Patents

Literature

70results about How to "Reduce the degree of variation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Executing multiple debug instructions

InactiveUS6343358B1Reduce the degree of variationEasy to implementElectronic circuit testingDetecting faulty computer hardwareComputer hardwareProcessor register

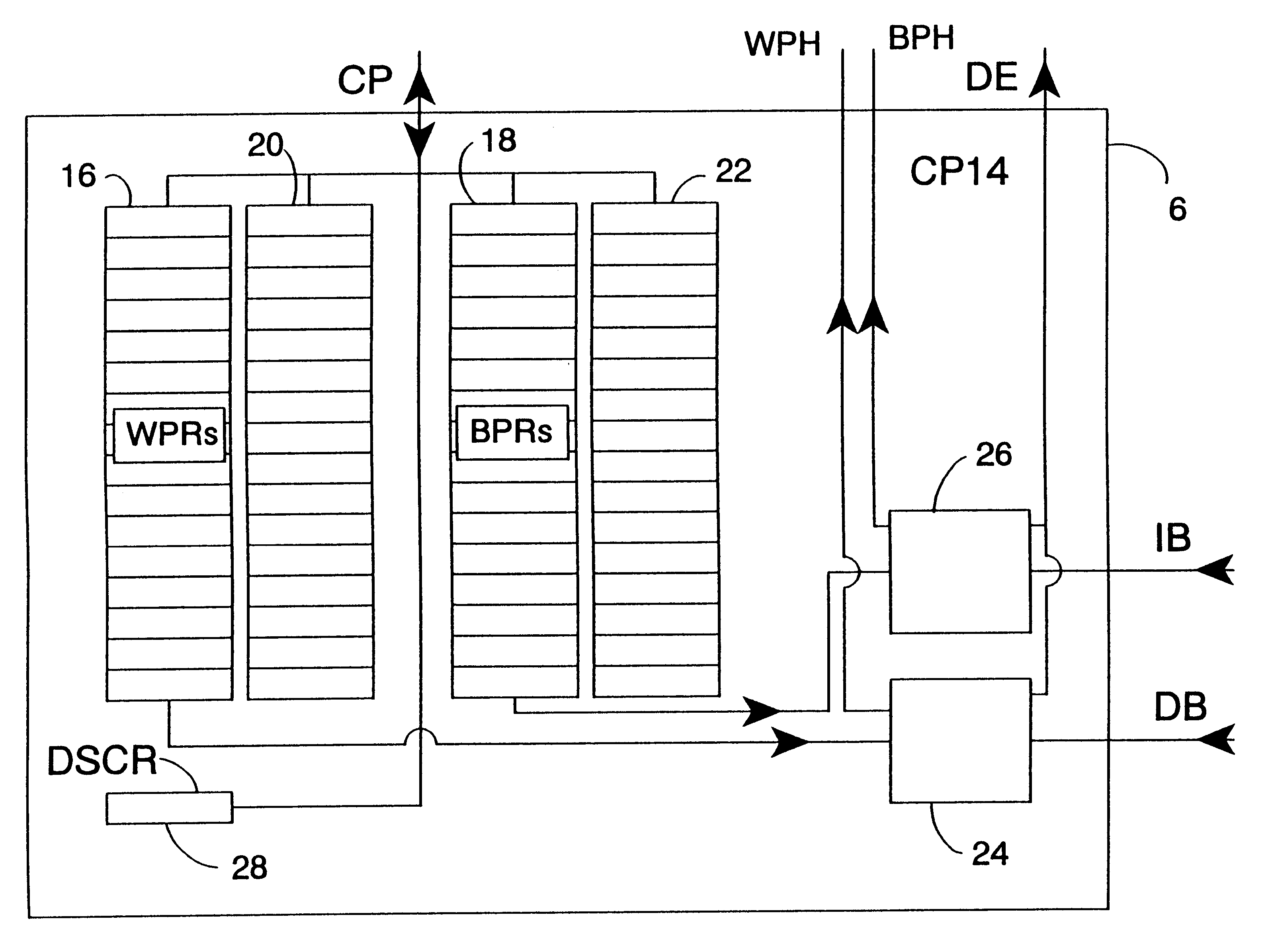

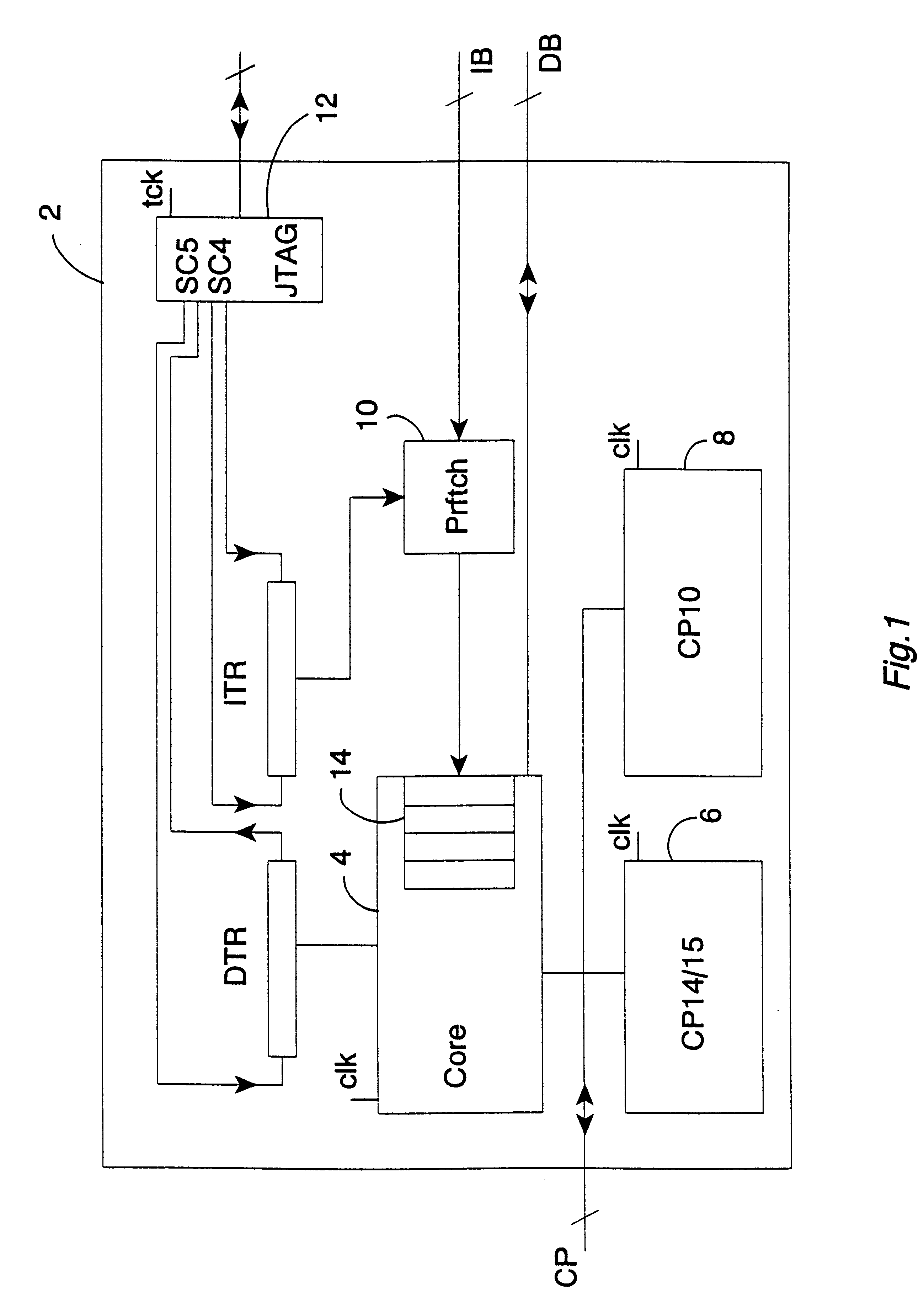

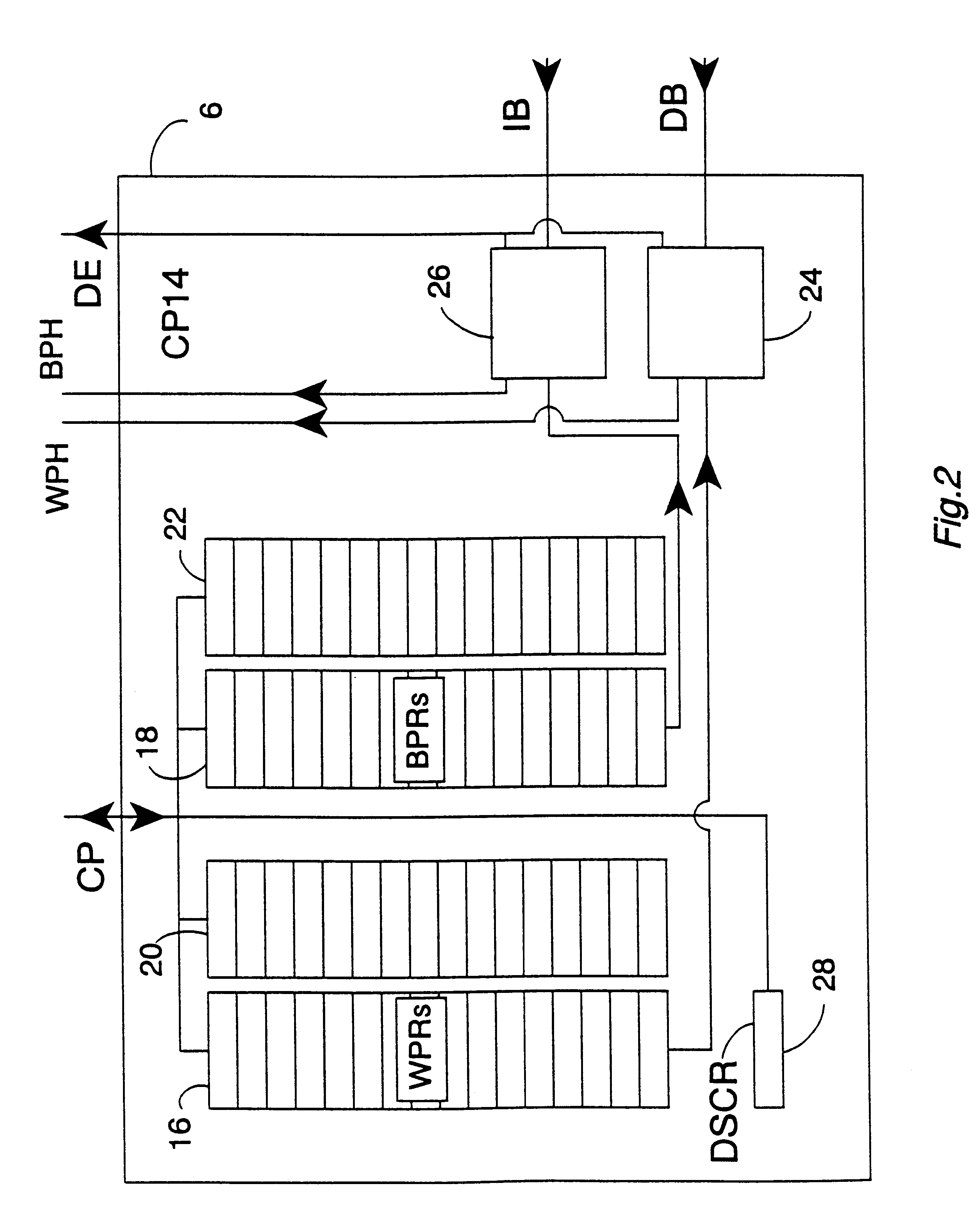

Apparatus for processing data is provided, said apparatus comprising: a main processor 4; an instruction transfer register ITR for holding a data processing instruction and accessible via a first serial scan chain SC4; a data transfer register DTR for holding a data value and accessible via a second serial scan chain SC5; debug logic 6, 12 for controlling said main processor 4, said instruction transfer register ITR and said data transfer register DTR such that a data processing instruction held within said instruction transfer register ITR is passed a plurality of times to said main processor 4 for execution upon a sequence of data values scanned into or from said data transfer register via said second serial scan chain. In this way operational speed of the debug mode is increased since the data processing instruction only needs to be transferred once.

Owner:ARM LTD

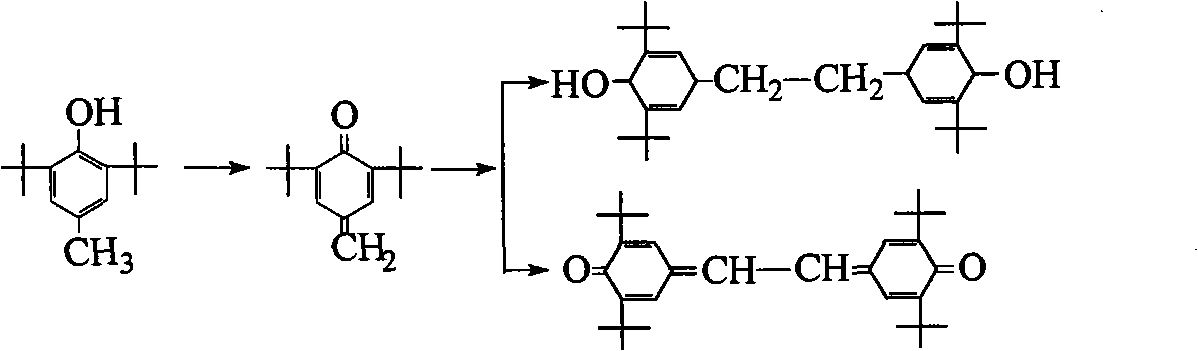

Method for preparing ternary complex antiager and emulsion and application thereof in neoprene

InactiveCN101665585AImprove thermal stabilityImprove antioxidant efficiencyTernary complexPolymer science

The invention provides a method for preparing ternary complex antiager and an emulsion and an application thereof in neoprene. The ternary complex antiager is prepared by formulation and mixing of a bisphenol mono-acrylate antiager, a hindered phenolic antiager and a sulfoether antiager according to specified proportioning. The preparation method comprises the following steps: dissolving the ternary complex antiager prepared by the above method with an organic solvent at room temperature; adding an emulsifying agent prepared by the mixture of disproportionated rosin acid soap water solution and sulfoacid anionicsurfactant water solution for fully mixing; and obtaining the ternary complex antiager emulsion after dispersing. In the process of synthesizing the neoprene rubber latex, the ratioof the dry glue of the neoprene in terms of the added ternary complex antiager emulsion is 1:0.03-0.07. The research of an aging test shows that the neoprene product prepared by adding the ternary complex antiager emulsion of the invention is superior to the neoprene product prepared by using the antiager BHT in the aspects of appearance color, Mooney viscosity, Mooney scorch time and mechanicalintensity property indexes.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

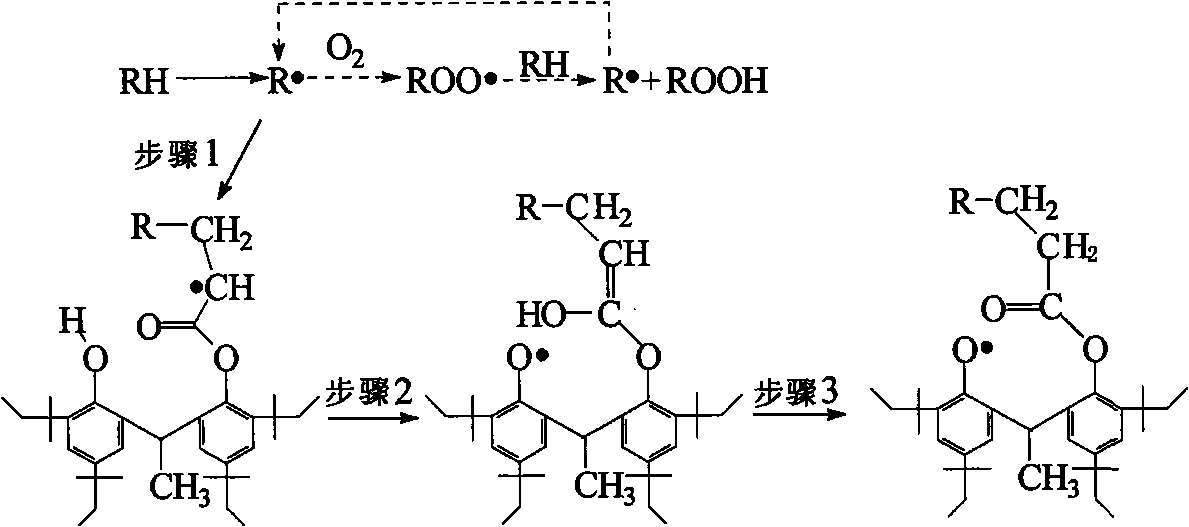

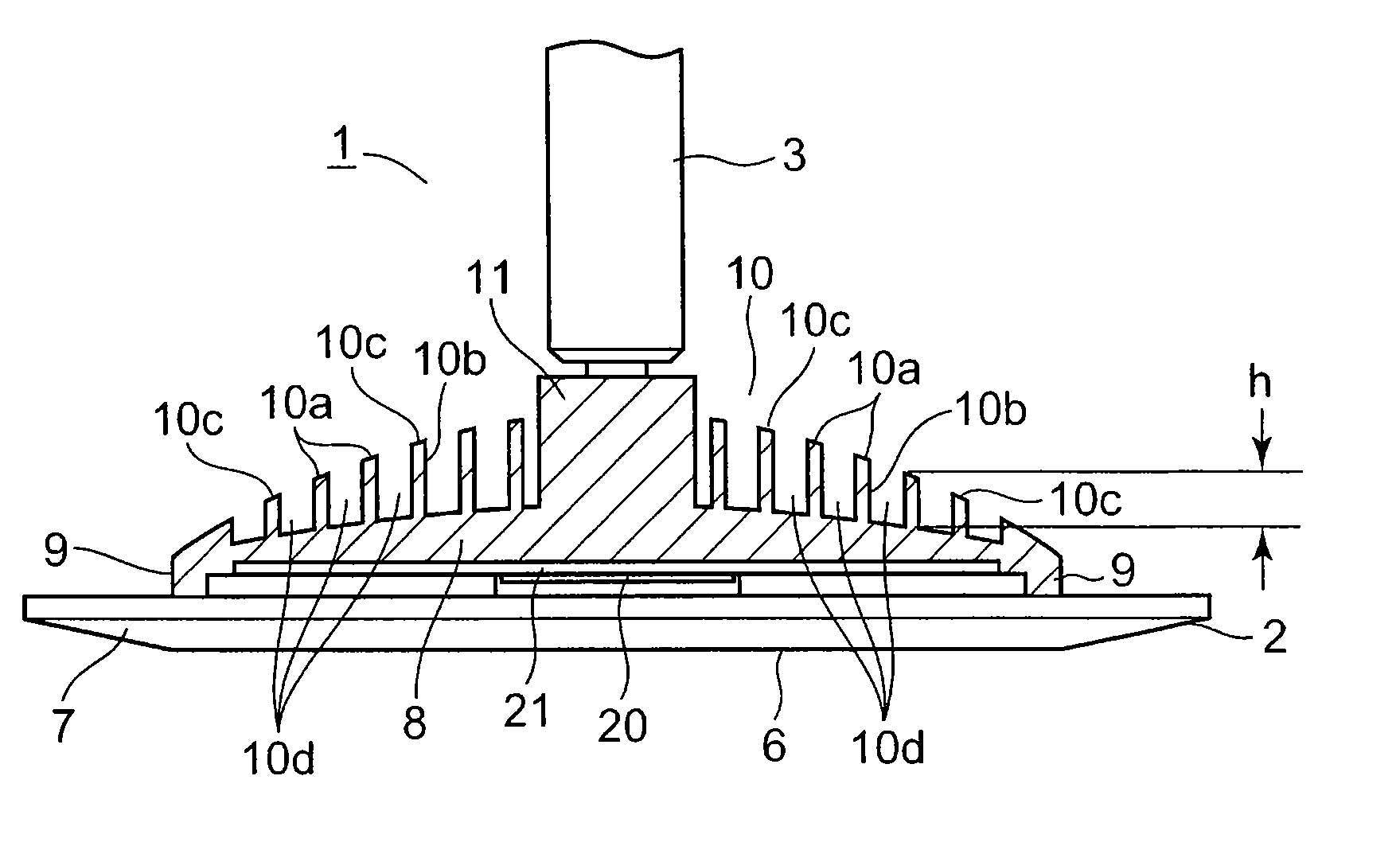

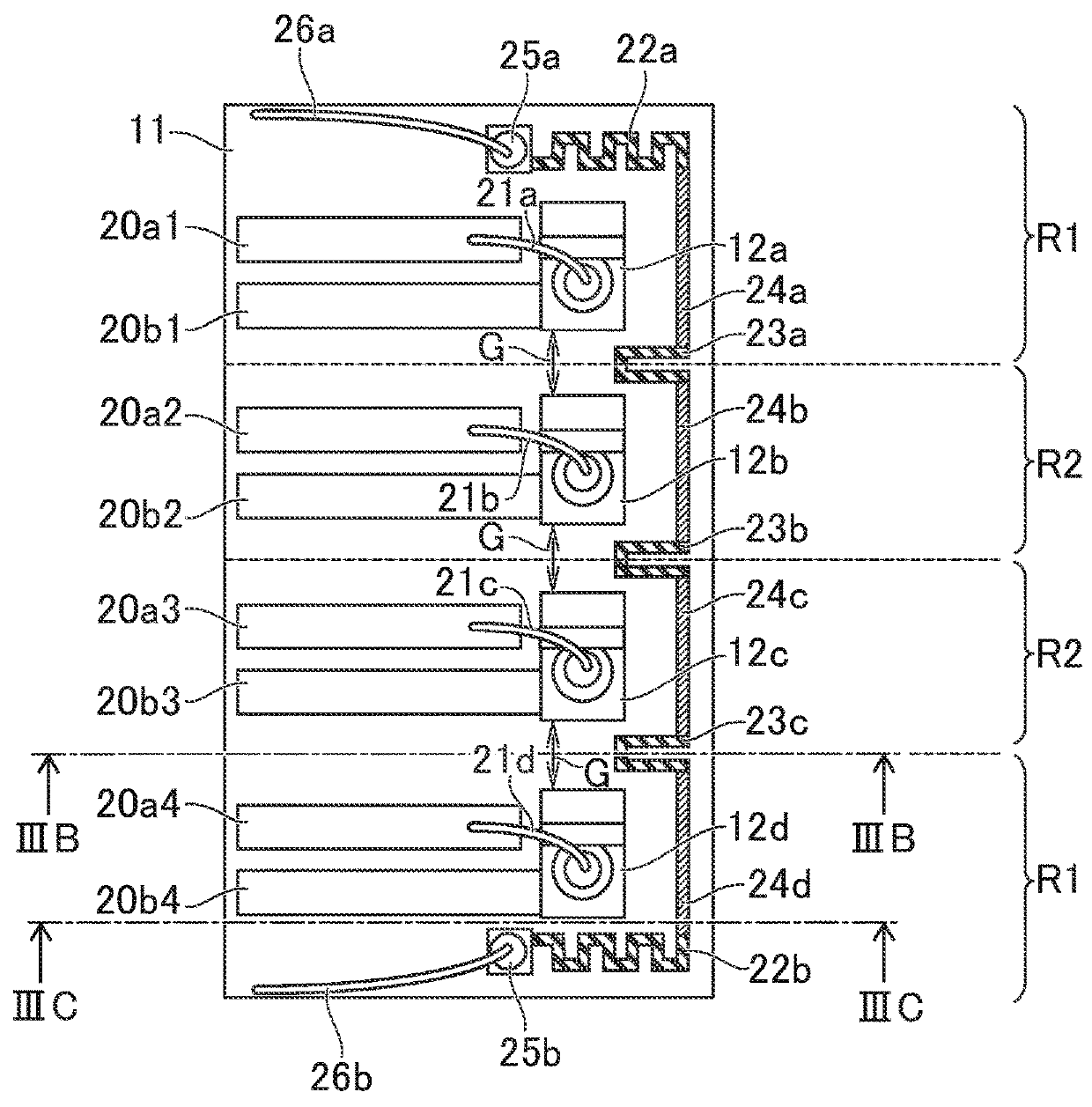

Lighting system

InactiveUS8414164B2Avoid disagreementRange of change in the light emission efficiency of light emitting elements can be made smallerPlanar light sourcesPoint-like light sourceEngineeringHeat sink

