Patents

Literature

349 results about "Ternary complex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ternary complex is a protein complex containing three different molecules that are bound together. In structural biology, ternary complex can also be used to describe a crystal containing a protein with two small molecules bound, for example cofactor and substrate; or a complex formed between two proteins and a single substrate. In Immunology, ternary complex can refer to the MHC–peptide–T-cell-receptor complex formed when T cells recognize epitopes of an antigen. Some other example can be taken like ternary complex while eukaryotic translation, in which ternary complex is composed of eIF-3 & eIF-2 + Ribosome 40s subunit+ tRNAi. A ternary complex can be a complex formed between two substrate molecules and an enzyme. This is seen in multi-substrate enzyme-catalyzed reactions where two substrates and two products can be formed. The ternary complex is an intermediate between the product formation in this type of enzyme-catalyzed reactions. An example for a ternary complex is seen in random-order mechanism or a compulsory-order mechanism of enzyme catalysis for multi substrates.

Compositions and methods for detection and isolation of phosphorylated molecules

ActiveUS7102005B2Simplifies subsequent analysisSilicon organic compoundsOther chemical processesTernary complexPhosphorylation

Owner:MOLECULAR PROBES

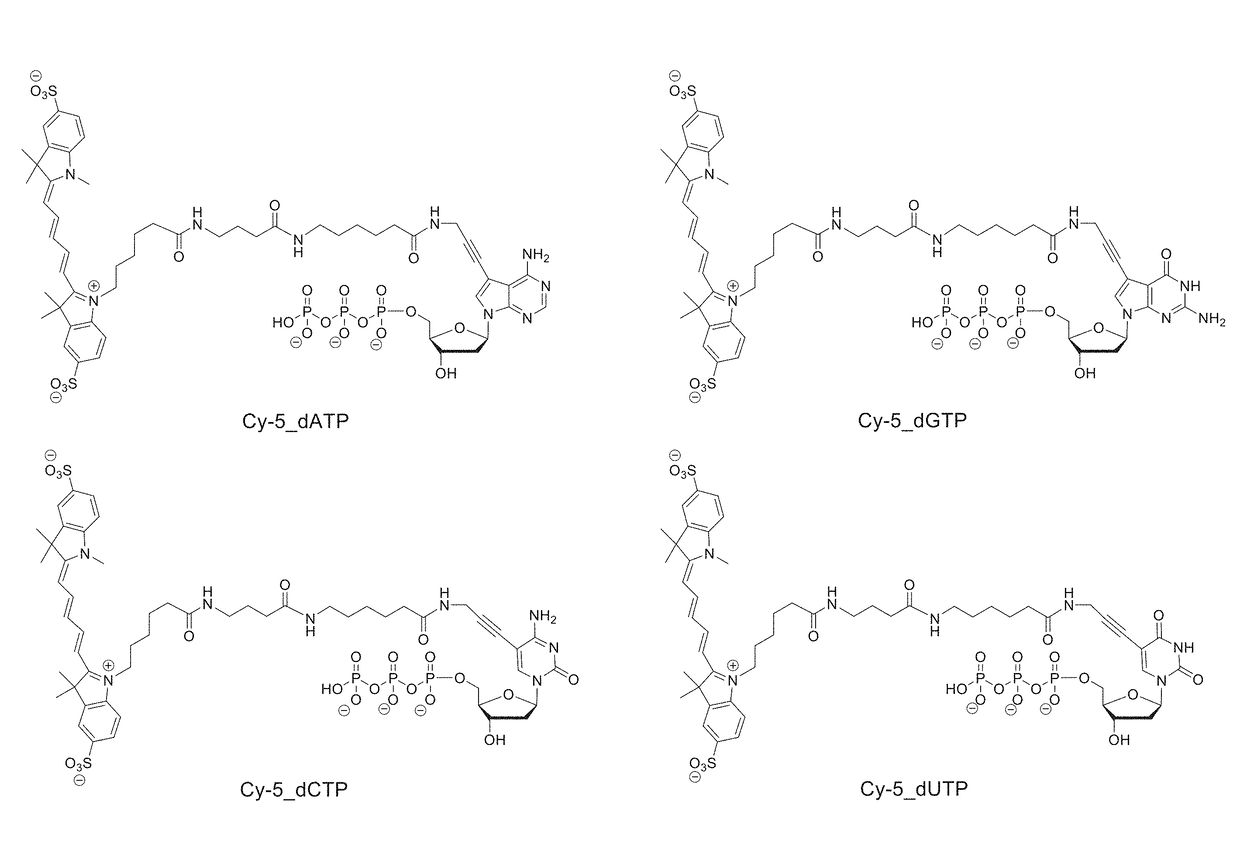

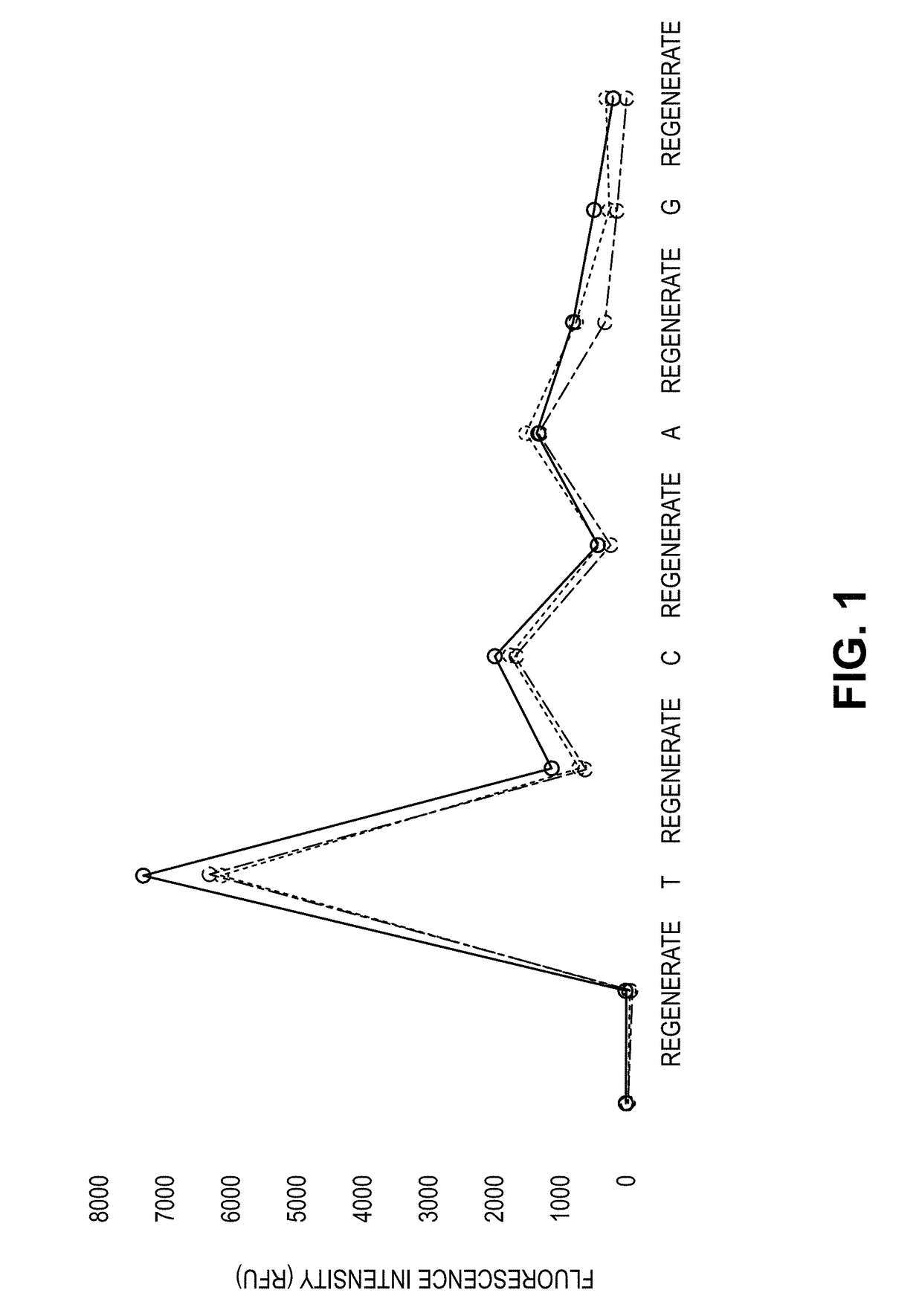

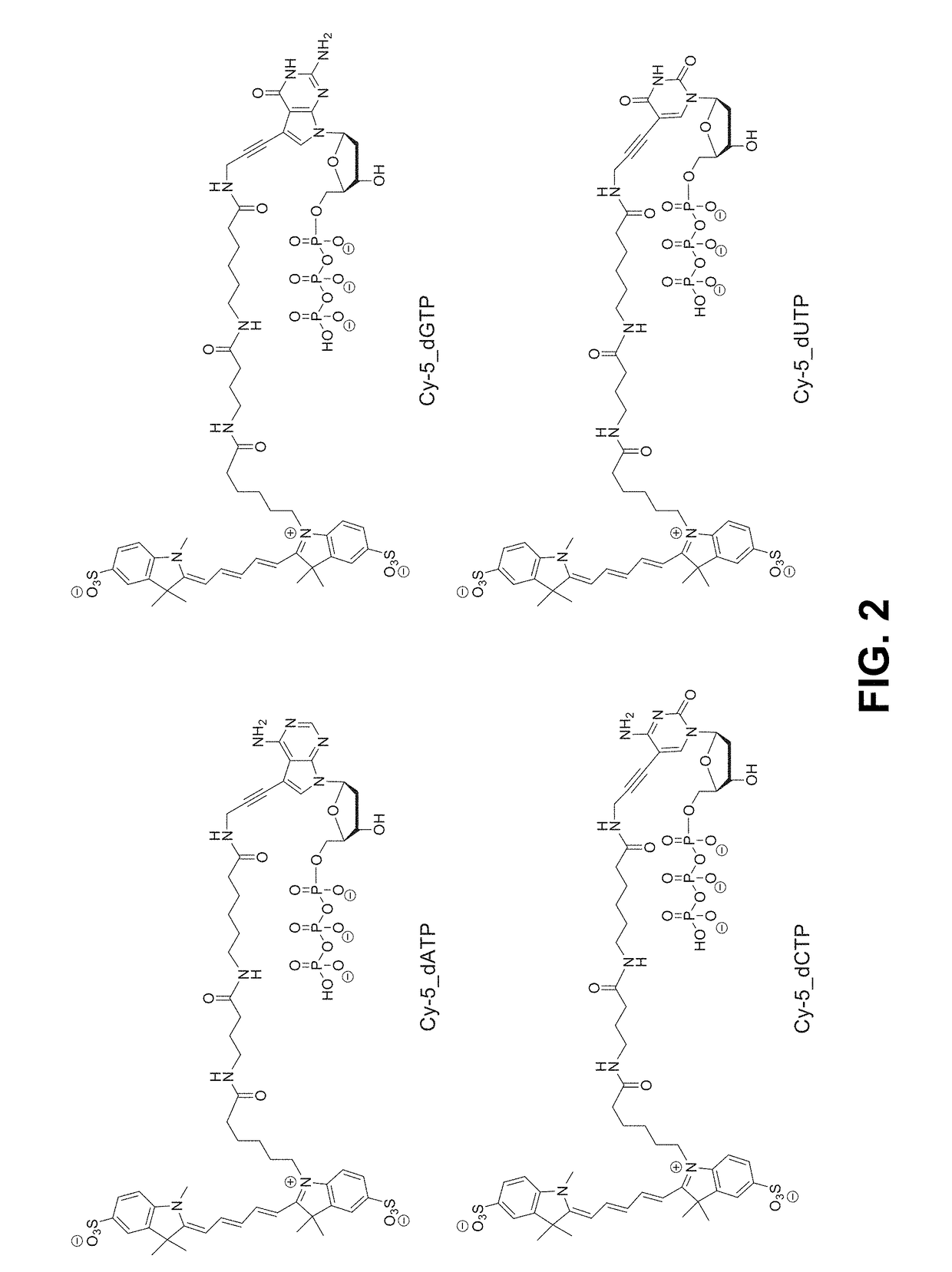

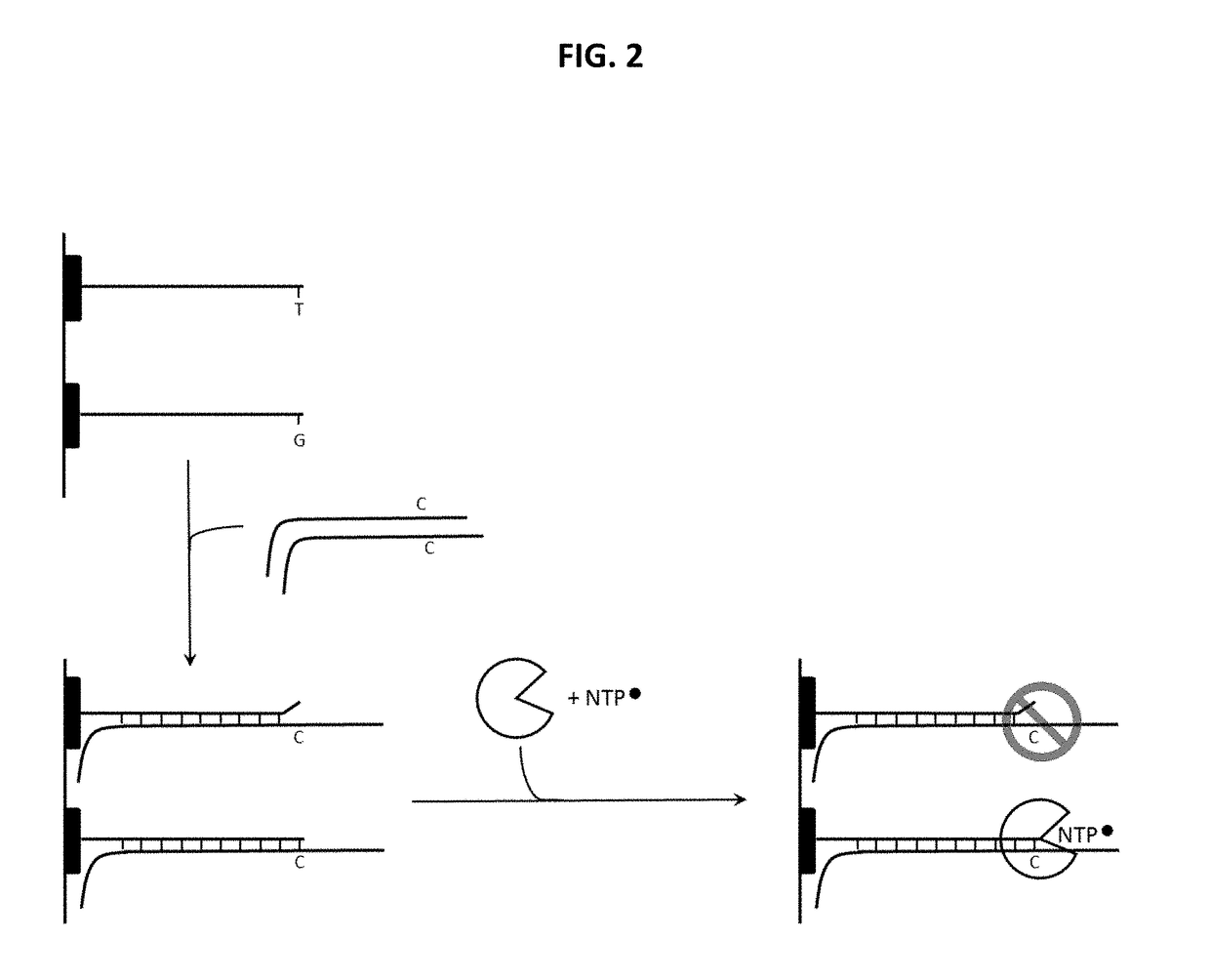

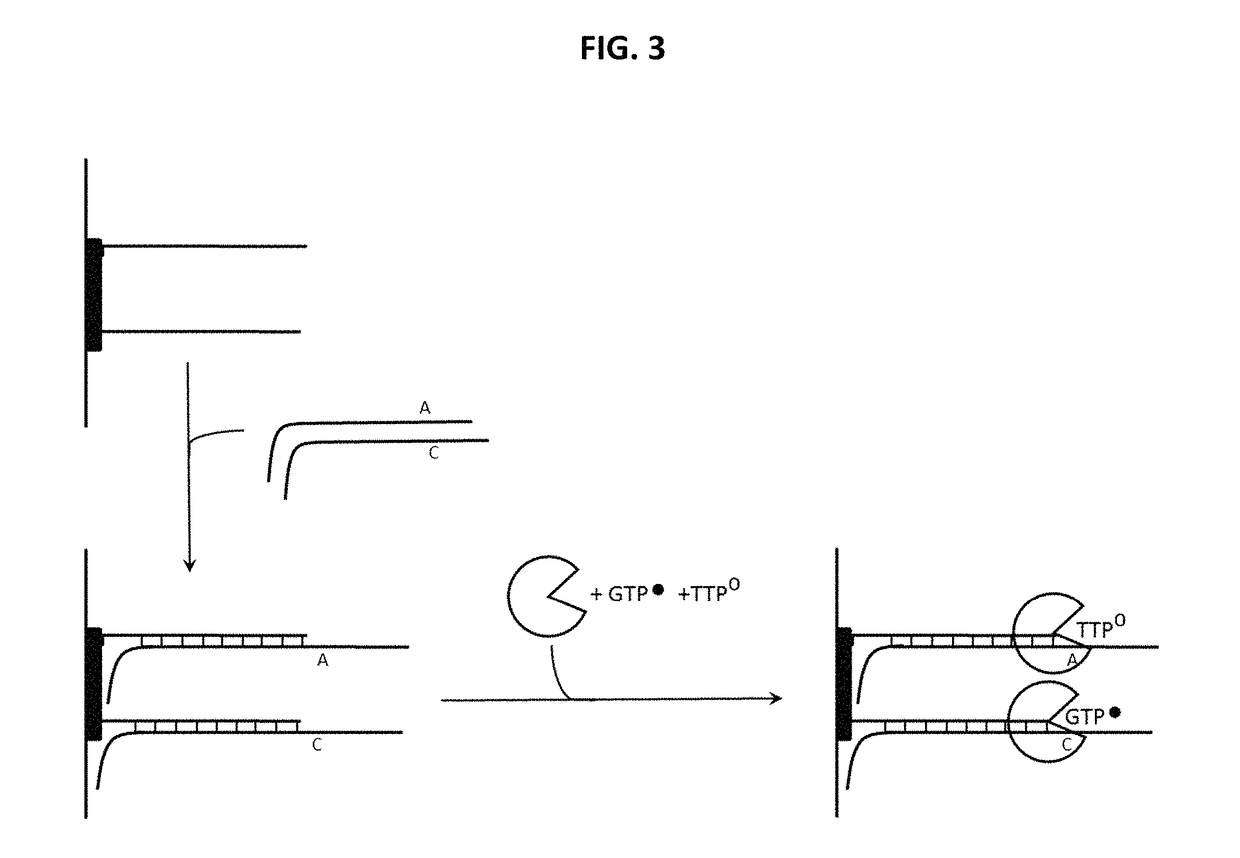

Process for cognate nucleotide detection in a nucleic acid sequencing workflow

Method and composition for identifying cognate nucleotides in a Sequencing By Binding™ procedure, wherein one or more labeled nucleotides are detected in ternary complexes but never incorporated. Labeled nucleotides can be incorporable nucleotides that contact preformed blocked primed template nucleic acids. Alternatively, labeled nucleotides are labeled non-incorporable nucleotides. Labeled nucleotides, including labeled non-incorporable nucleotides, can be detected in ternary complexes in the same reaction mixture that incorporates a reversible terminator nucleotide to create a blocked primed template nucleic acid. Detection of ternary complexes can take place in the presence of a catalytic metal ion.

Owner:PACIFIC BIOSCIENCES

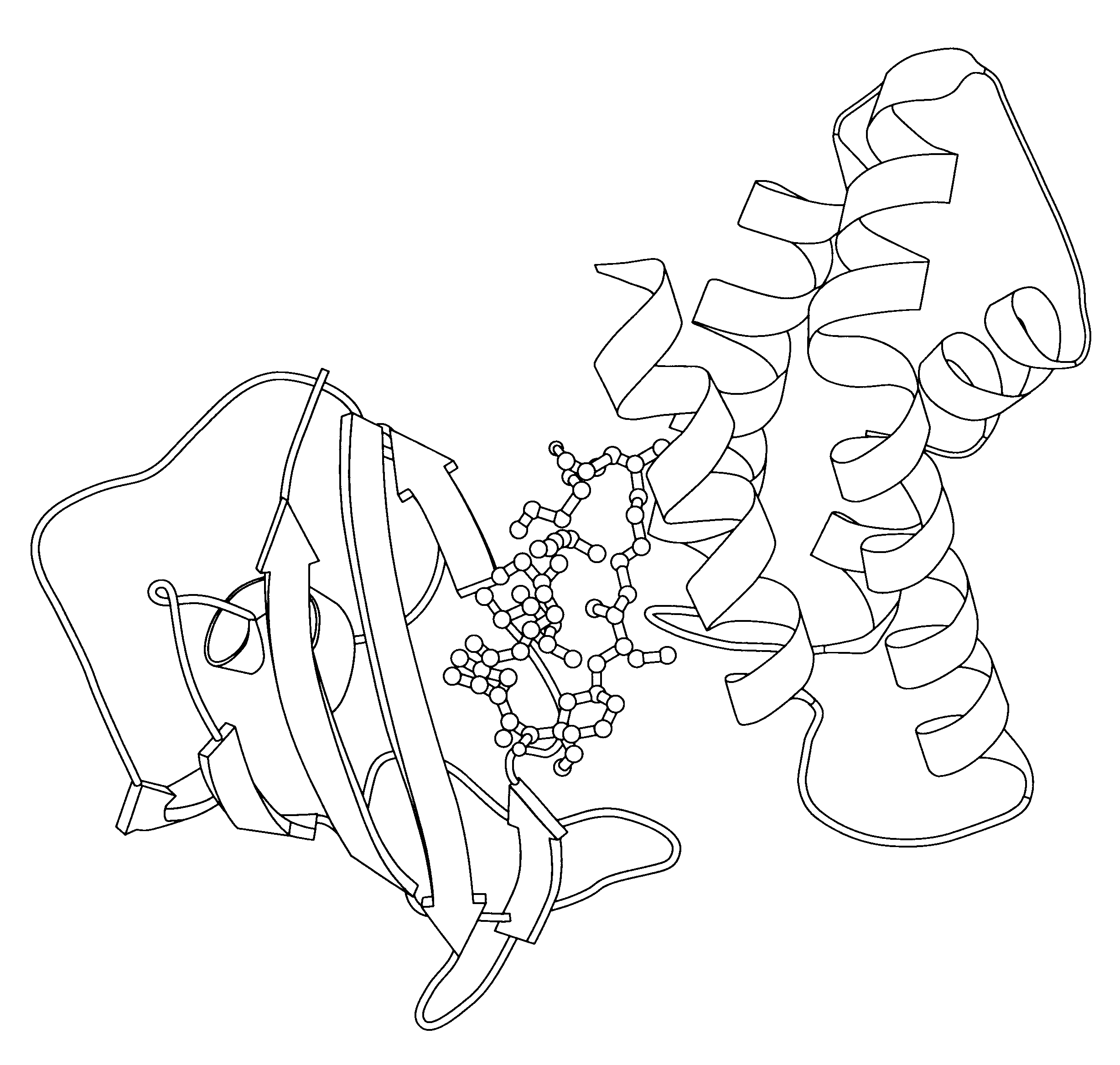

Crystalline frap complex

InactiveUS6532437B1Reduce the numberHigh resolutionTransferasesDigital computer detailsCrystallographyTernary complex

The invention relates to the human protein FRAP, and in particular to the FKBP12-rapamycin binding domain thereof and to the ternary complex formed by the FRB domain, rapamycin and FKBP12. A new crystalline composition comprising the ternary complex, coordinates defining its three dimensional structure in atomic detail, and uses thereof are disclosed.

