Patents

Literature

756 results about "Starch solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denaturated starch absorbable hemostatic material and preparation method thereof

InactiveCN101121041AHigh viscosityImprove water absorption speedSurgical adhesivesPharmaceutical delivery mechanismMedicineBlood plasma

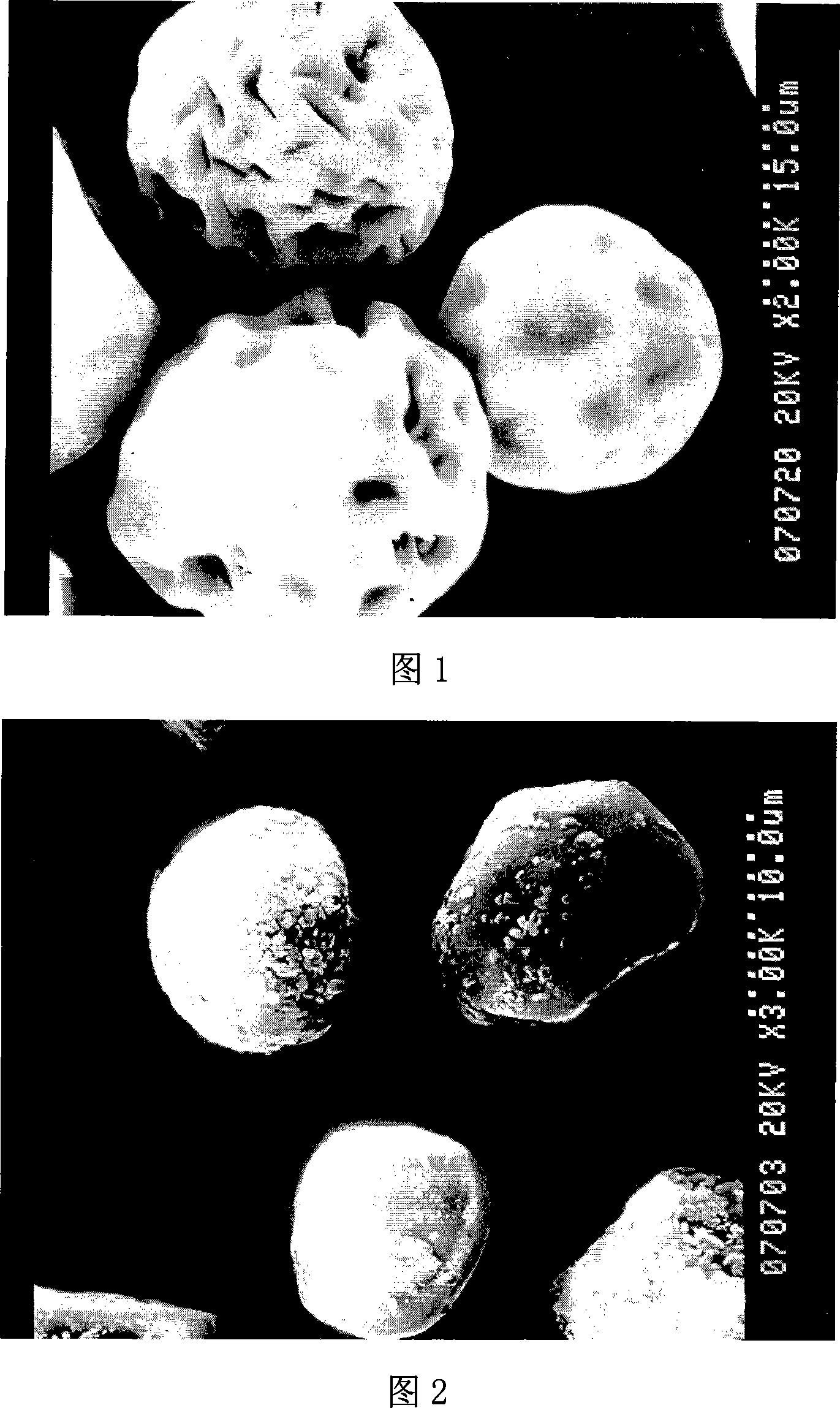

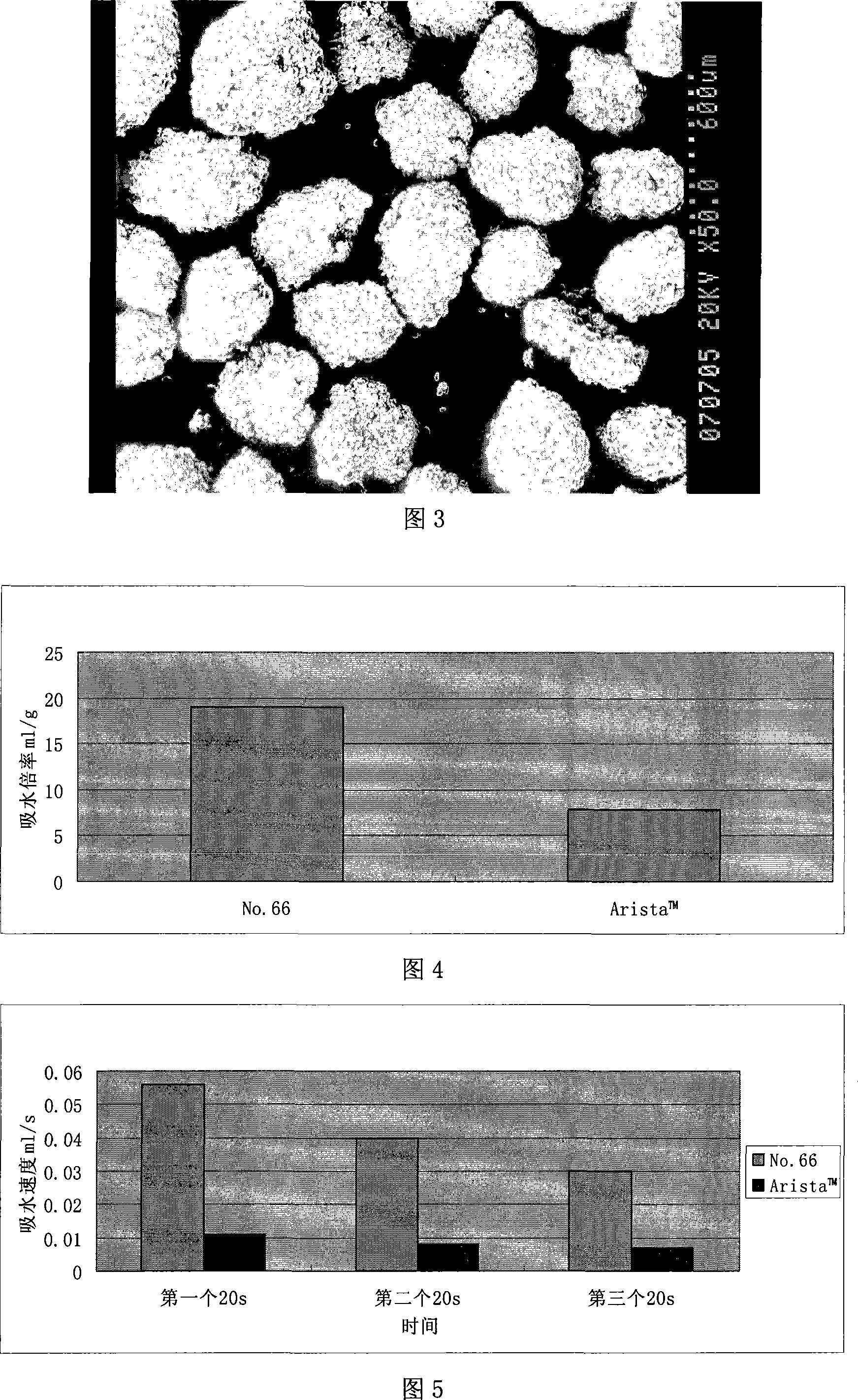

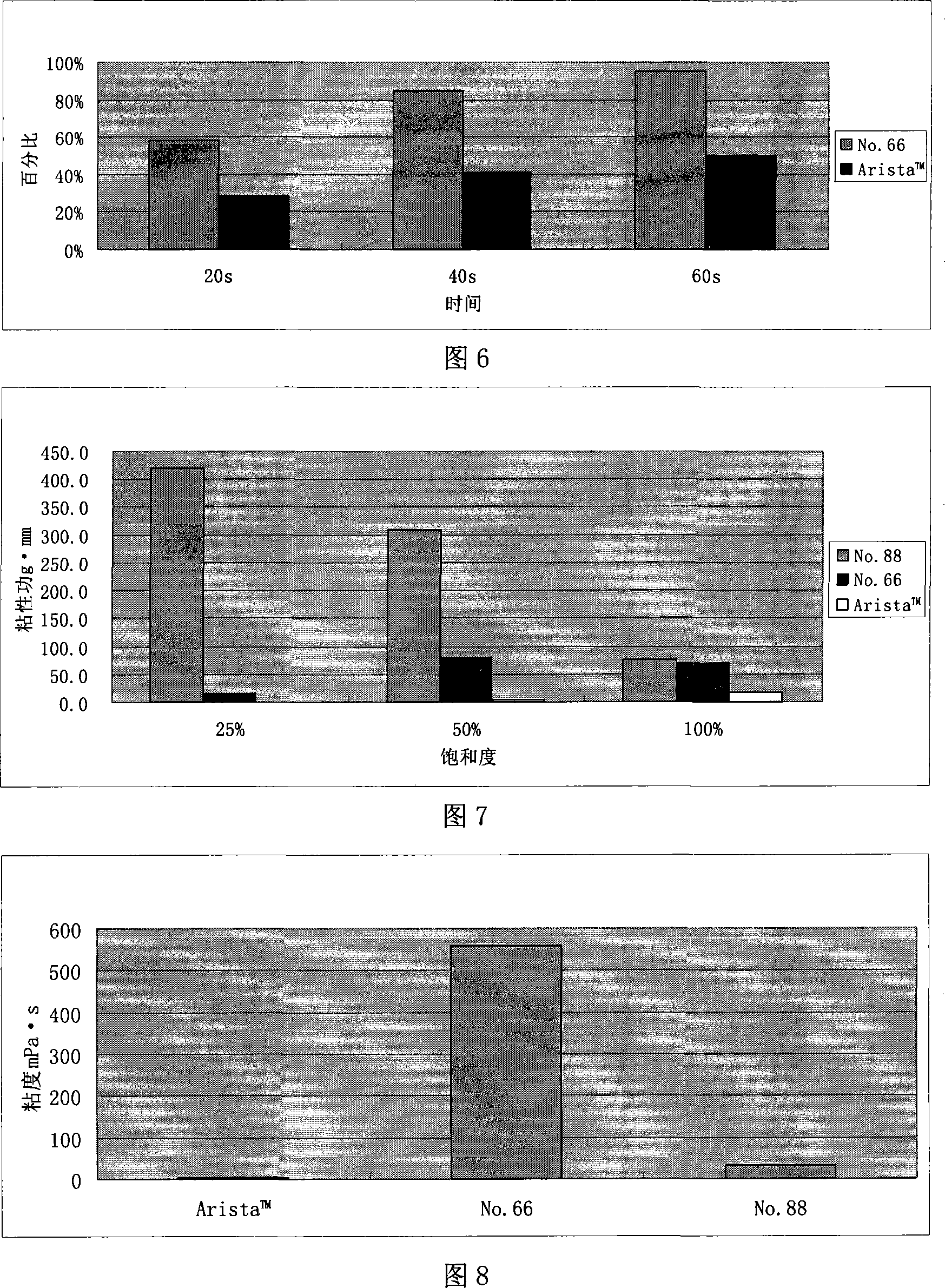

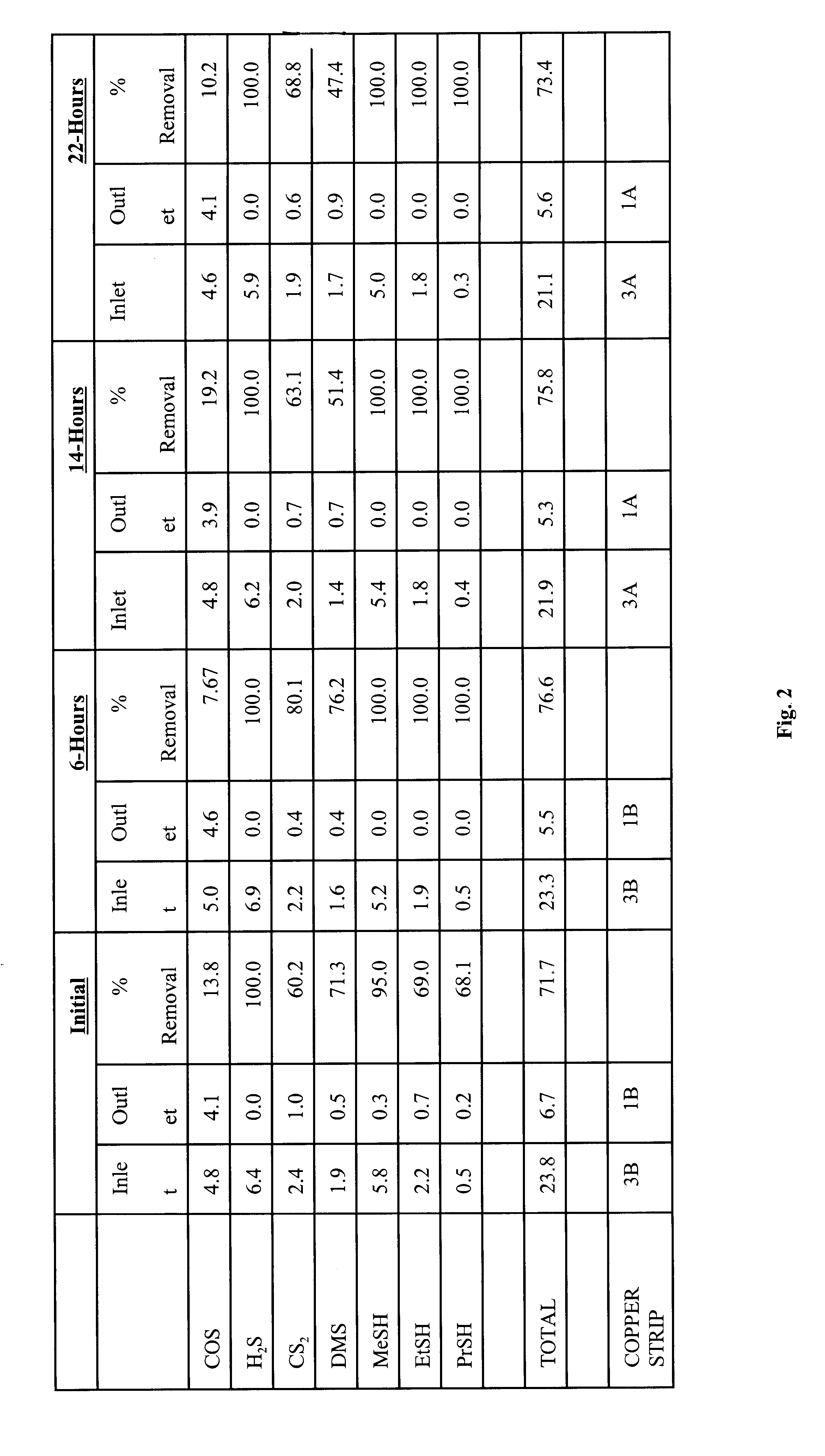

An absorbable modified starch hemostatic material and preparation thereof, wherein the hemostatic material is etherified starch, or a mixture of one or more etherified starches, crosslinked starches. The modified starch has a molecular weight of 15,000 - 10,000,000, a particle size of 10 - 1000µm, and a water absorption rate of 1 - 100. The biocompatible hemostatic material can directly effect on the wound with blood, concentrate the blood quickly to congulate blood; moreover, the gelatiniform mixture formed with blood has high viscosity, which can plug damaged tissue and blood vessel. The biocompatible hemostatic material is easy to swell in the water and easy to be washed so that the residue can be reduced; it is stable, not easy to decompose, and has long shelf life and storage advantage. The biocompatible hemostatic material can also be used as absorbable surgical antisticking material, promoting tissue healing material, surgical sealant and wound no-joint tissue adhesive.

