Patents

Literature

464 results about "Malt Grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Malt is germinated cereal grains that have been dried in a process known as "malting". The grains are made to germinate by soaking in water, and are then halted from germinating further by drying with hot air.

Method for preparing foliage fertilizer containing nucleic acid degradation product

InactiveCN101186534AFast absorptionPromote growthOrganic fertilisersNucleic acid metabolic processPurine

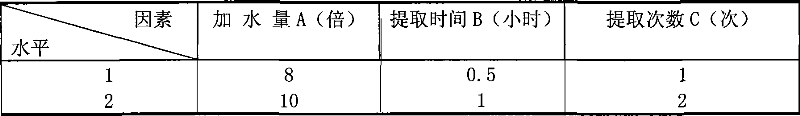

The invention relates to a preparation method of a foliar fertilizer which comprises nucleic acid degradation products. The invention is characterized in that: malt sprout is employed to obtain nuclease liquid with a low temperature water extraction method, nucleic acid solution and enzyme solution are blended according to a proportion by weight of 1 : 2 to 3 portions of nucleic acid and malt sprout, and the solution is hydrolyzed at a temperature of 65 DEG C and a condition of pH 5.6 for 3 to 4 hours, then a nucleic acid degradation product foliar fertilizer is obtained after enzyme dispelling, filtering, enzyme and milling. The preparation method of the invention is characterized by simple technique, easily available raw material, pollution free exhaust and low production cost; the prepared nucleic acid degradation products of the foliar fertilizer are nucleosides, nucleotides, pyrimidine, purine and other micromolecule, thus being beneficial to the metabolism process of nucleic acid, and the invention also contains a great amount of nutrient components such as glucide, protein and minerals, etc., which are needed by the growth of crops, thus promoting the growth of crops, strengthening resistance and obviously improving yield and quality; the yield of wheat is improved by 7 to 10 percent, protein content is improved by 1 percent and wheat gluten content is improved by 3 percent; solution is prepared by the foliar fertilizer of the invention according to requirements of the growth of crops to spray; absorption speed of foliage is fast, and brings no pollution to soil; the foliar fertilizer is a non polluted green fertilizer.

Owner:MICROBIOLOGY INST OF SHAANXI

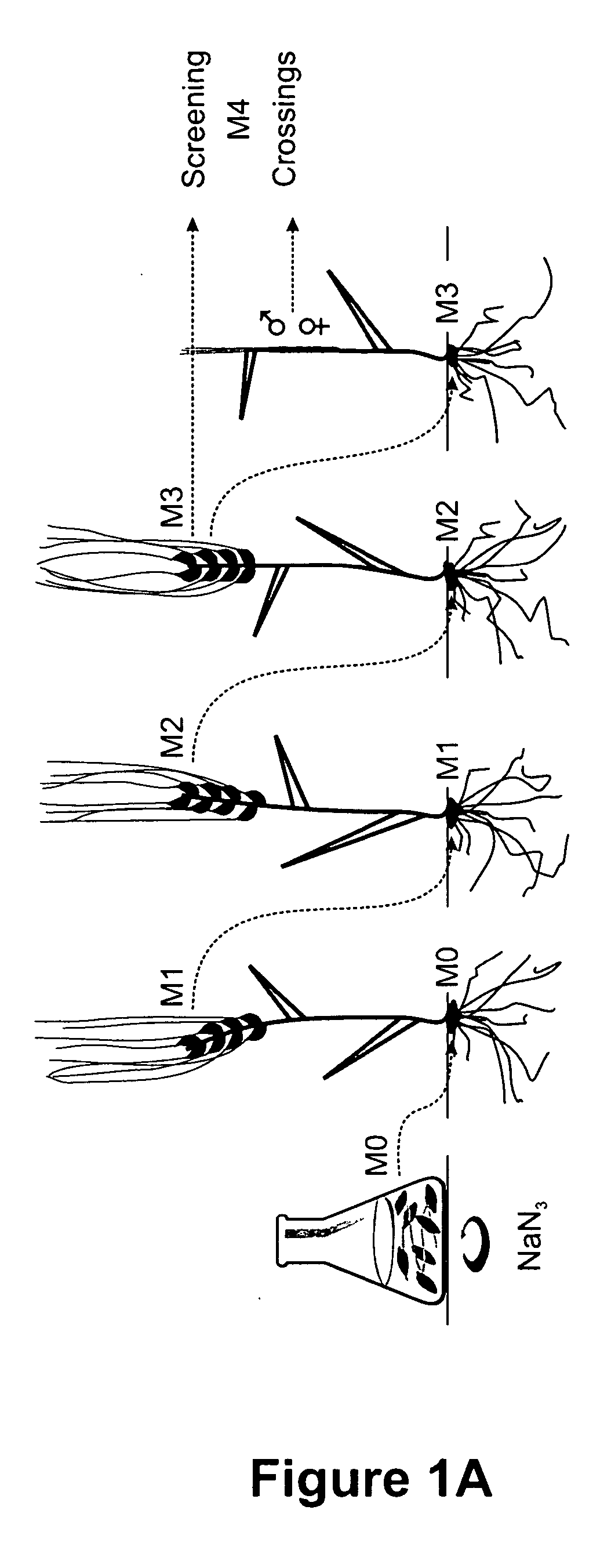

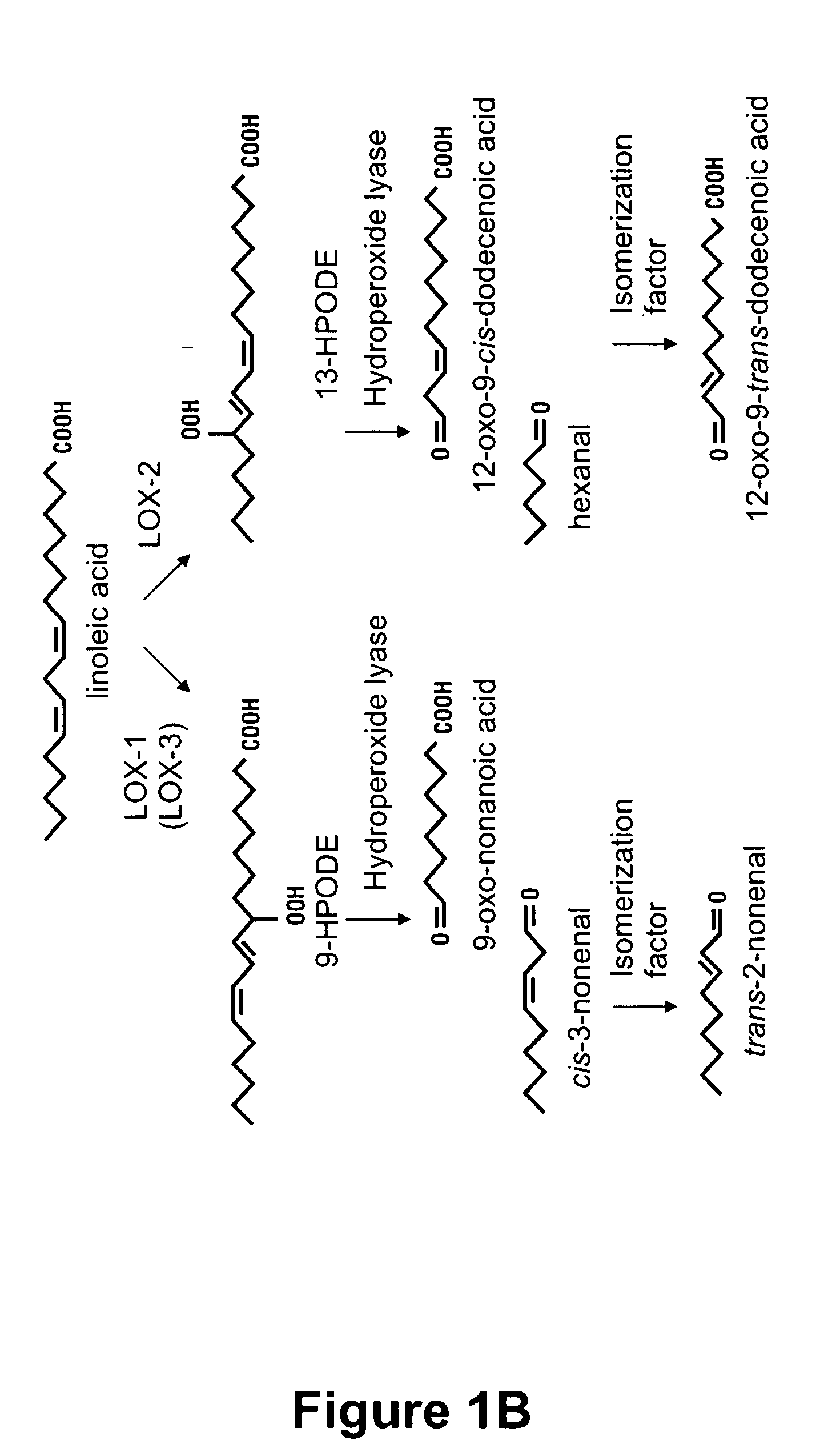

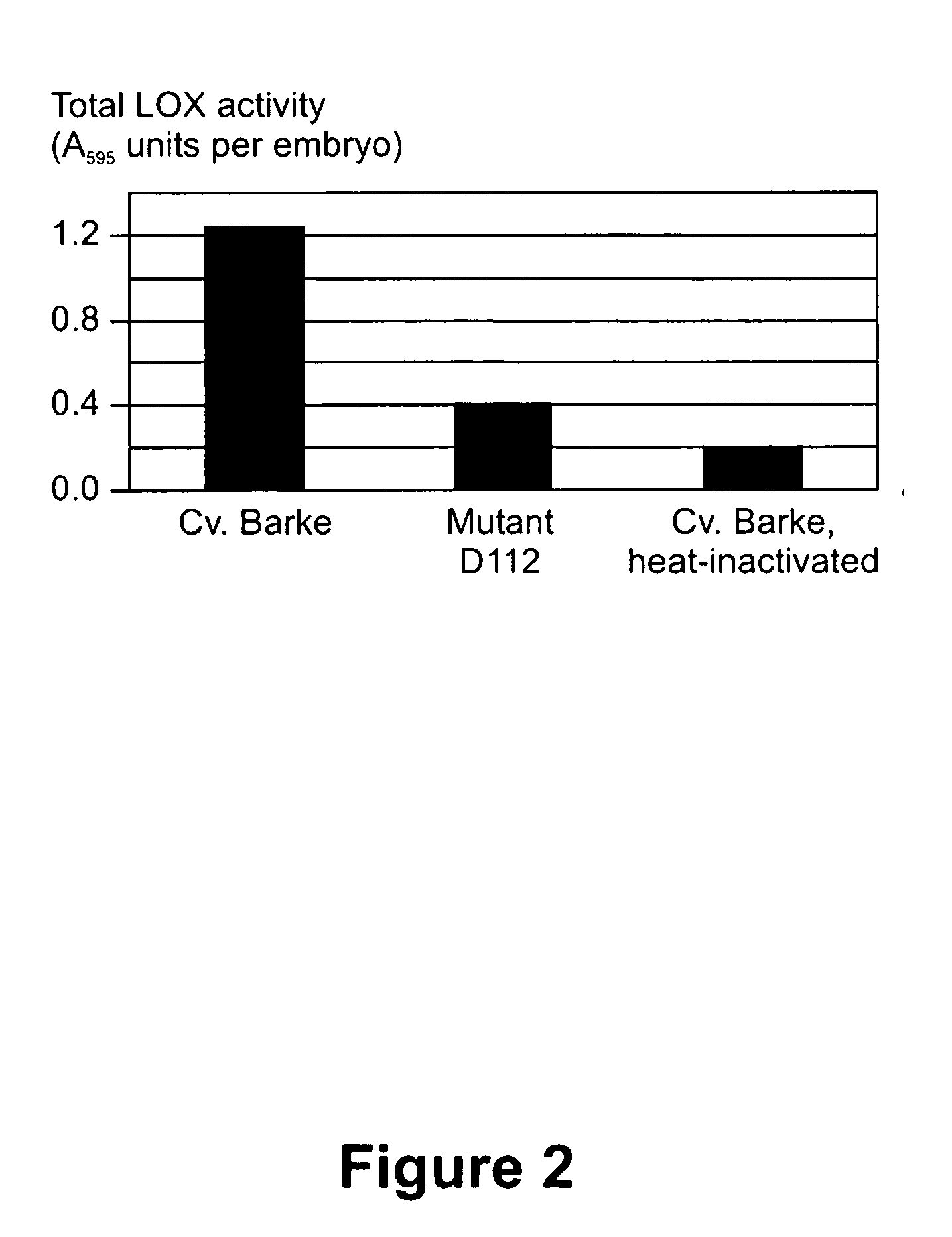

Barley for production of flavor-stable beverage

According to the invention, there is provided null-LOX-1 barley and plant products produced thereof, such as malt manufactured by using barley kernels defective in synthesis of the fatty acid-converting enzyme lipoxygenase-1. Said enzyme accounts for the principal activity related to conversion of linoleic acid into 9-hydroperoxy octadecadienoic acid, a lipoxygenase pathway metabolite, which—through further enzymatic or spontaneous reactions—may lead to the appearance of trans-2-nonenal. The invention enables brewers to produce a beer devoid of detectable trans-2-nonenal-specific off-flavors, even after prolonged storage of the beverage.

Owner:CARLSBERG BREWERIES AS

Cosmetic or dermatological preparations including hops or hop-malt extracts and methods of using same for the prophylaxis and treatment of skin symptoms

InactiveUS20050031572A1Without risk of side effectAvoid disadvantagesBiocideCosmetic preparationsHops extractMalt Grain

The invention is a cosmetic or dermatological preparation that includes hops or hop-malt extracts and to methods of using this preparation for the prophylaxis and treatment of the symptoms that result from certain skin conditions such as skin disease, inflammatory skin conditions and degenerative skin conditions.

