Patents

Literature

5120results about How to "Protect environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

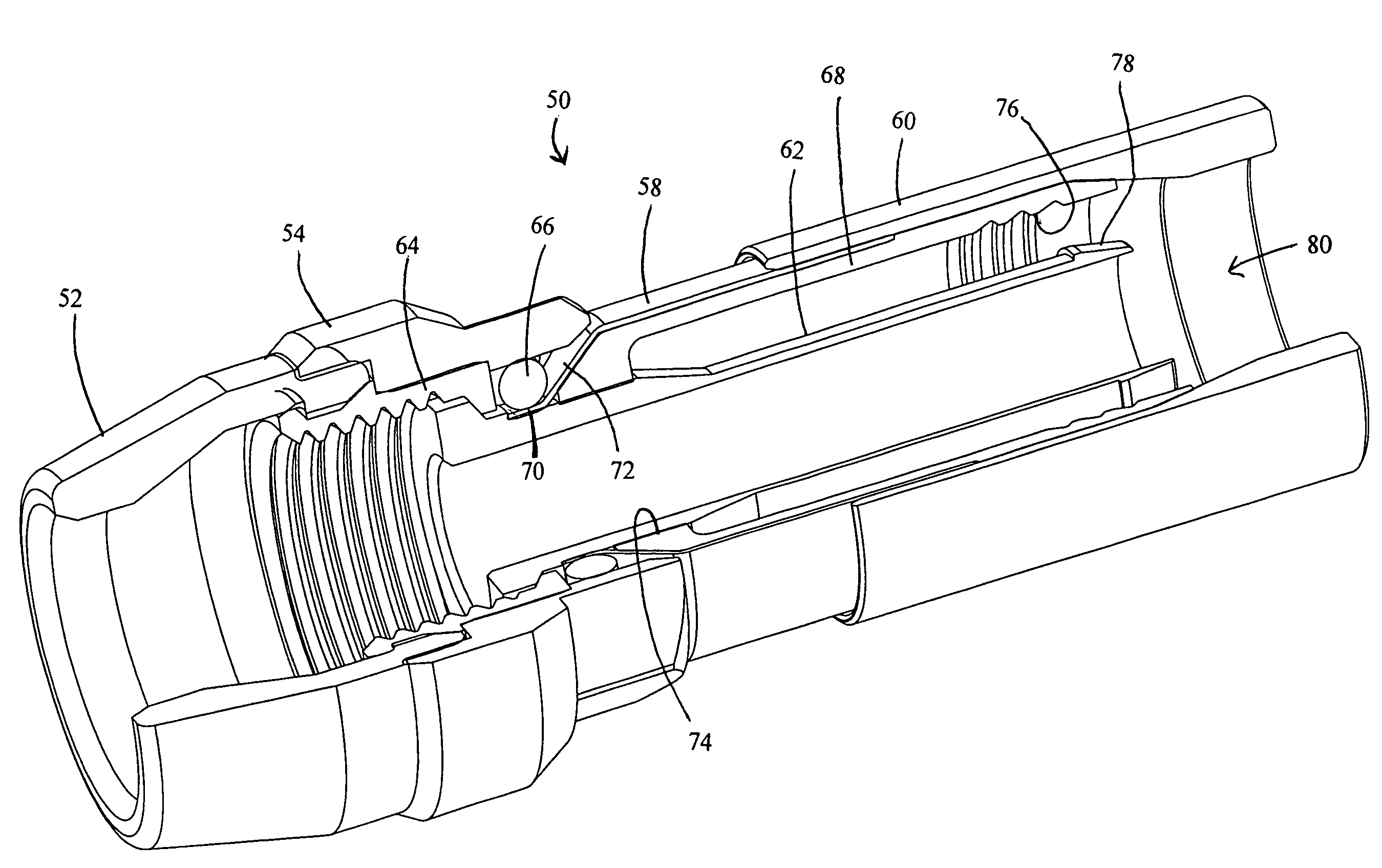

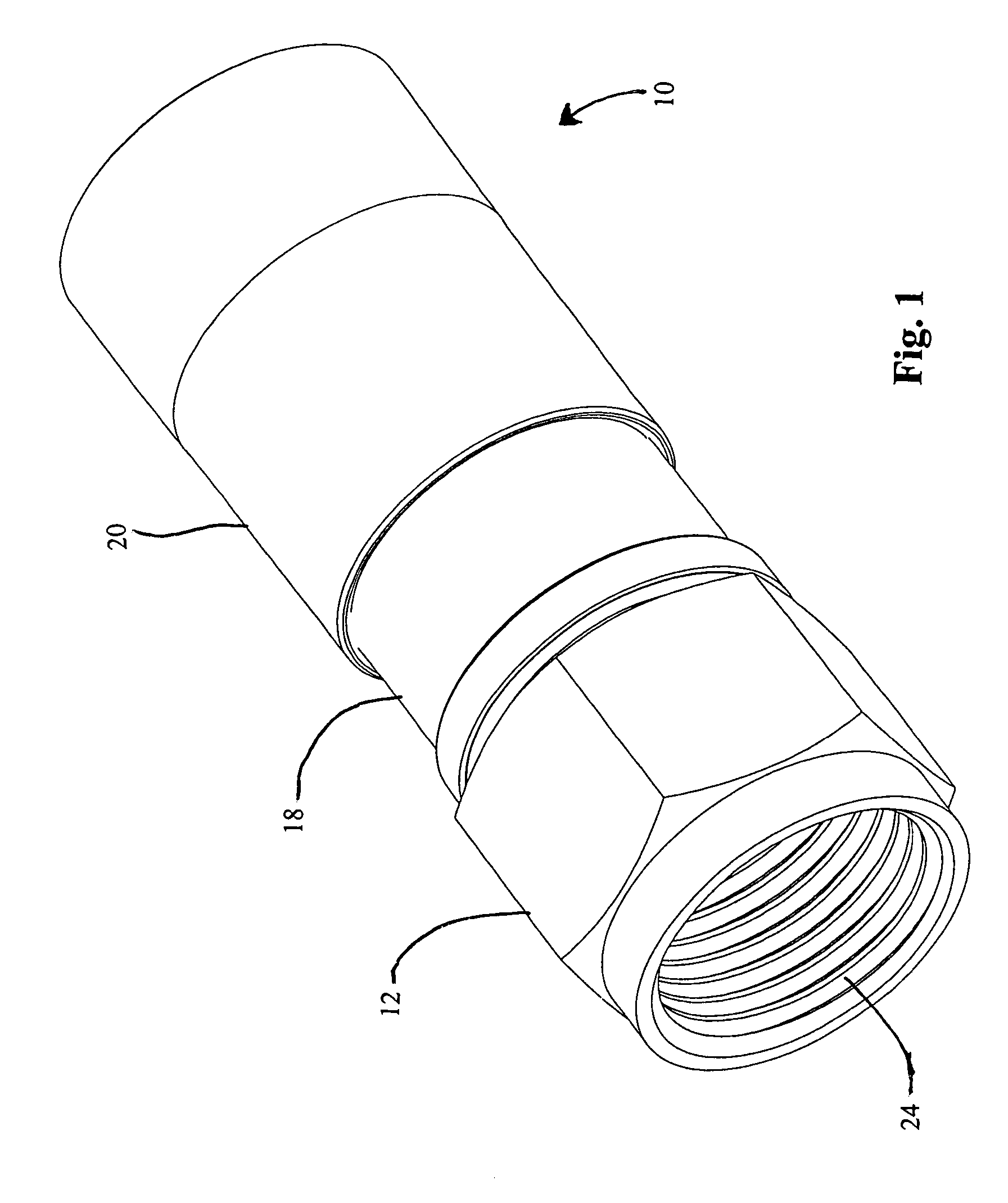

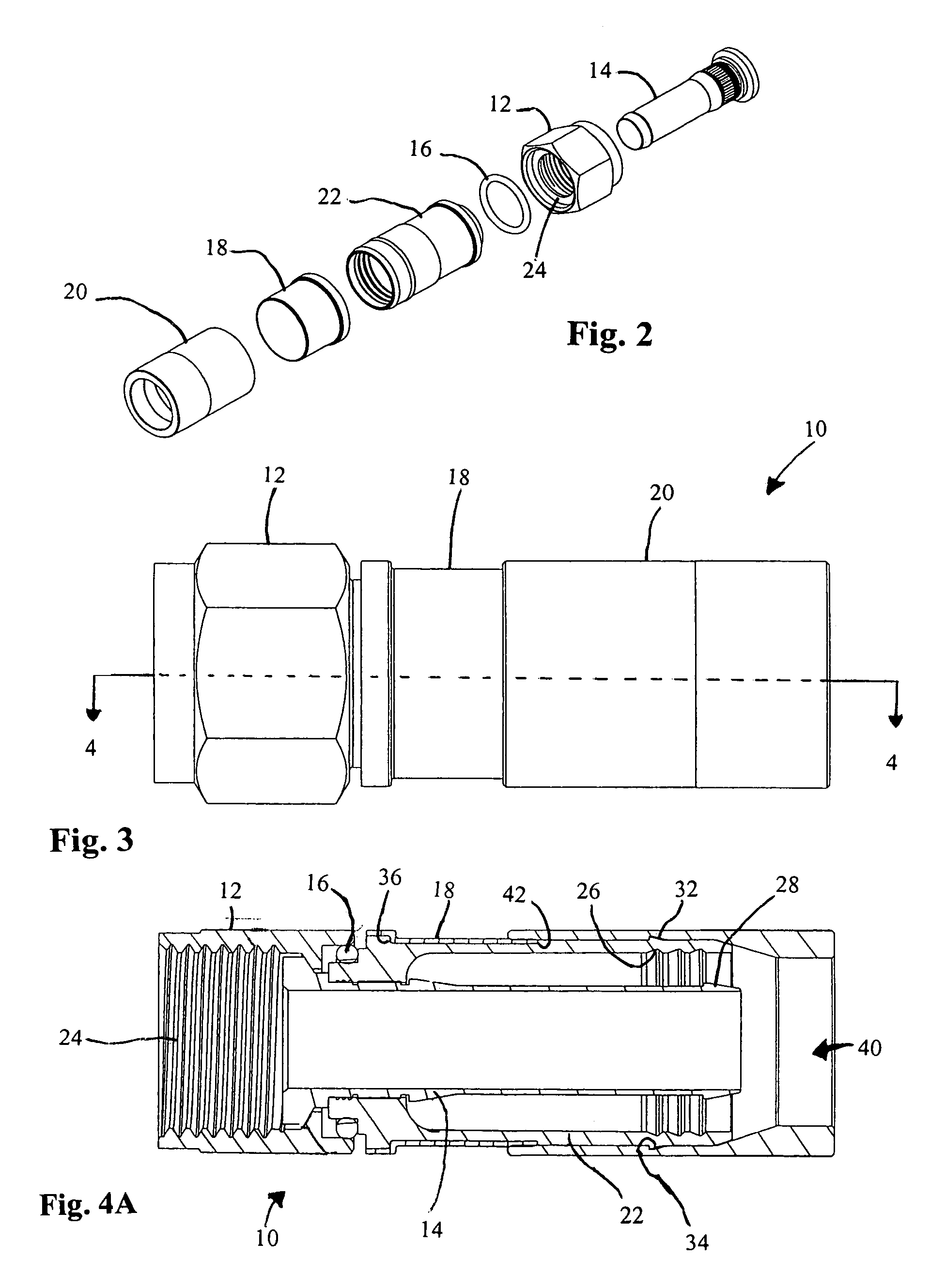

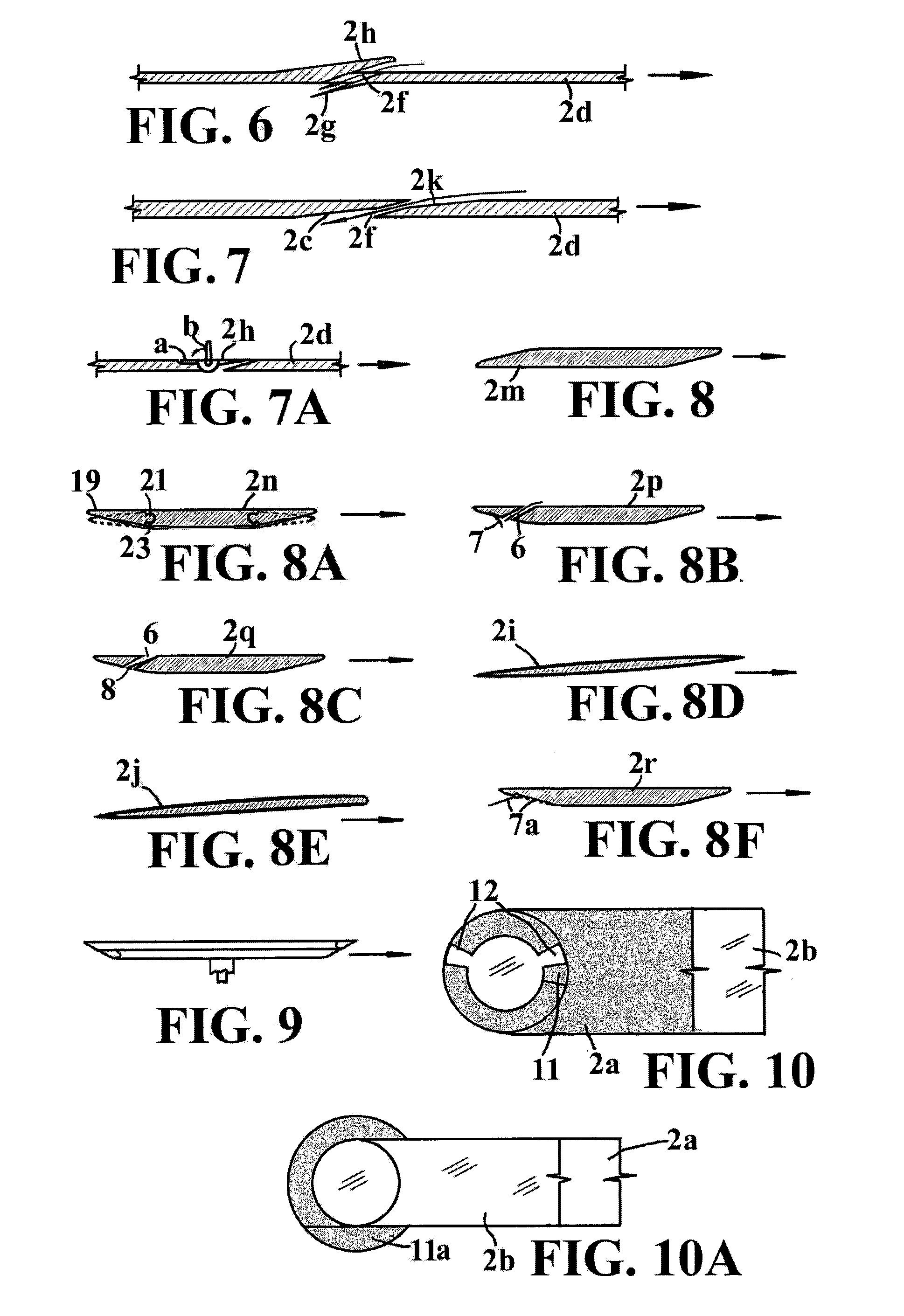

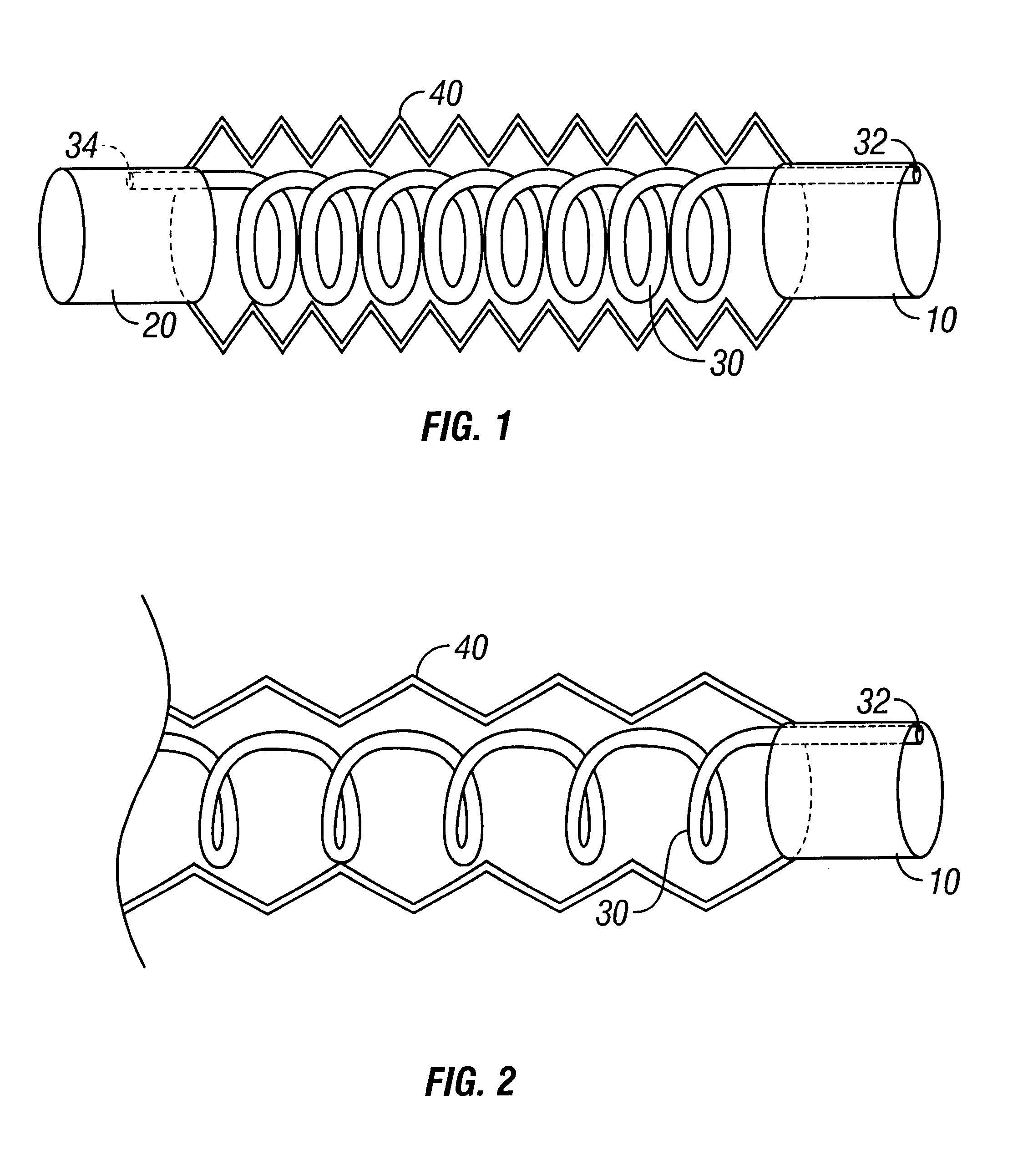

Coaxial cable compression connector

ActiveUS7255598B2Protect environmentElectrically conductive connectionsTwo pole connectionsCoaxial cableEngineering

A compression connector for a coaxial cable includes a unitary plastic body with a post connected inside the plastic body and a nut connected to the post. An O-ring seals the connection between the nut and the plastic body. A compression ring is connected to an outside of the plastic body. A reinforcing shield is also connected to the outside of the plastic body. The reinforcing shield serves to reinforce the plastic body when the compression ring is moved to its compressed position, so that softer plastics can be used for the plastic body. The reinforcing shield and compression ring also protect the entire outside of the plastic body from the environment.

Owner:PPC BROADBAND INC

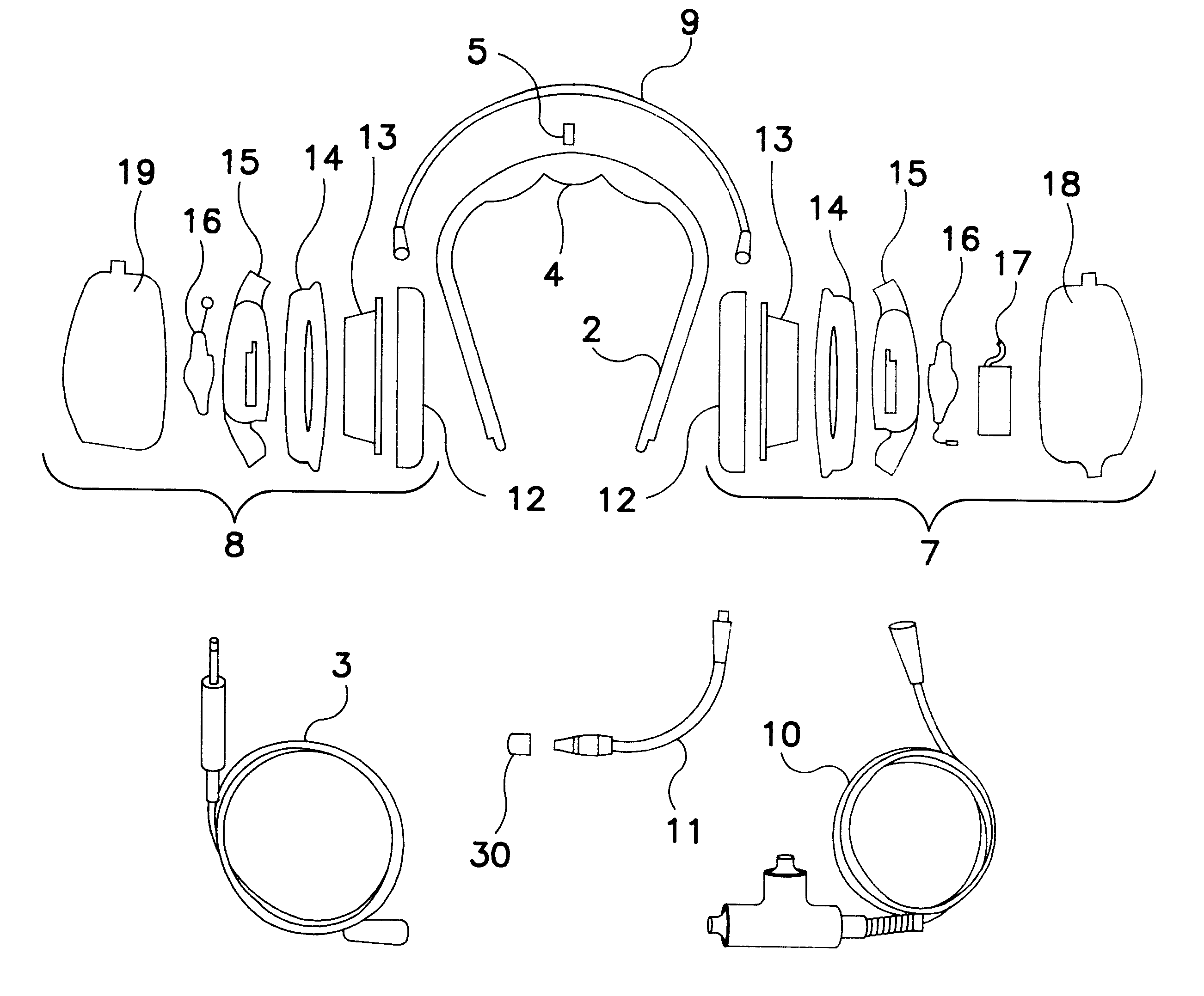

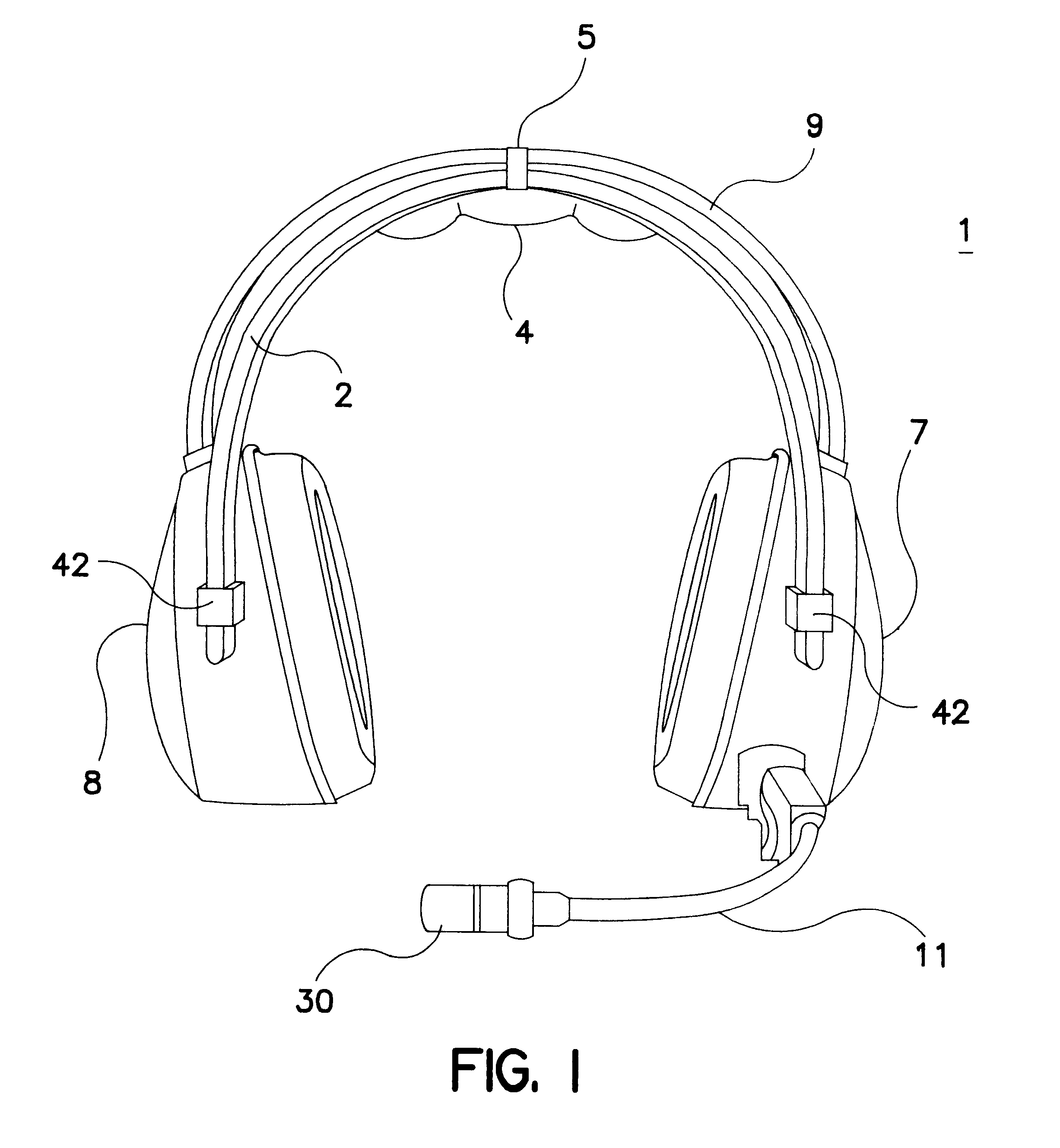

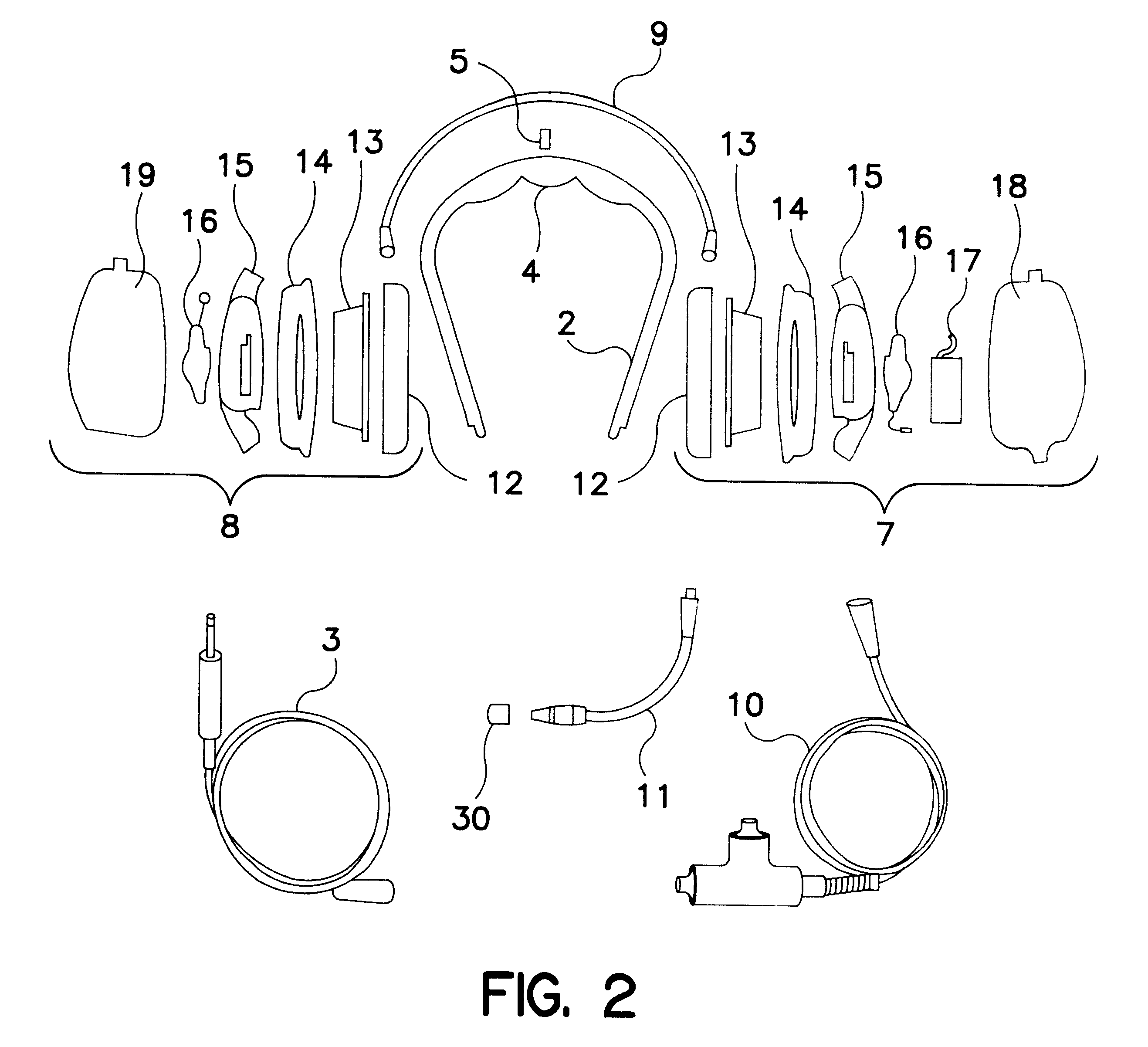

Weather resistant sound attenuating modular communications headset

InactiveUS6466681B1SanitationSimple procedureHeadphones for stereophonic communicationSupra/circum aural earpiecesField conditionsModularity

A weather resistant sound attenuating communications headset of modular construction includes two ear cup modules, a microphone boom module, a head band module, a headband cable module, and a termination cable module. The modular construction allows easy replacement of modules as well as selected components of the modules under field conditions without the need for tools. Replaceable water resistant thin film membranes are employed to provide weather protection as well as hygienic protection for the microphone, speaker and amplification electronics. The thin film membranes which cover areas which come into intimate contact with the wearer are easily replaceable under field conditions. Thus a headset that is shared by more than one user can be hygienically cleansed by simple replacement of the microphone and ear cup membranes.