Owner:美国淀粉医疗公司

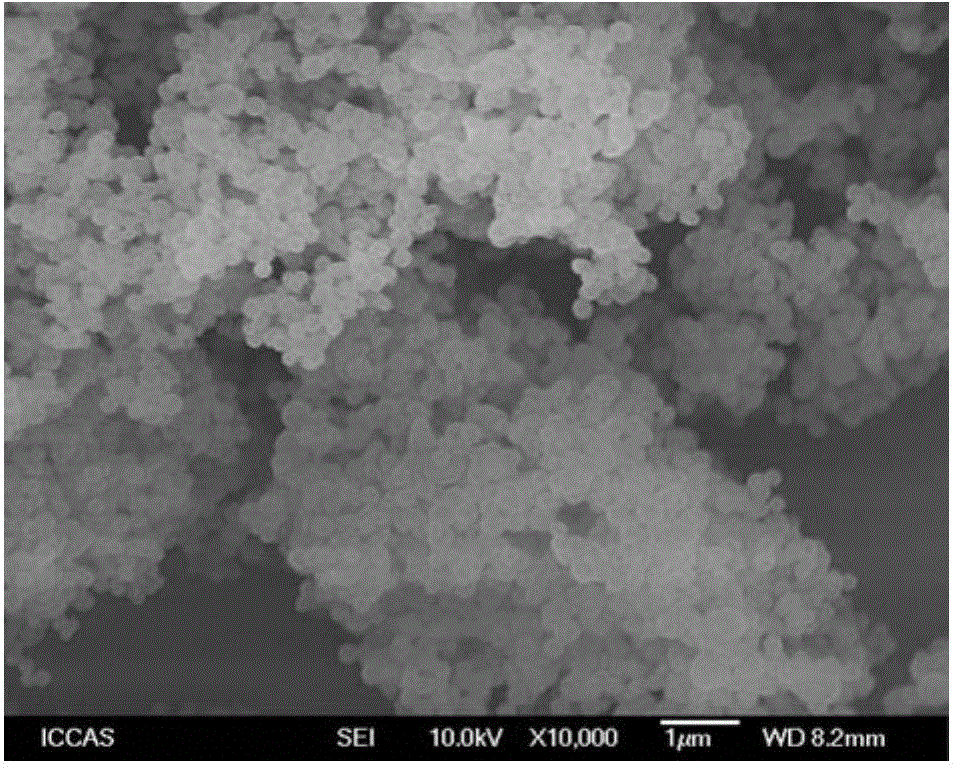

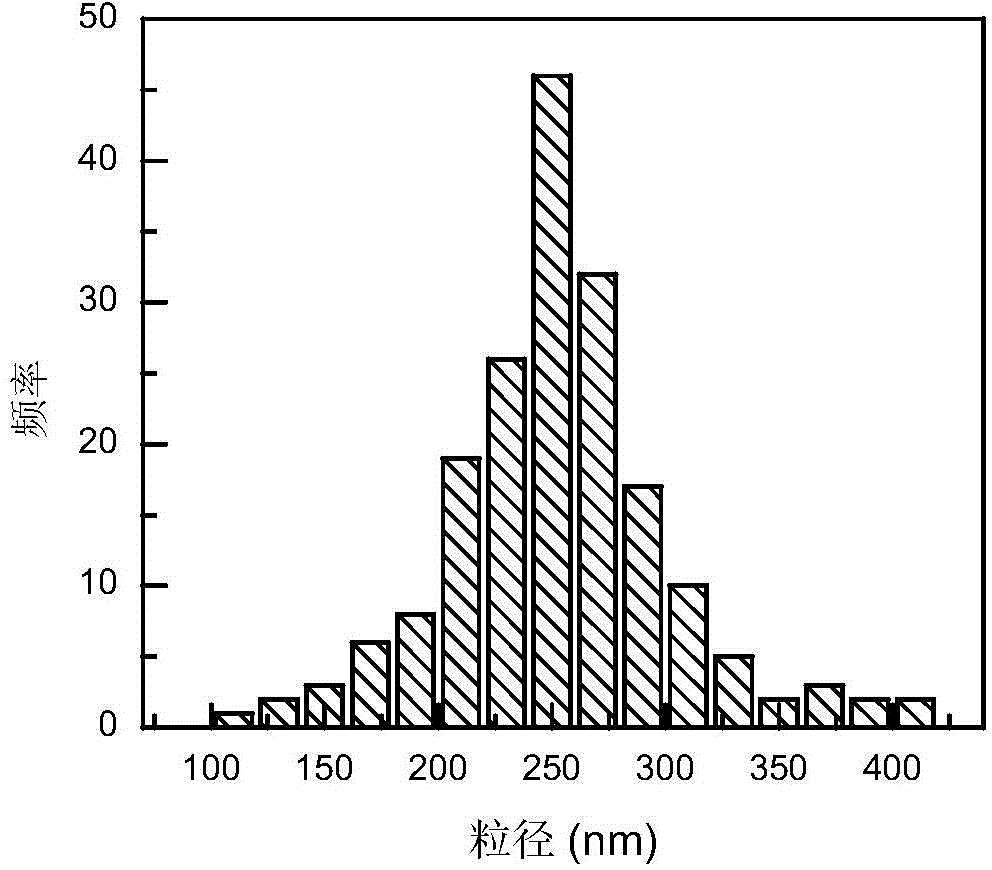

Preparation method for starch nanospheres

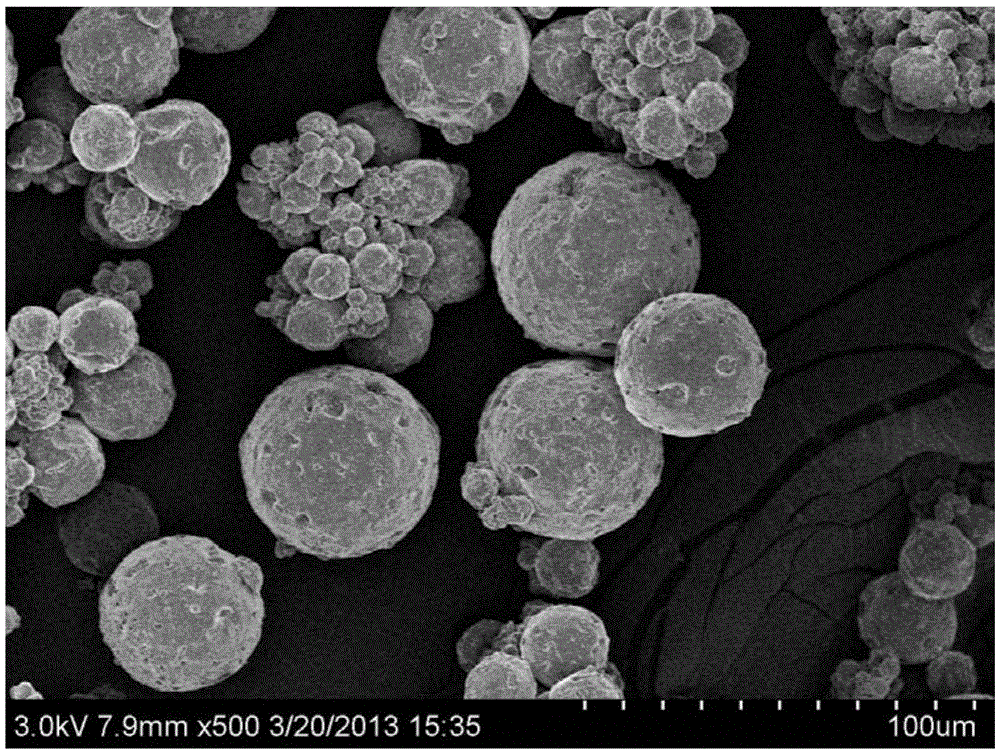

InactiveCN104785179AEasy to operateEasy to controlMicroballoon preparationMicrocapsule preparationFood additiveMicrosphere

The invention discloses a preparation method for starch nanospheres. The method comprises the following steps: (1) dissolving amylase in an alkaline solution, and stirring to obtain suspension; (2) completely freezing the suspension obtained in the step (1); (3) thawing a product obtained in the step (2), and obtaining a starch solution; (4) dialyzing the starch solution obtained in the step (3), and obtaining starch dispersion liquid; (5) filtering the starch dispersion liquid obtained in the step (4), and drying to obtain the starch nanospheres. The preparation method is energy-saving, environment-friendly and simple to operate, and a process is easy to control; the preparation method only adopts a general chemical reagent and simple experimental equipment, can realize large-scale production and is easy for industrialized promotion; the starch nanospheres prepared with the method are high in purity, and the starch structure is not changed; the starch nanospheres prepared with the method are controllable in particle size and uniform in particle size distribution, can be stably dispersed in water, and can be used for biomedical carriers and food additives.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of starch and fatty acid compound

The invention belongs to the technical field of natural polymer modification and discloses a preparation method of a starch and fatty acid compound. The method comprises the following steps: adding de-ionized water into starch and balancing moisture in a closed container; carrying out heat treatment to obtain the starch subjected to wet and hot treatment; then adding a buffering solution to prepare a starch solution; after pre-heating, adding 2 to 5u / g pullulanase liquid to react for 4 to 5 hours; after carrying out enzyme deactivation, centrifuging and separating to obtain enzyme treatment modified starch; then stirring and gelatinizing the starch in a boiled water bath for 25 to 45 minutes and cooling to 60 to 90 DEG C to obtain gelatinized starch; then transferring the gelatinized starch into a homogenizing machine and adding fatty acid to carry out homogenization and mixing; and keeping the heat of the water bath to synthesize for 30 to 40 minutes to obtain the starch and fatty acid compound. According to the preparation method, a greener and more environment-friendly new way is provided for synthesizing the starch and fatty acid compound through wet and hot treatment and controlled enzymolysis treatment by adopting a gelatinizing method.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of regenerated cellulose reinforced starch film

InactiveCN103965519ALow costThe preparation process is environmentally friendlyPolymer scienceThiourea

The invention discloses a preparation method of a regenerated cellulose reinforced starch film. The method comprises the steps of dissolving cellulose by taking an alkaline / urea mixed water solution or alkaline / thiourea mixed water solution as a solvent, and then, preparing regenerated cellulose by using water as a coagulating bath; blending the regenerated cellulose and a starch solution, and coating after carrying out vacuum degassing. The elasticity modulus and elongation at break of the composite film are remarkably increased as comparison with those of a starch matrix. The cellulose and starch are wide in source and low in price and can be completely dissolved, so that the starch film is expected to be applied to the food packaging field.

Owner:QILU UNIV OF TECH

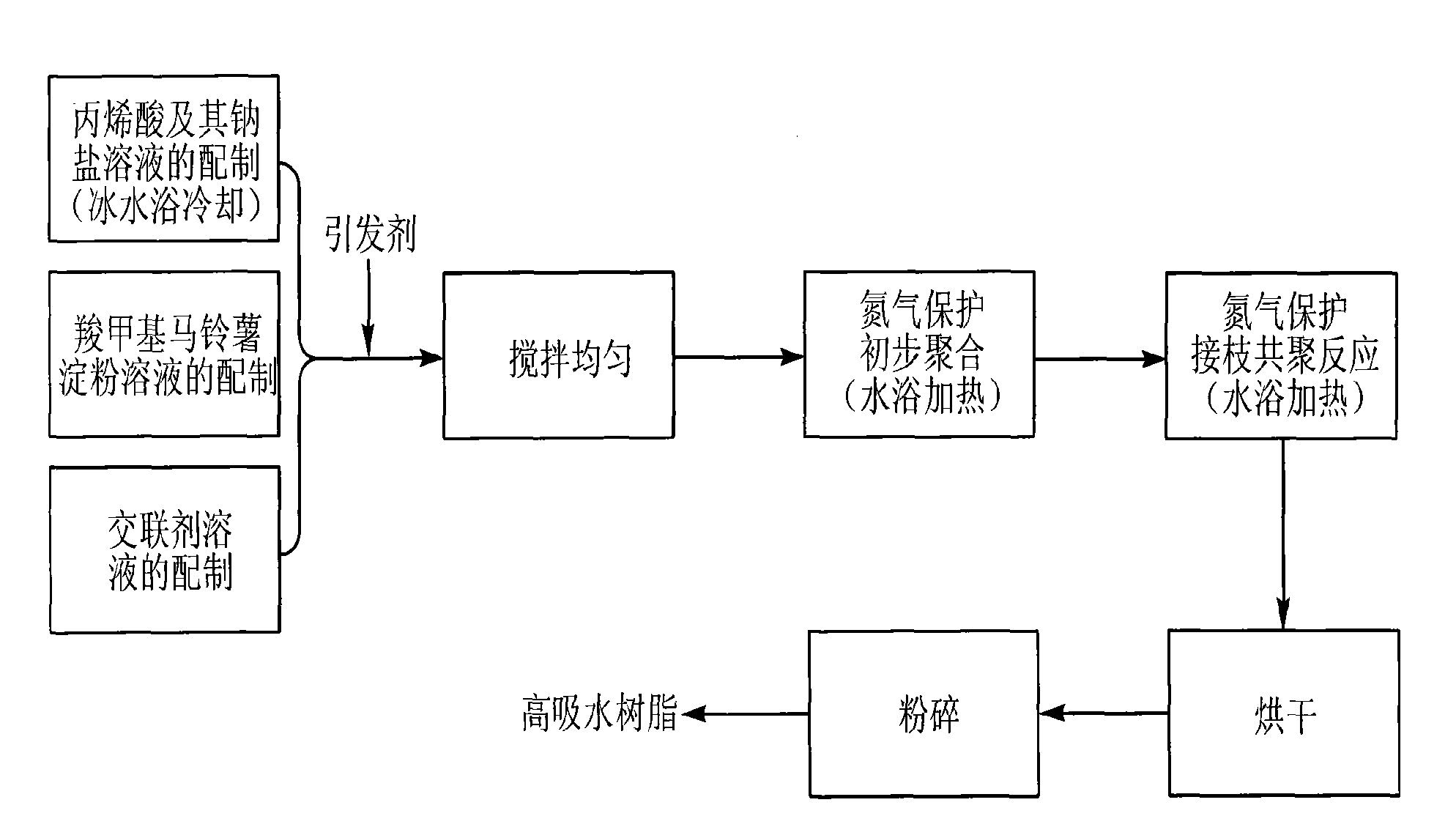

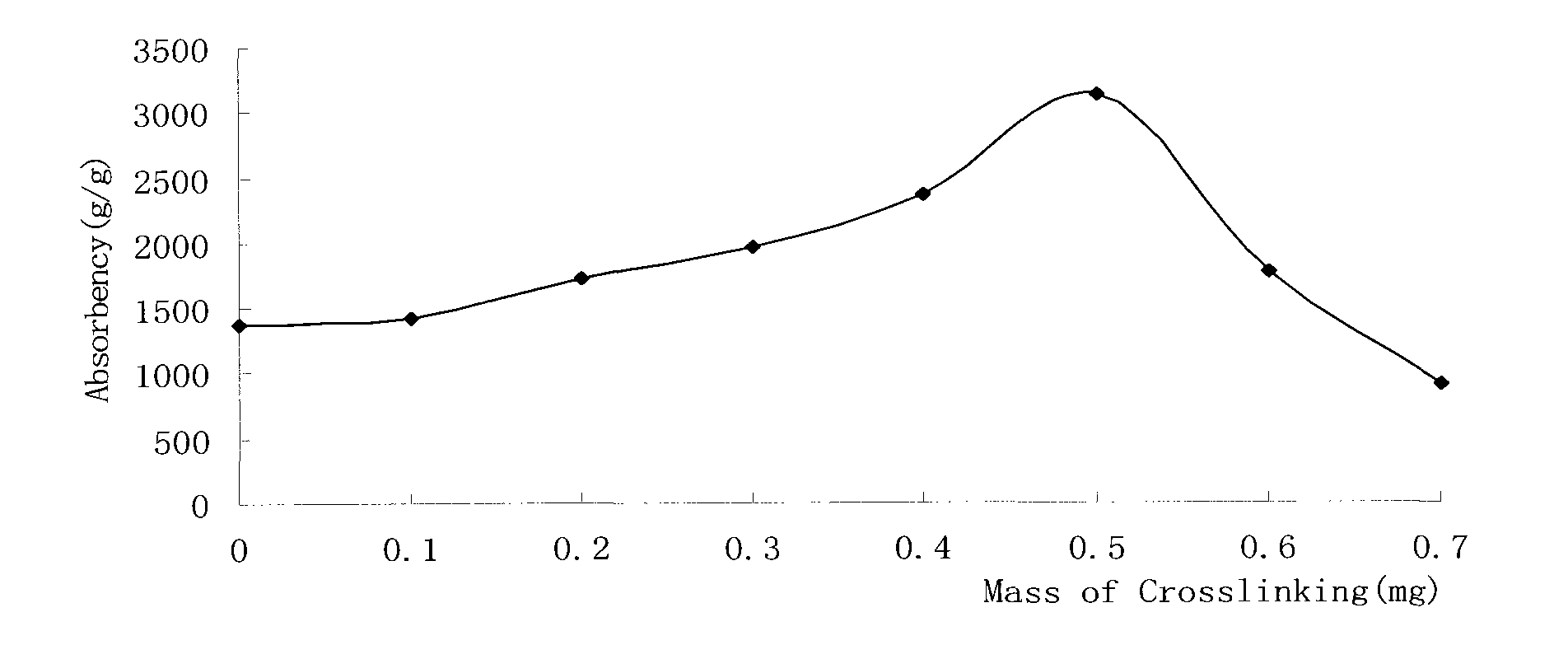

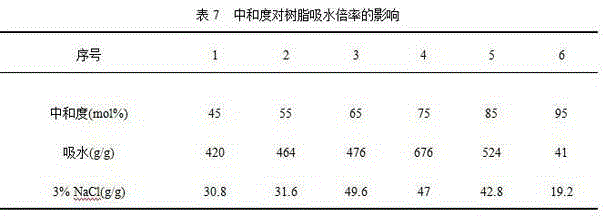

Method for preparing super absorbent resin by using carboxymethyl potato starch as raw material

The invention discloses a method for preparing super absorbent resin by using carboxymethyl potato starch as the raw material, which comprises the following main processes: carrying out neutralizationreaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing carboxymethyl potato starch with de-ionized water; mixing the prepared acrylic acid and the sodium salt solution thereof with the carboxymethyl potato starch solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature gradually so as to ensure that the carboxymethyl potato starch and the acrylic acid and the sodium salt thereof generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin by using carboxymethyl potato starch as the raw material. Compared with similar products, the water absorption of the super absorbent resin is greatly enhanced, the process of pasting is omitted incomparison with the process of using starch as the raw material and the preparation process is greatly improved. The super absorbent resin has great effect on the water conservation, the production of the physical hygiene sundries, the environmental improvement, the desert control, the plant growth promotion and the like of soil in dry regions.

