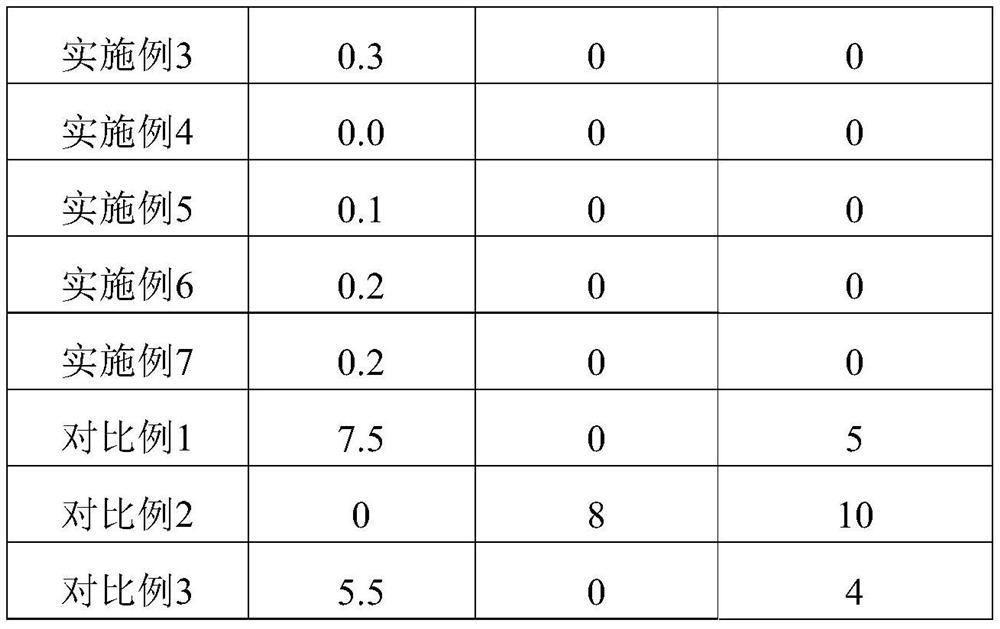

Patents

Literature

41results about How to "Excellent curl resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

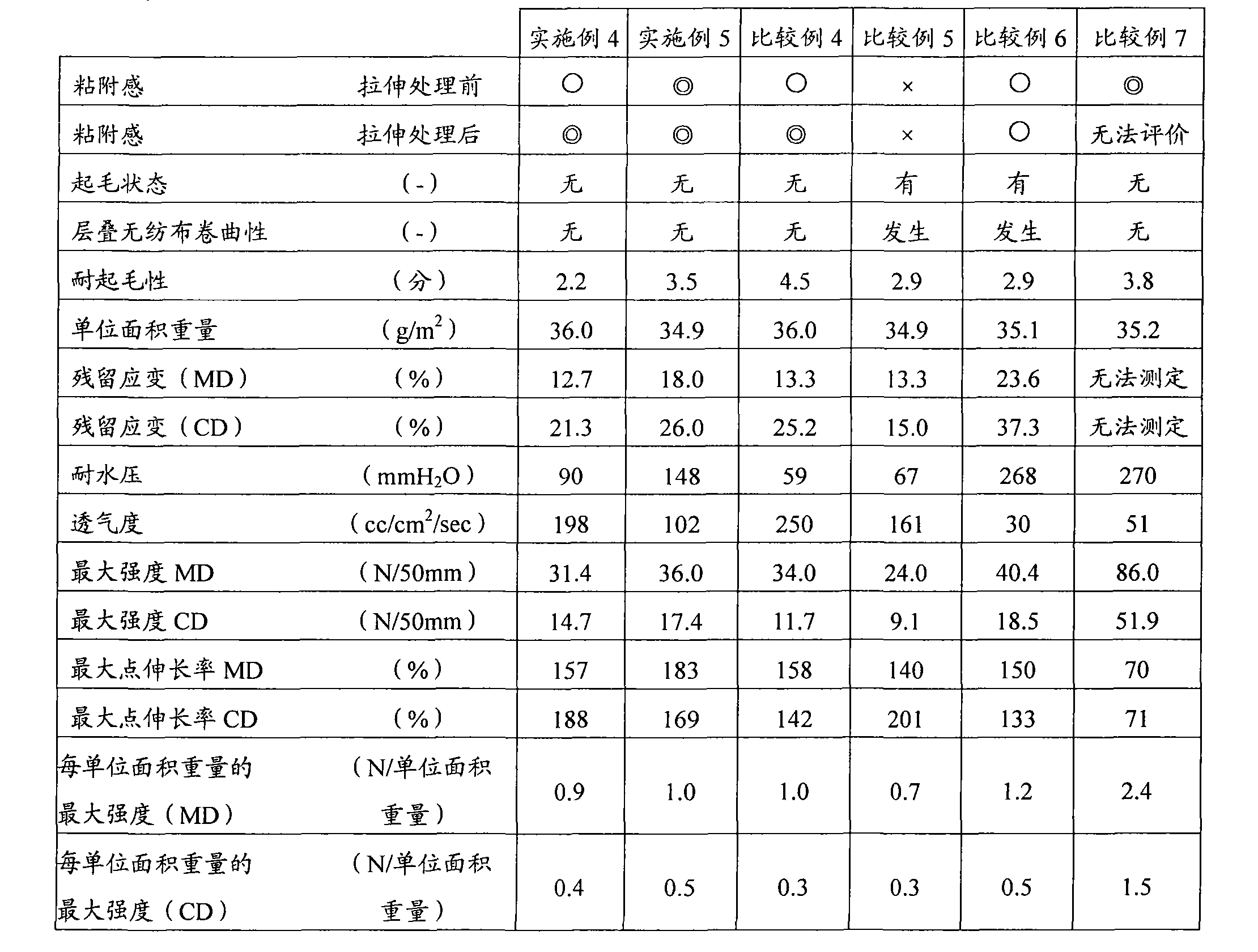

Foam core imaging element with gradient density core

InactiveUS7585557B2Increase stiffnessImprove smoothnessNatural cellulose pulp/paperDecorative surface effectsFoaming agentVolumetric Mass Density

The invention relates to a base comprising a closed cell foam core sheet having a closed cell foam layer with a density gradient between the center of the core and the surfaces of the core. The invention also relates to a method of making such a base by adding a first concentration of a first blowing agent to a first polymer to form a first mixture, adding a second concentration of a second blowing agent to a second polymer to form a second mixture, and extruding the mixtures to form the closed cell foam core sheet. The invention also relates to a method of making such a closed cell foam core sheet base comprising the steps of adding a blowing agent to a polymer to form a mixture, melting the mixture, extruding the mixture from a die, and rapidly quenching the mixture against a high heat transfer surface.

Owner:EASTMAN KODAK CO

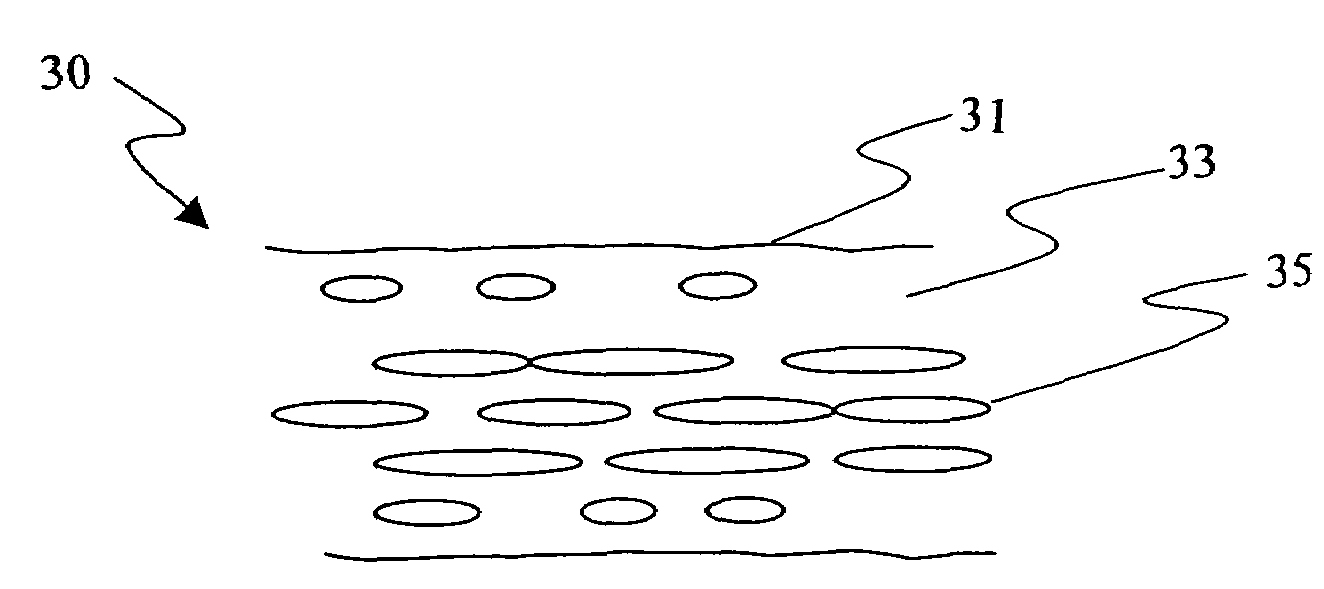

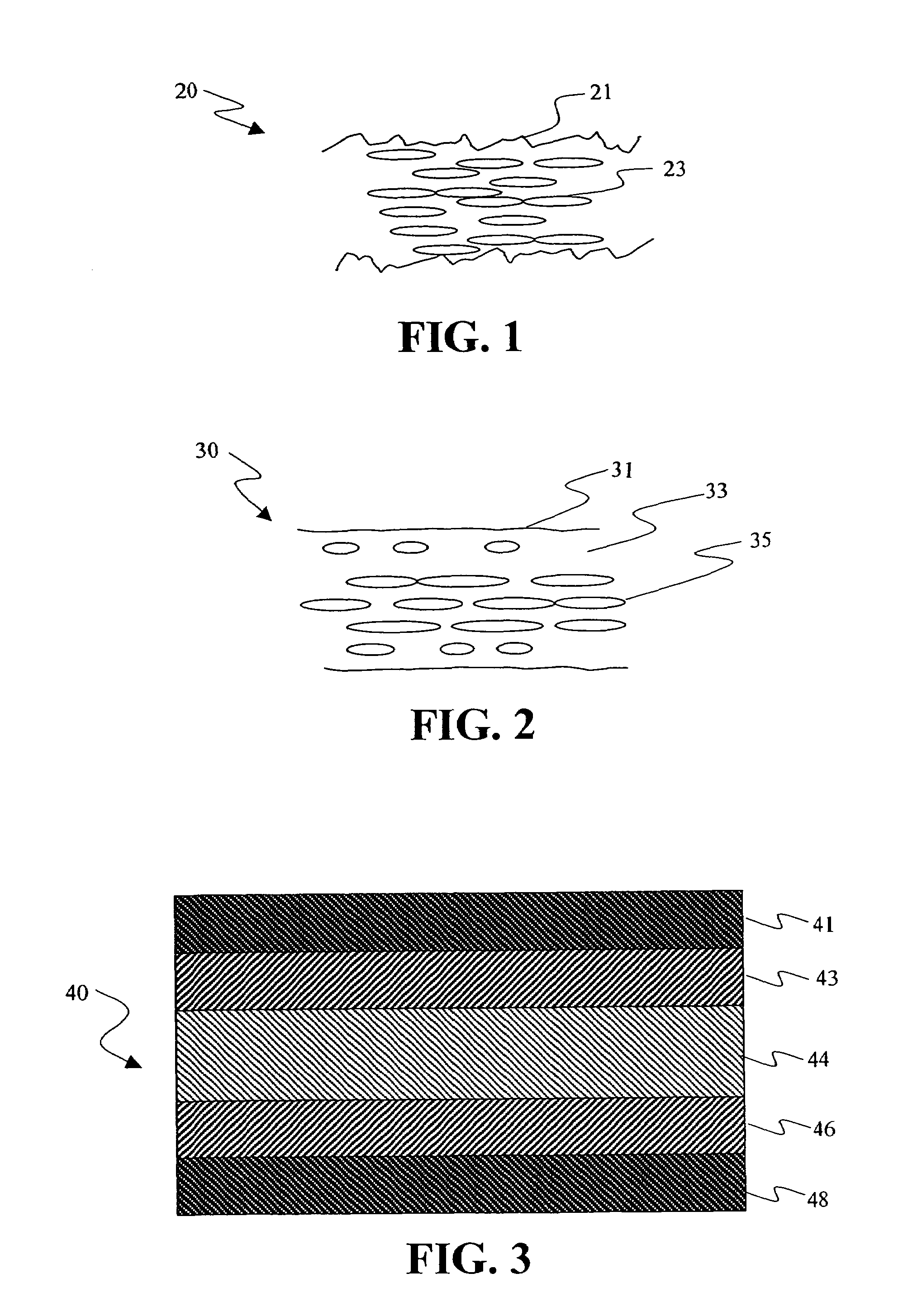

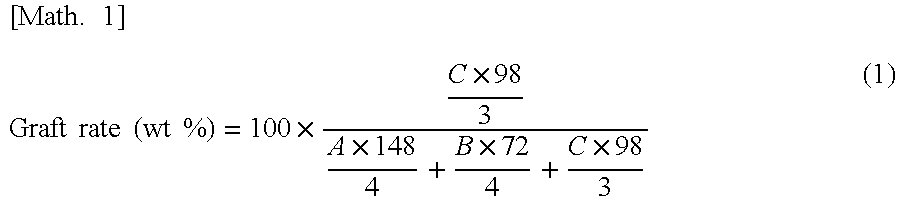

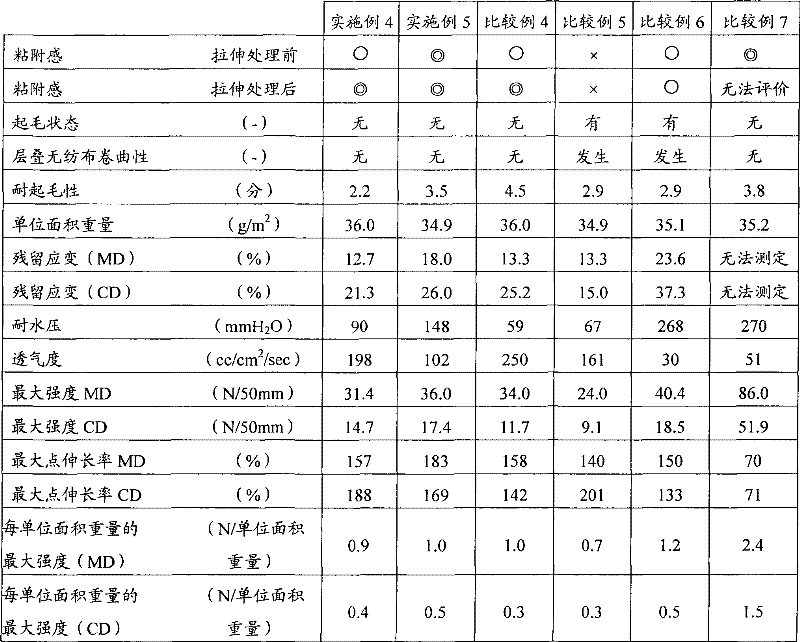

Non-woven fabric laminate and method for production thereof

ActiveCN101432478AImprove flexibilityGood flexibilityLayered productsNon-woven fabricsFiberThermoplastic elastomer

Disclosed is a non-woven fabric laminate which is excellent in shrink properties, flexibility, water-resistance, anti-fuzz properties and anti-curl properties and shows less stickiness. The non-woven fabric laminate comprises at least one meltblown non-woven fabric layer and a mixed spunbonded non-woven fabric layer laminated on the both sides of the meltblown non-woven fabric layer, wherein the mixed spunbonded non-woven fabric layer comprises a long fiber compose of a thermoplastic elastomer (A) and a long fiber composed of a thermoplastic resin (B) which is different from the thermoplastic elastomer (A) at a ratio of [10-90 wt%]:[90-10 wt%] (provided that the sum total of the components (A) and (B) is 100% by weight).