Owner:CORNELL RES FOUNDATION INC

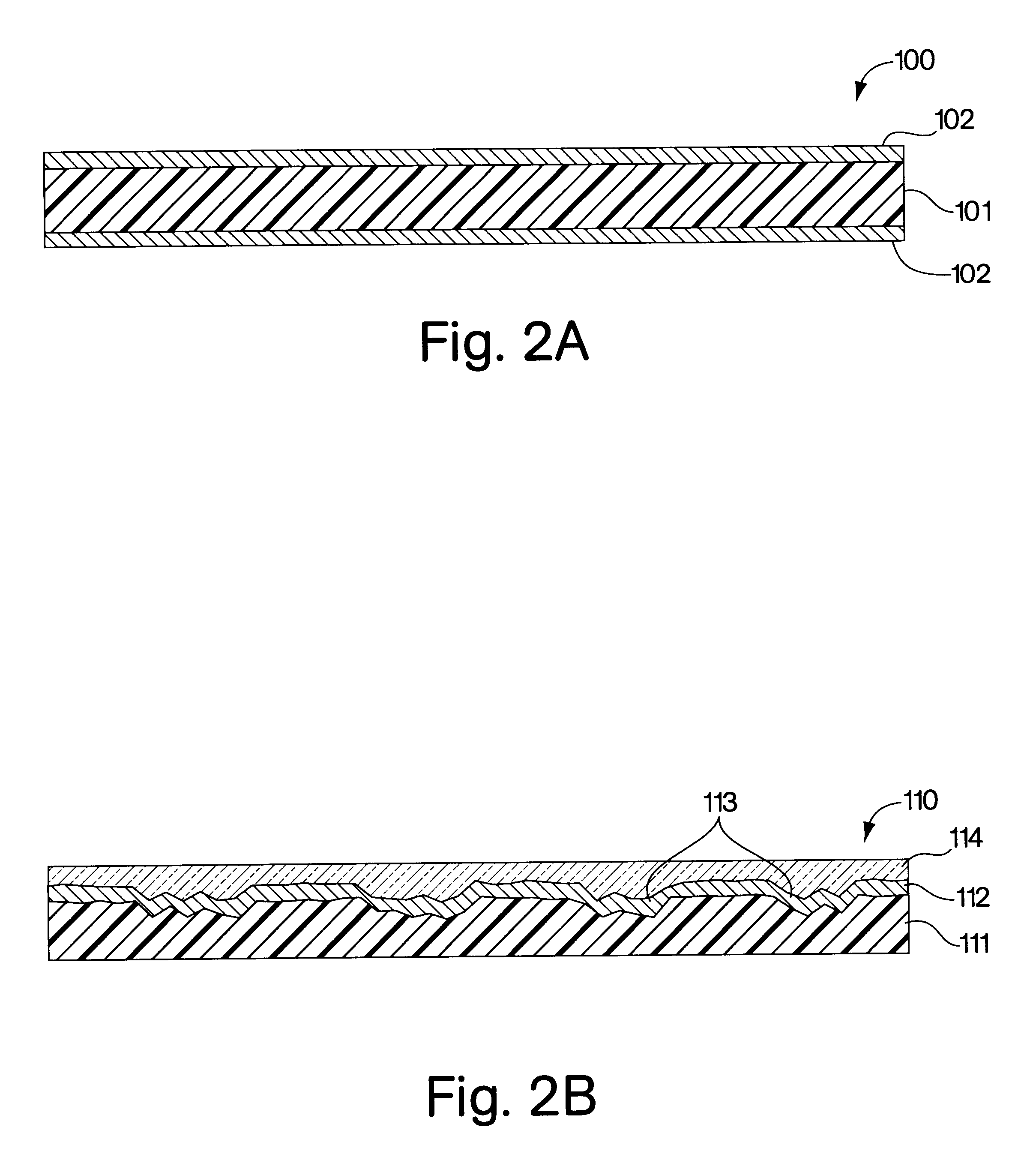

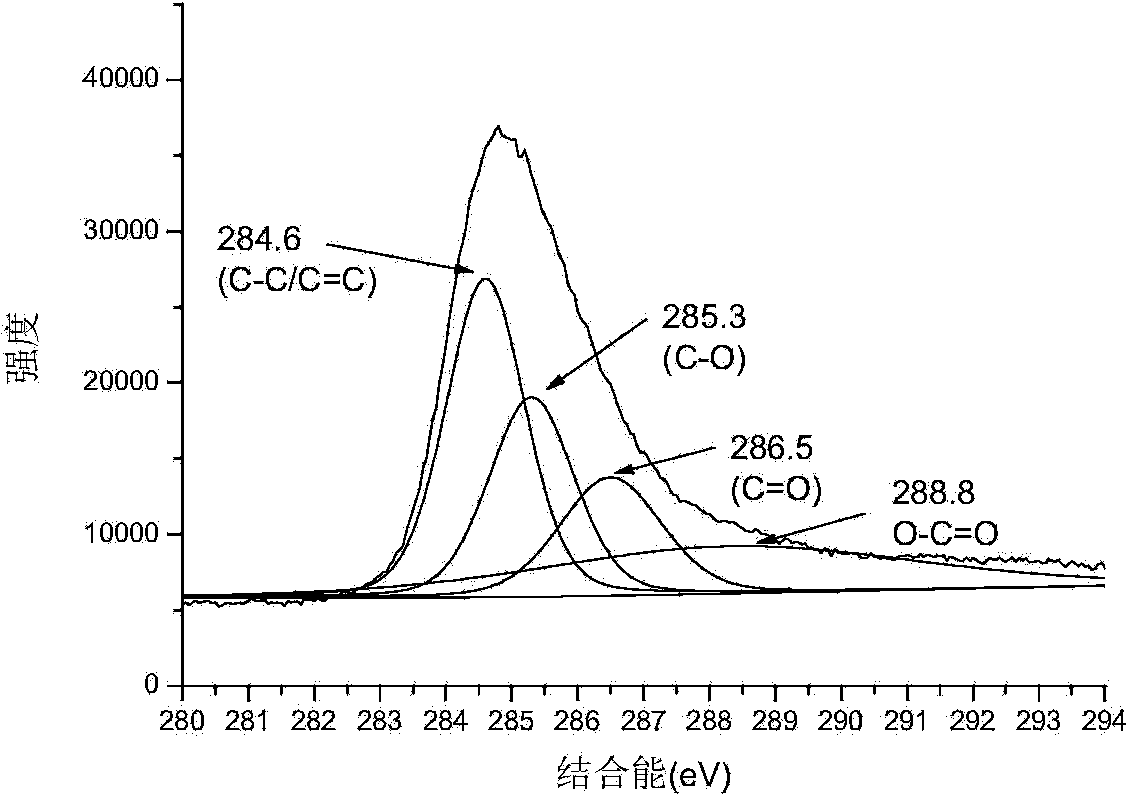

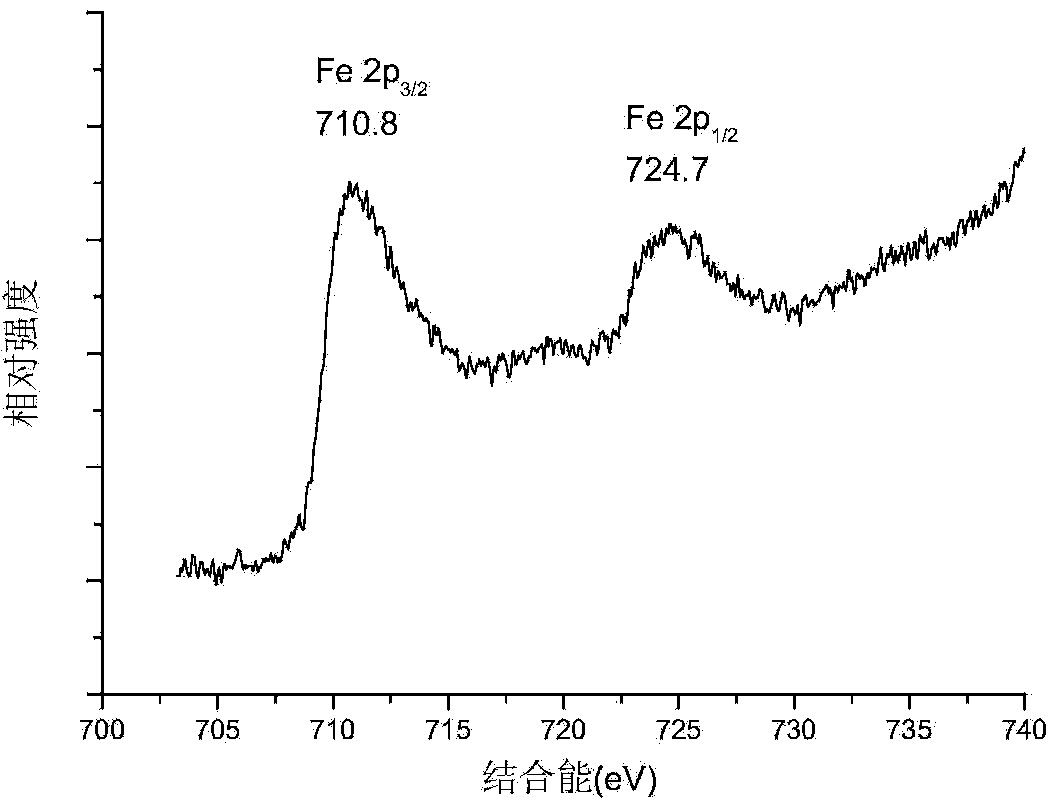

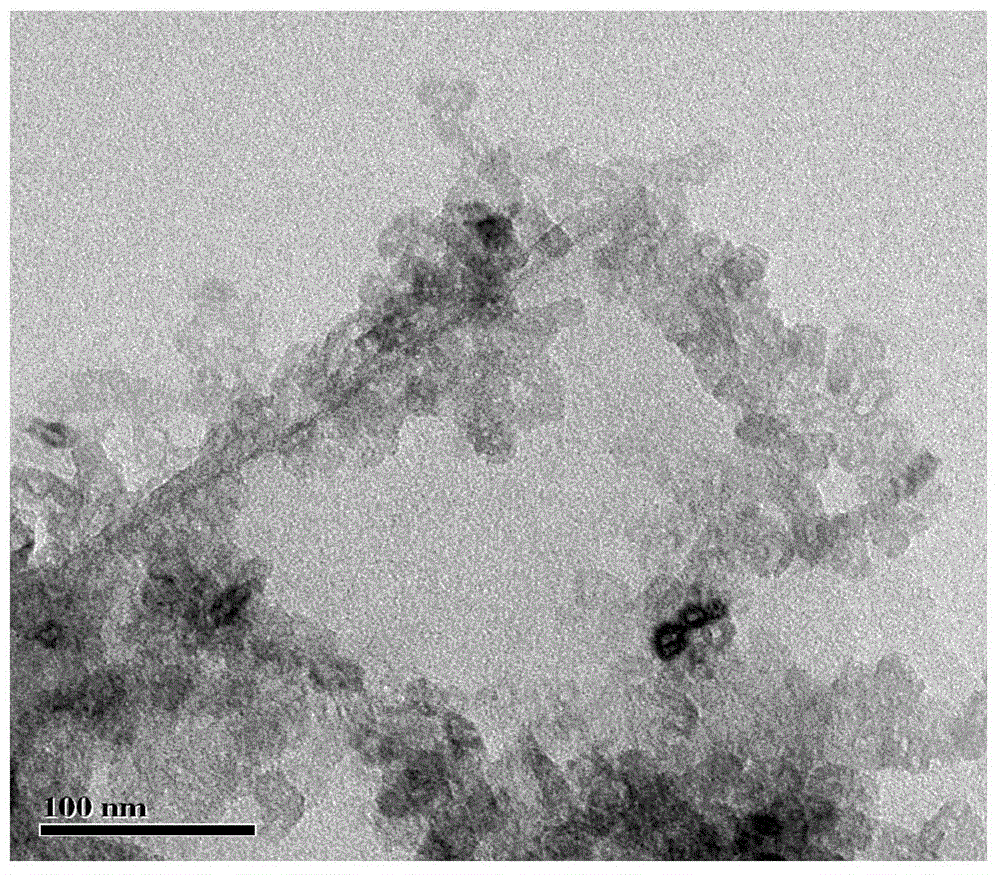

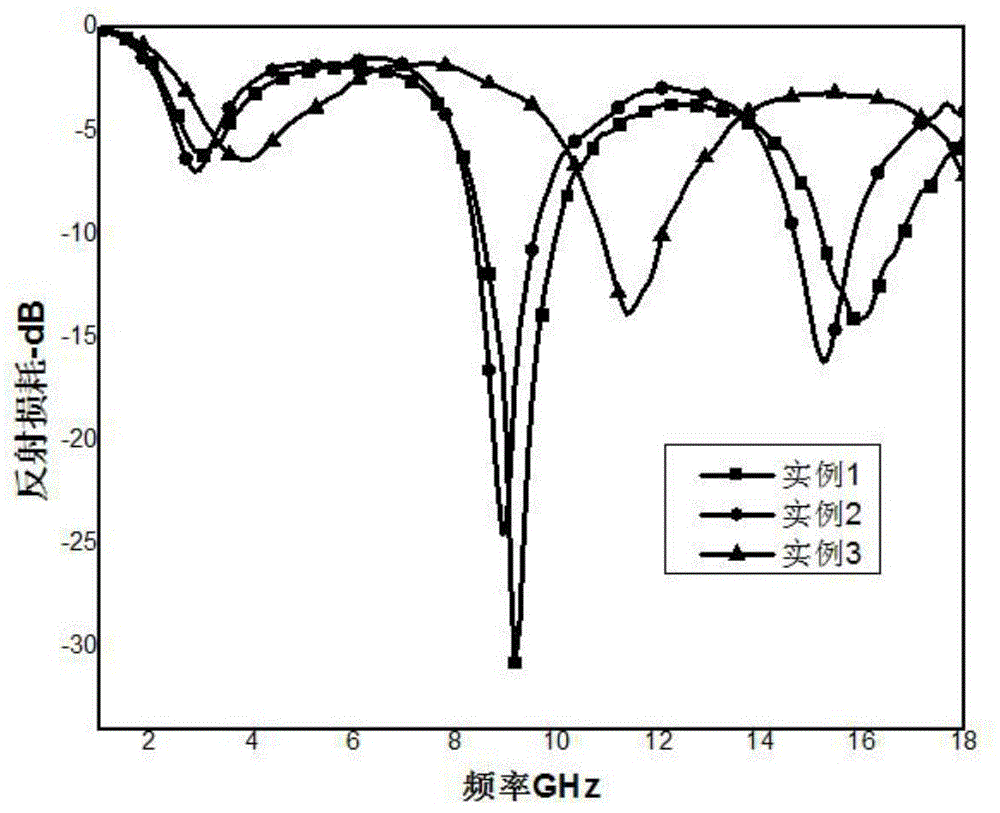

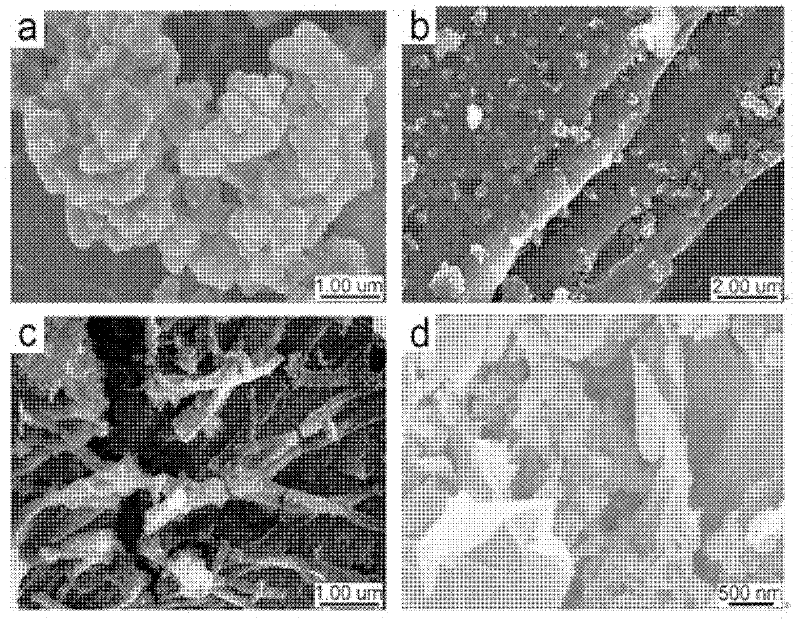

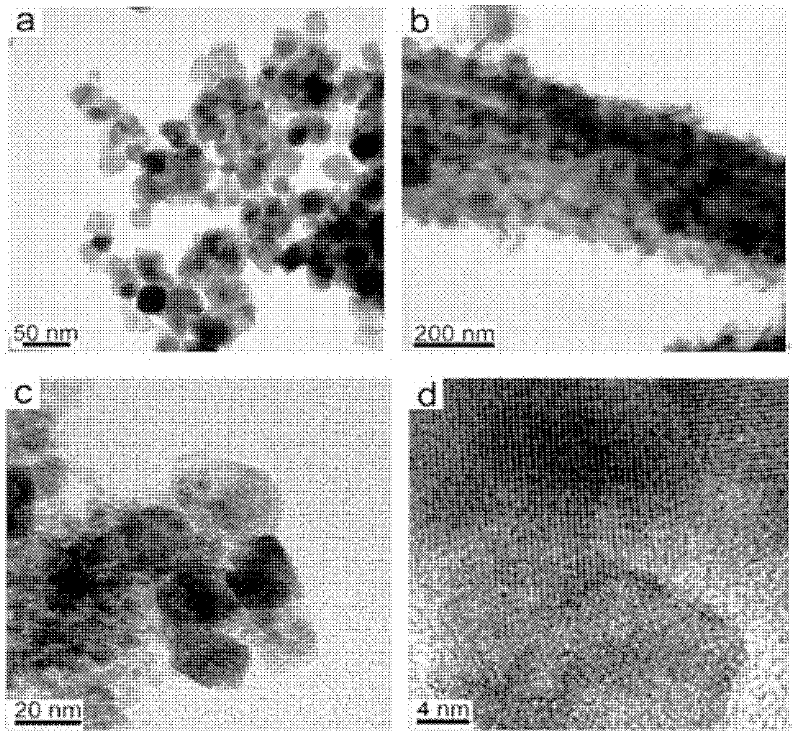

Polyaniline/oxidized graphene/ferriferrous oxide absorbing material and preparation method

InactiveCN104163919AStrong dielectric loss performanceHigh surface energyMaterials preparationTernary complex

The invention belongs to the field of electromagnetic wave absorbing material preparation and relates to a polyaniline / oxidized graphene / ferriferrous oxide composite material and its preparation method. The preparation method comprises the following steps: (1) preparing graphite oxide; (2) preparing ferriferrous oxide nanoparticles; (3) preparing a polyaniline / oxidized graphene / ferriferrous oxide ternary complex; and (4) weighing the polyaniline / oxidized graphene / ferriferrous oxide ternary complex and paraffin, and uniformly mixing to obtain the polyaniline / oxidized graphene / ferriferrous oxide absorbing material. The material provided by the invention has characteristics of low cost, simple preparation technology, strong electromagnetic wave absorbing capability, wide absorption band, low density and the like, has good electromagnetic property, and has important application value in the field of microwave absorption and electromagnetic shielding.

Owner:UNIV OF SCI & TECH BEIJING

Structure-based design and synthesis of FGF inhibitors and FGF modulator compounds

InactiveUS20050187150A1Promotes dimerizationTreat and ameliorate disorderCompound screeningApoptosis detectionTernary complexFGF Receptor

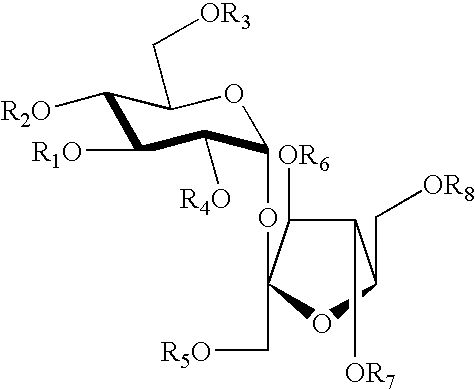

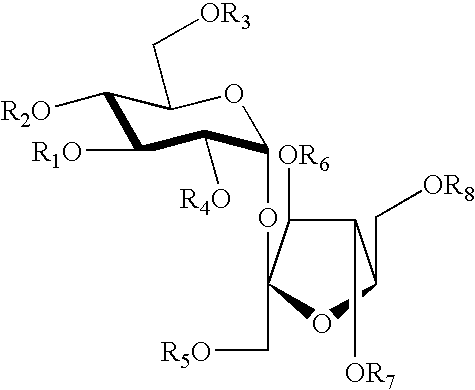

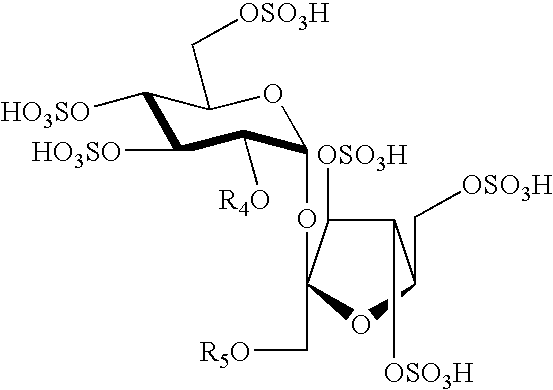

The present invention provides methods and compositions for modulating FGF-signaling and activities associated therewith, such as mitogenesis and angiogenesis. In particular, the invention provides crystal structure coordinates for a ternary complex of an FGF receptor, and FGF ligand, and a third compound, sucrose octasulfate, that binds to the FGF receptor and ligand to promote formation and dimerization of the ternary complex. Screening methods are provided by which novel agonists and antagonist for FGF-mediating signaling and activities may be identified using these crystal structure coordinates. Exemplary compounds are also provided that have novel utilities as agonists or antagonists of FGF-mediated signaling and activites.

Owner:NEW YORK UNIV +1

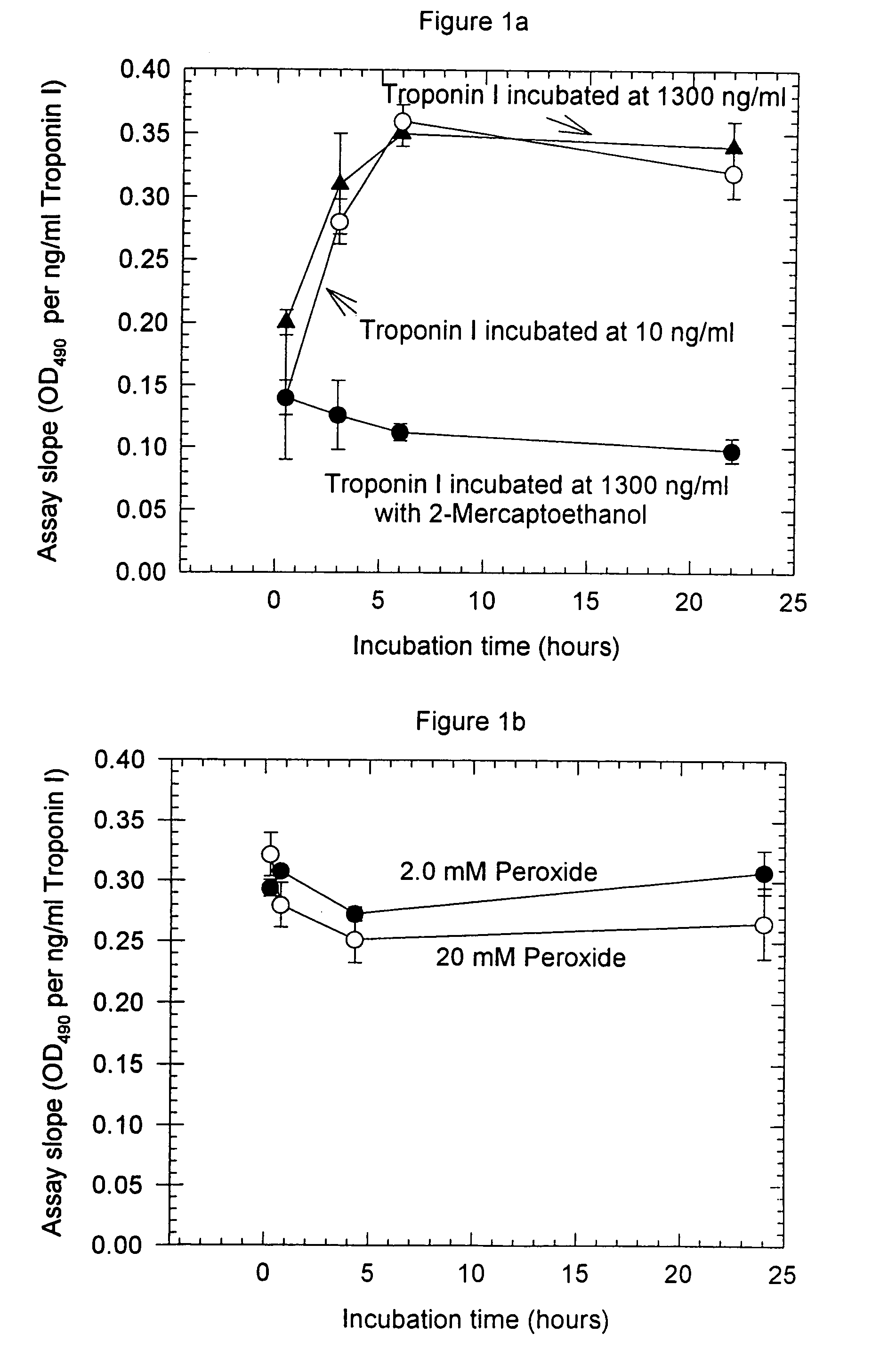

Methods for the assay of troponin I and T and complexes of troponin I and T and selection of antibodies for use in immunoassays

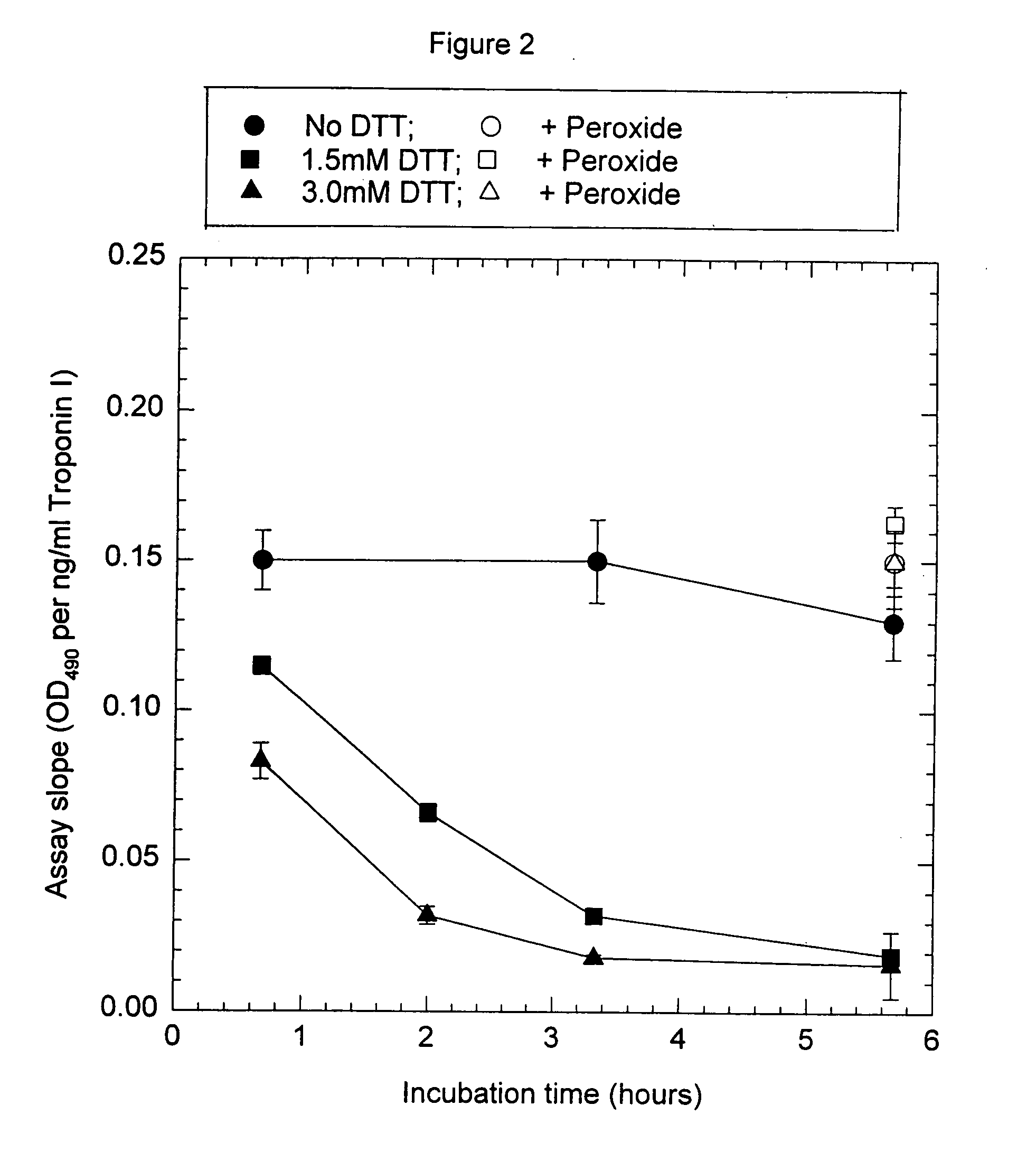

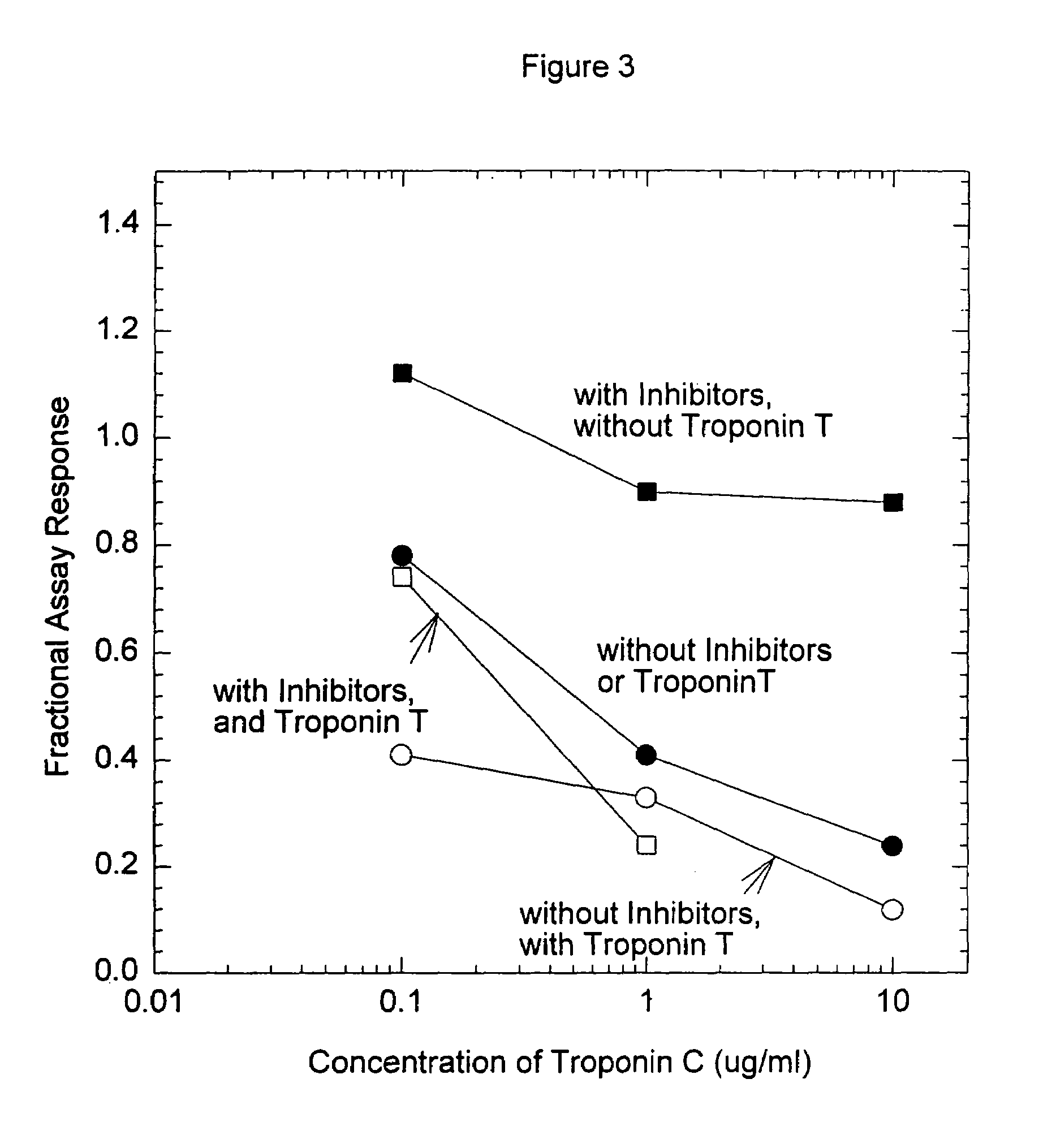

InactiveUS6939678B1Promote recoveryChemiluminescene/bioluminescenceEnzymologyCysteine thiolateBlood plasma

Assay systems and specialized antibodies for the detection and quantitation of troponin I and troponin T in body fluids as an indicator of myocardial infarction. Since troponin I and T exist in various conformations in the blood, the ratios of the monomeric troponin I an T and the binary and ternary complexes, as well as which form of troponin present in the blood, may be related to the metabolic state of the heart. Disclosed is a system to determine the presence of a troponin form or a group of troponin forms in a sample of whole blood, serum or plasma.Disclosed is a stabilized composition of troponin; the stabilized composition can comprise a stabilized composition of troponin I, wherein the troponin I is oxidized, the troponin I can be unbound or the troponin I can be in a complex.Disclosed is a method for improving the recovery of troponin I or T from a surface used in immunoassays.Also disclosed are antibodies which recognize, unbound troponin forms, the forms of troponin in binary complexes, the ternary complex of troponin I, T and C, and the conformations of troponin I having intramolecularly oxidized and reduced cysteines.

