Synthetic resin lens manufacturing method, reformed quality synthetic resin material manufacturing method and optical pickup device

A technology of synthetic resin and manufacturing method, which can be applied in the directions of beam guiding device, optical head manufacturing, recording/reproducing by optical method, etc., can solve the problems of high price, reduced laser intensity, unable to reduce the price of optical pickup device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

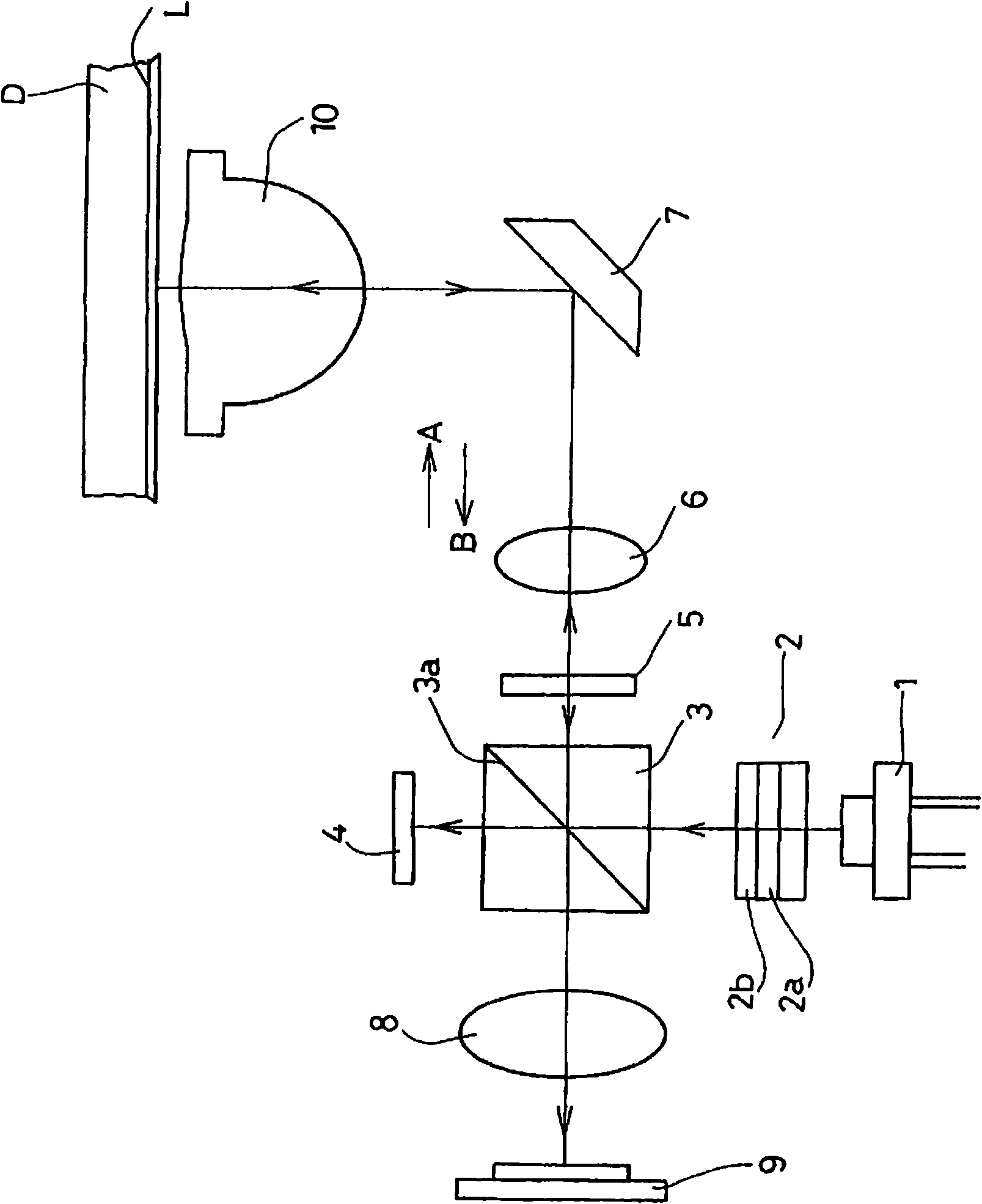