Owner:BEIERSDORF AG

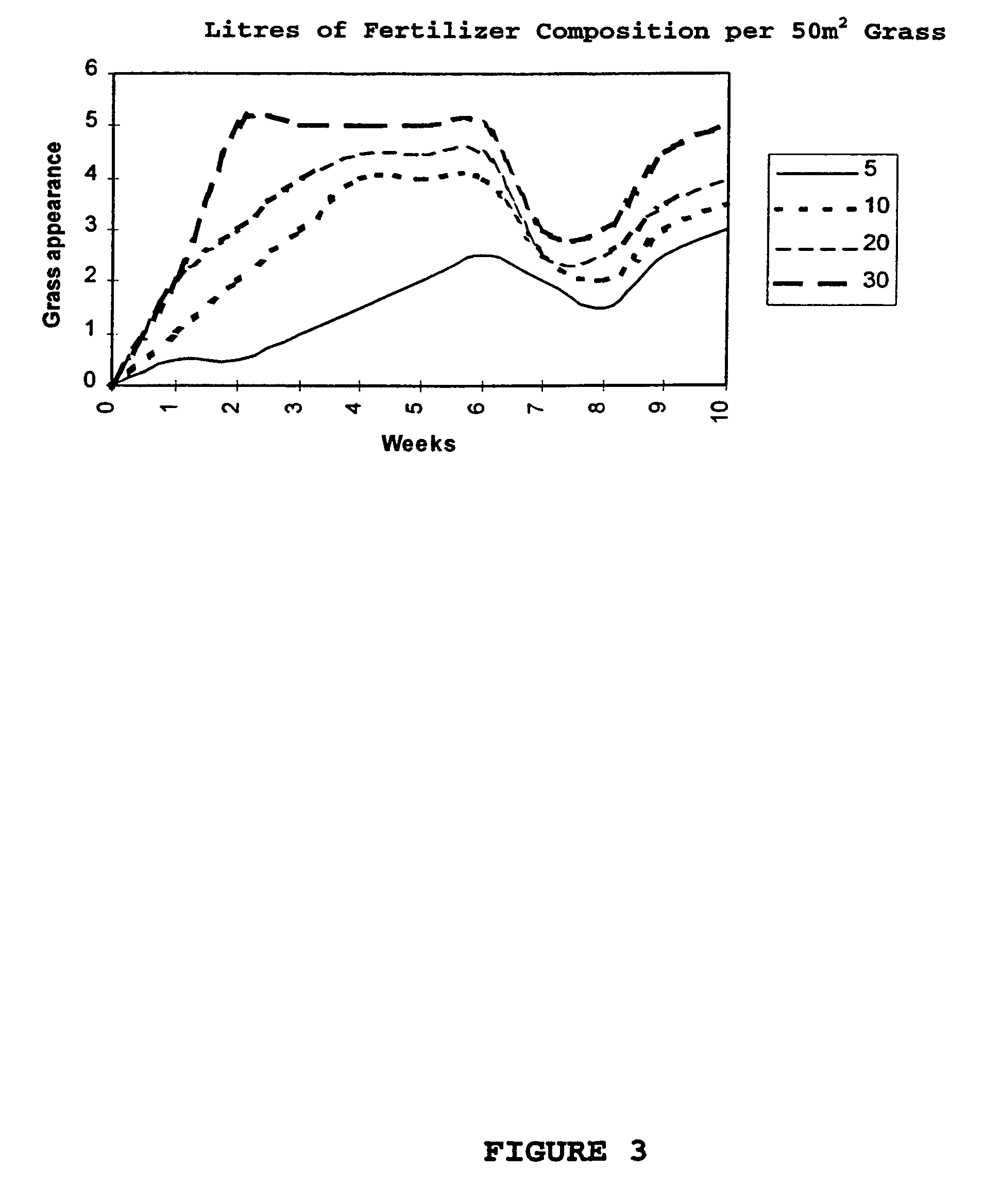

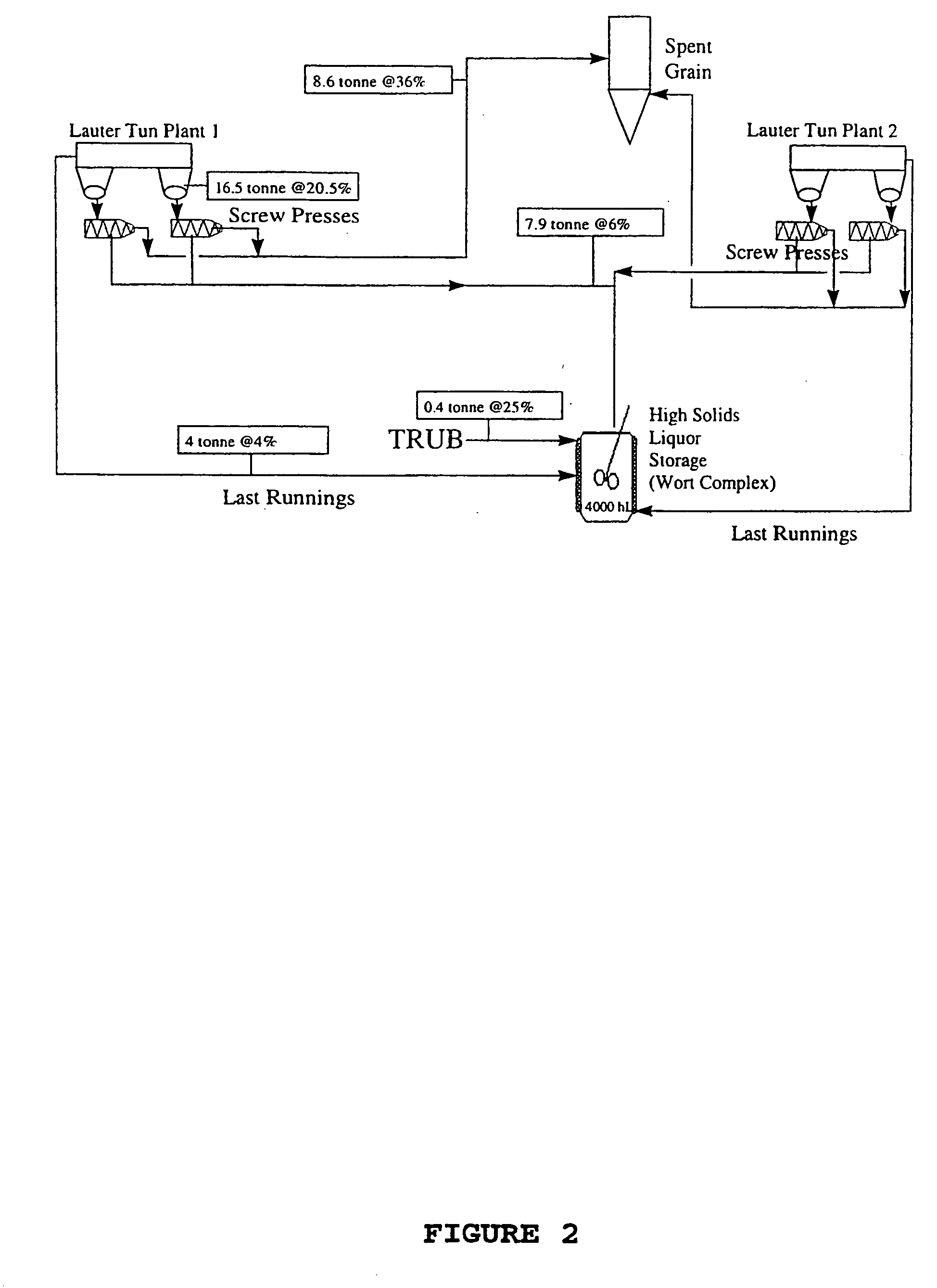

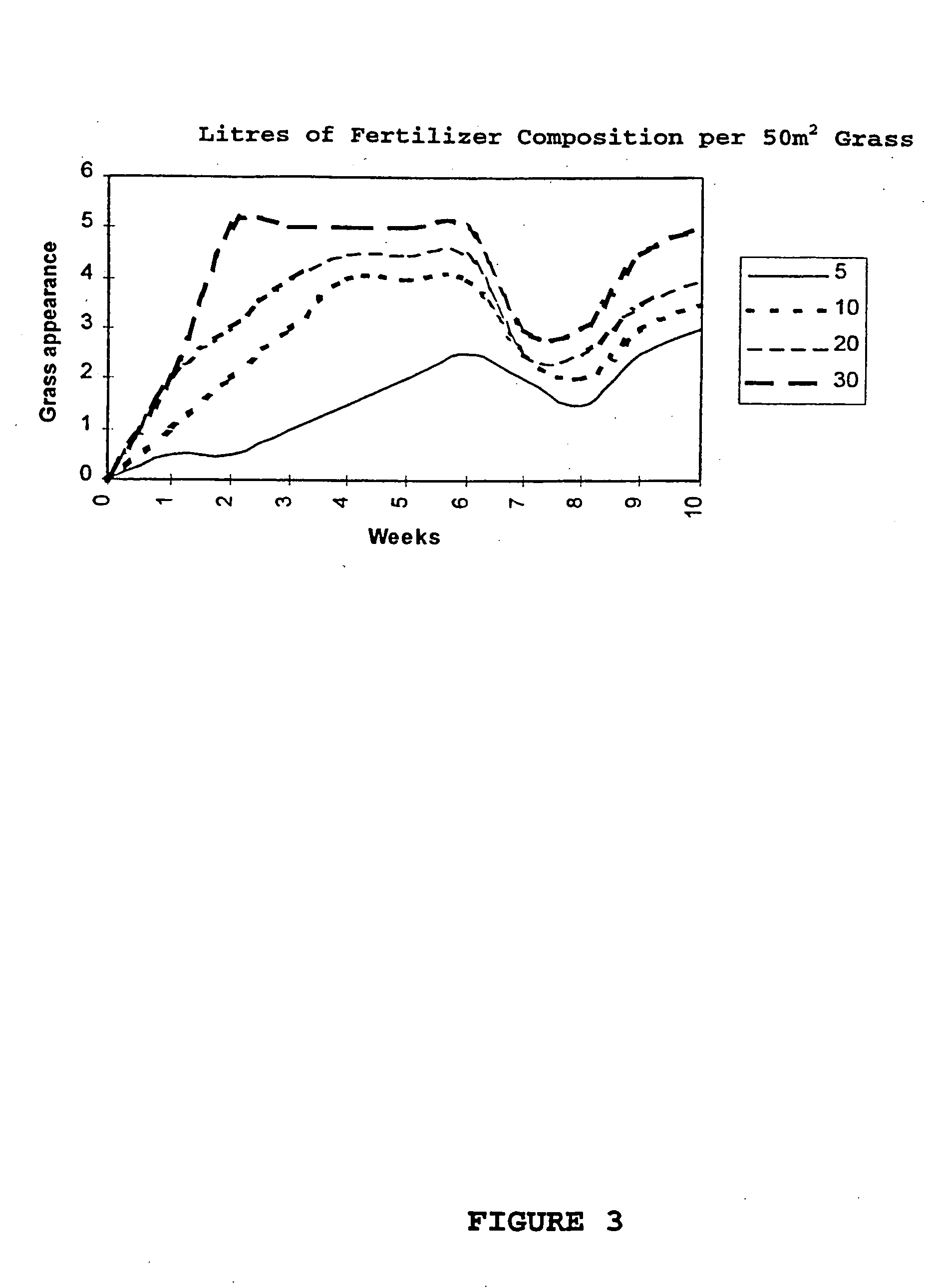

Malt extract or spent grain liquor based fertilizer

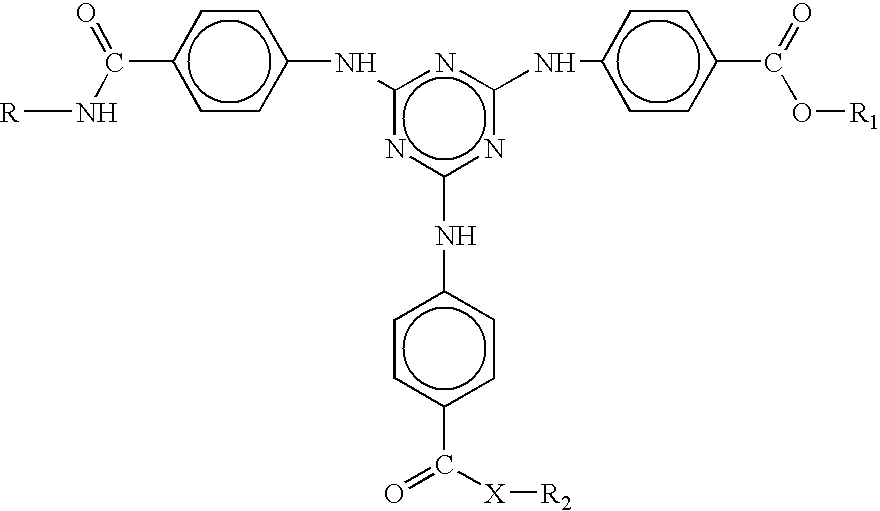

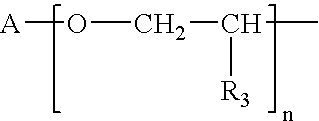

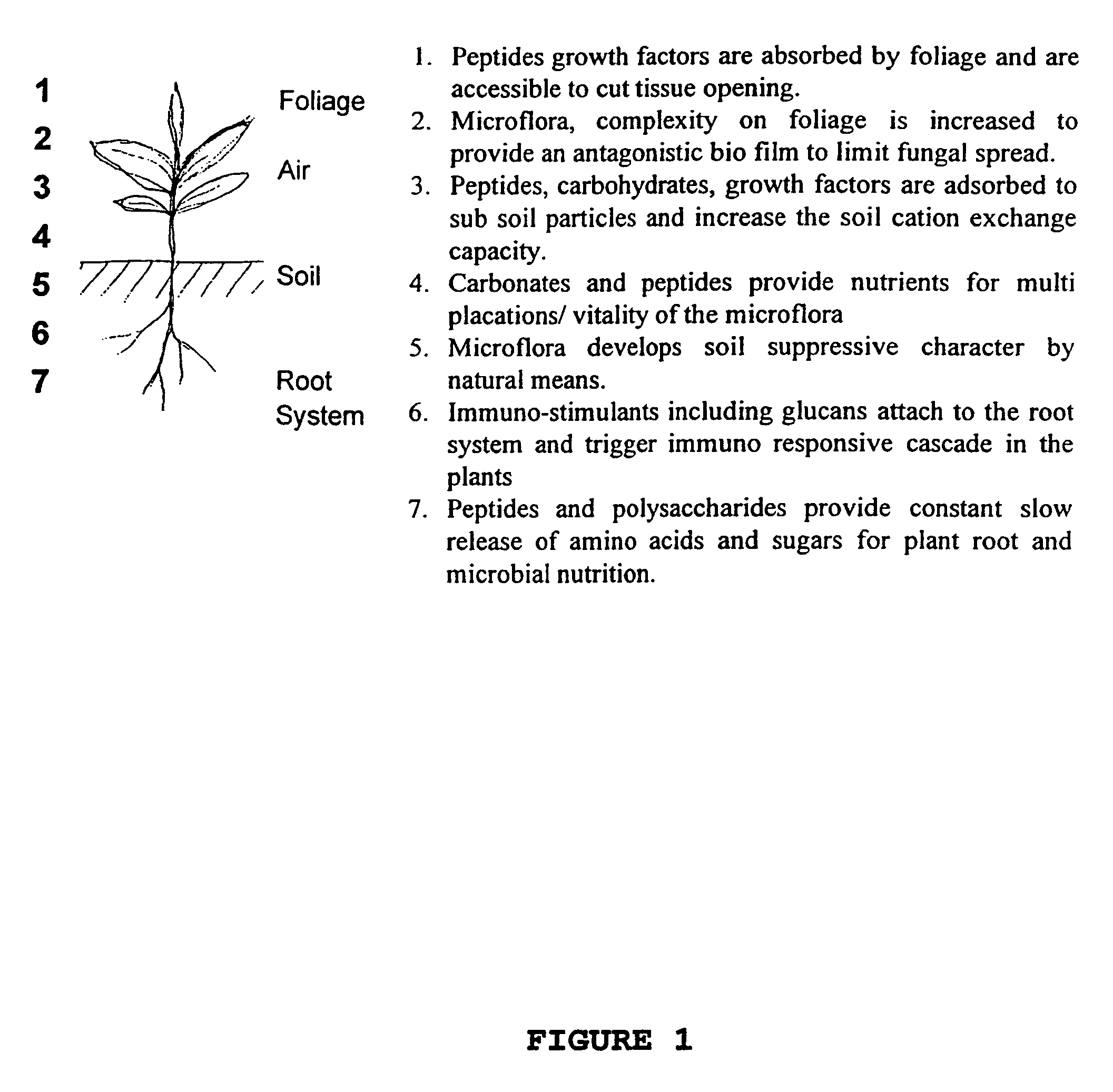

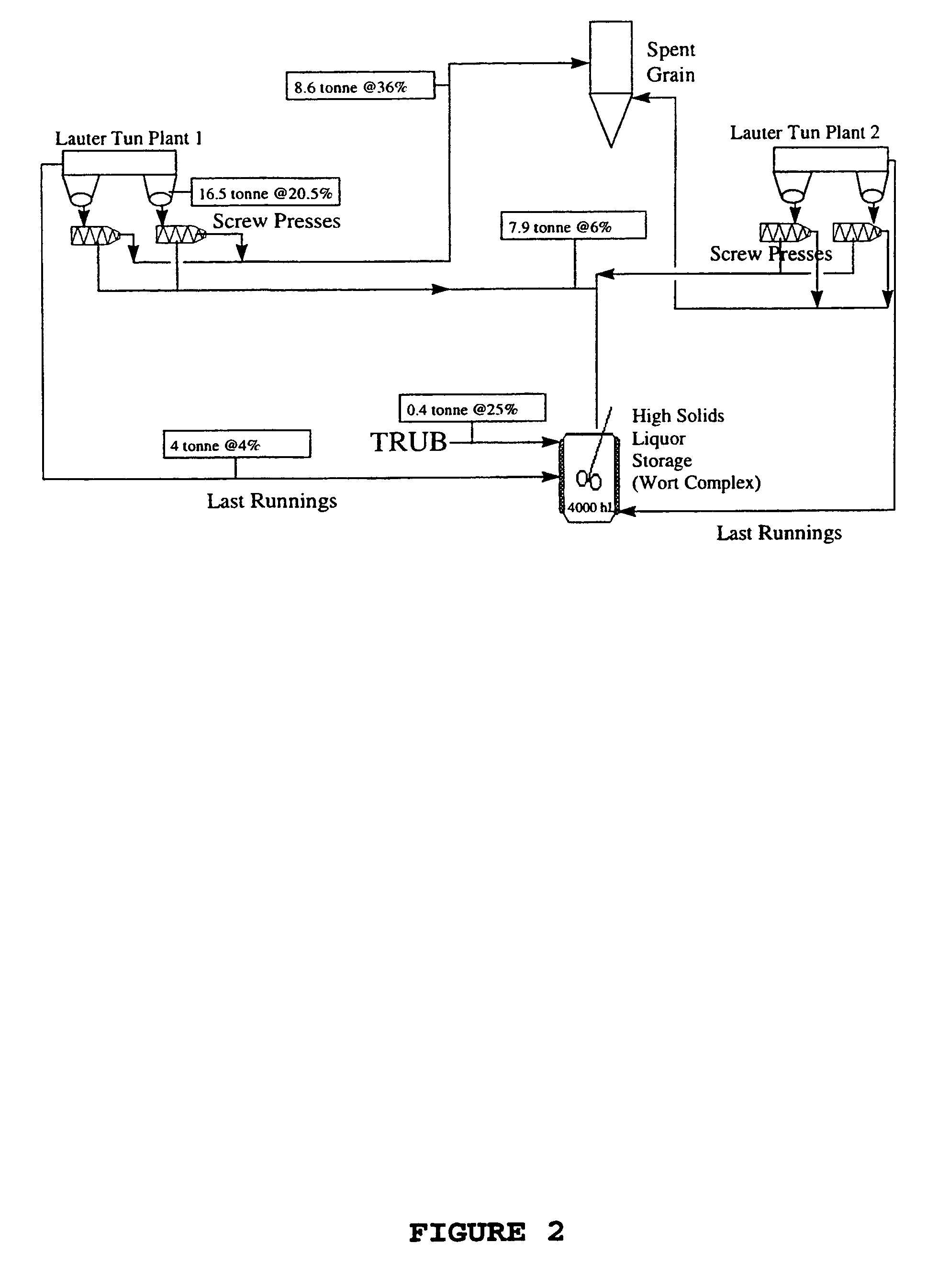

InactiveUS7074251B1Improve the degradation problemImprove soil conditionClimate change adaptationBioloigcal waste fertilisersFungicideMalt Grain

This invention relates to soil conditioner, fertilizer and fungicide compositions. In particular it relates to soil conditioner, fertilizer and fungicide compositions that utilizes by-products from brewing processes, and especially made from malt extract or spent grain liquor. The invention also relates to methods of manufacturing soil conditioners, fertilizers and fungicides.

Owner:CARLTON & UNITED BEVERAGES LTD (AU)

Natural Extract Containing Xanthohumol, and Method for the Production Thereof Products Produced Therefrom

The invention relates to a method for producing an extract containing xanthohumol (XN), which is obtained from toasted cereal products, cereal malt, coffee or cocoa. The XN-content in said extract is in the region of 10 mg / kg-2 g / kg xanthohumol. The use of XN-toasted extracts enables the XN-content of foodstuffs and pharmaceutical products to be increased in a natural manner.

