Patents

Literature

206results about How to "Less frizz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

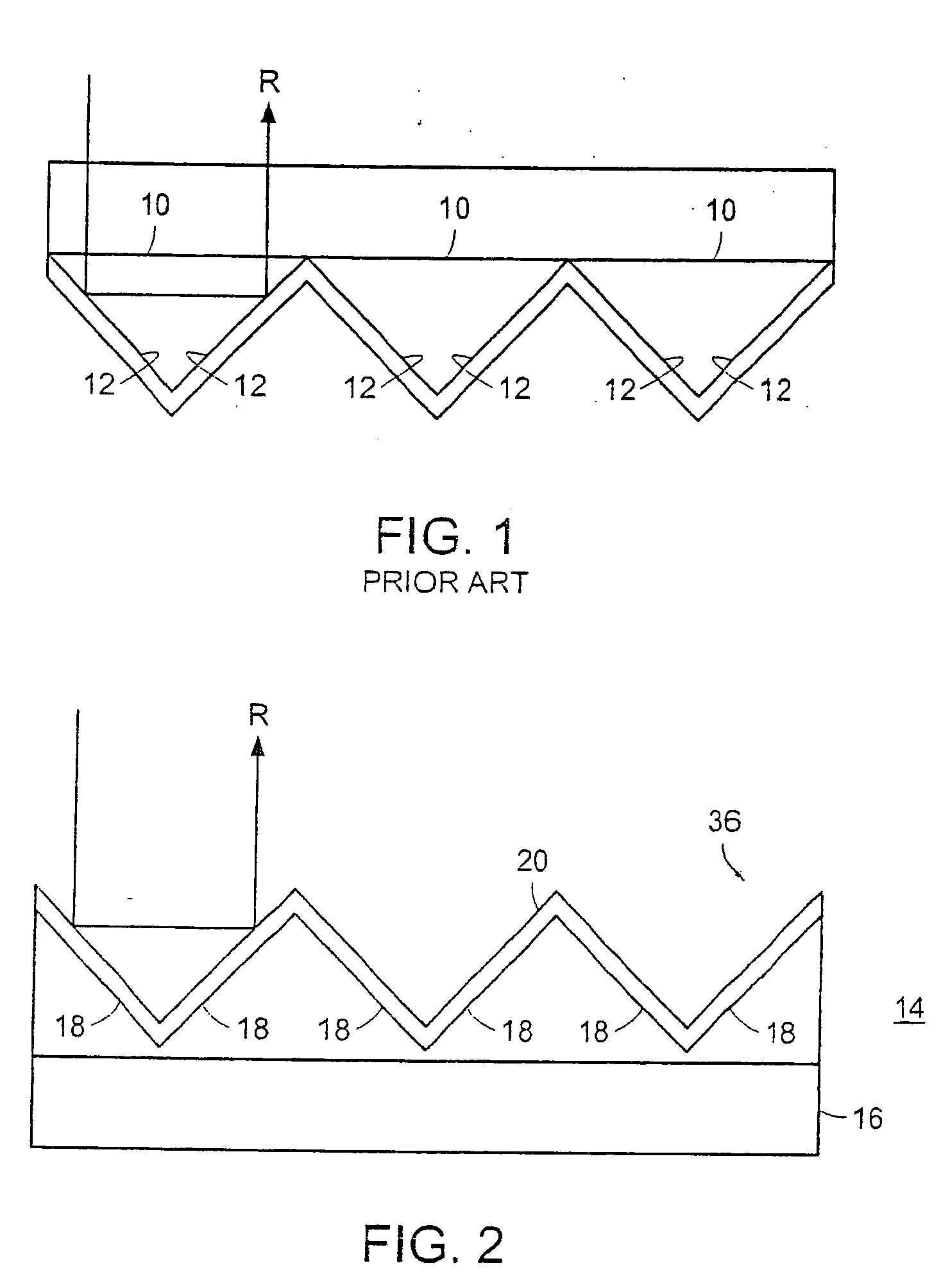

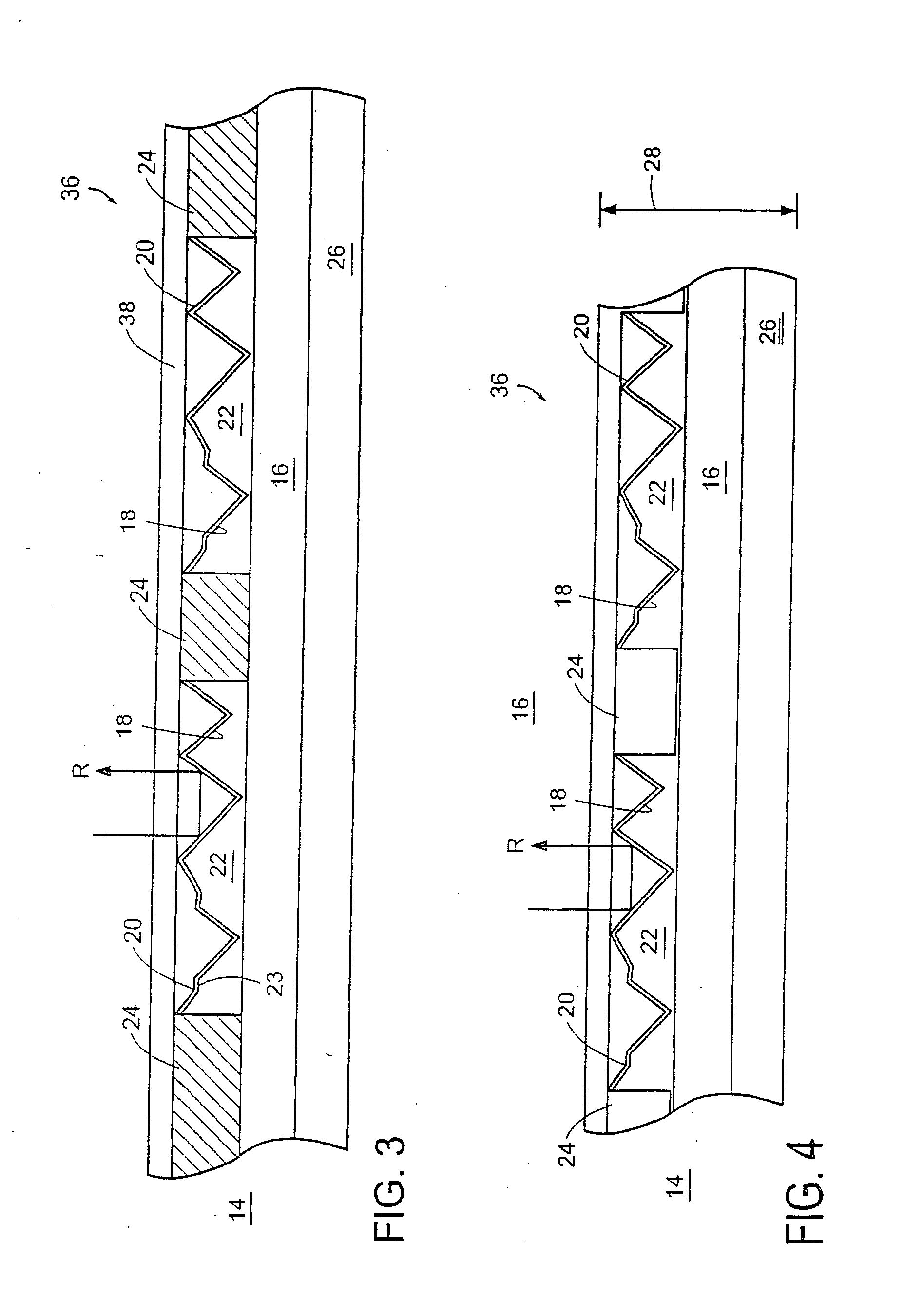

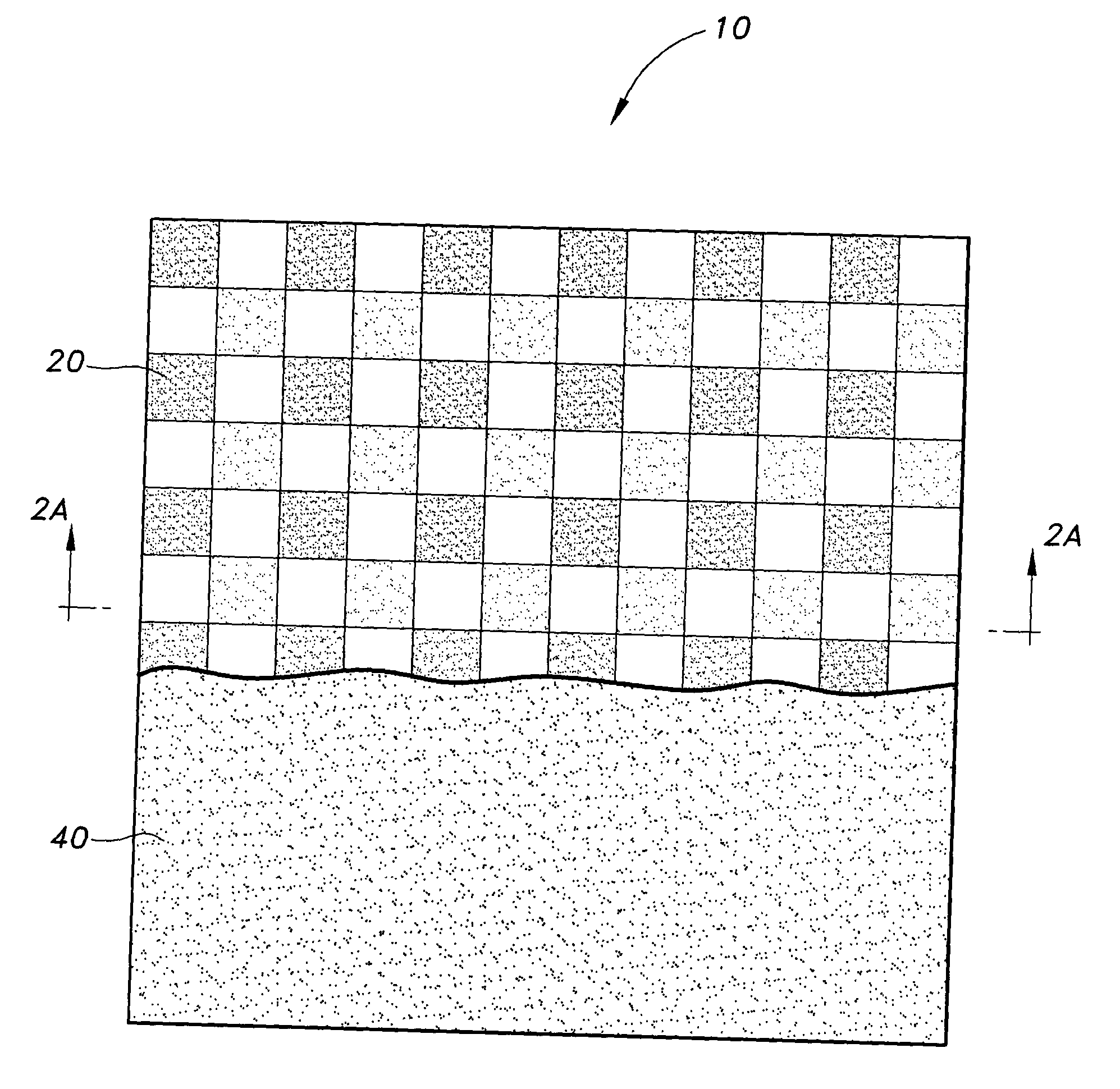

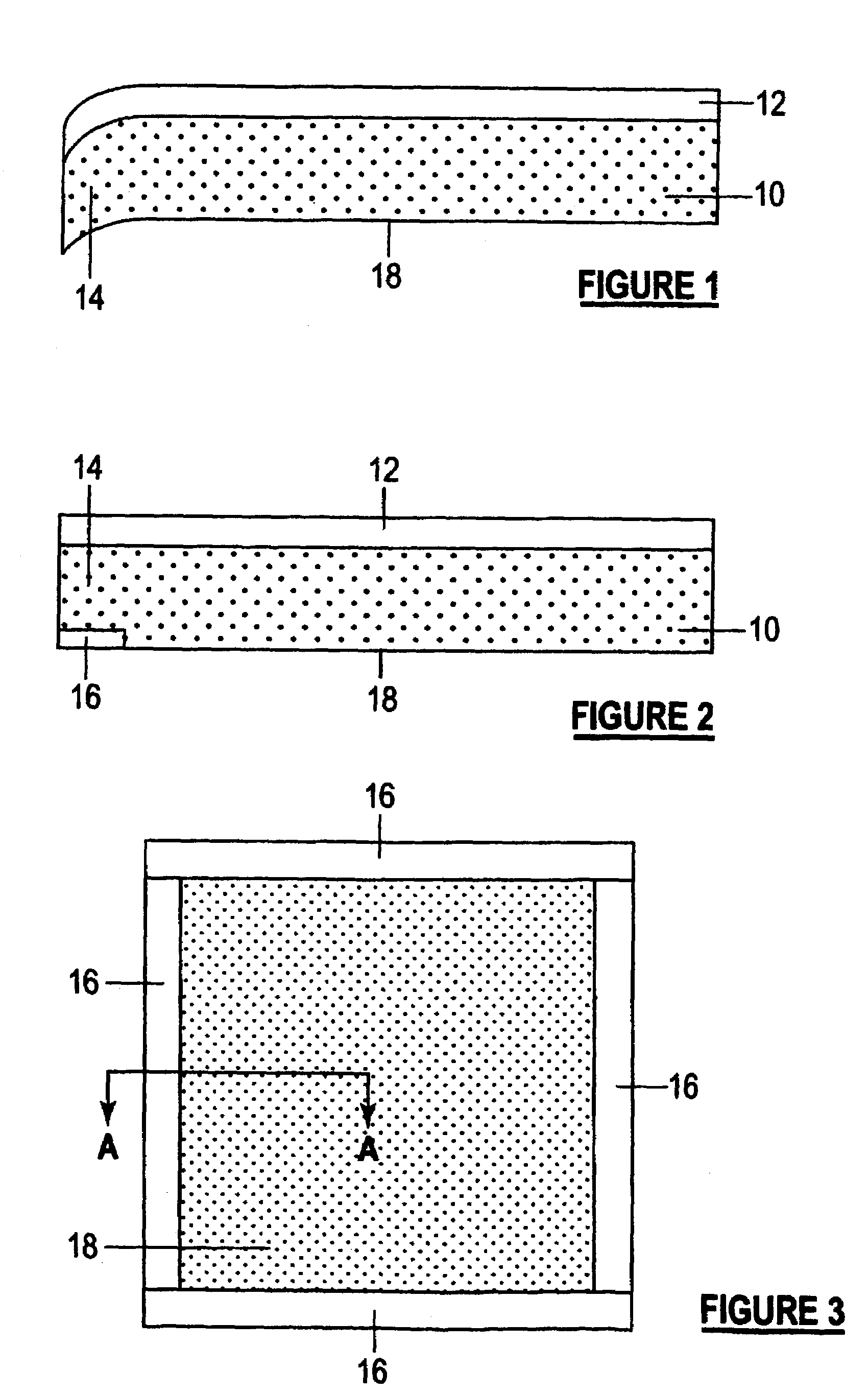

Durable, open-faced retroreflective prismatic construction

InactiveUS6967053B1Improve adhesionImprove the entrance angleReflex reflectorsThin material handlingOptical coatingPrism

