Production process of selenium-rich malt flour

A technology of selenium-enriched malt powder and production process, which is applied in the field of food processing, can solve the problems of unstable production process, unguaranteed product quality, low organic selenium content, etc., achieve high production efficiency, improve gastrointestinal digestion ability, and simple operation and control convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

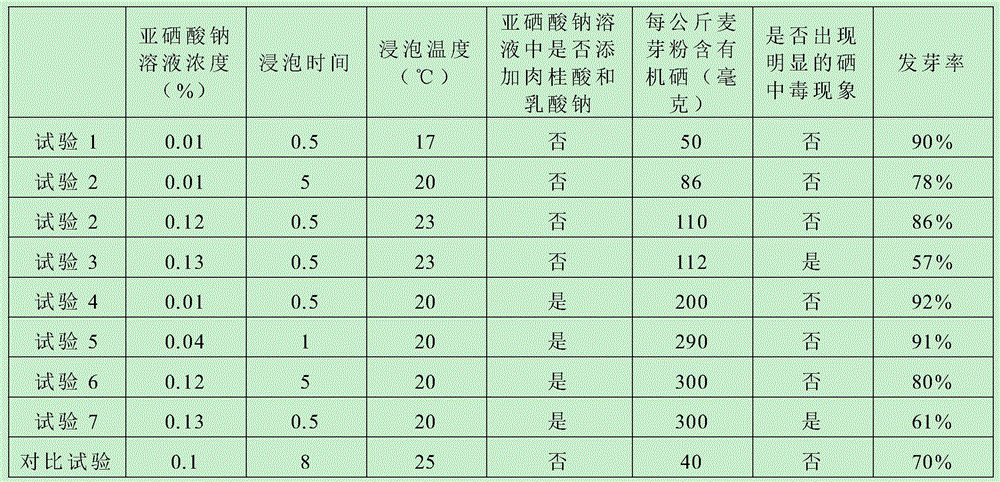

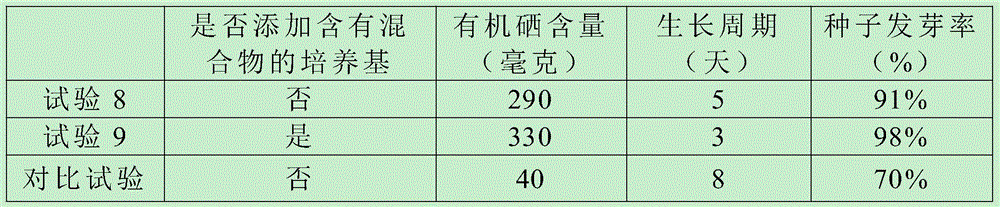

[0034] Soak the barley seeds in a sodium selenite solution with a temperature of 17°C and a concentration of 0.01% for 0.5 hours, and drain; place the soaked barley seeds in a culture tray at a room temperature of 18°C for cultivation, and the barley seeds germinate Finally, spray the malt with the above-mentioned sodium selenite solution every 4 hours; when the height of the malt grows to 2cm, first air-dry the malt at room temperature for 24 hours, and then dry it at 85°C for 20 hours, so that the water content of the malt is less than 5%. Then it is pre-crushed in a pulverizer to about 40 meshes, and then sent to a superfine pulverizer for pulverization to obtain selenium-enriched malt powder.

Embodiment 2

[0036] Soak barley seeds in a sodium selenite solution containing 0.01% sodium selenite, 0.02% cinnamic acid and 0.01% sodium lactate at a temperature of 17°C for 0.5 hours, and drain; At 18°C, put the soaked barley seeds in a culture tray for cultivation. After the barley seeds germinate, spray the malt with the above-mentioned sodium selenite solution every 4 hours; , and then pre-crushed in a pulverizer to about 40 meshes, and then sent to a superfine pulverizer for pulverization to obtain selenium-enriched malt powder.

Embodiment 3

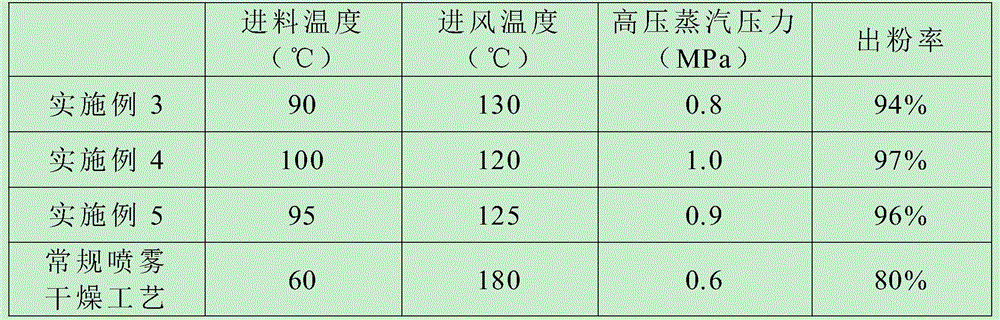

[0038] Barley seeds were soaked in a sodium selenite solution containing 0.12% sodium selenite, 0.005% cinnamic acid and 0.001% sodium lactate at a temperature of 23°C for 5 hours and drained; At 25°C, put the soaked barley seeds in a culture tray for cultivation. After the barley seeds germinate, spray the malt with the above-mentioned sodium selenite solution every 4 hours; Grinding and crushing to obtain malt grinding liquid, the grinding speed is 30 rpm, and then the feed temperature is 90°C, the inlet air temperature of the spray dryer is 130°C, the outlet air temperature is 85°C, and the high pressure steam pressure is 0.8MPa The mixed liquid is spray-dried under certain conditions to obtain selenium-enriched malt powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com