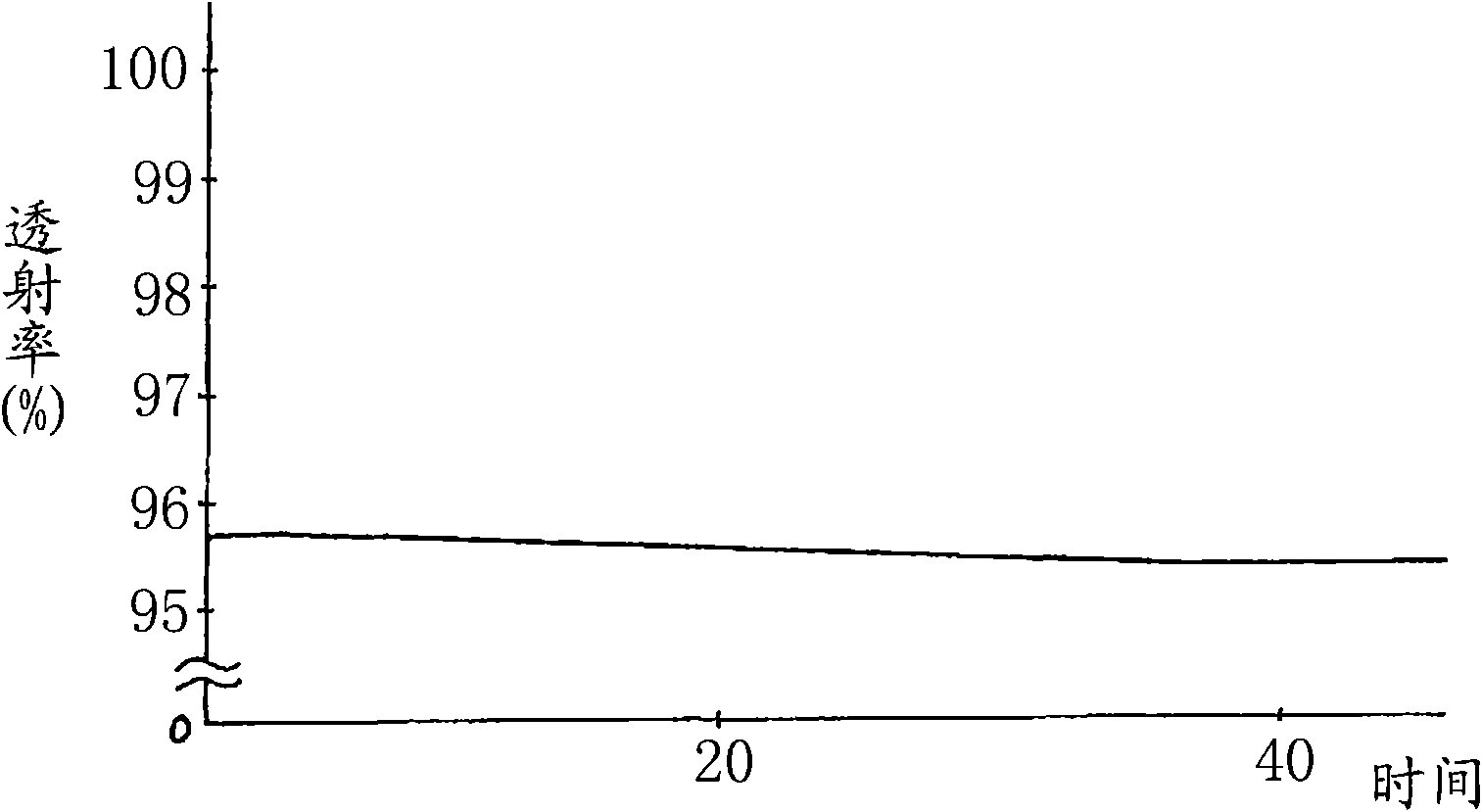

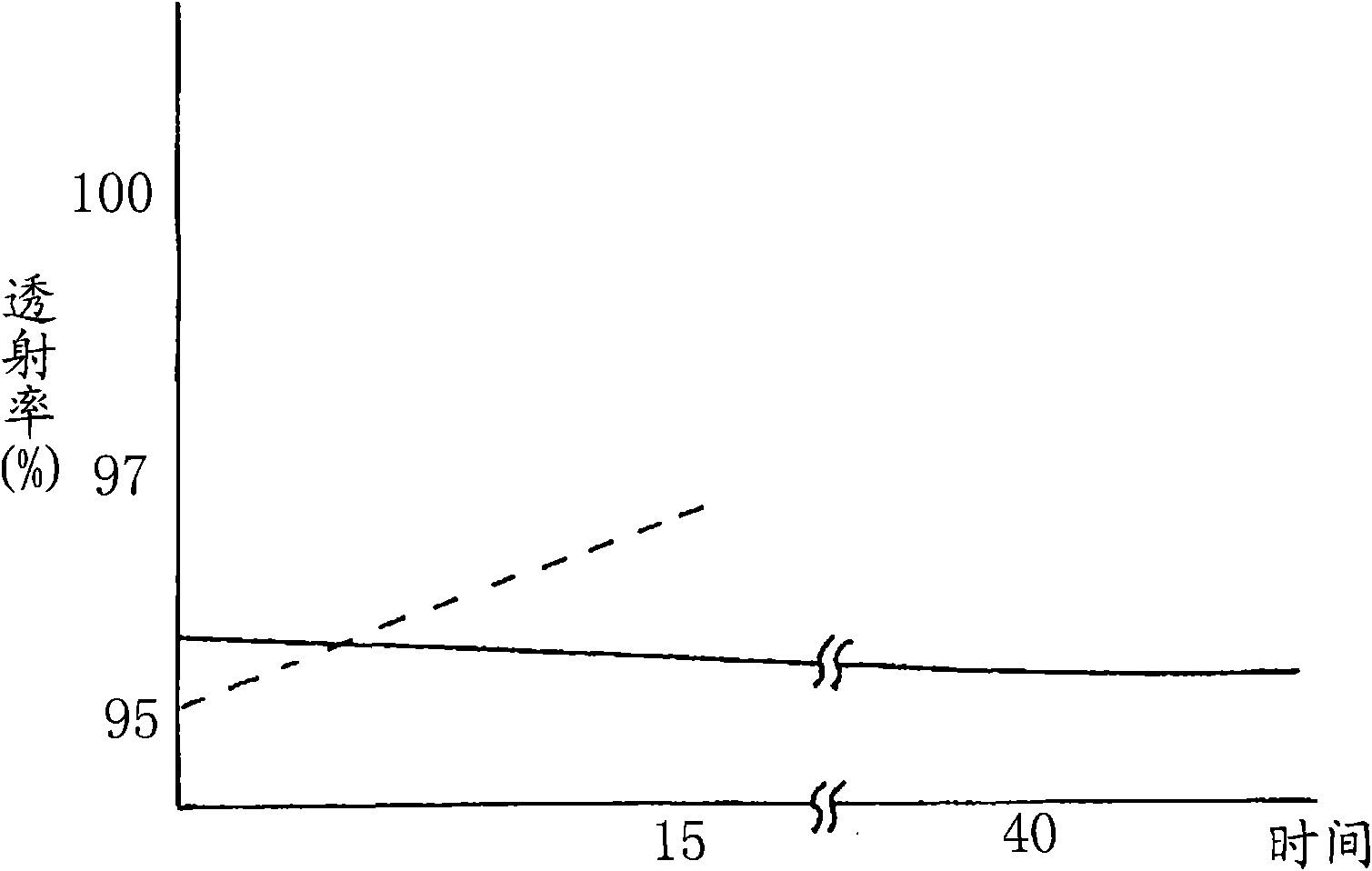

[0025] figure 1 It is a schematic configuration diagram showing an optical pickup device using the synthetic resin lens of the present invention as an objective lens, figure 2 It is a characteristic diagram showing the transmission characteristic of the synthetic resin lens of the present invention, image 3 It is a characteristic diagram for demonstrating the manufacturing method of the synthetic resin lens of this invention.

[0026] exist figure 1 Among them, reference numeral 1 is a laser diode for emitting laser light such as 405nm blue-violet light, reference numeral 2 is a diffraction grating on which the laser light emitted from the above-mentioned laser diode 1 is incident, and the diffraction grating 2 consists of a diffraction grating portion 2a Composed of a 1 / 2 wave resistance plate 2b, the diffraction grating portion 2a separates the laser light into a main beam as 0-order light and sub-beams as +1 order diffracted light and -1 order diffracted light, the 1 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com