Patents

Literature

773results about How to "Enhanced resistance to peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal alkyl borphydride polymerisation initiators, polymerisable compositions, and uses thereof

InactiveUS6844080B2Wide rangeImprove impact resistanceSynthetic resin layered productsOrganic non-macromolecular adhesiveLithiumPolyolefin

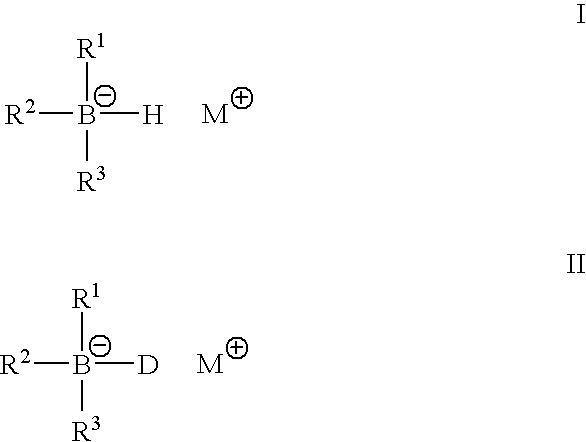

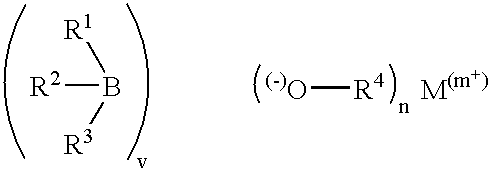

Metal alkyl borohydrides are used as initiators of polymerisation, particularly in adhesive compositions for bonding a wide range of substrates including low surface energy substrates such as polyolefins. As described, the metal alkyl borohydrides are of the formula I or II. whereinR1 is C1-C10 alkyl,R2 and R3, which may be the same or different, are H, D, C1-C10 alkyl or C3-C10 cycloalkyl, phenyl, or phenyl-substituted C1-C10 alkyl or C3-C10 cycloalkyl, provided that any two of R1-R3 may optionally be part of a carbocyclic ring, andM+ is a metal ion.In particular, alkali metal trialkyl borohydrides are used, the alkali metal salt being selected from: Lithium triethylborohydride, Sodium triethylborohydride, Potassium triethylborohydride, Lithium tri-sec-butylborohydride, Sodium tri-sec-butylborohydride, Potassium tri-sec-butylborohydride, and Lithium triethylborodeuteride. Other exemplified compounds which are less effective on low surface energy substrates include Lithium 9-borabicyclo [3.3.1]-nonane (9BBN) hydride, Lithium thexylborohydride, Lithium trisiamylborohydride and Potassium trisiamylborohydride.

Owner:HENKEL IP & HOLDING GMBH

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

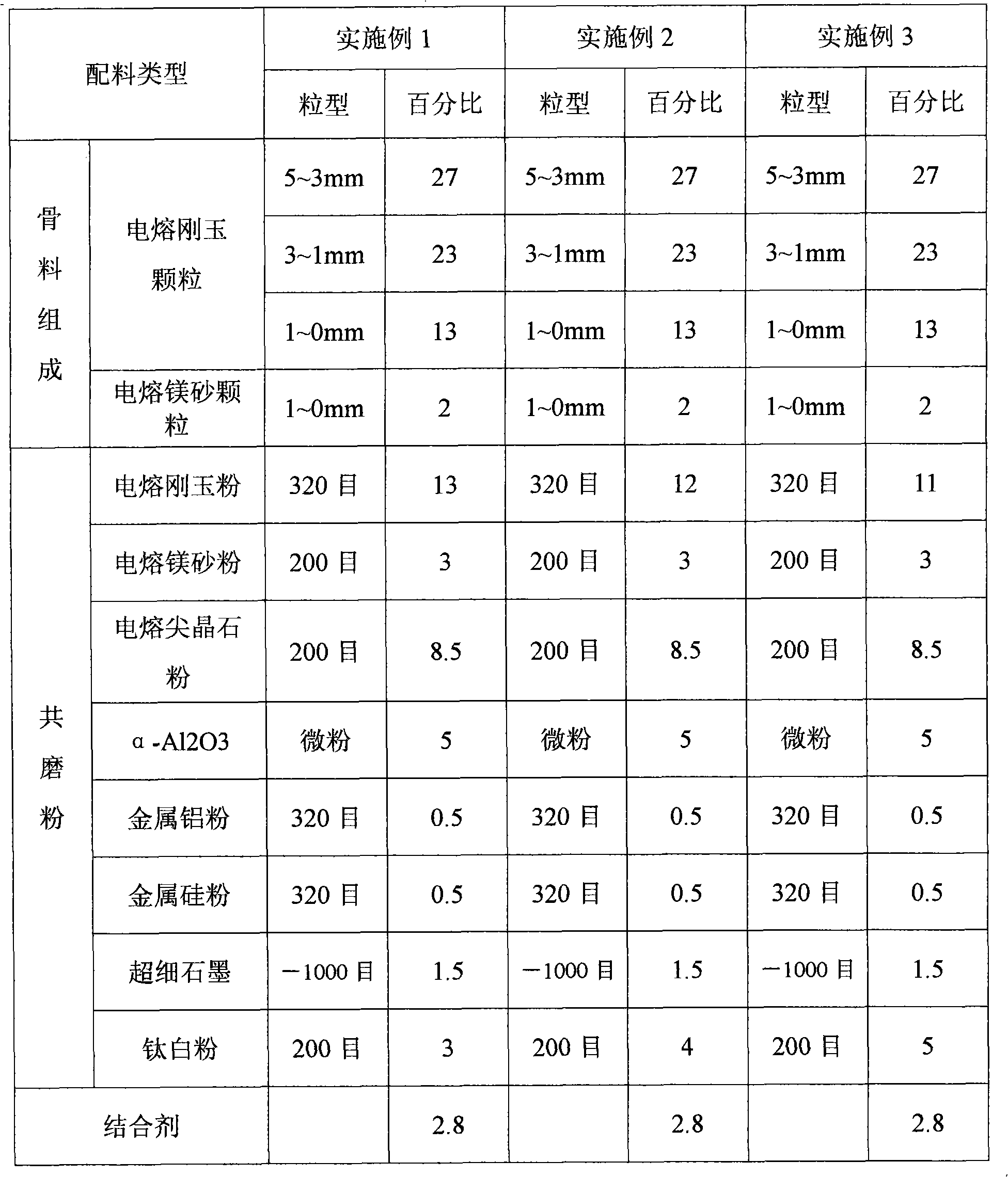

Low-carbon corundum spinelle brick for refined steel ladles and preparation method thereof

The invention relates to a low-carbon corundum spinelle brick for refined steel ladles and a preparation method thereof for overcoming the defect of overhigh carbon content in the prior carbon-contained fireproof material technology. The low-carbon corundum spinelle brick for refined steel ladles comprises the following components in percentage by weight: 60-70 fused corundum particles, 2-6 fused magnesite particles, 10-20 fused corundum fine powder, 2-10 fused magnesite fine powder, 5-15 fused spinelle fine powder, 3-6 alpha-Al2O3 micro powder, 0-2.0 metal aluminum fine powder, 0-2.0 metal silicon fine powder, 2-6 bond, 1-2 superfine graphite and 2-6 titanium white powder. The invention has good thermal stability at high temperature, resists high temperature and the erosion of molten steel and slag and has high mechanical strength, good thermal shock stability and high under-load softening point, thereby being widely applied to various steel ladles, in particular to steel ladles of refined low-carbon steel and ultra-low-carbon steel.

Owner:海城利尔麦格西塔材料有限公司 +2

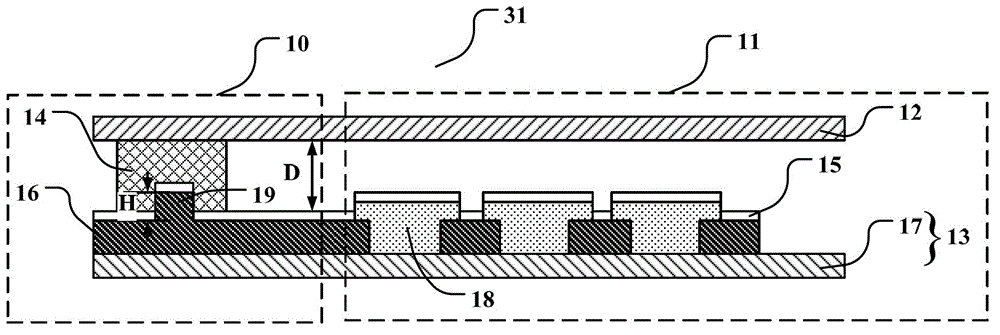

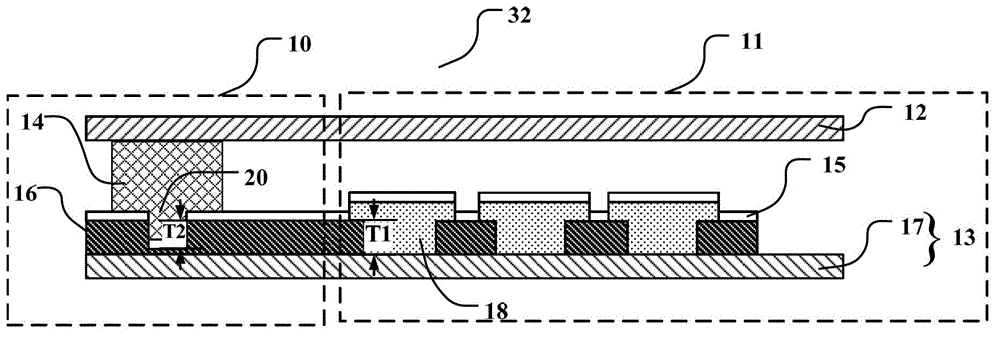

Color filter substrate, manufacturing method thereof and liquid crystal display panel

InactiveCN103941460AIncrease contact areaImprove adhesion strengthOptical filtersPhotomechanical apparatusLiquid-crystal displayAdhesion strength

The invention discloses a color filter substrate, a liquid crystal display panel comprising the color filter substrate and a manufacturing method of the color filter substrate. The color filter substrate comprises a substrate body, black matrixes and color filter patterns, wherein the substrate body is provided with display regions and non-display regions located on the peripheries of the display regions, the black matrixes are arranged on the substrate body, sub-pixel regions are defined on the black matrixes, corresponding to the display regions, of the substrate body and the surface of the black matrixes, corresponding to the non-display regions, of the substrate body are uneven surfaces and the color filter patterns are arranged in the sub-pixel regions. According to the color filter substrate, the black matrixes, located at the positions of the non-display regions, on the color filter substrate are provided with the uneven surfaces, the shape of the face, making contact with sealant, of the color filter substrate is changed, the contacting area between the color filter substrate and the sealant is increased, the adhesion strength between the color filter substrate and the sealant is enhanced, the stripping strength of the color filter substrate and a thin film transistor array substrate is enhanced and the problem that liquid crystal leakage is generated due to the fact that the color filter substrate and the sealant are easy to strip is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

