Tin soldering system of automatic tin soldering robot

A robot and automatic welding technology, which is applied in the direction of welding/welding/cutting objects, tin feeding devices, welding equipment, etc., can solve problems such as difficult to control precise travel, wear and tear, and affect the service life of welding equipment, so as to prolong the service life and reduce the wear, avoid the effect of frequent up and down movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

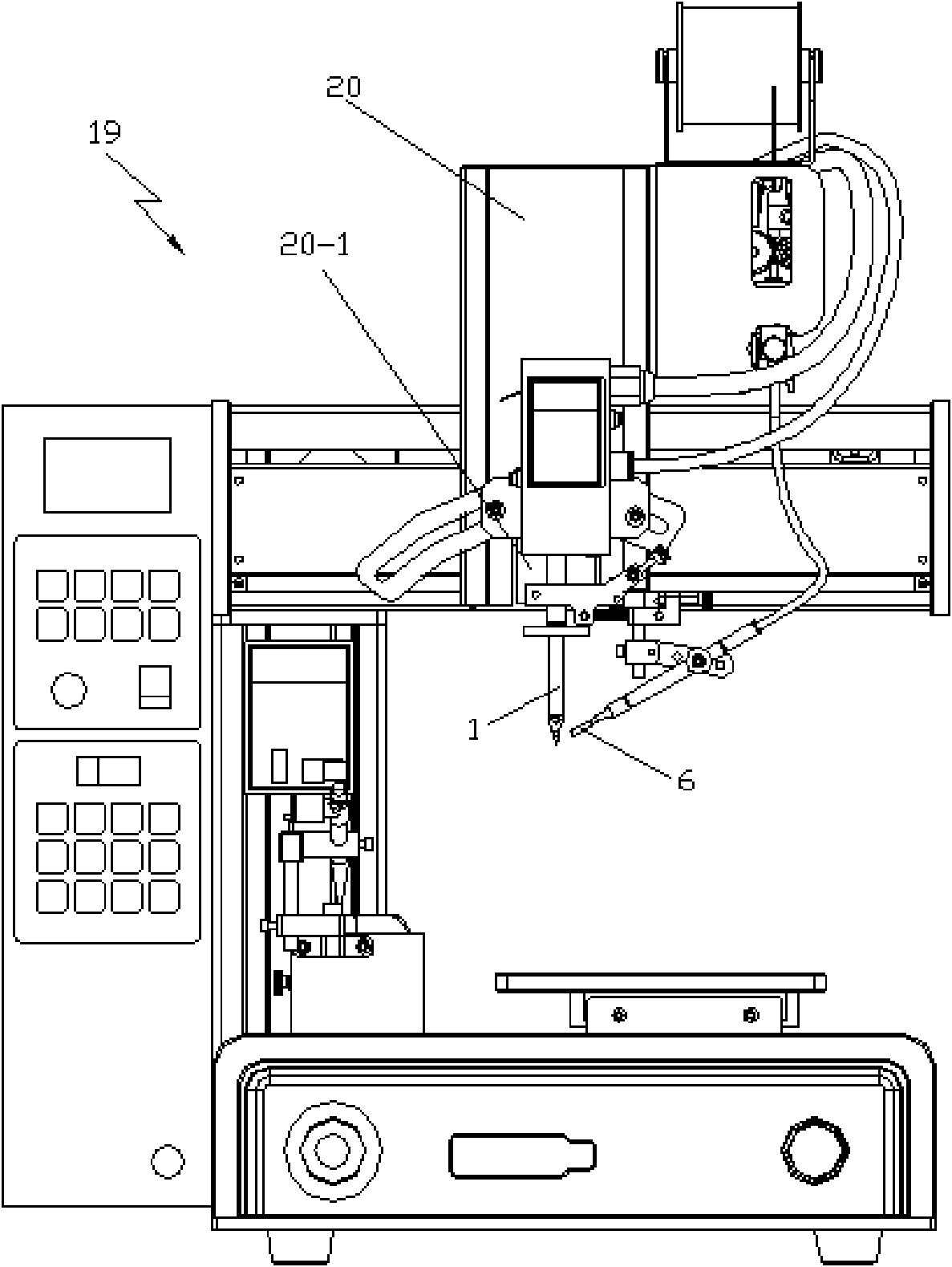

[0033] See figure 1 , the soldering iron tip movement mechanism of the soldering system of the automatic soldering robot of this embodiment is fixed on the Z-axis module 20 of the automatic soldering robot 19 that controls the movement in the up and down direction through the Z-axis connecting block 20-1, and the tin wire precise positioning mechanism is fixed on the soldering iron the upper end of head 1.

