Patents

Literature

232 results about "Stretch rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

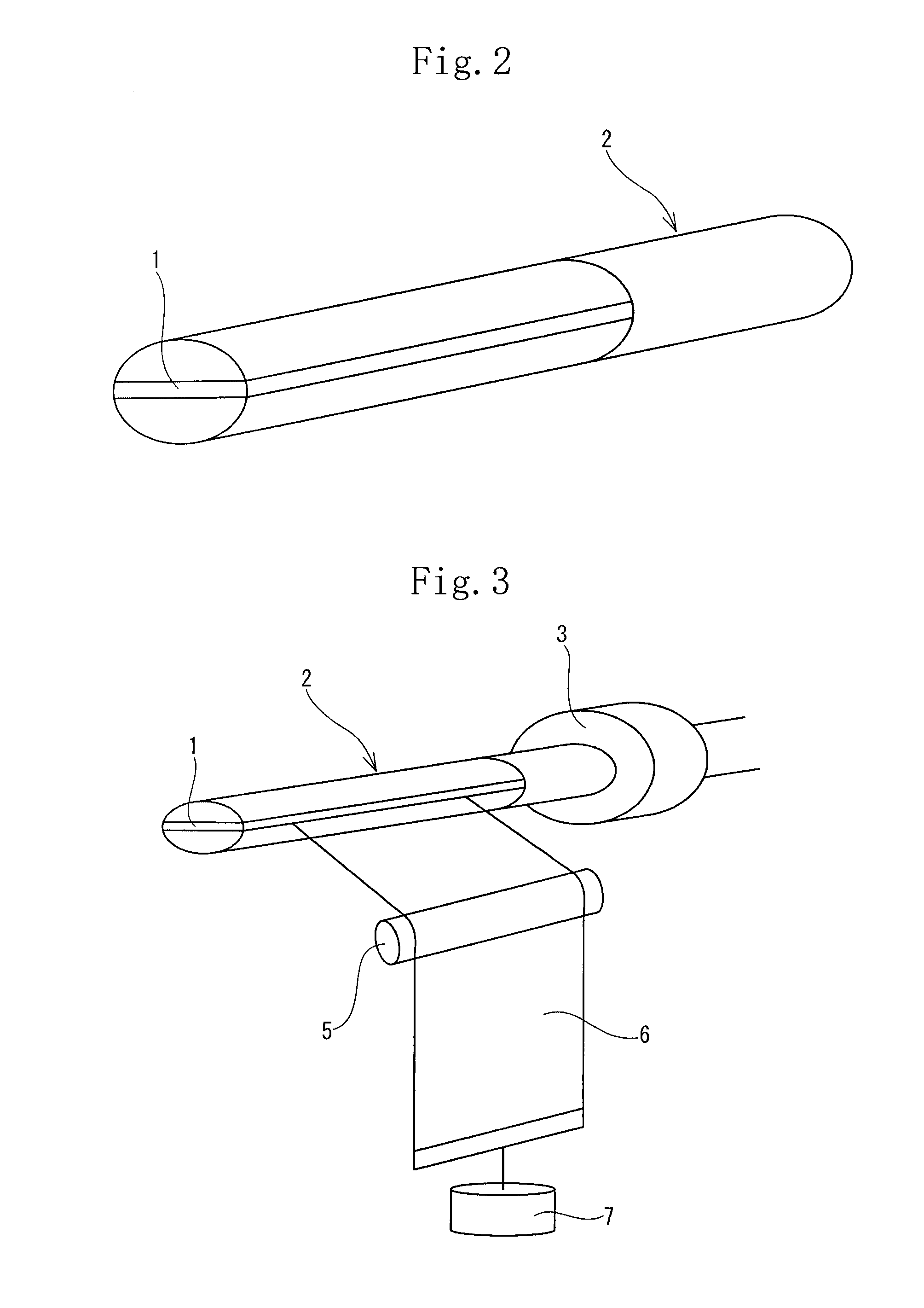

Process for drawing gel-spun polyethylene yarns

InactiveUS20050093200A1Domestic articlesMonocomponent polyolefin artificial filamentProduction rateForced convection

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

Process for drawing gel-spun polyethylene yarns

A process for drawing essentially diluent-free gel-spun polyethylene multi-filament yarns in a forced convection air oven and the drawn yarns produced thereby, The process conditions of draw ratio, stretch rate, residence time, oven length and feed speed are selected in specific relation to one another so as to achieve enhanced efficiency and productivity. The drawn yarns are useful in armor, composites, fishing line, ropes, sutures, fabrics and other applications.

Owner:HONEYWELL INT INC

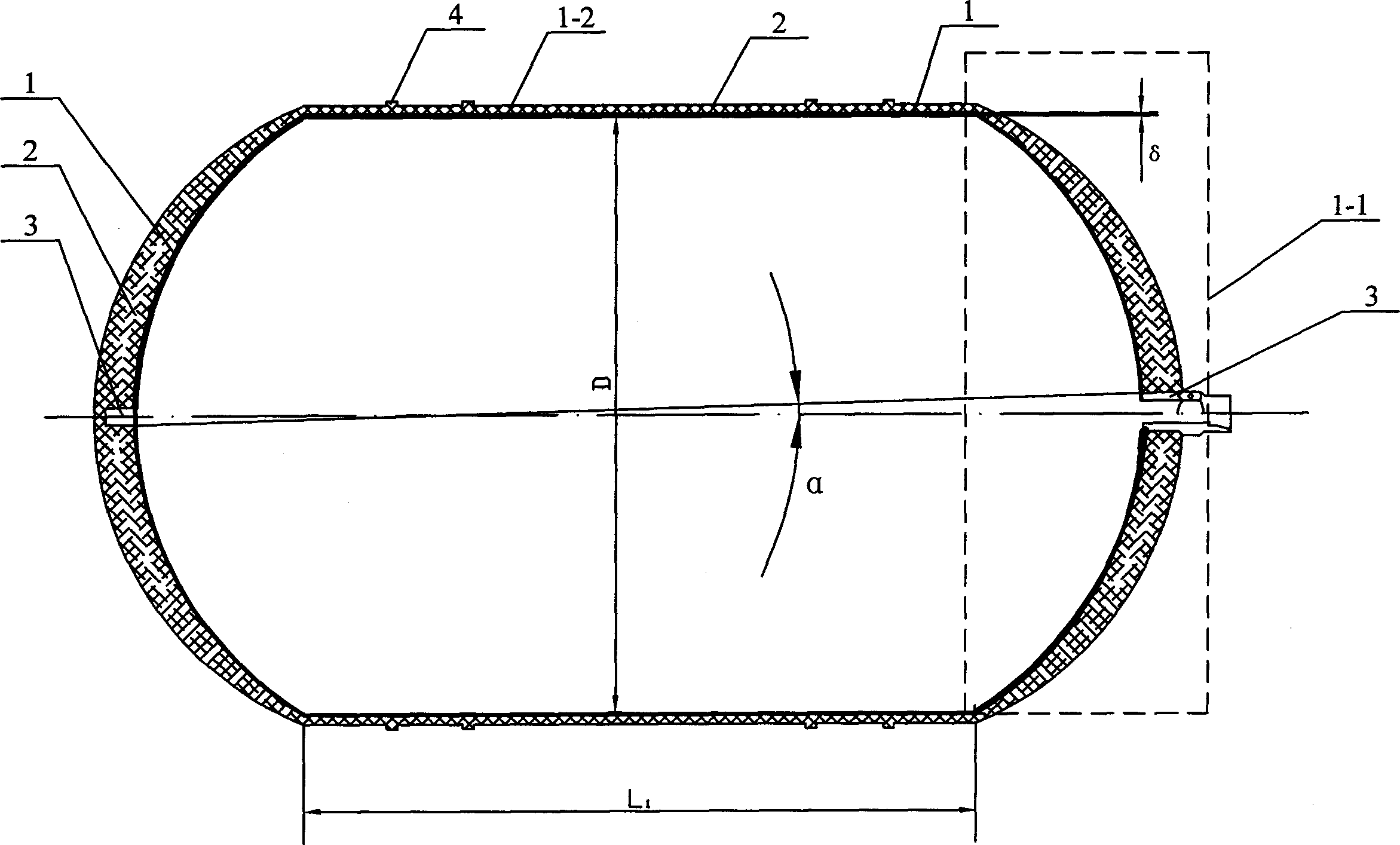

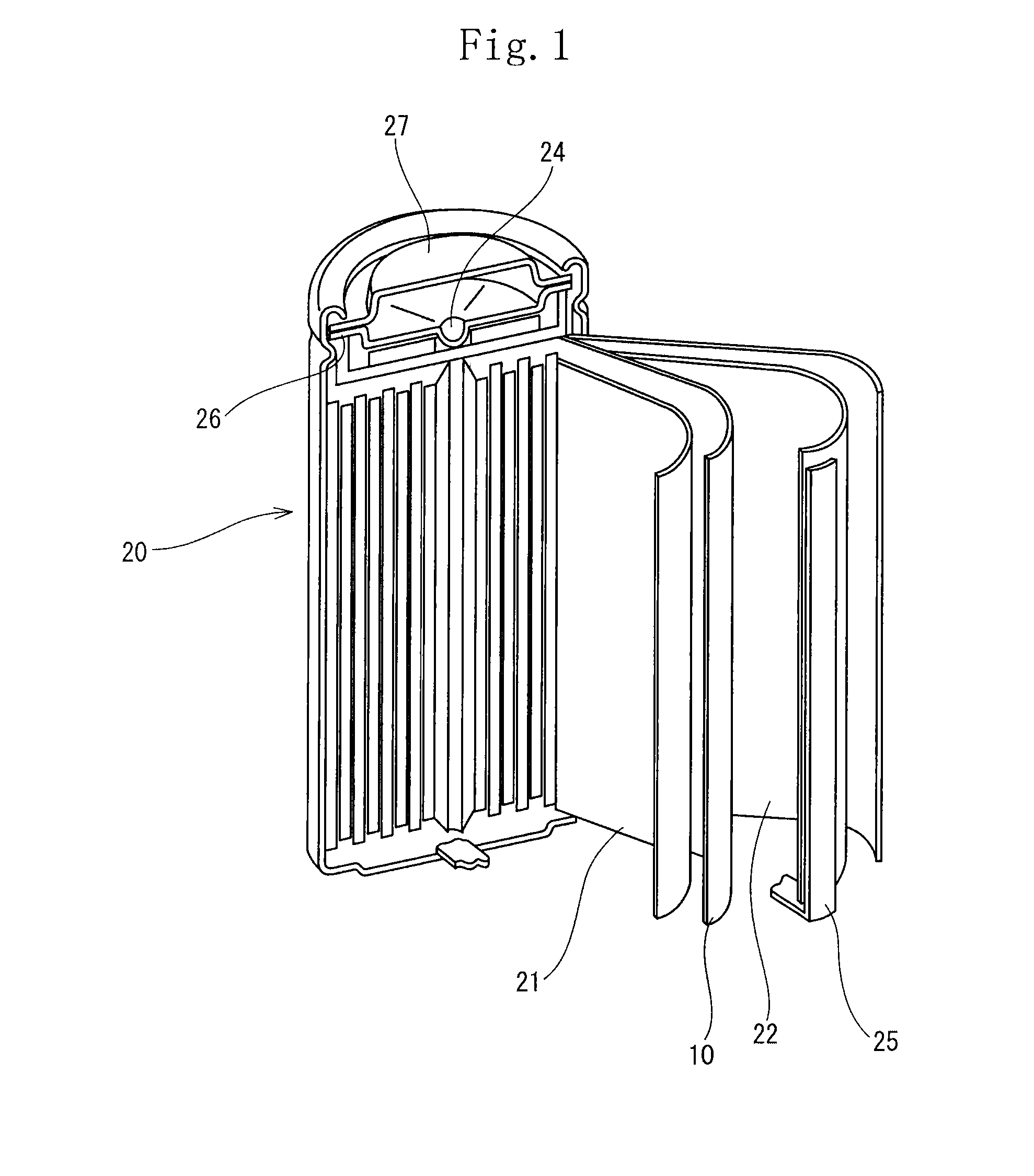

High pressure gas cylinder made from carbon fiber composite material and manufacturing method thereof

InactiveCN1734154AHigh PV/W characteristic valueImprove efficiencyPressure vesselsGas cylinderHigh pressure

This invention relates to a high-pressure gas jar for the carbon fiber compound material and it's making method, wherein it uses a fiber wrapped compound material. The capability of the carbon fiber compound material as follows: the metal liner is made of the titanium alloy, wherein the proportion between its stretching bending strength and its elasticity FTY / E is at least 0.6%, its stretch rate is at least 5%, and the shape of its closing head (1-1) is the three point circle. And the metal liner (1) is made by the following steps: spinning and stretching the closing head (1-1), crystallization annealing processing, end welding and integral welding; and the carbon fiber compound material layer (2) is the carbon fiber layer or the epoxy wrapping layer. The made method includes the following steps: fiber drying, glue confecting, glue immersing, wrapping, and solidified forming. Using this method can make the light weight, well gas sealing capability, high strength carbon fiber compound high-pressure gas jar.

Owner:HARBIN INST OF TECH

Electroplating preparation method for copper cladded aluminum wire or copper cladded magnesium alloy wire

InactiveCN101187046AAvoid it happening againImprove bindingSingle bars/rods/wires/strips conductorsSuperimposed coating processCopper platingZinc

The invention discloses a process for preparing copper cladding aluminum or copper cladding wire of aluminum magnesium alloy, which utilizes a continuous striking-wire copper plating pipeline of being in series connection with a plurality of lengthening electric plating aluminum-magnesium parts plating groove, sets out line uninterruptedly between adjacent plating grooves, and arranges a transiting water ditch between front groove and rear groove which can avoid wire to contact with air to generate oxide coating when changing the grooves. A problem of burning wire can be resolved by adjusting main plating current to about 300 A before having to shutdown in short time. Simultaneously, the invention employs technique of thickening dip galvanized coating and wiping off zinc cover of the zinc dipping by pickling to overcome the main difficulty of utilizing electric plating method to produce copper cladding aluminum wire or copper cladding wire of aluminum magnesium alloy. Compared with coating method, the invention has the advantages of great binding force between metals, high concentricity of copper layer and core wire, low production cost on producing high tensile strength and high stretch rate production, low reject rate, low product specific gravity and the like, and is a good method for producing copper cladding aluminum wire and copper cladding wire of aluminum magnesium alloy by the electroplating method.

Owner:仲庆

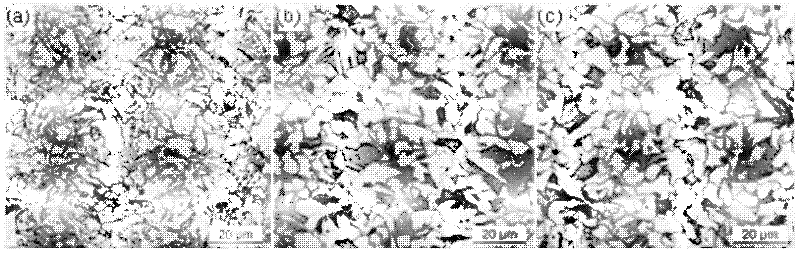

Hot rolled dual-phase steel sheets with high stretch-flangeability and manufacturing method thereof