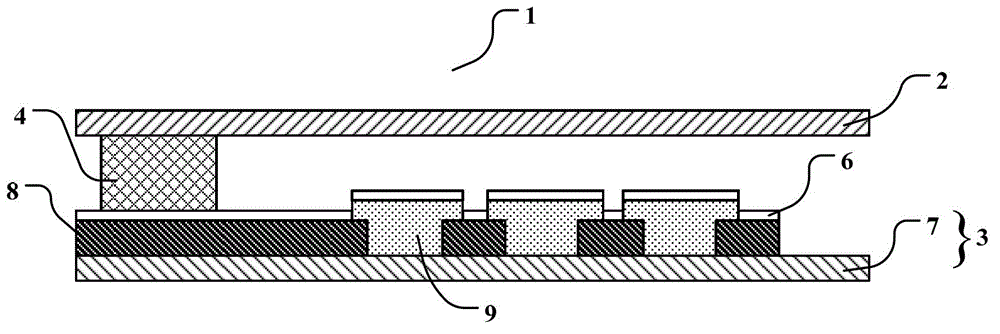

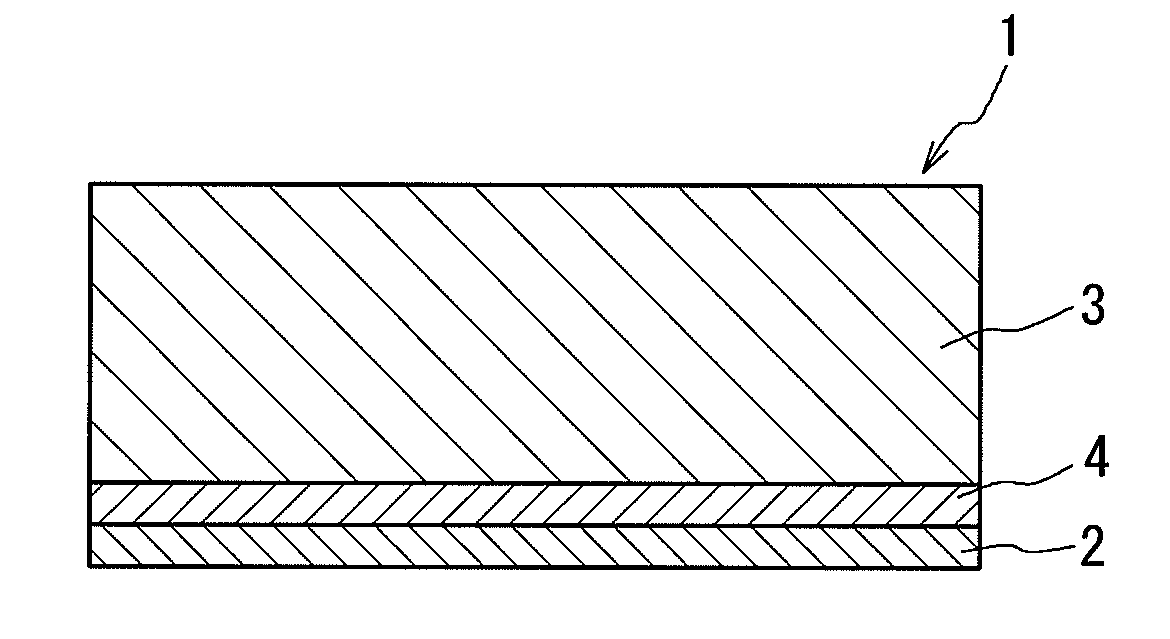

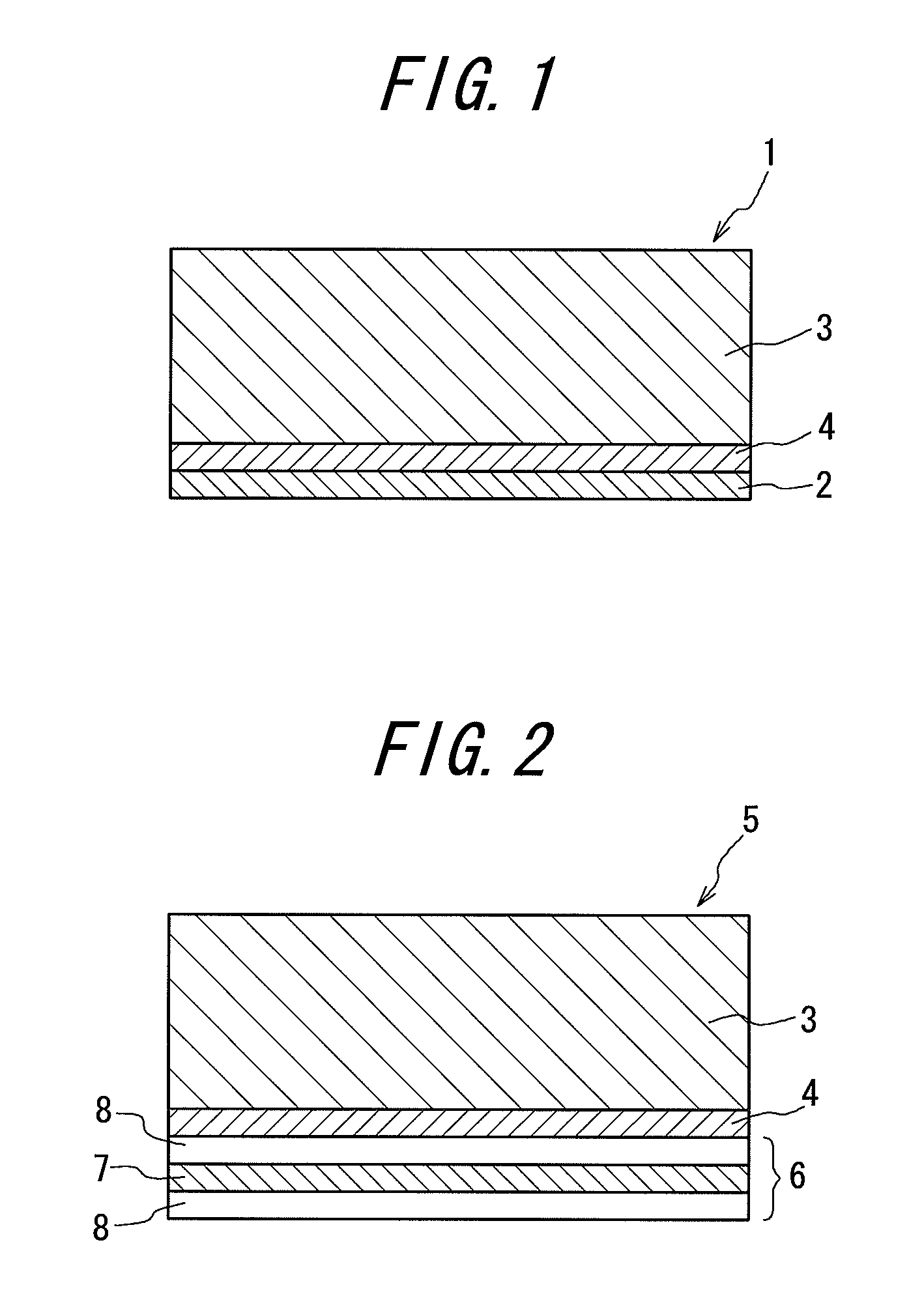

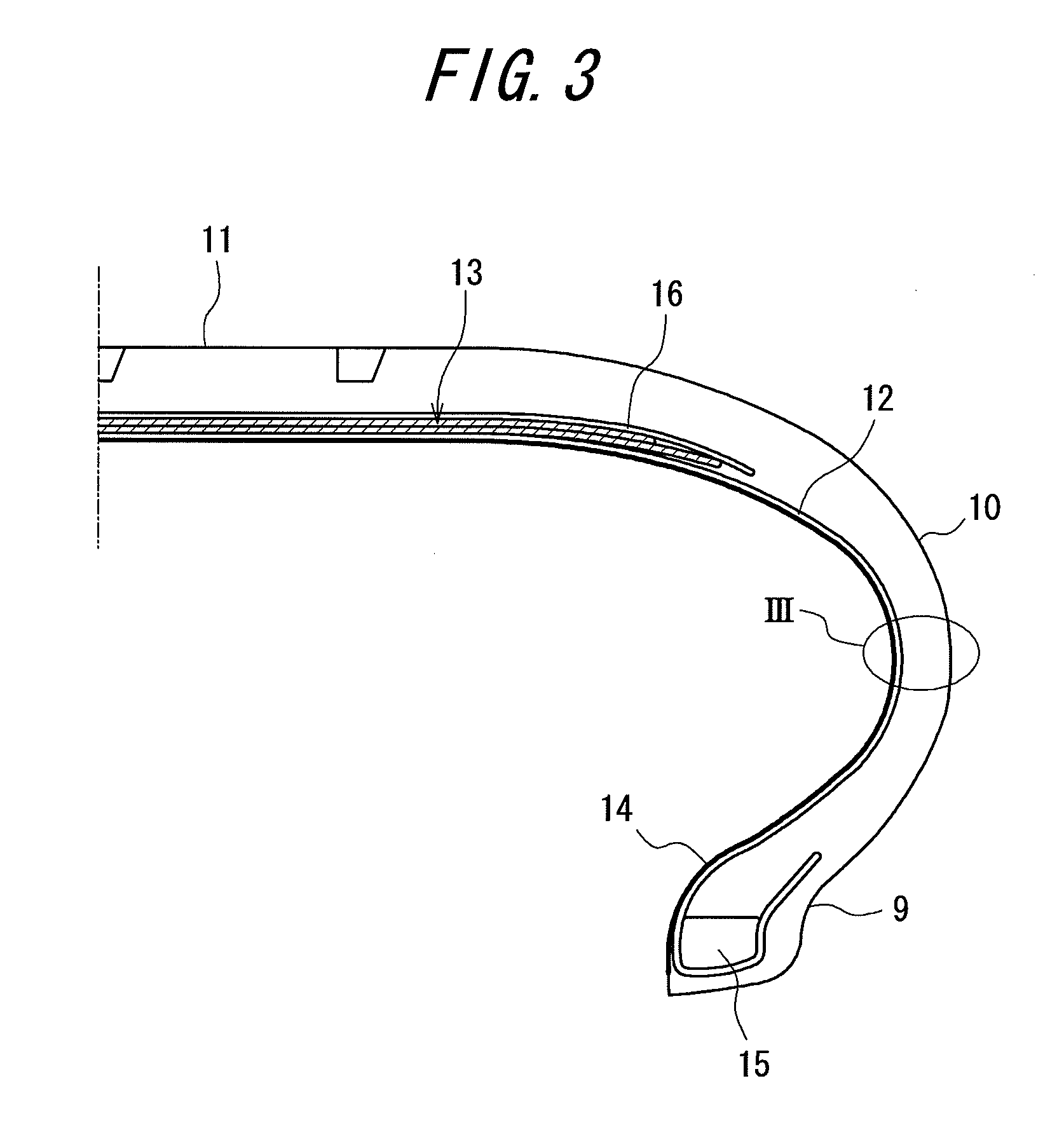

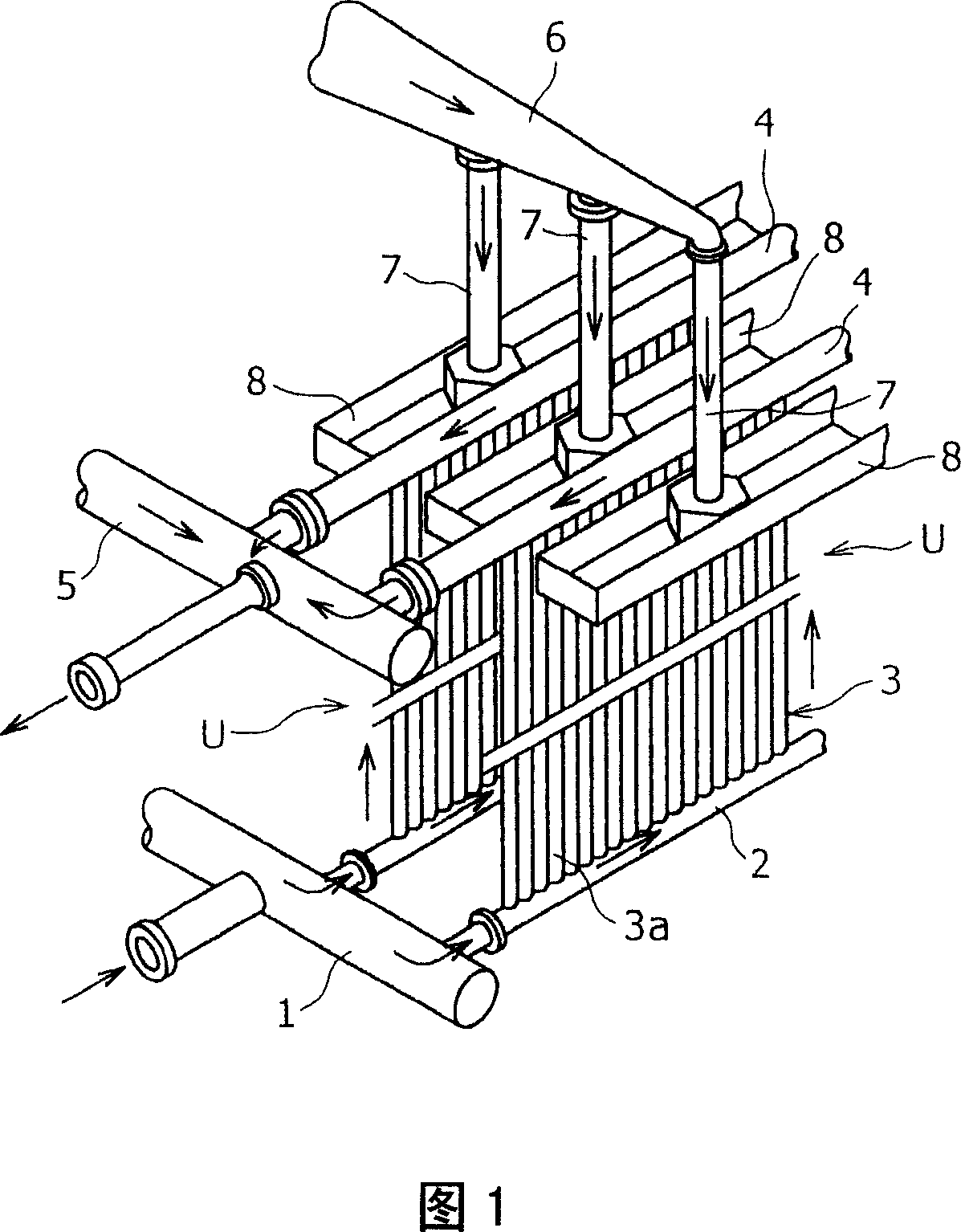

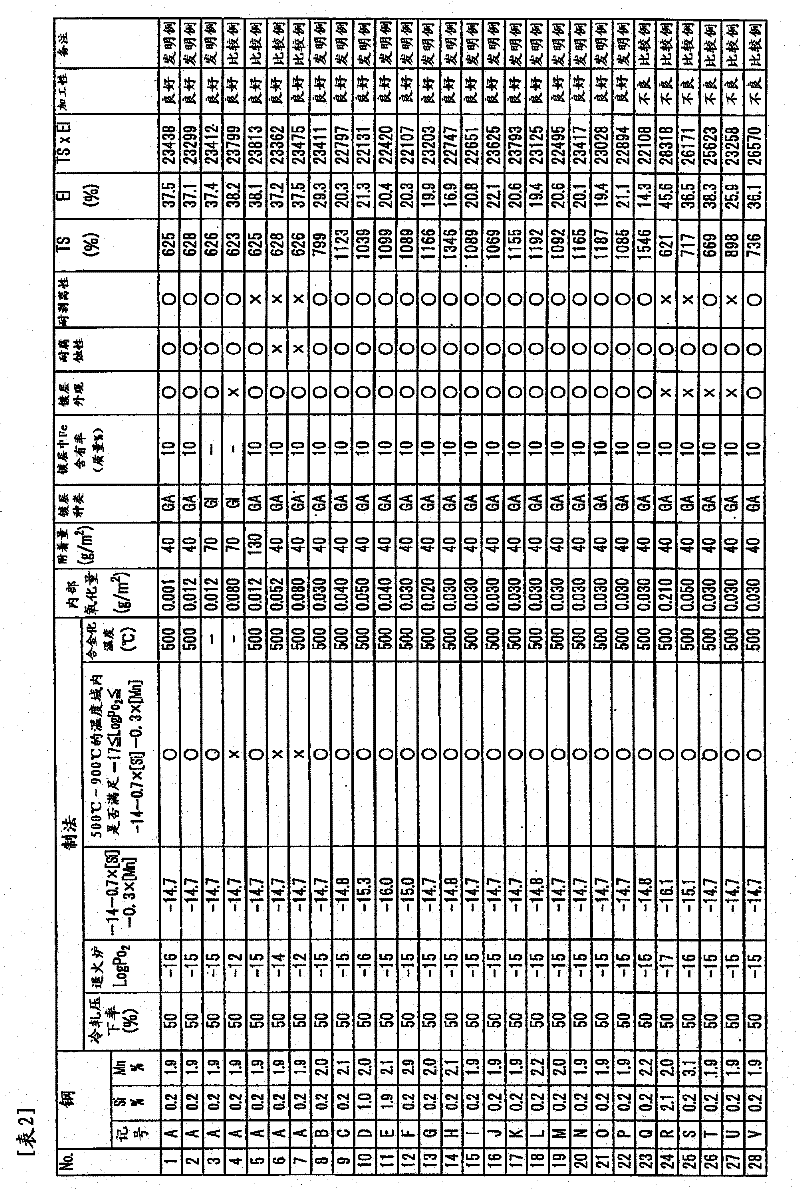

Laminated body and method of producing the same as well as innerliner for pneumatic tire and pneumatic tire

InactiveUS20090308517A1Improve machinabilityImprove anti-stripping performanceCoatingsWheelsElastomerYoung's modulus

The invention provides a laminated body (1) having a good workability during the production and an excellent peeling resistance, which is formed by joining a resin film layer (D) (2) comprising at least a layer composed of a resin composition (C) in which a soft resin (B) having a Young's modulus at 23° C. lower than that of a thermoplastic resin (A) is dispersed in a matrix made from the thermoplastic resin (A) and a rubbery elastomer layer (E) (3) through an adhesive layer (F) (4), wherein an adhesive composition (I) formed by compounding not less than 0.1 part by mass of at least one of a maleimide derivative (H) having not less than two reaction sites in a molecule thereof and poly-p-dinitrosobenzene based on 100 parts by mass of a rubber component (G) is applied to the adhesive layer (F) (4).