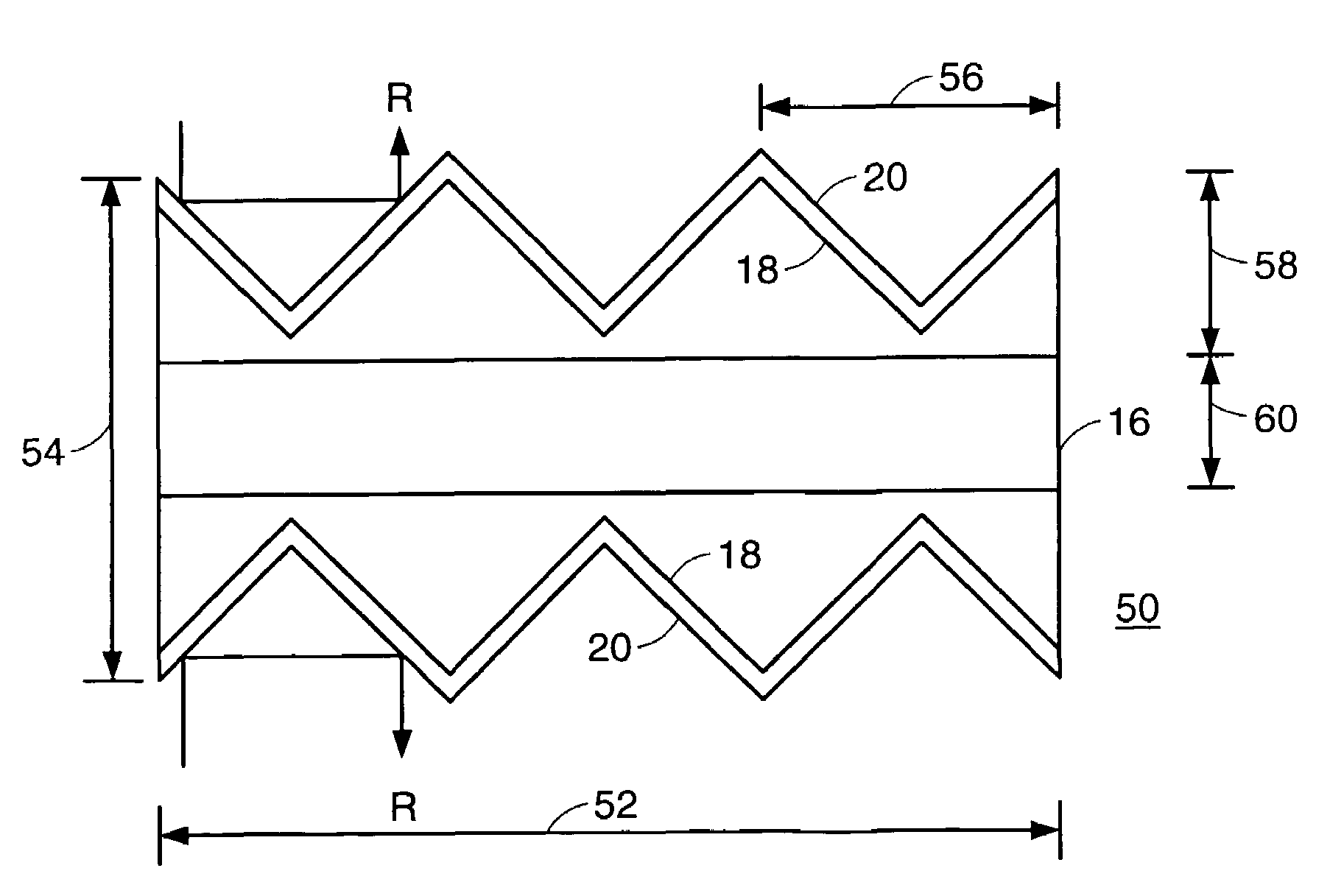

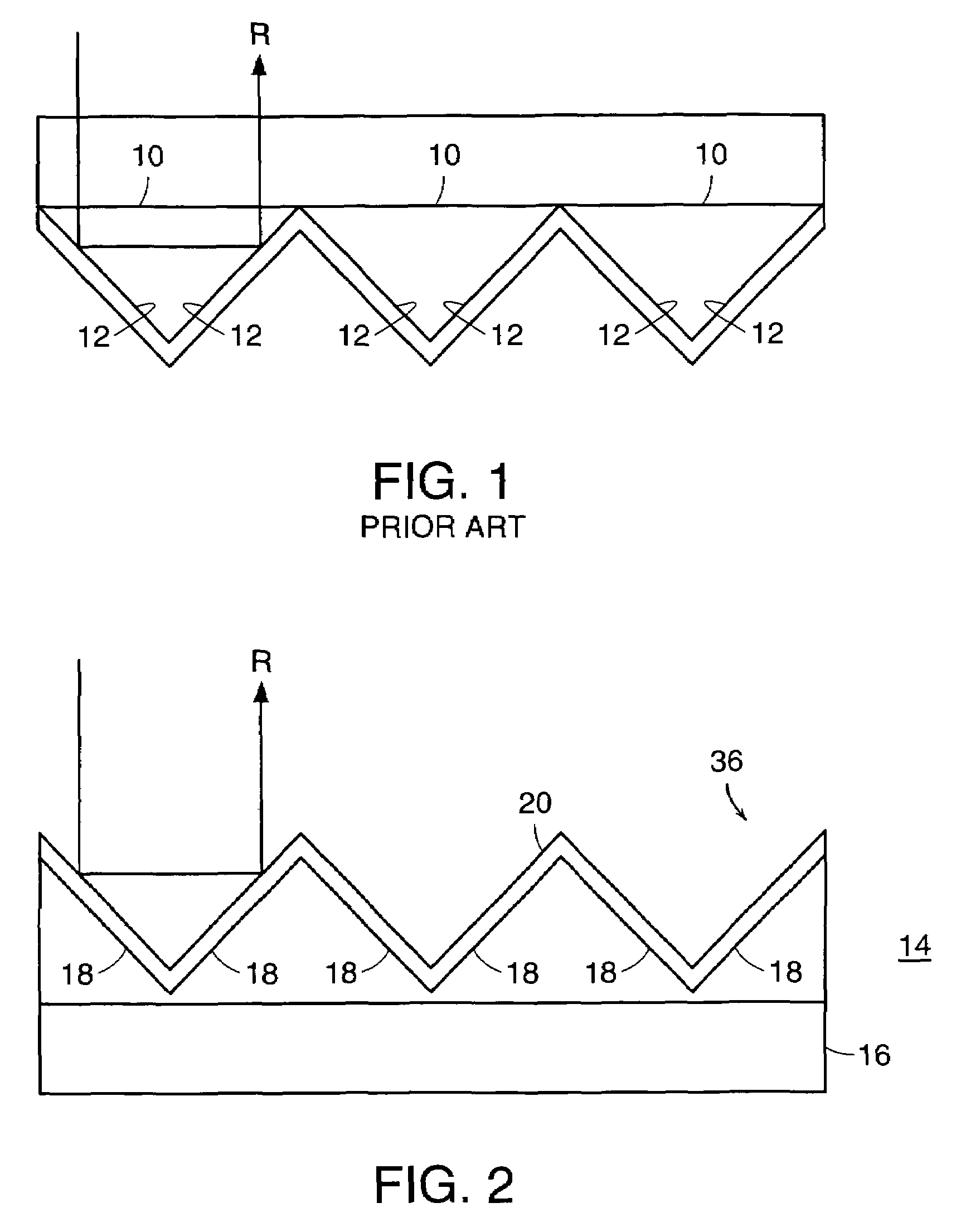

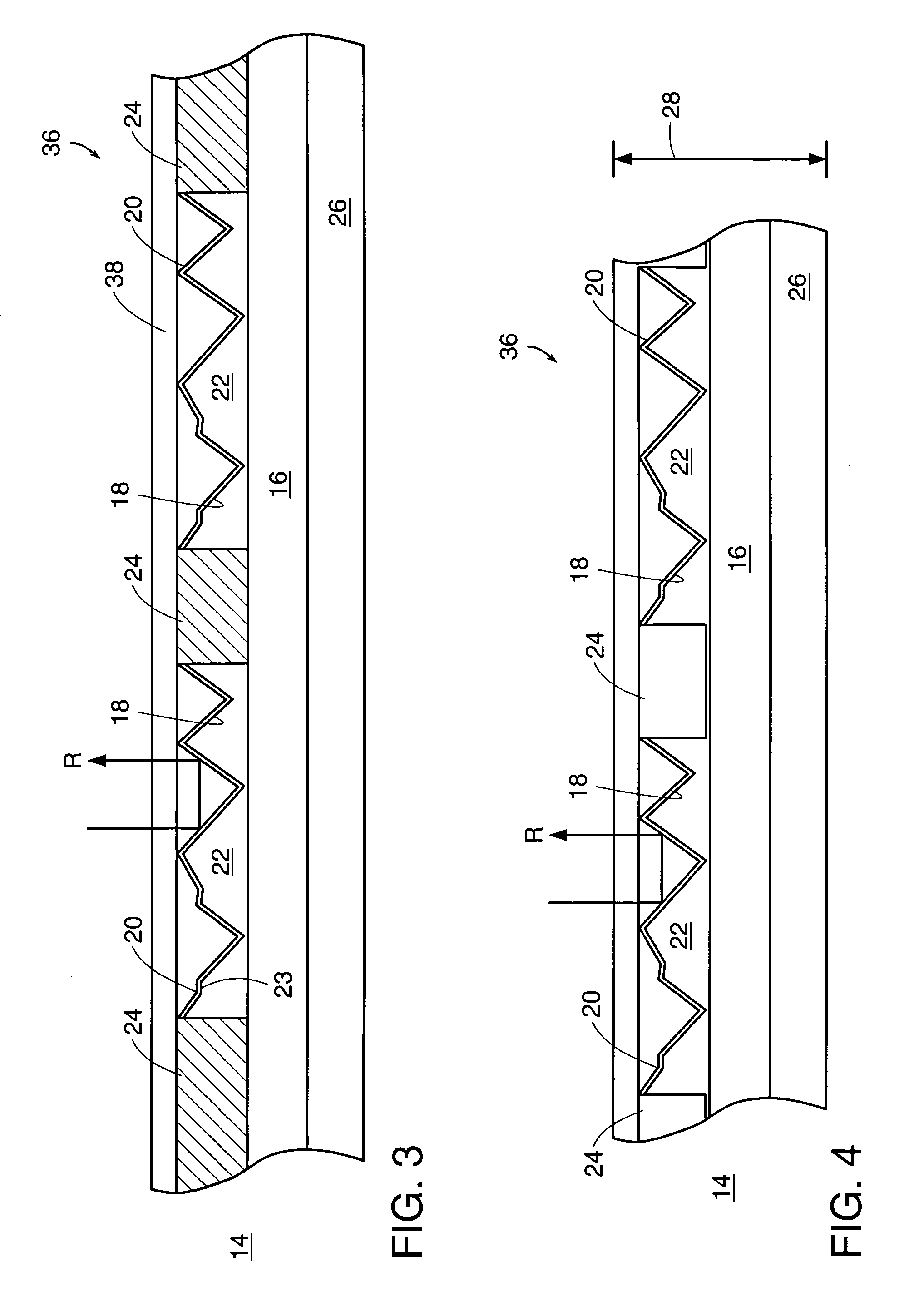

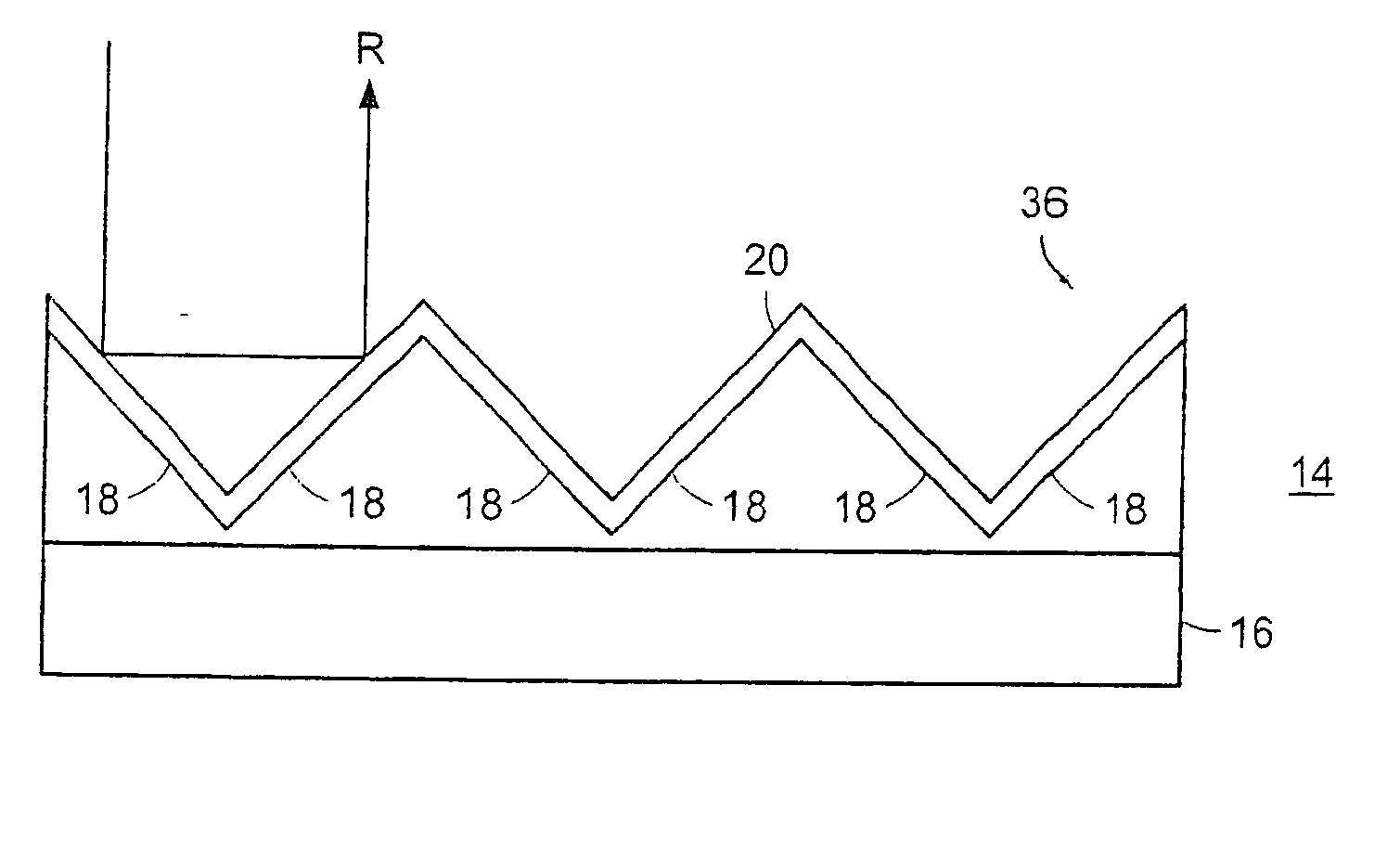

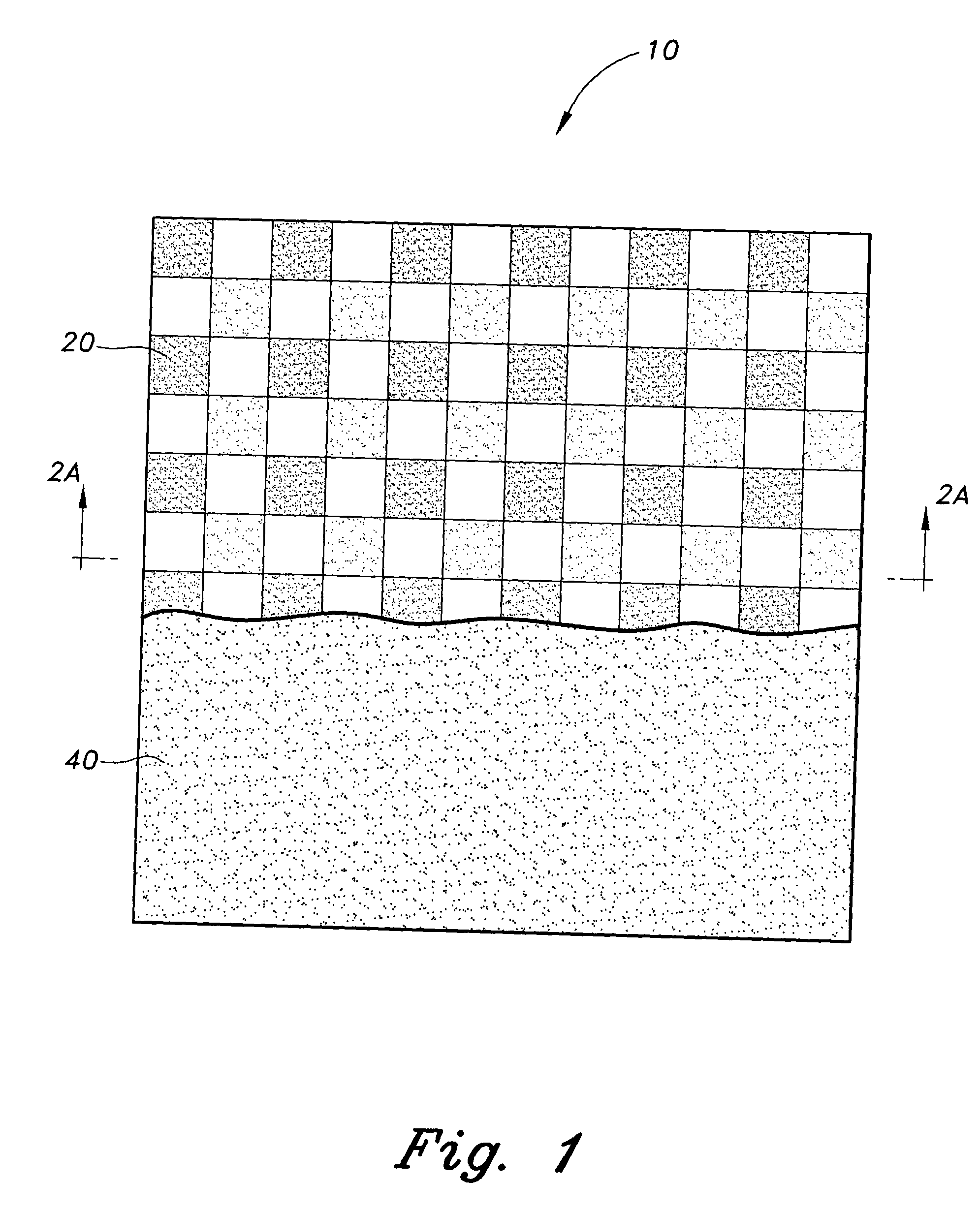

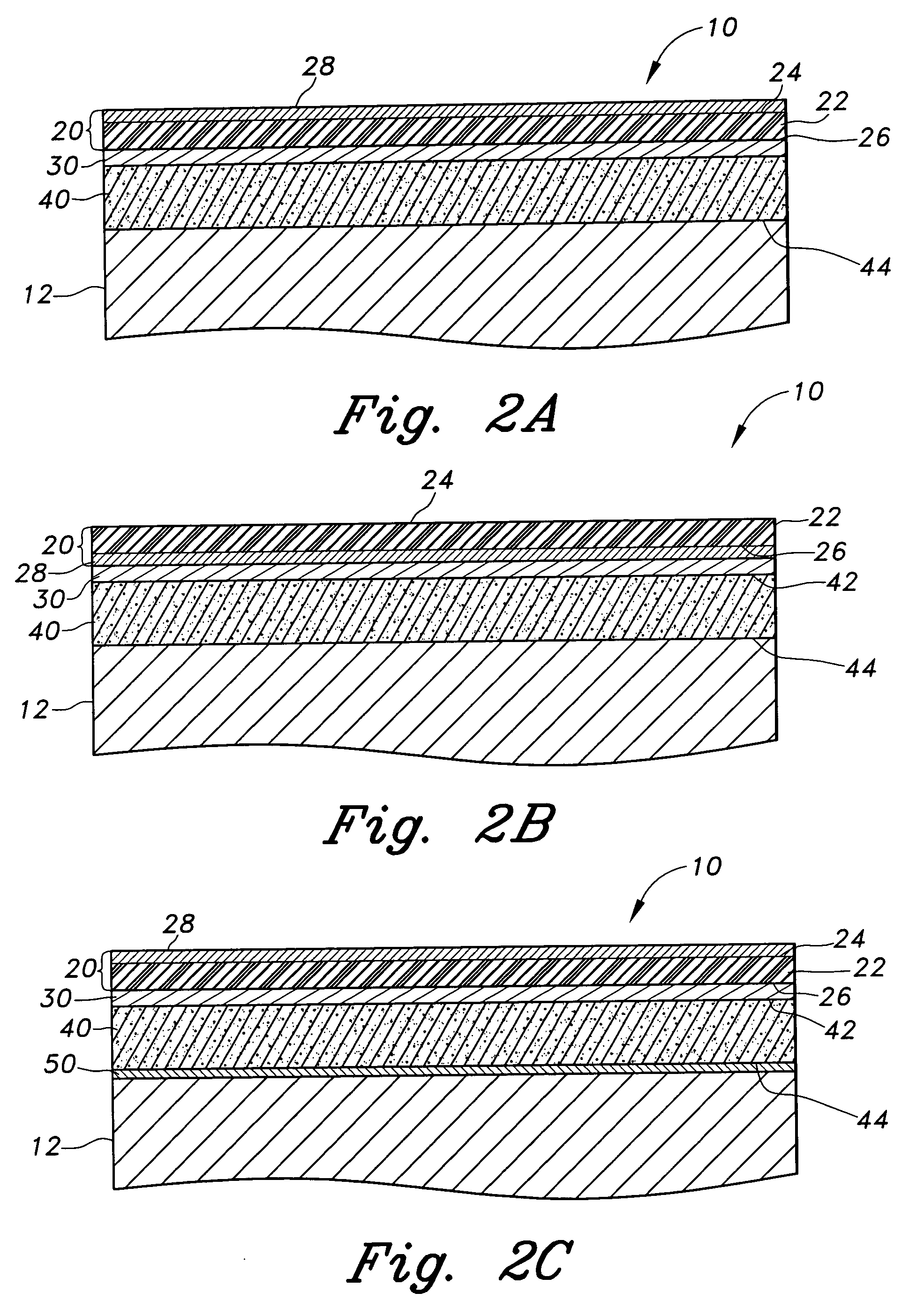

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. An optical coating is formed on the surfaces, and a fill layer is attached to at least a portion of the optical coating. A plurality of voids form the open-faced cube-corner surfaces.

Owner:ORAFOL AMERICAS

Durable, open-faced retroreflective prismatic construction

InactiveUS20050185279A1Improve adhesionImprove the entrance angleOptical elementsOptical coatingEngineering

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. A second plurality of open-faced cube-corner surfaces is formed from the substantially rigid material to keep the second plurality of open-faced cube-corner surfaces from flexing. The first and second open-faced cube-corner surfaces are configured to retroreflect light in opposite directions, that is, formed back-to-back in a particular embodiment. An optical coating can be formed on the surfaces. A plurality of voids forms the open-faced cube-corner surfaces. The retroreflective sheeting can be perforated in a particular embodiment.

Owner:REFLEXITE

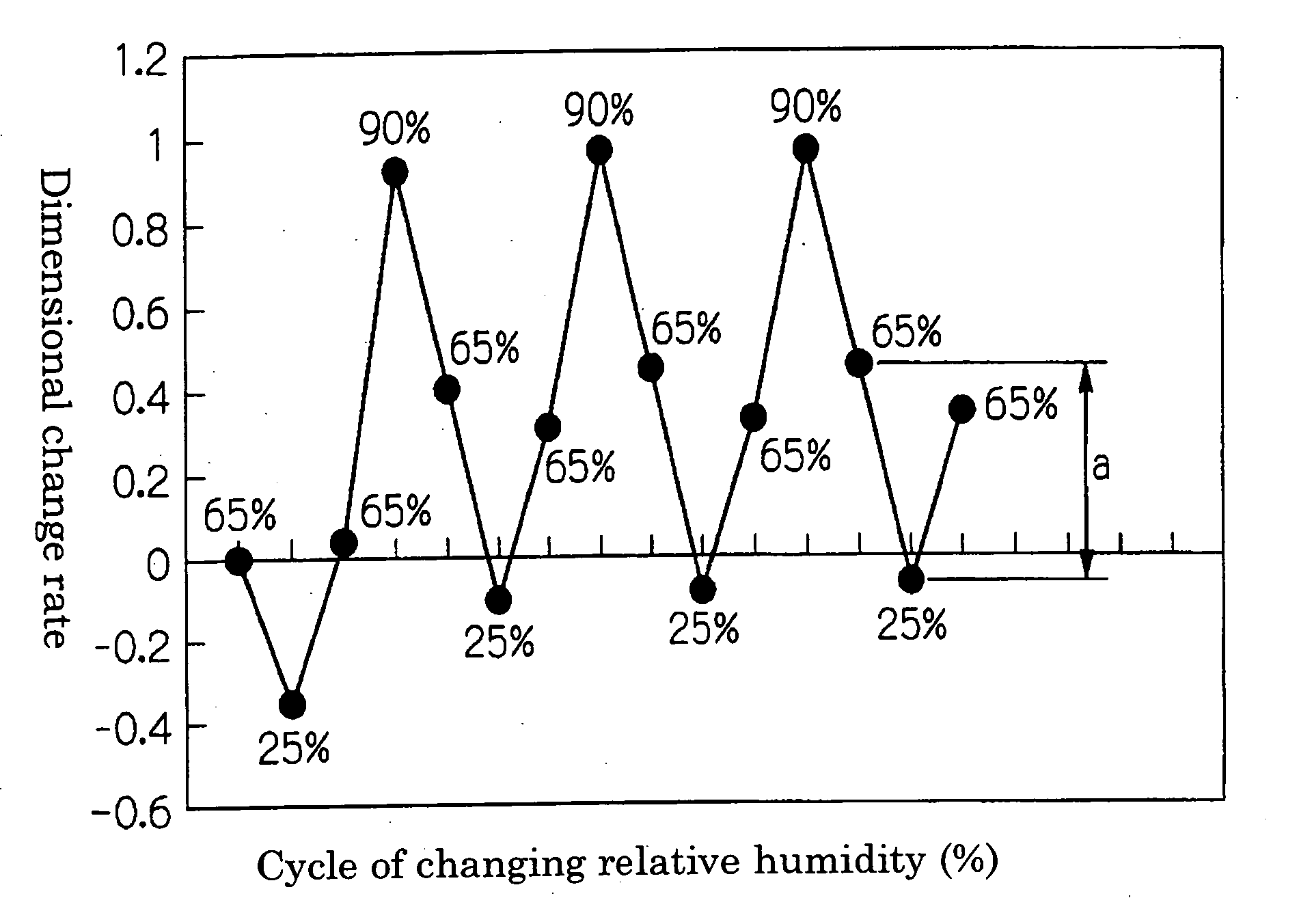

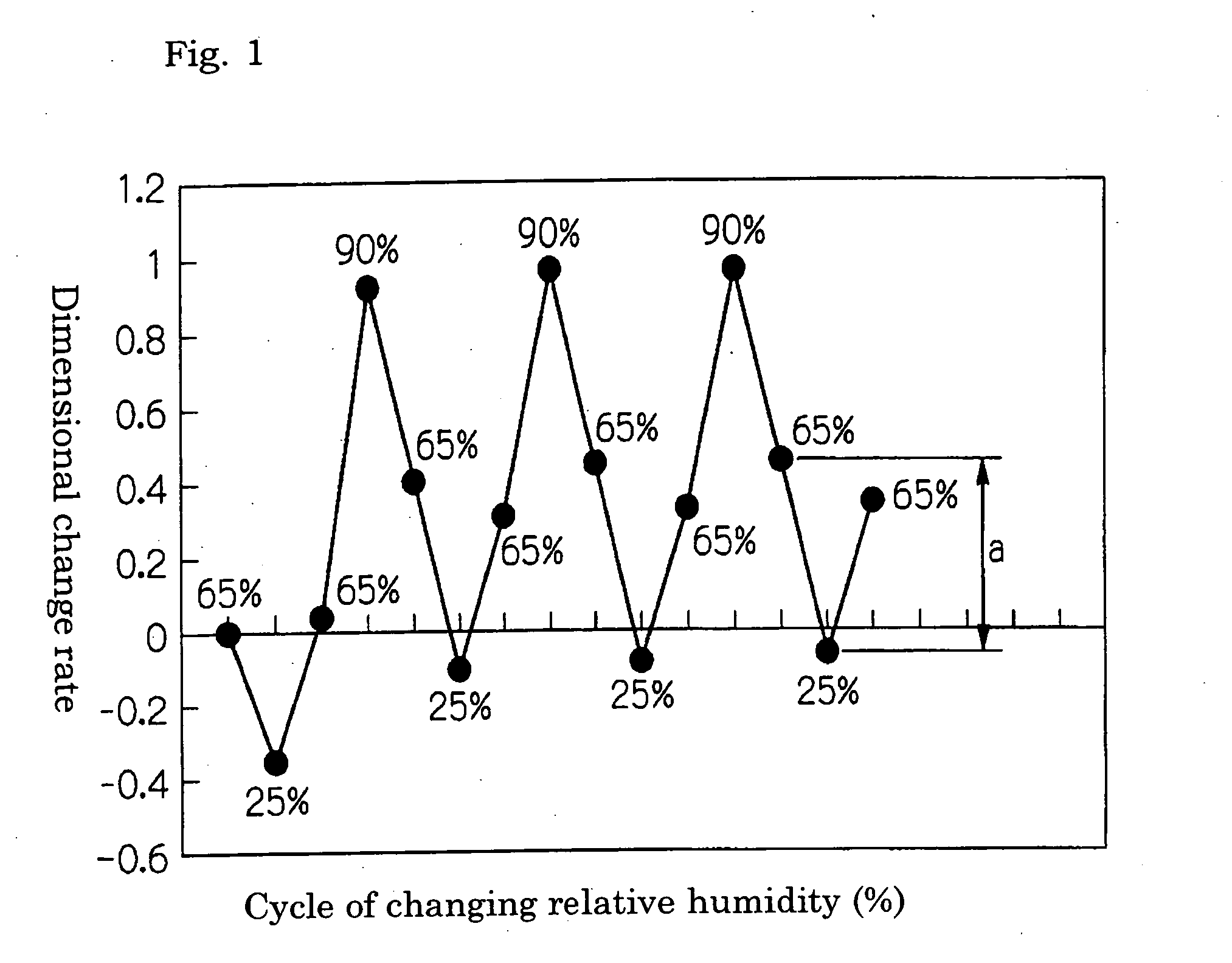

Ink jet recording method and ink jet recording paper

InactiveUS6880928B2Weaken expansion/shrinkage transmissionLess frizzSpecial paperMeasurement apparatus componentsFiberThird generation

In an ink jet recording method, a surface of a recording paper, in which a base paper contains a pulp fiber and a filler, one surface of the base paper being coated with a polyvalent metal salt in a coating amount of from 0.1 to 3 g / m2, having a basis weight of from 63 to 100 g / m2 and an internal bond strength of from 0.05 to 0.2 N·m is printed using an ink of at least one color made of at least a pigment, a water-soluble organic solvent, water and a surfactant and having a surface tension of from 25 to 37 mN / m. According to the method, the color reproduction is improved, the inter color bleeding and the feathering of characters are reduced, the double-sided printability is provided by reducing curling and cockling occurring immediately after printing, and curling and cockling occurring after allowing to stand and drying are also reduced.

Owner:FUJIFILM BUSINESS INNOVATION CORP

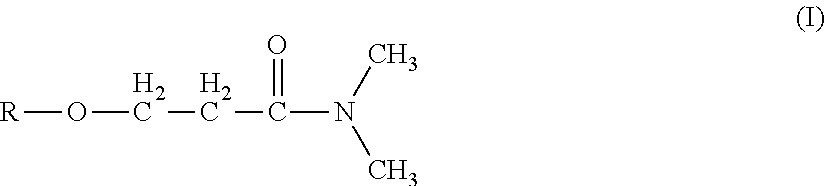

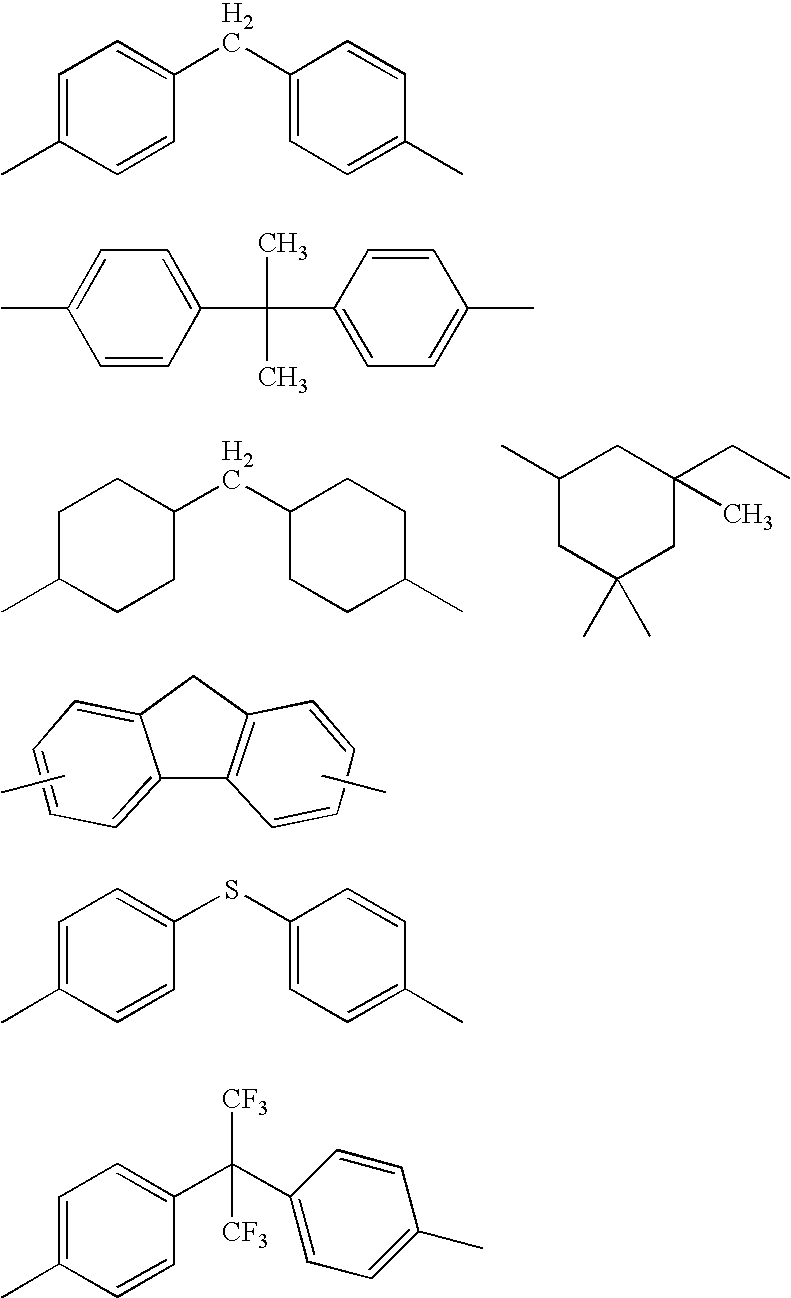

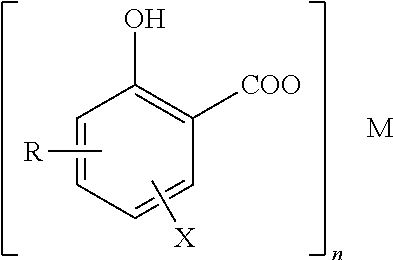

Anticurling agent, ink jet ink, method for ink jet recording and method for reducing curling

InactiveUS6966944B2Easy to operateReduce shape changeOrganic chemistryCurl-resistant paperShape changeImaging quality

The present invention provides an anti-curl agent containing an amide compound of specific structure and molecular weight, an ink jet ink containing the amide compound, a method for ink jet recording to form images by ejecting the ink, and a method for reducing curl of recording media using the ink. The anti-curl agent of the present invention can reduce shape changes of a printed paper with a lapse of time, i.e., the curl phenomenon, tending to occur in particular with a plain paper printed over the entire surface, without deteriorating image quality.

Owner:CANON KK

Polyester film for electrical insulation

InactiveUS6054224ALow densityReduce heatPower cables with screens/conductive layersInsulated cablesApparent densityPolyester

PCT No. PCT / JP97 / 02947 Sec. 371 Date May 6, 1999 Sec. 102(e) Date May 6, 1999 PCT Filed Aug. 25, 1997 PCT Pub. No. WO99 / 10417 PCT Pub. Date Mar. 4, 1999An electrical insulating polyester film has an apparent density of 1.37 to 0.85 g / cm3 and a tensile modulus of 2.0 to 4.5 GPa. A film having low oligomer content, low cost, high heat resistance, high impact resistance, superior machinability and processability, assembling stability, and superior visibility is obtained. Furthermore, leakage of current is reduced when it is used for motor insulation.

Owner:TORAY IND INC

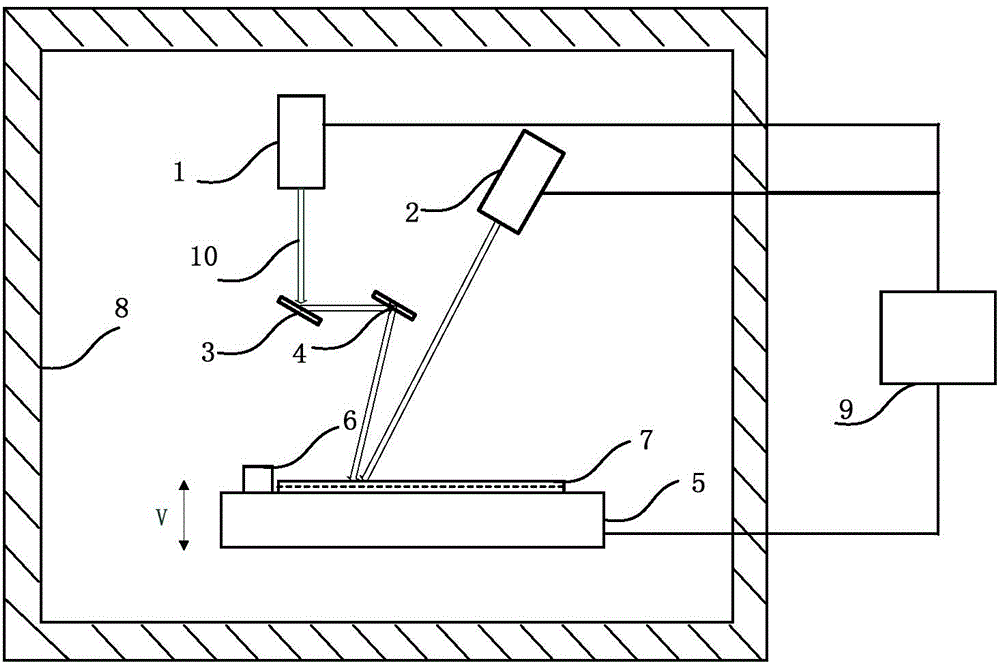

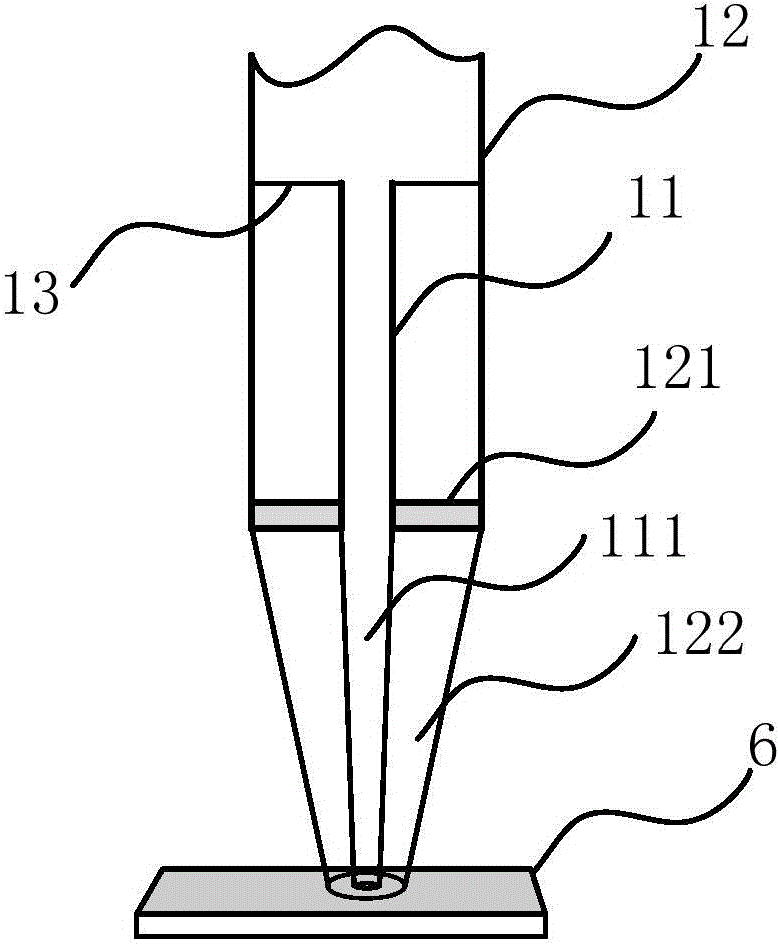

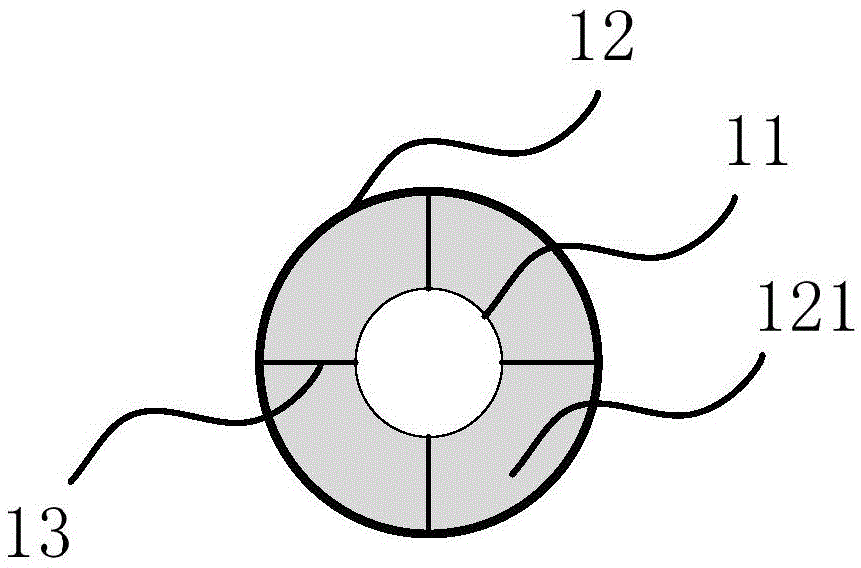

High polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control

ActiveCN103978307ALess frizzReduce temperature gradientAdditive manufacturing apparatus3D object support structuresUltravioletThermostat

The invention discloses a high polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control. The device comprises a thermostat, a laser head, a non-contact type temperature monitoring device, a scanning galvanometer, a machining platform, a powder paving device, a machining material and a computer control system. The laser head adopts a dual-tube core structure, an inner tube and an outer tube are coaxially fixed, one or more than one gradual-change neutral filter piece is arranged between the two tubes, and the laser transmittance of the filter piece(s) is radially reduced from the inner tube to the outer tube. The method comprises the following steps: presetting the machining temperature by the control system, in the process of machining, monitoring the temperature rise condition of an object to be machined in real time under the irradiation of laser by the non-contact type temperature monitoring device, feeding back to the control system, recording the increased value of the temperature within a certain time, and obtaining the absorption capability of the material to be machined to the laser and the temperature rise degree by the system, so that according to the preset machining temperature value, the laser output power can be calculated, the laser power can be timely adjusted, and the machining temperature can be precisely controlled.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

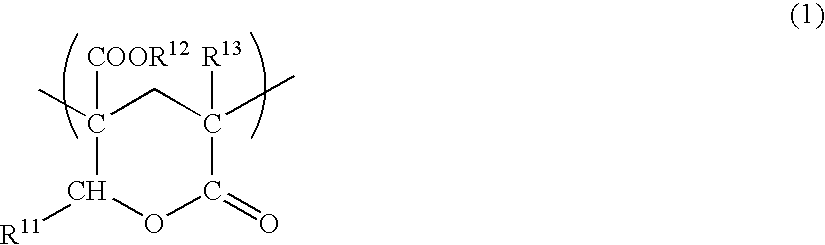

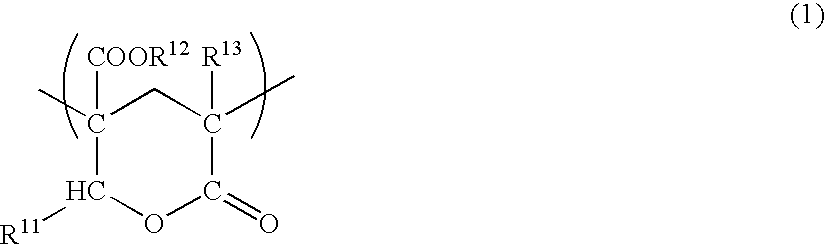

Image forming method

ActiveUS20130155145A1High quality imagingIncrease speedDuplicating/marking methodsInksPolyolOrganic solvent

An image forming method applying a pretreatment liquid on the surface of a recording medium; and applying an inkjet ink including a colorant, a hydrosoluble organic solvent, a surfactant and water on the surface applied with the pretreatment liquid, wherein the hydrosoluble organic solvent includes at least one polyol including an equilibrium water content in an amount not less than 30% by weight at 23° C. and 80% RH; an amide compound having the following formula (I); and at least one of compounds having the following formulae (II) to (IV), and wherein a pure water transfers to the recording medium in an amount of from 1 to 15 mL / m2 when measured by a dynamic scanning liquid absorptometer at a contact time of 100 ms.

