Patents

Literature

2751results about How to "Improve mechanical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

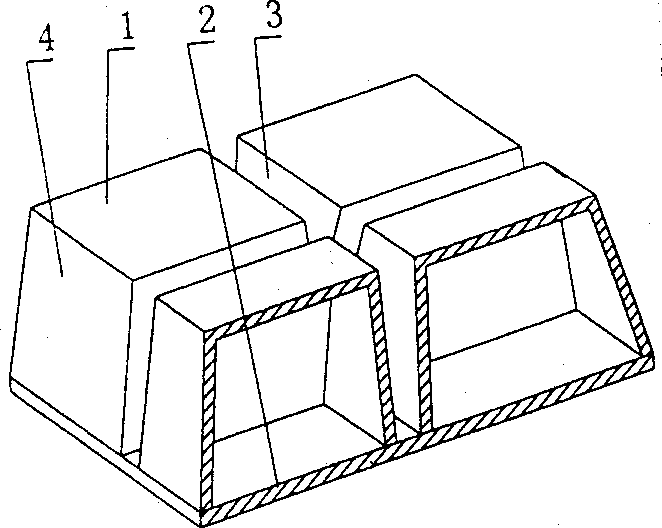

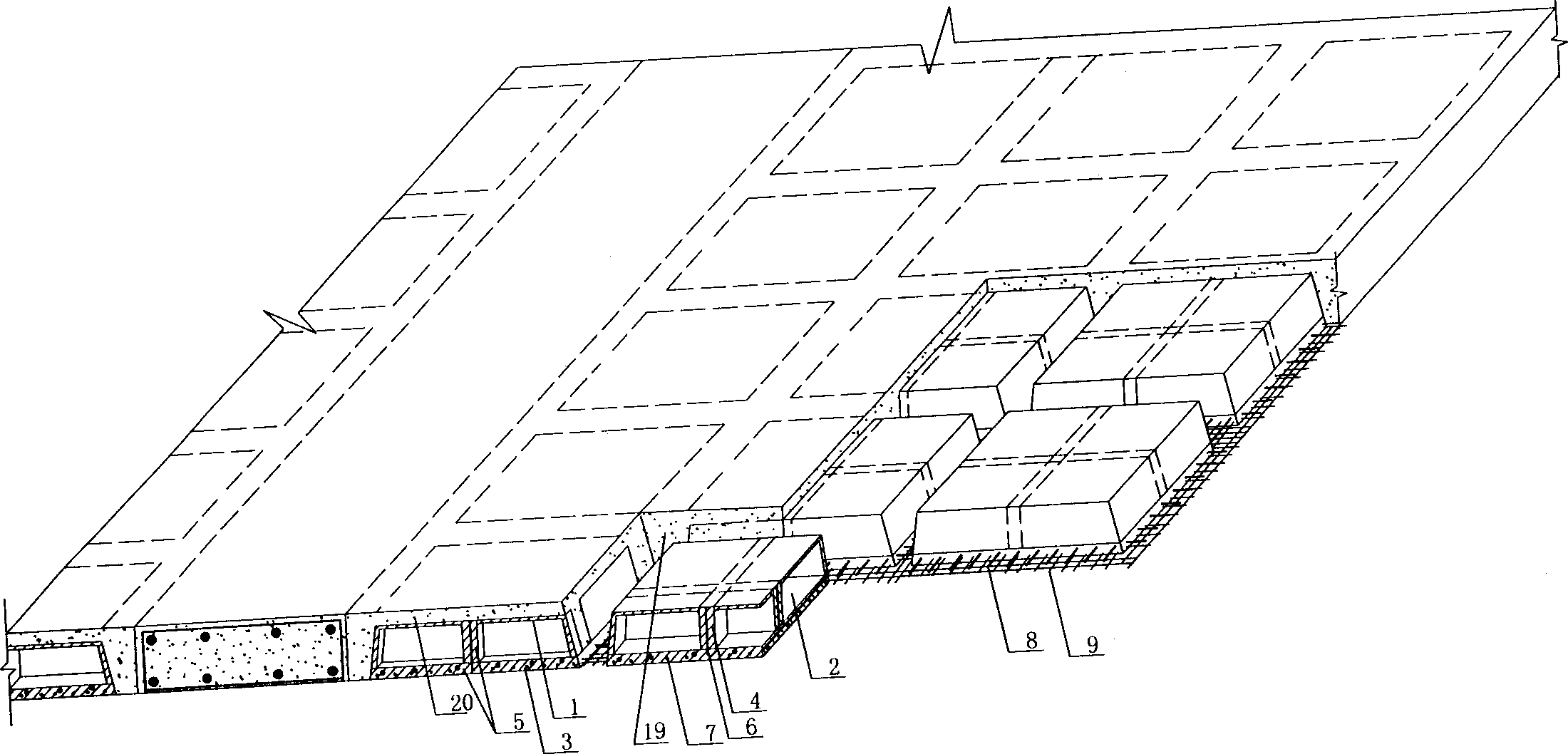

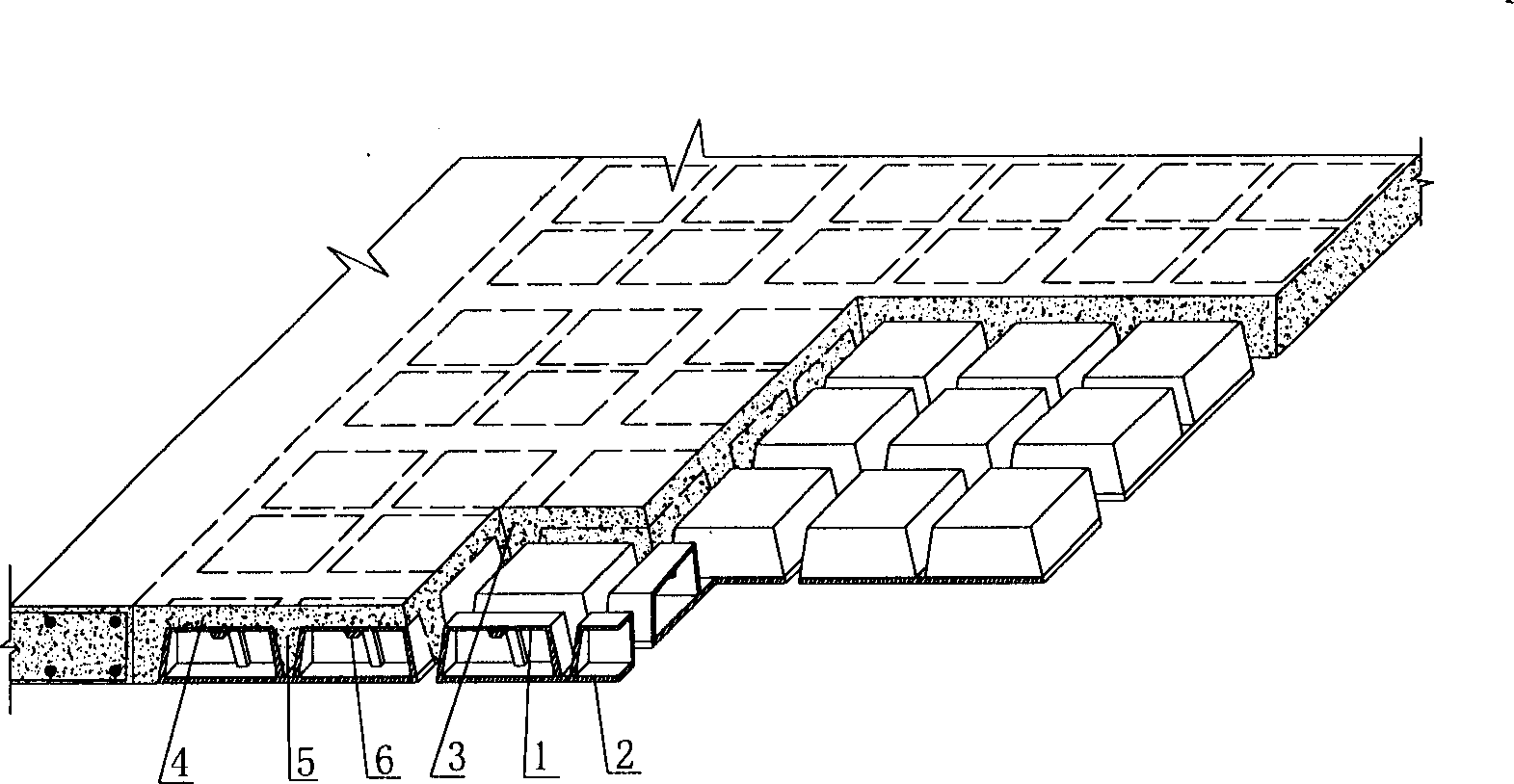

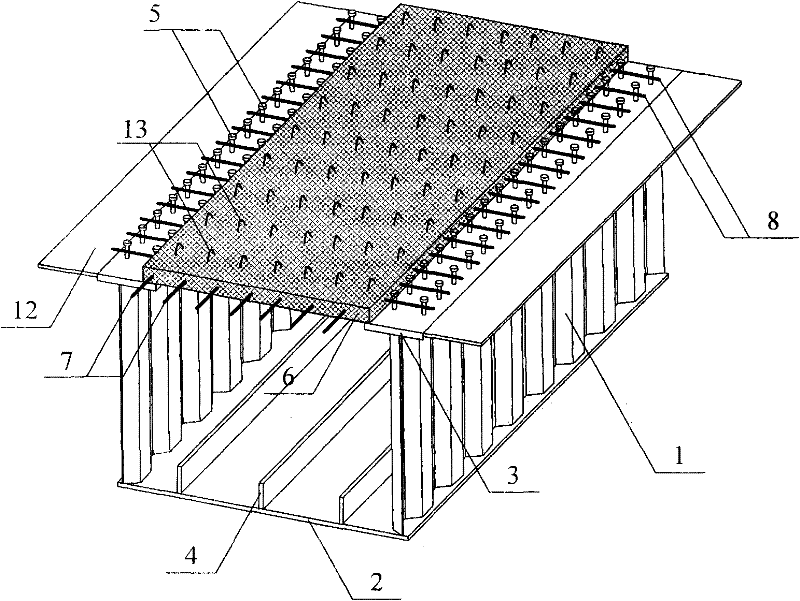

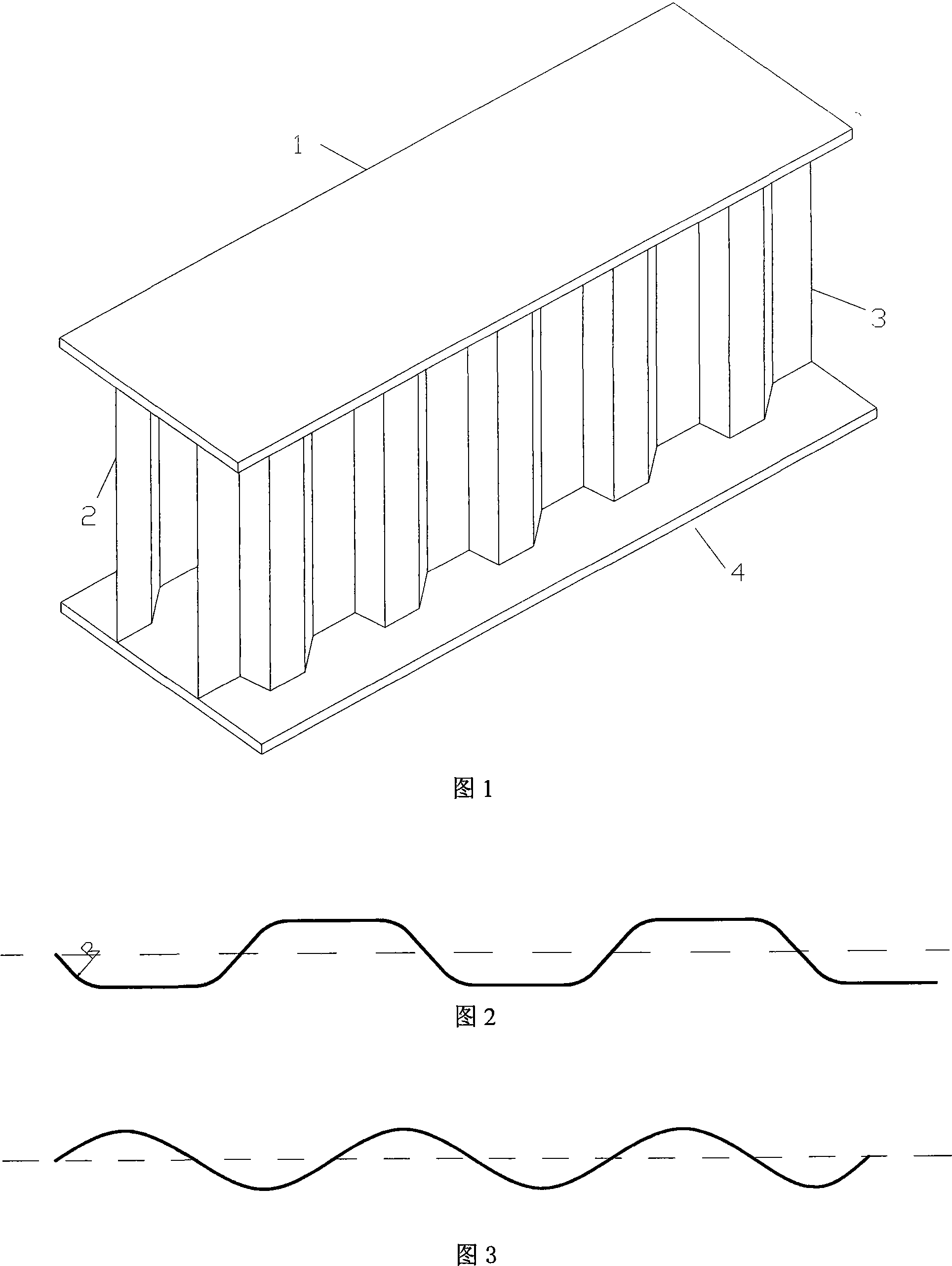

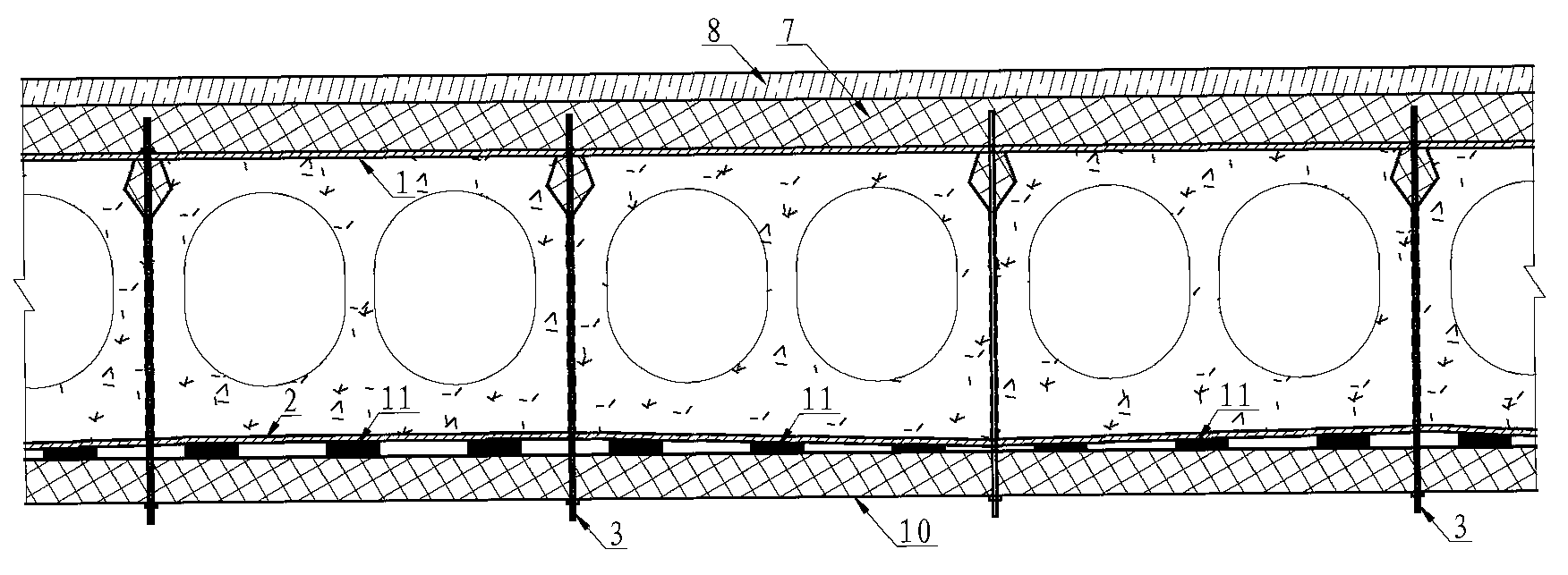

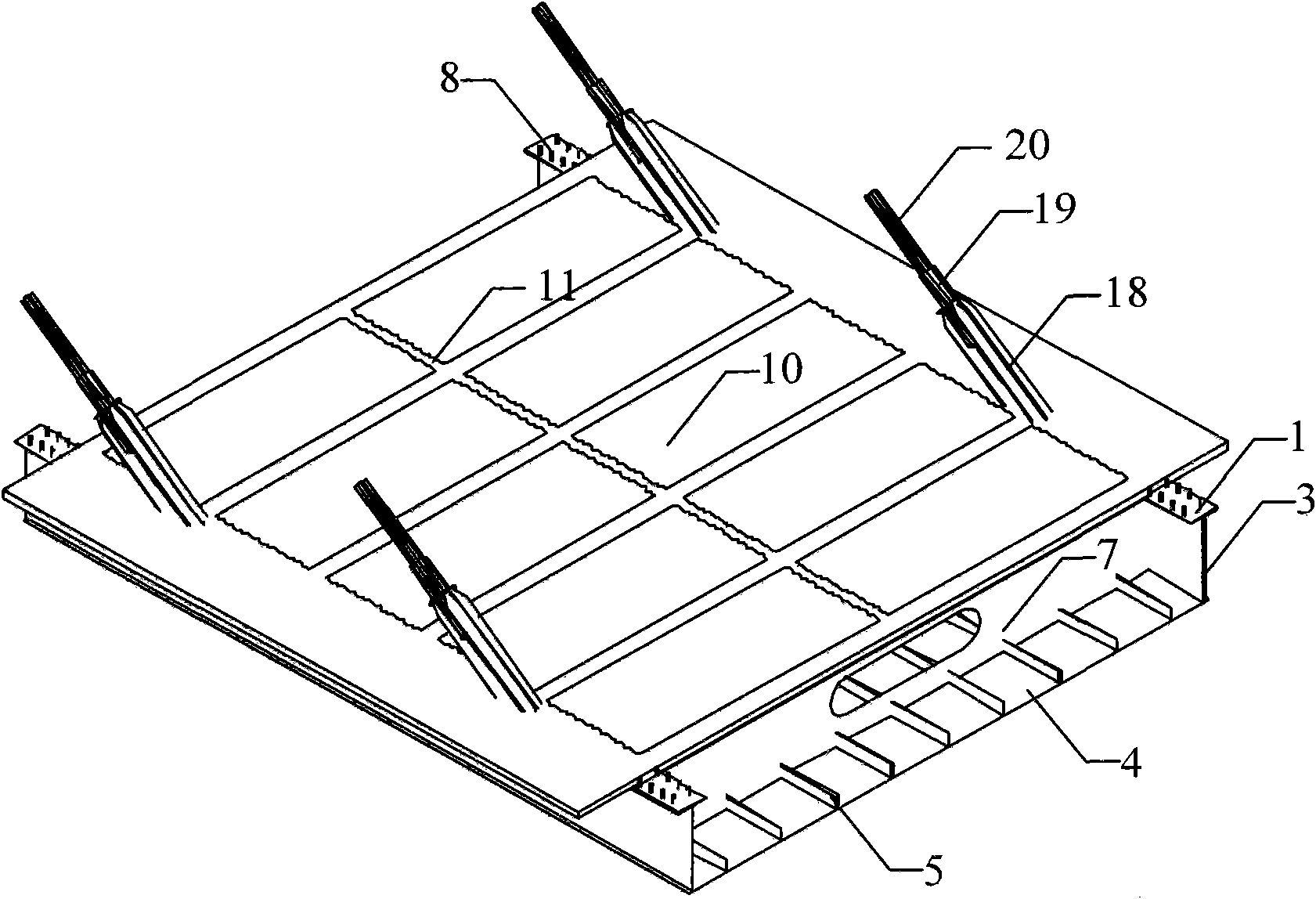

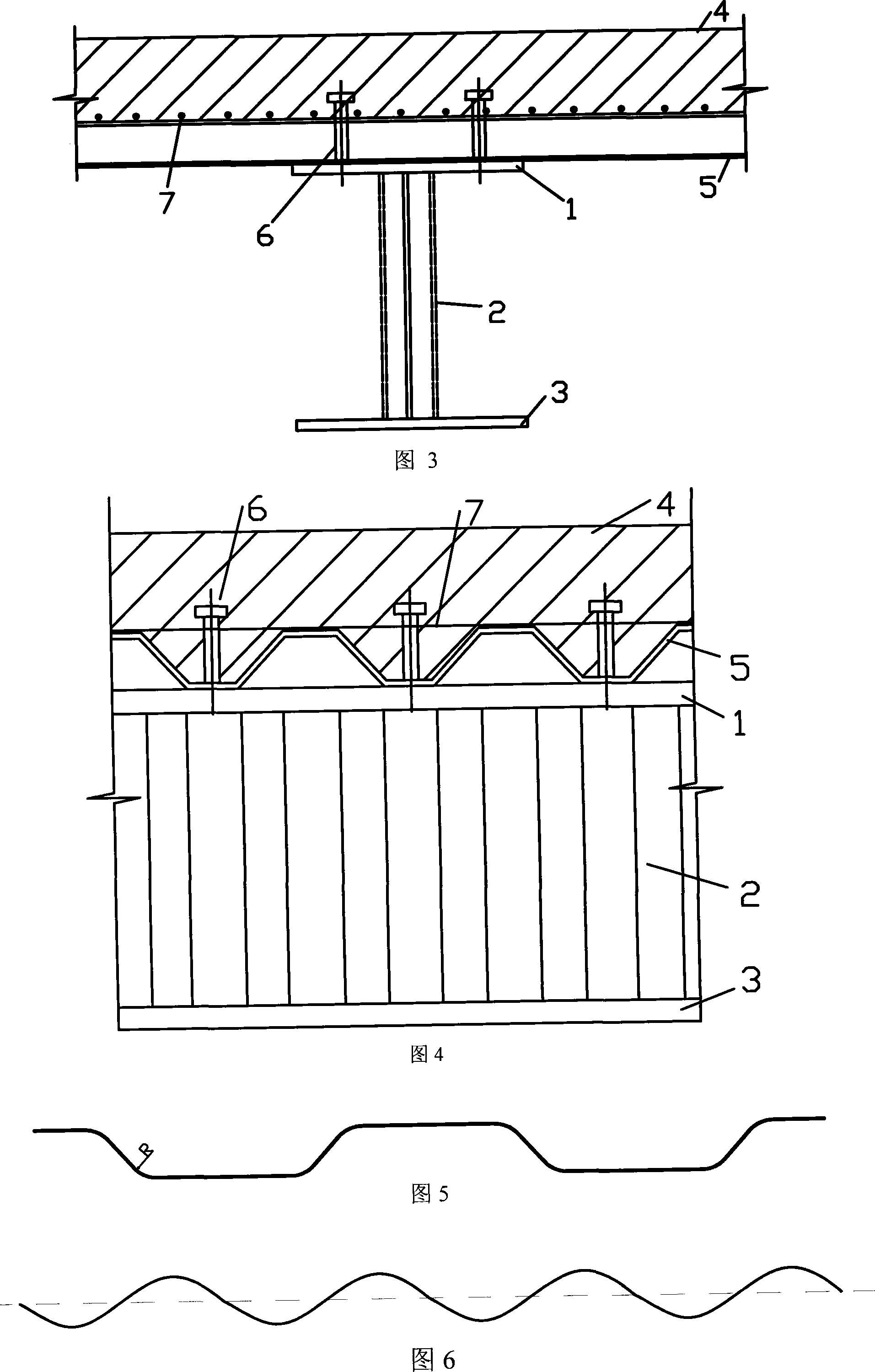

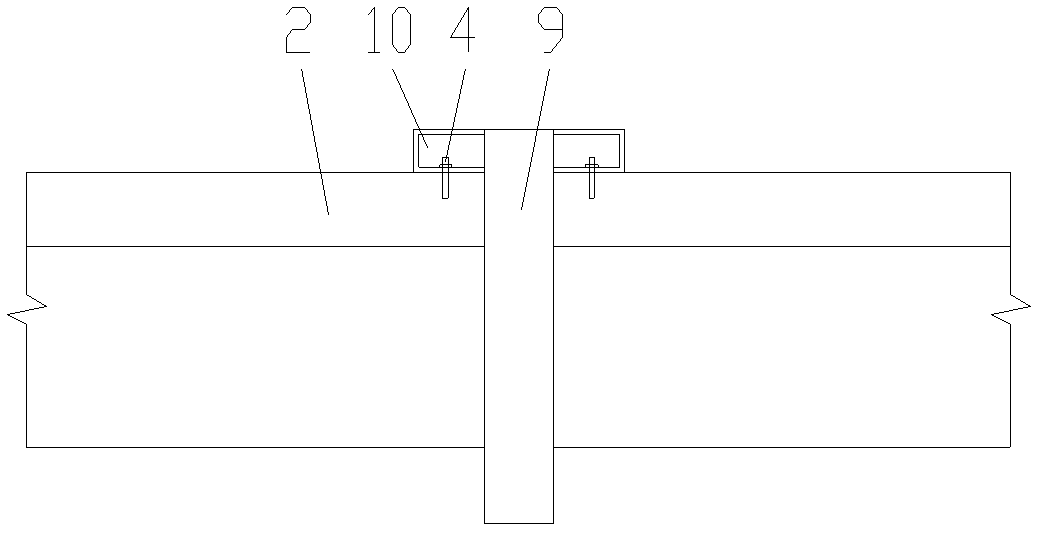

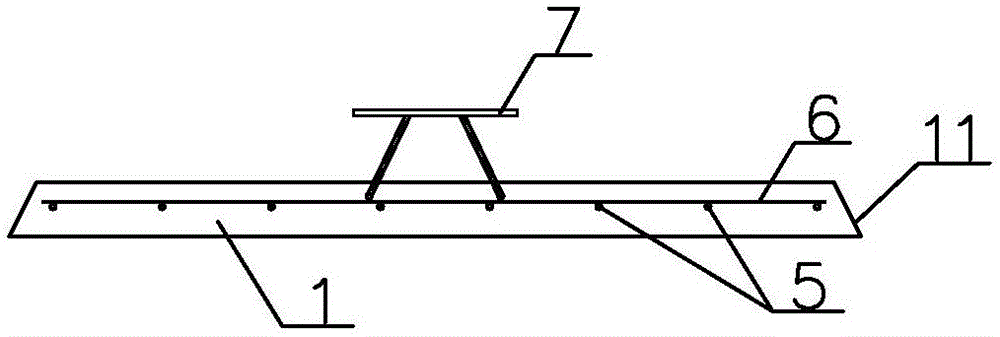

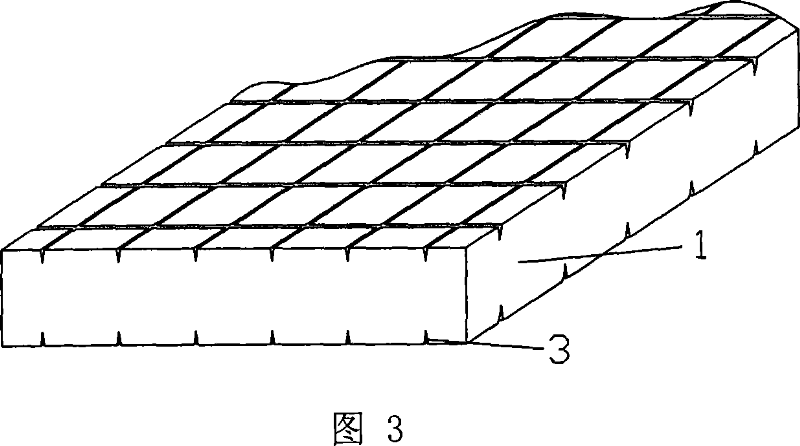

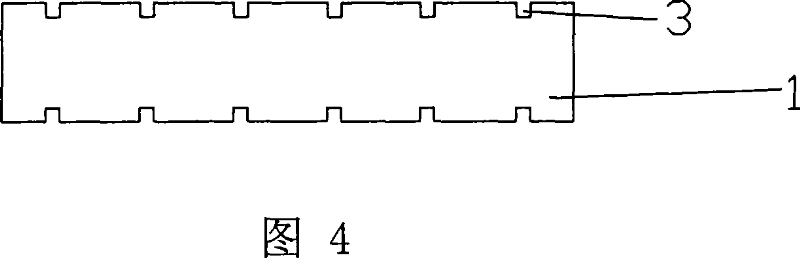

Comobined ribbed cavity member for spatial structure roof

A combined-rib cavity member for space-structure flooring includes cavity form and structure bottom plate, which are connected into one integral whole. It is characterized by that there are at least two cavity forms arranged alternate with each other on the structure bottom plate, its side forms with the structure bottle plate at least one subrit form cavity of casti-in-situ structure, and other other sides of the cavity form forms the side fromboard of main rib or beam or wall for cast-in-situ structure. By this, the subrib of cast-in-situ structure can be formed in the sub-rib form cavity on the structure battom plate, the sub-rib participates in load bearing of structural bottom slat, cast-in-situ main rib, cast-in-sita upper slab so to a load-bearing space structure, improved mechanical property, raise integrity and anti-shock property, decrease structural wt. lower cost and make construction be convenient.