Owner:MITSUI CHEM INC

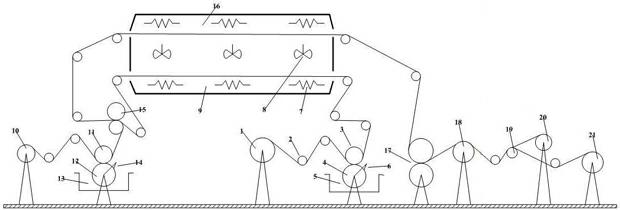

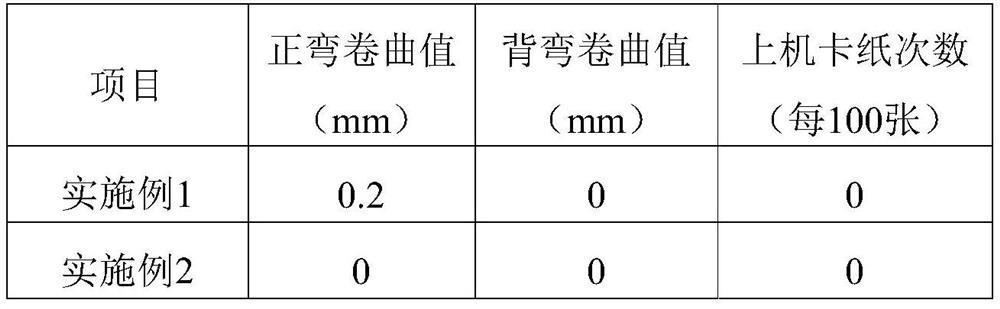

High-lustre mirror transferring coated paper as well as production technology and production equipment thereof

ActiveCN102154933AExcellent curl resistanceGuaranteed smoothnessPaper coatingCoatingsEnvironmental resistancePulp and paper industry

The invention discloses a high-lustre mirror transferring coated paper as well as a production technology and production equipment thereof. The high-lustre mirror transferring coated paper comprises a paper layer, a paper glaze coating and a paper back coating, wherein the thickness of the paper layer is 80-350mu m, the paper glaze coating is a styrene-acrylate resin painting layer with the thickness of 0.5-2mu m, and the paper back coating is the styrene-acrylate resin painting layer with the thickness of 0.5-2mu m. The invention also discloses a production technology and production equipment thereof of the transferring coated paper. Body paper is dried after being subjected to back coating processing to obtain base paper; a coated film and the base paper simultaneously enter composite equipment to obtain composite paper; then the composite paper is dried, cooled, rolled and stripped to obtain a basic film and transfer paper; and finally, the base film and the transfer paper are respectively rolled. The coated paper disclosed by the invention has the characteristics of high-lustre mirror, high smoothness, high anti-curling performance and the like and is environmentally friendly, good printing effect can be brought, the paper back coating is processed to eliminate the phenomenon that the back fluffs, and better anti-curling performance is provided for the paper.

Owner:云南伦恩纸业有限公司

Polymer foam surface smoothing materials and method

InactiveUS20050191569A1Superior imaging supportImprove surface smoothnessDiffusion transfer processesDuplicating/marking methodsPolymeric surfaceSolution polymerization

The present invention relates to an imaging element comprising at least one imaging layer and a base. The base comprises a foam core layer, which comprises a polymer that has been expanded through the use of a blowing agent, and at least one polymeric surface smoothing layer, which comprises a solution polymer.

Owner:EASTMAN KODAK CO

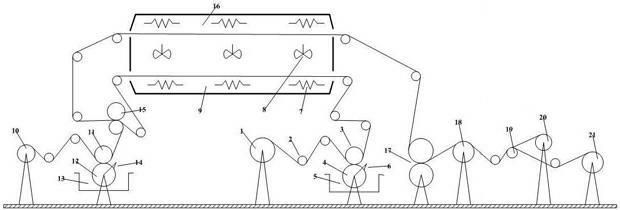

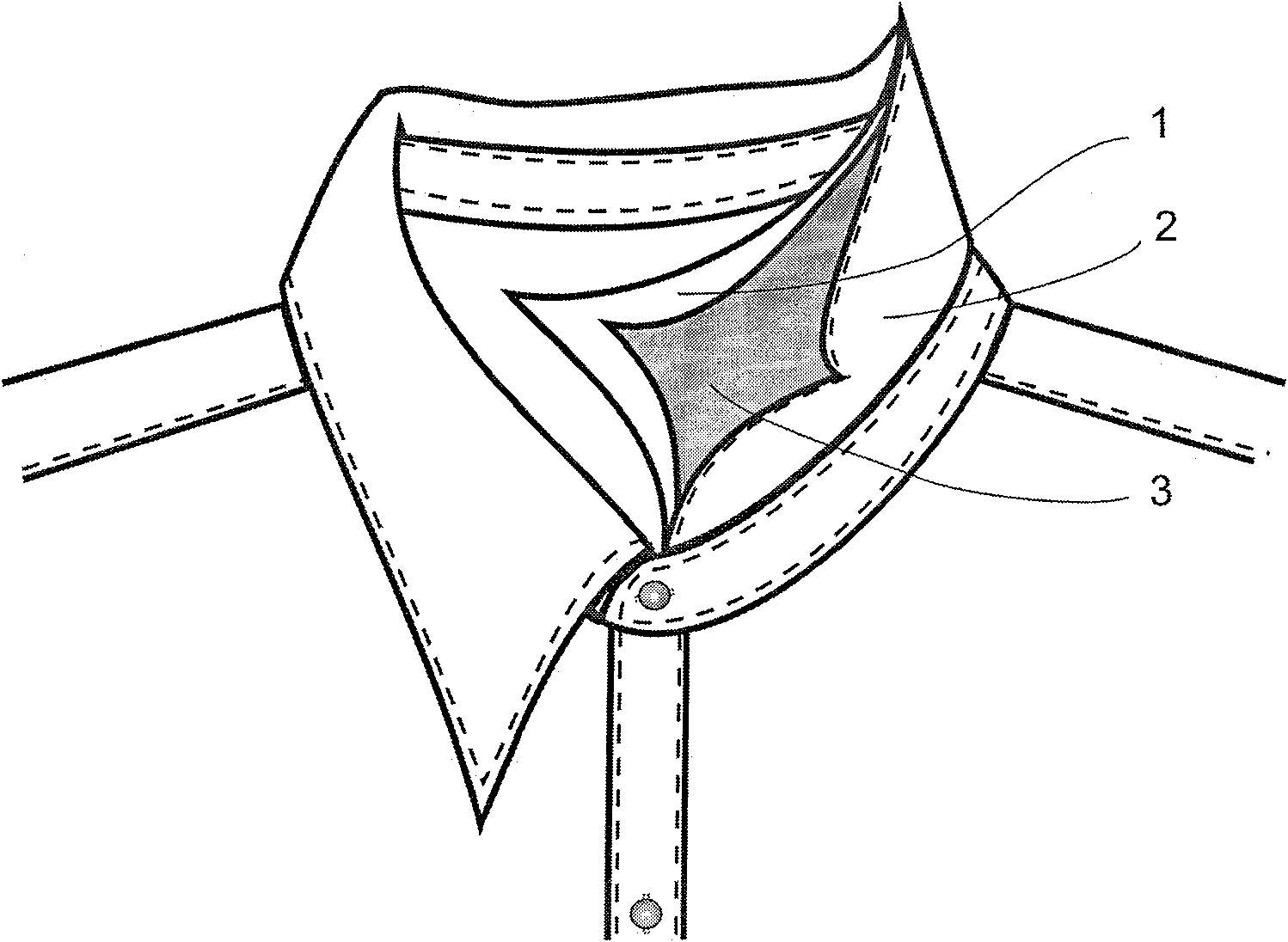

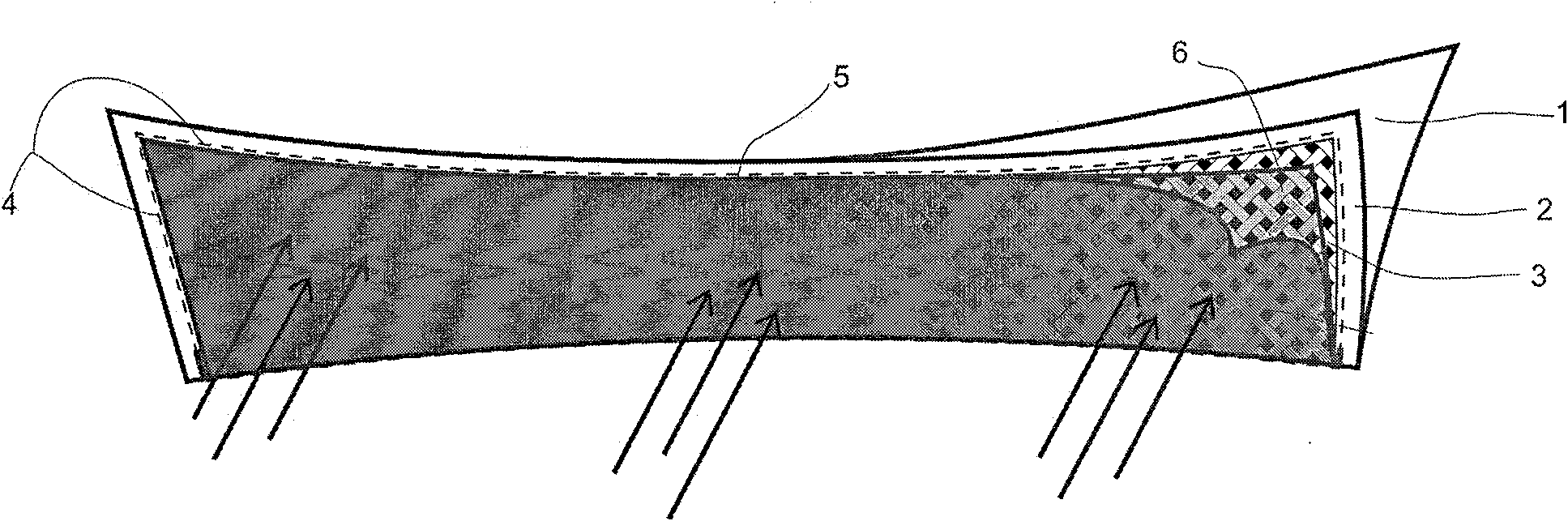

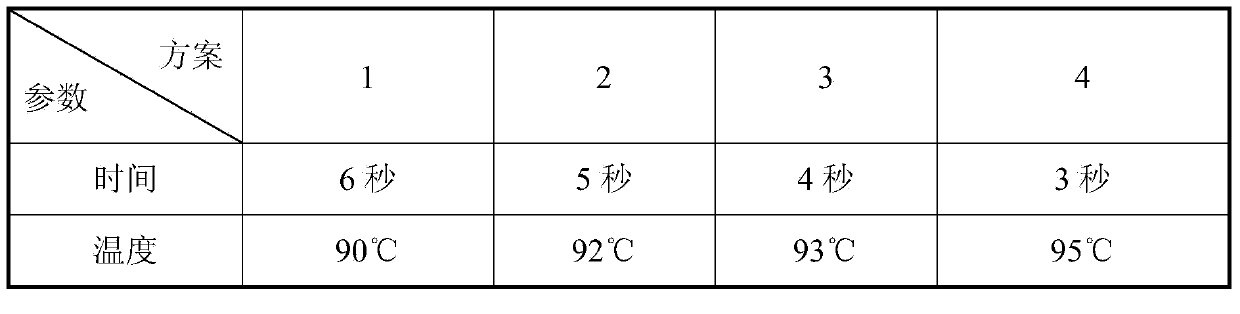

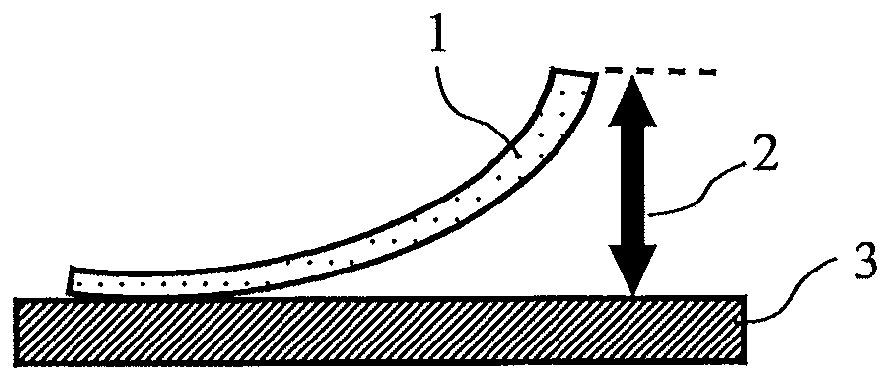

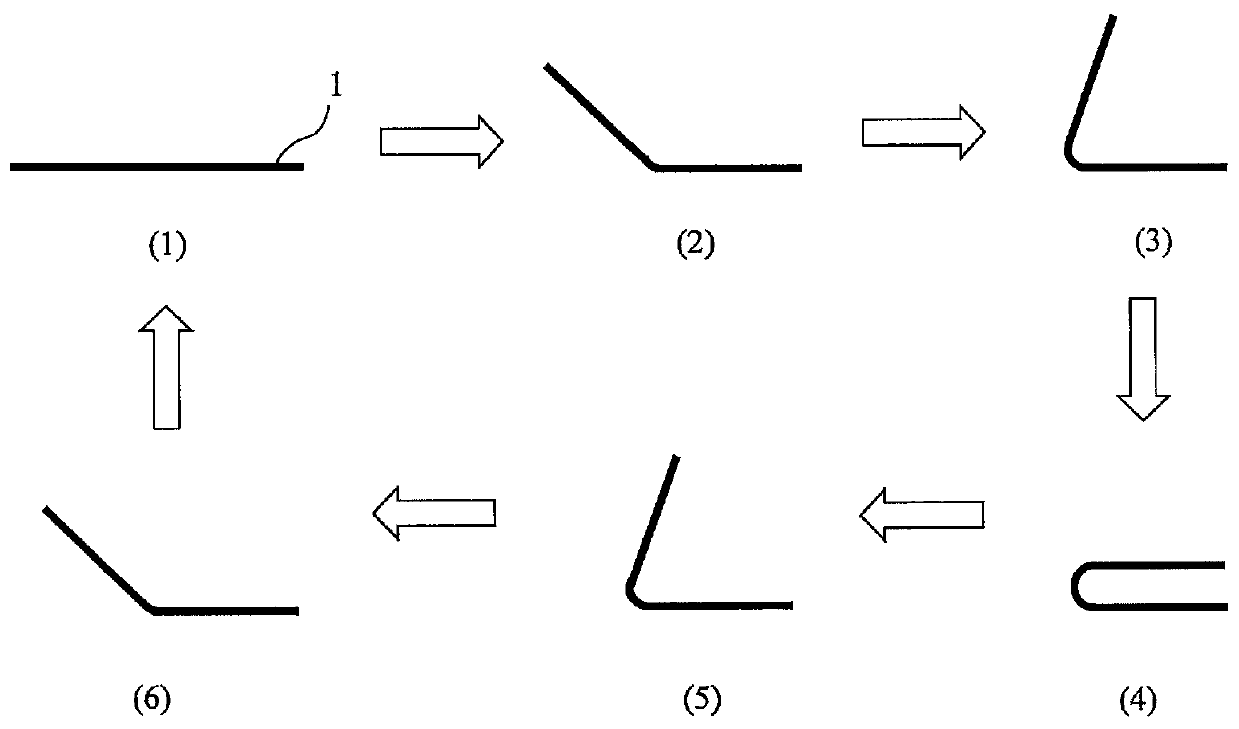

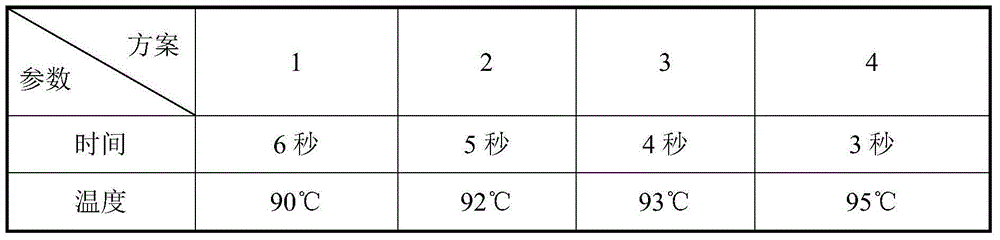

Manufacturing method of anti-curl collar

InactiveCN101596024AExcellent curl resistanceSimple preparation processFibre treatmentGarmentsPolyolefinPolyester

The invention discloses a manufacturing method of an anti-curl collar, comprising the following steps: a, setting thermoplastic adhesive material between a top collar and an under collar; b. hot pressing the thermoplastic adhesive material for 5-15seconds at the temperature of 90 DEG C-200 DGE C and under the pressure of 1.5-6.5bar, carrying out cooling after the thermoplastic adhesive material melting, immersing and bonding the upper surface and the lower surface of the contacting material to form the anti-curl collar; the thermoplastic adhesive material is selected from any one of polyamide, polyester, polyolefin, polyurethane and ethylene acetic acid ethylene copolymer. The invention has the advantages that manufacturing technology is simple and convenient, the collar has good anti-curl effect, and the collar point can keep straight and dose not curl after repeated washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Thermal transfer receiving sheet

InactiveUS20060194003A1High image stabilityWithout bleedingLayered productsAblative recordingAdhesiveEngineering

There is provided a thermal transfer receiving sheet comprising a substrate, a barrier layer laminated on said substrate, and an image receiving layer laminated on said barrier layer, wherein said barrier layer and said image receiving layer are laminated on at least one side of said substrate, characterized in that the major components of said barrier layer are a swellable lamellar inorganic component and an adhesive, wherein said swellable lamellar inorganic component has a mean particle diameter of at least 0.1 μm and not greater than 100 μm, and an aspect ratio (ratio of mean particle diameter to thickness of the lamellar composite) of at least 100 and not greater than 5000.

