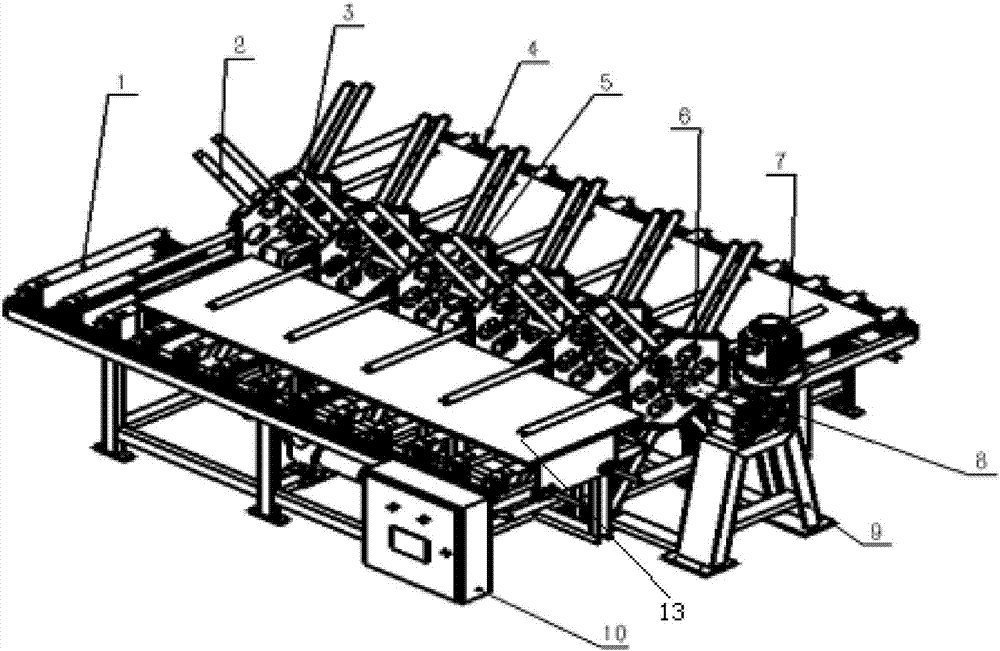

Plate overturning machine and plate overturning method

A panel turning machine and panel technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., to achieve the effect of not being easy to shift, high stability, and maintaining the quality of the panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