Owner:KURARAY CO LTD +1

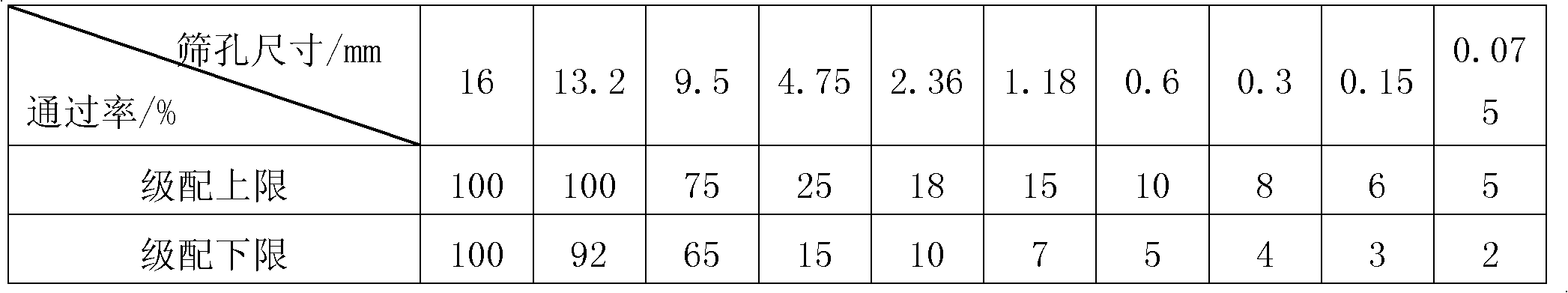

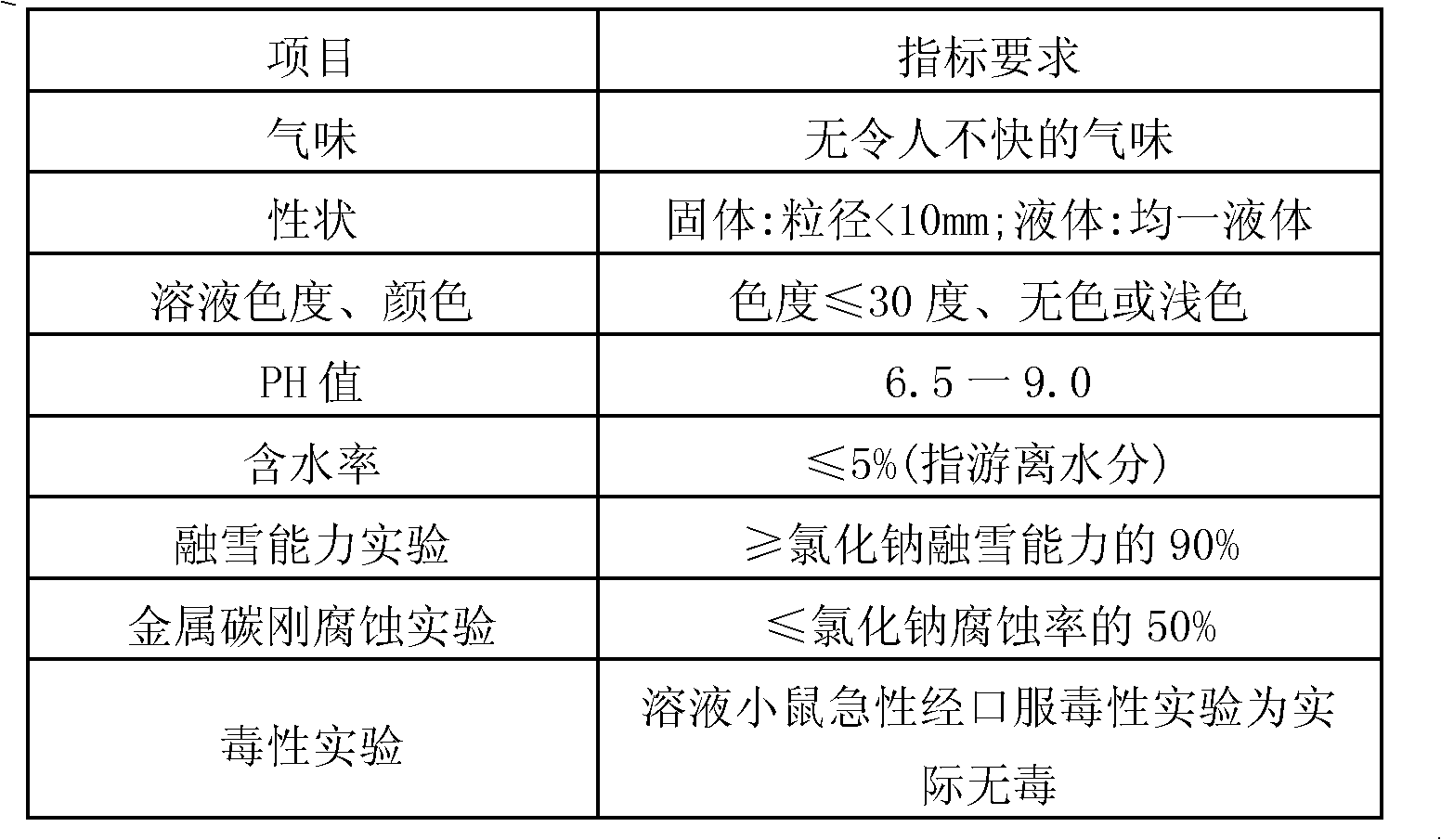

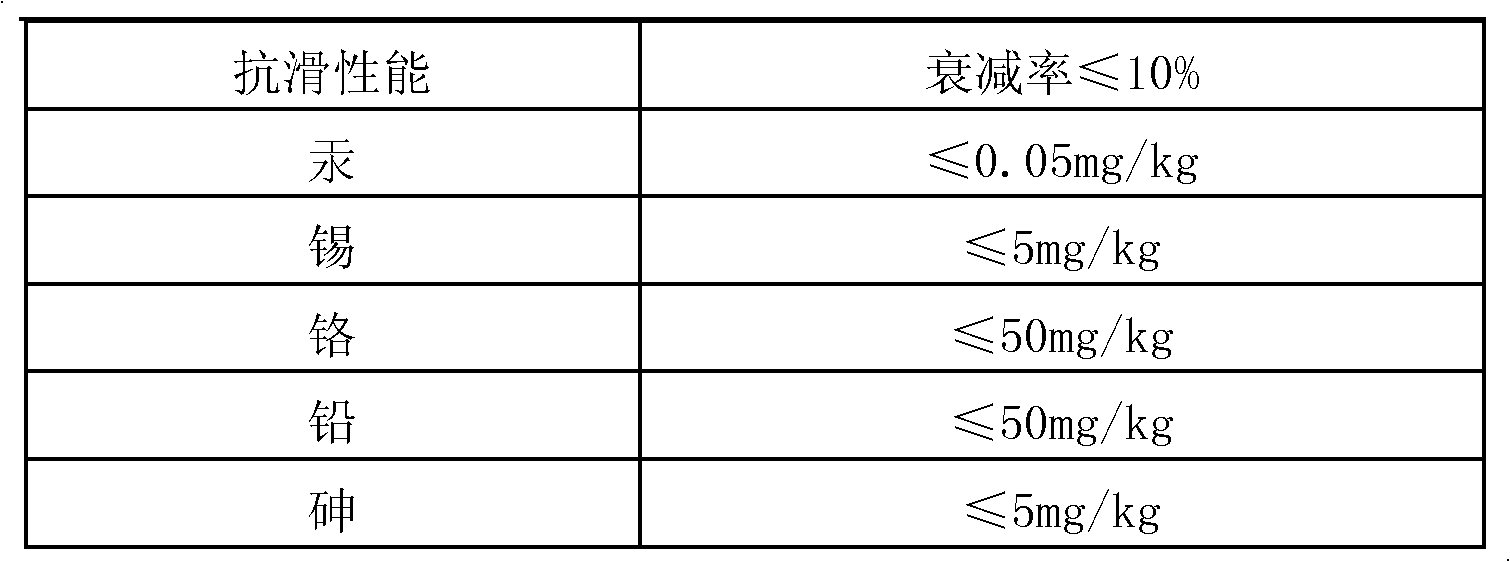

Preparation method for deicing, antiskid and denoising asphalt pavement material

The invention relates to a preparation method for a deicing, antiskid and denoising asphalt pavement material. The method is characterized by comprising the following steps: 1) preparation of rubber modified asphalt with high viscosity and high elasticity; 2) preparation of an organic / inorganic ice inhibiting material; 3) selection of mineral aggregate gradation; 4) preparation of the deicing, antiskid and denoising asphalt pavement material, which is realized by preparing mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and fibers according to a mass ratio of 100: 4.8-5.1: 1.05-2.1: 0.225-0.533, heating the rubber modified asphalt with high viscosity and high elasticity at a temperature of 165 to 175 DEGC, and mixing and stirring the mineral aggregate, the rubber modified asphalt with high viscosity and high elasticity, the organic / inorganic ice inhibiting material and the fibers at a temperature of180 to 190 DEG C for 60 to 90 s, with paving temperature being 165 to 180 DEG C, so as to obtain the deicing, antiskid and denoising asphalt pavement material. The asphalt pavement material prepared by using the method has the characteristics of ice removal, skid resistance and noise reduction.

Owner:WUHAN UNIV OF TECH

Novel fiber reinforced cellular board and preparation method thereof

InactiveCN101797822AImprove mechanical propertiesWon't hurtLaminationLamination apparatusEpoxyWhole body

The invention provides a novel fiber reinforced cellular board and a preparation method thereof. The novel fiber reinforced cellular board consists of panels on the two sides and a cellular core of a pyramid-shaped structure. The cellular core of the pyramid-shaped structure is prepared by the following steps: injecting high-strength dispersed short-cut fiber cotton / felt into an epoxy resin substrate; or presoaking the epoxy resin substrate by the high-strength dispersed short-cut fiber of 10 mm to 30 mm to form a pre-mixed molding material; and heating, pressurizing and molding the pre-mixed molding material. The prepared cellular core consists of a series of concave-convex staggered pyramid-shaped platform bodies which form a stable whole body together under the action of the two panels on the two sides, so the novel fiber reinforced cellular board has various high mechanical properties. The novel fiber reinforced cellular board has very simple molding process and low production cost, and can realize continuous high-efficiency production.