Owner:OJI PAPER CO LTD

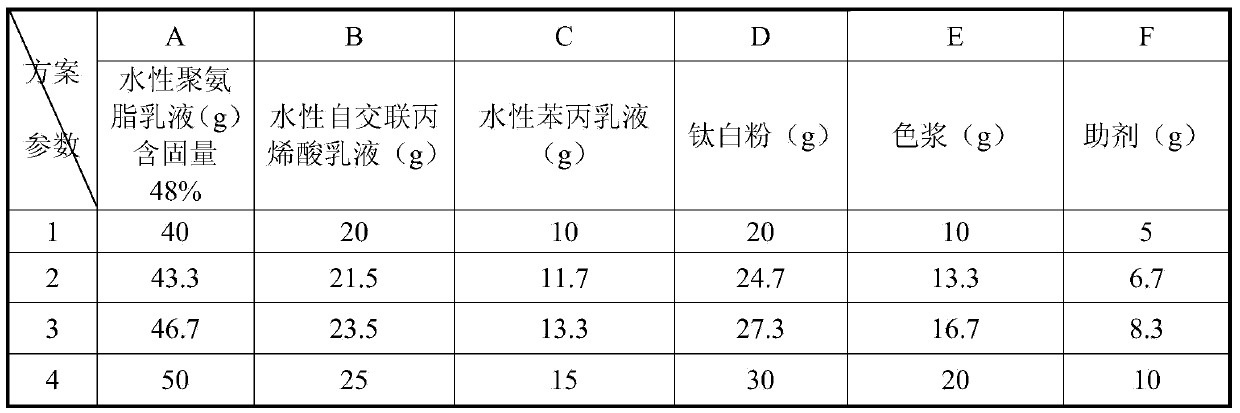

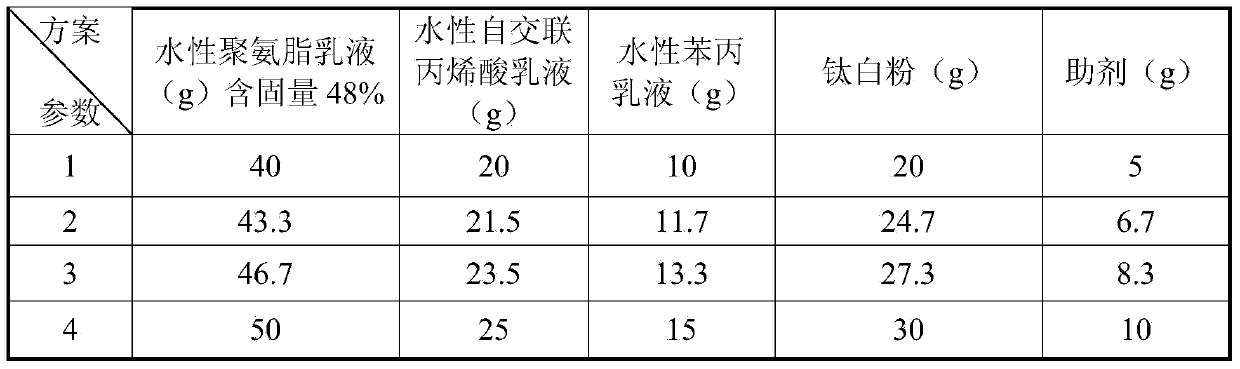

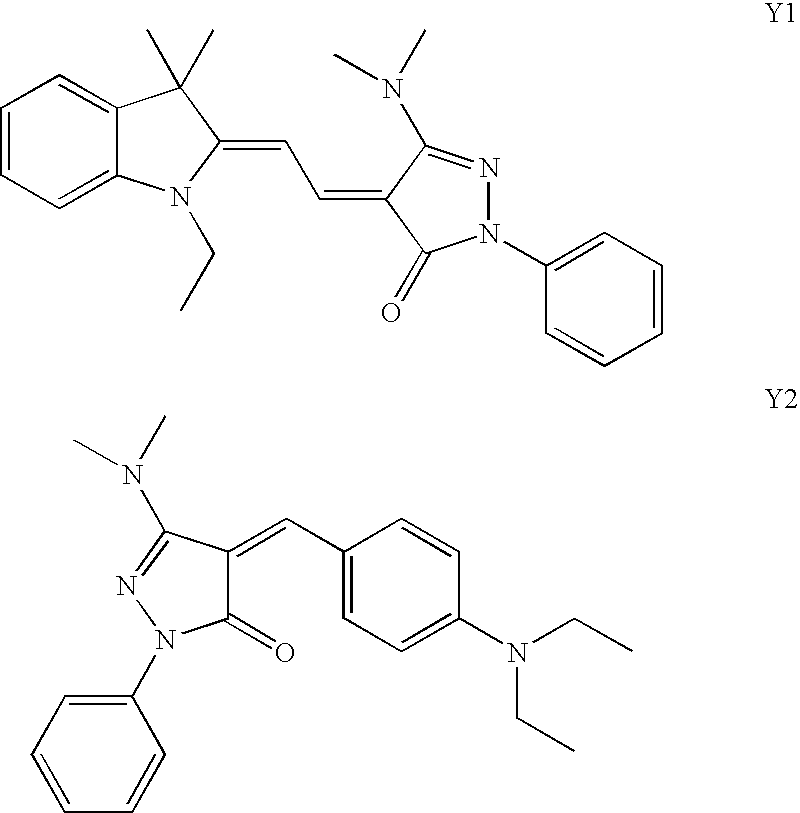

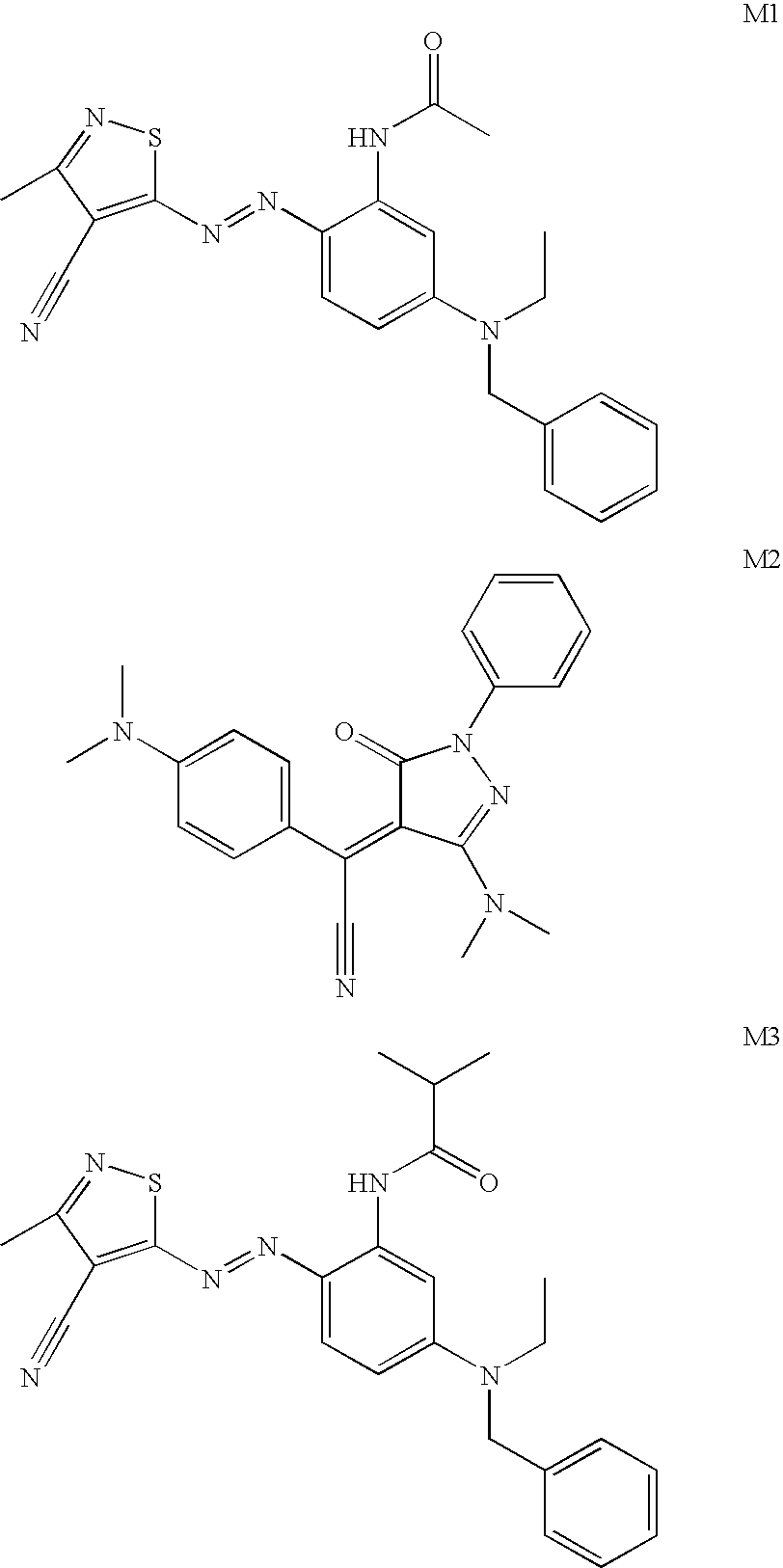

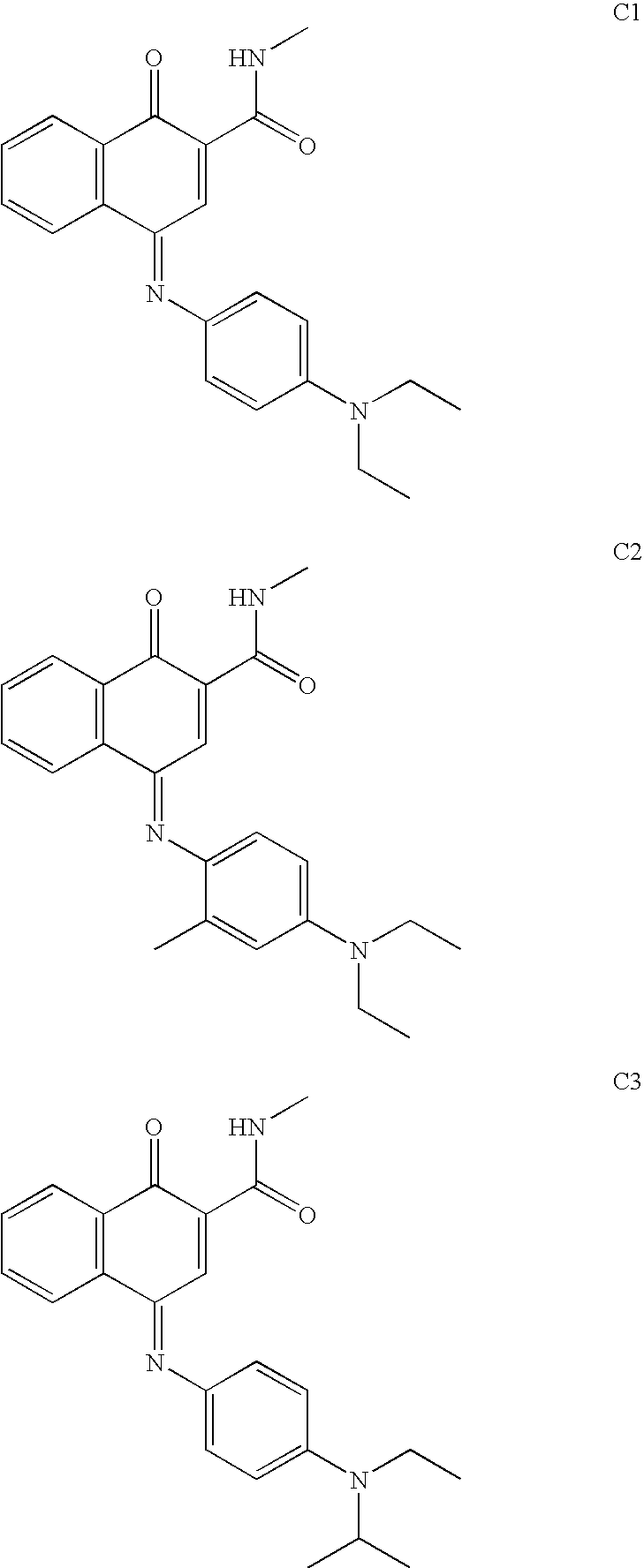

Umbrella water-based ink for satin fabrics and coating method of water-based ink

The invention discloses umbrella water-based ink for satin fabrics and a coating method of the water-based ink. The water-based ink comprises, in parts by weight, 40-50 parts of a waterborne polyurethane emulsion, 20-25 parts of a water-based self-crosslinking acrylic emulsion, 10-15 parts of a water-based styrene-acrylic emulsion, 20-30 parts of titanium dioxide and / or 10-20 parts of color paste and 5-10 parts of an assistant. The water-based ink has the advantages that products are good in leveling property and high in crimp resistance, reverse sticking and the damage to coatings can be avoided after finished umbrella covers are overlaid, scrapping is less, and pattern colors are more stable; and the water-based ink is safe, non-toxic, innocuous, non-ignitable, non-explosive, almost free of volatile gases and low in cost, has significant economic benefits and the like.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

Foamed image receiver

InactiveUS20090162580A1Increase stiffnessEfficient recyclingSynthetic resin layered productsElectrographic process apparatusPolyesterLow density

The present invention relates to an image receiver element comprising a single low density layer, wherein the single low density layer comprises non-crosslinked aliphatic polyester containing non-interconnected void space, and wherein the single low density layer does not absorb more than 3 weight % moisture at 80% RH and 21.3° C. as compared to the weight % moisture of said single low density layer at 20% RH and 21.3° C. The invention relates to a method of forming such an image receiver element, a printing system comprising an imaging material and the image receiver element, and a method of printing comprising obtaining an imaging material comprising a colorant layer; obtaining the image receiver element; superposing the colorant layer with the receiver element; and transferring colorant from the imaging material to the image receiver element.

Owner:EASTMAN KODAK CO

Thermal transfer receiving sheet

InactiveCN1767955AQuality improvementDoes not bleed over timeLayered productsThermographyAdhesivePolymer chemistry

The present invention discloses a thermal transfer-receiving sheet comprising a barrier layer and an image-receiving layer sequentially arranged on at least one surface of a carrier. The anti-seepage layer mainly contains swellable inorganic laminar compound and binder. The swellable inorganic layered compound has an average particle length of 0.1-100 microns and an aspect ratio (ratio of average particle length to thickness) of 100-5,000.