Owner:SHANDONG IRON & STEEL CO LTD

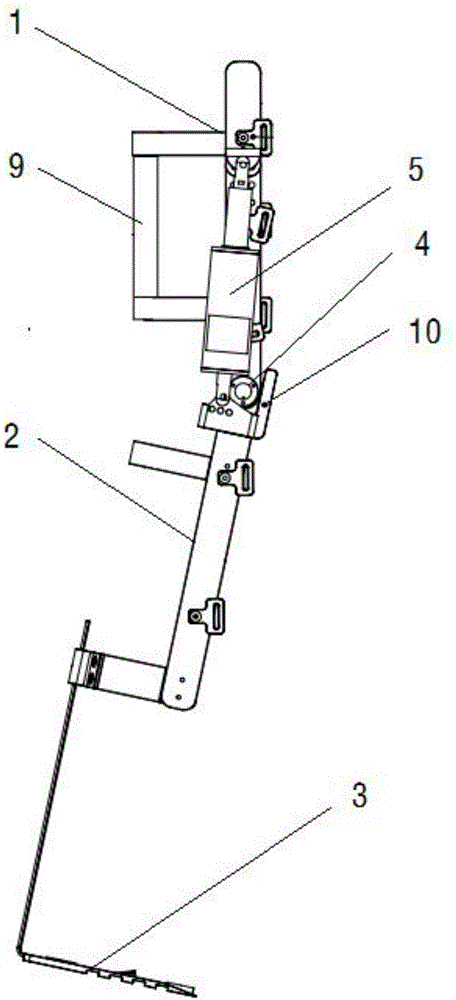

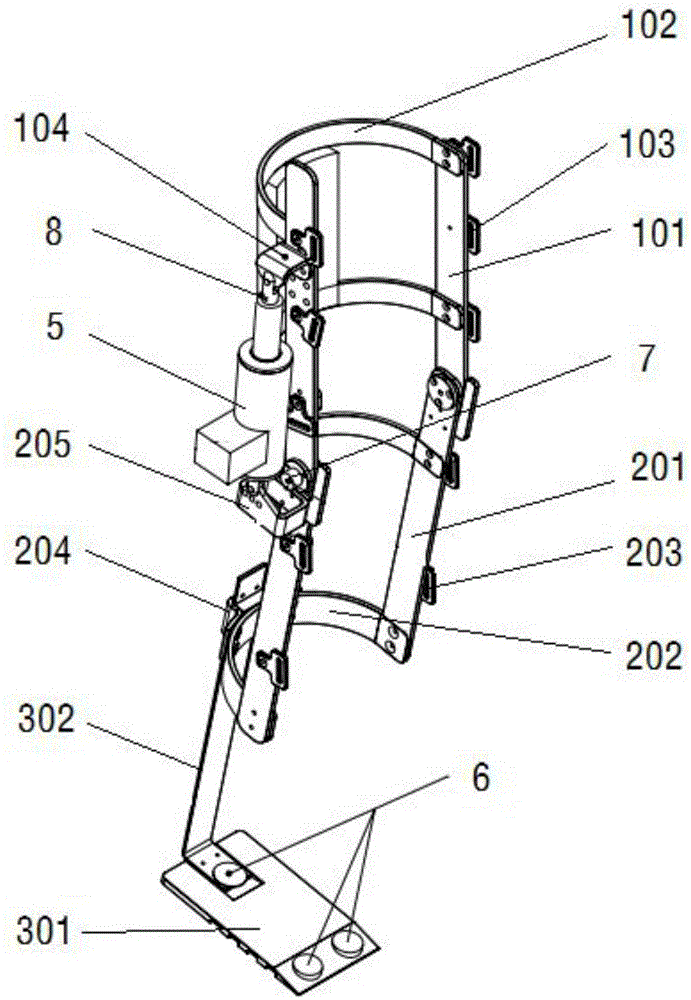

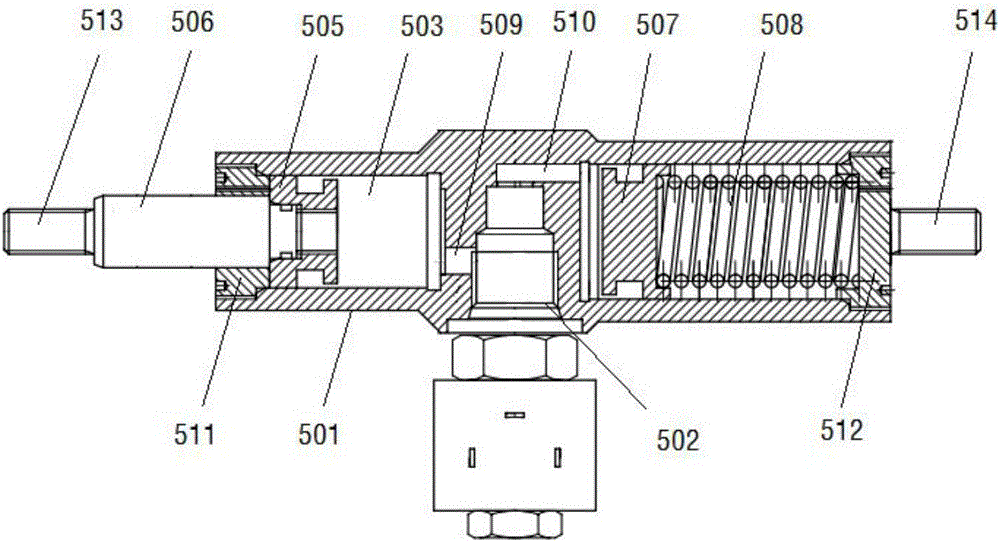

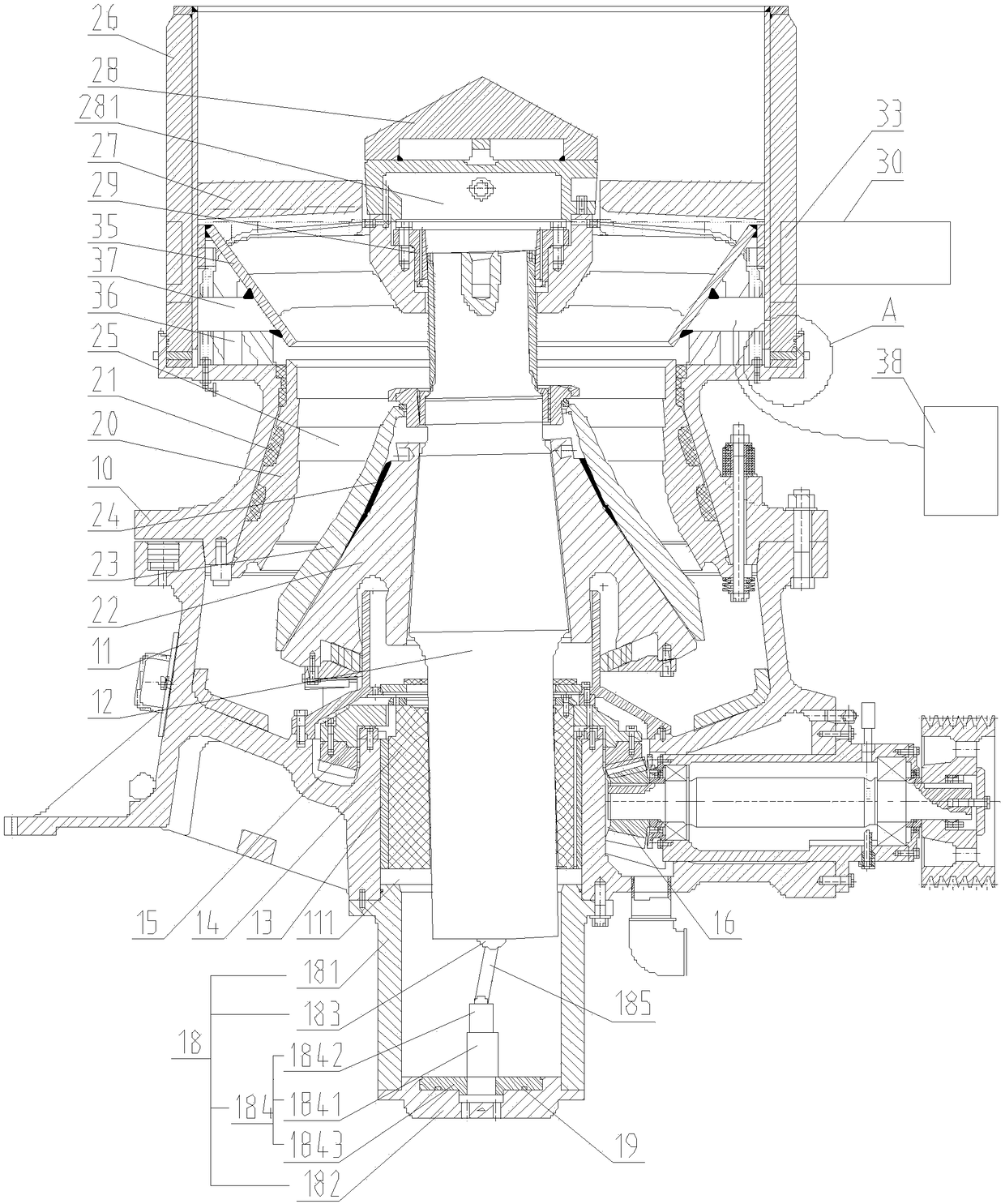

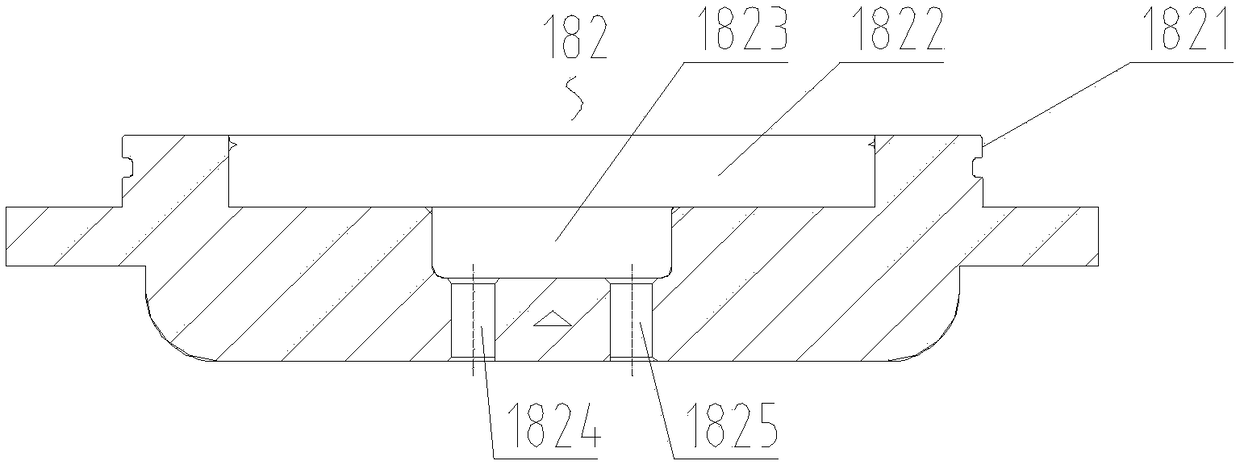

Single-lower-limb exoskeleton orthopedic apparatus and orthopedic control method

The invention relates to the technical field of orthopedic apparatuses, and in particular to a single-lower-limb exoskeleton orthopedic apparatus and an orthopedic control method. The orthopedic apparatus comprises a supporting mechanism, an adjusting mechanism and a control mechanism, wherein the supporting mechanism comprises a thigh supporting part, a calf supporting part and a planta supporting mechanism; the thigh supporting part and the calf supporting part are connected by virtue of a knee joint rotating shaft; the calf supporting part and the planta supporting part are connected; the adjusting mechanism comprises a hydraulic damper; two ends of the hydraulic damper are connected to the thigh supporting part and the calf supporting part; and the control mechanism comprises plantar pressure sensors, a knee joint angle sensor, a piston rod thrust sensor and a controller. The orthopedic apparatus provided by the invention can timely sense a human walking state and adjust the stretching rate of the hydraulic damper , so that piston motions of the hydraulic damper can passively adapt to the human walking status and can be adjusted in accordance with a walking speed; therefore, free walking of a human body can be kept to the greatest extent, and stability can be guaranteed.

Owner:BEIJING FORESTRY UNIVERSITY

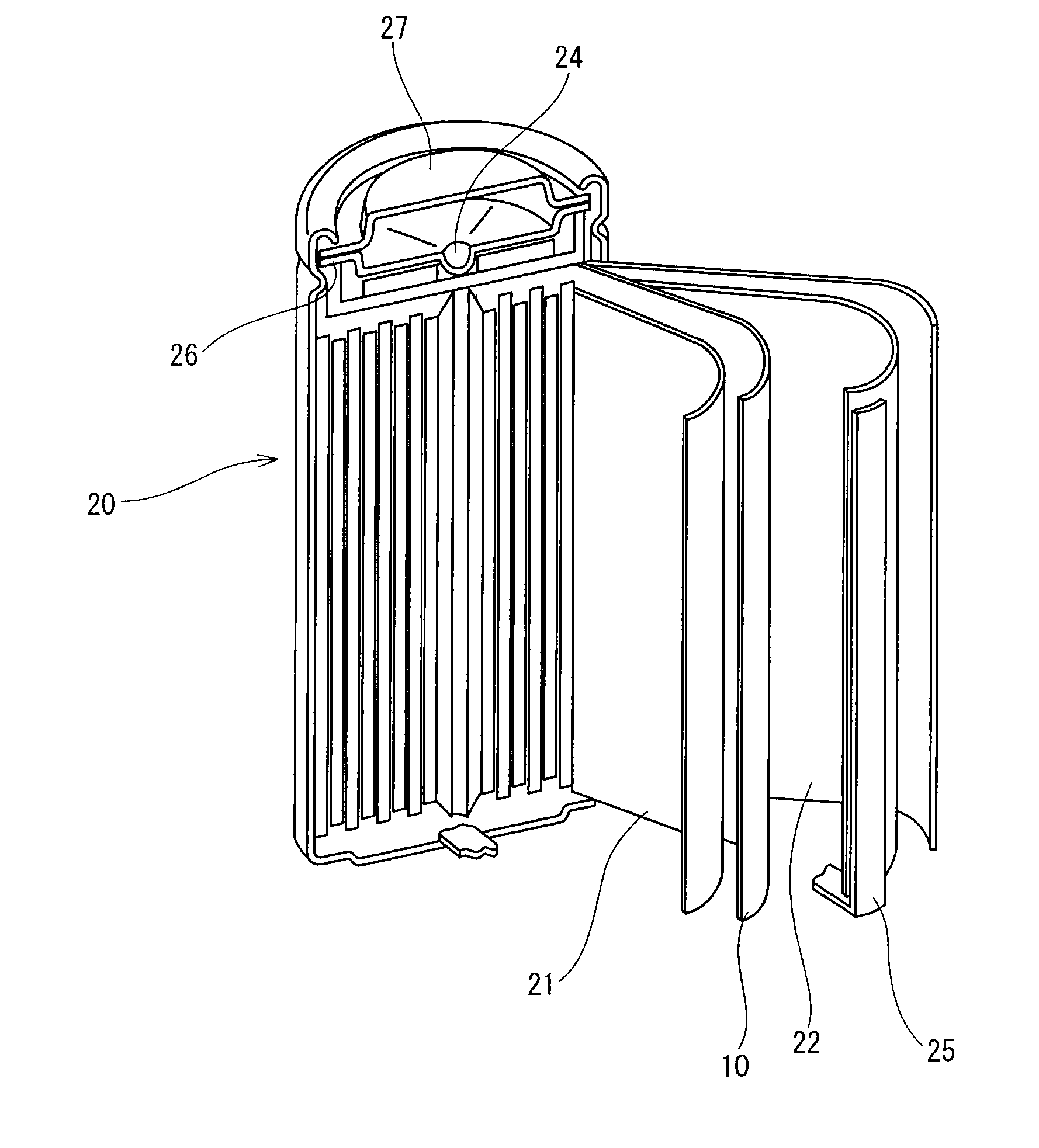

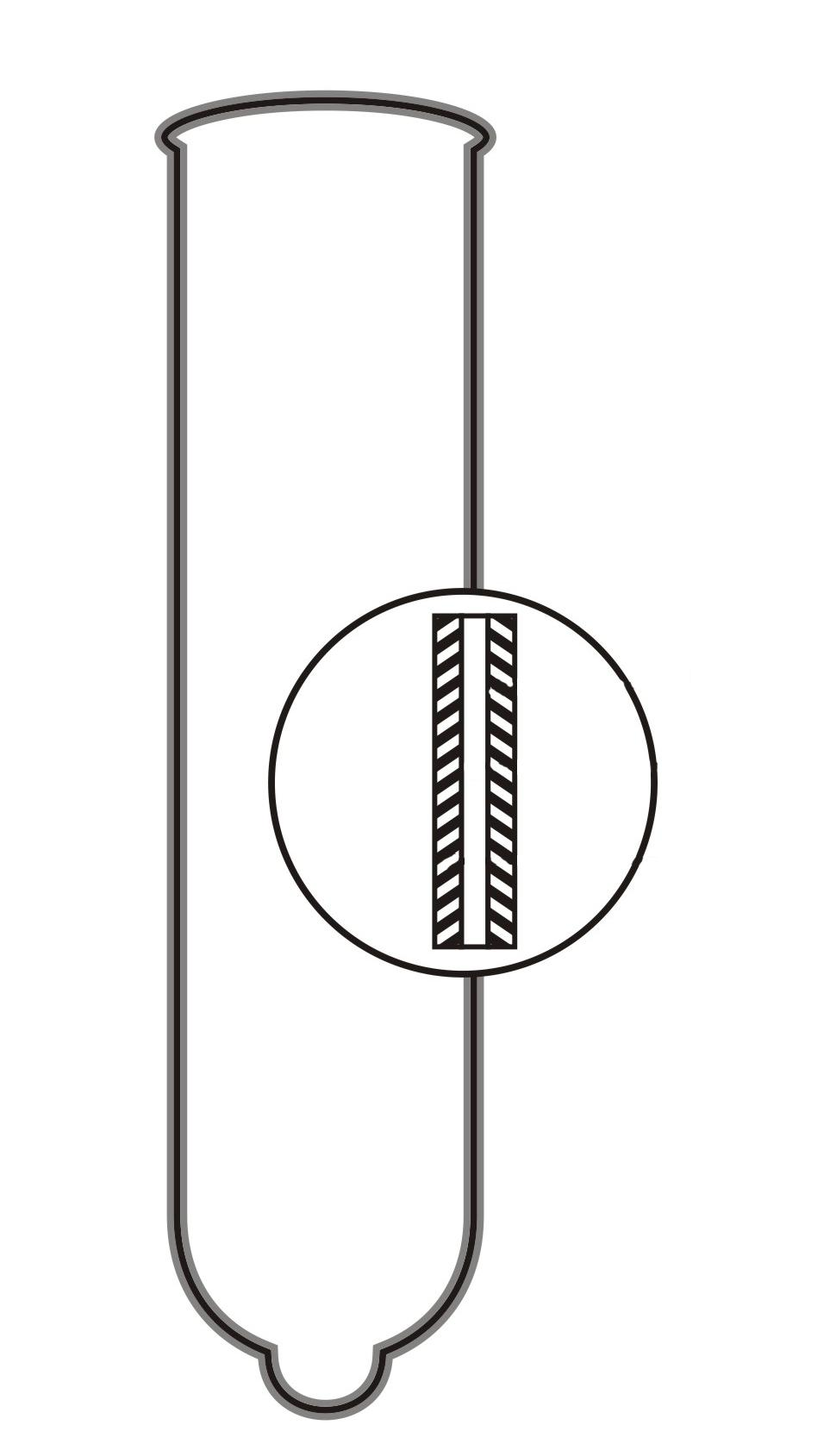

Laminated porous film, separator for battery, and battery

InactiveUS20120231323A1Improve slip performanceExcellent in its slip performance and performance of pullingFinal product manufactureSynthetic resin layered productsStatic friction coefficientPolyolefin

Disclosed is a laminated porous film which has both gas permeability and heat resistance and can exhibit excellent smoothness and excellent pin extraction properties when used as a separator for a battery. The laminated porous film is characterized by having a heat-resistant layer laminated on at least one surface of a polyolefin resin porous film, wherein the heat-resistant layer comprises a filler and a resin binder, and wherein the surface of the heat-resistant layer has a static friction coefficient of 0.45 or less, a gas permeability degree of 2000 sec / 100 ml or less and a tensile elastic modulus of 400 to 1000 MPa when the film is stretched in the lengthwise direction at a stretching rate of 3%.

Owner:MITSUBISHI PLASTICS INC

Manufacturing technology for aluminum alloy plate

ActiveCN107236883AReduce residual stressReduce the concentration of hydrogen slagThree levelManufacturing technology

The invention relates to a manufacturing technology for an aluminum alloy plate. The manufacturing technology includes the following steps of homogenizing, machining, preheating, hot rolling, edge cutting and head and tail cutting, stretching, solid-solution quenching, stretching, aging, solid-solution quenching, stretching and aging. By means of the manufacturing technology for the aluminum alloy plate, harmful impurities in aluminum melt are removed through the gas removing and slag removing process and the filtering process, and the quality of a cast aluminum alloy ingot blank is improved; the quenching pressure, the cooling rate and the cooling temperature are accurately controlled in a staged manner according to the quenching cooling rule, and therefore three-level quenching is conducted, the quenching degree of the aluminum alloy plate is improved, and meanwhile the quenching residual stress is reduced to the minimum; and the total stretching rate in the step (5), the step (7) and the step (10) of the technology is not larger than 3%, step-by-step stretching is conducted, the aluminum alloy plate obtained through stretching is high in strength, good in toughness and resistant to corrosion, and meanwhile, the residual stress generated by the aluminum alloy plate in the quenching process is reduced.

Owner:广西南南铝加工有限公司

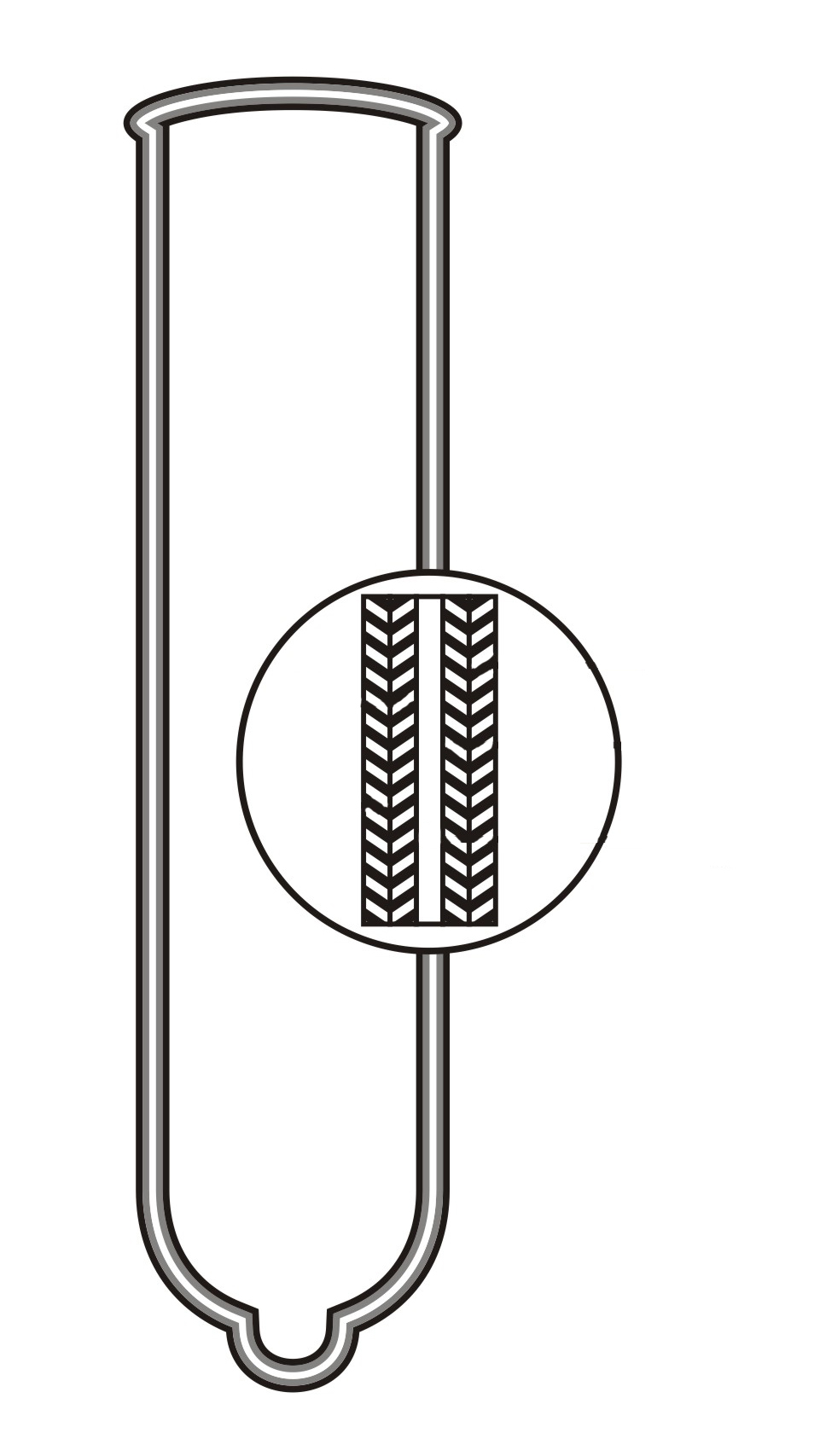

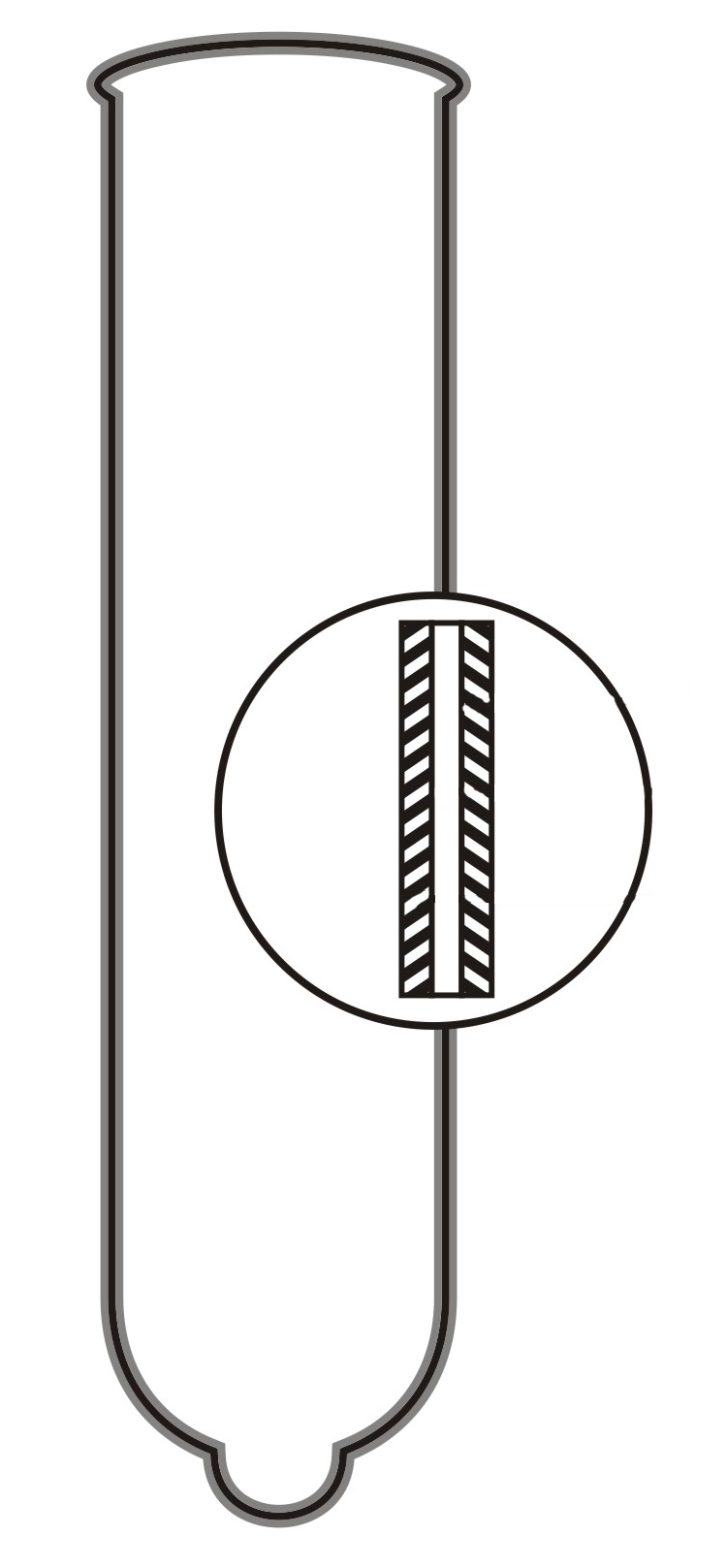

Double-layer sandwich or multi-layer sandwich multi-latex condom and preparation method thereof