Owner:BIOSITE INC

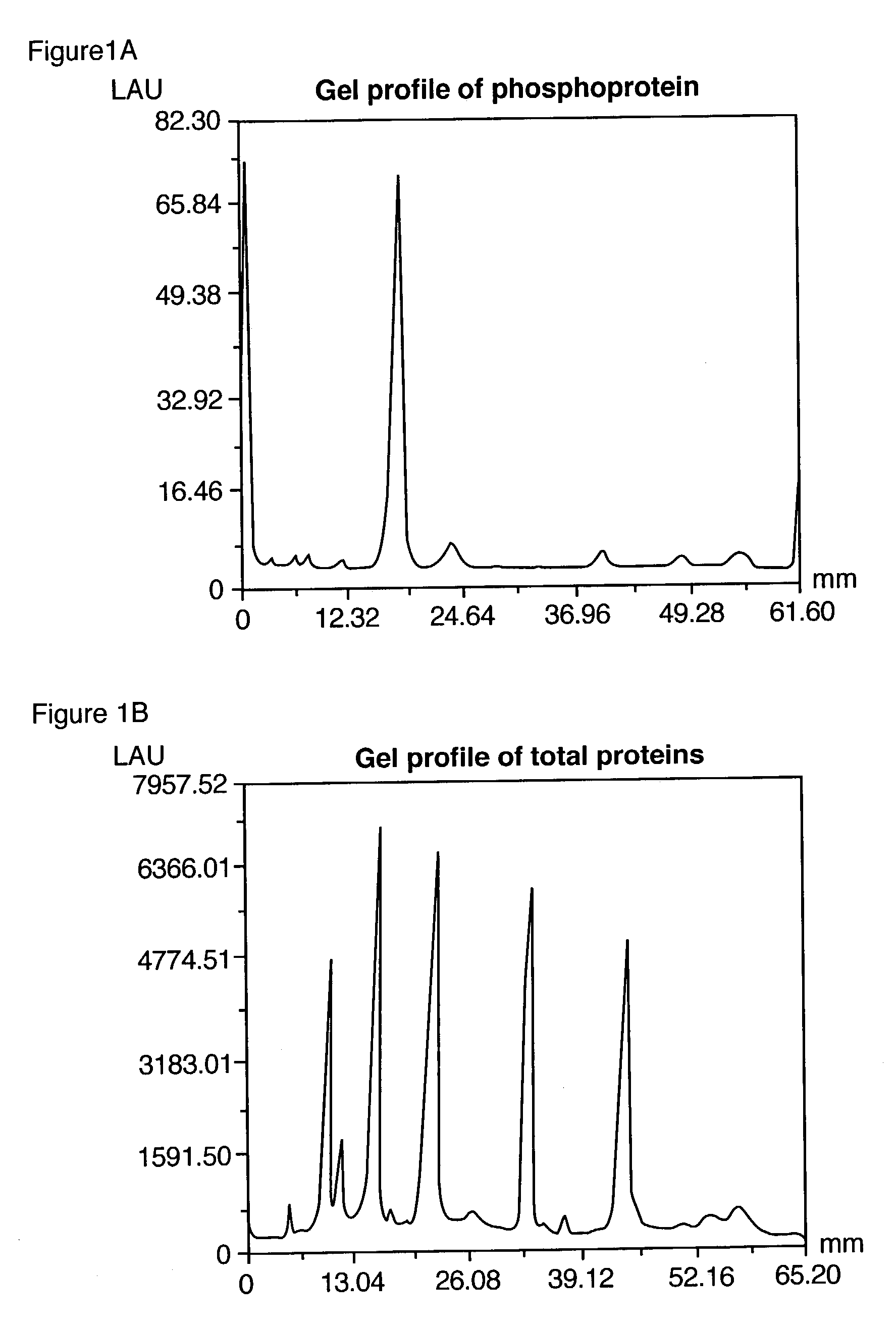

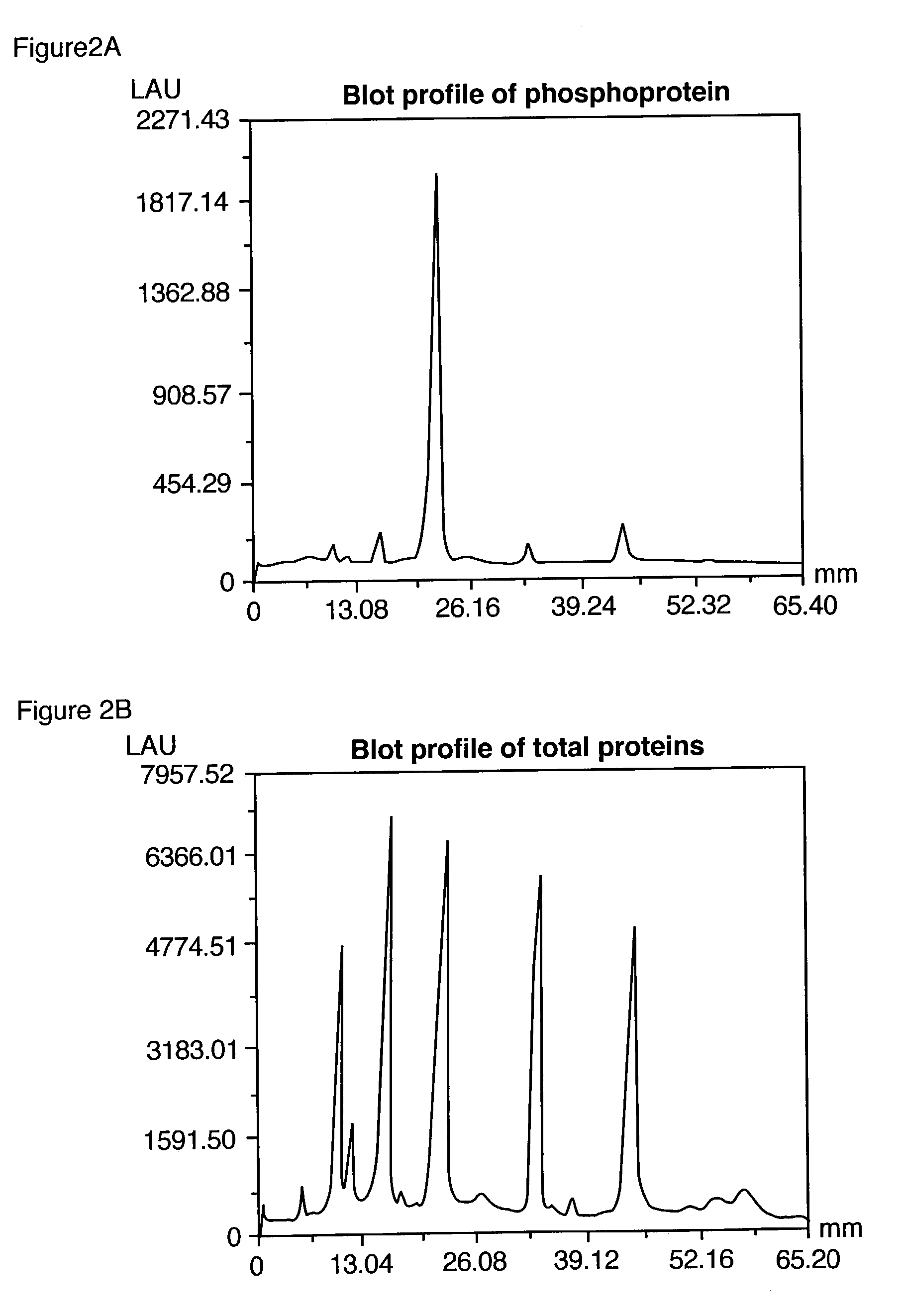

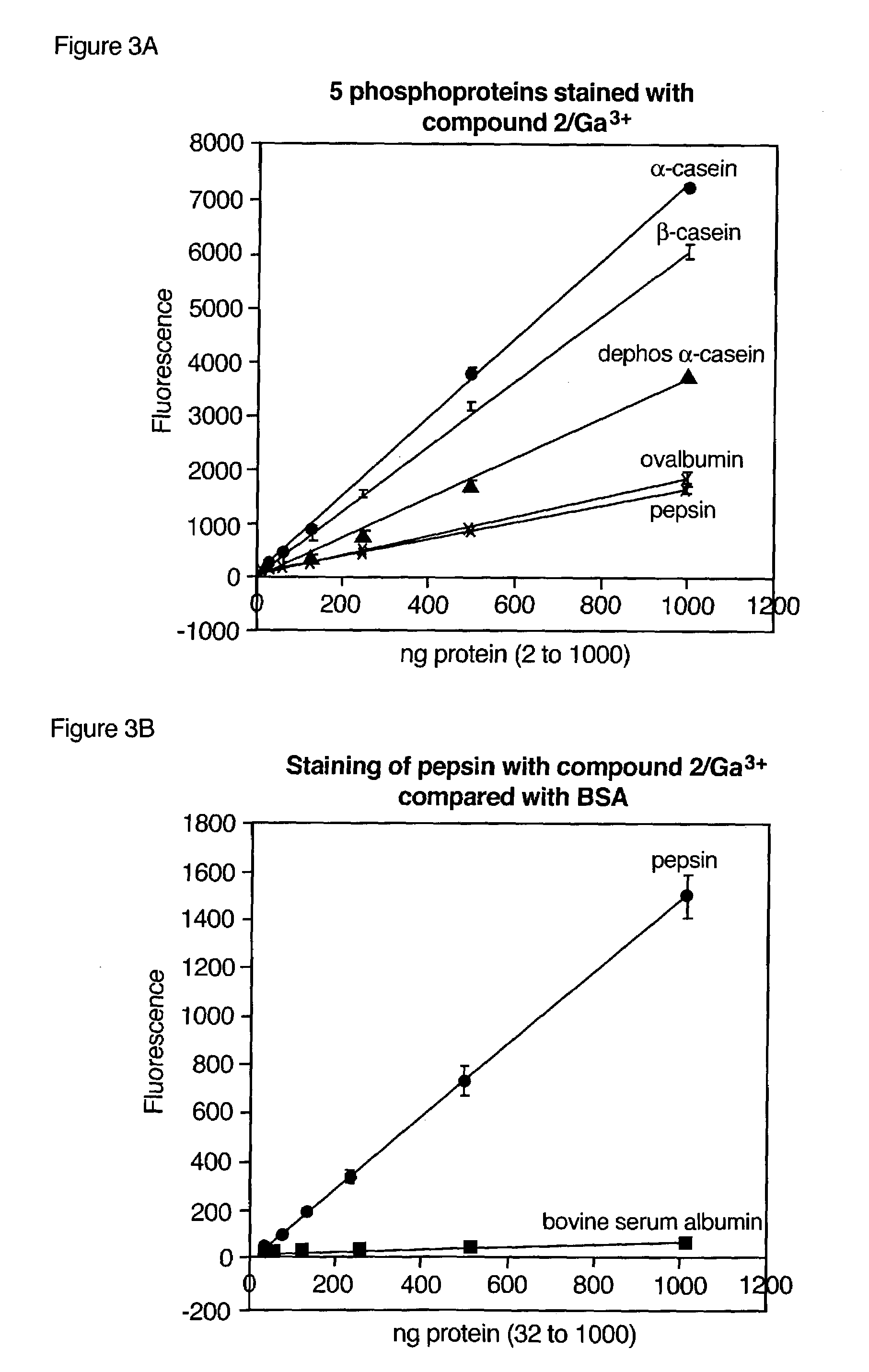

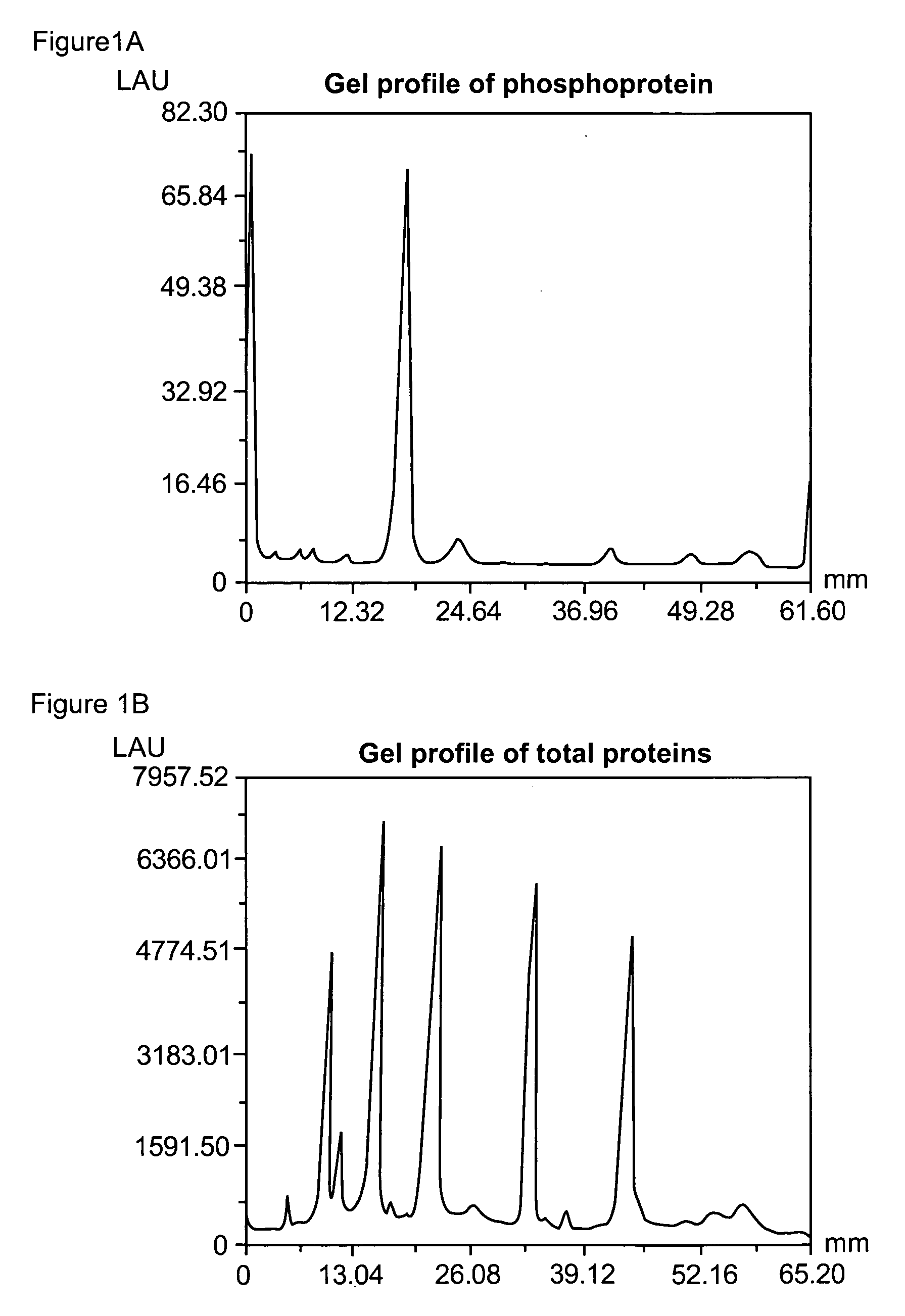

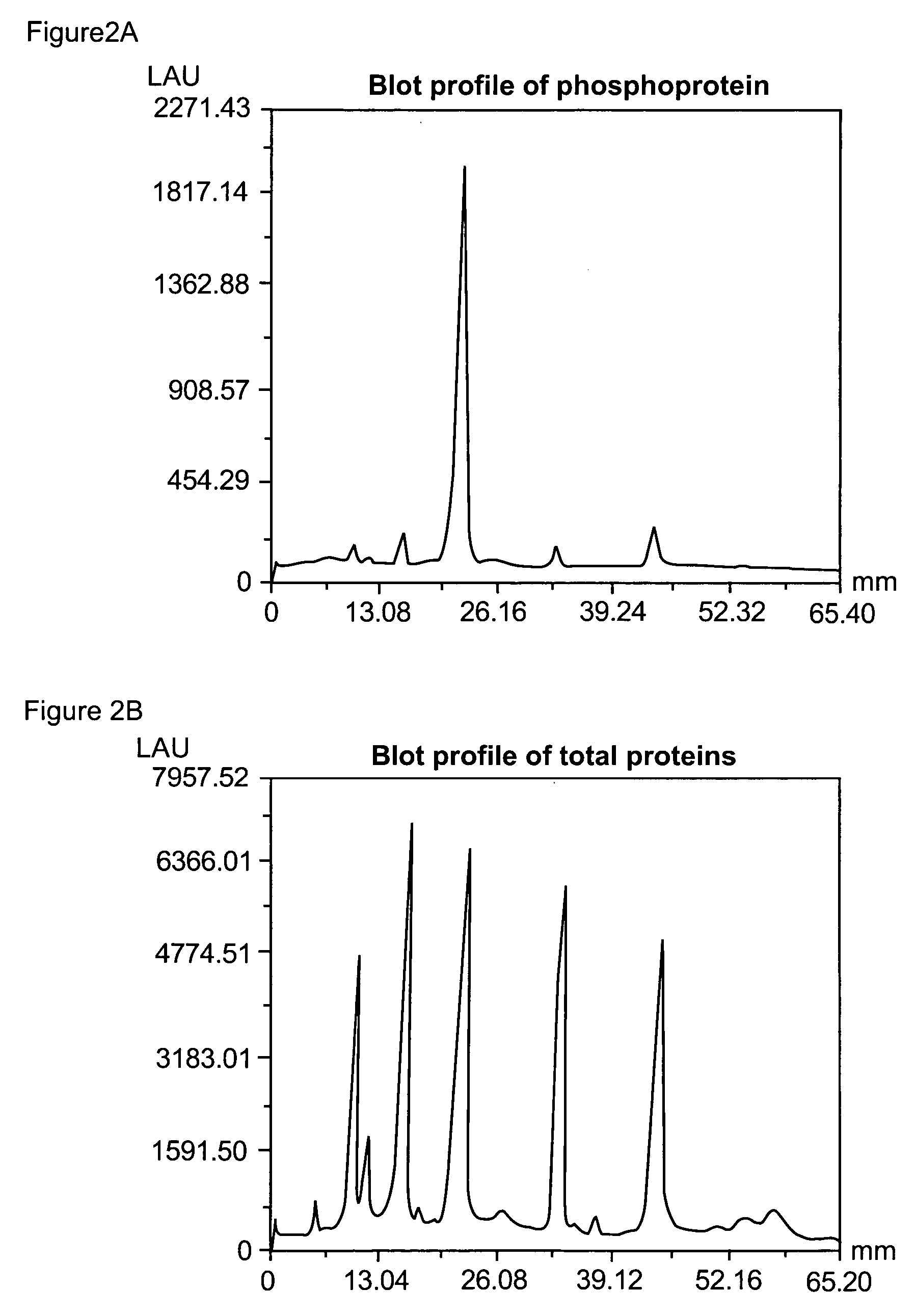

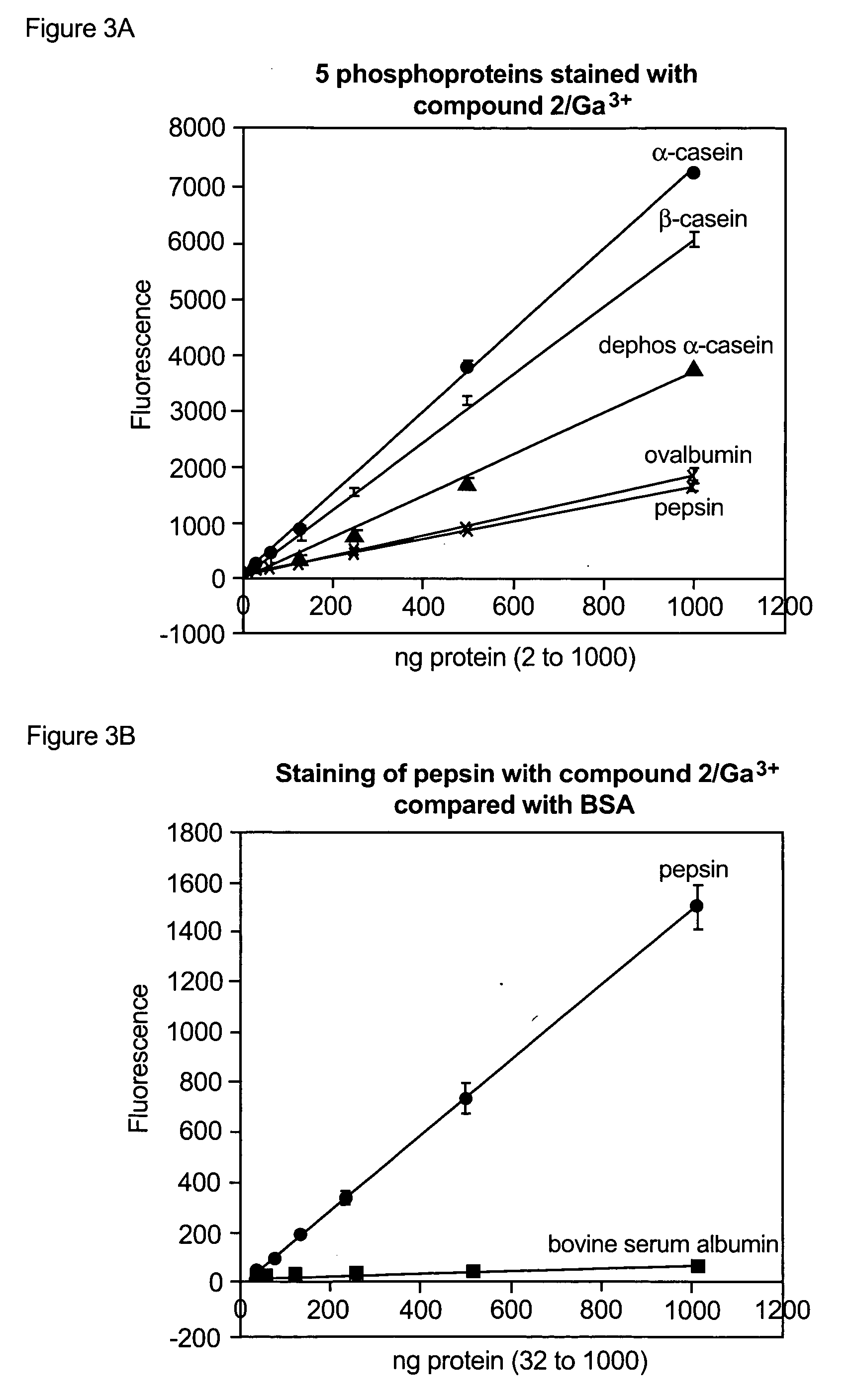

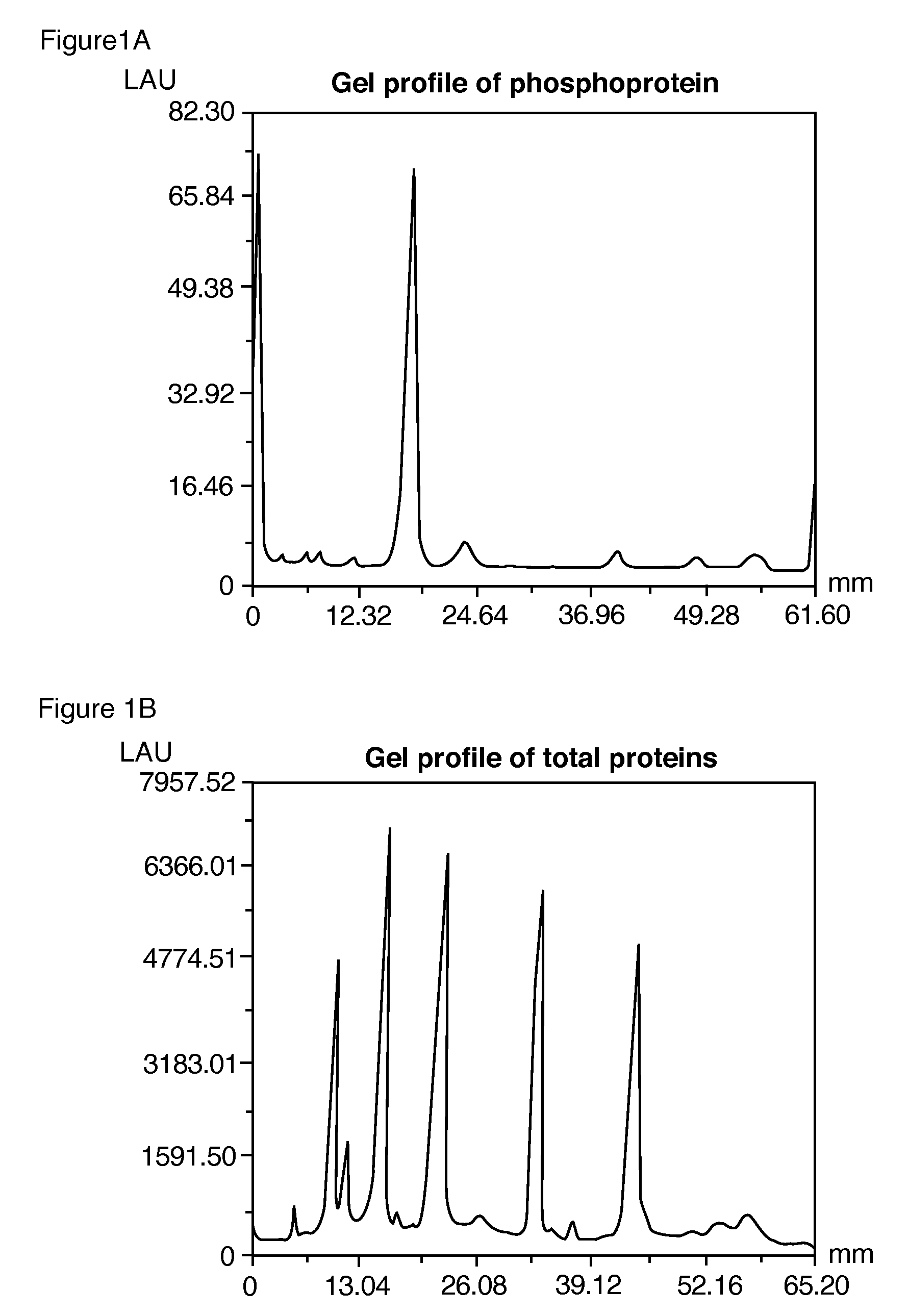

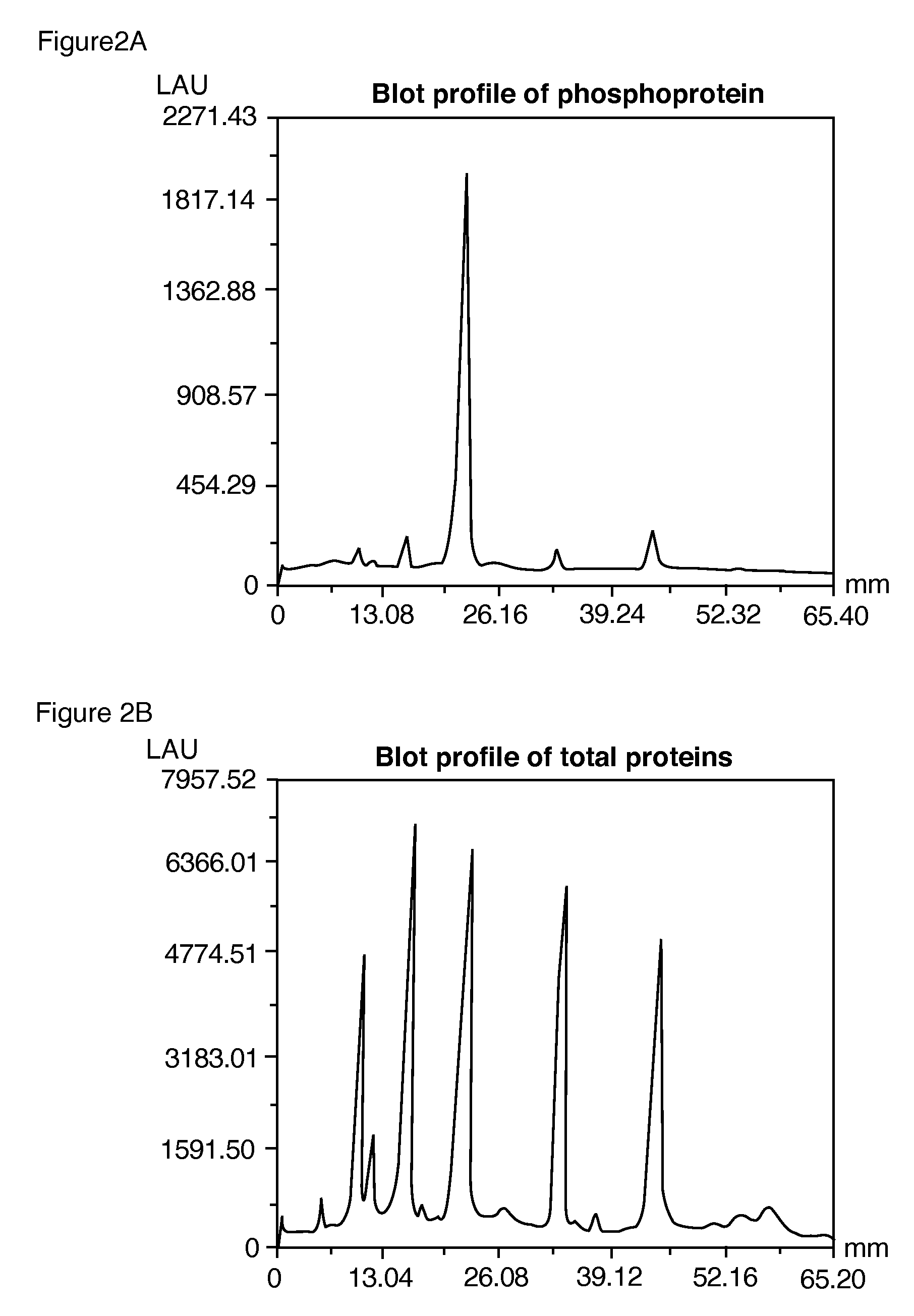

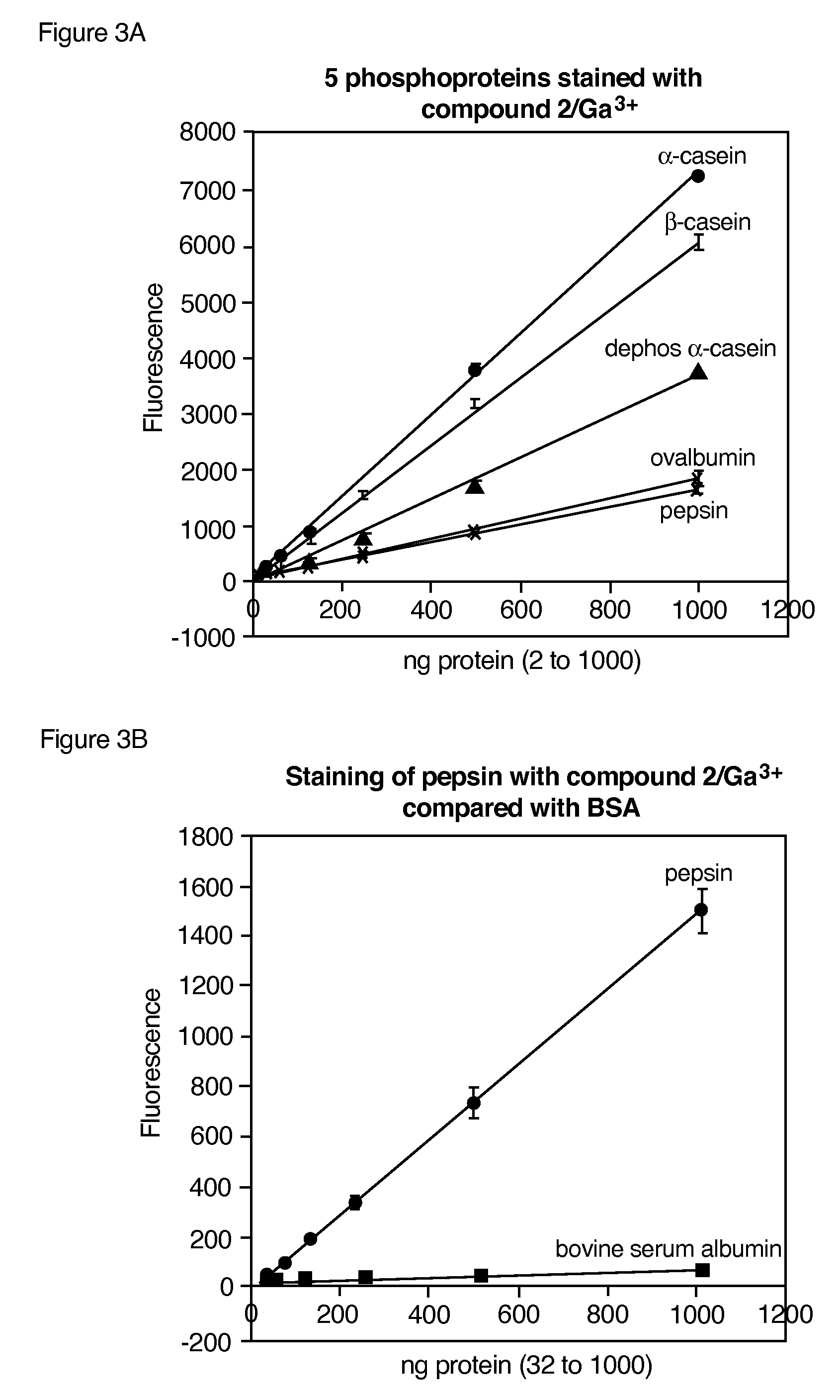

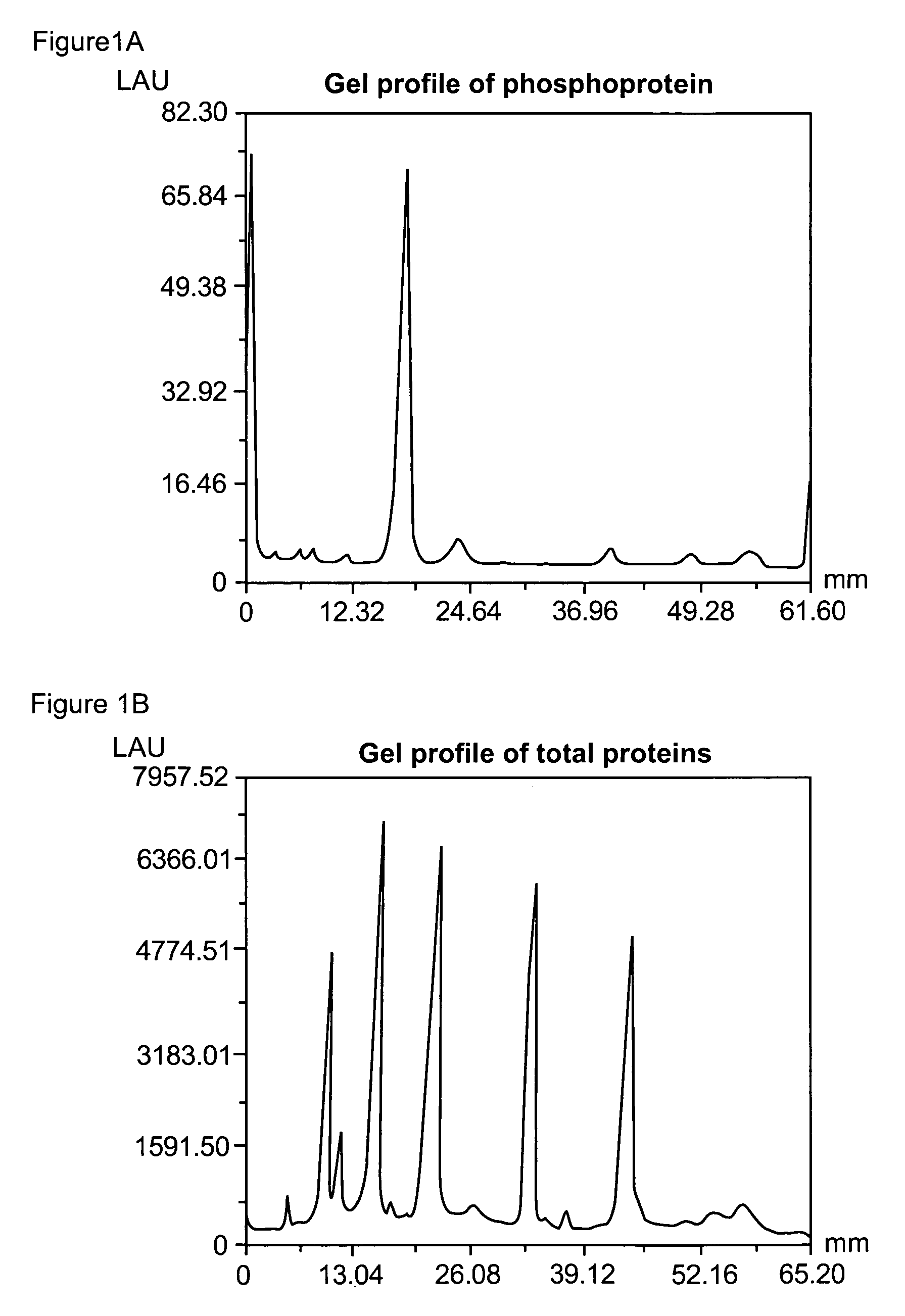

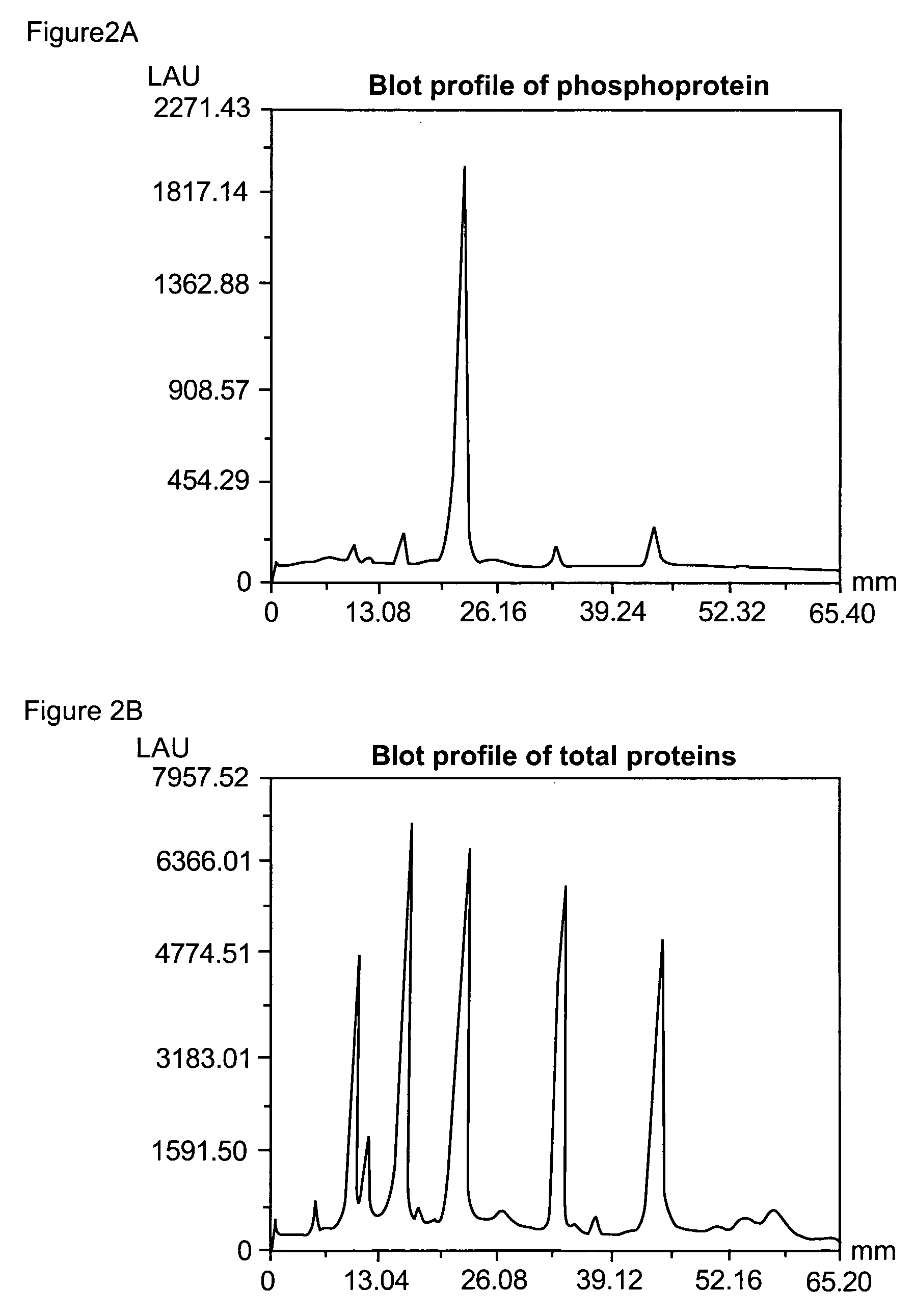

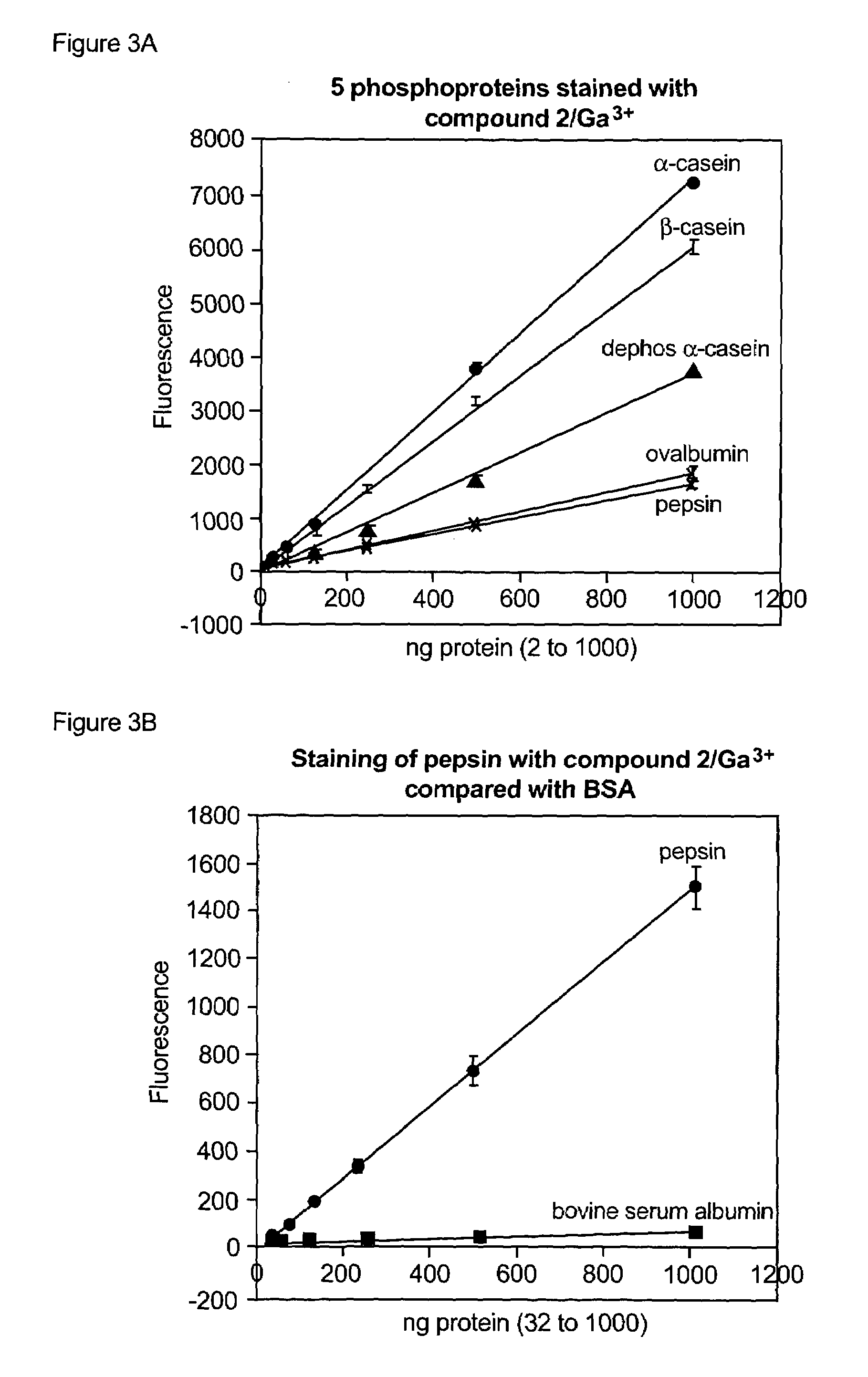

Compositions and methods for detection and isolation of phosphorylated molecules

ActiveUS20050014197A1Simplifies subsequent analysisSugar derivativesPeptide/protein ingredientsTernary complexPhosphorylation

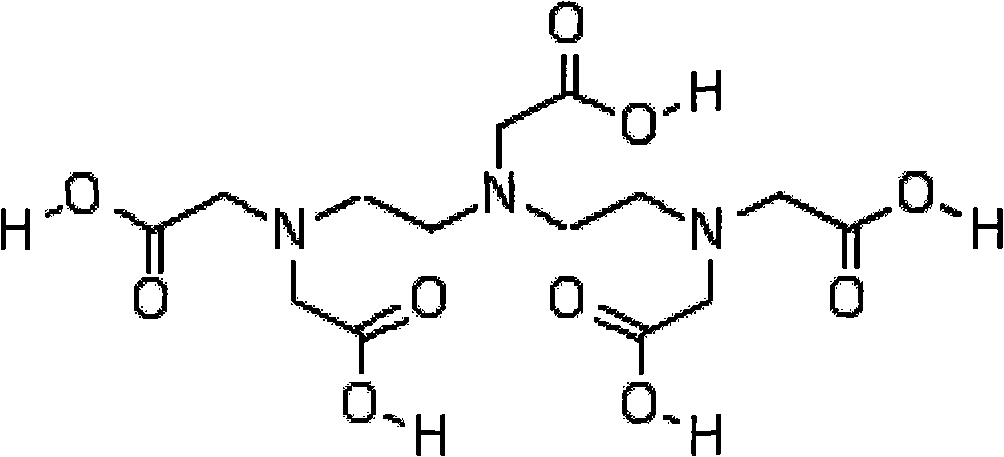

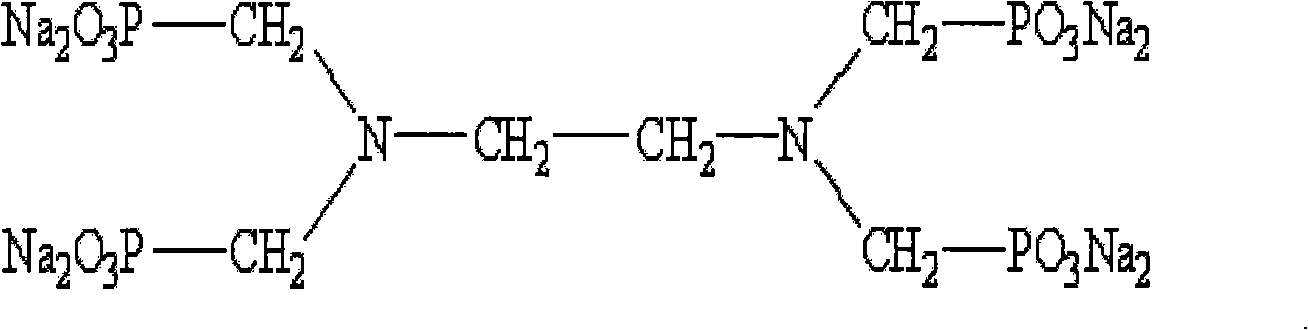

The present invention relates to phosphate-binding compounds that find use in binding, detecting and isolating phosphorylated target molecules including the subsequent identification of target molecules that interact with phosphorylated target molecules or molecules capable of being phosphorylated. A binding solution is provide that comprises a phosphate-binding compound, an acid and a metal ion wherein the metal ion simultaneously interacts with an exposed phosphate group on a target molecule and the metal chelating moiety of the phosphate-binding compound forming a bridge between the phosphate-binding compound and a phosphorylated target molecule resulting in a ternary complex. The binding solution of the present invention finds use in binding and detecting immobilized and solubilized phosphorylated target molecules, isolation of phosphorylated target molecules from a complex mixture and aiding in proteomic analysis wherein kinase and phosphatase substrates and enzymes can be identified.

