Vanadium-containing mud slurry treatment method

A mud and chlorination furnace technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of increasing operating costs, hindering production, and not being able to completely separate titanium tetrachloride and vanadium-containing mud, and achieve full High recovery and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

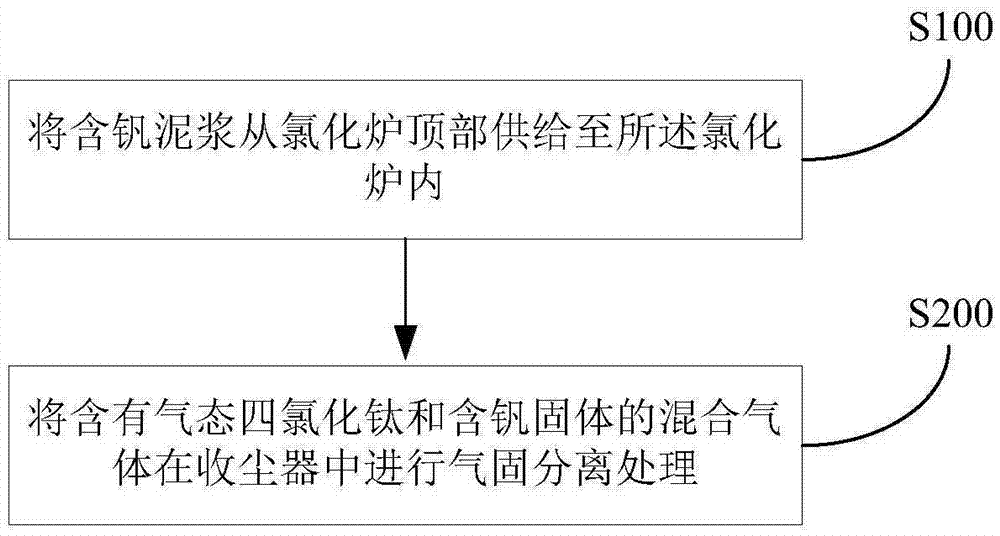

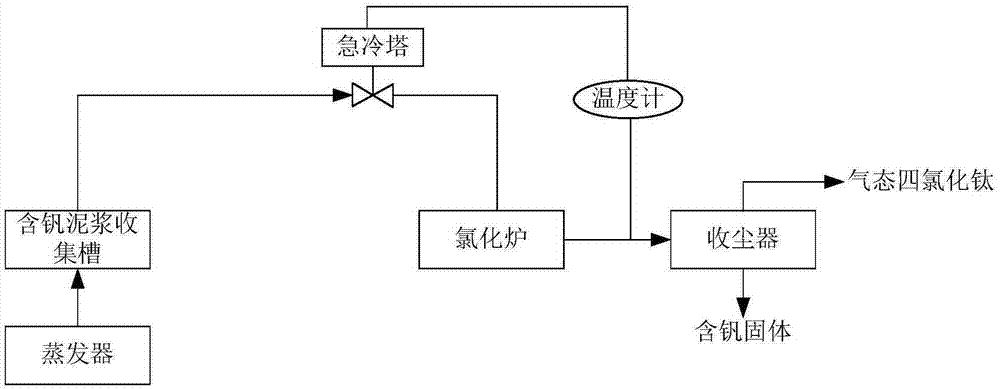

[0025] In one aspect of the invention, the invention provides a method for treating vanadium-containing mud. According to an embodiment of the present invention, the vanadium-containing mud contains titanium tetrachloride. According to a specific embodiment of the present invention, the method includes: (1) supplying vanadium-containing mud from the top of the chlorination furnace into the chlorination furnace, so that the vanadium-containing mud and the heat generated in the chlorination furnace The flue gas is contacted to obtain a mixed gas containing gaseous titanium tetrachloride and vanadium-containing solids; (2) the gas-solid separation process is carried out in a dust collector for the mixed gas containing gaseous titanium tetrachloride and vanadium-containing solids, so that Titanium tetrachloride and vanadium-containing solids were obtained respectively. The inventors have found that by supplying the vanadium-containing mud into the chlorination furnace, the vanadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com