Owner:湖南邱则有专利战略策划有限公司

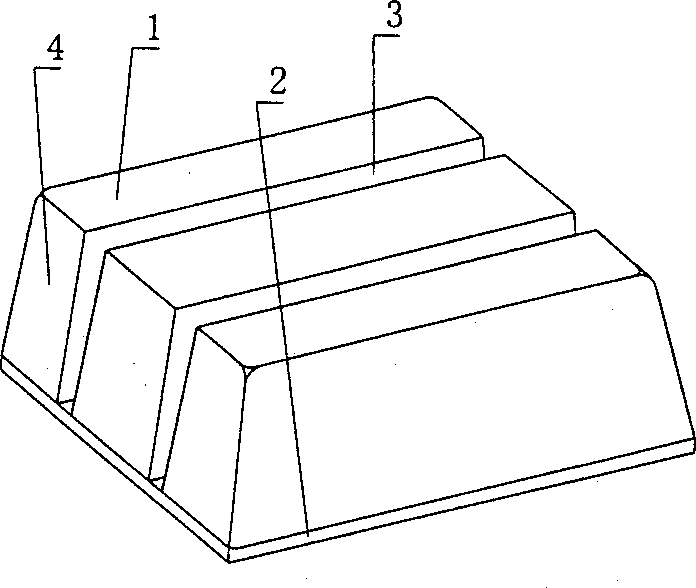

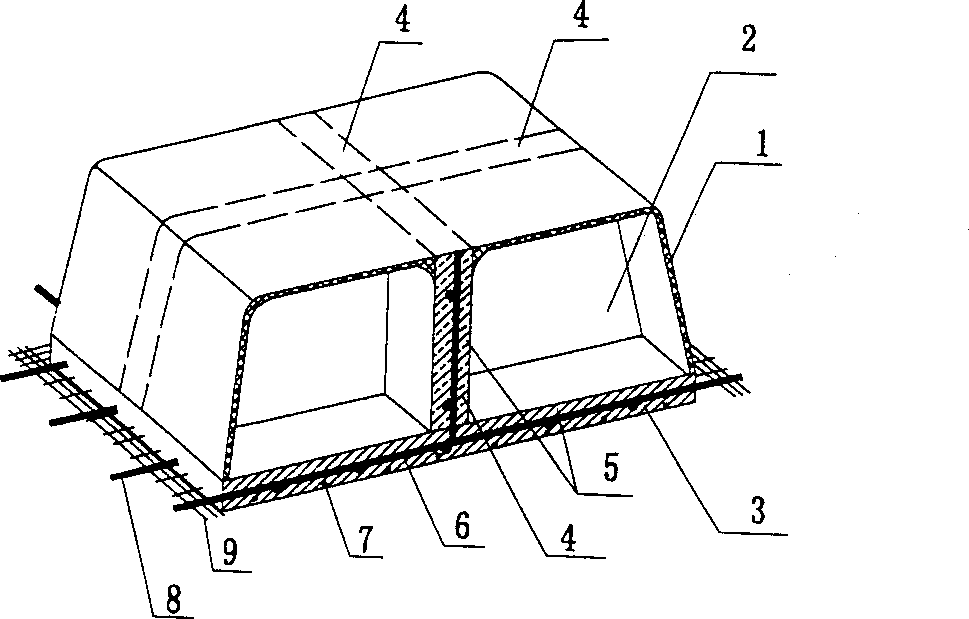

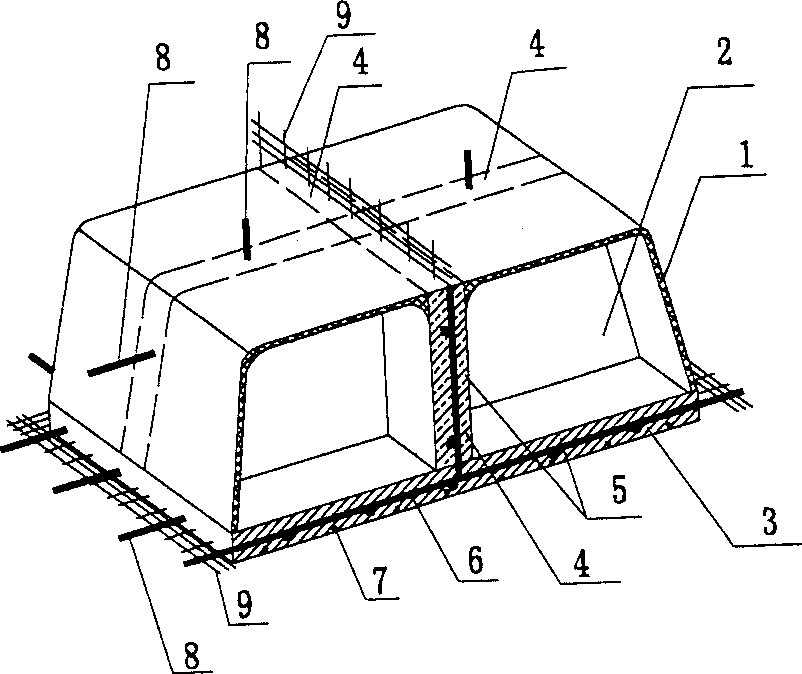

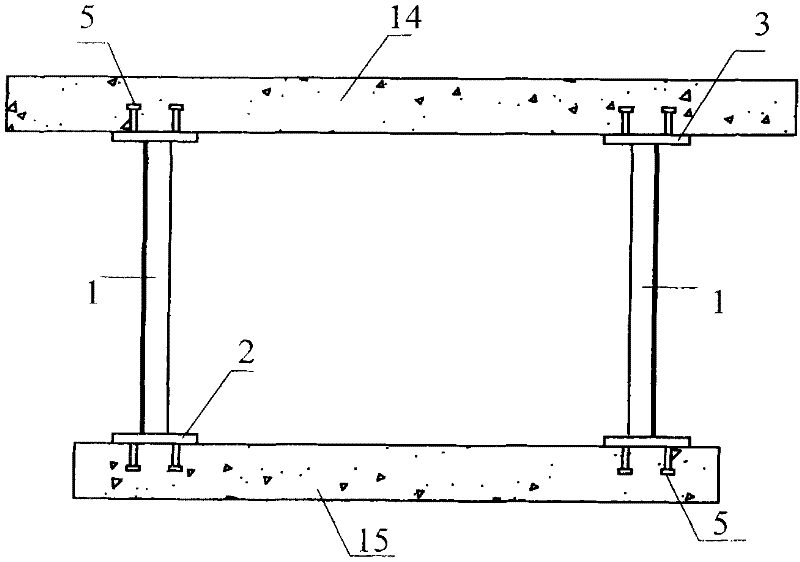

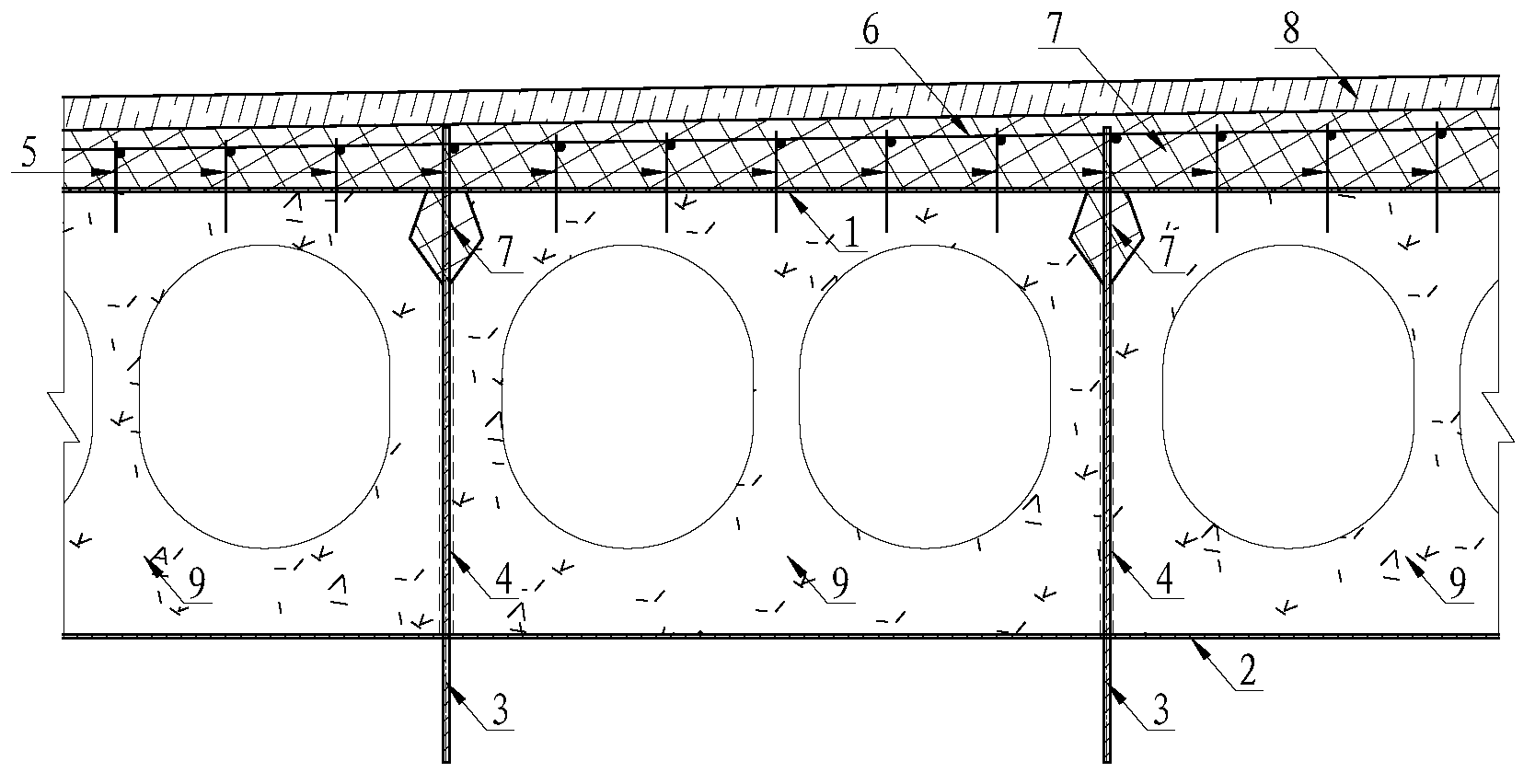

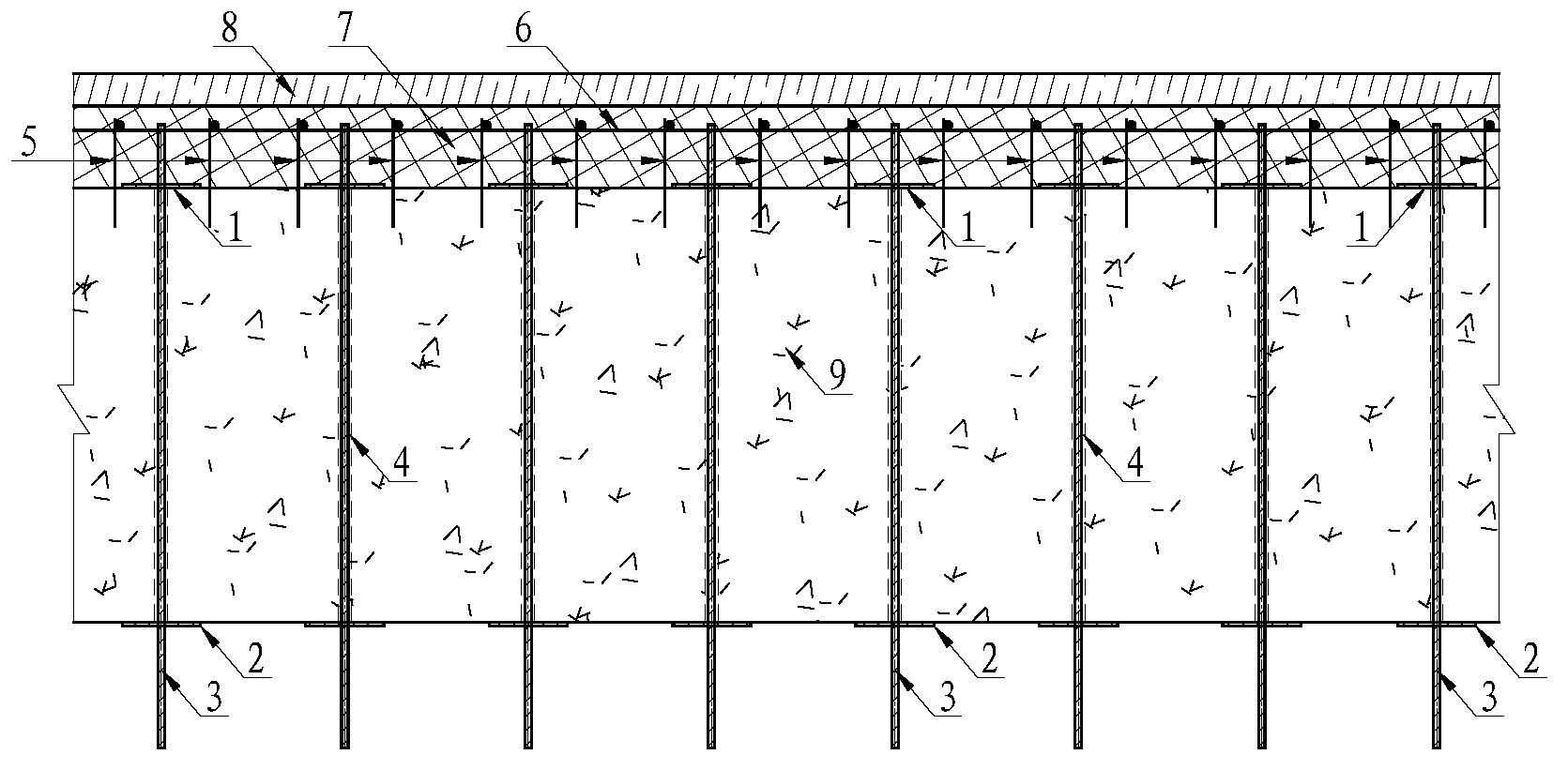

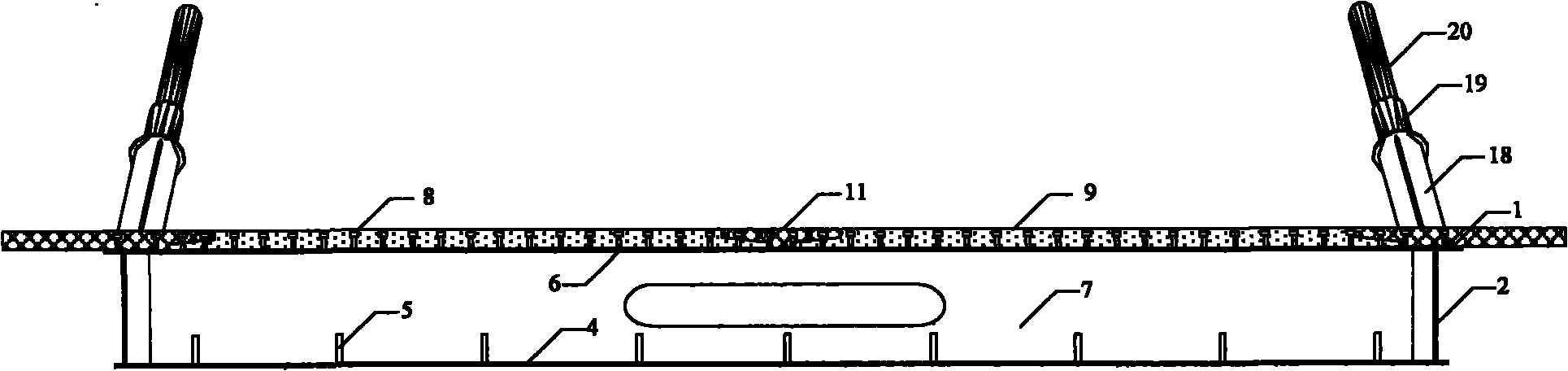

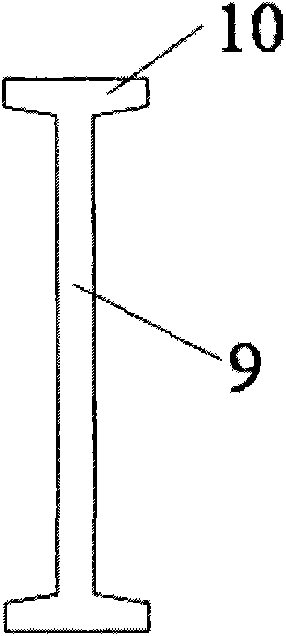

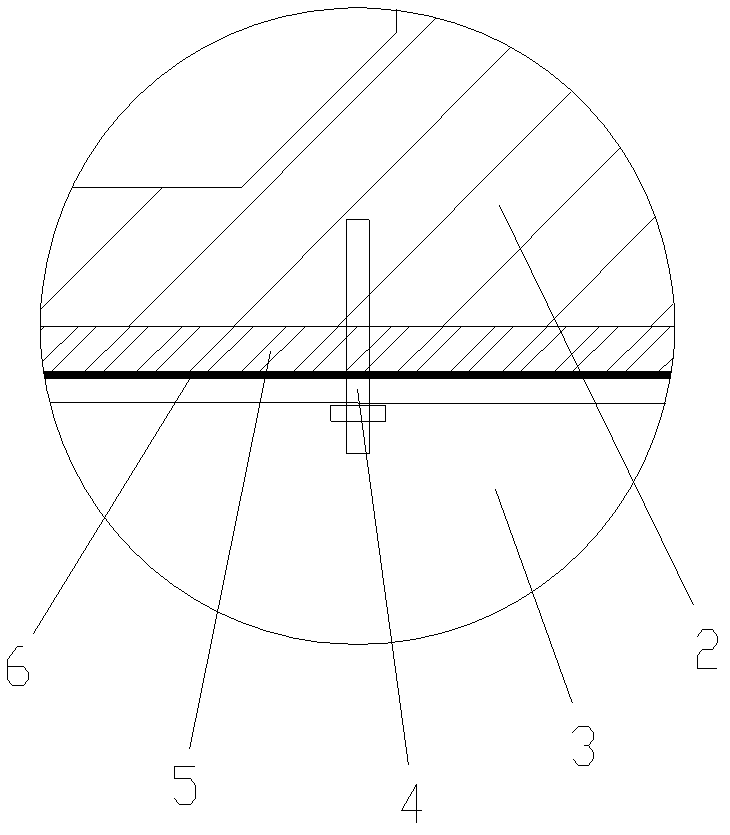

Prefabricated hollow member for roof with space structure and its application

InactiveCN1366118AImprove mechanical performanceImprove integrityFloorsSpatial structureShock resistance

The invention relates to a precast hollow floor board with spatial structure and its application. The floor board includes hollow form and cavity, and features including structural bottom slab and structural sub-rib. The structural bottom slab and structural sub ribs contain reinforcing bars or wire mesh to form an integrated load-bearing member with an inverted T-shape. There are exposed bars ormesh on the structural bottom slab. The thicknesses of structure bottom slab and structural sub-rib are larger than the thickness of hollow form whose upper part and side parts are connected to the structural sub-rib, and lower part is connected to the structural bottom slab so as to form a closed integral body. The invented precast hollow floor board possesses advantages of simple structure, high strength, easy for handlings, good shock resistance and reduced structural dead wt..