ActiveCN101961279APermeation barrierImprove compactnessContraceptive devicesPolymer scienceStretch rate

The invention provides a double-layer sandwich or multi-layer sandwich multi-latex condom and a preparation method thereof. The preparation method of the condom comprises the following steps: vulcanizing natural latex; emulsifying and dispersing polymer materials such as polyurethane or polyisoprene or butyronitrile or other non-natural latex and making the polymer materials into synthetic latex; and dipping a condom die in the natural latex and the synthetic latex respectively and then drying to finally obtain the double-layer sandwich or multi-layer sandwich multi-latex condom the middle layer of which is made from the natural latex or the synthetic latex, wherein, the innermost layer and the outermost layer of the condom can be made from the same material or different materials. The double-layer sandwich or multi-layer sandwich multi-latex condom of the invention has stretch rate and comfortability of the natural latex as well as high compactness of the synthetic latex, thus being applicable to obstructing penetration of small molecules such as hepatitis, AIDS virus and the like.

Owner:桂林恒保健康防护有限公司

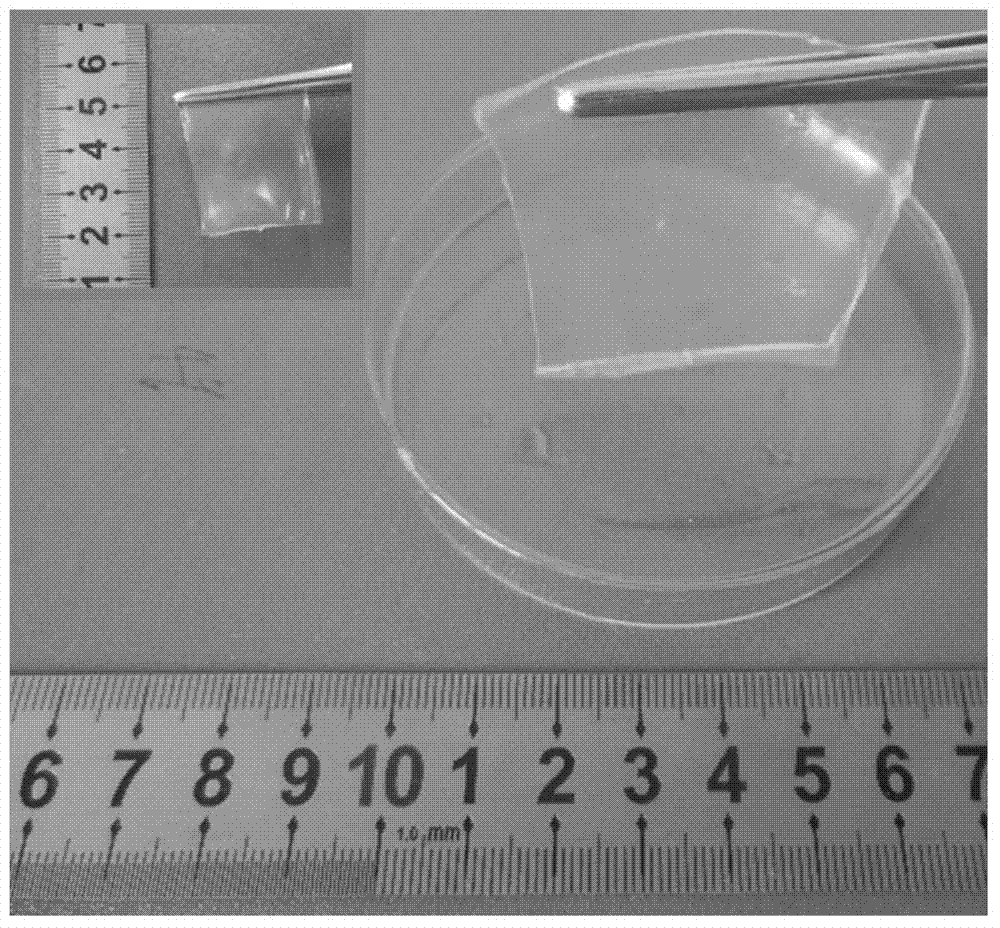

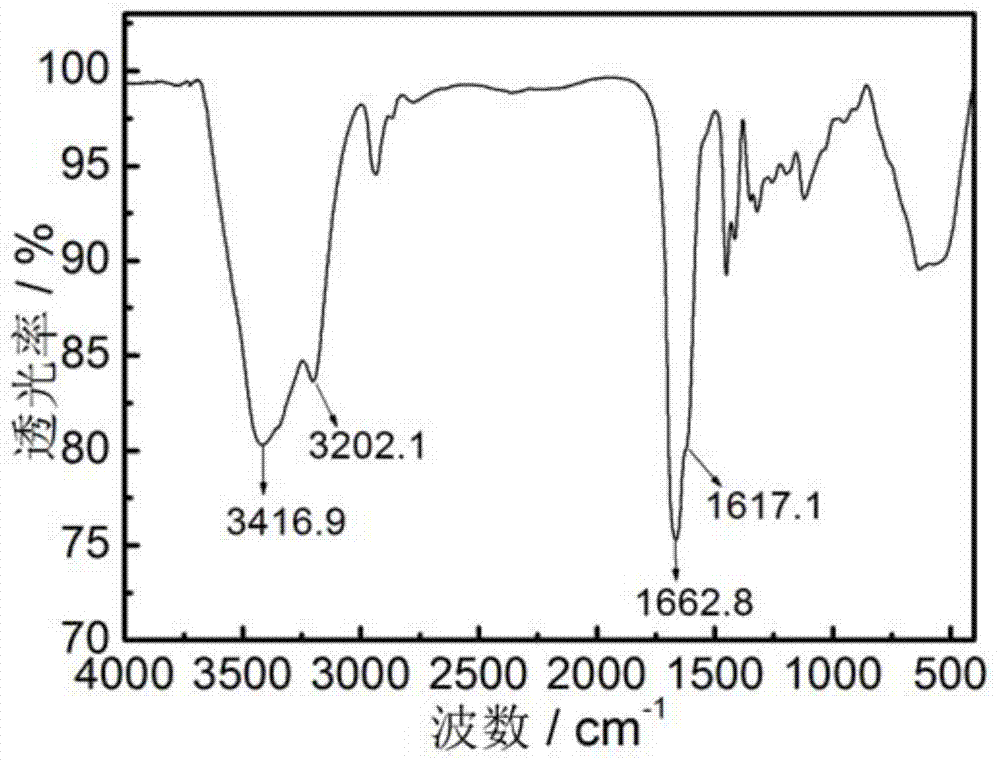

Stretchable flexible supercapacitor and preparation method thereof

ActiveCN104497229ASimplify the assembly processEasy to operateHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceSupercapacitor

The invention relates to a stretchable flexible supercapacitor and a preparation method of the stretchable flexible supercapacitor. The stretchable flexible supercapacitor takes an electrochemical active substance / carbon-based material supported composite material as an electrode, adopts polyacrylamide gel with high stretchability and high viscosity as electrolyte, and is of a sandwiched structure, wherein when the stretch rate of the stretchable flexible supercapacitor is up to 150%, the specific capacitance of the stretchable flexible supercapacitor is basically unchanged; the capacitance degradation of the stretchable flexible supercapacitor is less than or equal to 10% after the stretchable flexible supercapacitor is charged-discharged circularly for 3000 times at the electric current density of 3mA / cm<2>. The defect that in the existing assembling technology of the stretchable flexible supercapacitor, a stretchable substrate is required is eliminated by virtue of the strong adhesion between the gel electrolyte and the flexible electrode of the stretchable flexible supercapacitor, and the assembling process is simplified.

Owner:EAST CHINA UNIV OF SCI & TECH

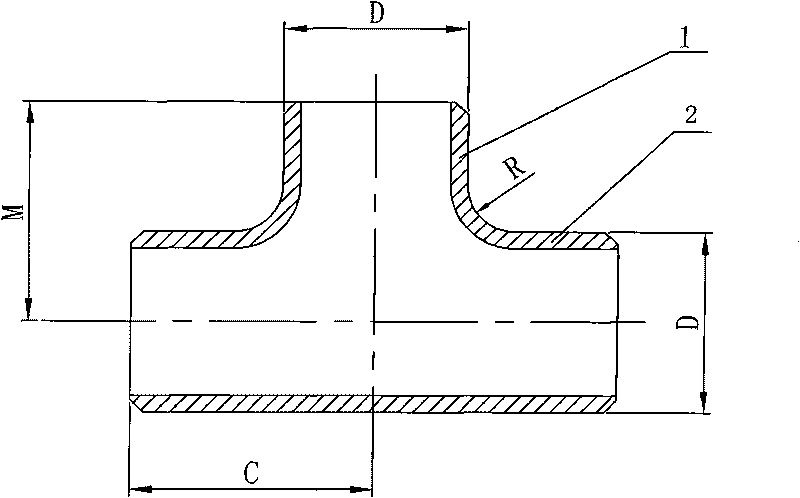

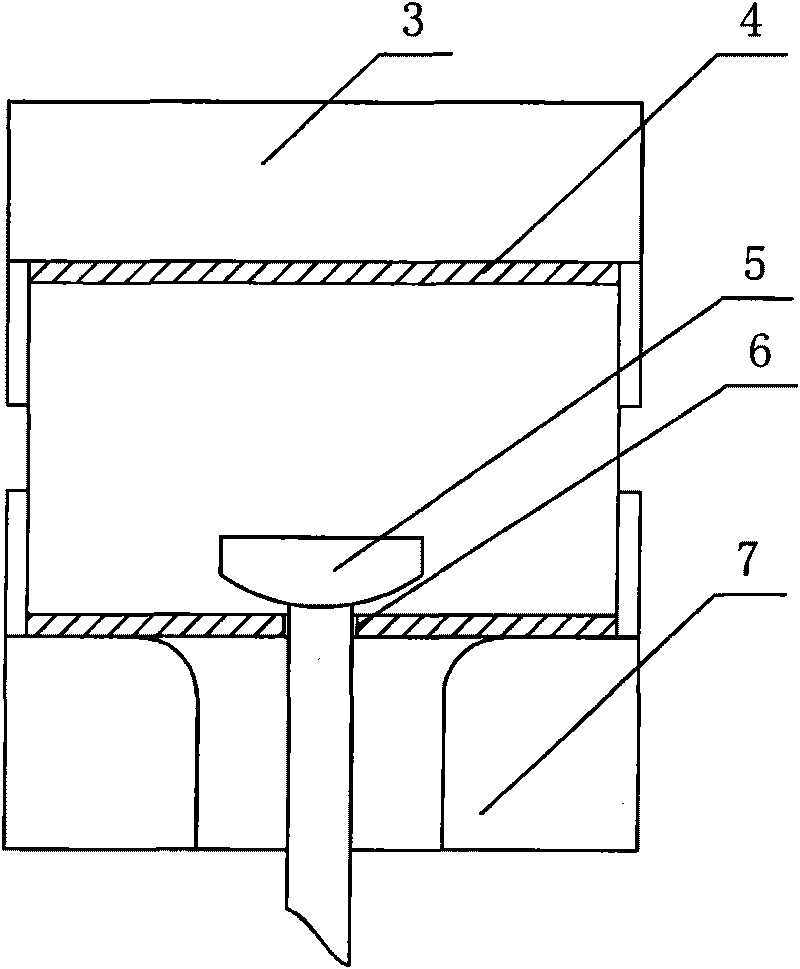

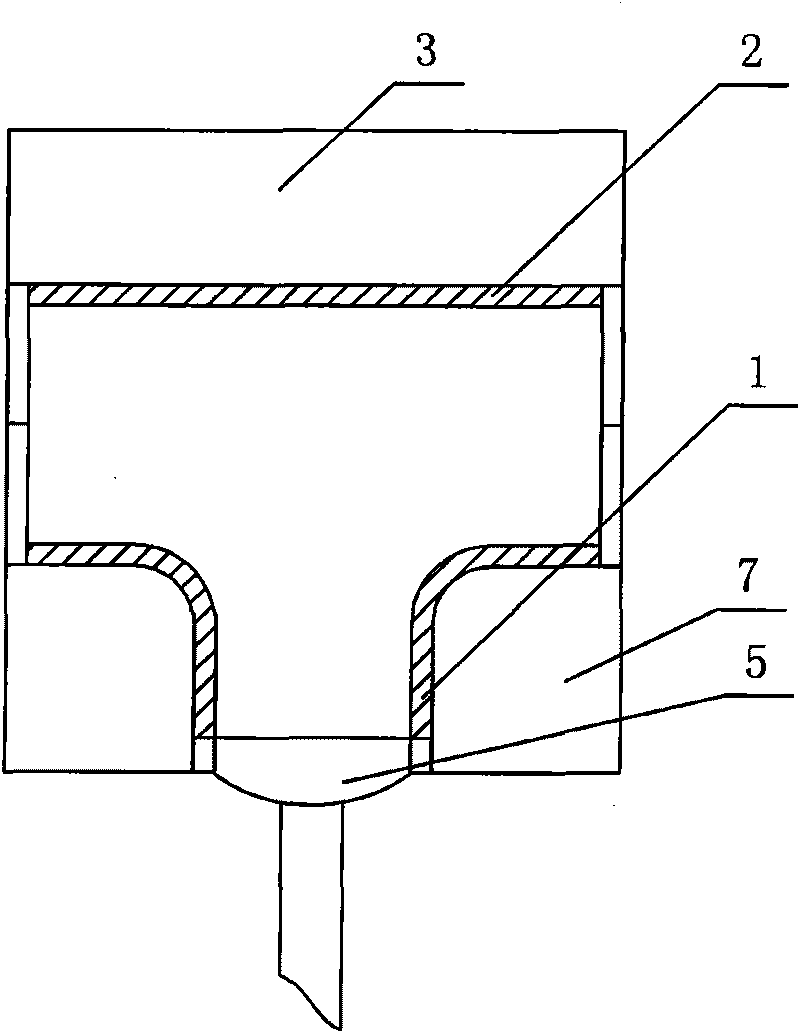

Hot pressing forming mould and hot pressing forming method of super long branch pipe three-way pipe fitting

ActiveCN101704055AGuaranteed tensile deformationSolve forming problemsShaping toolsPipe fittingEngineering

The invention relates to a hot pressing forming mould of a super long branch pipe three-way pipe fitting, comprising a first upper die, a second upper die, a first lower die, a second lower die, a third lower die, a fourth lower die and a draw bar. A primary forming mould consists of the first upper die and the first lower die; a secondary forming mould consists of the first upper die and the second lower die; a third forming mould consists of the first upper die and the third lower die; and a final forming mould consists of the second upper die, the fourth lower die and the draw bar. The invention also relates to a hot pressing forming method which adopts the mould to manufacture the super long branch pipe three-way pipe fitting. Two upper dies and four lower dies are adopted by the invention to be drawn and extruded step by step into a super long branch pipe; in each hot pressing forming process, the tensile deformation of the materials is ensured to be within the tensile rate limit by controlling the root R and the outer diameter D of the branch pipe to be decreased successively, thereby solving the forming problem of super long branch pipe tee (M>1.5C).

