Patents

Literature

1695results about How to "Full recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

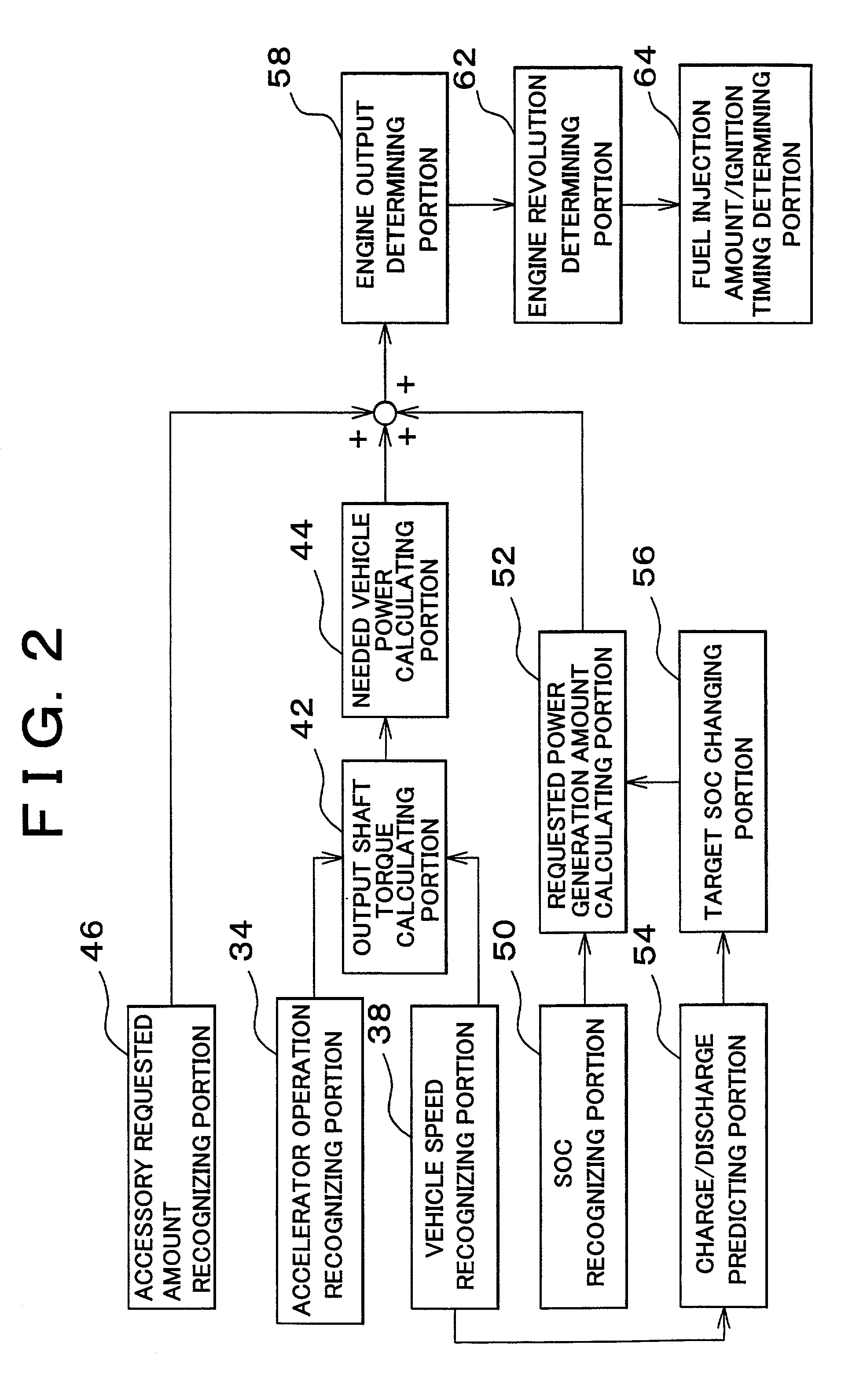

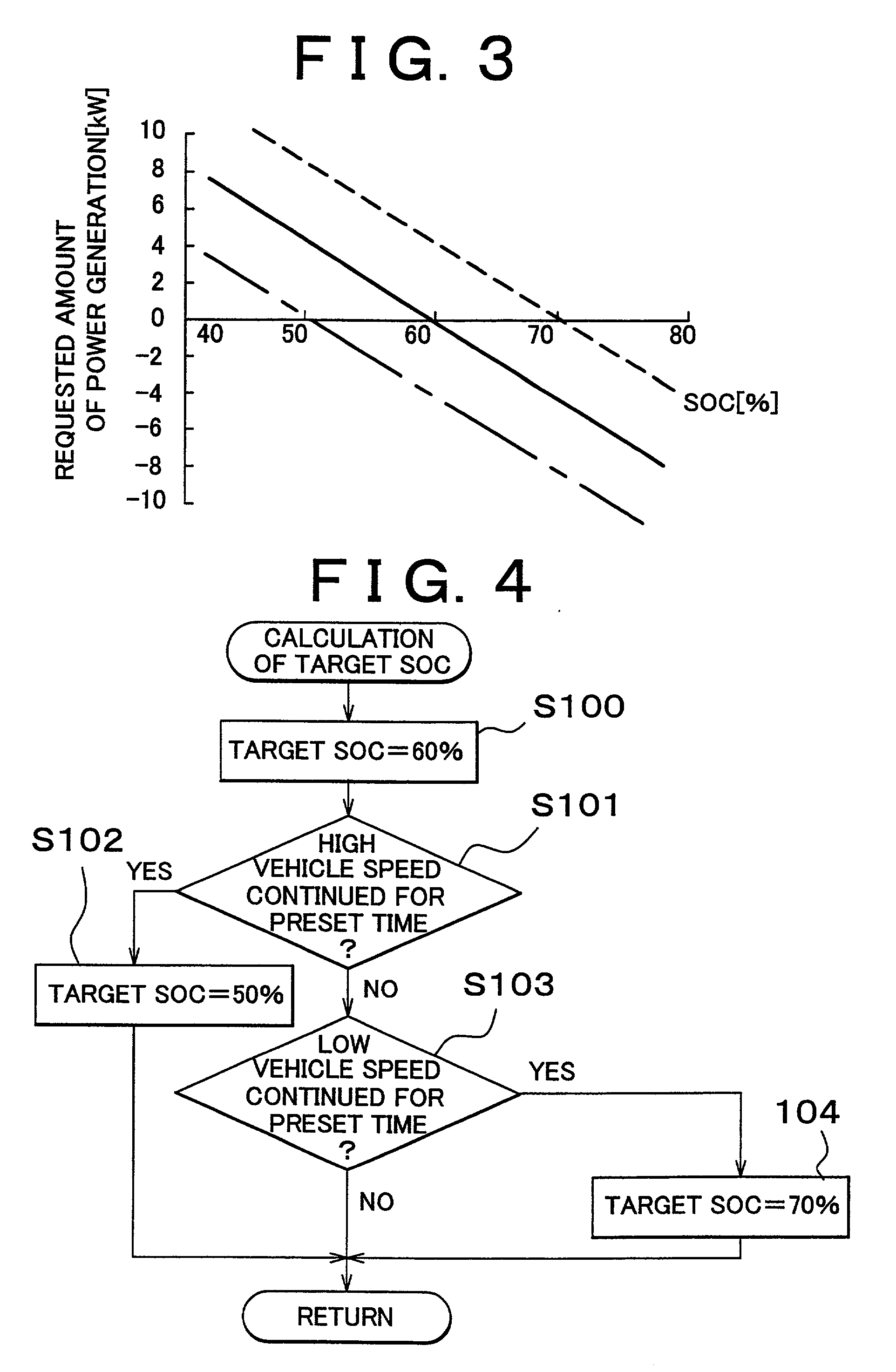

Electric energy charging control apparatus and method for hybrid vehicle

InactiveUS6344732B2Improve charging capacityReduce the amount of solutionHybrid vehiclesBatteries circuit arrangementsState of chargeCharge control

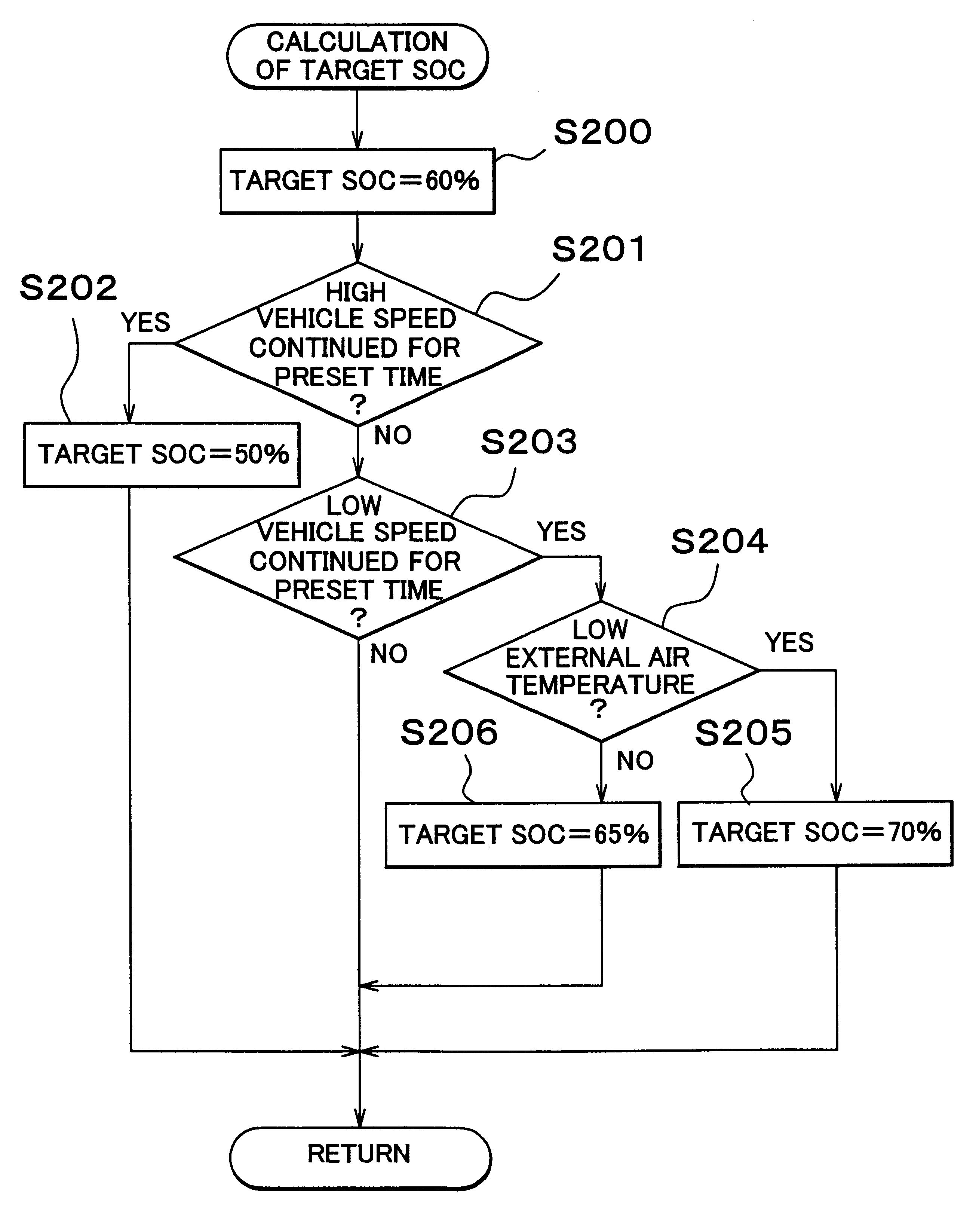

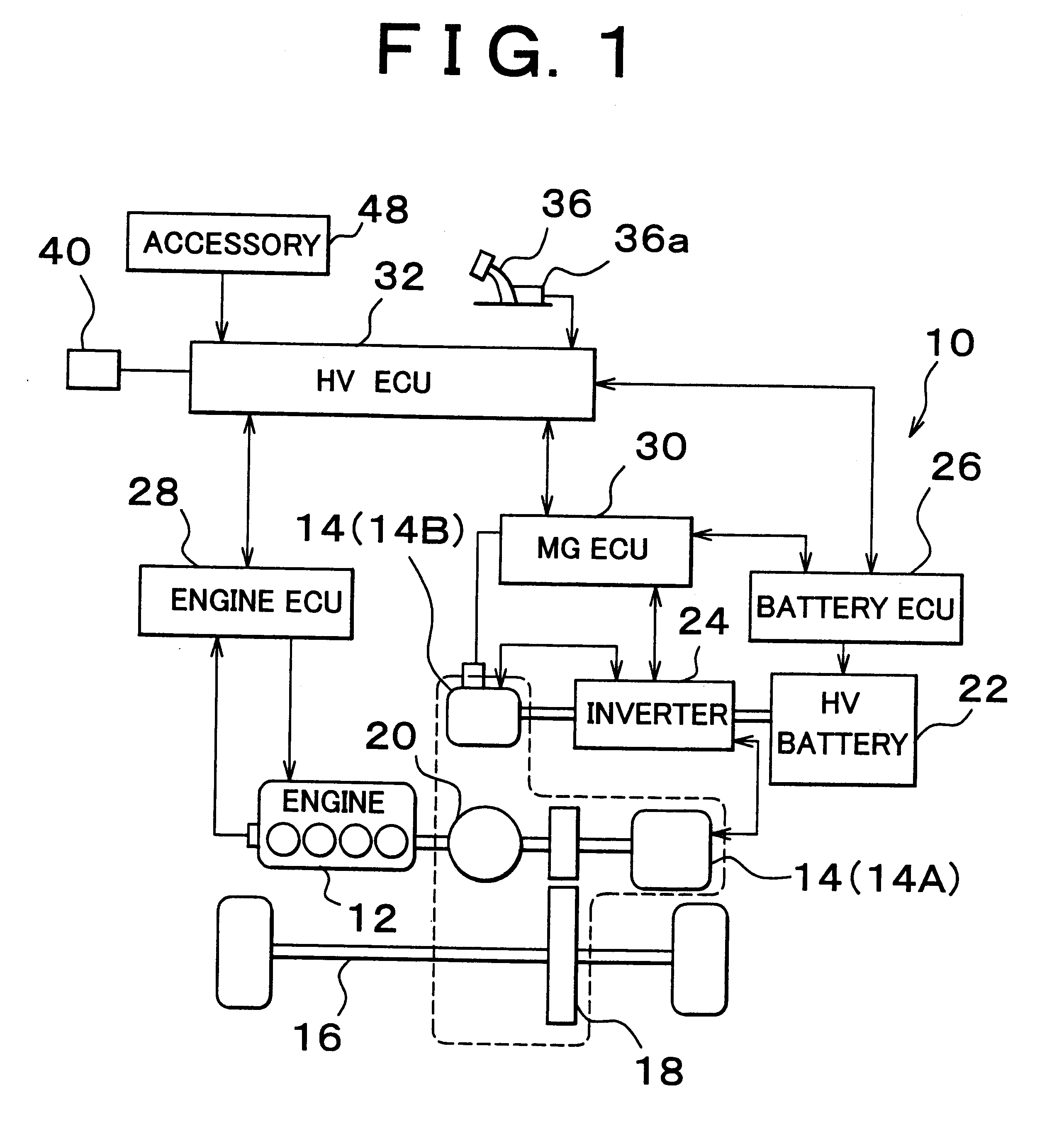

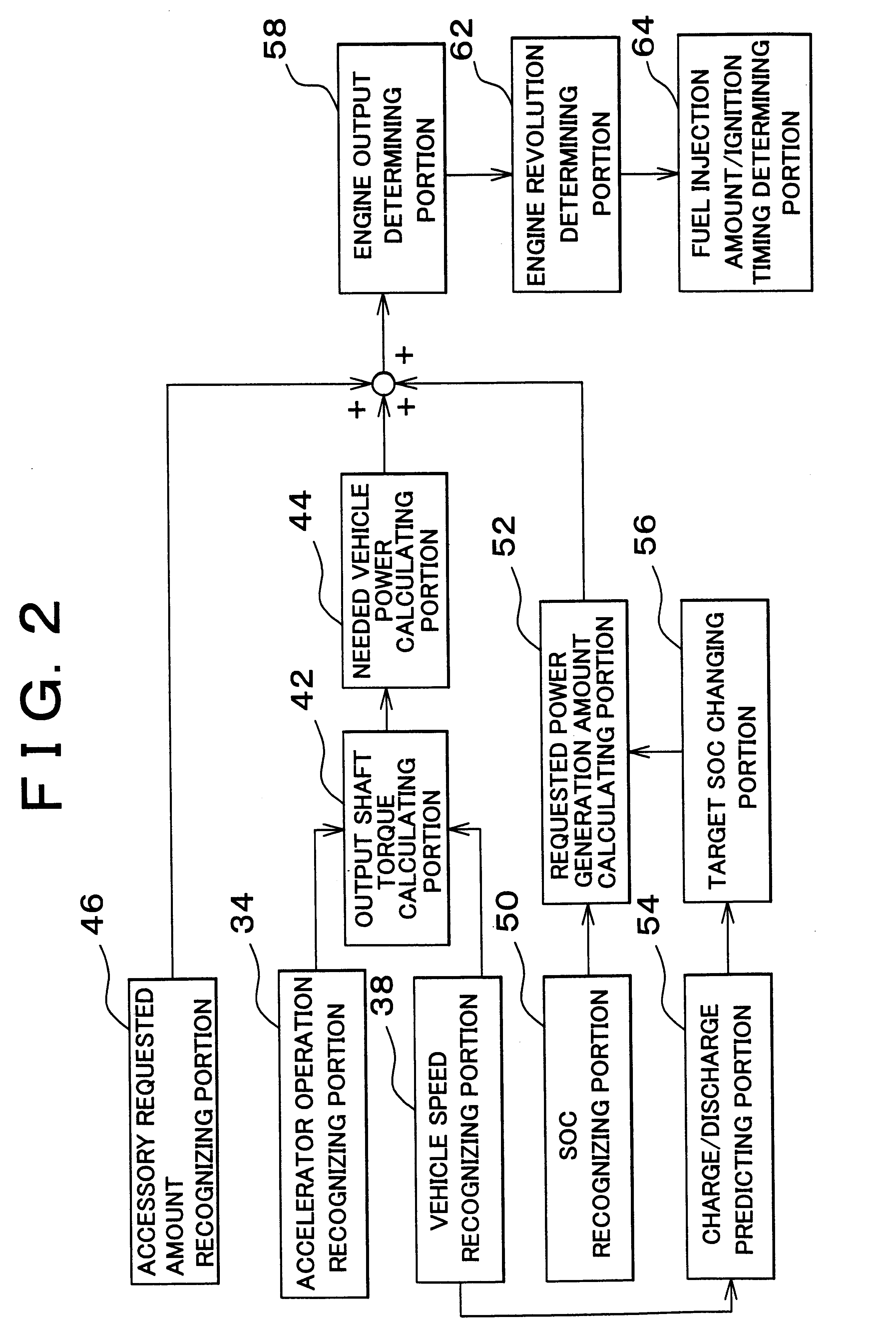

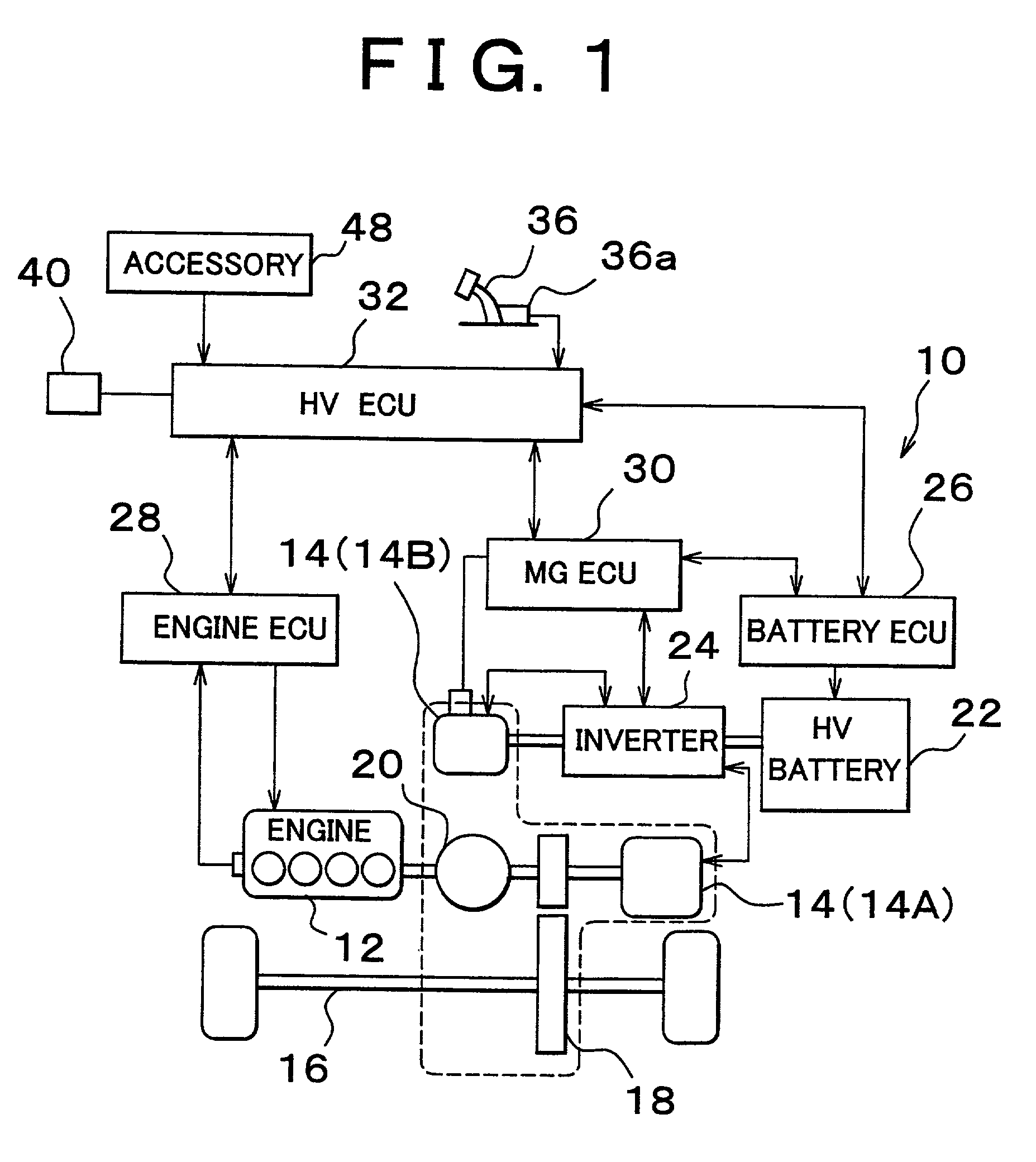

A controller predicts a requested state of charge / discharge corresponding to a future run of a hybrid vehicle. If it is predicted that the hybrid vehicle will be stopped and restarted, or will be greatly accelerated and therefore that a request for a great discharge will be outputted in the future, the controller increases a target SOC of an HV battery to increase the value to which the charge of the HV battery will be converged in preparation for the great discharge. If it is predicted that a great regenerative electric power will be generated by a vehicle deceleration and therefore that a request for charging will be outputted, the target SOC is reduced, and the amount of charge in the HV battery is reduced, so that the regenerative power generated can be efficiency recovered.

Owner:TOYOTA JIDOSHA KK

Electric energy charging control apparatus and method for hybrid vehicle

InactiveUS20010024104A1Improve charging capacityReduce the amount of solutionElectrical testingPlural diverse prime-mover propulsion mountingCharge controlState of charge

A controller predicts a requested state of charge / discharge corresponding to a future run of a hybrid vehicle. If it is predicted that the hybrid vehicle will be stopped and restarted, or will be greatly accelerated and therefore that a request for a great discharge will be outputted in the future, the controller increases a target SOC of an HV battery to increase the value to which the charge of the HV battery will be converged in preparation for the great discharge. If it is predicted that a great regenerative electric power will be generated by a vehicle deceleration and therefore that a request for charging will be outputted, the target SOC is reduced, and the amount of charge in the HV battery is reduced, so that the regenerative power generated can be efficiency recovered.