Owner:MOLECULAR PROBES

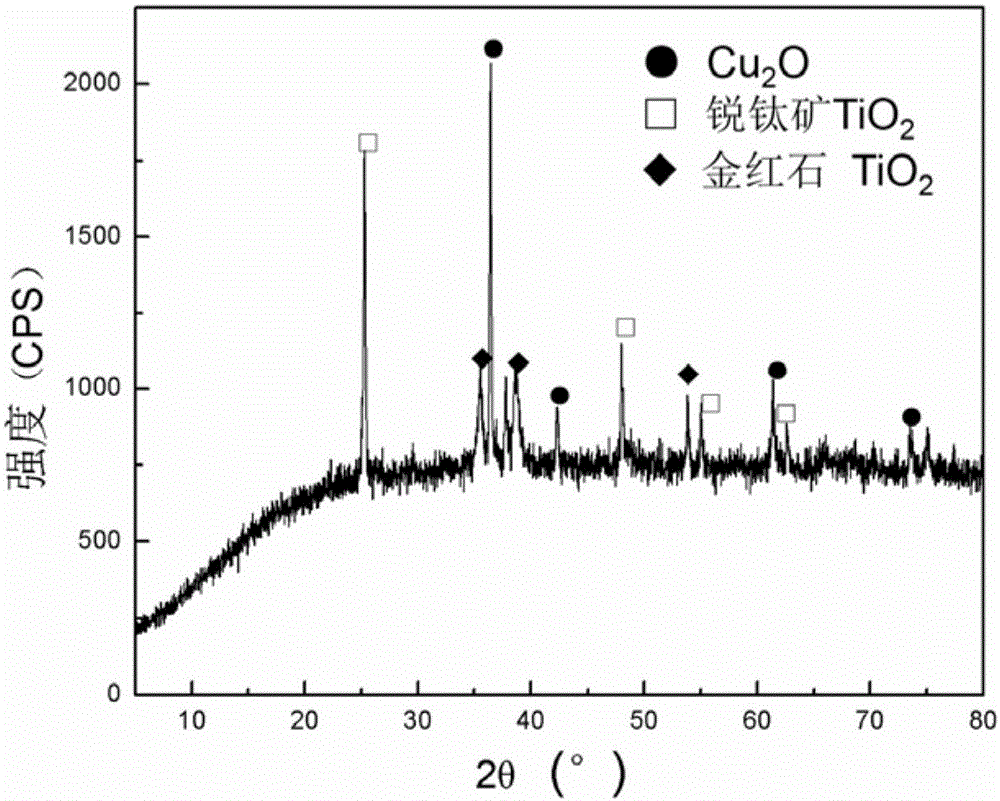

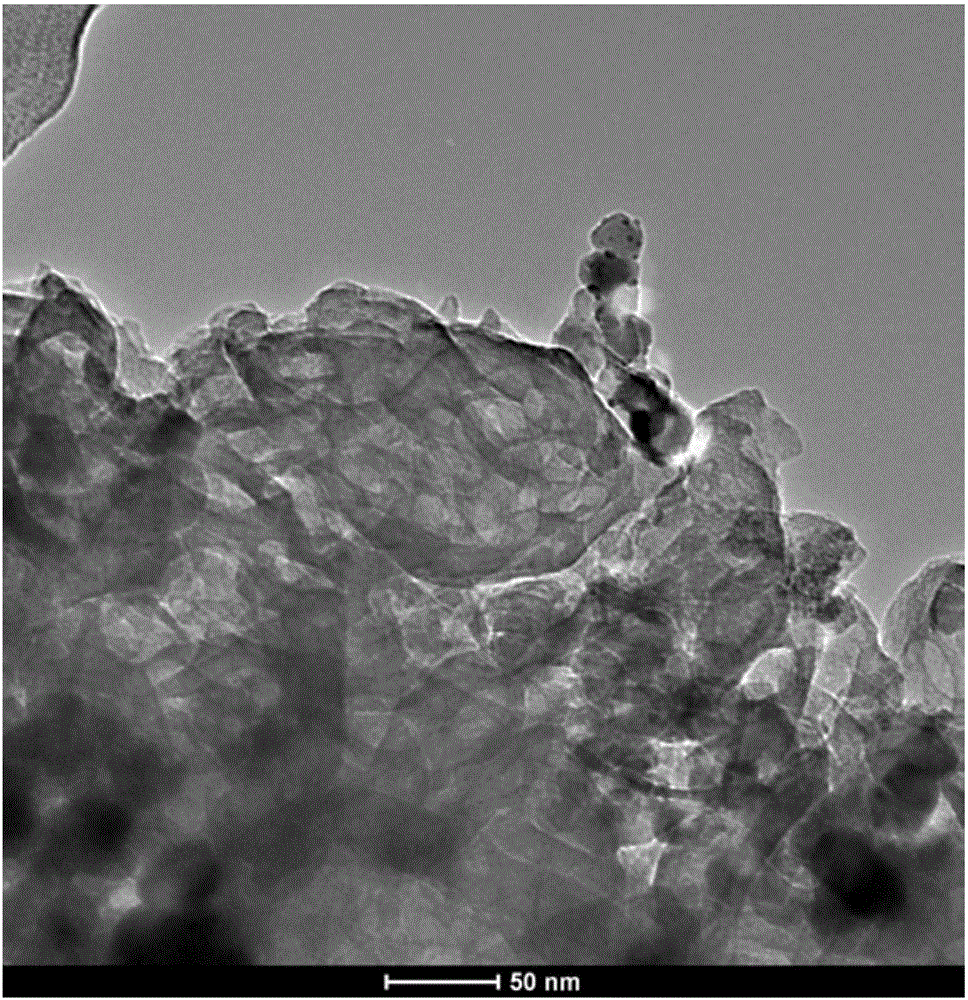

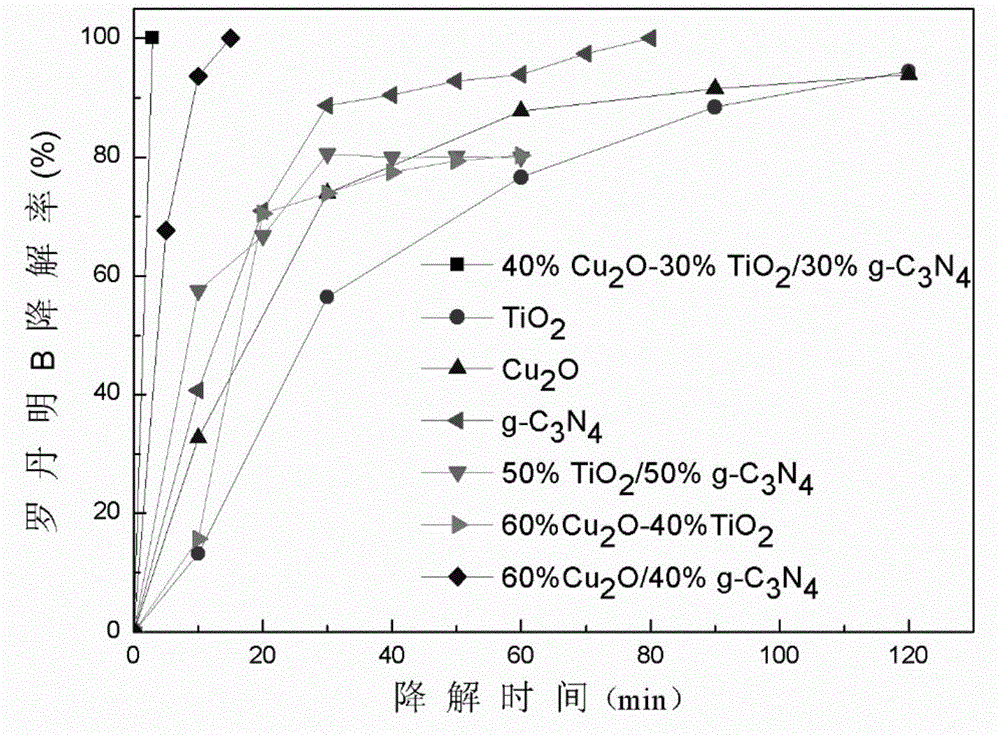

Cu2O-TiO2/g-C3N4 ternary complex and preparation and application method thereof

ActiveCN105032468AHigh catalytic activityHigh catalytic efficiencyPhysical/chemical process catalystsTernary complexPhotocatalytic water splitting

The invention discloses a Cu2O-TiO2 / g-C3N4 ternary complex and a preparation and application method thereof. The preparation method comprises the steps that firstly, urea and TiO2 are mixed through a simple physical method, water is added to the mixture, the mixture is dried by distillation, calcination is conducted, and then a binary complex of TiO2 / g-C3N4 is obtained; secondly, by means of sediment and reduction processes, the Cu2O-TiO2 / g-C3N4 ternary complex is prepared. The preparation method is simple, cost is low, and industrial production is facilitated. The prepared ternary complex serves as a visible-light-driven photocatalyst which has high catalytic activity in the visible region, the catalytic efficiency is high, and various organic pollutants in a solution can be degraded instantly; the prepared ternary complex can also serve as a visible-light-driven photocatalyst which is applied to hydrogen preparing of photocatalytic water splitting, degrading of volatile organic pollutants in air and the like, and very good application prospects are achieved.

