Adhesive film

A pressure-sensitive adhesive, pressure-sensitive adhesive technology, applied in pressure-sensitive films/sheets, adhesive types, ester copolymer adhesives, etc., can solve problems such as bulging over time, and achieve excellent impact resistance , The effect of excellent heat stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0099] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples.

[0100] Measurement and Evaluation Methods of Physical Properties

[0101] (i) Adhesion at a temperature of 5°C

[0102] After adjusting the state of the pressure-sensitive adhesive film for more than 24 hours in an environment with a temperature of 5° C. and a relative humidity of 50%, use Tuckine Chekka (Model HTC-1) of Toyo Seiki Manufacturing Co., Ltd. under the same environment, The pressure-sensitive adhesive of the pressure-sensitive adhesive film was measured under the conditions that the type of contact is a flat surface indenter (model AL-M1), the contact crimping force is 5N, the crimping time is 3 seconds, and the number of repeated tests is 5 times. Adhesion of the surface on the layer side (unit: N). The results reported in the table are the average value of 5 tests.

[0103] (ii) Adhesion at a temperature of 35°C

[0104] After conditionin...

example 1

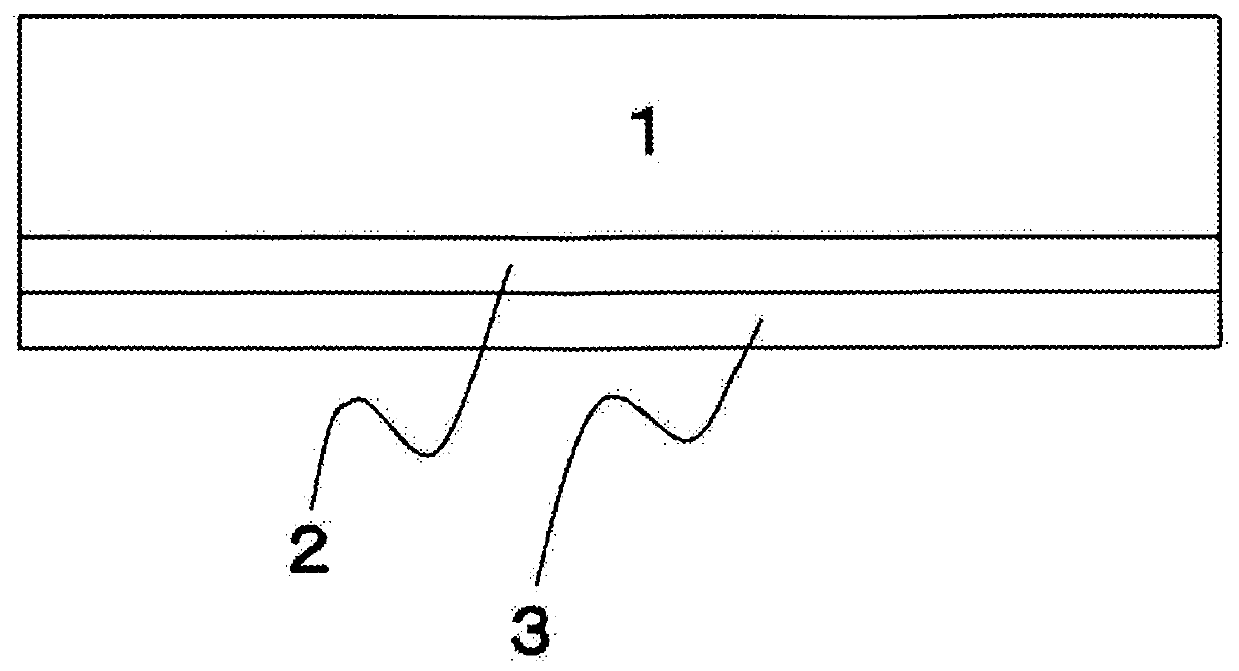

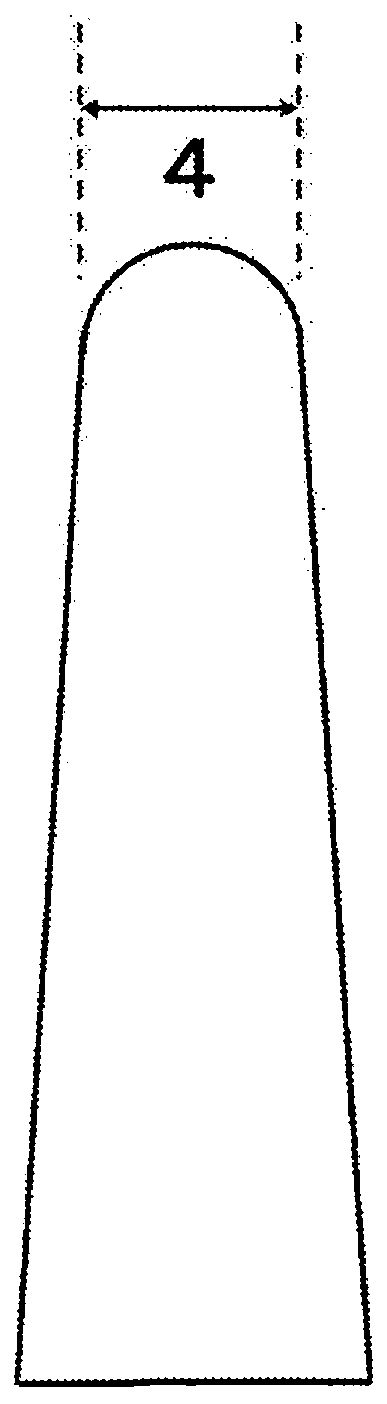

