Patents

Literature

1168 results about "Wheat gluten" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wheat gluten is a food made from gluten, the main protein of wheat.It is made by washing wheat flour dough with water until all the starch granules have been removed, leaving the sticky insoluble gluten as an elastic mass which is then cooked before being eaten.. The name seitan is now widely used in vegetarian, vegan, wholefood and macrobiotic circles for wheat gluten dishes.

Method for preparing foliage fertilizer containing nucleic acid degradation product

InactiveCN101186534AFast absorptionPromote growthOrganic fertilisersNucleic acid metabolic processPurine

The invention relates to a preparation method of a foliar fertilizer which comprises nucleic acid degradation products. The invention is characterized in that: malt sprout is employed to obtain nuclease liquid with a low temperature water extraction method, nucleic acid solution and enzyme solution are blended according to a proportion by weight of 1 : 2 to 3 portions of nucleic acid and malt sprout, and the solution is hydrolyzed at a temperature of 65 DEG C and a condition of pH 5.6 for 3 to 4 hours, then a nucleic acid degradation product foliar fertilizer is obtained after enzyme dispelling, filtering, enzyme and milling. The preparation method of the invention is characterized by simple technique, easily available raw material, pollution free exhaust and low production cost; the prepared nucleic acid degradation products of the foliar fertilizer are nucleosides, nucleotides, pyrimidine, purine and other micromolecule, thus being beneficial to the metabolism process of nucleic acid, and the invention also contains a great amount of nutrient components such as glucide, protein and minerals, etc., which are needed by the growth of crops, thus promoting the growth of crops, strengthening resistance and obviously improving yield and quality; the yield of wheat is improved by 7 to 10 percent, protein content is improved by 1 percent and wheat gluten content is improved by 3 percent; solution is prepared by the foliar fertilizer of the invention according to requirements of the growth of crops to spray; absorption speed of foliage is fast, and brings no pollution to soil; the foliar fertilizer is a non polluted green fertilizer.

Owner:MICROBIOLOGY INST OF SHAANXI

An ecological soft-shelled turtle complete compound feed

InactiveCN101548727APromote oxidative metabolismReduce depositionClimate change adaptationAnimal feeding stuffMicrobial agentBody colour

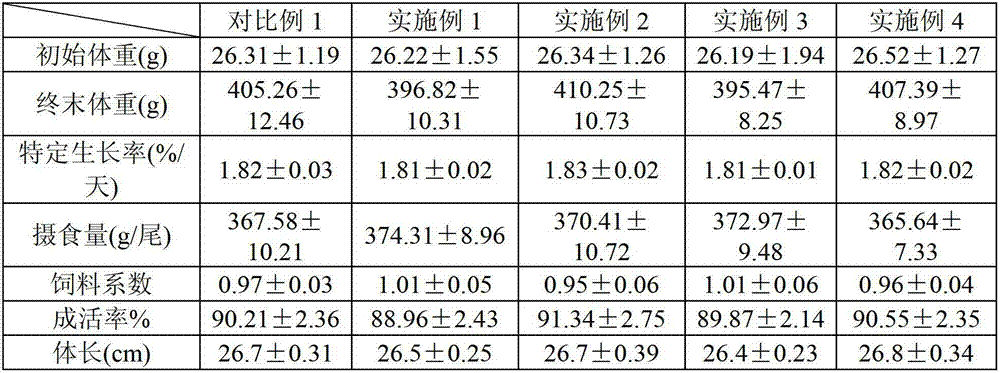

An ecological soft-shelled turtle complete compound feed The invention discloses an ecological soft-shelled turtle complete compound feed, including the following material components (each component is in the air-dry substance weight percentage): 30-40% of white fish meal, 15-25% of red fish meal, 4-8 % of fermented soybean mea, 3-6% of extruded soybean, 1-4% of wheat gluten, 4-8% of beer yeast, 3-6% of maize protein meal, 1-3% of marigold flower powder, 18-25% of pre-gelatinized starch, 1-2% of calcium phosphate, 0.1-0.3% of fat metabolism regulator, 0.05-0.3% of enzyme preparation, 0.1-0.4% of microbial agents, 0.1-0.3% of compound multivitamins, 0.5-1.5% of composite multi-ore, 0.2-0.5% of 50% choline chloride. The invention improves the appearance body colour and inherent quality of the artificial breeding soft-shelled turtle which can be comparable wit natural growth wild soft-shelled turtles, thereby enhancing the commodity value of soft-shelled turtles.