Owner:COMPREHENSIVE TECHN SOLUTIIONS

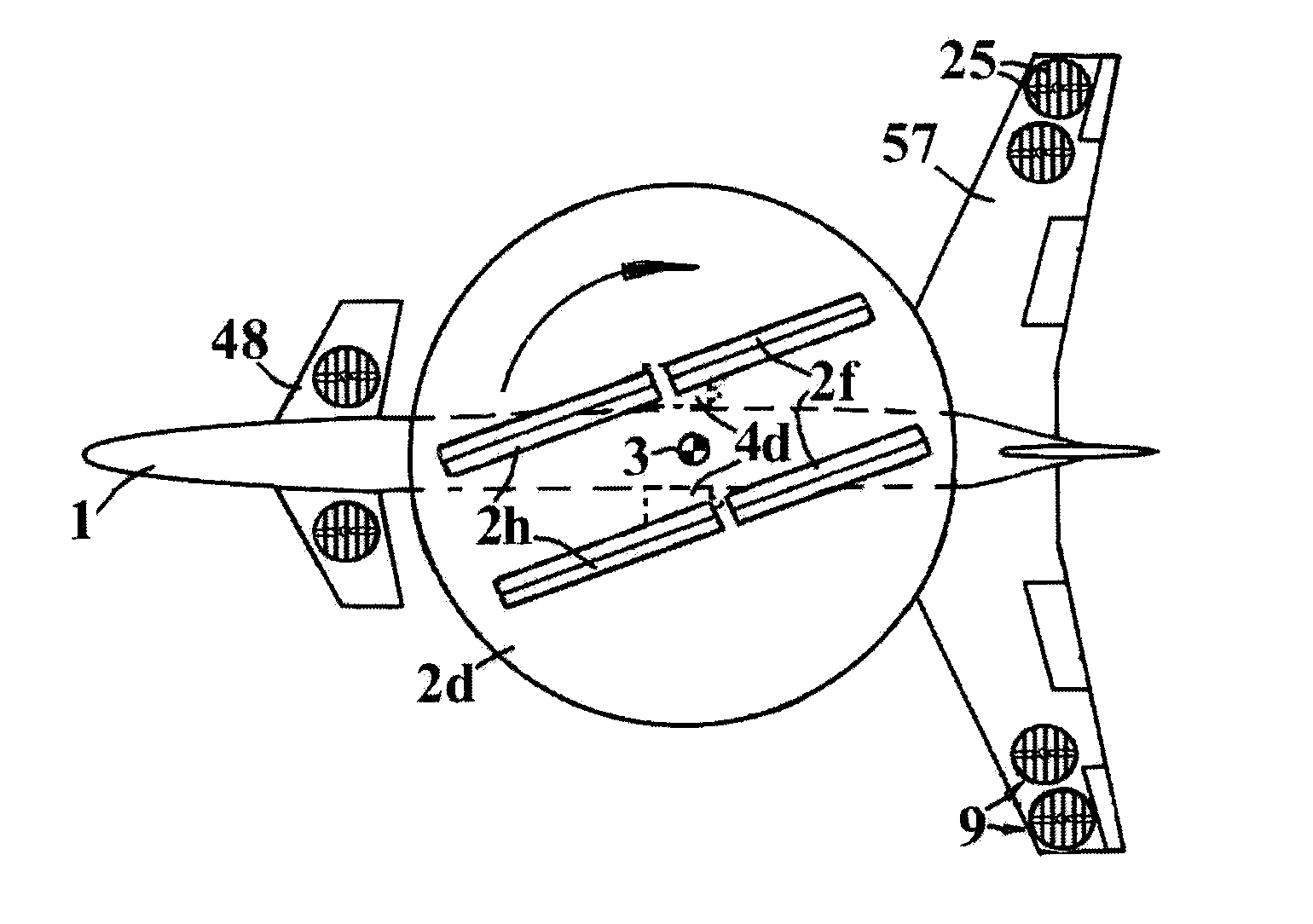

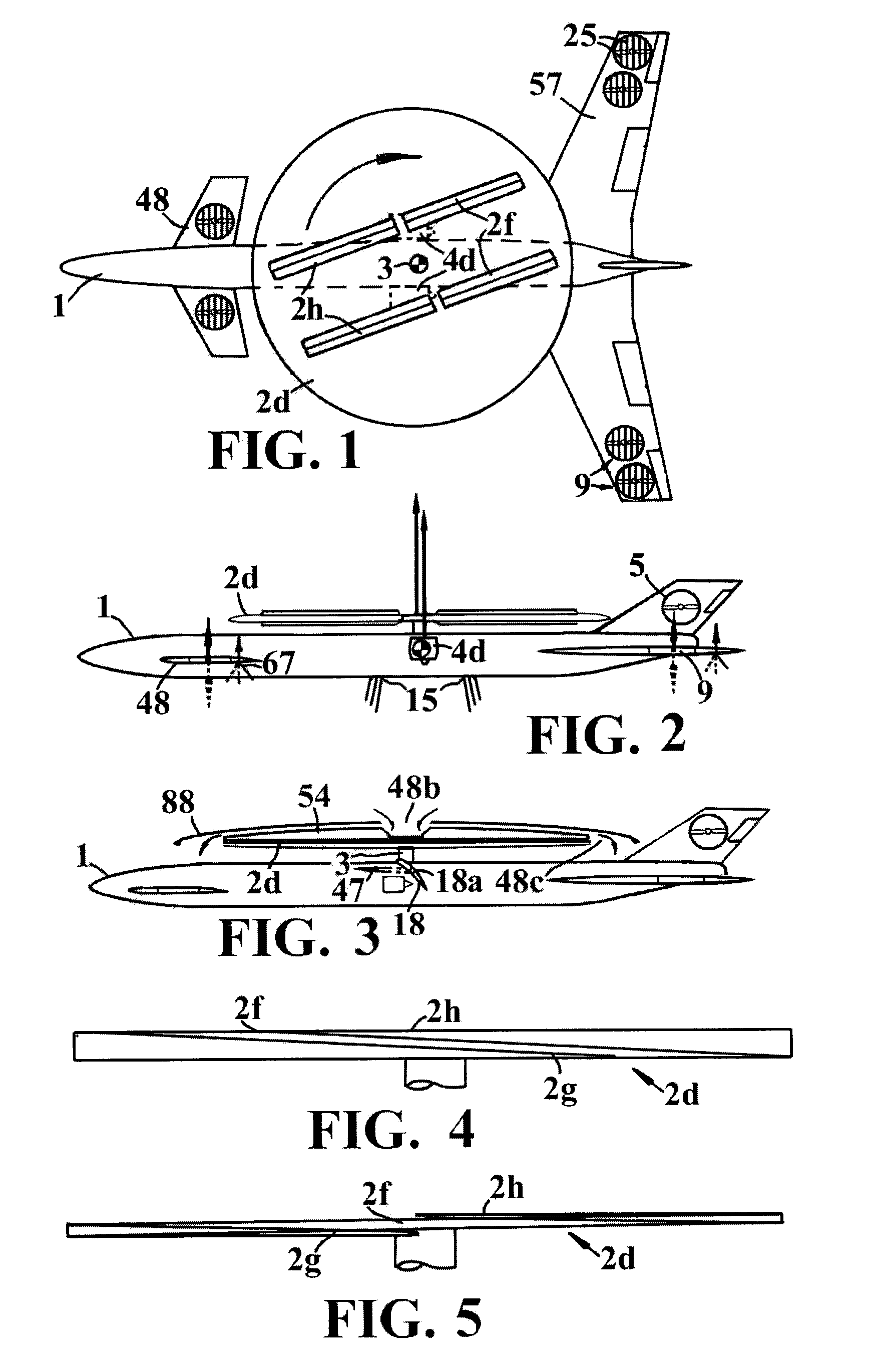

Lift Propulsion and Stabilizing System and Procedure For Vertical Take-Off and Landing Aircraft

InactiveUS20130251525A1Inhibition effectLow costElectric power distributionPropellersLeading edgeTurbine

Lift propulsion and stabilizing system and procedure for vertical takeoff and landing aircraft that consists in applying simultaneously and combined as lifters during the initial portion of the climb and at the end of the descent of: a) some fans or electric turbines, EDF, and b) at least one rotor with external blades and / or rotary and / or c) the engine flow directed downwards and / or d) pressure air jets injected on leading edges control fins, and / or e) water jets and / or f) supplemented with aerodynamic lift produced during frontal advance of the aircraft, the stabilization is achieved by the gyroscopic stiffness of the rotor and two or more lifting fans oscillating fins and / or air jets located on two or stabilizers more peripheral points in a plane perpendicular to the vertical axis of the aircraft.

Owner:SAIZ MANUEL M

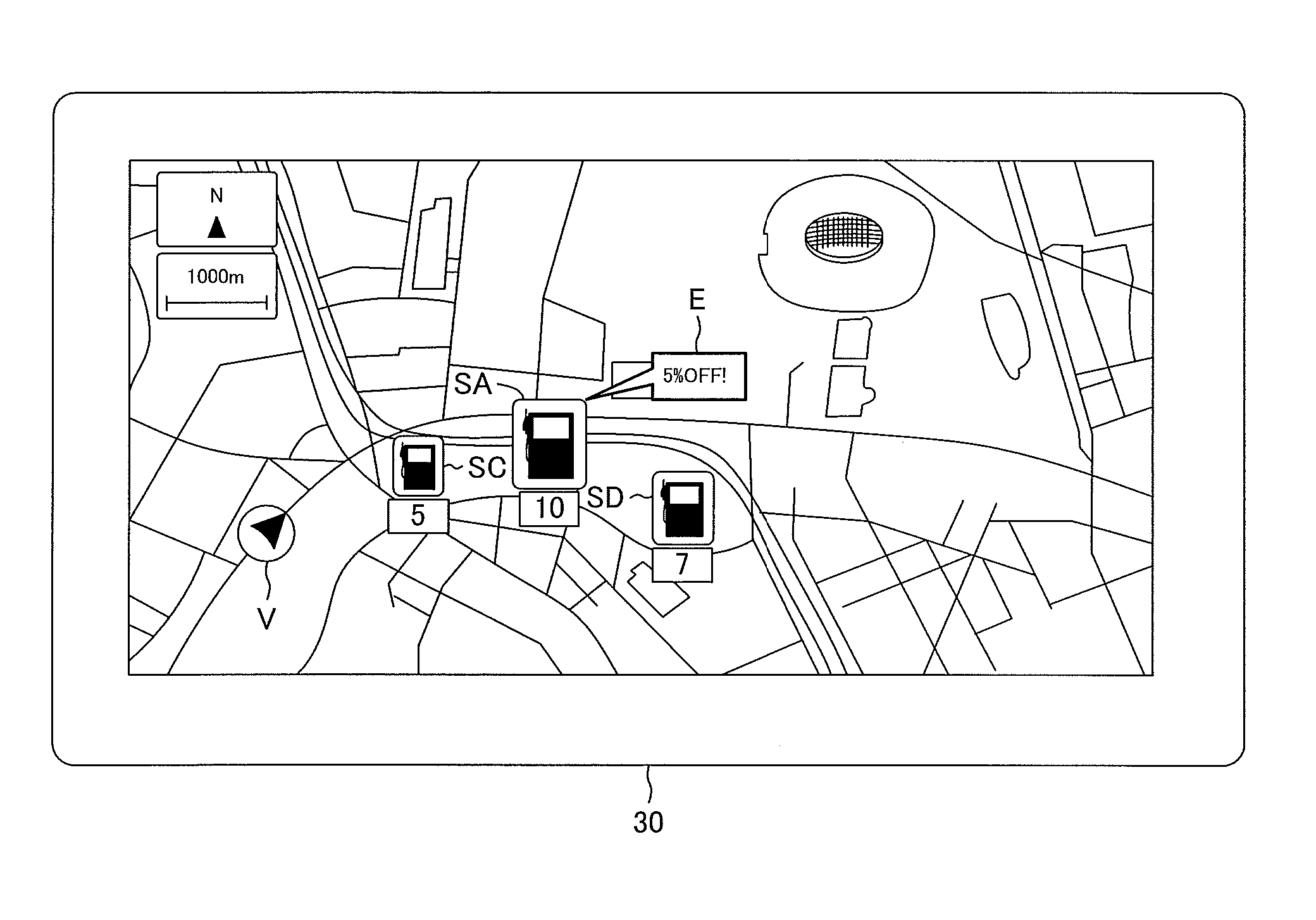

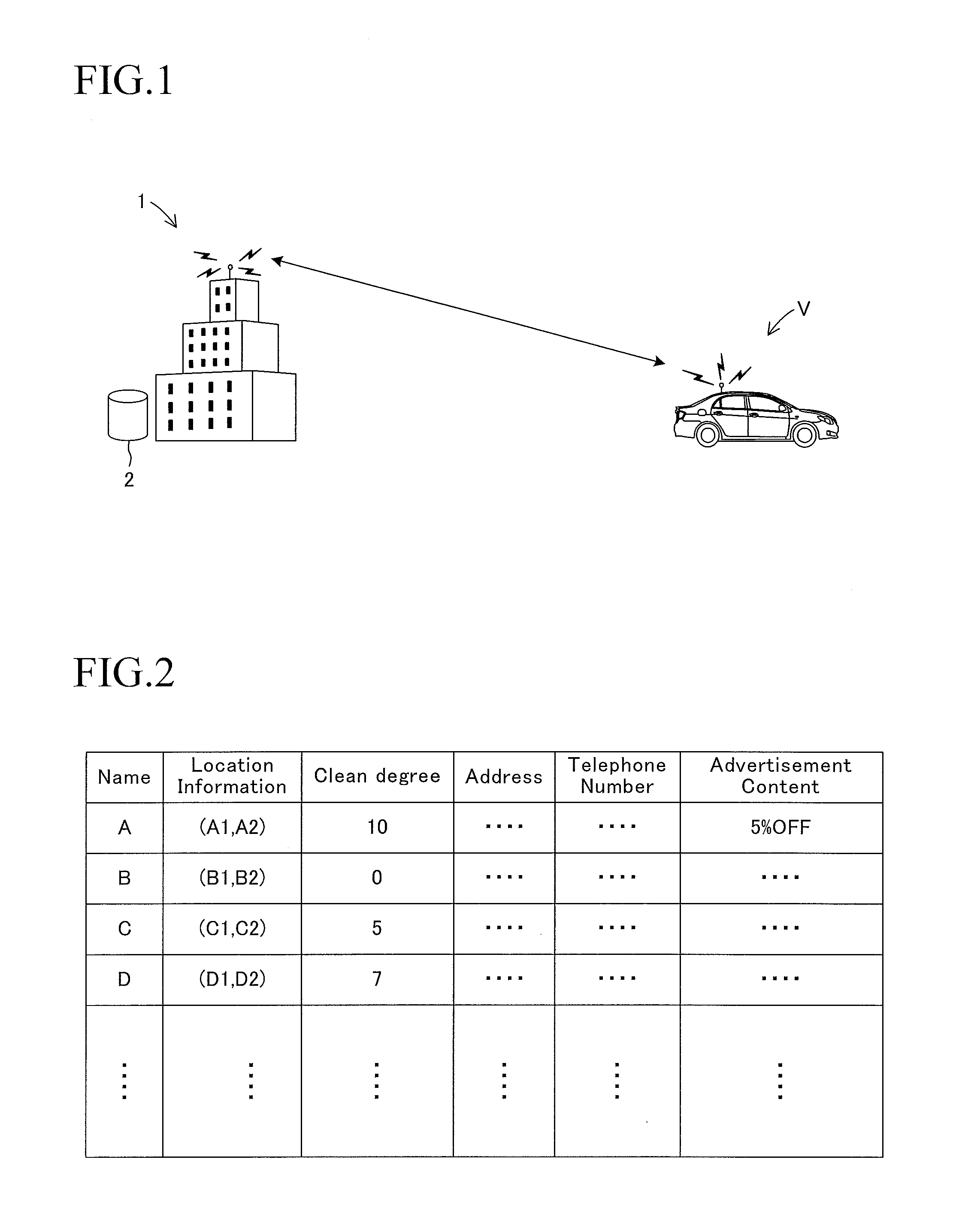

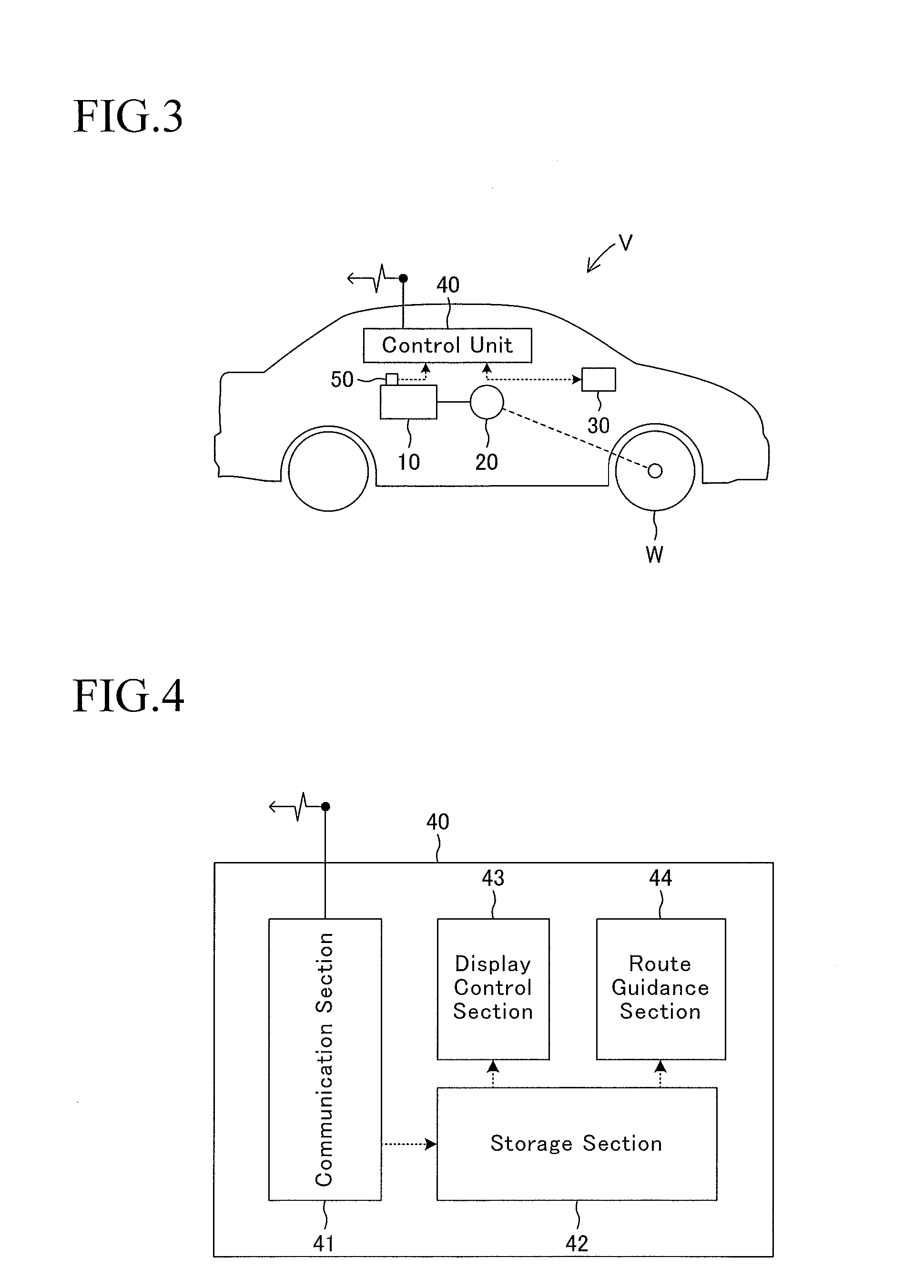

Charging information-providing apparatus

InactiveUS20140214321A1Reduce the burden onProtect environmentInstruments for road network navigationRoad vehicles traffic controlOn boardCharging station

An information providing apparatus is configured so as to provide, to an occupant of an electric vehicle, information indicating a location of a charging station together with information indicating whether or not the electric vehicle can be charged with a clean electric power at that charging station, through an on-board display. Accordingly, the occupant of the electric vehicle can go to the charging station at which the electric vehicle can be charged with electric power including the clean electric power, based on the provided location information of the charging station and a clean degree, and can charge the electric vehicle with the electric power including the clean electric power there. In this manner, the electric vehicle is charged with the electric power including the clean electric power, and thus, the demand for the clean electric power serving as the electric power for charging electric vehicles can be increased.

Owner:TOYOTA JIDOSHA KK

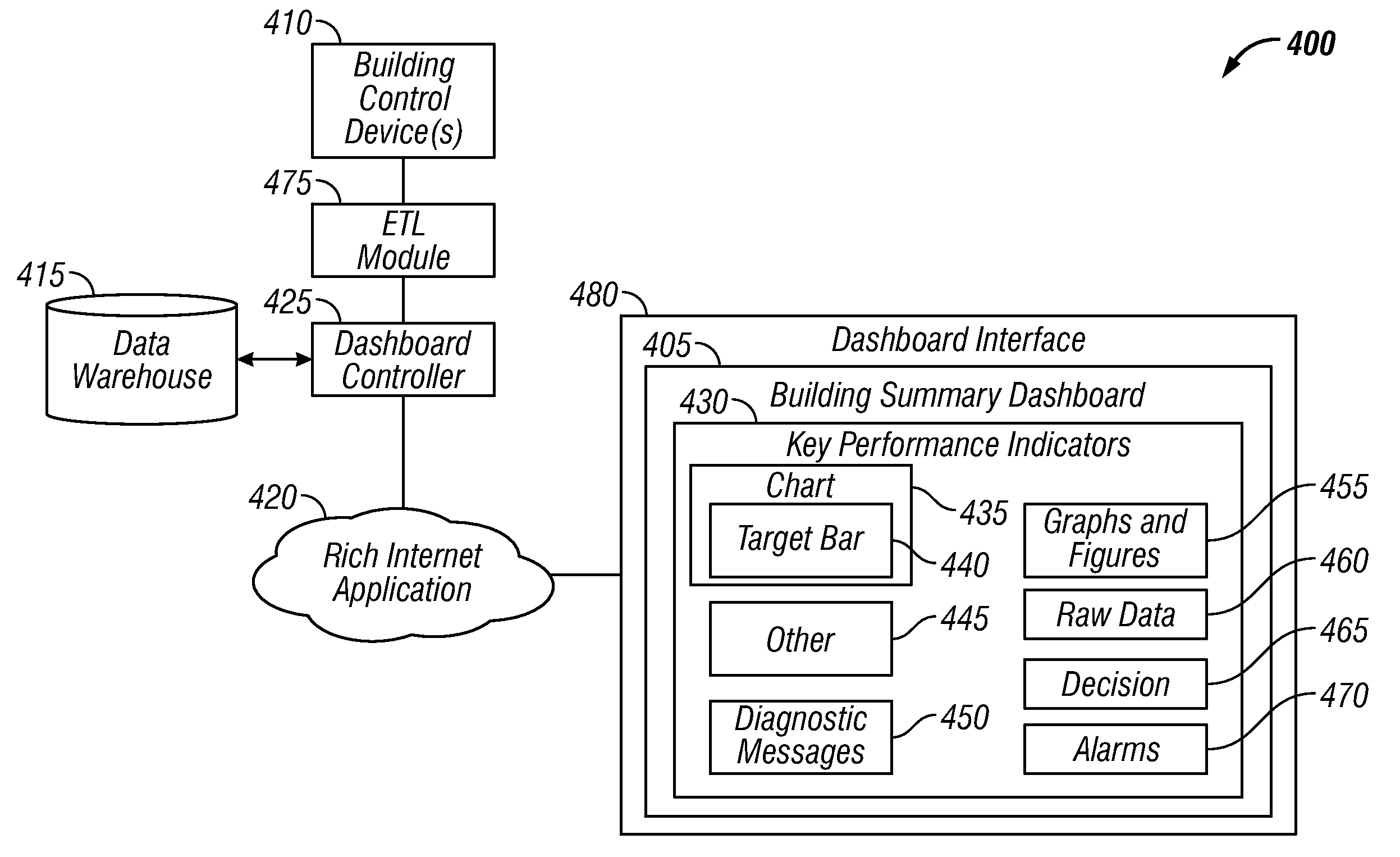

Method and System for Providing an Integrated Building Summary Dashboard

InactiveUS20100318200A1Improve energy efficiencyProtect environmentLevel controlTemperatue controlDashboardData warehouse

A method and system for providing an integrated building summary dashboard application. The dashboard can be implemented, for example, as a Rich Internet Application (RIA), which integrates with multiple data sources. A data warehouse can be utilized to consolidate and store the data related to a particular dashboard. The dashboard can be configured by integrating high-level metrics with key performance indicators to provide an overview, which can then be granularized to provide detailed information. The dashboard can also be configured to include a data chart that provides a “glimpse” of information associated with key performance indicators. The data chart can be configured to utilize a target bar as input to an interactive what-if analysis, and an output can be utilized to automatically drive control automation system changes.

Owner:HONEYWELL INT INC

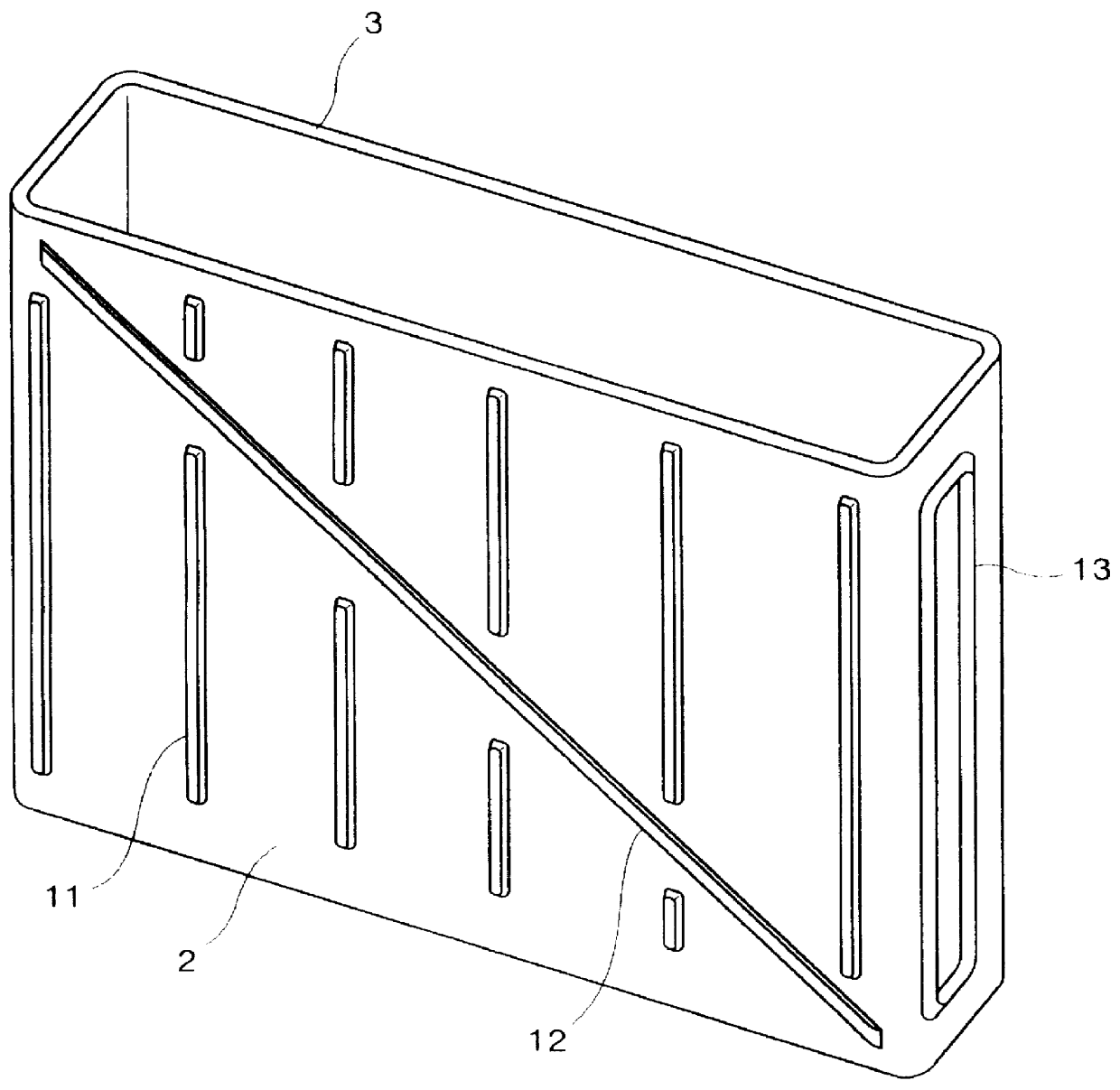

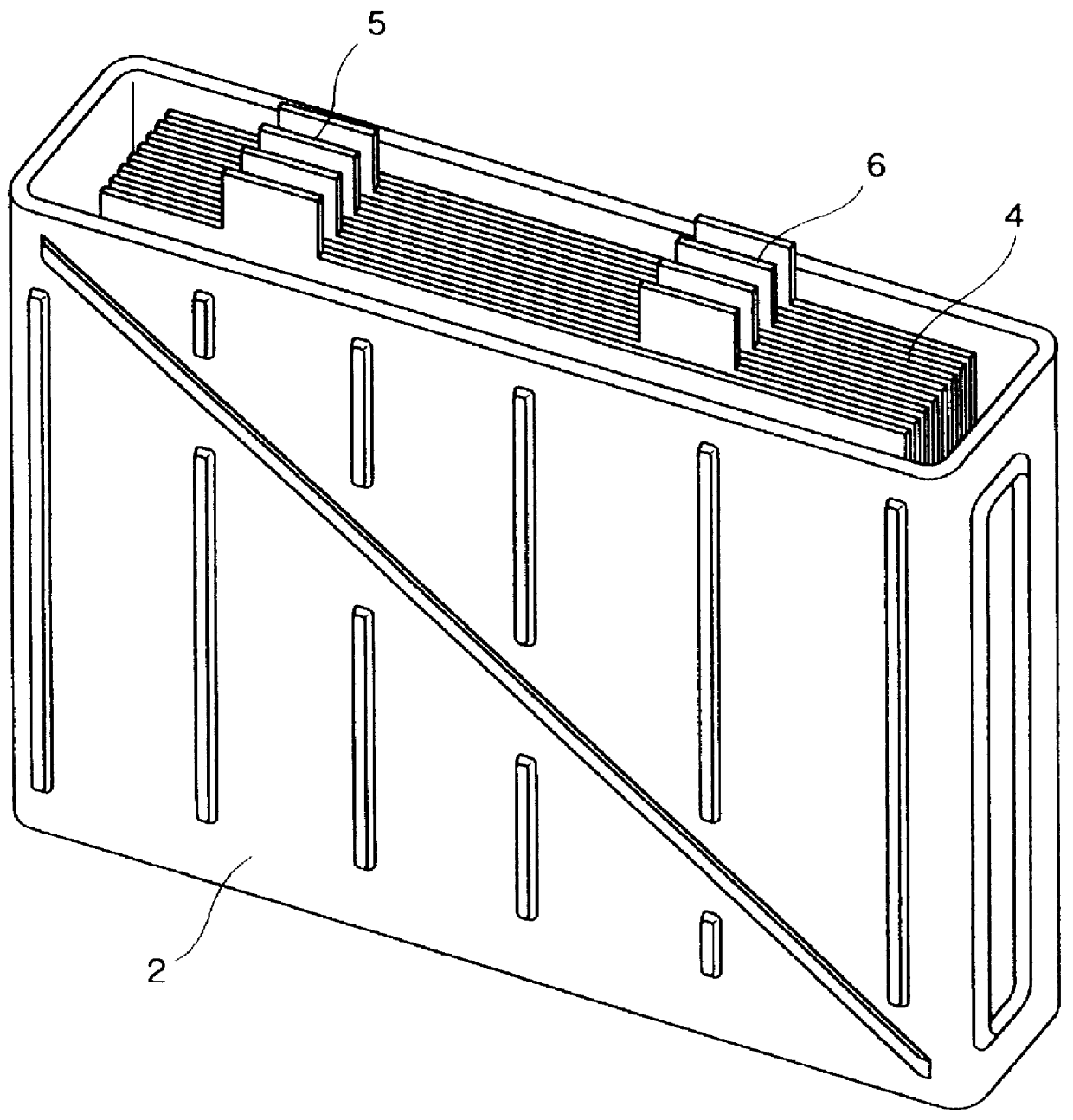

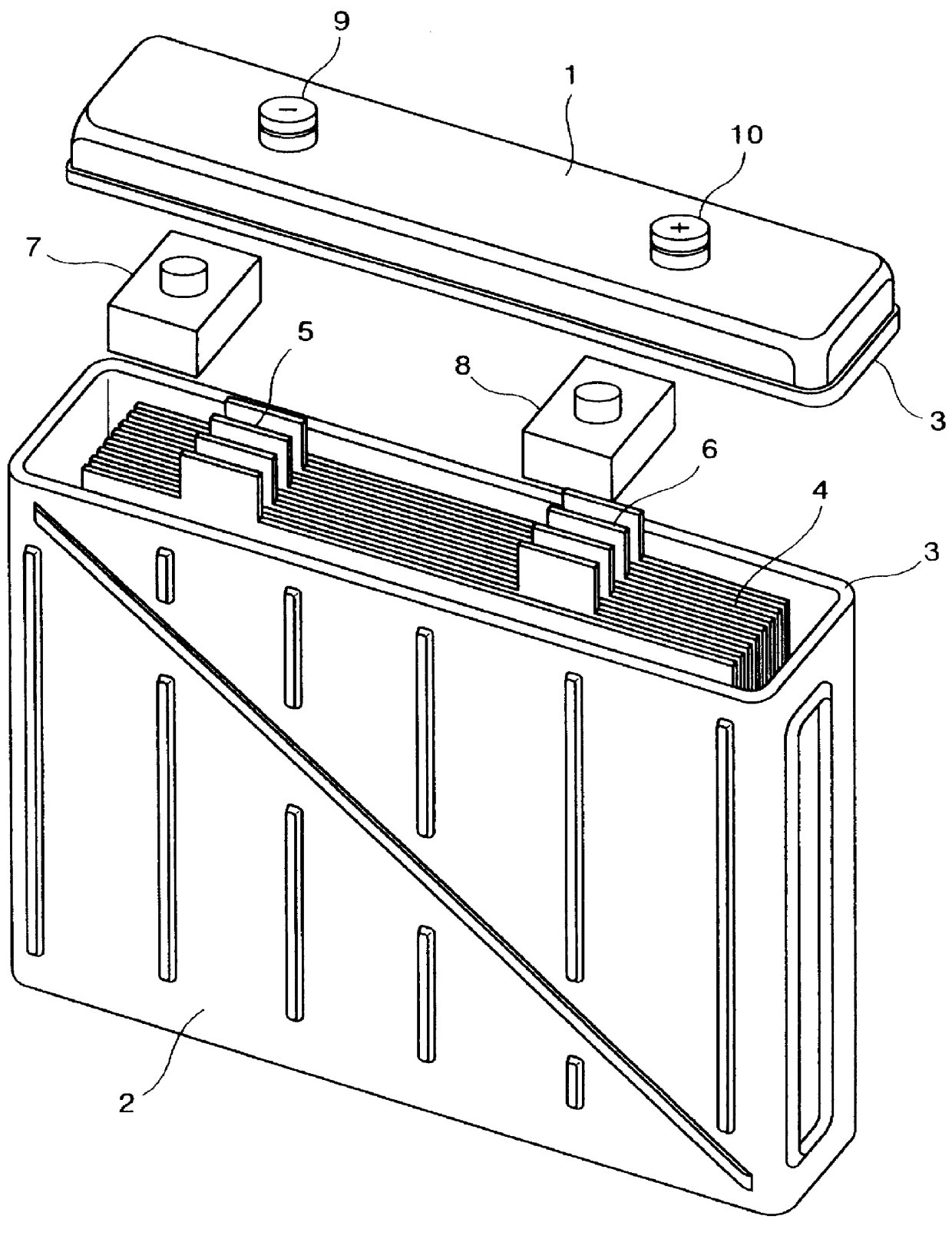

Resin composition and resin composition for secondary battery jar

InactiveUS6045883ASave resourcesProtect environmentSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPolypropyleneEther

PCT No. PCT / JP96 / 01794 Sec. 371 Date Dec. 8, 1997 Sec. 102(e) Date Dec. 8, 1997 PCT Filed Jun. 28, 1996 PCT Pub. No. WO97 / 01600 PCT Pub. Date Jan. 16, 1997A resin composition comprising a polypropylene resin, a polyphenylene ether resin and a compatibility agent wherein dispersion particles comprising the polyphenylene ether resin (b) are dispersed in a matrix comprising the polypropylene resin (a), a minor diameter of the dispersion particles is 2 mu m or less, and the ratio of major diameter / minor diameter is 1-10.