Owner:CENT SOUTH UNIV

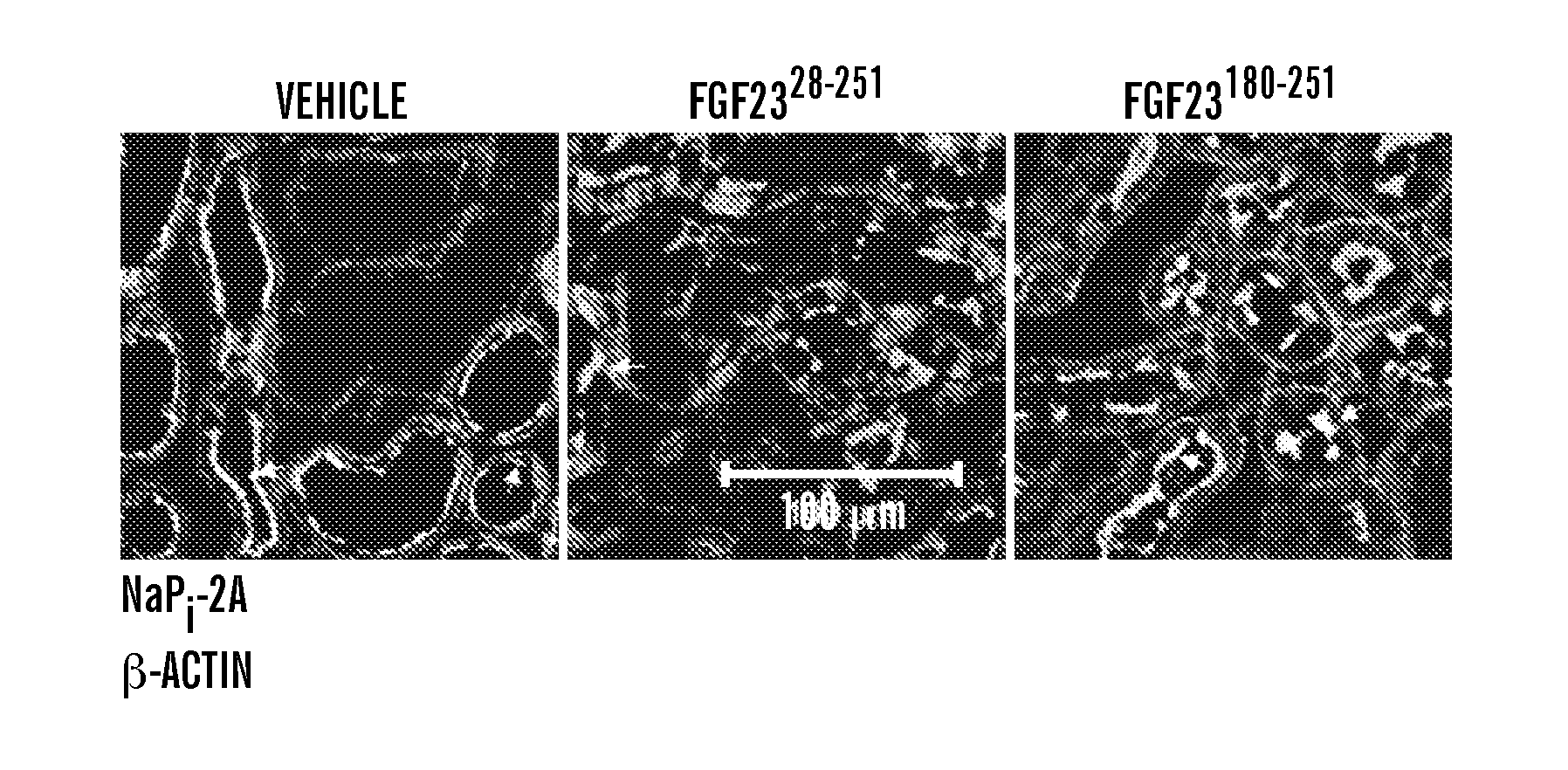

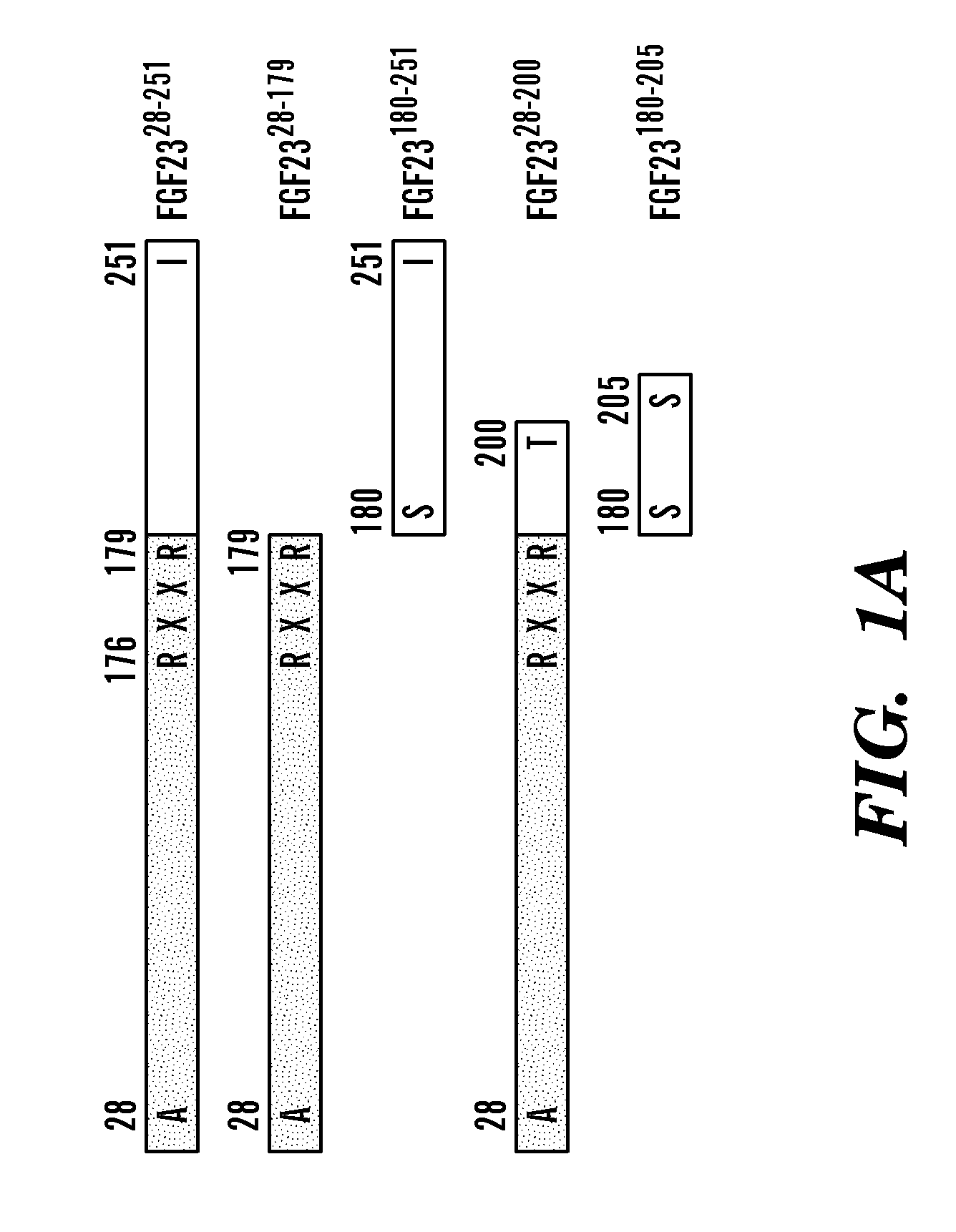

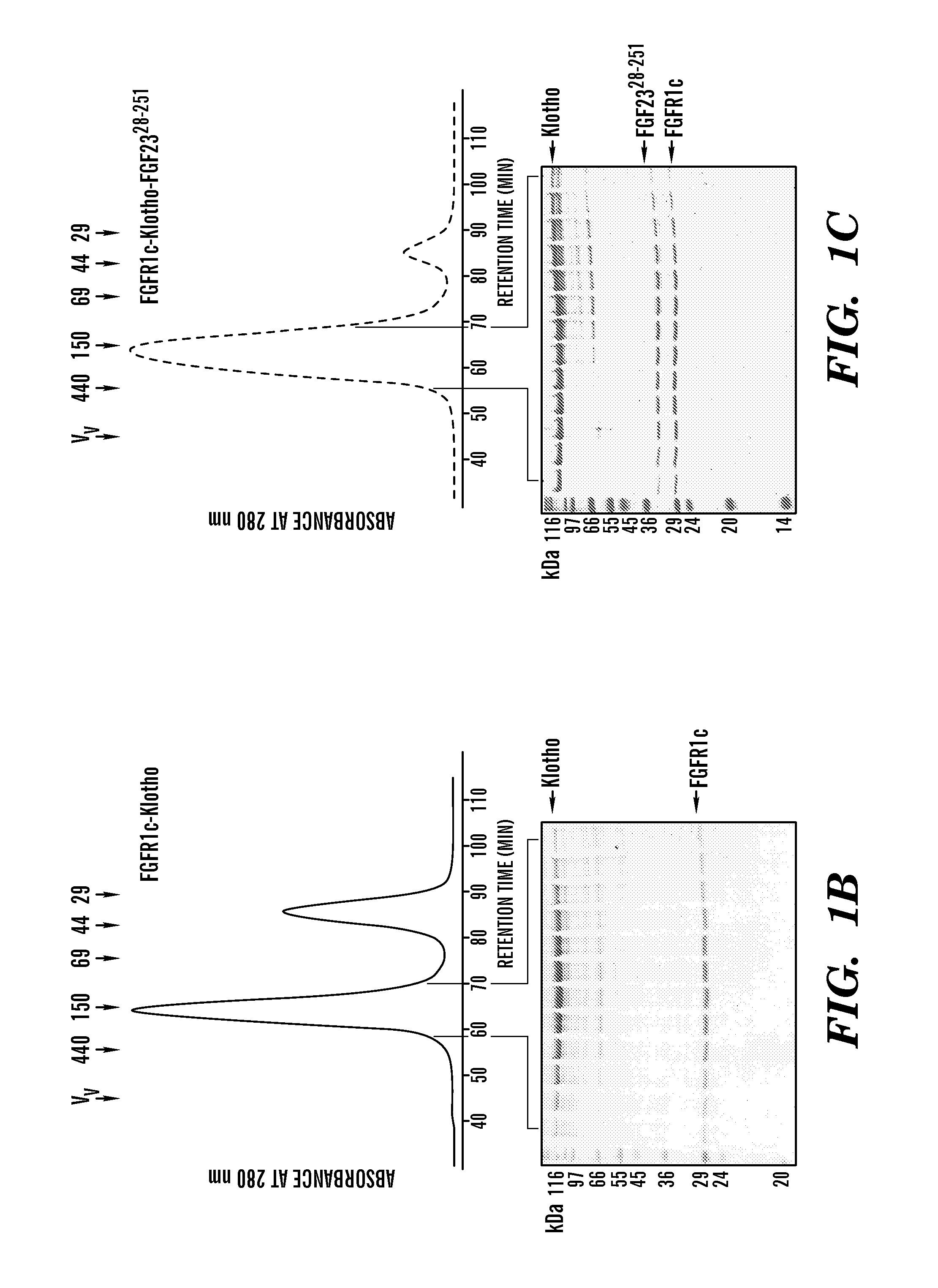

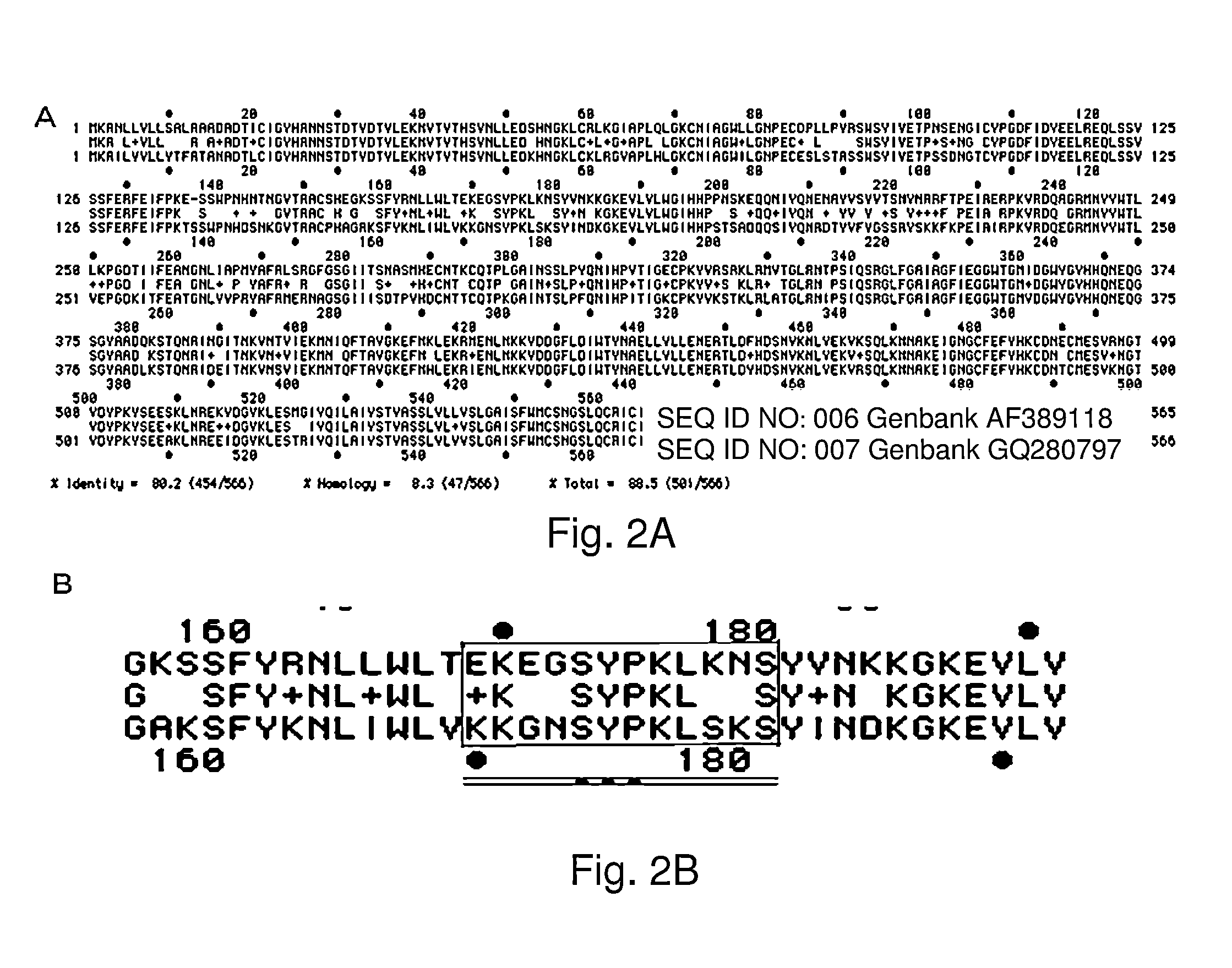

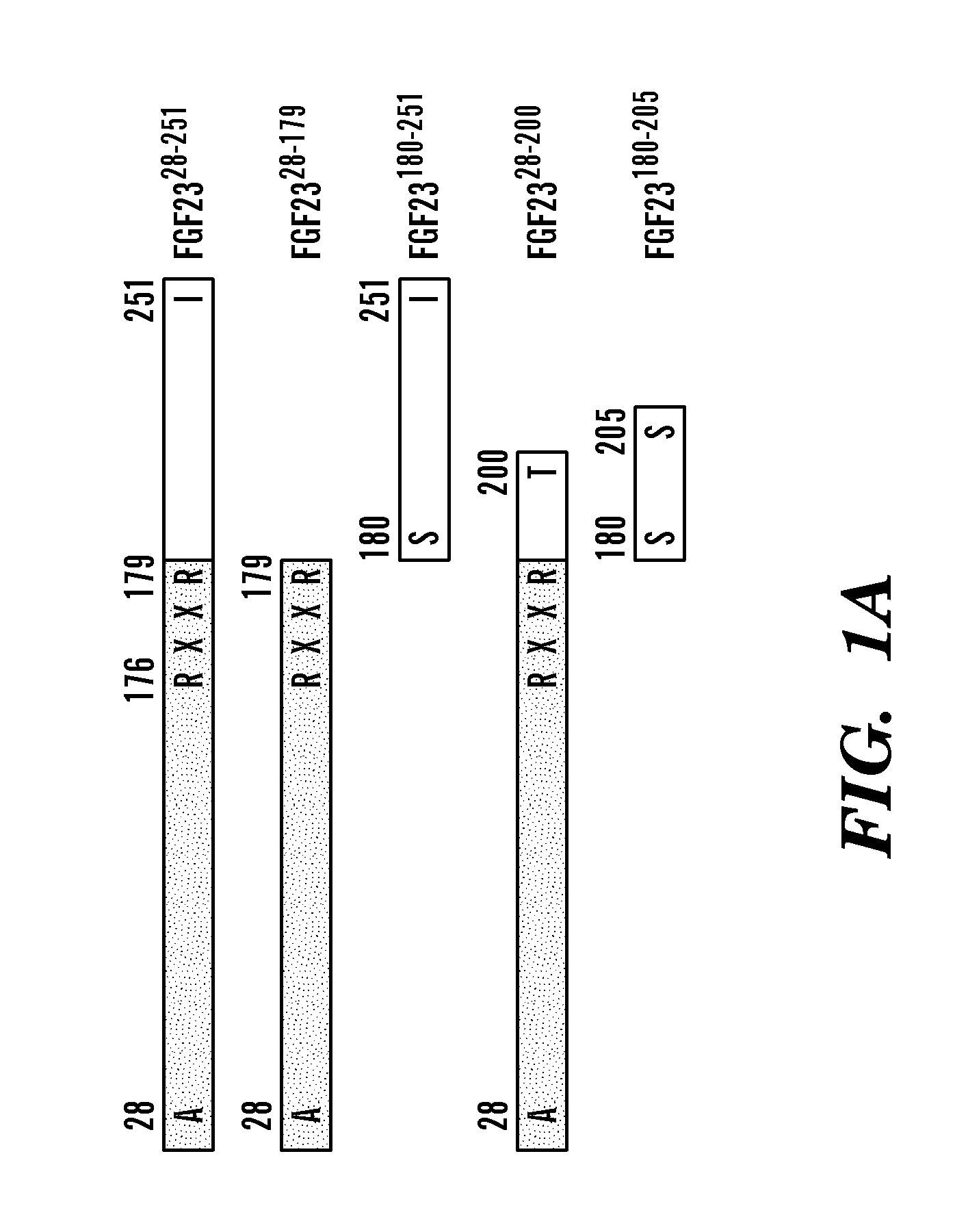

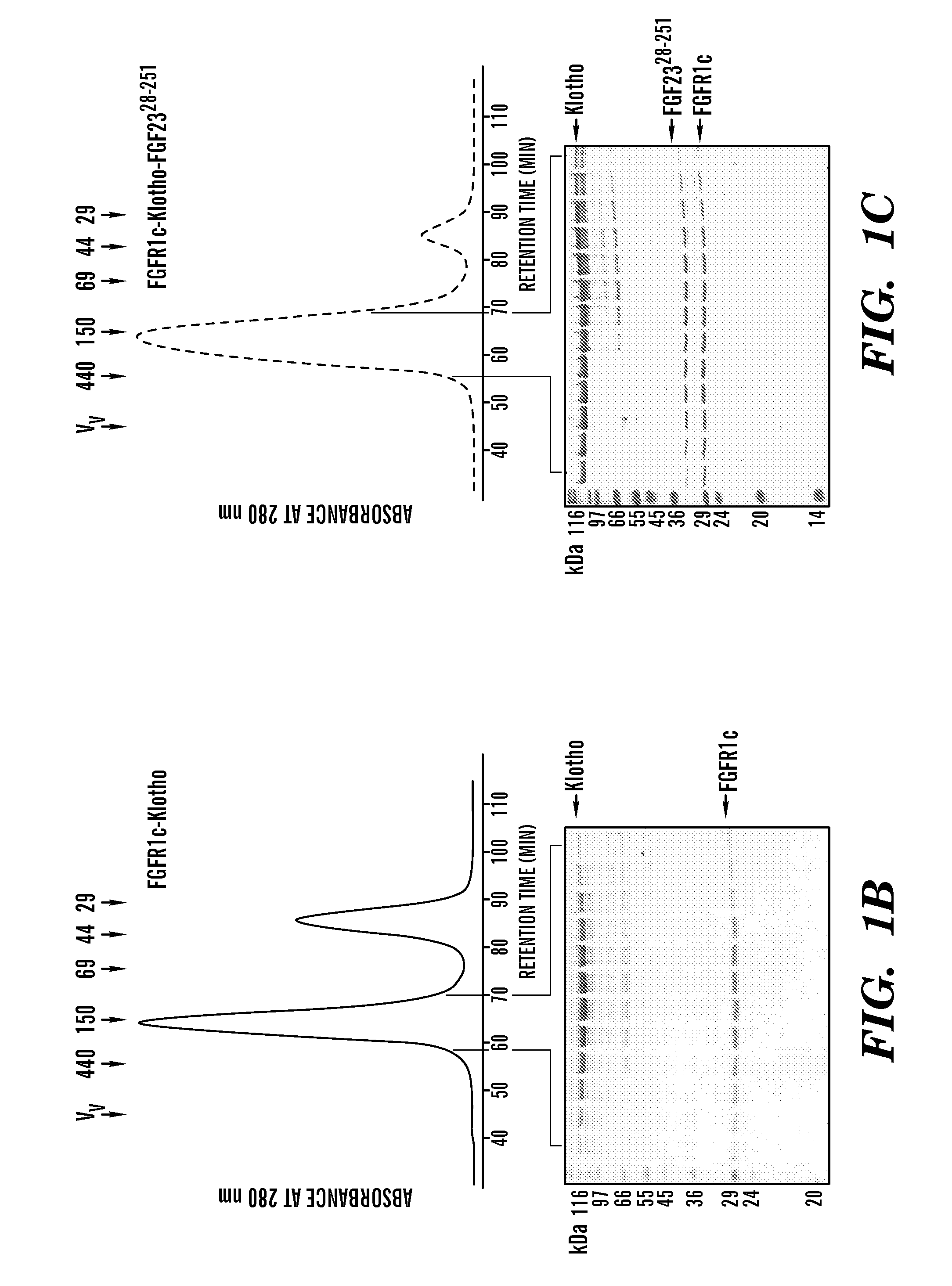

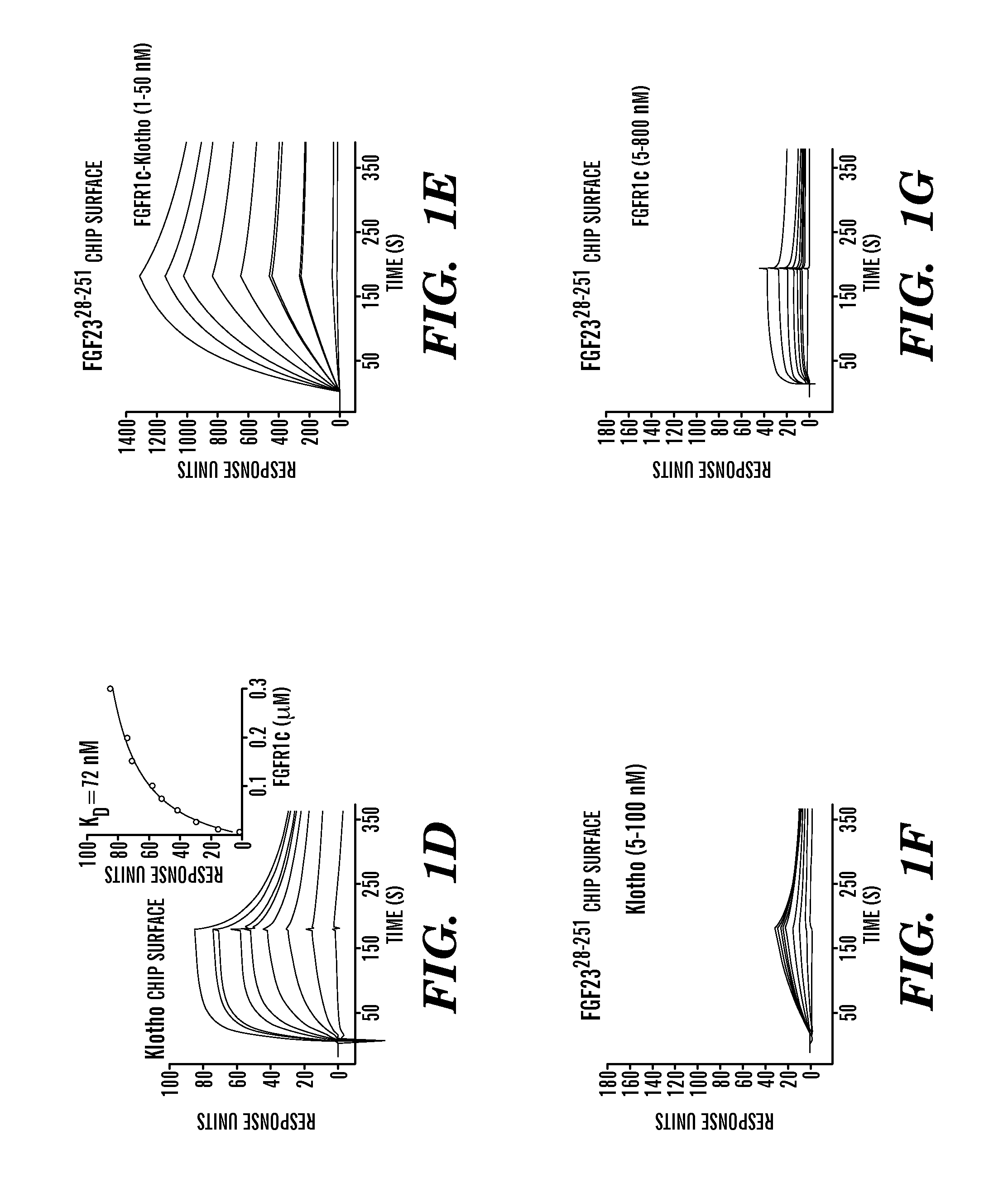

Inhibiting binding of fgf23 to the binary fgfr-klotho complex for the treatment of hypophosphatemia

ActiveUS20110190207A1Inhibit FGF2 signalingOrganic active ingredientsPeptide/protein ingredientsCompound specificTernary complex

The present invention is directed to a method of treating hypophosphatemia in a subject. This method involves selecting a subject with hypophosphatemia associated with elevated or normal FGF23 and administering to the selected subject an inhibitor of FGF23-Klotho-FGF receptor complex formation under conditions effective to treat the hypophosphatemia. The present invention is also directed to a method of screening for compounds suitable for treatment of hypophosphatemia associated with elevated or normal FGF23. This method involves providing FGF23, FGFR-Klotho complex, and one or more candidate compounds. The FGF23, the FGFR-Klotho complex, and the candidate compounds are combined under conditions effective for the FGF23 and the binary FGFR-Klotho complex to form a ternary complex if present by themselves. This method also involves identifying the candidate compounds, which prevent formation of the complex as being potentially suitable in treating hypophosphatemic conditions associated with elevated or normal FGF23. A method of screening the specificity of compounds which prevent formation of the FGF23-Klotho-FGFR complex is also disclosed.

Owner:NEW YORK UNIV

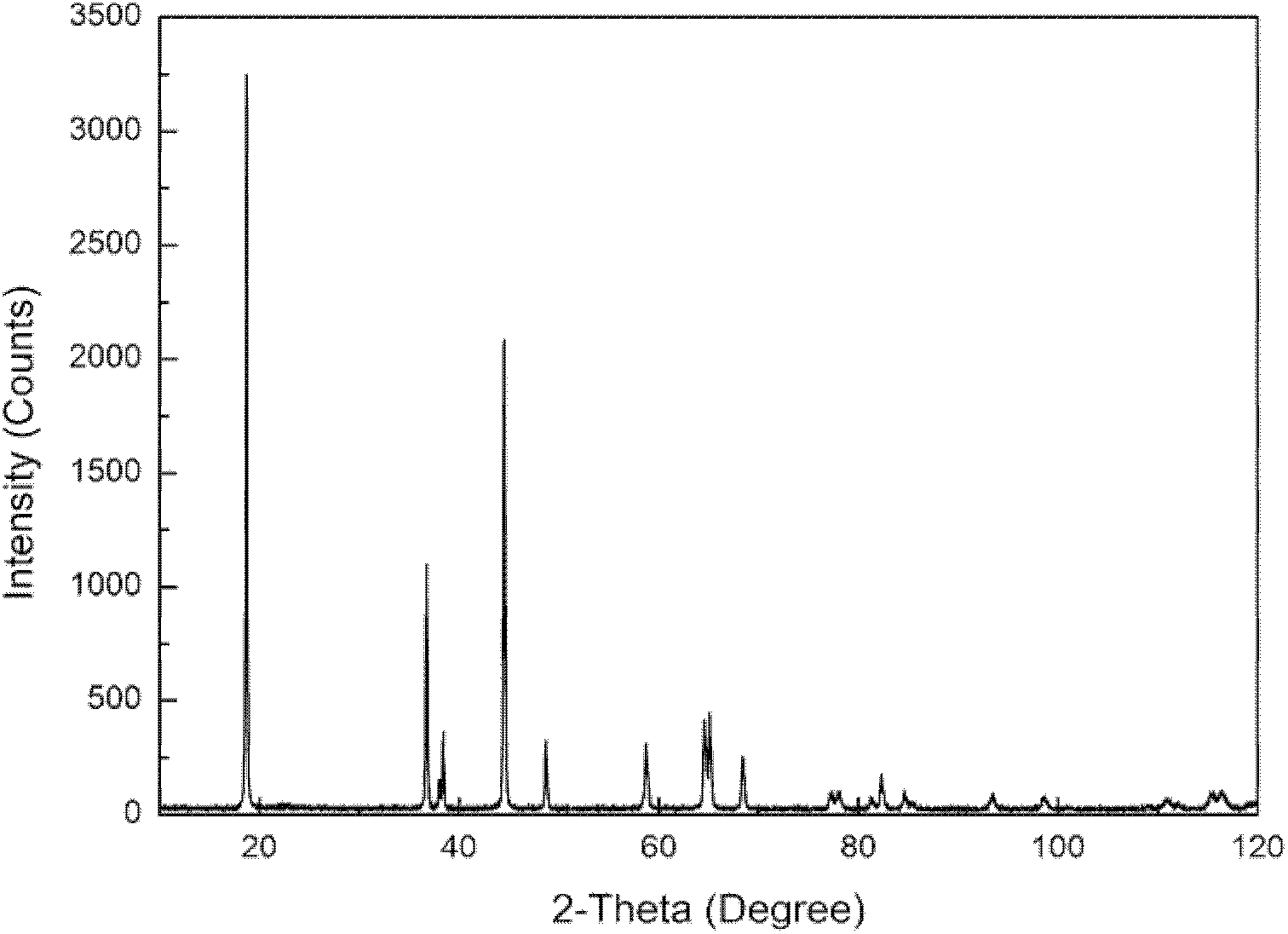

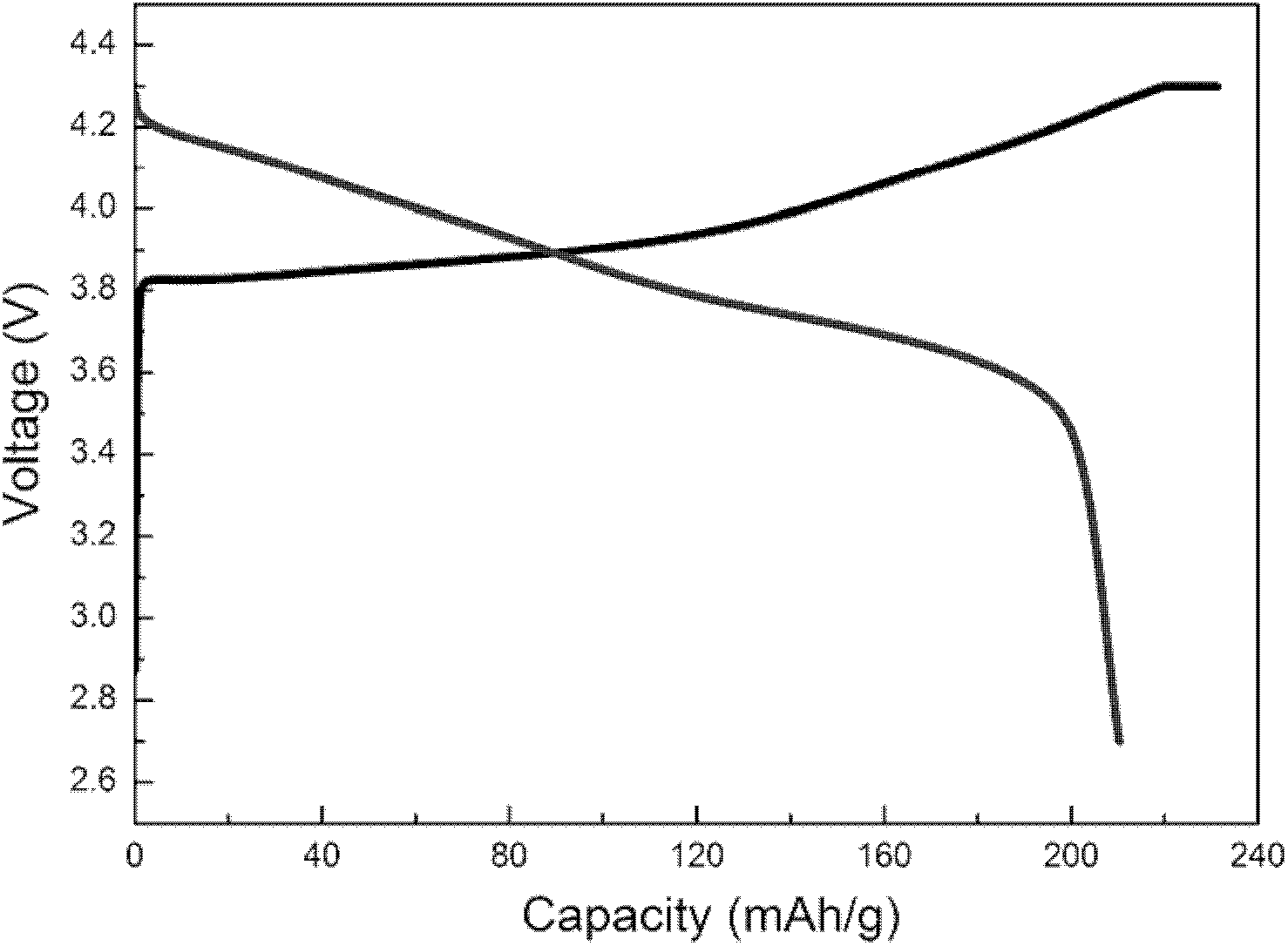

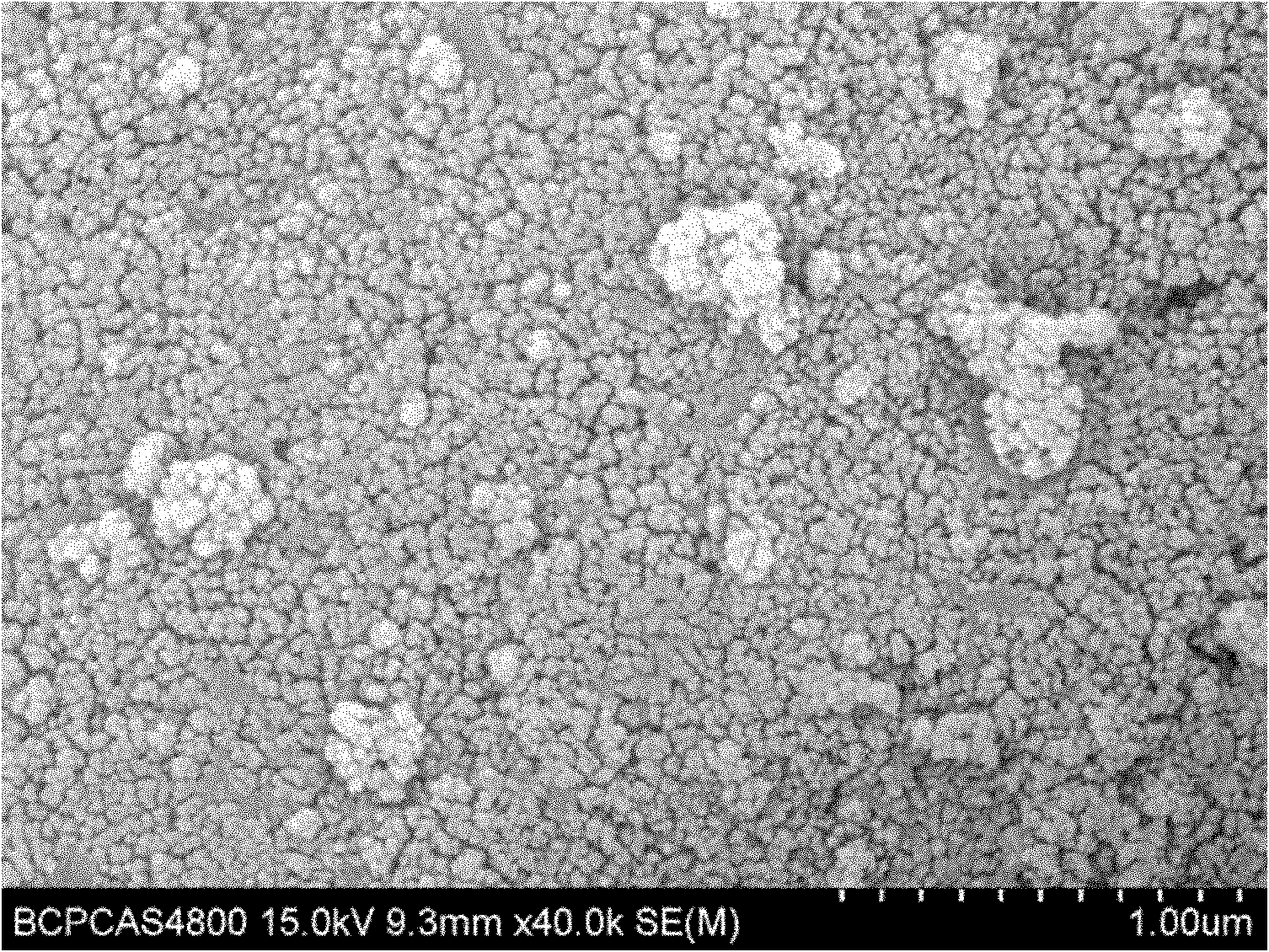

Method for preparing ternary complex anode material (LiNixCoyMn1-x-yO2)