Owner:广西珅信科技有限公司

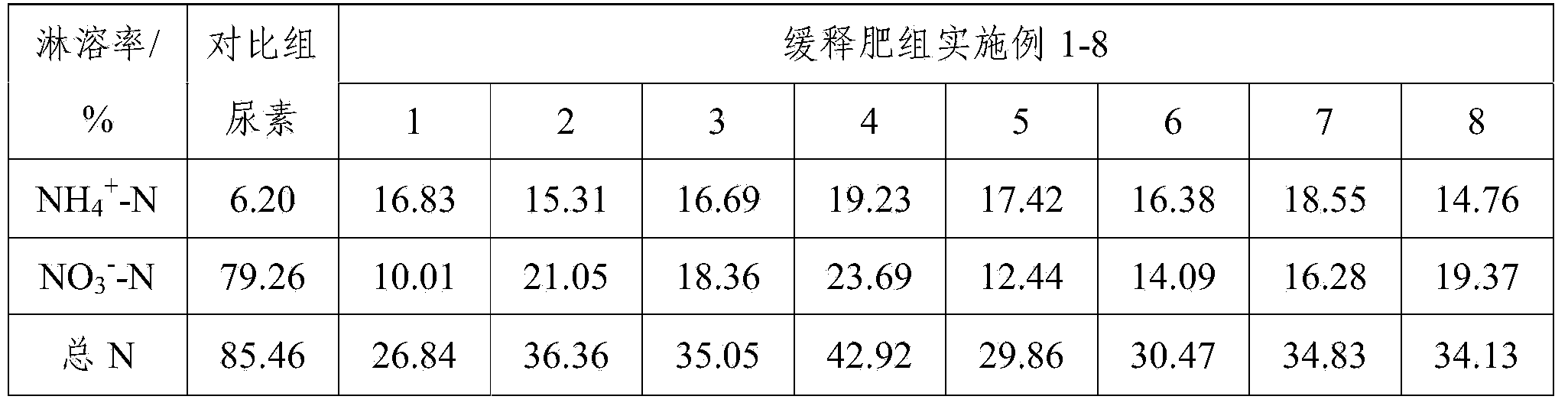

Charcoal-base polyaspartic acid slow-release urea as well as preparation method and application thereof

ActiveCN103804075ASolving Recycling ProblemsEmission reductionFertilizer mixturesField experimentDecomposition

The invention provides charcoal-base polyaspartic acid slow-release urea. The preparation method comprises the steps of 1) charring agricultural waste which is taken as a biomass raw material at 400-600 DEG C to obtain porous charcoal particles; 2) carrying out a reaction between urea and formaldehyde to obtain a modified urea solution; 3) adding polyaspartic acid and derivative thereof to the modified urea solution; 4) soaking the charcoal particles in the mixing solution obtained from the step 3) for 3-10 hours, and drying the soaked charcoal particles; 5) implementing a reaction between starch and a sodium hypochlorite solution to obtain an oxidized starch solution which serves as a binder; and 6) adding the dried charcoal particles to the binder, pelleting and drying to obtain the charcoal-base polyaspartic acid slow-release urea. The preparation method disclosed by the invention is low in cost, and can relieve conversion from NH4+-N to NO3--N, inhibit rapid decomposition and loss of the urea, prolong fertilizer efficiency, improve nitrogen use efficiency and relieve non-point source pollution; results of field experiments show that the slow-release urea product disclosed by the invention can effectively increase both production and income, and can achieve a yield-increasing effect under a circumstance of reducing application of fertilizer.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

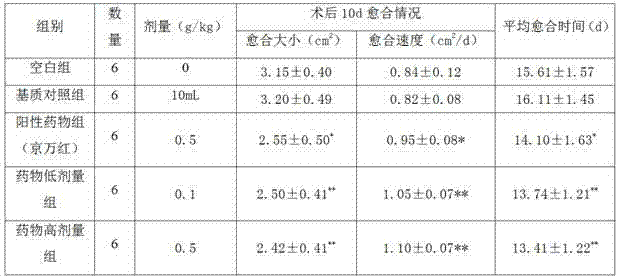

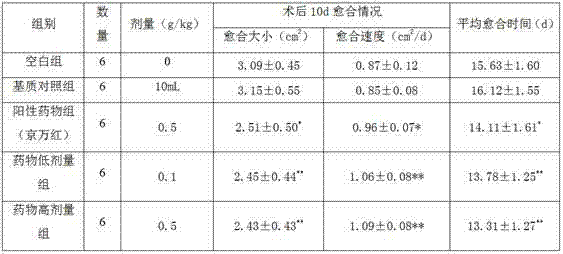

Preparation method and application of dendrobium officinale extract

ActiveCN104844723AGood industrial operabilityReduce manufacturing costOrganic active ingredientsDermatological disorderNeutral proteaseFreeze-drying

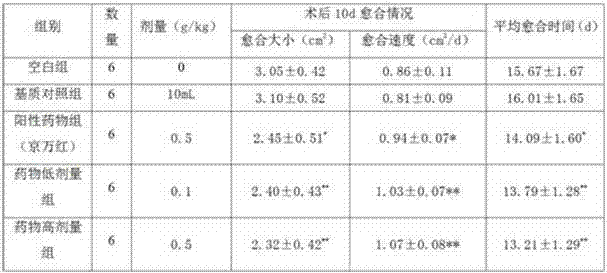

The invention discloses a preparation method of a dendrobium officinale extract. The method comprises the following steps: by taking fresh dendrobium officinale strips as a raw material, performing fermentation with neutral protease after juice squeezing; quickly freezing fermentation liquor, naturally unfreezing the fermentation liquor, and removing starch and other impurities from the fermentation liquor; removing a starch solution through treatment with strongly acidic cation exchange resin and weakly basic anion exchange resin; and finally performing concentration with a titanium stick filter, performing alcohol precipitation and centrifugation, collecting supernatant, and freeze-drying the supernatant to prepare the dendrobium officinale extract. The preparation method is simple to operate, low in cost and high in industrialization degree. The dendrobium officinale extract provided by the invention is used for preparing medicines for treating wounds. Compared with a control group, the dendrobium officinale extract is remarkably different in wound size, healing speed and mean healing time within 10 days after operation of rabbits; and the dendrobium officinale extract can speed up the healing of a wound of a wound model rabbit.

Owner:云南金九地生物科技有限公司

Method for preparing amphiprotic starch solution for papermaking

ActiveCN101759880ASolve aging problemsAging does not occurNon-fibrous pulp additionPaper/cardboardPotassium persulfateHigh concentration

The invention provides a method for preparing amphiprotic starch solution for papermaking, which belongs to the field of fine chemicals for papermaking. The amphiprotic starch solution is added at a papermaking wet end, and has a dry strengthening effect on paper. Starch is used as the basic material, water, sodium hydroxide, sodium hypochlorite or potassium persulfate and cationic etherifying agent are added. The amphiprotic starch solution is obtained after the aqueous solution is heated. The preparation method is fulfilled by the heating reaction of aqueous solution. The amphiprotic starchsolution has high concentration, can be diluted by cold water to any concentration and cannot be aged, so the technical problem of starch aging is solved. When in use, the amphiprotic starch solutioncan be added at the wet end without being heated to gelatinize, the amphiprotic starch solution as dry-strengthening agent for papermaking can notably increase the dry strength indexes of paper, suchas burst index and ring crush index, and under the circumstance of the same added amount, the amphiprotic starch solution has a better effect than the like product. The innovation of the invention isthat a simple technique for producing the amphiprotic starch solution is provided, the production time is not longer than 2 hours, the aging and retrograding problems of the amphiprotic starch are solved, and the invented amphiprotic starch solution can be directly added at the papermaking wet end without going through the step of gelatinization by heating.

Owner:GUANGDONG PAPER IND RES INST

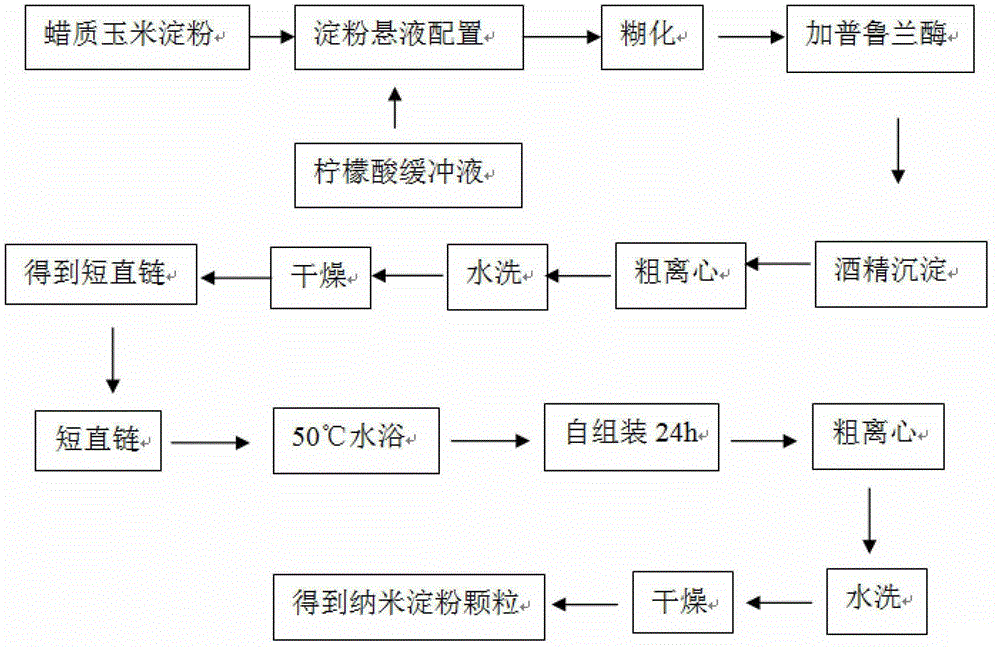

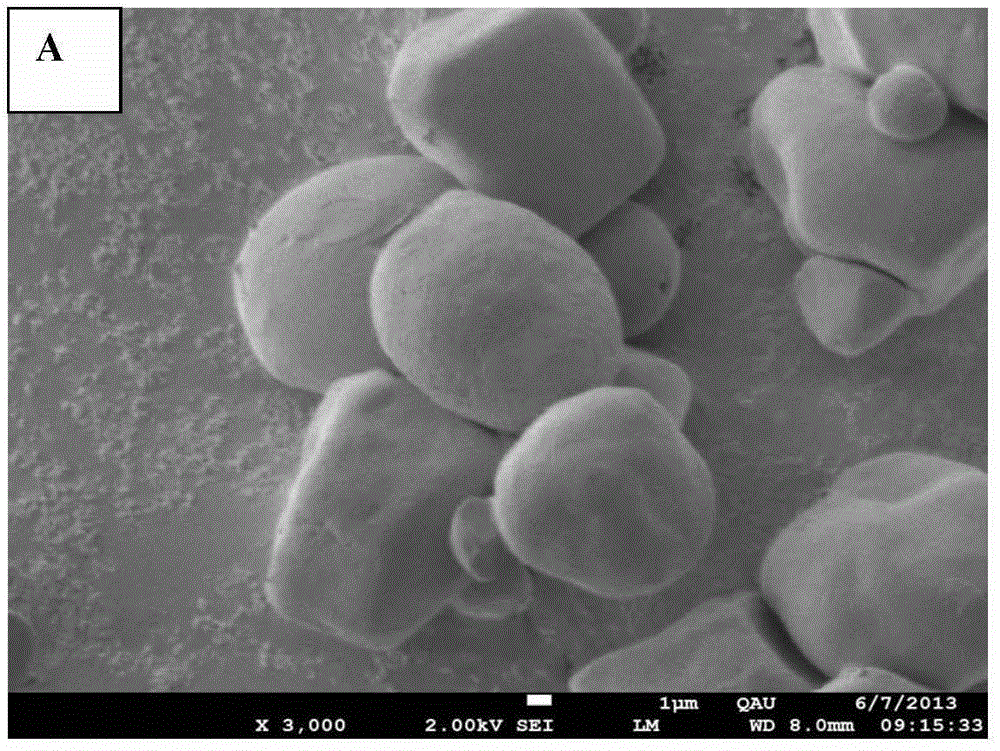

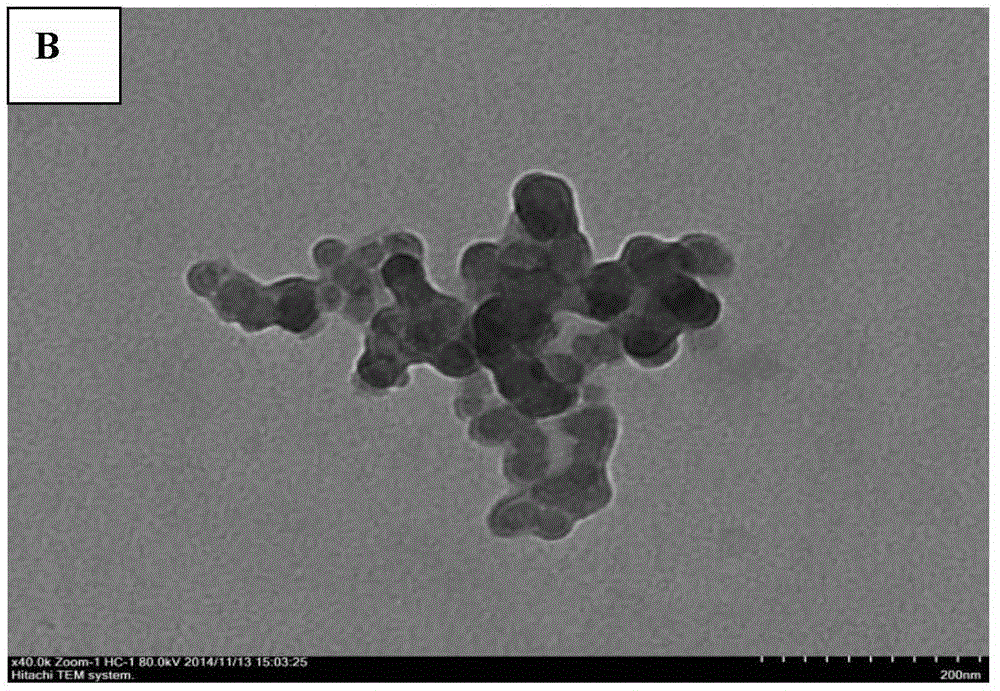

Process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose

The invention discloses a process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose. The process particularly comprises the following steps: (1) preparing a buffer solution; (2) preparing a starch water solution; (3) past-forming; (4) enzymolyzing, and then using anhydrous ethanol to precipitate the degreased starch solution; (5) preparing short amylose; (6) preparing nano starch. According to the process, enzyme hydrolysis starch is adopted to prepare nano starch at 30-70 DEG C in an anabiosis manner, the nano starch prepared by the method is high in productivity, low in cost, safer and more environment-friendly, and can serve as embedding materials of medicines, active ingredients and the like, and the application field of the process in the food industry is widened.

