Patents

Literature

433results about "Liquid/gas/vapor article treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

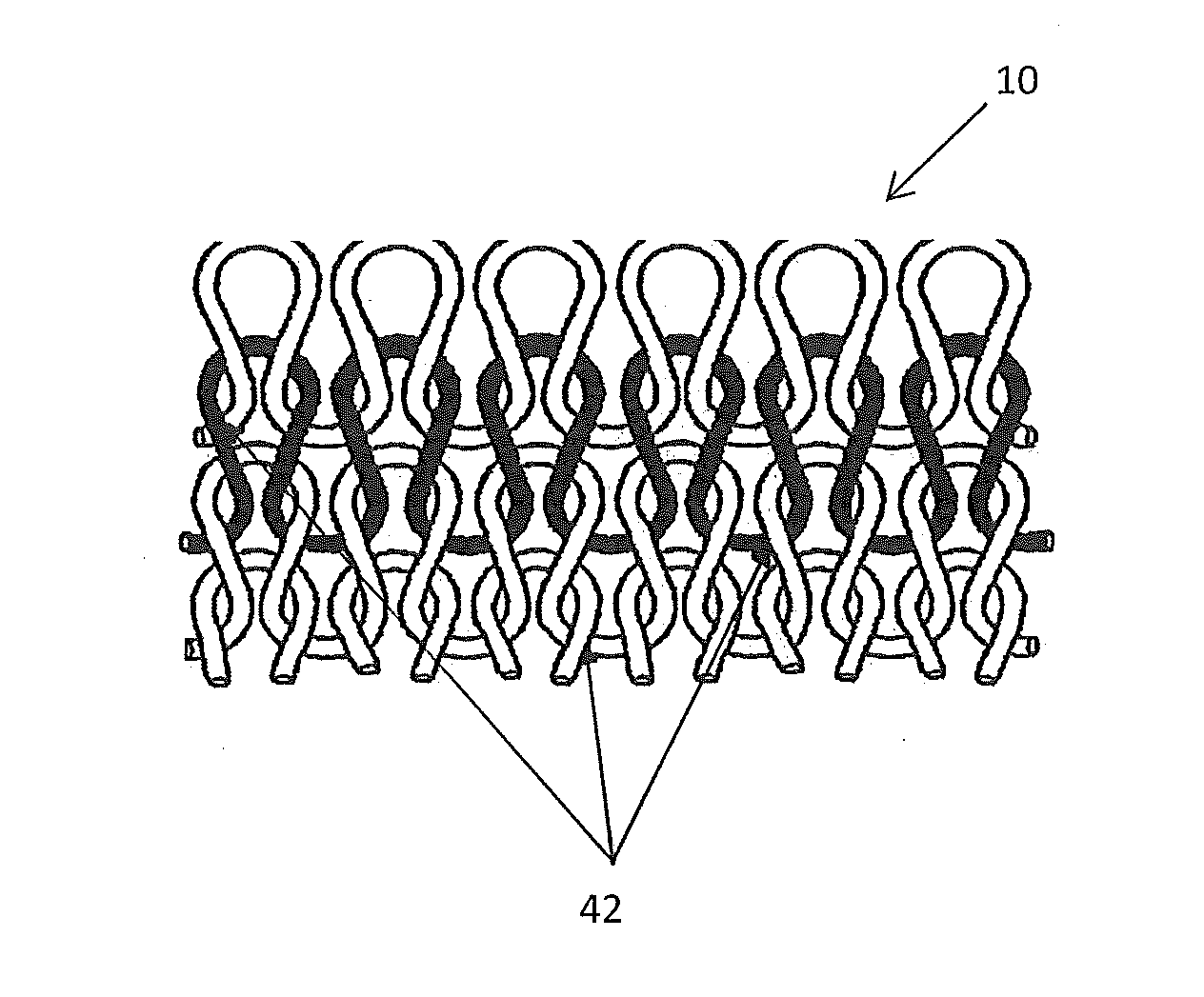

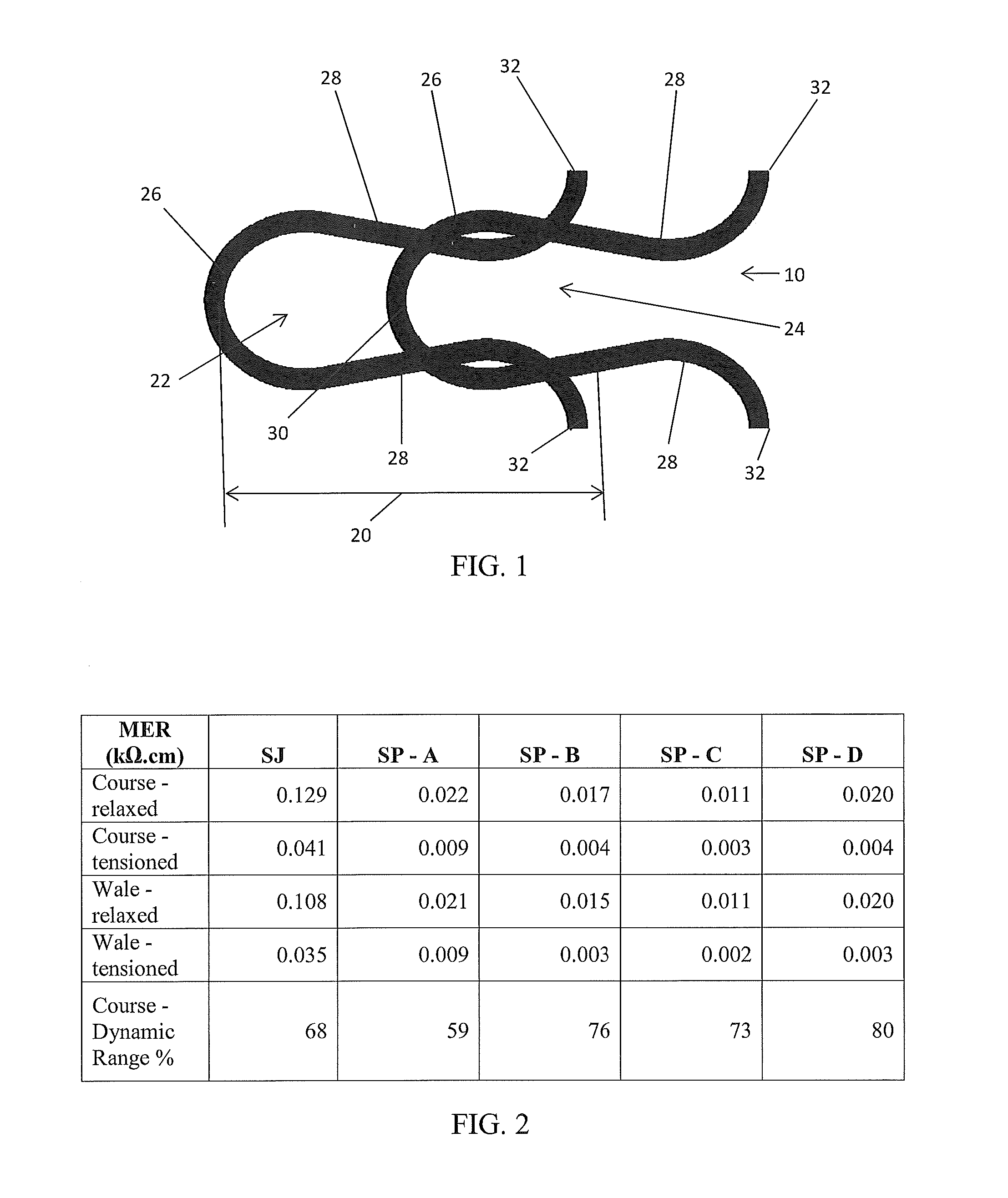

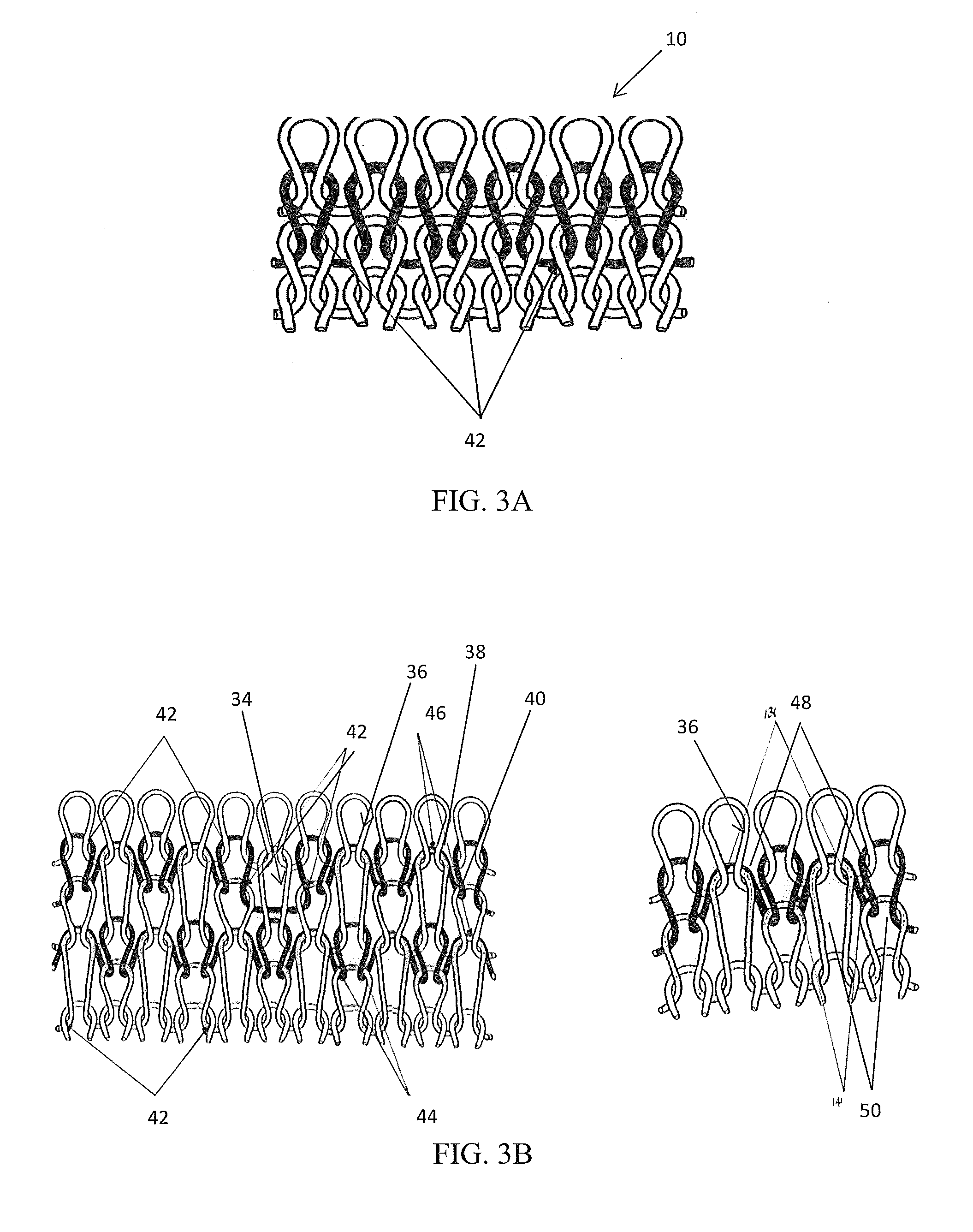

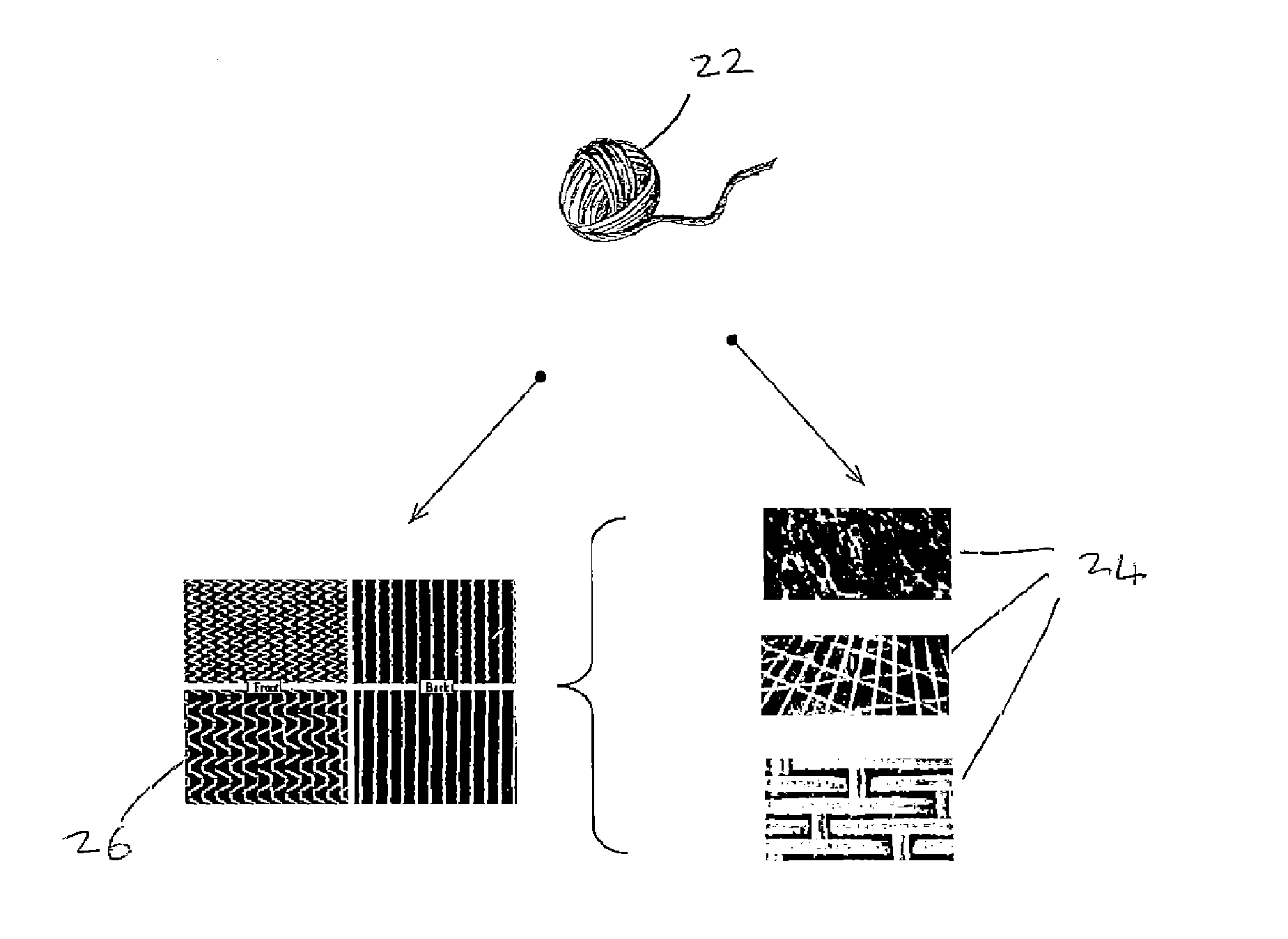

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

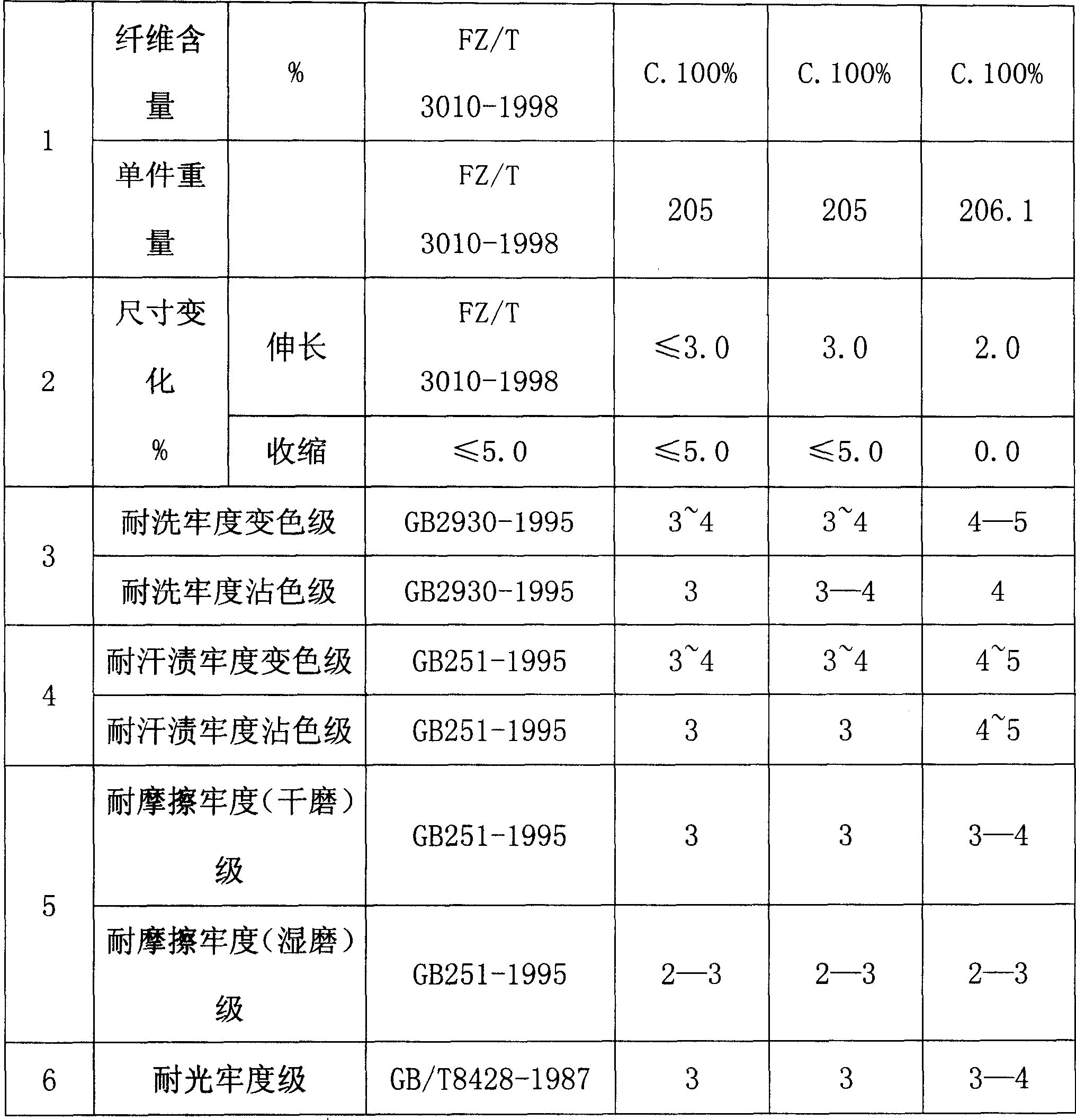

Production process of high-quality ecological antibacterial health-care sock

ActiveCN103815555AGood health effectImprove antibacterial propertiesLiquid/gas/vapor article treatmentPanty-hoseYarnEscherichia coli

The invention discloses a production process of a high-quality ecological antibacterial health-care sock. The production process of the high-quality ecological antibacterial health-care sock comprises the following steps of yarn manufacturing, sock weaving, seam allowance processing, reinforcing, setting, pre-drying, water bathing, drying and package detection. The production process of the high-quality ecological antibacterial health-care sock adopts the method that natural cotton fibers, aloe fibers and modal fibers are interlaced and makes full use of the good antibacterial effect of the aloe fibers, and the bottom of the sock adopts a flat structure, so that the fabric can meet the requirements for high air permeability and comfort. The aloe fibers are used for replacing traditional common viscose, and aloe isocitric acid calcium and other matter have the functions of improving the constitution, strengthening the heart, promoting blood circulation, softening hardened arteries, lowering the cholesterol content and expanding the blood capillaries, and have a certain inhibition effect on escherichia coli and staphylococcus aureus. Compared with the prior art, the high-quality ecological antibacterial health-care sock has good health-care performance and antibacterial performance.

Owner:浙江丰悦针纺有限公司

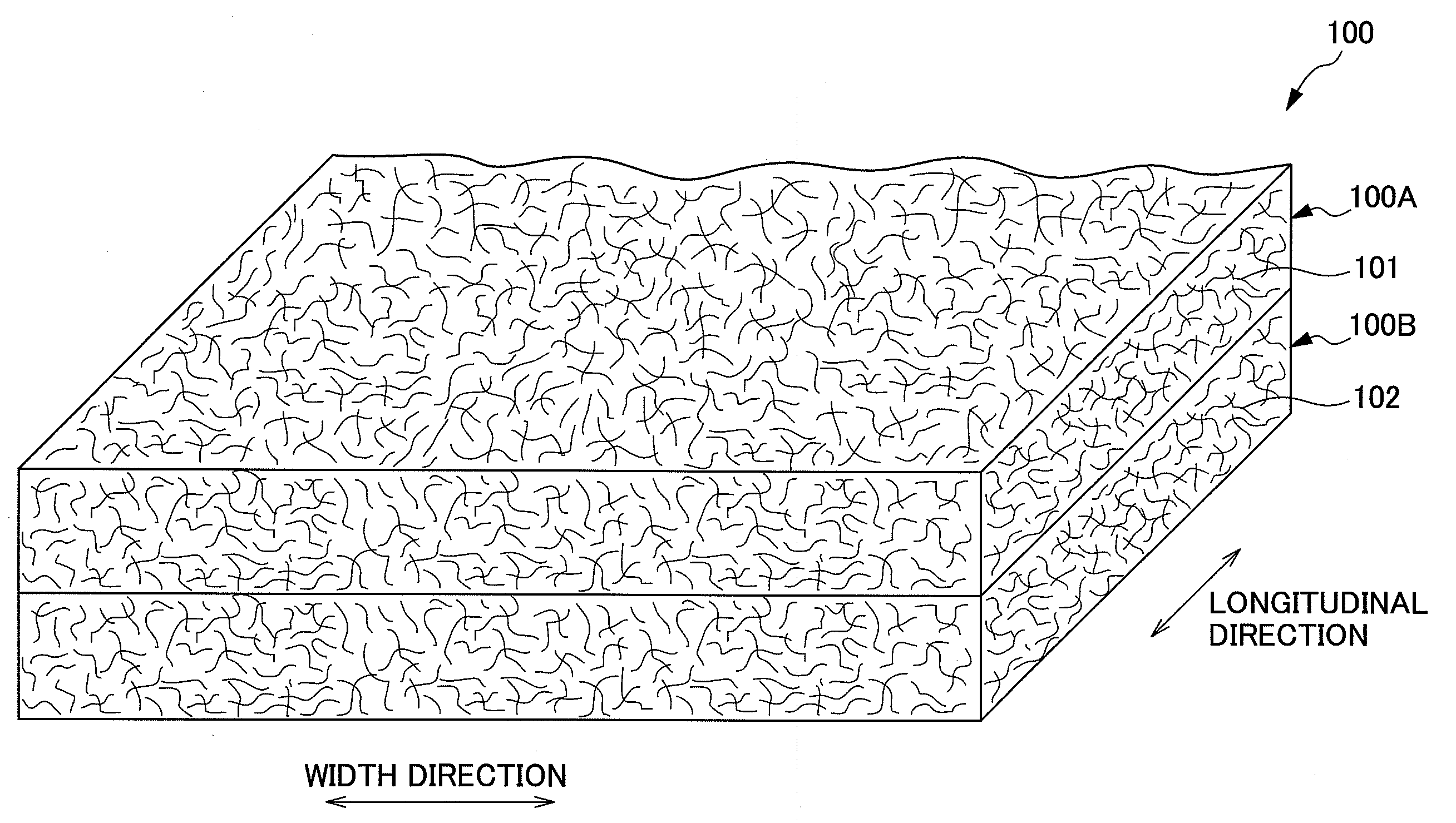

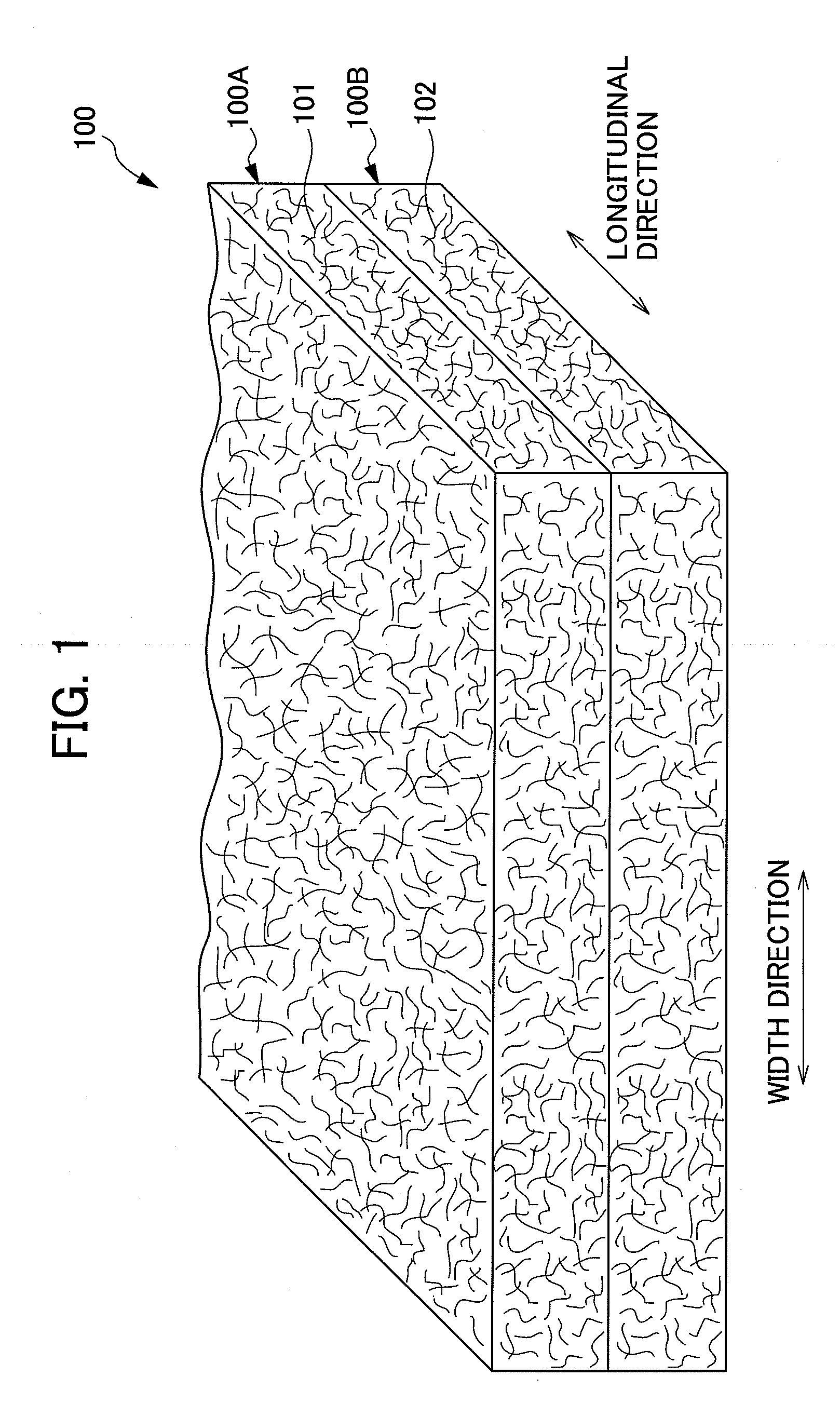

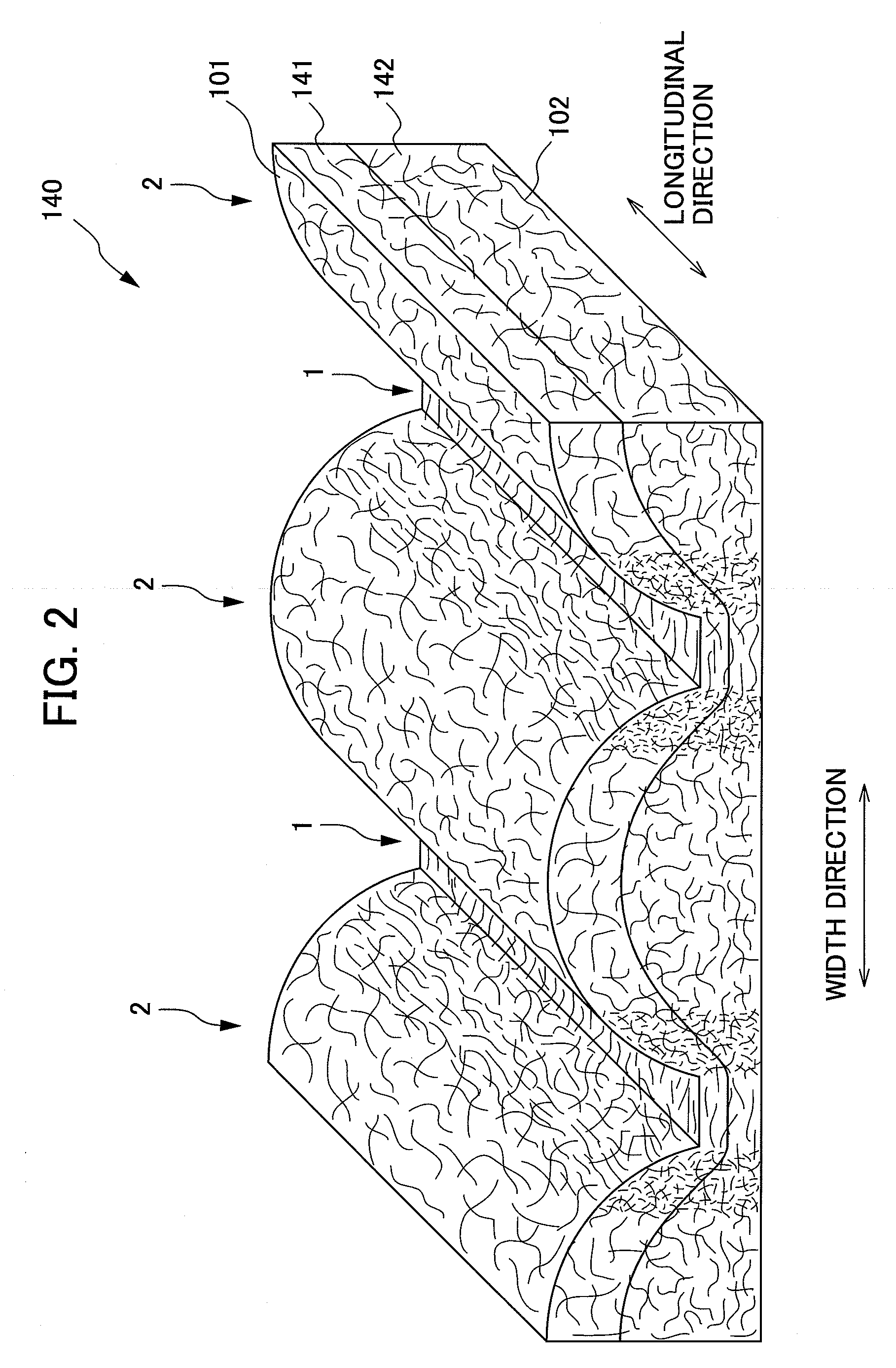

Multilayer nonwoven fabric and method of manufacturing the same

A multilayer nonwoven fabric comprises a first fiber layer and a second fiber layer laminated and arranged on a first surface of the first fiber layer, wherein a plurality of groove portions is formed along a prescribed direction in a shape depressed in a thickness direction of the multilayer nonwoven fabric and a plurality of raised ridge portions are formed adjacent to the plurality of groove portions in a shape projected in the thickness direction and in which the basis weight is greater than the basis weight in regions A constituting the bottoms of the groove portions 1 are formed, and the second fiber layer constituting each of the plurality of raised ridge portions is in such a shape that a surface, on the side of the first fiber layer, of the second fiber layer is projected in the same direction as the direction in which the second surface of the first fiber layer is projected.