Owner:ZHEJIANG JINDADI FEED

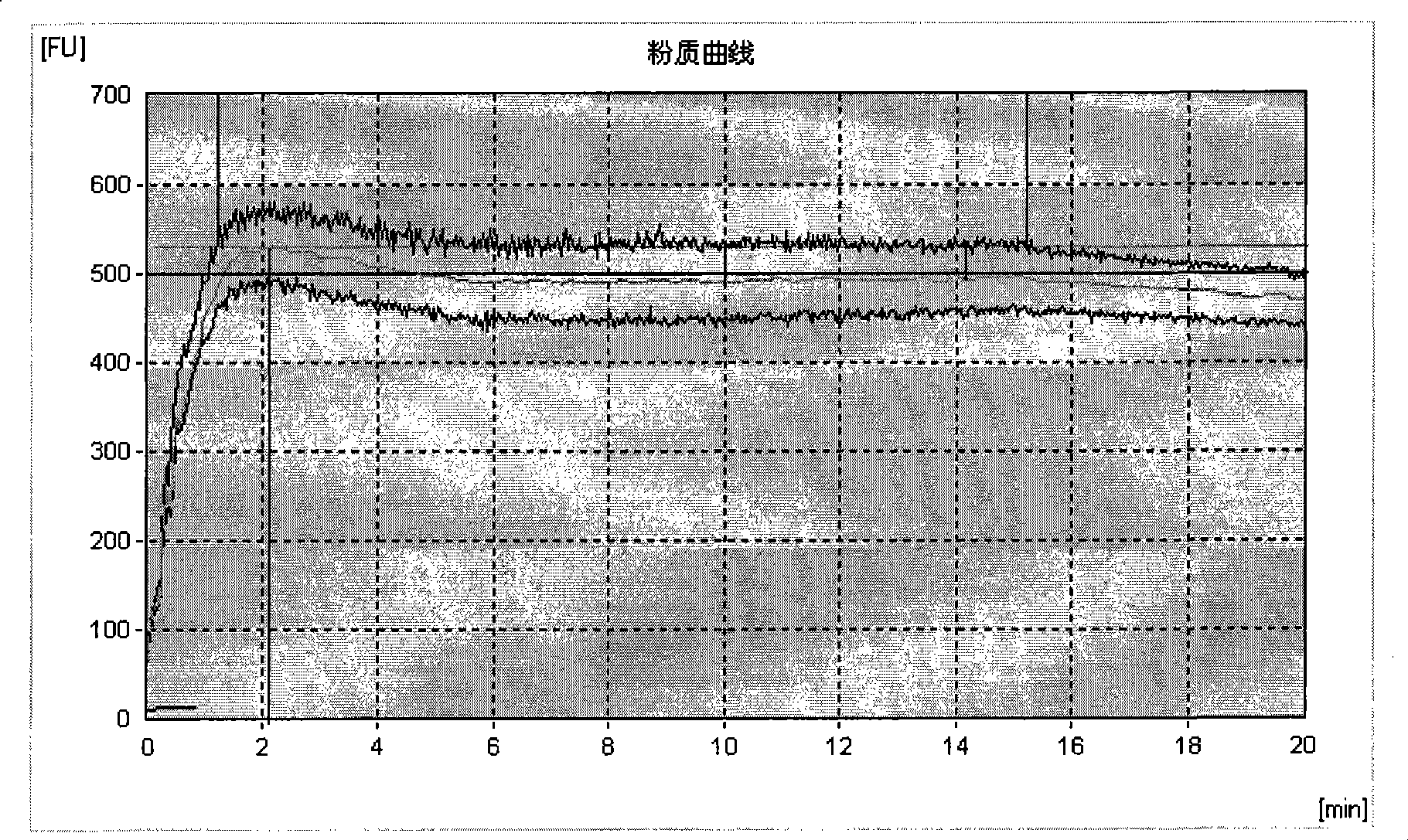

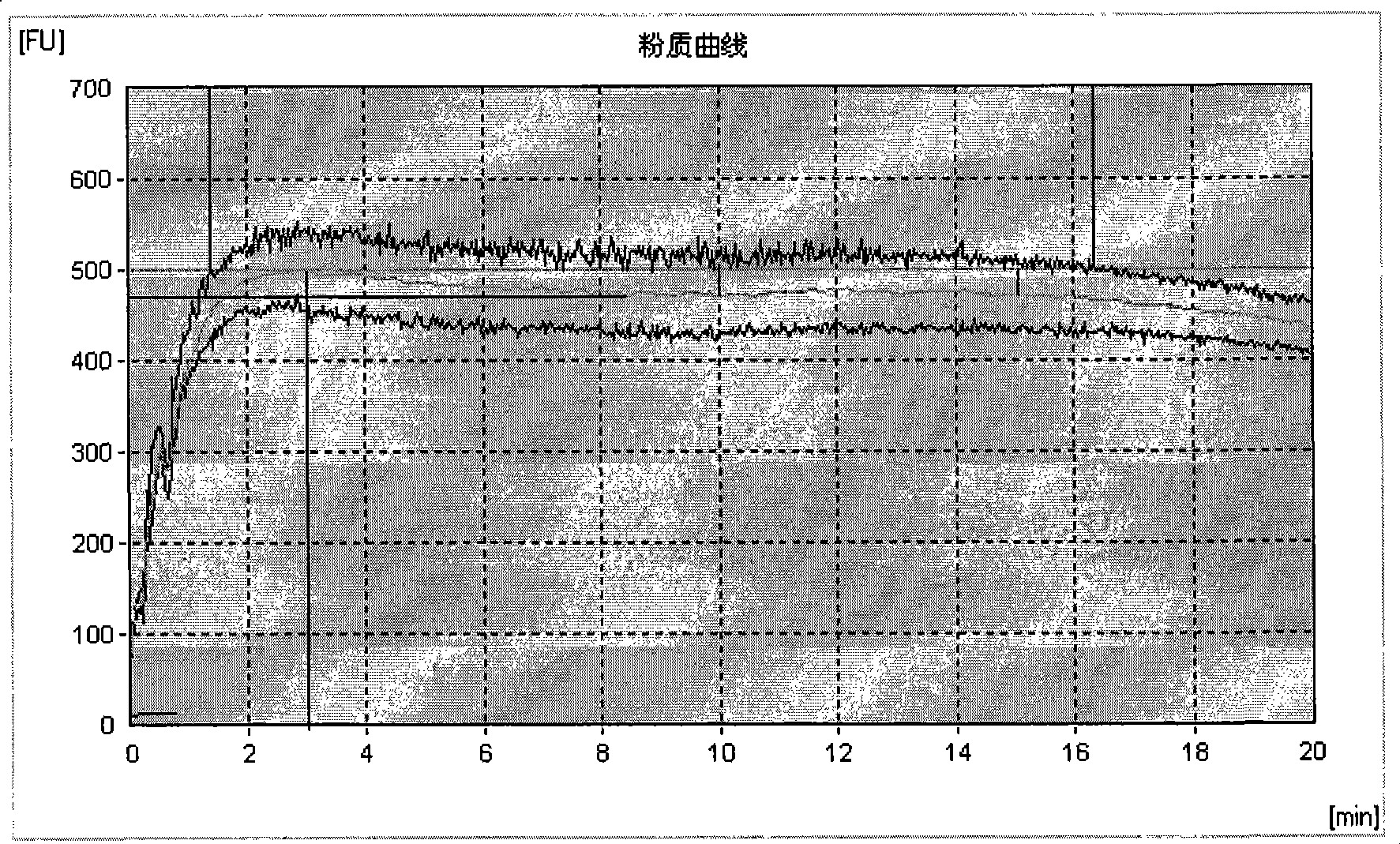

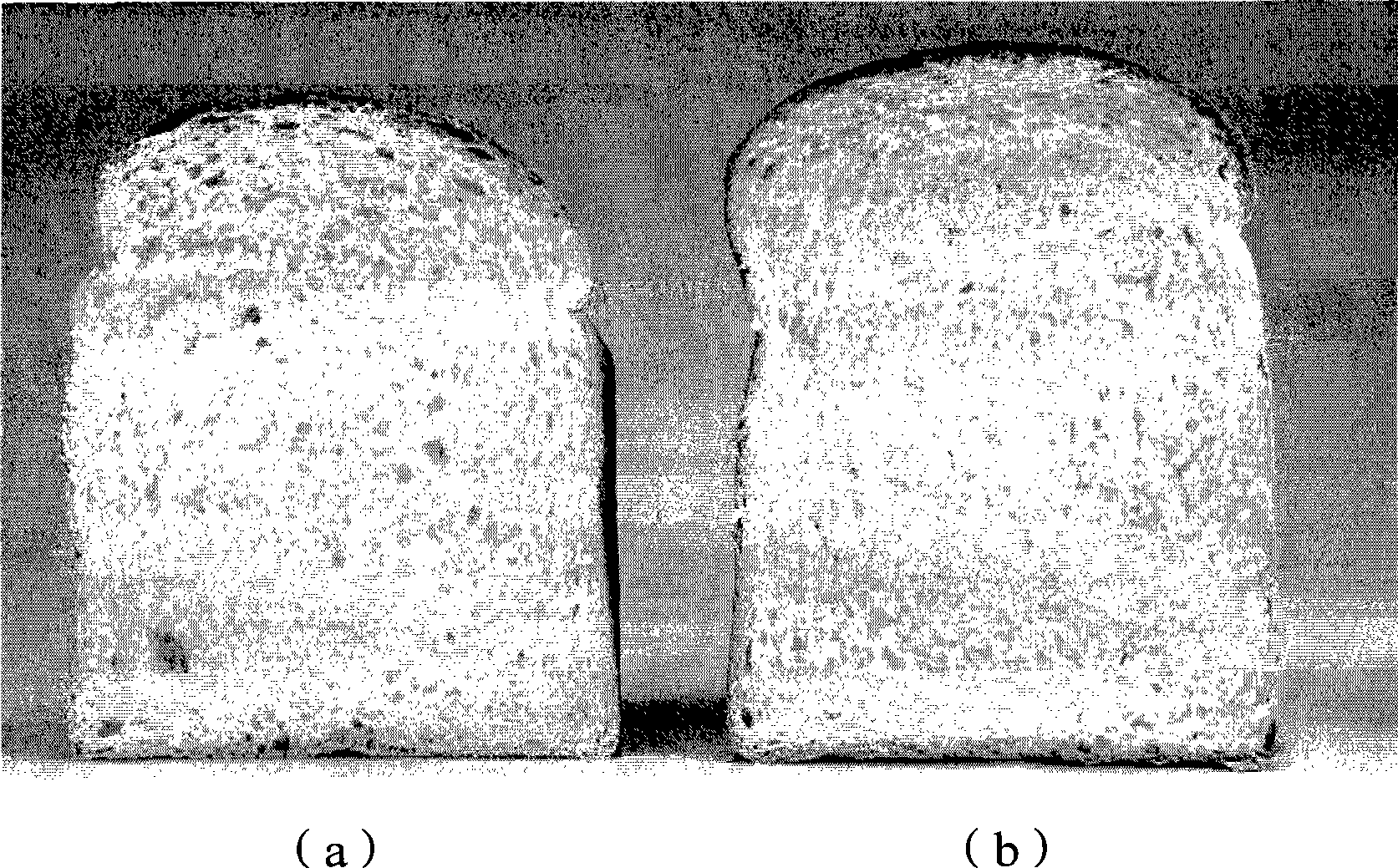

Freezing flour-dough improver and uses thereof

ActiveCN101411344AOvercome stabilityOvercome volumeDough treatmentPre-baking dough treatmentYeastVitamin C

The invention discloses a frozen dough modifying agent, which is prepared by evenly mixing an enzyme preparation (including one or a plurality of alpha-amylase, cellulose, hemicellulase, pentosanase, lipase, glucose oxidase, glutamine transaminage and so on), vitamin C, an emulsifying agent, a thickening agent, wheat gluten powder, lecithin and stuffing according to certain proportion. The frozen dough modifying agent has the advantages that the frozen dough modifying agent can effectively improve the stability of dough during fermentation and roasting processes, improve the freezing resistance property of yeasts, increase the volume of finished products, improve the tissue of the finished products, reduce the loss of the vitality of the yeasts during the freezing process, and effectively delay the aging of the finished products.

Owner:ANGELYEAST CO LTD

An environmentally-friendly soft-shelled turtle compound feed

InactiveCN101548726AImprove utilizationLow nutritional needsFood processingClimate change adaptationMicrobial agentChemistry

The invention discloses an environmentally-friendly soft-shelled turtle compound feed, including the following material components (each component is in the air-dry substance weight percentage): 30-35% of white fish meal, 15-25% of red fish meal, 5-10 % of fermented soybean mea, 3-6% of extruded soybean, 1-4% of wheat gluten, 5-10% of beer yeast, 18-25% of pre-gelatinized starch, 1-2% of calcium phosphate, 0.05-0.3% of enzyme preparation, 0.1-0.4% of microbial agents, 0.1-0.3% of compound multivitamins, 0.5-1.5% of composite multi-ore, 0.2-0.5% of 50% choline chloride. The inventive prescription can reduce the nitrogen and phosphorus content in the compound feed, improve the digestive absorption and deposition rate of the nitrogen and phosphorus in the soft-shelled turtle breeding, and can reduce the output of nitrogen and phosphorus in water to improve the breeding environment.

Owner:ZHEJIANG JINDADI FEED

Composition and method for making high-protein and low-carbohydrate food products

InactiveUS20050129823A1Effectively reducing the net carbohydrate total of the traditional productIncrease nutritionDough treatmentBaking mixturesAdditive ingredientProtein isolate

Conventional food compositions for use in making baked goods and extruded food products are improved by reducing the carbohydrate content. This is done by substituting the conventional flour in whole or in part by a combination of starch that is resistant to amylase digestion and / or from about 1-150 baker's percent of a first proteinaceous ingredient comprising at least about 70% by weight protein, and a second proteinaceous ingredient selected from the group consisting of (i) between about 0.5-100 baker's percent of a wheat protein isolate product; (ii), between about 0.5-100 baker's percent of a wheat protein concentrate product; (iii) between about 0.5-100 baker's percent of a devitalized wheat gluten product; (iv) between about 0.5-20 baker's percent of a fractionated wheat protein product; (v) between about 0.5-20 baker's percent of a deamidated wheat gluten product; (vi) between about 0.5-30 baker's percent of a hydrolyzed wheat protein product; and (vii) any combination of ingredients (i) to (vi).