Owner:QINGDAO AGRI UNIV

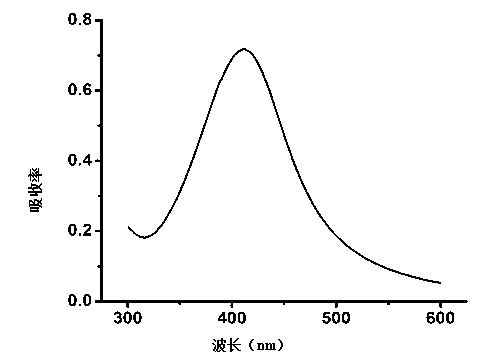

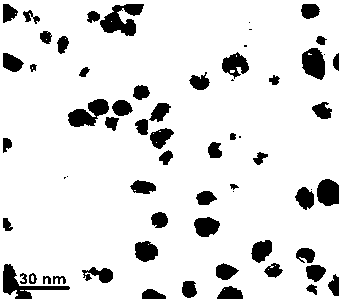

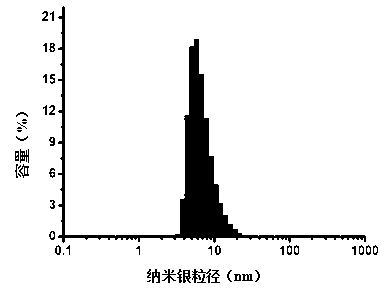

Method for preparing fibroin nano-silver hydrosol

InactiveCN102935521ANon-toxic and environmentally friendlyWide range of raw materialsHYDROSOLReducing agent

The invention discloses a method for preparing fibroin nano-silver hydrosol. The method comprises the following steps of: dissolving or dispersing soluble amylose in deionized water, stirring the mixture until the amylose is completely gelatinized to obtain a starch solution, adding a silver nitrate solution, and then mixing the mixture with a fibroin solution to obtain a fibroin-starch-silver nitrate ternary complex solution; adjusting the pH value of the ternary complex solution to be at 8-10 by ammonia water, and fully mixing at the temperature condition of 20-80 DEG C to obtain the fibroin nano-silver hydrosol with the silver particle size being 1-100nm. According to the method, micromolecule fibroin peptide is used as a capturing agent and a reducing agent, the soluble starch is used as a dispersing agent and a protective agent, and the micromolecule fibroin peptide and the soluble starch are used for reducing and preparing nano-silver. The prepared nano-silver hydrosol is small in silver particle size, uniform in distribution and good in stability, in the prepared process, the reaction is mild, the operation is convenient, the green and environment-friendly aim is realized, and the fibroin nano-silver hydrosol can be widely used as a functional nano-material.

Owner:SUZHOU UNIV

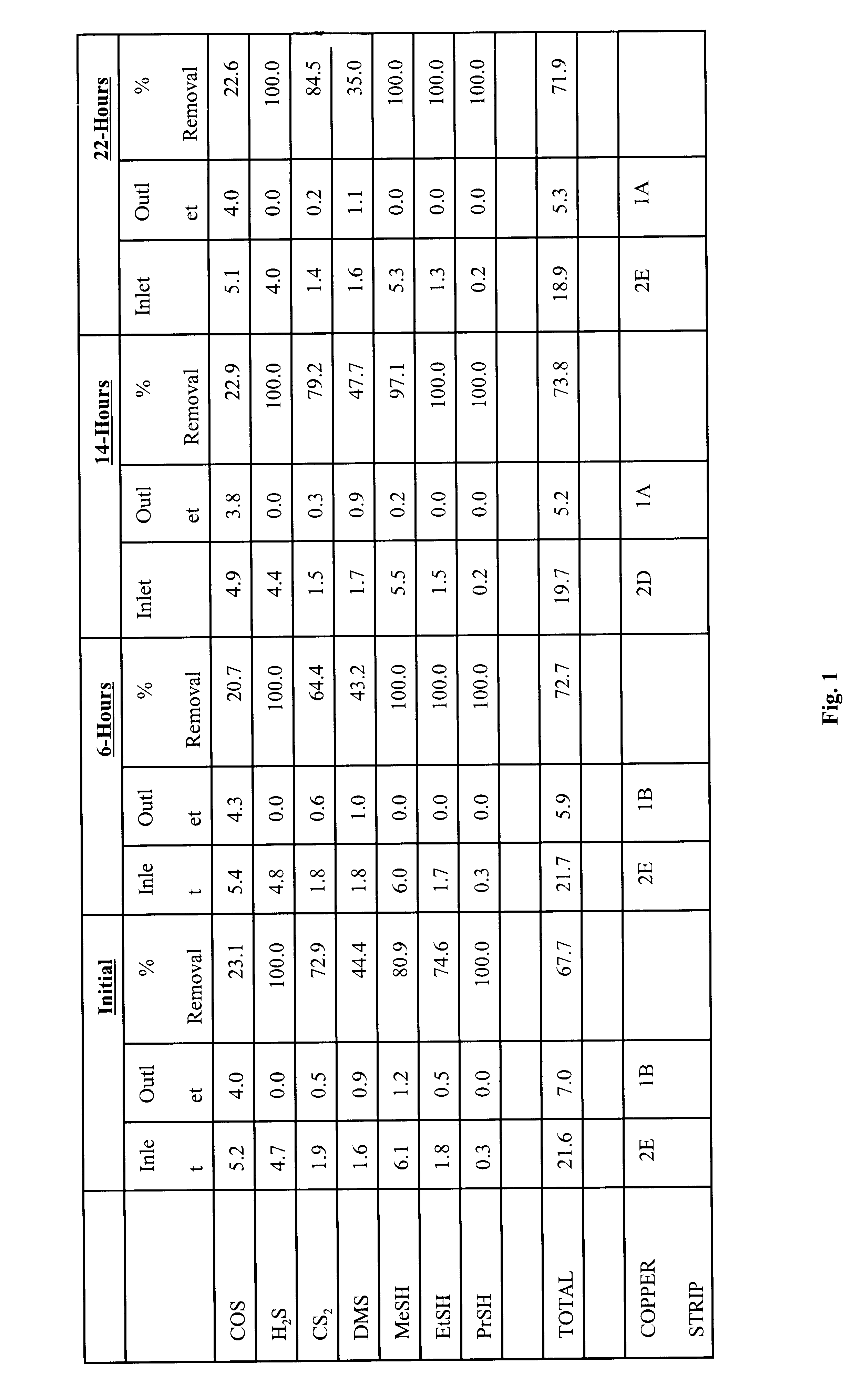

Compressed metal oxide product

InactiveUS6664210B1Increased sulfur holding capacitySufficient reactivityGas treatmentOther chemical processesPelletizingStarch solution

The present invention relates to a bound metal oxide particle comprised of metal oxide and a binder, with the binder preferably being a starch solution. The present invention also relates to a method for forming a bound metal oxide particle, with the preferred method including extruding and pelletizing a metal oxide and binder composition to form pelletized metal oxide particles.

Owner:MI

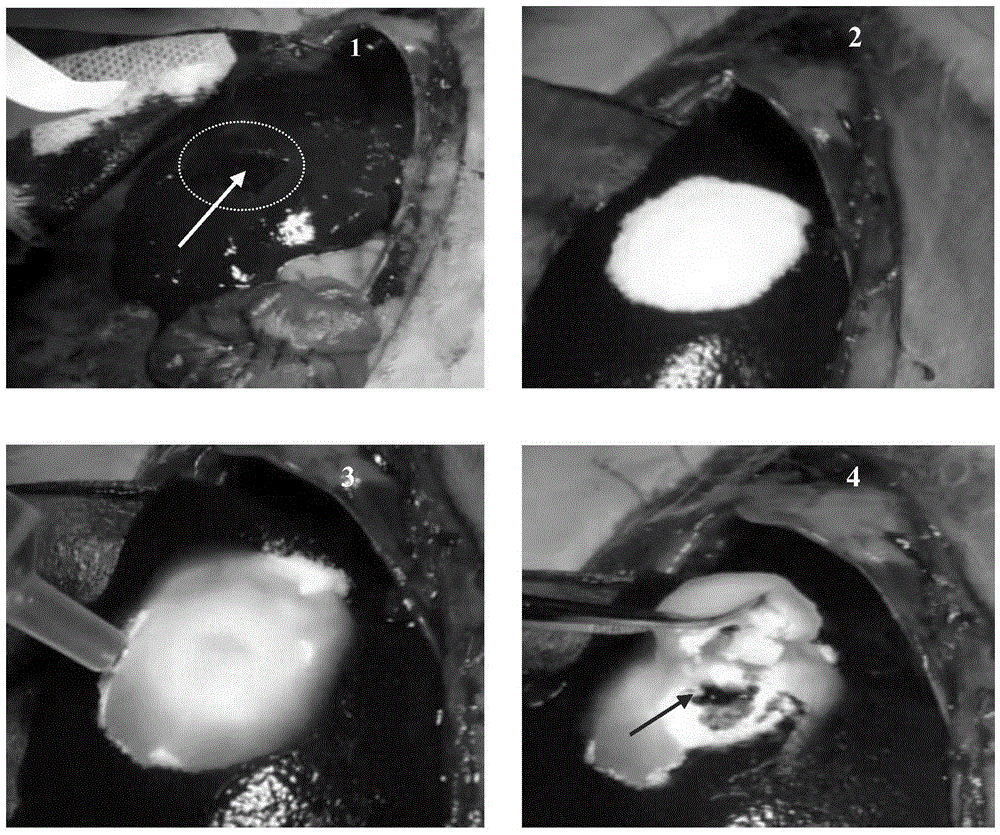

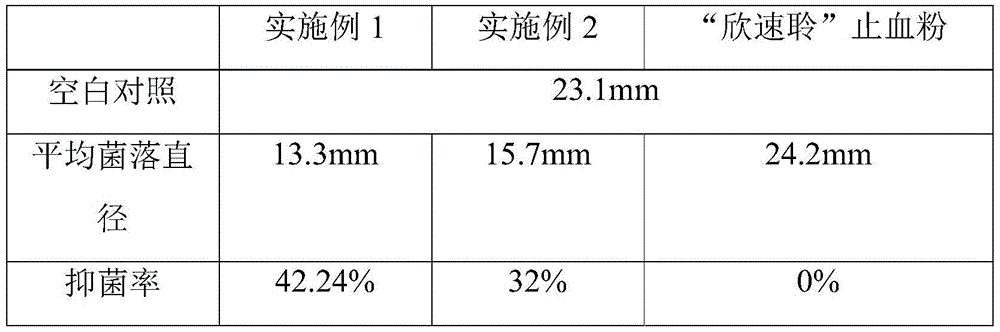

Multifunctional microporous styptic powder and preparation method thereof

ActiveCN105617449AImprove stabilitySimple methodSurgical adhesivesPharmaceutical delivery mechanismMicrowaveFiltration

The invention discloses multifunctional microporous styptic powder and a preparation method and application thereof. The preparation method comprises the following steps: 1) mixing starch with water to obtain a starch solution or starch pasty liquid; 2) mixing carboxymethyl chitosan with water to obtain a carboxymethyl chitosan solution; 3) mixing the starch solution or the starch pasty liquid with the carboxymethyl chitosan solution to obtain a blended solution; 4) dispersing a pore-forming agent into the blended solution to obtain blended dispersion liquid; 5) dropwise adding an ionic crosslinker into the blended dispersion liquid under a stirring condition, mixing the obtained mixed system with a dispersing agent and an emulsifying agent, and performing crosslinking reaction and suction filtration; 6) removing the pore-forming agent from a product obtained in the step 5), and drying; 7) performing microwave treatment on a product obtained in the step 6) to obtain the styptic powder. The preparation method adopts a dual crosslinking method of ionic crosslinking and microwave treatment; used reagents are environmentally friendly, and free of residues; the biological activity of an amino group in the carboxymethyl chitosan can be retained easily.

Owner:YANTAI ZHENGHAI BIO TECH

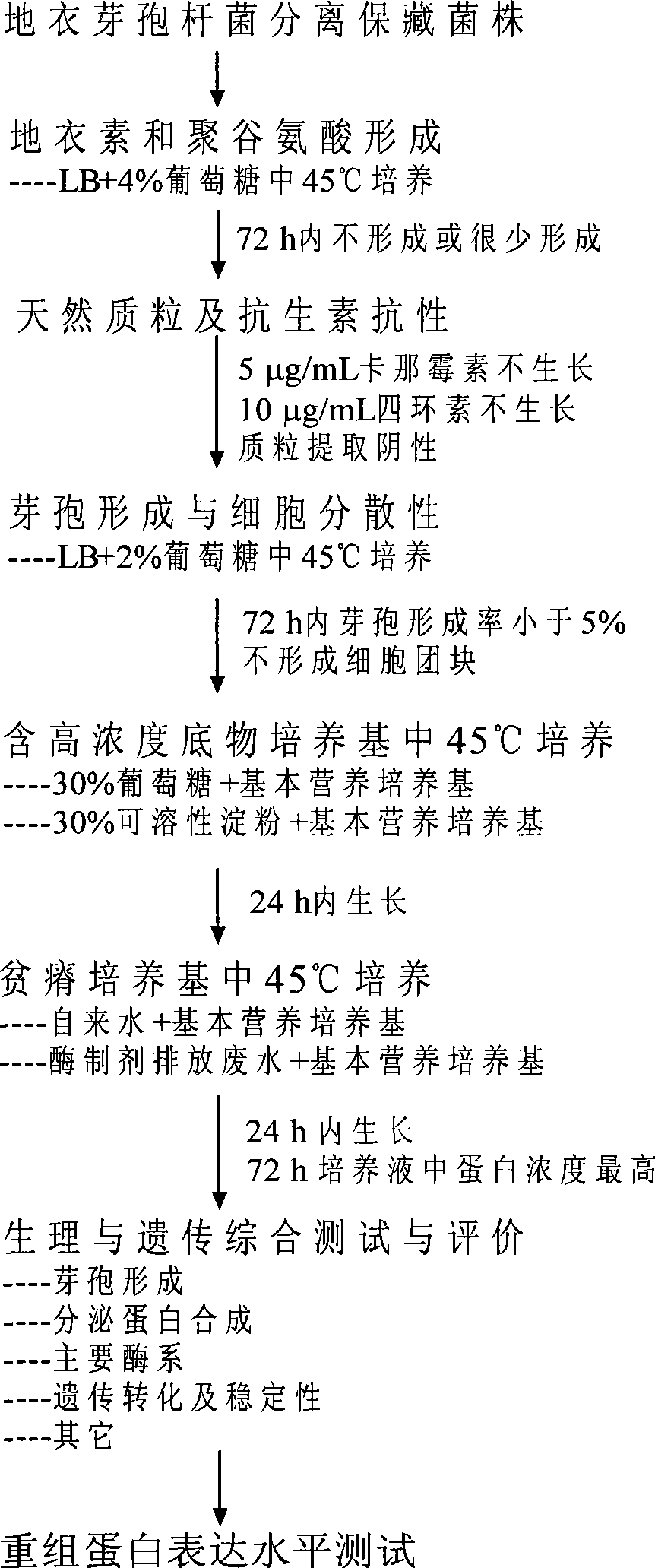

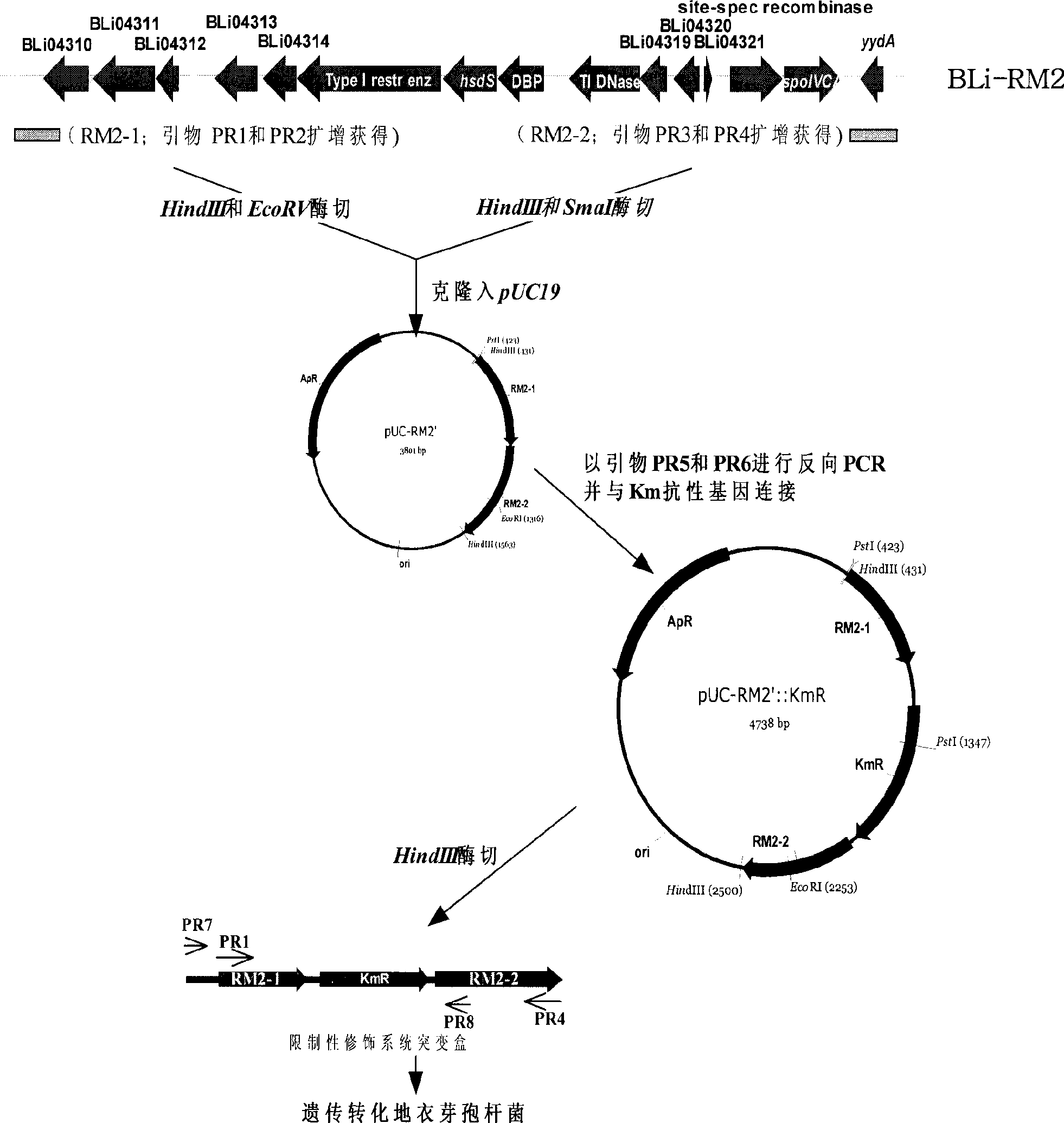

Host cell and method for efficient expression and secretion thereof in recombinant protein