Owner:湖南邱则有专利战略策划有限公司

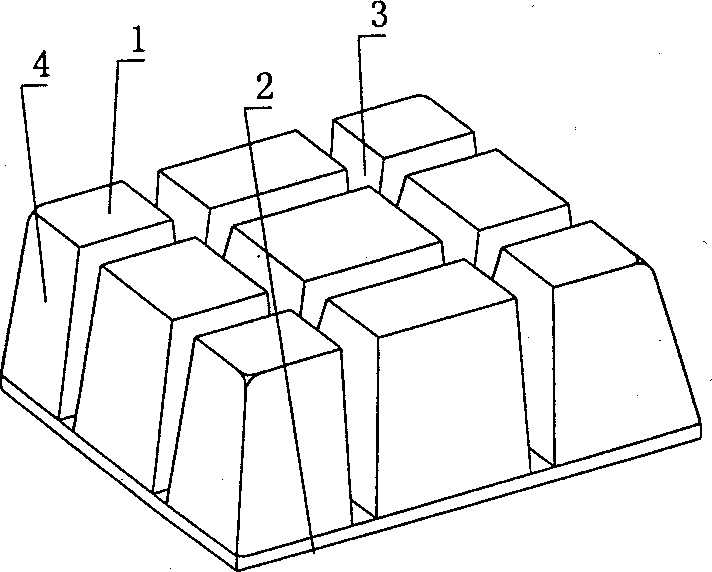

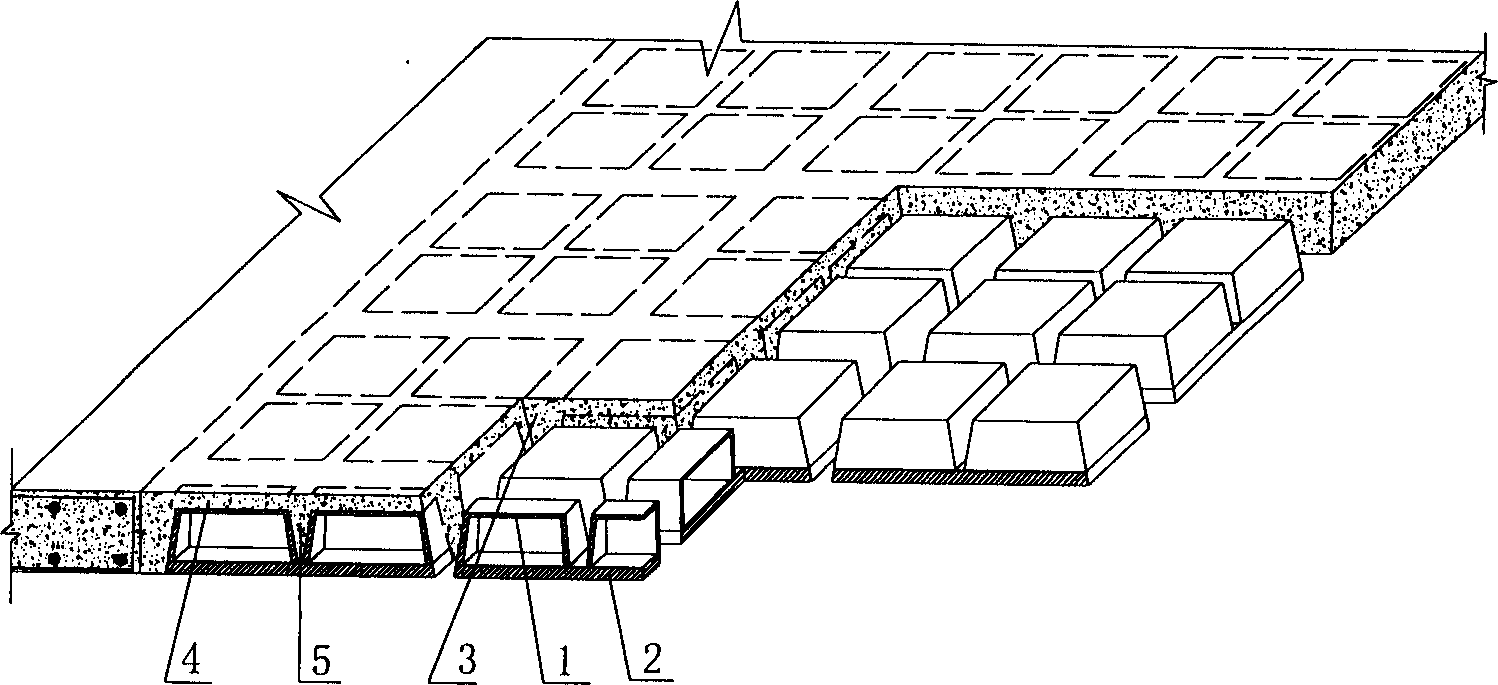

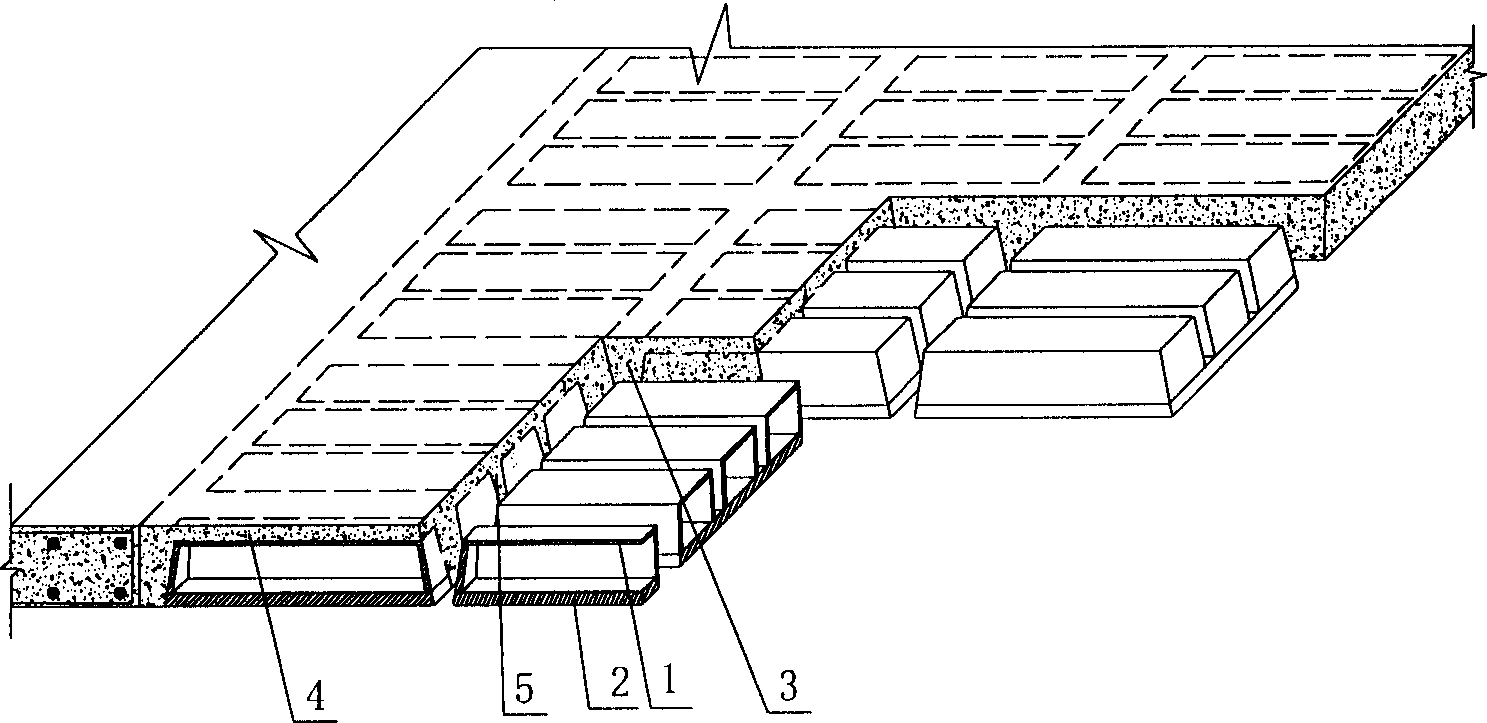

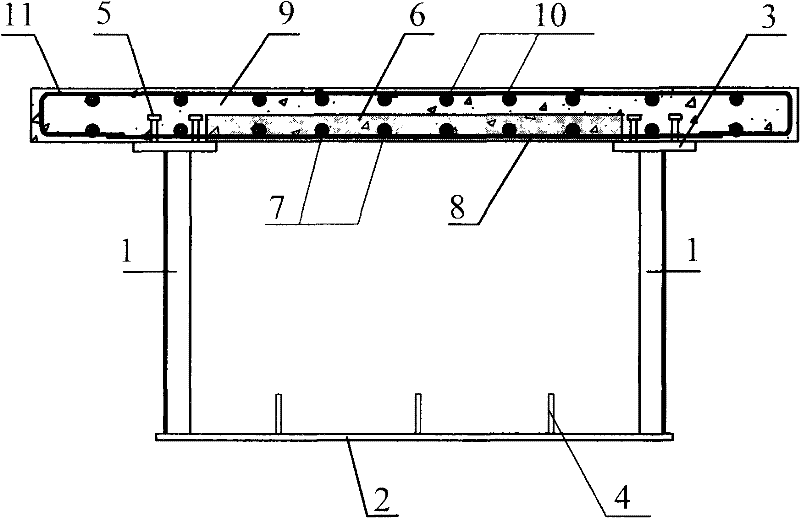

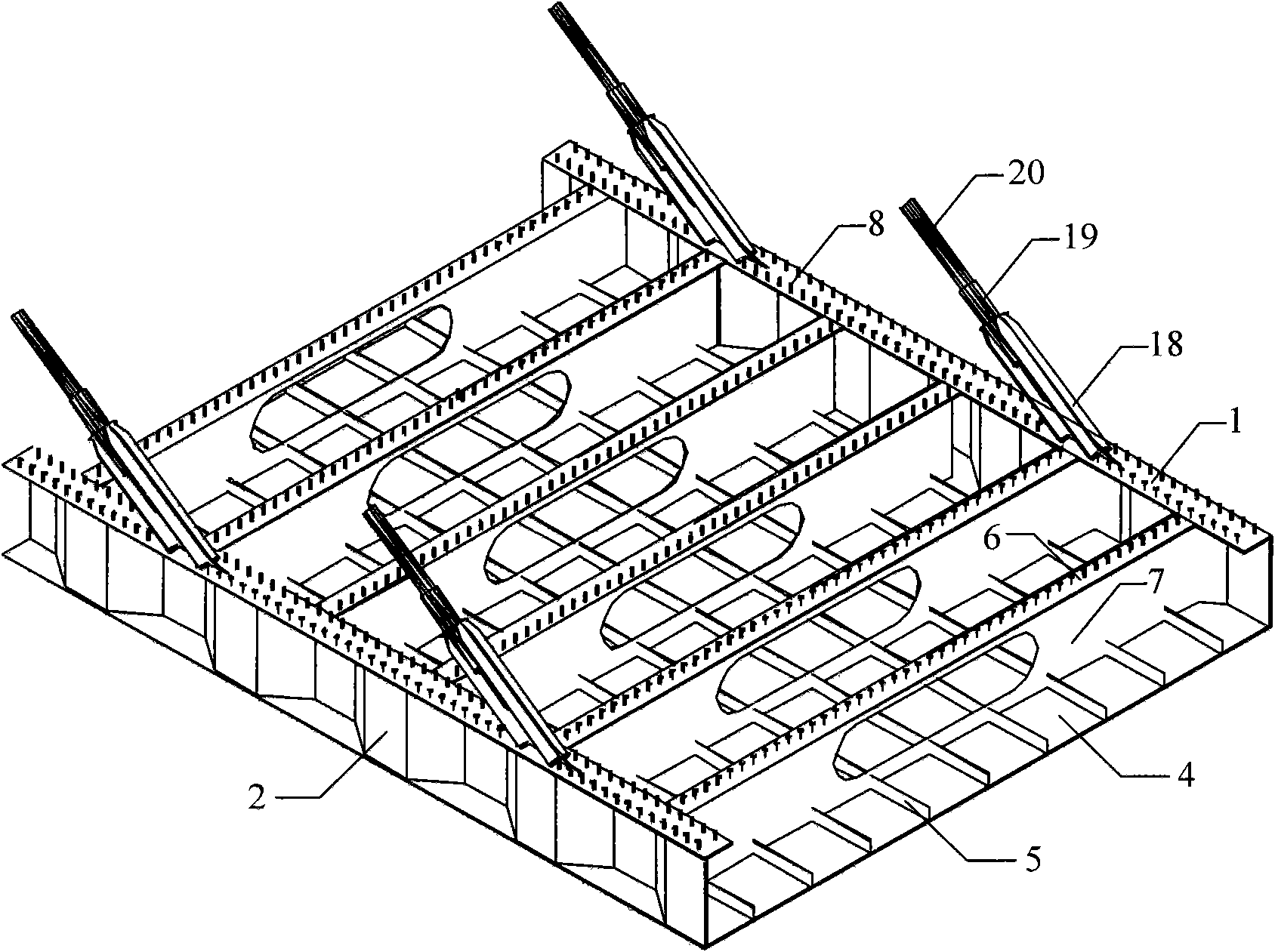

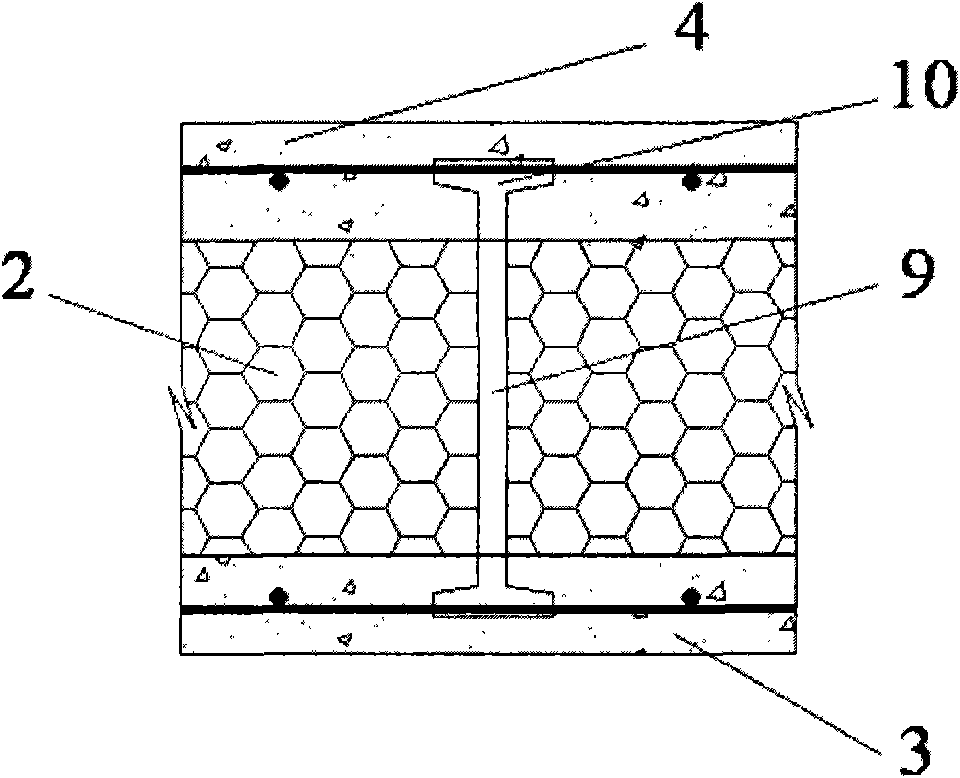

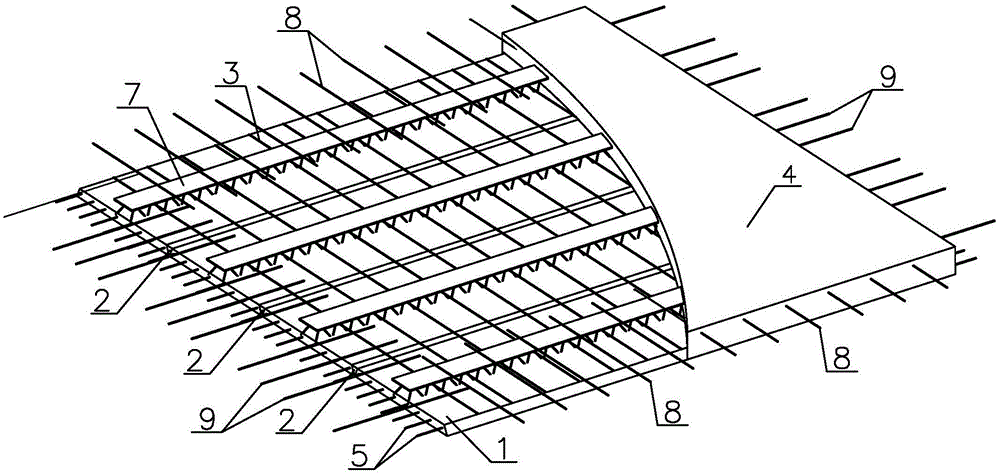

Floor with space structure

InactiveCN1356440AImprove mechanical performanceReduce thicknessFloorsReinforced concreteSpatial structure

A building roof with space structure is coposed of molded waffle members consisting of molded waffle and bottom plate, in-situ cast primary reinforced concrete rib, and in-situ cast reinforced concrete top plate. A prefabricated structured bottom plate has at least 2 molded waffle cavities and at least one in-situ cast secondary reinforced concrete rib. The said primary and secondary ribs constitute a hidden dense rib structure. Its advantages include high anti-earhquake performance and less thickenss, high strength.

Owner:湖南邱则有专利战略策划有限公司

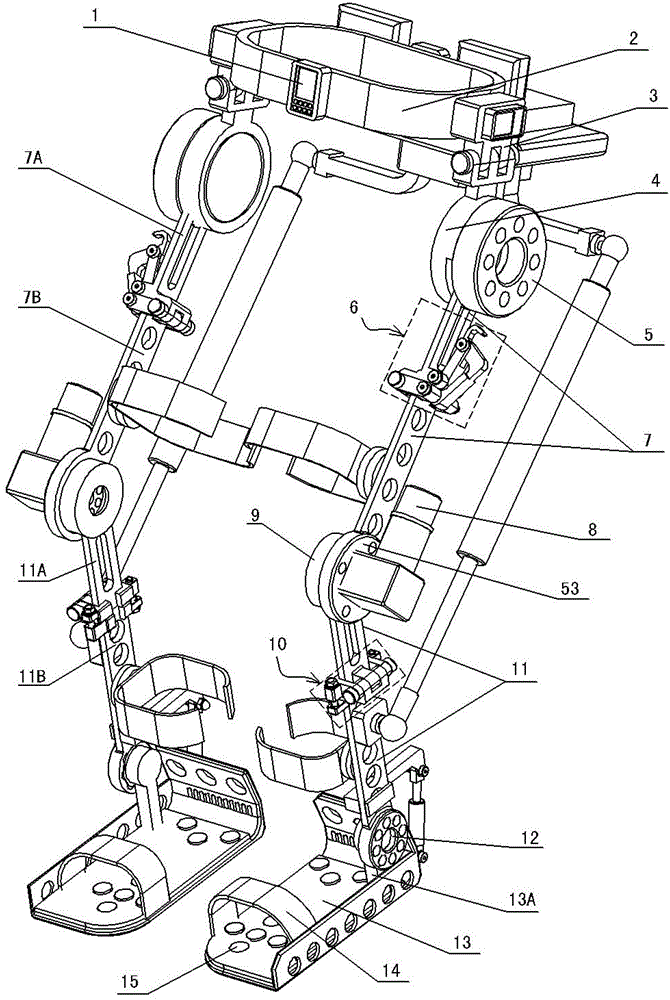

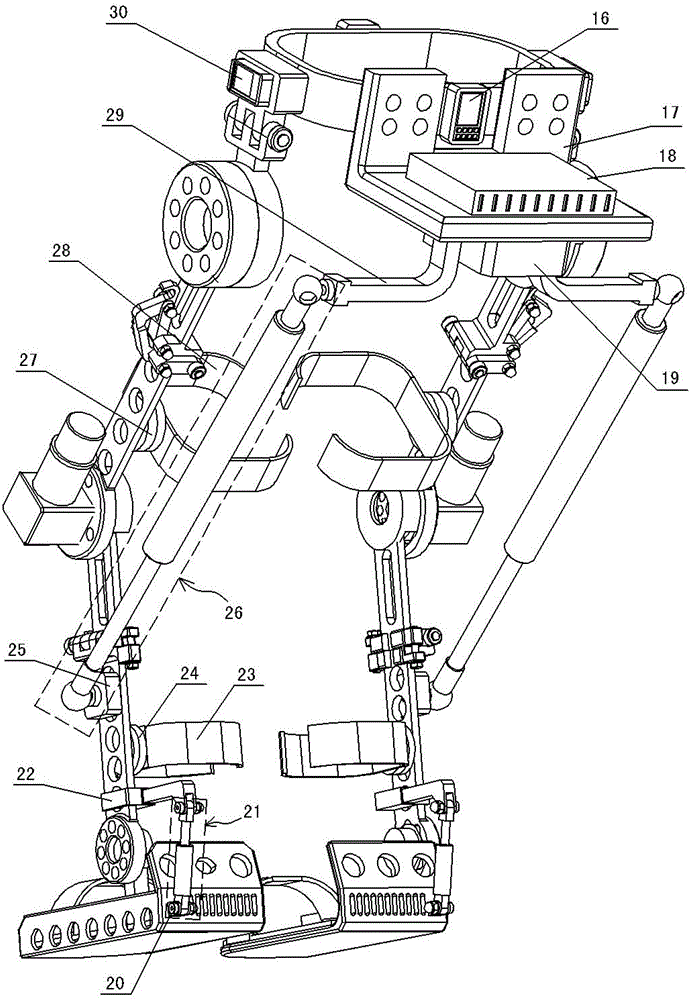

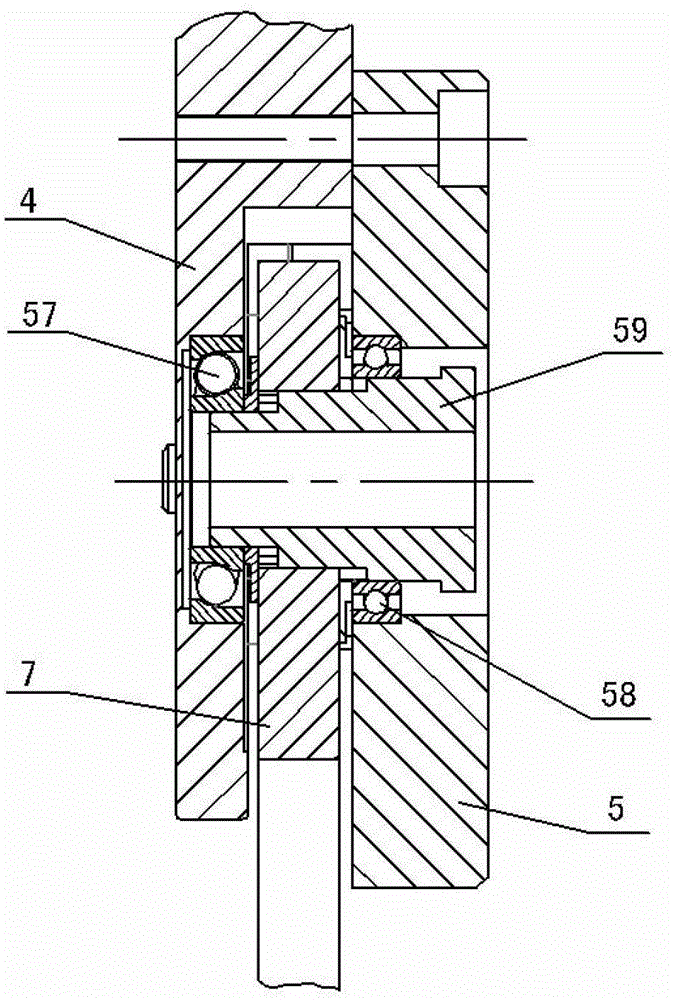

Wear type lower limb assistant robot, folding method thereof and hand luggage for carrying

ActiveCN103330635ASafe, Reliable and Reasonable BehaviorTimely and accurate judgmentWalking aidsLuggageMan machineEngineering

The invention discloses a wear type lower limb assistant robot, a folding method thereof and a hand luggage for carrying. The robot is characterized by comprising a lower limb assistant mechanical device and a servocontrol system, wherein the lower limb assistant mechanical device is provided with wearable assistant mechanical legs which are symmetrically arranged on the two sides of a wearable waistband. The wearing load on human bodies can be effectively relieved, and the robot has the characteristics of high safety performance, simple man-machine coordination control, good following assist effect, high cost performance and the like; the robot can be changed into a portable body which is compact in structure through the folding method, and a user can conveniently carry and store the robot in various manners through matching with the hand luggage for carrying, so that the nursing requirements of the middle-aged and the aged people on daily activities such as walking and walking up and down stairs can be better satisfied.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

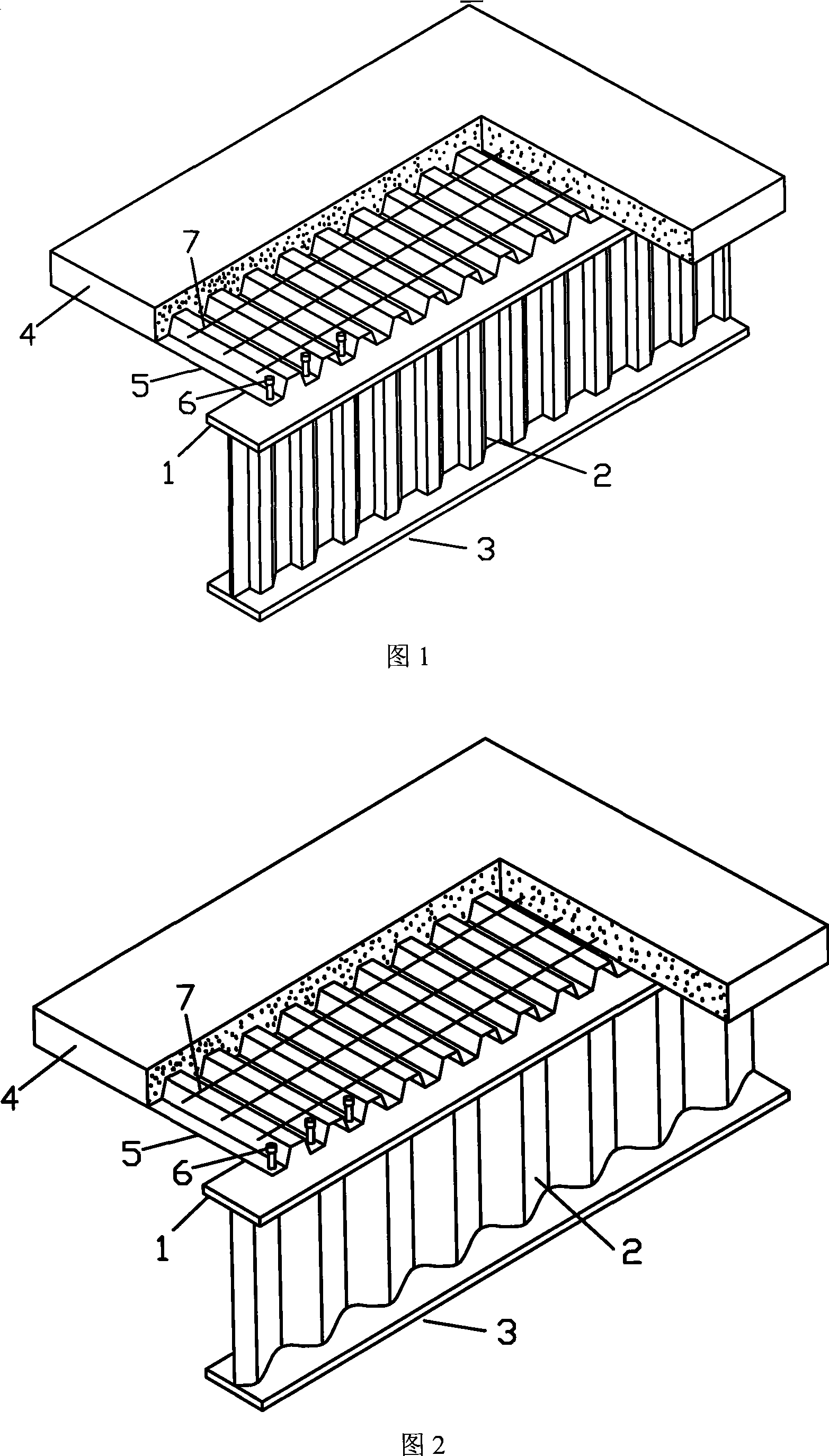

Steel-concrete composite beam adopting corrugated steel web and construction method thereof

The invention discloses a steel-concrete composite beam adopting a corrugated steel web, which relates to a corrugated steel web composite beam capable of being applicable to highway bridges and railway bridges. The beam comprises a top flange concrete composite plate, a corrugated steel web plate, a top flange steel plate, a box beam bottom plate and male pin connecting pieces, wherein the top flange comprises a precast concrete slab and a cast-in-place concrete layer; and the top flange concrete composite plate is connected with the top flange steel plate into a whole through the male pin connecting pieces welded on the top flange steel plate. By adopting the structure, the problems that the site workload and the construction difficulty for casting a bottom flange concrete slab of a traditional corrugated steel web composite beam are large, the construction quality is difficult to guarantee and the like are overcome on the premise that the quantity of steel is hardly increased, meanwhile, the tensile property of the steel plate is fully played, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved, therefore, the corrugated steel web composite beam has the advantages of simple structure, reasonable stress, quick and convenient construction, and good technical and economic benefits.