Owner:ARCAINI ANTONIO

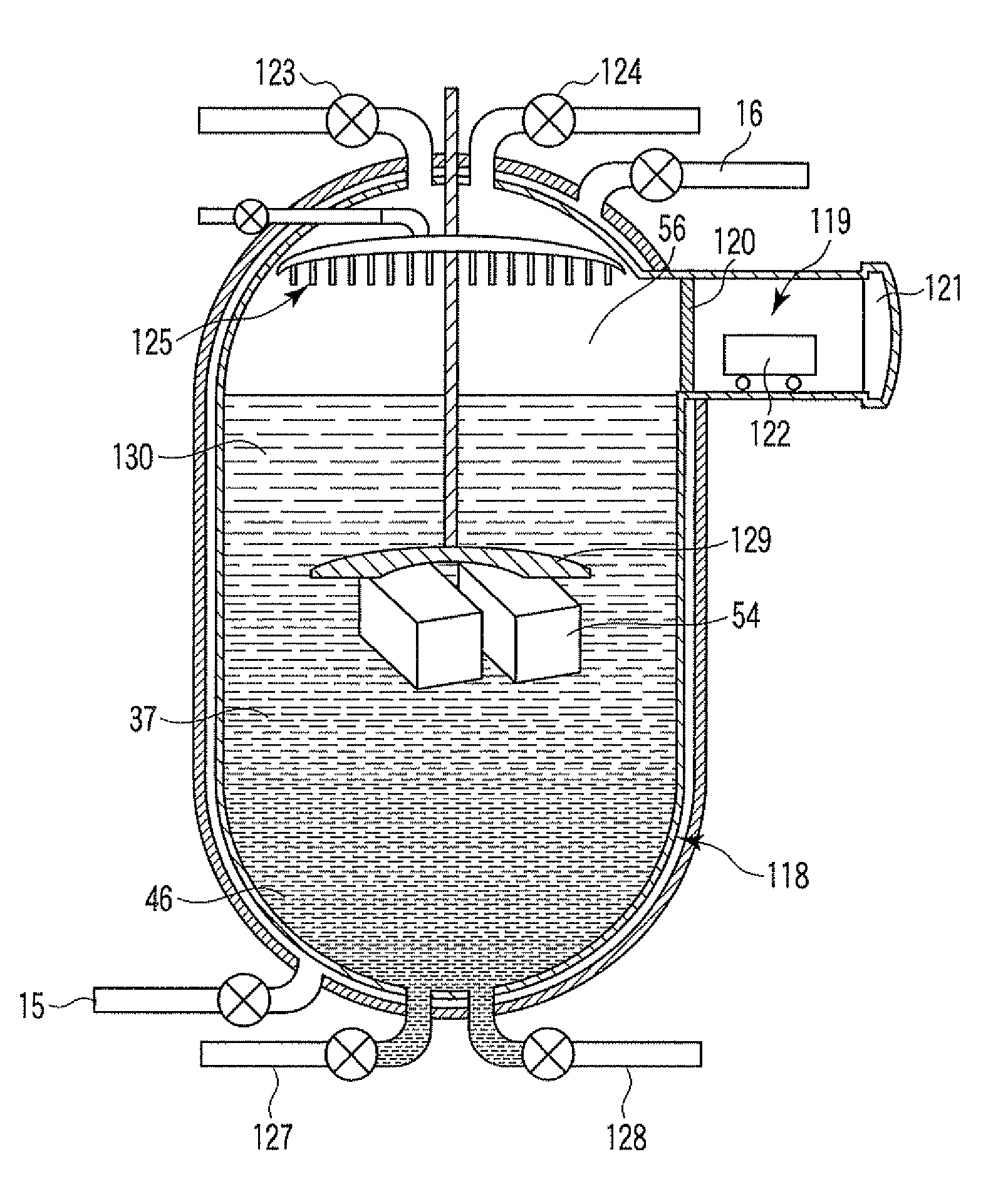

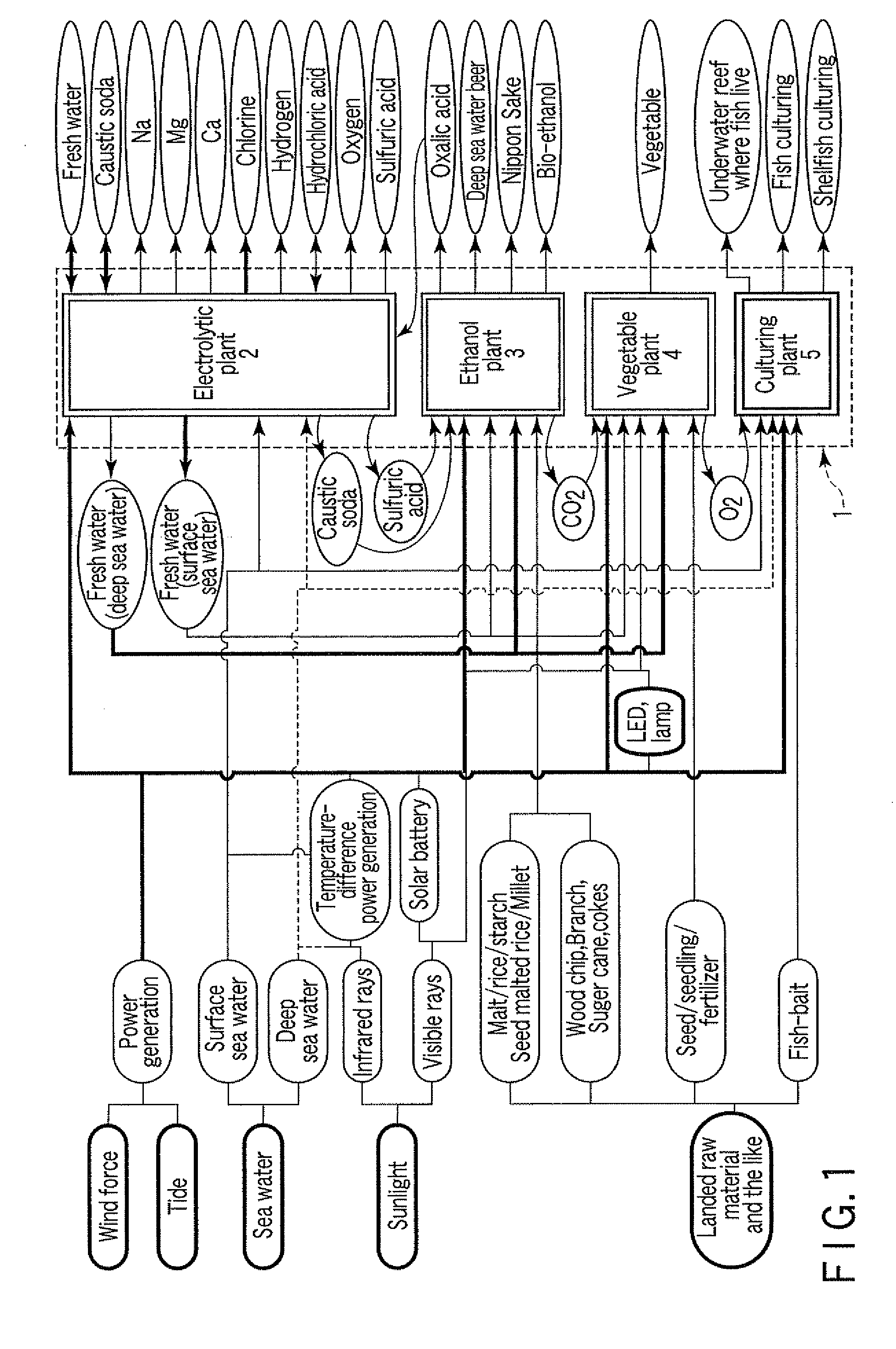

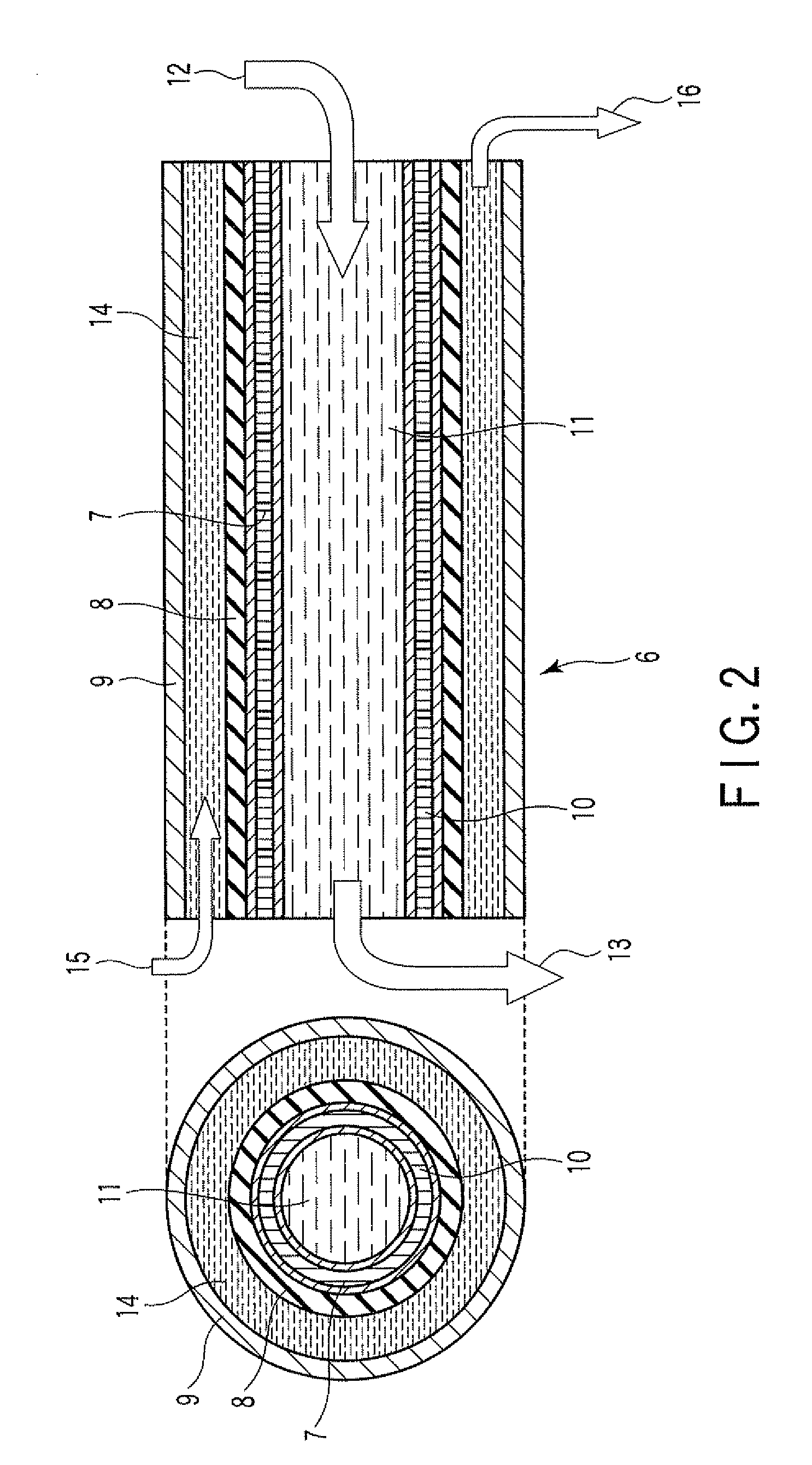

Onsite integrated production factory

ActiveUS20100051450A1Low costDemand is substantialSolar heating energyElectrolysis componentsFresh water organismPotassium

Using electric power obtained by marine wind force and a tide, sea water is electrolyzed to produce fresh water, sodium, magnesium, calcium, potassium, caustic soda, chlorine, hydrochloric acid, sulfuric acid, hydrogen, oxygen or the like, at the same time, unloaded malts, saw dust and the like are fermented to brew ethanol, carbon dioxide generated here is used for photosynthesis to culture vegetables and oxygen generated here is supplied to a fish preserve and an under reef where fish live to culture fishes and also returned to sea water dropped in the concentration of oxygen to suppress the generation of a red tide.

Owner:M HIKARI & ENERGY LAB

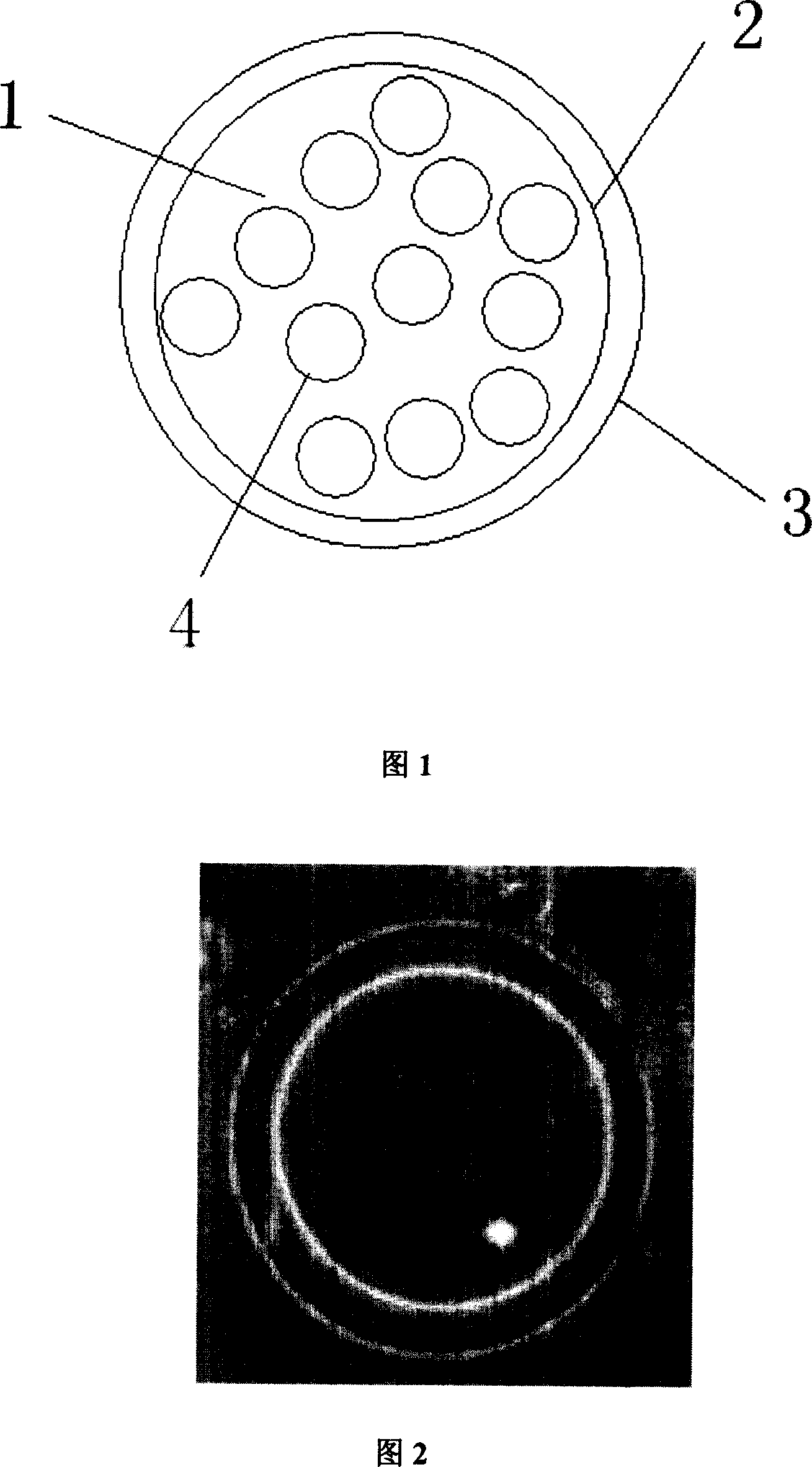

Method for producing liquid core microcapsule by electrostatic spraying

InactiveCN101152623AUniform particle sizeGood encapsulation performanceMicroballoon preparationMicrocapsule preparationCelluloseSprayer

The invention provides a method for preparation of liquid core microcapsule with static sprayer: calcium chloride solution of 2-3 percent is mixed with thickening agent and then is uniformly mixed with core material substance; a certain amount of mixed solution is taken out and then is put into solution containing sodium alginate of 0.6-1.5 percent with static sprayer while adopting a flat needle for adhesive deposite or an injection needle as a nozzle; after capsulated, liquid core sodium alginate microcapsule is filtered and then is cleaned with purified water; then liquid core sodium alginate microcapsule is put into calcium chloride solution for continuous solidification of 5-10 minutes; then microcapsule is filtered and then is cleaned with purified water; at last microcapsule is stored in storage solution with calcium ion concentration of 0.05-0.01 percent. High viscosity malt dextrin or sodium carbonxymethyl cellulose or xanthan gum is adopted as thickening agent. Microcapsule prepared with the invention has liquid core, with uniform particle size, good sacculation performance, simple process and high membrane thickness, therefore, microcapsule has high mechanical strength and can be widely used in the field of pharmaceutical chemical engineering, artificial organ implantation and food processing, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