Owner:TOSHIBA LIGHTING & TECH CORP +1

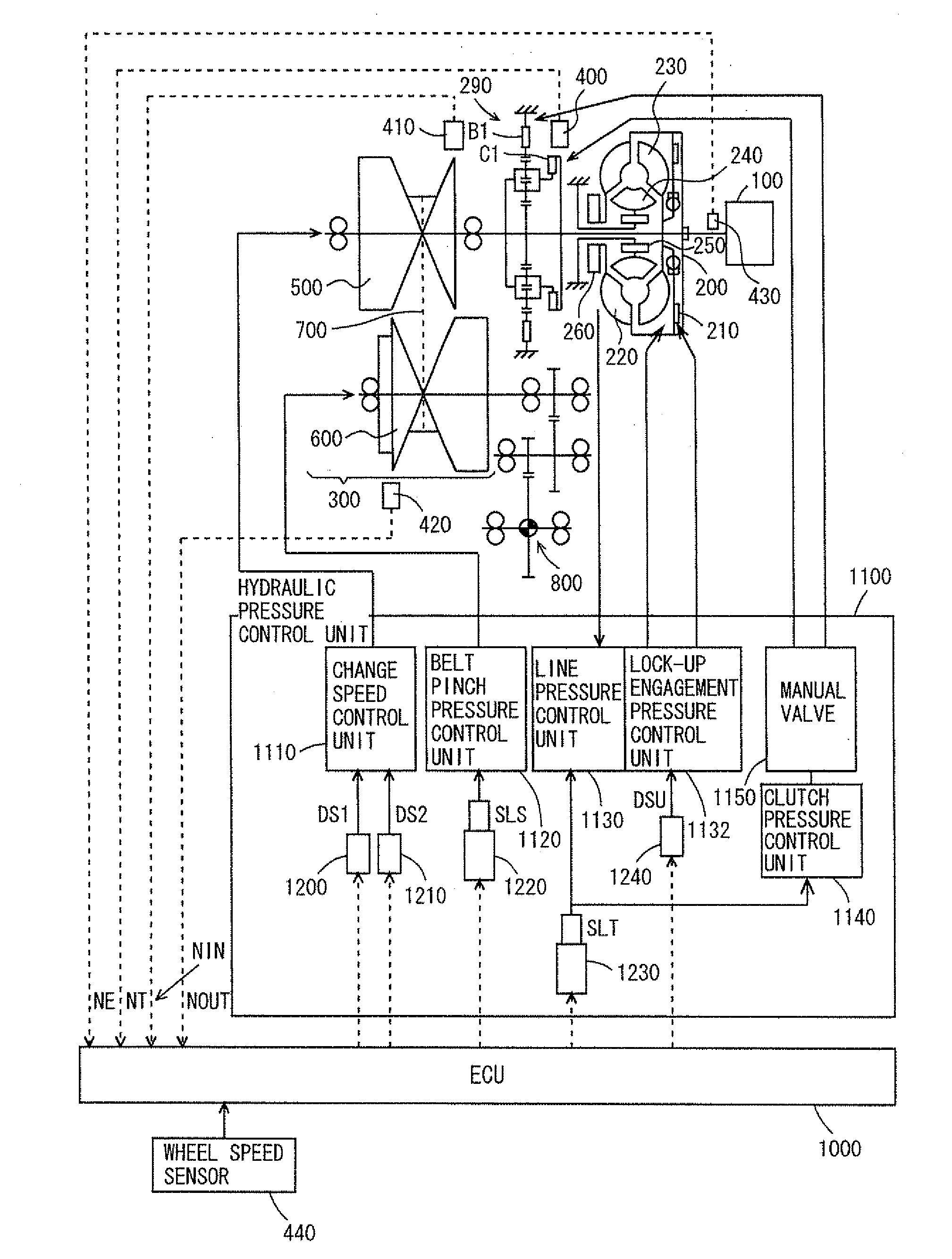

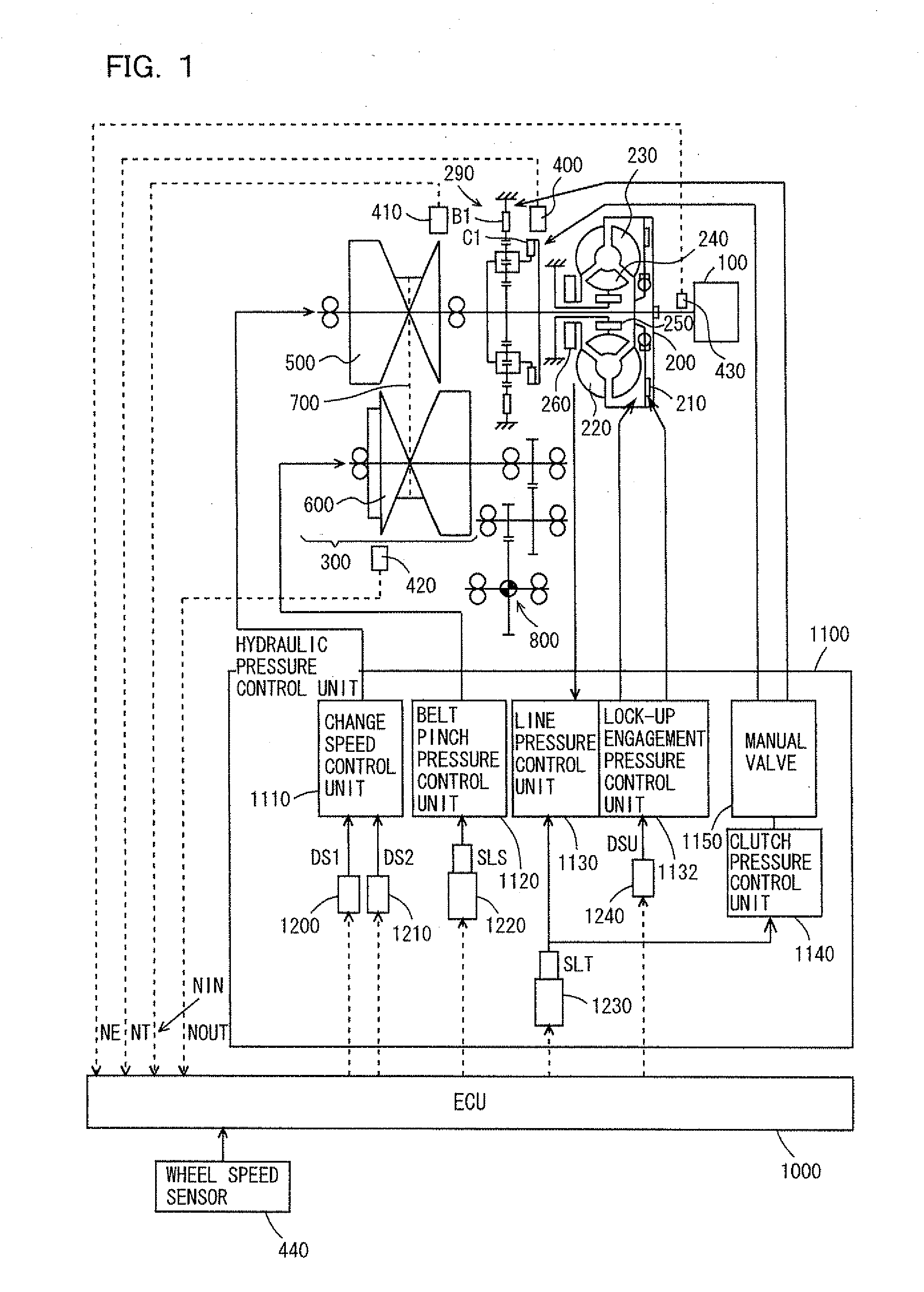

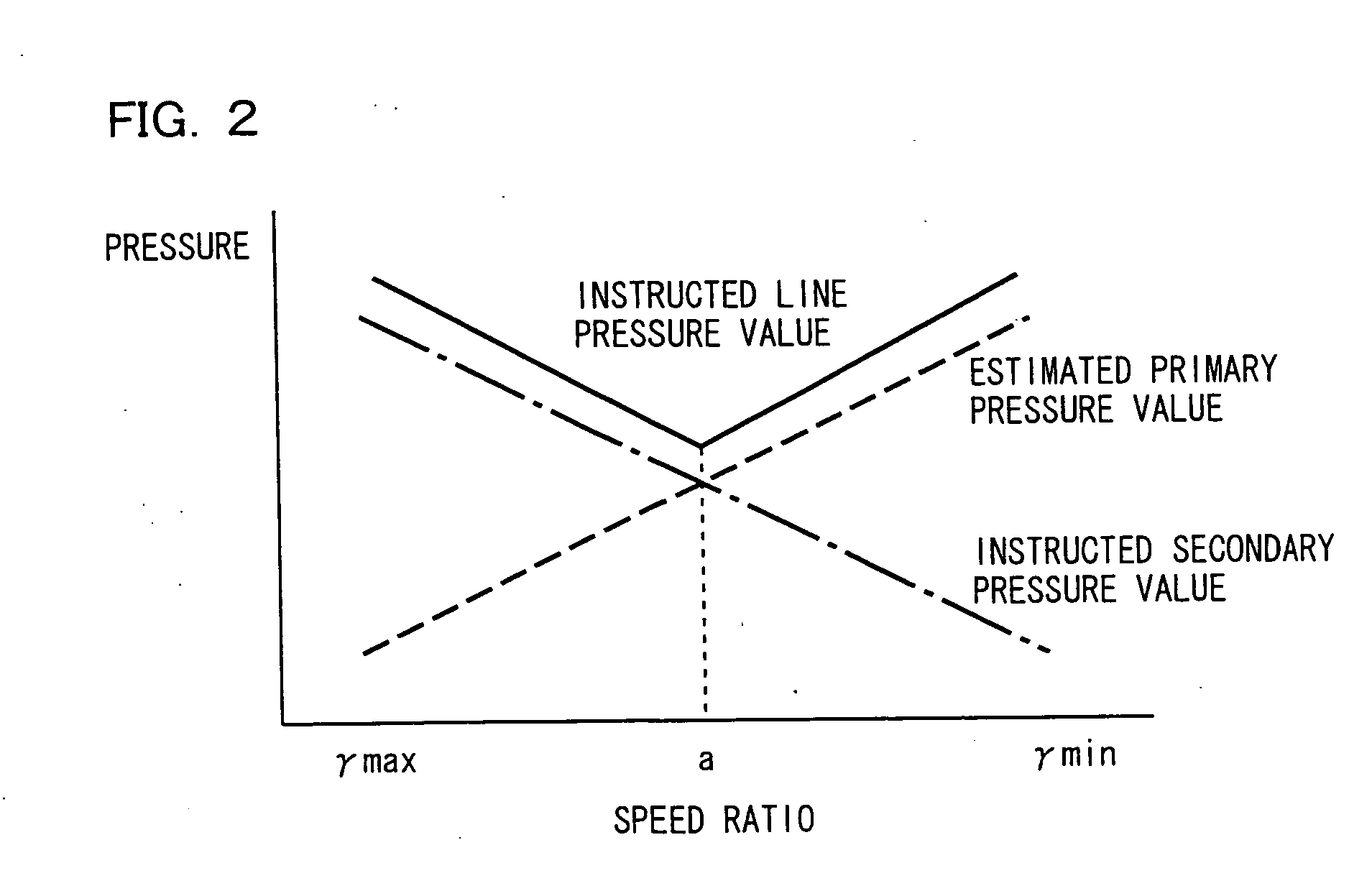

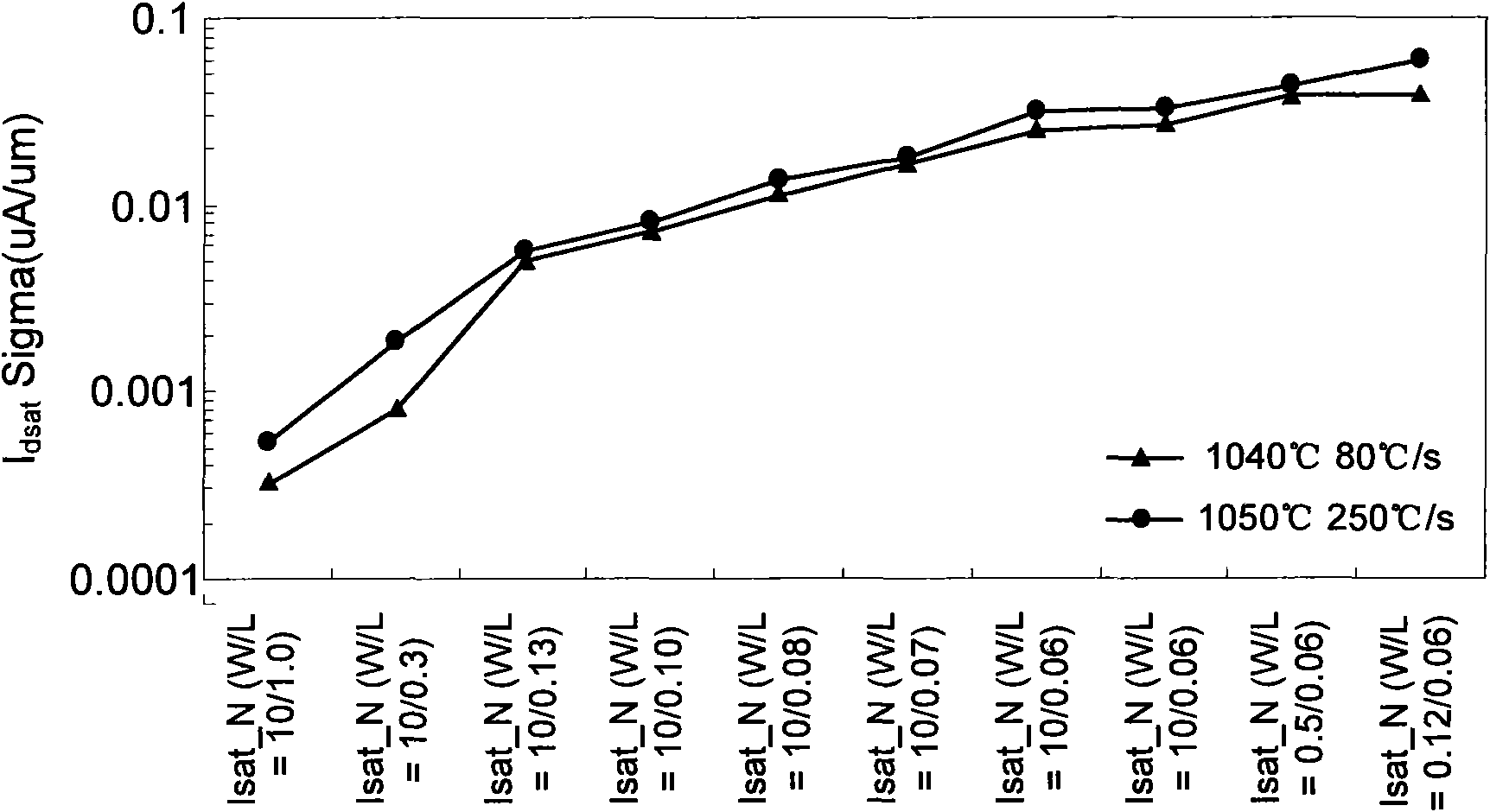

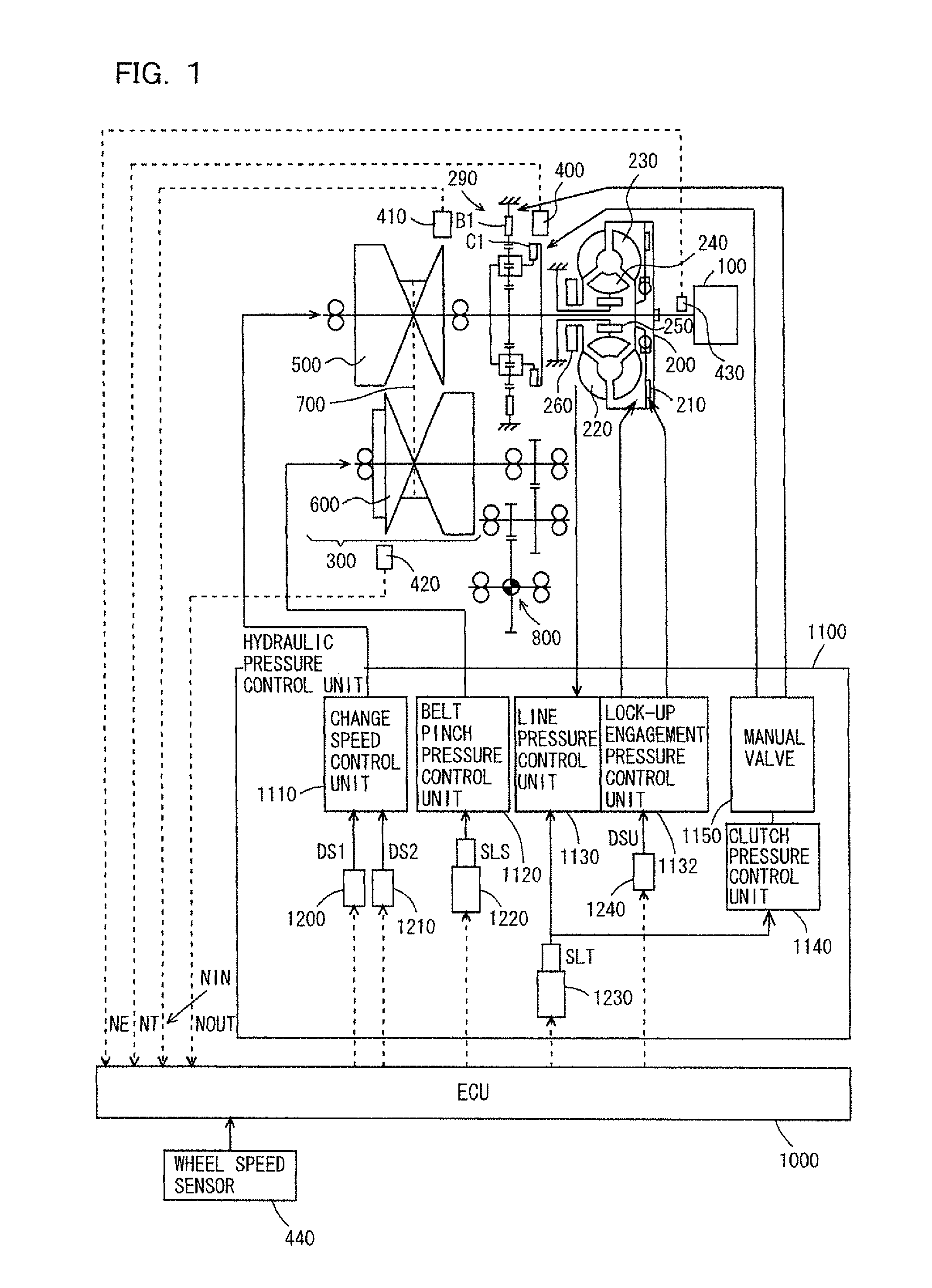

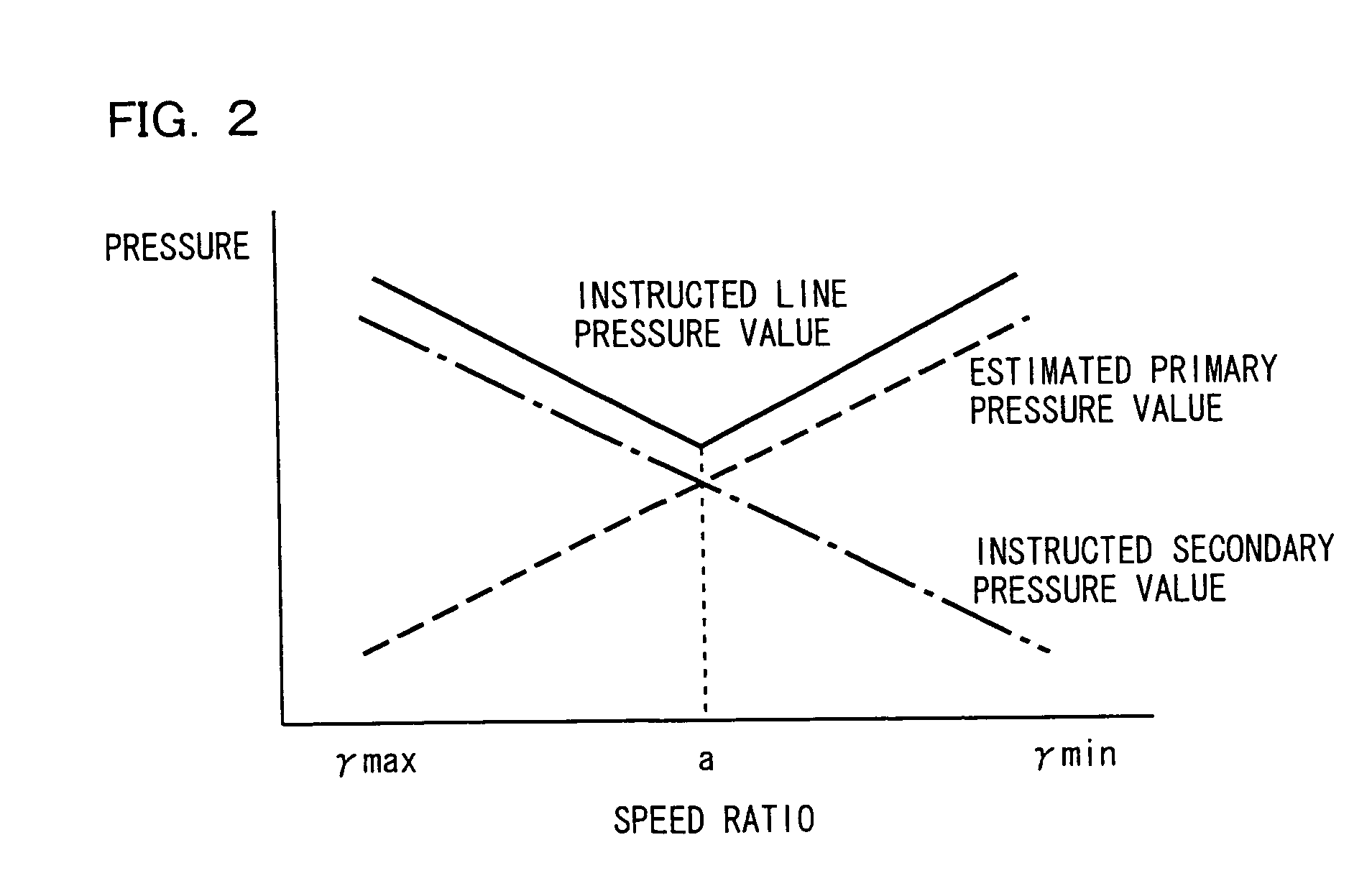

Failure determining device and failure determining method of continuously variable transmission

ActiveUS20100191407A1Reduce hydraulic pressureReduce the degree of variationVehicle testingRegistering/indicating working of vehiclesControl theoryVariator

Owner:TOYOTA JIDOSHA KK

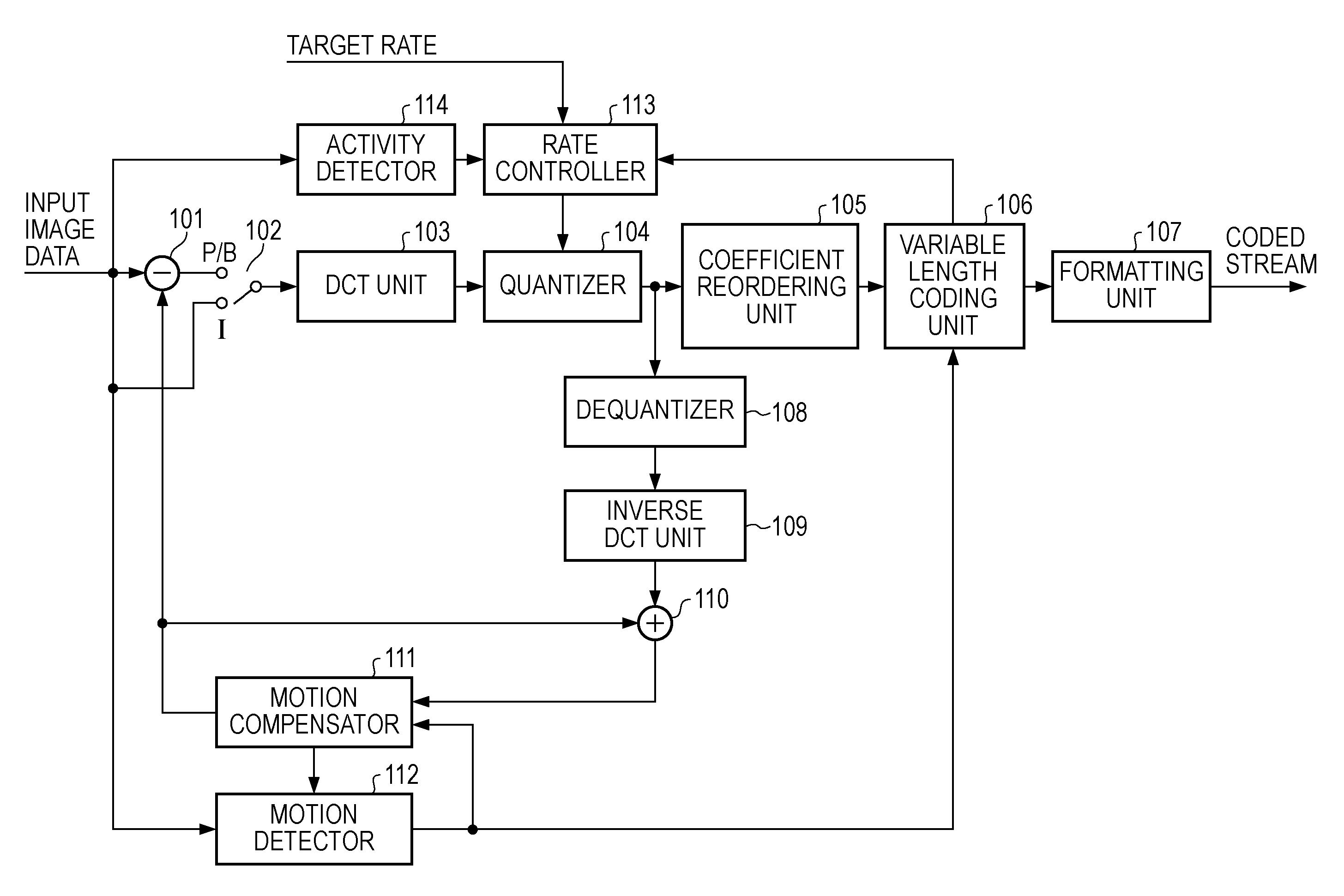

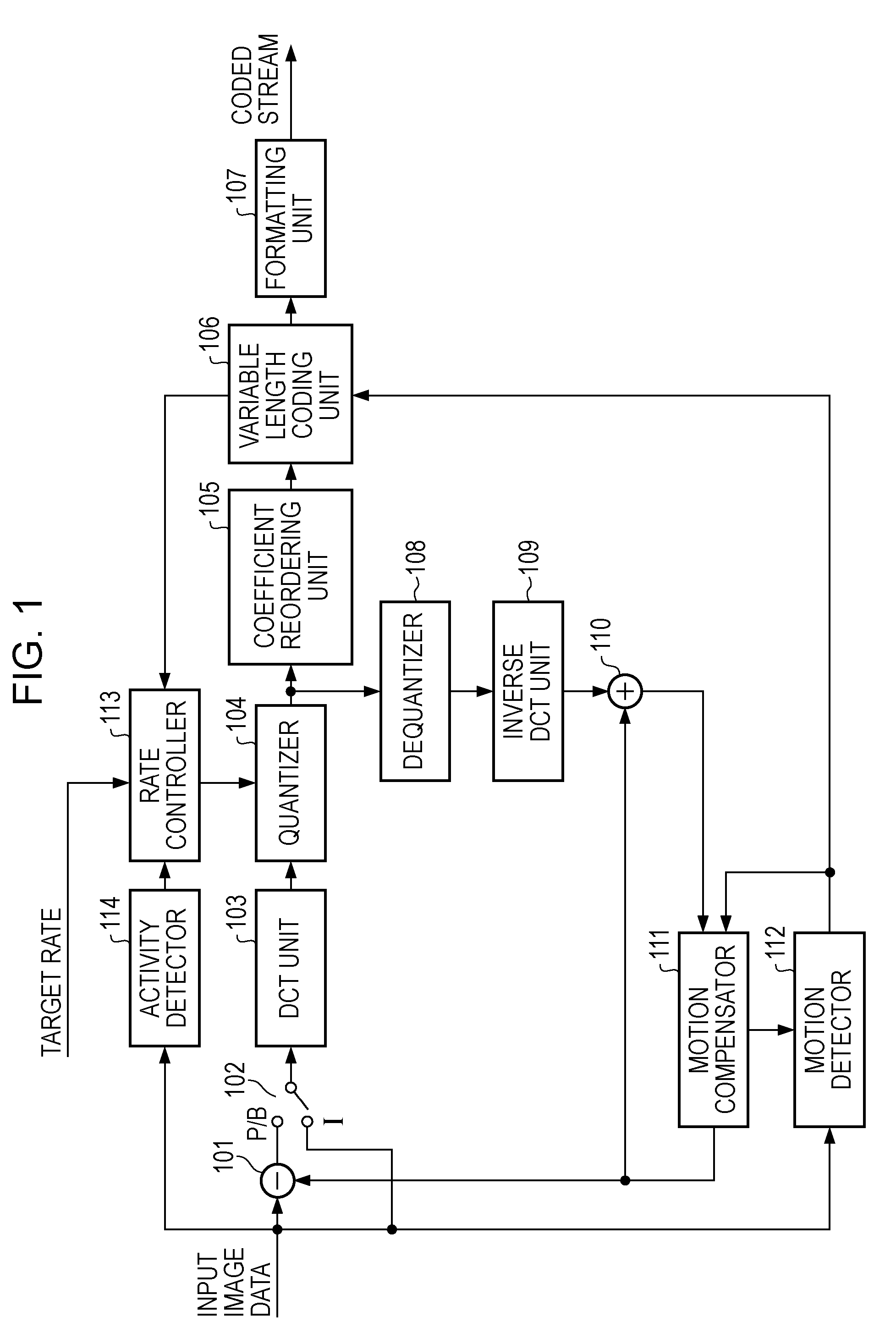

Image processing apparatus

InactiveUS20070177808A1Improve image qualityReduce the degree of variationCharacter and pattern recognitionDigital video signal modificationVariable-length codeImaging processing

An image processing apparatus includes a quantizing unit configured to quantize an input moving image signal using a set quantization scale; a coding unit configured to perform variable length coding on an output of the quantizing unit; an activity detecting unit configured to detect an activity of the input moving image signal; a quantization-scale determining unit configured to determine the quantization scale; a changing unit configured to change a value determined by the quantization-scale determining unit, and to set the changed value, as the quantization scale; and a filling level detecting unit configured to detect the filling level of a virtual buffer in a decoder which decodes the coded moving image signal, and to control the changing unit such that the degree of change in the quantization scale caused by use of the activity is reduced as the detected filling level decreases.