ActiveCN101418276AHighly secreted expressionLower Fermentation Manufacturing CostsBacteriaHydrolasesBacillus licheniformisBacillus megaterium

The invention relates to a host cell and a method for the host cell applied in efficient secretion expression of a recombinant protein, which belongs to the filed of microbiological engineering and fermentation engineering. The invention provides a bacillus licheniformis host cell CBB3008 which is preserved in the China Center for Type Culture Collection with the preserving number of CCTCC NO: M 208236. The invention transforms an expression plasmid of an industrial enzyme which is obtained by a gene cloning technology into the host cell to synthesize an industrial enzyme preparation in the host cell efficiently, and then secretes the synthesized enzyme protein into a culture medium efficiently through a protein secretion system of the host cell, thus the invention can guide efficient secretion production of the industrial enzyme preparation. Therefore, the invention is helpful to reduce the fermentative production cost of the industrial enzyme preparation, simplify the fermentative production process and reduce the environmental pressure of the fermentation industry. A method for host cell screening and genetic improvement of the invention can also be used for other types of host cells, in particular for the breeding of the host cells of bacillus subtilis, bacillus megaterium, bacillus pumilus, bacillus starch solution and the like.

Owner:福建福大百特生物科技有限公司

Method for producing fried peanut kernels with low peroxide number

The invention discloses a method for producing friend peanut kernels with low peroxide number for fried peanuts with strong oxidation resistance and long quality guarantee period. The method comprises the following steps of: (1). selecting peanut kernels; (2). charging nitrogen: continuously supplementing nitrogen for a frying pan through a nitrogen making machine, wherein the nitrogen charging time is 20-25 minutes, and the nitrogen charging purity is 98.5-99.5%; (3). frying with mixed water and oil, wherein the temperature of oil at the upper layer is within 130-200 DEG C, the temperature of oil at the lower layer is within 55-130 DEG C, and the temperature of the oil water demarcation face is controlled to be below 55 DEG C; (4) processing the fried peanut kernels; (5). coating a film:a film solution is prepared by a pea starch solution with the concentration of 5%, during preparation, the film solution needs to be gelatinized in a boiling water bath for 20 minutes, the temperature of the film solution is maintained to be within 30-40 DEG C, and then the film solution is coated on the surfaces of the fried peanut kernels; and (6). drying the fried peanut kernels subjected to film coating in a vacuum-freezing drying machine, wherein the freezing temperature is minus 35 DEG C, and the vacuum degree is 0.05 MPa.

Owner:QINGDAO BAOQUAN PEANUTS PRODS

Multiphase Fenton catalyst as well as preparation method and application thereof

ActiveCN103908966ASolving difficult recycling challengesPromote decompositionMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationSolubilityElectrolysis

The invention relates to a multiphase Fenton catalyst as well as a preparation method and application thereof and mainly solves the technical problems of poor mechanical strength and high ion solubility of an existing multiphase Fenton catalyst. The multiphase Fenton catalyst is prepared from reduced iron powder, active carbon powder, electrolytic copper powder and silicate. The preparation method comprises the following steps: (1) weighing the reduced iron powder, the active carbon powder, the electrolytic copper powder and the silicate; (2) firstly mixing the active carbon powder and the electrolytic copper powder to be uniform, then adding a silicate solution, mixing to be uniform, adding the active carbon powder, and mixing to be uniform so as to obtain mixed powder; (3) adding a starch solution serving as a binding agent into the mixed powder to prepare granules and drying; (4) sintering in nitrogen atmosphere, so as to obtain the multiphase Fenton catalyst. The multiphase Fenton catalyst prepared by utilizing the preparation method can be used as a sewage treatment catalyst.

Owner:HARBIN INST OF TECH

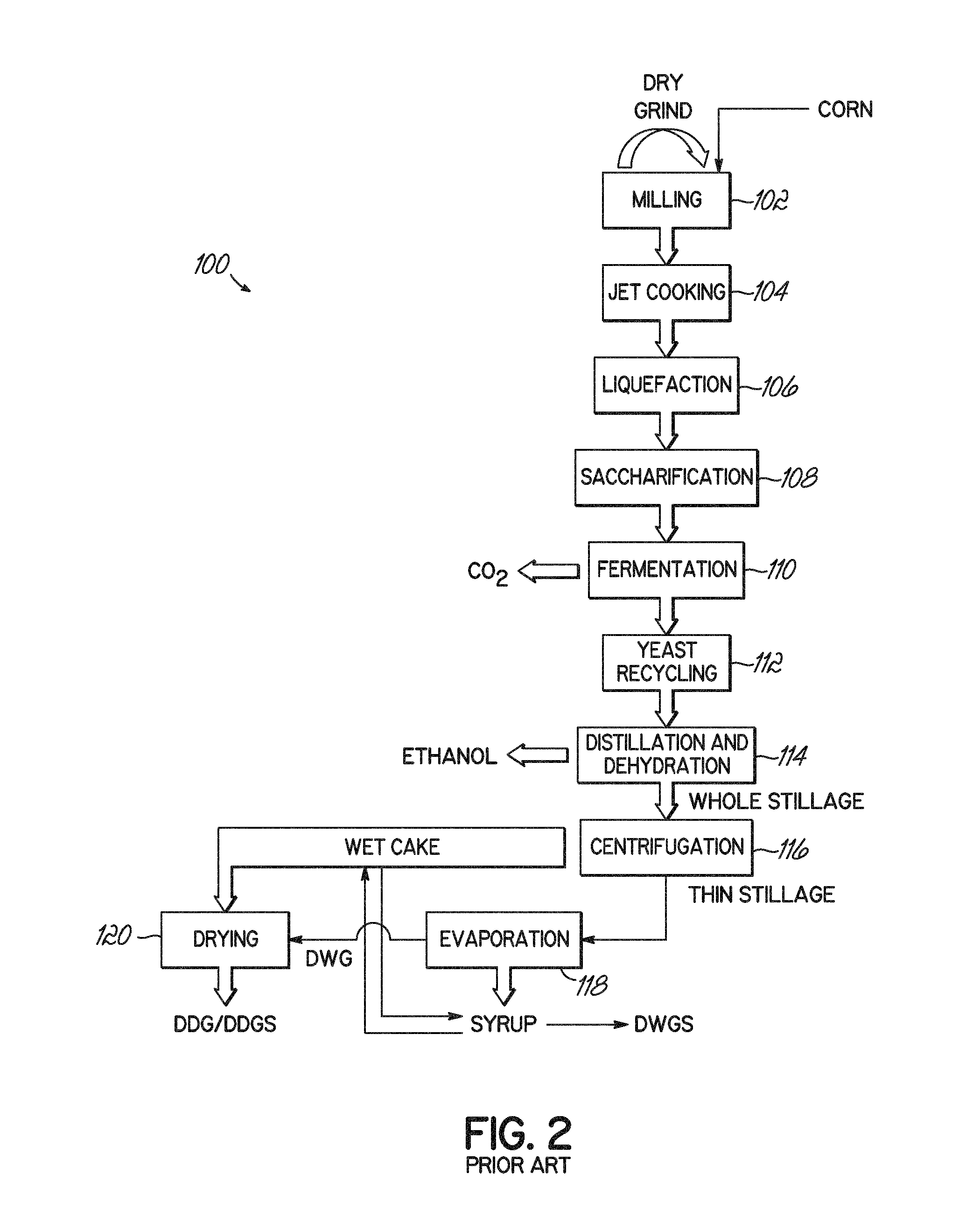

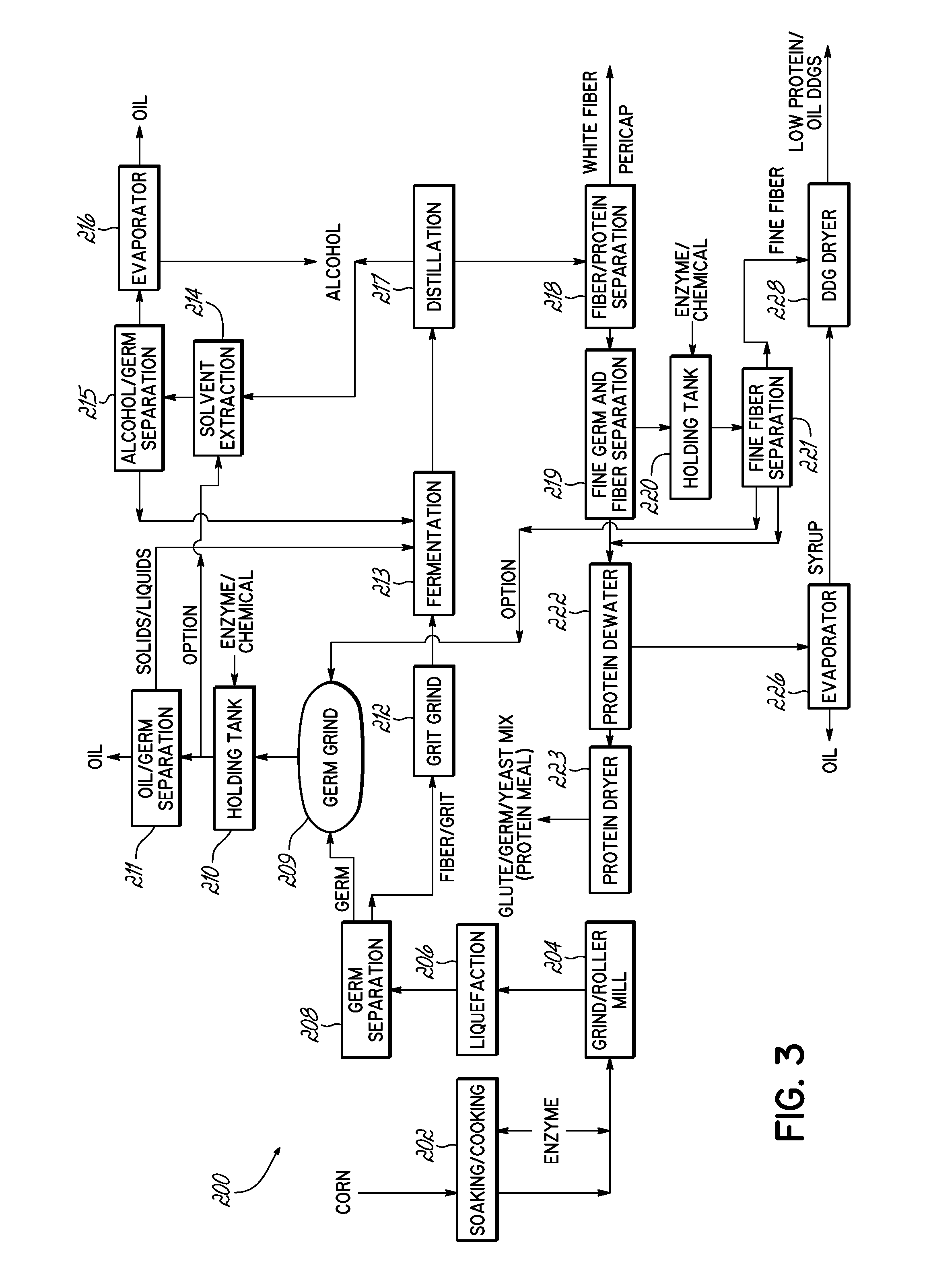

A system and method for separating high value by-products from grains used for alcohol production

ActiveUS20130236936A1Increase valueDesirable yieldBioreactor/fermenter combinationsBiological substance pretreatmentsFiberAlcohol production