Owner:WUXI XINFENG TUBE IND

Transparent paper supplementary with regenerated cellulose and manufacturing method thereof

ActiveCN106192550ASimple processShorten the production cycleSynthetic cellulose fibresProcess equipmentUltimate tensile strength

The invention discloses transparent paper supplementary with regenerated cellulose and a manufacturing method thereof. The method comprises the following steps: firstly, adding fine cellulose powder into EMIMMeOPO2H ionic liquid; heating cellulose till fully dissolving; slowly adding the cellulose solution into a regenerating solution under quick stirring state; cutting a large amount of accumulated cellulose molecules into countless small cellulose molecule groups under the high-speed shearing effect of an emulsifying machine, wherein the small groups are regenerated cellulose; mixing the regenerated cellulose with fully pulped plant fibers and forming into an end product of paper. The thickness of the transparent paper is 30-100mu m, the light transmissivity is 60-90%, the tensile strength is 20-60 Mpa and the stretch rate is (10-30)%. According to the invention, paper pulp is taken as the raw material, the process is environmentally friendly, the cost is low, the production period is short, only 30-120min is required by the whole process, the present paper machine, technique and equipment are locally modified and the industrial production can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

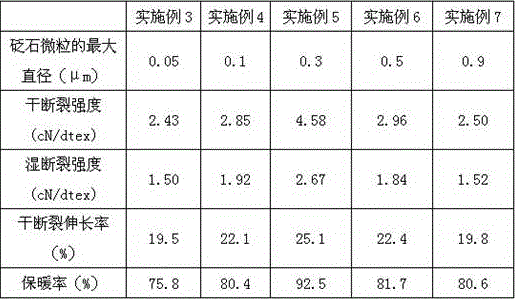

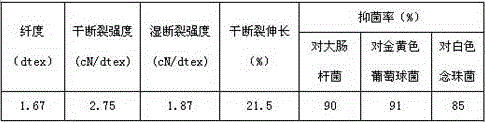

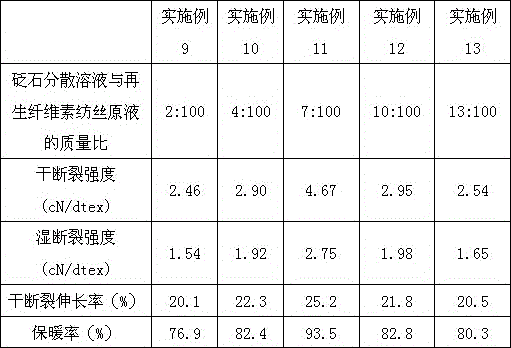

Stone needle-containing healthcare regenerated cellulose fiber and preparation method thereof

ActiveCN105970327APromote improvementSignificant improvementArtificial filaments from viscoseEscherichia coliBreaking strength

The invention provides a stone needle-containing healthcare regenerated cellulose fiber. The fiber has dry breaking strength more than or equal to 2.4cN / dtex, wet breaking strength more than or equal to 1.5cN / dtex and dry breaking stretching rate more than or equal to 19%. The invention also provides a preparation method for the fiber. The method comprises the step of preparing a co-blending spinning solution, wherein the mass ratio of a stone needle disperse solution to a regenerated cellulose spinning solution is 2:1000 to 1:10 in the step of preparing the co-blending spinning solution. The antibacterial rate of the acquired fiber according to the invention to staphylococcus aureus is more than or equal to 90.0%, the antibacterial rate to escherichia coli is more than or equal to 91.0%, and the antibacterial rate to candida albicans is more than or equal to 85.0%. The acquired fiber according to the invention has dry breaking strength more than or equal to 2.4cN / dtex, wet breaking strength more than or equal to 1.5cN / dtex and dry breaking stretching rate more than or equal to 19%. The stone needle-containing healthcare regenerated cellulose fiber prepared according to the invention contains 6-8% of stone needle.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

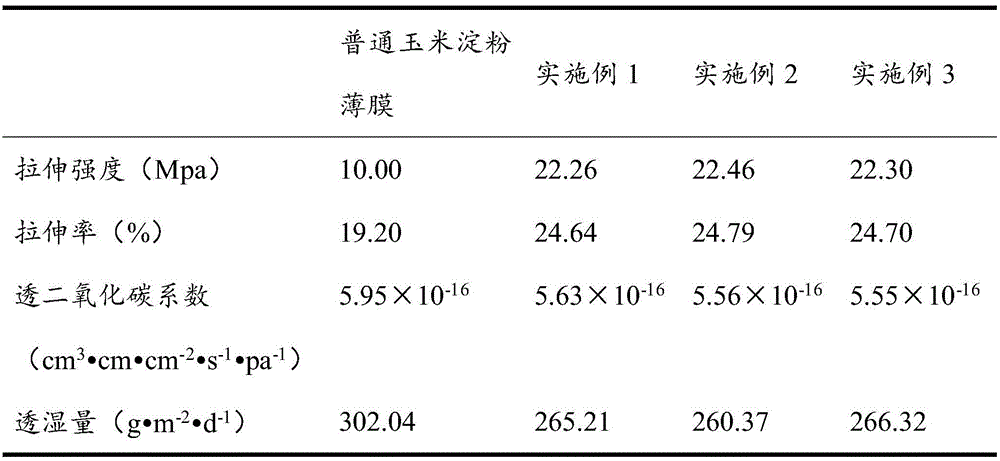

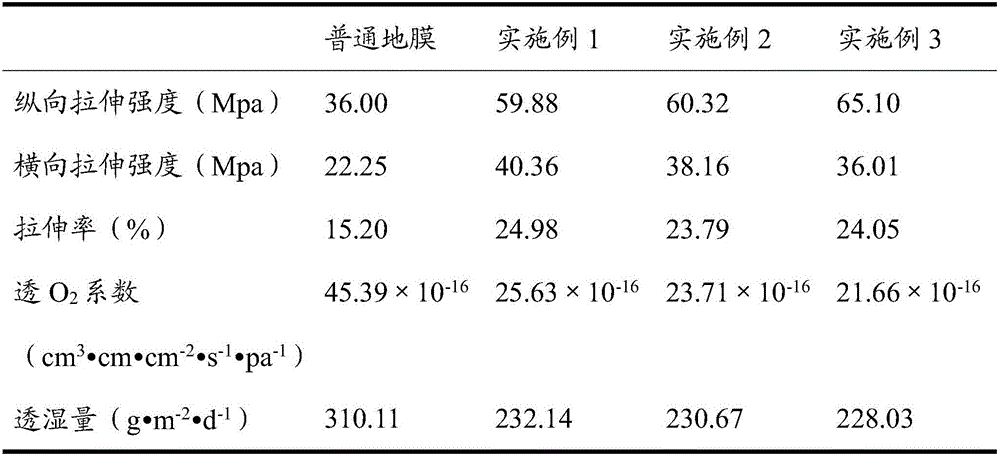

Degradable packaging film material and preparing method and application thereof

InactiveCN105885110AOvercoming poor mechanical propertiesIncrease manufacturing costFiberWater vapor

The invention discloses a degradable packaging film material. The degradable packaging film material is prepared from, by mass concentration, 0.90-1.10% of straw stalk fiber, 2.80-3.20% of corn crosslinked starch, 2.70-3.30% of polyvinyl alcohol-carboxymethylcellulose mixed liquor, 2.10-2.50% of glyoxal, 3.50-4.00% of glycerinum and 85.90-88.00% of deionized water, wherein the polyvinyl alcohol-carboxymethylcellulose mixed liquor is obtained by mixing polyvinyl alcohol with carboxymethylcellulose according to the mass ratio of 1:2. Compared with ordinary corn starch films, the degradable packaging film material has the advantages that tensile strength is improved by 122% or more, stretch rate is increased by 28% or more, water vapor transmission rate is reduced by 11% or more, damage does not occur easily, barrier property is high and manufacturing cost is low. At 4 DEG C, strawberry and mulberry preservation time can reach 8 d, and a good degradation effect is realized. The invention further provides a preparing method of the degradable packaging film material.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Copper alloy material for integrated circuit lead frame and manufacturing process thereof

InactiveCN1654690AImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesChemical compositionLead frame

The copper alloy material for integrated circuit lead frame consists of: Cu not less than 99.8 wt%, Fe 0.05-0.15 wt% and P 0.015-0.05 wt%. Its production process includes material inspection, weighing and compounding, smelting, semi-continuous casting, hot rolling, milling belt blank, cold initial rolling, cutting edges, annealing, cold intermediate rolling, intermediate annealing, 12 roller final rolling, cleaning, straightening, packing and other steps. It has tensile strength up to 390 MPa, high stretch rate and raised heat resisting performance.

Owner:SHANGHAI JINTAI COPPER IND

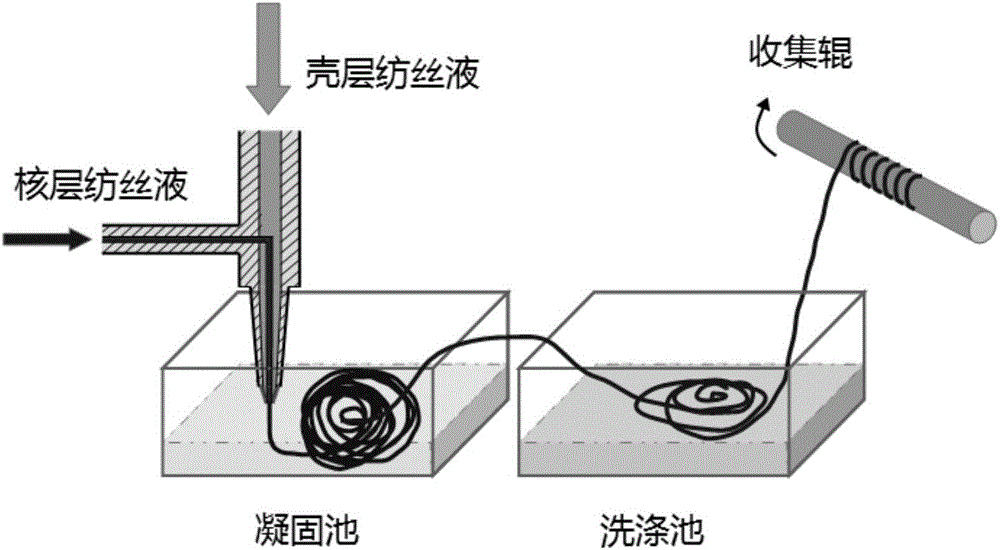

Core-shell structure fiber based on carbon nano material and preparation method thereof

InactiveCN107177892AConvenient ArrangementEasy to operateArtificial filament washing/dryingWet spinning methodsFiberReduction treatment

The invention discloses a core-shell structure fiber based on a carbon nano material and a preparation method thereof. The preparation method comprises the following steps: firstly uniformly dispersing the carbon nano material into an organic solvent, then uniformly mixing with organic silicon rubber, and preparing a core layer spinning solution, wherein shell layer spinning solution is pure liquid silicone rubber; secondly, adopting two injection pumps for injecting the core layer spinning solution and the shell layer spinning solution into coagulation bath by virtue of a coaxial spinning needle, curing and forming, then cleaning the cured composite fiber in a washing pool, and collecting by adopting a collecting device; and finally, carrying out drying treatment or reduction treatment on the composite fiber, so that a continuous core-shell structure composite fiber is obtained. The preparation method is simple, the fiber forming quantity is large, the diameter of the fiber is controllable, and the prepared core-shell structure fiber has flexibility and excellent stretch property, overcomes the defects of an existing carbon nano material composite fiber that the stretch rate is low and the mechanical strength is low, can be applied to the fields of sensors, flexible conductors and wearable electronic equipment, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

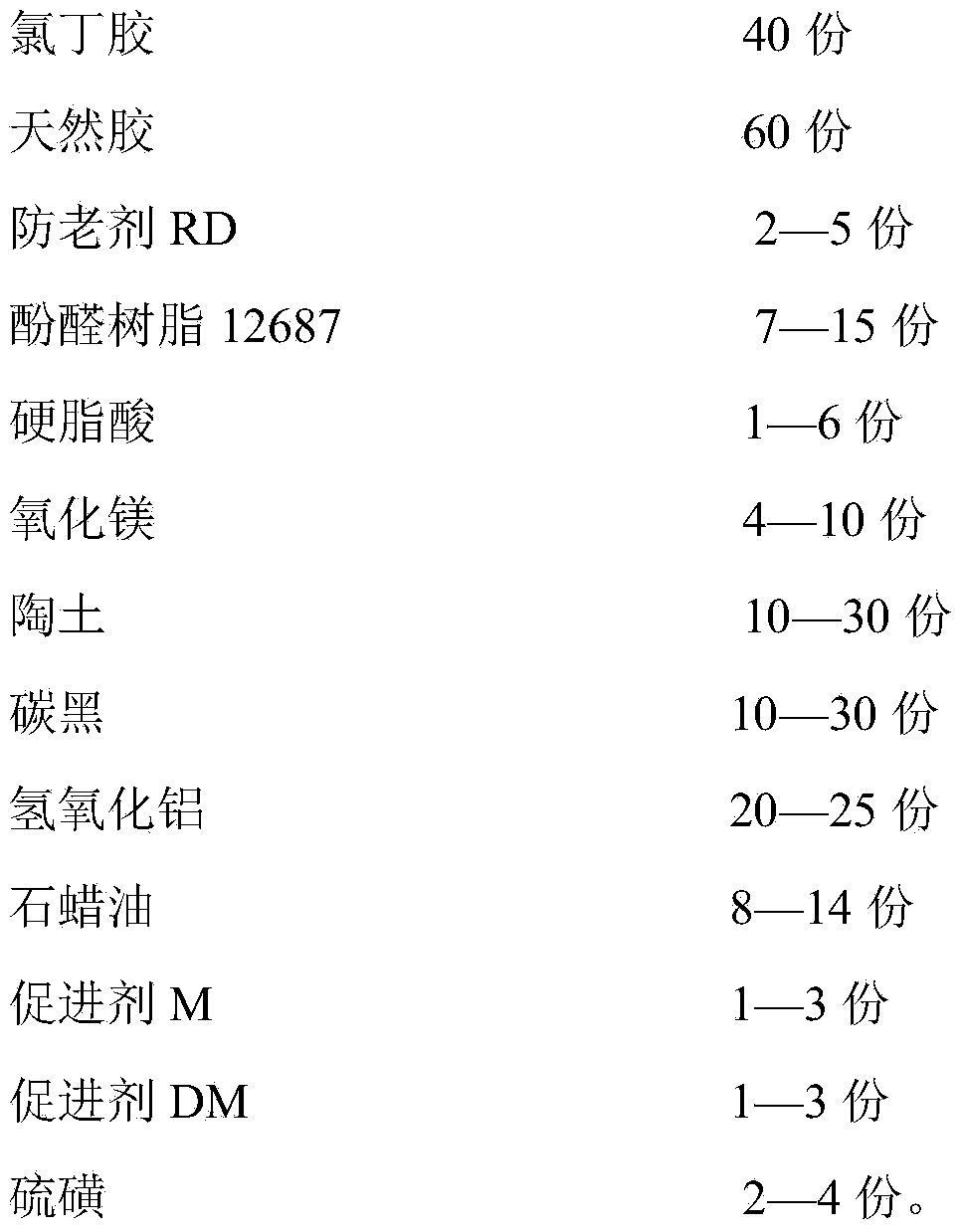

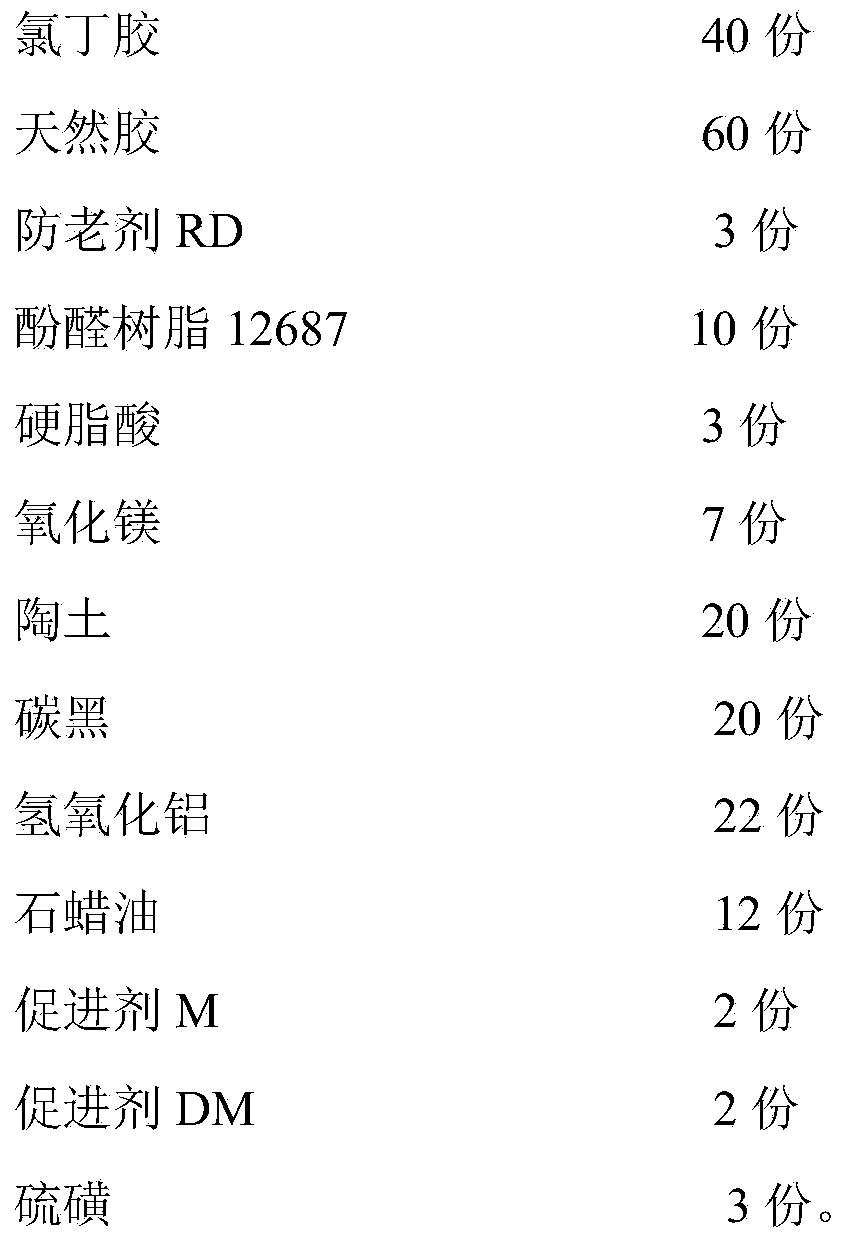

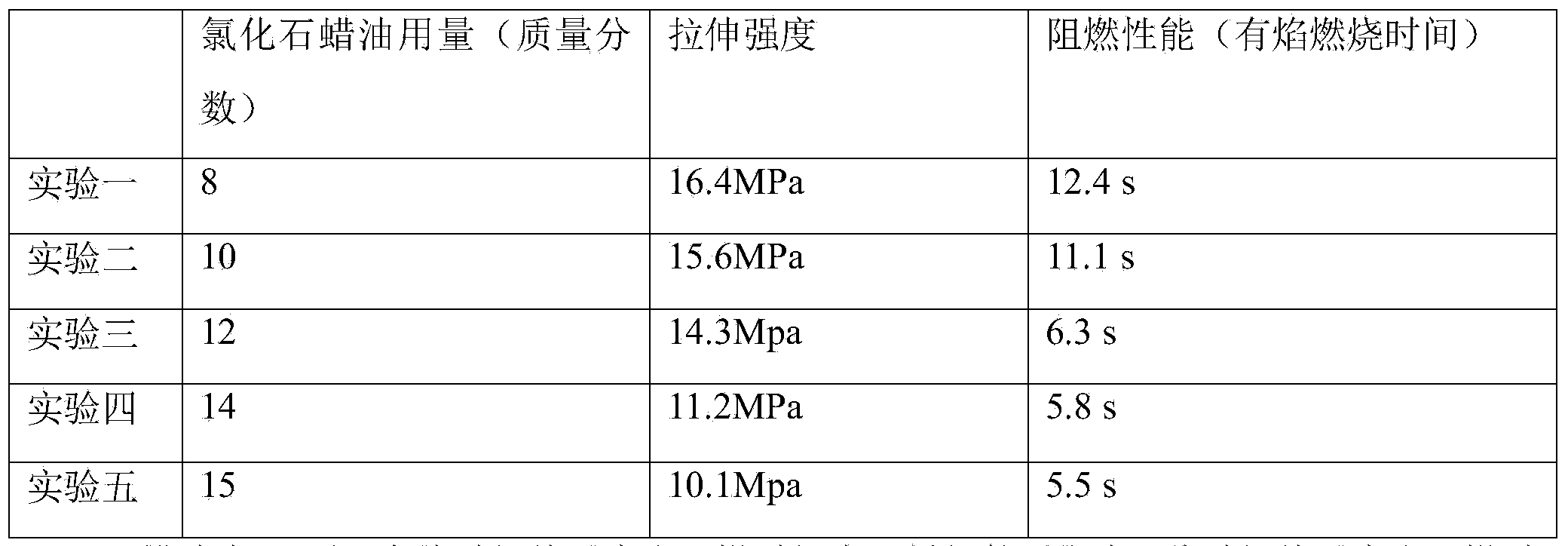

Aluminium hydroxide flame retardant adhesive and preparation method thereof

The invention discloses an aluminium hydroxide flame retardant adhesive and a preparation method thereof, and belongs to the field of flame retardant materials. The aluminium hydroxide flame retardant adhesive comprises the following components in parts by mass: 40 parts of a chloroprene rubber adhesive, 60 parts of natural rubber, 2 to 5 parts of an anti-aging agent RD, 7 to 15 parts of phenolic resin 12687, 1 to 6 parts of stearic acid, 4 to 10 parts of magnesium oxide, 10 to 30 parts of argil, 10 to 30 parts of carbon black, 20 to 25 parts of aluminium hydroxide, 8 to 14 parts of paraffin oil, 1 to 3 parts of an accelerant M, 1 to 3 parts of an accelerant DM, and 2 to 4 parts of sulphur. Aluminium hydroxide is processed in a plastication starting stage by using a two-stage plastication way. The aluminium hydroxide flame retardant adhesive provided by the invention has a good flame retardant efficiency, the escape of combustible gases can be prevented by using aluminium hydroxide, the formation of soot is avoided, a better flame retardant and smoke suppression effect is played, the tensile strength is high, the stretch rate is good, the production process is simple, and the manufacturing cost and the manufacturing difficulty are lowered.

