Patents

Literature

50 results about "Carbon flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

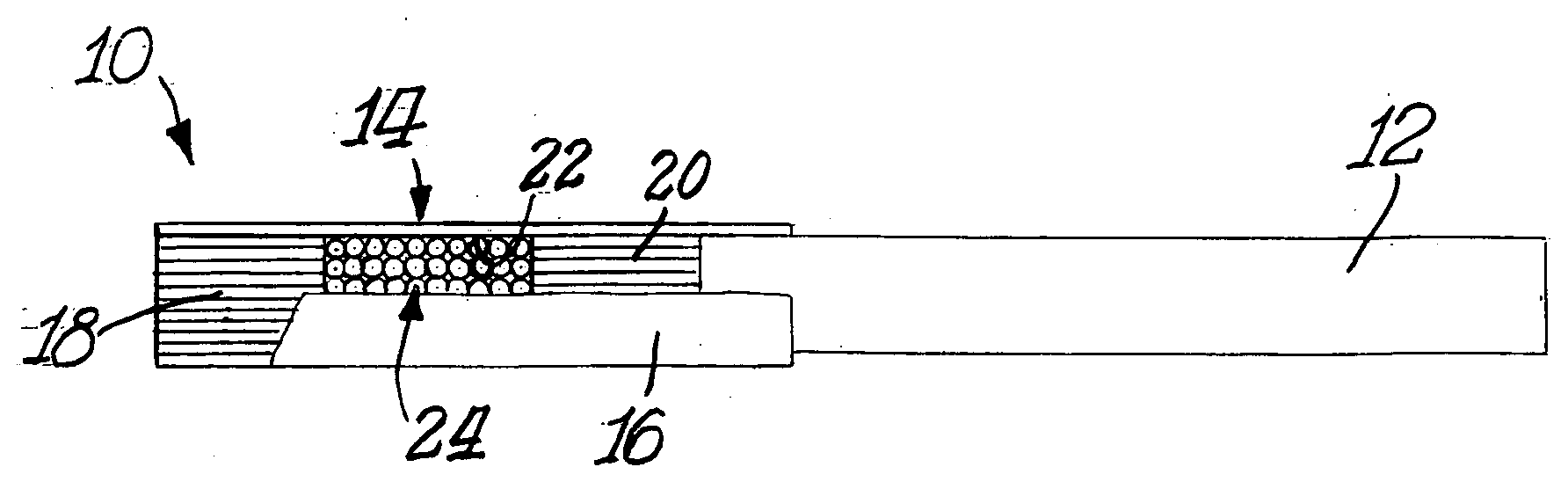

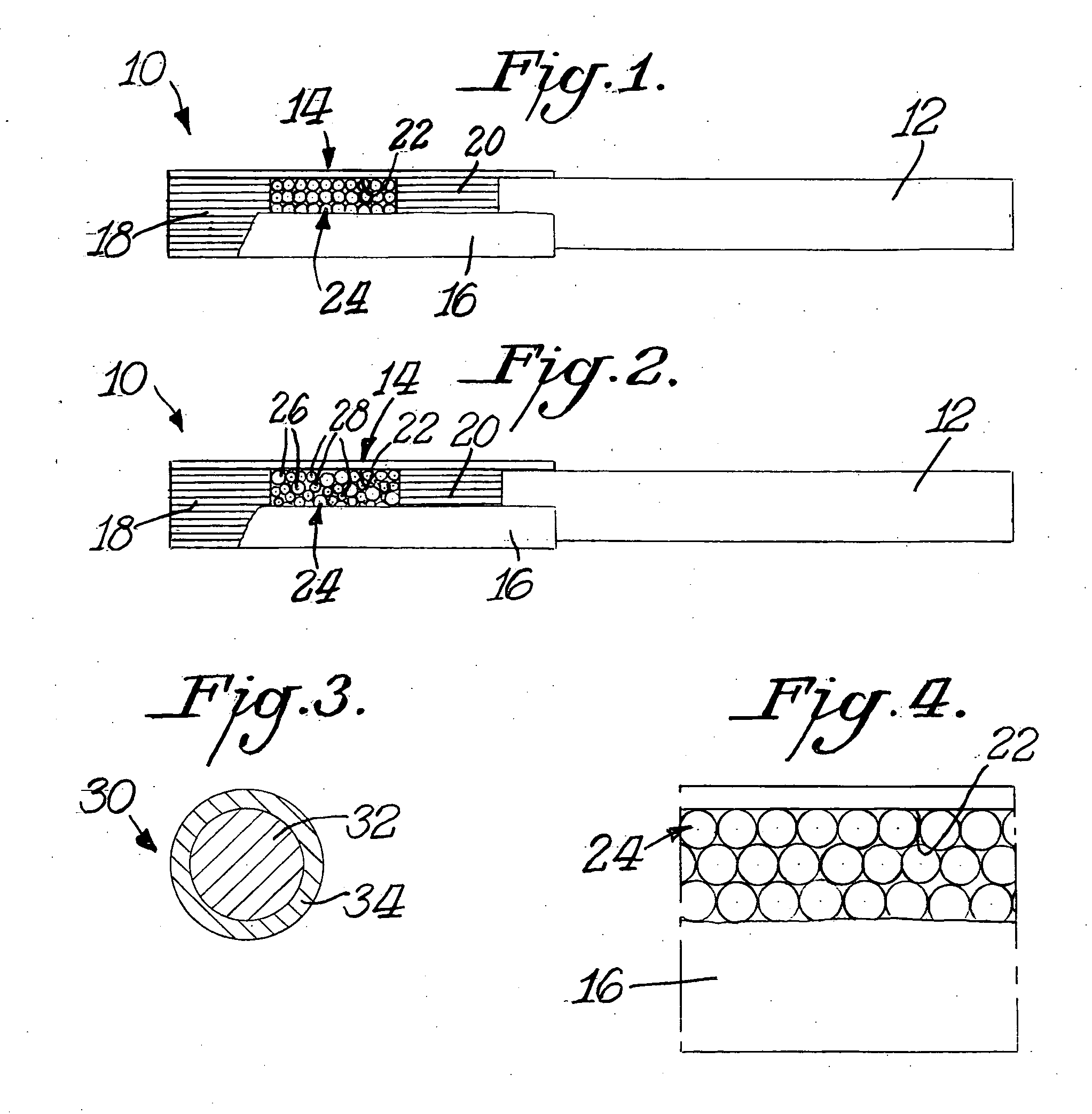

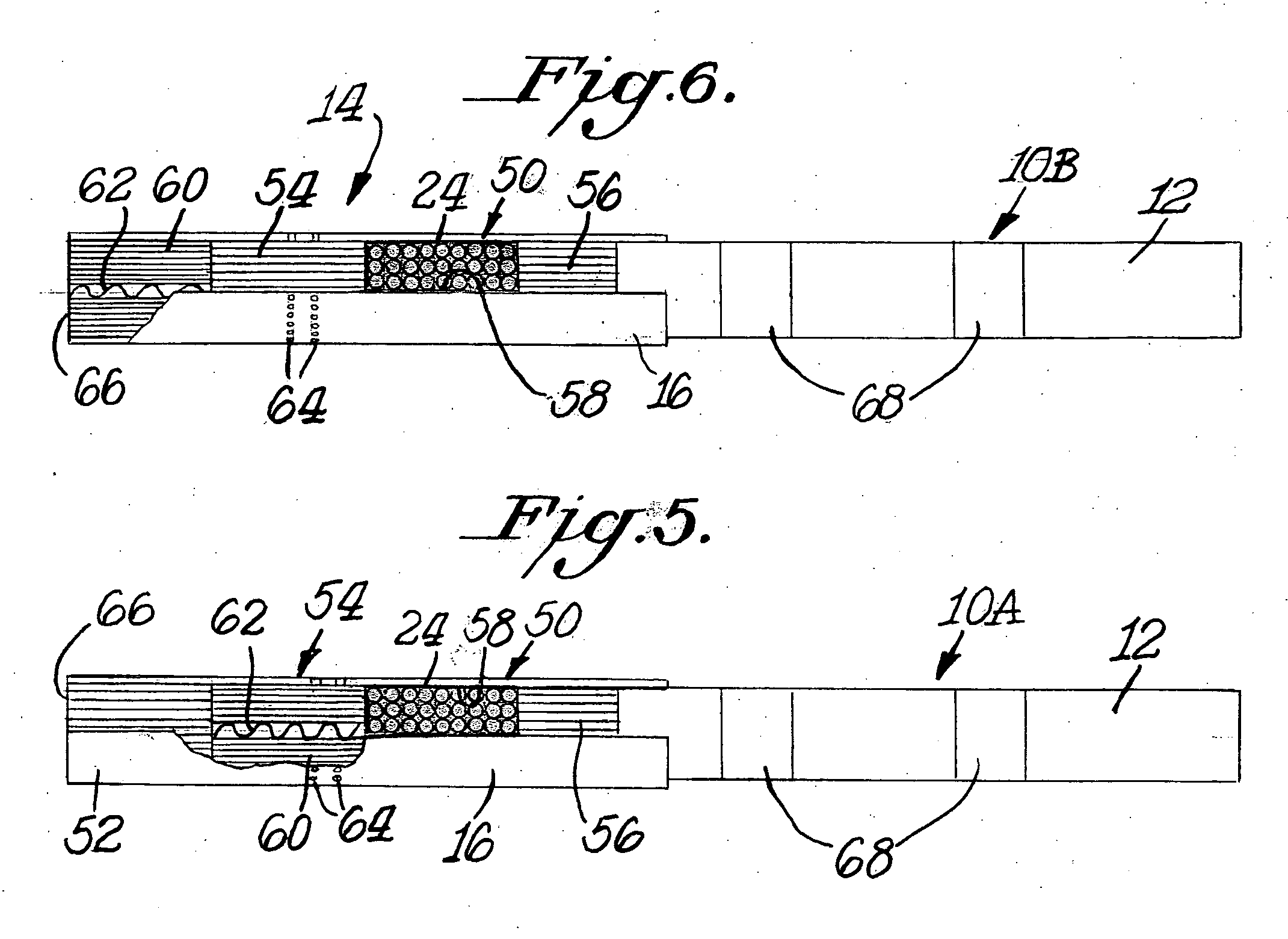

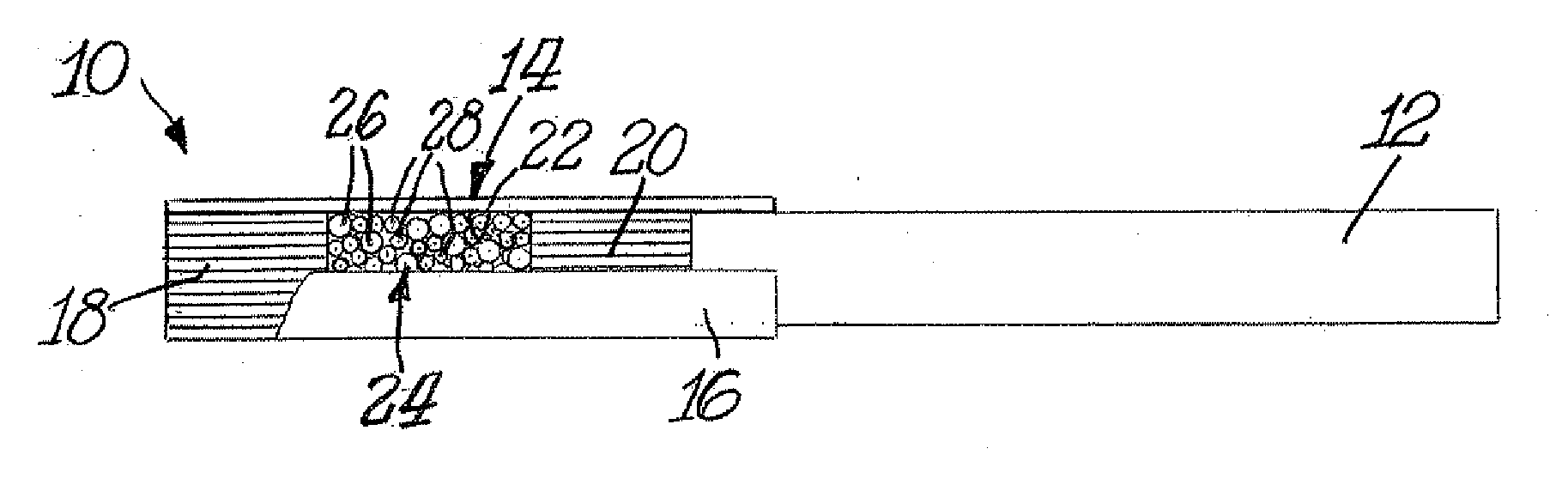

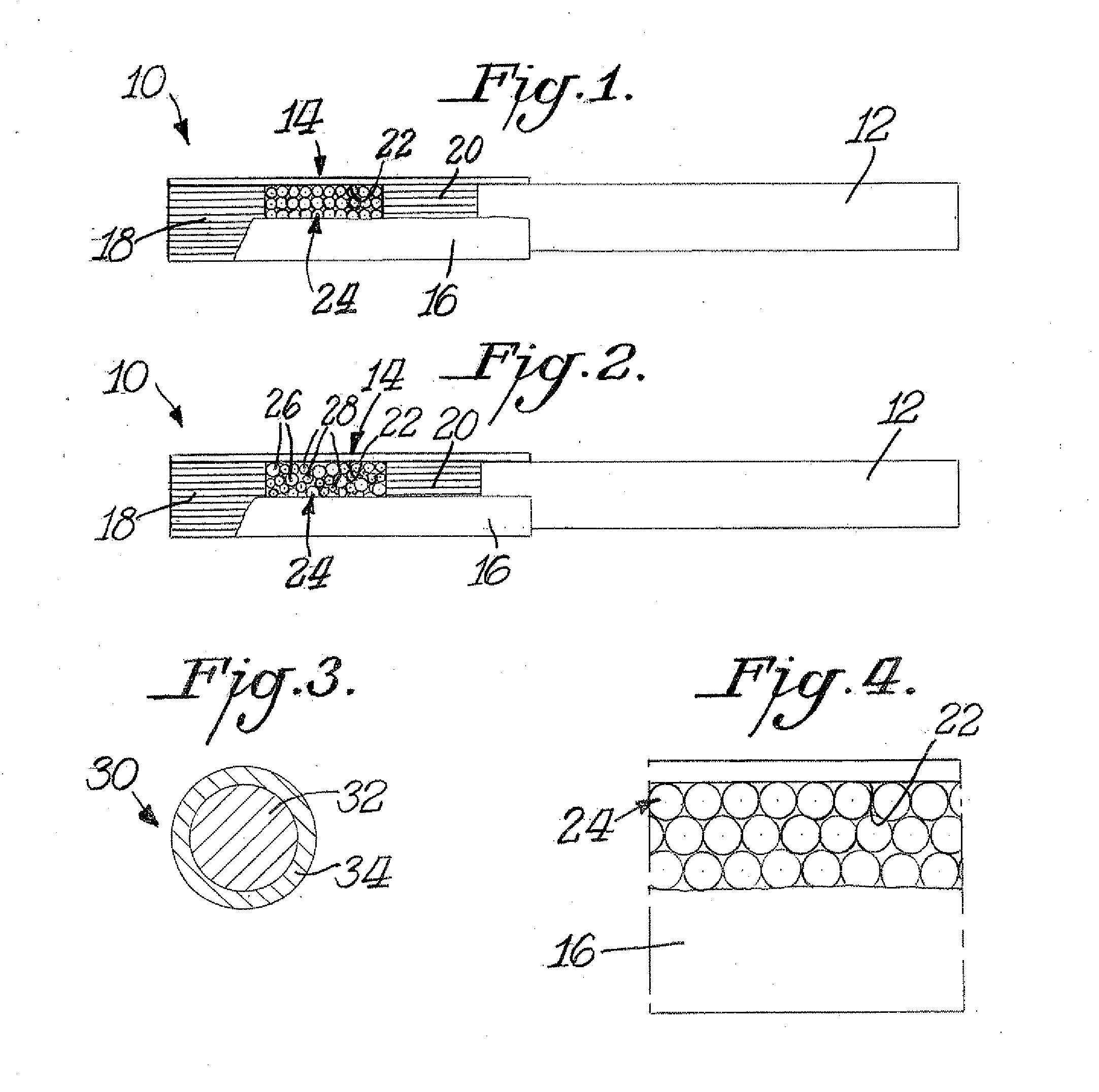

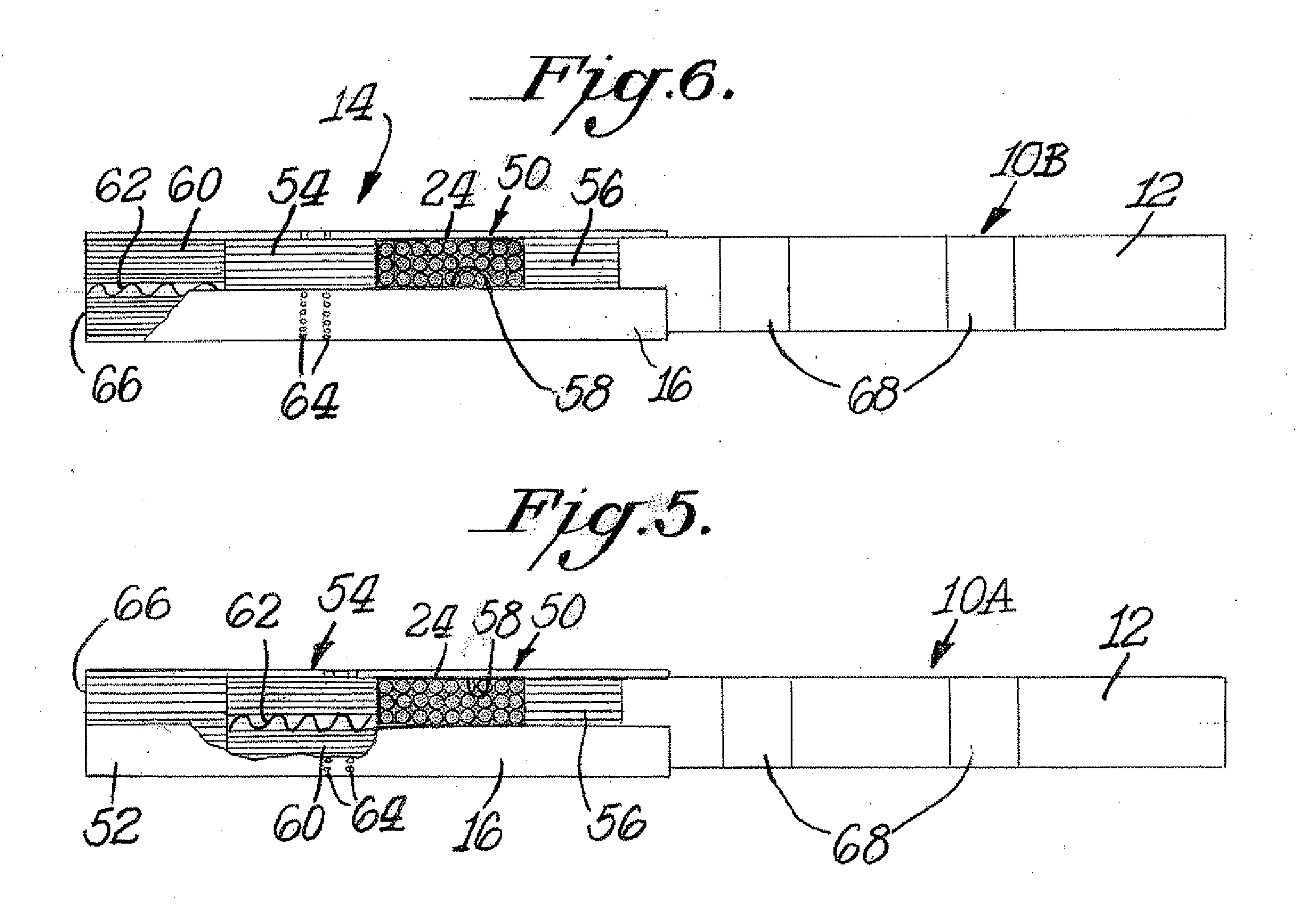

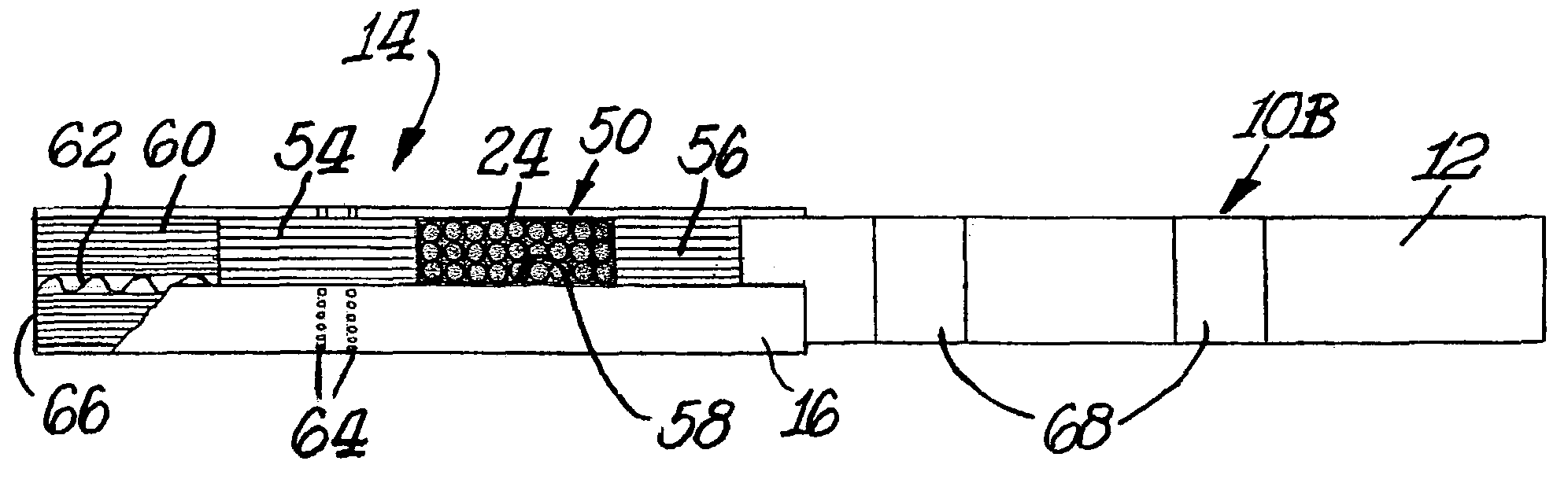

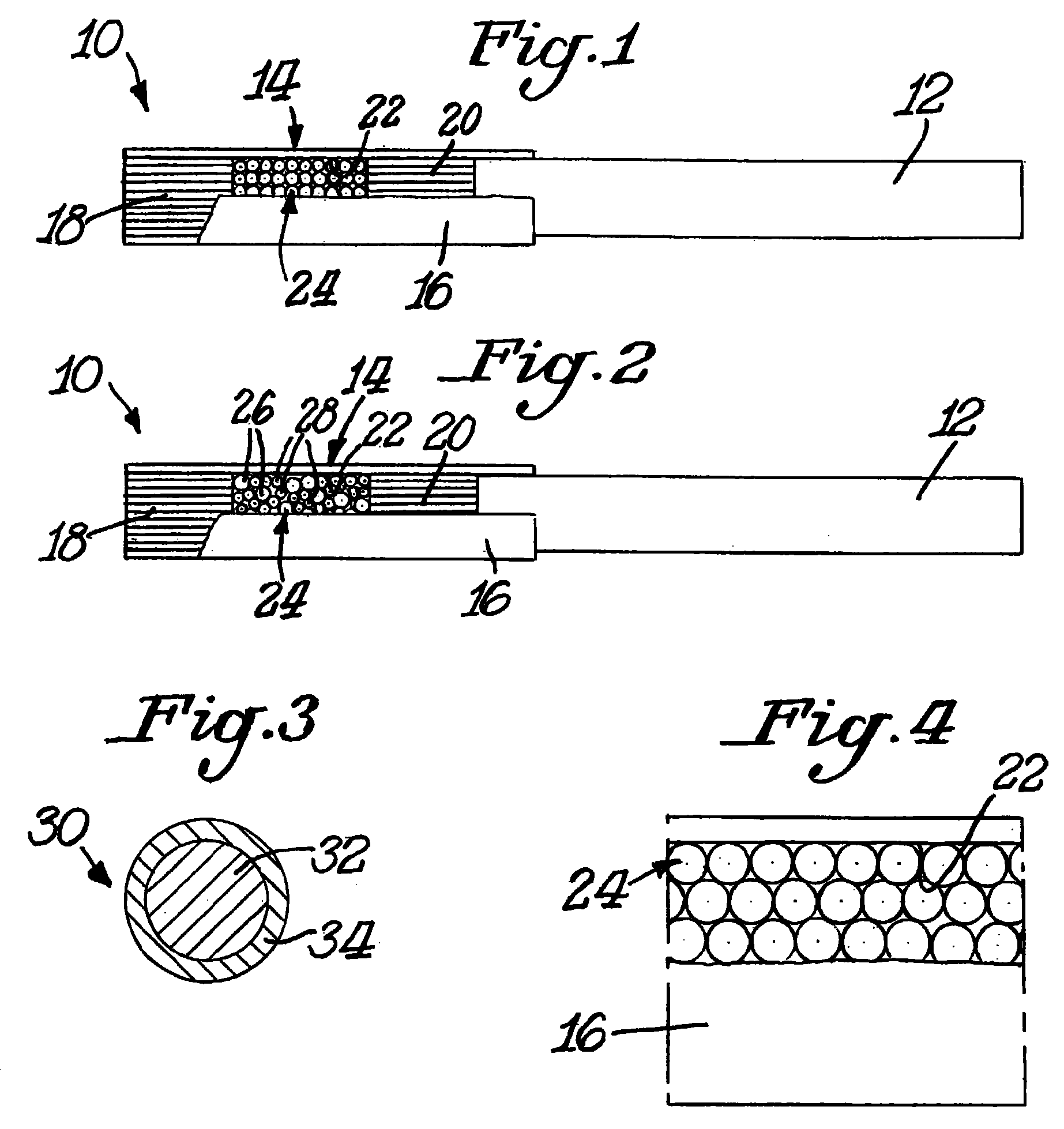

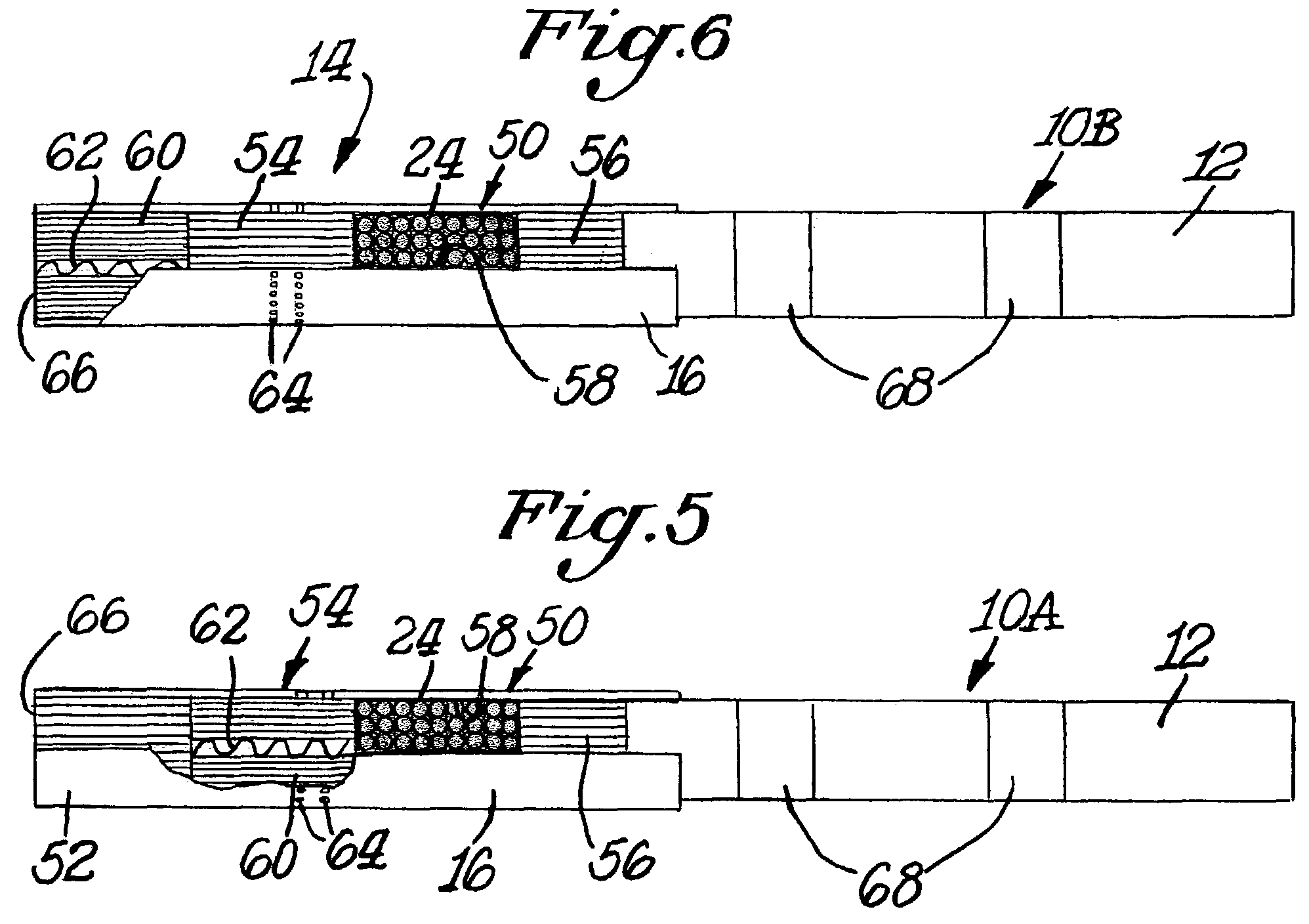

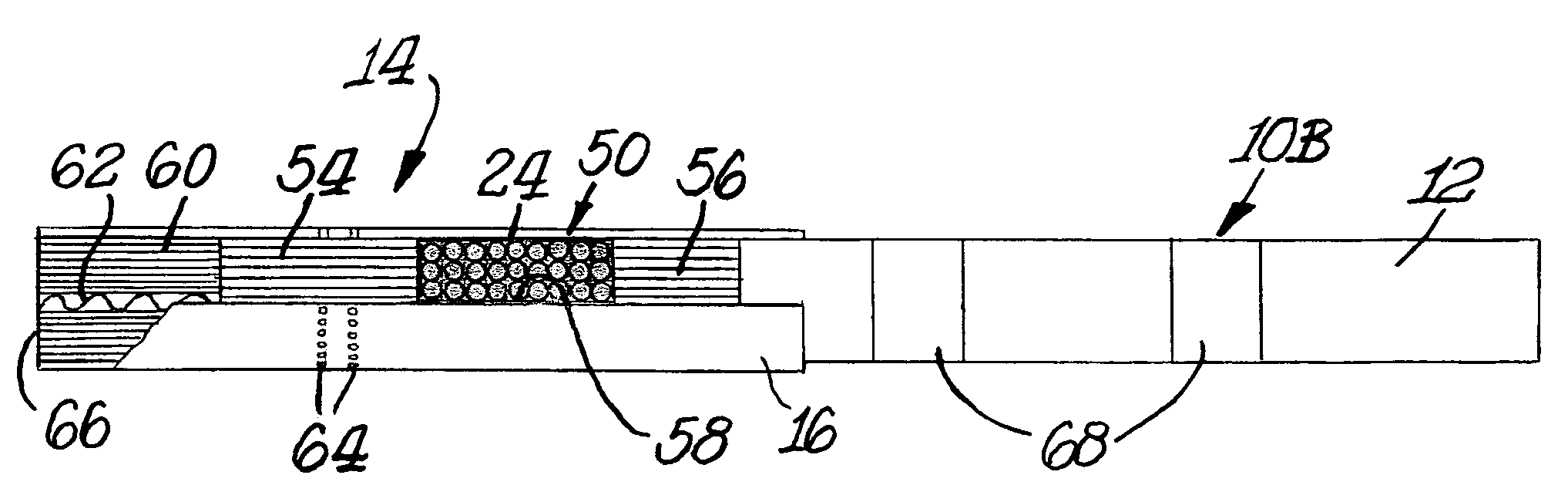

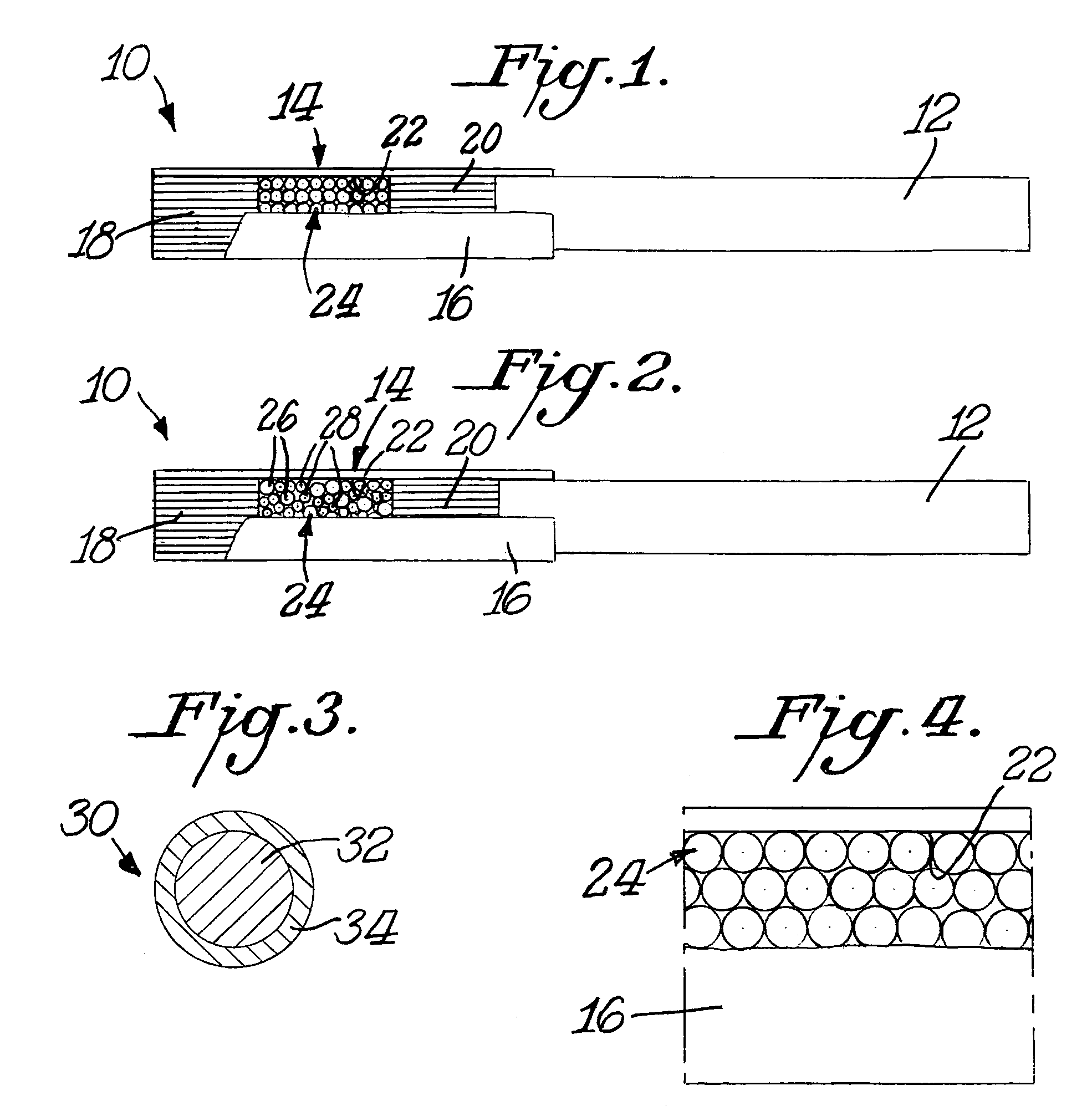

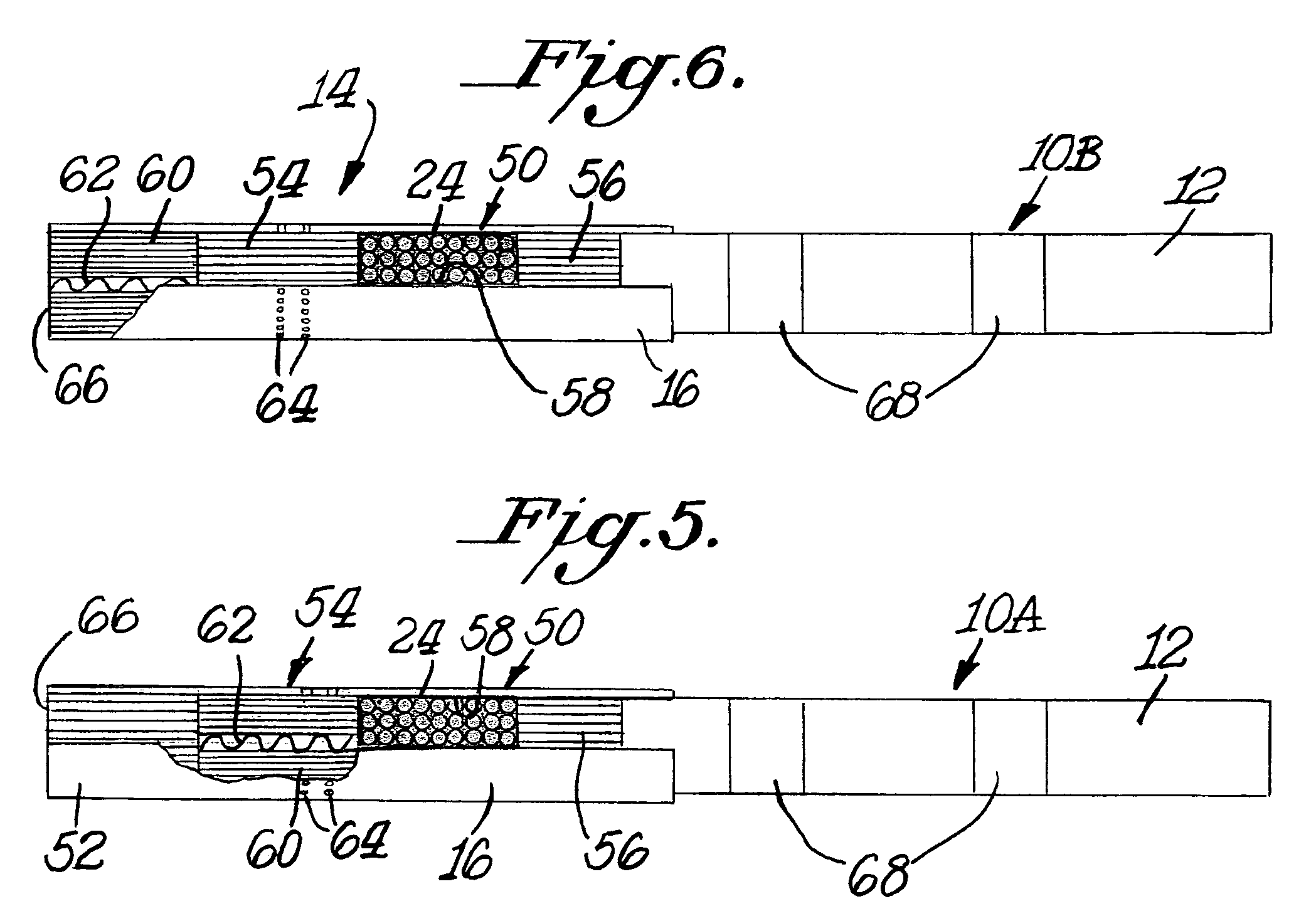

Cigarette filter with beaded carbon

ActiveUS20060180164A1Efficiently and effectively adsorbingAvoid excessive impactTobacco treatmentCigar manufactureGas phaseEngineering

A smoking article such as a cigarette comprises a tobacco rod and a filter component having a cavity filled with spherical beaded carbon. As mainstream tobacco smoke is drawn through the filter component, targeted gas phase smoke constituents are removed as the smoke passes through the carbon. During the filter manufacturing process the spherical beaded carbon flows like a liquid and substantially completely fills the cavity. Point-to-point contact between the spherical beads together with substantially complete filling of the cavity produces minimal channeling of ambulatory gas phase as well as maximum contact between the gas phase and the carbon surface of the spherical beads during smoking.