Owner:CANON KK

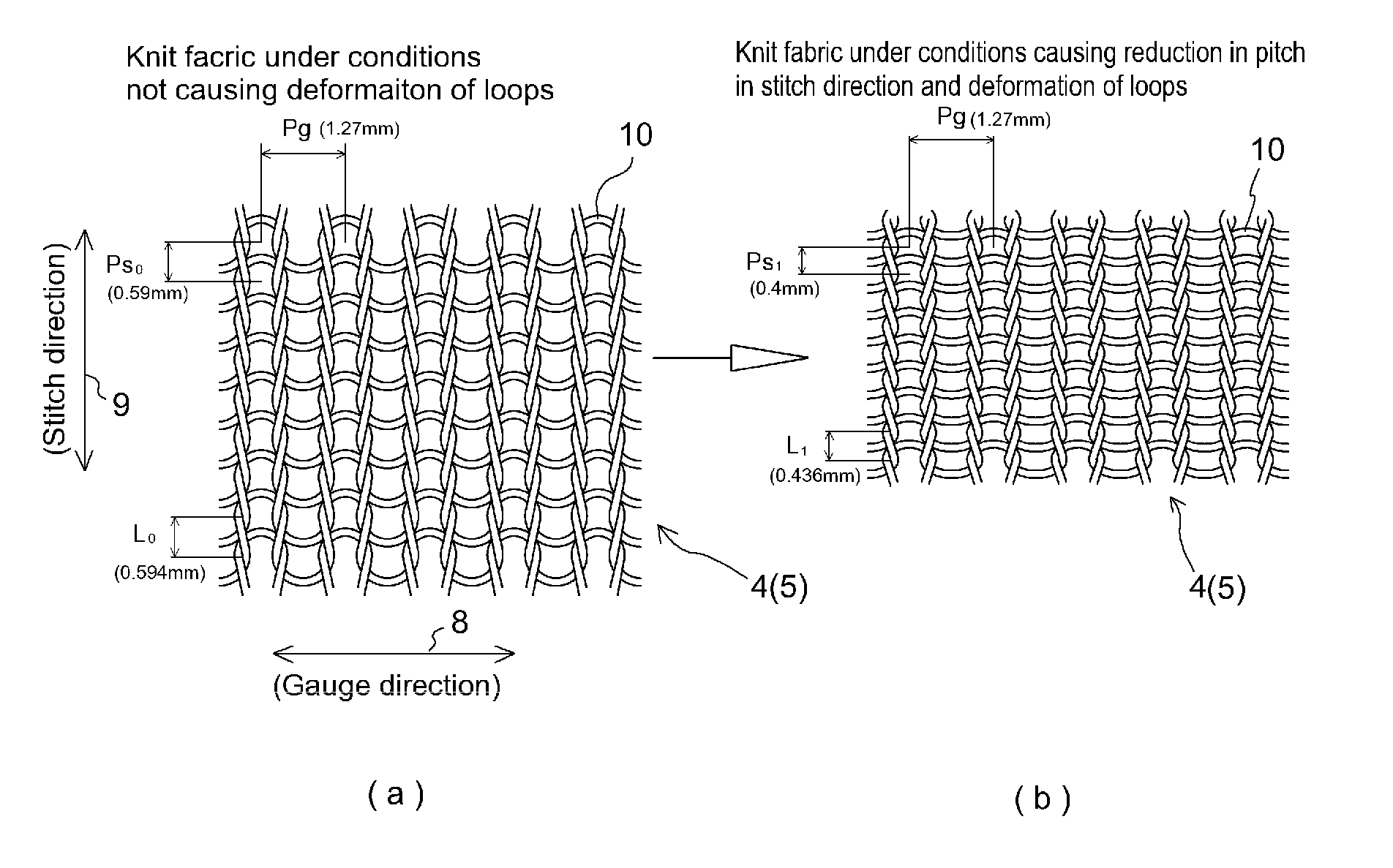

Conveyer belt and apparatus

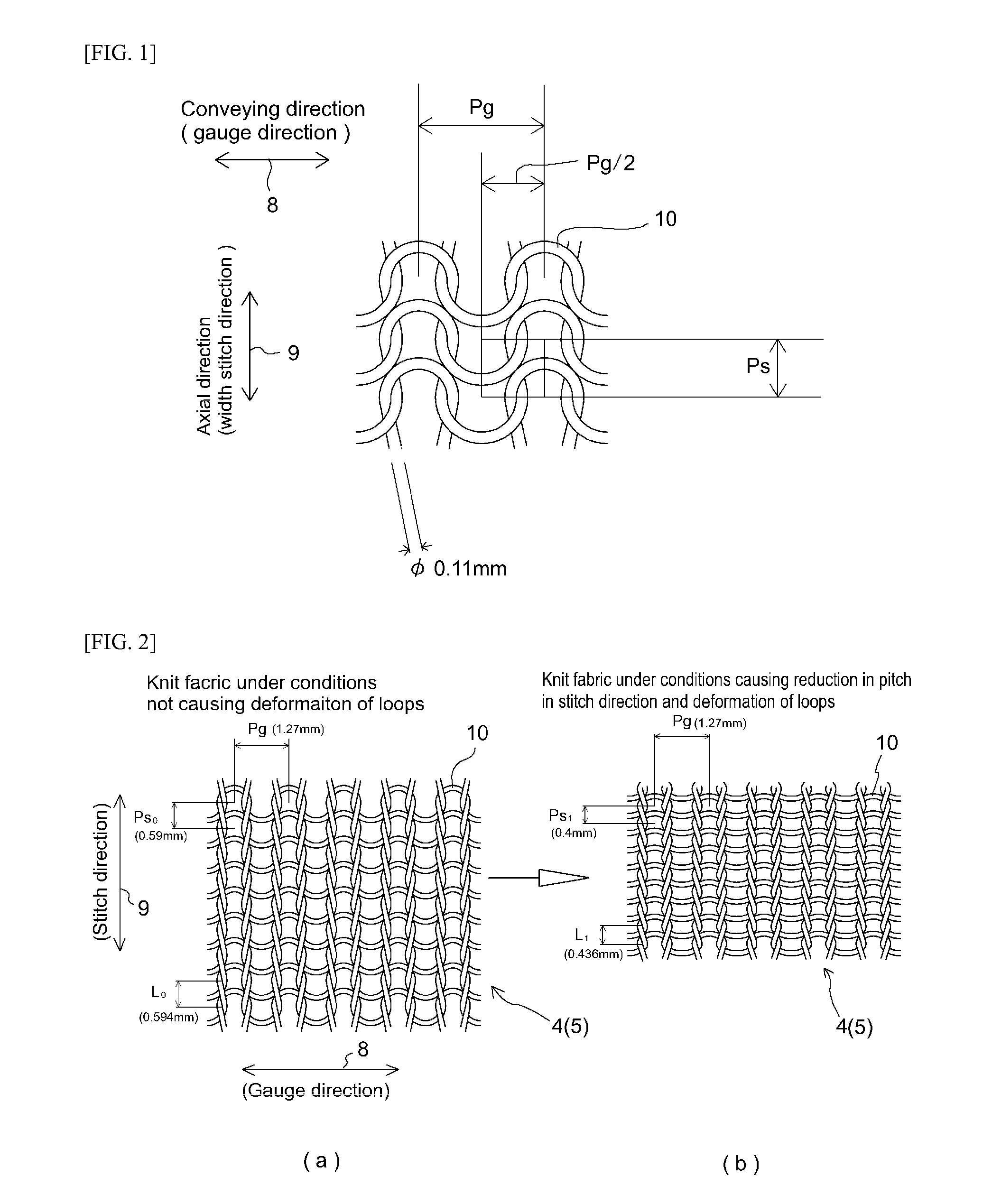

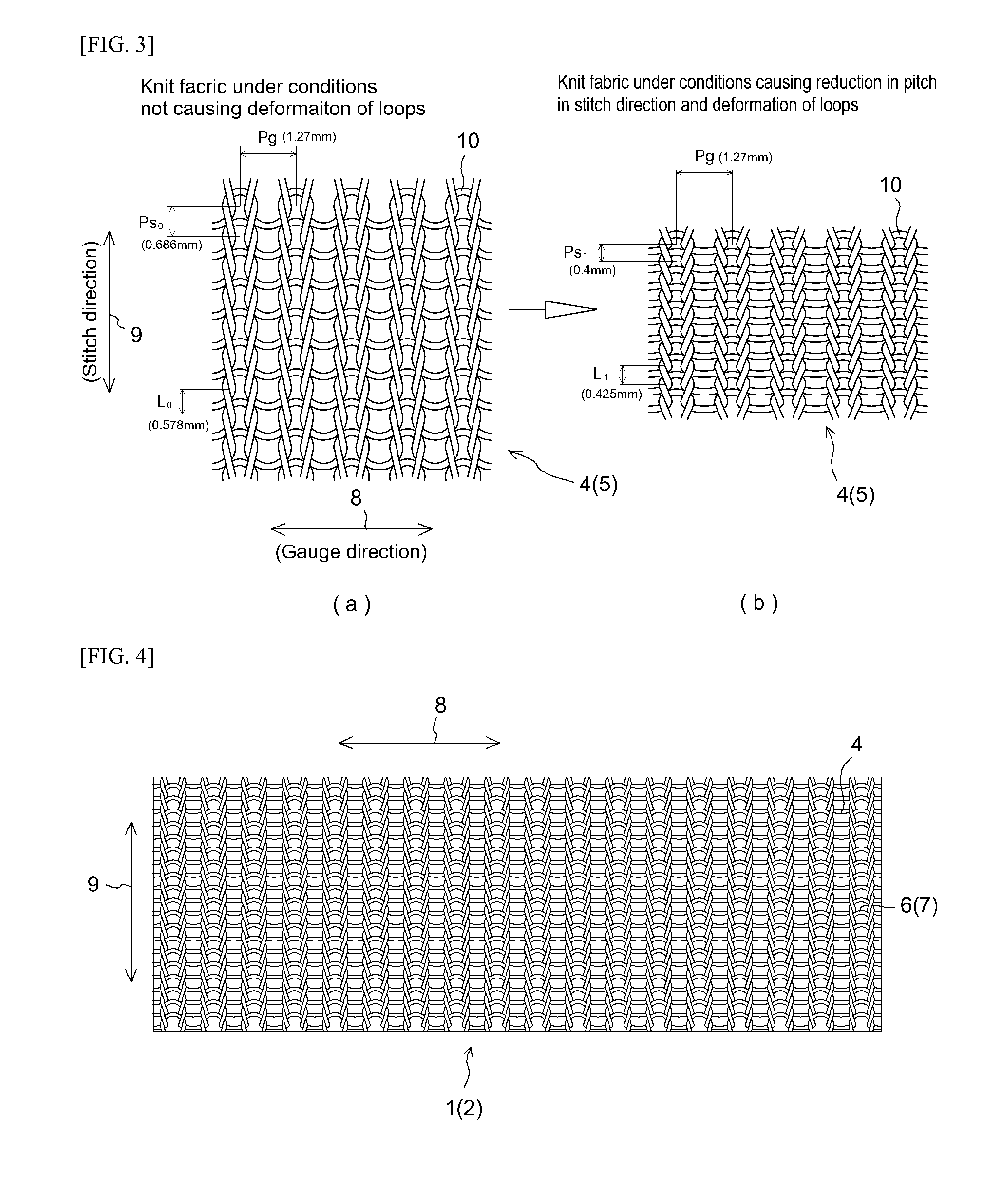

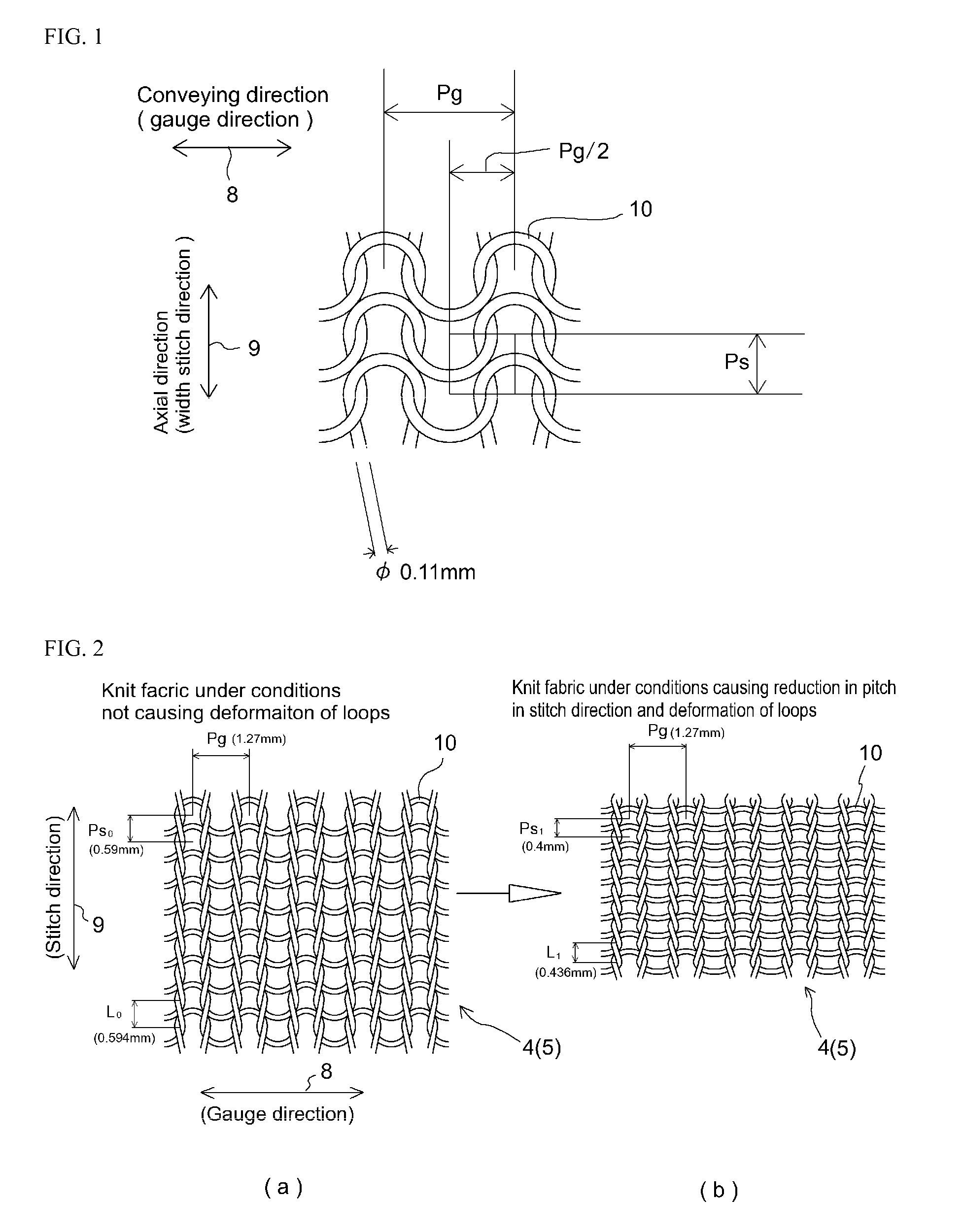

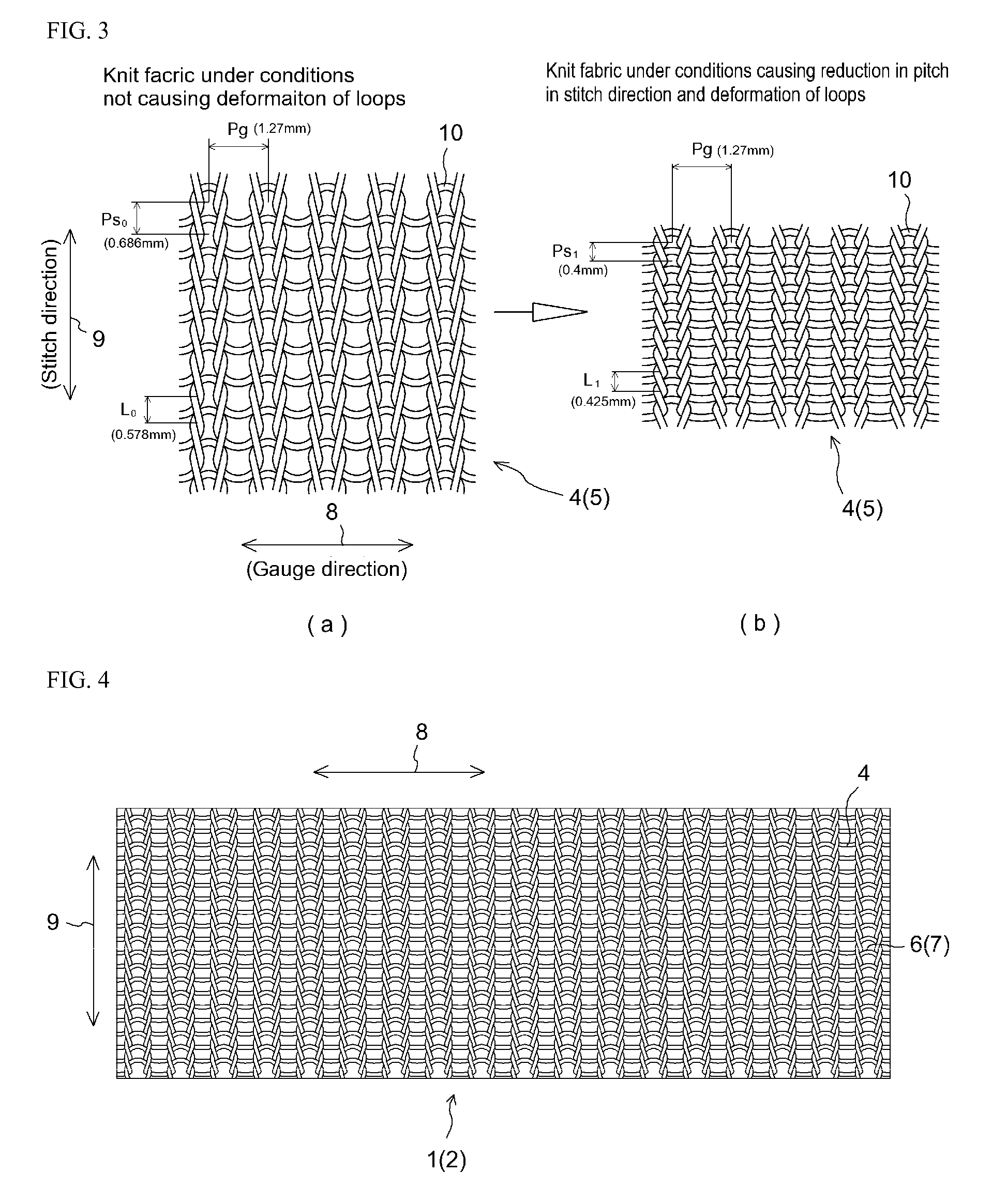

ActiveUS20140083824A1Increase curvatureDegree of change be reduceConveyorsWeft knittingPercent elongationEngineering

A conveyor belt comprising knit fabric of high practicality, and an apparatus which uses such a conveyor belt. The conveyor belt includes weft knit fabric. Suction of air from below belt(s) is used to convey sheet-like and / or small thing(s) which are object(s) to be conveyed that are placed. The strength of filament(s) of knit fabric at side end(s) is adequately maintained. Loops exhibit mutual intertwining of filament(s) Pitch Ps of loops in width direction is formed so as to be smaller than pitch Pg of loops in conveying direction. Adjacent loops are mutually flattened and filament(s) of loop(s) are entangled, mutual intertwining of filament(s) causes knit fabric to have suppressed percentage elongation and increased strength in conveying direction, fraying of filament(s) at side end(s) of belt(s) is prevented, and strength is adequately increased.

Owner:SHOJI SUSUMU +1

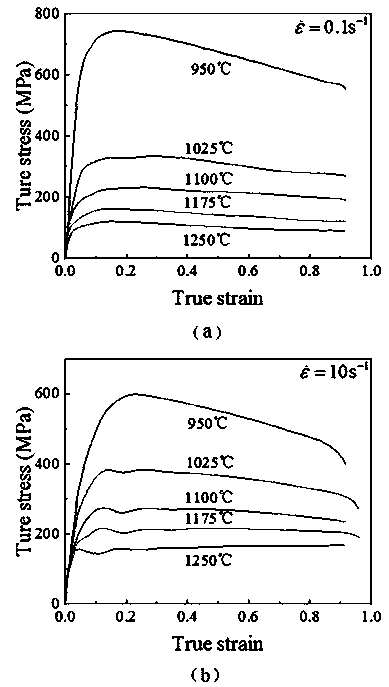

High-chromium nickel-based superalloy, diesel engine gas valve and diesel engine gas valve manufacturing process

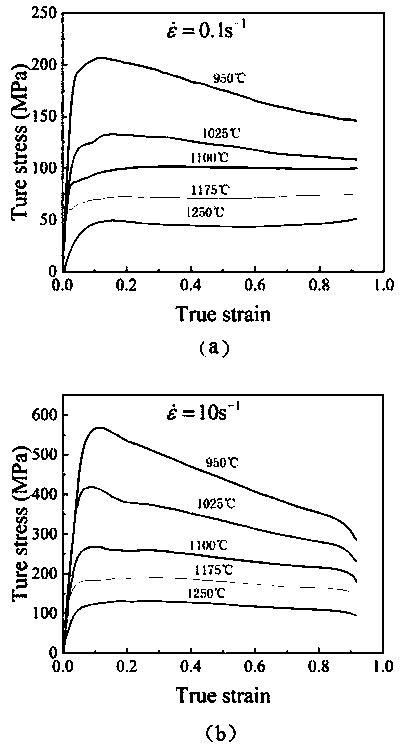

PendingCN111519070AHigh hardnessImprove high temperature resistanceValve arrangementsForging/hammering/pressing machinesManufacturing technologyChromium nickel

The invention discloses a high-chromium nickel-based superalloy, a diesel engine gas valve and a diesel engine gas valve manufacturing process. The high-chromium nickel-based superalloy comprises thefollowing essential elements: by mass, 35-45% of Cr, 1.0-5% of Al, 0.2-15% of Fe, 0.1-10% of Co, and the balance Ni and impurities, or Ni, impurities and any element. The diesel engine gas valve is made of the high-chromium nickel-based superalloy. The diesel engine gas valve manufacturing process adopts the electric upsetting-forging forming process; in the electric upsetting process, a high-order segmental dynamic loading mode is adopted to apply electric upsetting forming process parameters; the electric upsetting forming process parameters include the electric upsetting current; accordingto the high-order segmental dynamic loading mode, the electric upsetting process is subdivided into 10 segments or more, the corresponding electric upsetting forming process parameters are loaded to each segment of the electric upsetting process, and accordingly, the amplitude of variation of the electric upsetting forming process parameters is reduced. Through the high-chromium nickel-based superalloy, the diesel engine gas valve and the diesel engine gas valve manufacturing process, the hot forming property of the nickel-based superalloy can be improved, the crystal grain uniformity of electric upset parts is promoted, and surface waviness of the electric upset parts is improved. The hardness, high temperature resistance, corrosion resistance and creep resistance of the diesel engine gasvalve are improved.

Owner:NANJING INT MARINE EQUIP & SPARES

Moving-coil loudspeaker structure and audio playing device

ActiveCN105554656AReduce distortionReduce the degree of variationTransducer circuitsEngineeringLoudspeaker

The invention provides a moving-coil loudspeaker structure which comprises a vibration assembly, a magnetic circuit assembly and a basin stand. The vibration assembly comprises a vibration film and a voice coil. The magnetic circuit assembly comprises a magnetic core, a first power-on coil surrounding the magnetic core and a second power-on coil surrounding the first power-on coil. A magnetic clearance is formed between the magnetic circuit assembly and the basin stand, and the voice oil is suspended in the magnetic clearance. The invention further provides an audio playing device which comprises the moving-coil loudspeaker structure, a direct-current power circuit and a rectifying circuit. The direct-current power circuit supplies direct currents with constant voltage to the first power-on coil. Audio signals are rectified into direct-current signals through the rectifying circuit to be input into the second power-on coil, and the rectifying circuit is configured to enable a magnetic field generated by the second power-on coil and a magnetic field generated by the first power-on coil to be consistent in direction. The moving-coil loudspeaker structure can be used for reducing distortion of a loudspeaker, and the distortion degree of the loudspeaker can be reduced through the audio playing device.

Owner:GOERTEK INC

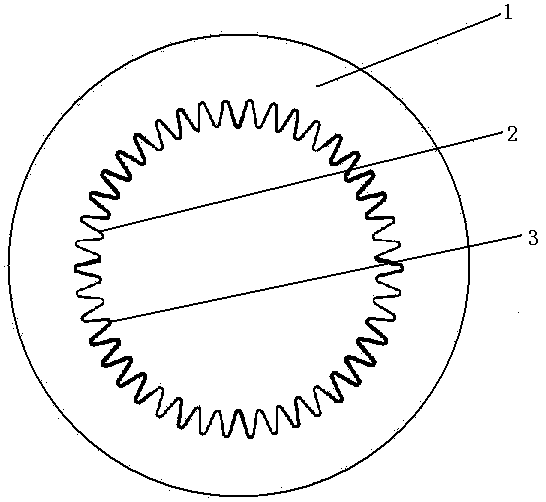

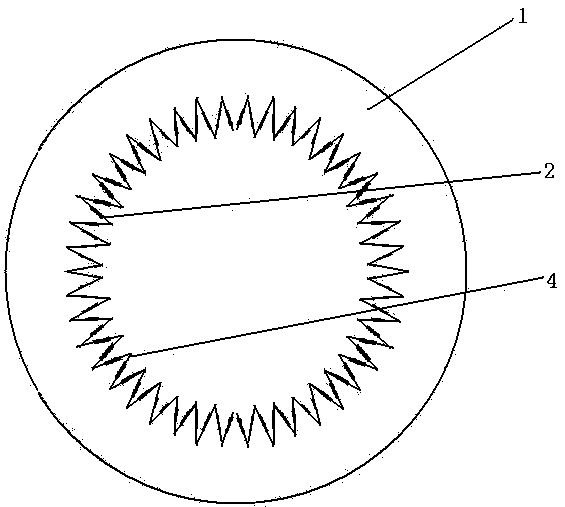

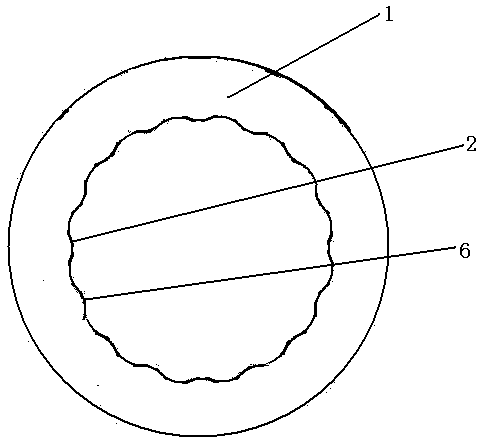

Self-cleaning pipeline

InactiveCN108916530ARealize self-cleaningReduce the degree of variationPipe elementsRigid pipesWrinkle skinThermal expansion

The invention belongs to the technical field of pipelines, and relates to a self-cleaning pipeline. The self-cleaning pipeline comprises a pipe body, and the surface of the inner wall of the pipe bodyis in a wrinkle shape. Specifically, the surface of the inner wall of the pipe body is made into an arc folded shape or a straight folded shape or an arced face folded shape or a wave folded state inthe longitudinal direction. In addition, the pipe body is provided with two layers or additionally provided with a fixing layer, the inner layer adopts a material high in coefficient of thermal expansion, and the fixing layer adopts a material low in coefficient of thermal expansion. The self-cleaning pipeline has the advantages that when thermal expansion and cold shrinkage happen, the shrinkageand expansion direction starts from the inner surface; due to the fact that the inner surface of the inner wall is in the wrinkle shape, extrusion borne by the inner surface of the pipeline due to thermal expansion and cold shrinkage becomes uneven, the outward convex parts of the rugged wrinkle-shaped inner surface are more convex, and the change degree of the inward concave parts is relativelysmall; and due to the fact that the change degrees of different portions on the inner surface are not synchronous, when the shrinkage and expansion amplitude of the inner surface reaches a certain degree, dirt attached to the inner surface can be staggered and gradually separated, and therefore self cleaning is achieved.

Owner:CHONGQING GONGQI TECH CO LTD

Conveyer belt and apparatus

ActiveUS8783448B2High strengthFraying of yarn filament at belt side ends is preventedConveyorsWeft knittingPercent elongationConveyor belt

A conveyor belt comprising knit fabric of high practicality, and an apparatus which uses such a conveyor belt. The conveyor belt includes weft knit fabric. Suction of air from below belt(s) is used to convey sheet-like and / or small thing(s) which are object(s) to be conveyed that are placed. The strength of filament(s) of knit fabric at side end(s) is adequately maintained. Loops exhibit mutual intertwining of filament(s) Pitch Ps of loops in width direction is formed so as to be smaller than pitch Pg of loops in conveying direction. Adjacent loops are mutually flattened and filament(s) of loop(s) are entangled, mutual intertwining of filament(s) causes knit fabric to have suppressed percentage elongation and increased strength in conveying direction, fraying of filament(s) at side end(s) of belt(s) is prevented, and strength is adequately increased.