Owner:OJI PAPER CO LTD

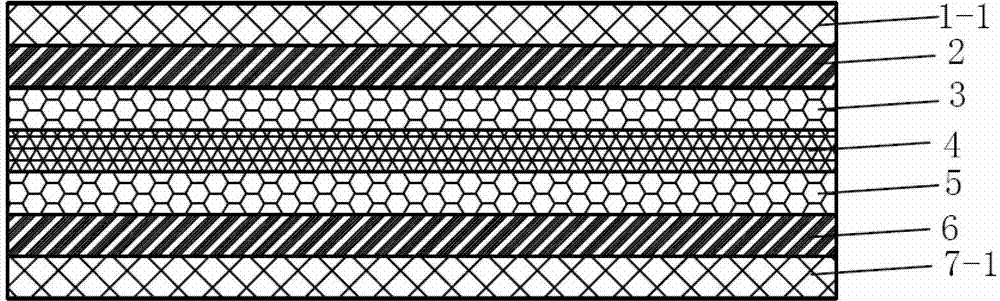

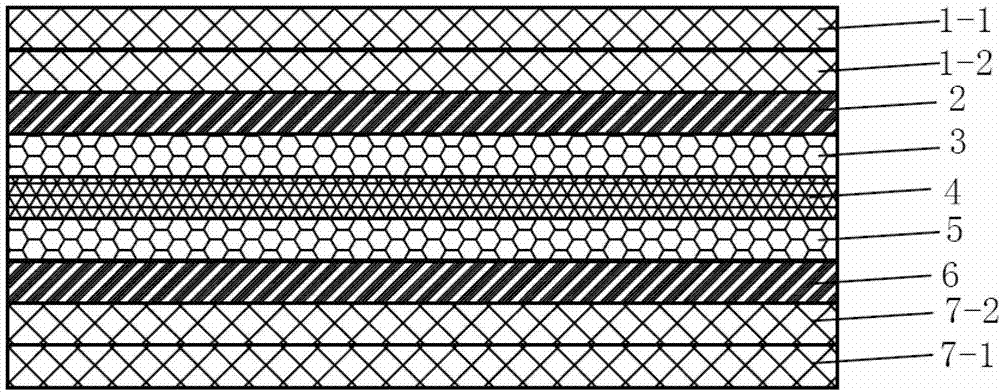

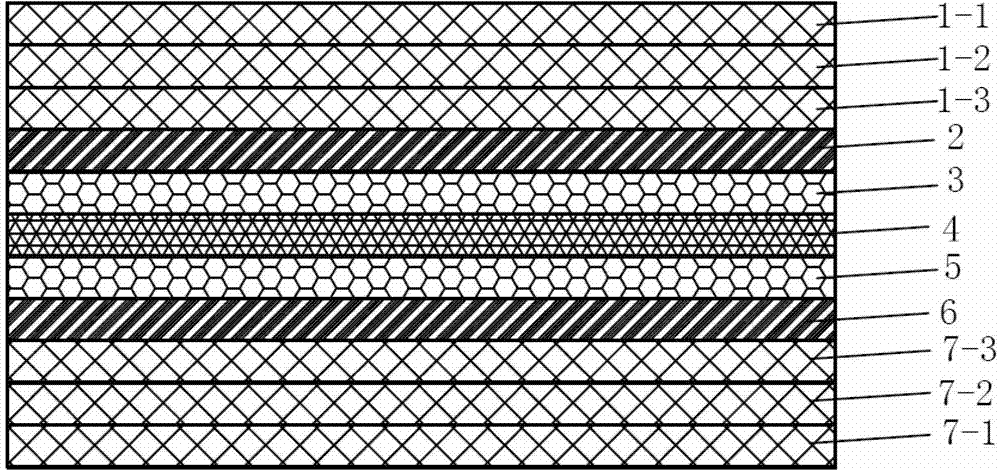

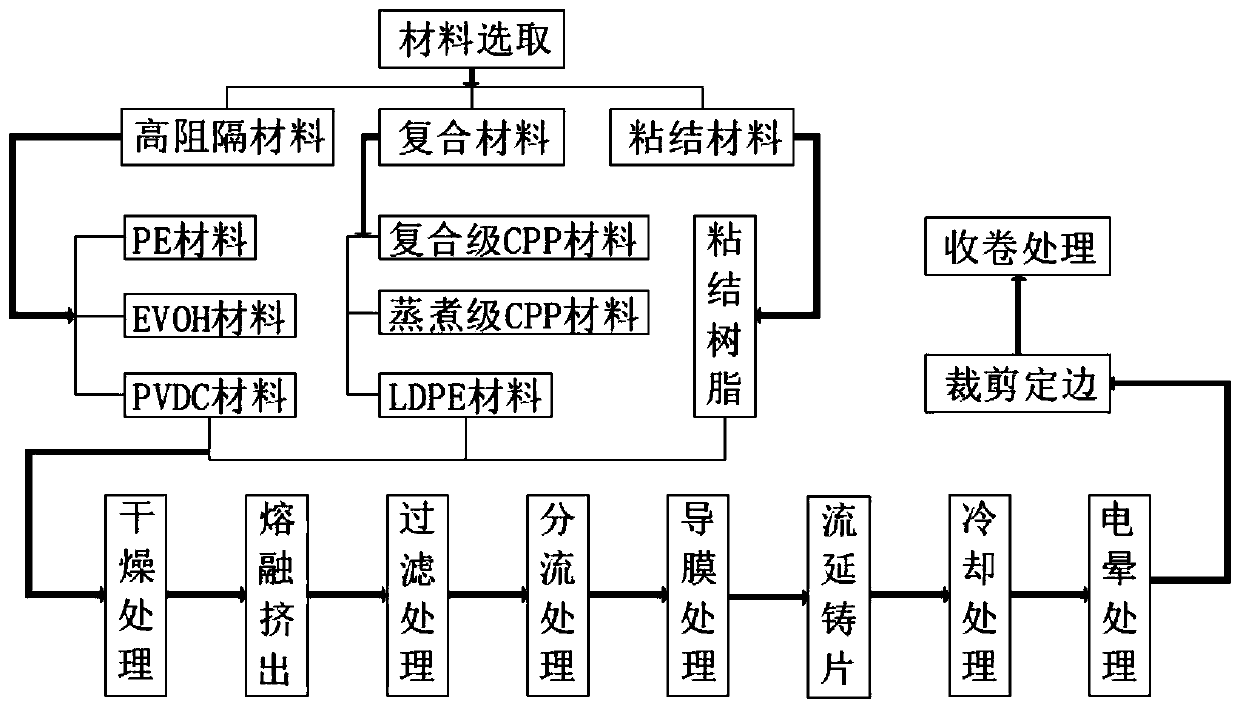

Bag for automatic cheese canning

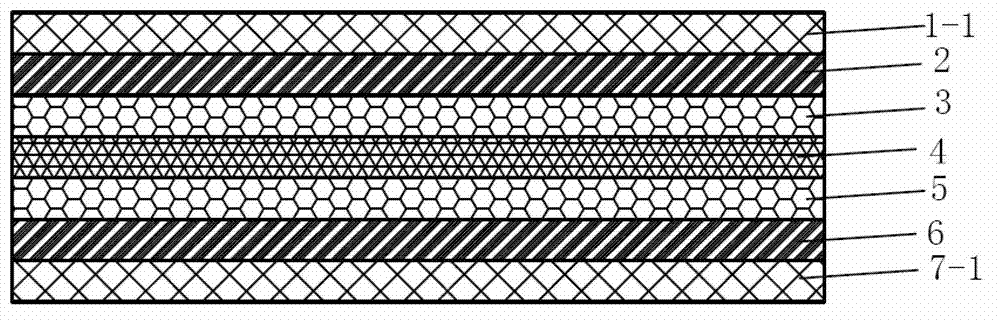

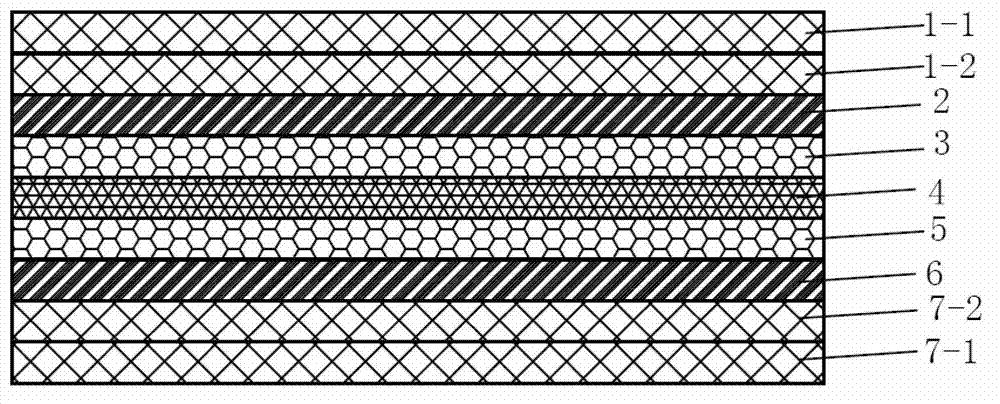

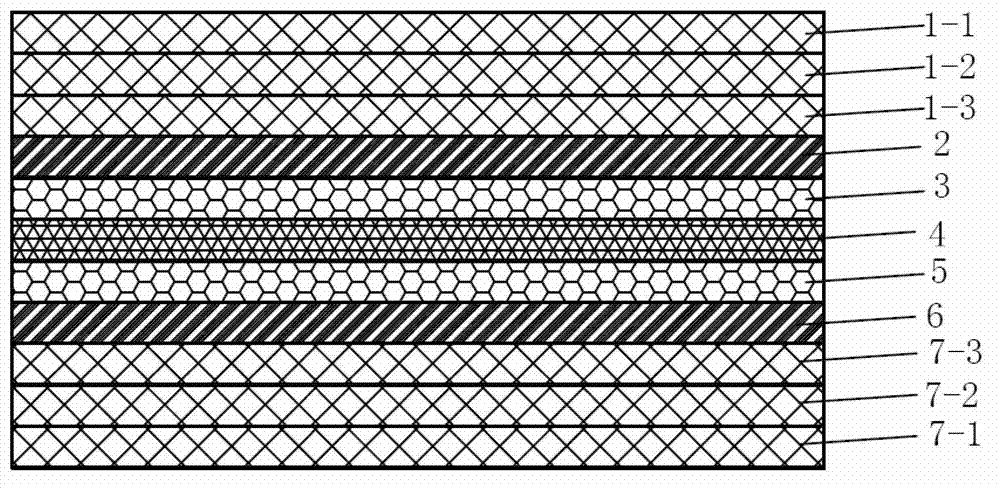

ActiveCN103042730AMeet the storage requirementsMeet the requirements of automated canning processSynthetic resin layered productsBagsEdge structureMoisture barrier

The invention discloses a bag for automatic cheese canning, which comprises a bag body with an insert edge structure; the bag body comprises a front surface, a back surface and insert edges on the left side and the right side; a certain width of bottom sealing line penetrating through the front surface, the back surface and the two insert edges is formed at the bottom of the bag body; a lower oblique angle is formed at the lower part of the bag body; the bag body consists of layered co-extrusion blown thin films with symmetrical structures of which the number of layers is seven-eleven; and each layered co-extrusion blown thin film is provided with an inner heat-sealed moisture barrier layer, an inner bonding layer, an inner oxygen barrier layer, an incense keeping core layer, an outer oxygen barrier layer, an outer bonding layer and an outer heat-sealed moisture barrier layer from inside to outside in sequence. The bag has the beneficial effects that a three-dimensional structure of the bag body is stable, the inner layer friction performance and the outer layer friction performance of the bag body are properly set, used materials are saved, and the strength is high. The bag is particularly suitable for automatic cheese canning.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

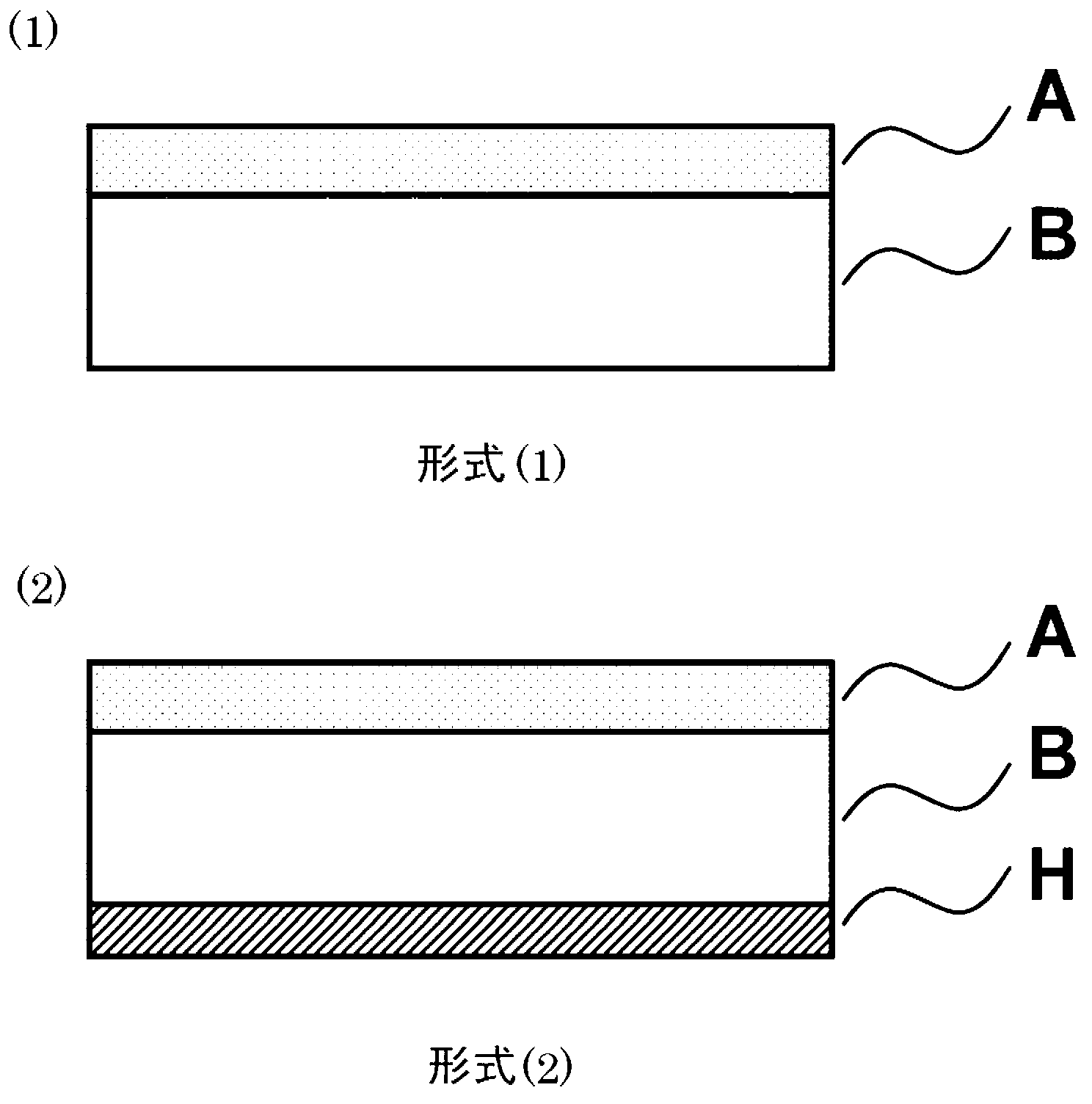

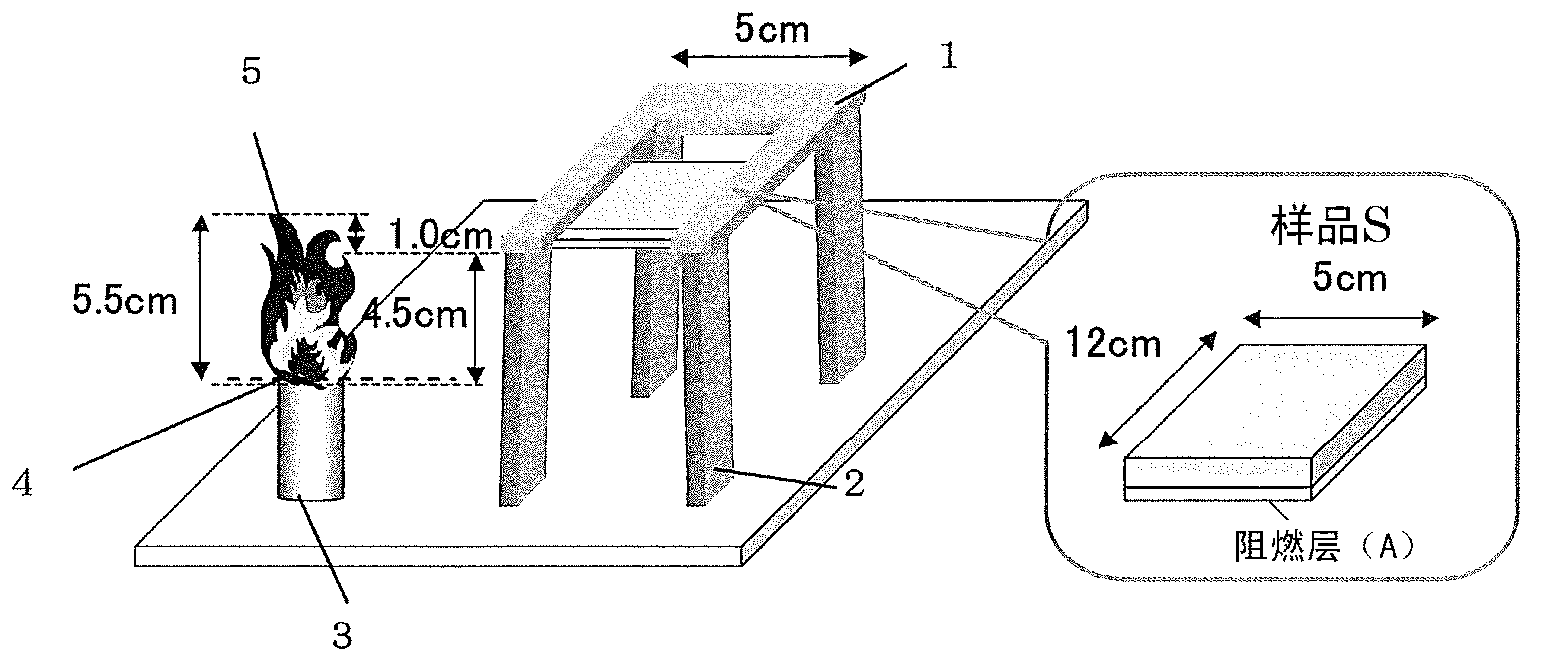

Flame-retardant polymer member, flame-retardant product, and flame-retarding method

InactiveCN102883883AImprove flame retardant performanceAdvantageously maintains flexibilitySynthetic resin layered productsCoatingsInorganic compoundFire retardant

Disclosed is a flame-retardant member that is flexible and highly flame retardant. Specifically disclosed is a flame-retardant polymer member which has a polymer layer (B) and a flame-retardant layer (A) on at least one surface of the polymer layer (B), wherein the flame-retardant layer (A) contains a stratified inorganic compound (f) in a polymer (X).