Owner:TSINGHUA UNIV

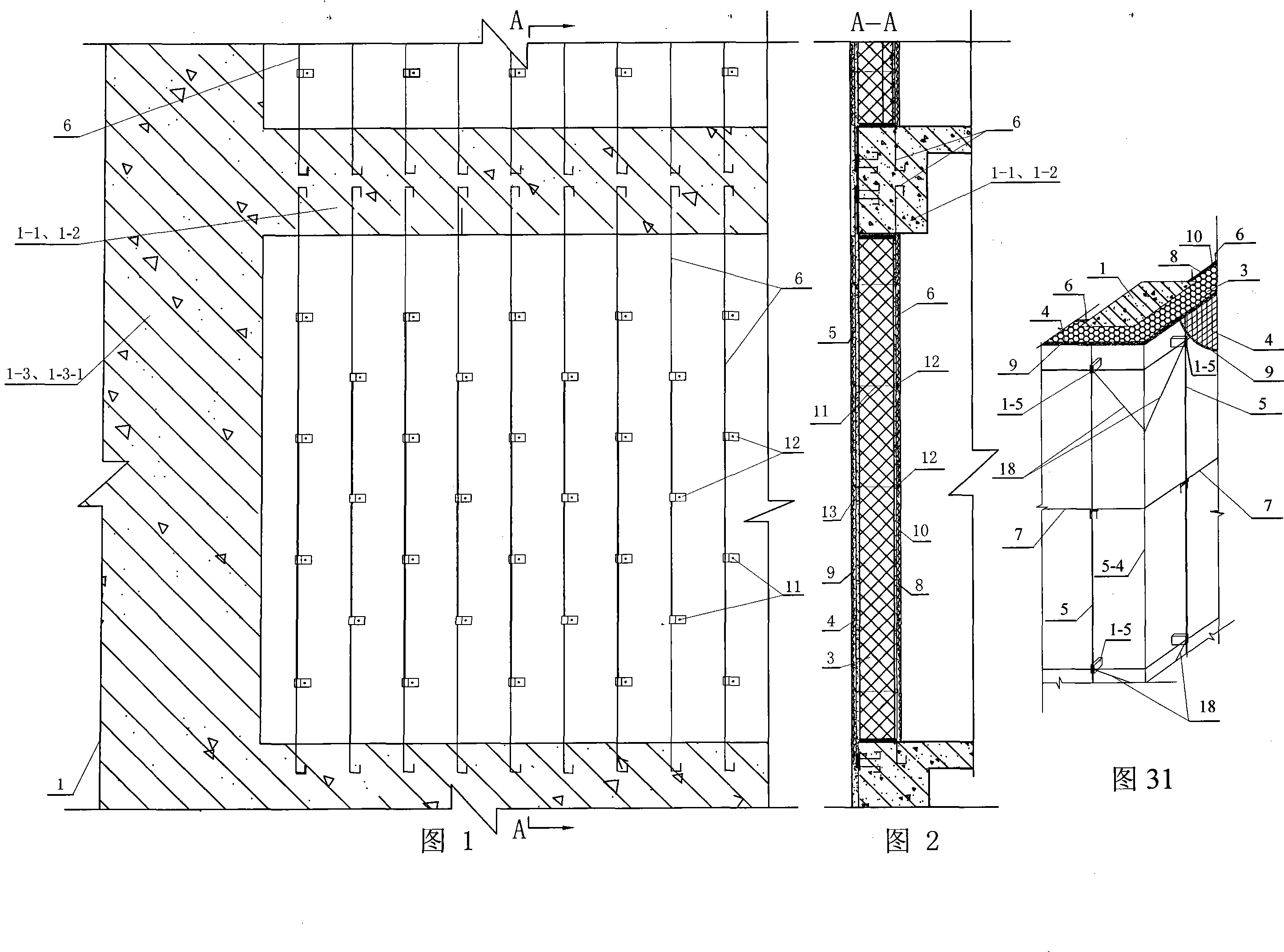

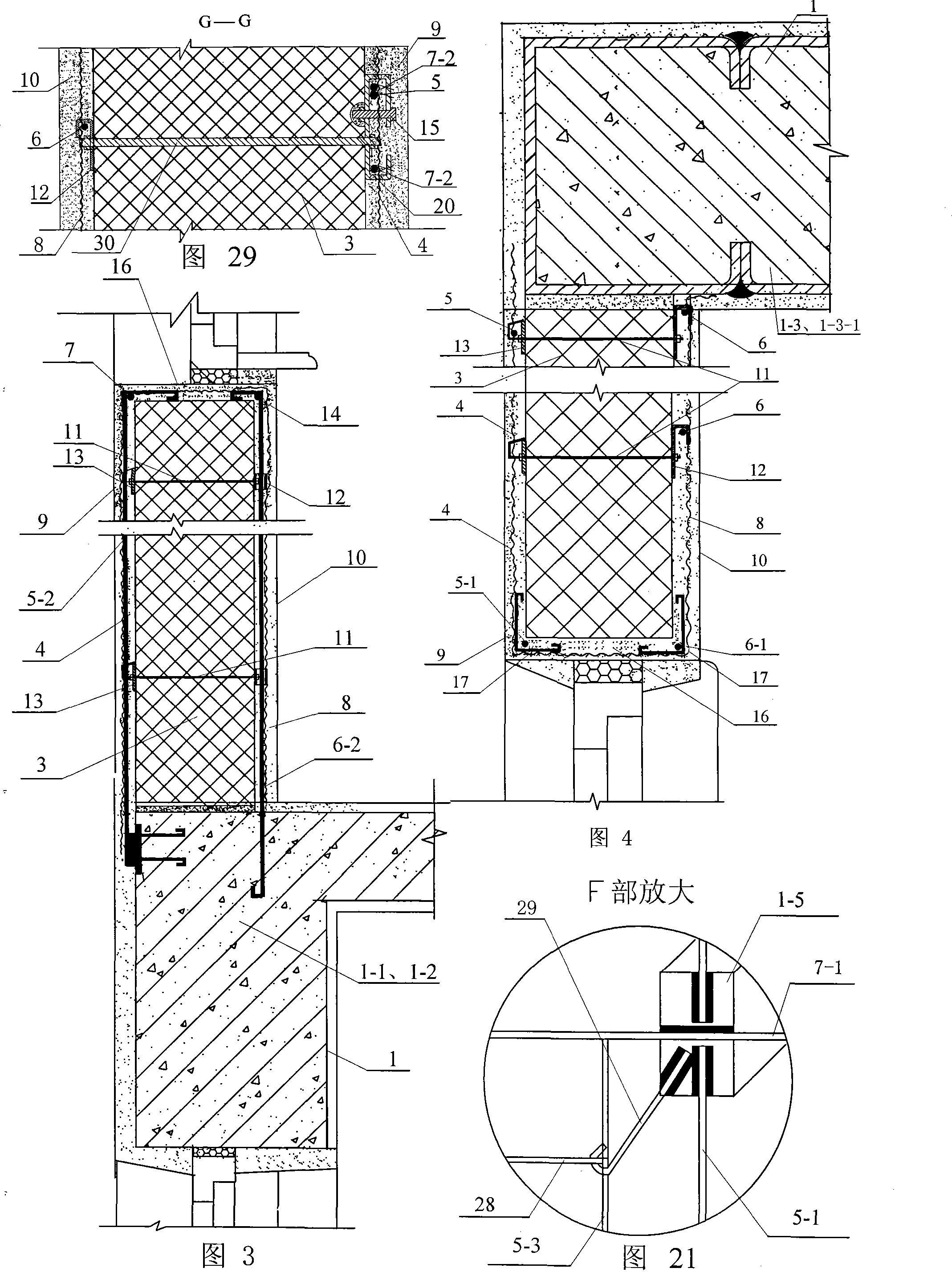

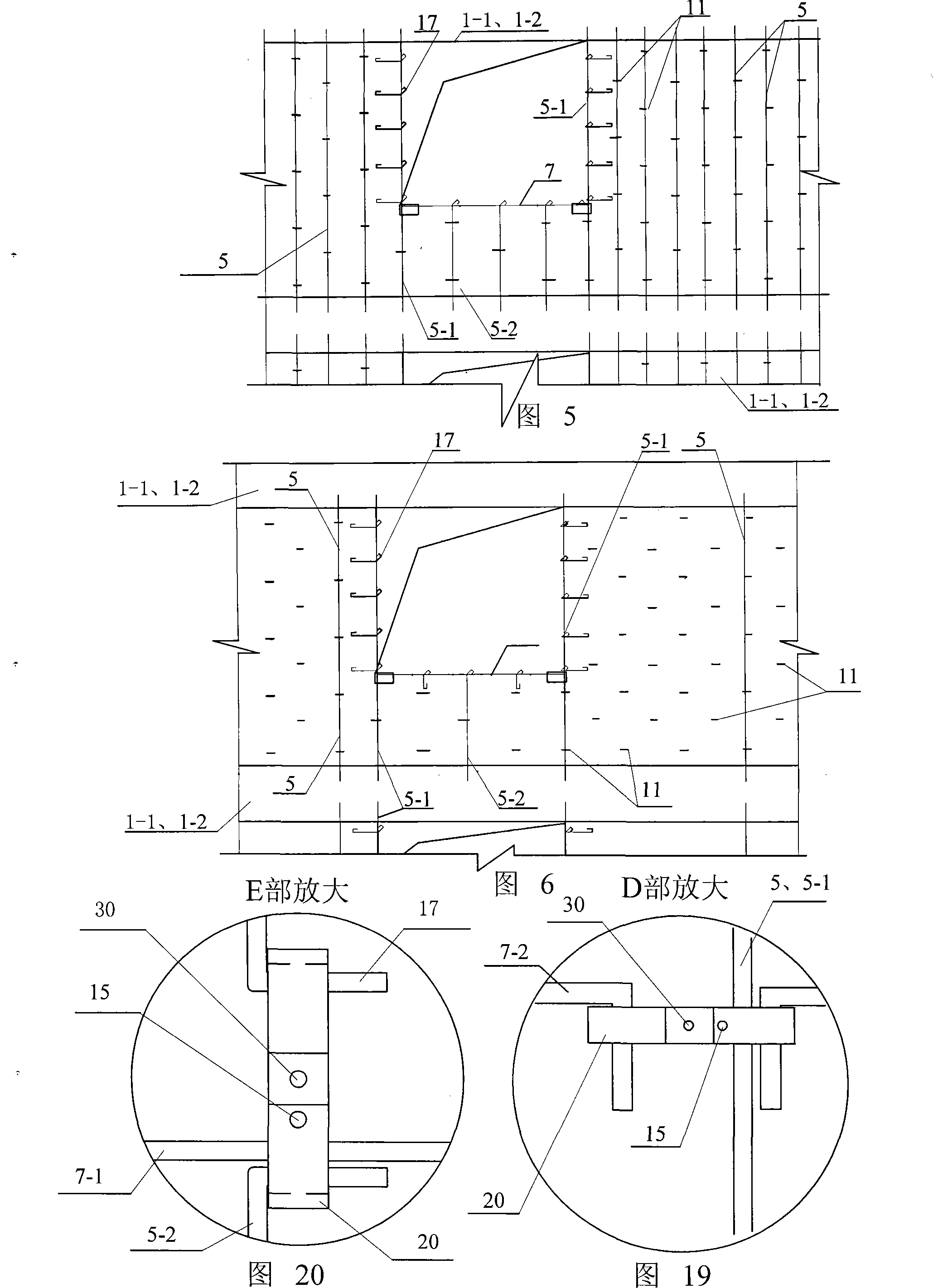

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

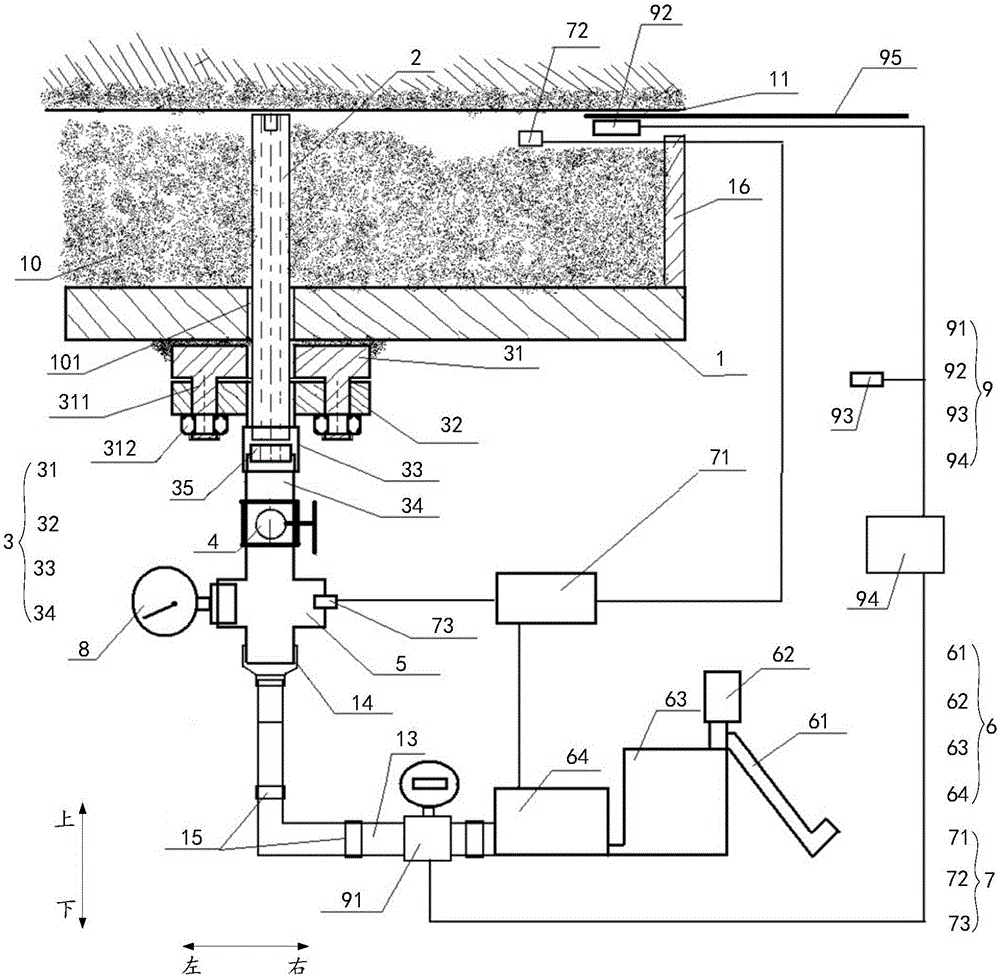

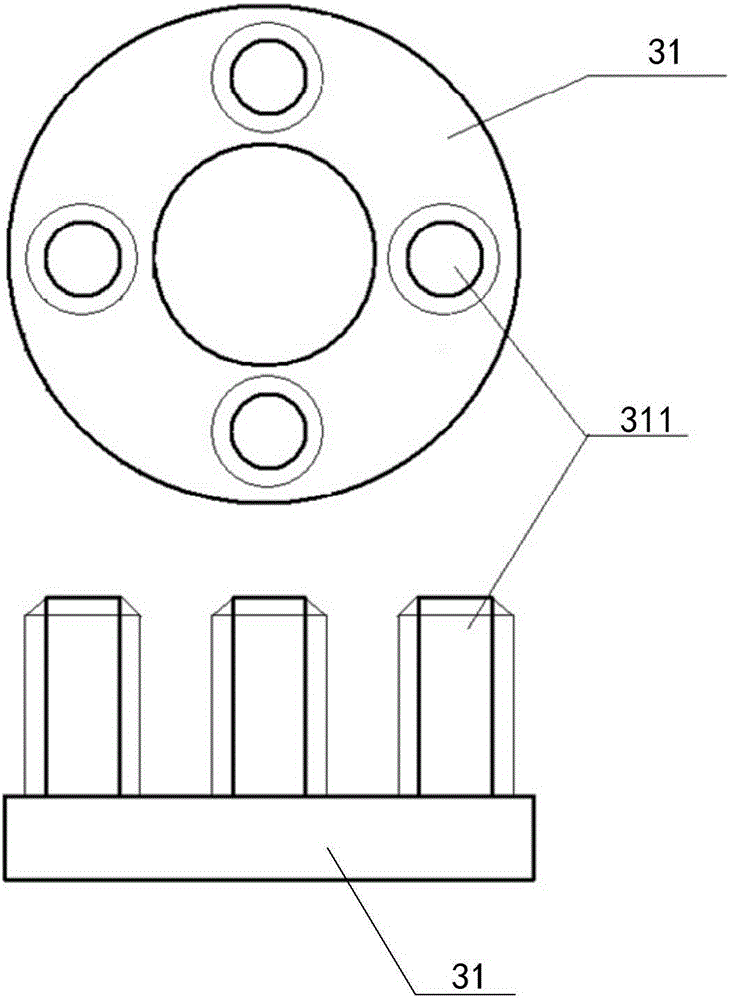

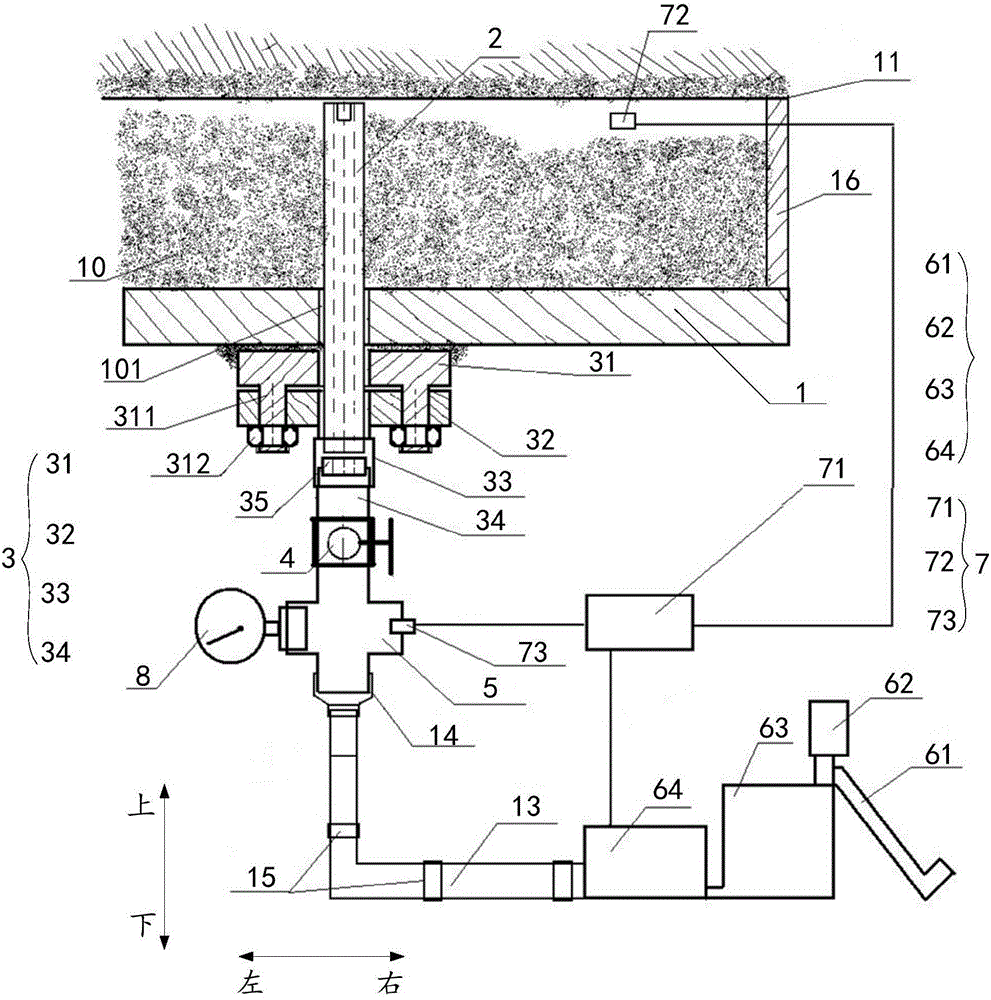

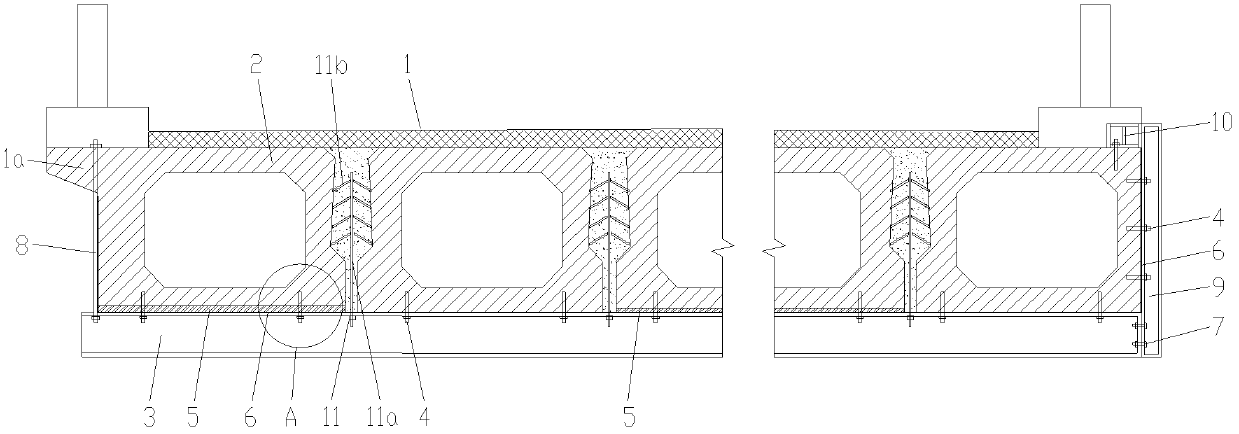

Grouting device and grouting technique for tunnel lining vault with mould

ActiveCN106014454AImprove mechanical performanceSimple structureUnderground chambersTunnel liningWater leakagePunching

The invention provides a grouting device and grouting technique for a tunnel lining vault with a mould. The grouting device comprises a lining concrete pouring template, a grouting pipe, a fixing device, a throttling device, a flow-splitting device, a feeding device and a control device, wherein a mounting hole is formed in the lining concrete pouring template; the grouting pipe penetrates through the mounting hole, and the fixing device is used for fixedly connecting the grouting pipe; one end of the throttling device is communicated with the grouting pipe while the other end is communicated with an output port of the flow-splitting device; the feeding device is communicated with an input port of the flow-splitting device and is used for conveying grouting slurry to the grouting pipe; and the control device is connected with the feeding device and is used for controlling the starting / stopping of the feeding device. According to the invention, the water leakage problem of the secondary lining concrete caused by the waterproof plate being easily broken in the traditional later punching grouting process is solved, and the filled grouting liquid and concrete are formed into a stressed whole body, so that the empty lining and the defect of two-layer skin of the traditional grouting technique are overcome, and the risks in cracking and falling of the lining concrete are reduced.