Owner:SHOJI SUSUMU +1

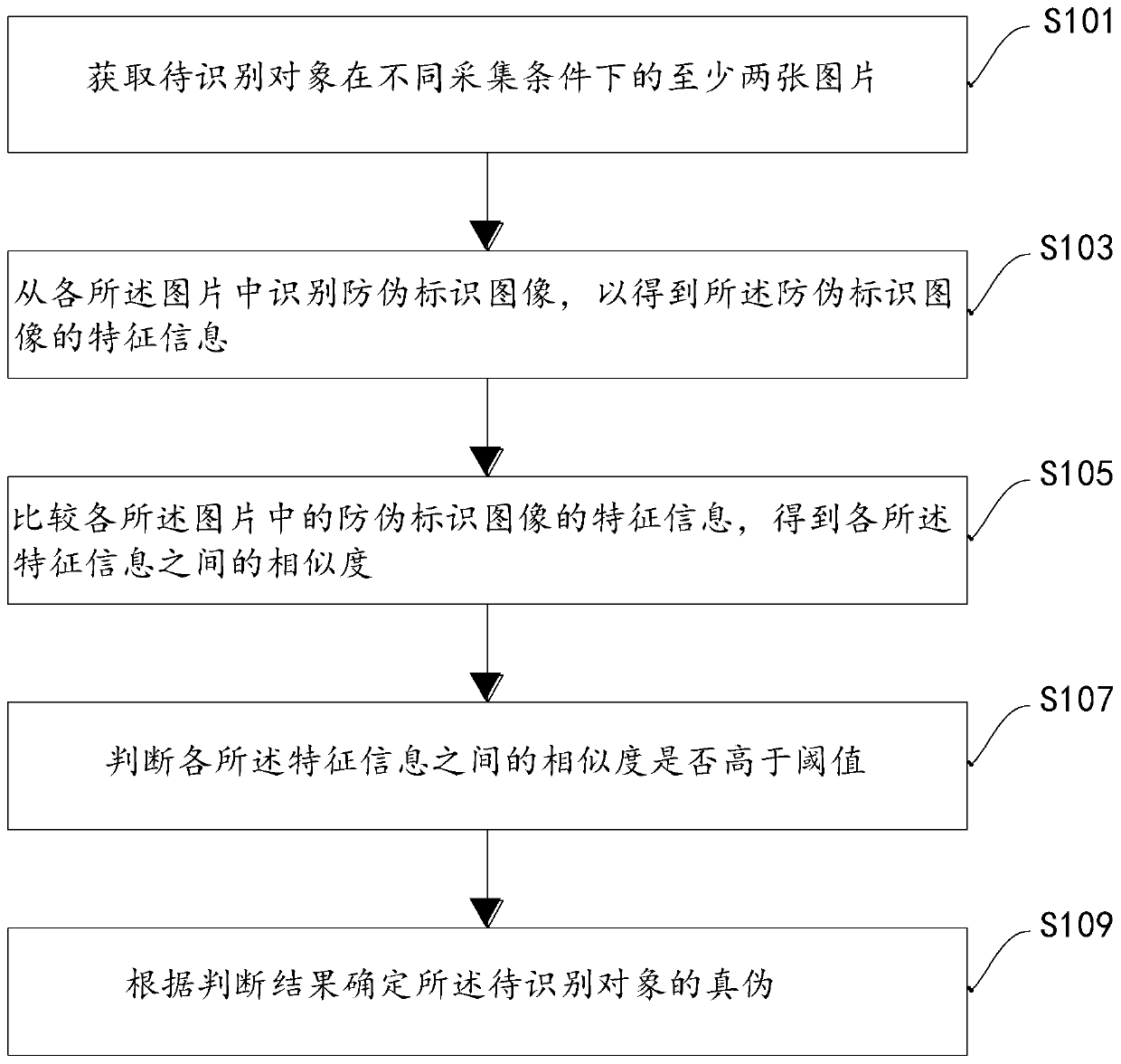

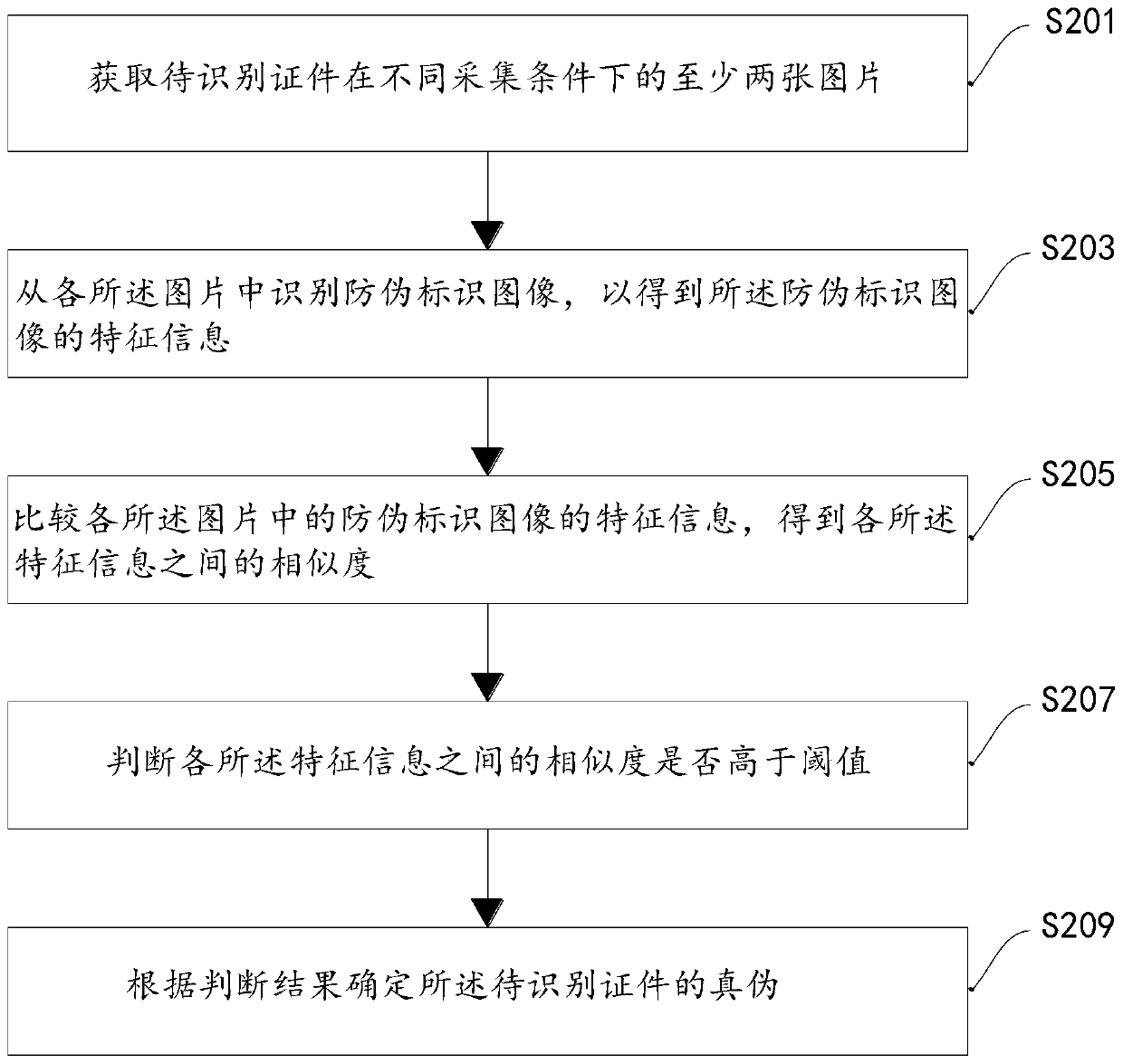

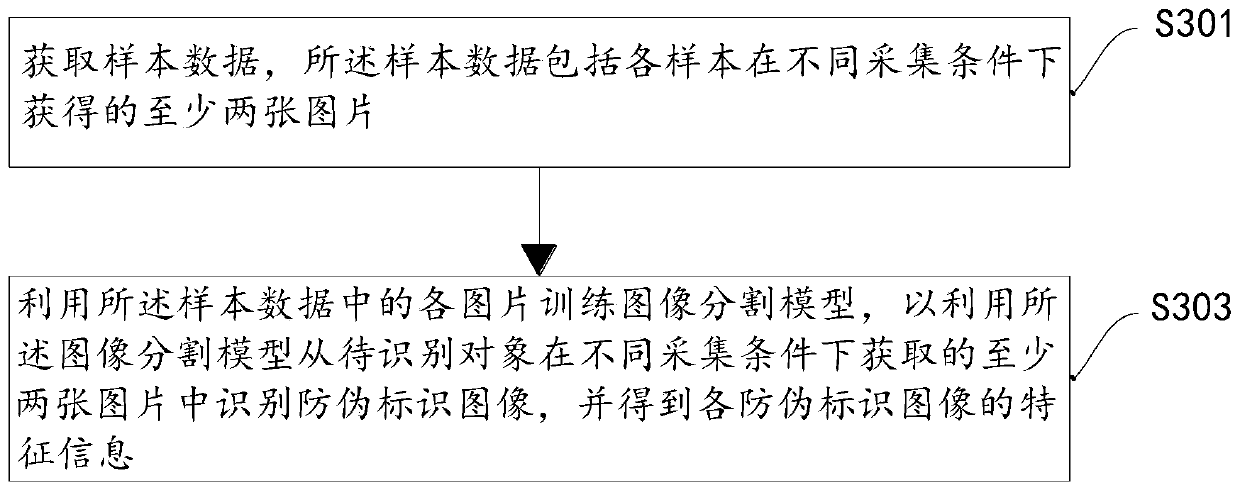

Anti-counterfeiting identification method and device and electronic equipment

PendingCN111291797AReduce the degree of variationImprove recognition accuracyCharacter and pattern recognitionAlgorithmEngineering

Embodiments of the invention disclose an anti-counterfeiting identification method and device, and electronic equipment. The method comprises the steps of obtaining at least two pictures of a to-be-identified object under different collection conditions; identifying an anti-counterfeiting mark image from each picture to obtain feature information of the anti-counterfeiting mark image; comparing the feature information of the anti-counterfeiting mark image in each picture to obtain the similarity between the feature information; judging whether the similarity among the feature information is higher than a threshold value or not, wherein the threshold value is determined according to the similarity difference among the feature information of each anti-counterfeiting mark image obtained by the anti-counterfeiting mark in the real identification object under different acquisition conditions; and determining the authenticity of the to-be-identified object according to a judgment result.

Owner:ALIPAY LABS SINGAPORE PTE LTD

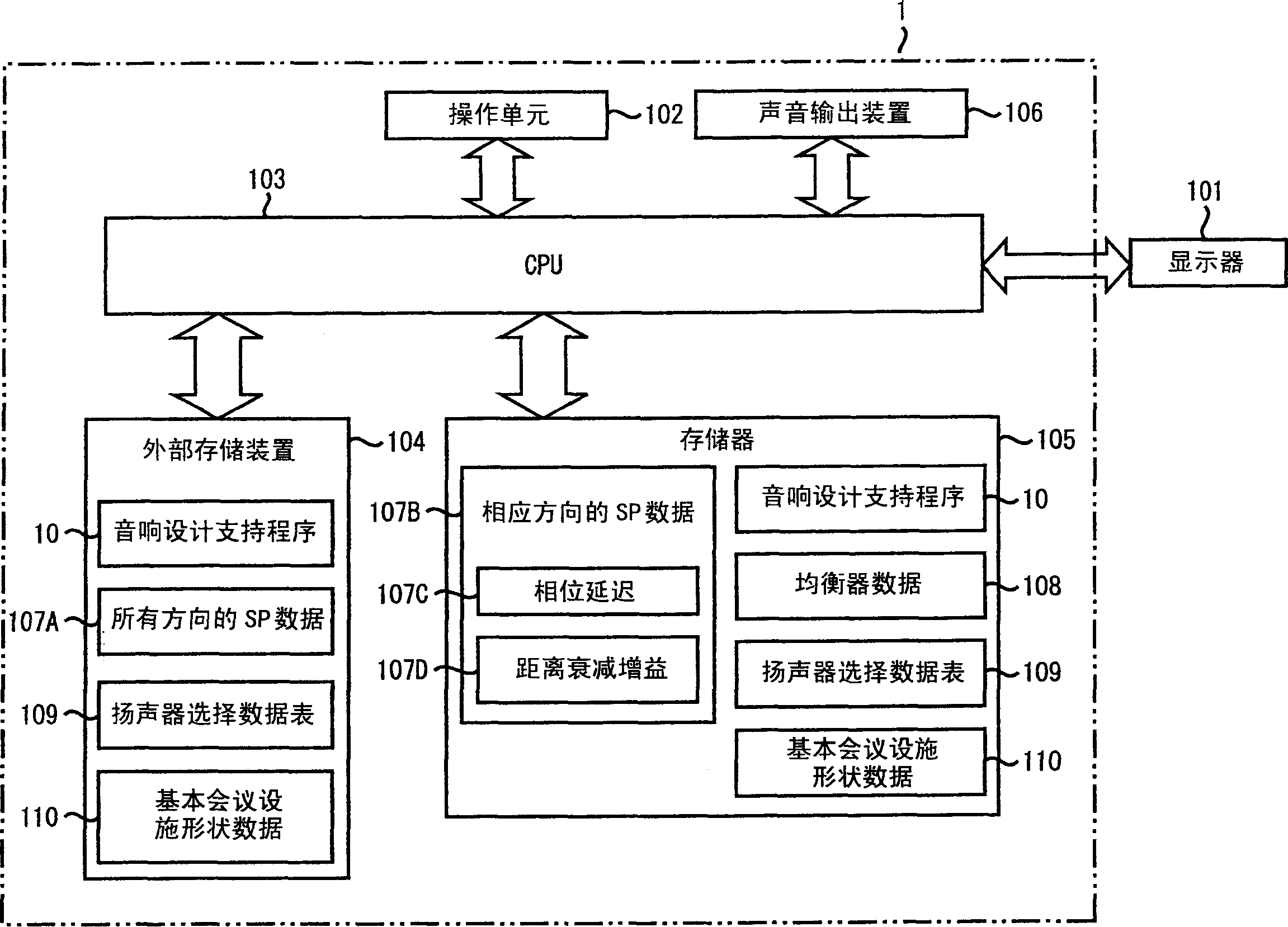

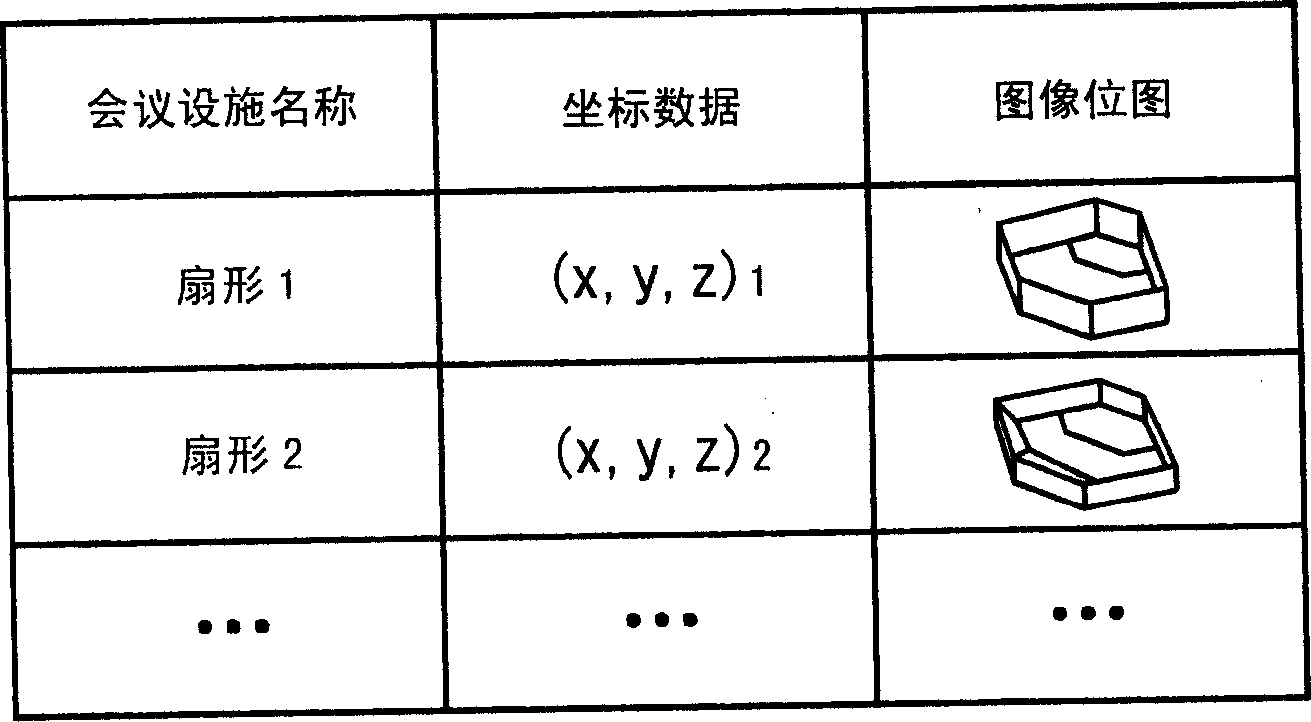

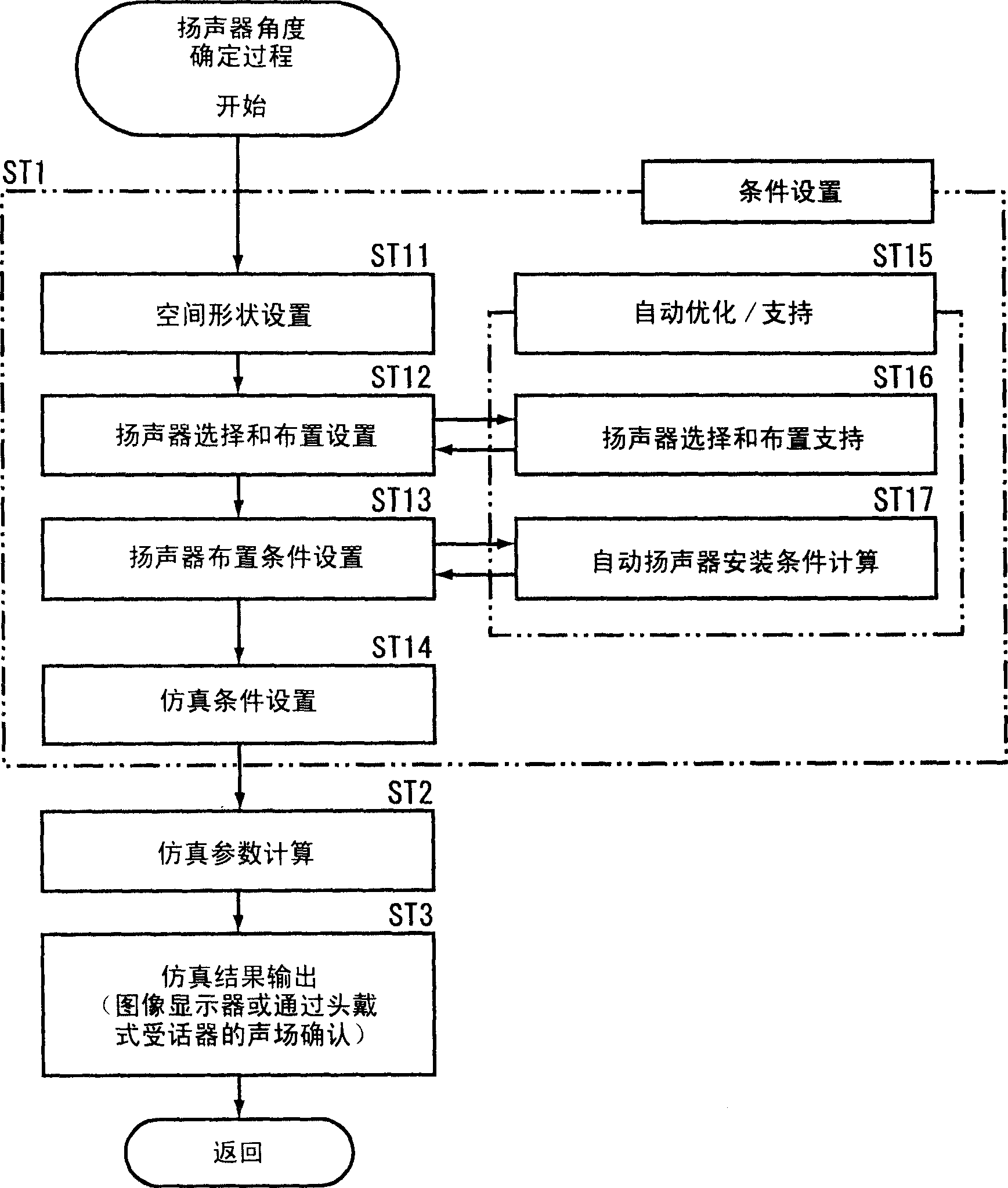

Acoustic design support apparatus

InactiveCN1901755AEfficient and Simplified Design ProcessEfficient and simplified repositioning processFrequency/directions obtaining arrangementsTransducer circuitsEngineeringLoudspeaker

In an acoustic design support apparatus, a speaker selection supporter selects a desired speaker as a candidate for use in a given space based on shape information representing a shape of the space. A speaker mounting angle optimizer calculates an optimal mounting direction of the selected speaker by selecting a mounting direction pattern which minimizes a degree of variation among sound pressure levels at a plurality of positions on a sound receiving surface defined in the space. An acoustic parameter calculator calculates a variety of acoustic parameters at sound receiving points within the space based on both of the shape information of the space and the optimal mounting direction of the speaker.

Owner:YAMAHA CORP

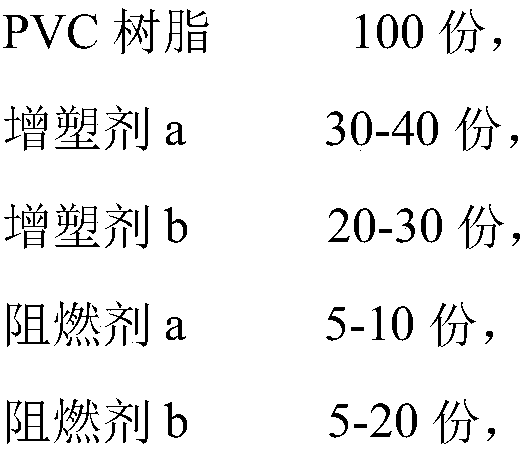

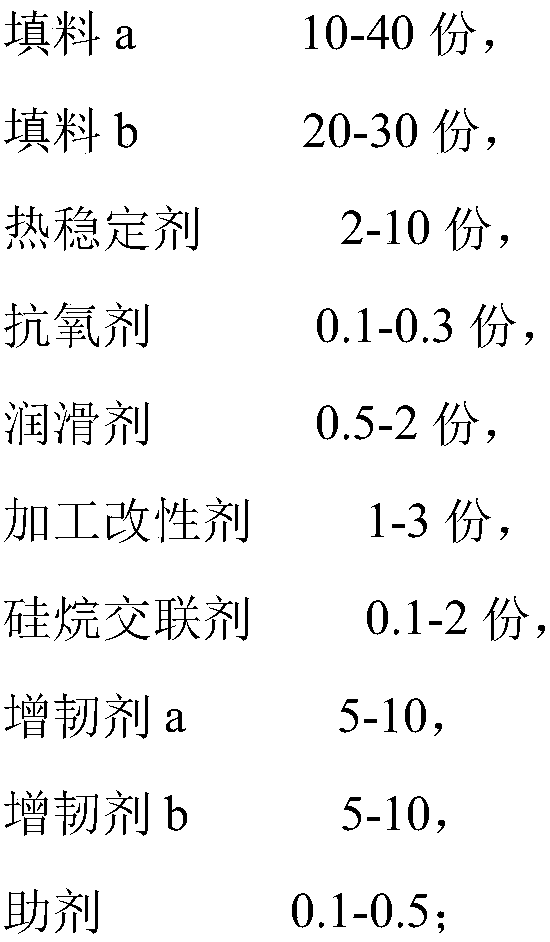

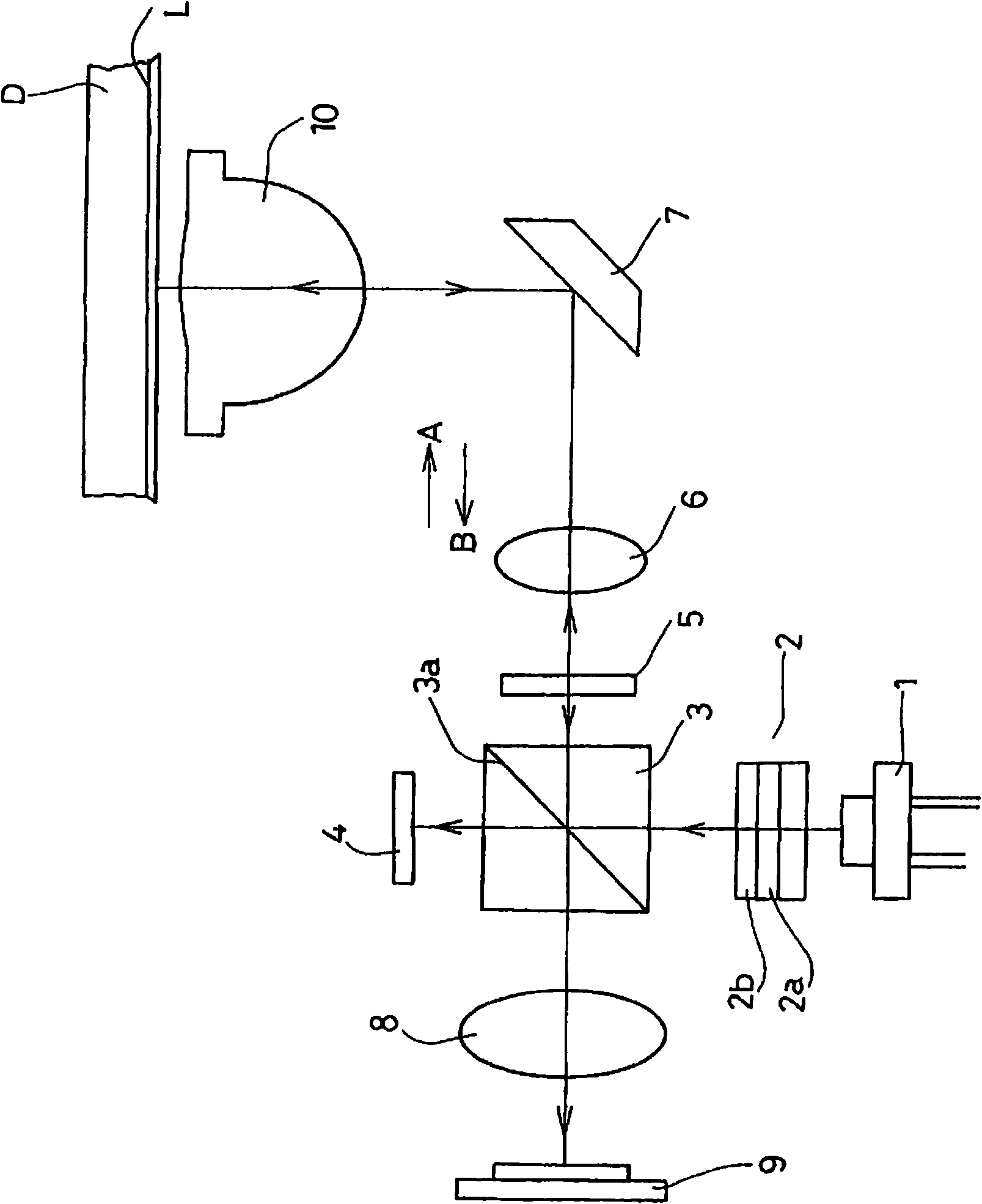

Silane-crosslinking flame-retardant polyvinyl chloride cable material and preparation method thereof

ActiveCN109593290AImprove heat resistanceReduce volatilityPlastic/resin/waxes insulatorsPlasticizerHeat resistance

The invention relates to a silane-crosslinking flame-retardant polyvinyl chloride cable material and a preparation method thereof. The cable material contains the following components: 100 parts of PVC resin, 30-40 parts of a plasticizer a, 20-30 parts of a plasticizer b, 5-10 parts of a flame-retardant agent a, 5-20 parts of a flame-retardant agent b, 10-40 parts of a filler a, 20-30 parts of a filler b, 2-10 parts of a heat stabilizer, 0.5-2 parts of a lubricant, 0.1-0.3 part of an antioxidant, 0.1-2 parts of a silane cross-linking agent, 5-10 parts of a flexibilizer a, 5-10 parts of a flexibilizer b and 0.3-0.8 part of an aid, wherein the silane cross-linking agent is a mixture of silane a, silane b and silane c. The silane-crosslinking flame-retardant polyvinyl chloride cable materialis mainly applied to the domestic sites with requirements on high temperature resistance and high strength, has relatively high gel rate, relatively good mechanical strength and color stability and high strength, heat resistance and creep resistance, and lead salt does not need to be taken as a catalyst.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