Owner:NITTO DENKO CORP

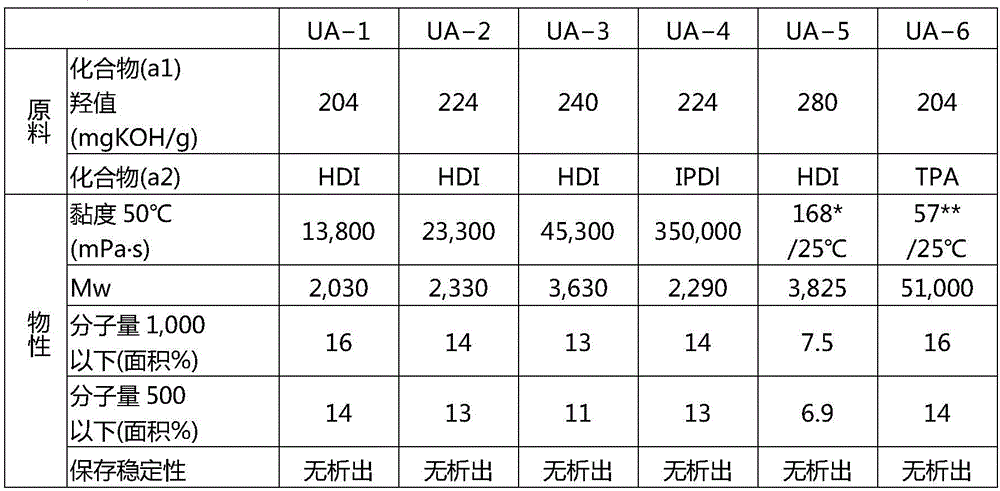

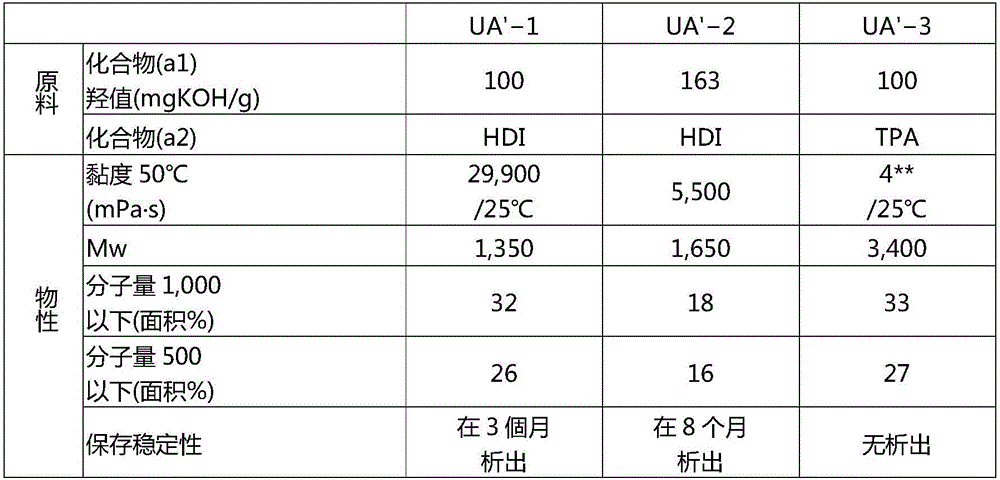

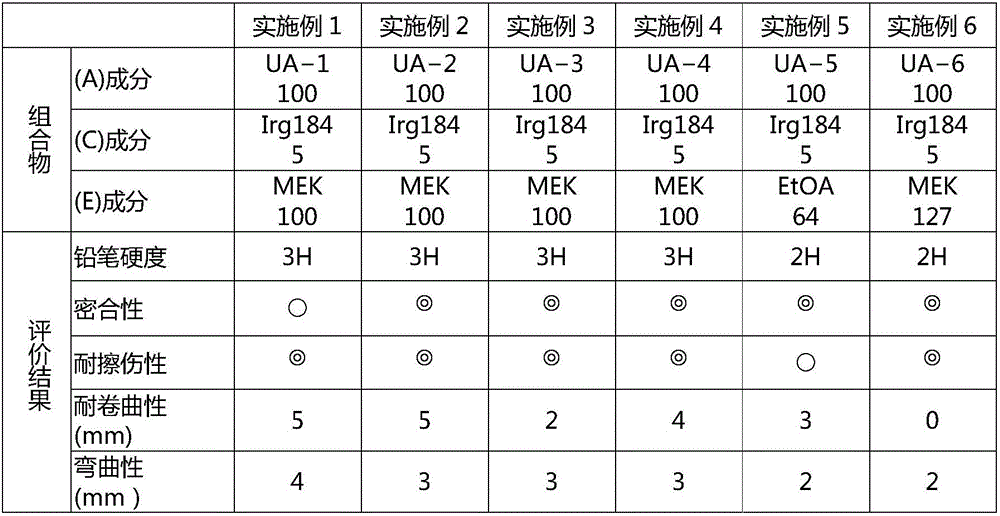

Curable composition

ActiveCN106459329AGood storage stabilityExcellent handlingPolyurea/polyurethane coatingsPentaerythritolIsocyanate compound

[Problem] The problem addressed by the present invention is to provide a curable composition having superior hardness, adhesion, and flexibility of a cured film thereof, having greater superiority in curl resistance, and superior storage stability such that clouding does not arise even after long-term storage. [Solution] The curable composition contains a urethane (meth)acrylate-containing reaction product (A) resulting from reacting: a compound (a1) that is the result of adding (meth)acrylic acid to pentaerythritol and that has a hydroxyl value of 180-300 mgKOH / g; and a polyvalent isocyanate compound (a2).

Owner:TOAGOSEI CO LTD

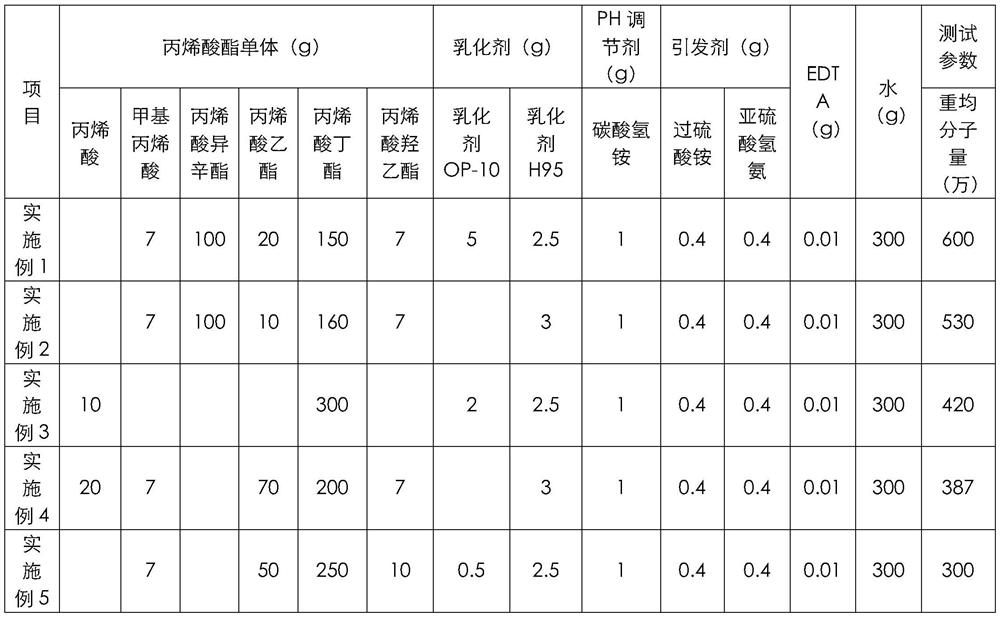

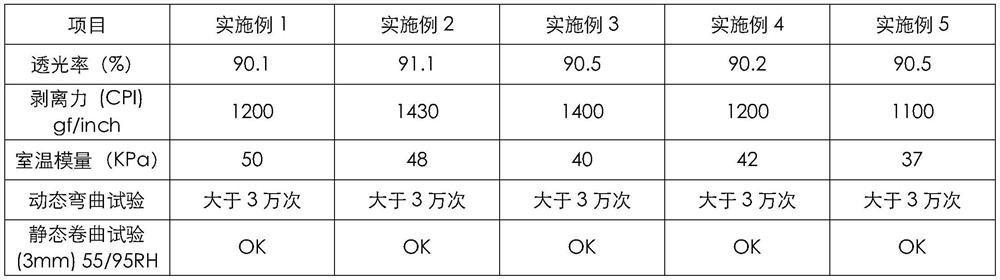

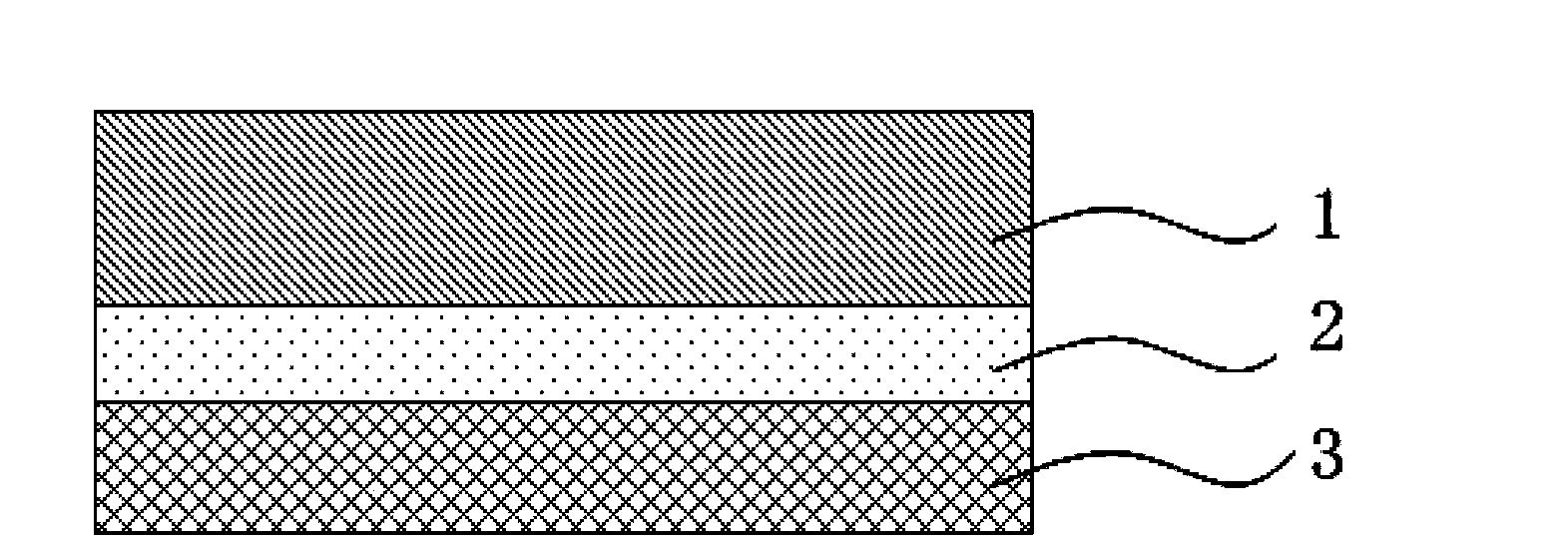

Optical adhesive layer, preparation method thereof, optical adhesive and flexible display device

InactiveCN112251172AIncreased durabilityReduce pollutionFilm/foil adhesivesEster polymer adhesivesOptical bondingPolymer science

The invention discloses an optical adhesive layer and a preparation method thereof, and belongs to the technical field of polymer synthesis. Specifically, the optical adhesive layer contains an ultra-high molecular weight (meth) acrylate polymer and an additive, wherein based on 100 parts by weight of the (methyl) acrylate polymer, the weight of the additive is 0.01-20 part by weight; the (methyl)acrylate polymer is prepared by adopting an emulsion polymerization method, and the weight-average molecular weight reaches more than 3 millions. The optical adhesive layer prepared by the inventionis environment-friendly in synthesis process, small in environmental pollution, good in film-forming property and strong in durability, and can fully fit the physical properties required by the current flexible display device when being applied to the market as an optical adhesive.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Opening intensive type printed circuit board covering film