Owner:王韬

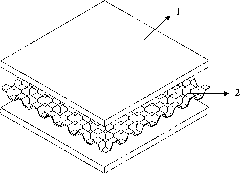

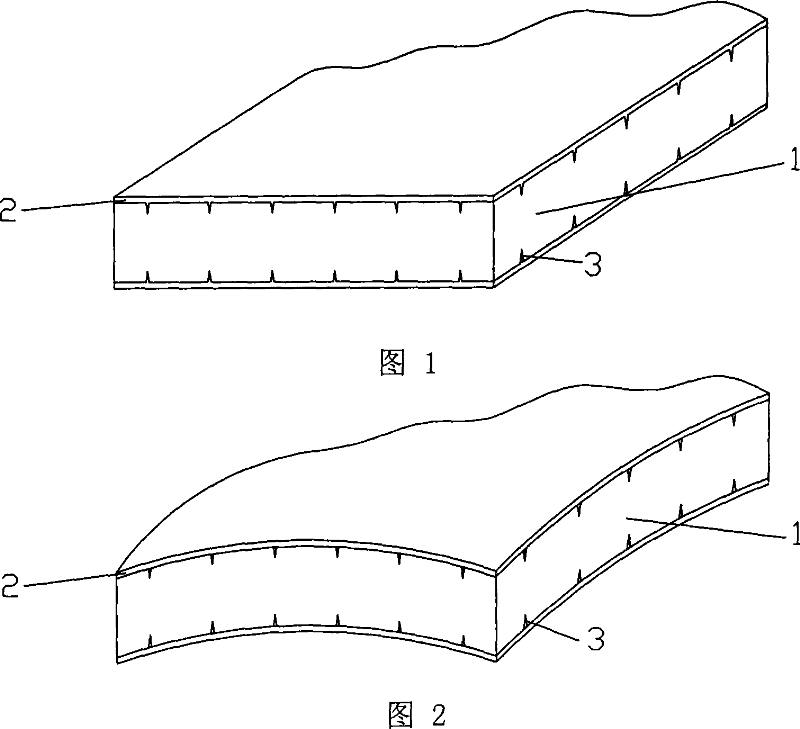

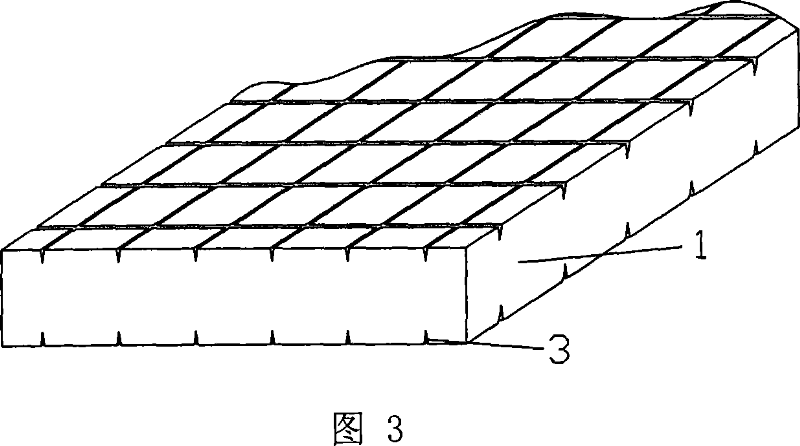

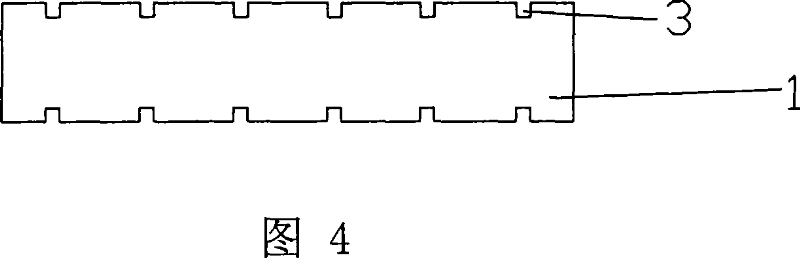

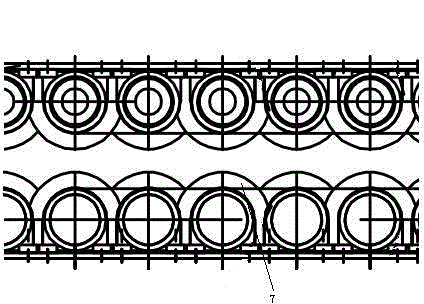

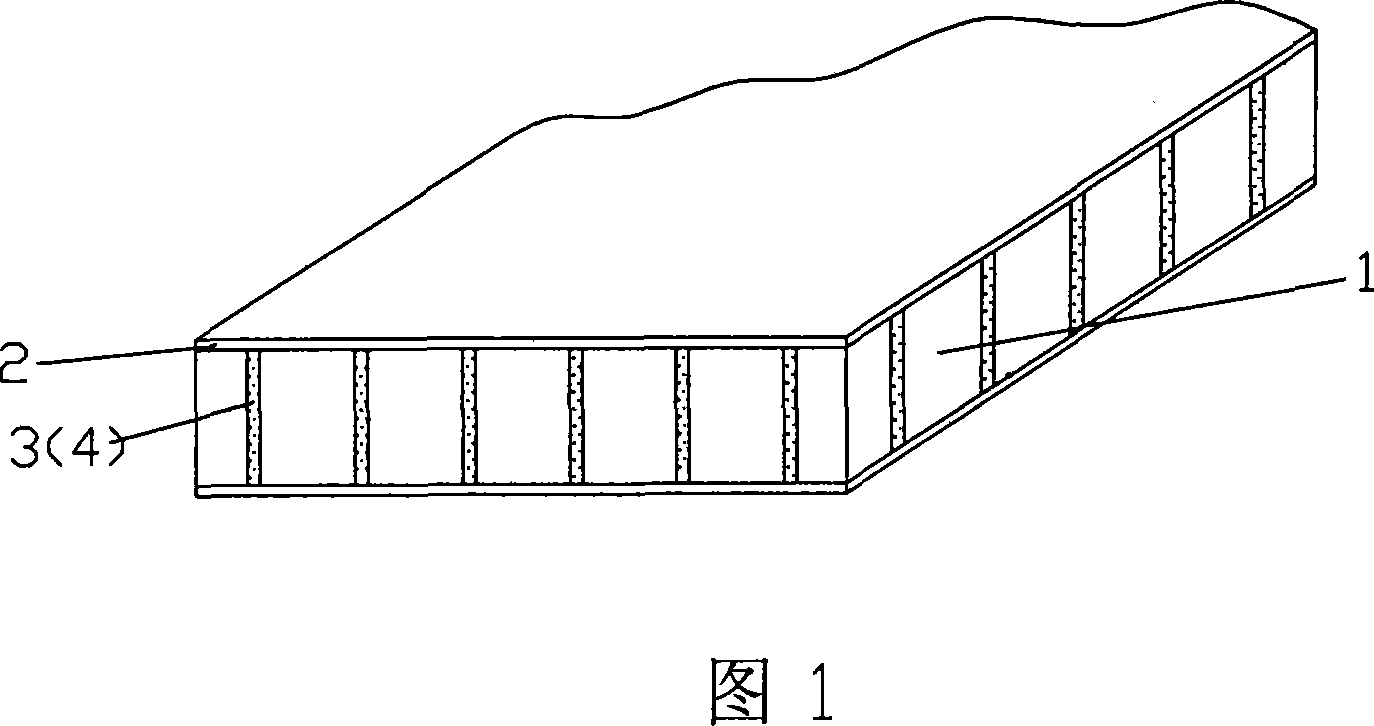

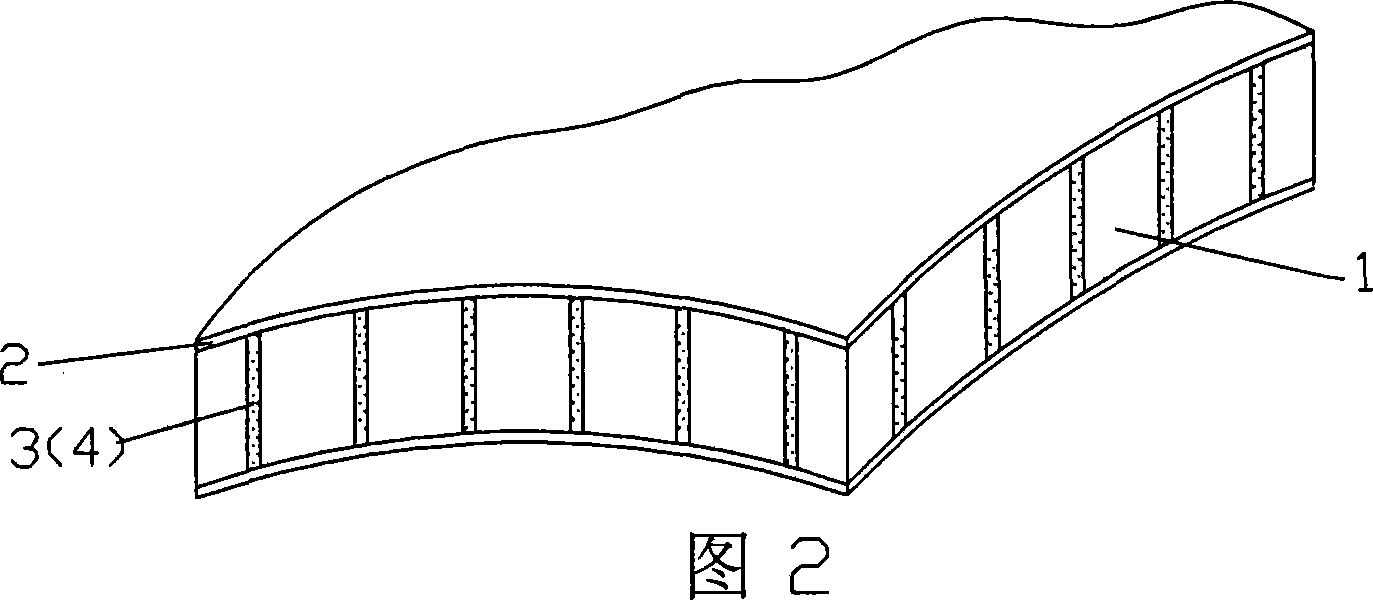

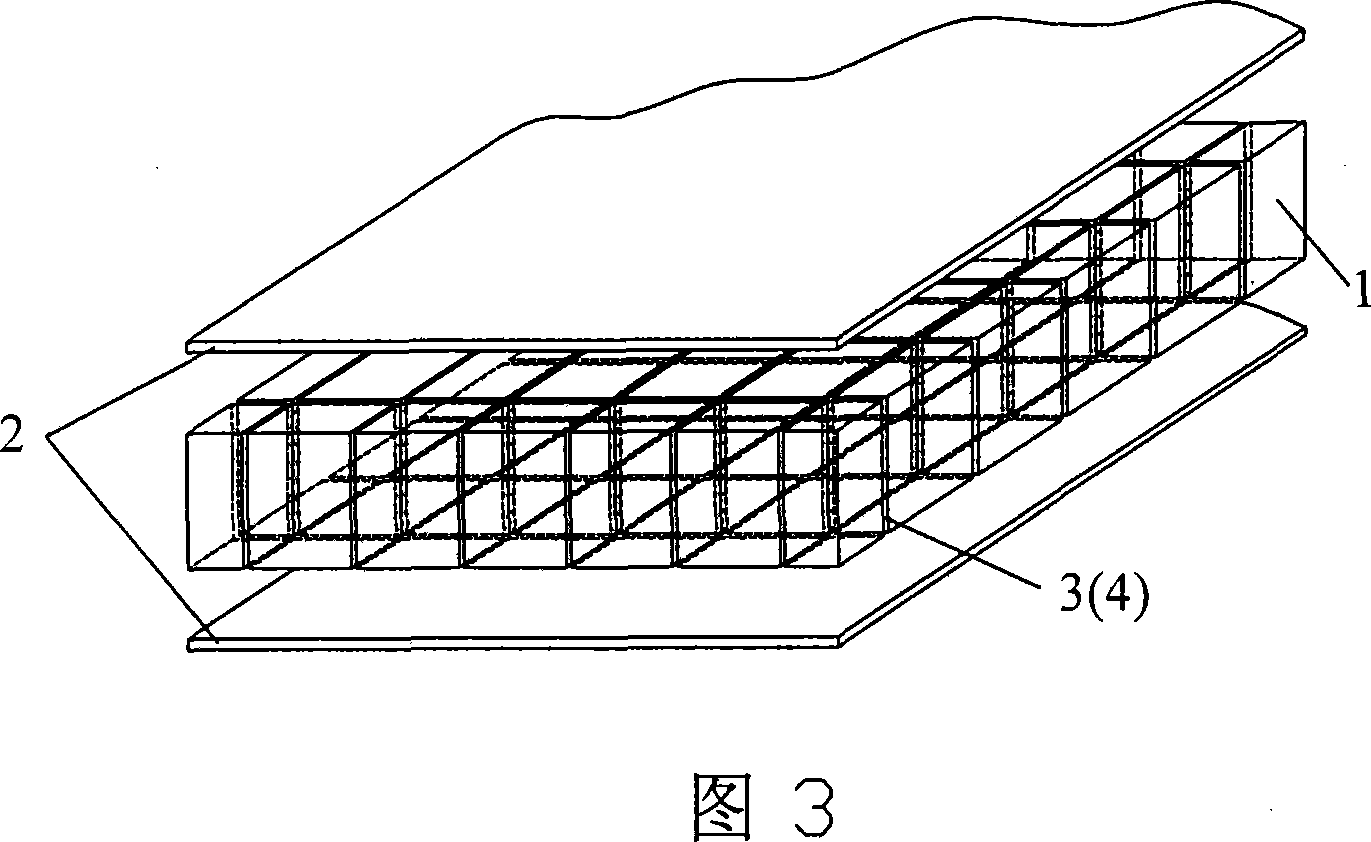

Alveolus type interlayer structure of the composite material

InactiveCN101041278AImprove mechanical performanceEnhanced resistance to peelingWallsLayered productsEngineeringWall material

The invention relates to a cogging composite sandwich structure comprising core material (1) and face plate (2), characterized in that net concave grooves (3) are set at top and bottom faces of core material (1) and face plates (2) are put on top and bottom faces of core material (1) by resin. Compared with other products, the biggest characteristic is that concave grooves filled with resin fully can enhance the anti-stripping ability of face plates and core material obviously and it makes the whole forced performance and the usage effect of composite sandwich structure be improved obviously. It is applied in aerospace, ship and vehicle so on universally and it is also applied in building fields such as roof board, building template and wall material so on.

Owner:NANJING TECH UNIV

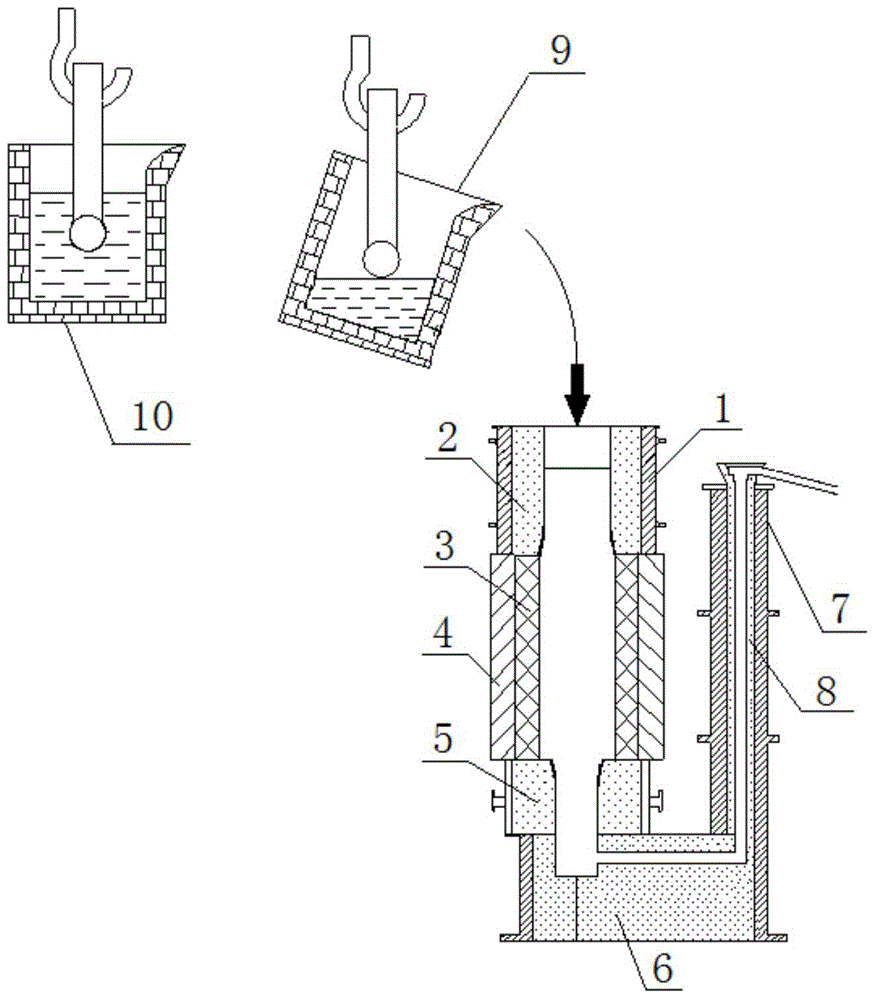

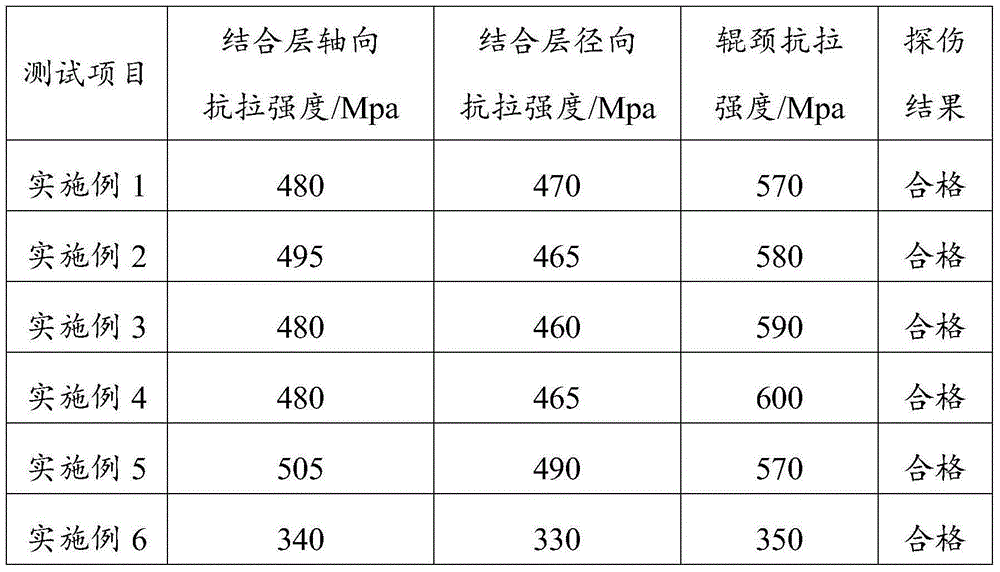

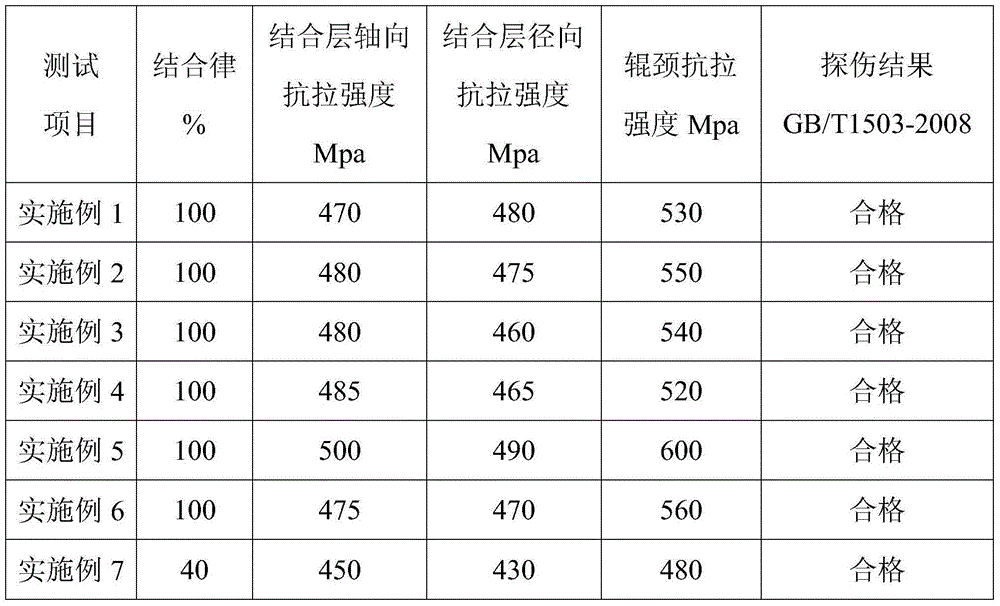

High-speed steel roller manufacturing method

ActiveCN104525889AHigh bonding strengthEnhanced resistance to peelingCarbideUltimate tensile strength

The invention discloses a high-speed steel roller manufacturing method which is suitable for small steel rolling machines and bar mills. The manufacturing method comprises the three process steps of raw material smelting, casting moulding, machining and heat treatment. On the basis that high-speed molten iron is centrifugally poured, firstly, transition layer molten iron is poured, and then the complete replacement of the transition layer molten iron is achieved by pouring core part molten iron. According to the high-speed steel roller manufacturing method, the combination strength of outer layer high-speed steel and the core part molten iron is obviously increased and increased to 500 Mpa or higher from around 350 Mpa in the past, and thus the anti-stripping performance of the combination layer of a roller body of a high-speed steel roller is greatly improved. Meanwhile, the amount of carbide forming elements generated by corrosion to the outer layer by the core part molten iron can be effectively reduced, so that the texture of a roller neck is improved, the tensile strength of the roller neck is increased, and the phenomenon of roller breakage in the using process is effectively eradicated.

Owner:邢台轧辊线棒辊有限责任公司

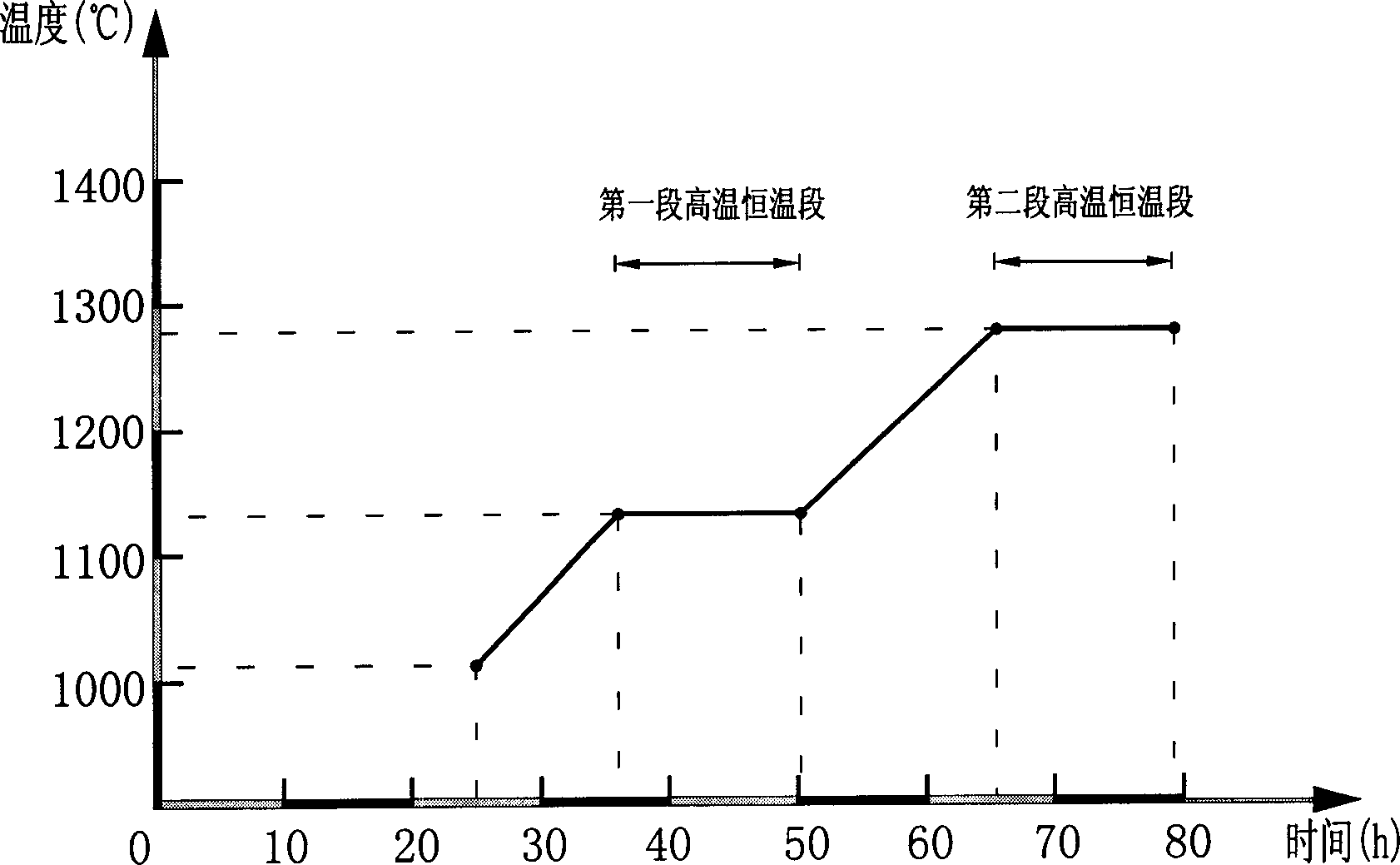

Ltigh crystalline structure iolite mullite kiln, kiln refractory product and calcining technology

The present invention relates to a kind of high crystal structure cordierite-mullite kiln furniture, kiln furnace refractory product and roasting process. Its raw material includes (by weight portion) 50-80 portions of main crystal phase material and 20-50 portions of combined compound matrix material, in the above-mentioned raw material a proper quantity of crystal nucleus formation agent can be added. Its roasting process includes two stages of high-temperature constant-temperature microcrystallization nucleation intensification treatment. Said invention also provides the concrete steps of every stage.