The invention discloses a method for preparing a ternary complex anode material (LiNixCoyMn1-x-yO2), which is characterized in that the lithium ion battery anode material (LiNixCoyMn1-x-yO2) is prepared by adopting a coprecipitation-silicon cladding-high temperature sintering-desilicication integrated method, and specifically comprises the following steps: mixing a nickel source and a cobalt source with a manganese source according to molar ratio of nickel-cobalt-manganese: x:y:(1-x-y), adding with water, stirring to form a solution, adding with a certain amount of ammonia water and a sodium hydroxide solution to generate a uniform NixCoyMn1-x-y(OH)2 ocyhydrate precursor, washing and filtering the precursor, adding with a certain amount of polyvinylpyrrolidone, stirring for a certain period, adding with a certain quantity of organosilicon reagents, stirring continuously to obtain an ocyhydrate precursor wrapped by organosilicon reagent-polyvinylpyrrolidone, washing, filtering, drying and then mixing the ocyhydrate precursor with a lithium source, calcining the mixture under air or an oxygen atmosphere under the temperature of 450-950 DEG C for 2-48 hours, and removing a silicon wrapping layer on a product by the utilizing a sodium hydroxide solution, thus obtaining the nanoscale or standard nanoscale lithium ion battery ternary complex anode material (LiNixCoyMn1-x-yO2). The particle size of the anode material prepared by the invention ranges from 80nm-180nm, the initial charging / discharging performance achieves 194.4-210.3mAh / g, and the electrochemical performance is excellent.

Owner:CENT SOUTH UNIV

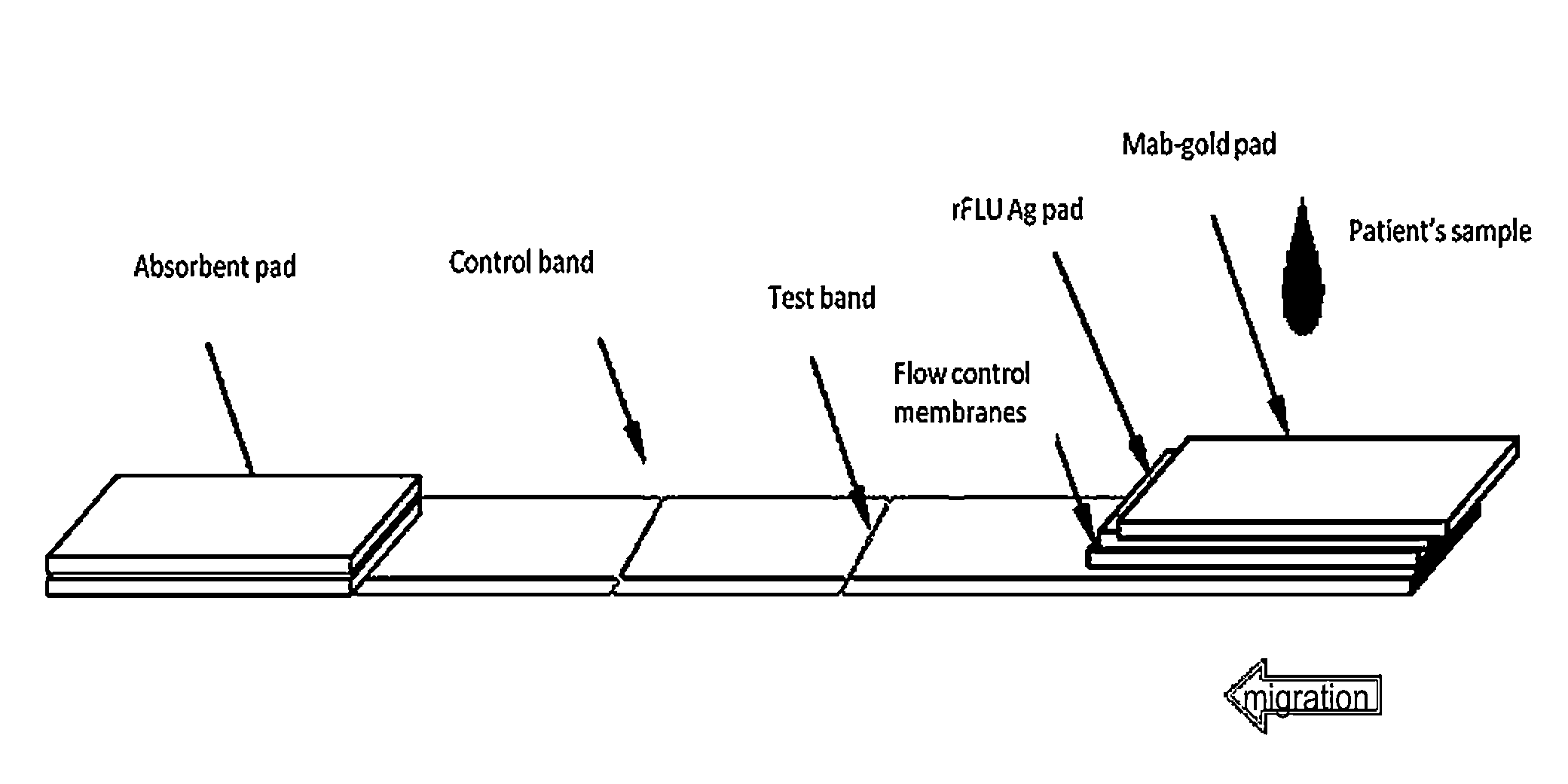

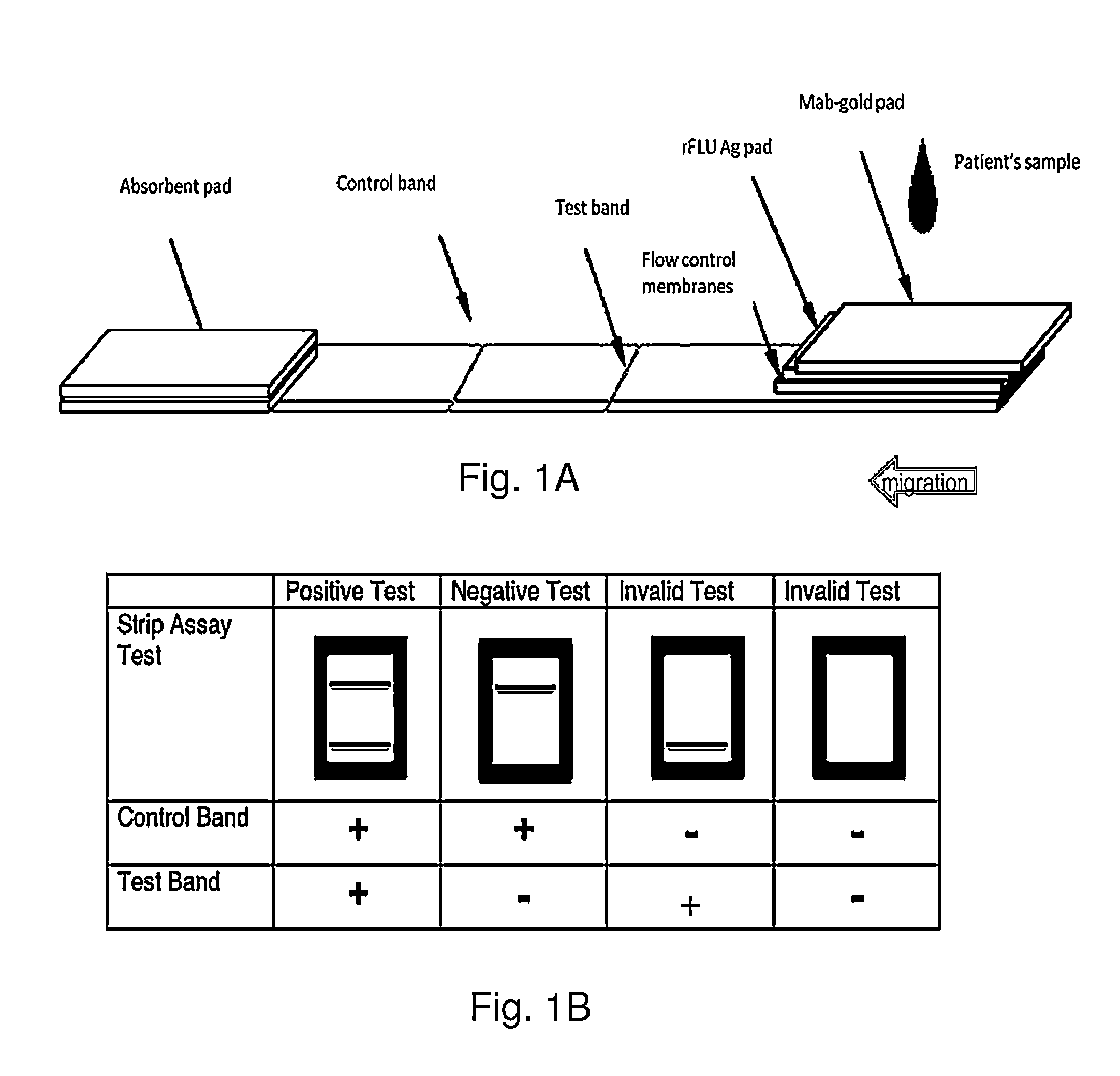

Compositions and methods for determining successful immunization by one or more vaccines

ActiveUS8956859B1Bioreactor/fermenter combinationsAnalysis using chemical indicatorsTernary complexIgM binding

A host antigen-specific antibody testing system and method. The a ternary complex of the antigen, a ligand-bound anti-host IgM, and a non-host anti-antigen IgG detector conjugate selectively form a quaternary complex with host antibodies, wherein the host antibodies and IgG compete for the antigen, and the IgM binds the host antibodies. The quaternary complex is retained by an immobilized IgM ligand binding agent, and any residual ternary is retained by a later encountered immobilized anti-non-host IgG. If sufficient host antibodies have a high affinity for the antigen, the complex is detected at the quaternary complex detection region based on the presence of the detector, and if there are insufficient high affinity host antibodies, the ternary complex migrates past the quaternary complex detection region and is retained and detected at a control region.

Owner:AVIEX TECH

Inhibiting binding of fgf23 to the binary fgfr-klotho complex for the treatment of hypophosphatemia

ActiveUS20120288886A1Organic active ingredientsPeptide/protein ingredientsCompound specificTernary complex

Owner:NEW YORK UNIV

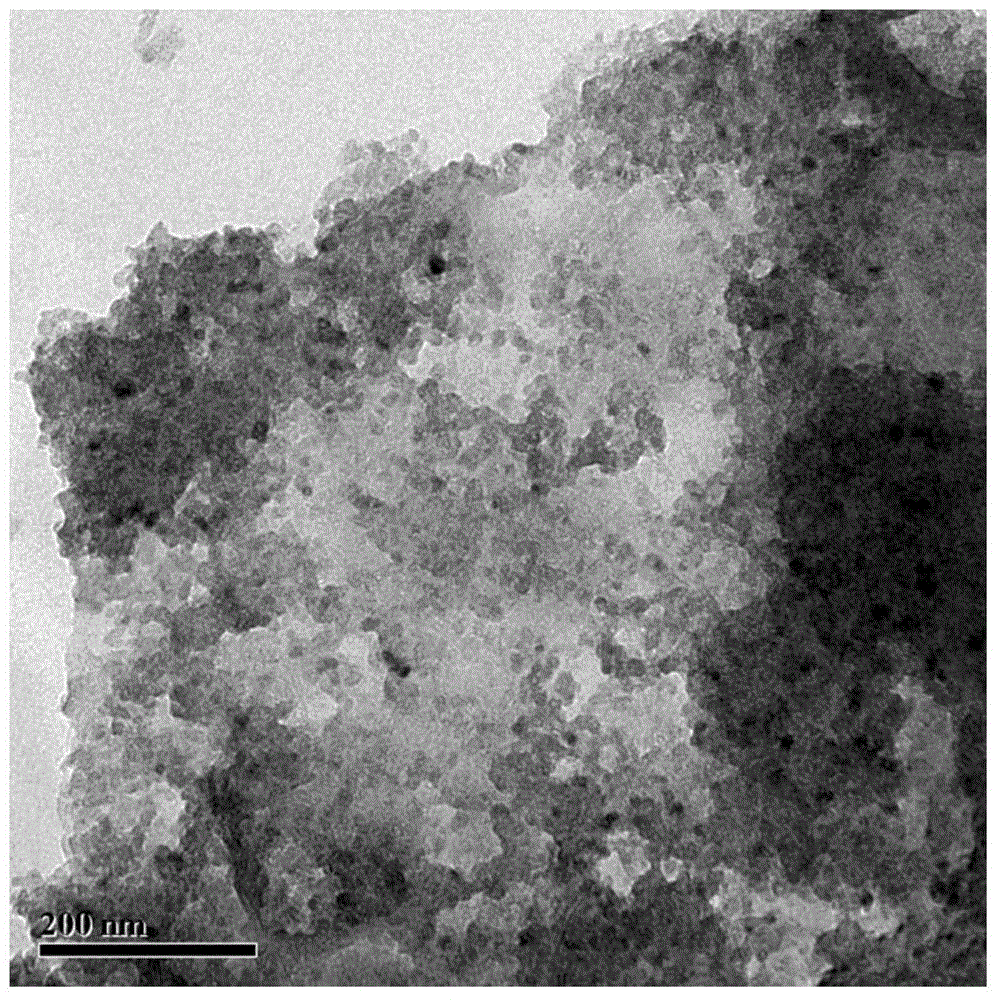

Graphene/polyaniline/cobalt composite wave-absorbing material and preparation method

InactiveCN103554908AStrong dielectric loss performanceLow densityOther chemical processesRadiation-absorbing paintsTernary complexMicrowave

The invention relates to a graphene / polyaniline / cobalt composite wave-absorbing material and a preparation method thereof, belonging to the field of preparing an electromagnetic wave absorption material. The wave-absorbing material comprise a film forming material and an electromagnetic wave absorbent, wherein paraffin is adopted as the film forming material, a graphene / polyaniline / cobalt ternary complex is adopted as the electromagnetic wave absorbent, and the mass ratio of the graphene / polyaniline / cobalt ternary complex to the paraffin is 1:1. The preparation method of the material comprises the following steps: (1) preparing graphite oxide; (2) preparing the graphene / polyaniline binary complex; (3) preparing the graphene / polyaniline / cobalt ternary complex; (4) weighing graphene / polyaniline / cobalt ternary complex and paraffin, and evenly mixing to obtain a graphene / polyaniline / cobalt wave-absorbing material. The material has the characteristics of being low in cost, simple in preparation technology, strong in electromagnetic wave absorption capability, wide in absorption frequency band, small in density and the like, achieves good electromagnetic property and stability, and has important application values in the fields of microwave absorption and electromagnetic shielding.

Owner:UNIV OF SCI & TECH BEIJING

Expandable graphite/polyaniline/cobalt ferrite wave-absorbing material and preparation technology thereof

InactiveCN102604395AStrong dielectric loss performanceLow densityInorganic material magnetismTernary complexAlcohol

The invention discloses an expandable graphite / polyaniline / cobalt ferrite wave-absorbing material with an anti-electromagnetic interference function and a preparation technology thereof. The invention aims to provide an expandable graphite / polyaniline / cobalt ferrite wave-absorbing material which has strong electromagnetic wave absorbing capability and wide absorption frequency bandwidth and is convenient to use without causing environmental pollution and a preparation technology thereof. According to the invention, the wave-absorbing material consists of paraffin serving as a film forming material and an expandable graphite / polyaniline / cobalt ferrite ternary complex serving as an electromagnetic wave absorbent. The preparation technology of the expandable graphite / polyaniline / cobalt ferrite wave-absorbing material comprises the following steps of: (1) preparing expandable graphite; (2) preparing absolute ethyl alcohol containing expandable graphite; (3) preparing an expandable graphite / polyaniline binary complex; (4) preparing the expandable graphite / polyaniline / cobalt ferrite ternary complex; and (5) weighing the expandable graphite / polyaniline / cobalt ferrite ternary complex and the paraffin, uniformly mixing the expandable graphite / polyaniline / cobalt ferrite ternary complex and the paraffin and performing ball milling to obtain the expandable graphite / polyaniline / cobalt ferrite wave-absorbing material.

Owner:ZHEJIANG NORMAL UNIVERSITY

Production of cationic microsphere with crosslinked swelling function

InactiveCN101029109AEasy speed controlControllable swelling ratioDrilling compositionCross-linkPersulfate

Production of cationic micro-sphere with cross-linking swelling function is carried out by taking persulfate and sulfite or persulfate and azo-diisobutyl nitrile binary composite or persulfate, sulfite and 2,2'-azo-(2-(2-imidazoline-2-radical)propane)dihydrochloride(VA-044)ternary composite as initiating agent, adding into dispersant and cross-linking agent, initiating DMC monomer and AM monomer in mixed medium of cyclohexane-water or industrial white oil-water or 120#solvent oil-water and reverse suspension polymerizing to obtain the final product. The grain size is 1-50 mu m, it has controllable swelling speed ratio and can be used for third oil-extraction plugging materials.

Owner:JIANGNAN UNIV

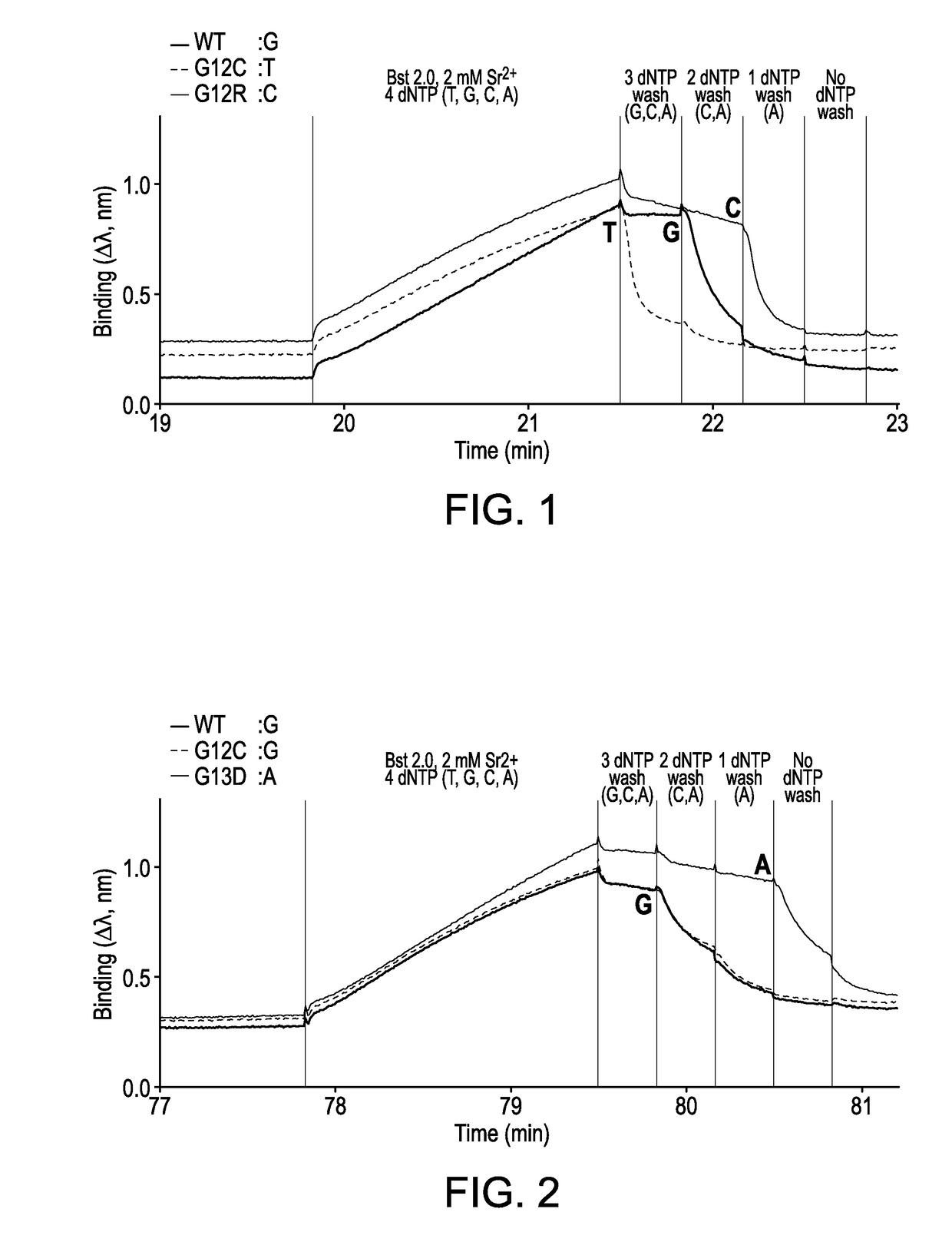

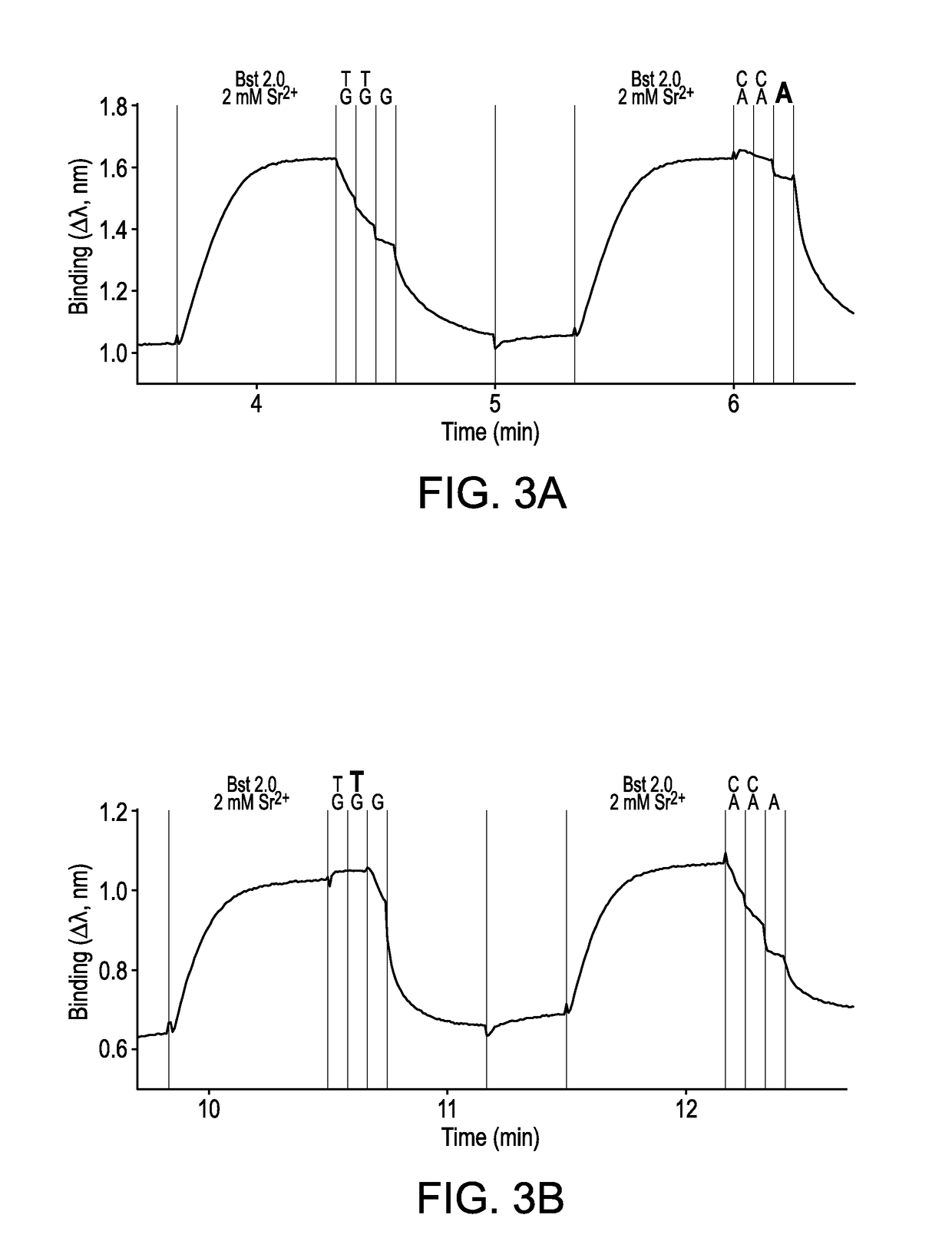

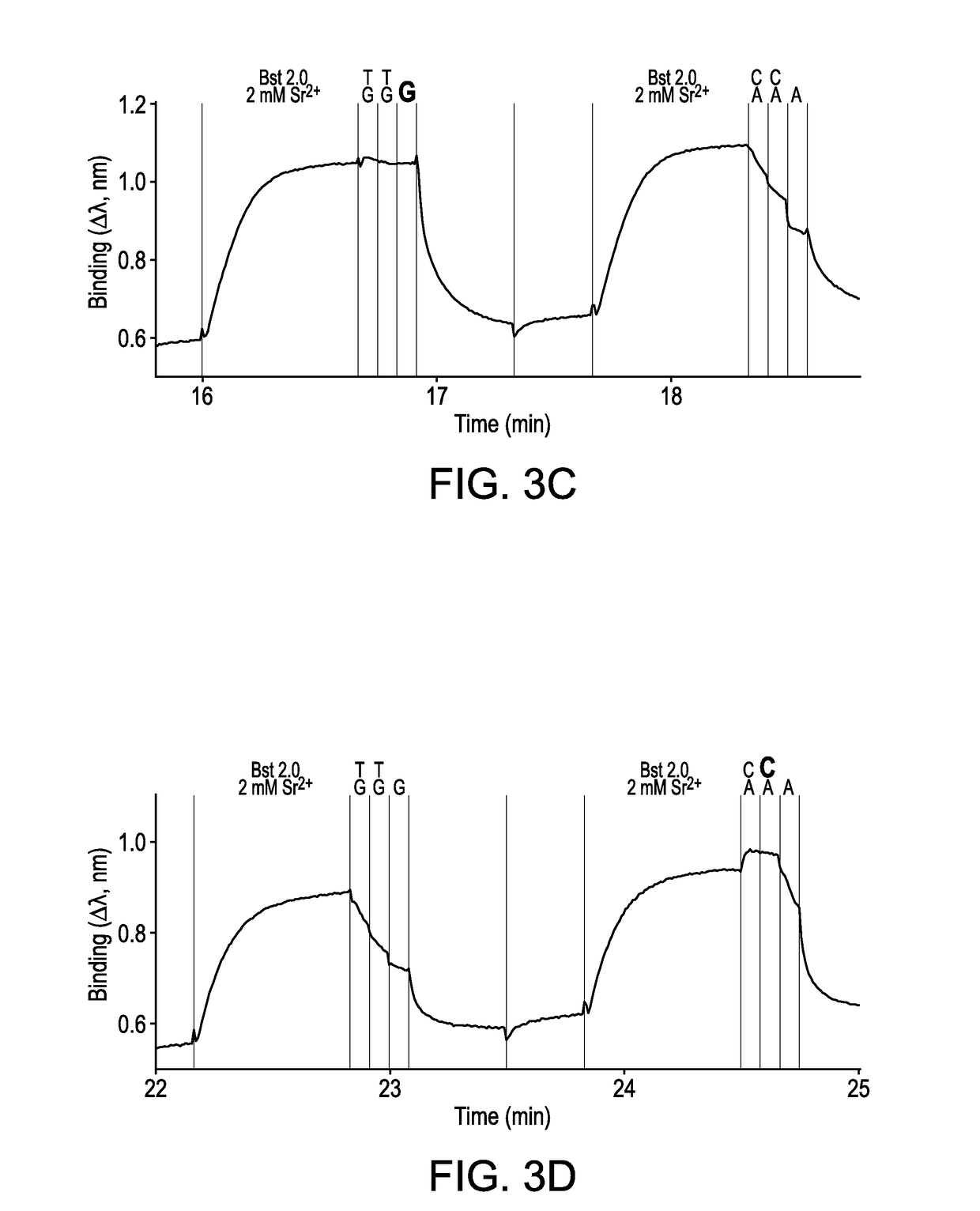

Sequencing method employing ternary complex destabilization to identify cognate nucleotides

Provided are methods and systems for detecting formation of nucleotide-specific ternary complexes comprising a DNA polymerase, a nucleic acid, and a nucleotide complementary to the templated base of the primed template nucleic acid. The methods and systems facilitate determination of the next correct nucleotide without requiring chemical incorporation of the nucleotide into the primer. These results can even be achieved in procedures employing unlabeled, native nucleotides.