Owner:RICOH KK

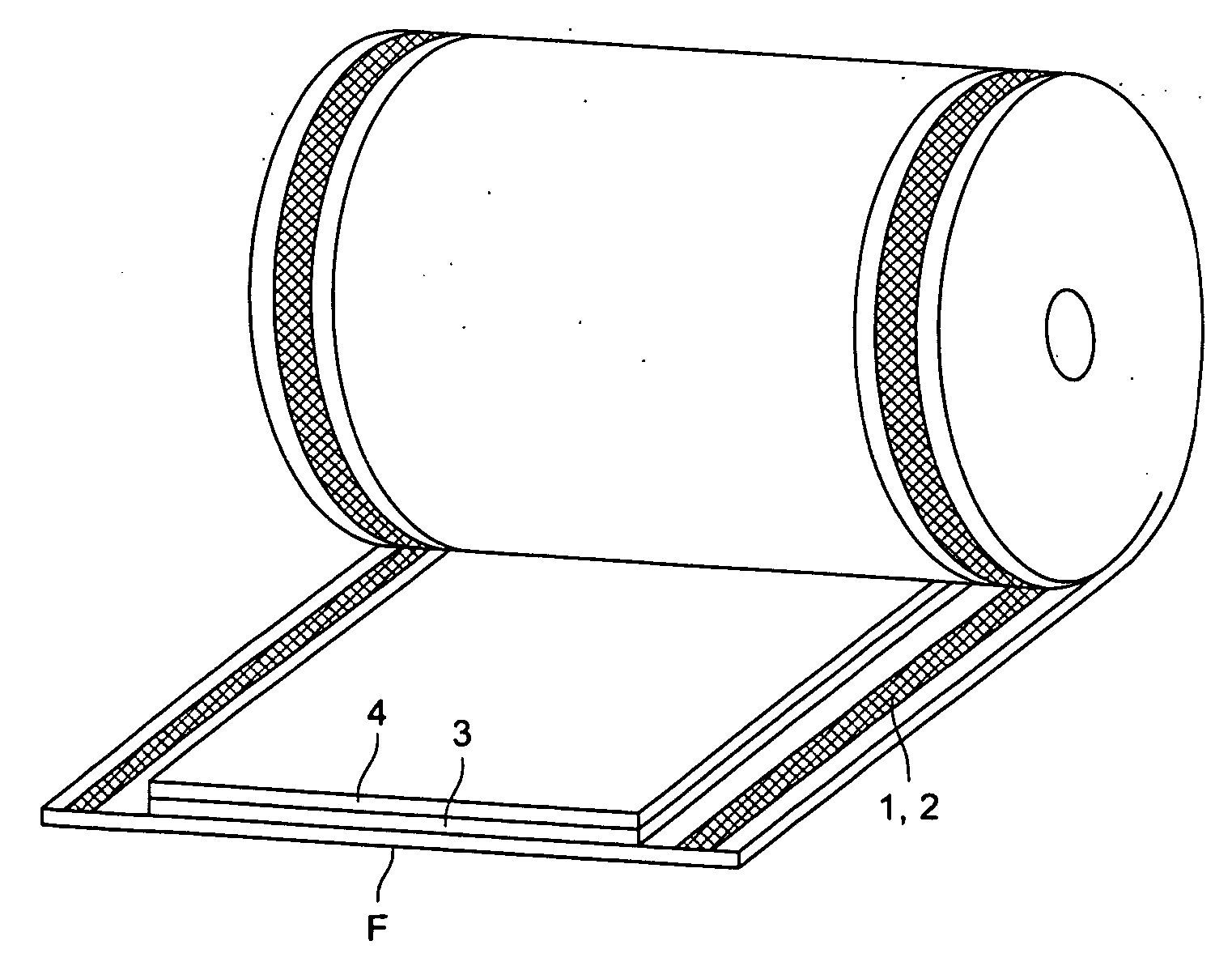

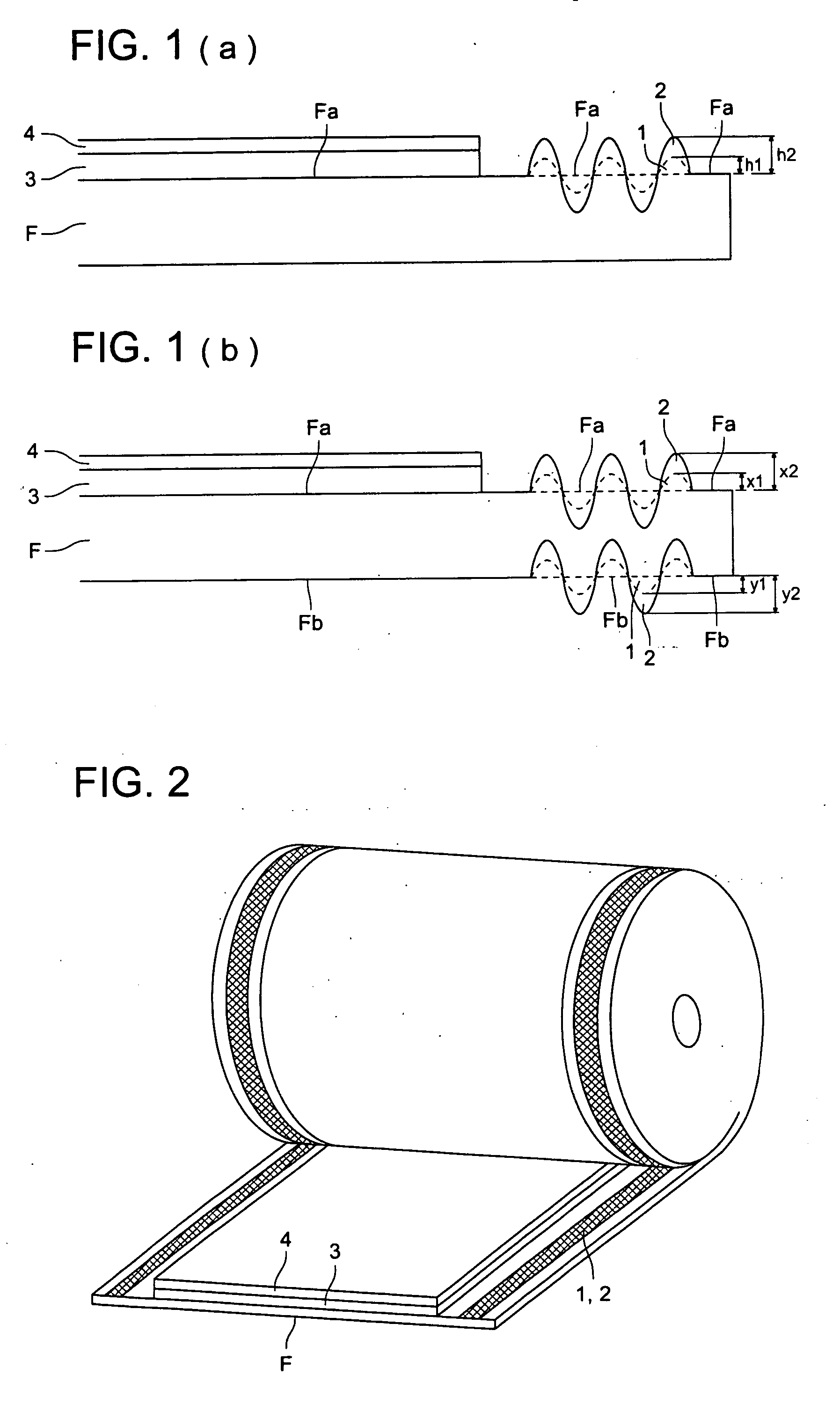

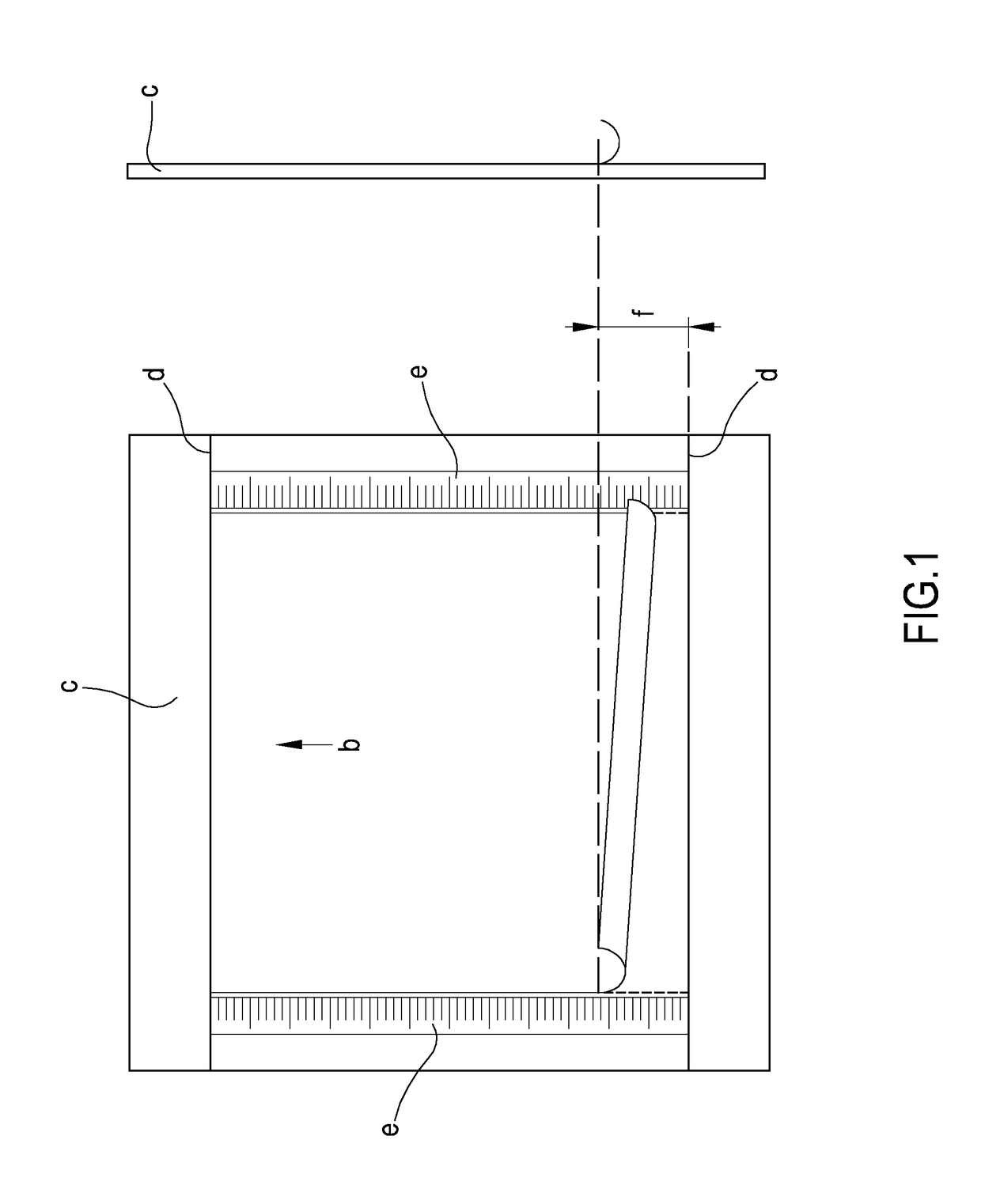

Production method of rolled optical film having coating layer, rolled optical film, polarizing plate and liquid crystal display

InactiveUS20060198991A1Less frizzSmall differencePretreated surfacesPolarising elementsLiquid-crystal displayEngineering

A method for producing a roll film provided with a coat layer comprising the steps of: (i) producing a roll film; (ii) applying a first embossing treatment along a longitudinal direction of the roll film on a part of a lateral direction of the roll film; (iii) applying a coat layer on the roll film; (iv) applying a second embossing treatment along a longitudinal direction of the roll film on a part of a lateral direction of the roll film; (v) heat treating the roll film at a temperature of 50 to 150° C. for a duration of 1 to 30 days while the roll film is rolled in a roll.

Owner:KONICA MINOLTA OPTO

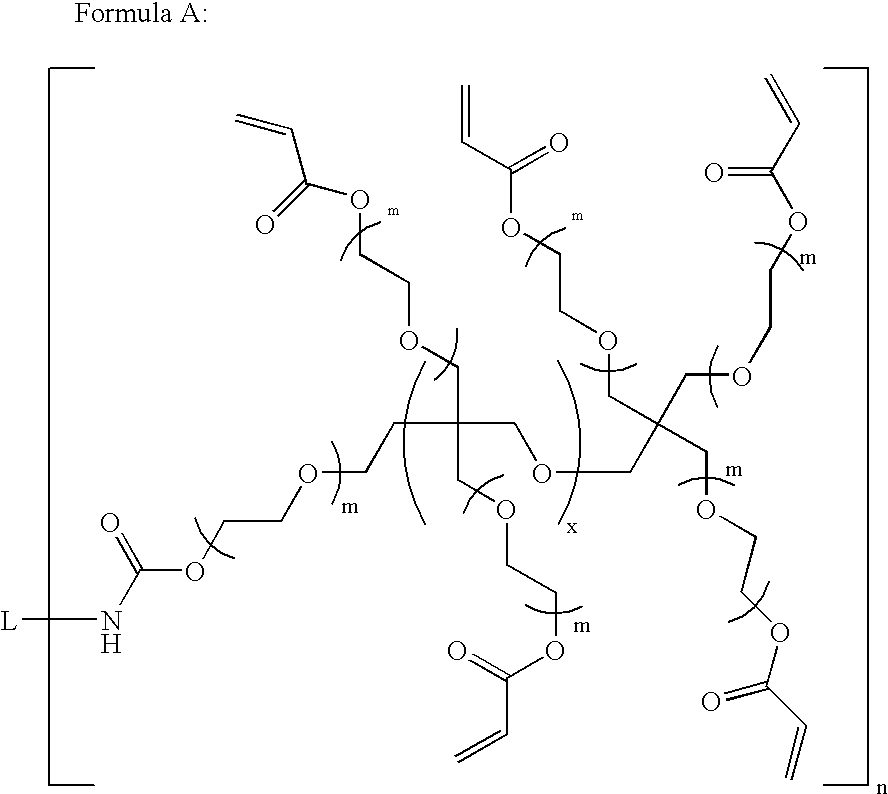

Optical film, antireflection film, and polarizing plate and display device using the same

ActiveUS20080131674A1Reduce curlingImprove brittlenessLiquid crystal compositionsSynthetic resin layered productsPolarizerChemistry

An optical film includes a transparent support; and a hardcoat layer that is a layer formed by curing a coating solution containing (A) an octa- to pentadeca-functional urethane (meth)acrylate-based compound having a molecular weight of 800 to 2,000 and having two or more urethane bonds in its molecule, and a photopolymerization initiator.