Owner:UNI CHARM CORP

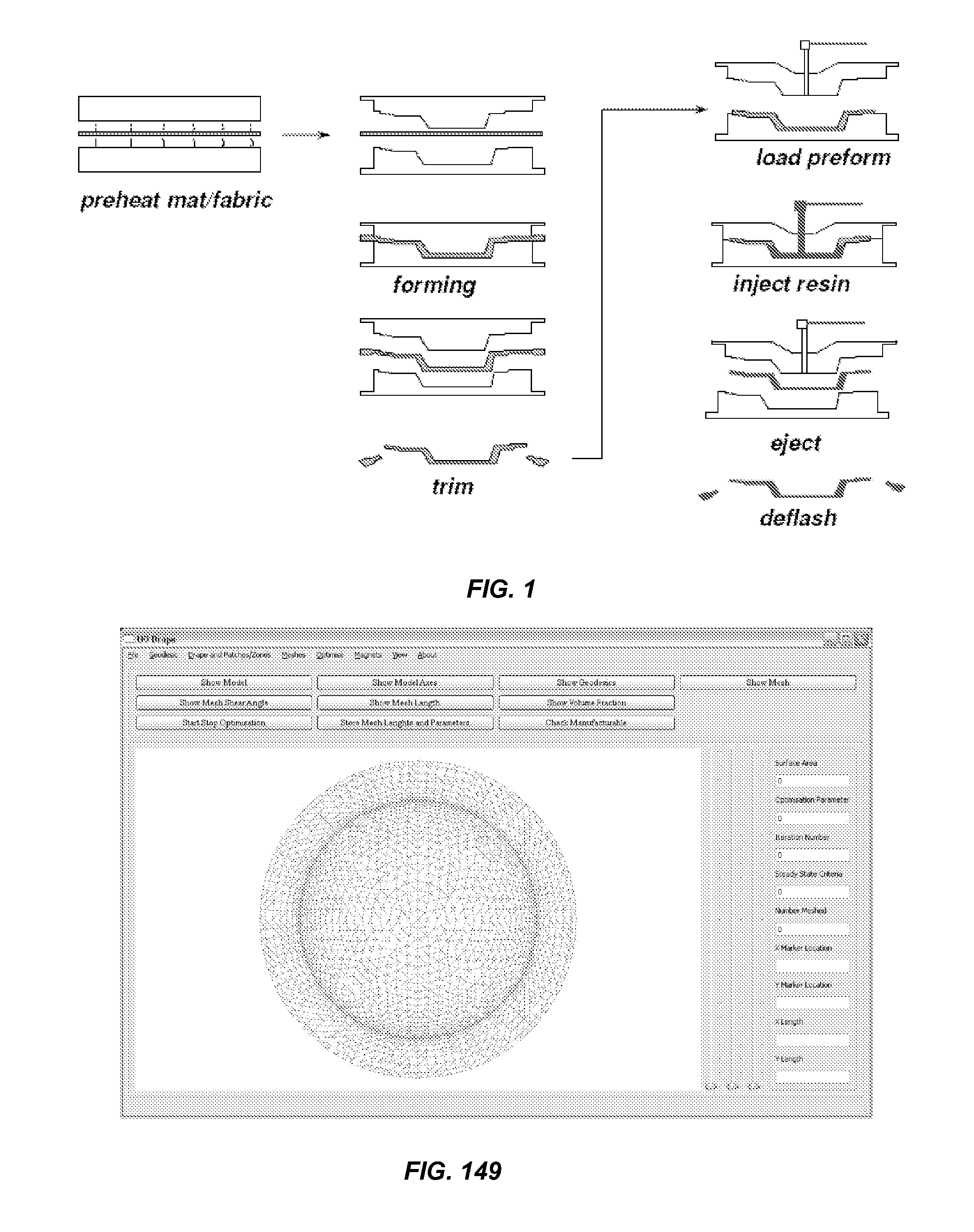

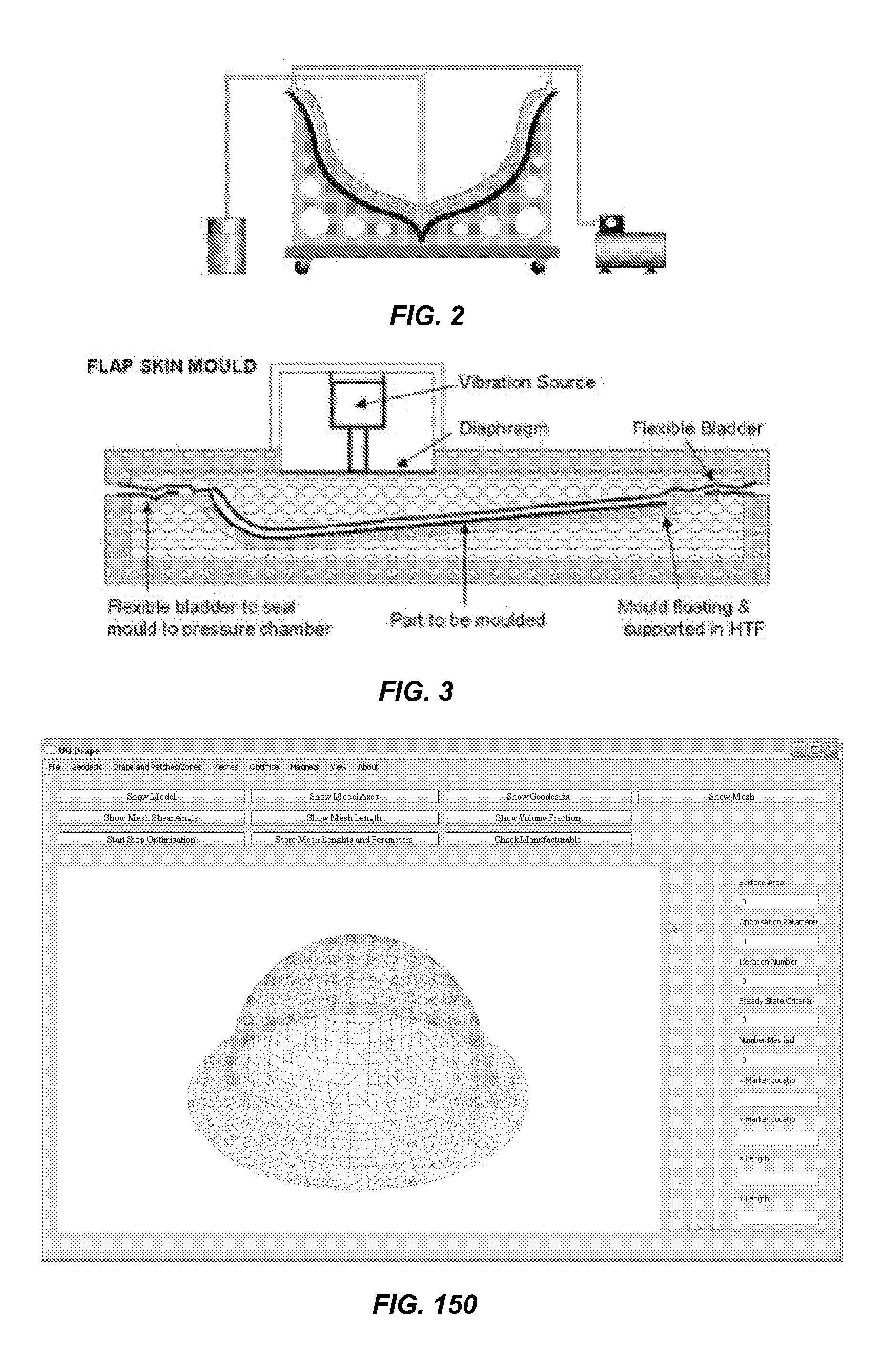

Novel composite parts, methods and apparatus for manufacturing the same

Owner:UNIVERSITY OF OTTAWA

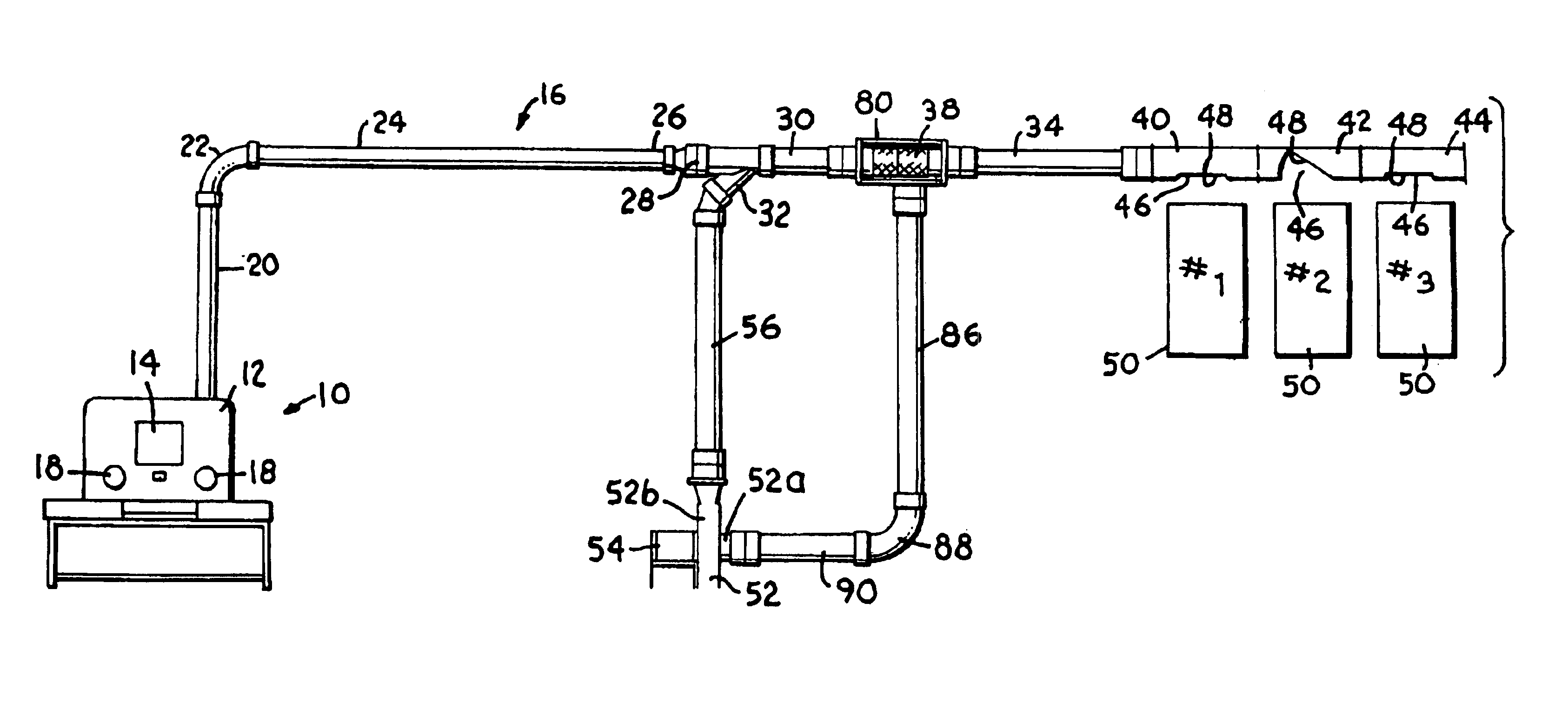

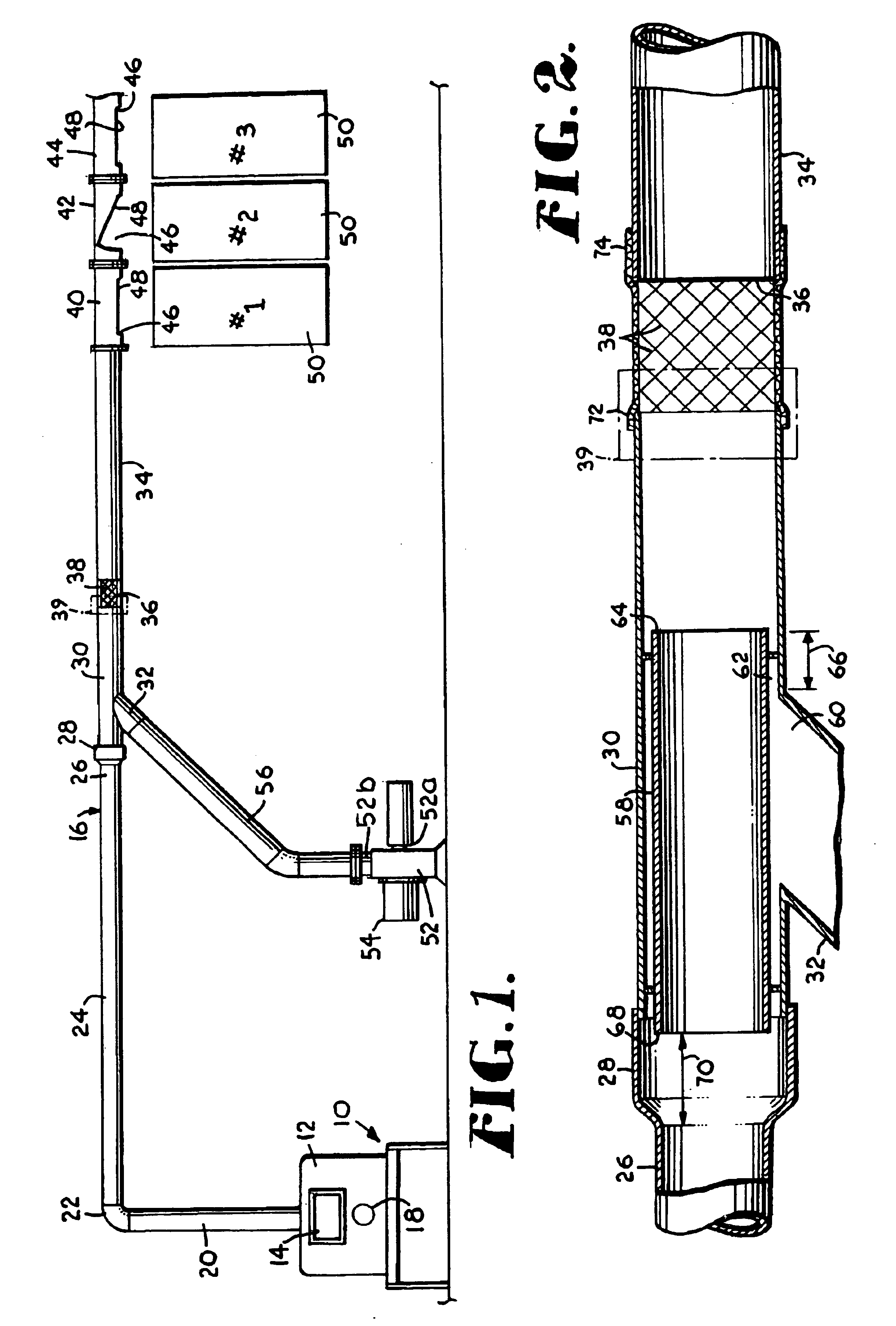

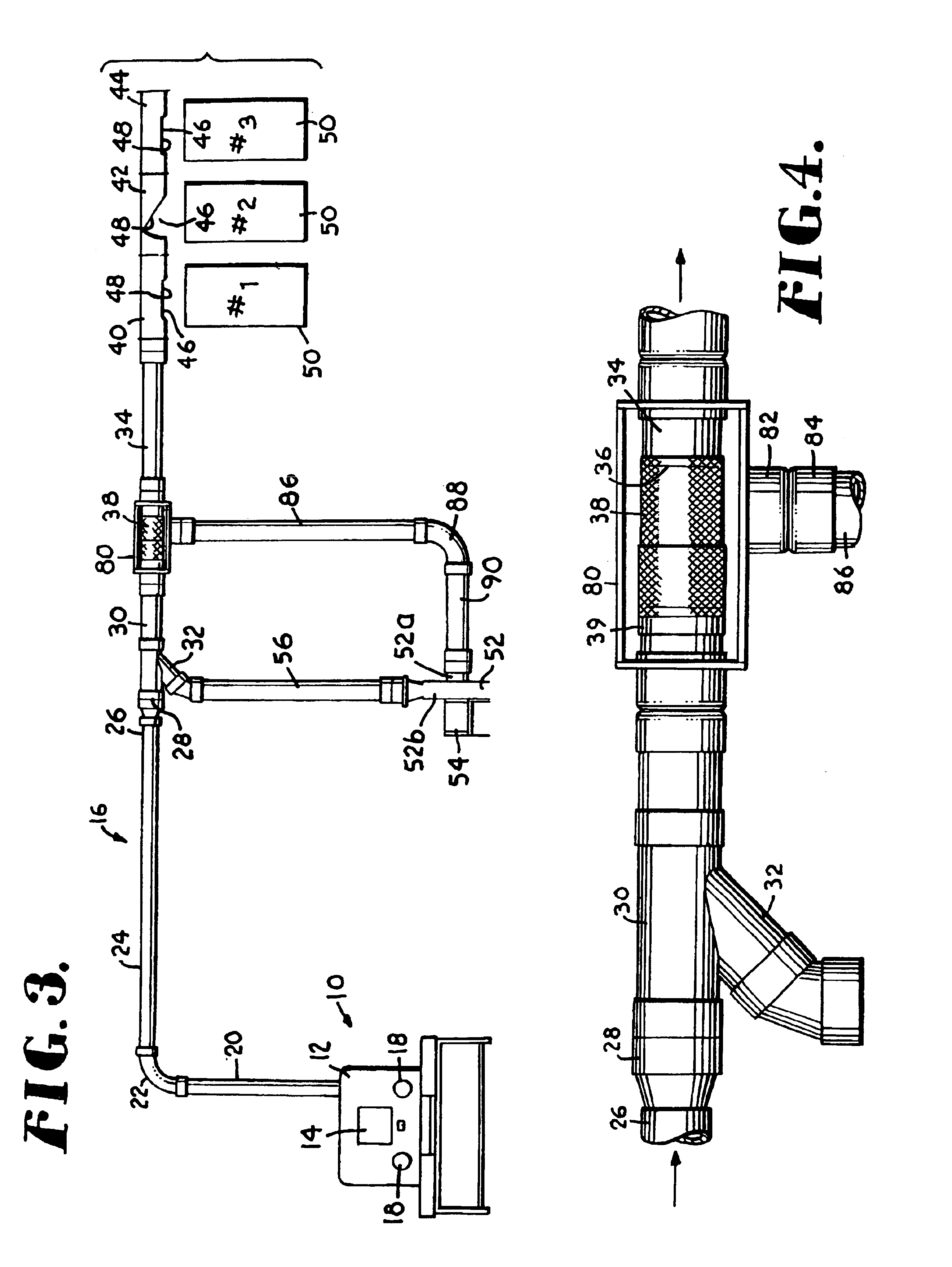

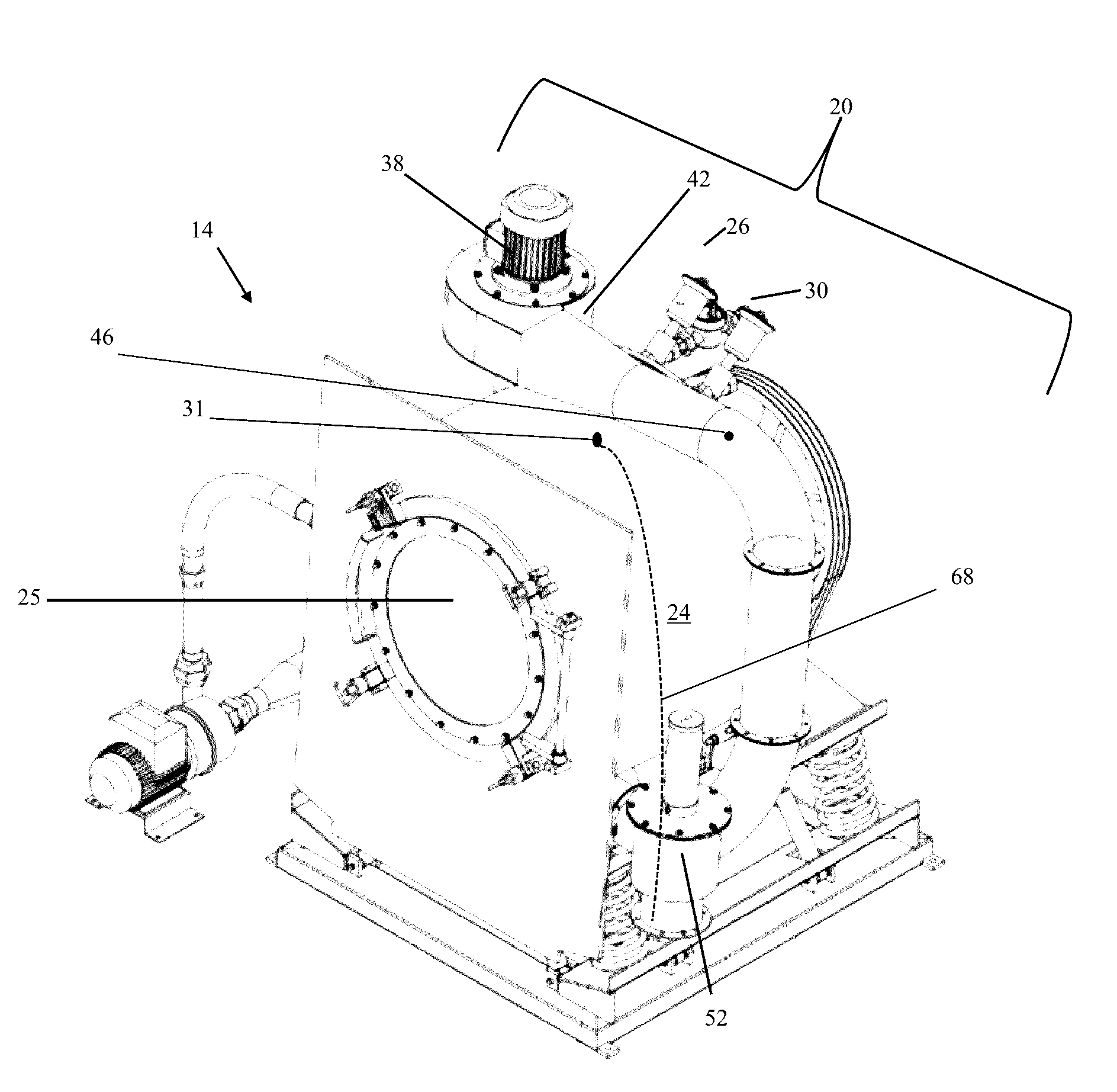

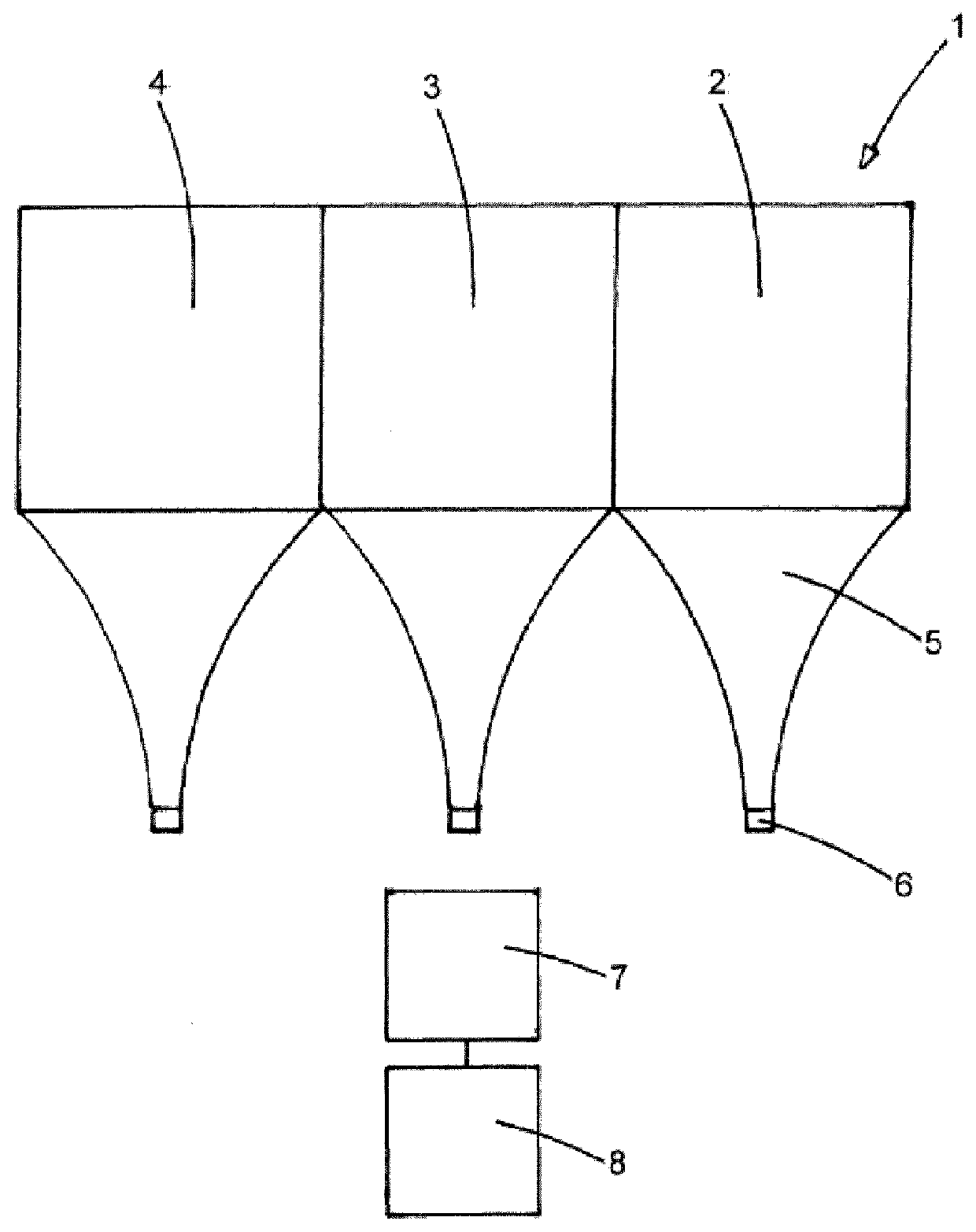

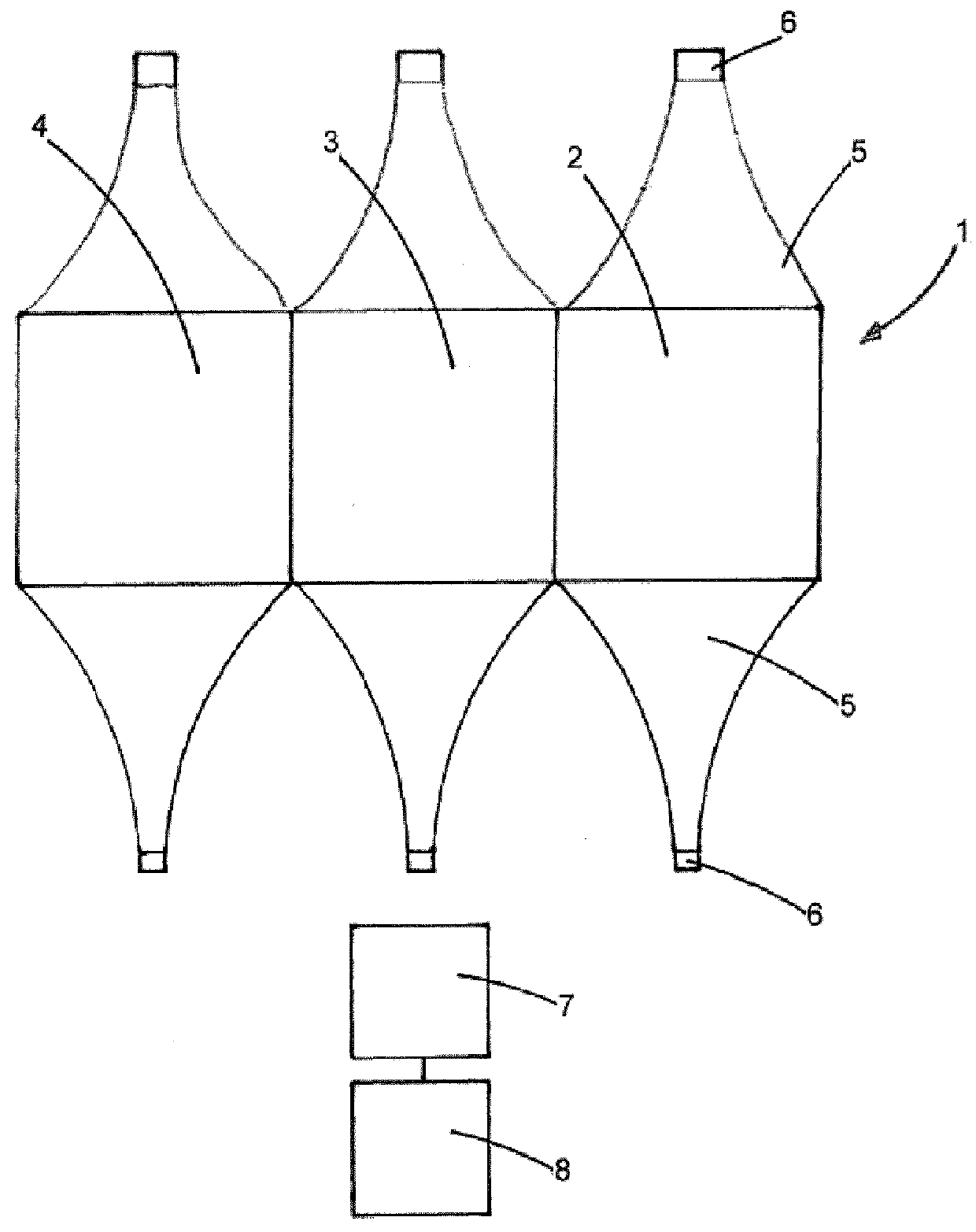

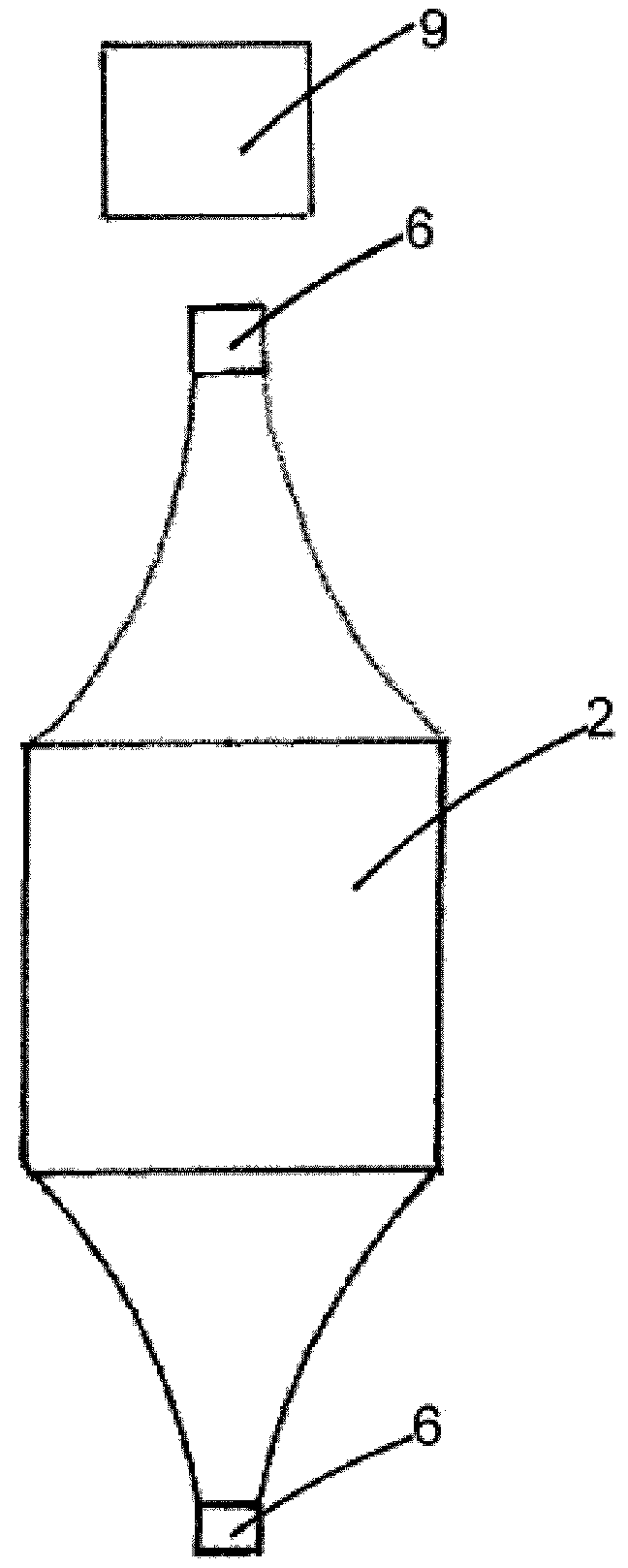

Venturi system using closed loop air return for conveying flexible fabrics

InactiveUS6942133B2Avoid disadvantagesReduces equipment cost and labor cost and space requirementLiquid/gas/vapor article treatmentBulk conveyorsAcute angleNoise level

Owner:AUTOMATION DYNAMICS

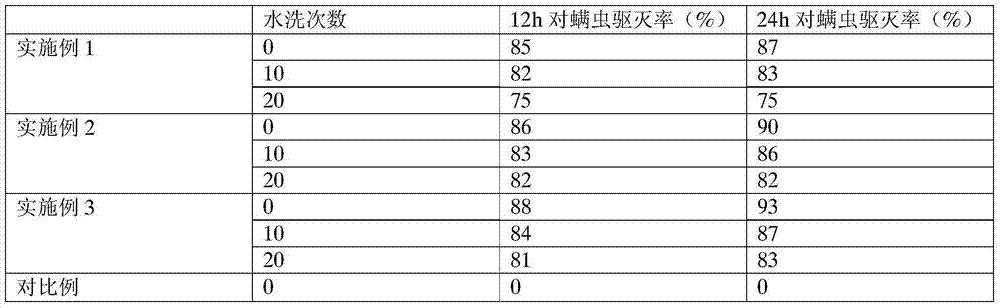

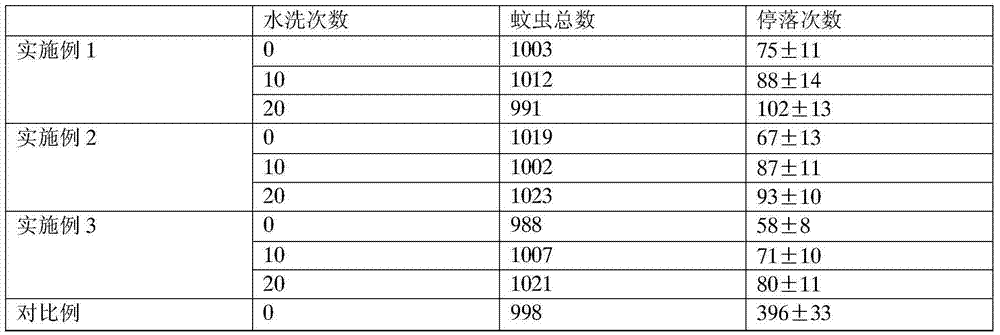

Mosquito-repelling and mite-resisting finishing agent for silk stockings and silk stocking production technology

The invention provides a mosquito-repelling and mite-resisting finishing agent for silk stockings, which comprises the following raw materials by mass percentage: 10-30% of lavender, 5-10% of aloe, 2-8% of tuberose flower, 1-5% of plant demodicidin and 47-82% of water. The invention also provides a production technology for the mosquito-repelling and mite-resisting finishing agent for silk stockings, and the mosquito-repelling and mite-resisting finishing agent is added in an arrangement step. The mosquito-repelling and mite-resisting finishing agent can keep original permeability and flexibility of silk stocking and has lasting mosquito-repelling and mite-resisting effect.