Owner:ASAHI KASEI KK

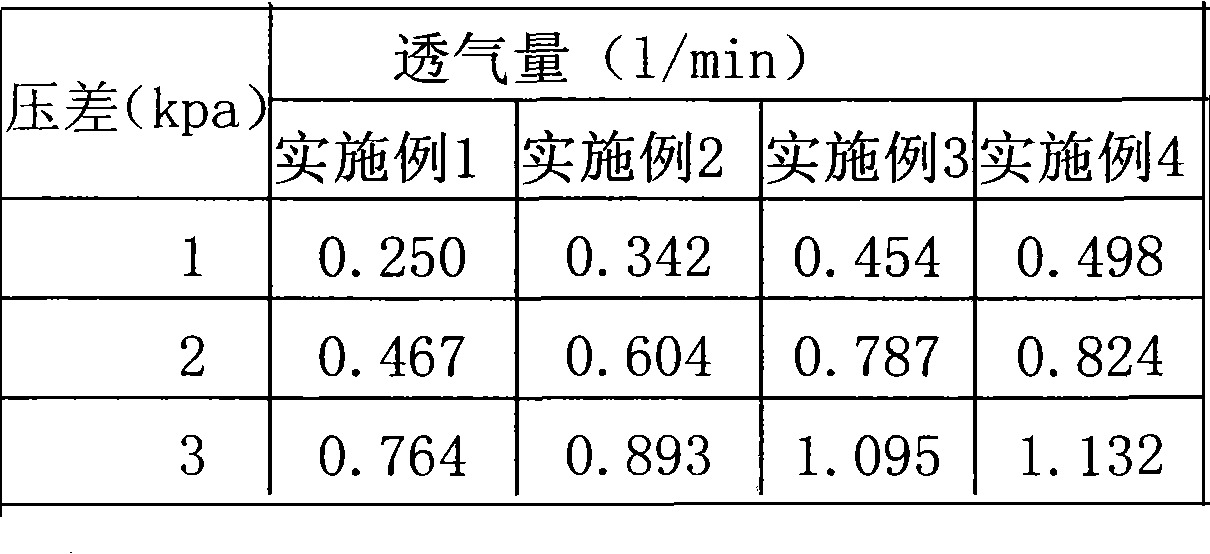

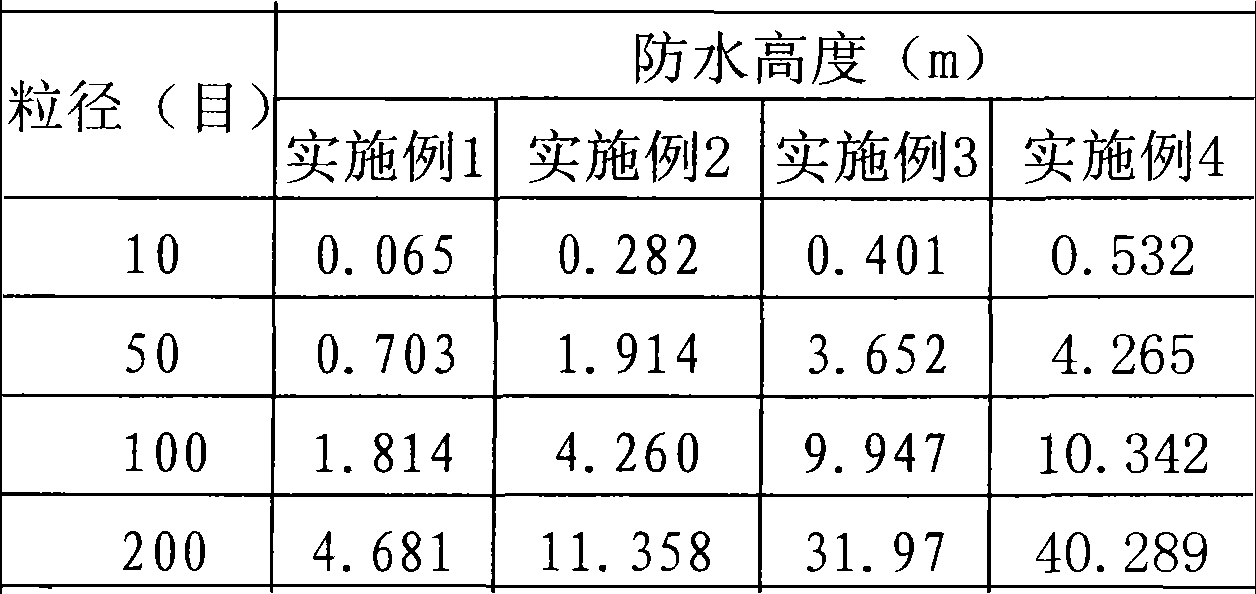

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

High temperature foamer formulations for downhole injection

ActiveUS7122509B2Increase heightReduce pointsOrganic detergent compounding agentsAnionic surface-active compoundsFoaming agentDecomposition

Owner:WHITEBOX ADVISORS +1

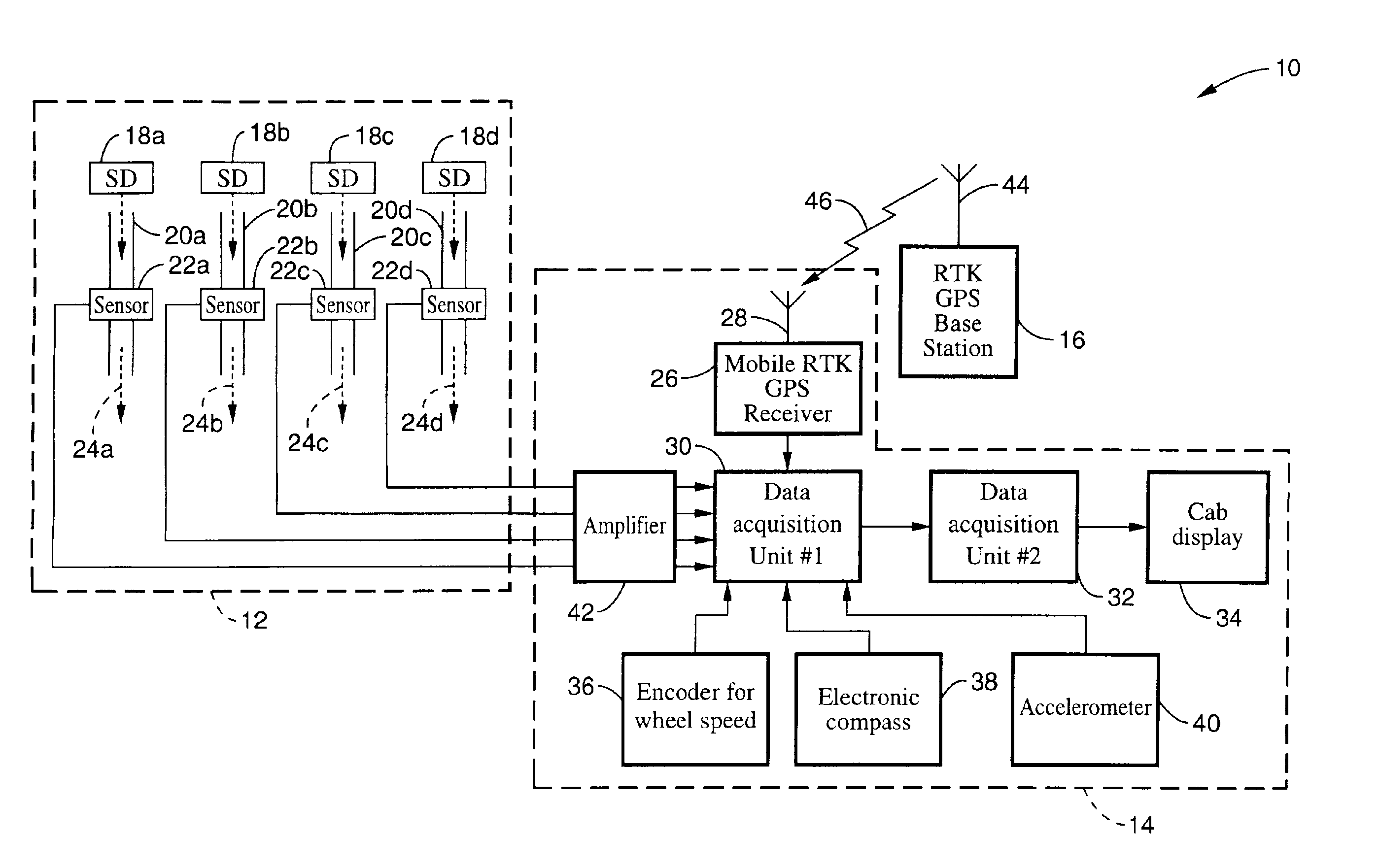

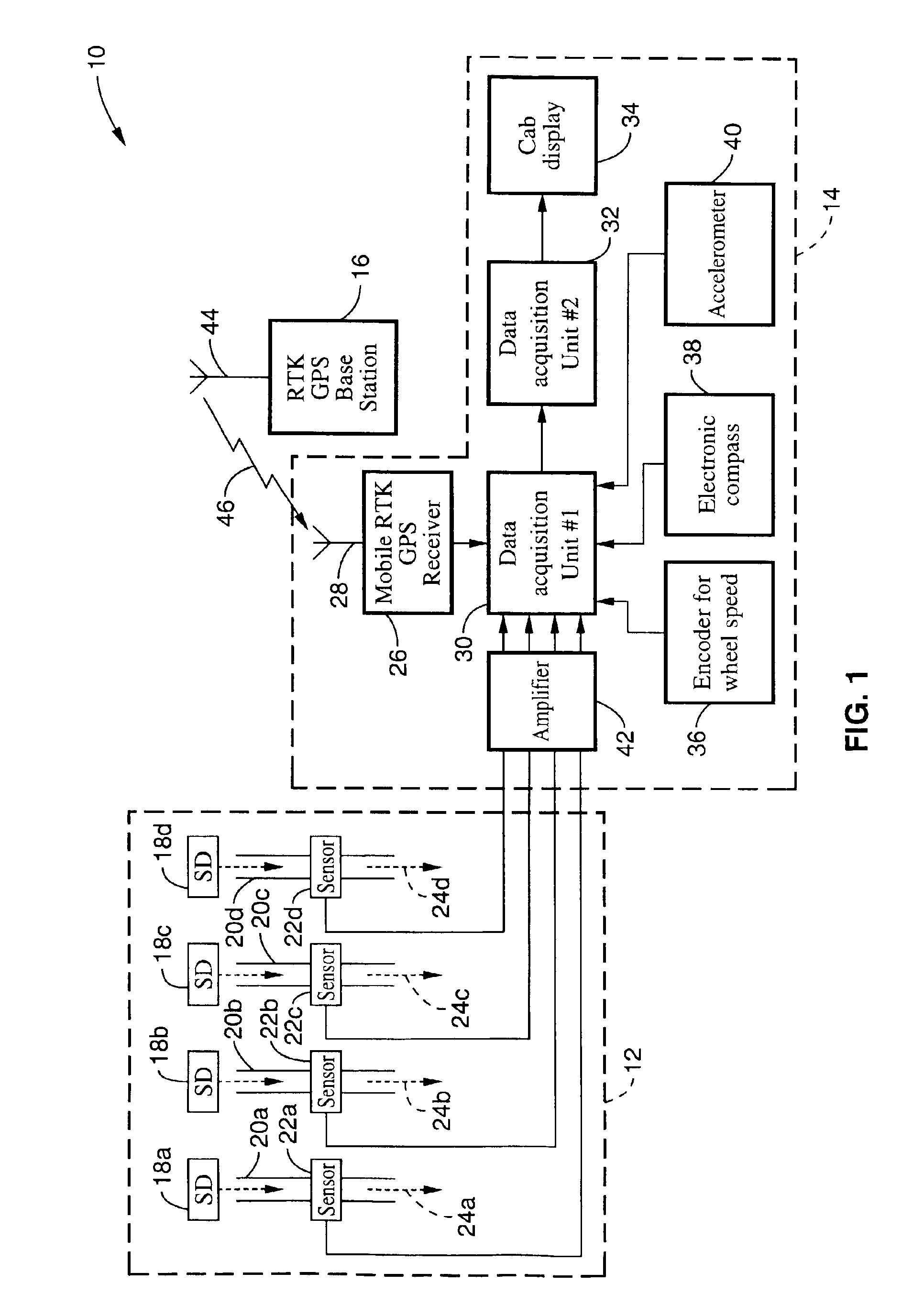

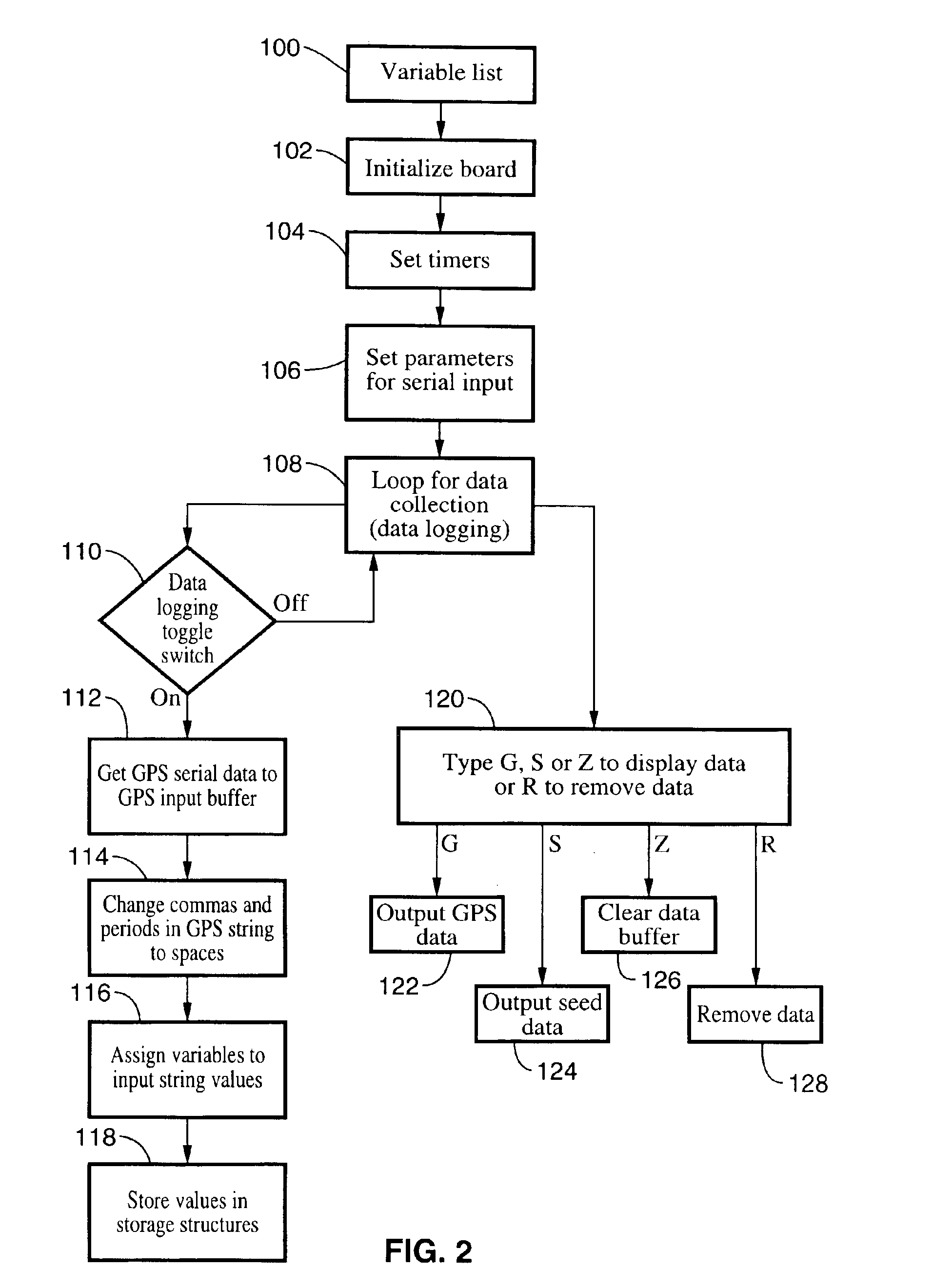

Method and apparatus for ultra precise GPS-based mapping of seeds or vegetation during planting

InactiveUS6941225B2Application can be controlledLow costMowersFertiliser distributersVegetationGps receiver

An ultra precise seed planter apparatus and method for generating a centimeter accuracy map of the location of seeds or vegetation as they are planted from an agricultural planting machine. The apparatus is fitted with a GPS receiver feeding a data logger, and optical sensors that are placed adjacent seed or vegetation dispenser. The data logger monitors GPS time and UTM coordinates, as well as the optical sensors. Ground speed and azimuth are also monitored. The seeds or vegetation are time-tagged as they are dispensed, and software is used to process the dispensing time and GPS location data and estimate the exact coordinates of each seed or plant and its distance from adjacent seeds or plants. As a result, a precise planting map is generated. The invention may also be used to determine the location to dispense seeds or vegetation, and activating the dispenser when that location is reached.

Owner:RGT UNIV OF CALIFORNIA

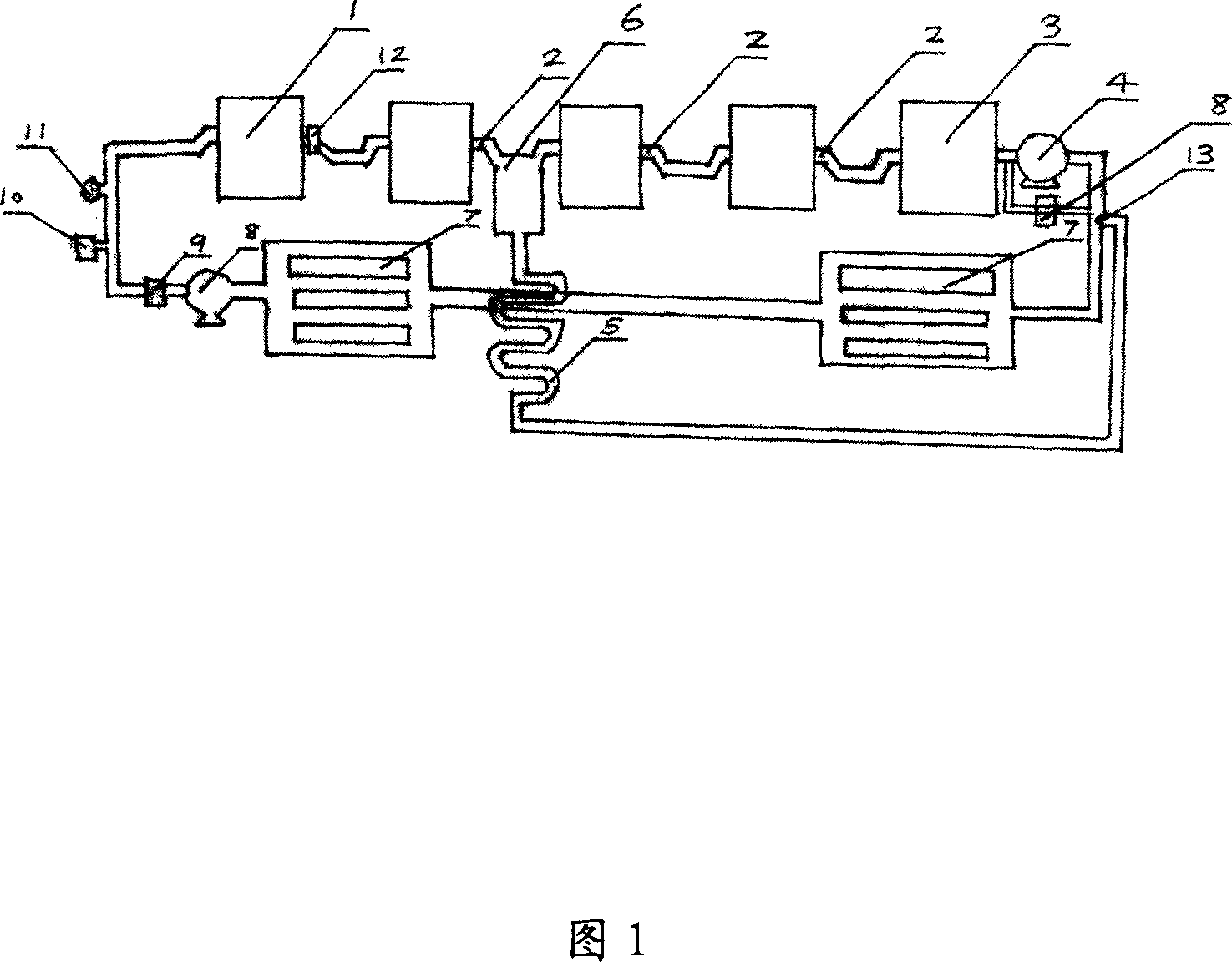

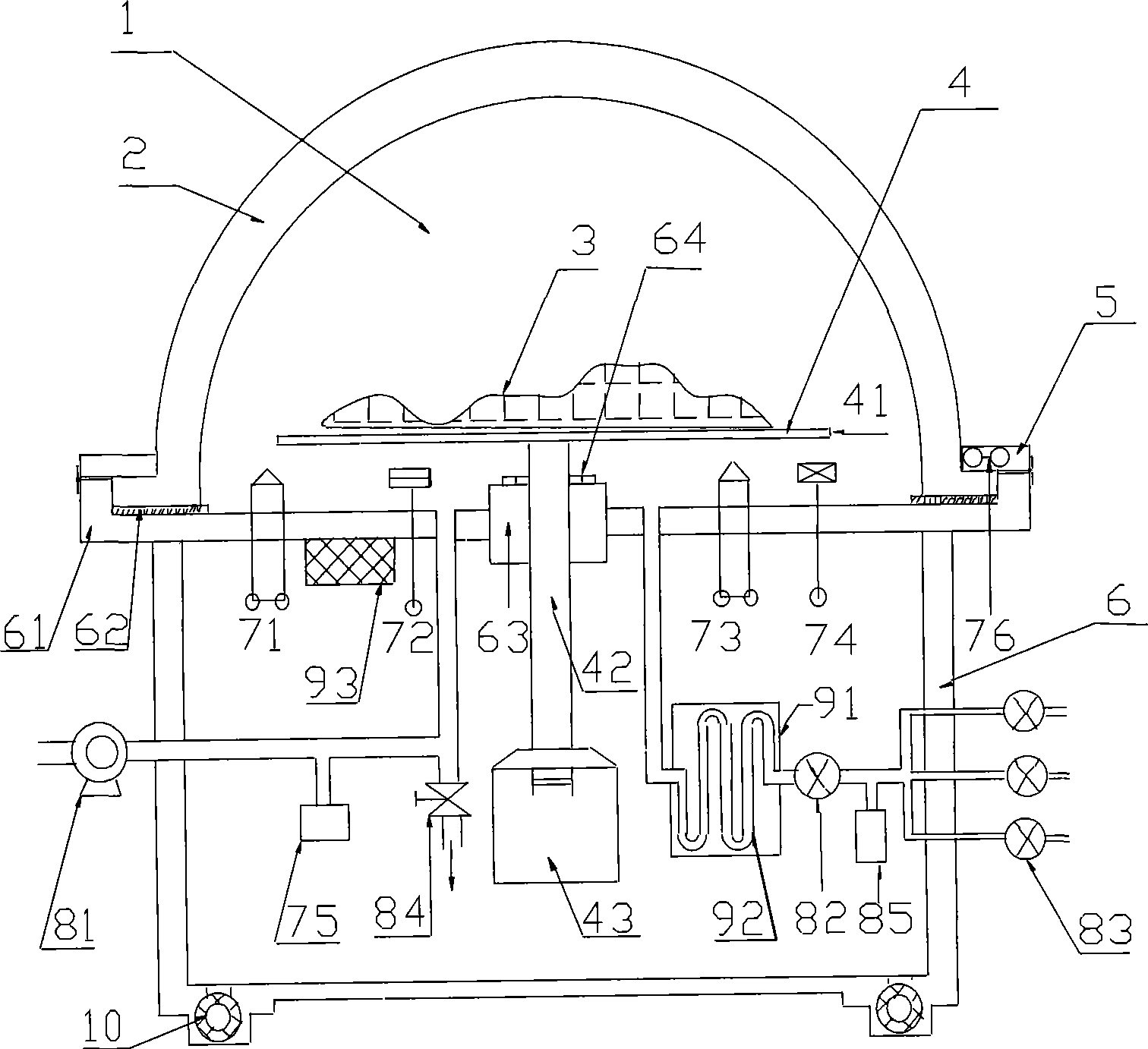

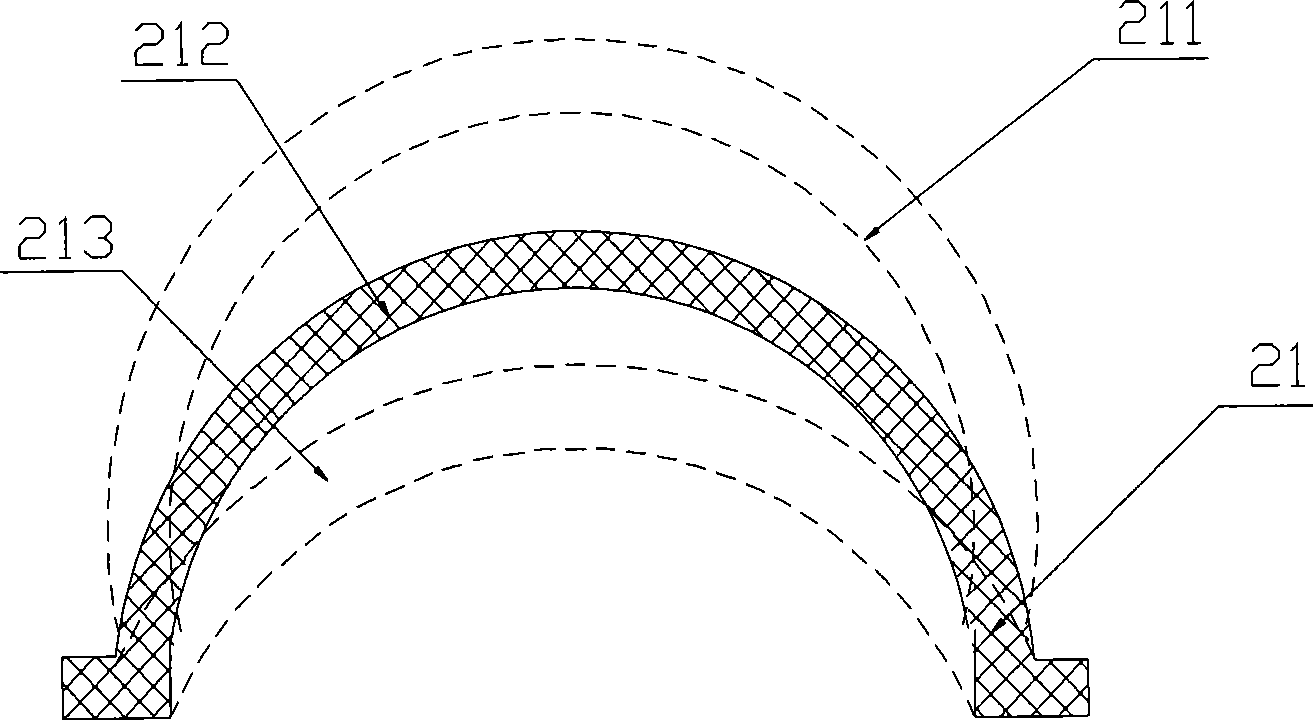

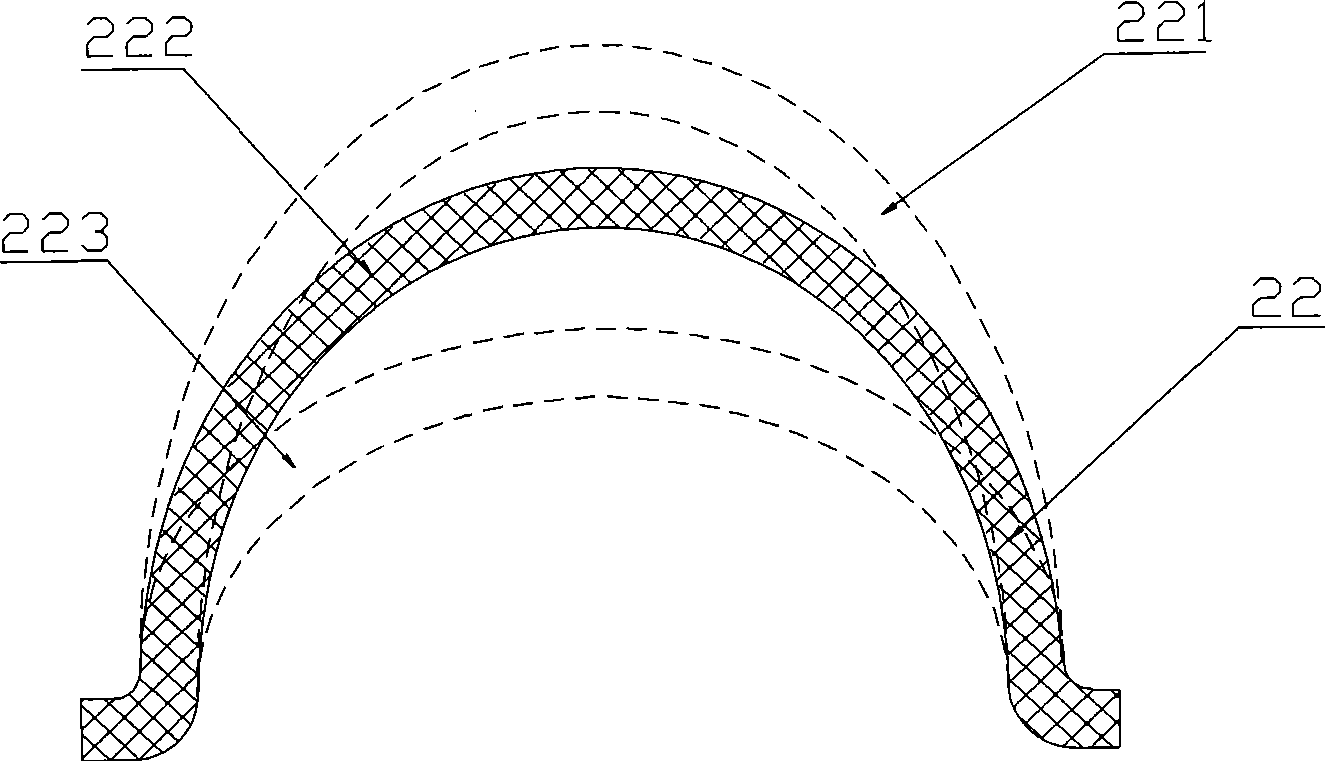

Solar energy closed medium circulating electricity generating method and its device

InactiveCN101060293AScientific and reasonable conceptionSimple equipment installationSolar heating energyFrom solar energyCarbon dioxideElectric generator

The disclosed solar energy closed medium cycle power generation comprises: forming a heat-collection unit array with multi-level solar reflection plates and heat-collection pipes, heating the closed medium water dissolved NH3 or CO2 to generate high-temperature high-pressure gas and drive the assembly for generating power; applying the cooling pipes to discharge heat of high-pressure gas into water; after passing the hydraulic pump, recombining the separated water and gas into the relative closed medium. This invention has solid scientific base, uses simple equipments and low cost, and thereby has bright application future.

