Hydrogen extraction method capable of adjusting hydrogen-carbon ratio of natural gas direct cracking circulation reaction gas

A cyclic reaction, natural gas technology, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve the problems of high hydrogen yield, high methane conversion rate and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

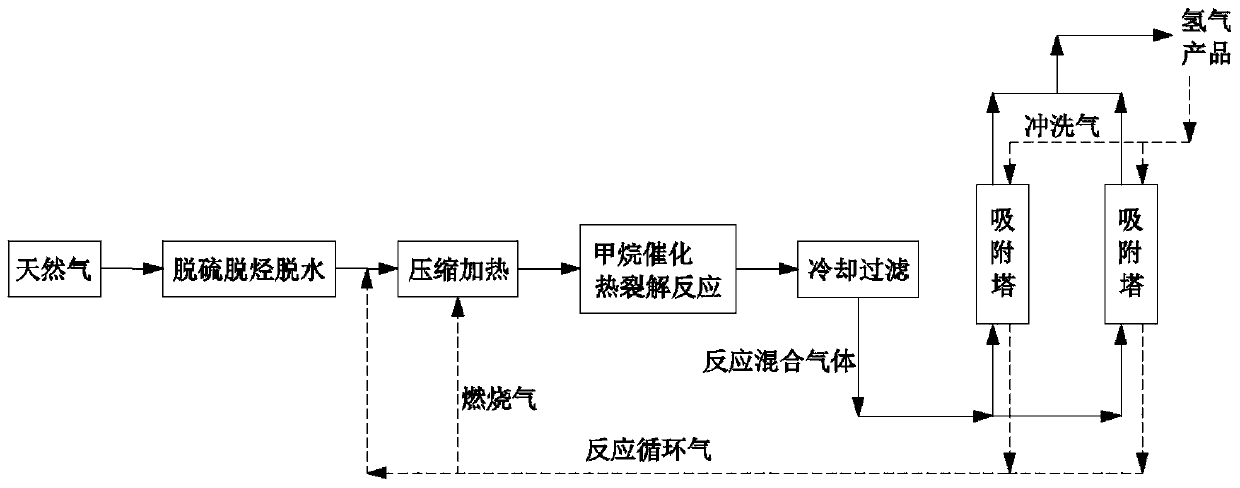

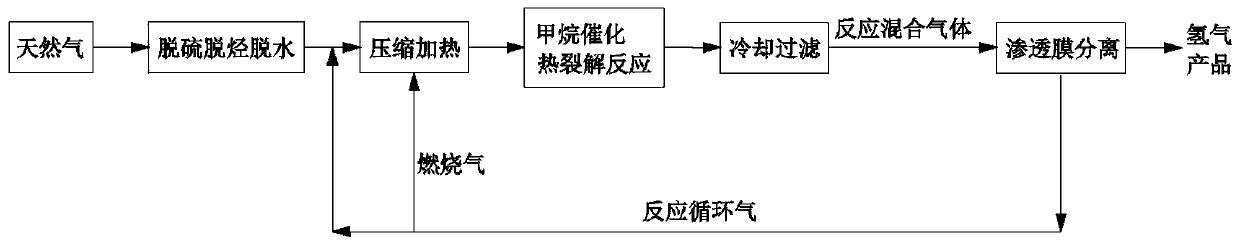

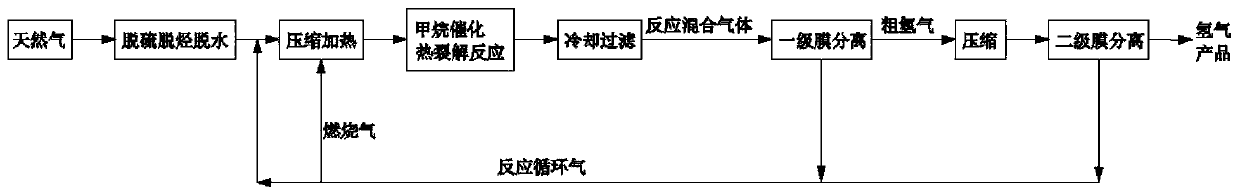

Embodiment 1

[0036] A hydrogen extraction method capable of adjusting the hydrogen-to-carbon ratio of natural gas direct cracking cycle reaction gas, comprising the following steps:

[0037] (1) Feed gas: the reaction mixture gas from methane catalytic pyrolysis hydrogen production (that is, natural gas direct cracking hydrogen production), in which hydrogen (H 2) concentration is 50-60% (volume ratio, the following is similar), methane (CH 4 ) concentration is 40-49%, the rest is a small amount of carbon monoxide (CO), carbon dioxide (CO 2 ), ethane, water (H 2 O), and solid powder particles, the temperature is 550-600°C and the pressure is 2.0-2.4MPa, and the flow rate is 5000Nm 3 / h, after cooling and heat exchange to 40-60 ° C and removing solid particles through two-stage filtration, enter the next process, that is, the hydrogen extraction system. The hydrogen extraction system in this embodiment adopts pressure swing adsorption (PSA) hydrogen extraction .

[0038] (2) Pressure sw...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that in the described pressure swing adsorption purification process, the switching time of the regulating valve and the program control valve connected to the inlet and outlet pipelines of the adsorption tower in the adsorption state are adjusted according to the sequence arrangement. The length of the adsorption time can be adjusted by the switch degree, and the adjustment of the "hydrogen-carbon concentration ratio" can be realized, and the adsorption time can be reduced to 150-180 seconds. It is 1:3.

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that in the described pressure swing adsorption (PSA) hydrogen extraction process, the regulating valves, The switching time and switching degree of the program control valve, and the operating mode are used to adjust the outflow ratio of the pressure equalization gas, and the 6-2-2V / P operating mode is changed to the 6-1-2V / P mode, that is, the original two adsorption towers are changed to 1 adsorption tower is adsorbed, and the number of times of pressure equalization is still 2 times, and the adsorption time of each adsorption tower is constant, and the time of desorption regeneration is extended to be 1.2~1.4 times of original, realizes the hydrocarbon flow ratio 1 by original embodiment 1: 2 is adjusted to 1:3, and the ratio of carbon to hydrogen concentration remains at 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com