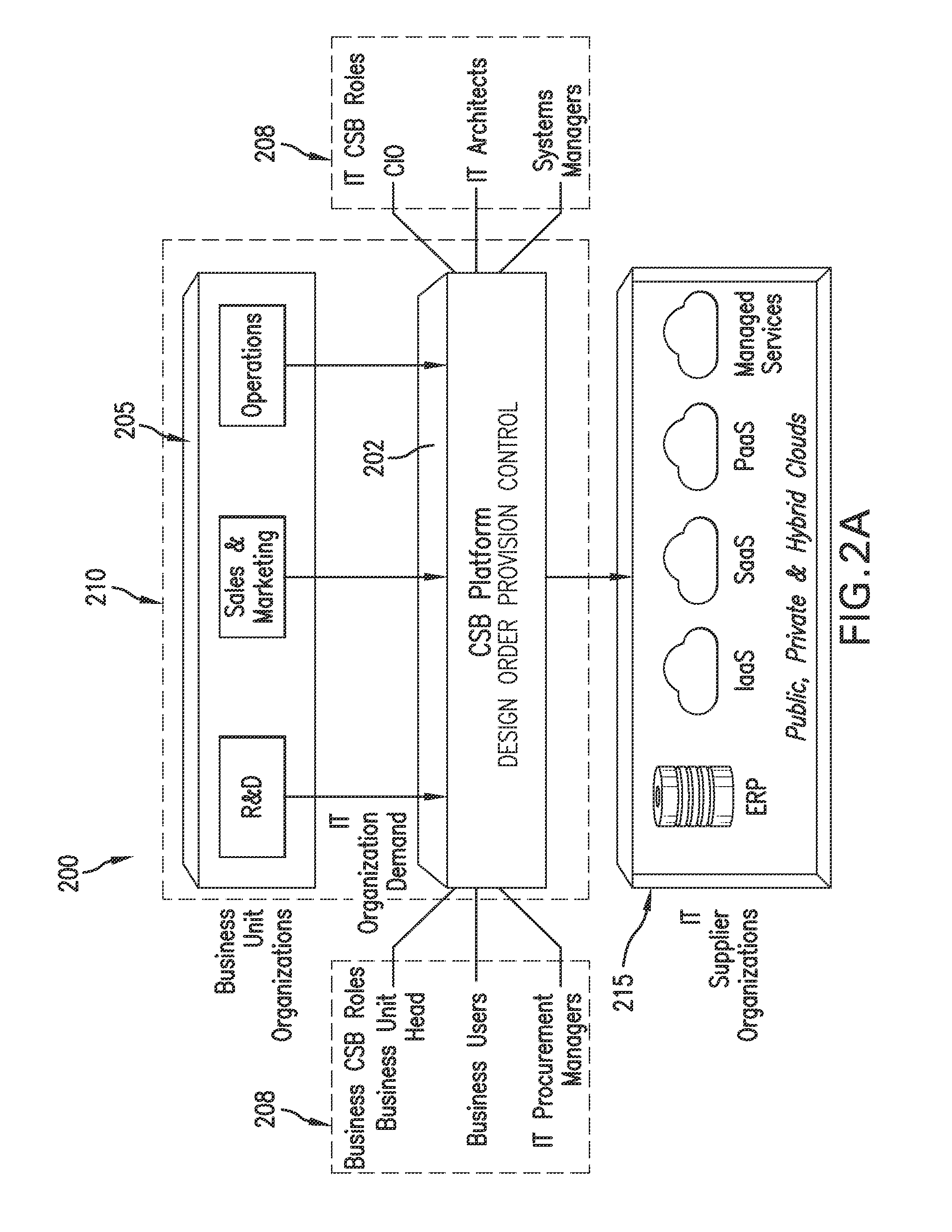

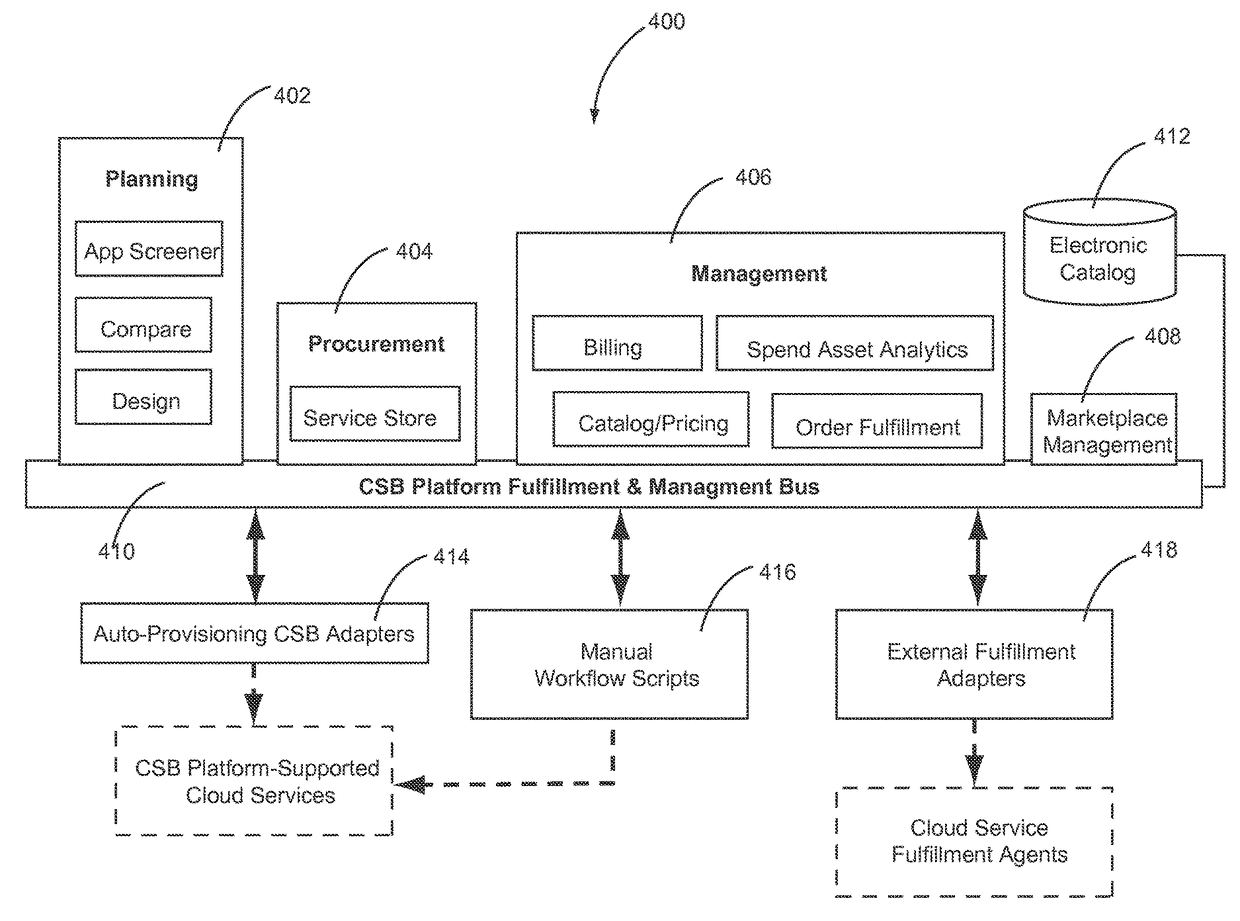

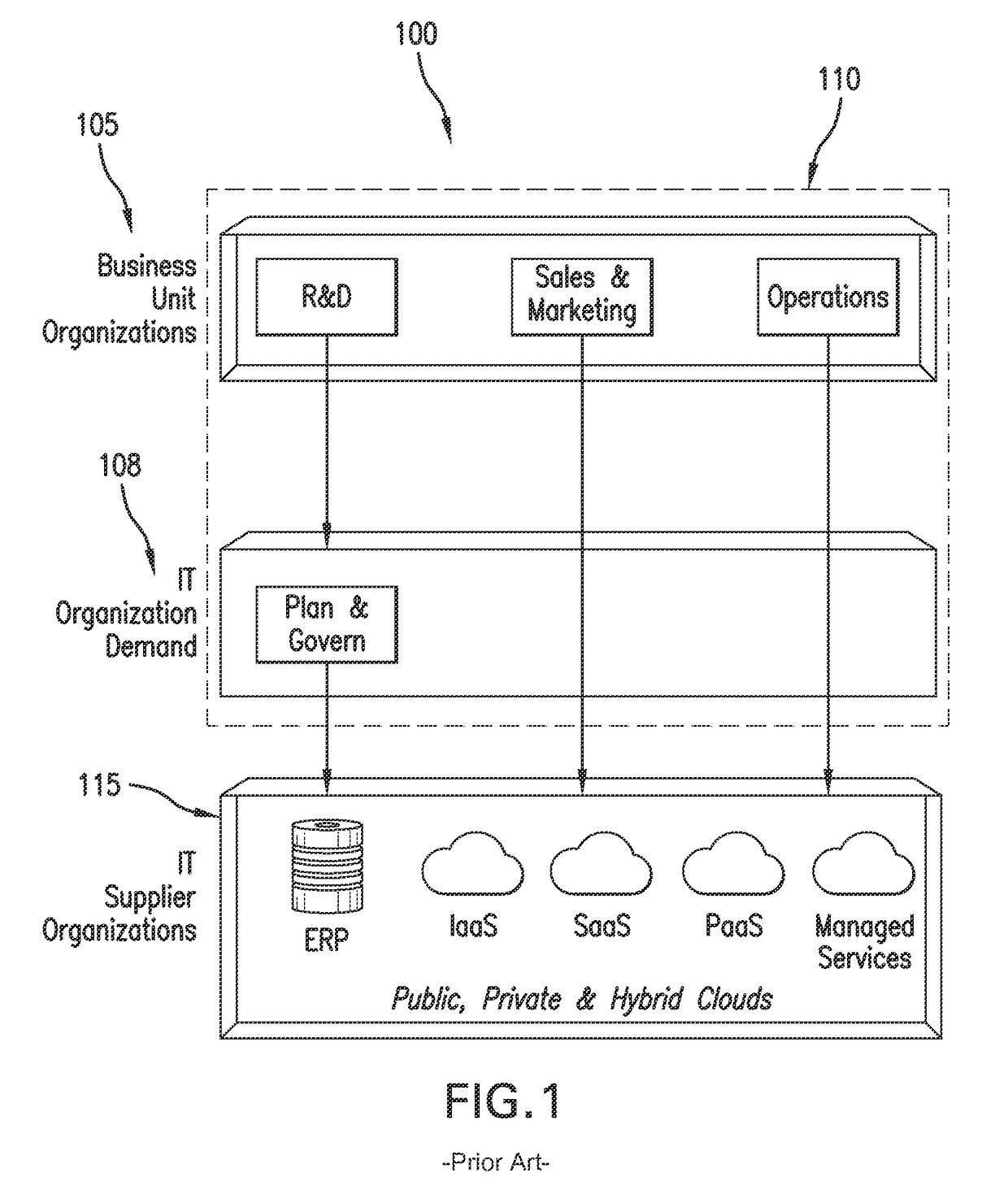

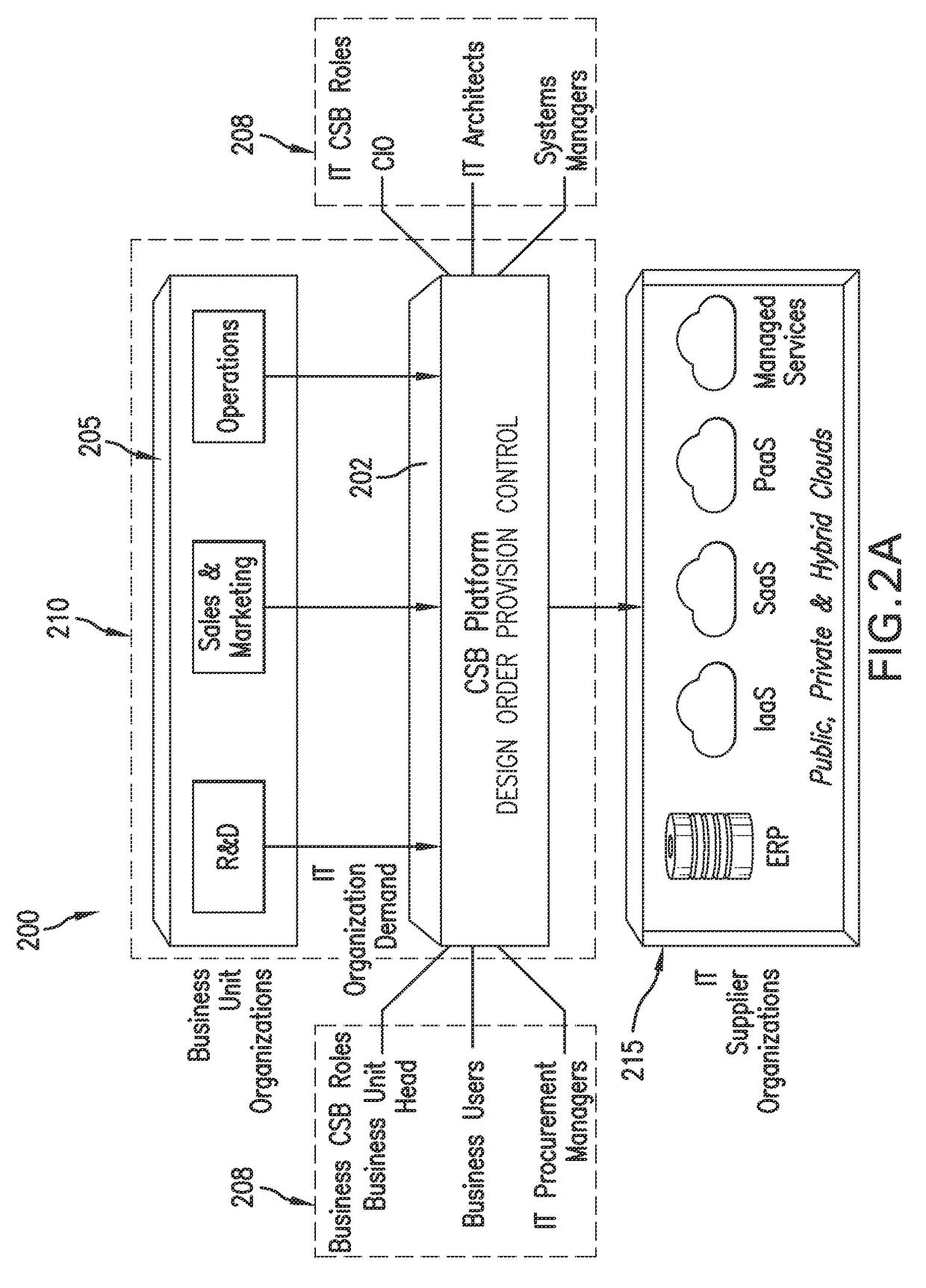

Fulfillment of cloud service orders

ActiveUS20160065417A1Efficient and effectiveMaintain securityResource allocationFinanceAuto-configurationWorkflow

A fulfillment bridge orchestrates various types of fulfillment that fall generally into three categories of fulfillment: CSB platform based automated provisioning; external automated provisioning; and manual workflow provisioning. External automated provisioning is implemented through fulfillment agents. The fulfillment agents can implements self-registration for allowing the fulfillment bridge to understand the capabilities of the fulfillment agent. Examples of such capabilities include, but are not limited to, supported actions and input / output parameters. Adapters of the fulfillment bridge interface with the fulfillment agents and fulfillment scripts that are independently operated with respect to the CSB platform can be use to interface with the fulfillment adapters.

Owner:HCL TECH LTD

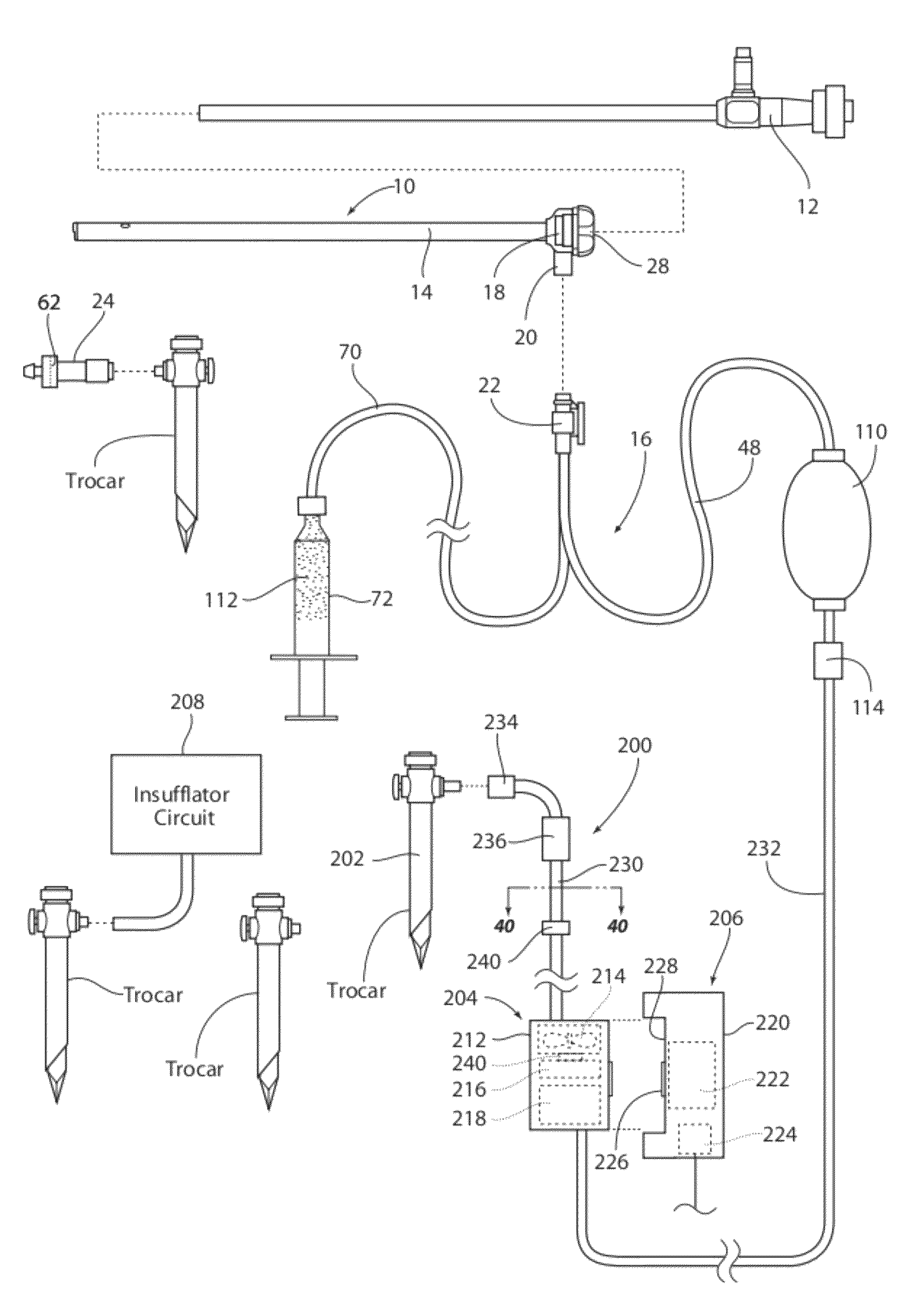

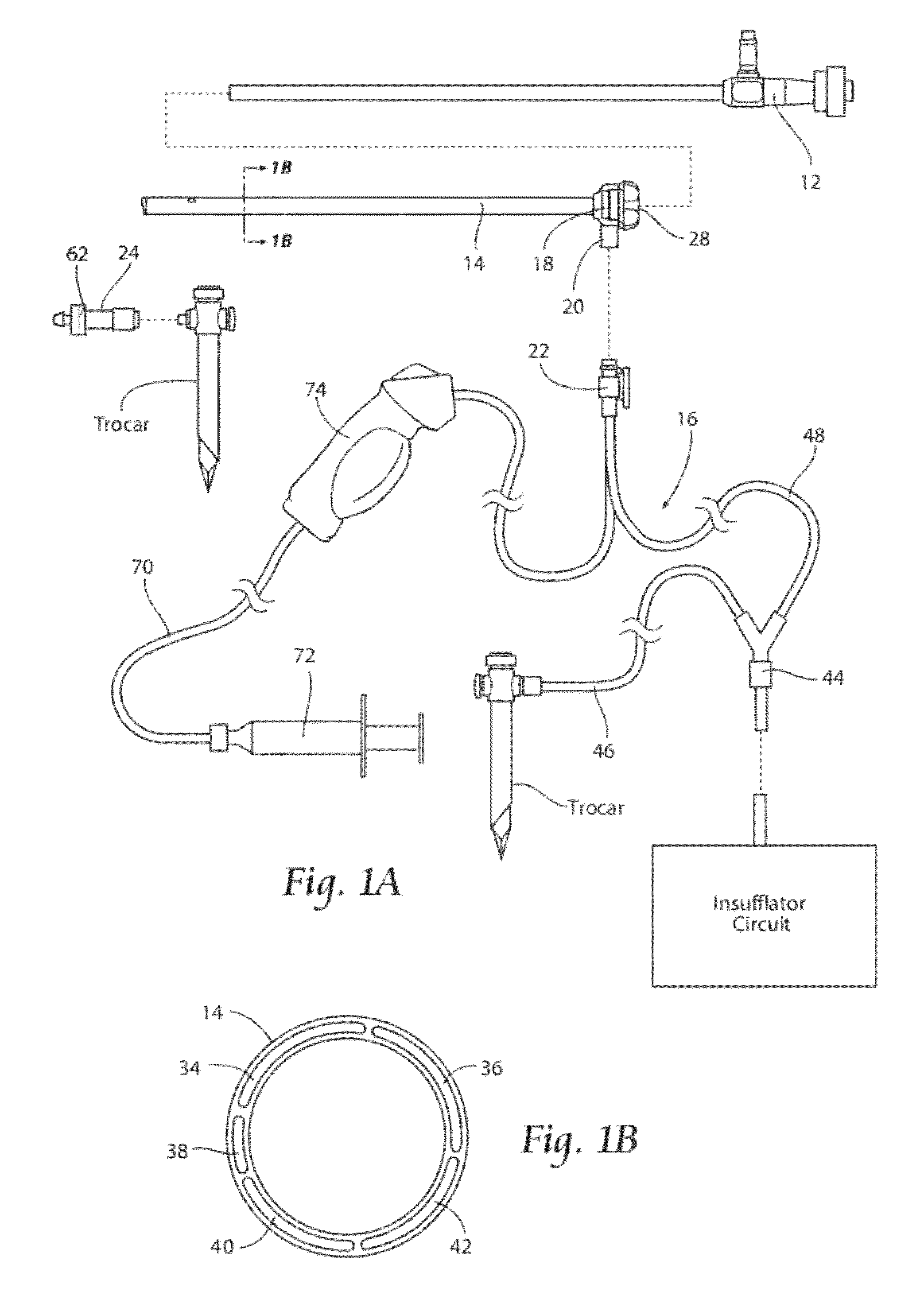

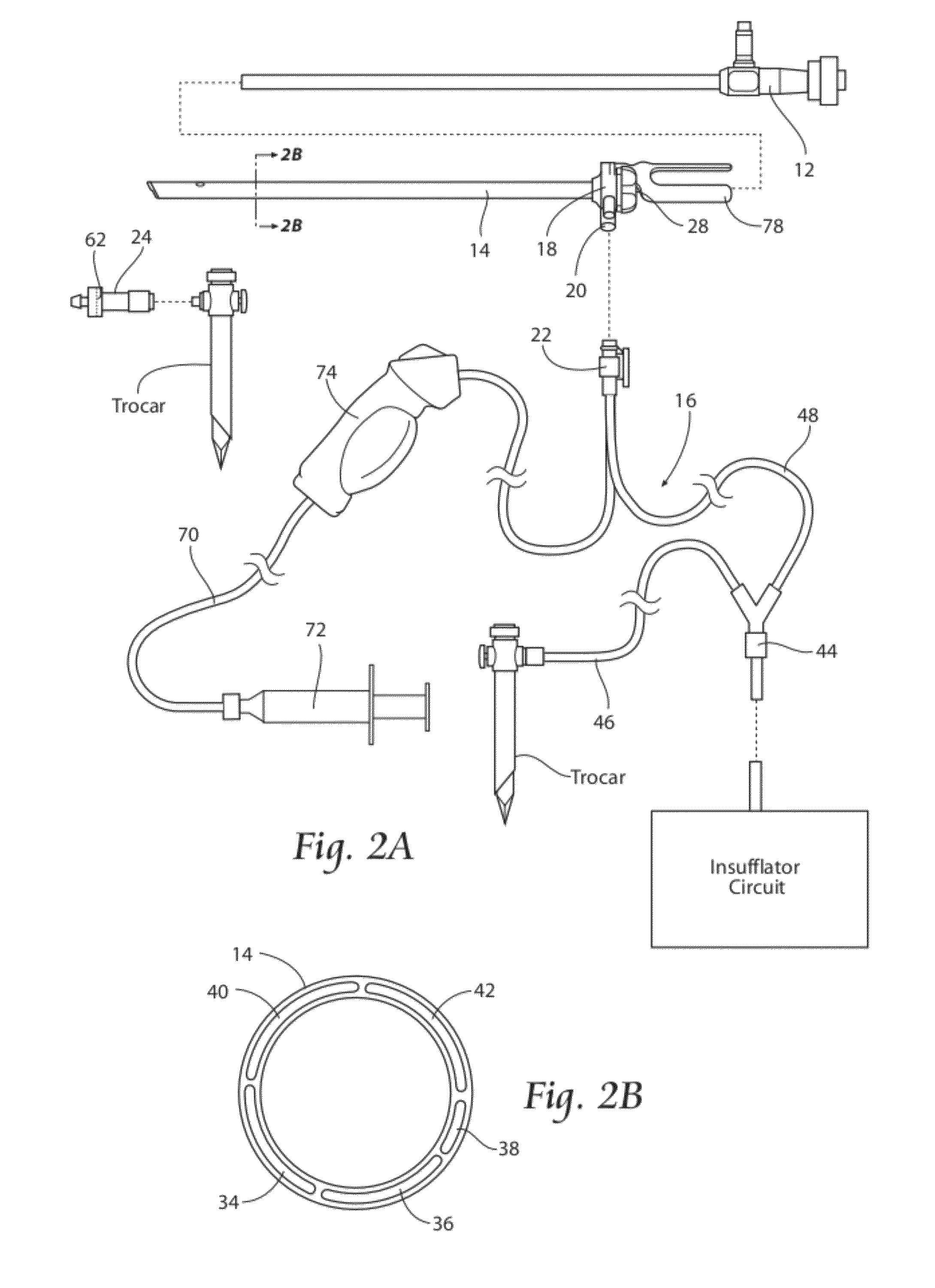

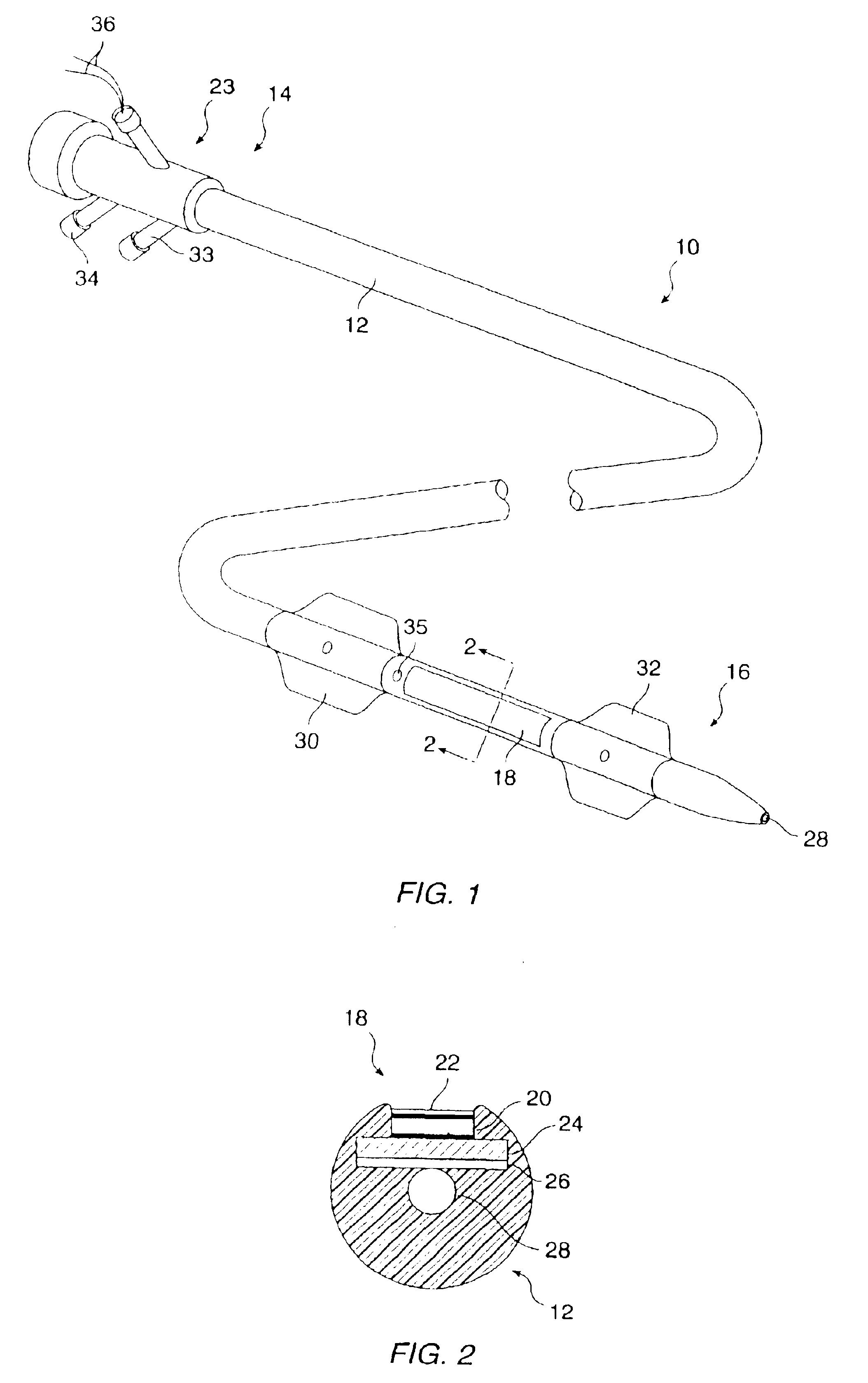

Systems and methods for optimizing and maintaining visualization of a surgical field during the use of surgical scopes

InactiveUS9078562B2Improve visualizationFunction increaseCannulasSurgical needlesSurgical ManipulationSurgical mirror

Systems and methods condition air for passage across a laparoscopic lens to prevent fogging, deflect debris, and maintain visualization of an operating cavity. The systems and methods provide an access device sized and configured to provide communication with an insufflated CO2 environment maintained by operation of an insufflations circuit. The access device is coupled to an air conditioning set, which interacts with an air conditioning driver to condition air from the insufflated environment for continuous passage across the laparoscopic lens, to thereby maintain visualization by the laparoscopic lens of the operating cavity, independent of operation of the insufflator circuit.