Owner:TOYOTA JIDOSHA KK

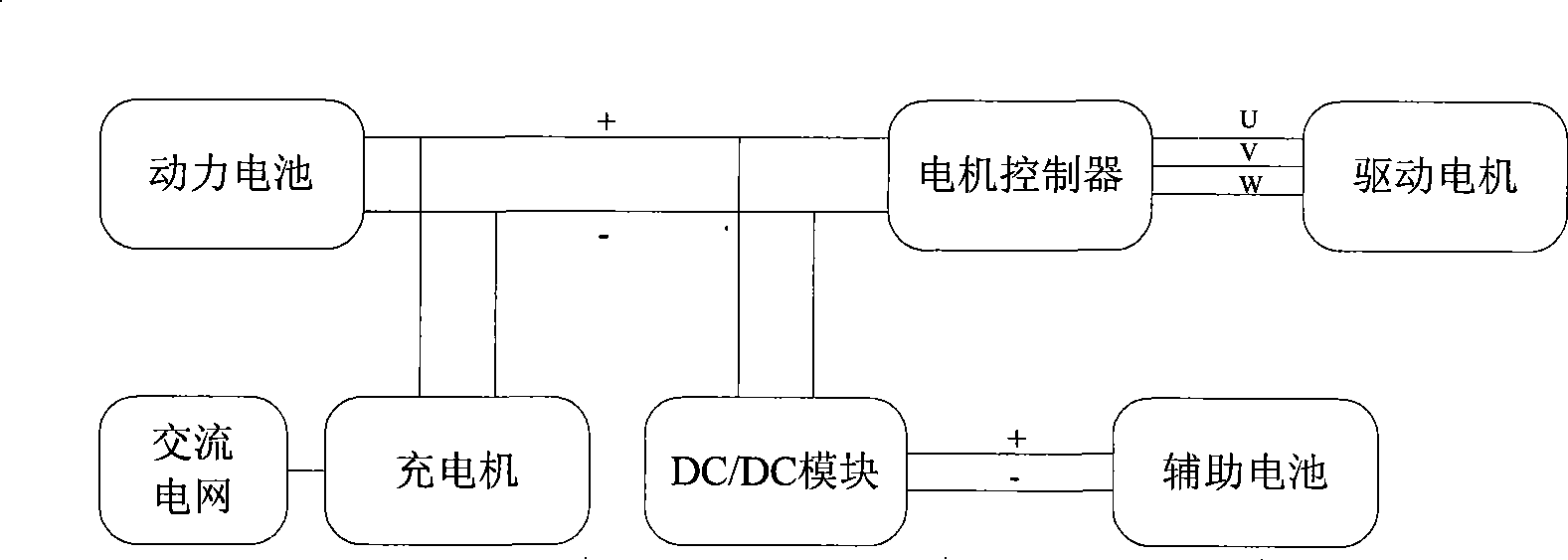

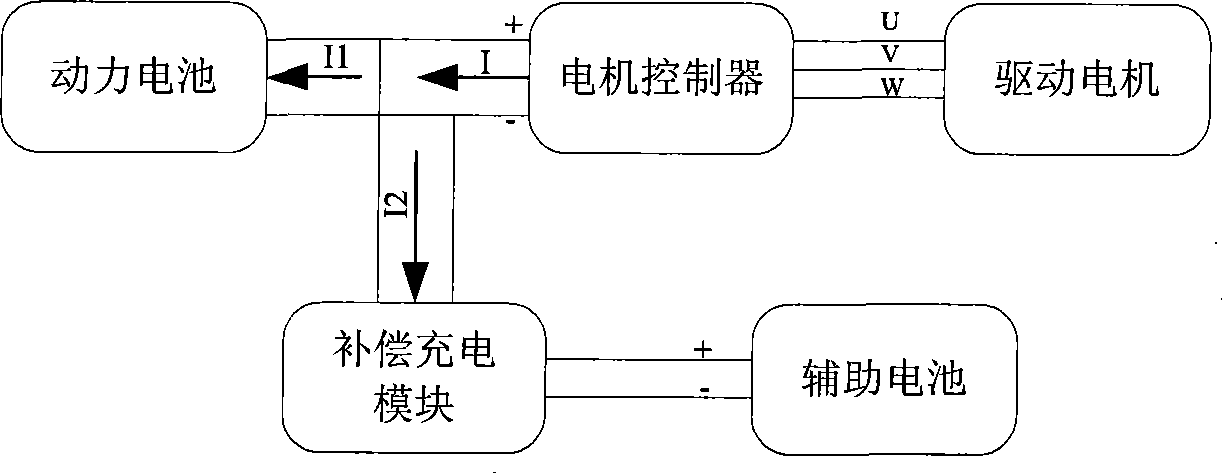

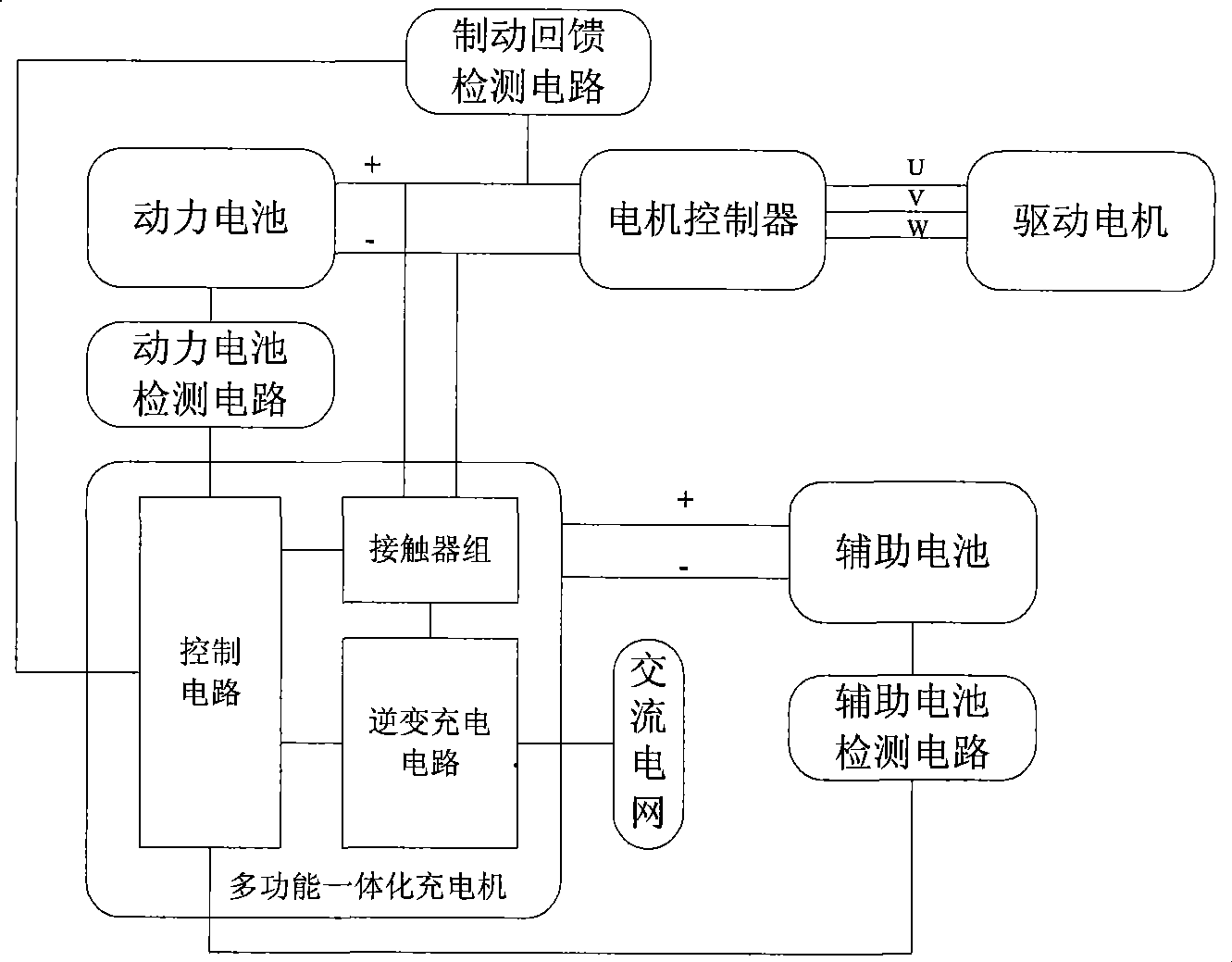

Multifunctional integrated charger for electric automobile having compensation charging function

InactiveCN101499673ARealize switchingEfficient multiplexingBatteries circuit arrangementsElectric powerCapacitancePower battery

The invention belongs to the field of charging technology of an electric automobile and relates to a multifunctional integrated charging machine which is used for the electric automobile and has a compensation charging function. The multifunctional integrated charging machine comprises a rectifier bridge, an inverter charging circuit, a control circuit, a contactor group, a power battery, an auxiliary battery, a brake feedback energy detection circuit, a power battery energy detection circuit and an auxiliary battery energy detection circuit; the output terminal of the rectifier bridge is connected with the inverter charging circuit which comprises a capacitance filter circuit, an IGBT inverter bridge with the duty cycle controlled by the control circuit, a high-frequency transformer and a rectifier filter circuit; different charging modes are changed by controlling the contactor group. The multifunctional integrated charging machine highly integrates four charging functions including compensation charging and the like into a charging machine, improves the integrity of the charging machine and leads the electric automobile to recover more brake energy.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

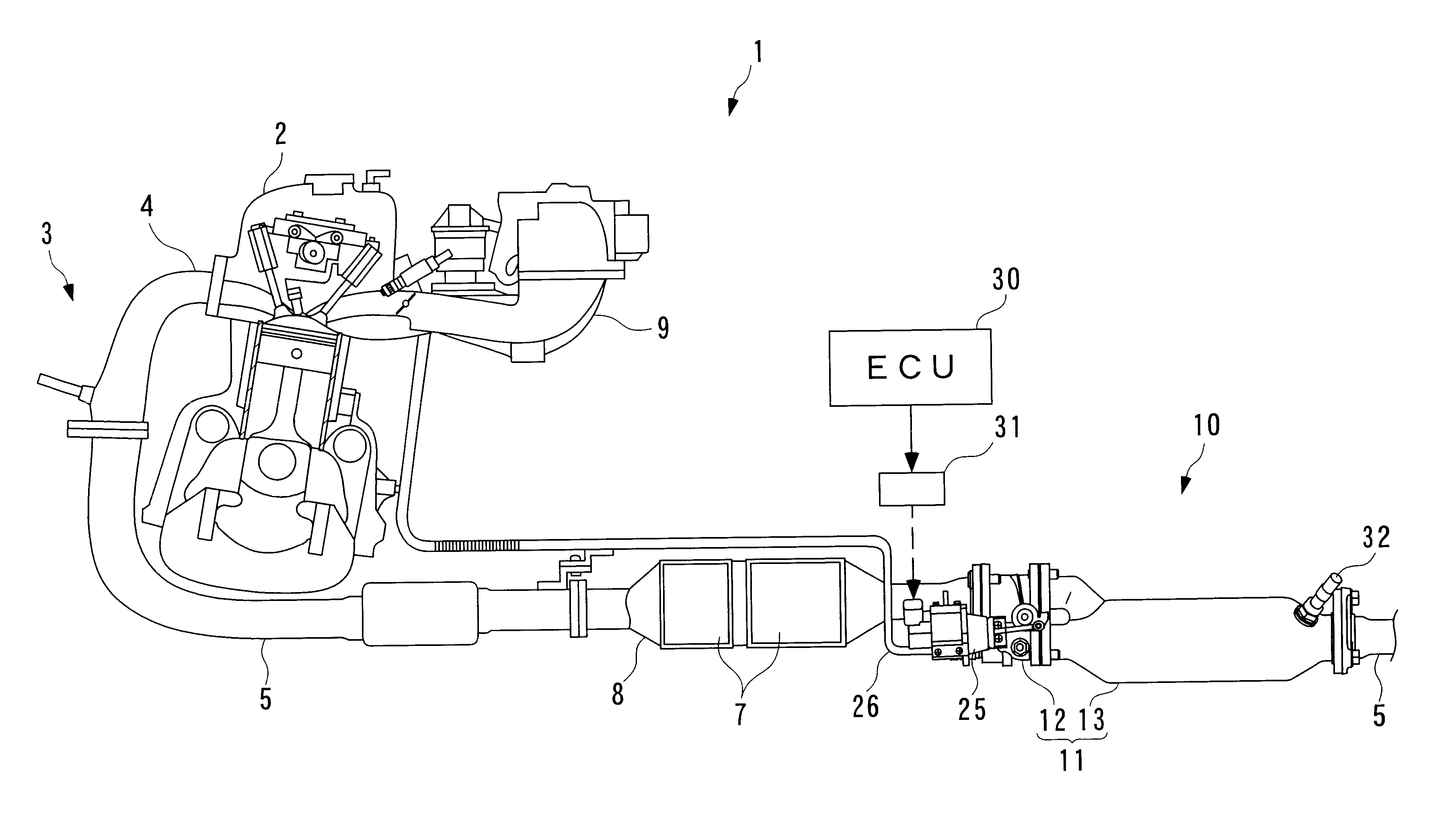

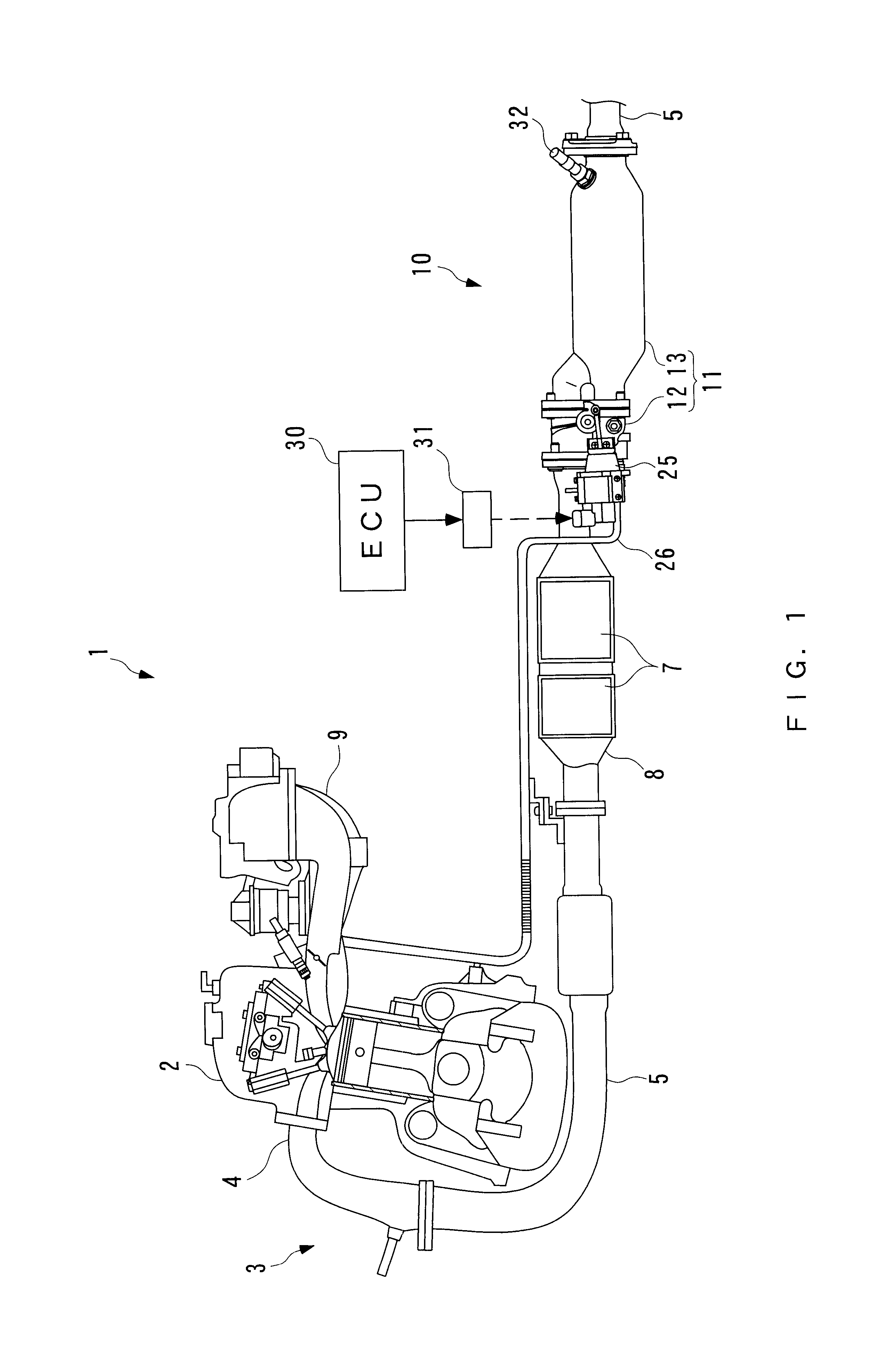

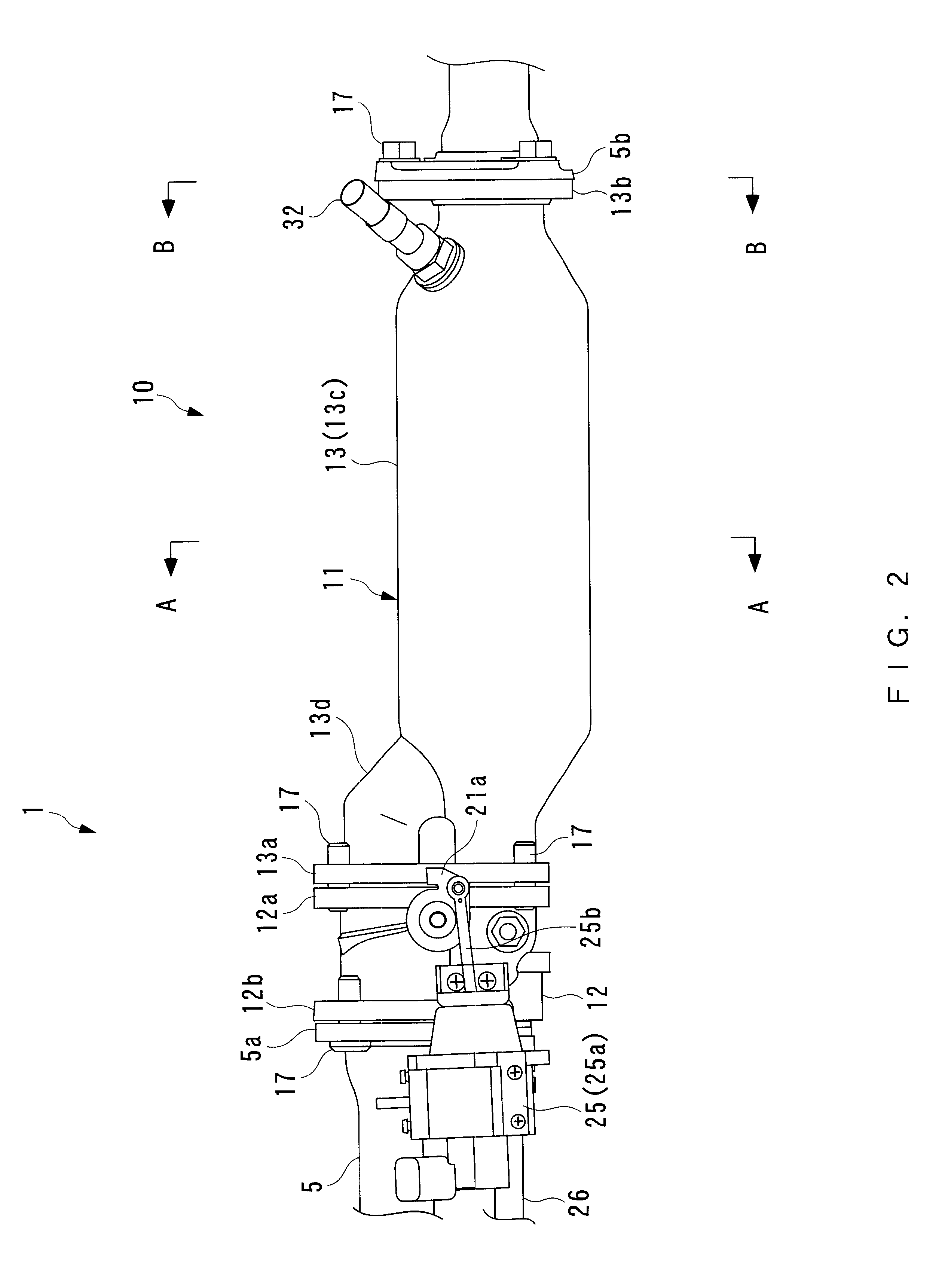

Exhaust gas purifying apparatus for internal combustion engine

InactiveUS6422006B2Full recoveryIncrease exhaust resistanceInternal combustion piston enginesExhaust apparatusDesorptionExternal combustion engine

Owner:HONDA MOTOR CO LTD

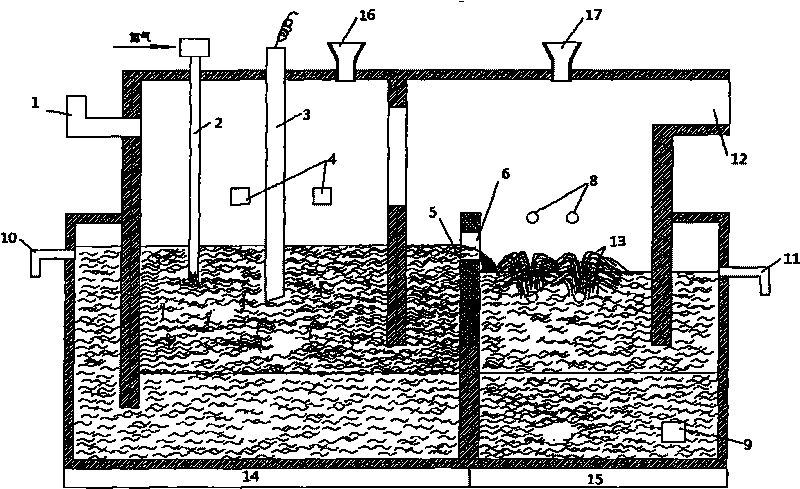

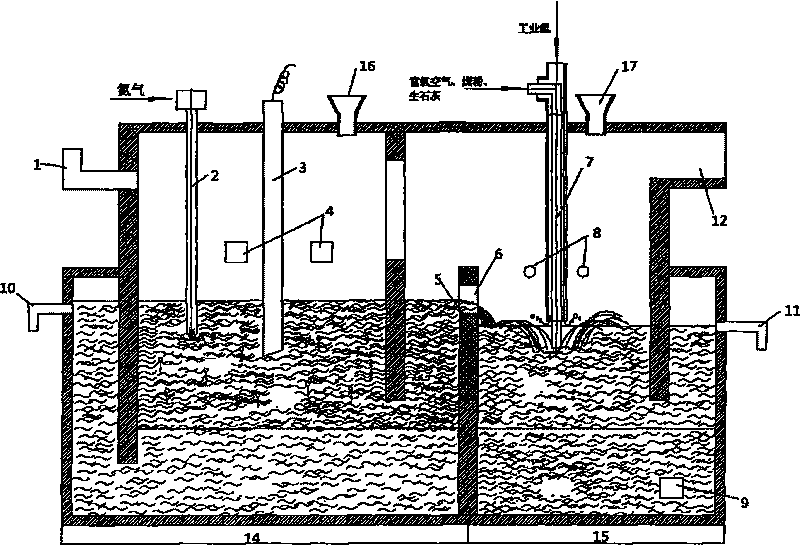

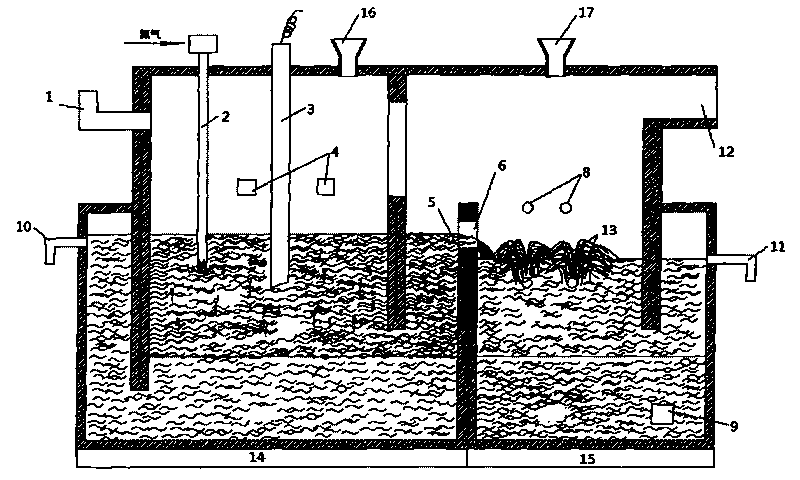

Copper-smelting thermal slag iron-extracting process and device

ActiveCN101705360ASave energy and costReduce equipment investment and floor spaceProcess efficiency improvementThermal energyNitrogen gas

The invention discloses a copper-smelting thermal slag iron-extracting process and a device. The copper-smelting thermal slag is processed in a same furnace to deplete copper and reduce iron. The copper extraction is performed in a first furnace hearth (copper depleting area). Electrode arc or fuel is used for supplying heat. Small matte particle is impacted to grow up by stirring with nitrogen to realize settlement separation. The depleted slag automatically flows into a second furnace hearth (iron reducing area). Coal, quicklime and oxygen-enriched air are blown in from side or top to reduce iron. The invention has the advantages that copper and iron are sufficiently recycled from the copper-smelting slag, the recycling rate of copper is more than 90%, the recycling rate of iron is more than 95%, heat of thermal slag is sufficiently used, the energy source and the cost are saved, the copper extraction and the iron extraction are realized in a same furnace, and the equipment investment and the floor space are both saved.