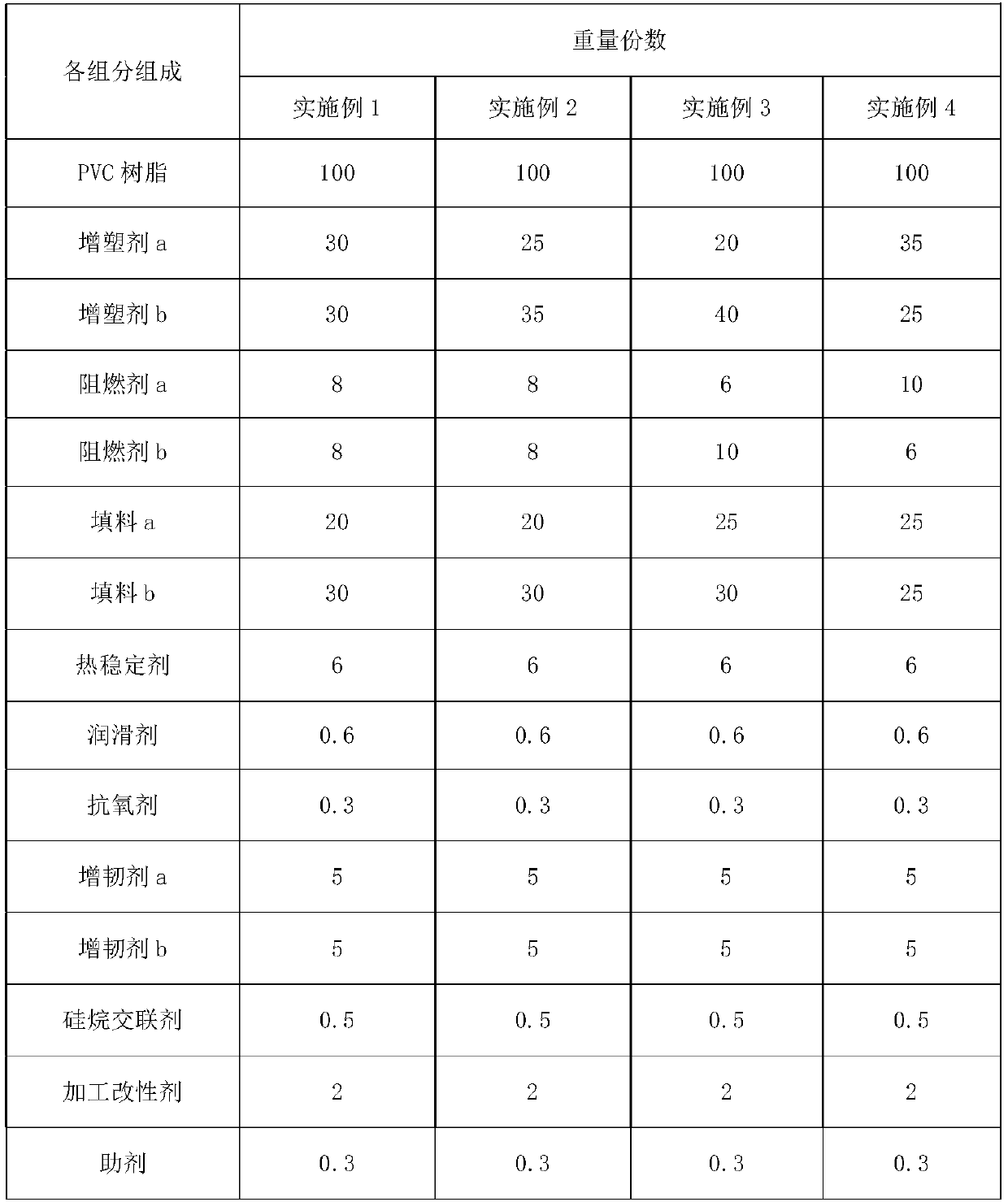

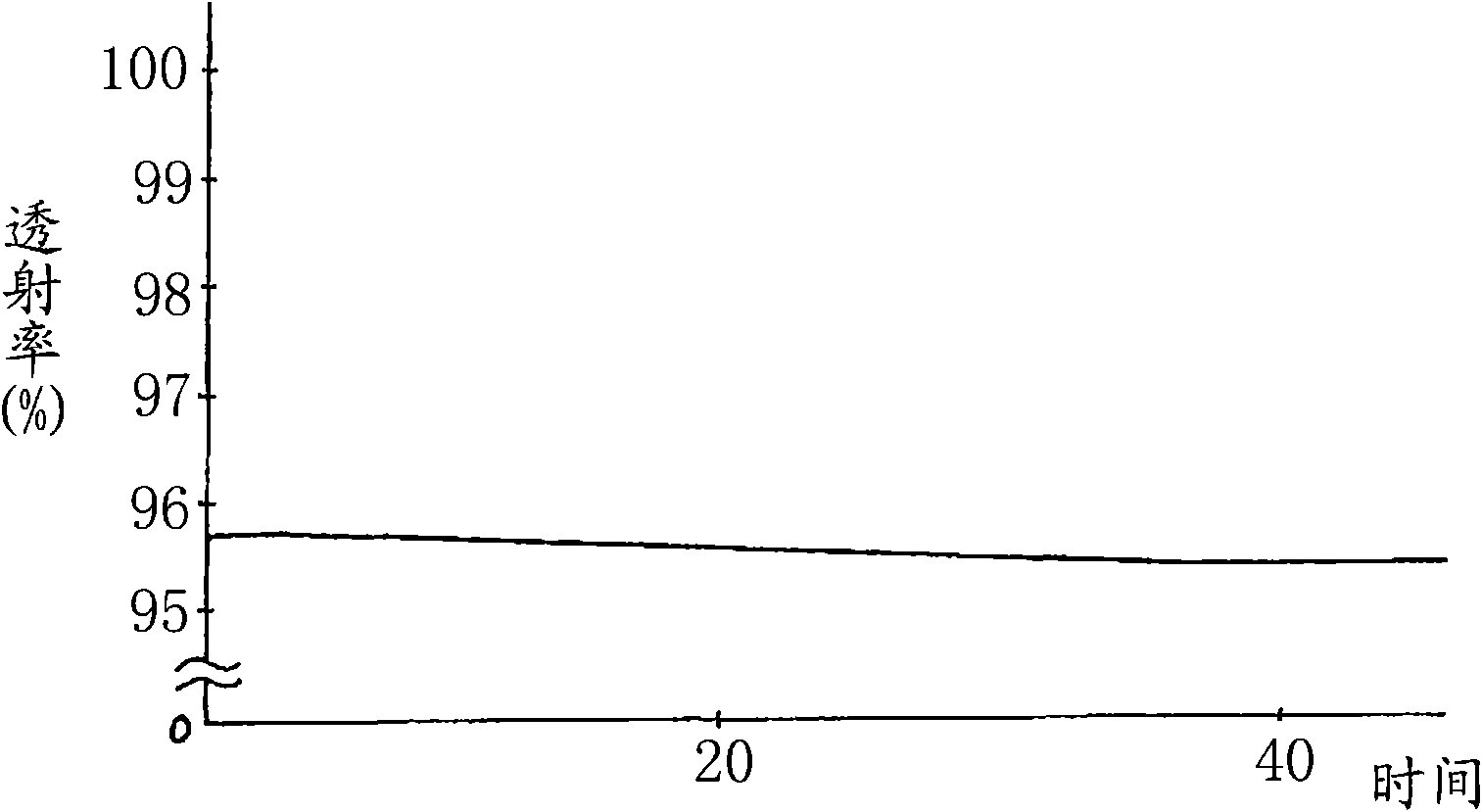

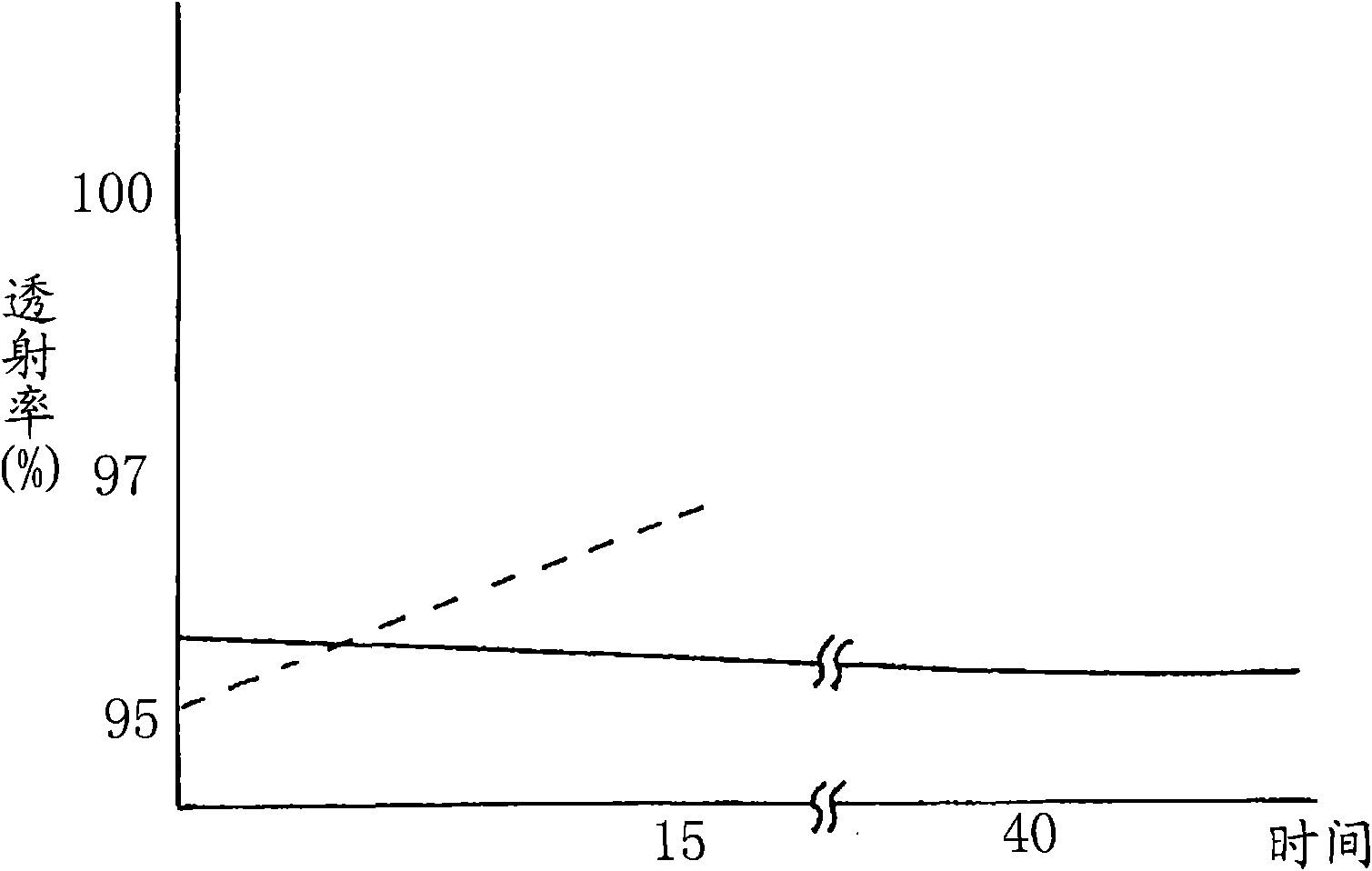

Synthetic resin lens manufacturing method, reformed quality synthetic resin material manufacturing method and optical pickup device

InactiveCN101568963AReduce transmittanceReduce the degree of variationOptical beam sourcesRecord information storageTransmittanceLength wave

The invention provides a synthetic resin lens manufacturing method, a reformed quality synthetic resin material manufacturing method and an optical pickup device. A synthetic resin material, which is small in decreasing degree of the transmissivity of red laser light due to accumulated irradiation of the red laser light but is large in decreasing degree of the transmissivity of blue-violet laser light due to accumulated irradiation of the blue-violet laser light, has been widely used as an objective lens material in compliance with the requirement for the red laser light. The synthetic resin material, however, has not been able to be put into practical use for an objective lens material in compliance with the requirement for the blue-violet laser light. It is an object to make the synthetic resin material usable as such an objective lens material for the blue-violet laser light. An electromagnetic wave with a shorter wavelength than that of a blue-violet laser light is irradiated to a lens member made of a synthetic resin material so that the degree of the transmissivity change of the blue-violet laser light is adjusted in the lens member due to accumulated irradiation of the blue-violet laser light.

Owner:SANYO ELECTRIC CO LTD +1

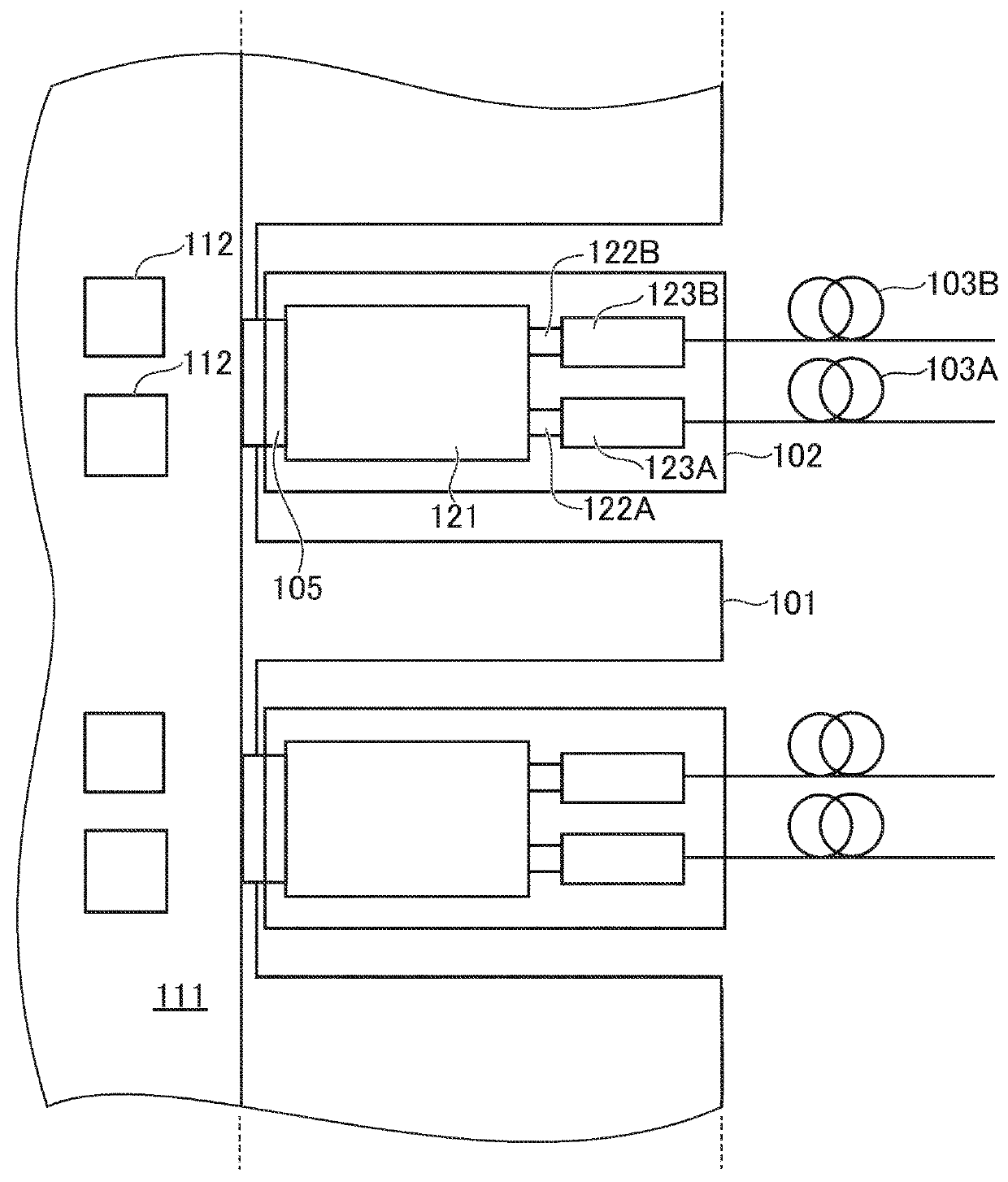

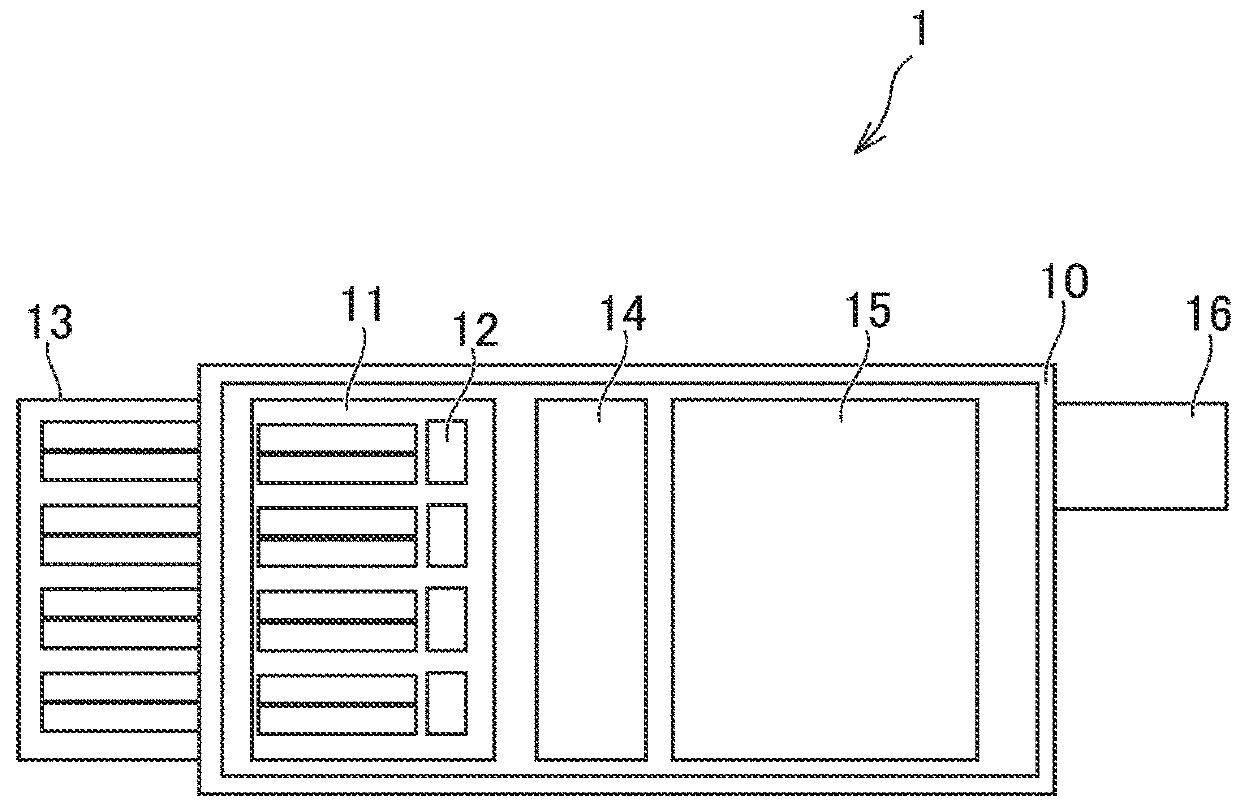

Submount, optical transmitter module, optical module, optical transmission equipment, and control method therefor

ActiveUS20180278020A1Low costSlow changeLaser detailsLaser optical resonator constructionOptical ModuleComputer module

A submount which has a mounting surface on which three or more semiconductor lasers are arranged in a first direction, and includes a heat generator configured to increase the temperatures of the three or more semiconductor lasers, in which, where the heat generator generates heat, a first heat of the heat absorbed by a first semiconductor laser of the three or more semiconductor lasers disposed at one end along the first direction is larger than a second heat of the heat absorbed by a second semiconductor laser of the three or more semiconductor lasers disposed to be adjacent to the first semiconductor laser on the mounting surface.

Owner:LUMENTUM JAPAN INC

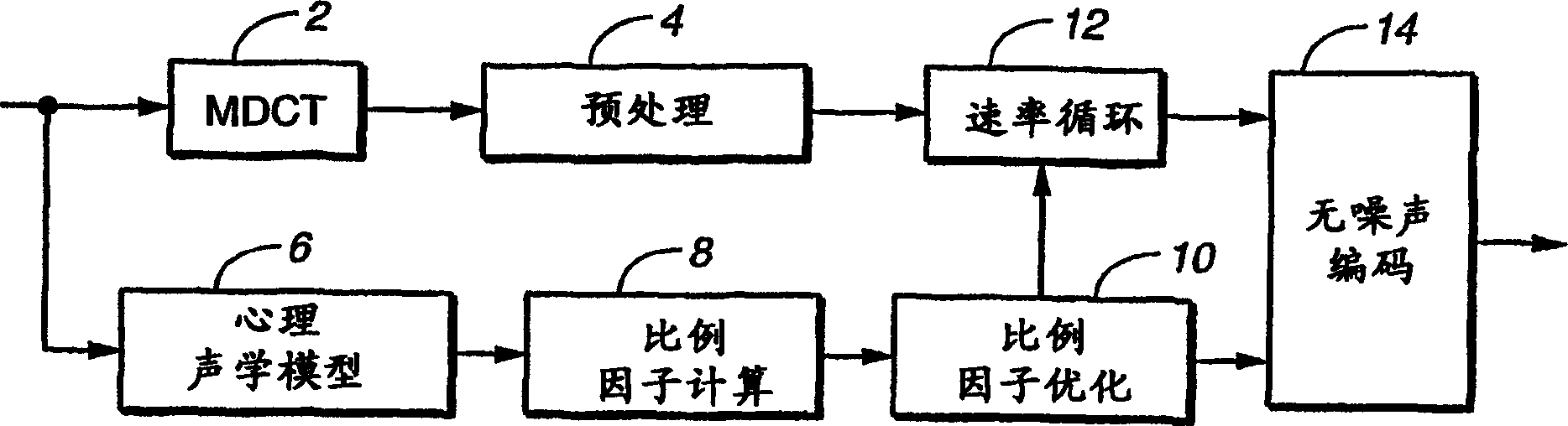

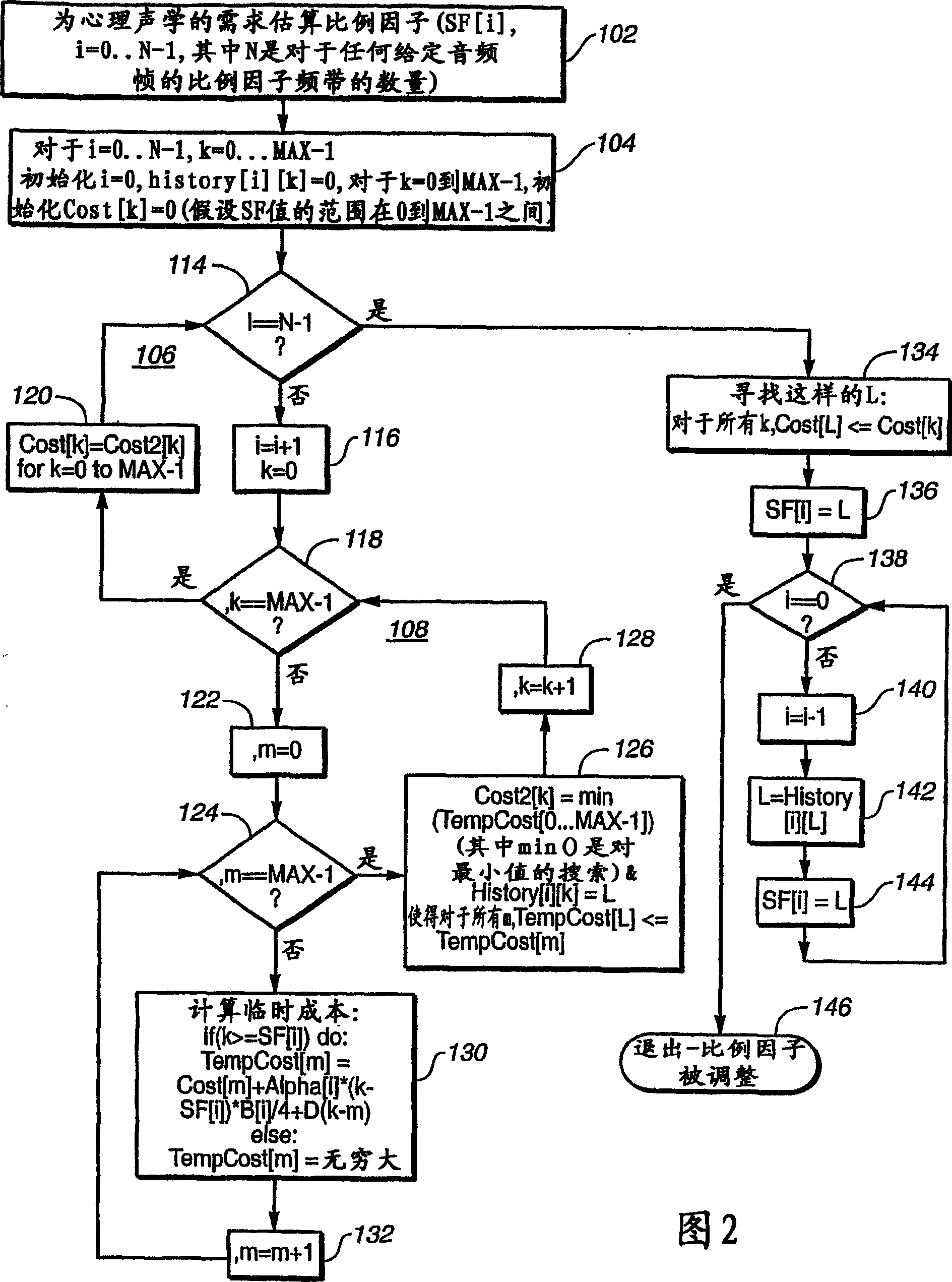

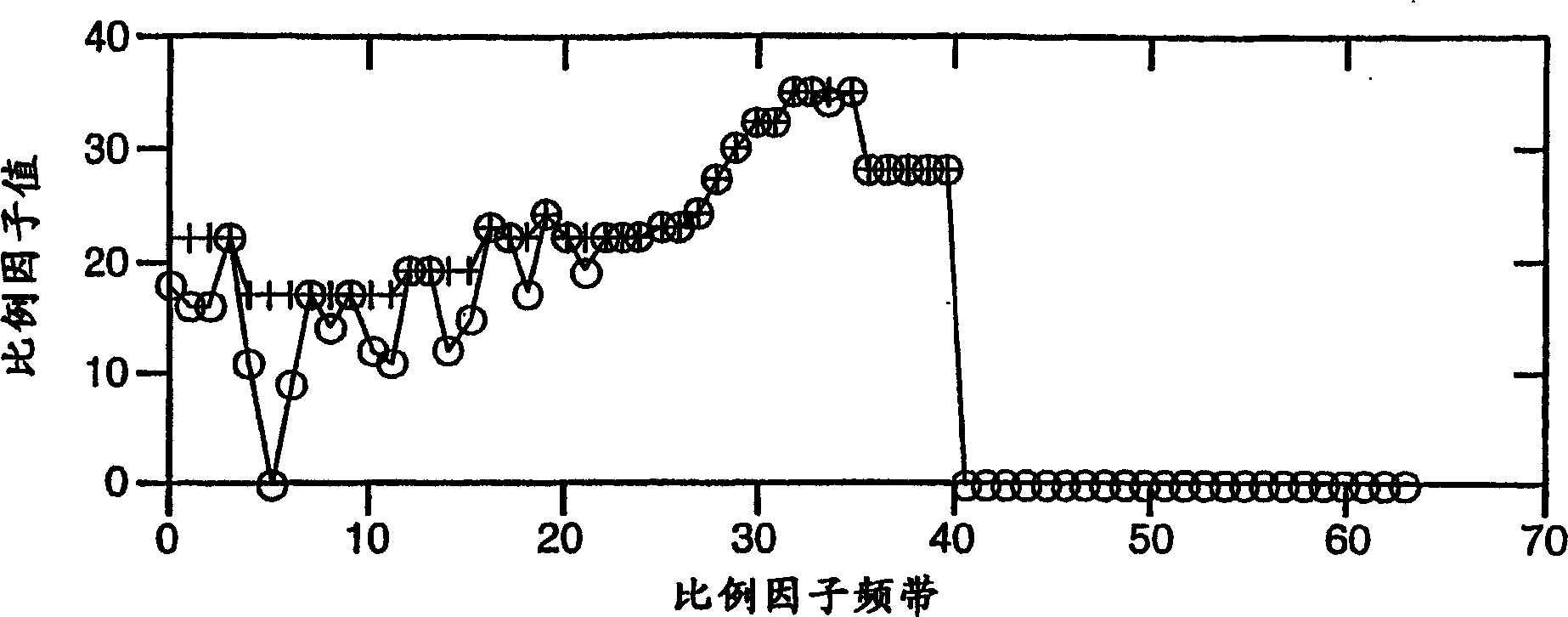

Reducing scale factor transmission cost for MPEG-2 AAC using a lattice

InactiveCN1735925ABit cost reductionReduce the degree of variationSpeech analysisAudio frequencyMesh grid

A perceptual encoder divides an audio signal into successive time blocks, each time block is divided into frequency bands, and a scale factor is assigned to each of ones of the frequency bands. Bits per block increase with scale factor values and band-to-band variations in scale factor values. A preliminary scale factor for each of ones of the frequency bands is determined, and the scale factors for the each of ones of the frequency bands is optimized, the optimizing including increasing the scale factor to a value greater than the preliminary scale factor value for one or more of the frequency bands such that the increase in bit cost of the increasing is the same or less than the reduction in bit cost resulting from the decrease in band-to-band variations in scale factor values resulting from increasing the scale factor for one or more of the frequency bands.