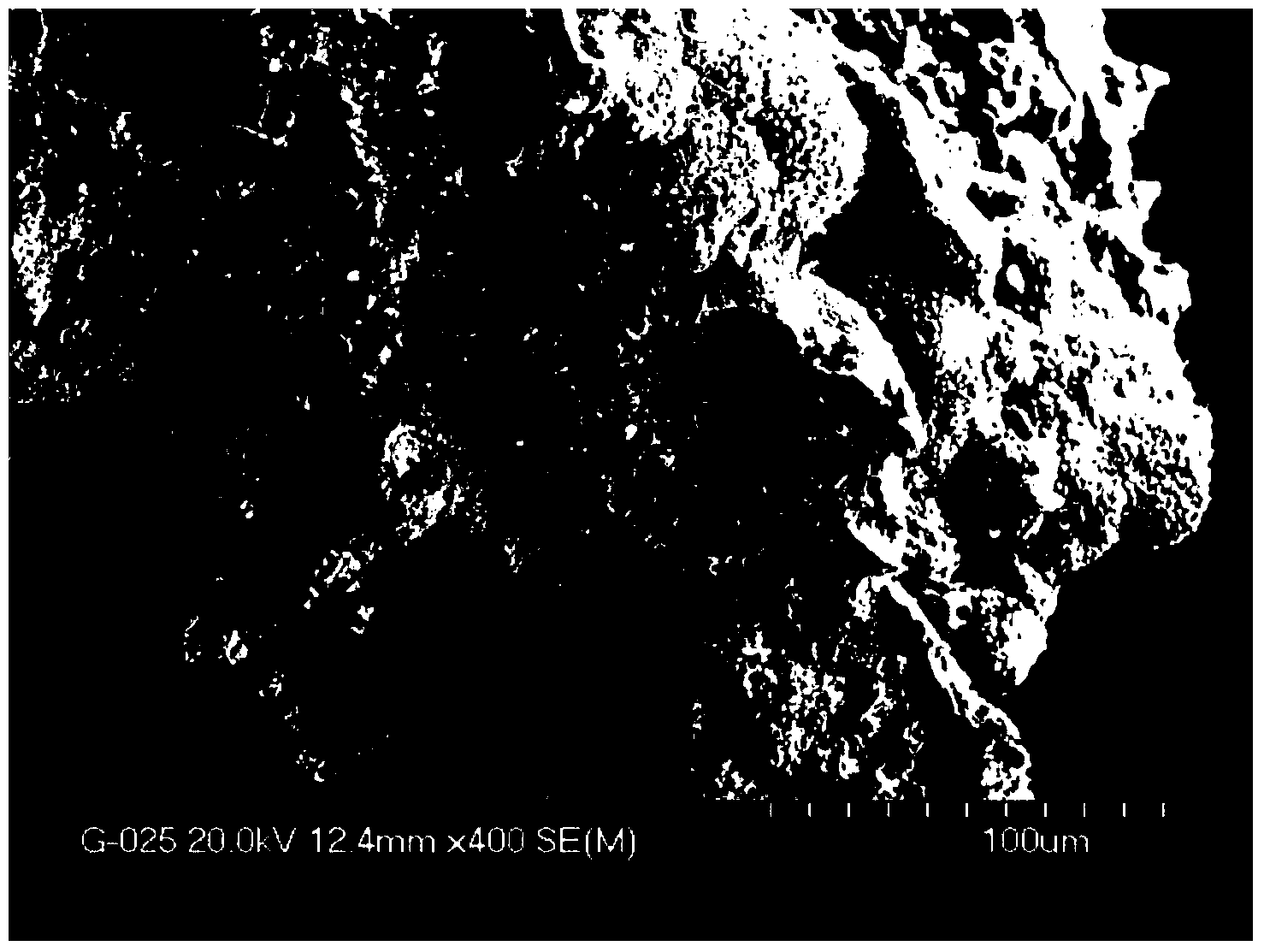

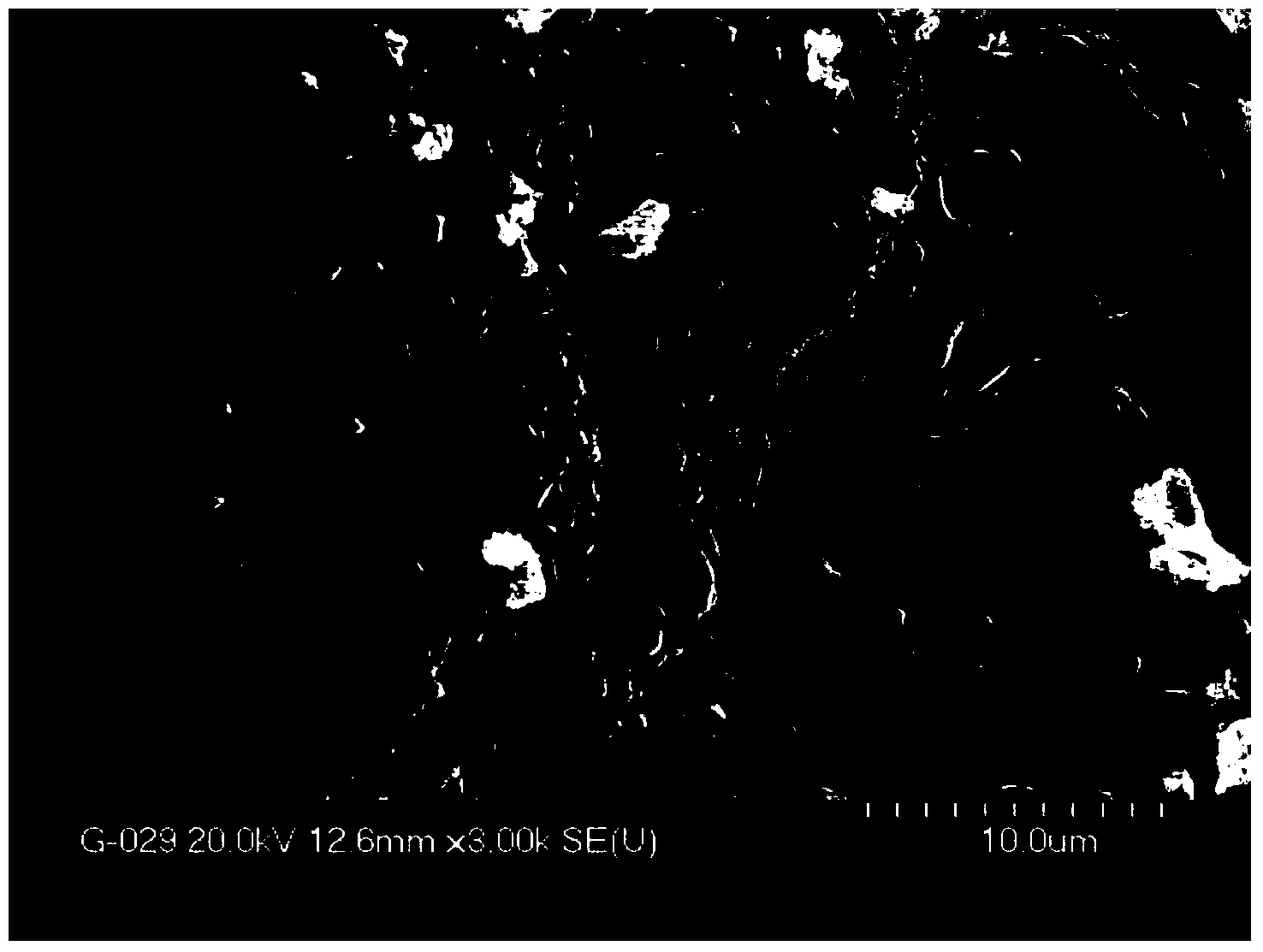

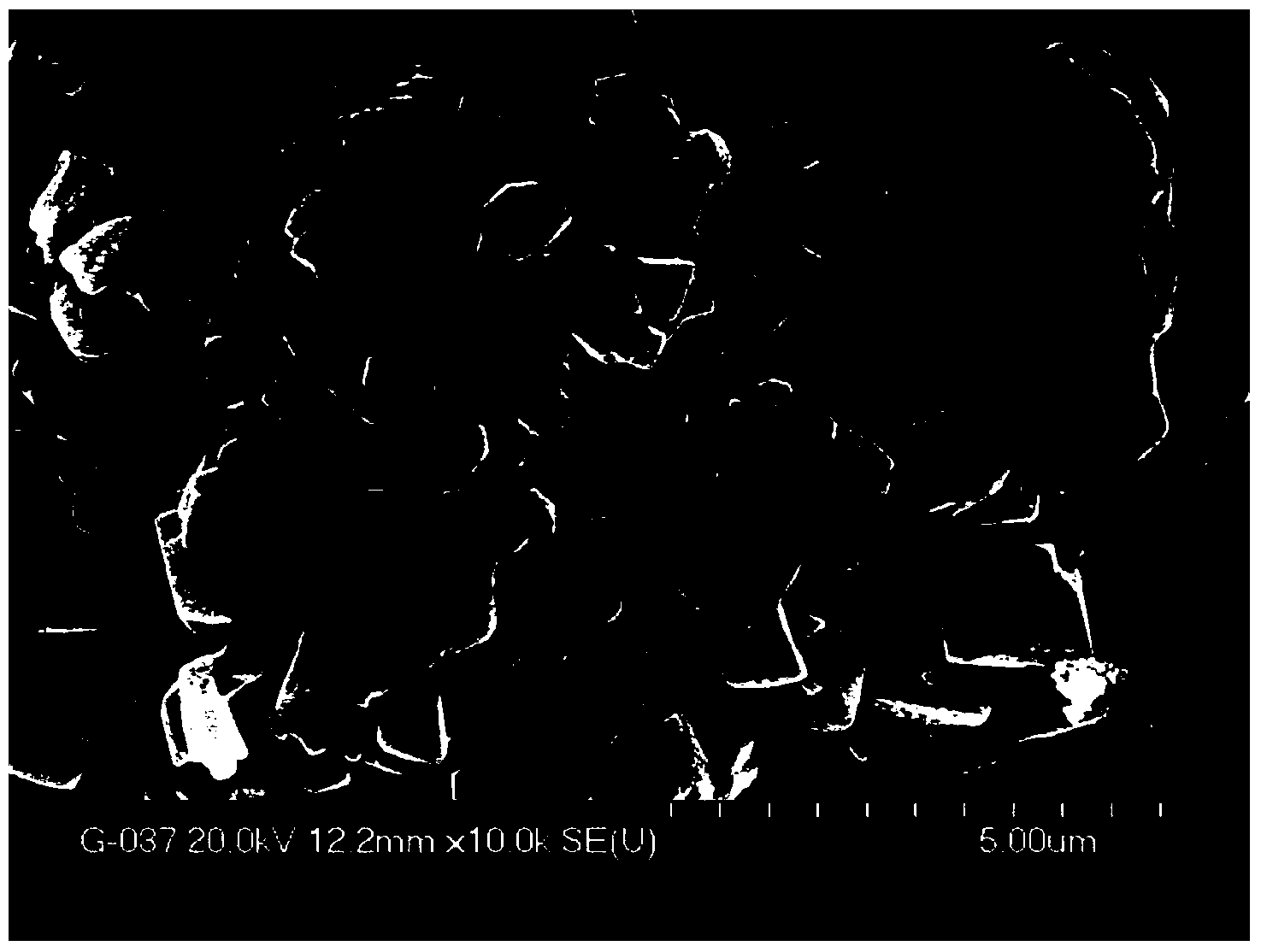

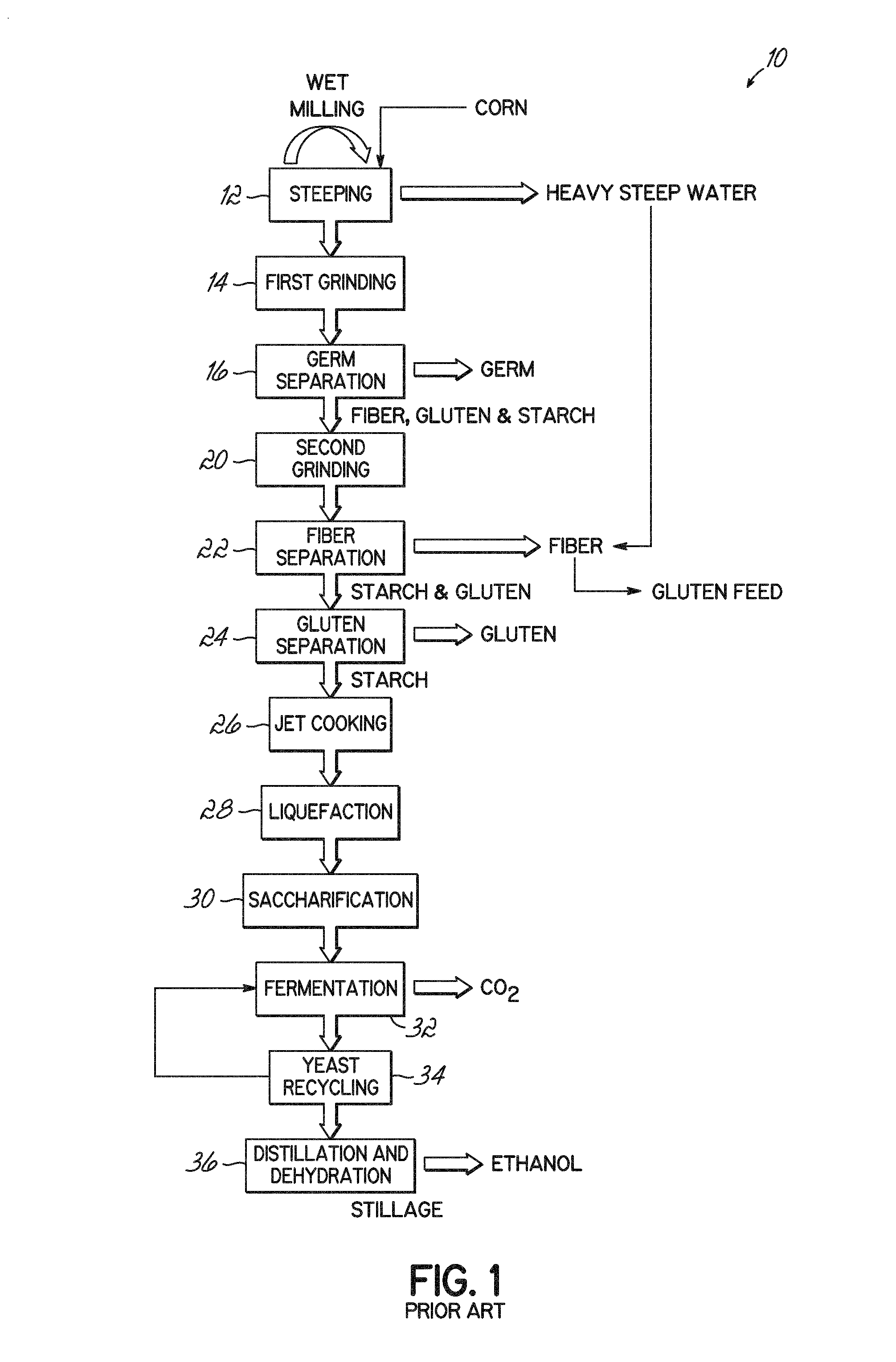

Systems and methods are provided for separating high value by-products, such as oil and / or germ, from grains used for alcohol production. In one embodiment, a method for separating by-products from grains used for alcohol production includes, subjecting milled grains to liquefaction to provide a liquefied starch solution including fiber, protein, and germ. The germ is separated from the liquefied starch solution. The separated germ is ground, e.g., to a particle size less than 50 microns, to release oil to provide a germ / oil mixture. Then, prior to fermentation, the oil is separated from the germ / oil mixture to yield an oil by-product. The pH of the germ / oil mixture can be adjusted to about 8 to about 10.5 and / or cell wall breaking enzymes or chemicals may be added to help release oil from the germ. In one example, the oil yield is greater than 1.0 lb / Bu.

Owner:LEE CHIE YING

Preparation method of starch-based composite flocculant and application thereof

InactiveCN102060362AGood flocculation effectSettling fastWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationSolventAluminium salts

The invention discloses a preparation method of a starch-based composite flocculant and application thereof. The method is characterized by taking sodium silicate, aluminium salt and iron salt as main raw materials and water as a reaction solvent to prepare ferro-silico aluminium and compounding an alkaline modified starch solution with the ferro-silico aluminium to prepare the starch-based composite flocculant. The starch-based composite flocculant is mainly applied to printing and dyeing wastewater treatment. The starch-based composite flocculant has the advantages of high decolorization rate and CODCr removal rate, high sedimentation velocity, less sludge quantity and no secondary pollution.