Owner:YANGGU XIANGGUANG COPPER

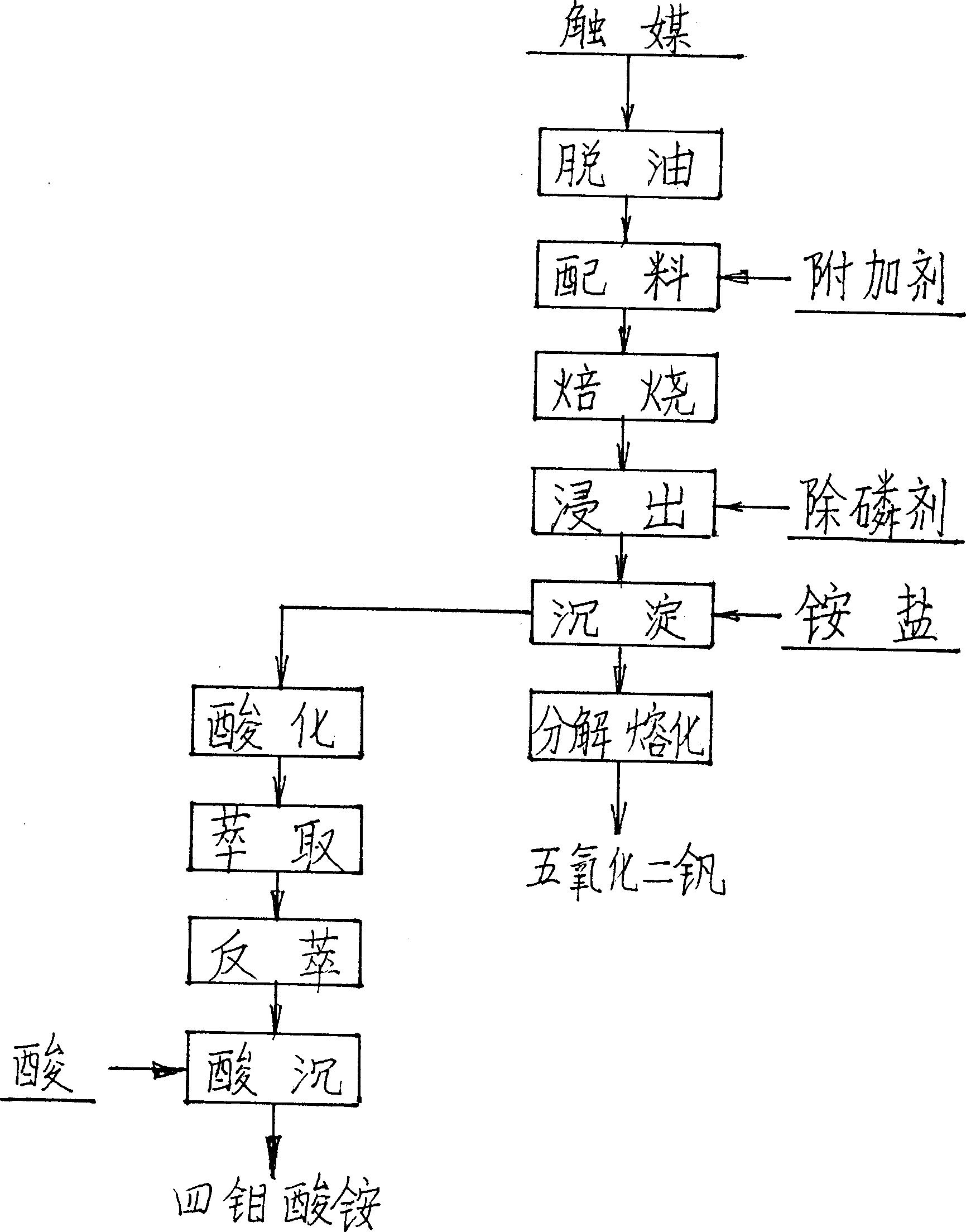

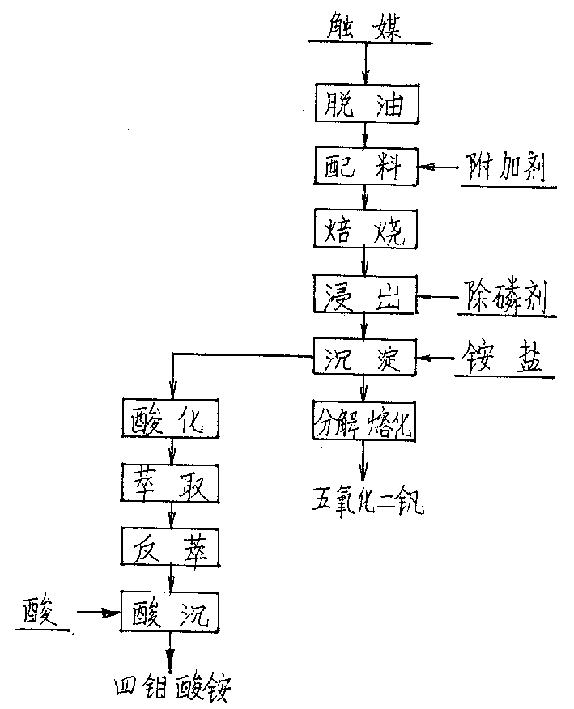

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

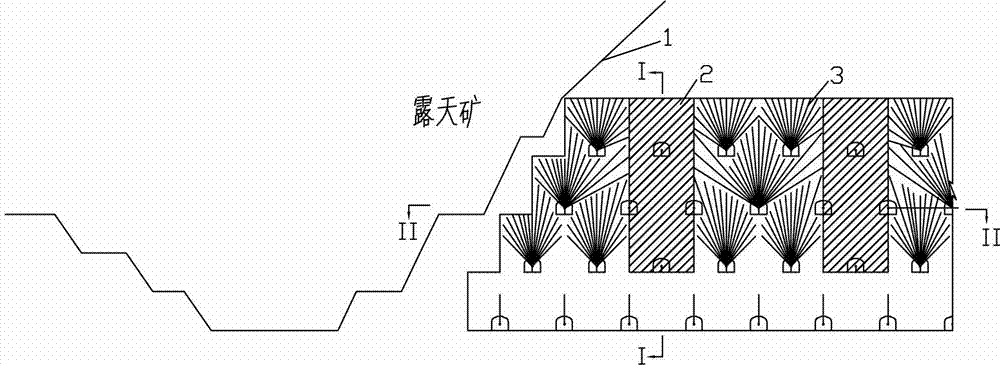

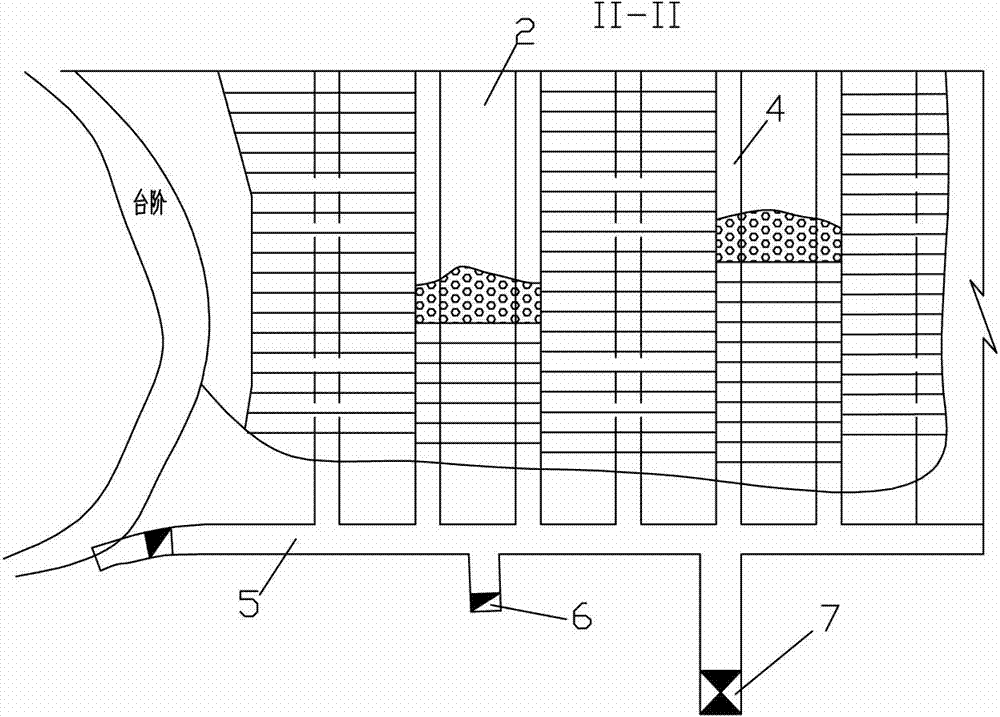

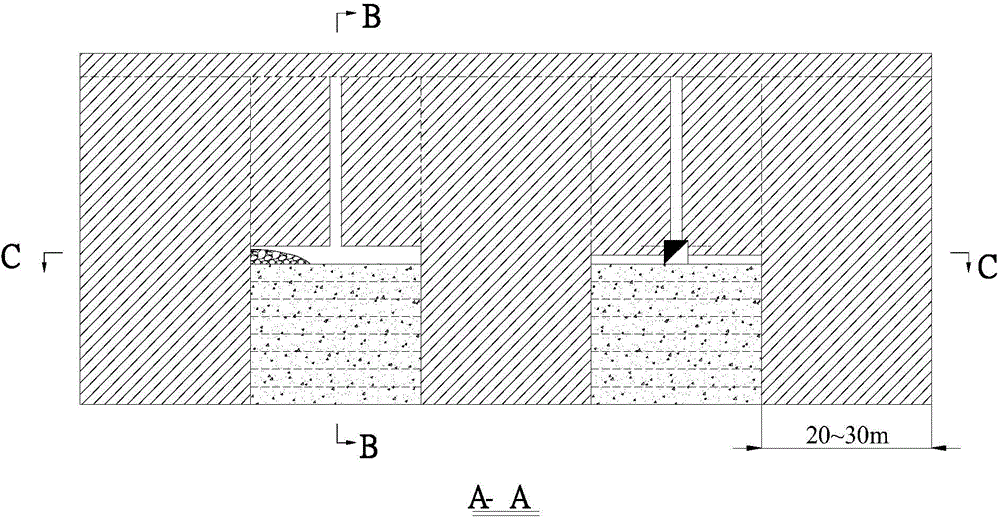

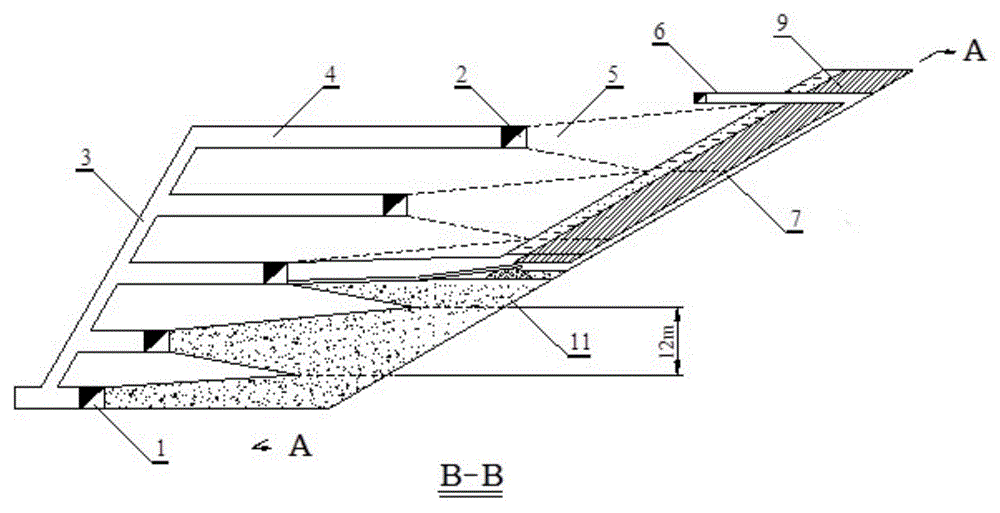

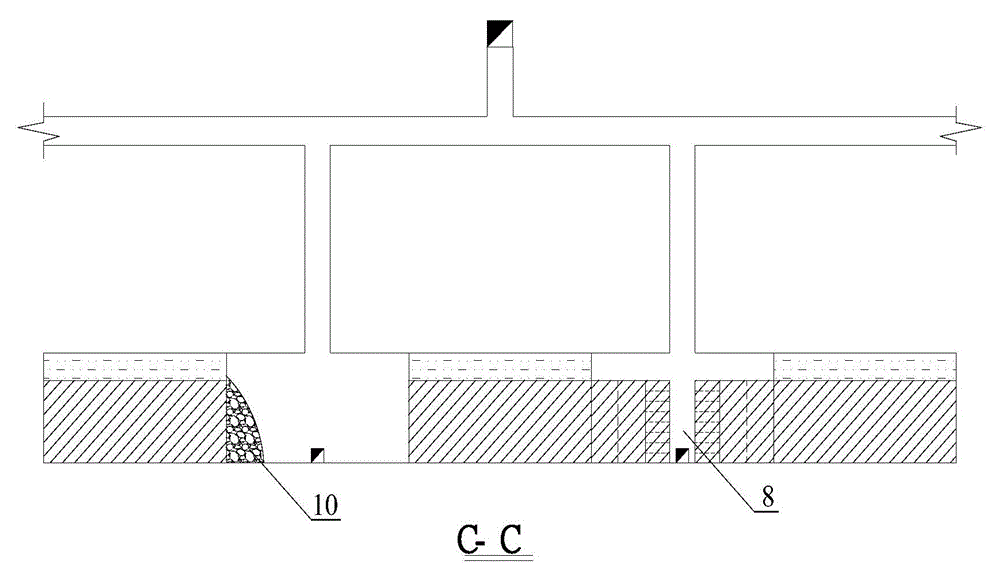

Drift-pillar-free sublevel barnyard caving mining method of open pit transferred underground transitional period

ActiveCN103089266ADecrease the sampling factorReduce the amount of quasi-engineeringUnderground miningBlastingOpen-pit miningRock cutting

The invention relates to a drift-pillar-free sublevel barnyard caving mining method of an open pit transferred underground transitional period. The drift-pillar-free sublevel caving mining method comprises the following steps of: carrying out sublevel recovering; and finishing rock drilling, blasting and ore removing in a feeding path. The drift-pillar-free sublevel caving mining method is characterized in that at an open pit transferred underground recovering transitional period, open pit mining and underground hanging wall ore recovering are carried out at the same time; a barnyard method and a drift-pillar-free sublevel caving method are combined to recover hanging wall ore; when open pit ore is mined, a drift-pillar-free sublevel barnyard method is used for recovering a hanging wall ore sublevel feeding path; and after the open pit mining is finished, a drift-pillar-free sublevel caving method is used for carrying out large-scale blasting and ore removing on safety pillars, other sublevel ores and barnyard-method residual ores. The drift-pillar-free sublevel barnyard caving mining method disclosed by the invention has the advantages of effectively reducing accurate mining coefficient and saving economic cost. The accurate mining engineering amount is greatly reduced and the accurate mining invest is reduced at the same time; and the extracted ore amount and the production capability of unit accurate mining engineering are increased and the economic benefit is effectively improved.

Owner:ANSTEEL GRP MINING CO LTD

Bulky sheet material having three-dimensional protrusions

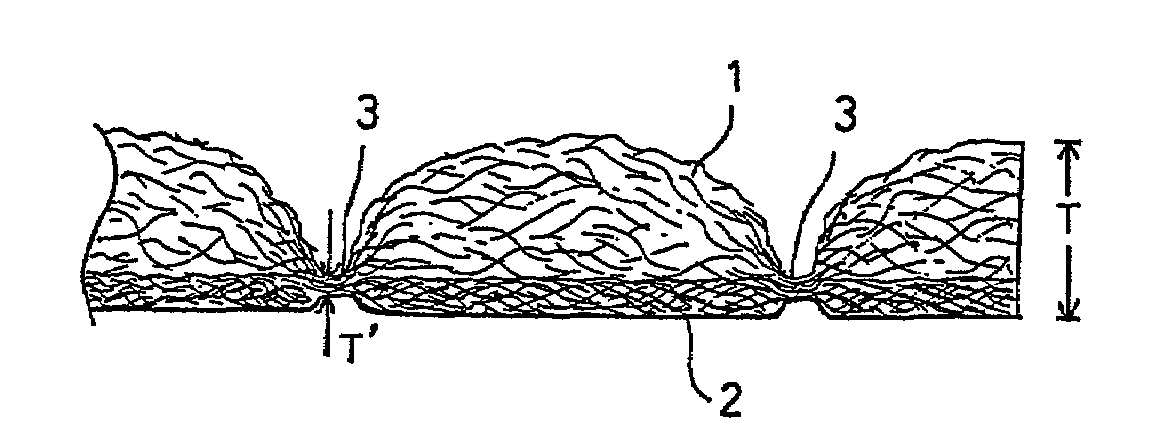

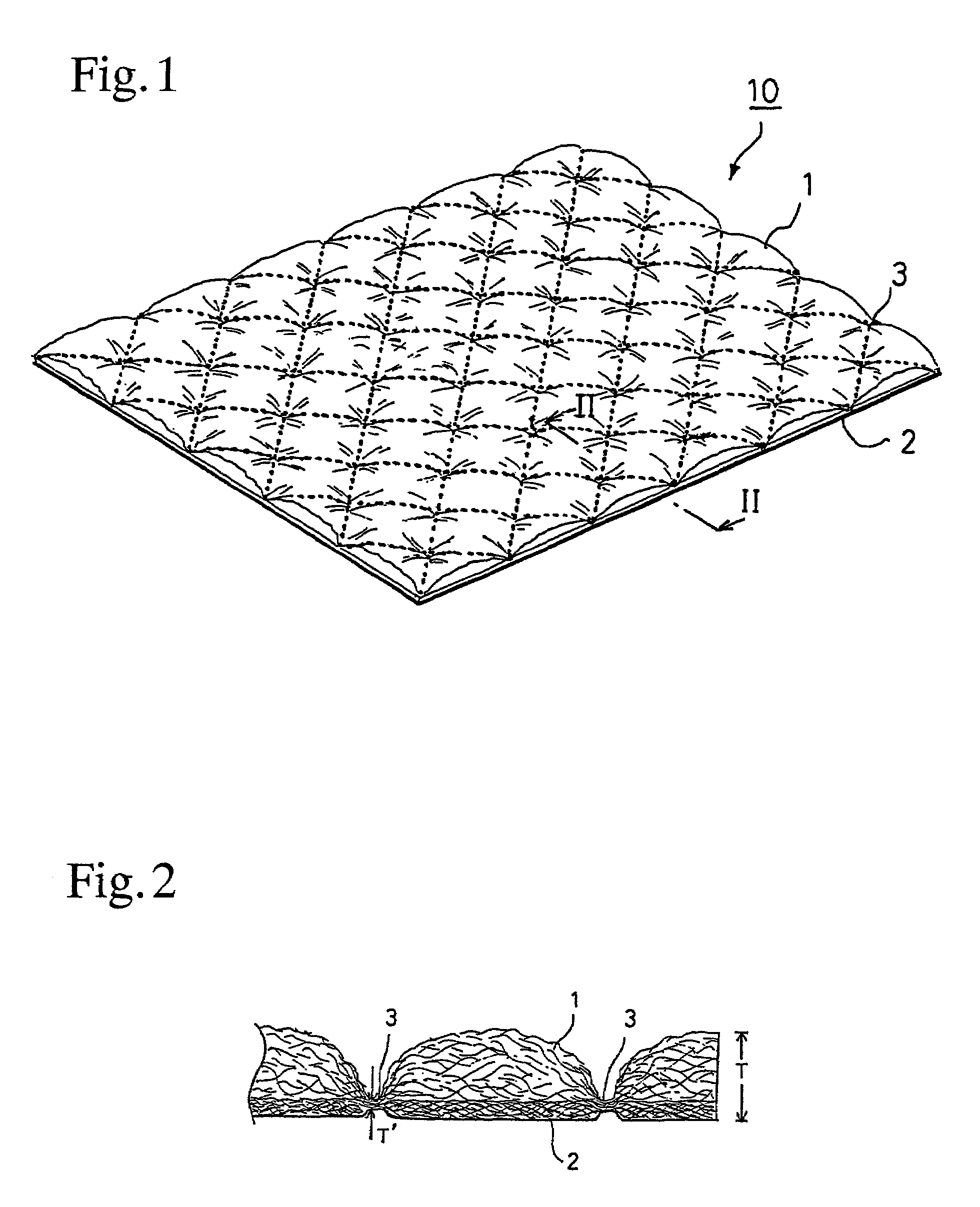

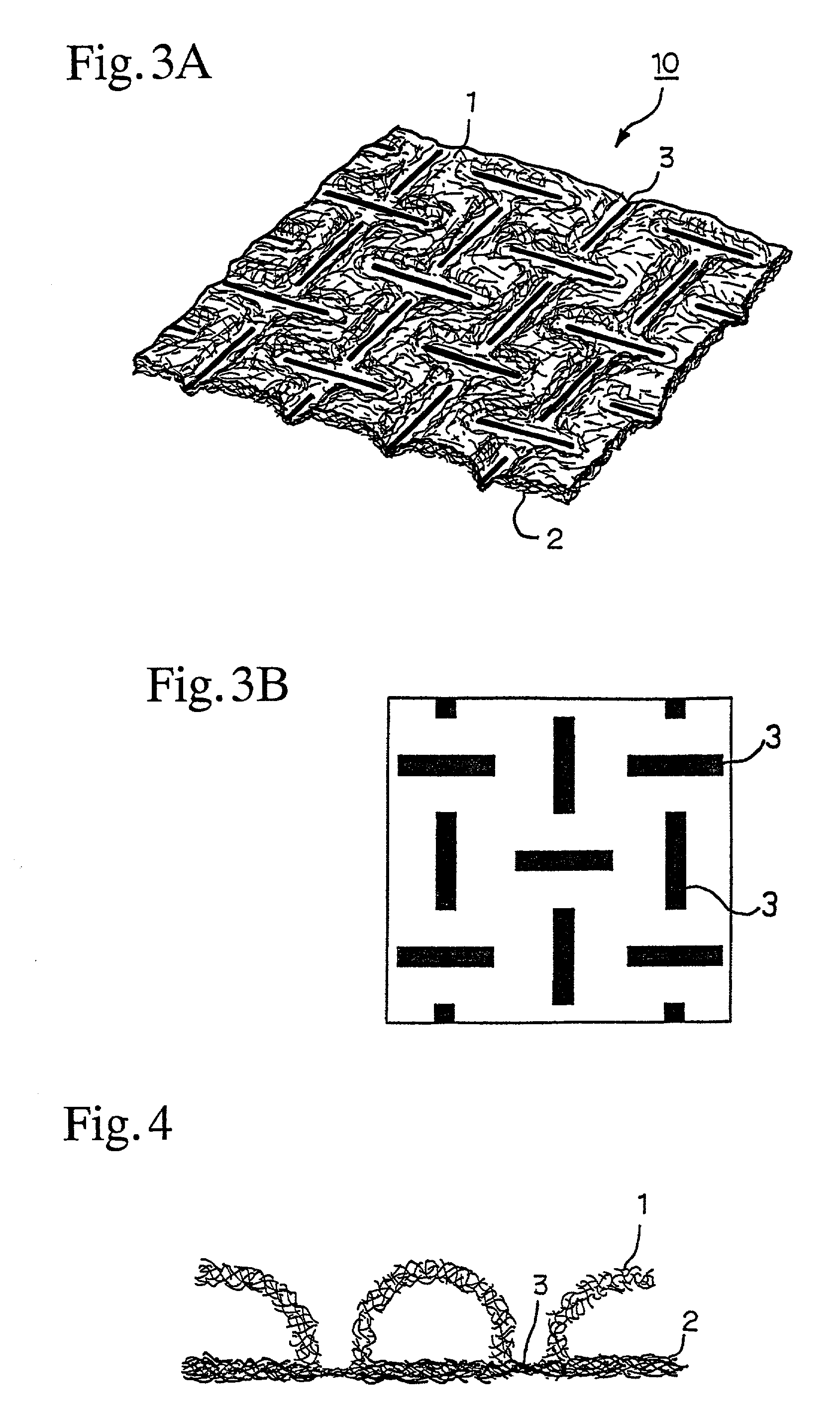

InactiveUS7303808B2Relative density is smallFull recoverySynthetic resin layered productsHeating/cooling textile fabricsBiomedical engineeringSecondary layer

A bulky sheet material having three-dimensional protrusions 10 is disclosed. The sheet material comprises a first layer 1 and a second layer 2 adjacent to the first layer 1. The first layer 1 and the second layer 2 is partly joined together at joints 3 in a prescribed pattern. The first layer 1 has a number of raised portions which are located among the joints 3. The second layer 2 comprises a material which exhibits elastomeric behavior. The bulky sheet material 10 exhibits elastomeric behavior as a whole and breathability.

Owner:KAO CORP

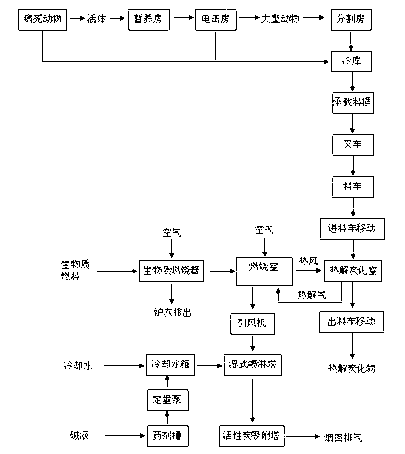

Urban kitchen waste recycling utilization and harmless treatment technology

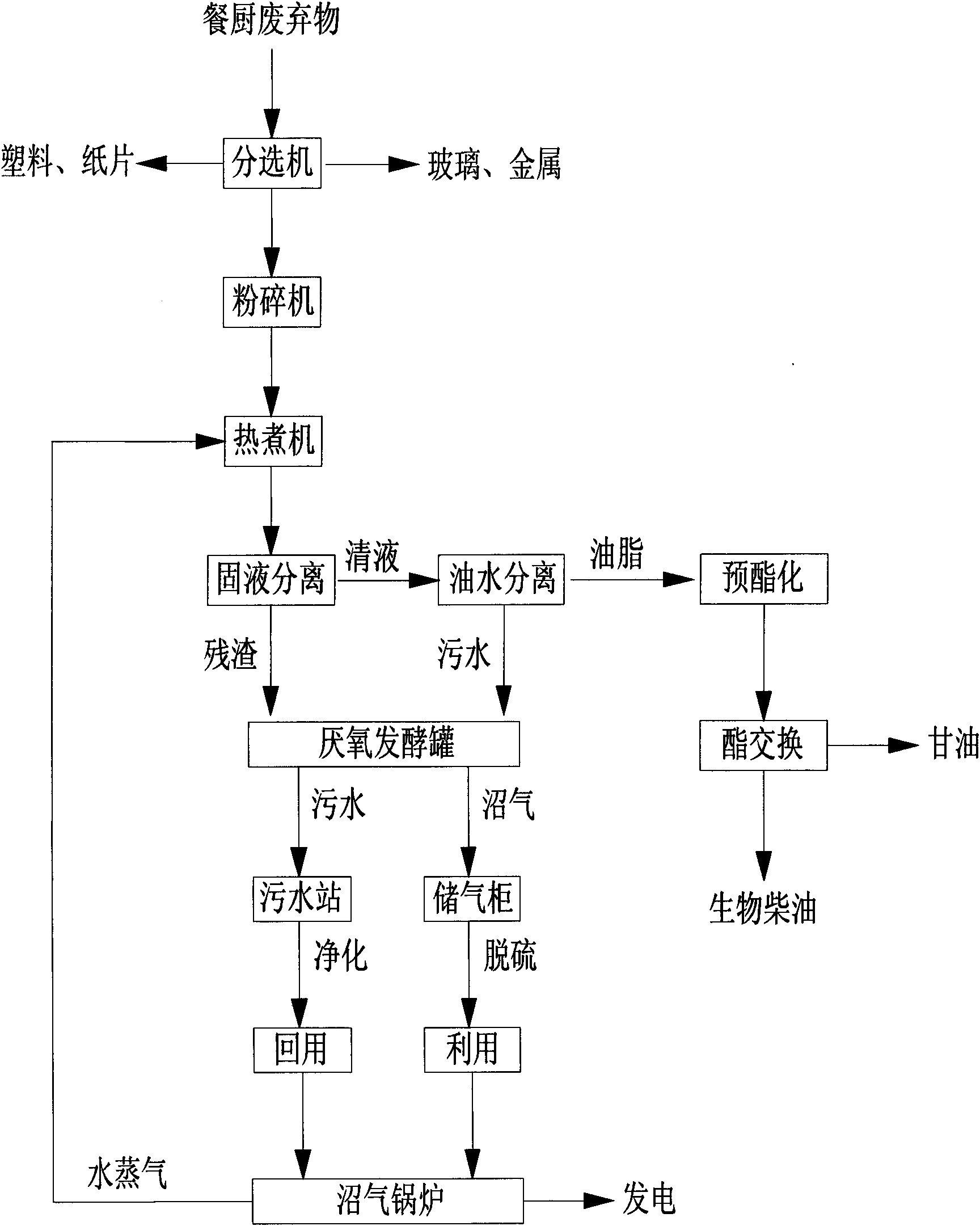

ActiveCN102688881AReasonable process designSimple processBiological substance pretreatmentsFatty acid esterificationBiodieselWater vapor

The invention relates to an urban kitchen waste recycling utilization and harmless treatment technology. The urban kitchen waste recycling utilization and harmless treatment technology is characterized by grinding and sorting kitchen waste by a crushing sorting machine, separating out inorganic substances, carrying out high-temperature steam pyrolysis of organic matter slurry, and carrying out solid-liquid and oil-water separation, wherein separated residues and sewage are fed into a biogas fermentation tank and are subjected to anaerobic fermentation to produce biogas for power generation or civil heating; and separated waste oil undergoes an acid-base reaction to produce glycerin and biodiesel. The urban kitchen waste recycling utilization and harmless treatment technology realizes maximum recycle of active resources of kitchen waste, reduces the pollution and the damage on the environment, and has environmental, economic and social benefits.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

Method for recycling metal from waste catalyst containing molybdenum and nickel

ActiveCN102041388AReduce the introductionIncrease valueProcess efficiency improvementOperabilityAmmonia