Owner:ZHEJIANG MENGNA SOCKS & HOSIERY

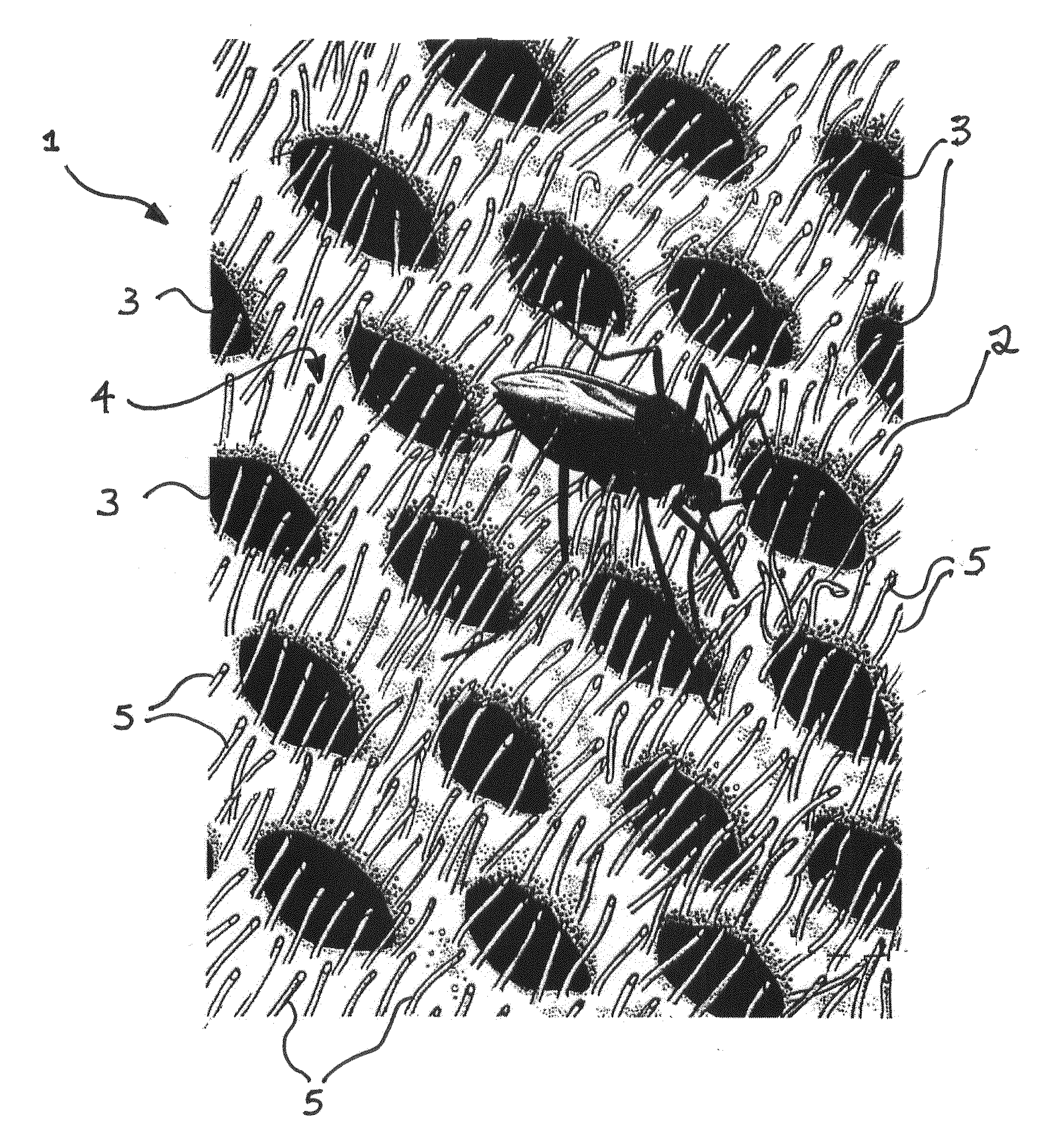

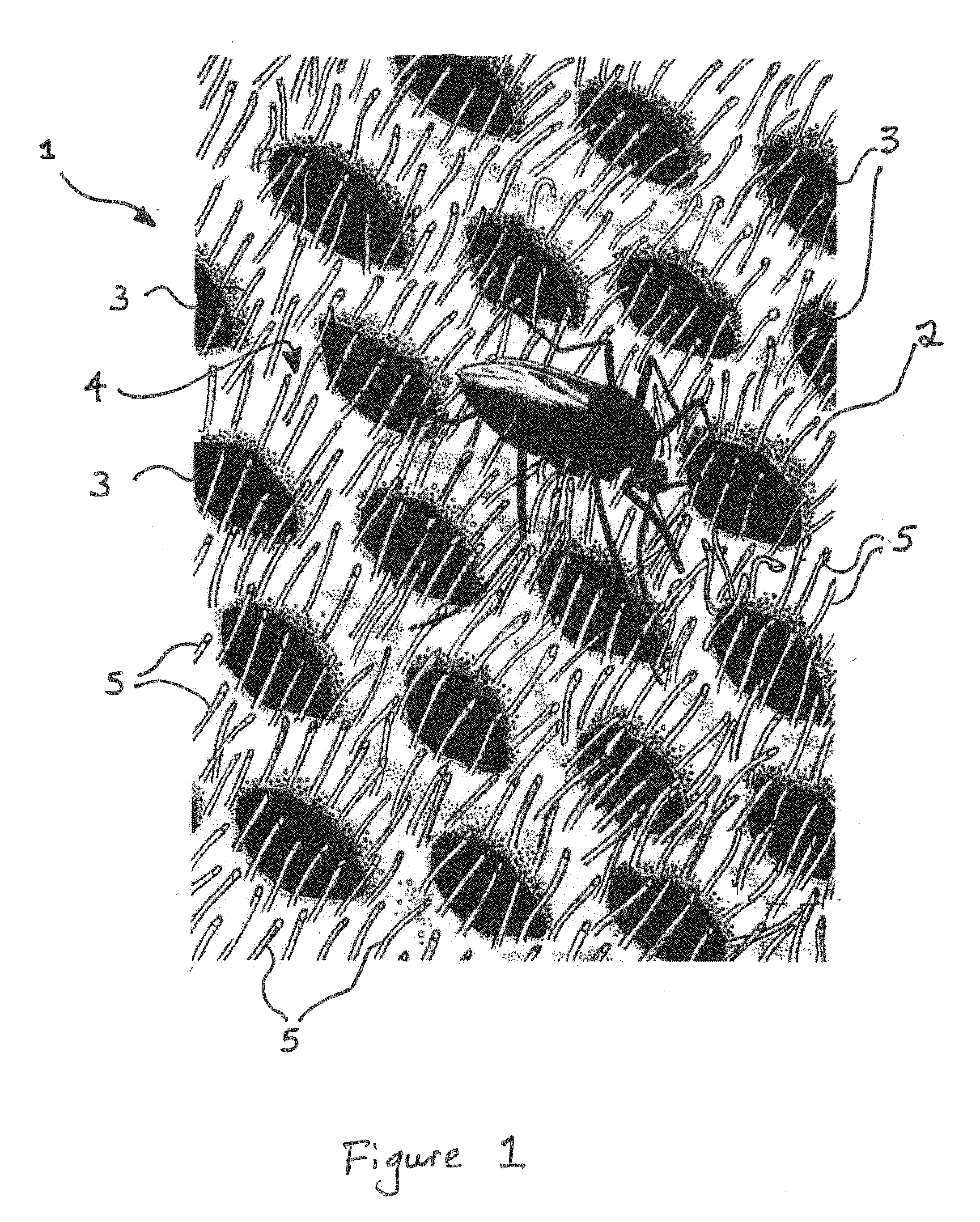

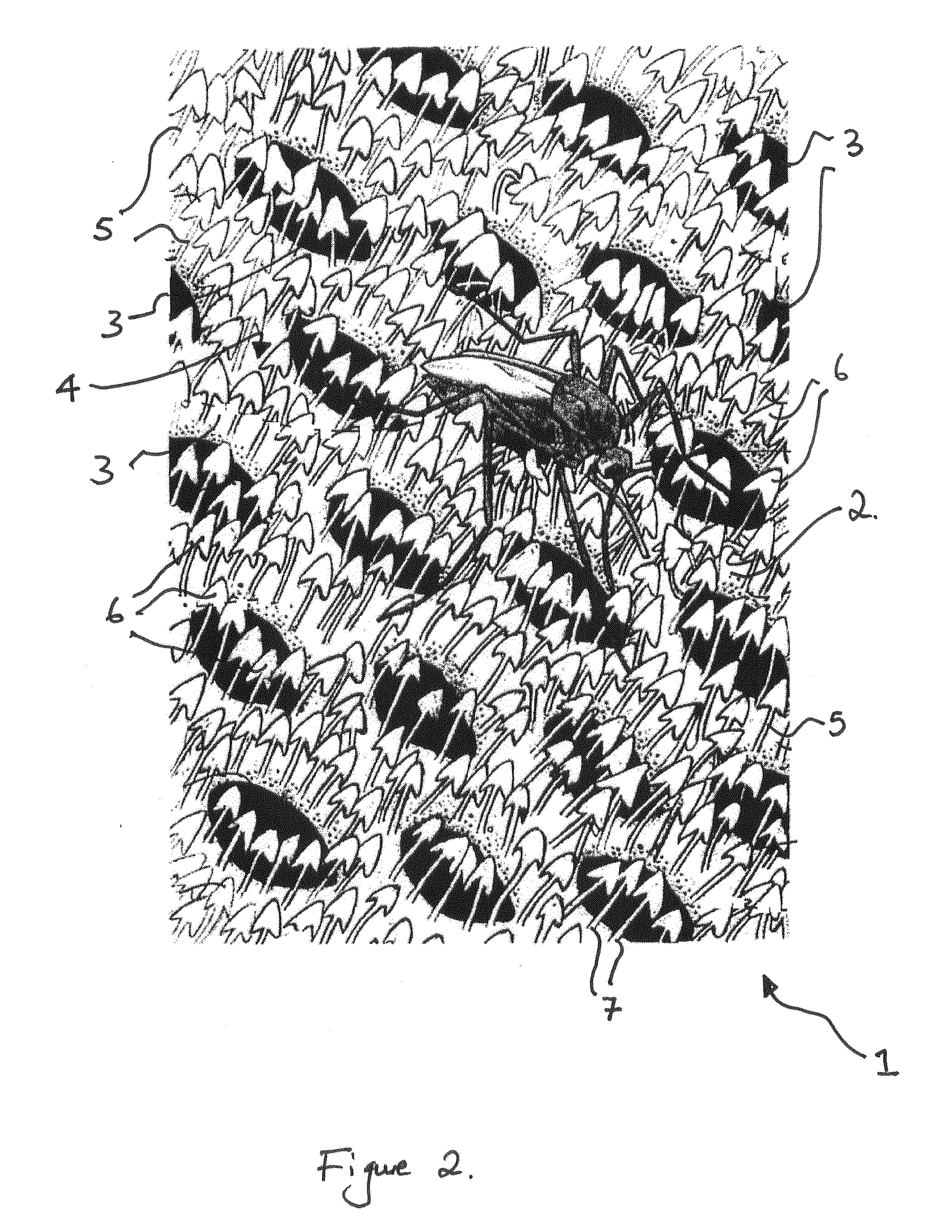

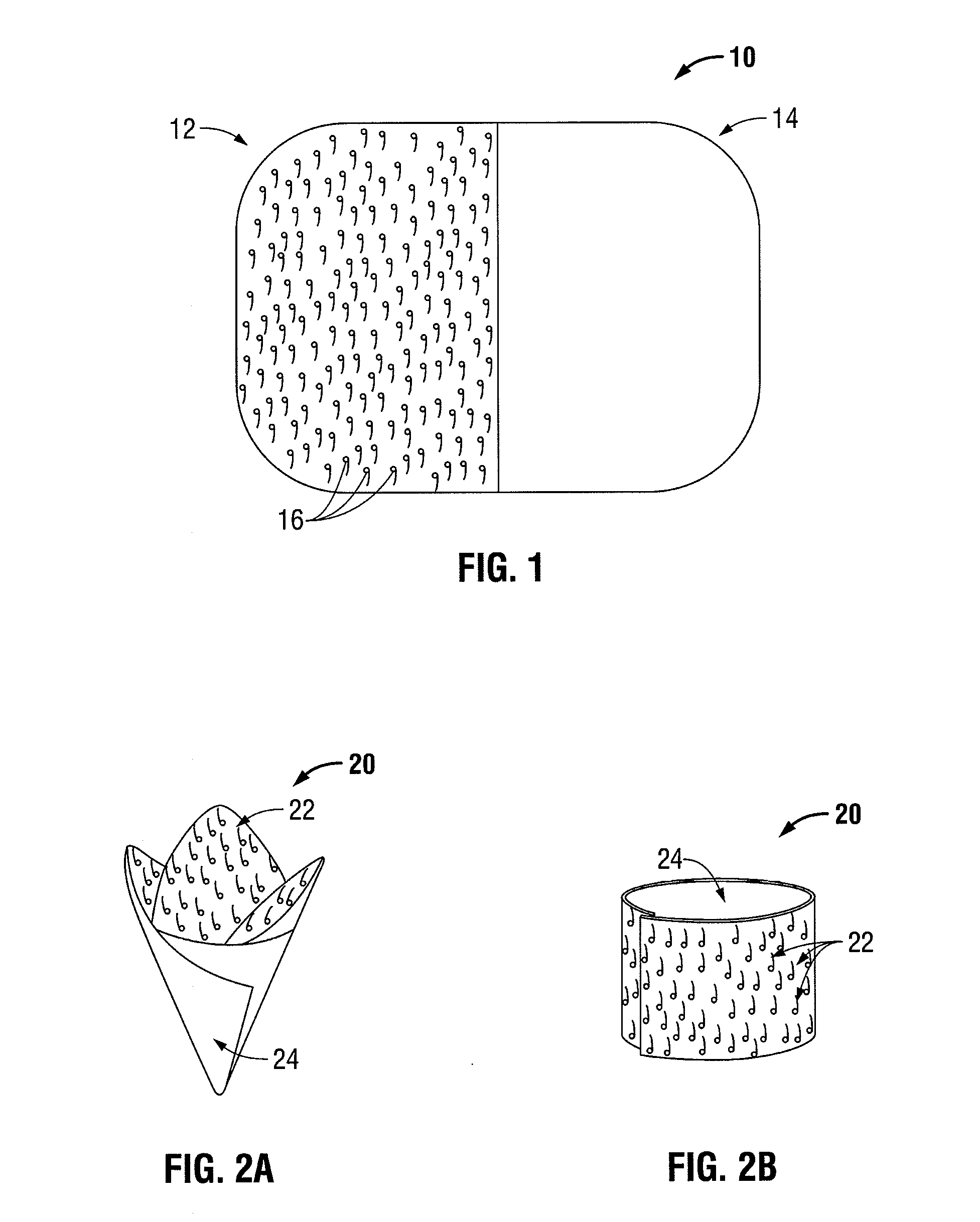

Pest control materials

InactiveUS20140041285A1Facilitate abrasionFacilitate mechanical interactionCrochetingTravelling sacksPaleontologyPest control

An open mesh insect control material is described which includes an insect contact surface, an internal surface, apertures communicating both surfaces and a plurality of filamentous projections protruding from the insect contact surface the projections at least partly occlude the apertures. The structure is suitable for use in pest control especially as a mosquito net.

Owner:INSECTSHIELD

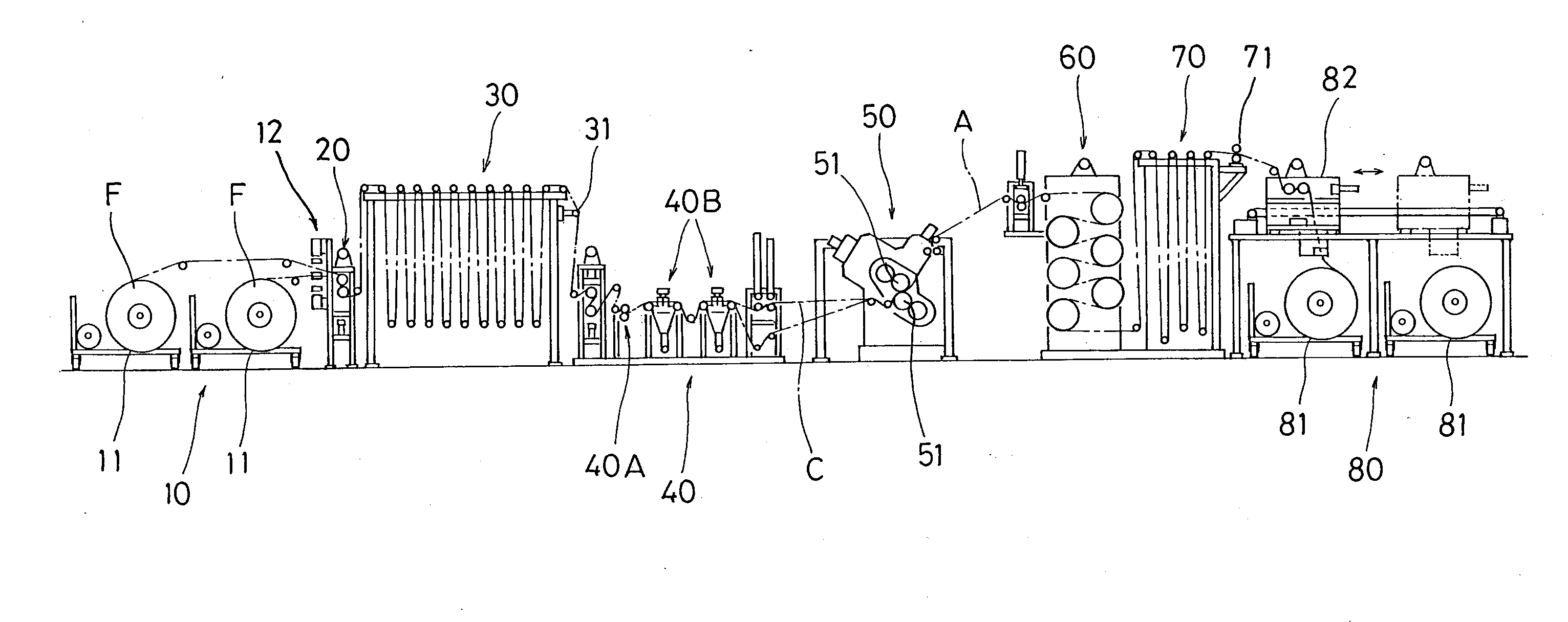

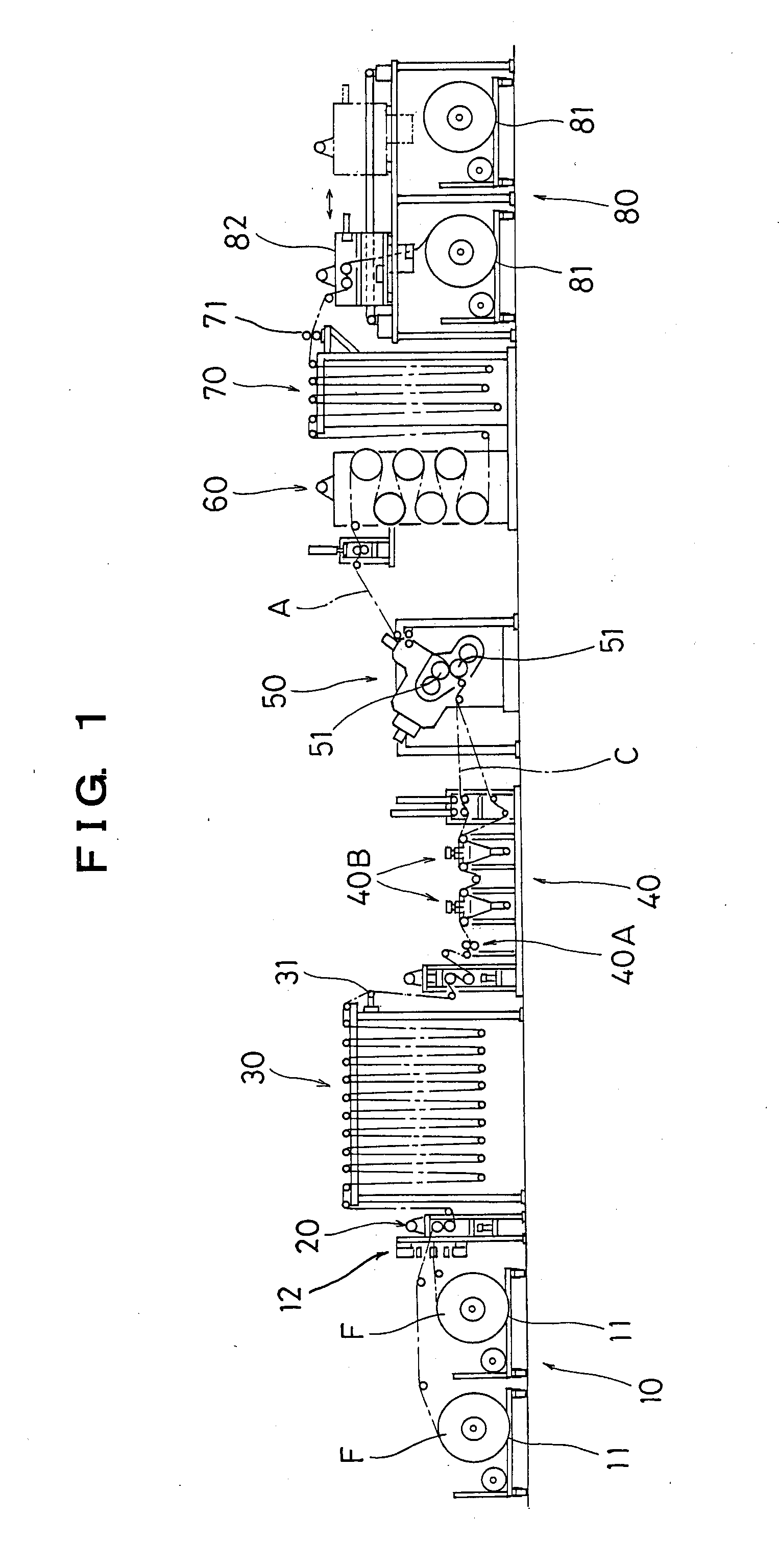

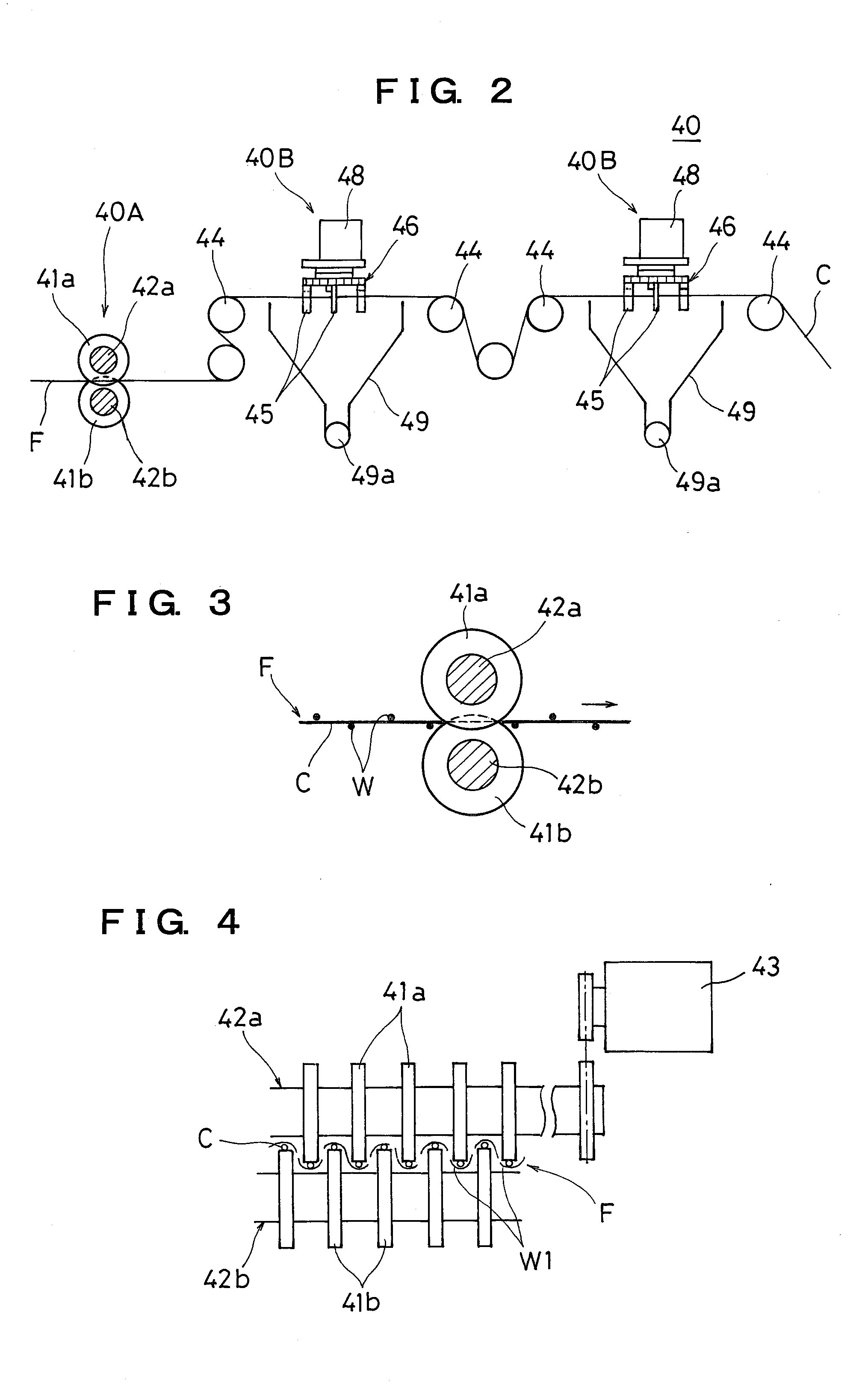

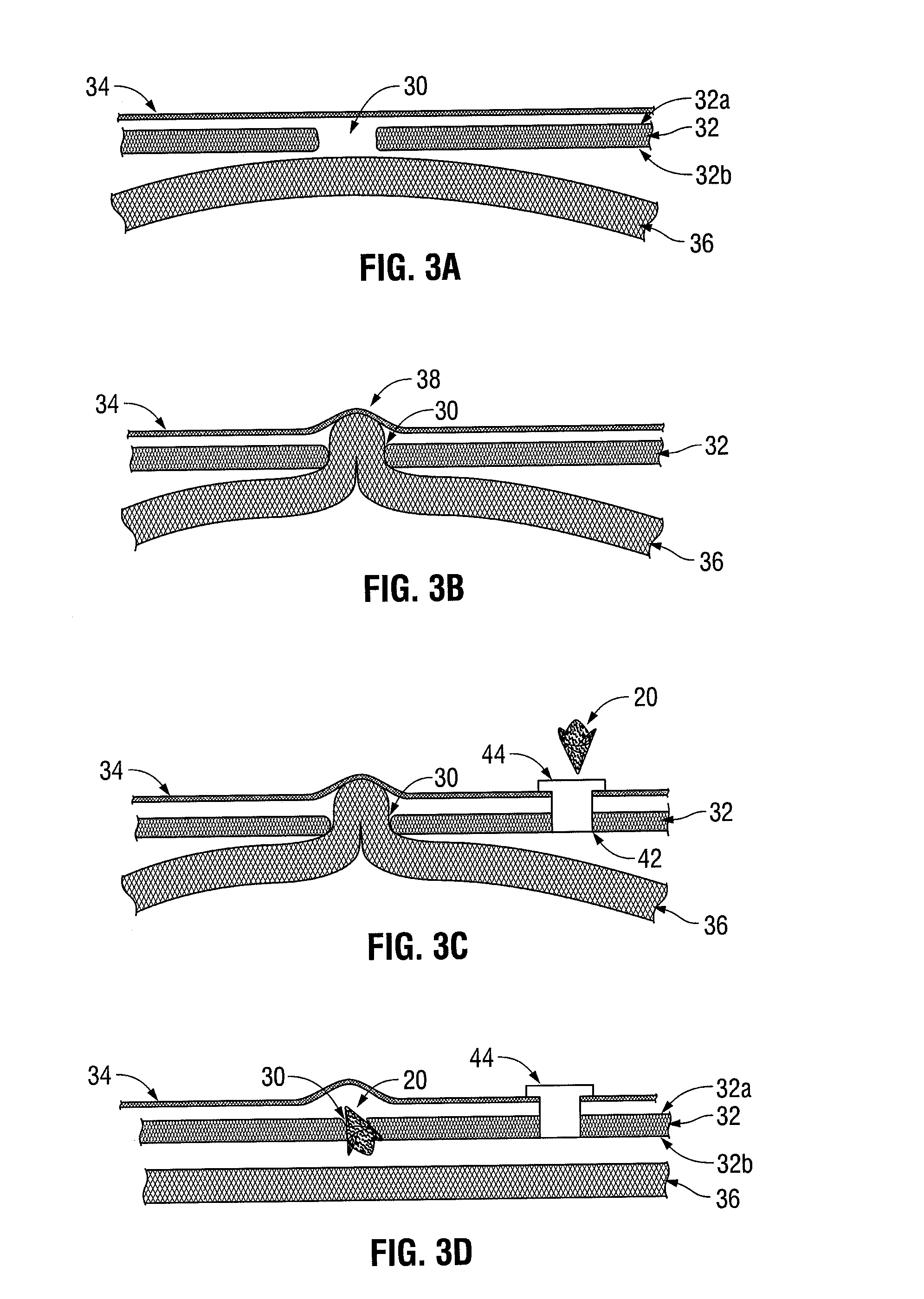

Method and apparatus of removing weft of cord fabric for topping sheet

ActiveUS20090249597A1Reduce failureQuality improvementCrochetingPaper/cardboard articlesEngineeringTextile

The invention can firmly and easily remove a finely divided weft piece without leaving the weft piece by constituting a method and an apparatus of removing weft from a cord fabric for a topping sheet in a calender line for topping rubber on a number of pieces of aligned cords by a calender roll. In the midst of transferring a cord fabric (F) transferred to a calender apparatus, weft is finely divided by passing the cord fabric (F) through weft dividing means, thereafter, a plurality of blades (45) arranged movably in a width direction on an upper face side of the cord fabric (F) are reciprocally moved in the width direction over an entire width thereof to be brought into contact with the cord fabric (F), and the divided weft piece (W1) is wiped off to remove by respectively striking respective cords (C) of the cord fabric (F) by the respective blades (45).

