Production method of high temperature resistance type rubber-dipped canvas for heat-resistant conveying belt

A heat-resistant conveyor belt and high-temperature-resistant technology, which is applied in the field of chemical fiber textiles, can solve the problems of easy deformation of heat-resistant conveyor belts and easy delamination of conveyor belts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of the pre-dipping liquid used in the pre-dipping process: the pre-dipping liquid is an isocyanate aqueous dispersion impregnation liquid blocked by end groups, and the content of the pre-dipping liquid dipping formula is: desalinated water is 94 ± 4%, isocyanate 5 ±2%, epoxy resin 1±0.5%.

[0038] Preparation of the second immersion solution for the second dipping process: the second immersion solution is based on the conventional resorcinol-formaldehyde-based water-based adhesive system RFL solution, and an appropriate amount of isocyanate and an appropriate amount of natural latex are added to the formula The specific formula is: softened water 1444±7.22kg, caustic soda 3.0±0.009kg, resorcinol 50±0.25kg, formaldehyde 75±0.375kg (concentration 37%), ammonia 40±0.2kg (concentration 28%), Pilatex 1170±5.85kg, natural latex 60~150kg, isocyanate 20~60kg.

[0039] After the second dipping process, it is also coiled and packaged to finally form a finished produ...

Embodiment 1

[0040] Embodiment 1: High temperature resistant EG-150 type

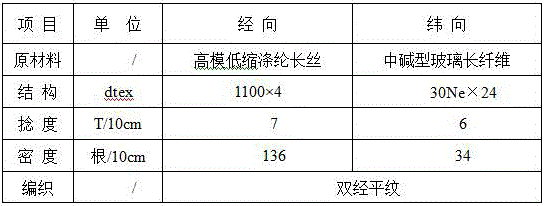

[0041] 1. See the following table for material selection and twist weaving process:

[0042]

[0043] 2. Use the double-bath dipping process route for dipping. The dipping process is: dipping speed 25m / min, 1# drying zone temperature 175°C, thermal stretching zone temperature 230°C, 2# drying zone temperature 135°C , the temperature in the heat setting area is 215°C; the stretch rate between 1# tension frame and 2# tension frame (1# dipping tank) is 100%, between 2# tension frame and 3# tension frame (1# is dry and drawn) Stretching area) The draft rate is 100%, between 3# tension frame and 4# tension frame (2# drying area), the draft rate is 99.5%, between 4# tension frame and 5# tension frame (drying heat setting area) The draft rate is 97.5%.

[0044] 3. The dipping formula used is as follows: the pre-dipping liquid is an isocyanate aqueous dispersion impregnation liquid blocked by end groups. The specific ...

Embodiment 2

[0048] Embodiment 2: high temperature resistant EG-200 type

[0049] 1. See the following table for material selection and twist weaving process:

[0050]

[0051] 2. Adopt double-bath dipping process route for dipping. The dipping process is as follows: dipping speed 23m / min, 1# drying zone temperature 177°C, thermal stretching zone temperature 230°C, 2# drying zone temperature 130°C , the temperature in the heat setting area is 216°C; the stretch rate between 1# tension frame and 2# tension frame (1# dipping tank) is 100%, between 2# tension frame and 3# tension frame (1# is dry and drawn) Stretching zone) draft rate 100.2%, between 3# tension frame and 4# tension frame (2# drying area) draft rate 99.0%, between 4# tension frame and 5# tension frame (drying heat setting area) The draft rate is 97.5%.

[0052] 3, the dipping formula that adopts is identical with example 1 dipping formula.

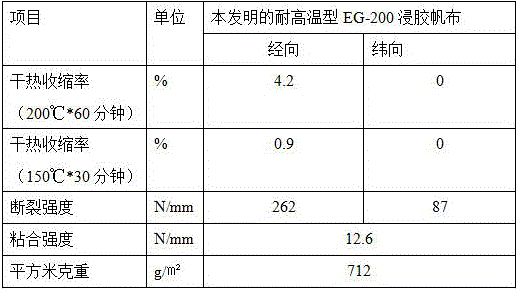

[0053] 4. Product quality index of embodiment 2:

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com