Owner:GUANGDONG UNIV OF TECH

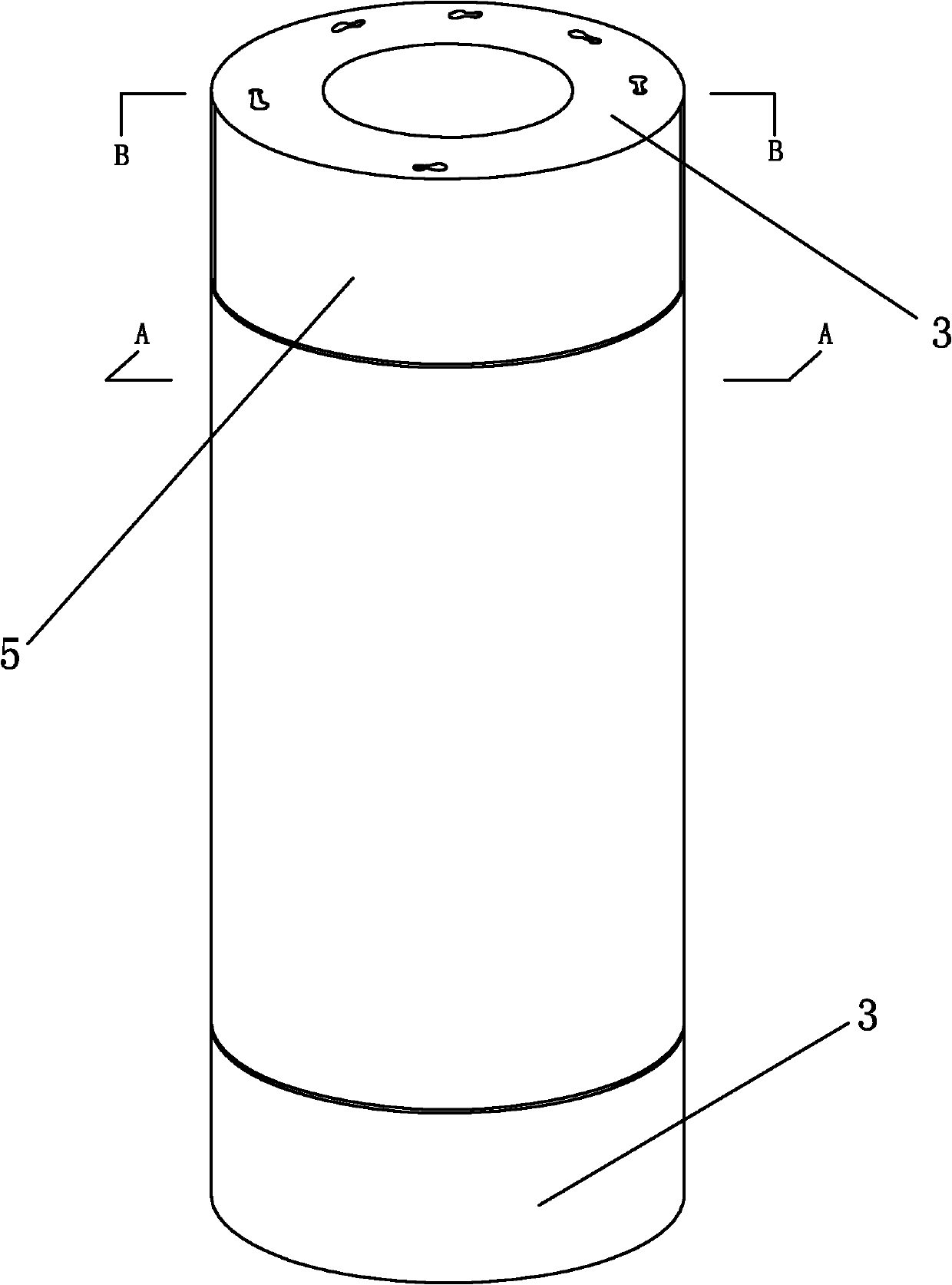

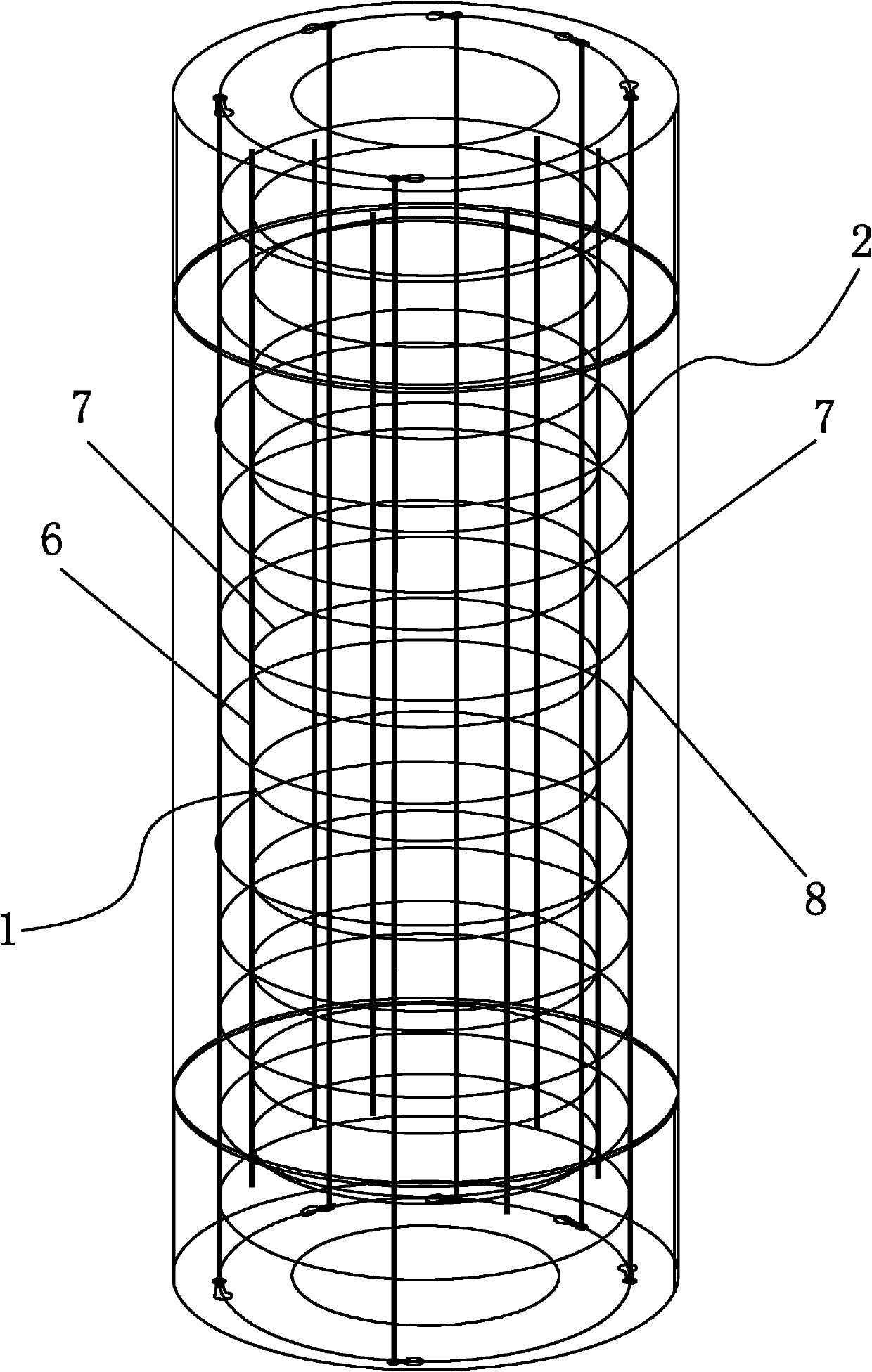

Production method of pretensioning prestressed concrete dynamic load piles

ActiveCN102166788AImprove performanceImprove the bending capacityCeramic shaping apparatusBulkheads/pilesPre stressPre stressing

The invention discloses a production method of pretensioning prestressed concrete dynamic load piles, comprising the following steps: arranging a welded non-prestressed steel reinforcement framework cage in a prestressed steel reinforcement cage; cleaning a corresponding steel die; coating a separant; suspending the double-layer steel reinforcement framework cage in a lower die body of the steel die; respectively arranging the end plates of a connected hooping plate at the two ends of the double-layer steel reinforcement framework cage; casting concrete material to the lower die body of the steel die; carrying out die assembly and pre-stressed tensioning; performing centrifugal shaping; pouring out the surplus starch solution on the inner wall; and carrying out steam curing and secondary steam curing. The production method provided by the invention aims to overcome the shortages in the prior art. The invention provides a method for producing a pretensioning prestressed concrete dynamic load dynamic load pile with horizontal anti-bending bearing capacity, high shearing resistance, high bearing capacity of a single pile, and strong shock resistance.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

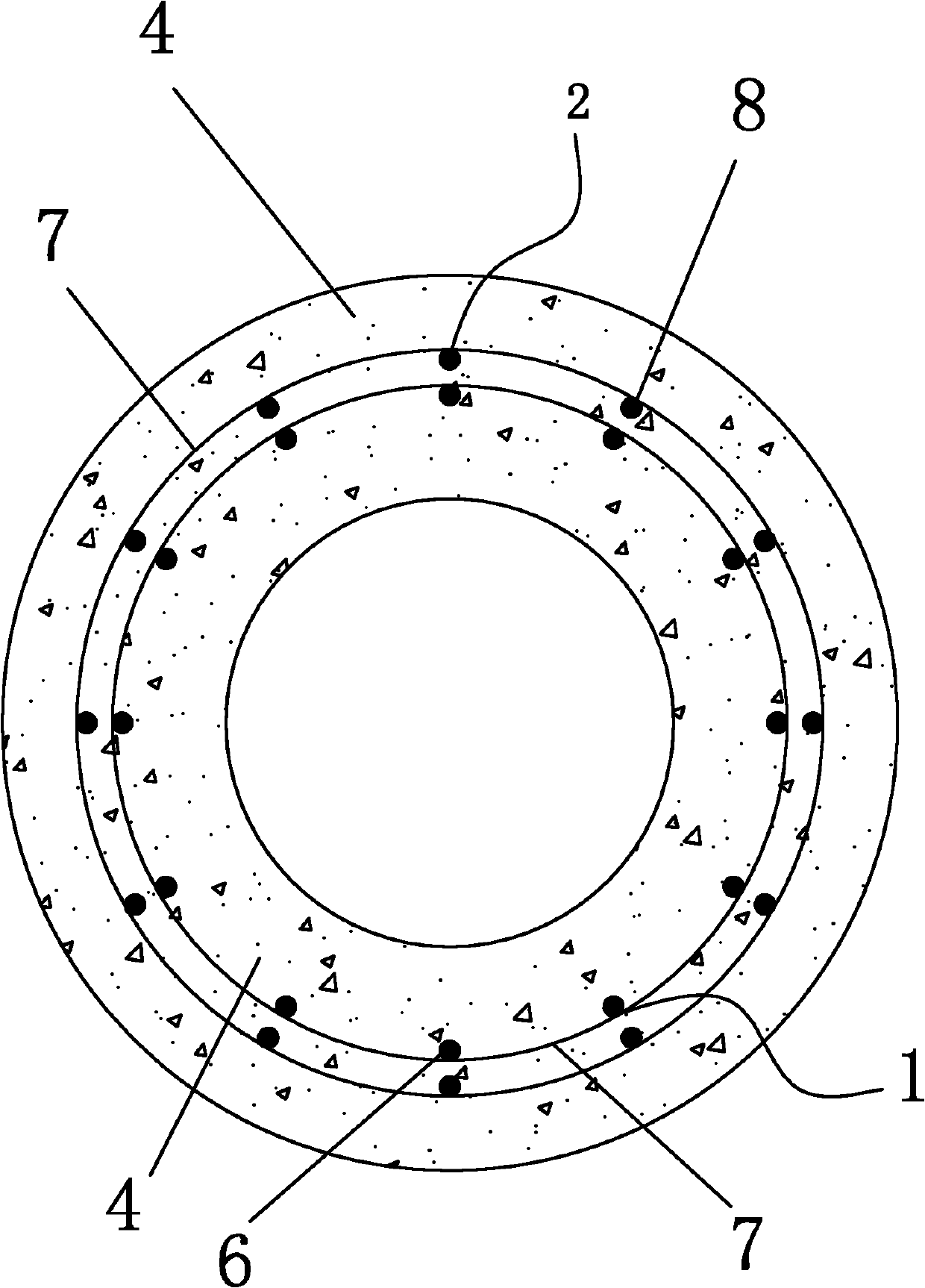

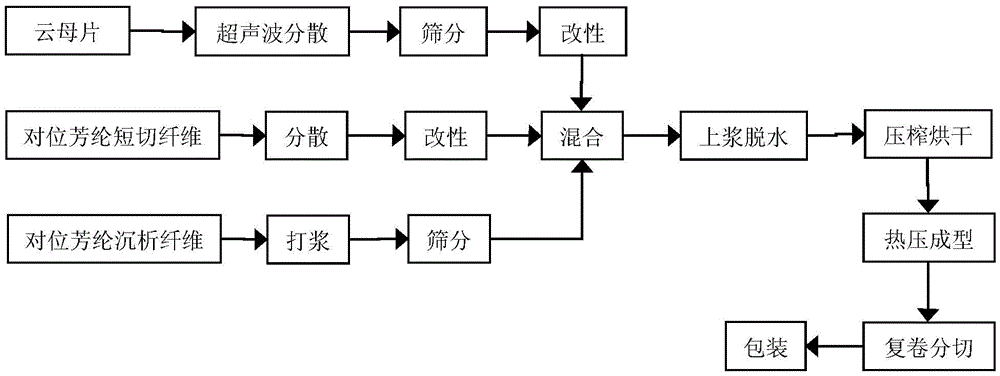

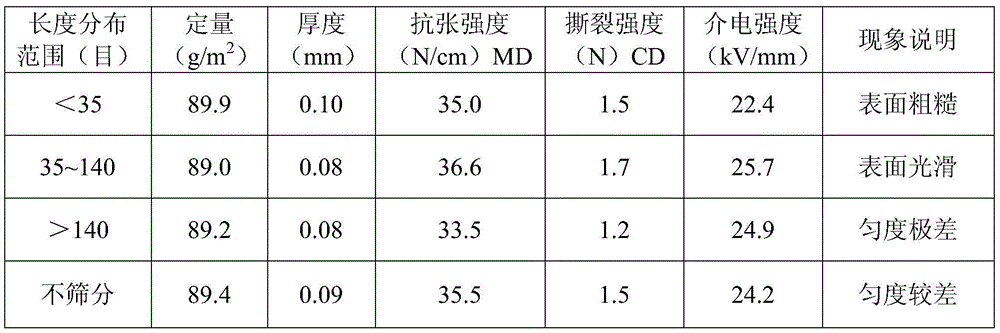

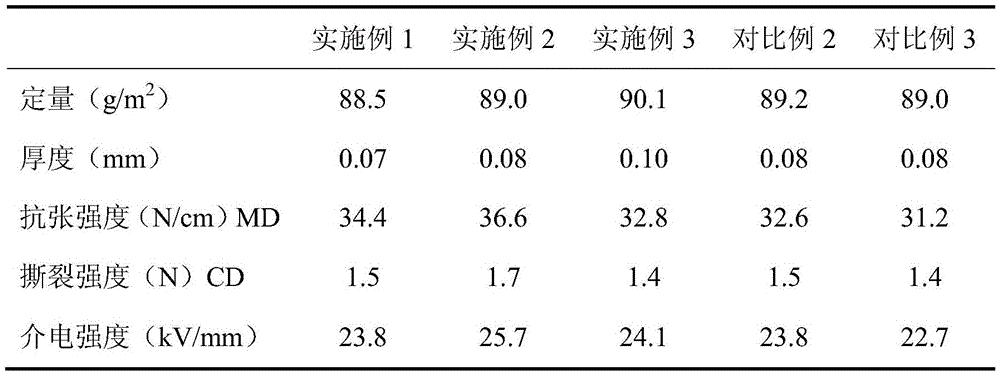

Preparation method of p-aramid fiber-mica paper

ActiveCN105544286AHigh strengthImprove evennessInorganic fibres/flakesPhysical paper treatmentDielectric breakdown strengthSlurry

The invention relates to a preparation method of a p-aramid fiber-mica paper. The preparation method comprises defibering and dispersing silane coupling agent-modified p-aramid chopped fibers to obtain slurry A, carrying out screening on the p-aramid fibrids with a beating degree of 40-65 degrees SR to obtain slurry B, modifying mica plates through an ionic starch solution to obtain modified mica plates, mixing the slurry A, the slurry B and the modified mica plates to obtain uniform mixed slurry, wherein the uniform mixed slurry comprises, by mass, 10-20% of p-aramid chopped fibers, 20-40% of the p-aramid fibrids and 40-70% of the mica plates, carrying out sizing, dehydration and formation on the mixed slurry, carrying out squeezing and drying and carrying out hot press molding to obtain the p-aramid fiber-mica paper. The p-aramid fiber-mica paper obtained through fiber screening and modification, wet method paper making and hot pressing molding has good evenness, excellent mechanical strength, excellent dielectric breakdown strength and high temperature resistance stability.

Owner:YANTAI METASTAR SPECIAL PAPER

Edible package film based on chitosan and preparation method thereof

The invention relates to an edible package film based on chitosan and a preparation method thereof. At present, industrial production and actual commercial application of the edible package film are not promoted due to the most important reasons that the edible package film is poor in mechanical strength and has no hot-sealing property. In the invention, a calendering method is employed, wherein the preparation method includes the steps of: mixing a chitosan solution with a gelatin solution or a starch solution, adding glycerol, propolis and lysozyme, performing temperature-constant blend cooling and then ultrasonic degassing, and allowing the mixture to stand to prepare a composite film liquid; and spreading the composite film liquid in a flat dish, and vacuum-drying the film liquid to prepare the edible package film. Through addition of the gelatin, the starch and the like bio-macro-molecular components, the film-forming performance of the chitosan is improved. The chitosan composite film is improved in mechanical performance, and meanwhile, with addition of the natural anti-bacterial components, propolis and lysozyme, which have synergistic effects, the chitosan composite film, as food packages, can inhibit reproduction of microorganisms and prolong the shelf life of the foods largely, so that the edible package film can be used in industrial production and has a wide application prospect.

Owner:上海翔伟印刷包装有限公司

Amphipathic octenyl succinic short-straight chain starch nano-particles and preparation method thereof

ActiveCN106580879AReduce lossesEfficient deliveryHydroxy compound active ingredientsPharmaceutical non-active ingredientsSide effectPullulanase

The invention relates to preparation process of amphipathic octenyl succinic short-straight chain starch nano-particles. The preparation process comprises the following steps: (1) performing enzymolysis on gelatinized starch by using pullulanase, and obtaining short straight chain starch; (2) preparing a short straight chain starch solution, performing gelatinization, adding an octenyl succinic anhydride solution which accounts for 25-100% of the weight of dry powder of short straight chain starch, and continuously stirring for 6-10 hours, so as to obtain a modified octenyl succinic short straight chain starch solution; preparing a 1-10mg / mL solution of the octenyl succinic short-straight chain starch, stirring for 6-10 hours at 37-40 DEG C, and cooling to the room temperature, thereby obtaining a amphipathic octenyl succinic short-straight chain starch nano-particle solution. The particle size of the nano-particles is within 5-100nm, the nano-particles are good in tissue adhesion property, are capable of wrapping hydrophobic active substances, are high in loading rate and low in cost, the conveying efficiency of lyophobic active components by gastrointestinal tracts can be improved, and the bioavailability of the nano-particles can be improved. The lyophobic active components can be protected, the stability of the lyophobic active components can be improved, and the release of adverse flavor can be shielded; in addition, the addition amount and the toxic and side effects of bioactive components can be effectively reduced.