Owner:TOYO TIRE & RUBBER CO LTD

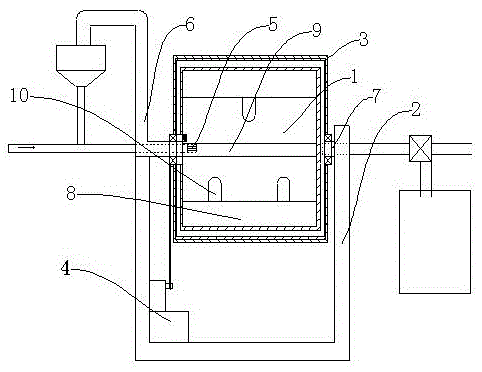

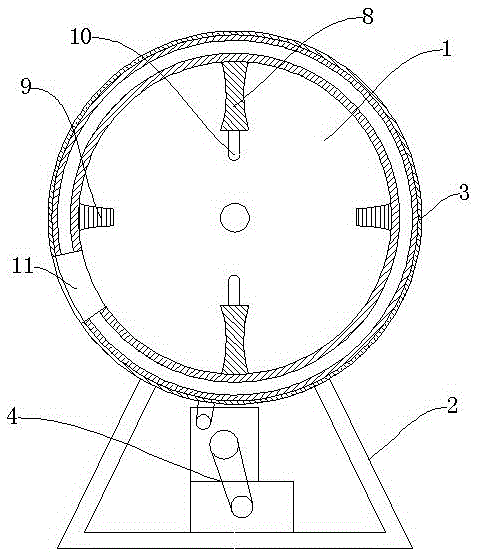

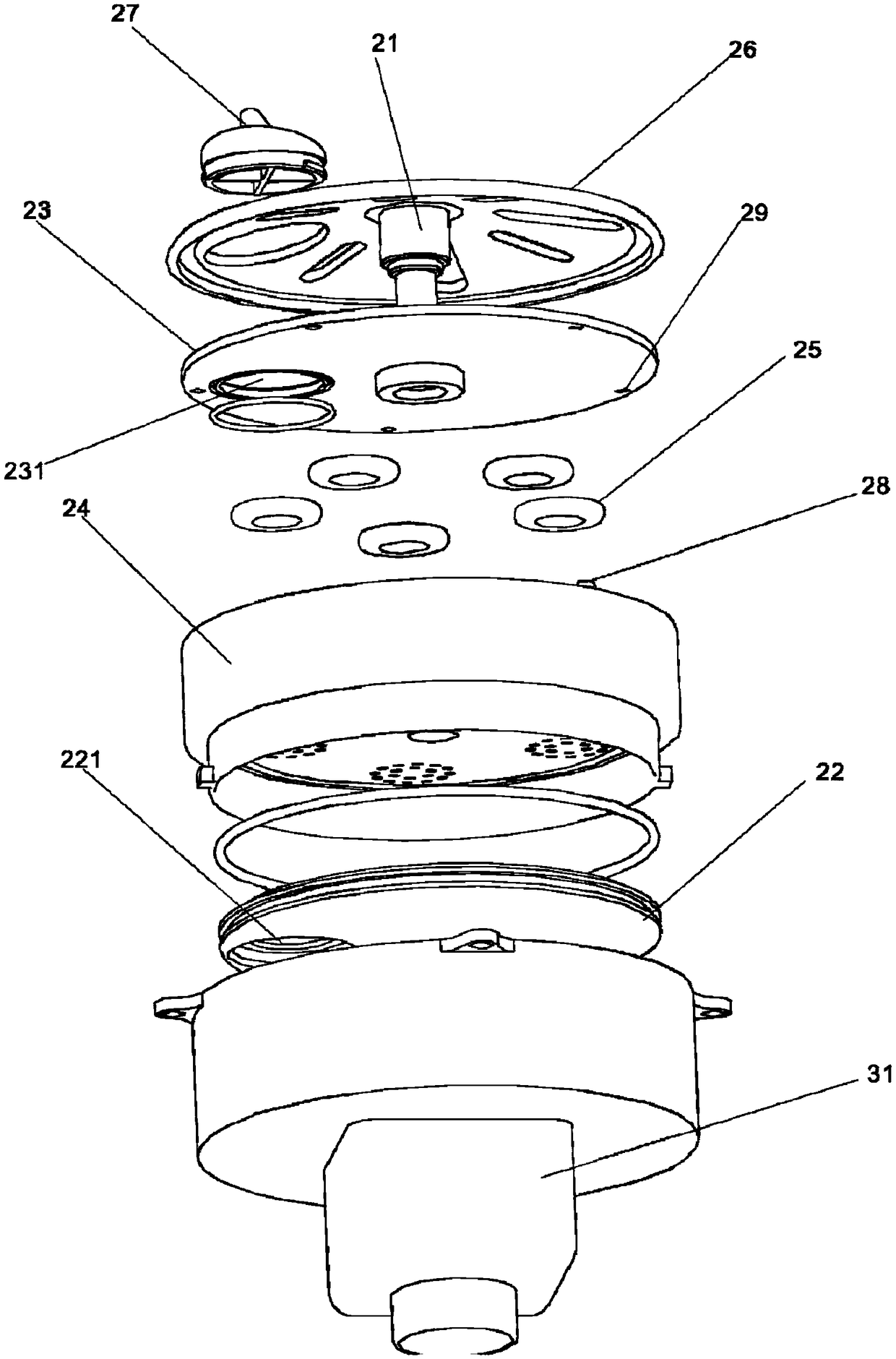

Woolen sweater dyeing machine

InactiveCN105568594ASituation that causes knotsReduce usageTextile treatment containersLiquid/gas/vapor article treatmentDyeing wastewaterAtmospheric pressure

The invention relates to the field of dyeing equipment, in particular to a woolen sweater dyeing machine. The woolen sweater dyeing machine comprises a machine frame, wherein a rotary drum is arranged on the machine frame, the outside of the rotary drum is wrapped with a layer of outer housing, a power mechanism in driving connection with the rotary drum is arranged on the machine frame, and a dye atomization mechanism, an air pressure balancing mechanism and a steam heating mechanism are arranged on the machine frame. Two main baffles are arranged on the inner wall of the rotary drum at an interval, an auxiliary baffle is arranged between the adjacent main baffles, and one or more radial shifting rods are arranged on the radial end face of each main baffle. A feeding door is arranged on the rotary drum between one group of adjacent main baffles and the auxiliary baffle and on the outer housing. The woolen sweater dyeing machine is simple in structure, can effectively utilize the rotary drum to dye woolen sweaters, does not cause a knitting phenomenon, is stable in using performance and reduces the using amount of water for dyeing and discharge of dyeing wastewater.

Owner:TONGXIANG NEW ERA FUR

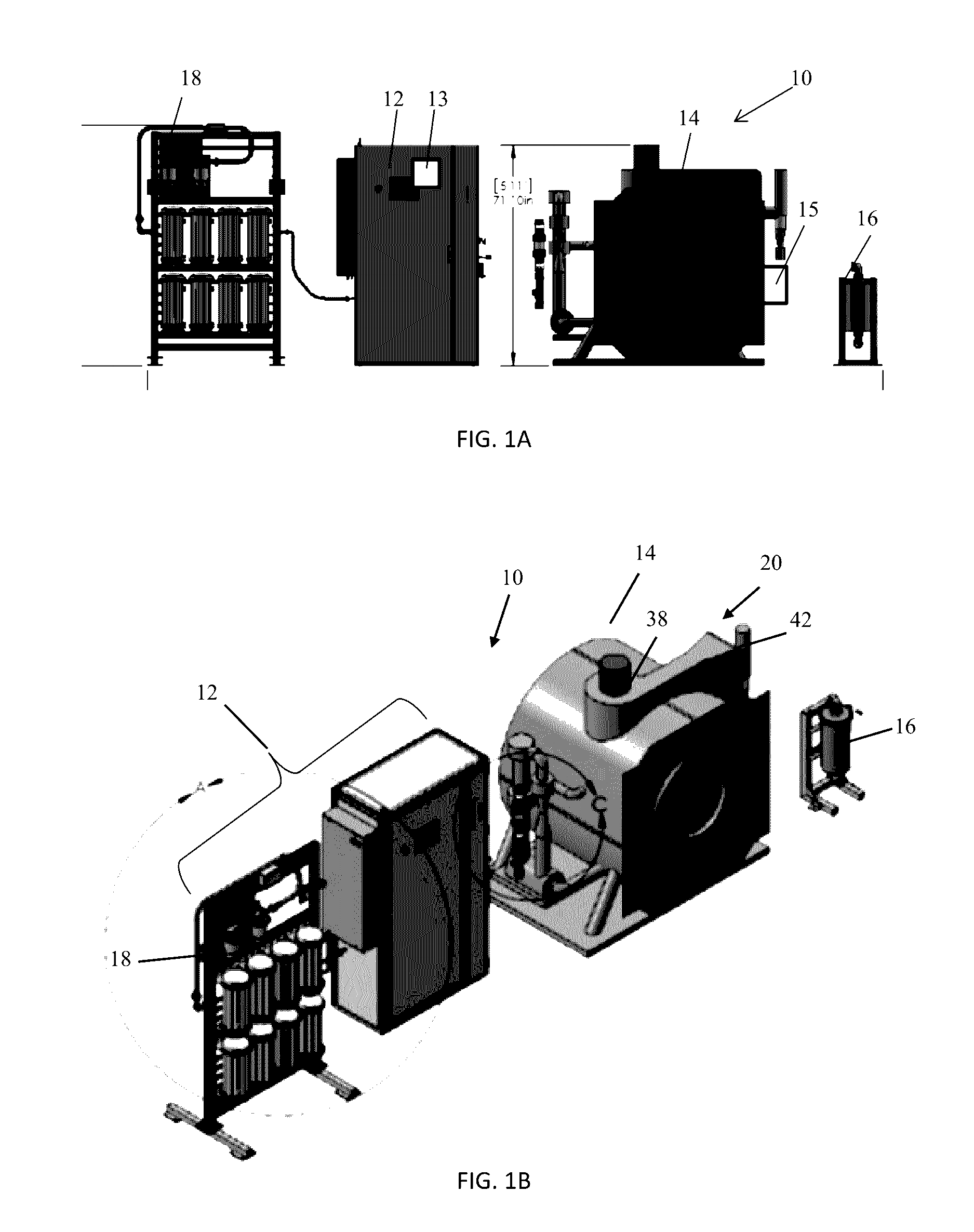

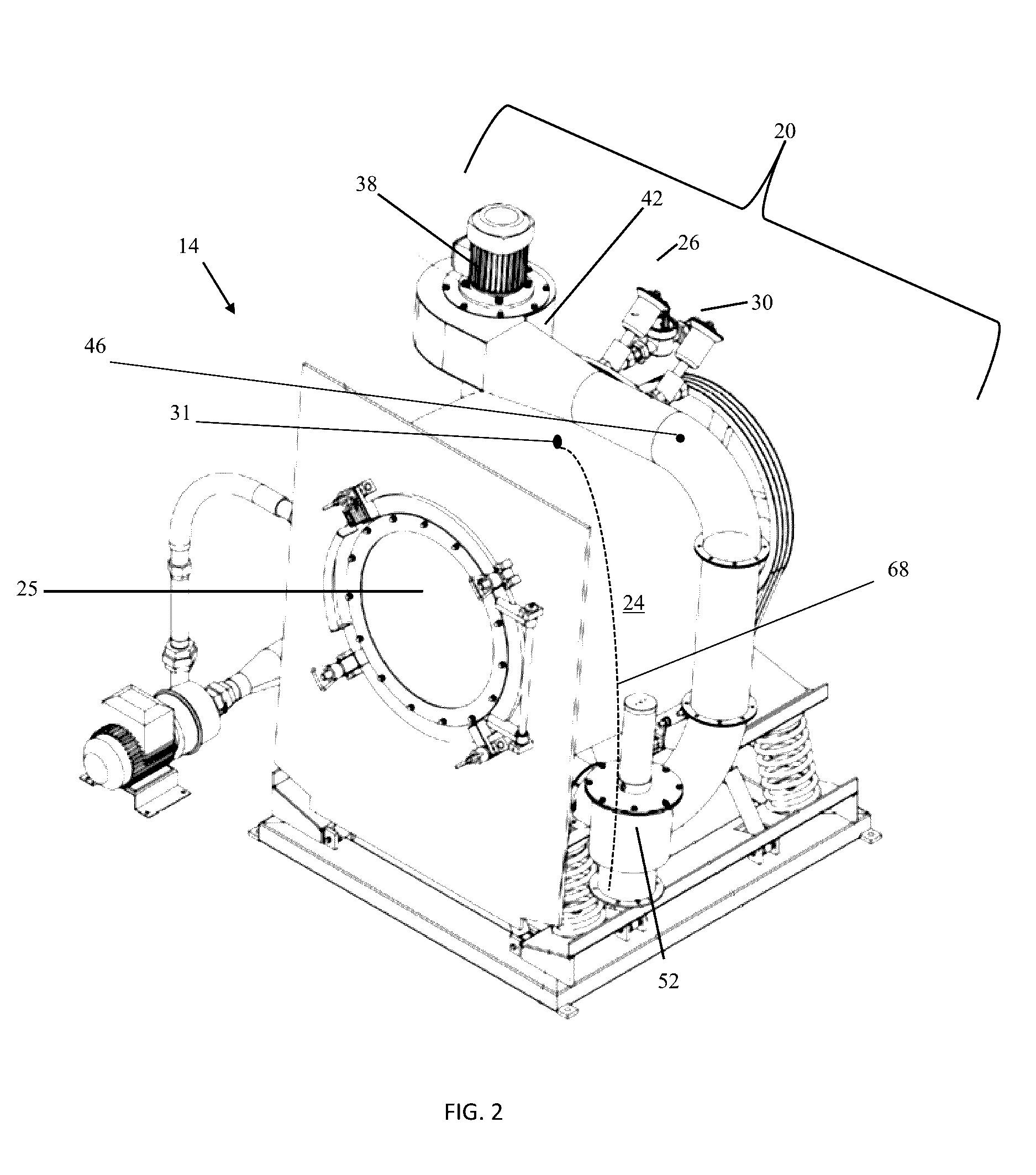

Ozone process for color removal

ActiveUS20170016175A1More reliable and reproducibleTextile treatment containersLiquid/gas/vapor article treatmentControl systemWastewater

Embodiments relate generally to methods and systems for bleaching textiles using ozone gas that incorporates a color removal step. In one example, there is provided a hybrid machine that incorporates certain features of a washer, but that also includes an integrated blower for gas distribution inside the machine. There is also provided an ozone dosing control system that allows for maintenance of a constant concentration of ozone in the machine. In one embodiment, the ozone output measured in grams / hour at this constant concentration in conjunction with the weight of product measured being treated may be referred to as the “bleaching factor.” There is further provided a wastewater dye removal step, in which ozone is used to clean the water and remove dyes and other colors that may be deposited via denim or other garments.

Owner:GUARDIAN MFG

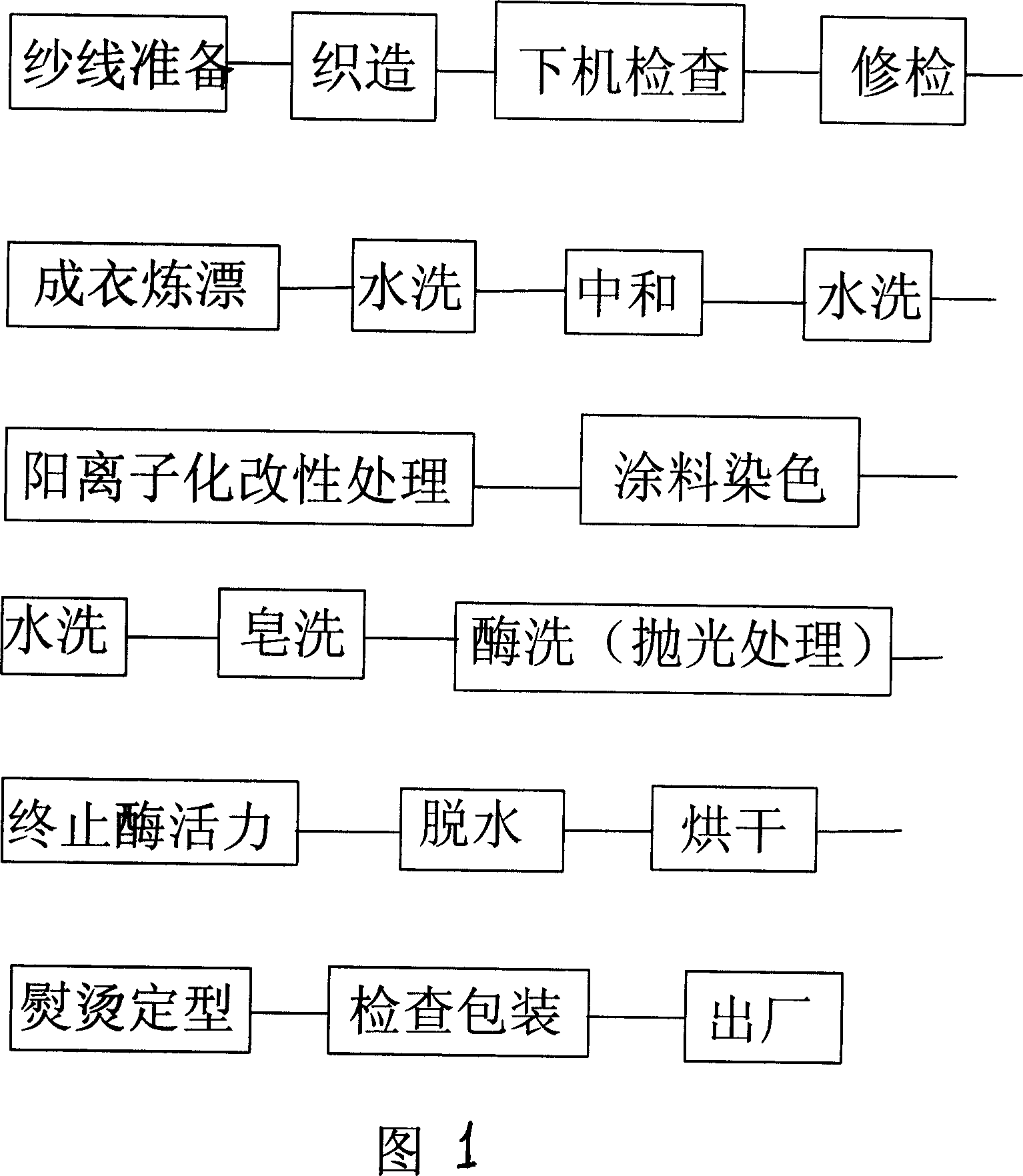

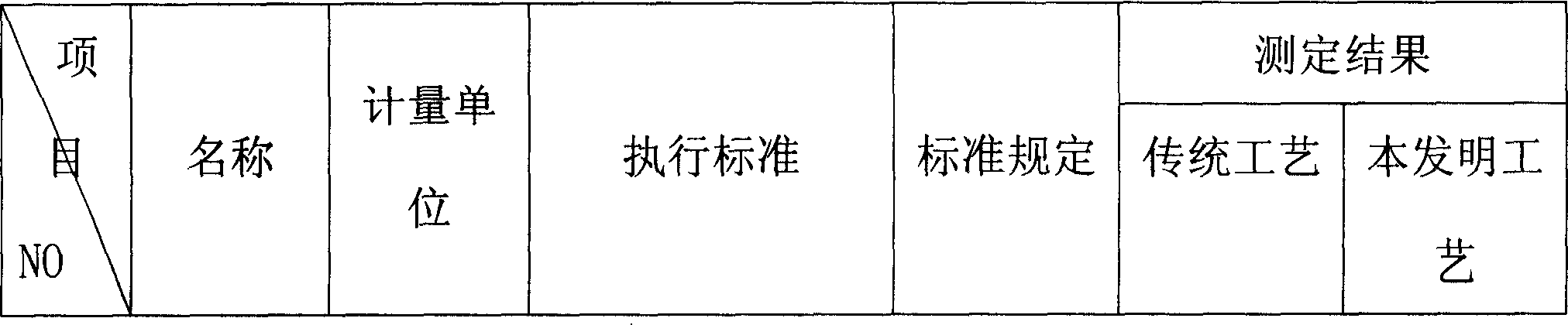

Technical method of pigment wash, dye, and general finish for ready-made clothes in pure cotton

InactiveCN101003952AIncrease profitImprove pass rateLiquid/gas/vapor article treatmentDyeing processFiberCellulose

The present invention relates to a pure cotton garment washing, dyeing and finishing process. Said process successively includes the following steps: preparing cotton yarn, weaving, placing pure cotton garment into garment dyeing machine, preparing scouring and bleaching solution according to technological formula, scouring and bleaching to predefined time, washing, neutralization, washing; using cationic modifying agent whose dose is 1-3% of garment weight to make cotton fiber undergo the process of cationic modification treatment to predefined time; thermostatical dyeing to predefined time, washing, soaping, washing; using cellulose whose dose is 2% of garment weight to make enzymatic washing (polishing treatment) to predefined time, under the alkaline condition stopping enzymatic active action; dewatering, drying and finalizing the design.

Owner:海城市宏泰纺织印染有限公司

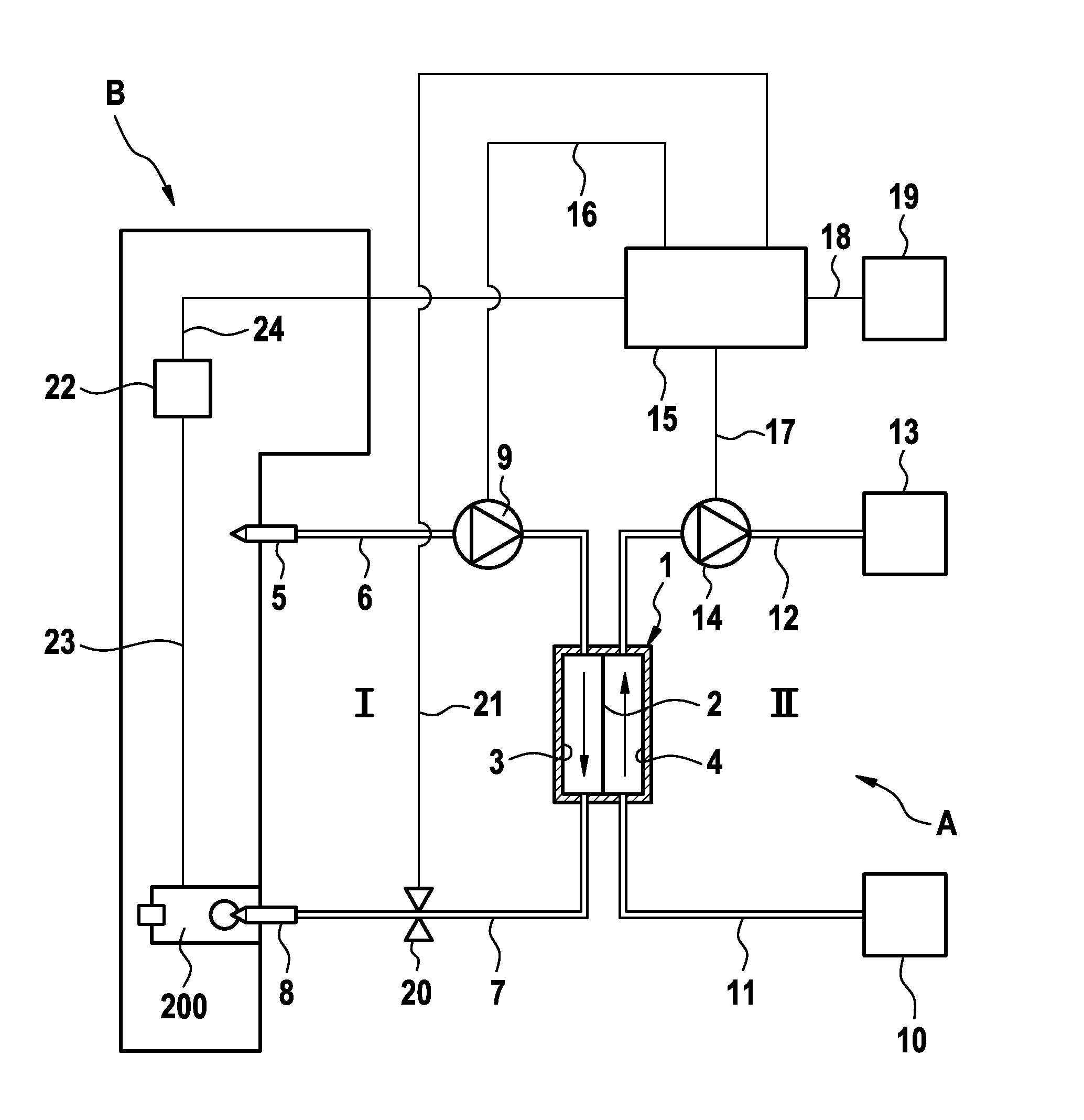

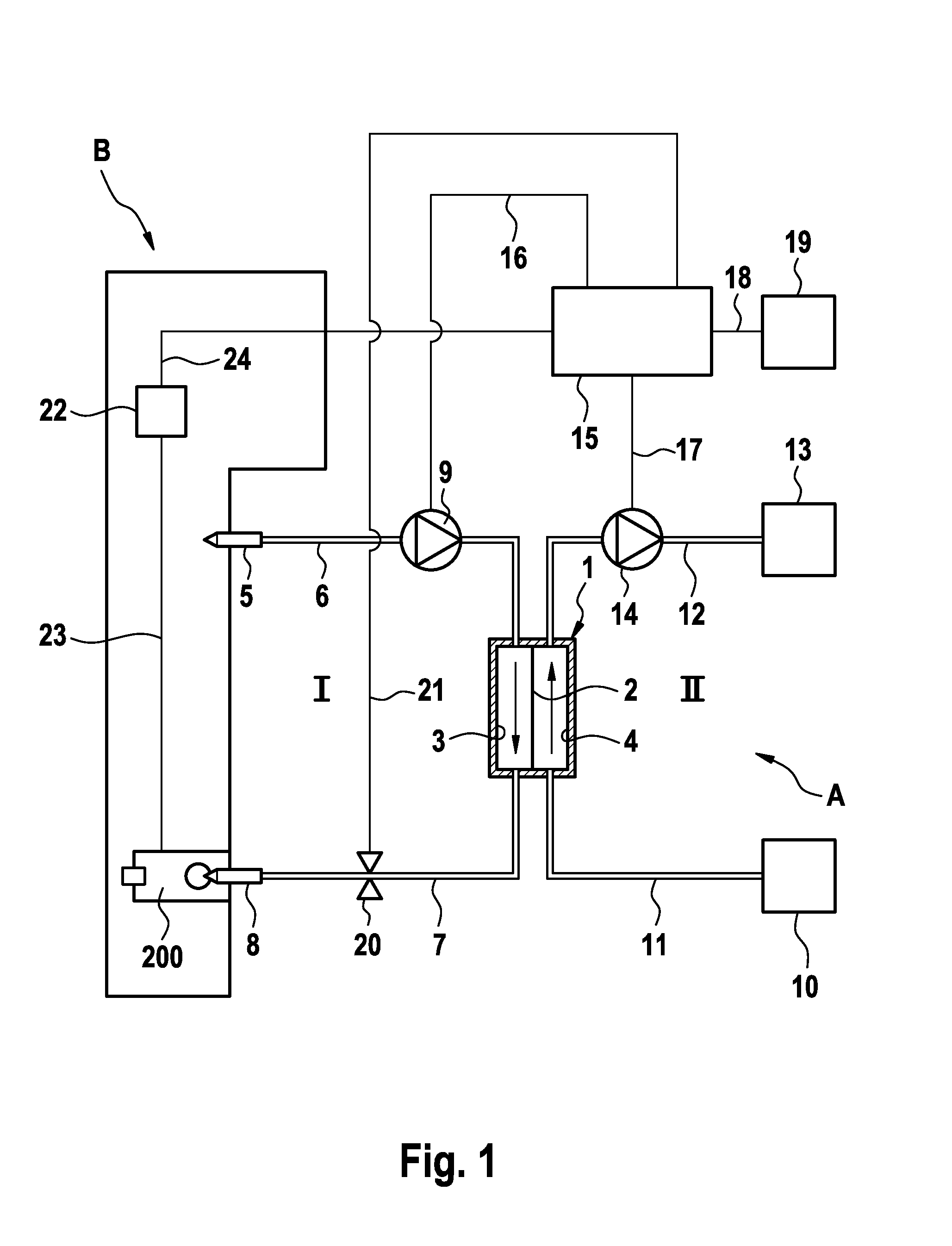

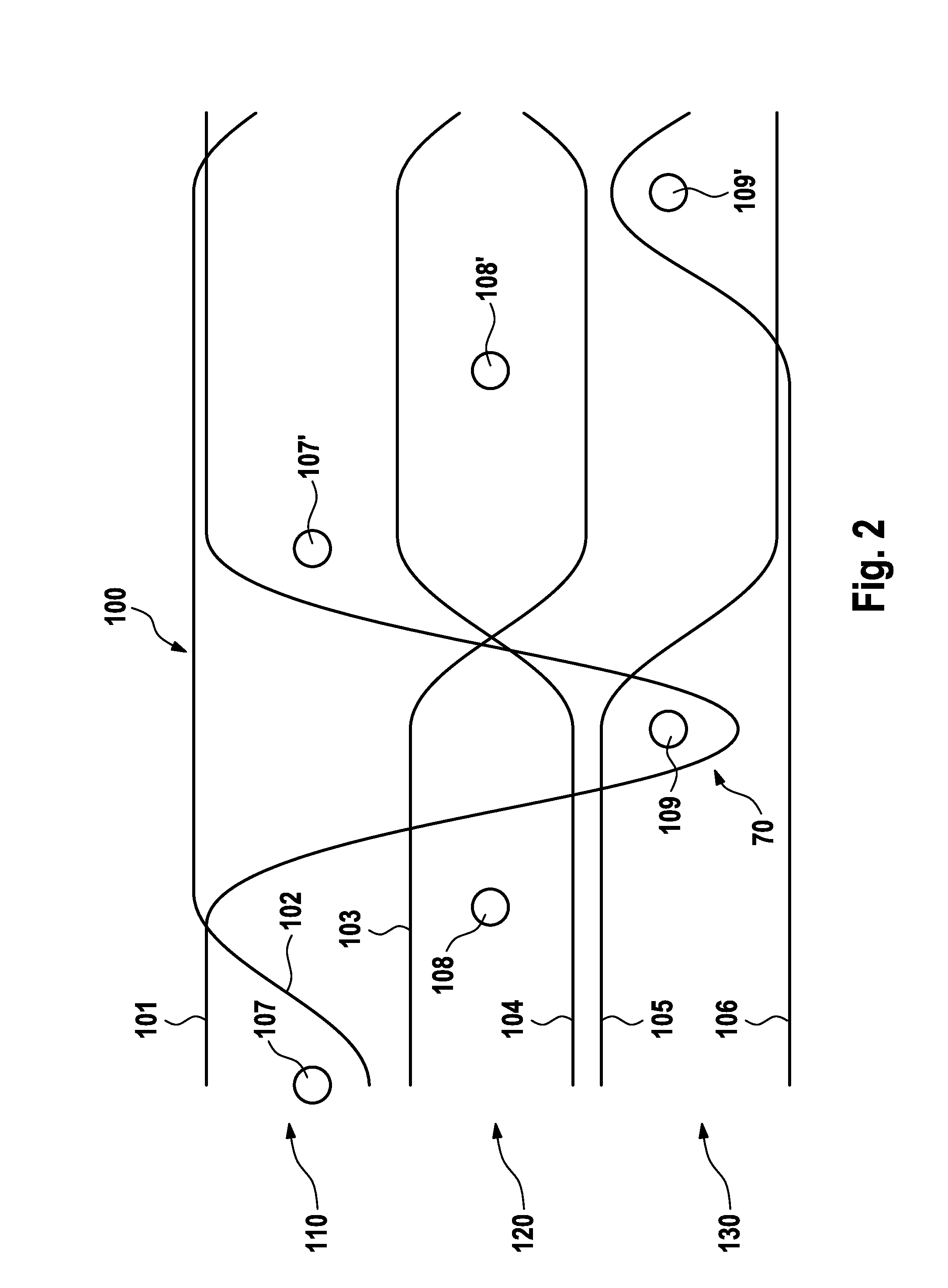

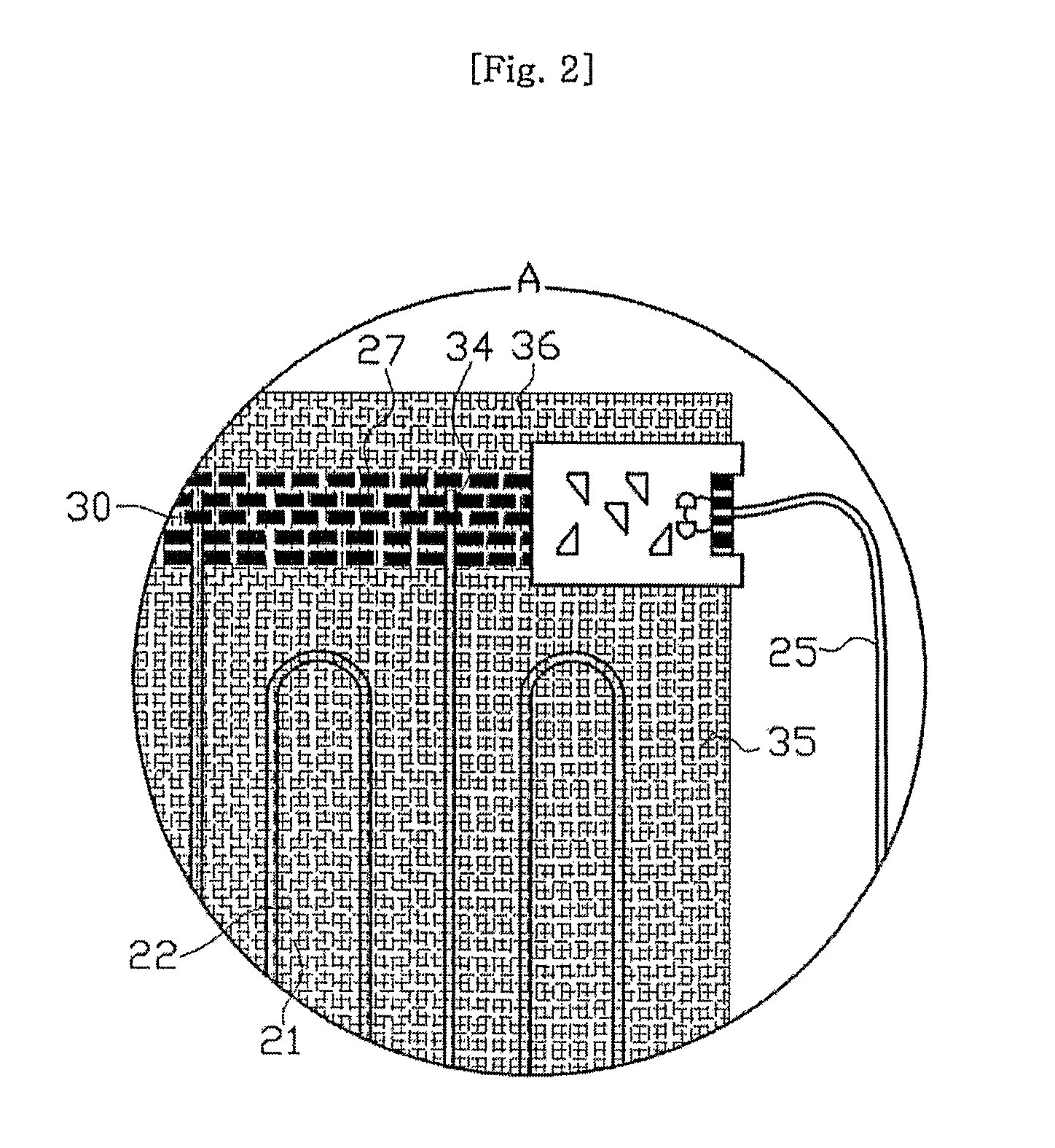

Weaving method for producing a plurality of moisture sensors for a device for monitoring a patient access