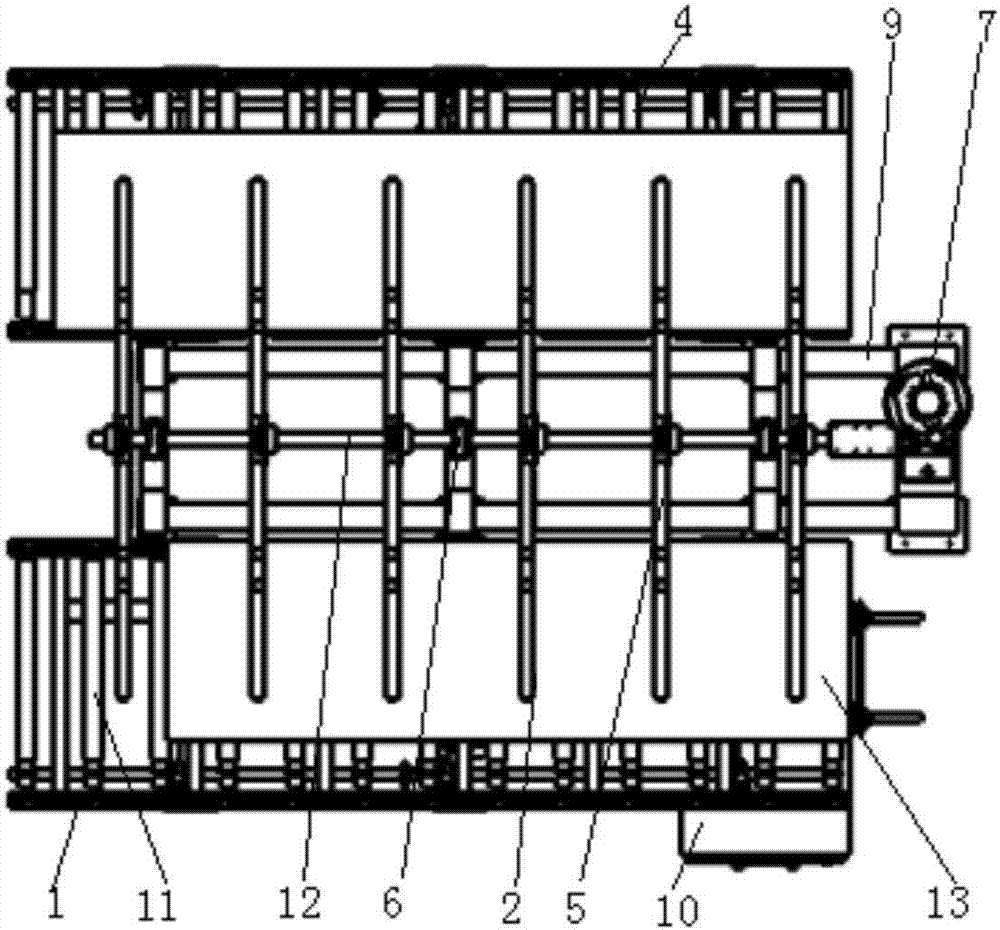

[0036] In order to facilitate the installation of parallel forks, in this embodiment, preferably, the left view of the mounting plate 5 is a regular hexagonal structure, and the parallel forks 2 are respectively installed in the middle of the six end faces of the mounting plate 5 of 6 groups. By setting a mounting plate in the shape of a regular hexagon, when installing the parallel fork, the two rod bodies constituting the parallel fork can be conveniently fixed on the mounting plate, and the parallel fork can be positioned conveniently, so that the two rod bodies constituting the parallel fork The length is easier to control. During installation, parallel forks are respectively set on the 6 end faces of the mounting plate, so that they can be used to clamp the plate.

[0037] When the rotating shaft rotates, through the parallel forks arranged on the six end surfaces, the parallel forks on the two opposite end surfaces are respectively parallel to the feeding conveyor and th...

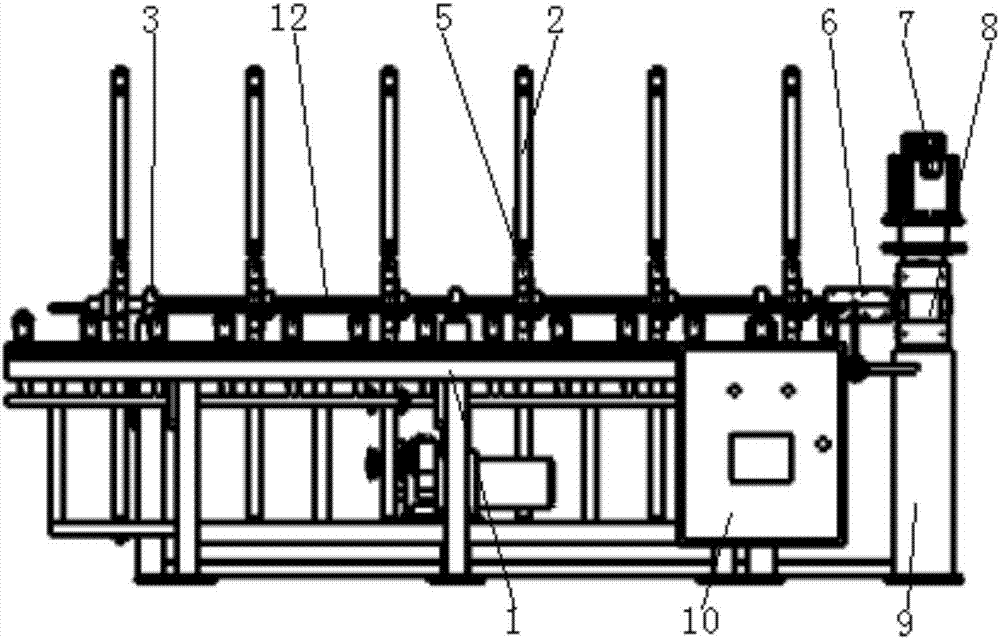

Embodiment 2

[0041] In order to improve the stability of the rotating shaft, in this embodiment, preferably, uniformly distributed brackets are arranged on the frame 9 , and the rotating shaft 12 is rotatably connected to the upper end of the bracket through the bearing seat 3 . By setting the bracket, the rotating shaft is rotatably connected to the bearing seat at the upper end of the bracket, and when the rotating shaft rotates relatively, the bracket supports the rotating shaft from the end far away from the coupling, thereby avoiding the rotating shaft from tilting when the force on both ends of the rotating shaft is uneven.

[0042] When transporting the sheet, once the force exerted by the sheet on the rotating shaft is unbalanced, causing unequal forces on both ends of the rotating shaft, the bracket structure in this embodiment can provide support for the rotating shaft from below to keep the sheet in a stable state.

[0043] In order to facilitate the centralized control of the op...

Embodiment 3

[0045] At the same time, the invention also discloses a board turnover method, which includes the following steps:

[0046] S1: Fix the parallel fork: start the servo motor 7, and drive the rotating shaft 12 to rotate through the matching reducer 8, so that the mounting plate 5 on the rotating shaft 12 drives the parallel fork 2 to rotate, so that the two rods constituting the parallel fork 2 All parallel to the conveying roller 1 of the feed conveyor 1, so that the upper end surface of the cavity 15 formed between the two rods is higher than the upper end surface of the conveying roller 1, and the servo motor 7 is stopped to keep the parallel fork 2 stable , stop the servo motor 7;

[0047] S2: Input plate: place the plate on the conveying roller 1 of the feeding conveyor 1, and when the driving device drives the conveying roller 1 to rotate, when the plate 13 moves along the feeding conveyor 1, the plate 13 is plugged into the step Inside the cavity 15 formed in S1;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com