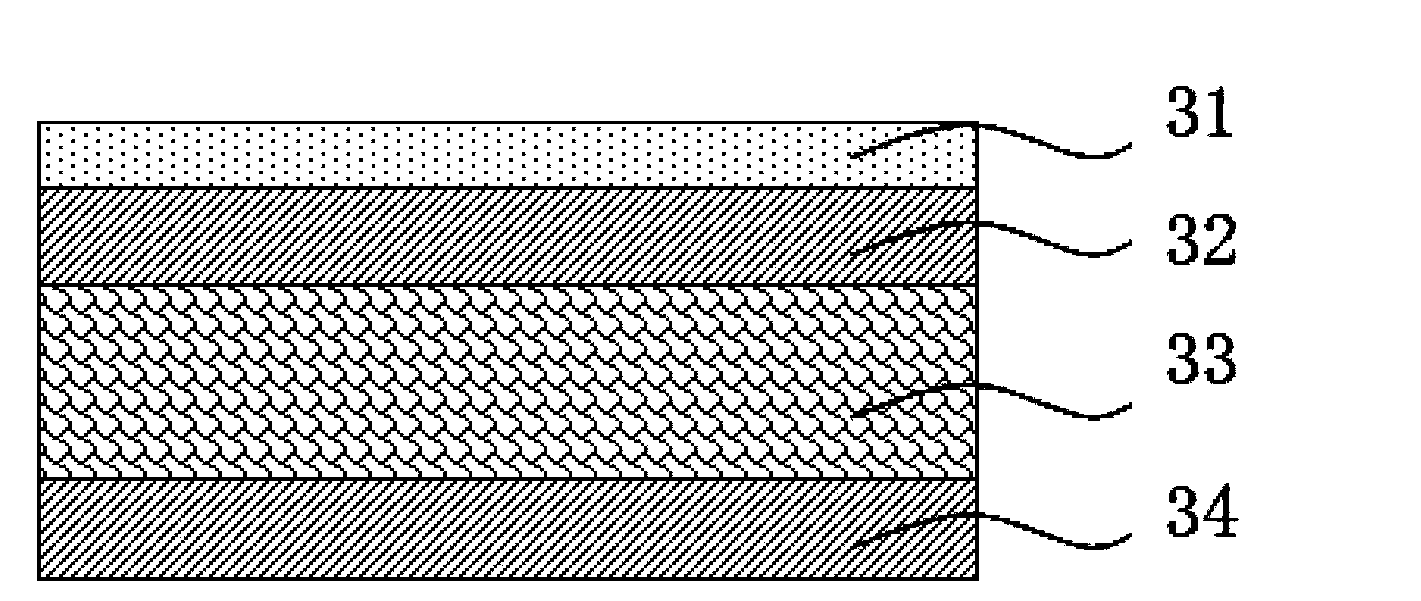

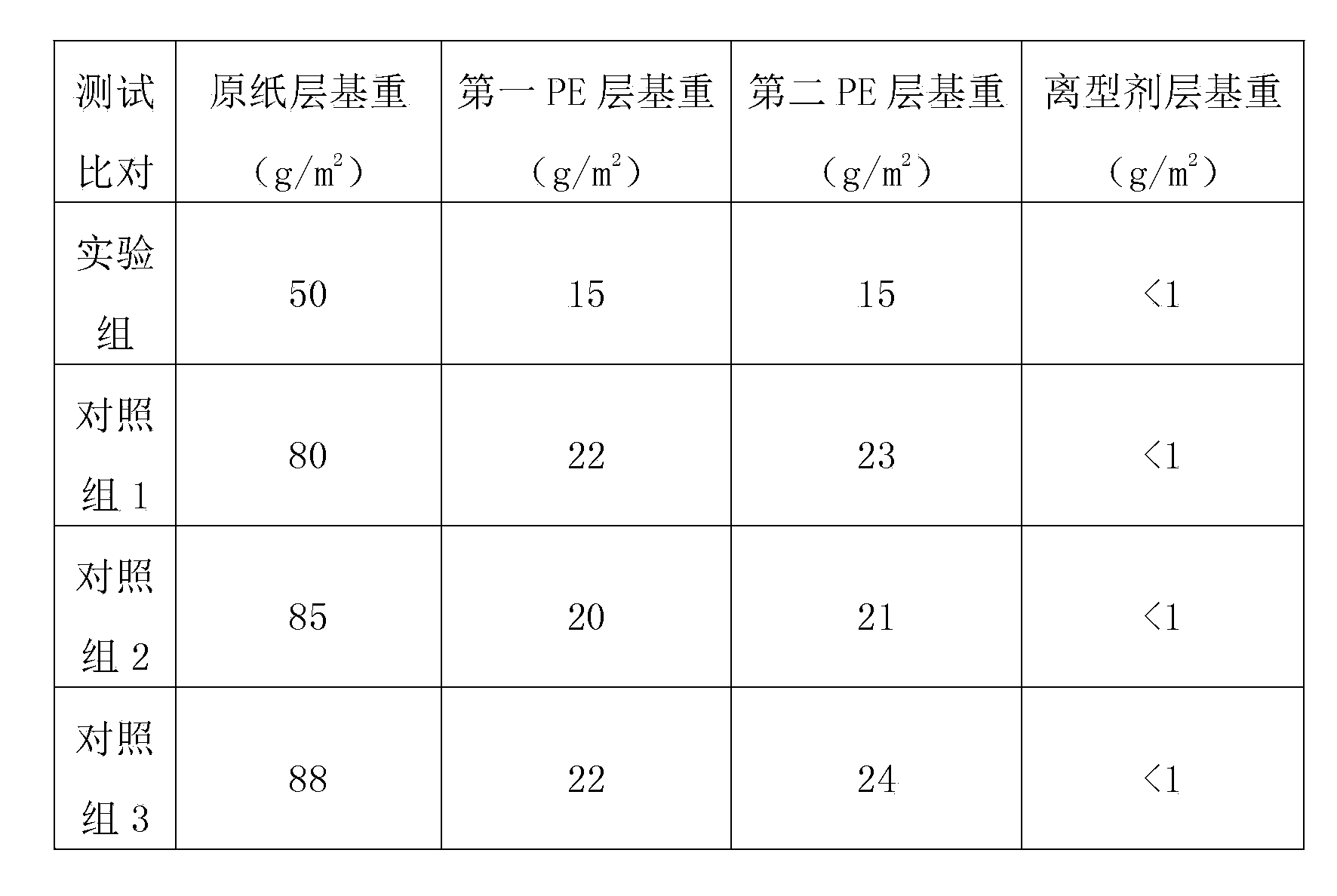

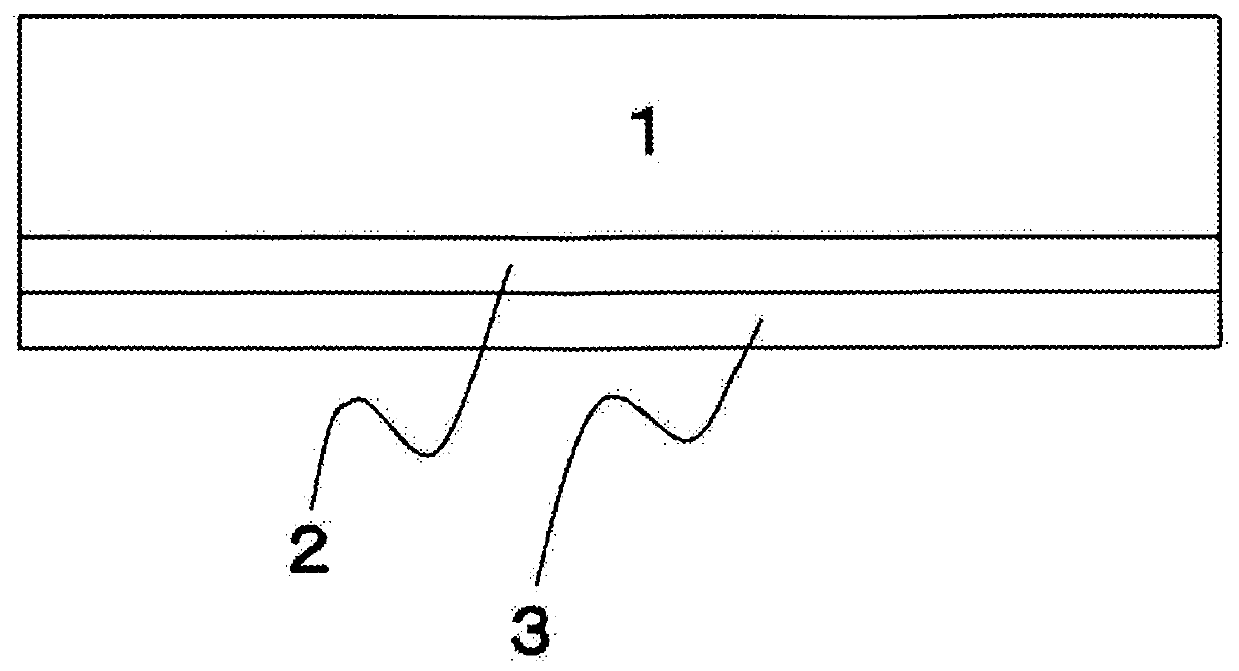

InactiveCN103635008AReduce basis weightLow hygroscopicityPrinted circuit detailsSynthetic resin layered productsHigh densityMicrometer

Disclosed in the invention is an opening intensive type printed circuit board covering film comprising a polyimide film, an adhesion layer, and a piece of release paper. The release paper is formed by a release agent layer, a first PE layer, a body paper layer and a second PE layer successively. The thickness of the release agent layer is less than 1 micrometer, the thickness of the first PE layer is 10 to 20 micrometers, the thickness of the body paper layer is 40 to 60 micrometers, the thickens of the second PE layer is 10 to 30 micrometers, and the thickness of the release paper is 90 to 100 micrometers; and the basis weight of the release paper is 40 to 60g / m<2> and the release force of the release paper is 2 to 8g / 5cm. Because the release paper with low basis weight, low thickness and low release force is used, the covering film has performance of low basis weight and low hygroscopicity and the excellent curling-resistant performance, so that the covering film is especially suitable for the high-density small hole opening and half-cutting printed circuit board. Therefore, the environment protection requirement is met; the environment pollution is reduced; the paperless trend of the covering film in the industry is followed; and the sustainable development demand can be satisfied.

Owner:KUSN APLUS TEC CORP

Polarizing plate, image display and liquid crystal display device

ActiveCN106164720AExcellent curl resistancePolarising elementsNon-linear opticsTectorial membraneLiquid-crystal display

The purpose of the present invention is to provide a polarizing plate that does not easily curl due to environmental changes, and an image display and liquid crystal display device provided with the polarizing plate. This polarizing plate is provided with, a polarizing element, a protective film and a release film, in that order. The modulus of elasticity of the release film is at least 2.0 GPa. The thickness P (micrometer) of the polarizing element, the thickness Q (micrometer) of the protective film, and the thickness T (micrometer) of the release film satisfy formula (A). Formula(A): T>=(2.8*P-1.2*Q)+50

Owner:FUJIFILM CORP

Polymer foam surface smoothing materials and method

InactiveUS7037634B2Eliminate disadvantagesStable supportDiffusion transfer processesDuplicating/marking methodsPolymeric surfacePolymer science

Owner:EASTMAN KODAK CO

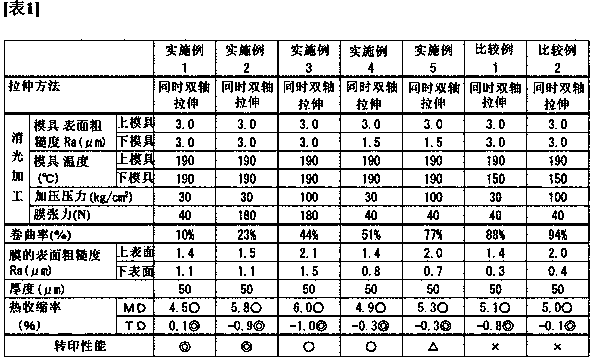

Polyester film for high sensitive thermal mimeorgraph stencil paper

InactiveCN1717333AExcellent curl resistancePlate printingFoil printingPolyesterDynamic viscoelasticity

A highly sensitive thermosensitive polyester film for porous printing base paper which is a biaxially oriented polyester film of 1.0 to 7.0 mum thickness comprising a composition of three or more types of polyesters, the polyester film having a Young's modulus of 3000 Mpa or greater and exhibiting a primary dispersion temperature E''(t) of dynamic viscoelasticity temperature characteristics, measured by the dynamic viscoelasticity method, of 60 to 75 C. This film is excellent in perforation sensitivity and realizes enhanced resolution at printing, plate making strain and plate wear resistance.

Owner:MITSUBISHI CHEM CORP

Foamed image receiver

InactiveUS7838106B2Increase stiffnessEfficient recyclingDuplicating/marking methodsSynthetic resin layered productsPolyesterLow density

Owner:EASTMAN KODAK CO

Multilayer stretched polyamide film

ActiveUS8999466B2Increase resistanceImprove retentionEnvelopes/bags making machineryRecord information storageElastomerPolyester

An object of the present invention is to provide a multilayer stretched polyamide-based film having excellent bending resistance, thermal dimensional stability and aroma retention, whose lamination strength is measureable when a sealing layer is laminated thereon.Specifically, the invention provides a multilayer stretched polyamide-based film obtained by biaxially stretching a multilayer laminate including three layers consisting of a polyester layer (Layer A), an adhesive layer (Layer B), and a polyamide layer (Layer C), whereinLayer A contains a crystalline polyester,Layer B contains a modified polyester-based elastomer,Layer C contains an aliphatic polyamide, andLayer C has a thickness of 5 μm or more, andwherein a sealing layer is to be laminated on Layer C by a lamination method, after biaxially stretching the multilayer laminate.

Owner:MITSUBISHI CHEM CORP +1

Non-woven fabric laminate and method for production thereof

ActiveCN101432478BImprove flexibilityGood flexibilityLayered productsNon-woven fabricsFiberThermoplastic elastomer

Disclosed is a non-woven fabric laminate which is excellent in shrink properties, flexibility, water-resistance, anti-fuzz properties and anti-curl properties and shows less stickiness. The non-woven fabric laminate comprises at least one meltblown non-woven fabric layer and a mixed spunbonded non-woven fabric layer laminated on the both sides of the meltblown non-woven fabric layer, wherein the mixed spunbonded non-woven fabric layer comprises a long fiber compose of a thermoplastic elastomer (A) and a long fiber composed of a thermoplastic resin (B) which is different from the thermoplasticelastomer (A) at a ratio of [10-90 wt%]:[90-10 wt%] (provided that the sum total of the components (A) and (B) is 100% by weight).