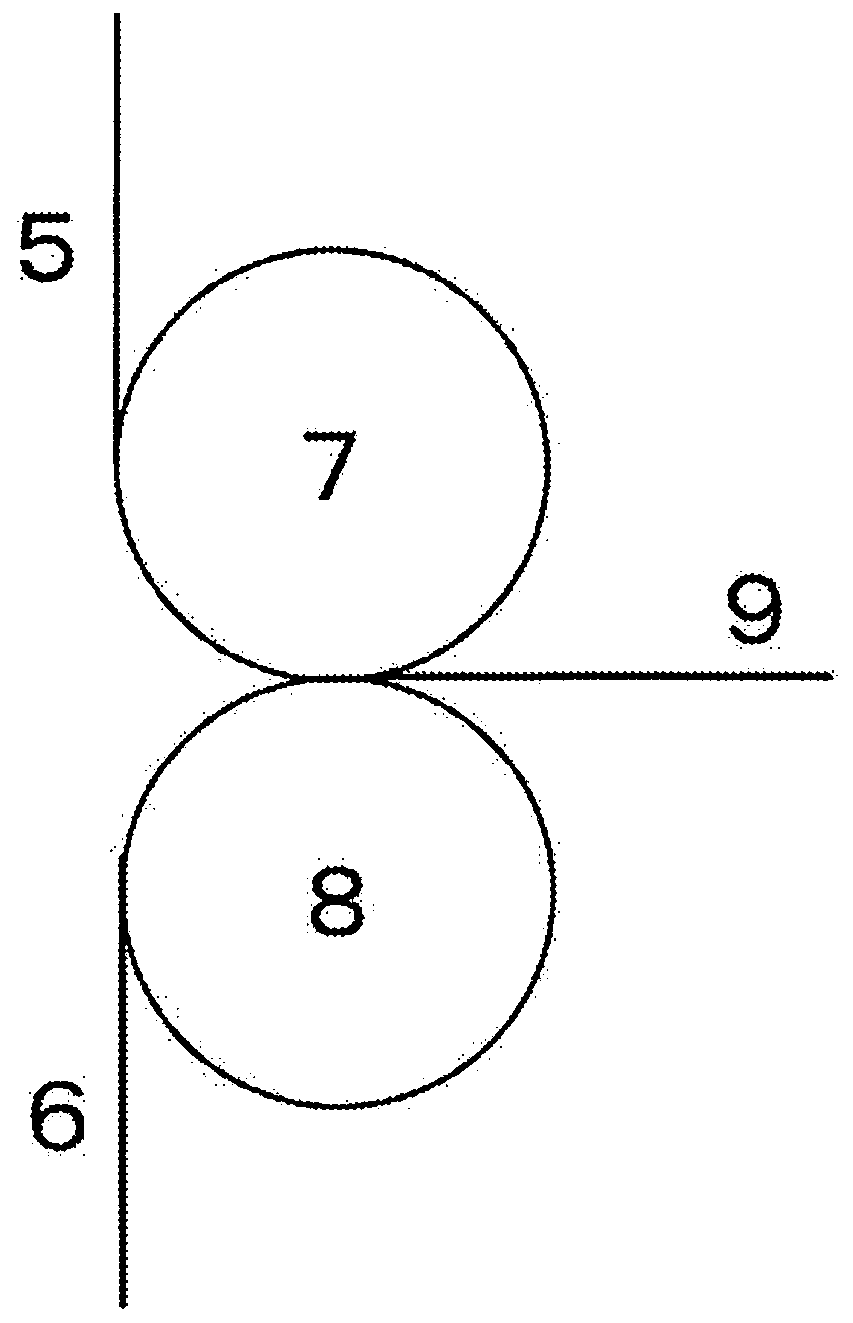

[0140] 100 parts by mass of the above-mentioned component (A-1), 1.22 parts by mass of the above-mentioned component (B-1) (in terms of solid content), 22.5 parts by mass of the above-mentioned component (C-1), 7.5 parts by mass of the above-mentioned component (C-2) and 69 parts by mass of the above component (C-3) were mixed and stirred to obtain a pressure-sensitive adhesive. Next, the pressure-sensitive adhesive obtained above was coated on the release surface of the release paper using a roll coater so that the thickness after drying became 45 μm, and dried in a drying oven to form a pressure-sensitive adhesive layer. Next, use the image 3 The device shown in the conceptual diagram in , the laminate 5 of the release paper and the pressure-sensitive adhesive layer obtained above, the above-mentioned (α-1) polyvinyl chloride-based resin film 6 and the pressure-sensitive adhesive layer of the laminate 5 In such a manner that the above-mentioned (α-1) polyvinyl chloride-bas...

example 2~7

[0142] Except having changed the compounding quantity (parts by mass) of the pressure-sensitive adhesive as shown in Table 1, it carried out similarly to Example 1, and performed the measurement and evaluation test of the manufacture of a pressure-sensitive adhesive film and a physical property. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com