Owner:FUJIFILM CORP

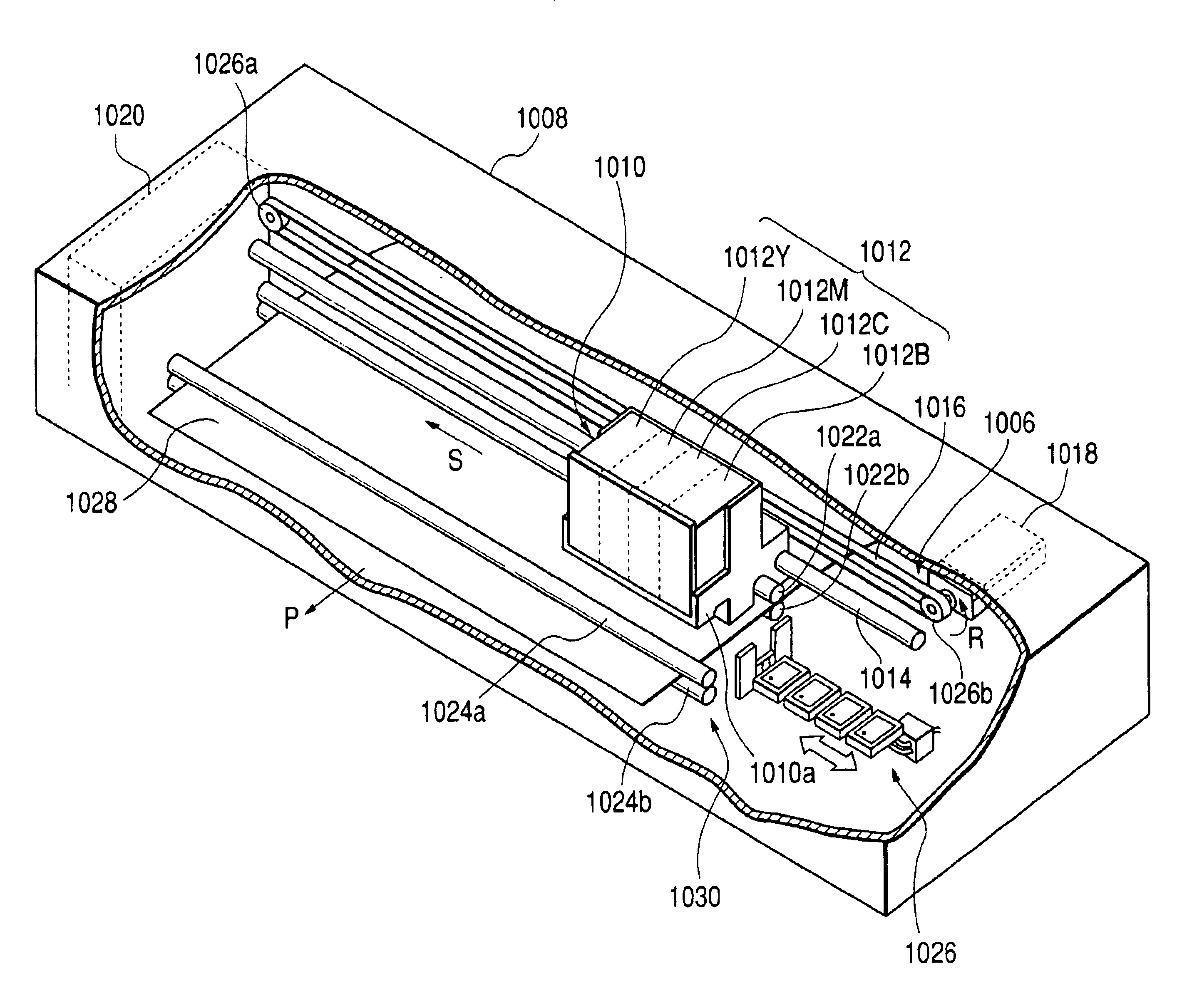

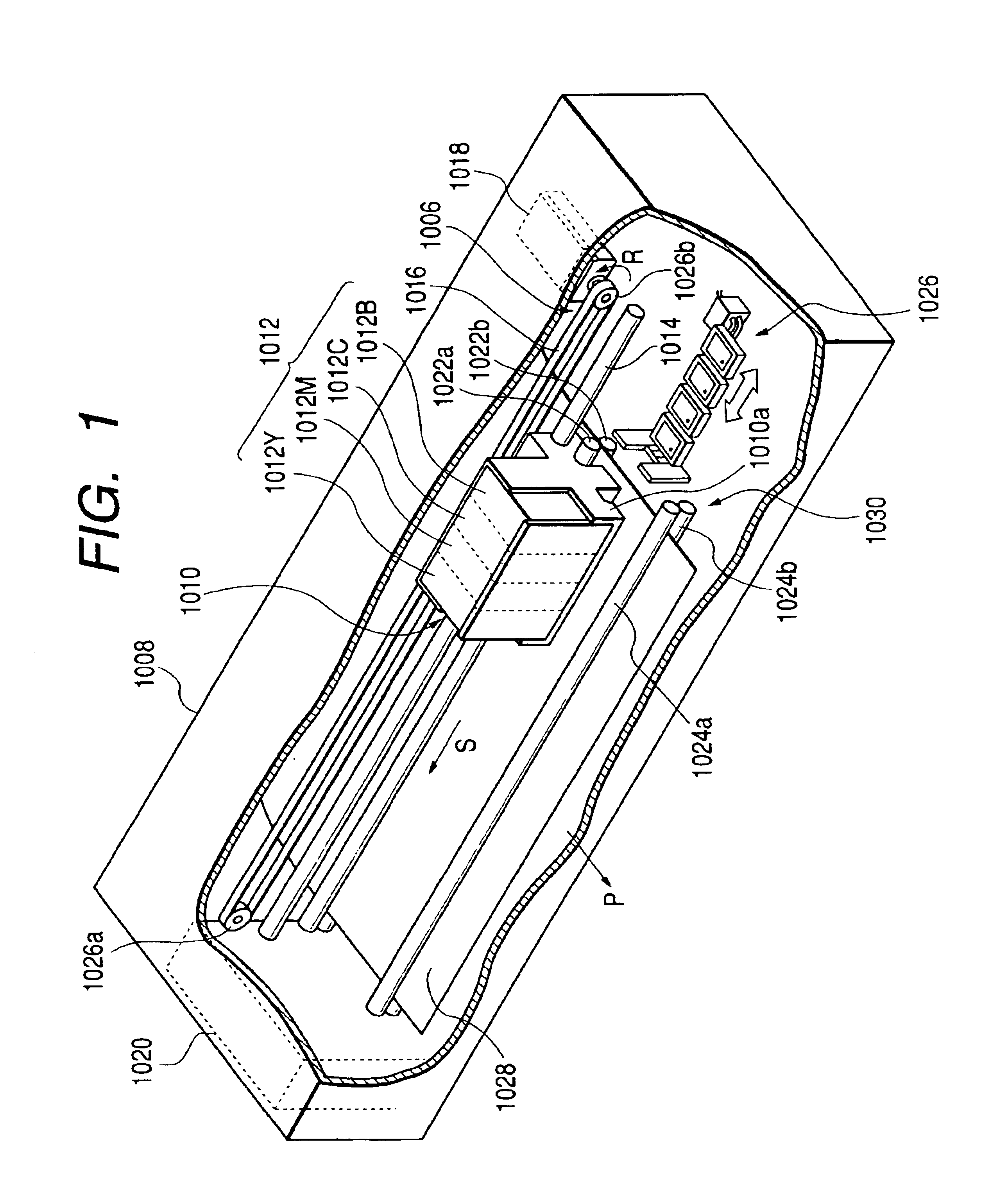

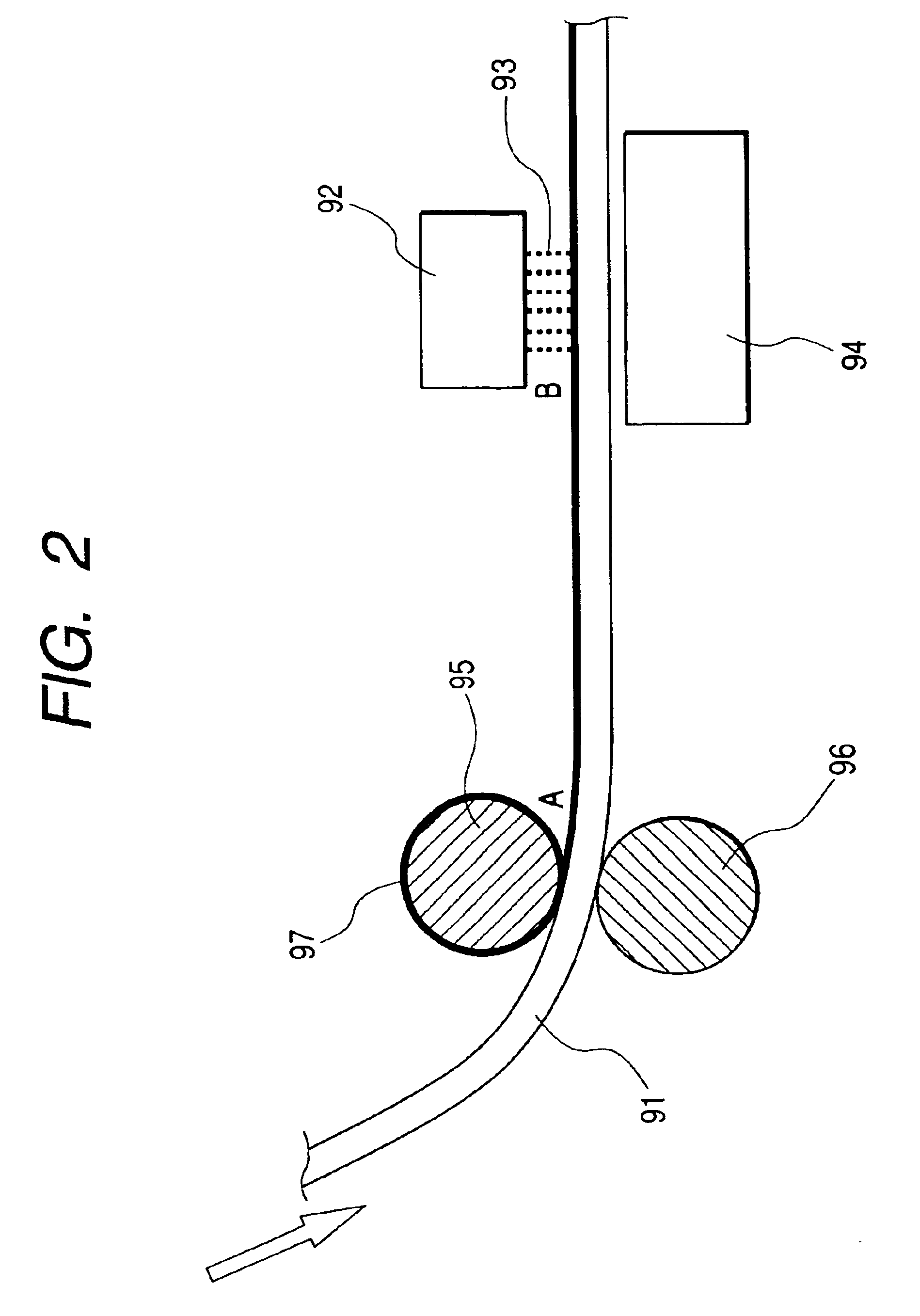

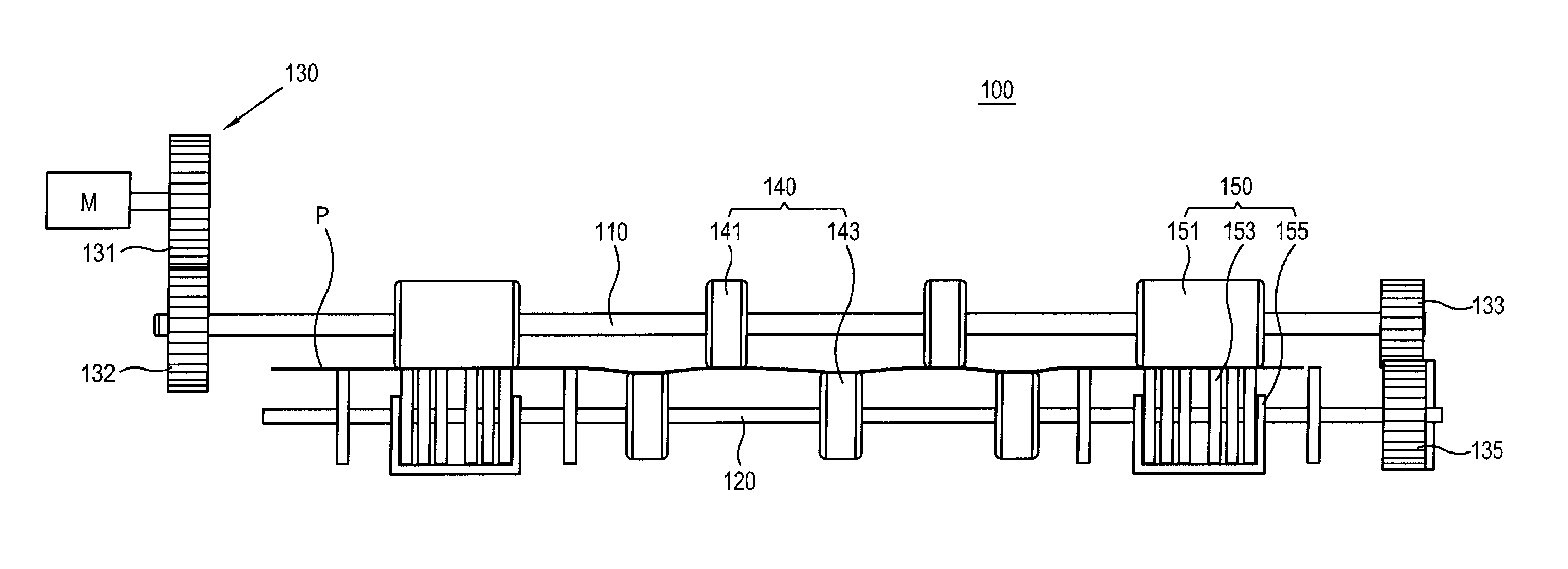

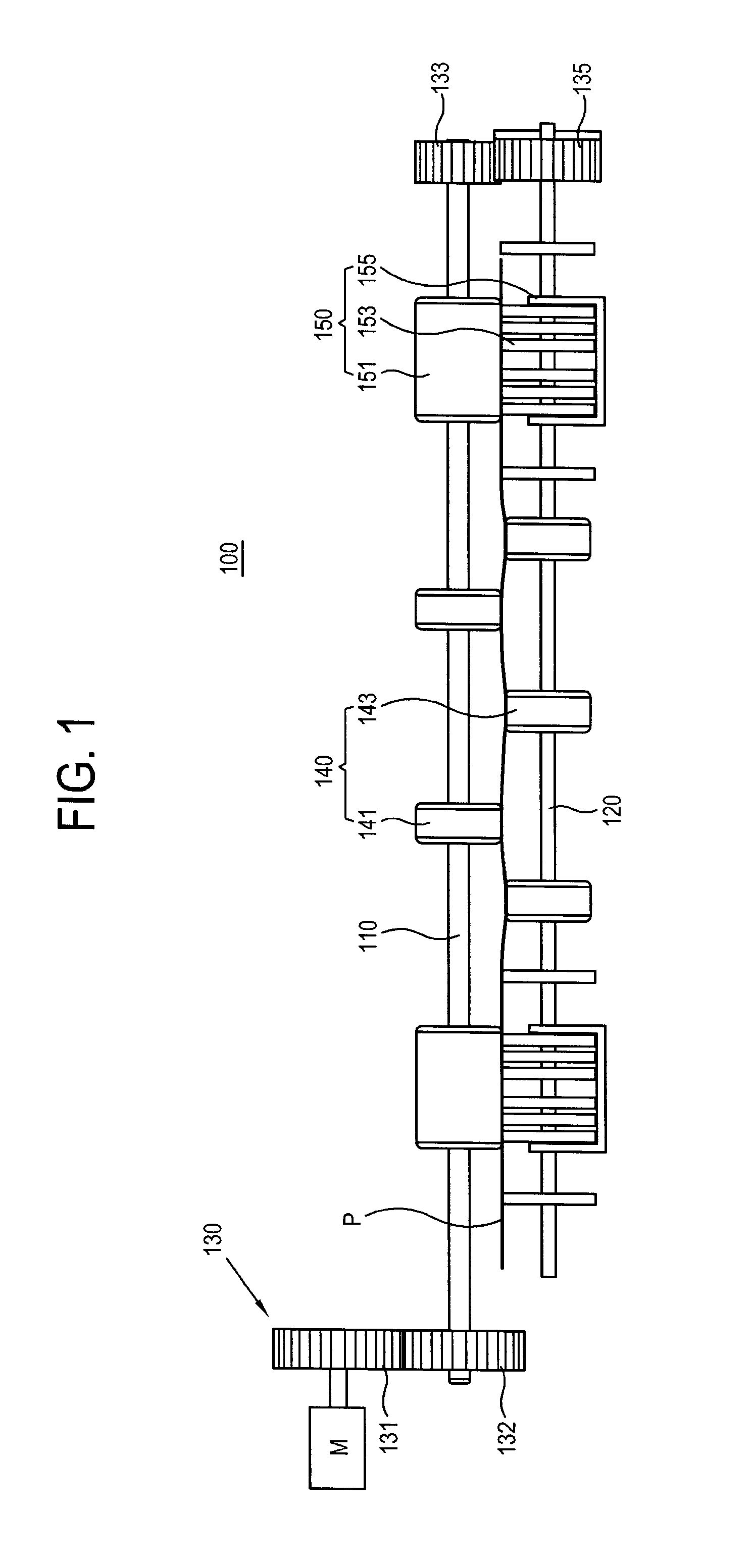

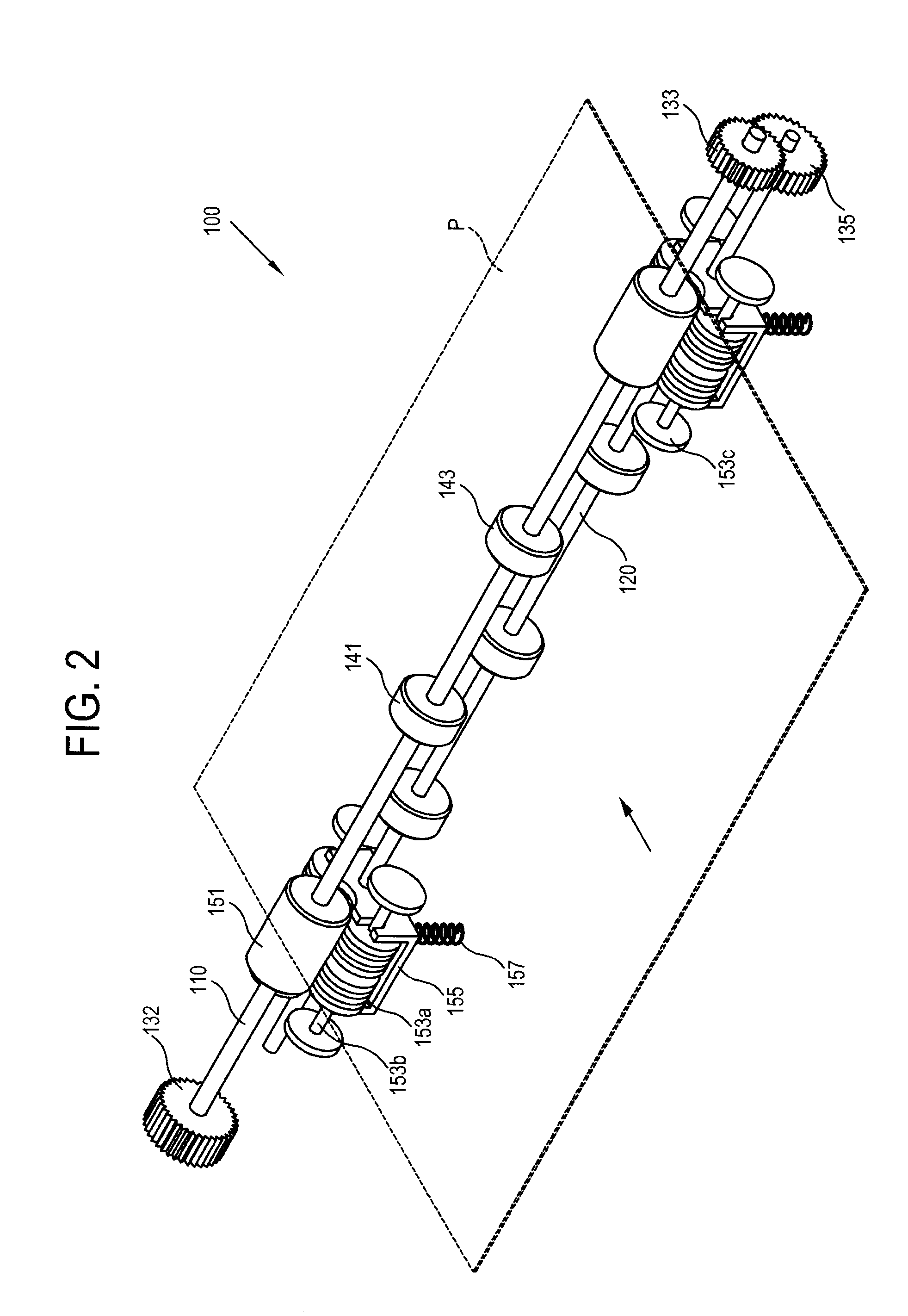

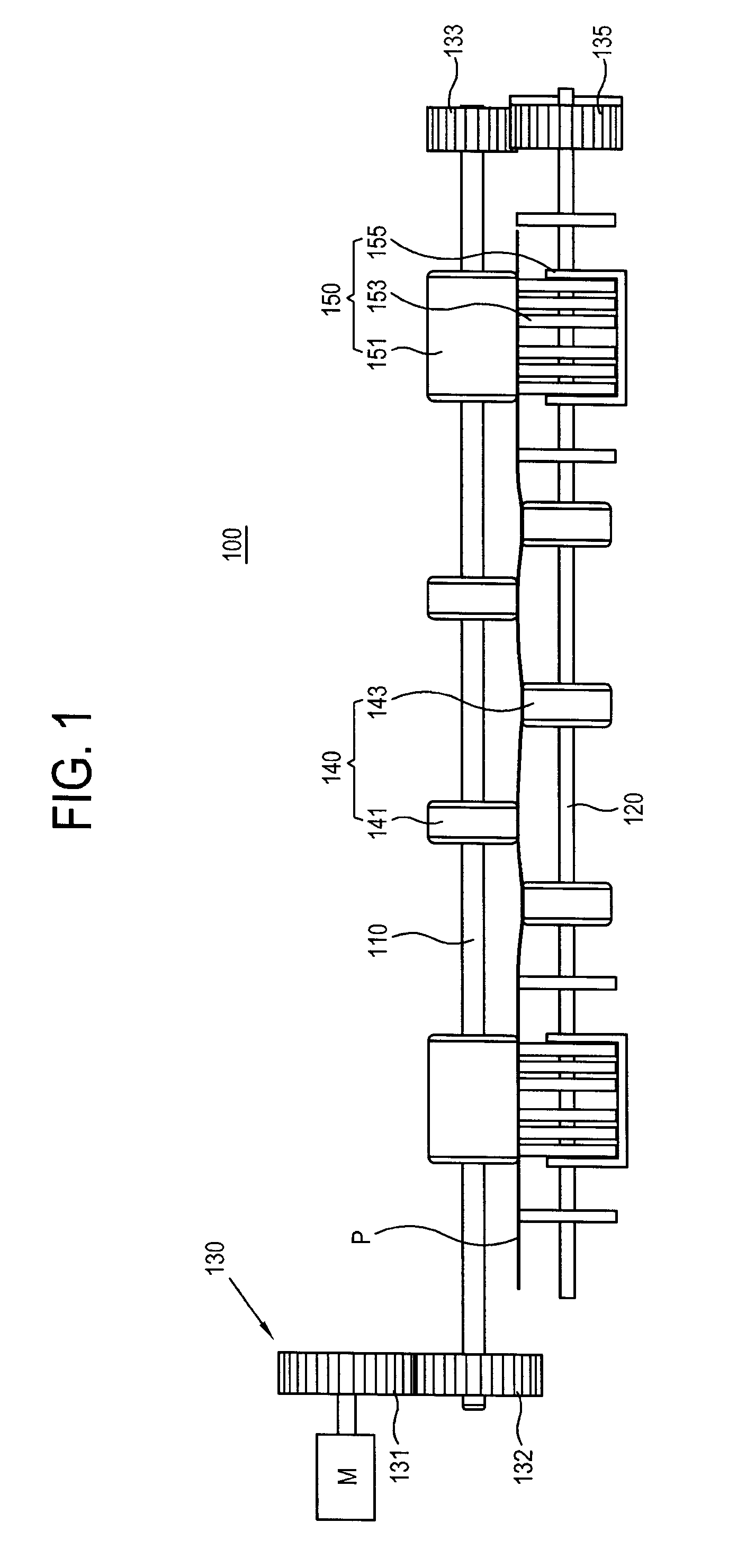

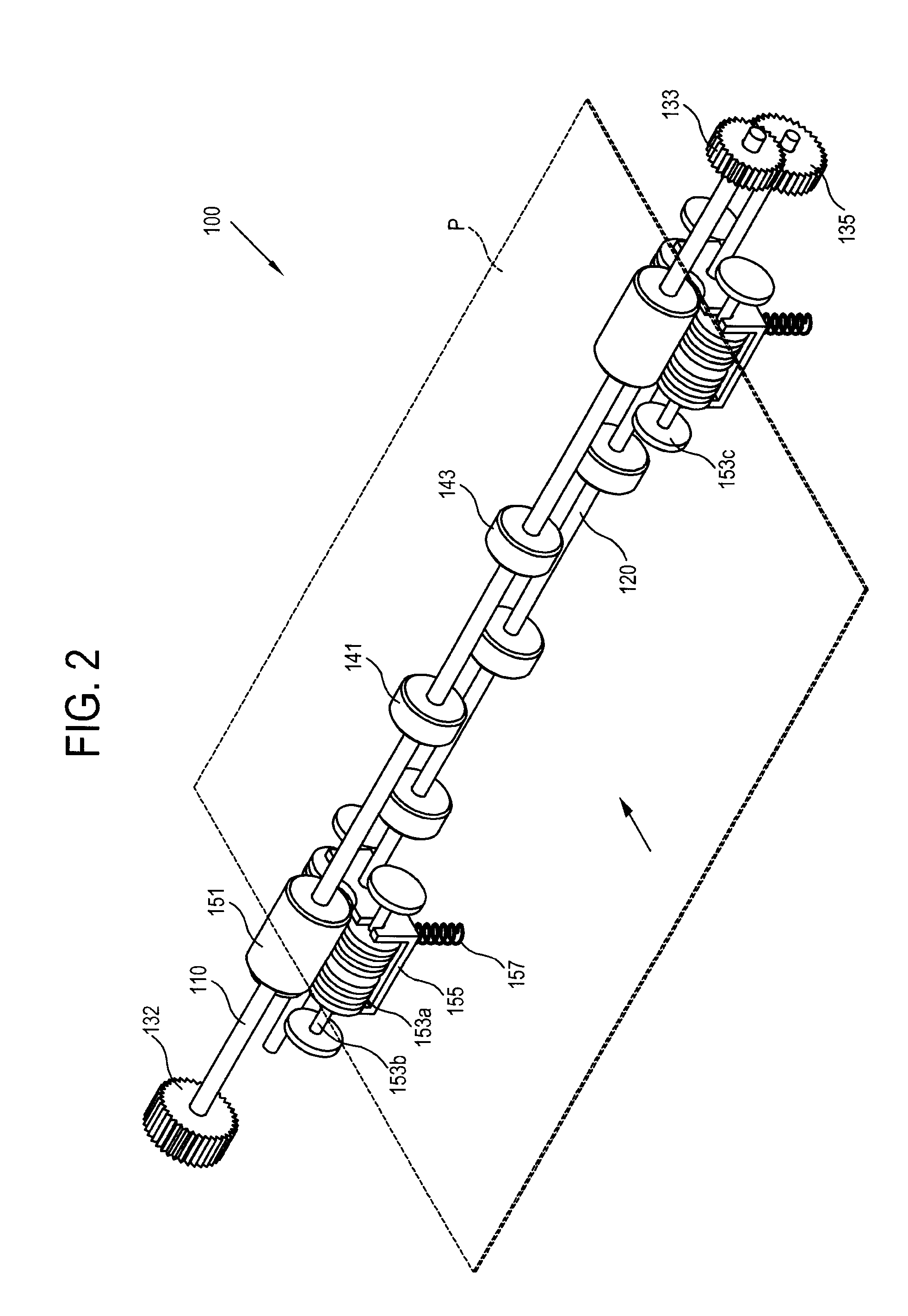

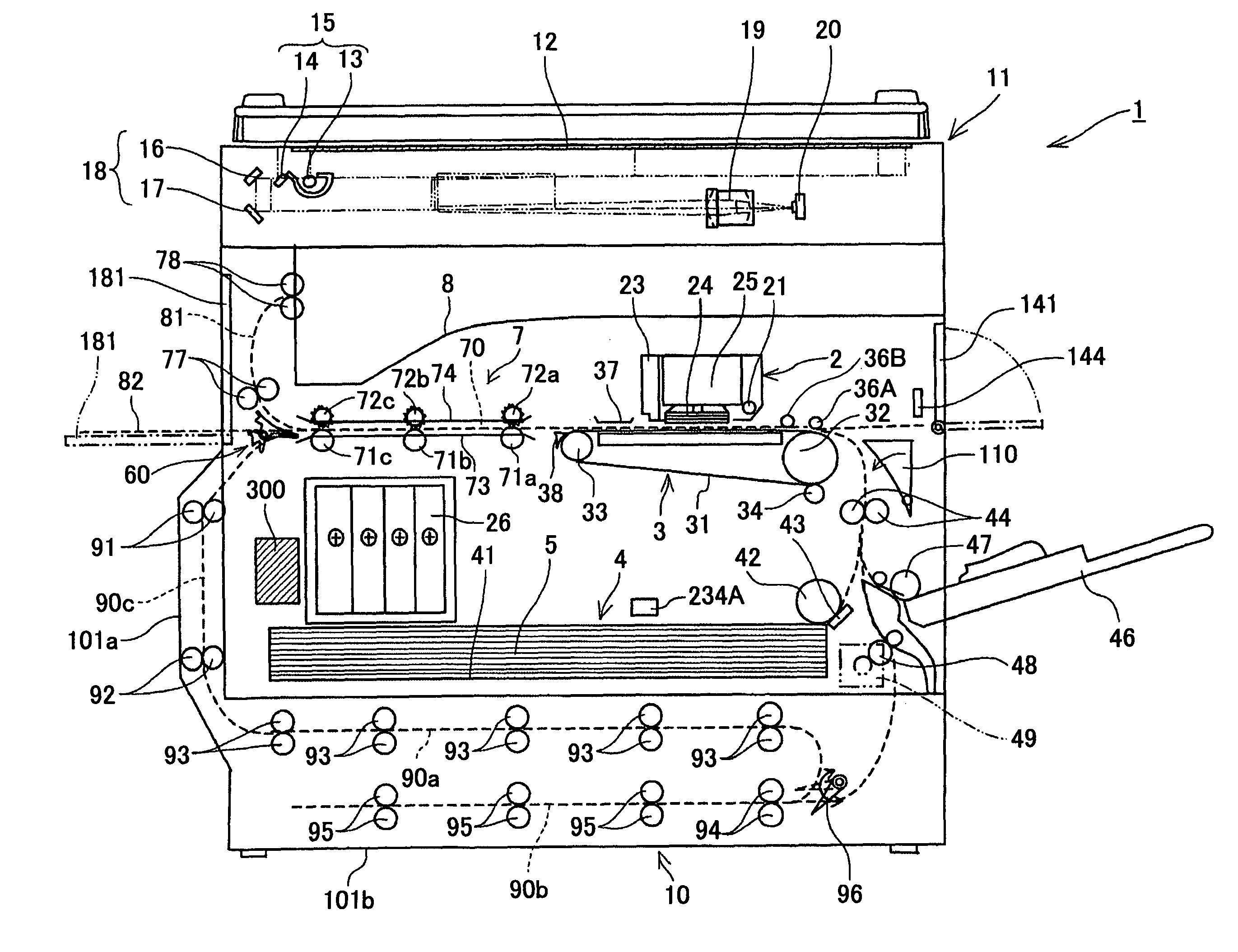

Discharging unit and image forming apparatus having the same

ActiveUS20080310900A1Less frizzDifferent thicknessElectrographic process apparatusOther printing apparatusImage formationMechanical engineering

A discharging unit for discharging a printing medium from an image forming apparatus includes an elastic roller and a curl preventing roller to oppose each other in a pressing relationship forming a nip therebetween to reduce curling of a print medium passing through the nip. At least one of the elastic roller and the curl preventing roller is allowed to move towards or away from the other roller so that the nip can be adjusted to accommodate different thicknesses of varying types of printing medium.

Owner:HEWLETT PACKARD DEV CO LP

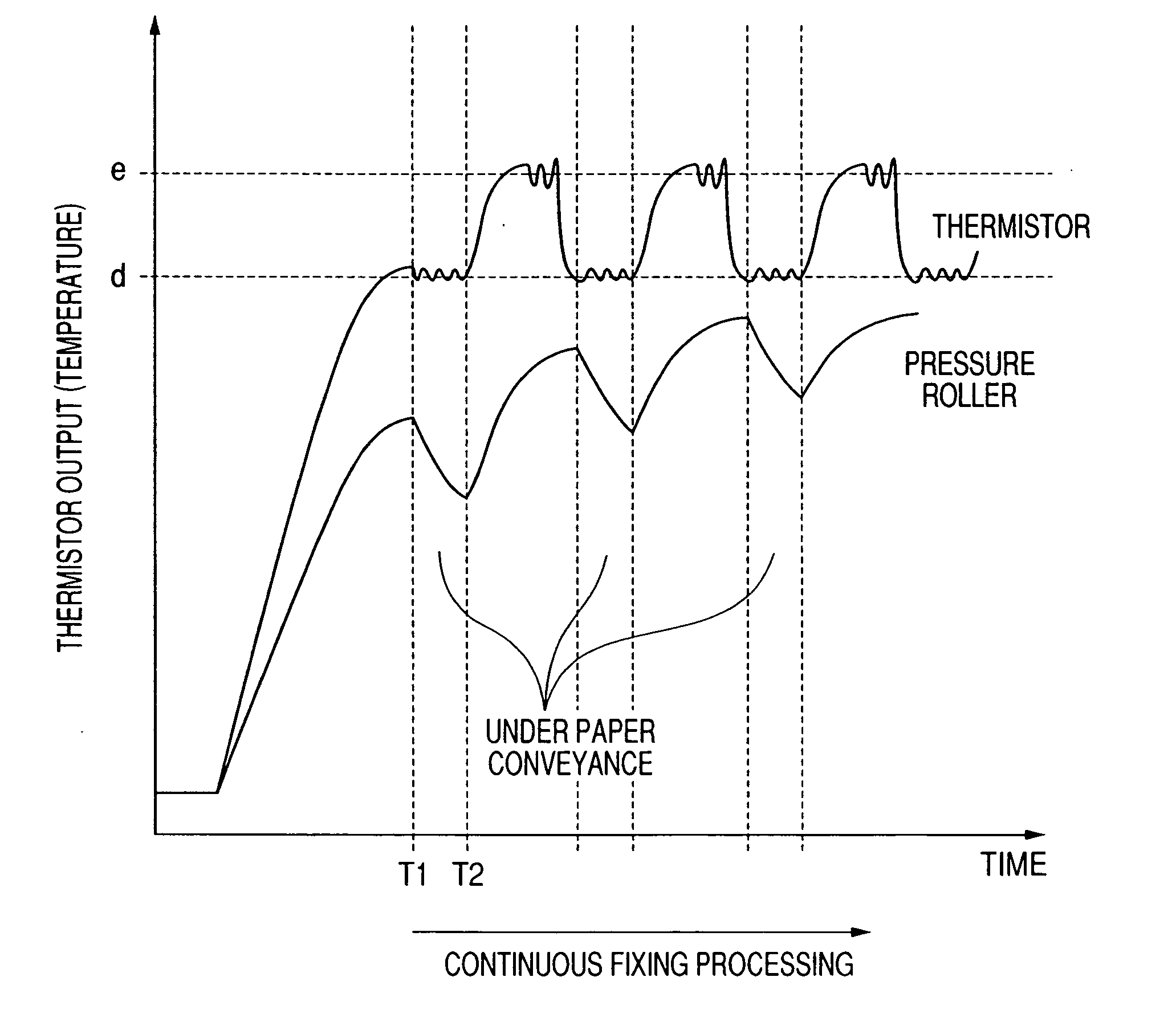

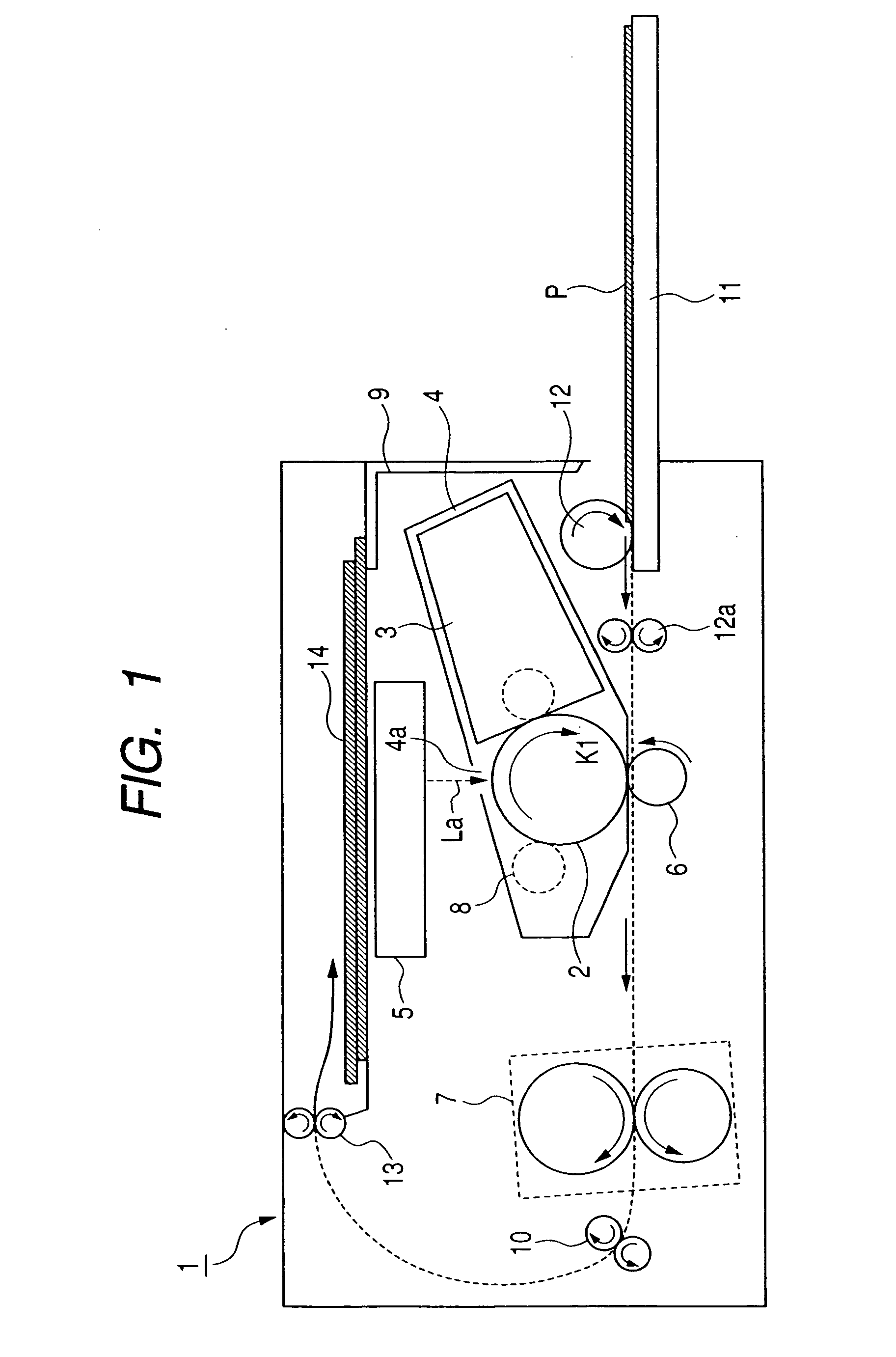

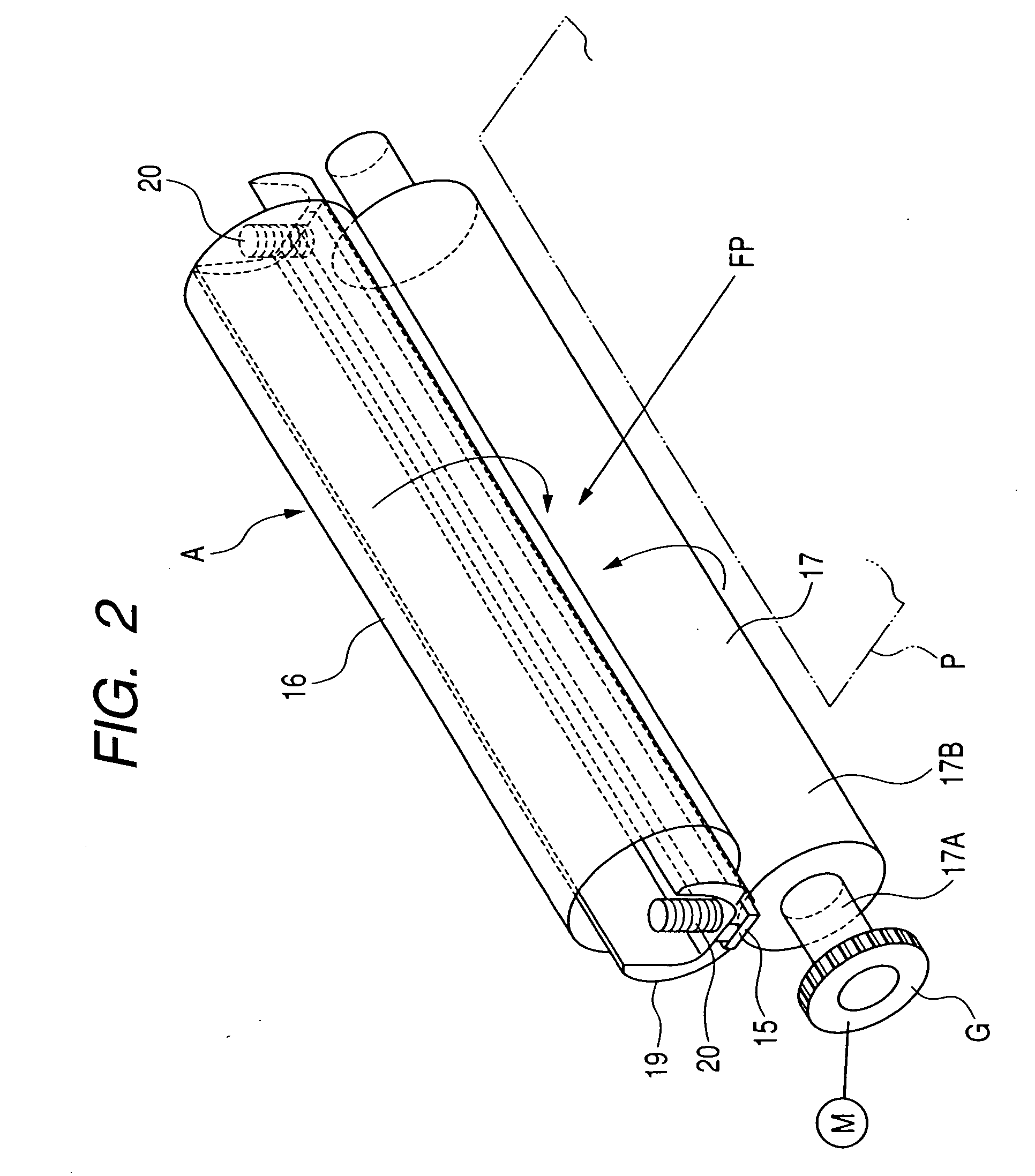

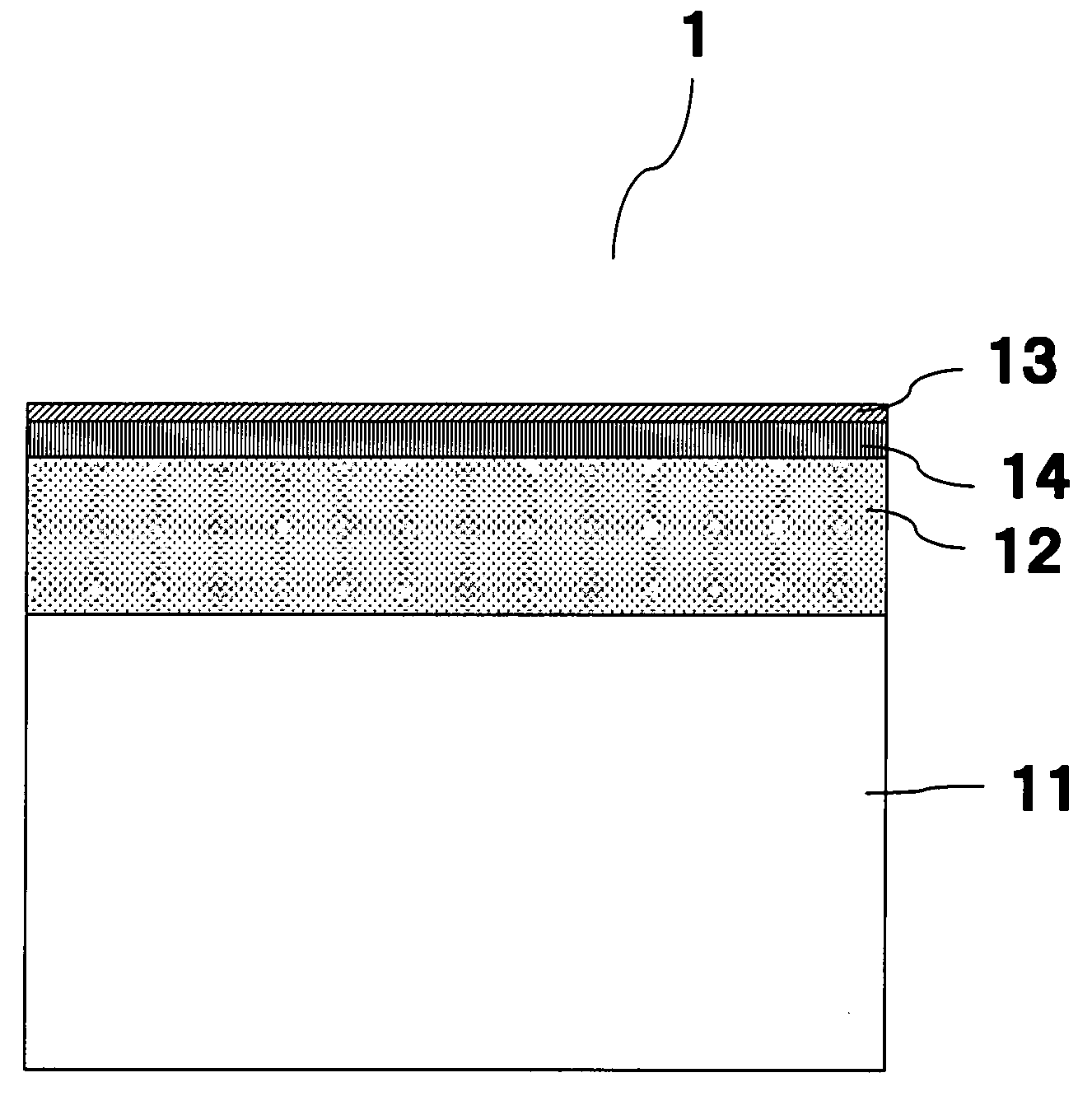

Heating apparatus and image forming apparatus

ActiveUS20060051117A1Avoid curlInhibit outputElectrographic process apparatusImage formationEngineering

The heating apparatus has a heating member and a pressure member which are mutually pressure-welded to hold and convey and heat a heated member to be heated by a nip portion formed between the heating member and the pressure member, includes a temperature detector, power control means, and a curl reduction mode for setting a paper conveyance interval temperature which is the target temperature of the heating member set in a paper conveyance interval which is a period from end of heating the M-th member to be heated up to start of heating the M+1-th member to be heated in continuous heating of N members to be heated or in a certain period in the paper conveyance interval to a temperature higher than the heating temperature of a member to be heated which is the target temperature of the heating member when heating the M+1-th member to be heated.

Owner:CANON KK

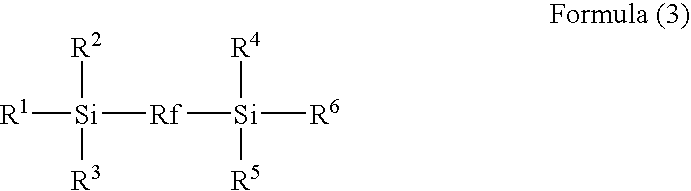

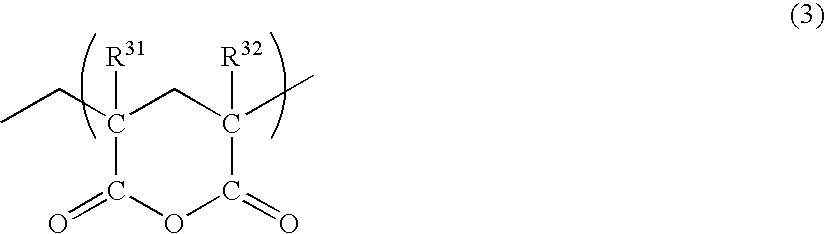

Hard coat film

InactiveUS20080193722A1High surface hardnessLess frizzCellulosic plastic layered productsRecord information storageMeth-Crosslinked polymers

According to one embodiment of this invention, there is provided a hard coat film including a triacetylcellulose film and a hard coat layer formed on the triacetylcellulose film. The hard coat layer can be formed by a coating step for forming a coating film on the triacetylcellulose film by directly applying a hard coat layer-forming coating liquid on the triacetylcellulose film, a drying step for drying the coating film, and a curing step for curing the coating film by irradiating the coating film with ionizing radiation. The hard coat layer forming-coating liquid includes a polyfunctional monomer (A) containing two or more (meth)acryloyl groups in one molecule and a crosslinking polymer (B) having a carbon-carbon unsaturated bonding. The crosslinking polymer (B) is contained in the hard coat layer-forming coating liquid at a ratio of from 10 parts by weight or more to 40 parts by weight or less with respect to 100 parts by weight of the total of the polyfunctional monomer (A) and the crosslinking polymer (B).