ActiveUS20130075018A1Produced cost-effectivelyLow production costCrochetingLiquid/gas/vapor article treatmentBlood treatmentsElectrical conductor

A weaving method for producing a plurality of moisture sensors for a device for monitoring an access to a patient, in particular for monitoring the vascular access in an extracorporeal blood treatment, wherein the moisture sensors are woven. During the weaving of the moisture sensors, non-conductive warp threads, non-conductive weft threads, conductive warp threads and conductive weft threads are disposed in the textile two-dimensionally extending structure, such that spatially demarcatable structures of electrical strip conductors are created. The strip conductor structures can be produced by spatial separation or contacting of the conductive warp or weft threads. In order to be able to produce the moisture sensors cost effectively in large numbers, a plurality of individual moisture sensors are repeatedly woven each time beside one another normal to the production direction on a common woven fabric web as the web progressively advances, so that the width of the woven fabric web is occupied in the best possible way by as many moisture sensors as possible. The individual moisture sensors are separated from one another after weaving.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

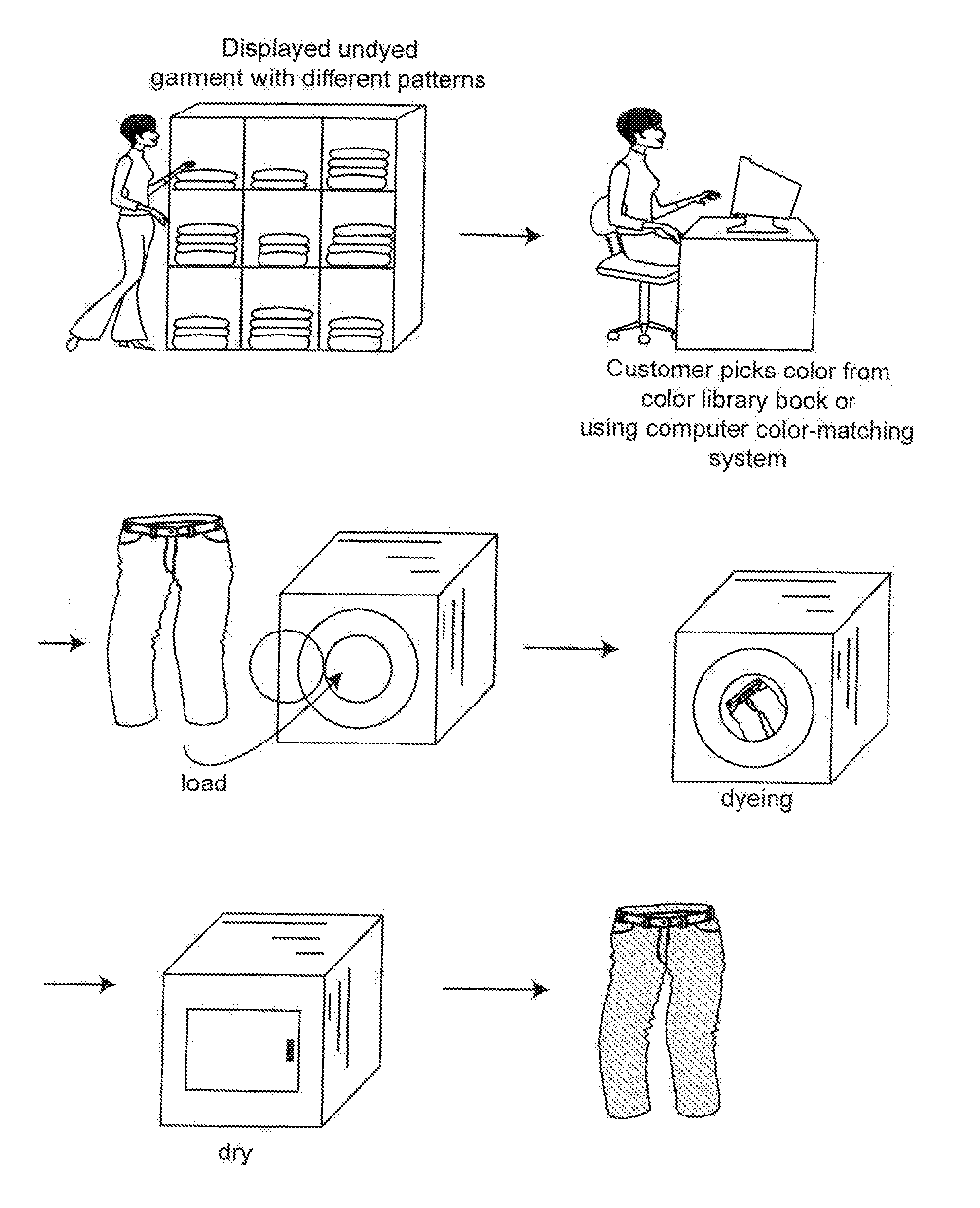

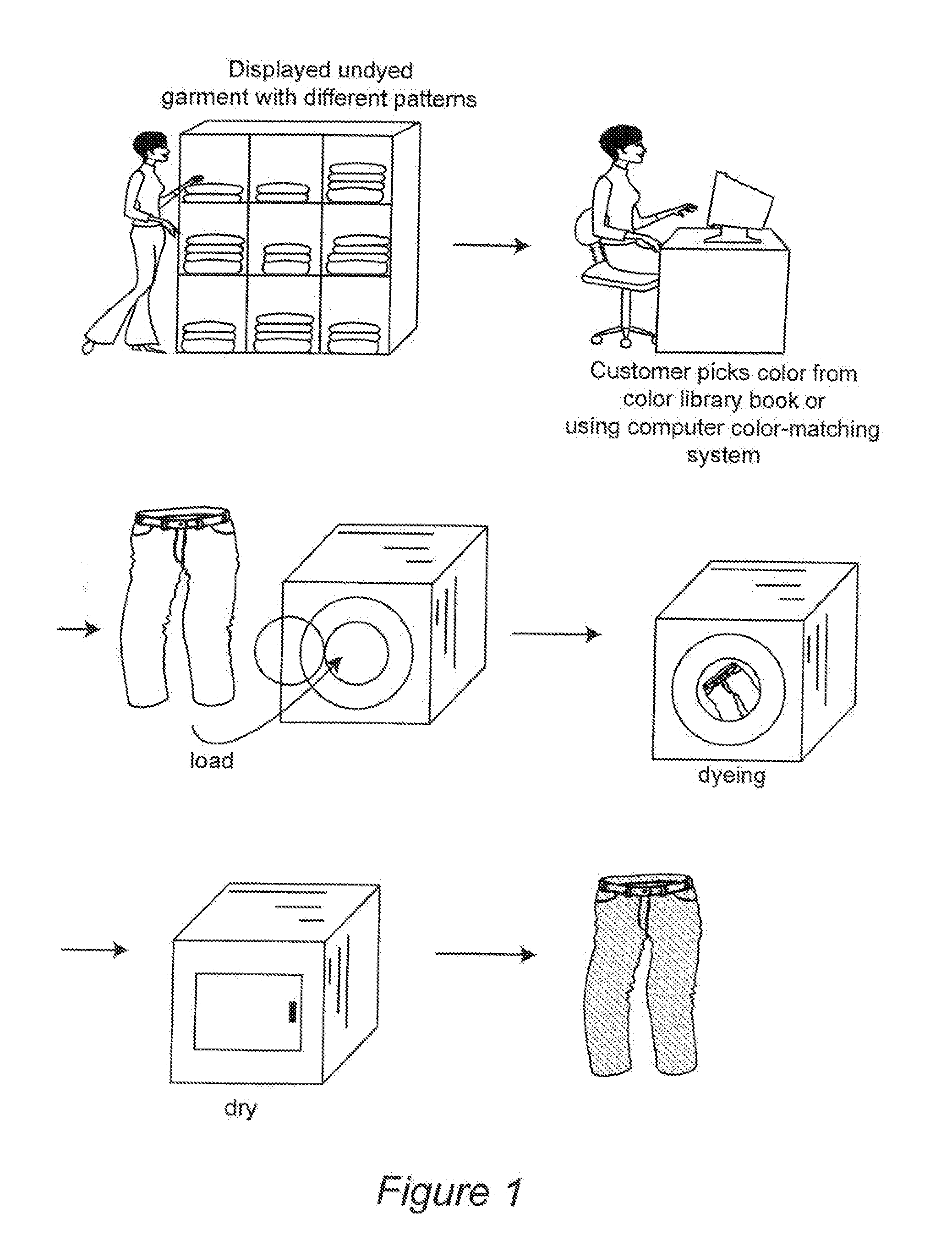

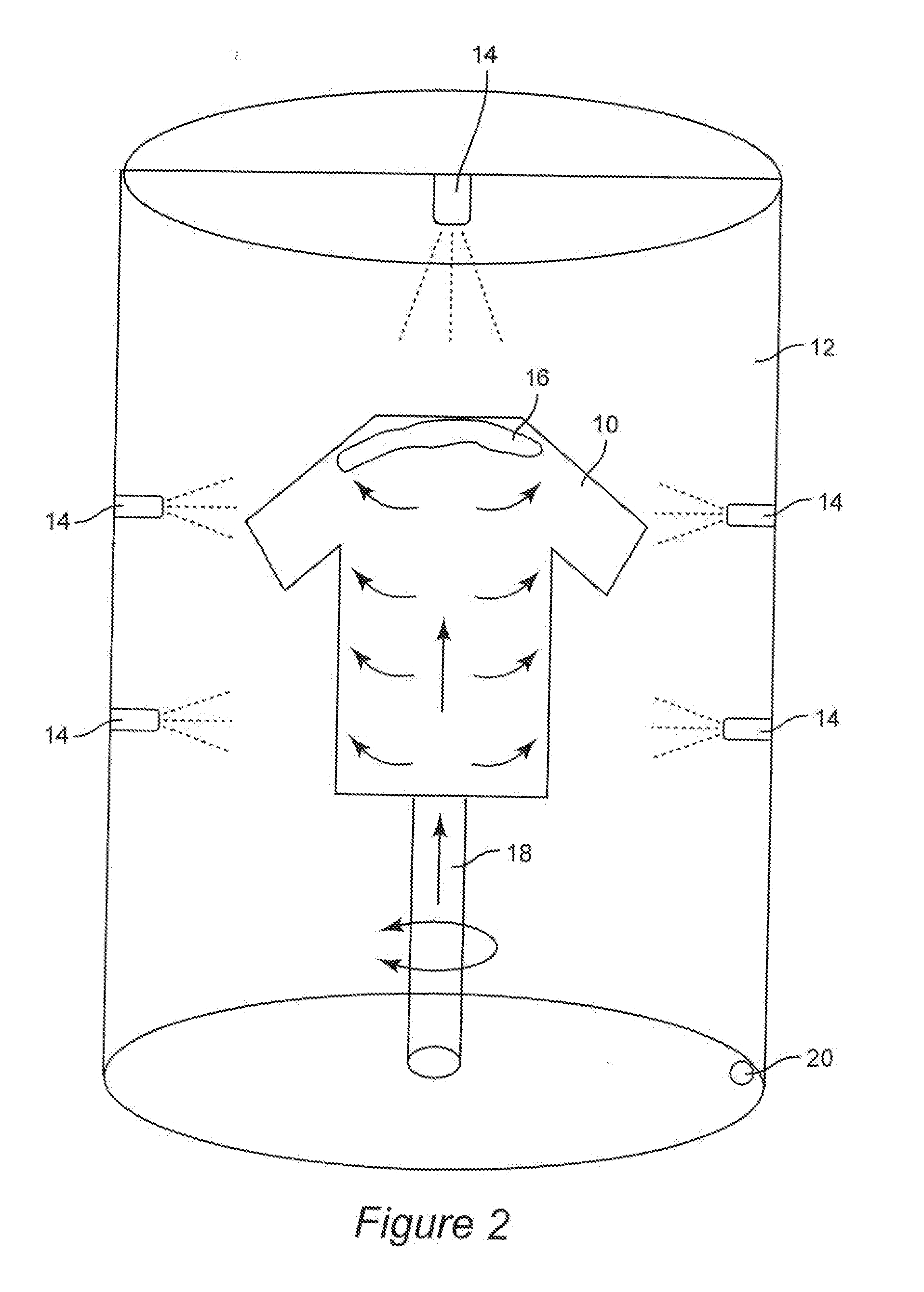

Customer-Created Textiles and Customer-Oriented Garment Dyeing Machine

ActiveUS20110016019A1Enhance educational experienceImprove entertainment experienceTextile treatment containersLiquid/gas/vapor article treatmentYarnEngineering

Customers obtain customized textile materials by selecting style, shape, size, pattern and color for an undyed textile product. Based on a selection made by the customer, the textile product is transformed by a dyeing operation performed on a single item (or multiple items selected to be dyed the same) to yield a product, such as a shirt, pants, or jacket, which has a color and pattern of his or her own choosing, in the size and style he or she desires. The process can be performed in a retail setting using a dye apparatus which allows the process to be viewed by the customer. Preferably, the textile material is constructed from yarns which include cationic cellulosic fiber alone or in combination with natural or synthetic fibers, and using anionic dyes, such as a fiber reactive dye, such that the dye is exhausted during the process and effluent from the dye machine is environmentally friendly without excess dye, salts, and alkalis. To enhance the educational and entertainment experience of the customer, the dyeing operation can be performed in a transparent tank or water kettle in the retail outlet so that the customer can view, for example, the garment as it is being dyed to the customer's specifications.

Owner:TINTORIA PIANA US

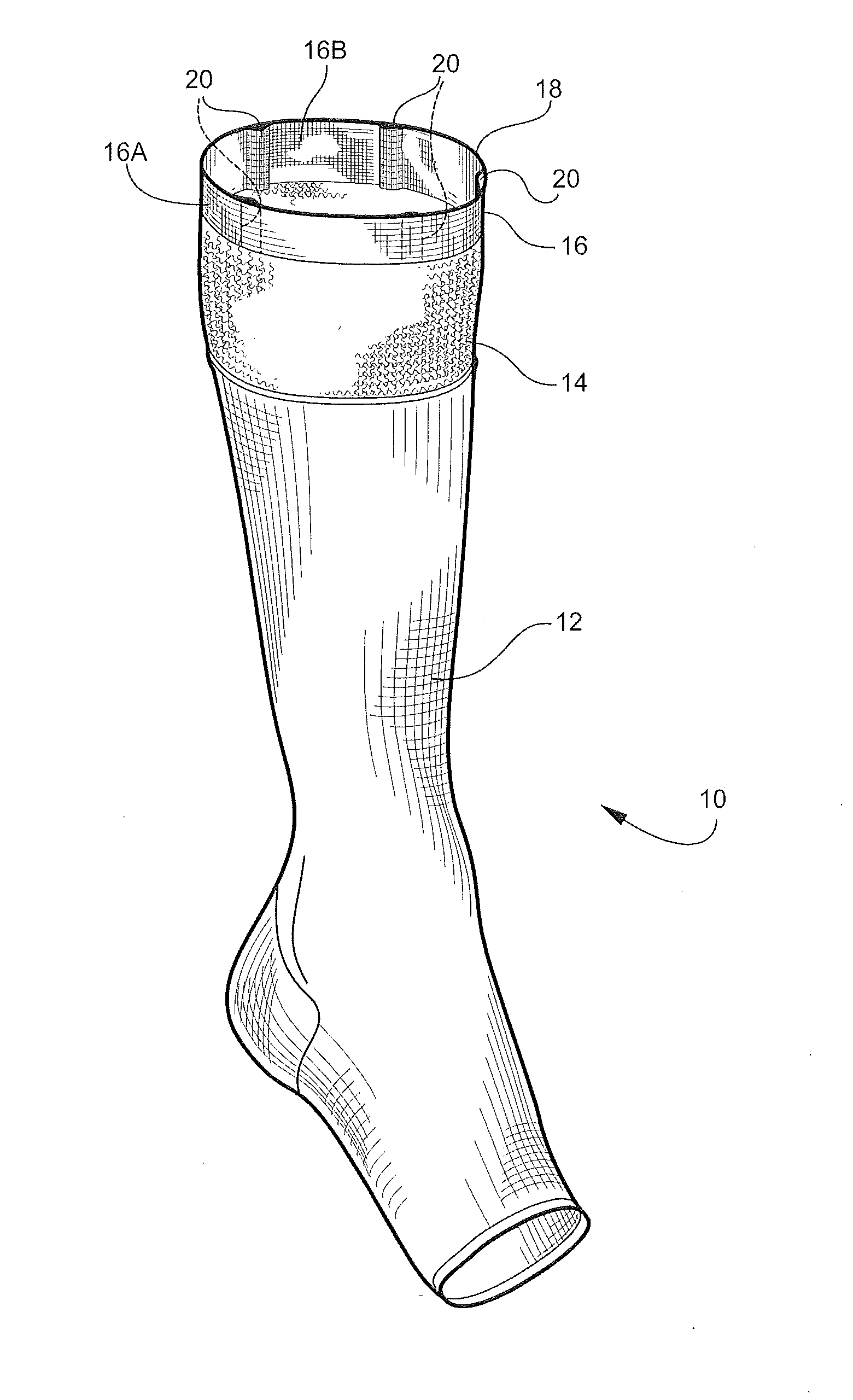

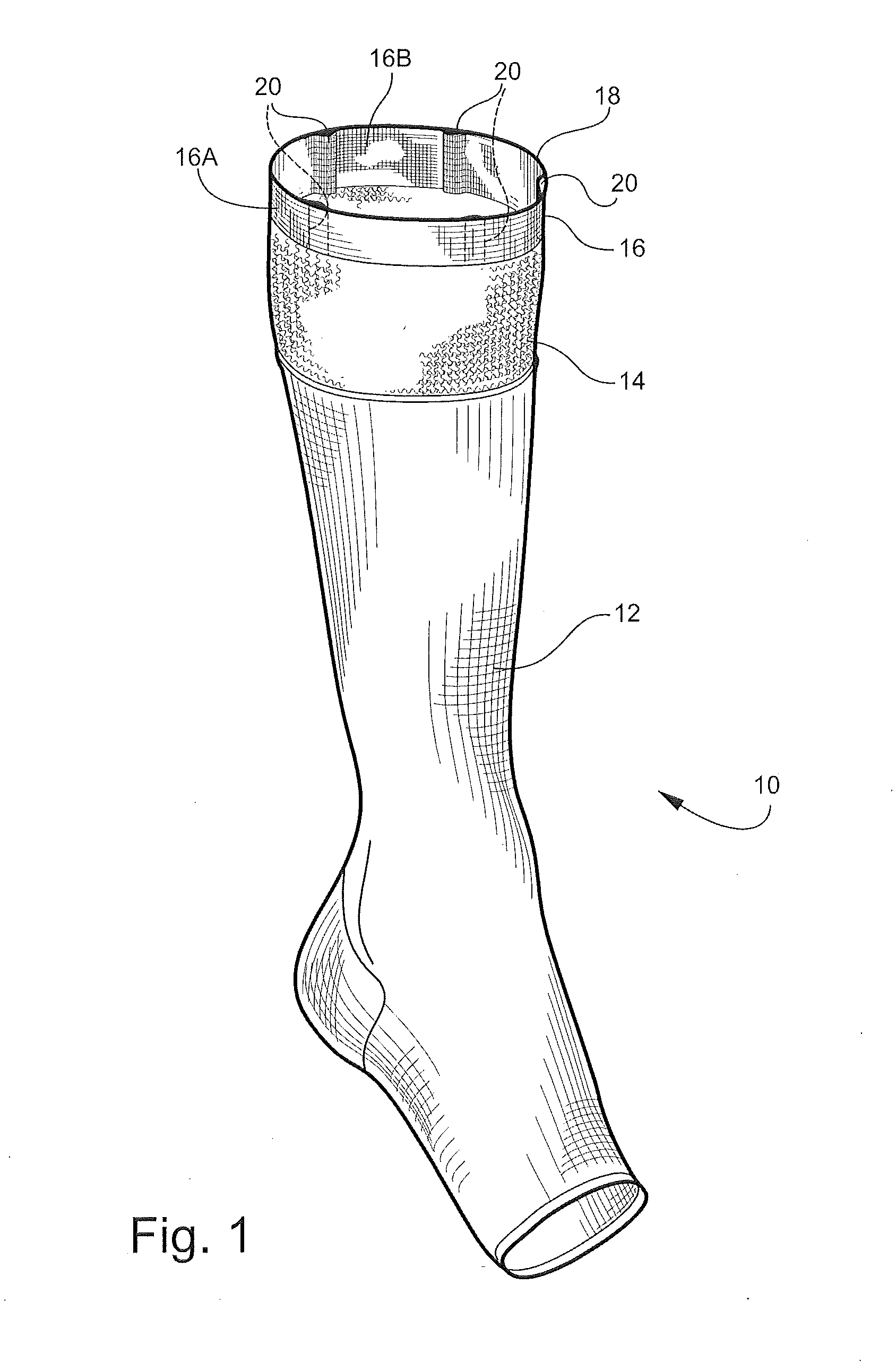

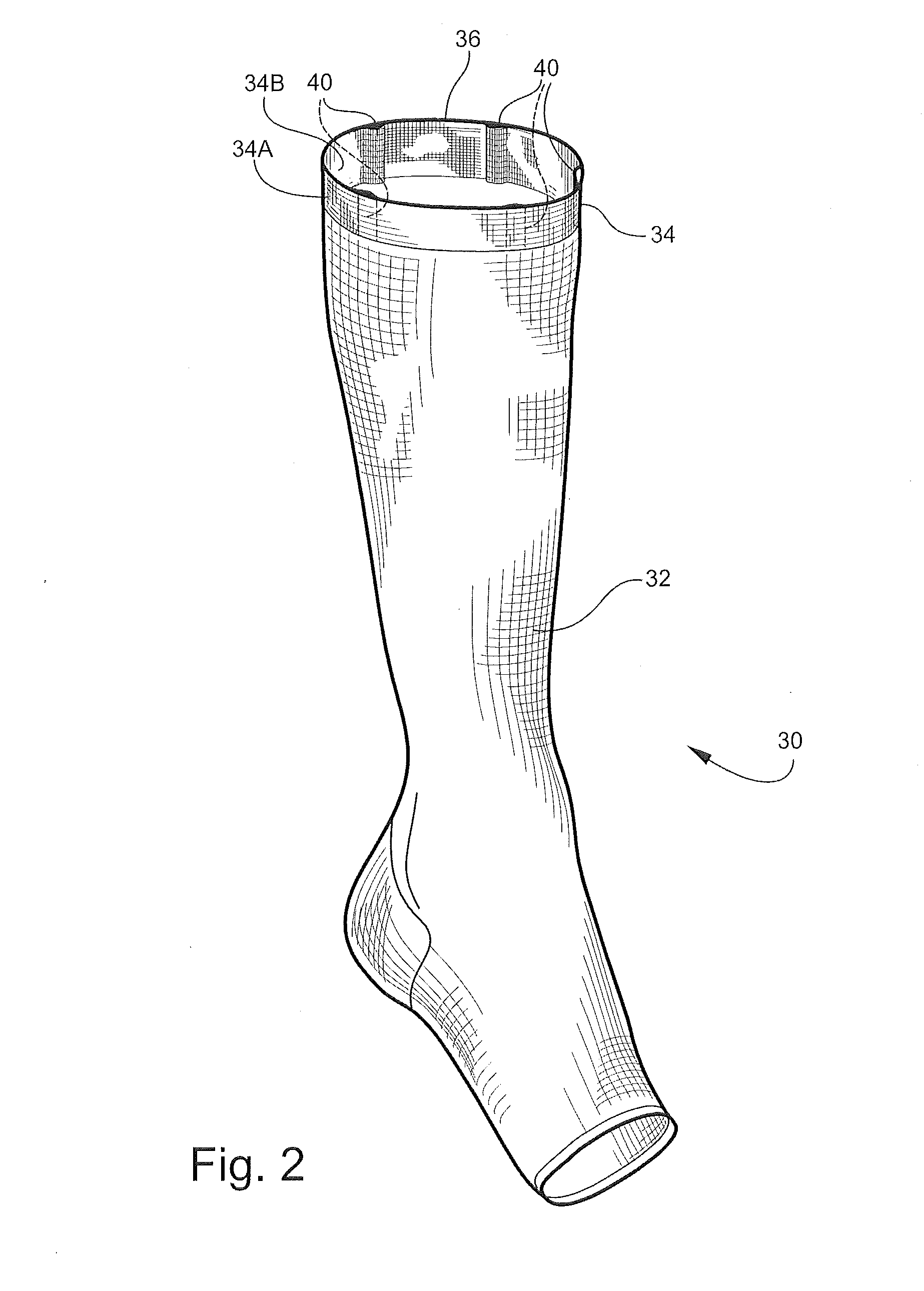

Therapeutic medical compression garment and method

ActiveUS20160038346A1Inhibit wearWelt becomes stableShrinkingNon-adhesive dressingsEngineeringBiomedical engineering

A therapeutic medical garment including a knitted welt proximate one end thereof with a surface adapted for residing against the wearer's skin. The garment includes a ground yarn and a plurality of raised, skin-engaging stabilizer elements, such as elongate bars extending in spaced-apart relation around an inner surface of the welt and along a longitudinal axis of the garment to reduce a tendency of the welt to roll over on itself.