Owner:武瑞

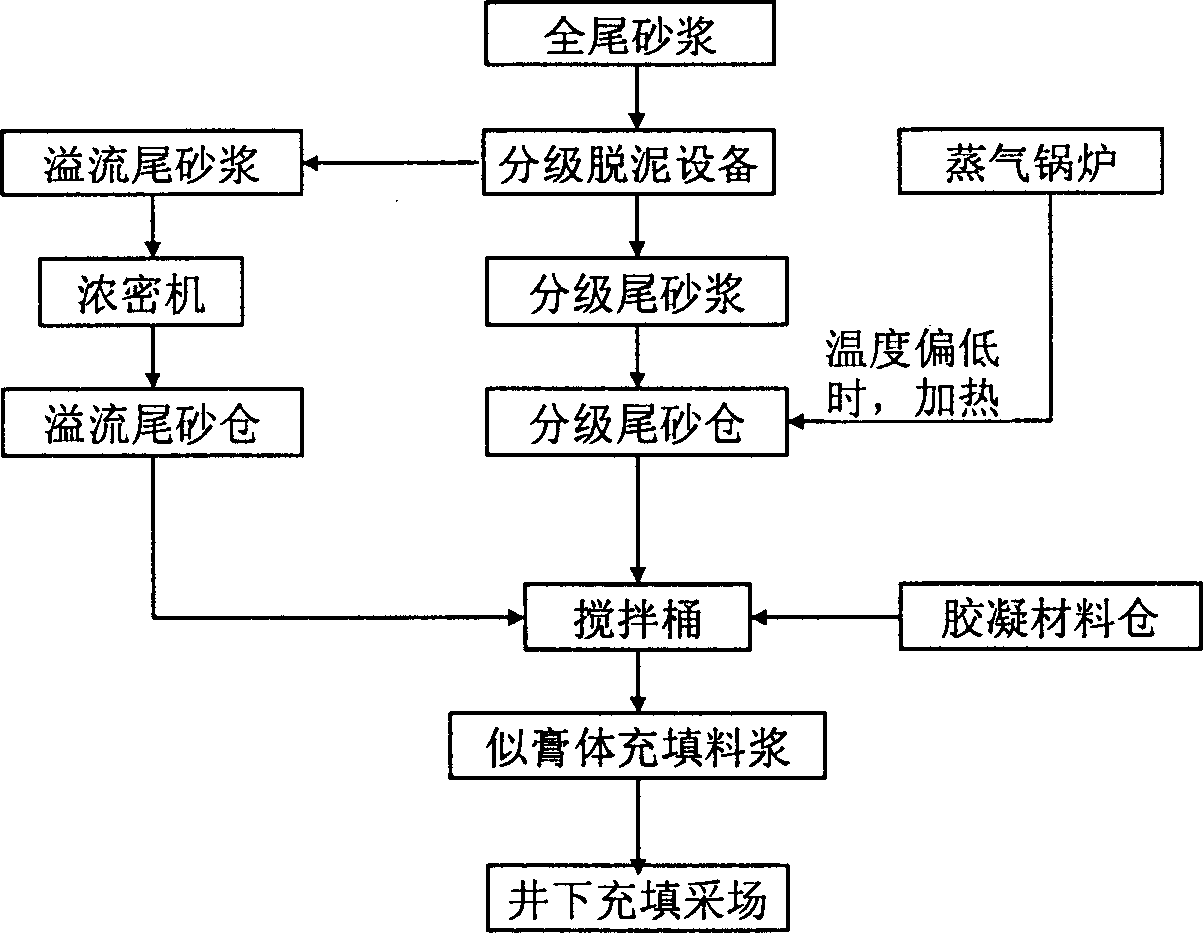

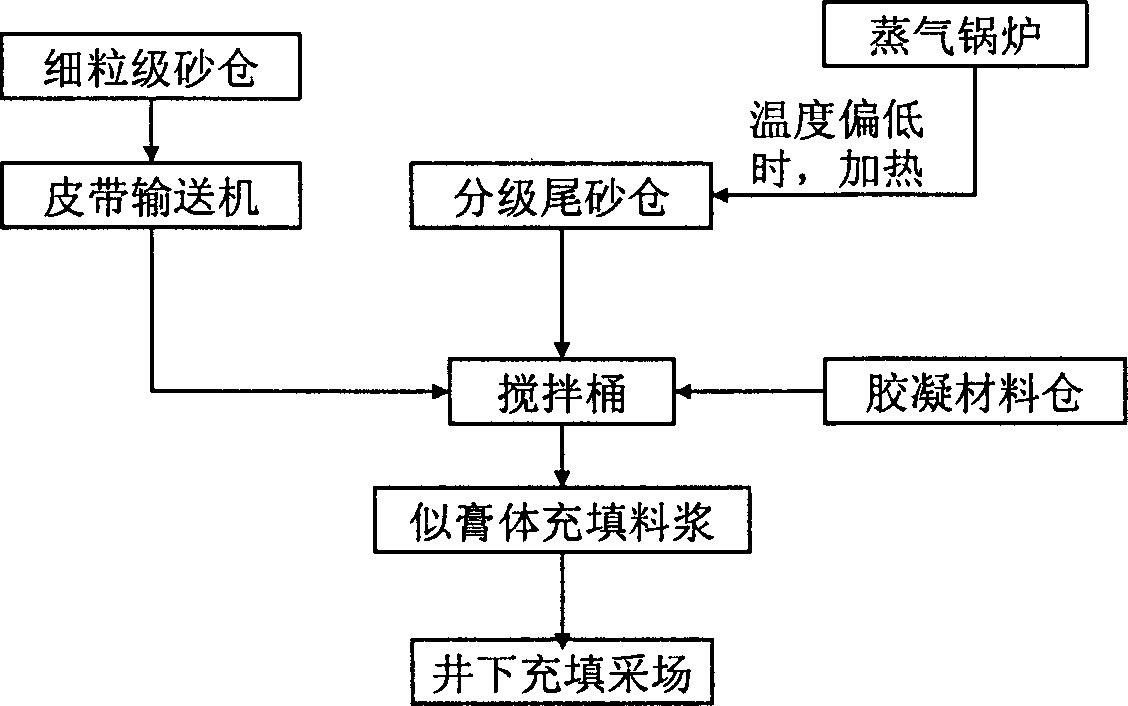

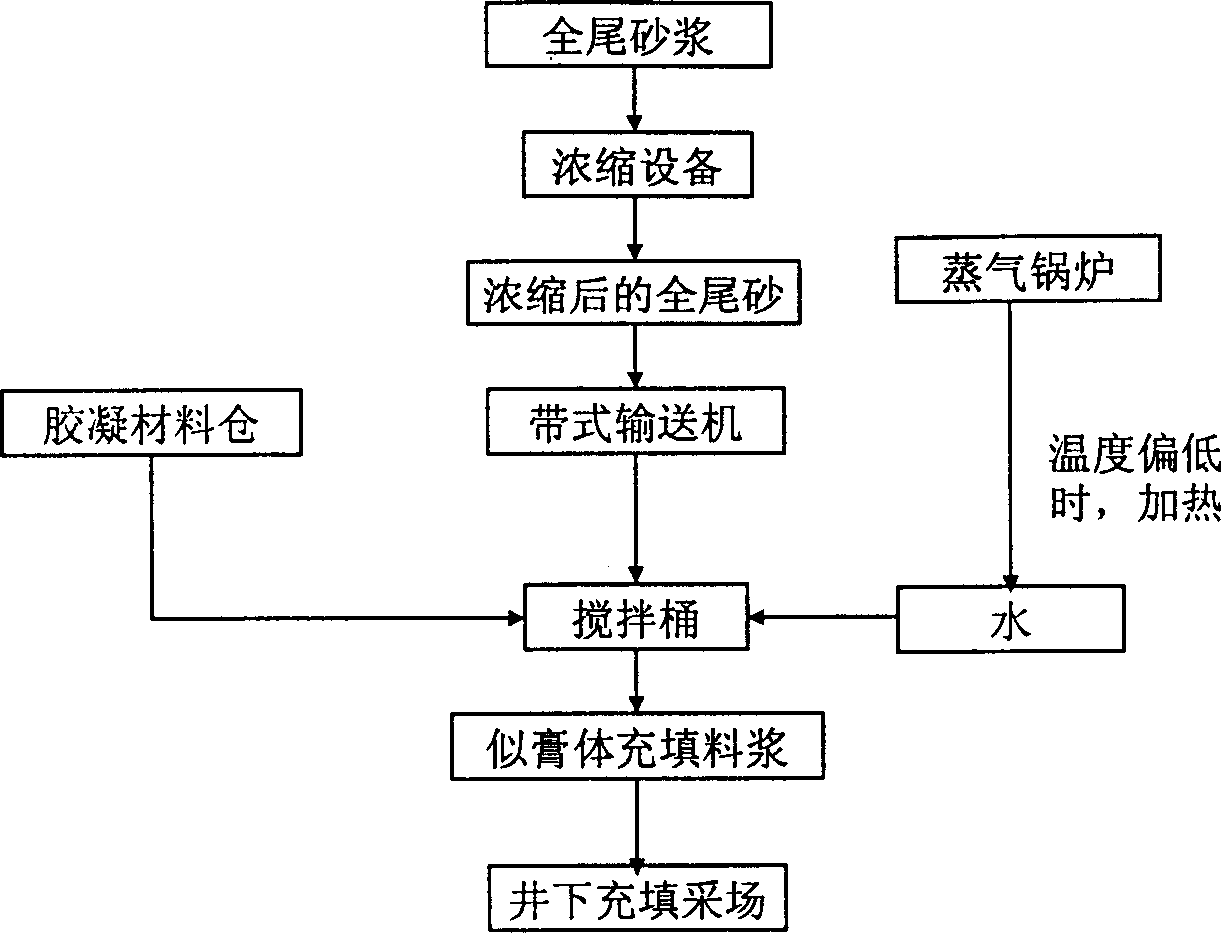

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

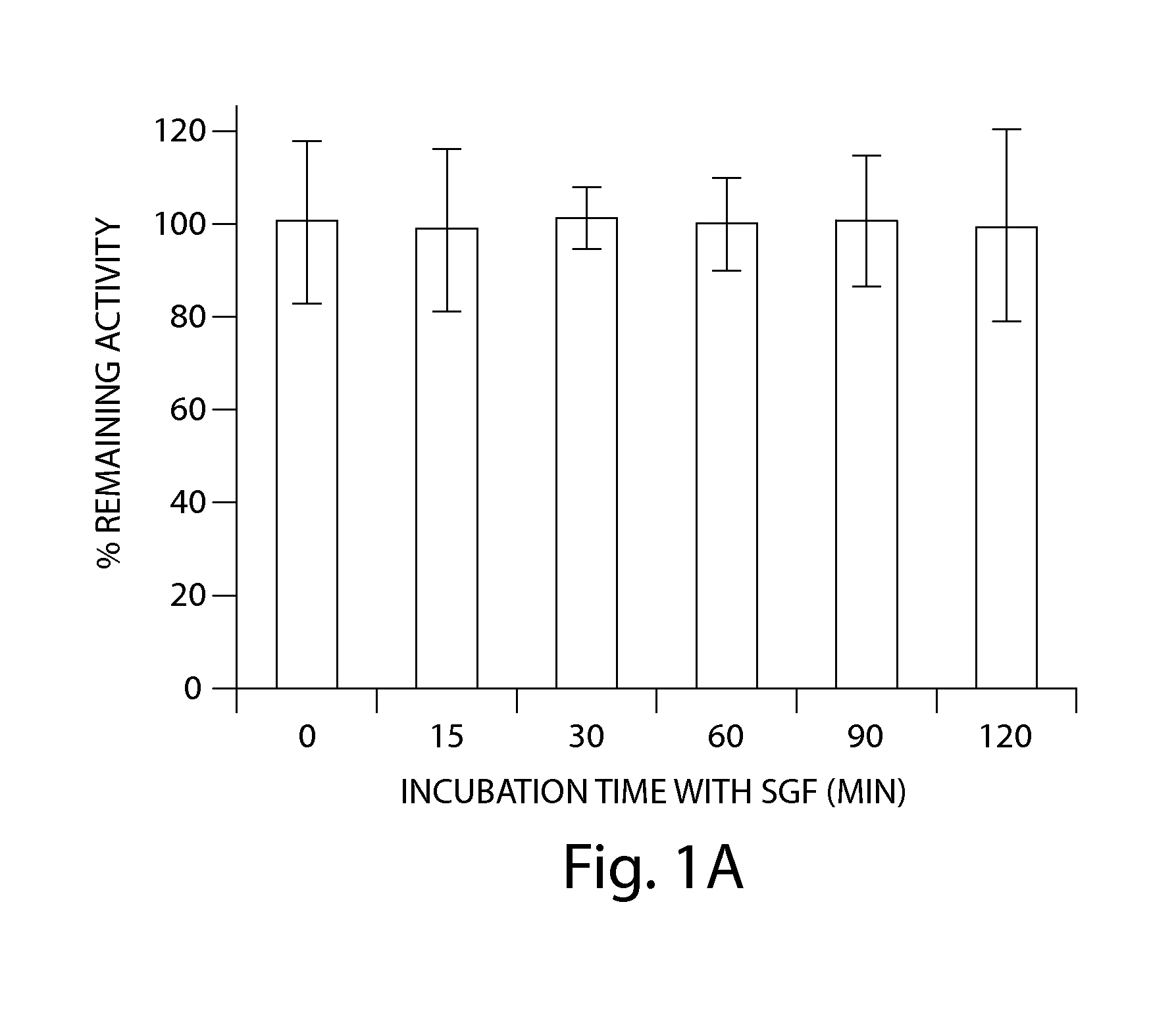

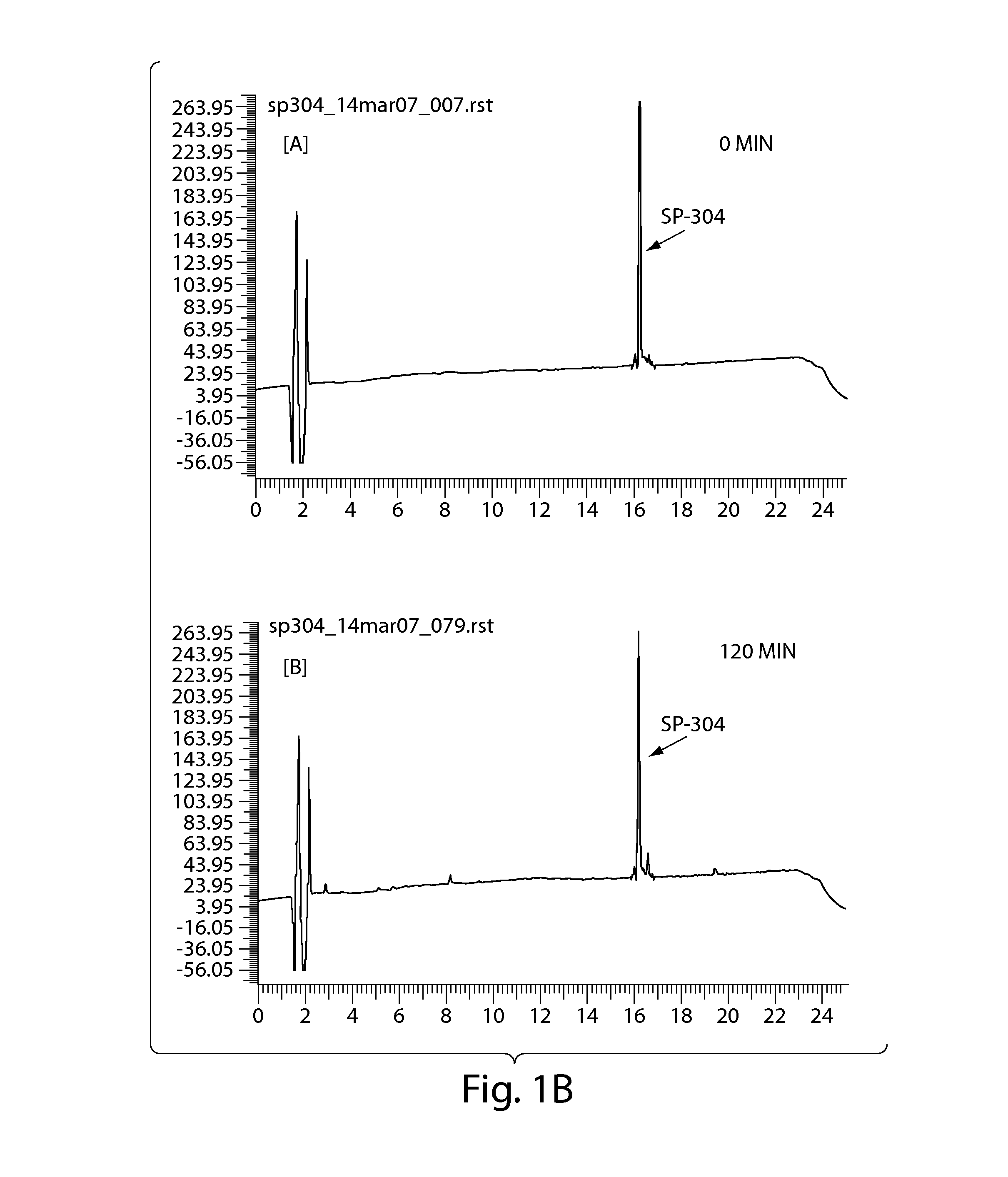

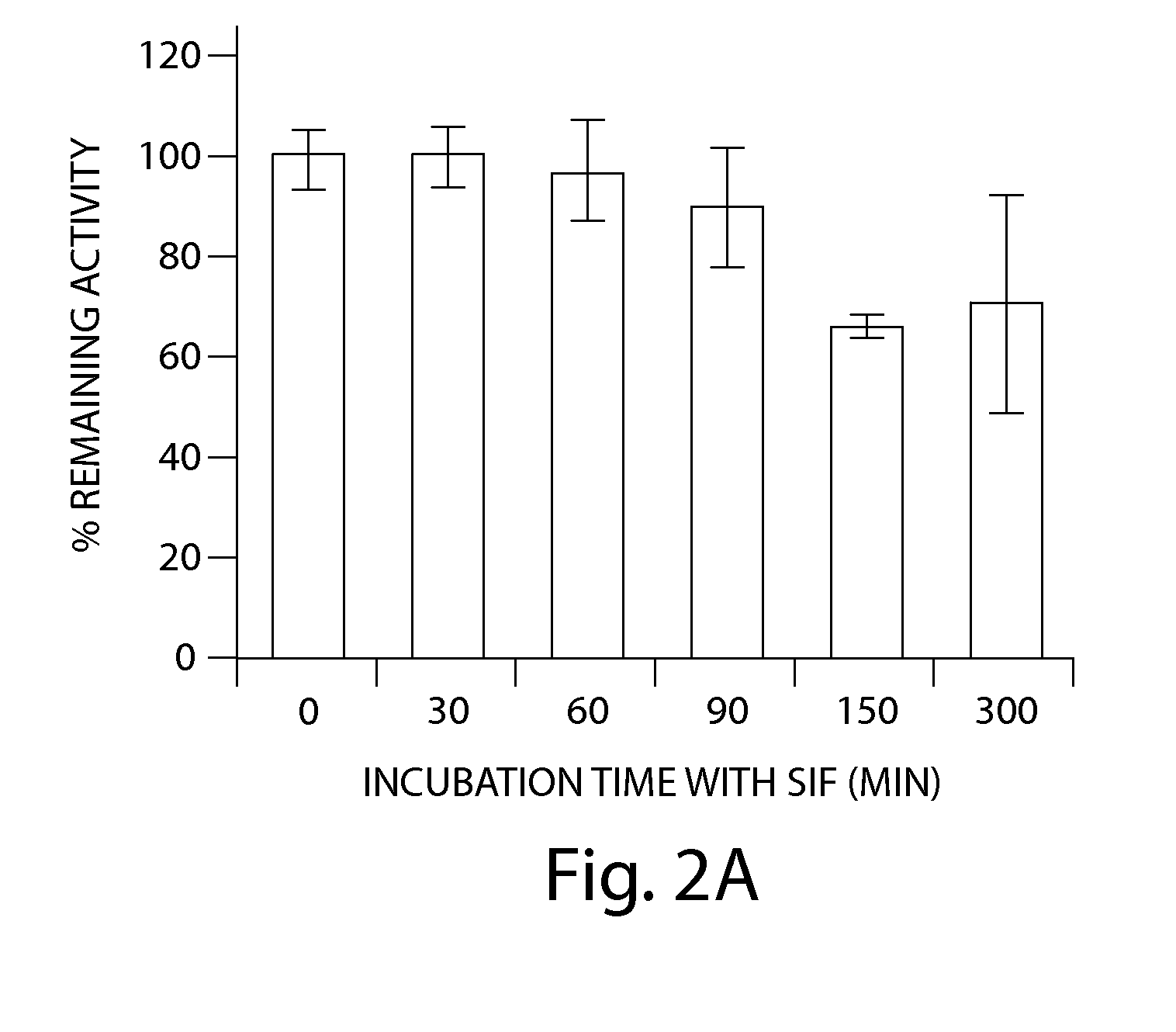

Formulations of guanylate cyclase c agonists and methods of use

InactiveUS20100221329A1Minimize exposureReducing and eliminating degradationAntibacterial agentsBiocideDiseaseGastrointestinal cancer

The invention provides novel formulations of guanylate cyclase-C (“GCC”) agonist peptides and methods for their use in the treatment of gastrointestinal diseases and disorders, including gastrointestinal cancer. The GCC agonist formulations of the invention can be administered either alone or in combination with one or more additional therapeutic agents, preferably an inhibitor of cGMP-dependent phosphodiesterase or a laxative.

Owner:SYNERGY PHARMA

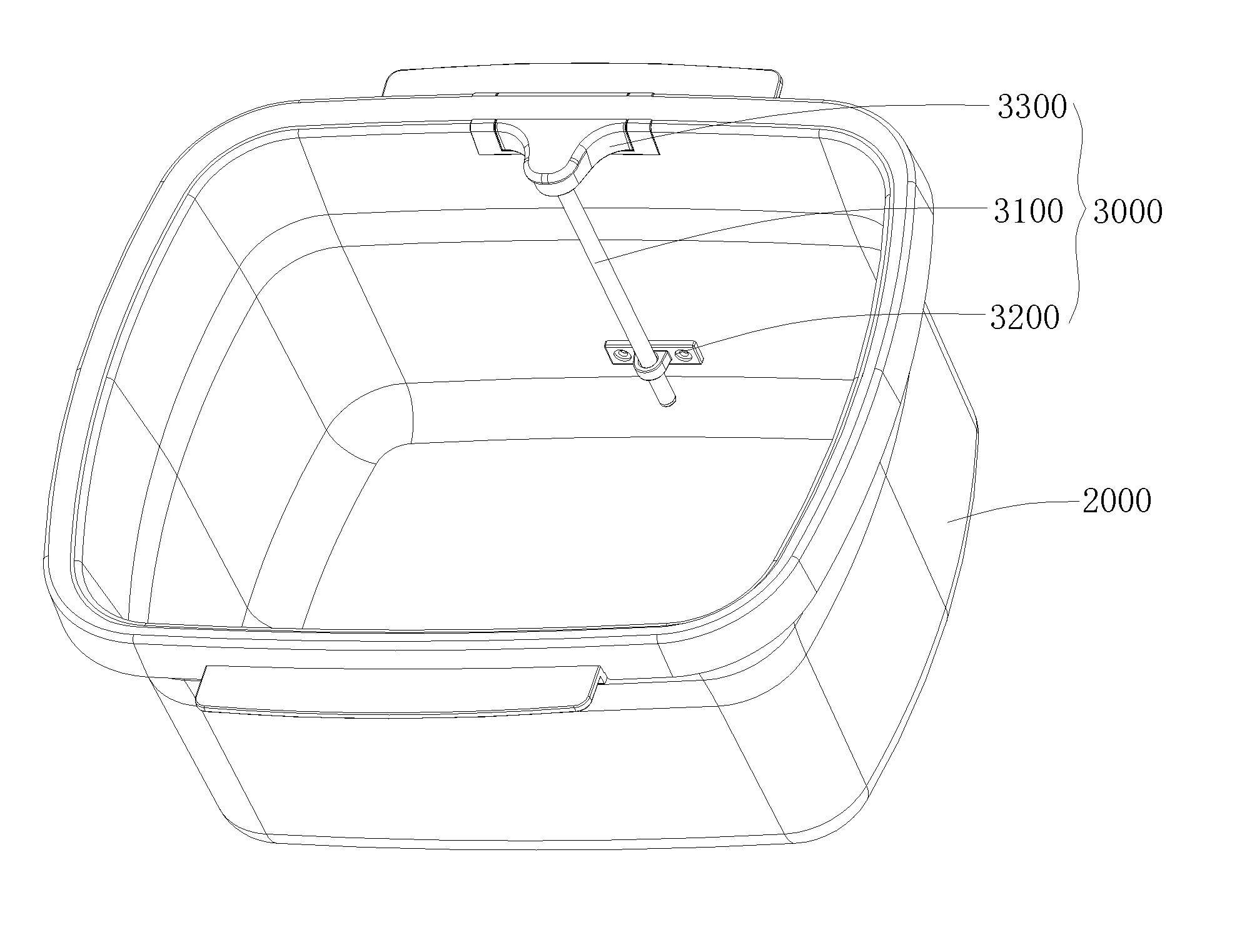

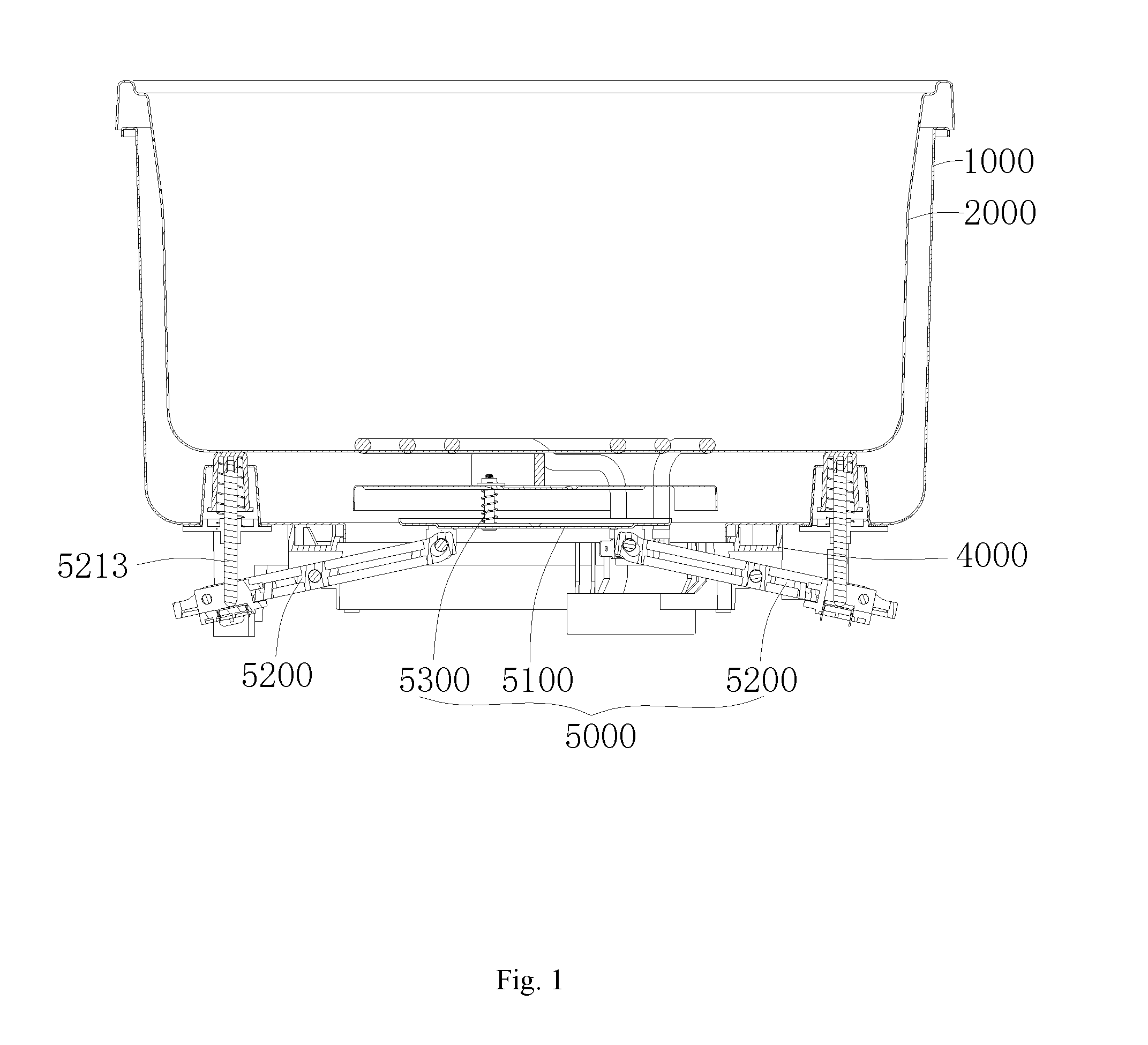

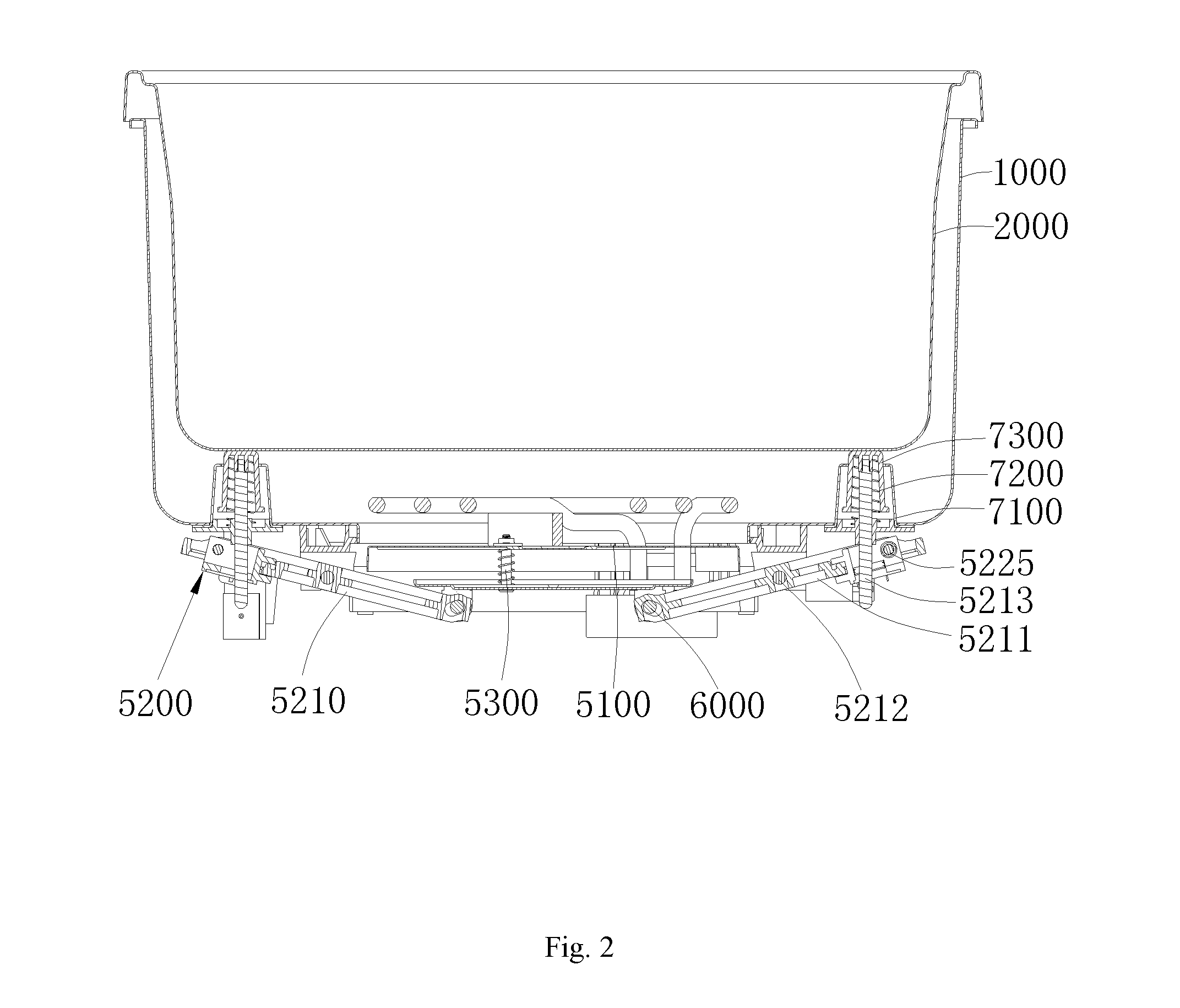

Slow cooker

ActiveUS20160367061A1Ensuring qualityAccurate detectionWarming devicesVessels with intergral heatingEngineeringControl circuit

A slow cooker comprises a case; a control circuit component and an inner pot for receiving food are disposed inside the case; the inner pot is arranged inside the case in a pick-and-place manner; a temperature detection component for temperature detection is arranged on the sidewall of the inner pot, and a mount seat connected to the case is arranged at the bottom of the inner pot; a liftable heating apparatus is arranged on the mount seat; the heating apparatus comprises a heating component and a lifting mechanism which can drive the heating component upwards and downwards. A temperature detection component arranged in the slow cooker is capable of detecting the temperature in the inner pot precisely; a lifting mechanism arranged in the slow cooker is capable of adjusting the distance from the inner pot to preheat the inner pot, improving cooking efficiency.