Owner:MAANSHAN TIANXIN ROLL IND

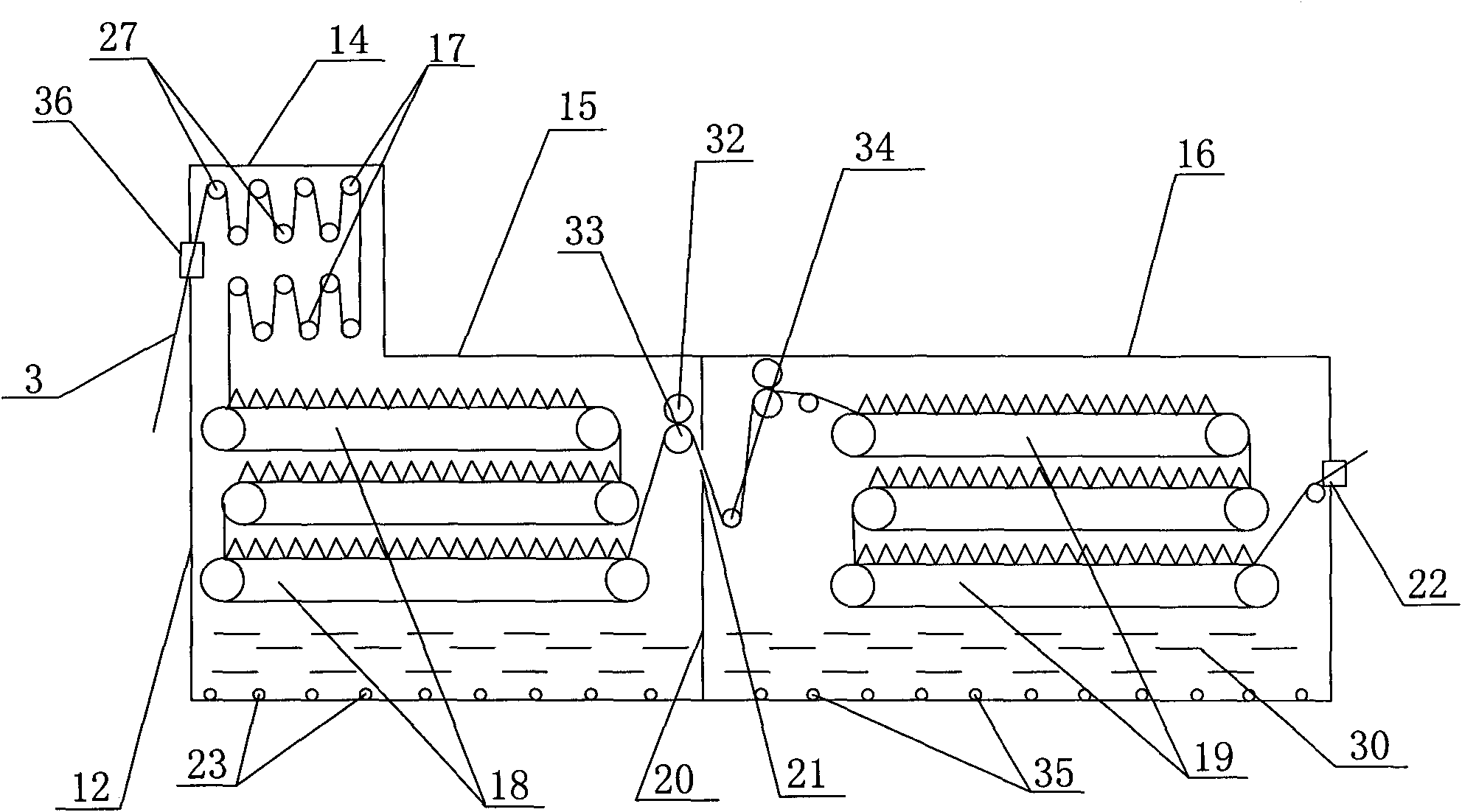

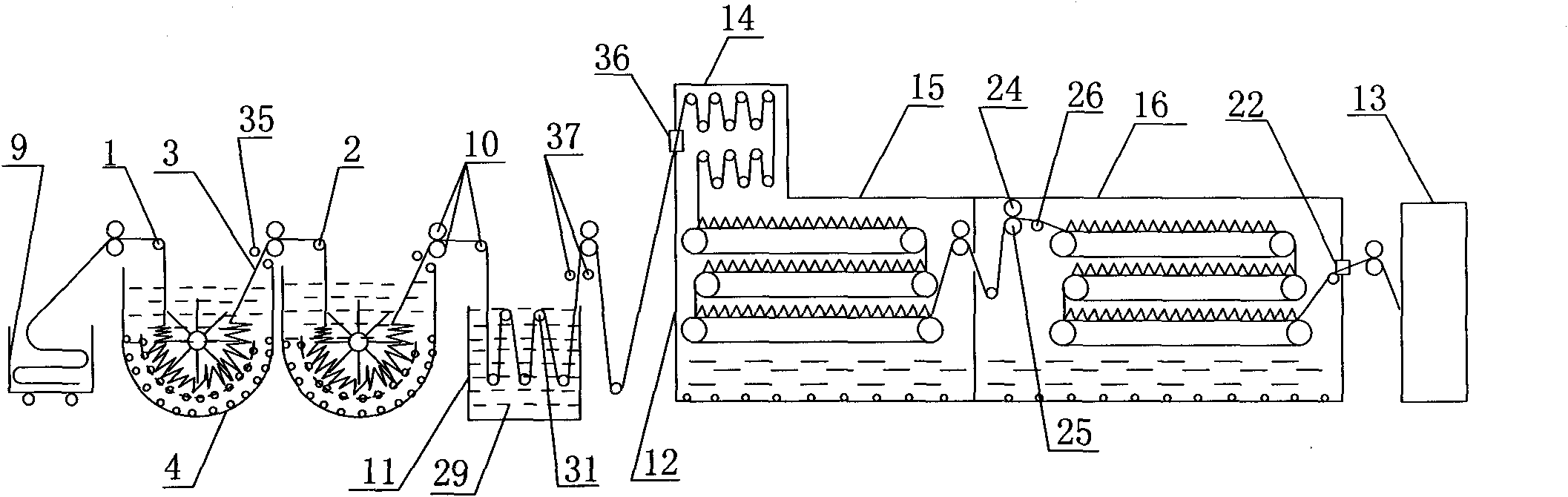

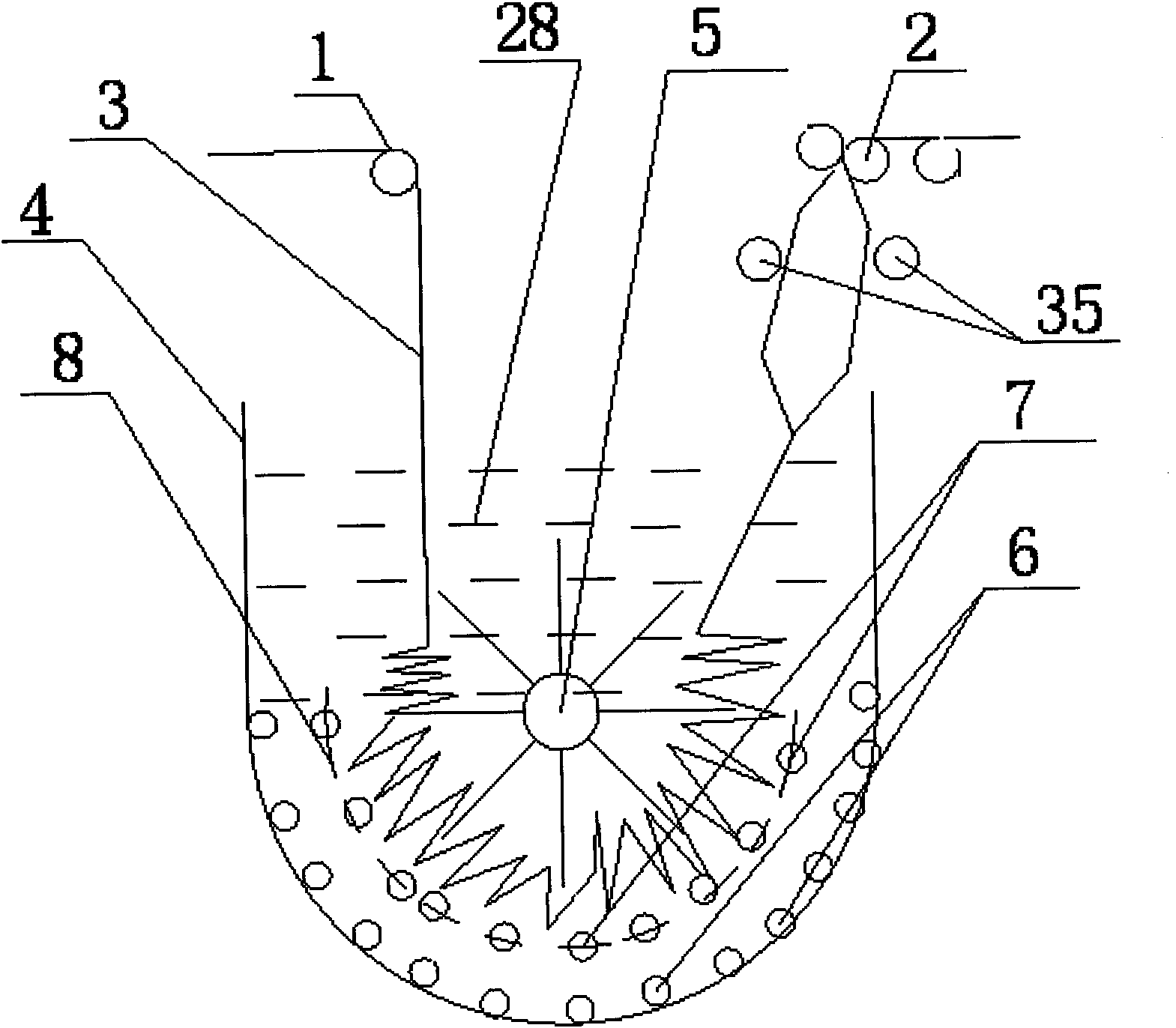

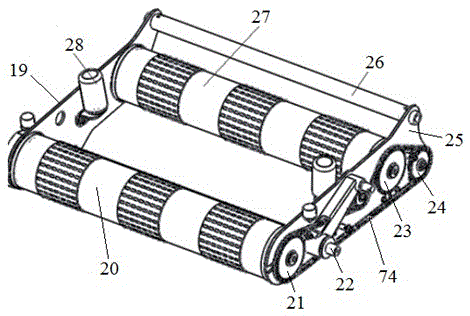

Steam box used for scouring and bleaching equipment, scouring and bleaching equipment and steaming method

ActiveCN101781837AImprove flatnessHigh whitenessTextile treatment containersTextile treatment machine arrangementsEngineeringStretch rate

The invention discloses a steam box used for scouring and bleaching equipment, scouring and bleaching equipment and a steaming method. The steam box comprises a preheating zone, a first temperature zone and a second temperature zone; a steam box guide roller used for transmitting fabrics is arranged in the preheating zone; a first crawler belt set and a second crawler belt set are respectively arranged in the first temperature zone and the second temperature zone; the transmission directions of adjacent crawler belts in the first crawler belt set and the second crawler belt set are opposite; the crawler belts are staggered in parallel to form the continuous transmission of the fabrics, thereby enabling the fabrics to be stacked on the crawler belts and continuously transmitted; the steam box is arranged in the scouring and bleaching equipment and treats the fabrics according to certain process flows. The invention thoroughly solves the problems that the scouring and bleaching effect is not ideal, the cloth cover evenness of the fabrics is poorer, the dimensional stability is poor because the textile stretch rate is overlarge, the effects of energy saving and consumption reducing are not ideal and the like, thereby continuously producing the fabrics with high evenness, high whiteness and high capillary effect but without creases.

