Heat transfer tube for LNG vaporizer, its production method, and LNG vaporizer using such heat transfer tubes

A heat transfer tube and vaporizer technology, applied in the field of LNG vaporizers, can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

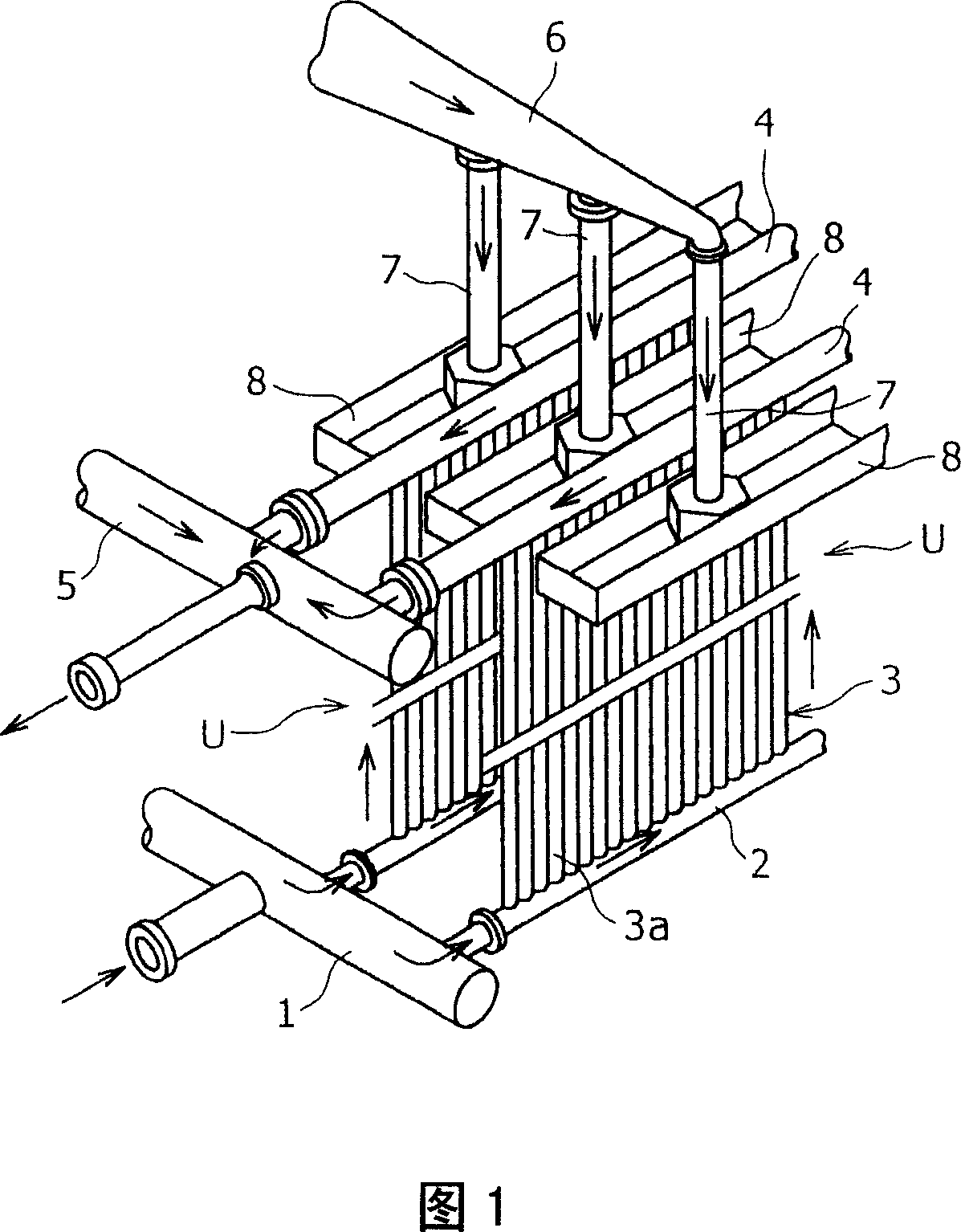

[0048] 【0037】

[0049] In order to simulate the environment near the panel 3 and the lower header 2 of an LNG vaporizer (ORV) (see Figure 1), a pure aluminum disc with a diameter of 16 mm and a thickness of 4 mm was prepared, defined by a straight line passing through the center of the disc. On one surface of the disk, a coating having the composition shown in Table 1 was thermally sprayed to have a thickness of 300 micrometers. Test specimens were obtained after thermal spraying without further treatment. The Peltier element was brought into close contact with the rear surface of the sample on the side not subjected to thermal spraying, thereby cooling the rear surface of the sample to 20° C. below the freezing point. The surface of the side on which the thermal spray coating was formed at 20° C. below the freezing point was exposed to commercially available artificial seawater (Marine Art Hi, produced by Tomita Pharmaceutical Co., Ltd.) at 30° C. for 20 hours, and The degr...

Embodiment 2

[0053] One side of a 200 mm x 200 mm aluminum alloy (A5083) plate having a thickness of 5 mm was machined to have various degrees of surface roughness, and the plate was used as an aluminum substrate. The centerline average roughness Ra75 of the aluminum substrate was evaluated using a surface roughness meter immediately after machining. For each group of test conditions, prepare 10 (n=10) aluminum substrates that are machined with the same target surface roughness, and the average value of Ra 75 of these 10 aluminum substrates is used as the The roughness (Ra 75) of the boundary between coats is shown in Table 2. In order to achieve satisfactory adhesion to the aluminum substrate, a 300 μm thick Al- 5% by mass Mg coating. On a partially machined aluminum substrate, an Al-90%Mg coating with a thickness of 300 μm was formed by flame spraying using a wire of Al-90% by mass Mg. The test specimens were obtained after thermal spraying without further treatment. The composition ...

Embodiment 3

[0059] A 200 mm×200 mm aluminum alloy (A5083) plate having a thickness of 5 mm was used as the aluminum base material. An Al-5 mass% Mg alloy was thermally sprayed on one side of this aluminum substrate to form an Al-5 mass% Mg alloy coating. After the thermal spray coating was formed, different post-treatments were performed on the aluminum substrates, and samples 1 to 7 as shown in Table 3 were prepared. Eleven samples were prepared for each post-treatment type.

[0060] make up

No

(microns)

after thermal spraying

after thermal spraying

reason

Pore surface

Product (%)

Blister Peel

area of hundreds

Ratio (%)

note

1

300

No

not dealt with

17.1

44.2

comparative example

2

300

No

inject sealant

18.2

20.4

comparative example

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com