Owner:揭东县热金宝新材料科技有限公司 +2

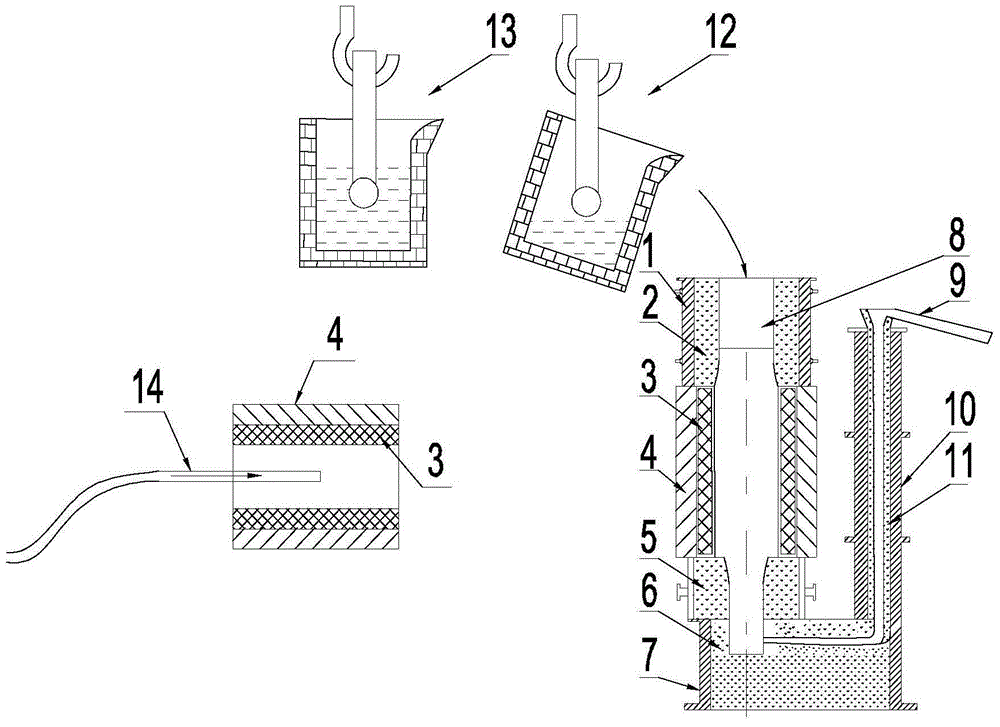

Manufacturing method for high-vanadium high-speed steel composite roll

The invention discloses a manufacturing method for a high-vanadium high-speed steel composite roll suitable for a narrow strip rolling mill. The manufacturing method comprises the steps that an outer layer of a roll body is poured by adopting a centrifugal pouring method, and after the outer layer of the roll body is poured with high-vanadium high-speed liquid steel, inert gas is continuously pumped into a cavity of the outer layer of the roll body; a centrifuge stops rotating when the outer layer temperature of high-vanadium high-speed steel reaches 1220-1280 DEG C, the inert gas is stopped being blown in, and then liquid iron in the core of the roll body is poured through mould closing. According to the manufacturing method for the high-vanadium high-speed steel composite roll, the bonding rate of the high-vanadium high-speed steel of the outer layer and the liquid iron in the core is significantly improved, the binding rate is improved from 40 percent to 100 percent, the bonding strength is improved from about 350 Mpa in the past to about 450 Mpa, and therefore the anti-stripping performance of a roll body bonding layer of the high-vanadium high-speed steel roll is greatly improved; meanwhile, the element amount formed by carbide on the corrosion outer layer of the liquid iron of the core is removed, therefore, roll neck tissues are improved, the tensile strength of the roll neck is improved, and the roll breakage phenomenon in use is effectively and completely eradicated.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

High-performance magnesium-aluminum-chromium composite spinel brick and manufacturing method thereof

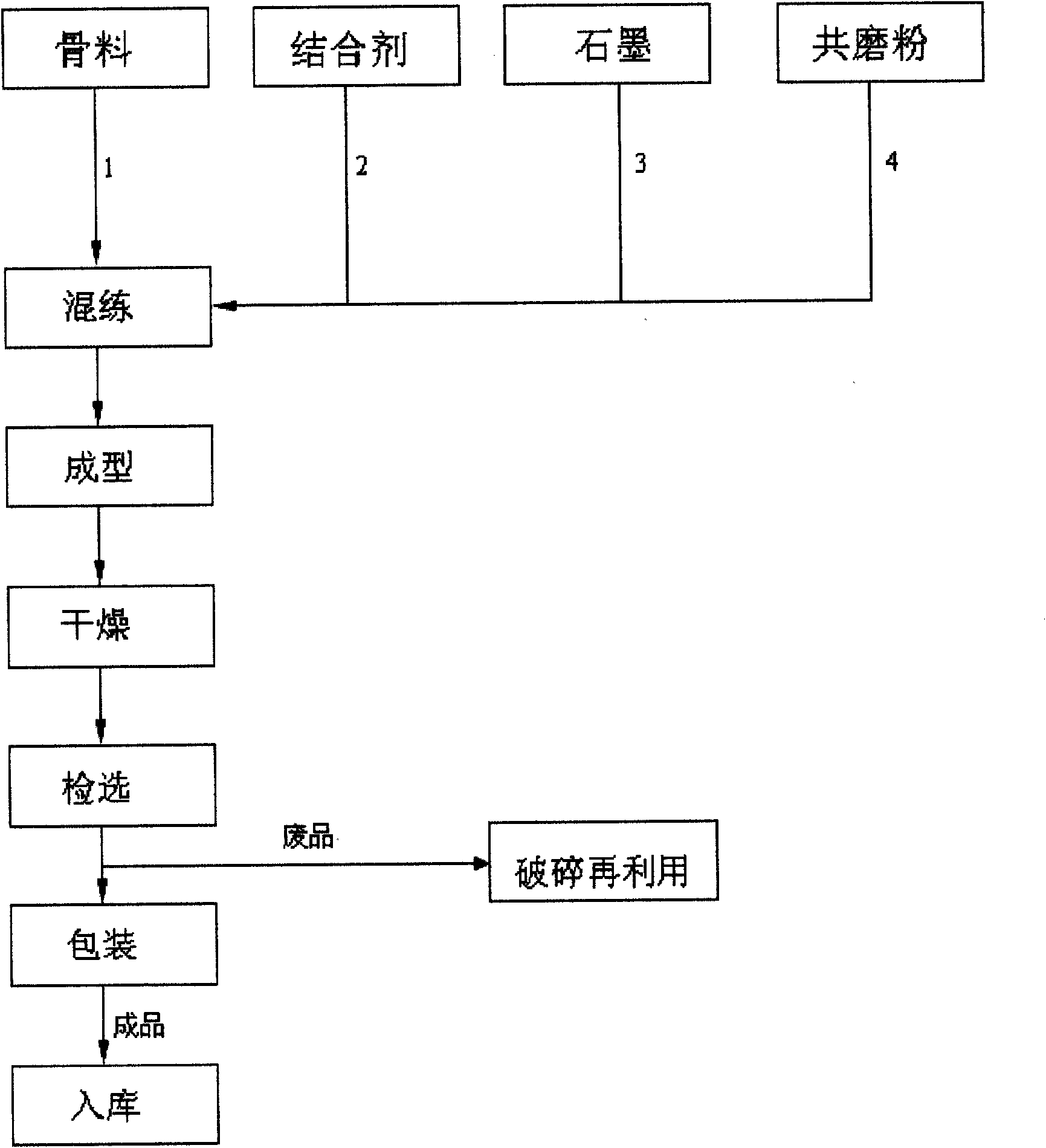

The invention relates to a high-performance magnesium-aluminum-chromium composite spinel brick for RH refining furnace dip pipes and non-ferrous smelting furnaces. The high-performance magnesium-aluminum-chromium composite spinel brick is characterized by comprising the following raw materials: 14.0-20.0 parts of low-chromium fused magnesium chromium sand (6-8% of Cr2O3, at least 78% of MgO), 71.6-82.0 parts of high-purity fused magnesite, 2.0-4.4 parts of nano Cr2O3 powder, 2.0-4.0 parts of uf-Al2O3 micropowder and 2-4 parts of binder. The manufacturing method comprises the following steps: mixing, molding, drying, firing and the like. The magnesium-aluminum-chromium composite spinel brick provided by the invention has the advantages of high sintering tendency, high crystal compactness, low porosity (at most 10%), high compressive strength (at least 100 MPa), high thermal shock stability (at least 18 times by 1100 DEG C water cooling) and the like. The Cr2O3 content of the product isat most 6%, thereby reducing the Cr2O3 content in the brick, lowering the production cost and finally effectively reducing the environmental pollution of waste magnesium-chromium bricks after use.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

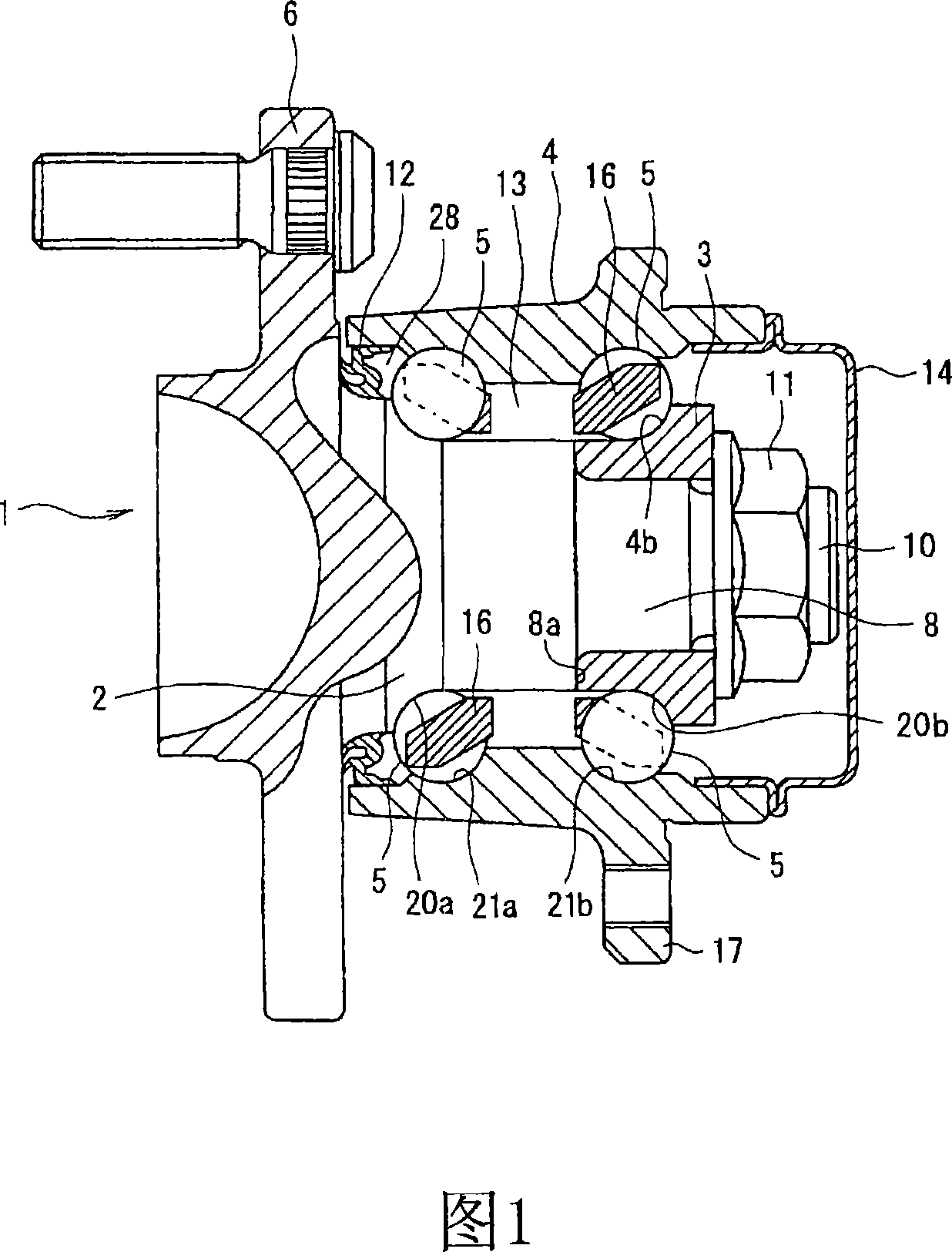

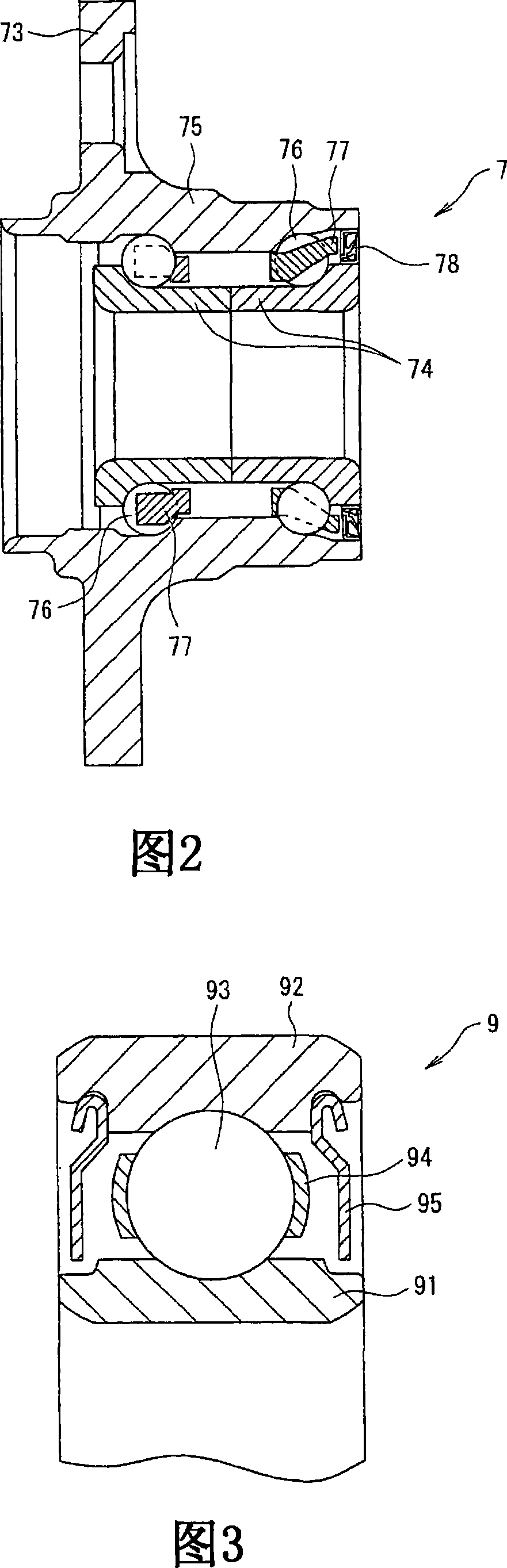

Grease composition for hub unit bearing, and hub unit bearing for vehicles

InactiveCN101107347AEnhanced resistance to peelingImprove water resistanceHubsBall bearingsEngineeringBase oil

This invention provides a grease composition that, even when water has entered, can maintain a good lubrication state for a long period of time and can suppress white texture separation and corrosion. There is also provided a hub unit bearing for vehicles that, even when used in such an environment that water enters, is less likely to cause white texture separation and corrosion and can realize a prolonged service life. A rolling bearing is also provided in which a grease composition characterized by adding an additive having a water-resistant film forming property has been sealed. The grease composition for hub unit bearing is characterized by comprising a base oil composed mainly of at least one oil selected from mineral oils and synthetic oils, a thickening agent, and a separation preventive agent. The hub unit bearing for vehicles comprises the above grease composition sealed therein.

Owner:NSK LTD +1

Titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron

InactiveCN102248325AEasy to use on siteImprove wear resistanceWelding/cutting media/materialsSoldering mediaMachine partsWear resistant

The invention discloses a titanium carbide ceramic-enhanced visible arc self-shielded flux-cored wire for high-chromium cast iron, and the flux-cored wire provided by the invention comprises the following chemical components in percentage by weight (wt%): 60 to 70% of high-carbon ferrochrome, 1 to 2% of high-carbon ferromanganese, 1 to 3% of ferrosilicon, 1 to 3% of ferrovanadium, 1 to 3% of ferromolybdenum, 2 to 8% of TiC, 15 to 25% of graphite, and 1 to 2% of aluminum / magnesium powders; and the flux-cored wire has a low-carbon steel strip serving as an outer wrapper. The flux-cored wire is made by use of flux-cored wire production equipment which has a flux powder filling rate of 37%to 45%, and drawn by a wire drawing machine 2 to 5 times until the outside diameter of the flux-cored wire reaches the level F4. The flux-cored wire disclosed by the invention can be applied to overlay-welding under the conditions of no preheating before welding and no heat treatment after welding, and is very convenient in on-site use. By virtue of overlay-welding using the flux-cored wire disclosed by the invention, deposited metals have a high hardness up to HRC63-67 and better wear resistance andare not liable to stripping, and the service lives of large-sized high-chromium cast iron wear-resistant parts are 2 to 4 times those of integrally-machined parts.