Owner:QINGDAO UNIV

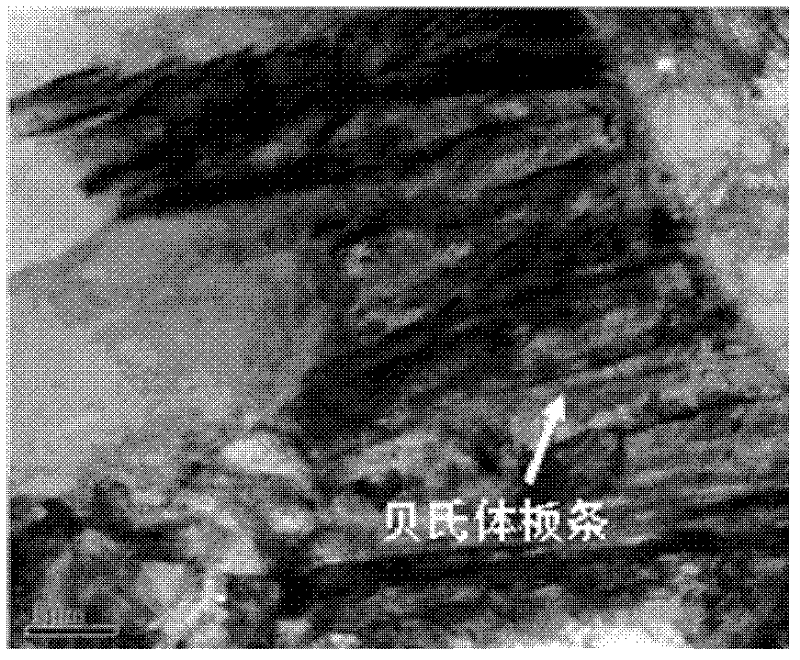

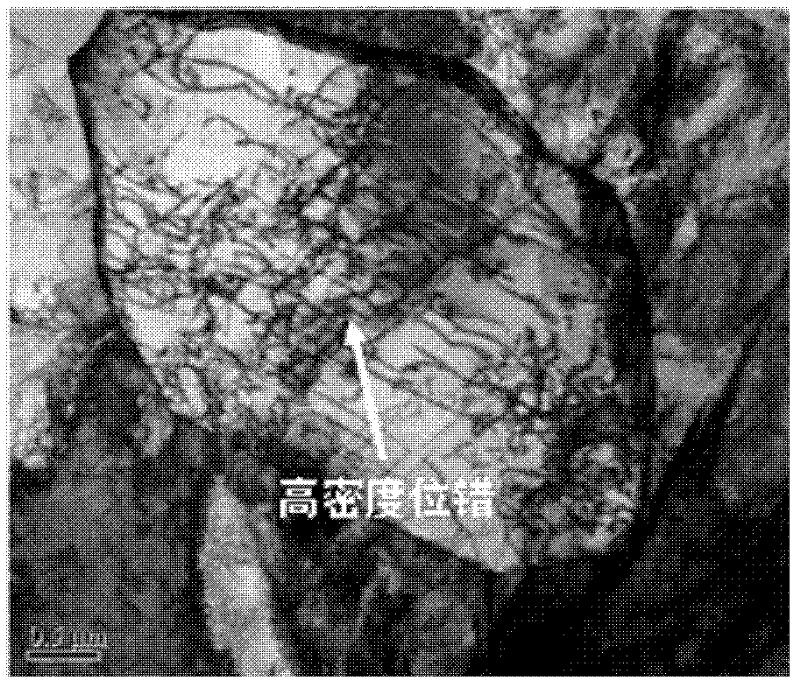

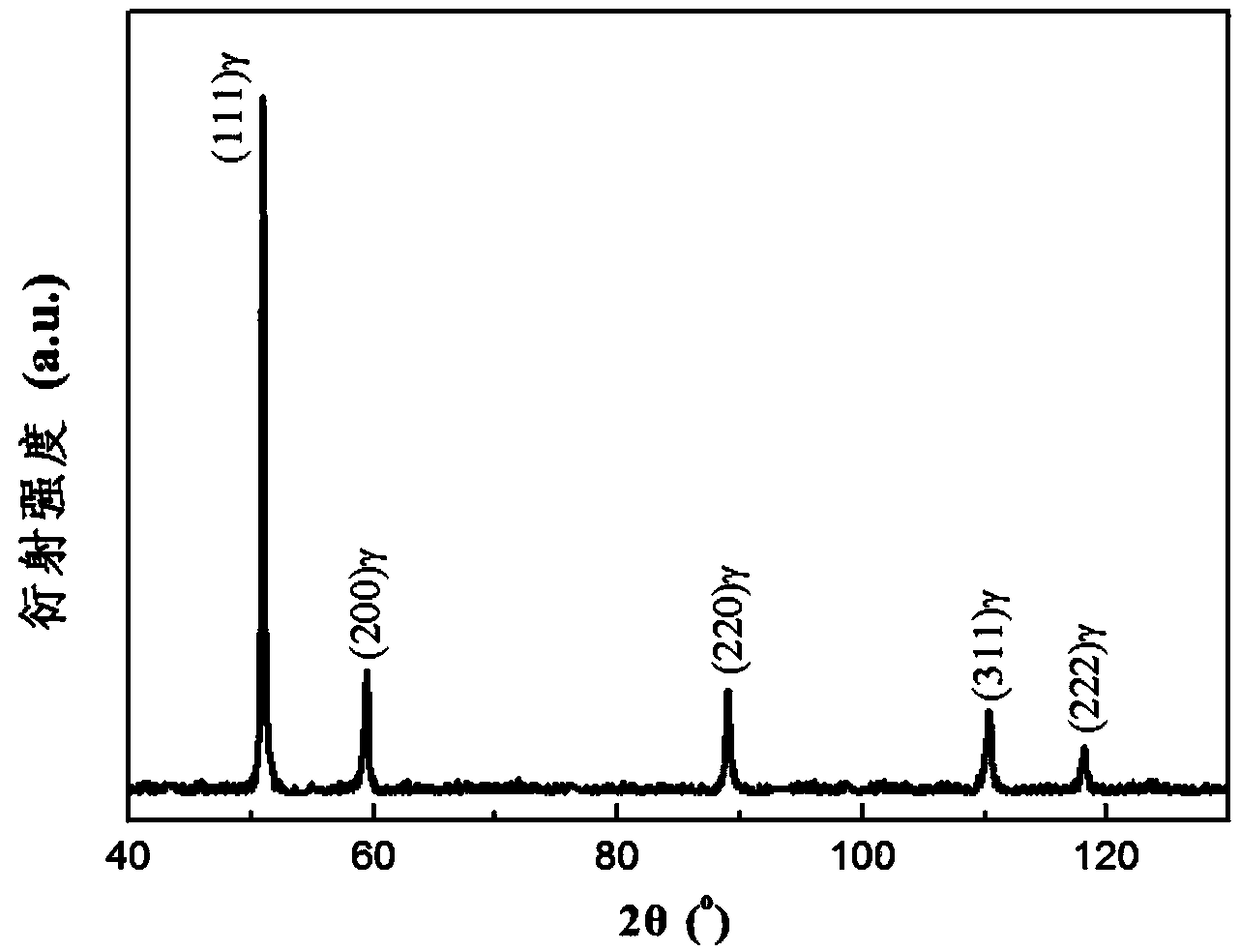

High-entropy alloy and preparation method thereof

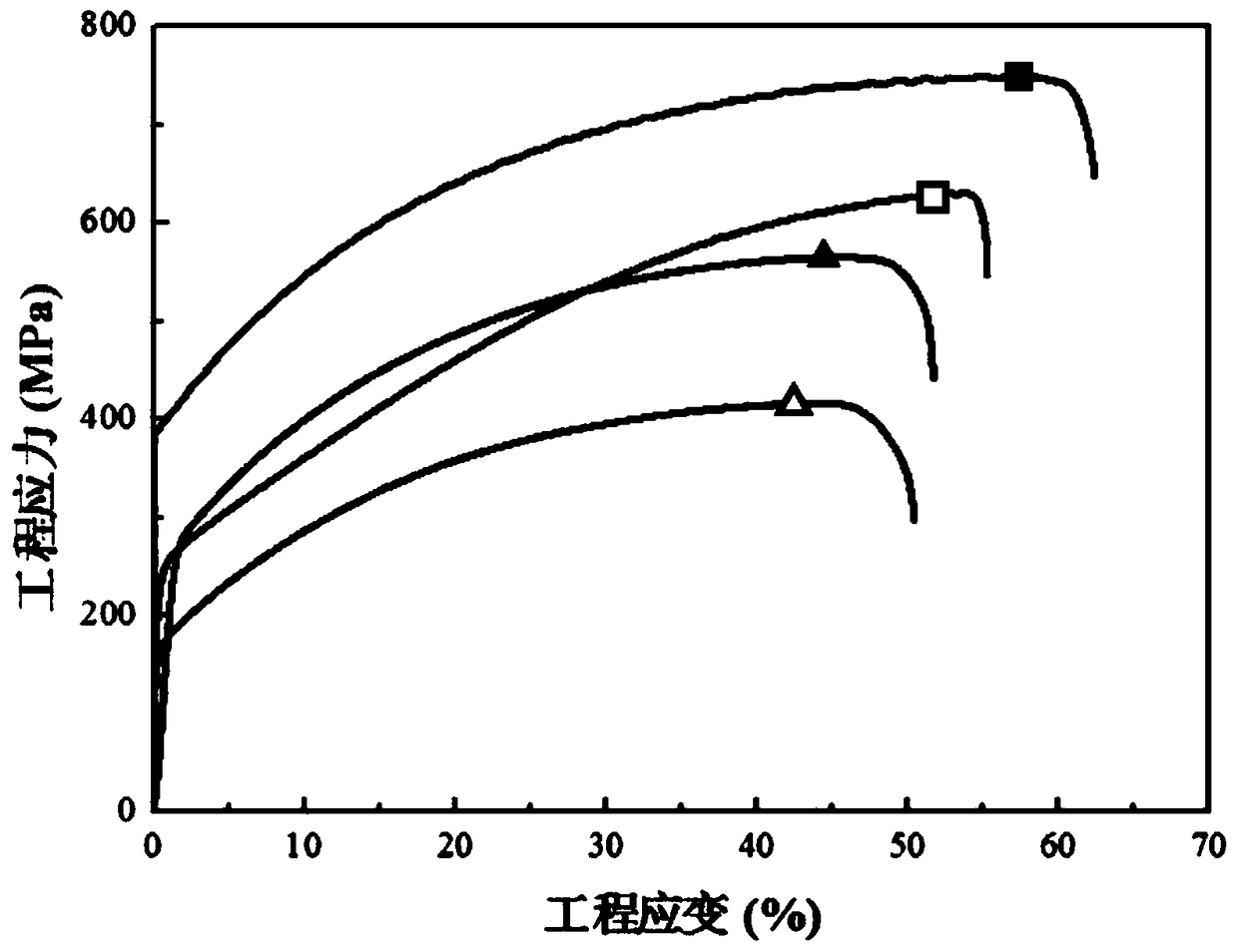

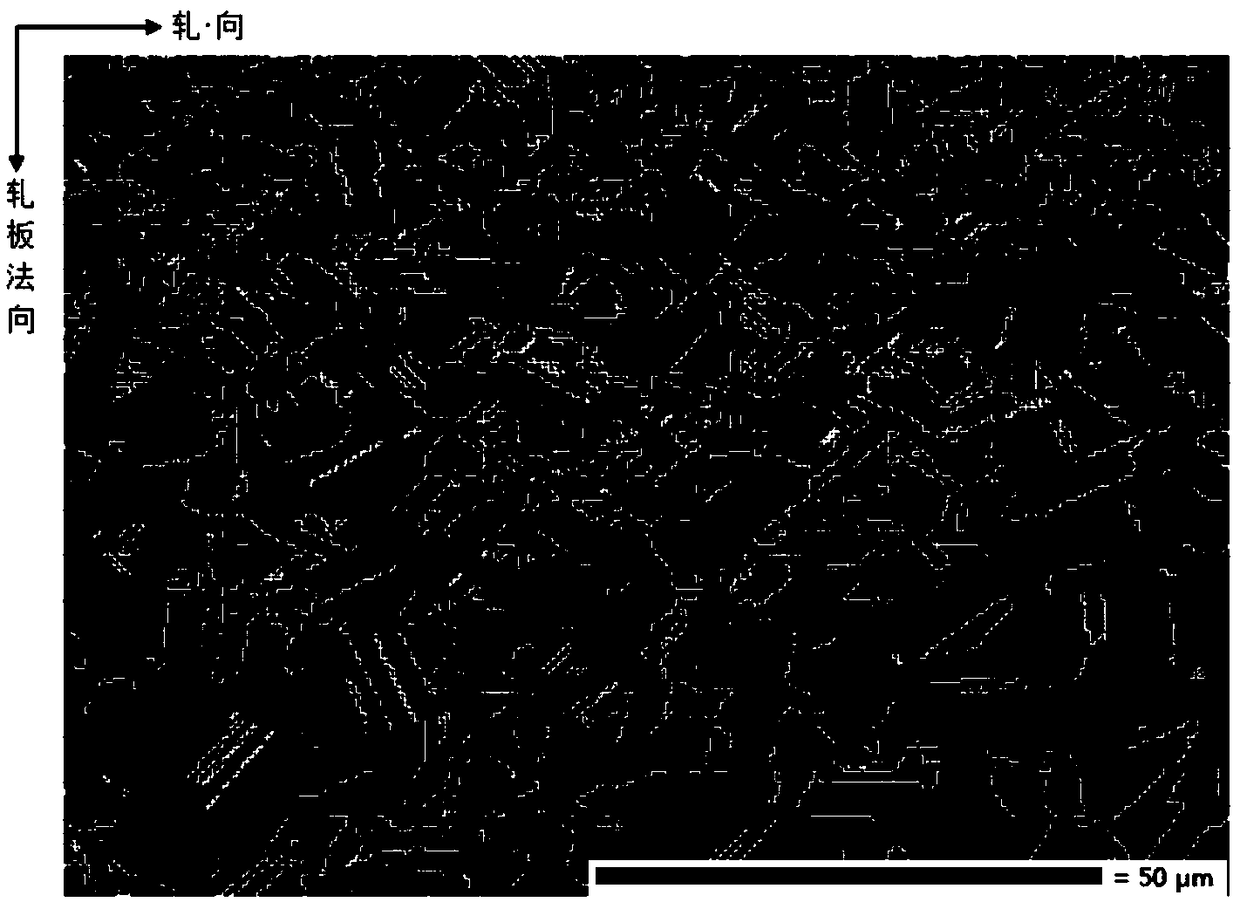

InactiveCN108823481AImprove plastic deformation abilityUniform Plastic Deformation CapabilityHigh entropy alloysRoom temperature

The invention provides a high-entropy alloy, which relates to the technical field of a metal material. The high-entropy alloy comprises the following elements by atom percentage content: 39.0-41.0% ofFe, 9.0-11.0% of Co, 39.0-41.0% of Mn, and 9.0-11.0% of Cr. A stacking fault energy theoretical value of the high-entropy alloy is 35 mJ / mol, and the stacking fault energy is in favor of keeping a single-phase austenite structure when the high-entropy alloy is placed under environment lower than room temperature; stress load is bear under low temperature condition, dislocation glide and mechanical twining are generated, deformation induces austenite to change to martensite, when the high-entropy alloy is 173 K, the yield strength is 670 M, the stretching rate reaches 62%, and the tensile strength can reach 750 MPa; and the plasticity and intensity are higher than the mechanical properties of a steel product used for low temperature in a traditional method.

Owner:NORTHEASTERN UNIV

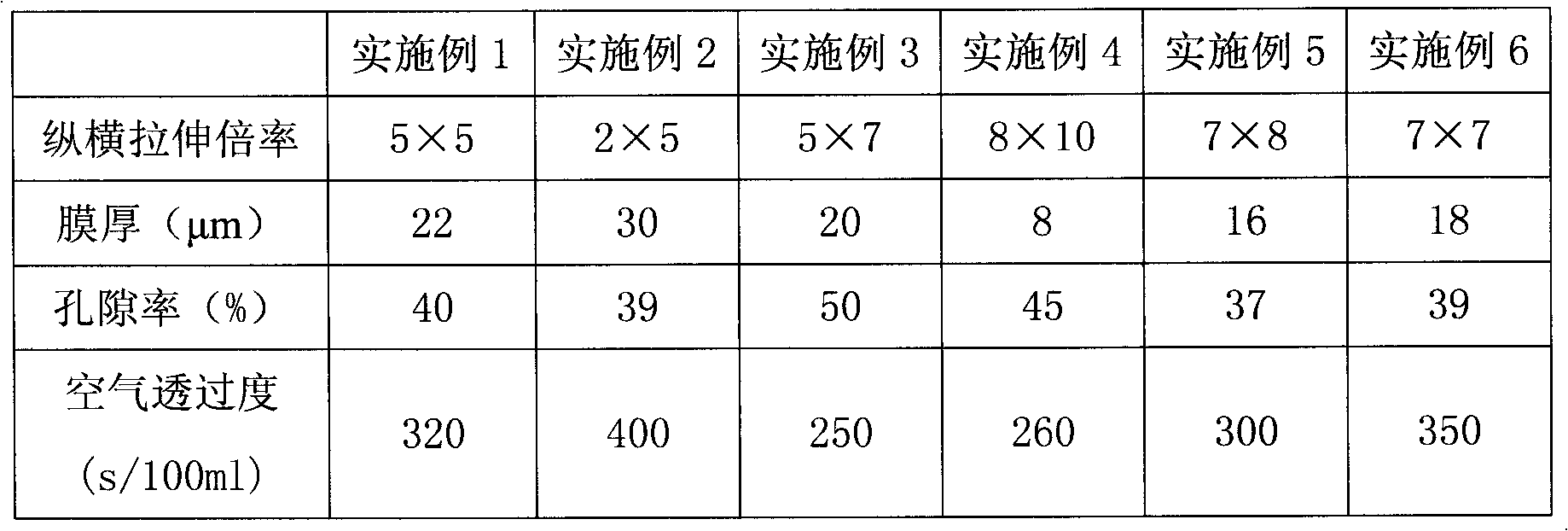

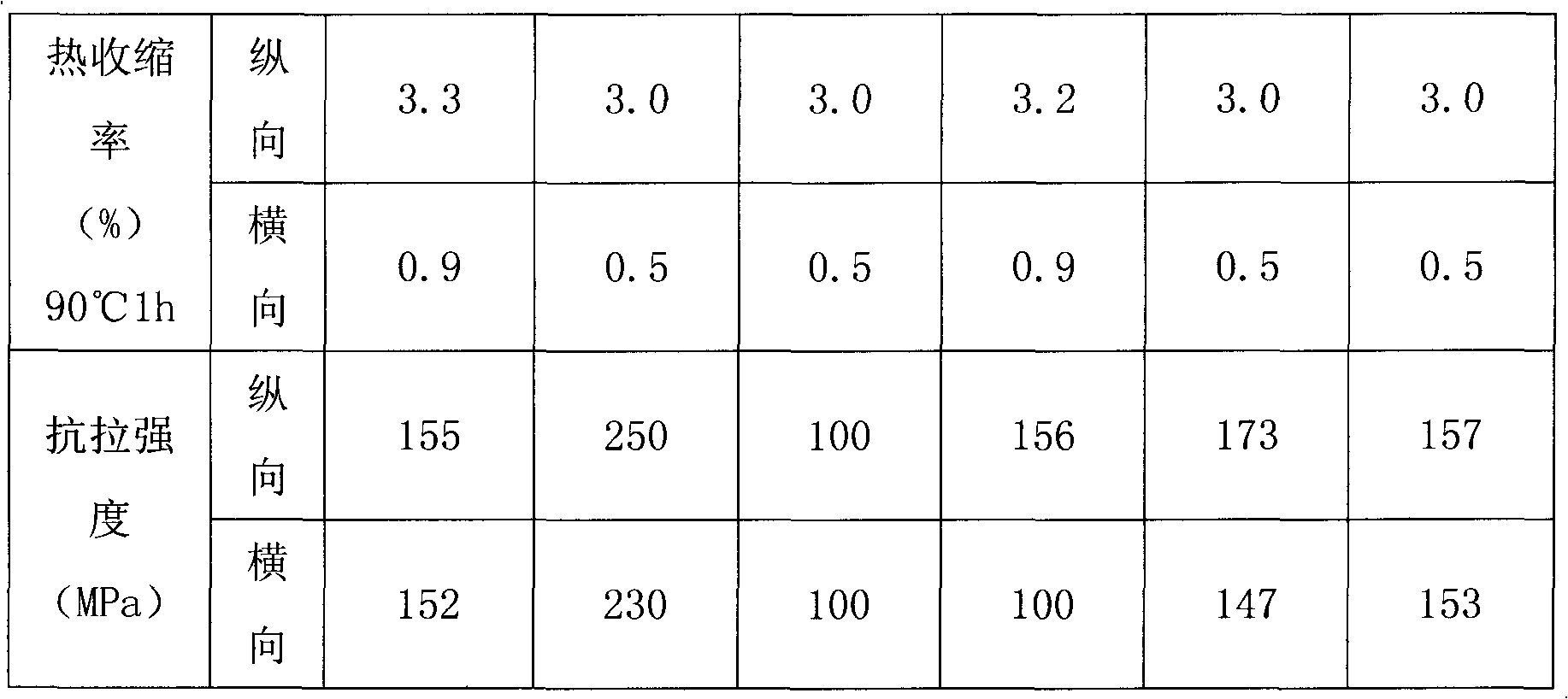

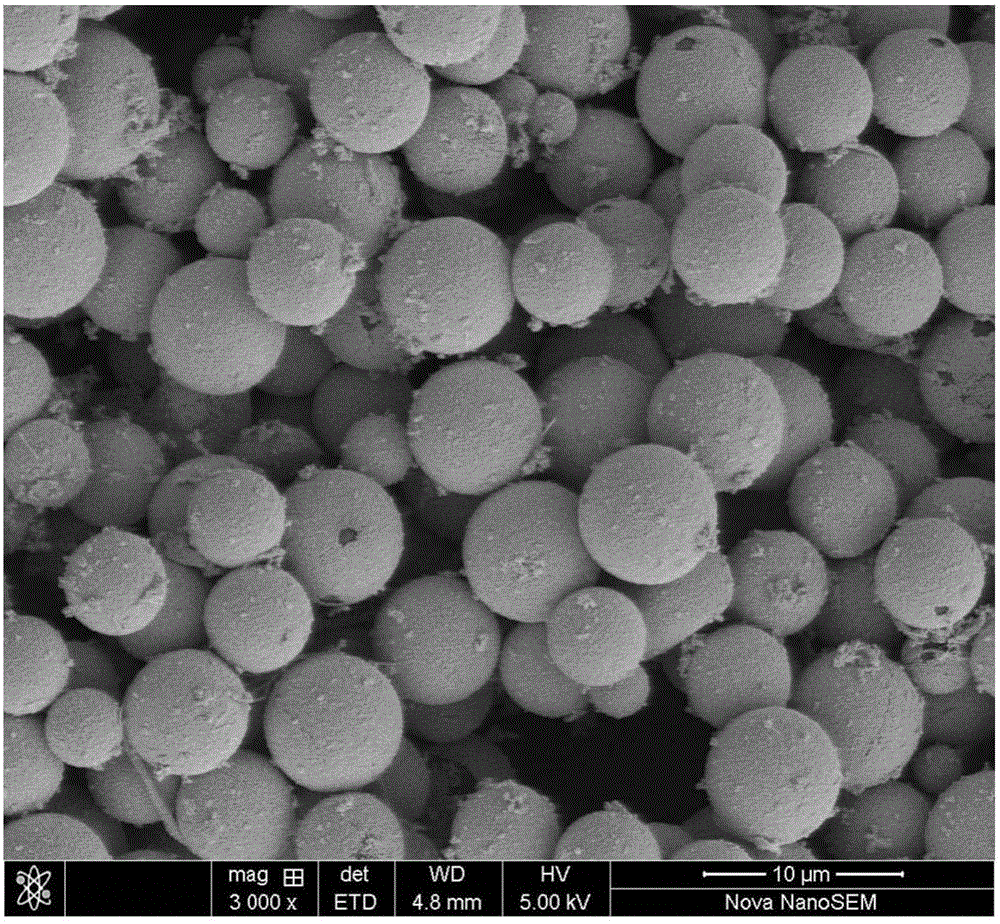

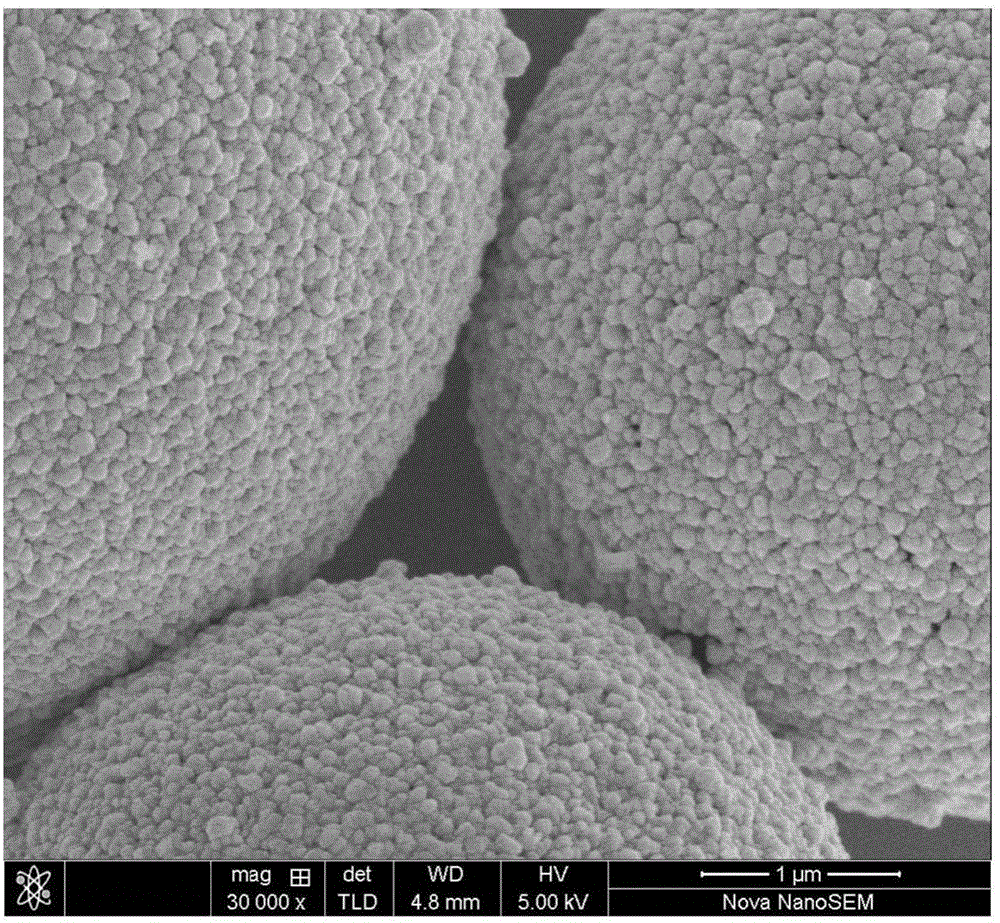

A kind of polyolefin microporous film for lithium battery and preparation method thereof

The invention discloses a polyolefin microporous film for a lithium battery and a preparation method thereof. The preparation method comprises the following steps that 1, one or more polyolefin resins, one or more porous modification agents and a plasticizer are melted into a uniform solution at a temperature of 150 to 280 DEG C; 2, the melted solution obtained by the step 1 is extruded from a mold head and is cooled on a cooling roll at a temperature of 5 to 30 DEG C to be cast into a thick sheet; 3, the thick sheet is stretched in double directions to be made into a film, wherein the thick sheet is stretched in the vertical direction first and then is stretched in the transverse direction; a stretching temperature value is less than a value equal to the sum of a resin melting point temperature value and 10; and a total stretching rate is in a range of 10 to 80 times; and 4, the plasticizer is extracted from the film obtained by the step 3 and the polyolefin microporous film is obtained through heat shaping at a temperature of 80 to 150 DEG C. Through the added one or more porous modification agents with a high boiling point or a high flash point, aperture shapes and aperture sizes of the polyolefin microporous film are adjusted to realize that an average aperture size of the polyolefin microporous film is appropriate; the aperture shapes are nearly circular; and strength in either direction is uniform and consistent.

Owner:XINXIANG ZHONGKE SCI&TECH

Production method of aluminum alloy core cable

InactiveCN104143369AGood weather resistanceExtended service lifeInsulated cablesPower cablesNickel alloyStretch rate

Disclosed is a production method of an aluminum alloy core cable. The aluminum alloy core cable comprises an aluminum alloy core material, a nickel alloy layer outside the core material and an insulating layer at the outermost layer. The tensile strength of the aluminum alloy core cable produced according to the production method is greater than 15 kg / mm<2>, the yield strength is greater than 13 kg / mm<2>, the stretching rate is 8%, and the electric conductivity is greater than 67%IACS.

