Degradable packaging film material and preparing method and application thereof

A packaging film and raw material technology, applied in the preparation of degradable packaging film materials, in the field of degradable packaging film materials, can solve the problems of poor mechanical properties, high production cost, poor fresh-keeping effect, etc., to reduce moisture permeability and reduce production costs Low, good barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

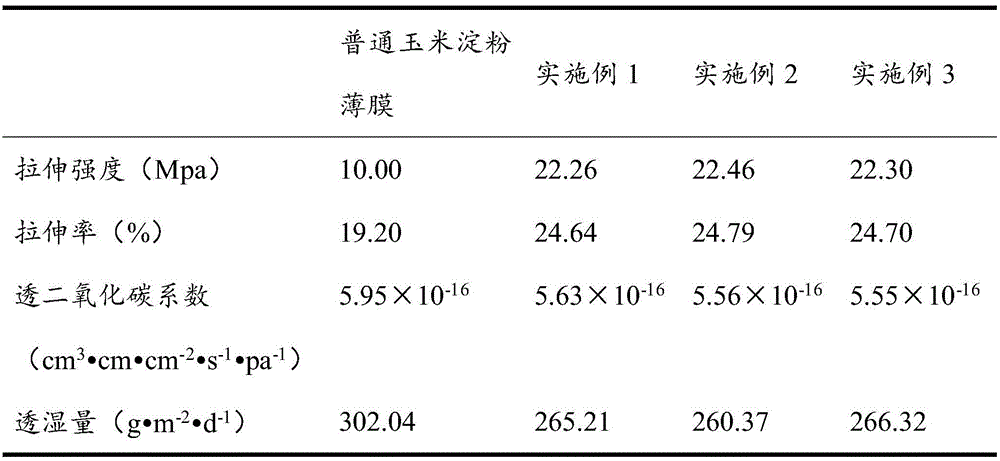

Examples

Embodiment 1

[0025] The degradable packaging film material of embodiment 1, its raw material is made of 1.00% rice straw fiber, 3.00% corn cross-linked starch, 3.00% polyvinyl alcohol-carboxymethyl cellulose mixed solution, 2.28% Glyoxal, 3.79% glycerin, 86.93% deionized water, and the polyvinyl alcohol-carboxymethyl cellulose mixture is formed by mixing polyvinyl alcohol and carboxymethyl cellulose in a mass ratio of 1:2, specifically Follow the steps below to implement:

[0026] Step 1, weigh the rice straw fiber with a mass concentration of 1.00%, 3.00% corn cross-linked starch, 3.00% polyvinyl alcohol-carboxymethyl cellulose mixture, 2.28% glyoxal, and 3.79% glycerin , 86.93% deionized water;

[0027] Step 2, fully mix the corn cross-linked starch weighed in step 1 and part of the deionized water, and stir in a constant temperature water bath at 90°C until gelatinized to obtain a corn cross-linked starch solution, in which the amount of deionized water accounts for the total Half of ...

Embodiment 2

[0031] The degradable packaging film material of embodiment 2, its raw material is made of 0.90% rice straw fiber, 2.85% corn cross-linked starch, 3.20% polyvinyl alcohol-carboxymethyl cellulose mixed solution, 2.45% Glyoxal, 3.50% glycerin, 87.10% deionized water, and the polyvinyl alcohol-carboxymethyl cellulose mixture is formed by mixing polyvinyl alcohol and carboxymethyl cellulose in a mass ratio of 1:2, specifically Follow the steps below to implement:

[0032] Step 1, weigh the rice straw fiber with a mass concentration of 0.90%, 2.85% corn cross-linked starch, 3.20% polyvinyl alcohol-carboxymethyl cellulose mixed solution, 2.45% glyoxal, and 3.50% glycerin , 87.10% deionized water;

[0033] Step 2, fully mix the corn cross-linked starch weighed in step 1 and part of the deionized water, and stir in a constant temperature water bath at 94°C until gelatinization to obtain a corn cross-linked starch solution, in which the amount of deionized water accounts for the total...

Embodiment 3

[0037] The degradable packaging film material of embodiment 3, its raw material is made of 1.10% rice straw fiber, 3.20% corn cross-linked starch, 2.80% polyvinyl alcohol-carboxymethyl cellulose mixed solution, 2.15% Glyoxal, 3.90% glycerin, 86.85% deionized water, and the polyvinyl alcohol-carboxymethyl cellulose mixture is formed by mixing polyvinyl alcohol and carboxymethyl cellulose in a mass ratio of 1:2, specifically Follow the steps below to implement:

[0038] Step 1, weighing the mass concentration percentage is 1.10% rice straw fiber, 3.20% corn cross-linked starch, 2.80% polyvinyl alcohol-carboxymethyl cellulose mixed solution, 2.15% glyoxal, 3.90% glycerin , 86.85% deionized water;

[0039] Step 2, fully mix the corn cross-linked starch weighed in step 1 and part of the deionized water, and stir in a constant temperature water bath at 92°C until gelatinization to obtain a corn cross-linked starch solution, in which the amount of deionized water accounts for the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com