Owner:YANSHAN UNIV

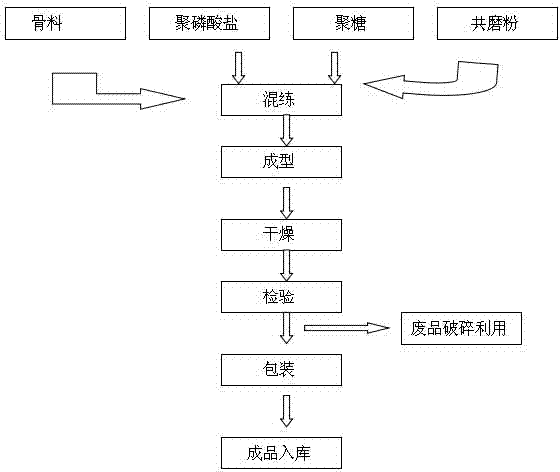

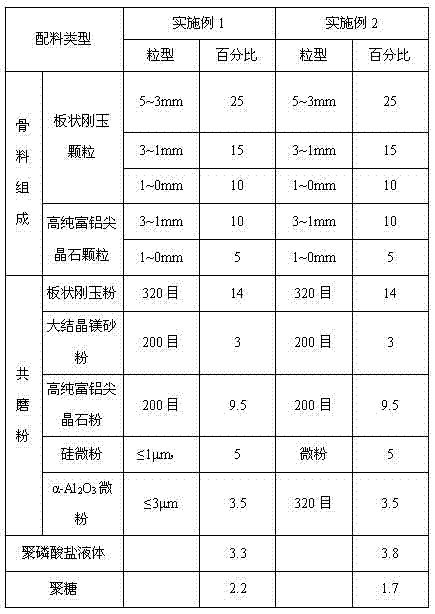

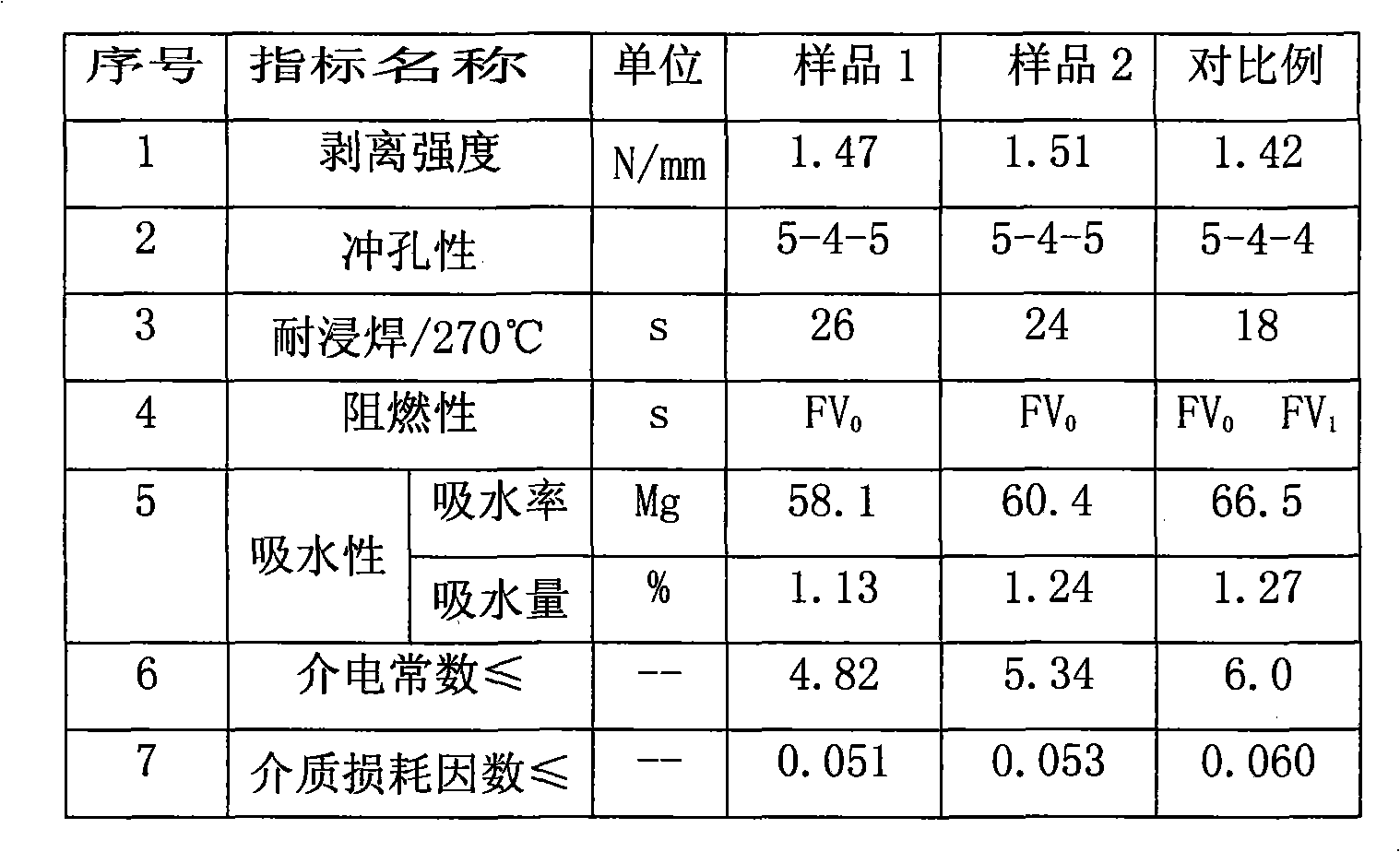

Mechanically-pressed carbon-free corundum spinel ladle brick as well as preparation method thereof

The invention discloses a mechanically-pressed carbon-free corundum spinel ladle brick. The mechanically-pressed carbon-free corundum spinel ladle brick comprises the following components in percentage by weight: 30%-50% of plate-shaped corundum particles, 10%-20% of high-purity aluminum-rich spinel particles, 10%-20% of plate-shaped corundum fine powder, 1%-9% of large crystallized magnesia fine powder, 5%-15% of high-purity aluminum-rich spinel fine powder, 1%-10% of high-purity silicon micro powder, 2%-10% of imported multimodal alpha-Al2O3 micro powder, 1%-4% of metal silicon and a bonding agent which is composed of 1%-5% of polyphosphate and 1%-3% of polysaccharide. The mechanically-pressed carbon-free corundum spinel ladle brick disclosed by the invention adopts an organic-inorganic compound combining system, is wet-milled and mixed under high pressure, formed under high pressure, high in density, good in thermal stability under high temperature, and resistant to molten steel and slag, and does not pollute the molten steel; moreover, production efficiency can be greatly improved, and therefore, the mechanically-pressed carbon-free corundum spinel ladle brick can be extensively applied to various ladles, especially refined low-carbon steel and ultralow-carbon ladles.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Method for manufacturing composite mineral wool board for building insulation

ActiveCN102501300AEasy constructionHigh tensile strengthCeramic shaping apparatusHeat proofingAdhesiveVolumetric Mass Density

The invention discloses a method for manufacturing a composite mineral wool board for building insulation. The method uses special interface agents as adhesives, a fiberglass mesh fabric completely wraps the surface of the high-density mineral wool board for the building to improve defects of an inorganic mineral wool board, and the mineral wool board can meet the requirements of national or industrial relevant standards and becomes a level-A non-combustible, flexible, high-strength, waterproof, air-permeable, high-weatherability and heat-insulation mineral wool material for the building. Experiments prove that the composite mineral wool board for building insulation, manufactured by the method, meets the relevant requirements of the national or industrial standards of Rock wool products for exterior insulation and finish systems (GB / T25975-2011), External thermal insulation composite system based on expanded polystyrene (JG149-2003), fire prevention regulations for buildings (GB50016) and the like.

Owner:CHANGAN UNIV

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Heat transfer tube for LNG vaporizer, its production method, and LNG vaporizer using such heat transfer tubes

InactiveCN1932428AEnhanced resistance to peelingSatisfactory Sacrificial Corrosion ProtectionStationary conduit assembliesCoatingsThermal sprayingAlloy substrate

A heat transfer tube for an LNG vaporizer in which damage in the surface of the Al alloy substrate by corrosion is effectively prevented even when it is used in the lower portion of the panel or in the lower header where the surface is vigorously cooled and formation of the oxide coating is less likely to take place. This heat transfer tube is used in an LNG vaporizer equipped with an Al alloy panel unit including a panel composed of a plurality of heat transfer tubes arranged in a row in the form of a curtain, and a lower header and an upper header respectively connected to the panel at its lower end portion and its upper end port ion; wherein the LNG is vaporized by heat exchange between seawater flowing down along the surface of the panel from the upper end portion of the panel unit and the LNG flowing through theheattransfertubes. In this LNG vaporizer, the outer surface of the heat transfer tube at least in the lower end portion of the panel and the outer surface of the lower head are subjected to surface roughening by blasting, and then, a coating of an Al-Mg alloy containing Mg at a content in the range of 1 to 80% by mass, and having a thickness of 100 to 1000 m was formed by thermal spraying to realize protection by sacrificial corrosion. Formation as the corrosion protective of an A1 alloy coating containing Zn and / or Mn at a content in the range of 0.3 to 3.0% by mass with the proviso that the content of (Zn + Mn) is in the range of 0.3 to 3.0% by mass and containing Mg at a content in the range of 0. 3 to 5% by mass is also effective.

Owner:KOBE STEEL LTD

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

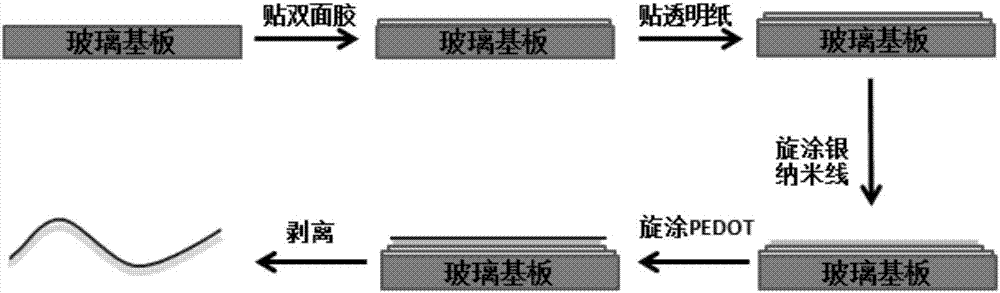

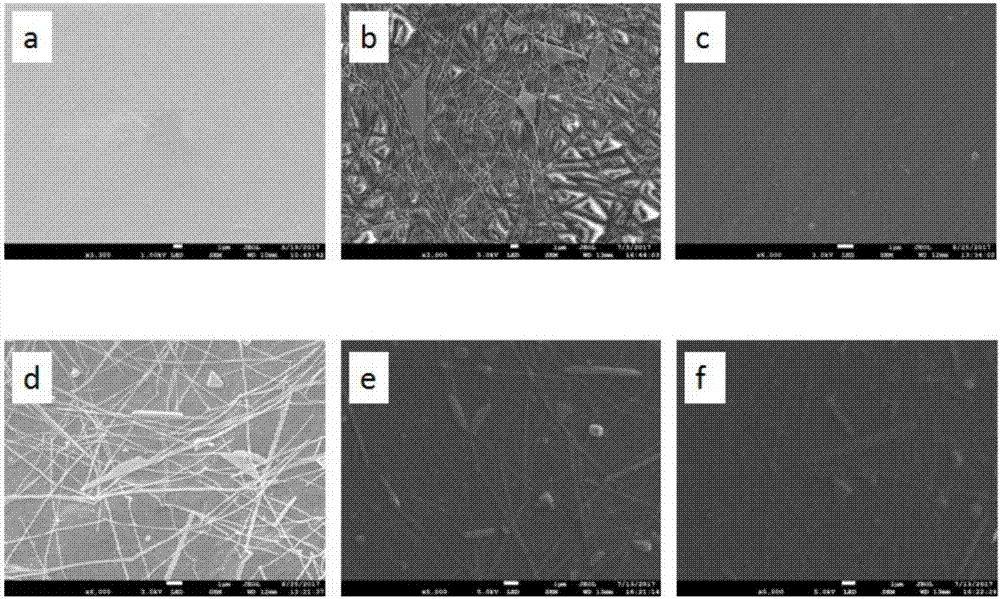

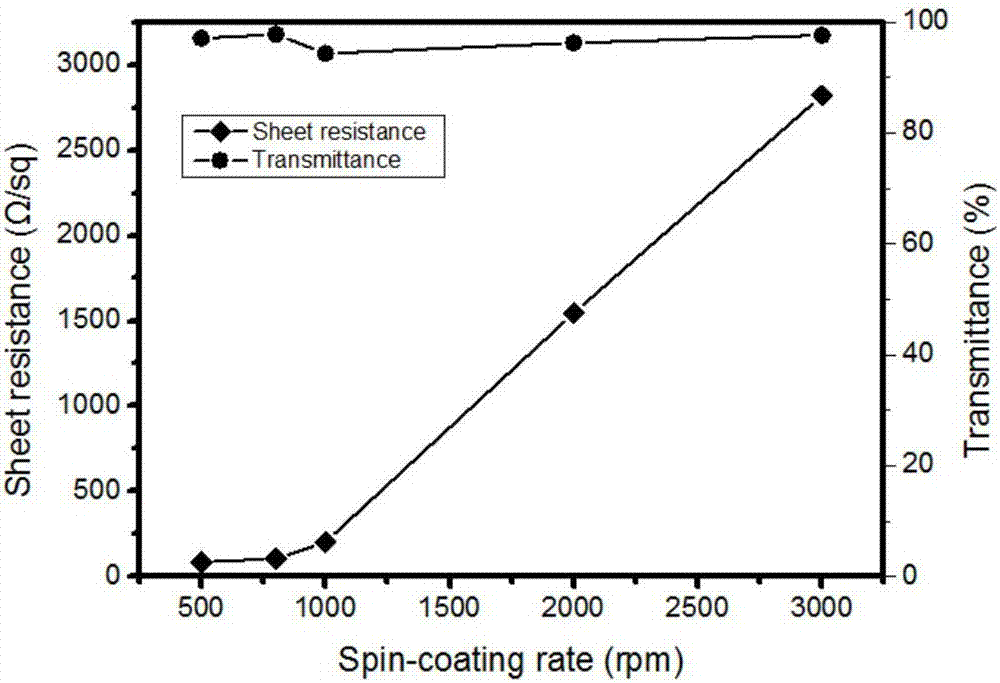

Rapid preparation method of paper-based flexible transparent electrode based on silver nanowires and PEDOT

InactiveCN107507676ANo pollution in the processLow costApparatus for manufacturing conducting/semi-conducting layersPaper basedViscose

The present invention discloses a rapid preparation method of a paper-based flexible transparent electrode based on silver nanowires and PEDOT, belonging to the nanometer photoelectric material technology field. The method comprises: dissolving a certain amount of linters into pre-cooling urea solution to form viscose solution and then form film of cement gel after film curing, and preparing transparent paper after drying of the film of cement gel; and uniformly performing spin coating of the silver nanowires on the surface of the transparent paper, performing spin coating of the PEDOT at the surface of the silver nanowires, and finally forming a final paper-based flexible transparent electrode after the silver nanowires with the PEDOT are thoroughly dried. The flexible transparent electrode provided by the invention is simple to operate and low in cost, is degradable and is wide in application range. The method is rapid and simple and can perform large-area preparation, and the prepared paper-based flexible transparent electrode is flexible, foldable and stable in electrical property.