Owner:FLOSHIELD INC

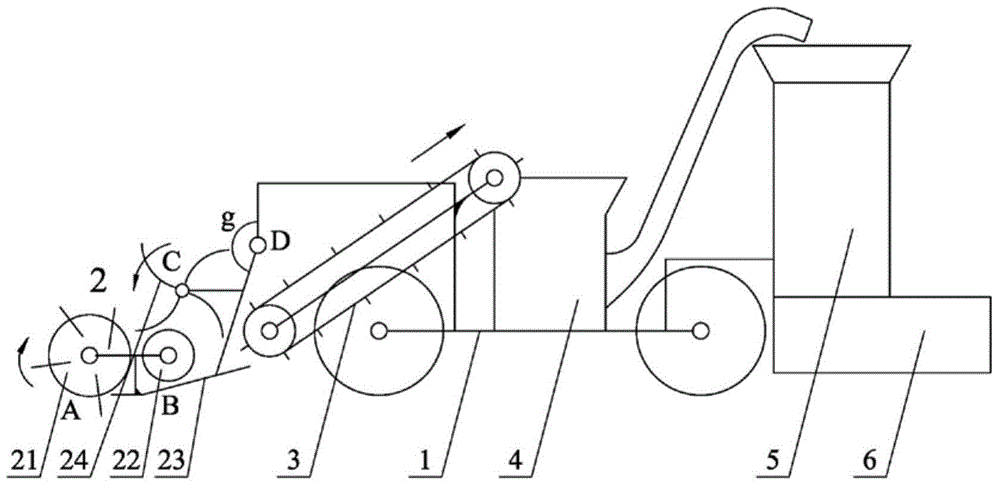

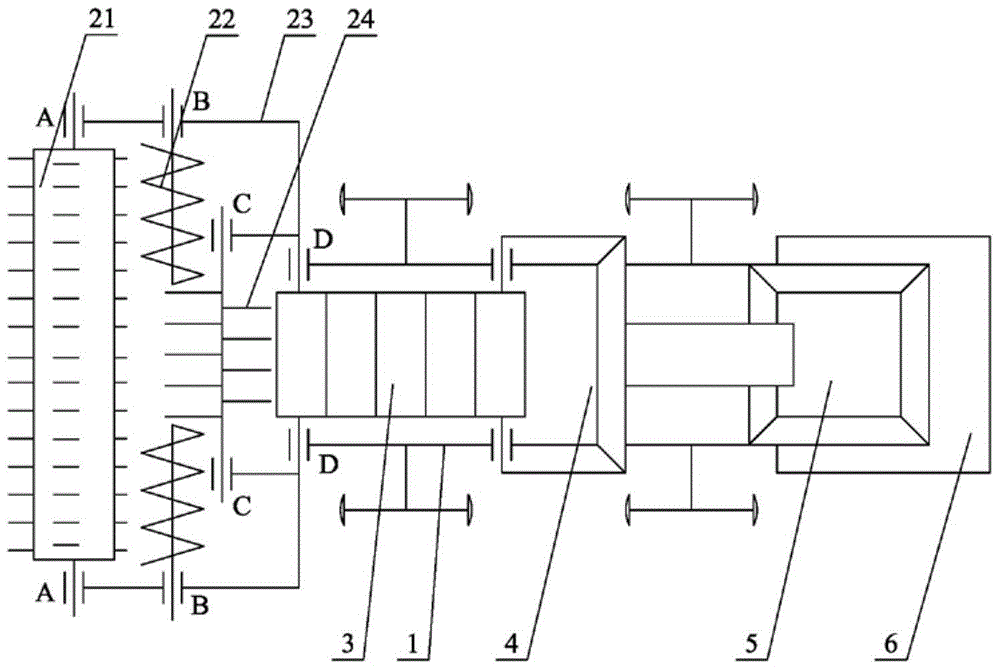

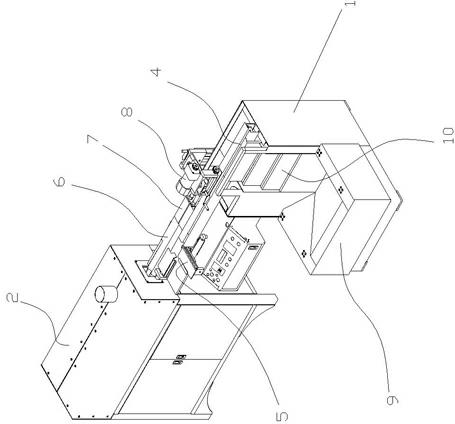

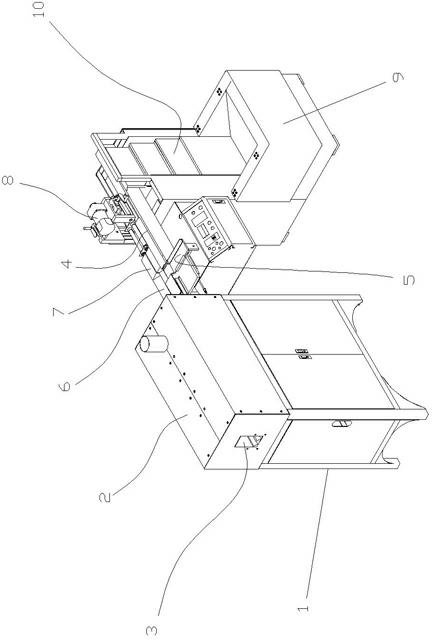

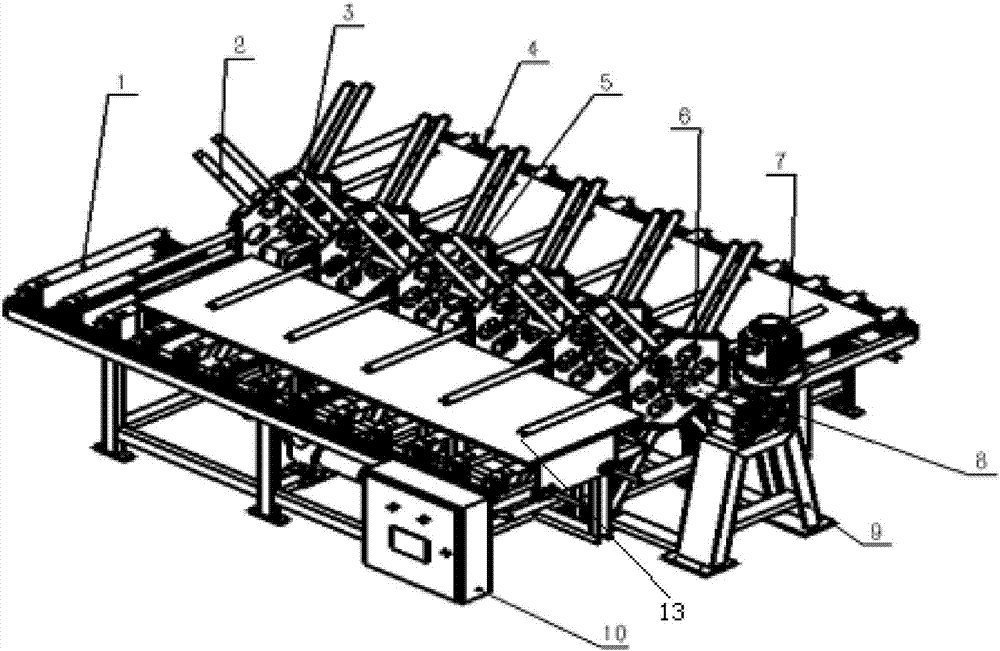

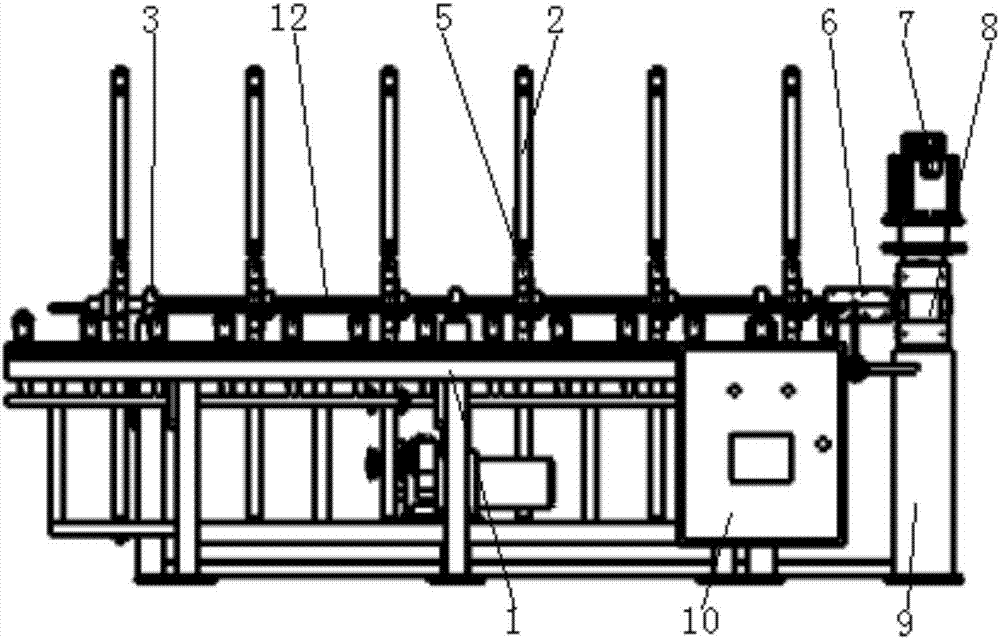

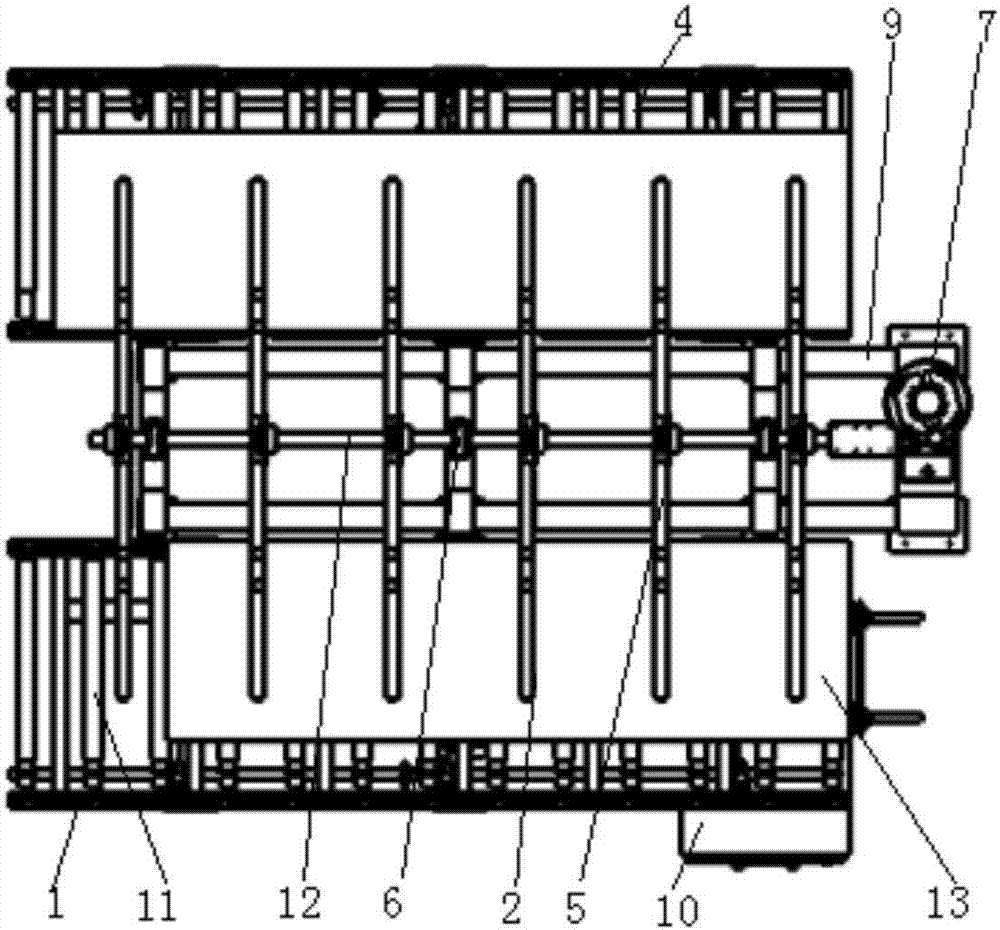

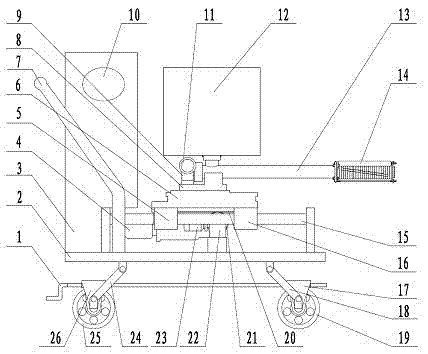

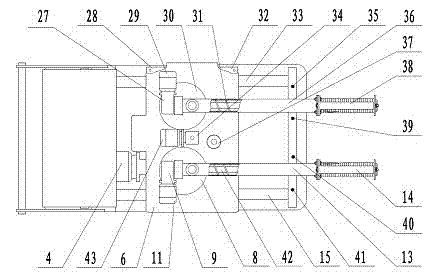

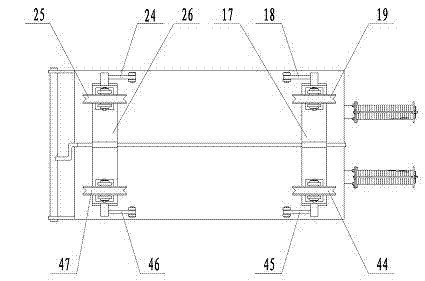

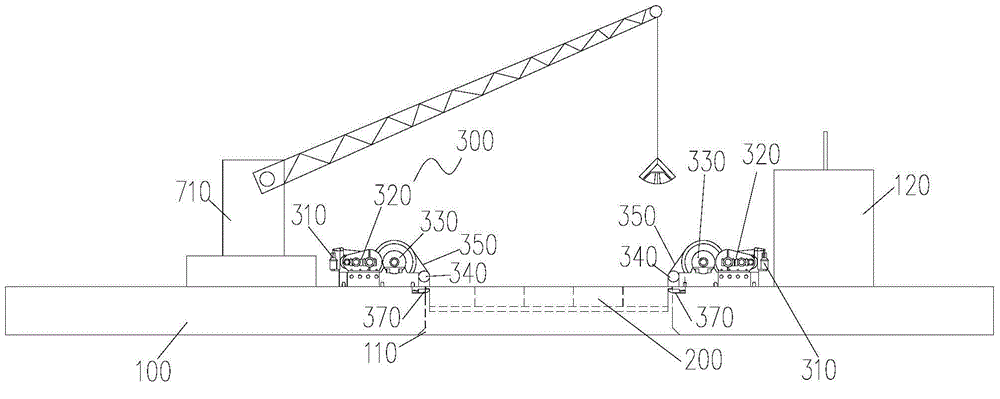

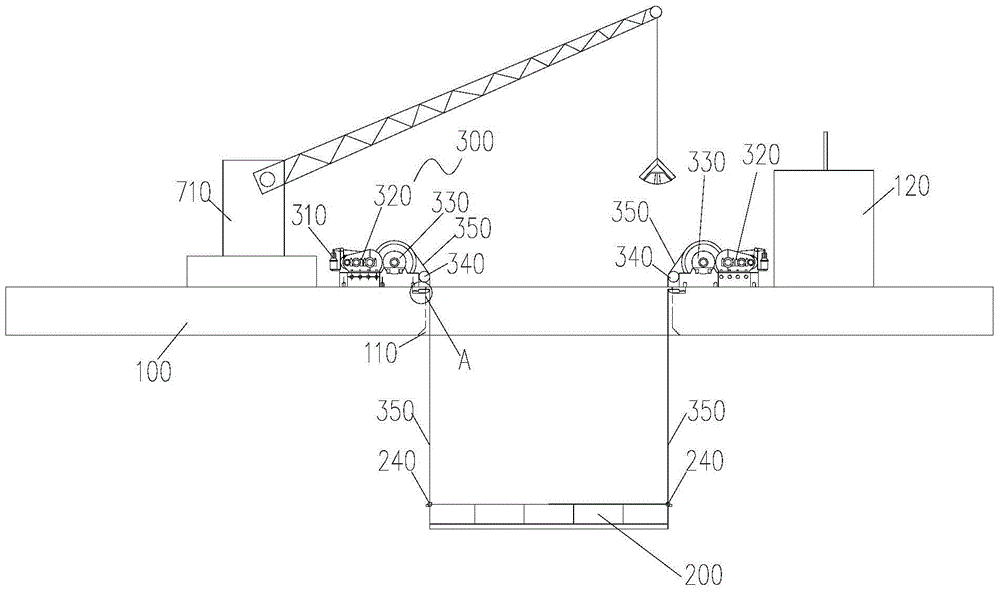

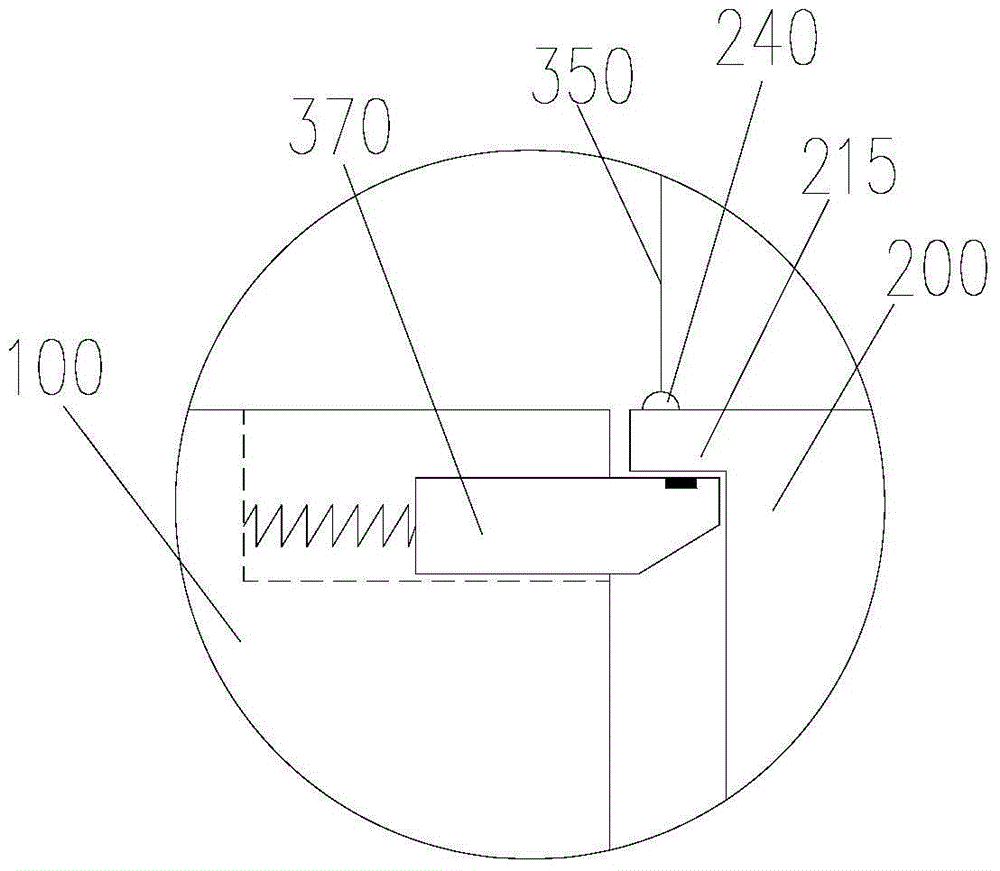

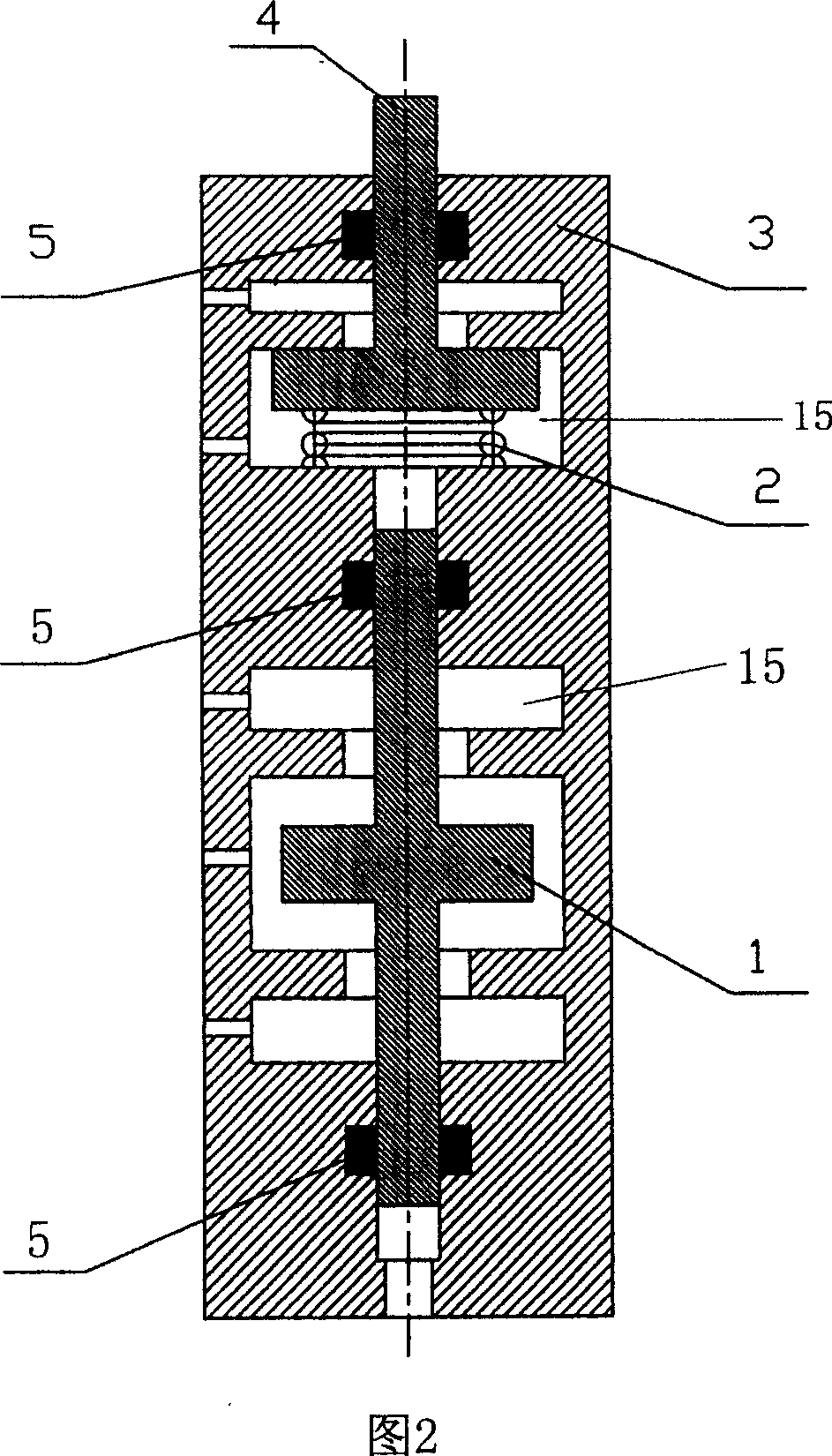

Straw collecting and briquetting vehicle

ActiveCN104813811AContinuous collectionContinuous deliveryLoadersCuttersBuilding materialEngineering

The invention relates to the technical field of straw collection, pressing and bundling through agricultural machines, and discloses a straw collecting and briquetting vehicle which comprises a chassis, a collecting device, a conveyer belt, a hay cutter, a multistage roll straw forming device and a collecting hopper. During a working process of the vehicle, the collecting device picks up straws on the ground to a collecting bench, a material poking wheel conveys straws on the collecting bench to the conveyer belt, and the conveyer belt conveys straws into the hay cutter. The hay cutter chops straws in certain length and conveys the straws into the multistage roll straw forming device, straws in the multistage roll straw forming device are rolled into high-density straw bars by continuous multistage rolls, and the straw bars are cut by a cutter to form high-density straw blocks which fall onto the collecting hopper from a discharge hatch. The straw collecting and briquetting vehicle realizes continuous collection, conveying and multistage rolling, and is a self-propelled combined operation device which shape straw blocks with high-density and no bundling ropes. The high-density straw cubes can be used as agricultural building materials or fuel.

Owner:CHINA AGRI UNIV

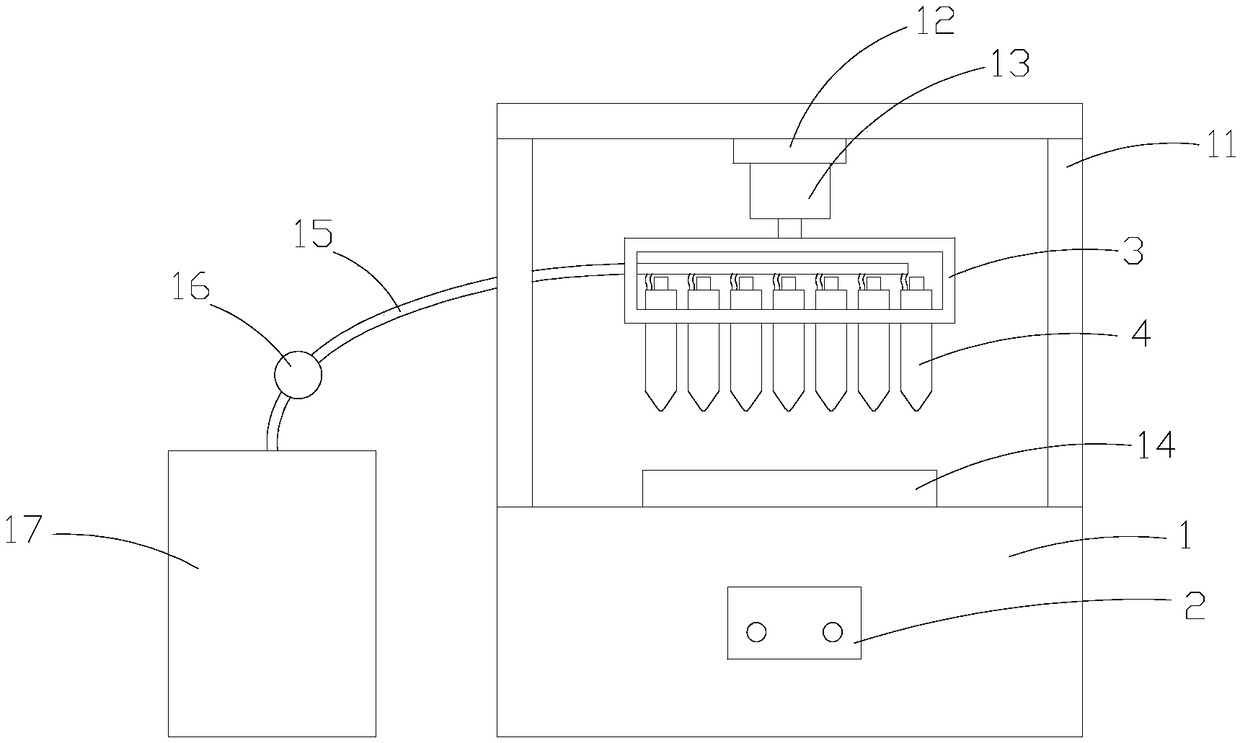

Automatic light adhesive material feeding vibration hopper

InactiveCN104444132AContinuous deliveryConvey evenlyJigging conveyorsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic light adhesive material feeding vibration hopper which comprises a main magnetic vibration machine and a material tray. The vibration hopper generates electromagnetic force through an electromagnetic coil of the main magnetic vibration machine, the material tray with vibration plate springs is stimulated to vibrate, boosting nuts in the material tray vibrate and ascend along a spiral feeding rail, light adhesive materials in the material tray are cyclically boosted to transmit along the feeding rail, and in the discharging stage, air blowing pipes are used for blowing air in an oriented mode, so that the materials are finally conveyed. The air blowing pipes located accurately are used in cooperation with the boosting nuts, so that the light adhesive materials are automatically and rapidly fed in order. According to the automatic light adhesive material feeding vibration hopper, structural design is reasonable, certain universality is achieved, the materials which are adhesive, low in mass, small in inertia and the like can be continuously and evenly conveyed to the position to be machined, the conveying speed is high, work efficiency is improved, and production cost is reduced.

Owner:SOUTHEAST UNIV

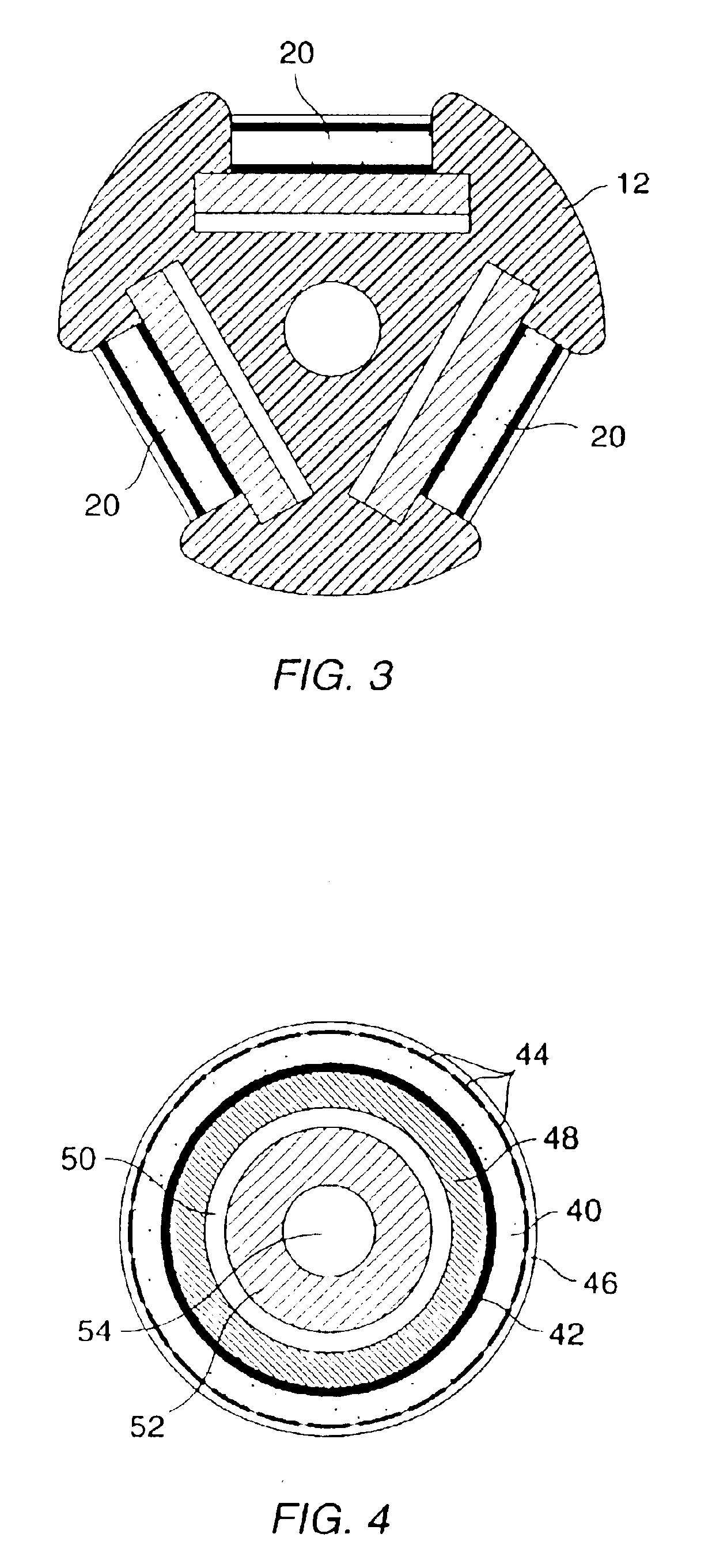

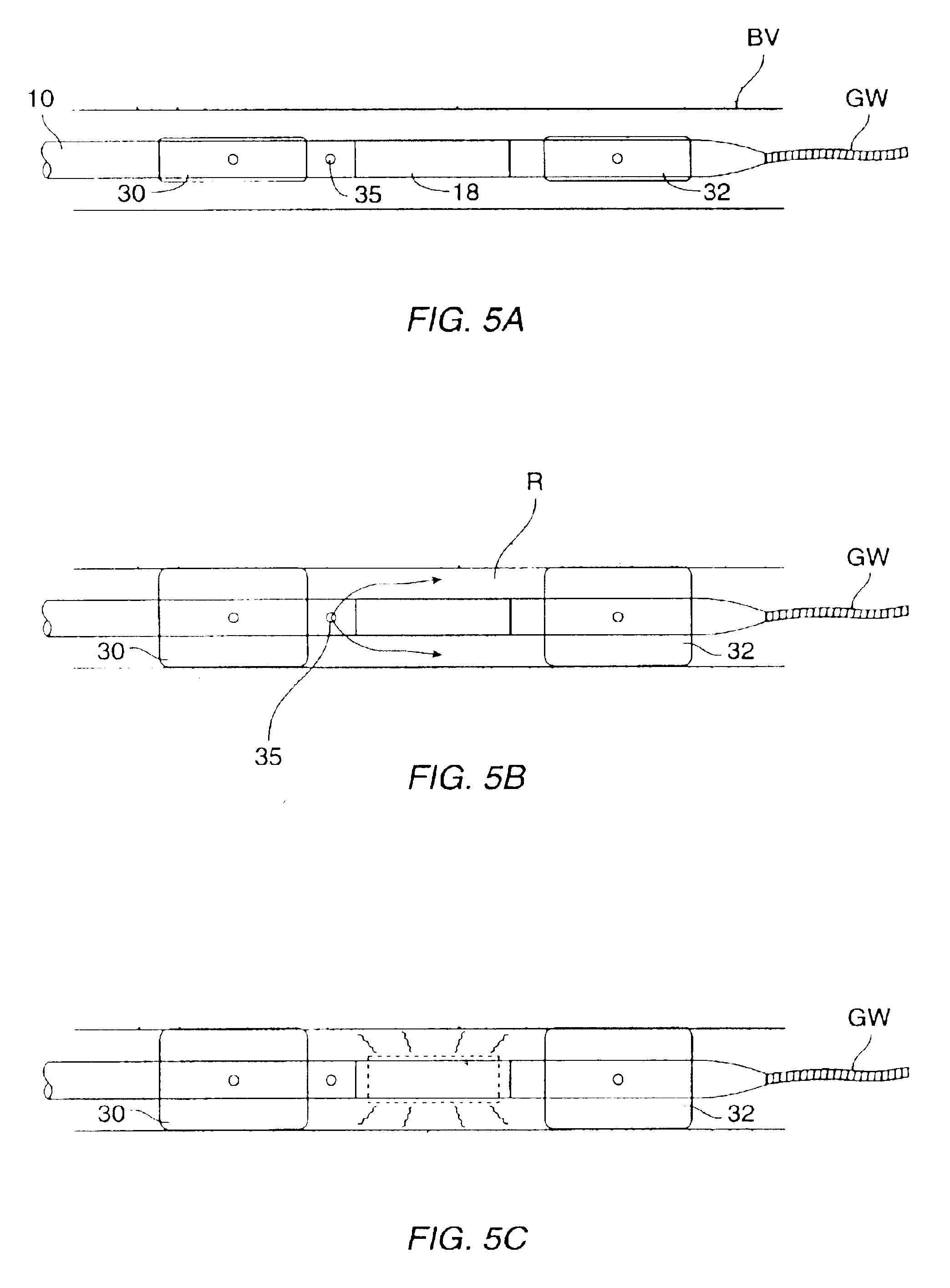

Methods, systems, and kits for intravascular nucleic acid delivery

InactiveUS6794369B2Transfection of vascular smooth muscle cells with naked DNA is enhancedLow efficiencyOrganic active ingredientsElectrotherapyTransfectionVibrational energy

Nucleic acid transfection of vascular smooth muscle cells is enhanced by the application of vibrational energy to the cells. By applying vibrational energy at frequency in the range from 1 kHz to 10 MHz and at an intensity in the range from 0.01 W / cm.sup.2 to 100 W / cm.sup.2, significant enhancement of the uptake of nucleic acids into vascular smooth muscle cells can be achieved.