Owner:广州市凯博电线电缆有限公司

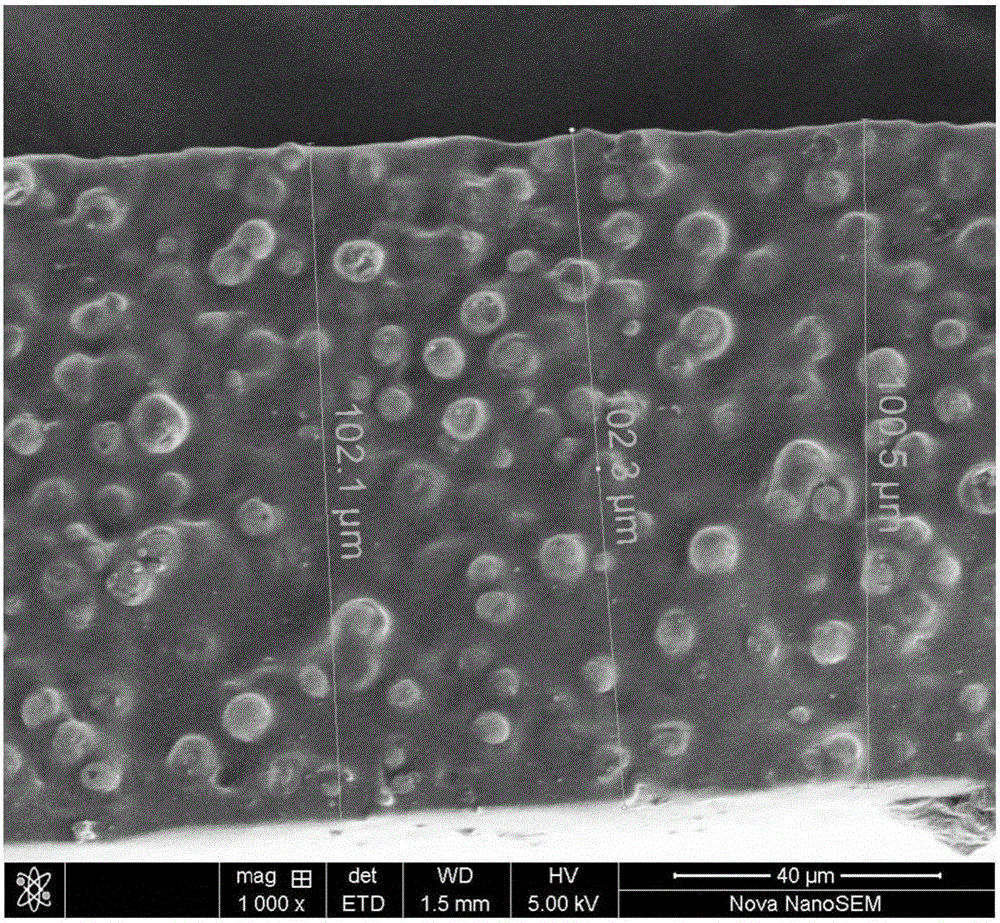

Stretchable flexible conductive composite material as well as preparation method and application thereof

The invention provides a stretchable flexible conductive composite material which comprises metal plated conductive granules and an elastic polymer, wherein the metal plated conductive granules adopt polymer granules as kernels, and the surfaces of the kernels are plated with a metal. The metal plated conductive granules are not liable to deposit in an elastic polymer solution, the prepared stretchable flexible conductive composite material is uniform in structure, stable in property and free of support structure, in addition, the particle sizes of the metal plated conductive granules can be easily regulated and controlled, the metal plated conductive granules can be processed to be of appropriate sizes, the percolation threshold of a conductive composite material can be reduced, and a flexible conductive film of which the thickness is less than 100 [mu]m can be prepared. In addition, the conductivity of the stretchable flexible conductive composite material provided by the invention is 6.5*10<2>-2*10<5>S / m, and besides, the inherent stretch rate of 30-80% of the elastic polymer can be maintained.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

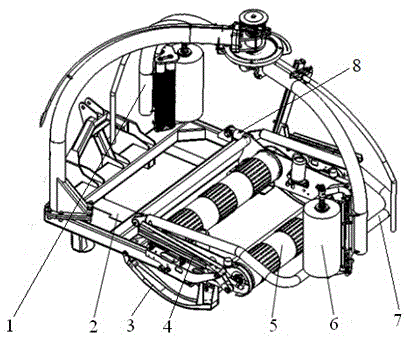

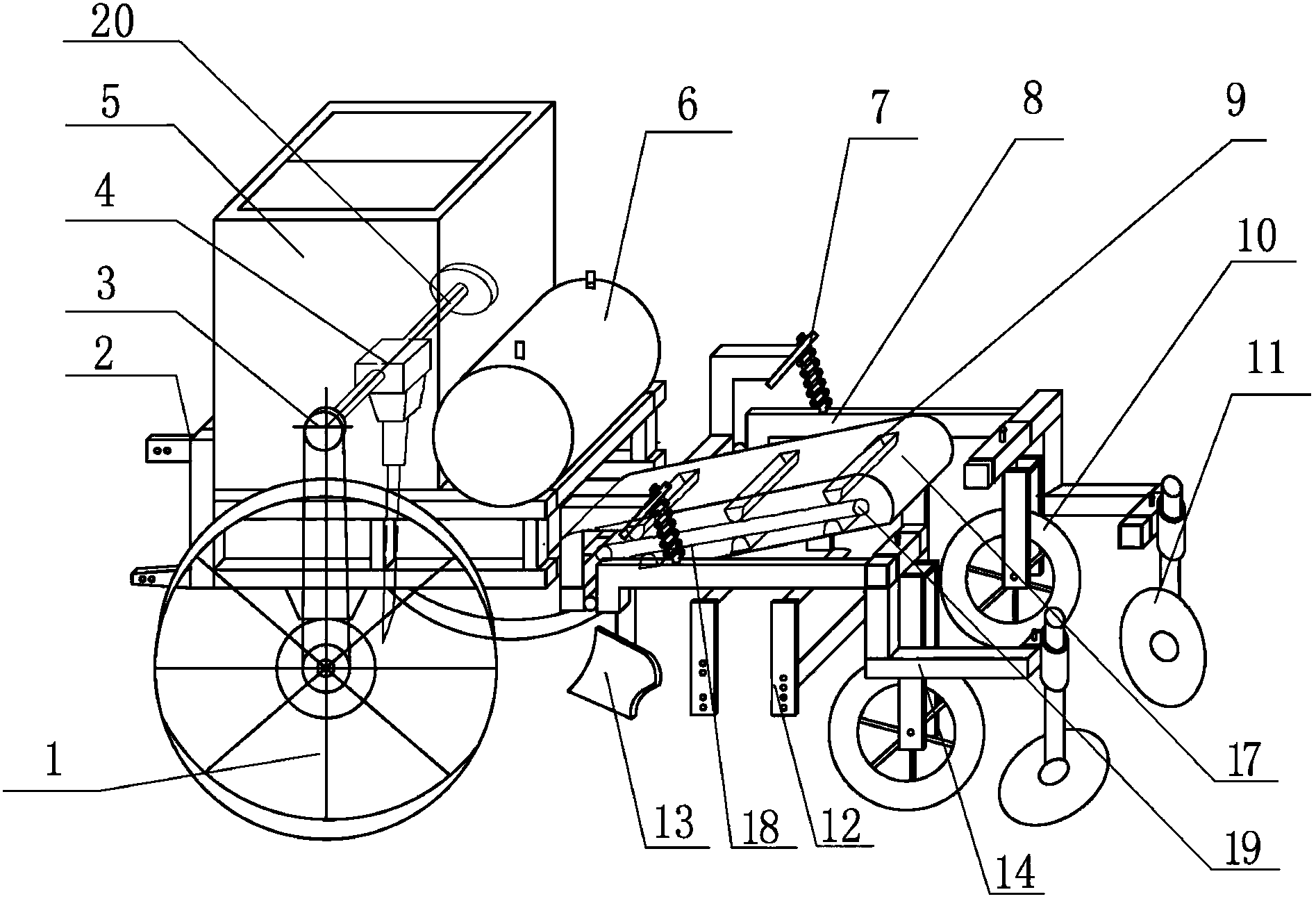

Novel suspension type silage round bale film wrapping machine

ActiveCN105460257ARealize full hydraulic controlEven wrappingWrapping with article rotationHydraulic cylinderEngineering

The invention provides a novel suspension type silage round bale film wrapping machine. The novel suspension type silage round bale film wrapping machine comprises a hydraulic system and a chassis mechanism. A rotary component, a ground support, a film cutting component, a support roll frame hydraulic cylinder, a U-shaped material picking rod and a support roll frame mechanism are installed on the chassis mechanism. The material picking rod and the support roll frame mechanism are used for clamping a grass bale. The rotary component wraps a plastic thin film on the surface of the grass bale on the support roll frame mechanism. The film cutting component is used for cutting off the plastic thin film. According to the film wrapping machine, full hydraulic control is achieved, power is transmitted to all the moving components of the film wrapping machine. Film wrapping of the grass bale is even, the work quality is high, and the film wrapping efficiency is high. The wrapping airtightness is good, the film stretching rate is high, and the work efficiency of silage grass is improved.

Owner:甘肃金科脉草业有限责任公司

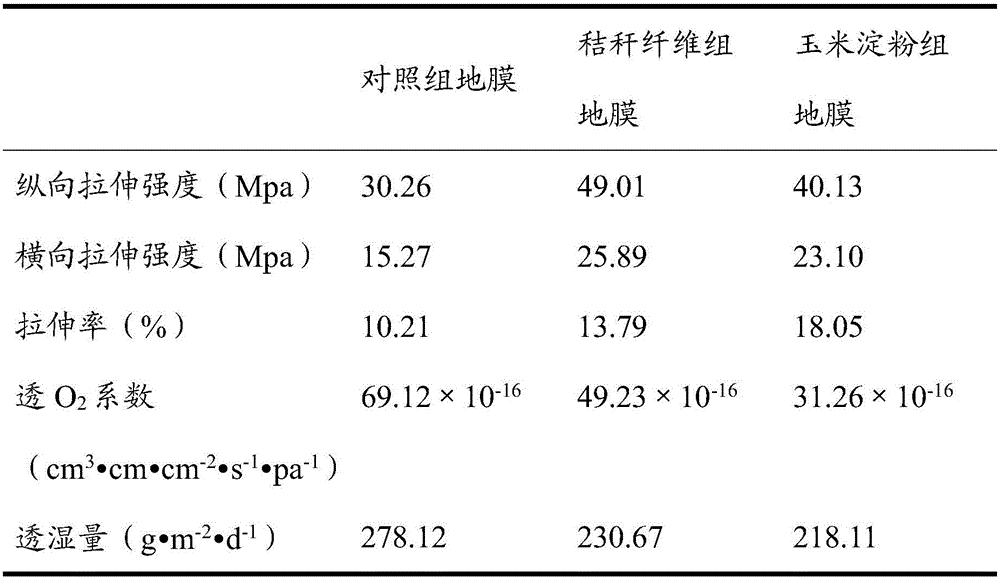

High-barrier-property biodegradable mulching film and preparation method thereof

The invention discloses a high-barrier-property biodegradable mulching film. The high-barrier-property biodegradable mulching film is prepared from the following raw materials in parts by weight: 9 to 12 parts of wheat straw fibers, 25 to 35 parts of corn starch, 3 to 5 parts of sodium hydroxide, 1 to 2 parts of polyvinyl alcohol, 1 to 2 parts of carboxymethylcellulose, 3 to 5 parts of glyoxal, 5 to 10 parts of glycerinum, 0.5 to 1 part of cellulase, 1 to 2 parts of stabilizer, and 90 to 100 parts of deionized water. According to the high-barrier-property biodegradable mulching film, corn starch and wheat straw fibers are used as main preparation raw materials, so that the preparation cost is low, the preparation method is simple, and a novel way is provided for recycling the crop straws; compared with the ordinary mulching film, the longitudinal tensile strength of the high-barrier-property biodegradable mulching film is increased by 66 percent or more, the transverse tensile strength is increased by 66 percent or more, and the stretch rate is increased by more than 58 percent, and the mulching film is uneasy to damage; the water vapor transmission rate is reduced by more than 25 percent, and the barrier property is good; and in addition, the mulching film can be completely degraded after being buried in soil for 60 days, so that the degradation effect is good.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

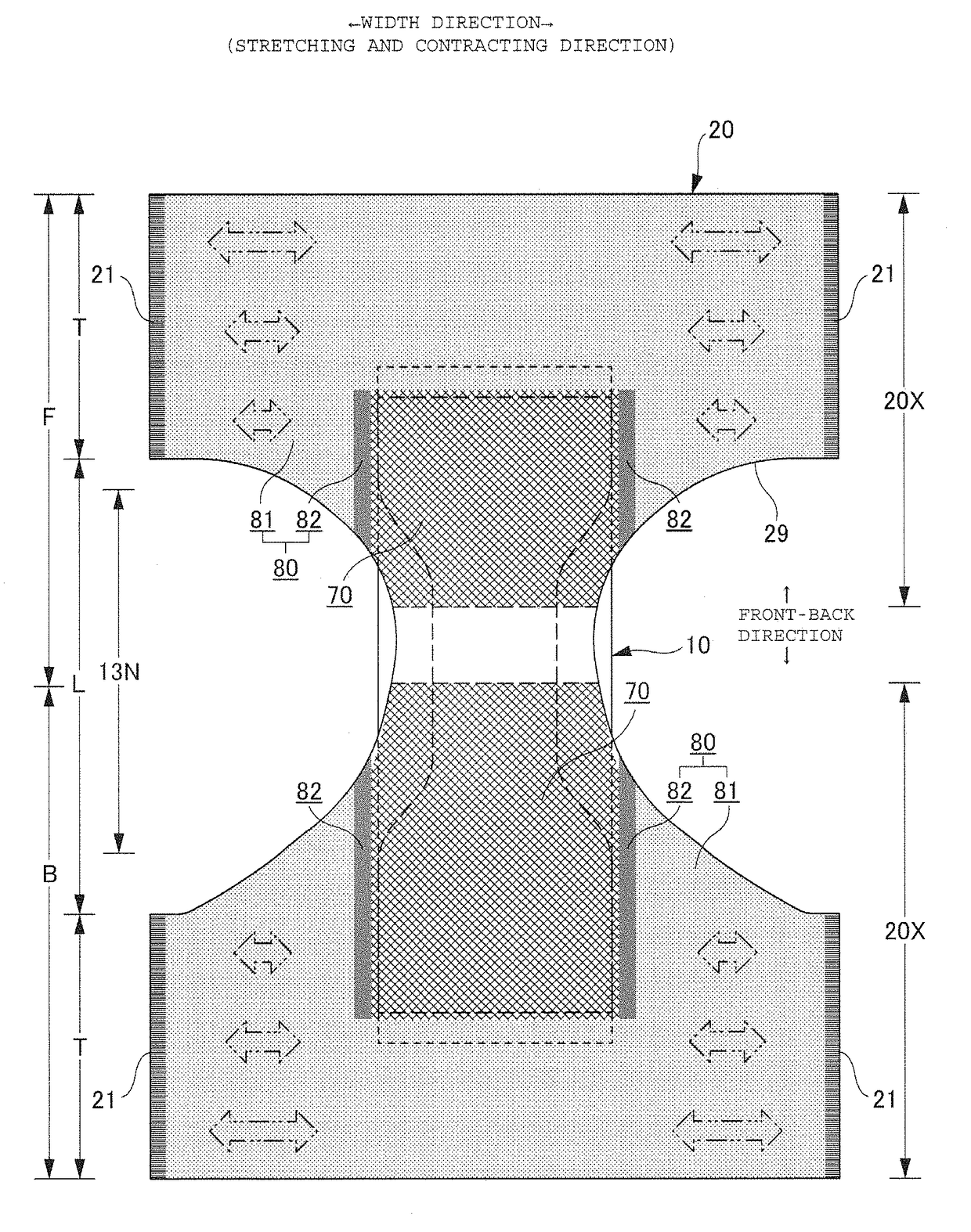

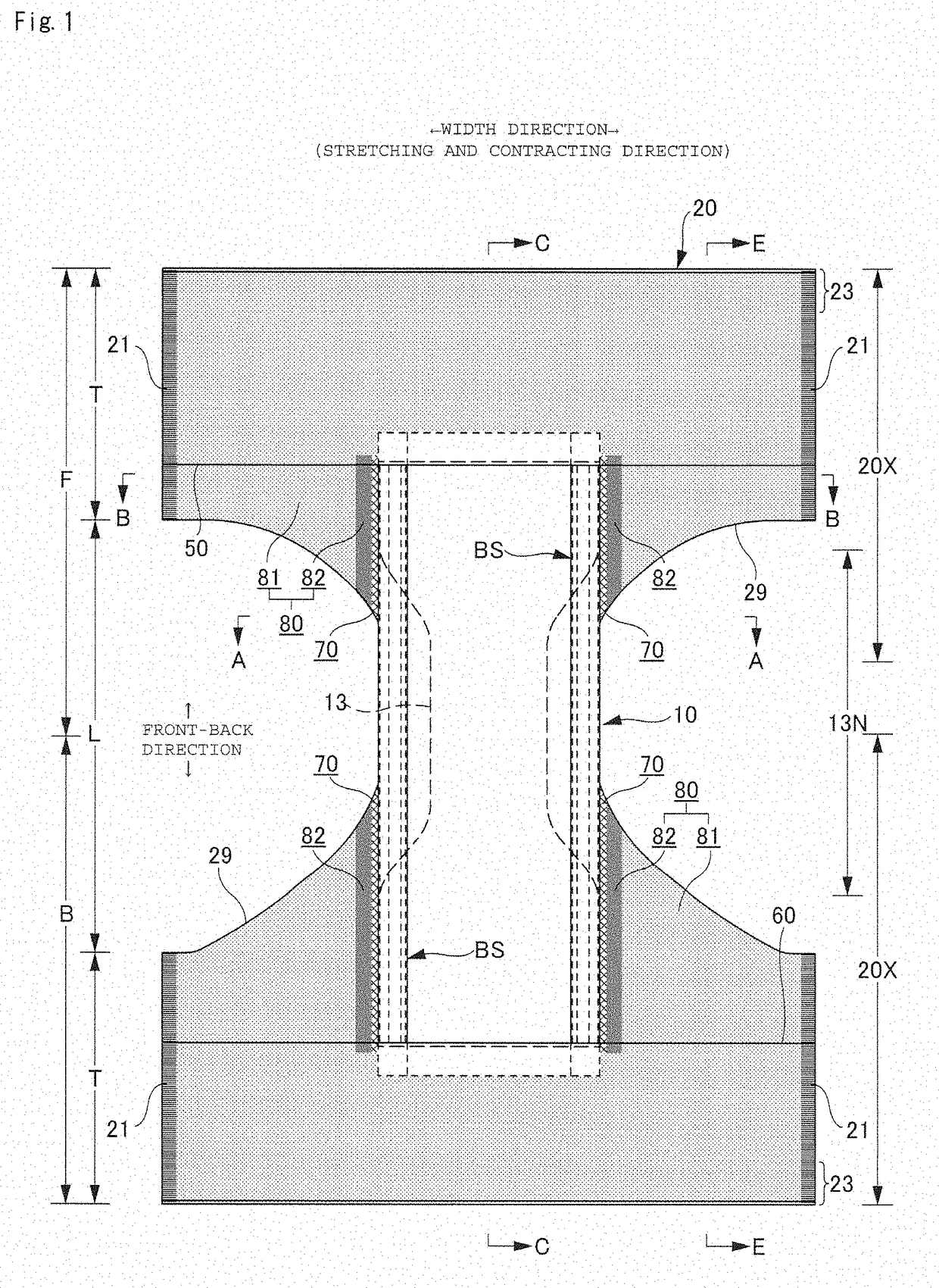

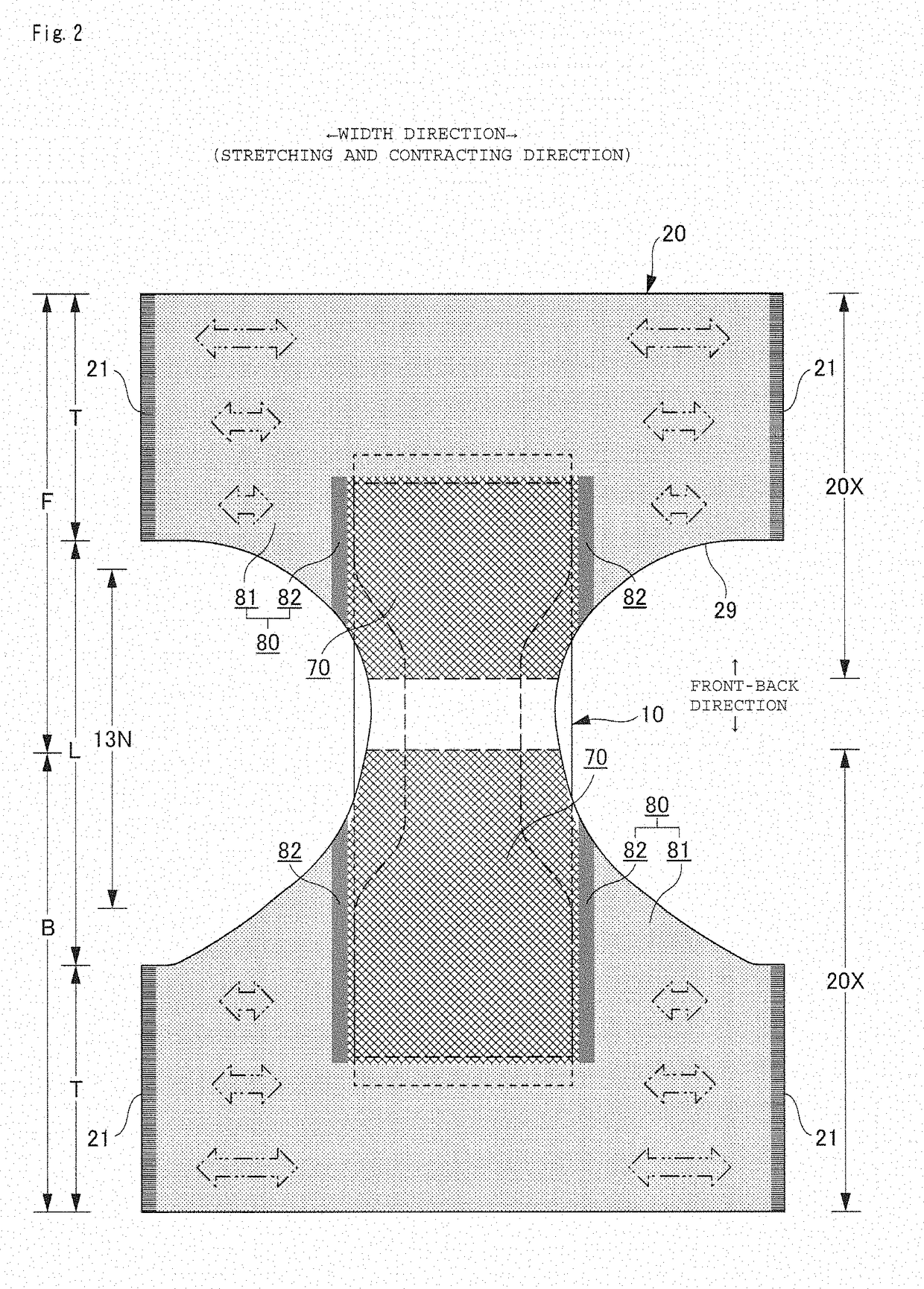

Absorbent Article and Method for Producing Same

An absorbent article having an elastic film stretchable region in which a stretch rate changes depending on the part, and a method of manufacturing the same. The above problem is solved when a stretchable region being stretchable at least in a width direction is included in a lower-torso region having a waist portion of an outer body of a front body and an outer body of a back body, and in the stretchable region, in a state in which an elastic film is stretched in a stretching and contracting direction at a stretch rate continuously increasing from a crotch side toward a waist opening side, a first sheet layer and a second sheet layer are joined.