Owner:T F ELECTRICAL TECH SHENZHEN

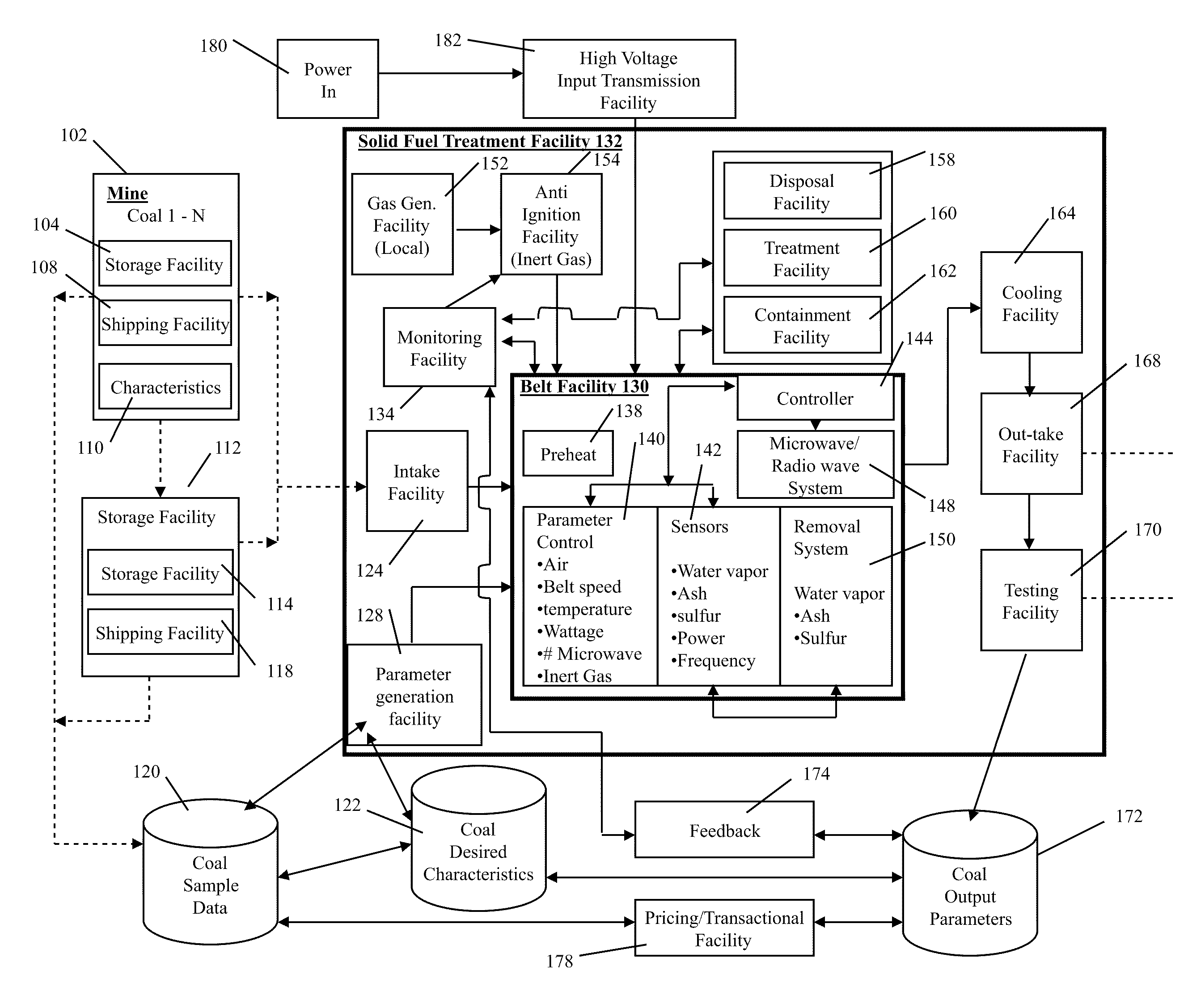

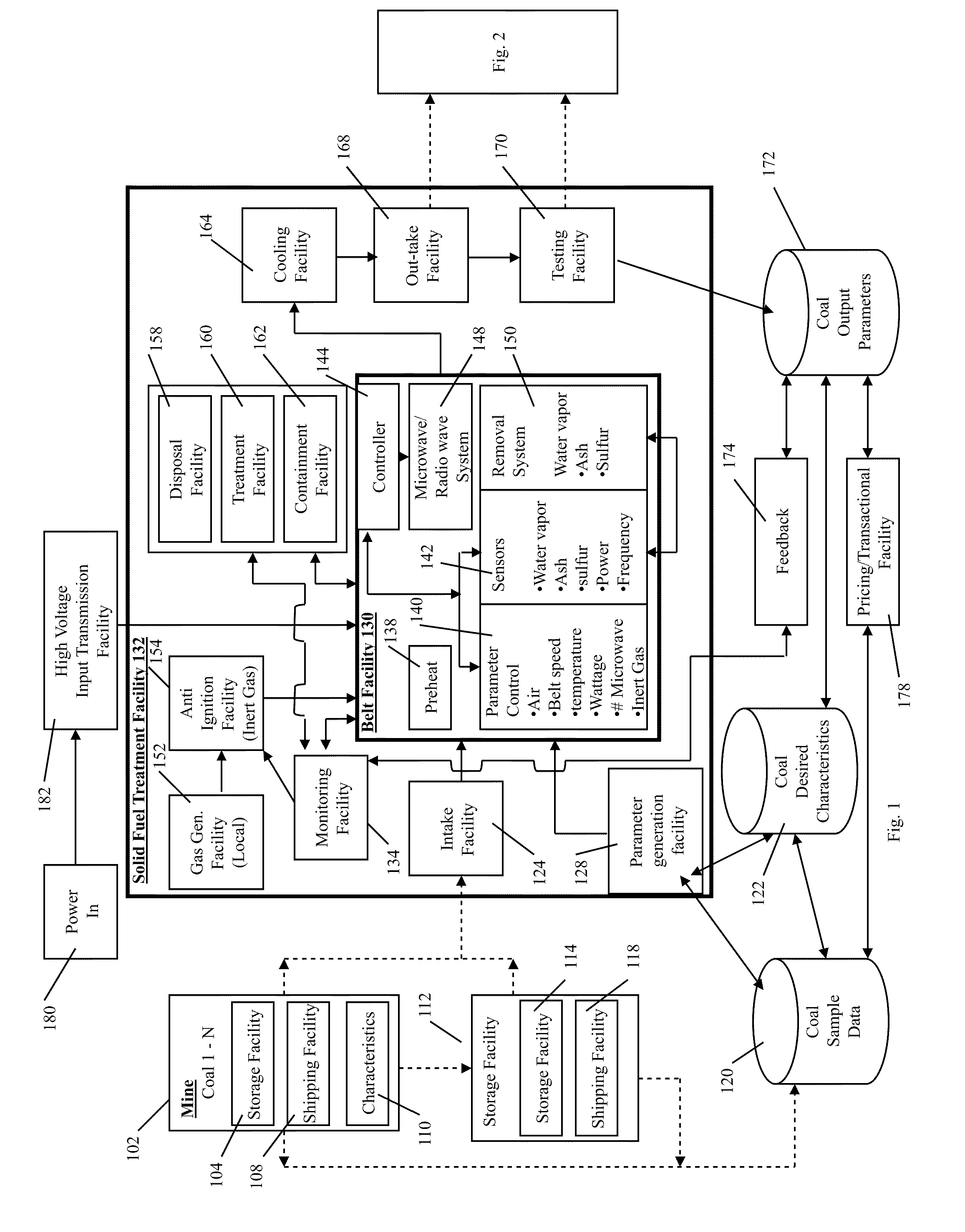

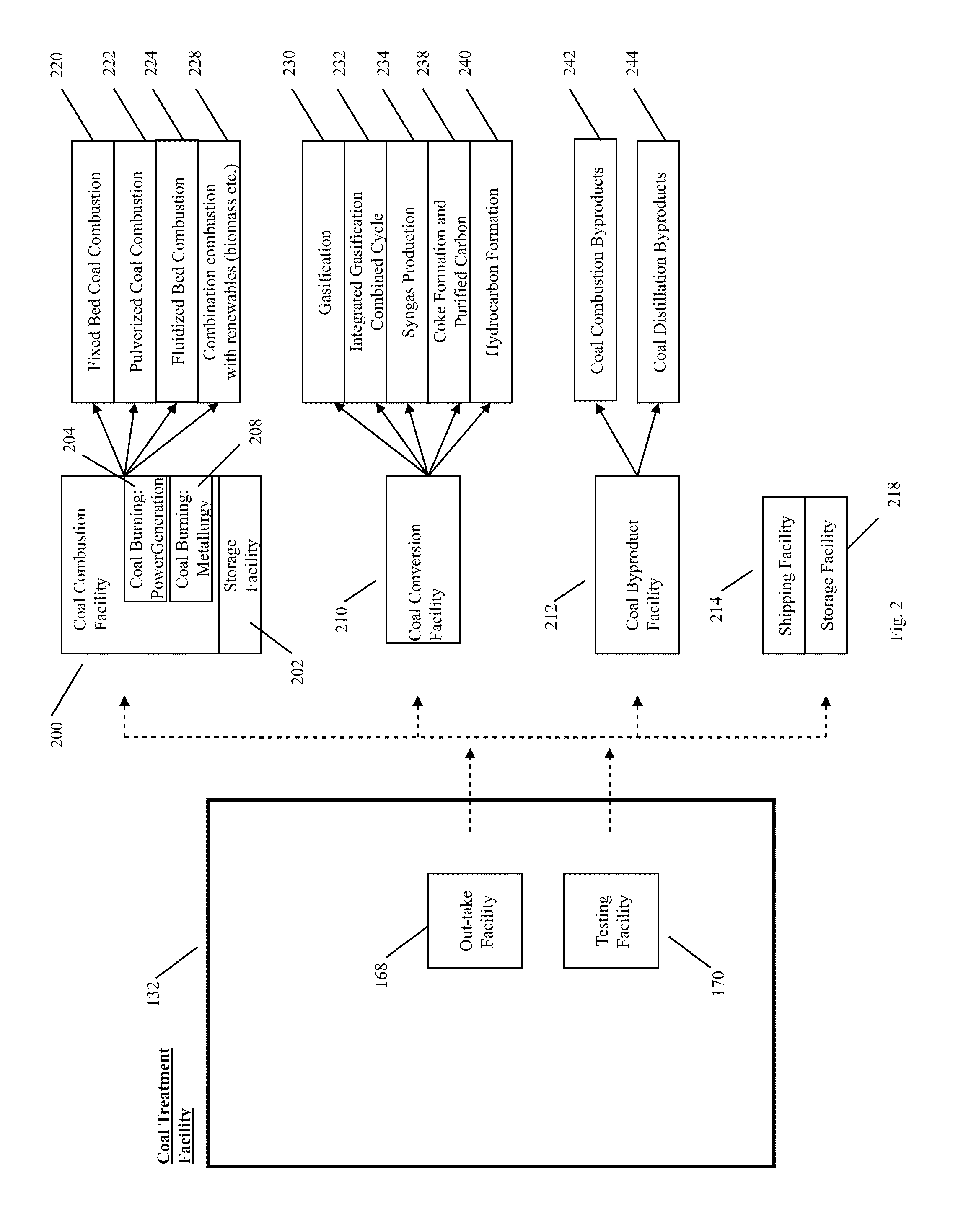

Methods and systems for processing solid fuel

InactiveUS20090272028A1Minimize return lossLow microwave lossBiofuelsSolid fuelsFuel treatmentSolid fuel

In embodiments of the present invention, a method of heat treating a solid fuel briquette may include heating the solid fuel briquette using energy from at least one of a heat furnace or an electromagnetic energy system of a solid fuel treatment facility as the solid fuel briquette is moved through the treatment facility to a specified internal temperature, and sealing the heat-treated solid fuel briquette in a vessel for a duration of time.

Owner:COALTEK INC

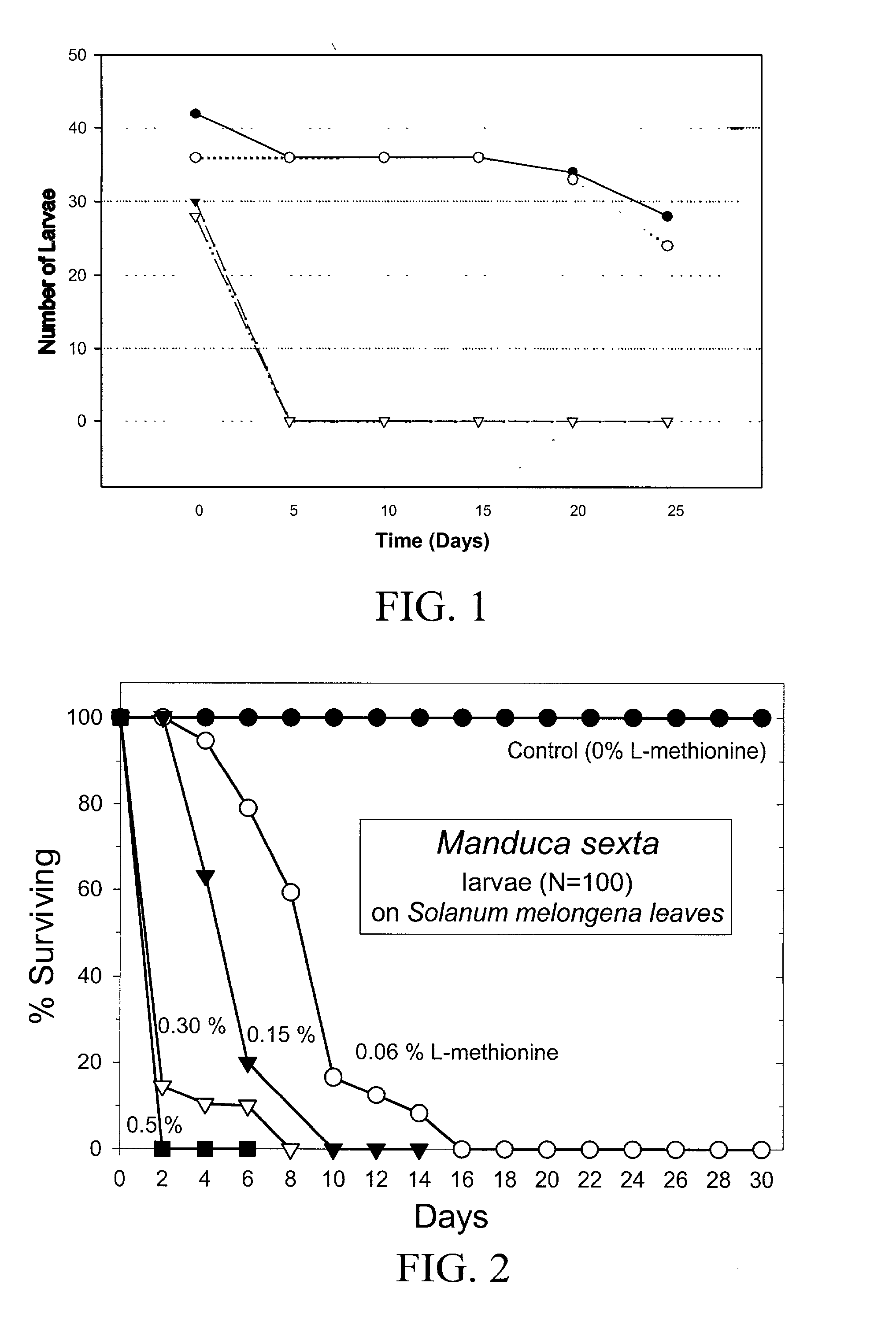

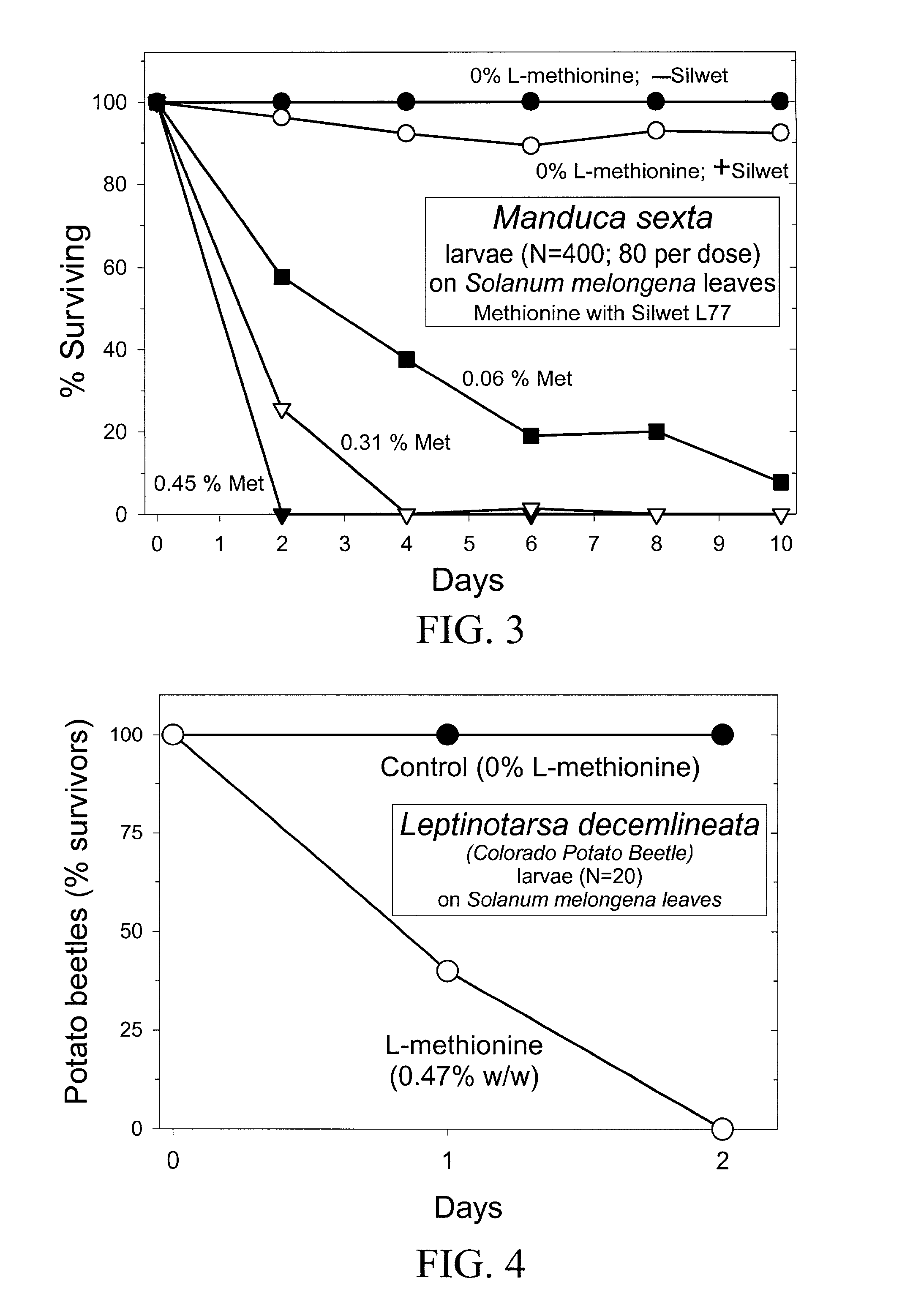

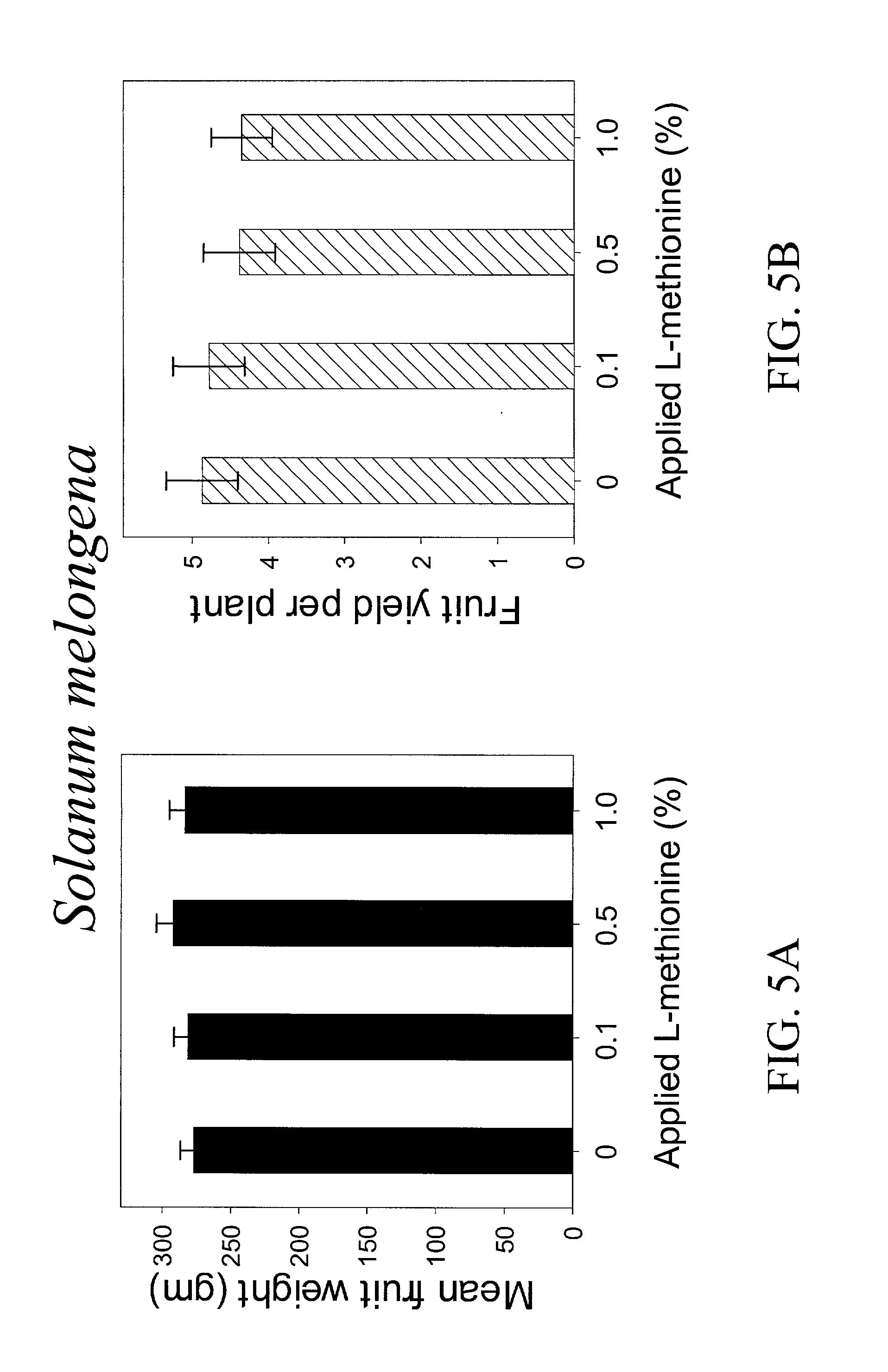

Materials and methods for controlling pests

InactiveUS20030154508A1Low toxicitySustainable, pesticide-free food supplyOrganic active ingredientsBiocideSolute transportersMethionine biosynthesis