Owner:PHILIP MORRIS USA INC

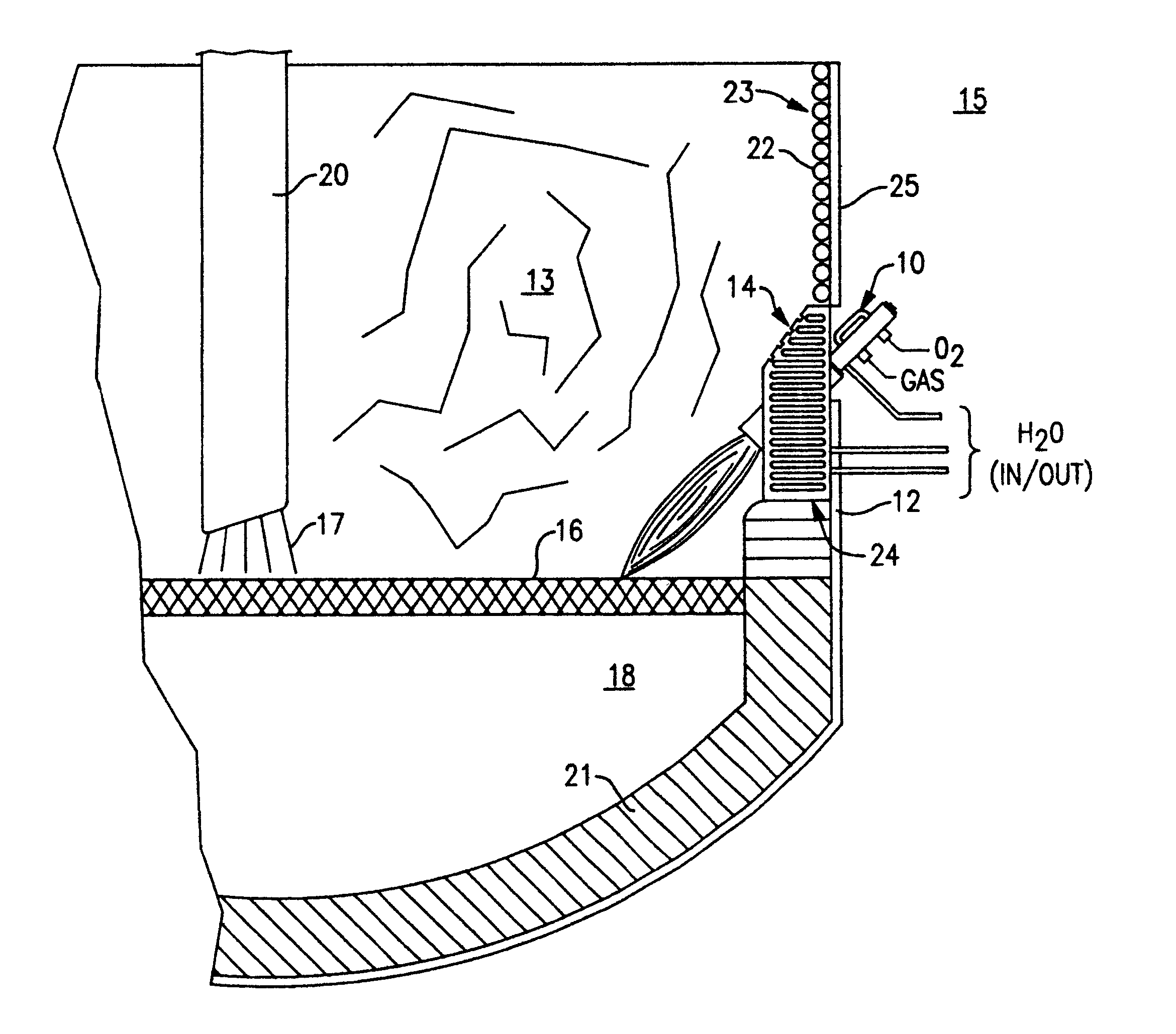

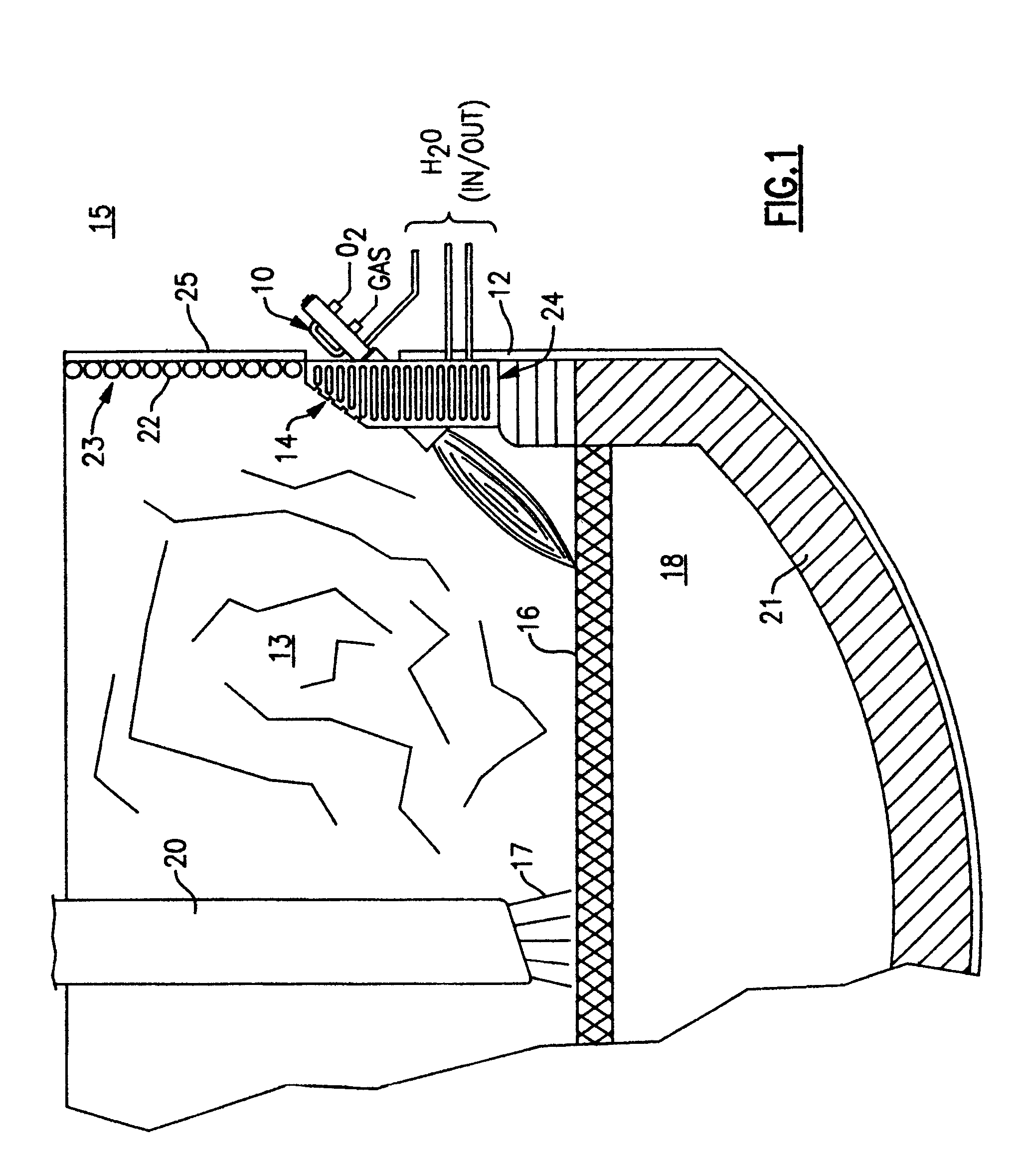

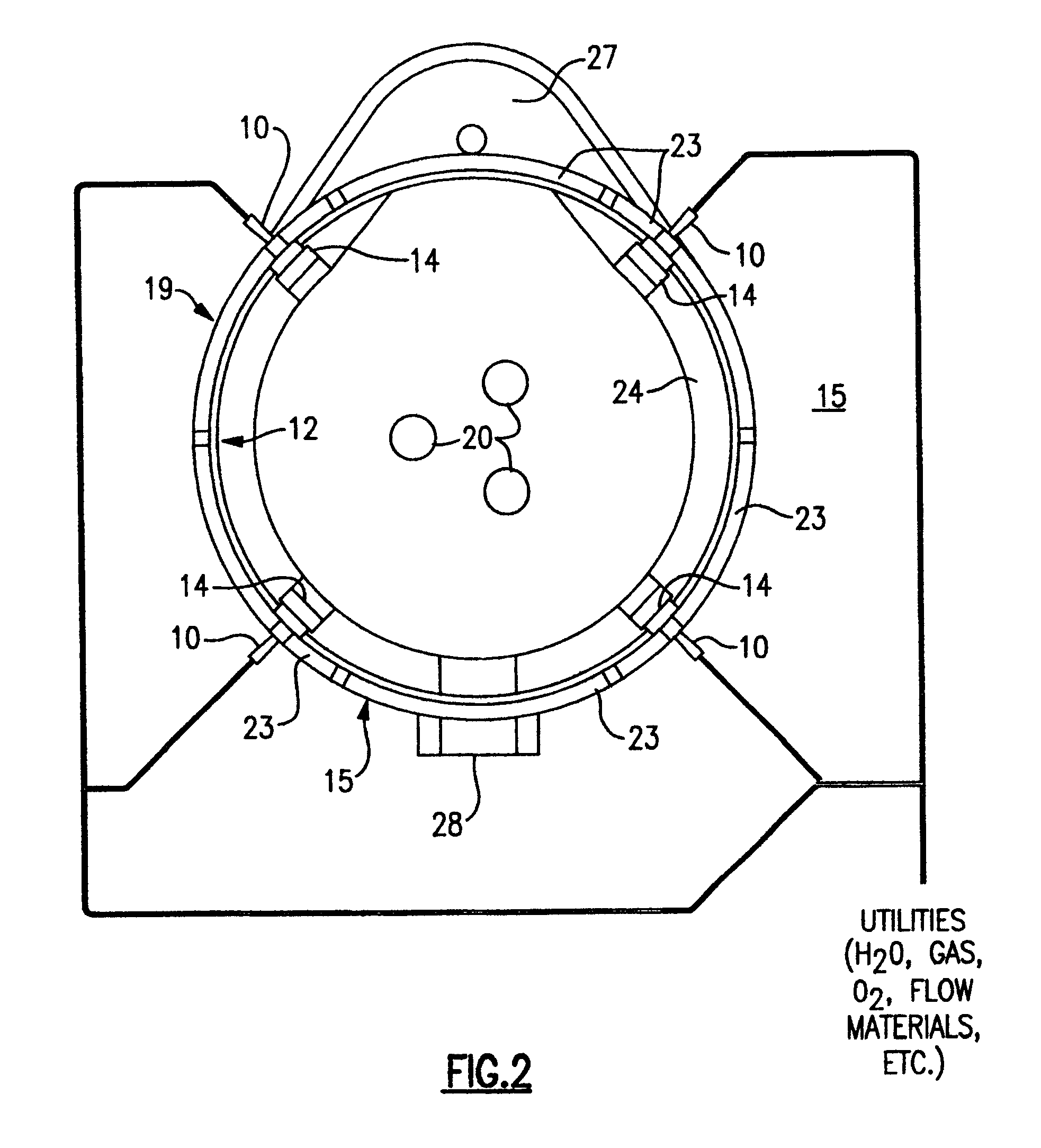

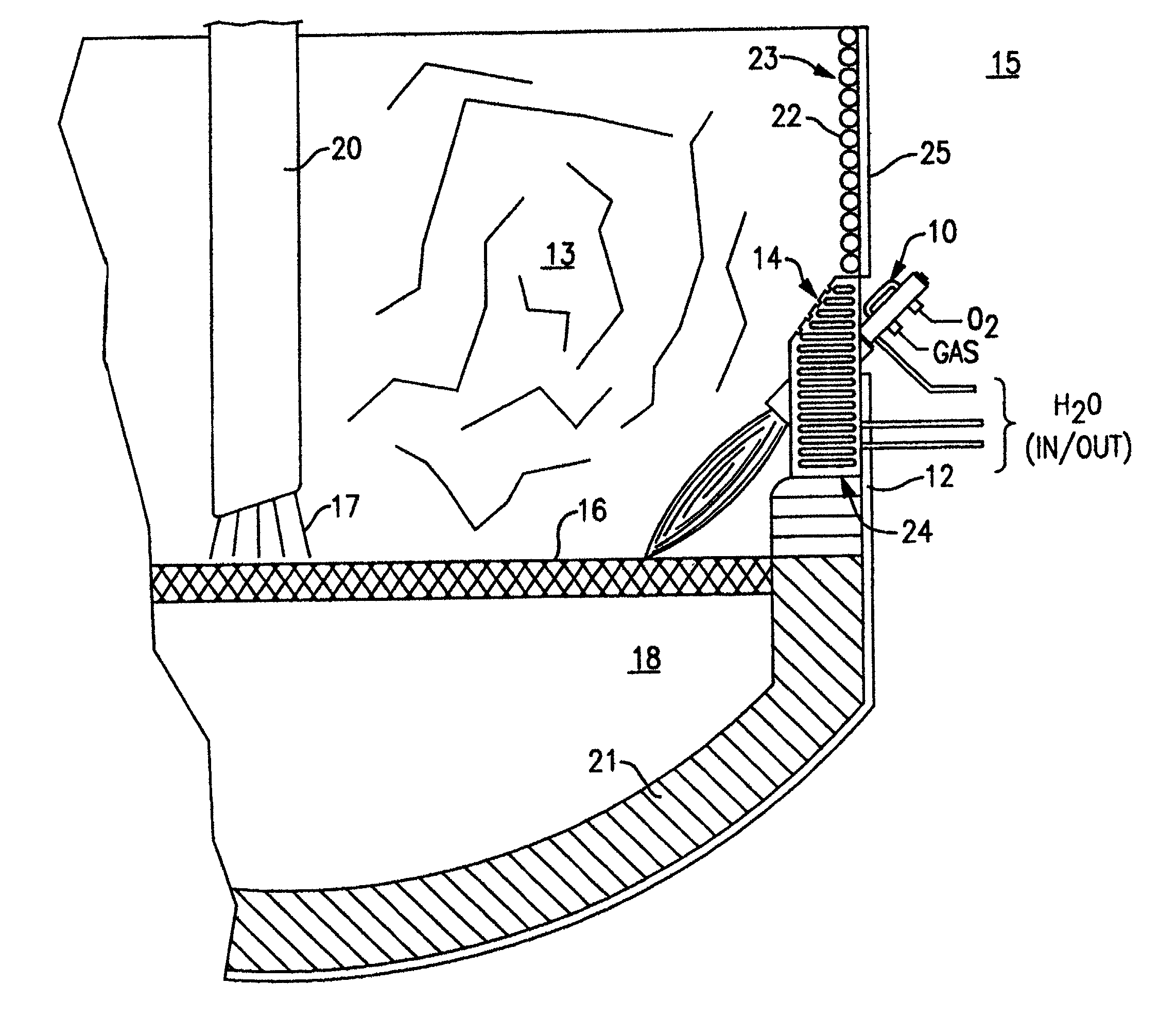

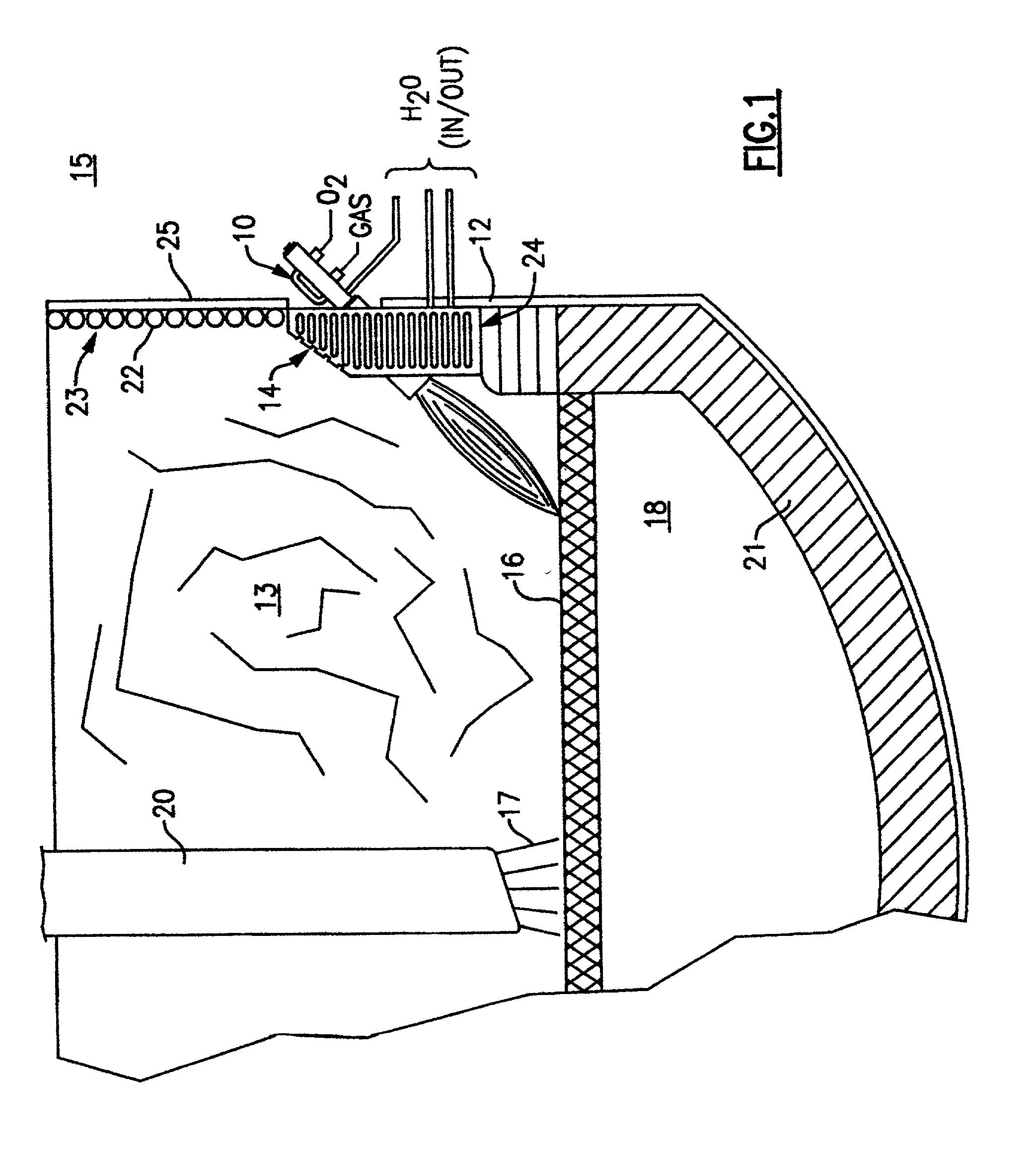

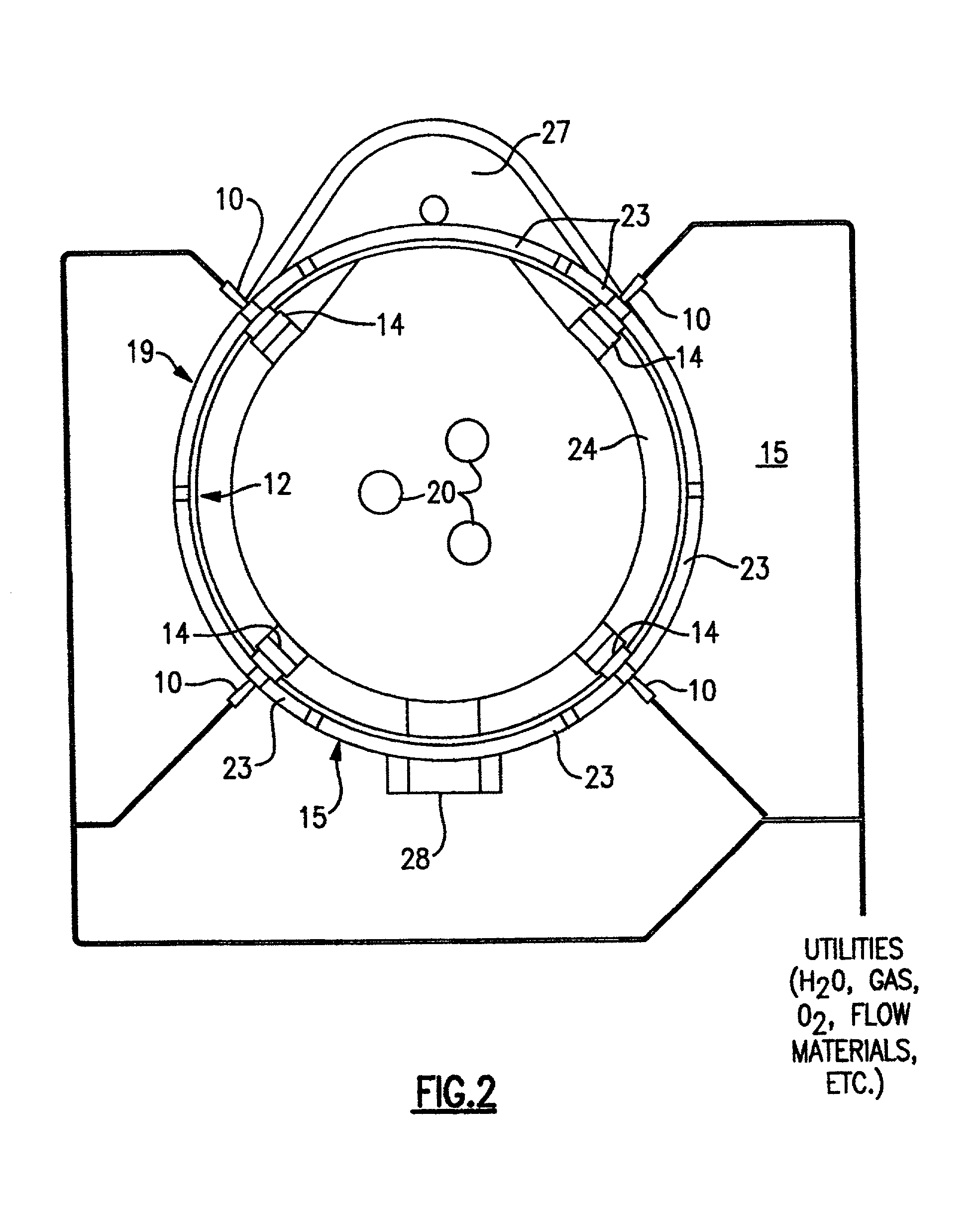

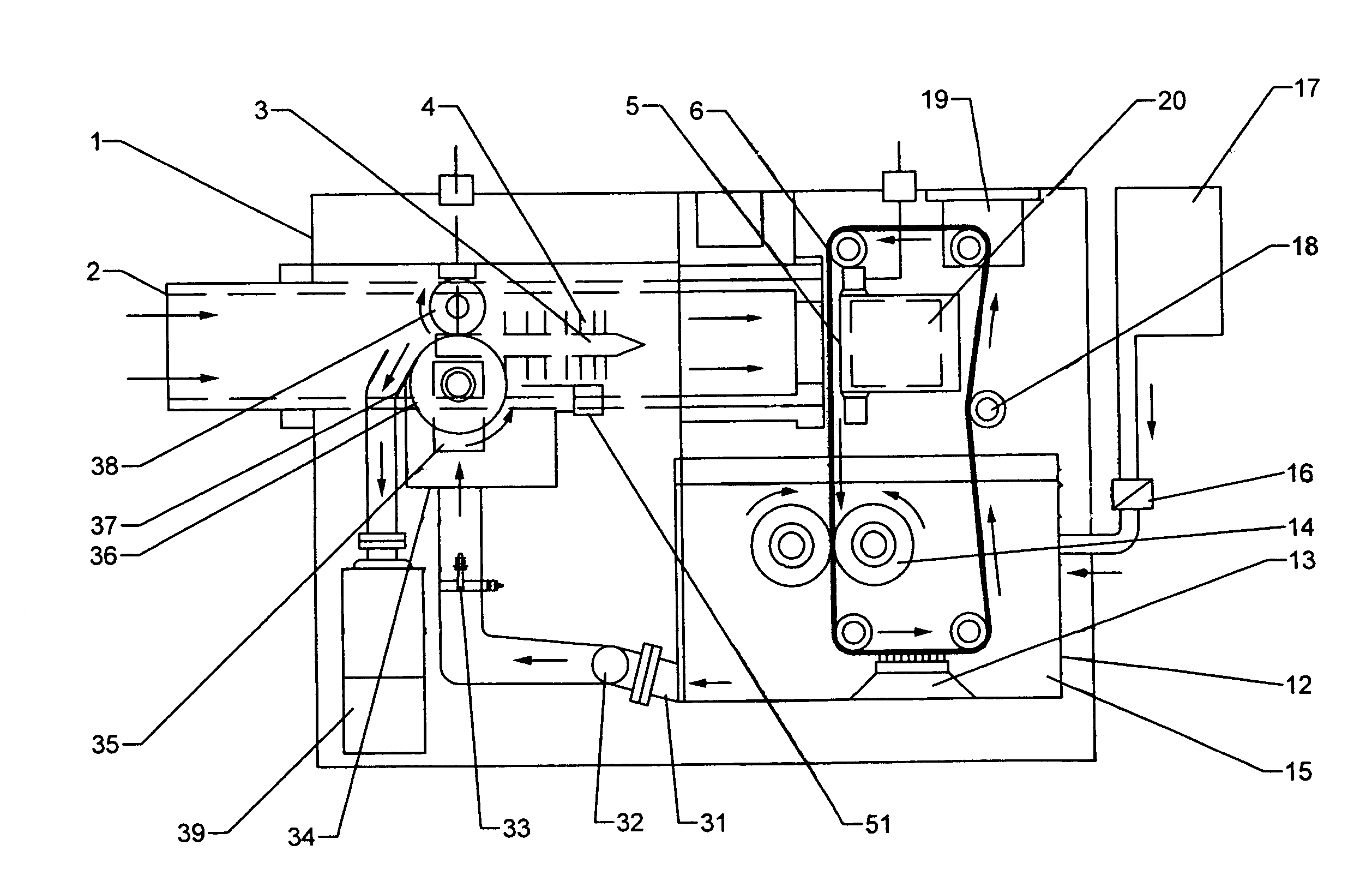

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

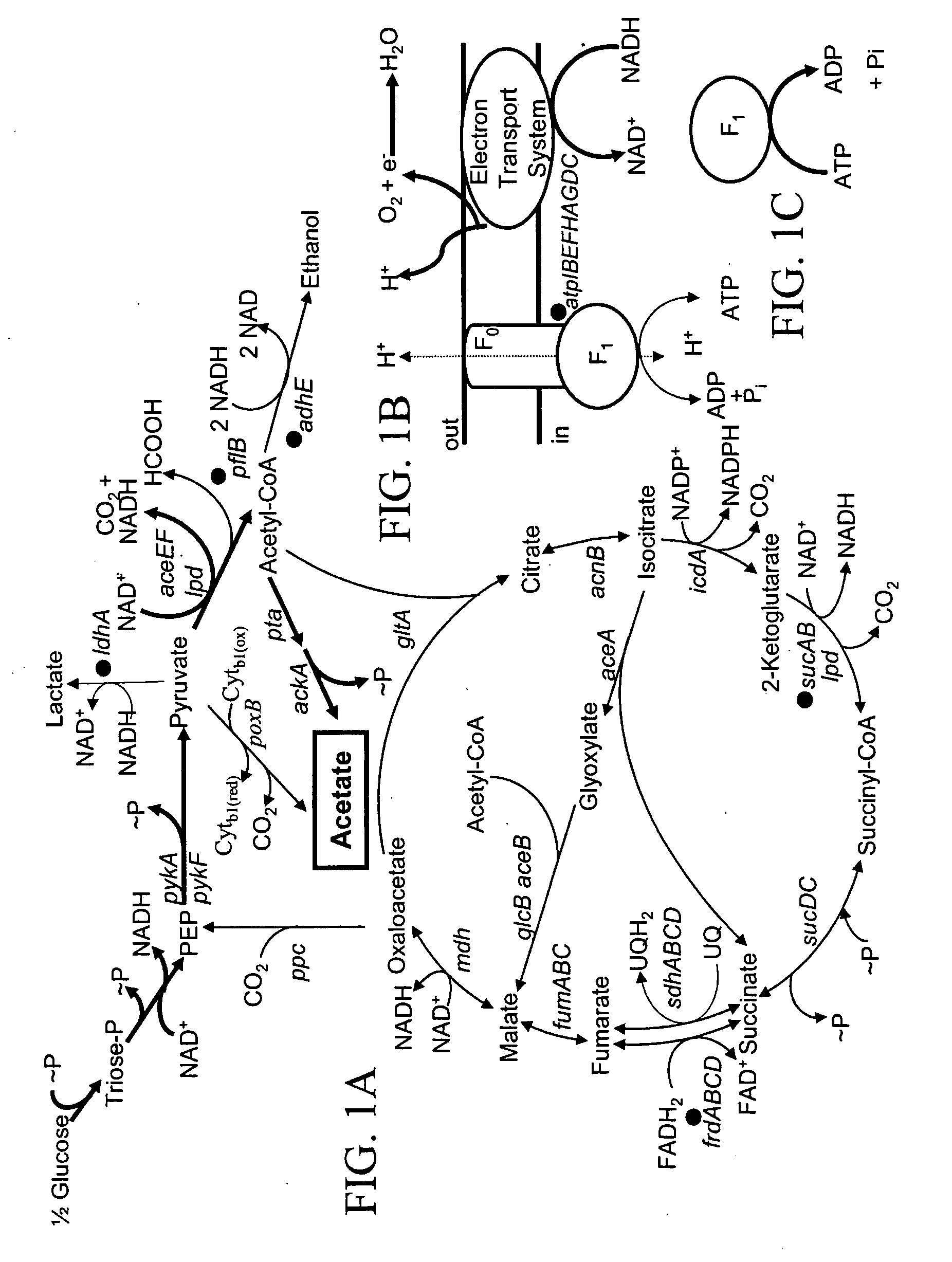

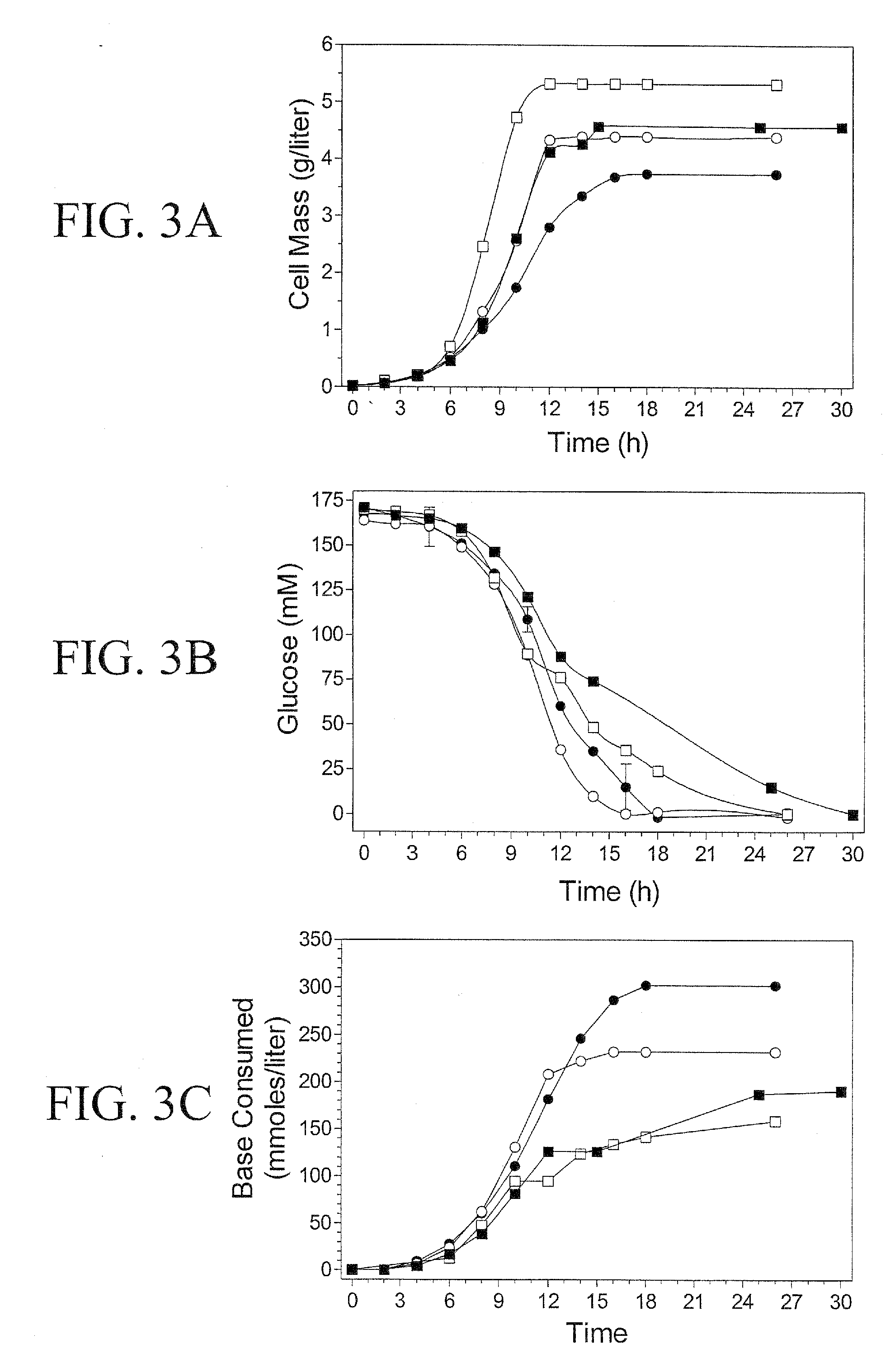

Materials and methods for the efficient production of acetate and other products

InactiveUS20090148914A1Doubled the loss of carbon as volatile productsReduce probabilitySugar derivativesBacteriaAcetic acidProviding material

The subject invention provides materials and methods wherein unique and advantageous combinations of gene mutations are used to direct carbon flow from sugars to a single product. The techniques of the subject invention can be used to obtain products from native pathways as well as from recombinant pathways. In preferred embodiments, the subject invention provides new materials and methods for the efficient production of acetate and pyruvic acid.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Mounting arrangement for auxiliary burner or lance

InactiveUS20020001332A1Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

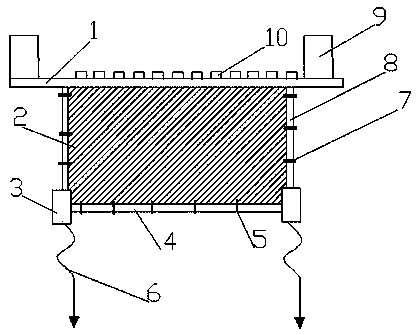

Carbon separation and collection device used for high performance dust collector

InactiveUS6958088B1Improve technological disadvantageImprove performanceWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsEngineeringLiquid tank

A carbon separation and collection device used for a high performance dust collector includes a water supply tube, a water pump, a high pressure negative electrode discharge device, a high pressure positive electrode discharge device, a rotary brush, a removing plate, a carbon collector, a liquid tank, and a speed change device and an exhausting tube. The two discharge devices serve to achieve a function of electrolyte. When the cleaning liquid with carbon flows into the water supply tube by using the water pump. The carbon is adhered to the high pressure positive electrode discharge device. The high pressure positive electrode discharge device is driven to rotate by the speed change device. The carbon is moved from the high pressure positive electrode discharge device by the rotary brush and removing plate. Then, the removing carbon drops into the carbon collector.