Owner:DOLBY LAB LICENSING CORP

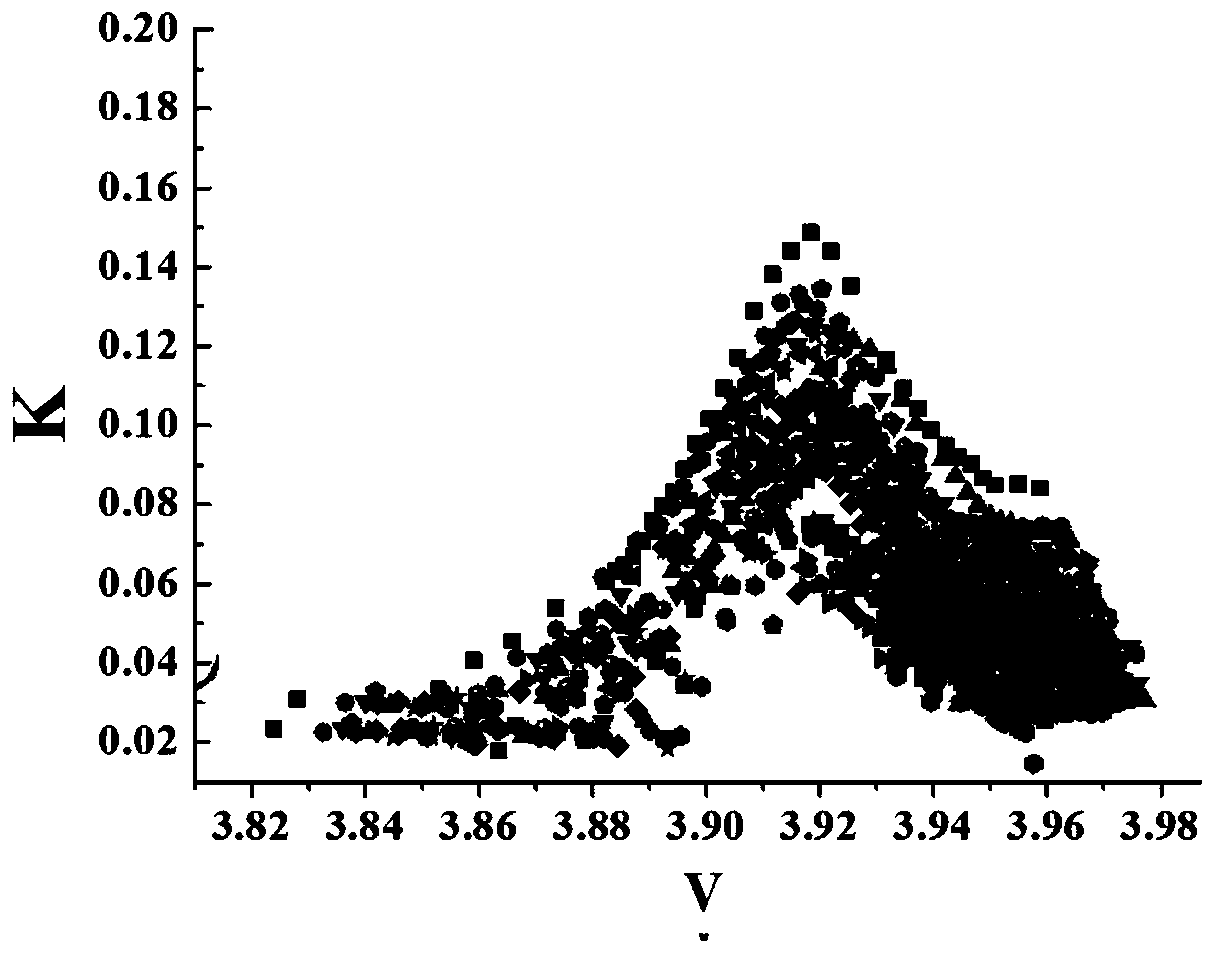

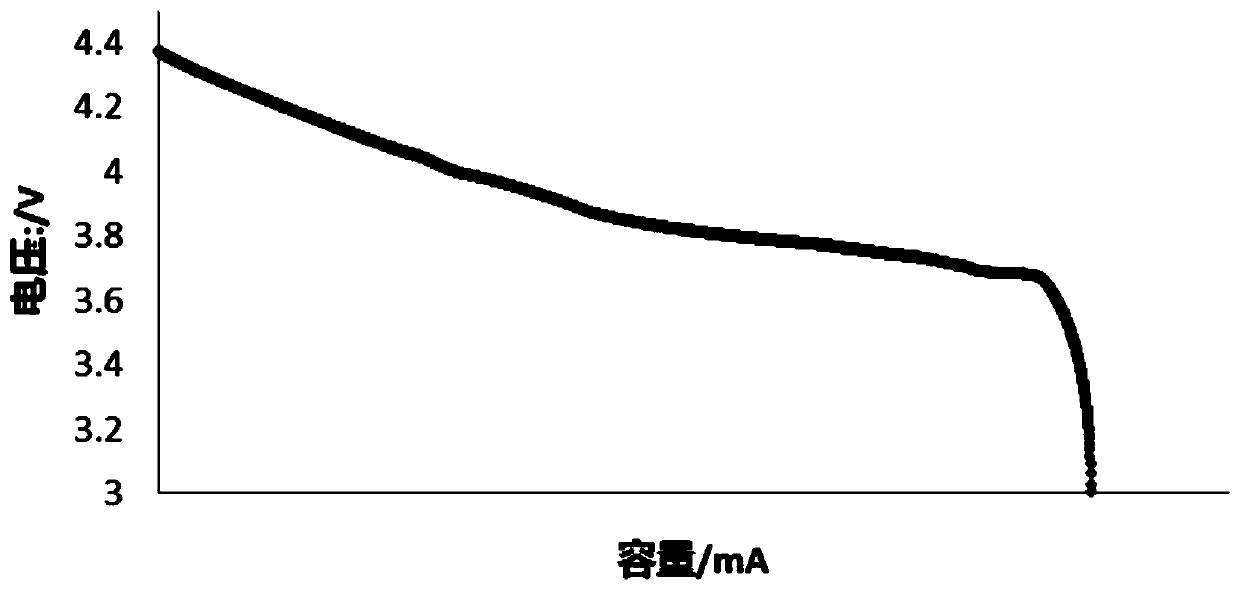

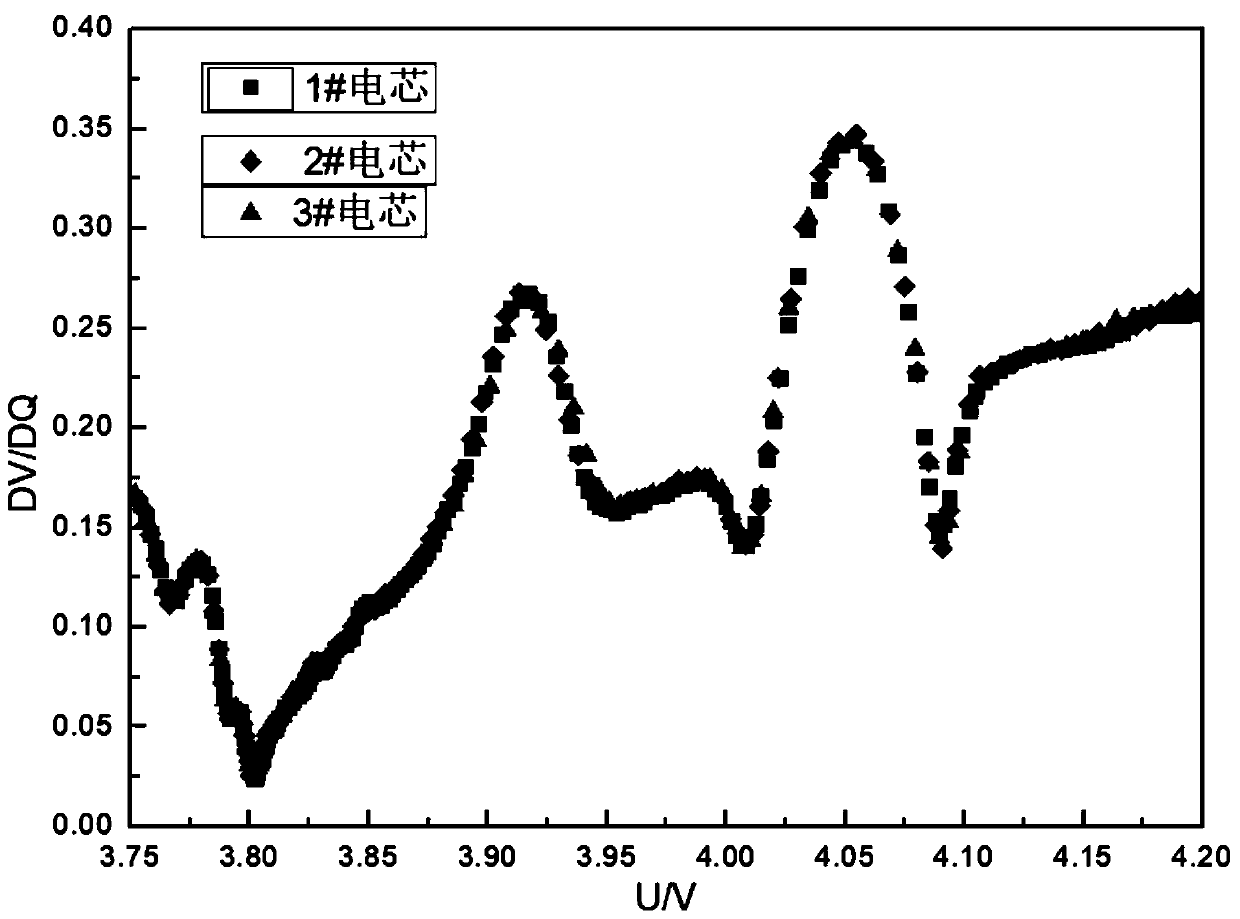

Method for detecting self-discharge current of battery cell

The invention provides a novel method for detecting the quality of a lithium battery / battery pack. According to the method, the self-discharge current of the battery is predicted through the self-discharge current of the battery; the method for the self-discharge current of the battery cell comprises the following steps: 1) charging and discharging a sample battery, simulating a self-discharge process of the sample battery to obtain a V-Q curve of the sample battery, and differentiating the V-Q curve to obtain a dV / dQ-V curve; 2) testing the K value of the sample battery under each voltage inthe long-term placement process; 3) calculating the self-discharge current of the battery cell according to the following formula: F (V) = dV / dQ = dV / d (T * I) = dV / d (T) * / I = K / I; i=K / F(V). The change degree of the battery self-discharge current obtained by the method under different voltages is very small, the influence of voltage change is avoided (the existing K value detection value fluctuates under different voltages), and the quality and the storage time of the battery can be more accurately predicted.

Owner:ZHUHAI COSMX BATTERY CO LTD

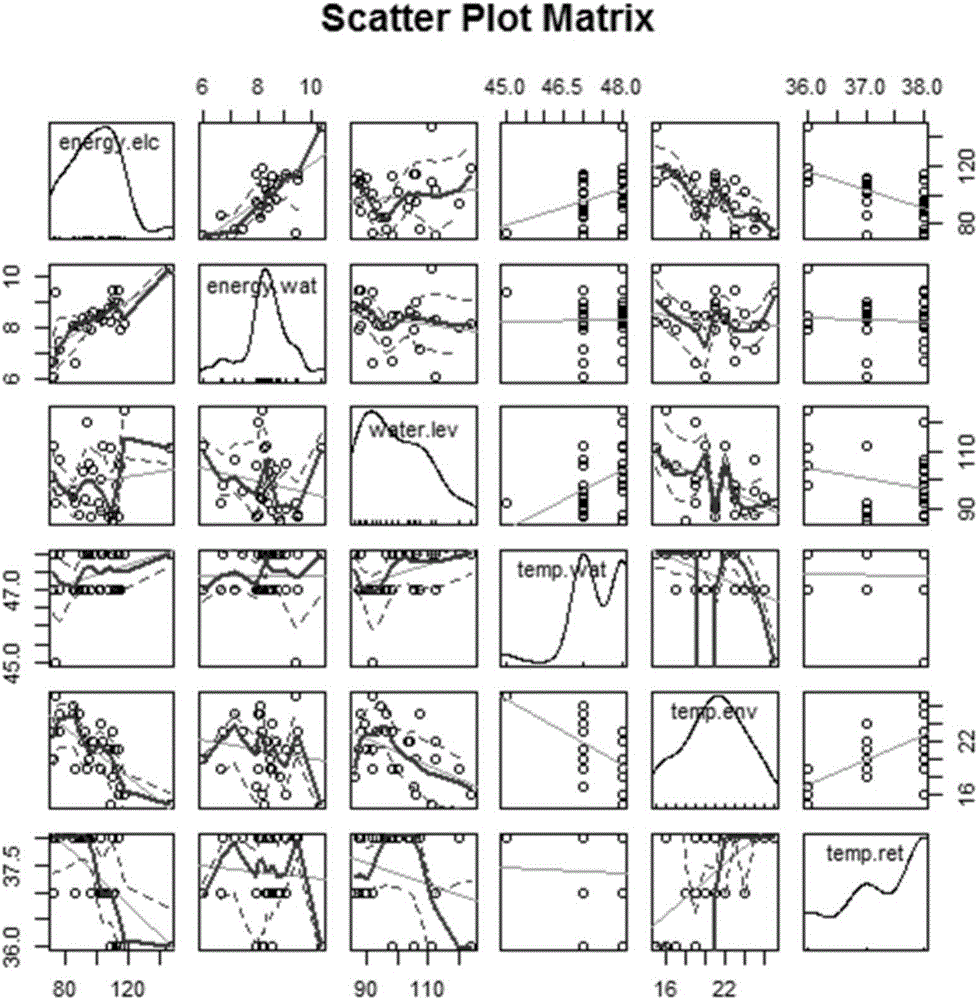

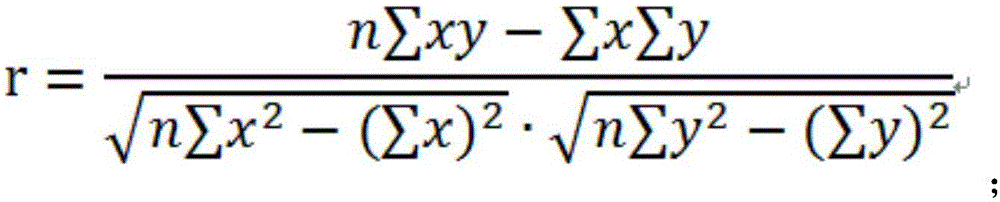

Self-adaptive operation-maintenance and parameter adjusting method based on energy supply system

ActiveCN106056474AReduce the degree of variationOptimization parametersData processing applicationsSelf adaptiveSupply energy

The invention provides a self-adaptive operation-maintenance and parameter adjusting method based on an energy supply system. The self-adaptive operation-maintenance and parameter adjusting method comprises the steps of: S1, establishing a regression model of optimal hot water system energy consumption; S2, and carrying out optimization adjustment on each daily mean parameter value of a hot water system according to the regression model of the optimal hot water system energy consumption, wherein the daily mean parameter values include electric energy consumption, water energy consumption, water level, water temperature, ambient temperature and return water temperature. The self-adaptive operation-maintenance and parameter adjusting method can reduce the water supplementary amount, the return water temperature and water tank temperature as much as possible on the premise of satisfying use demand of users in self-adaptive adjustment, the ambient temperature is an important factor regarded as force majeure, but a controllable unit can be used for heating when the ambient temperature is high, thus the important factor, namely, the ambient temperature can be utilized reasonably. Therefore, the parameters of the hot water system can be optimized in real time, and the energy conservation purpose is achieved.

Owner:武汉企鹅能源数据有限公司

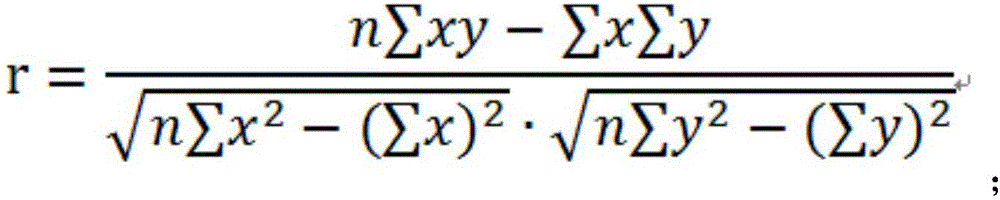

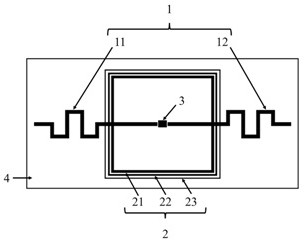

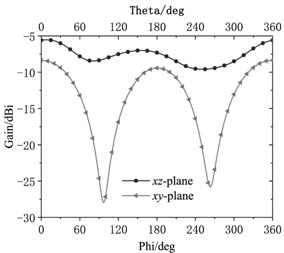

Liquid-insensitive ultrahigh-frequency RFID flexible tag antenna

PendingCN112151935AThe degree of change in impedance value is reducedReduce the degree of variationAntenna supports/mountingsRadiating elements structural formsUltrahigh frequencyRadio frequency

The invention relates to a liquid-insensitive ultrahigh-frequency RFID flexible tag antenna. The liquid-insensitive ultrahigh-frequency RFID flexible tag antenna comprises a folding dipole arm, a multi-loop matching structure, a radio frequency identification chip and a flexible dielectric substrate, wherein the folded dipole arm and the multi-loop matching structure are formed by mechanically engraving a copper-clad flexible dielectric substrate, and a radio frequency identification chip is placed in the center; Due to the impedance adjusting effect of the multi-loop matching structure, impedance matching between the tag antenna and the radio frequency chip in the air is good, and the impedance mismatching degree is greatly reduced when the tag antenna works on the liquid surface; in addition, adjustment of the dipole arms can significantly improve the gain of the tag antenna, so the reading distance of the tag antenna can reach 8 meters and 5.6 meters in the air and on the surface ofthe liquid respectively. The RFID tag antenna is low in cost and easy to manufacture, and the problem that a traditional RFID tag antenna cannot work on the surface of liquid is solved; and meanwhile, the flexible dielectric substrate can enable the tag antenna to be conformal with any bottle body or tank body, so the tag antenna can be conveniently matched with an identified object.

Owner:GENGUAN INTELLIGENT TECH HANGZHOU CO LTD

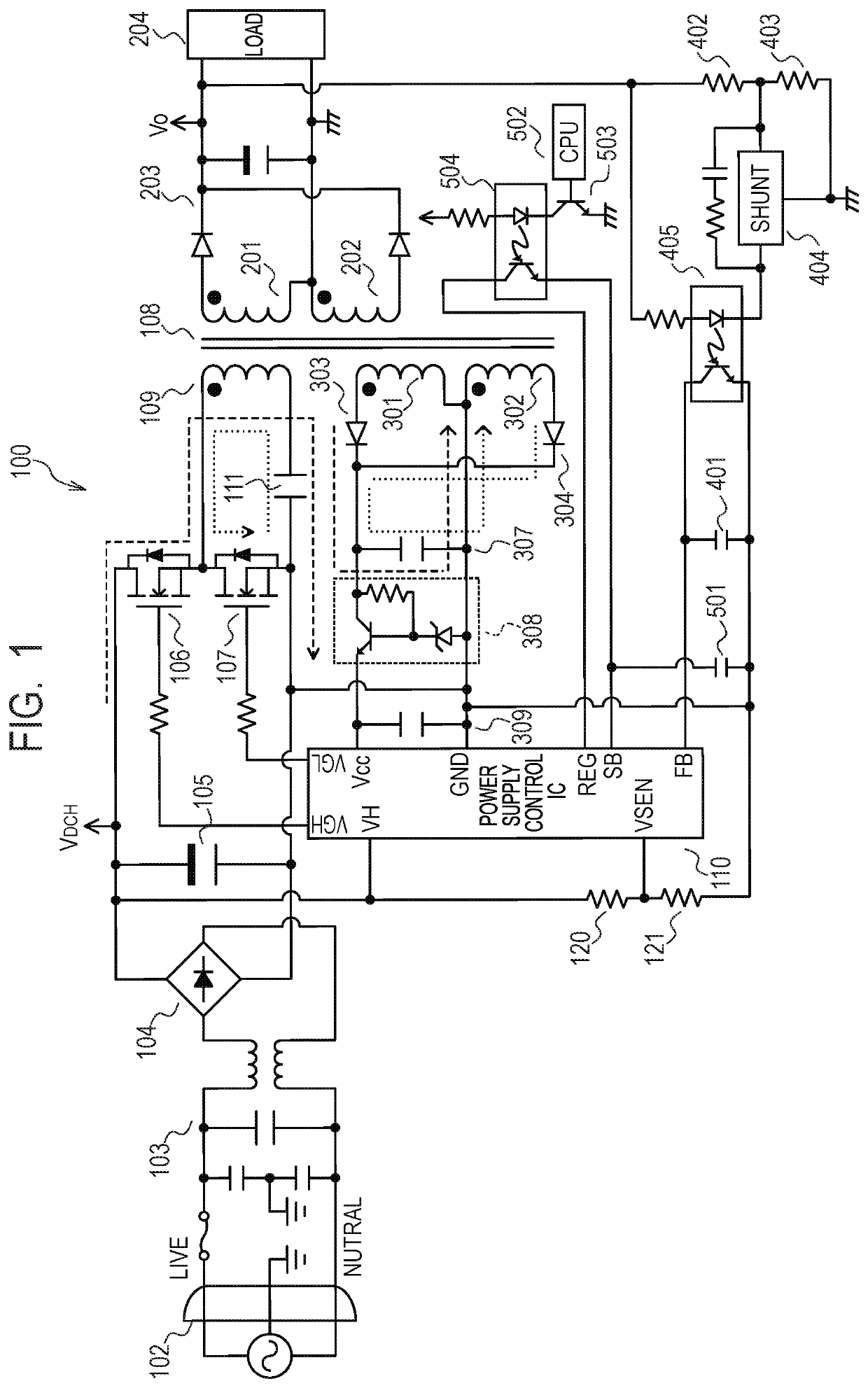

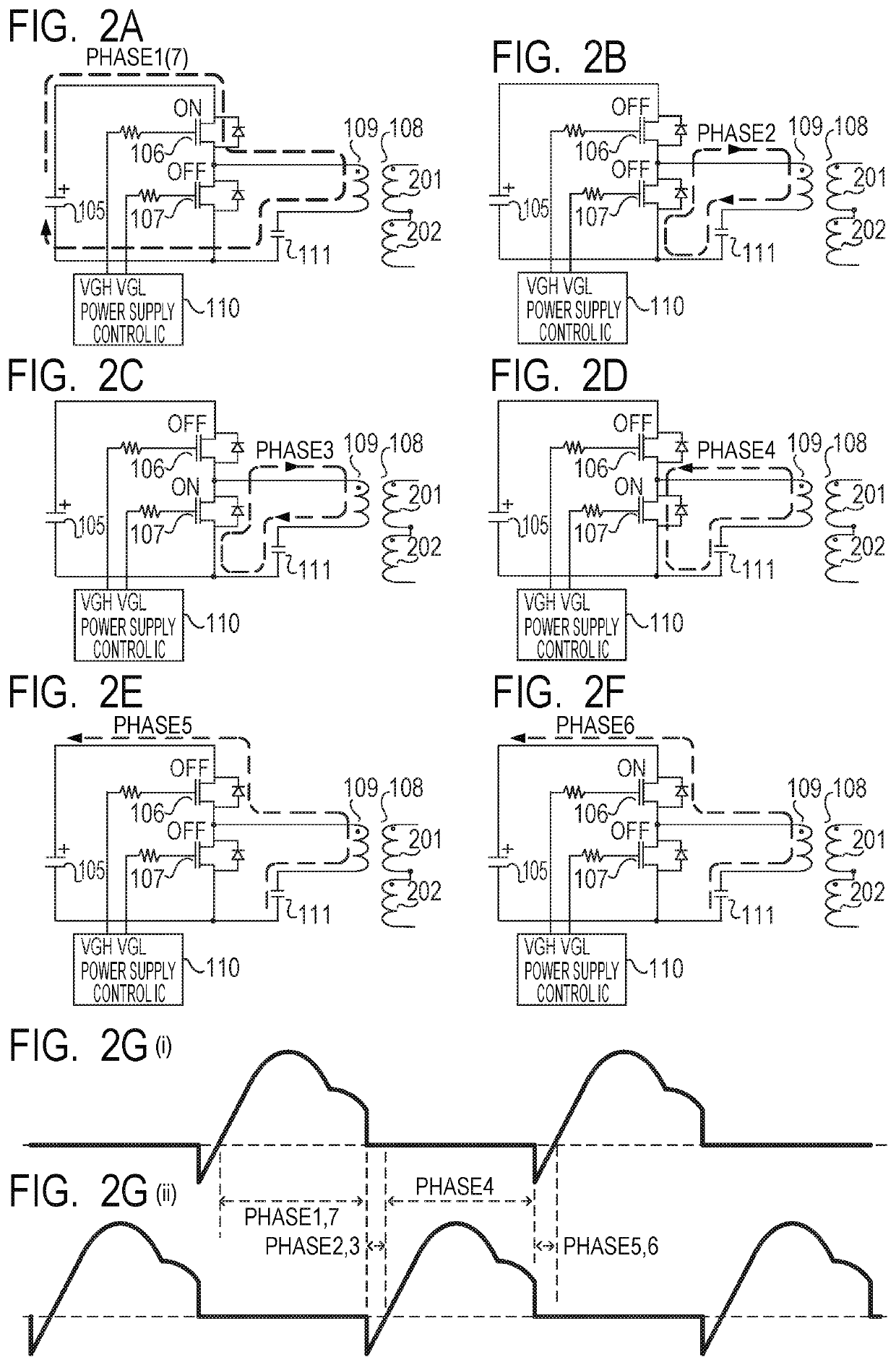

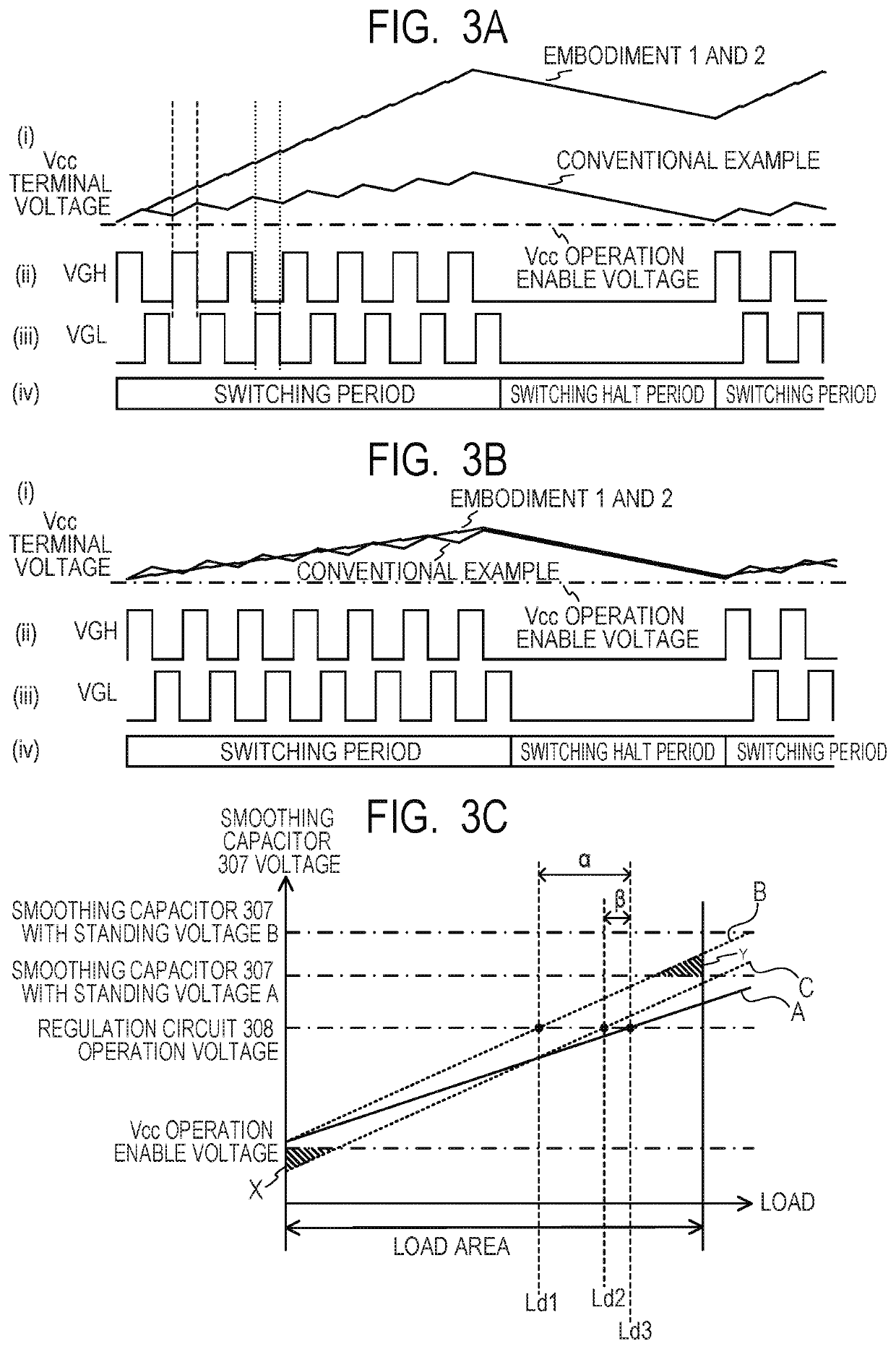

Power supply apparatus and image forming apparatus

ActiveUS10547244B2Reduce the degree of variationEfficient power electronics conversionDc-dc conversionTransformerImage formation

The power supply apparatus having two switching elements connected to a primary winding of a transformer includes an adjustment unit for adjusting a voltage and supplying the voltage to a control unit. This voltage results from application of a voltage induced in an auxiliary winding while current is flowing in a predetermined direction with respect to the auxiliary winding as a result of the first switching element turned on and the second switching element turned off, and a voltage induced in the auxiliary winding while current is flowing in the direction opposite to the predetermined direction with respect to the auxiliary winding as a result of the first switching element turned off and the second switching element turned on.

Owner:CANON KK

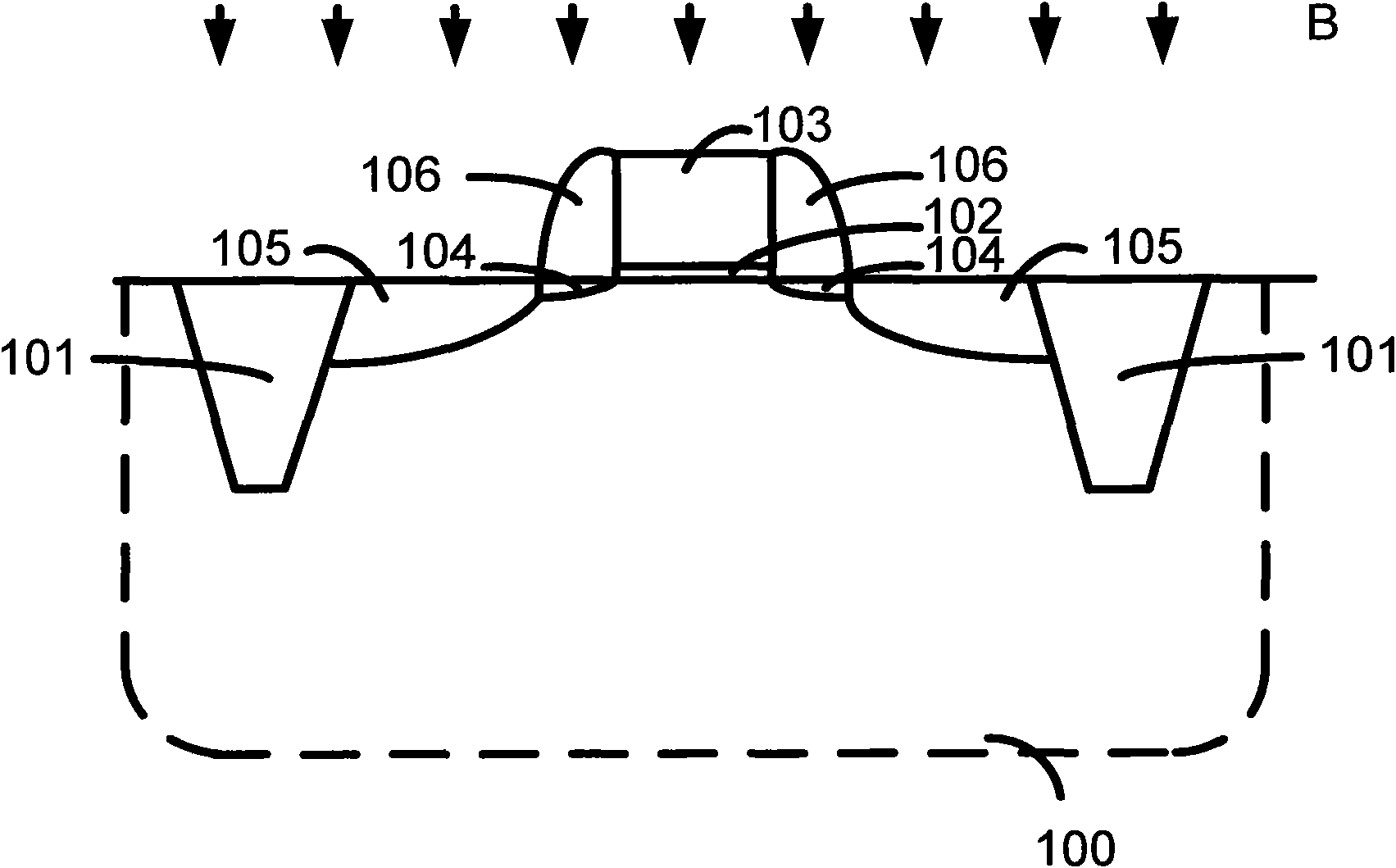

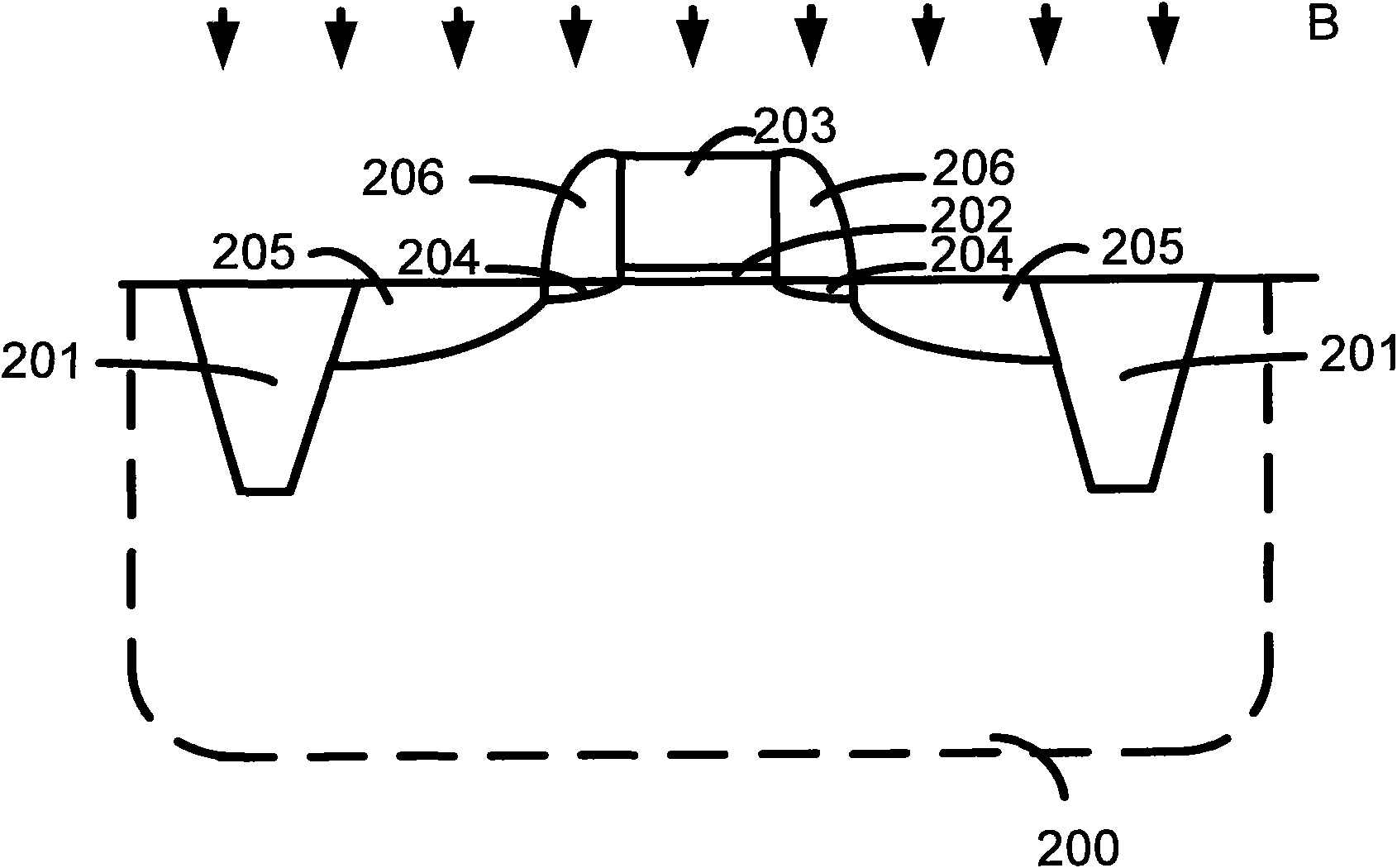

Method for preparing semiconductor device

InactiveCN102044436AReduce the degree of variationImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceOxide

The invention discloses a method for preparing a semiconductor device, which comprises the following steps of: providing a substrate, wherein a shallow trench isolation region and a well region are formed on the substrate; forming a gate oxide layer on the well region and the shallow trench isolation region; forming a grid on the gate oxide layer; performing lightly doped ion implantation to form a lightly dope drain region on the substrate by taking the grid as a mask; forming an oxide layer on the grid and the gate oxide layer and etching the oxide layer to form a side wall oxide layer on the side wall of the grid; performing ion implantation with the grid and the side wall oxide layer as masks to form a source electrode and a drain electrode on the substrate; and performing fast thermal annealing process and raising the annealing temperature at the speed of 50-200 DEG per second till the annealing temperature reaches 900-1100 DEG C. The change degree of static current Idsat of the transistors with the same size can be reduced according to the control method of peak annealing temperature so as to improve the yield of the device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Failure determining device and failure determining method of continuously variable transmission

ActiveUS8275510B2Reduce the degree of variationIncrease hydraulic pressureVehicle testingRegistering/indicating working of vehiclesControl theoryVariator

Owner:TOYOTA JIDOSHA KK

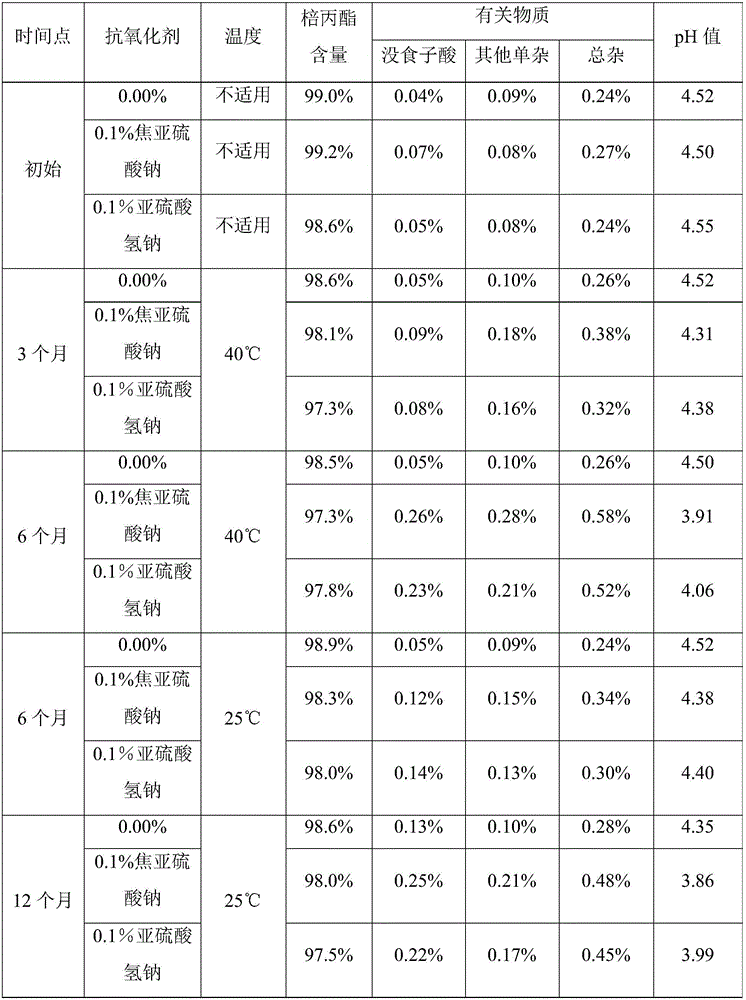

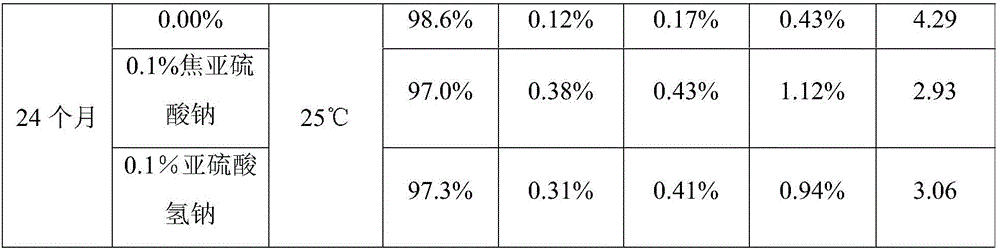

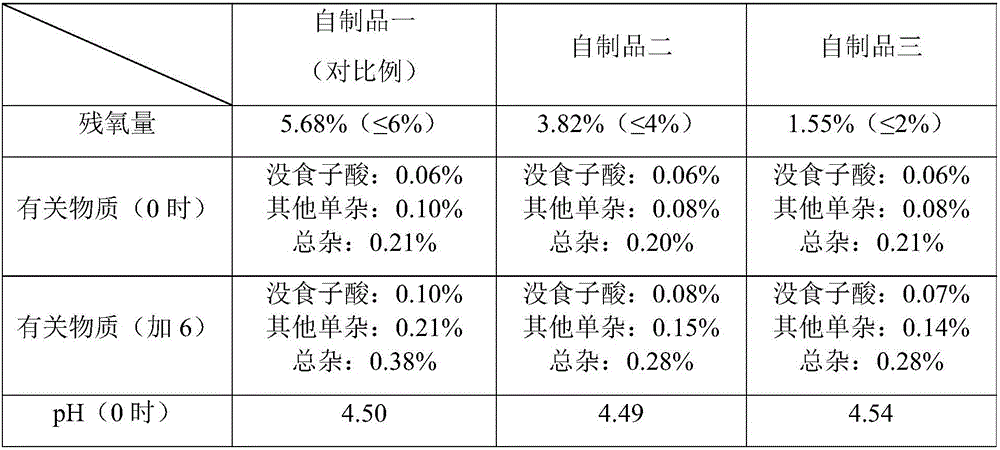

Propylgallate injection, and preparation method and application of propylgallate injection

ActiveCN106821973AImprove stabilityReduce the overall heightOrganic active ingredientsPharmaceutical delivery mechanismHydrogenAntioxidant

The invention discloses a propylgallate injection, and a preparation method and application of the propylgallate injection. The propylgallate injection comprises the following raw material ingredients: propylgallate, propylene glycol, edetate disodium, a pH (potential of hydrogen) regulator and water for injection, excluding an antioxidant. The preparation method of the propylgallate injection comprises the following steps: (1) adding propylene glycol, edetate disodium and propylgallate into the water for injection, uniformly mixing, then adding the pH regulator till a pH value is 3.0-5.0, (2) purging an injection obtained in step (1) with nitrogen, replacing air, allowing the injection to flow through a sterilization filter, and (3) loading an injection obtained in step (2) into a vial or an ampoule purged by the nitrogen to form an injection with a remaining oxygen content of less than or equal to 5%, and carrying out sterilization. The prepared propylgallate injection can achieve better stability on the premise of not containing the antioxidant.

Owner:SHANDONG WEIZHI BAIKE PHARM CO LTD +1

Delay composition for fireworks

InactiveCN109896916AEasy to manufactureGuaranteed storage stabilityExplosivesFireworksDelay composition

The invention discloses a delay composition for fireworks. The delay composition for the fireworks is prepared from the following raw materials in percentage by weight: 20-80% of tungsten powder, 10-60% of barium chromate, 5-10% of potassium perchlorate and 1-5% of calcium fluoride. According to the delay composition for the fireworks, the delay compositions with different burning speeds can be obtained through compounding the tungsten powder, the barium chromate, the potassium perchlorate and the calcium fluoride in different proportions; the delay composition is easy to prepare; in addition,the calcium fluoride is added into the delay composition, and the combustible matter content is increased after the addition, so that the storage stability of the delay composition can be better ensured; and the delay precision is reduced to some extent after half-year storage, but the change degree is relatively small.

Owner:张金希

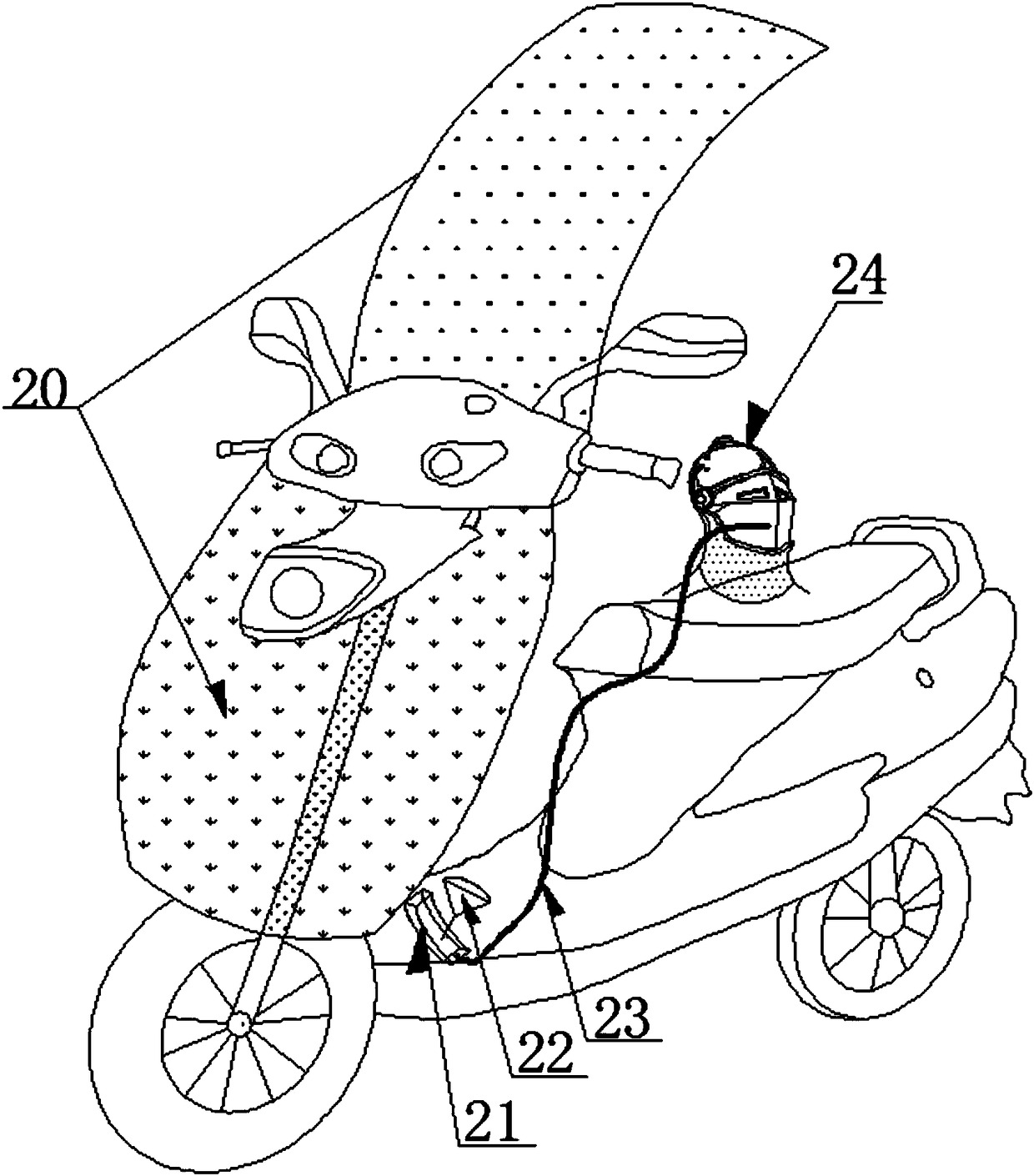

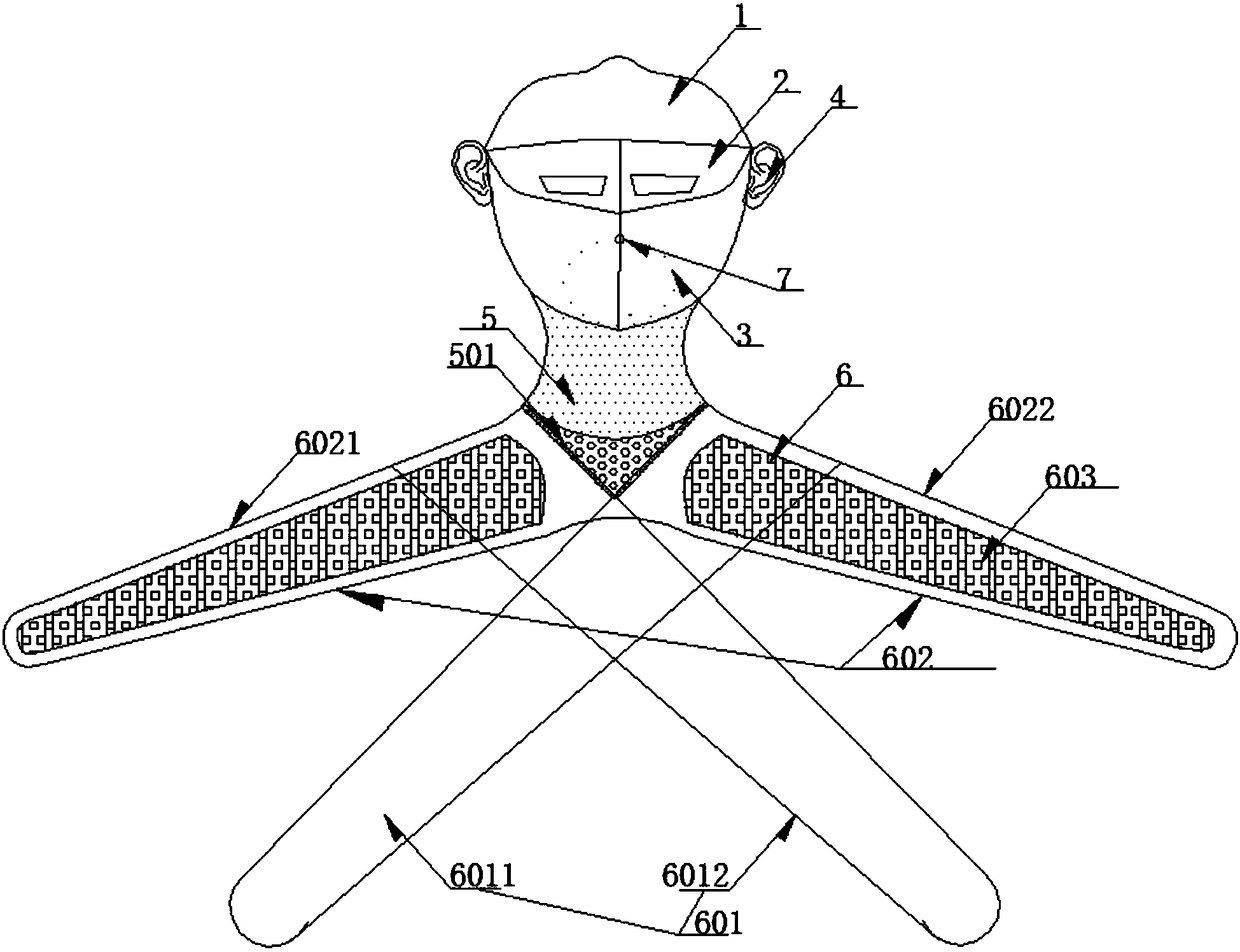

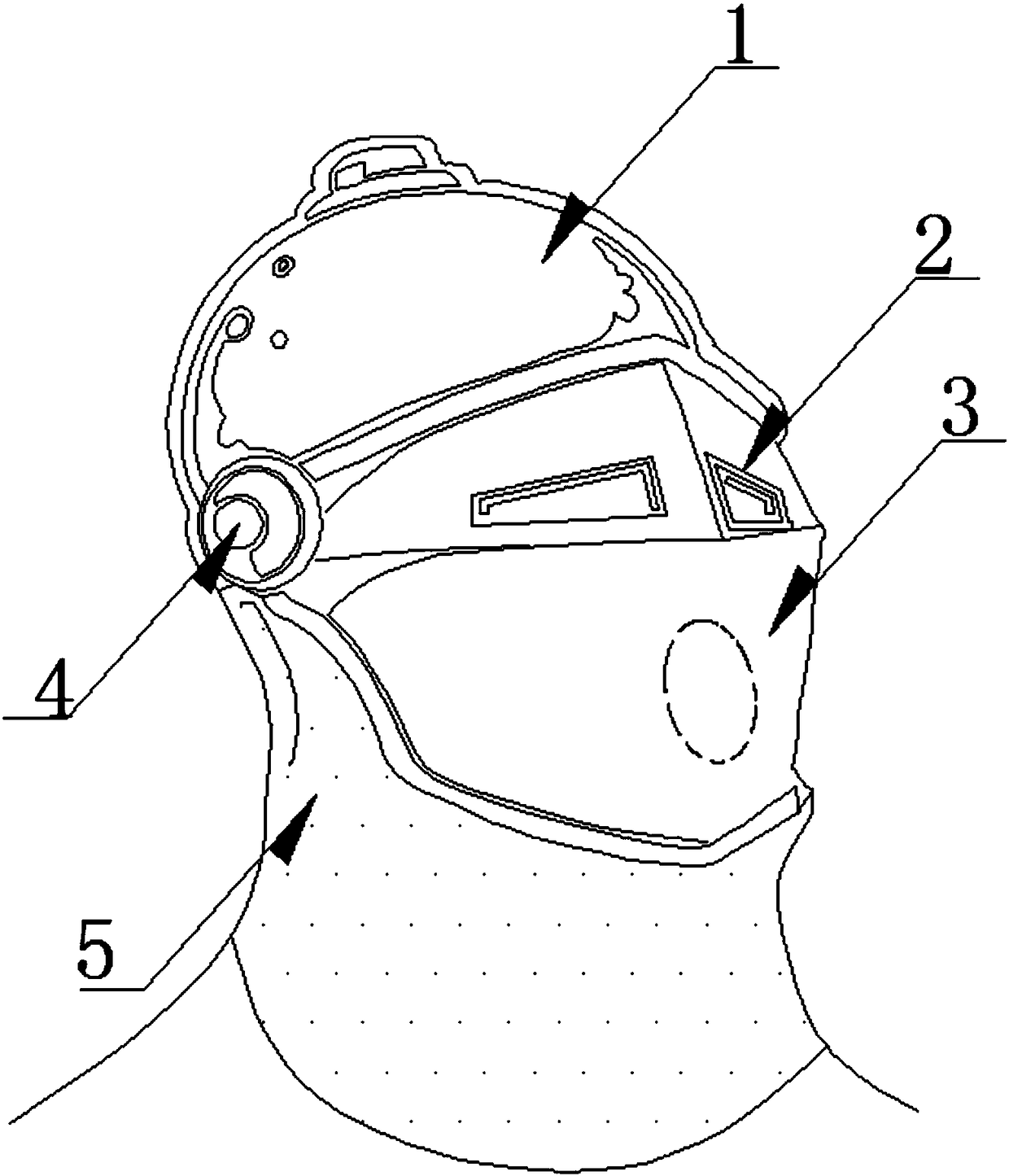

Anti-haze electric bicycle

PendingCN108438109AReduce the degree of variationStable speedWeather guardsHelmetsAir filterEngineering

The invention belongs to the technical field of electric bicycles and particularly relates to an anti-haze electric bicycle which comprises a front wheel, a rear wheel and a bicycle body. A wind shield is arranged on the front side of the bicycle body and arranged perpendicular to the wind direction. A wind catcher is arranged on the leeward side of the wind shield and connected with an air inletof an air filter device. An air outlet of the air filter device is connected with one end of a wind guide pipe. The other end of the wind guide pipe is connected with an anti-haze helmet. The wind catcher is arranged on the leeward side of the wind shield. In the operating process, wind is stopped by the wind shield and does not directly enter the region behind the wind shield, the wind caught bythe wind catcher is the wind of the leeward face of the wind shield, the change degree of the wind speed of the leeward face is far lower than the change degree of the wind speed of the windward faceof the wind shield, the speed of the wind caught by the wind catcher is stable, so that the speed of the wind entering the air filter device is stable, the situation that air enters the human body without being completely filtered in the air filter device is avoided, and in other words, the quality of air entering the human body is stable.

Owner:余文博

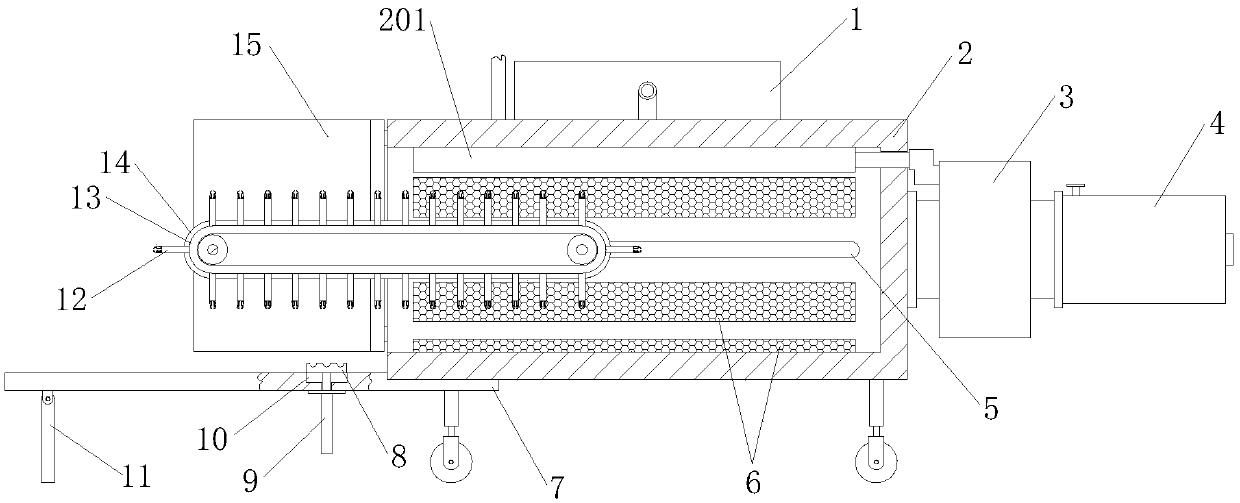

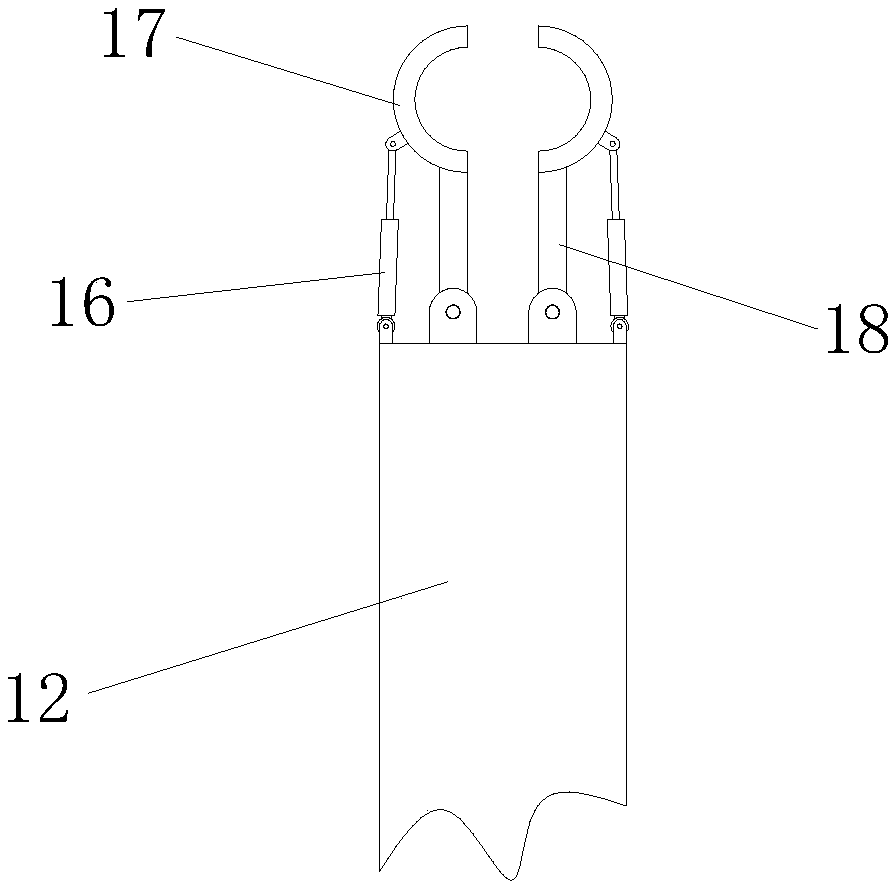

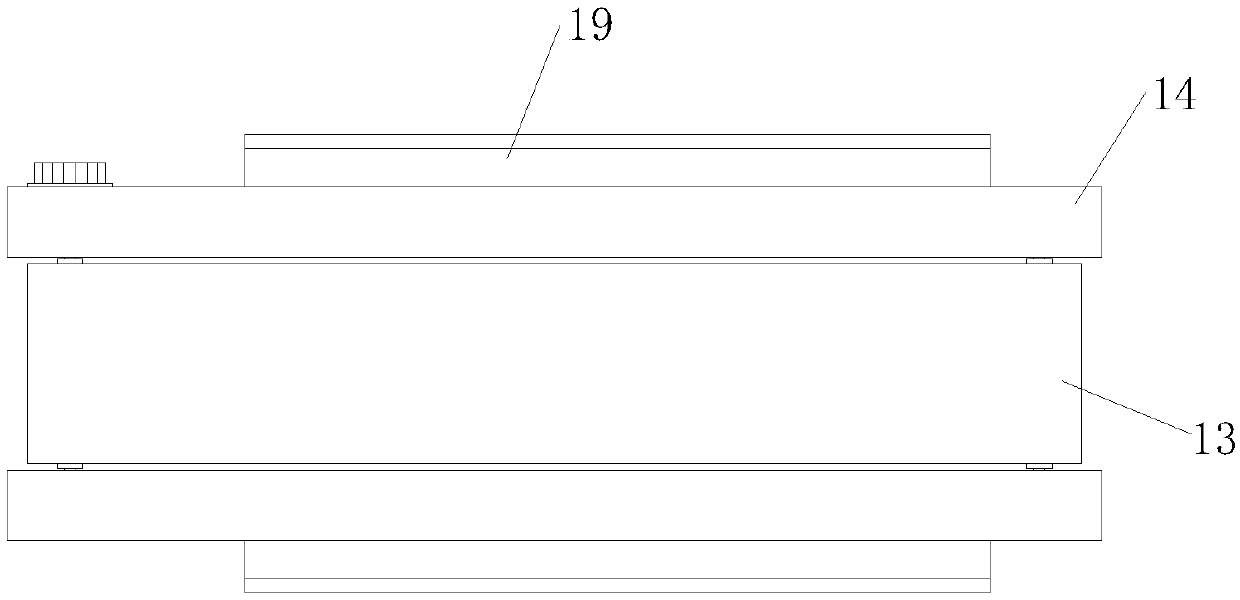

Motor rotor heat sleeve rotating shaft cooling machine

ActiveCN109623261AConvenient for centralized placementEasy to clamp and fixMetal working apparatusStress changeEngineering

The invention belongs to the technical field of cooling machines, and particularly relates to a motor rotor heat sleeve rotating shaft cooling machine. The cooling machine comprises a compression refrigerator, a box body frame, a suction fan, an iron sheet tube, a strip-shaped sliding groove, strip-shaped grooves, a strip-shaped carrying plate, a square toothed plate, a pneumatic pushing rod, a rectangular groove, a supporting rod, support rods, a conveying belt, a strip-shaped side plate, a door plate, telescopic rods, semicircular clamping blocks, round rods and strip-shaped sliding blocks.The machine has the function of sequentially clamping and moving heat sleeve rotating shafts, the to-be-cooled heat sleeve rotating shafts can be rapidly placed in the cooling structure in a centralized mode, the cooling uniformity of the heat sleeve rotating shafts is facilitated, and the degree of stress changes, caused by non-uniform cooling, of the heat sleeve rotating shafts is reduced. A cold air cooling mode is used, high-temperature air enters an evaporation strip cover according to the principle that cold air descends and hot air rises, and an atomizing nozzle sprays mist-shaped liquid, so that the mist-shaped liquid is instantly vaporized and discharged through the suction fan as heat, and better heat dissipation and heat recycling are facilitated.