The invention relates to a method for recycling metals from a waste catalyst containing molybdenum and nickel, which comprises the following steps of: roasting and smashing the waste catalyst containing the molybdenum and nickel; mixing with an alkaline substance and roasting; leaching by using a mixed acid liquid; depositing by using an alkaline solution, wherein molybdenum is deposited out in the form of ammonium molybdate; further dissolving the ammonium molybdate by using ammonia water; regulating a pH value to obtain ammonium molybdate deposition; and drying to obtain an ammonium molybdate product. The method is particularly suitable for extracting high-purity ammonium molybdate from the aluminum-based waste catalyst containing the molybdenume, and has the advantages of simple process, strong operability, low energy consumption, and stable produced product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

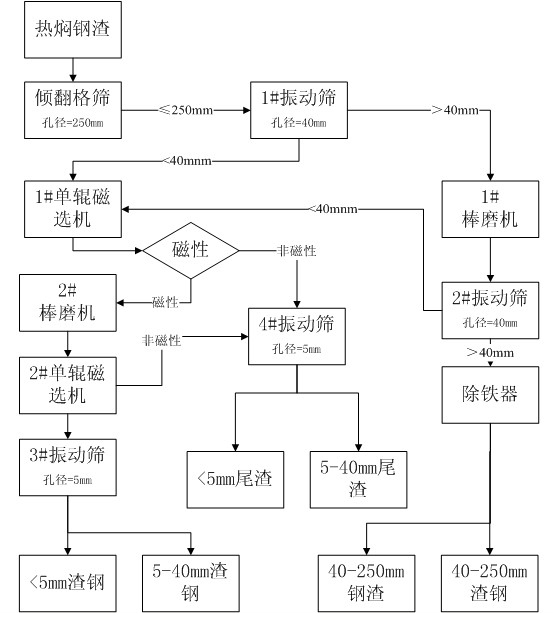

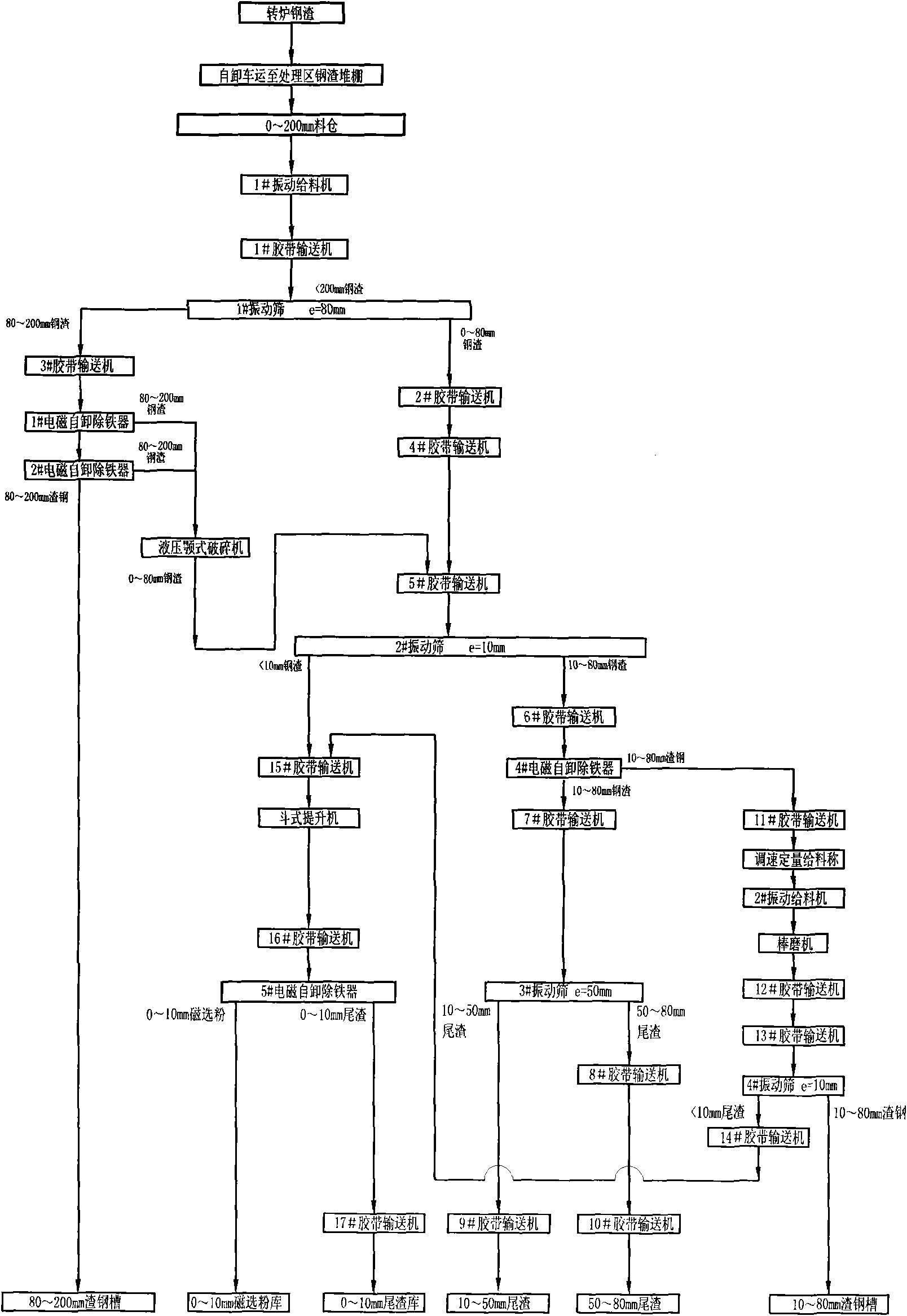

Method for reusing common steel slag

The invention relates to a method for reusing common steel slag. The method comprises the process links of performing hot closed treatment on slag, airing, sieving, performing magnetic separation and grinding and particularly comprises the following steps of: transporting red hot common steel slag to a hot splashing field and performing hot splashing; preliminarily crushing large common steel slag with the grain size of more than 2 m to the slag with the grain size of less than 2 m; placing the common steel slag into a hot closed treatment pool and uniformly heating for 30 minutes; covering a cover of the hot closed treatment pool; continuously and uniformly spraying water on the steel slag by using a spraying device in the cover, wherein the water spraying flow is 20 tons per hour and the water spraying time is 7 hours; after stopping spraying water, continuously performing hot closed treatment for more than 5 hours; opening the cover and measuring the temperature to 50 to 80 DEG C and the water content of the common steel slag is 6 to 8 percent; and conveying the steel slag subjected to hot closed treatment to a stacking field and airing for more than 24 hours, wherein the water content is 4 to 6 percent. Compared with the traditional treatment process, the method has the advantages that: metal recycling capacity is high; product grade is high; all the common steel slag can be treated; and the product can be utilized well.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

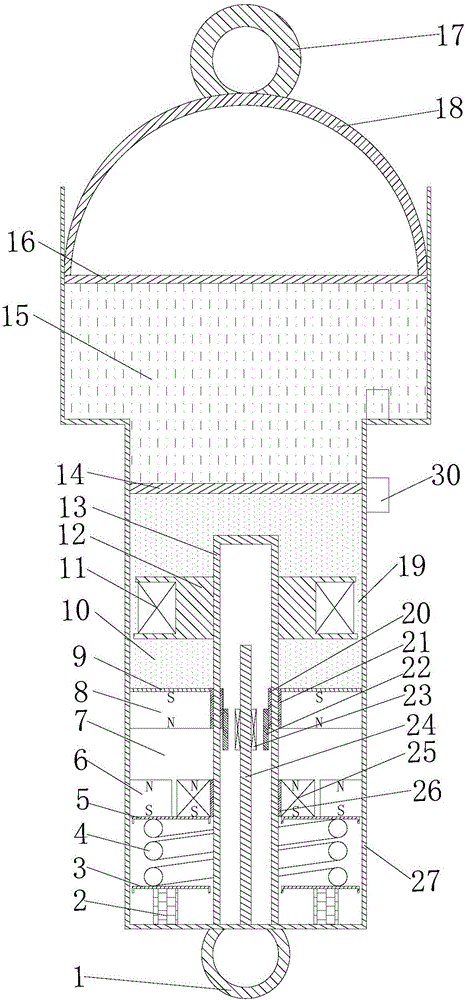

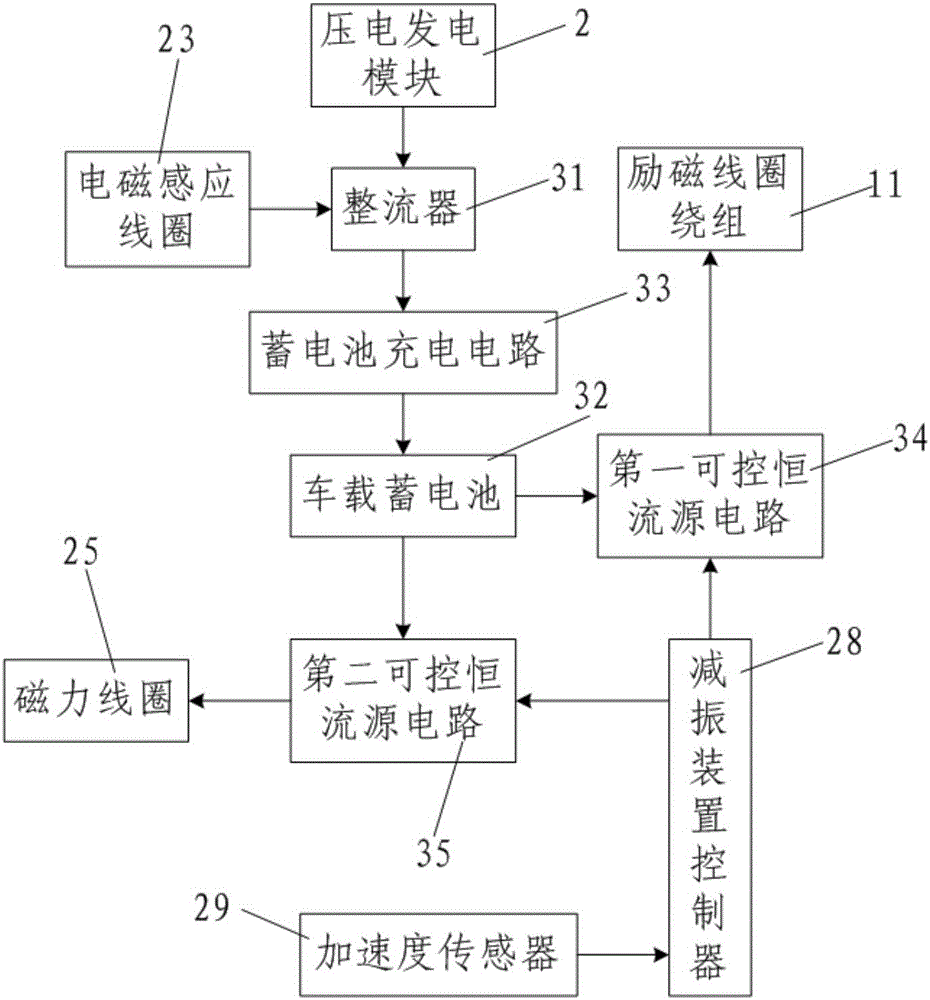

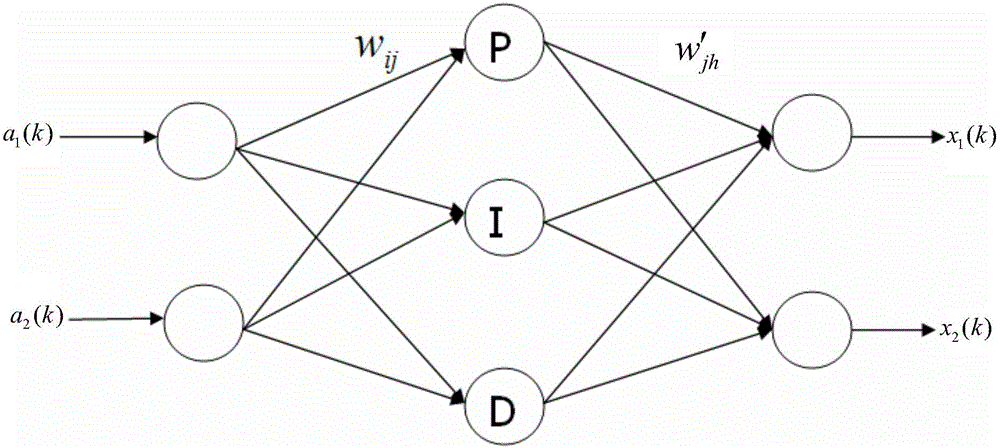

Piezoelectric and electromagnetic induction dual energy feedback type magneto-rheological vibration damper and control method thereof

ActiveCN106286685ASimple structureNovel and reasonable designSpringsNon-rotating vibration suppressionConstant current sourceDual energy

The invention discloses a piezoelectric and electromagnetic induction dual energy feedback type magneto-rheological vibration damper which comprises a vibration damper body and a vibration damper controller. The vibration damper body comprises a cylinder barrel, a pressure supporting floating piston, a middle isolation floating piston, a piston rod, piezoelectric generation modules, a spring pressing plate, a force transfer spring, a spring clamping seat, a lower permanent magnet, a magnetic coil, an upper permanent magnet, a magnetism isolating plate, a piston, an excitation coil winding, an electromagnetic induction coil fixing rod and an electromagnetic induction coil. A control box is arranged on the outer wall of the cylinder barrel, the vibration damper controller is arranged inside the control box, and a rectifier, a storage battery charging circuit, a first controllable constant current source circuit and a second controllable constant current source circuit are further arranged inside the control box. The invention further discloses a control method of the piezoelectric and electromagnetic induction dual energy feedback type magneto-rheological vibration damper. The piezoelectric and electromagnetic induction dual energy feedback type magneto-rheological vibration damper has the piezoelectric and electromagnetic induction dual energy feedback function, can achieve not only a damping change function but also a rigidity change purpose, and has good vibration damping performance.

Owner:XIAN UNIV OF SCI & TECH

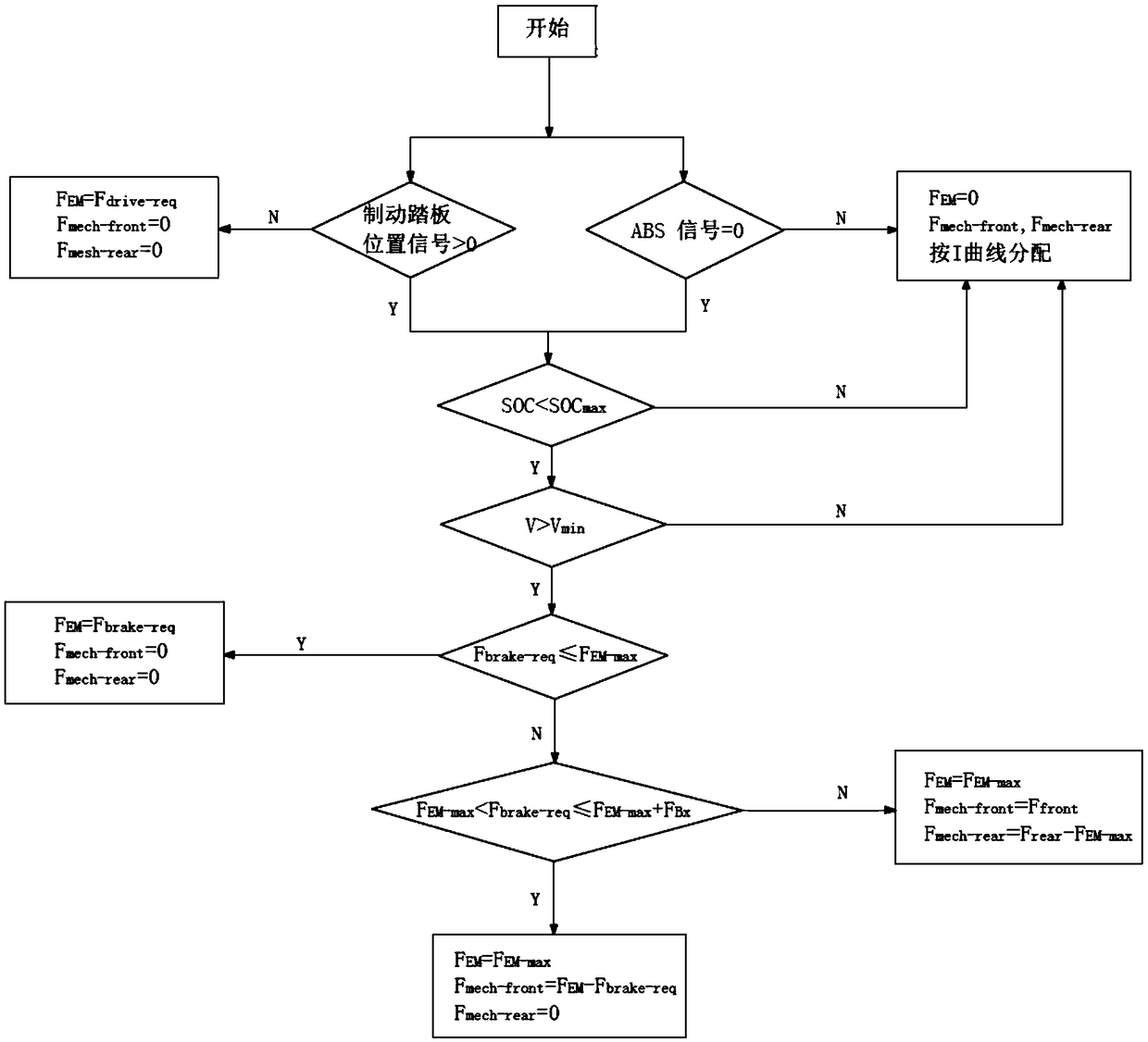

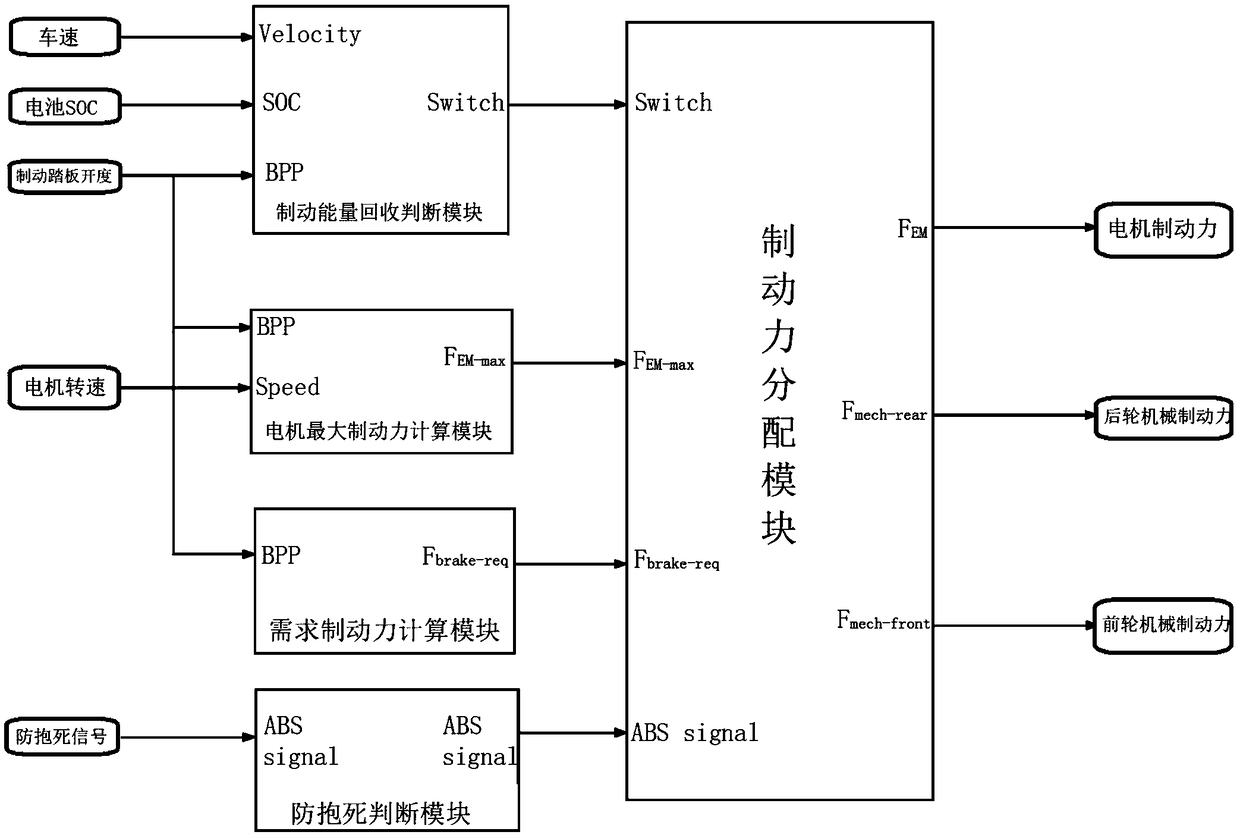

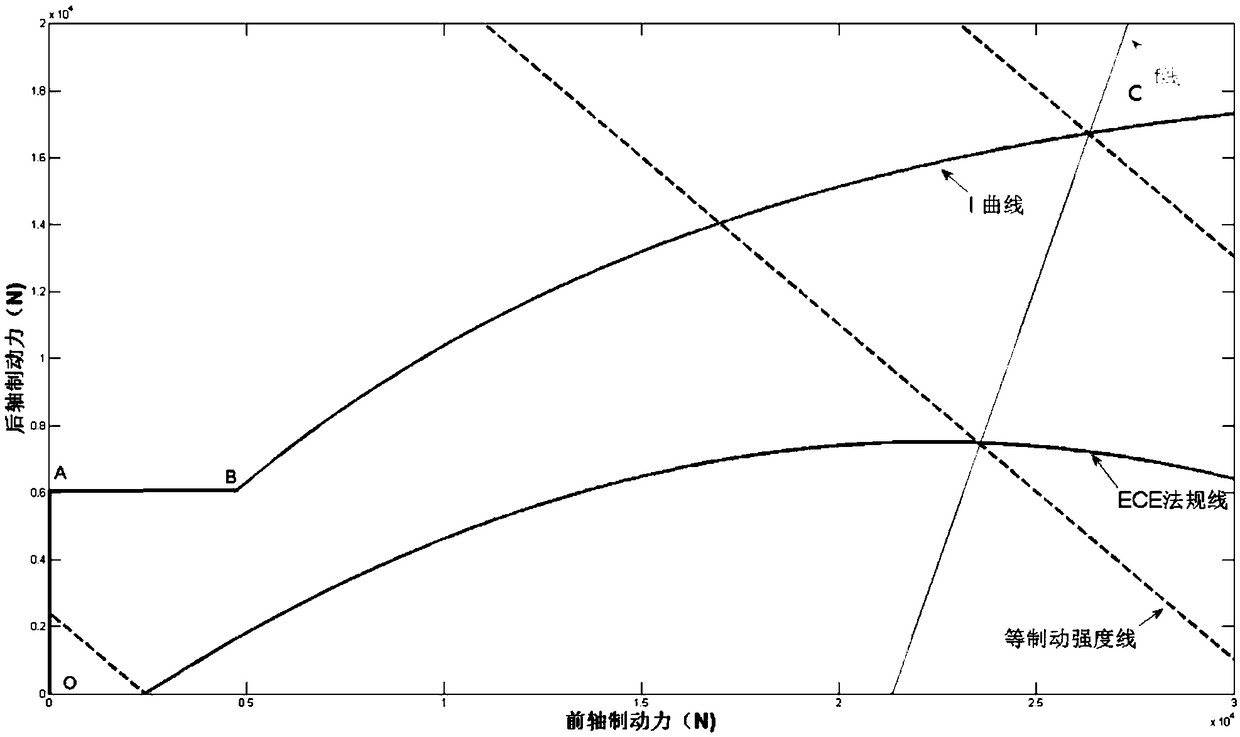

Braking energy recovery control method and device of rear wheel drive pure electric vehicle

ActiveCN109278566AImprove recycling efficiencyIncrease mileageElectrodynamic brake systemsControl devicesPower batteryRegenerative brake

The invention relates to the technical field of electric vehicles, specifically to a braking energy recovery control method and device of a rear wheel drive pure electric vehicle. The braking energy recovery control method of the rear wheel drive pure electric vehicle comprises the steps of a braking energy recovery mode judging step, a maximum regenerative braking force calculating step, a demandbraking force calculating step, a braking force distributing step and an anti-lock judging step; in the automobile braking process, distribution of a mechanical braking force and a regenerative braking force is controlled; on the basis of guaranteeing braking safety and braking efficiency, a regenerative braking force distribution coefficient is furthest increased; wasted energy in the braking process is sufficiently recovered by using the feeding capacity of a motor to charge a power battery; the braking energy recovery efficiency is enhanced; the braking energy loss is reduced; and the running range of the vehicle is optimized.