Owner:PHARMASONICS

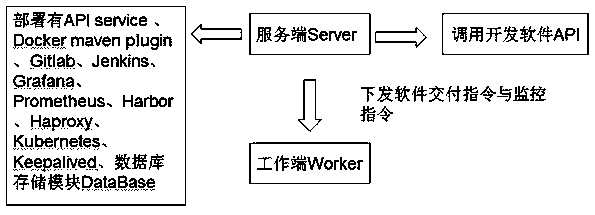

Optimized deployment resource and software delivery platform in cloud computing environment

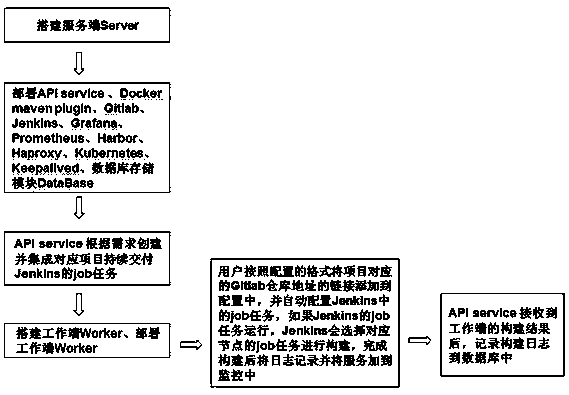

PendingCN110764786AImprove convenienceReduce investmentSoftware testing/debuggingSoftware designResource utilizationSoftware engineering

The invention discloses an optimized deployment resource and software delivery platform in a cloud computing environment, the software delivery platform comprises a server and a Worker, the server isresponsible for calling a development software API, and issuing a software delivery instruction and a monitoring instruction to the Worker; an API (Application Program Interface) service, Docker mavenplug, Gitlab, Jenkins, Grafana, Prometheus, Harbor, Haproxy, Kubernetes, Keepalived, and a database storage module DataBase are deployed in the server. The resource utilization rate in a cloud computing environment is improved, and configuration is simplified; and the cost expenditure is reduced, the investment of operation and maintenance personnel is reduced, and the continuous service deliveryis more, fast, good, economical and stable. Business lateral extensions are realized.

Owner:KAITAIMING BEIJING TECH

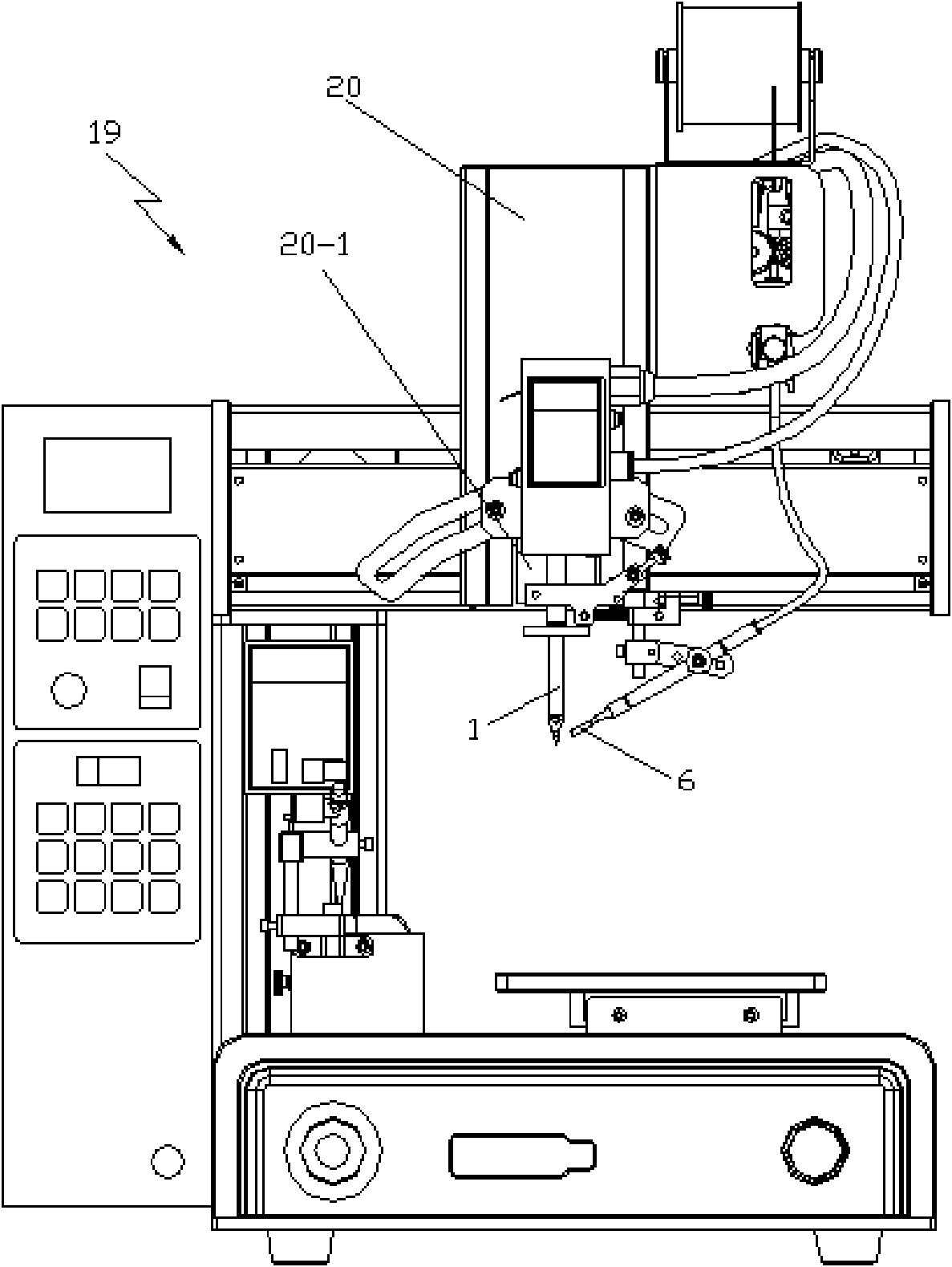

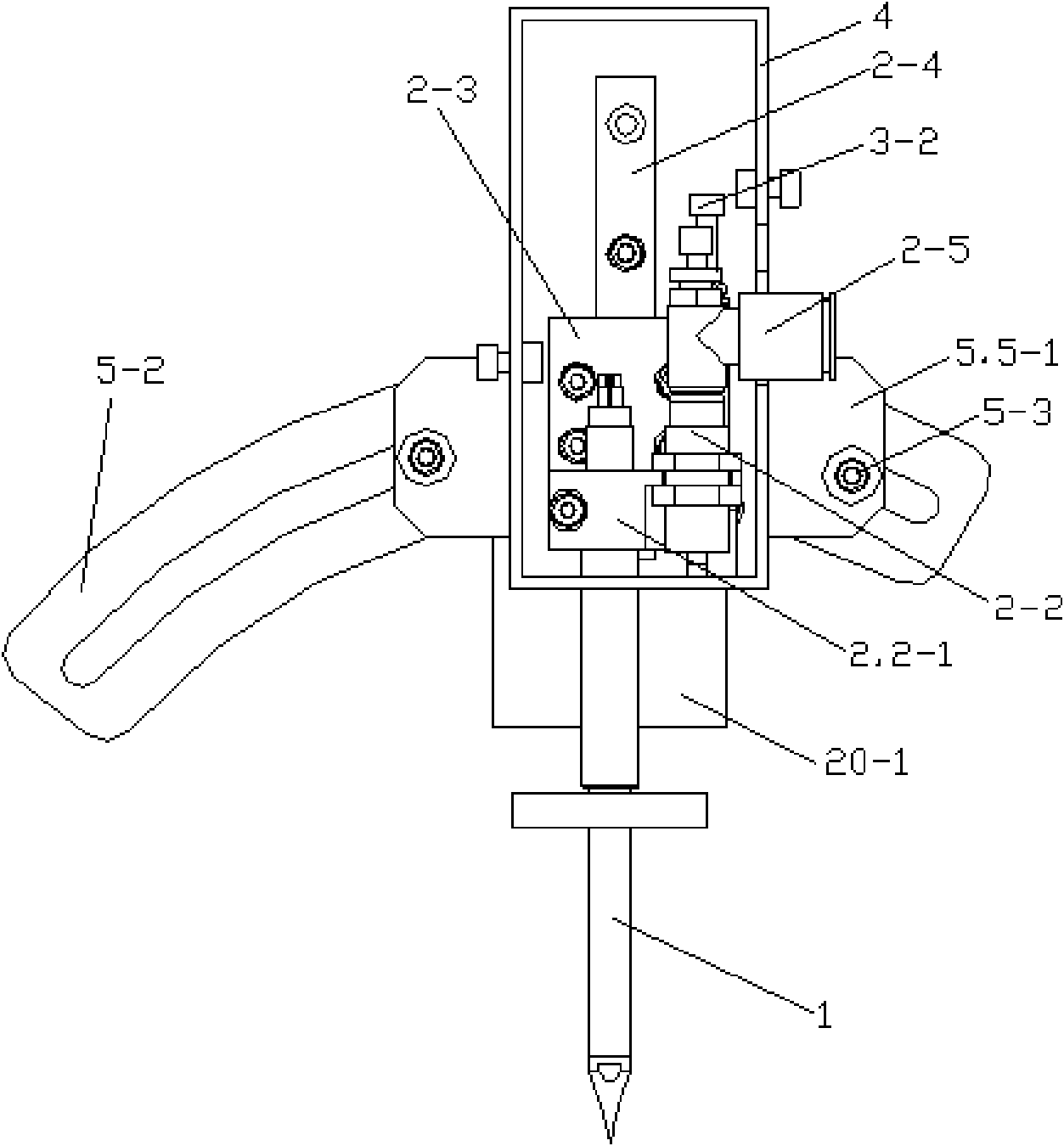

Tin soldering system of automatic tin soldering robot

ActiveCN102069254AGuaranteed accuracyReduce wearPrinted circuit assemblingWelding/soldering/cutting articlesEngineeringSlide plate

The invention discloses a tin soldering system of an automatic tin soldering robot, which comprises a soldering bit, a soldering bit moving mechanism and a tin wire accurate positioning mechanism, wherein the soldering bit moving mechanism comprises a moving device connected with the soldering bit; the moving device comprises a connecting block, an air cylinder, a sliding plate and a linear sliding rail; the upper end of the soldering bit and the cylinder body of the air cylinder are connected together by the connecting block, and the connecting block is also connected with the sliding plate; the sliding plate is in sliding connection with the linear sliding rail; a tin wire guide nozzle of the tin wire accurate positioning mechanism is connected with the connecting block through a connecting rod, the connecting block is connected with a connecting shaft, a deflection block is fixedly connected with the connecting shaft, the connecting shaft is connected with a pitching block in a rotating mode, the pitching block is connected with a clamping block, the clamping block is fixed on the upper end of the soldering bit, a horizontal adjustment screw is connected with the deflection block in a rotating mode, and the front end of the horizontal adjustment screw is connected with the pitching block in a sliding mode. The invention can reduce the abrasion of a mechanism which drives the soldering bit to move up and down, ensures the precision of the repeating motion of the soldering bit in tin soldering, and can enable transported tin wires accurately to be positioned to a tin soldering point of the soldering bit.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

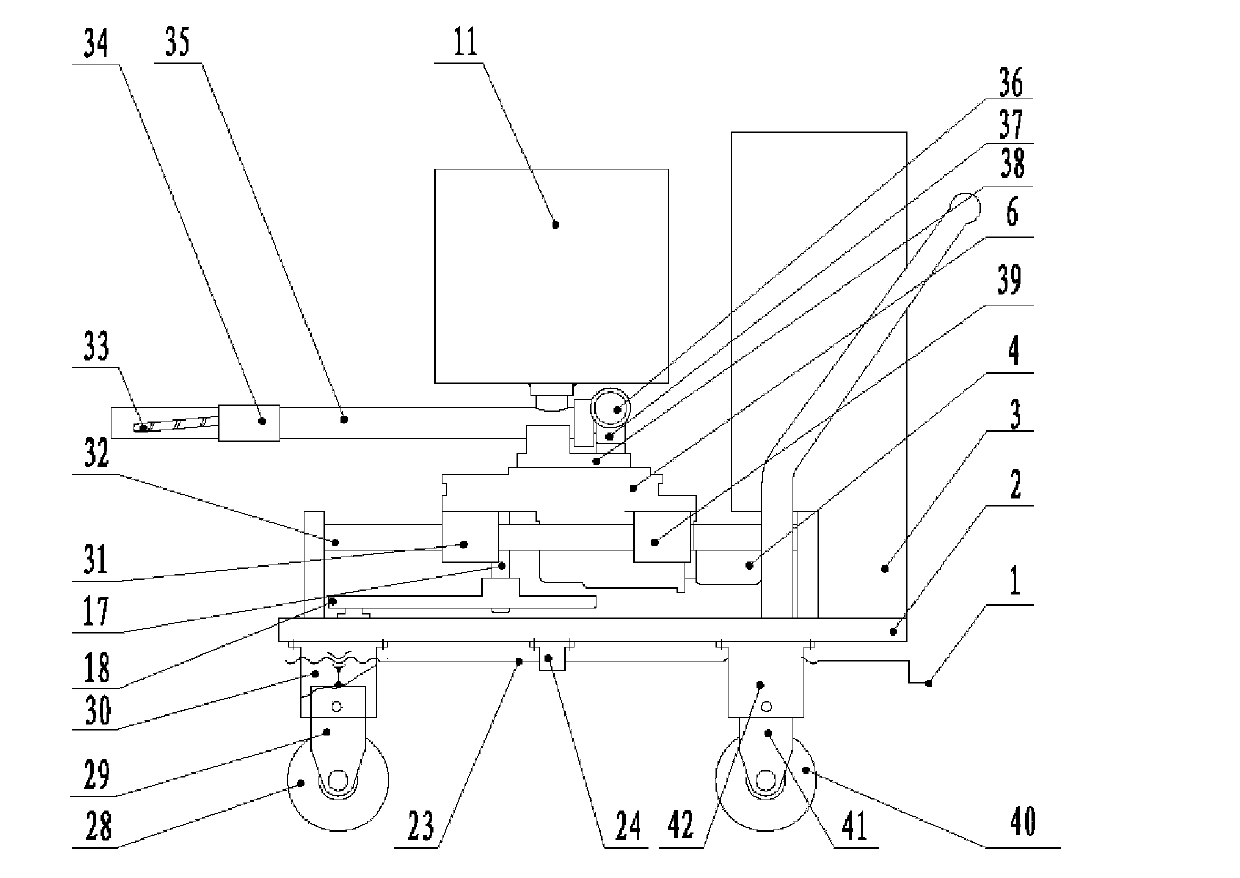

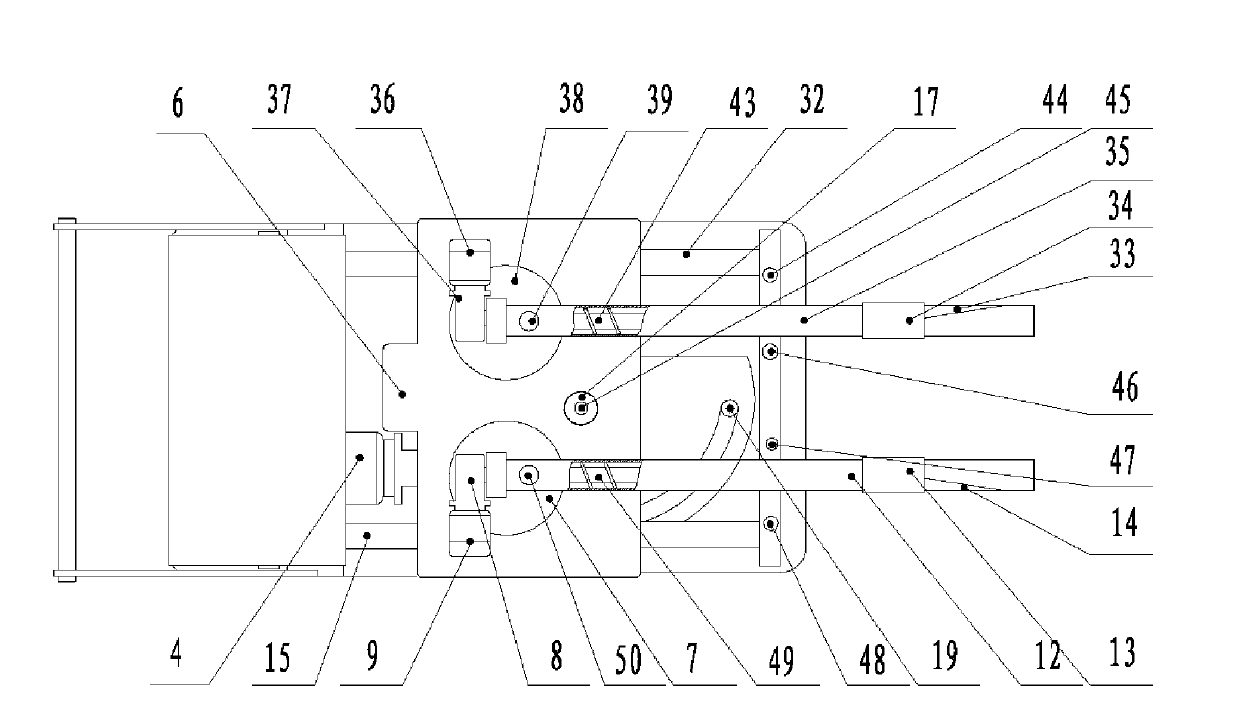

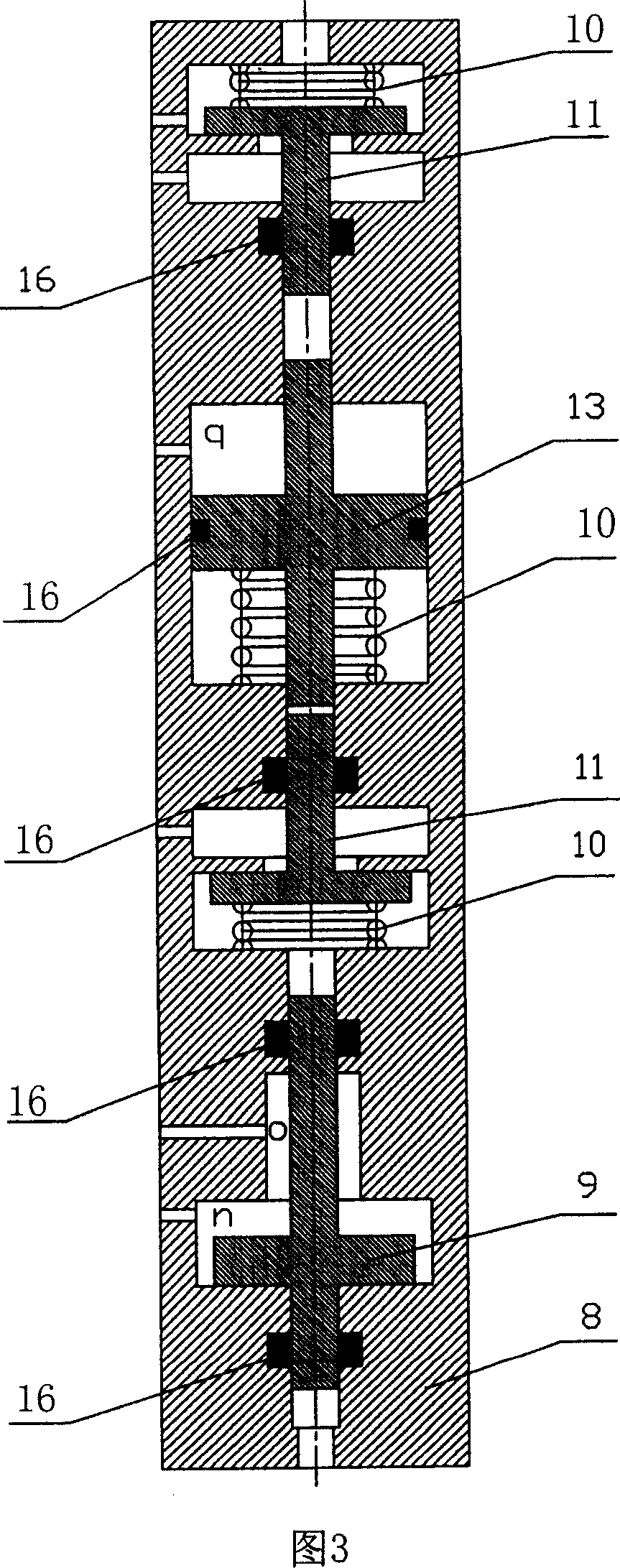

Double-barrelled automatic slag adding machine

The invention relates to a double-barrelled automatic slag adding machine. The technical scheme comprises that the slag adding machine comprises a frame, a slag adding system and an electric control system. The slag adding system is in the structure that: a vibrating motor (4) respectively drives two feed delivery pipe supporting discs (7 and 38) to rotate by virtue of two vibrating output shaftsof a third reduction box (6), namely a first feed delivery pipe (12) and a second feed delivery pipe (35) are driven to vibrate in the horizontal plane; and a translation compensation output shaft (17) of the third reduction box (6) drives a translation compensation cam (18) to rotate, thus the reciprocating linear motion of the slag adding system is realized. Two feed delivery motors (9 and 36) respectively drive a first feed delivery screw rod (49) and a second feed delivery screw rod (43) to rotate, thus a granular material is pushed towards the exit direction. The slag adding machine provided by the invention has the characteristics of compact structure, uniform slag addition, high degree of automation and wide application range and is simple in operation and applicable to automatic, continuous and uniform casting powder addition of a large-section crystallizer of which all the material spreading regions have the lengths in the range of 300-2500mm and the widths in the range of 0-300mm.

Owner:WUHAN UNIV OF SCI & TECH

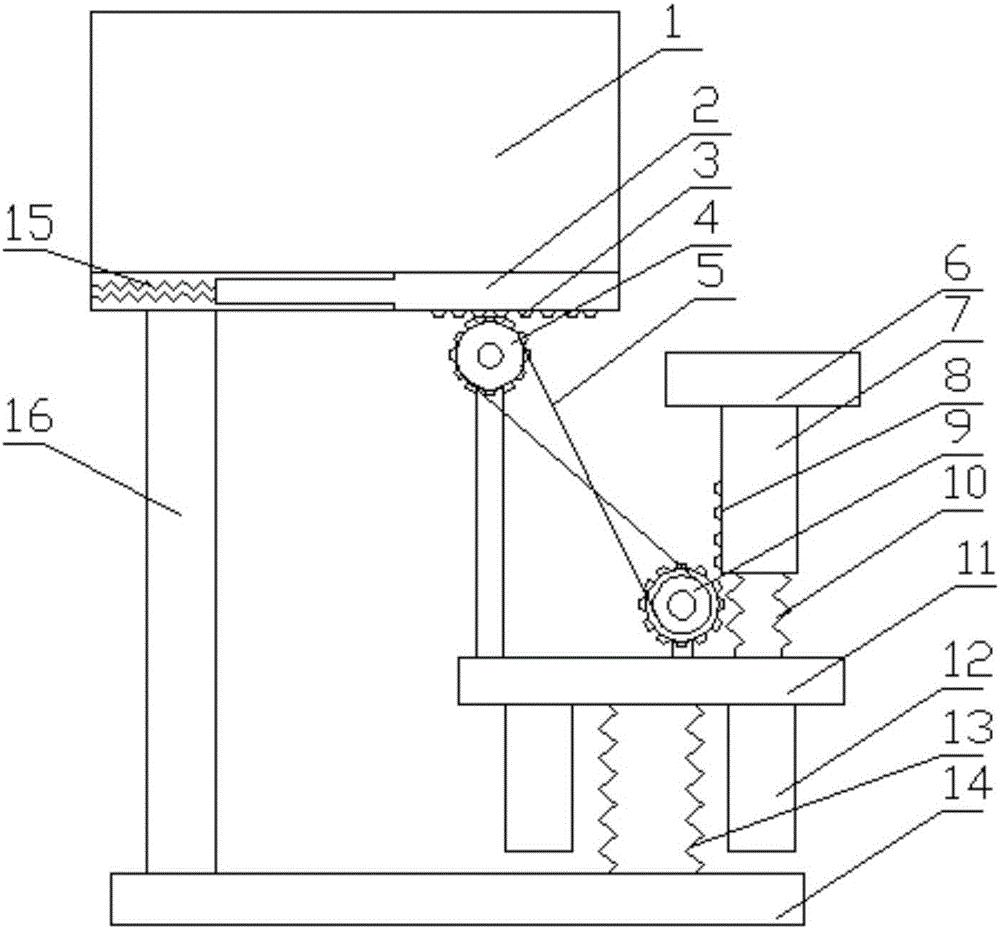

Poultry feeding device with continuous quantitative feeding function

ActiveCN106069848AWith continuous quantitative feeding functionExquisite designAnimal feeding devicesAvicultureGear wheelEngineering

The invention relates to a poultry feeding device with a continuous quantitative feeding function. The poultry feeding device comprises a feed bin, a supporting rod, a base plate and a treading mechanism, wherein the feed bin is fixed above the base plate by virtue of the supporting rod, the feed bin comprises a bin body, a sliding plate and a first strip-shaped gear, and the treading mechanism comprises a pedal, a first stop block, a first spring, a second strip-shaped gear, a first circular gear, a second circular gear, a supporting plate, a second stop block and a second spring. The poultry feeding device with the continuous quantitative feeding function is delicate in design and smart in structure, and when livestock treads the pedal, firstly the first spring with relatively low elasticity is compressed, the sliding plate slides away and feed in the feed bin is given out, and then the second spring with relatively high elasticity is compressed, so that the first circular gear is separated from the first strip-shaped gear, the sliding plate is reset, and the feed bin is closed. Therefore, food is continuously thrown in, the condition that too much food is thrown in at a time can not appear, the livestock can take more exercise, and health degree of the livestock is improved.