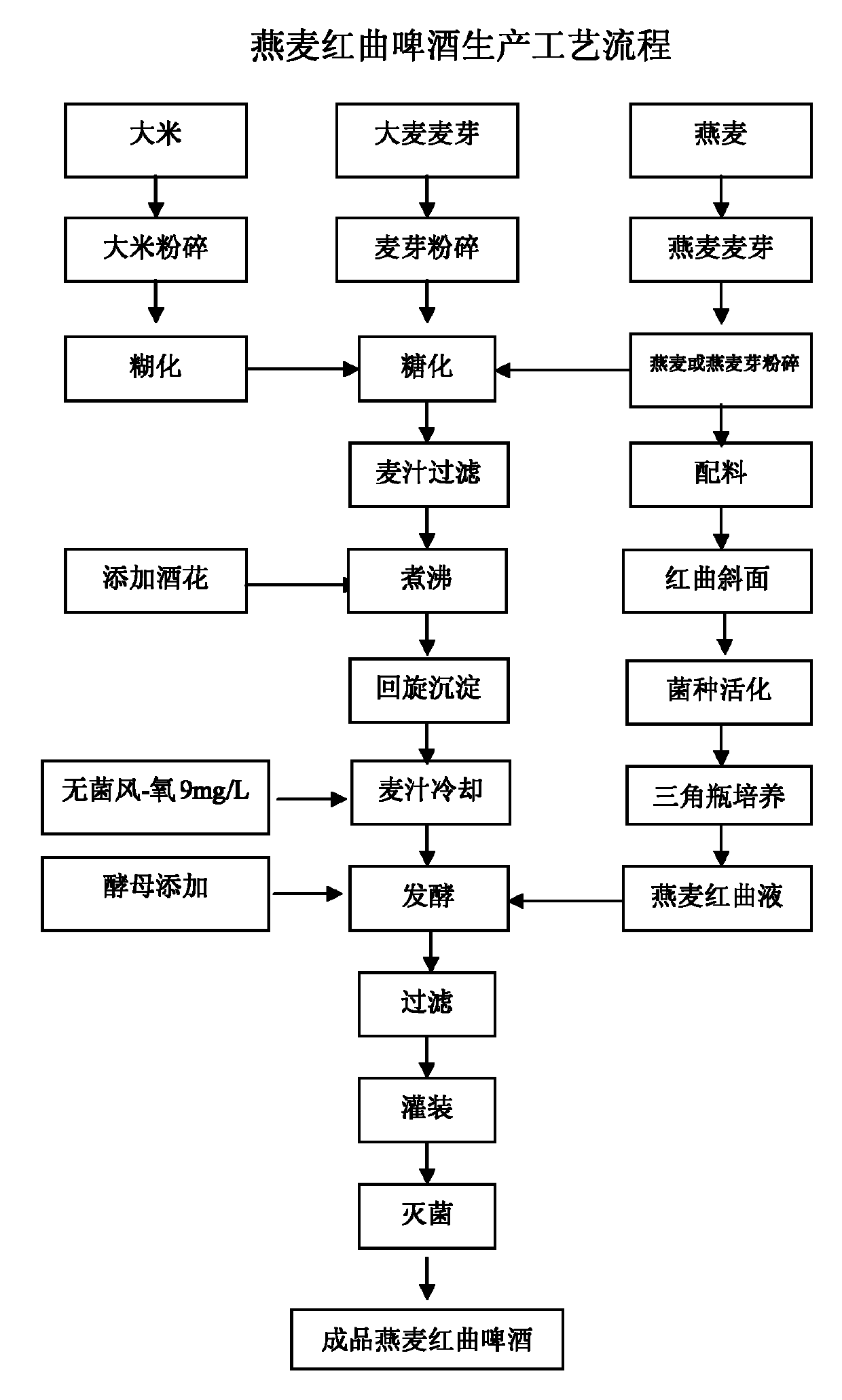

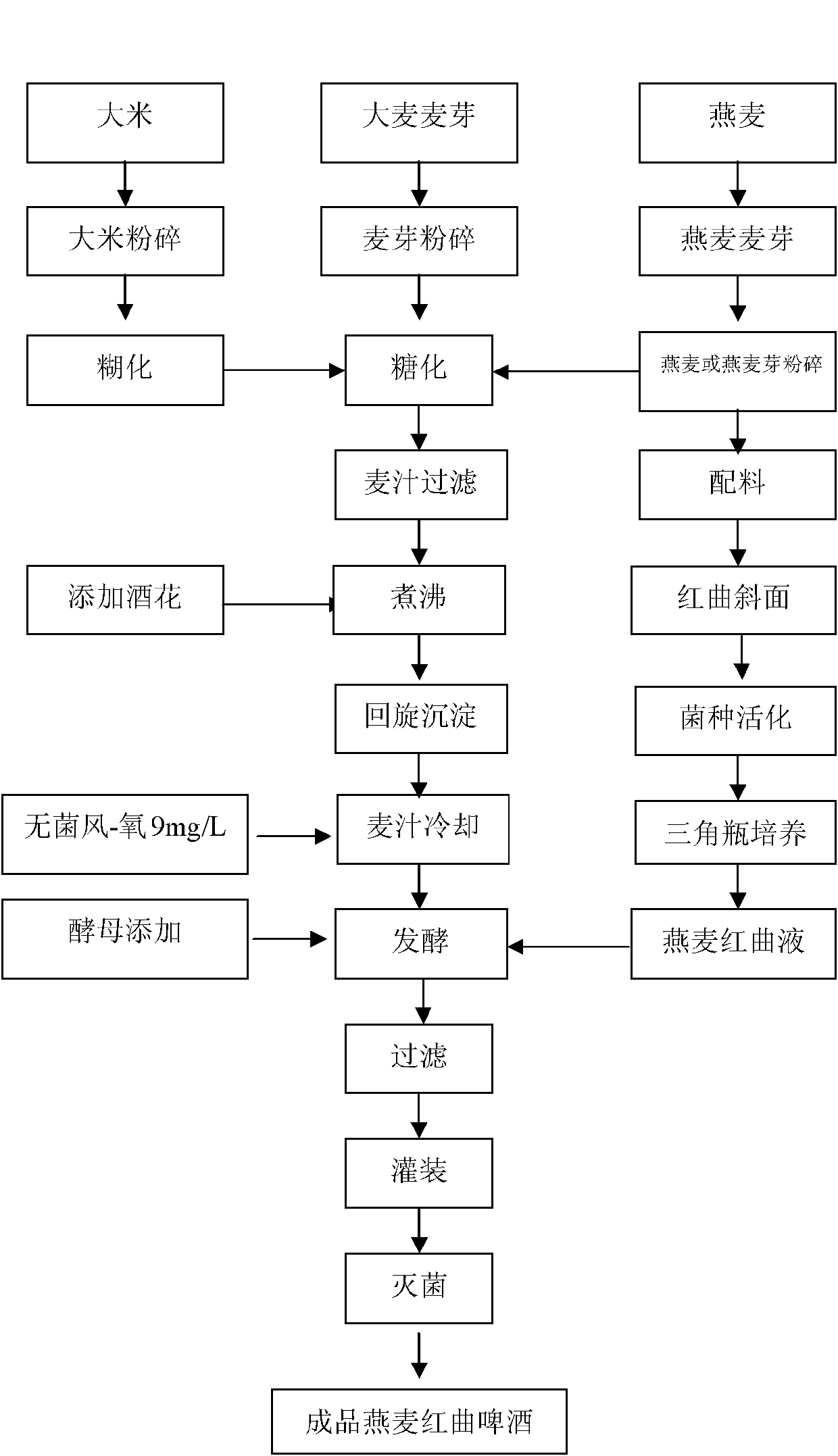

Oat red yeast rice beer and brewing method thereof

The invention relates to oat red yeast rice beer and a brewing method thereof. Barley malt, oat malt, rice, burnt malt, and brewing water are taken as raw materials, and the brewing method comprises the following steps of: preparing wort through pasting, saccharifying, filtering, adding hops, boiling, and cooling; inoculating monascus in the boiled malt so as to prepare oat red yeast rice; crushing, and leaching to prepare the oat red yeast solution; and compounding the wort and the oat red yeast solution, inoculating yeasts for fermentation, and brewing into the oat red yeast rice beer. The oat red yeast rice beer brewed by the invention is red-brown, has pure white and fine foams, maintains the flavor of the traditional beer, contains nutrient components and functional factors of the oat and monascus metabolic products, and improves the nutrient health-care value of the beer. Therefore, the oat red yeast rice beer becomes novel beer which integrates the nutrition and health care, and fills the gap of research and production for the domestic oat red yeast rice beer.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

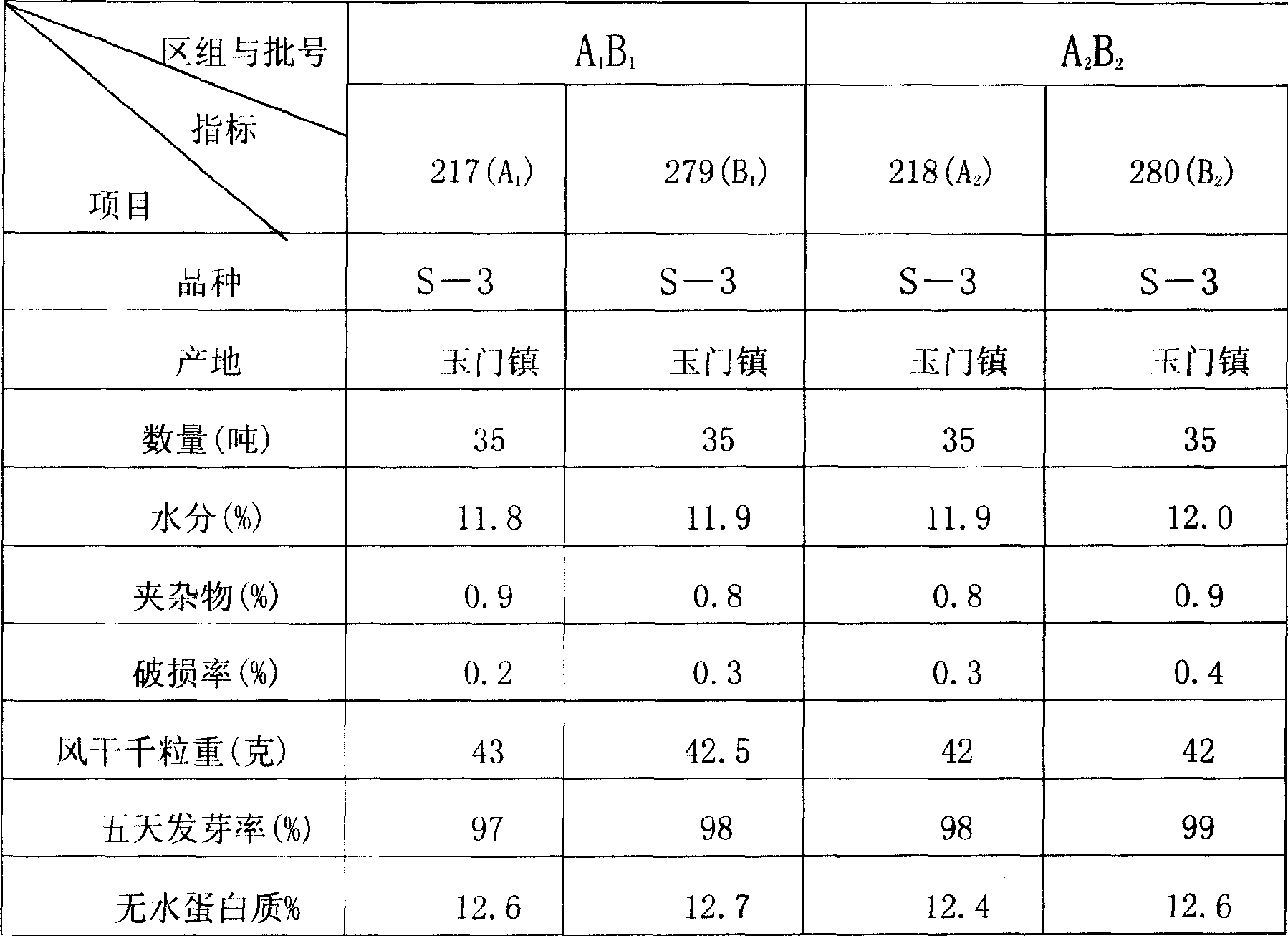

Production of malt

Production of malt is carried out by immersing for wheat grain, germinating and drying. It can supply sufficient hydrolase for saccharification to decompose protein into soluble nitrogen; it can supply alpha-amino-nitrogen and dissolve albuminous cell wall to degrade starch grain. It's controllable, has better physical-bio-chemical reaction and quality.

Owner:邱虎

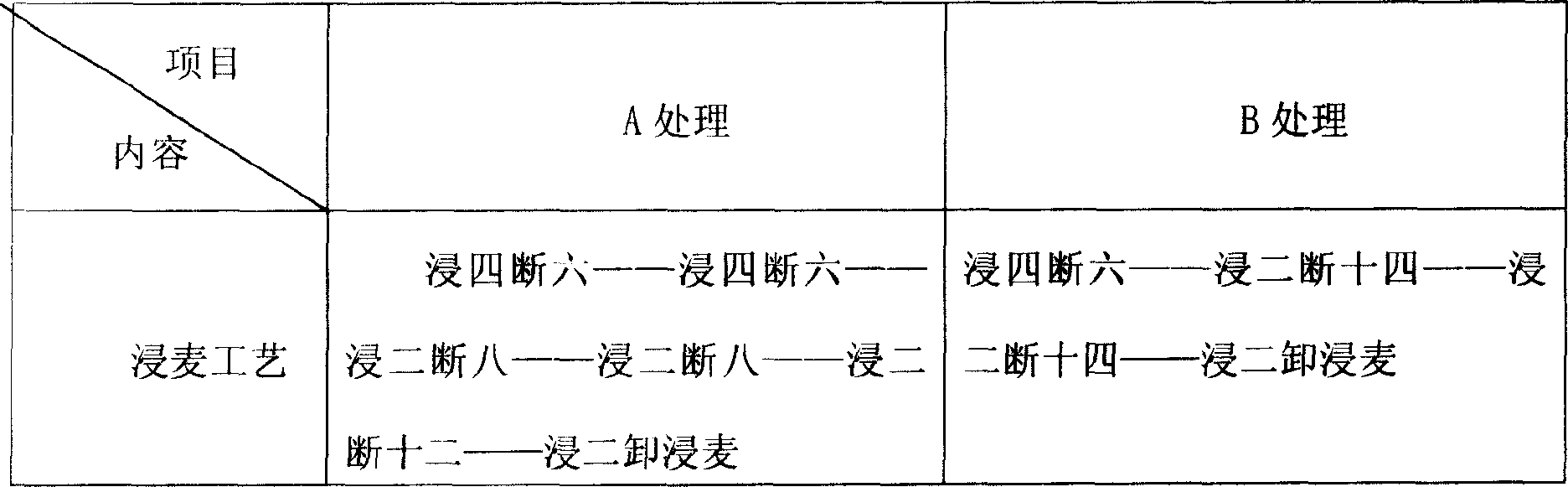

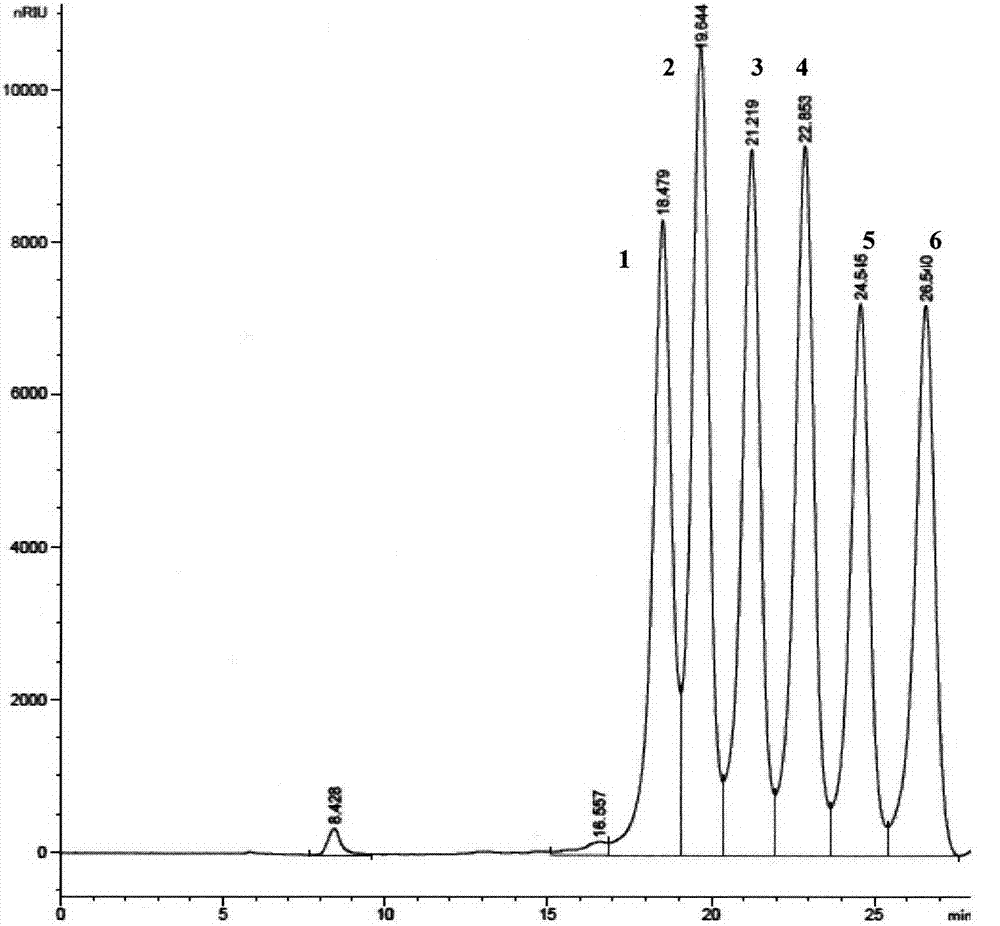

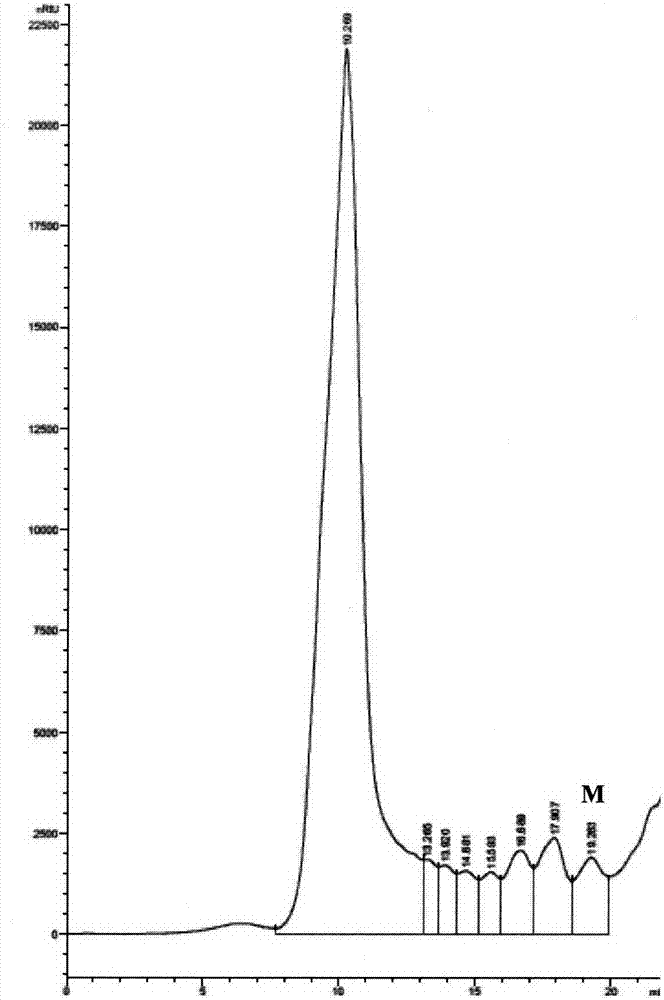

High performance liquid chromatography determination method for identifying starch syrup adulteration in honey

InactiveCN104749290AEasy to handleMeet the testing needsComponent separationMalt GrainOligosaccharide

The invention discloses a high performance liquid chromatography determination method for identifying starch syrup adulteration in honey. The invention aims to find out the determination method for starch syrup adulteration in the honey aiming at a starch syrup adulteration situation in the honey at present, wherein the determination method is simple to operate, easy to popularize and low in cost. Through pretreatment and high performance liquid chromatography detection on a sample, honey mixed with starch syrup has characteristic oligosaccharide 'fingerprint regions' (DP6-13) and a typical 'fingerprint peak' M between maltohexaose and maltoheptaose, and the fingerprint regions and the fingerprint peak are used as indices for determining that the starch syrup is mixed into the honey. The lowest detection limit of the starch syrup adulteration is 1%, and the method is applicable to identification of the starch syrup adulteration of all varieties of honey.