Owner:BSN MEDICAL INC

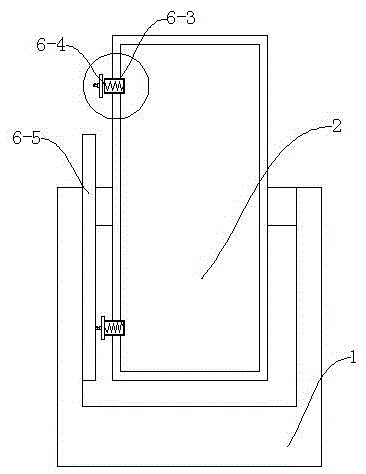

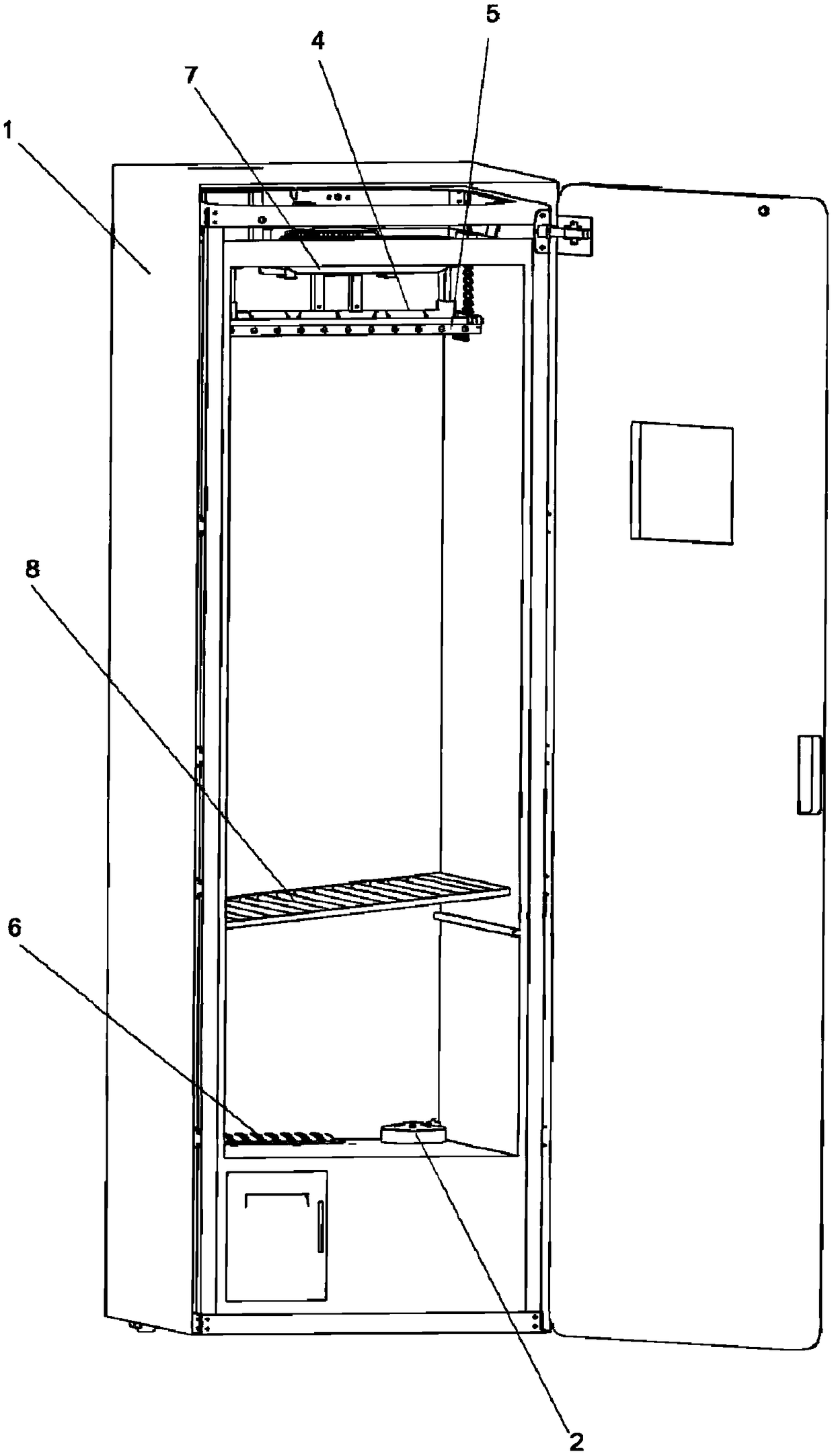

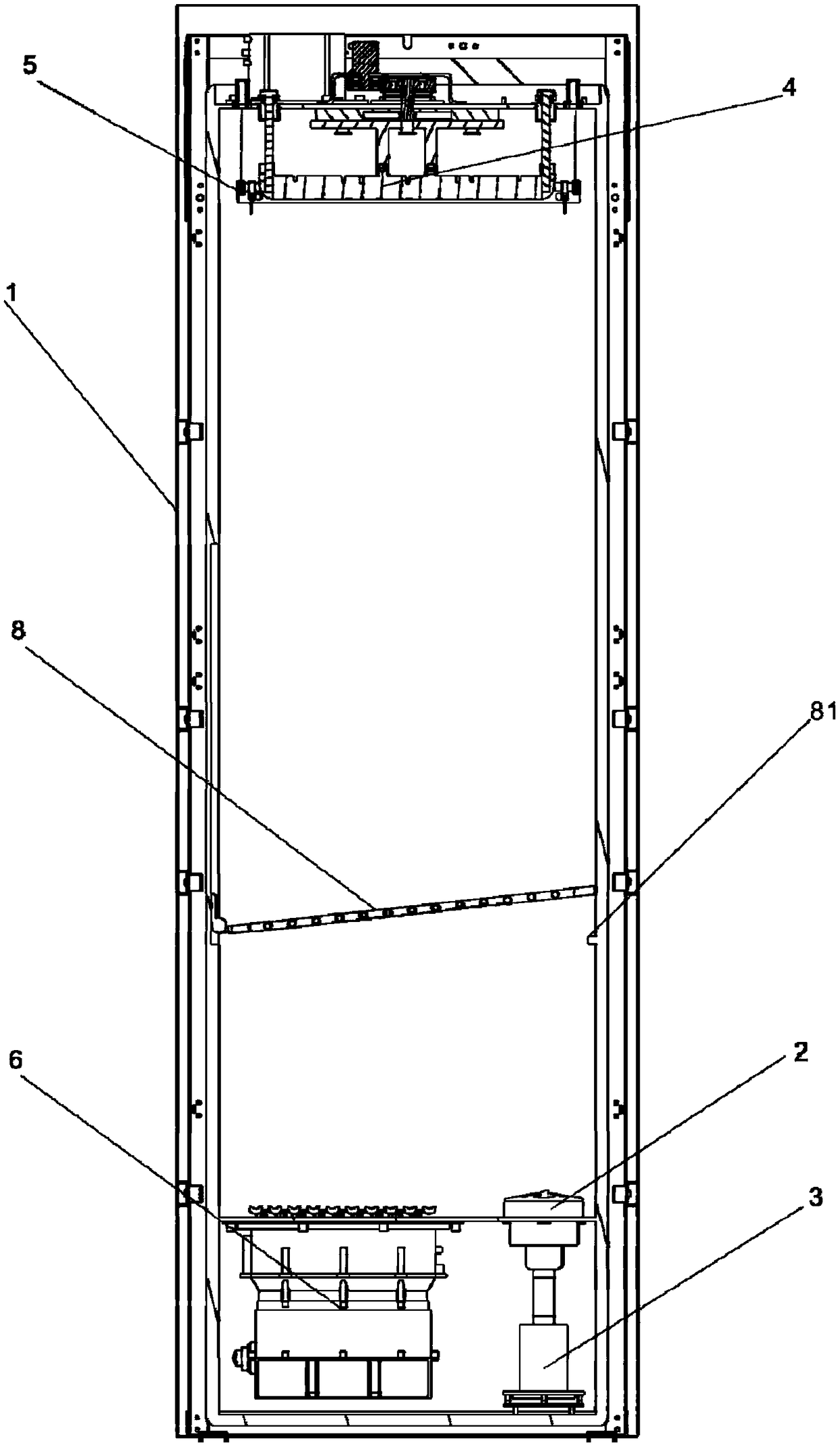

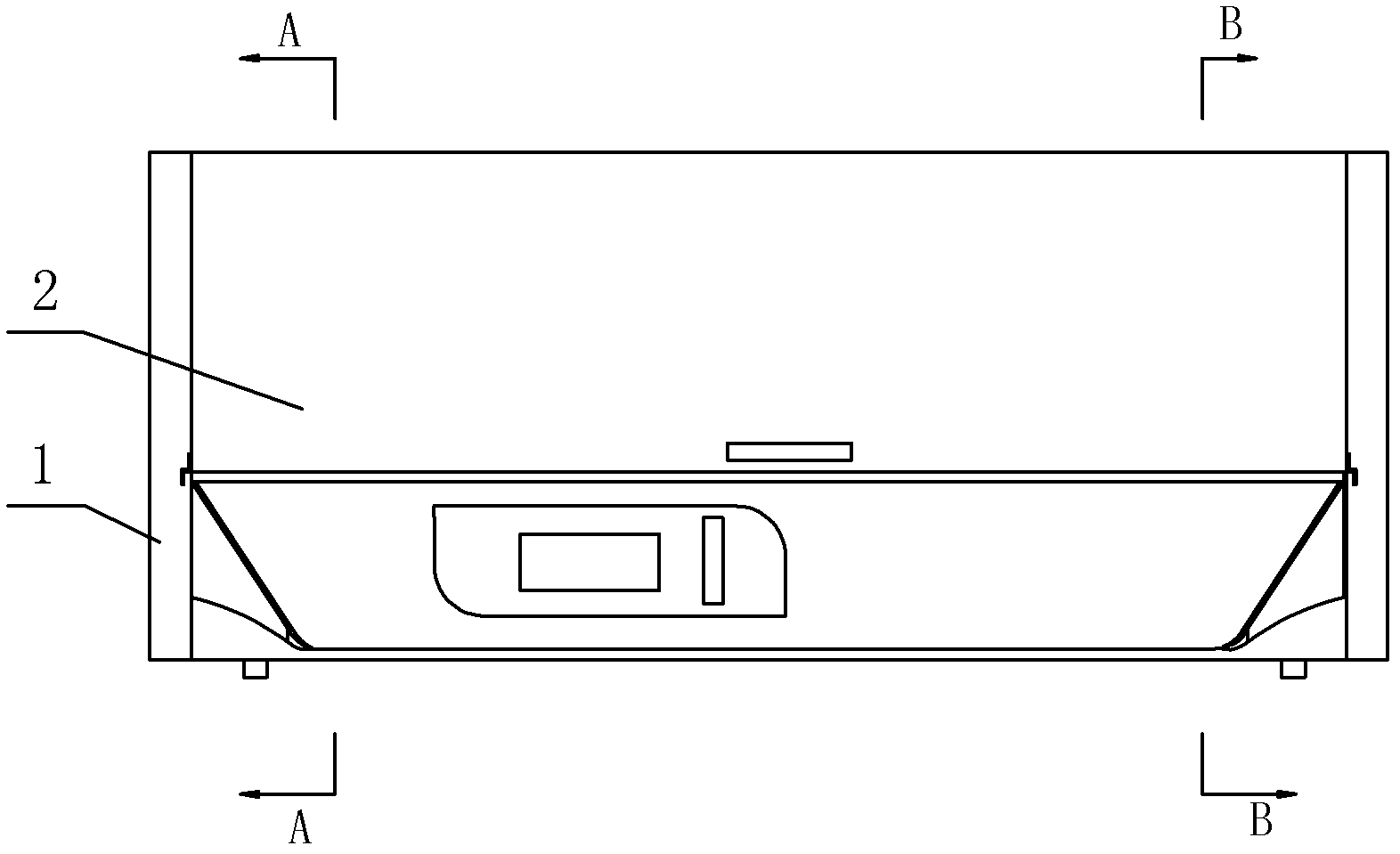

Clothing care machine

ActiveCN109082867AIncrease exerciseImprove diffusion efficiencyLiquid/gas/vapor article treatmentIroning apparatusAromatherapyEngineering

The invention discloses a clothing care machine. The machine includes a cabinet, a steam generator and an aromatherapy device, wherein the steam generator and the aromatherapy device are fixedly connected with the inside of the cabinet. The cabinet has a space for accommodating clothing, the aromatherapy device is communicated with the output end of the steam generator, and steam output by the steam generator is diffused in the space, used for accommodating the clothing, in the cabinet through the aromatherapy device. By the clothing care machine with the above structure, high-temperature steam can accelerate the movement of aromatherapy molecules in the aromatherapy device when passing through the aromatherapy device, the aroma diffusion efficiency of the aromatherapy device is improved,and thus steam ironing and deodorizing aromatherapy of the clothing can be completed in a relatively short time.

Owner:JOMOO KITCHEN & BATHROOM

Preparation method of ultrahigh molecular weight polyethylene monofilament knotted fishing net

ActiveCN103572502AReduce processing costsReduce the degree of fixationNew-spun product collectionLiquid/gas/vapor article treatmentFiberPolymer science

The invention discloses a preparation method of an ultrahigh molecular weight polyethylene monofilament knotted fishing net. The preparation method comprises the following steps: performing melted extrusion on ultrahigh molecular weight polyethylene raw materials by using an extruding machine; cooling the extruded melt and pre-stretching the melt under the action of a drawing roller; putting initial raw filaments which are formed by cooling into a stretching machine to be subjected to three-stage stretching so as to prepare ultrahigh molecular weight polyethylene monofilaments; reeling monofilament fiber on a reeling machine; weaving the reeled monofilaments into a fishing net on a knotted net weaving machine; performing follow-up treatment and other steps on the woven fishing net, wherein nanometer molybdenum disulfide and nano-graphite are added into the ultrahigh molecular weight polyethylene raw materials. According to the preparation method, the process flow is short; the fiber processing cost is low; the prepared ultrahigh molecular weight polyethylene monofilament knotted fishing net can effectively resist impact of wind wave and large predators, prolongs the service life of meshes and reduces the attached amount of marine organisms.

Owner:王庆昭

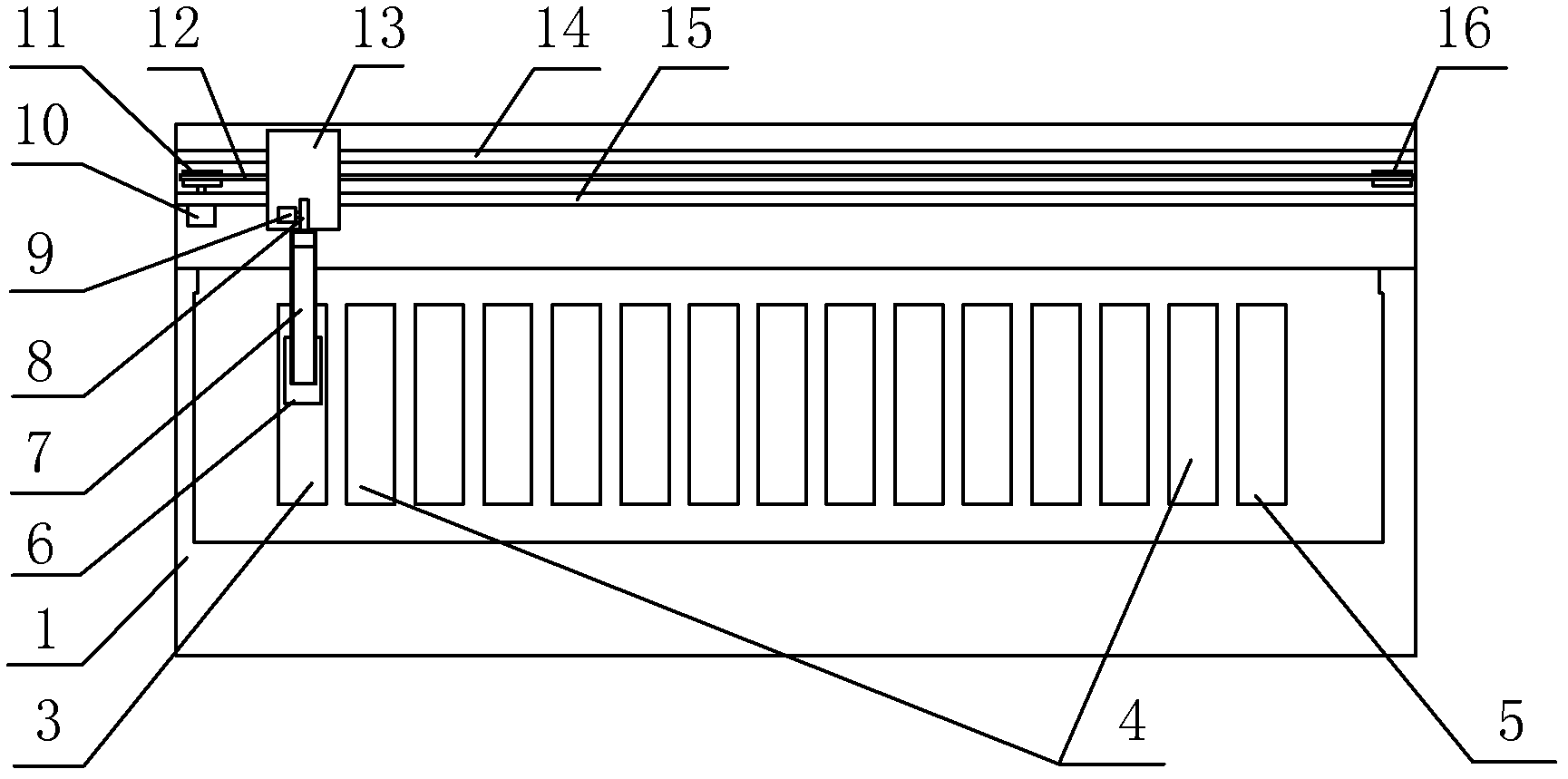

Staining machine

InactiveCN102560929AAvoid contaminationAvoid pollutionLiquid/gas/vapor article treatmentLiquid/gas/vapor removalVertical barStaining

The invention belongs to the technical field of medical equipment, and particularly relates to a staining machine, which is used for staining biological tissues and comprises a body and reagent bottles. The body is provided with an inner cavity, and six to twenty reagent bottles are fixedly transversely disposed in the cavity of the body. The staining machine is characterized in that a washing device and a drying device are disposed in the cavity of the body, a washing cylinder of the washing deice, a drying cylinder of the drying device and all the reagent bottles are positioned on the front lower portion of the inside of the cavity of the body, a hanger frame is positioned on the front upper portion of the inside of the cavity of the body and fixedly connected with a transverse bar of a 7-shaped support bar, a vertical bar of the 7-shaped support bar is disposed on a lifting device, the lifting device is disposed on a connecting plate which is disposed on a transverse displacement device, and the transverse displacement device is disposed on the rear lower portion of the inside of the cavity of the body. The washing device and the drying device are added, so that thorough cleaning and drying of residual liquid of each step of staining are guaranteed, pollution of next reagent is avoided, and high-purity staining is achieved.

Owner:湖北泰维科技实业股份有限公司

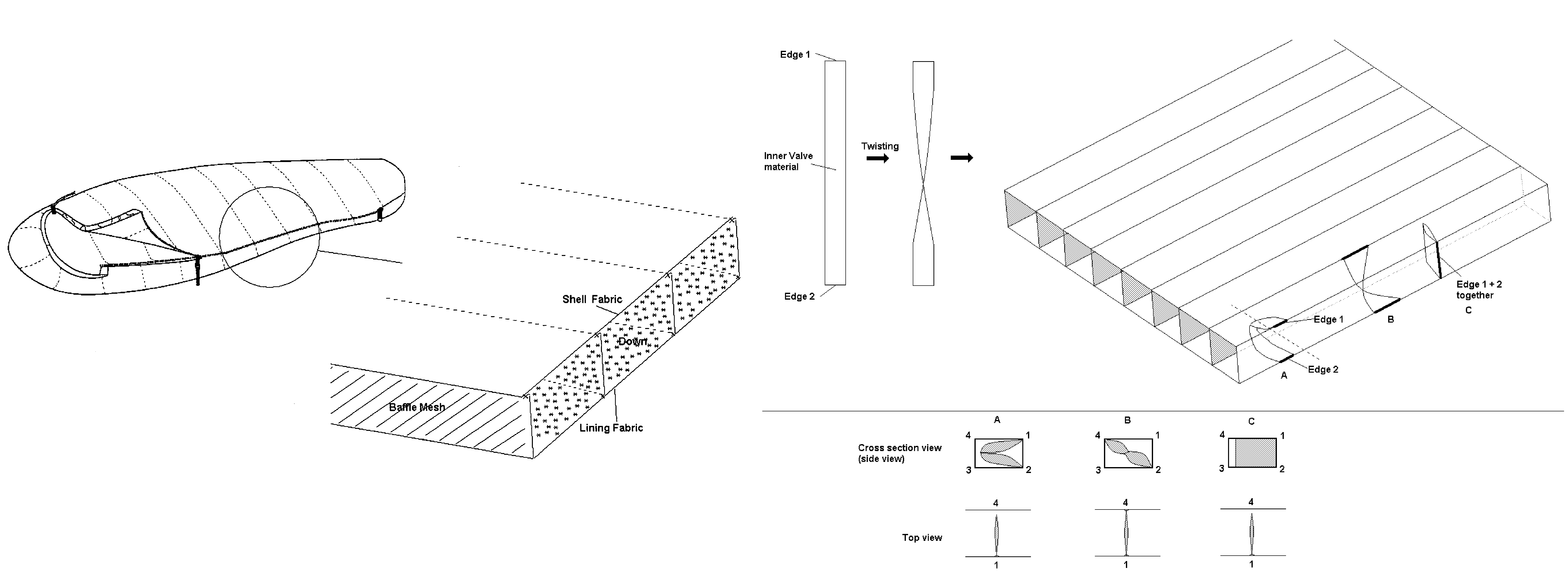

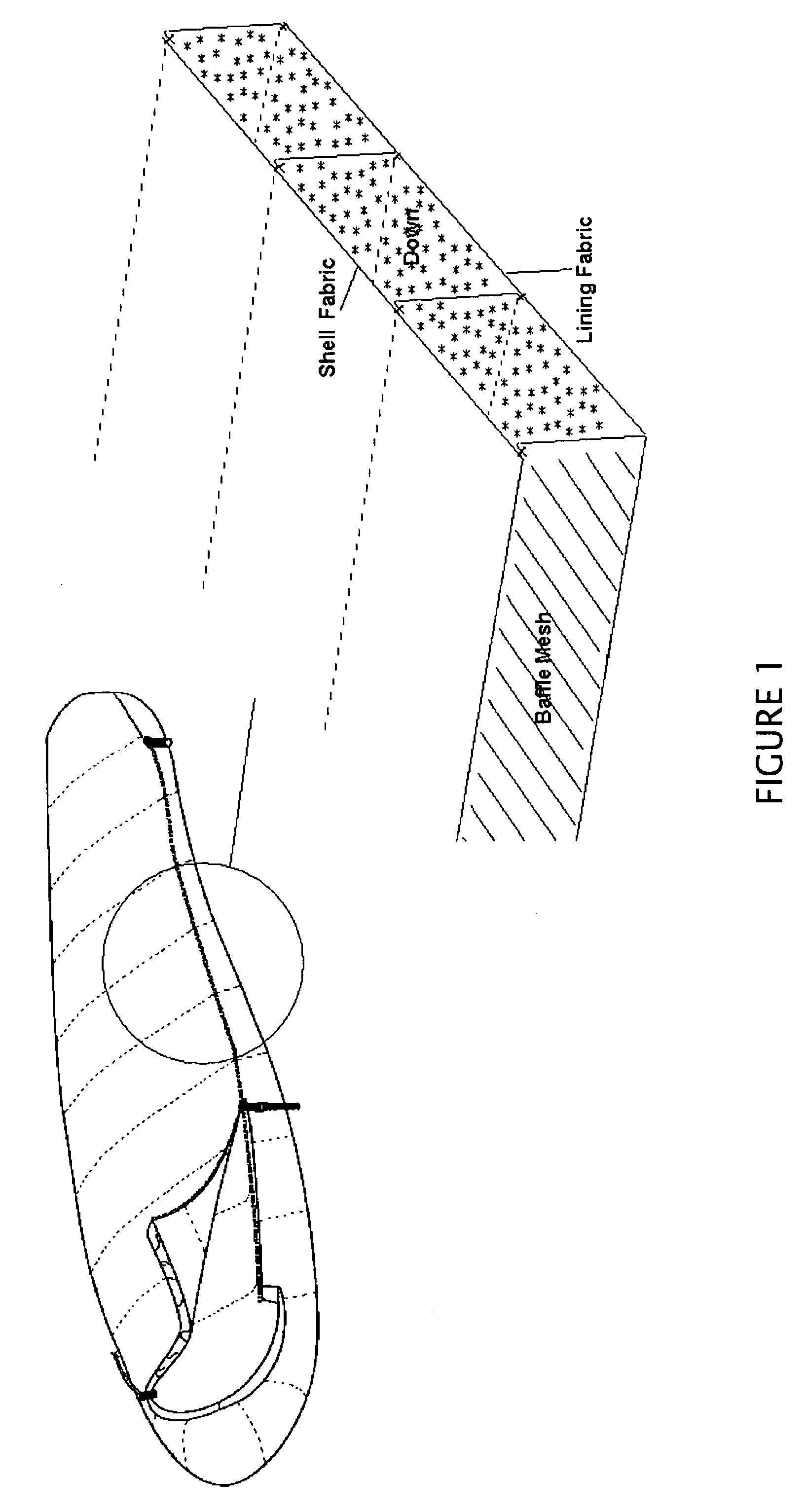

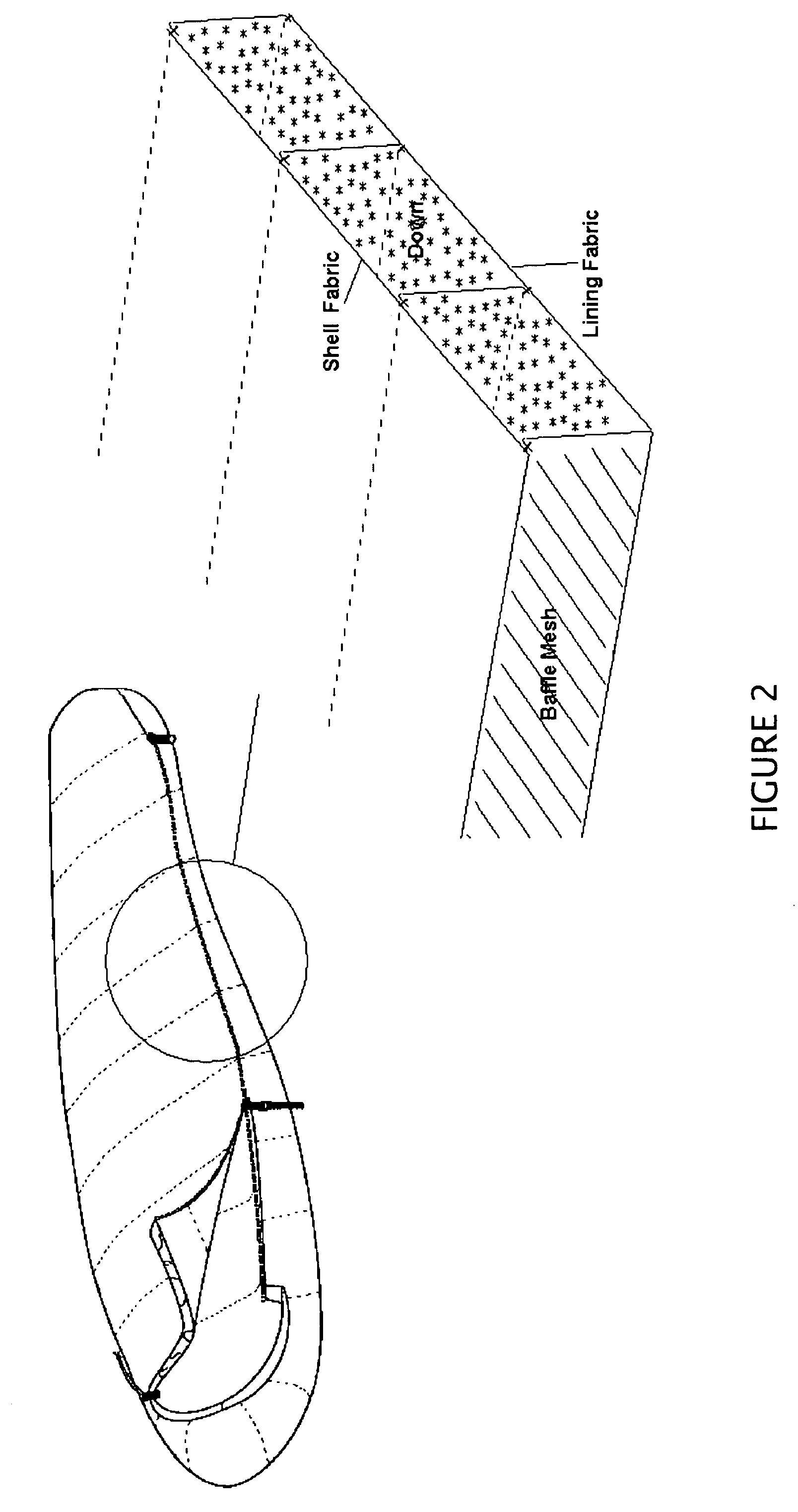

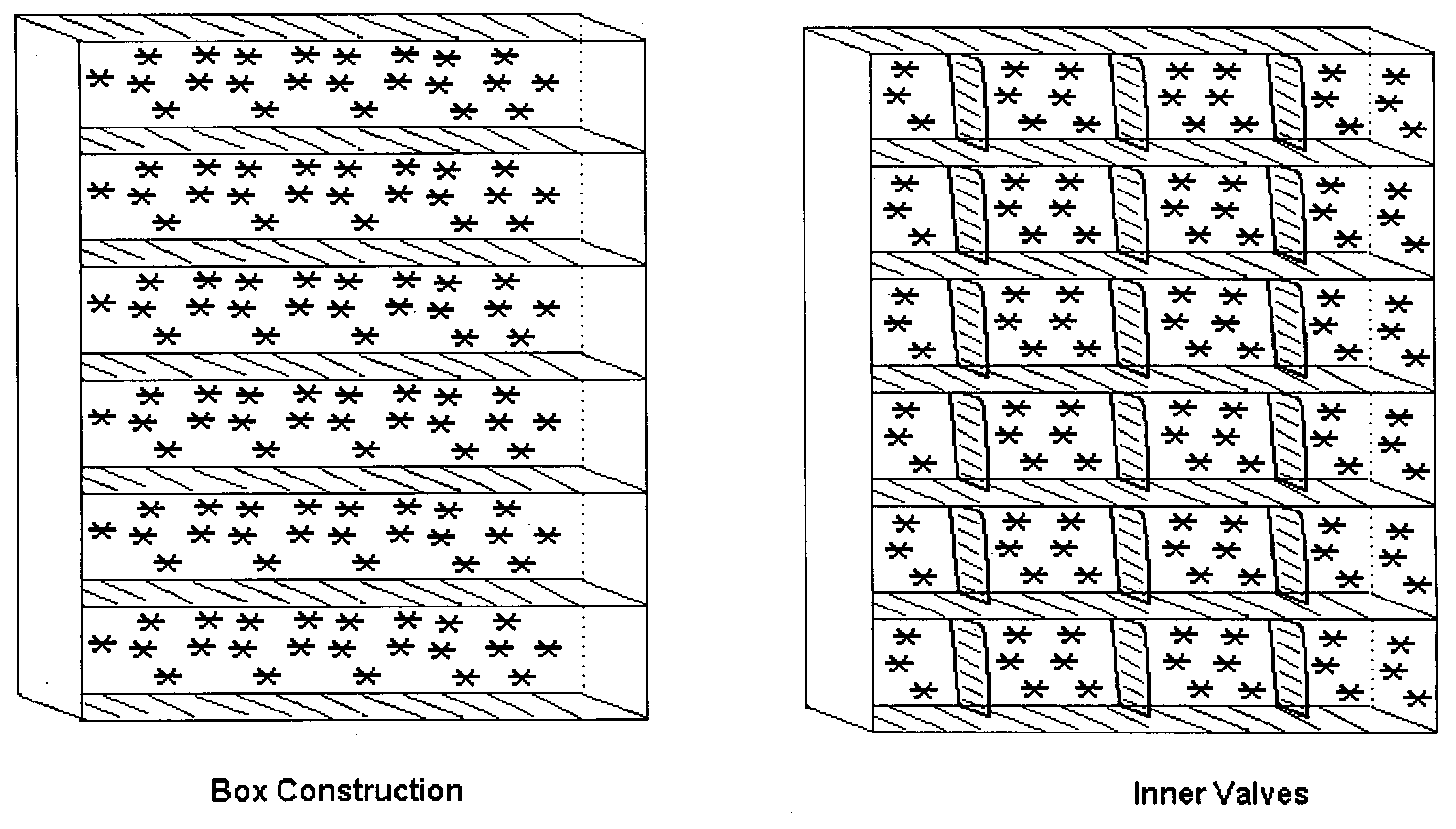

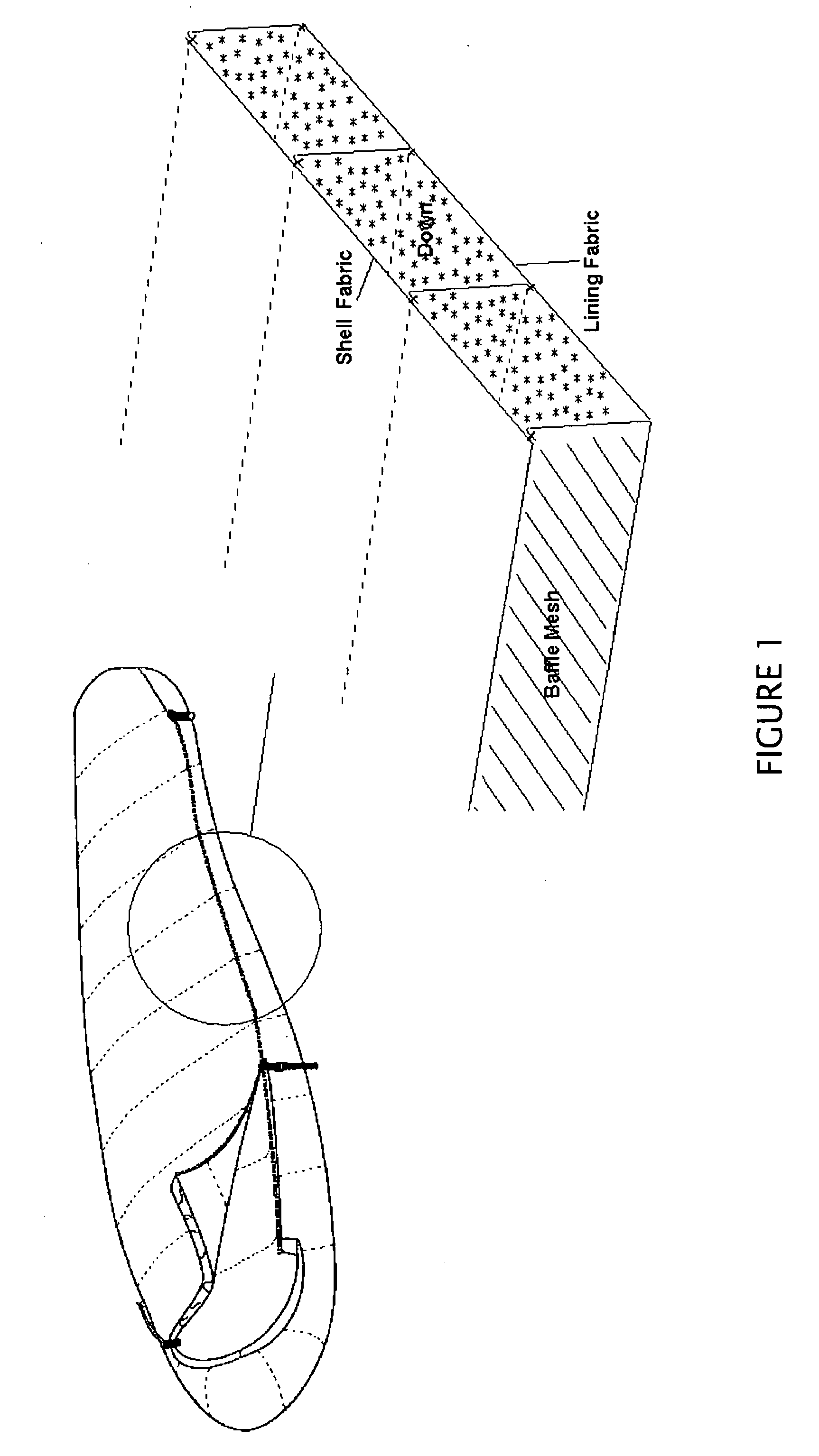

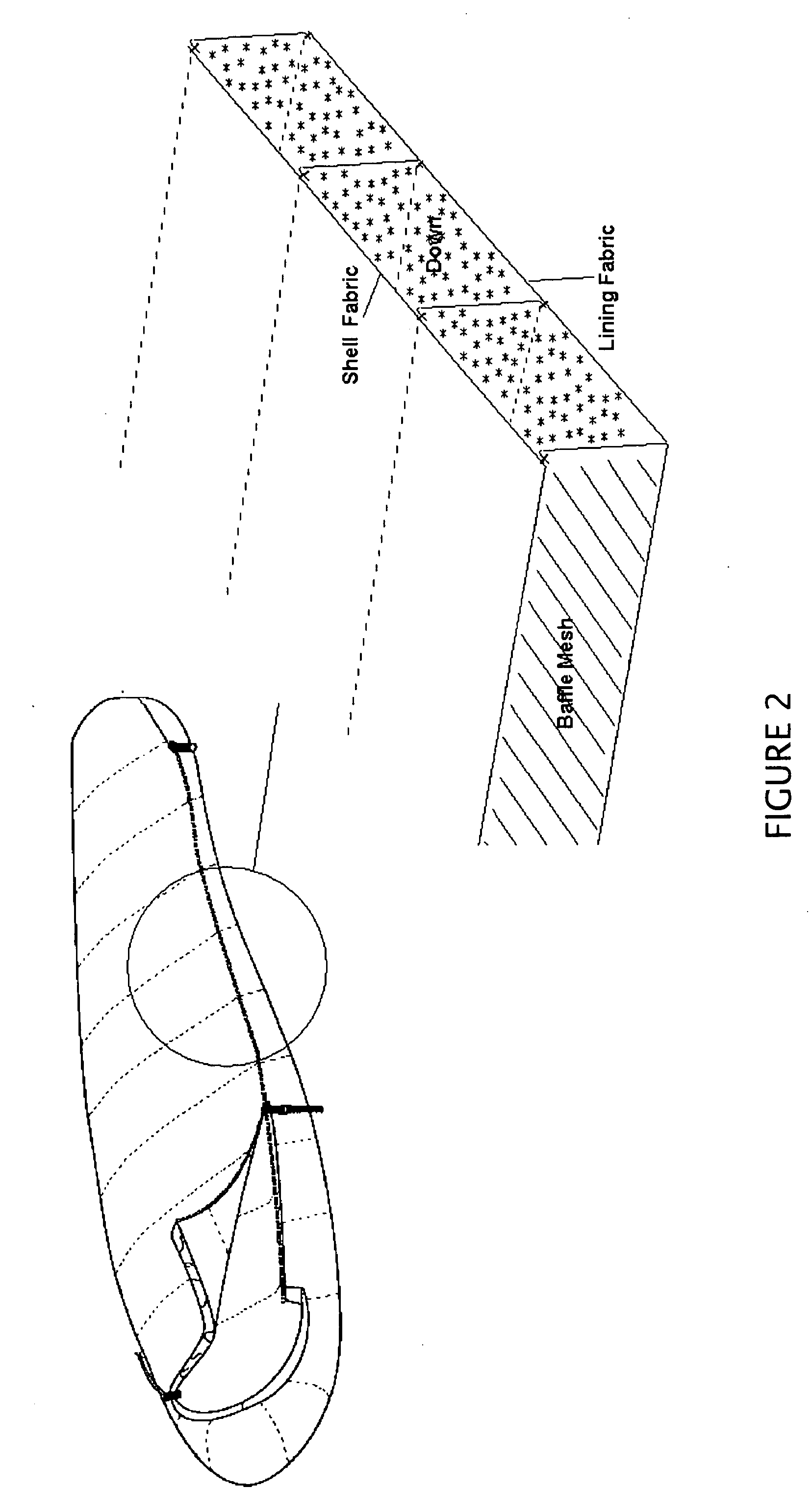

Insulated product

InactiveUS7818834B2More appearanceDesign moreCrochetingGarment special featuresEngineeringVALVE PORT