Owner:ARCHTEK DENTAL LLC

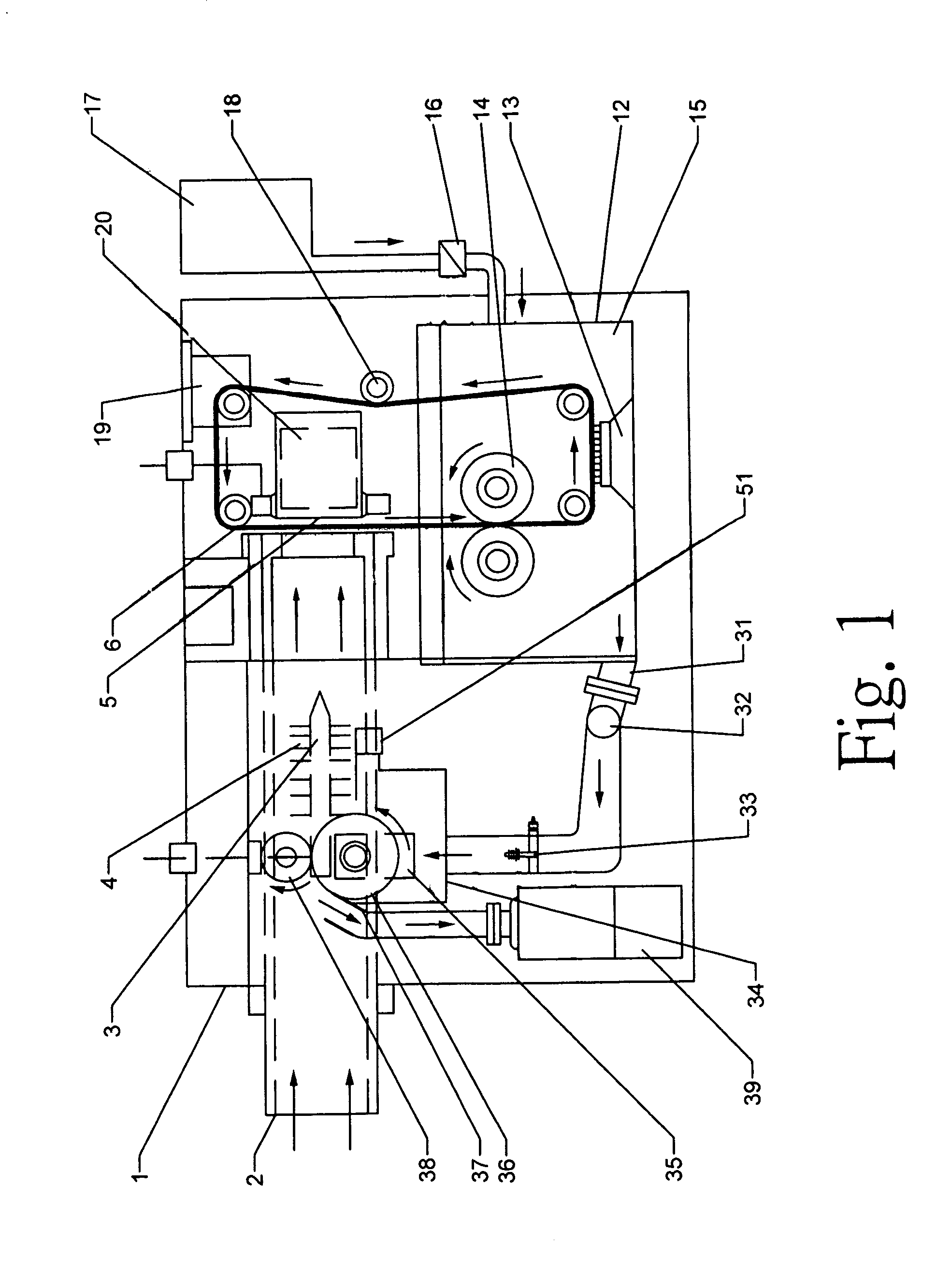

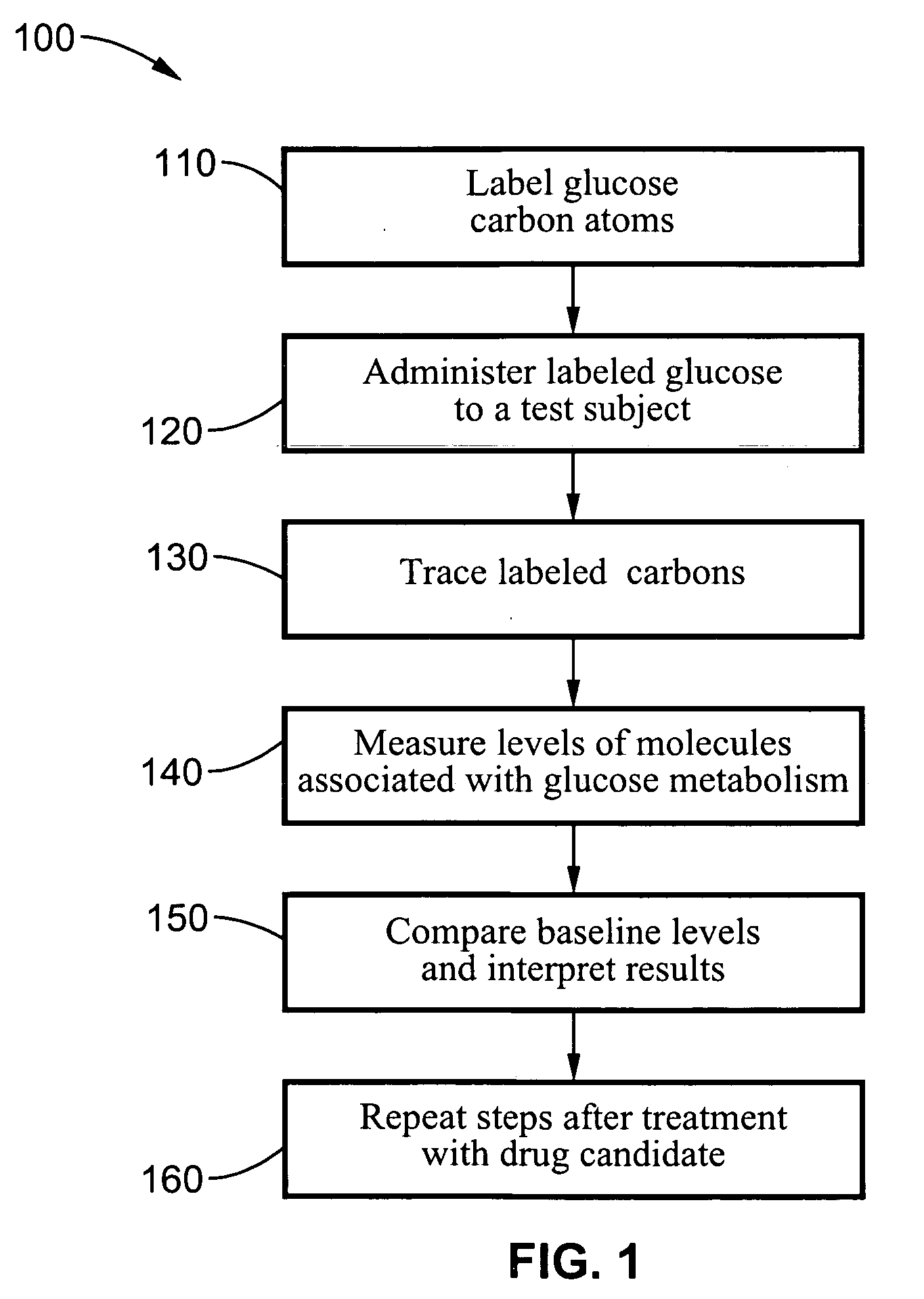

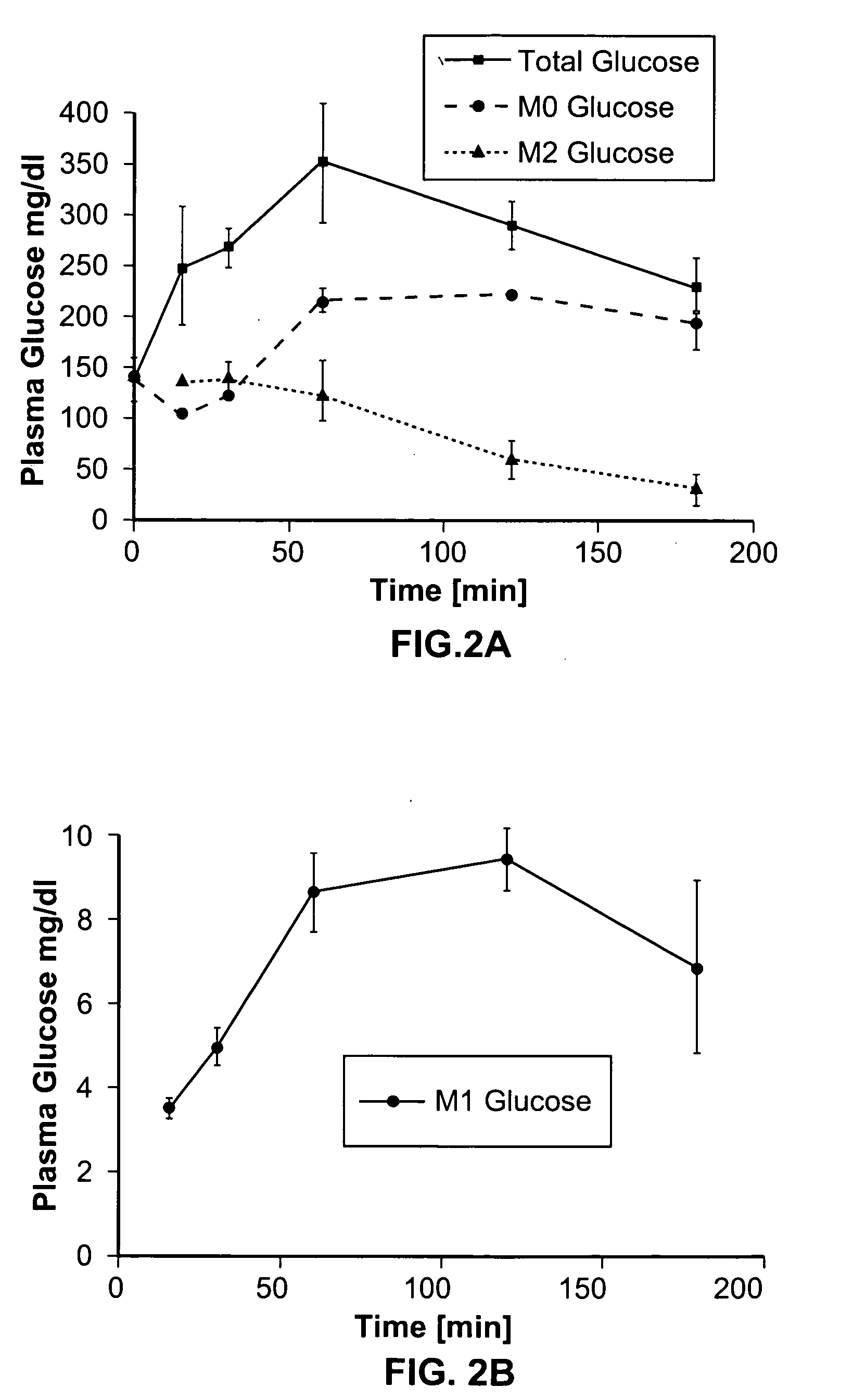

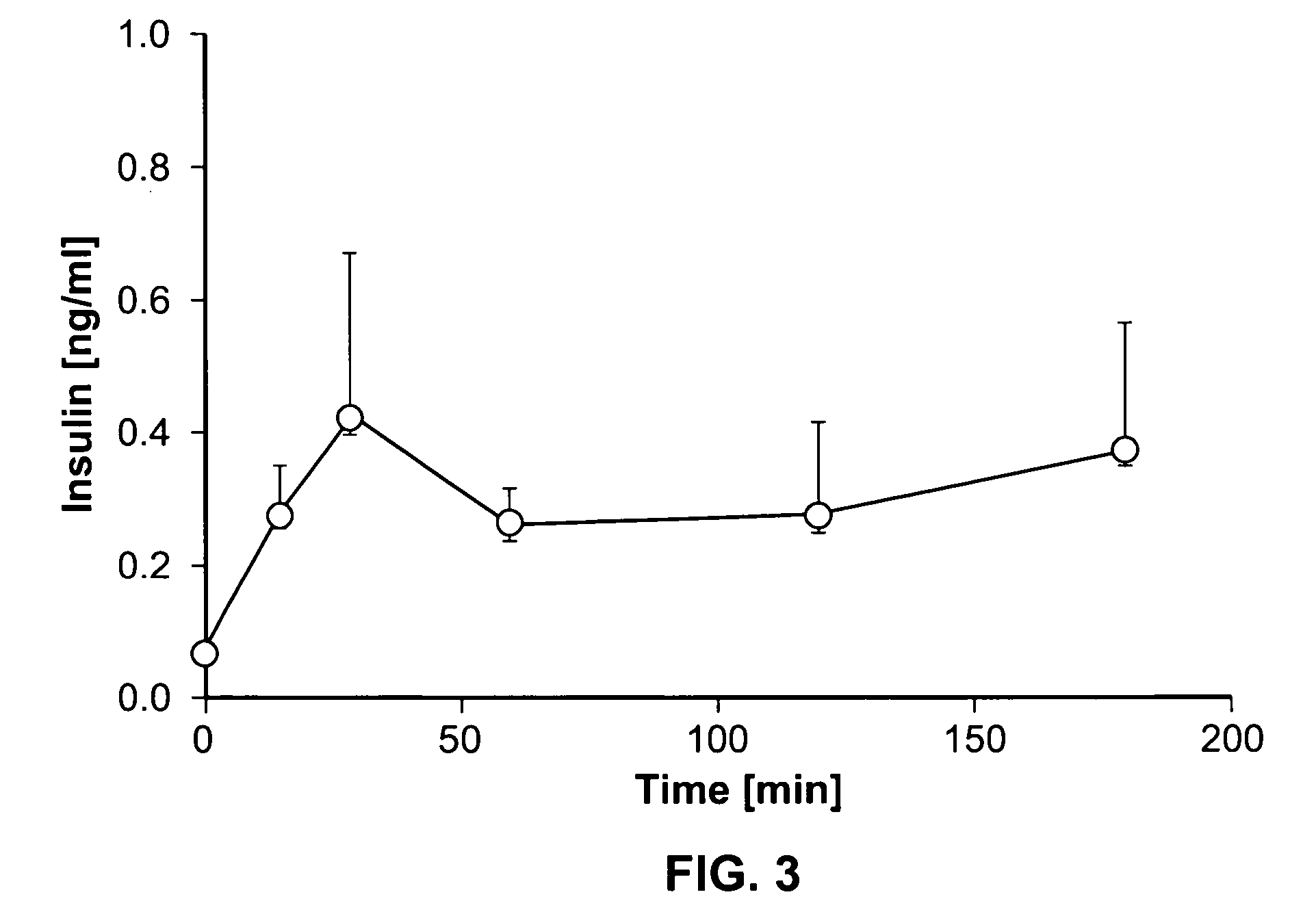

Dynamic hepatic recycling glucose tolerance test

Systems and methods are described providing a hepatic recycling glucose tolerance test for the diagnosis of types and subtypes of diabetes mellitus and other hyperglycemic or hypoglycemic conditions. A method is also provided for screening candidate drugs for treating various types of abnormal glucose metabolism and to monitor whether the course of treatment is effective. The method also allows the correlation of gene activity, hormone and metabolite levels with glucose flux and recycling and an assessment of the degree of hepatic insulin resistance. The method utilizes a preferably non-radioactive stable labeled glucose to asses the relative rates of carbon flow in the liver and provides a hepatic recycling constant that is a measure of the relative rate of glucose recycling. The labeled glucose may be introduced to the patient orally, intravenously or by intraperitoneal administration for the desired effect.

Owner:RGT UNIV OF CALIFORNIA

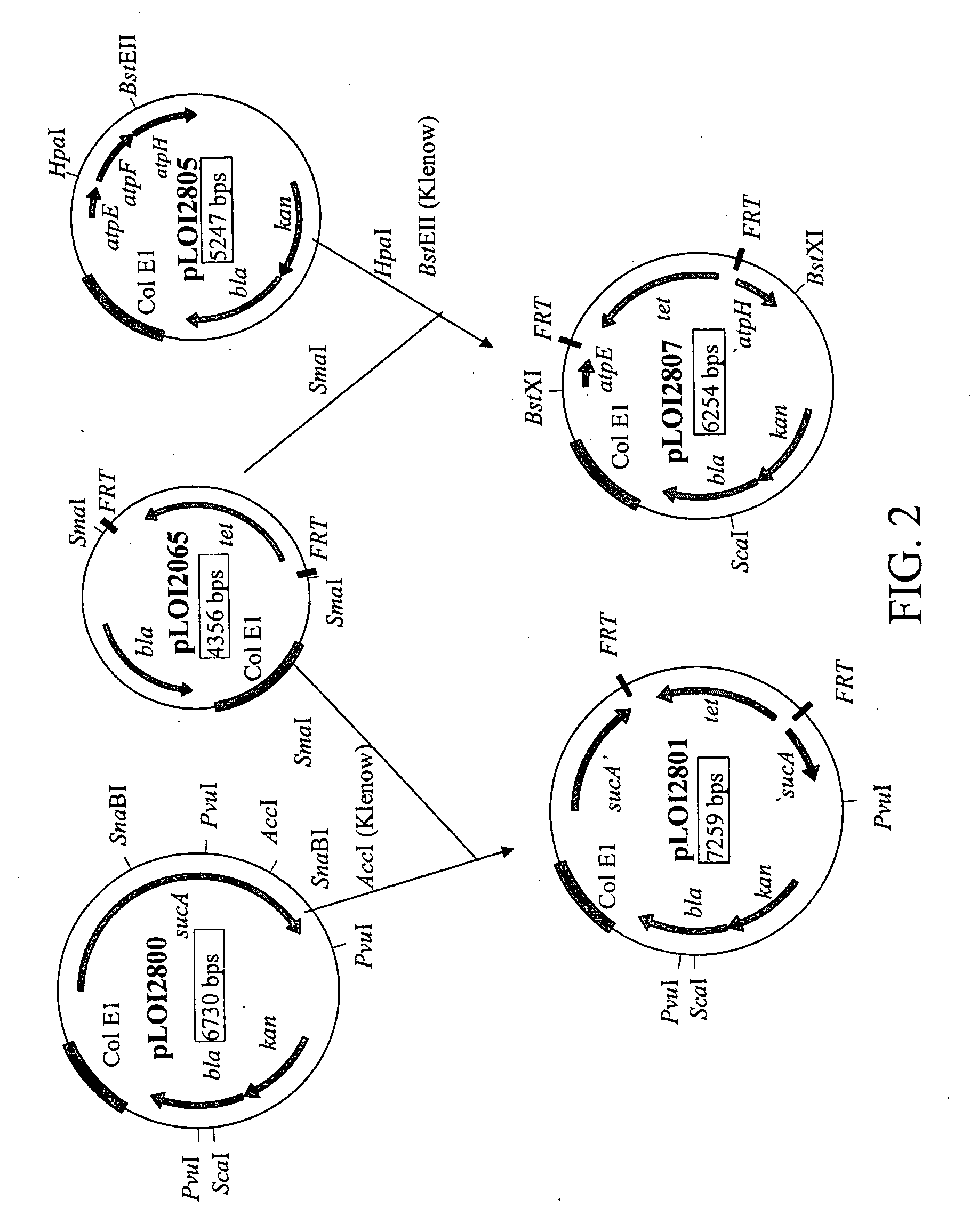

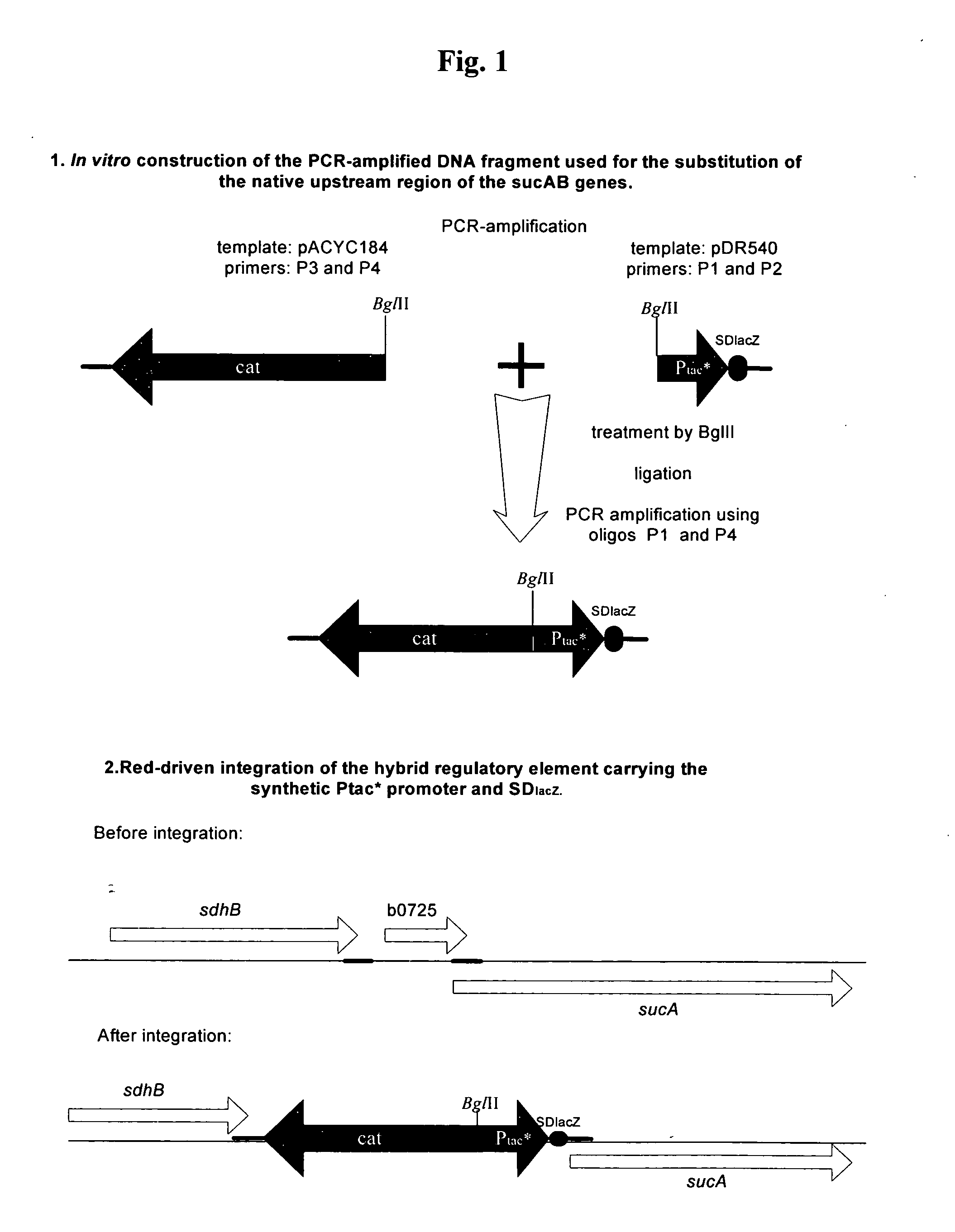

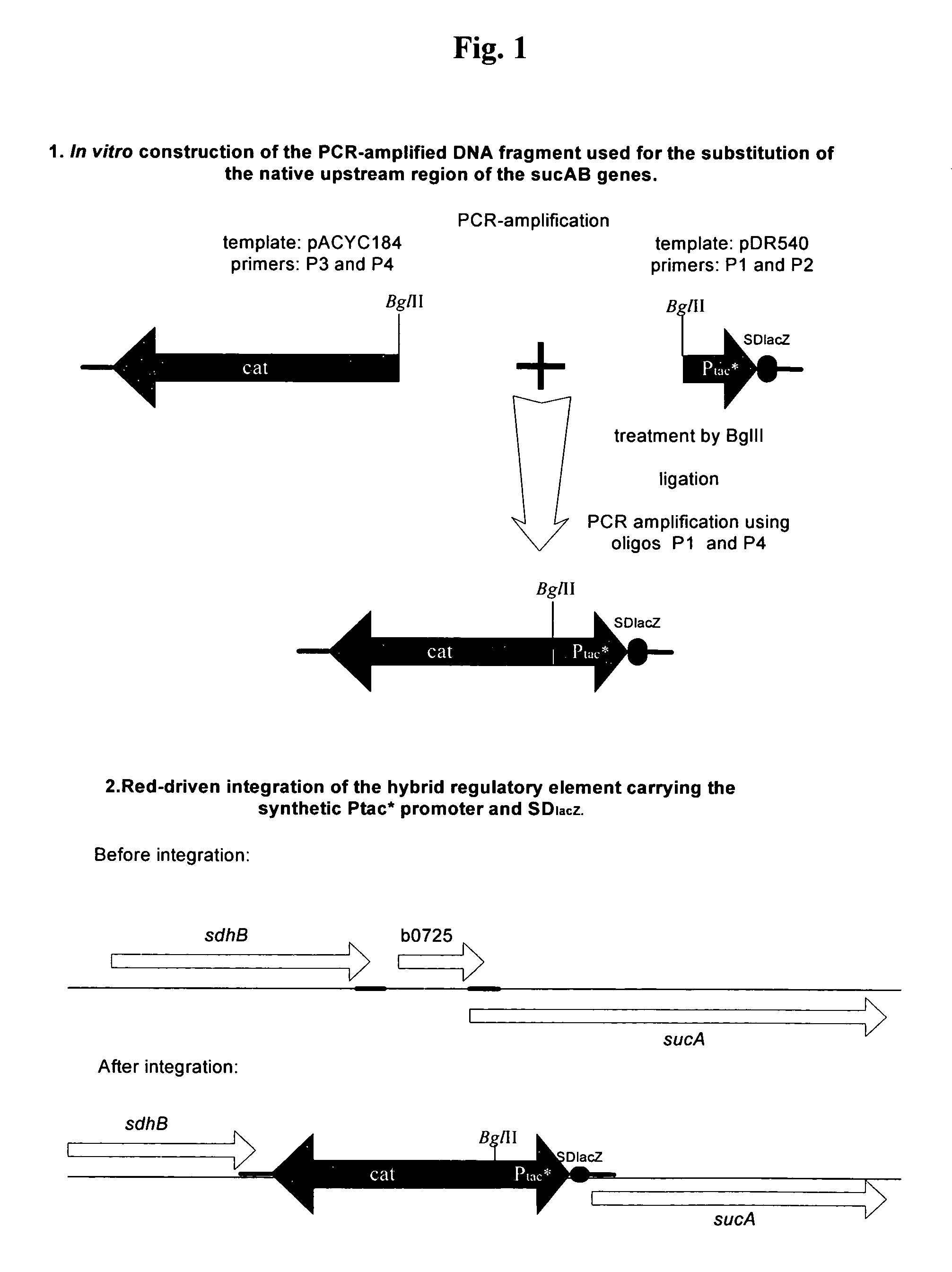

Method for producing an L-amino acid using a bacterium with an optimized level of gene expression

A method is provided for obtaining an L-amino acid or nucleic acid-producing bacterium belonging to the genus Escherichia with an optimized level of expression of the gene which influences the distribution of carbon flow, such as the sucAB genes, comprising introducing into the chromosome of the bacterium a set of in vitro constructed DNA fragments which contain regulatory elements for gene expression instead of the native elements of the regulatory region of the gene, and selecting the colonies with increased L-amino acid productivity. Also, a method is provided for producing an L-amino acid, such as L-glutamic acid, L-proline, L-arginine, L-glutamine, L-leucine, using the bacterium with an optimized level of expression of the sucAB gene.

Owner:AJINOMOTO CO INC

Cigarette filter with beaded carbon

ActiveUS20080053469A1Efficiently and effectively adsorbingAvoid excessive impactCigar manufactureTobacco smoke filtersGas phaseEngineering

A smoking article such as a cigarette comprises a tobacco rod and a filter component having a cavity filled with spherical beaded carbon. As mainstream tobacco smoke is drawn through the filter component, targeted gas phase smoke constituents are removed as the smoke passes through the carbon. During the filter manufacturing process the spherical beaded carbon flows like a liquid and substantially completely fills the cavity. Point-to-point contact between the spherical beads together with substantially complete filling of the cavity produces minimal channeling of ambulatory gas phase as well as maximum contact between the gas phase and the carbon surface of the spherical beads during smoking.

Owner:PHILIP MORRIS USA INC

Cigarette filter with beaded carbon

ActiveUS7784470B2Efficiently and effectively adsorbingAvoid excessive impactTobacco treatmentCigar manufactureGas phaseEngineering

A smoking article such as a cigarette comprises a tobacco rod and a filter component having a cavity filled with spherical beaded carbon. As mainstream tobacco smoke is drawn through the filter component, targeted gas phase smoke constituents are removed as the smoke passes through the carbon. During the filter manufacturing process the spherical beaded carbon flows like a liquid and substantially completely fills the cavity. Point-to-point contact between the spherical beads together with substantially complete filling of the cavity produces minimal channeling of ambulatory gas phase as well as maximum contact between the gas phase and the carbon surface of the spherical beads during smoking.

Owner:PHILIP MORRIS USA INC

Method for producing an L-amino acid using a bacterium with an optimized level of gene expression

A method is provided for obtaining an L-amino acid or nucleic acid-producing bacterium belonging to the genus Escherichia with an optimized level of expression of the gene which influences the distribution of carbon flow, such as the sucAB genes, comprising introducing into the chromosome of the bacterium a set of in vitro constructed DNA fragments which contain regulatory elements for gene expression instead of the native elements of the regulatory region of the gene, and selecting the colonies with increased L-amino acid productivity. Also, a method is provided for producing an L-amino acid, such as L-glutamic acid, L-proline, L-arginine, L-glutamine, L-leucine, using the bacterium with an optimized level of expression of the sucAB gene.

Owner:AJINOMOTO CO INC

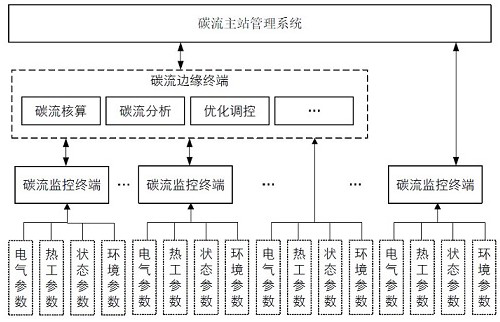

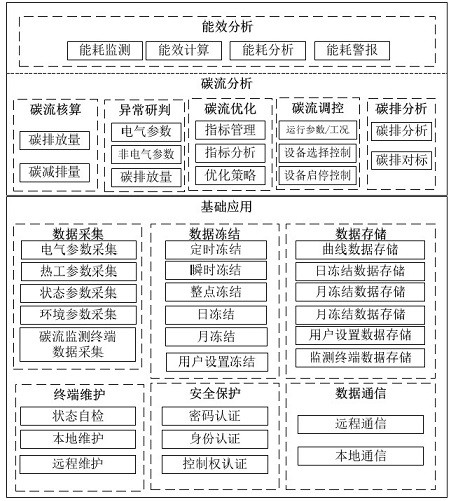

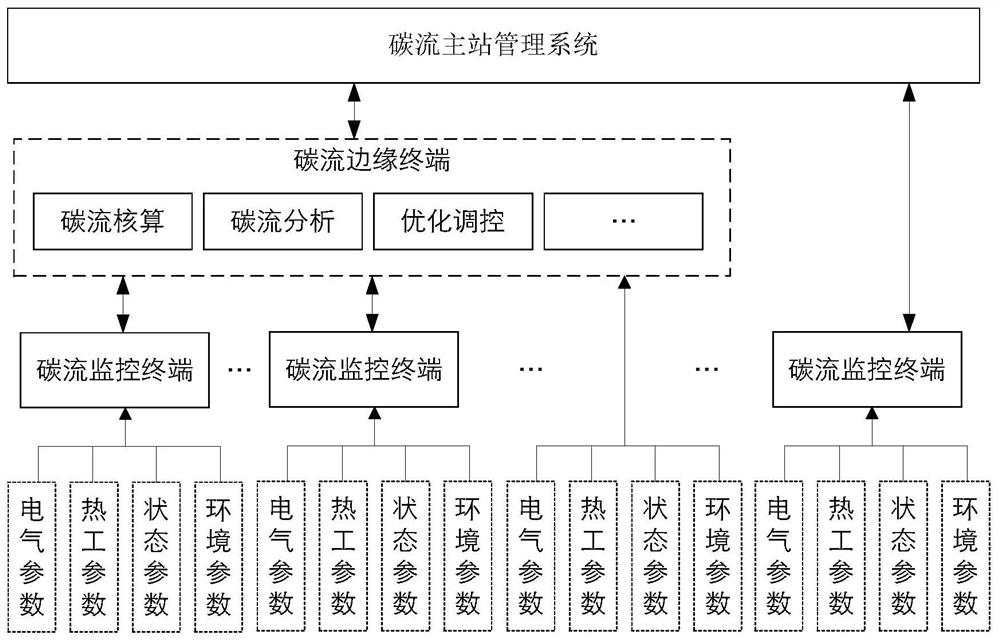

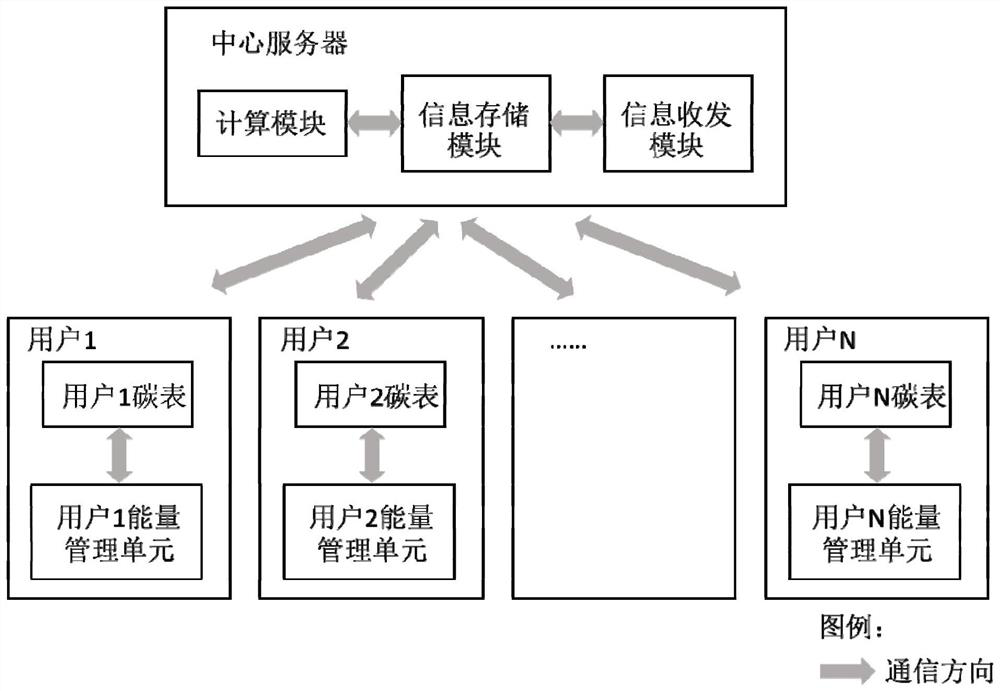

Demand side carbon flow edge analysis method, terminal and system

ActiveCN113642936APromote low-carbon productionImprove regulation efficiencyTechnology managementResourcesMaster stationProcess engineering

The invention provides a demand side carbon flow edge analysis method, terminal and system. The system comprises a carbon flow monitoring terminal connected with a carbon flow edge terminal, a demand side energy consumption terminal and a carbon flow master station; the carbon flow edge terminal collects field data of each energy consumption end of a demand side energy consumption unit; carbon flow accounting, carbon emission analysis and energy efficiency analysis are carried out according to energy types on the basis of all field data; a regulation and control command is formed based on the carbon flow accounting result, the carbon emission analysis result and a pre-stored regulation and control strategy; the regulation and control command is issued to an energy consumption end and / or a carbon flow monitoring terminal; and the field data, the carbon flow accounting result, the carbon emission analysis result and the energy efficiency analysis result are uploaded to a carbon flow master station. The carbon flow edge terminal can perform edge calculation and analysis on the field data of the energy consumption end, so that the local application response efficiency can be enhanced, and the energy consumption end can be subjected to optimization control.