Owner:NANJING TECH UNIV

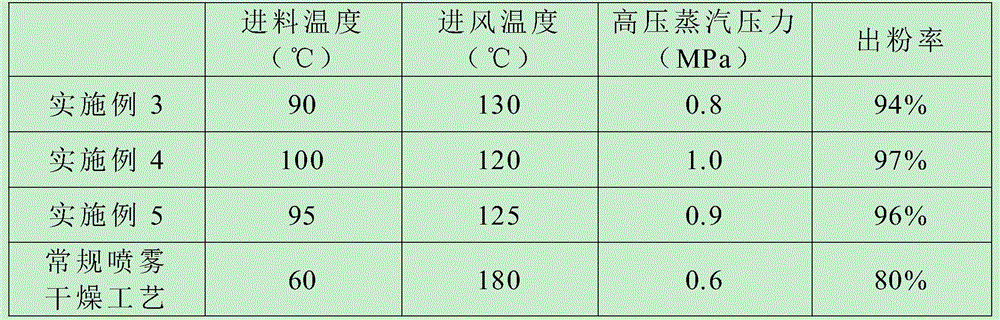

Preparation technique of resistant maltodextrin

ActiveCN1908017AIncrease glucose levelsIncrease the content of dietary fiberFood preparationActivated carbonMalt Grain

The invention discloses a preparing method of resistant malt dextrin, which comprises the following steps: adopting starch as raw material; generating dextrin through acid heat; hydrolyzing through biological enzyme agent; decolouring through activated carbon; desalting through ionic exchanging resin; spraying and drying to obtain the product.

Owner:NANTONG CHANGHAI FOOD ADDITIVE +2

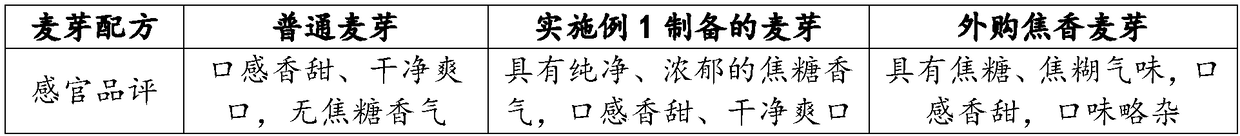

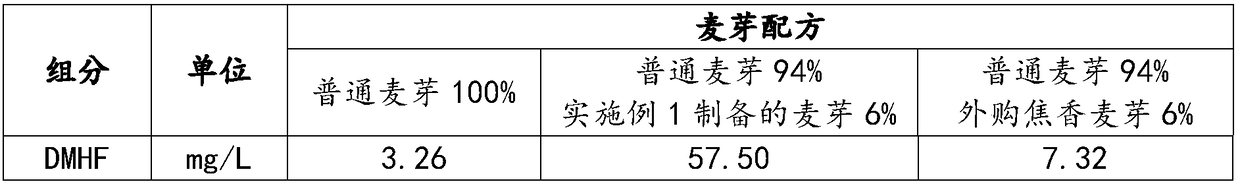

Preparation method of burnt malt with high caramel aroma and beer

ActiveCN108102825AFully stimulate vitalityIncrease concentrationMalt preparationMaillard reactionHordeum vulgare

Belonging to the malt manufacturing field, the invention provides a preparation method of burnt malt with high caramel aroma and beer. The malt preparation method includes the steps of: barley selection, raw material pretreatment, wheat dipping, germination, green malt saccharification, baking and root removal. Specifically, during barley selection, barley with moderate protein content is adoptedas the raw material; the wheat dipping process provides barley grains sufficient internal moisture content to fully stimulate the vitality of the endogenous enzyme system of malt, thus providing sufficient conditions for subsequent acquisition of a Maillard reaction substrate; the saccharification process is carried out in four stages, so that green malt can effectively degrade cellulose, proteinand starch under an appropriate water condition, and the concentration of the Maillard reaction substrate is increased; and then baking is carried out at an appropriate generation temperature of DMHFso as to enrich DMHF product substantially. The obtained malt has significant caramel aroma, the aroma is pure and strong, sensory evaluation indicates that the malt is free of scorched flavor, burntflavor and other foreign and miscellaneous smell, and can be used for production of beer with high caramel aroma.

Owner:TSINGTAO BREWERY

Casting sand mixing auxiliary material

InactiveCN101898226ANo pollution in the processNo smellFoundry mouldsFoundry coresWater basedGlycerol

The invention provides a casting sand mixing auxiliary material. The casting sand mixing auxiliary material is prepared by the following steps of: adding the following raw materials into a reaction kettle to stir and mix and heating the mixed materials to 100 DEG C for 1.5 hours; and then pouring the mixed materials in the reaction kettle out and processing the mixed materials into powder, namely the casting sand mixing auxiliary material. The raw materials comprises the following components in part by weight: 200 parts of modified starch, 1 part of malt sugar, 1 part of glycerol, 4 parts of sodium hydroxide, 8 parts of woodmeal, 10 parts of cast pulverized coal, 4 parts of ferric oxide, 2 parts of carboxymethyl starch and 10 parts of water. The modified starch is prepared by the following steps of: adding one or more vegetable flour into a starch reaction kettle and heating the vegetable flour to 140 DEG C for 1.5 hours; pouring the materials in the starch reaction kettle out and drying the materials through spinning; performing water-based acidizing treatment on the materials; drying and pulverizing the materials into powder to obtain the modified starch. The casting sand mixing auxiliary material has the advantages of good casting effect, no toxicity, no harm and no pollution.

Owner:XINCAI DONGBANG FOUNDRY

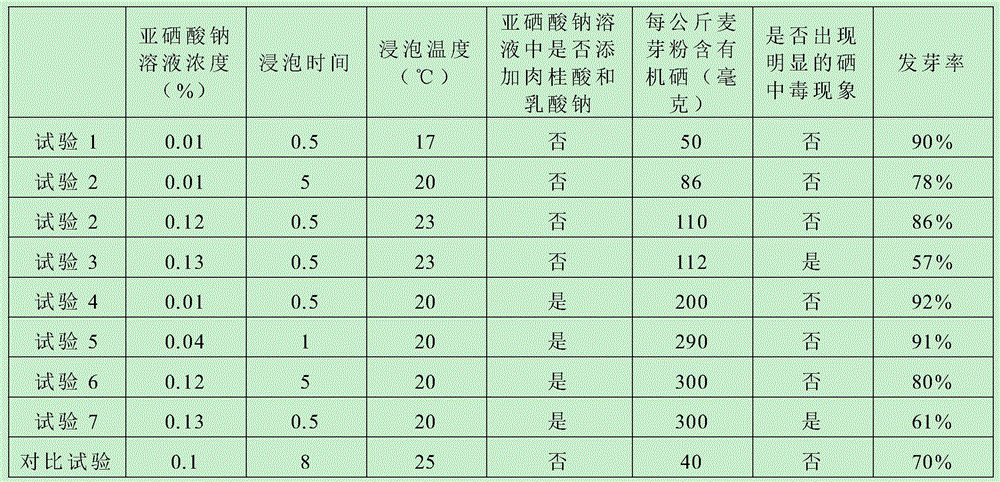

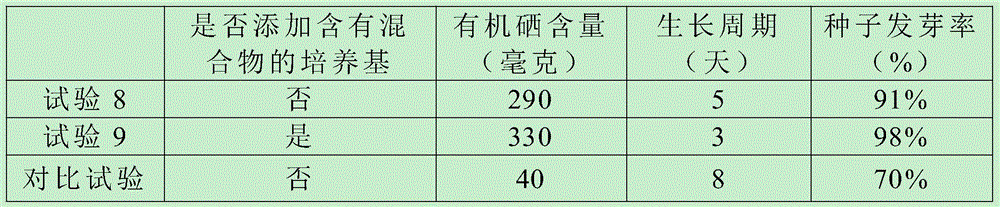

Production process of selenium-rich malt flour

InactiveCN105901521AImprove physical functionGood health effectSeed and root treatmentFood ingredientsMalt GrainHordeum vulgare

The invention provides a production process of selenium-rich malt flour. The production process comprises the following steps of (1) soaking barley seeds in a sodium selenite solution with the temperature being 17 DEG C to 23 DEG C and the concentration being 0.01 percent to 0.12 percent for 0.5 to 5 hours, and performing draining; (2) at the room temperature being 18 DEG C to 25 DEG C, culturing the soaked barley seeds in a culture disc to be cultured, and after the barley seed sprouting, spraying the sodium selenite solution in the first step onto the malt every four hours; (3) when the malt grows a height of 2-4cm, crushing and drying the malt and obtaining the selenium-rich malt flour. The production process has the advantages that the production process is simple; the production efficiency is high; the stability is high; the produced selenium-rich malt flour uses barley seeds as raw materials; the organic selenium content is high; rich vitamin E is contained; the absorption of the organic selenium and the health care effect can be facilitated; the product particles are fine; the quality is high; the taking mouthfeel is good; the selenium-rich malt flour is suitable for long-time administration.

Owner:BEIJING JINZHONG CHENGKUN BIOTECH INST

Combination with antialcoholism action and preparation method thereof

ActiveCN101380433ALess discomfortIncrease alcohol consumptionNervous disorderPill deliveryAgaricAdditive ingredient

The invention discloses a composite which has the effect of anti-inebriation and a preparation method thereof, belonging to the filed of medicine, health-care food and ordinary food. The technical problem to be solved by the invention is to provide the composite which has the effect of anti-inebriation and can increase drinking amount. The composite comprises the following active components by weight proportion: 50-150 parts of flower of kudzuvine, 50-150 parts of radix puerariae, 50-100 parts of chrysanthemum, 10-50 parts of hawthorn, 50-100 parts of malt, and also can comprises 100 parts of Semen Hoveniae, 100 parts of agaric, and 100 parts of alisma orientale. The composite mainly alleviate a hangover, has the efficacy of liver-protection, promoting digestion, strengthening the stomach, clearing damp and promoting dieresis, is suitable for taking before drinking, in drinking, and excess drinking, can significantly increase drinking amount and alleviate discomfort of the stomach after excess drinking.