Owner:樱源有限公司

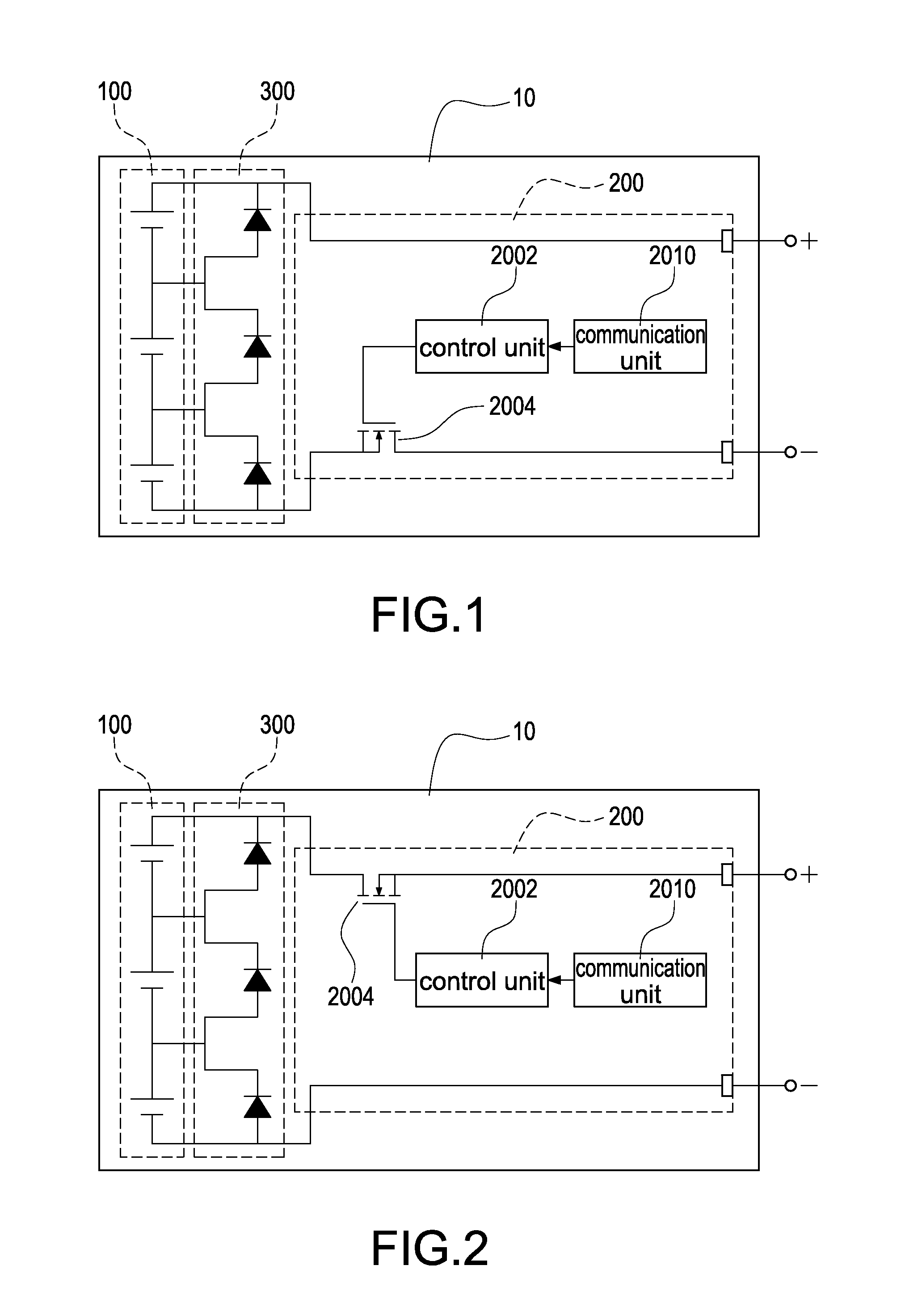

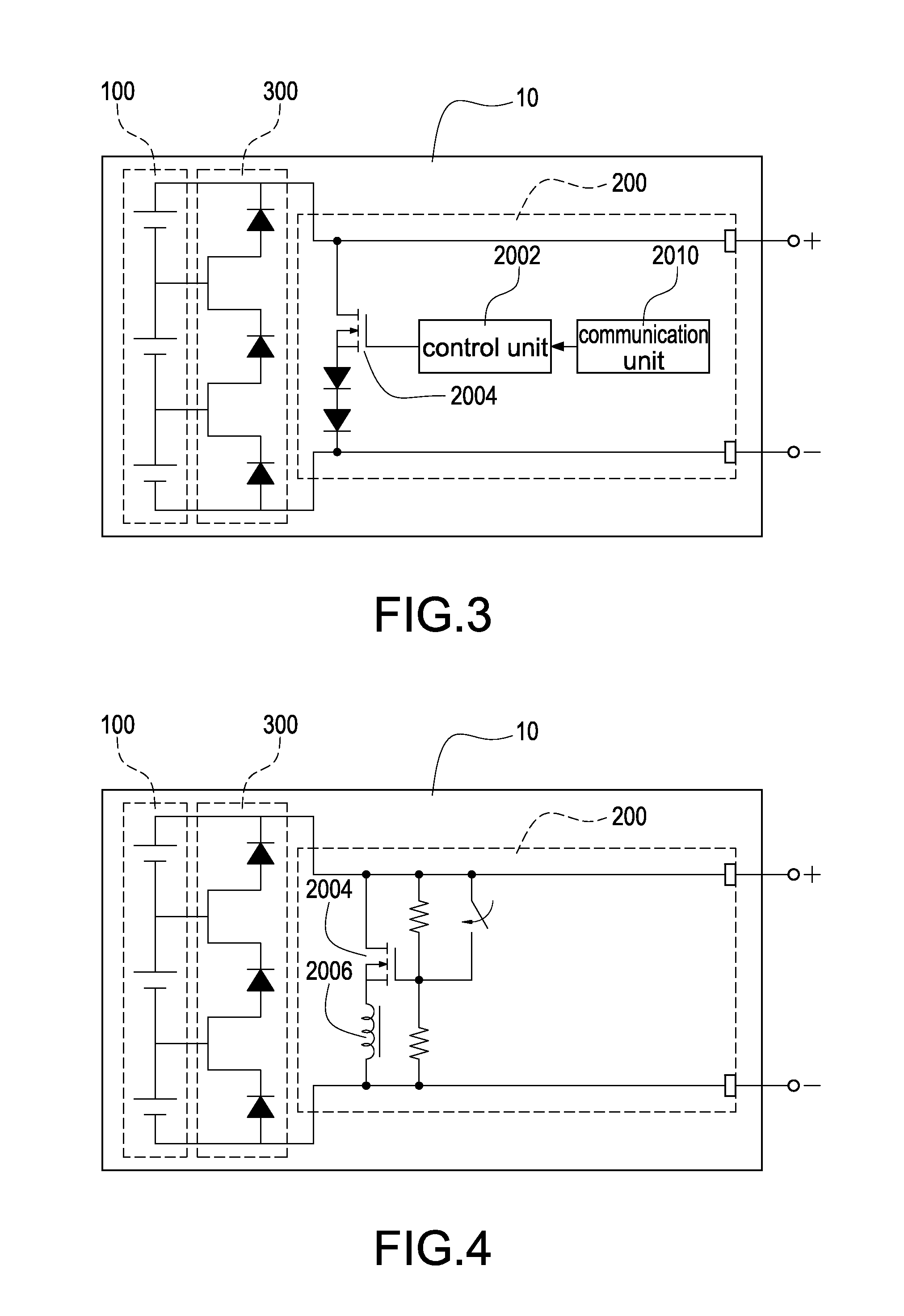

Photovoltaic power system with generation modules

InactiveUS20130320767A1Continuous deliveryDc network circuit arrangementsPhotovoltaic energy generationElectricityEngineering

A photovoltaic power system includes a plurality of generation modules and a main communication apparatus. Each generation module has a photovoltaic panel assembly, a switch integrated apparatus, and a junction apparatus. The photovoltaic panel assembly has a plurality of photovoltaic panels electrically connected in series. The switch integrated apparatus has a control unit and a switch unit. The junction apparatus is electrically connected between the photovoltaic panel assembly and the switch integrated apparatus to collect electricity generated from the photovoltaic panels and deliver collected electricity to output terminals of the photovoltaic power generation module. The main communication apparatus is connected to the switch integrated apparatuses to turn on or turn off the switch unit according to magnitude of the output voltage, thus controlling continuously delivering electricity or discontinuously delivering electricity generated from the photovoltaic panels.

Owner:DELTA ELECTRONICS INC

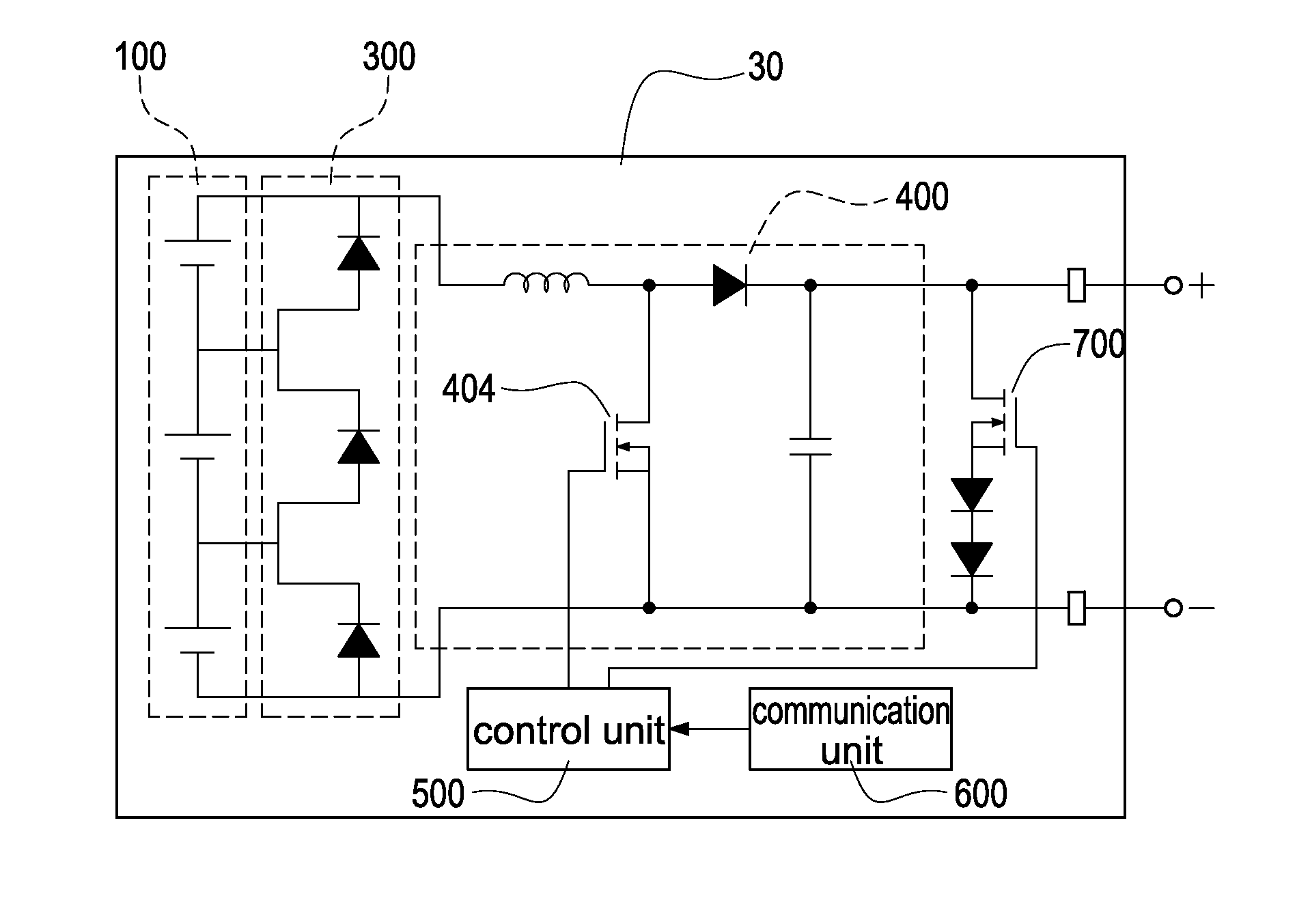

Fulfillment of cloud service orders

ActiveUS9716634B2Efficient and effectiveMaintain securityResource allocationFinanceAuto-configurationWorkflow

A fulfillment bridge orchestrates various types of fulfillment that fall generally into three categories of fulfillment: CSB platform based automated provisioning; external automated provisioning; and manual workflow provisioning. External automated provisioning is implemented through fulfillment agents. The fulfillment agents can implements self-registration for allowing the fulfillment bridge to understand the capabilities of the fulfillment agent. Examples of such capabilities include, but are not limited to, supported actions and input / output parameters. Adapters of the fulfillment bridge interface with the fulfillment agents and fulfillment scripts that are independently operated with respect to the CSB platform can be use to interface with the fulfillment adapters.

Owner:HCL TECH LTD

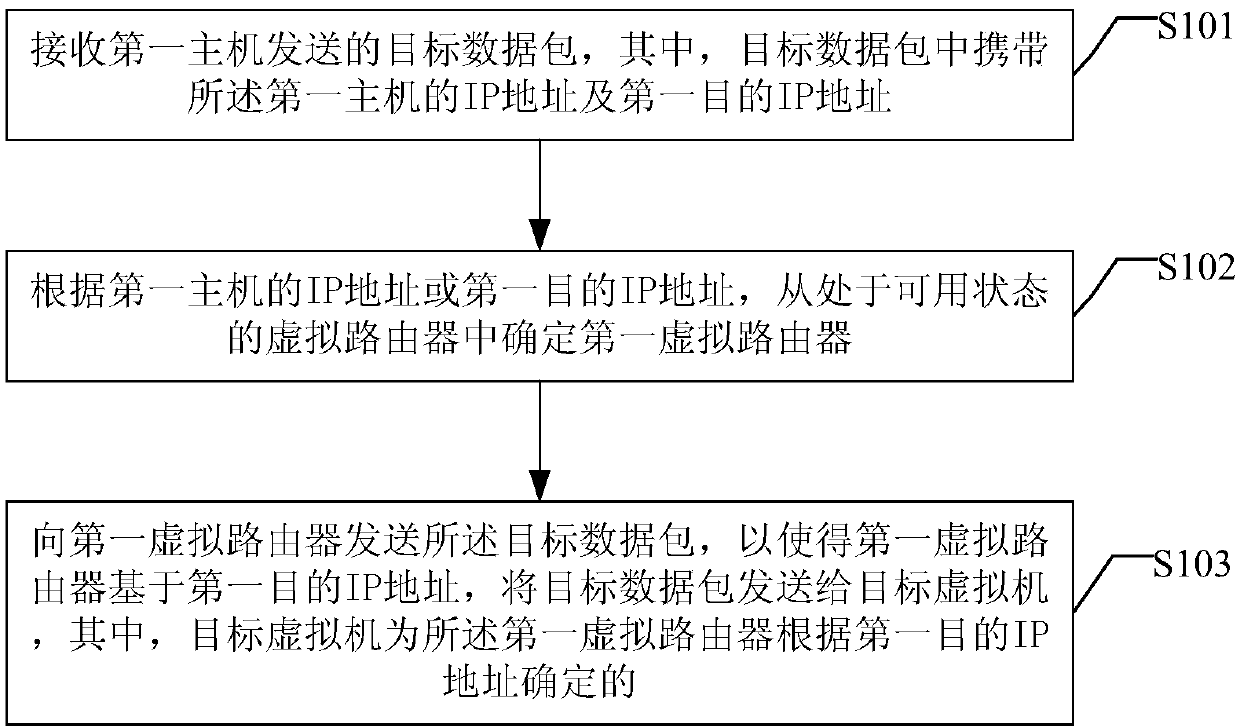

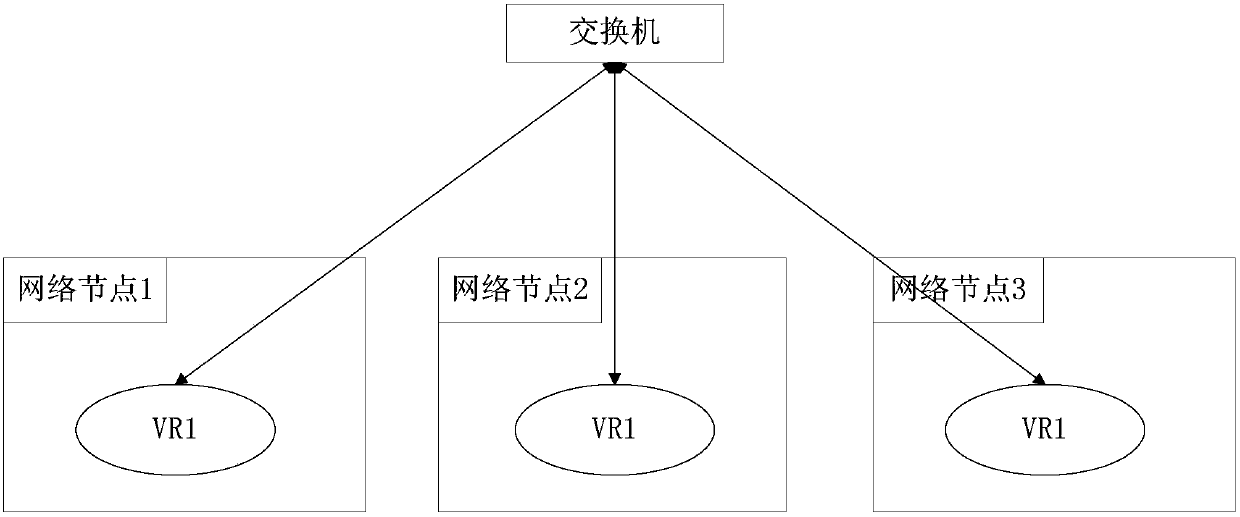

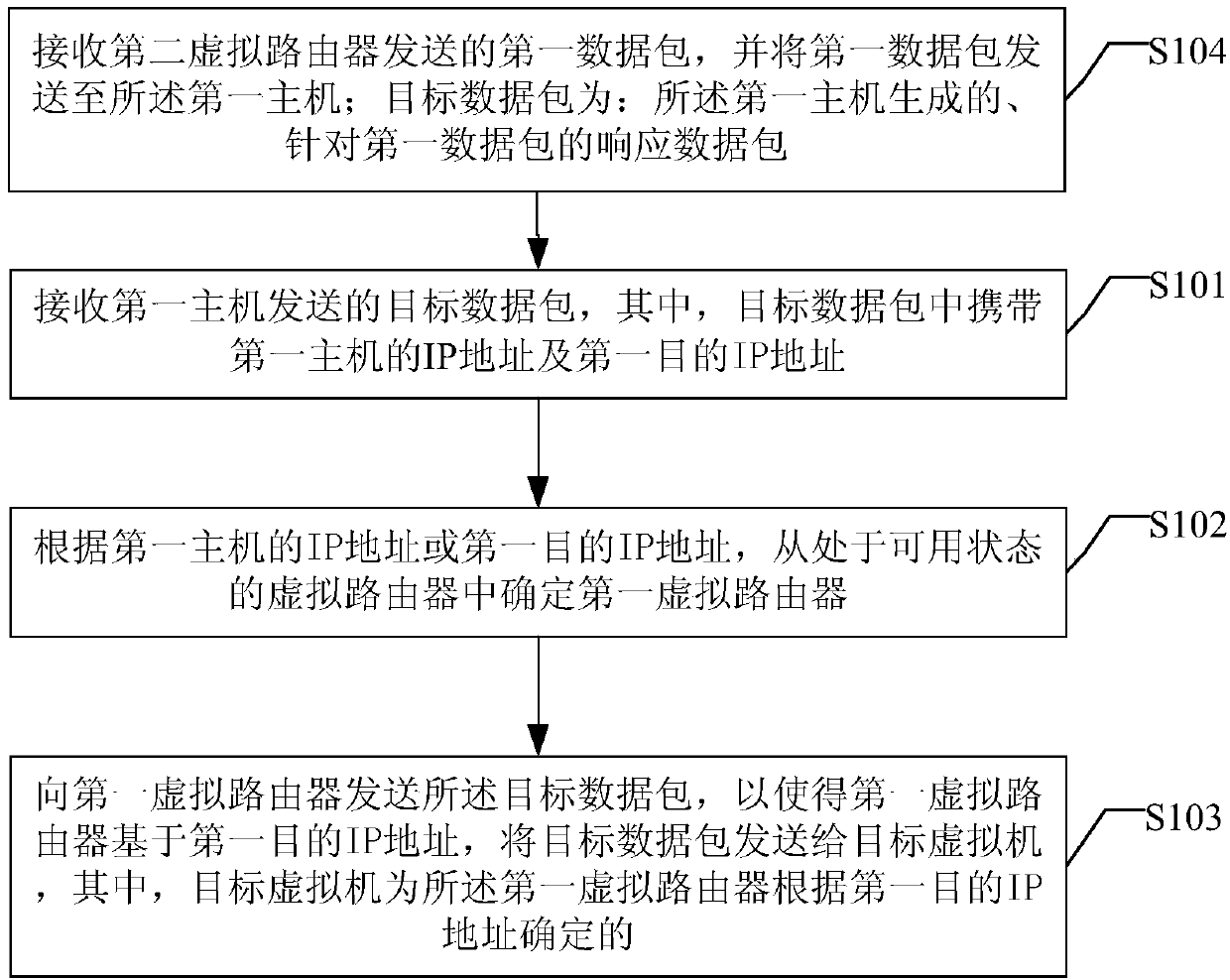

Data transmission method and device, and network system

The embodiment of the invention discloses a data transmission method and device, and a network system. The network system comprises a switch, at least one computing node, and at least one network node, wherein the initial status of each virtual router configured in each network node is an active status, and at least one virtual machine is configured in each computing node. The method applied to the switch of the network system comprises the following steps: receiving a target data packet sent by a first host, wherein the target data packet carries an IP address of the first host and a first target IP address; according to the IP address of the first host or the first target IP address, determining a first virtual router from the virtual routers in the active status; and sending the targetdata packet to the first virtual router, so that the first virtual router sends the target data packet to a target virtual machine based on the first target IP address, wherein the target virtual machine is determined by the first virtual router according to the first target IP address. The data transmission method and device and the network system provided by the embodiment of the invention havethe advantage that continuous data transmission can be guaranteed.