Owner:北京鸿锐嘉科技发展有限公司 +1

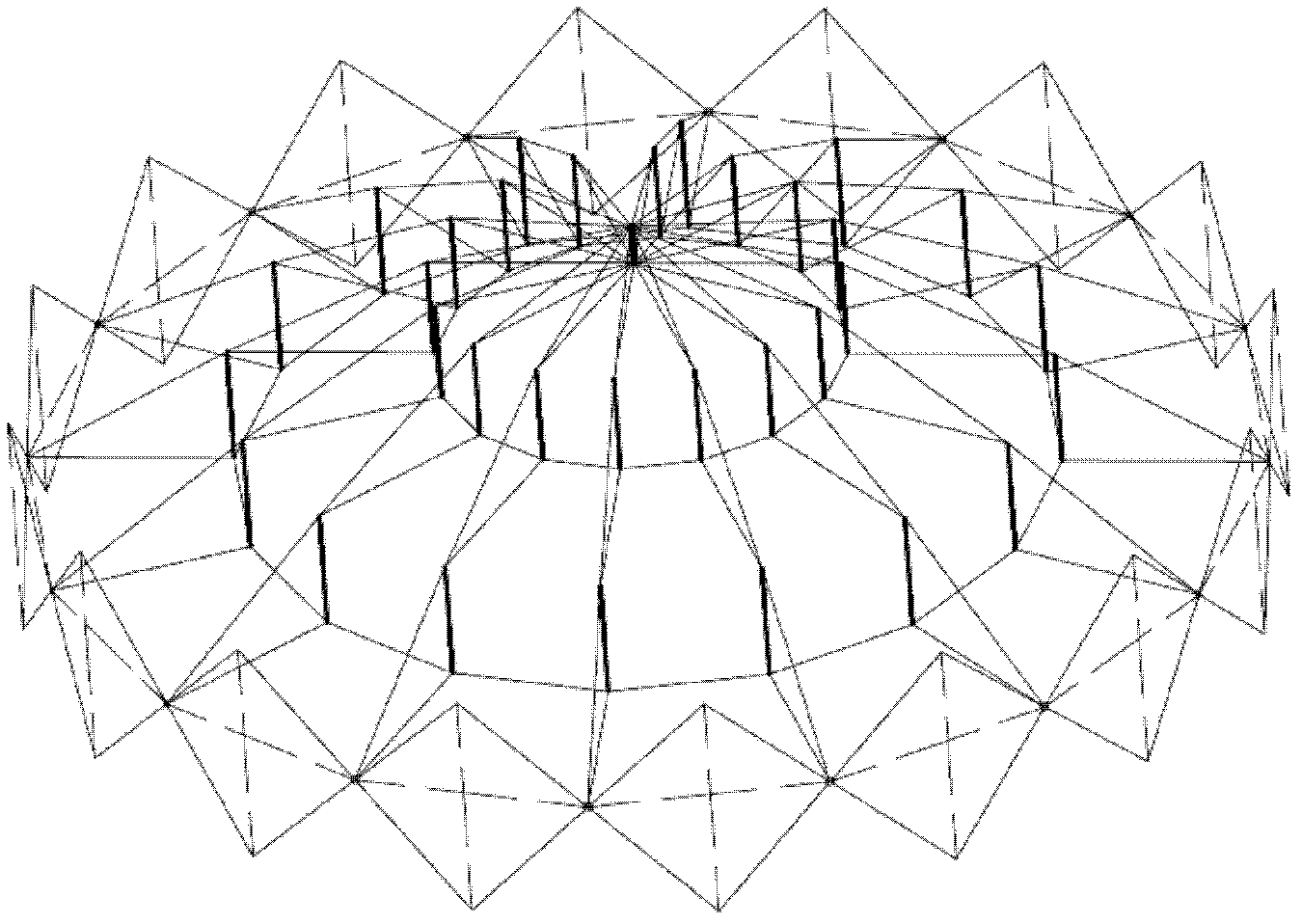

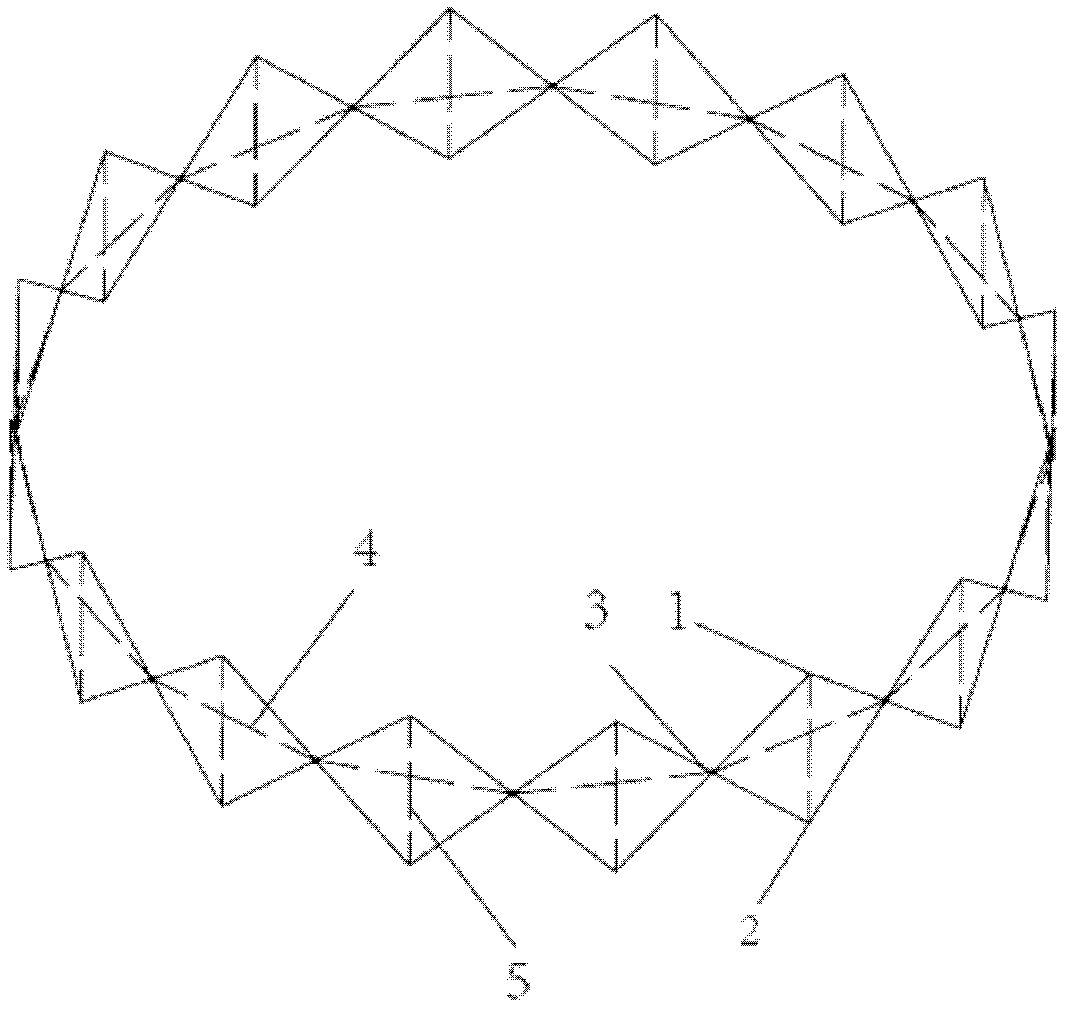

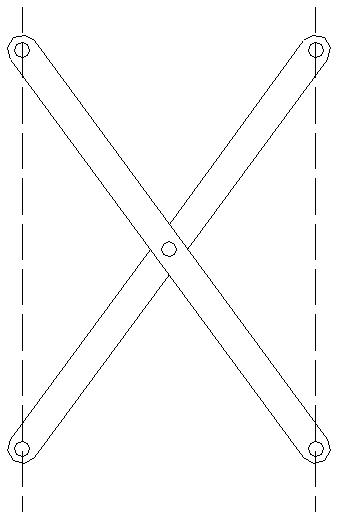

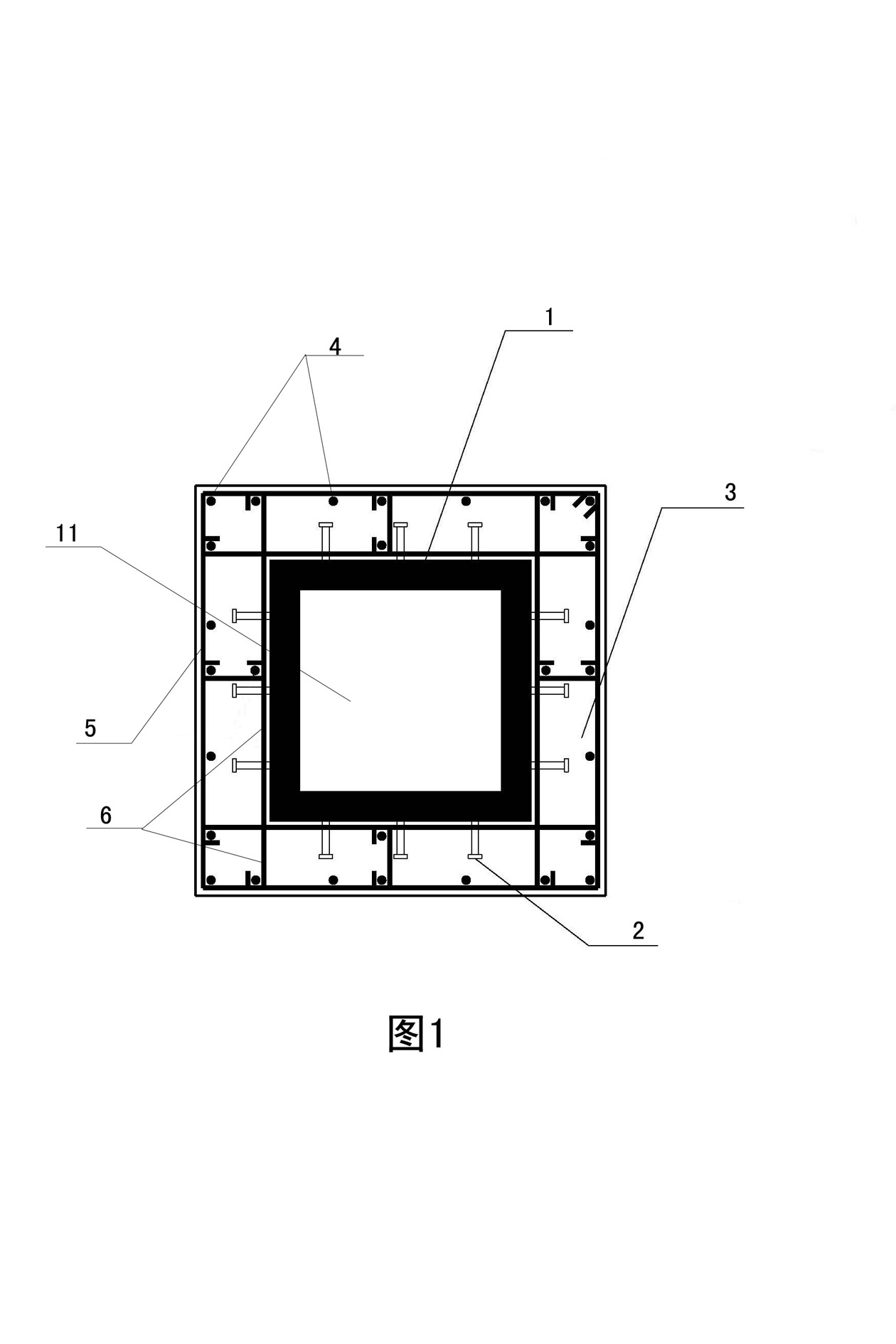

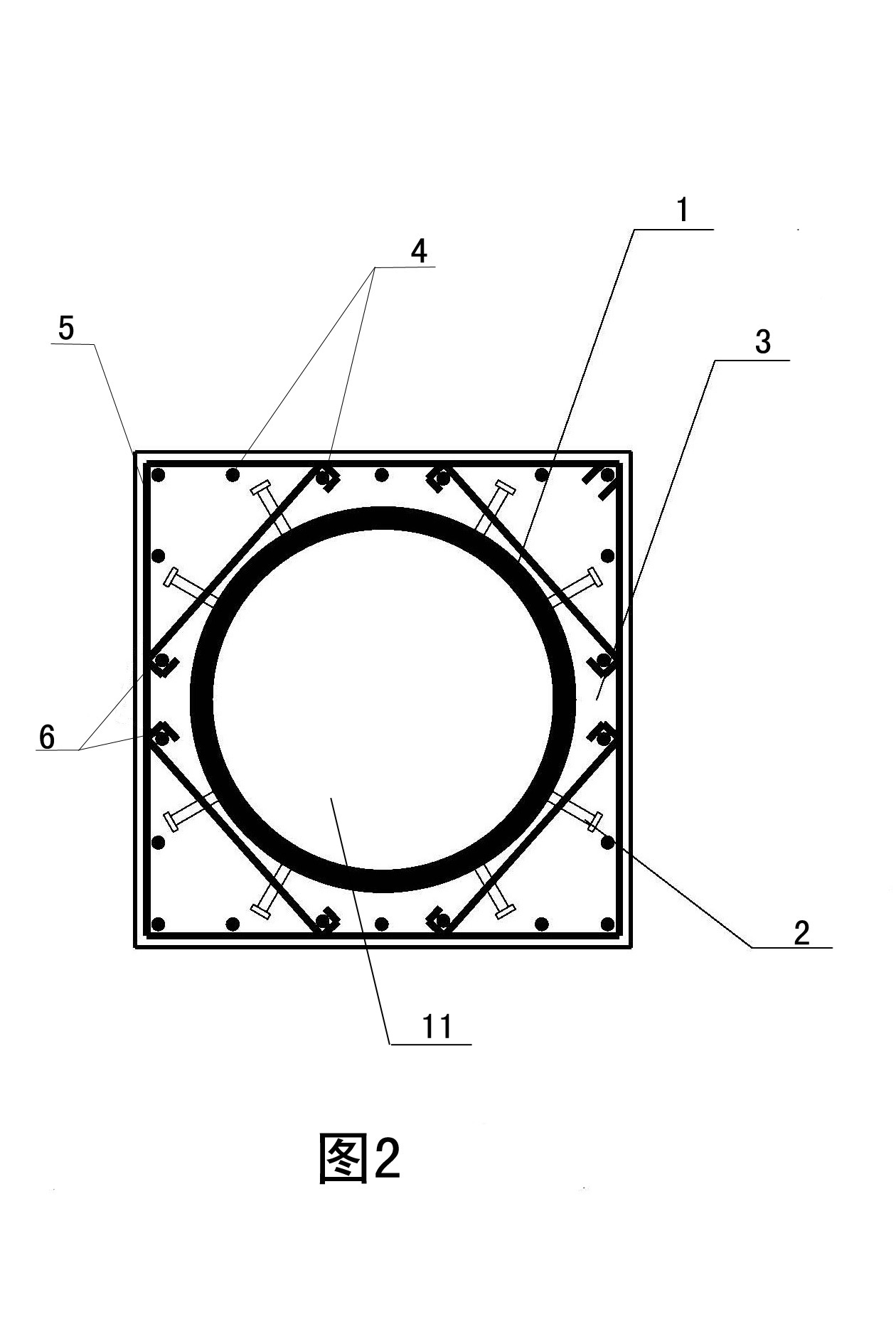

Deployable cable pole dome structure

InactiveCN102605861AIncrease stiffnessReduce in quantityArched structuresVaulted structuresActive cableFull extension

The invention discloses a deployable cable pole dome structure, comprising an inner cable pole body and an external single-freedom-degree annular connecting bar mechanism, wherein the single-free degree annular connecting bar mechanism comprises at least four shearing type units, a passive cable and an active cable. The invention uses the single-freedom-degree annular connecting bar mechanism to drive the dome structure to fold and unfold, thus number of driving devices is reduced; the active cable and the passive cable are arranged in the external annular connecting bar mechanism, and the prestressing force exists at a full extension state, so that the rigidity of the structure is increased and the material does is reduced; only the active cable needs to be fixed at a full extension state, and an additional locking device is not needed; a coverage range of the dome structure is provided by the inner cable pole body, thus, the external load of the structure is mainly born by the inner cable pole body; the inner cable pole body is composed of a high-strength inhaul cable and a pressure bar; the self weight is light; and the rigidity is mainly provided by the prestressing force, and the stress performance is excellent.

Owner:SOUTHEAST UNIV

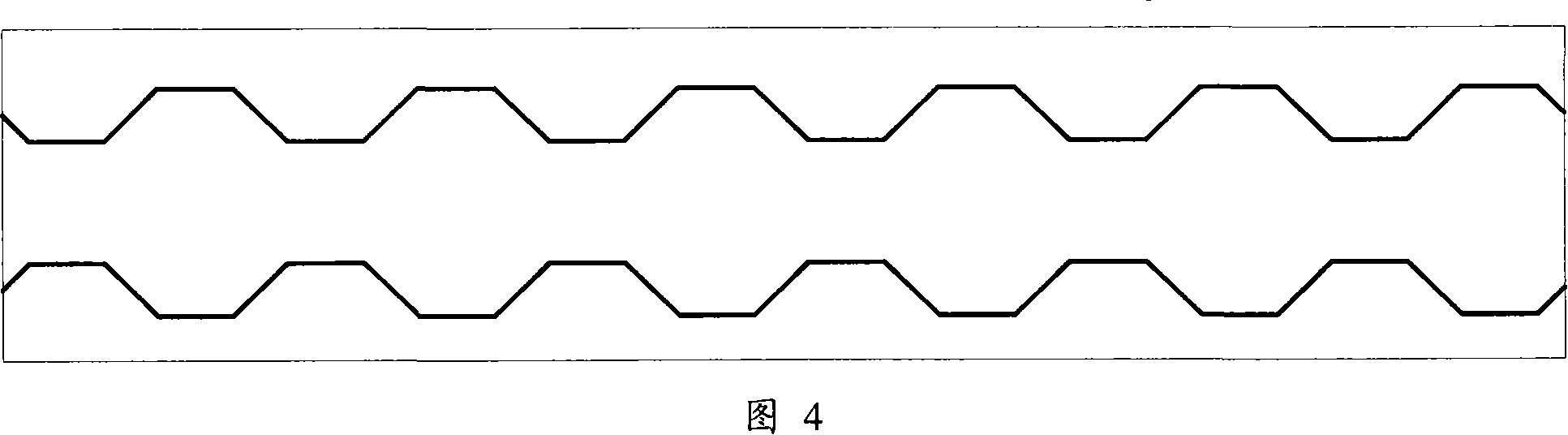

Double corrugated web plate steel box girder

The invention belongs to the technical field of building materials and in particular relates to a double undulated web slab steel box girder. The cross-section fracture shape is composed of a middle web slab, an upper flange and a lower flange which are integrated, wherein the upper flange is parallel to the lower flange, a double web slab is vertically located between the upper flange and the lower flange, the double web slab is arranged symmetrically and takes a honeycomb structure, the web slab and the flange slabs adopt one side fillet weld to connect, the web slab is an undulated web slab whose length direction are periodically repeated evenly or unevenly, and the undulated cross section takes circular arc angle trapezoid and sinusoidal curve. The product can replace products such as normal welded box steel girders, hot rolled H-shaped steel, I-shaped steel and the like, has wider usage compared with the products, and can realize maximization and can be used in the special fields and special places including the building of bridges with large spans, the manufacture of ships and the like.

Owner:TONGJI UNIV +1

Single plate force-bearing reinforcing method of hollow slab bridge

InactiveCN103061271AAvoid destructionImprove reliabilityBridge erection/assemblyBridge strengtheningWhole bodyBridge deck

The invention relates to a single plate force-bearing reinforcing method of a hollow slab bridge. The single plate force-bearing reinforcing method includes that the original bridge deck pavement is shoveled, hinge joint concrete is removed, defects and cracks of the original hollow slab bridge beam body are processed, strip-shaped steel plates are transversely pasted on the upper surface and the lower surface of the hollow slab bridge in the longitudinal bridge direction at certain intervals, split screws penetrate through drilled holes at the hinge joint position, a counter-force frame is arranged, a wedge-shaped block is embedded between the counter-force frame and the steel plates, and the steel plates are pressurized and pasted in sealing mode and then are positioned and fixed; the counter-force frame is demounted after sticky steel glue is cured; cavities in beam joints are subjected to pressure grouting, shear reinforcements are placed into the top surface of a hollow slab, a reinforcement mesh is reconstructed, and the bridge deck reinforcement mesh and the implanted reinforcements are connected in binding or point welding mode to form a whole body; steel fiber reinforced concrete is poured and waterproof coatings are sprayed; and bituminous concrete is paved. The single plate force-bearing reinforcing method improves transverse load distribution, steel plate pasting reliability and bridge integral force-bearing performance on the premise of preventing hollow slab beam body damage, not changing a structural force-bearing system and not interrupting the traffic.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

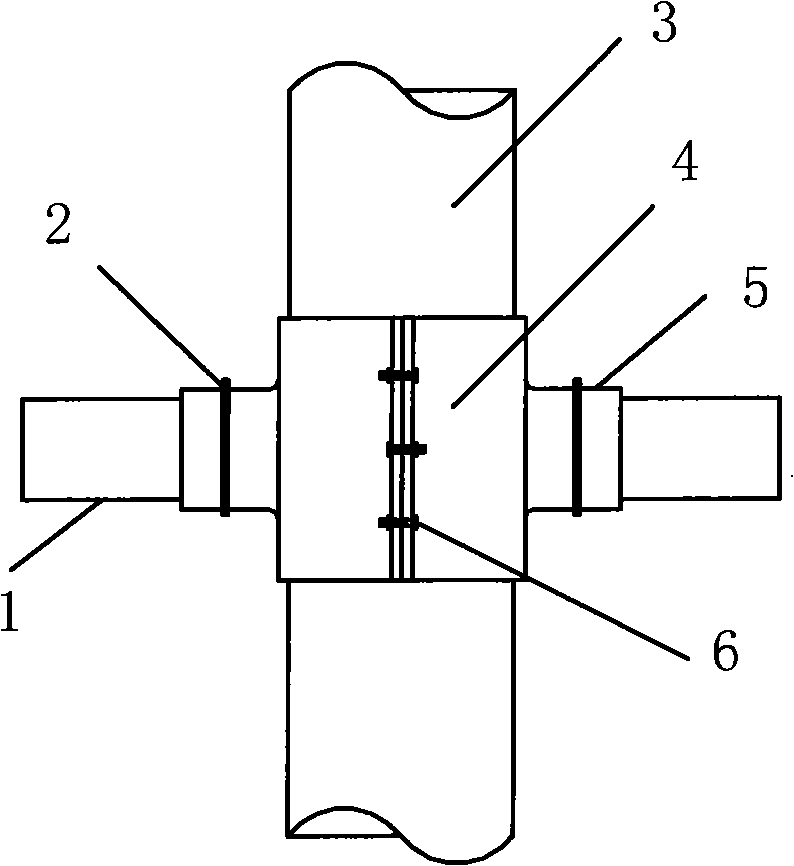

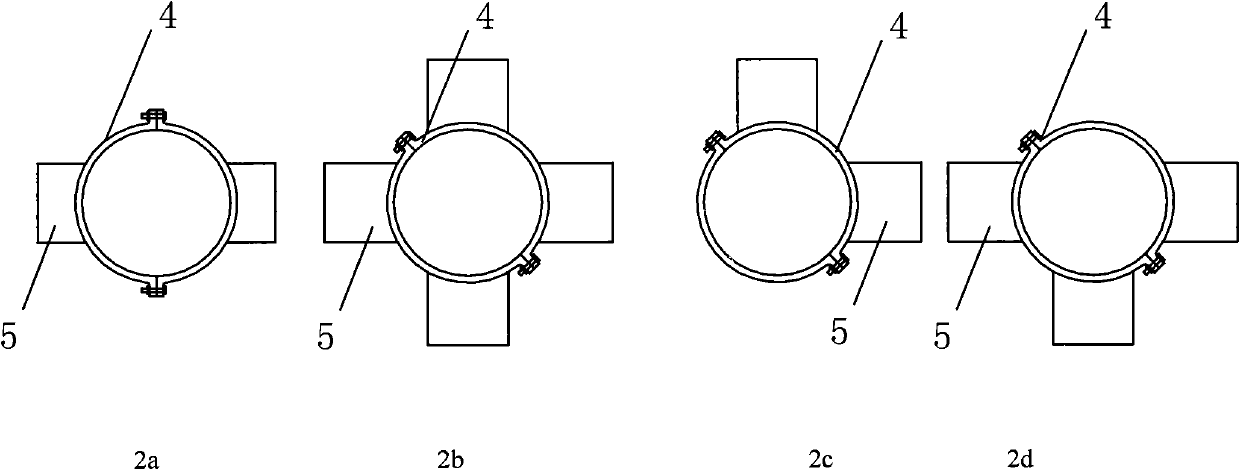

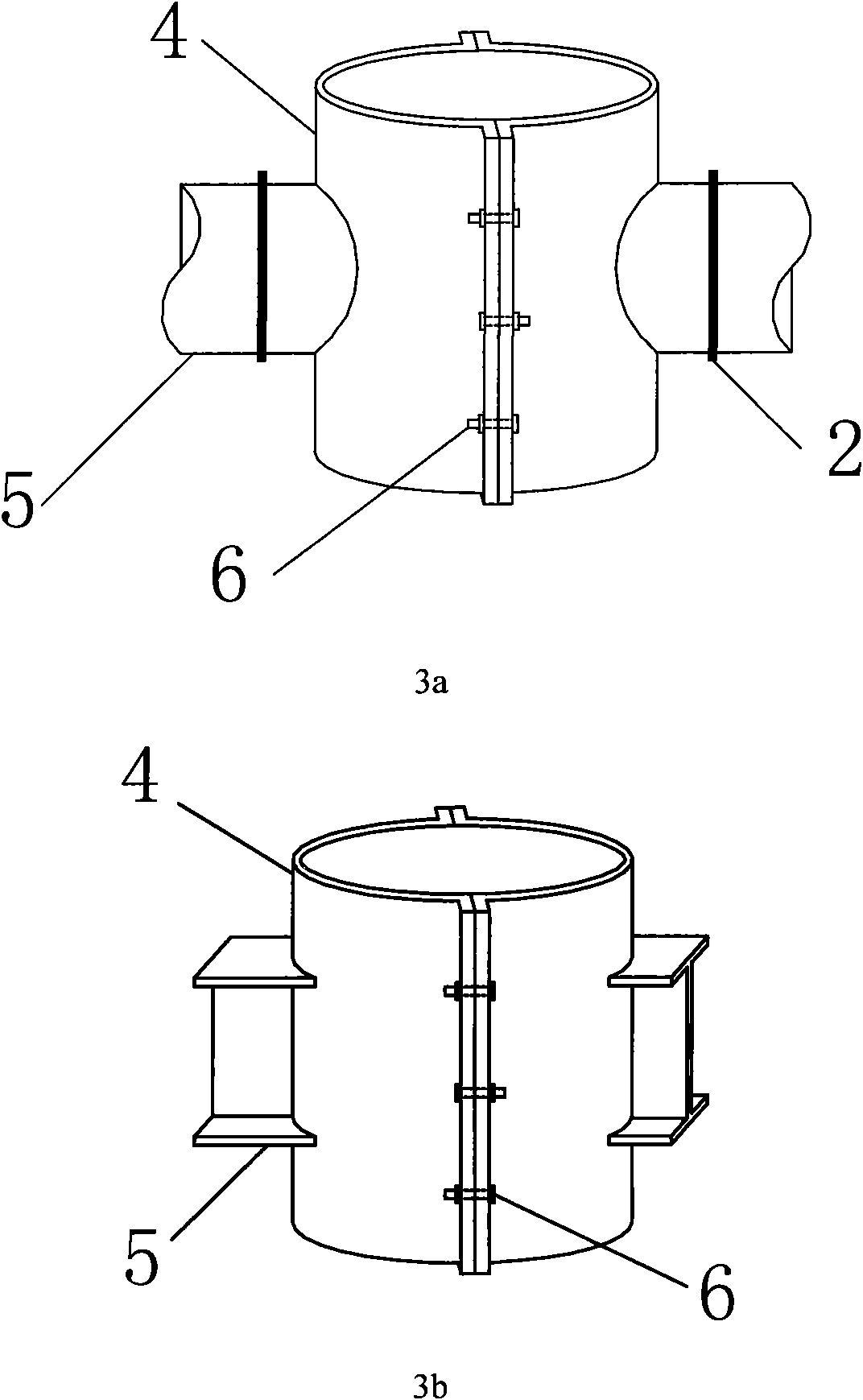

Circular steel tube concrete column and beam node connecting structure

InactiveCN101769011AFirmly connectedNode structure is simpleBuilding constructionsConcrete beamsEngineering

The invention discloses a circular steel tube concrete column and beam node connecting structure, which is characterized in that: the connecting structure comprises a node fastener, a bolt, a circular steel tube concrete column and a beam; the node fastener is composed of two sections of fastening rings and a joint, and the joint is in sleeve type and horizontally H-shaped type, the circular steel tube concrete column penetrates in the fastening rings and is fastened by the bolt, and the beam is connected by the joint on the fastener; the field installation is convenient without welding and the construction is rapid; the fastener is composed of two sections and is connected by the bolt after being fixed, and the circular steel tube concrete column is fixed by tightening force of the fastener; the circular steel tube concrete column is inserted in the sleeve type joint and is fixedly connected with the sleeve type joint by the bolt, and a concrete beam steel bar and a steel girder are welded with the horizontally H-shaped type joint; besides welding of the concrete beam steel bar and the horizontally H-shaped type joint, in the whole process, welding and complex distributed steel do not need, the construction is simple and rapid.

Owner:HOHAI UNIV

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

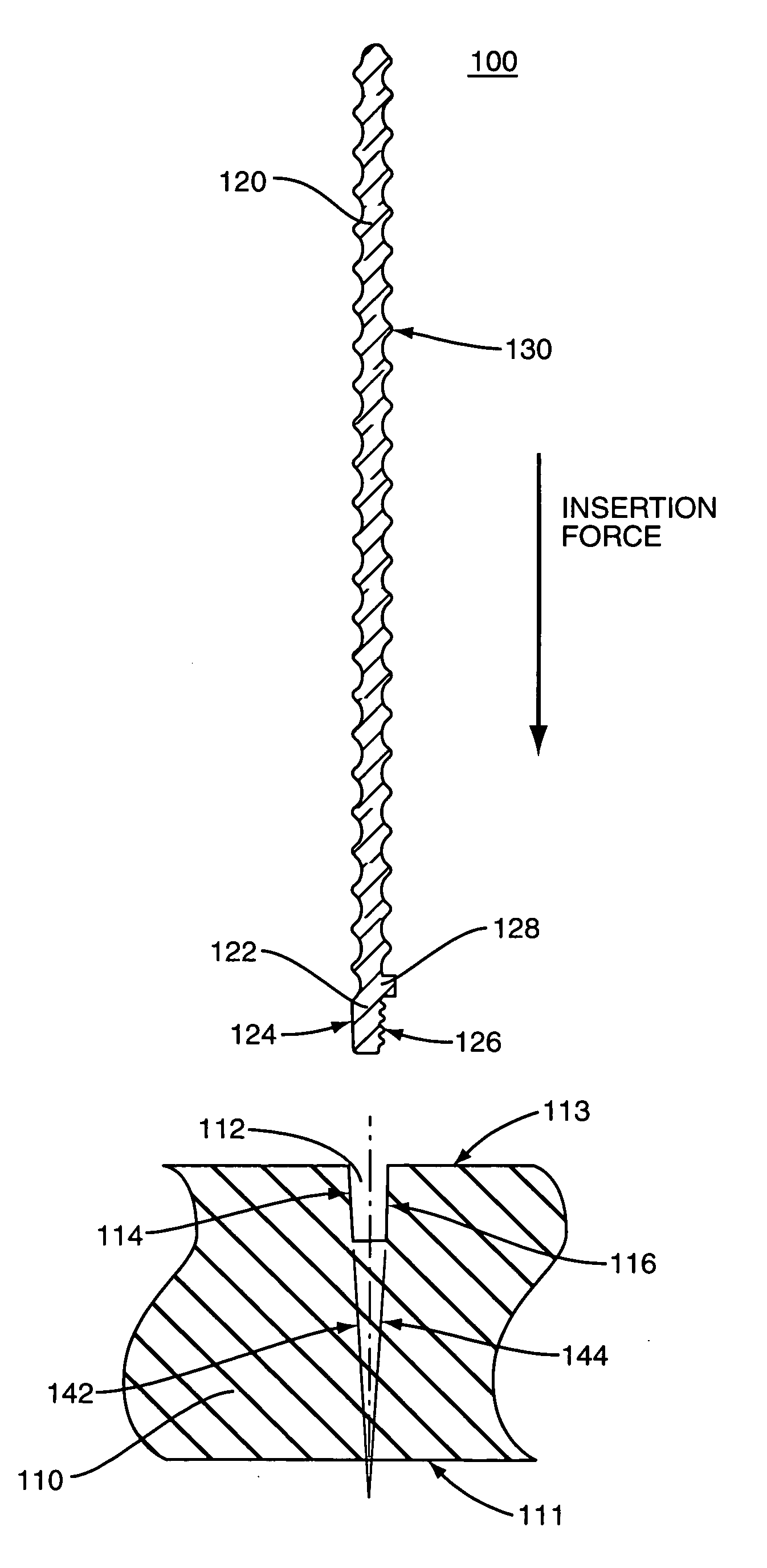

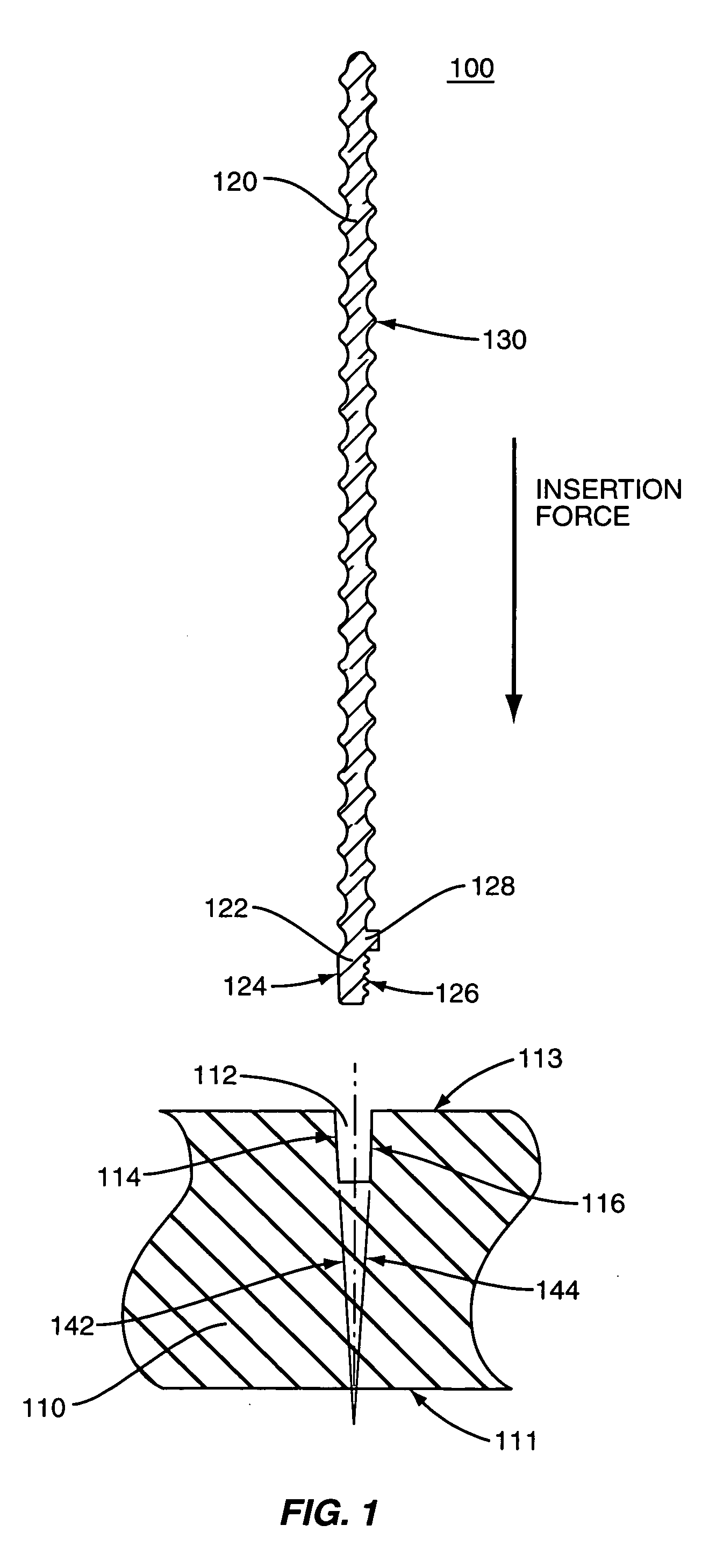

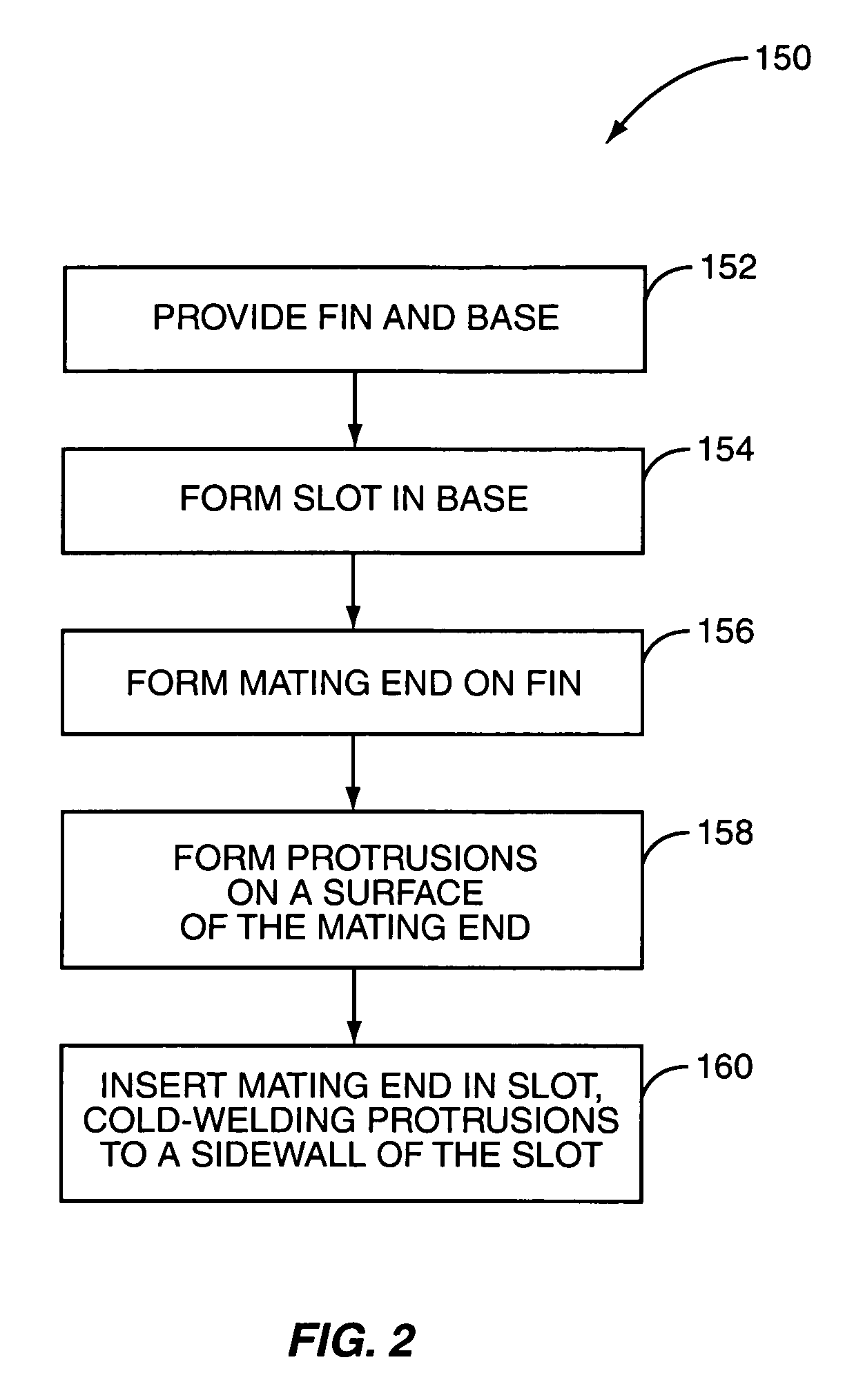

Heat sink

InactiveUS20070074850A1Reduce manufacturing costImprove mechanical performanceSemiconductor/solid-state device detailsSolid-state devicesLeading edgeEngineering

A heat sink assembly comprises a base having one or more slots, and further comprises one or more fins, each having an end configured for insertion into a respective one of the slots. Each fin end has a first surface that is configured for conformally engaging a first slot sidewall for good thermal conduction from the base into the fin, and has a second surface configured for cold welding to a second slot sidewall for good mechanical fastening of the fin to the base. The combined thermal bonding and cold-welding engagement are produced by pressing the fin ends of the fins into the base slots at a controlled pressing rate. Further, leading and / or trailing edges of the fins may be beveled to improve airflow directed edgewise across the fins.