Owner:MGP INGREDIENTS

Tartary buckwheat noodles and preparation method thereof

ActiveCN101836709AIncrease stickinessImprove toughnessDough treatmentFood preparationPolygonum fagopyrumAgaric

The invention relates to the field of food, in particular to tartary buckwheat noodles prepared by taking tartary buckwheat as a main raw material, and a preparation method thereof. In order to solve the technical problem, the invention provides the tartary buckwheat noodles with relatively higher tartary buckwheat content and high cooking performance. The tartary buckwheat noodles are prepared from the following components in percentage by weight: 65 to 93 percent of tartary buckwheat flour, 0 to 28 percent of wheat flour, 0 to 5 percent of additive, 0.3 to 0.8 percent of konjaku powder, 0.8to 1.5 percent of salt and 0.1 to 0.3 percent of alkali, wherein the additive may be one of wheat gluten, fruit and vegetable powder, black fungus powder and mushroom powder, or may be a natural plant auxiliary material for toning and seasoning. The key point of the preparation method for the noodles is that: by adopting a microwave pre-gelatinization process and utilizing the characteristic thatthe konjaku powder encounters the alkali to form irreversible gel after being swelled, the processing performance, such as viscosity, toughness and the like, of the tartary buckwheat flour dough is remarkably improved, and the defects of easy noodle breakage and the turbidity and easy burning of noodle soup are overcome.

Owner:西昌航飞苦荞科技发展有限公司

High-protein, low-carbohydrate bakery products

InactiveUS20050013900A1Good source of nutritionLow glycemic indexMilk preparationDough treatmentResistant starchProtein isolate

A high-protein, low-carbohydrate bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

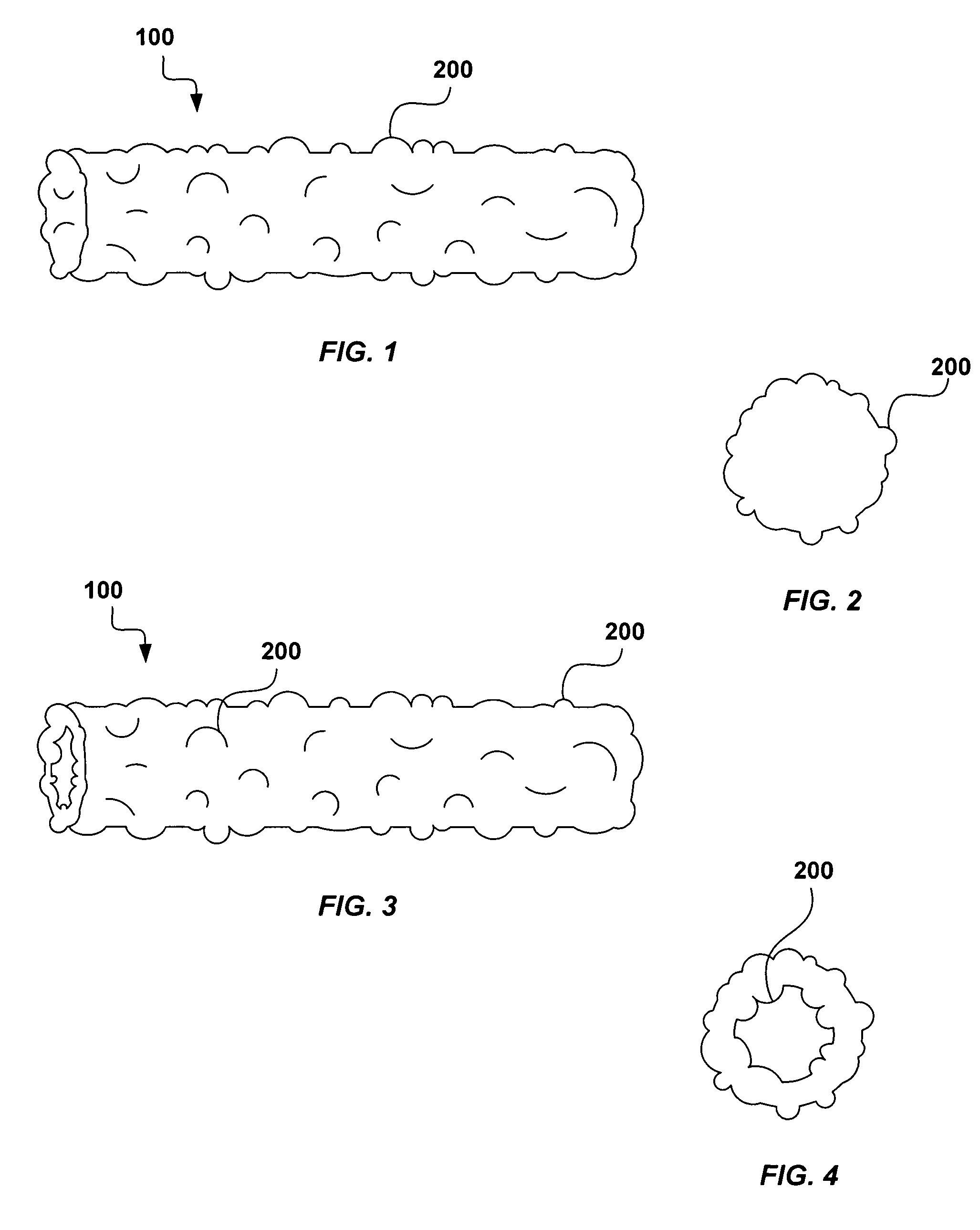

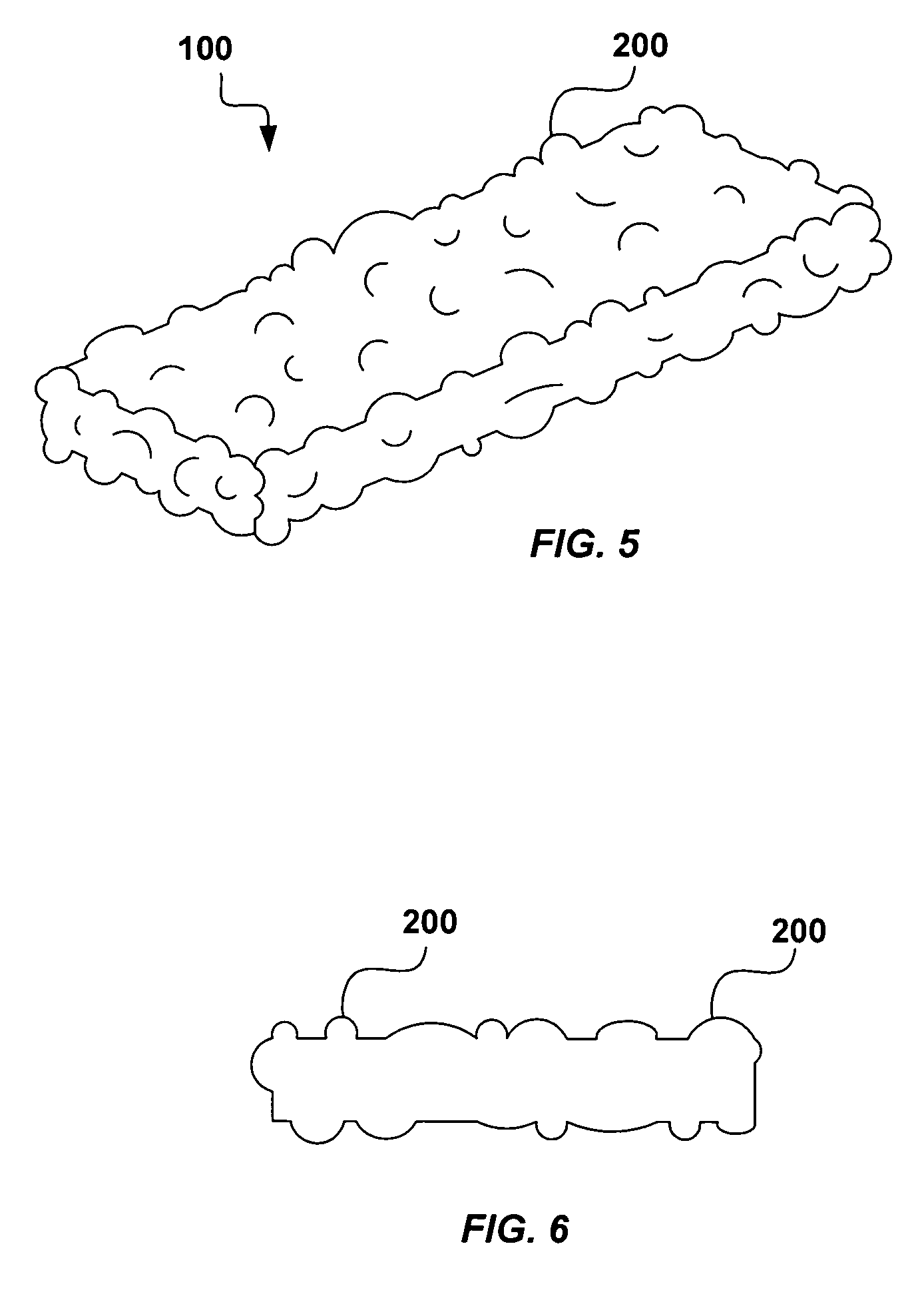

Pet treats with rough surface texture

A pet treat with a rough surface texture and appearance is produced from a matrix binder and at least one granular filler having a particle size between 0.1 mm to 6 mm. The matrix binder may be selected from gelatinized starches, gelatinized flours, wheat gluten, soy protein, casein, caseinates, gelatin, hydrocolloids, gums and mixtures thereof. The granular filler may be selected from mill feeds, whole grains, distillers dried grains, pork grind, bird seed and mixtures thereof.

Owner:MGP INGREDIENTS

Frozen instant noodles and processing method thereof

InactiveCN102178171AStrong fresh-keeping abilityNot subject to storage conditionsFood preparationMixed materialsInstant noodle

The invention relates to frozen instant noodles and a processing method thereof. The frozen instant noodles comprise raw materials of flour, starch, wheat gluten, albumen powder, vegetable jelly, alkali, common salt, food dye and water. During processing, the mixed materials are synchronously placed in dough kneading equipment, vacuum stirred and then are let stand; the dough is subjected to rolling and pulling type composite calendaring for multiple times, is cured and is subjected to rolling and pulling type continuous calendaring and is chopped into short noodles; and finally, the noodles are boiled, washed and sub-packaged into boxes and refrigerated at a temperature of -18DEG C.