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD +1

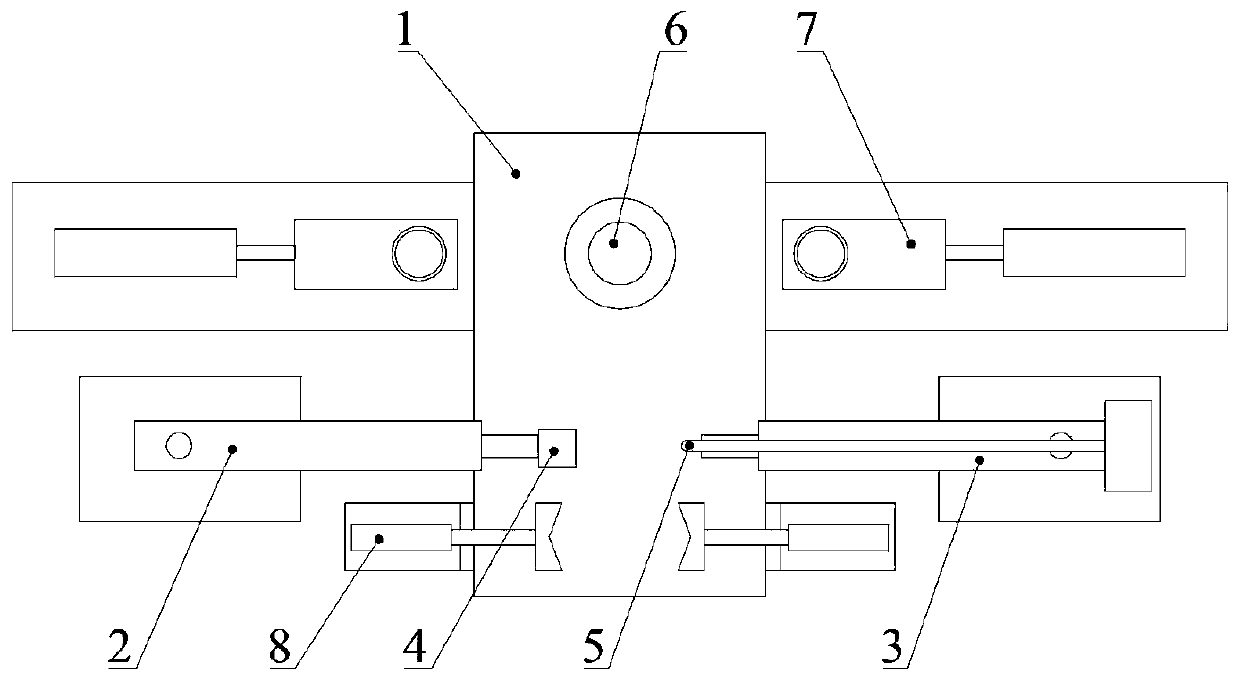

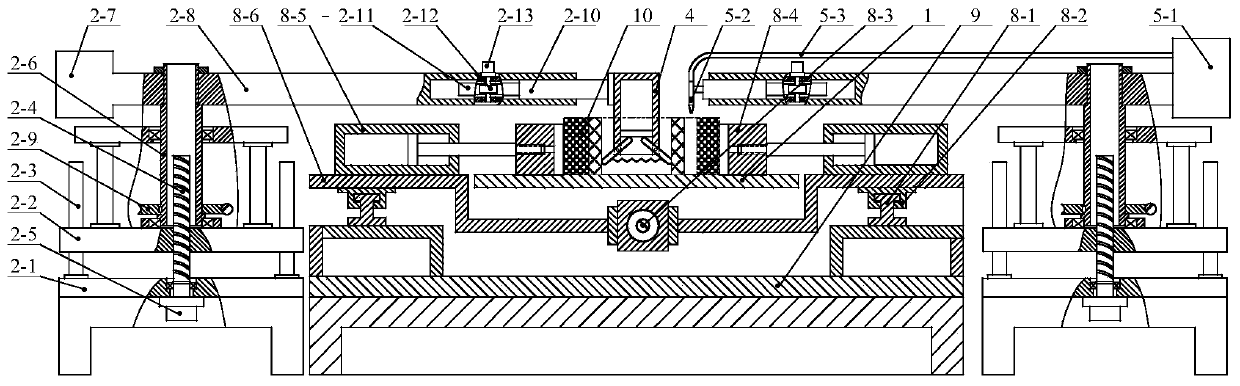

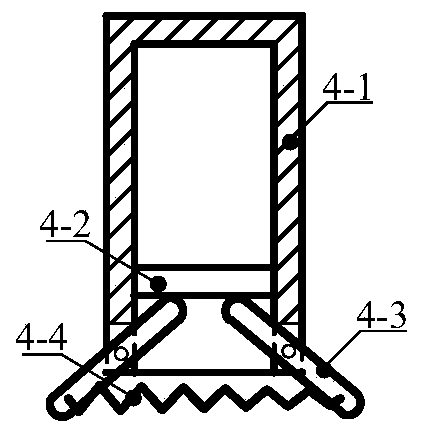

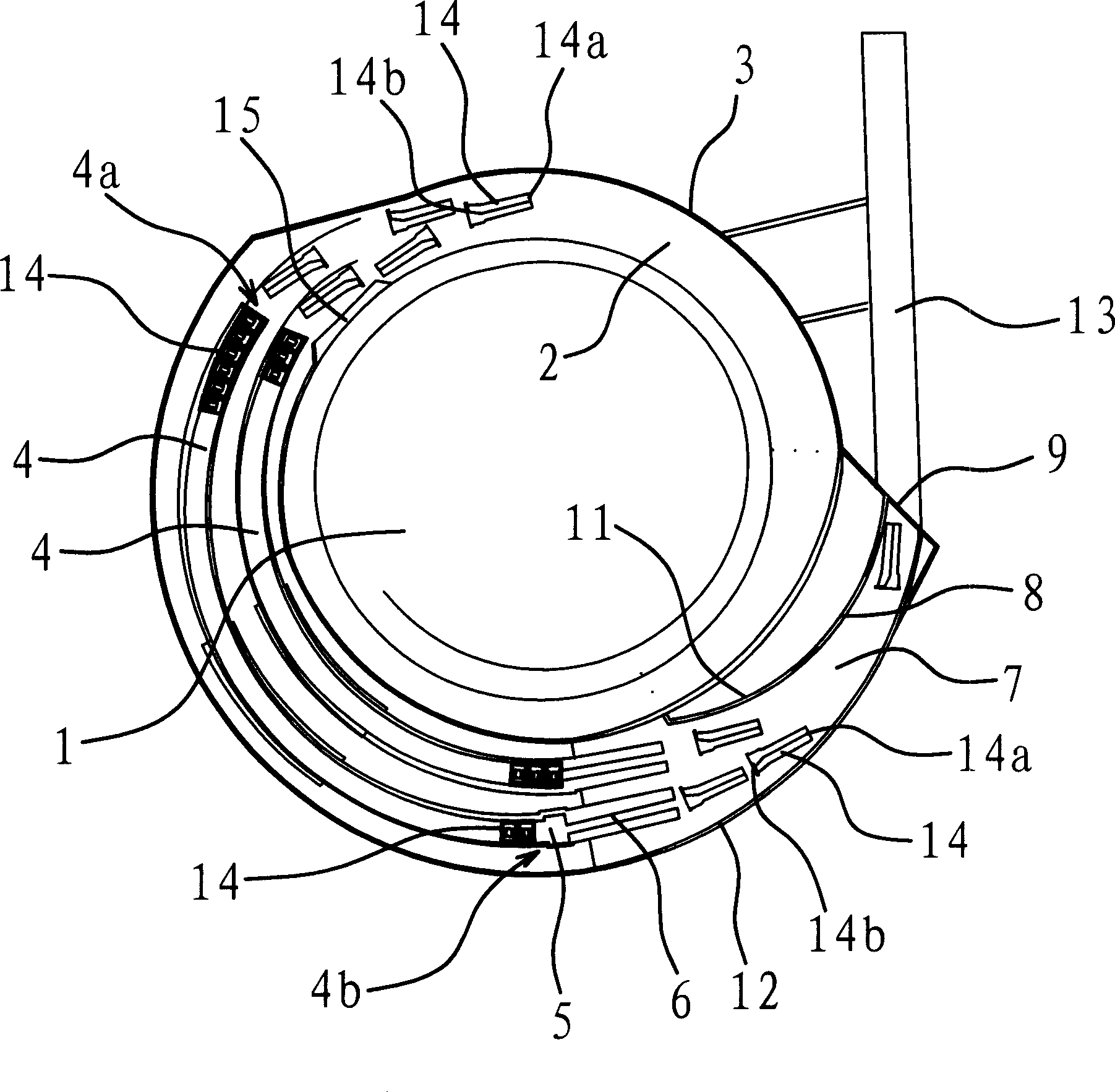

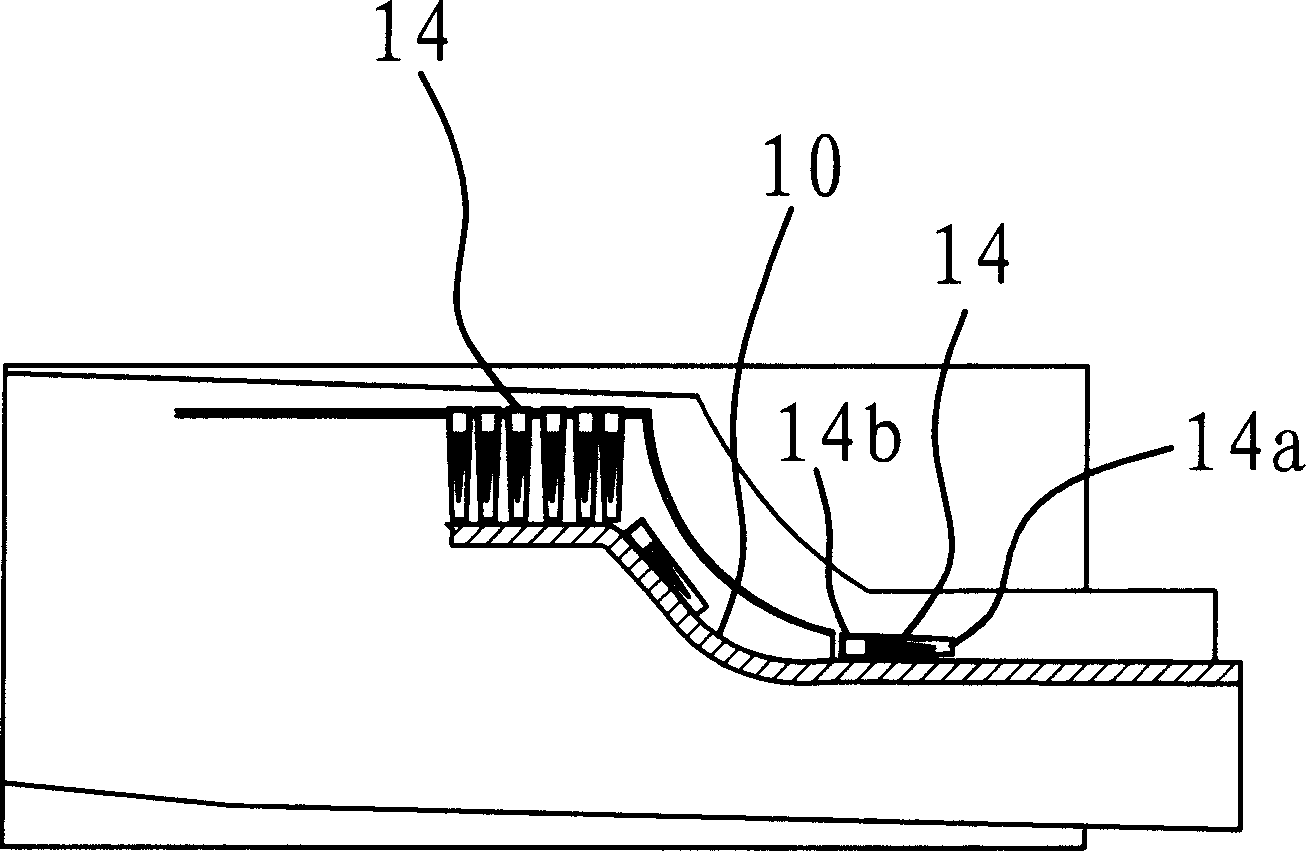

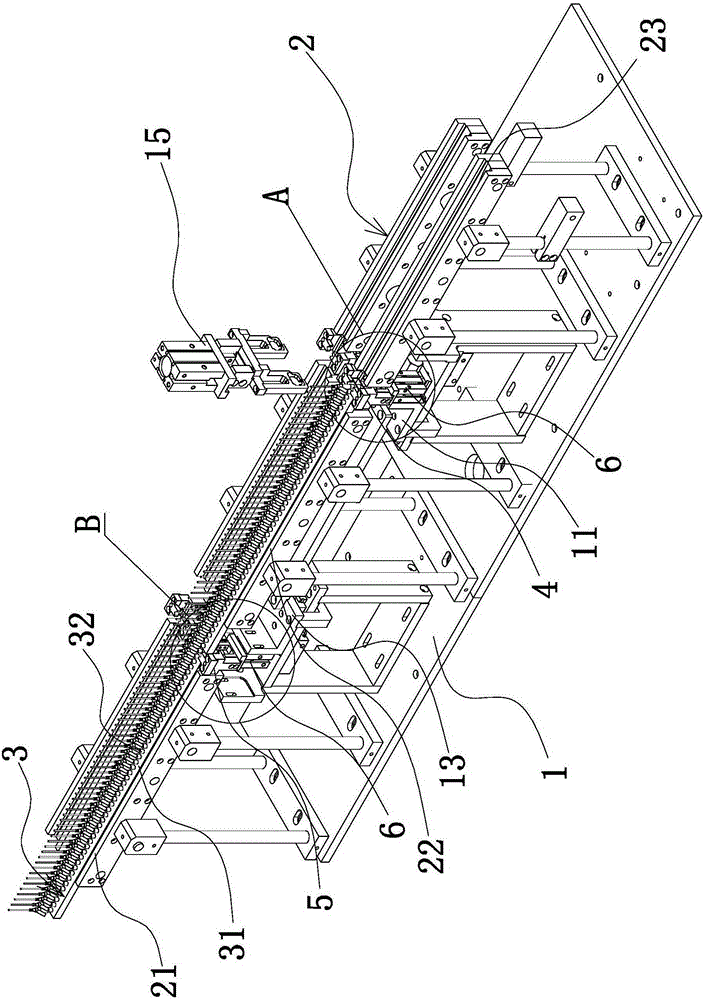

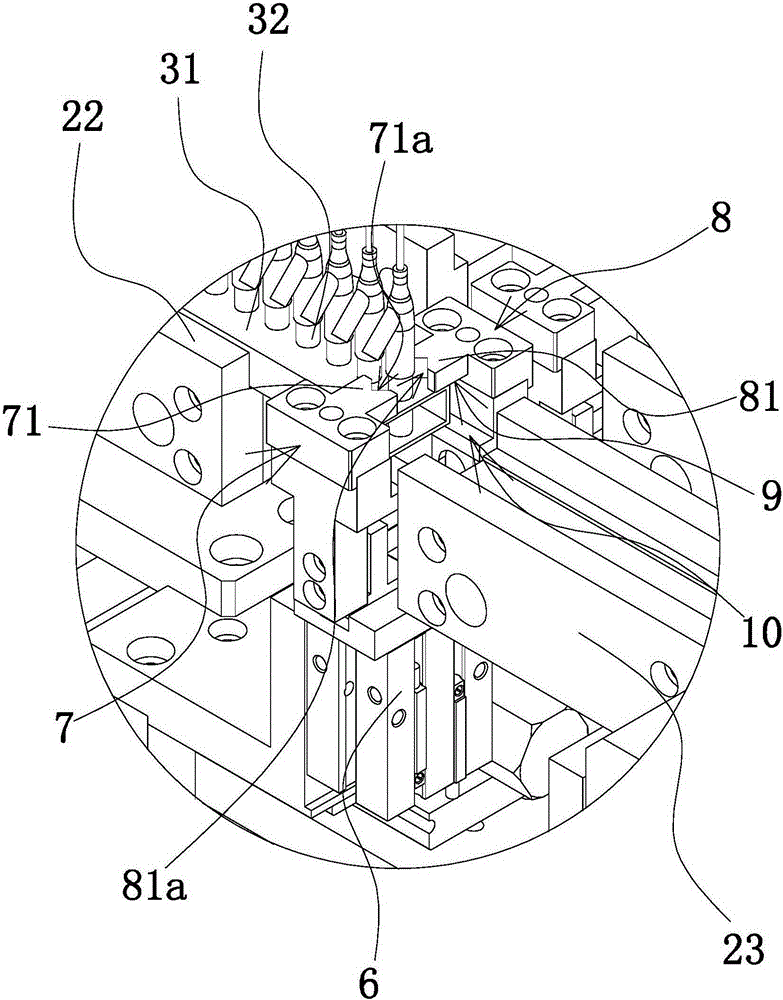

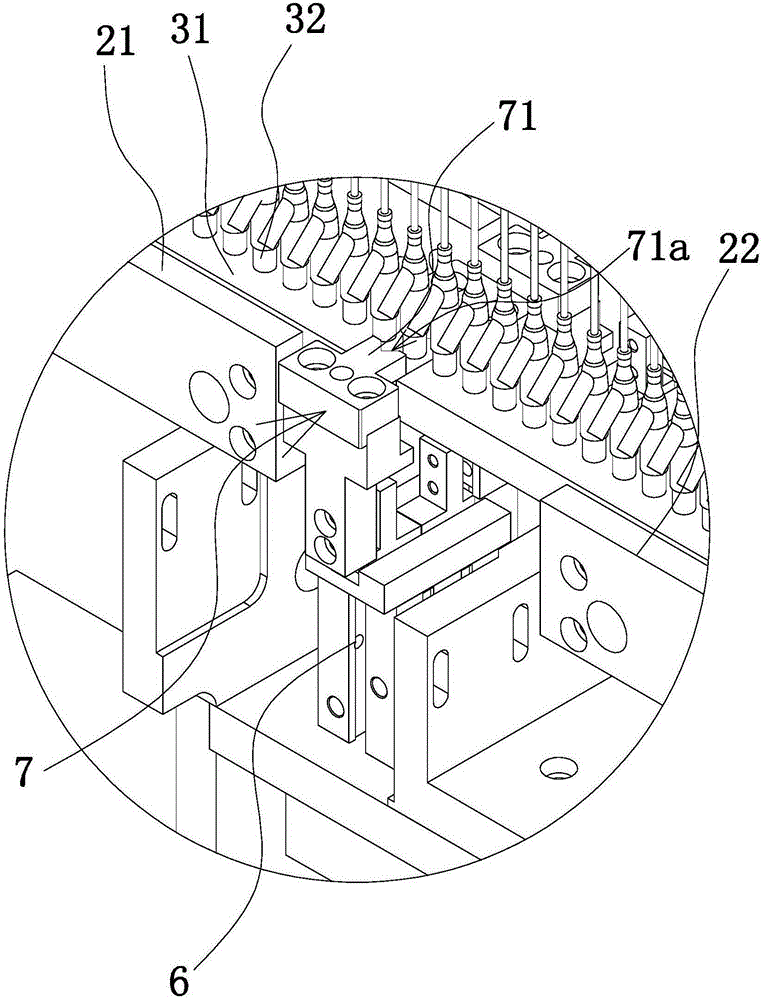

Bearing assembly all-in-one machine and assembly method thereof

ActiveCN110185711AGuaranteed precision and consistencySimple mechanical structureBearing componentsNozzleEngineering

The invention discloses a bearing assembly all-in-one machine and an assembly method thereof. The assembling of bearing balls and press-fitting of a bearing retainer are important processes in the assembly of rolling bearings. The machine comprises an operating platen, a ball loading module, a retainer pressing-in module, a station switching mechanism and a base, wherein the ball loading module comprises an inner ring triaxial mechanical arm, a ball triaxial mechanical arm, an inner ring mounting chuck and a ball blowing mechanism; the retainer pressing-in module comprises a pressing-down mechanism and a retainer pushing mechanism; the ball blowing mechanism comprises an air pressure ball bin, an on-off valve, a nozzle and a ball conveying pipe; and the retainer pushing mechanism comprisesa feeding device seat, a feeding air cylinder, a return spring, a T-shaped locking pin, a feeding bottom plate, a feeding device, a feeding inclined rail and a retainer storage bin. By matching the station switching mechanism, the ball loading module and the retainer pressing-in module, the assembly of an inner ring, an outer ring, the balls and the retainer of the bearing can be completed fullyautomatically, and the assembly precision and uniformity of the bearing are effectively guaranteed.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

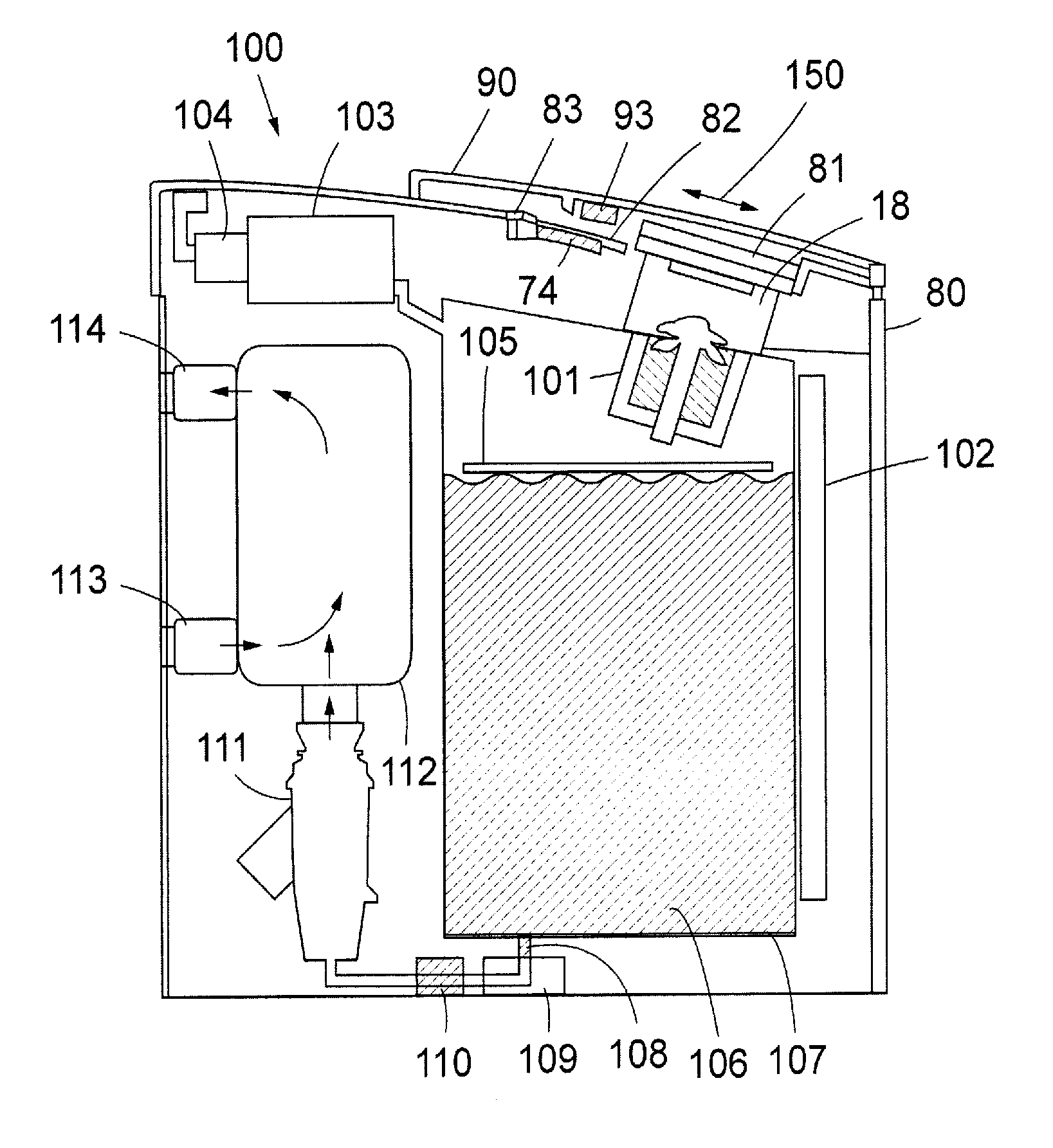

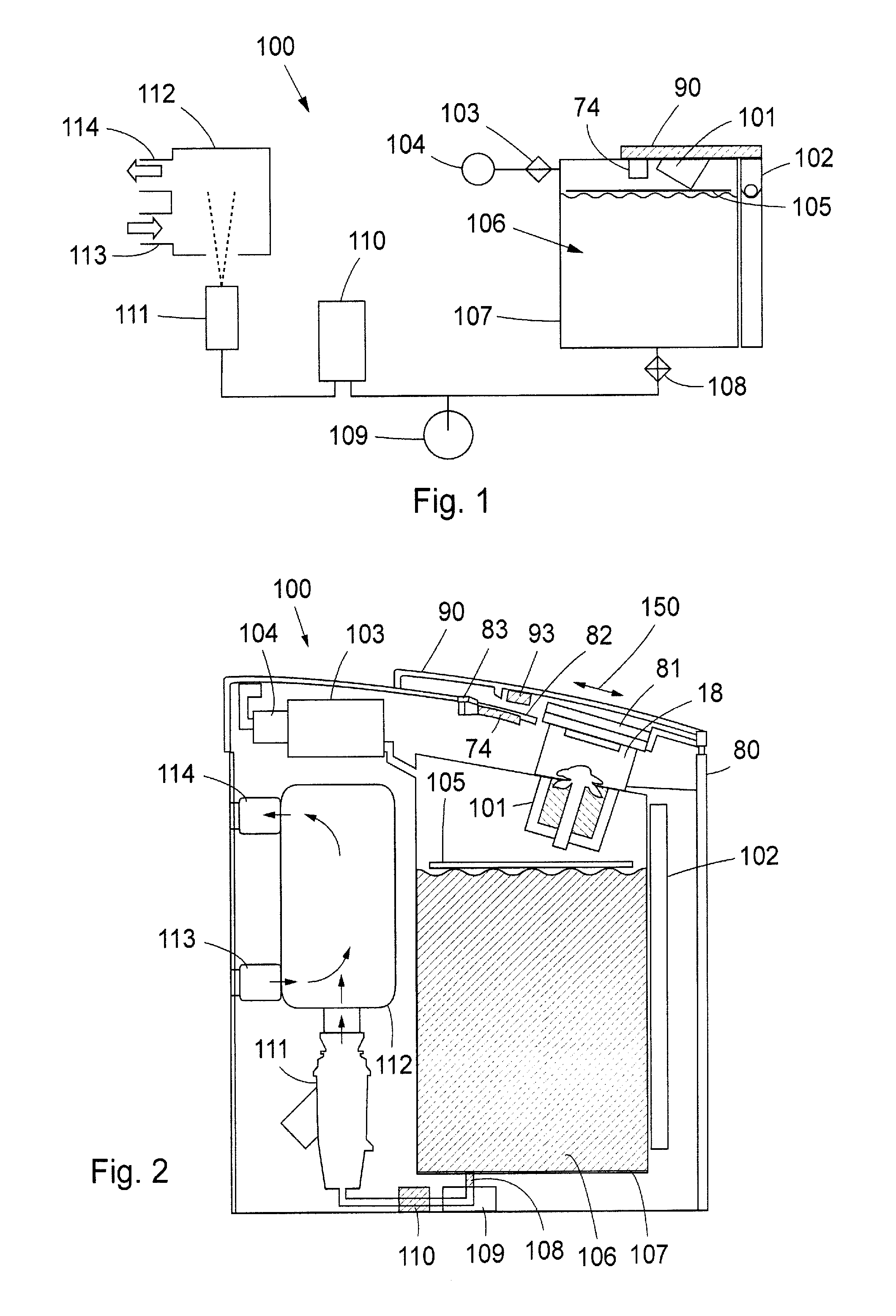

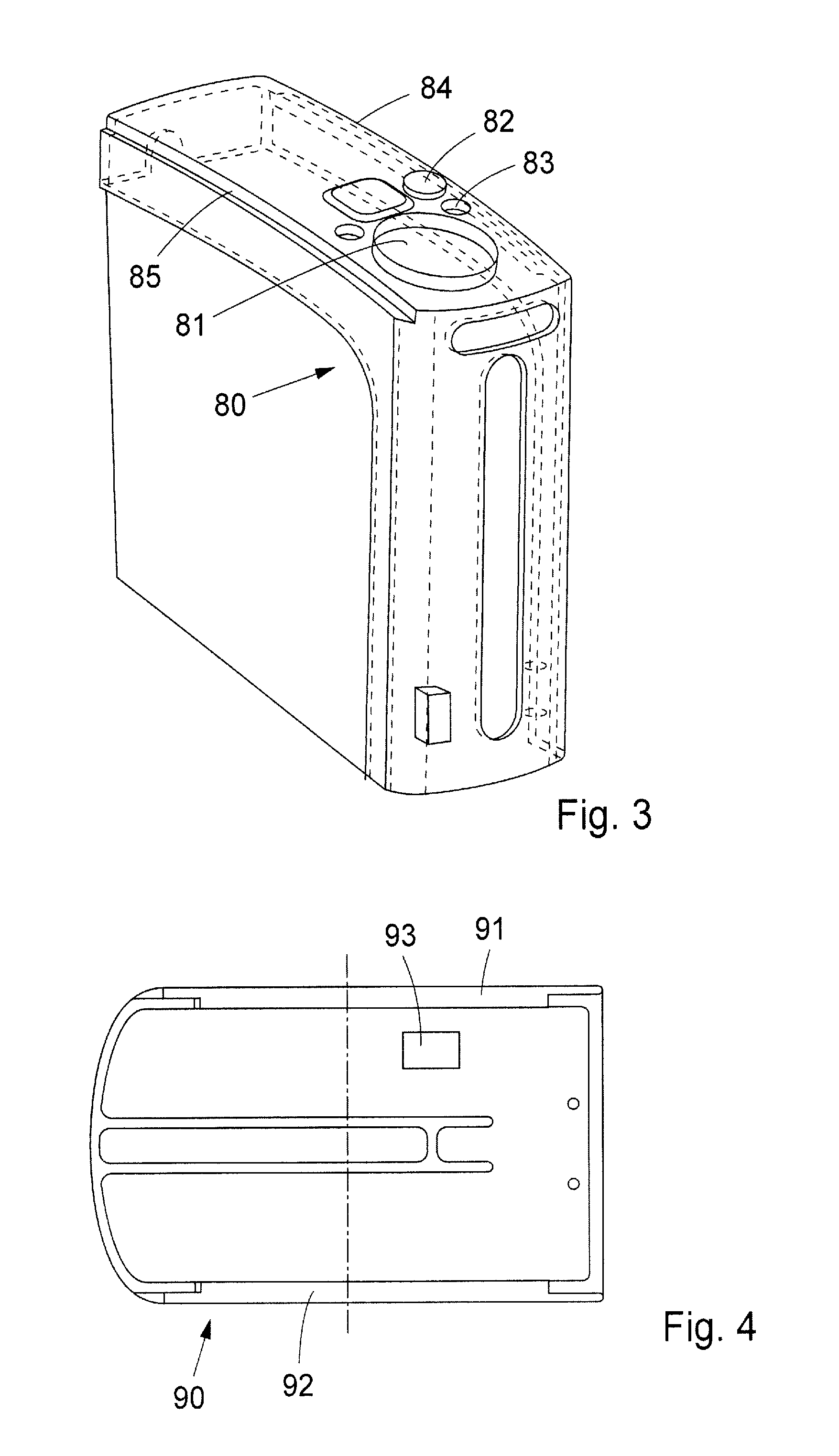

Safety system for a breathing apparatus for delivering an anesthetic agent

ActiveUS20100269820A1Improve securityContinuous deliveryRespiratorsRespiratory device testingSurgeryVALVE PORT

A safety system for a breathing apparatus for delivery of an anesthetic agent having an anesthetic agent vaporizer having a reservoir for containing a liquid anesthetic agent has a reservoir for containing a liquid medical agent, a port for filling the reservoir with the liquid anesthetic agent, and a sensor device for sensing a filling action of the port. A change of position of a lid covering the port can be detected, or insertion of a fill vessel into the port can be detected. Thus safety of the equipment is improved by being able to de-pressurize the reservoir before opening a filling valve for communication of the port with the interior of the reservoir.

Owner:MAQUET CRITICAL CARE

Heating furnace

InactiveCN102538449AImprove heating efficiencyHigh degree of automationFurnace typesEngineeringHeating furnace

The invention relates to a heating furnace, which comprises a framework. A heating chamber is arranged on the framework, a feeding device and a conveying device are disposed on the framework, the conveying device is used for conveying a workpiece to be processed into the heating chamber, a discharge outlet of the feeding device is communicated with the conveying device, the conveying device is communicated with the heating chamber, and a discharge outlet is disposed at the tail of the heating chamber. Special auxiliary equipment is configured for the heating chamber, the workpiece to be processed is automatically fed to the conveying device by the feeding device, the workpiece is conveyed into the heating chamber to be heated by the conveying device, and is discharged from the discharge outlet after being heated, automation degree of an integral heating process is high, labor intensity of workers is greatly reduced, heating efficiency of the workpiece is greatly improved, and the heating furnace is suitable for batch production and is favorable for lowering production cost.

Owner:NINGBO SHENGAN ROBOT TECH CO LTD

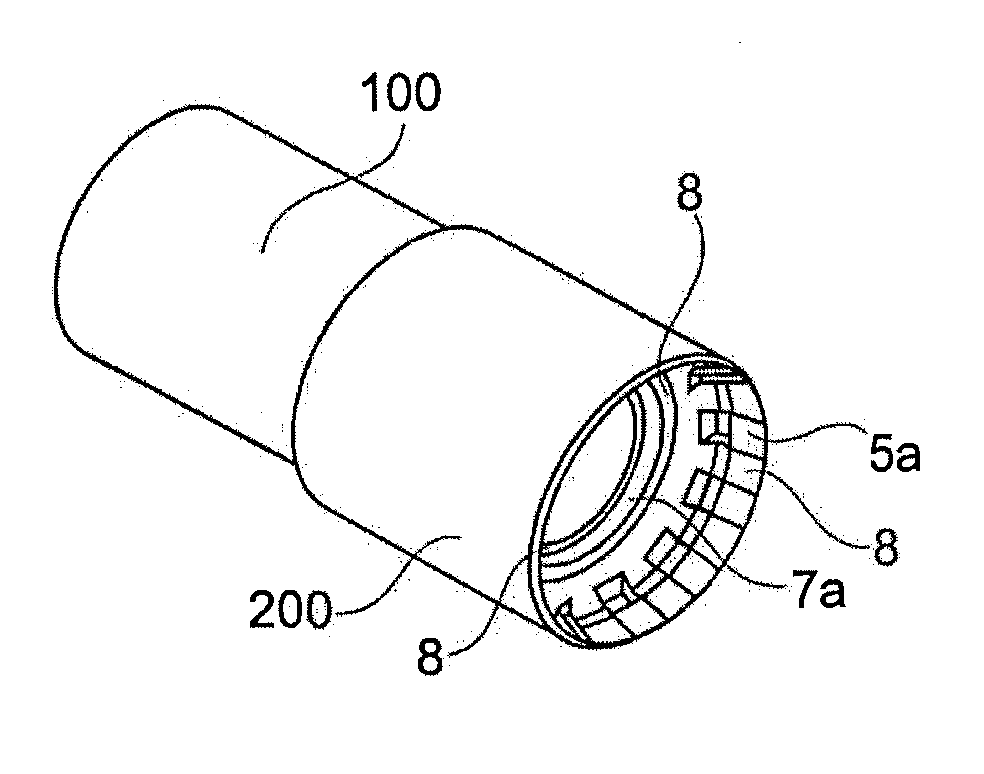

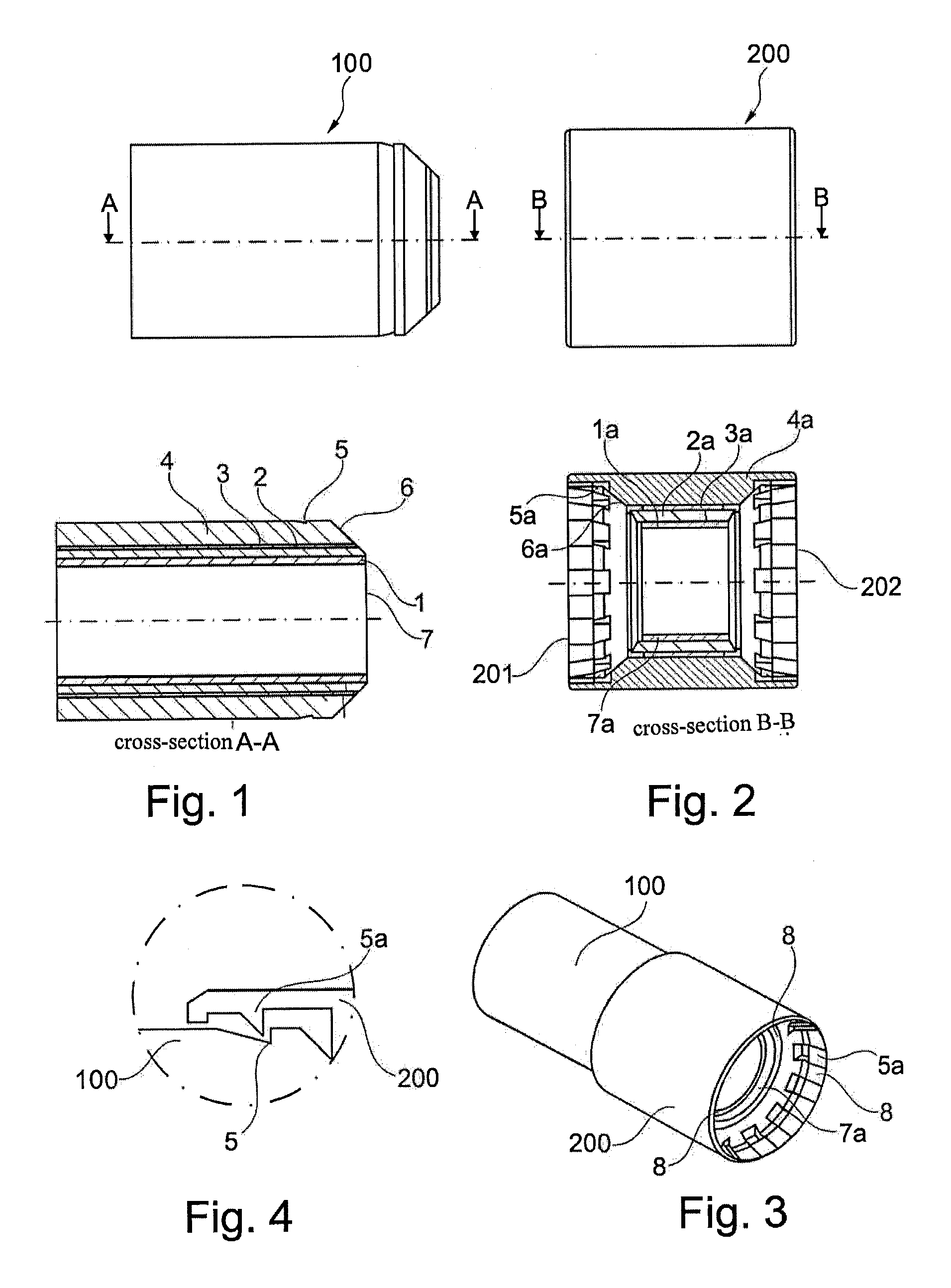

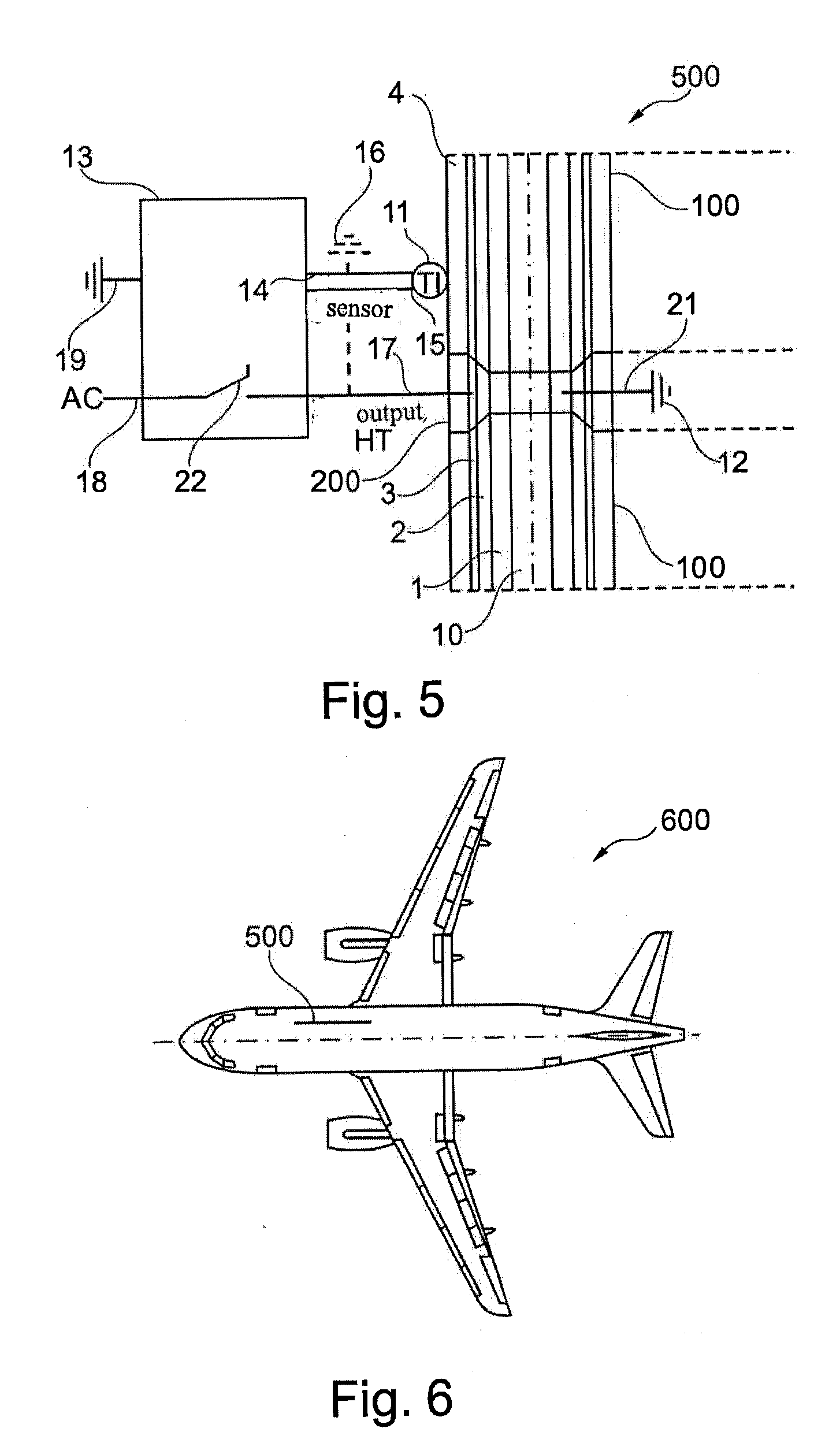

Protection of water conduits against frost

ActiveUS20130048128A1Simple systemImprove heat transfer performanceSleeve/socket jointsDe-icing equipmentsFrostWater transport

A water-transporting line includes an integrated heater system for protection against frost and the appropriate connection, attachment and control elements. A self-heating water conduit segment is provided that has an integrated heating device, which device encloses the outer surface of the water conduit segment. The various segments may be connected mechanically and electrically using corresponding connecting elements.