Owner:DAU GMBH & CO KG

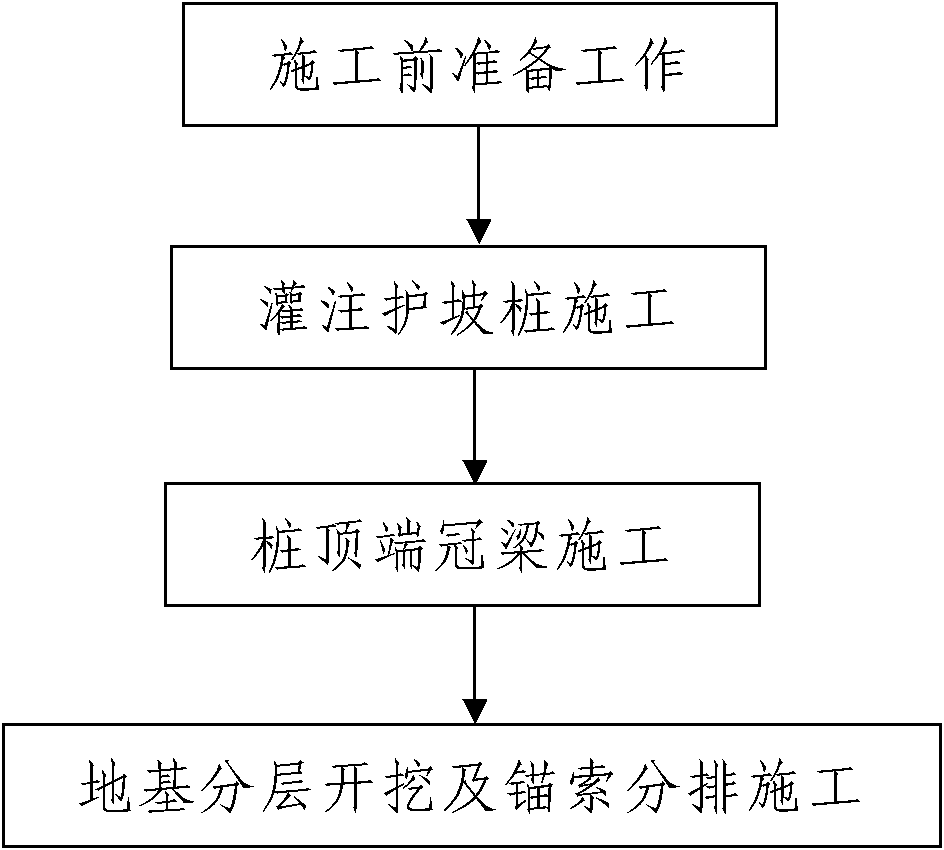

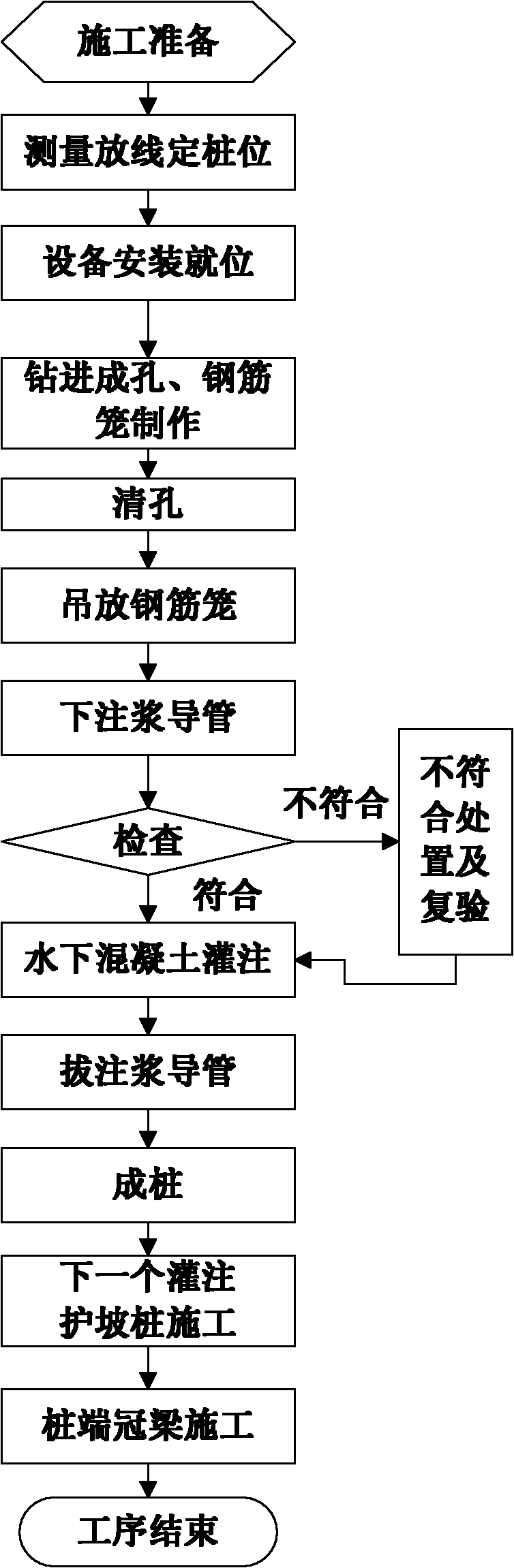

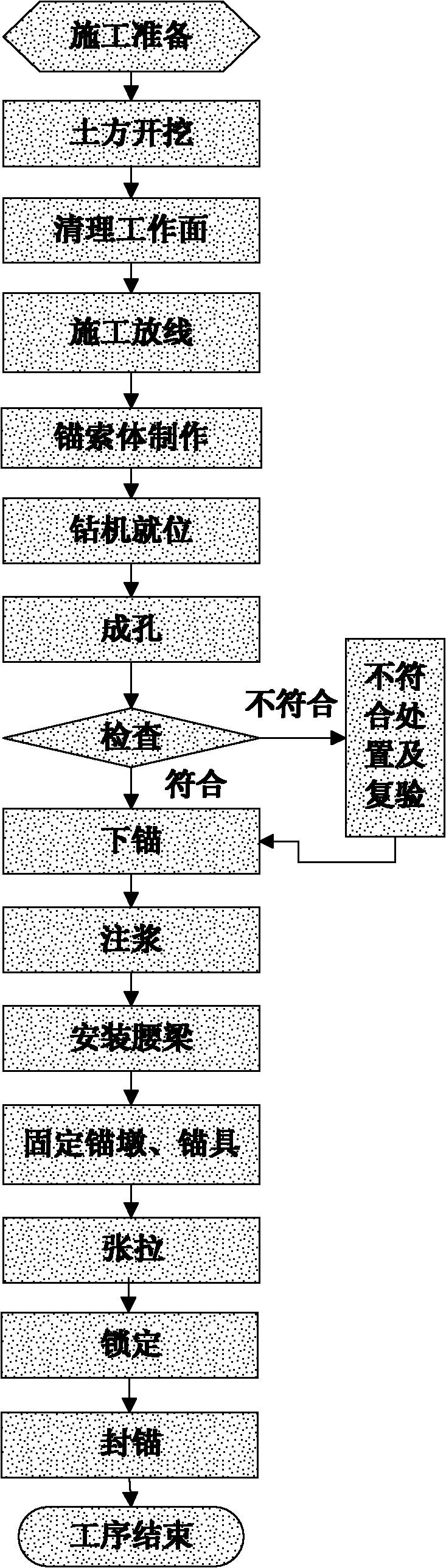

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

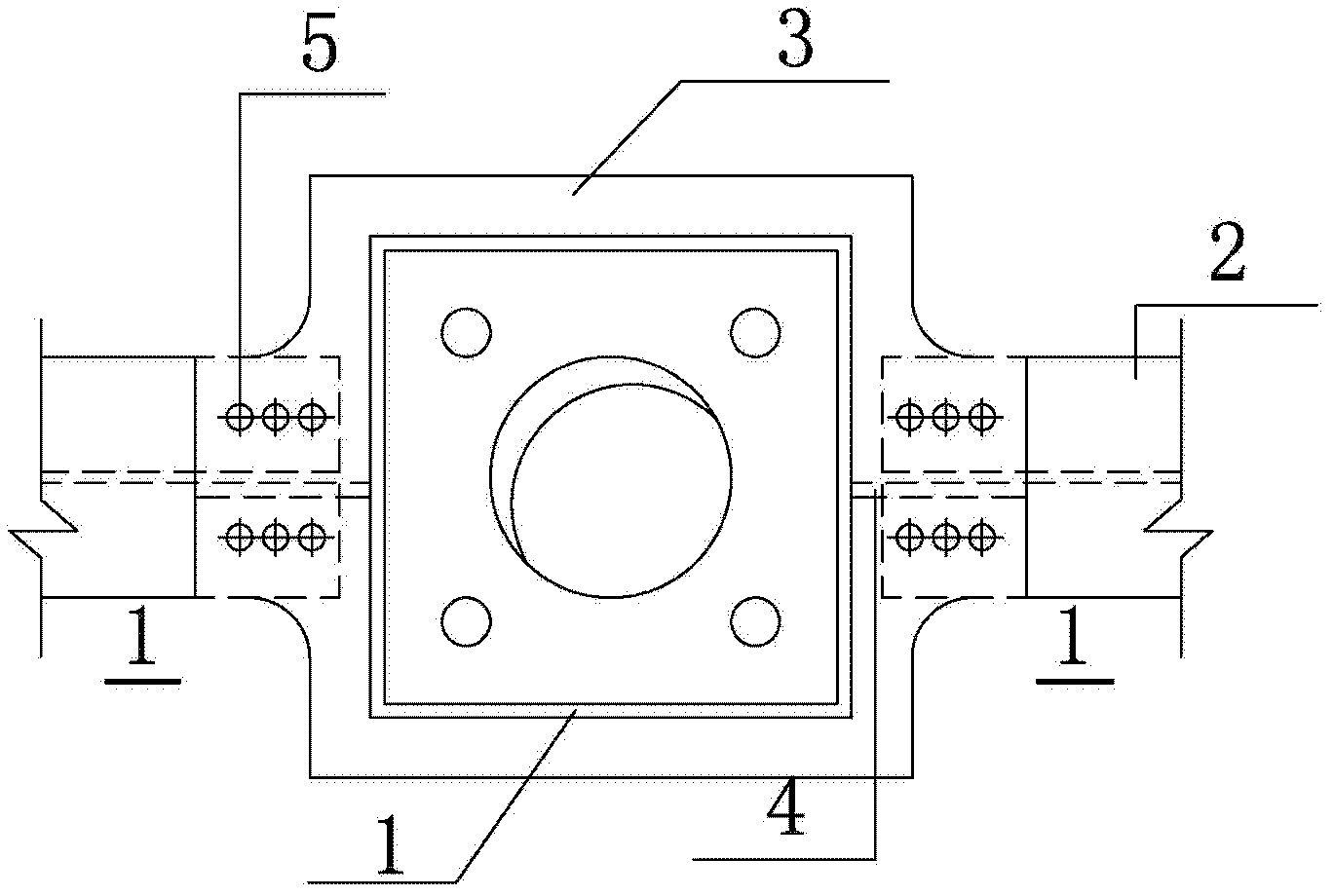

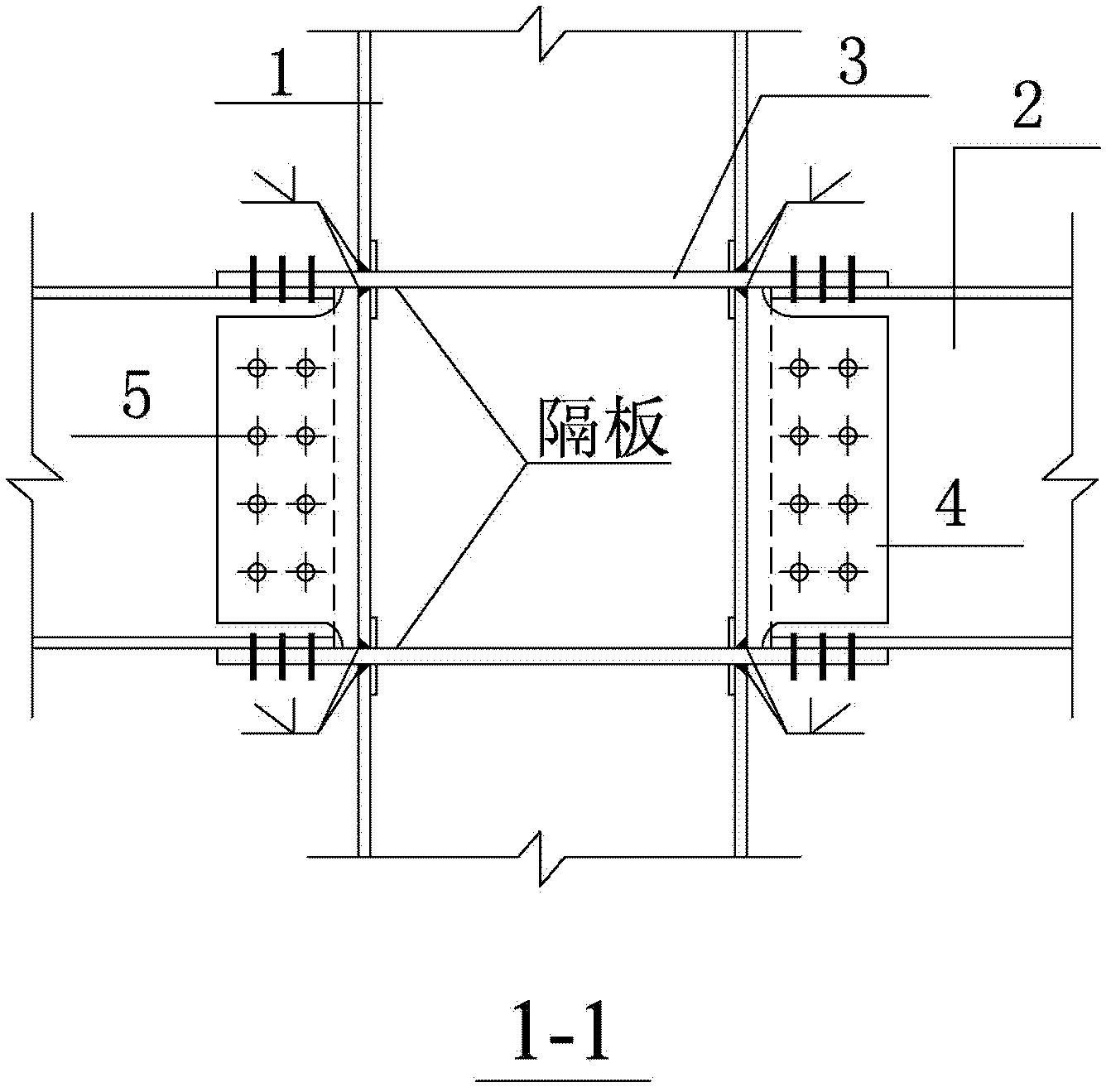

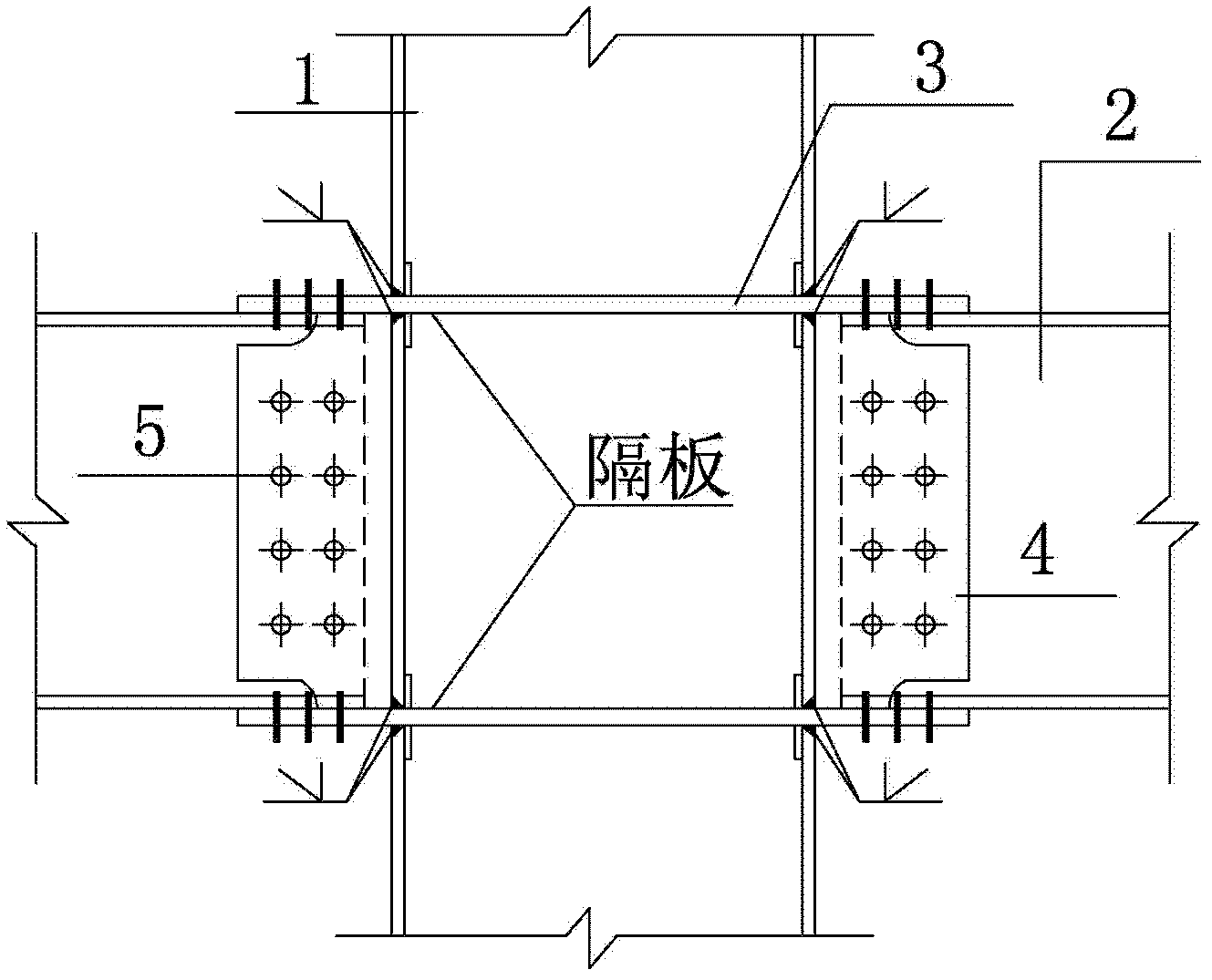

Rectangular steel tube concrete column and steel beam all-bolt connecting joint

ActiveCN102561530AAvoid multiple weldingReduce concentrated stressBuilding constructionsPlastic hingeMaterials science

The invention belongs to the technical field of building structure engineering, and relates to a rectangular steel tube concrete column and steel beam all-bolt connecting joint, which comprises a rectangular steel tube concrete column, a steel beam, an upper through partition board, a lower through partition board, a connecting plate and high-strength bolts. The upper through partition board and the lower through partition board penetrate through a wall of the rectangular steel tube concrete column, and are connected with the periphery of the wall of the rectangular steel tube concrete column via grooved weld joints, the connecting plate is welded with a side wall of the column, the upper through partition board and the lower through partition board, a web plate of the steel beam is connected with the connecting plate via the high-strength bolts, and an upper flange and a lower flange of the web plate of the steel beam are respectively connected with the upper through partition board and the lower through partition board via the high-strength bolts. The invention further discloses a method for manufacturing the rectangular steel tube concrete column and steel beam all-bolt connecting joint. The joint is fast in construction, simple in structure and fine in stress performance and seismic performance, and can meet requirements of outwards movement of plastic hinges.

Owner:TIANJIN UNIV

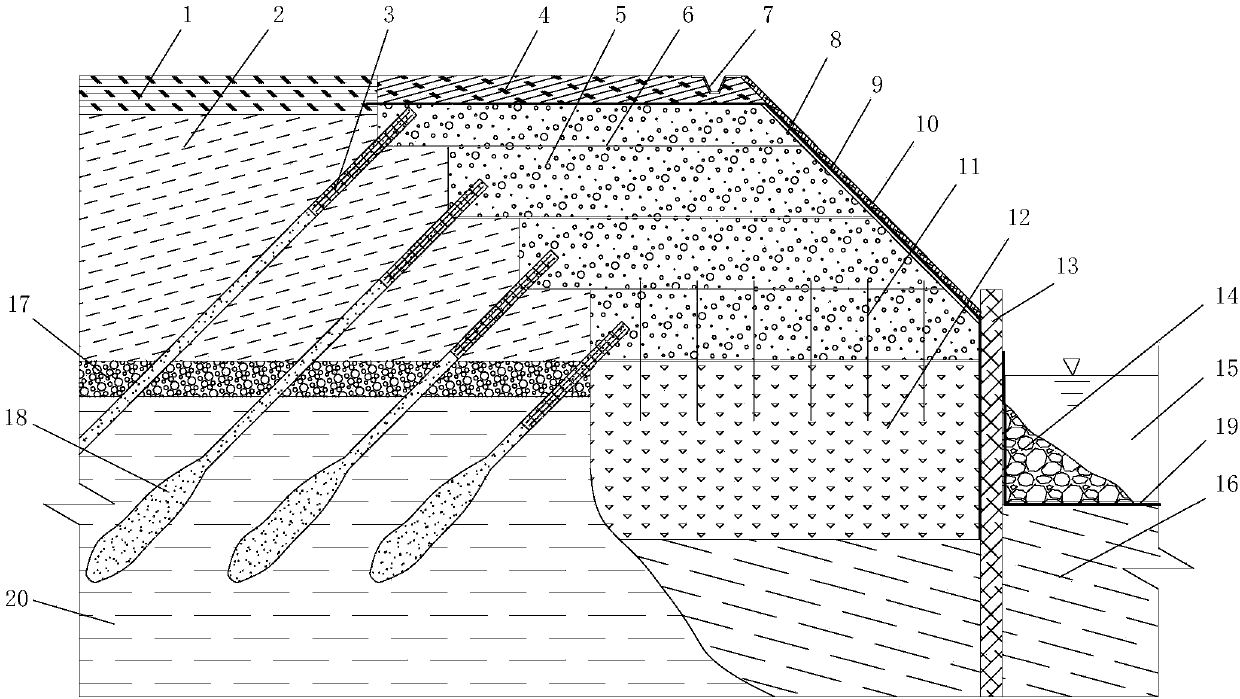

Waterside road broadened embankment structure and construction method thereof

ActiveCN103628378AImprove connection strengthImprove mechanical performanceRoadwaysClimate change adaptationEconomic benefitsStructural engineering

The invention relates to a waterside road broadened embankment structure, which is characterized in that the waterside side of a new embankment is provided with a waterproof maintenance pile, and the outer side of the maintenance pile is provided with a dumping stone weights body; the lower part of the new embankment is a solidified soil layer, the upper part of the new embankment is a lightweight filler layer, and the contact part of the solidified soil layer and the lightweight filler layer is provided with a horizontal reinforced body and a vertical reinforced body; a grouting strengthened body is arranged in an original embankment, and the front end of the grouting strengthened body is a reinforced connecting section; and the side slopes on the top surface and outer side of the new embankment and the two sides of the maintenance pile are respectively provided with a waterproof later, and the bottom of the dumping stone weights body is provided with an impervious blanket. According to the invention, the connection strength and integrity of the new and original embankments can be enhanced, an outside water body is prevented from permeating in the embankments from multiple beddings, and the anti-uplift performance of the embankment can be improved, therefore, the embankment structure has good technical and economic benefits. The invention also provides a construction method of the broadened embankment structure.

Owner:江苏镇江路桥工程有限公司

Prefabricated heat preservation wall body

InactiveCN101538903APrevent peelingImprove integrityWallsHeat proofingStructure and functionSteel bar

The invention belongs to the technical field of civil engineering, and concretely relates to prefabricated heat preservation wall body. The prefabricated heat preservation wall body consists of a heat preservation layer, a concrete internal wall panel, a concrete external wall panel and an FRP connecting piece, the concrete internal wall panel is internally provided with longitudinally arranged steel bars and transversely arranged steel bars, the concrete external wall panel is internally provided with longitudinal arranged steel bars and transversely arranged steel bars, the FRP connecting piece is of a recumbent H structure and consists of a ventral shield and flange girths, two flange girths are provided in the invention and are respectively arranged at the two ends of the ventral shield; the heat preservation layer is arranged between the concrete internal wall panel and the concrete external wall panel and is internally provided with hole slots which are arranged in a crisscross way, and the FRP connecting piece is inserted in the hole slots; the end of the heat preservation wall body is provided with a splice bar which is of a U-shape structure, the two ends of the splice bar are respectively inserted into the concrete external wall panel and the concrete internal wall panel. The invention realizes a novel prefabricated heat preservation wall body with an integral structural function, has the advantages of low heat conductivity coefficient, good corrosive nature, simple and convenient construction and the like, and has relatively extensive application prospect in the field of constructional engineering.