Owner:SHAANXI AUTOMOBILE GROUP

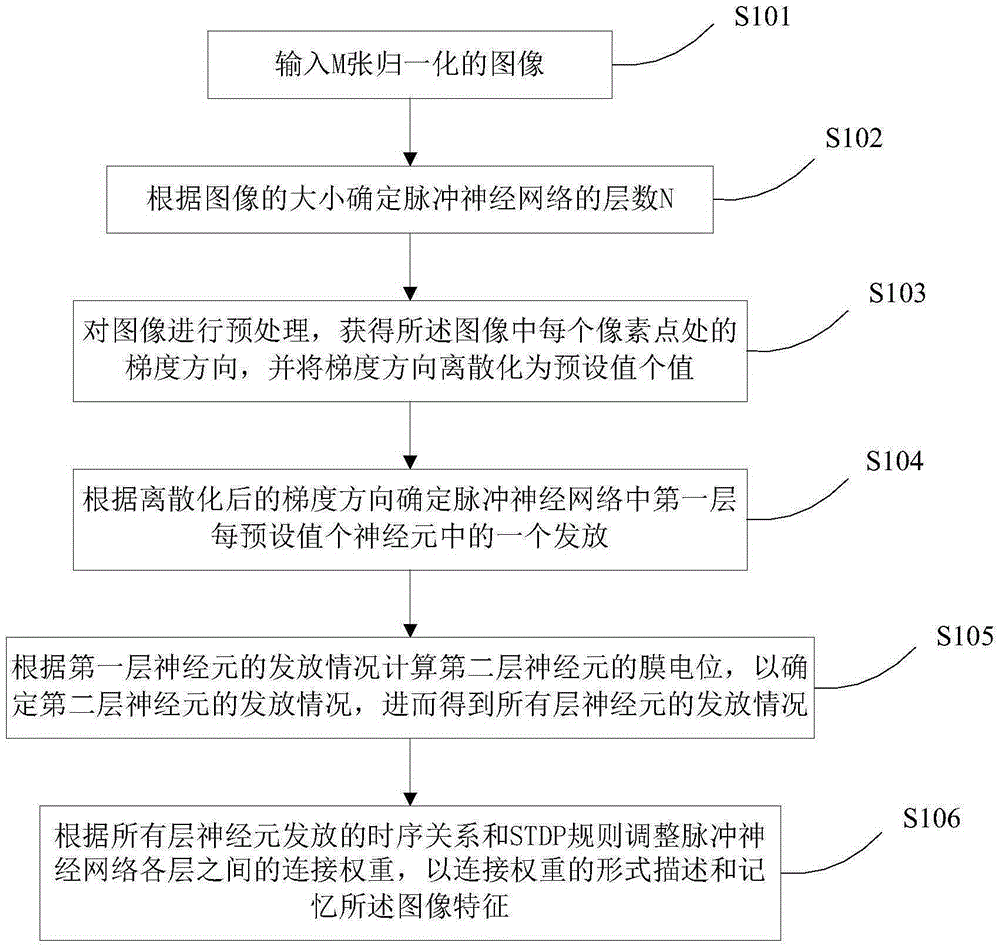

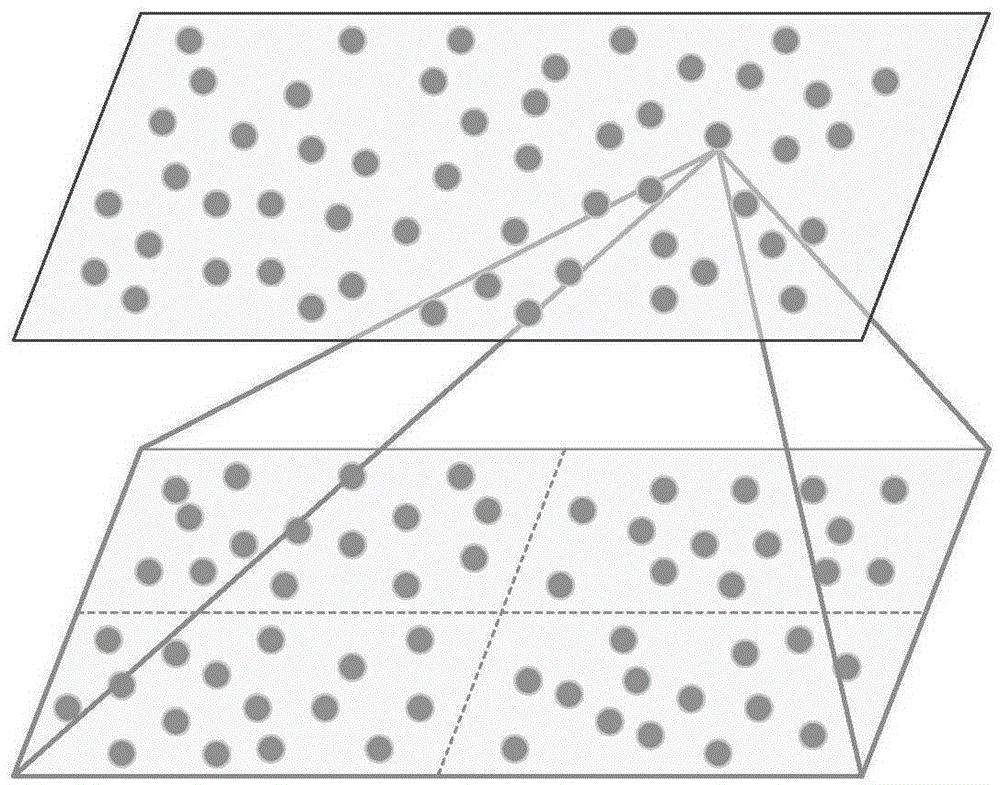

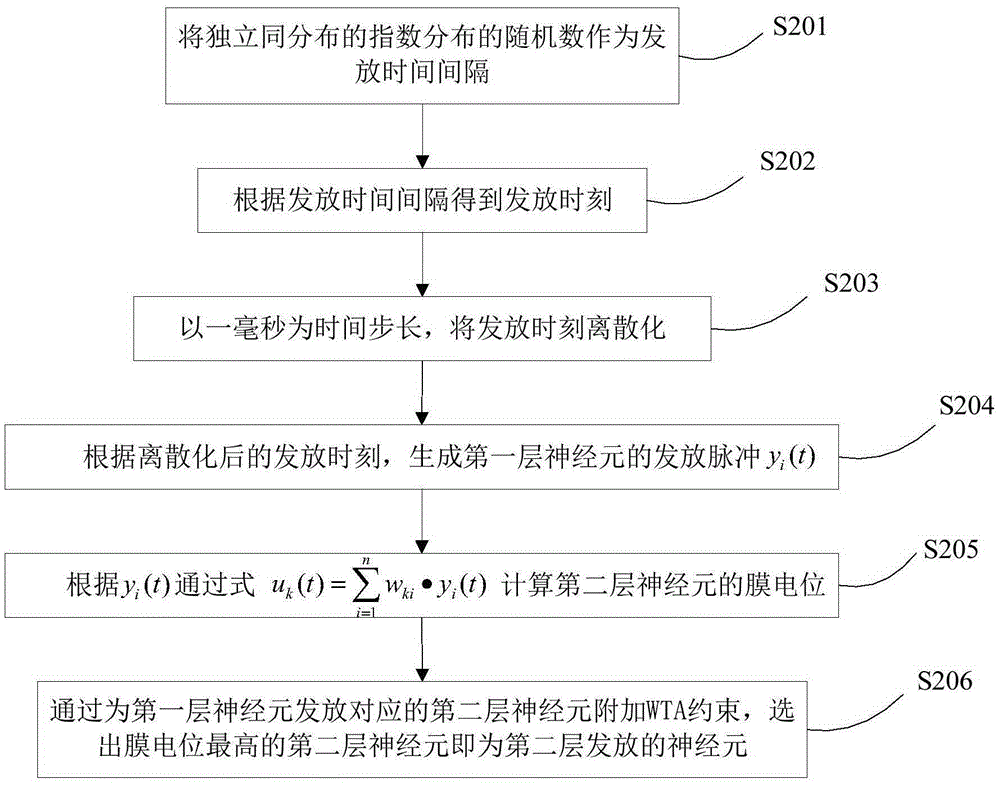

Impulsive neural network-based image feature describing and memorizing method

ActiveCN105404902AFull recoveryWith image classification functionCharacter and pattern recognitionNeural architecturesSpike-timing-dependent plasticityImaging Feature

The invention provides an impulsive neural network-based image feature describing and memorizing method. the method comprises steps: M normalized images are inputted, the layer number of the impulsive neural network is determined according to the size of the image, a gradient direction at each pixel point is acquired when pretreatment is carried out on the images, the gradient direction is discretized into a preset individual value, distribution of one of each preset value number of neurons in the first layer in the impulsive neural network is determined according to the discretized gradient direction, membrane potential of neurons in the second layer and the distribution condition of the neurons in the second layer are calculated according to the distribution condition of the neurons in the first layer, the distribution conditions of the neurons in all layers are obtained, a connection weight of each layer of the impulsive neural network is adjusted according to a timing relationship for distribution of neurons in all layers and a STDP (Spike Timing-dependent Plasticity) rule, and the image features are described and memorized in a connection weight form. The method of the invention can describe and memorize images of various kinds, can completely restore an image, and also has an image classification function.

Owner:TSINGHUA UNIV

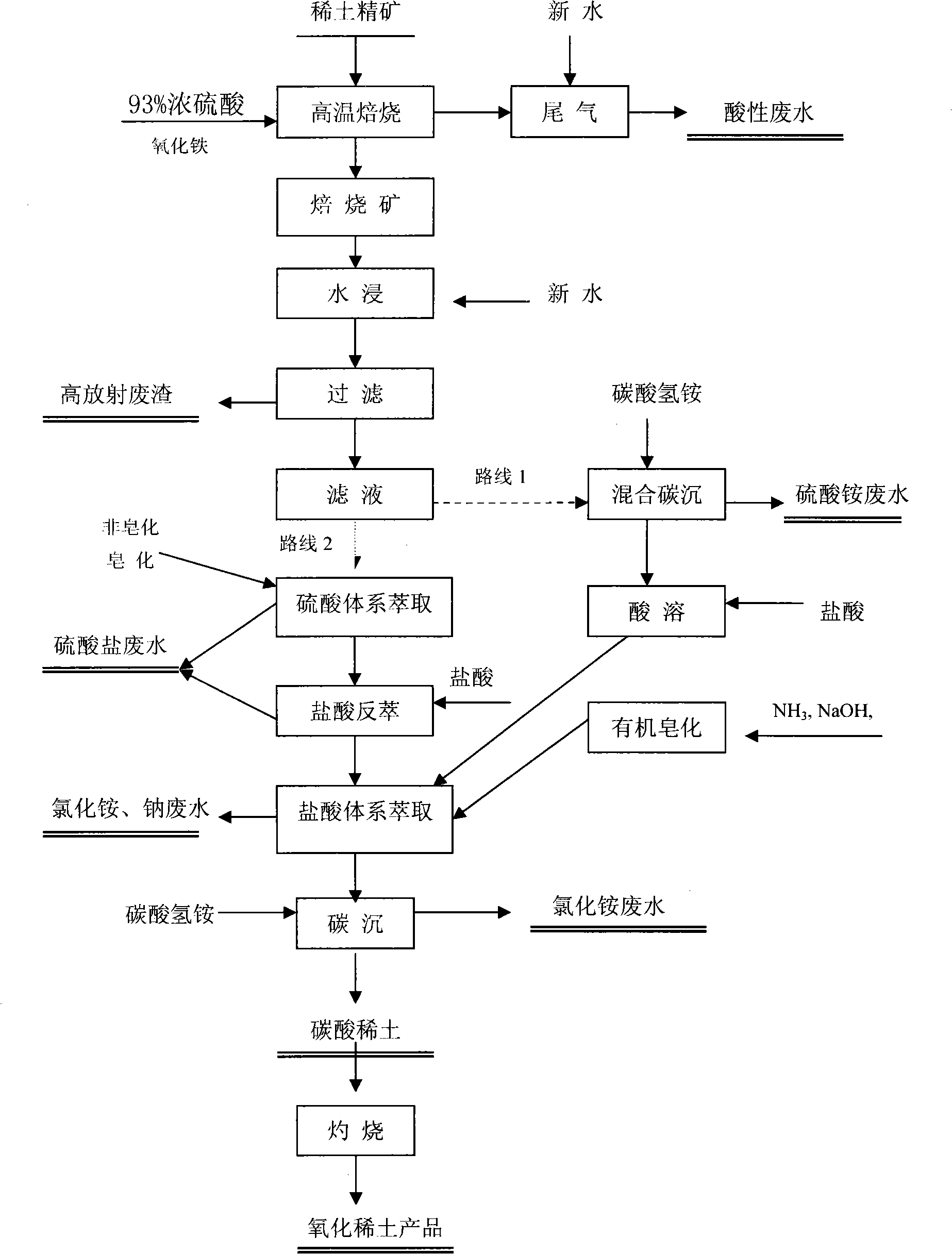

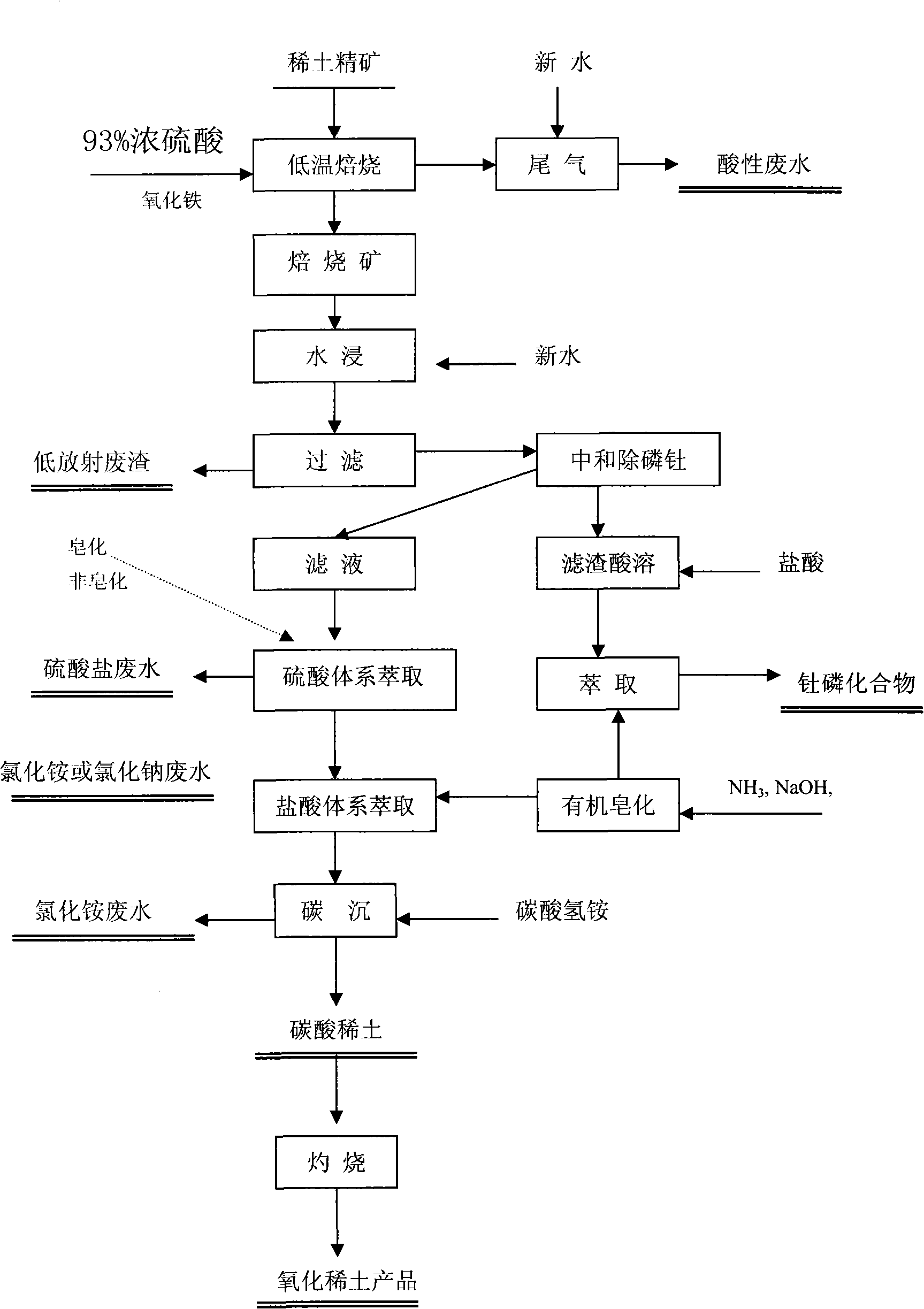

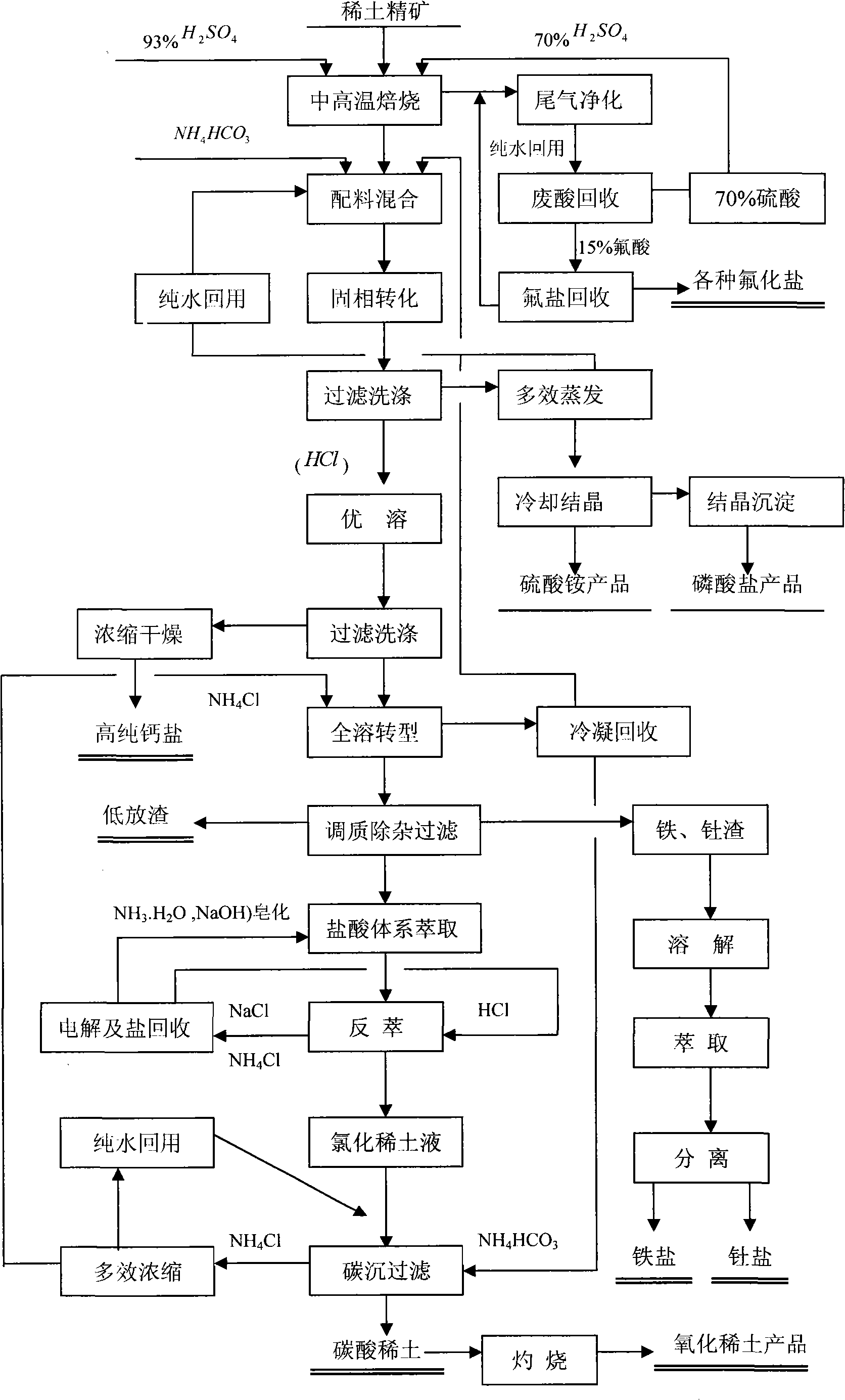

Process for rare-earth smelting resource reclamation and cyclic production

InactiveCN101880782AAchieve governanceAchieve recyclingProcess efficiency improvementIndustrial waste waterSmelting process

The invention relates to a process for rare-earth smelting resource reclamation and cyclic production. The process has the main characteristic of comprehensively and systematically solving the problems of environmental protection and industrial promotion of the whole rare-earth industrial chain by adopting innovative integrated technical means. The process mainly comprises administration and comprehensive utilization of waste gas, waste water and waste slag, revolution of a rare-earth smelting process, and reclamation and repeated utilization of various important resources such as sulfur, fluorine, ammonium, thorium, phosphorus, calcium and the like so as to achieve smokeless and harmless treatment of the waste gas, full utilization of the resources and zero discharge of industrial waste water and fulfill the final goal of cyclic production. The process radically solves the maximum environment-friendly bottleneck problem in a sustainable development process of the Baotou rare-earth industry from resource advantage to industrial advantage, in particular the historical key environment-friendly technical problem, reduces energy consumption of a large amount of resources and pollutiondischarge, greatly reduces the production cost, upgrades the rare-earth industry, and extends the larger industrial chain at the same time.

Owner:马克印 +1

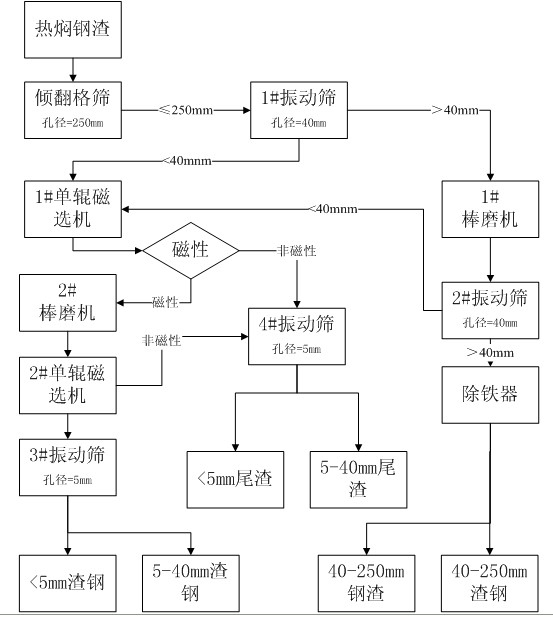

Optimized process for processing steel slag by magnetic separation

The invention relates to an optimized process for processing steel slag by magnetic separation, which is characterized by comprising the following steps: (1) screening steel slag by using a No.1 vibrating screen, separating out the steel slag and slag steel by using a No.1 magnetic separator to separate the oversize material, feeding the slag steel to a slag steel tank, and feeding the steel slagto a jaw crusher; (2) feeding the screen underflow of the No.1 vibrating screen and the discharge of the jaw crusher to a No.2 vibrating screen together, separating the oversize material by using a No.2 magnetic separator, feeding the separated slag steel to a rod mill, and stripping steel slag on the slag steel by the vibration effect of the rod mill; (3) feeding the steel slag separated out by the No.2 magnetic separator to a No.3 vibrating screen, feeding the oversize material to a large-size tailing storeroom, and feeding the screen underflow to a medium-size tailing storeroom; and (4) feeding the discharge of the rod mill to a No.4 vibrating screen, feeding the oversize material the iron content of which is no less than 90% to the slag steel tank, feeding the screen underflow to a No.3 magnetic separator, feeding the separated steel slag magnetic separation powder to a magnetic separation powder storeroom, and feeding the steel slag to a small-size tailing storeroom. By using theinvention, high-quality slag steel the iron content of which is more than 90% can be obtained, thereby fully recovering the iron in the steel slag.

