Method for preparing fibroin nano-silver hydrosol

A silk protein and hydrosol technology, applied in the field of nanomaterials, can solve problems such as resource waste and environmental pollution, and achieve the effects of wide range of raw materials and simple and effective preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Disperse 0.2g of cornstarch in 10ml of deionized water, stir at 80°C until gelatinized to obtain a cornstarch solution, add it to 10ml of silver nitrate solution with a concentration of 0.05mol / L, and mix evenly to obtain a starch-silver nitrate binary compound solution.

[0027] Mix papain and sericin solution at a mass ratio of 1:20, adjust the pH value and temperature to the optimum conditions for the activity of the corresponding protease, and stop the reaction after hydrolyzing for 40 minutes under stirring conditions. The pore filter membrane is filtered, and the filtrate is concentrated and dried to obtain sericin peptide powder with a molecular weight of 1-5 KDa.

[0028] Take 2.4g small molecule sericin peptide powder and dissolve it in 120ml deionized water to obtain a sericin peptide solution with a concentration of 2 wt %, add it to the above-mentioned starch-silver nitrate composite solution, and mix evenly to obtain sericin peptide - The ternary composite...

Embodiment 2

[0030] Disperse 0.15g of tapioca starch in 5ml of deionized water, stir at 90°C until gelatinized to obtain a tapioca starch solution, add it to 20ml of silver nitrate solution with a concentration of 0.2mol / L, mix well to obtain starch-silver nitrate binary compound solution.

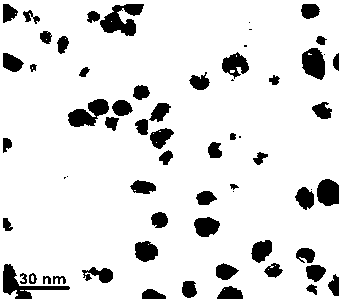

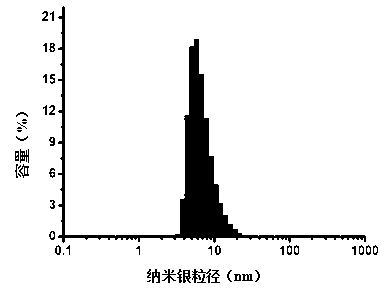

[0031] Take 3g of small-molecule silk fibroin peptide powder with a molecular weight of 1-5KDa and dissolve it in 100ml of deionized water to obtain a silk fibroin peptide solution with a concentration of 3wt%. Add it to the above-mentioned starch-silver nitrate composite solution and mix evenly to obtain A ternary composite solution of silk fibroin peptide-starch-silver nitrate, adjusting the pH value of the solution to 9.2, and stirring at 70°C for 180 minutes to obtain a nano-silver hydrosol with a particle size of 3-25nm.

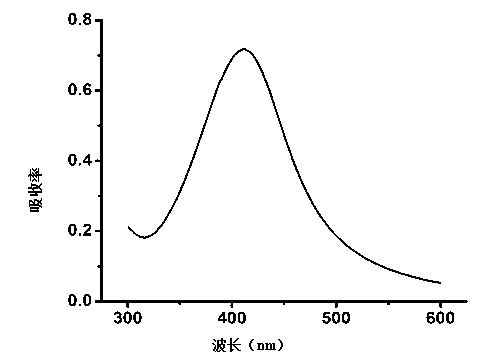

[0032] See attached figure 1 , which is the ultraviolet-visible absorption spectrum (UV-Vis figure) of the fibroin nano-silver hydrosol obtained in this embodiment, by figure ...

Embodiment 3

[0036]Disperse 0.1g of wheat starch in 10ml of deionized water, stir at 90°C until gelatinized to obtain a wheat starch solution, add it to 20ml of silver nitrate solution with a concentration of 0.1mol / L, mix well to obtain starch-silver nitrate binary compound solution. Take 1.2g of small-molecule sericin peptide with a molecular weight of 1-5KDa and the composite powder of small-molecule silk fibroin peptide and dissolve it in 60ml of deionized water to obtain a silk protein peptide solution with a concentration of 2 wt%, and add it to the above-mentioned In the starch-silver nitrate composite solution, mix evenly to obtain a ternary composite solution of silk protein peptide-starch-silver nitrate, adjust the pH value of the solution to 9.5, stir at 80°C for 120min, and obtain a nano-silver hydrosol with a particle size of 2-20nm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com