Owner:NANJING UNIV OF TECH

Preparation method of interior wall putty

ActiveCN103351683AAvoid defectsStrong environmental protectionFilling pastesMethyl cellulosePolyacrylamide

The invention discloses a preparation method of interior wall putty. The interior wall putty is composed of the following ingredients in parts by weight: 46-50 parts of diatomaceous earth, 10-12 parts of purified attapulgite, 3-5 parts of talcum powder, 14-16 parts of expanded corn starch, 5-8 parts of hydroxypropyl methyl cellulose, 1-3 parts of polyacrylamide and 5-7 parts of titanium dioxide. The preparation method comprises the following steps: S1. sequentially pouring the talcum powder, expanded corn starch and titanium dioxide into a stirrer to be mixed and stirred, and stirring for 5-10 minutes; S2. sequentially pouring the diatomaceous earth and the purified attapulgite into the mixture in the step S1, and stirring for 10-15 minutes; and S3. adding the polyacrylamide and hydroxypropyl methyl cellulose in the mixture in the step S2, stirring for 20-30 minutes, and then, sieving the mixture through a sieve of 250 meshes.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

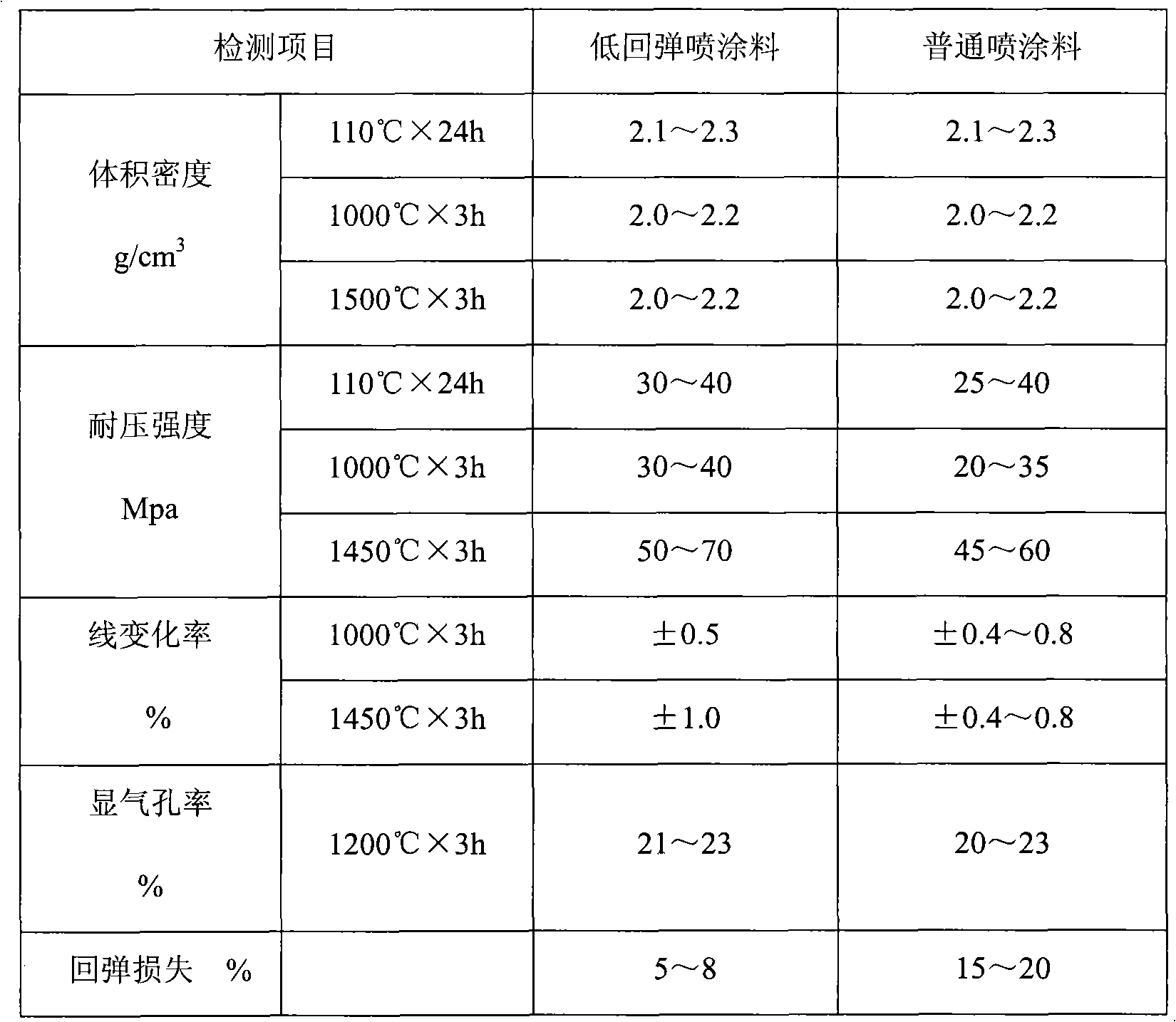

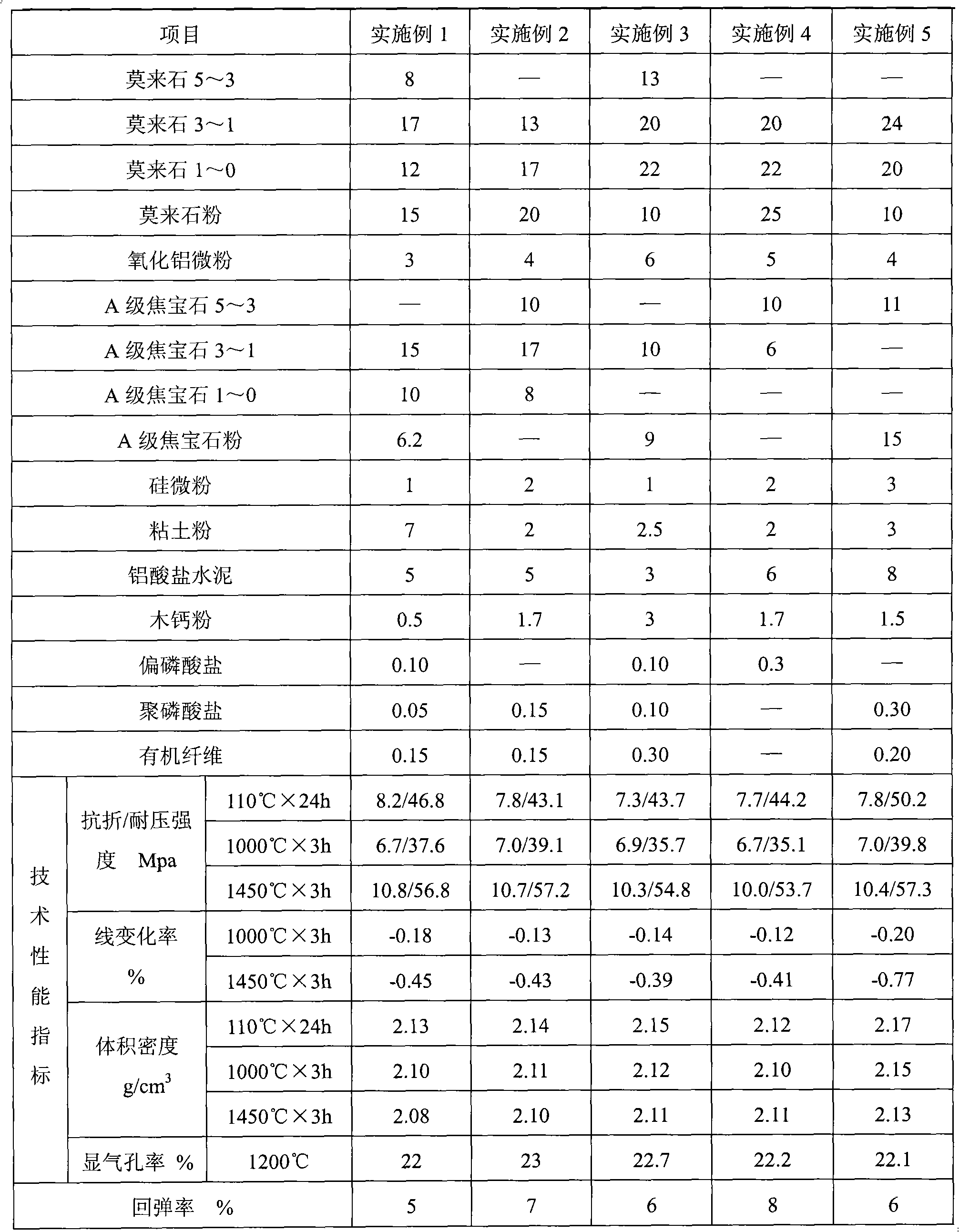

Low springback rate spraying and coating material for thermal-state blast furnace maintenance and preparation method thereof

The invention provides a low springback rate spraying and coating material for thermal-state blast furnace maintenance and a preparation method thereof. The spraying and coating material comprises the following raw materials in percentage by weight: 30-50% of synthetic mullite particles with the diameter of 5-0mm, 30-50% of A-level flint clay particles with the diameter of 5-0mm, 10-25% of synthetic mullite powder of 200-325 meshes, 0-15% of A-level flint clay powder of 200-325 meshes, 3-8% of aluminate cement, 2-7% of clay powder, 1-3% of silica micropowder of 2-5mu, 3-6% of aluminum oxide micropowder of 5mu, 0-0.3% of polyphosphate, 0-0.3% of metaphosphate, 0.5-3% of lignosulphonate calcium powder and 0-0.3% of organic fiber,The invention has the outstanding characteristics that the springback loss is small, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEGC and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance. The invention has the outstanding characteristics that the springback loss issmall, waste of raw materials in the process of construction is reduced on one hand, and the start-up operation of the furnace is facilitated on the other hand; and the spraying and coating material provided by the invention meets the performance requirements on performances such as strength, scouring resistance, scouring and permeation resistance, rapid construction at 150-300 DEG C and the like, and is especially suitable for an unshaped refractory for thermal-state blast furnace lining maintenance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

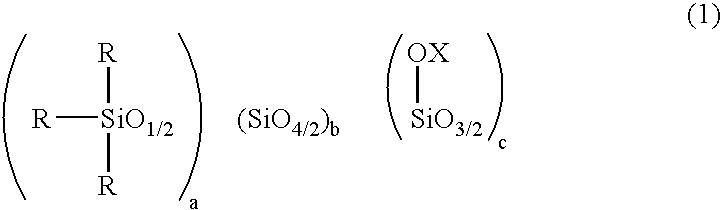

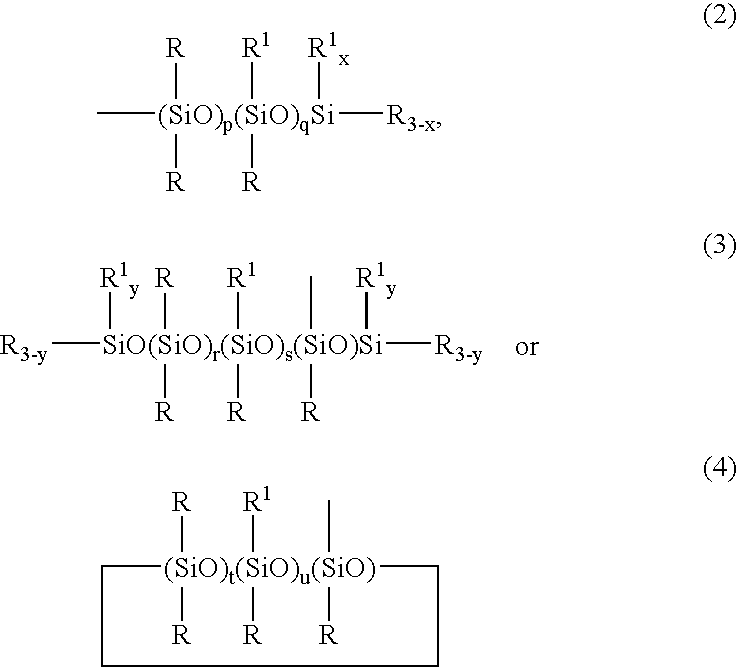

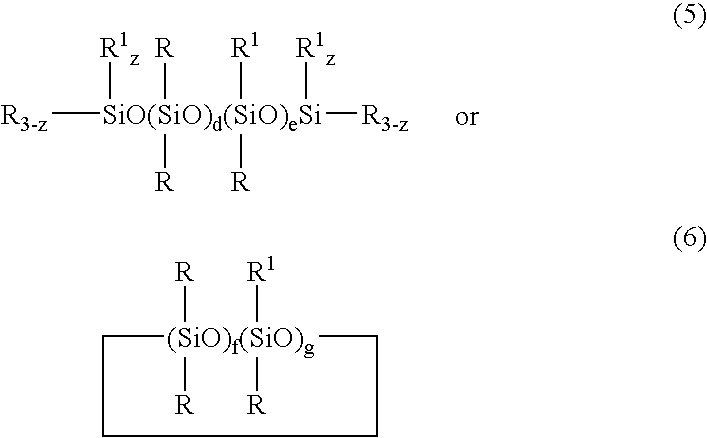

Ultraviolet-curable silicone composition

InactiveUS6875795B2Easy to giveEnhanced resistance to peelingLayered productsCoatingsEpoxyPolymer science

The invention provides a silicone composition curable by ultraviolet irradiation to give a cured film on a substrate surface exhibiting surface releasability against sticky surfaces. Advantageously, peeling works of a sticky surface from the cured surface of the inventive composition can be carried out with no or little generation of peeling noises which deteriolate the working environment. The composition comprises three different types of organopolysiloxane compounds of which the first is a so-called MQ siloxane, the second is a linear or cyclic diorganopolysiloxane having epoxy-containing substituents on the silicon atoms other than the chain terminal silicon atoms and the third is a straight or branched linear organopolysiloxane compound substituted by an epoxy-containing substituent on each of the chain terminal silicon atoms in a specified weight proportion of these three. The composition contains an onium salt compound as a photoreaction initiator to promote the ultraviolet-induced curing.

Owner:SHIN ETSU CHEM IND CO LTD

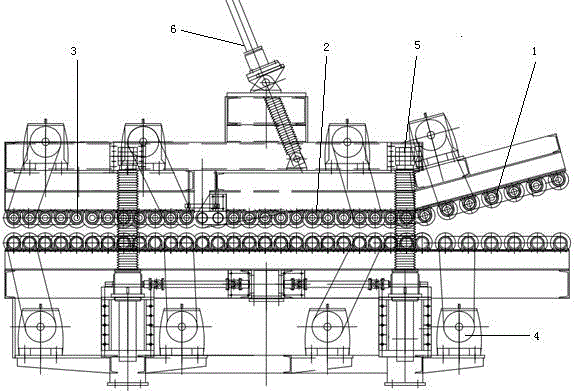

Grid structural reinforced composite material sandwich structure

InactiveCN101067343AImprove mechanical performanceEnhanced resistance to peelingConstruction materialGirdersFiberCompressive strength

The composite material reinforced sandwich structure includes core material and fibrous face plates, and features the core material of resin or composite material comprising resin and fiber fabric, and the face plates formed with fiber fabric and resin. Compared with available similar product, the present invention has higher compression strength and shearing strength, reinforced stripping resistance and higher integral mechanical performance. The present invention is used as structural member bearing great load, such as deck plate, container bottom plate, bridge plate, etc.