Owner:SICHUAN YIBIN WULIANGYE GROUP

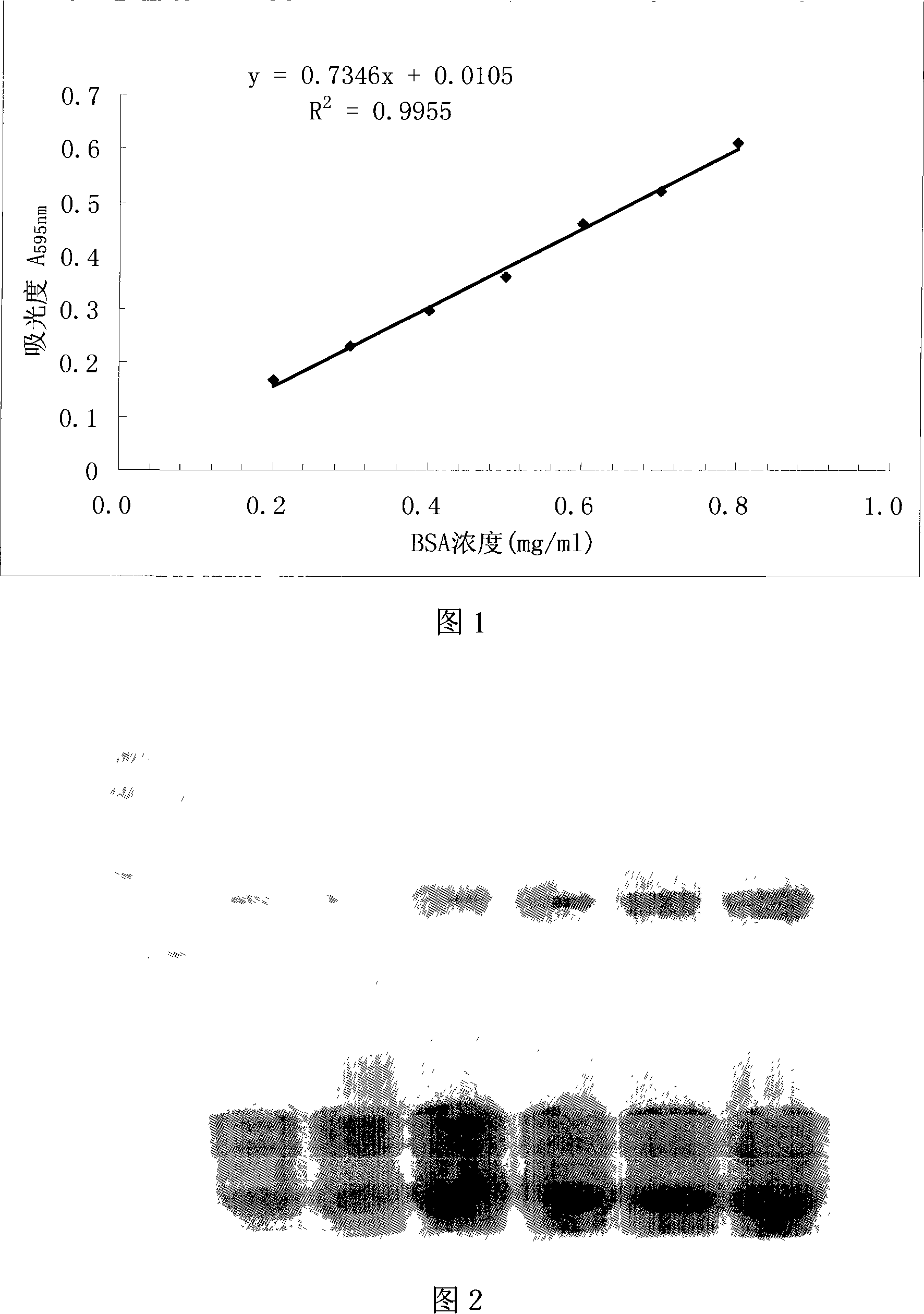

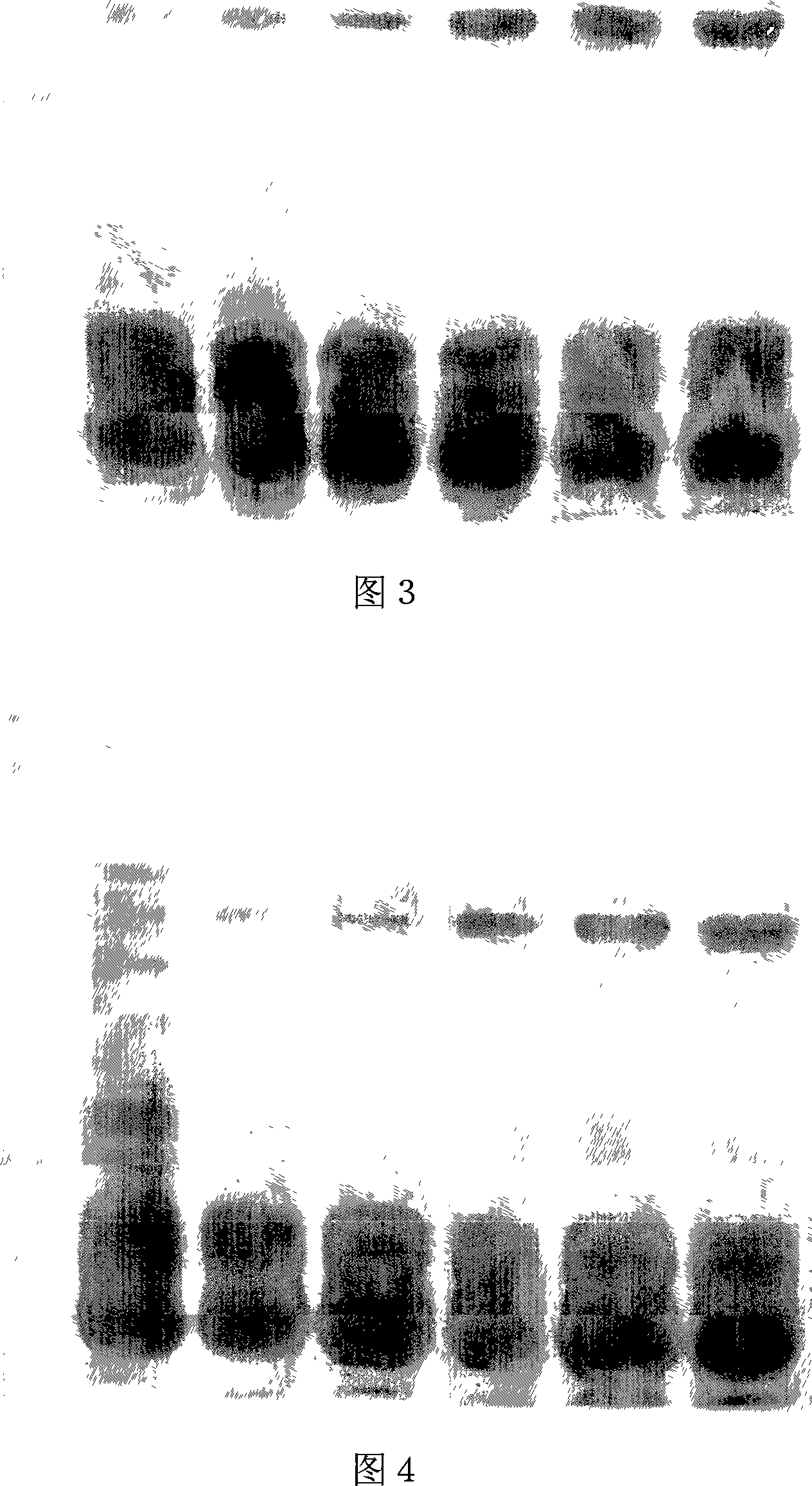

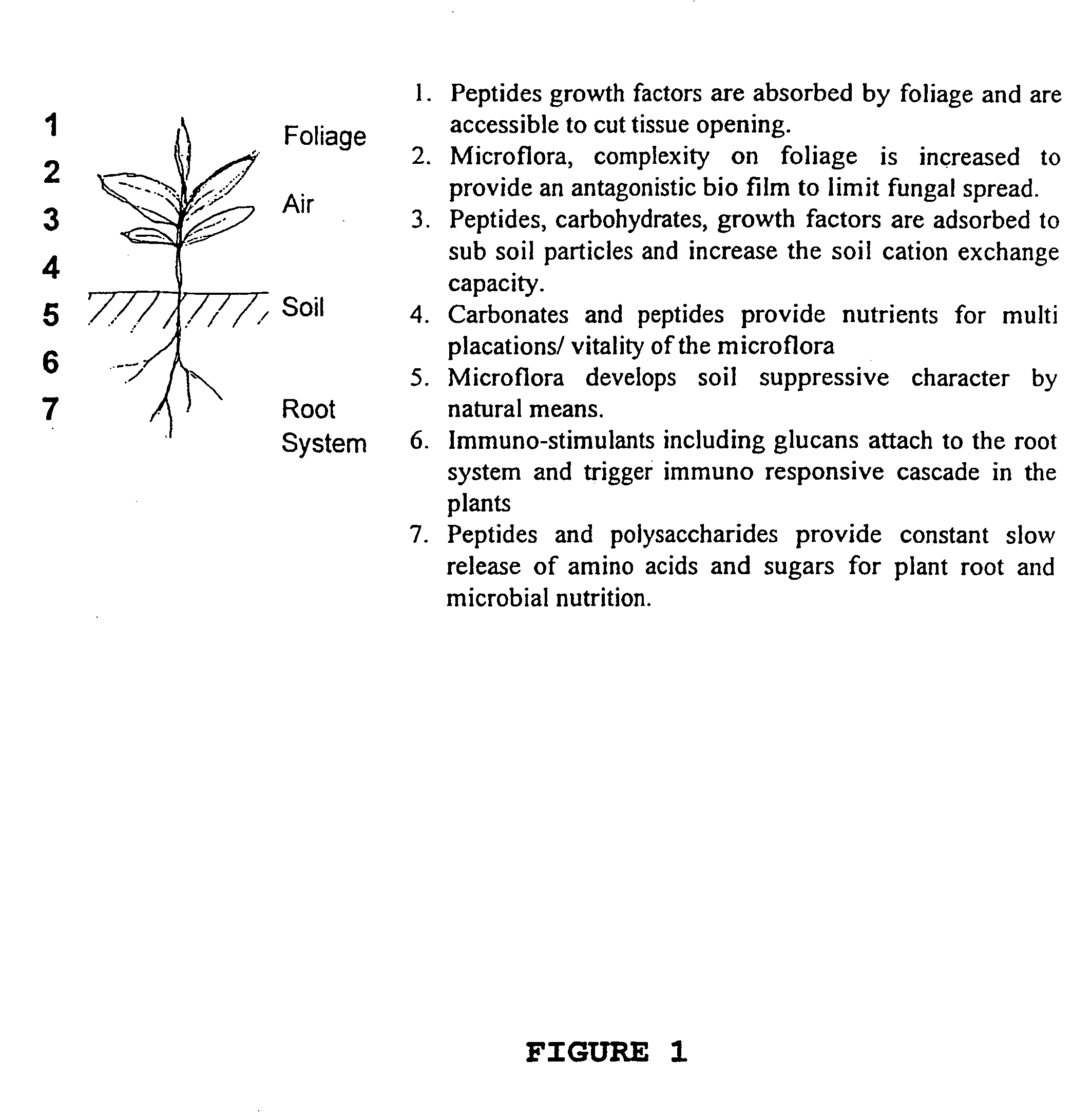

Method for detecting total foam protein component and content of beer barley and malt

InactiveCN101144823AAccurate and intuitive content changesImprove foam propertiesPreparing sample for investigationColor/spectral properties measurementsMalt GrainElectrophoresis

The present invention uses an optimized albumen extracting method, can test the constituent and the content of the foam albumen in the beer barley and the malt using the dodecyl sodium sulfate - polyacrylamide gel (SDS-PAGE) electrophoresis technology, and can detect the change of the constituents and the content of the foam albumen during the germinating process of the beer barley and the malt.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Malt extract or spent grain liquor based fertilizer

InactiveUS20050204791A1Improve the degradation problemImprove soil conditionAnimal corpse fertilisersClimate change adaptationFungicideMalt Grain

This invention relates to soil conditioner, fertilizer and fungicide compositions. In particular it relates to soil conditioner, fertilizer and fungicide compositions that utilizes by-products from brewing processes, and especially made from malt extract or spent grain liquor. The invention also relates to methods of manufacturing soil conditioners, fertilizer and fungicides.

Owner:CARLTON & UNITED BEVERAGES LTD (AU)