Owner:LI YICK LAP

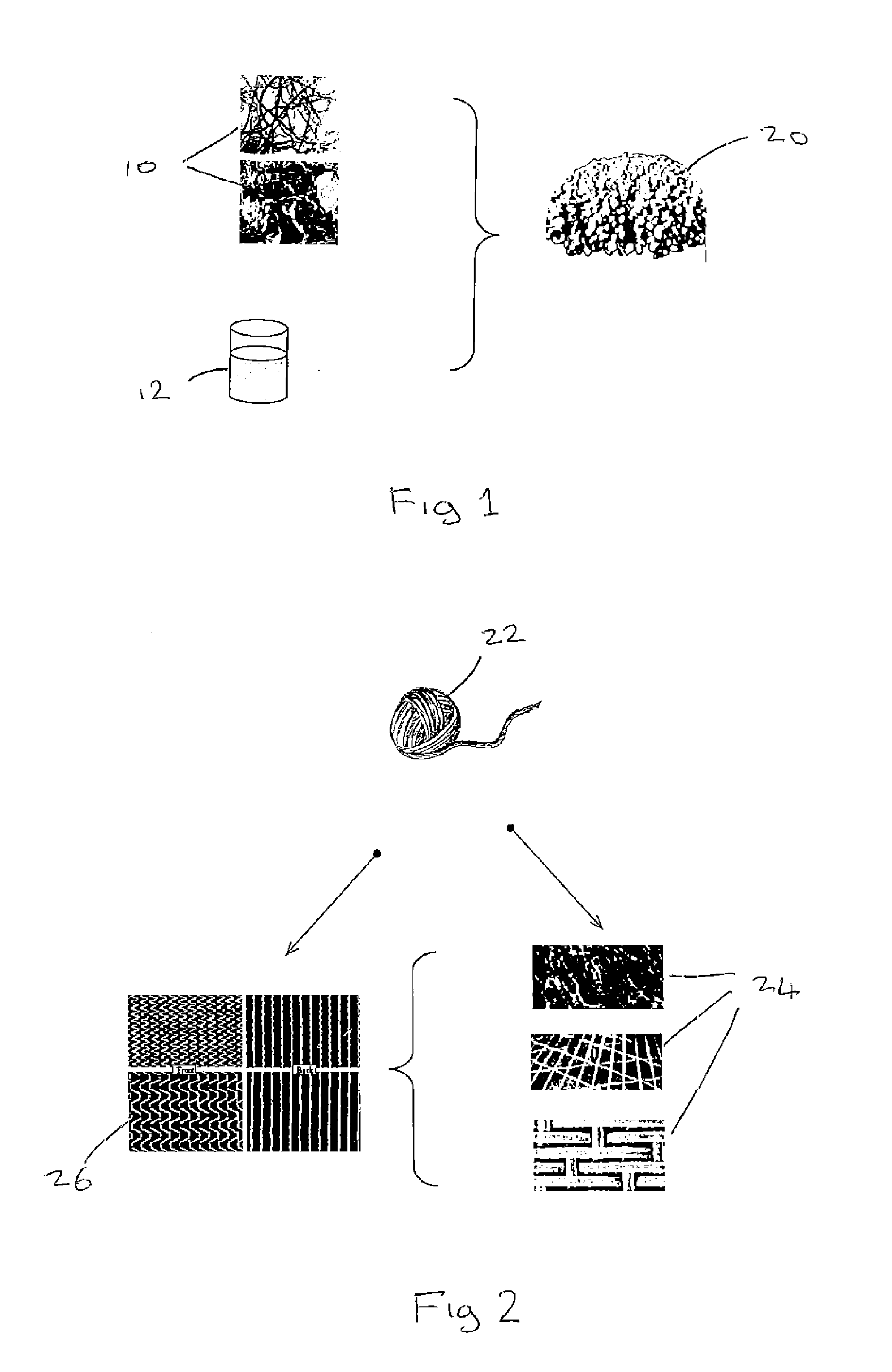

Method of forming a composite material with added nanoparticles and carrier material containing nanoparticles

A method of forming a nanocomposite material that includes nanoparticles includes disposing in a forming apparatus a fiber material, a carrier material with nanoparticles dispersed therein, the carrier material having a releasing trigger to release the nanoparticles, the releasing trigger being at least one of a releasing temperature and a releasing pressure, and a resin having an infusion temperature, increasing the temperature within the forming apparatus to a temperature at least equal to the infusion temperature of the resin to allow the resin to impregnate the fiber material without triggering the releasing trigger of the carrier material, and triggering the releasing trigger of the carrier material in the forming apparatus by increasing at least one of the temperature and the pressure within the forming apparatus to cause dispersion of the nanoparticles.

Owner:SHORT BROTHERS

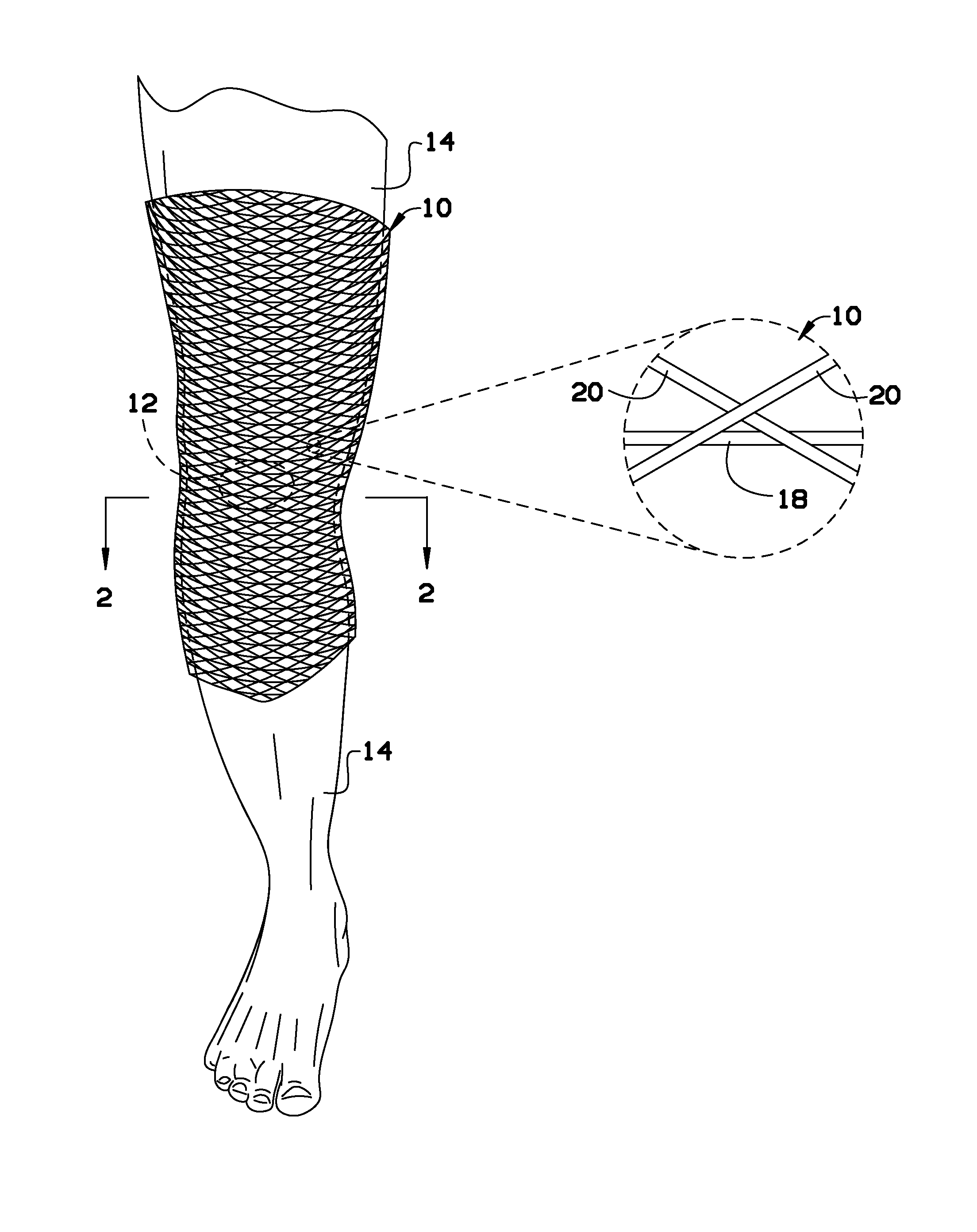

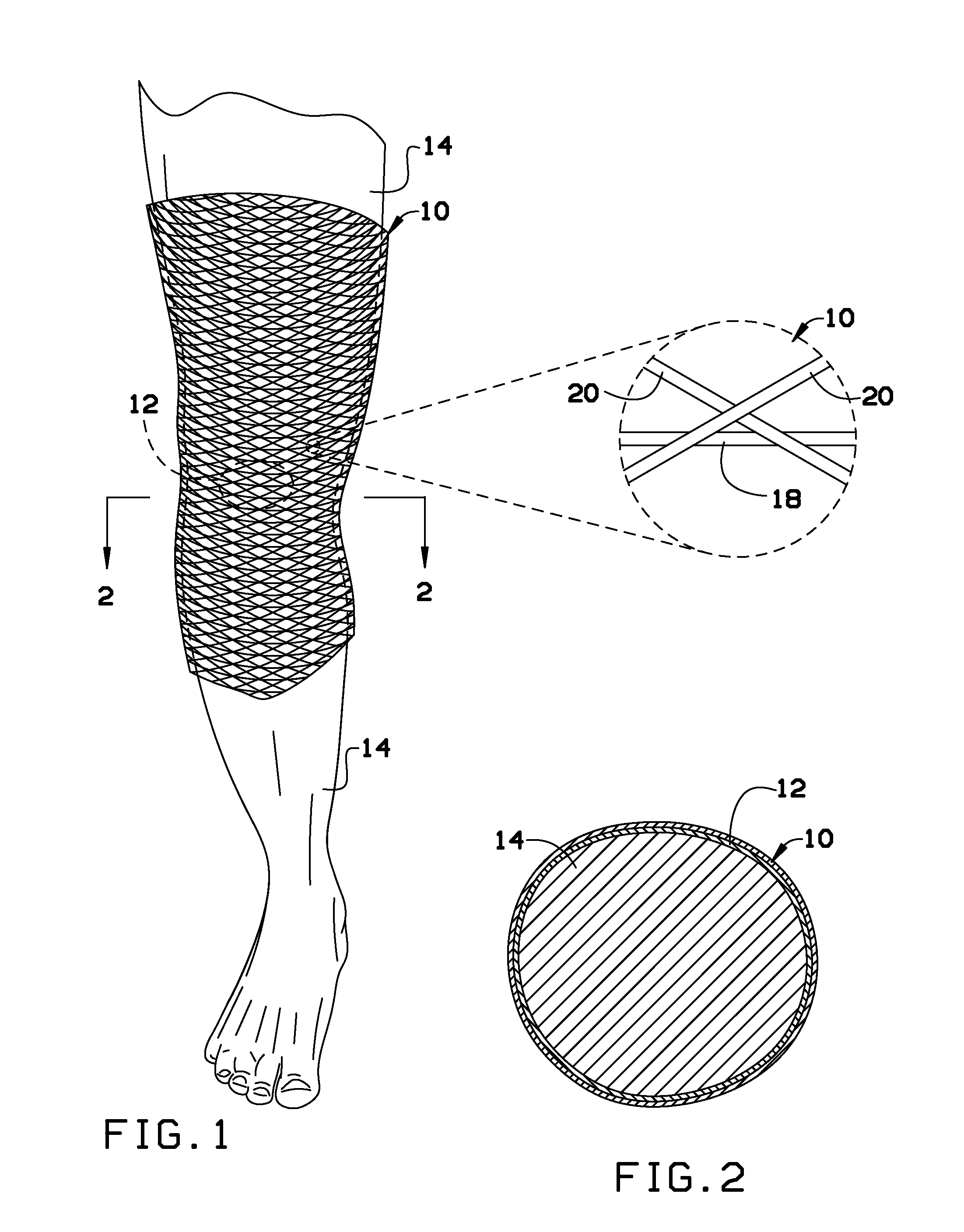

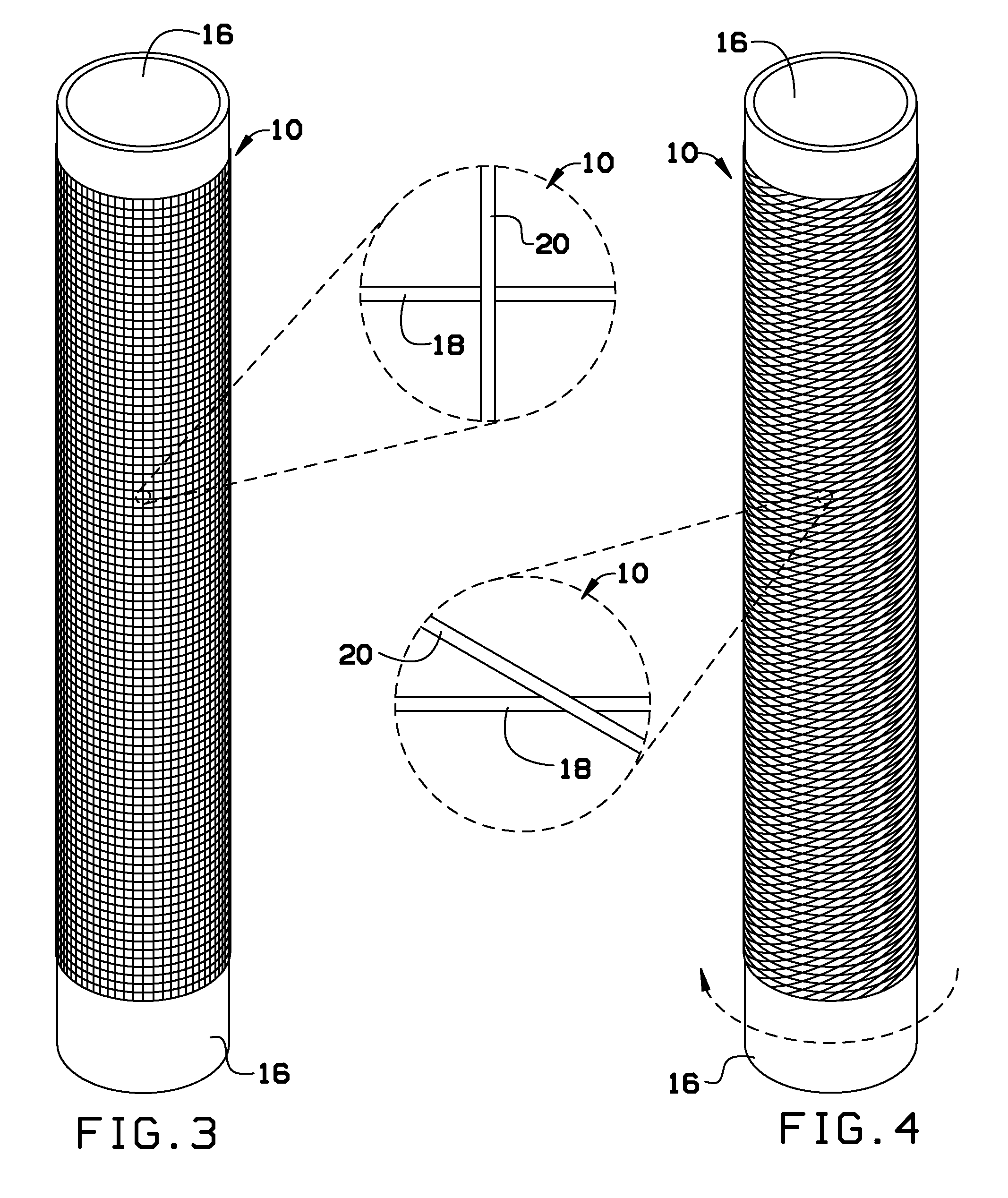

Joint support device

A joint support device is provided. The joint support device may include a first tubular layer and a second tubular layer both made of crisscrossing fibers. The crisscrossing fibers of the first tubular layer may be oriented in a spiral in a first direction and the crisscrossing fibers of the second tubular layer may be oriented in a spiral in an opposite direction of the first direction. The first and second tubular layers may be layered together and may be attached to an existing elastic knee brace.

Owner:CHANDLER JR FRANKLIN WOODROW

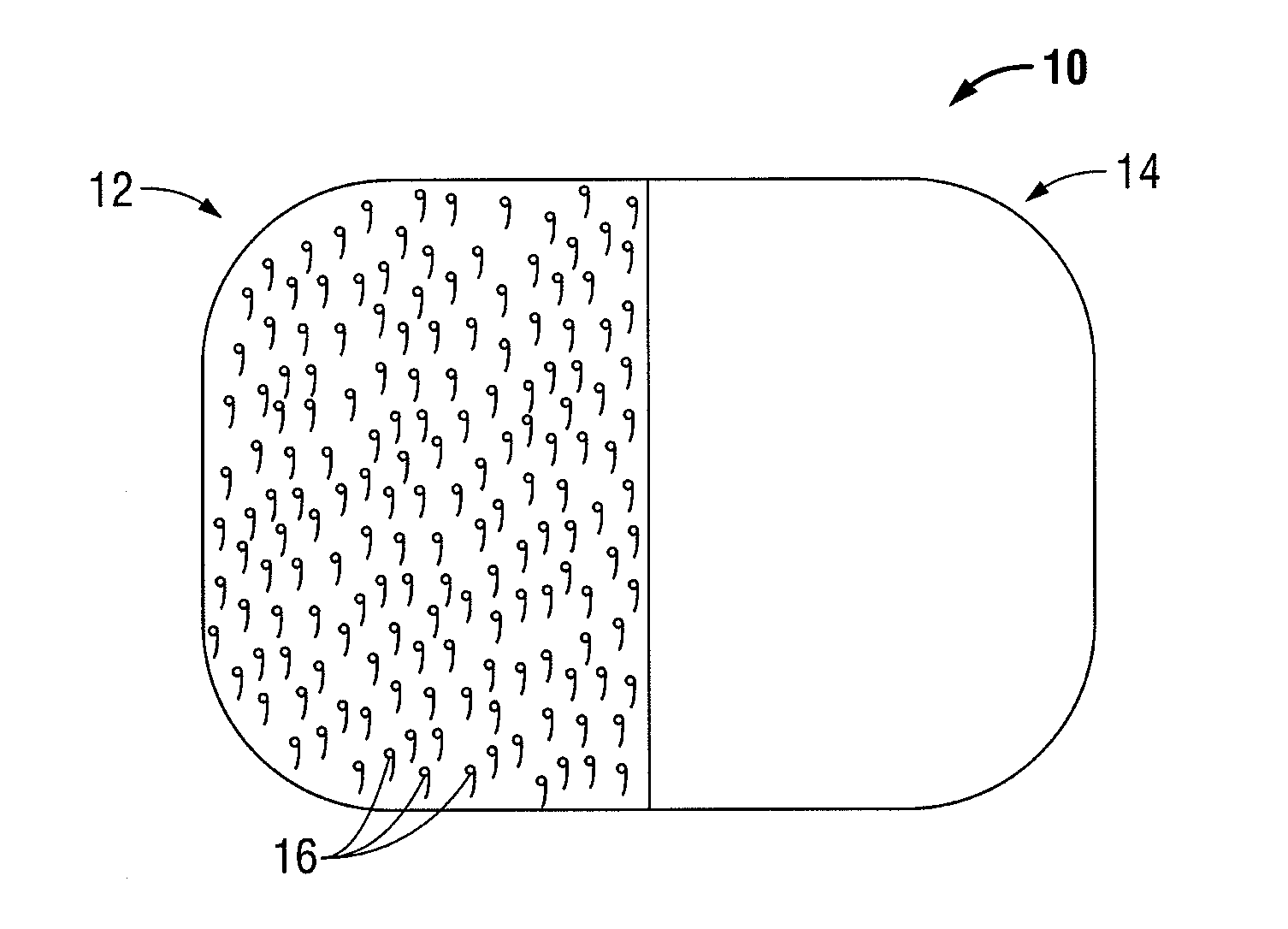

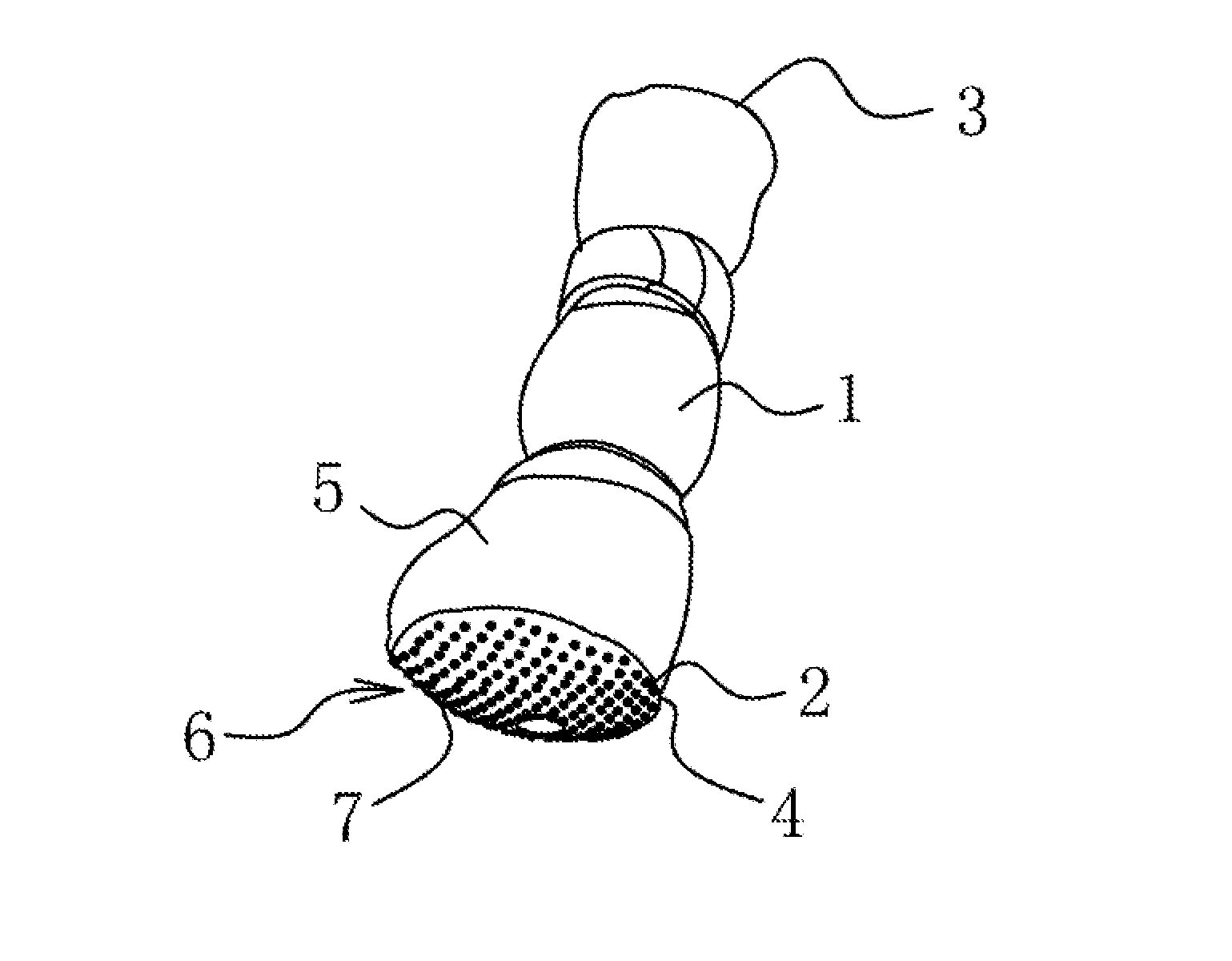

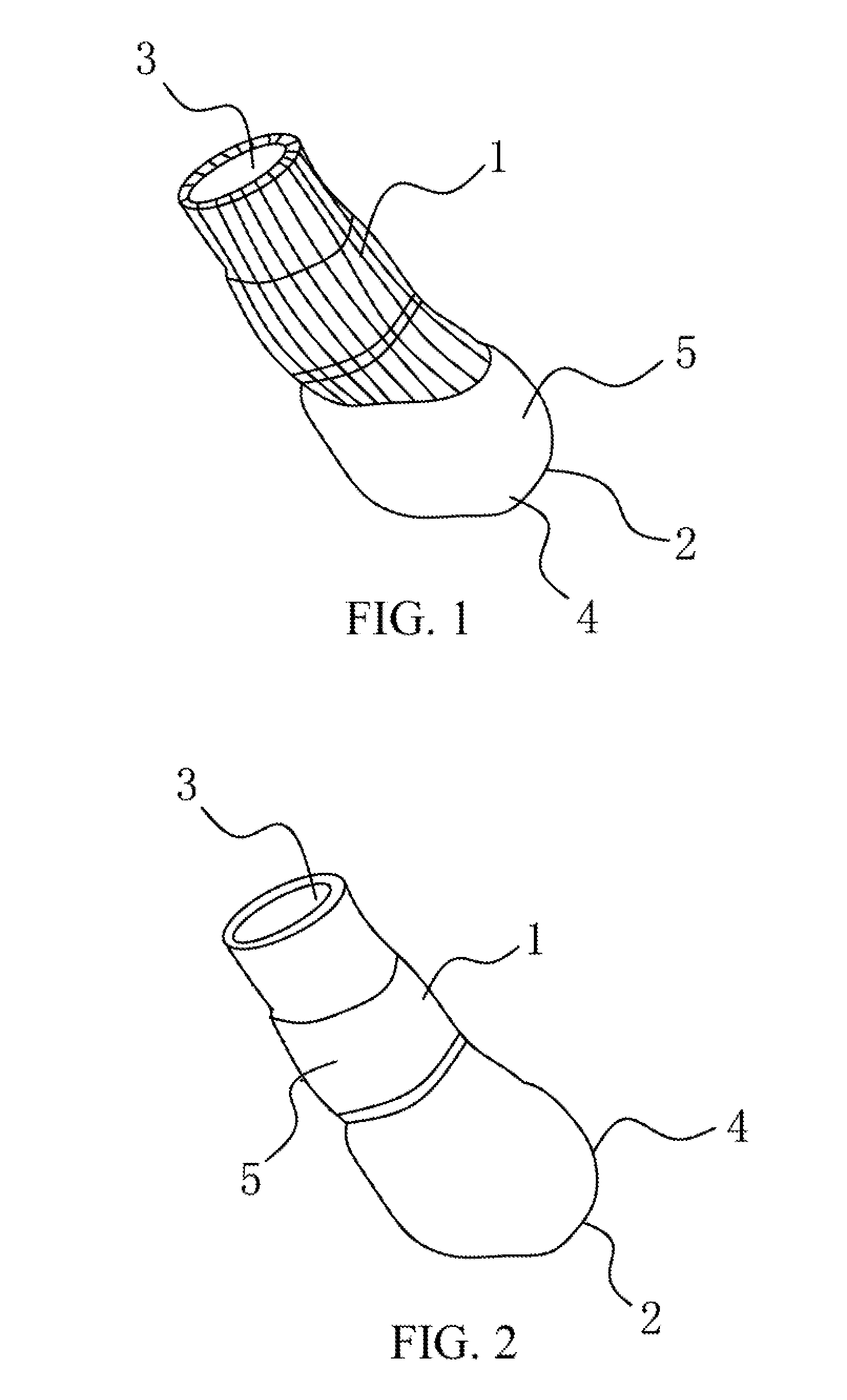

Three-dimensional surgical implant

Three-dimensional surgical implants include a grip-type knit mesh folded into a three-dimensional structure. Spiked naps provided on the mesh grip pores on the mesh to hold the implant in the three-dimensional structure.