Owner:牛选欣

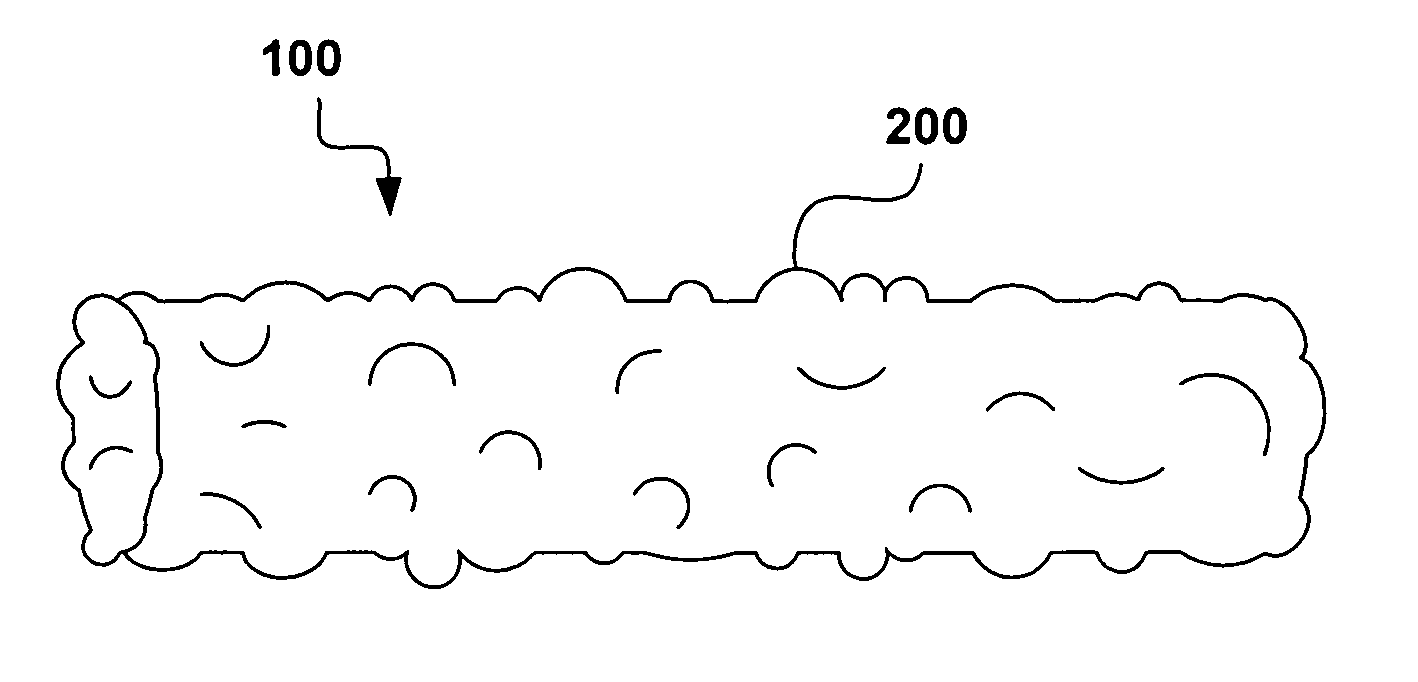

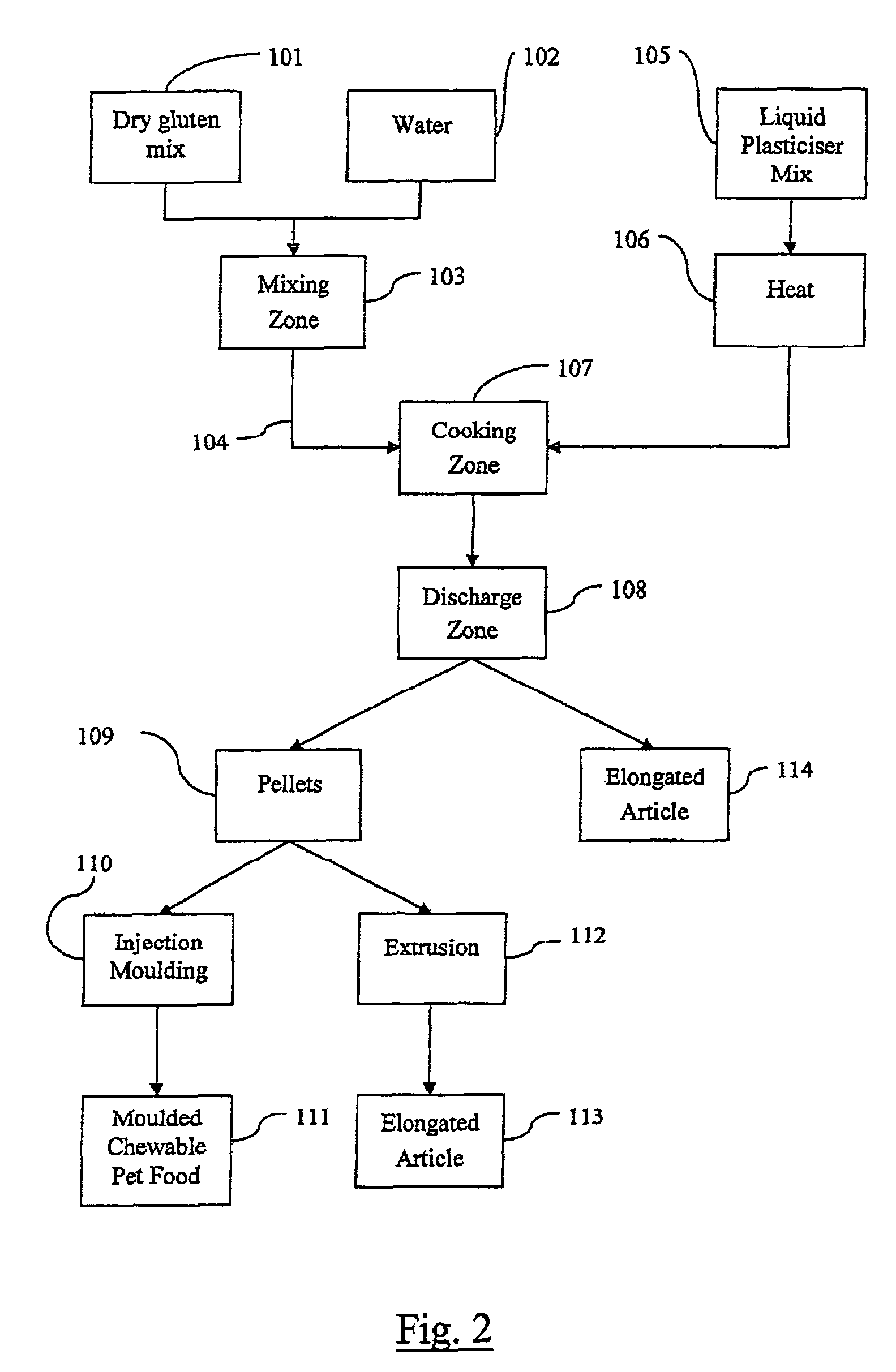

Process for preparing a chewable pet food

InactiveUS7390520B2Control of moisture contentUniform consistencyConfectioneryAnimal feeding stuffPlasticizerInjection moulding

A process for preparing an extrudable product suitable for forming into a chewable pet food and comprising between about 56% to about 80% dry wheat gluten mix, between about 9% to about 28% liquid plasticizer mix and between about 8% to about 18% moisture by weight of the product is disclosed. The process comprises mixing the dry wheat gluten mix with water in an extruder, to form a moist wheat gluten mix, and mixing the moist wheat gluten mix with a liquid plasticizer mix and extruding at a temperature of less than 70° C. to form the extrudable product. The invention also relates to the extrudable product and to the chewable pet food formed therefrom by means of either further extrusion or injection moulding.

Owner:GAINES TREATS

Semi-hard dentifrice

InactiveUS20050152851A1Extended shelf lifeHigh melting pointCosmetic preparationsToilet preparationsSodium bicarbonateSodium stearate

The invention comprises a formulation for a semi-hard stick-type dentifrice optimally for use in an oral hygiene device which utilizes such semi-hard stick-type dentifrice, most often used when traveling. The dentifrice includes a primary base material such as glycerin. Sodium benzoate is included as a preservative. Sodium coco-sulfate and a mixture of wheat gluten proteins and potassium cocoate provide a foaming material. Cleansers are included and the dentifrice is strengthened by vegetal-based sodium stearate and vegetal-based stearyl alcohol. Whitening materials are included, as is an absorption material and sodium bicarbonate as an abrasive.

Owner:KAMINSKI BASIA

Fresh-keeping method for fresh wet noodle

The invention relates to a method for keeping raw wet noodle fresh, which includes the steps that: (1) before dough making, ultraviolet lamp is switched on to irradiate the dough for 30min to 1.5h; (2)during the dough making, purified water or sterile water with an amount controlled between 25 to 32 percent is added to the dough and at least one of the three antistaling agents, salt, sodium dehydroacetate and calcium propionate in proportions respectively of 2 to 7 percent, 0.02 to 0.05 percent and 0.1 to 0.3 percent, is added to the water; additionally, 0.1 to 0.3 percent of phosphate, 0.1 to 0.3 percent of sucrose ester, 0 to 0.3 percent of guar gum and 0 to 0.3 percent of edible alkali as well as 5 to 10 percent of wheat gluten powder are added; (3) sterilization treatment is applied to cooking equipment, strip press and the like and noodle strip after pressing is thermally insulated and cooked; (4) asepsis treatment is applied to wet noodle strip and the moisture of the product is controlled between 18 to 28 percent; (5) sterilization is applied to the product before packaging. The method of the invention does not affect the flavor and color of products and the raw wet noodle is characterized by bright appearance, cream white color and strong tenacity and has a shelf life of two months at normal temperature and as long as six months at the temperature below 10 DEG C (cold storage).

