Waste heat circulation energy-saving printing and dyeing water utilization method and system

A waste heat recycling, printing and dyeing water technology, applied in chemical instruments and methods, heating water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as waste, save operating costs, reduce waste heat pollution, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

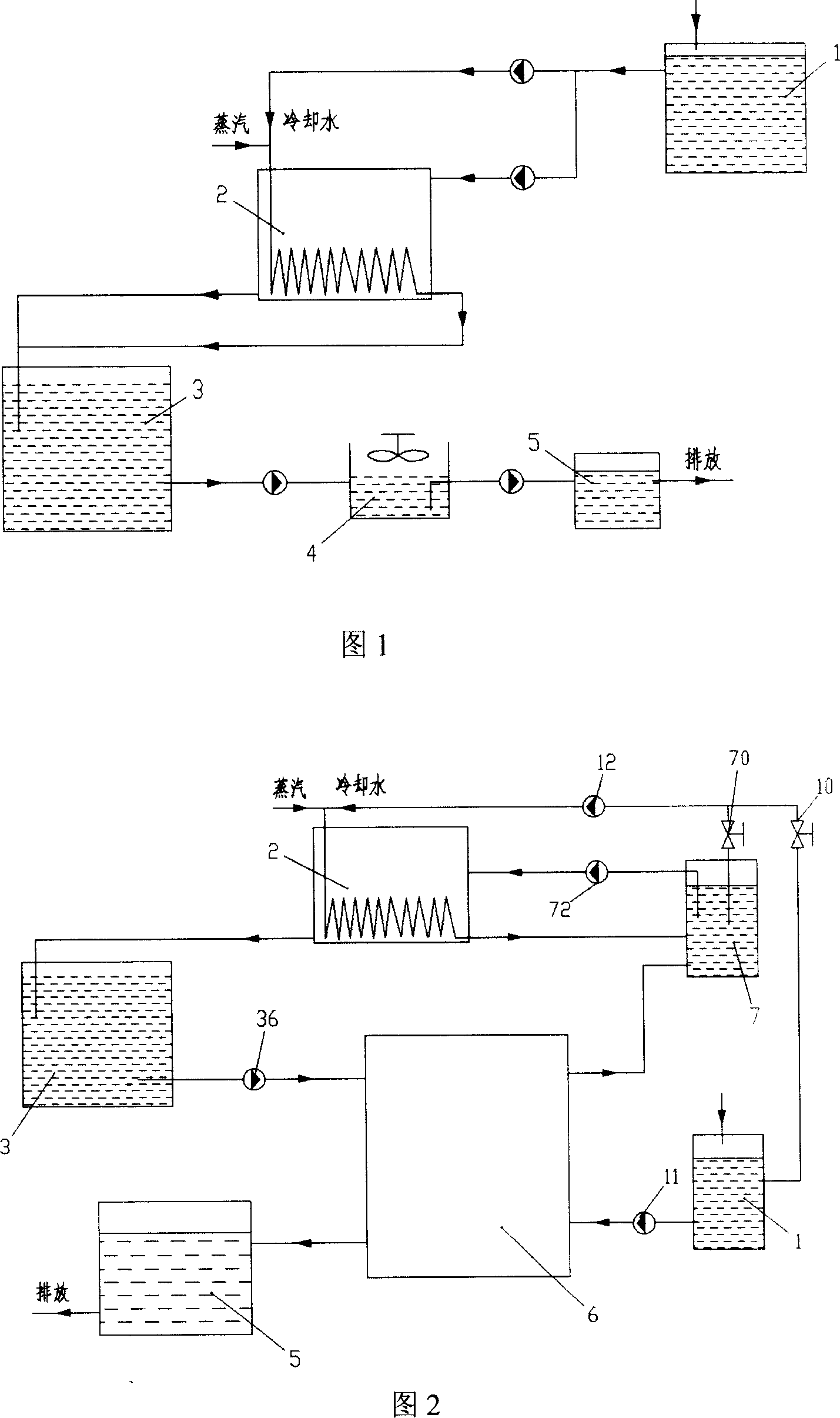

[0037] Below, a preferred embodiment of the present invention is given according to FIG. 2 and described in detail so that those skilled in the art can more easily understand that the structural features and functional features of the present invention are not intended to limit the scope of the present invention.

[0038] The waste heat cycle energy-saving printing and dyeing water utilization system of the embodiment includes a softening refrigerator (1), a process production equipment (2), a waste water mixing pool (3), and a biochemical treatment pool (5). The feature is: a waste water source heat pump unit (6) and a hot water pool (7) are provided, wherein: the cold refrigerator (1) is connected to the hot water pool (7) through two series connection valves (10, 70); The cooling water supply pump (12) connected in series with it is connected to the process production equipment (2); and the waste water source heat pump unit (6) is connected through the cold water supply pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com