Owner:鸡西德元电器有限公司

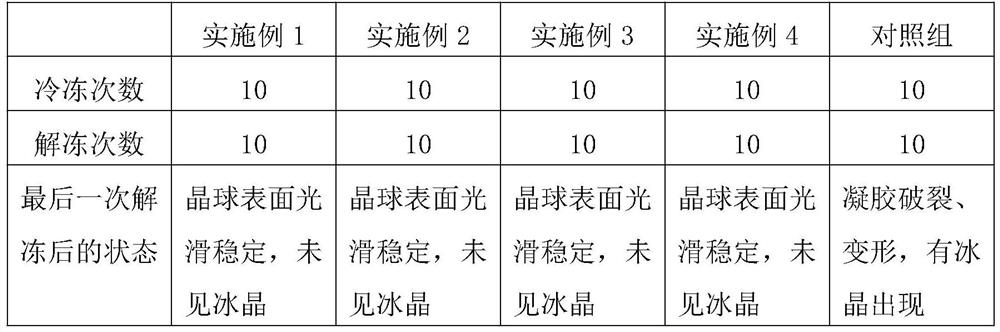

Preparation process of freezing-resistant crystal balls

The invention provides a preparation process of freezing-resistant crystal balls. The preparation process comprises the steps of step-by-step gelling, heating, forming, sugaring concentration and the like; (1) sodium alginate, agar, carrageenan, konjac gum and locust bean gum powder as raw materials; (2) a physical means of adding coconut oil and a water-soluble emulsifier to refine water distribution is used; (3) a high and new technology for compounding gel with rigid gel and elastic gel by high-temperature instant forming and low-temperature slow forming is used; and (4) the solid content is increased by sugaring. The technical problem that ice crystals are formed due to gel freezing volume expansion in the freezing process of crystal balls to cause that a gel structure is prone to damage in the prior art is solved. The preparation process disclosed by the invention is reasonable in design, and the prepared freezing-resistant crystal balls have the advantages that the ice crystals are not prone to form after freezing, the gel structure is not prone to damage, and the mouthfeel is good.

Owner:青岛至纯生物科技有限公司

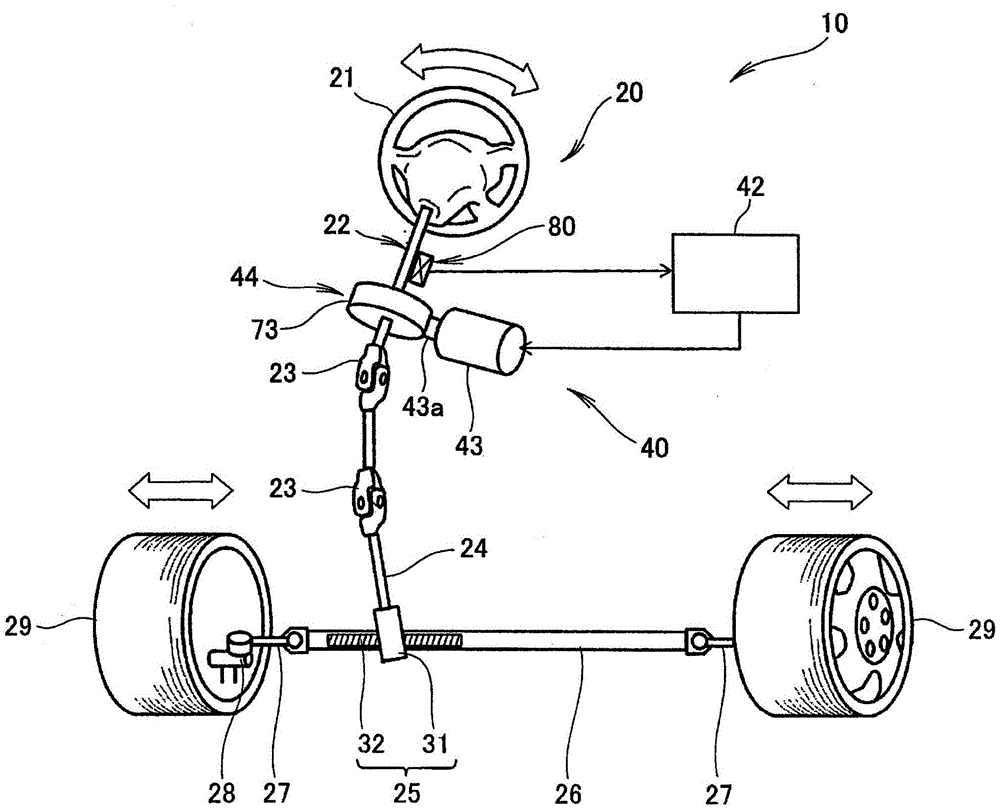

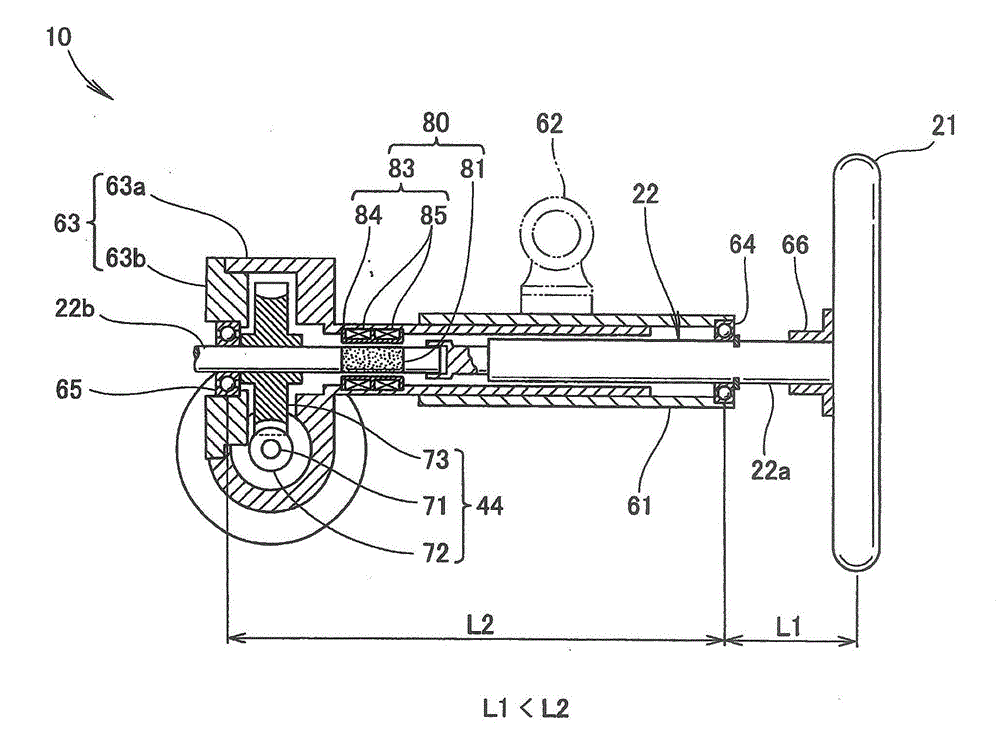

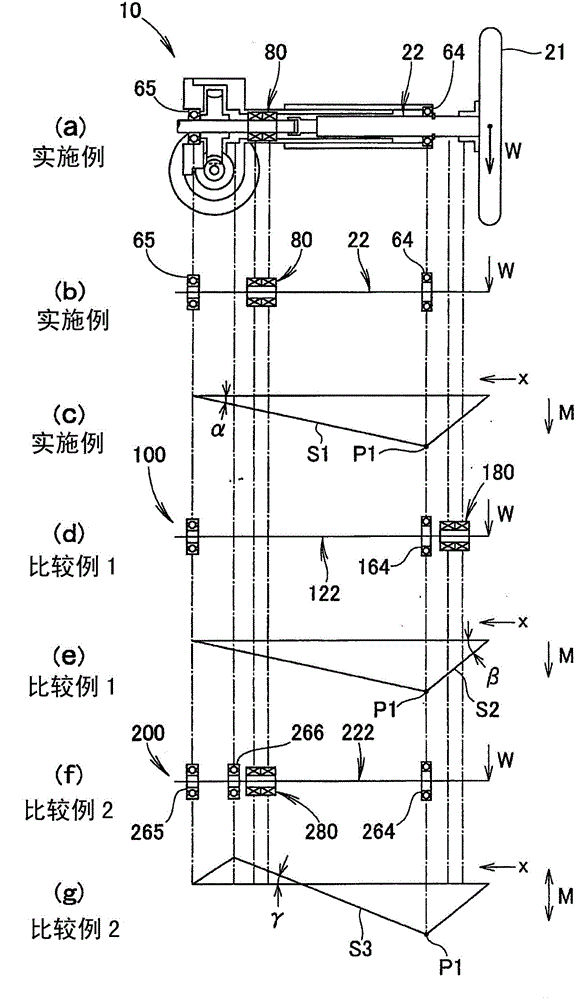

Electric power steering device

ActiveCN104684790AReduce the degree of variationImprove detection accuracyWork measurementAutomatic steering controlElectric power steeringSteering column

A column-assist type electric power steering device (10) is provided with: a steering shaft (22); a magnetostrictive type torque sensor (80) that detects a torque produced in the steering shaft (22); and bearings (64, 65) that rotatably support the steering shaft (22). The magnetostrictive type torque sensor (80) includes a magnetostrictive film (81) disposed on an outer peripheral surface of the steering shaft (22), and a detection unit (83) that is disposed opposite the magnetostrictive film (81) and that detects a change in permeability. The bearings (64, 65) are installed at two locations in the axial direction of the steering shaft (22) in such a manner as to sandwich the detection unit (83).

Owner:HONDA MOTOR CO LTD

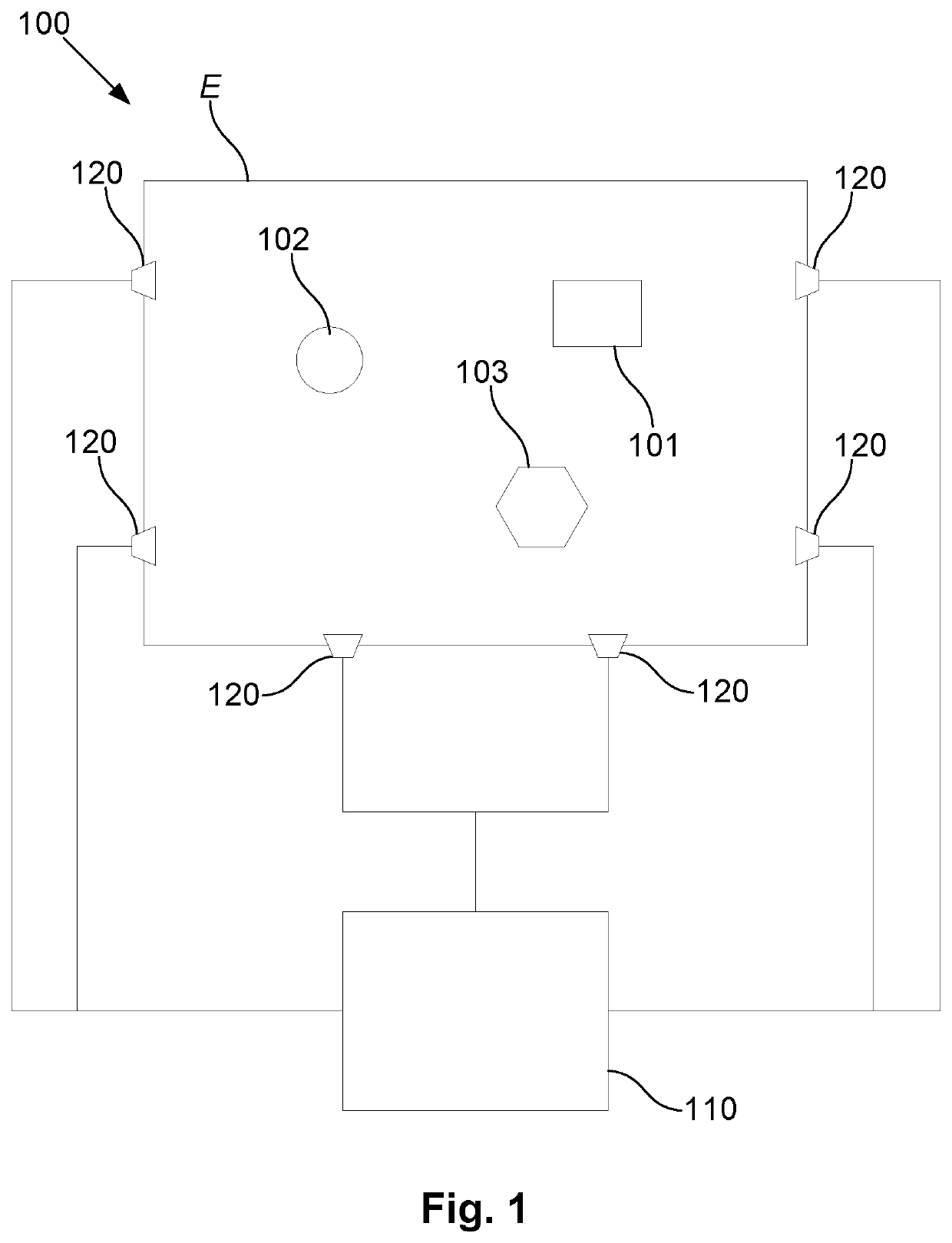

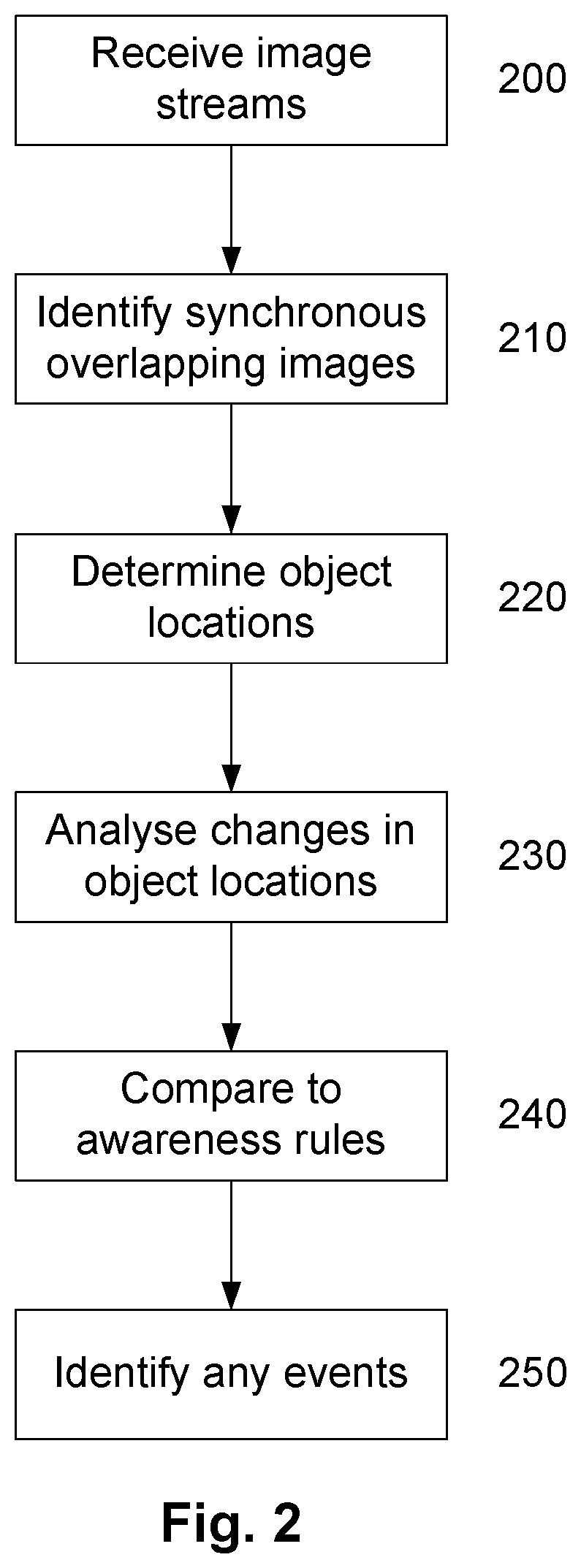

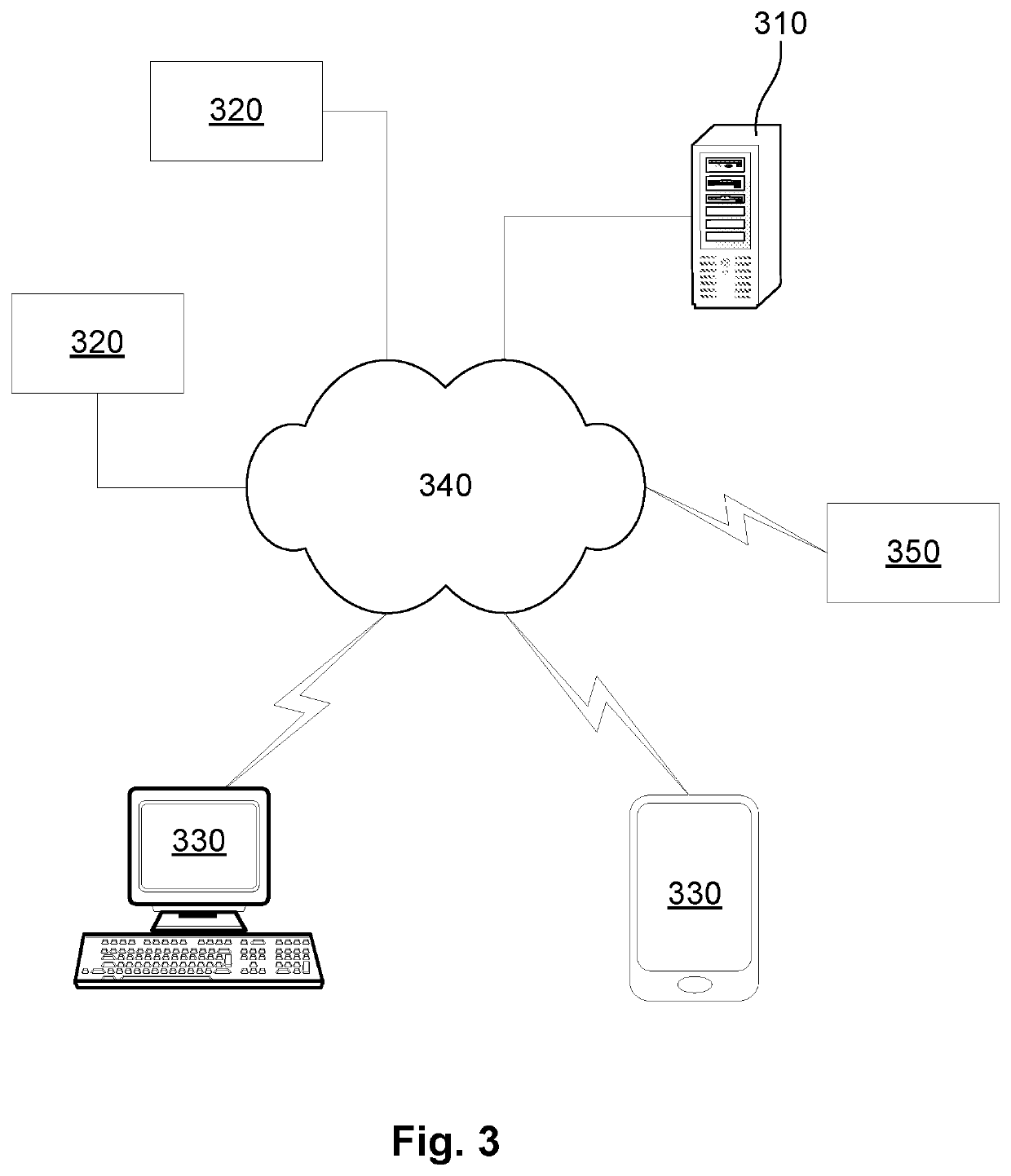

Situational awareness monitoring

ActiveUS20220004775A1Reduce degree of changeReduce the degree of variationImage enhancementData processing applicationsNuclear medicineImage capture

A system for situational awareness monitoring within an environment, wherein the system includes one or more processing devices configured to receive an image stream including a plurality of captured images from each of a plurality of imaging devices, the plurality of imaging devices being configured to capture images of objects within the environment and at least some of the imaging devices being positioned within the environment to have at least partially overlapping fields of view, identify overlapping images in the different image streams, the overlapping images being images captured by imaging devices having overlapping fields of view, analyse the overlapping images to determine object locations within the environment, analyse changes in the object locations over time to determine object movements within the environment, compare the object movements to situational awareness rules and use results of the comparison to identify situational awareness events.

Owner:COMMONWEALTH SCI & IND RES ORG

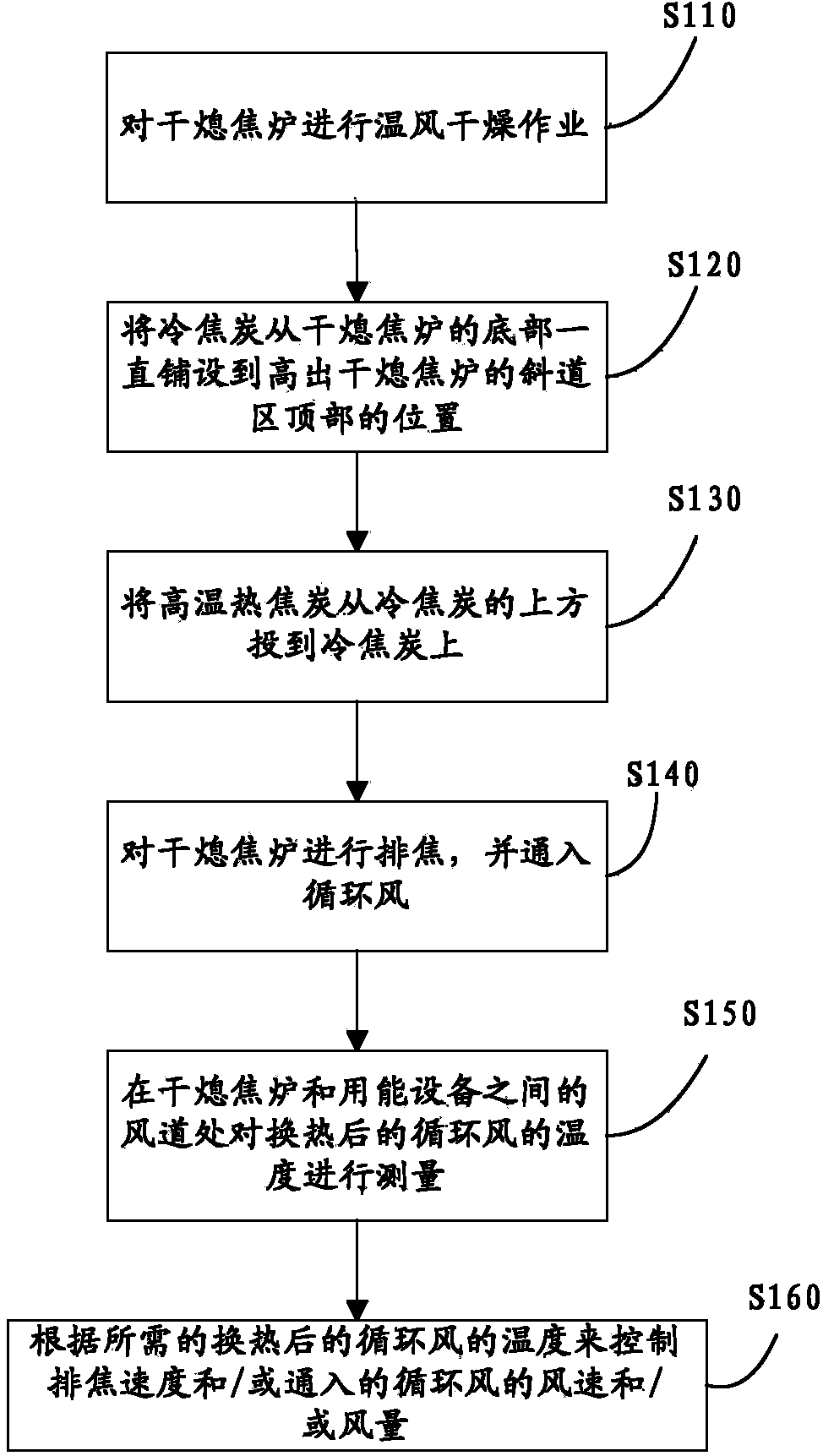

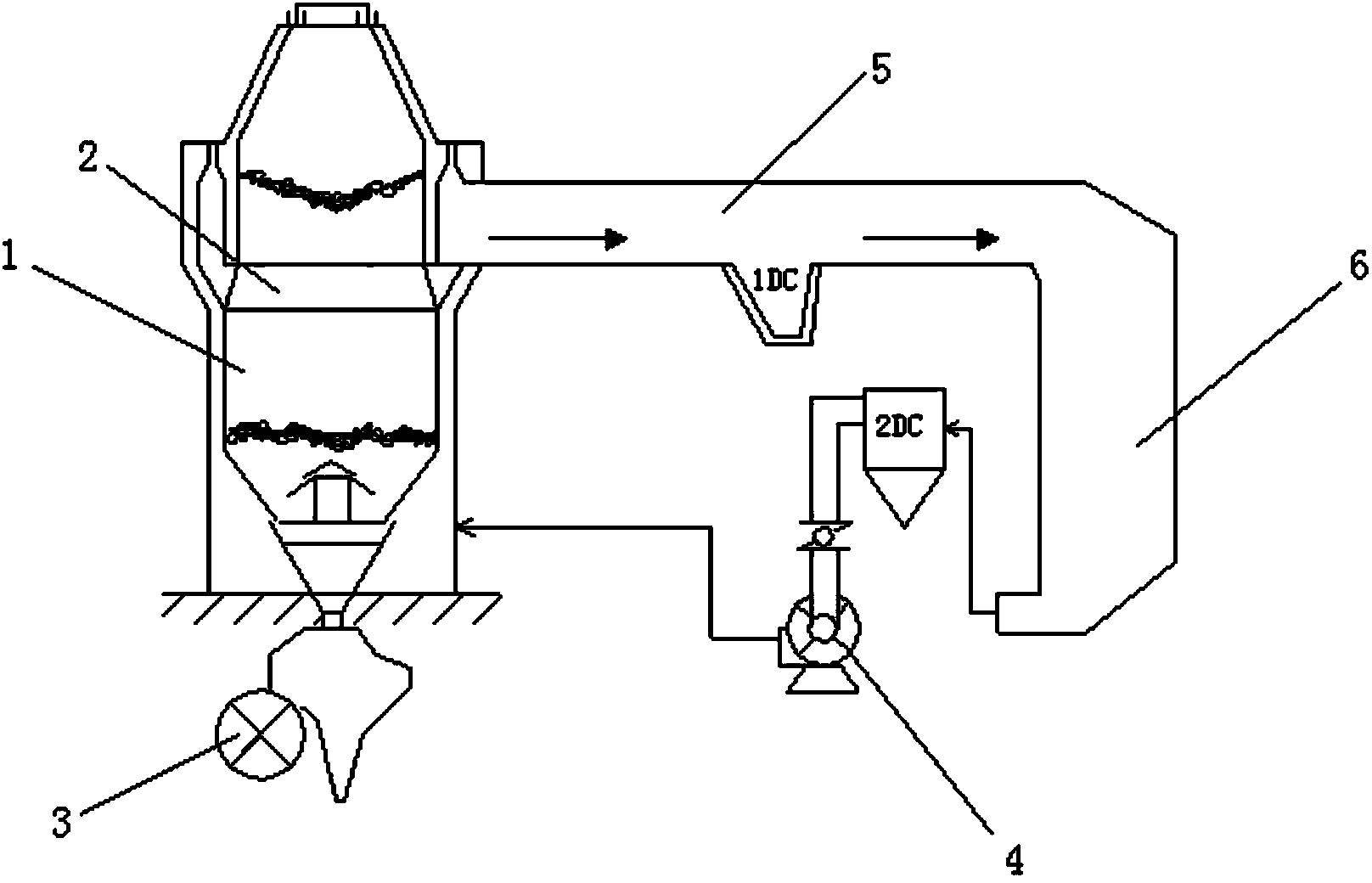

Temperature-raising method and system for coke dry quenching furnace

The invention relates to the technical field of energy recovery and discloses a temperature-raising method and a temperature-raising system for a coke dry quenching furnace. The method comprises the steps of laying cold coke from the bottom of the coke dry quenching furnace to a position higher than the top of the chute zone of the coke dry quenching furnace; putting hot coke on cold coke from the position above cold coke; carrying out coke discharging on coke dry quenching furnace, and introducing the circulating air; and controlling the coke discharging speed and / or air speed and / or air quantity of the introduced circulating air according to the temperature of the circulating air required for heat exchange. By virtue of the method disclosed by the invention, cold coke in the coke dry quenching furnace is slowly heated, the direct contact between the chute zone of the coke dry quenching furnace and high-temperature hot coke is avoided, the degree of change of the thermal stress is reduced, the integrity of the refractory material at the chute of the coke dry quenching furnace is ensured, the temperature-raising period is shortened and the service life of the refractory material is prolonged.

Owner:唐山首钢京唐西山焦化有限责任公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com