Owner:CHINA ELECTRIC POWER RES INST

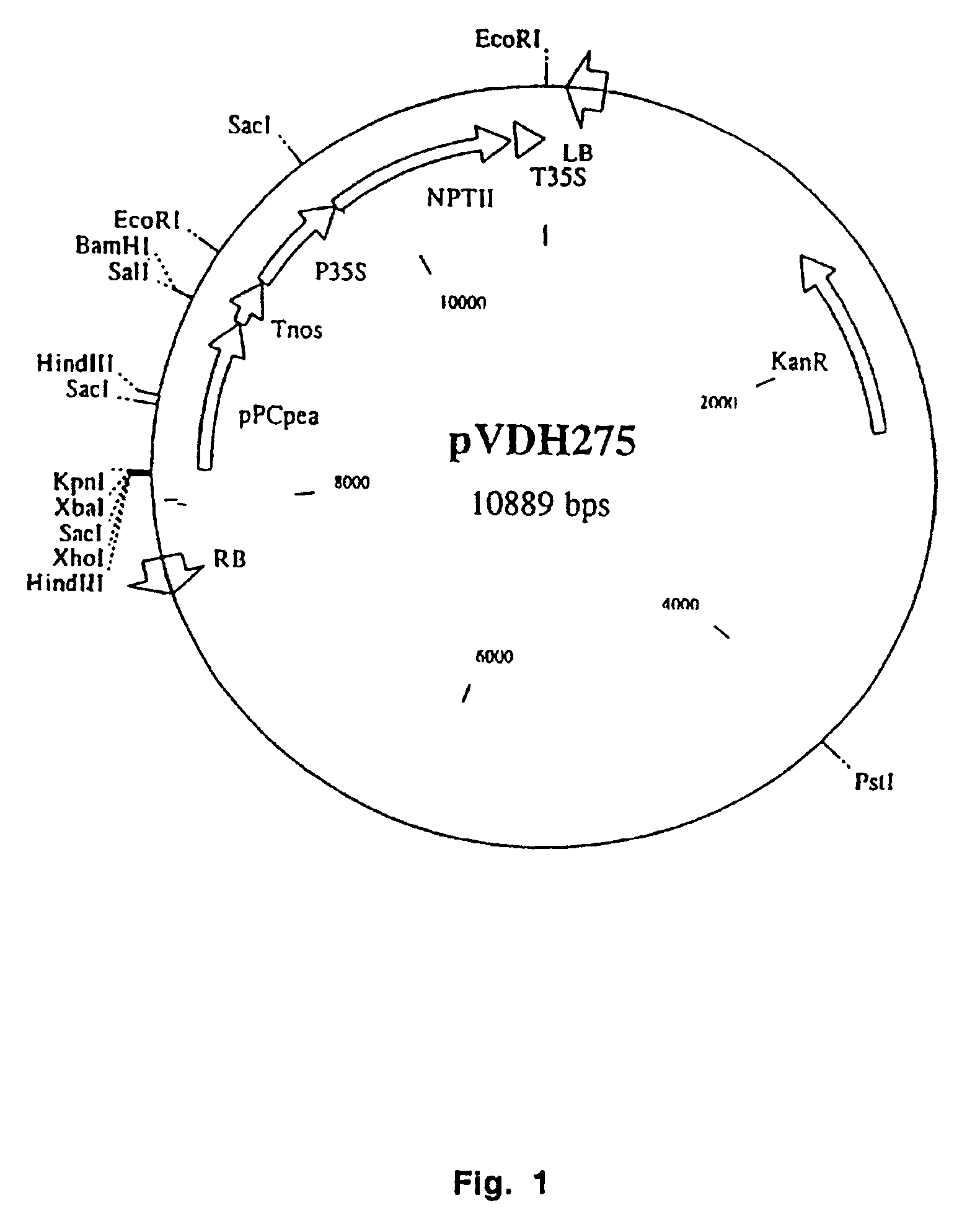

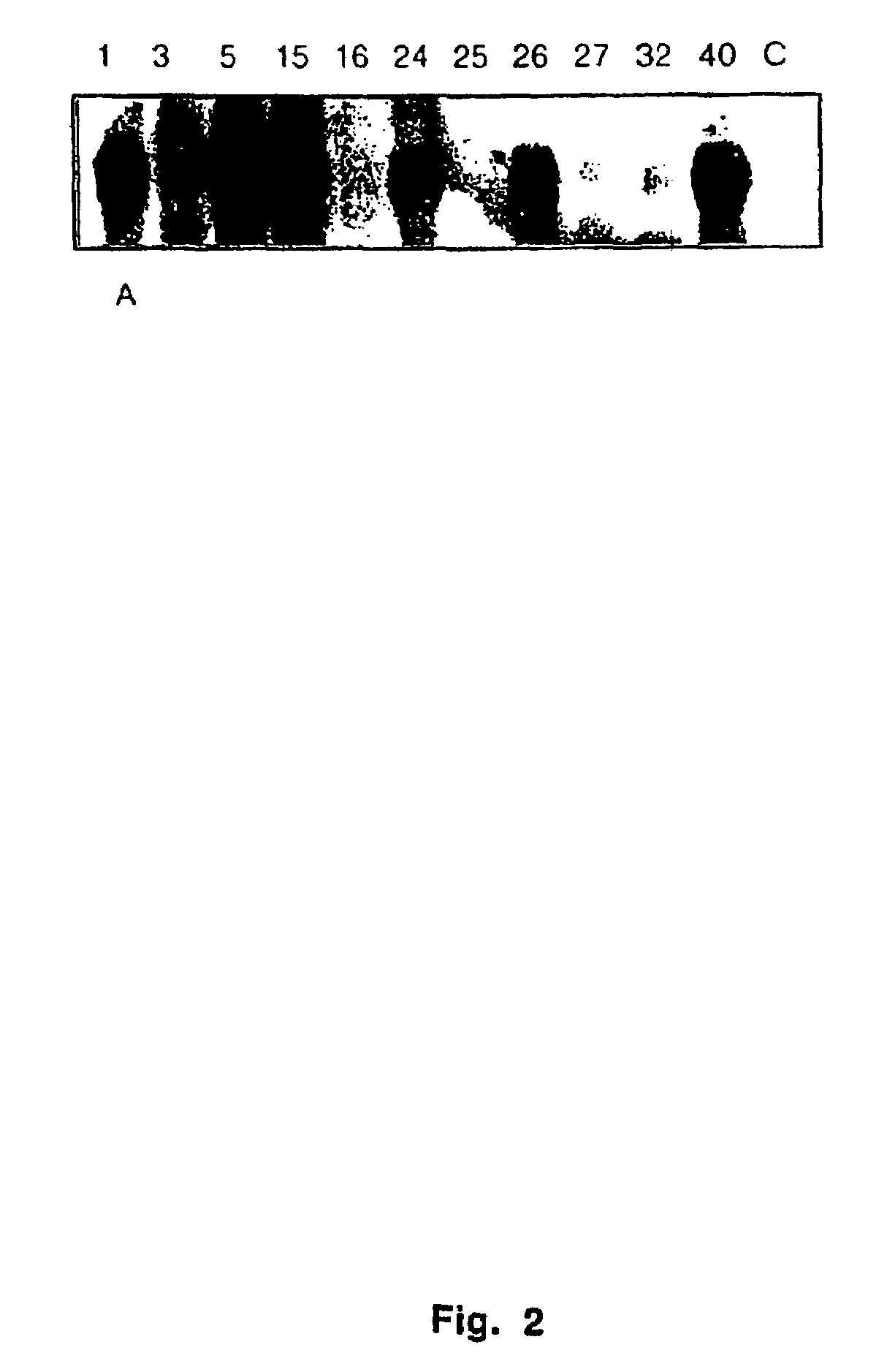

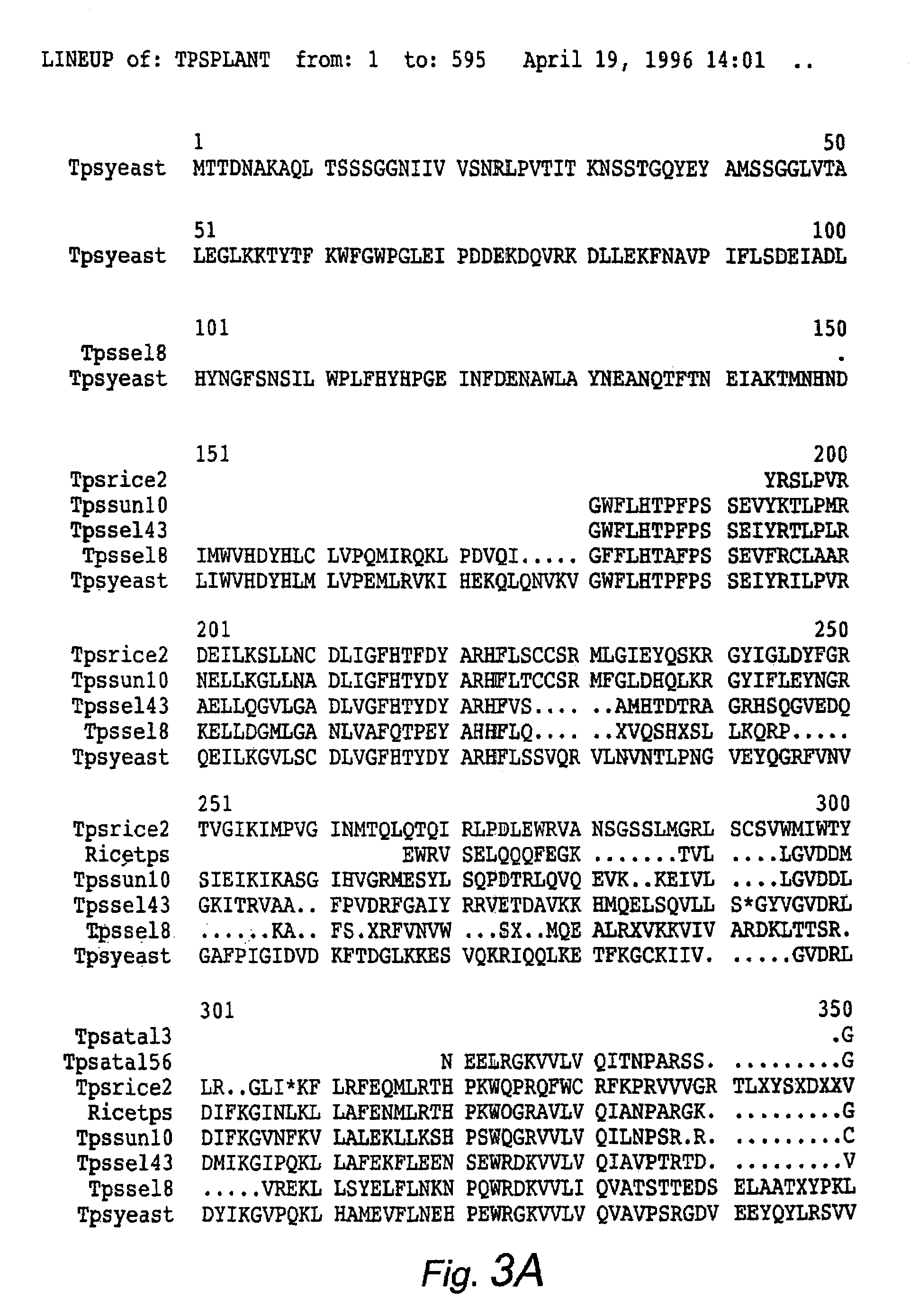

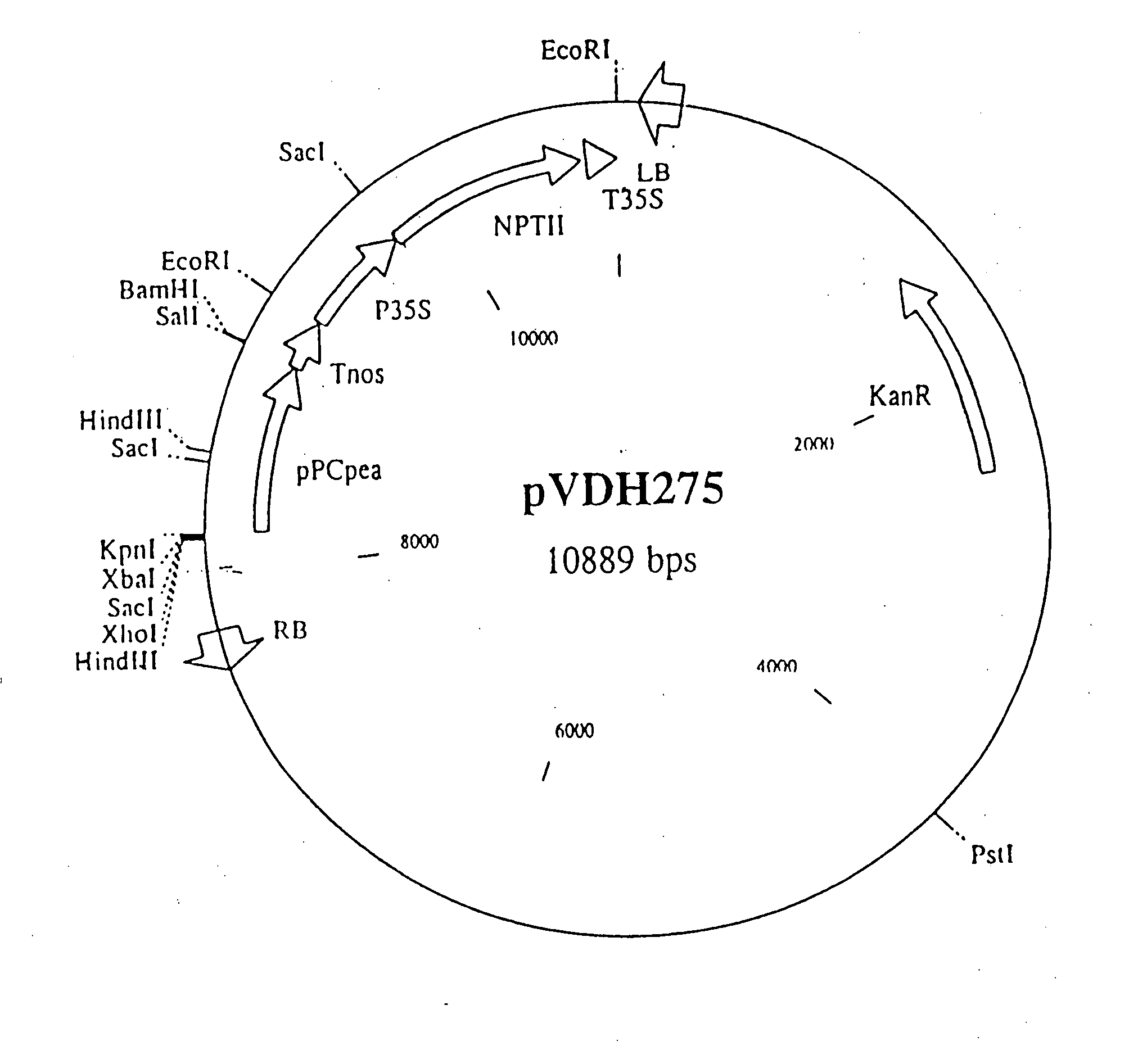

Regulating metabolism by modifying the level of trehalose-6-phosphate

Method for the inhibition of carbon flow in the glycolytic direction in a cell by increasing the intracellular availability of trehalose-6-phosphate.

Owner:SYNGENTA MOGEN BV

Cigarette filter with beaded carbon

ActiveUS7784471B2Efficiently and effectively adsorbingAvoid excessive impactTobacco treatmentCigar manufactureGas phaseEngineering

A smoking article such as a cigarette comprises a tobacco rod and a filter component having a cavity filled with spherical beaded carbon. As mainstream tobacco smoke is drawn through the filter component, targeted gas phase smoke constituents are removed as the smoke passes through the carbon. During the filter manufacturing process the spherical beaded carbon flows like a liquid and substantially completely fills the cavity. Point-to-point contact between the spherical beads together with substantially complete filling of the cavity produces minimal channeling of ambulatory gas phase as well as maximum contact between the gas phase and the carbon surface of the spherical beads during smoking.

Owner:PHILIP MORRIS USA INC

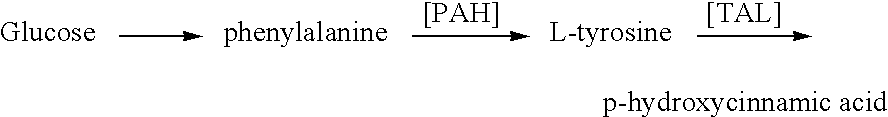

Methods for the production of tyrosine, cinnamic acid and para-hydroxycinnamics acid

Genes encoding phenylalanine ammonia-lyase (PAL), tyrosine ammonia lyase (TAL) and phenylalanine hydroxylase (PAH) have been introduced into a host organism for the production of Para-hydroxycinnamic acid (PHCA). The introduction of these genes results in the redirection of carbon flow in the host, optimizing the flow of carbon from glucose to PHCA. The intermediates, tyrosine and cinnamic acid are also produced.

Owner:ORMON CORP +1

Process for directly preparing oxygen-free copper from waste red impure copper

The invention relates to preparation of oxygen-free copper, in particular to a process for directly preparing oxygen-free copper from waste red impure copper. The process comprises the steps of conducting melting refining on the waste red impure copper through a refining furnace; conducting impurity removal, deoxidation and purification on smelted molten copper; putting the purified molten copperin a standing furnace to conduct standing and then deoxidation; and leading out the molten copper subjected to standing and deoxidation through an up-drawing furnace to obtain an oxygen-free copper product. Through the process, oxygen-free copper bars or oxygen-free copper products are directly prepared just from the waste red impure copper; the requirements for the oxygen content and the copper content in the early period are met through the two impurity removal and deoxidation processes of oxidation reduction and rare earth refining agents; and the re-deoxidation process is completed througha carbon filter tank, a sealing carbon flow channel and standing furnace carbon reduction at a copper outlet. Through the optimized short process, resources are saved, and meanwhile, the high-qualityoxygen-free copper products can be directly prepared.

Owner:湖南金龙国际铜业有限公司

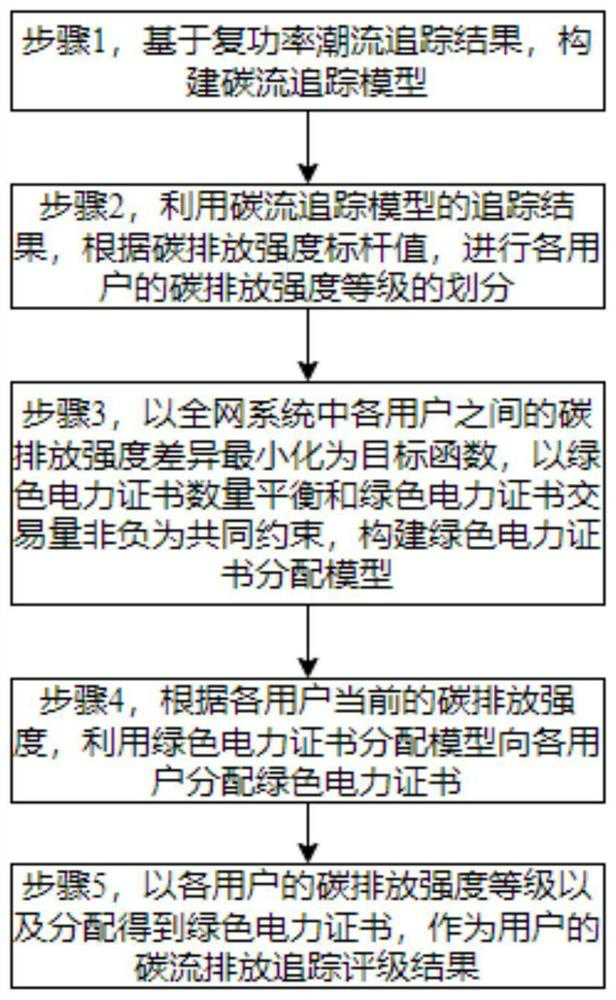

Carbon flow emission tracking rating method based on complex power flow

PendingCN114662877AMultiple emission reduction responsibilitiesReduce emission intensityDesign optimisation/simulationResourcesSimulationElectric power

The invention discloses a carbon flow emission tracking rating method based on complex power flow. The method comprises the following steps: step 1, constructing a carbon flow tracking model based on a complex power flow tracking result; step 2, dividing the carbon emission intensity grade of each user according to the carbon emission intensity benchmark value by using the result of the carbon flow tracking model; step 3, taking minimization of carbon emission intensity difference among users in the whole network as a target function, and taking green power certificate number balance and green power certificate transaction volume nonnegative as a common constraint to construct a green power certificate distribution model; step 4, according to the current carbon emission intensity of each user, allocating a green power certificate to each user by using a green power certificate allocation model; and step 5, taking the carbon emission intensity grade and the green power certificate of each user as a carbon flow emission tracking rating result of the user. According to the method, the understanding of the power consumer on the emission of the production activity is enhanced, the development of the green power certificate market is promoted, and market support is provided for the renewable energy source foremaking policy.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD MARKETING SERVICE CENT +2

Saccharomyces cerevisiae gene engineering bacteria for producing succinic acid and application thereof

ActiveCN105838632ARealize accumulationReduce lossesFungiMicroorganism based processesWild typeSuccinic acid

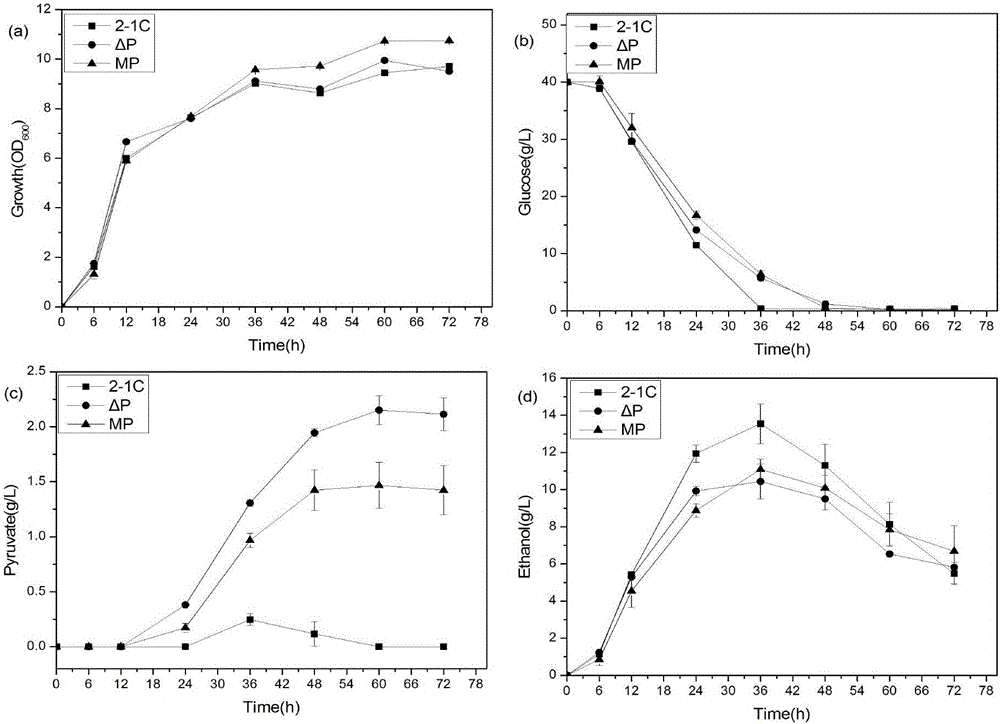

The invention discloses saccharomyces cerevisiae gene engineering bacteria for producing succinic acid and application thereof, and belongs to the fields of genetic engineering and fermentation engineering. Malate dehydrogenase gene RoMDH from rhizopus oryzae is adopted to replace PDC1, the yield of ethanol obtained by fermentation of wild saccharomyces cerevisiae reaches the maximum value 13.55 plus or minus 1.062g / L, and the yield of improved strain MP ethanol is 11.09 plus or minus 0.539g / L, and compared with the yield obtained by adopting the wild type, the yield is reduced by 18.15 percent. On the basis, SDH2 gene is knocked out. After culture medium optimization, MP Delta S deleted strain can accumulate succinic acid by 0.698 plus or minus 0.0285g / L, and by contrast, the wild saccharomyces cerevisiae does not accumulate succinic acid. The saccharomyces cerevisiae gene engineering bacteria can effectively reduce the loss of a carbon flow, creates a condition for the engineering yeast to efficiently produce succinic acid, and has a good industrial application value and prospect.

Owner:JIANGNAN UNIV

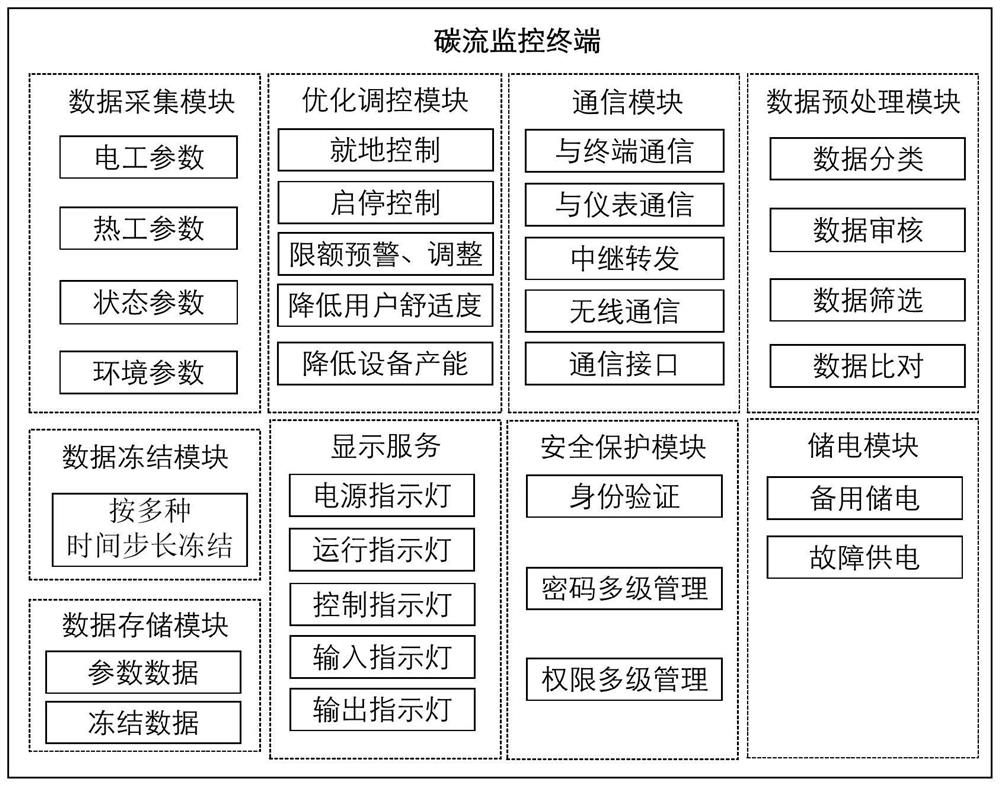

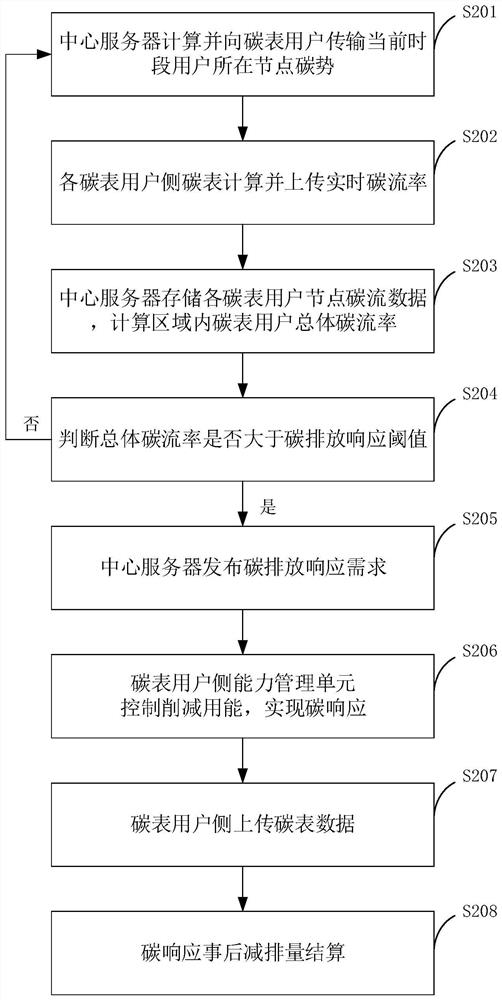

Demand side carbon flow monitoring terminal, monitoring method and system

PendingCN114040004AImprove the efficiency of on-site responseEasy to checkTransmissionControl engineeringMaster station

The invention provides a demand side carbon flow monitoring terminal, monitoring method and system, and the system comprises a data collection module, an optimization regulation and control module and a data communication module, and the data collection module is used for collecting the field data of an energy consumption end; the optimization regulation and control module is used for matching a proper regulation and control strategy from a plurality of regulation and control strategies stored locally by utilizing an optimization model based on field data; the data communication module is used for sending the matched regulation and control strategy to the energy consumption end, sending field data to a carbon flow edge terminal and a carbon flow master station, receiving regulation and control commands of the carbon flow edge terminal and the carbon flow master station and forwarding the regulation and control commands to the energy consumption end; the carbon flow monitoring terminal can directly formulate an on-site regulation and control strategy according to on-site data, and can also carry out regulation and control according to a command of a carbon flow master station or an edge terminal, so that the on-site response efficiency is improved, and meanwhile, the regional regulation and control target is considered, and the carbon emission is reduced to the maximum extent; and meanwhile, the monitoring terminal uploads field data to the edge terminal and the carbon flow master station, so that comprehensive analysis of the energy flow and the carbon flow is realized.