Owner:TOPPAN PRINTING CO LTD

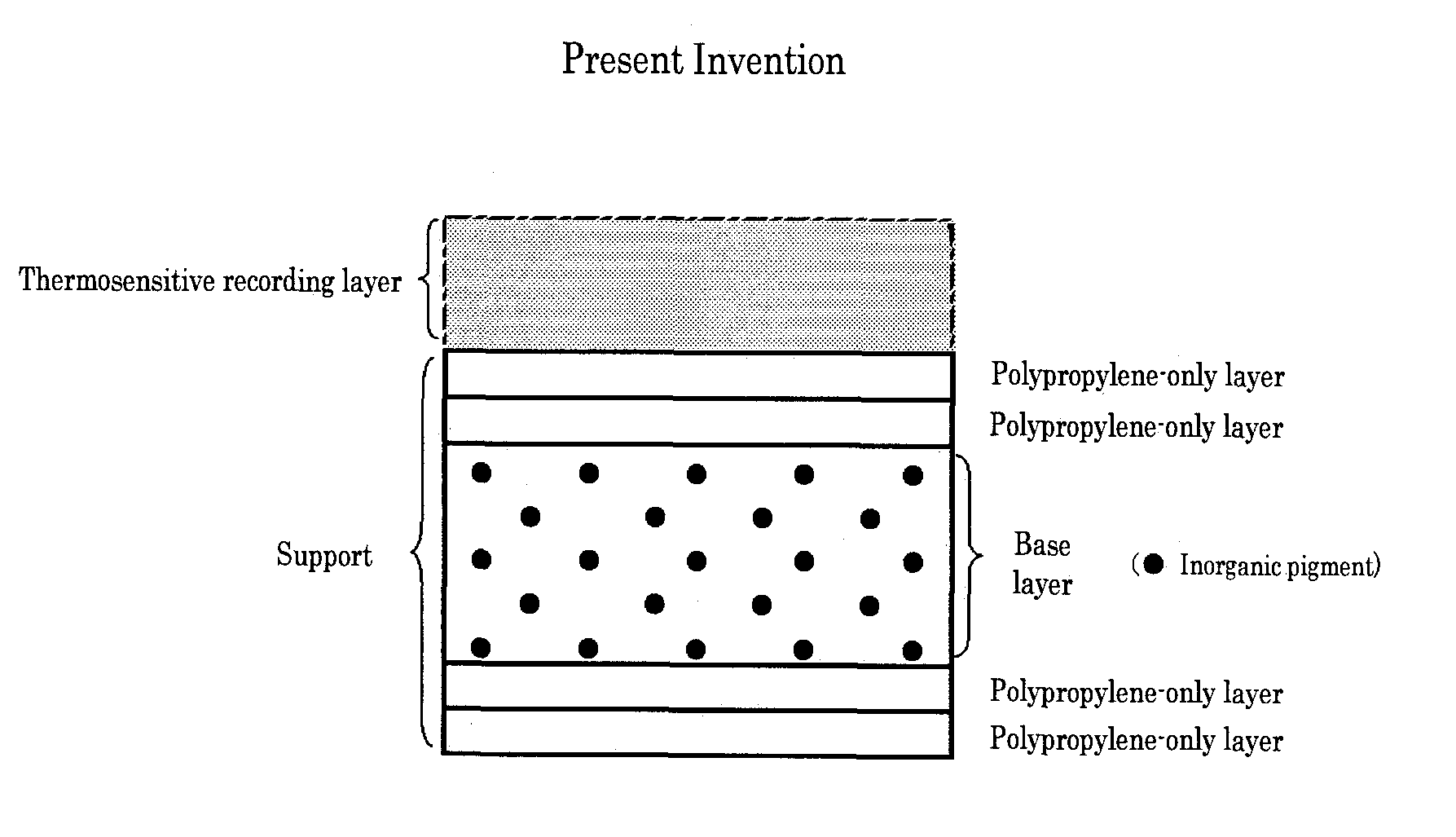

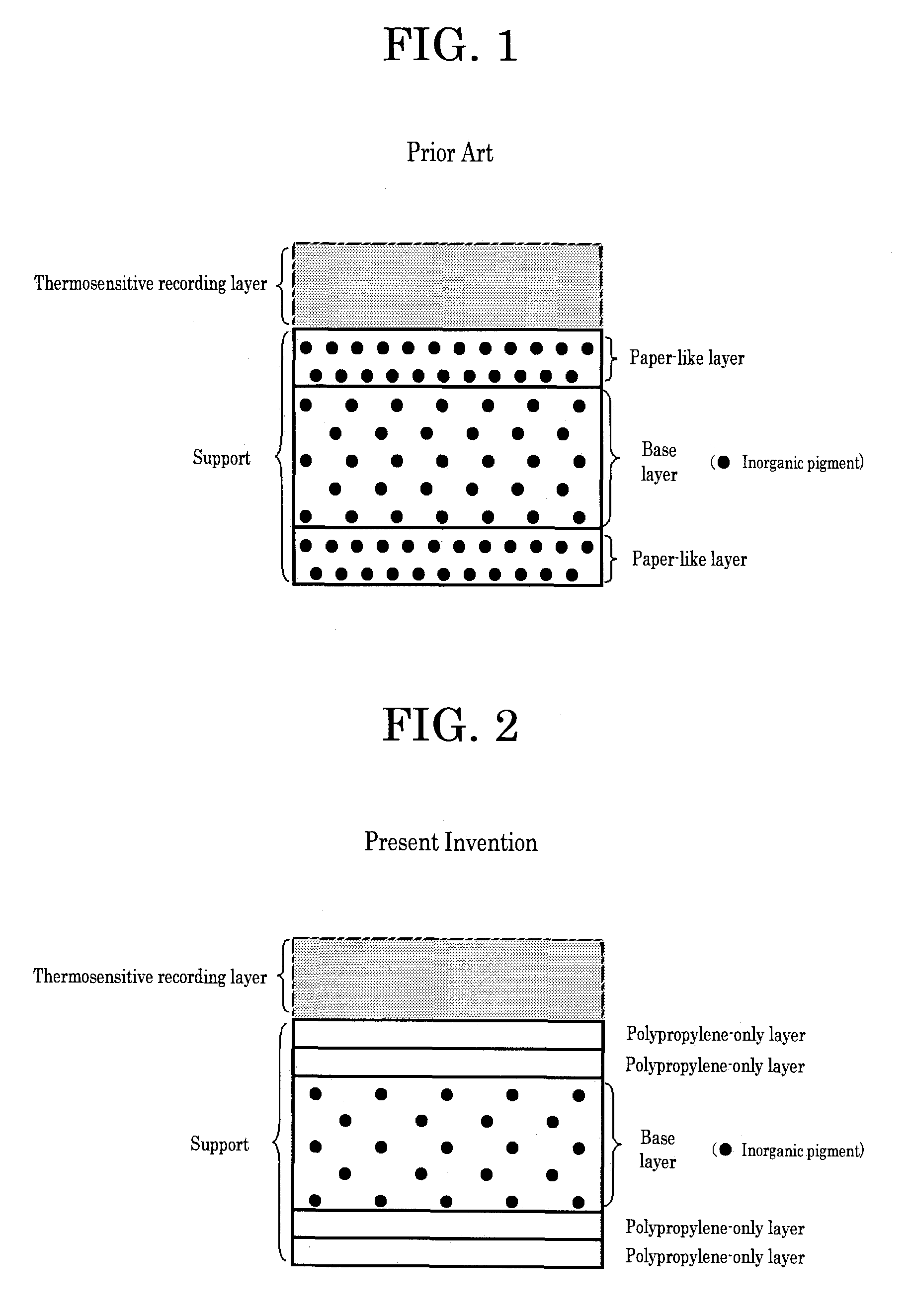

Thermosensitive recording material

Owner:RICOH KK

Recording sheet and image recording method using the same

InactiveUS20050104947A1High strengthCurl and cockle can be suppressedSpecial paperDuplicating/marking methodsPolymer scienceImage recording

A recording sheet comprising a cellulose pulp, wherein a water retention value C of the sheet according to the following formula (1) is 50 to 100% and a wet tensile strength residual ratio R of the sheet in CD according to the following formula (2) is 5 to 20%: Water retention value C(%)={(A−B) / B}×100 Formula (1) Wet tensile strength residual ratio R (%) in CD=(Sw / S)×100. Formula (2)

Owner:FUJIFILM BUSINESS INNOVATION CORP

Shelf liner

InactiveUS20050037190A1Enhances fused bonding of layerConsistent thicknessLamination ancillary operationsSynthetic resin layered productsPolyvinyl chlorideEngineering

The shelf liner is a multi-layered thermoplastic composite sheet of consistent thickness, with a non-slip bottom side and a decorative top side. A decorative top sheet is fused to a top surface of a substrate layer. The substrate layer comprises a nonwoven fabric or material that is coated on both sides, and can be fully impregnated, with a foamed plasticized polyvinyl chloride. The foamed plasticized polyvinyl chloride coating on the bottom side of the substrate layer gives the shelf liner a non-slip characteristic. An interlayer of polyvinyl chloride plastisol is disposed between the top sheet and the substrate to enhance the fused bonding of the layers. A bottom surface of the substrate layer may be fully or partly covered with a bottom coating to modify the non-slip nature of the shelf liner.

Owner:MARKETING & SALES MANAGEMENT CORP

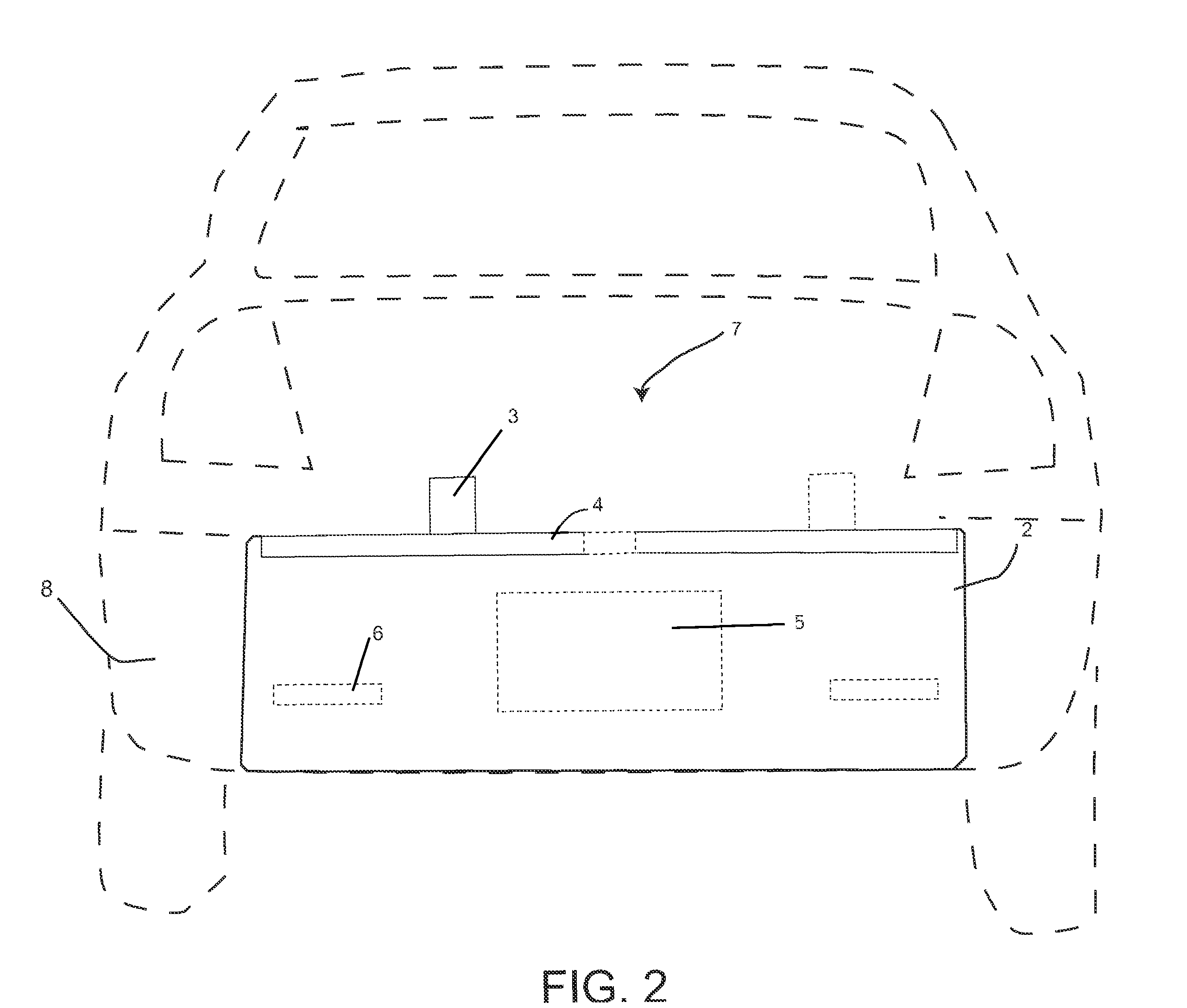

Protective vehicle cover

InactiveUS7866715B2Easy to installResistant to curling and twistingBumpersEngineeringMechanical engineering

Owner:KEYSTONE GLOBAL

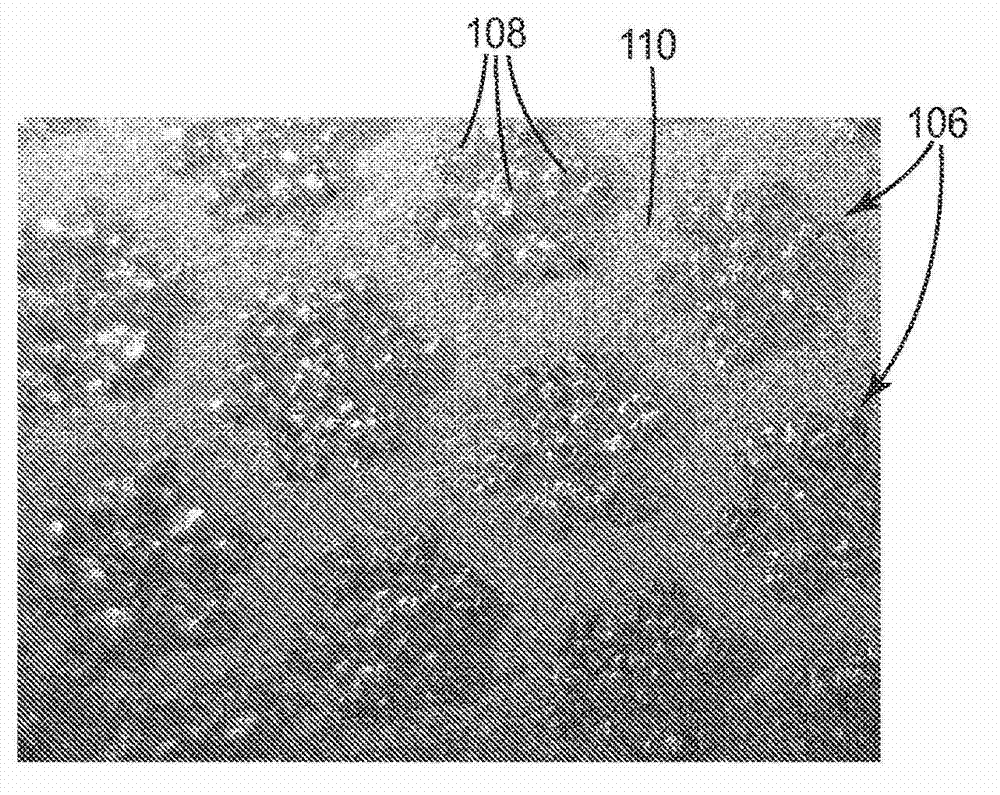

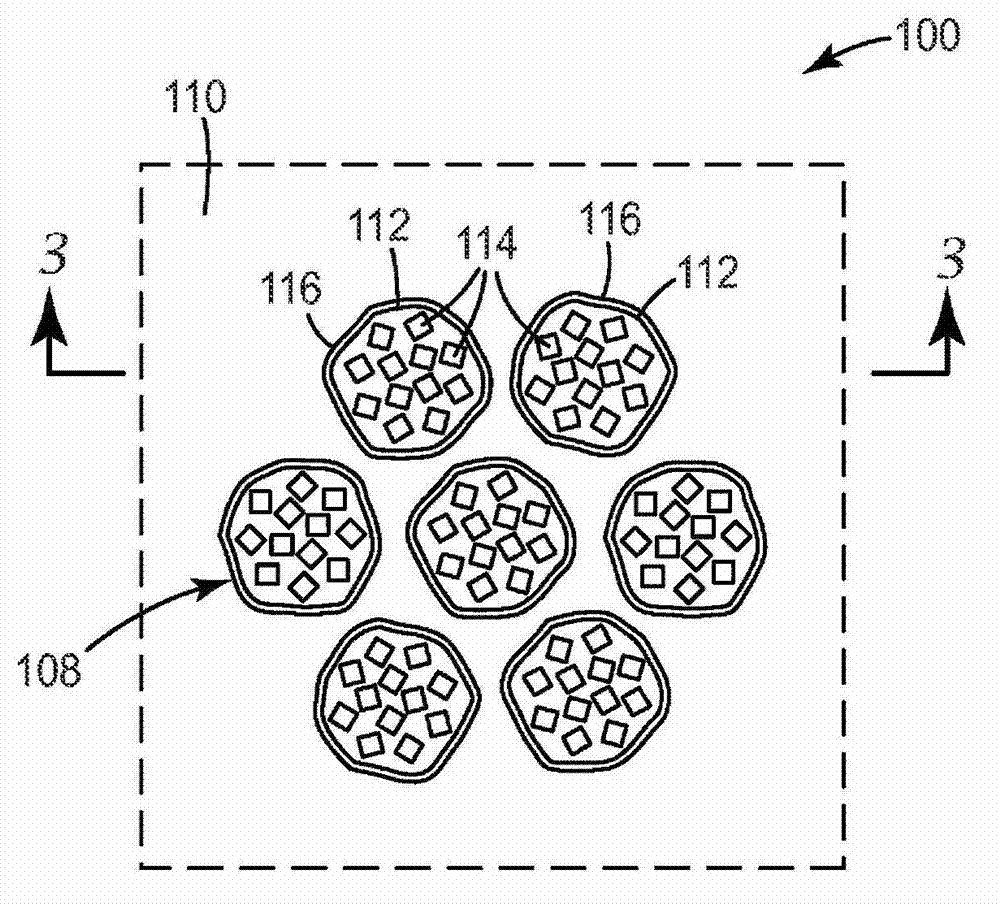

Coated abrasive articles

ActiveCN103079768AExcellent curl resistanceGood flexibilityAbrasion apparatusGrinding devicesPliabilityMaterials science

Provided are abrasive articles in which the make layer, abrasive particle layer, and size layer are coated onto a backing according to a pre-determined coating pattern. All three components are generally in registration with each other, thereby providing a pervasive uncoated area extending across the backing. Advantageously, this configuration provides a coated abrasive that displays superior curl-resistance compared with previously disclosed abrasive articles. Moreover, this configuration resists loading, resists de-lamination, has enhanced flexibility, and decreases the quantity of raw materials required to achieve the same level of performance as conventional abrasive articles.

Owner:3M INNOVATIVE PROPERTIES CO

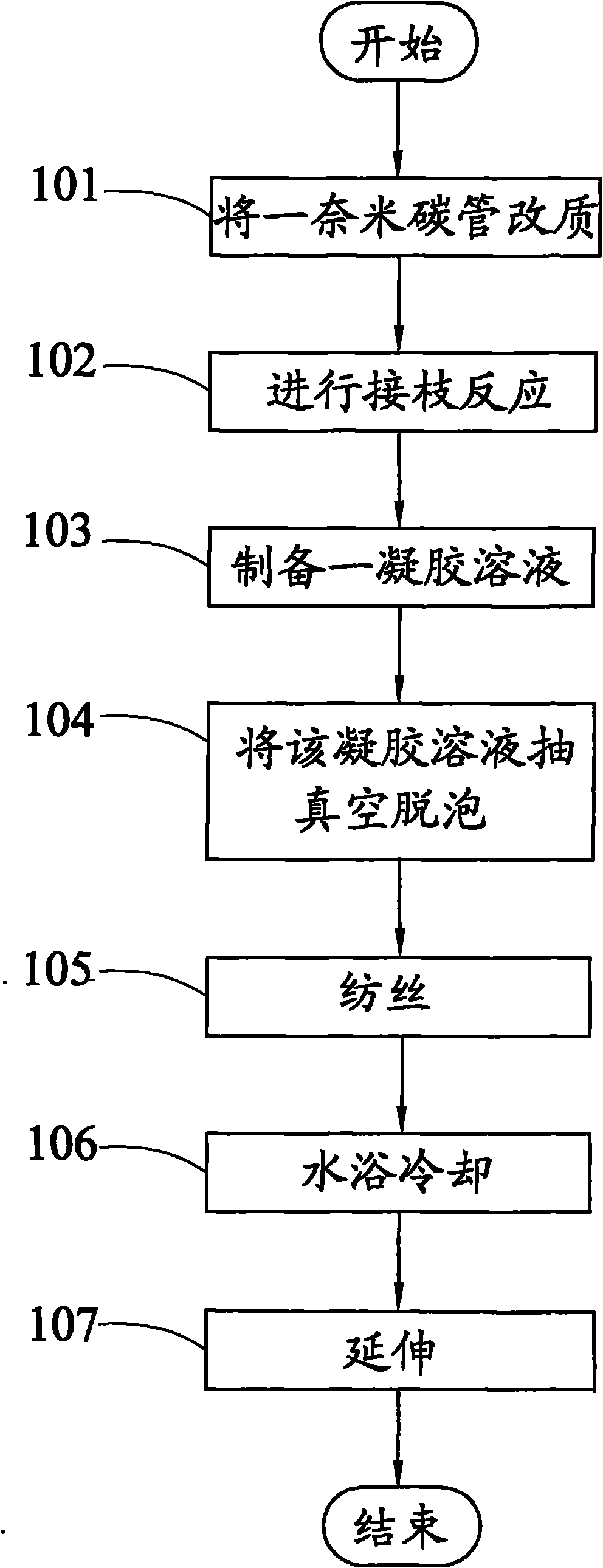

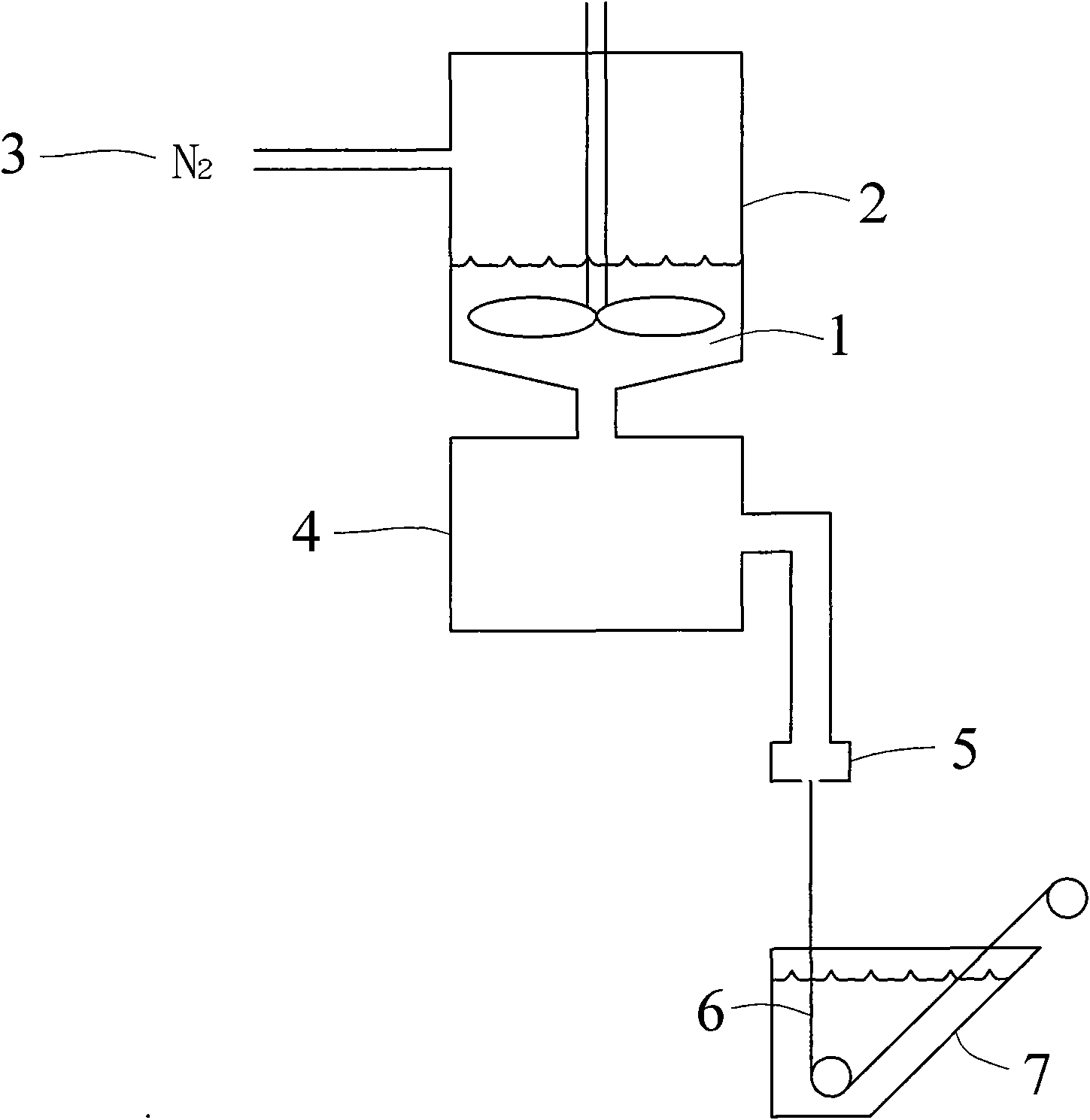

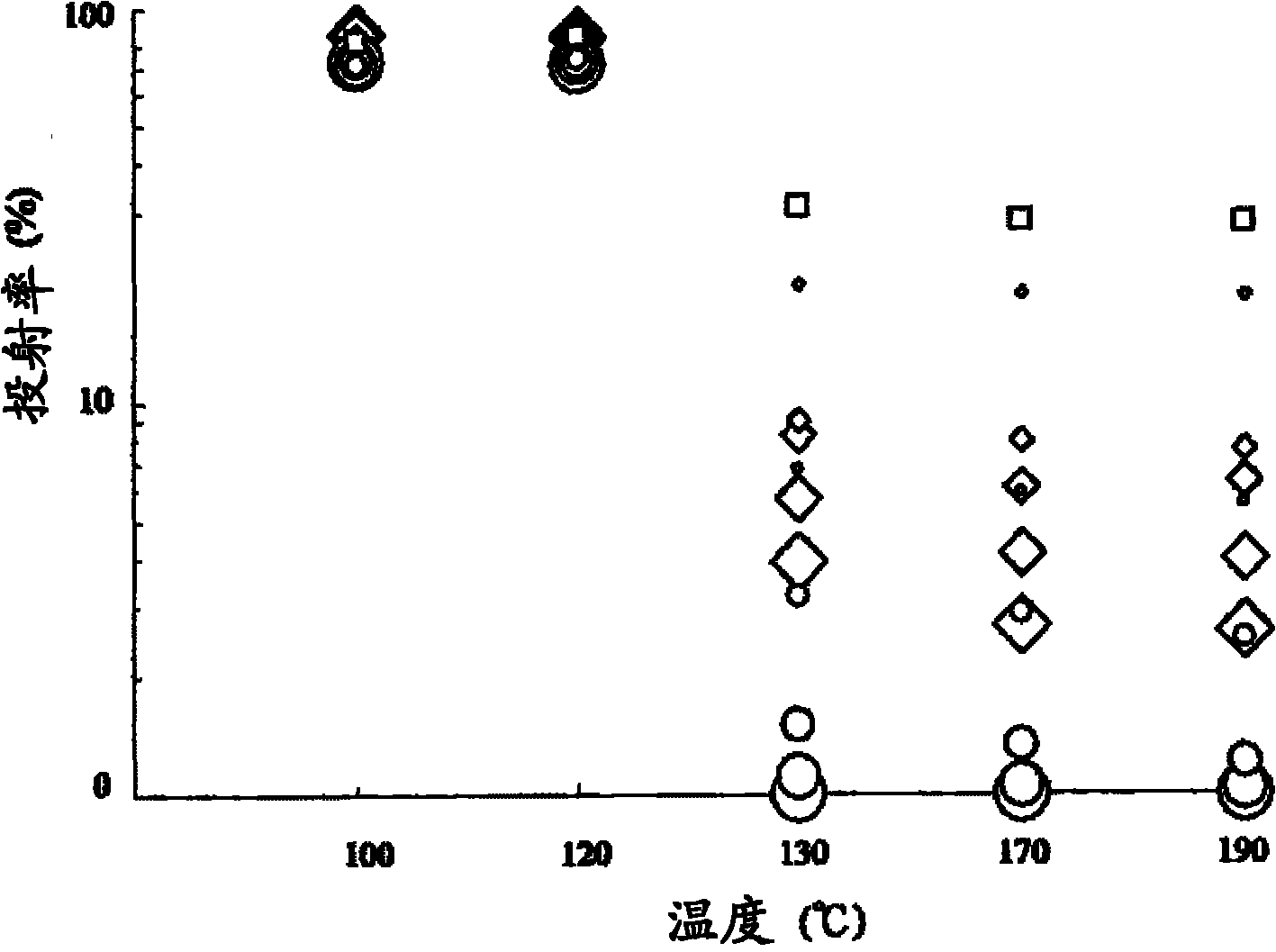

Ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and manufacturing method of high-performance fiber thereof

InactiveCN101988221AHigh fiber strengthLess frizzMelt spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses an ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and a manufacturing method of high-performance fiber thereof, belonging to the field of a composite material.The manufacturing method of the composite material comprises the following steps: preparing UHMPE and a nano-inorganic substance, such as attapulgite, a carbon nanotube, sepiolite, wollastonite, montmorillonite and the like into gel solution; in the case of light transmittance close to zero under certain concentration, heating the gel solution for dissolving; and vacuumizing, defoaming, spinning with different spinneret boards containing various spinneret angles as well as feed length and discharge length, carrying out air-quenching, carrying out aqueous-phase curing, performing multi-segment temperature change extension and the like to finally obtain the composite material for the ultra-high strength fiber the light transmittance of which is close to zero. The obtained composite material can increase the strength and modulus of UHMPE fiber and solve the defects of the UHMPE fiber, such as high crimp, high creep, light transmittance and the like.