Owner:AIRBUS OPERATIONS GMBH

Plate overturning machine and plate overturning method

PendingCN107416484AEnables continuous processingInhibit sheddingConveyorsConveyor partsCouplingControl engineering

The invention discloses a plate overturning machine. The plate overturning machine comprises a frame, and a feed conveyor and a discharge conveyor symmetrically arranged on two sides of the frame; conveying rollers are uniformly distributed on the feed conveyor and the discharge conveyor; driving devices for driving the conveying rollers to rotate are respectively arranged below the feed conveyor and the discharge conveyor; the frame is provided with a servo motor and a matched speed reducer; a rotating shaft is arranged above the frame; the speed reducer drives the rotating shaft to rotate through a coupling; at least two mounting plates are arranged on the rotating shaft; parallel forks for clamping plates are arranged on the mounting plates; and when the mounting plates are rotated along with the rotating shaft, the parallel forks can clamp the plates to overturn from the feed conveyor onto the discharge conveyor. The plate overturning machine can be used for improving the defect of manual overturning of the plates in traditional processing equipment.

Owner:QUANYOU FURNITURE

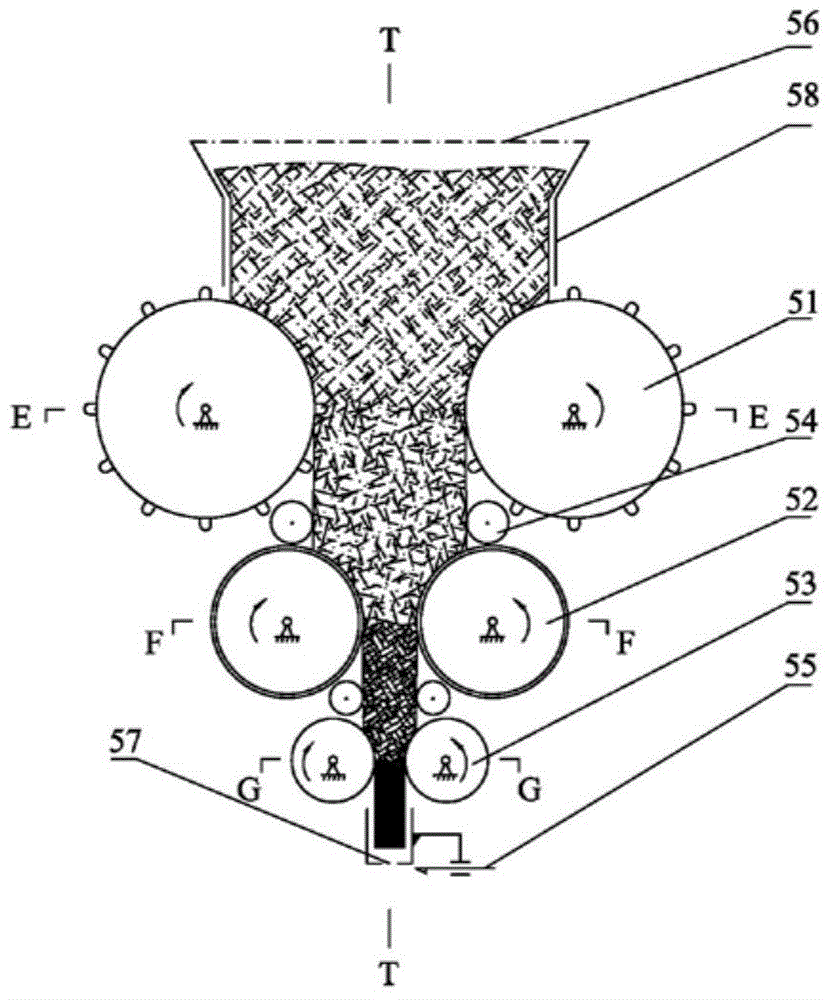

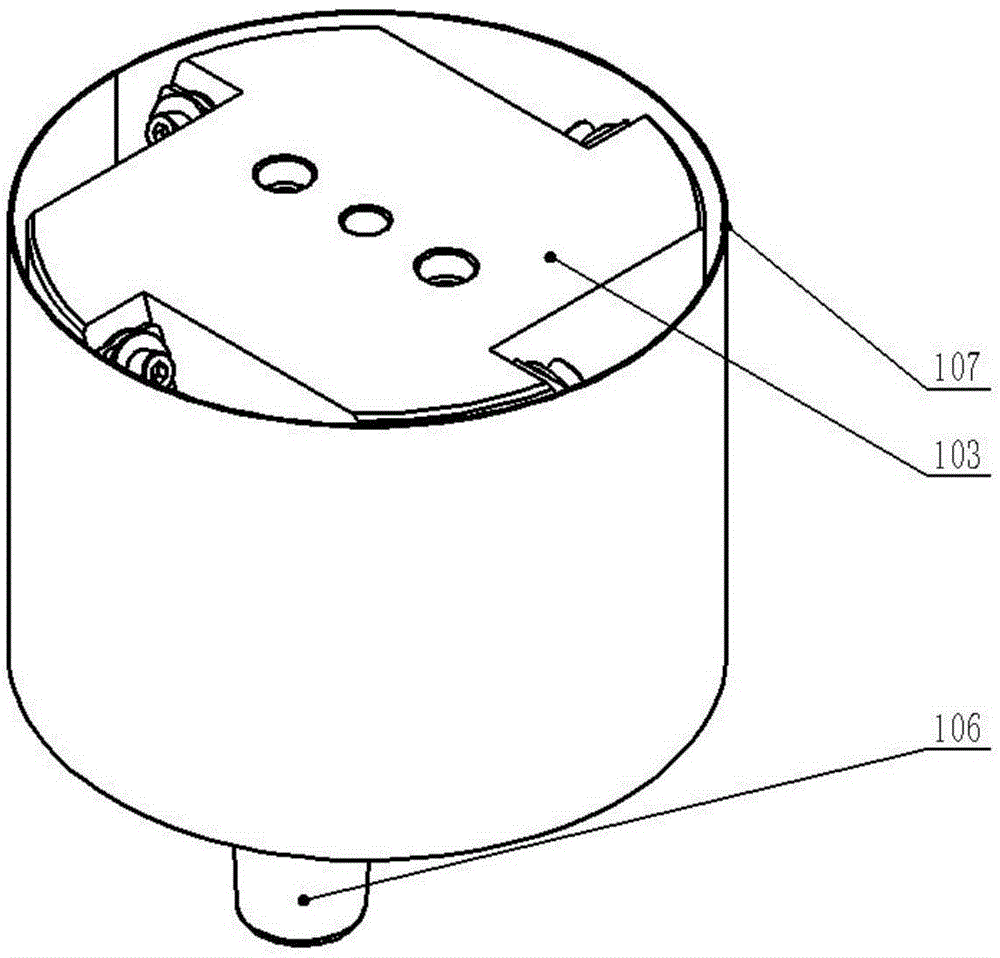

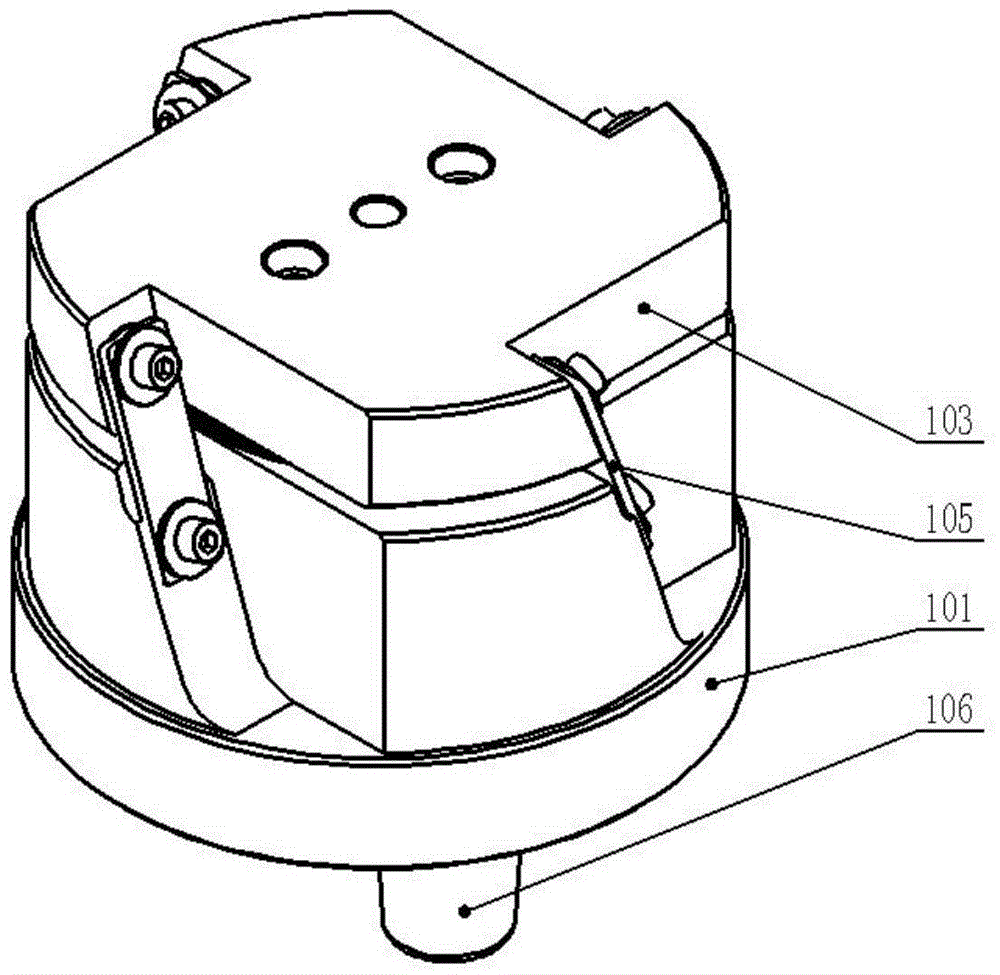

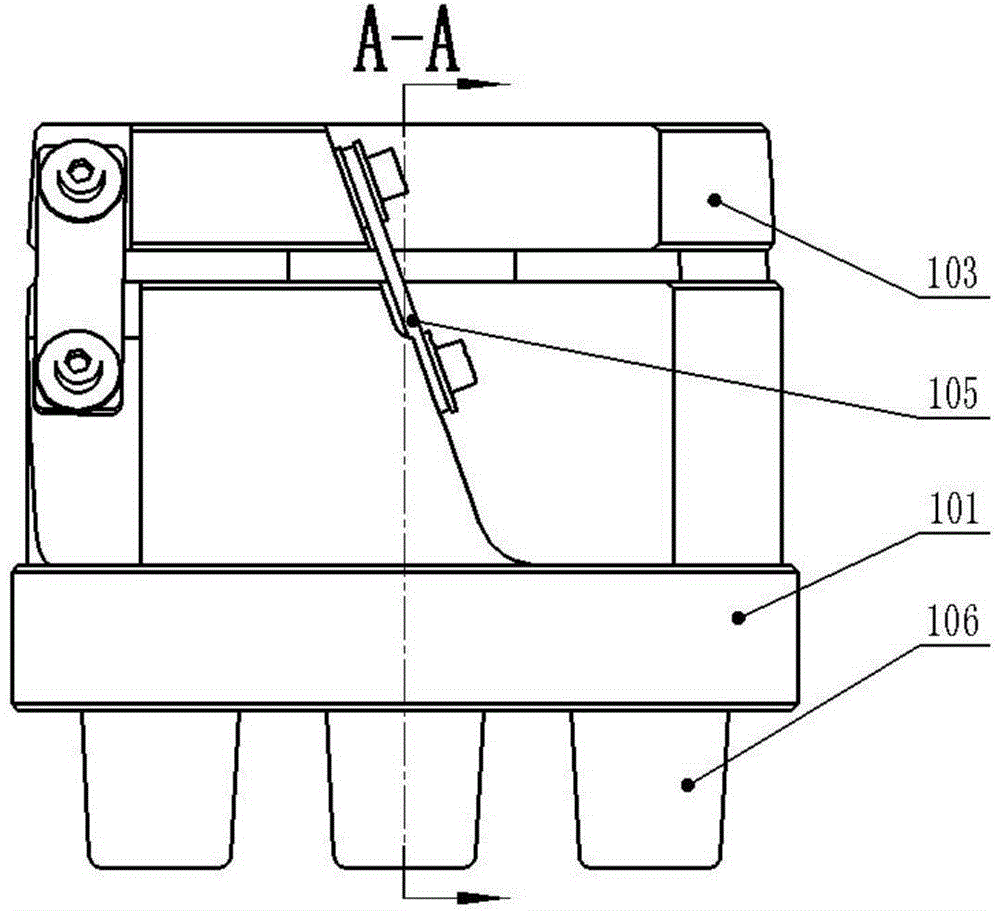

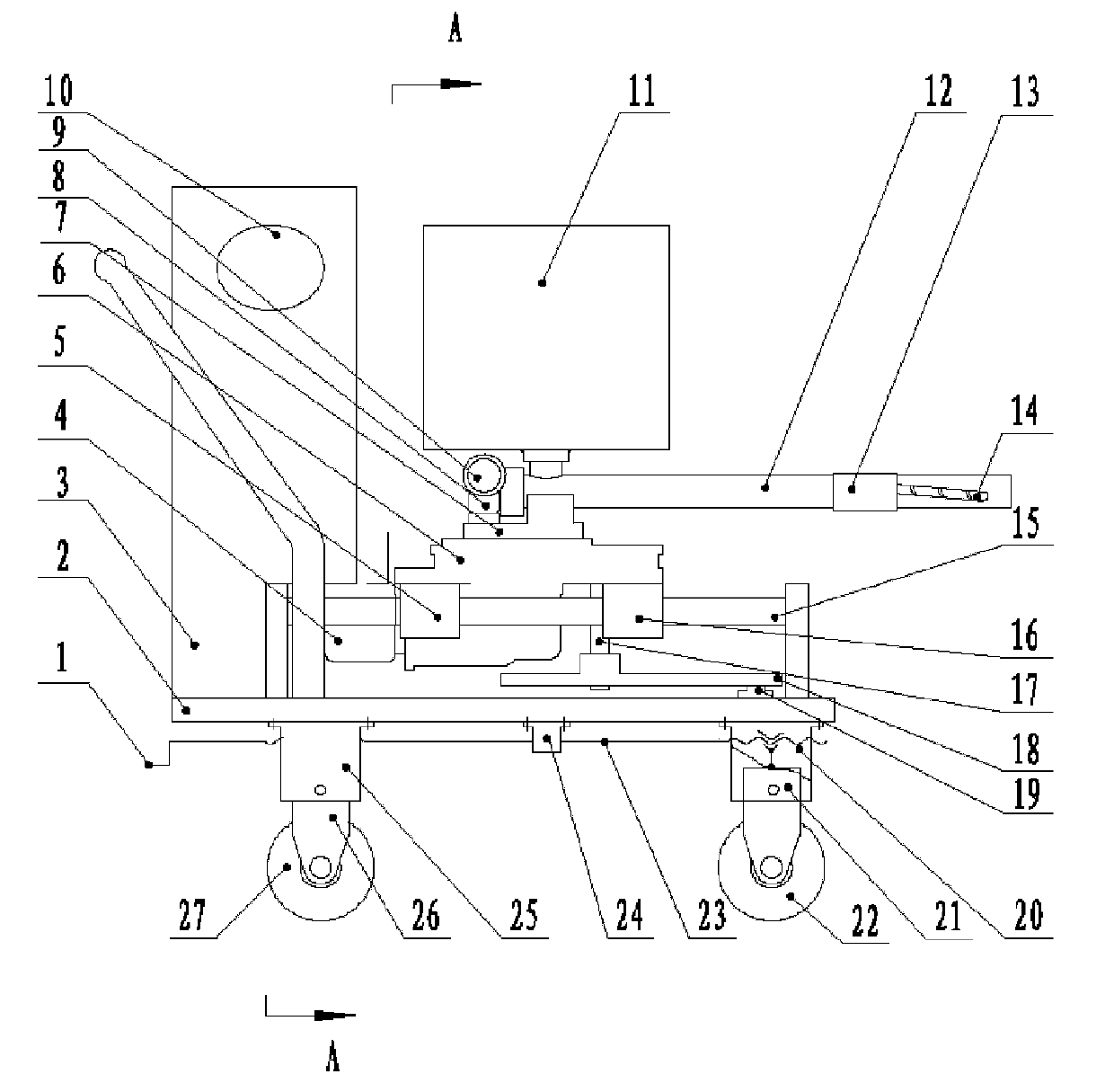

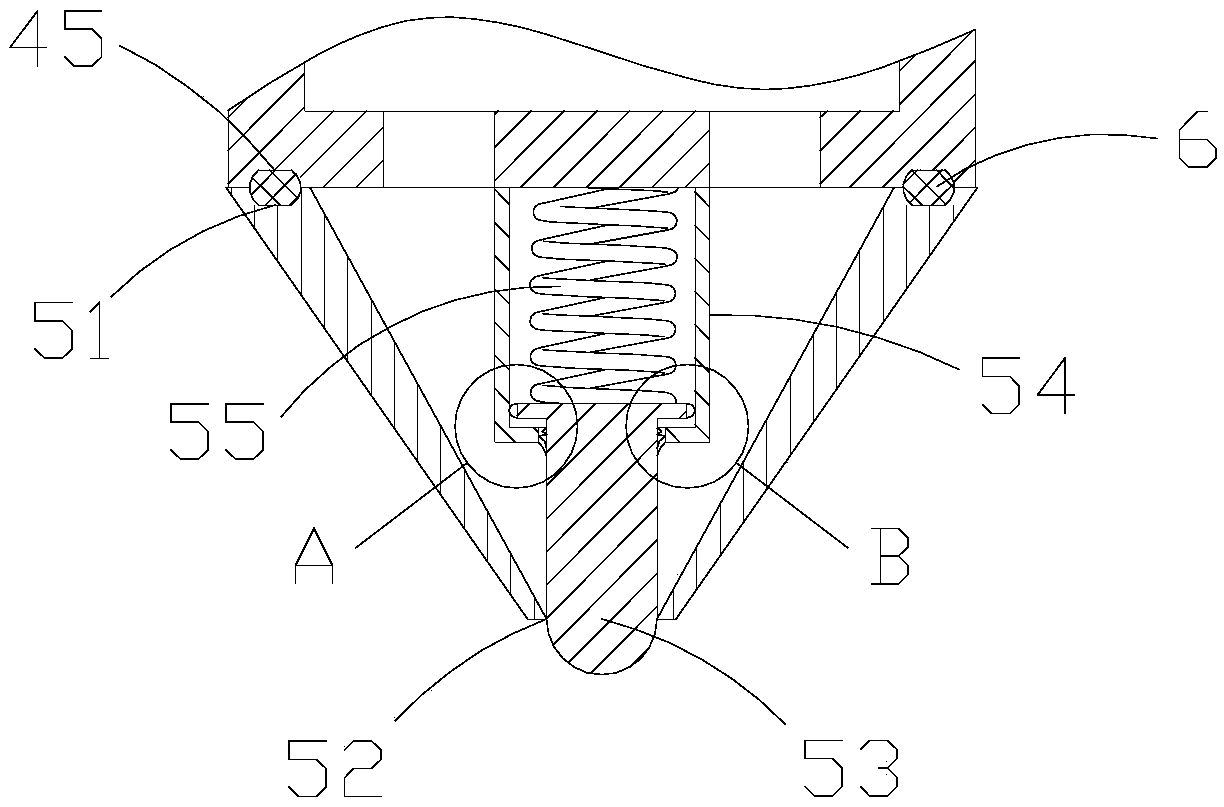

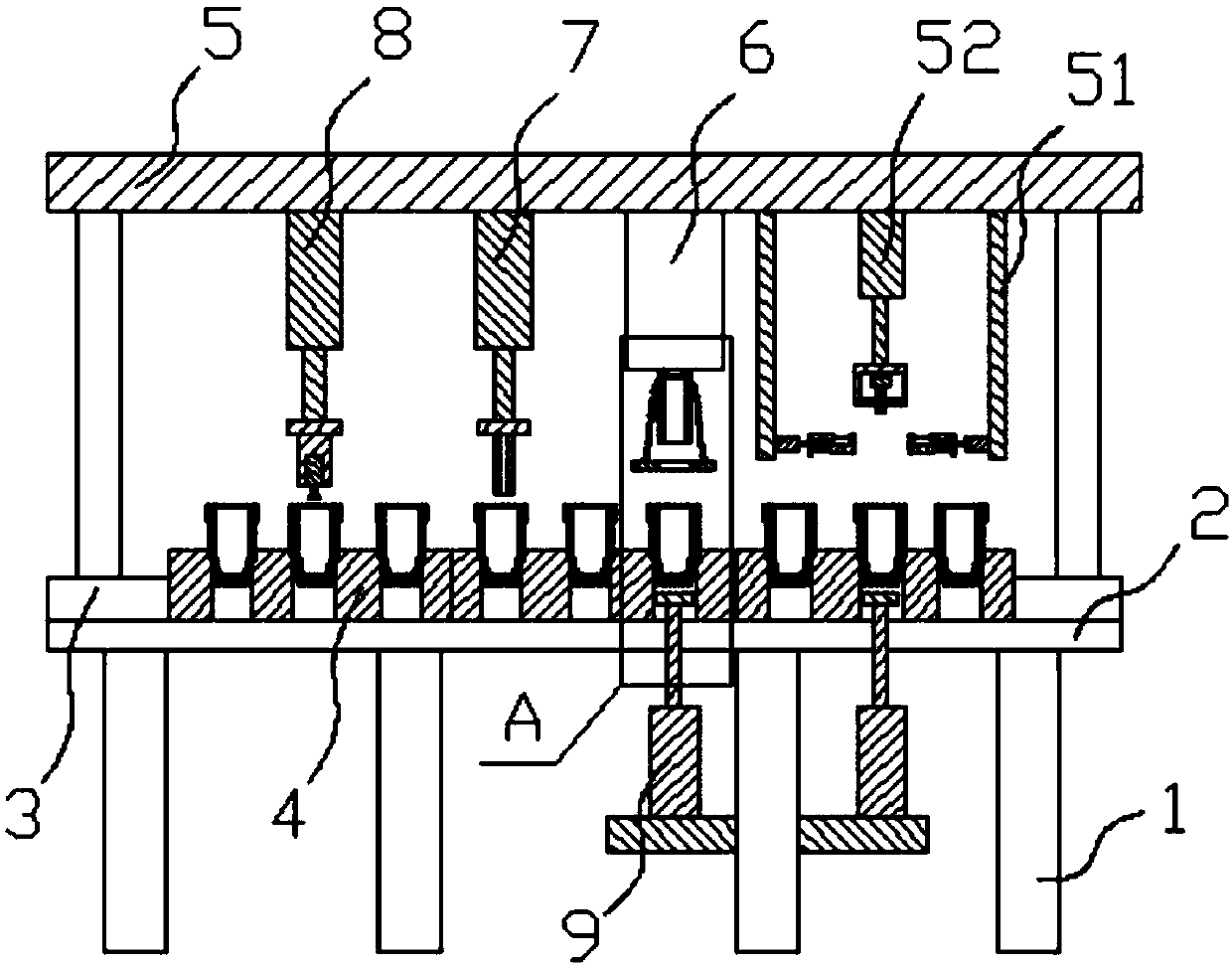

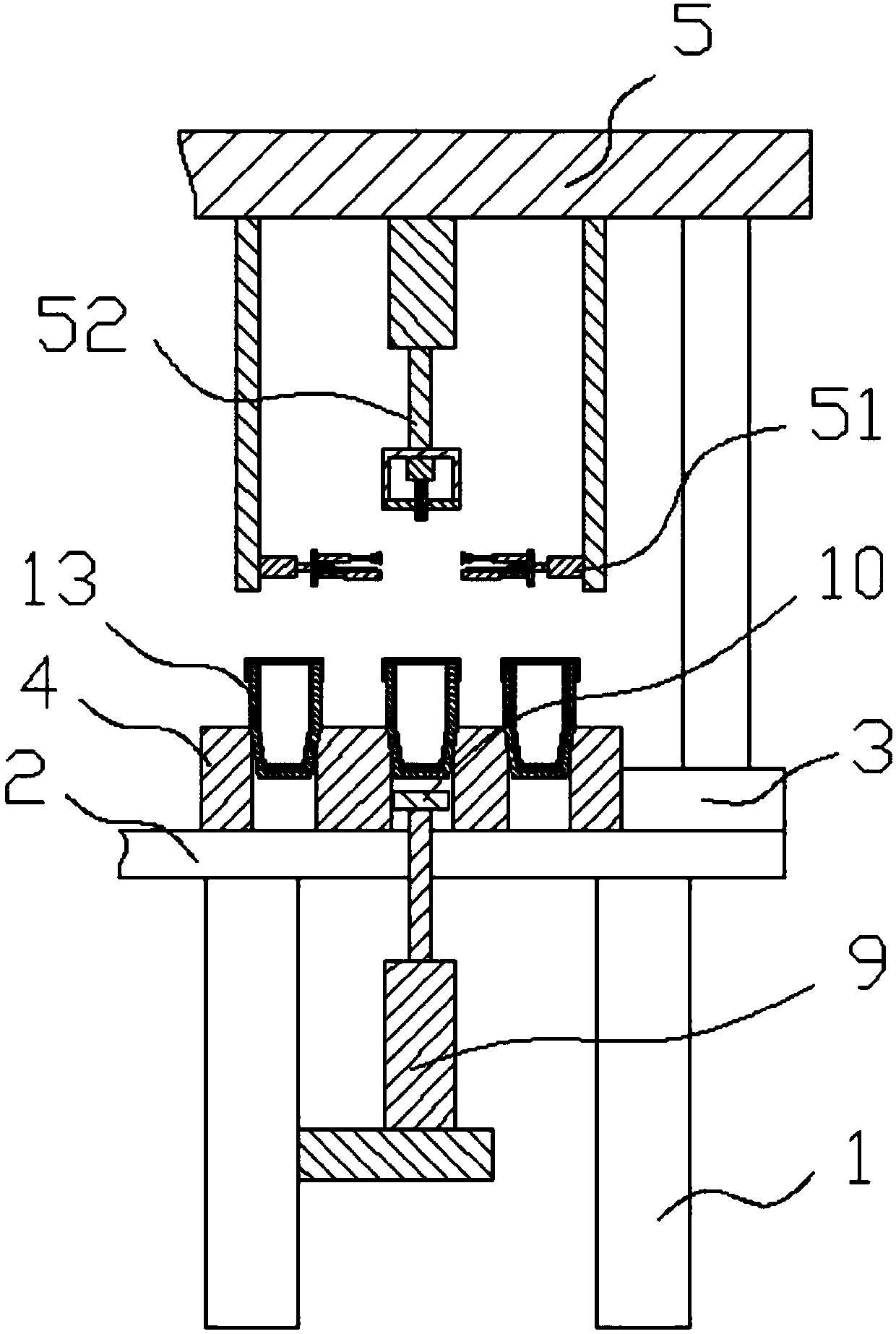

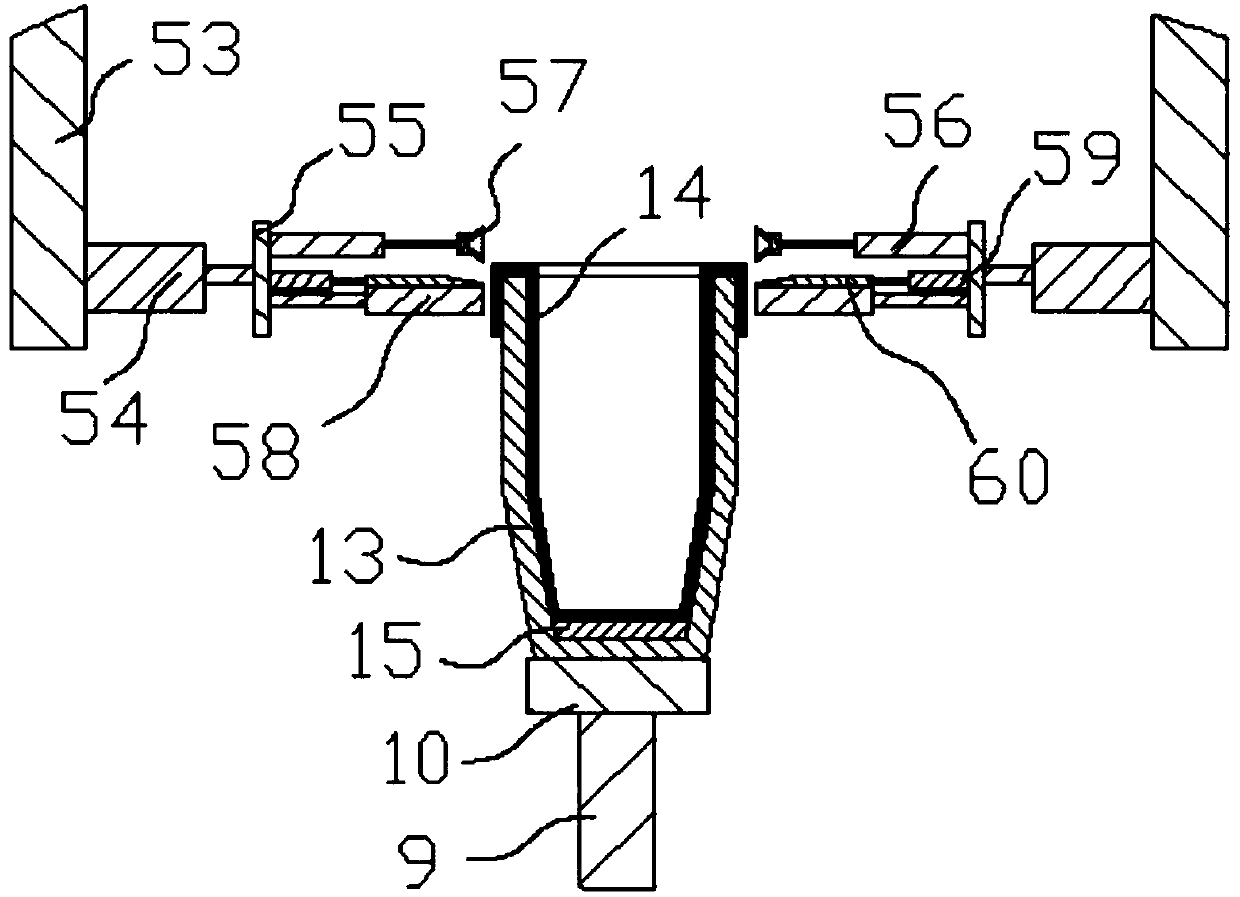

Automatic slag feeding machine for continuous casting crystallizer

The invention relates to an automatic slag feeding machine for a continuous casting crystallizer. In the technical scheme, the automatic slag feeding machine comprises a lifting frame, a slag feeding system and a control system, wherein in the slag feeding system, a third motor (4) drives corresponding first and second material delivery pipes (13 and 36) to swing in a horizontal plane by two output shafts of a third speed reducer (6); a first motor and a second motor (11 and 29) drive corresponding first and second material delivery spiral rods (42 and 31) to rotate, so that granular materials are outputted by first and second adjustable discharging devices (14 and 38); the first and second adjustable discharging devices (14 and 38) have the same structure; an integral ring (54), a notch ring (52), an integral ring (52) and a right flange (51) are tightly close to a left flange sequentially from left to right; a fifth motor (23) drives a gear (21) to rotate by a fifth speed reducer (22); and the gear (21) is in meshed transmission with a rack (20), so that a slag feeding system makes reciprocating linear motion. The automatic slag feeding machine has the characteristics of compactstructure, high automaticity and wide application range, and can feed slag uniformly and is easy to operate.