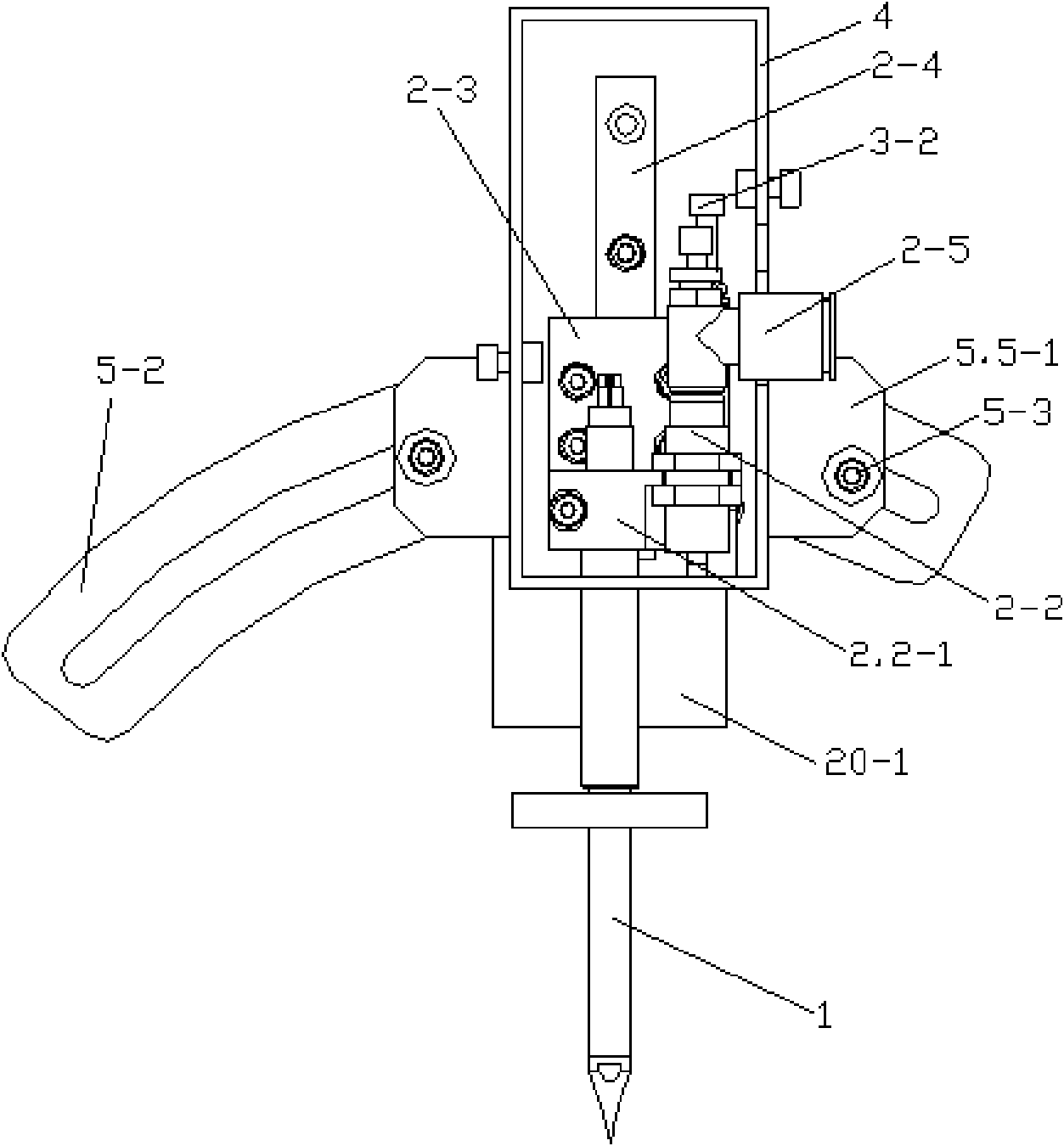

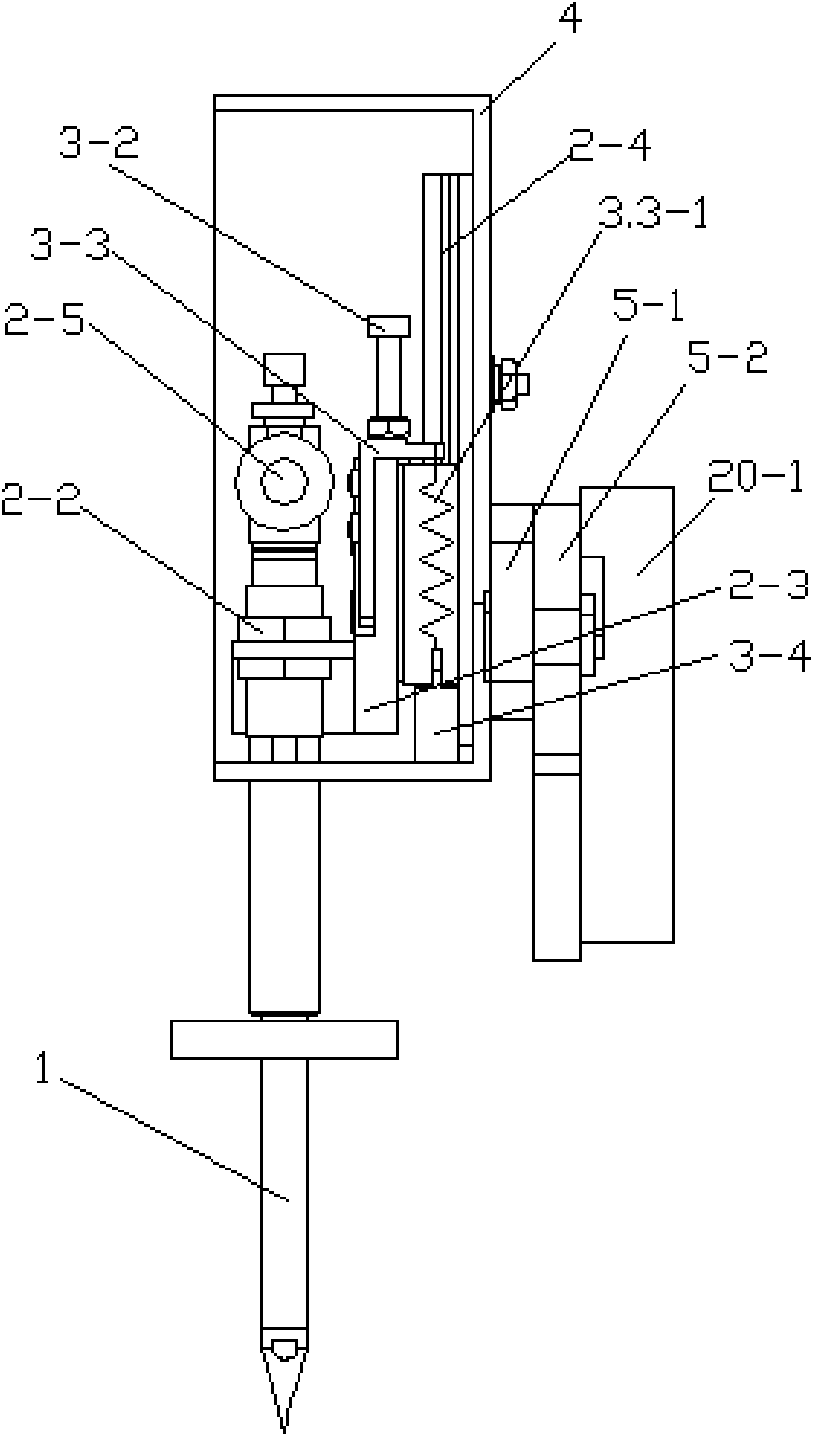

[0034] See Figure 2 to Figure 4 , The soldering iron tip movement mechanism of the soldering system of the automatic soldering robot includes a soldering iron tip 1, a moving device 2, a pressure regulating device 3, a box body 4 and an angle regulating device 5. The moving device 2 and the pressure regulating device 3 are arranged in the box body 4 .

[0035] The mobile device 2 includes a connecting block 2-1, a cylinder 2-2, a slide plate 2-3, a linear slide rail 2-4 and a speed regulating joint 2-5. The connection block 2-1 connects the upper end of the soldering i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com