Owner:鞍钢绿色资源科技有限公司

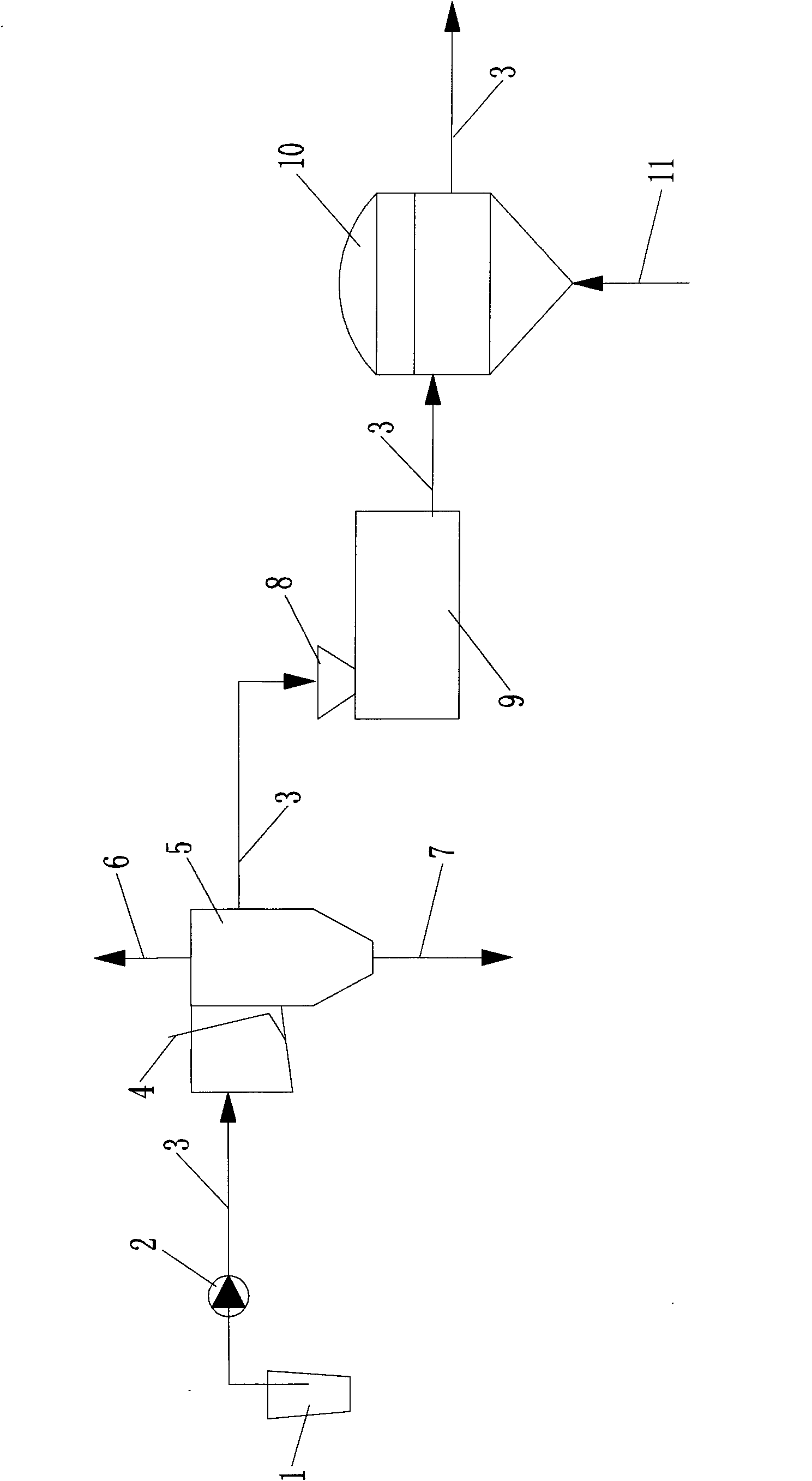

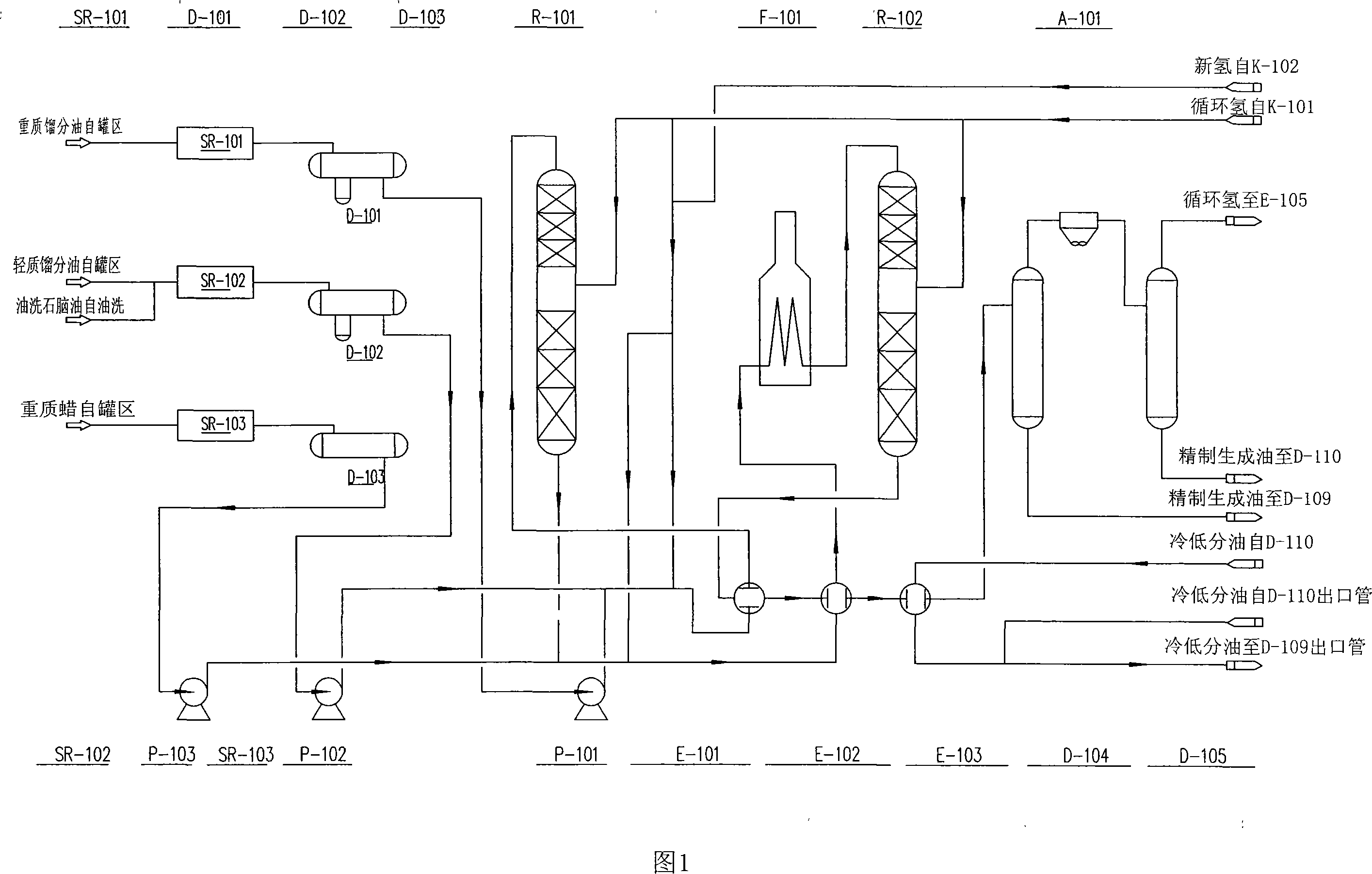

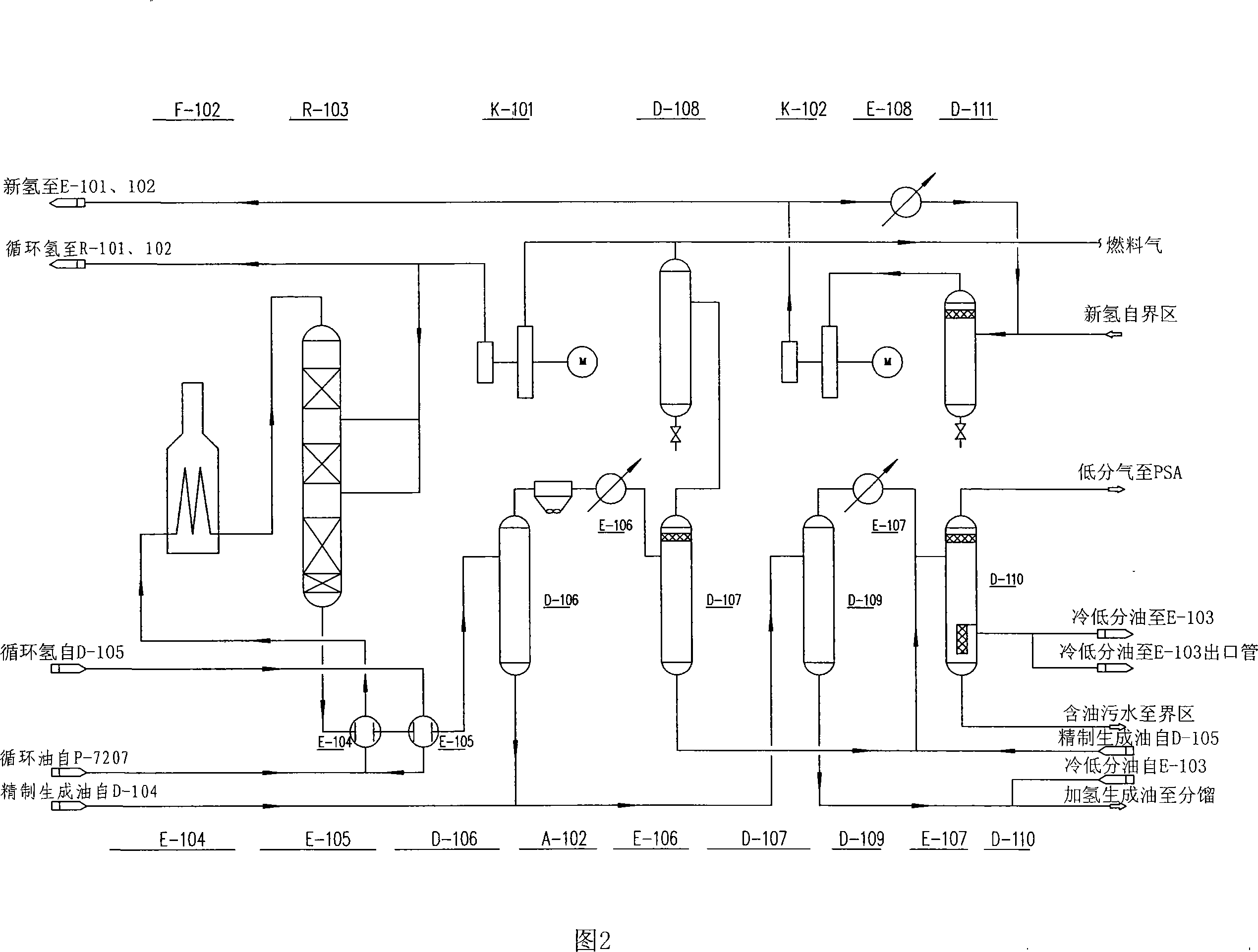

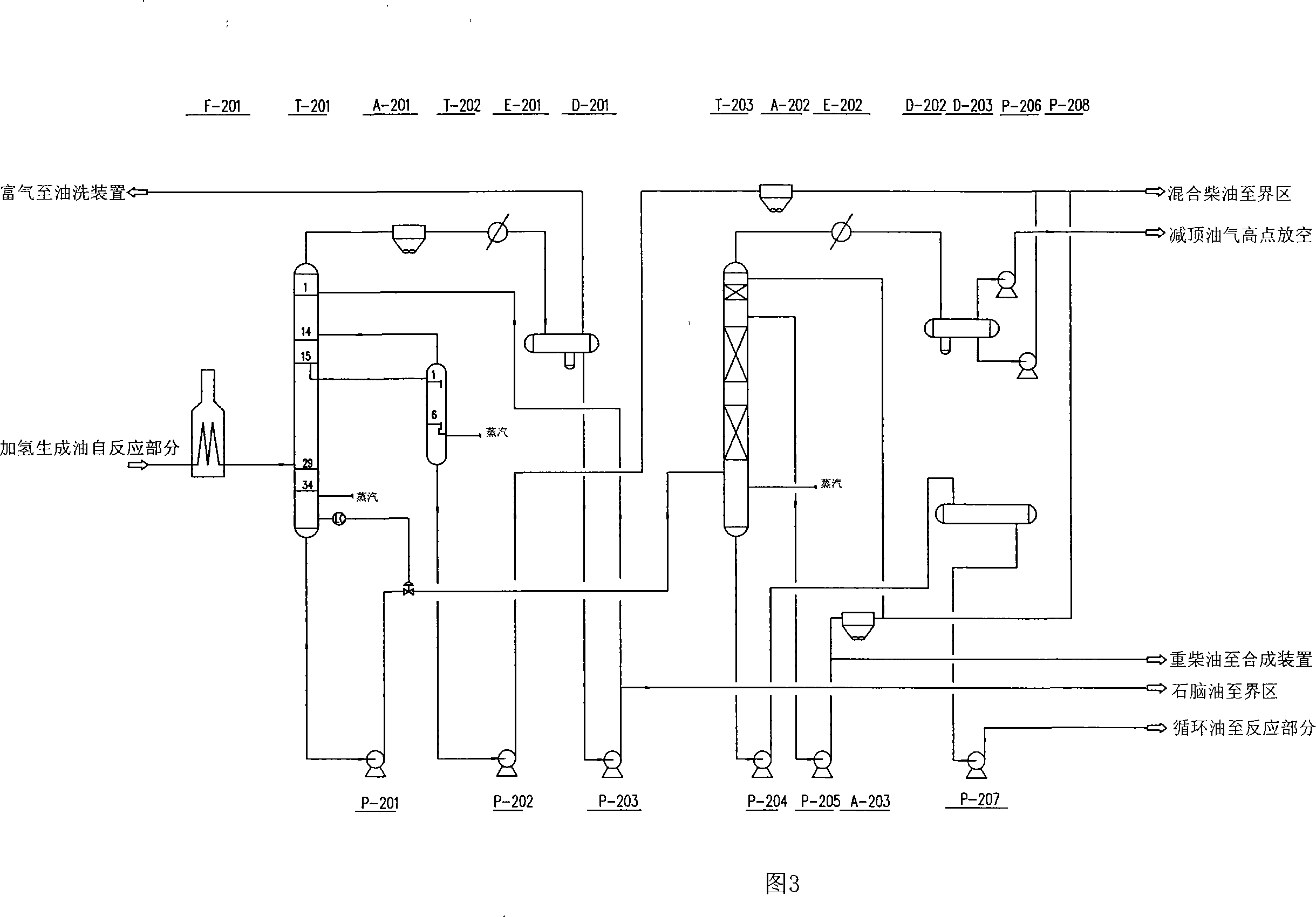

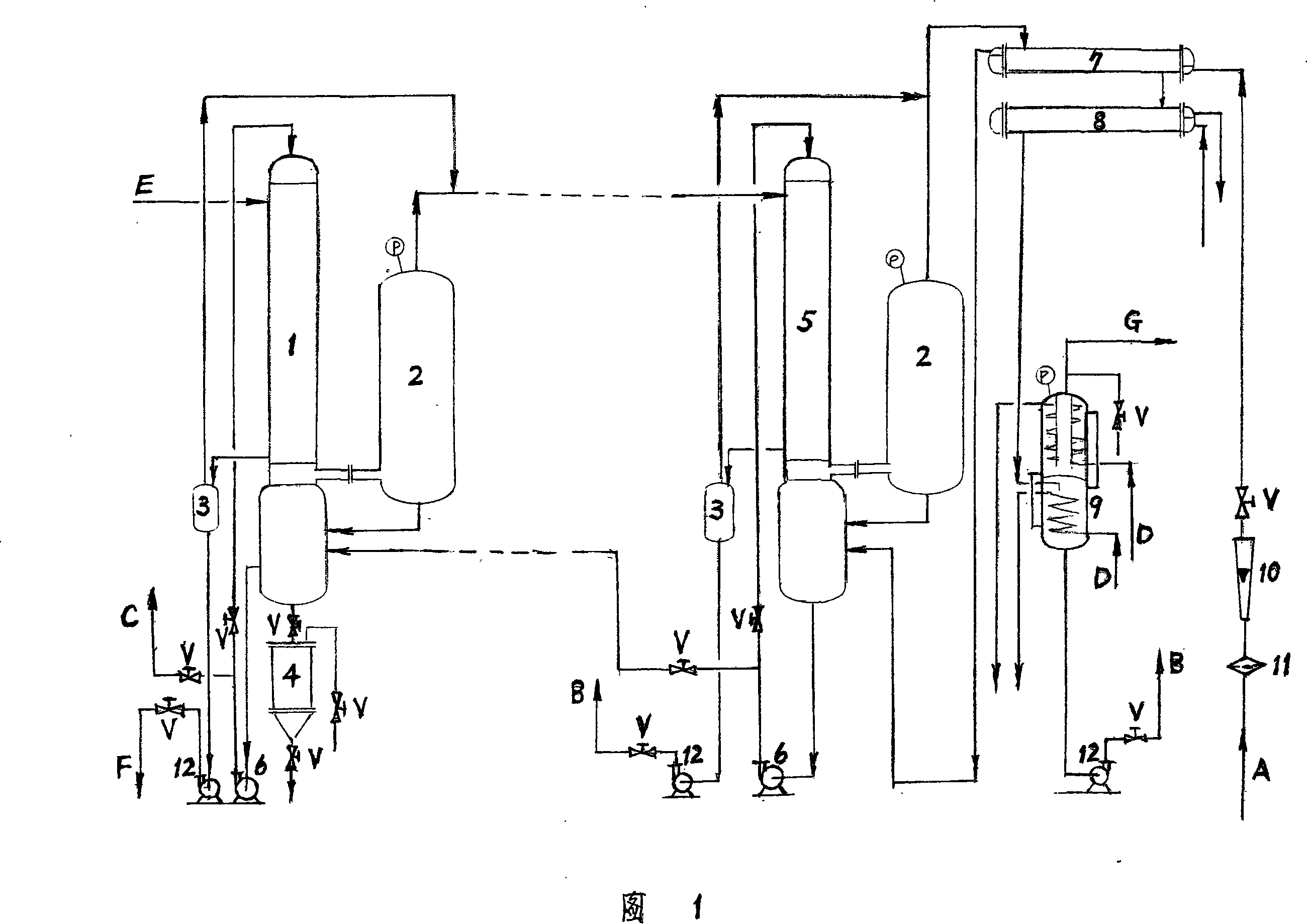

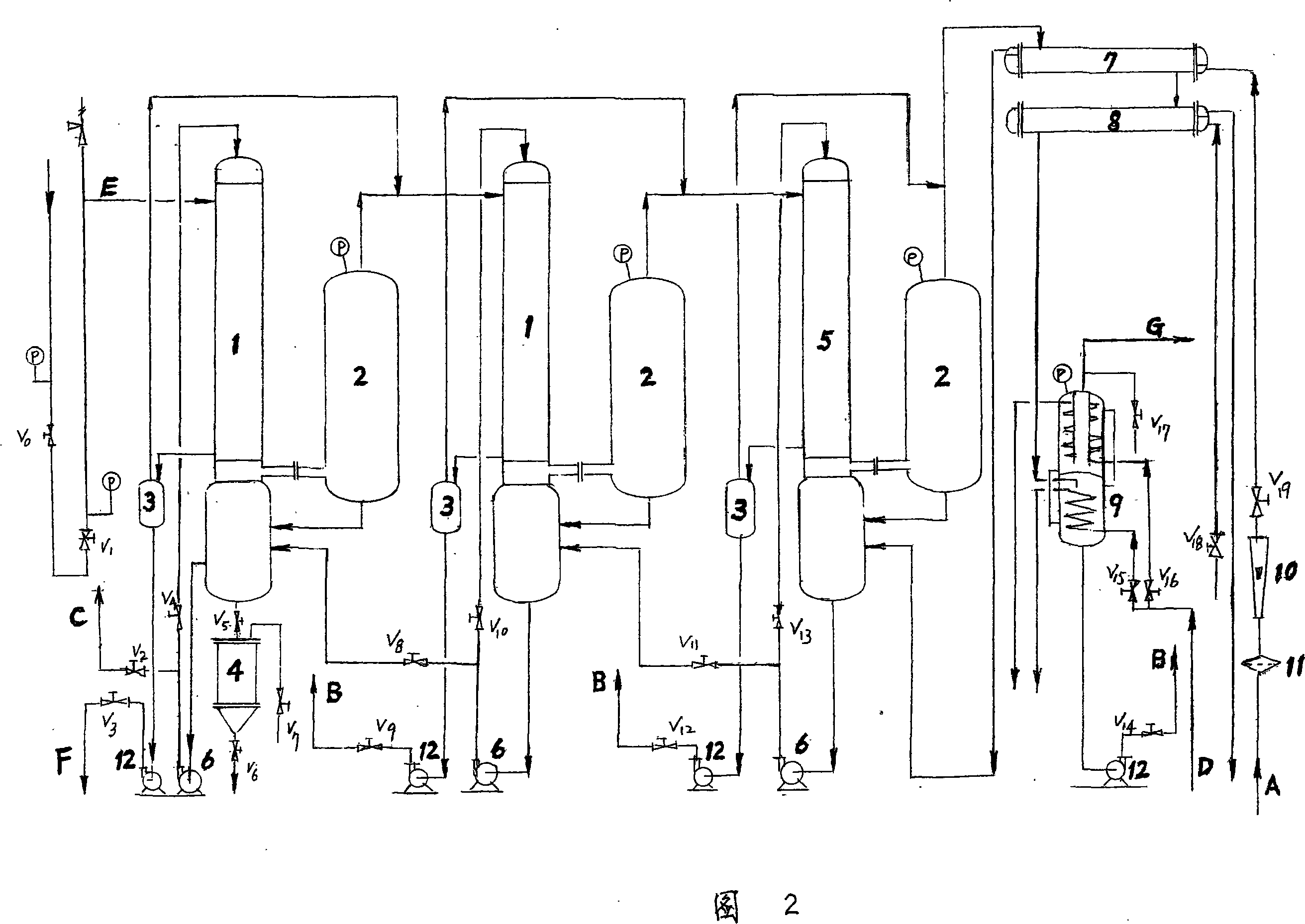

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

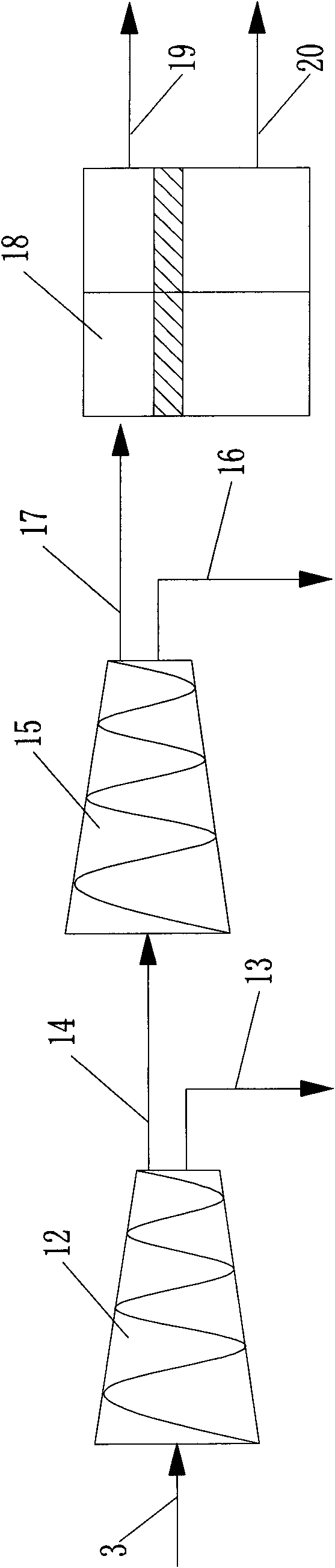

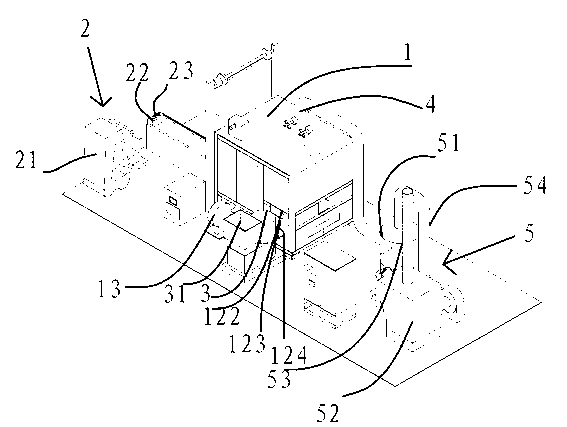

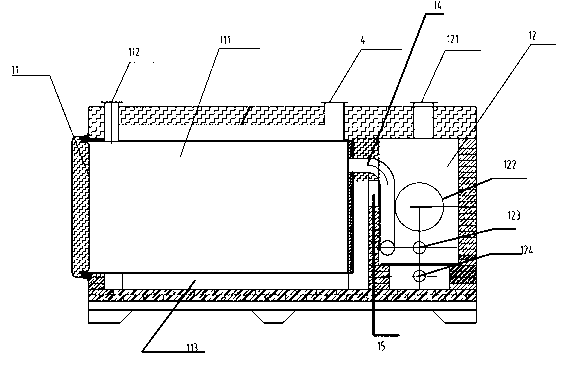

Carbonization treatment process and device thereof of animals died of illness

ActiveCN103254916AReduce post-maintenance costsReduce heat lossSpecial form destructive distillationCombustion chamberFlue gas

The invention relates to a carbonization treatment process and in particular relates to a carbonizing treatment process and device thereof of animals died of illness. The carbonizing treatment process comprises the following steps of: carrying out anaerobic pyrolysis and carbonization treatment for bodies of animals died of illness at the temperature of 300-600 DEG C, automatically outputting combustible pyrolysis gas generated in the pyrolysis and carbonization process and combusting the gas under the condition at the temperature of 800-1300 DEG C, wherein high-temperature flue gas generated by combusting is capable of supporting pyrolysis and carbonization and realizing recycling of heat energy of pyrolysis gas; and subsequently, purifying the flue gas. The device disclosed by the invention comprises a pyrolysis-carbonization device, wherein a pyrolysis-carbonization chamber and a combustion chamber are arranged in the pyrolysis-carbonization device; a pyrolysis-carbonization tank and a cyclic space are arranged in the pyrolysis-carbonization chamber; the pyrolysis-carbonization chamber is connected with a connection opening which is connected with the cyclic space and formed in the pyrolysis-carbonization chamber and the combustion chamber; and a pyrolysis gas exporting tube is connected between the pyrolysis-carbonization tank and the combustion chamber. The carbonization treatment process of animals died of illness can directly treat without need to break the bodies of the animals died of illness, is high in weight and capacity reducing rate, energy-saving and environment-friendly.