Owner:FLORIDA UNIV OF A FLORIDA +1

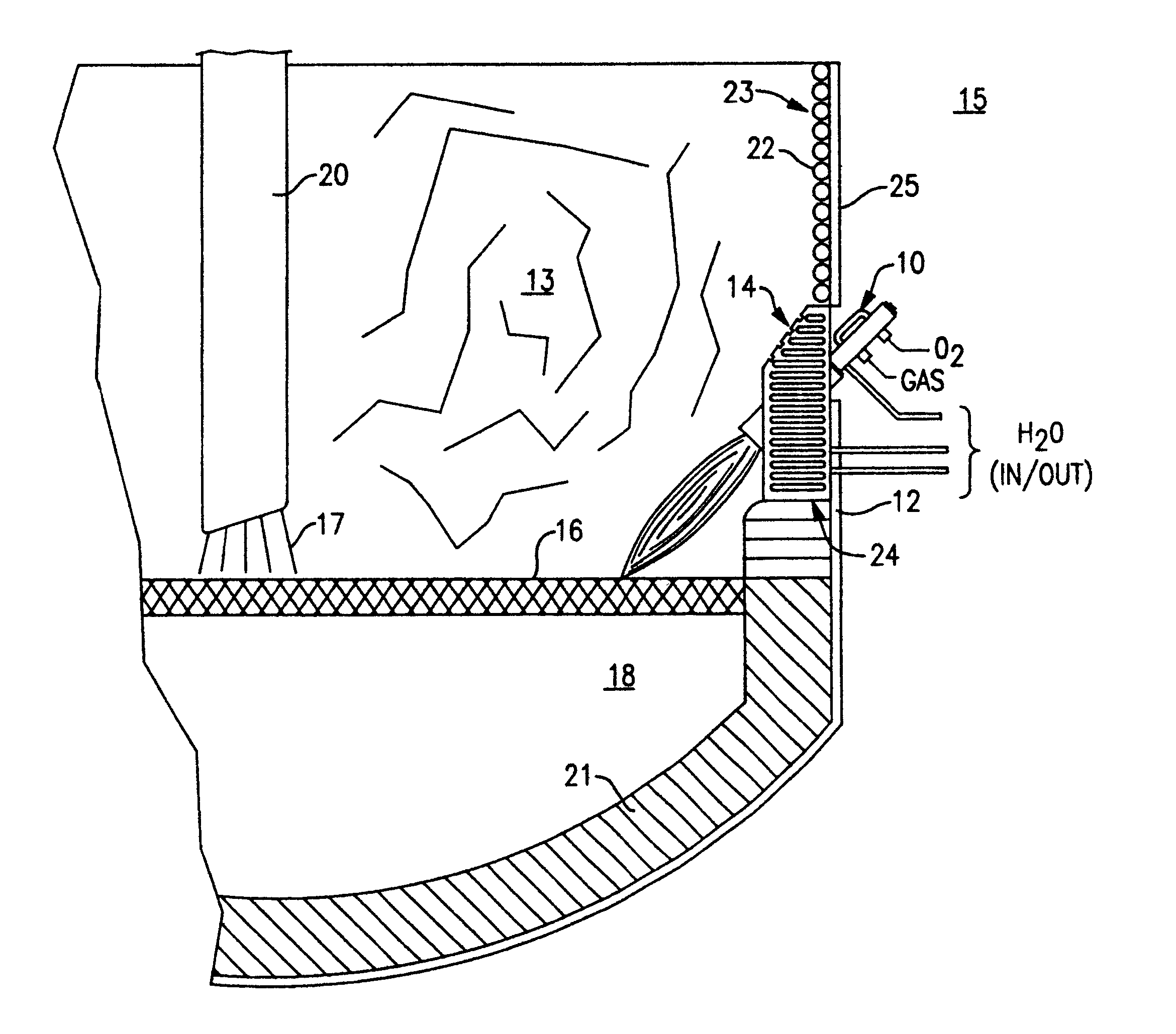

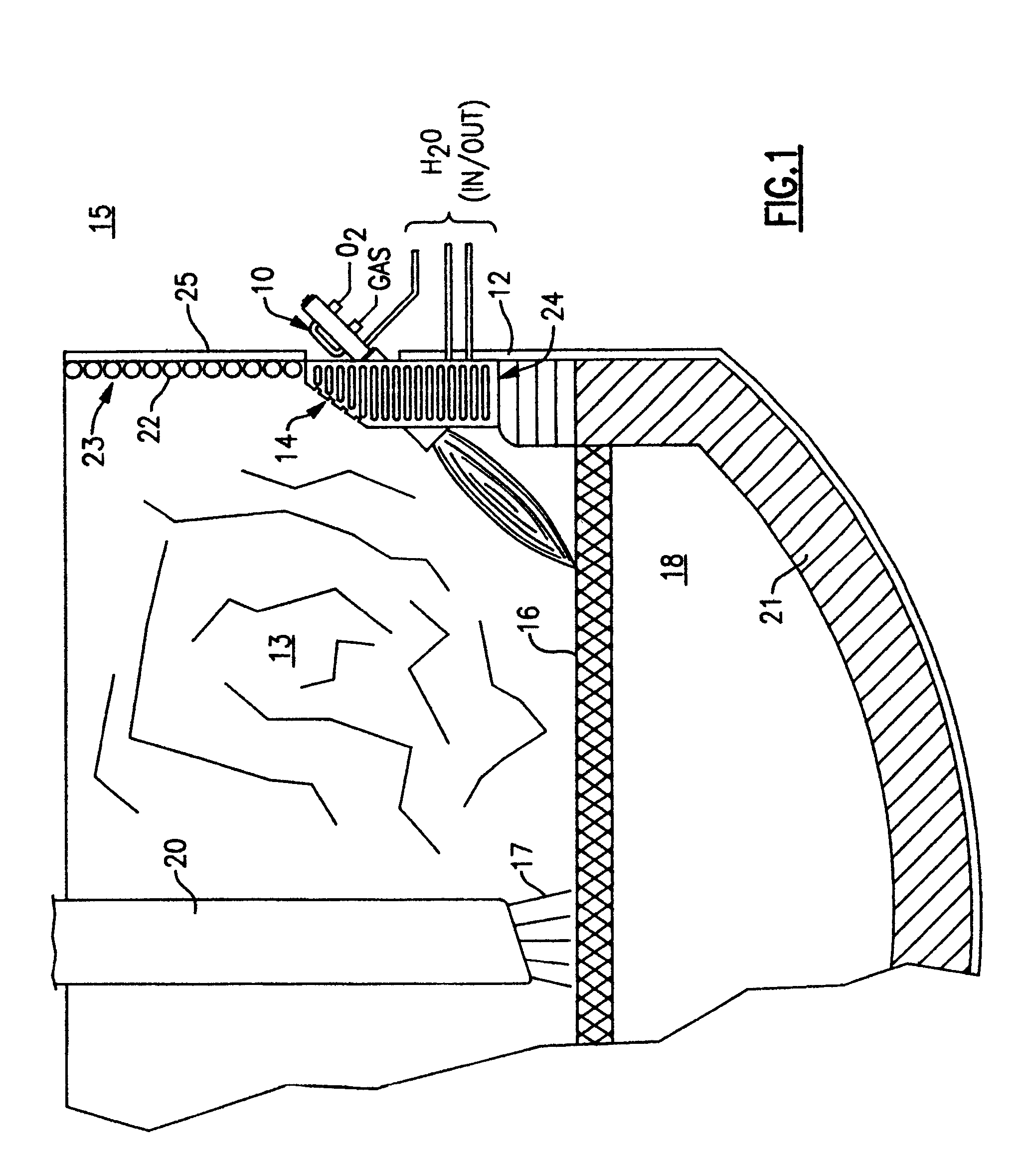

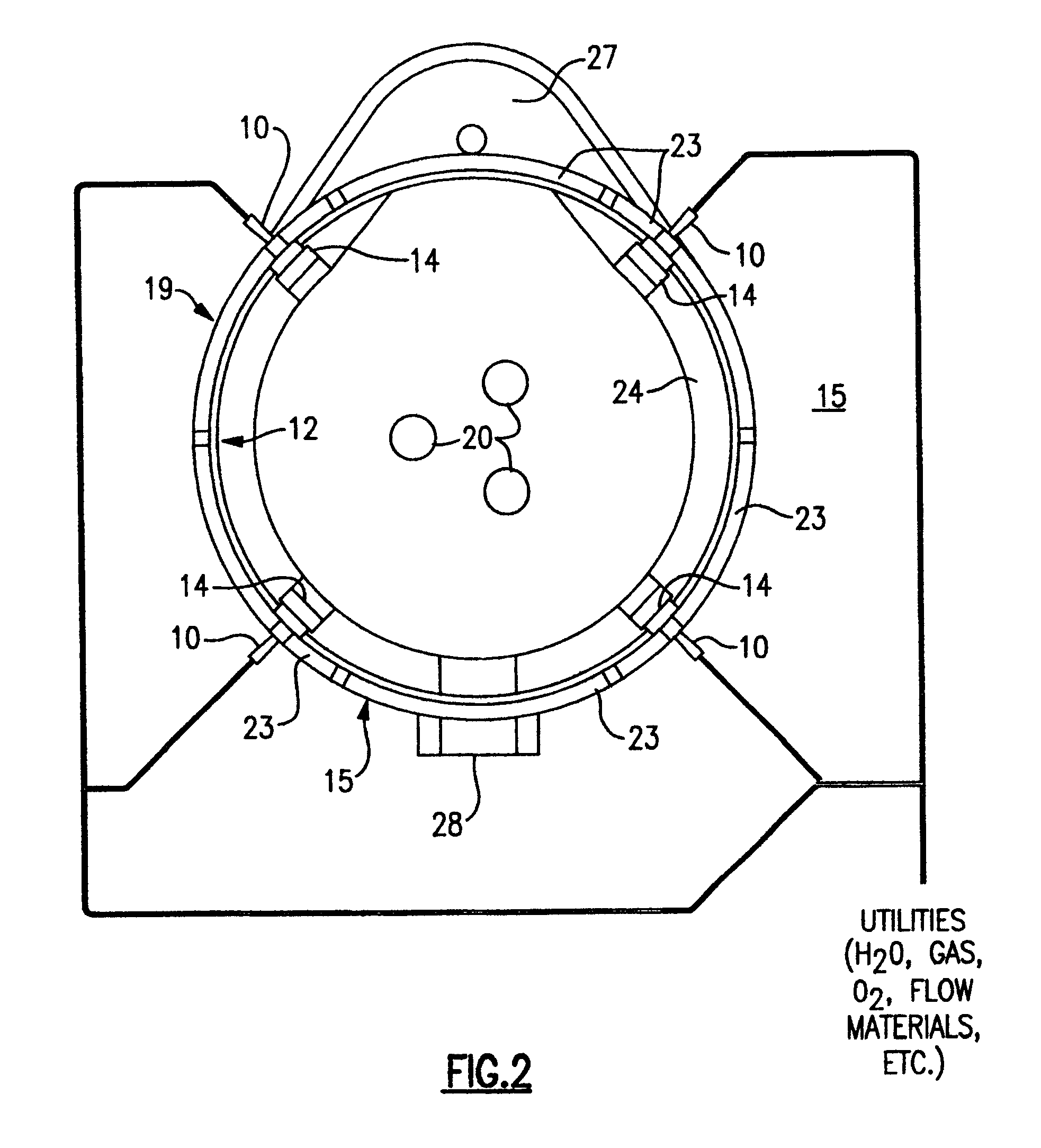

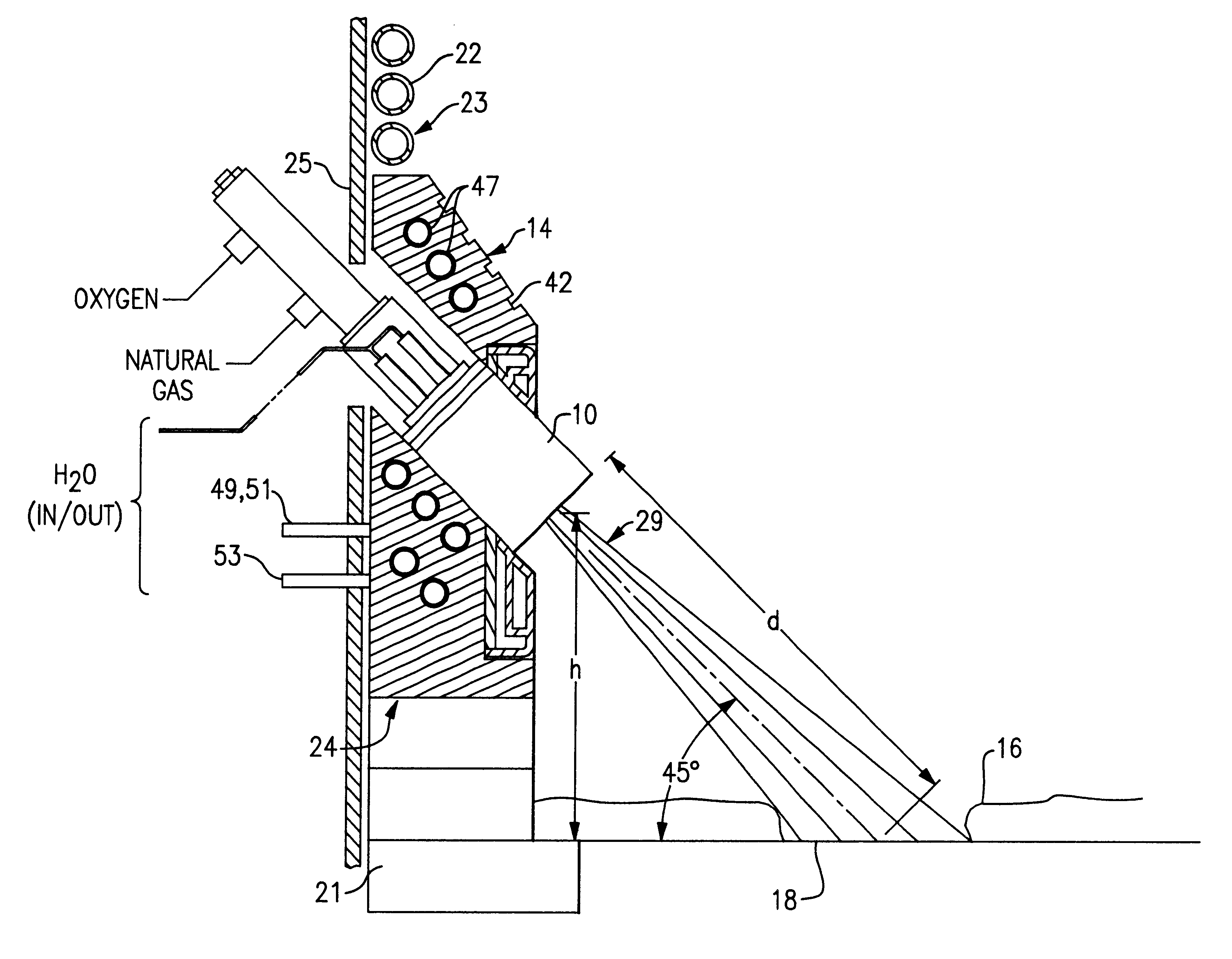

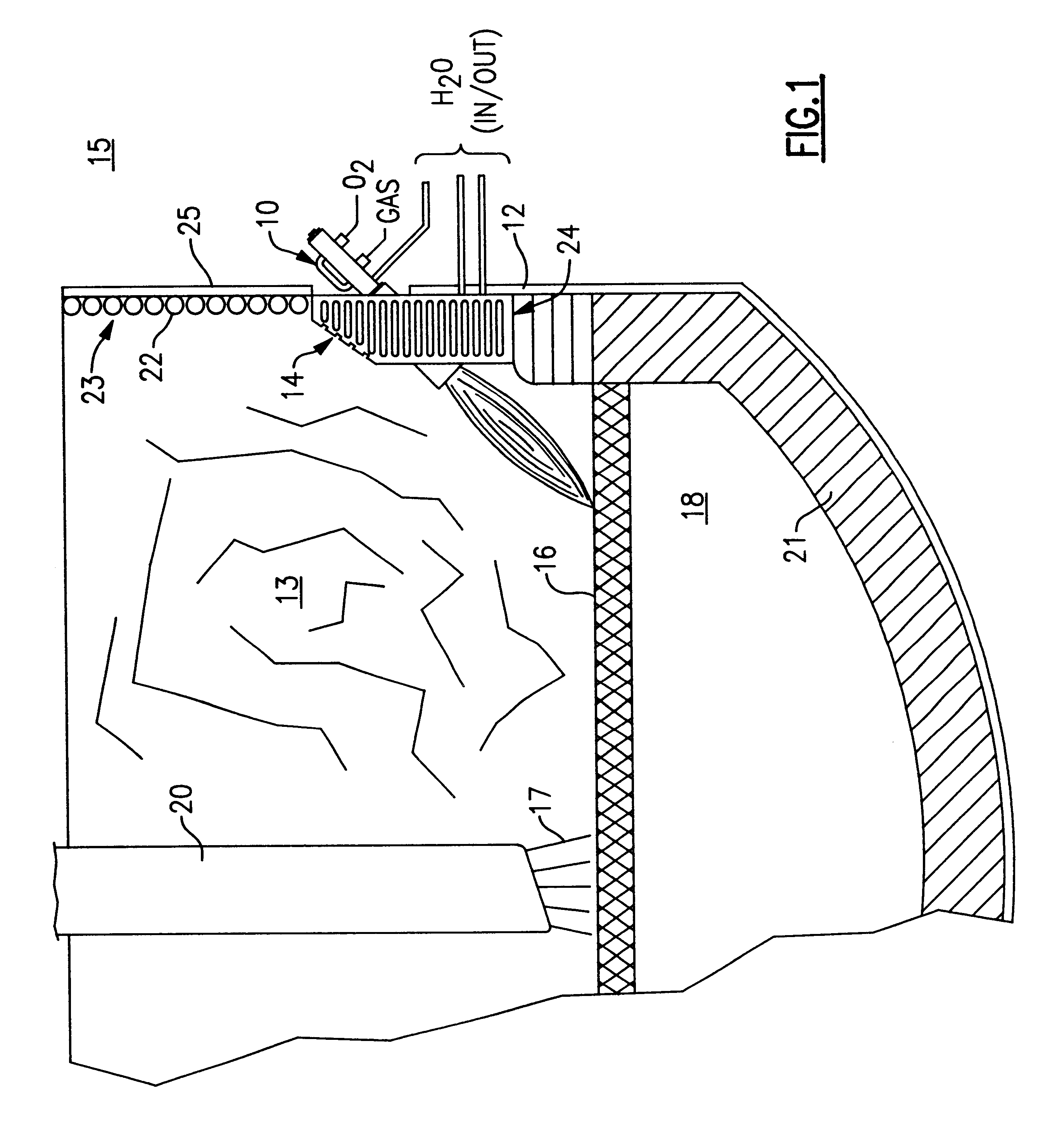

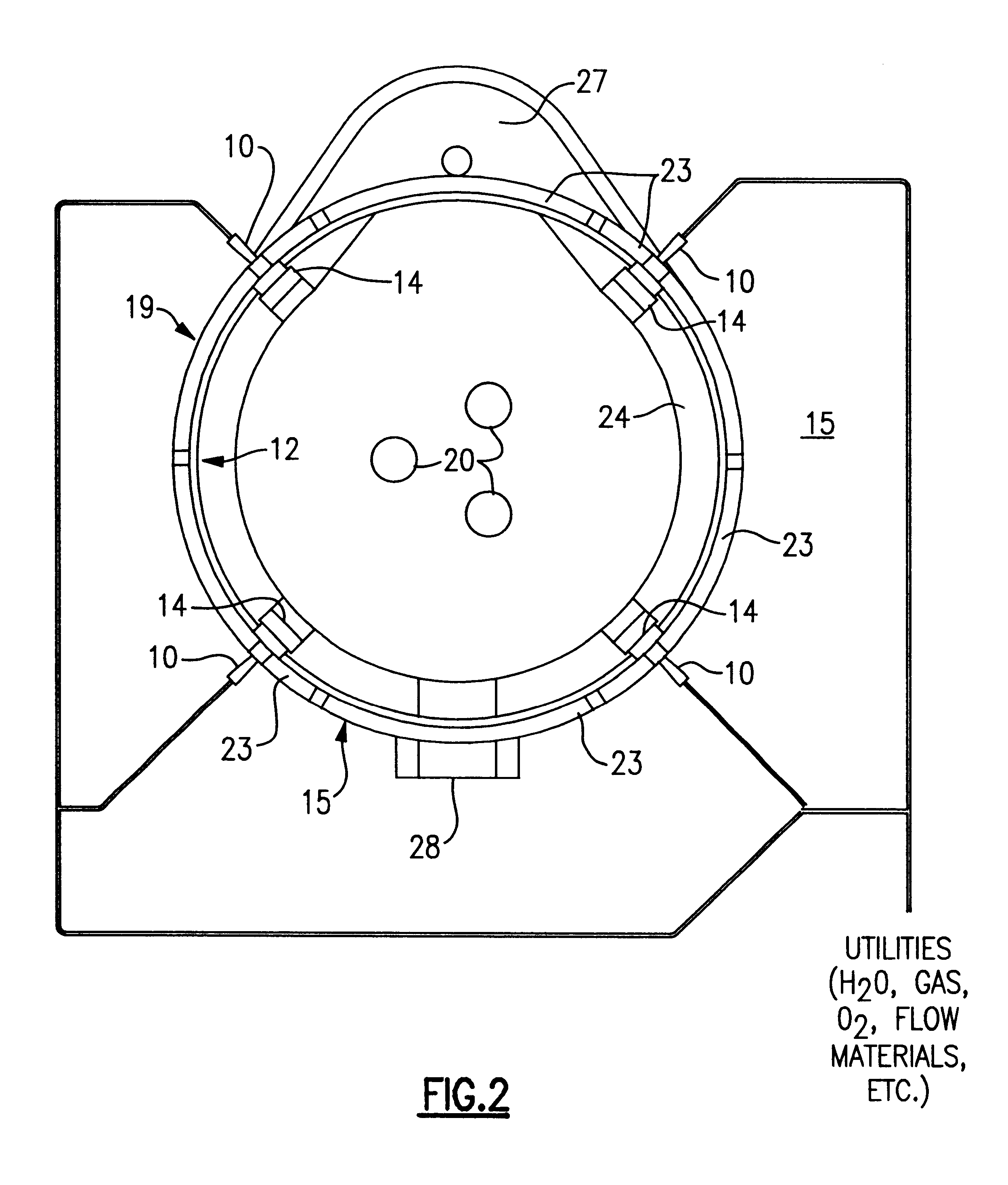

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

Mounting arrangement for auxiliary burner or lance

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

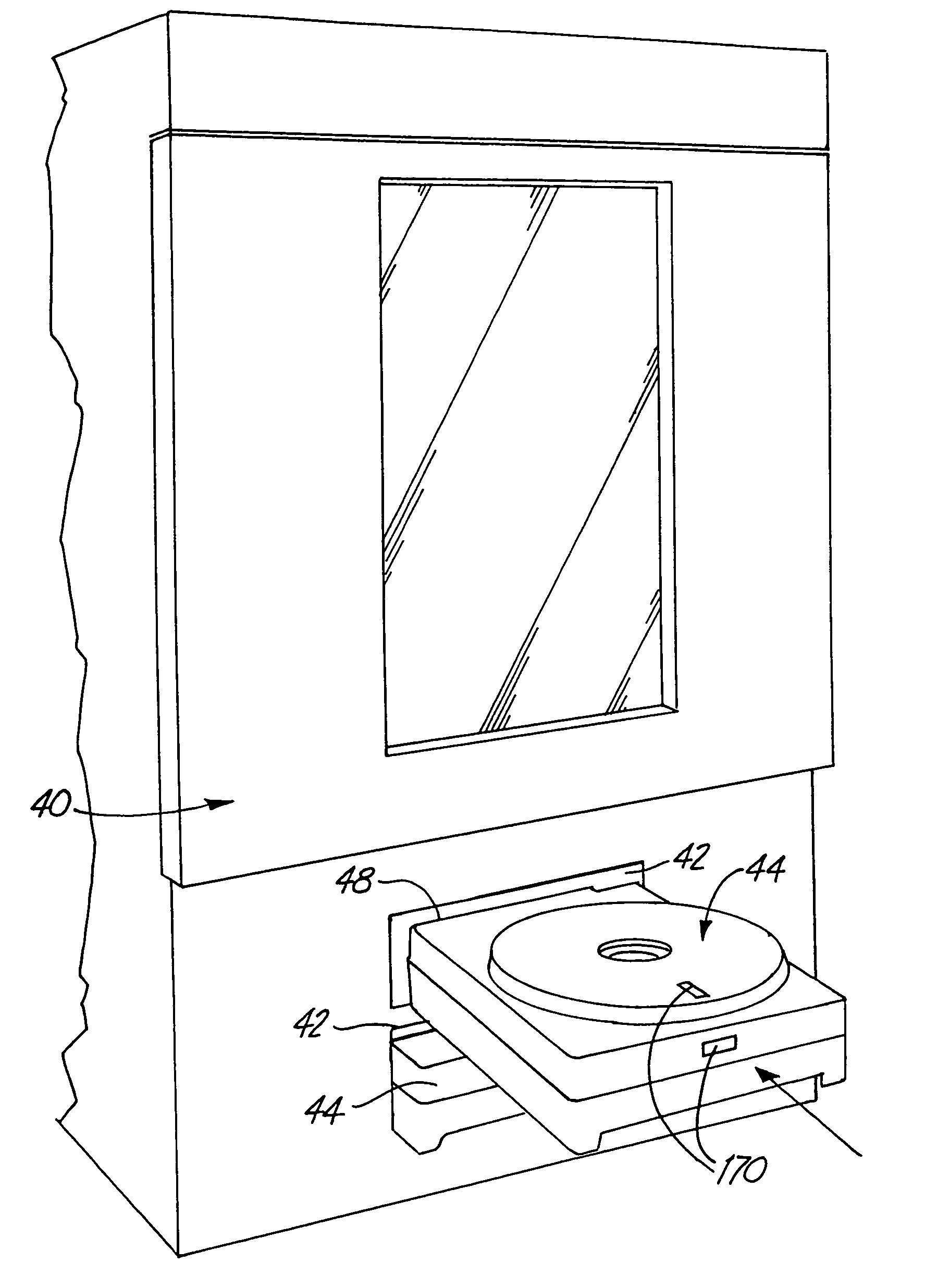

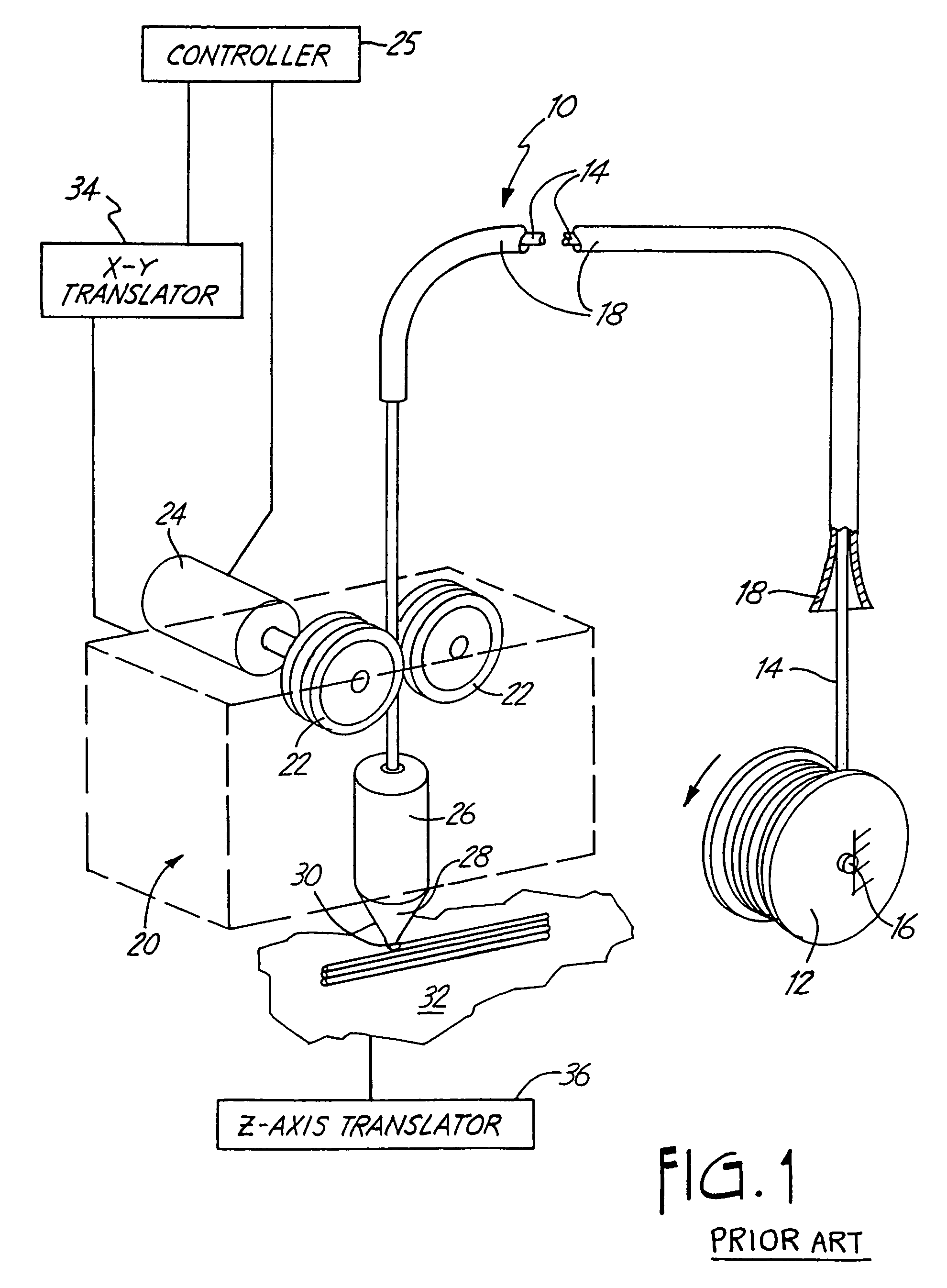

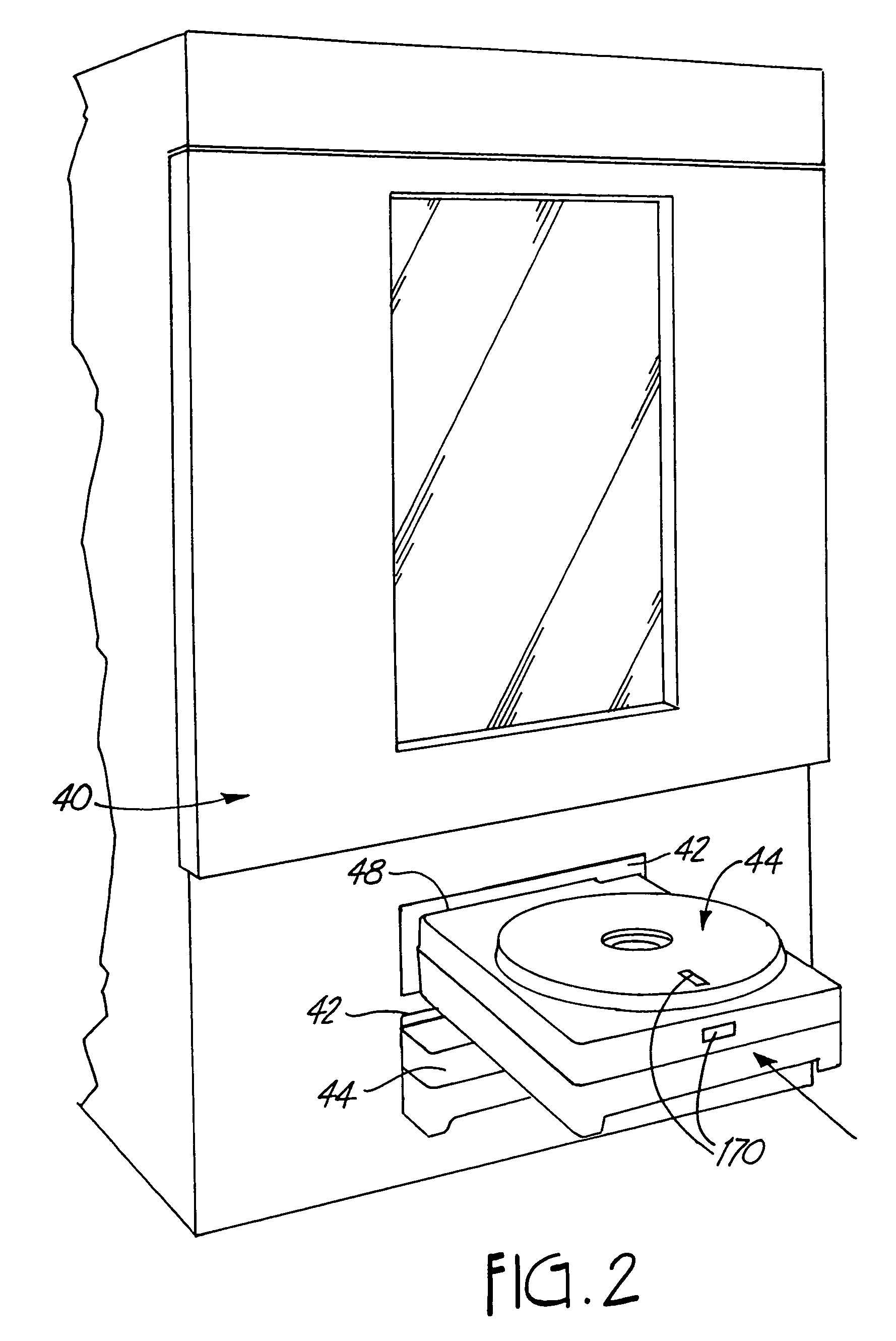

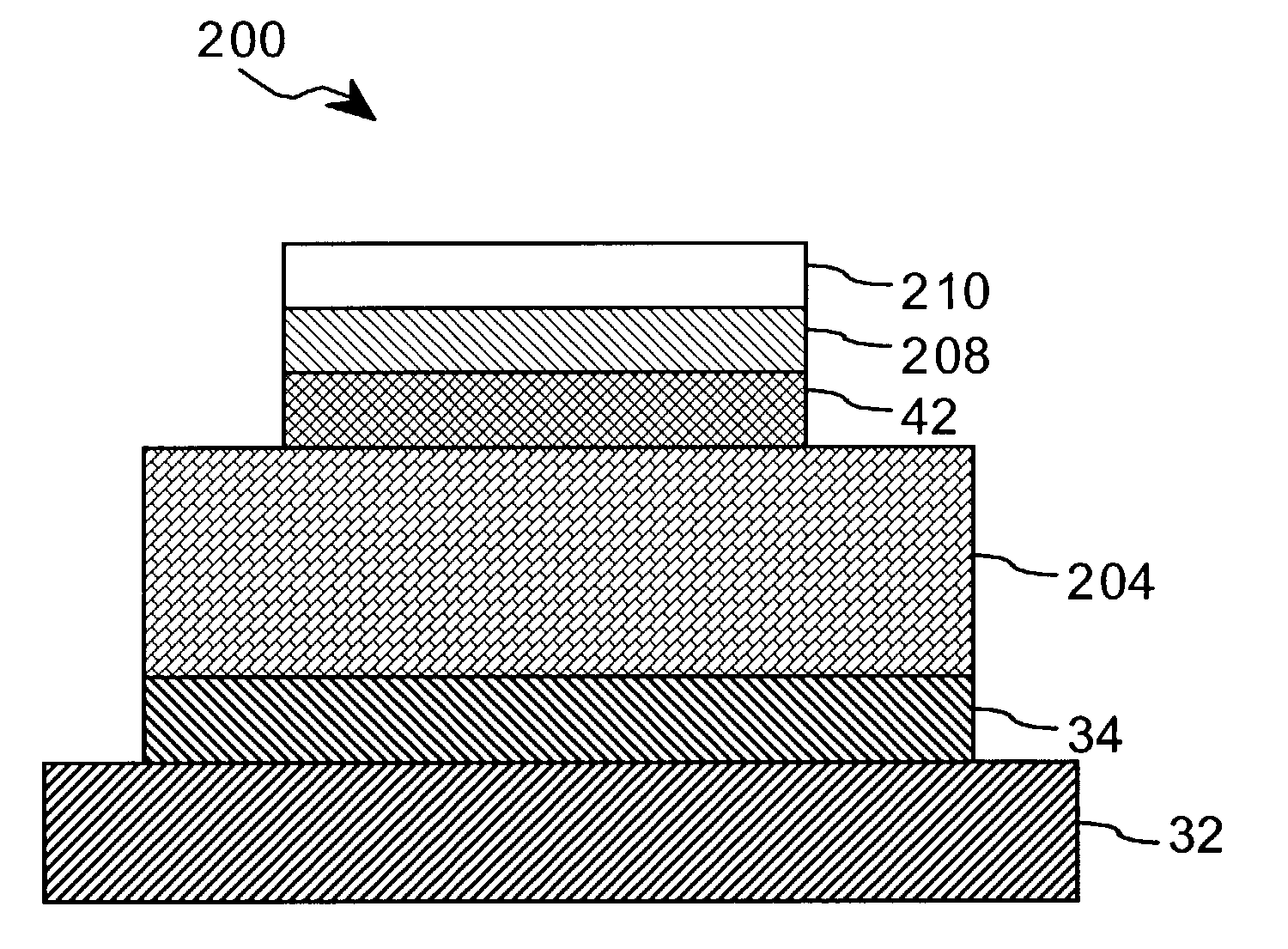

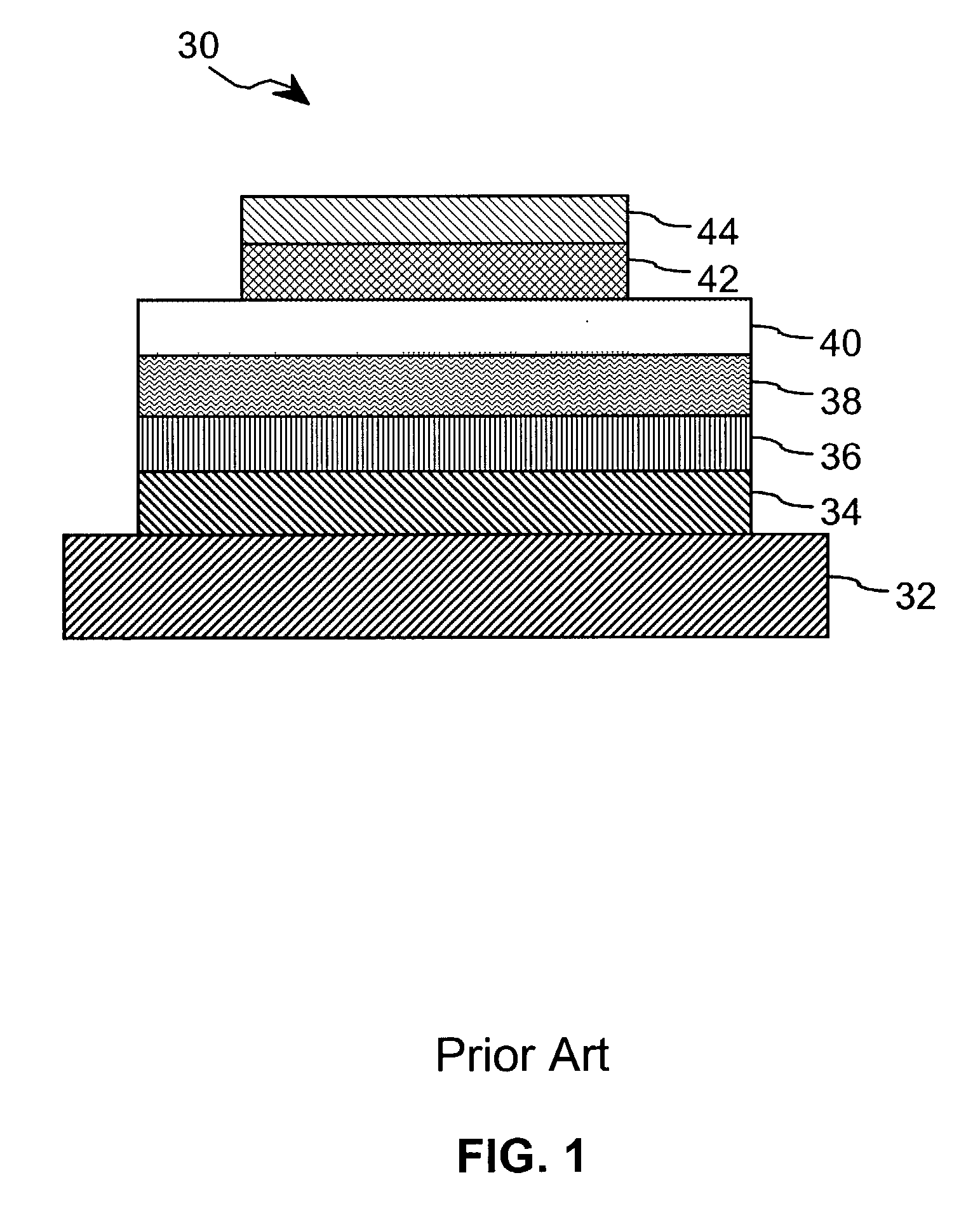

Method for loading filament in an extrusion apparatus

InactiveUS7169337B2Protect environmentProgramme controlAdditive manufacturing apparatusDimensional modelingMoisture

Filament is loaded into an extrusion apparatus, such as a three-dimensional deposition modeling machine, by inserting a cassette containing filament into the apparatus. A filament strand from the cassette is then advanced into the machine, such as by operating a thumb wheel or a follower wheel on the cassette. The filament loading method of the present invention provides a convenient manner of loading and unloading filament in a three-dimensional modeling machine, and can be implemented in a manner that protects the filament from environmental moisture.

Owner:STRATSYS INC

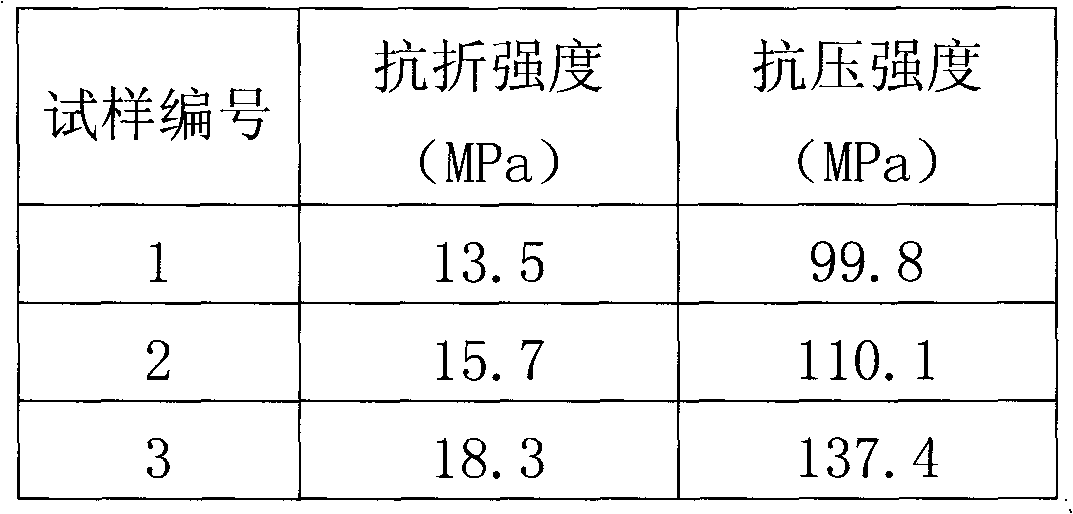

Mineral polymeric material based active powder concrete and preparation method thereof

ActiveCN102001846AHigh strengthIncreased durabilitySolid waste managementCeramic shaping apparatusFiberUltimate tensile strength

The invention relates to a mineral polymeric material based active powder concrete and a preparation method thereof. The mineral polymeric material based active powder concrete is made of a gelled material, aggregate, an exciting agent, water, a water reducer and steel fiber in a mass ratio of 1: 0.8-1.3: 0.01-0.2: 0.1-0.3: 0.005-0.07: 0.01-0.25. The preparation method comprises the steps of: pouring the weighed gelled material, aggregate and steel fiber in an agitator and agitating evenly, adding the water in which the exciting agent and the water reducer are dissolved, mixing evenly and molding through vibration or compression, and carrying out autoclave curing or steamed curing on a molded test piece to obtain the mineral polymeric material based active powder concrete. By adopting thepreparation thought of introducing the mineral polymeric material, abundant solid wastes are mixed in the active powder concrete successfully; and the prepared active powder concrete not only has high strength and good durability, but also achieves the effects of reducing the cost and protecting the environment.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

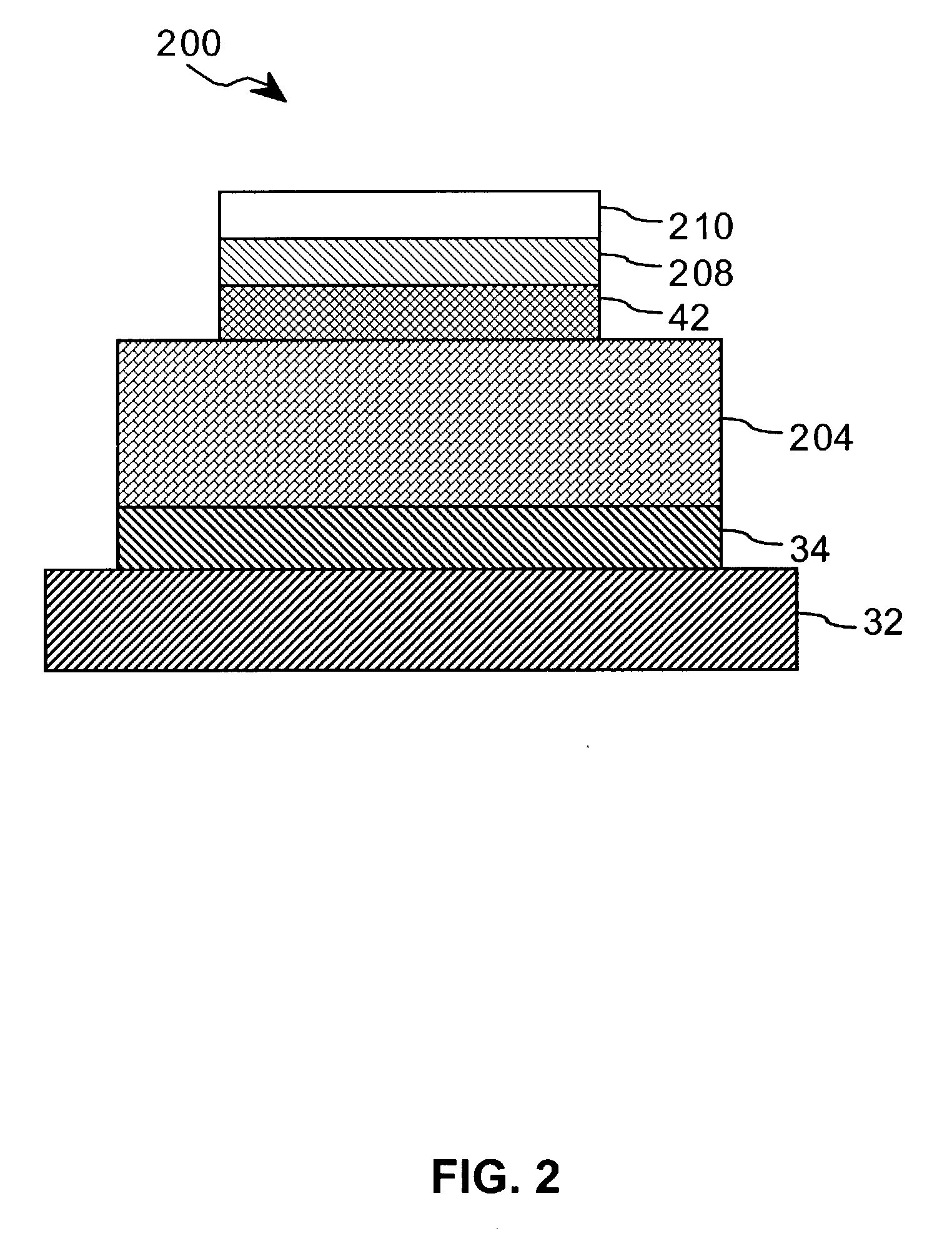

Low temperature process for passivation applications

InactiveUS20040113542A1Improve encapsulation propertyLow etch rateDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceAnode

An organic electroluminescent device comprising an anode layer on a substrate, an organic layer on the anode layer, and a cathode layer on the organic layer. In one embodiment, the cathode layer is subjected to H2 plasma prior to deposition of a protective layer over the cathode. In another embodiment, the organic electroluminescent device is encapsulated with an inner encapsulation layer on the cathode layer, and an outer encapsulation layer on the inner encapsulation layer. The inner layer is optimized for adhesion to the cathode layer.

Owner:APPLIED MATERIALS INC

Device with culture relics exhibiting and protecting function

InactiveCN101390700APrevent oxidationInhibition of photodegradationShow cabinetsShow shelvesMicroorganismGlass cover

The invention provides a device which can exhibit and protect cultural relics. The device is characterized in that the device comprises a base; a base plate is arranged at the top of the base; the bottom of a glass cover is fixed on the base plate through a safety lock reed, and a safety alarm is arranged on the safety lock reed; a gland bush is arranged at the butt joint of the glass cover and the base plate; a rotating bushing is arranged at the middle part of the base plate and a gland bush is arranged on the rotating bushing; rotating shafts are arranged inside the rotating bushing and the base; showcase stands are arranged at the top parts of the rotating shafts, and step motors are arranged at the tail ends of the rotating shafts; a temperature sensor, a pressure sensor, a humidity sensor and a gas composition sensor are arranged at two sides of the base plate; and a cavity refrigerating / heating device is arranged at the bottom of the base plate. The device has the advantages that the device can well exhibit the cultural relics and can create a manual protecting environment without damages. The device prevents oxidation, photodegradation, overheating volatilization, mould development and microorganisms and has the function of protecting the cultural relics and the precious article inside the cavity.