Owner:DAIO PAPER CORP

Extrusion production process of Al-Zn-Mg alloy profile for high-speed rail car body

The invention discloses an extrusion production process of an Al-Zn-Mg alloy profile for a high-speed rail car body, relating to the technical field of aluminum alloy processing. The extrusion production process comprises the steps of ingot heating, mold heating, container heating, extruding production, on-line quenching, breaking, stretching and straightening, artificial ageing and the like. By controlling the parameters of ingot temperature, mold temperature, container temperature, extruding speed, stretching rate, ageing temperature, ageing time and the like, the overall performance of Al-Zn-Mg alloy car body profile for high-speed rail is improved, the evenness of mechanical property is controlled, the stability of industrial production is improved, and therefore the production efficiency of a profile product for the high-speed rail car body is improved.

Owner:广西南南铝加工有限公司

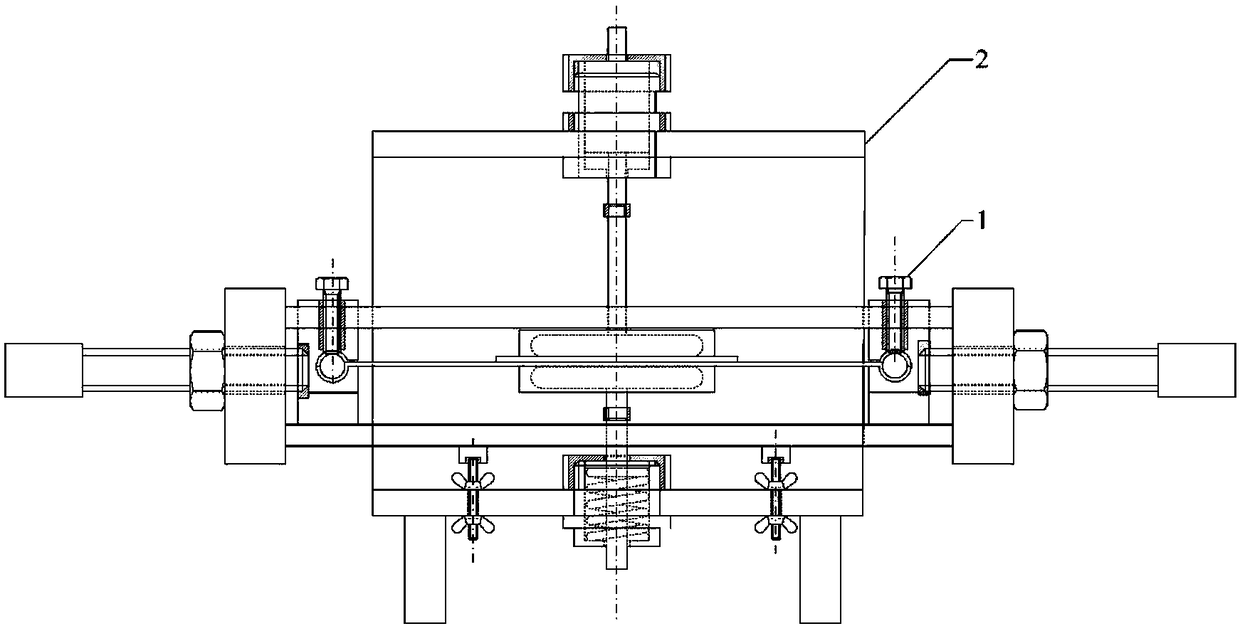

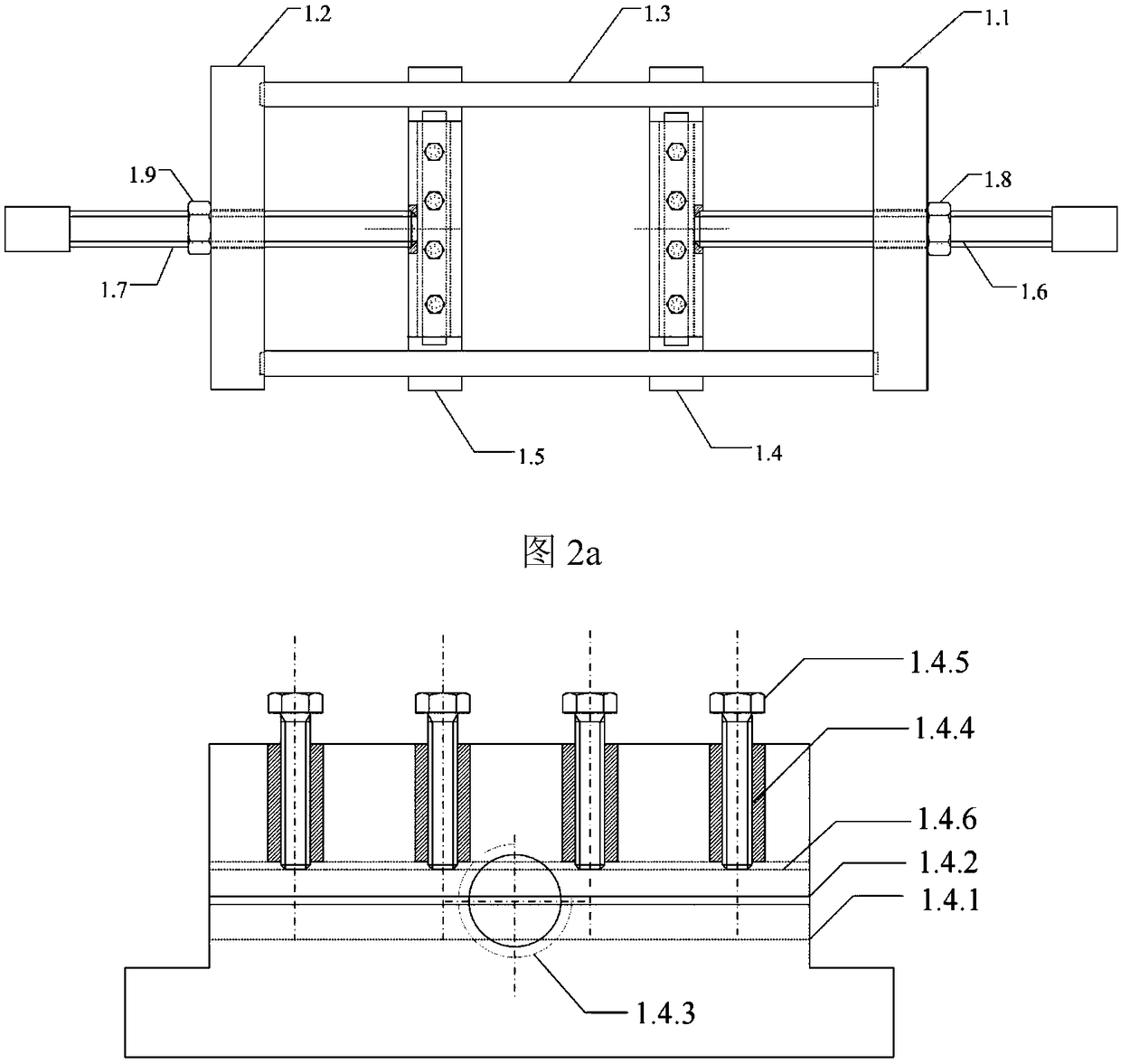

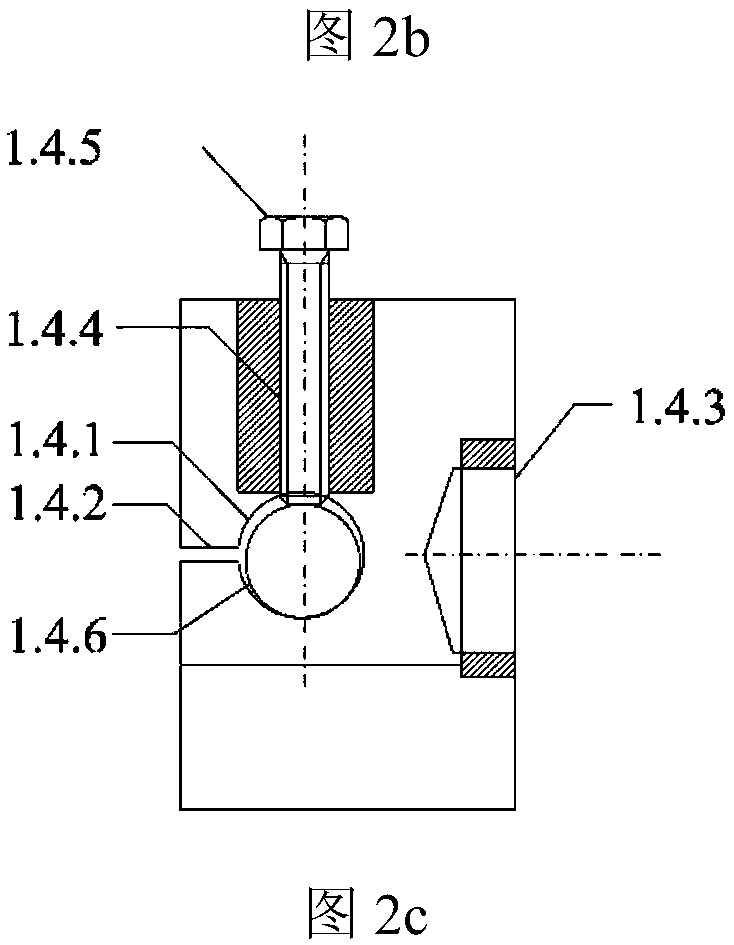

XLPE electric cable accessory interface multi-stress coupling simulation test device and method

ActiveCN108957263AIncrease the fixed areaPrevent slippingTesting dielectric strengthMechanical stretchingElectric stress

An XLPE electric cable accessory interface multi-stress coupling simulation test device and method are disclosed. The device comprises a tensile stress applying device and a U-shaped electrical stressand interface pressure applying device, wherein the tensile stress applying device consists of a fixed support rack, a clamping tool, a fixed block, a drawing screw rod and a hexagon screw nut; a rubber test piece can be fixed and stretched for a long time via the tensile stress applying device; the U-shaped electrical stress and interface pressure applying device consists of a U-shaped electrodesupport rack, an interface pressure adjusting device, a high-voltage electrode, a grounding electrode, a spring device and a height adjusting device; the U-shaped electrical stress and interface pressure applying device can be used for applying electrical stress and interface pressure on a crosslinked polyethylene and rubber interface at the same time; the tensile stress applying device and the U-shaped electrical stress and interface pressure applying device are used in a cooperative manner, the electrical stress and the interface pressure can be applied on a crosslinked polyethylene and rubber interface, and mechanical stretching stress can be applied on the rubber test piece, multi-stress coupling working conditions of a electric cable accessory interface can be well simulated; maximumvoltage of 50 kV and maximum interface pressure of 0.5 MPa can be applied via the device; maximum stretch rates of the rubber test piece can reach 200%, and different interface conditions in which operation is normal or defects exist can be simulated.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Conical crushing device

ActiveCN108176439AGood technical effectTimely adjustment of eccentric angleGrain treatmentsGear wheelAgricultural engineering

The invention relates to the field of crushing, and discloses a conical crushing device, which comprises an upper shell, a lower shell and a main shaft. One end of the main shaft stretches into the lower shell; the other end of the main shaft stretches out of the upper shell; an installation hole for the main shaft to pass through is formed in the lower end of the lower shell; a positioning sleeveis inlaid in an inner wall of the installation hole; a rubber sleeve is fixed onto an outer circumferential wall of the lower end part of the main shaft, and stretches into the positioning sleeve; alarge conical gear is further arranged in the lower shell and is fixedly connected with the rubber sleeve through bolts; a drive device for driving a bevel pinion to rotate is arranged on an outer side wall of the lower shell; and an oscillation adjusting device is arranged on the lower end of the lower shell. According to the conical crushing device provided by the invention, an eccentric angle of the main shaft can be controlled through controlling the stretching rate of a telescopic device, and when the stretching rate of the telescopic device is increased, the eccentric angle of the main shaft becomes larger to replace an original eccentric sleeve structure, so that the conical crushing device provided by the invention can be used for adjusting the eccentric angle of the main shaft intime, and a gap size of a crushing channel can be adjusted.

Owner:HANGZHOU HEXING MACHINE

Montmorillonite modified silicone seal gum and preparation method thereof

InactiveCN101215454AAdapt to expansion and contraction requirementsAvoid enteringNon-macromolecular adhesive additivesOther chemical processesMetasilicateCation exchange reaction

The invention relates to montmorillonite modified silicone fluid sealant and a process for preparation, the fluid sealant is composed of silicone crude rubber, metasilicate montmorillonite, organic treating agent, cross-linker, plasticizing agent, viscosity increaser and initiating agent, the process for preparation comprises cation exchange reaction between the montmorillonite and the organic treating agent, then, organic modified montmorillonite is evenly scattered in the silicone crude rubber, and then the cross-linker, the initiating agent and other additives are added, solidified, and shaped. The fluid sealant has good binding power, excellent weather fastness, perfect ultra-violet resisting anti-aging performance and water-resistant performance to bridges, tunnels and road projects and concrete elements of buildings, can keep excellent flexibility and stretch rate in environments of sun, rain, snow, extreme high or extreme low-temperature, has non pollution to environment and road surface, and can be widely applied to seal concrete dilatation joints in the bridges, the tunnels, the road projects, airport runway, construction works and the like, to repair cracking concrete structures, and to treat metal surface with anti-corrosion.

Owner:WUHAN UNIV OF TECH

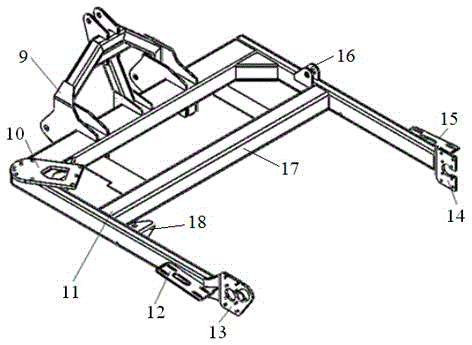

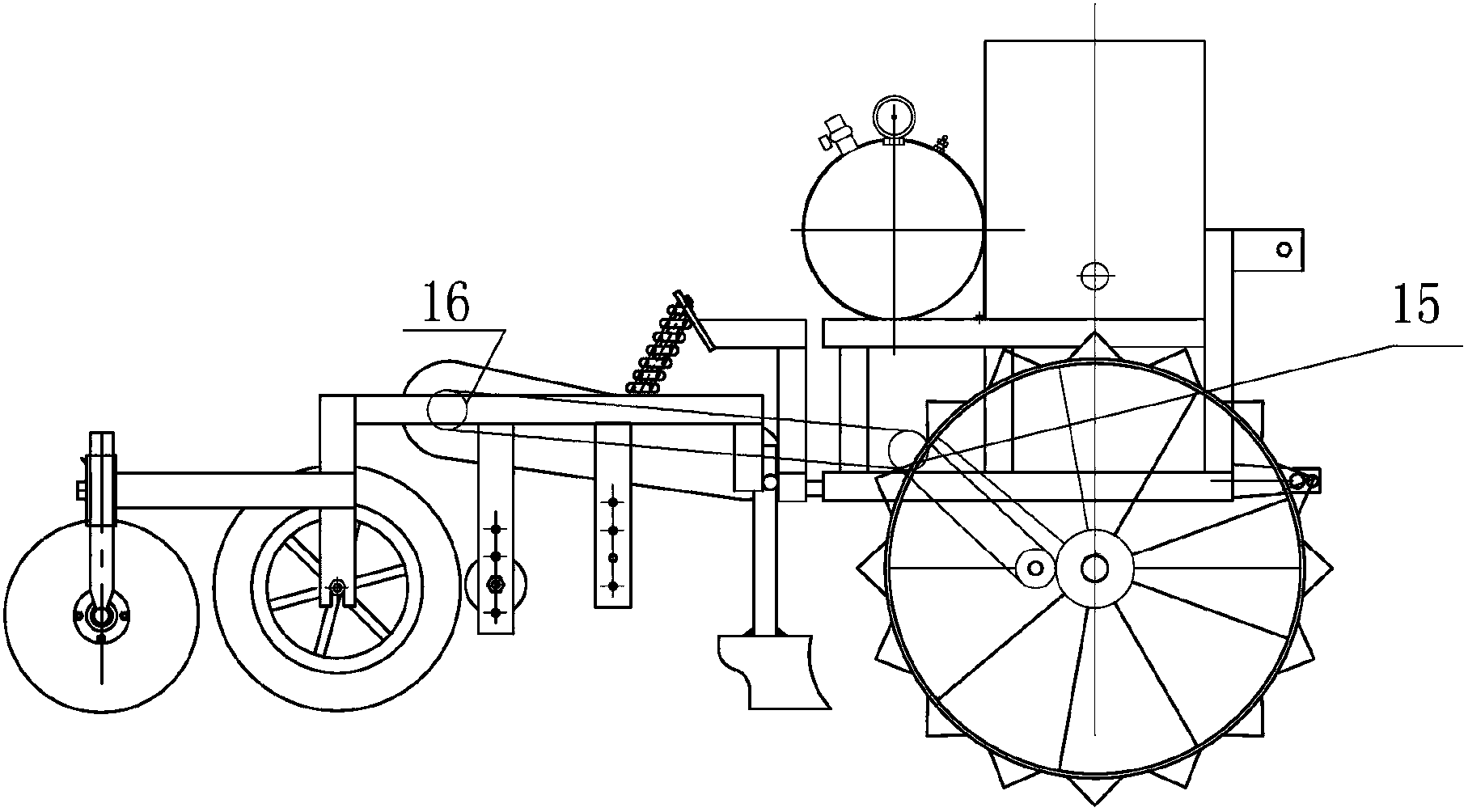

Four-wheeled film mulching machine

ActiveCN103004538AHigh elongationReasonable designFertiliser distributersPlant protective coveringsAgricultural engineeringSoil quality

The invention relates to a four-wheeled film mulching machine, which comprises a traction device, wherein two ground wheels are connected beneath the traction device, the two ground wheels are connected with each other through a rotating shaft A, the traction device is provided with two parallel fertilizer boxes, a fertilizer discharging device is arranged inside the fertilizer box, the right side of the traction device is connected with a support, the support is provided with a soil compacting device, the left lower end of the support is connected with a furrowing device, the lower end of the center of the support is connected with two parallel film mulching wheel carrier, the front end and the rear end of the support are respectively connected with an L-shaped frame, the lower end of the L-shaped frame is connected with a film pressing wheel, and the outer side of the L-shaped frame is provided with a soil covering wheel. The four-wheeled film mulching machine has the beneficial effects that the reasonability in design, simplicity in structure and convenience in operation can be realized, the ditching, the fertilizer application, the medicine spraying, the film lamination and the soil covering are integrated, stability in running and uniformity in mulching can be realized, the operation quality is good, the stretching rate of the ground film is high, simplicity in repairing is realized, a great amount of manpower and material resource can be saved, the four-wheeled film mulching machine is applicable to different dry land with different soil qualities in different areas and particularly applicable to the film mulching operation of the large field such as farm or cooperation.

Owner:SHANDONG YUAN QUAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com