Owner:TYCO HEALTHCARE GRP LP

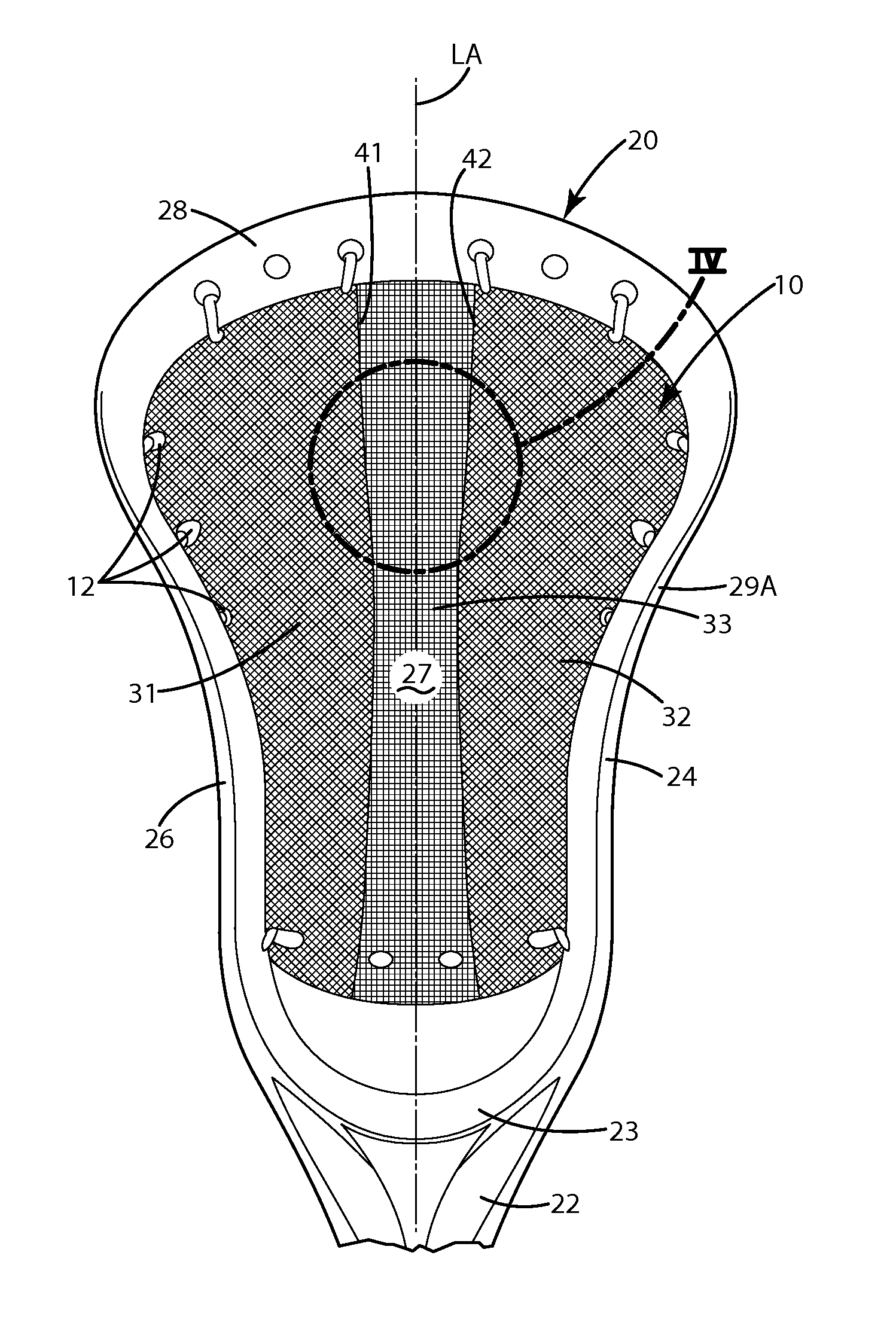

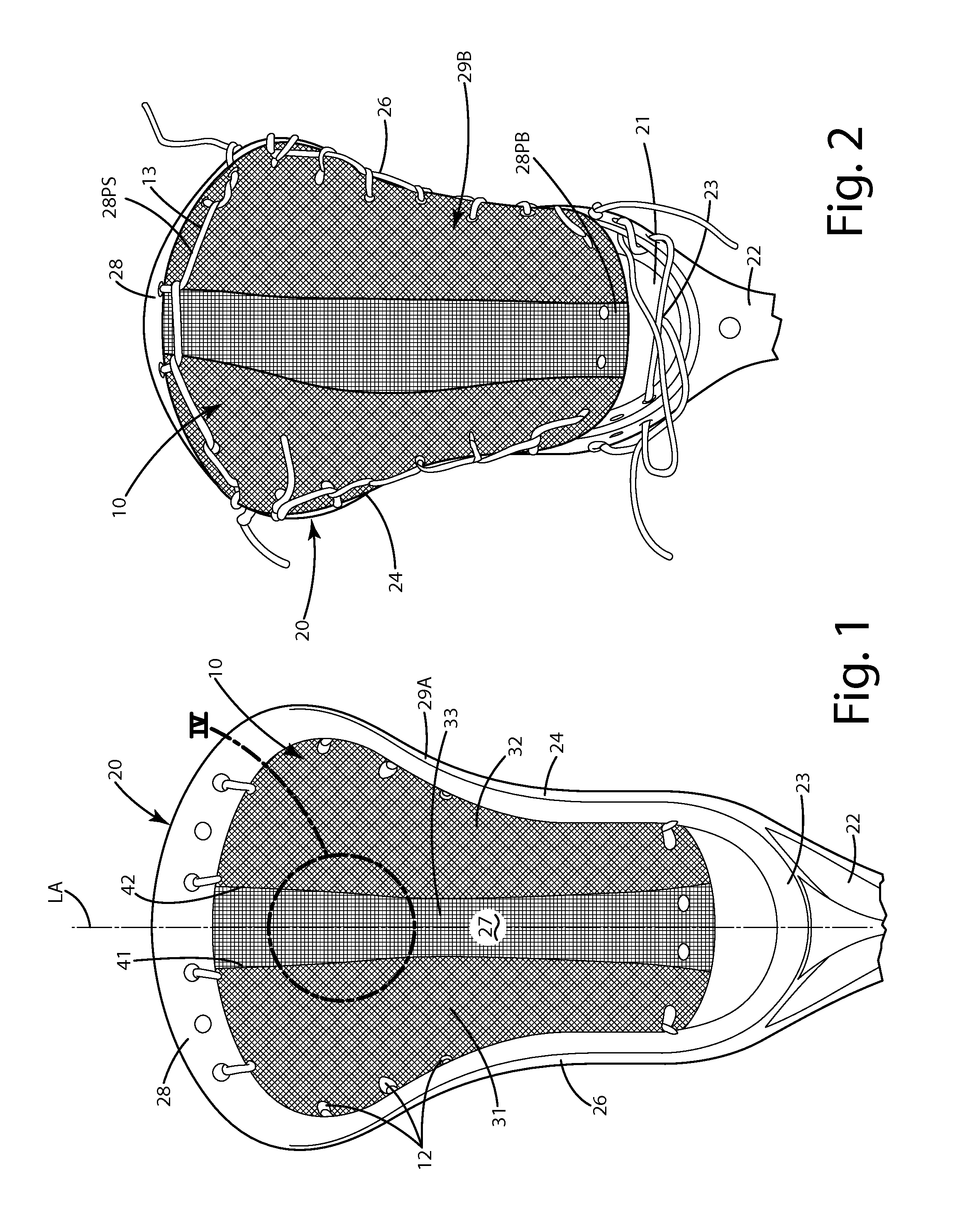

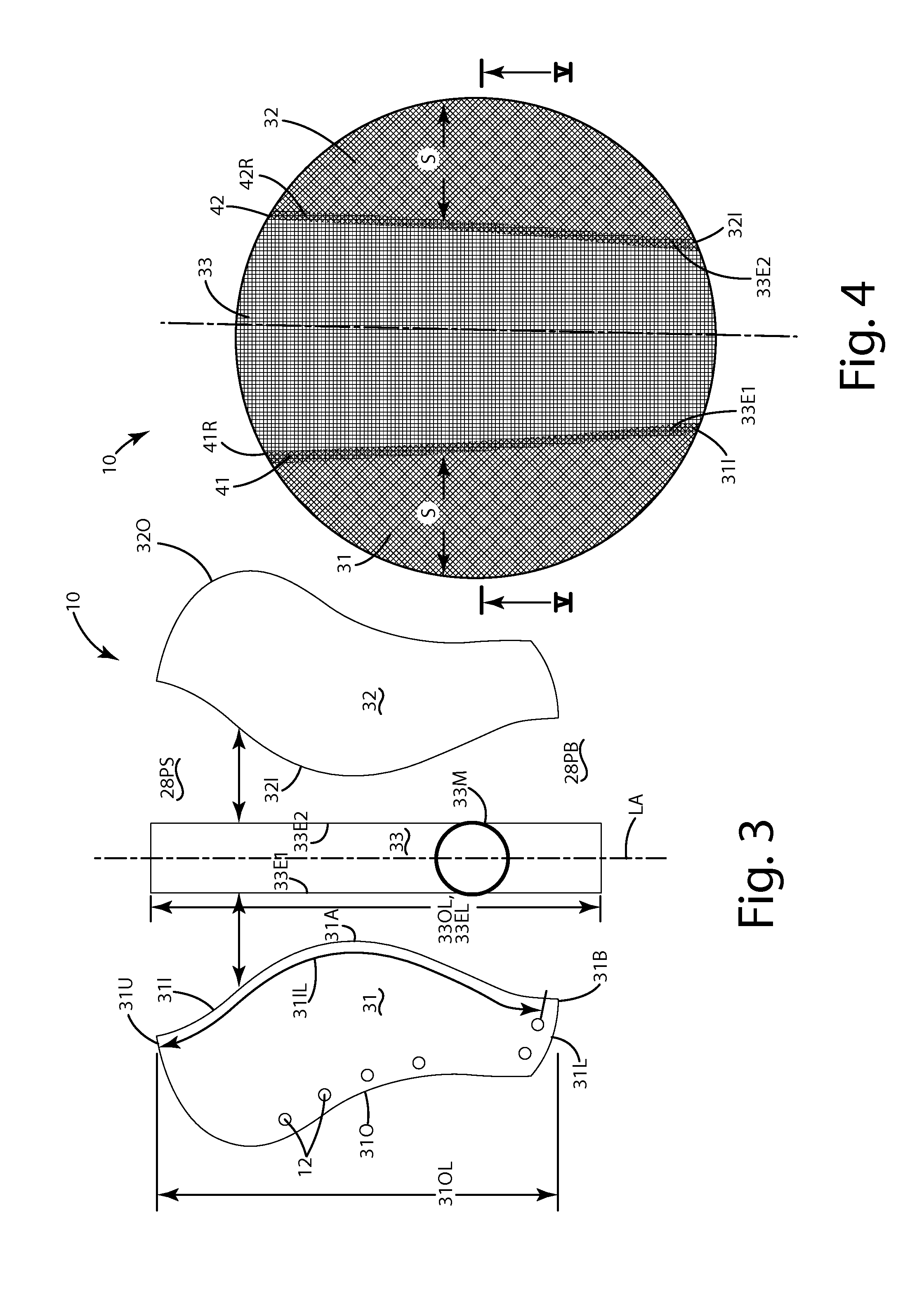

Lacrosse head pocket and related method of manufacture

ActiveUS20160038802A1Easy to manufactureEasy to replaceCrochetingOrnamental textile articlesEngineeringMechanical engineering

A lacrosse head pocket and a related method of manufacture are provided to facilitate consistent, repeatable and / or custom manufacture of lacrosse equipment. The pocket can be constructed from multiple different sections joined with one another, or can be knitted, weaved or otherwise assembled on an automated assembly machine from strands, and / or can be formed as a unitary textile material having regions / sections with different physical and / or mechanical properties. The pocket can be integrally molded within portions of a lacrosse head to eliminate manually constructed connections between the pocket and lacrosse head. The lacrosse head can be integrally molded with a lacrosse handle to provide a one-piece unitary lacrosse stick. Related methods of manufacturing also are provided.

Owner:WARRIOR SPORTS INC

Insulated product

InactiveUS20100024125A1More aesthetic appearanceMore appearance performanceCrochetingGarment special featuresEngineeringElectrical and Electronics engineering

Owner:LI YICK LAP

Technology for manufacturing anti-ultraviolet socks

InactiveCN103876308AUV stable and reliableSimple processSolvent-treatmentLiquid/gas/vapor article treatmentYarnPolytrimethylene terephthalate

The invention discloses a technology for manufacturing anti-ultraviolet socks. The technology includes particular steps of firstly, weaving bamboo fibers and cotton fibers via blowing, combing, silvering and fine spinning procedures to obtain bamboo fiber yarns; secondly, weaving the bamboo fiber yarns and polytrimethylene terephthalate yarns to obtain gray cloth of socks; thirdly, cutting the gray cloth according to sock manufacturing methods and requirements and then processing the cut gray cloth to obtain the socks; fourthly, soaking the socks in water with ultraviolet absorbents for 1 hour; fifthly, taking the socks out of the water, dehydrating the socks, and drying the socks in a dryer at the drying temperature of 150 DEG C for 10 minutes; sixthly, ironing the dried socks, finishing the socks and setting the socks to obtain the anti-ultraviolet socks. The proportion of the water to the ultraviolet absorbents is 10:1. The technology has the advantages that the technology is simple and is easy to understand, anti-ultraviolet components are uniformly distributed on the socks and are stably combined with the socks, and accordingly the stability and the reliability of the anti-ultraviolet performance of the socks can be guaranteed.

Owner:赵建英

Processing technology for nanometer antifouling and antibacterial coating textile and clothing

InactiveCN1552973AImprove wash resistanceGood flexibilityLiquid/gas/vapor article treatmentUltrasonic/sonic fibre treatmentCross-linkEngineering

A process for nano antifouling and bactericidal fabrics and garment includes: 1) wetting fabrics in the traditional processes due to various fabrics, 2) preparing a nano antifouling bactericidal finishing agent in a container with 100 - 200Kg volume capacity to form the said agent and a solution, the weight of the agent is 3 - 8% of that of the fabrics and the weight of the solution is equal to the that of fabrics, 3) putting the fabrics into the wetting container and soaking to make them coated, and 4) drying. This technology dissolves weaknesses in the prior arts, such as hard feeling, easily stained, worse in bactericidal effect and in water washing resistance. It enhances cross-linking strength of binding material in the nano coating layer and achieves in softness and washing resistance.

Owner:陕西班博实业集团有限公司

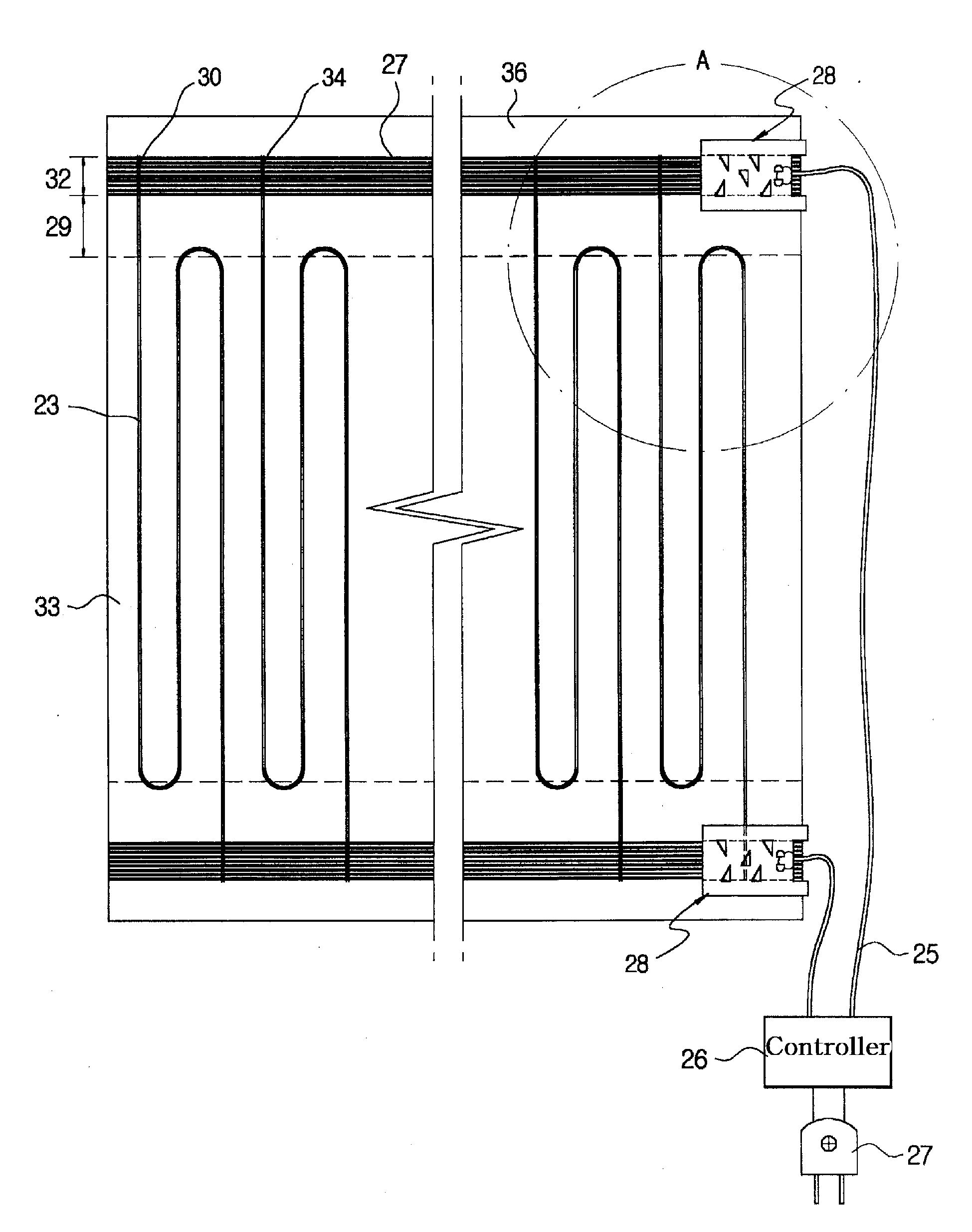

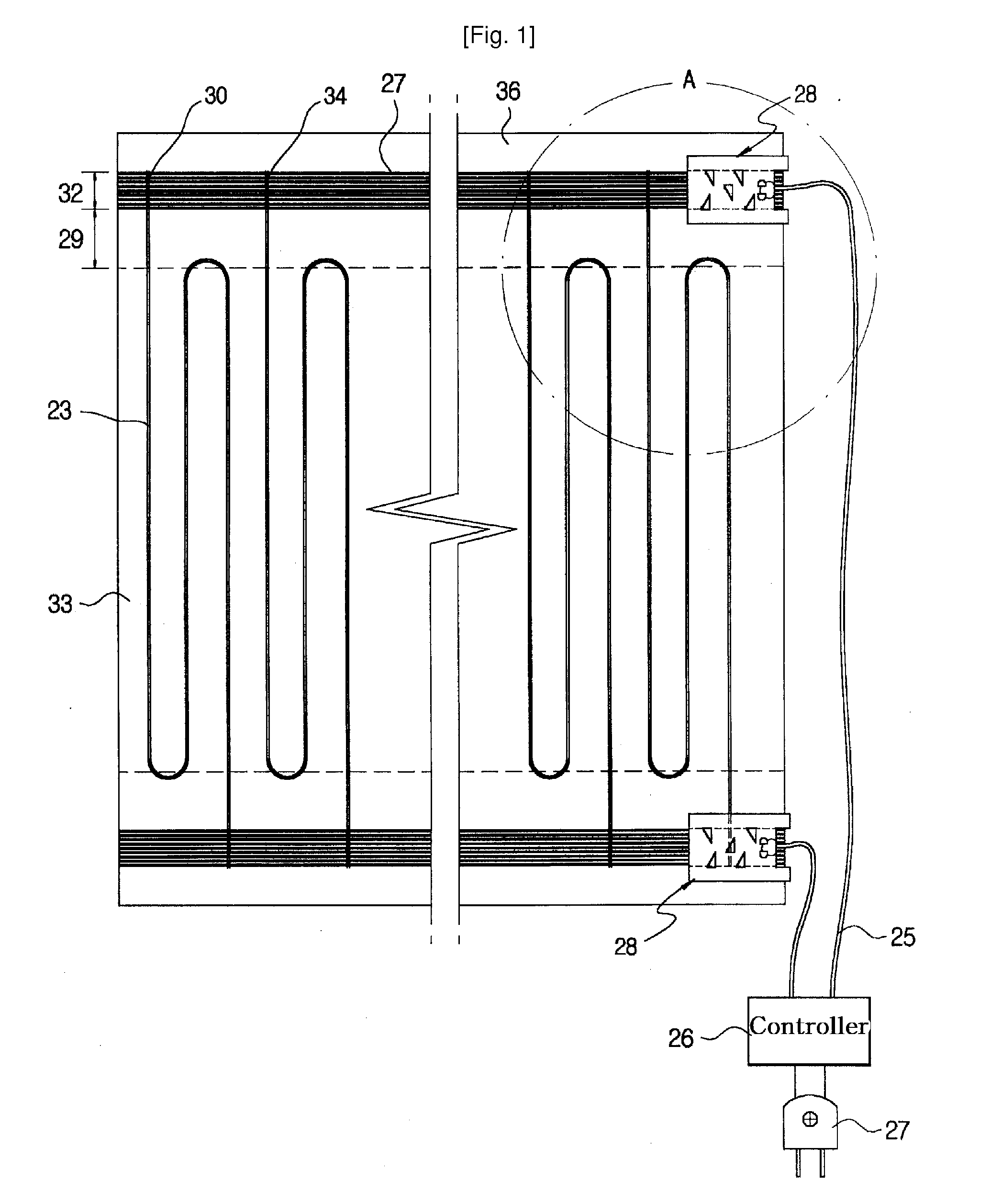

Heating Fabric and Manufacturing Method Thereof

InactiveUS20080135120A1Firmly connectedReduce product failureCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Pet socks and manufacturing method thereof

InactiveUS20150053148A1Rational designSimple structureCrochetingFabrics trimmingEngineeringCompanion animal

Owner:ZHUJI LONGBOW KNITTING

Method for preparing electrically conductive reinforced finger glove

ActiveCN109222290AHigh surface finishImprove mechanical propertiesLiquid/gas/vapor article treatmentGlovesOne passNitrile rubber

The invention relates to a method for preparing an electrically conductive reinforced finger glove. The method comprises the following steps: firstly, preparing a conductive carbon black dispersion liquid, carrying out one-pass latex dispersion composite liquid slurry, and then mixing the conductive carbon black dispersion liquid with a presulfurized latex to prepare a two-pass latex dispersion composite liquid slurry, after a glove base is soaked in a coagulator, soaking in the one-pass latex dispersion composite liquid slurry, and then, a finger part soaking in the two-pass latex dispersioncomposite liquid slurry, then, performing prevulcanization and high-temperature vulcanization to obtain the conductive reinforced finger glove. The gloves provided by the invention can effectively reduce the production cost. And the gloves are soft and comfortable in use and flexible in fingers. At that same time, the insulation at the palm of the hand is also achieved, such as nitrile rubber gloves. When the thickness of the palm of the hand is 0.2 mm, the instantaneous breakdown voltage is 1.5 KV.

Owner:SHANDONG XINGYU GLOVES

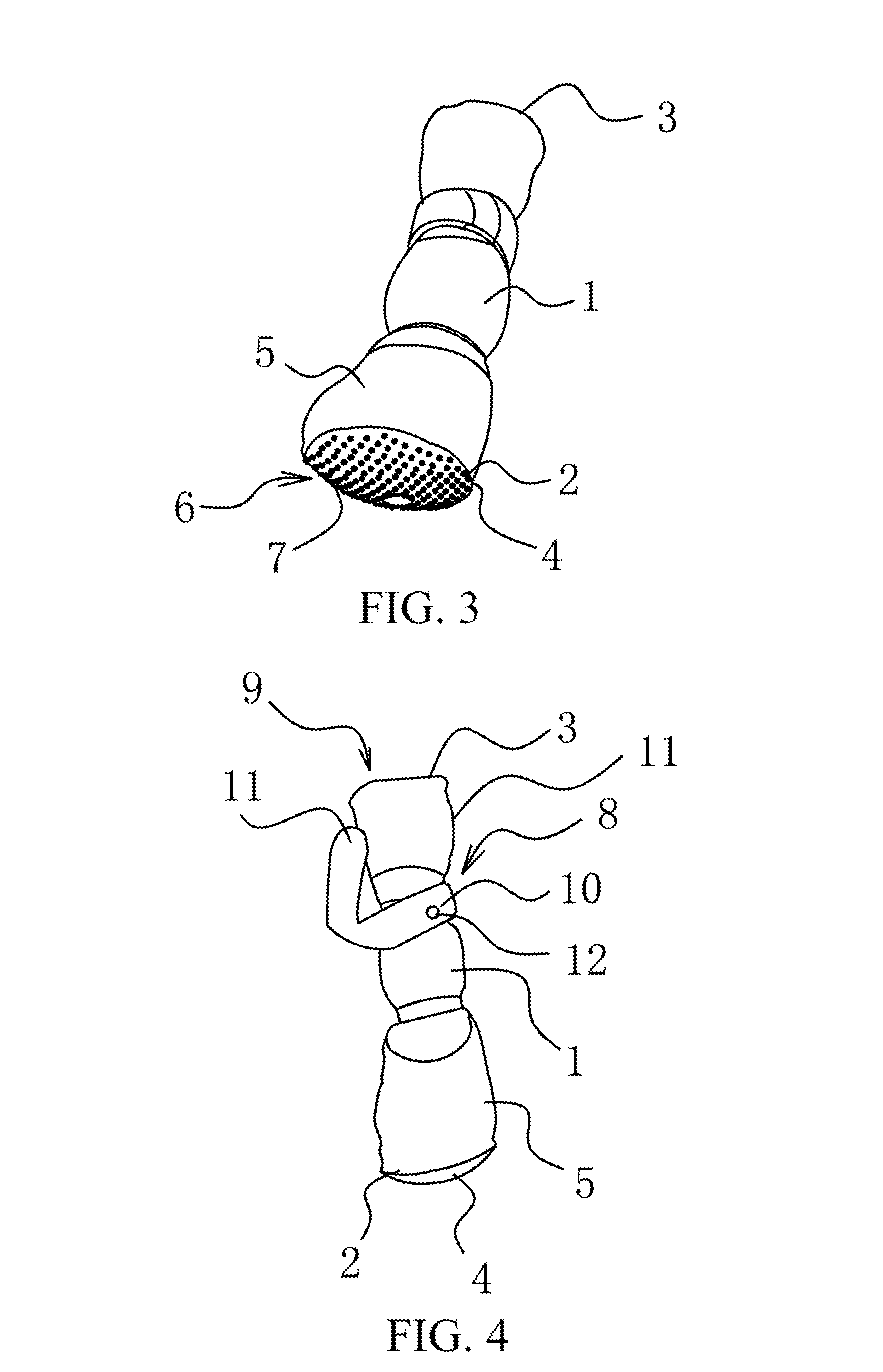

Medical Device, its Preparation Method and Applications Thereof

InactiveUS20160051832A1Facilitated DiffusionImprove homogeneityCrochetingElectrotherapyEngineeringLight emission

A medical device (1) comprising a flexible light source wherein said flexible light source comprises two or more individually manageable areas (2, 3, 4) of light emission and wherein each area (2, 3, 4) comprises a light diffuser textile comprising optical fibres (10) providing side diffusion of a light, method for its manufacture and medical uses.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

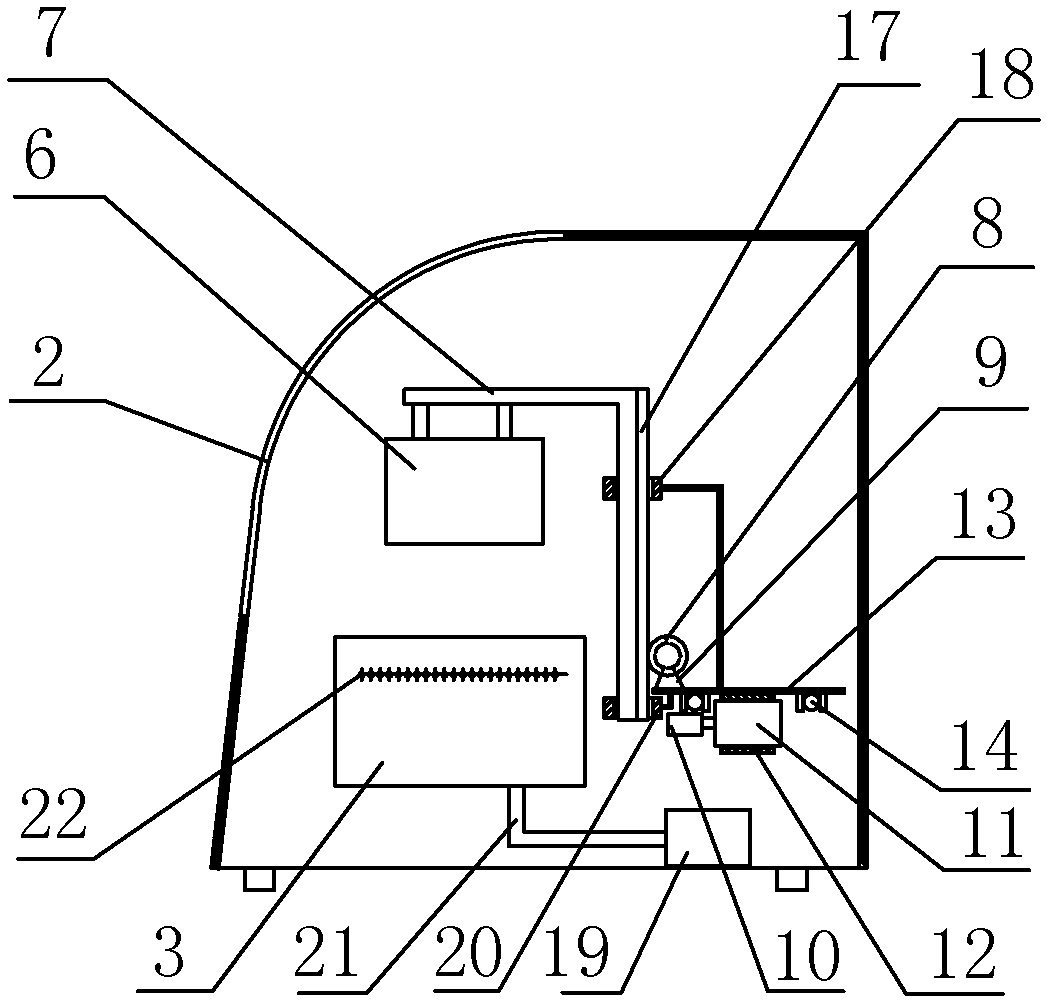

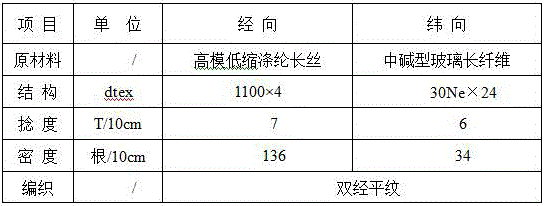

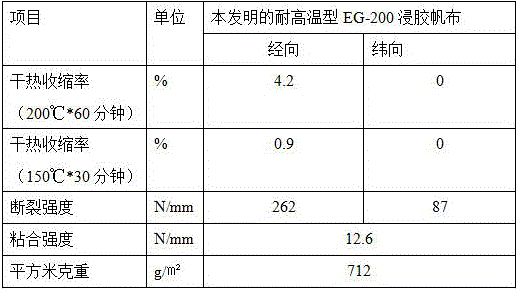

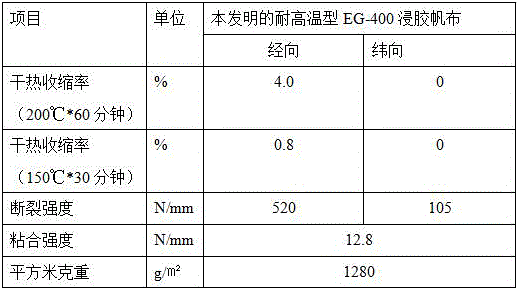

Production method of high temperature resistance type rubber-dipped canvas for heat-resistant conveying belt

InactiveCN106012385AImprove high temperature resistanceImprove adhesionSucessive textile treatmentsLiquid/gas/vapor article treatmentEngineeringTemperature resistance

The invention provides a production method of high temperature resistance type rubber-dipped canvas for a heat-resistant conveying belt. The production method of the high temperature resistance type rubber-dipped canvas for the heat-resistant conveying belt comprises a rubber dipping step; the rubber dipping is double-bath-method rubber dipping; the double-bath-method rubber dipping comprises a pre-dipping process and a secondary dipping process; the flow path of the pre-dipping process comprises the following steps of unwinding greige cloth, carrying out tensioning through a 1# tension bracket, carrying out rubber dipping through a 1# rubber dipping groove, carrying out the tensioning through a 2# tension bracket, carrying out baking through a 1# drying area, carrying out stretching through a hot stretching area, and carrying out tensioning through a 3# tensioning bracket; the flow path of the secondary rubber dipping process comprises the following steps of taking over the 3# tension bracket, afterwards, carrying out the rubber dipping through a 2# rubber dipping groove, carrying out the baking through a 2# drying area, carrying out the tensioning through a 4# tension bracket, carrying out stentering through a heat setting area (tentering), and carrying out tensioning through a 5# tension bracket. The production method of the high temperature resistance type rubber-dipped canvas for the heat-resistant conveying belt has the advantages that the high temperature resistance performance is good, the adhesion performance is good, and the dimensional stability is good.

Owner:SHANDONG HELON POLYTEX CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com