Owner:叶正涛 +1

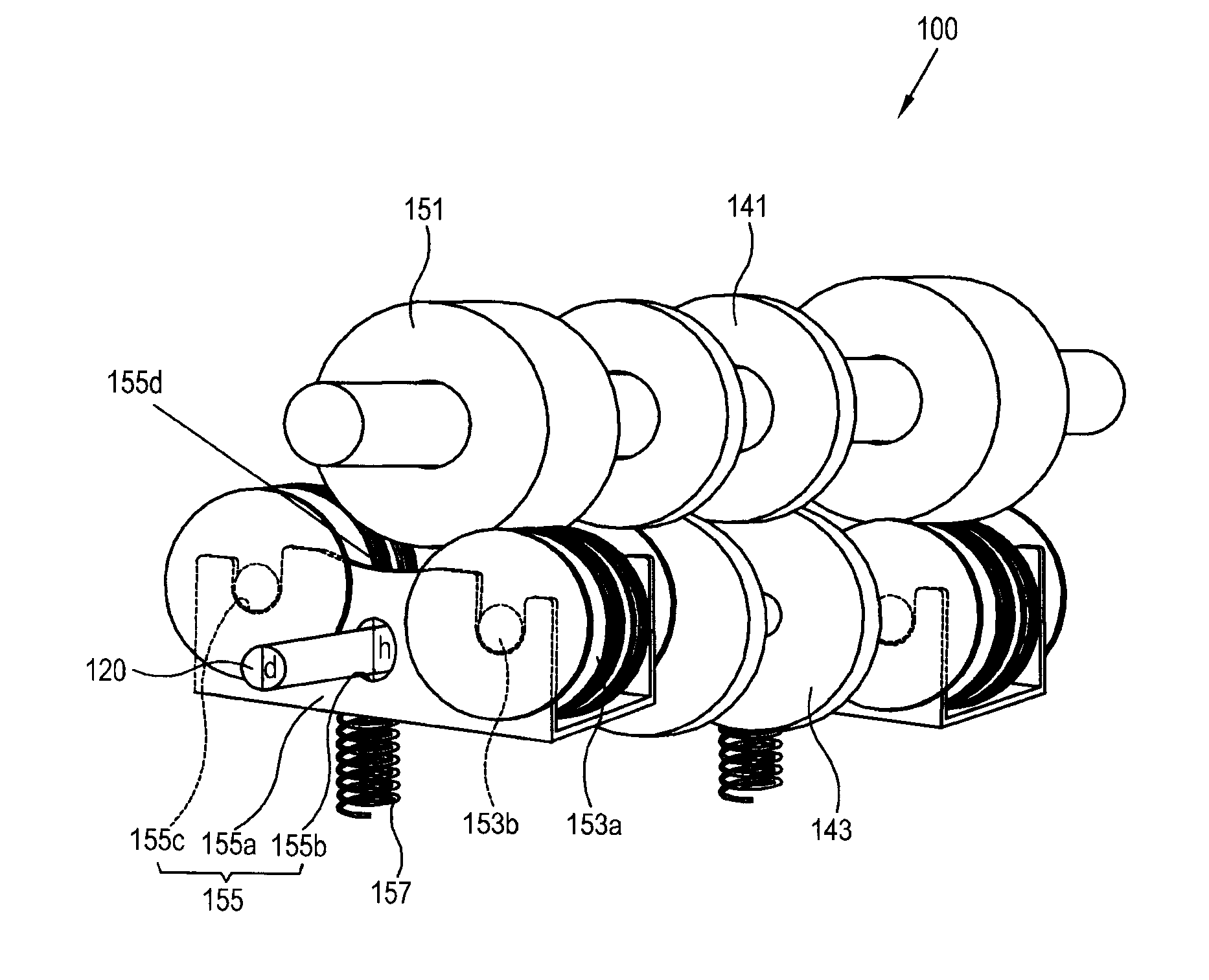

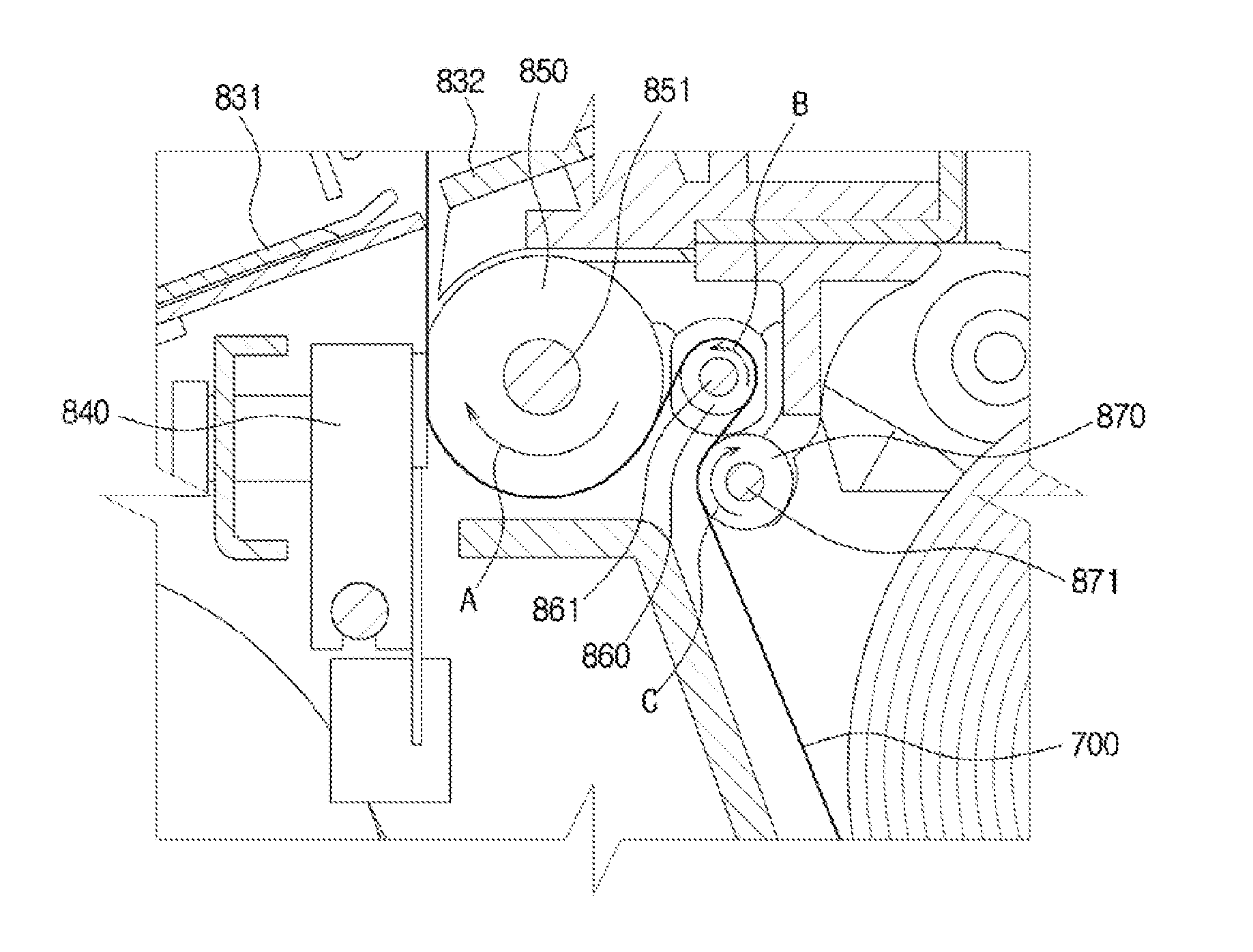

Discharging unit and image forming apparatus having the same

ActiveUS7865128B2Less frizzDifferent thicknessElectrographic process apparatusOther printing apparatusImage formationEngineering

A discharging unit for discharging a printing medium from an image forming apparatus includes an elastic roller and a curl preventing roller to oppose each other in a pressing relationship forming a nip therebetween to reduce curling of a print medium passing through the nip. At least one of the elastic roller and the curl preventing roller is allowed to move towards or away from the other roller so that the nip can be adjusted to accommodate different thicknesses of varying types of printing medium.

Owner:HEWLETT PACKARD DEV CO LP

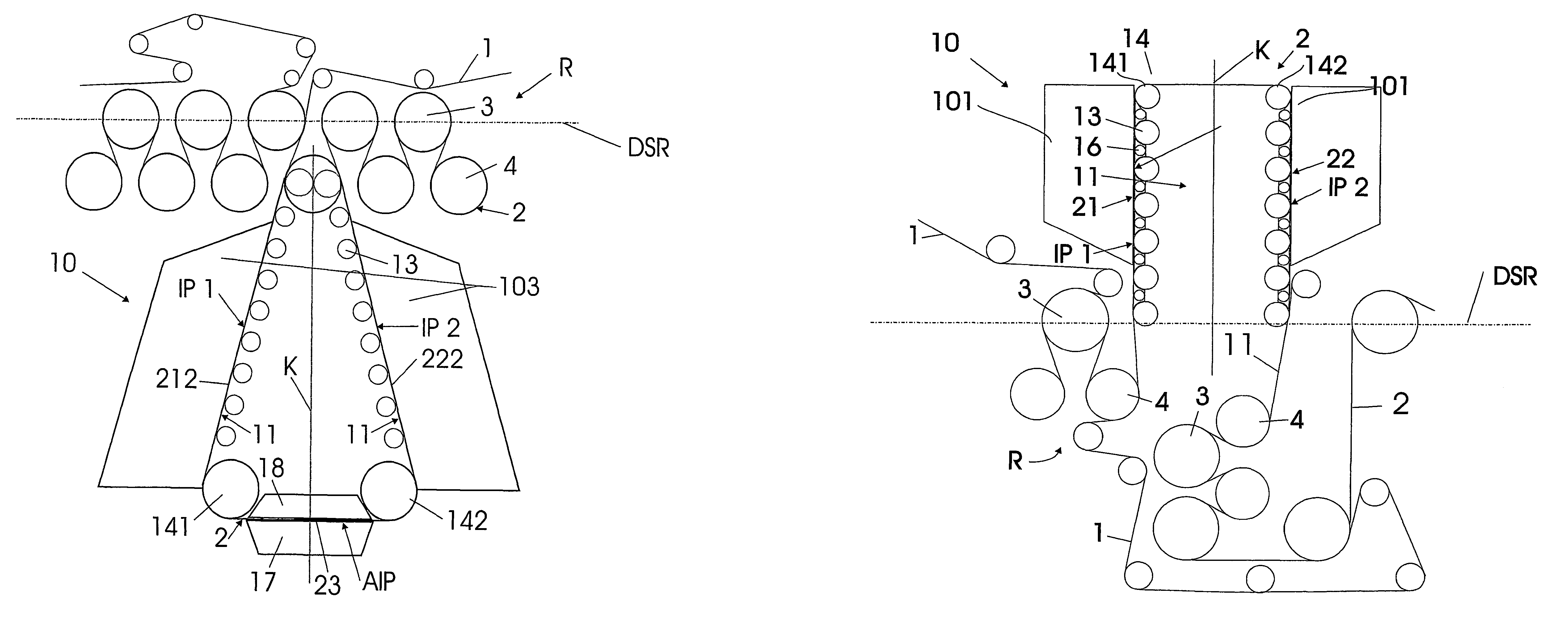

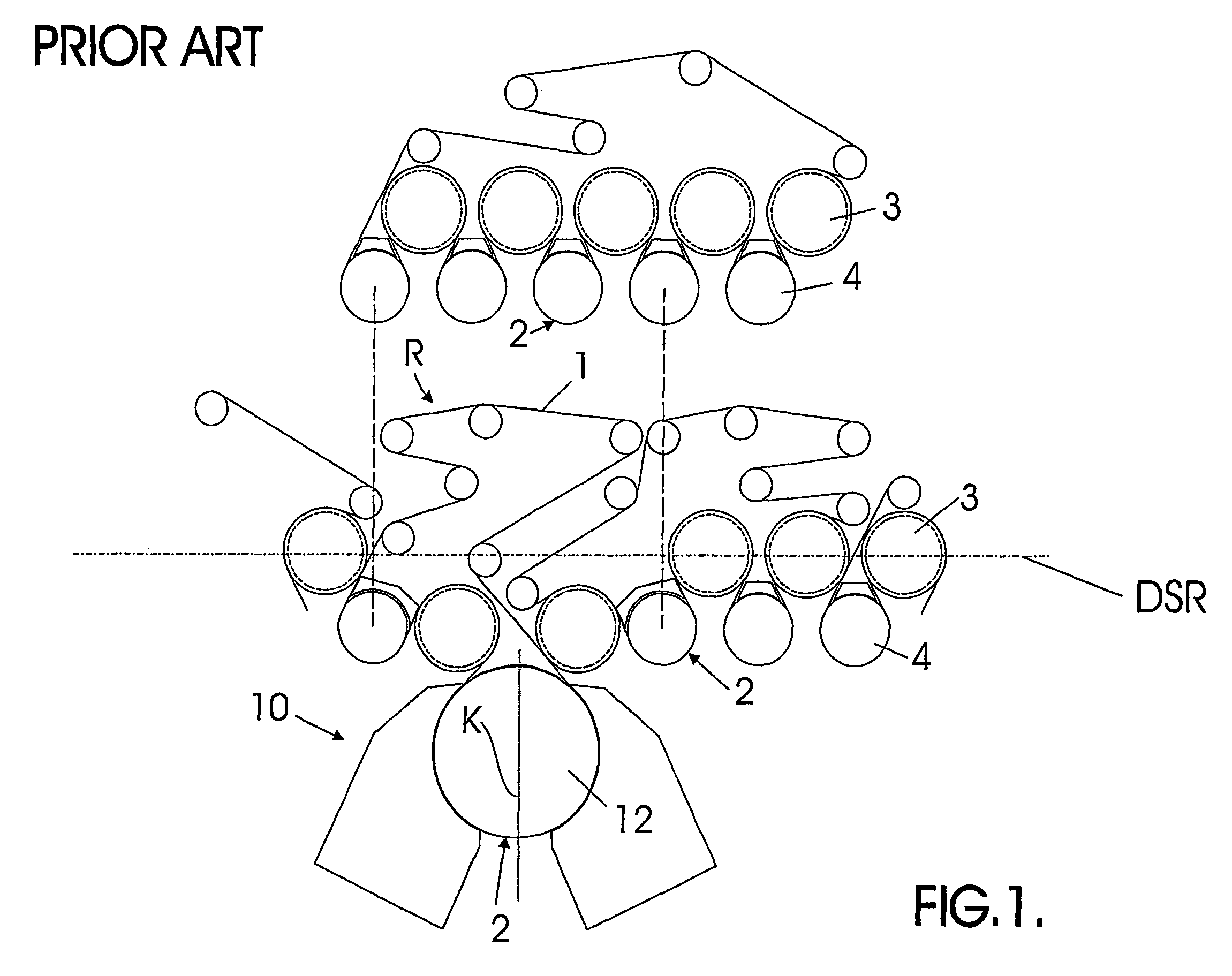

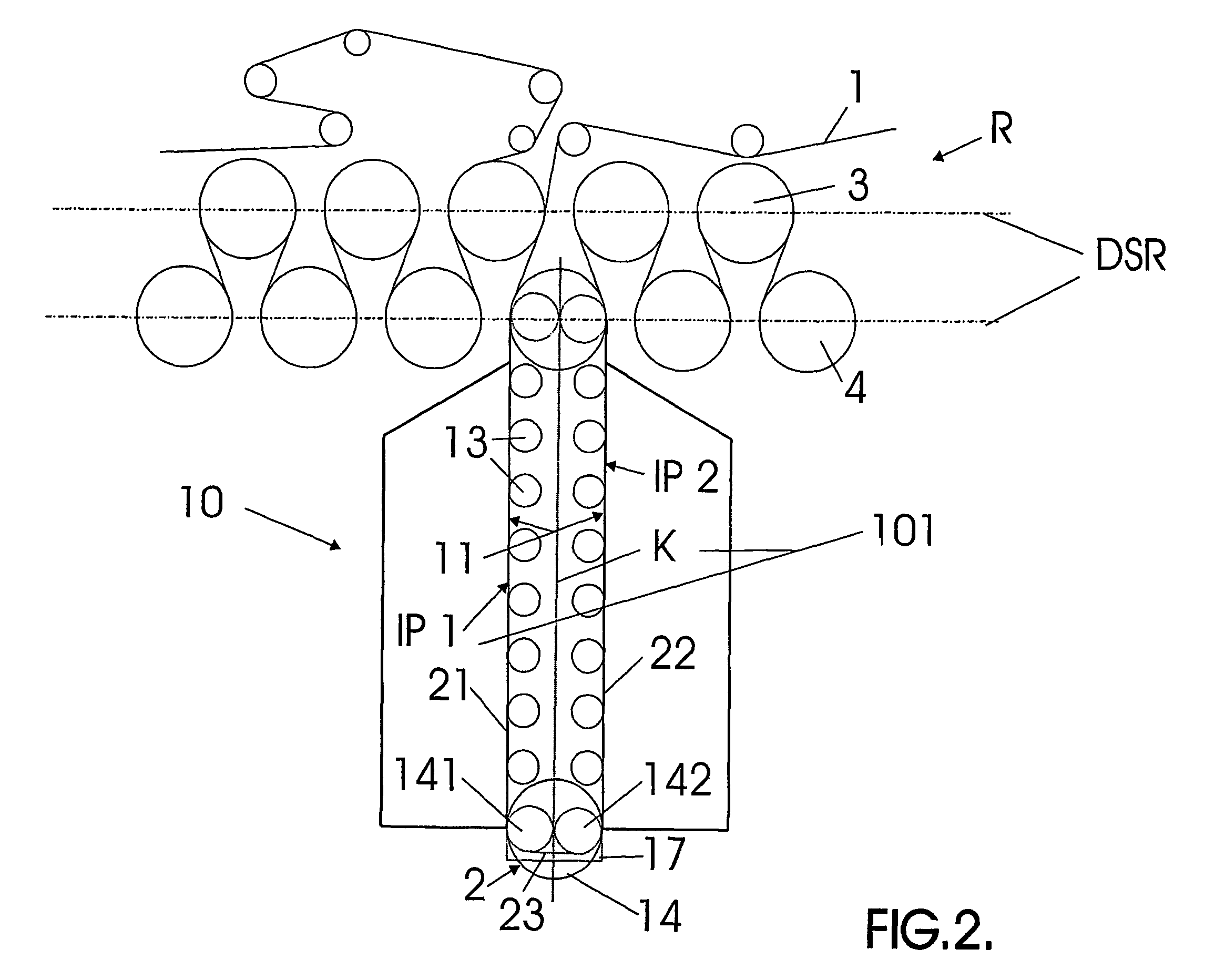

Impingement drying unit and a dryer section

InactiveUS7036242B2Improve runnabilityLess revolving massDrying solid materials with heatDryer sectionCardboardPlane parallel

An apparatus for a dryer section of a paper or board machine has a drying group (R) and an impingement drying unit (10) which is placed above and / or below a row (DSR) of drying cylinders (3). A drying fabric (1) supported paper or board web (2) is conducted past the impingement drying unit (10) having at least one impingement surface (IP1, IP2) the side profile of which is straight, changeably curved in its radius of curvature, in the shape of a broken line or a selectable combination of these, and that the impingement surface or a tangent line to the impingement surface or a line passing via the beginning and the end of the impingement surface or an extension of the line forms on the impingement side an angle with a horizontal plane parallel to the machine level, which angle is ≦120°, advantageously 120°–60°, most advantageously about 90°.

Owner:VALMET TECHNOLOGIES INC

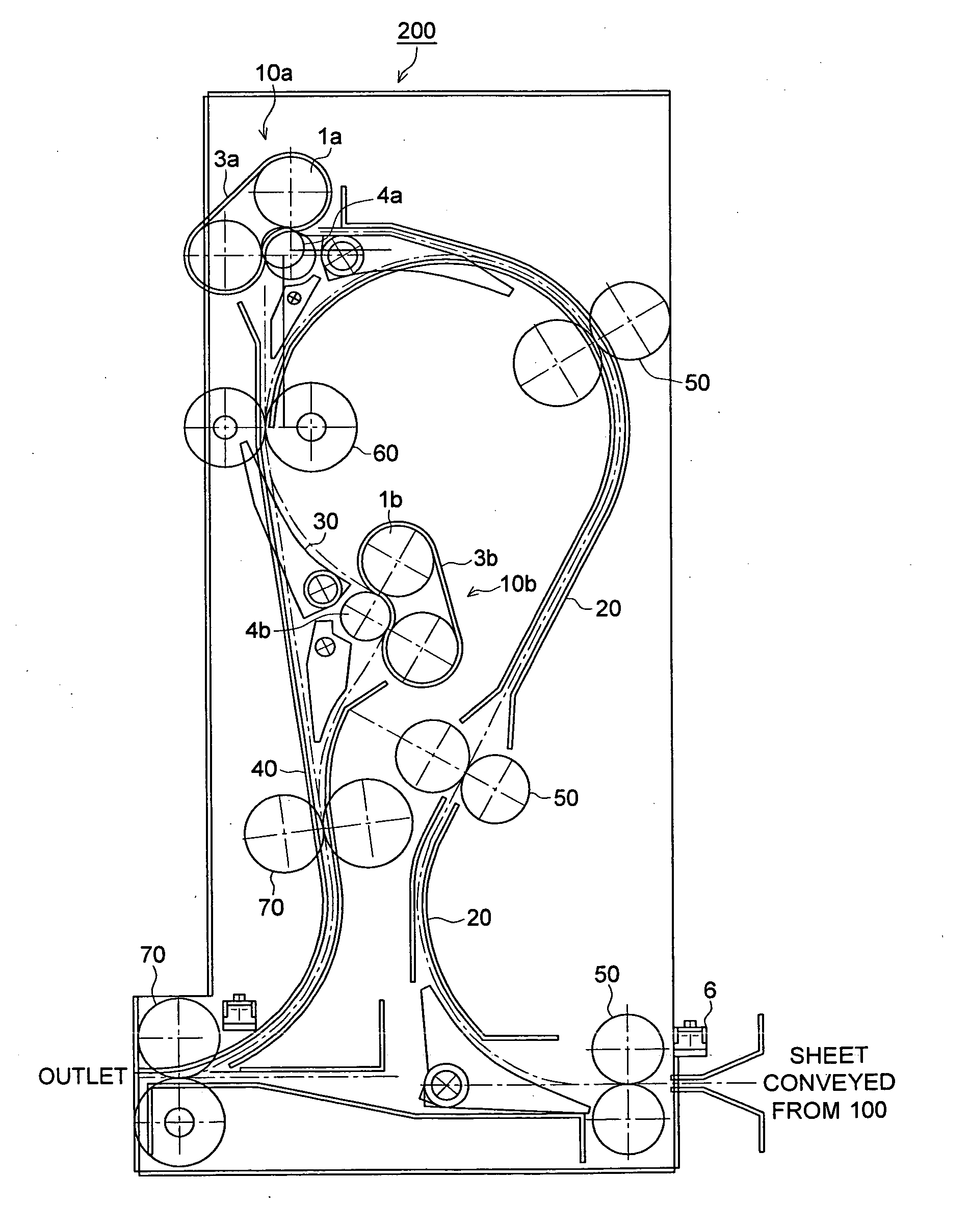

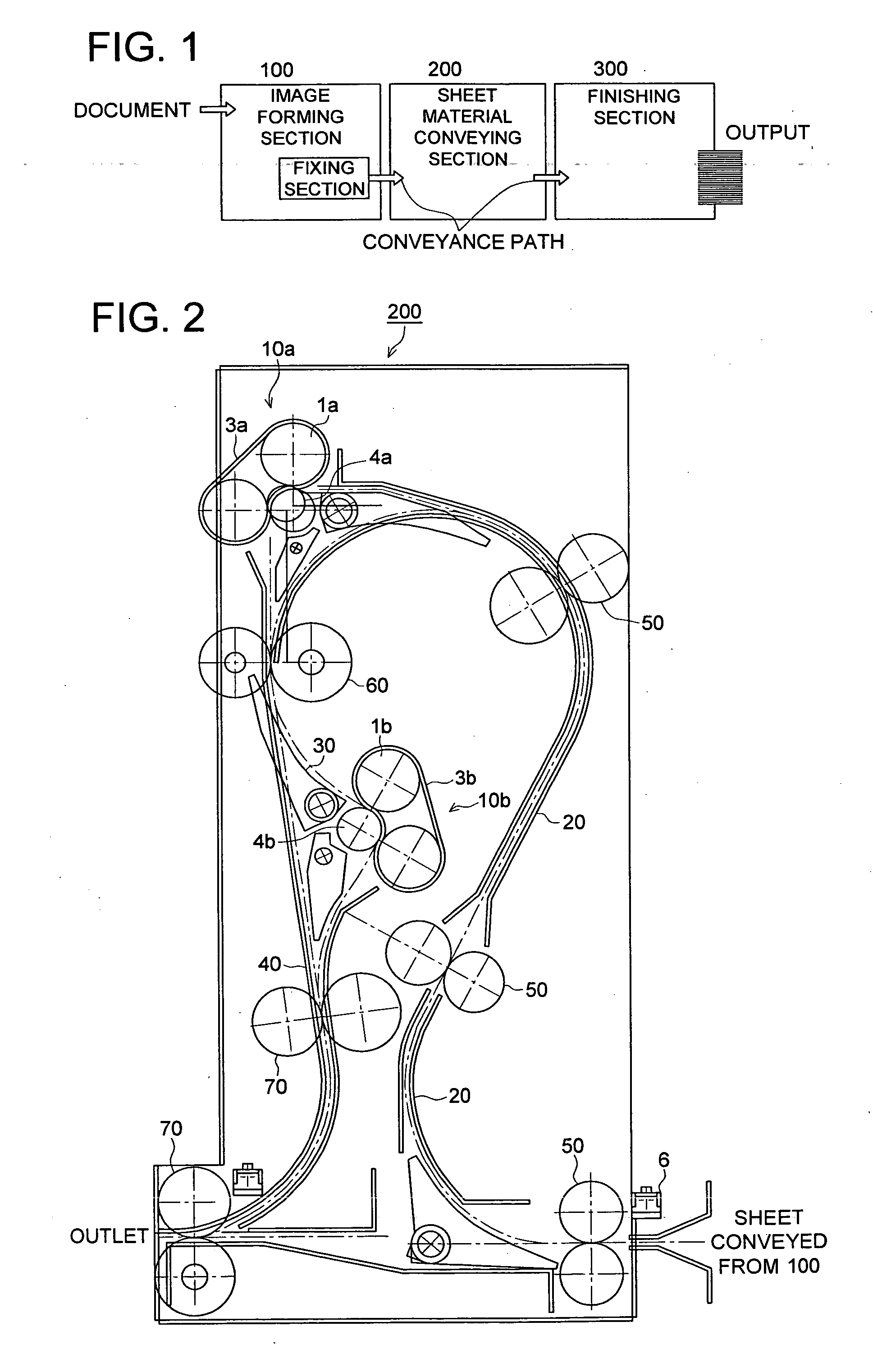

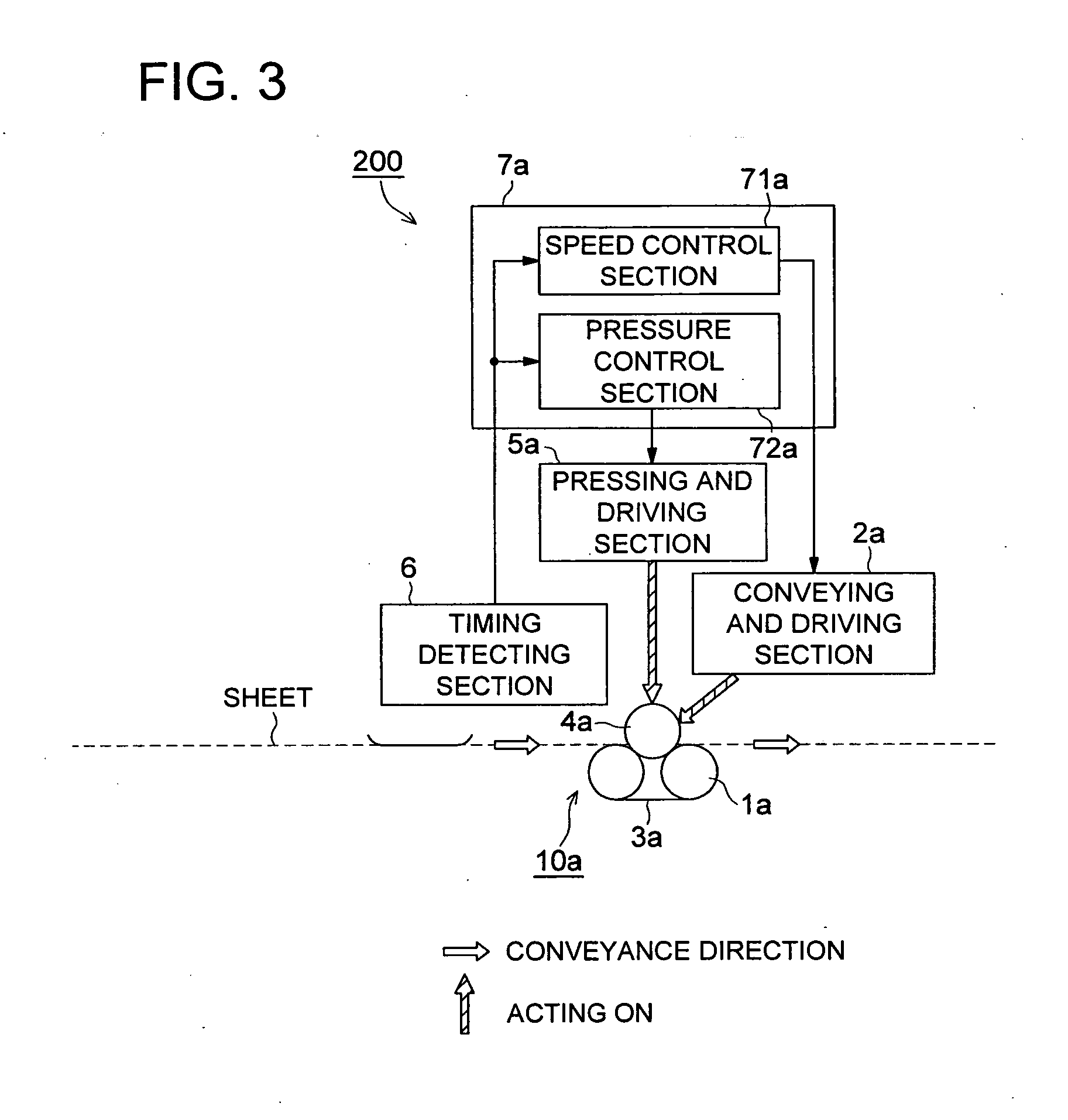

Image forming apparatus and sheet material conveyance device used therein

InactiveUS20070132174A1Less frizzImprove productivityFunction indicatorsElectrographic process apparatusImage formationEngineering

An image forming apparatus comprising: an image forming section which forms an image on a sheet material; a curl correcting mechanism which interposes and conveys the sheet material on which the image has been formed by the image forming section. Pressure applied to one surface of the sheet material during an interposing operation and a conveying speed of the sheet material can be changed, the curl correcting mechanism changes the conveying speed from an initial speed vs to a target speed vo higher than the initial speed (vo>vs) while the sheet material is pressed, and the curl correcting mechanism changes the pressure to a high pressure in response to a change of the conveying speed, whereby a curl of the sheet material is reduced.

Owner:KONICA MINOLTA BUSINESS TECH INC

Water transfer printing paper and preparation method thereof

The invention discloses water transfer printing paper and a preparation method thereof. The water transfer printing paper comprises a hydrosol layer, a film-forming adhesive layer, carrier backing paper and an opposite colloid layer sequentially from top to bottom, wherein the opposite colloid layer is a starch layer; the film-forming adhesive layer comprises an activity colloid layer and a white colloid layer sequentially from top to bottom; the activity colloid layer is obtained by coating and drying a mixed aqueous solution of a brightening agent and the starch; the mass fractions of the brightening agent and the starch are respectively 0.5%-1% and 35%-45%; and the white colloid layer is a starch layer. The hydrosol layer is obtained by coating and drying a mixed aqueous solution of kaolin, a butylbenzene emulsion, a dispersing agent and polyvinyl alcohol; and the mass fractions of the kaolin, the butylbenzene emulsion, the dispersing agent and the polyvinyl alcohol are respectively 40%-50%, 10%-15%, 1%-3% and 3%-5%. The water transfer printing paper disclosed by the invention has the advantages of a smooth and flat surface, rational thickness of coated glue layers, higher de-molding speed, uniform water absorbability, and uniform and smooth glue surface.