Owner:WUHAN UNIV OF SCI & TECH

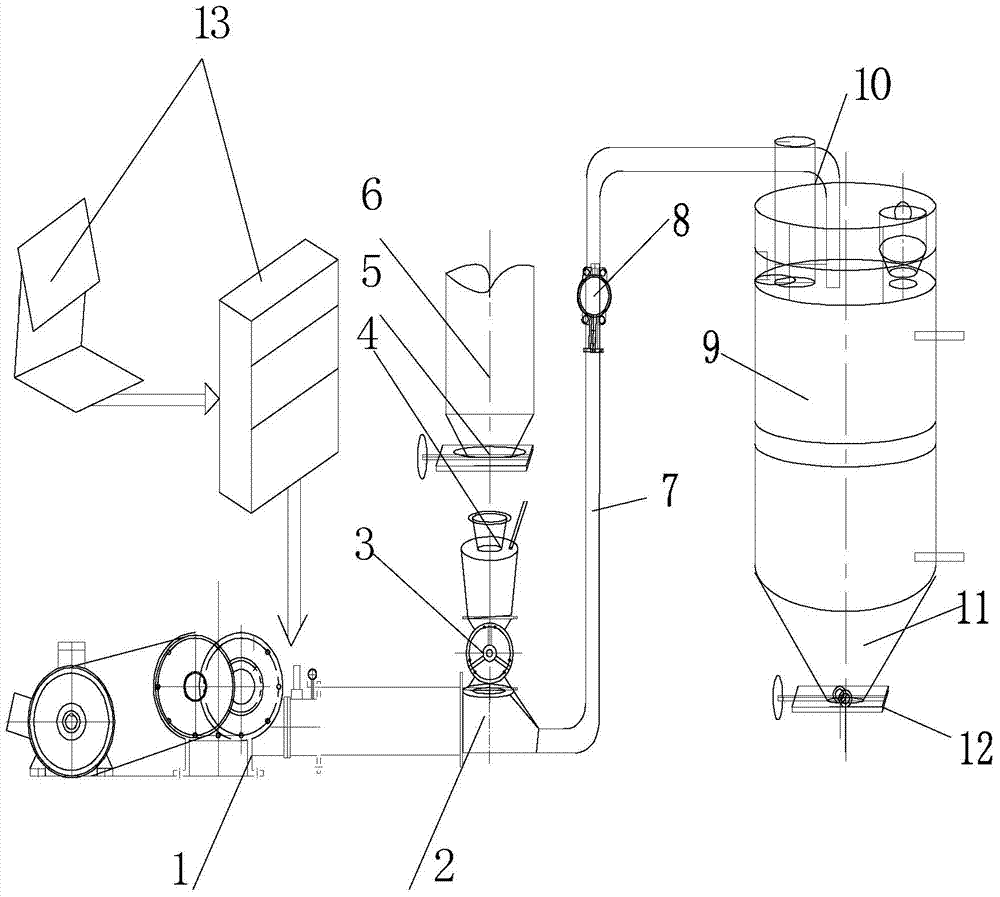

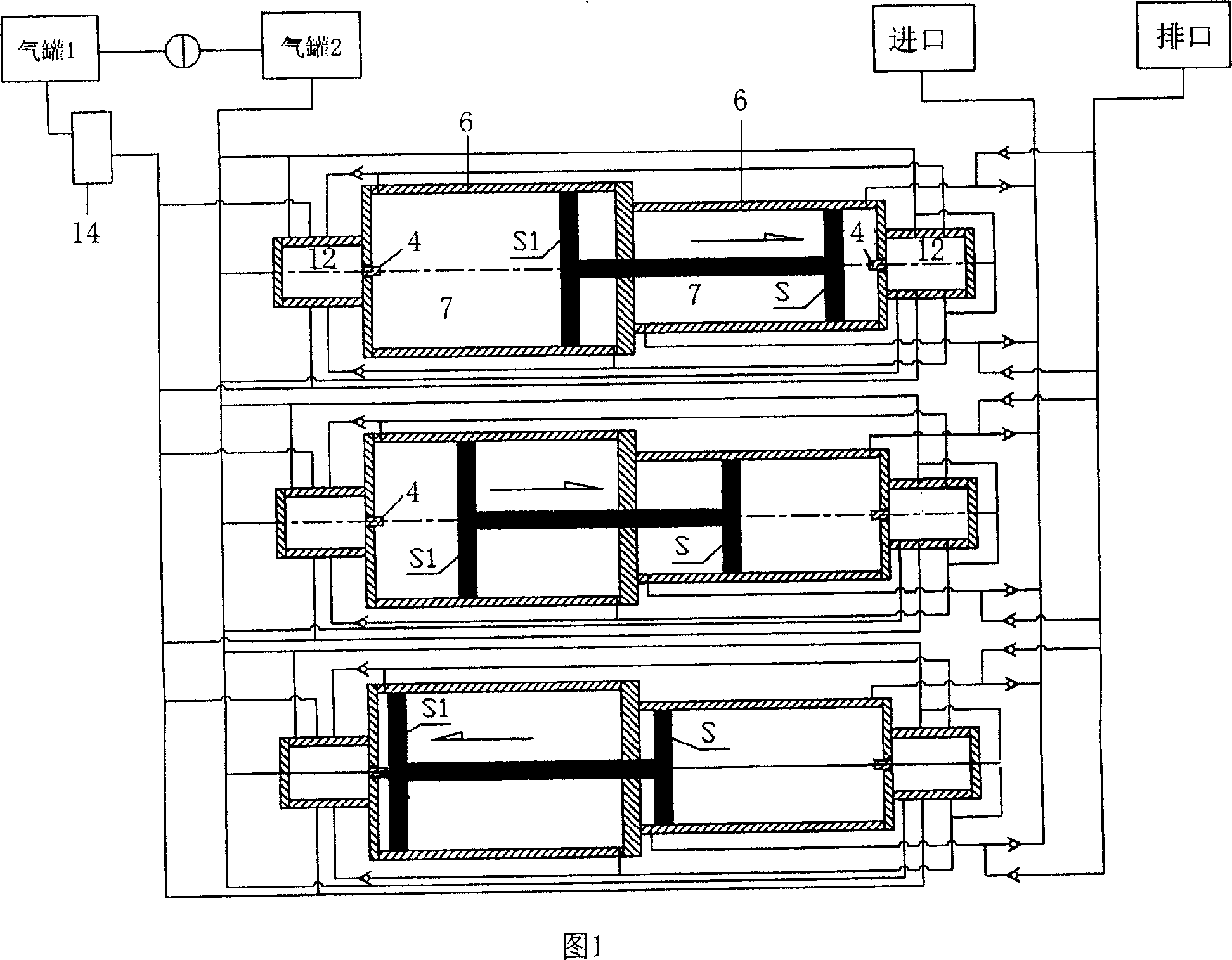

Boiler dust removal pneumatic transmission system

The invention relates to a boiler dust removal pneumatic transmission system, particularly to a boiler dust removal pneumatic transmission system applicable to the positive-pressure dilute phase of a rotary feeder. The boiler dust removal pneumatic transmission system comprises a Roots blower 1, a gas-solid mixing accelerating chamber 2, an electric rotary feeder 3, an suction chamber 4, a pneumatic gate valve 5, a material hopper 6, a material and compressed air transmission pipe 7, a pneumatic reversing valve 8, a storage bin 9, a pulse jet pocket type bin dust cleaner 10, a storage bin activating hopper 11, a storage bin pneumatic discharging valve 12 and an electric control system 13. The boiler dust removal pneumatic transmission system has the advantages of, through combination of the rotary feeder and the Roots blower, achieving uniform and continuous transmission and being simple and easy to maintain.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

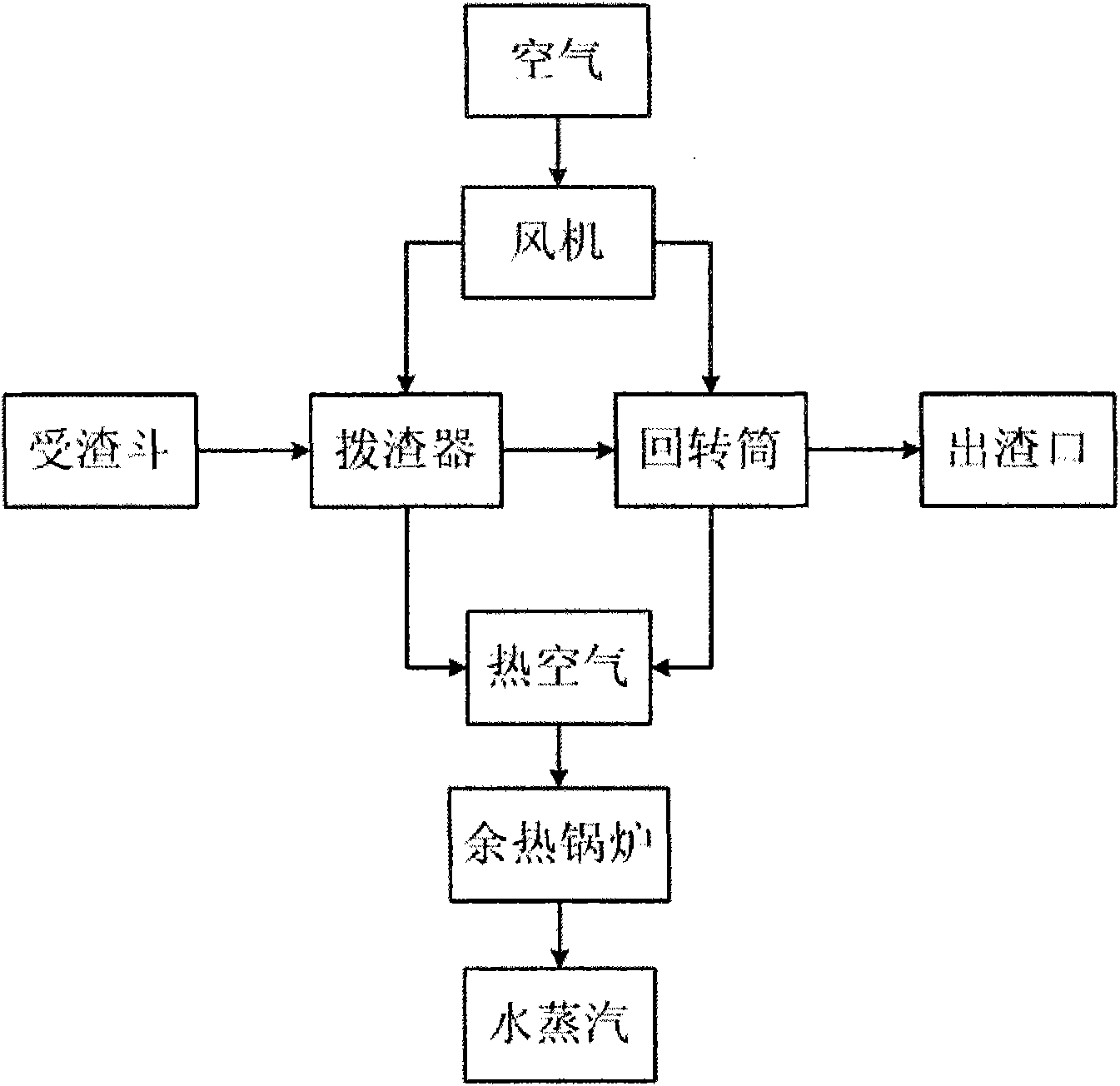

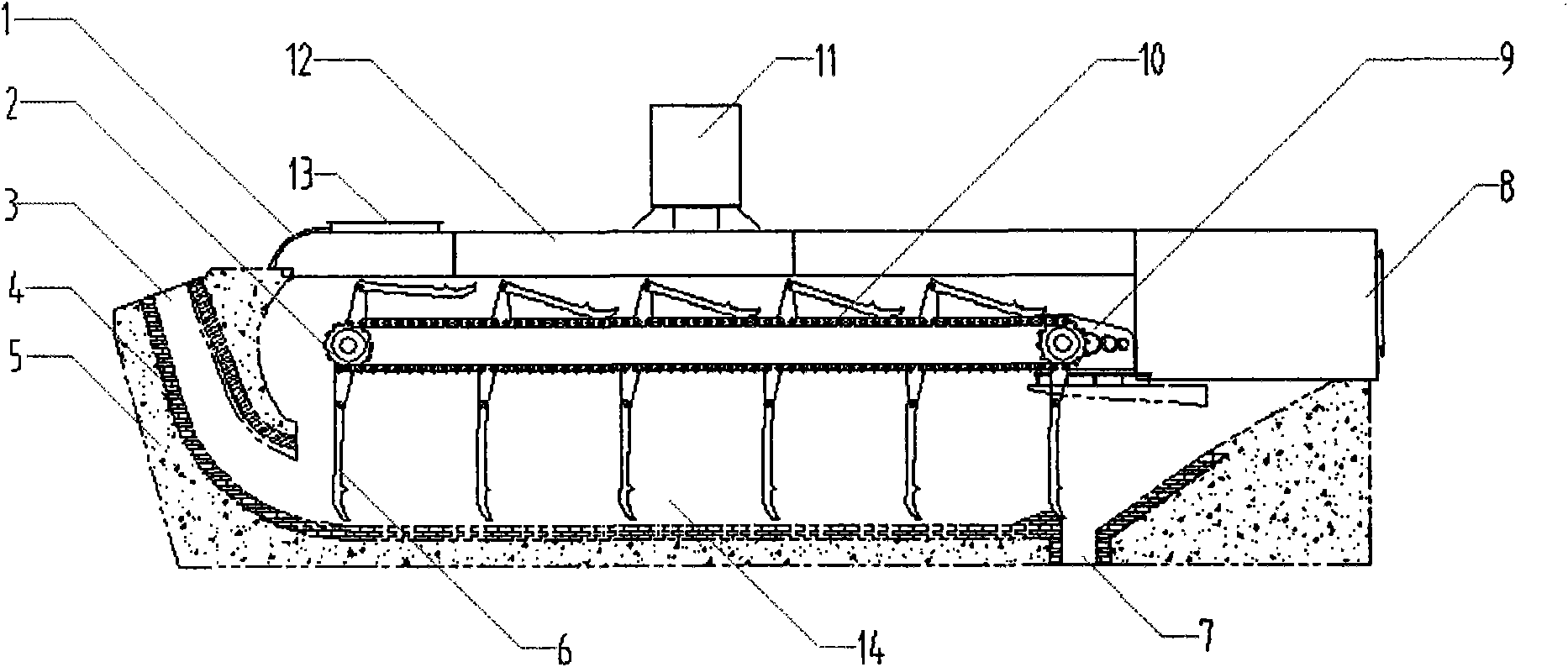

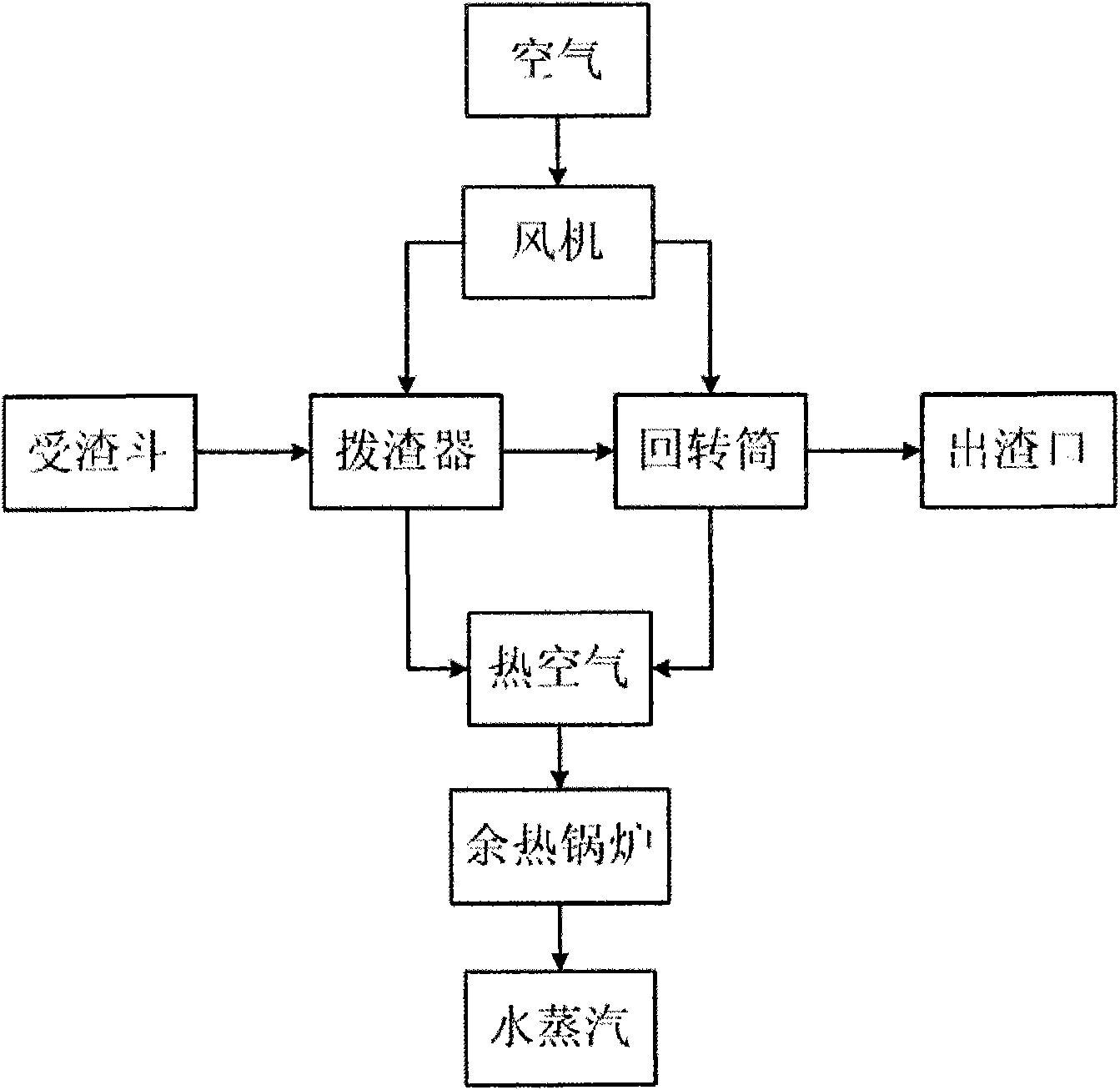

System and method for recovering waste heat of continuous hot steel slag

InactiveCN101880737ARelease completelySmooth releaseIncreasing energy efficiencyRecycling and recovery technologiesSlagSprocket

The invention relates to a system and a method for recovering waste heat of continuous hot steel slag, which belong to the technical field of steel-making waste heat recovery. The system comprises a slag-receiving hopper, a slag-poking device, a revolving drum, a fan, a waste heat recovery system and a slag outlet, wherein the slag-poking device has a tunnel type structure and consists of a slag slot, a scraper blade, a chain and a chain wheel; the scraper blade is arranged on the chain; the scraper blade is driven by the chain to move in the slag slot and continuously push the hot steel slag to the revolving drum; slag-disintegrating teeth and a material-lifting plate are distributed on the inner wall of the revolving drum; and the steel slag exchanges heat with circulate air conveyed by the fan in the whole dynamically conveying process to generate high-temperature air flow. The system and the method have the advantages of suitability for a steel slag waste heat recovery process, high adaptability to the mobility of the steel slag, high steel slag processing capacity, easy control, continuous and stable heat recovery and capacity of disintegrating large blocks of the steel slag into small blocks which are convenient to recycle.

Owner:SHOUGANG CORPORATION

Box-type deepwater positioning throwing boat and usage method thereof

ActiveCN105015717AGuarantee the construction qualityHigh efficiency assurance rateWaterborne vesselsSpecial purpose vesselsMarine engineeringRear quarter

The present invention provides a box-type deepwater positioning throwing boat and a usage method thereof which relate to the throwing boat technology field. The box-type deepwater positioning throwing boat comprises a boat body, wherein the boat body is equipped with a cabin port penetrating to the bottom surface of the boat body; a caisson arranged in the cabin port and comprising a box body side plate and a box body bottom door in movable connection with the box body side plate; an elevating system arranged on the boat body and connected with the box body side plate of the caisson; a positioning system arranged on the boat body and used for detecting the underwater landform and the sinking depth of the caisson; a central controller arranged on the boat body, connected with the elevating system and the positioning system and controlling the box body bottom door to open and close. The throwing boat of the present invention integrates the positioning, packing, metering and throwing as one, can work circularly, is in automatic joint control and visual operation, and is high in work efficiency guarantee rate.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST +1

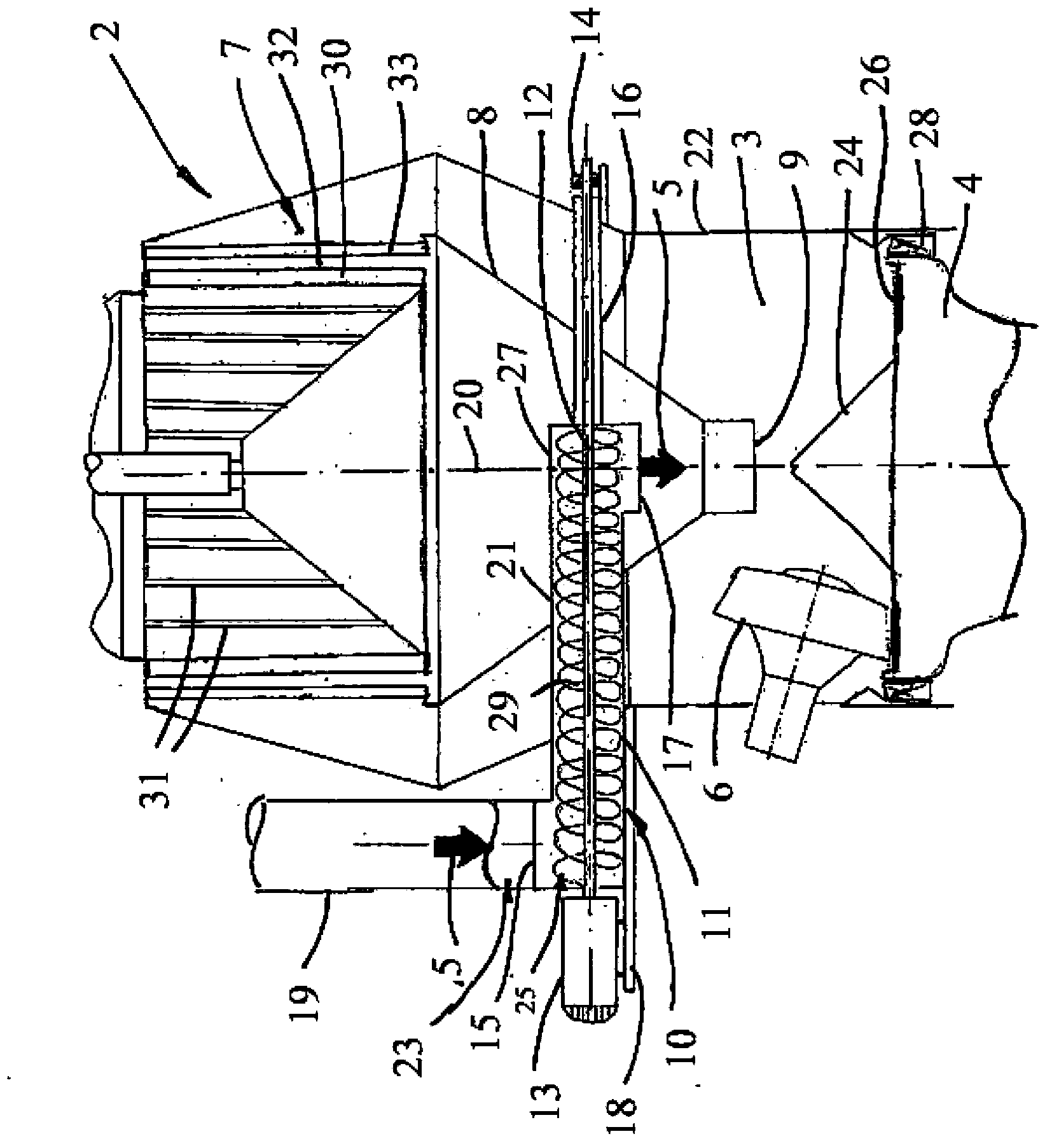

Roller mill

InactiveCN103764290AContinuous deliveryUniform and disturbance-free deliveryGrain treatmentsEngineeringScrew conveyor

The invention relates to a roller mill, in particular a coal mill, having a feed system which has an integrated screw feeder. The screw feeder is arranged virtually horizontally in the region of a grit cone and has a worm shaft which is guided through the roller mill and along the longitudinal axis thereof, both end sides of which are arranged in each case outside the roller mill and which is mounted at one end by way of a drive device and at the other end in a mounting outside the roller mill. The feed material is supplied to the screw conveyor outside the roller mill and is forcibly conveyed therein up to a trough-side ejection opening above a cone opening in the grit cone, and drops centrally onto the grinding bowl together with coarse grain rejected in the classifier. A uniform distribution of the feed material and improved running smoothness of the roller mill and a saving of energy are achieved, and soiling of the worm shaft is prevented.

Owner:LOESCHE GMBH

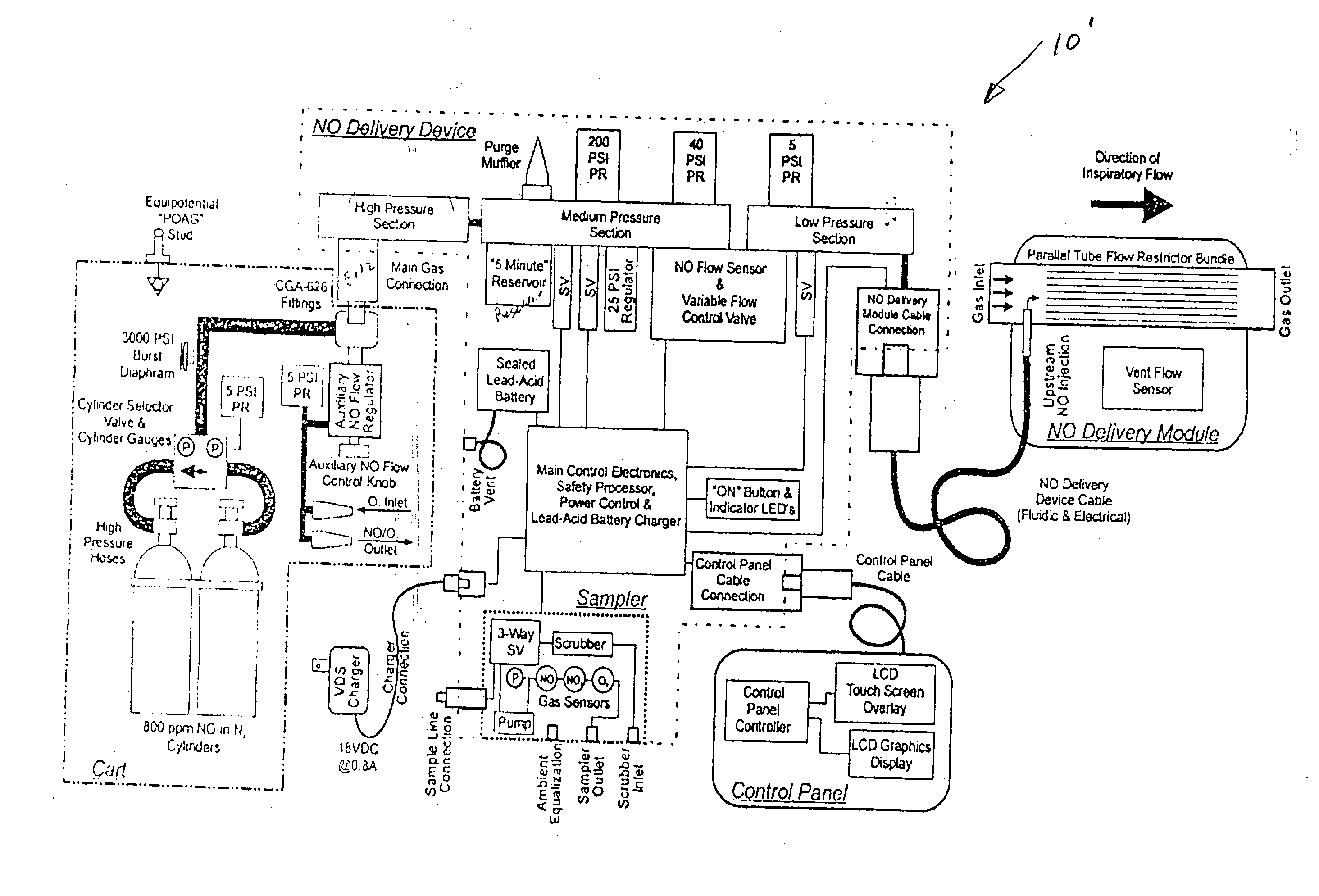

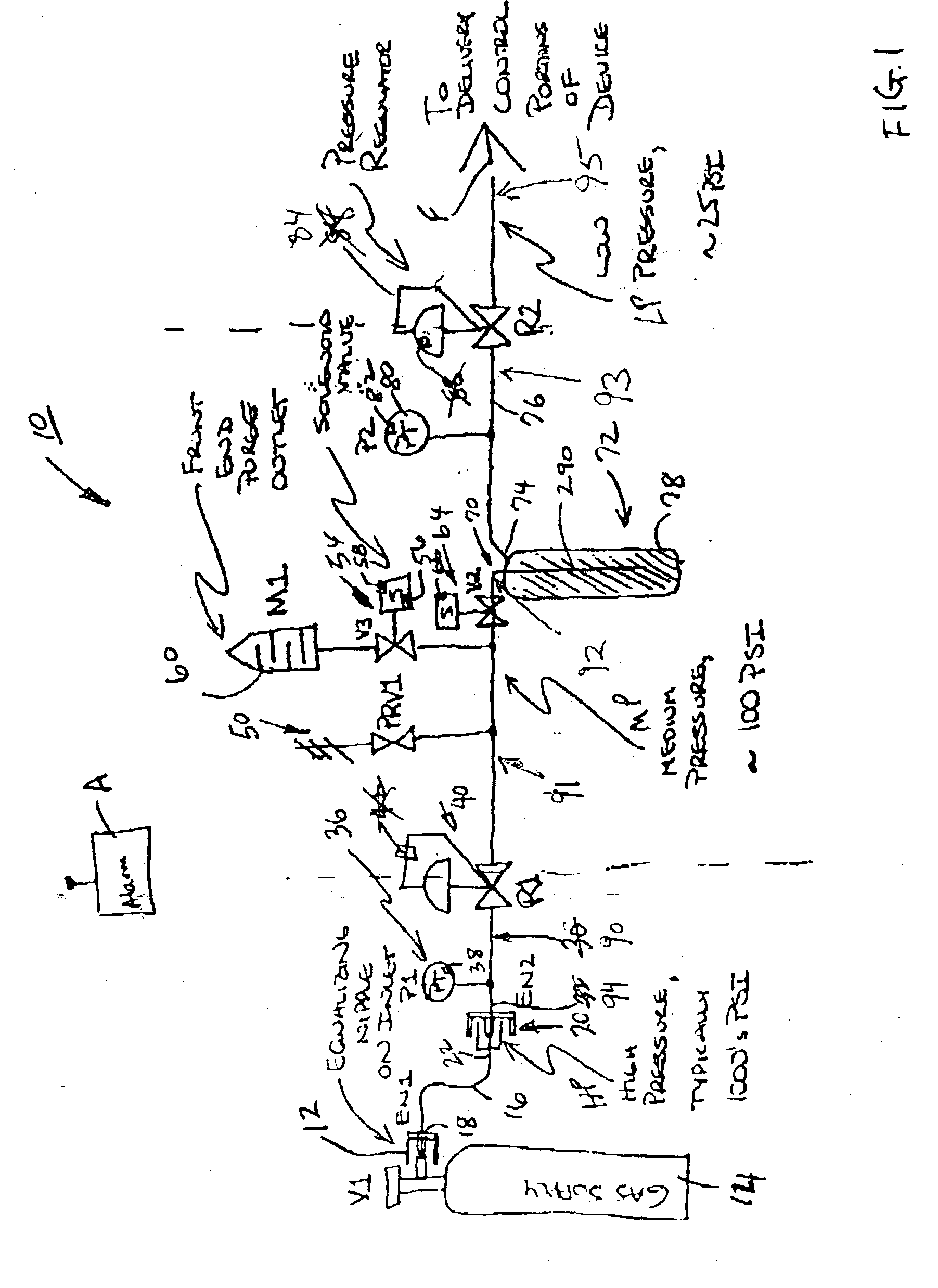

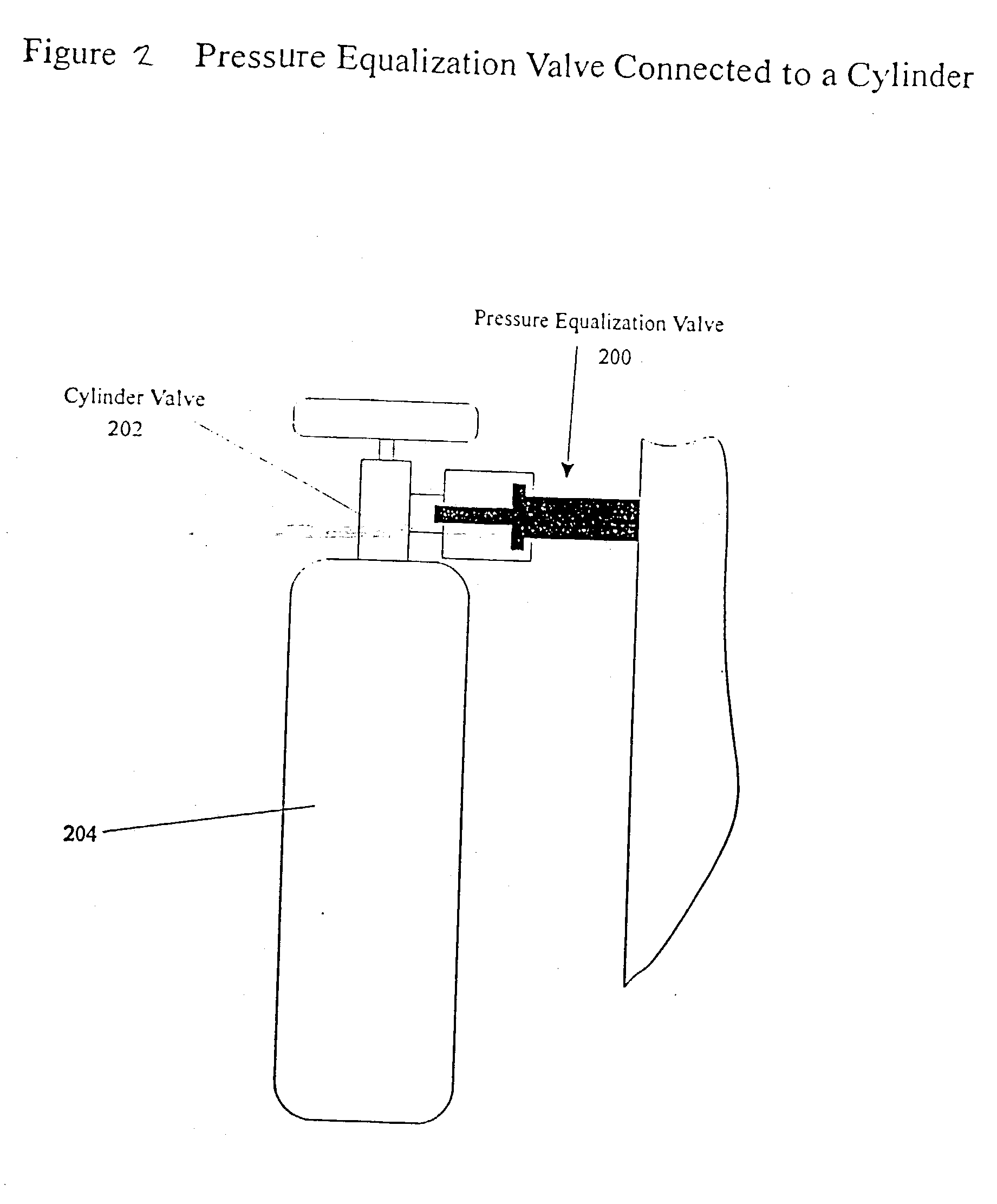

System for use in administrating therapeutic gas to a patient

InactiveUS20030131849A1Reduced Possibility of ContaminationContinuous deliveryRespiratory masksMedical devicesVALVE PORTCardiology