Owner:TONGJI UNIV

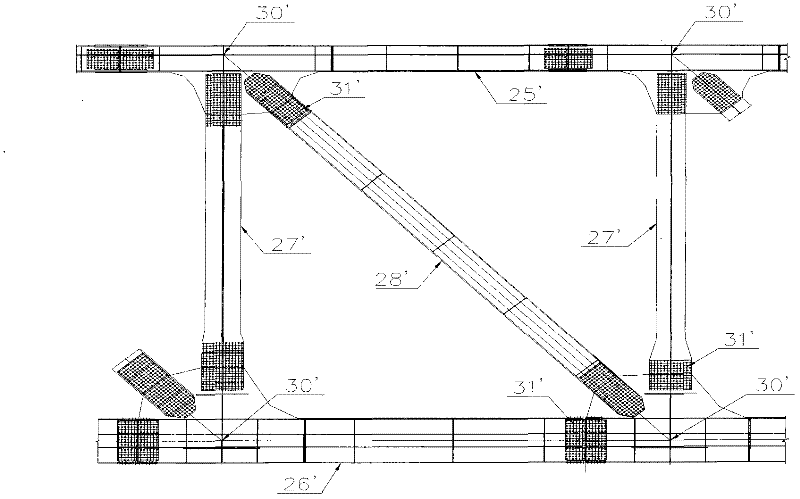

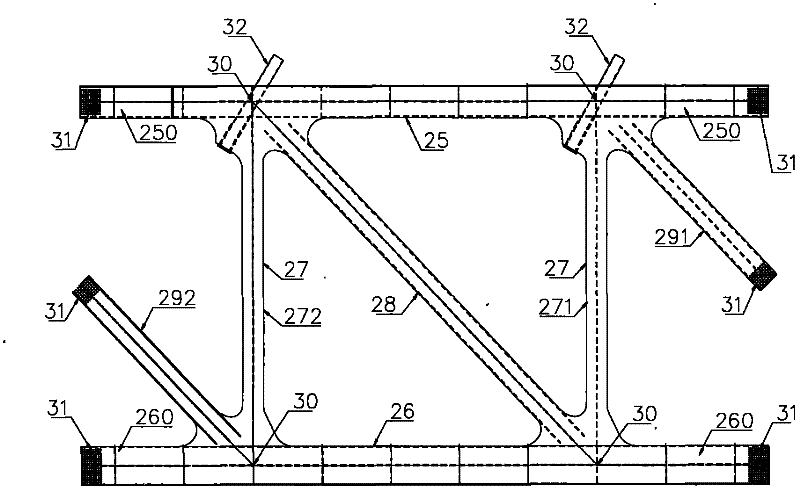

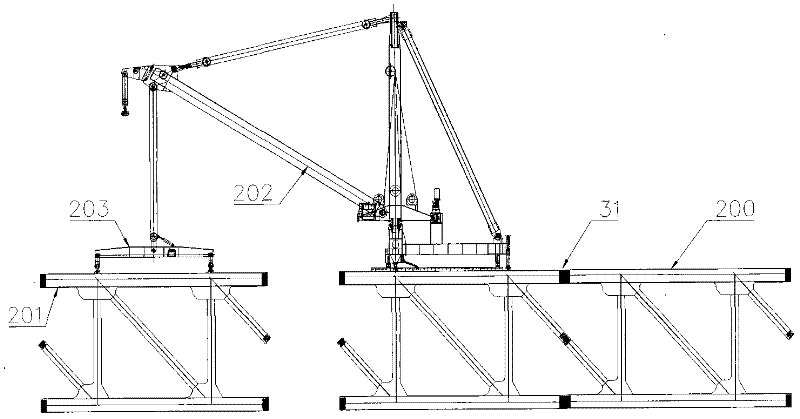

Truss sheet unit of steel truss girder, steel truss girder structure and mounting method thereof

ActiveCN102352604AImprove the quality of ex-factory productsAvoid extensive on-site constructionTruss-type bridgeBridge erection/assemblyHeavy dutySpandrel

The invention discloses a truss sheet unit of a steel truss girder, a steel truss girder structure and a mounting method thereof, relating to the design and the construction techniques of heavy-duty and large-span bridges. The steel truss girder structure consists of a plurality of the truss sheet units which are welded into a whole, wherein the truss sheet units comprise upper chord rods, low chord rods, first web rods and second web rods; the upper chord rods, the lower chord rods, the first web rods and the second web rods are welded into a rectangular frame body; two across corners of the rectangular frame body are connected by a diagonal rod; two ends of each upper chord rod further extend to form two upper connecting rods; two ends of each lower chord rod further extend to form two lower connecting rods; simultaneously, first oblique connecting rods which extend downwards are arranged among the first web rods and the upper connecting rods; and second oblique connecting rods which extend upwards are arranged among the second web rods and the lower connecting rods. When the steel truss girder is assembled, the whole truss sheet units are lifted each time; furthermore, the truss sheet units occupy two internodal lengths; the lifting times are less; the filed assembly is simple; the quantity of high-strength bolts is reduced; and the influence of the screwing of the high-strength bolts on a construction period is decreased.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

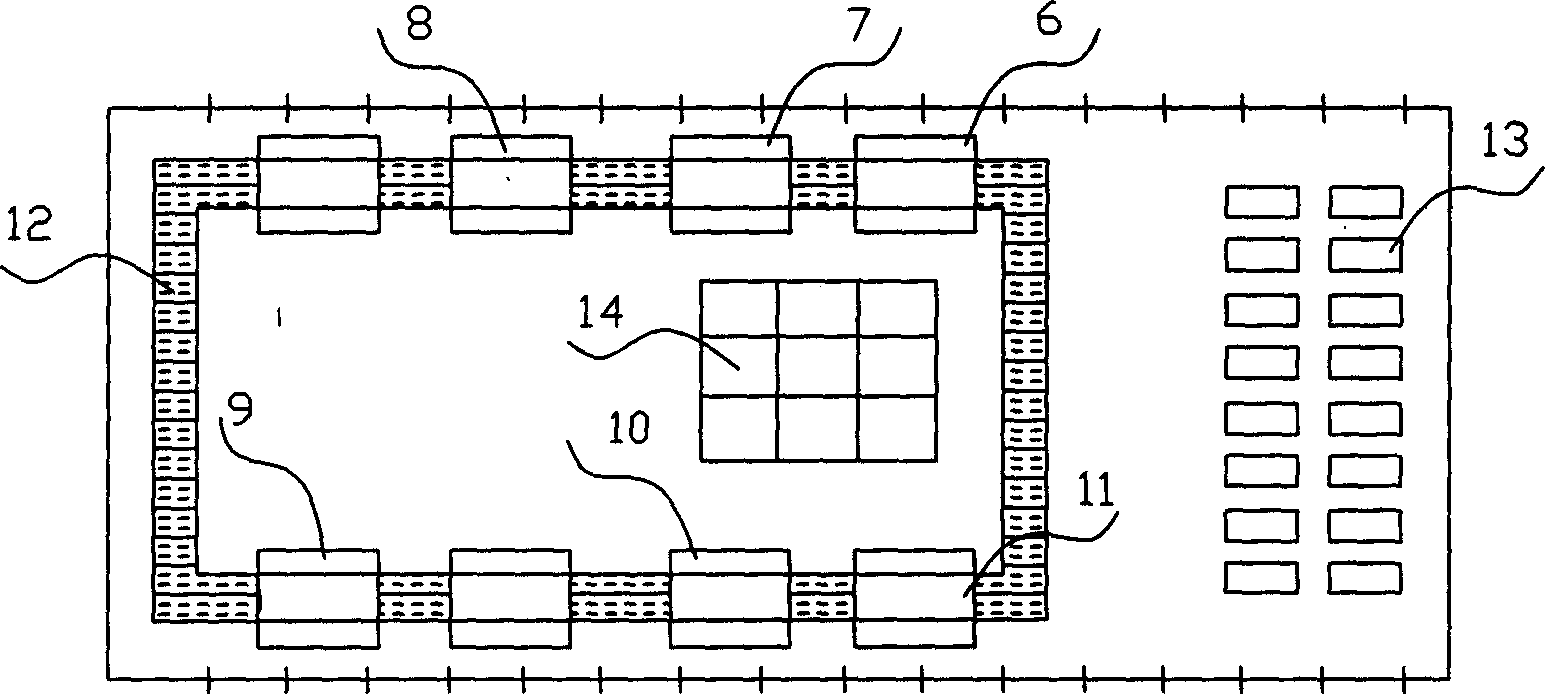

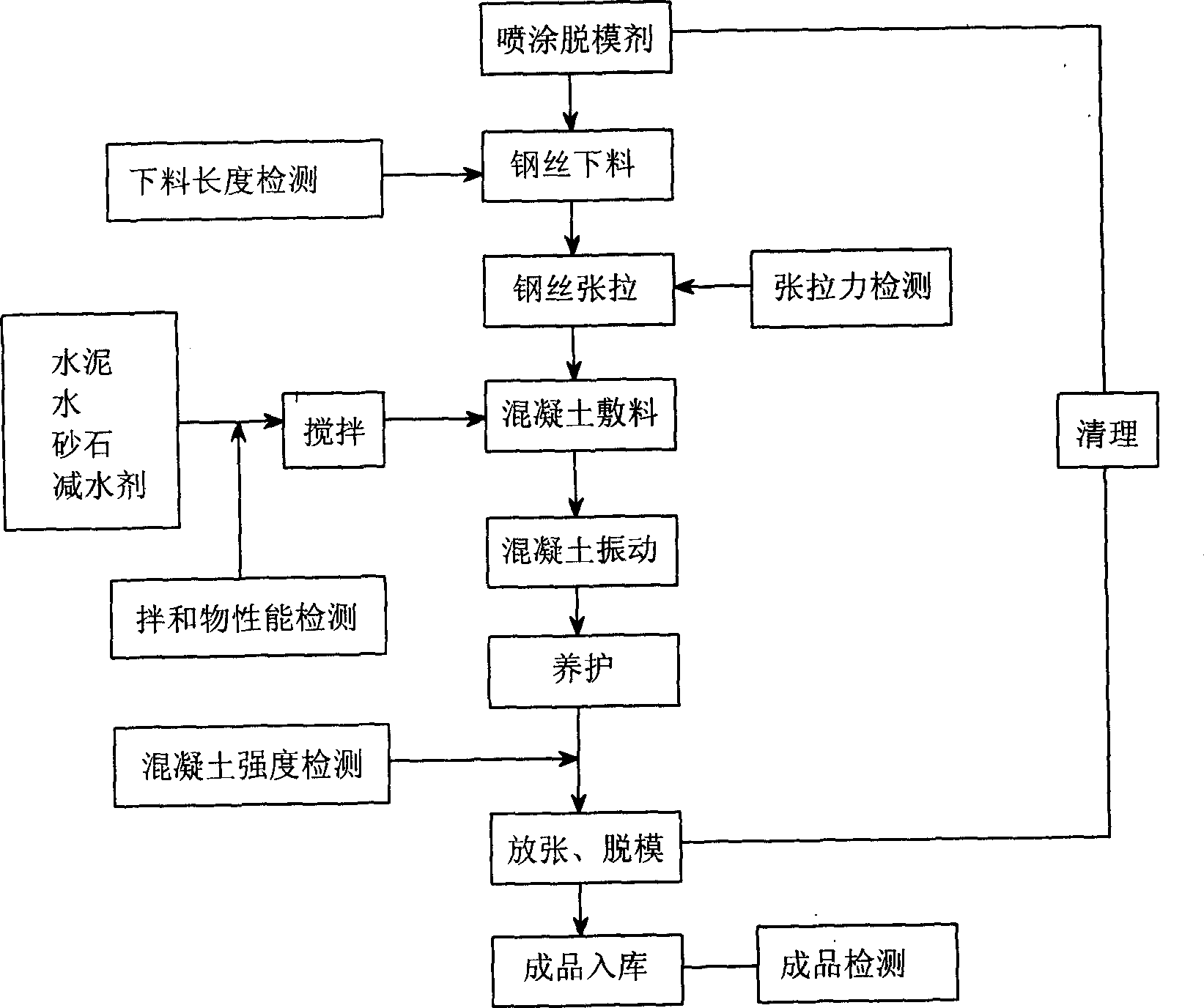

Bidirectional pretensioning method prestressed concrete railway board and assembly machine sets method production process

InactiveCN1865593AReduced creep warpageReduces the possibility of creep warpingBallastwayCeramic shaping plantsProduction linePre stress

The invention relates to a bidirectional pre-stress concrete track plate with significant electric property and lower producing cost, and relative production line. Wherein, the track plate is a cuboid, with several preset structures; there are at least two layers of steel wires inside the track plate along its length and width directions; the steel wires in said two directions do not contact each other; said pre-stress concrete track plate are tensioned along the length and width directions; the production method comprises: spraying demoulding agent, feeding material, tensioning, coating concrete, vibrating, maintaining, tensioning and demoulding. The invention can overcome the defects of present technique, with simple method, while it can be used to build high-speed railway.

Owner:欧阳炎

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

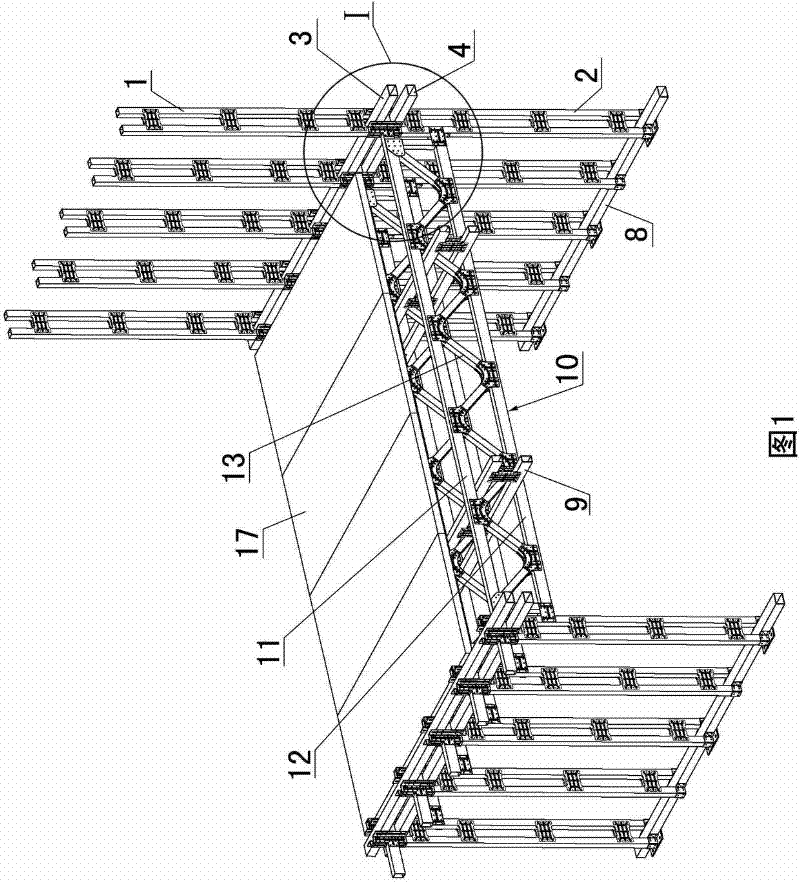

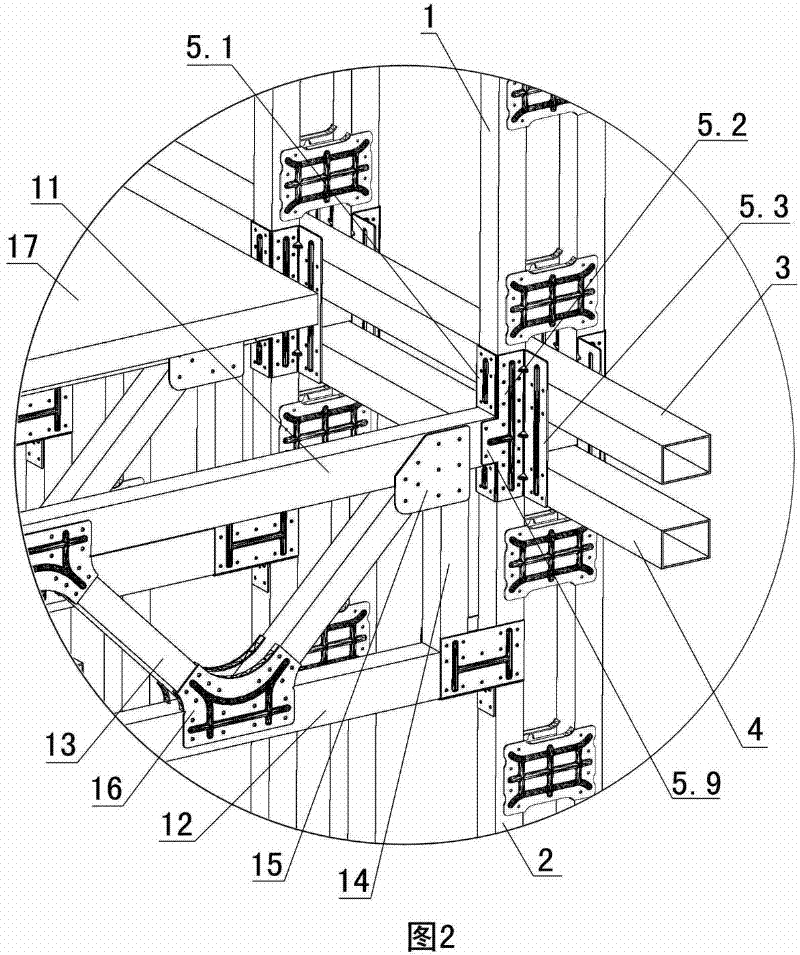

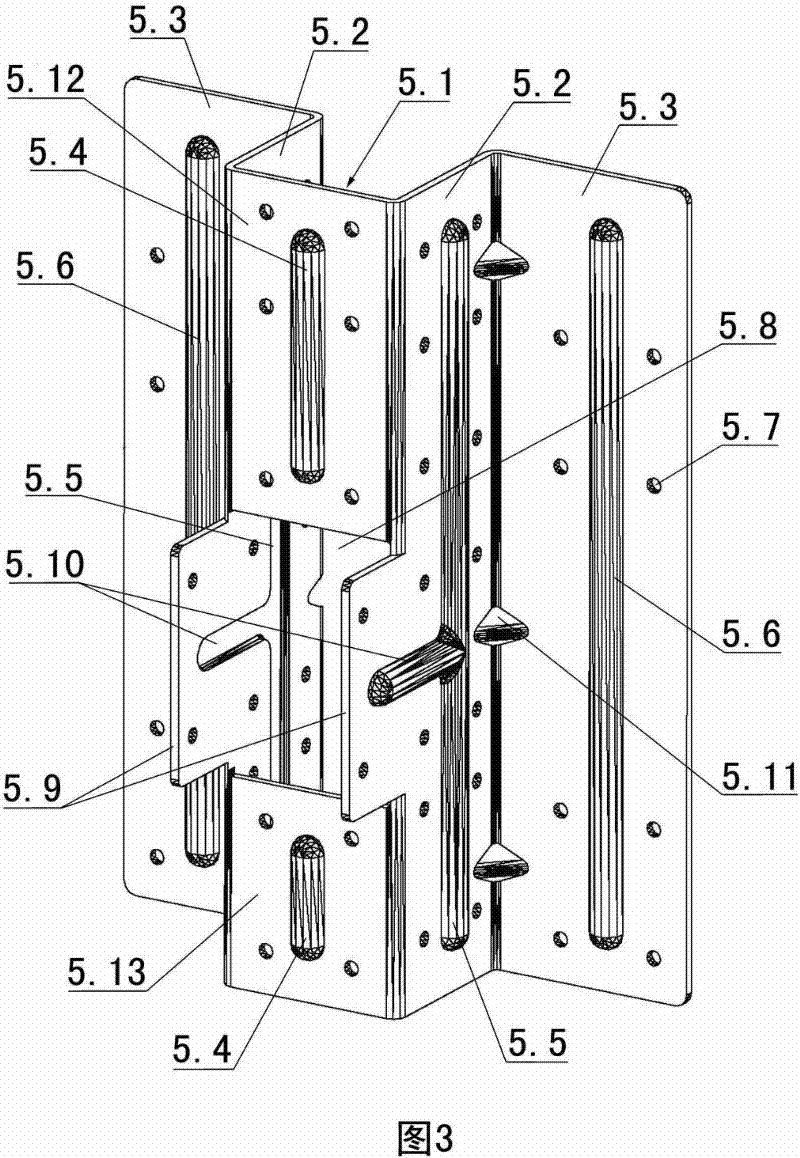

Truss combined beam and upper and layer connected light steel structure and construction method thereof

InactiveCN102359180ATroubleshoot simultaneous connectionsSolve the shortcomings that the pressure is not easy to meet the force requirementsGirdersJoistsRear quarterKeel

The invention discloses a truss combined beam and upper and layer connected light steel structure and a construction method thereof. The light steel structure comprises upper wall sheet columns distributed at intervals, lower wall sheet columns distributed at intervals, upper wall sheet column lower connecting pipes connected among the lower parts of the upper wall sheet columns, lower wall sheet column upper connecting pipes connected among the upper parts of the lower wall sheet columns, and truss combined beams connected between the upper wall sheet columns and the lower wall sheet columns through upper and lower connectors, wherein the upper and lower connectors are beam passing buckles, the web plates of the beam passing buckles consist of upper web plates and lower web plates, a square connecting port is formed between the upper web plates and the lower web plates, upper chord member connecting plates are extended from the left and right sides of the square connecting ports, and the upper chord member connecting plates and side plates of the beam passing buckles are positioned in the same plane. Through the light steel structure, the structural stability of a light steel keel house system is enhanced, and the floor surface beams, the connecting pipes and the floor panels do not easily vibrate.

Owner:筑巢(北京)科技有限公司

Concrete hollow slab bridge reinforced by transverse steel beams

InactiveCN102635060AStable structural strengthImprove structural strengthBridge structural detailsSingle plateBridge deck

The invention discloses a concrete hollow slab bridge reinforced by transverse steel beams. The concrete hollow slab bridge comprises a bridge deck beam constituted by arranging a plurality of hollow plate beams in parallel and at least one stiffening cross beam which is arranged on the bottom surface of the bridge deck beam and is used for transversely reinforcing the bridge deck beam so as to enable all the hollow plate beams to transversely transfer loads on the hollow plate beams, wherein the stiffening cross beam is fixedly connected with the hollow plate beams. According to the concrete hollow slab bridge reinforced by the transverse steel beams, disclosed by the invention, the overall structural strength is high, the bearing capacity of the bridge is strong, the single-plate stress can be avoided by reinforcing through the transverse steel beams, the service life of the bridge is prolonged, and the concrete hollow slab bridge has the advantages of simple structure construction, easiness in ensuring engineering construction quality, good stress performance, obvious reinforcing effect, convenience and quickness in construction, lower requirements for machines, tools and equipment required for construction and significant economic benefits, and is further conductive to popularization.

Owner:茅桥交通科技(东莞)有限公司 +1

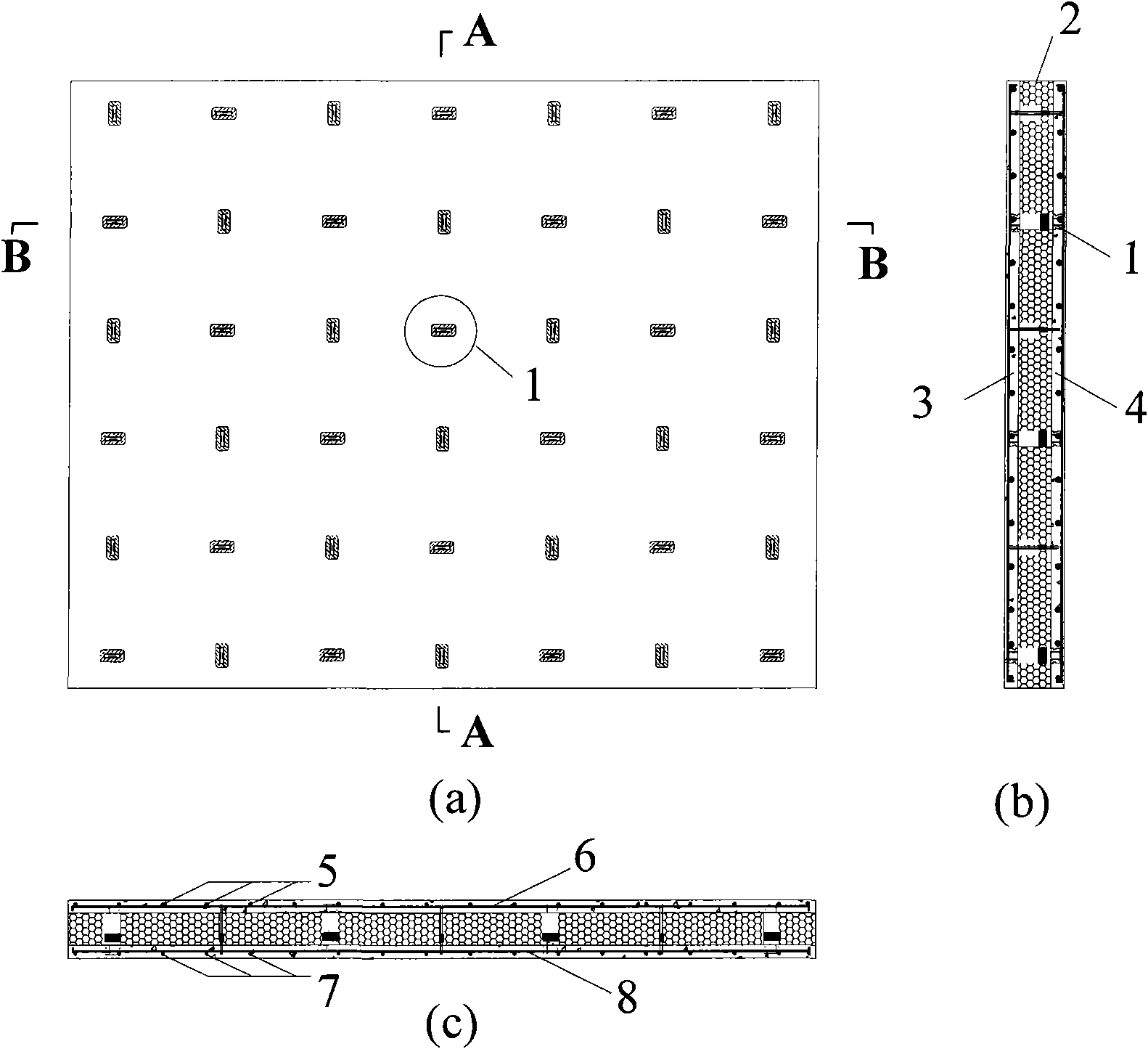

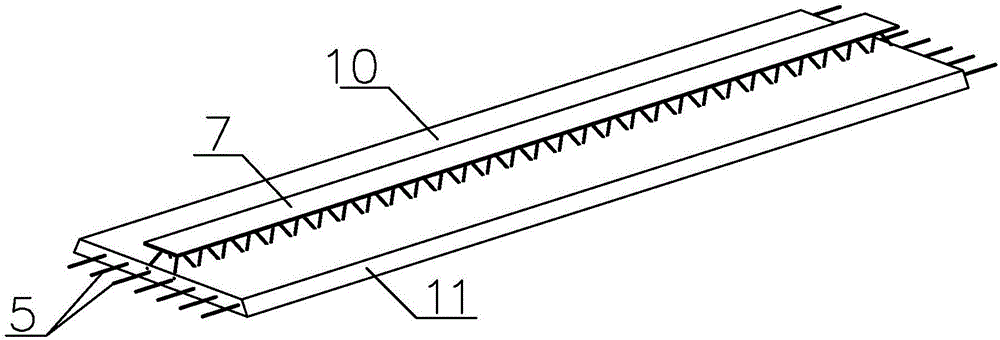

Prestressed concrete superimposed sheet with steel trusses and manufacturing method

InactiveCN106703269AIncreased out-of-plane stiffness and load carrying capacityApplicable span is largeFloorsBuilding material handlingRebarPre stress

The invention discloses a prestressed concrete superimposed sheet with steel trusses and a manufacturing method, and belongs to the technical field of architectural engineering. The prestressed concrete superimposed sheet structurally comprises prefabricated bottom plates, transverse steel bars and a superimposed layer, two sides faces, in the length direction, of each prefabricated bottom plate are inclined faces, a wedge-shaped edge joint is formed between every two adjacent prefabricated bottom plates, the wedge-shaped edge joints are filled with high-strength grouting materials, longitudinal prestress steel bars are distributed in the prefabricated bottom plates in the length direction, and the transverse distribution steel bars are arranged in the width direction. The upper portion of each prefabricated bottom plate is provided with at least one steel truss in the length direction, the transverse steel bars are arranged below the steel trusses in the width direction of the prefabricated bottom plates in a penetrating mode, the prefabricated bottom plates can be connected together, the superimposed layer is poured to the prefabricated bottom plates, and superimposed layer transverse steel bars and superimposed layer longitudinal steel bars are arranged in the superimposed layer. The prestressed concrete superimposed sheet has the advantages of being good in overall stress performance, large in application span, excellent in fireproof effect and high in factory production efficiency, enabling site operation to be easy and convenient and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