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

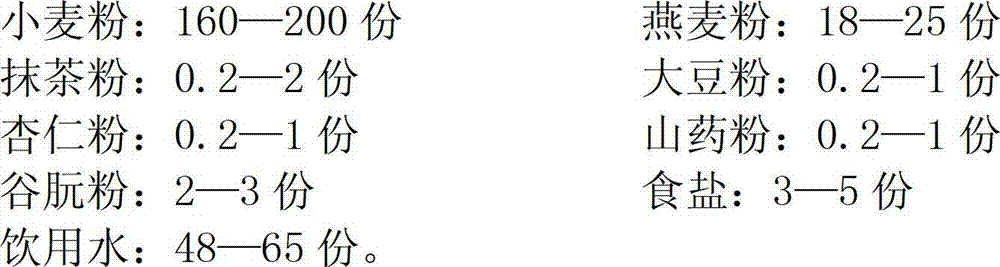

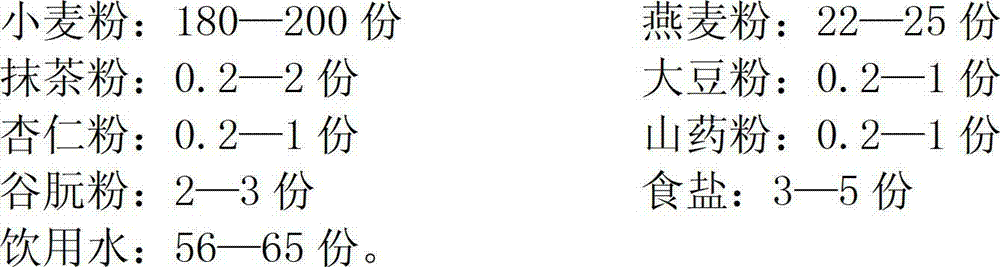

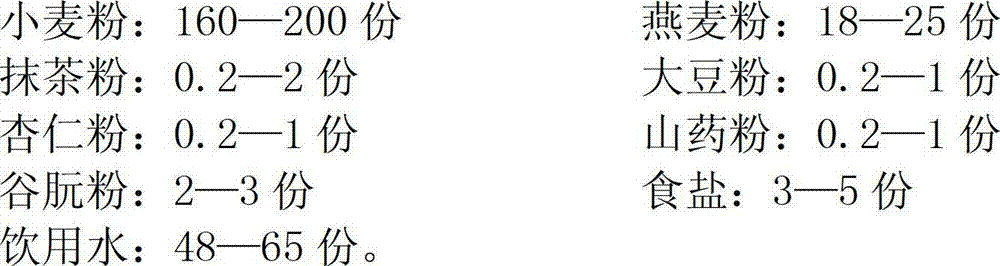

Nutritional vermicelli and making method thereof

InactiveCN102894279AGreat tasteMeet dietary requirementsFood preparationNutritive valuesAdditive ingredient

The invention provides a nutritional vermicelli and a making method thereof. Wheat flour is taken as the basic material of the nutritional vermicelli and oat powder, matcha powder, soybean meal, almond meal, yam meal, wheat gluten, drinking water and table salt are added. The nutritional vermicelli also comprises purple sweet potato powder, wolfberry powder and jujube powder. The making method of the nutritional vermicelli comprises the following steps: (1) kneading dough; (2) curing; (3) tabletting and cutting to strips; (4) drying; and (5) cutting off, measuring and packaging. Wheat flour is adopted as the main raw material and other raw materials with higher nutritive value are added. Compared with the traditional vermicelli, the nutritional vermicelli has rich nutritional ingredients, tastes good and effectively meets the requirements for dietary nutrition by people at present. As the nutritional vermicelli is rich in various microelements, the nutritional vermicelli is beneficial for lowering blood sugar level, reducing blood fat, preventing cardiovascular diseases and hypertension and improving immunity of human body.

Owner:宜垦(天津)农业制品有限公司

Industrial production method of hydrolyzed wheat protein for feeding

InactiveCN101627793AConfiguration highAdvanced configurationAnimal feeding stuffAccessory food factorsHydrolysateCombined treatment

The invention discloses an industrial production method of hydrolyzed wheat protein for feeding, belonging to the technical field of feed additive production. In the method, through the method of synergy of multiple enzymes and combined treatment of multiple steps, the hydrolyzed wheat protein for feeding is prepared by taking wheat gluten meal and water with weight ratio of 1:10-1:2 and adding compound enzyme, ensuring the mass percent concentration of the compound enzyme in the solution is 0.2-1.4%, hydrolyzing the mixture for 1-13h under the conditions that the temperature is 30-70 DEG C and pH value is 5.0-10.0, then carrying out such processes as filtering, decoloring and drying, etc. Compared with the traditional methods, the method of the invention features mild hydrolysis conditions, sanitation and safety and maintains the original nutritive composition of amino acid free of loss; the hydrolysate is low in salt content, mellow in mouth feel and high in yield which is up to 98%. The tests that the hydrolyzed wheat protein is added in the feed for suckling pigs, chicks, calves, aquaculture and the like to be used show that the hydrolyzed wheat protein has the advantages and evident effects of improving daily feed intake, reducing diarrhea rate, enhancing immunity, slowing weanling stress, improving growth performance and the like.

Owner:郑州新威营养技术有限公司

High-protein, reduced-carbohydrated flat bakery and other food products

InactiveUS20050031754A1Effectively reducing the “net” carbohydrate totalIncrease nutritionDough treatmentBaking mixturesAdditive ingredientProtein isolate

A high-protein, low-carbohydrate flat bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydrolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

Method for preparing barley maltsyrup by using wheat flour

InactiveCN101665843AComply with the policy requirements of energy saving and emission reductionIncrease health functionMaltose productionActivated carbonFiltration

The invention relates to a method for preparing barley maltsyrup by using wheat flour. The method comprises the following steps: after wheat gluten is extracted from wheat flour, screening obtained starch milk; concentrating the starch milk by a concentration separator; conditioning the starch milk; adjusting the pH value of the starch milk; introducing high temperature resistant alpha-amylase forspray liquefaction, laminar insulation and cooling on the starch milk; saccharifying the starch milk by saccharifying enzyme, and inactivating enzyme; adding flocculant and filter aid for filtration;decoloring the starch milk by adding activated carbon; filtering the starch milk to obtain clear filtrate; carrying out cation resin exchange and cathode resin exchange of the filtrate; reducing pressure and distilling the filtrate; inspecting quality of the filtrate; measuring and packaging the filtrate. The method solves the problems that the syrup cannot be filtered, and the finished product syrup has poor clarity in a process for manufacturing a finished product barley maltsyrup by using wheat A-type starch and B-type starch. The method saves rectification separation and drying processesof starch, and reduces the numbers of liquefaction times in sugaring, improves the syrup yield by 15 percent, has simple process and standard syrup quality, and reduces manufacturing cost and environmental pollution.

Owner:石济民

Health staple food flour special for diabetes patients and preparation method thereof

InactiveCN101564162AStrong targetingNutritional balanceDough treatmentFood preparationDiabetes mellitusDisease

The invention discloses a health staple food flour special for diabetes patients, which is prepared from full wheat flour taken as a raw material, and tartary buckwheat swelling powder, oat swelling powder, soybean protein powder, young oat powder, wheat gluten and stevia rebaudiana taken as accessories in certain proportion. The preparation method for the health staple food flour special for the diabetes patients comprises that: high-quality full wheat flour, the tartary buckwheat swelling powder, the oat swelling powder, the soybean protein powder, the young oat powder, the wheat gluten are firstly selected and baked respectively, weighted in proportion, mixed evenly, screened and packaged into a finished product. The health staple food flour special for the diabetes patients and the preparation method thereof have scientific formula and strong pertinency, change the current situation that more diseases are generated due to nutrition deficiency and physical condition deterioration caused by depending on the control of the staple food in the prior diabetic treatment, and provide a novel food therapy concept of sufficient staple food, balanced nutrition and systematic interference.

Owner:田向东

Novel process for preparing esculent film using glutamine transaminage modified protein

InactiveCN101199314AOvercome the disadvantages of poor elongation and low tensile strength of wheat gluten filmOvercome the disadvantage of low tensile strengthVegetable proteins working-upIsolated Soy ProteinPack material

The invention discloses a new technique for preparing an edible membrane by glutamine transaminase modified protein, which has main materials such as isolated soybean protein and wheat gluten protein and adopts transglutaminase for modification, thus achieving the complex edible membrane with good performance. The invention has advantages in the following aspects: 1. the strengths of both single substrate material isolated soy protein film and wheat gluten protein film are fully exerted so as to make the edible membrane with good tensile strength and extensibility; 2. the transglutaminase is adopted for the first time as a modifier to modify the protein composite membrane, thereby greatly enhancing the tensile strength and getting the compound edible membrane with good performance; and 3. the invention has the greatly expanded scope of applications of protein and provides a new effective approach for solving the environmental pollution. The edible high quality composite membrane is applied to food packaging, and can be directly eaten with other food, and some can be used as feeding materials, completely free of environmental contamination, so the invention is an authentic green packaging material.