Owner:NANJING UNIV OF TECH

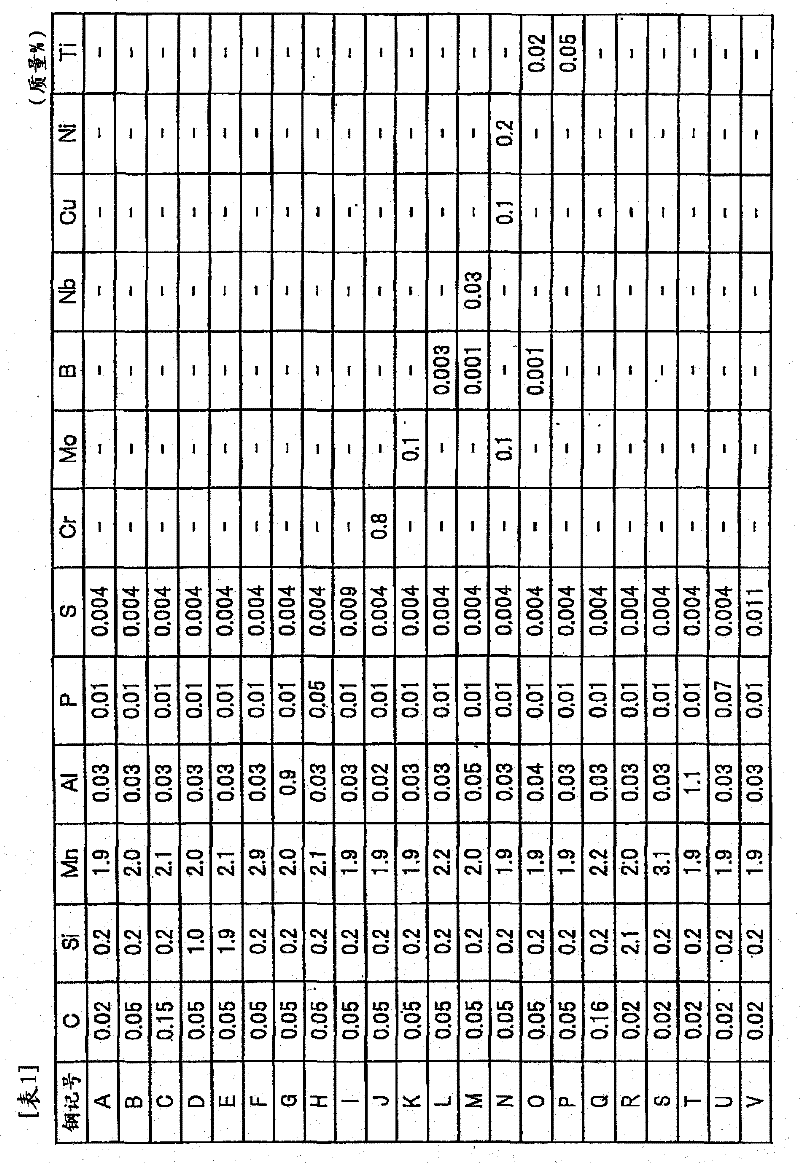

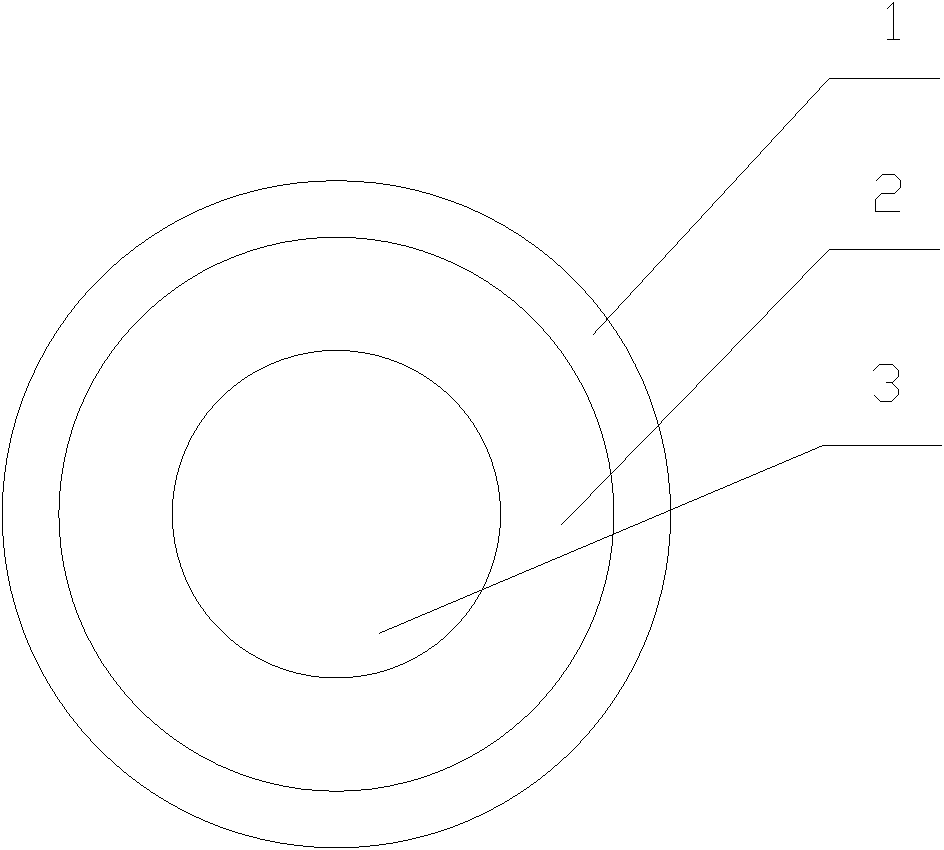

Hot-dip galvanized steel sheet and manufacturing method thereof

ActiveCN102224269AEnhanced resistance to peelingHigh strengthHot-dipping/immersion processesFurnace typesSurface layerUltimate tensile strength

The hot-dip galvanized steel sheet has a galvanized layer formed on the surfaces of steel sheet which contains, in mass%, C: 0.01- 0.15%, Si: 0.001-2.0%, Mn: 0.1-3.0%, Al: 0.001-1.0%, P: 0.005-0.060%, S ? 0.01%, and the remainder of which comprises Fe and inevitable impurities. The quantity of adhesion per surface in the galvanized layer is 20-120 g / m2. There is a total of 0.05 g / m2 or less per surface of one or more kinds of oxides selected from those of Fe, Si, Mn, Al, and P inside the surface layer portion of the steel sheet no more than 100 [mu]m deep from the base steel sheet surface directly below the galvanized layer. The steel sheet has excellent corrosion resistance, resistance to galvanized coat peeling with a high degree of processing, and strength.

Owner:JFE STEEL CORP

High-speed steel, extrusion roller containing high-speed steel and production method of extrusion roller

ActiveCN102251187AThere is no problem of poor roundnessSimple heat treatment processFurnace typesGrain treatmentsHigh-speed steelExtrusion

The invention discloses high-speed steel. The high-speed steel comprises the following components in percentage by weight: 1.0 to 2.0 percent of C, 0.3 to 1.0 percent of Si, 0.3 to 1.0 percent of Mn, 2.0 to 5.0 percent of Cr, 0.5 to 1.0 percent of Ni, 2.0 to 4.0 percent of Mo, 1.0 to 3.0 percent of V, 0.5 to 1.5 percent of W, and the balance of Fe. The invention also discloses an extrusion rollercontaining the high-speed steel and a production method of the extrusion roller. The high-speed steel disclosed by the invention has low cost and good abrasion resistance; and according to the extrusion roller containing the high-speed steel and the production method of the extrusion roller, the problems of a surfacing extrusion roller in the prior art are solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

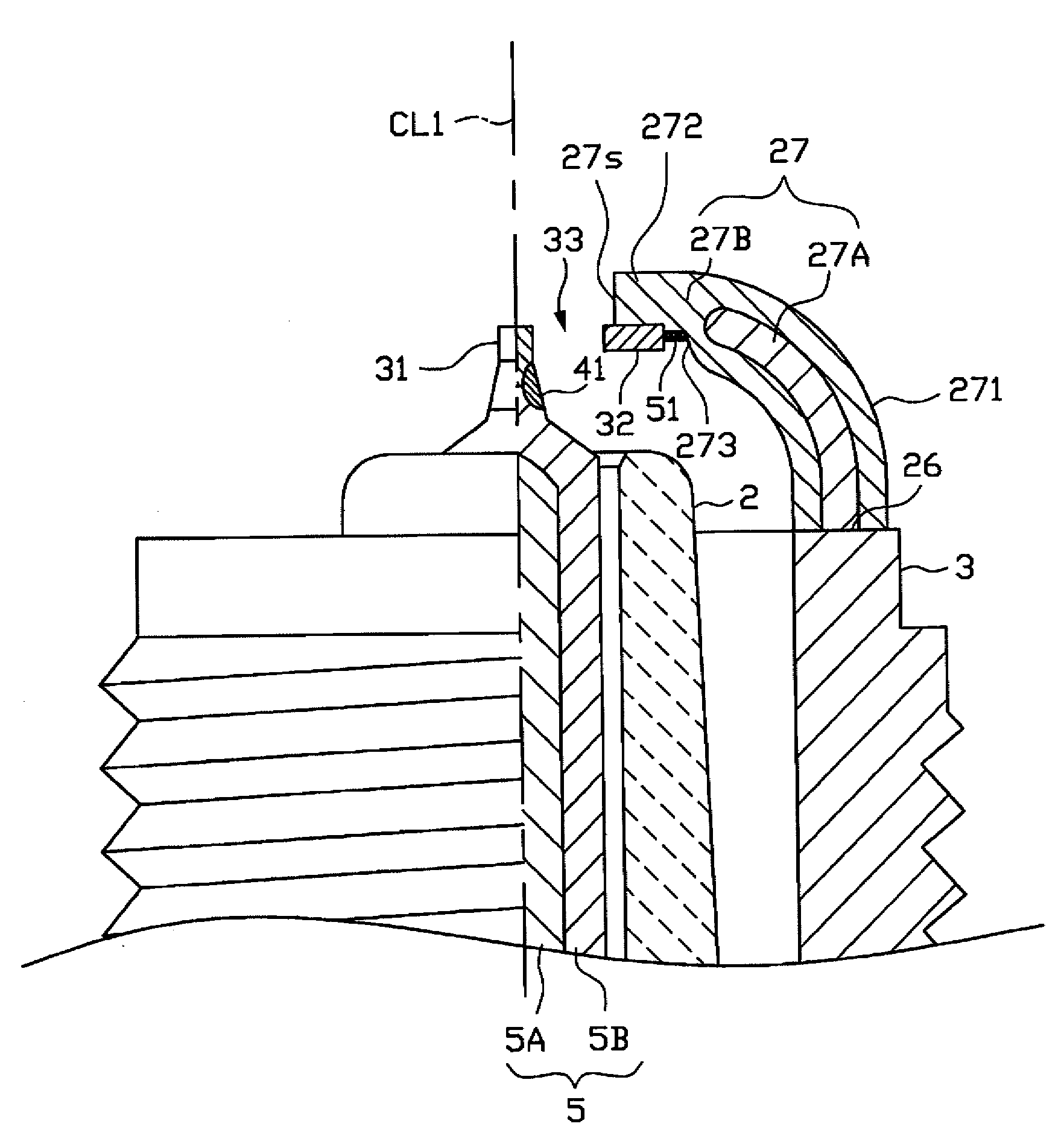

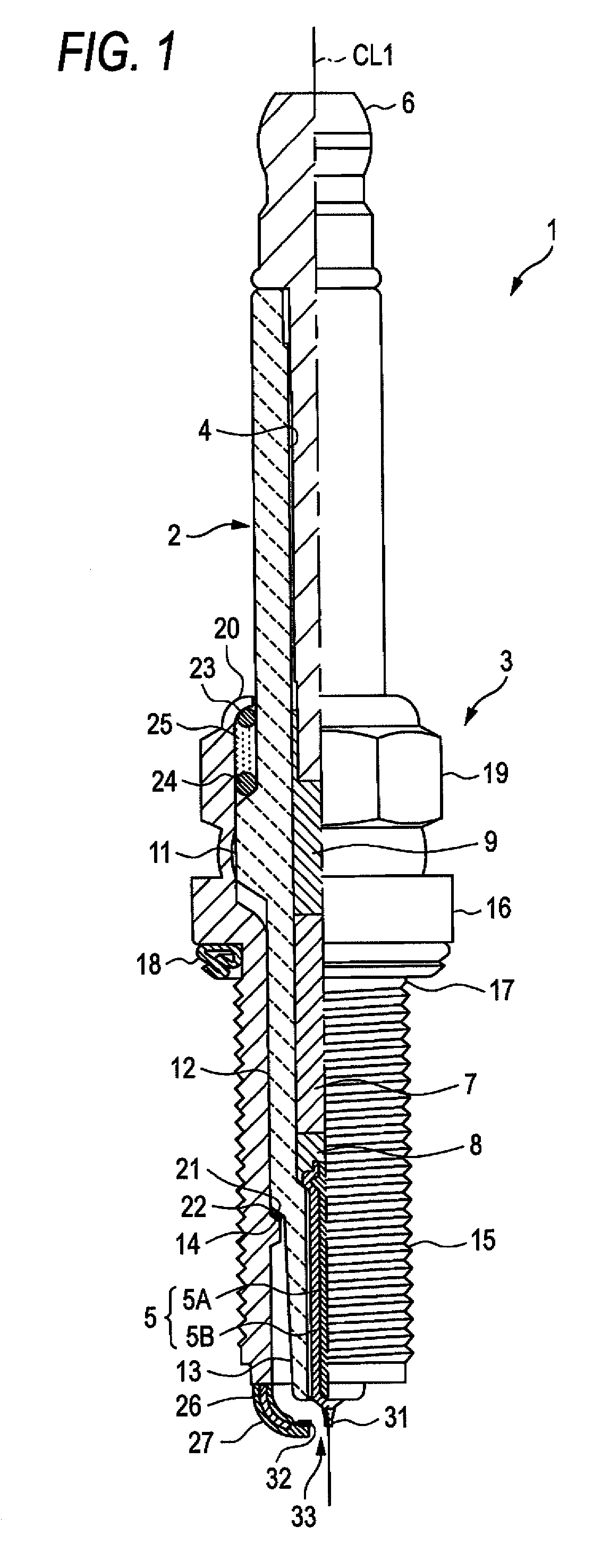

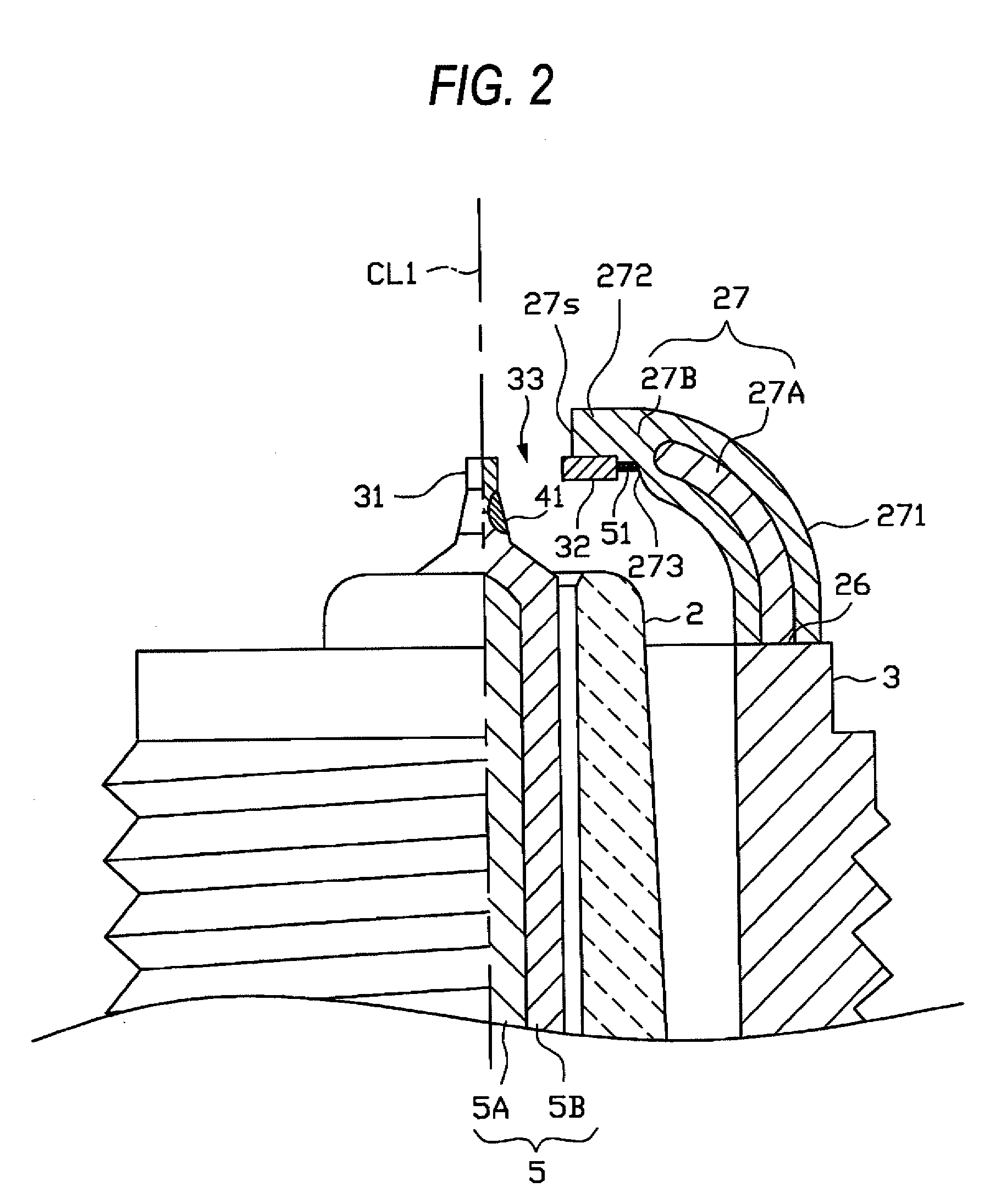

Spark plug for internal combustion engine and method for producing the spark plug

ActiveUS20090134764A1Reliably obtainedEnhanced resistance to peelingSpark gapsFuel injection apparatusEngineeringInternal combustion engine

A spark plug including: a ground electrode including a thick portion provided on a base end side, a thin portion provided on a distal end side, and a stepped portion provided on an inner peripheral surface between the thick portion and the thin portion; a noble metal tip partially embedded in an inner peripheral surface of the thin portion; and a bulge portion provided on the inner peripheral surface of the thin portion between the stepped portion and the noble metal tip. When viewed from a side surface of the ground electrode, a relationship [a protruding height of the noble metal tip from the inner peripheral surface of the thin portion]≧[a protruding height of the bulge portion from the inner peripheral surface of the thin portion].

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com