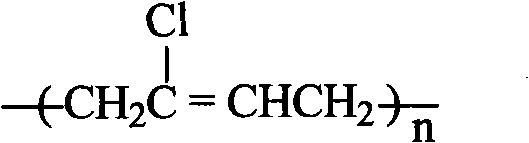

Method for preparing ternary complex antiager and emulsion and application thereof in neoprene

A technology of ternary compound and manufacturing method, which is applied in the manufacture of ternary compound anti-aging agent and emulsion and in the application field of chloroprene rubber, which can solve the problems of poor anti-aging performance and environmental pollution, and achieve good thermal stability , high anti-oxidation efficiency, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

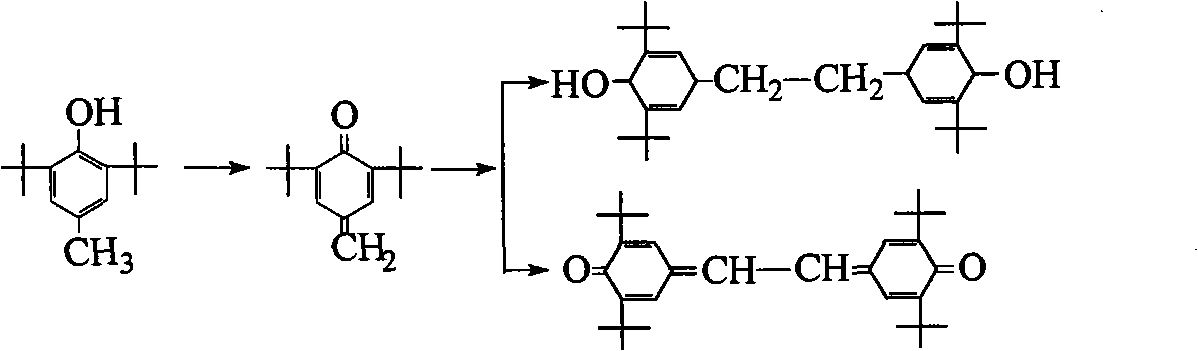

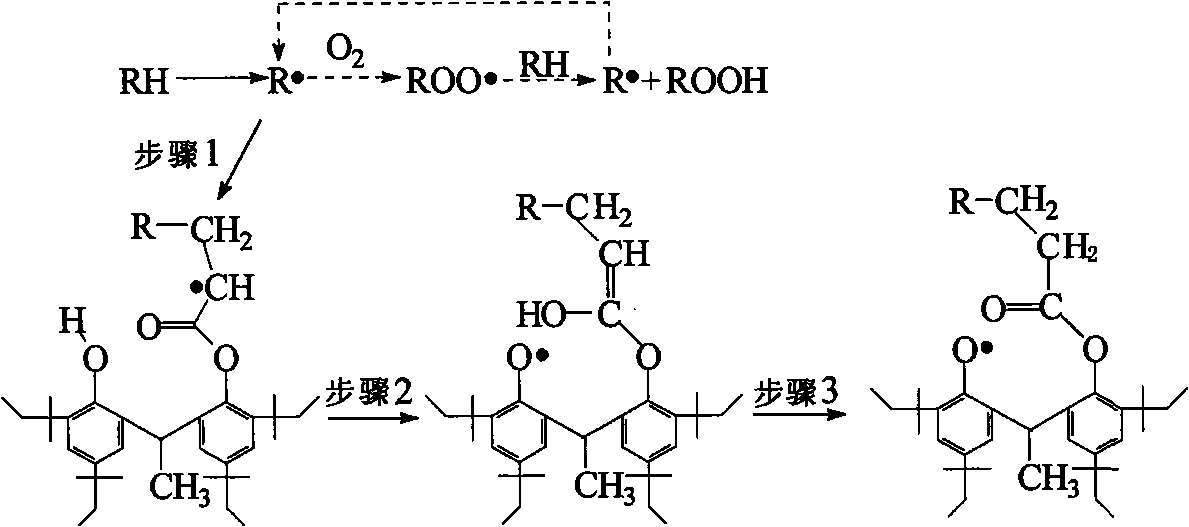

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Weigh 3000 grams of CR244 neoprene emulsion and 46 grams of 1# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing and drying, a neoprene product with stable properties was obtained, that is, the 1# sample.

Embodiment 2

[0073] Weigh 3000 grams of CR244 neoprene emulsion and 26 grams of 2# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing, and drying, a neoprene product with stable performance was obtained, that is, the 2# sample.

Embodiment 3

[0075] Weigh 3000 grams of CR244 neoprene emulsion and 76 grams of 3# ternary composite anti-aging agent emulsion, stir well and mix evenly. After coagulation, washing, and drying, a neoprene product with stable performance was obtained, that is, the 3# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com