Owner:ZHEJIANG WUNENG ENVIRONMENTAL TECH DEV

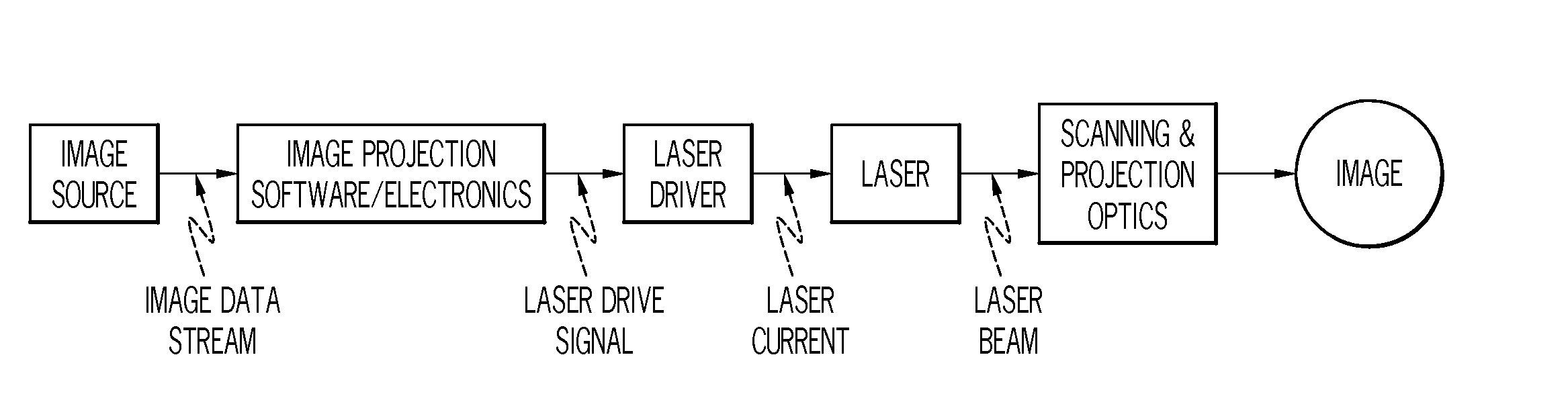

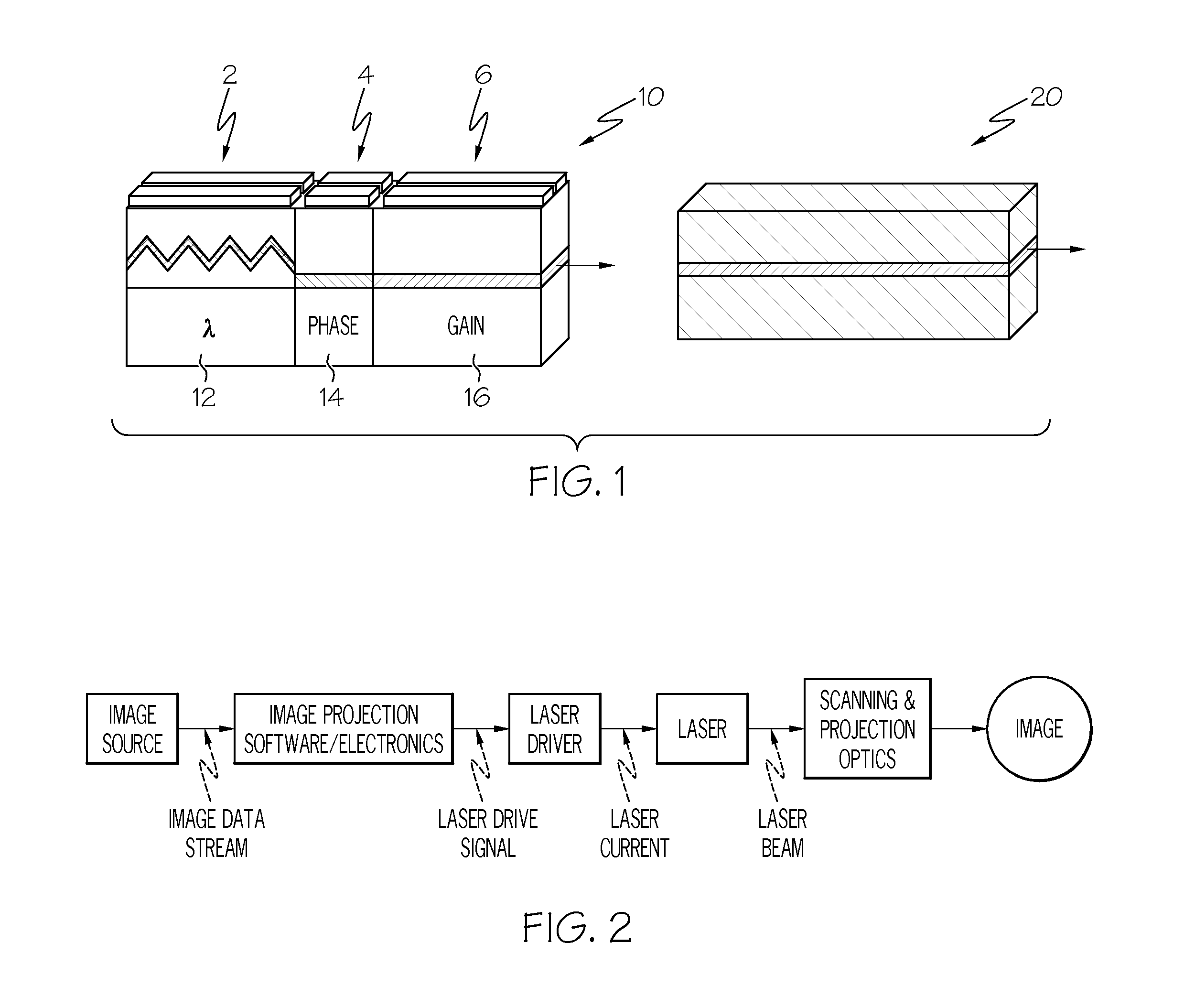

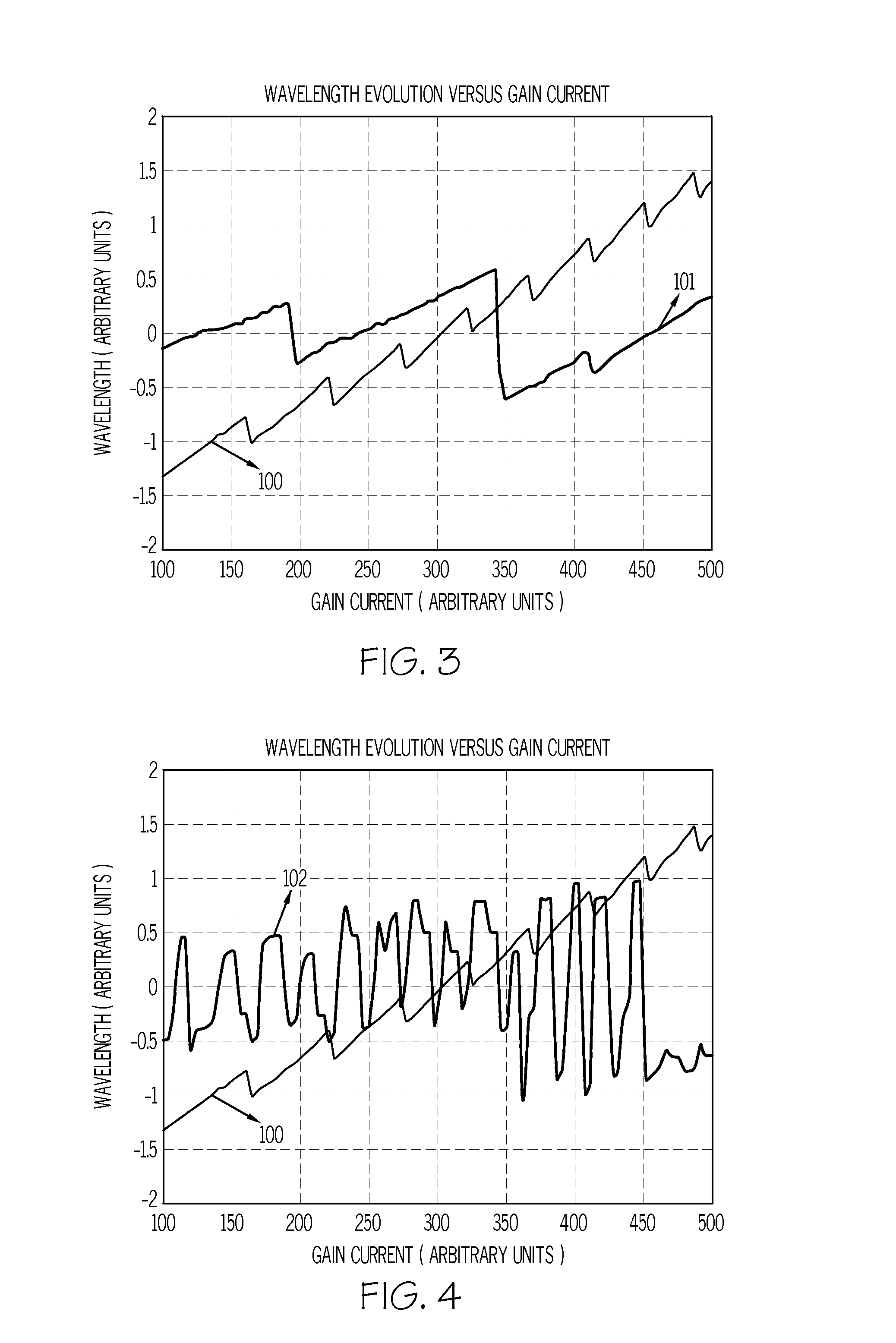

Wavelength control in semiconductor lasers

InactiveUS20080089373A1Minimizing wavelength variationFull recoveryLaser detailsColor television detailsDriving currentGain compression

The present invention relates generally to semiconductor lasers and laser scanning systems and, more particularly, to schemes for controlling wavelength in semiconductor lasers. According to one embodiment of the present invention, a method of minimizing laser wavelength variations in a semiconductor laser is provided. According to the method, one or more of the laser drive currents is configured to comprise a drive portion and a wavelength recovery portion. The wavelength recovery portion of the drive current comprises a recovery amplitude IR that is distinct from the drive amplitude ID and a recovery duration tR that is less than the drive duration tD. The recovery amplitude IR and duration tR are sufficient to recover carrier density distribution distorted by gain compression effects prior to recovery. Additional embodiments are disclosed and claimed.

Owner:CORNING INC

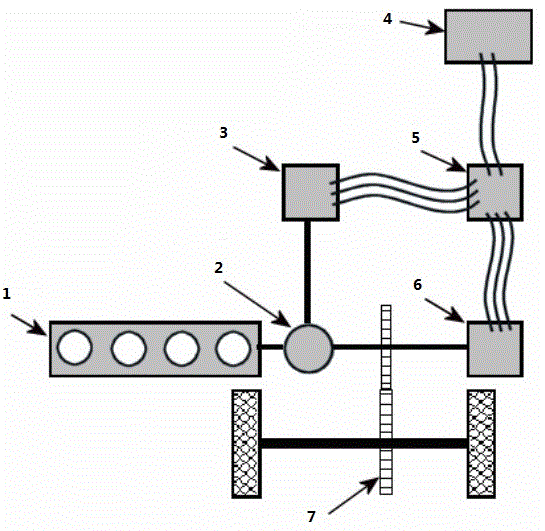

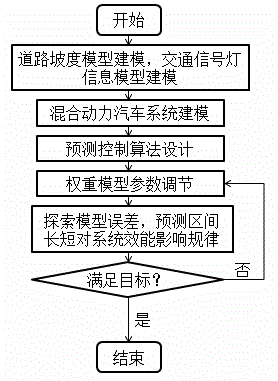

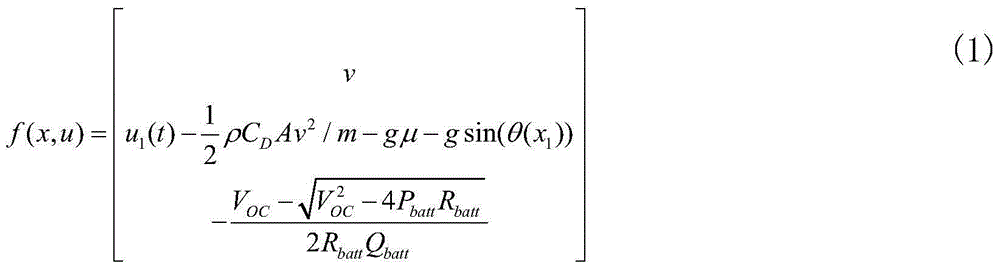

Hybrid electric vehicle energy conservation predictive control method based on traffic signal lamp information

InactiveCN104590247AFull recoveryResolve discontinuityHybrid vehiclesTraffic control supervisionOperating pointTraffic signal

The invention discloses a hybrid electric vehicle energy conservation predictive control method based on traffic signal lamp information. Real-time road grades and the traffic signal lamp information are acquired from the global positioning system and an intelligent transportation system to serve as system input, and a hybrid electric vehicle mathematic model is established to serve as a reference for predicting further vehicle states; a hybrid electric vehicle energy management optimal control problem is defined, and a functional equation for solving the optimum control quantity is provided; optimum control is fed back in real time to solve the optimum control quantity; under the condition of meeting hybrid electric vehicle storage battery electric quantity balance and rotation speed and torque physical limit restraints, energy flow of a hybrid electric vehicle is adjusted and optimized on line according to practical vehicle driving working conditions, the system optimal performance of the hybrid electric vehicle is obtained, a planetary gear mechanism is used to serve as an electric infinitely variable transmission, an engine is made to constantly work at the best operating point, road traffic information is used for predicting the charge state of a target storage battery, the energy flow of the hybrid electric vehicle is adjusted on line, and therefore the purposes of energy conservation and emission reduction are achieved.

Owner:HENAN POLYTECHNIC UNIV

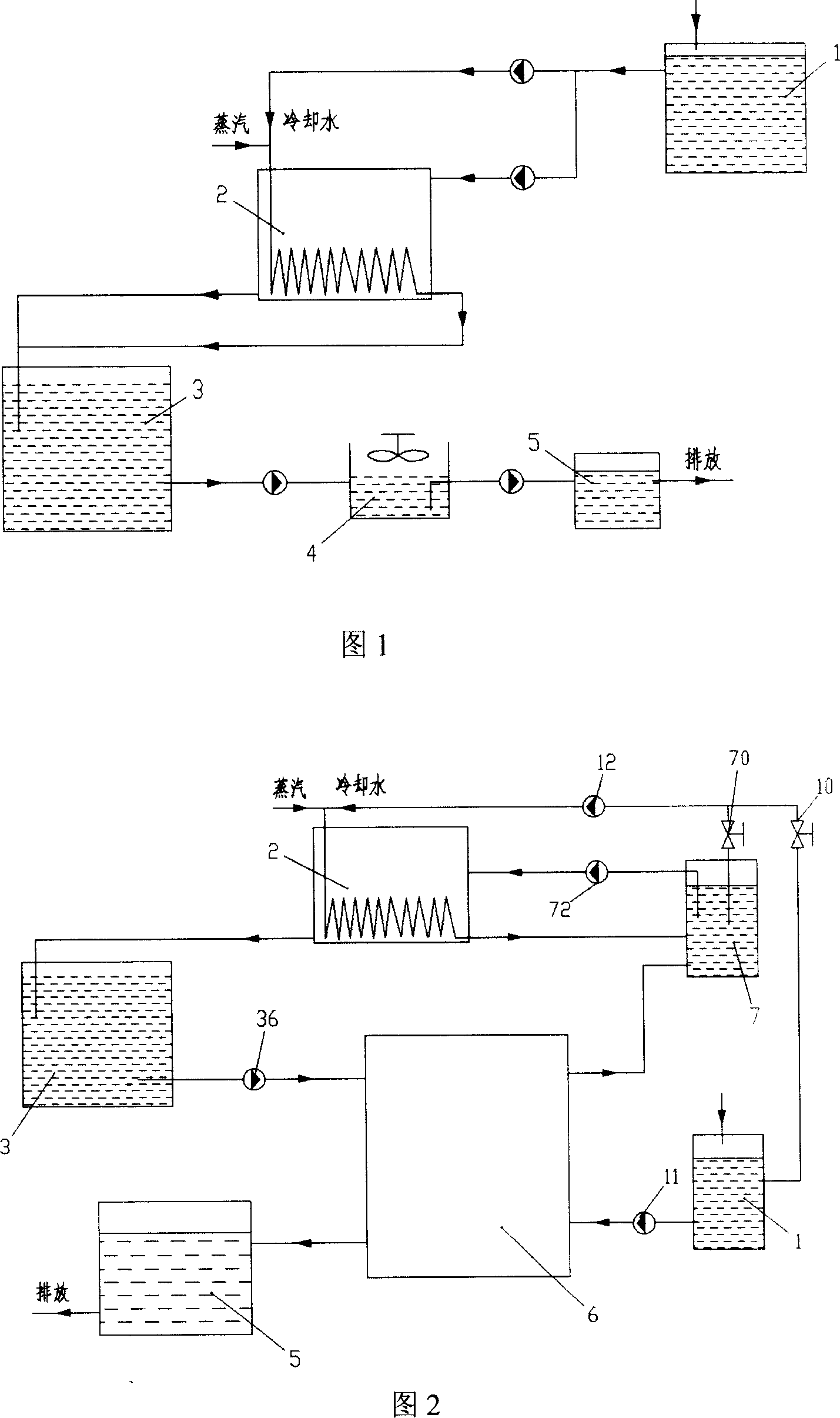

Waste heat circulation energy-saving printing and dyeing water utilization method and system

InactiveCN1951829AReduce usageLow costWater/sewage treatment by heatingBiological water/sewage treatmentWater source heat pumpWater source

The invention discloses a utilizing method and system of energy-saving printing and dyeing water through circulated waste heat, which comprises the following parts: refrigerator, technical manufacturing equipment, waste water mixing pond, waste water source heat pump set, hot water pond and biochemical disposing pond, wherein the technical manufacturing equipment drains the clean water into waste water mixing pond, which heats cool water in the waste hot pond after pumping the hot water by hot water source pump set; the hot water supplying pump pumps the water into technical manufacturing equipment, which forms circulating system.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Method for recycling molybdenum of molybdenum-contained waste catalyst

ActiveCN101724758AThe process is simpleSimple equipmentProcess efficiency improvementAmmonium molybdateChemistry

The invention relates to a method for recycling molybdenum of a molybdenum-contained waste catalyst, which comprises the following steps of: roasting and pulverizing the molybdenum-contained waste catalyst; then mixing and roasting with an alkaline substance; extracting by using mixed acid; depositing by using an alkaline solution; depositing the molybdenum in an ammonium molybdate way; further dissolving the ammonium molybdate by using ammonia water and readjusting the pH value to obtain an ammonium molybdate sediment; and drying to obtain the ammonium molybdate product. The method is particularly suitable for the process of extracting high-purity ammonium molybdate by using a aluminium-based molybdenum-contained waste catalyst, and has simple process, high maneuverability, low energy consumption and stable quality of the prepared product.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

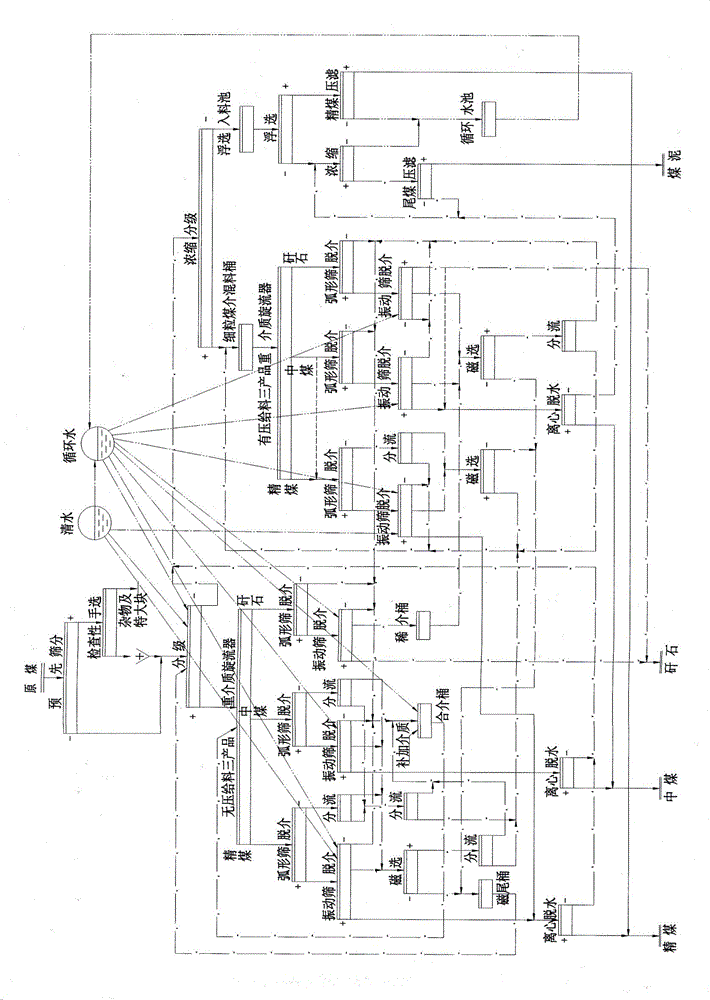

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

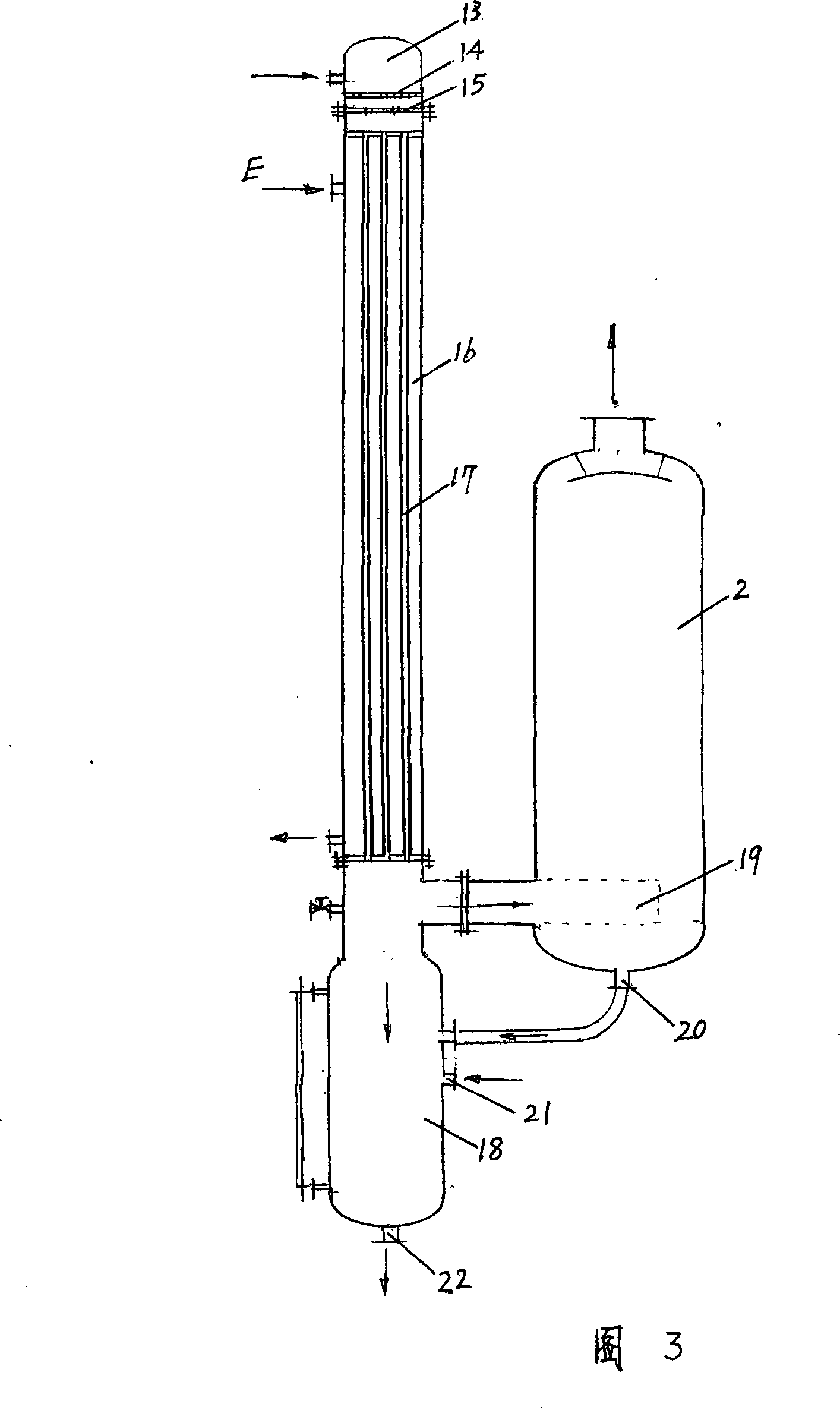

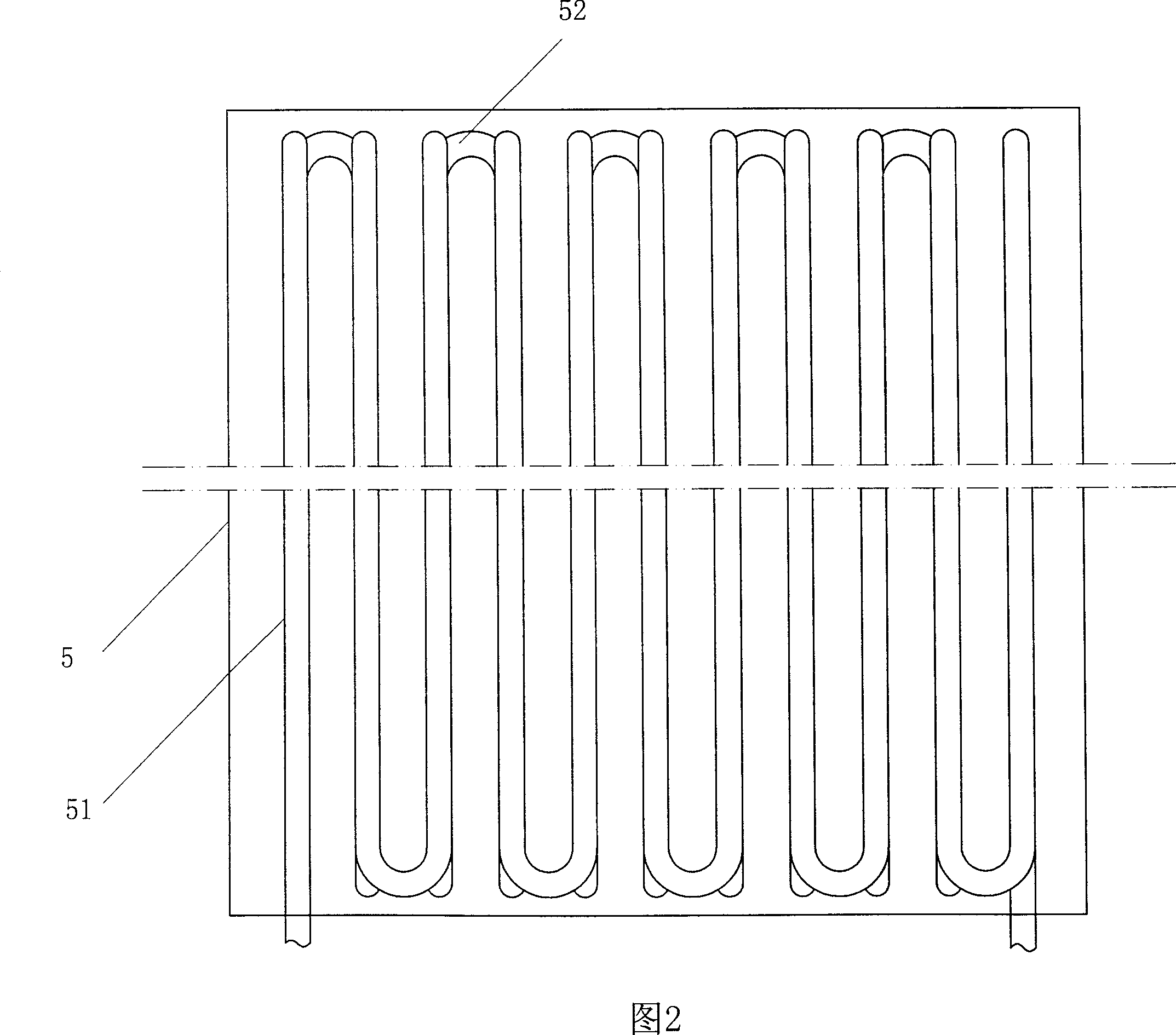

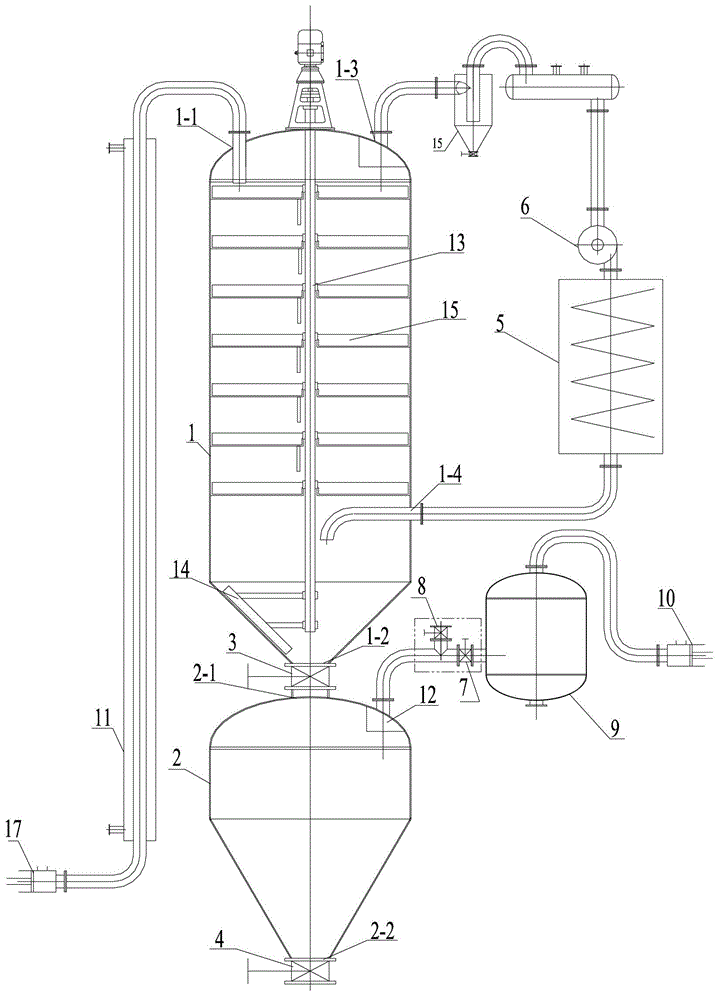

Pleietrepie counter current falling film evaporator of organic solvent recycle

InactiveCN101229449AControl circulation volumePromote circulationMultiple-effect evaporationSteam condensationGas phase

The invention provides a multiple effective reflux falling film evaporation system used for recycling organic solvent. The invention is mainly used for recycling the solvent in water solution of the organic solvent during the concentration production process of plant extractions in food industry and biopharmaceutical industry. The invention adopts falling film evaporators with high heat transmission coefficient and small terminal temperature difference to form the multiple effective evaporation system. Each evaporator is provided with a solution circulating pump which increases down-flow quantity in a heat transfer tube and avoids dry wall of a heat transfer surface and enhances heat transferring, thus having great evaporation ability and high efficiency. The condensate of each evaporator enters into a corresponding condensate tank respectively and is discharged by the pump and recycled. A gas-phase communicating pipe is arranged between the condensate tank and a gas-liquid separator, which guarantees the discharge of noncondensable gas under vacuum operation condition, thus being beneficial for improving condensing and heat transferring efficiency. The invention is a new technique, new technology and new device used in concentration process of the extractions of the organic solvent and used for recycling solvent, which has high recycling rate, little energy consumption and convenient operation and can use a vacuum low temperature evaporation concentration production device in continuous and intermittent production operation.