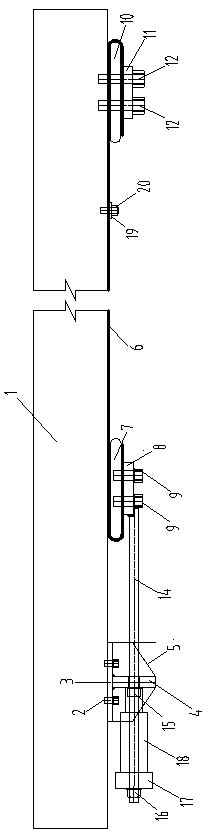

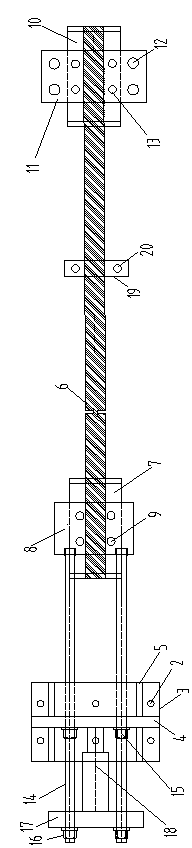

Construction method of reinforcing large-span concrete structure with prestressed carbon fiber sheet

InactiveCN103321430AWidely applicable reinforcementImprove mechanical performanceBridge erection/assemblyBuilding material handlingFiberCarbon fibers

A construction method of reinforcing a large-span concrete structure with prestressed carbon fiber sheet comprises the following steps of forming bolt embedding holes on the side surface to be reinforced of the large-span concrete structure, and embedding high-strength bolts of different specifications into the bolt embedding holes through adhesive glue; fabricating stretch sheet fixing portions, stretch sheet moving portions and stretch power fixing portions; mounting the stretch sheet fixing portions, stretch sheet moving portions, stretch sheet assembling units, stretch power fixing portions and stretch power portions, wherein the stretch sheet assembling units, the stretch power fixing portions and the stretch power portions are made of carbon fiber materials; stretching stretch sheet; and removing stretching power and tightly pressing and adhering the stretch sheet onto the surface of the large-span concrete structure. The construction method of reinforcing the large-span concrete structure with the prestressed carbon fiber sheet can achieve the gapless adhesion between the prestressed stretch sheet and the concrete structure to be reinforced, facilitate the coordination of the uniform stress force of the same sections of the carbon fiber filaments of the stretch sheet, improve the integral stress performance of the prestressed carbon fiber sheet and the coordination deformation capability of the prestressed carbon fiber sheet and the concrete structure and give full play to the high-strength characters of the carbon fiber sheet.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

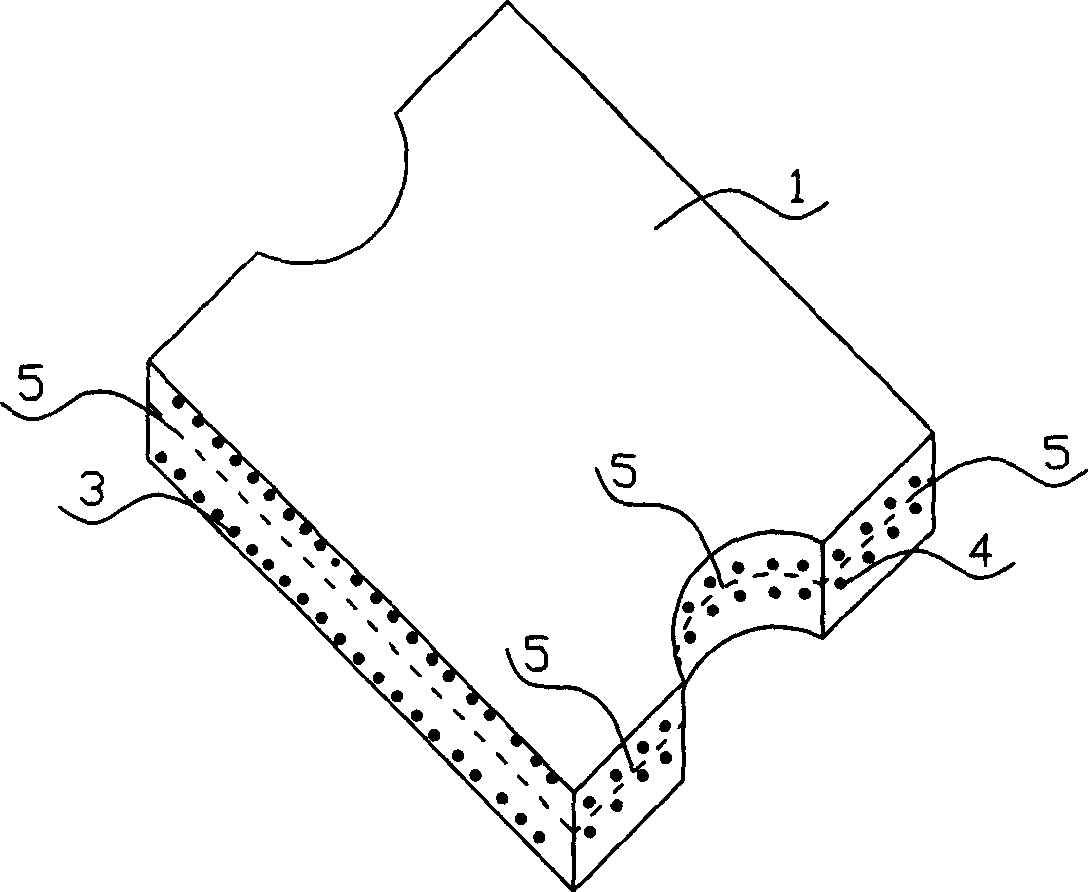

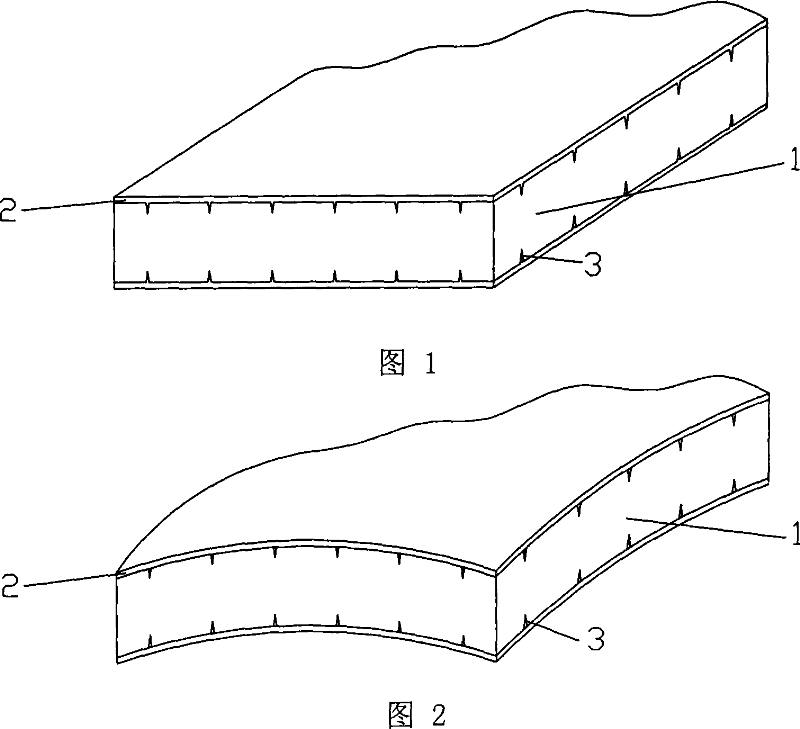

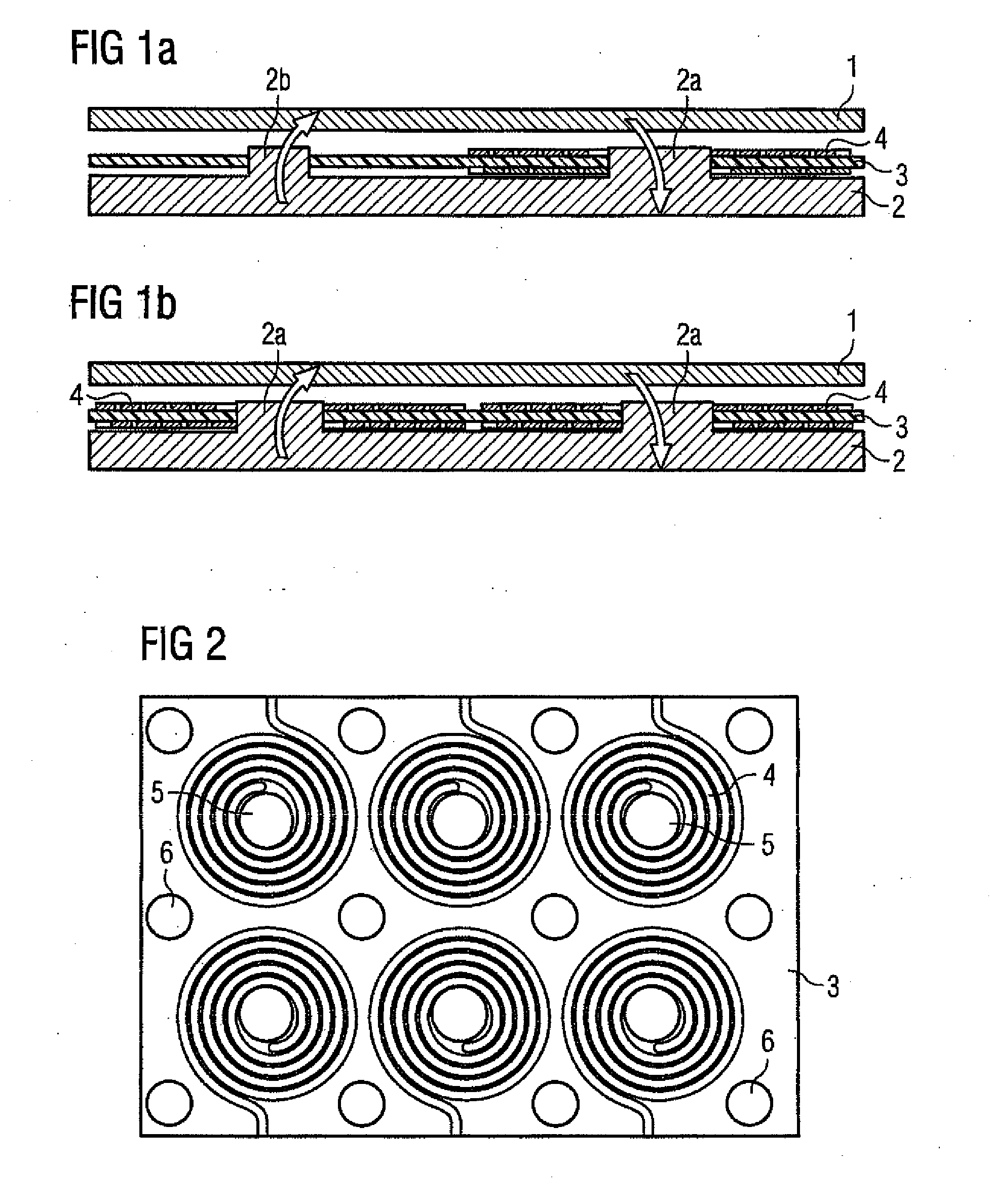

Alveolus type interlayer structure of the composite material

InactiveCN101041278AImprove mechanical performanceEnhanced resistance to peelingWallsLayered productsEngineeringWall material

The invention relates to a cogging composite sandwich structure comprising core material (1) and face plate (2), characterized in that net concave grooves (3) are set at top and bottom faces of core material (1) and face plates (2) are put on top and bottom faces of core material (1) by resin. Compared with other products, the biggest characteristic is that concave grooves filled with resin fully can enhance the anti-stripping ability of face plates and core material obviously and it makes the whole forced performance and the usage effect of composite sandwich structure be improved obviously. It is applied in aerospace, ship and vehicle so on universally and it is also applied in building fields such as roof board, building template and wall material so on.

Owner:NANJING TECH UNIV

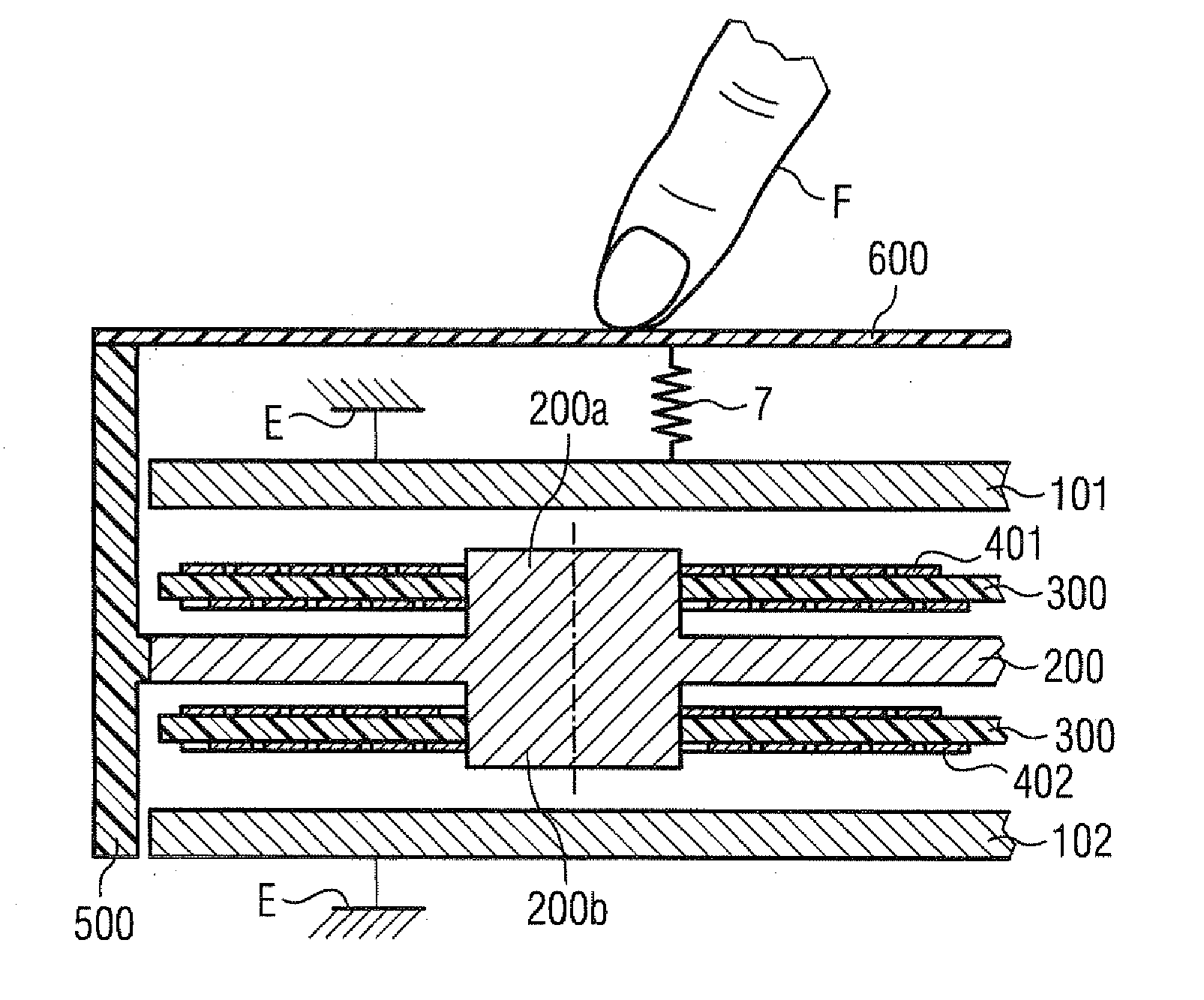

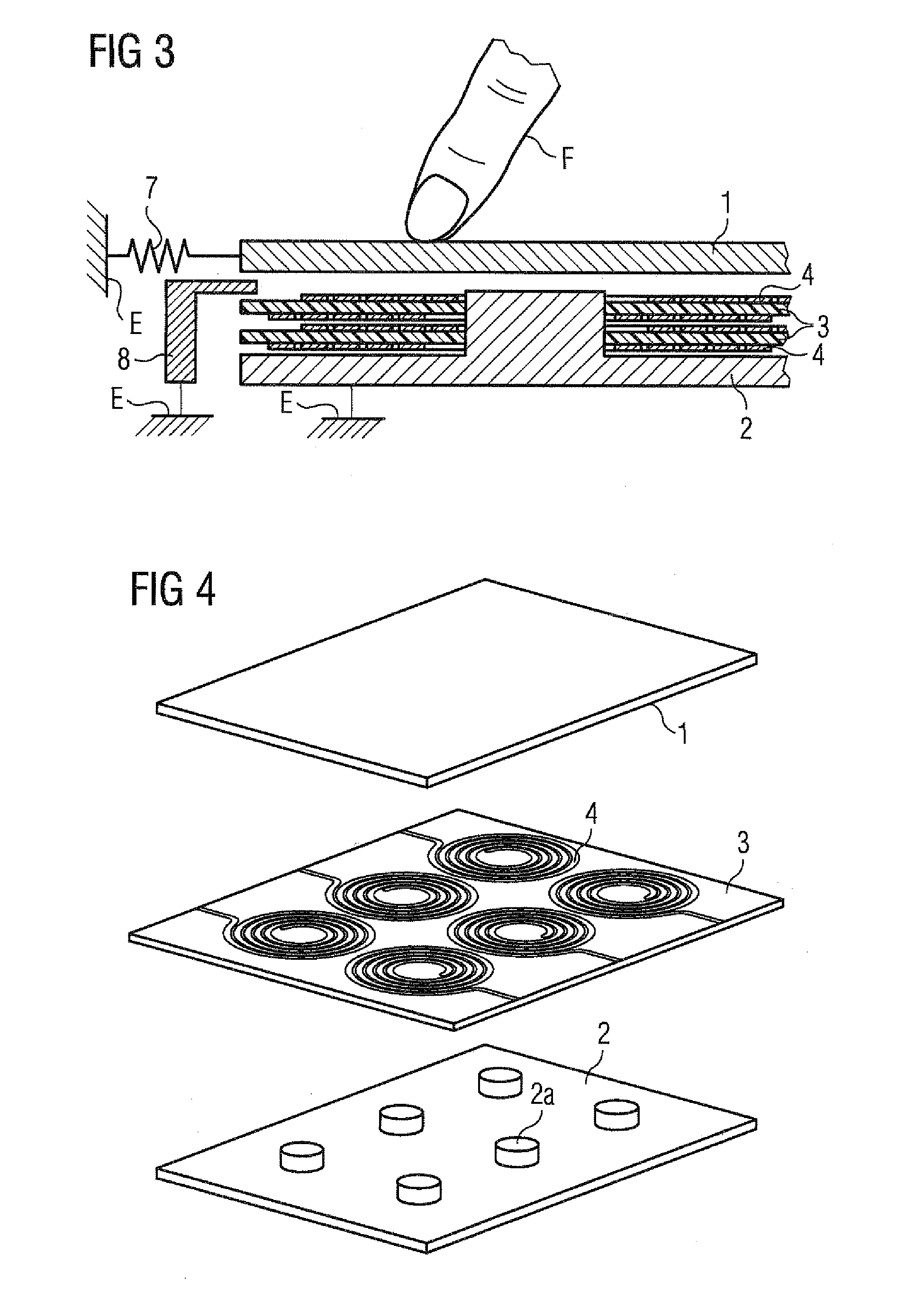

Operating Device

ActiveUS20120306798A1Small installation spaceSimple designRepeater circuitsTactile signalling systemsHaptic sensingElectrical and Electronics engineering

An operating device having an operating element with haptic feedback. The operating element can be actuated by an operator by means of an input member, the operating device includes two ferromagnetic planar components and a flat coil. The largest surfaces of the ferromagnetic planar components are oriented toward each other and the components can be moved relative to each other. The flat coil is disposed between the ferromagnetic components and the ferromagnetic planar components can be moved toward each other by energizing the flat coil. The movement of one of the ferromagnetic planar components can be perceptible to the tactile sense of the operator on the operating element either directly or by a coupling device.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Strengthening concrete frame structure and construction method thereof

InactiveCN101845850AImprove fire performanceImprove mechanical performanceBuilding material handlingReinforced concreteSteel bar

The invention relates to a strengthening concrete frame structure. A frame column is formed by integrally pouring a stem steel rib and peripheral column reinforced concretes, wherein the concrete is poured inside the stem steel rib; studs which are vertical to the steel rib are arranged on the periphery of the stem steel rib; the stem steel rib is embedded in the column reinforced concrete structure; the reinforced steel bar in the column reinforced concrete structure comprises a stud, a column stirrup and a drag hook; the beam tendons at the upper part of a beam column joint are a main penetration tendon and a column winding tendon; when the upper column winding tendon passes by the stem steel rib in the frame column, the column winding tendon is bent outwards at a gradient of 1: 6; and when the upper main penetration tendon penetrates a reserved hole on the stem steel rib in the frame column, one end of a lower beam tendon is anchored in the column reinforced concrete structure or is bent upwards. The invention solves the problems that the reinforcing steel bar in the steel rib-concrete structure beam column joint areas is difficult to penetrate the stem steel rib, the concrete is inconvenient to pour and vibrate and the pouring effect is inferior. The structure of the invention can be widely applied to a long span high-rise frame structure.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

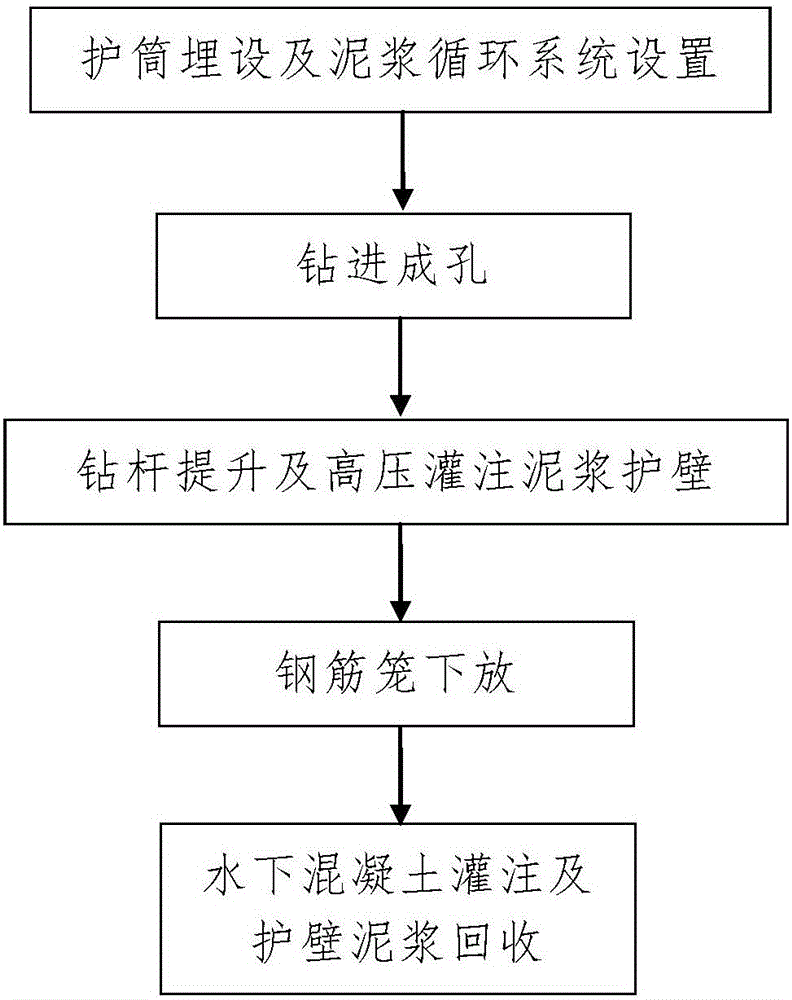

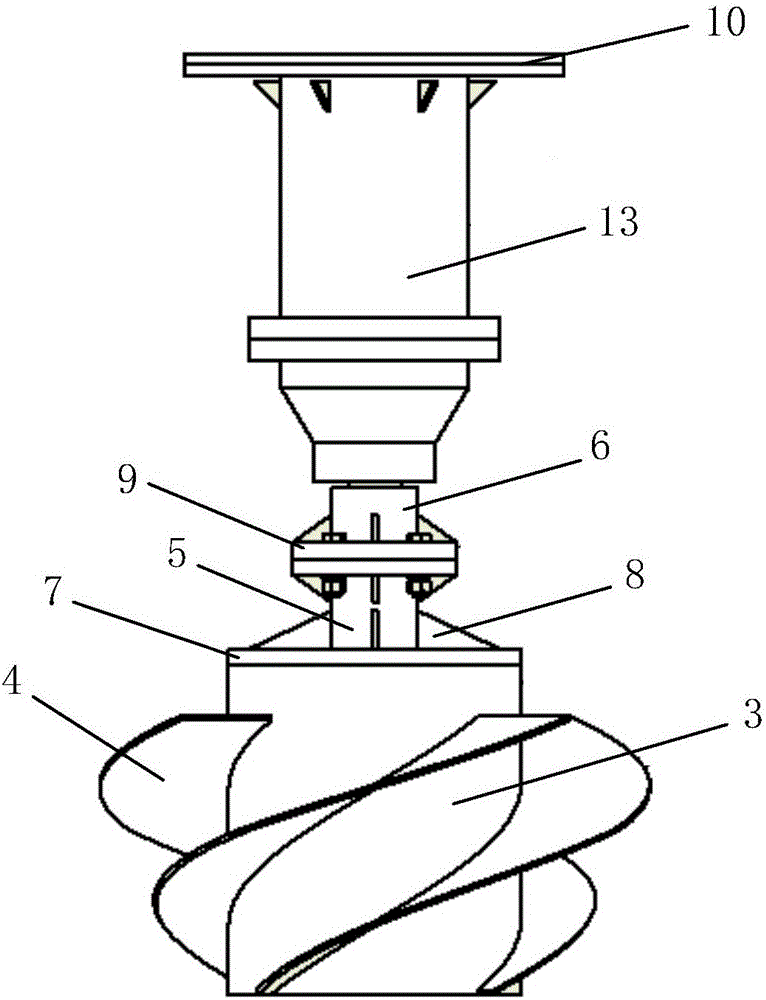

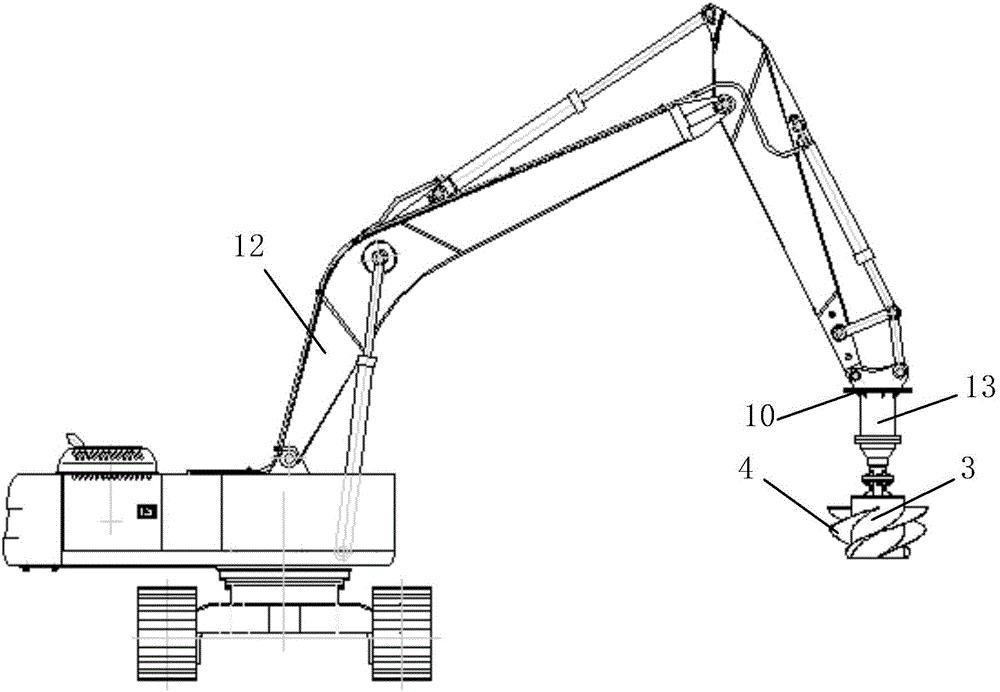

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com