Owner:MITSUI CHEM INC

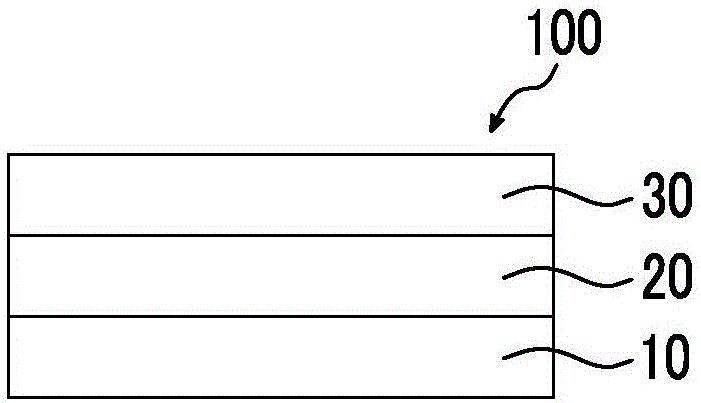

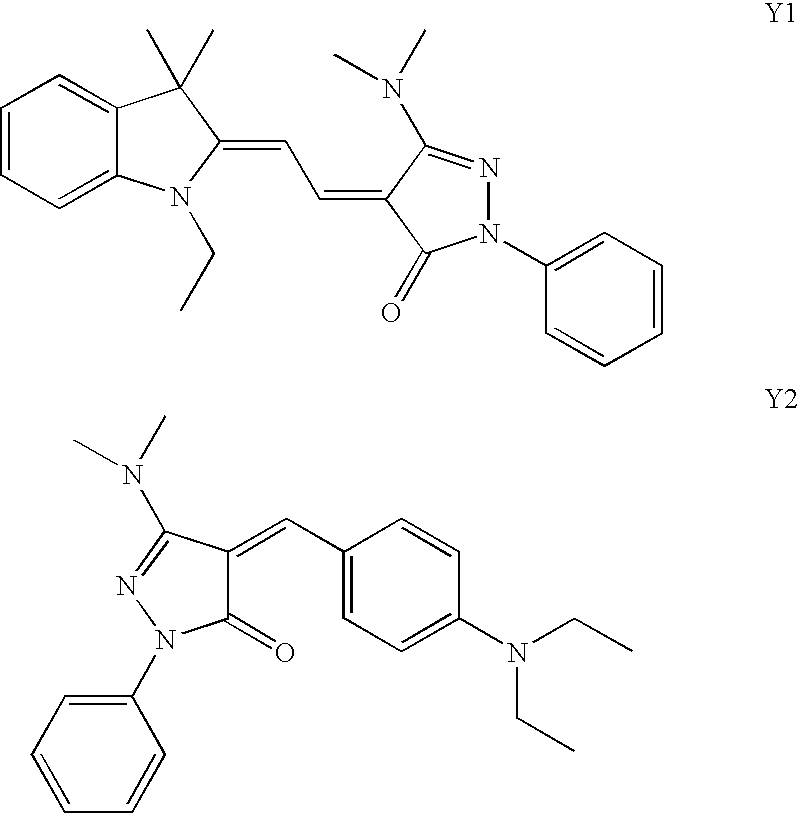

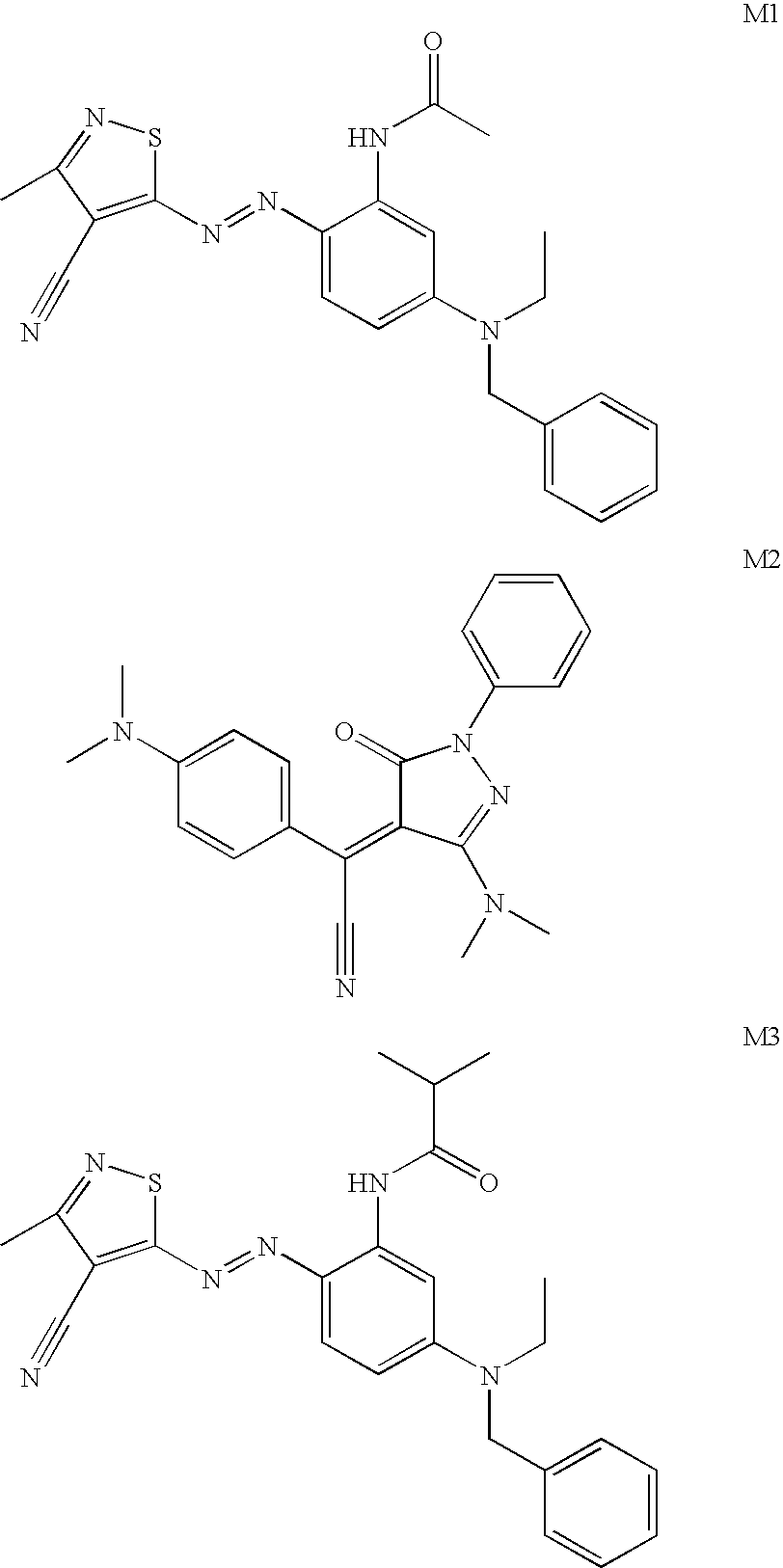

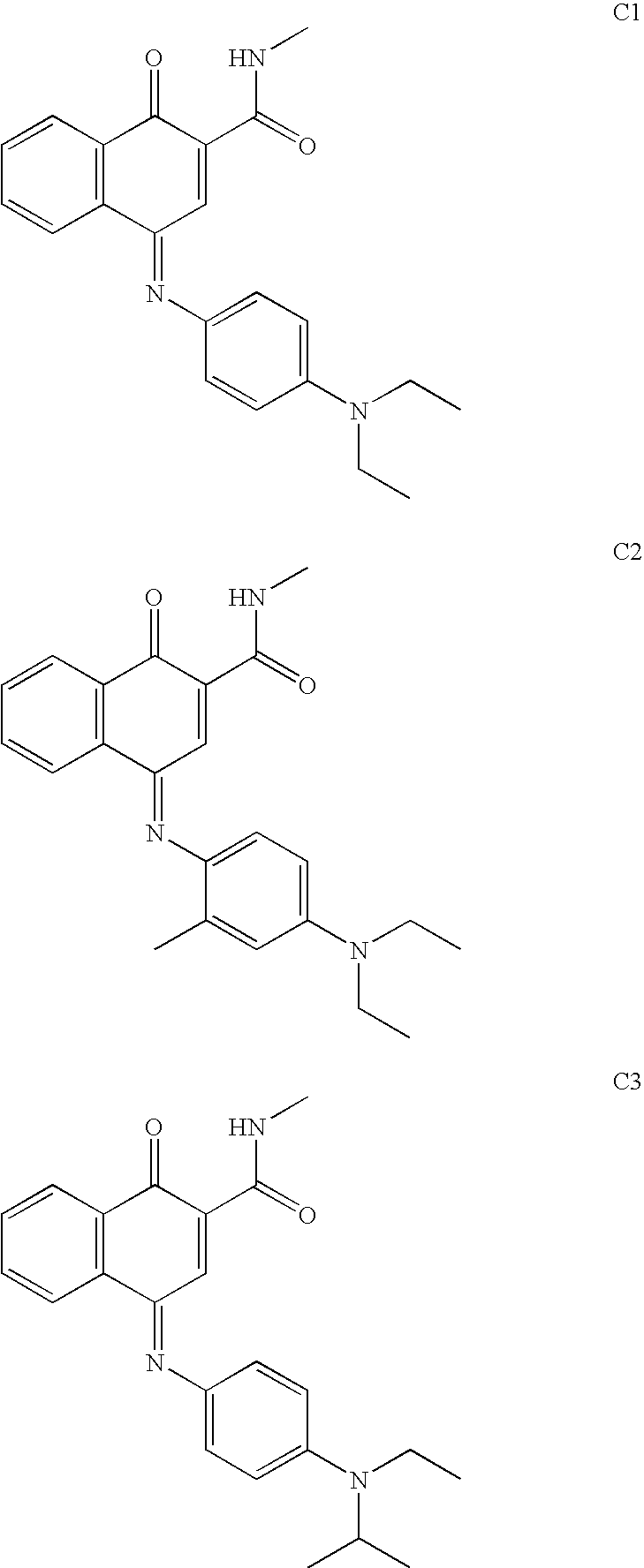

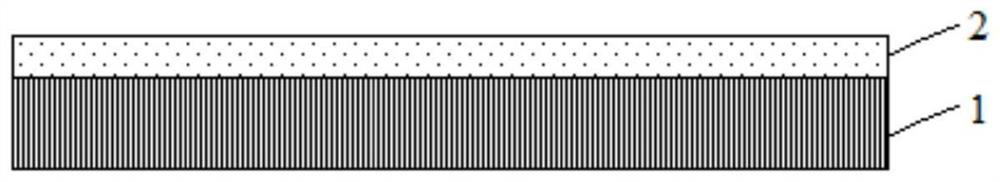

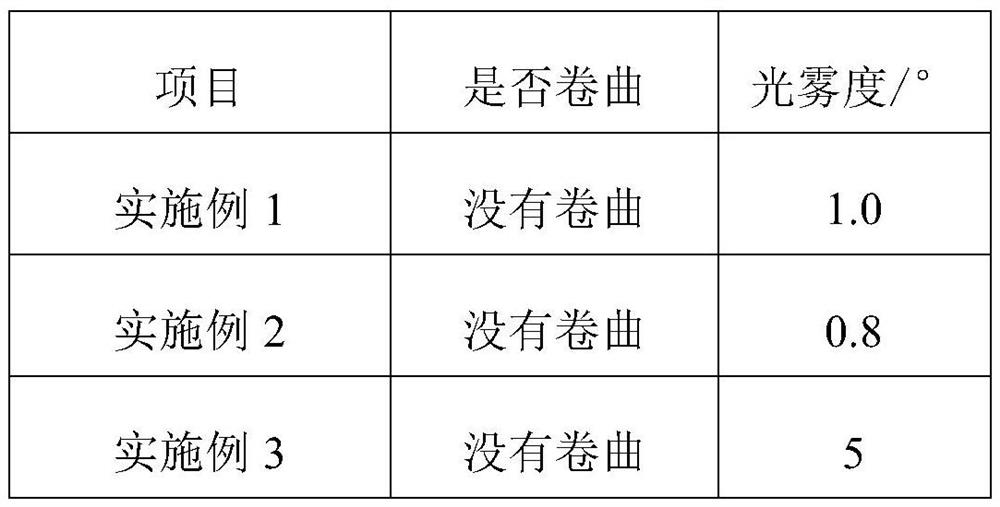

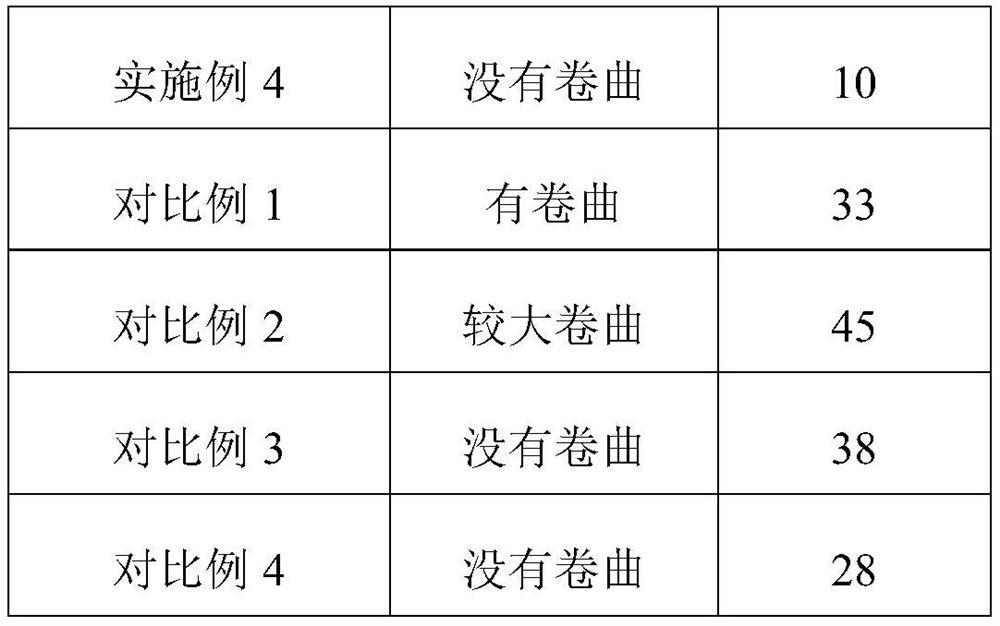

Anti-curling image recording material and preparation method thereof

PendingCN114442419AExcellent curl resistanceReduce manufacturing costPaper coatingCoatingsInorganic particleAdhesive

The invention discloses an anti-curling image recording material and a preparation method thereof. The image recording material comprises a support body and an image recording layer arranged on one side of the support body, the image recording layer is obtained by drying a coating liquid, and based on the total mass of the coating liquid, the coating liquid comprises inorganic particles with the content of 8-33 wt%, and a solvent with the content of 10-30 wt%, a water-based adhesive, wherein the content of the water-based adhesive is 1.5-7.5 wt%; the content of the silane coupling agent is 1 to 5 weight percent; a cross-linking agent, wherein the content of the cross-linking agent is 0.01 to 0.1 wt%; an organic solvent, wherein the content of the organic solvent is 6-20 wt%; and deionized water, wherein the content of the deionized water is 54.49 wt%-83.49 wt%. Therefore, the shrinkage internal stress, generated in the drying process, of the coating can be obviously reduced, and the hidden danger of curling in the drying process is effectively eliminated; in addition, the coating process of the curling control layer can be omitted, the curling resistance of the image recording material is improved, the production cost can be remarkably reduced, and large-scale production of the image recording material is facilitated.

Owner:乐凯胶片股份有限公司

Adhesive film

ActiveCN109863217AExcellent initial pressure sensitive adhesionEnhanced resistance to peelingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSurface layerAdhesive

Owner:RIKEN TECHNOS CORP

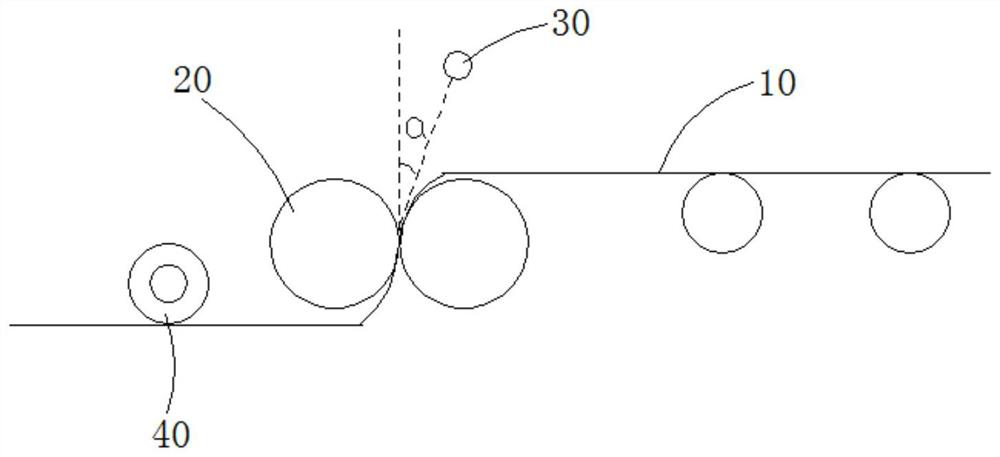

Preparation method of water-based leather release paper

PendingCN112878102AUniform curingCuring can be more evenly heatedMechanical paper treatmentPaper/cardboardPaper sheetComposite material

The invention discloses a preparation method of water-based leather release paper, which comprises the following steps: placing body paper between a pattern roller and an auxiliary roller, spraying a film spraying material between the pattern roller and the body paper through a film spraying head, applying pressure to the body paper sprayed with the film spraying material through the pattern roller so as to form a film spraying material layer with a pattern structure on the surface of the body paper, so as to obtain semi-cured release paper, wherein the film spraying direction of the film spraying head does not coincide with the tangential direction of a contact point of the body paper on the pattern roller, and the film spraying head is arranged on the side away from the pattern roller; and cooling the semi-cured release paper through a cooling roller to obtain the water-based leather release paper. By adjusting the positions of the film spraying head and the pattern roller, the curing of resin on paper can be more uniformly heated, and then through the step-by-step cooling cooperation of the pattern roller and the cooling roller, the temperature is slowly reduced, so that the obtained release paper has a better anti-curling effect, and the gloss and haze of patterns meet the requirements; and the quality stability of the synthetic leather is ensured.