Owner:杭州飞乐印刷材料有限公司

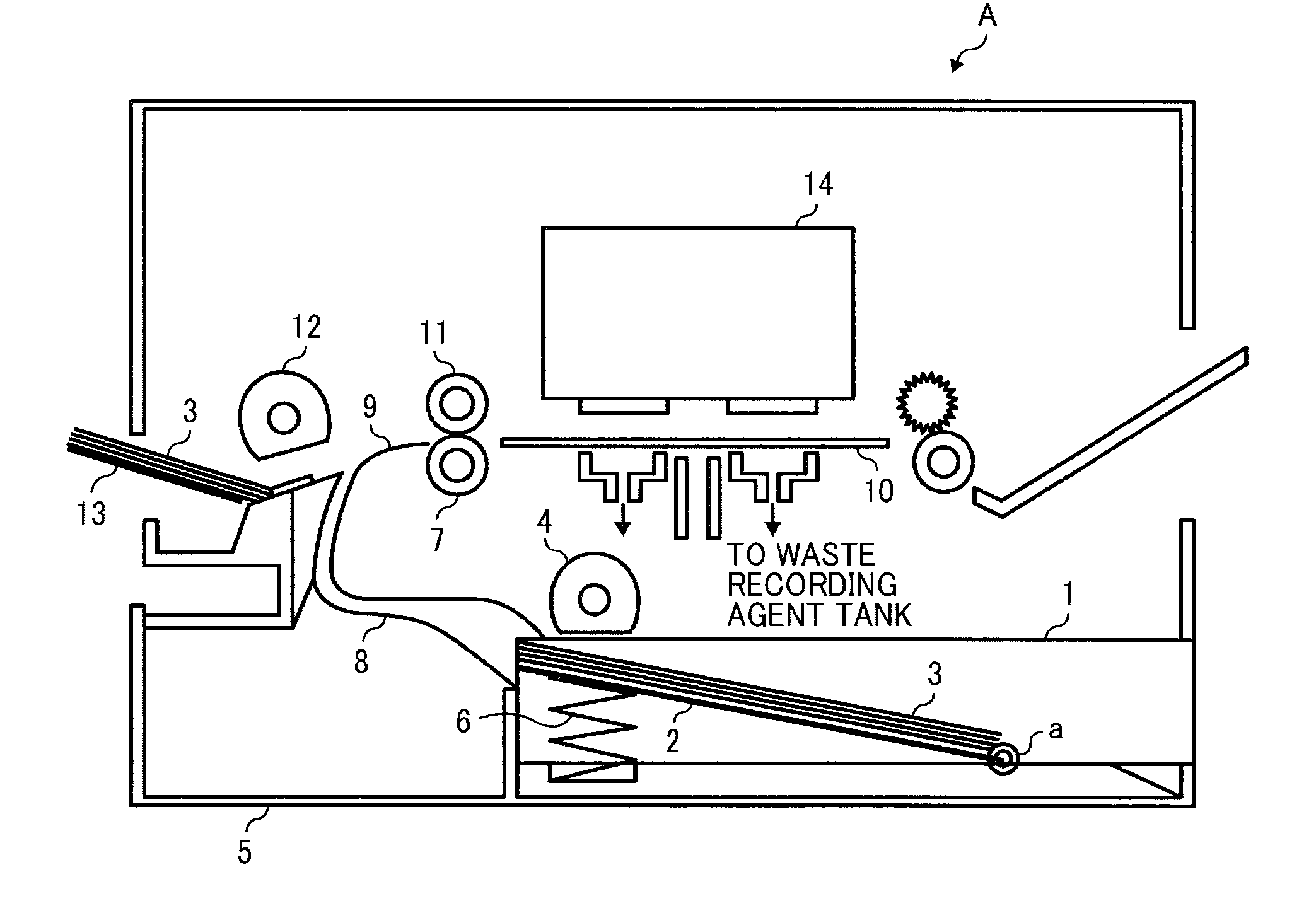

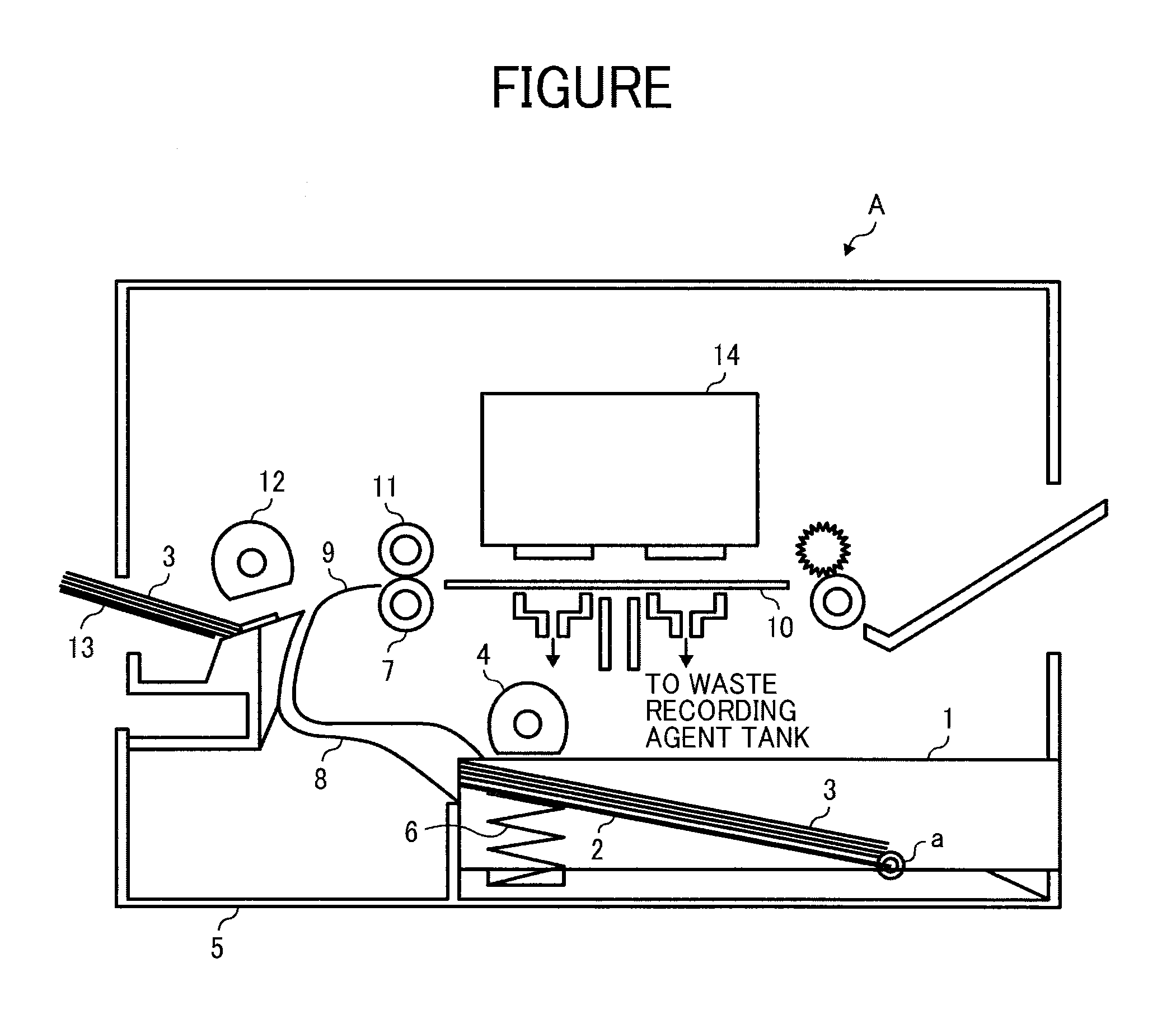

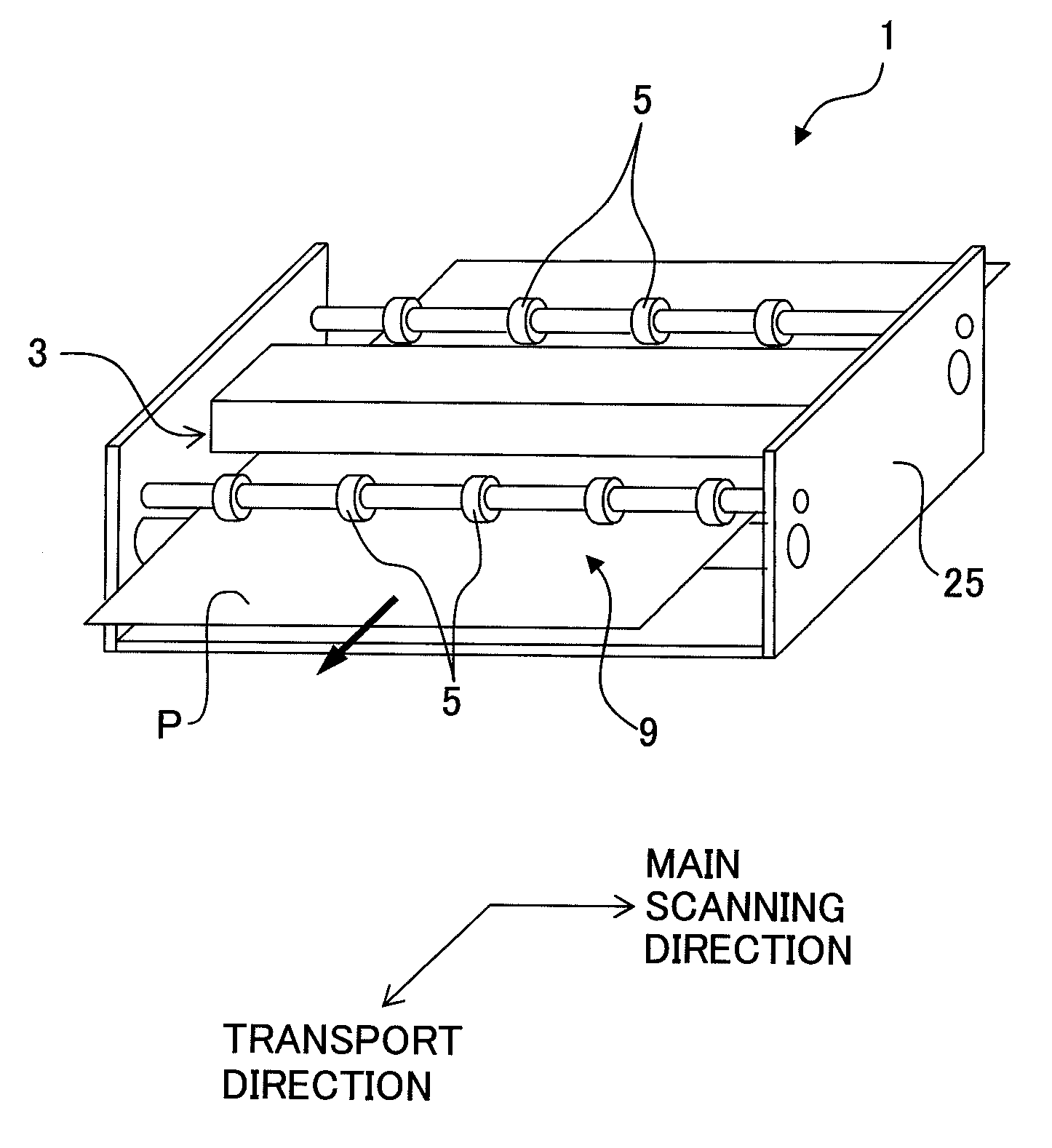

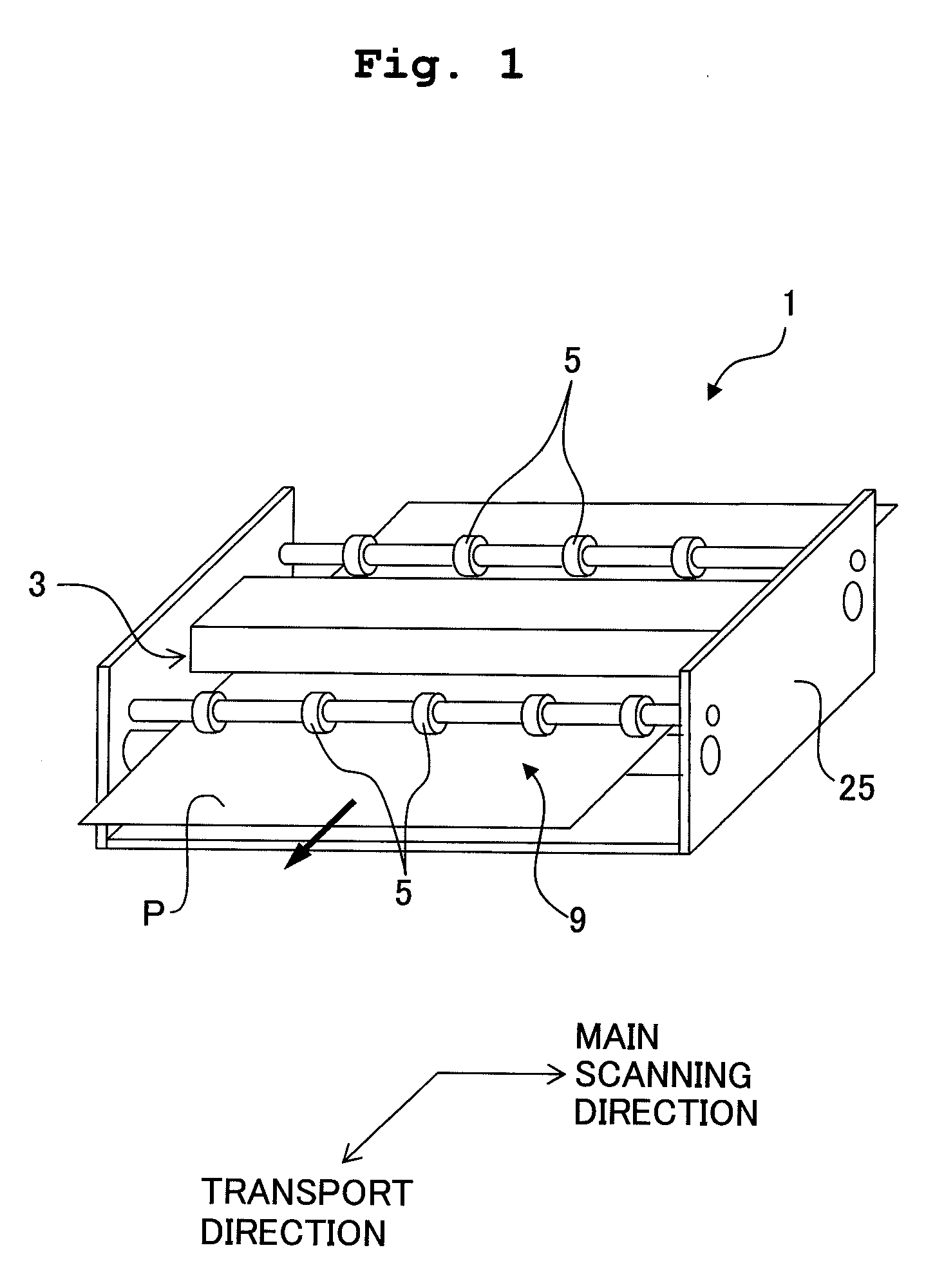

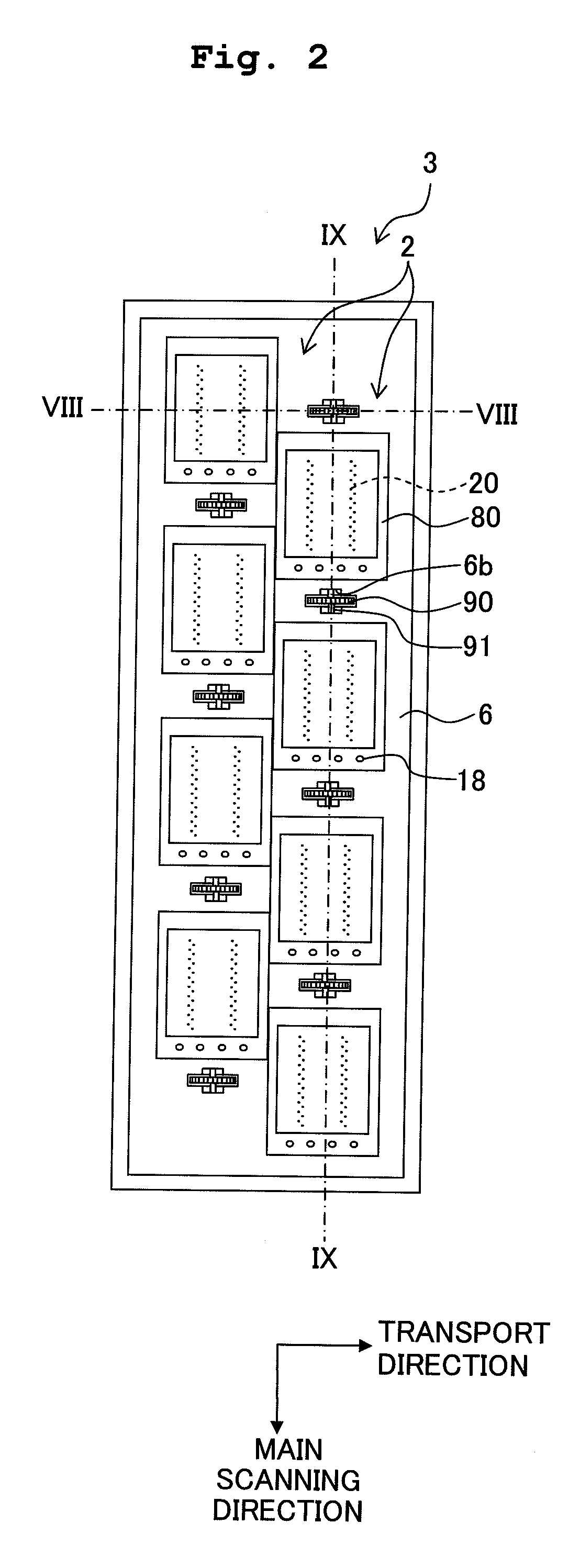

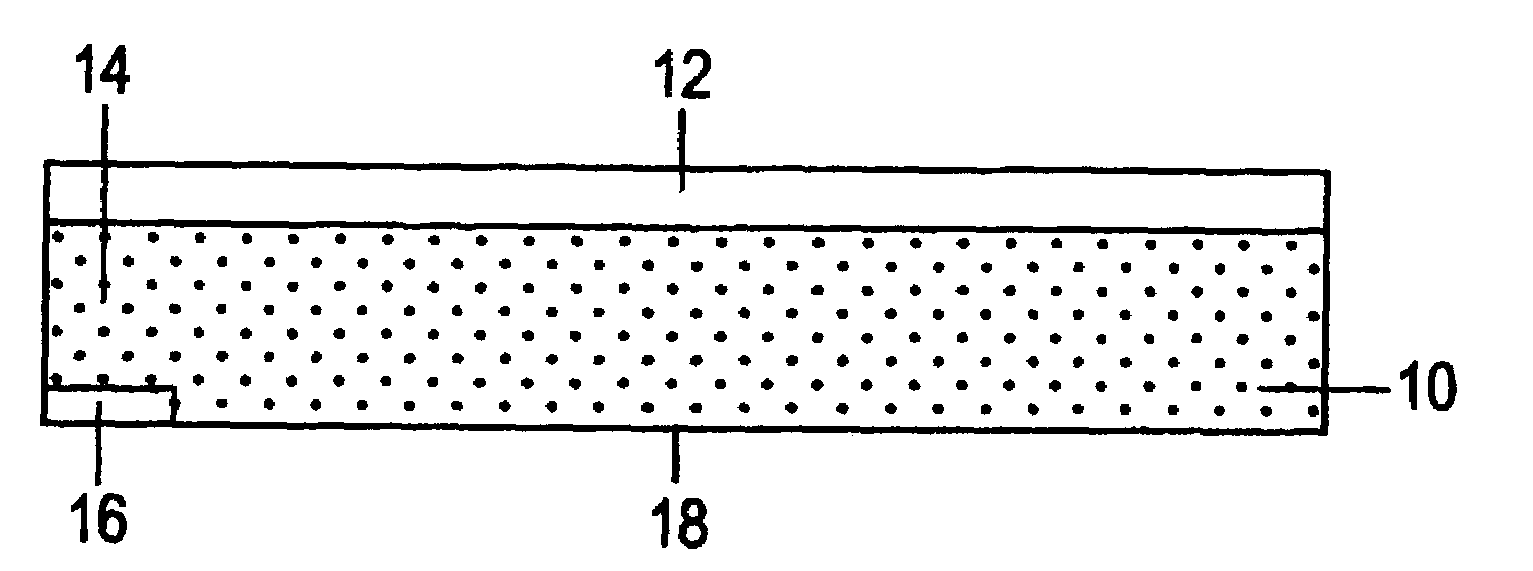

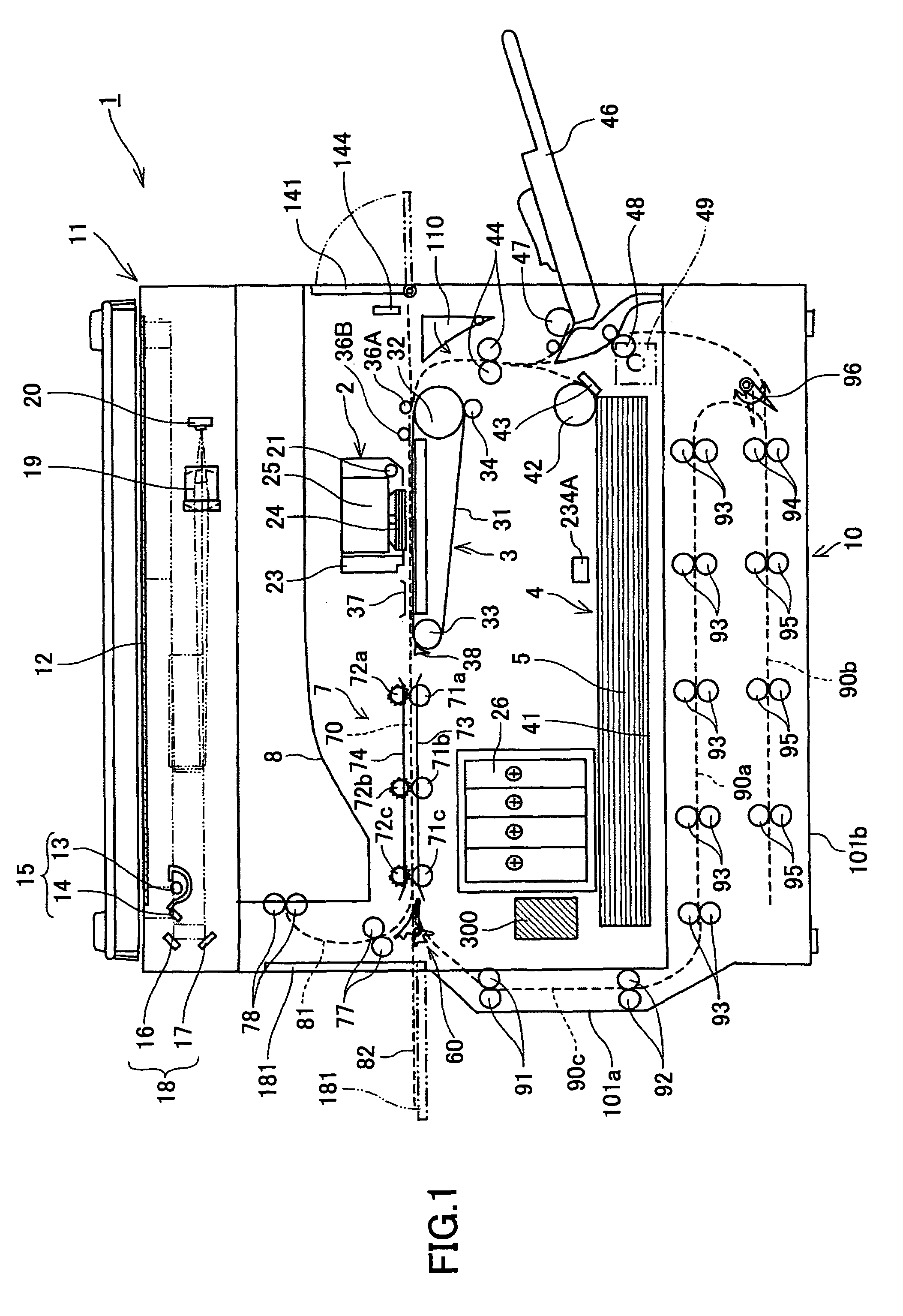

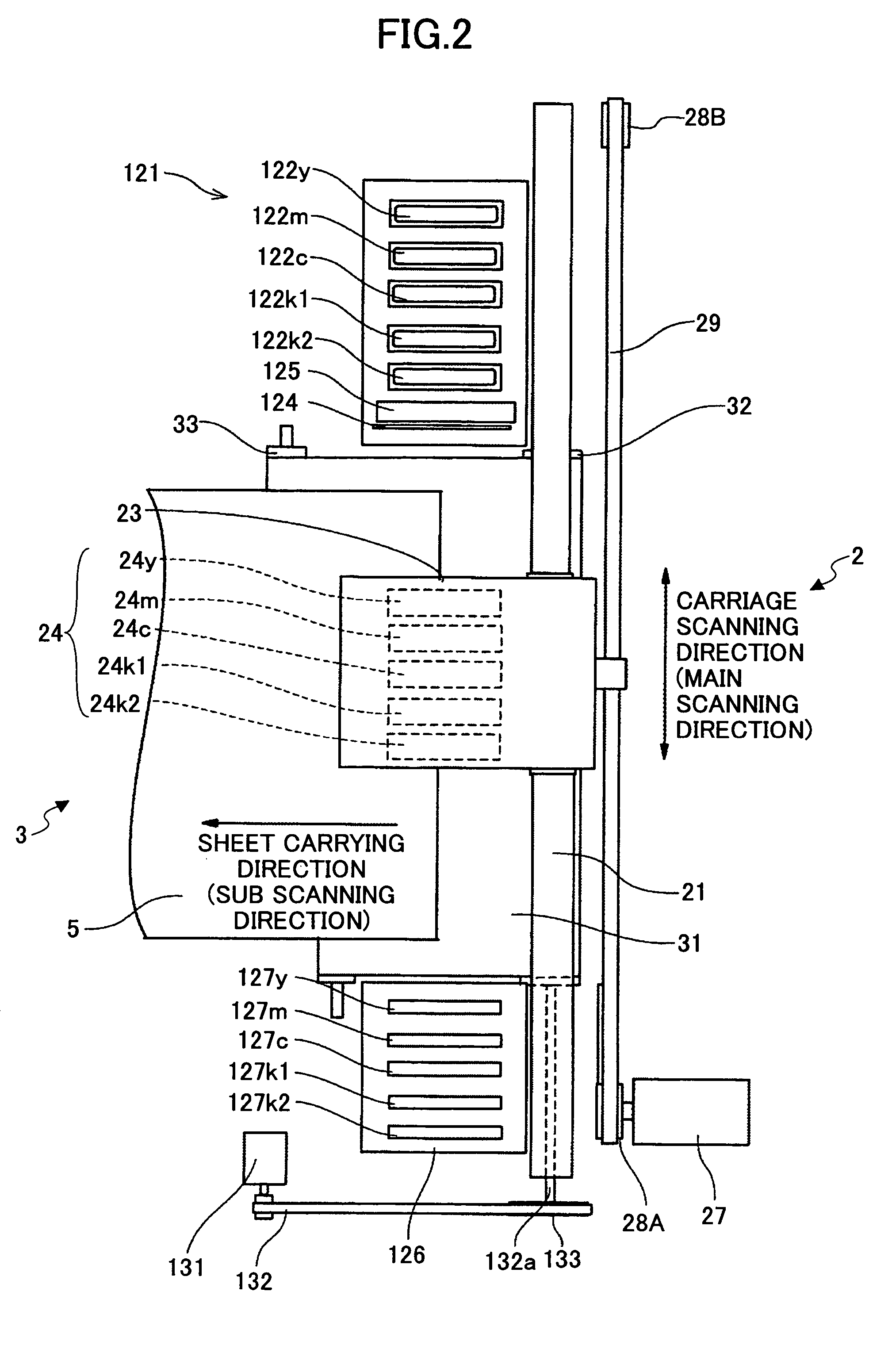

Liquid droplet jetting apparatus

ActiveUS20090244240A1Less frizzCurl suppressionInking apparatusPower drive mechanismsGear wheelEngineering

An ink-jet printer has a line ink-jet head which includes a plurality of heat units arranged in two rows in a zigzag form along a main scanning direction, and a spur which is arranged to be in line in the main scanning direction, with a first head unit belonging to one row, and to overlap a second head unit adjacent to the first head unit, which belongs to the other row, in a direction intersecting the main scanning direction. The spur presses a recording paper from a side of the head unit. Accordingly, it is possible to suppress curling of the recording paper in a direction intersecting a transport direction.

Owner:BROTHER KOGYO KK

Laminated structure and method of forming same

A method of alleviating edge curling when laminated structures comprising layers of green material having different shrinkage rates are sintered comprises applying to a face (18) of edges (14) the first layer (10) having the higher shrinkage rate green sinterable material, opposite to the second layer (12) having the lower shrinkage rate green sinterable material, an edge strip (16) of a green sinterable material also having a shrinkage rate lower than the first layer, and then firing the laminated structure. The edge strip may be partly or, advantageously, wholly embedded in the first layer. The sinterable materials of the second layer and edge strip may be the same or similar. The invention is particularly applicable to solid oxide fuel cell sub-structures in which the first layer is the anode layer and the second layer is the electrolyte layer.