Owner:HENAN AGRICULTURAL UNIVERSITY

Processing method of quick-freeze seafood crystal boiled dumplings

The invention relates to a processing method of quick-freeze seafood crystal boiled dumplings, which comprises the steps: selecting 30-60% (by weight percent) of powder with higher wheat gluten degree, 30 -60% by weight of wheat starch and 10-40% by weight of crystal deformed starch as wheat dough wrapper, charging salt, food gums and water to stir up into dough and rise, selecting fresh seafood as raw material to mince or cut into small pieces and prepare for use, selecting fresh vegetables to boil in hot water, cut up and prepare, mixing pig fat meat and treated seafood with the proportion of 1:3 to 5, preparing the stuffing materials in percentage by weight: 60-75%of pig fat meat and seafood meat, 8-12% of vegetables, 3-5% of shallot, 1-3% of ginger, 1-2% of table salt, 0.2-0.5% of aginomoto, 1-3% of edible oil and12-18% of water, making up dough to prepare boiled dumplings with stuffing materials and shaping to quickly freeze. The boiled dumplings produced in the invention have the advantages of scientific dosing, balanced nutrition, beautiful appearances, rational processing method and strong operational performance, and are applicable to factory production.

Owner:TAIXIANG GRP TECH DEV

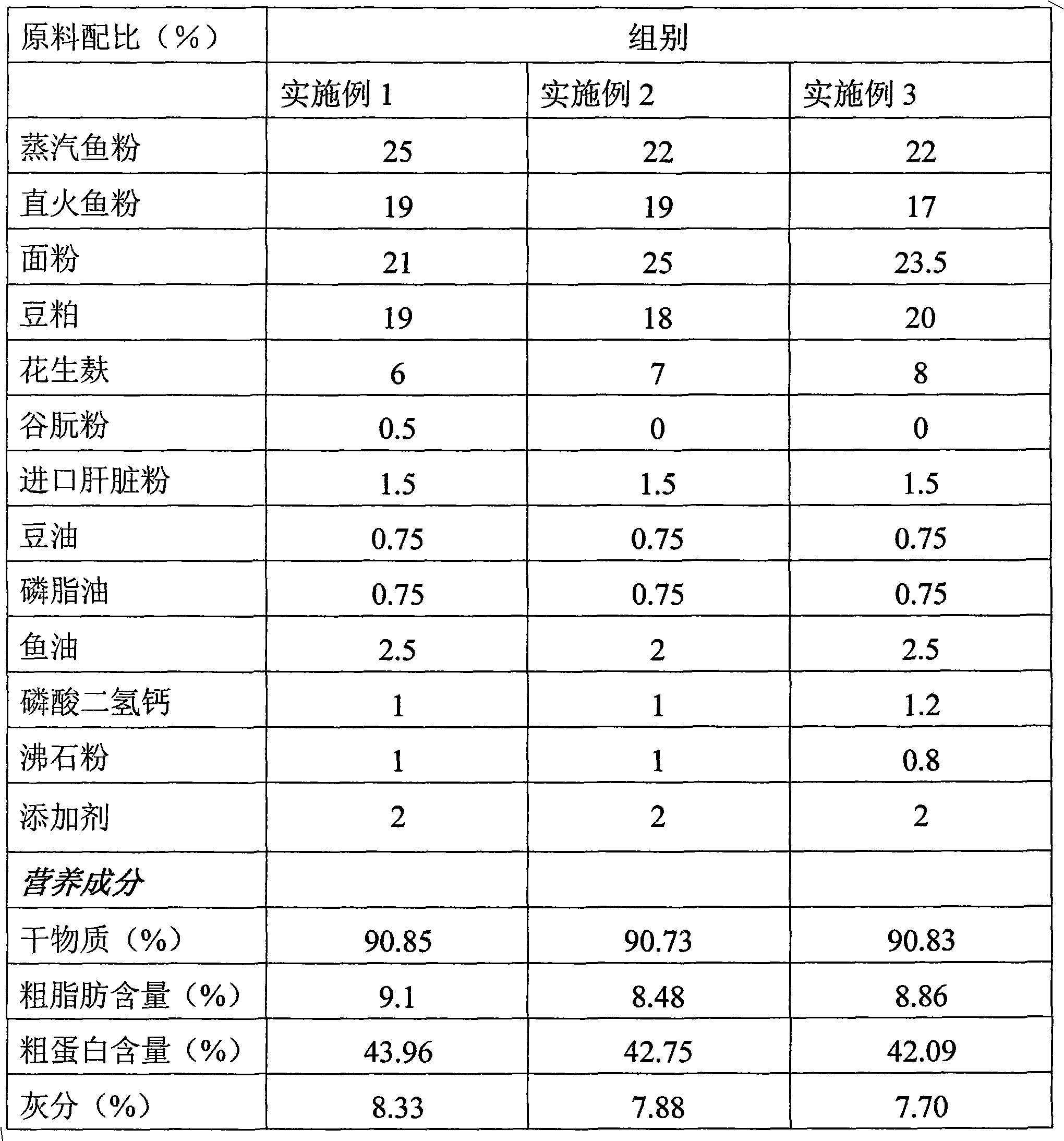

Compound feed for snakehead fish

ActiveCN101632416AIncrease attractivenessIncrease appetiteClimate change adaptationAnimal feeding stuffAntioxidantAdditive ingredient

The invention discloses compound feed for snakehead fishes, aiming at providing compound feed for snakehead fishes having the advantages of low feed coefficient, balanced and comprehensive nutrition, strong palatability and high subaqueous stability. The invention is prepared from the following ingredients by weight percent: 20-29% of steam fish meal, 17-19% of direct firing fish meal, 21-26% of flour, 10.5-21% of soybean meal, 6-8% of peanut bran, 1-2% of imported liver powder, 0-1% of wheat gluten meal, 0.75-1% of soybean oil, 0.75-1% of phospholipid oil, 1.5-3% of fish oil, 0.8-1.2% of monocalcium phosphate, 0.8-1.2% of powdered zeolite and the balance of additives; and the additives contain complex vitamin, compound minerals, Vc organic phosphate, choline chloride, salt, mildew preventive and oxidation preventive. The compound feed for snakehead fishes can be widely applied to the field of snakehead fish aquaculture.

Owner:ZHUHAI SHIHAI FEED

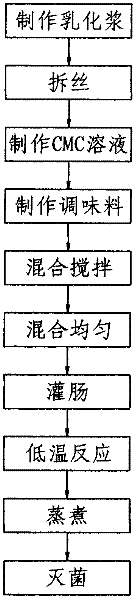

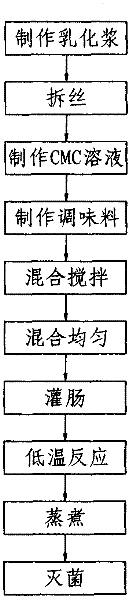

Peanut vegetarian meat ham and production method thereof

Owner:QINGDAO CHANGSHOU FOOD

High-protein, reduced-carbohydrate bakery and other food products

InactiveUS20050037125A1Effectively reducing the “net” carbohydrate totalIncrease nutritionDough treatmentBaking mixturesProtein isolateAdditive ingredient

A high-protein, low-carbohydrate bakery product comprising a first proteinaceous ingredient and a second proteinaceous ingredient selected from the group consisting of wheat protein isolate, wheat protein concentrate, devitalized wheat gluten, fractionated wheat protein, deamidated wheat gluten, hydrolyzed wheat protein, and combinations thereof are provided. Preferred bakery products further comprise an amount of resistant starch which replaces a portion of digestible carbohydrate therein.