Owner:QINGDAO AGRI UNIV

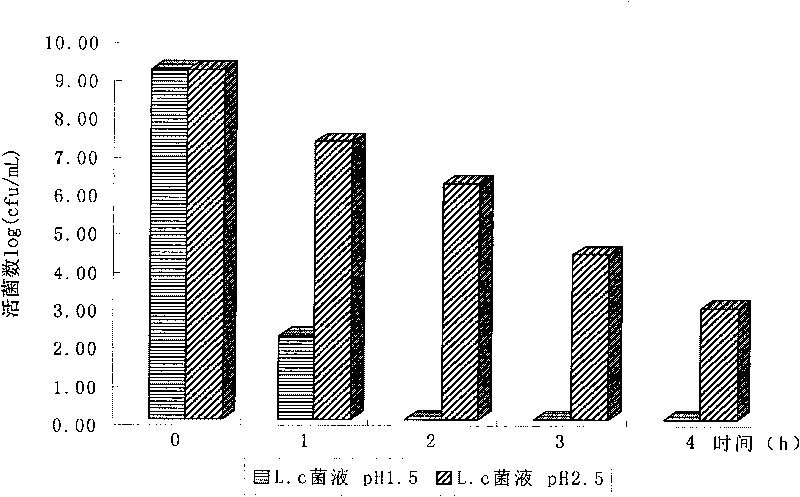

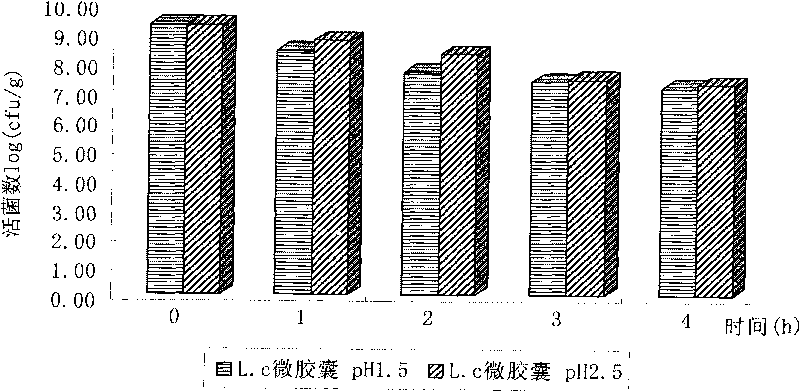

Method for preparing Lactobacillus casei microcapsule

InactiveCN101724622AImprove survival rateRich varietyMilk preparationMetabolism disorderIon exchangeStrong acids

The invention relates to a method for preparing a Lactobacillus casei microcapsule. 2-6 percent of microporous starch solution and 2-6 percent of sodium alginate solution are respectively taken as inner and outer wall materials of the microcapsule; the characteristic that small holes overspread on the surface of the microporous is utilized to absorb a bacteria solution; then sodium alginate and calcium chloride are utilized to generate ion exchange to form a sodium alginate coating; and double layer embedment is carried out on Lactobacillus casei. After the Lactobacillus casei microcapsule is dried at the temperature of 2-6 DEG C for 36-72h, the obtained microcapsule has stronger acid resistance and cholate resistance and high storage stability, i.e. the microcapsule is not dissolved in simulated gastric fluid basically and does not leak but is immediately disintegrated in simulated intestinal fluid; after the Lactobacillus casei microcapsule is treated in 0.3 percent of cholate solution for 1h, the thalli survival rate is 88 percent, and the number of viable bacteria is increased to 1.24*109cfu / g from 5.80*109cfu / g after the Lactobacillus casei microcapsule is stored at the temperature of 4 DEG C for 1 month. The invention greatly increases the survival rate of Lactobacillus casei in products and the use ratio of Probiotics and also enriches the variety of the Probiotics microcapsule.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

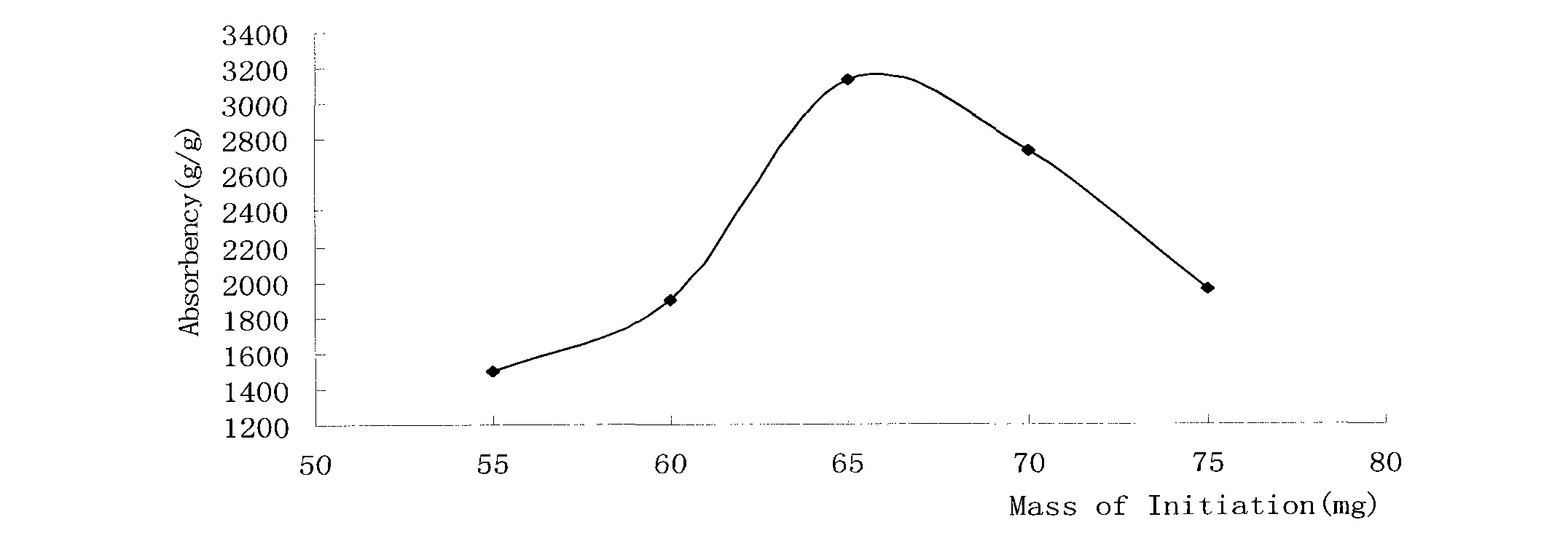

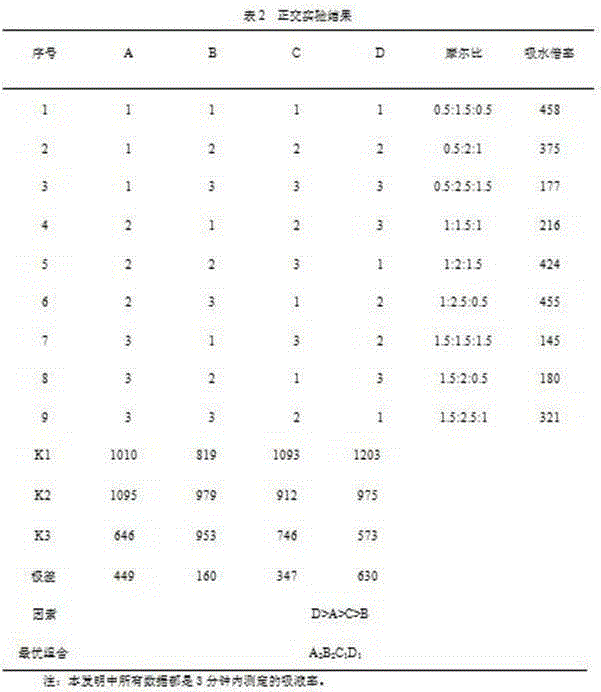

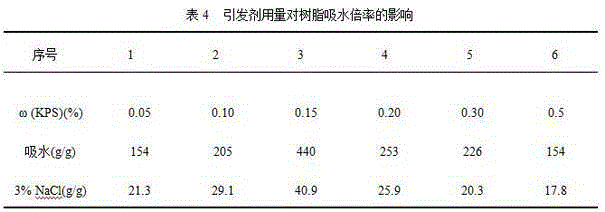

Preparation method of superabsorbent resin

The present invention discloses a preparation method of a superabsorbent resin containing starch grafted acrylic acid (AA), acrylamide (AM) and 2-acrylamido-2-methyl propane sulfonic acid (AMPS). The preparation method of the superabsorbent resin is as below: adding an initiator into gelatinized starch to conduct initiation; then neutralizing the AA and AMPS solution with NaOH or KOH solution under the condition of sufficient cooling; then adding the monomer mixture of AA, AM and AMPS into the starch solution to conduct a starch graft polymerization reaction. The method uses starch as a graft monomer material, which is widely available, inexpensive, biodegradable, environmentally friendly and easy to operate and more friendly to the environment; the obtained resin has good salt resistance and high water absorption rate, and can reach imbibition equilibrium within 5 min.

Owner:LANZHOU UNIVERSITY +1

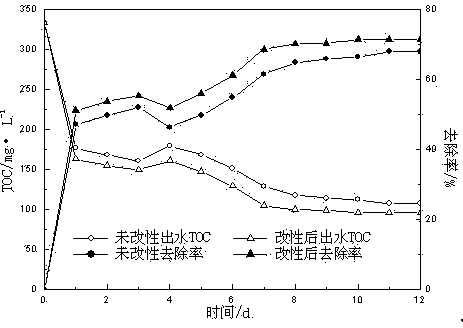

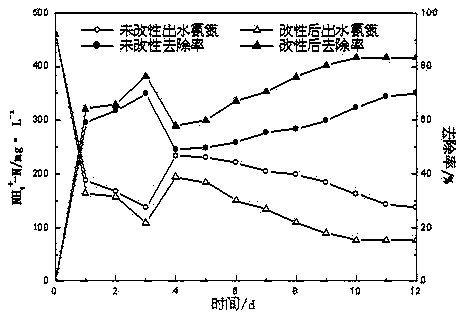

Preparation method of hydrophilic polymer-modified polyurethane foaming plastic carrier

ActiveCN103627015ASimple processEasy to operateBiological water/sewage treatmentCross-linkPolymer modified

The invention discloses a preparation method of a hydrophilic polymer-modified polyurethane foaming plastic carrier. The preparation method comprises steps of: 1) cutting polyurethane flexible foam into pieces; 2) preparing an aqueous starch solution having a proper concentration, an aqueous sodium carboxymethylcellulose solution having a proper concentration, a N,N-dimethyl formamide solution of polybutanimide having a proper concentration; 3) dipping polyurethane foaming plastic into the aqueous starch solution, the aqueous sodium carboxymethylcellulose solution and the N,N-dimethyl formamide solution of the polybutanimide; and then transferring the polyurethane foaming plastic into an aqueous cross-linking agent solution and heating; and 4) taking the foaming plastic out, washing and drying. The preparation method is simple in technology and convenient in operation. A microbial carrier which has an advantage of cost performance and is used for sewage treatment can be obtained after modification.

Owner:山东青素环保材料有限责任公司

Method for preparing corn starch

The invention provides a method for preparing corn starch, which comprises the following steps of: a) soaking corn, coarsely crushing the corn, and separating germs to obtain coarse starch milk; b) finely crushing the coarse starch milk, and separating proteins and fibers to obtain starch milk; c) adding aqueous alkali into the starch milk to form starch solution with the temperature of between 40 and 60 DEG C; and d) filtering the starch solution to obtain amylose starch and amylopectin. In the method, after the corn starch milk is prepared by directly separating germs and proteins, the amylose starch and the amylopectin are filtered and separated by utilizing the different solution natures of the amylose starch and the amylopectin in hot water that the amylose starch is dissolved in the aqueous alkali and the amylopectin is insoluble. The amylose starch and the amylopectin are directly separated in the technological process of preparing the corn starch without secondary processing, so the method has the advantages of simple process and lower cost.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

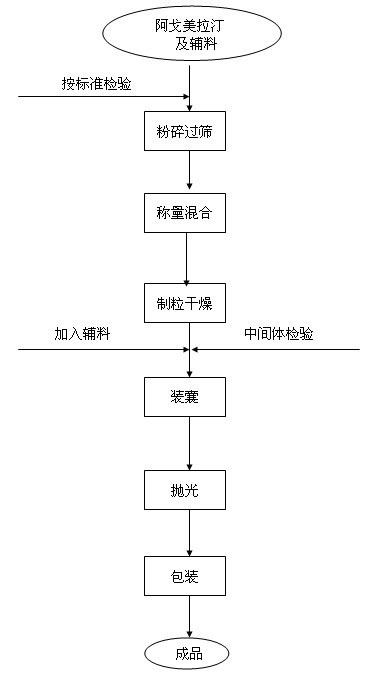

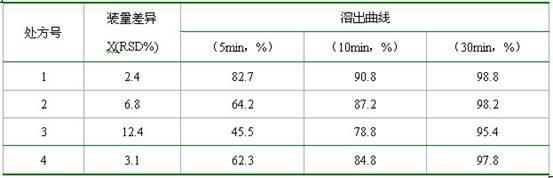

Stable Agomelatine capsule medicine composition

InactiveCN101991559AMask the smellMask bitternessOrganic active ingredientsNervous disorderMannitolBioavailability

The invention discloses a stable Agomelatine capsule medicine composition which is characterized in that 1000 capsules comprise the following components of 15-30g of Agomelatine, 70-140g of mannitol, 0.5-1g of superfine silica powder and a proper amount of 10 percent pre-gelatinized starch. The invention also relates to a preparation method of an Agomelatine capsule. The Agomelatine capsule prepared by adopting the formula and the preparation method provided in the invention has the advantages of good flowability, good dissolution rate, small content uniformity, high bioavailability and good treatment effect.

Owner:TIANJIN HANKANG PHARMA BIOTECH

Disinfectant health-care aromatic hand paper towel and preparation method thereof

ActiveCN104846685ALow costReduce manufacturing costCosmetic preparationsToilet preparationsAntibacterial agentAntibacterial property

The invention discloses a disinfectant health-care aromatic hand paper towel and a preparation method thereof. The hand paper towel comprises the following components: softwood sulfite pulp, bamboo-pulp paper fiber, straw pulp, a cationic starch solution, a wet strength agent, a powerful antibacterial agent, an aromatic agent and titanium dioxide, wherein the wet strength agent is polyethylene ethylamine resin, the powerful antibacterial agent is composed of pure-oxygen-based quaternary ammonium salt, Sophora flavescens, common cnidium fruit, honeysuckle, borneol, isatis root, ethanol and distilled water, and the aromatic agent is composed of chitosan, ethanol, essence extract, deionized water, glycerin and triphosphoric acid. The prepared disinfectant health-care aromatic hand paper towel in the invention has the characteristics of no toxicity, harmlessness, environmental protection, highly-efficient antibacterial property and emission of aroma, can efficiently avoid contact-type cross infection with bacteria in public places and is safer and more secure to use.

Owner:ZHEJIANG HUACHUAN IND GRP

Novel solid acid catalyst preparation method

InactiveCN101249447AEasy to recycleSimple preparation processPreparation by ester-hydroxy reactionOrganic compound preparationPorosityBiodiesel

The invention discloses a method for preparing a novel solid acid catalyst. The method adopts porous high temperature-resistance media as carriers and includes adding soluble sugar or starch solution; evaporating to dryness for a plurality of times; igniting; washing in water; drying; reacting with concentrated sulfuric acid; washing until a neutral condition with hot water; filtering; and drying to obtain the novel solid acid catalyst. The obtained solid acid catalyst is linked with sulfonic groups and loaded on the porous high temperature-resistance medium based on hydrophobic amorphous carbon structure prepared by calcining different glycosyl groups, and has the advantages of porosity, large specific surface area, even particle size and easy separation and filling into a tubular reactor. The catalyst has an activity higher than the conventional solid acid catalyst which can be reutilized and easily recovered and is an excellent catalyst for preparing biodiesel oil from waste edible oil such as trench oil and acidification oil.

Owner:HUAQIAO UNIVERSITY

Starch-based porous hydrogel and preparation method thereof

The invention discloses a starch-based porous hydrogel prepared from a starch liquid, an initiating agent, a monomer and a cross-linking agent. The preparation method comprises the following steps: adding the initiating agent, the monomer and cross-linking agent into the starch liquid; after each component is added, mixing uniformly, and heating for full reaction, thereby obtaining a starch-based hydrogel; and washing and swelling the obtained starch-based hydrogel, immerging the washed and swelled starch-based hydrogel into an organic solvent-water mixed solution with specific components so as to perform gradient solvent exchange, and drying, thereby obtaining the starch-based porous hydrogel. The starch-based porous hydrogel has the characteristics of simple and convenient preparation method, good open pore property, controllable porous structure and stable three-dimensional structure.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for producing high intensity modified starch

The present invention provides a method for producing high intensity modified starch, including a neutralization reaction, casting stock and precipitating; a clarified starch solution is sucked into a reaction tank, aqueous vapor is injected into the reaction tank, then the clarified starch solution is heated until 65 DEG C, during which agitating the solution continually to play a function of conditioning and high-temperature enzyme extinguishing, the heating and agitating time is from 20 to 40 minutes; then wood carbon dust is added to discolor and desludge; a clear starch solution will be obtained after filtering by a compressor; the impurity in the starch is removed step by step by steps of concentrating, batching and high speed centrifugation, the technique is reasonable, the high intensity modified starch has high purity and adequate quality, and the product grade is improved.

Owner:界首市鸿顺生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com