Production of malt

A preparation process and malt technology, applied in the field of malt preparation technology, can solve the problems of affecting process control, large loss of malting, low leaching rate, etc., and achieve the effects of shortening the macerating time and increasing the dew point rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

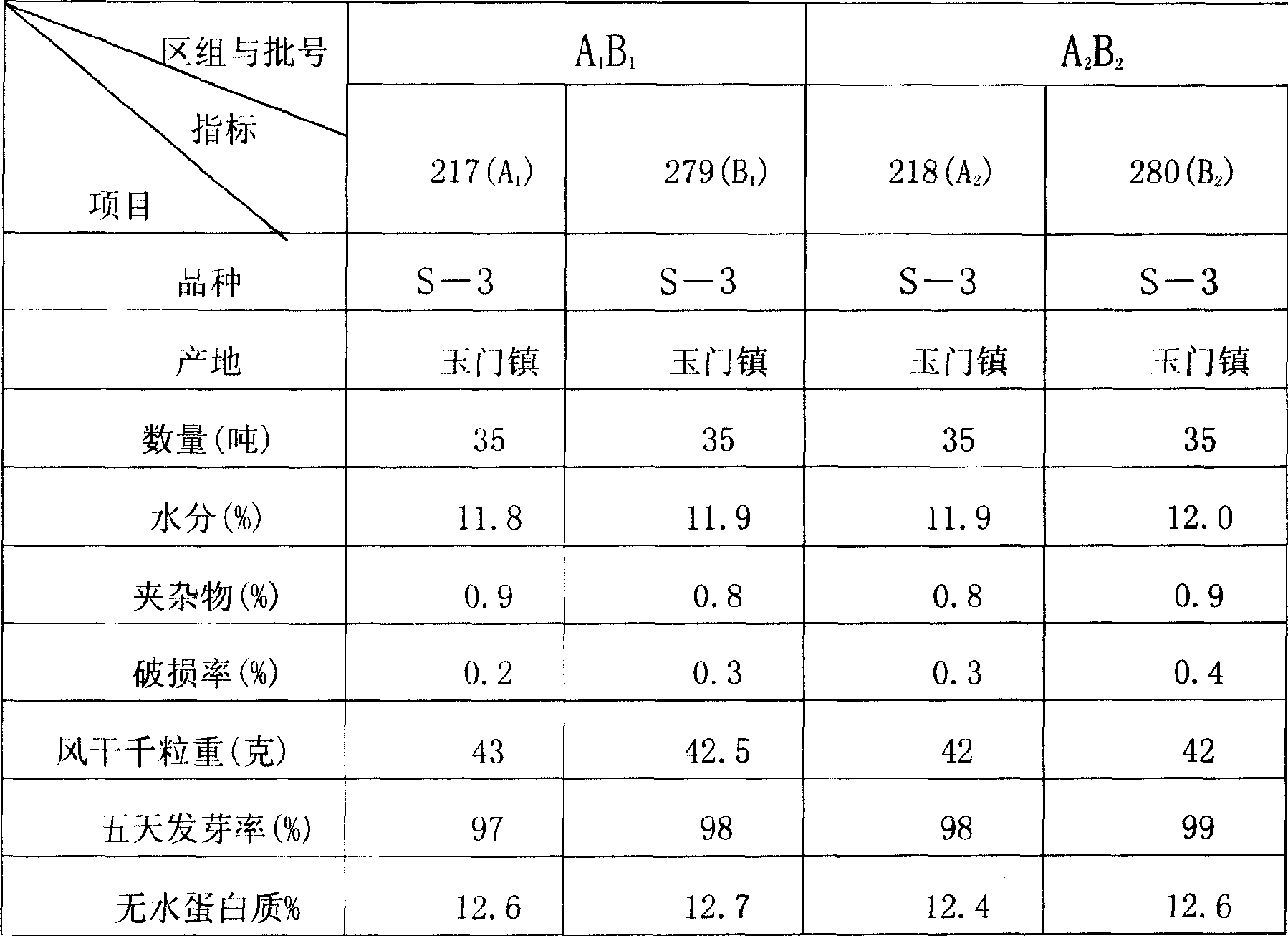

Embodiment 1

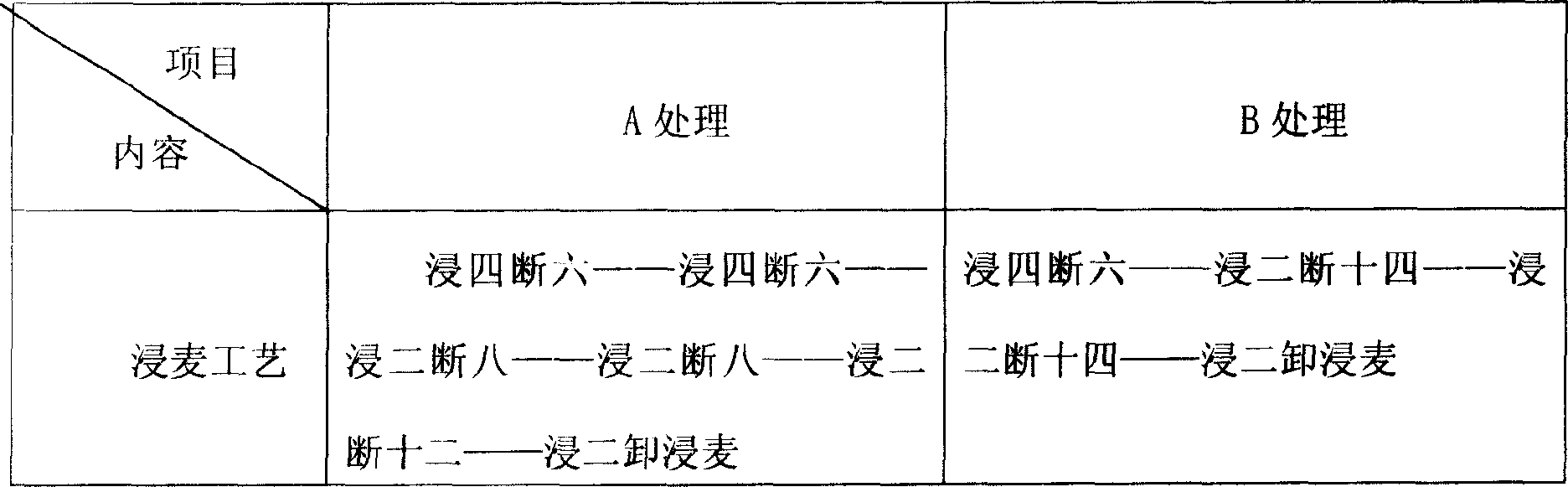

[0062] 1st soaking stage

[0063] Put 35 tons of selected barley into the barley soaking tank, inject water into the wheat soaking tank, soak the above barley in water for 4 hours, and keep the water temperature of the soaking water at 13°C; then release the water in the above wheat soaking tank, put The barley is placed for 6 hours. During the placement period, the barley is sprayed with atomized water mist every 3 hours for 10 minutes to ensure that the temperature of the wheat in the soaking tank is kept at 15°C; Soak the barley in water for 2 hours, and keep the temperature of the soaking water at 14°C; then release the water in the barley immersion tank above, and place the barley for 14 hours. During the placement period, spray atomized water mist on the barley every 3 hours through the nozzle for 10 Minutes to ensure that the wheat temperature in the soaking tank is kept at 16°C; pour water into the above-mentioned soaking tank again to soak the barley in water for 4 ho...

Embodiment 2

[0074] 1st soaking stage

[0075] Put 50 tons of selected barley into the barley soaking tank, inject water into the wheat soaking tank, soak the above barley in water for 4 hours, and keep the water temperature of the soaking water at 13°C; then release the water in the above wheat soaking tank, put The barley is placed for 6 hours. During the placement period, the barley is sprayed with atomized water mist every 3 hours for 10 minutes to ensure that the temperature of the wheat in the soaking tank is kept at 15°C; Soak the barley in water for 2 hours, and keep the temperature of the soaking water at 14°C; then release the water in the barley immersion tank above, and place the barley for 14 hours. During the placement period, spray atomized water mist on the barley every 3 hours through the nozzle for 10 Minutes to ensure that the wheat temperature in the soaking tank is kept at 16°C; pour water into the above-mentioned soaking tank again to soak the barley in water for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com