Owner:CHINA ELECTRIC POWER RES INST

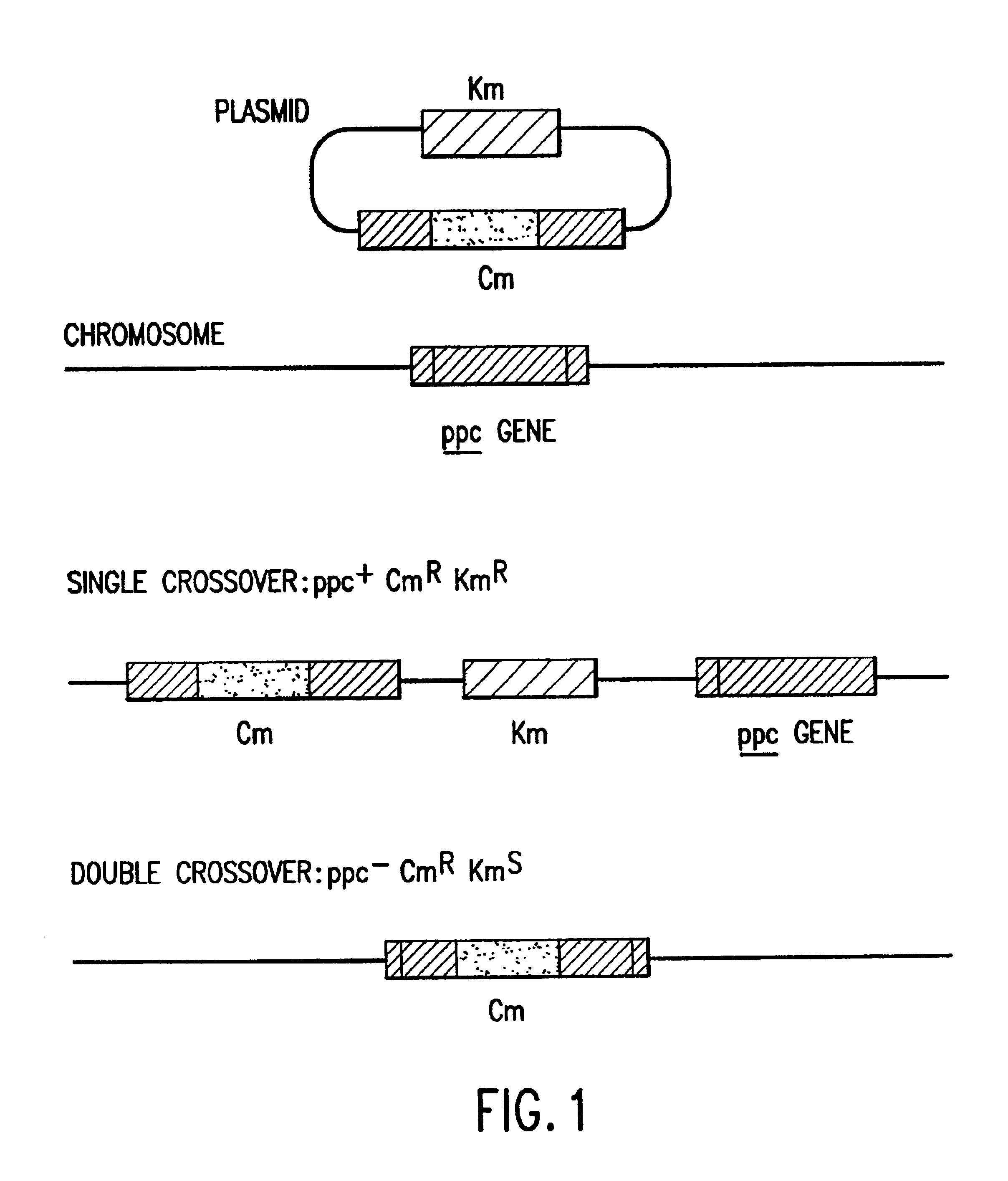

Regulation of carbon assimilation

InactiveUS6919190B2Improve conversion rateIncrease productionBacteriaSugar derivativesCarbon assimilationBiological activation

The present invention provides a method of increasing the productivity of a microorganism by improving the assimilation of carbon dioxide. Specifically, the invention provides a polypeptide having phosphoenolpyruvate carboxylase activity which does not require acetyl coenzyme A for activation and is desensitized to feedback inhibition by aspartic acid, and to genes coding for this polypeptide. A gene encoding a PEP carboxylase that is not regulated by acetyl-CoA or aspartic acid can improve carbon flow from the three carbon intermediate PEP to the four carbon intermediate OAA, contribute to compounds derived from OAA, and increase amino acid biosynthesis. The invention further provides recombinant DNA molecules containing these genes, bacteria transformed with these genes, and a method of producing amino acids using the transformed bacteria.

Owner:ARCHER DANIELS MIDLAND CO

Method for regulating and controlling carbon flow of phytoplankton

ActiveCN109392680AReduce churnReduce fugitive emissionsClimate change adaptationAgricultural fishingWater sourceEngineering

The invention relates to a method for regulating and controlling the carbon flow of phytoplankton. With phytoplankton as an example, by calculating the carbon flow of phytoplankton, regulation and storage of water reservoir are carried out according to relevant factors of carbon flow formation of phytoplankton so as to generate a man-made flood peak, a large-aperture interception device and a stirring device are arranged below a water source, the interception device can effectively intercept off large solid waste and floating objects, and decrease the impact strength to the stirring device, and meanwhile the stirring device can stir a water body and make the water body dissolve plenty of oxygen and undergo sufficient illumination for eliminating anaerobic reaction. Carbon fixation organisms are thrown into the water body reasonably for promoting absorption of natural food organisms in the water body and fixing carbon in the water body, so that the carbon flow is as close as possible toa value before dam construction.

Owner:BEIJING NORMAL UNIVERSITY

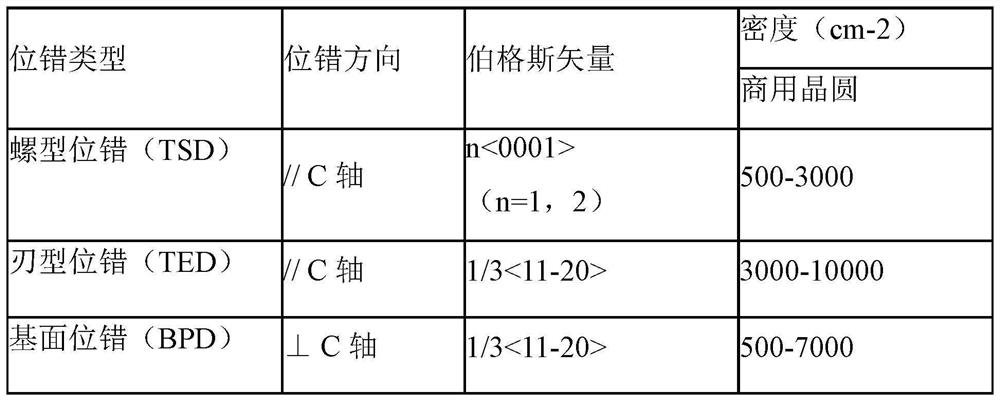

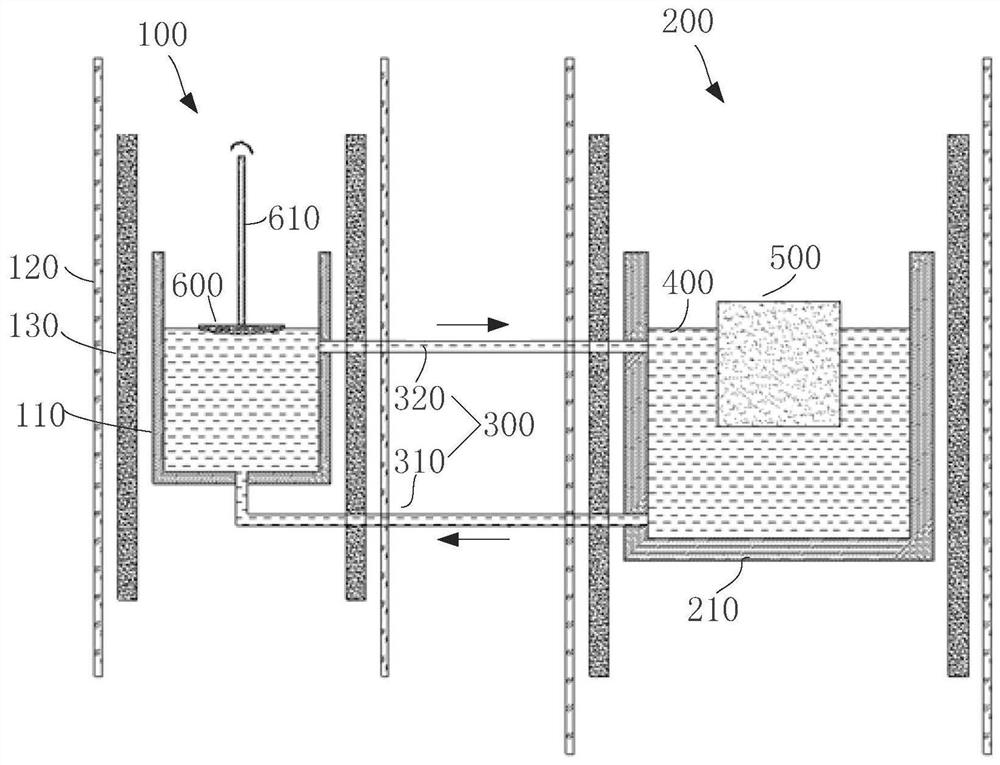

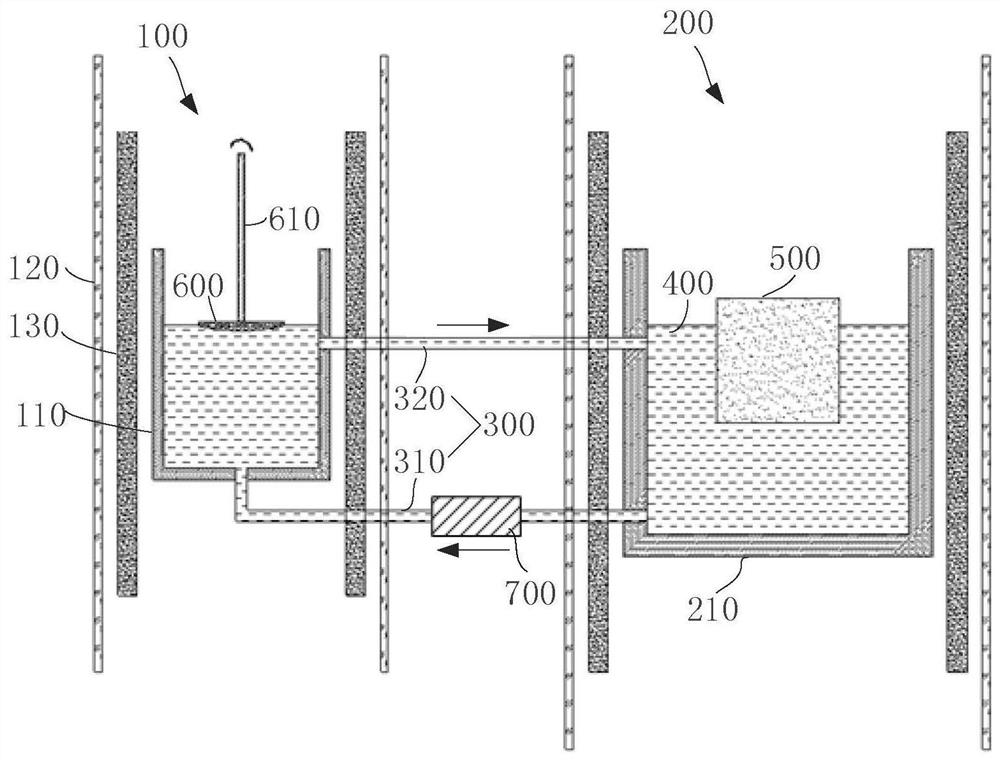

Liquid phase growth device and liquid phase growth method of silicon carbide single crystal

InactiveCN112921399AImprove dislocation defectsEasy accessPolycrystalline material growthBy pulling from meltCarbide siliconCrucible

The invention discloses a liquid phase growth device and a liquid phase growth method of silicon carbide single crystal, the device comprises: a first growth assembly, a second crucible and a graphite pipe assembly, the first growth assembly is used for accommodating a first crucible used for providing a liquid phase growth place for the silicon carbide single crystal; the second crucible is contained in the second growth assembly, and a space for containing raw material carbon is formed in the second crucible; the first crucible and the second crucible are connected through the graphite pipe assembly to form a passage, a silicon solution and carbon flow and diffuse in the first crucible and the second crucible through the passage, and a supersaturated solution of the carbon in the silicon solution is formed in the first crucible; and liquid phase growth is performed to obtain the silicon carbide single crystal. According to the invention, the problems that the solubility of carbon in the silicon dissolving solution is too low and the crystal cannot grow up can be effectively solved, and the dislocation defect of the silicon carbide single crystal is effectively improved.

Owner:CEC COMPOUND SEMICON CO LTD

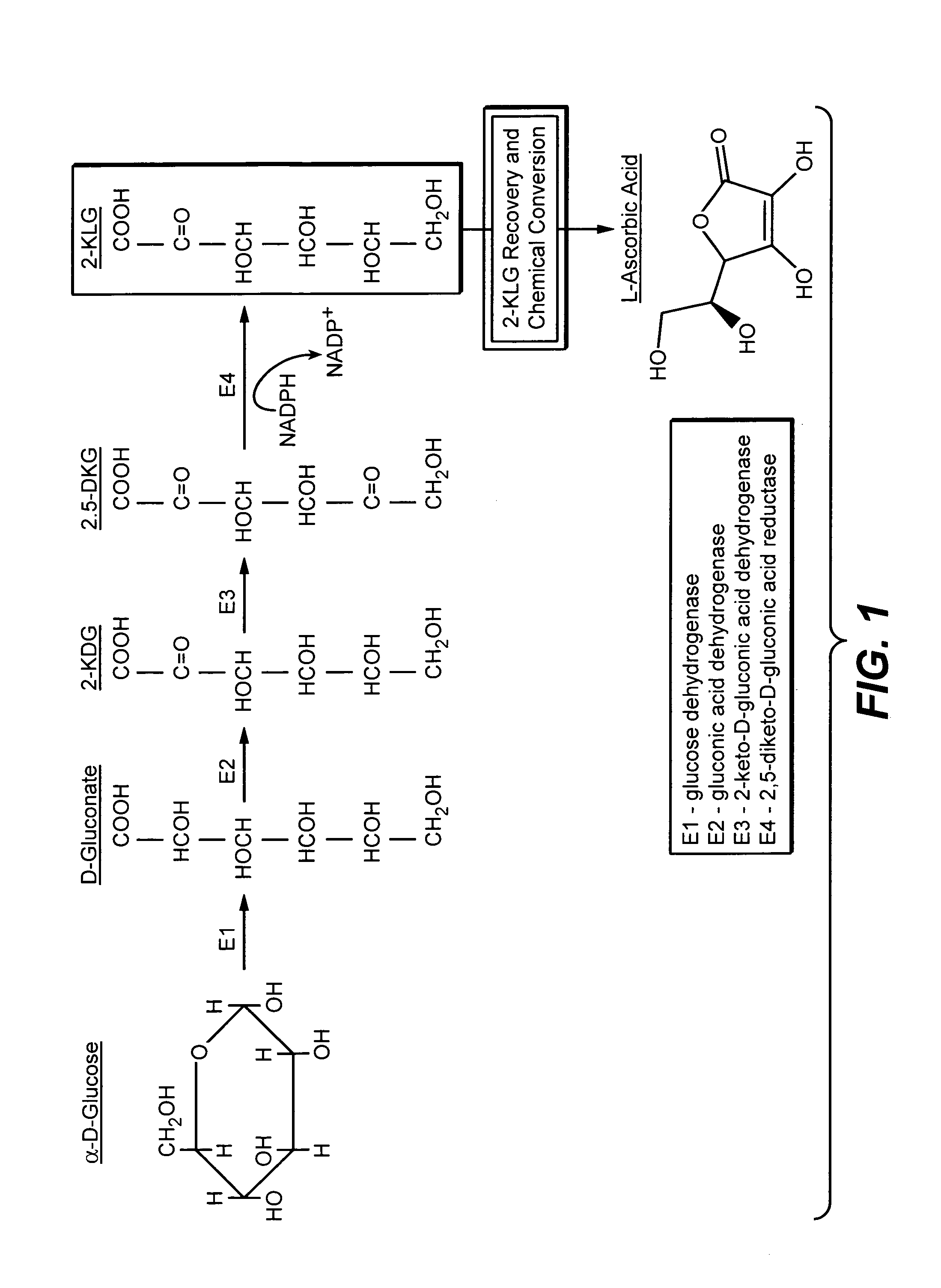

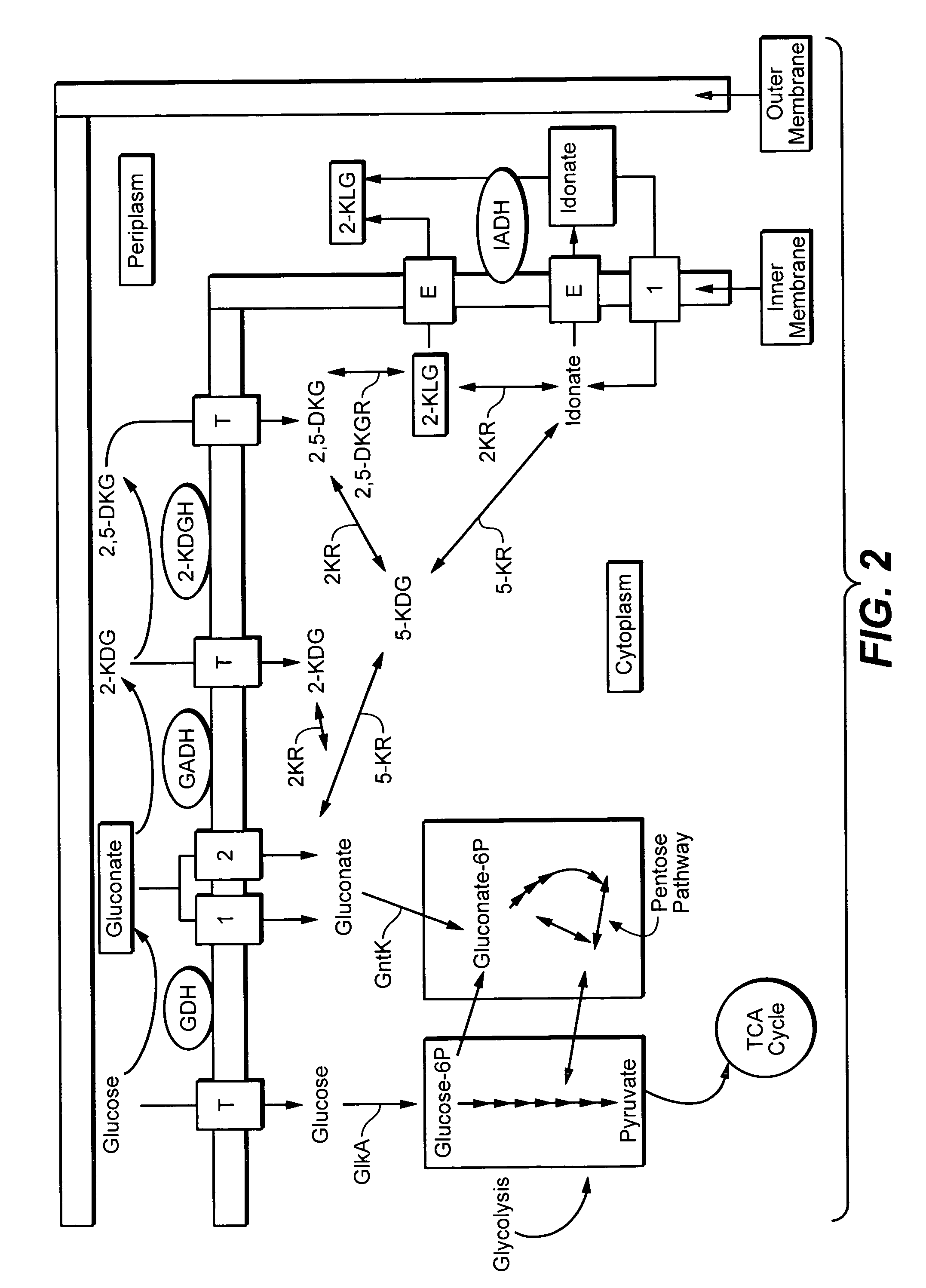

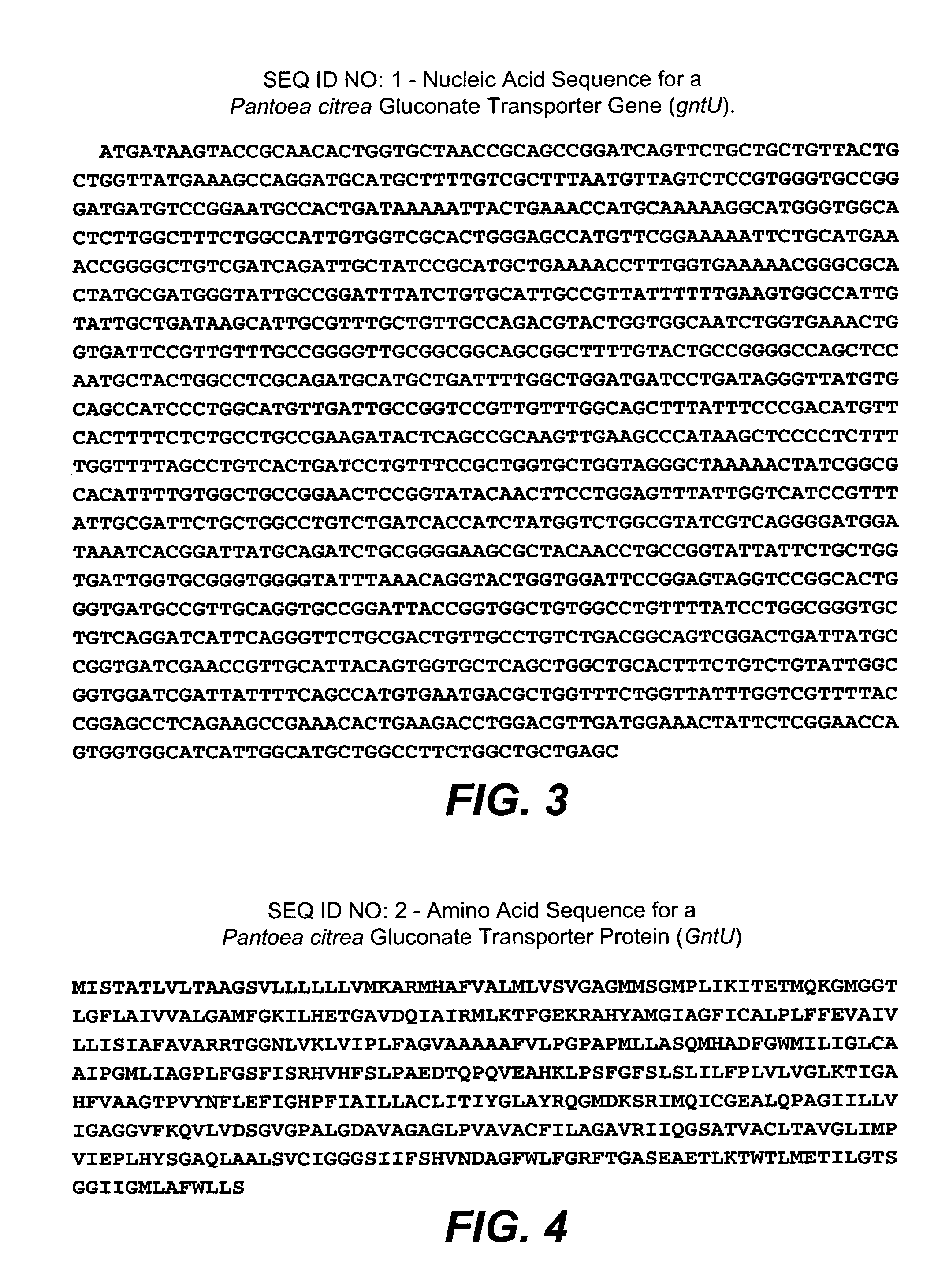

Metabolically engineered bacterial strains having non-functional endogenous gluconate transporters

InactiveUS7419795B2Improve productivityIncrease productionBacteriaPeptide/protein ingredientsMicrobiologyBacterial strain

The present invention relates to engineering metabolic pathways in bacterial host cells which results in enhanced carbon flow for the production of ascorbic acid (ASA) intermediates. In particular, the invention relates to increasing the production of ASA intermediates in bacterial cells by enhancing the availability of gluconate resulting from the inactivation of endogenous gluconate transporter genes.

