System for recycling PVA (Polyvinyl Alcohol) slurry from printing and dyeing wastewater and desizing wastewater

A technology for desizing wastewater and pulp recovery, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve difficult biochemical treatment, difficult biodegradation, treatment High cost and other issues, to achieve the effect of improving biodegradability, reducing COD, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

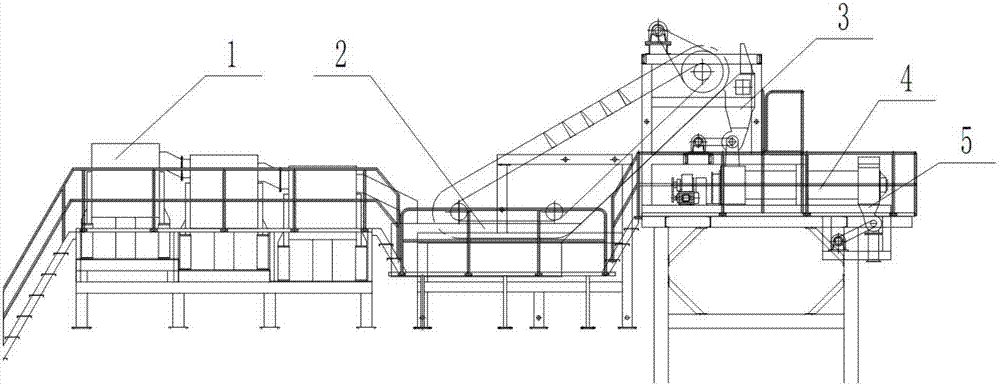

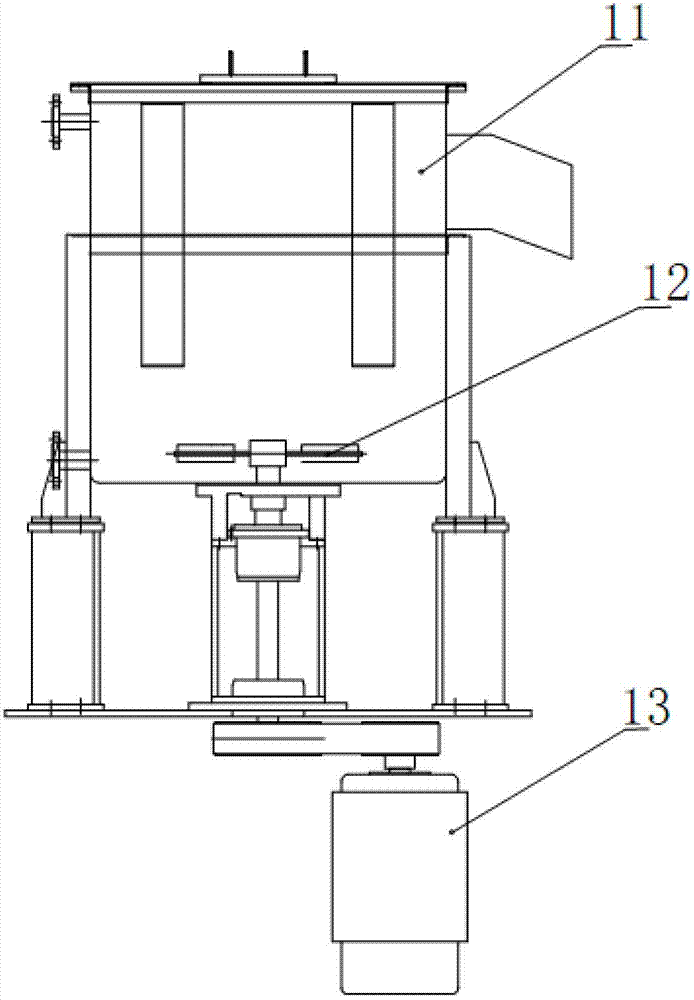

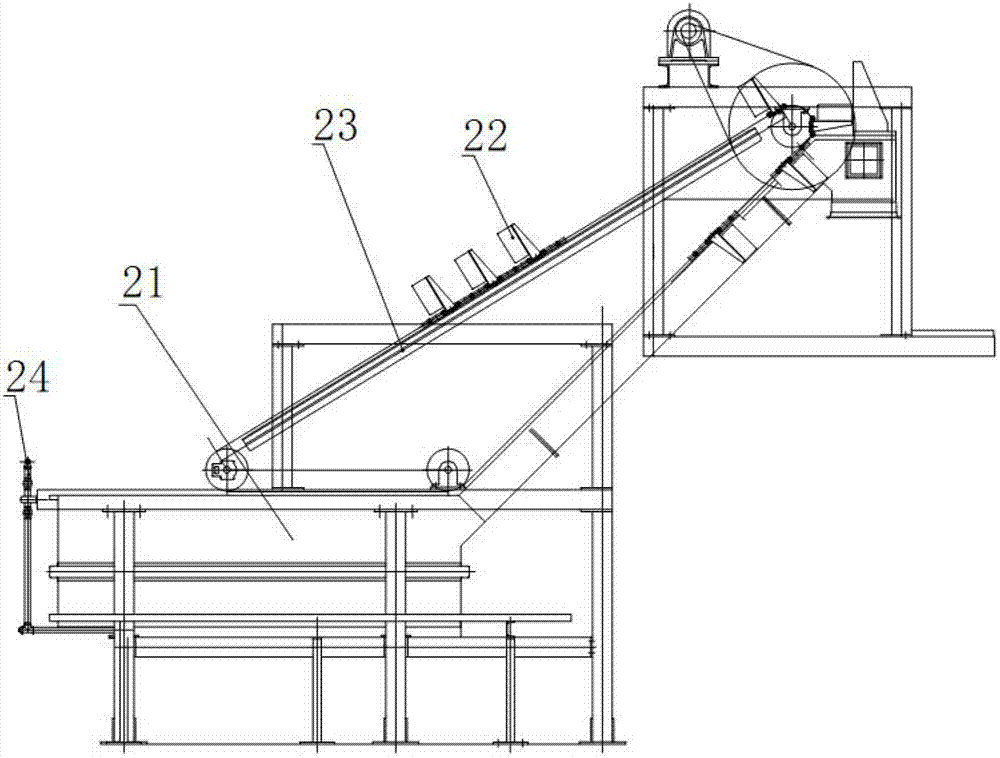

[0024] Such as figure 1 Shown is a printing and dyeing desizing wastewater PVA slurry recovery system, which includes a reaction device 1, a solid-liquid separation device 2, a feed crushing device 3, a dehydration device 4 and a discharge crushing device 5; the reaction device 1 is equipped with a stirring The reaction tanks of the mechanism are connected in series, and are used to react and coagulate the PVA in the desizing wastewater into flocs; the solid-liquid separation device 2 is provided with a transmission mechanism with a fishing baffle for transporting the reaction device The flocs in the mixture of flocs and waste liquid are caught and sent to the feed crushing device; the feed crushing device 3 is a box with a crushing mechanism, which is used to crush the solid-liquid separation device. The flocs are then transported to the dehydration device; the dehydration device 4 is a barrel with an extrusion dehydration mechanism, which is used to extrude and dehydrate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com