Owner:DONGHUA UNIV

Technological process for preparing active powder concrete by using iron tailing

A technological process for preparing active powder concrete by using iron tailing is characterized by performing screening and mechanical-chemical activation to iron tailing, using partial iron tailing after screening as fine aggregate of the active powder concrete, using activated tailing as component of the active powder concrete, and preparing the active powder concrete. The invention substitutes partial cement, quartz powder and silica fume with mechanically-activated iron tailing and fly ash or slag, and quartz sand or river sand with screened iron tailing fine aggregate, and prepares high-strength active powder concrete under standard curing or high-temperature high-pressure curing condition; and compared with conventional method, the invention reduces raw material cost, improves iron tailing comprehensive utilization rate, reduces natural resource consumption amount, and promotes development of ecological environment protection and circular economy promotion.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

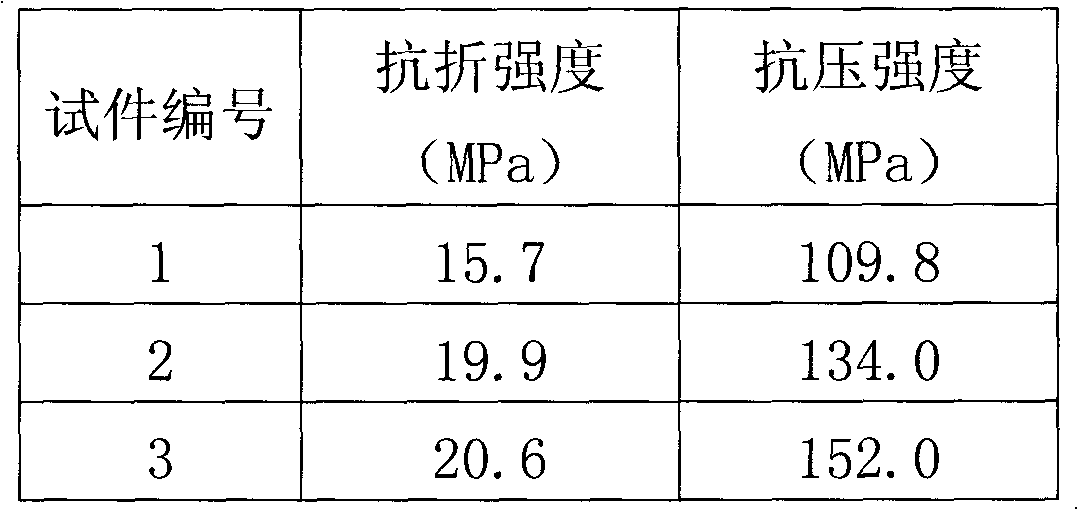

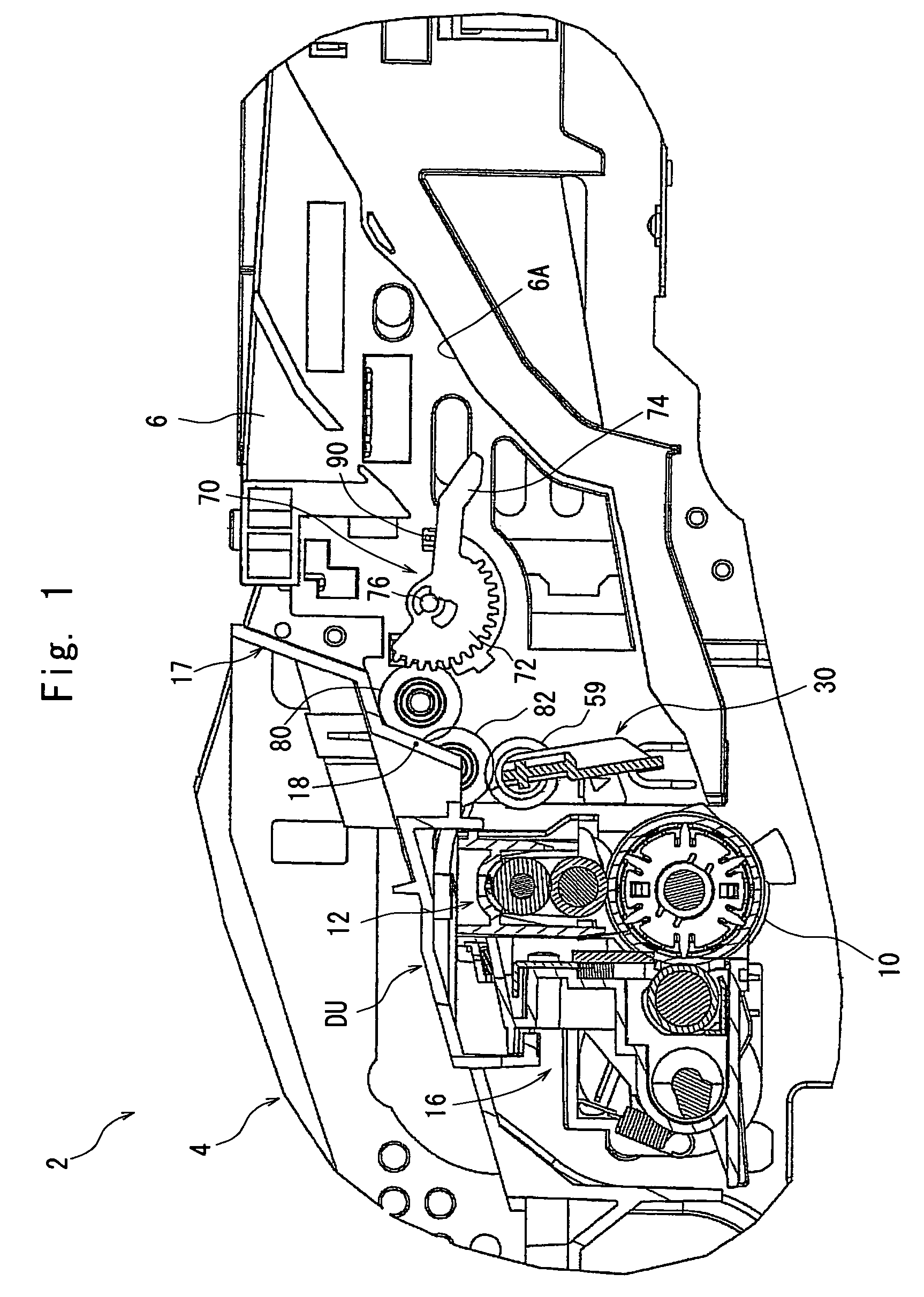

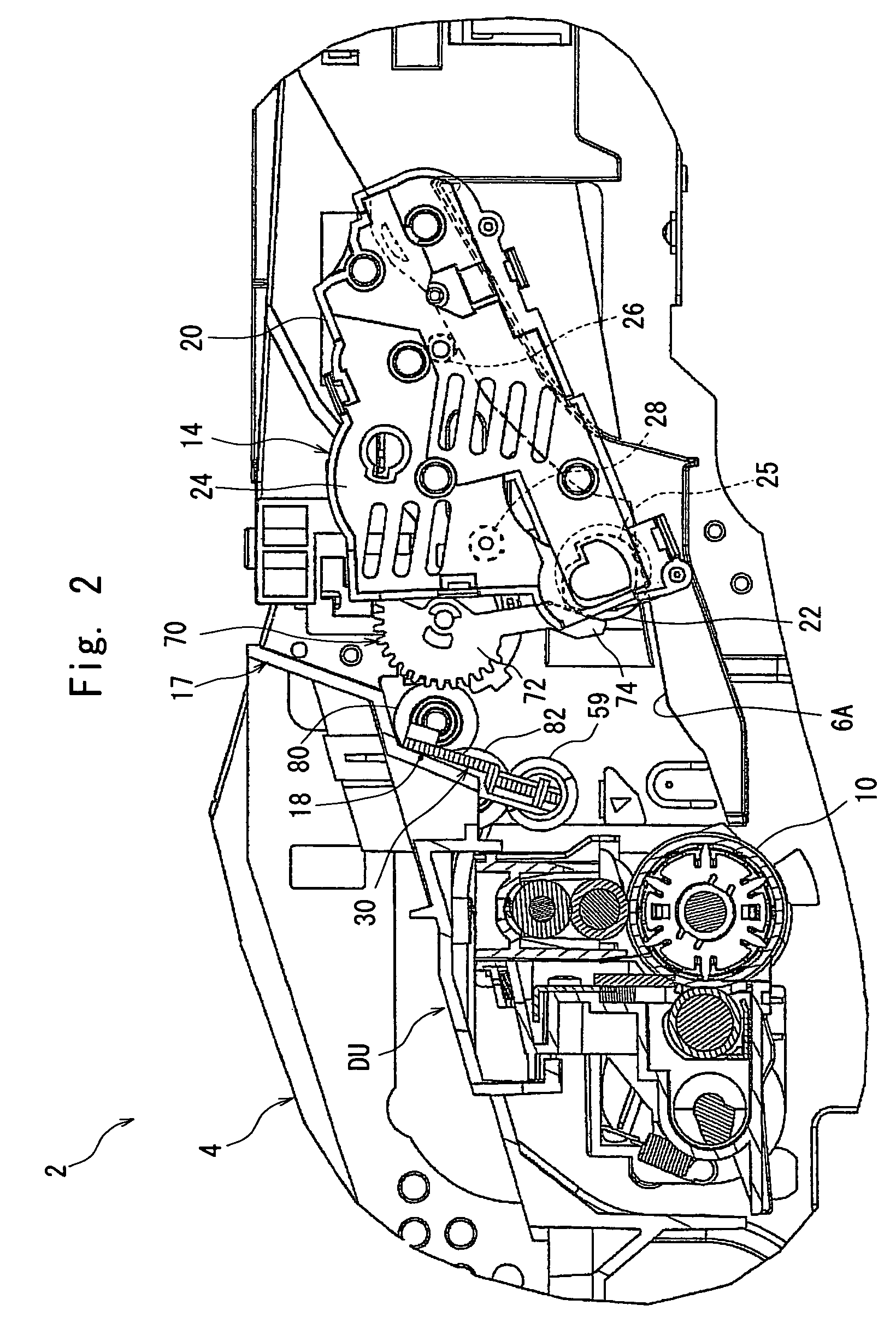

Image-forming machine

InactiveUS7684729B2Low costProtect environmentElectrographic process apparatusImage formationEngineering

An image-forming machine includes a photosensitive material drum, a developer mounted on a machine body so as to move in a direction to approach, and separate away from, the photosensitive material drum along guide means arranged in the machine body, and a protection cover that opens and closes a portion of the peripheral surface of the photosensitive material drum. The protection cover is supported by the machine body so as to rotate between a closed position and an opened position. An arm member is rotatably arranged in the machine body being drive-coupled to the protection cover so as to open and close the protection cover. An end of the arm member is so positioned as to be present on a locus of motion of the developer.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

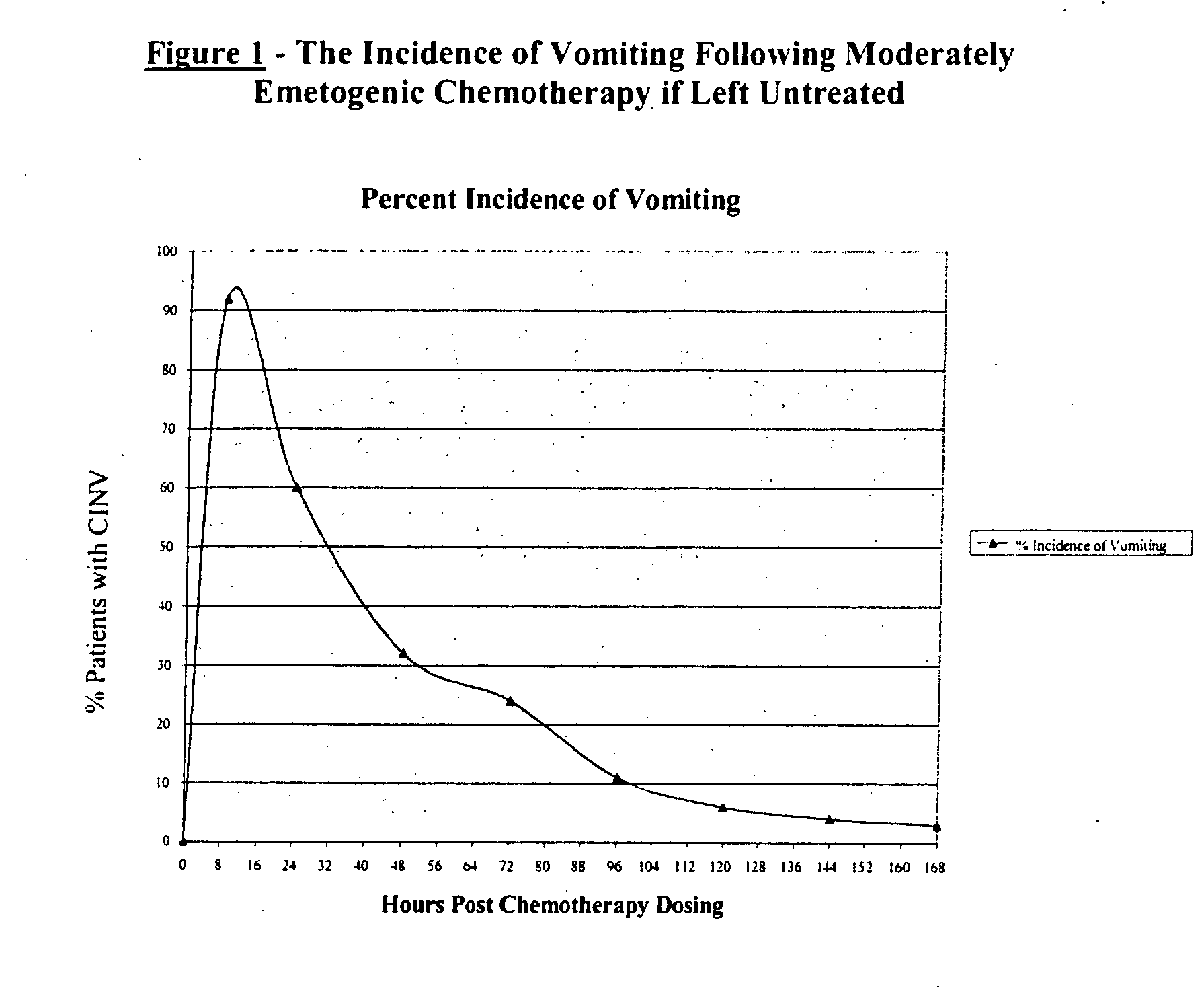

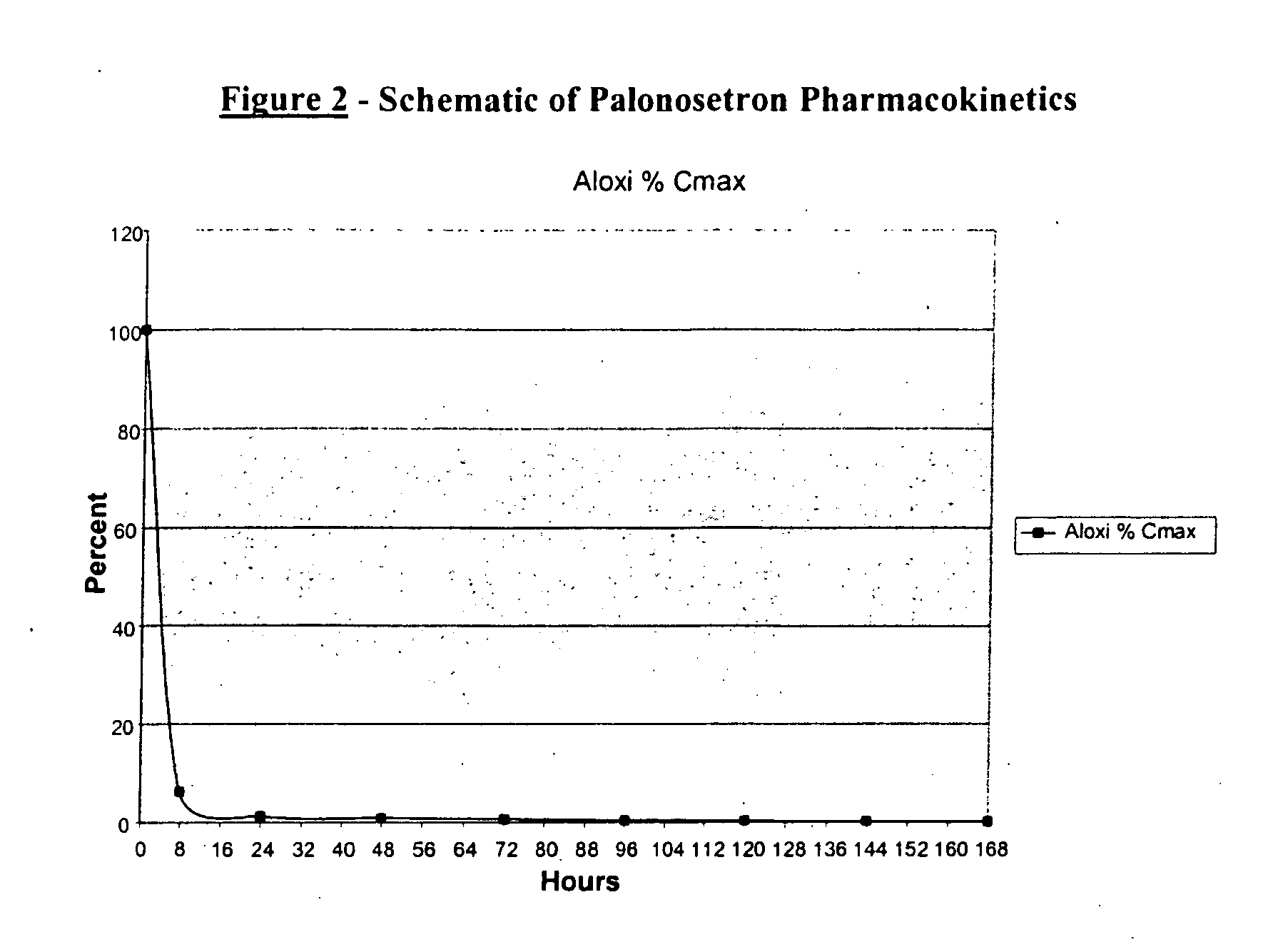

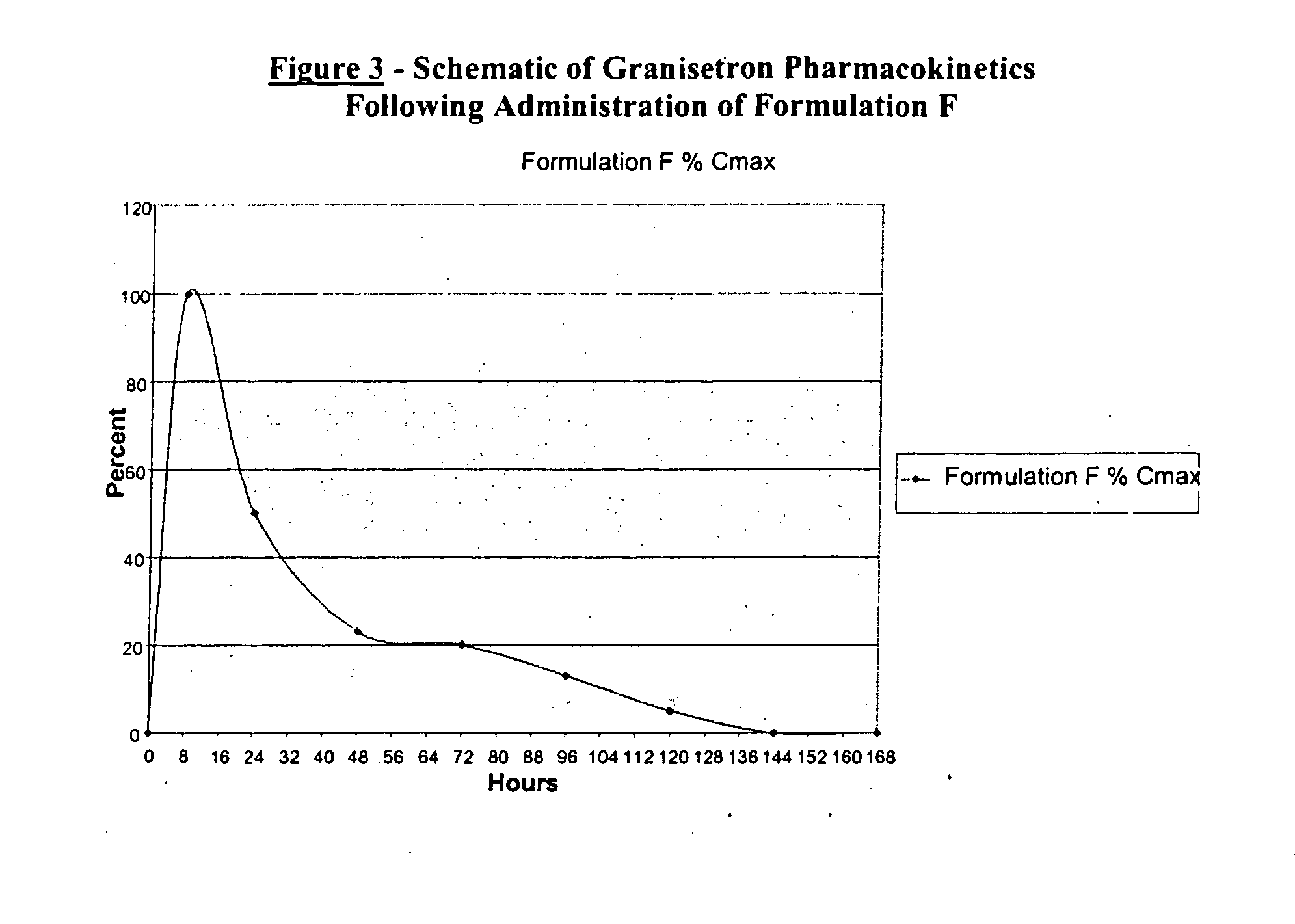

Methods for the prevention of acute and delayed chemotherapy-induced nausea and vomiting (CINV)

InactiveUS20070265329A1Eliminate the effects ofProlong the action timeBiocideDigestive systemControl releaseEmetogenic chemotherapy

A pharmaceutical composition for the sustained release of an effective amount of a selective 5-hydroxytryptamine 3 (5-HT3) receptor antagonist for the prevention, reduction or alleviation of acute and delayed chemotherapy-induced nausea and vomiting (CINV) following a course of emetogenic chemotherapy, wherein the composition is administered by subcutaneous injection, the composition comprising a 5-HT3 receptor antagonist, a semi-solid delivery vehicle and a pharmaceutically acceptable liquid excipient; wherein the composition, when administered in a single dosage, provides a controlled release of the 5-HT3 receptor antagonist and prolonging the release of the 5-HT3 receptor antagonist that tracks the profile of the incidence of vomiting.

Owner:AP PHARMA INC

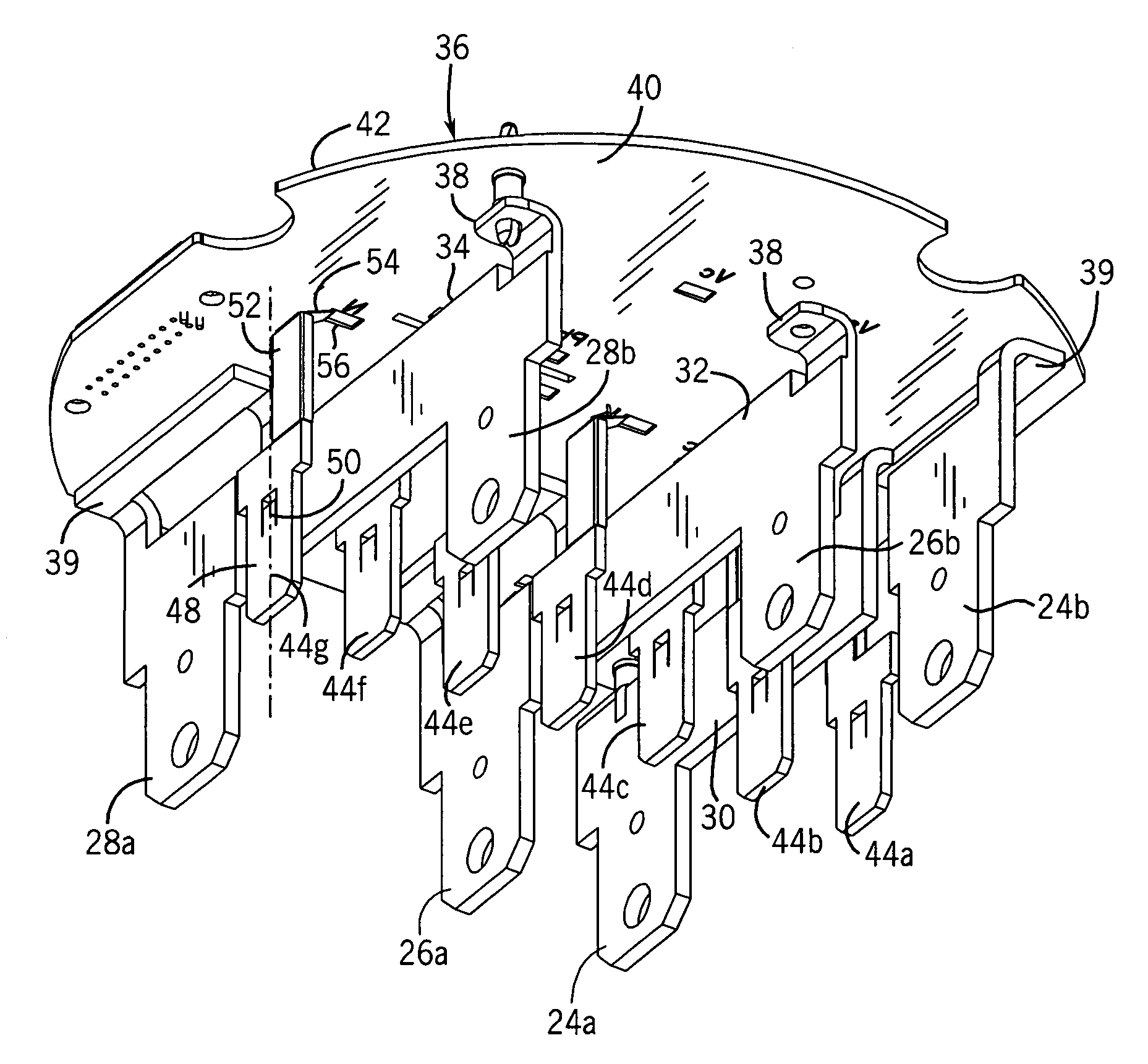

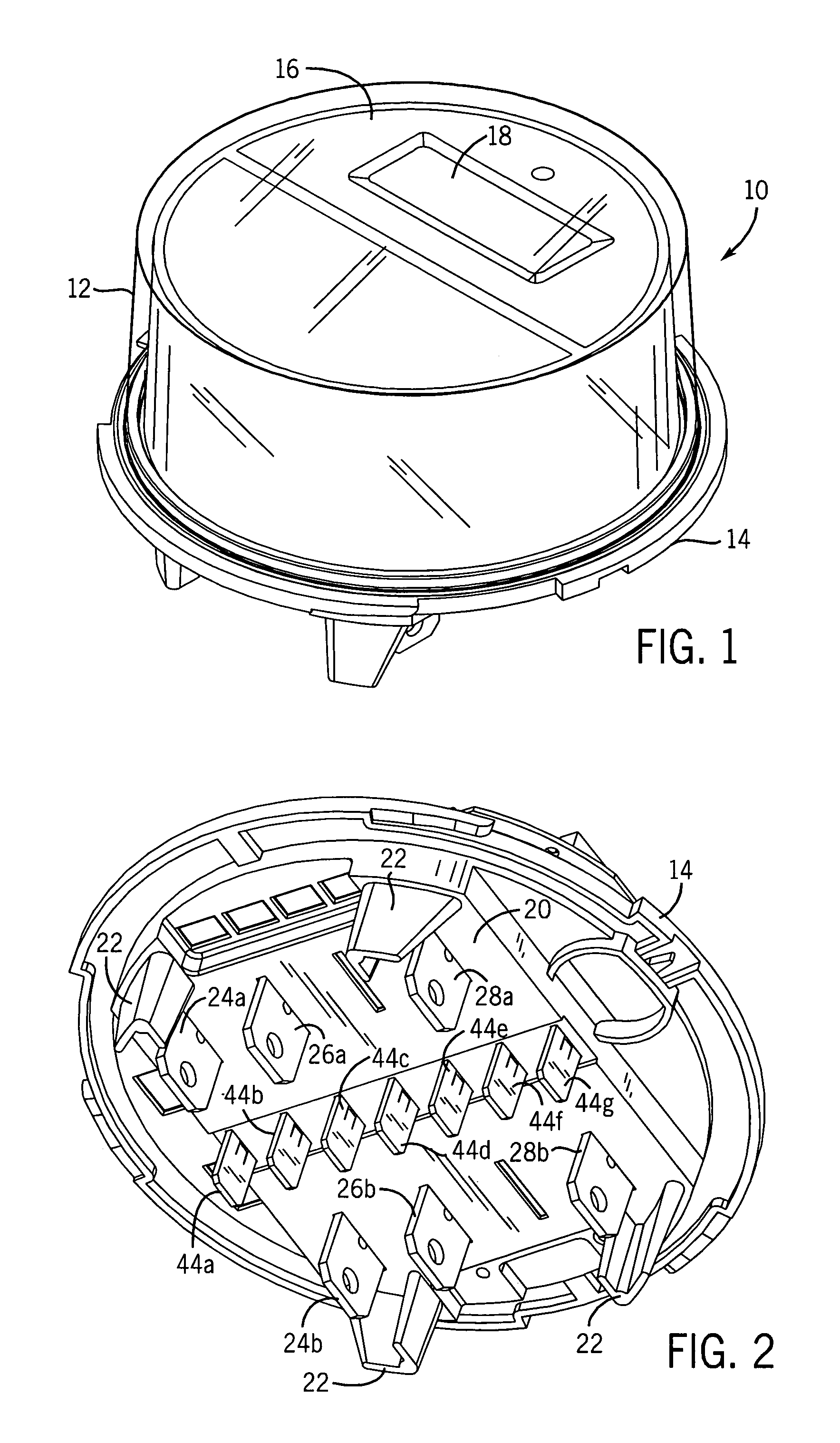

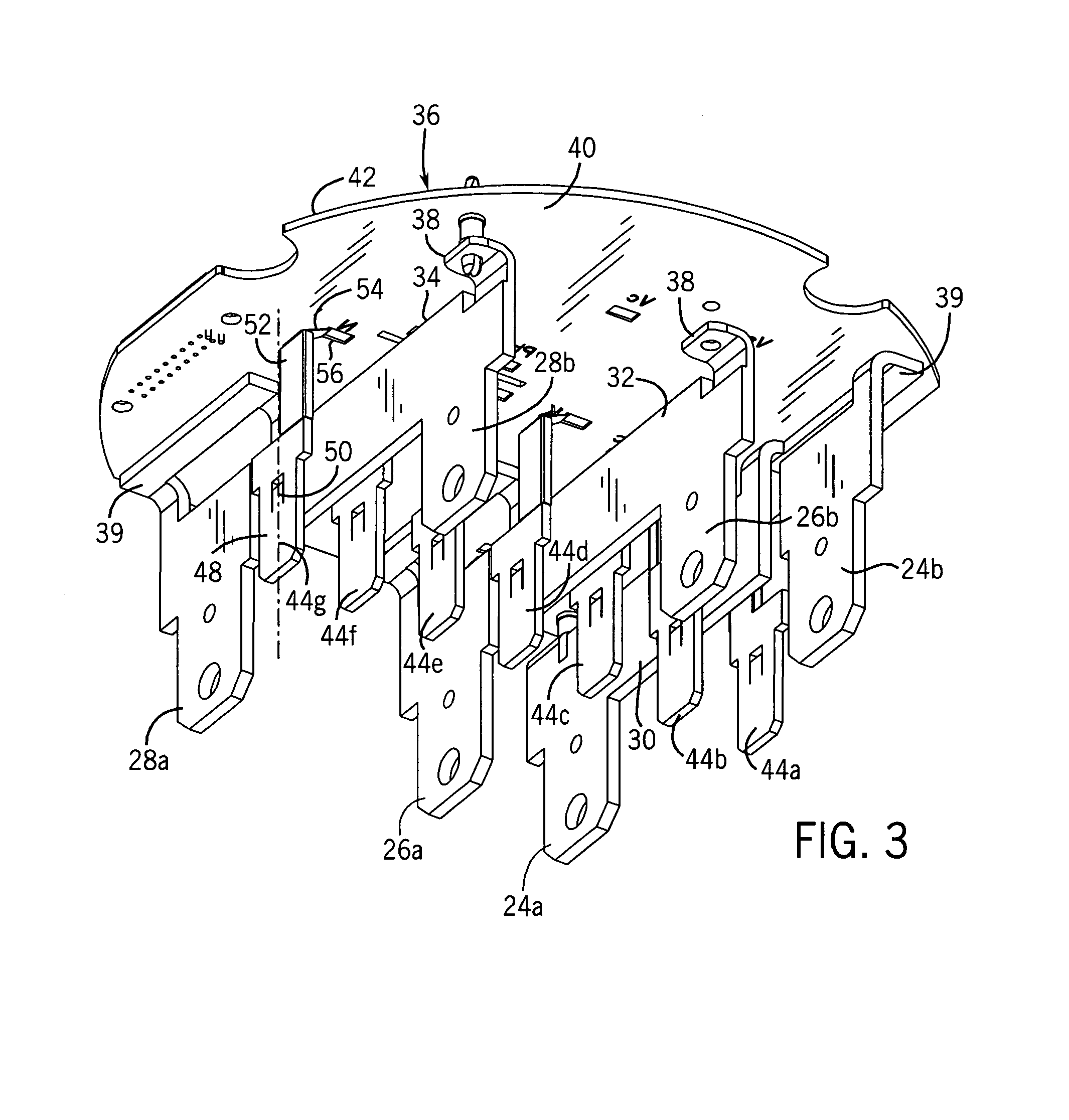

Electronic electricity meter having configurable contacts

ActiveUS6972555B2Protect environmentEliminate needCurrent/voltage measurementSpecial tariff metersMeter-BusEngineering

A three-phase electronic electricity meter that includes configurable voltage sensing blades such that the electricity meter can be configured for use with various electrical service types. The electricity meter includes a base having a configuration to correspond to standard ANSI-type sockets. The meter base includes a plurality of individual voltage sensing blades that are received by the ANSI socket. At least one of the voltage sensing blades is movable between a first and a second position such that the voltage sensing blade contacts different areas on a meter circuit board in the first and second positions. A common circuit board can be utilized for different electrical service types and the contact arrangement can be selectively configured by moving the voltage sensing blades between their first and second positions.