Owner:DANISCO US INC

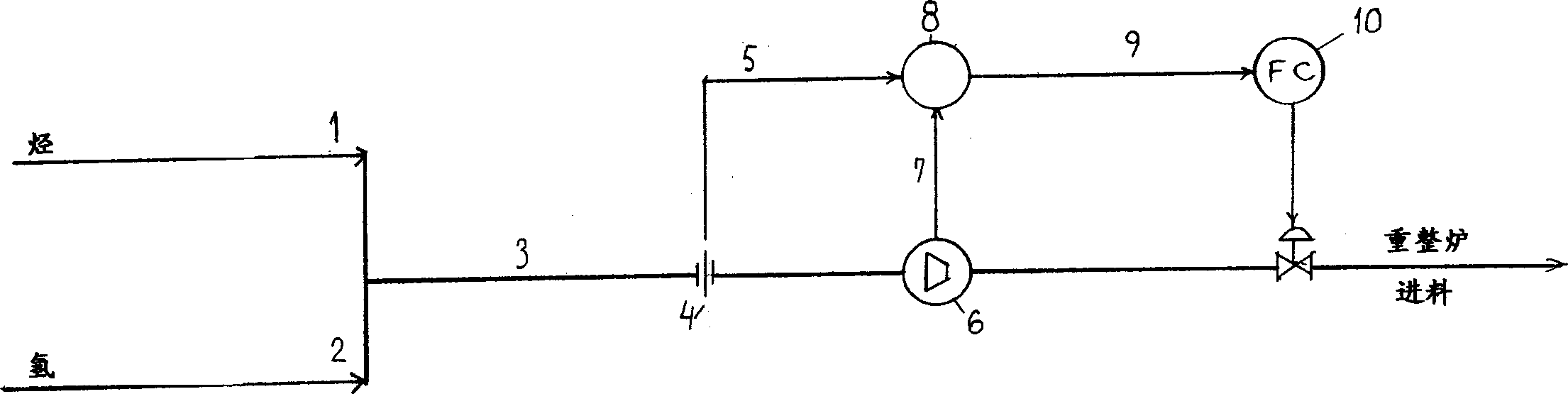

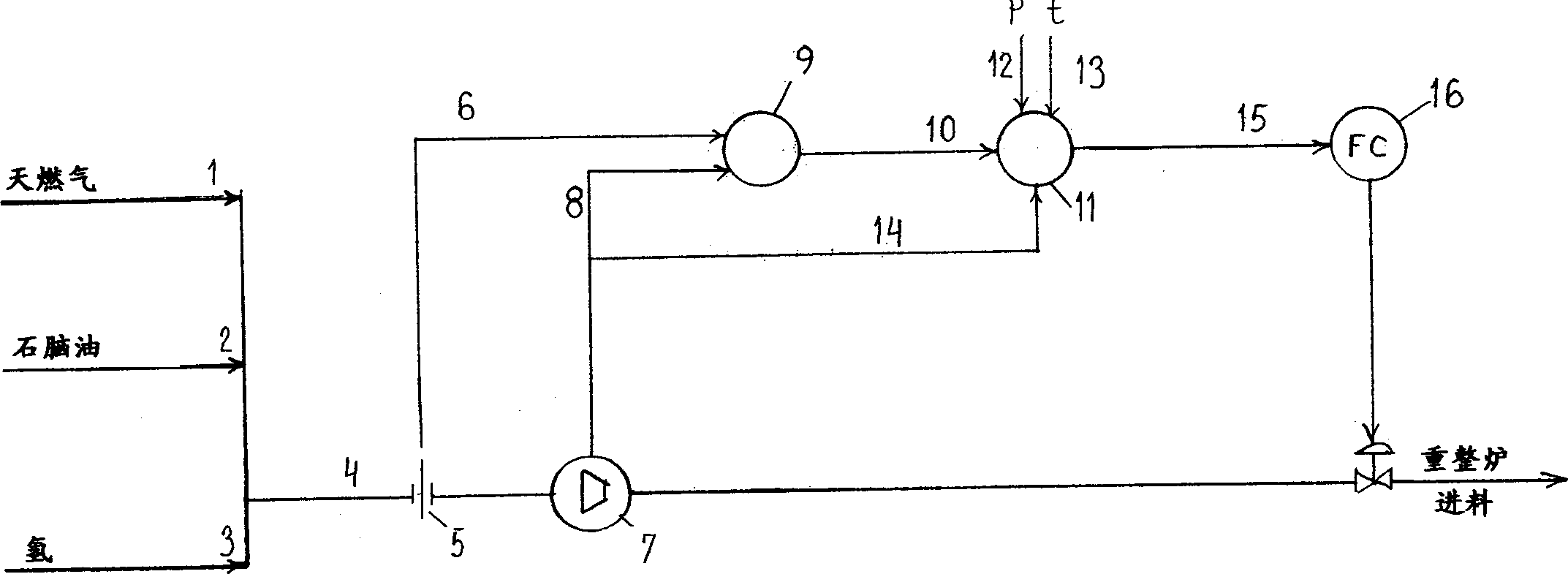

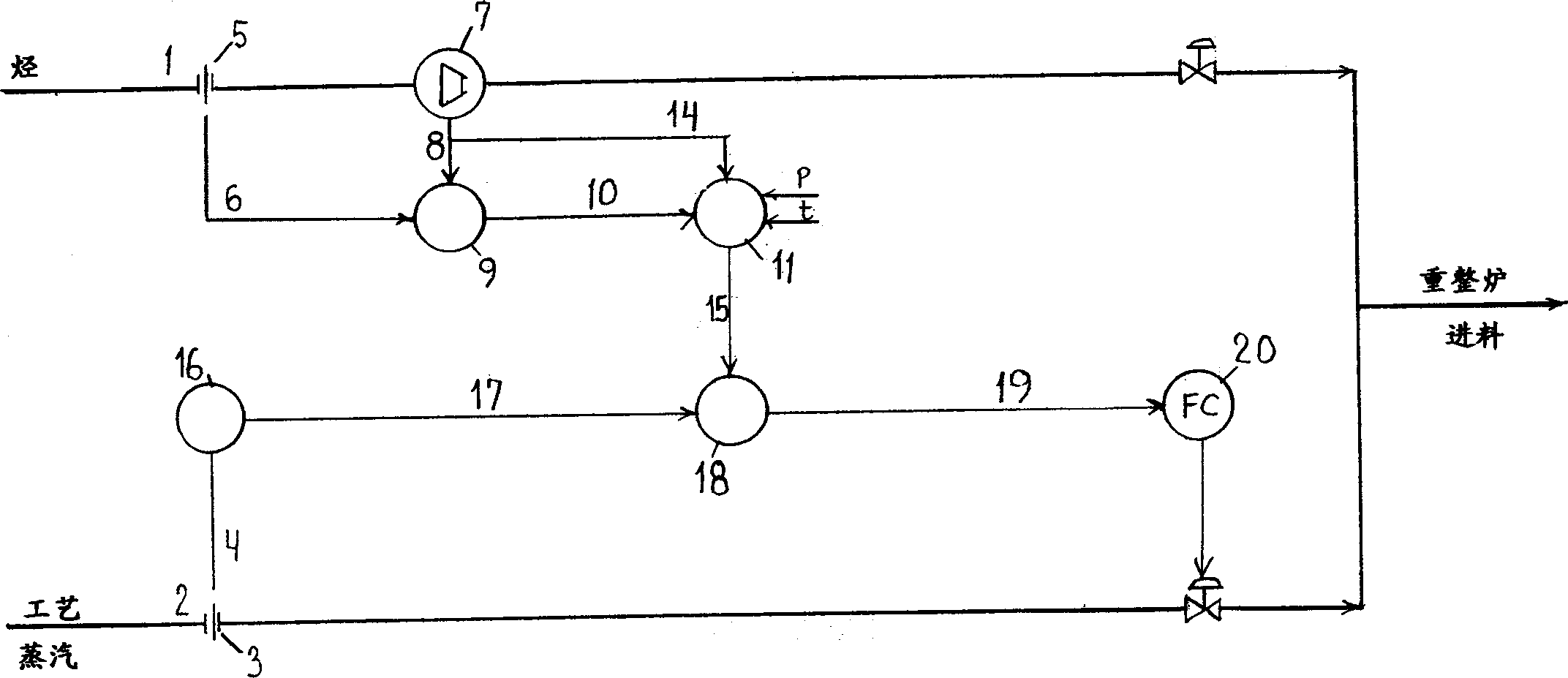

Mass flow rate and density measuring method for technological matter

InactiveCN1357752ALess permanent stressSpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesChemical physicsHydrogen

A method for controlling mass flow of a hydrocarbon feed stream to a steam reformer said stream consisting of hydrogen and of natural gas, naphtha, off-gas, LPG, or a mixture hereof, and control molar carbon flow of a hydrocarbon feed stream and molar steam carbon ratio, comprising the steps of measurement of said process stream with a conventional differential pressure flow measuring element, providing a signal S' = k' x p x V<2>, measurement of same said process stream with a conventional vortex flow measuring element, providing a signal S'' = k'' x V, and determination of the mass flow and density of process stream from signals from both said flow measuring elements by the above formulae and M = p x V, as S' / S'' = k x rho x V = k x M and S' / (S'')<2> = k x rho .

Owner:HALDOR TOPSOE AS

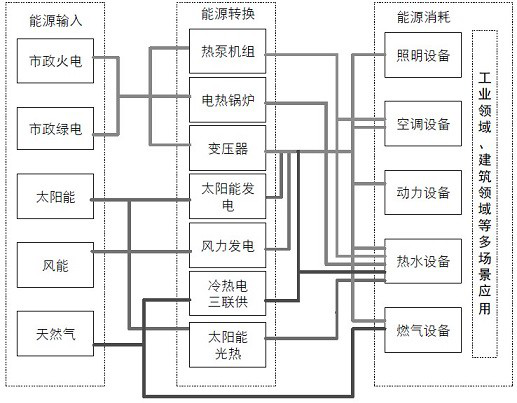

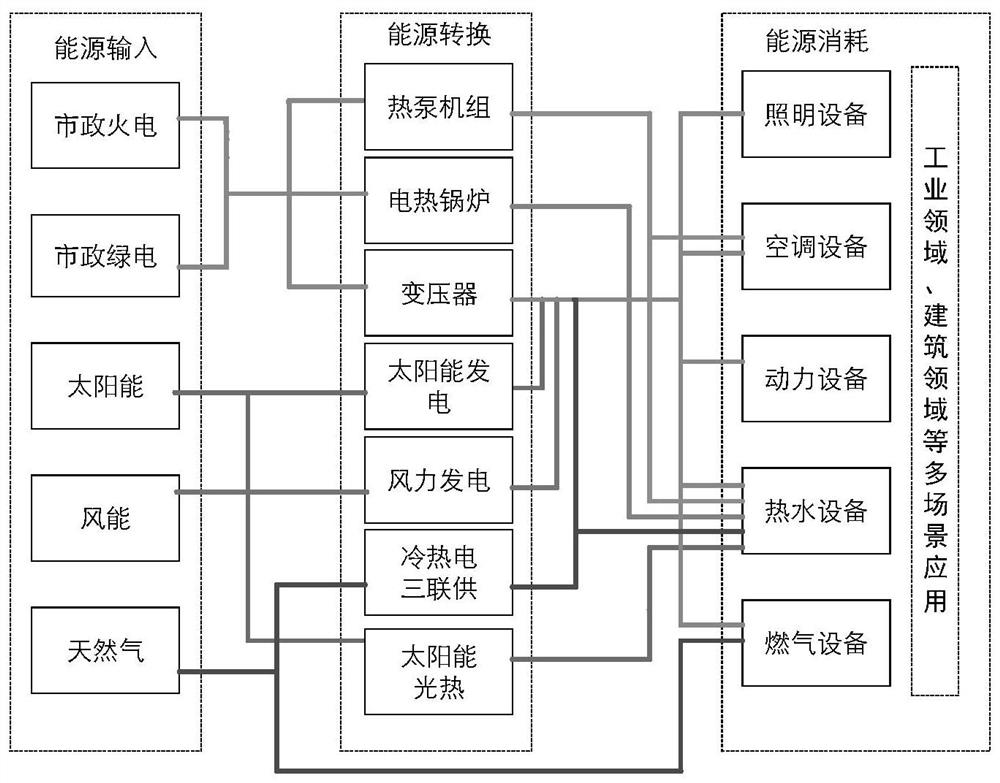

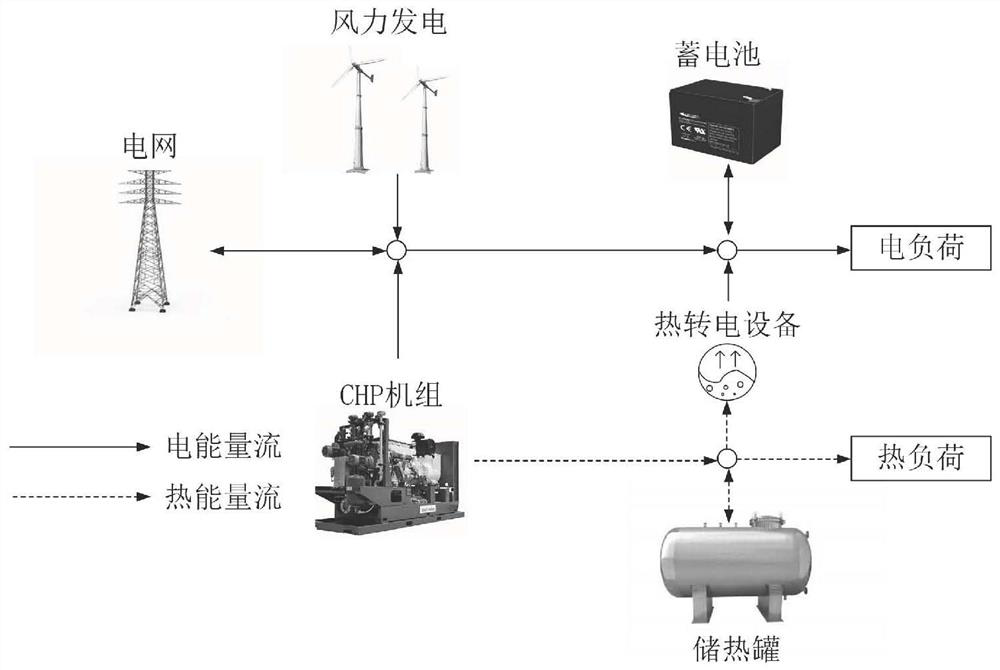

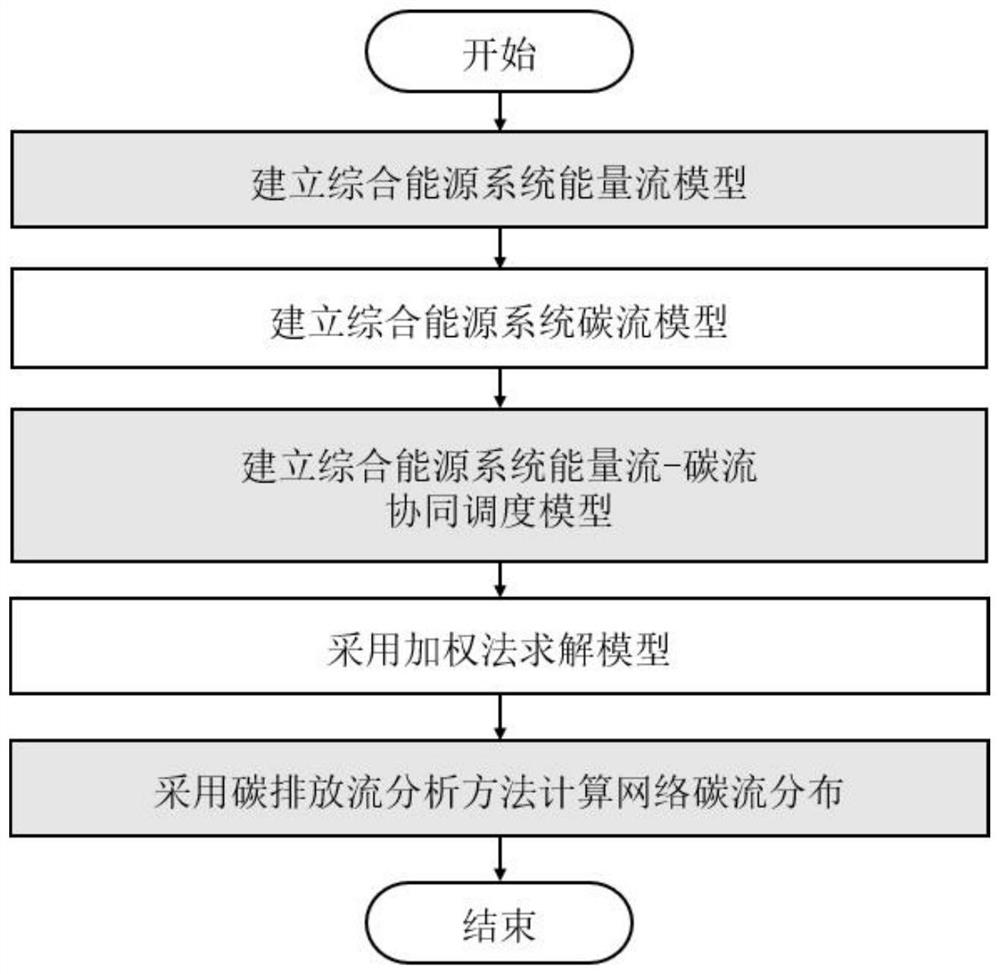

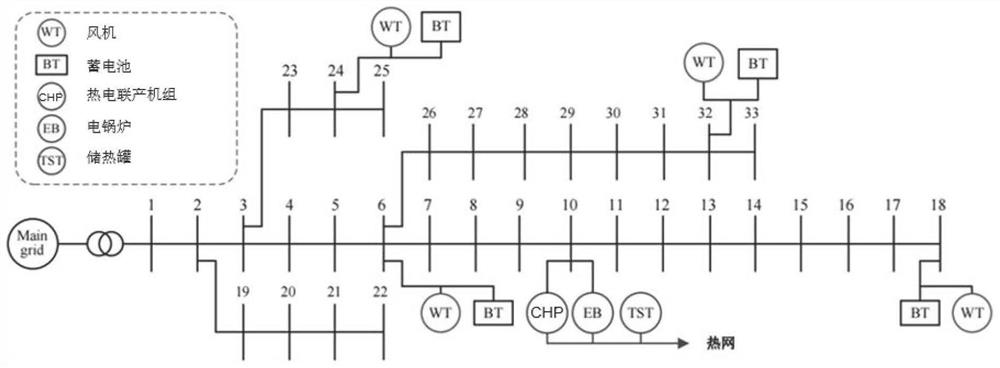

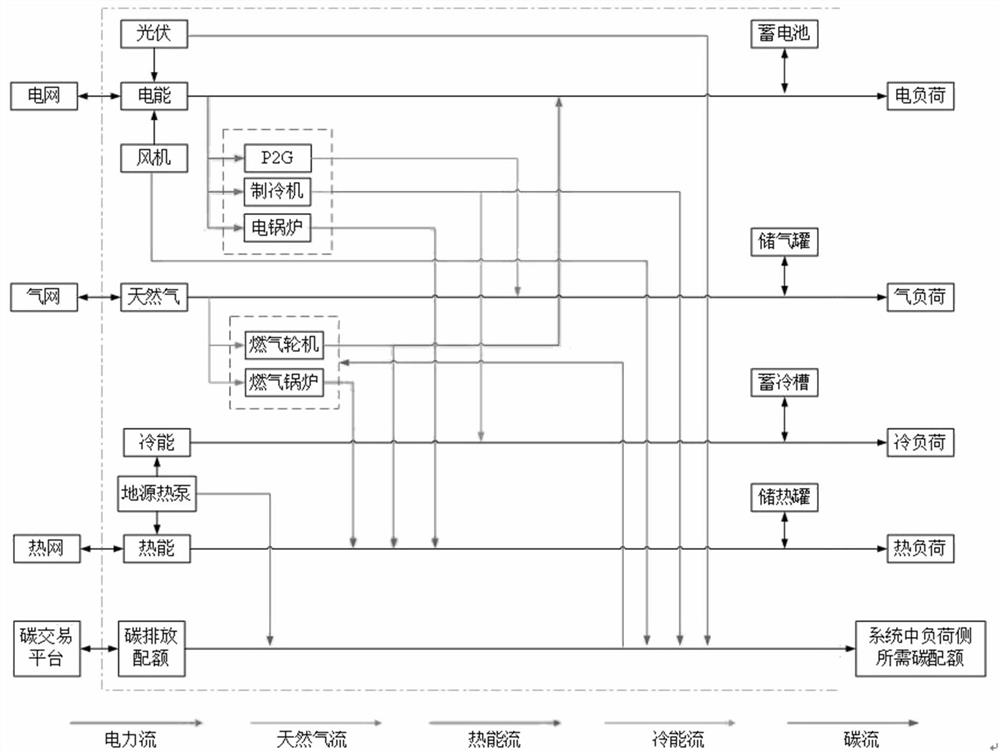

Calculation method for energy flow and carbon flow distribution of integrated energy system

PendingCN114723175AHigh emission intensityForecastingResourcesThermodynamicsIntegrated energy system

The invention discloses a calculation method for energy flow and carbon flow distribution of an integrated energy system, and belongs to the field of integrated energy systems. An integrated energy system energy flow and carbon flow distribution calculation method comprises the following steps: establishing an integrated energy system energy flow model; establishing a comprehensive energy system carbon flow model; establishing an energy flow-carbon flow collaborative optimization model of the integrated energy system; solving the model by adopting a weighting method; calculating network carbon flow distribution by adopting a carbon emission flow analysis method; according to the carbon emission flow calculation method for the heterogeneous energy flow in the comprehensive energy system, the carbon emission flow distribution corresponding to the multiple energy flows of the comprehensive energy system is obtained, and the source, the flowing direction and the distribution condition of carbon emission in a multi-energy network can be more visually analyzed through the method; and network nodes with relatively high carbon emission intensity can be identified to guide the formulation of a low-carbon policy.