Owner:PACIFIC BIOSCIENCES

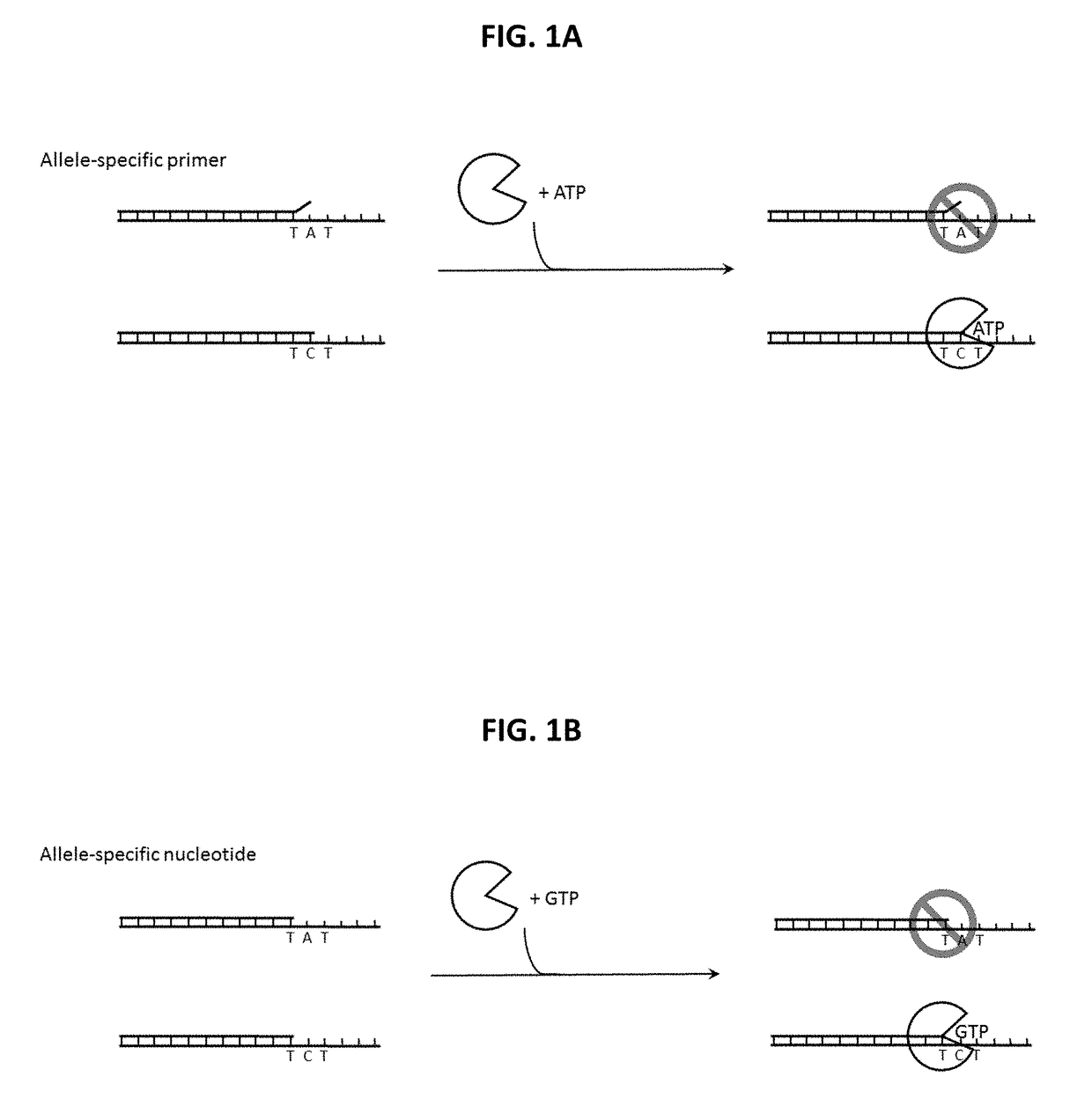

Genotyping by polymerase binding

A method for identifying target alleles, that includes steps of (a) forming a plurality of stabilized ternary complexes at a plurality of features on an array, wherein the stabilized ternary complexes each has a polymerase, a template nucleic acid having a target allele of a locus, a primer hybridized to the locus, and a next correct nucleotide having a cognate in the locus, wherein either (i) the primer is an allele-specific primer having a 3′ nucleotide that is a cognate nucleotide for the target allele, or (ii) the primer is a locus-specific primer and the next correct nucleotide hybridizes to the target allele; and (b) detecting stabilized ternary complexes at the features, thereby identifying the target alleles.

Owner:PACIFIC BIOSCIENCES

Methods and apparatus that increase sequencing-by-binding efficiency

Owner:PACIFIC BIOSCIENCES

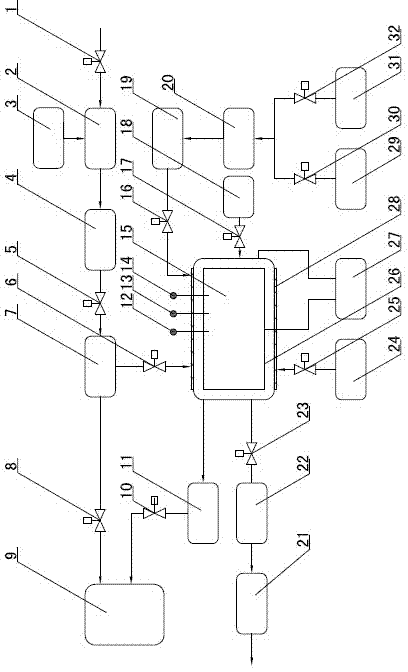

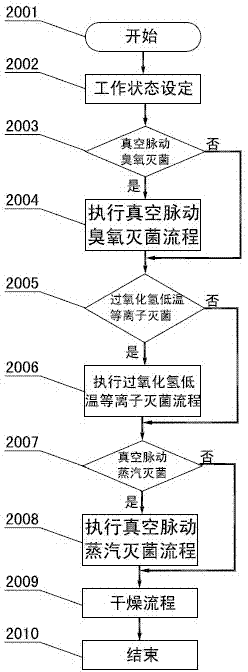

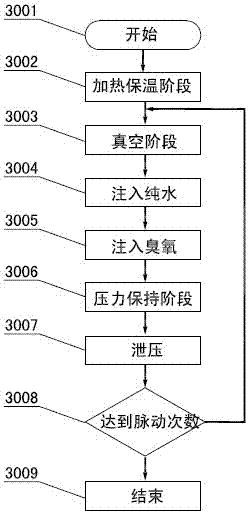

Ternary complex sterilizing method and device

ActiveCN103083698ASterilization is targetedSafe and reliable sterilization processLavatory sanitoryHeatTernary complexEngineering

The invention provides a ternary complex sterilizing method and device, and belongs to the field of medical sterilization equipment. The ternary complex sterilizing method and device provided by the invention provides a vacuum pulse ozone sterilization manner, a hydrogen peroxide low-temperature plasma sterilization manner and a vacuum pulse vapor sterilization manner; and an operator can choose one or more manners for sterilizing according to an object to be sterilized. The ternary complex sterilizing device comprises a sterilization chamber (15), an ozone preparation and transmission pipeline, an emptying pipeline, a vacuum pipeline, an injection pipeline, a vapor pipeline and a drying pipeline, wherein the ozone preparation and transmission pipeline, the emptying pipeline, the vacuum pipeline, the injection pipeline, the vapor pipeline and the drying pipeline are mounted at the periphery of the sterilization chamber (15) in a connected manner. The ternary complex sterilizing method and device provided by the invention can provide the three different sterilization manners in work and use intelligent control in an entire sterilization process, and can be used by randomly selecting one or more manners in a combined manner, so that the ternary complex sterilizing method and device is specific and has wide application range in a sterilization process.

Owner:淄博康元医疗器械有限公司

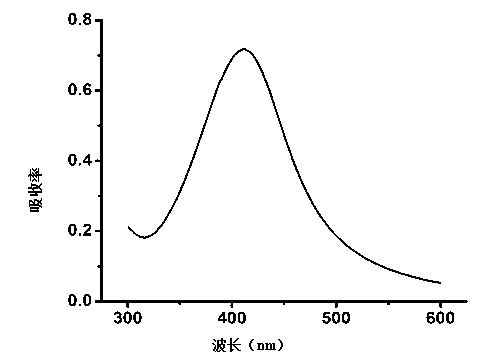

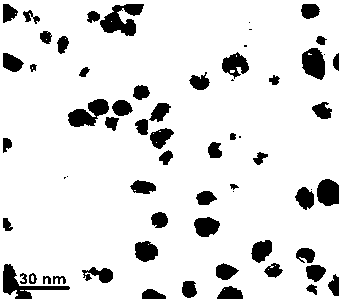

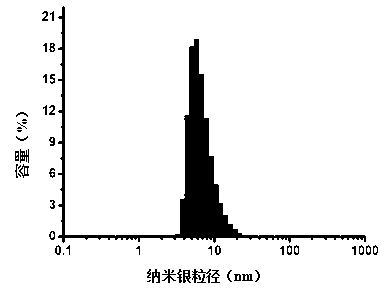

Method for preparing fibroin nano-silver hydrosol

InactiveCN102935521ANon-toxic and environmentally friendlyWide range of raw materialsHYDROSOLReducing agent

The invention discloses a method for preparing fibroin nano-silver hydrosol. The method comprises the following steps of: dissolving or dispersing soluble amylose in deionized water, stirring the mixture until the amylose is completely gelatinized to obtain a starch solution, adding a silver nitrate solution, and then mixing the mixture with a fibroin solution to obtain a fibroin-starch-silver nitrate ternary complex solution; adjusting the pH value of the ternary complex solution to be at 8-10 by ammonia water, and fully mixing at the temperature condition of 20-80 DEG C to obtain the fibroin nano-silver hydrosol with the silver particle size being 1-100nm. According to the method, micromolecule fibroin peptide is used as a capturing agent and a reducing agent, the soluble starch is used as a dispersing agent and a protective agent, and the micromolecule fibroin peptide and the soluble starch are used for reducing and preparing nano-silver. The prepared nano-silver hydrosol is small in silver particle size, uniform in distribution and good in stability, in the prepared process, the reaction is mild, the operation is convenient, the green and environment-friendly aim is realized, and the fibroin nano-silver hydrosol can be widely used as a functional nano-material.

Owner:SUZHOU UNIV

Compositions and methods for detection and isolation of phosphorylated molecules

InactiveUS20070054304A1Simplifies subsequent analysisPeptide/protein ingredientsMicrobiological testing/measurementTernary complexPhosphate

The present invention relates to phosphate-binding compounds that find use in binding, detecting and isolating phosphorylated target molecules including the subsequent identification of target molecules that interact with phosphorylated target molecules or molecules capable of being phosphorylated. A binding solution is provide that comprises a phosphate-binding compound, an acid and a metal ion wherein the metal ion simultaneously interacts with an exposed phosphate group on a target molecule and the metal chelating moiety of the phosphate-binding compound forming a bridge between the phosphate-binding compound and a phosphorylated target molecule resulting in a ternary complex. The binding solution of the present invention finds use in binding and detecting immobilized and solubilized phosphorylated target molecules, isolation of phosphorylated target molecules from a complex mixture and aiding in proteomic analysis wherein kinase and phosphatase substrates and enzymes can be identified.

Owner:LIFE TECH CORP

Compositions and methods for detection and isolation of phosphorylated molecules

ActiveUS7445894B2Simplifies subsequent analysisSugar derivativesPeptide/protein ingredientsTernary complexPhosphate

The present invention relates to phosphate-binding compounds that find use in binding, detecting and isolating phosphorylated target molecules including the subsequent identification of target molecules that interact with phosphorylated target molecules or molecules capable of being phosphorylated. A binding solution is provide that comprises a phosphate-binding compound, an acid and a metal ion wherein the metal ion simultaneously interacts with an exposed phosphate group on a target molecule and the metal chelating moiety of the phosphate-binding compound forming a bridge between the phosphate-binding compound and a phosphorylated target molecule resulting in a ternary complex. The binding solution of the present invention finds use in binding and detecting immobilized and solubilized phosphorylated target molecules, isolation of phosphorylated target molecules from a complex mixture and aiding in proteomic analysis wherein kinase and phosphatase substrates and enzymes can be identified.

Owner:MOLECULAR PROBES

Methods and apparatus that increase sequencing-by-binding efficiency

ActiveUS20180305749A1Improve accuracyIncrease speedMicrobiological testing/measurementTernary complexNucleotide

A method of determining a nucleic acid sequence that includes steps of: (a) contacting a primed template nucleic acid with a series of mixtures for forming ternary complexes, wherein each of the mixtures includes a polymerase and nucleotide cognates for at least two different base types suspected of being present at the next template position of the template nucleic acid; (b) monitoring the next template position for ternary complexes formed by the series of mixtures, wherein a signal state indicates presence or absence of ternary complex formed at the next template position by each individual mixture, thereby determining a series of signal states that encodes a base call for the next template position; and (c) decoding the series of signal states to distinguish a correct base call for the next template position from an error in the base call.

Owner:PACIFIC BIOSCIENCES

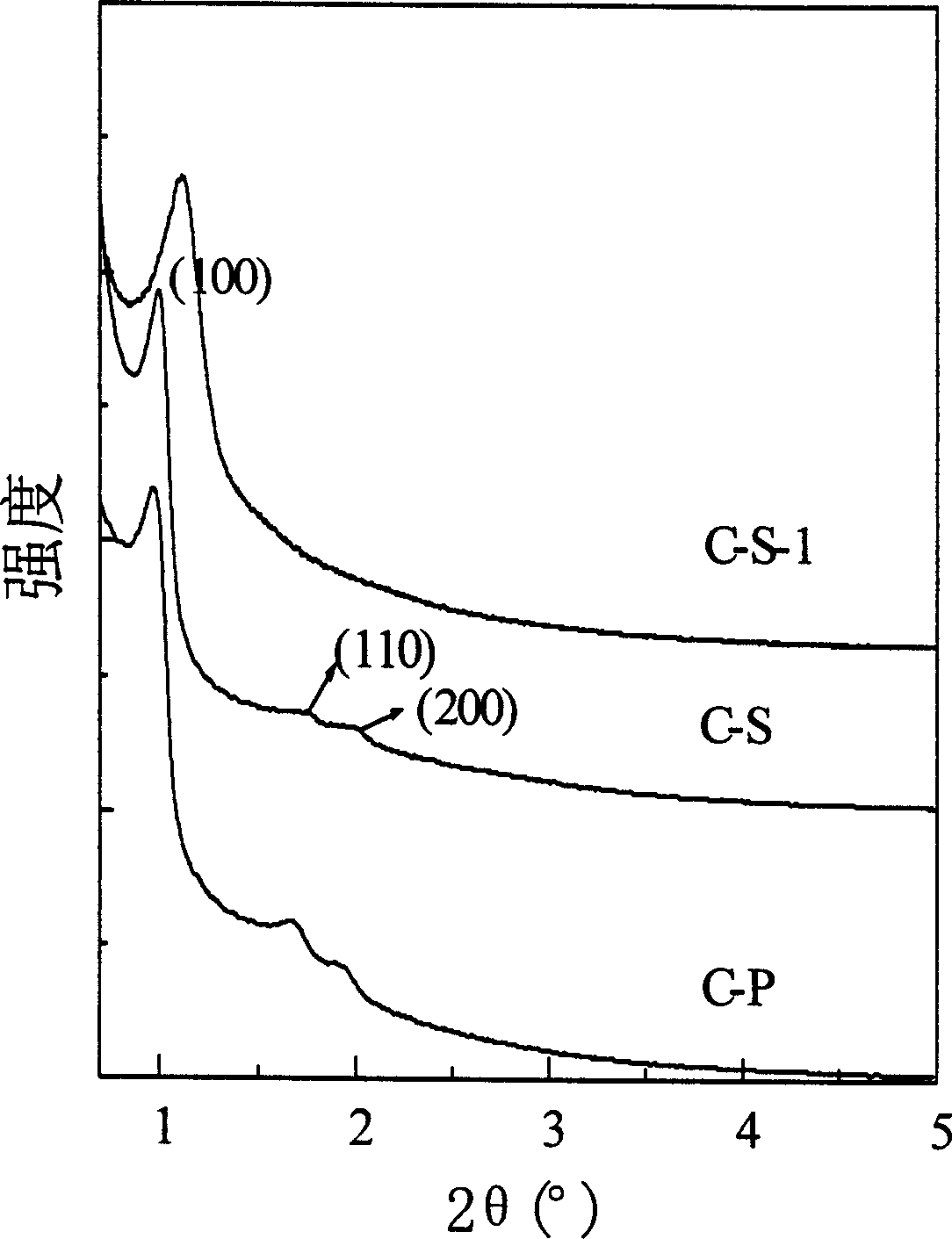

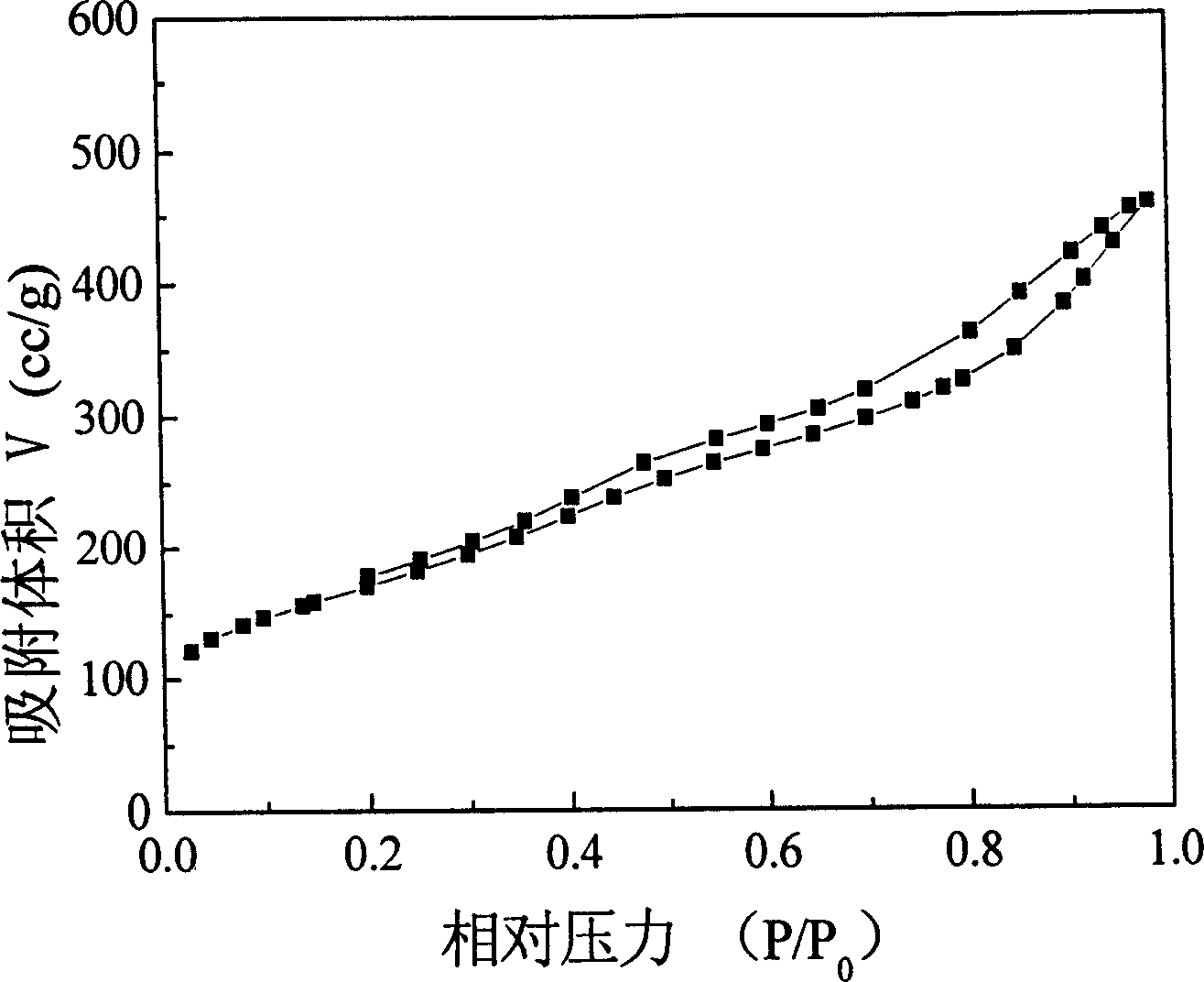

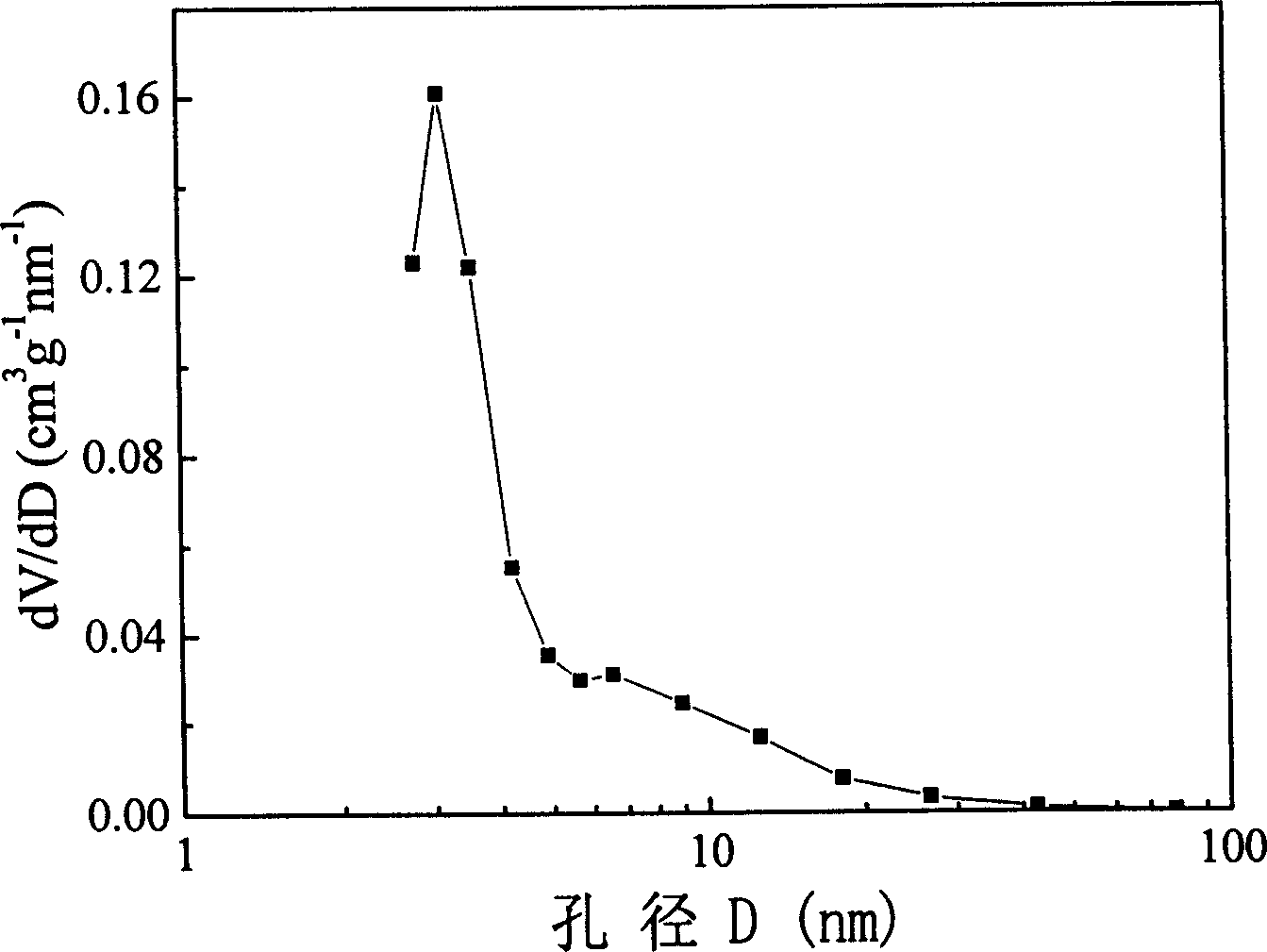

Method for preparing ordered mesoporous carbon

The process of preparing ordered mesoporous carbon material includes the following steps: dissolving three block polyoxene-polypropylene epoxide-polyoxene copolymer and saccharide carbohydrate in the weight ratio of 3-4 in acid solution through stirring at 35 deg.c, adding silicon source in the amount of 7-10 ml for each gram of the saccharide carbohydrate, stirring for 24 hr; crystallizing the obtained solution inside a sealed still at 80-130 deg.c for 24-72 hr, filtering, washing and drying at room temperature to obtain ternary composition of saccharide carbohydrate, three block copolymer and silicon; and pre-carbonizing, carbonizing and eliminating silicon to obtain ordered mesoporous carbon material. The process has low cost, high carbon forming rate homogeneous pore size and other features.