Owner:ADVANCED INHILATION THERAPIES AIT LTD

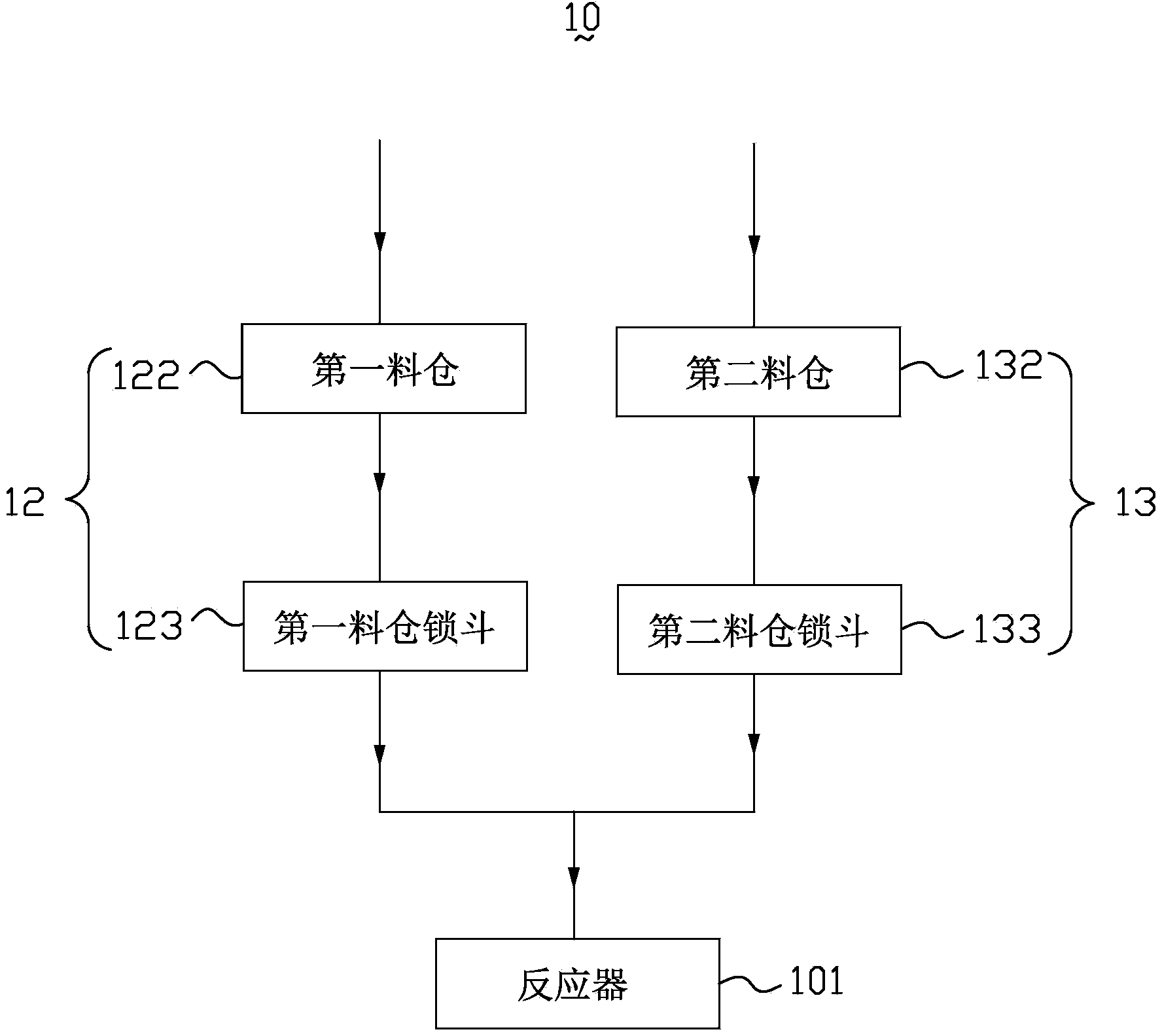

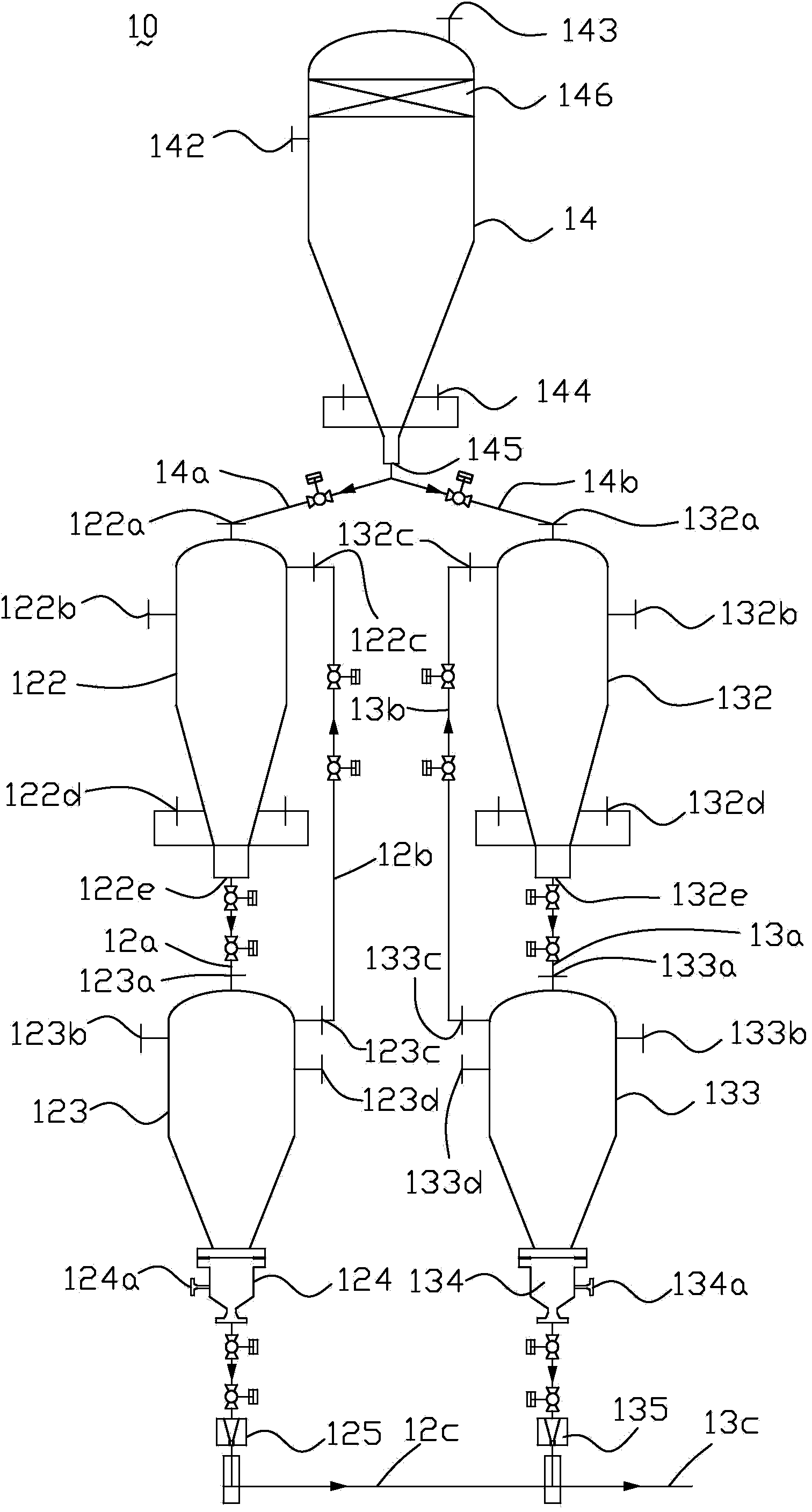

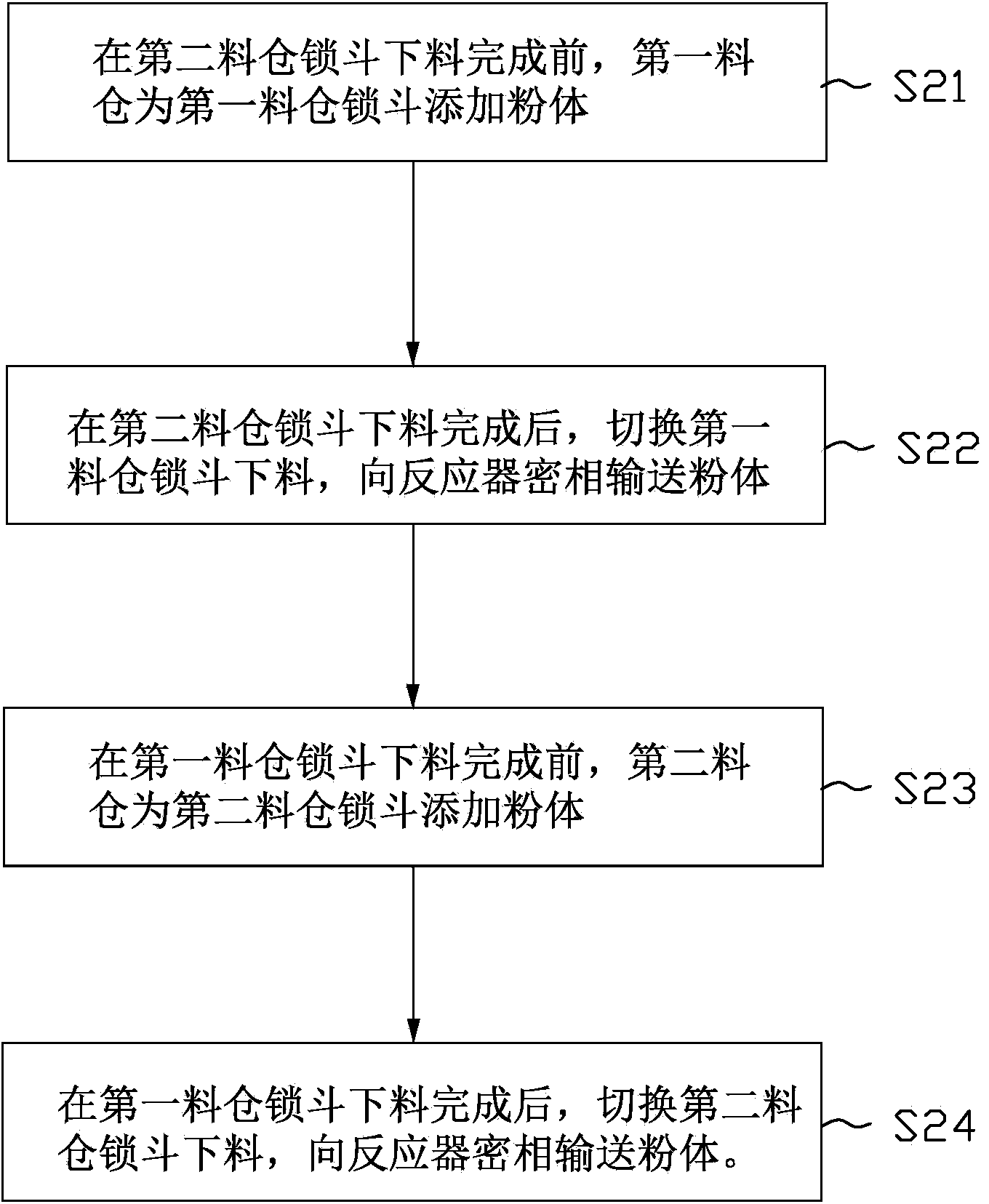

Dense-phase conveying system and method

A dense-phase conveying system is used for conveying powder to a reactor. The dense-phase conveying system comprises at least two conveying systems, each conveying system comprises stock bin lock hoppers and stock bins used for adding the powder into the stock bin lock hoppers. At least two stock bin lock hoppers are communicated with the reactor in parallel and used for alternately conveying the powder to the reactor. The invention further provides a dense-phase conveying method. The dense-phase conveying system and method can continuously and stably transport the powder.

Owner:ENN SCI & TECH DEV

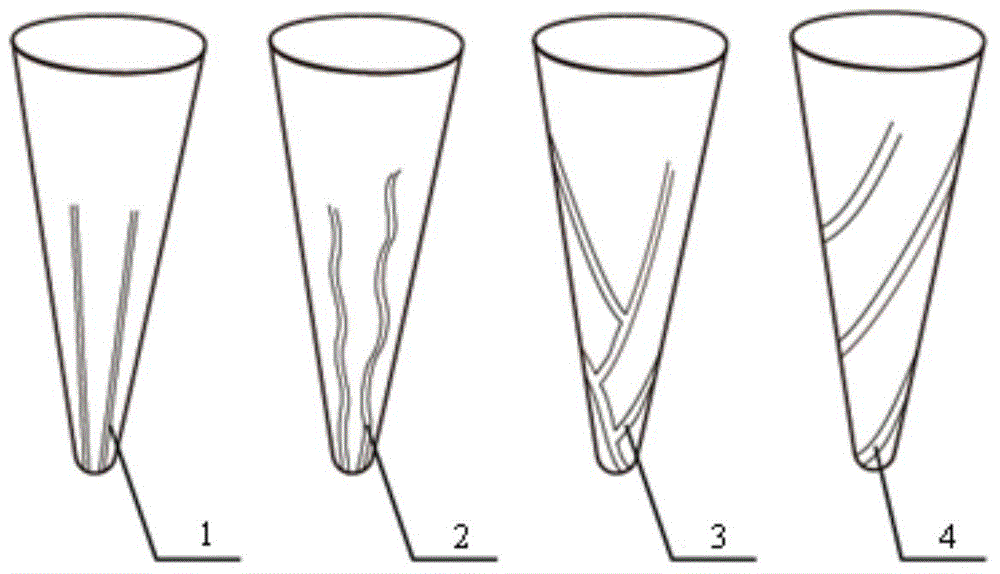

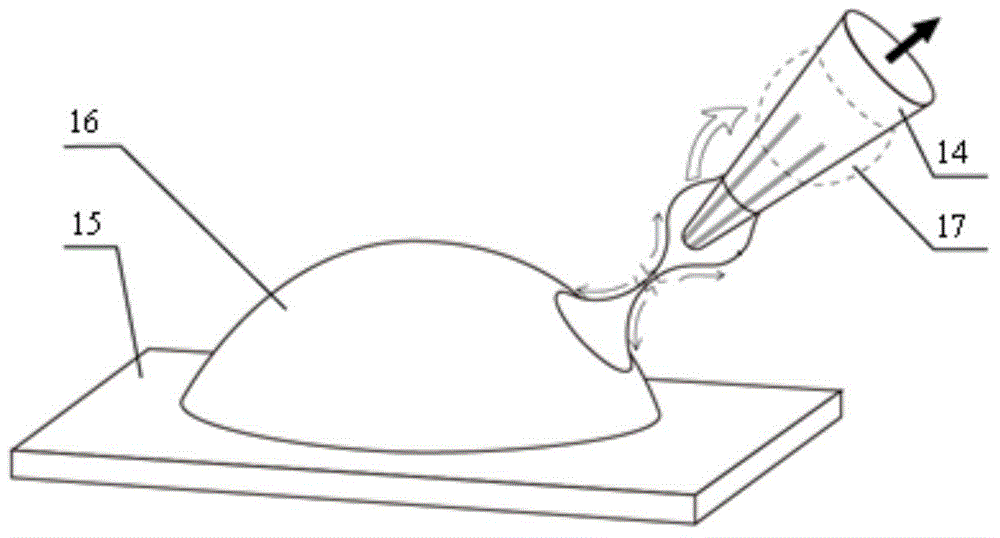

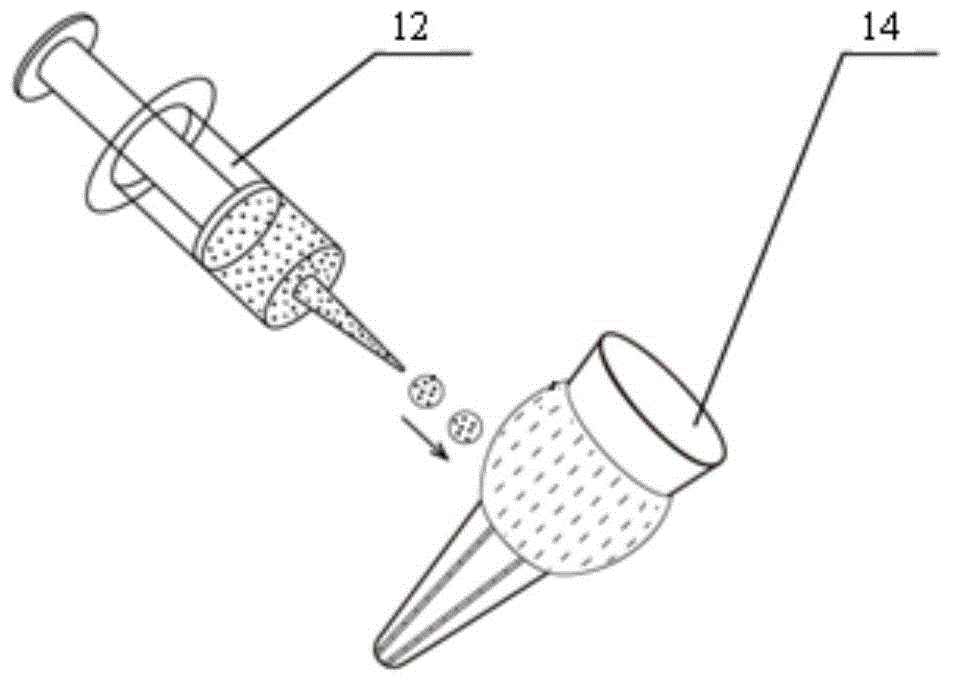

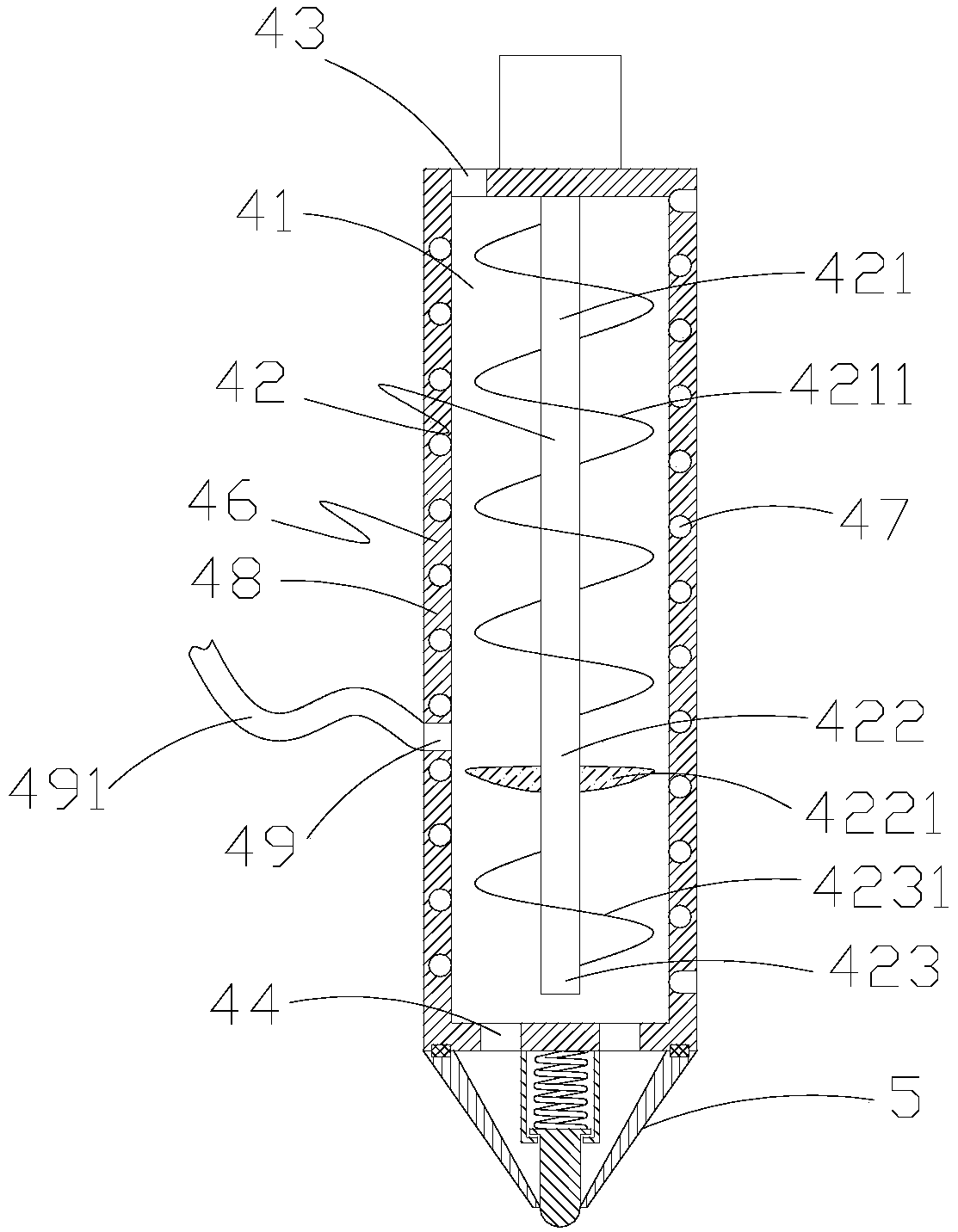

Micro needle tip with orientation structure and method thereof for continuously conveying liquid

ActiveCN105036052AContinuous deliveryAchieve precision manufacturingSemi-permeable membranesFixed microstructural devicesMicro nanoImage resolution

The invention discloses a micro needle tip with an orientation structure and a method thereof for continuously conveying liquid, belonging to the technical field of micro-nano manufacture. The tapered micro needle tip has a thin tip and a thick root. An oriented micro-nano groove-shaped structure is manufactured on the surface of the micro needle tip. Liquid drops are put on or supplemented to the micro needle tip with the micro-nano groove-shaped structure. Under the action of surface tension, the liquid drops automatically move to a liquid storage position of the micro needle tip. Under the control of a mobile device, the micro needle tip with the liquid drops moves to a target position. Under the action of capillary force of the micro-nano groove-shaped structure on the surface of the micro needle tip, liquid drops flow downward along the micro needle tip to a substrate of the target position. The liquid drops are solidified and stacked on the substrate of the target position so as to form a pattern or a stereostructure. The micro needle tip can be manufactured precisely from bottom to top. Compared with the prior art, the micro needle tip has the advantages of good continuity, controllable size, simple device, high resolution, and broad application range.

Owner:SHENZHEN TSIMEC CO LTD

Vibrating bunker

A sort of vibrating hopper is disclosed, which overcomes the problem of present vibrating hopper, which caní»t uniformly and continuously transform materials to packing site. The hopper comprises a base and a tube-like side wall. A spiral oblique face is provided on the base, an outlet is provided at the side wall and between the oblique face and the outlet are provided with at least two parallel discharge channels. The two ends of the channel are respectively the inlet of material that is near to the highest part of the oblique face and the discharge end that is near the outlet. Advantages: continuous and uniform transfer of material; high assembling speed, simple and compact structure.

Owner:浙江东美智能设备有限公司

LED chip glue dispensing machine

InactiveCN109465153ANot easy to solidifyPrevent solidificationLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention discloses an LED chip glue dispensing machine. The LED chip glue dispensing machine comprises a base, a control device arranged on the base, a glue gun rack capable of moving up and down, a glue gun arranged on the glue gun rack and a feeding device connected with the glue gun. The glue gun is internally provided with a stirring cavity. A stirring shaft is arranged in the stirring cavity. The top of the stirring cavity is provided with a feed port. According to the LED chip glue dispensing machine, the stirring cavity and the stirring shaft are arranged in the glue gun to conductstirring on glue in the glue gun, and then the glue is made to flow continuously. Accordingly, the phenomenon that the glue gun gets blocked due to glue solidification is avoided.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

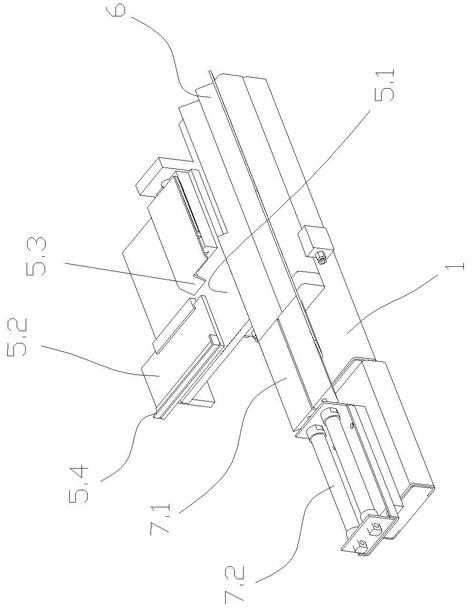

Carrier conveying device

ActiveCN105197577AContinuous deliveryStable and precise deliveryConveyor partsEngineeringMechanical engineering

The invention provides a carrier conveying device and belongs to the technical field of medical accessory assembling machines. The technical problem that an existing carrier conveying device is low in conveying precision is solved. The carrier conveying device comprises a machine frame and a guide rail arranged on the machine frame and extending in the linear direction. The guide rail is provided with a plurality of carriers which can horizontally move along the guide rail. The carriers are sequentially arranged in the length direction of the guide rail. The machine frame is provided with a first clamping jaw capable of being opened and closed. The first clamping jaw can achieve relative positioning with one carrier when closed. The machine frame is provided with a pushing mechanism capable of pushing the other carriers towards the first clamping jaw. The machine frame is further provided with a first driving mechanism capable of driving the first clamping jaw to move back and forth in the length direction of the guide rail. The carrier conveying device has the advantages of being high in conveying precision, compact in structure and the like.

Owner:MAIDER MEDICAL IND EQUIP

Packaging machine capable of realizing continuous bag sealing

InactiveCN107934059AReduce manual operationsImprove bag sealing efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPackaging machine

The invention relates to a packaging machine capable of realizing continuous bag sealing. The packaging machine comprises a rack, conveying devices, conveying protecting plates and a receiving conveying block; receiving mounting grooves are formed in the receiving conveying block; receiving sleeves are mounted in the receiving mounting grooves; receiving bags are sleeved with the receiving sleeves; a discharging frame is arranged on the conveying protecting plates; a discharging device and a bag sealing device are arranged below the discharging frame; ejecting devices are matched at the lowerparts of the receiving sleeves where the discharging device and the bag sealing device are matched; the bag sealing device comprises two bag sealing mounting blocks; bag sealing air cylinders are arranged on the inner sides of the bag sealing mounting blocks and are connected with bag sealing moving seats; edge sealing and bag clamping air cylinders are arranged at the upper parts of the bag sealing moving seats; hot-pressing edge sealing blocks are connected at the lower parts of the bag sealing moving seats; and edge sealing and bag clamping air cylinders are connected with edge sealing andbag clamping suction cups. The shapes of the receiving sleeves are matched with the structure of an edge sealing device, the receiving bags arranged on the outer sides of the receiving sleeves in a sleeving manner can be clamped and sucked tightly, the receiving bags can be partially separated from the receiving sleeves, edge sealing can be performed on the upper parts of the receiving bags, and continuous and automatic edge sealing can be realized.

Owner:DONGGUAN UNIV OF TECH

Automatic-boosting reciprocating pump

ActiveCN1952390AIncrease boost gearIncrease boost levelPump controlPiston pumpsReciprocating pumpAutomatic control

The invention relates to an automatic pressurized reciprocating pump controlled by mechanical valve, comprising a group of pressurized reciprocating device at least. Said pressurized reciprocating device is characterized in that two-pole or multi-pole cylinder is connected in the same axis, automatic controlling switch valve units are set on two ends of cylinder respectively, one end of contact tip in automatic controlling switch valve units and cylinder piston are set in the inner cavity of cylinder. Each group of pressurized reciprocating device is connected in parallel. The invention improves not only pressurized grade but also discharge grade. It is provided with low cost, good sealing, good safety and stability so on.

Owner:张志英 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com