Owner:MGP INGREDIENTS

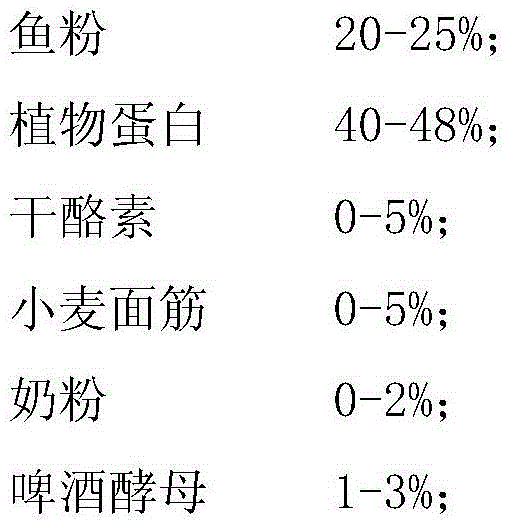

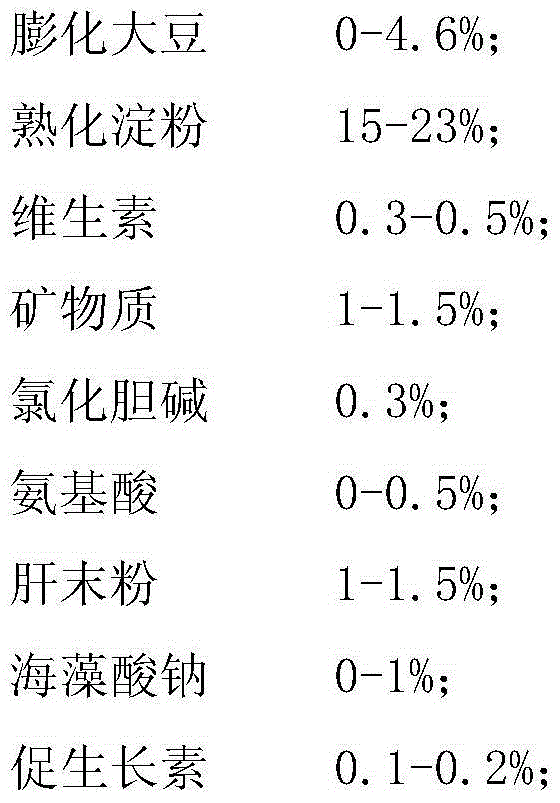

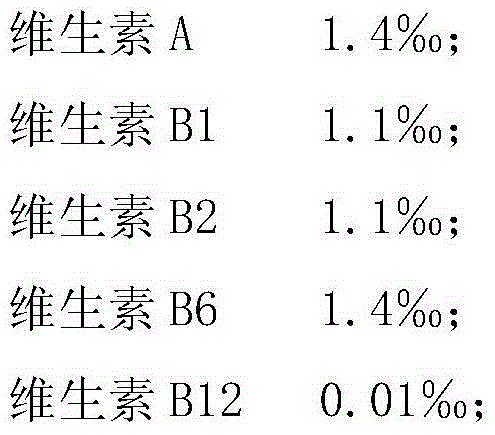

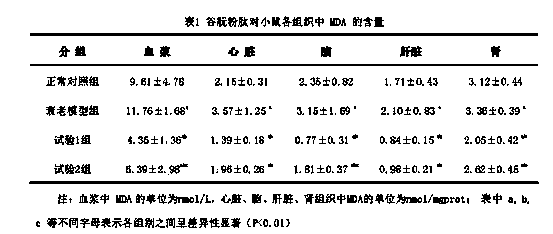

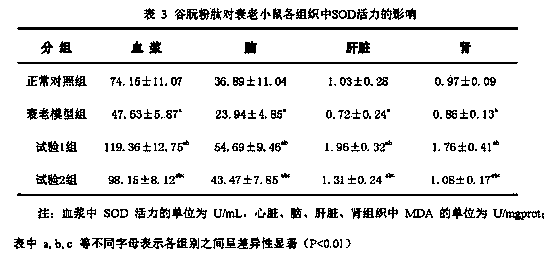

Andrias davidianus compound feed

ActiveCN103549220AHigh viscoelasticityFast formingClimate change adaptationAnimal feeding stuffFeed conversion ratioAdditive ingredient

The invention discloses an andrias davidianus compound feed which is mixed with an attractant for feeding andrias davidianus. The andrias davidianus compound feed comprises the following components: fish meal, vegetable protein, casein, wheat gluten, milk powder, beer yeast, extruded soybeans, cured starch, vitamins, mineral substances, choline chloride, amino acid, minced liver, sodium alginate, and somatotropin. The andrias davidianus compound feed disclosed by the invention has the advantages that the compound feed has complete nutrition, namely the andrias davidianus compound feed is rich in various necessary protein sources, trace elements, special mineral substances, vitamins and the like to meet the demand of the andrias davidianus on various nutritional ingredients in various stages; the andrias davidianus compound feed is good in inducing property and easy to digest and absorb, and has a high feed conversion ratio; the andrias davidianus compound feed is wide in applicability, and can meet the demands of the andrias davidianus in various stages.

Owner:林世琛

Process technique for preparing wheat gluten powder peptide by fermentation and enzymolysis method

InactiveCN104263794AIncrease vitalityGood effectMicroorganism based processesFermentationBiotechnologyTotal protein

The invention discloses a process technique for preparing wheat gluten powder peptide by a fermentation and enzymolysis method. A wheat gluten powder active peptide product with relatively high antioxidant activity is obtained by using a microbial fermentation and enzymolysis method, hoping for providing technique support for industrial production of preparing antioxidative peptide by using wheat gluten powder, thereby expanding the application range of the wheat gluten powder and improving the production additional value of the wheat gluten powder. The wheat gluten powder product obtained by adopting ultrasonic-assisted enzymolysis and an aerobic anaerobic two-step fermentation process is white in color and luster, powdery and free from impurities and bitter taste. The total protein content is greater than or equal to 97%, and the content of peptide with the molecular weight which is smaller than 1000 Dalton in total protein is greater than or equal to 98%. The reducing capacity of the wheat gluten powder peptide reaches 0.486 and the ABTS free radical scavenging capacity reaches 1.85mmol / L Trolox. The method disclosed by the invention is short in production period, low in cost and free from generation of any toxic and harmful substances. The obtained product is high in safety and good in functional activity and can be widely applied to the fields such foods, drugs, health products and biological synthesis.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Preparation method for improving gel hardness of fish balls

The invention relates to a preparation method for improving the gel hardness of fish balls, which is characterized by comprising the following steps of: separating fish meat by using a meat separator, removing fish bones and black films, putting fish fillets into 5 to 8 percent salt solution and soaking for 20 to 40 minutes with continuous stirring; putting the fish meat from which fishy smell is removed into clear water in an amount which is 4 to 6 times that of fish meat, slowly stirring for 8 to 10 minutes, repeatedly washing by using circulating water, dissolving 2 to 4 percent of salt in water, adding into minced fillets, milling for 2 to 4 minutes, adding 0.1 to 0.6 percent of transglutaminase (TGase), milling for 6 to 10 minutes, adding seasonings into the minced fillets, and milling for 1 to 4 minutes; adding 3 to 6 percent of wheat gluten into the minced fillets, and milling for 2 to 5 minutes; putting the minced fillets into a 0 DEG C refrigerator for 1 to 3 hours, forming by using a ball making machine, and ensuring that the weight of each ball is 7 to 15g; and heating the fish balls to the temperature of between 37 and 45 DEG C, keeping for 15 to 25 minutes, putting into a 70 to 85 DEG C water bath for 20 to 30 minutes, fishing out, quickly cooling, quickly freezing, and packaging. The fish balls prepared by the method have smooth and mellow appearance, smooth mouthfeel, high elasticity and rich nutrition.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing and preserving hot-boiling-stable fish noodles

InactiveCN102429168AImprove thermal processing stabilityPleasant flavorFood preparationNutritive valuesNano zinc oxide

The invention discloses a method for preparing and preserving hot-boiling-stable fish noodles, which belongs to the technical field of food processing. The method comprises the following steps of: preparing fishes into minced fillet; adding salt and seasonings for chopping; kneading dough, slowly and uniformly adding a sodium alginate aqueous solution, wheat gluten and a nano-zinc oxide aqueous solution in a dough kneading and stirring process; and curing, tableting, slitting, drying and packing to obtain a hot-boiling-stable fish noodle product. In the method, raw materials are processed into seasoning minced fillet, so that the fish noodles have the strong fragrance of fish; sodium alginate and the wheat gluten are added, so that the rheological characterization of the flour dough can be changed under the coaction of the sodium alginate and the wheat gluten, the gel property of the minced fillet is improved, and the hot-boiling stability of the fish noodles is improved; the nano-zinc oxide is added, so that the preserving property of the fish noodles is improved, the content of zinc in the fish noodles is increased, and the nutritional value of the fish noodles is raised; and at last, the fish noodles are packed by charging inert gas in vacuum, so that the shelf life of the fish noodles is prolonged, and the nutritional value of the fish noodles is kept to the maximum extent in the preserving process.

Owner:江苏省山水食品有限公司 +1

Fishmeal-free buoyant puffed feedstuff for micropterus salmoides and preparation method of feedstuff

The invention discloses fishmeal-free buoyant puffed feedstuff for micropterus salmoides and a preparation method of the feedstuff. One thousand kilograms of feedstuff comprises the following components: 41-53 kg of dephenolized cottonseed protein, 20-30 kg of spray-dried animal blood cells, 200-240 kg of soy protein concentrate, 180-220 kg of rice protein powder, 150-170 kg of fish soluble protein, 30-32 kg of calcium dihydrogen phosphate, 30kg of wheat gluten protein, 220kg of wheat flour, 20kg of lecithin oil, 30kg of fish oil, 5kg of fish trace elements, 2.5kg of betaine hydrochloride, 3kg of salt, 1.75kg of multi-vitamines for fish, 1kg of choline chloride, 1kg of L-carnitine, 1kg of a mildew inhibitor, 1.55kg of zeolite powder, and 0.2kg of ethoxyquinoline. The feedstuff use animal by-products and vegetable proteins to replace fish meal feedstuff, and the various raw materials are in synergistic combination to achieve cost minimization and benefit maximization of the feedstuff and solve the problem of high breeding cost.

Owner:SHANGHAI NONGHAO FEED

Mulberry leaf and tartary buckwheat fine dried noodles and preparation method thereof

ActiveCN103621901AIncrease varietyGreat tasteDough treatmentFood ingredient functionsBiotechnologyNutrition

The invention provides mulberry leaf and tartary buckwheat fine dried noodles. The mulberry leaf and tartary buckwheat fine dried noodles are prepared from 55-70 parts by mass of tartary buckwheat flour, 15-30 parts by mass of wheat gluten, 5-15 parts by mass of high gluten wheat flour, 3-10 parts by mass of mulberry leaf powder, 0.5-1.5 parts by mass of edible salt, 0.3-0.7 part by mass of sodium carbonate, 0.1-0.3 part by mass of konjac gum, 0.1-0.3 part by mass of xanthan gum and 35-42 parts by mass of drinking water. A preparation method of the mulberry leaf and tartary buckwheat fine dried noodles comprises the processes of preparation of a noodle improver solution, dough kneading, ripening, tabletting, drying, packaging and the like. The products are unique in formula, have excellent taste, are rich in nutrients, have prominent health care functions and are suitable for all kinds of people to eat, especially patients with constipation, obesity, diabetes mellitus, hypertension and coronary heart diseases.

Owner:甘肃世邦星达生物科技有限公司

Vegetarian food and preparation method thereof

InactiveCN102578591AIncreased vegetable protein contentLess fatFood preparationCelluloseShiitake mushrooms

The invention discloses vegetarian food which uses wheat gluten powder as a main raw material and a preparation method of the vegetarian food, belonging to the field of food processing. The vegetarian food is made of the following raw materials in parts by weight: 10-18 parts of wheat gluten powder, 10-18 parts of textured soybean protein, 10-18 parts of egg liquid, 10-15 parts of Chinese yam, 5-10 parts of burdock, 5-10 parts of carrots, 5-10 parts of fresh bamboo shoots, 5-10 parts of shitake mushrooms, 5-10 parts of Exidia auricula Judae, 5-10 parts of Tremella fuciformis, 5-10 parts of red dates, 5-10 parts of corn kernels, 1-2 parts of black sesame, 1-2 parts of walnut kernels, 1-2 parts of kelps, 1-2 parts of lavers, 2-5 parts of starch, 0.1-0.3 part of seasoning flour, 1-3 parts oftable salt, 5-10 parts of plant oil and 25-35 parts of water. The vegetarian food disclosed by the invention is rich in nutrients such as high-quality proteins, minerals, vitamins and cellulose, the nutrients are rich and balanced, the taste is adjustable and the vegetarian food is particularly suitable for fat people and people who lack for vitamins to eat.