Owner:DALIAN UNIV OF TECH

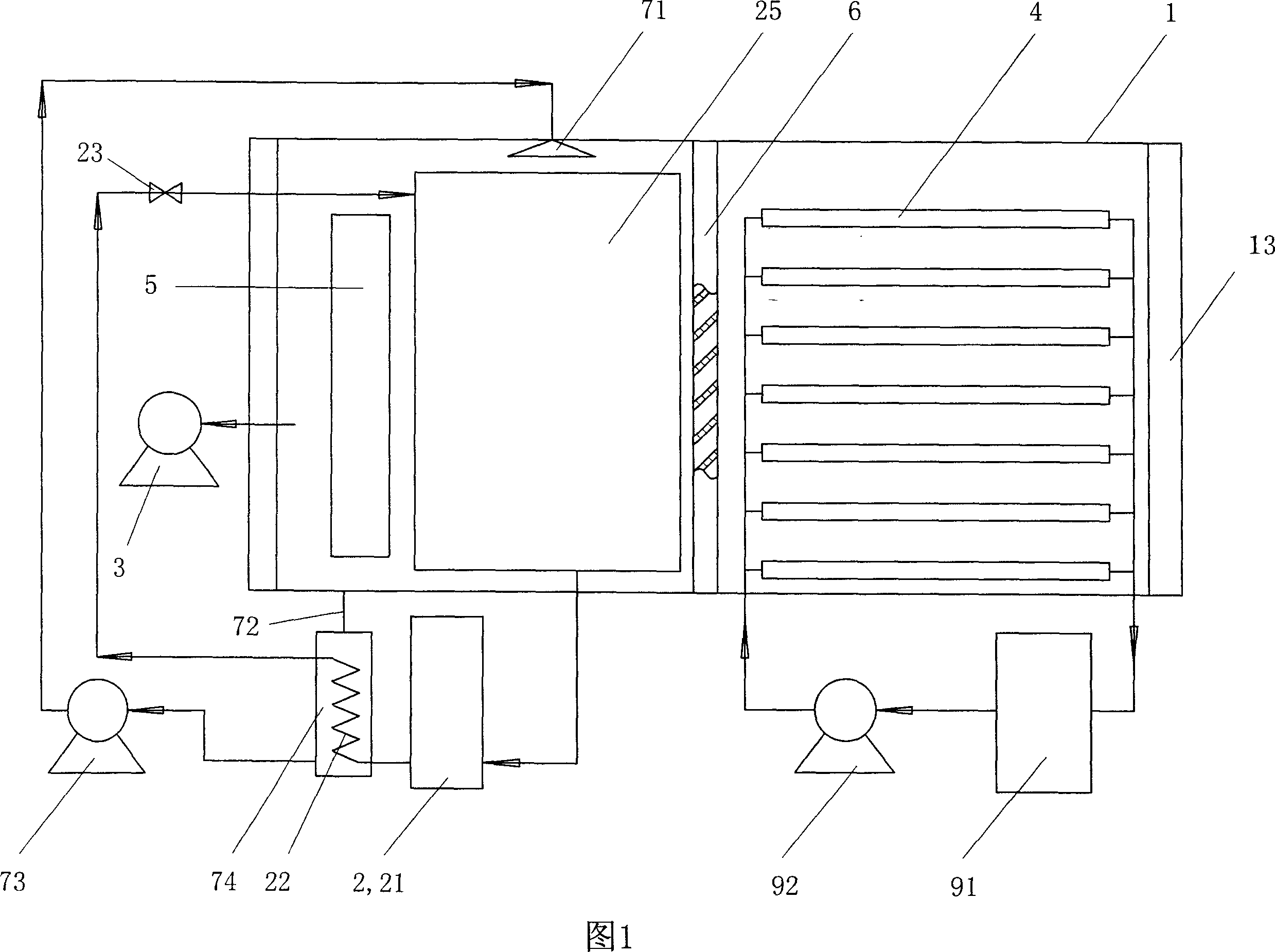

Freezing drying machine

InactiveCN101025329ADoes not affect circulationIncrease contact areaDrying solid materials without heatDrying machines with local agitationFreeze-dryingEngineering

This invention is about a kind of freeze-drying set, composing of case; freezing engine set vacuum pump and hot plate. The freezing engine set composes of compressor, heat exchanger, expansion valve and evaporator; the hot plate is set in front of the case, and the evaporator of the freezing engine set is set in rear of the case; there are louver interboards between the evaporator and hot plate, and fan in rear of the evaporator. The invention consumes less energy and be manipulated conveniently.

Owner:李志平 +1

Assembly line-type grinding and polishing workstation based on robots

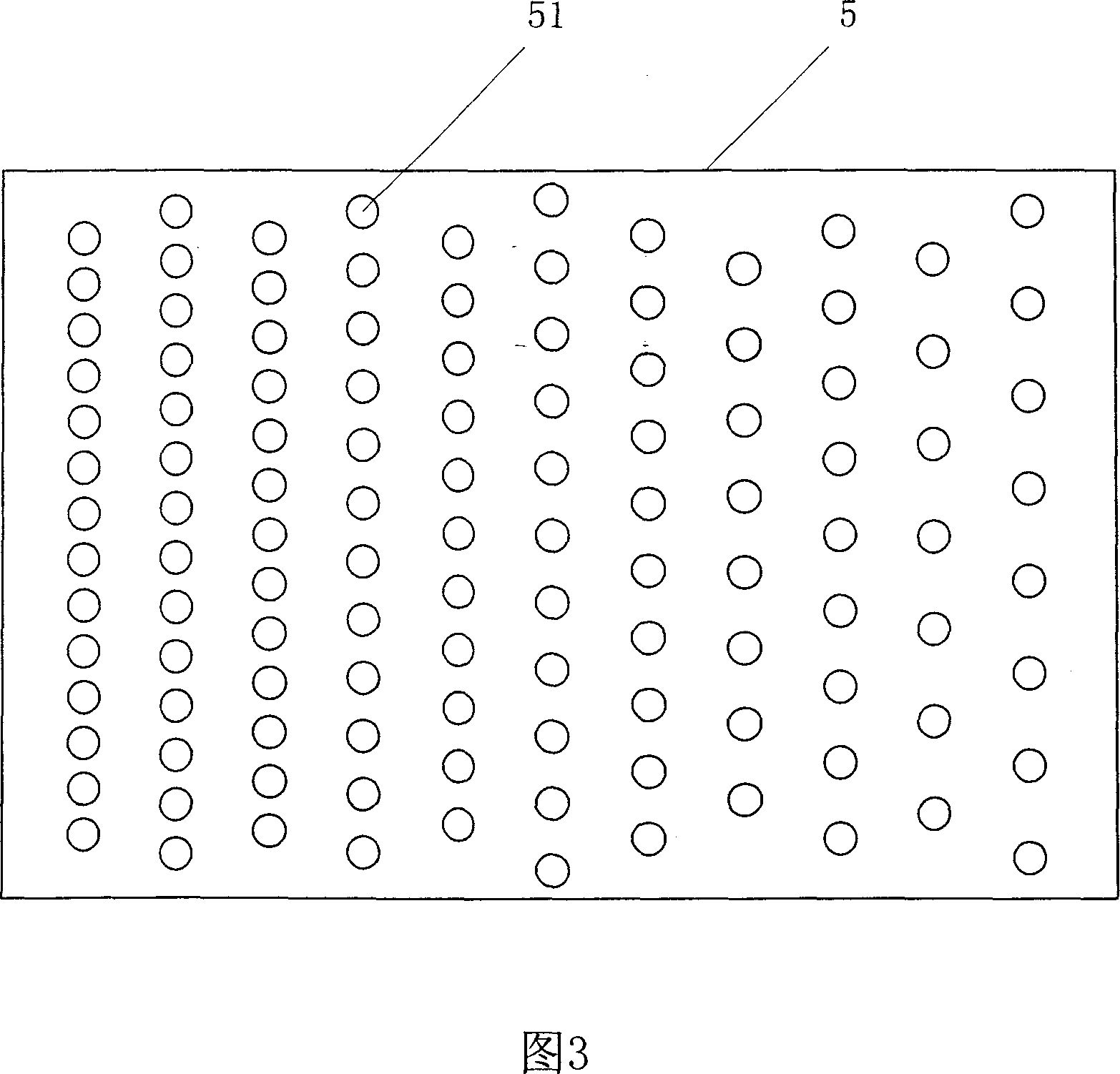

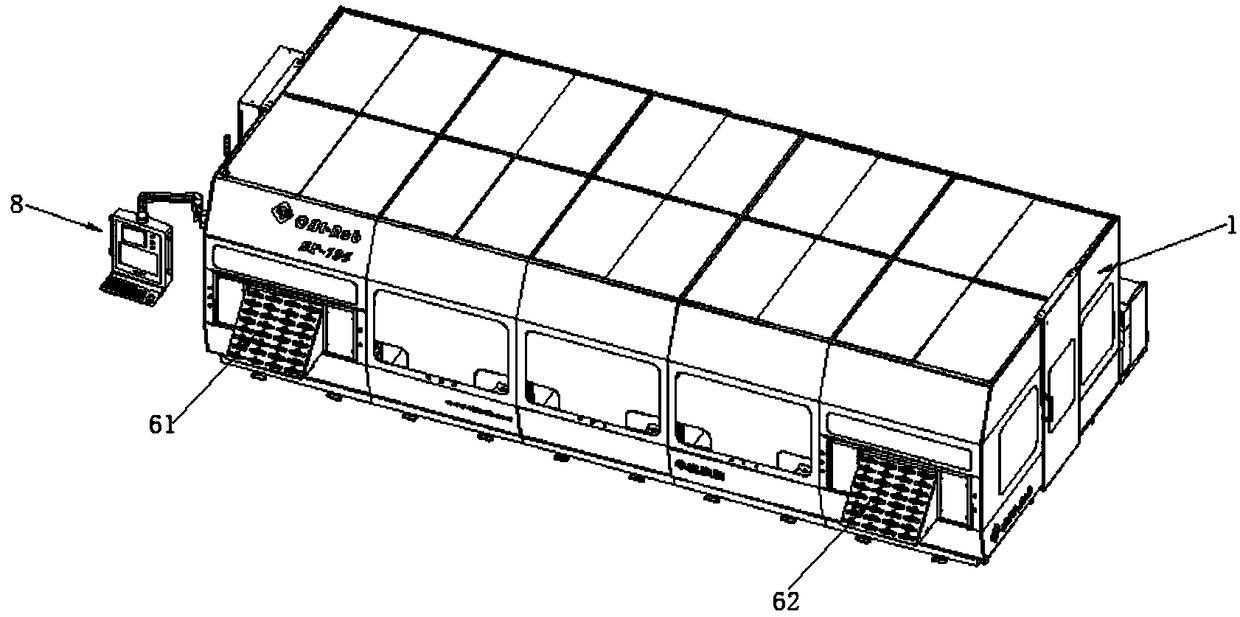

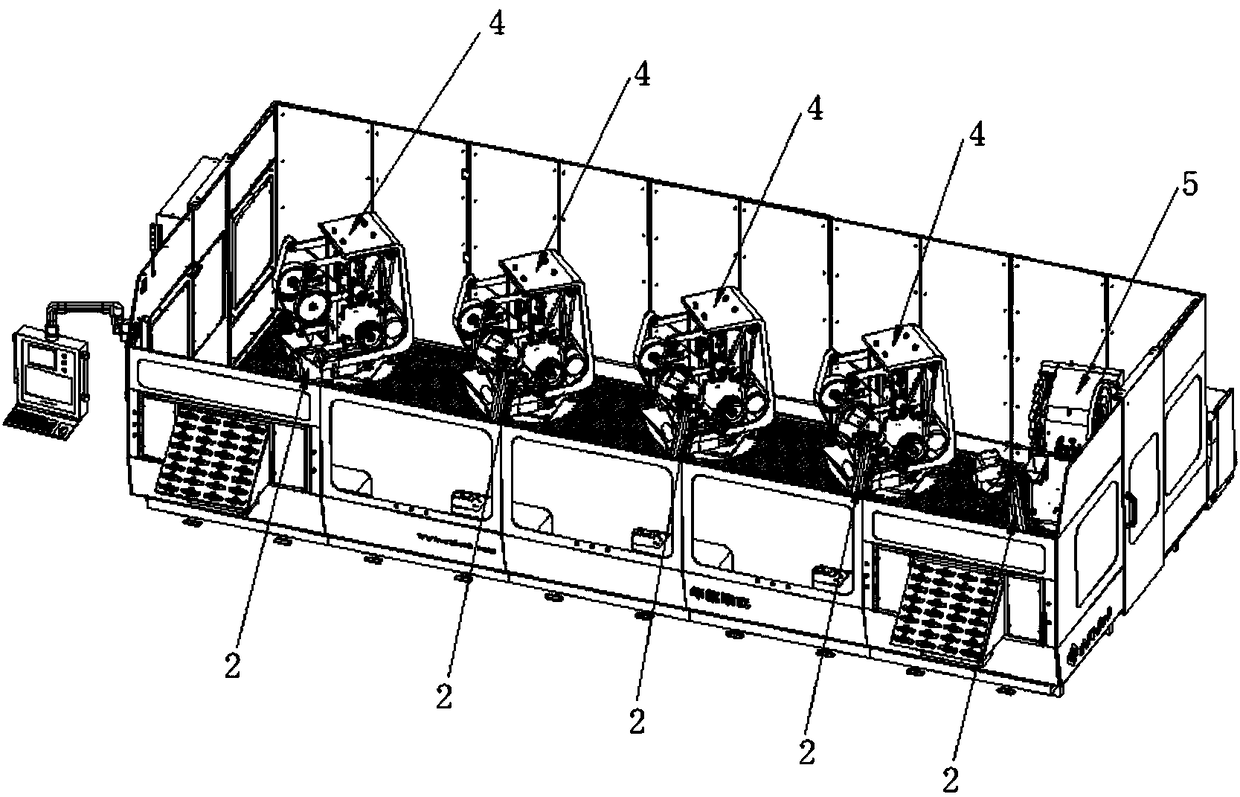

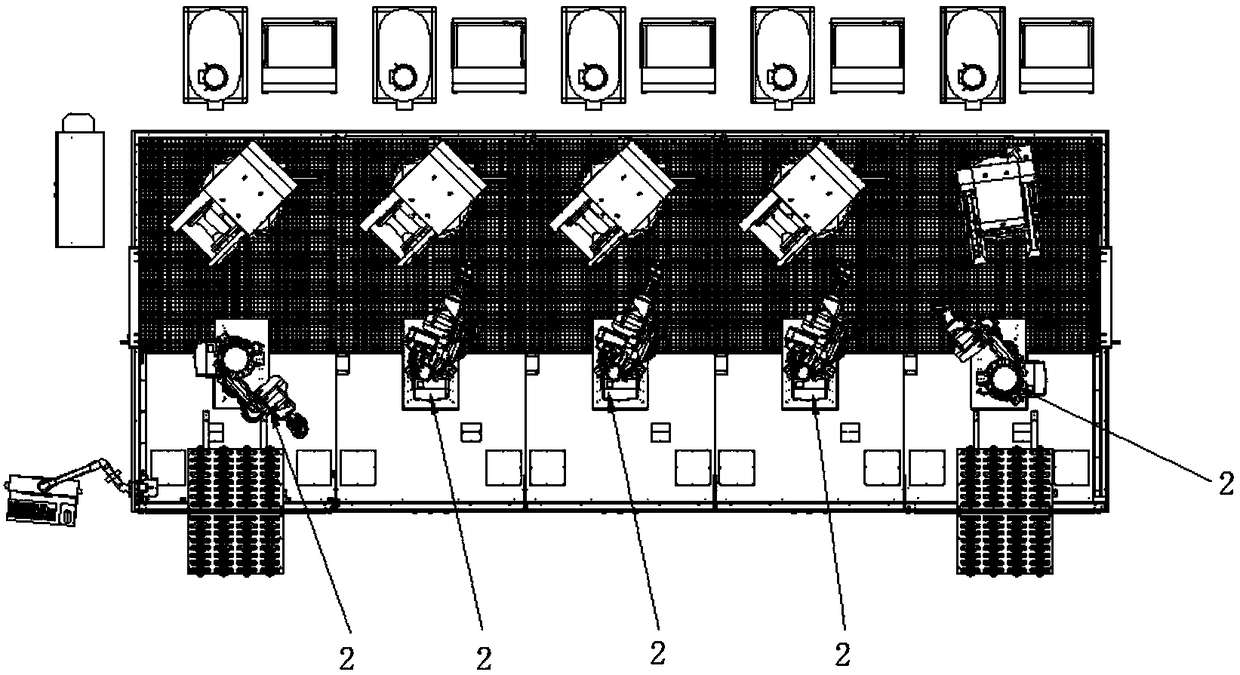

PendingCN108161669APrecisely control the running trackAvoid interferenceBelt grinding machinesAutomatic grinding controlSanderControl system

The invention relates to an assembly line-type grinding and polishing workstation based on robots. The assembly line-type grinding and polishing workstation comprises a polishing safety chamber arranged on the peripheral side. The robots, belt sanders and polishing machines are installed inside the polishing safety chamber. A feeding workbench and a discharging workbench are installed at the two sides of the polishing safety chamber correspondingly. The at least four sets of the belt sanders are placed in a spaced mode. The number of the polishing machines is at least one, and the polishing machines are placed in a spaced mode. Transfer tables are arranged between the adjacent robots. The polishing robot located at the leftmost left clamps workpieces on the feeding workbench and is furtherplaced on the corresponding transfer tables after getting close to the belt sanders to complete polishing machining for the first time. The subsequent polishing robots and polishing robots clamp theworkpieces to complete corresponding grinding and polishing machining. The polishing robot located at the rightmost side clamps the workpieces and put the workpieces onto the discharging workbench. The belt sanders are double-station belt sanders. The polishing machines are double-station polishing machines. Different machining procedures can be completed at the same time, production efficiency isimproved and production cost is reduced. A control system accurately controls the moving trajectories of the robots and is further matched with the transfer tables, and interference between the robots is avoided.

Owner:BEIJING C H L ROBOTICS CO LTD

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

Superheat steam drying device

InactiveCN102914134AEasy accessEnsure normal dischargeDrying using combination processesDrying machine combinationsEngineeringProcess engineering

The invention provides a superheat steam drying device which comprises a steam drying mechanism, a vacuum drying mechanism, a first discharging valve, a second discharging valve and a steam heating part. A superheat steam drying and vacuum drying combined structure is adopted by the superheat steam drying device, namely, a full-closed belt pressing drying system is adopted; the structure is simple; the steam heat energy for drying and evaporating materials is fully recycled; a waste heat recovery device is simple or the waste heat is directly sent to the other heating device; the energy consumption is greatly reduced; the whole set of device is full-automatically controlled; the device can continuously produce; the operating flexibility is high; and the handling capacity is high.

Owner:曾应祥

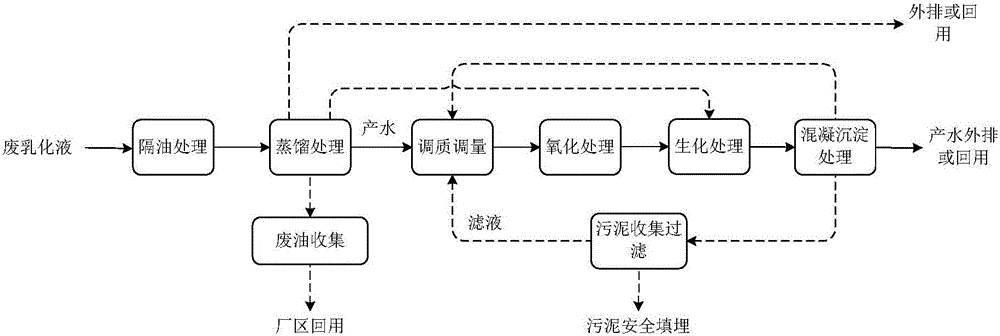

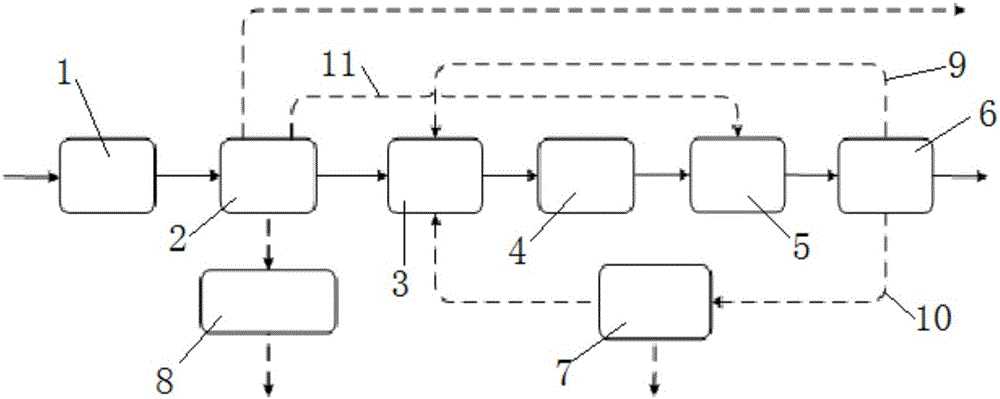

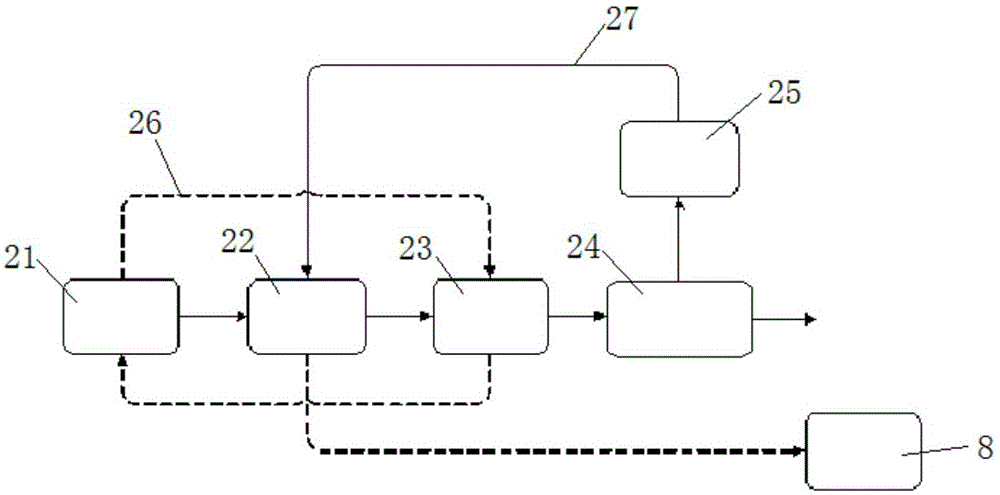

Treatment method and device for extremely-high-concentration waste emulsion

ActiveCN105731706AWill not destroy the componentsWill not destroy natureFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationEmulsion

The invention discloses a treatment method and device for extremely-high-concentration waste emulsion. The treatment method comprises the following steps that firstly, the waste emulsion is subjected to oil separation treatment to remove floating oil on the upper layer of the waste emulsion, and the waste emulsion obtained after oil separation treatment is obtained; secondly, the waste emulsion obtained after oil separation treatment is subjected to distillation pretreatment, and waste oil and waste water are obtained. The device comprises an oil separation system and a distillation system which are connected in sequence, wherein the oil separation system is used for regulating the flow of the waste emulsion and removing the floating oil on the surface of the waste emulsion, and the distillation system is used for carrying out demulsification and achieving oil and water separation of the waste emulsion obtained after oil separation treatment. Demulsification and oil and water separation are achieved at the same time through distillation treatment, selectivity is avoided, and the method and the device can be widely applied to treatment of various kinds of waste emulsion; recycling is easy, a demulsification agent does not need to be added, the component and nature of waste oil cannot be damaged, and decrease of the utilization value of the waste oil can be avoided.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

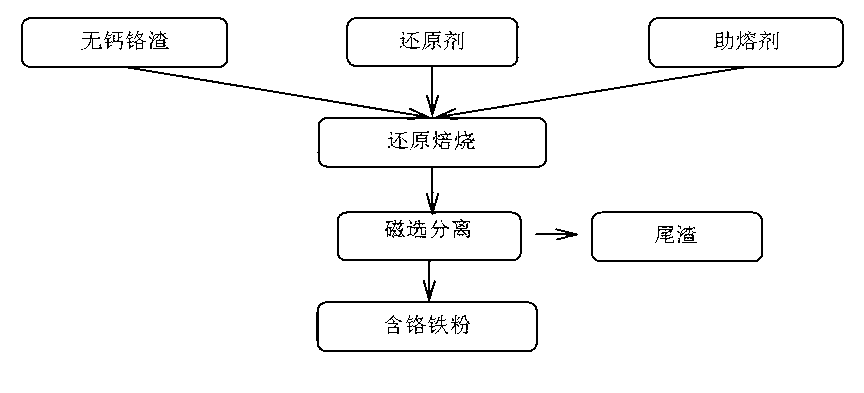

Method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag

ActiveCN102796879AHigh degree of resource utilizationEfficient separationProcess efficiency improvementIron powderMixed materials

The invention discloses a method for preparing chromium-containing iron powder by direct reduction of calcium-free chromium slag, which belongs to the technical field of comprehensive utilization of chromium slag. The method comprises the following steps of: firstly, material preparation, wherein the calcium-free chromium slag is mixed with a reducing agent and fluxing agents comprising alumina, and the four-element alkalinity m(MgO+CaO) / m(SiO2+Al2O3) of the mixed material is equal to 0.9 to 1.3; secondly, agglomeration, wherein the mixed material is pressed or pelletized to obtain agglomerates; thirdly, reduction roasting, wherein the agglomerates are roasted in reducing atmosphere at a reduction temperature of 1,250 to 1,350 DEG C for 30 to 240 minutes; fourthly, crushing and fine grinding, wherein the roasted agglomerates are crushed and ground to be fine; and fifthly, magnetic separation, wherein the finely ground powder is subjected to magnetic separation at magnetic induction intensity of 100 to 200 mT, thereby separating the chromium-containing iron powder. According to the method, the calcium-free chromium slag is completely detoxified and fully recycled, the grade sum of calcium and iron in the prepared chromium-containing iron powder is over 80 percent, the chromium recovery rate and the iron recovery rate are respectively over 78 percent, and the method is low in energy consumption and free from secondary pollution.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com