Owner:CHAOZHOU THREE CIRCLE GRP

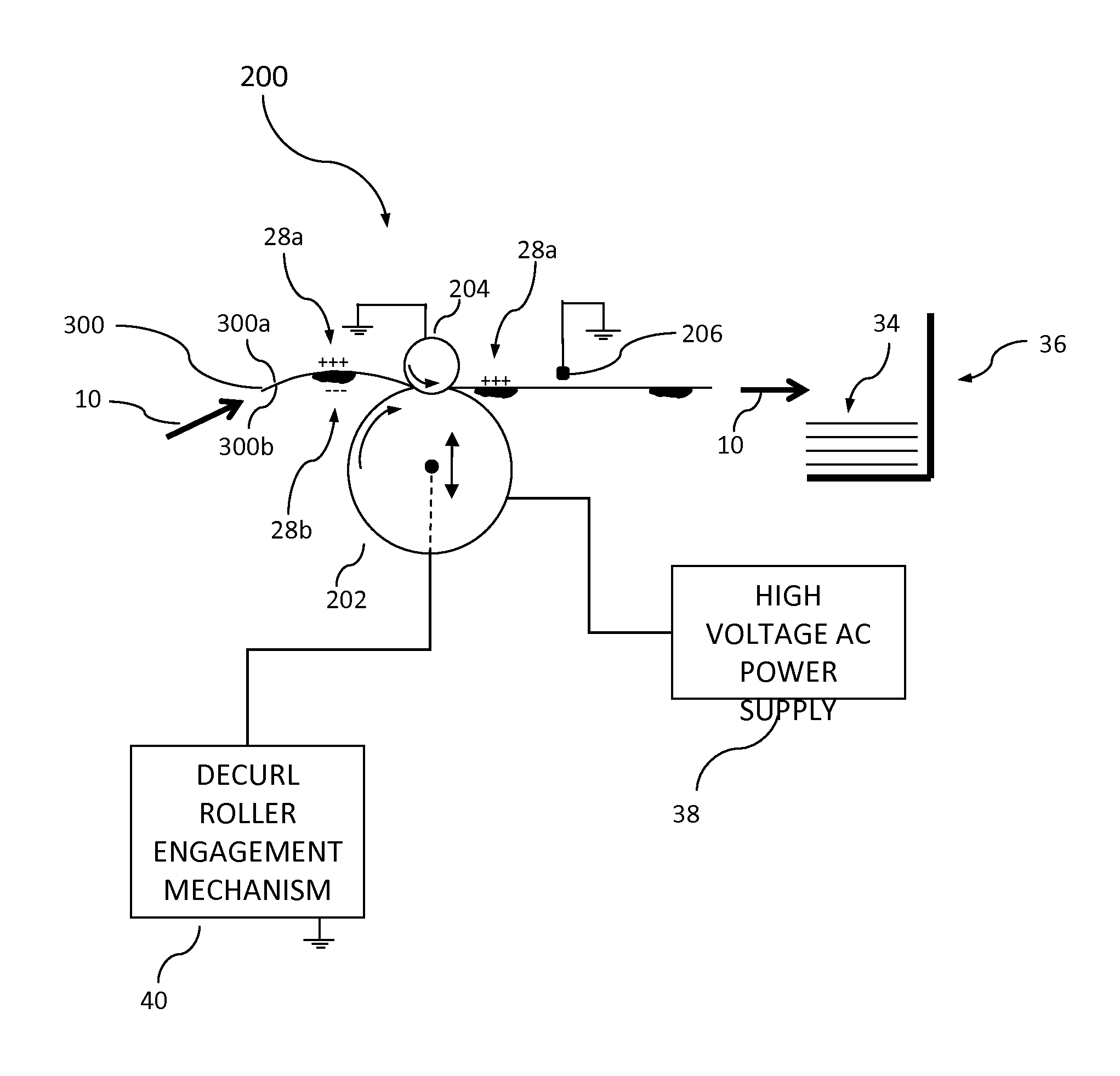

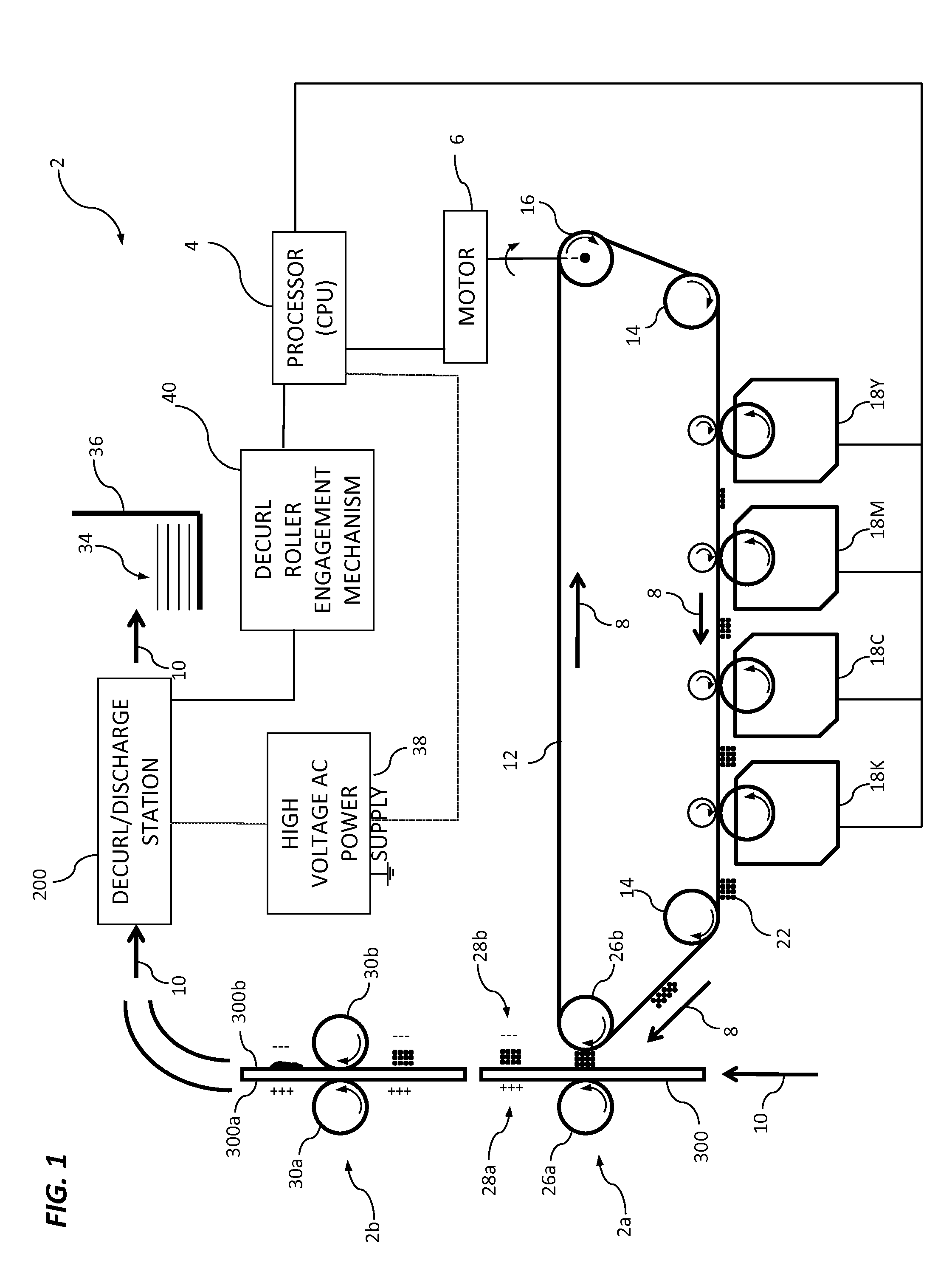

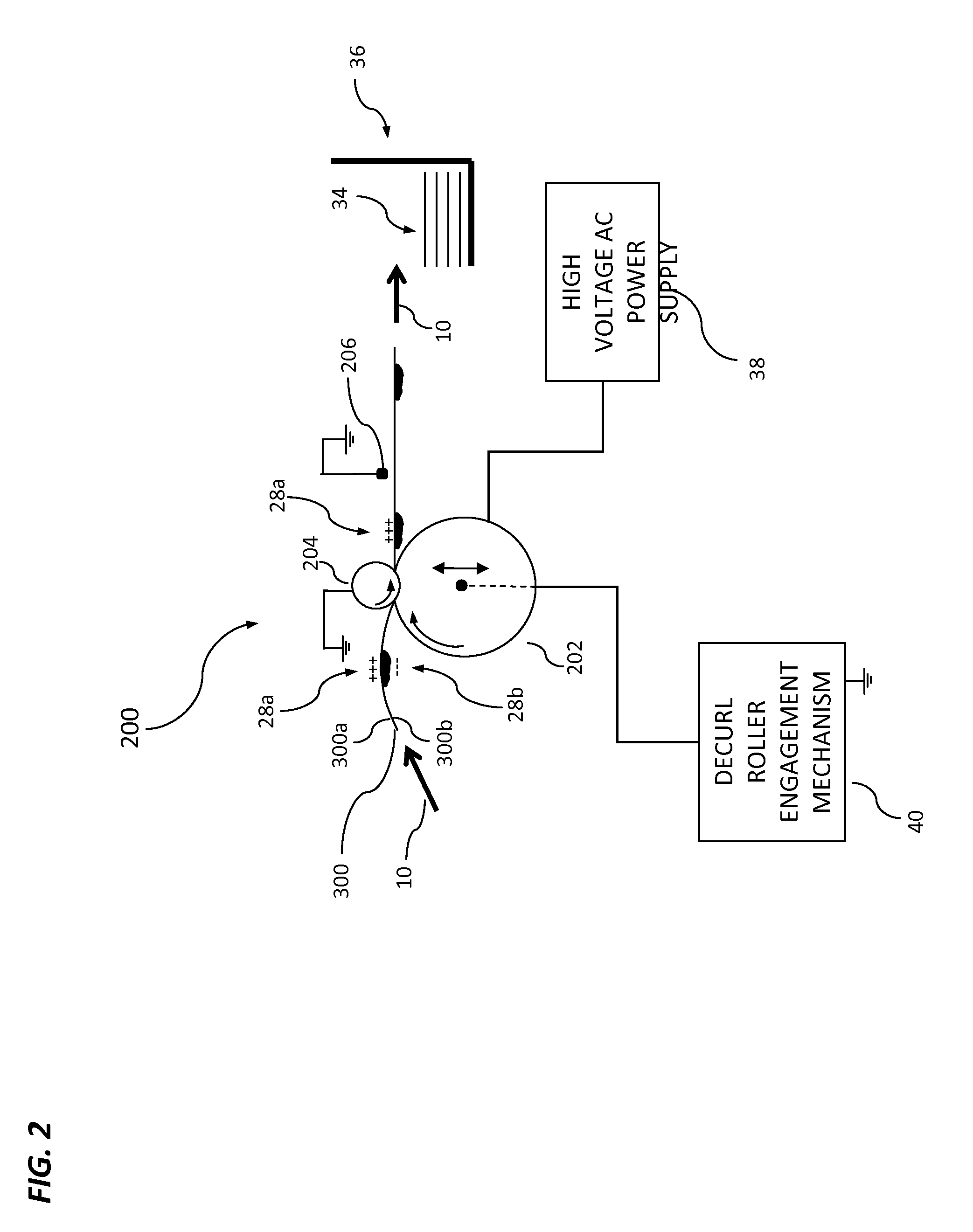

Concurrently removing sheet charge and curl

InactiveUS20120099911A1Less frizzReduce size and costElectrographic process apparatusEngineeringVoltage

Decurling a charged sheet and removing charge from the charged sheet prior to stacking, includes forming a nip between a roller and a compliant surface and applying pressure between the roller and compliant surface so that the nip has a decurling shape and when the nip engages the sheet it will perform a decurling function; and moving the charged sheet through the nip while the compliant surface has an AC voltage applied thereto so that a first side of the charged sheet is in contact with the compliant surface and has its charge substantially dissipated, whereby charge substantially remains on a second side of the charged sheet in contact with the roller and curling of the charged sheet is reduced. The method further includes using at least one non-contact charge removal device to remove charge from the second side of the charged sheet; and stacking the discharged sheet.

Owner:EASTMAN KODAK CO

Multilayer Heat Shrinkable Films

InactiveUS20170198123A1Good optical performanceImprove adhesionSynthetic resin layered productsBagsEngineeringPolymer

The present invention relates to a polymer blend and to multilayer heat shrinkable films containing at least a layer made of said polymer blend, to flexible containers made of said film, such as bags, pouches and the like, useful for packaging articles, in particular food items. The invention also relates to a process for the manufacturing of such multilayer heat shrinkable films.

Owner:CRYOVAC ILLC

Hardcoat laminate

InactiveUS20090130472A1Low transparencyHigh transparencySynthetic resin layered productsThin material handlingGlutaric anhydrideOrganic solvent

A hardcoat laminate including: a support formed from a thermoplastic resin composition; and a hardcoat layer formed from a hardcoat layer forming coating composition, wherein the thermoplastic resin composition contains a polymer having a lactone ring unit or a glutaric anhydride unit, and the hardcoat layer forming coating composition contains at least a component (a), a component (b) and a component (c) and contains substantially no organic solvent: (a) a curable compound having three or more polymerizable groups within one molecule, (b) a polymerization initiator, and (c) a diluent having from one to three polymerizable groups within one molecule.

Owner:FUJIFILM CORP

Image forming apparatus

InactiveUS7775619B2Curling of the sheet can be decreasedPrevent image degradationTypewritersOther printing apparatusImage formationEngineering

An image forming apparatus includes a transport belt rotating around rollers that transports a sheet by attaching the sheet thereto by an electrostatic force, an image forming unit which forms an image on the sheet transported by the transport belt by ejecting ink droplets from a recording head onto the sheet, and an duplex print unit which reverses the sheet, the first side of which has been printed, so as to form an image on the second side of the sheet. The apparatus stops the transportation of the sheet to the image forming unit after the image is formed on the first side of the sheet and before the image is formed on the second side of the sheet until at least the tip of the second side of the sheet is not apart from the transport belt.

Owner:RICOH KK

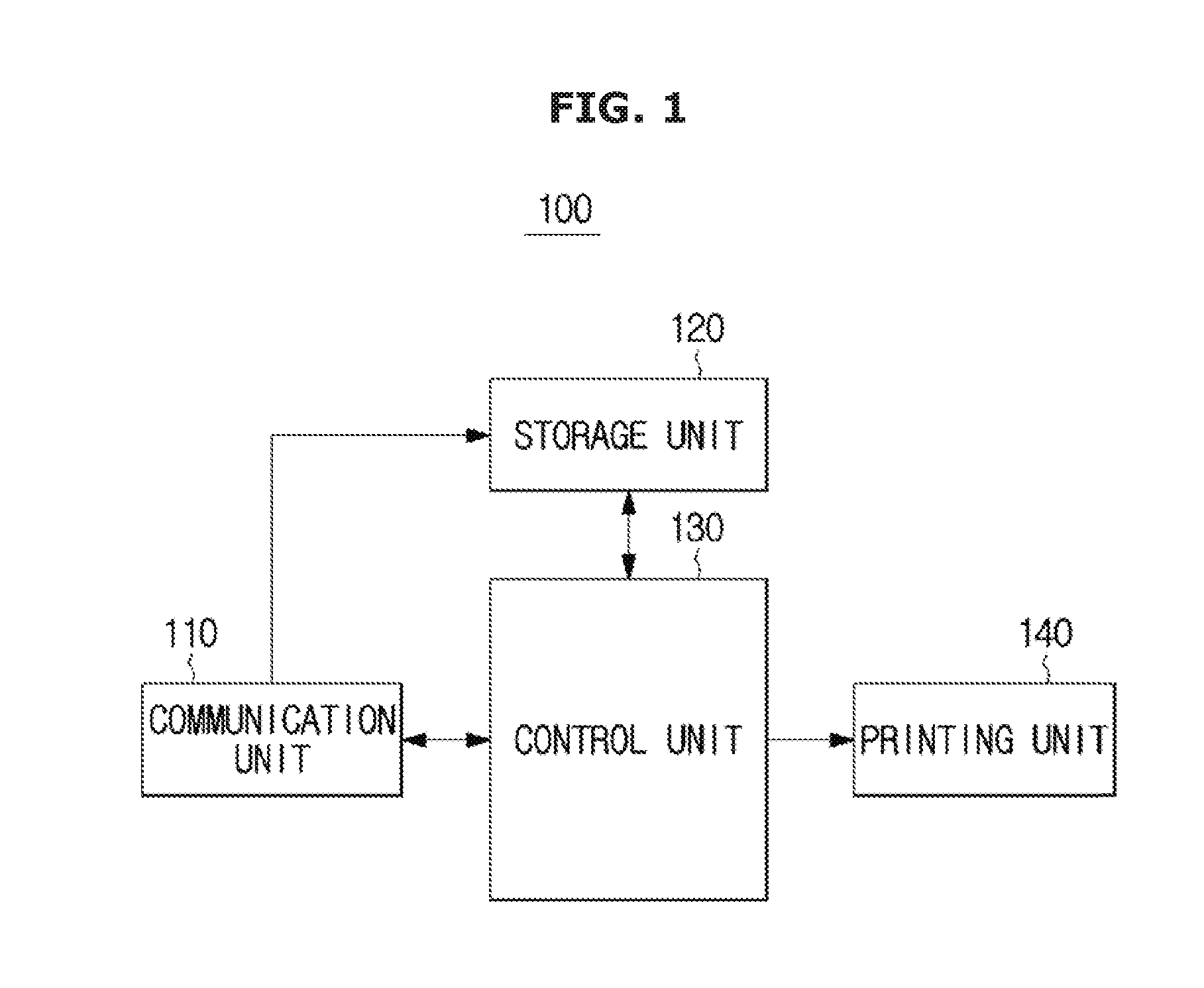

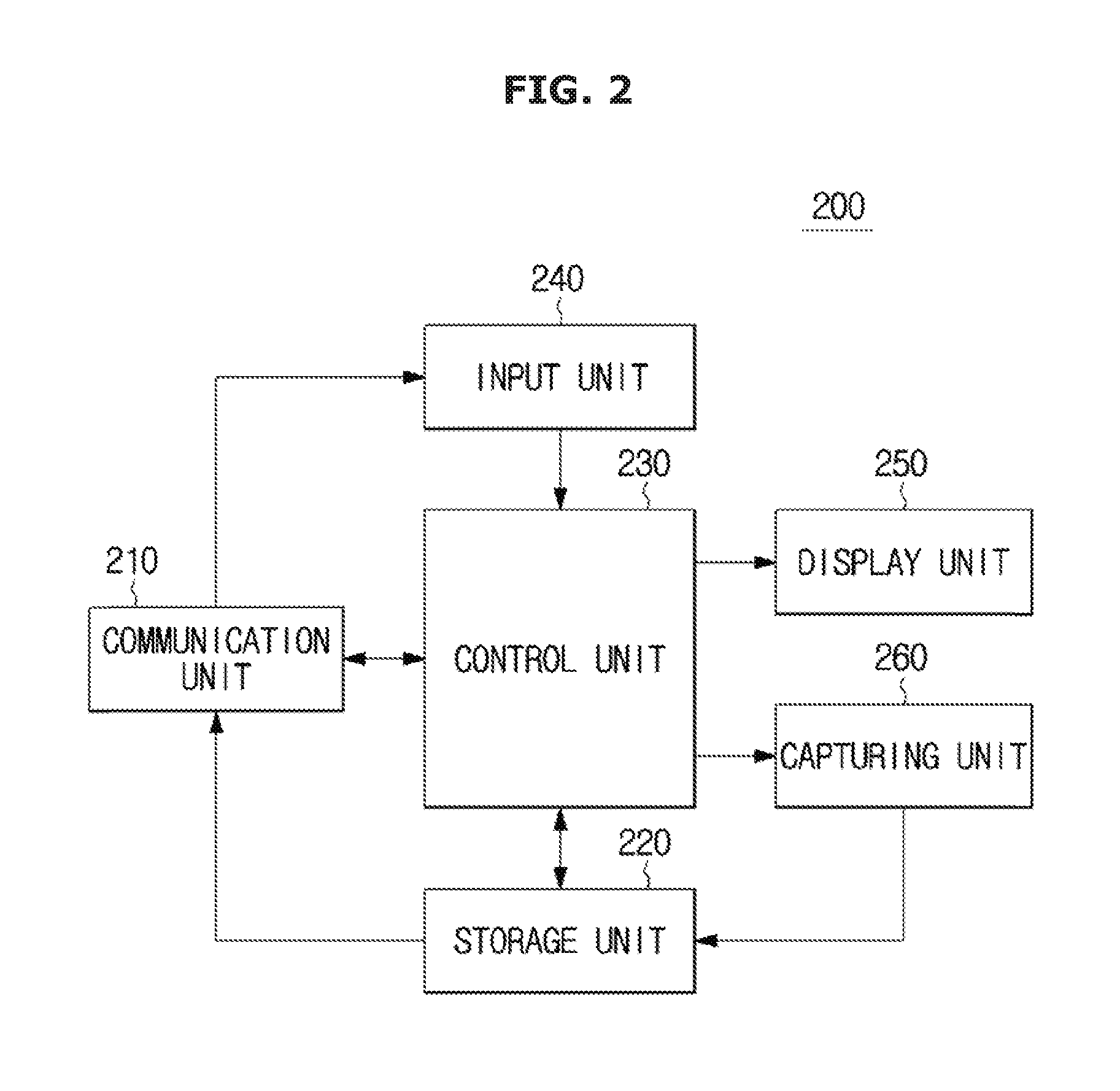

Image forming apparatus, recording medium, terminal, server, note printing method, and storage medium

ActiveUS20160221363A1Easily printImprove qualityTypewritersOther printing apparatusControl unitRecording media

A terminal receives contents to be written on a note by a user, a server stores and manages print data generated by a plurality of users and outputs the print data to an image forming apparatus which outputs the print data in the form of an adhesive note. The image forming apparatus includes a de-curl unit for correcting the curl of a recording medium and causes the recording medium on which printing is performed to be popped out through an outlet. The server communicates with a plurality of terminals and includes a control unit which generates a virtual conference space by assigning a storage address to the virtual conference space when a request of generating a virtual conference space and identification information on an image forming apparatus to be used in the virtual conference space from among the plurality of terminals is received.

Owner:HEWLETT PACKARD DEV CO LP

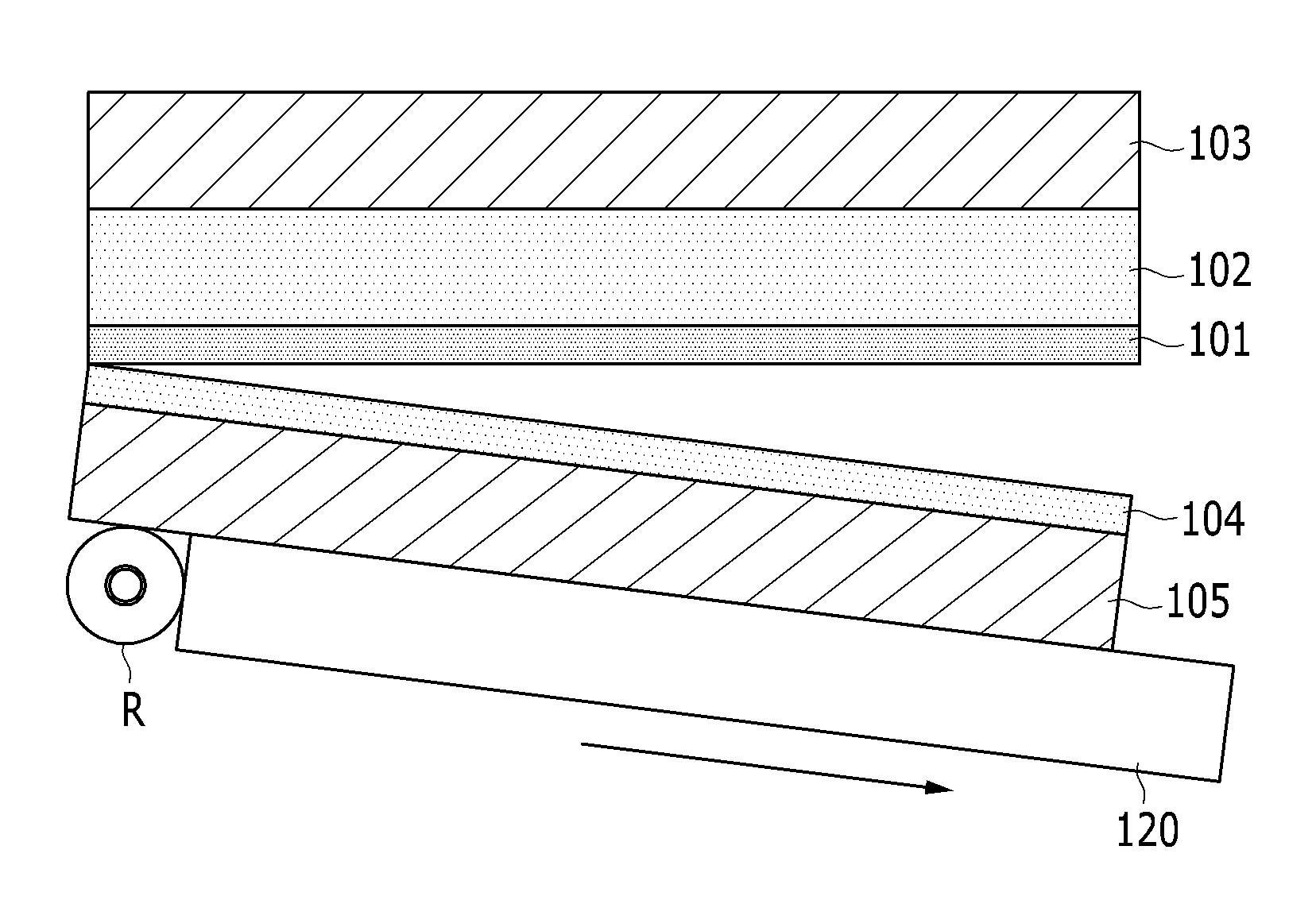

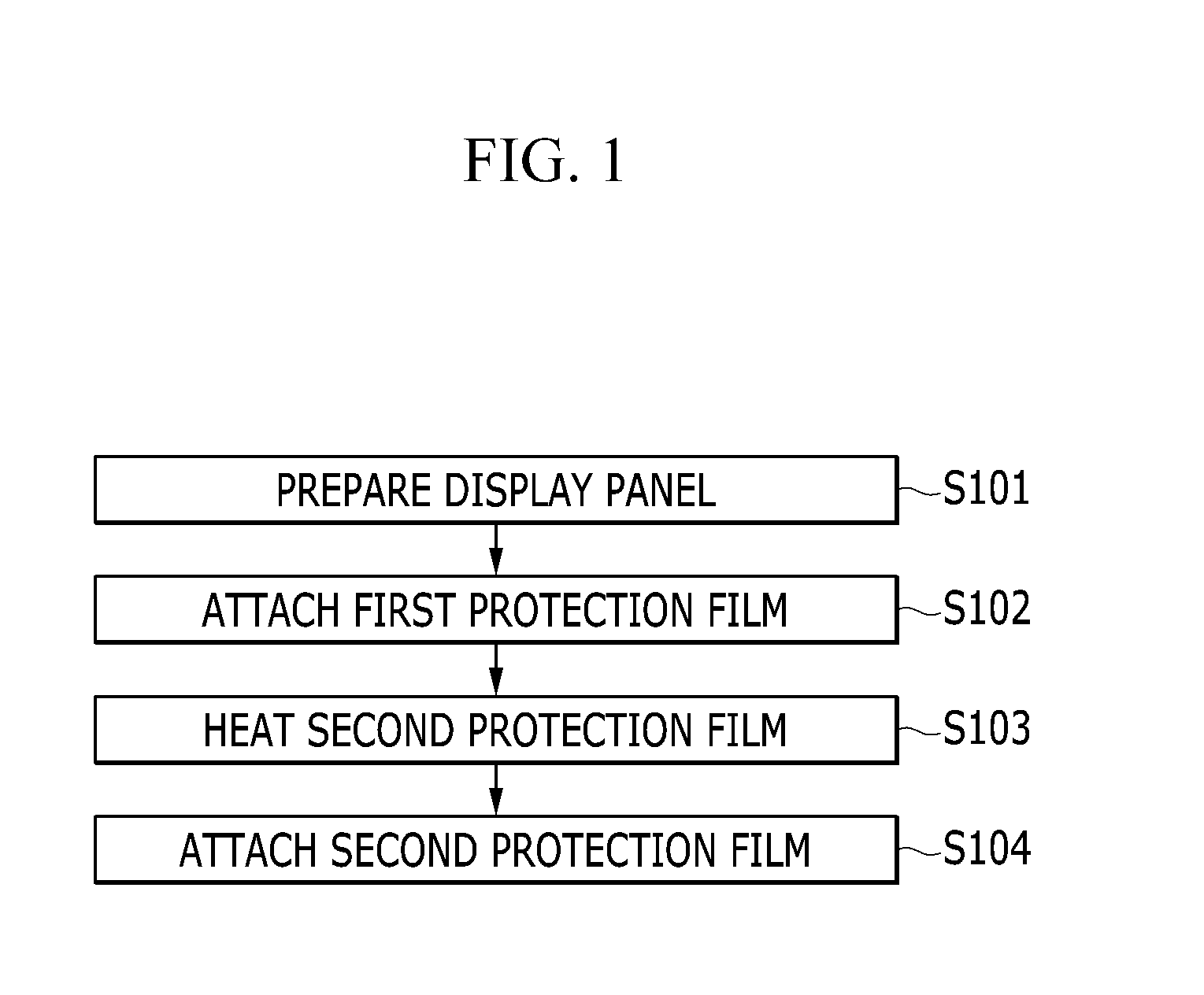

Method of manufacturing an organic light emitting display device

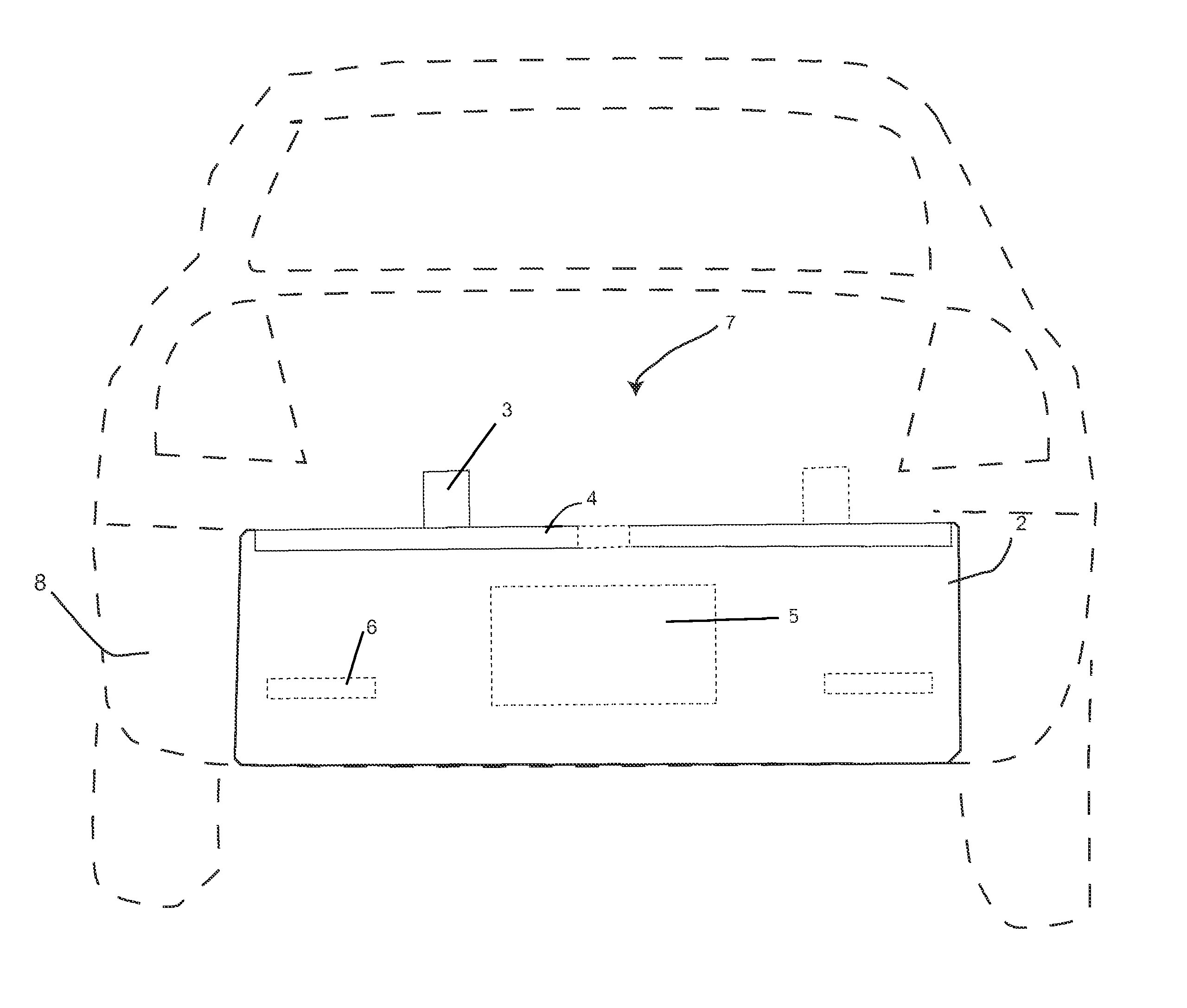

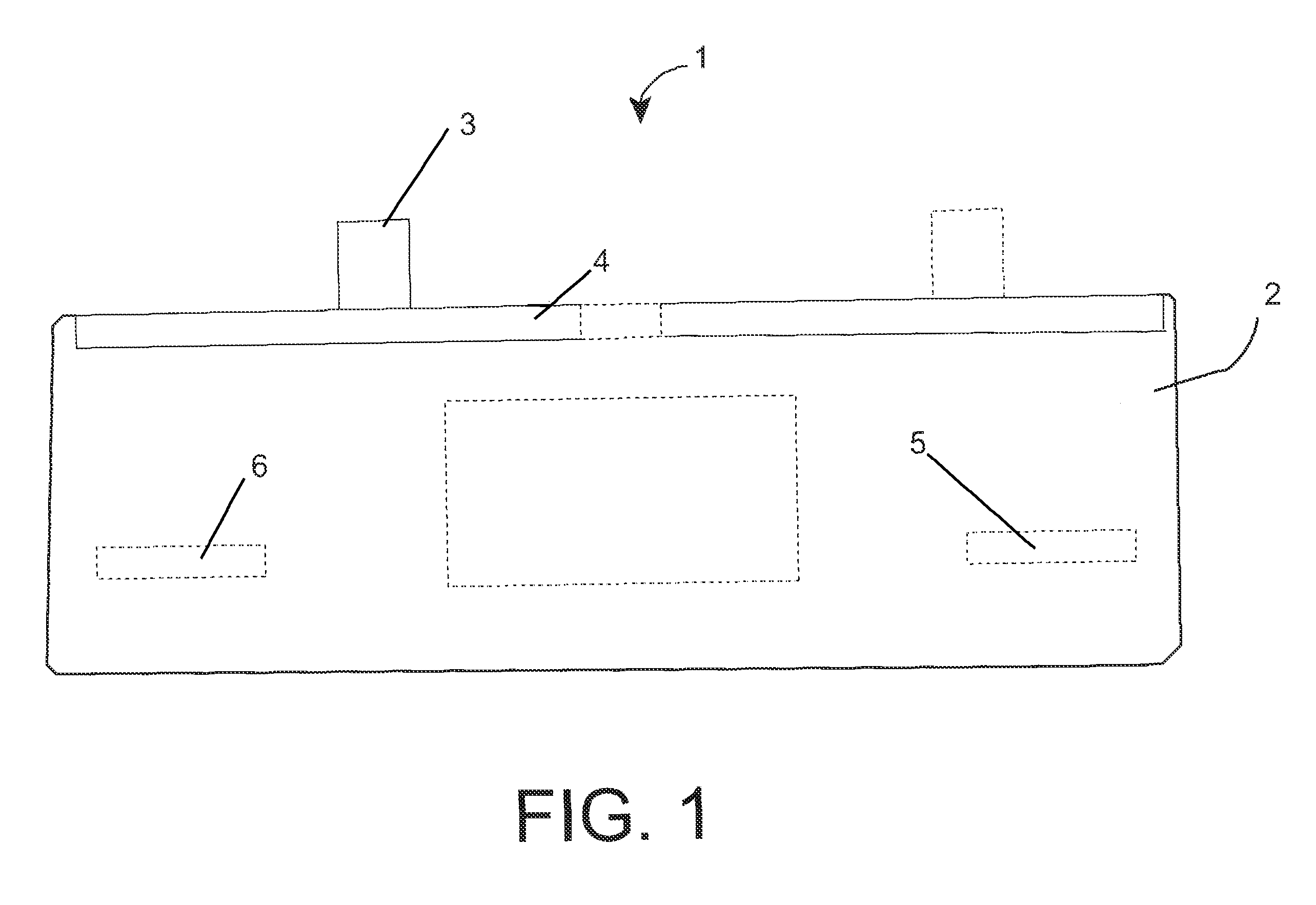

ActiveUS20150079707A1Avoid curlLess frizzElectroluminescent light sourcesSolid-state devicesTectorial membraneAdhesive

A manufacturing method of an organic light emitting diode (OLED) display is disclosed. The manufacturing method in accordance with an exemplary embodiment includes: preparing a flexible substrate and a display panel including a thin film encapsulation (TFE) layer for covering and protecting an OLED formed on the flexible substrate; attaching a first protection film to the TFE layer by using a first adhesive to be opposite to the TFE layer; heating a second protection film; and pressing and attaching a second protection film onto the flexible substrate by using a second adhesive.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com