Owner:陈研库

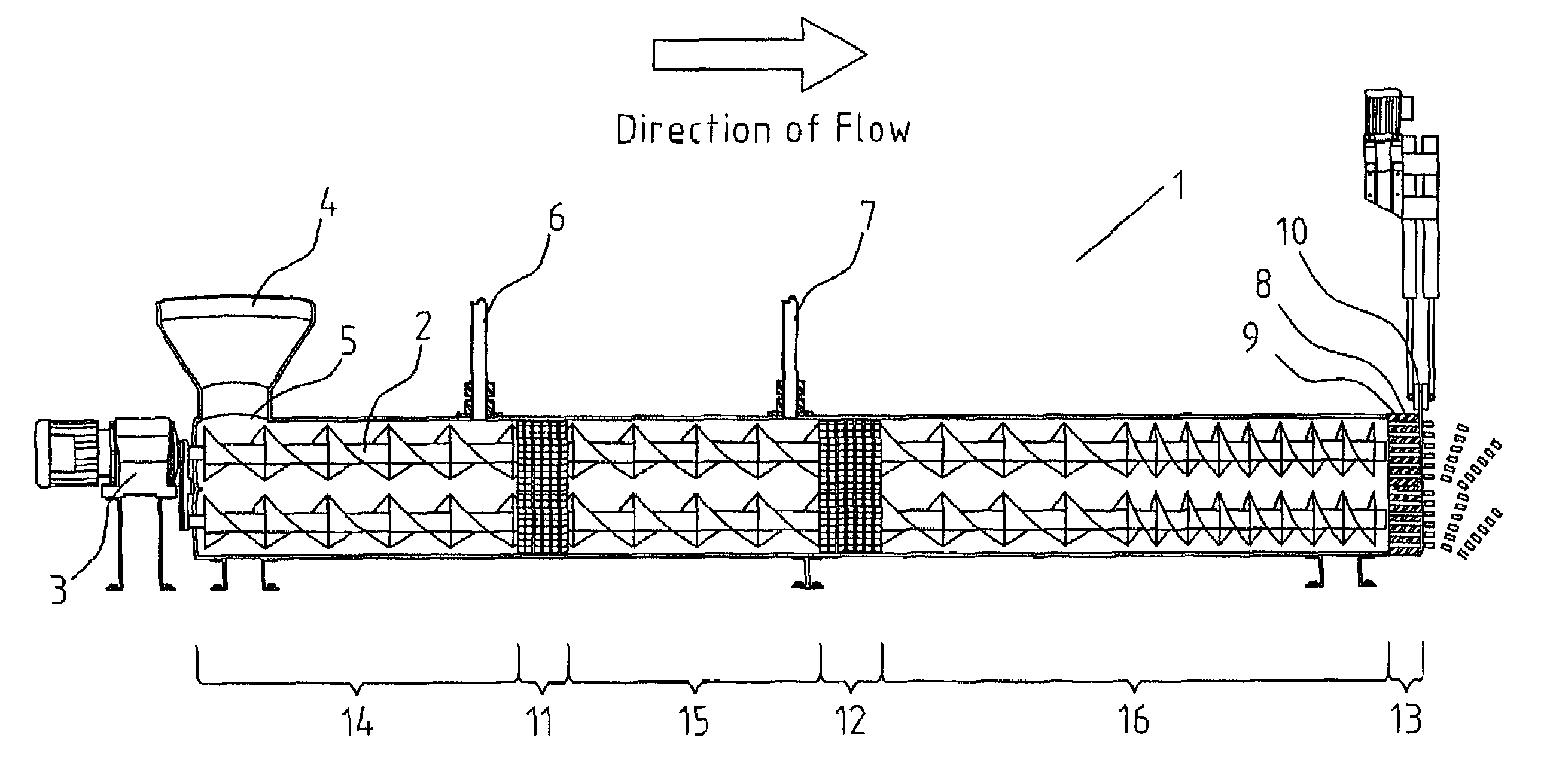

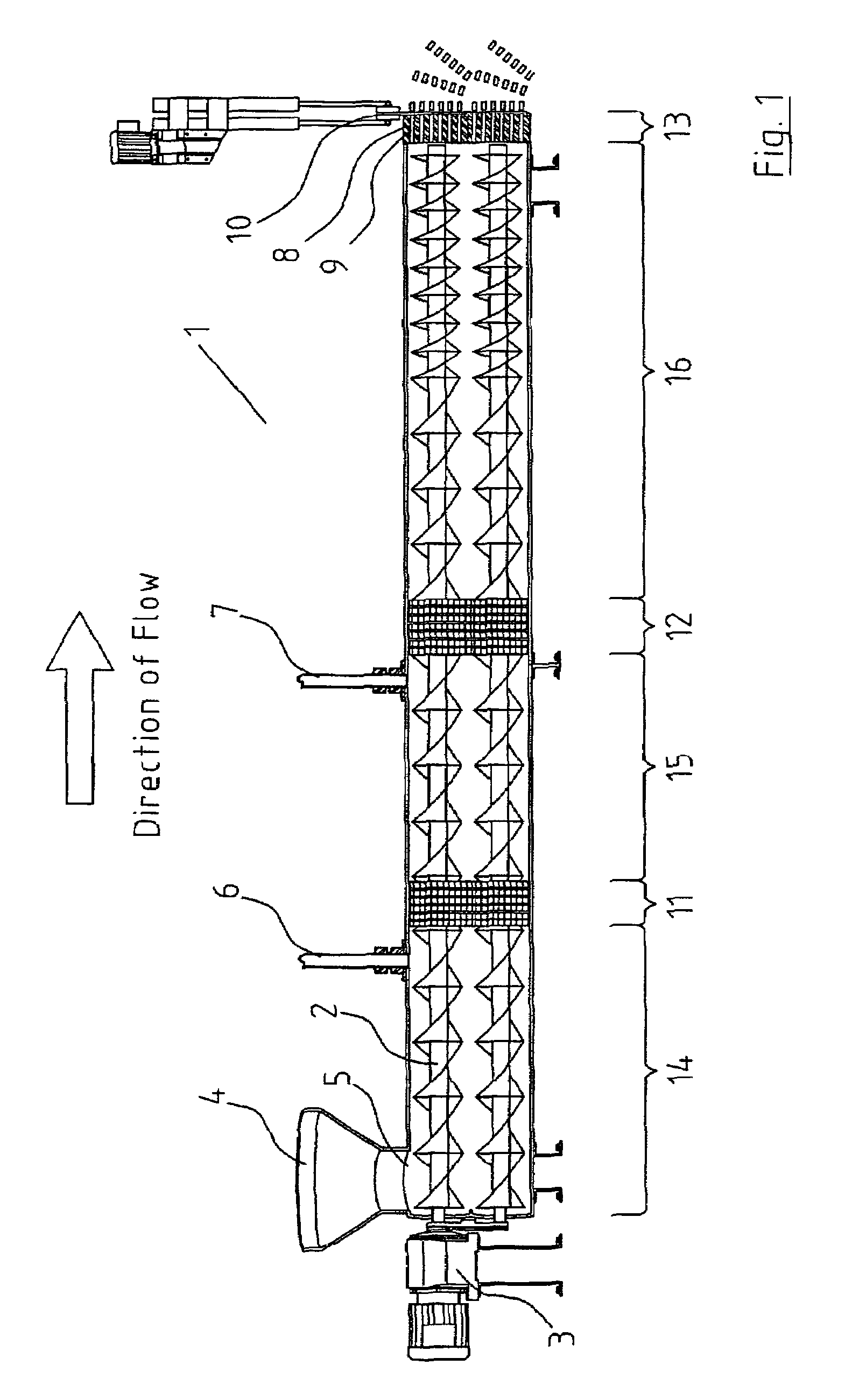

Method for producing vegetarian ham sausages through twin-screw extrusion

InactiveCN103190525AFine surface structureSmooth surface structureProteins working-up by texturisingVegetable proteins working-upSmall footprintContinuous mixing

The invention discloses a method for producing vegetarian ham sausages through twin-screw extrusion. The vegetarian ham sausages are produced by performing pretreatment on vegetable protein powder, isolated soy protein and vital wheat gluten as raw materials through, and then mixing and stirring the pre-treated raw materials by adopting a twin-screw extruder and a twin-screw extrusion technology for completing the processes such as extrusion curing, denaturation and texturization forming for one time. The method completely takes the vegetable protein powder as the raw material without adding any additives or auxiliary materials, so that the vegetarian ham sausages are good in texturization structure, high in protein content, similar to meat taste in taste, smooth in appearance, compact in structure and stable in quality, the moisture content of final products can be up to 50%, and the vegetarian ham sausages can be eaten as leisure food and staple food. By utilizing the twin-screw extruder for production, the method is a continuous mixing, melting and forming process, and as a high-temperature instantaneous biochemical reactor, the twin-screw extruder has the outstanding advantages of high efficiency and energy, low cost, energy consumption and the like, and also has the characteristics of high volume of the production, continuous production process, realization of the large-scale industrialized production, stable product quality, high degree of automation, small occupying area for the production and the like.

Owner:湖南富马科食品工程技术有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com