Owner:CHINA PETROLEUM & CHEM CORP +1

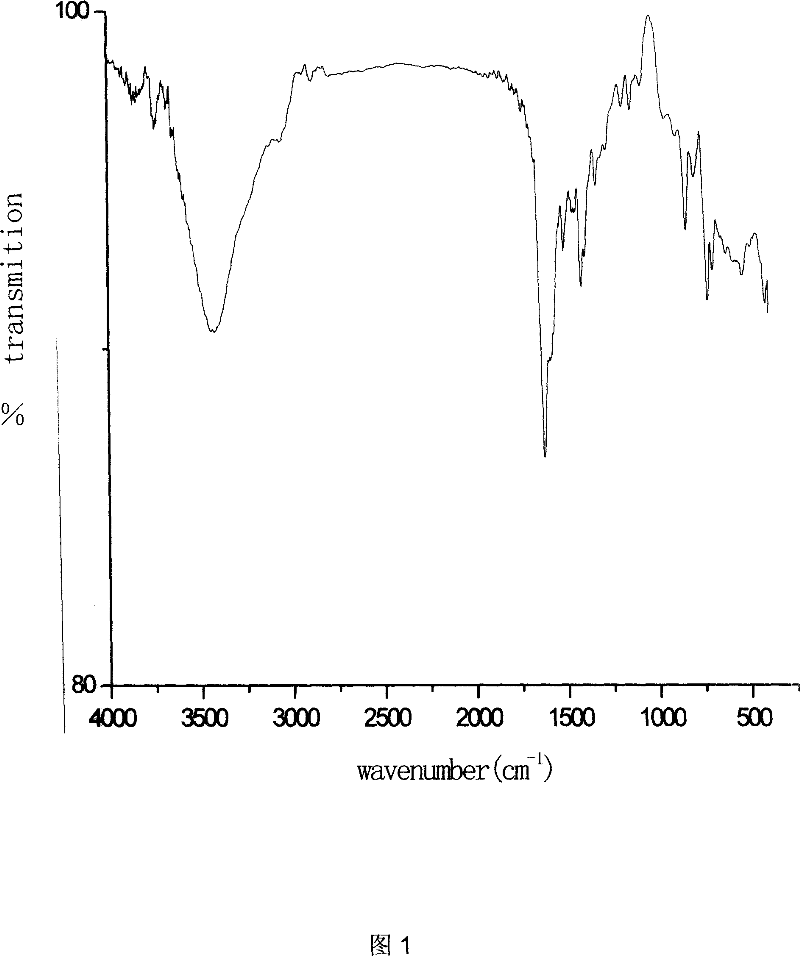

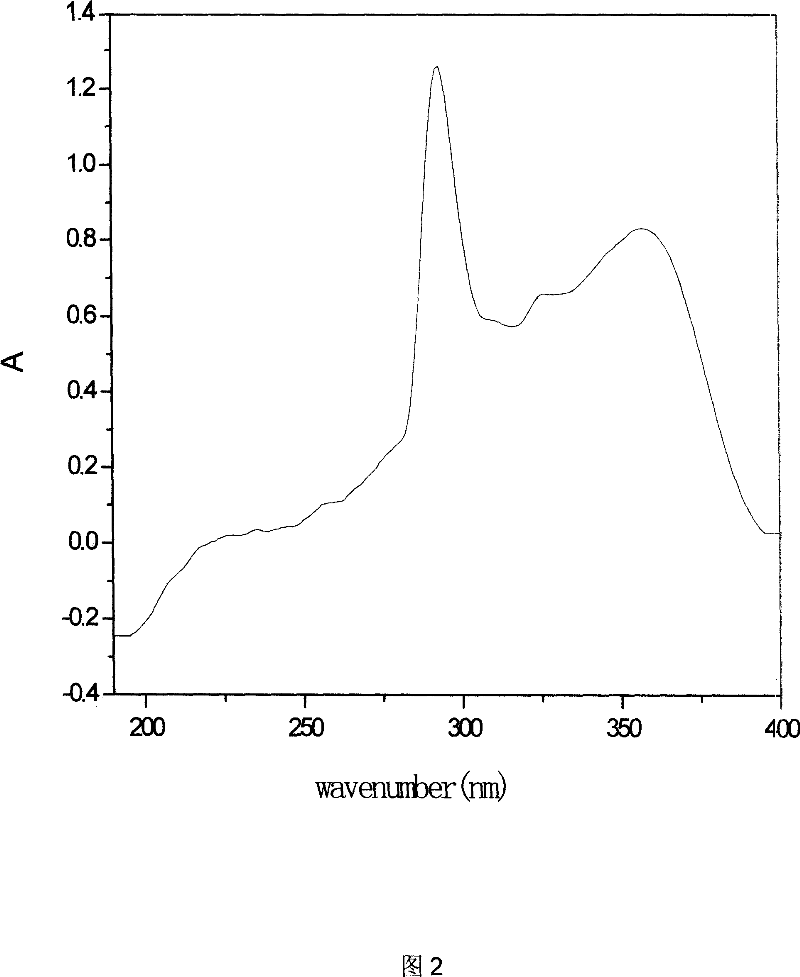

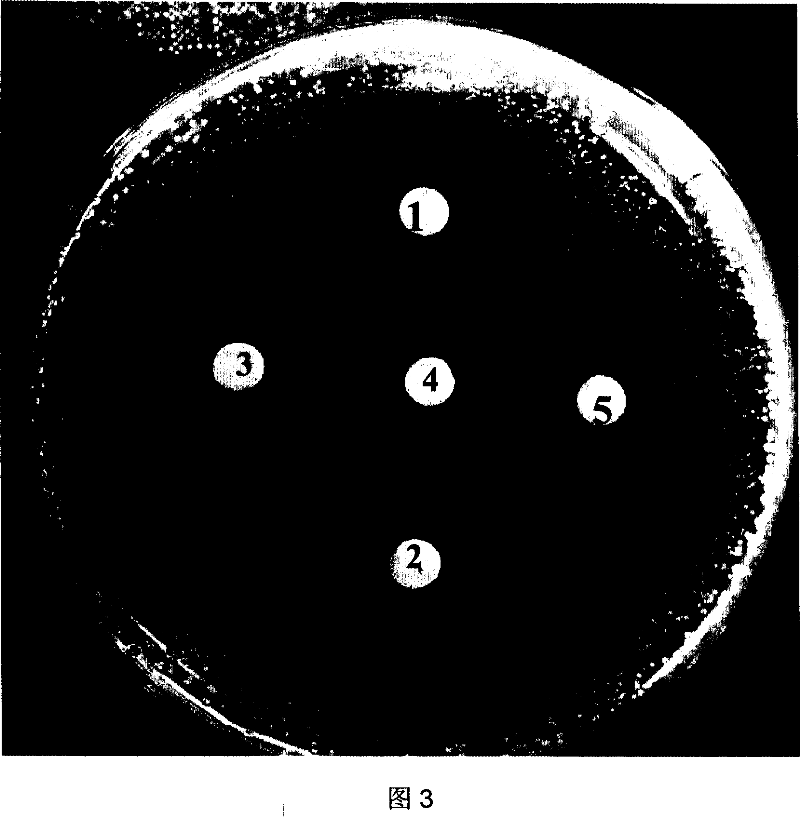

Antibiosis rare earth ternary complexes and preparation method and application thereof

InactiveCN101041666AGood chemical stabilityImprove thermal stabilityBiocideFungicidesTernary complexAntibiosis

The invention discloses a making method of antibiotic rare-earth ternary complex and application in the antibiotic material, whose chemical formula is RE (L) (A) (H2O), wherein RE is selected from one or more of La3+, Ce3+, Pr3+, Nd3+, Sm3+, Eu3+, Y3+, Er3+ or Gd3+; L is schiff bases salicylal anphenylalanine or schiff bases salicylal anaspartic acid; A is ortho-phenanthroline or pyridine.

Owner:SHANGHAI NORMAL UNIVERSITY

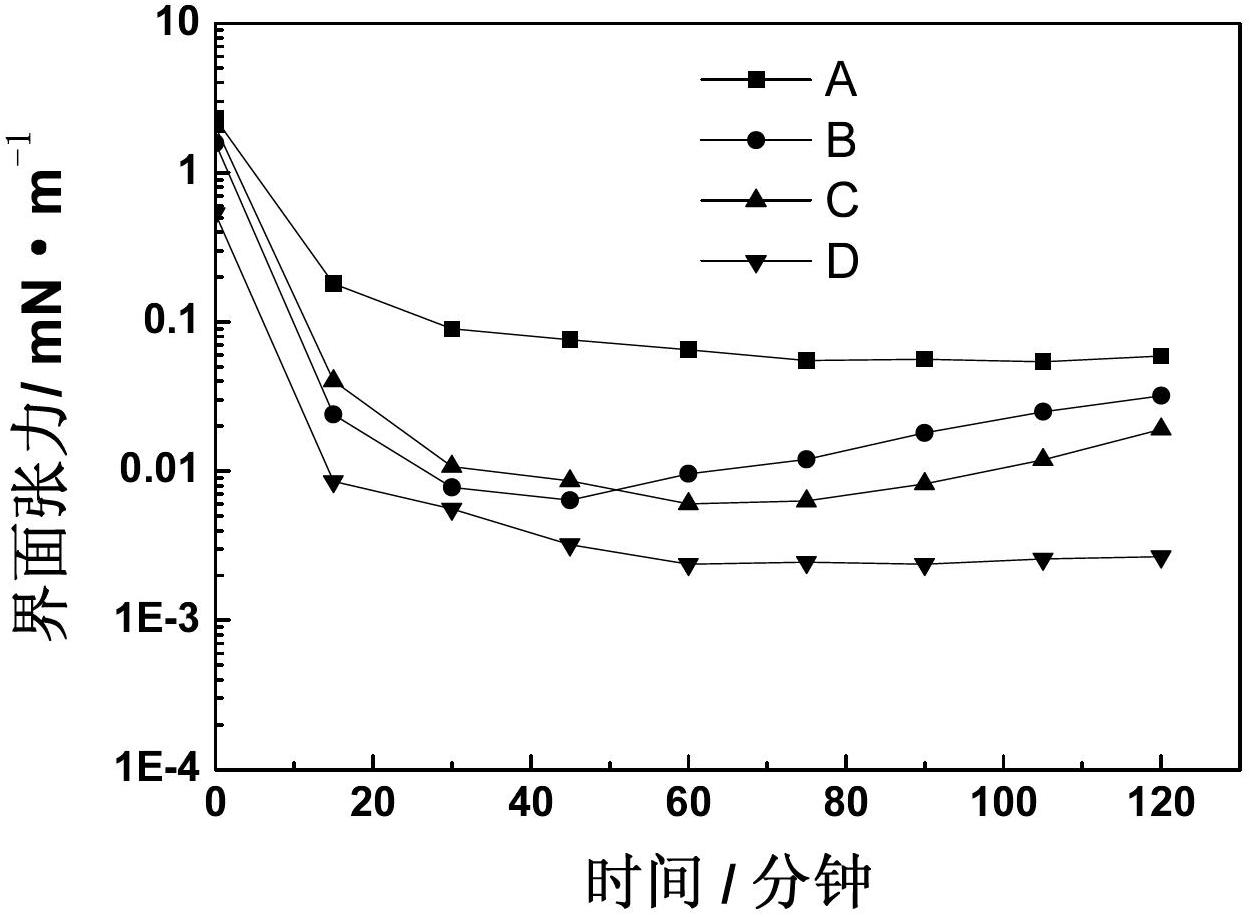

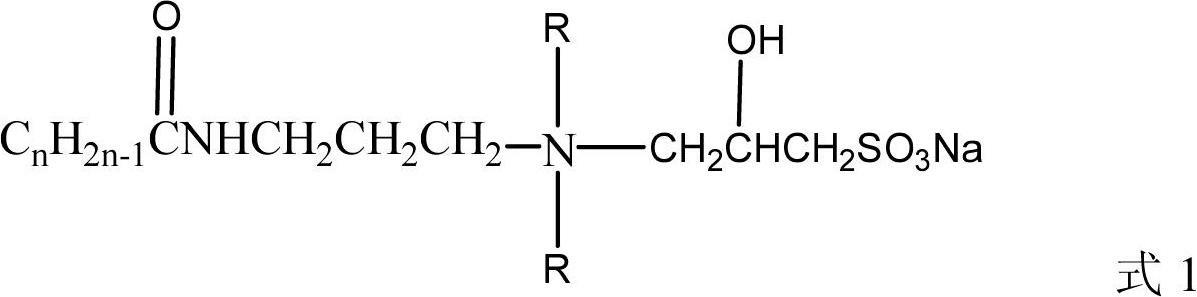

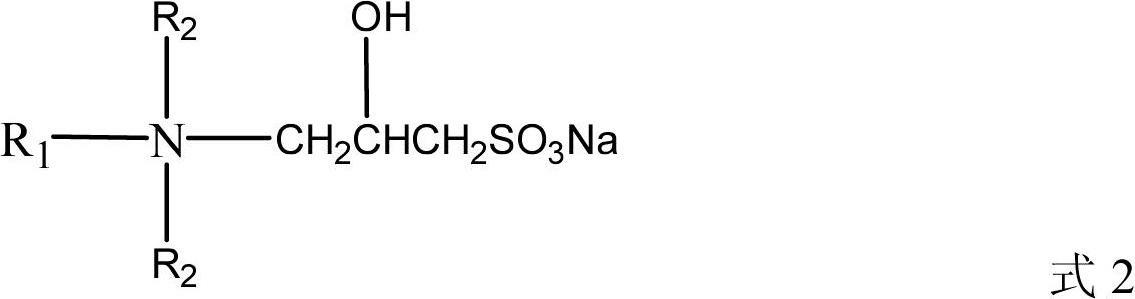

Ternary complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application thereof

ActiveCN102690642AImprove interface performanceGood emulsificationFluid removalDrilling compositionTernary complexMass ratio

The invention relates to a ternary complex composition for flooding, suitable for high-temperature and high-salinity reservoir, and application of the composition. The ternary complex composition for flooding is composed of the following components measured by total weight of the ternary complex composition for flooding: 0.05-0.3% of complex surfactants, 0.1-0.25% of polymers, 0.05-2.0% of alkaline matters and the balance of water; wherein the complex surfactants are composed of two kinds of hydroxysulfobetaine with different structures and a mass ratio of 9: 1-4: 6. The invention further provides the application of the ternary complex composition for flooding in tertiary oil recovery. The ternary complex flooding composition of the complex surfactants provided by the invention is featured with high flooding efficiency and low cost of oleamide hydroxysulfobetaine, and is capable of reducing flooding cost.

Owner:PETROCHINA CO LTD

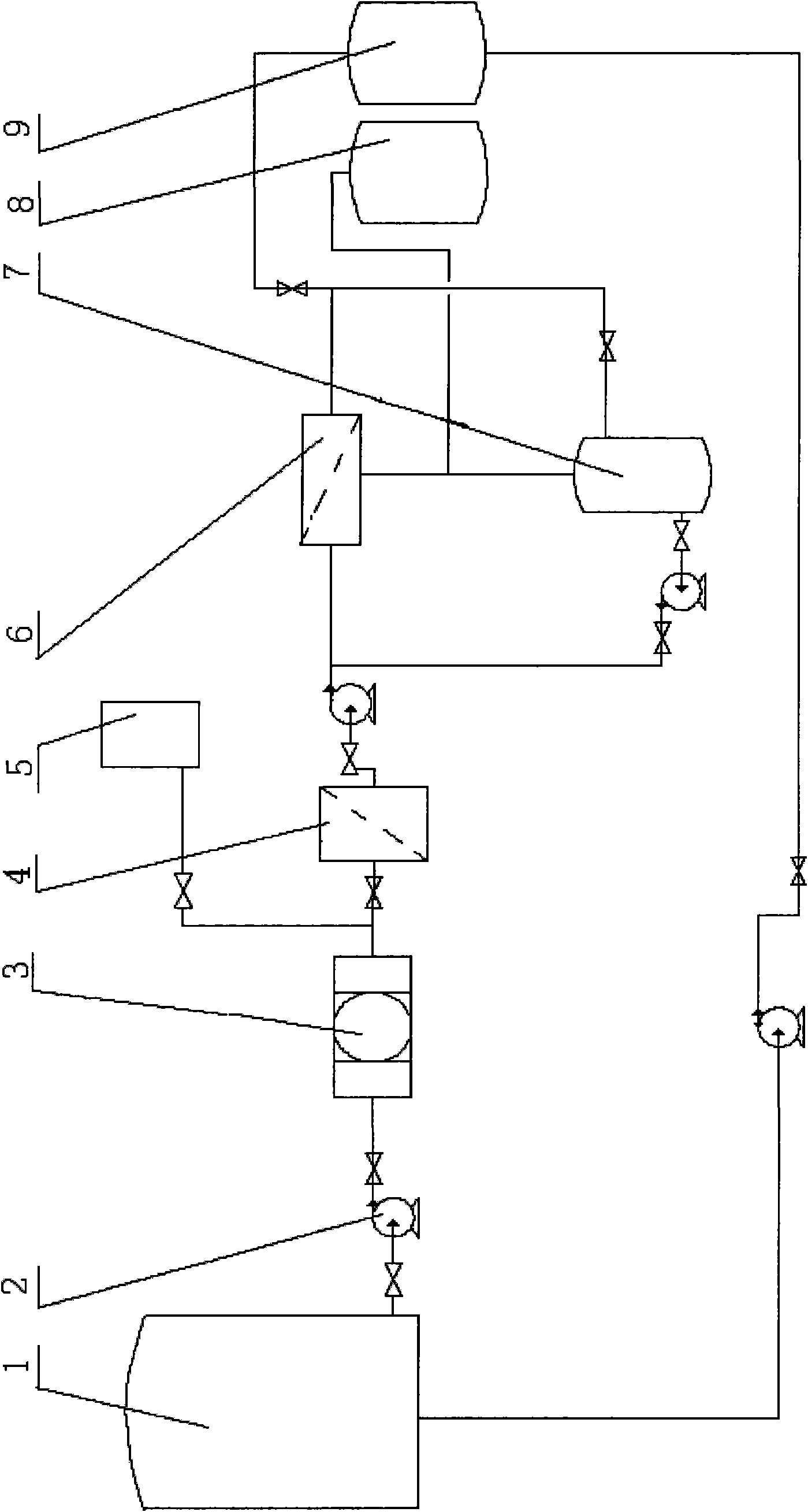

Method for removing sulfate radical from injected water in oil field for anti-scaling

ActiveCN101525986AGuaranteed stable productionReduce water injection pressureCleaning apparatusDrilling compositionSulfate radicalsFiltration

A method for removing sulfate radical from injected water in oil field for anti-scaling is applied in anti-scaling of oil fields and oil-water wells. The method is characterized by firstly pumping injected water into a coarse filtration system by a high-pressure pump for carrying out the coarse filtration treatment and then into a fine filtration system for treatment; and further pumping the injected water after the two-stage filtration by the coarse filtration system and the fine filtration system into a nanofiltration system for treatment. The injected water after the treatment is divided into clear water and condensed water. The clear water is directly re-injected to the underground target layer position. A ternary complex scale cleaning agent is added before the injected water enters the fine filtration system. The method has the effects that a nanofiltration film is adopted to remove sulfate ions in the injected water, thereby solving barium and strontium scales generated by incompatibility of the injected water and formation water, and the anti-scaling rate can be more than 80 percent; the ternary complex scale cleaning agent is added in the injected water before the injected water enters the fine filtration system, thereby leading the clear water after the treatment to be capable of reducing the formation scales and further reducing the scales of the nanofiltration film of the nanofiltration system.

Owner:PETROCHINA CO LTD

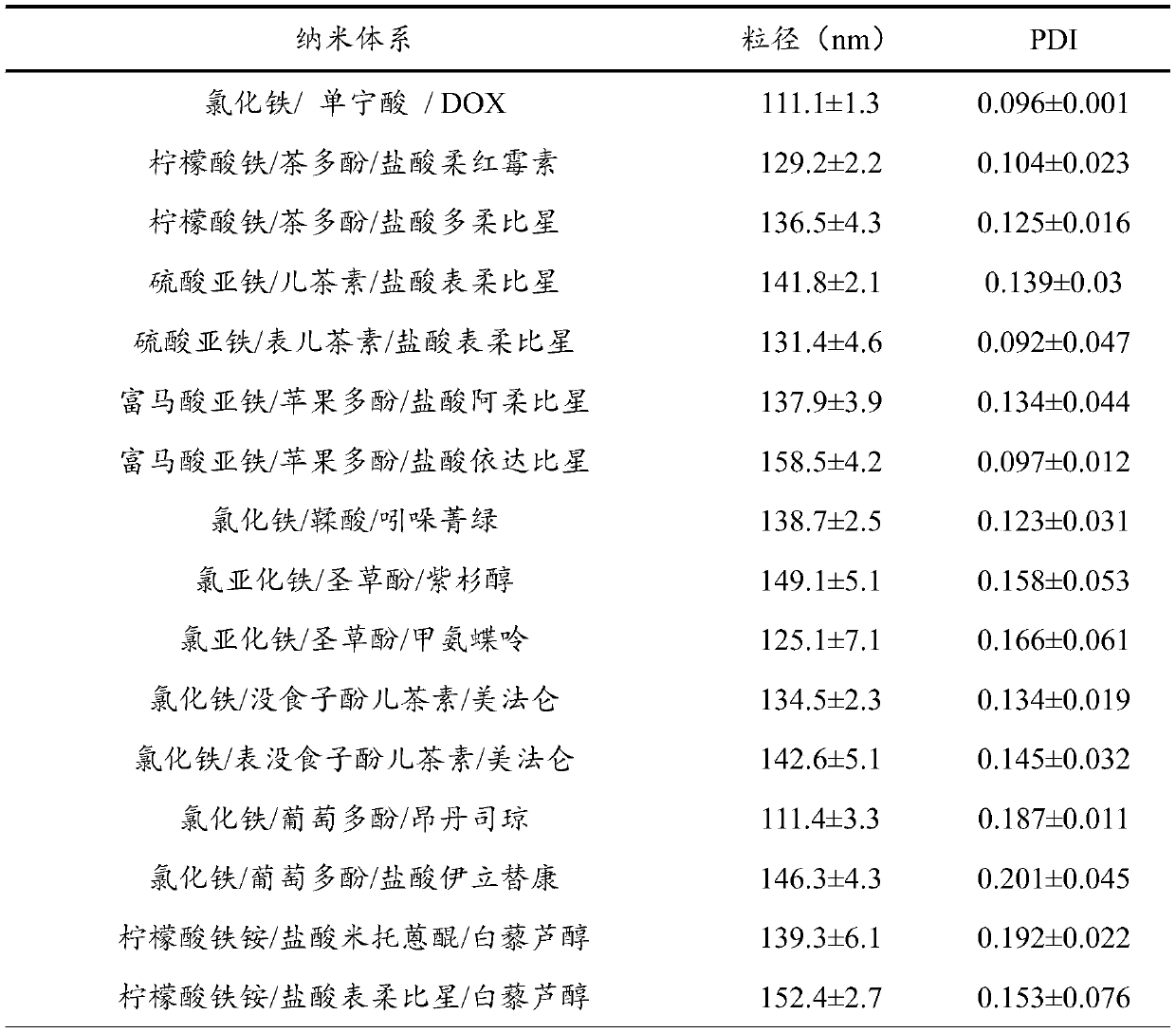

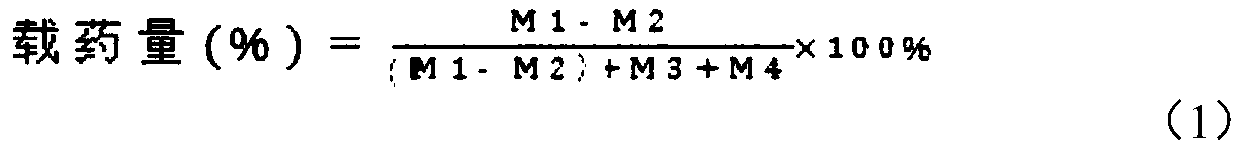

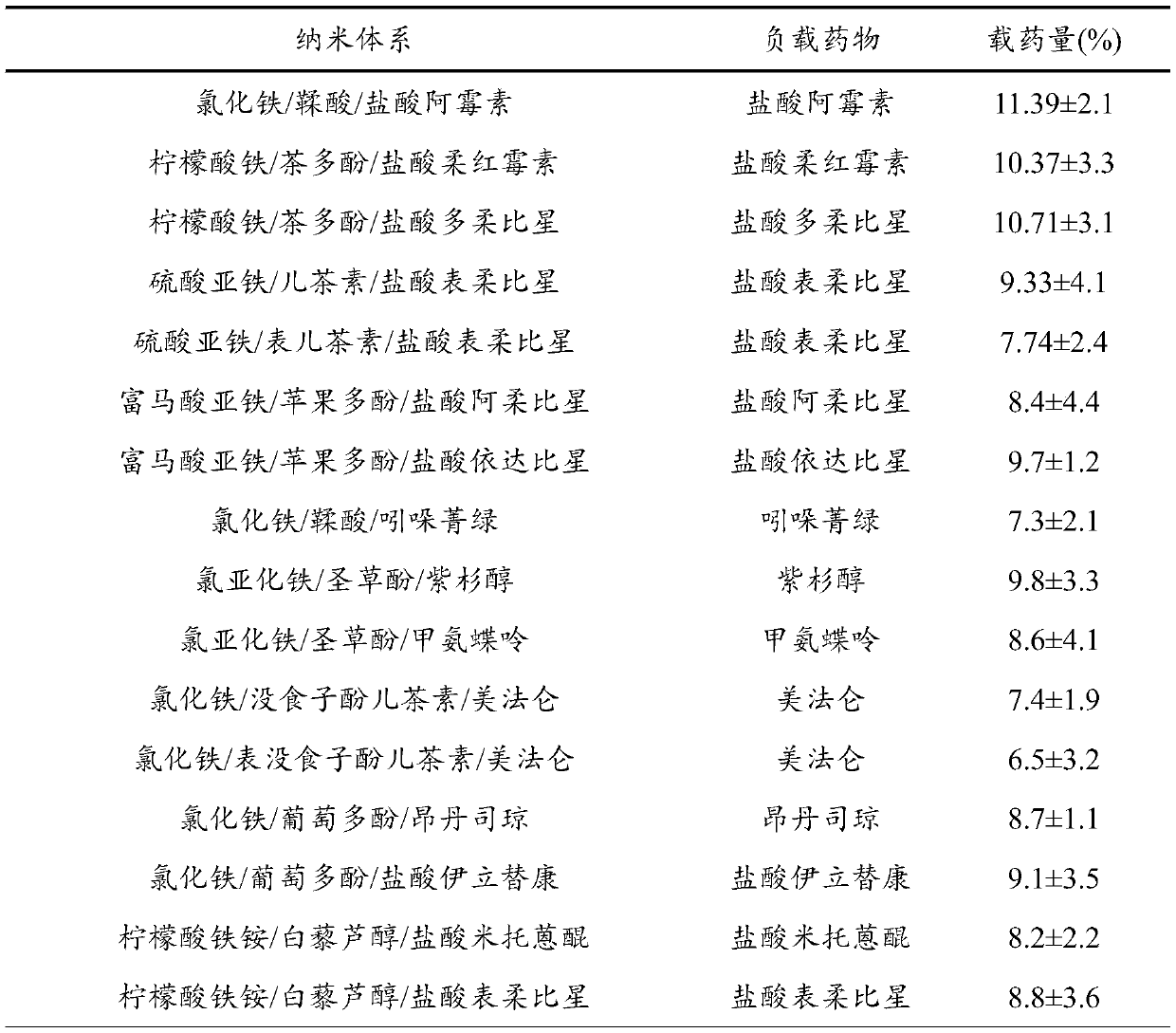

Ternary complex nanometer system and preparation method and application thereof

ActiveCN109806252AGood photothermal effectEnhance killing activityOrganic active ingredientsPharmaceutical non-active ingredientsFenton reactionTernary complex

Owner:CHINA PHARM UNIV

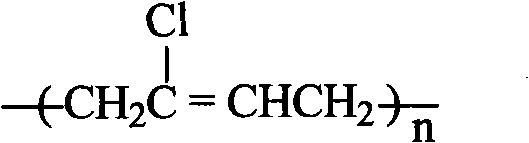

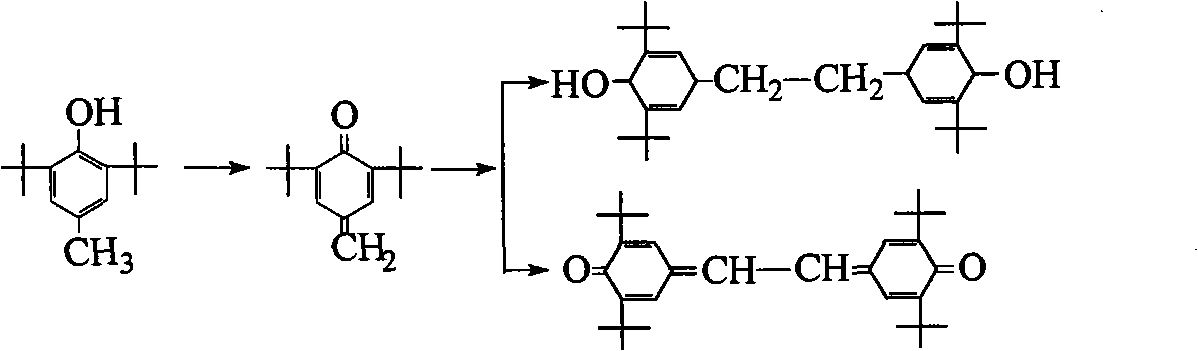

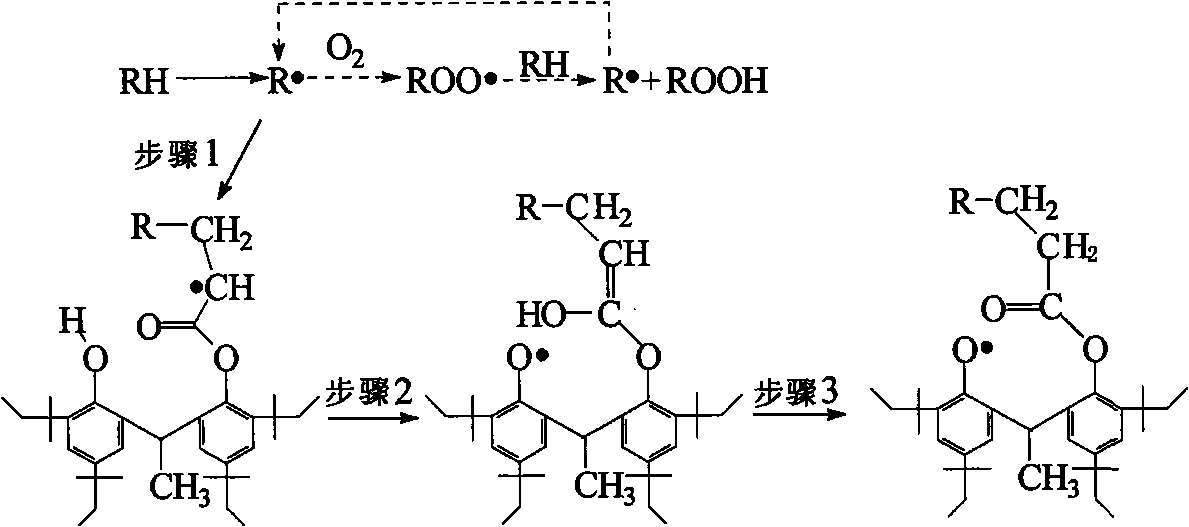

Method for preparing ternary complex antiager and emulsion and application thereof in neoprene

InactiveCN101665585AImprove thermal stabilityImprove antioxidant efficiencyTernary complexPolymer science

The invention provides a method for preparing ternary complex antiager and an emulsion and an application thereof in neoprene. The ternary complex antiager is prepared by formulation and mixing of a bisphenol mono-acrylate antiager, a hindered phenolic antiager and a sulfoether antiager according to specified proportioning. The preparation method comprises the following steps: dissolving the ternary complex antiager prepared by the above method with an organic solvent at room temperature; adding an emulsifying agent prepared by the mixture of disproportionated rosin acid soap water solution and sulfoacid anionicsurfactant water solution for fully mixing; and obtaining the ternary complex antiager emulsion after dispersing. In the process of synthesizing the neoprene rubber latex, the ratioof the dry glue of the neoprene in terms of the added ternary complex antiager emulsion is 1:0.03-0.07. The research of an aging test shows that the neoprene product prepared by adding the ternary complex antiager emulsion of the invention is superior to the neoprene product prepared by using the antiager BHT in the aspects of appearance color, Mooney viscosity, Mooney scorch time and mechanicalintensity property indexes.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Preparation method of nano-ternary complex lithium-ion battery cathode material

InactiveCN101944602AImprove consistencyAvoid uneven mixingCell electrodesWater bathsLithium-ion battery

The invention provides a preparation method of a nano-ternary complex lithium-ion battery cathode material, which comprises the following steps: 1) respectively dissolving soluble Li, Ni, Co and Mn compounds into deionized water according to the molar ratio of 1: x: y: z, mixing four kinds of solution, fully stirring and obtaining the uniform mixed solution, wherein x is not less than 0 and not more than 0.5, y is not less than 0.2 and not more than 0.6, z is not less than 0 and not more than 0.5, and x plus y plus z is equal to 1; 2) adding citric acid into the mixed solution as a metal ion chelating agent; and 3) transferring the mixed solution into a water bath pot for heating, carrying out full reaction, forming sol, carrying out vacuum drying on the obtained sol, then carrying out high-temperature sintering in air and obtaining the cathode material with the primary particle diameter of below 100nm and the molecular formula of LiNixCoyMnzO2. Compared with the prior art, the preparation method can prepare the LiNixCoyMnzO2 ternary material with primary particles of below 100nm by adopting the sol-gel method.

Owner:IRICO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com