Coated abrasive articles

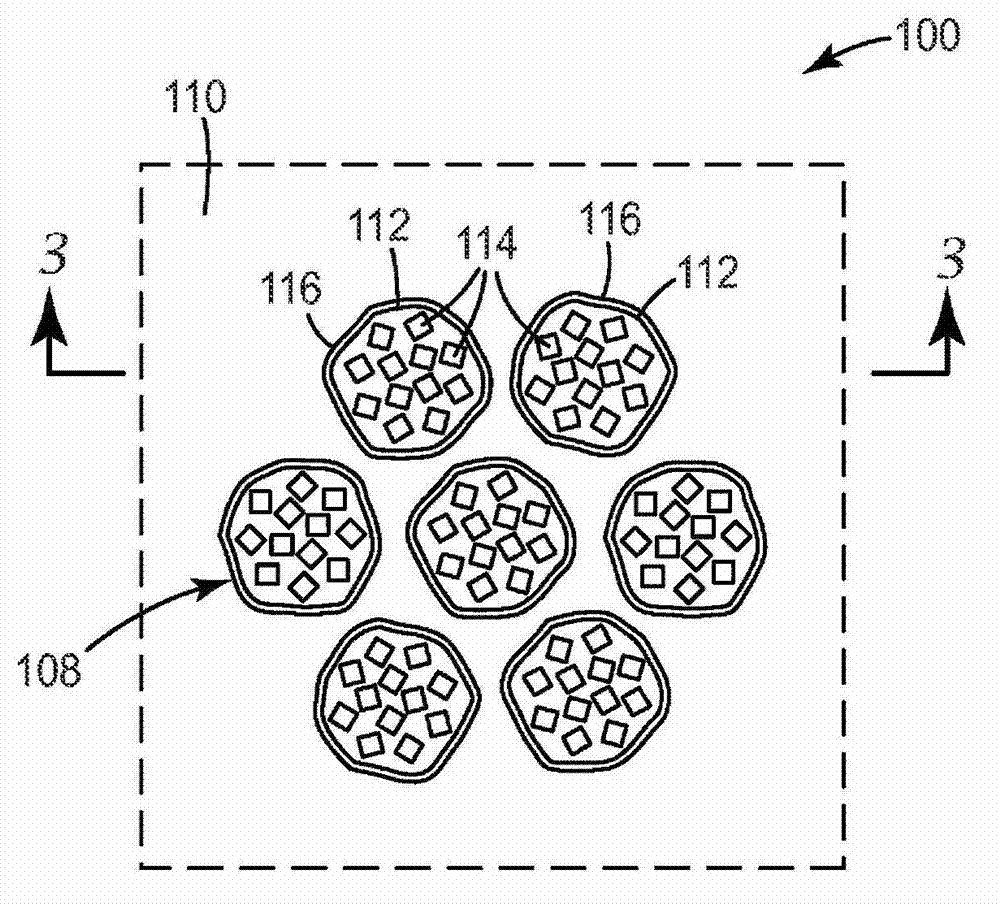

An abrasive product and coating technology, applied in abrasives, grinding devices, manufacturing tools, etc., to reduce the amount of raw materials and enhance flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0148] The stencil was taped to the screen frame of a screen printing machine (model "AT-1200H / E", obtained from ATMA Champ Ent. Corp., Taipei, Taiwan) middle. A 12 inch by 20 inch (30.48 by 50.8 cm) piece of CWT paper was taped to the press backing plate and the plate was secured in registration in the screen printer. Approximately 75 grams of phenolic primer was applied to the stencil at 70°F (21.1°C) using a urethane squeegee, and the stencil was printed onto a paper backing. The backing board and coated paper assembly was immediately removed from the screen printing machine. Mineral GC-80 was electrostatically applied to the phenolic primer resin using a powder coater (model "EASY01-F / 02-F" from ITW Gema, St. Gallen, Switzerland), and cured in an oven at 230°F (110°C) for 30 minutes. Meanwhile, clean the stencil with ethanol-soaked paper towels. The backing board and coated paper assembly was removed from the oven and allowed to cool. Excess minerals are removed by li...

example 2

[0150] The general procedure as described in Example 1 was repeated with the GC-80 abrasive mineral replaced by F150X.

example 3

[0152] The stencil was taped into the frame of a mini screen printer (APR Novastar, LLC, Huntington Valley, Pennsylvania). A 12 inch by 20 inch (30.48 by 50.8 cm) piece of CWT paper was taped to a metal plate set on the press backing plate and the plate was secured in registration within the screen printer. Approximately 35 grams of an acrylic primer was applied to the stencil at 70°F (21.1°C) using a urethane squeegee, and the stencil was printed onto a paper backing. The backing board and coated paper assembly was immediately removed from the screen printing machine. Mineral GC-80 was electrostatically applied to the acrylate primer resin using a powder coater and passed through a UV treater (available from American Ultraviolet Company, Murray Hill, New Jersey) in two passes. Jersey) was cured using a series of two D-type bulbs operating at 400 W / inch (157.5 W / cm) and a web speed of 40 ft / min (12.19 m / min)) and allowed to cool. Meanwhile, clean the stencil with ethanol-soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com