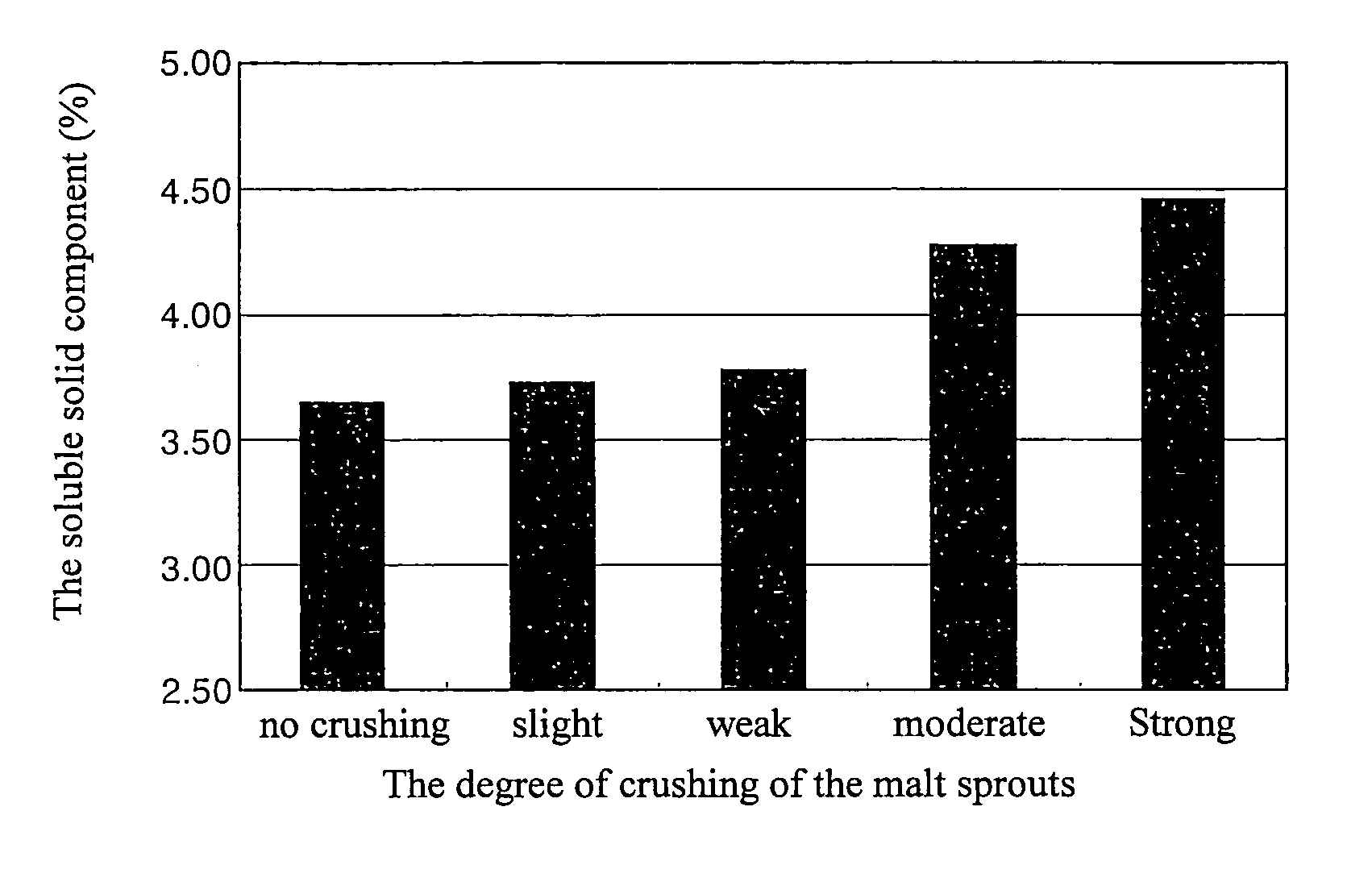

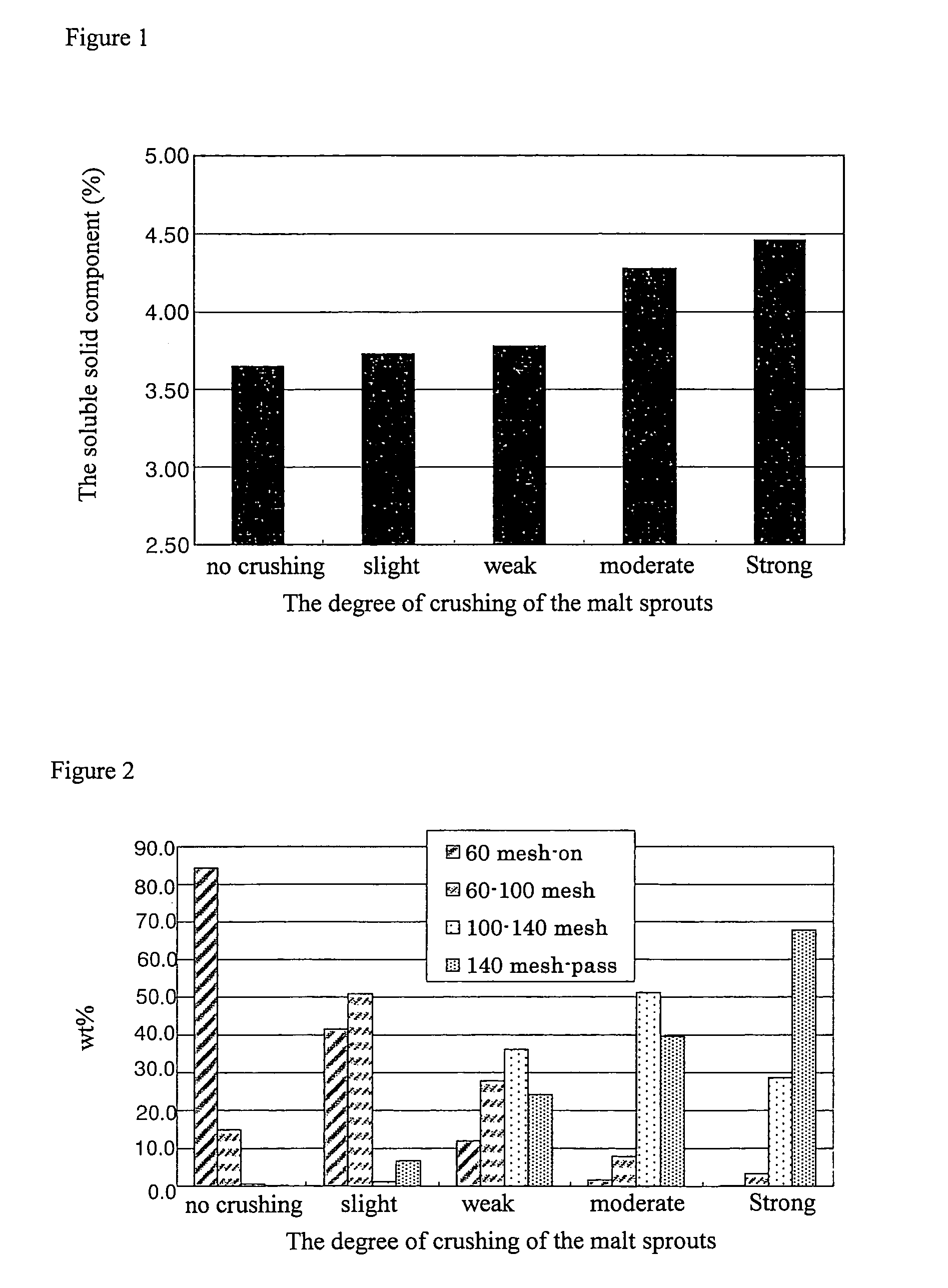

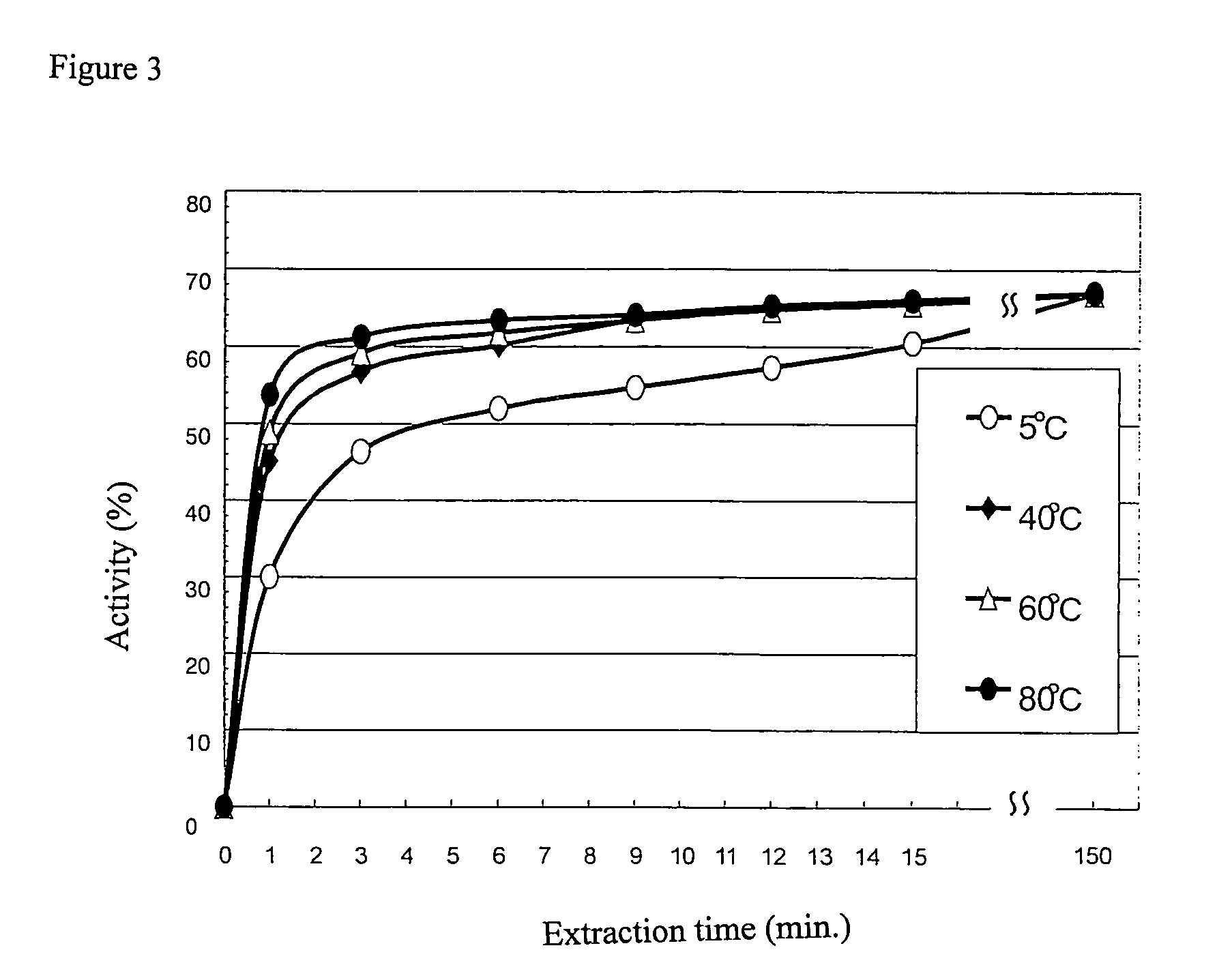

Process for producing food and beverage products from malt sprouts

Owner:SUNTORY HLDG LTD

Methods of enhancing the immune response to autoantigens in mucosal associated lymphatic tissue

InactiveUS20070010859A1Enhance down-regulatory Th immune responseEnhance low dose mucosal tolerancePeptide/protein ingredientsAntipyreticAntigenCo administration

Owner:CODMAN & SHURTLEFF INC

Production method of selenium enriched malt or bean sprout

The present invention discloses the production process of selenium-rich wheat and bean sprout. The production process includes soaking wheat or bean in sodium selenite solution of concentration lower than 0.07 % at temperature 15-30 deg.c, germinating to obtain selenium-rich wheat or bean sprout, and drying at temperature lower than 70 deg.c. The selenium-rich wheat or bean sprout is further milled into selenium-rich wheat or bean sprout powder with certain selenium content depending on the concentration of the sodium selenite solution. The selenium-rich wheat or bean sprout powder connects rich organic selenium and is used as food additive or for medicine purpose.

Owner:田亮

Plant fermentation enzyme powder and making technology

The invention discloses plant fermentation enzyme powder. The plant fermentation enzyme powder is prepared from the following raw materials of salacca zalacca, mulberries, mangosteens, sugar oranges, decaisnea fargesii, waxberry fruits, silver berries, fragile blueberry fruits, loquats, haws, kiwi fruits, passion fruits, guavas, rosa roxburghii, nephelium lappaceum, wax apples, smallanthus sonchifolius, stephania erecta, passiflora foetida, miquel brookweed roots and leaves, lepidium meyenii, white funguses, hericium erinaceus, black funguses, shiitake mushrooms, soybean sprouts, malt, spinach, tomatoes, Chinese yam, carrots, broccoli, black rice flour, millet flour, sweet potato flour, coix seeds, Chinese wolfberry fruits, radish seeds, purslane herbs, endothelium corneum gigeriae galli, honeysuckle flowers, mulberry leaves, poria cocos, plantain herbs, angelica keiskei, motherwort, semen cassiae, licorice roots, pummelo peel, hemp seeds, curcuma zedoaria, nutgrass galingale rhizomes, radix angelicae pubescentis, honey, brown sugar, compound probiotics, and peptone. The invention further discloses a making technology of the plant fermentation enzyme powder. The plant fermentation enzyme powder is multiple in functions, fully guarantees activity of enzymes and facilitates human health.

Owner:江西仁仁健康产业有限公司

Composition having stomachic, liver-care, and hypermnesia functions and the preparing technique

The invention discloses health products or drug combinations and preparation techniques and quality detection methods with functions of strengthening the stomach, nourishing the liver and improving the memory. The health products or drug combinations are composed of root kudzuvine, haw, malt, mum, mulberry leaf and lotus leaf. During preparing the health products or drug combinations, different components are processed by distillating, filtering, immersing, decocting, condensing, decompressing to make the effectine drug ingredients into full play. The invention also provides quality control methods for components identification and assay of the health products or drug combinations. The health products or drug combinations have functions of strengthening the stomach, nourishing the liver and improving the memory.

Owner:谢鸣

Malt preparation lowering beta-dextran in malt

The invention provides a malt preparation method which can lower the content of beta-hyskon in malt. The method mainly comprises the following steps: A. malt immersion: a small amount of NaOH can be added to lower active levels of microbes, and gibberellic acid is added to treat barley, which can further speed up the related enzymic reaction, and the ventilation and the oxygen supply must be paid attention in the process of the malt immersion and the germination, which facilitates the generation of beta-dextranase, endopeptidase and alfa-amylase; B. germinating: firstly intermediate temperature air, secondly high temperature air and thirdly low temperature air are continuously transferred to supply fresh air; and C. drying: the low temperature long-time moisture expelling method adopted can continuously exert effects of the beta-dextranase and other enzymes. In the invention, three steps of preparing the malt are organically combined, all indexes of the malt are in a proper range, so that the high quality malt which has the advantages of lower content of beta-hyskon and good indexes of leaching rate, ammonia nitrogen and glycation rate, etc. can be prepared.

Owner:HUBEI JINWEI MALT

Preparation method of trehalose anhydrous

ActiveCN104262413ASolve technical problems that are difficult to get rid ofKeep drySugar derivativesDispersed particle separationChromatographic separationHigh concentration

The invention relates to a preparation method of trehalose anhydrous. The preparation method comprises the following step: by adopting a trehalose reaction solution prepared from high-concentration malt syrup by enzymatic conversion as a raw material, performing processes such as enzymolysis and impurity removal, activated carbon decolorization, ion exchange, simulated moving bed chromatographic separation and belt-type vacuum continuous drying and dehydration to prepare series products containing trehalose anhydrous with the purity of 50-99.5wt% so as to meet the special requirements of trehalose anhydrous as a drying agent in different fields of drying. A trehalose anhydrous production process disclosed by the invention is simple and low in cost, and can be used for saving energy and reducing consumption in a production process.

Owner:BAOLINGBAO BIOLOGY

Foliar fertilizer and preparation method thereof

The invention discloses a foliar fertilizer composed of traditional Chinese medicines, vitamin, and trace element, prepared by maybush, malt, pantotrichum, epimedium, vinegar, vitamin, nitrogen, phosphorus-potassium, calcium, manganese, copper according to a certain proportion. The preparation method is as follows: crushing maybush, malt, pantotrichum, epimedium; using vinegar to dip materials three times; putting materials into the pan with opposite openings; using mud to seal the hole; heating and burning to form carbon; pressing the burned carbon into fine powder; mixing with trace element and vitamin uniformly; preparing powder or granular formulation. After the foliar fertilizer is applied on the rice, the rice yield is increased by 250-350 kg in every mu (6 acre); the wheat yield is increased by 100-200 kg in every mu (6 acre); the rape yield is increased by 50-100 kg in every mu (6 acre); the corn yield is increased by 100-200 kg; the yield-increasing effect is obvious.

Owner:秦祖模

Germination technology of plant seed

InactiveCN101606453AImprove germination rateUniform temperatureGerminating apparatusVacuum pumpingMalt Grain

The inventing relates to a germination technology of plant seed, in particular to an industrialized germination production technology of crop seeds, such as rice sprout, malt and the like, and a germination technology before sowing plant seed. A wet breathing germination technology is performed by adopting water injection and drainage, a dry breathing germination technology and a double breathing germination technology are performed by adopting vacuum pumping, by adopting the properties of water, such as high thermal capacity, shapelessness, low viscosity and easy flowing, water injection and drainage and vacuum pumping operation processes are performed to plant seeds in a container through water temperature controlling, to enable the plant seeds to obtain moisture, temperature and fresh air required by germination, to exhaust the waste gas released by the seeds during the germination process, and to rapidly and efficiently accomplish the seed germination process. The technology has the advantages that the germination cycle is short, the operation is simple, the production costs of dry and wet breathing methods are extremely low, the germination percentage can be larger than 95 percent under the conditions that no germinator and nutrient solution are added, and the technology is suitable for the large-scale industrialized production.

Owner:蔡宝昌 +1

Food grade antioxidant and flavorant from roasted wheat malt

InactiveUS20060280851A1Prevent rancidityImprove flavor and flavor stabilityCosmetic preparationsFood ingredient as antioxidantFlavorFood grade

A food grade antioxidant and a baked food flavorant is isolated from roasted wheat malt containing bran. The germinated wheat is roasted until the malt's naturally occurring enzymes are substantially destroyed. The roasted wheat malt is milled into fine particles that may be physically separated into a fraction that is primarily homogeneous bran particles and into a fraction that is primarily heterogeneous endosperm and germ particles. The bran fraction is useful as a food flavorant and the endosperm and germ fraction may be used directly as an antioxidant for oils and fats, or foods, pharmaceuticals and cosmetics containing oils and / or fats or the antioxidant may be chemically extracted. The milled homogeneous bran and heterogeneous endosperm and germ particles may be recombined in customized proportions and thus used as a dually functional food ingredient.

Owner:AGRI FOOD PURSUITS

Production of fungal extracellular immune stimulating compounds

InactiveUS20050163800A1Improve isolationEasy to processBiocideOrganic active ingredientsLiquid mediumCell culture media

A process is described for the production of an immunostimulant by submerged cultivation of Lentinus edodes in which mycelium from agar plates or a fermentation broth is added to a liquid medium in a shake flask or a bioreactor containing nutrients such as malt extract, yeast extract, peptone and glucose having access to air or to which air is added, and which is kept in constant movement at approx. 28° C. At the proper conditions, there will be an increase in the production of extracellular lentinan, which is shown to be a better immunostimulant than intracellular lentinan. The extracellular product is precipitated from the growth medium by means of methods for the precipitation of microbial polysaccharide.

Owner:MEDIMUSH

Treating method for suppressing hair growth

InactiveUS7211278B2Excellent hair growth inhibitory effectStrong growth inhibitory effectCosmetic preparationsBiocideMalt GrainChymotrypsin

treating method for hair growth inhibition, which comprises administering (A) the extract of a plant of the family Juniperus or a malt. In addition, the present invention relates to a dermatologic composition for external use, which comprises (B) an elastase inhibitor or neutral endopeptidase inhibitor, and the above-described component (A) and / or (C) at least one proteolytic enzyme selected from the group consisting of papain, trypsin, chymotrypsin, pepsin, bromelain, ficin and pancreatin.

Owner:KAO CORP

Process for producing low-alcoholic beer-like drink and low-alcoholic beer-like drink

InactiveUS20060016513A1Great tasteSuperior in foam propertyLiquid fillingBeer fermentationMalt GrainAlcoholic spirits

It is intended to provide a processing method for producing beer-like low-alcoholic beverage by using usual beer and / or low-malt beer without using any special systems other than those commonly employed in producing beer. Beer and / or low-malt beer obtained by the process commonly employed in producing beer are diluted with carbonated water to lower the alcoholic concentration to less than 1%. After adding additives capable of imparting visual and tasty characteristics thereto, beer-like low-alcoholic beverage can be obtained.

Owner:SAPPORO BREWERIES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com