Owner:SENSUS SPECTRUM LLC

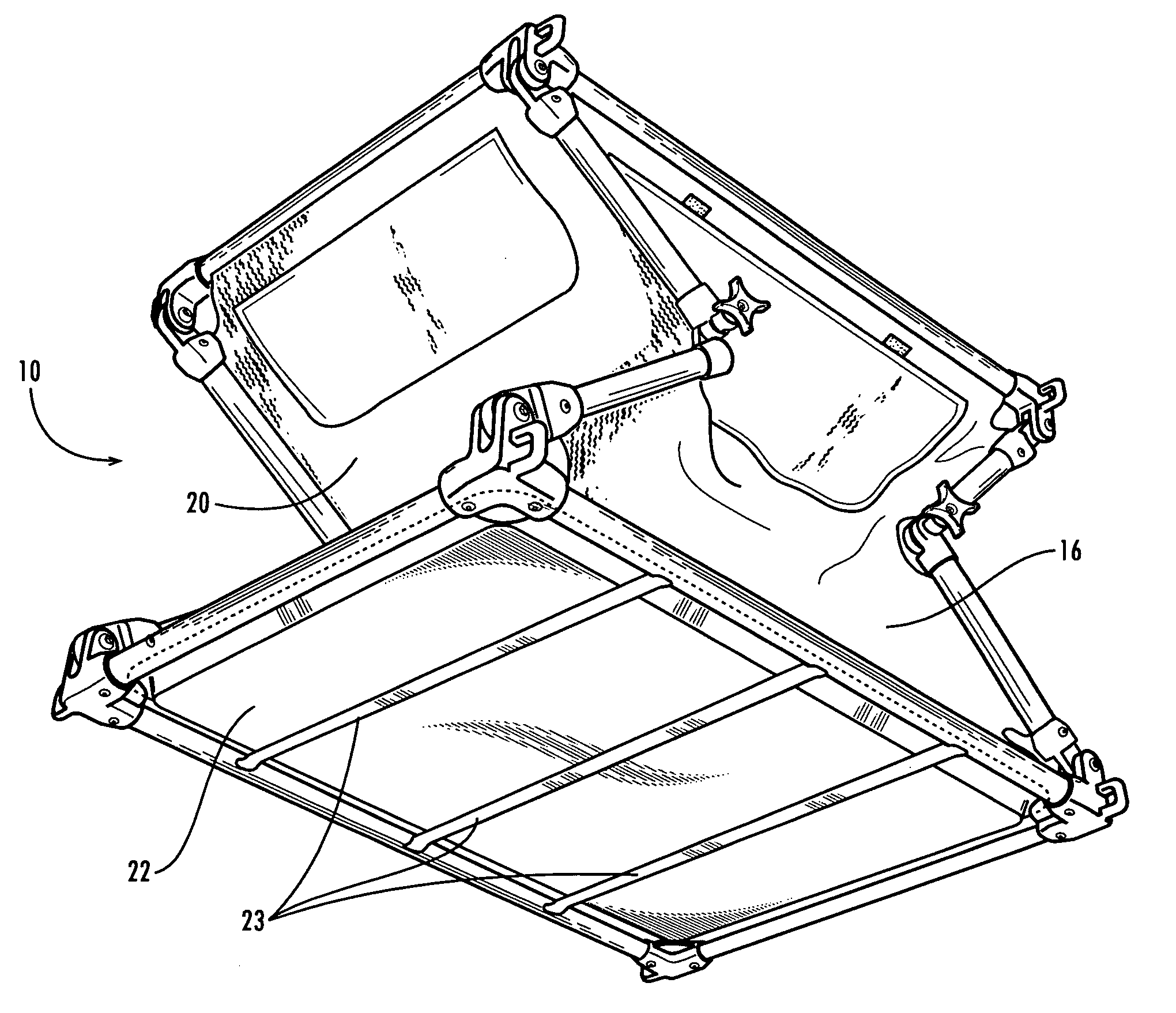

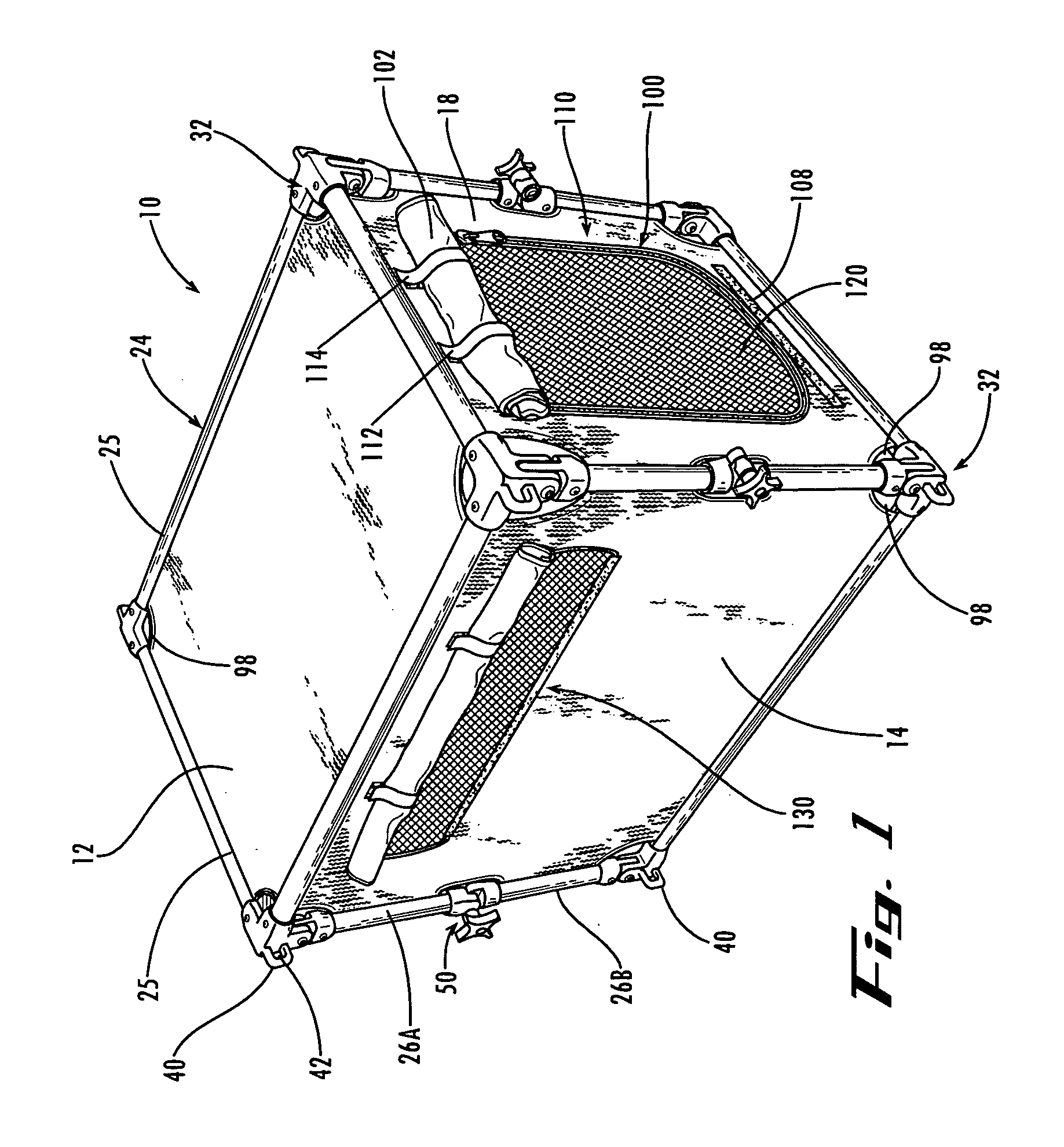

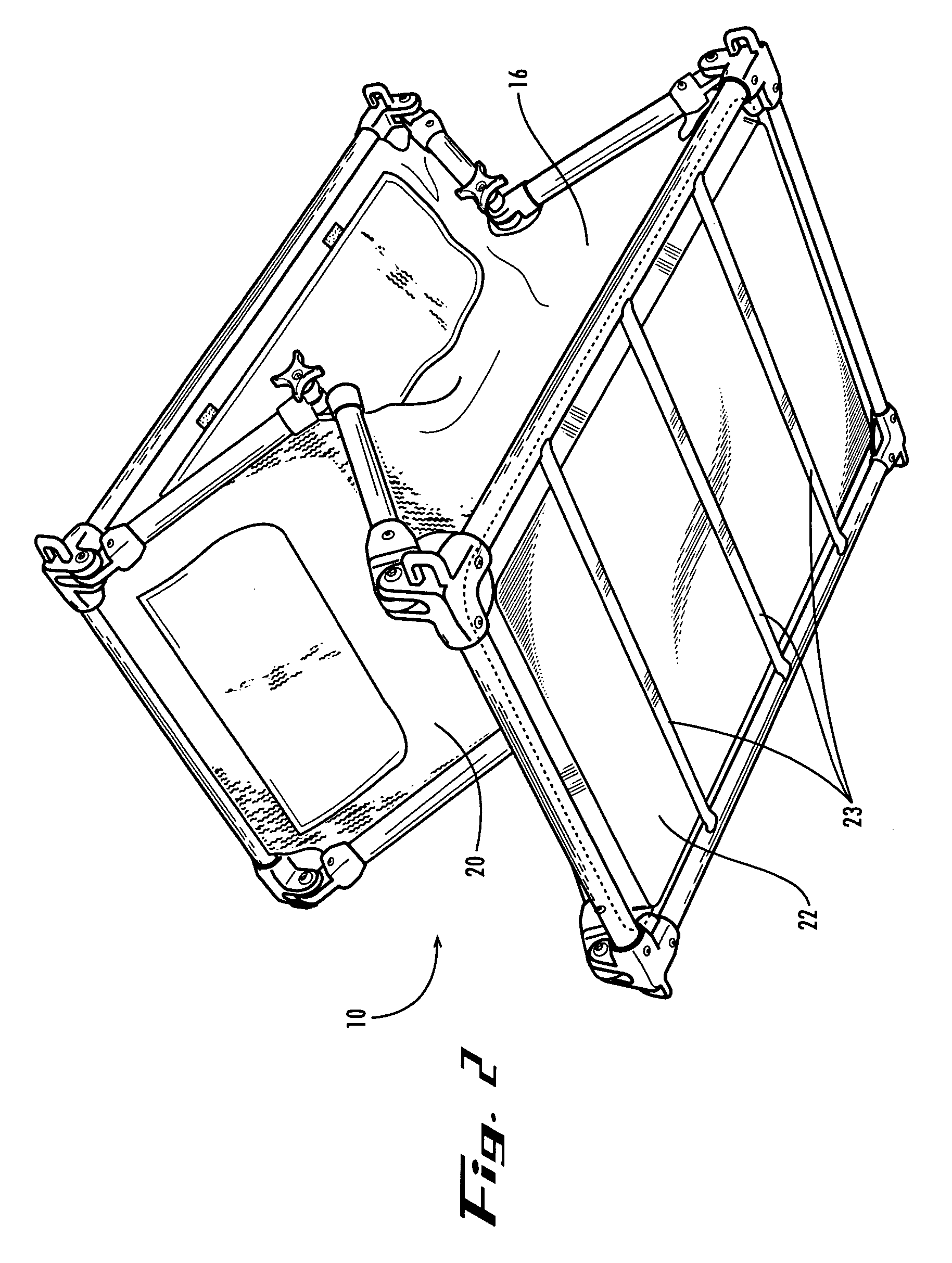

Collapsible pet housing

Owner:SIMPSON JEFFREY M

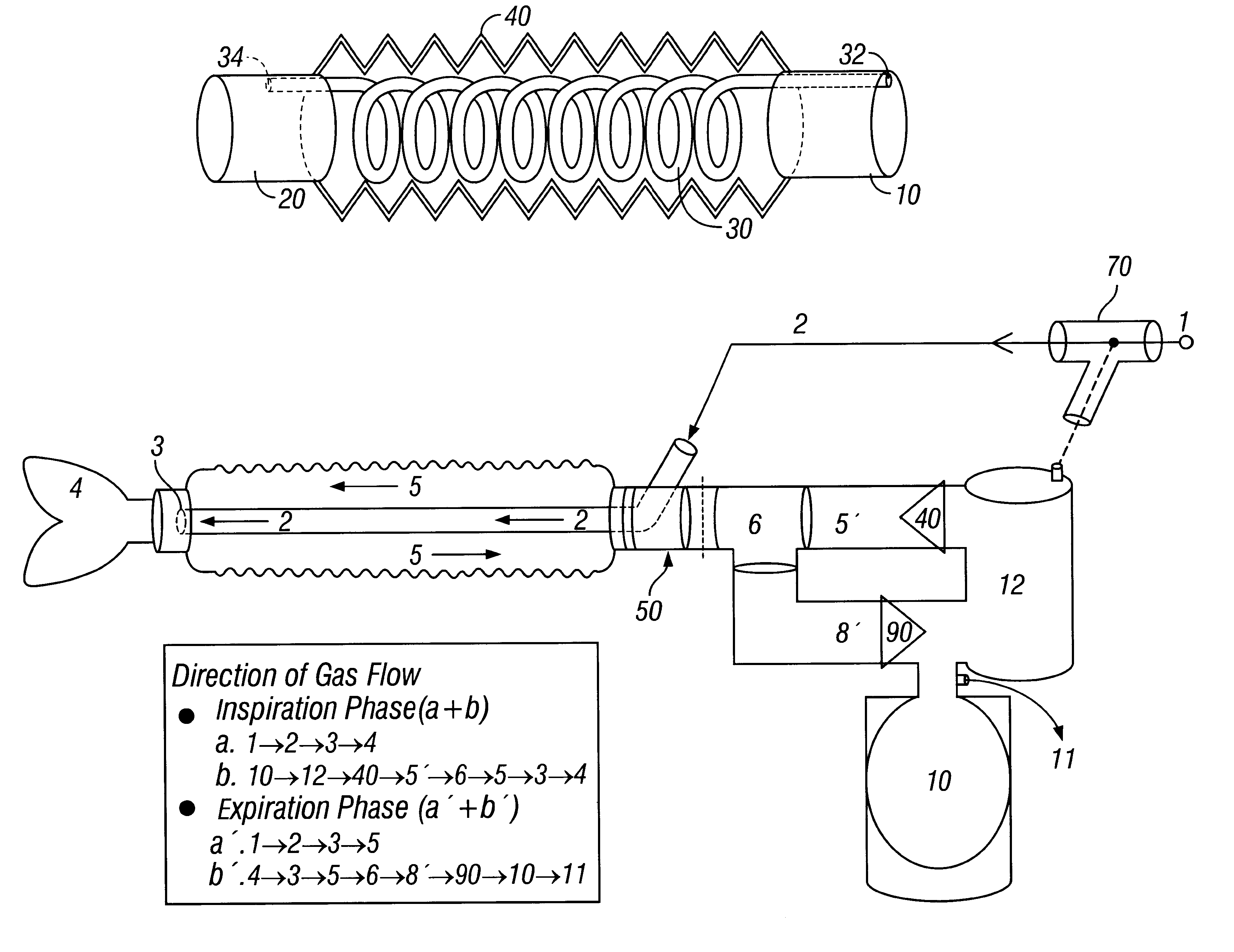

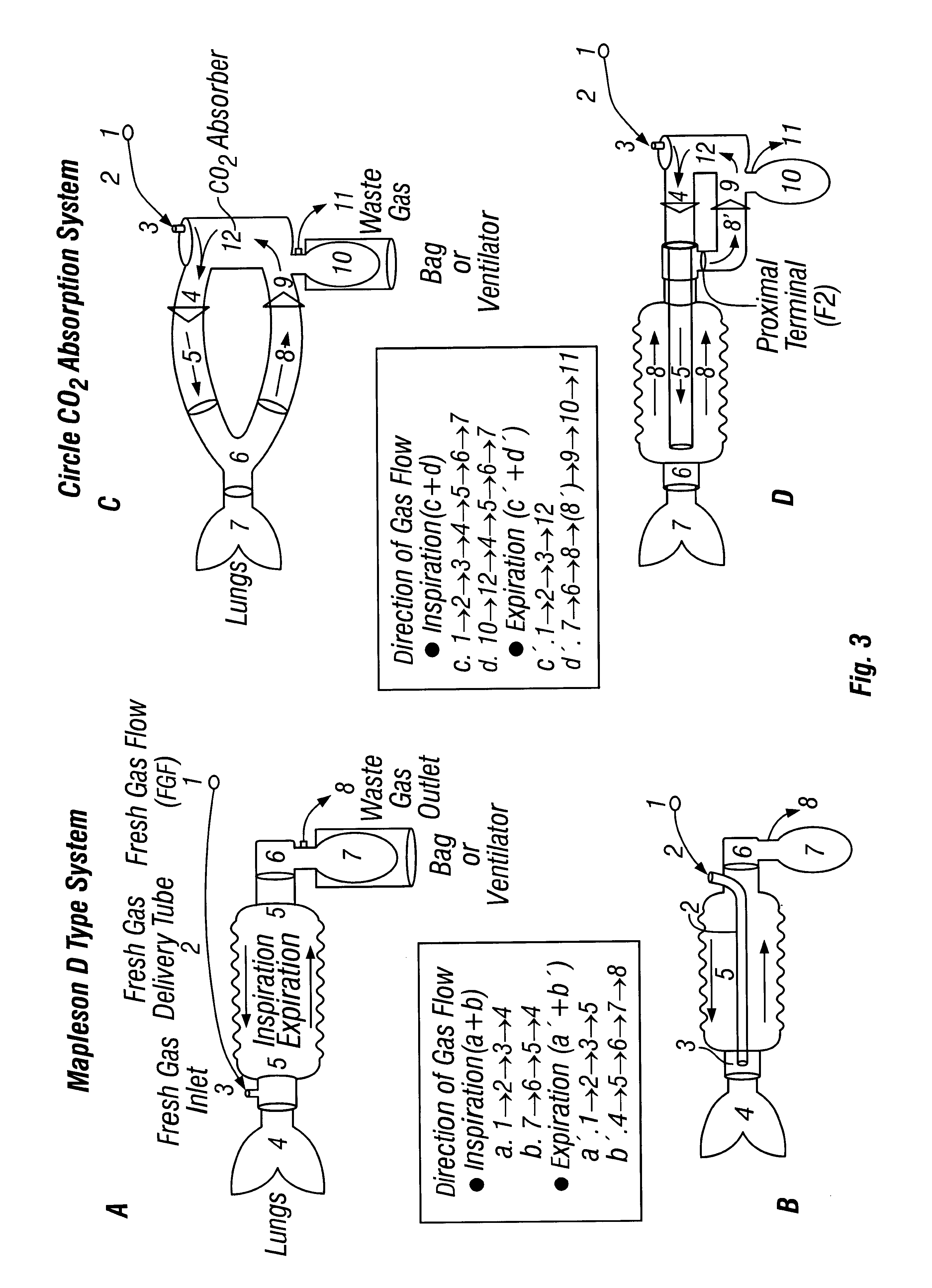

Breathing circuits having unconventional respiratory conduits and systems and methods for optimizing utilization of fresh gases

InactiveUS6874500B2Regulate securityOptimizing the utilization of anesthetic gasesRespiratorsSurgeryBreathing gasCatheter

A breathing circuit comprising first and second conduits, wherein at least one of the conduits is a non-conventional conduit. In an embodiment, a multilumen unilimb breathing circuit has first and second conduits, wherein when the proximal ends of said first and second conduits are each connected to an inlet and outlet fitting, respectively, movement of the distal end of the first conduit causes a corresponding movement of the distal end of the second conduit. In an embodiment, at least one of said conduits is coiled. In another embodiment, a coiled conduit is contained within an outer flexible conduit that is axially extendable and compressible, forming a unilimb multilumen respiratory circuit. The outer flexible conduit may be pleated to provide for non-rebounding axial extension and contraction. The multilumen respiratory circuit can provide a variable rebreathing volume. In an embodiment, at least one tube in a multilumen respiratory conduit is radially collapsible and radially expandable to a maximum radius for carrying respiratory gases to and from a patient. The methods and systems can be used to administer anesthesia and for other purposes.

Owner:AMBU AS

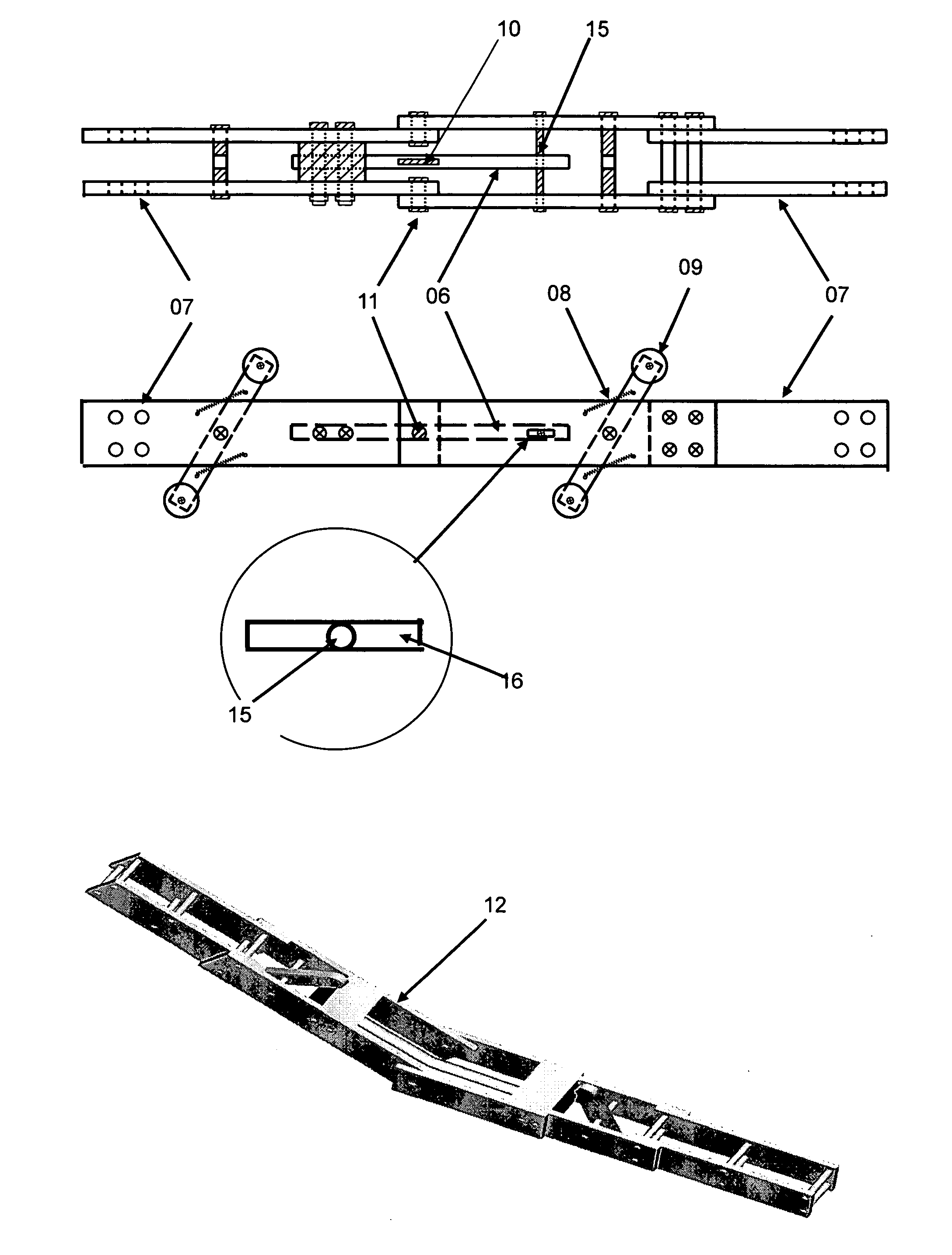

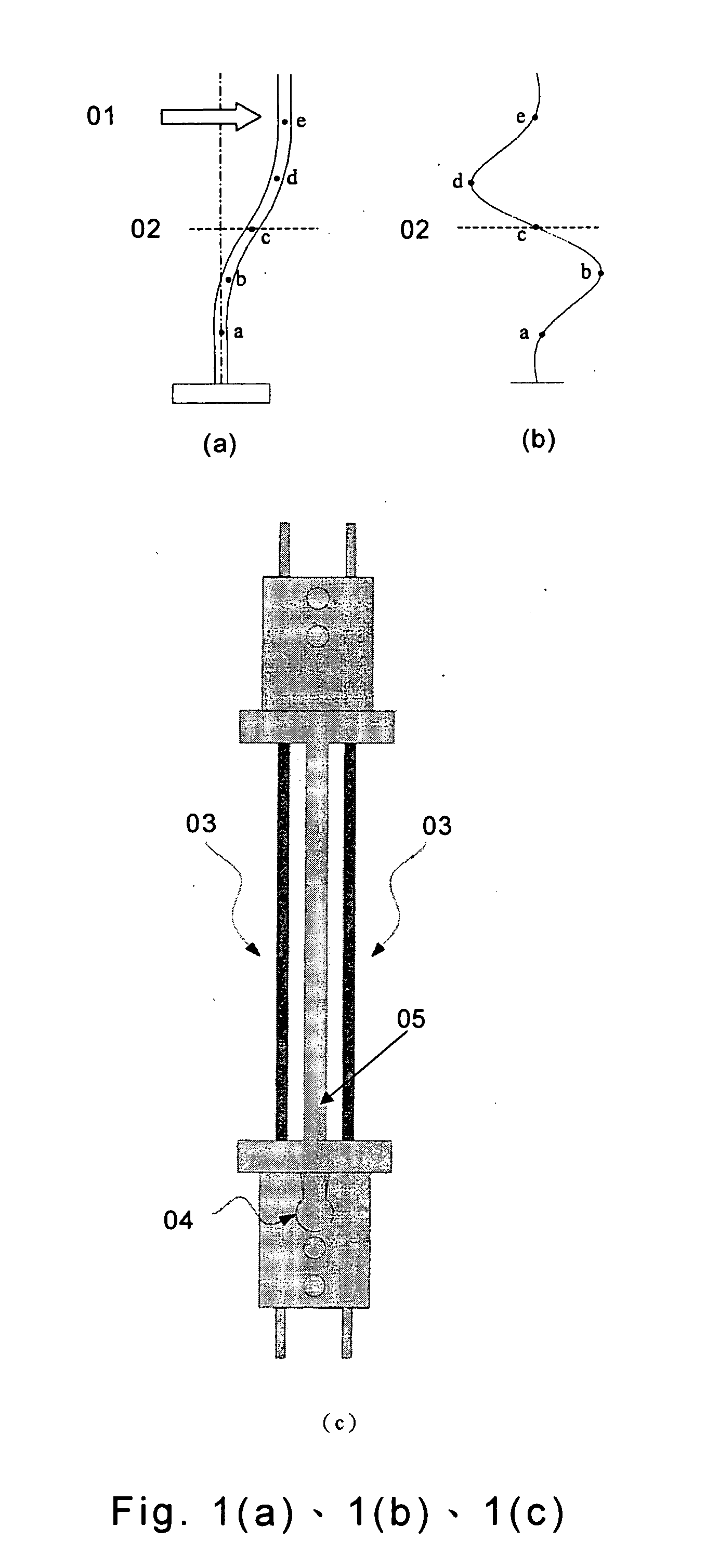

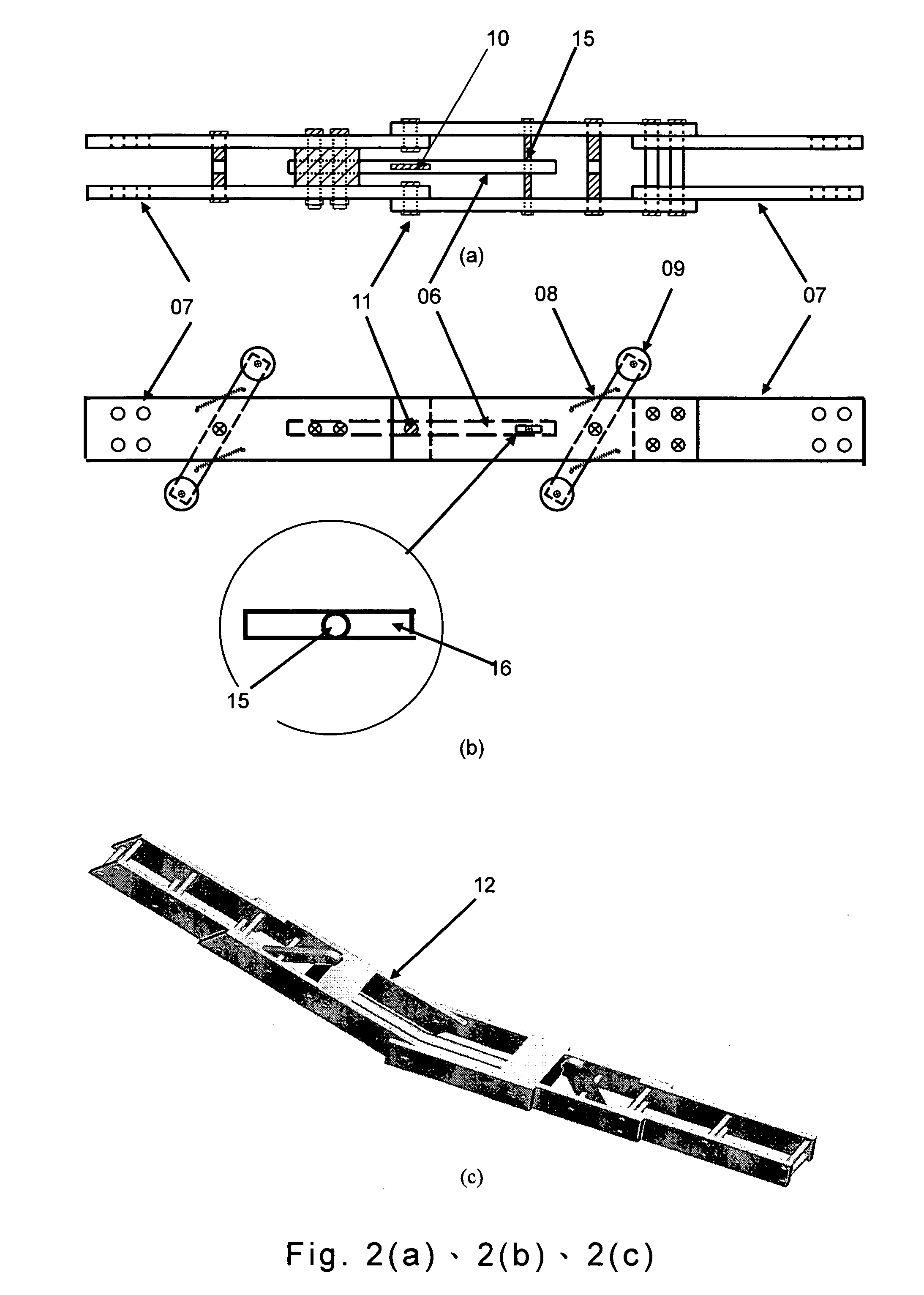

Fiber bragg grating sensored segmented deflectometer for ground displacement monitoring

InactiveUS20070069115A1Protect environmentRadiation pyrometryForce measurementGratingFiber Bragg grating

The invention provides a monitoring device mainly for sensing ground displacement, including the fiber Bragg grating sensored deflectometer and the signal interrogator / computer system. The device uses a segmented design that consists of a flexible tube (referred to as the flexible segment) and two rigid segments and thus referred to as the FBG segmented deflectometer (FBG-SD). For field installation, multiple FBG-SD units are connected together to form a string as it is inserted into a grouted-in-place inclinometer casing. The distortion of the inclinometer casing induced by ground movement causes relative rotation of the inserted FBG-SD. All of the FBG-SD units are connected to an FBG interrogator / computer system situated on ground surface. The FBG signals are recorded and analyzed by the interrogator / computer system.

Owner:NAT CHIAO TUNG UNIV

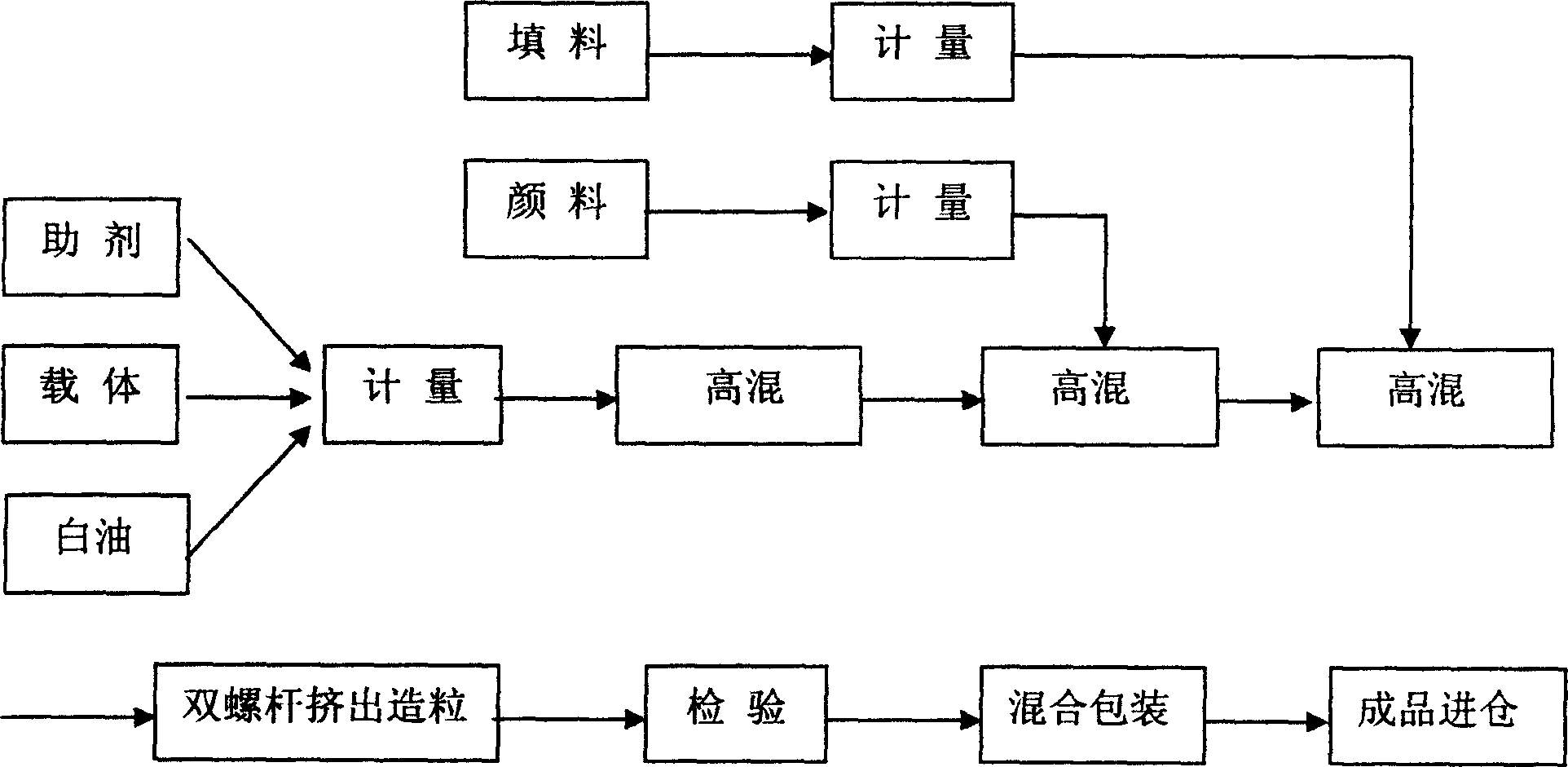

Natural-like multifunctional color batch and use thereof

The present invention features that the color concentrate is prepared with main carrier resin A, matched carrier resin X, compatizer, pigment, inorganic stuffing, antistatic agent, light stabilizer, antioxidant and pigment lubricating dispersant. The main carrier resin an and the matched carrier resin X, which has obviously different compatibility and smelting behavior from that of the basic resin B in the product, may constitute alloy carrier resin. The said materials may be altered to result in various decoration effects.

Owner:GUANGDONG SHENGHENGCHANG CHEM IND

Bioadhesive progressive hydration tablets and methods of making and using the same

InactiveUS6248358B1Protect environmentOrganic active ingredientsNervous disorderBioadhesiveBULK ACTIVE INGREDIENT

Owner:COLUMBIA LAB BERMUDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com