Owner:SOUTHEAST UNIV

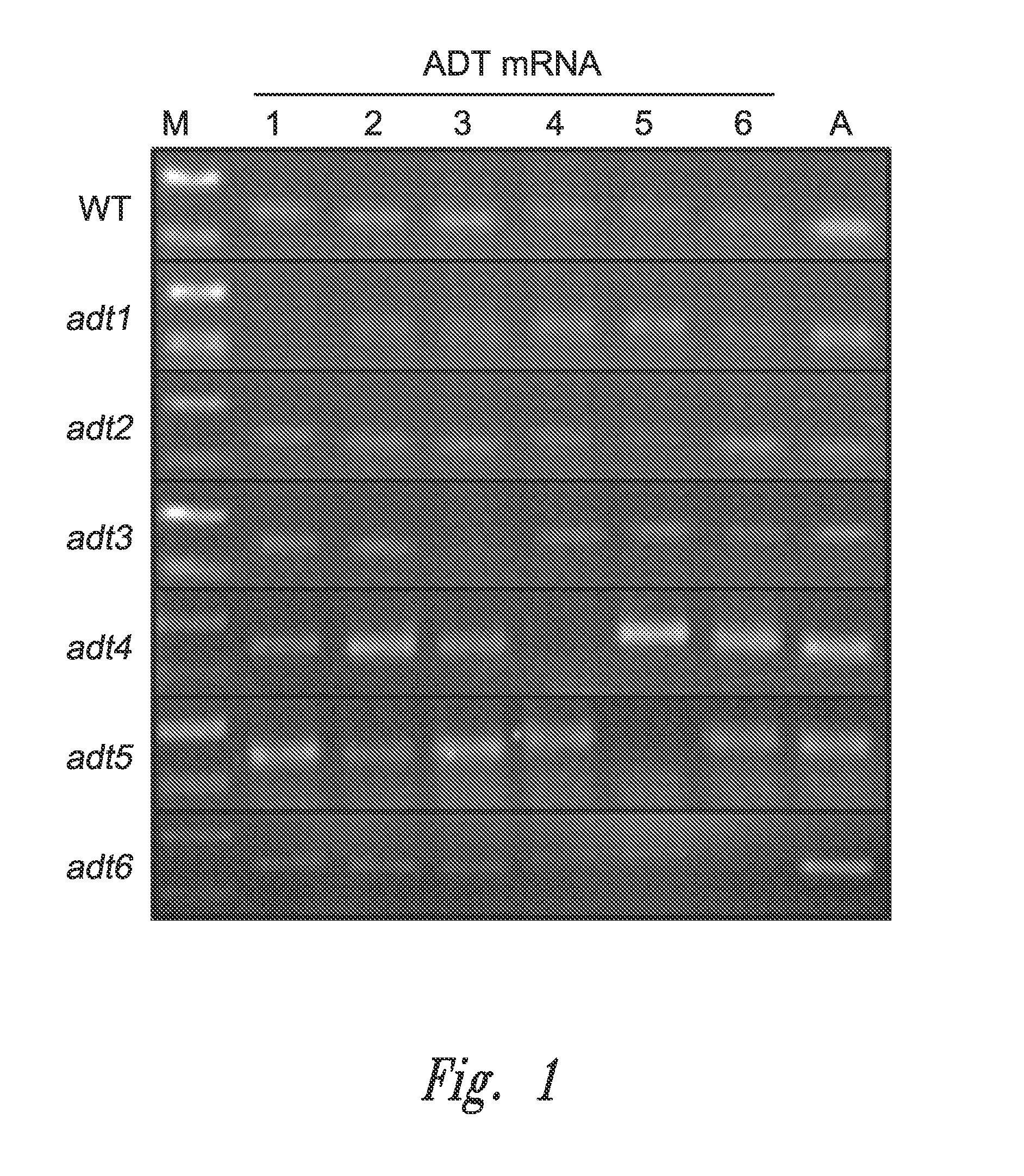

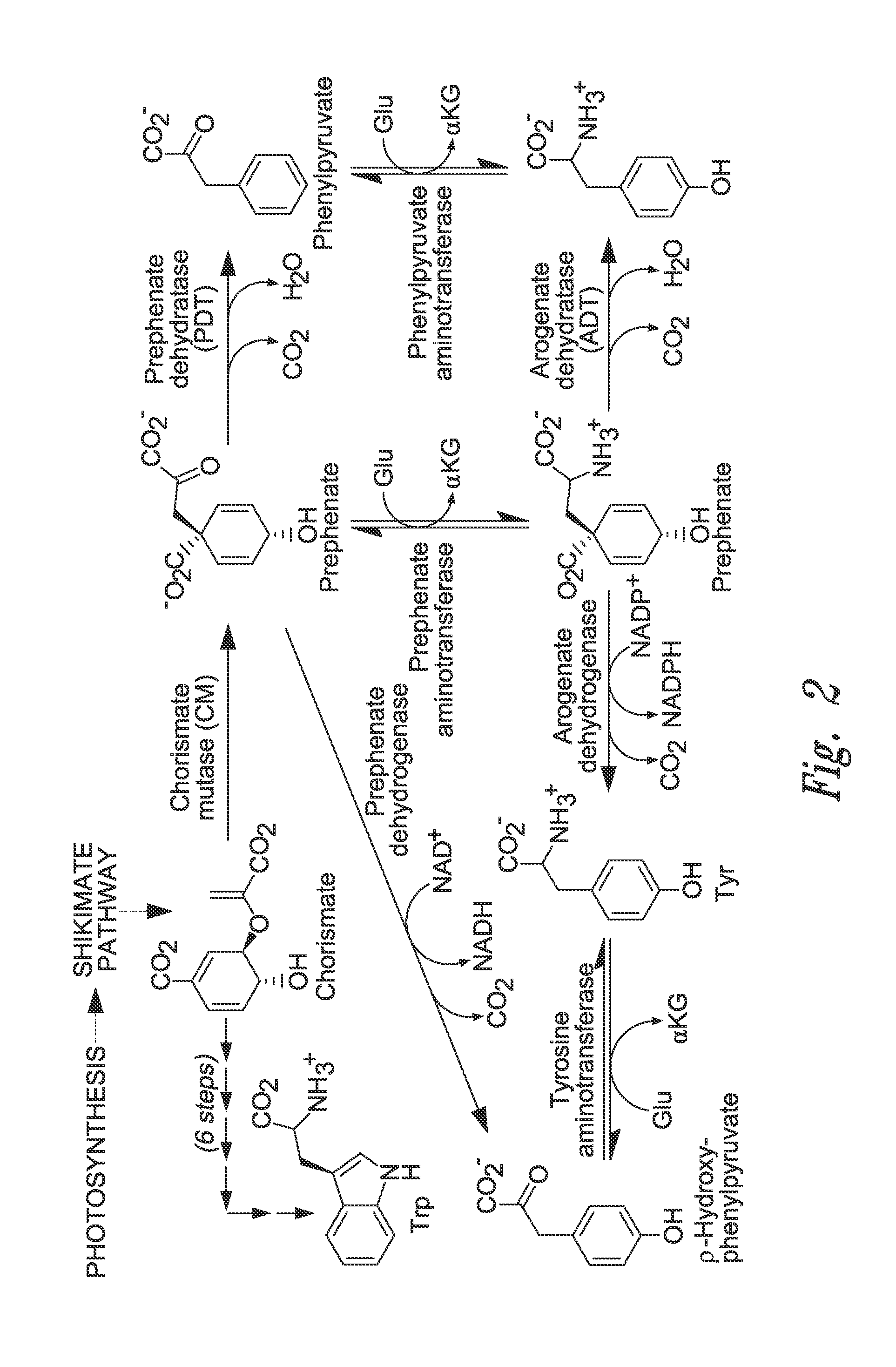

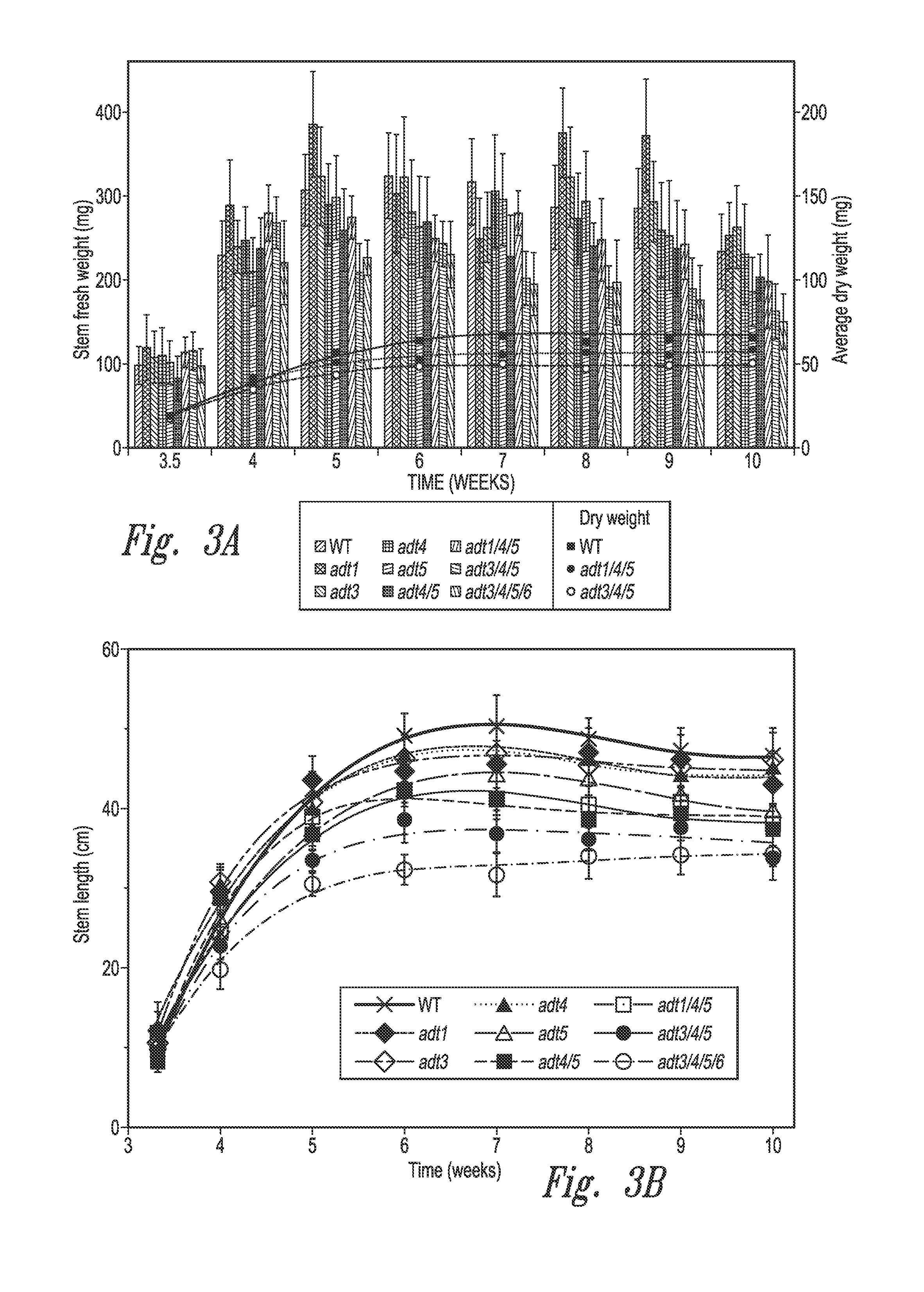

Arogenate dehydratases and lignification

InactiveUS20130318653A1Low lignin contentReduce the impactSolid fuelsAnimal feeding stuffPhenylpropanoidChloroplast

Provided are methods for decreasing carbon flow into lignin in plants, comprising reducing or eliminating, using mutagenesis and / or recombinant means, expression and / or activity of at least one chloroplast-localized arogenate dehydratase (ADT) sufficient to reduce phenylalanine (Phe) availability for metabolism into Phe-derived phenylpropanoids, wherein the amount, level or distribution of lignin is reduced relative to control plants. In particular aspects, the plant has a plurality of chloroplast-localized ADTs, and reducing or eliminating comprises reducing or eliminating expression and / or activity of at least two of the plurality of ADTs. Also provided are recombinant plants or parts or cells thereof, comprising at least one mutation, genetic alteration or transgene that reduces or eliminates the expression and / or activity of at least one chloroplast-localized ADT, wherein the amount, level or distribution of lignin is reduced relative to normal. Further provided are reduced lignin plant products.

Owner:WASHINGTON STATE UNIVERSITY

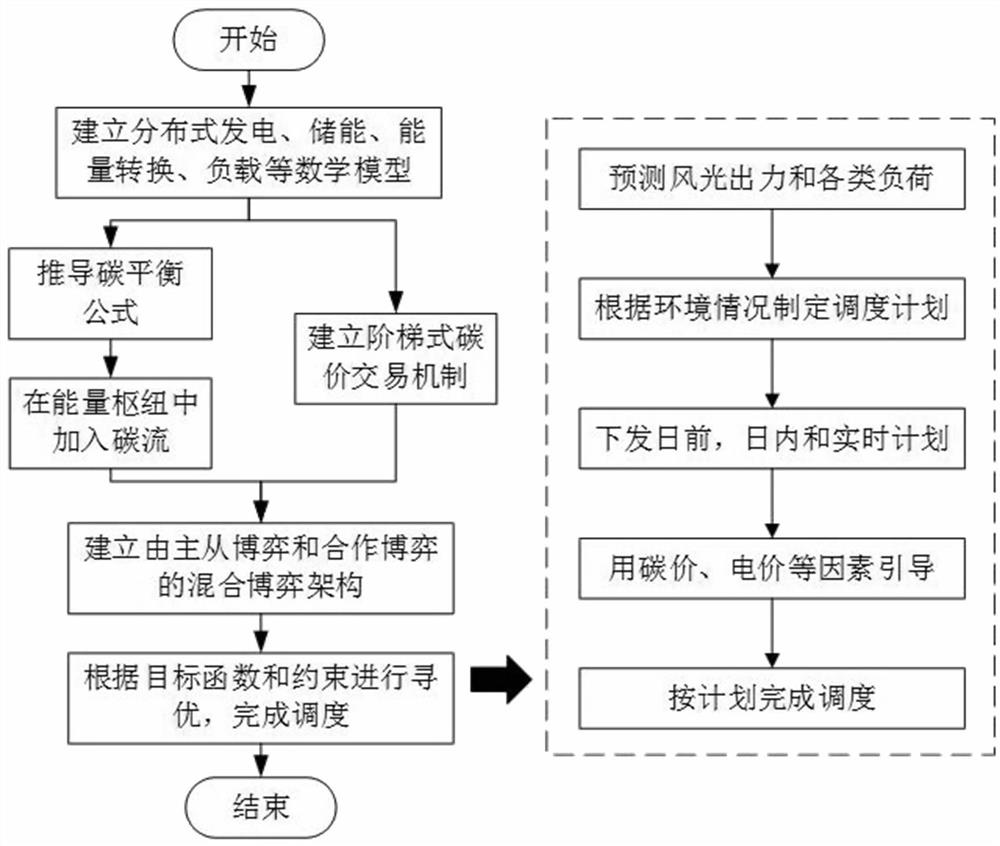

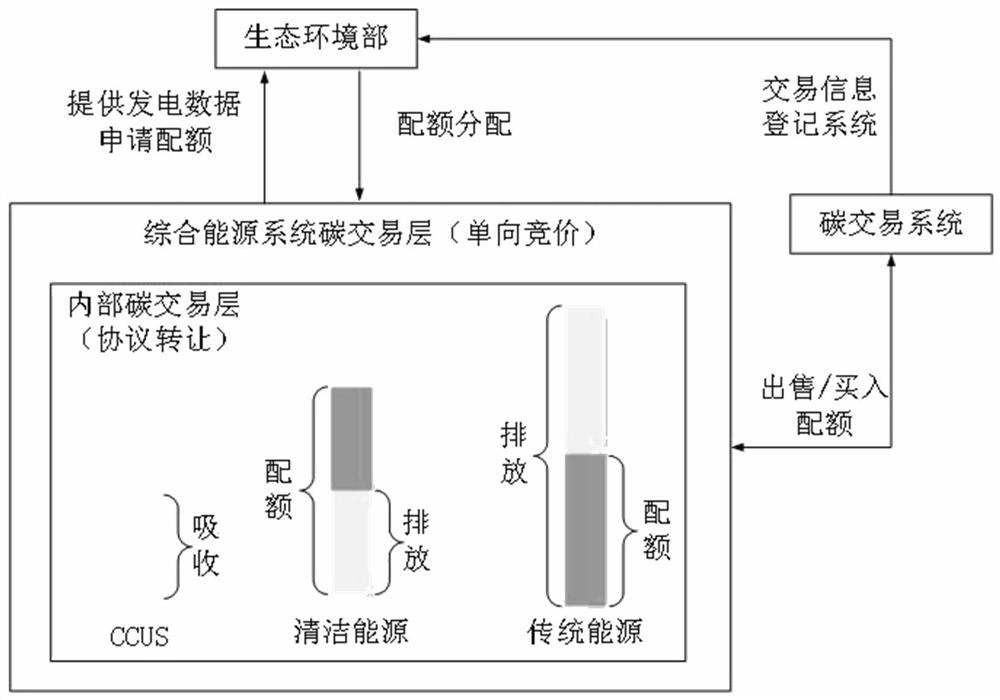

Integrated energy system energy hub management and control method considering carbon flow

PendingCN114050571APromote digestionTaking into account the operating economySingle network parallel feeding arrangementsPower oscillations reduction/preventionIntegrated energy systemMathematical model

The invention belongs to the technical field of multi-energy hub optimization operation, and particularly relates to an integrated energy system energy hub management and control method considering carbon flow. Reasonable scheduling among each main body, an internal transaction center, a power grid, a gas grid and a carbon transaction center can be ensured more effectively and reliably. The method comprises the following steps: 1, establishing mathematical models of energy production equipment and energy conversion equipment in the integrated energy system; 2, establishing a stepped carbon price transaction mechanism model of a carbon emission permit quota model, an actual carbon emission model and a stepped carbon price model; 3, according to interaction of electricity, gas, carbon, heat and cold, establishing a comprehensive energy system energy hub mathematical model with introduced carbon flow; 4, establishing a mixed game architecture of cooperative games between the subjects and master-slave games between the subjects and the integrated energy system transaction center. 5, establishing an objective function and constraint conditions of the integrated energy system internal scheduling hybrid game model, and solving an optimal solution through a particle swarm algorithm.

Owner:SHENYANG POLYTECHNIC UNIV

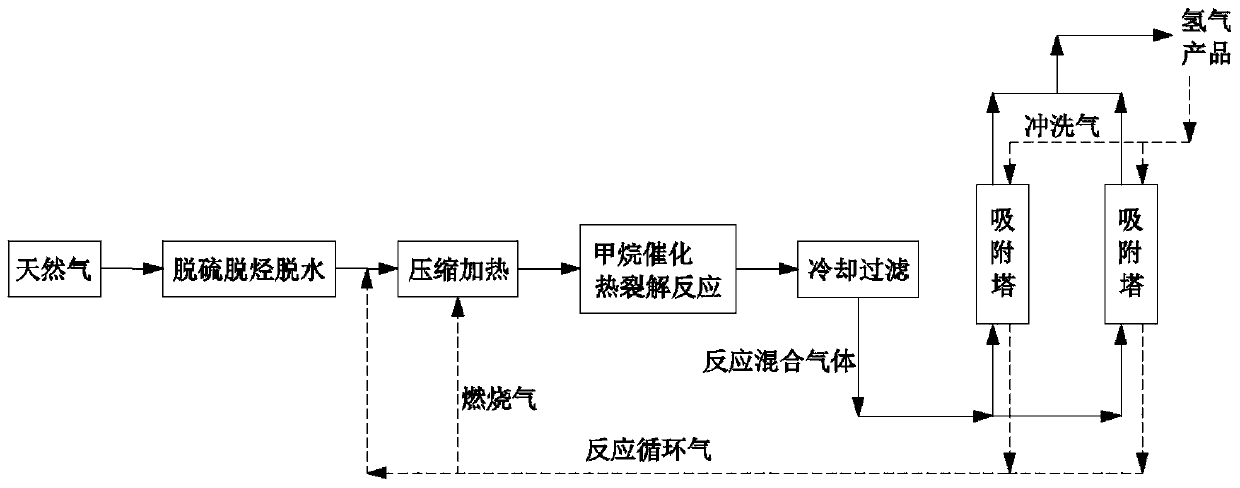

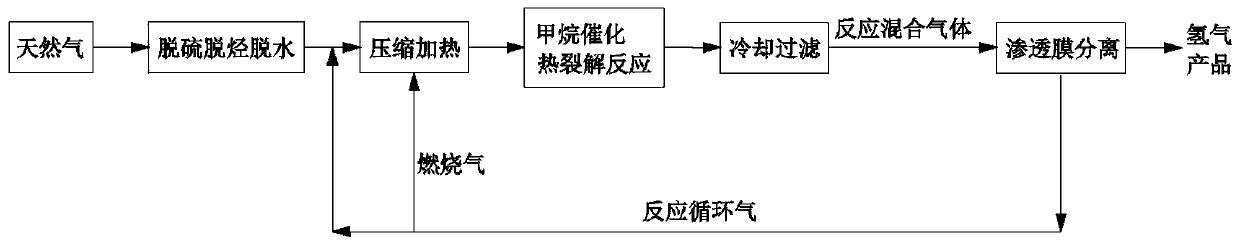

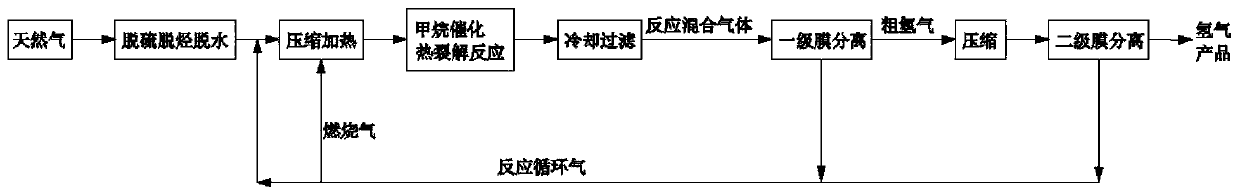

Hydrogen extraction method capable of adjusting hydrogen-carbon ratio of natural gas direct cracking circulation reaction gas

ActiveCN111232923AImprove conversion rateIncrease profitHydrogen separationHydrogen/synthetic gas productionMixed gasHydrogen system

The invention discloses a hydrogen extraction method capable of adjusting the hydrogen-carbon ratio of natural gas direct cracking circulation reaction gas. Reaction mixed gas obtained by methane catalytic thermal cracking hydrogen production is adopted as raw material gas, and the method includes pretreating the raw material gas, introducing the pretreated raw material gas into a hydrogen extraction system to obtain a hydrogen product and circulation reaction gas. When the hydrogen extraction system is a PSA hydrogen extraction system, the hydrogen-carbon flow ratio and the hydrogen-carbon concentration ratio are adjusted by adjusting the adsorption time and adjusting the pressure equalizing frequency; when the hydrogen extraction system is an osmotic membrane separation hydrogen extraction system, the hydrogen-carbon flow ratio is adjusted by adjusting the flow rate of the adjusting valve on the non-osmotic side and the osmotic membrane, and the hydrogen-carbon concentration ratio isachieved through several stages of osmotic membranes. According to the process, the hydrogen-carbon flow ratio and the hydrogen-carbon concentration ratio of the circulating reaction gas can be adjusted according to the reaction conditions of the methane catalytic direct cracking hydrogen production reactor so as to meet the reaction requirements, and the problems of high methane conversion rate,high utilization rate and high hydrogen yield and selectivity in the natural gas direct cracking hydrogen production process are solved.

Owner:SICHUAN TECHAIRS

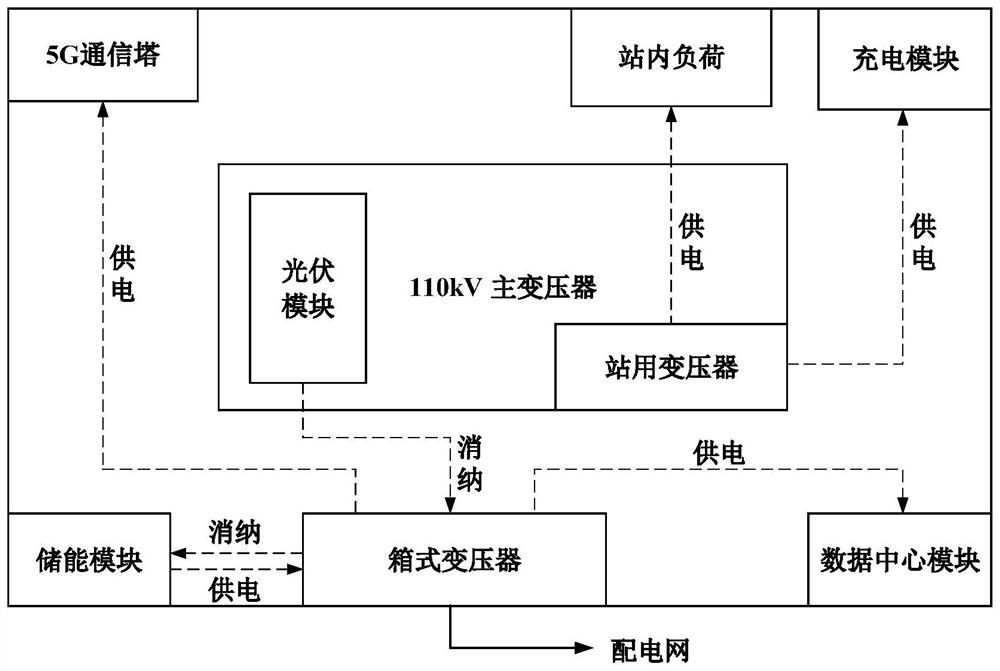

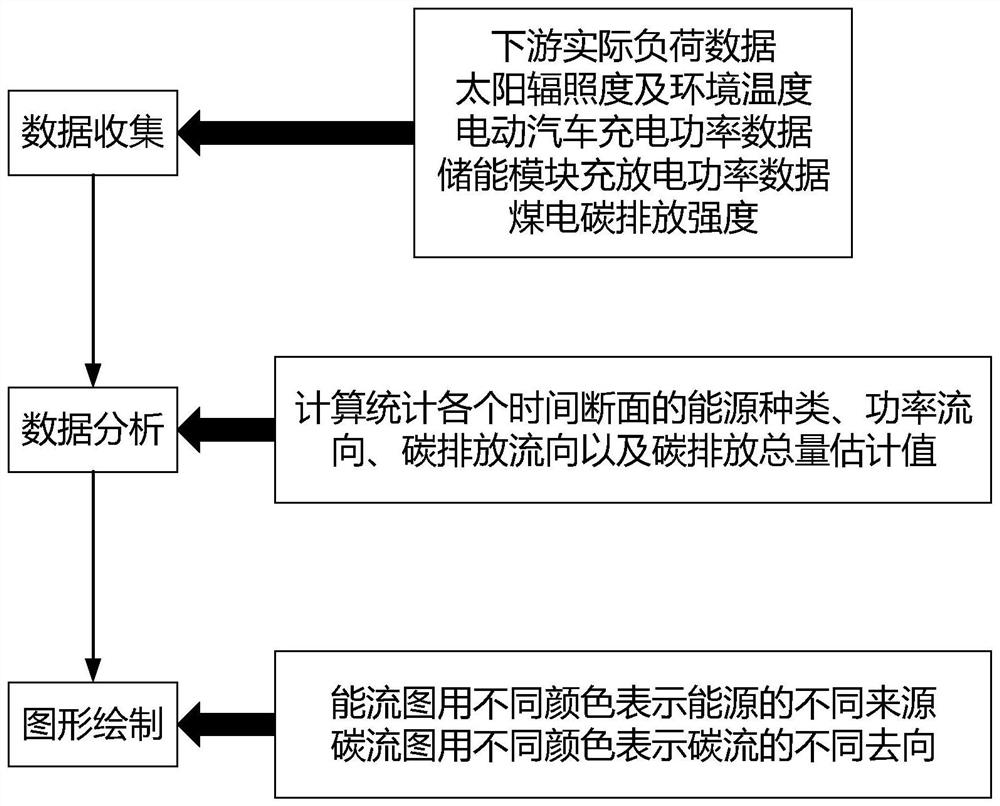

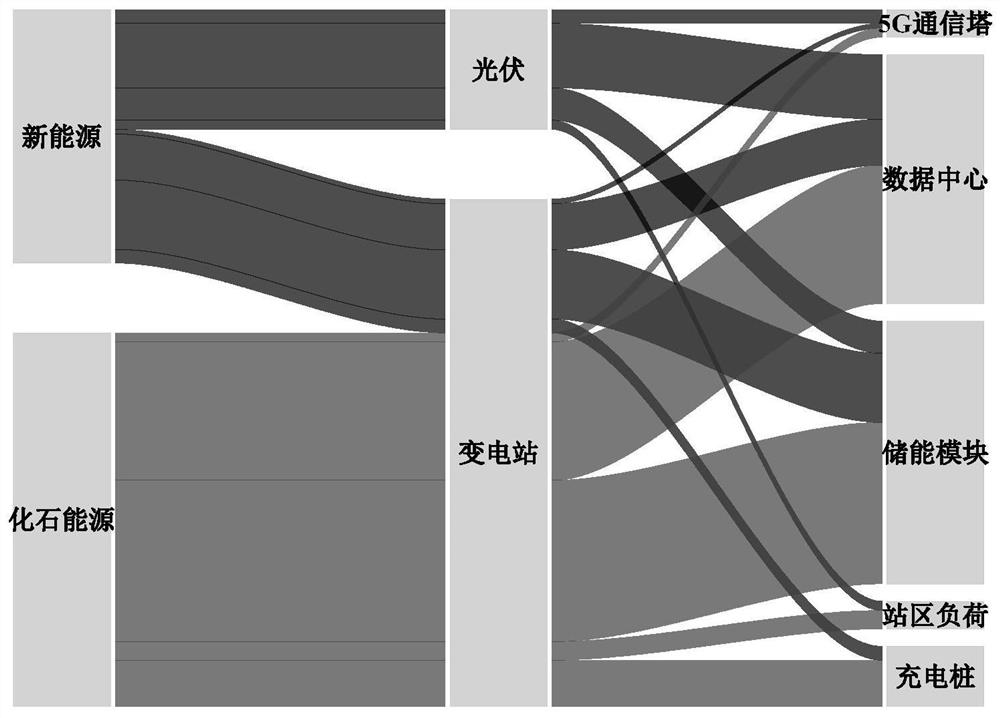

Multi-station fusion comprehensive energy station carbon flow situation awareness and low-carbon operation method

PendingCN114492997AImprove primary energyBooster transformerForecastingDesign optimisation/simulationEnergy technologyProcess engineering

The invention discloses a carbon flow situation awareness and low-carbon operation method for a multi-station integrated comprehensive energy station, and belongs to the technical field of electric energy. The method comprises the following steps: firstly, determining a main body structure, capacity configuration, an arrangement form and a wiring mode of the comprehensive energy station based on a principle of maximum utilization and most efficient construction and function positioning; drawing an energy flow-carbon flow diagram, tracking a carbon source, and sensing a carbon flow situation; according to the load capacity and photovoltaic power generation characteristics of various facilities of the comprehensive energy station, energy flow and carbon flow information is analyzed, main factors influencing carbon emission are obtained, and a low-carbon optimization operation model is constructed. Real-time sensing and low-carbon operation of the carbon flow situation of the comprehensive energy station are achieved, the energy structure, the energy flow direction and the carbon flow information of the comprehensive energy station are visually displayed, and an energy conservation and emission reduction strategy is provided for operation of an existing comprehensive energy station and planning of a to-be-built comprehensive energy station.

Owner:STATE GRID JIANGSU ECONOMIC RES INST

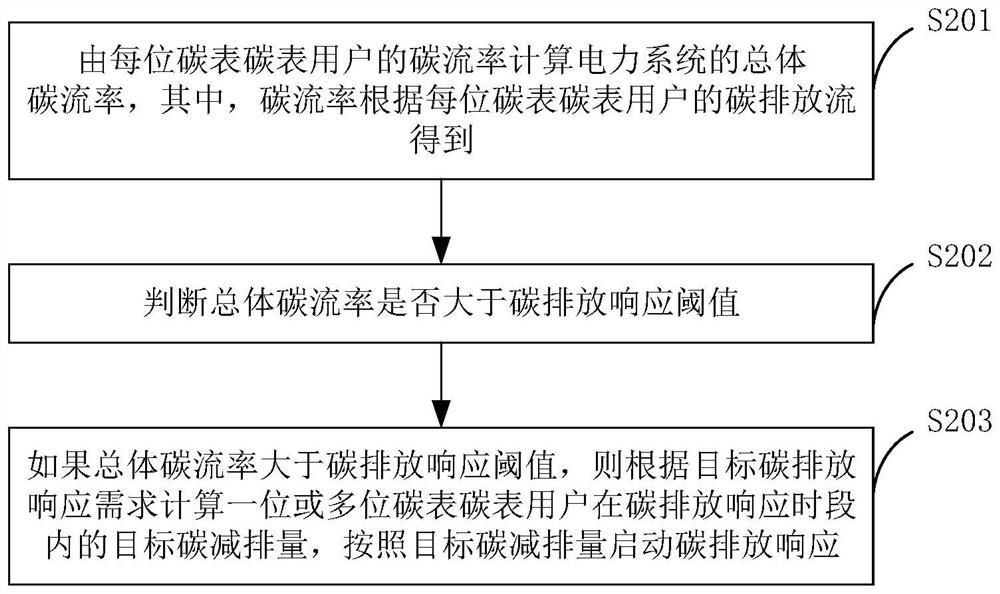

Carbon emission response calculation method and device based on carbon emission flow

PendingCN114548562AReal-time access to indirect emission data of energy consumptionLower emission levelsForecastingTechnology managementElectricity systemEnvironmental engineering

The invention discloses a carbon emission response calculation method and device based on a carbon emission flow, and the method comprises the steps: calculating the overall carbon flow rate of a power system through the carbon flow rate of each carbon meter user, and enabling the carbon flow rate to be obtained according to the carbon emission flow of each carbon meter user; judging whether the total carbon flow rate is greater than a carbon emission response threshold value or not; and if the total carbon flow rate is greater than the carbon emission response threshold, calculating a target carbon emission reduction amount of the one or more carbon table users in the carbon emission response period according to the target carbon emission response demand, and starting the carbon emission response according to the target carbon emission reduction amount. Therefore, the problems that the actual energy consumption carbon emission intensity of the carbon meter user demand side cannot be distinguished in the related technology, so that the power system cannot effectively adjust the carbon emission, the carbon emission regulation and control capability of the demand side response technology is low, and the low-carbon emission demand cannot be met are solved.

Owner:TSINGHUA UNIV

Regulating metabolism by modifying the level of trehalose-6-phosphate

InactiveUS20080138903A1Increased biomass productionIncrease productionFungiBacteriaPhosphoric acidBiology

Method for the inhibition of carbon flow in the glycolytic direction in a cell by increasing the intracellular availability of trehalose-6-phosphate.

Owner:SYNGENTA MOGEN BV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com