Owner:SHENZHEN WANJI TECH CO LTD

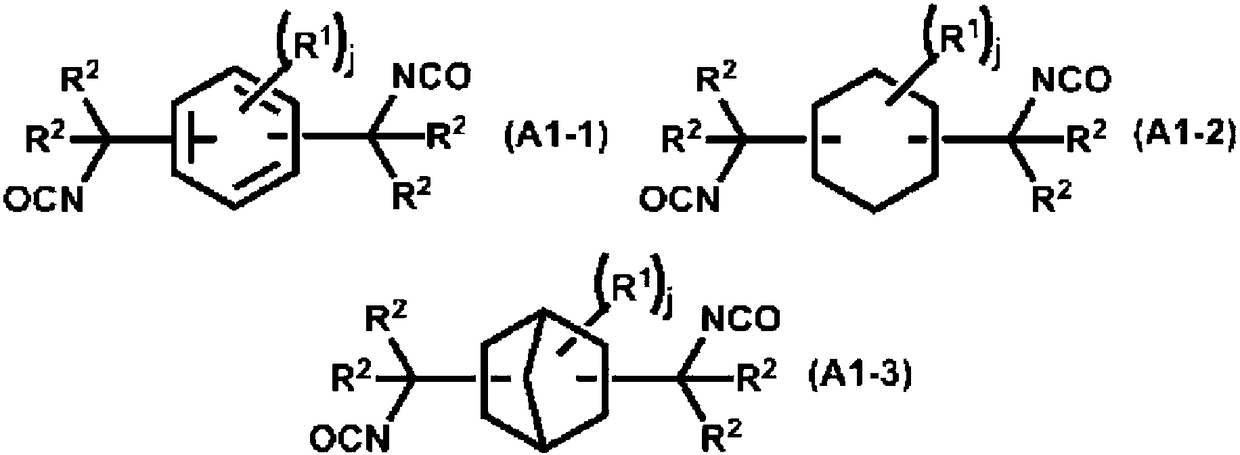

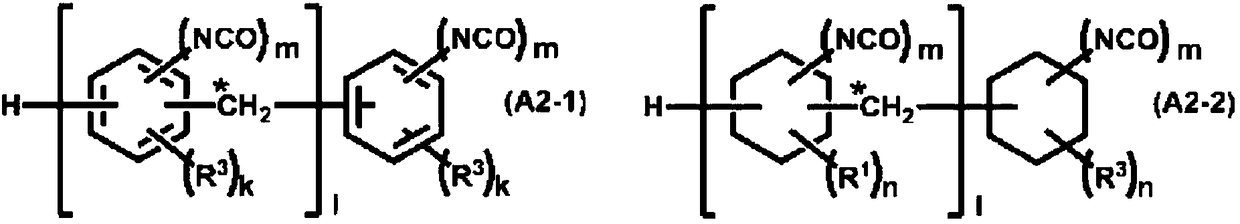

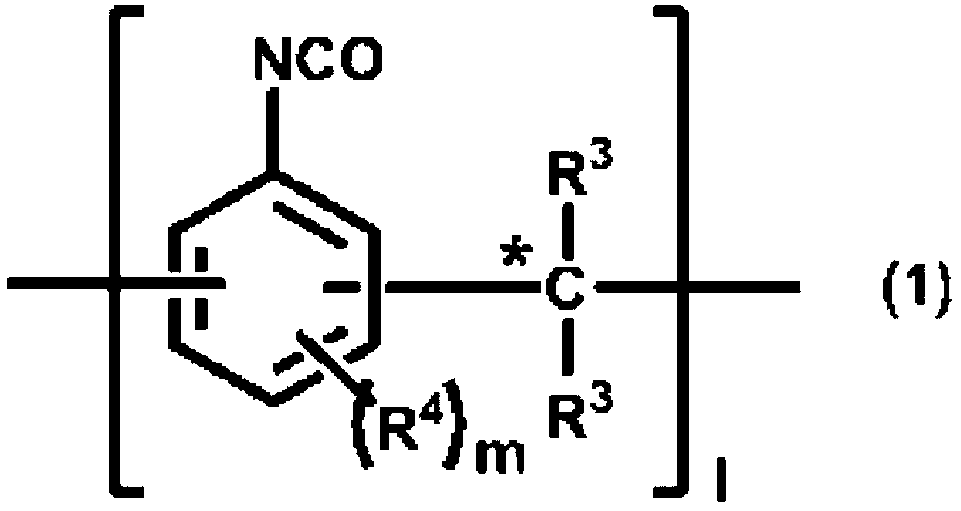

Urethane (METH)acrylate resin and laminated film

PendingCN109312047AImprove scratch resistanceExcellent curl resistanceSynthetic resin layered productsCoatingsMethacrylatePolymer science

Provided are a urethane (meth)acrylate resin, the cured coating film of which has various excellent properties such as scratch resistance, curl resistance, flexibility, and impact resistance, a curable composition and cured product thereof containing the same, and a laminated film. A urethane (meth)acrylate resin having as essential reaction raw materials a polyisocyanate compound (A) having an aromatic ring or alicyclic structure in the molecule and a dipentaerythritol (meth)acrylate (B), a curable composition and cured product thereof containing the same, and a laminated film.

Owner:DIC CORP

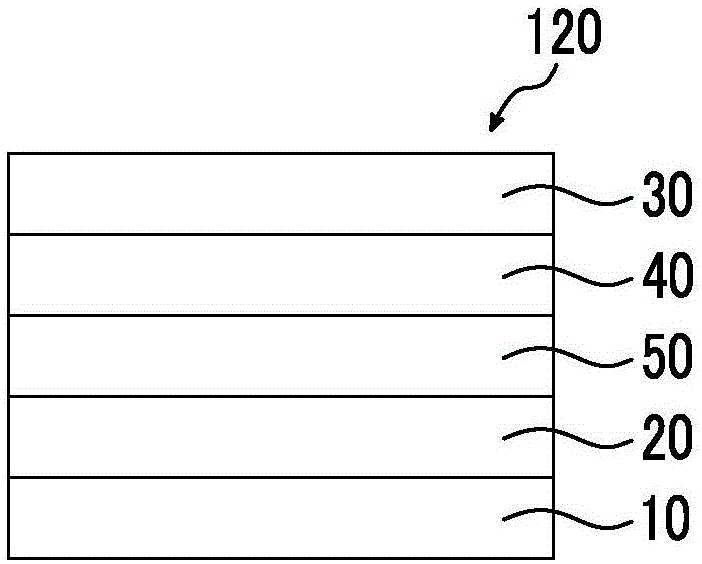

Laminated body and flexible device provided with said laminated body

InactiveCN111093978AImprove flexibilityIncreased durabilityMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesCrazingAdhesive

Provided is a laminated body comprising a thinned glass plate and a resin film which are bonded together by means of an adhesive and having excellent bending resistance. A laminated body according tothe present invention has a configuration in which a glass plate having a thickness of 150 um or less and a resin film are laminated together via an adhesive layer, and has a bending resistance of 10or more according to the following test. Bending resistance test: A set of operation comprises bending the laminated body by 180 degrees from a stretched state so as to have a bending radius of 3 mm in a direction in which a surface of the glass plate becomes concave, and then stretching the laminated body again. The operation is performed at the rate of 43 sets per minute, and the number of the sets when a crack has occurred in the laminated body is regarded as an index of the bending resistance.

Owner:DAICEL CHEM IND LTD

Bag for automatic cheese canning

ActiveCN103042730BEasy to carryMeet the storage requirementsSynthetic resin layered productsBagsEdge structureOblique angle

The invention discloses a bag for automatic cheese canning, which comprises a bag body with an insert edge structure; the bag body comprises a front surface, a back surface and insert edges on the left side and the right side; a certain width of bottom sealing line penetrating through the front surface, the back surface and the two insert edges is formed at the bottom of the bag body; a lower oblique angle is formed at the lower part of the bag body; the bag body consists of layered co-extrusion blown thin films with symmetrical structures of which the number of layers is seven-eleven; and each layered co-extrusion blown thin film is provided with an inner heat-sealed moisture barrier layer, an inner bonding layer, an inner oxygen barrier layer, an incense keeping core layer, an outer oxygen barrier layer, an outer bonding layer and an outer heat-sealed moisture barrier layer from inside to outside in sequence. The bag has the beneficial effects that a three-dimensional structure of the bag body is stable, the inner layer friction performance and the outer layer friction performance of the bag body are properly set, used materials are saved, and the strength is high. The bag is particularly suitable for automatic cheese canning.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Release film

InactiveCN105358308BExcellent heat resistance and dimensional stabilityExcellent curl resistancePolystyrenePolymer chemistry

The present invention provides a polystyrene mold-release film having sufficiently excellent heat dimension stability and curl resistance. The present invention pertains to a mold-release film composed of a biaxially oriented polystyrene film containing a syndiotactic polystyrene resin, the mold-release film being characterized in that at least one surface is matt-finished and the curl rate of the mold-release film is 80% or less.

Owner:KURASHIKI BOSEKI KK

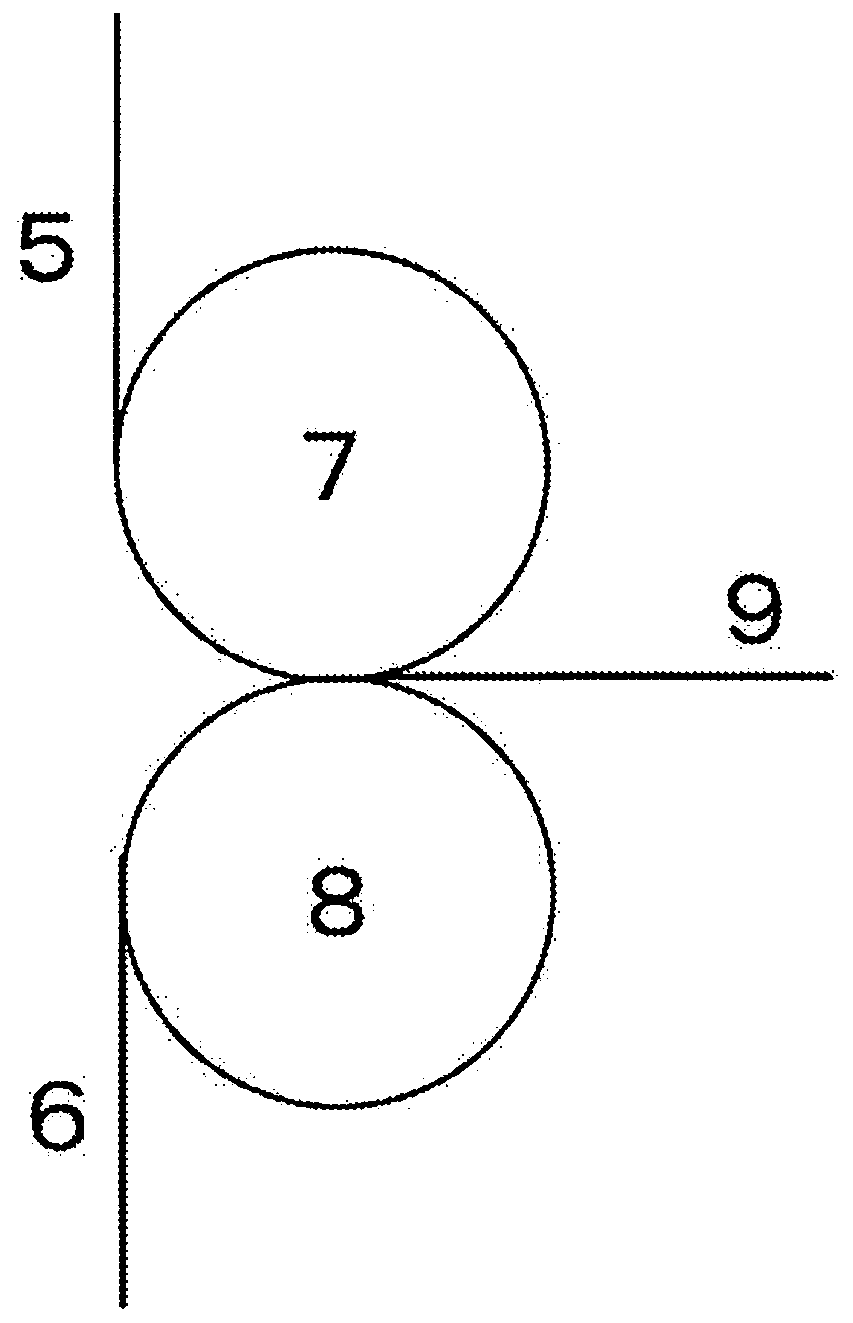

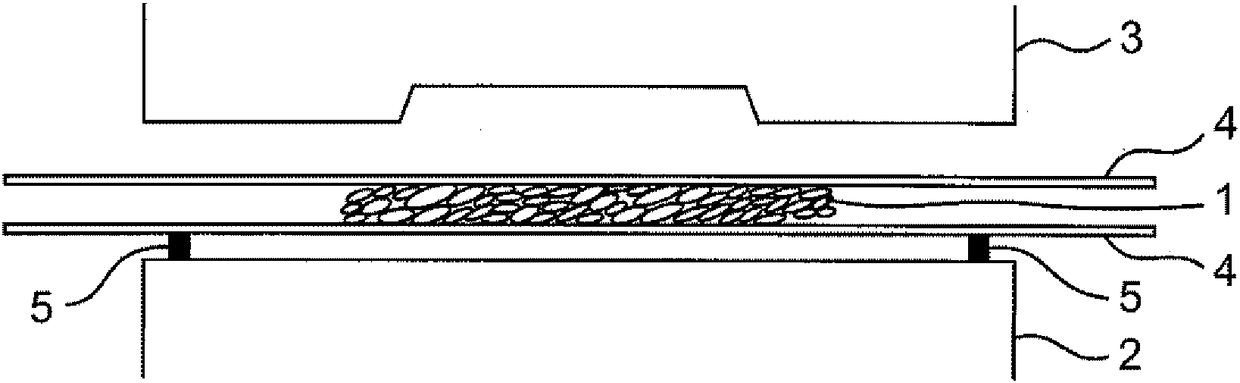

Processing technology of curl-resistance PE cast film

InactiveCN111016233AGood optical performanceImprove uniformityFlat articlesHigh volume manufacturingThin membrane

The invention discloses a processing technology of a curl-resistance PE cast film. The cast film prepared by the technology has excellent optical performance and thickness uniformity, a very high production speed can be obtained due to adoption of a quenching roller, and the form structure of the film is improved; the curl-resistance property and flatness of the film can be effectively improved, the characteristics of good curl-resistance property, good flatness and the like are achieved, meanwhile, the advantages of high production speed, high yield and the like are achieved, large batch production is facilitated, the thickness control precision of products is high, meanwhile, the thickness uniformity is good, the transparency and glossiness are made excellent synchronously, the balance performance in all directions is outstanding, all layers of melt can be uniformly distributed after spreading on a die head, mutual mixing among all layers of materials can be prevented, the overall thickness can be monitored and adjusted, and the thickness of certain key functional layers can be monitored and adjusted.

Owner:常州唯尔福卫生用品有限公司

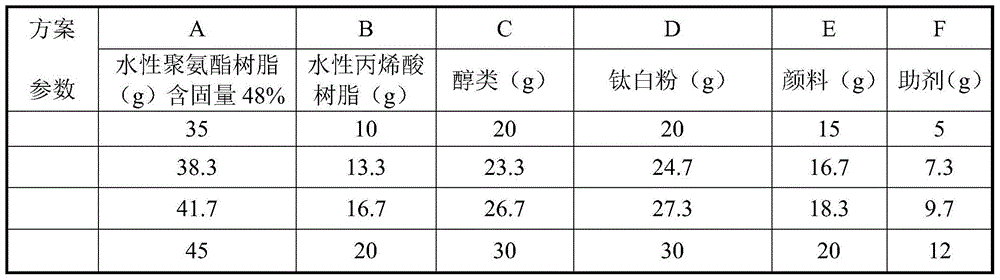

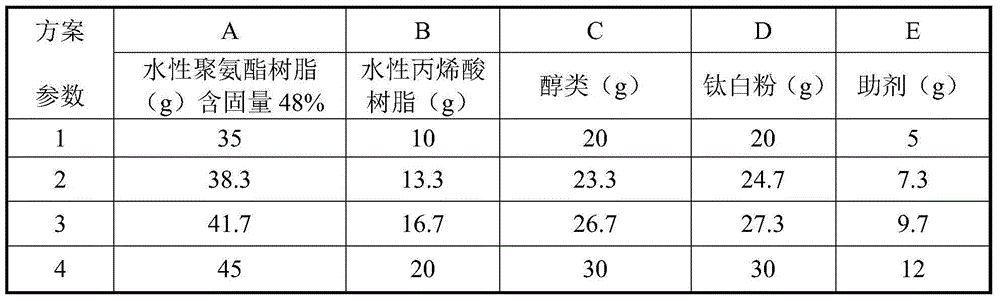

A kind of umbrella water-based ink for impacting cloth fabrics and its coating method

The invention discloses umbrella water-based ink for pongee fabrics and a coating method of the water-based ink. The water-based ink comprises, in parts by weight, 35-45 parts of waterborne polyurethane resin, 10-20 parts of water-based acrylic resin, 20-30 parts of alcohols, 20-30 parts of titanium dioxide and / or 15-20 parts of color paste and 5-12 parts of an assistant. The water-based ink has the advantages that products are good in leveling property and high in crimp resistance, reverse sticking and the damage to coatings can be avoided after finished umbrella covers are overlaid, scrapping is less, and pattern colors are more stable; and the water-based ink is safe, non-toxic, innocuous, non-ignitable, non-explosive, almost free of volatile gases and low in cost, has significant economic benefits and the like.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

Preparation process of anti-curling polyimide thin film

InactiveCN110551282AUniform particle size distributionEvenly dispersedPolyimide substratePolymer science

The invention relates to the technical field of preparation of polyimide thin films, in particular to a preparation process of an anti-curling polyimide thin film. The preparation process comprises the following steps: preparation of calcium molybdate nanopowder, preparation of modified nanopowder, synthesis of polymer resin, resin regulation and film formation. The surfaces of calcium molybdate nanoparticles are modified through KH550, the nanoparticles are prevented from being agglomerated in the polymer resin through volume steric hindrance of a long chain organic part, meanwhile, the compatibility between inorganic nanoparticle calcium molybdate and an organic polymer is also improved, and thus the nanoparticles are more evenly dispersed in a polyimide substrate; and a continuous and complete three-dimensional network is formed in the KH550-CaMoO4 nanoparticle polyimide substrate, thus the rigidity of polymer molecular chains is enhanced, acting force between the molecular chains is enhanced, energy needed for bending and cracking of the polymer molecular chains at the high temperature is increased, and the prepared thin film is good in anti-curling performance.

Owner:合肥中汇睿能能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com